Patents

Literature

28575results about "Drilling casings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

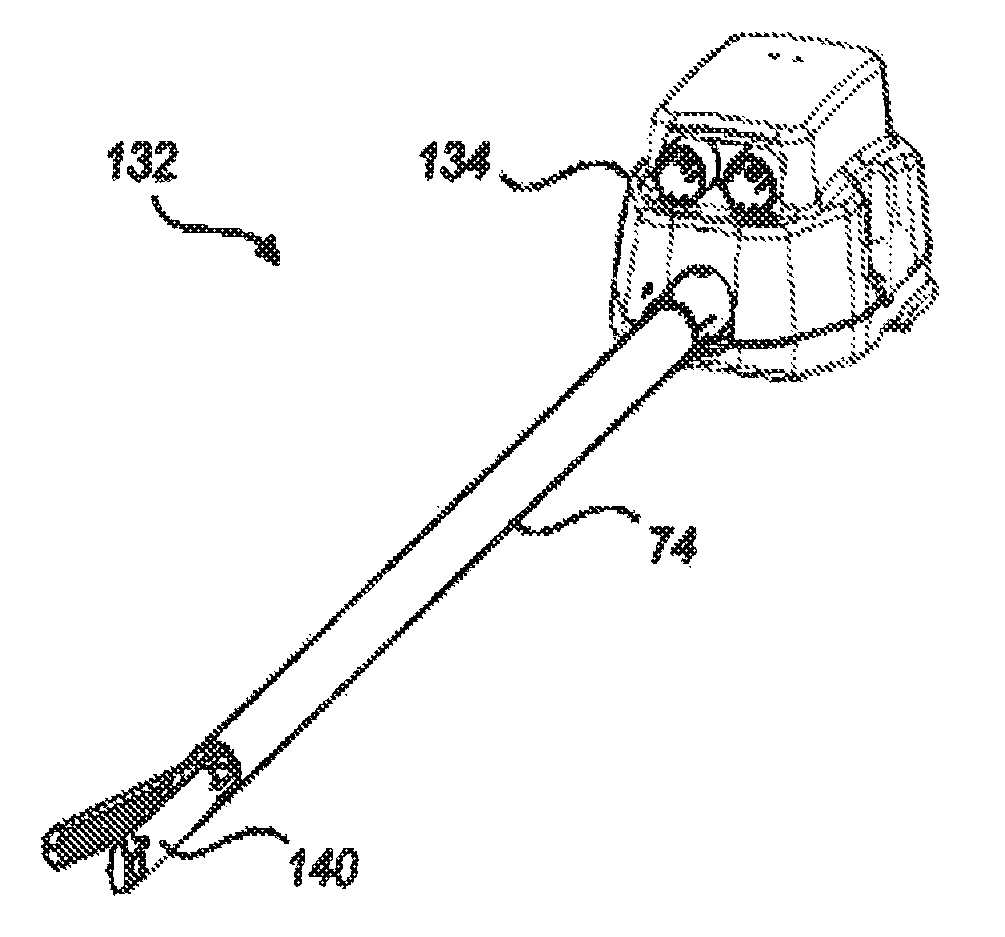

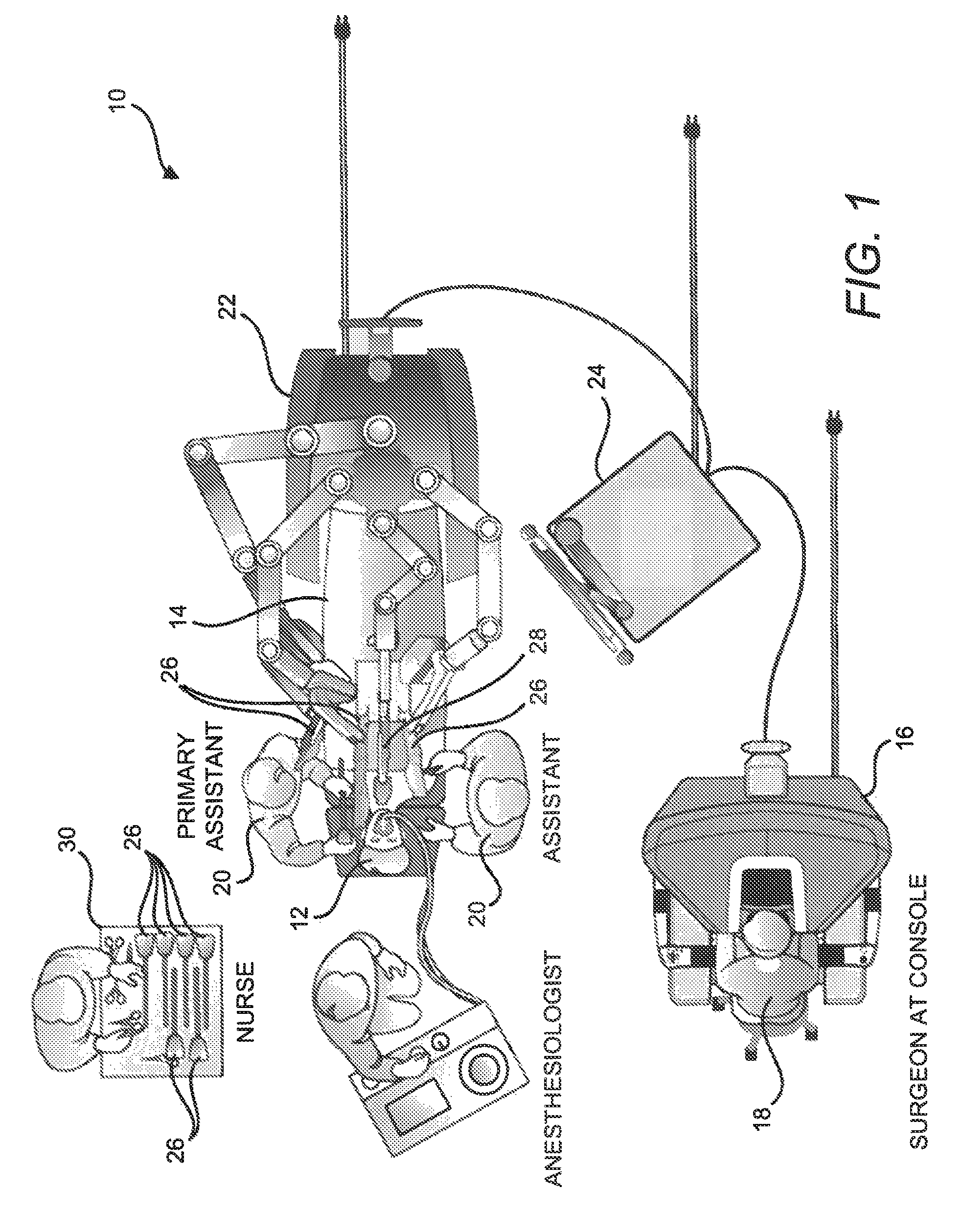

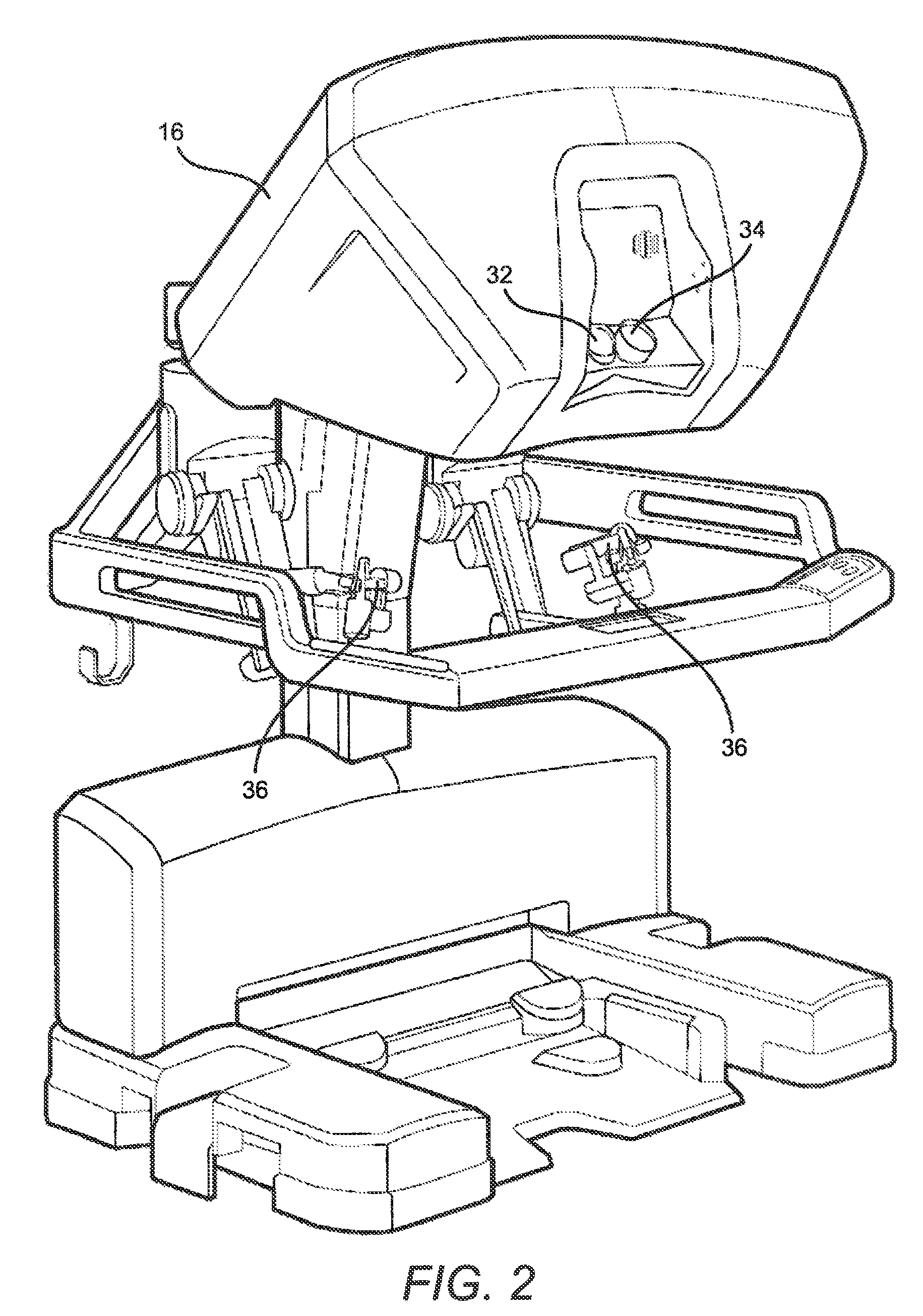

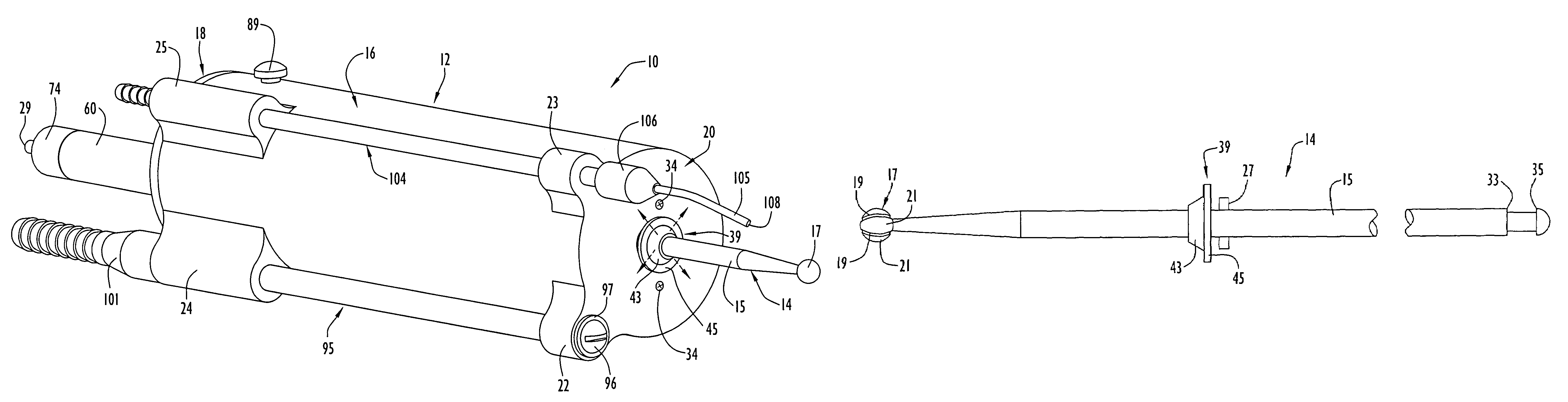

Motor interface for parallel drive shafts within an independently rotating member

ActiveUS8640788B2Force articulationIncrease clamping forceDrilling rodsConstructionsRotational axisDrive shaft

Owner:INTUITIVE SURGICAL OPERATIONS INC

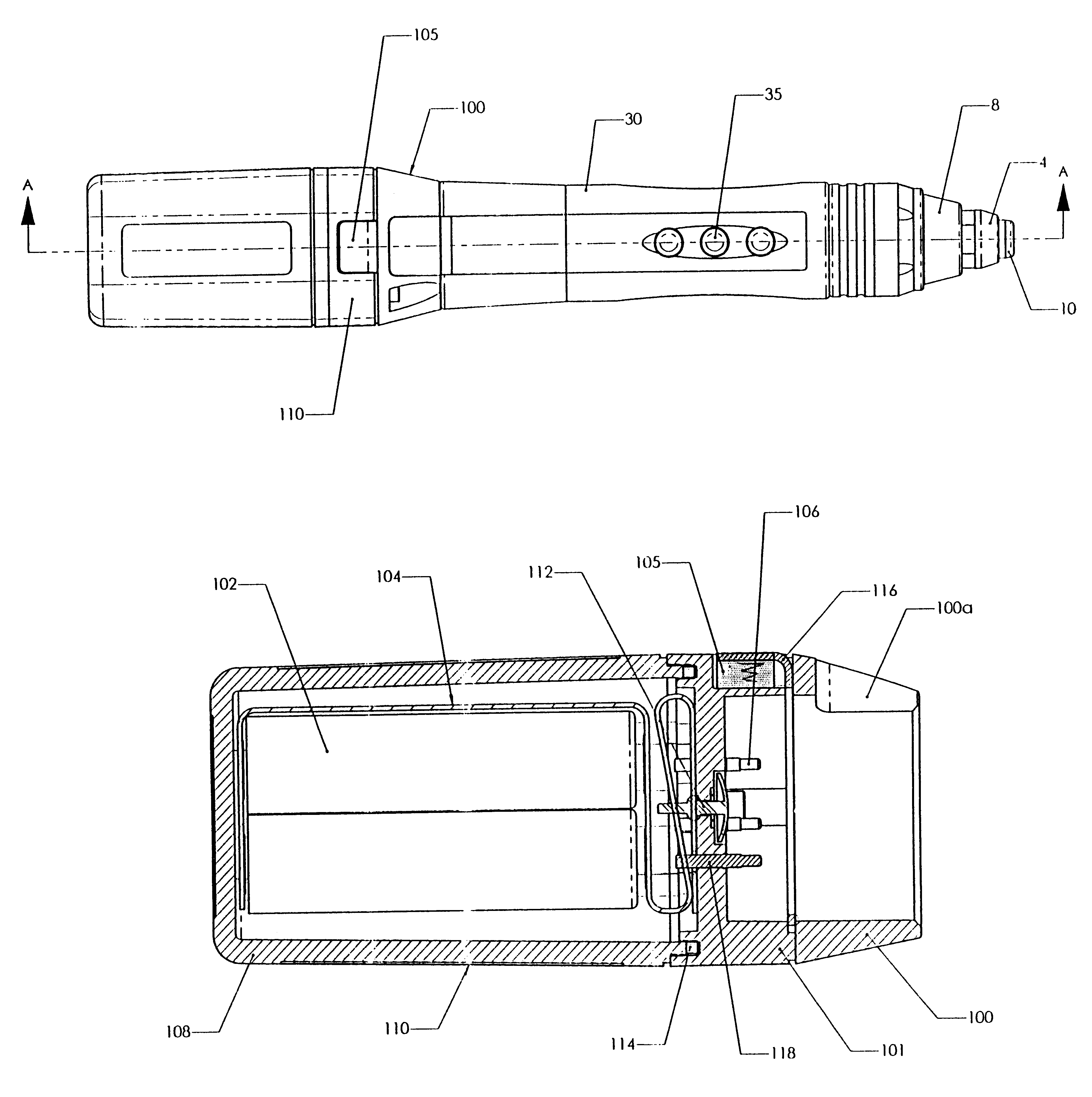

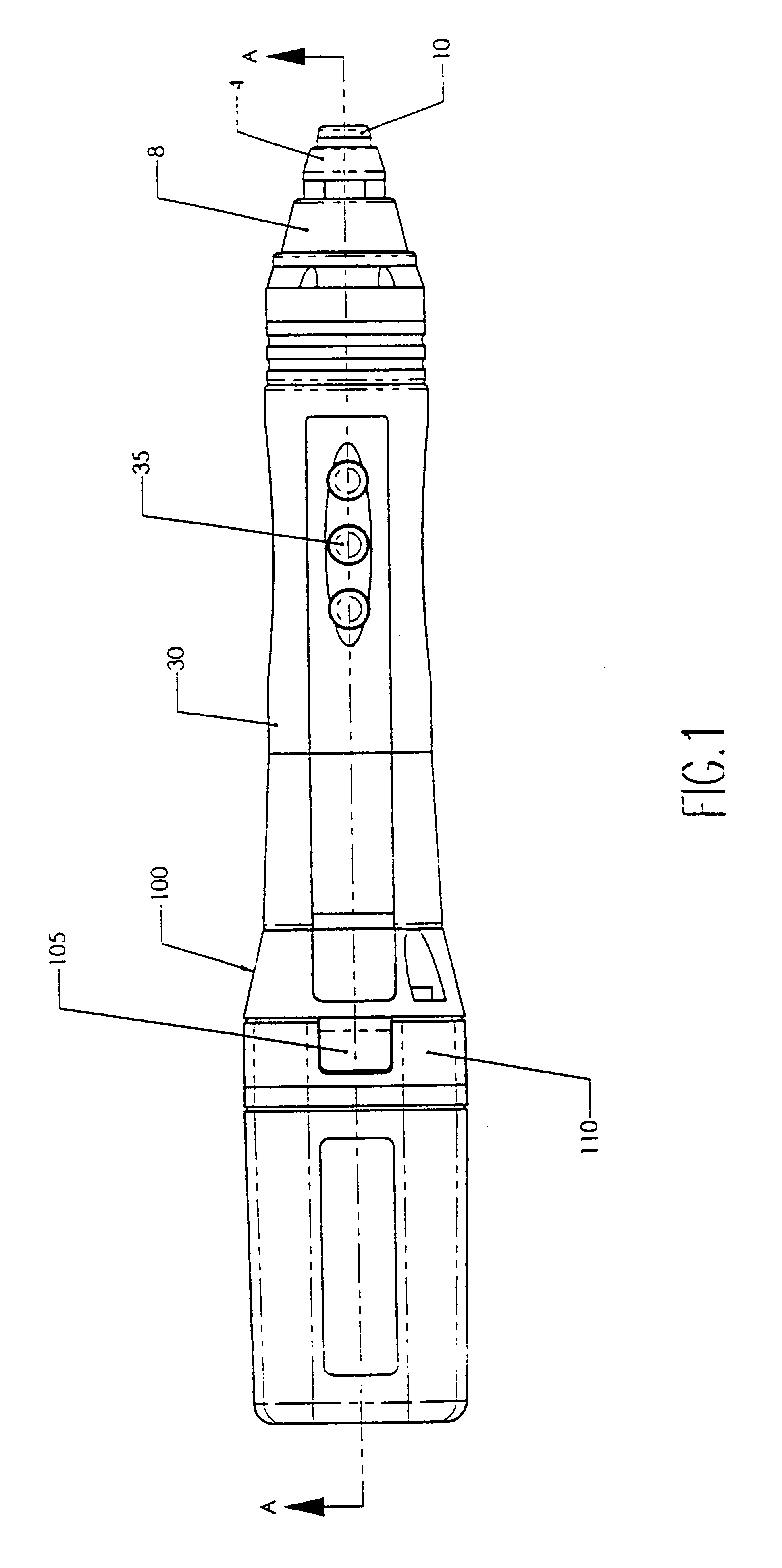

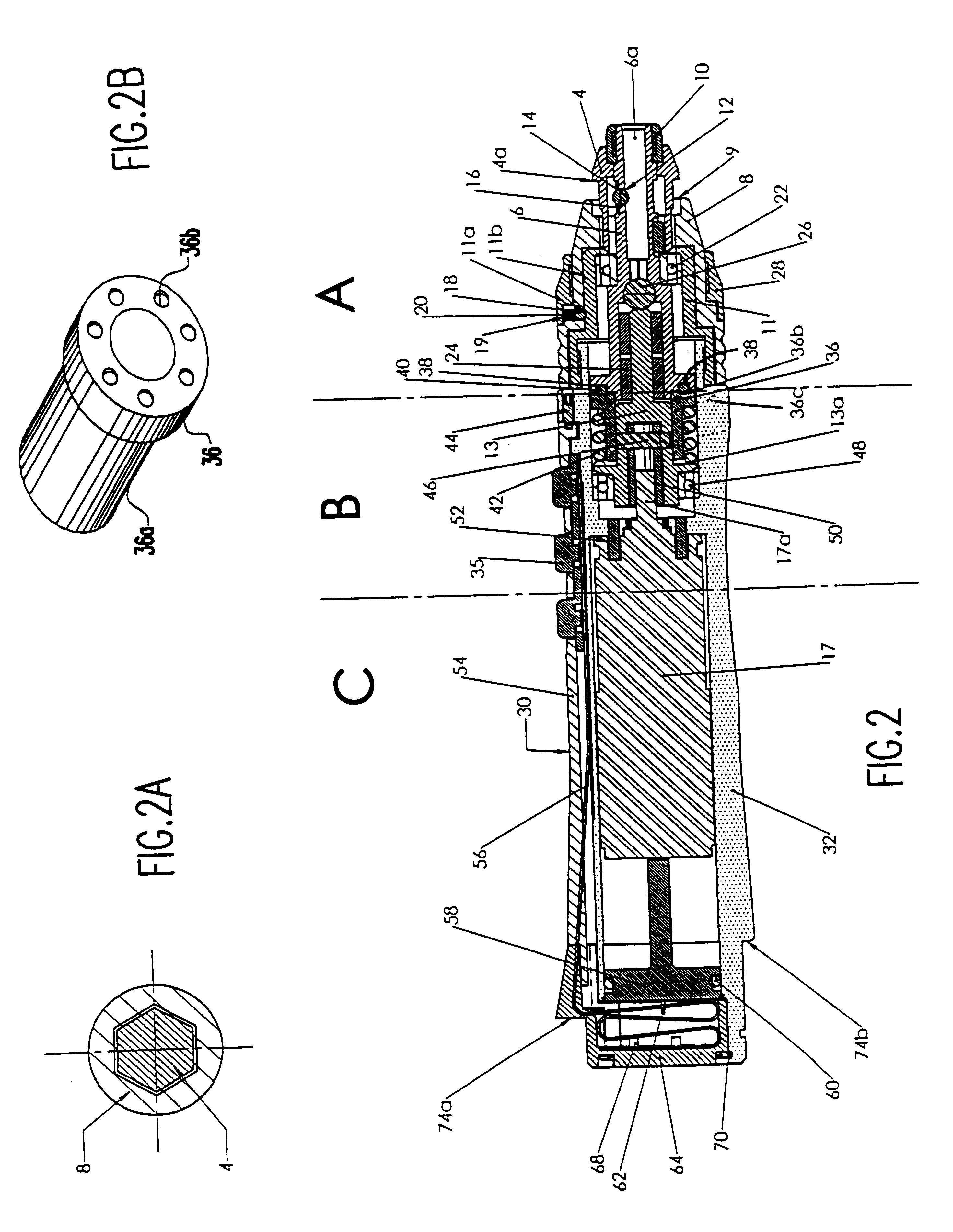

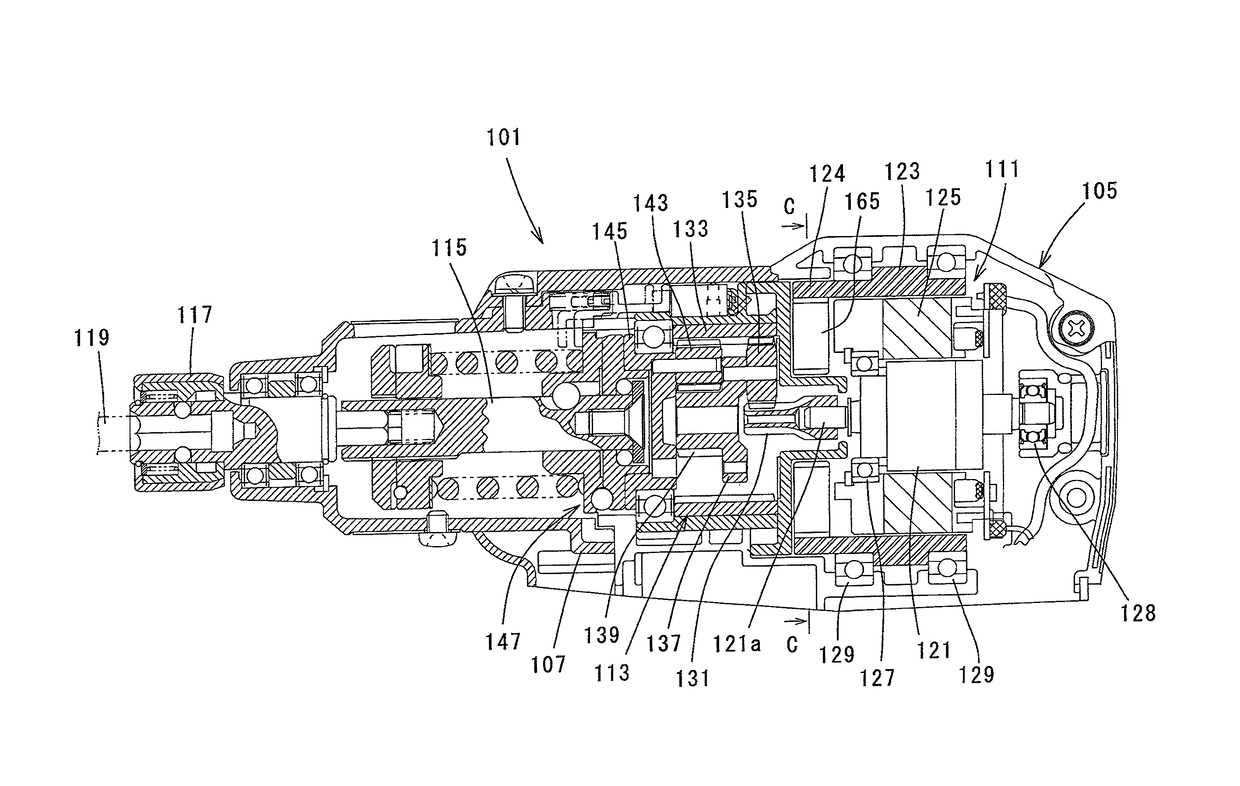

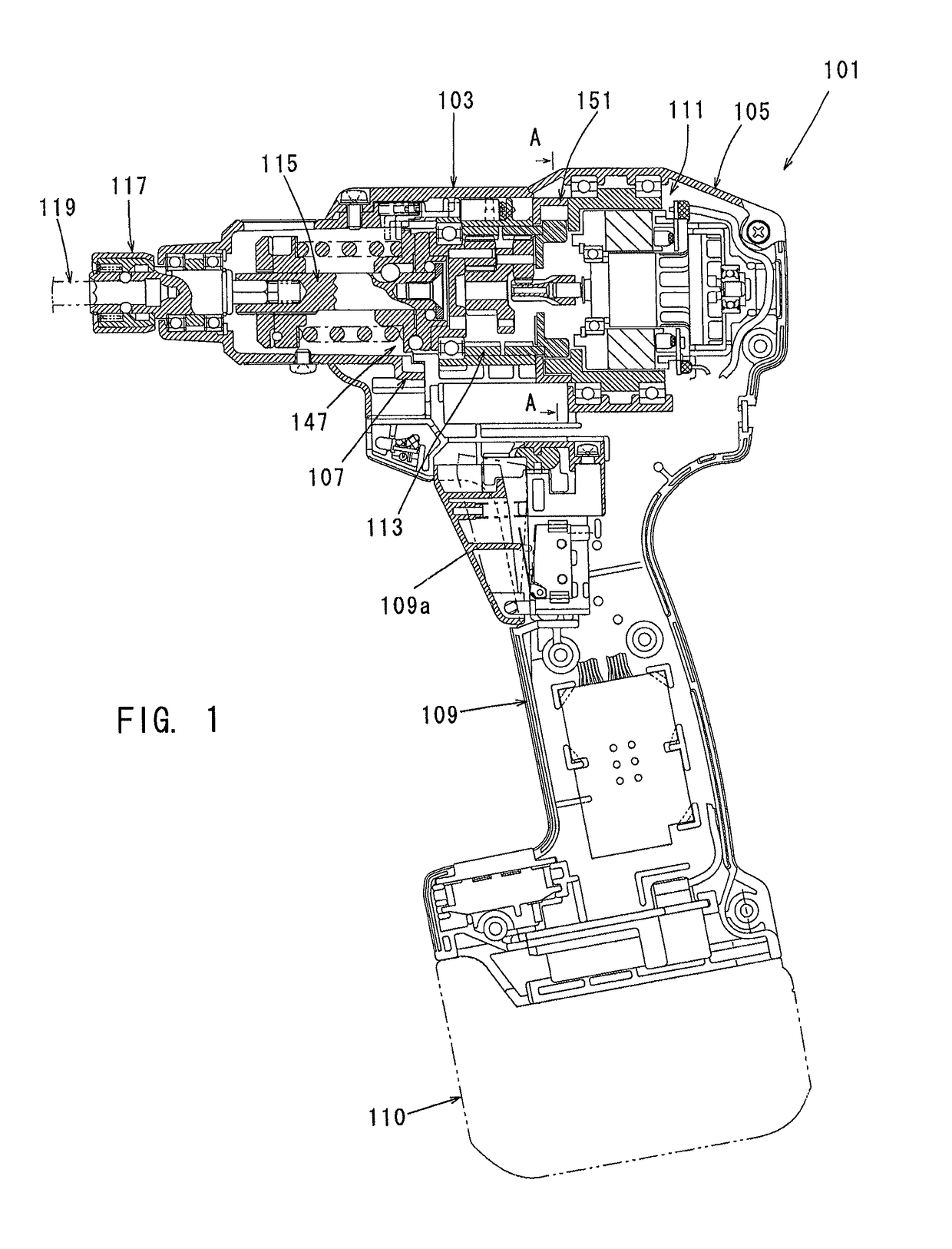

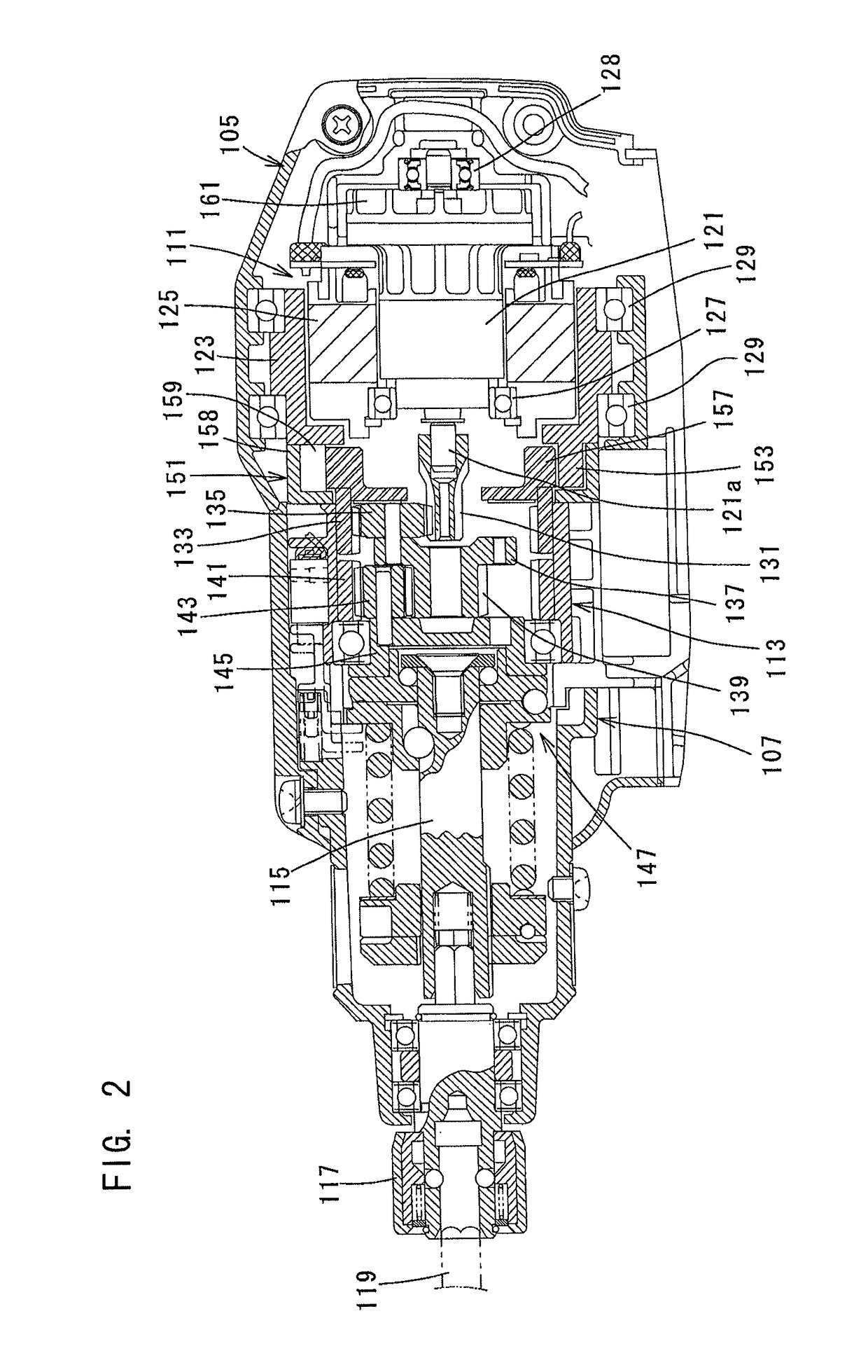

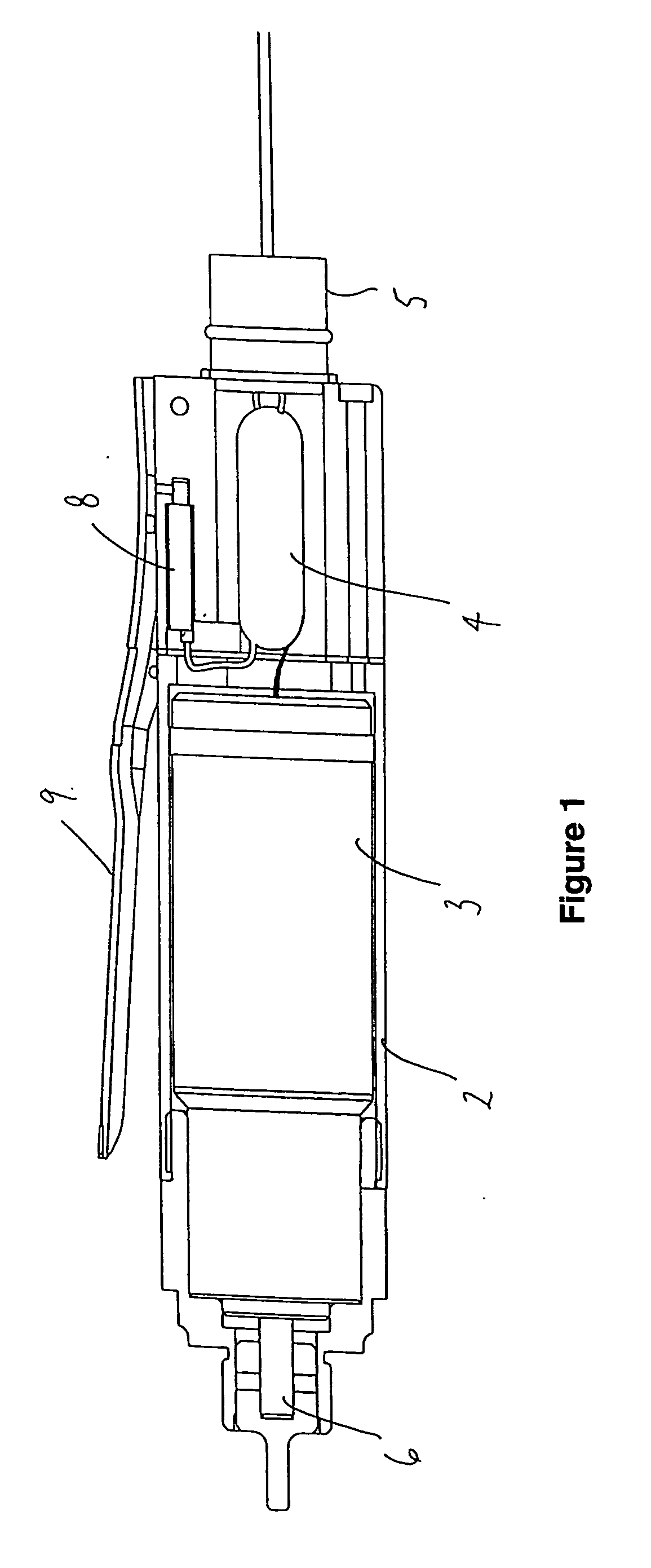

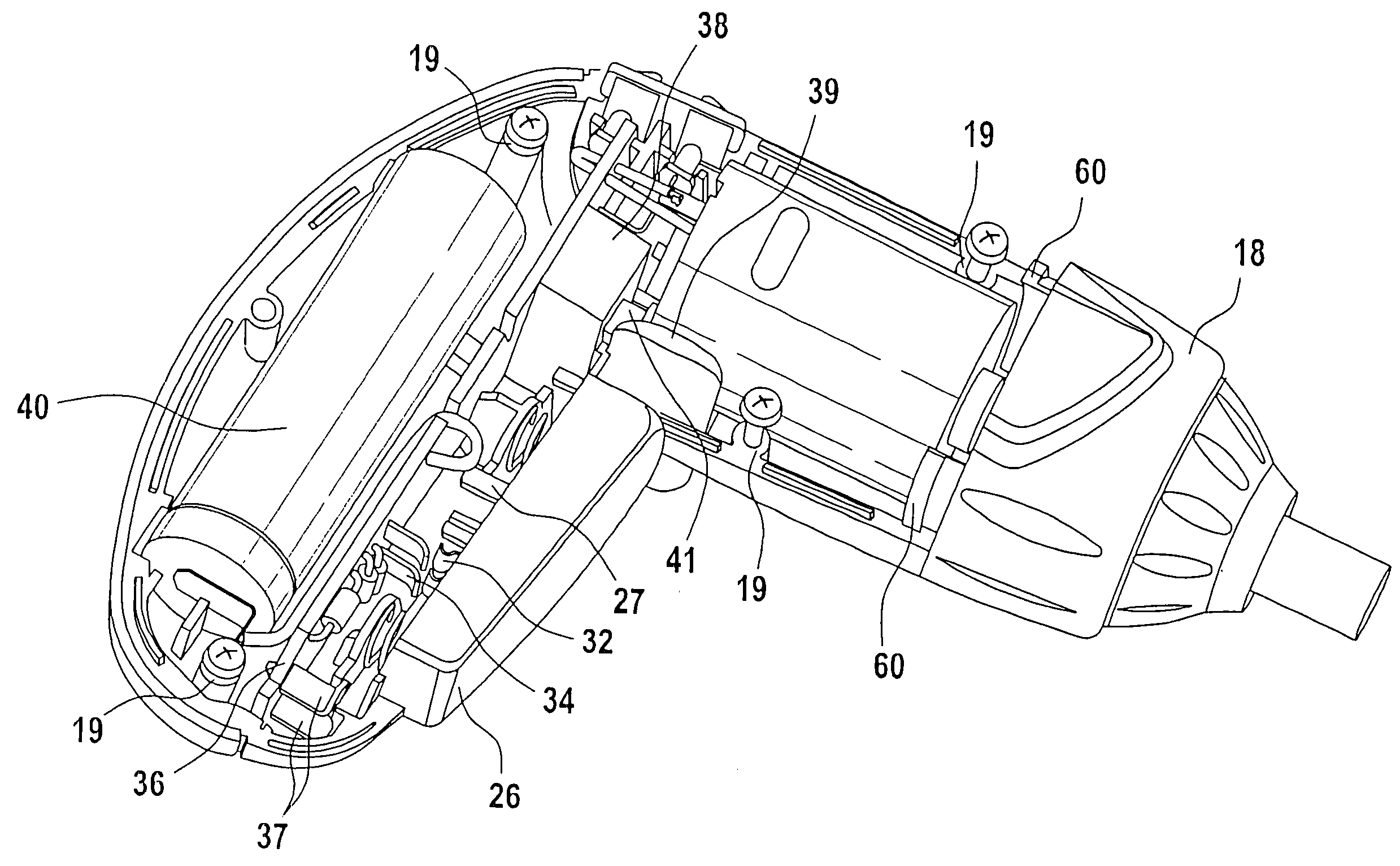

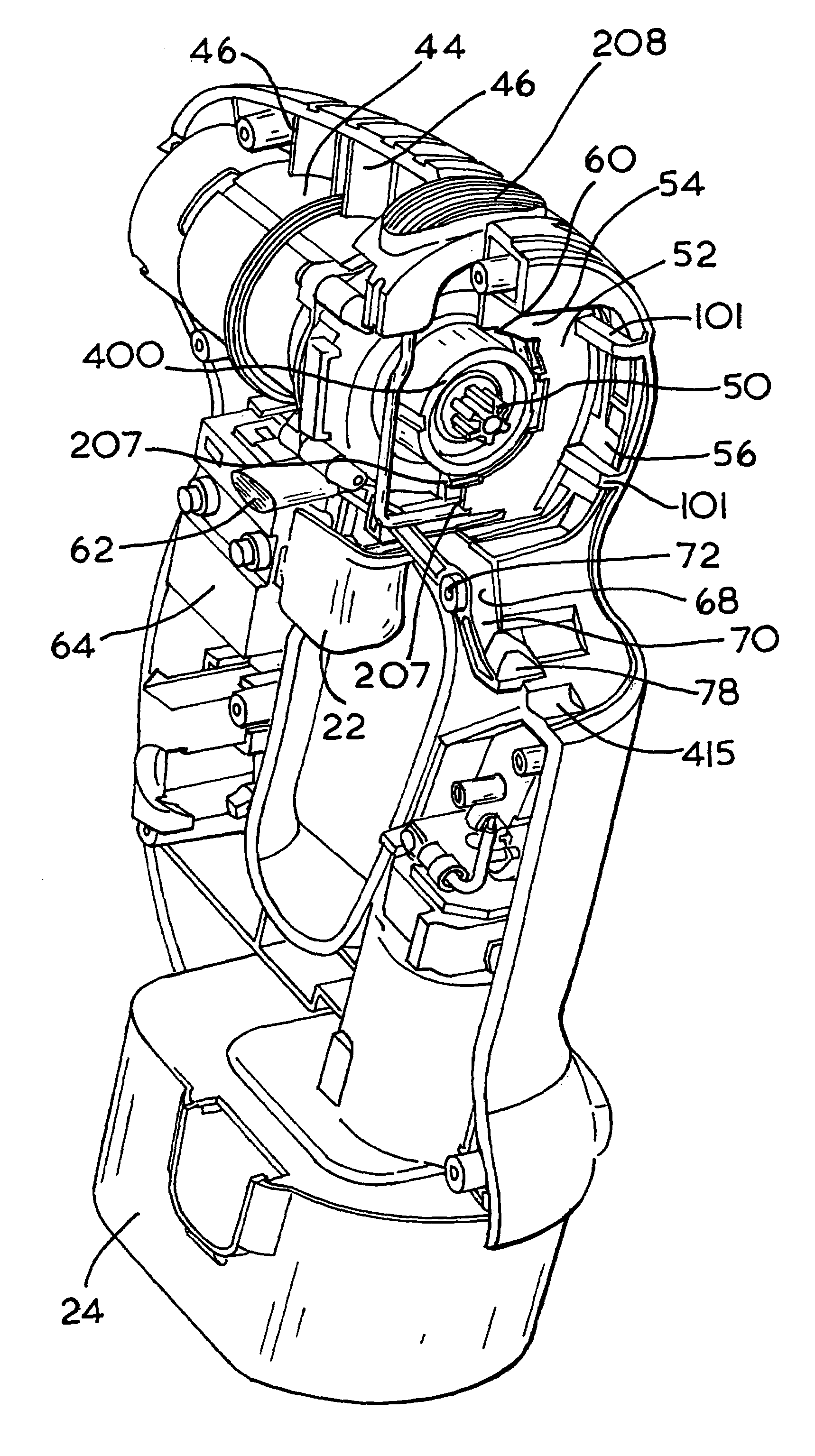

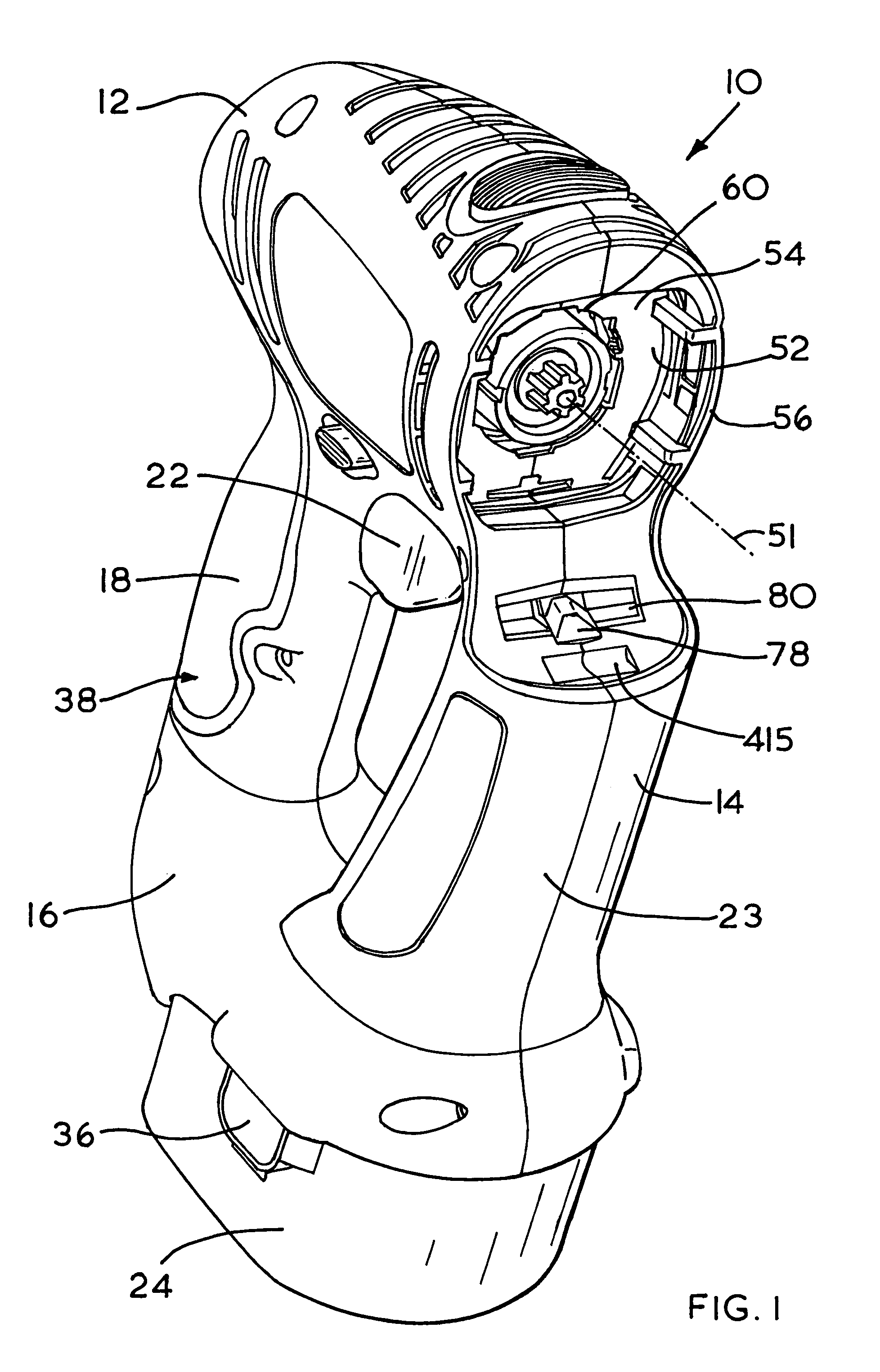

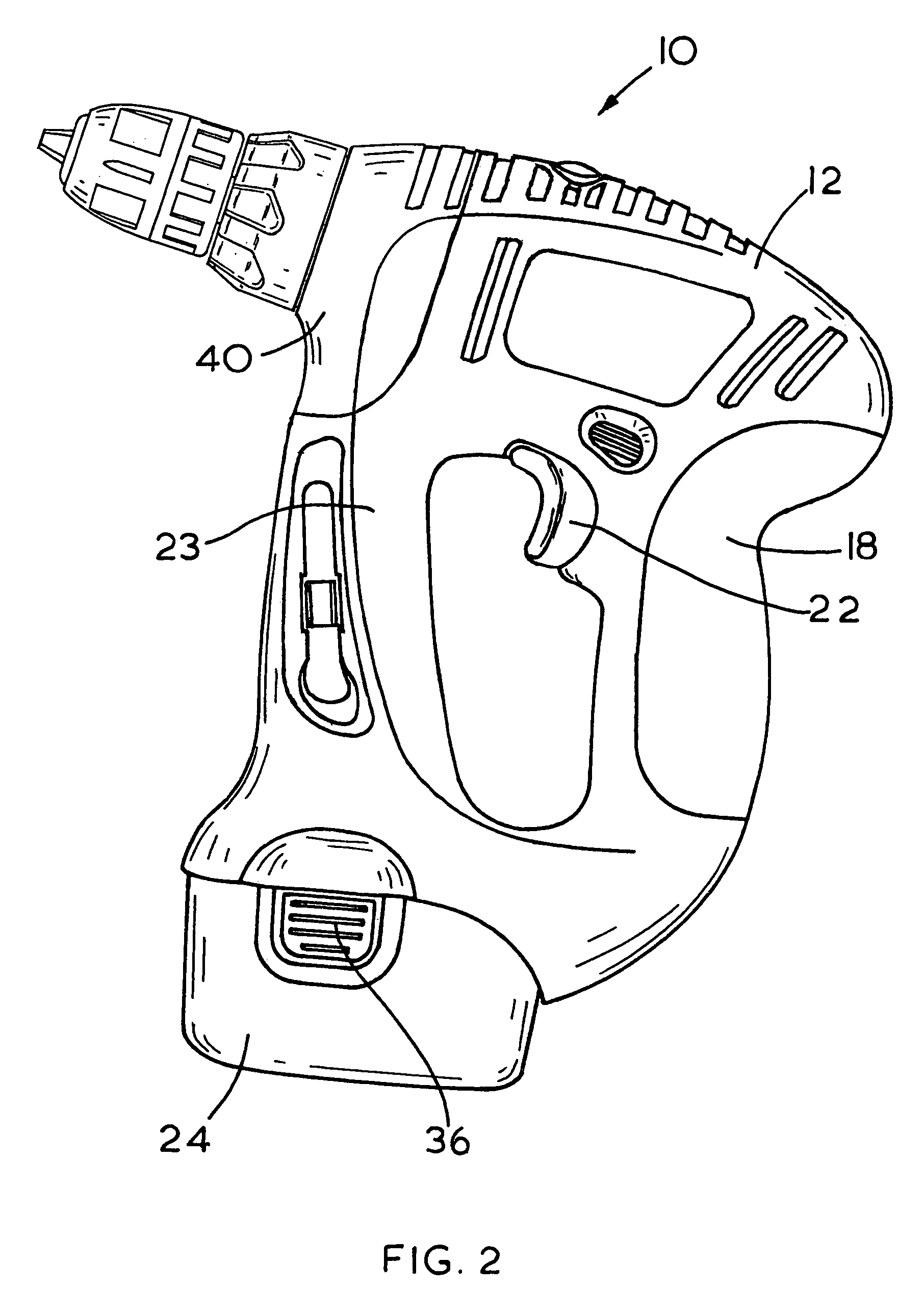

Powered surgical instrument having locking systems and a clutch mechanism

InactiveUS6220368B1Easy to mountEasy to removeDrilling rodsConstructionsLocking mechanismDrive shaft

A surgical instrument having a locking mechanism for preventing an output shaft of the surgical instrument from rotating and a further locking mechanism for mounting a battery pack to a distal end of a housing of the surgical instrument. The surgical instrument further includes a clutch mechanism for limiting the torque of a drive shaft of the surgical instrument. The locking mechanism for preventing the output shaft from rotating includes a locking switch which mates with a locking cap disposed on the output shaft. The locking mechanism for mounting the battery pack to the housing includes a groove at the distal end of the housing and a retaining ring which engages the groove when the battery pack is mounted on the housing. The clutch mechanism includes a clutch plate that interfaces with both the output shaft and the drive shaft and prevents failure of the motor shaft.

Owner:MICROAIRE SURGICAL INSTR

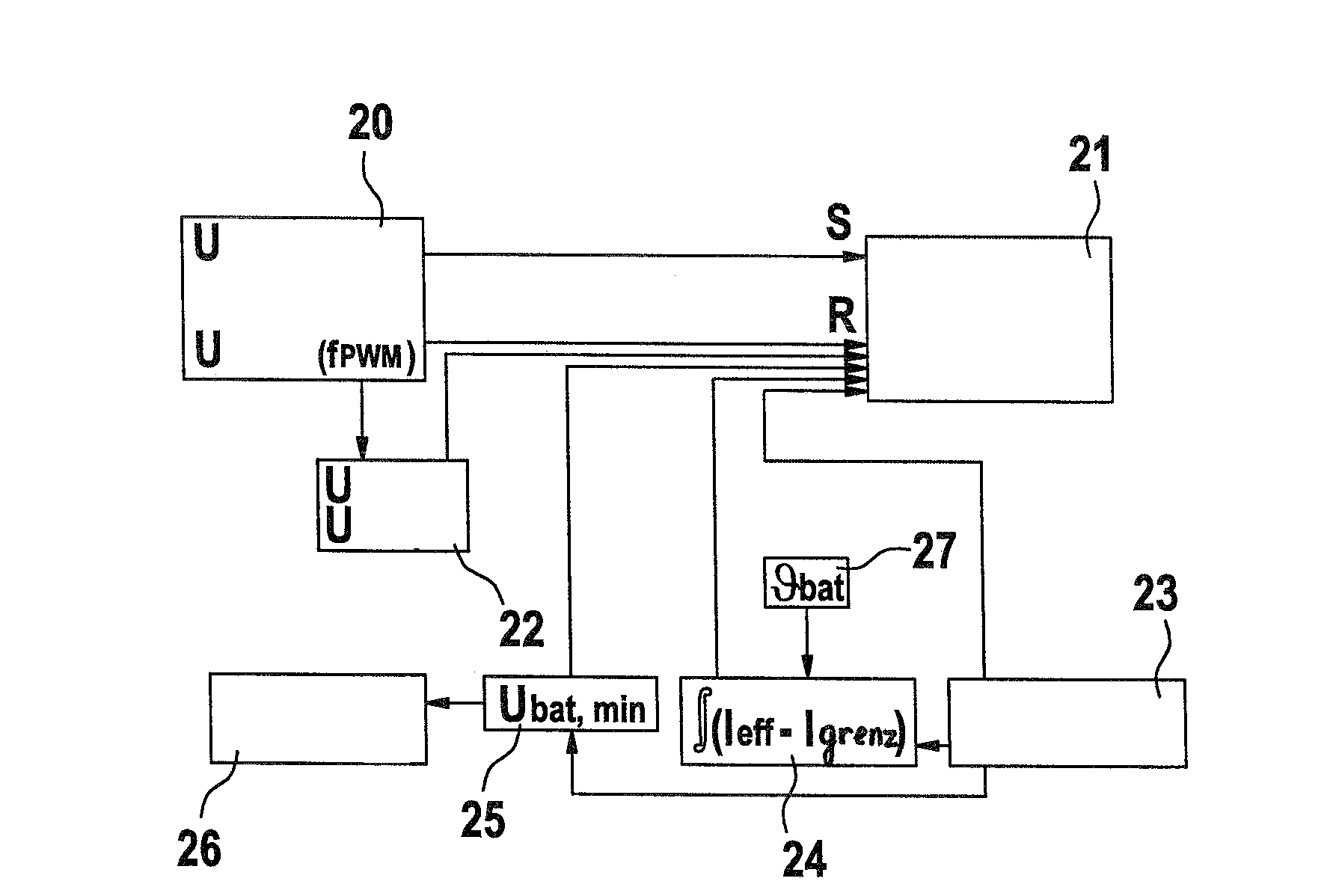

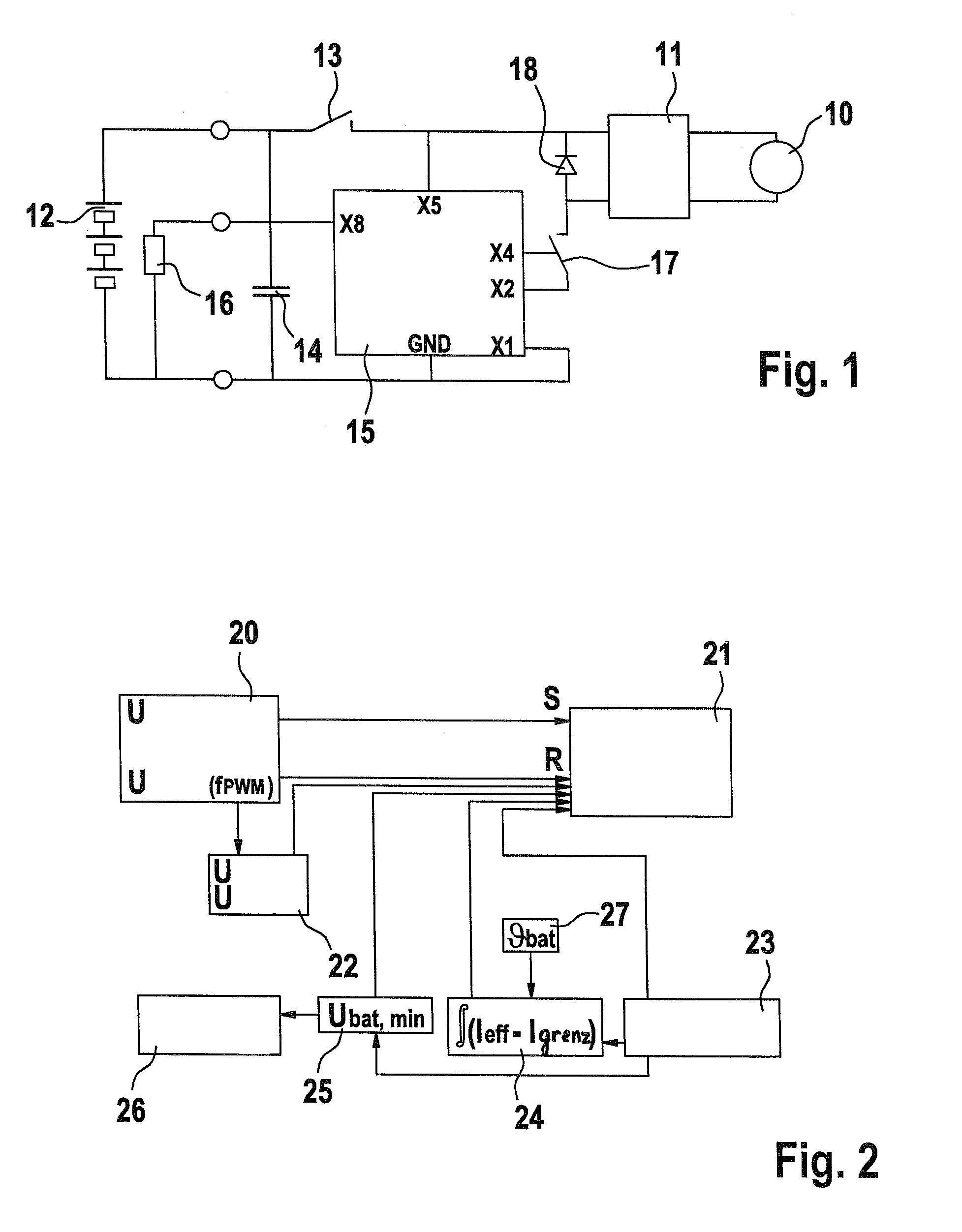

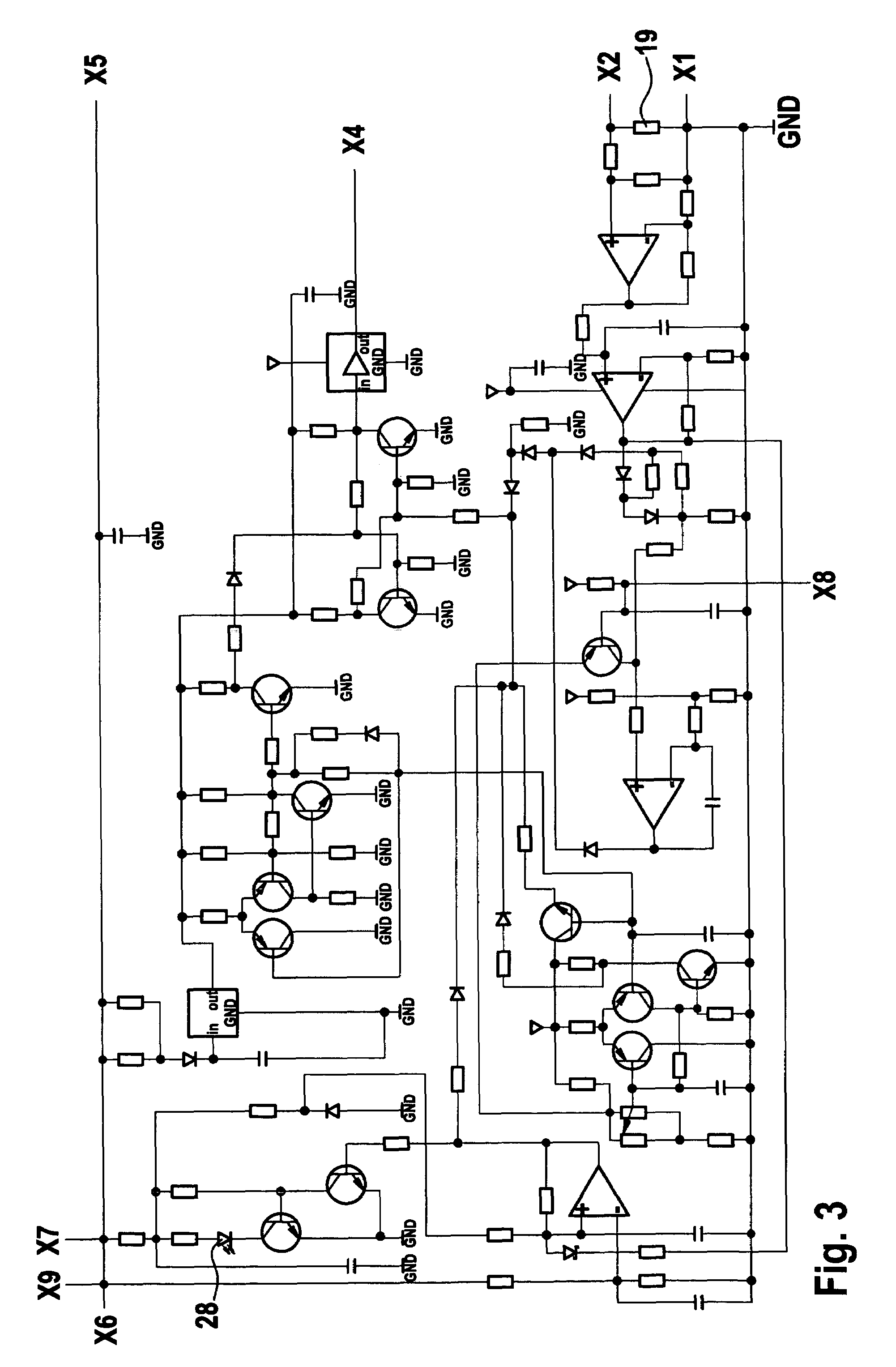

Method for operating a power tool

ActiveUS7336048B2Maintain good propertiesReduce widthTemperatue controlEmergency protective arrangements for automatic disconnectionMOSFETElectricity

In a method for operating a power tool with an energy accumulator, in particular a rechargeable energy accumulator, which supplies power to an electric drive motor, a clock frequency is generated by an electronic unit, with which a gate of a MOSFET—which supplies operating voltage to the drive motor—is switched on with each cycle, and a switching-off of the MOSFET is carried out within one cycle using different signals, as a function of operating parameters.

Owner:ROBERT BOSCH GMBH

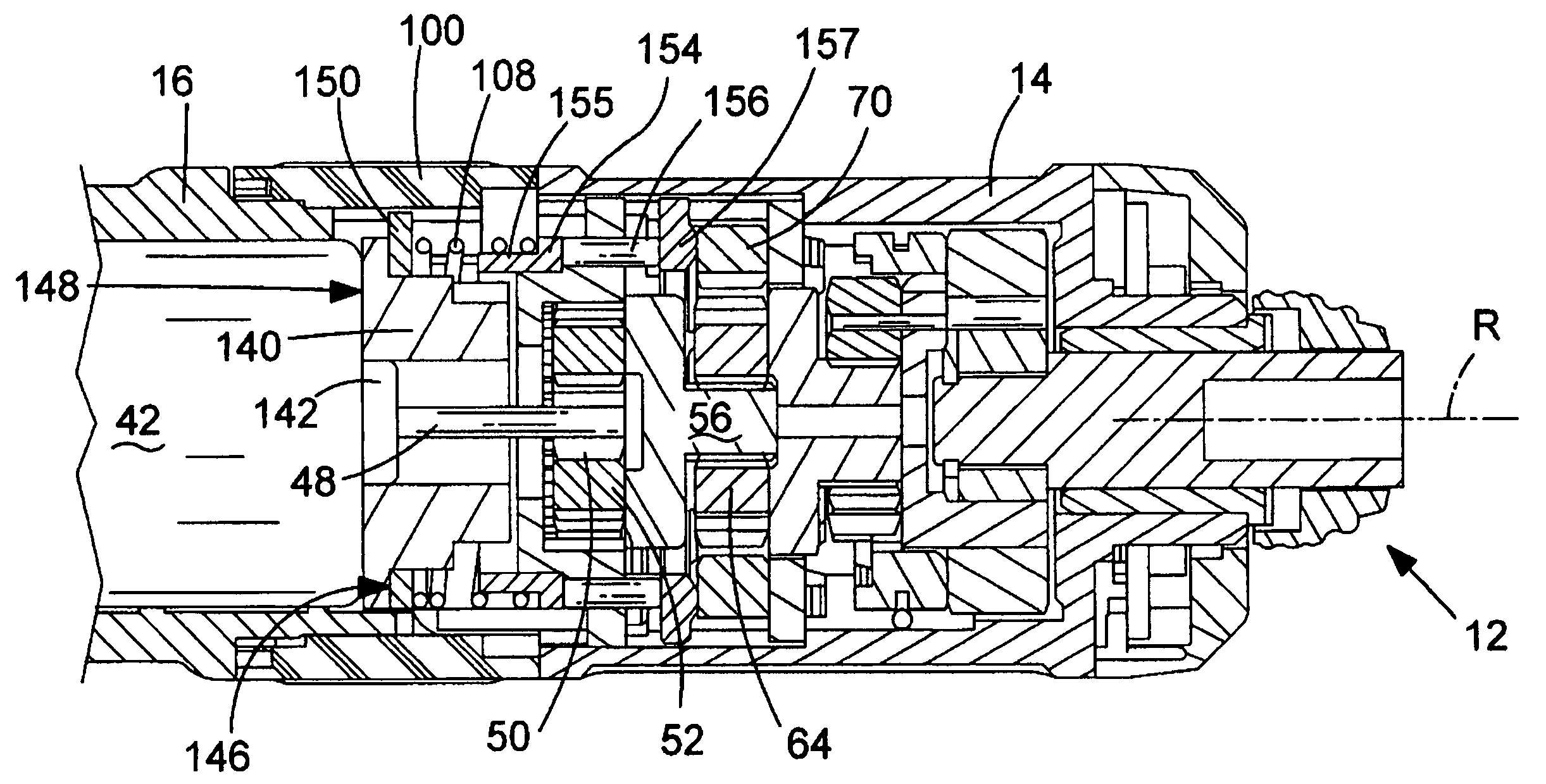

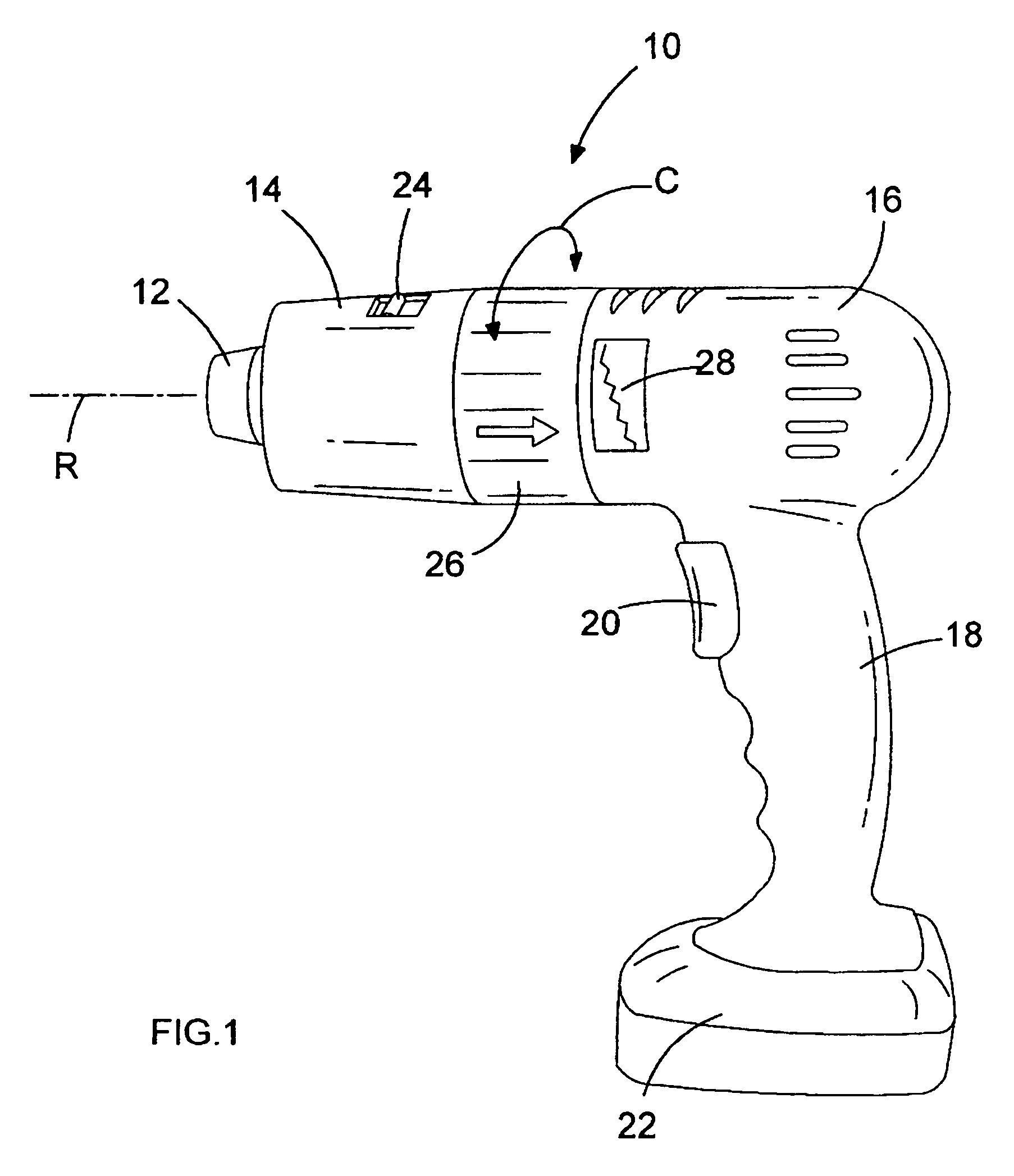

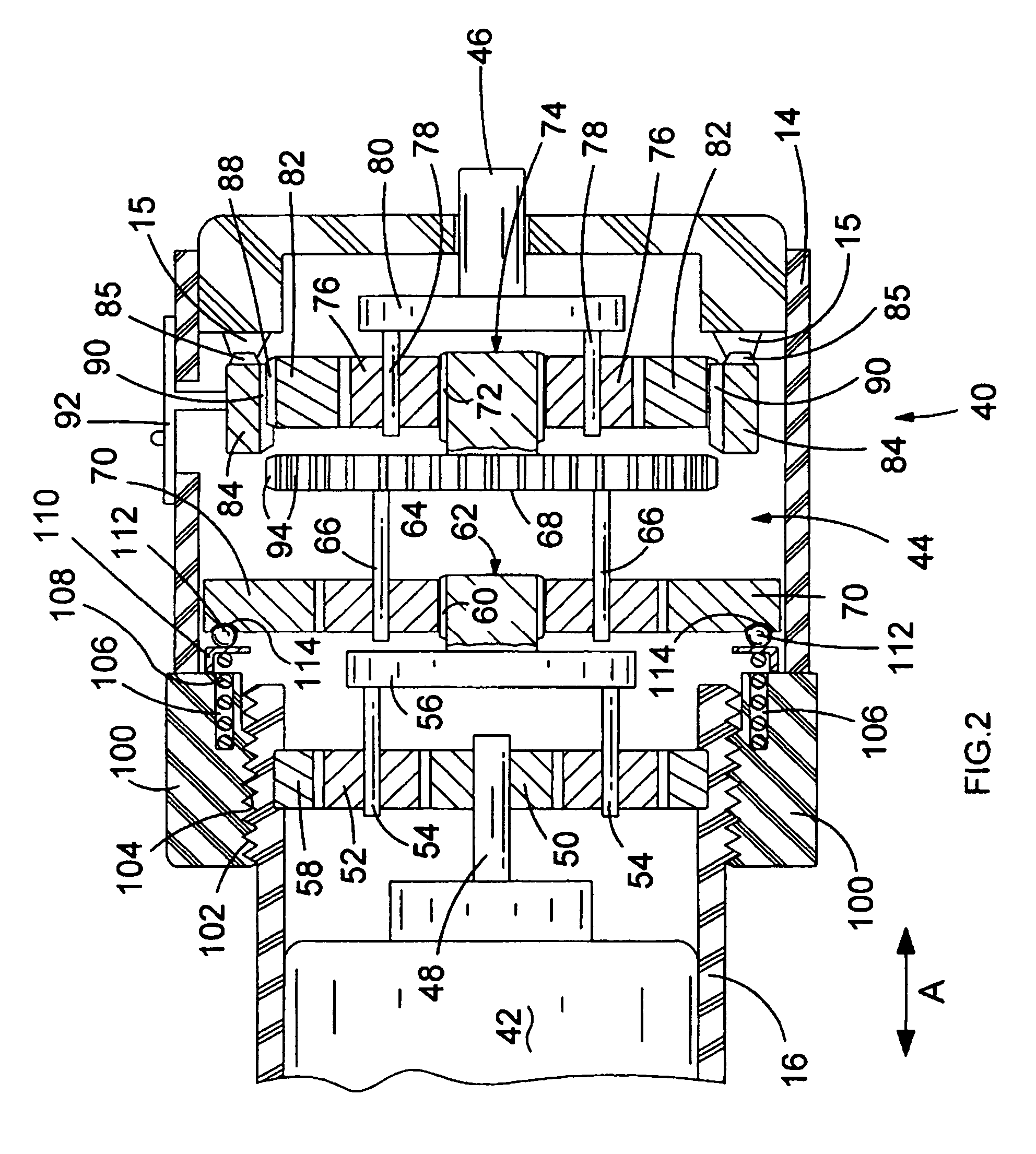

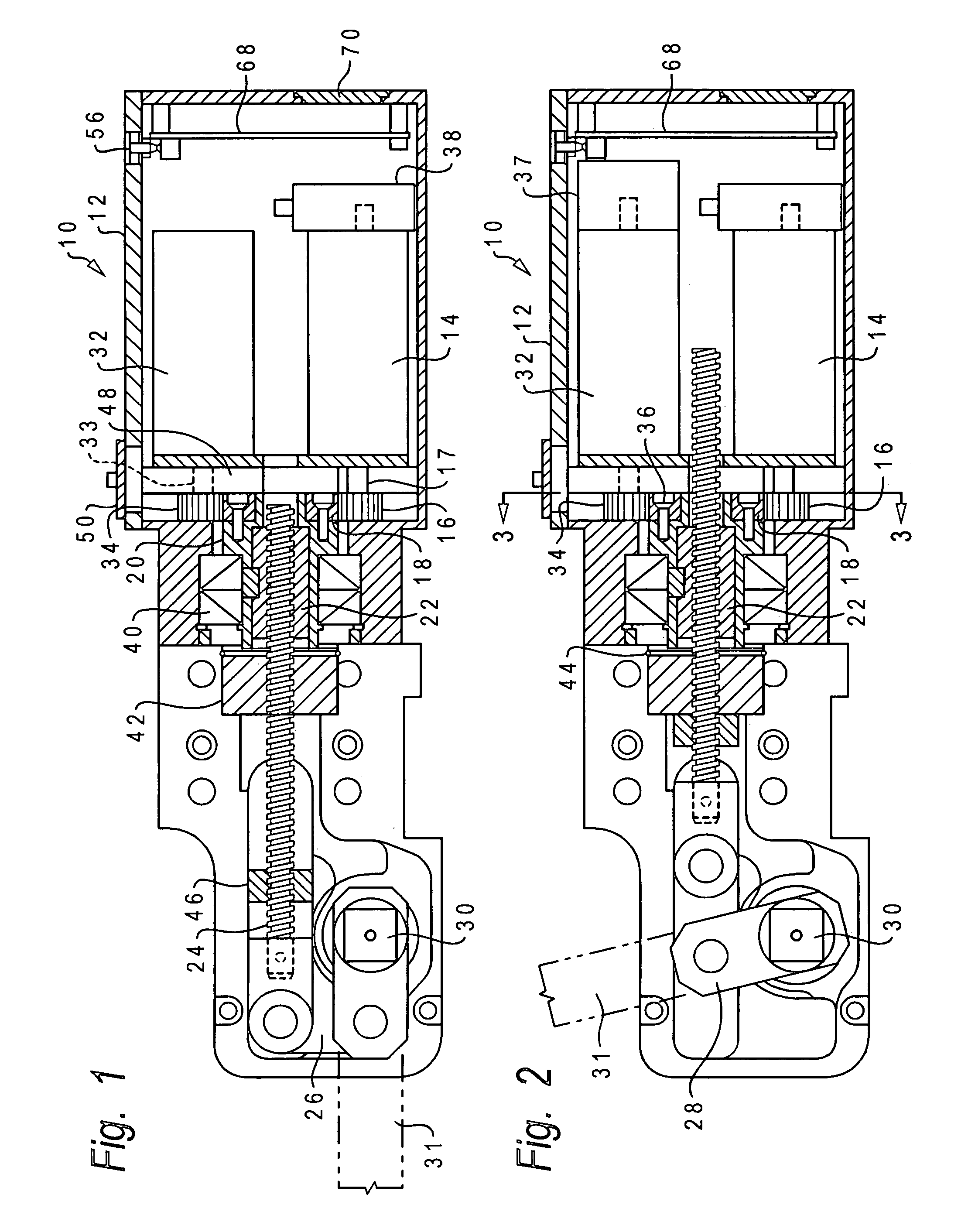

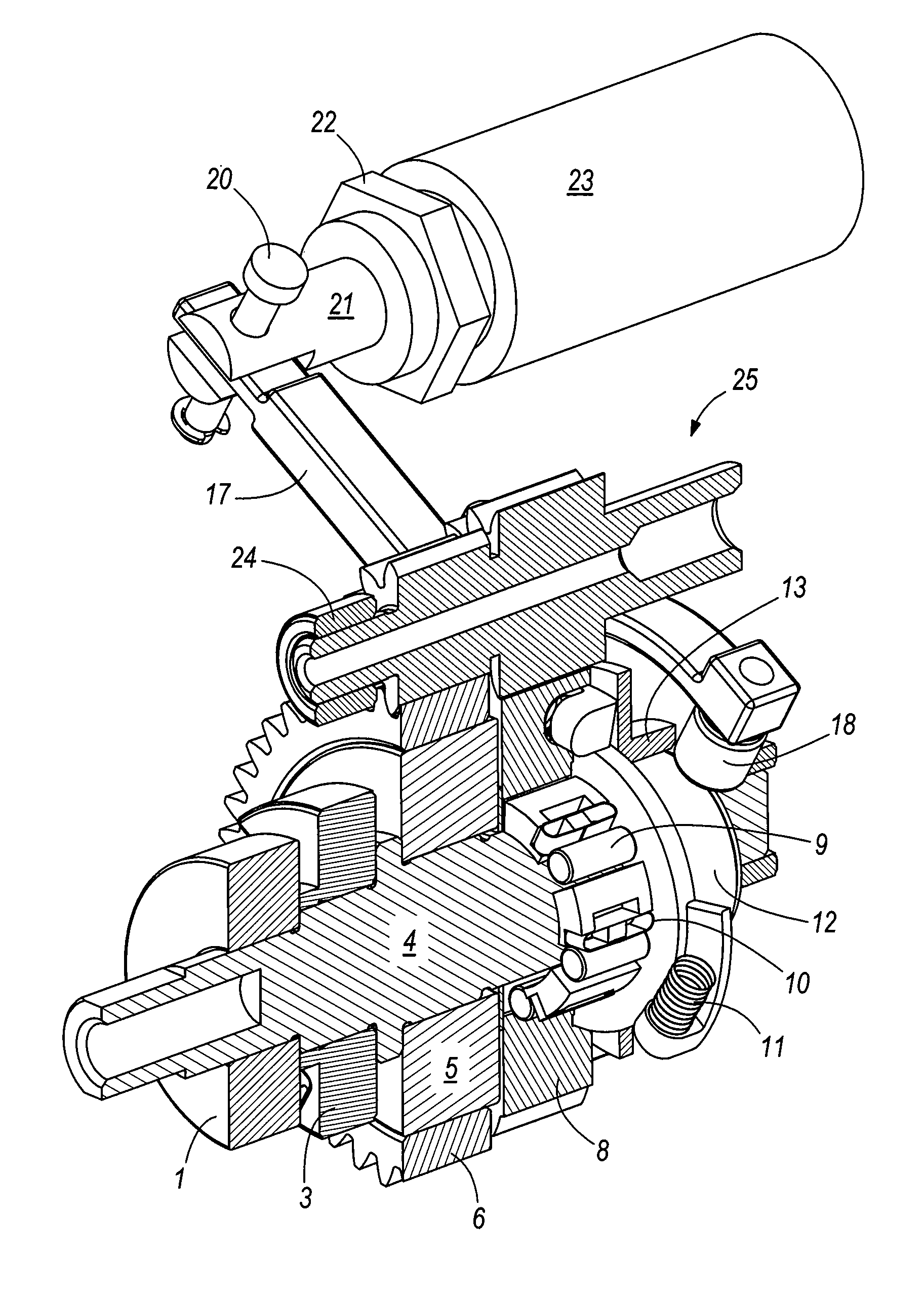

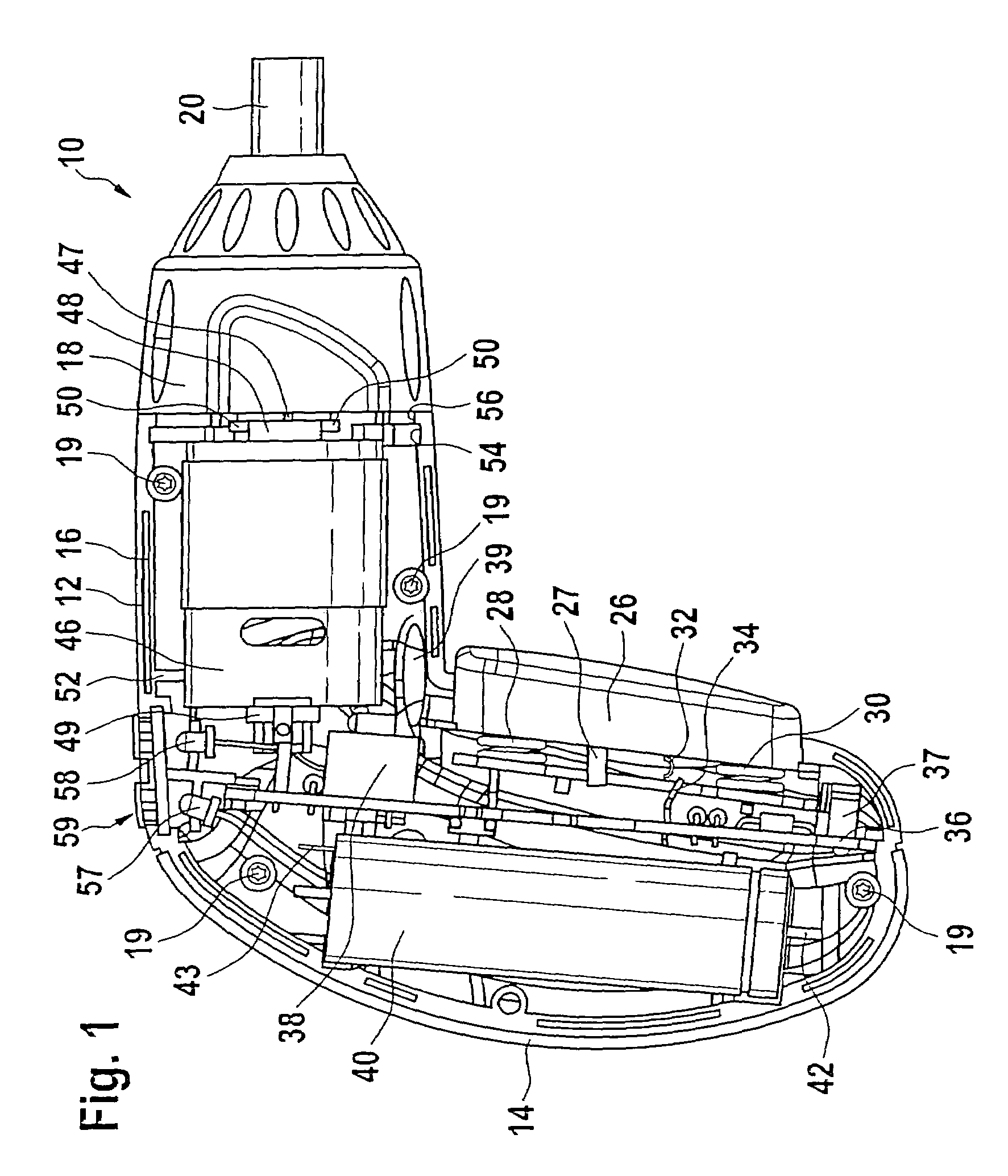

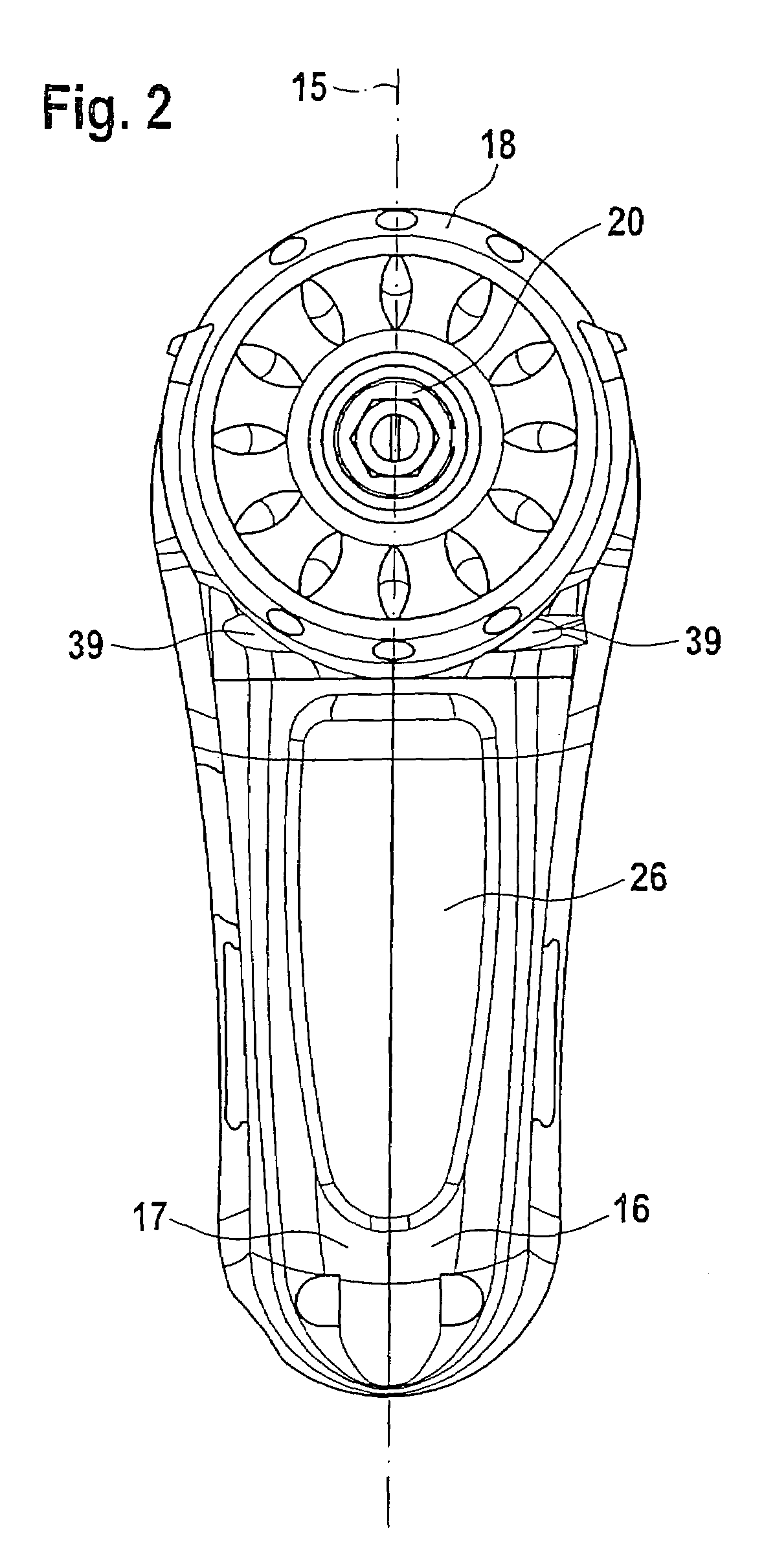

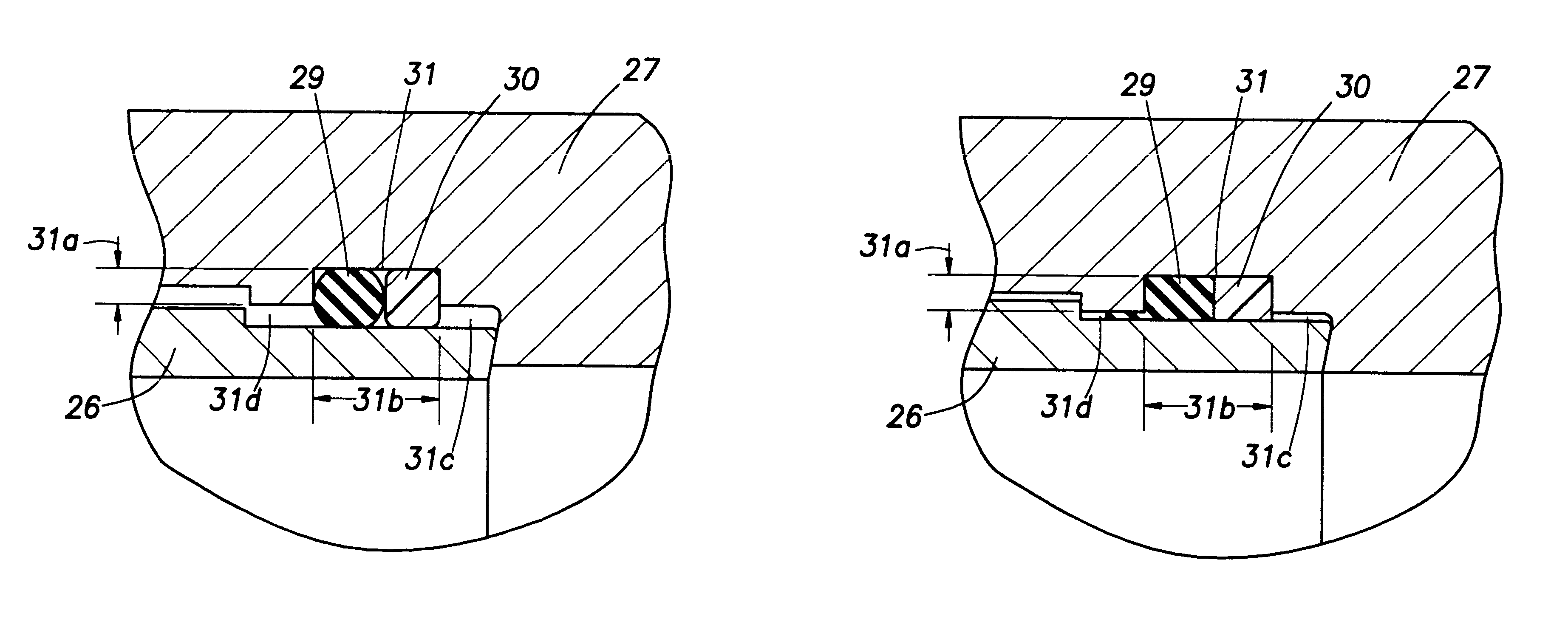

Power tool gear-train and torque overload clutch therefor

A power tool transmission is described in which an overload clutch mechanism is arranged to provide a relatively compact power tool. A torque adjustment dial is arranged between the visible portions of the motor housing and the gearbox, and the dial is coupled to a compression spring such that rotation of the dial cause the spring to be compressed or decompressed, thereby adjusting the torque at which the clutch overloads and ratchets. The compression spring is arranged at least partially between the motor and gearbox or gear train, in a space which conventional power tools do not utilized for this purpose. Thus, the dimensions of the power tool's transmission can be reduced with respect to conventional power tools. Furthermore, the space on the gearbox immediately behind a chuck can be used for another purpose other than accommodating the adjustment collar, as is the case with conventional power tools.

Owner:BLACK & DECKER INC

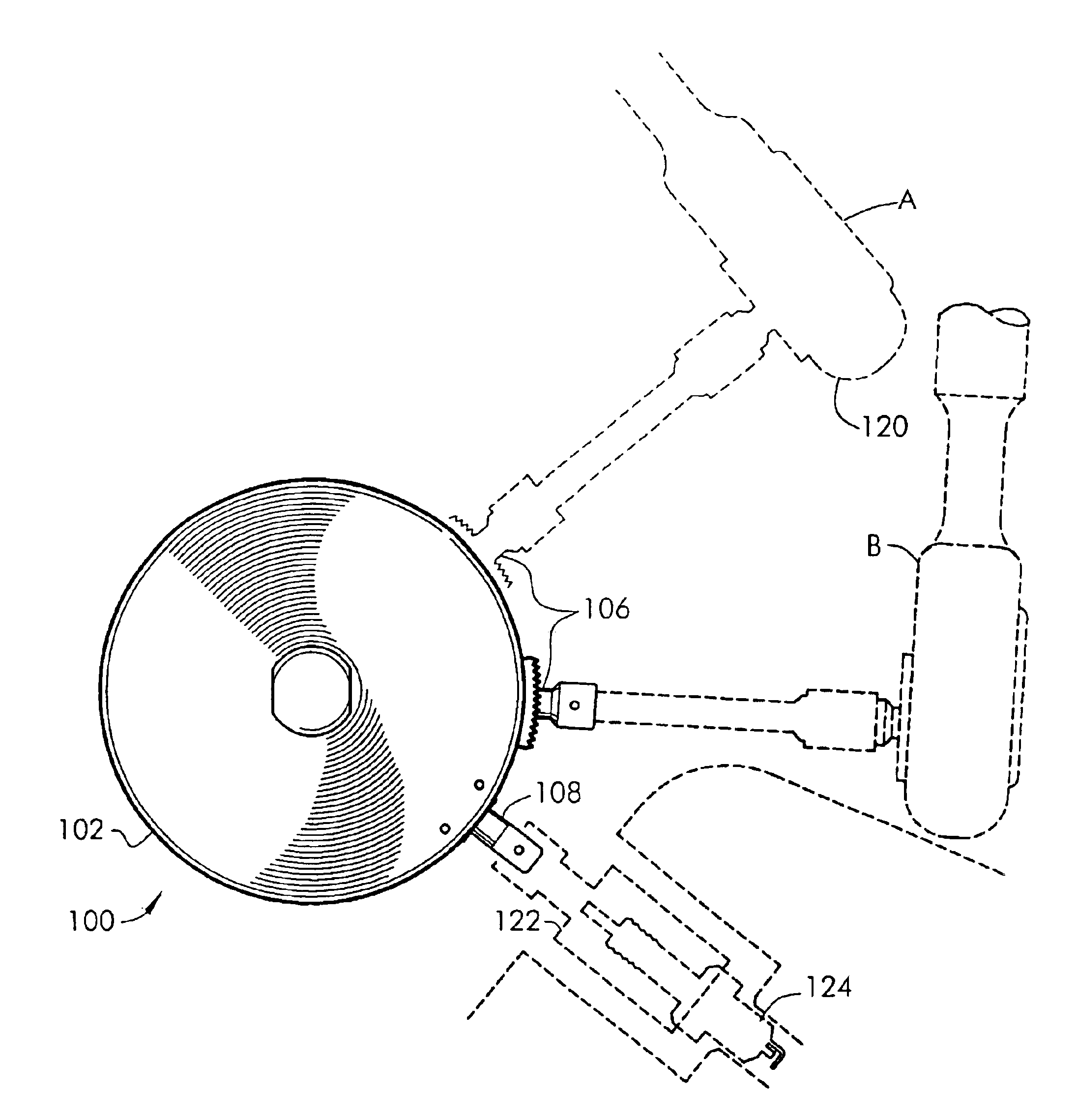

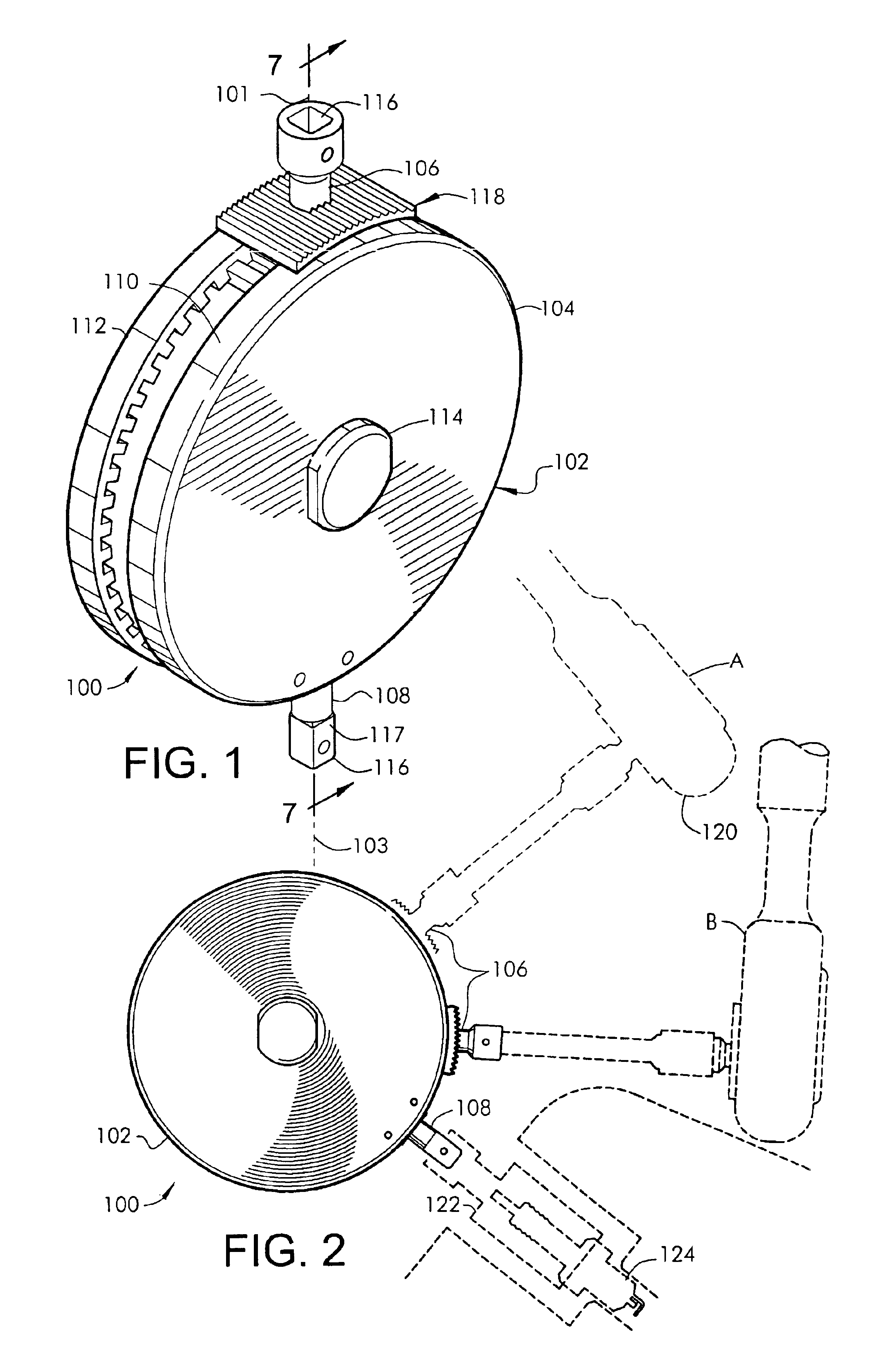

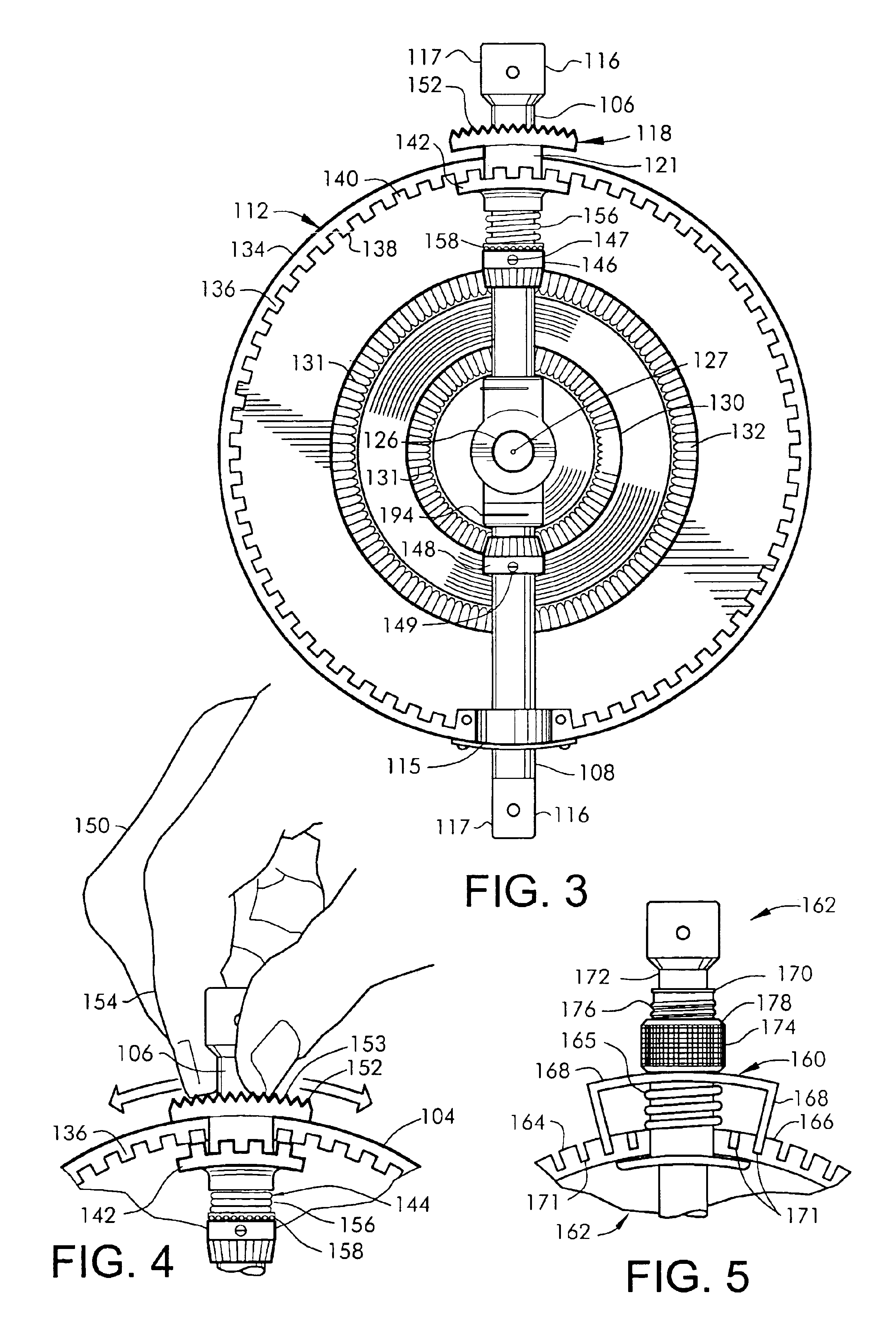

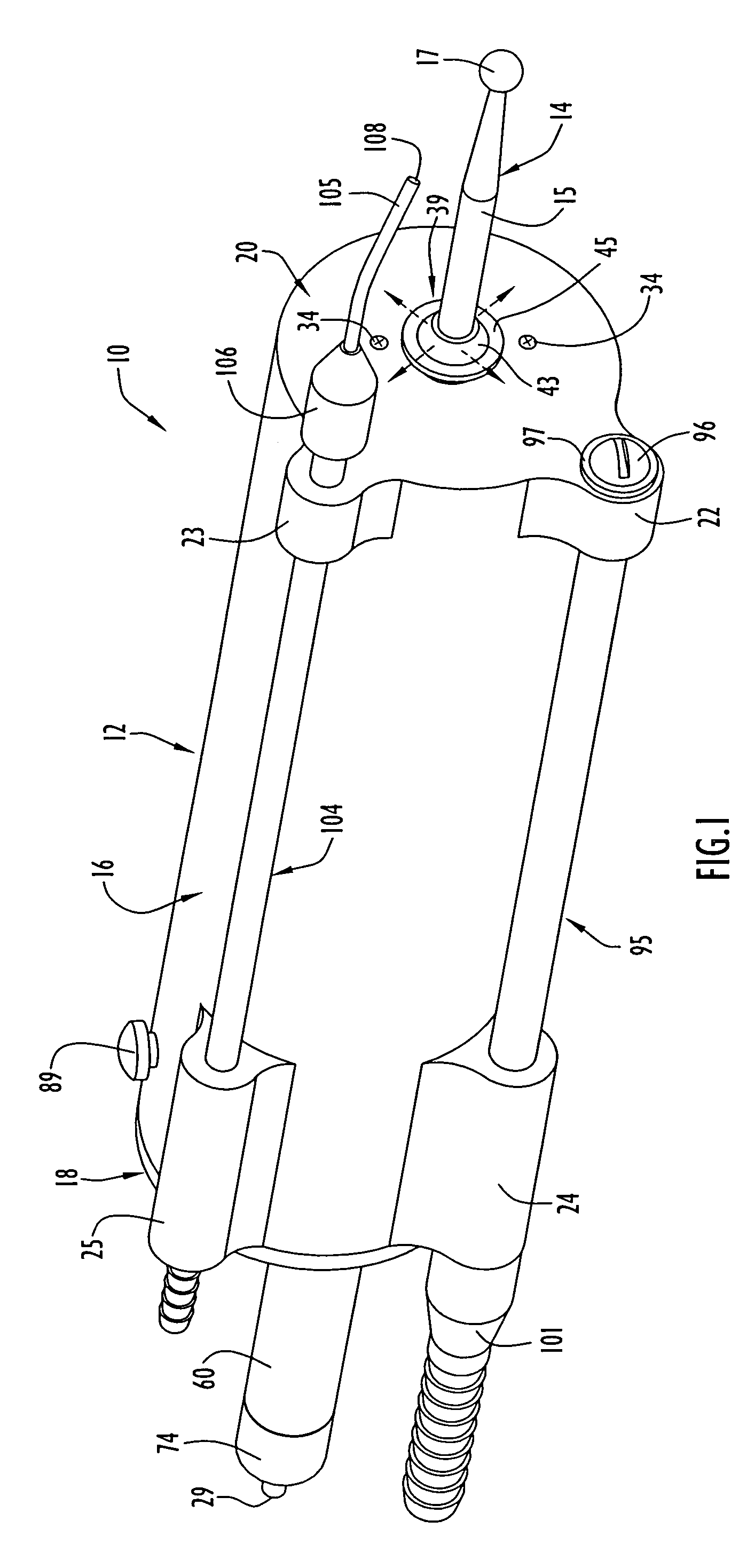

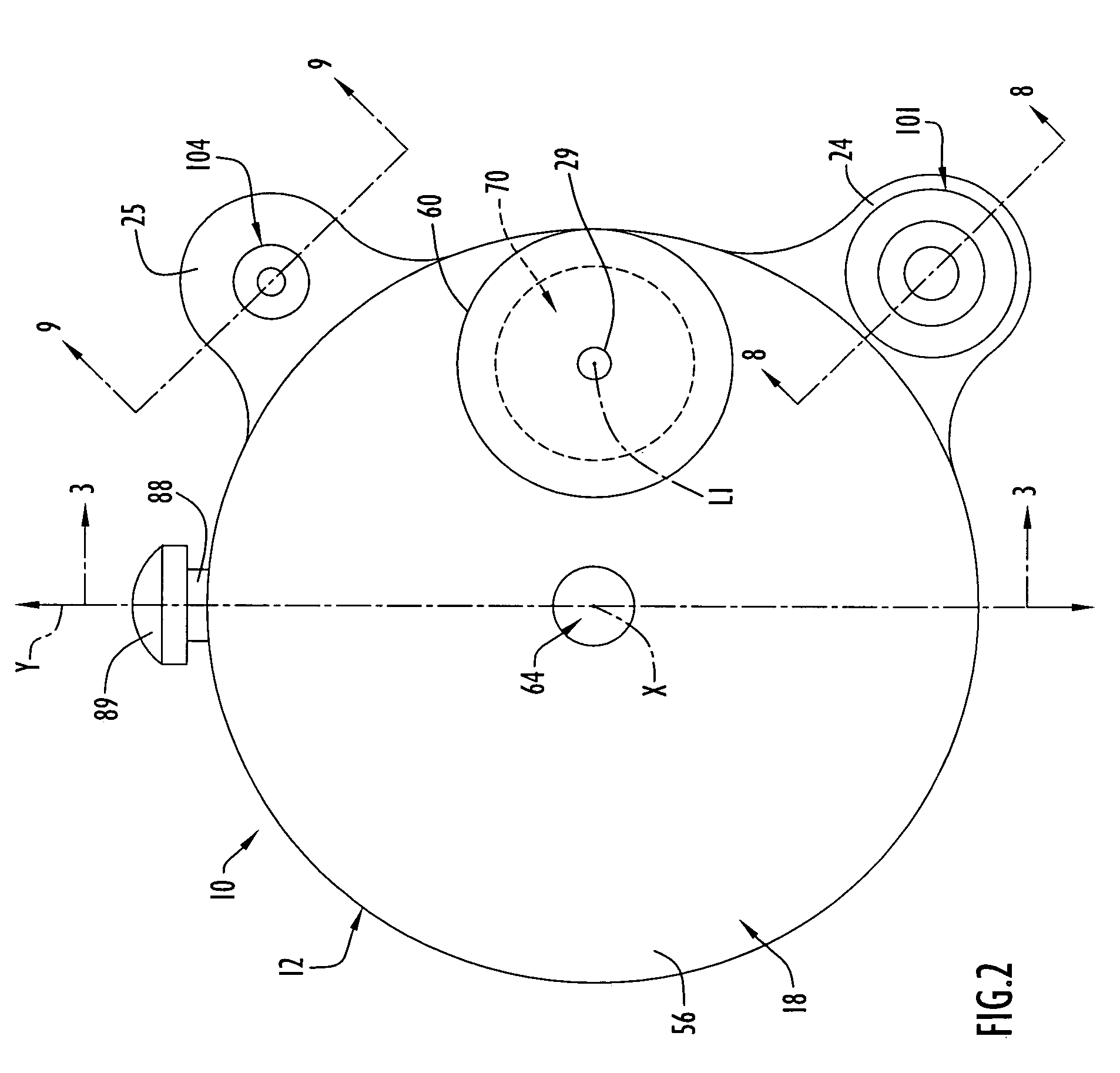

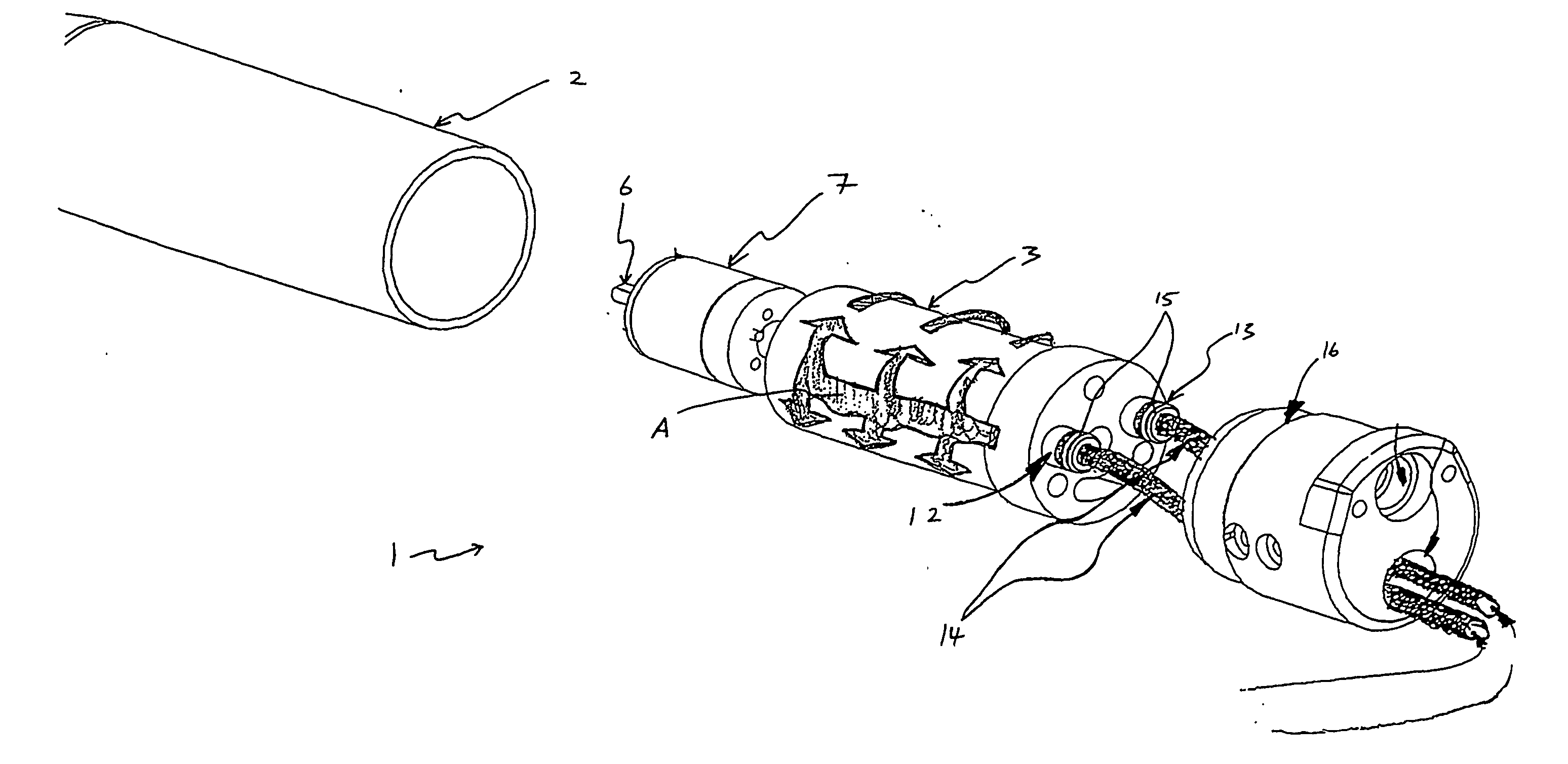

Tool drive system

A tool drive system for transferring rotational power from a rotational tool, such as a drill or ratchet, to at least one input drive shaft which then transfers the power to at least one output drive shaft. The angle of at least one input drive shaft being adjustable relative to at least one output shaft. The tool drive system comprises a round housing with an angle adjuster attached to the input shaft that assists in adjusting and locking the angle of the input shaft relative to the output shaft in an almost circular span. The input and output shafts may be positioned in a user-selected gear ratio from the input to output shafts or vice versa.

Owner:ULLAH RIZWAN

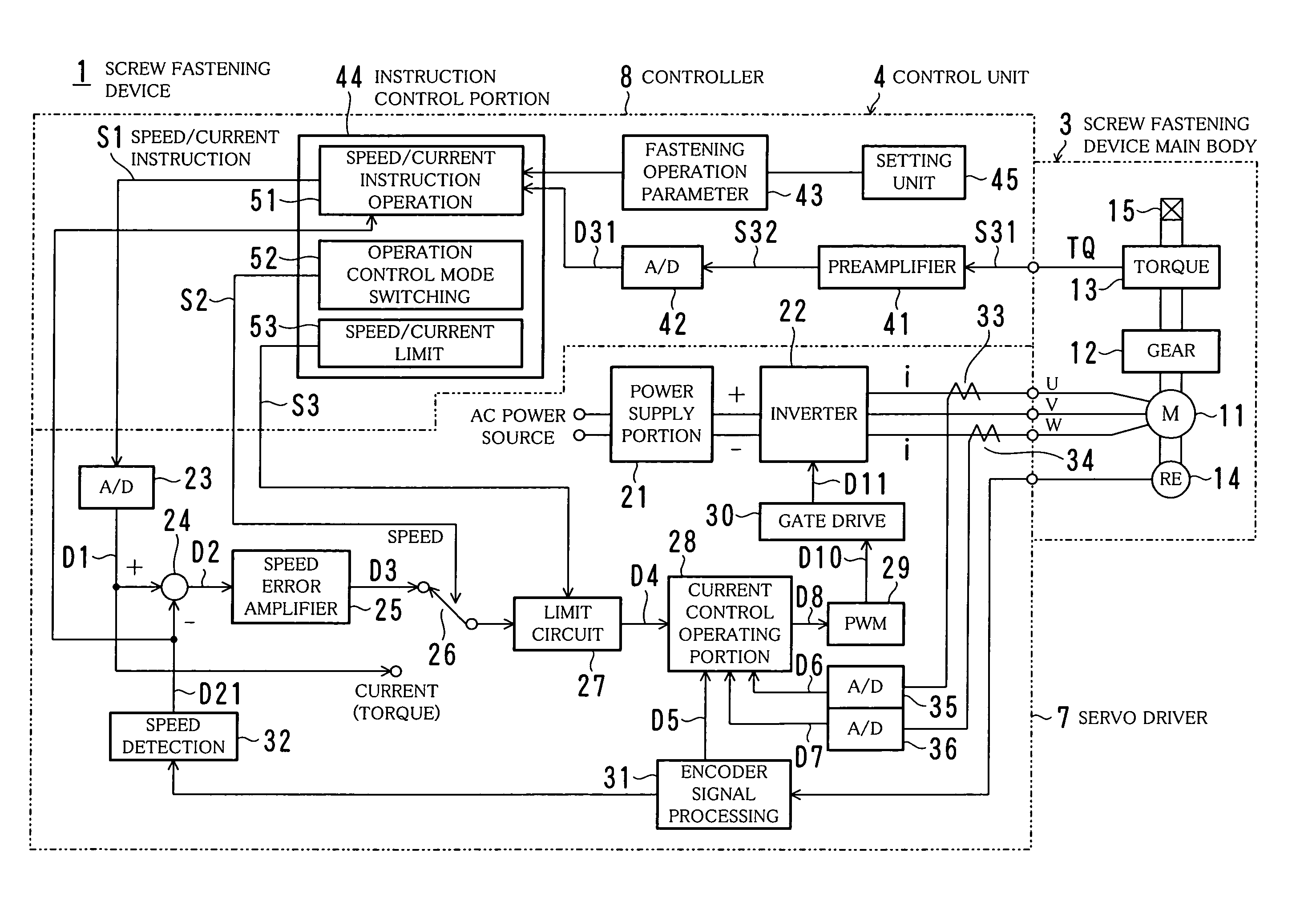

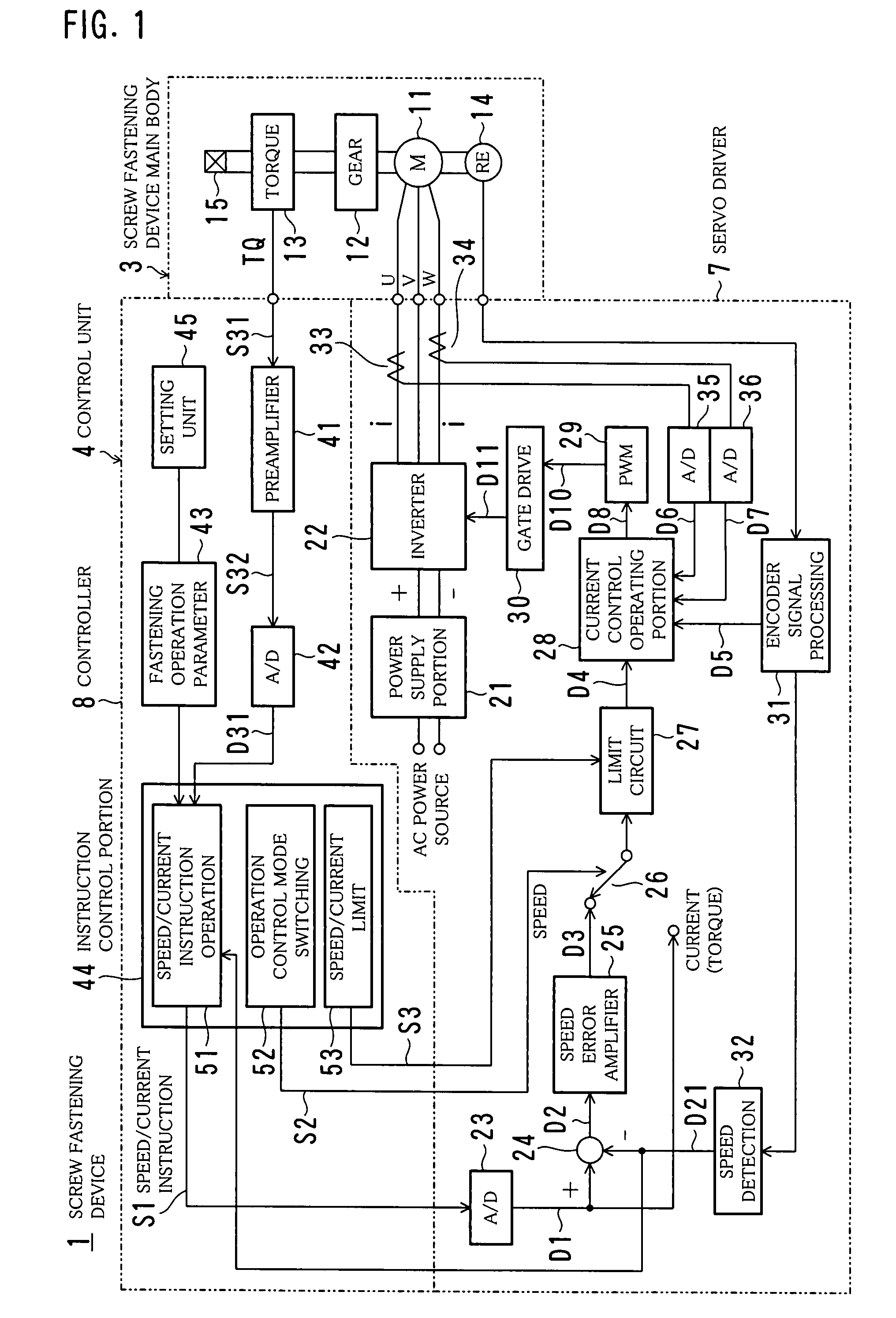

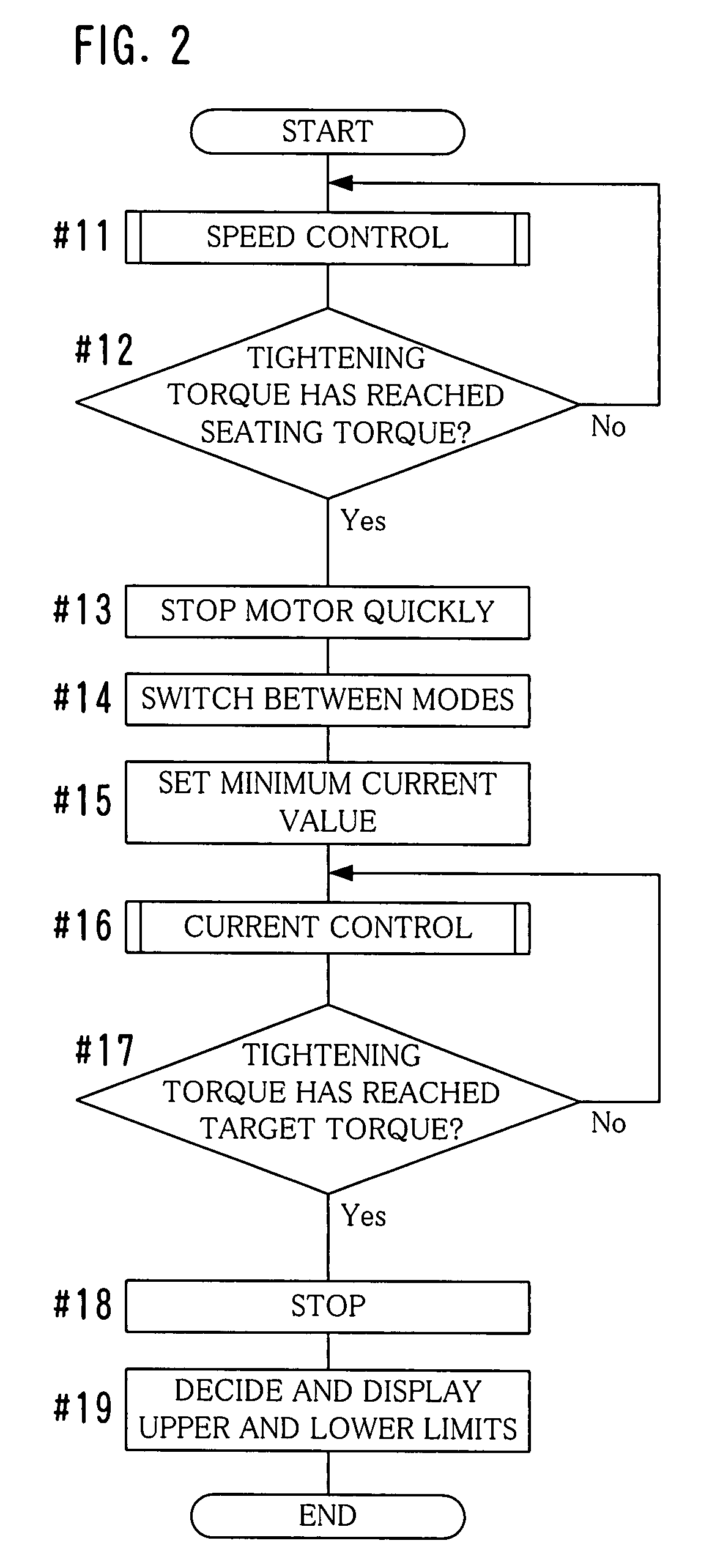

Control method and control unit for impact type screw fastening device

ActiveUS7770658B2Improve accuracyImprove fastening accuracyDrilling rodsConstructionsControl theoryElectrical current

An object is to improve accuracy of tightening torque and to shorten time necessary for fastening a screw in an impact type screw fastening device that uses an electric motor as a rotation driving source. A control method for the impact type screw fastening device that uses an electric motor as a rotation driving source includes the steps of driving the motor to rotate by supplying current to the motor intermittently so that torque exerted on a load by rotation of the motor becomes like pulses on the time axis, and controlling the current of every time of each pulse so that an increment of every time of each pulse of the torque after the torque reaches a target approach torque TQN that is a first set value becomes smaller than that before it reaches the target approach torque TQN.

Owner:ESTIC CORP

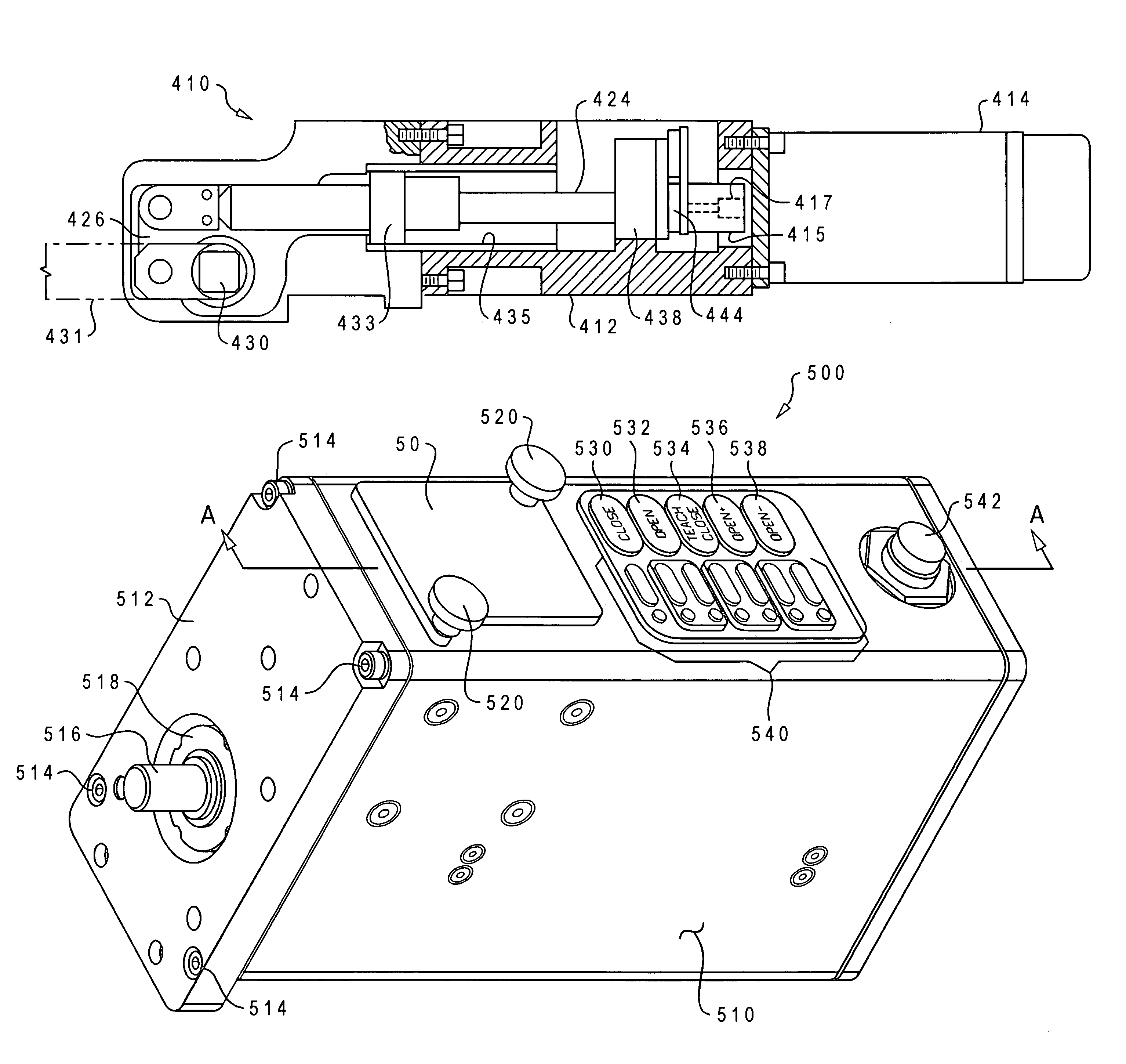

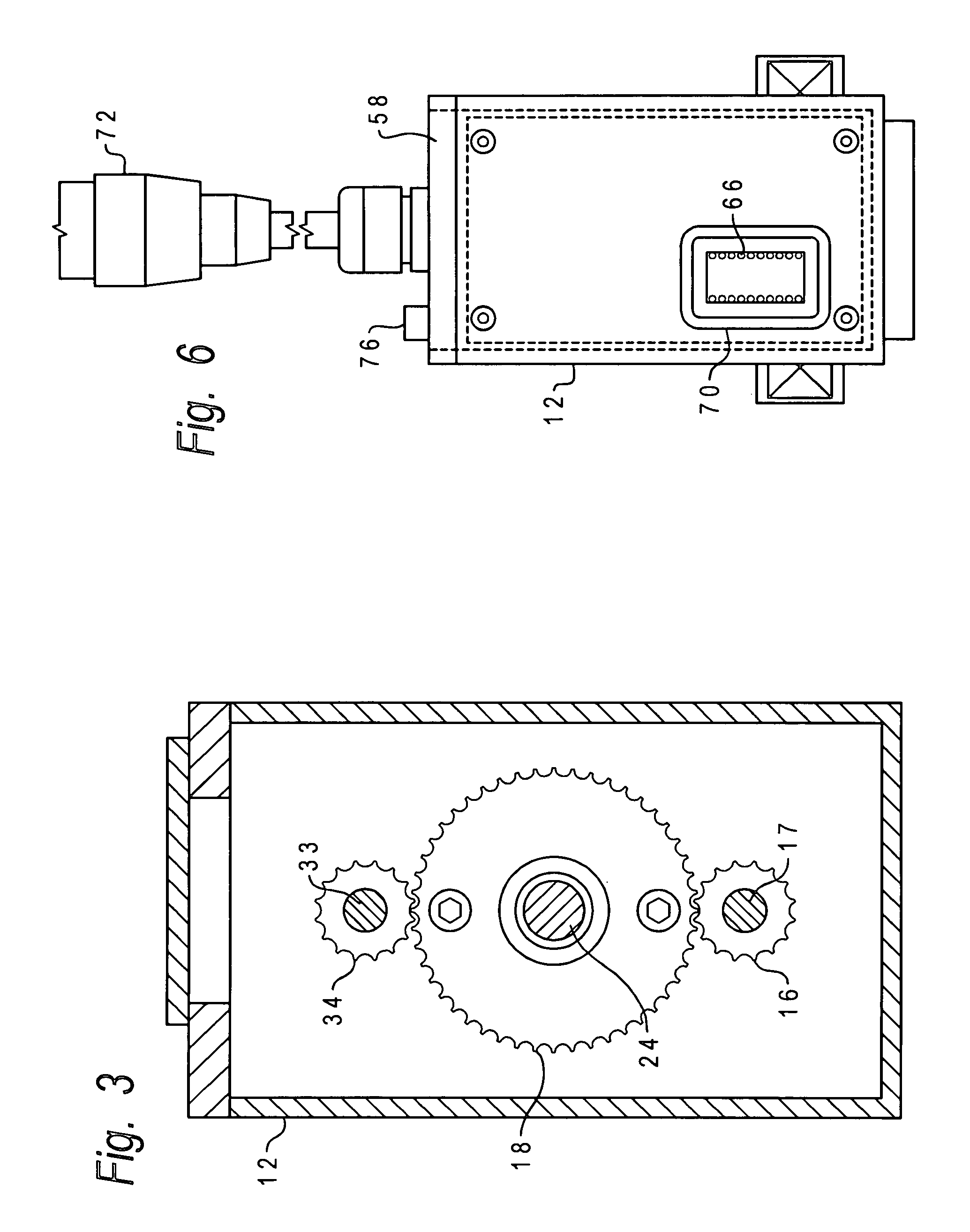

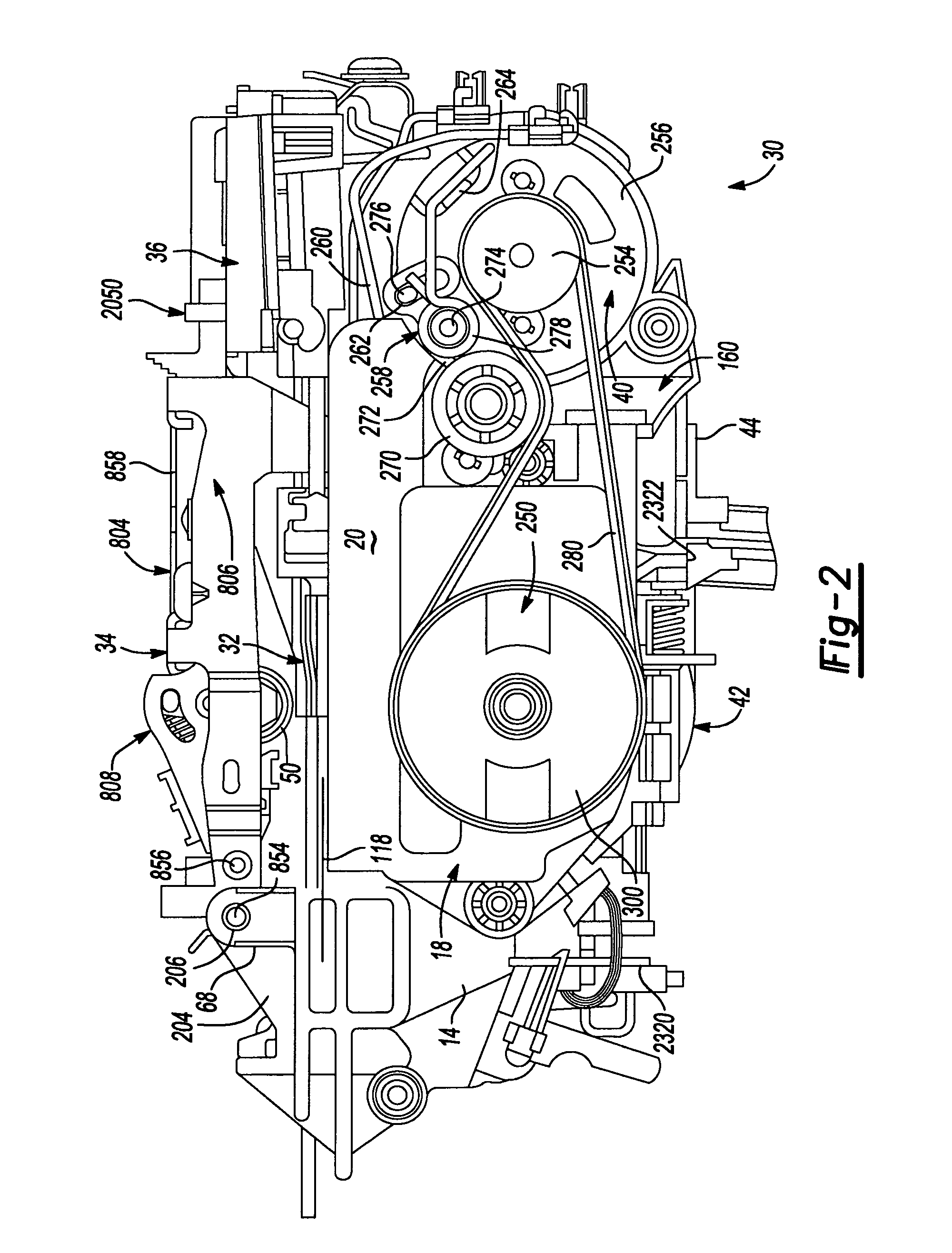

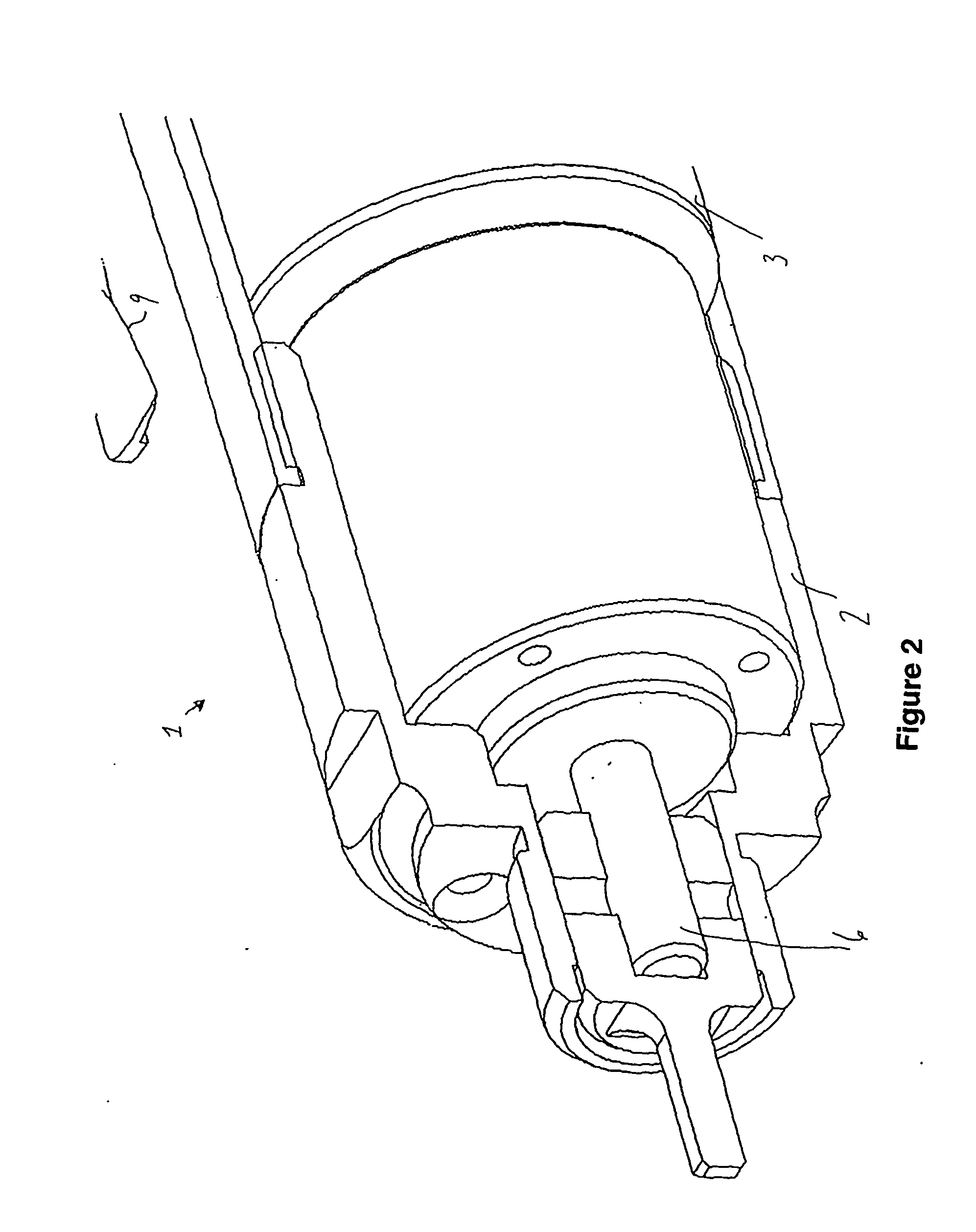

Motor pack for automated machinery

A motor pack for an electrically driven tool includes at least one electric motor and a linearly displaceable member coupled to the electric motor such that the linearly displaceable member is displaced axially by operation of the at least one electric motor. The motor pack further includes a housing enclosing the electric motor and at least partially enclosing the linearly displaceable member. The housing includes a front plate to which a tool head may be removably coupled. The front plate has an aperture formed therein through which the linearly displaceable element can be coupled to a moveable element in the tool head. The motor pack also includes tool control circuitry enclosed within the housing and electrically coupled to the electric motor to control operation thereof.

Owner:DELAWARE CAPITAL FORMATION INC +1

Automatic transmission for a power tool

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

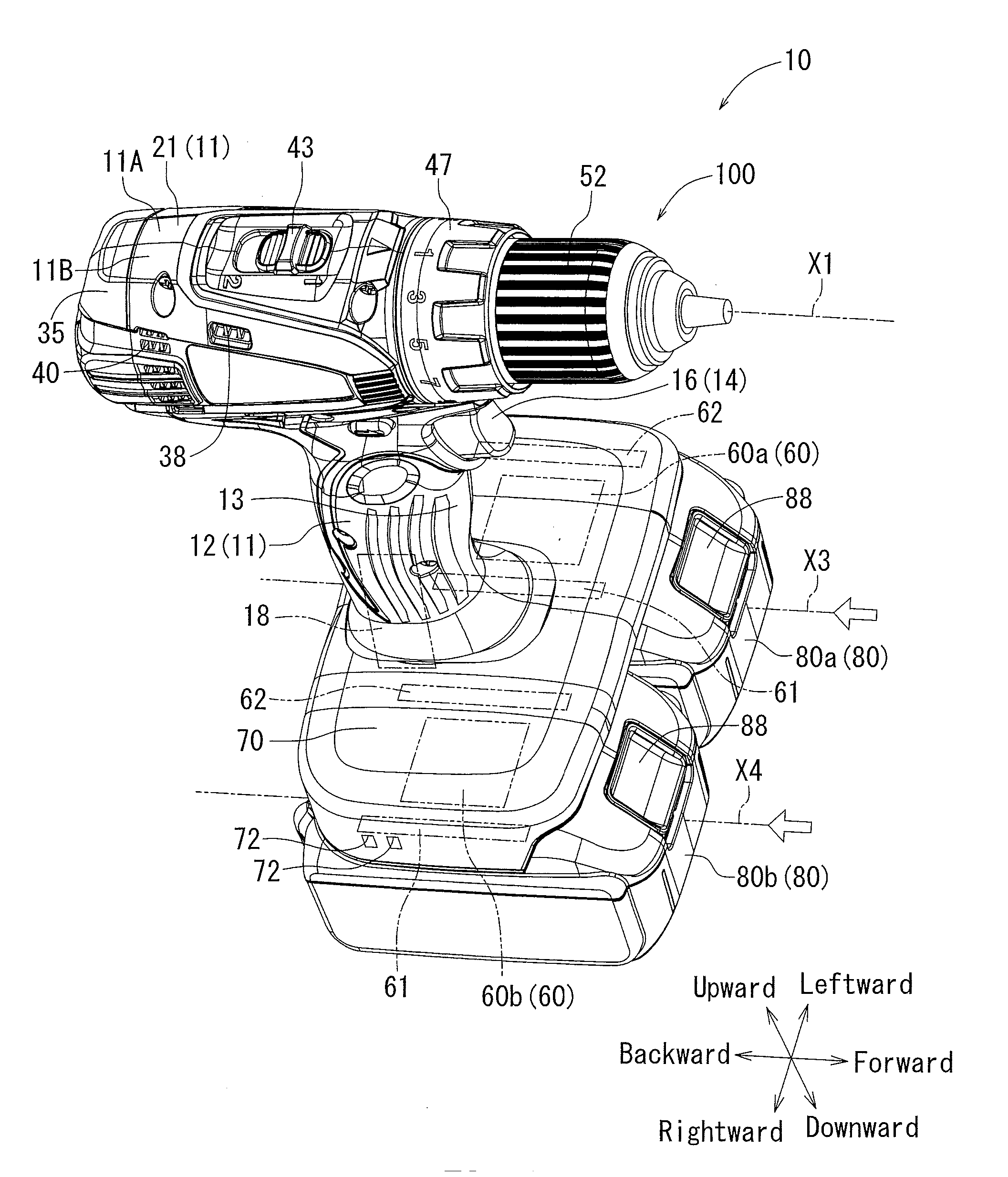

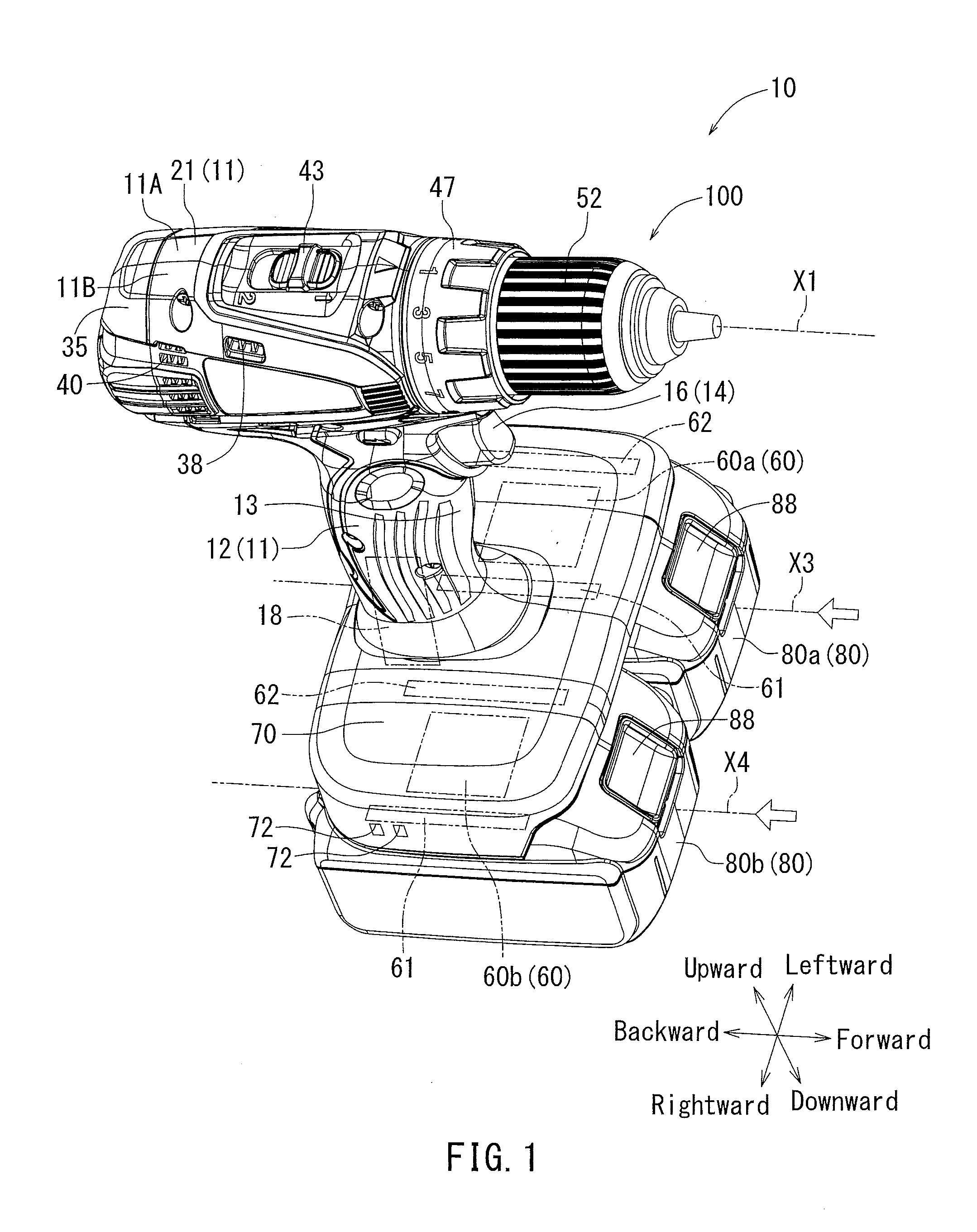

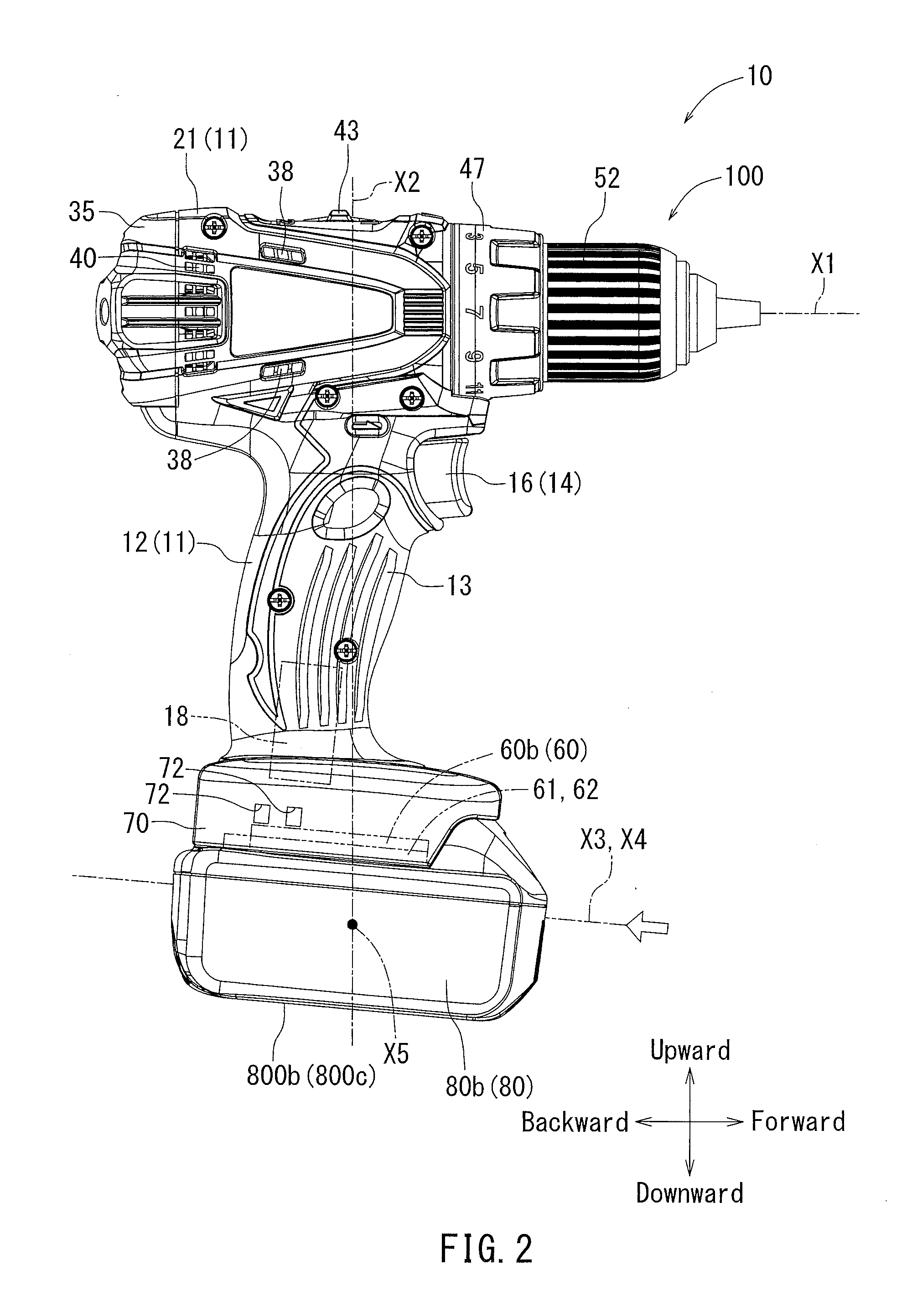

Power tool

InactiveUS9731410B2Simplify device configurationEasy to understandDrilling rodsConstructionsHand heldEngineering

Owner:MAKITA CORP

Motorized surgical handpiece

A motorized surgical handpiece comprises a housing enclosing an interior containing a motor and an output shaft for being driven in rotation by the motor. The output shaft has a central longitudinal axis, a bore extending therethrough for receiving a shank of a surgical tool to be rotatably driven by the output shaft, a forward end portion extending forwardly beyond the motor and a rearward end portion extending rearwardly beyond the motor. The housing has a continuous lumen extending entirely therethrough formed in part by the output shaft bore for insertion of a bore brush through the lumen for cleaning when the surgical tool is removed from the handpiece. The handpiece has forward and rearward labyrinth seals comprising rotor components respectively attached to the forward and rearward end portions of the output shaft for rotation in corresponding stator components with there being a labyrinthine clearance between each rotor component and its stator component to receive pressurized air during use and during cleaning of the handpiece to avoid the entry of contaminants.

Owner:ROGERS WILLIAM G

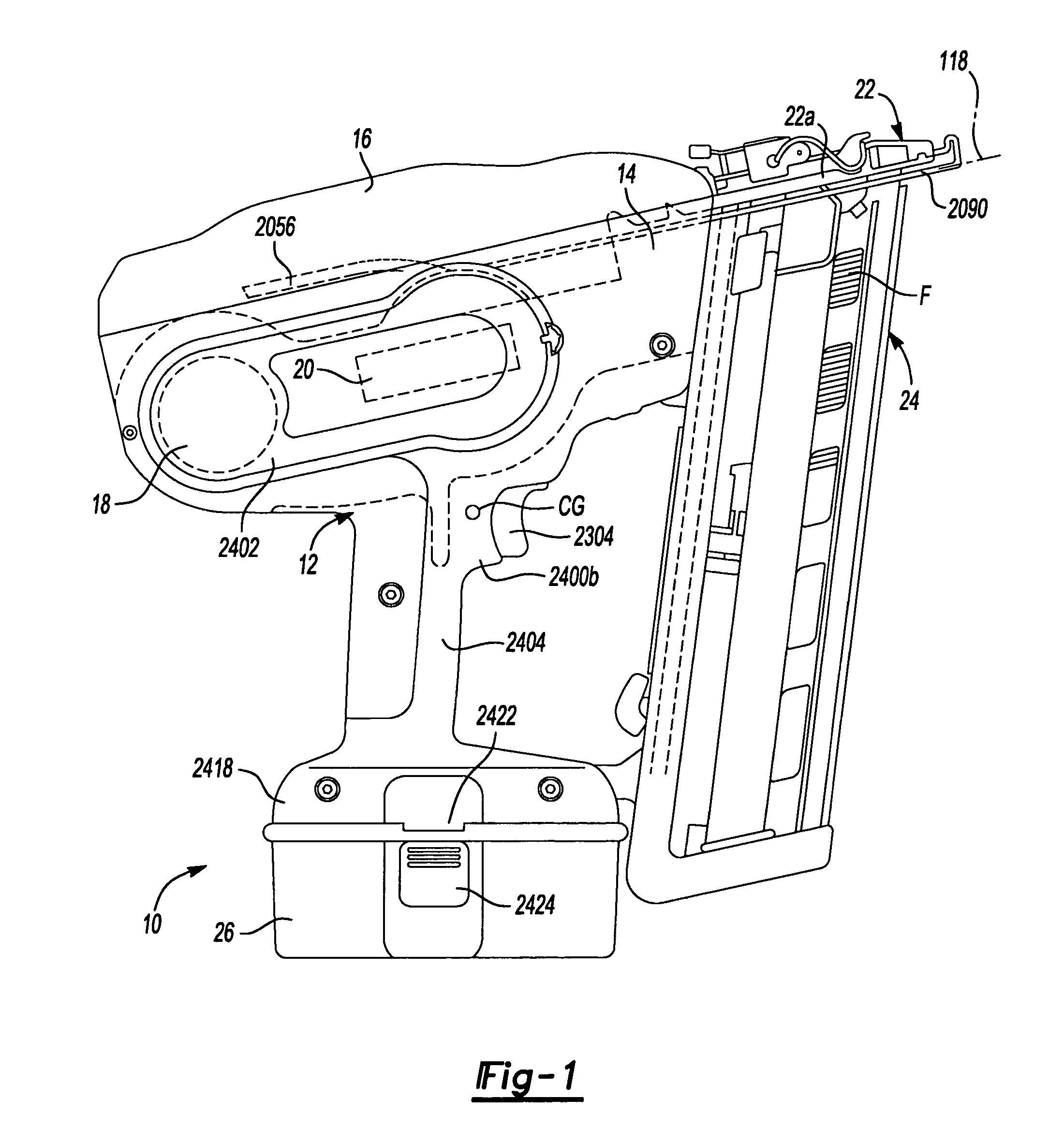

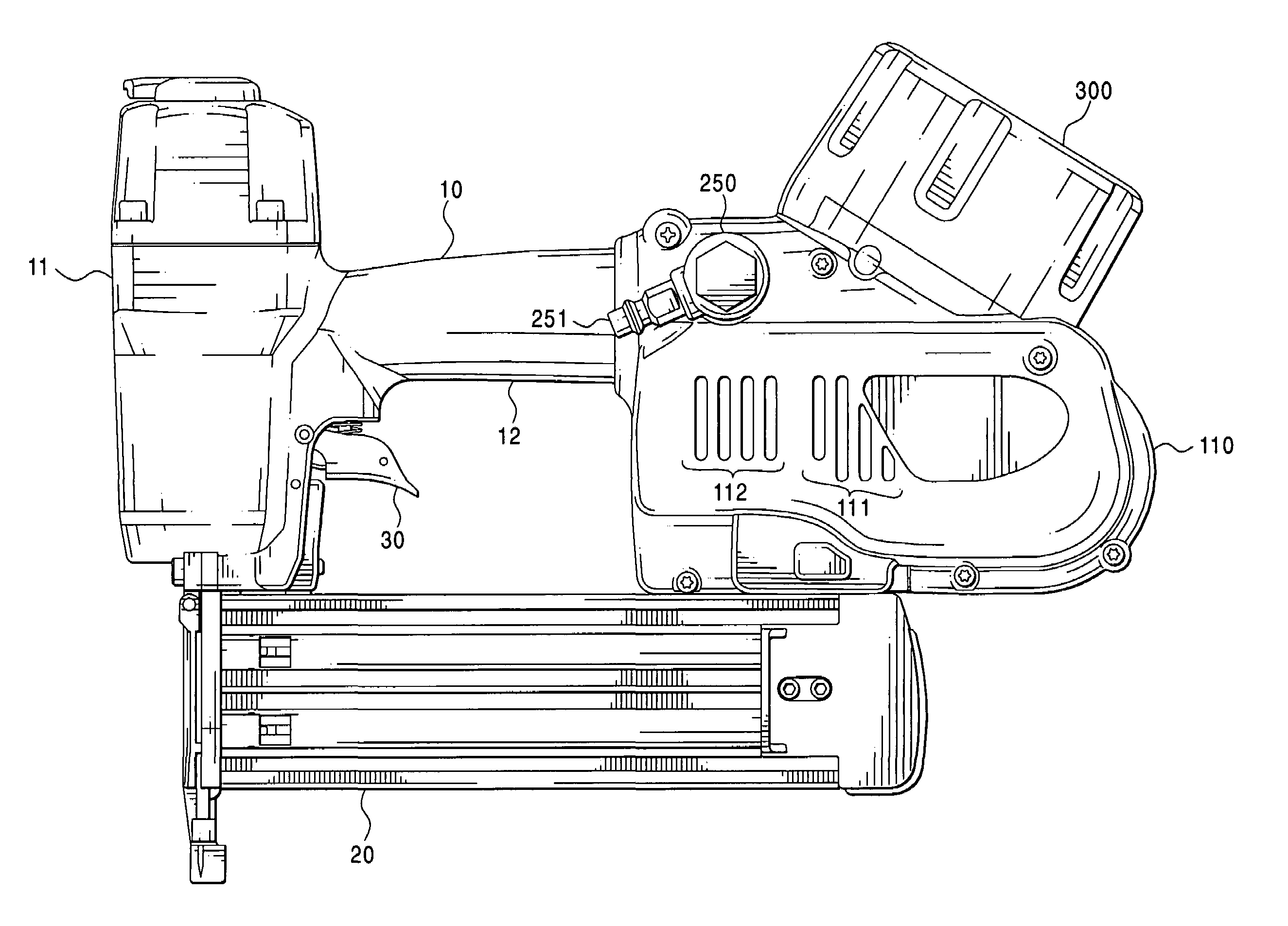

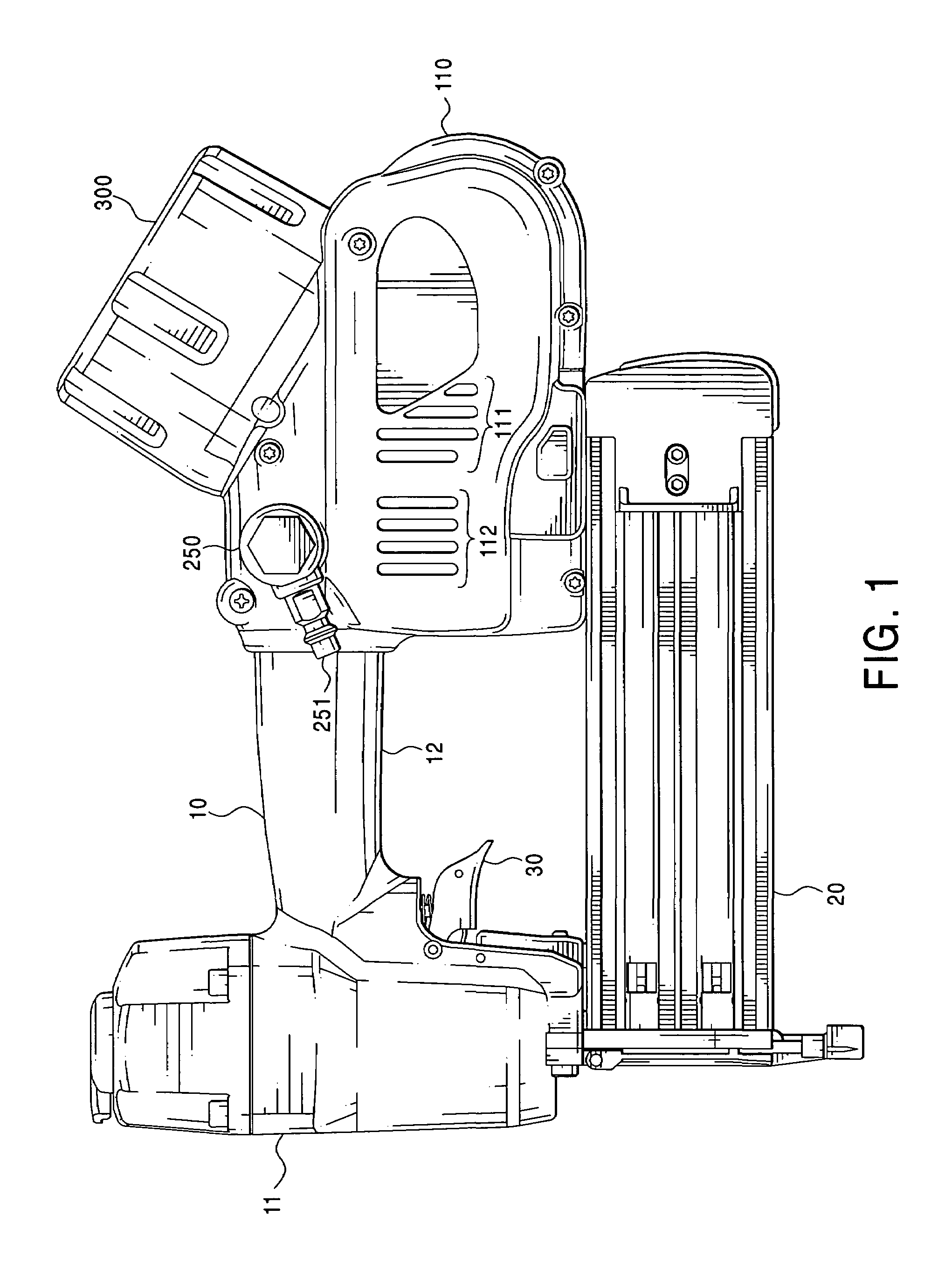

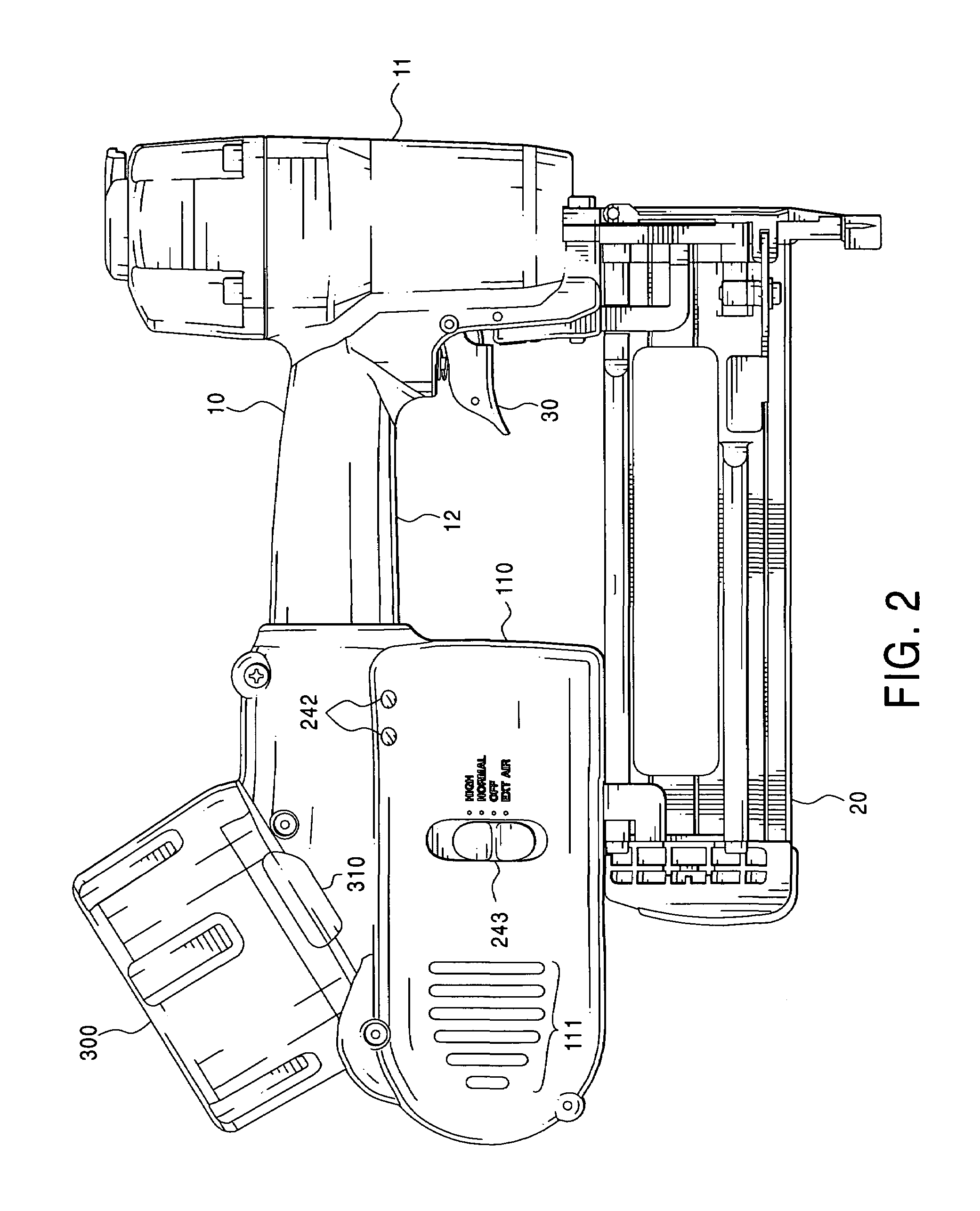

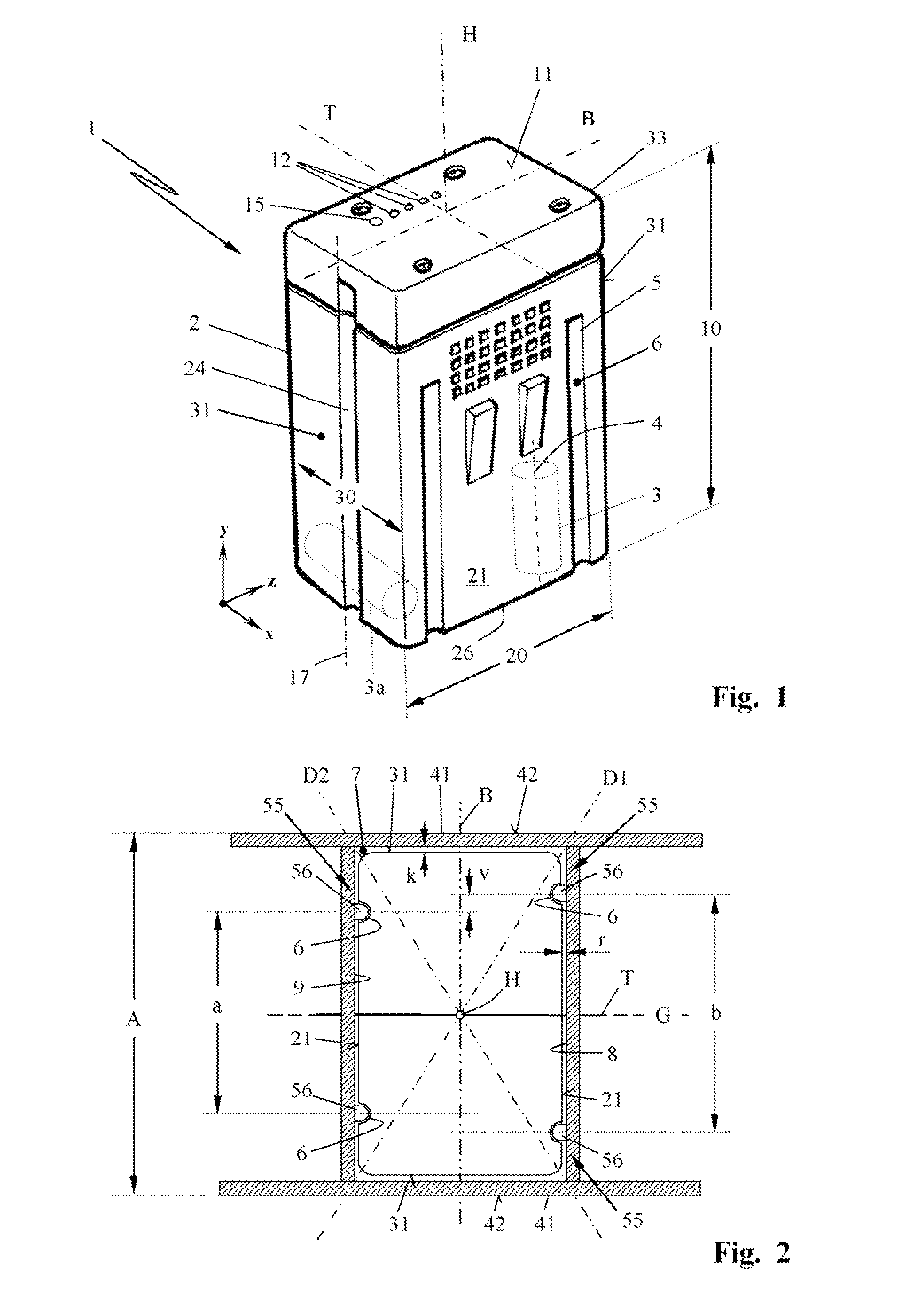

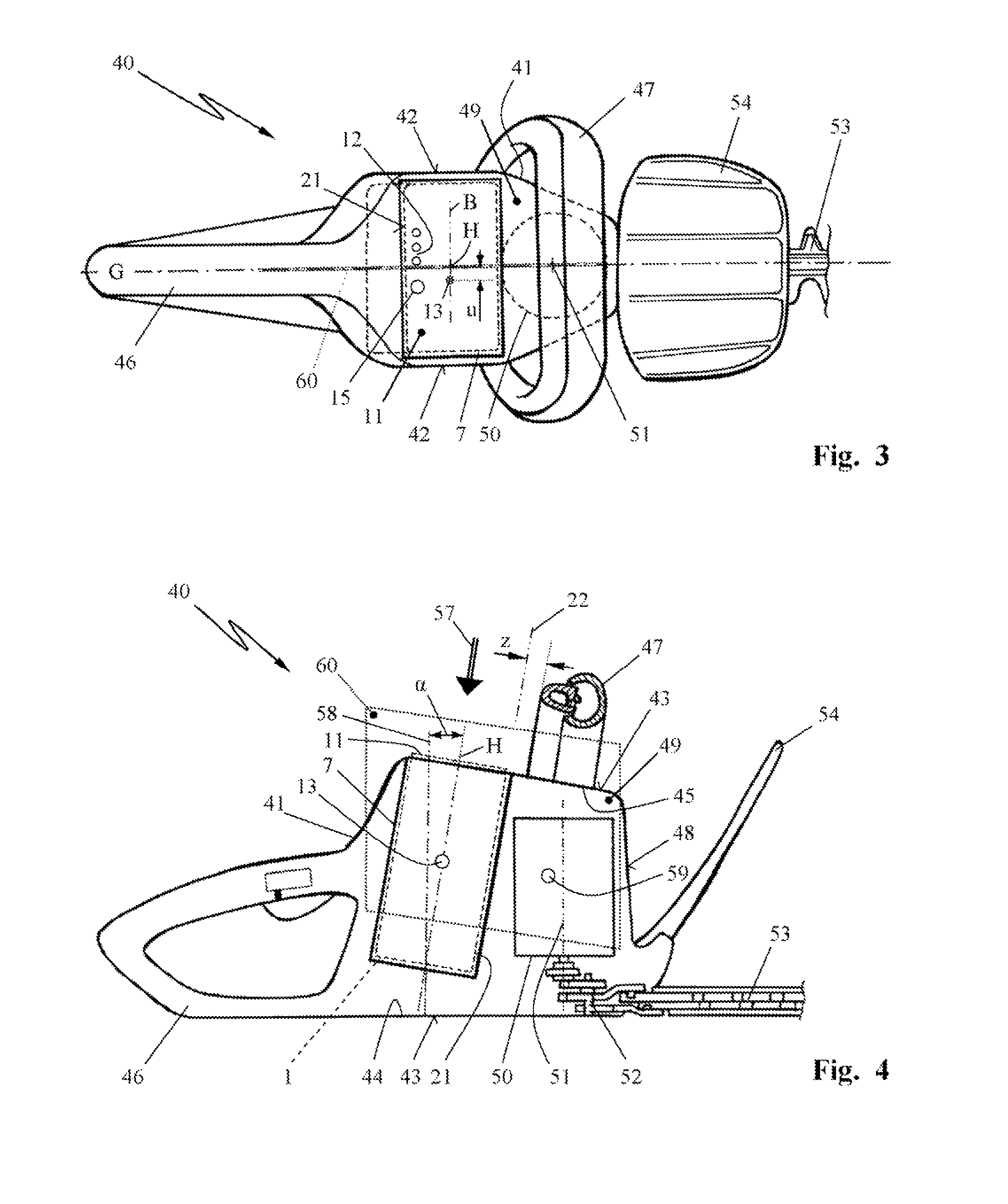

Lock-out for activation arm mechanism in a power tool

A power tool, such as a nailer, having a driver, a flywheel and an activation arm for selectively driving the driver into contact with the flywheel to transfer energy therebetween to cause the driver to translate. The power tool includes a bar that may be moved so as to resist movement of the activation arm in a direction that would bring the driver into contact with the flywheel. A method for operating a power tool is also provided.

Owner:BLACK & DECKER INC

Portable, battery-powered air compressor for a pneumatic tool system

Owner:BLACK & DECKER INC +1

Powered Hand Tool

The invention relates to a hand tool for use with attachments. The hand tools of the invention may be used with attachments with various speed and torque requirements. Preferred hand tools comprise a body with a brushless DC motor and means. which control the energisation of the motor. In use the brushless DC motor of the preferred hand tool is electrically supplied to drive a power output means connected to said motor. Another preferred hand tool comprises a body with a motor contained therein, a void space between an internal surface of the body and at least a part of the motor, a fluid inlet port provided and a fluid outlet port provided in or on the body, and ducting means which provides a channel for fluid supplied via the fluid inlet port to and from the void space and then on to the fluid outlet port.

Owner:IBEX INDS

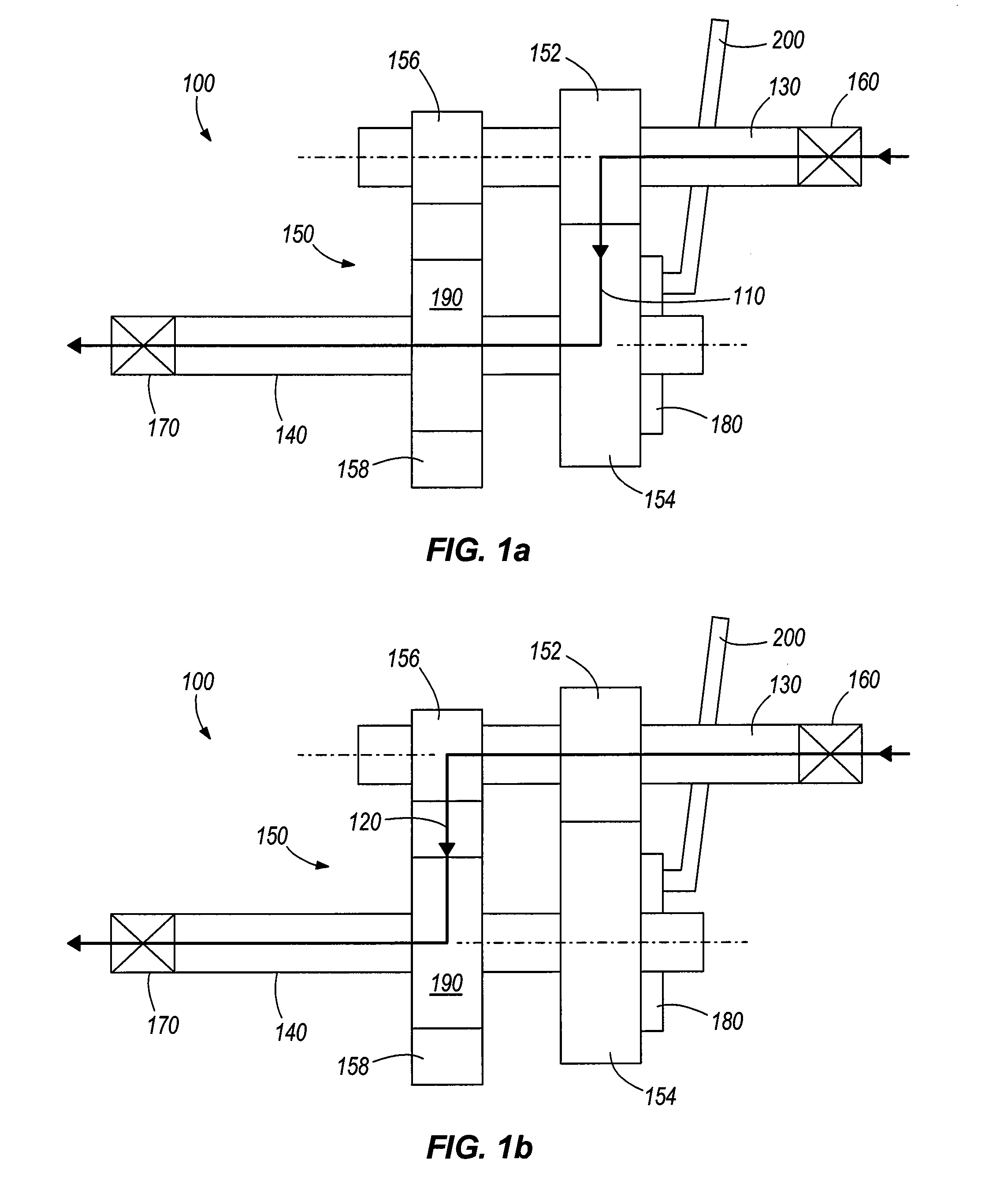

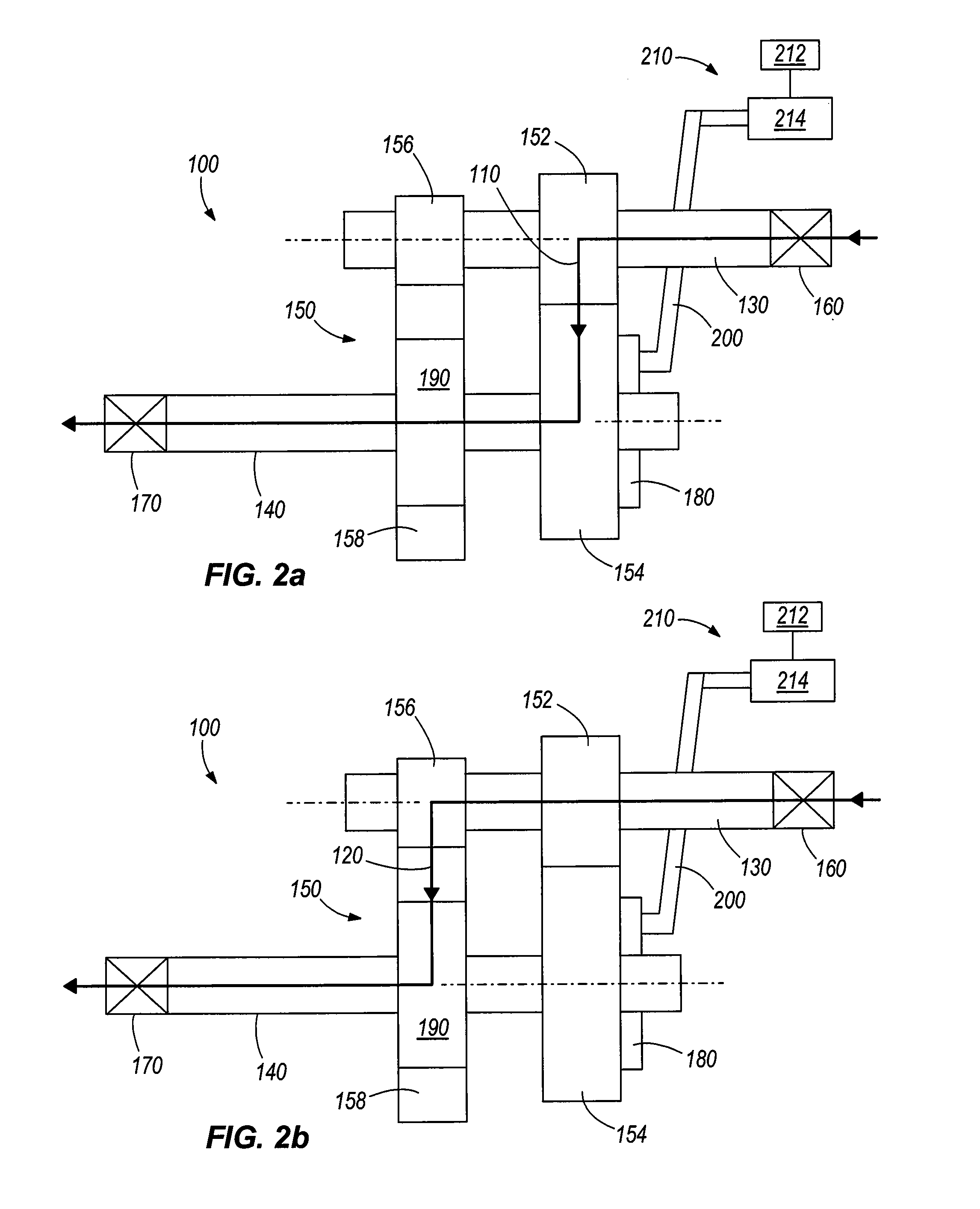

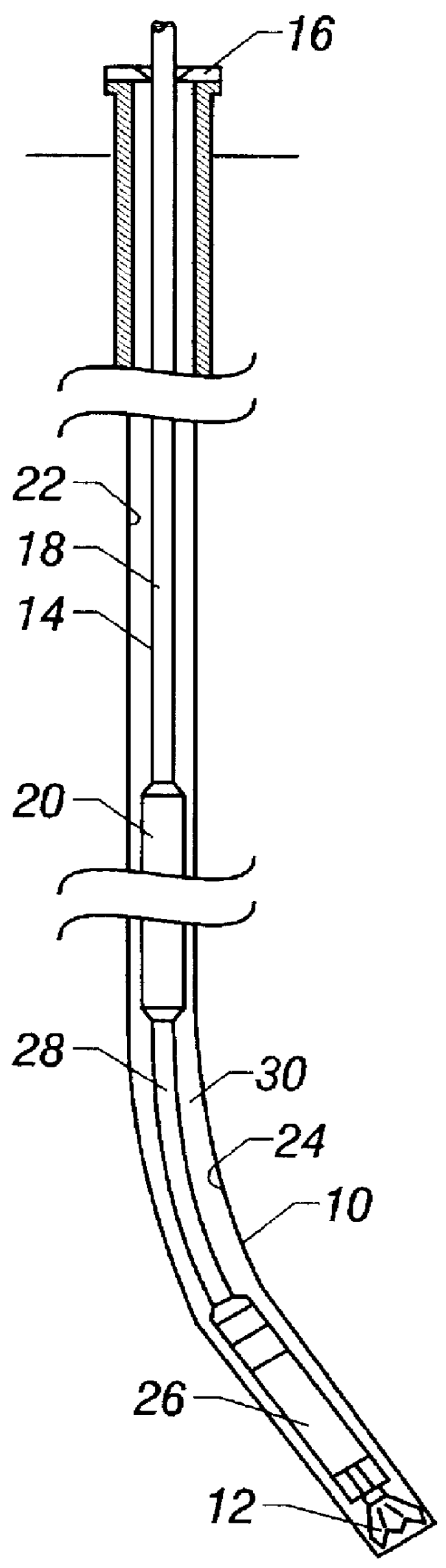

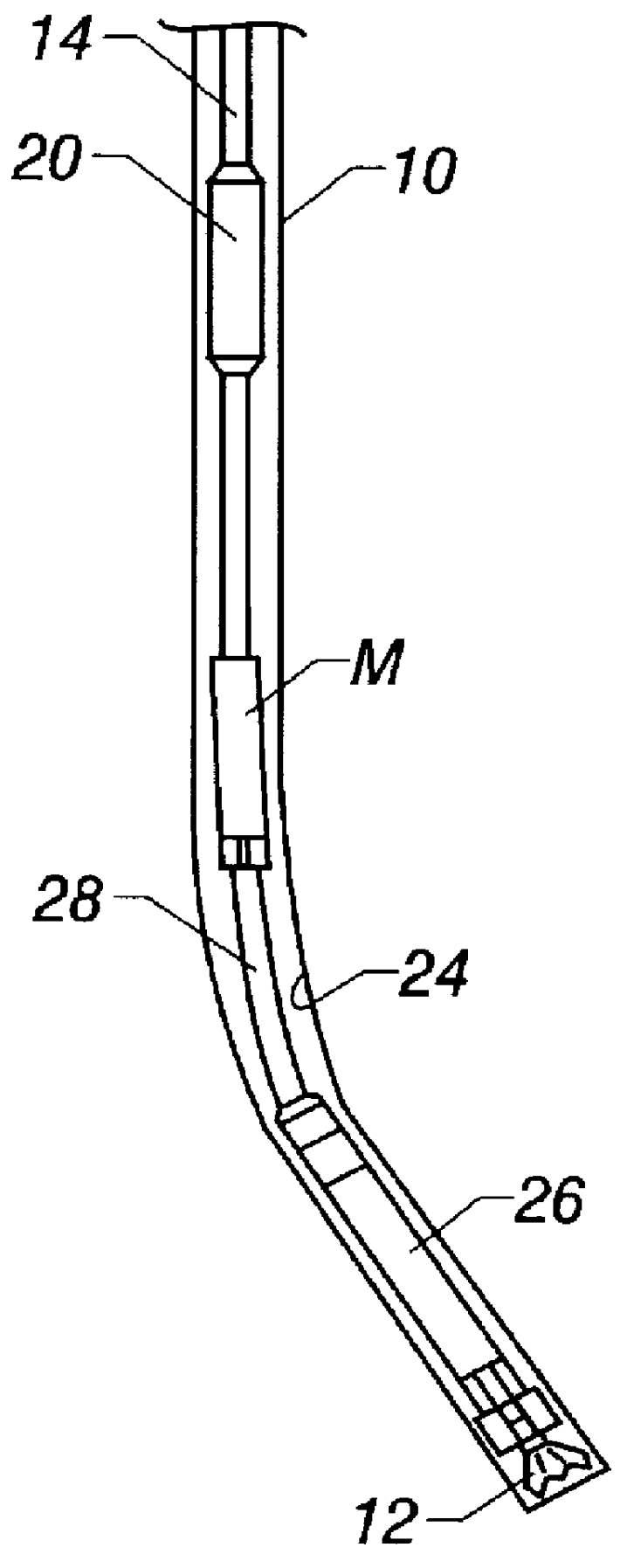

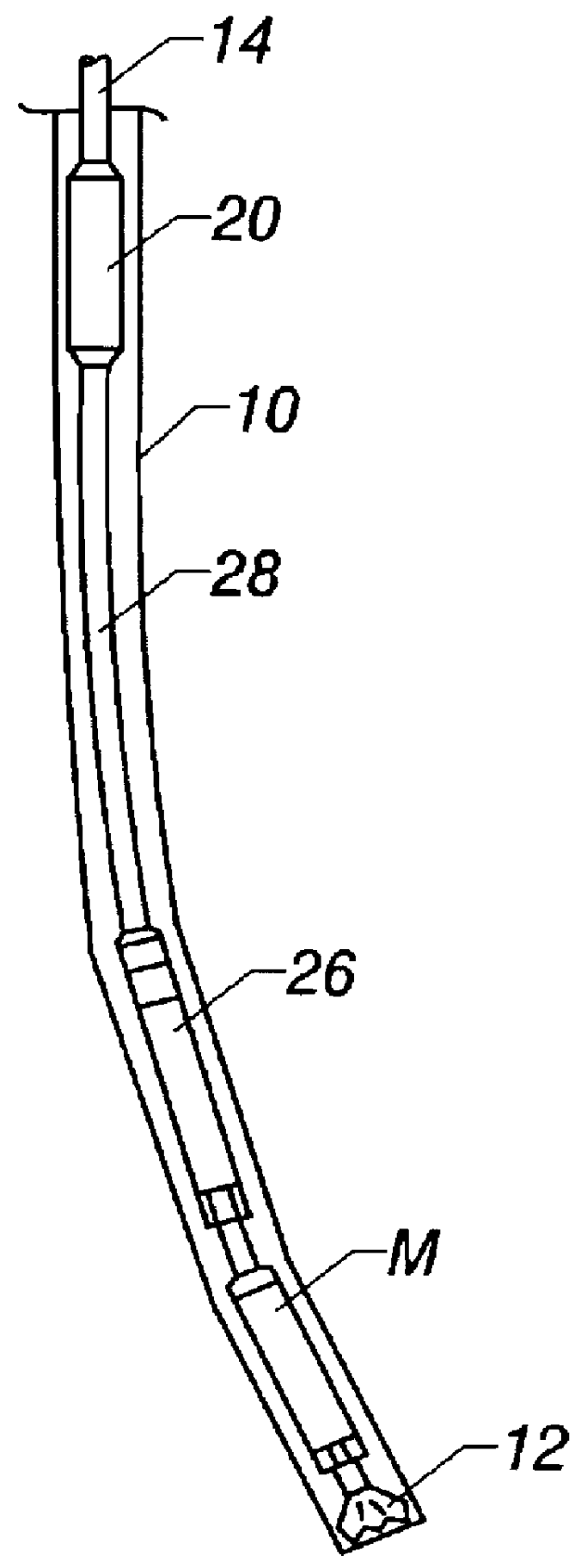

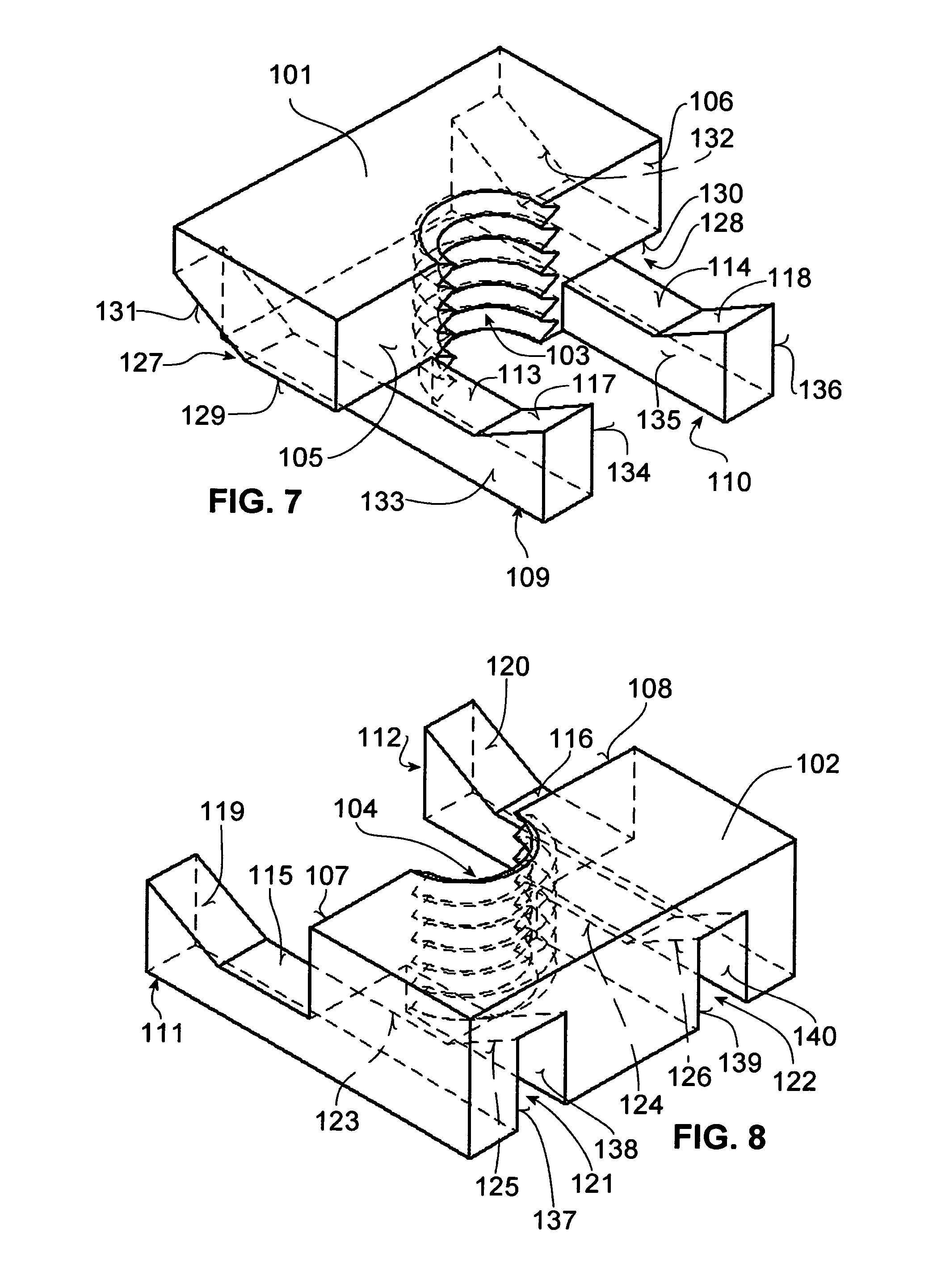

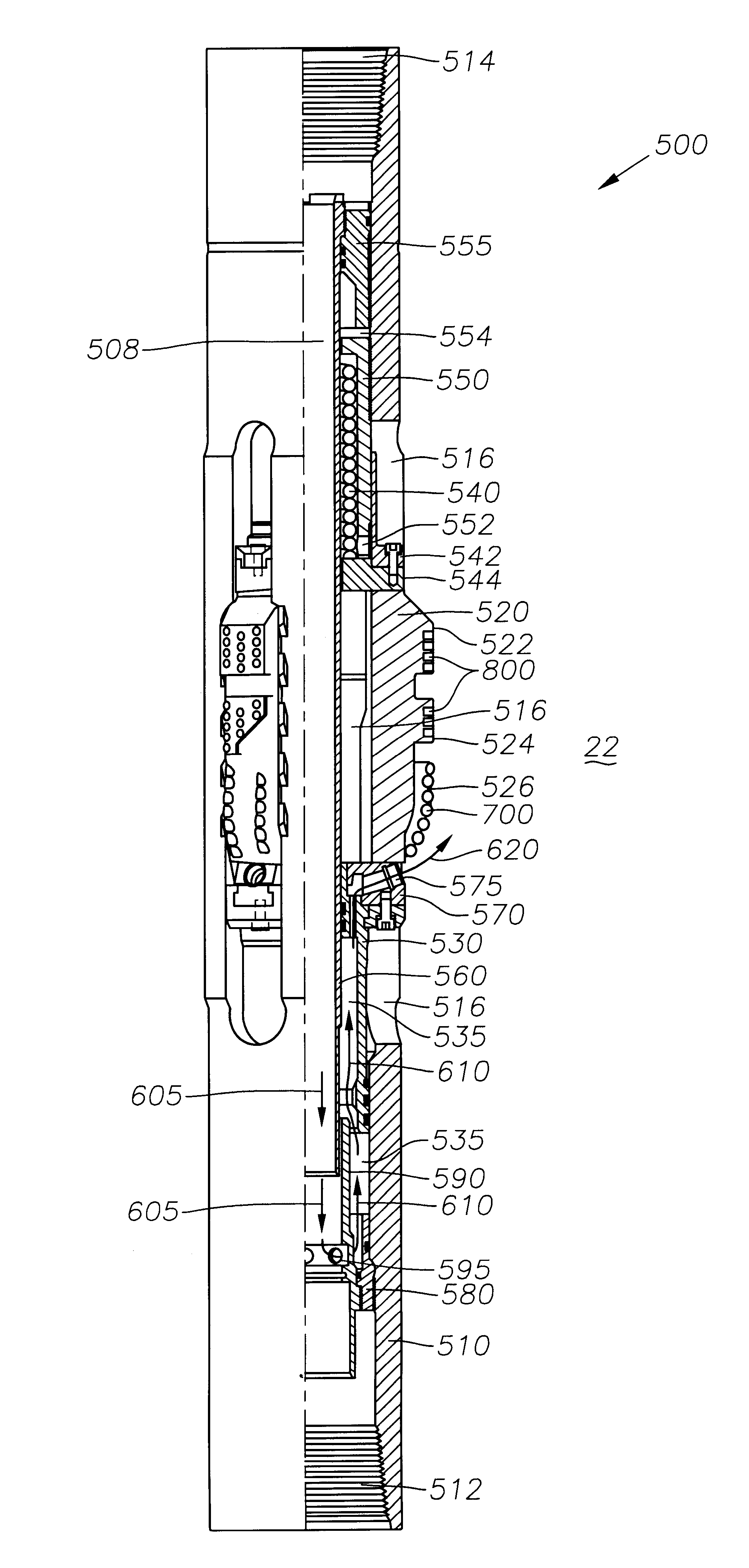

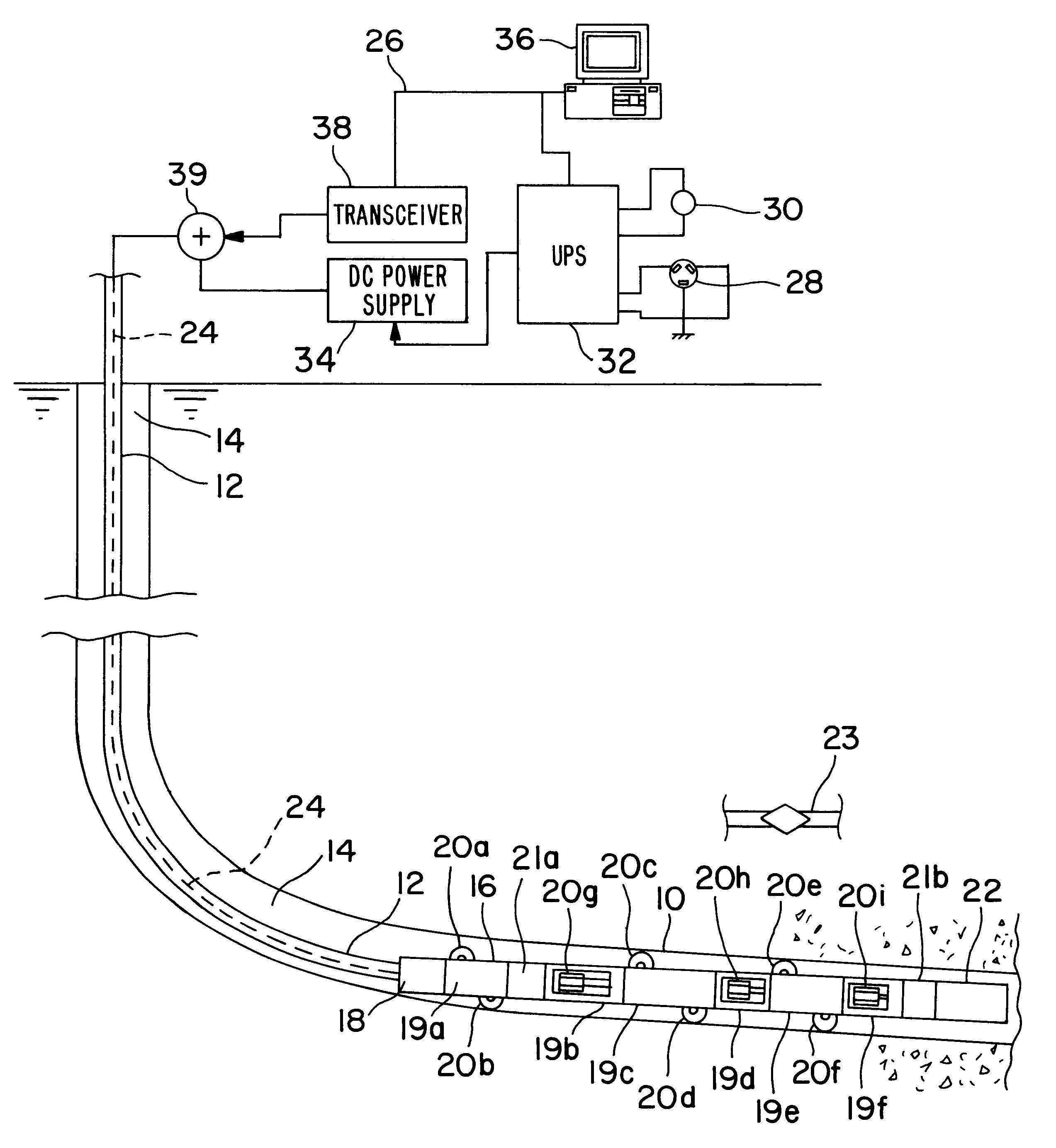

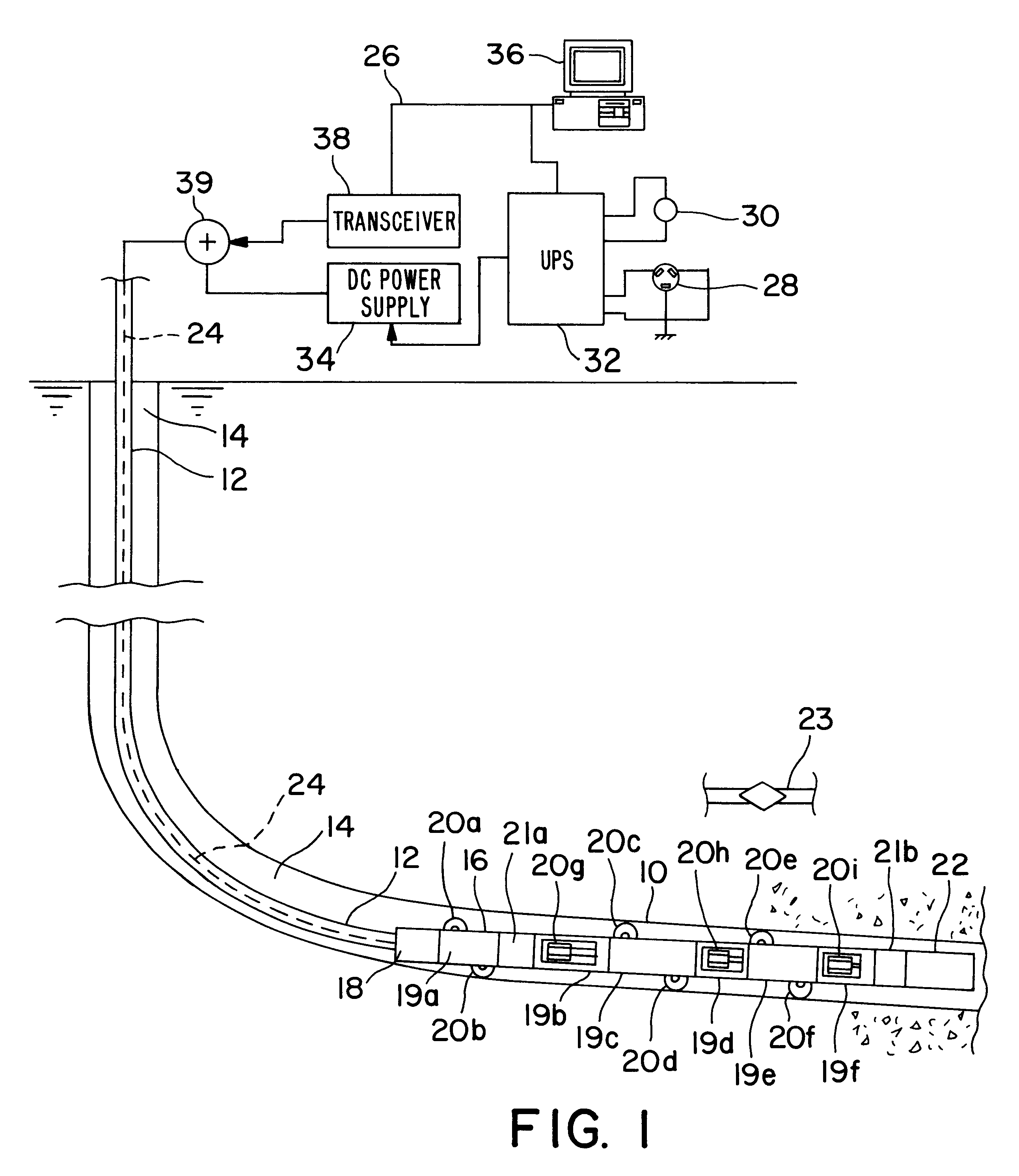

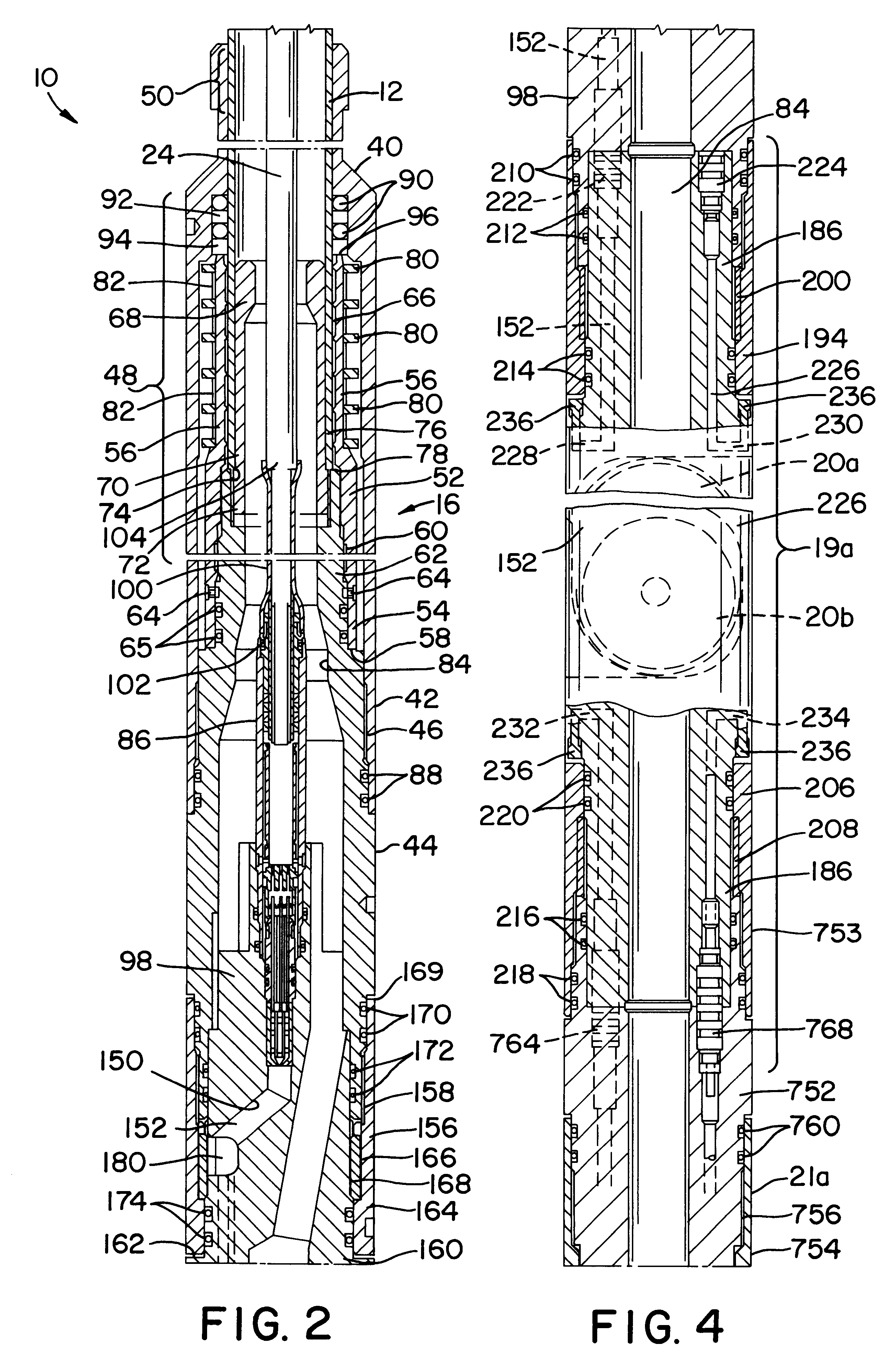

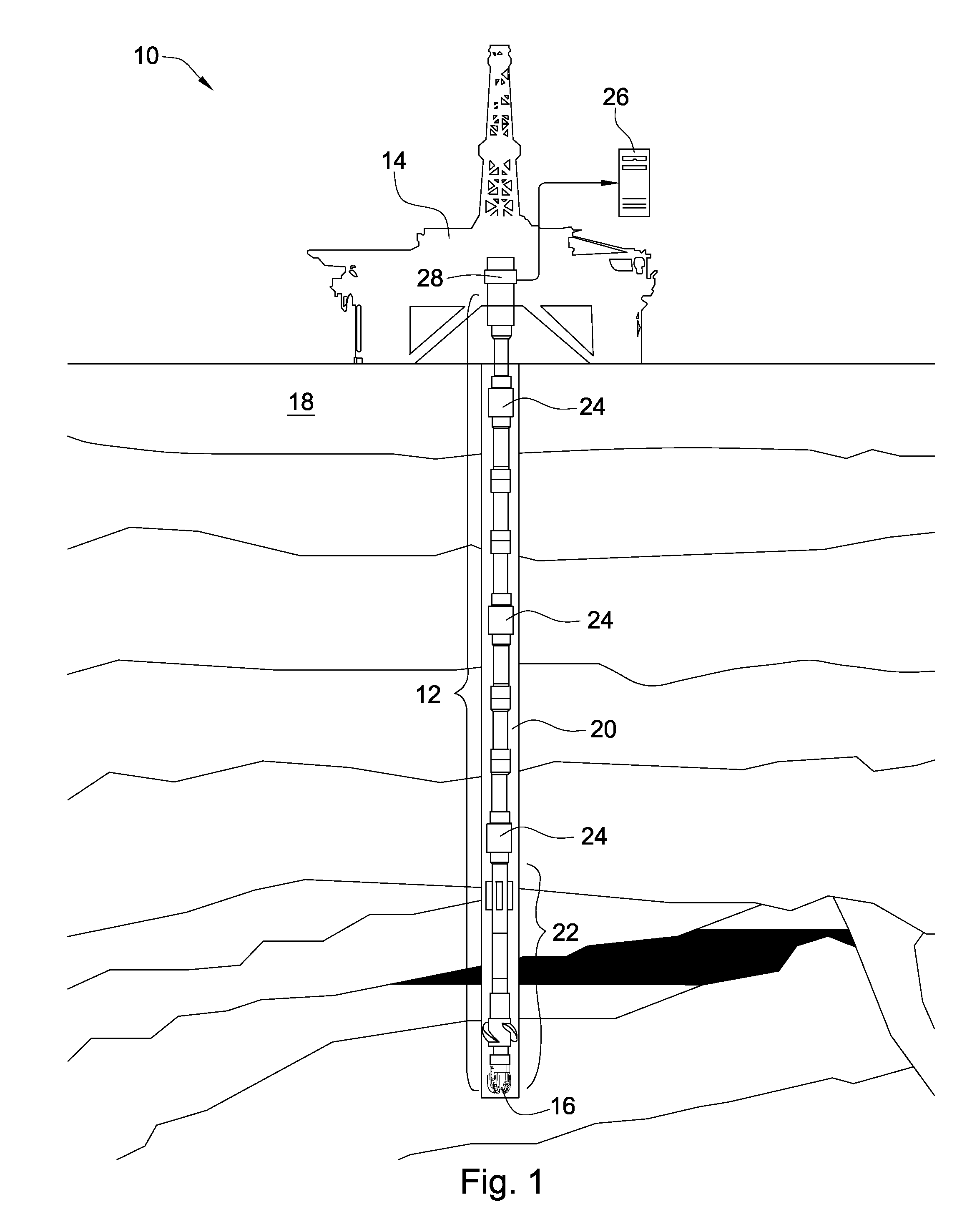

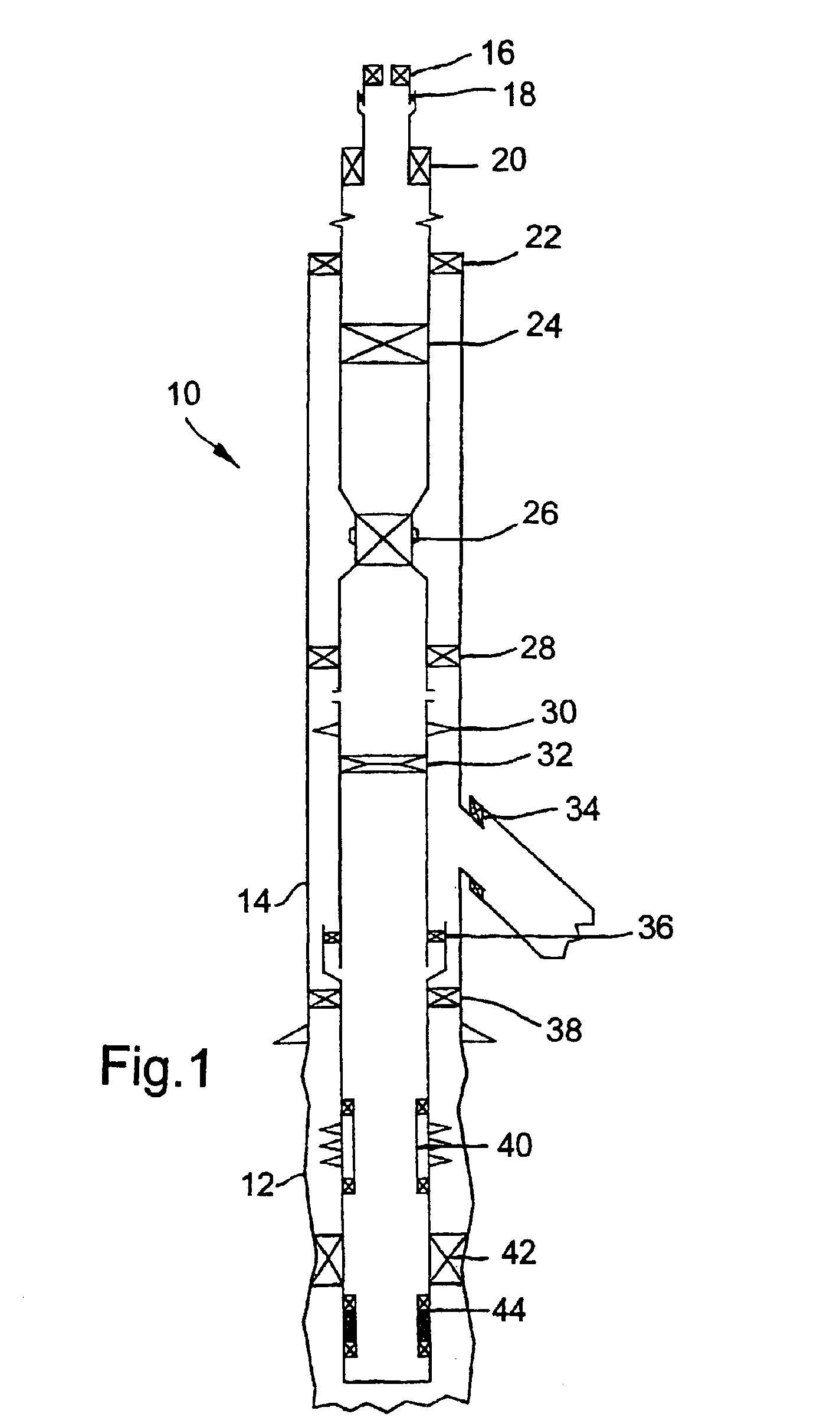

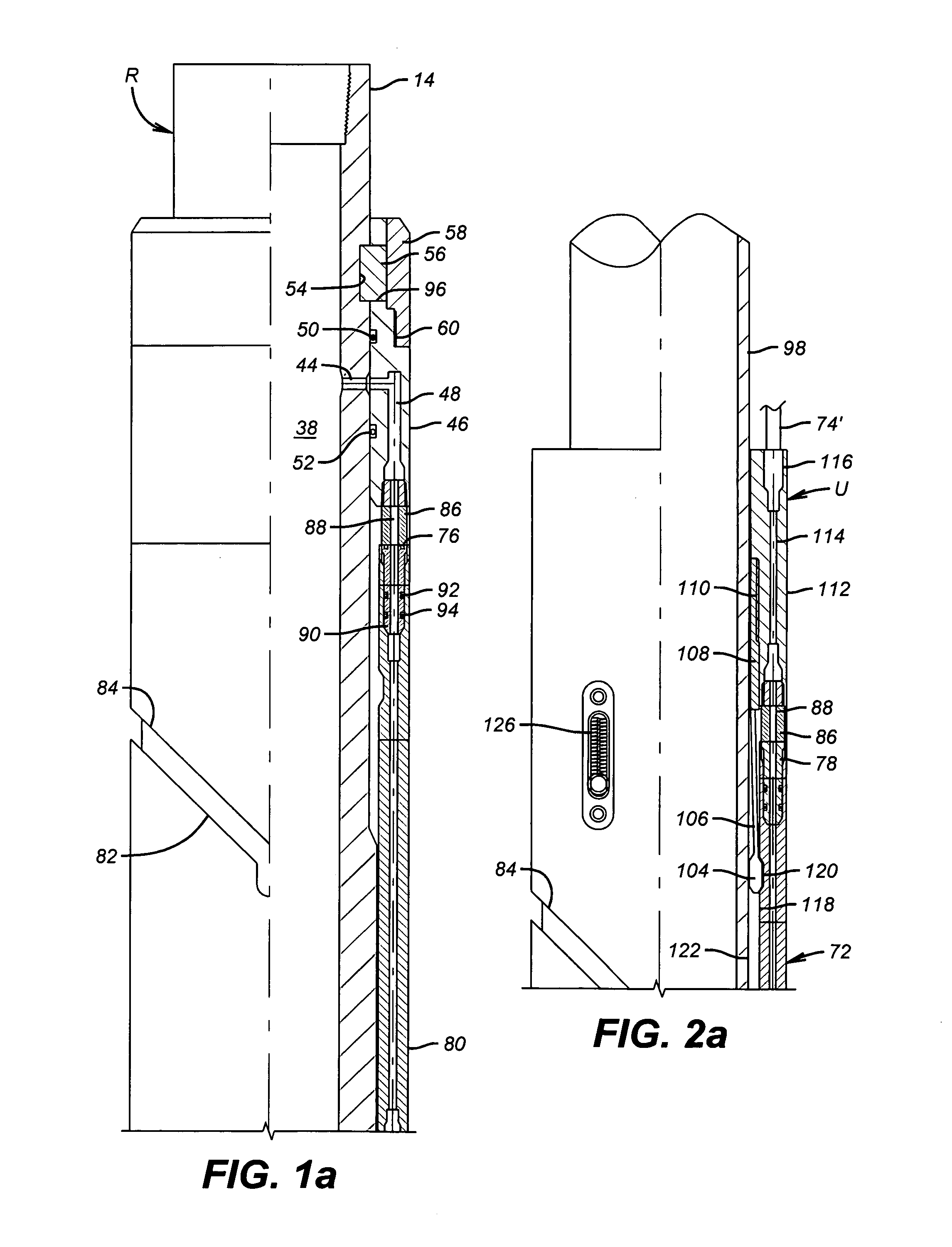

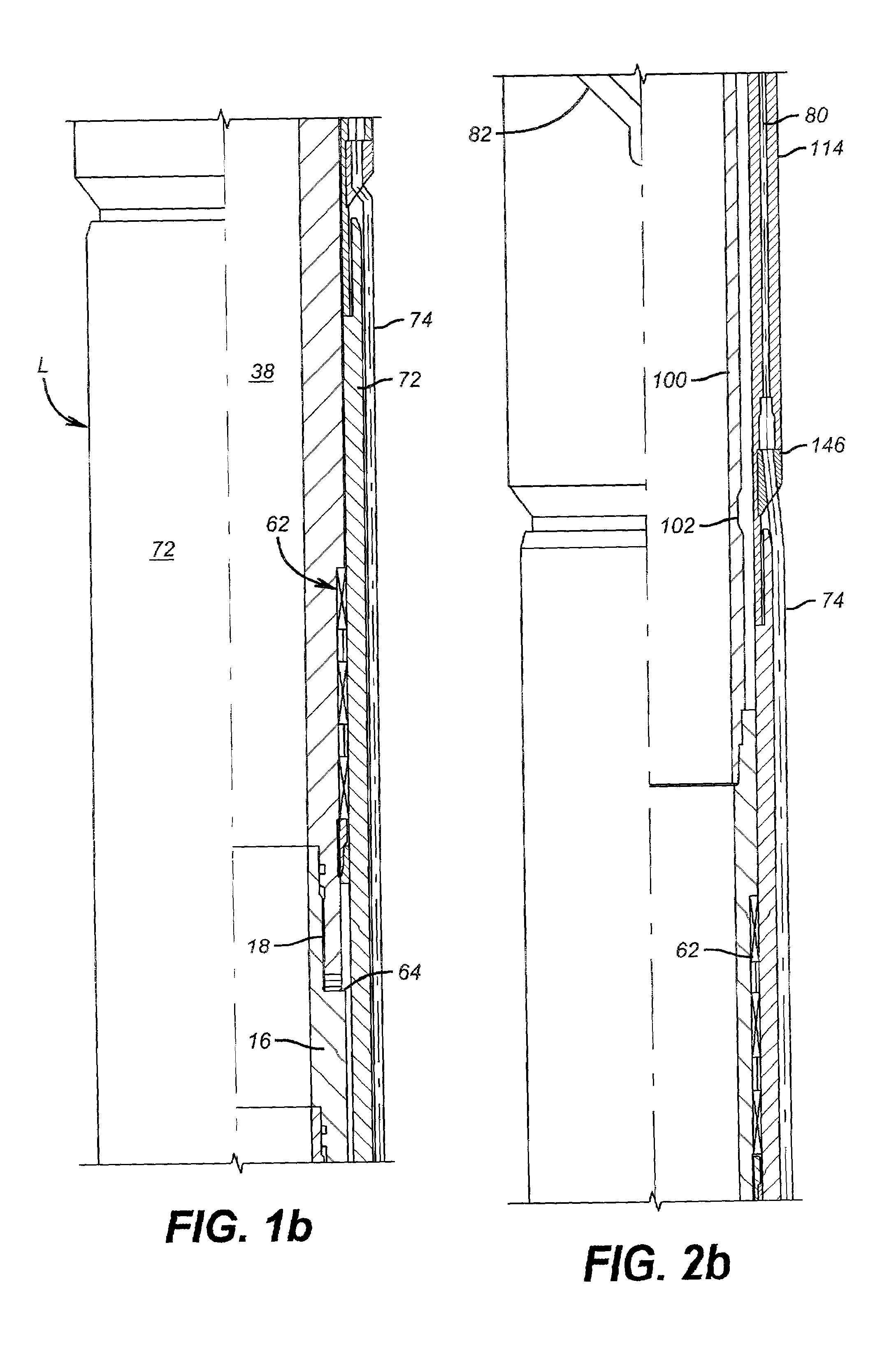

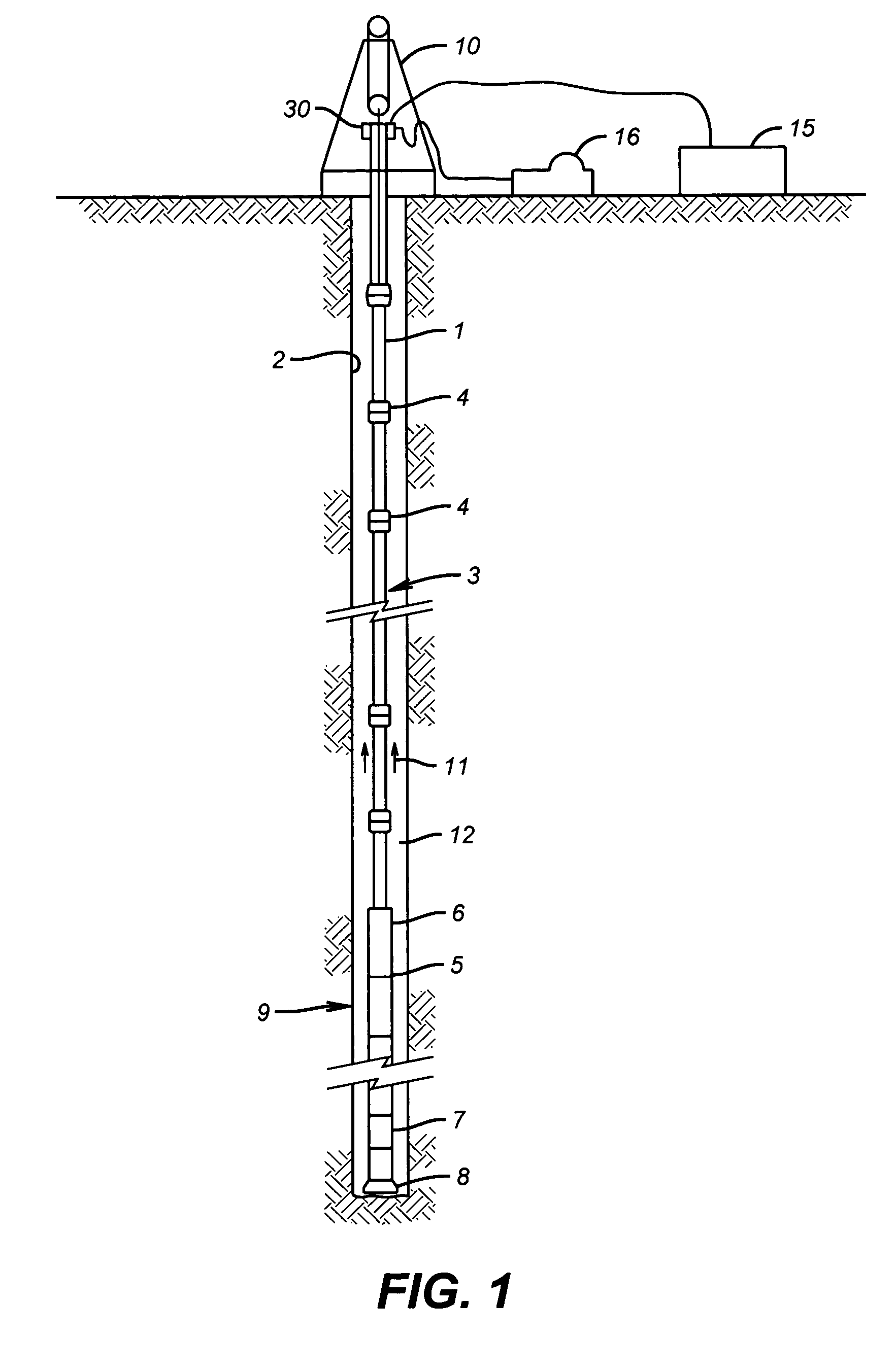

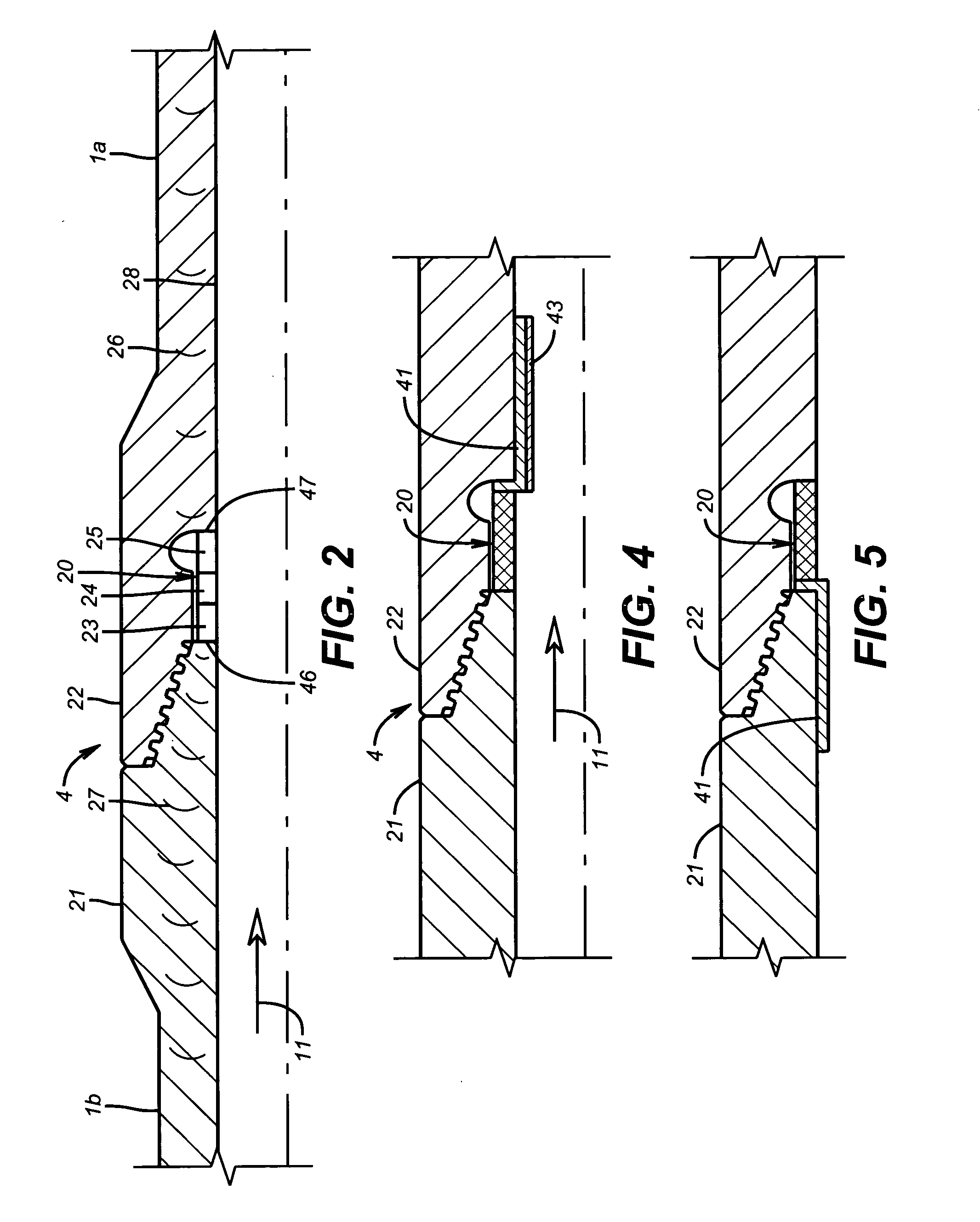

Actively controlled rotary steerable system and method for drilling wells

InactiveUS6092610AEfficient rotary speedPromote productionDrilling rodsConstructionsAccelerometerDirectional drilling

An actively controlled rotary steerable drilling system for directional drilling of wells having a tool collar rotated by a drill string during well drilling. A bit shaft has an upper portion within the tool collar and a lower end extending from the collar and supporting a drill bit. The bit shaft is omni-directionally pivotally supported intermediate its upper and lower ends by a universal joint within the collar and is rotatably driven by the collar. To achieve controlled steering of the rotating drill bit, orientation of the bit shaft relative to the tool collar is sensed and the bit shaft is maintained geostationary and selectively axially inclined relative to the tool collar during drill string rotation by rotating it about the universal joint by an offsetting mandrel that is rotated counter to collar rotation and at the same frequency of rotation. An electric motor provides rotation to the offsetting mandrel with respect to the tool collar and is servo-controlled by signal input from position sensing elements such as magnetometers, gyroscopic sensors, and accelerometers which provide real time position signals to the motor control. In addition, when necessary, a brake is used to maintain the offsetting mandrel and the bit shaft axis geostationary. Alternatively, a turbine is connected to the offsetting mandrel to provide rotation to the offsetting mandrel with respect to the tool collar and a brake is used to servo-control the turbine by signal input from position sensors.

Owner:SCHLUMBERGER TECH CORP

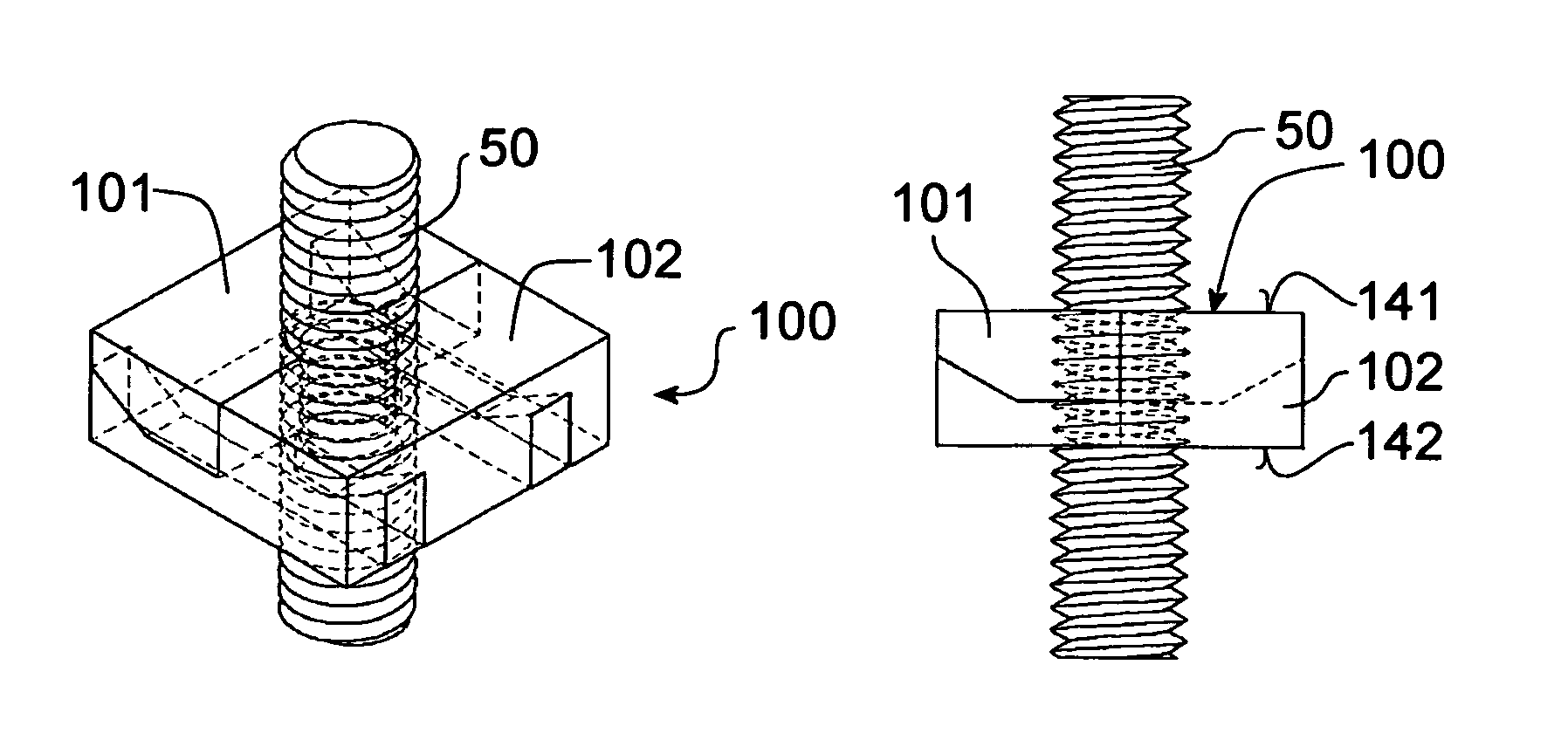

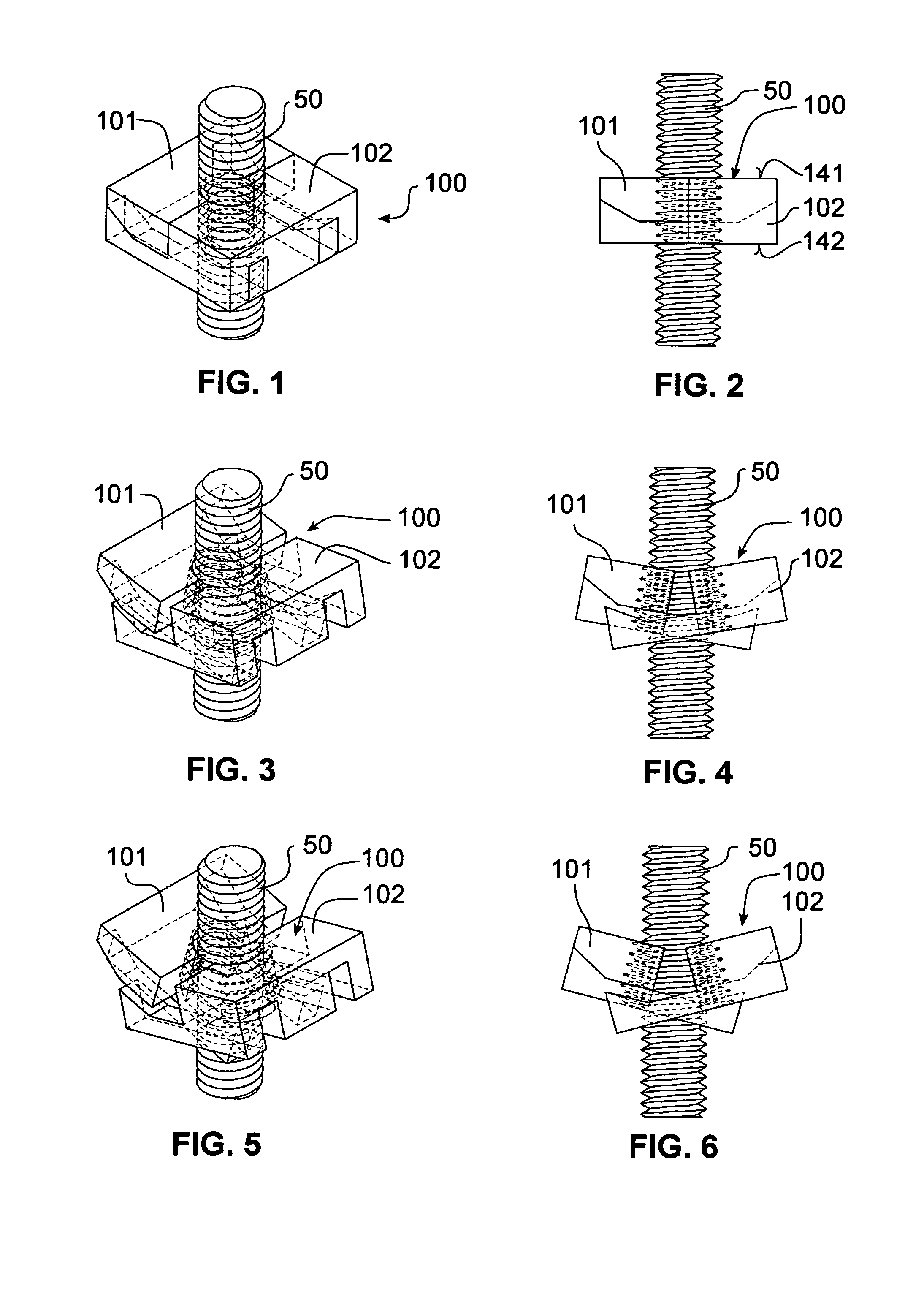

Nut having at least two parts

ActiveUS7934896B2Avoid cloggingIncrease the number ofDrilling rodsNutsRelative displacementEngineering

A nut includes an internal thread and at least two parts, each of the parts having a section of the internal thread which can be pushed onto an external thread in the radial direction. The parts may have connecting elements which interact and permit a relative displacement of the parts in a direction running radially to the axis of the internal thread into a position of use. The connecting elements may have guide surfaces which are inclined at an angle to the plane running radially to the axis of the internal thread and guide the parts in a rotational movement about an axis of rotation running transversely to the axis. A part may have a locking arm with a guide surface only on one side which produces the rotational movement during the displacement of the parts and bears against a complementary guide surface of the other part.

Owner:SCHNIER DIETMAR

Battery-driven screwdriver

InactiveUS7134364B2Fit tightlyBatteries circuit arrangementsDrilling rodsElectrical and Electronics engineering

Owner:ROBERT BOSCH GMBH

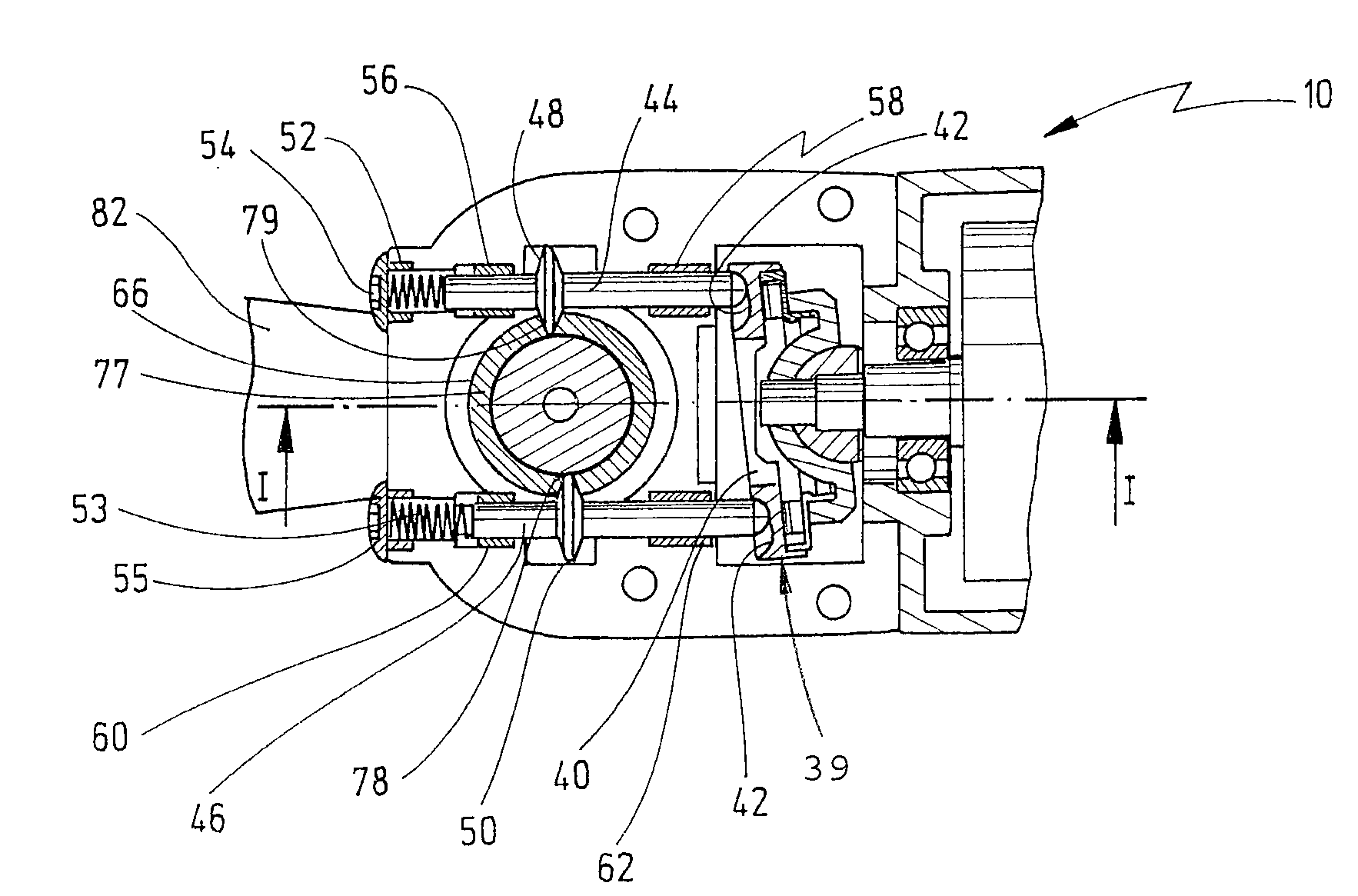

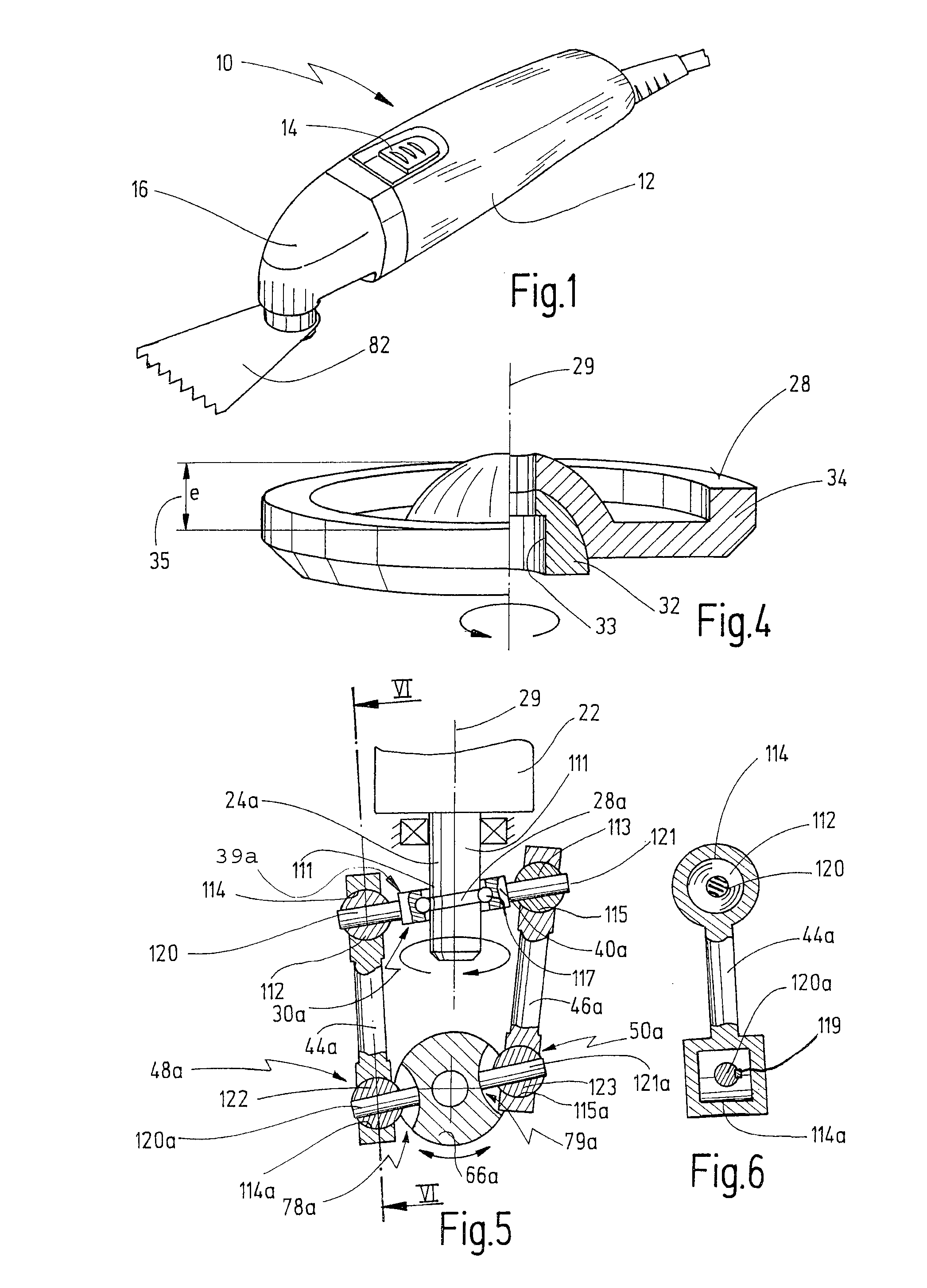

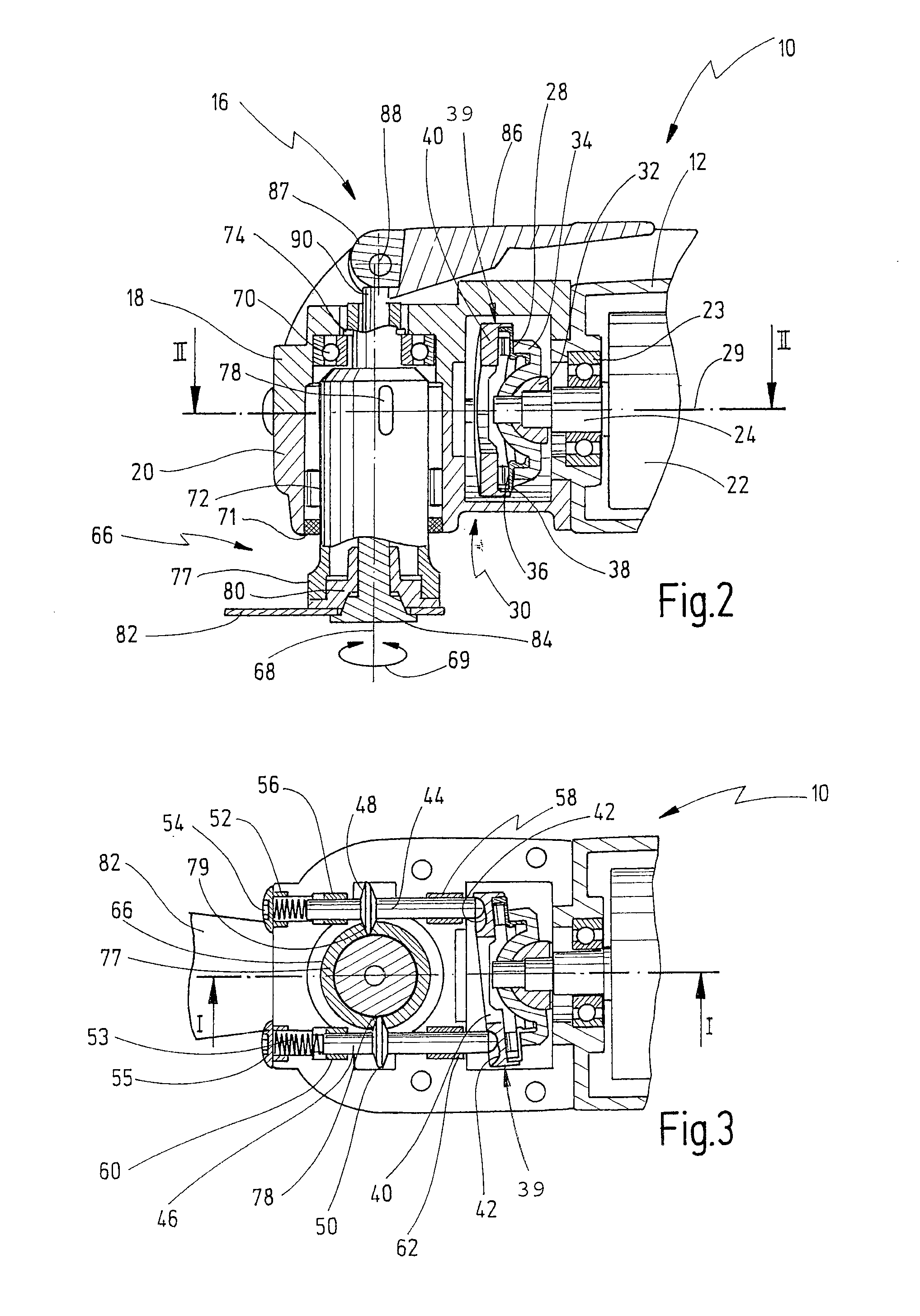

Hand tool machine having an oscillatory drive

A hand tool is disclosed, comprising a housing, a motor shaft being coupled to a drive motor, a working spindle configured for being driven rotatingly oscillatingly about its longitudinal axis, and a coupling element being driven rotatingly by the motor shaft and having a closed guide surface that revolves around the motor shaft. The guide surface is coupled, via transmission means, to at least one driver for driving the latter. The at least one driver is arranged movably relative to the working spindle and engages the working spindle at a circumferential region thereof for driving the latter rotatingly oscillatingly.

Owner:C & E FEIN GMBH & CO KG

Power tool

A power tool includes a body housing a motor with a first output shaft and an attachment for engagement with the output shaft. The attachment includes an output shaft which transmits rotational motion derived from the rotational motion of the motor and further includes a gear mechanism enabling a gear change in rotational speed between its input and output. A combination of the body and the attachment thereby provides a plurality of serially-coupled gear mechanisms.

Owner:BLACK & DECKER INC

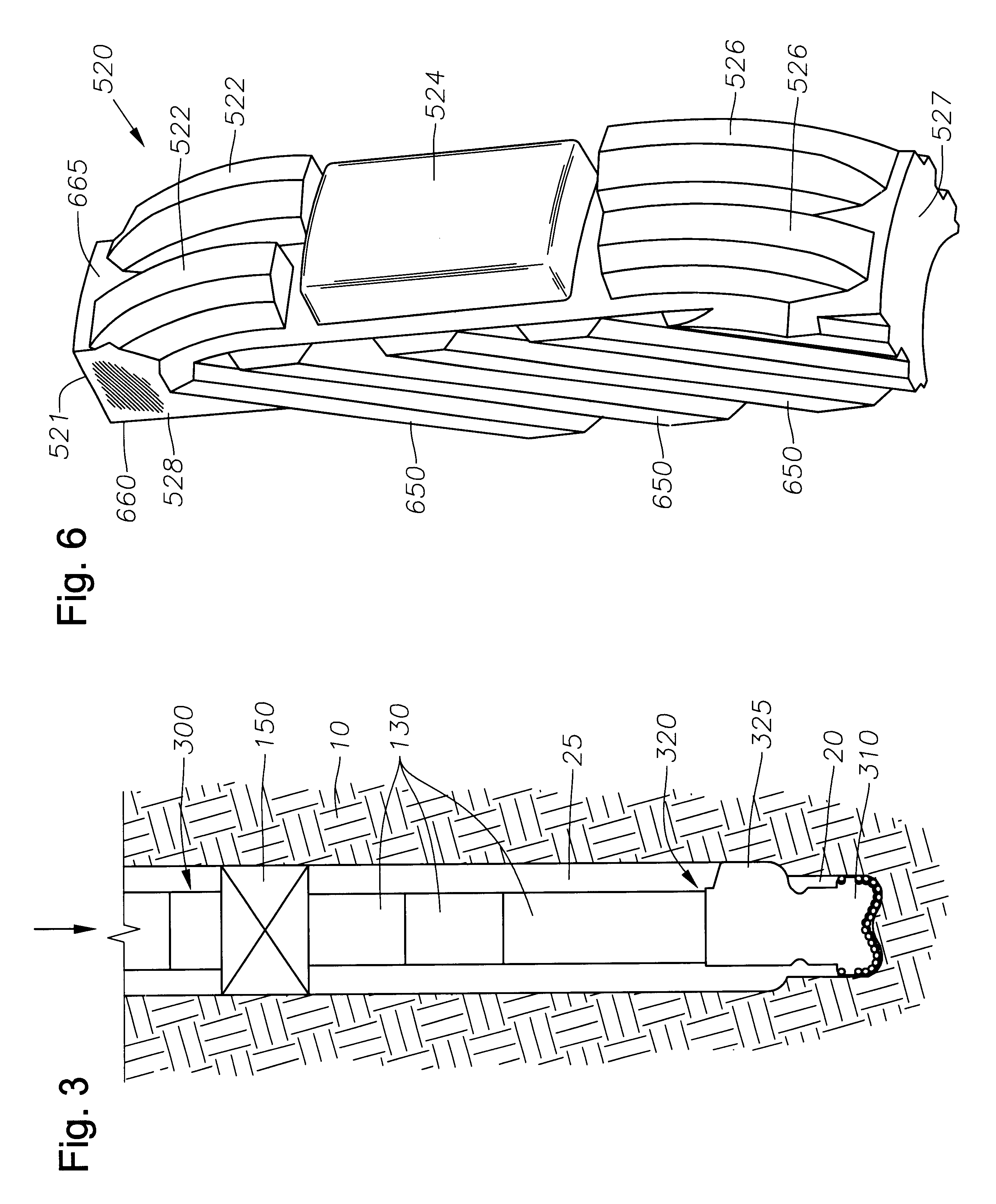

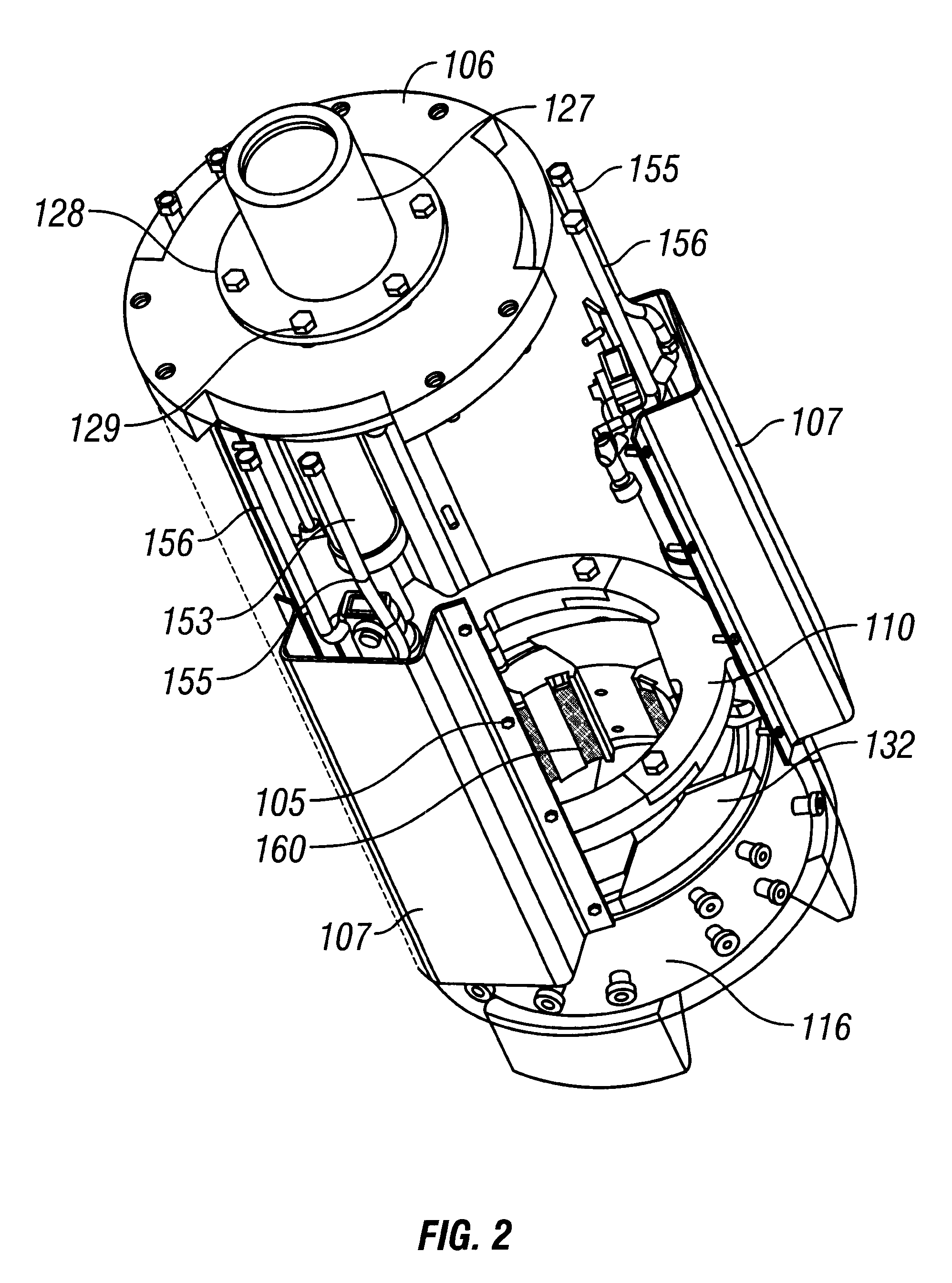

Expandable underreamer/stabilizer

A downhole tool that functions as an underreamer, or alternatively, as a stabilizer in an underreamed borehole. The tool includes one or more moveable arms disposed within a body having a flowbore therethrough in fluid communication with the wellbore annulus. The tool alternates between collapsed and expanded positions in response to differential fluid pressure between the flowbore and the wellbore annulus. In one embodiment, the tool moves automatically in response to differential pressure. In a second embodiment, the tool must be selectively actuated before it is moveable. When the tool expands, the arms are preferably translated axially upwardly, while simultaneously being extended radially outwardly from the body. The expanded tool diameter is adjustable at the surface without changing components. The arms may include borehole engaging pads that comprise cutting structures or wear structures or both, depending upon the function of the tool.

Owner:SMITH INT INC

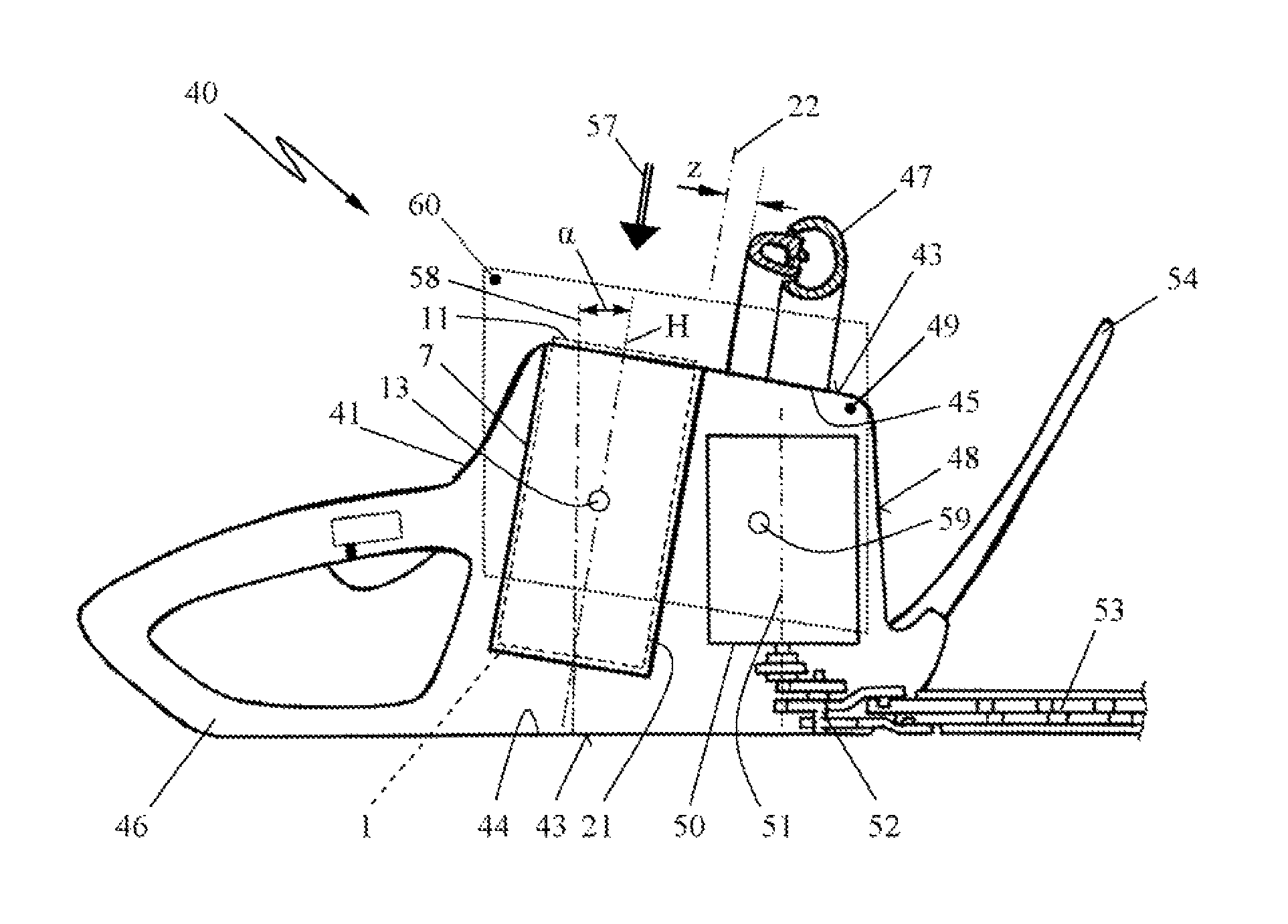

Electric power tool with battery pack

ActiveUS8869912B2Handling of the electric power tool is not impairShorten the lengthDrilling rodsConstructionsElectric driveEngineering

An electric power tool has a device housing with a rear grip extending in the longitudinal direction of the device housing. The device housing has first opposed housing sides and second opposed housing sides. An electric drive motor and its electronic control are arranged in the device housing. A battery pack compartment arranged in the device housing receives a battery pack that has a parallelepipedal shape and extends in a direction of a height axis, width axis and depth axis. The battery pack is arranged such that the width axis and the height axis extend transversely to the longitudinal axis of the device housing. The battery pack has narrow sides extending approximately parallel and at a minimal spacing relative to the first opposed housing sides, respectively. The battery pack has opposed end faces neighboring the second housing sides, respectively.

Owner:ANDREAS STIHL AG & CO KG

Electrical power tool

InactiveUS20150367497A1Low maneuverabilityHigh voltageDrilling rodsConstructionsElectrical batteryRechargeable cell

A driver drill may have two battery attachment portions to which two rechargeable batteries can be attached. Therefore, the driver drill can meet a need for an increased voltage or an increased discharge capacity. Further, the two battery attachment portions may be constructed as slide-fitting battery attachment portions. A combined gravity center of the rechargeable batteries attached to the first and second battery attachment portions may be positioned on a vertical line through a gravity center of a tool main body in a condition in which the two rechargeable batteries are detached therefrom.

Owner:MAKITA CORP

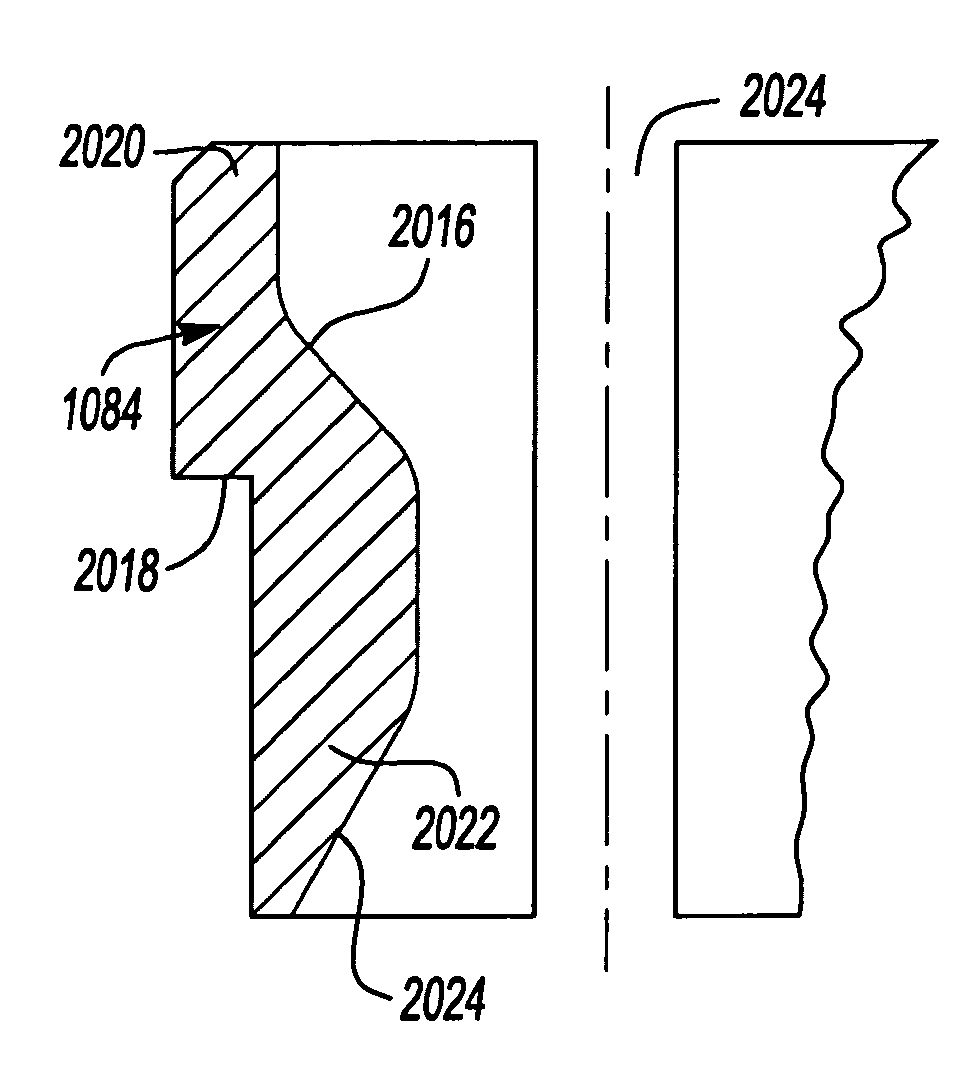

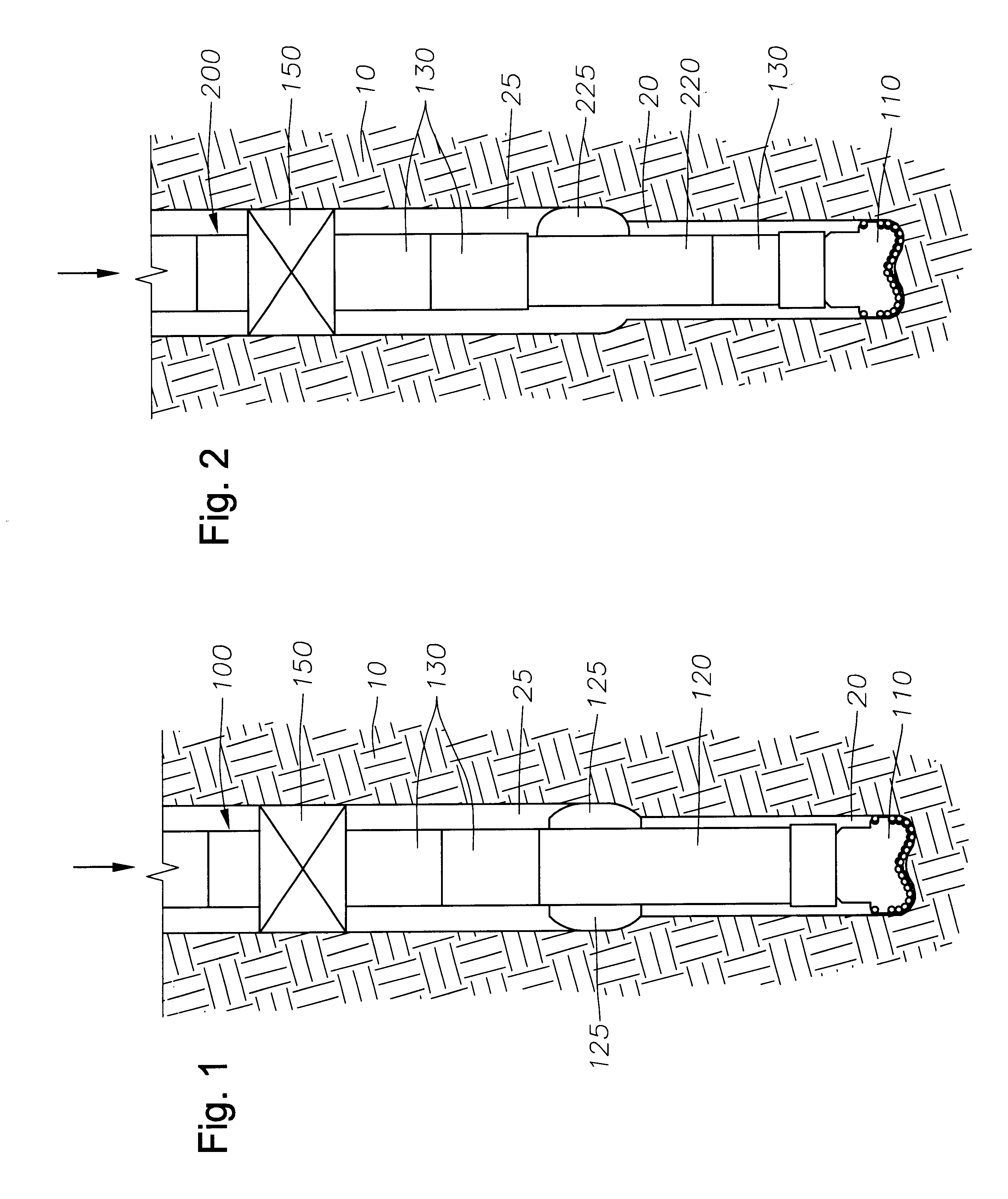

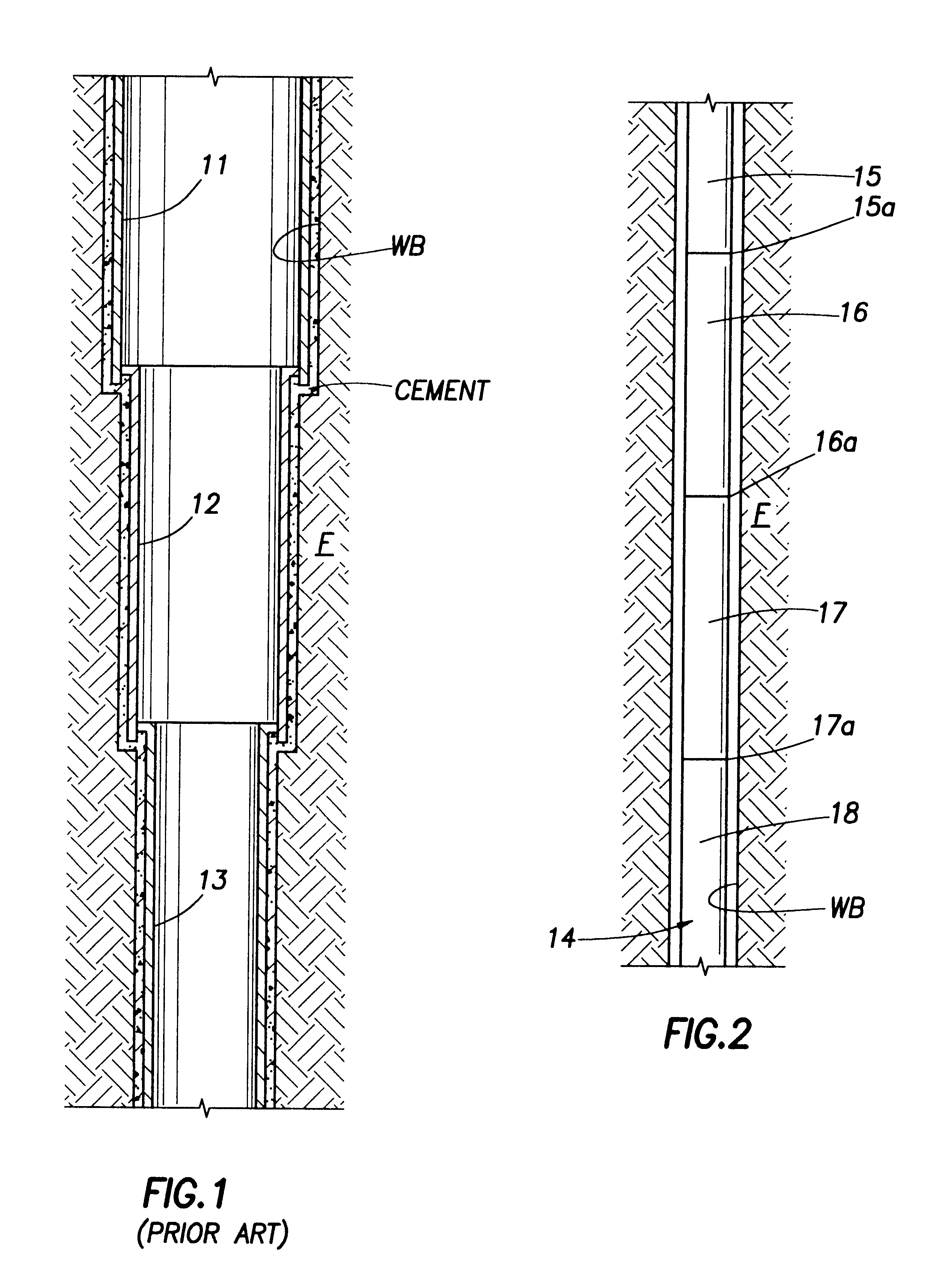

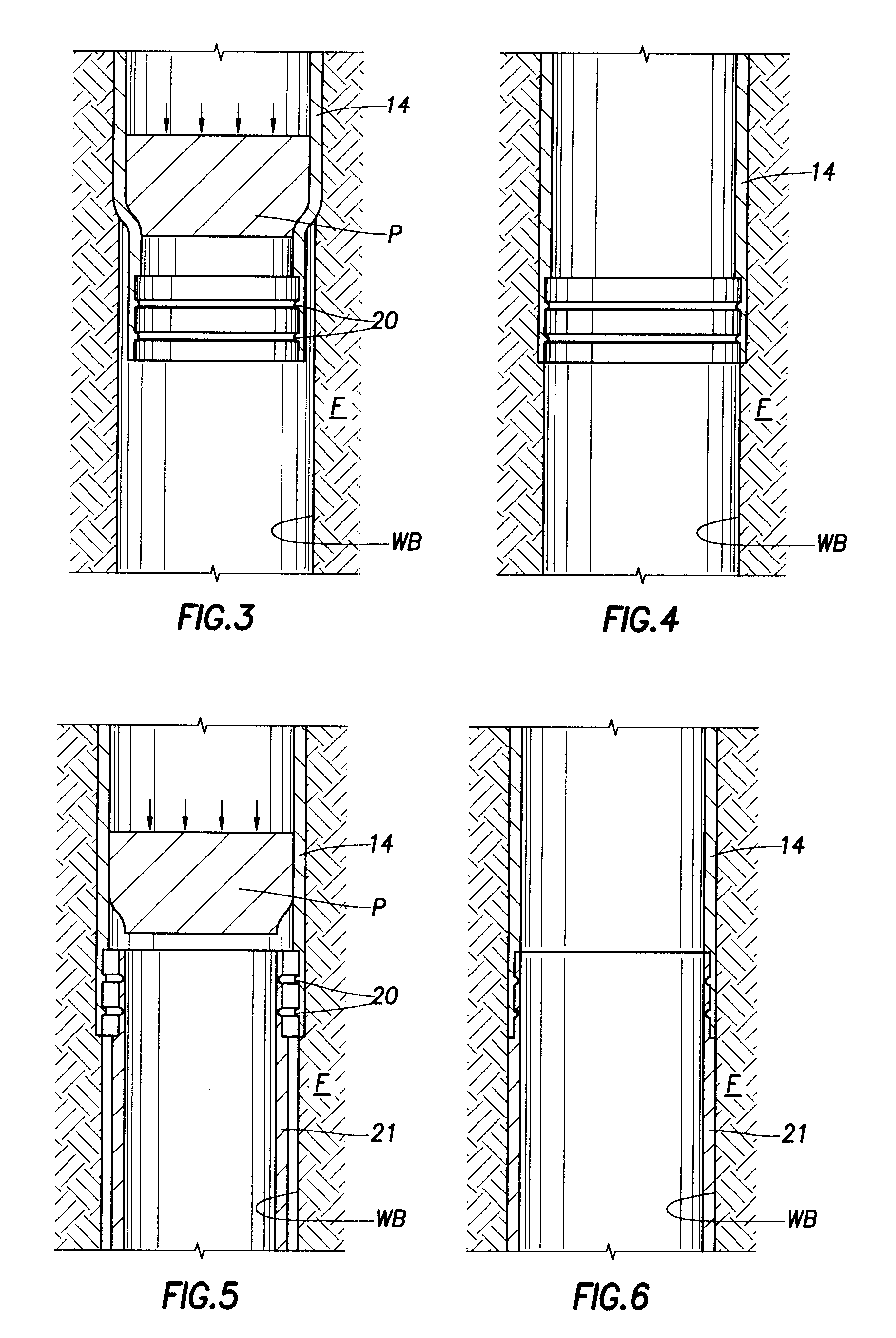

Expandable joint connector

InactiveUS6409175B1Lessen and eliminate radial engagementRadial expansionDrilling rodsCable inlet sealing meansEngineeringScrew thread

Methods and apparatus are provided for obtaining a secure mechanical connection and a pressure-tight seal in the overlapping area of two telescoping tubular bodies. The two bodies, including the overlapping area, are radially expanded to increase the inside diameter of the bodies. The expansion forces an annular seal in the overlapping area into a pressure-sealing engagement between the bodies. A string of pipe assembled from joints secured to each other by telescoping, threadedly engaged expanded pin and box connections may be radially expanded into a surrounding well bore to provide a cased well having an internal diameter greater than the original internal diameter of the pipe string. The seal in the connection comprises an annular elastomeric seal ring and an annular Teflon spacer ring carried in a specially dimensioned groove formed in either the box or the pin, or both members of the connection. Radial expansion of the connection causes axial contraction of the groove, which acts with the spacer ring to expand the seal ring radially to seal the annular space created between the expanded pin and box.

Owner:ENVENTURE GLOBAL TECH LLC

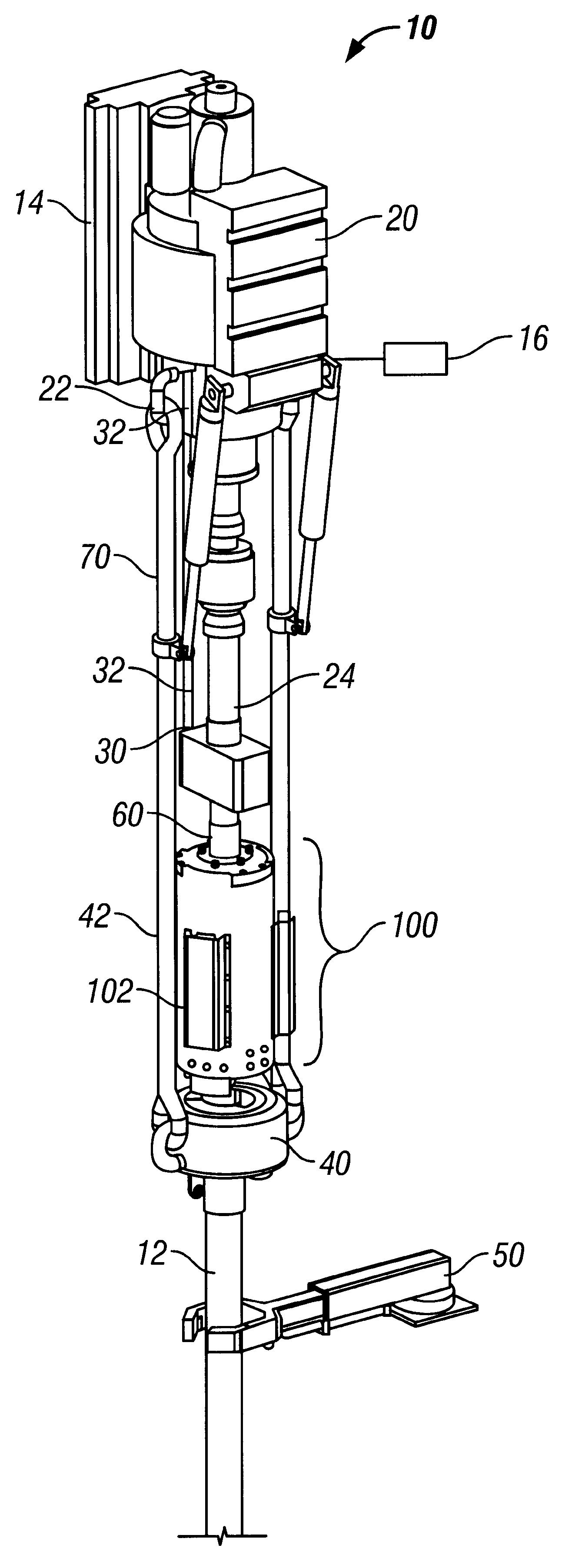

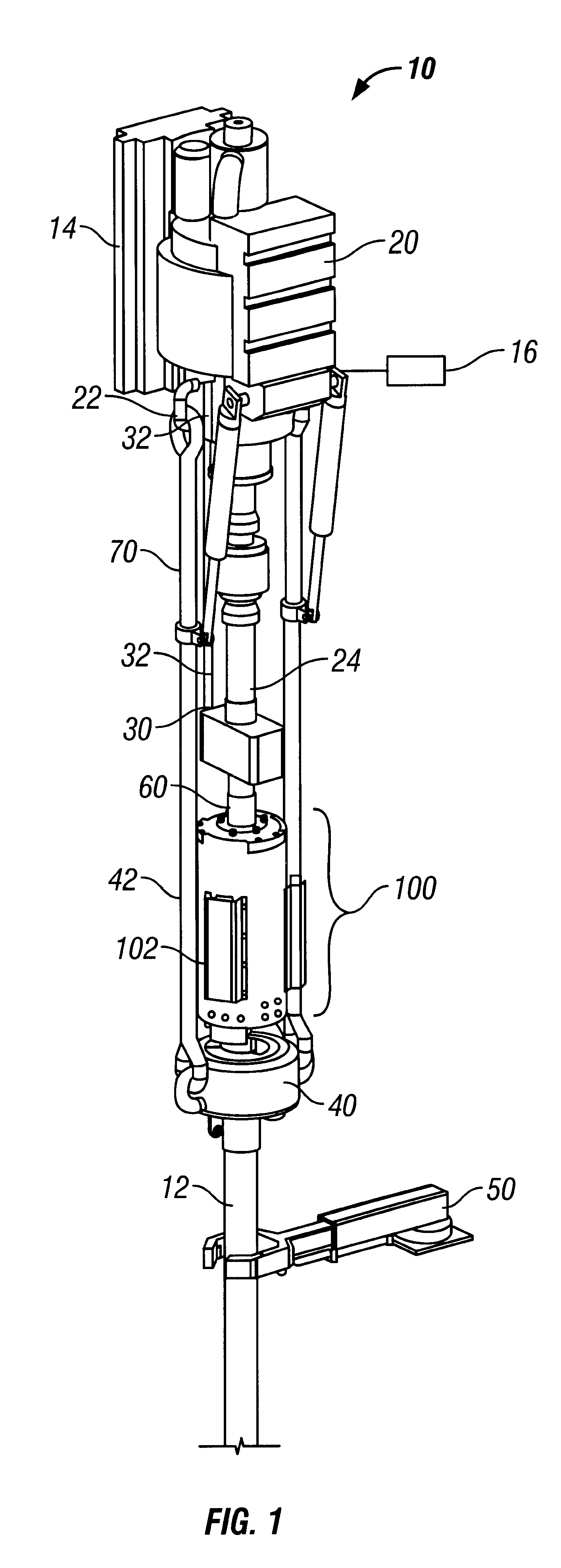

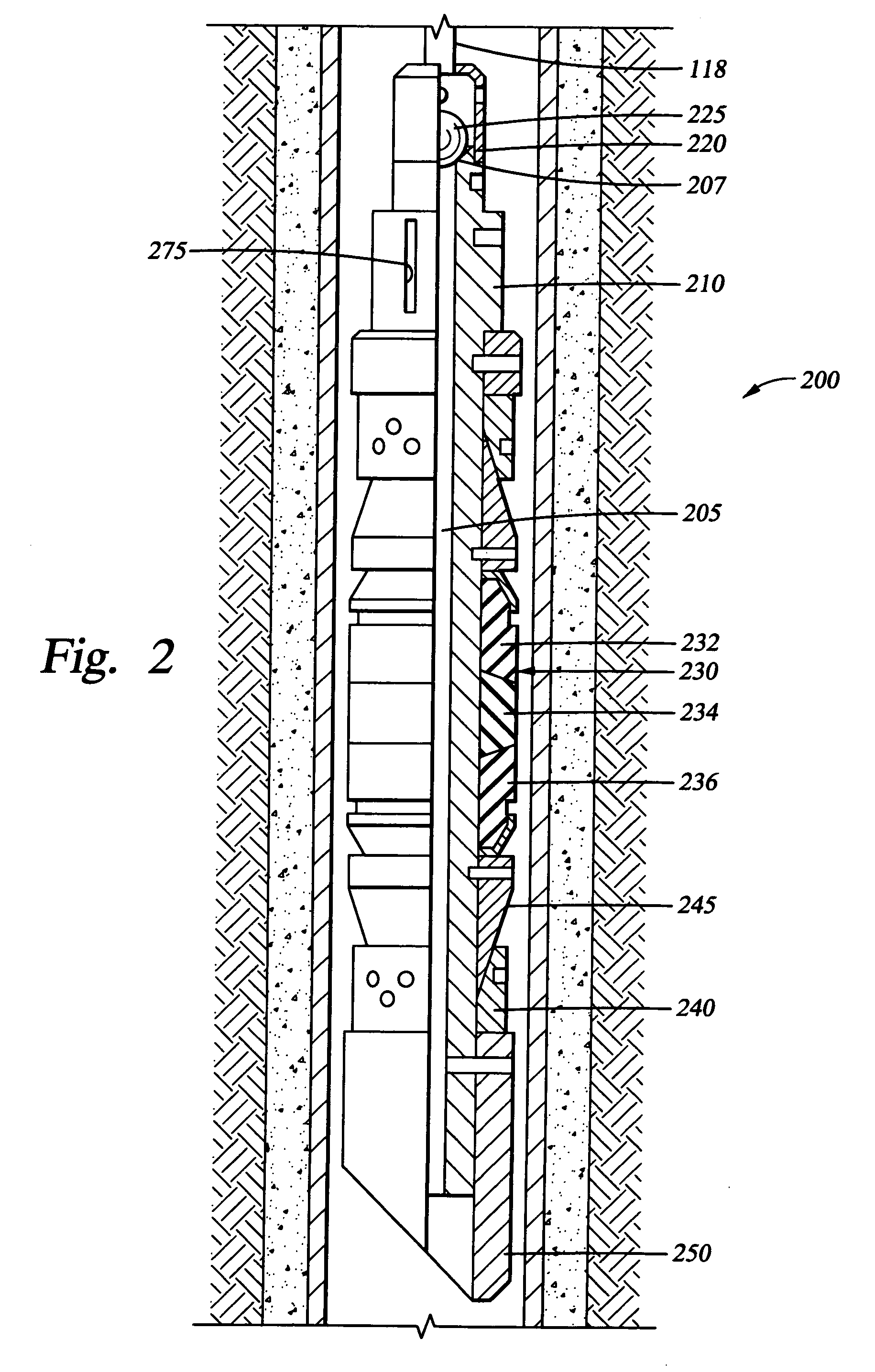

Top drive casing system

InactiveUS6536520B1Reduce the possibilityAvoid vertical movementDrilling rodsConstructionsTop driveRelative motion

Owner:WEATHERFORD TECH HLDG LLC

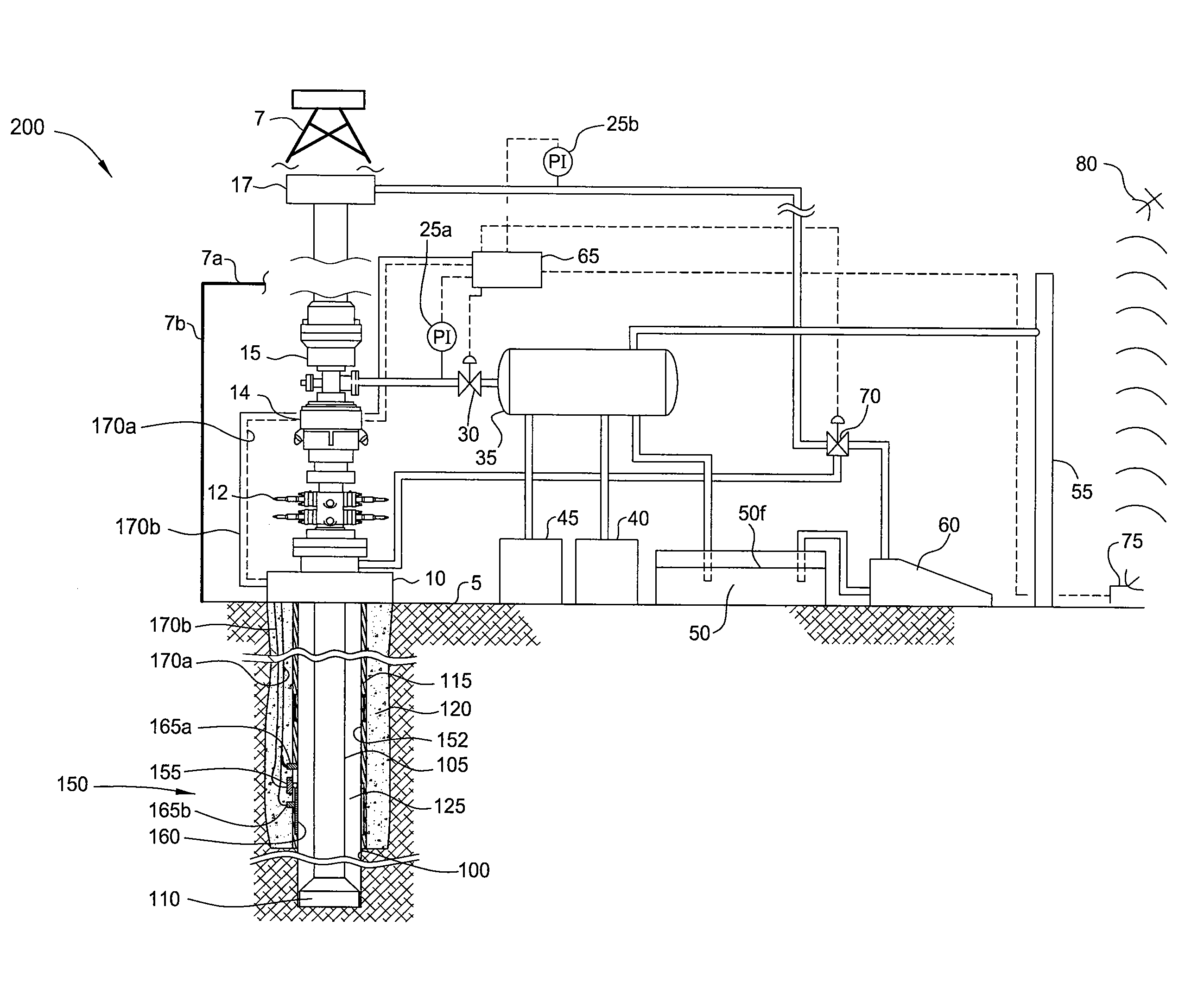

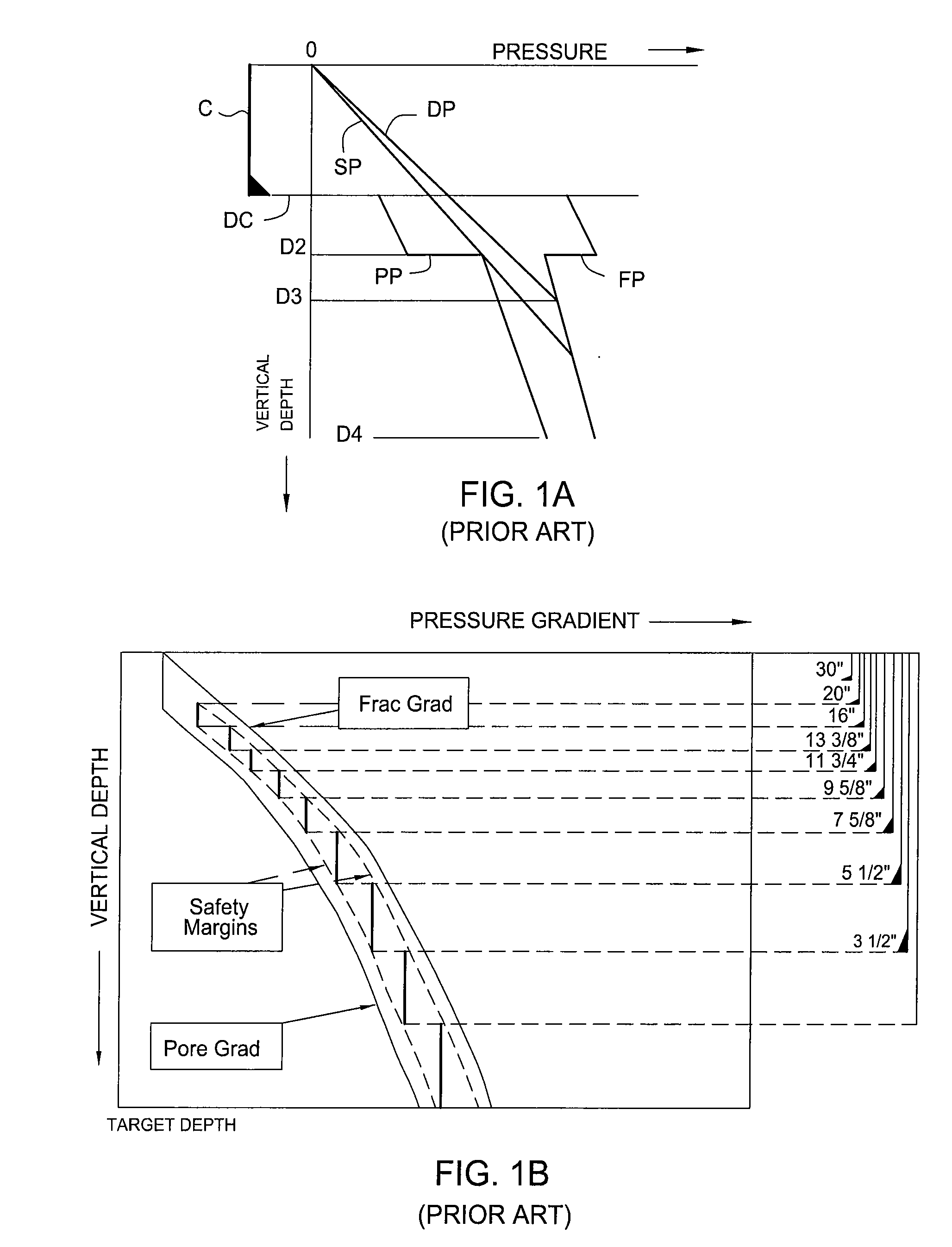

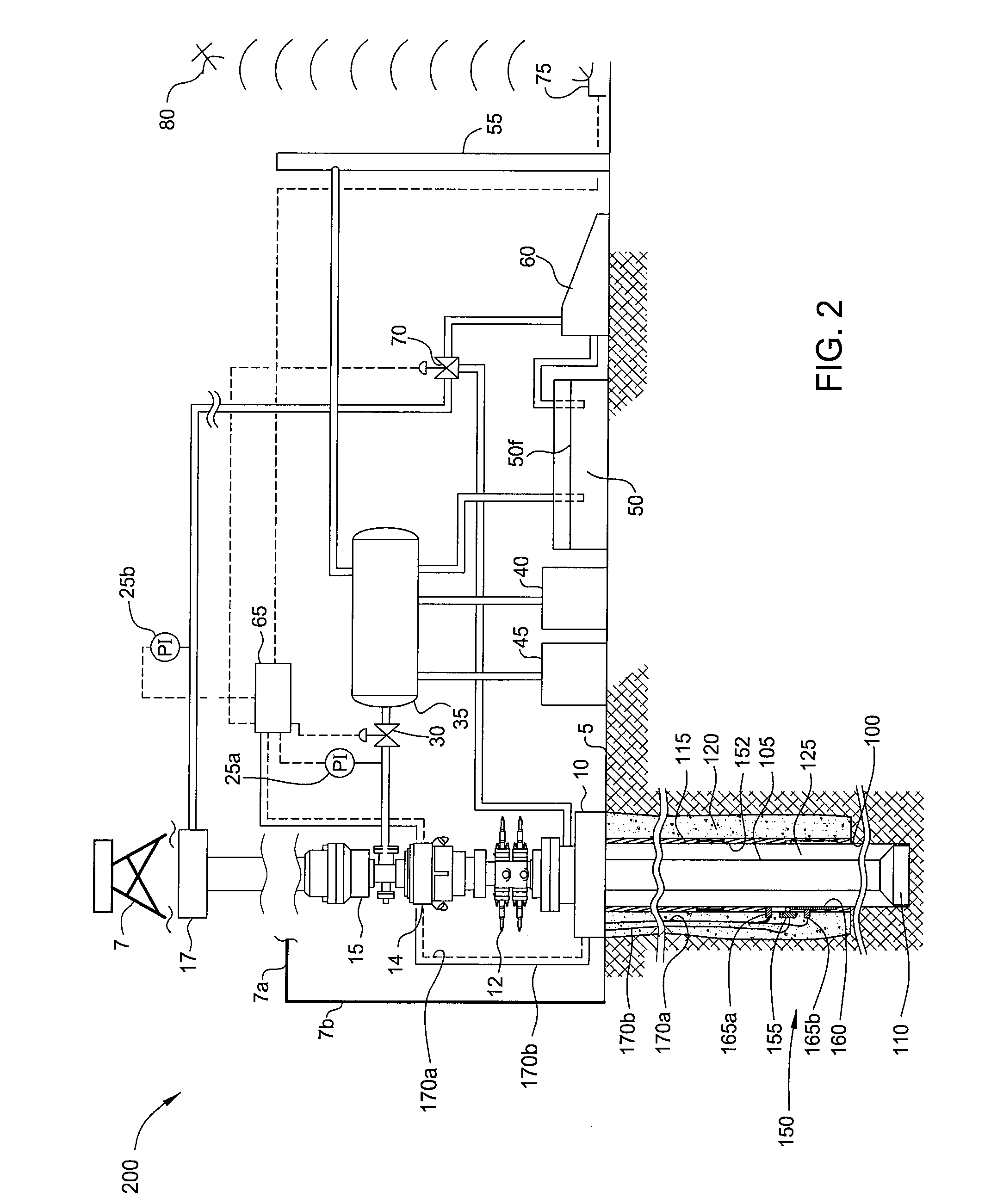

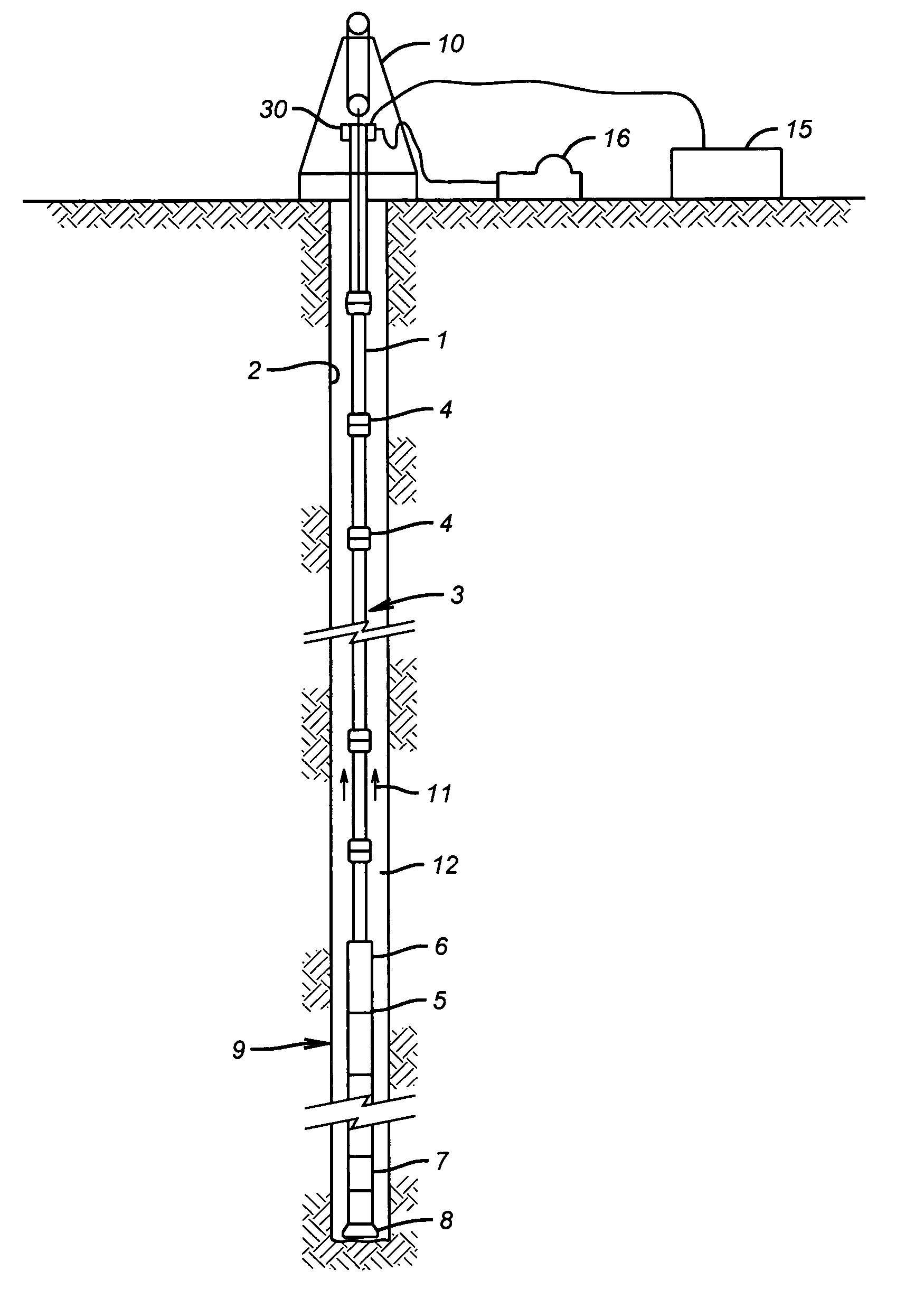

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

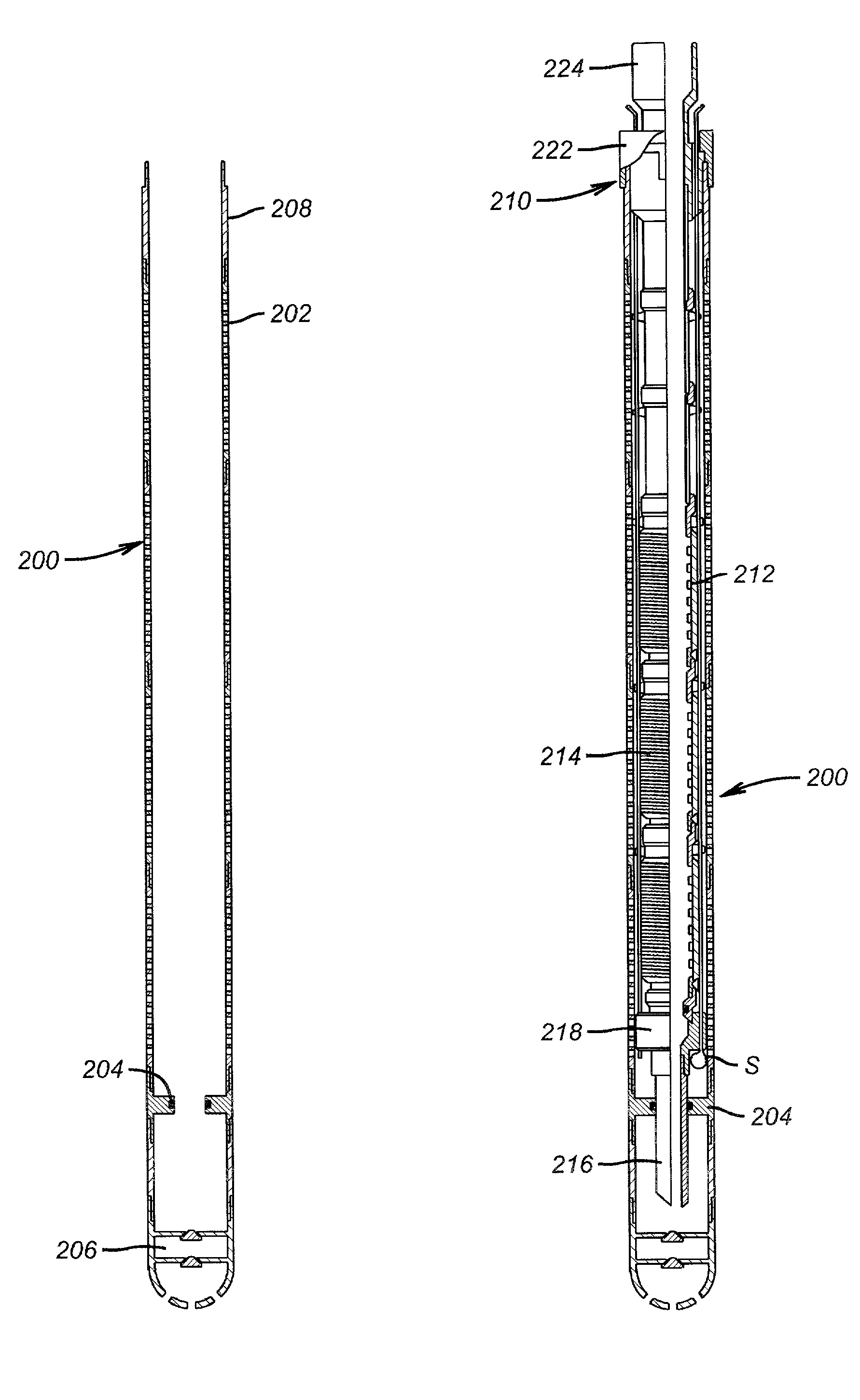

Downhole tractor

A downhole tractor is provided that includes a housing and a first wheel assembly coupled to the housing that is operable to translate away from the housing in a first direction. The first wheel assembly has a first electric motor, a first wheel, and a first reduction gear assembly coupled between the first electric motor and the first wheel. A second wheel assembly is coupled to the housing and is operable to translate away from the housing in a second direction that is opposite to the first direction. The second wheel assembly has a second electric motor, a second wheel, and a second reduction gear assembly coupled between the second electric motor and the second wheel. A fluid ram is coupled to the first and second wheel assemblies for selectively translating the first and second wheel assemblies toward and away from the housing. A first controller is provided for controlling the flow of current to the first and second electric motors. On-board and surface control systems may be incorporated to permit selective active of the wheels assemblies. In addition, couplings and connectors employing shape-memory materials may be included to secure the tractor to coiled tubing or a wireline.

Owner:HALLIBURTON ENERGY SERVICES INC

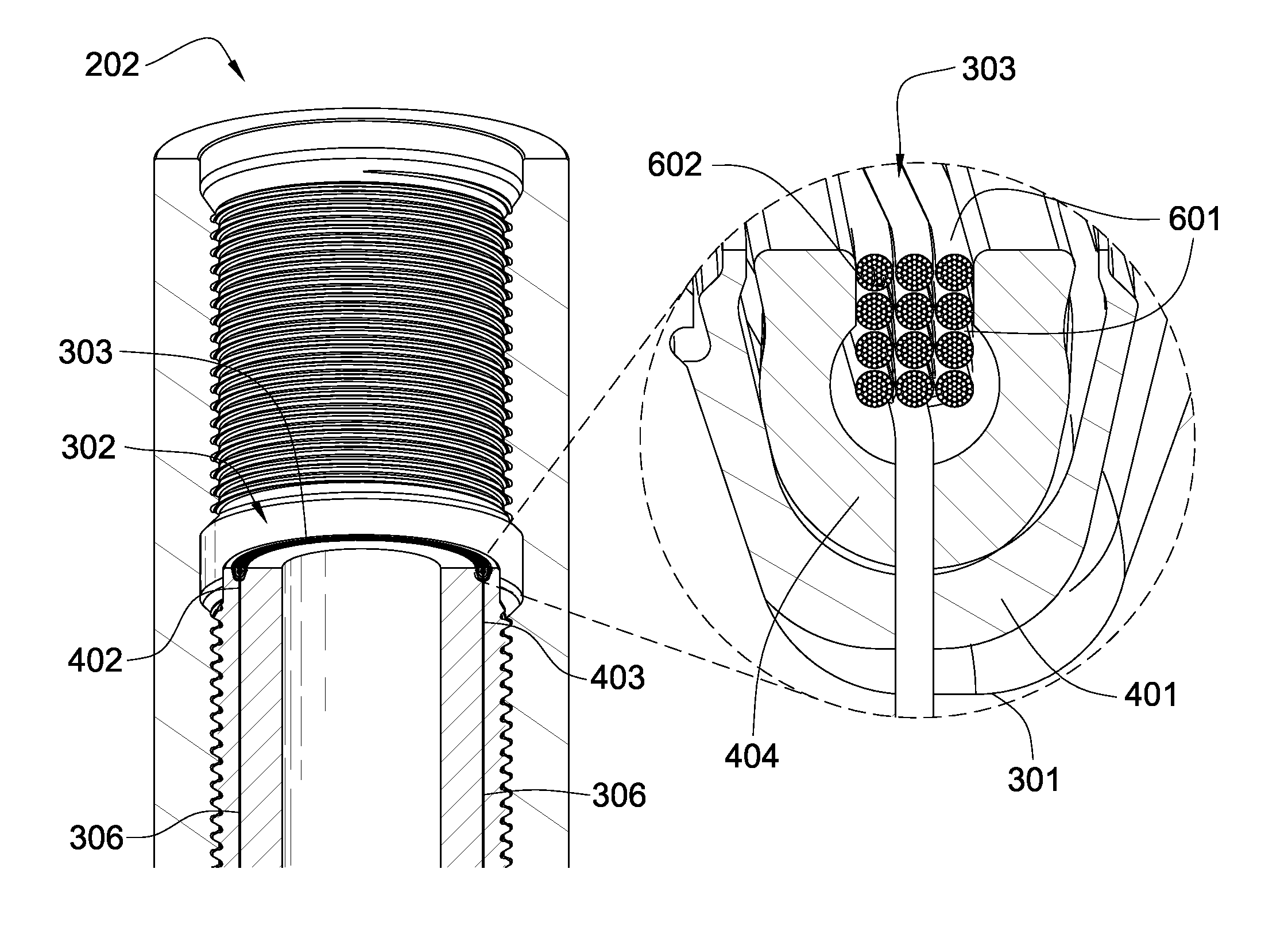

Downhole Coils

In one aspect of the invention, a downhole tool string component comprises a tubular body with at least one end adapted for threaded connection to an adjacent tool string component. The end comprises at least one shoulder adapted to abut an adjacent shoulder of an adjacent end of the adjacent tool string component. An annular magnetic coupler is disposed within an annular recess formed in the at least one shoulder, and the magnetic coupler comprises a coil in electrical communication with an electrical conductor that is in electrical communication with an electronic device secured to the tubular body. The coil comprises a plurality of windings of wire strands that are electrically isolated from one another and which are disposed in an annular trough of magnetic material secured within the annular recess.

Owner:SCHLUMBERGER TECH CORP

Dissolvable downhole tools

A disposable downhole tool comprises a material that dissolves when exposed to a chemical solution, an ultraviolet light, a nuclear source, or a combination thereof. In an embodiment, the material comprises an epoxy resin, a fiberglass, or a combination thereof. In another embodiment, the material comprises a fiberglass and a binding agent. The material may also be customized to achieve a desired dissolution rate of the tool. In an embodiment, the disposable downhole tool further comprises an enclosure for storing the chemical solution. The tool may also comprise an activation mechanism for releasing the chemical solution from the enclosure. In an embodiment, the disposable downhole tool is a frac plug. In another embodiment, the tool is a bridge plug. In yet another embodiment, the tool is a packer.

Owner:HALLIBURTON ENERGY SERVICES INC

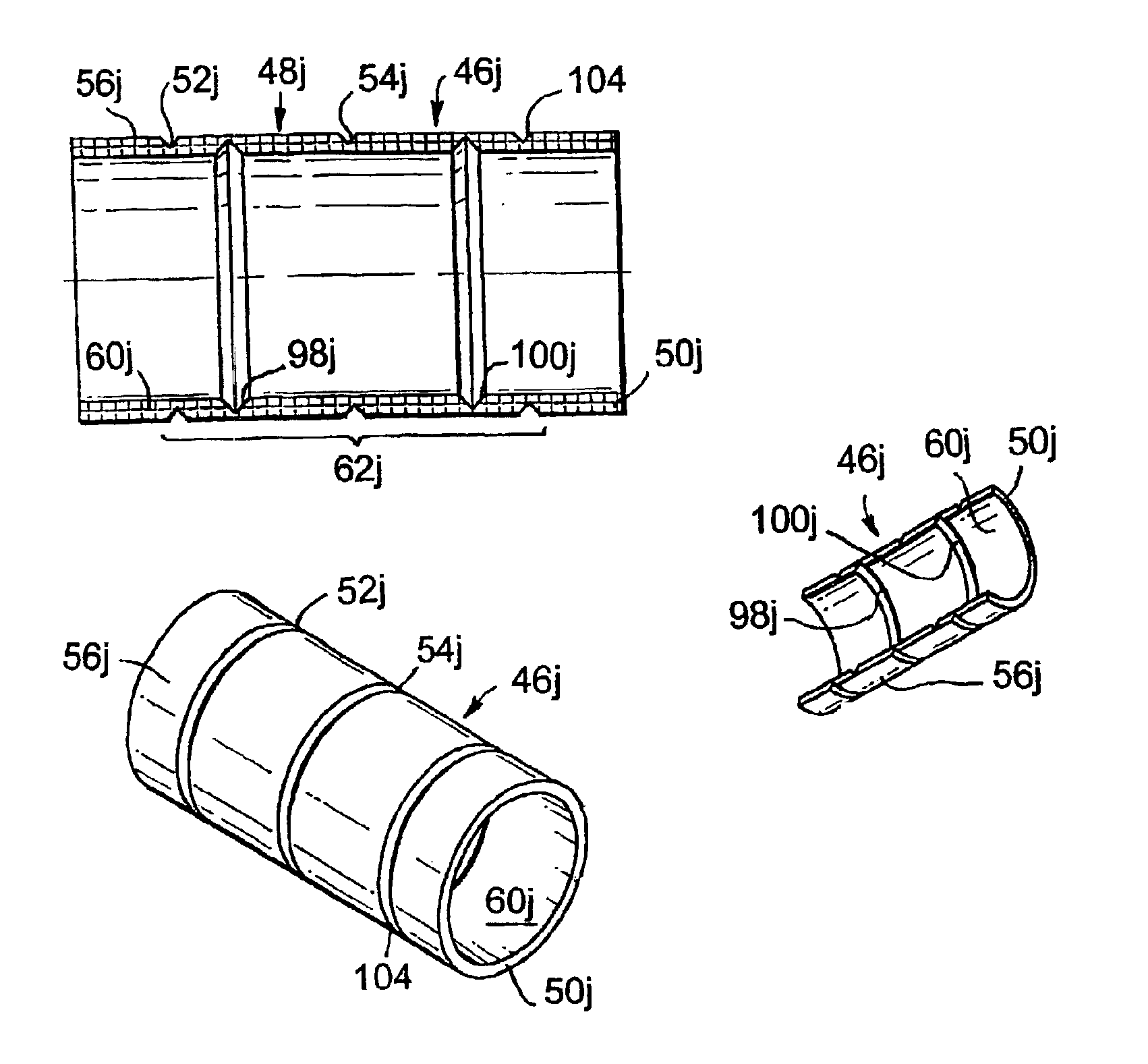

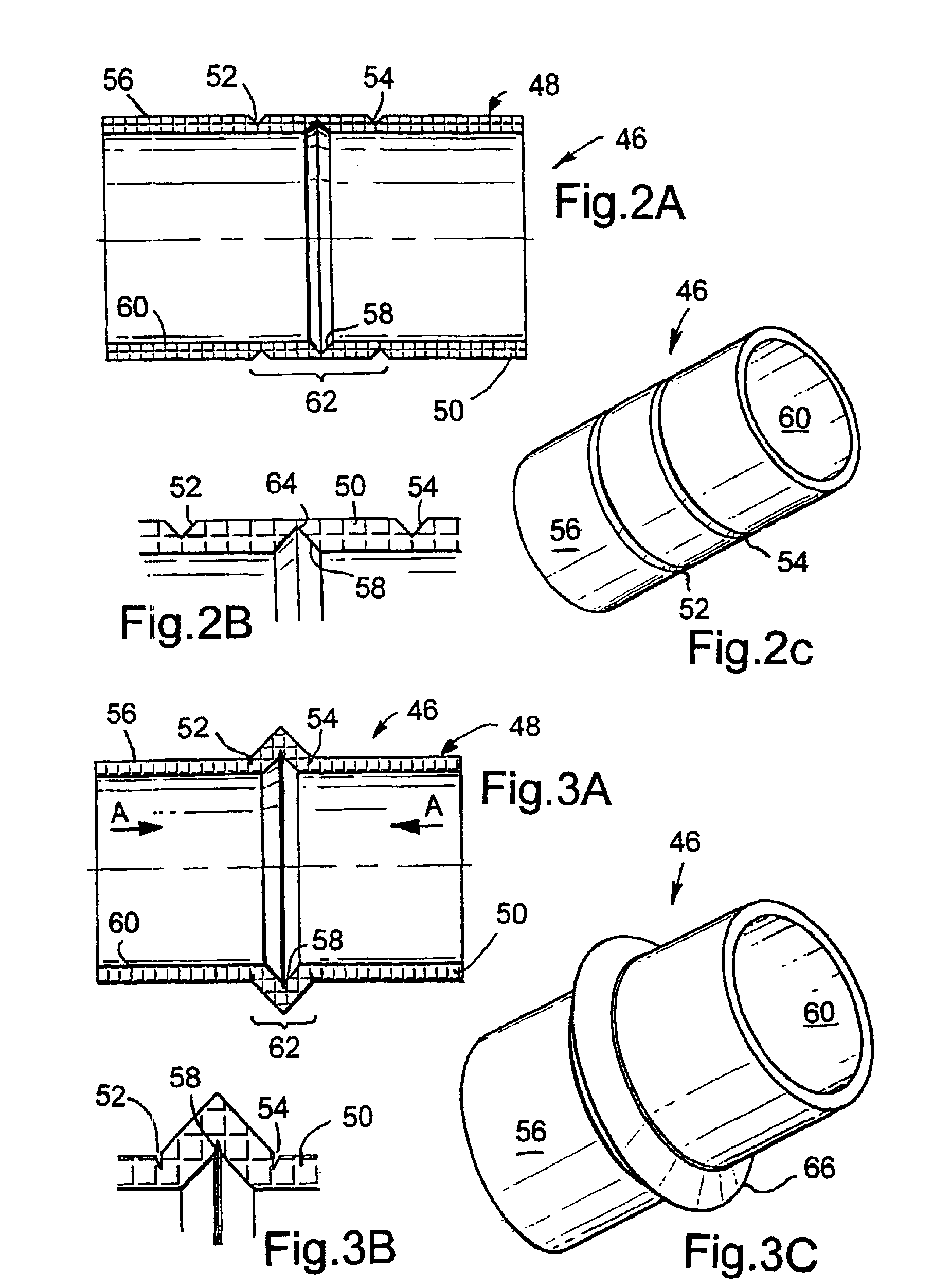

Deformable member

A deformable member can be used in a well tool for use in downhole oil / gas wells. In one embodiment, a deformable member (46) is described which is deformable between undeformed and deformed positions, and comprises a generally hollow cylindrical body (48) defining a wall (50). The wall (50) includes three circumferential lines of weakness in the form of grooves, with two grooves (52, 54) provided in an outer surface (56) of the member wall (50), and the other groove (58) provided in an inner surface (60). The member (46) is deformed outwardly by folding about the lines of weakness (52, 54, 56) and is used in particular to obtain sealing contact with a tube in which the member (46) is located.

Owner:ZEROTH TECH

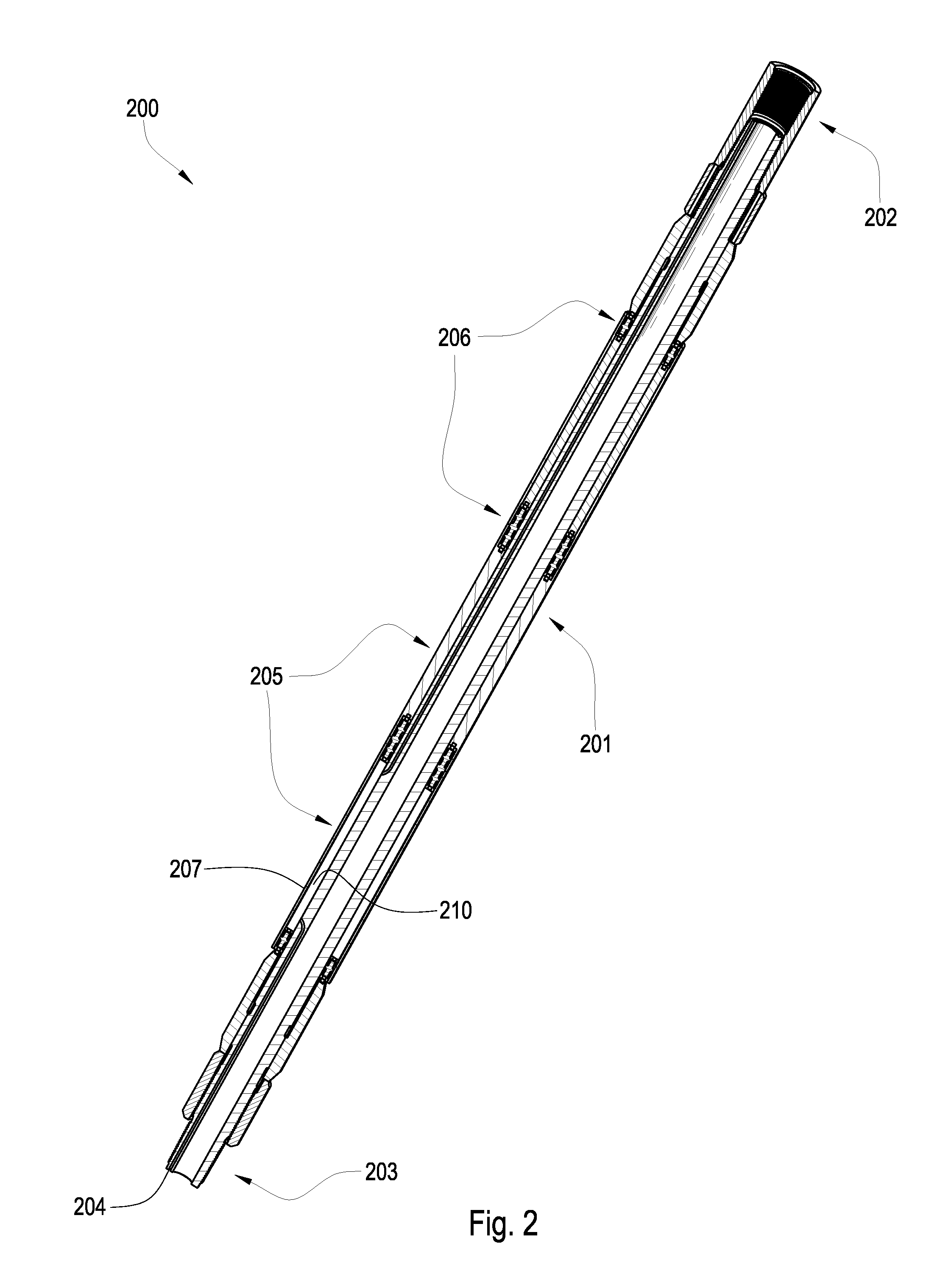

Method of providing hydraulic/fiber conduits adjacent bottom hole assemblies for multi-step completions

A technique for providing auxiliary conduits in multi-trip completions is disclosed. The technique has particular applicability to liner mounted screens which are to be gravel packed. In the preferred embodiment, a protective shroud is run with the gravel pack screens with the auxiliary conduits disposed in between. The auxiliary conduits terminate in a quick connection at a liner top packer. The gravel packing equipment can optionally be secured in a flow relationship to the auxiliary conduits so as to control the gravel packing operation. Subsequent to the removal of the specialized equipment, the production tubing can be run with an auxiliary conduit or conduits for connection down hole to the auxiliary conduits coming from the liner top packer for a sealing connection. Thereafter, during production various data on the well can be obtained in real time despite the multiple trips necessary to accomplish completion. The various completion and / or production activities can also be accomplished using the auxiliary conduits such as actuation of down hole flow control devices, chemical injection, pressure measurement, distributed temperature sensing through fiber optics, as well as other down hole parameters.

Owner:BAKER HUGHES INC

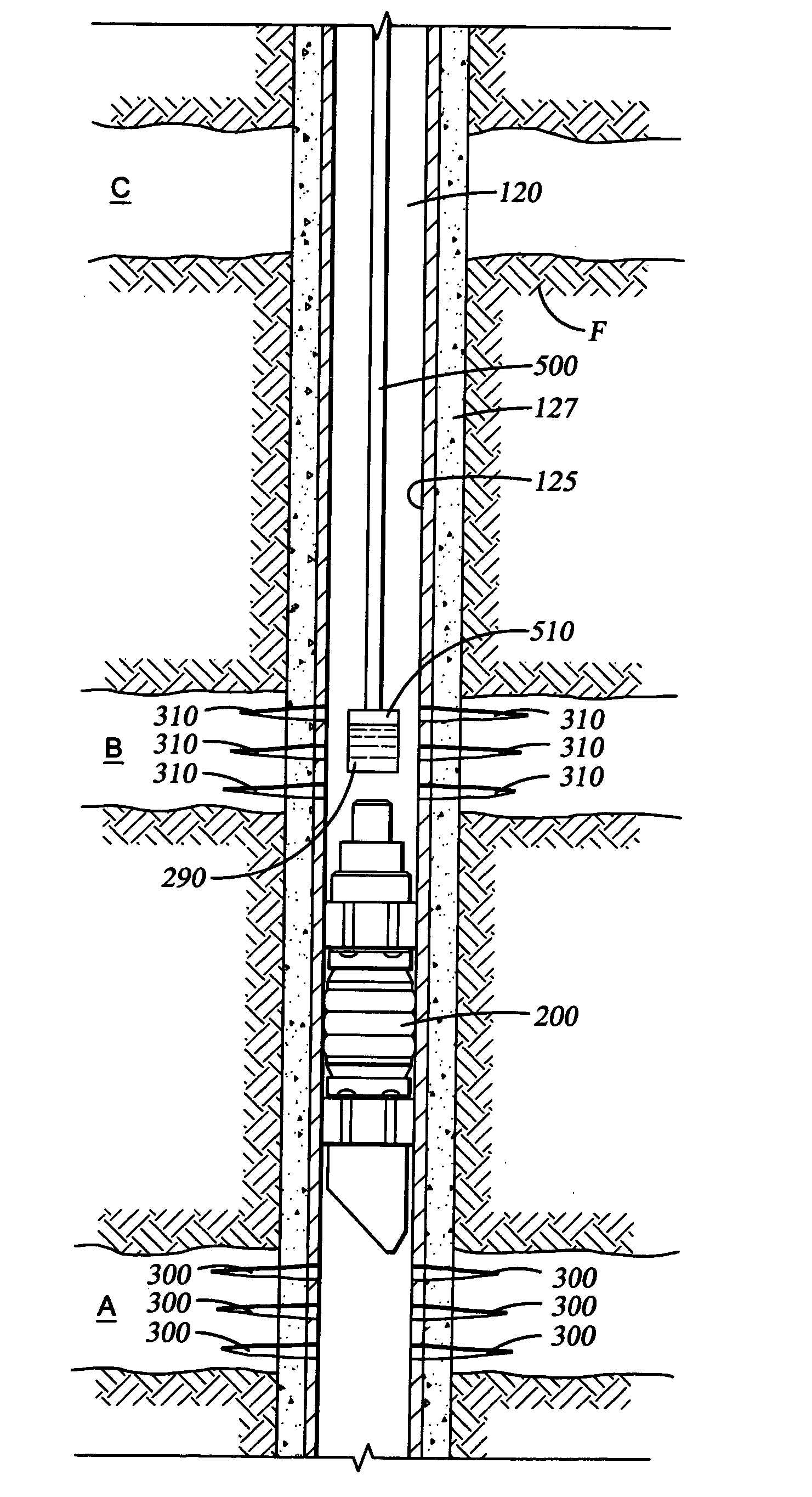

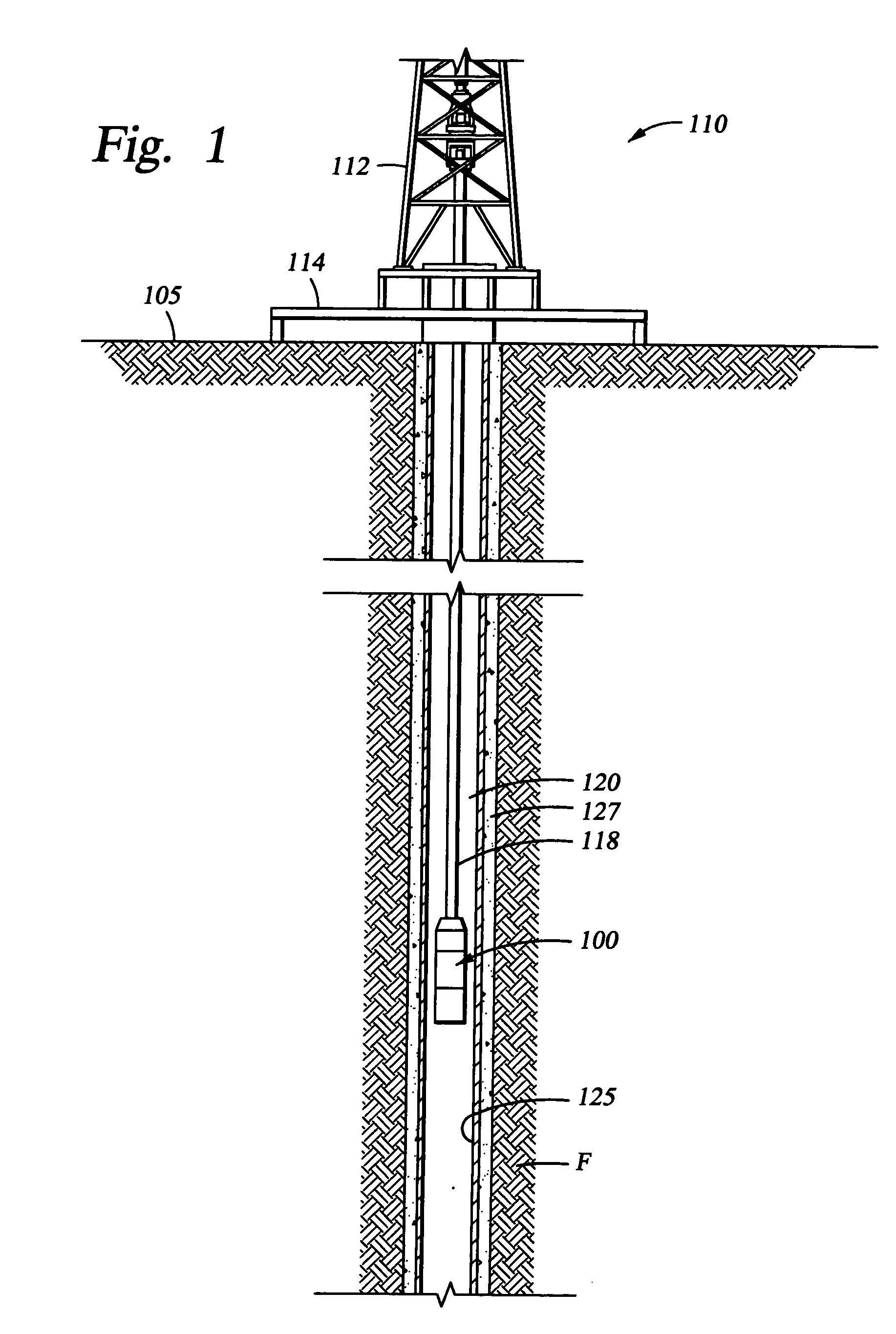

Apparatus and methods for self-powered communication and sensor network

A measurement and communication system for use with a tubular string, comprises a tubular string having a plurality of self-powered, autonomous telemetry stations disposed at predetermined locations along the tubular string. Each autonomous telemetry station is adapted to receive at least one first signal and transmit at least one second signal related to the at least one first signal. Power is extracted from potential energy sources proximate each autonomous telemetry station. A method of communicating information along a tubular string comprises, disposing an autonomous telemetry station at predetermined locations along the tubular string. A preferred transmission path is autonomously determined at each of the autonomous telemetry stations. Information is transmitted along the tubular string according to the autonomously determined preferred path.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com