Oil field well workover operation machine

A technology for manipulating machines and well repairing, which is applied to drilling equipment, drilling equipment and methods, earthwork drilling and mining, etc., to achieve the effects of simple installation, reduced manufacturing costs, and flexible and changeable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings.

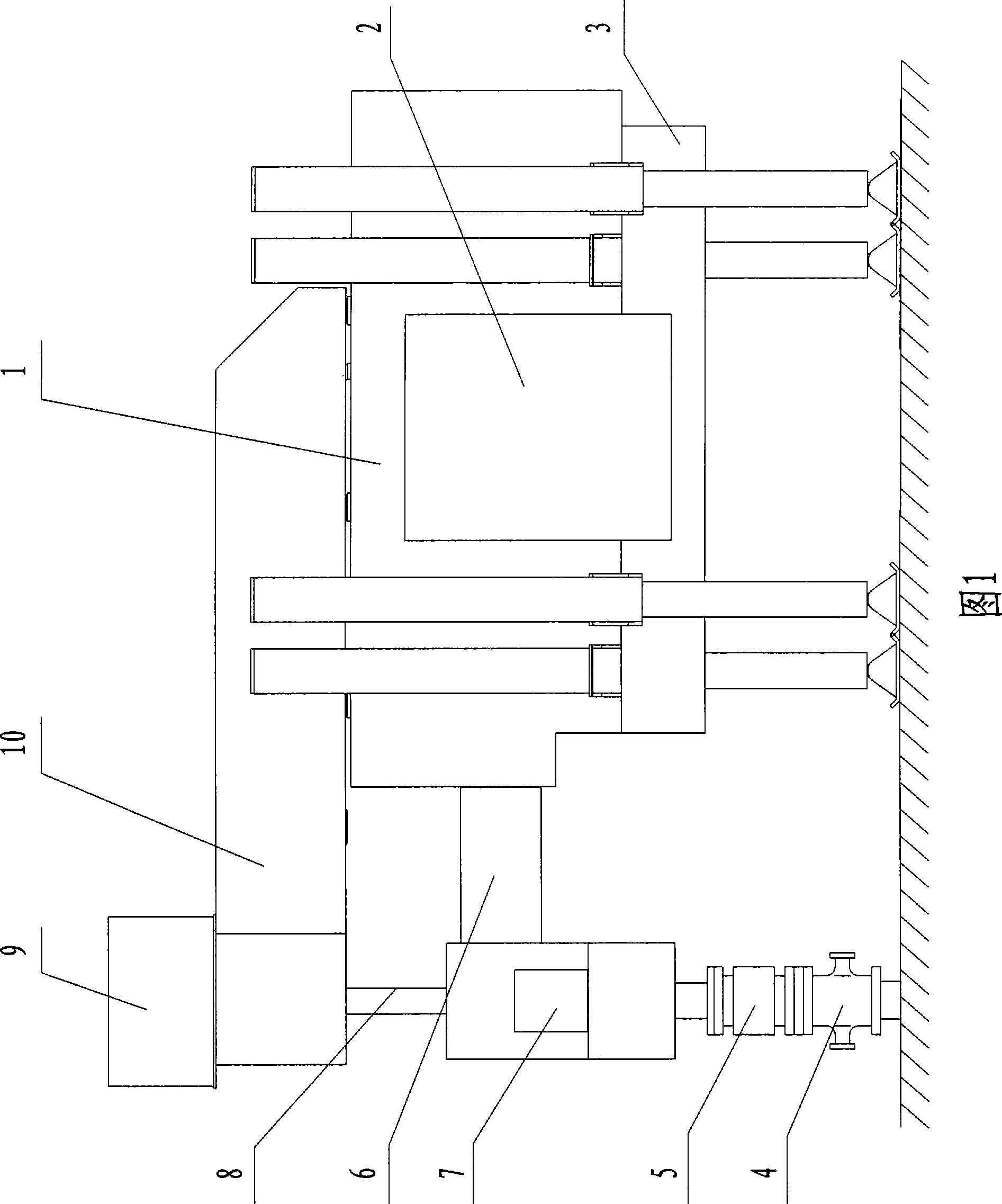

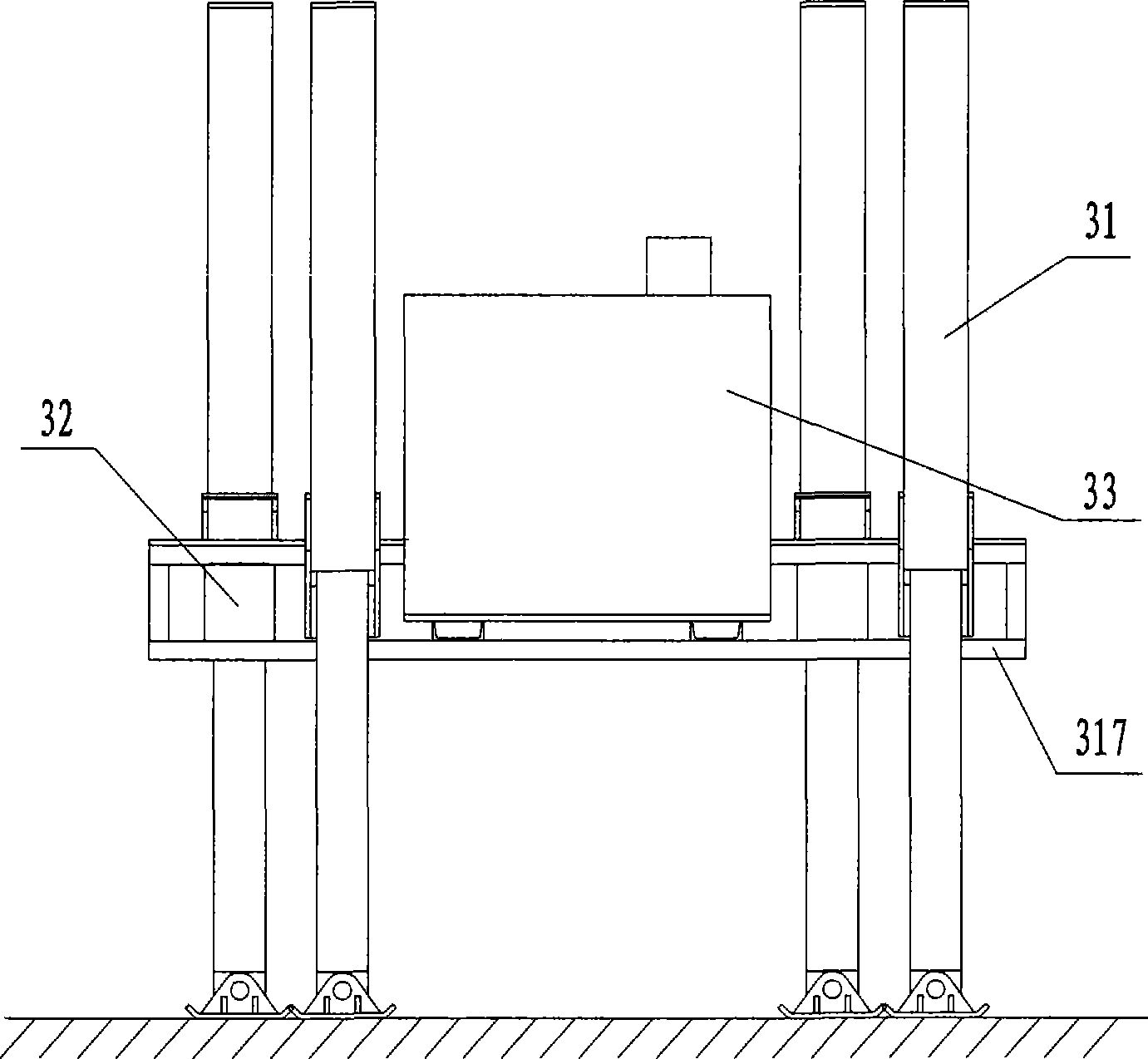

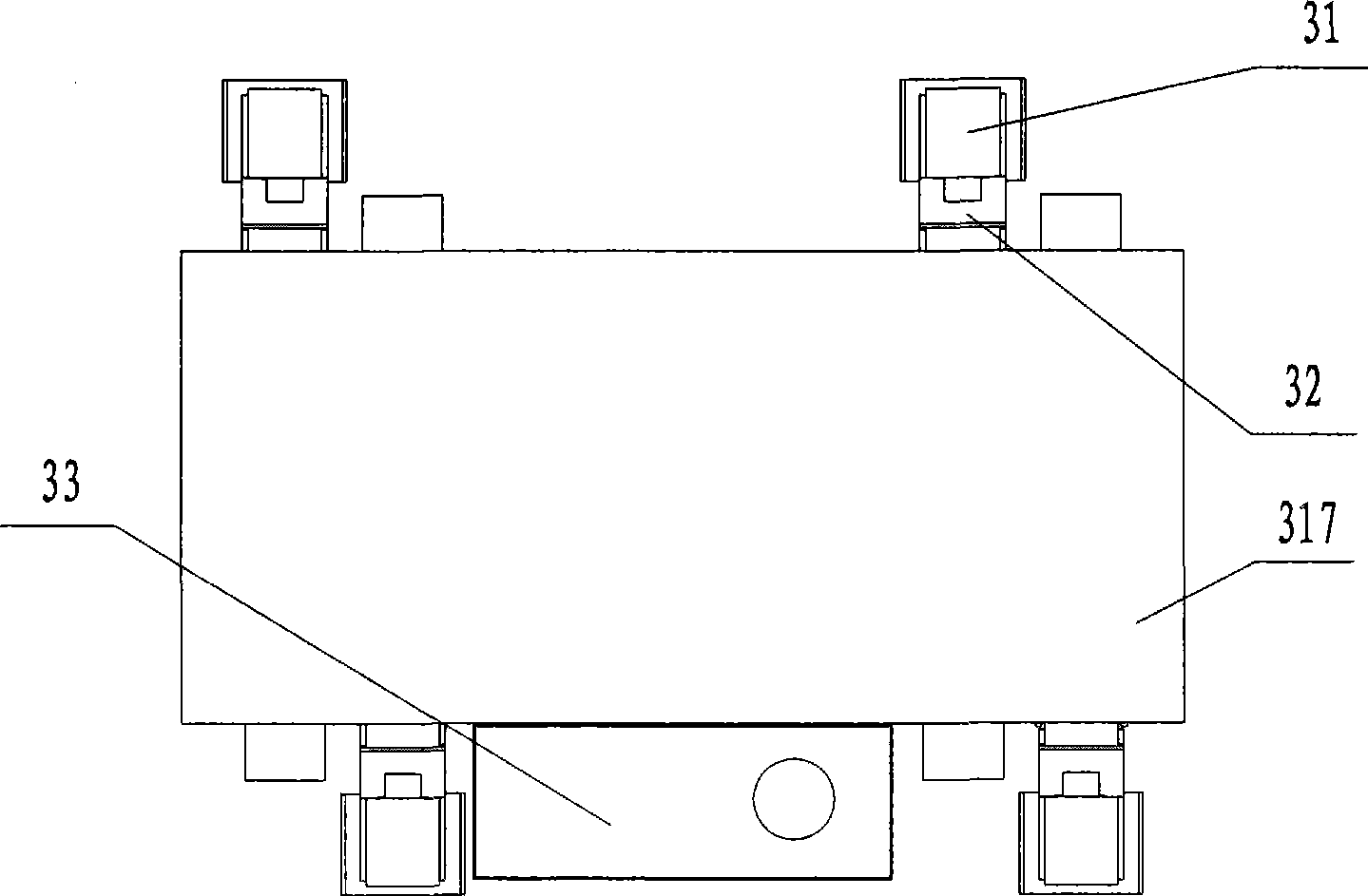

[0062] As shown in Fig. 1, the present invention includes a fuselage 1, a control cabinet 2, a hydraulic bearing travel device 3, a deck 5, a hydraulic clamp 6, an elevator device 7, a pipe throwing device 9 and a faucet 10, and the fuselage 1 is installed in a hydraulic The load-carrying device 3 is connected with the hydraulic load-carrying device 3 through a rectangular slideway; the hydraulic clamp 6 is connected to the telescopic frame on the fuselage 1, and can extend and retract with the telescopic frame; the deck 5 is located under the hydraulic clamp 6 , set on the wellhead 4; the elevator device 7 is suspended below the working machine, and can be pulled by the working machine to move up and down along the center line of the wellhead 4 through the faucet 10; Part of the structure of the device 9 is distributed on the faucet 10 and the fuselage 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com