Patents

Literature

1477results about How to "Increase clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

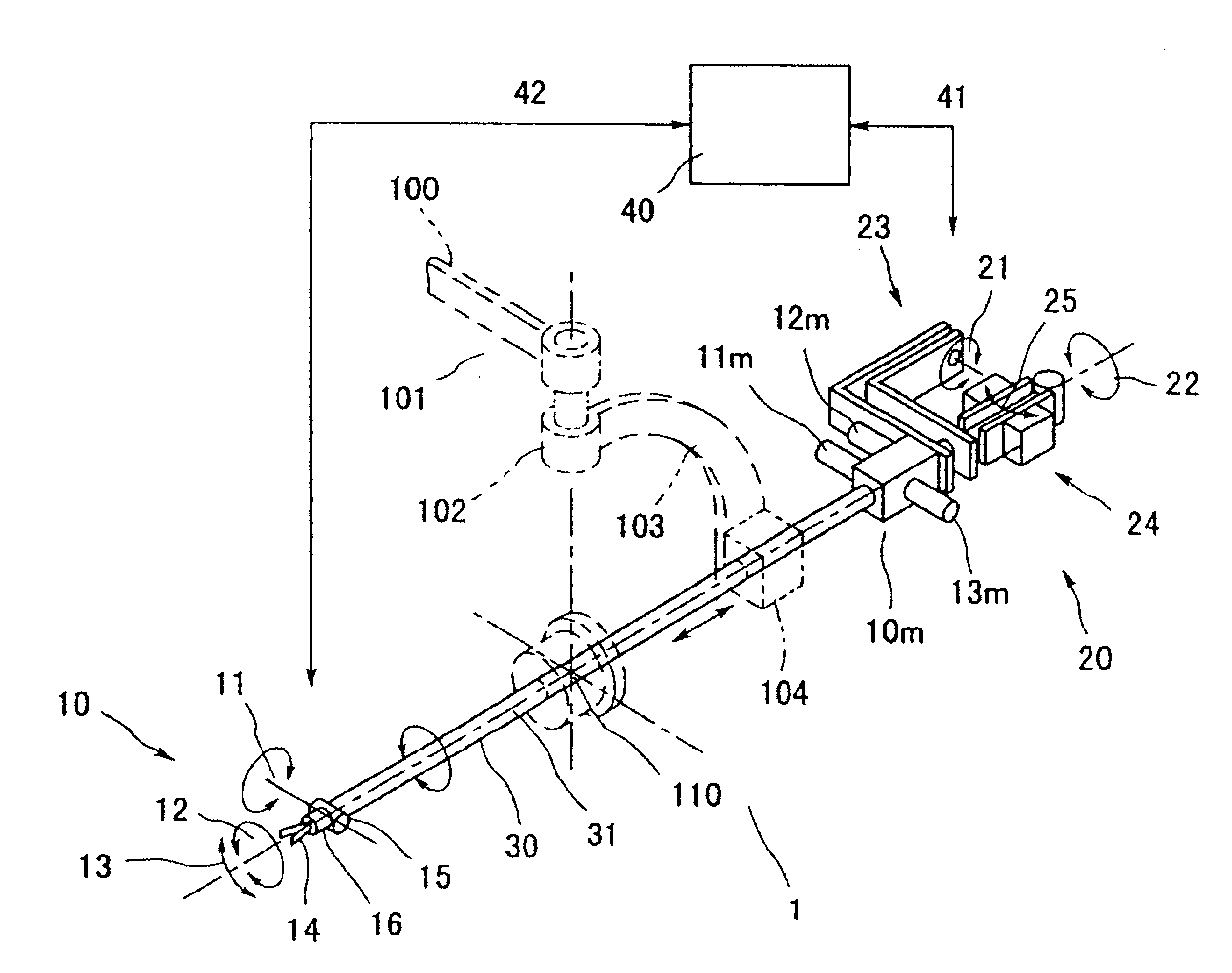

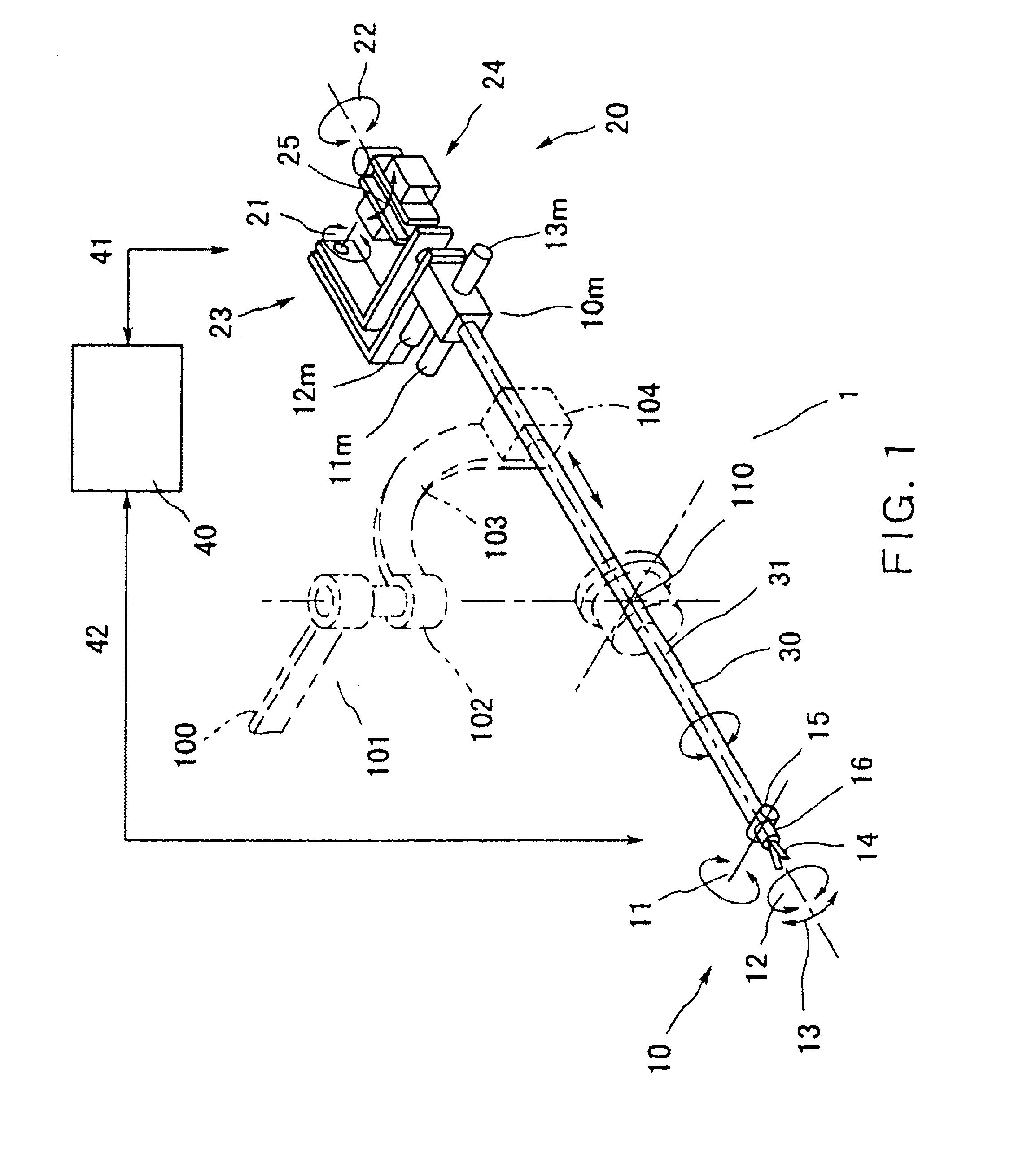

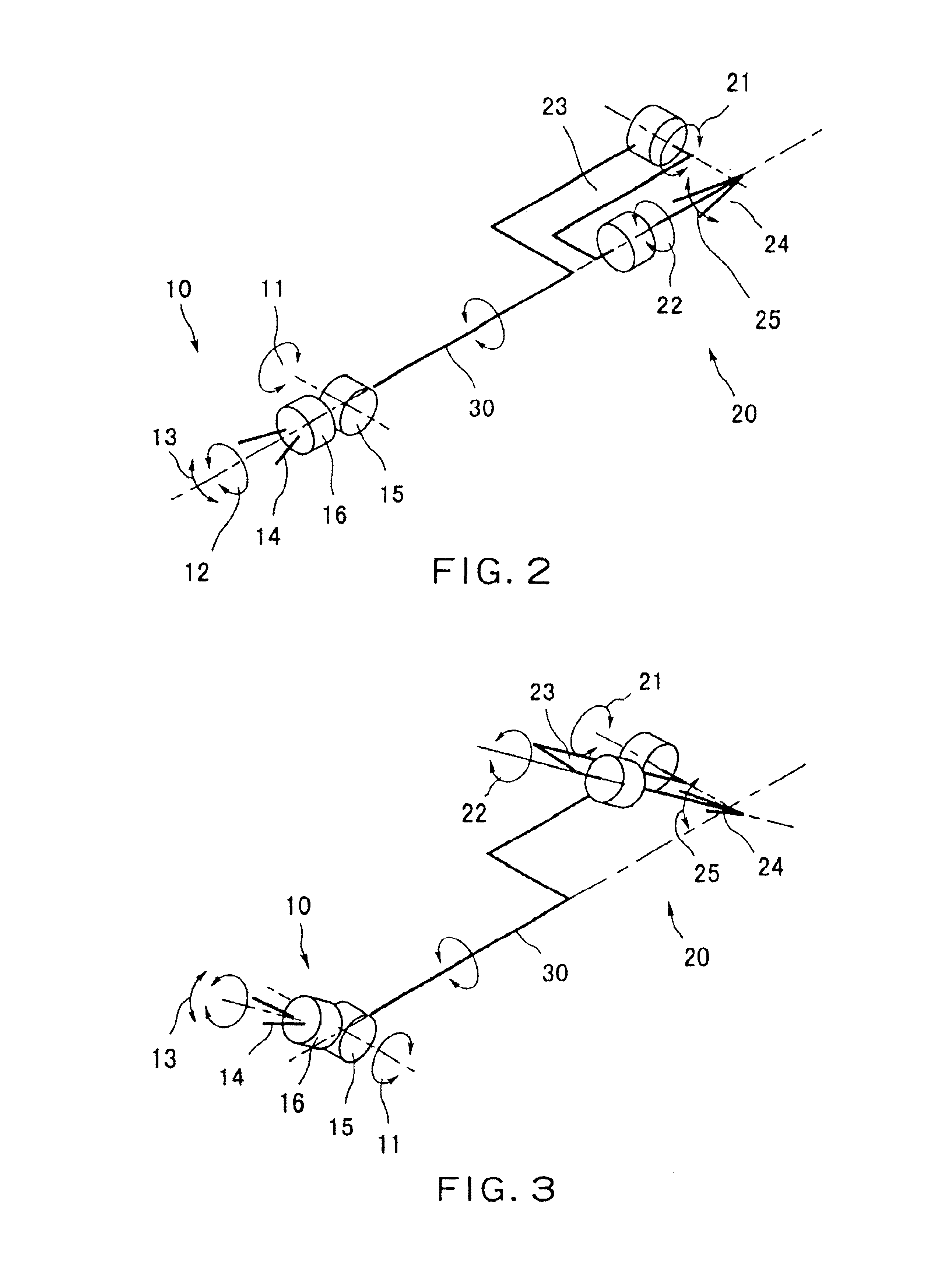

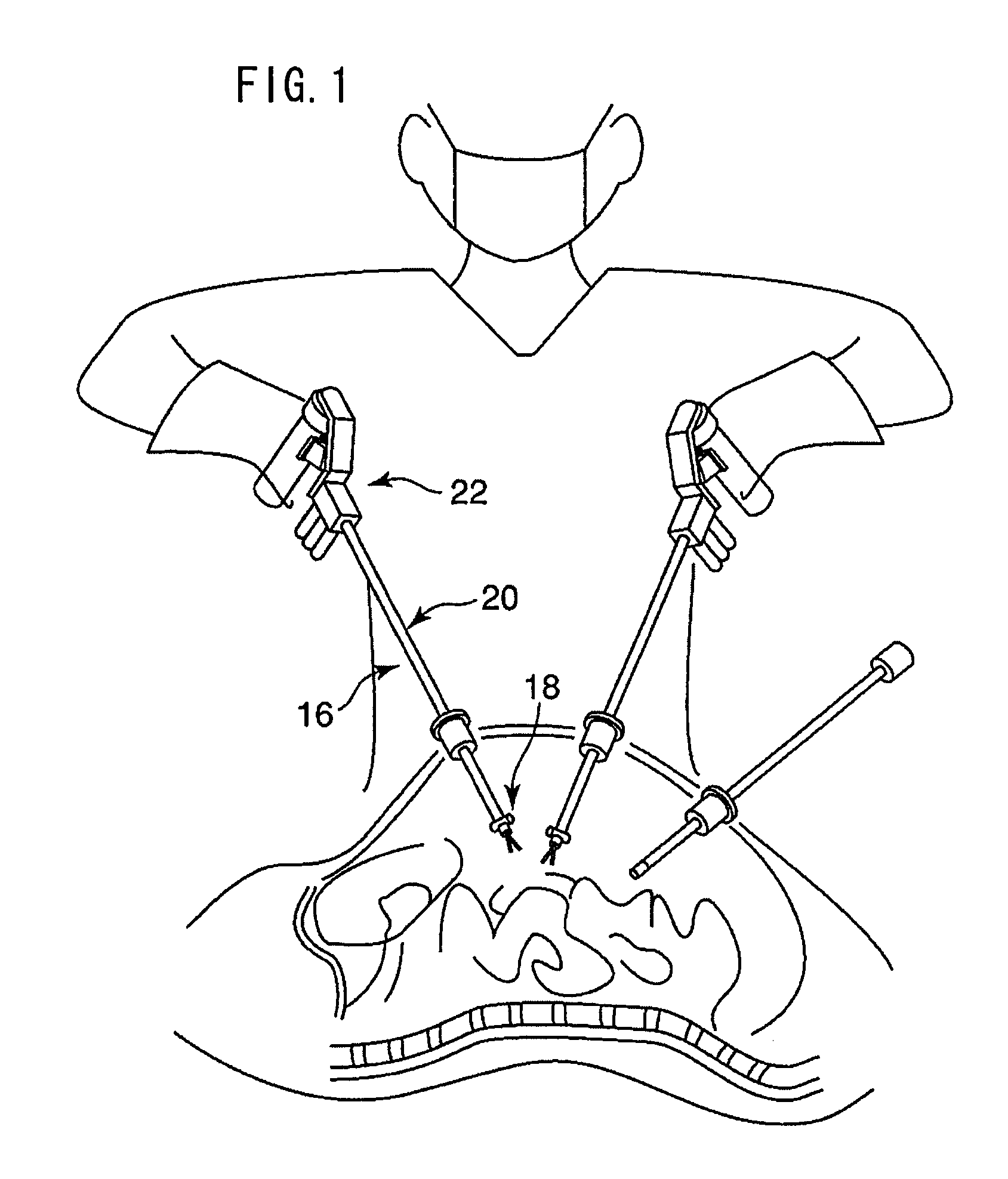

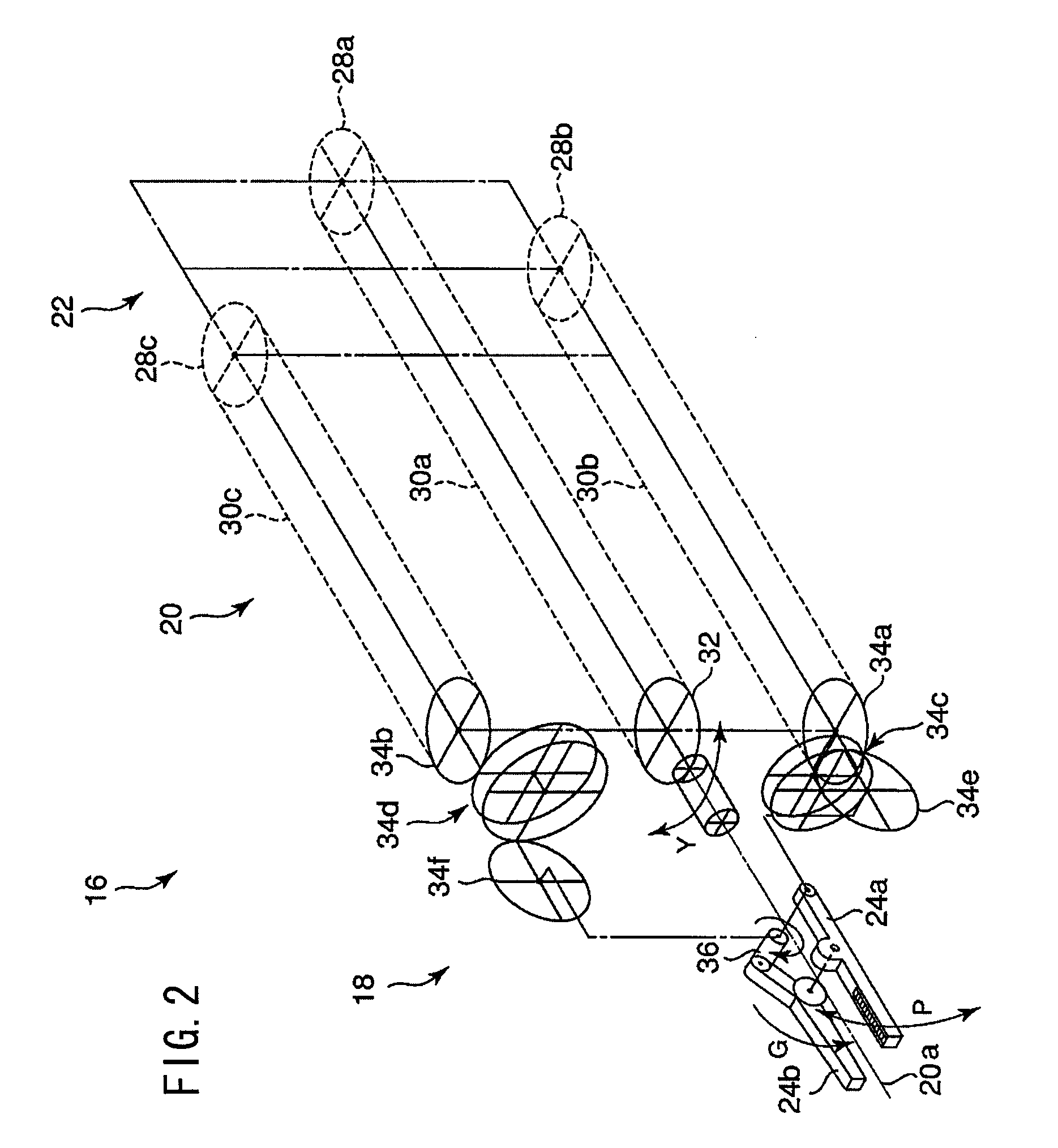

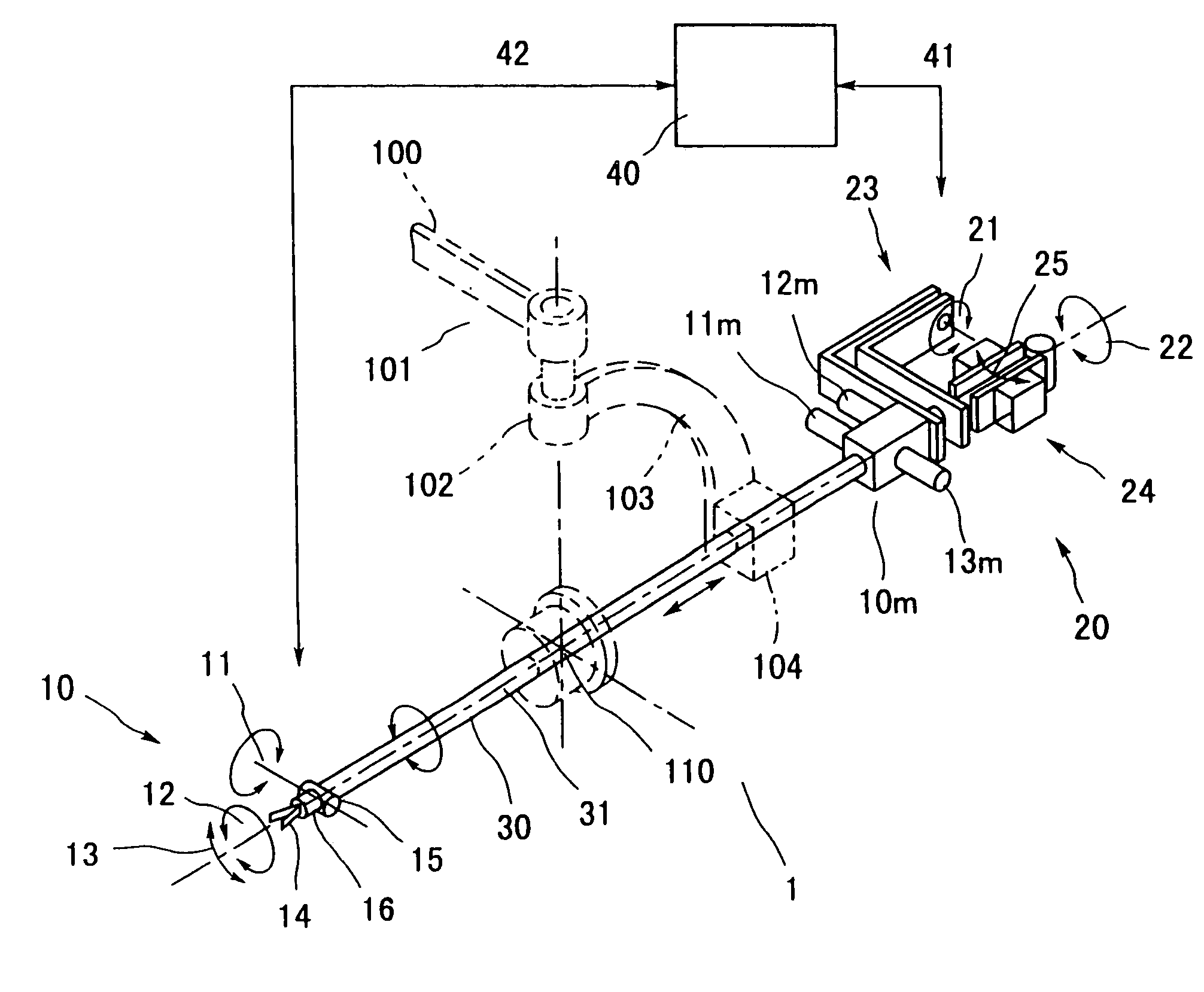

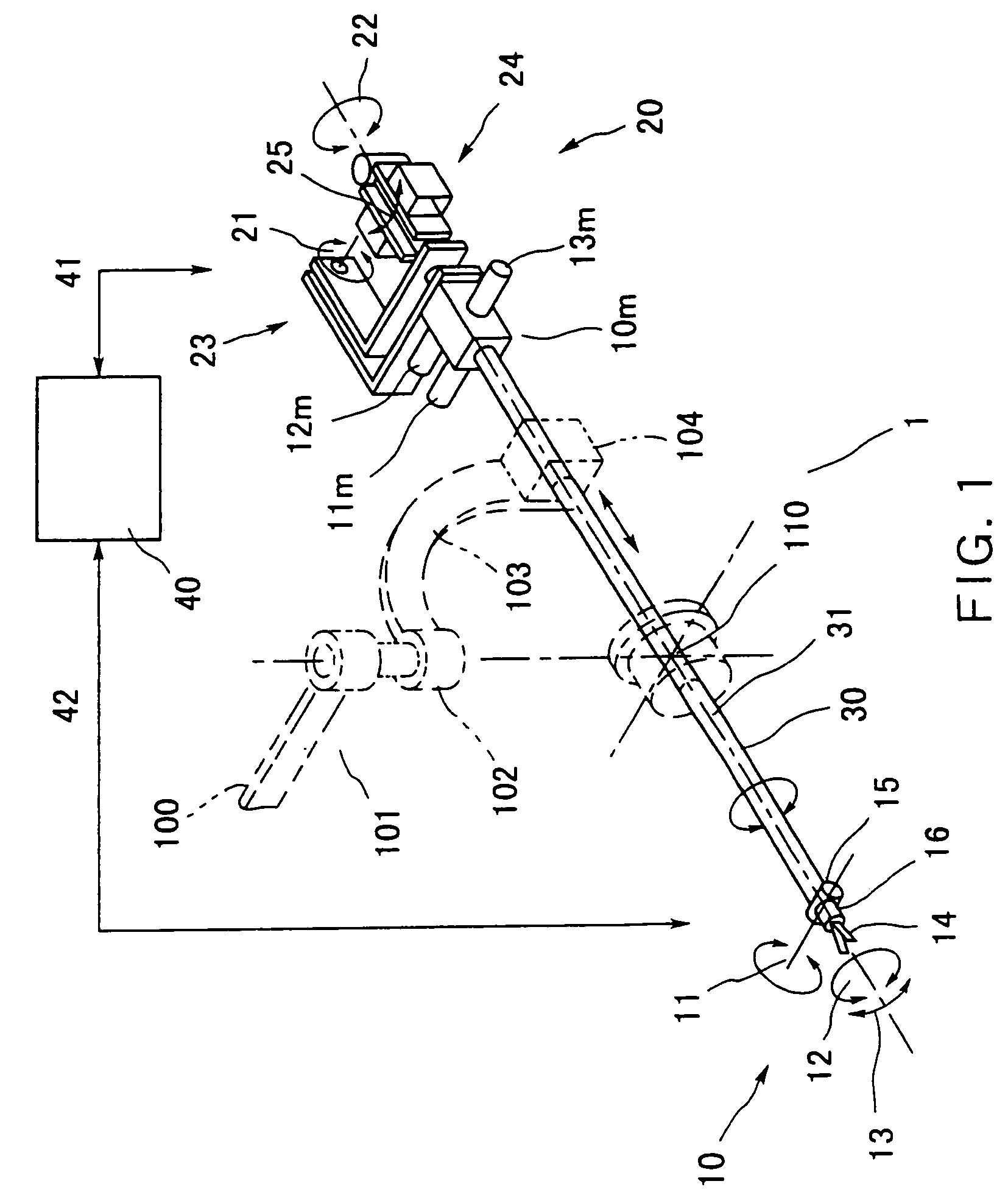

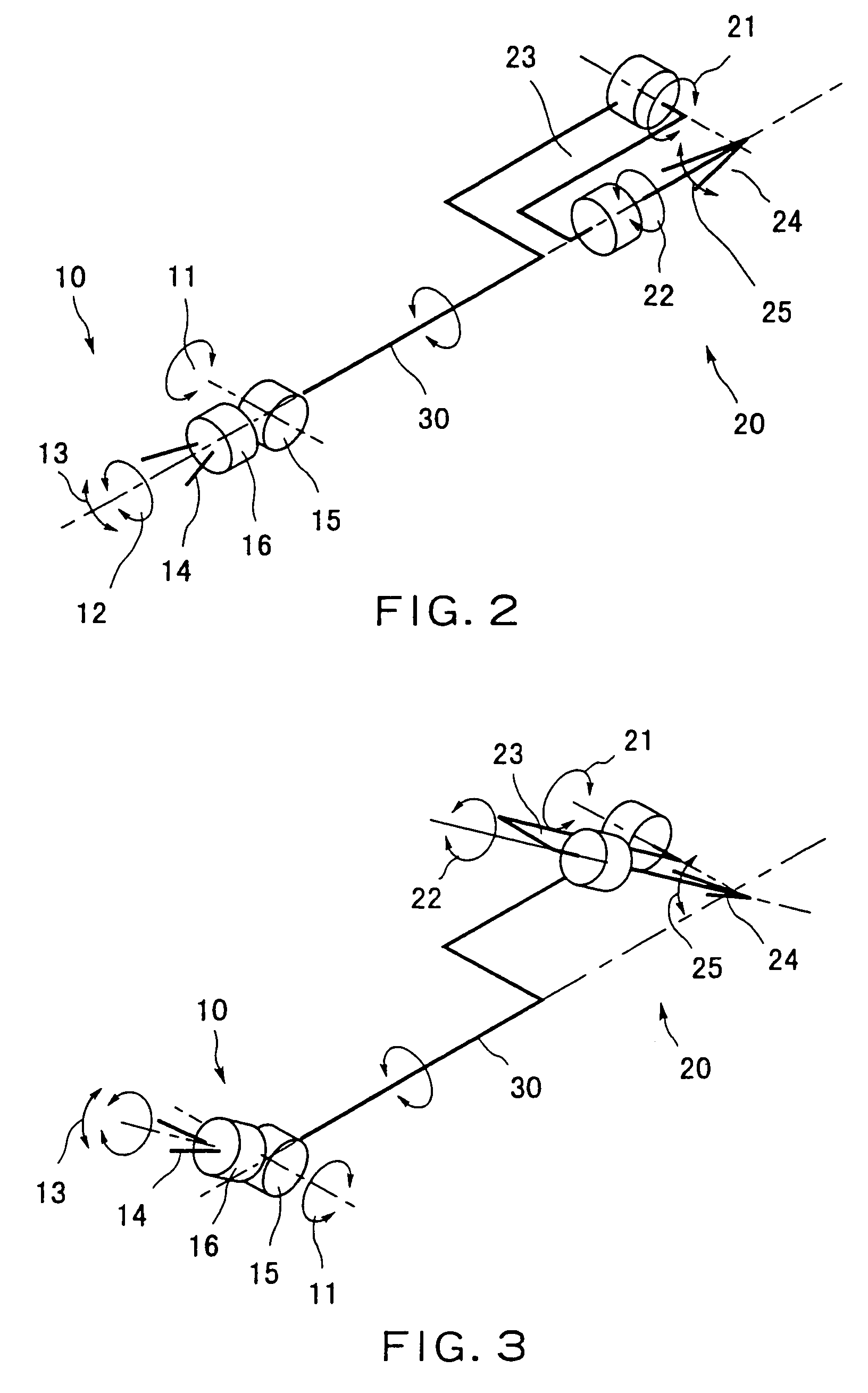

Manipulator

A manipulator comprises an operation command unit provided with an attitude adjusting unit and an end effector control unit, a connecting unit having one end connected to the operation command unit, a working unit connected to the other end of the connecting unit and provided with an end effector and a support unit supporting the end effector for motions, and a control unit that transmits an operation command provided by the attitude adjusting unit to the support unit to adjust the attitude of the end effector and transmits an operation command provided by the end effector control unit to the end effector to operate the end effector. The support unit includes a first joint capable of turning about a first axis perpendicular to the center axis of the connecting unit, and a second joint capable of turning about a second axis perpendicular to the first axis. The end effector can be turned for rolling about an axis substantially parallel to the second axis of the second joint. The attitude adjusting unit has a third joint having a third axis perpendicular to the center line of the connecting unit. The end effector control unit is formed such that the fingers of an operator gripping operating members included in the end effector control unit extend substantially in parallel to the fourth axis.

Owner:KARL STORZ GMBH & CO KG

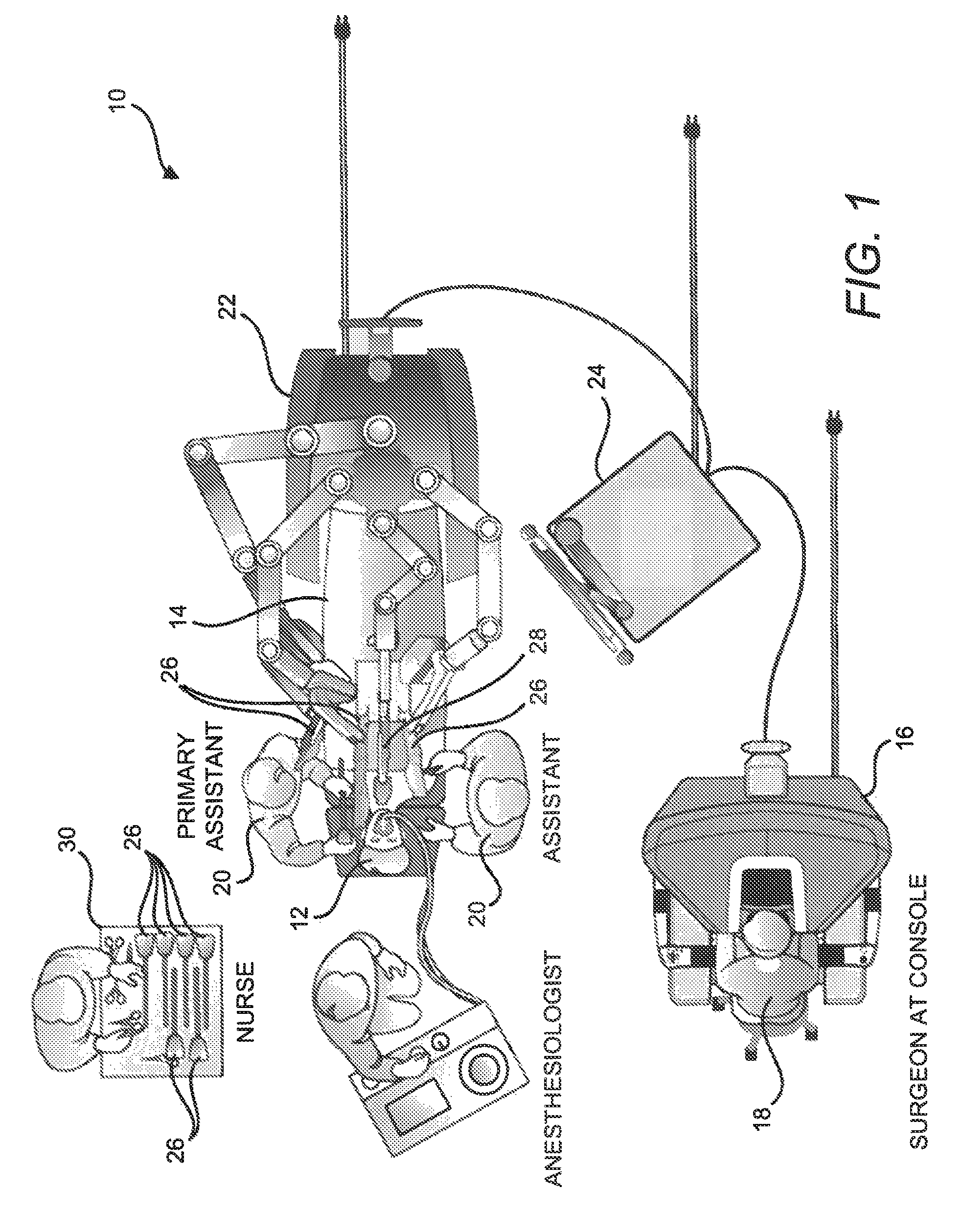

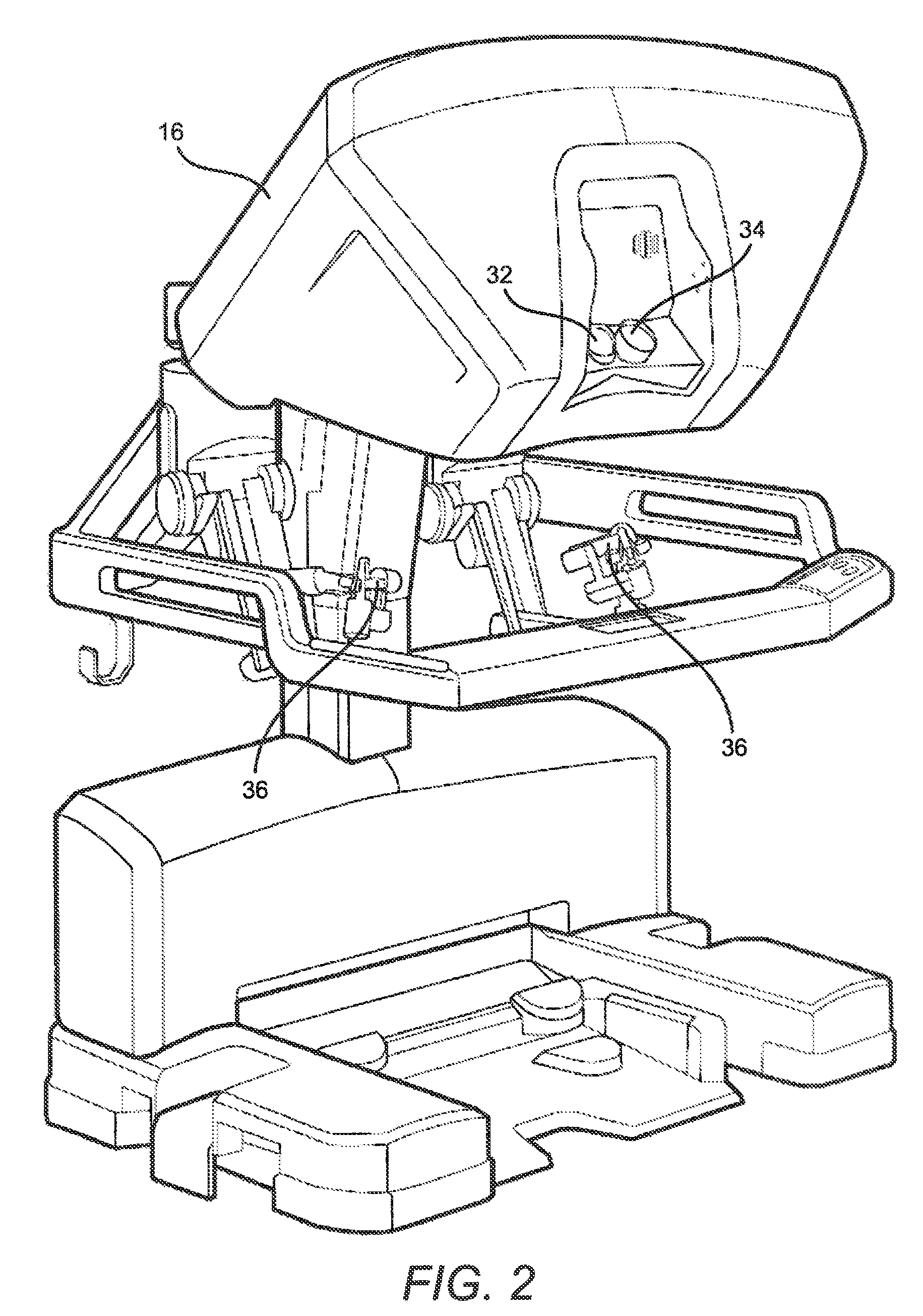

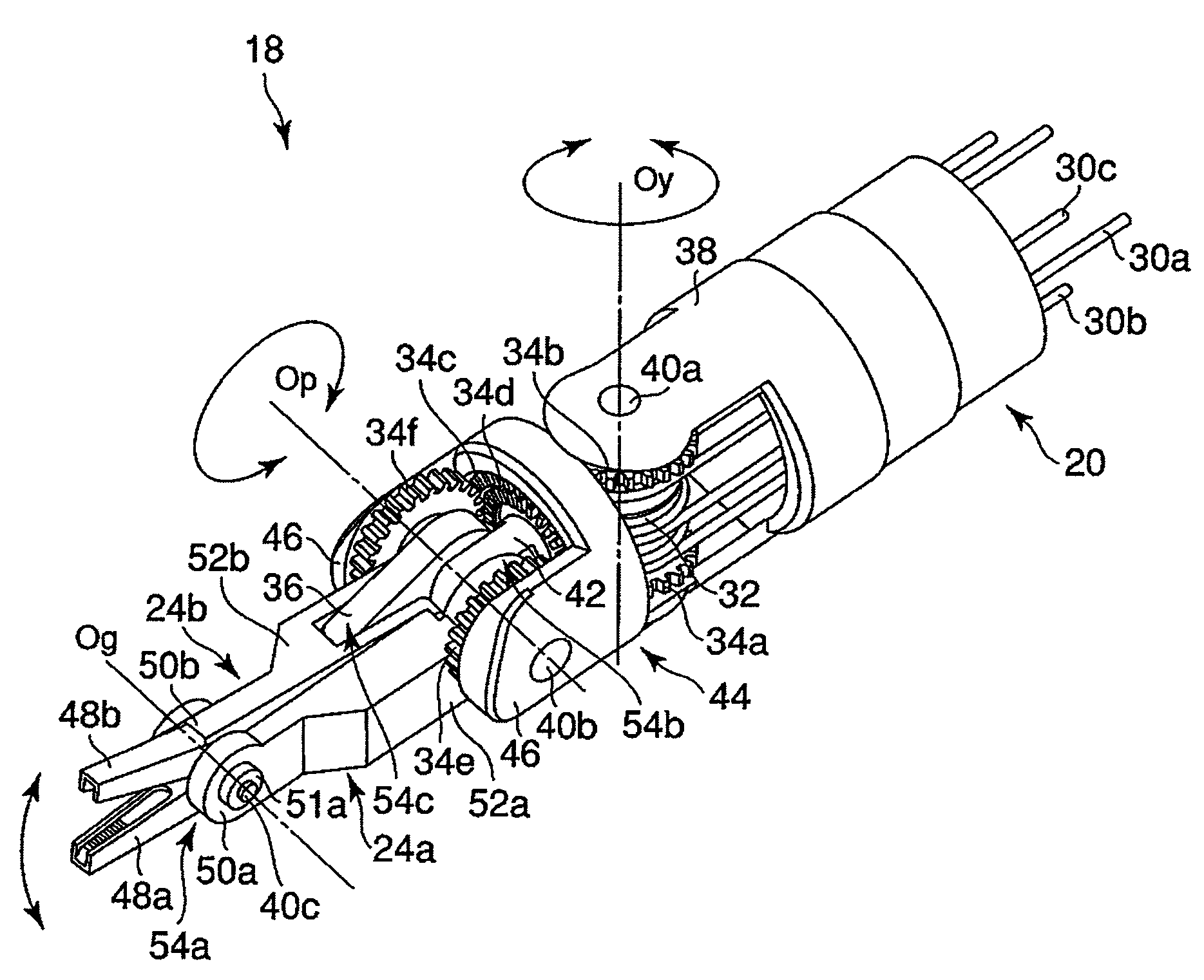

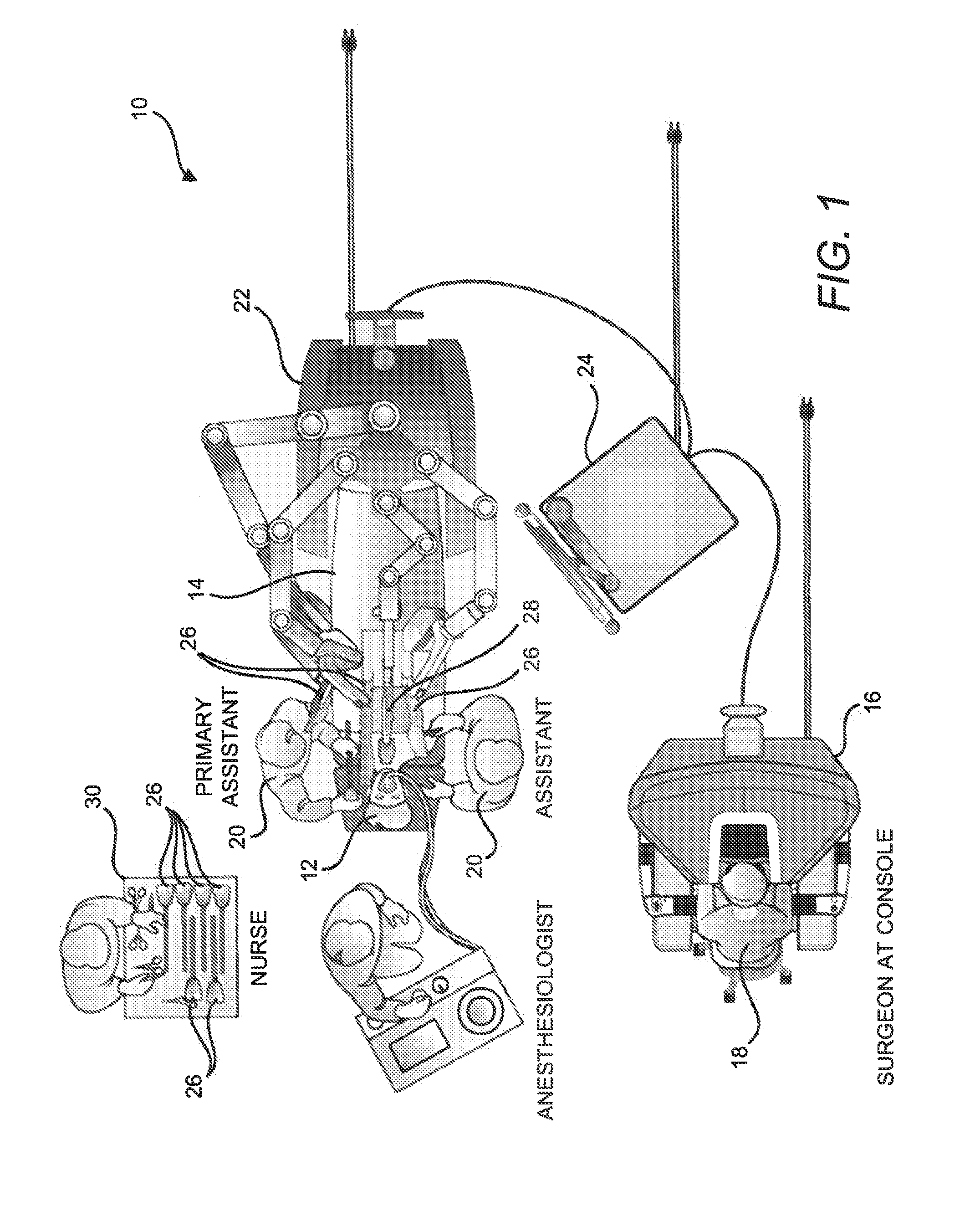

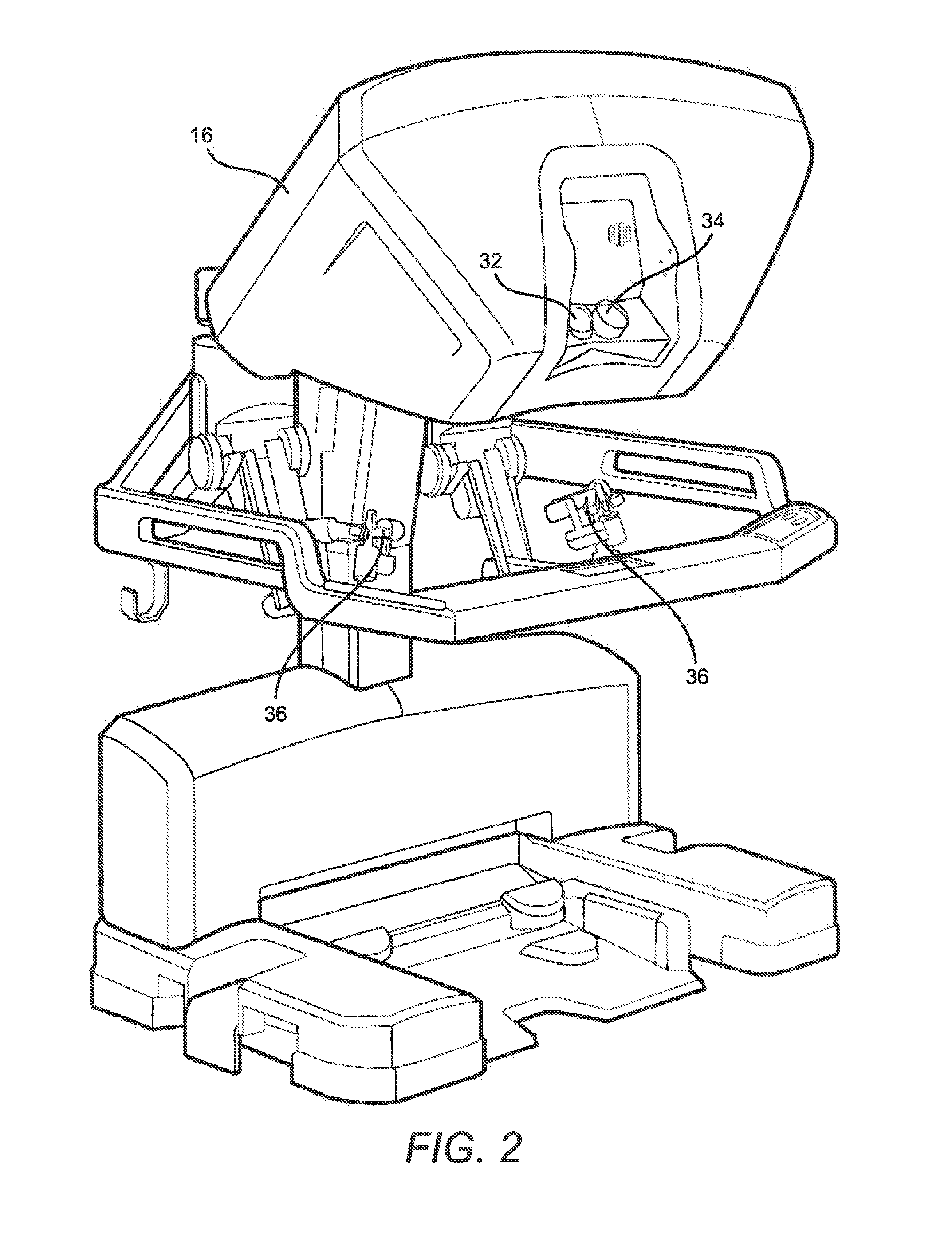

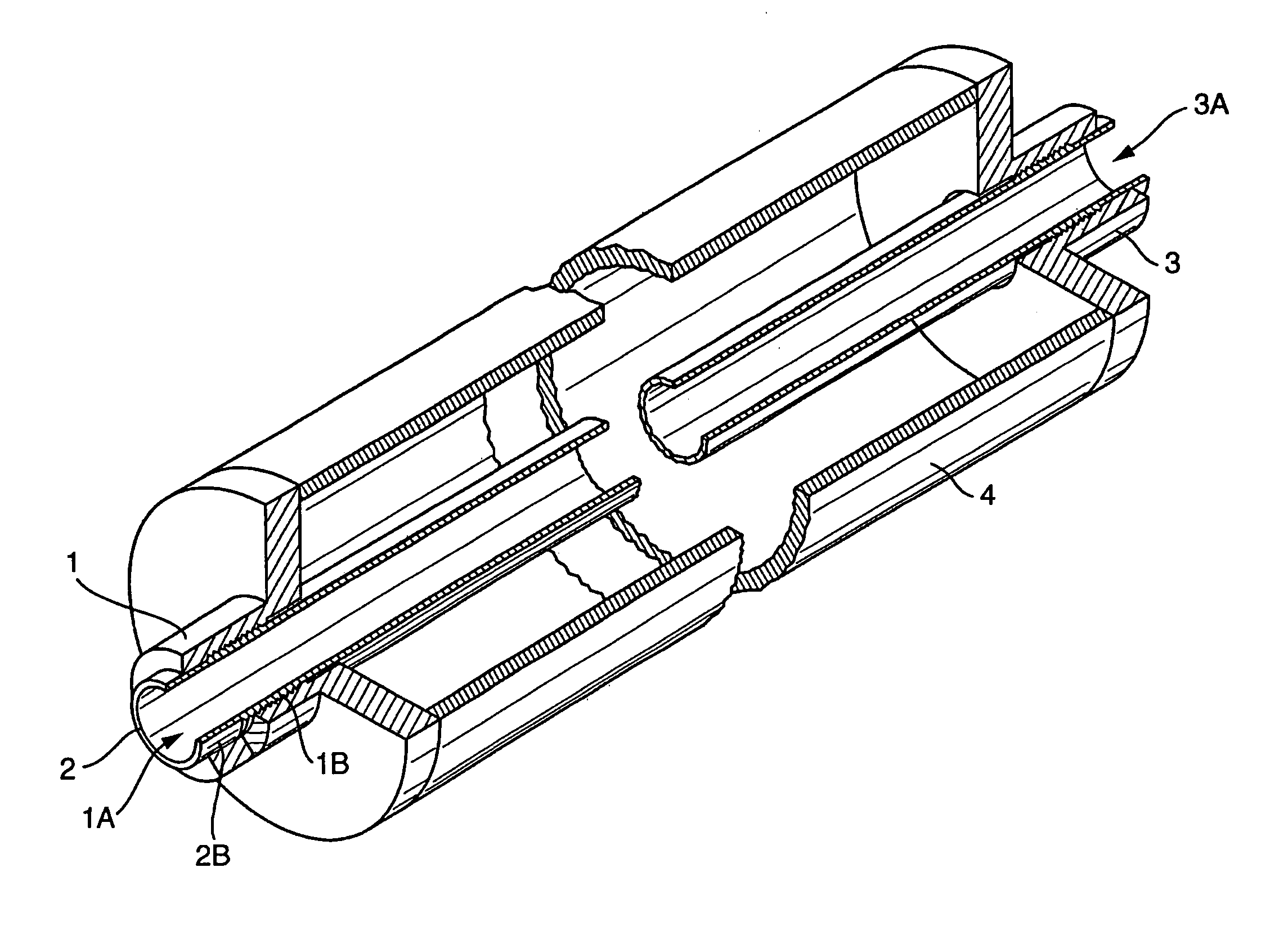

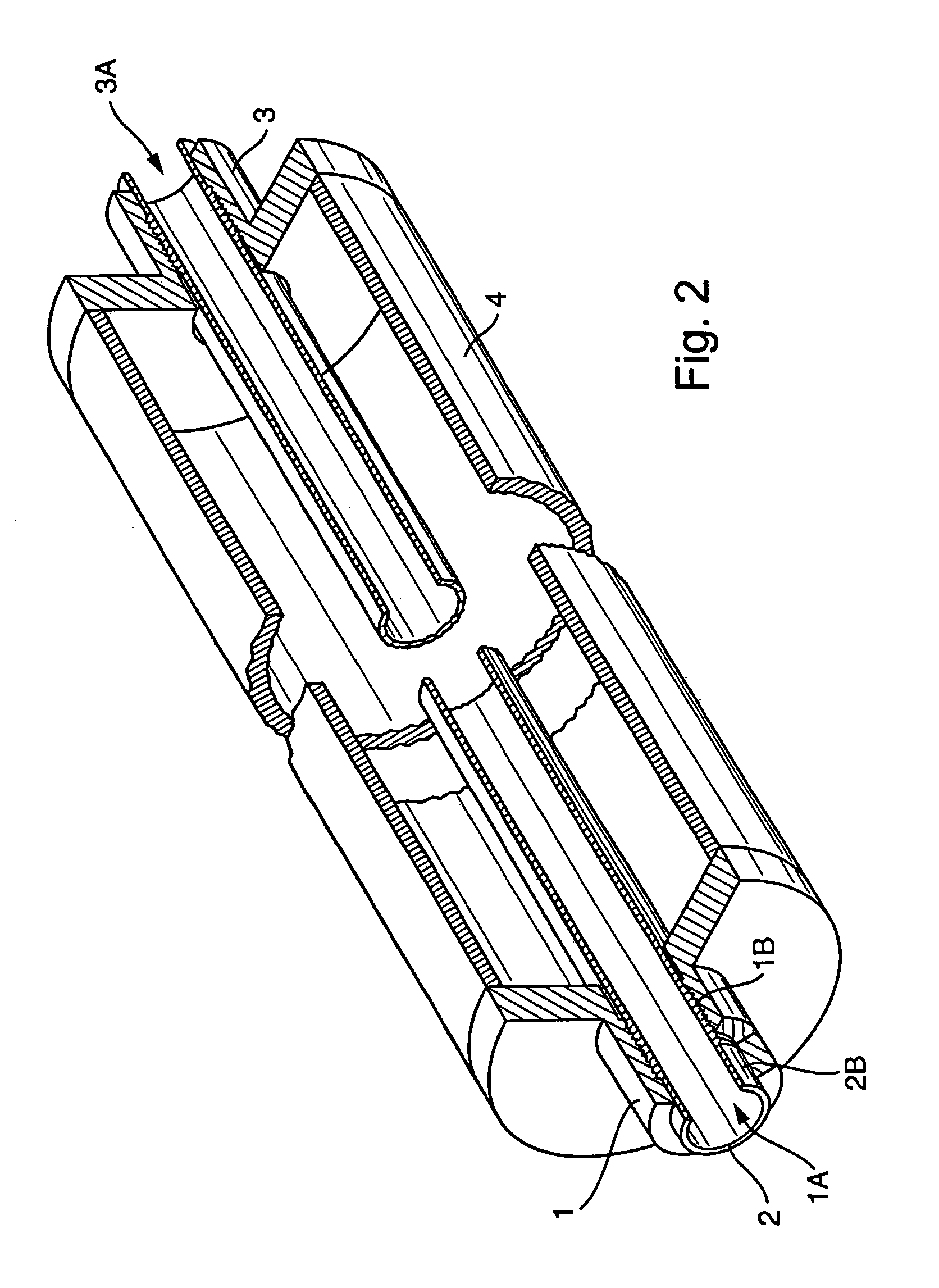

Motor interface for parallel drive shafts within an independently rotating member

ActiveUS8640788B2Force articulationIncrease clamping forceDrilling rodsConstructionsRotational axisDrive shaft

Owner:INTUITIVE SURGICAL OPERATIONS INC

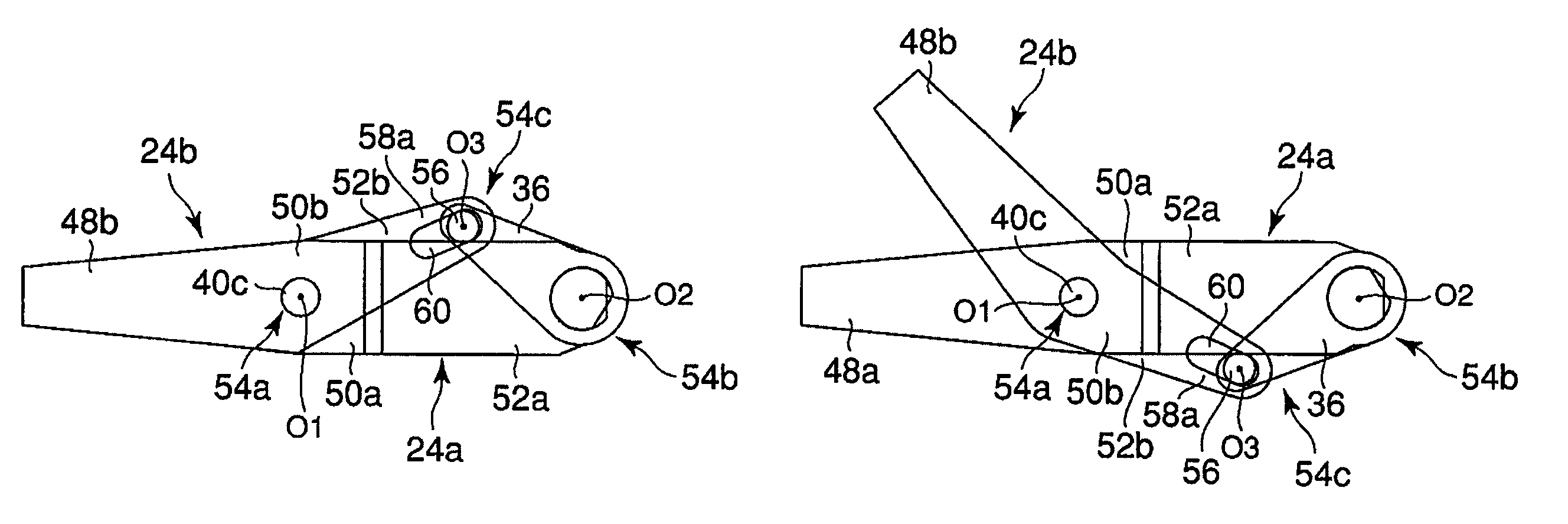

Manipulator

A manipulator has a working unit in which when at least a first end effector finger and a second end effector finger are maximally closed on each other, at least the distance between a third joint axis and a first joint axis is greater than the distance between the first joint axis and a distal end of the second end effector finger, or the distance between the third joint axis and the first joint axis is greater than the distance between third joint axis and a second joint axis, or the angle formed between a direction from the third joint axis to the first joint axis and a direction from the third joint axis to the second joint axis is not π.

Owner:KARL STORZ GMBH & CO KG

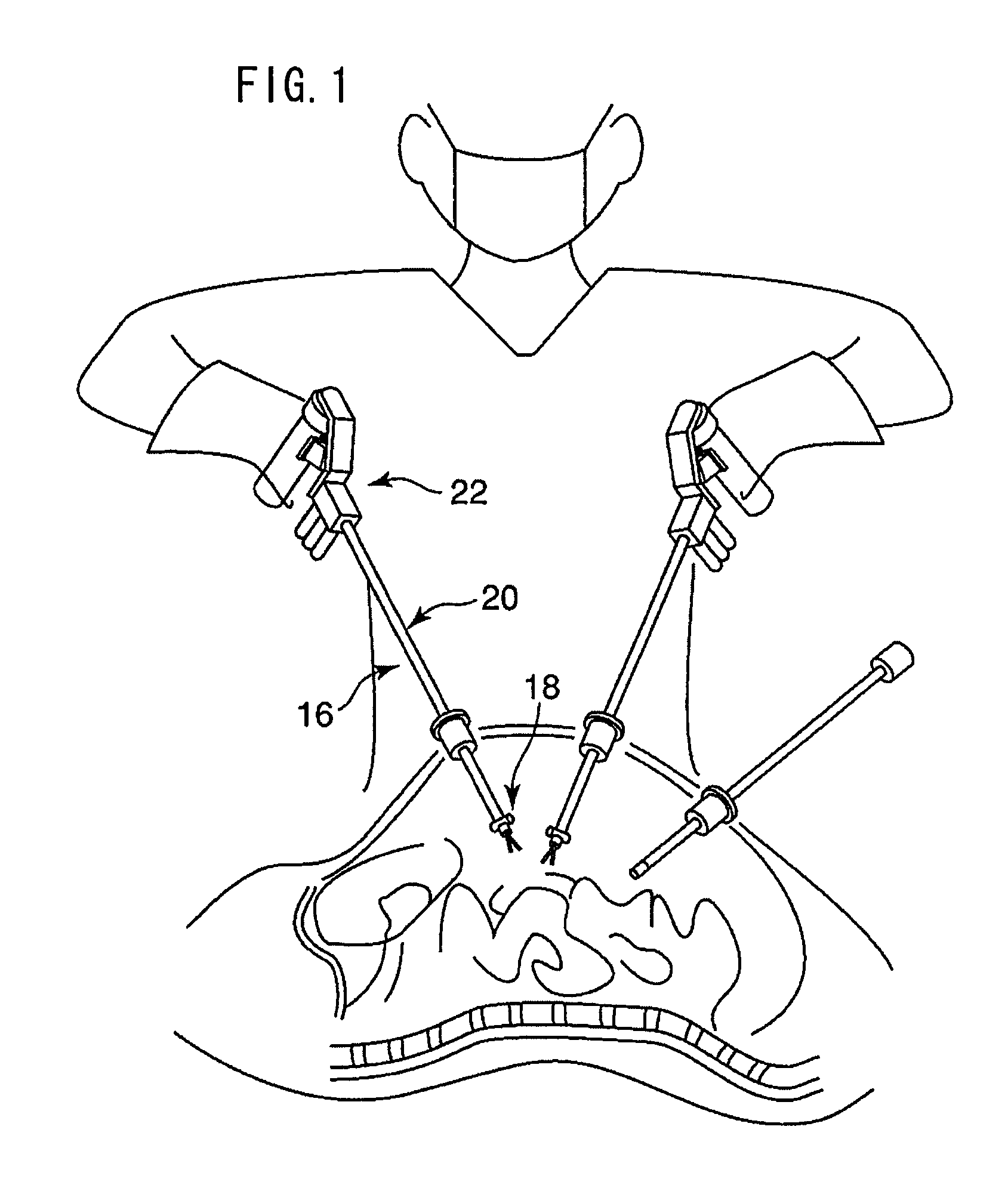

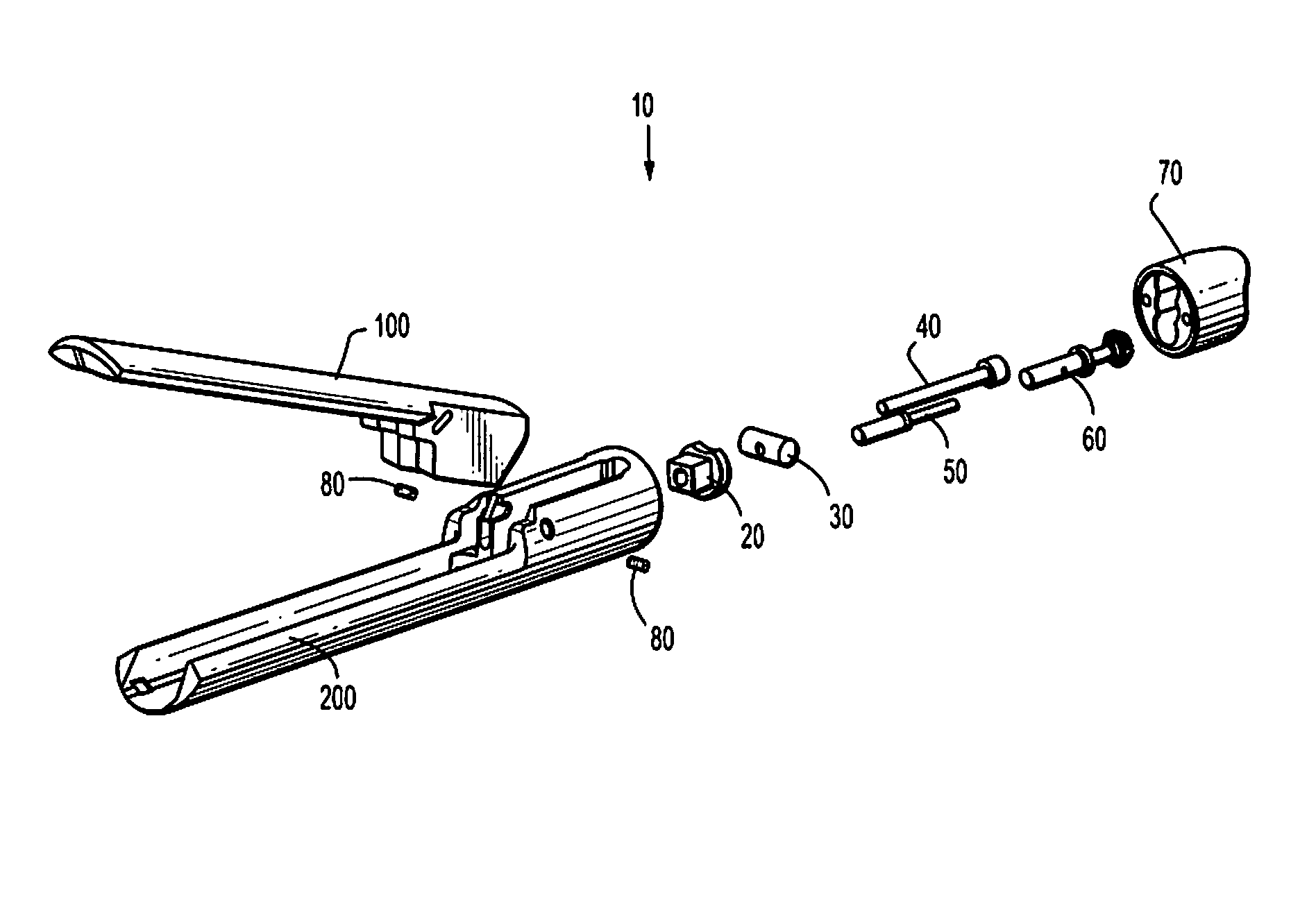

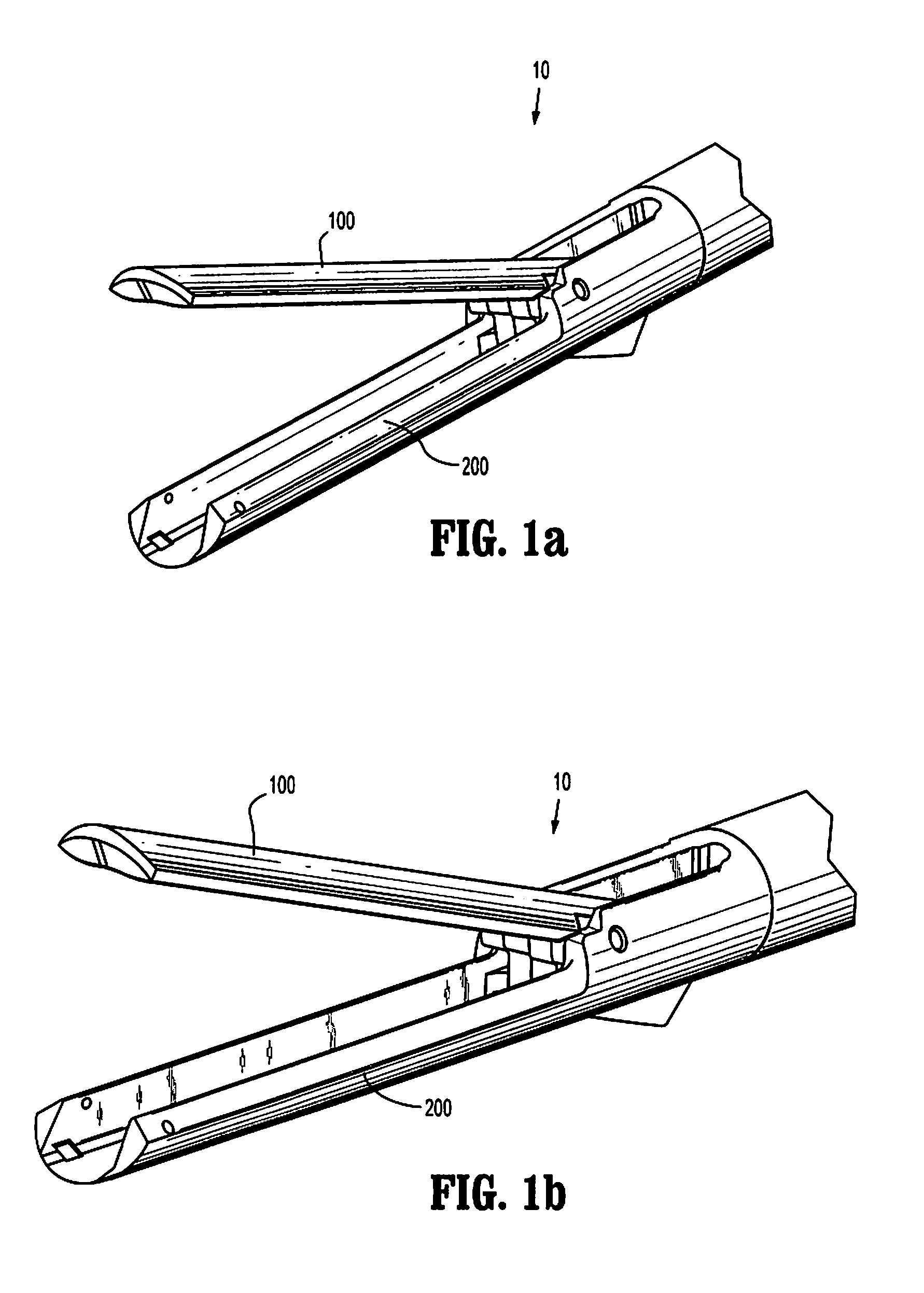

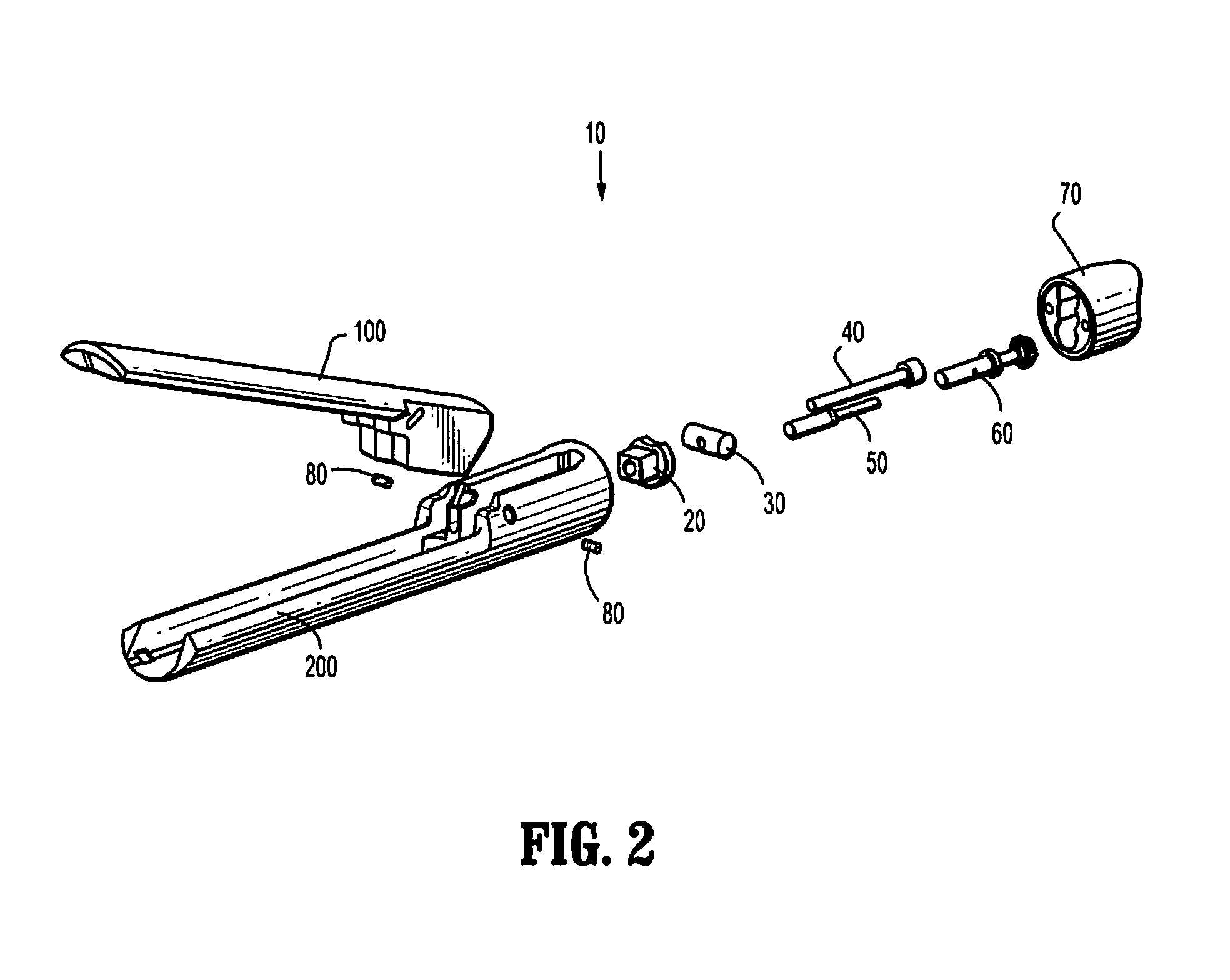

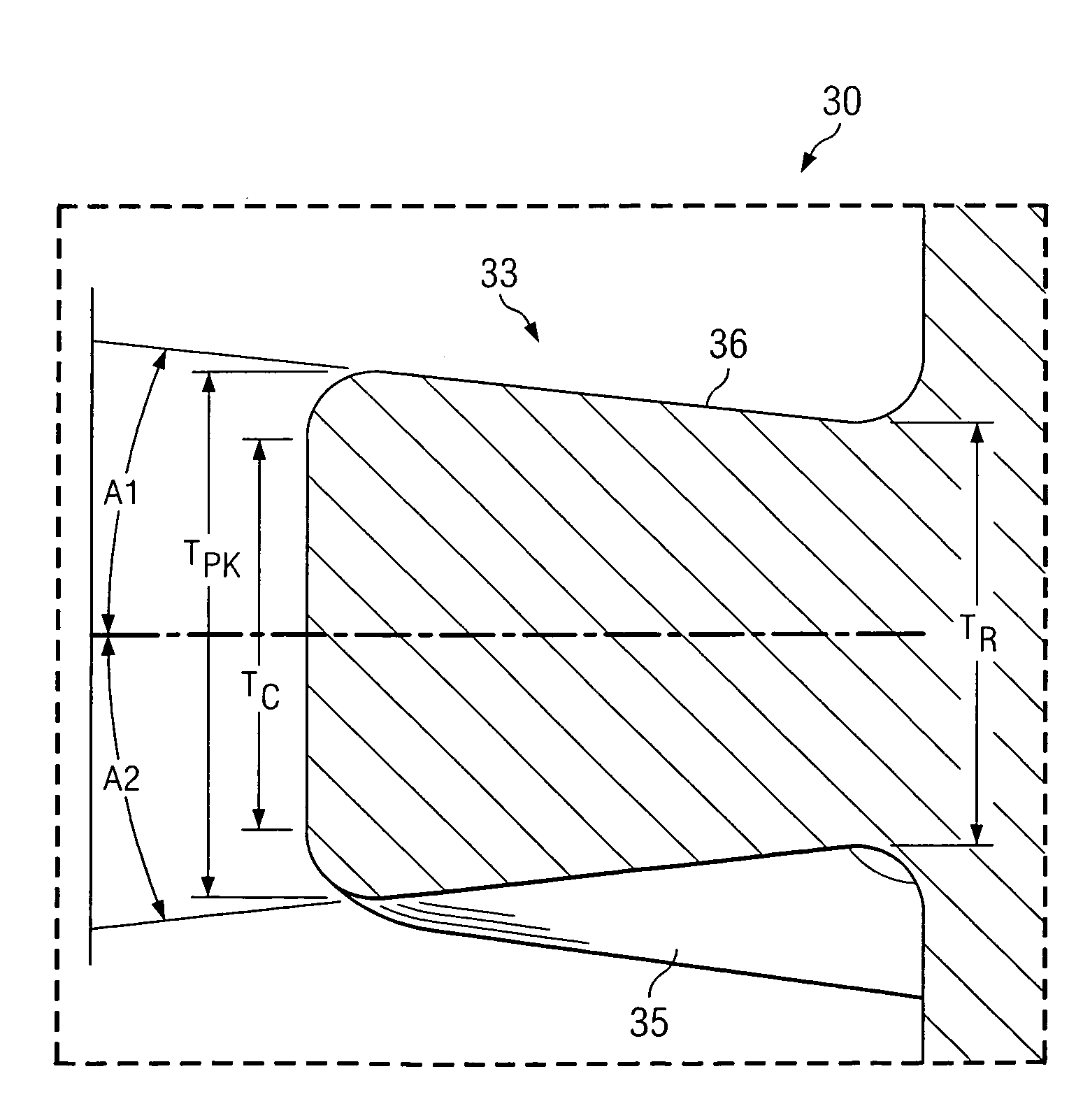

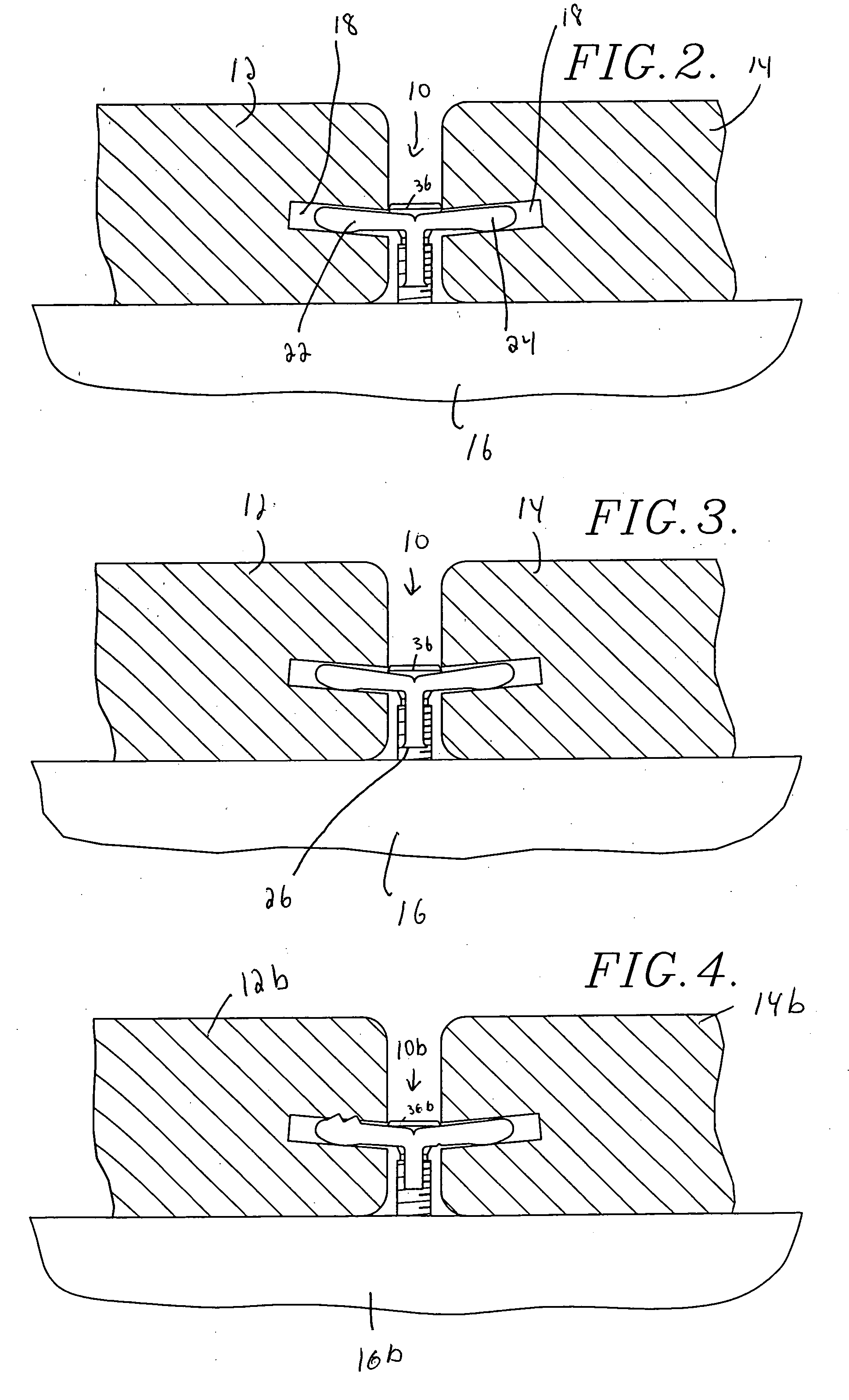

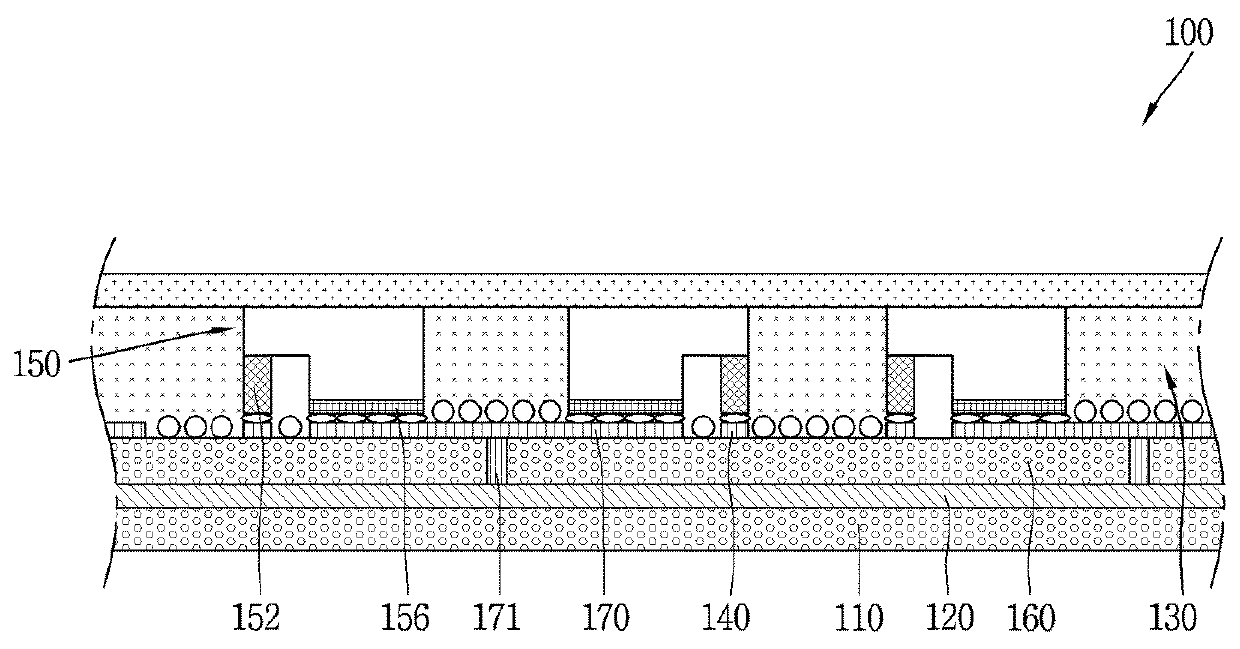

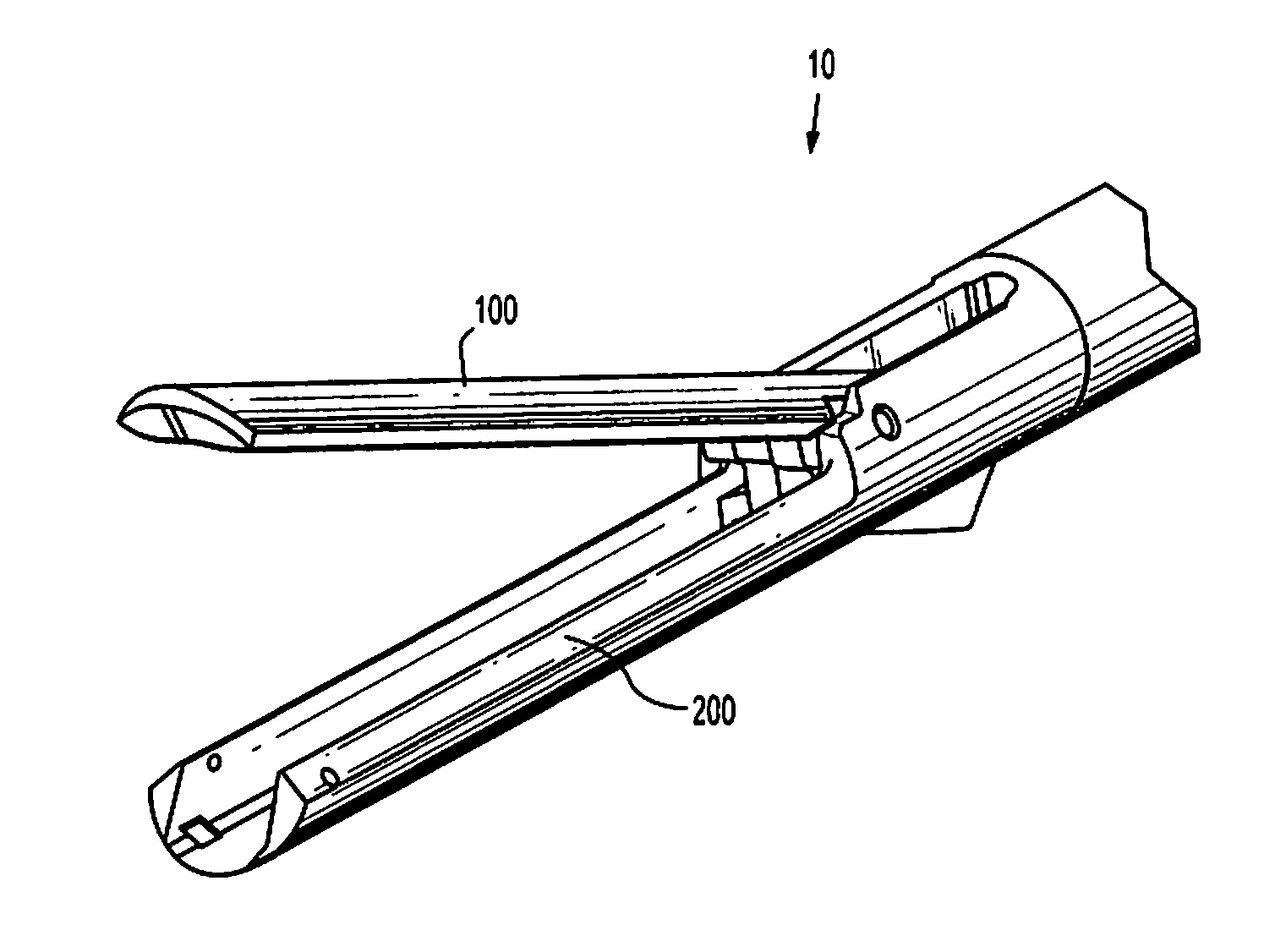

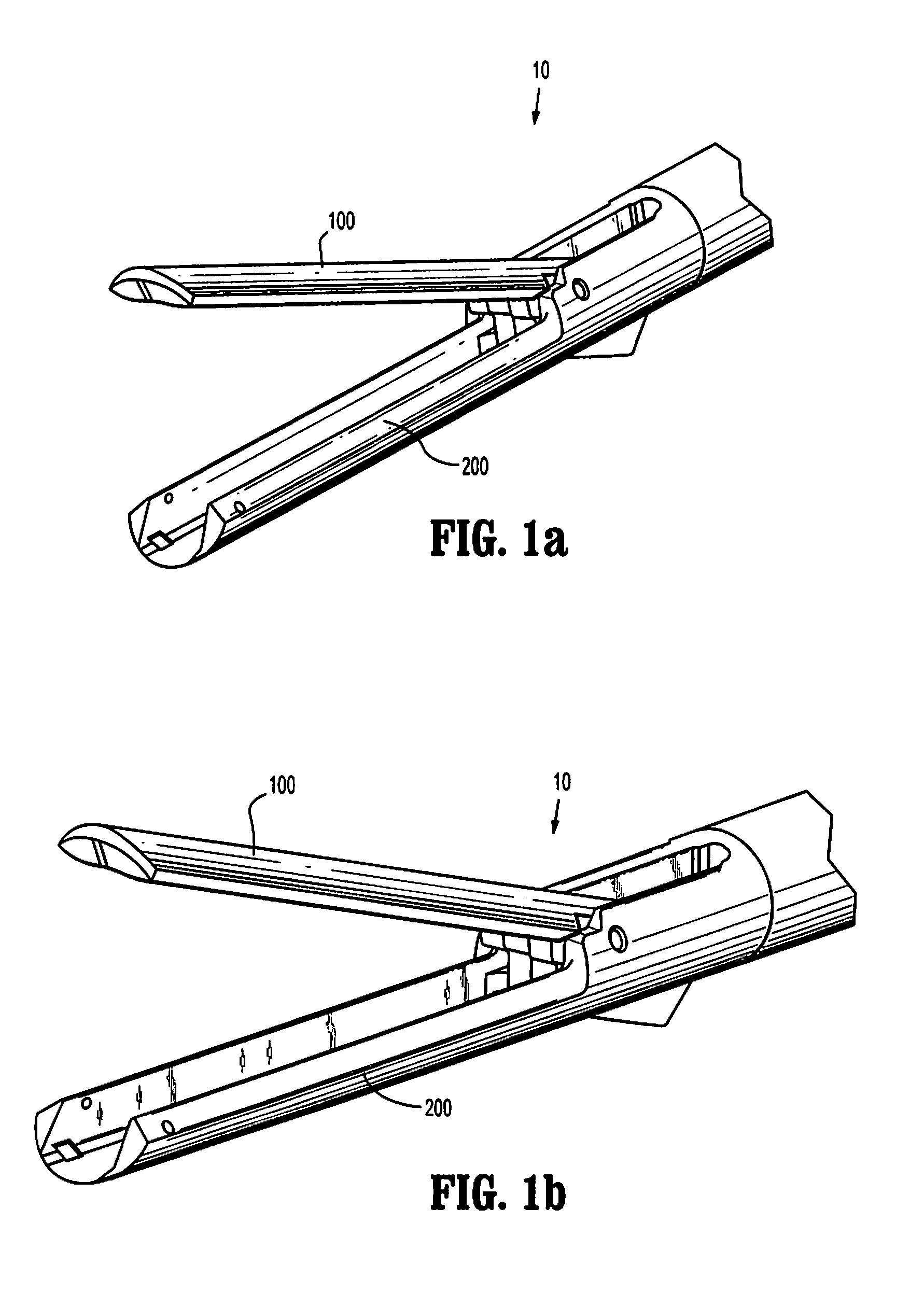

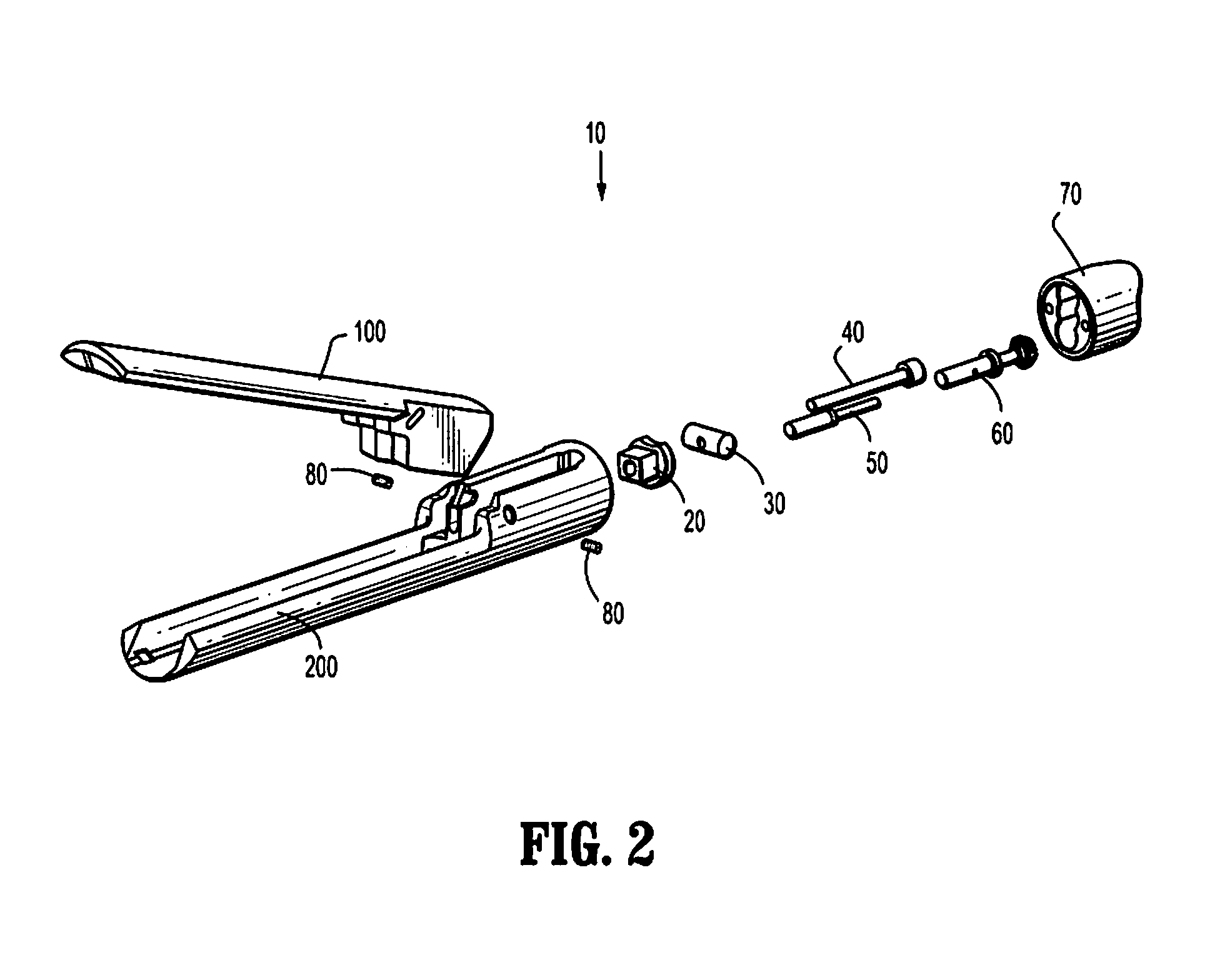

Surgical stapling device with captive anvil

ActiveUS8235272B2Less deflectionIntegrity is not compromisedSuture equipmentsStapling toolsDistal portionSurgery

A device for clamping tissue includes a first jaw having a distal portion for communicating with tissue and a proximal portion having a first wing and a second wing. The device also includes a second jaw having a distal portion for communicating with tissue and a proximal portion having a first slot and a second slot, the first slot disposed between a middle structure and a first lateral structure, the second slot disposed between the middle structure and a second lateral structure. The first jaw is rotatably coupleable to the second jaw with the first wing extending into the first slot and the second wing extending into the second slot.

Owner:TYCO HEALTHCARE GRP LP

Manipulator

A manipulator has a working unit in which when at least a first end effector finger and a second end effector finger are maximally closed on each other, at least the distance between a third joint axis and a first joint axis is greater than the distance between the first joint axis and a distal end of the second end effector finger, or the distance between the third joint axis and the first joint axis is greater than the distance between third joint axis and a second joint axis, or the angle formed between a direction from the third joint axis to the first joint axis and a direction from the third joint axis to the second joint axis is not π.

Owner:KARL STORZ GMBH & CO KG

Motor interface for parallel drive shafts within an independently rotating member

ActiveUS20110118754A1High desired clamping forceLimited response rateDrilling rodsConstructionsRotational axisEngineering

Mechanisms, assemblies, systems, tools, and methods incorporating the use of an offset drive shaft within an independently rotating member are provided. An example mechanism includes a base and a main shaft mounted to rotate relative to the base, a first drive shaft mounted inside the main shaft, and a first drive feature engaged with the first drive shaft. The main shaft includes a proximal end, a distal end, and a main shaft rotational axis defined therebetween. The first drive shaft is offset from the main shaft rotational axis. A first drive feature rotational axis is defined for the first drive feature and is fixed relative to the base as the main shaft rotates. The first drive feature rotates the first drive shaft.

Owner:INTUITIVE SURGICAL OPERATIONS INC

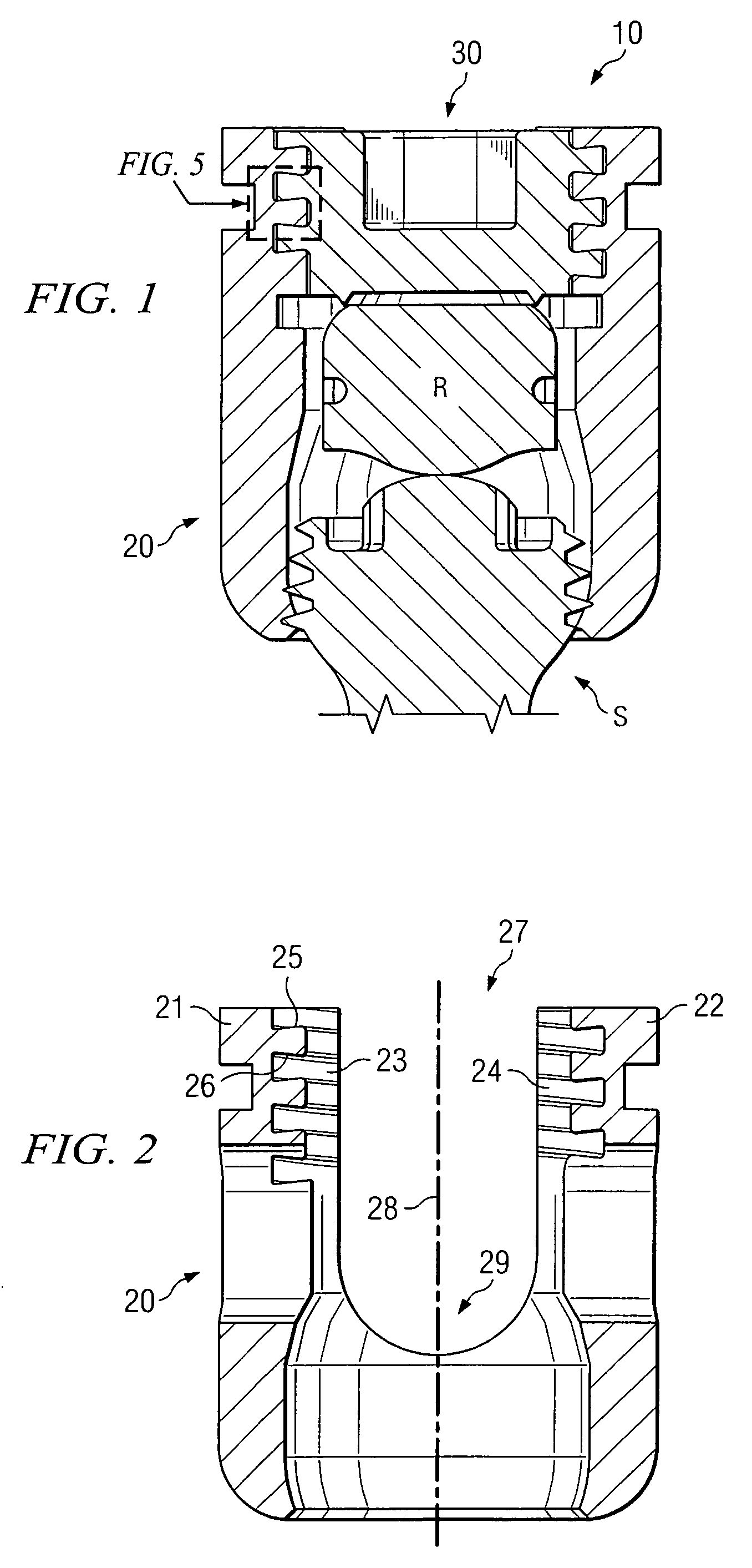

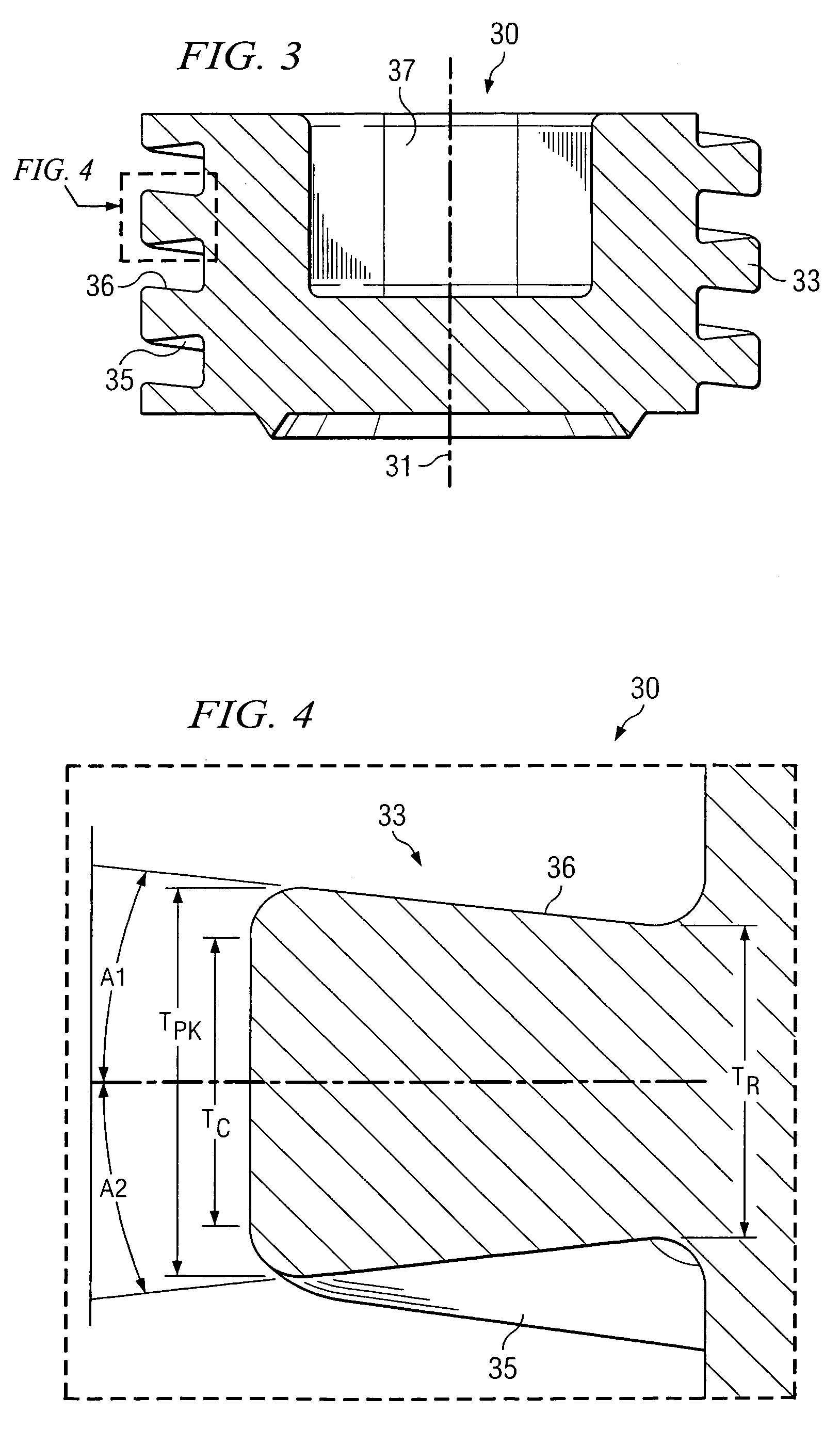

Closure member for a medical implant device

InactiveUS7214227B2Prevent openingIncrease clamping forceInternal osteosythesisJoint implantsLeading edgeSet screw

A closure member, such as a set screw, and complementary receiving member are included in a medical implant device. The receiving member has a plurality of noncontiguous, threaded walls substantially defining a bore for receiving the threaded closure member. When the closure member is inserted into the receiving member, their respective threads interlock to join the noncontiguous walls of the receiving member. The closure member has an outer thread configured to interlock with the inner walls of the receiving member in a manner that aids in preventing the noncontiguous walls of the receiving member from moving away from the closure member. In certain embodiments, the closure member's outer thread includes a trailing edge having a point that is rearward of the trailing edge's root, and the outer thread includes a leading edge having a point that is forward of the leading edge's root.

Owner:THEKEN SURGICAL LLC

Tissue spreading vascular clips with locking mechanism and non-slip clamping surfaces

A surgical clip includes a pair of opposed arms joined at one end by an integrally formed flexible hinge and a hinge lock. A male head element near the free end of one arm is configured to spread tissue when the male head element is urged towards a head mating element near the end of the opposite arm. The clamping side of an arm may include a protruding feature, such as a wedge shape elongated ridge, while the clamping side of the opposite arm includes a corresponding trough or aperture that receives the protruding feature. Clamping surfaces may include non-slip protrusions, such as ribs, ridges, cones or pins. An applicator holding feature, such as a boss, near the hinge prevents the clip from yawing and becoming askew during application.

Owner:TYCO HEALTHCARE GRP LP

Closure member for a medical implant device

InactiveUS20050216000A1Prevent openingIncrease clamping forceSuture equipmentsInternal osteosythesisLeading edgeSet screw

A closure member, such as a set screw, and complementary receiving member are included in a medical implant device. The receiving member has a plurality of noncontiguous, threaded walls substantially defining a bore for receiving the threaded closure member. When the closure member is inserted into the receiving member, their respective threads interlock to join the noncontiguous walls of the receiving member. The closure member has an outer thread configured to interlock with the inner walls of the receiving member in a manner that aids in preventing the noncontiguous walls of the receiving member from moving away from the closure member. In certain embodiments, the closure member's outer thread includes a trailing edge having a point that is rearward of the trailing edge's root, and the outer thread includes a leading edge having a point that is forward of the leading edge's root.

Owner:THEKEN SPINE

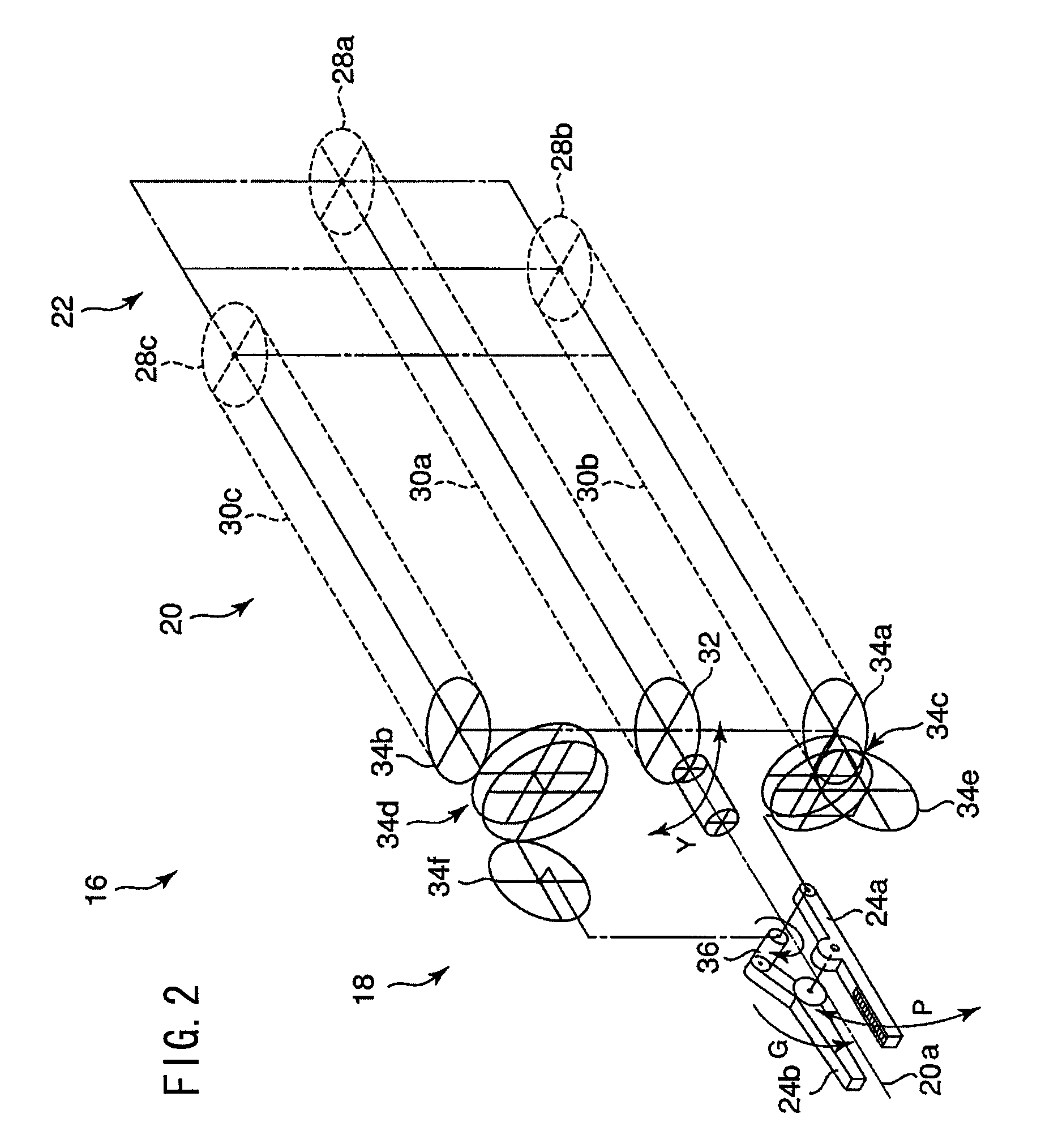

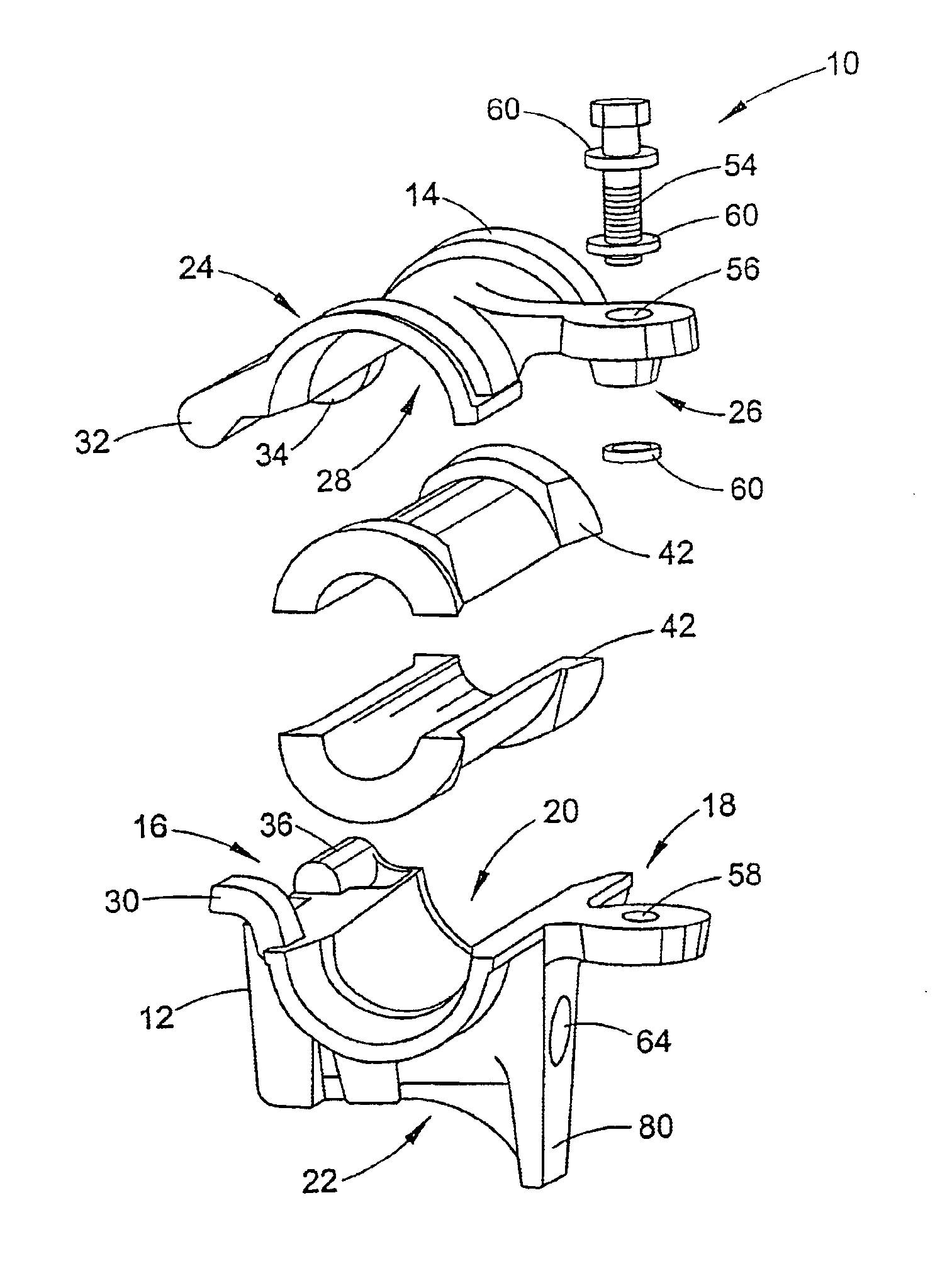

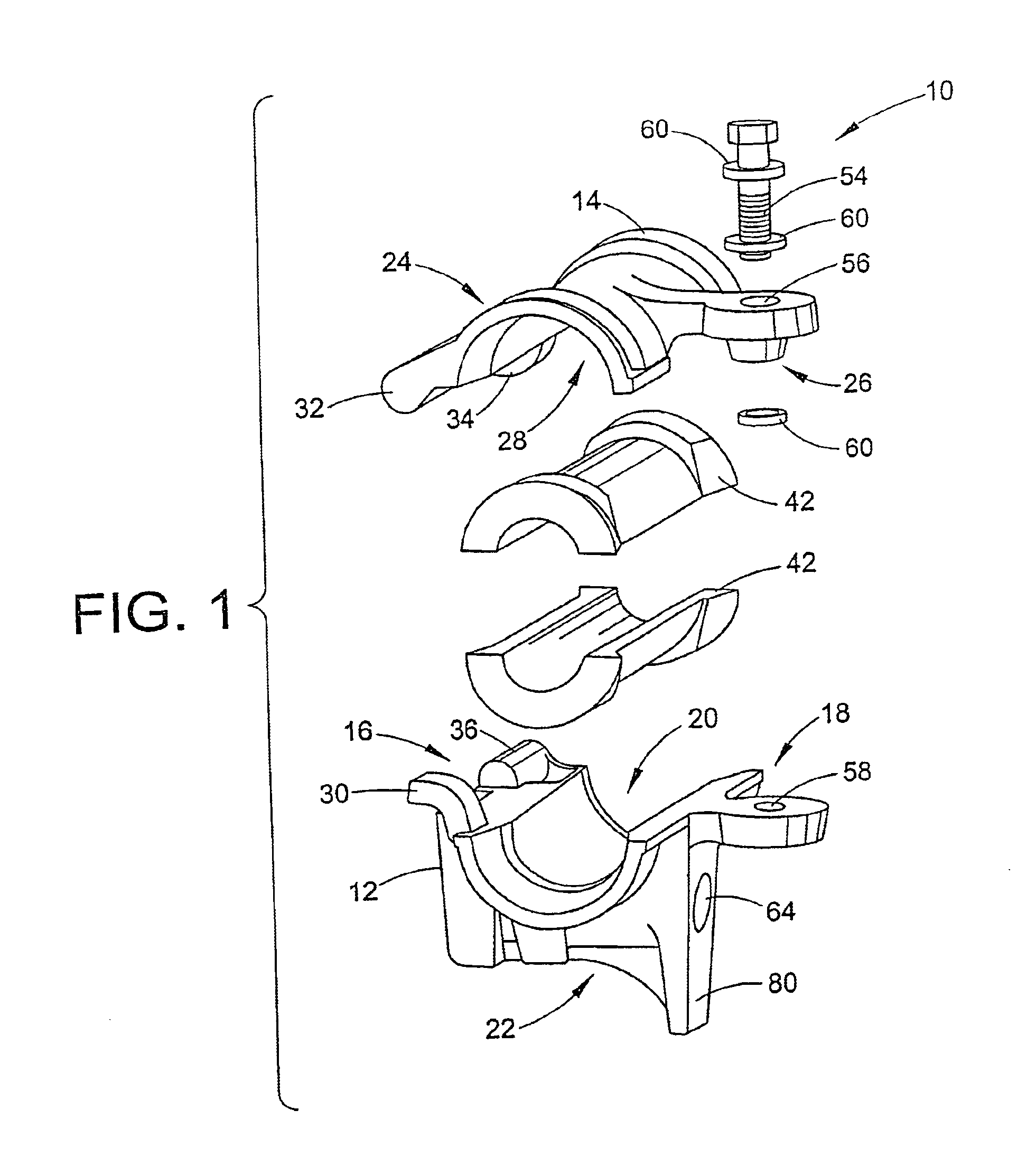

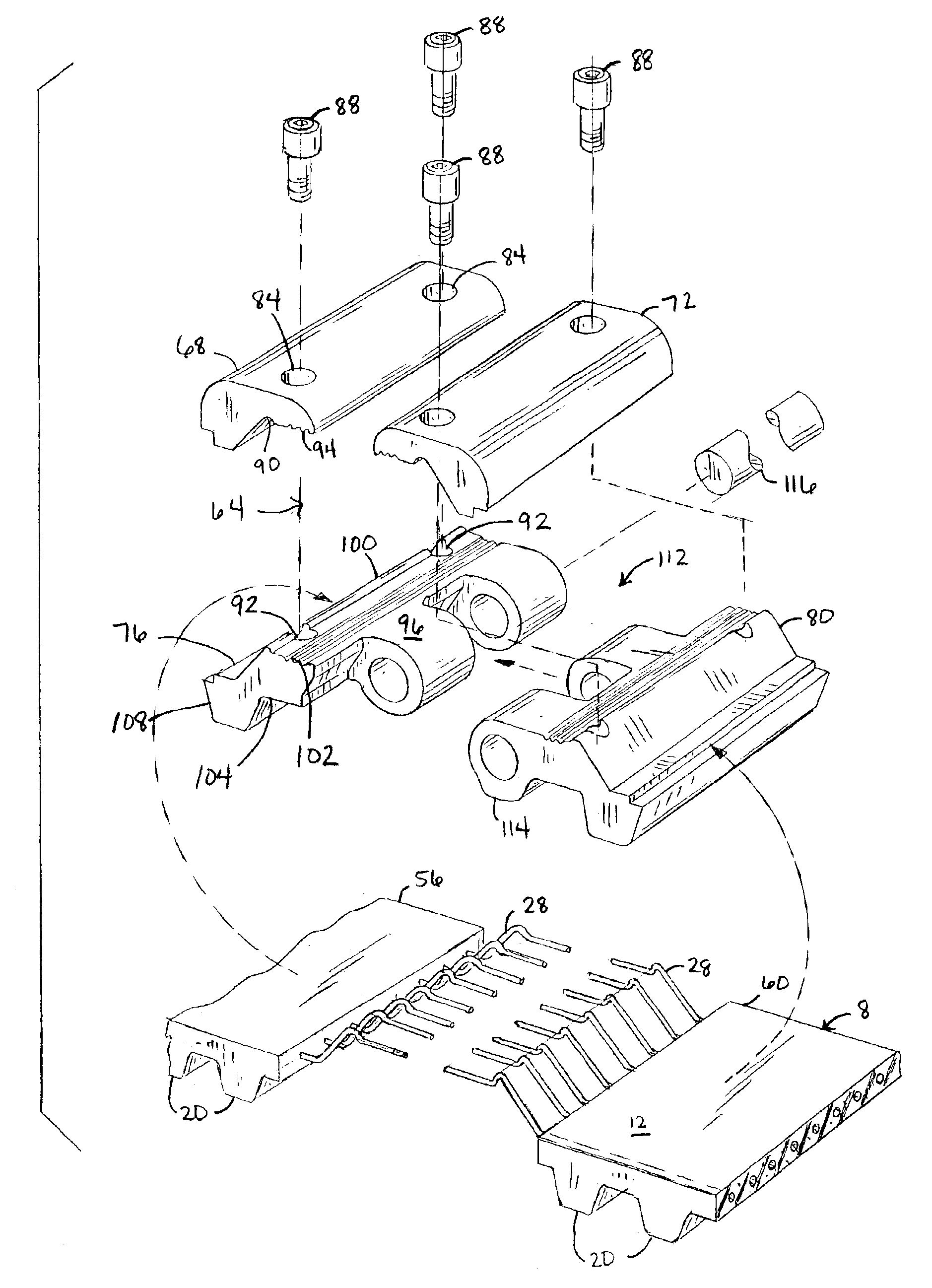

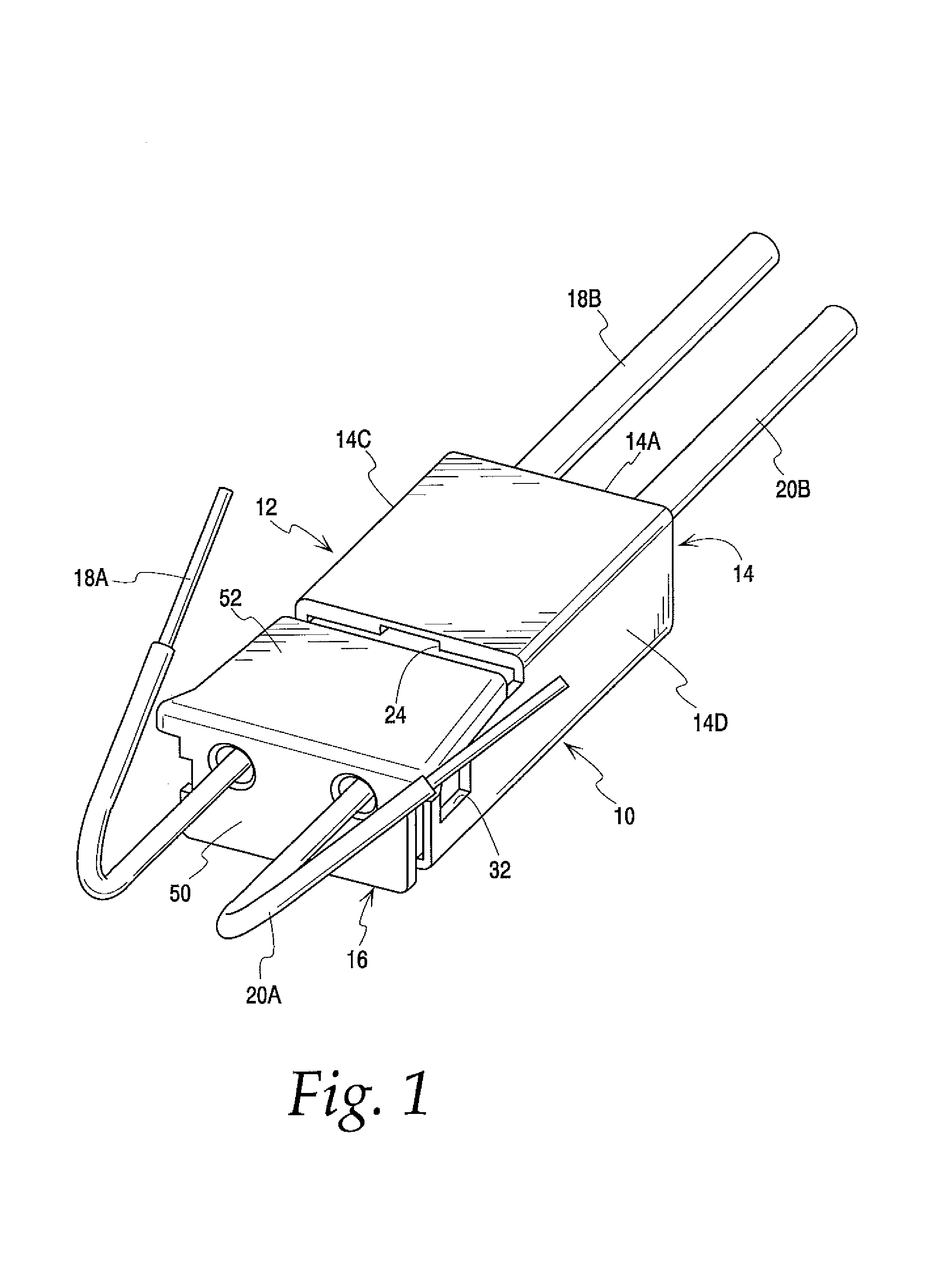

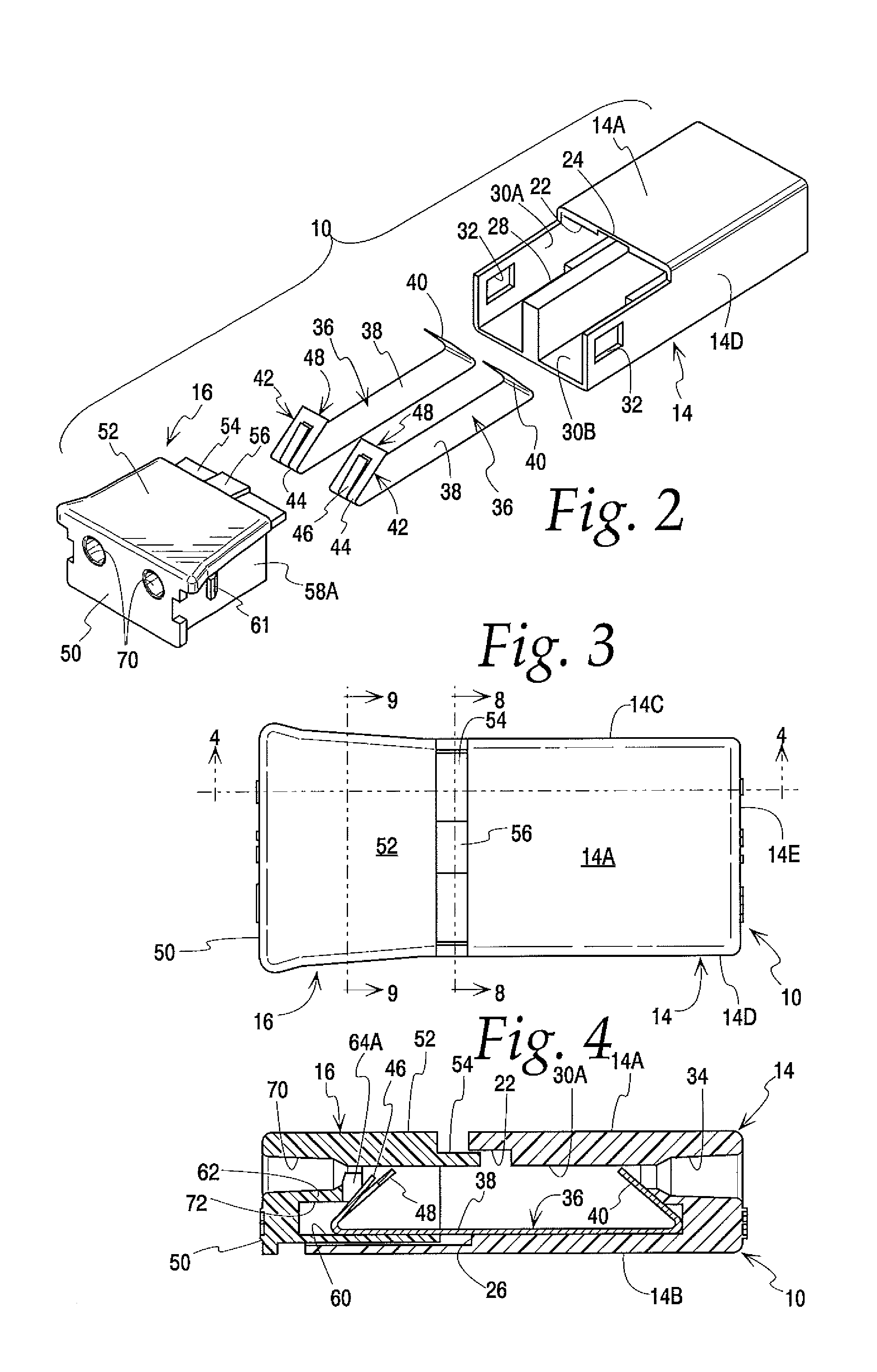

Modular cable support apparatus, method, and system

InactiveUS6892990B2Reduce the possibilityBig gapPipe supportsCandle holdersSupporting systemEngineering

A cable support system includes a plurality of first components (12) and a plurality of second components (14). Each first component (12) has a hinge edge (16), a tightening region (18) disposed on an opposite side from the hinge edge (16), a cable channel (20) arranged between the hinge edge (16) and the tightening region (18), and an interconnecting structure (22). Each second component (14) has a hinge edge (24), a tightening region (26) disposed on an opposite side from the hinge edge (24), and a cable channel (28) arranged between the hinge edge (24) and the tightening region (26). A first cable support device (10) is constructable by hingeably combining selected first and second components (12, 14) via the hinge edges (16, 24). A second cable support device (100) is constructable by hingeably combining selected two second components (14) via the hinge edges (24).

Owner:PREFORMED LINE PROD CO

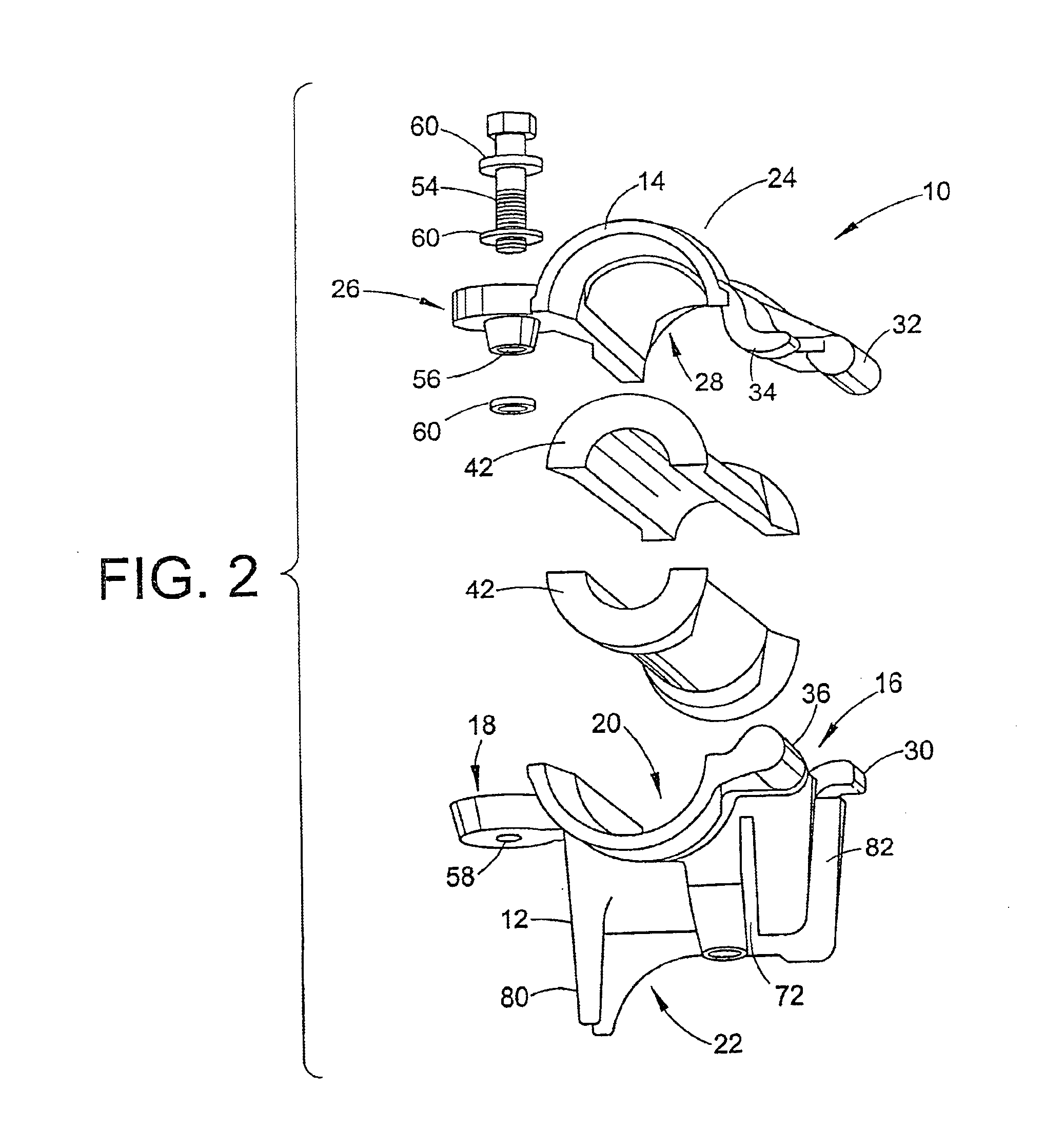

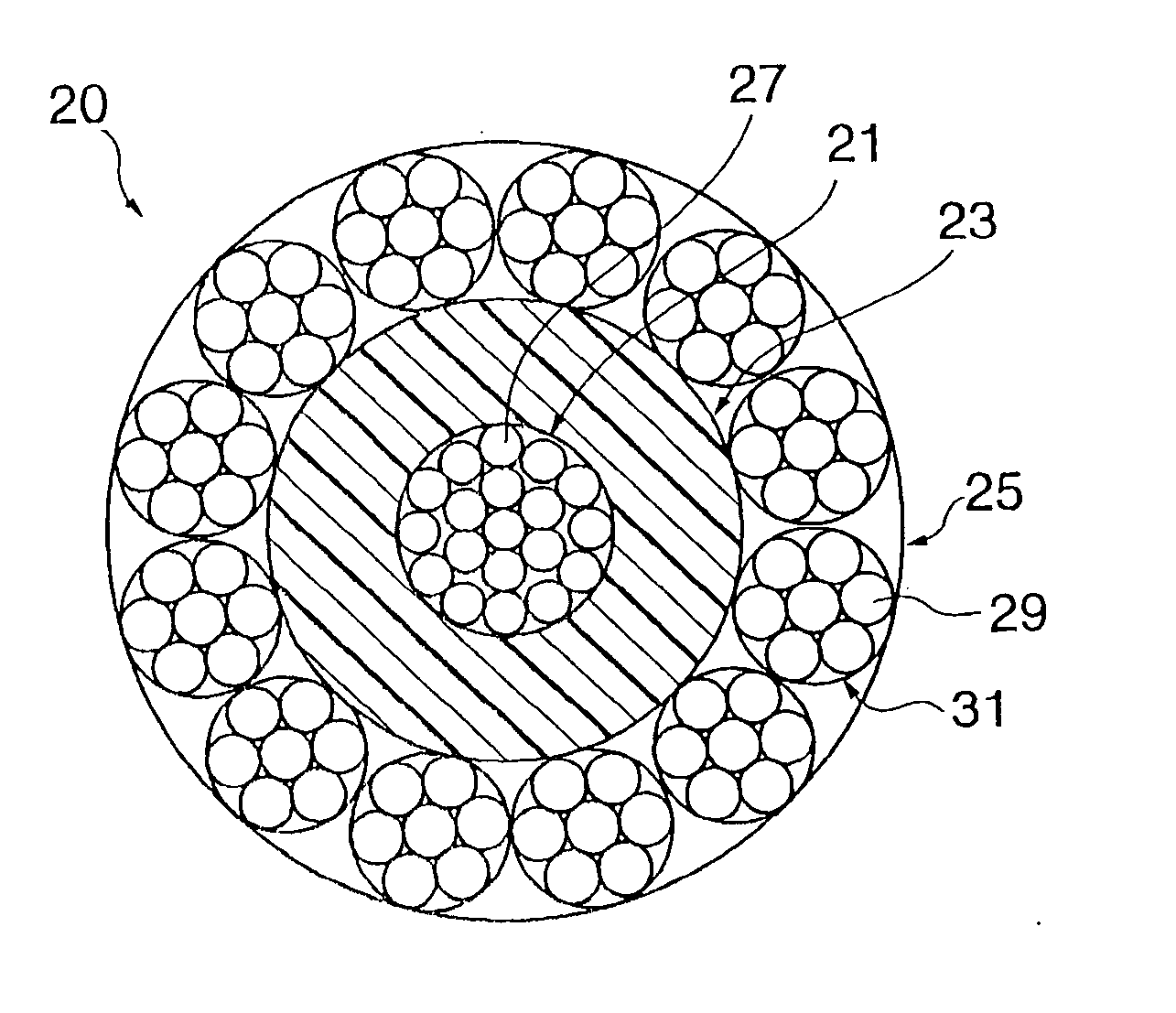

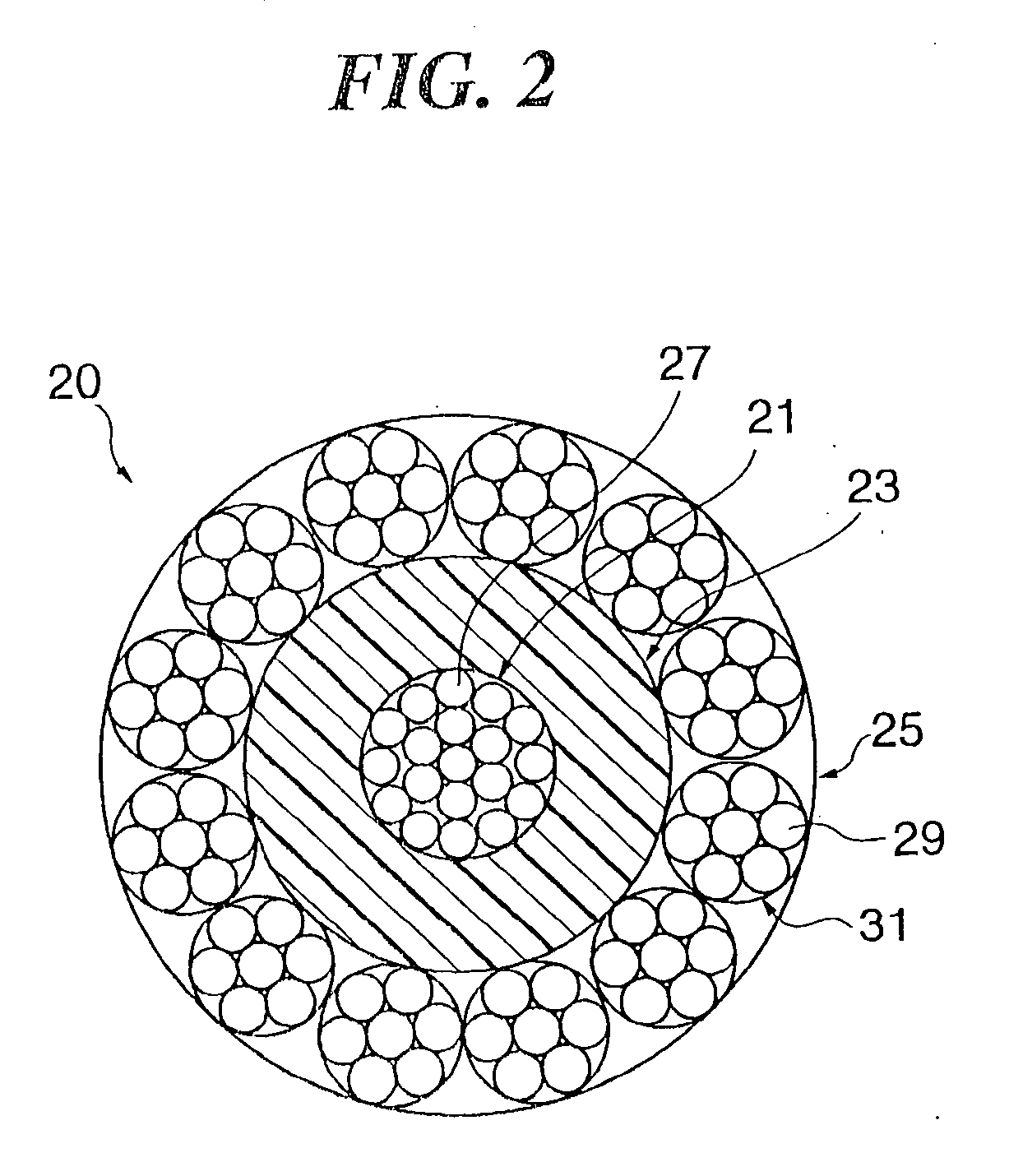

Power supply wire, wire grip, electric appliance suspending device, and electric appliance suspending method

ActiveUS20060000634A1Easy to handleReadily contractedNon-insulated conductorsLighting support devicesElectrical conductorEngineering

The electrical apparatus suspension unit 1 is provided with two power supply wires 20-1 and 20-2 by which the electrical apparatus 3 is conducted and suspended from the ceiling 5. Each of the wires 20 is connected to the hung member of the electrical apparatus 3 at the lower end by the a lower holder 40, and connected to the rail 9 laid on the ceiling 5 at the upper end by an upper holder 100. The power supply wire 20 comprises a core wire 21, an insulating layer 23 covering the core wire 21 and an outer layer 25 covering the insulating layer 23. The core wire 21 of the power supply wire 20-1 conducts to a grounded conductor cable W1 and the core wire 21 of another power supply wire 20-2 conducts to a voltage applied conductor cable W2. The power supply wires 20 having high tensile strength enables to suspend the electrical apparatus and also supply power thereto.

Owner:A G K

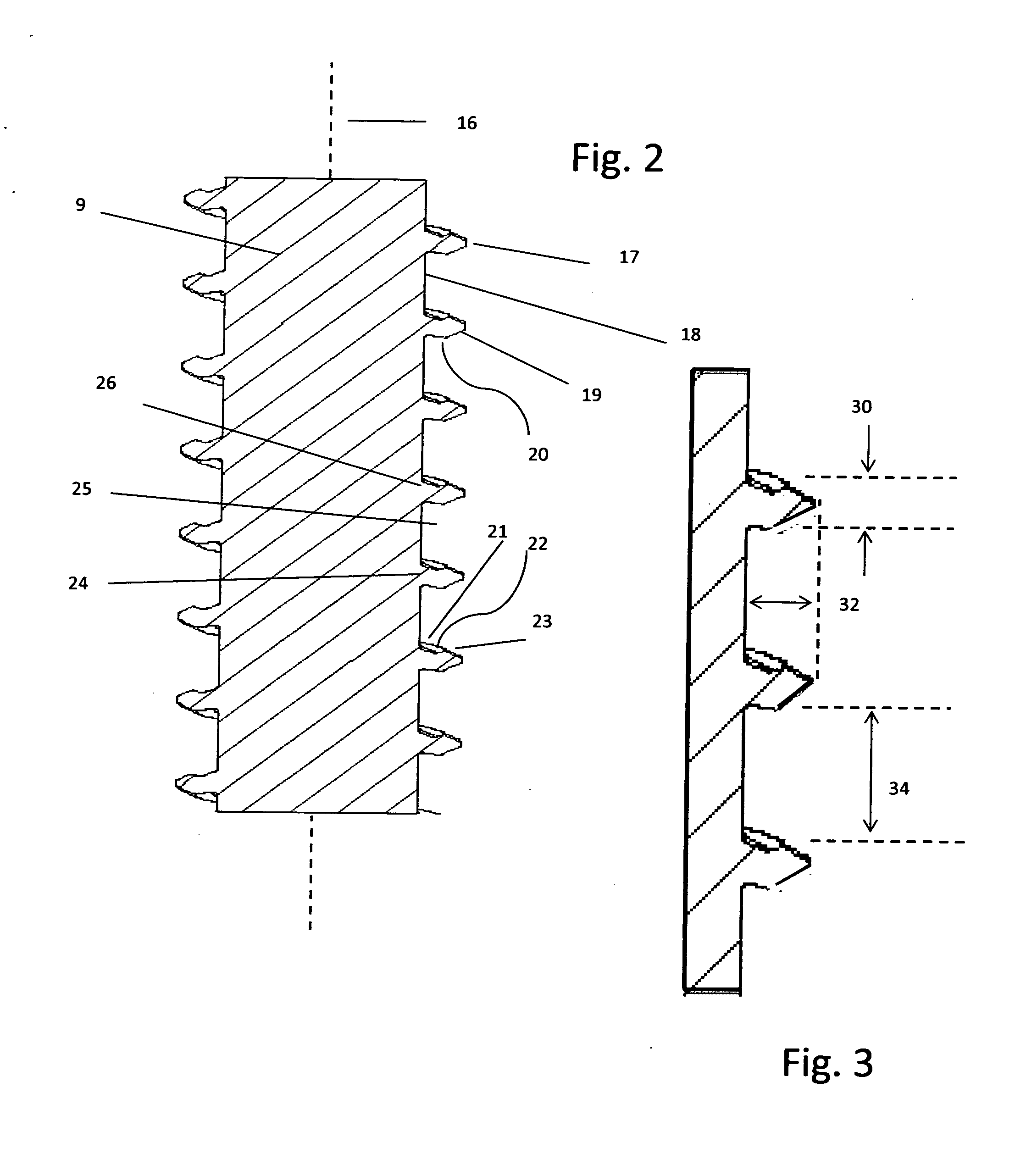

Composite system, method for its manufacture, and measurement pickup using such a composite system

ActiveUS7299699B2Stable, high-strength and lasting,Increased pull-out strengthMaterial analysis using sonic/ultrasonic/infrasonic wavesPig casting plantsEngineeringCompound system

A composite system includes a first component, for instance of metal, and a second component extending at least partly through the first component along an imaginary longitudinal axis of the composite system. The second component contacts, with an at least partially curved, especially cylindrical, outer surface, an inner surface of the first component flushly such that the first component at least sectionally, at least partly, grips around the second component. Joining surfaces of the composite system, which are formed by the mutually contacting surfaces of the two components, are formed in such a manner that the two components exhibit contour portions in the area of these joining surfaces embodied as self-closing, peripheral surfaces. The contour portions fit at least partly into one another, to form a mechanical interference locking effective, at least in part, likewise in the direction of the longitudinal axis. Additionally, the second component, with its outer surface, contacts the inner surface of the first component flushly, such that the two components are mechanically tightly connected together also by means of a frictional locking effective at least partly in the direction of the longitudinal axis. Alternatively, or in supplementation thereof, at least one of the components is subjected at least partly to lastingly elastic, especially mixed plastic-elastic, deformations. The composite system is distinguished by a high pull-out strength, even in the presence of repeatedly arising vibrations in one of the components and is, therefore, especially suited also for use in a vibration-type measurement pickup.

Owner:ENDRESS HAUSER FLOWTEC AG

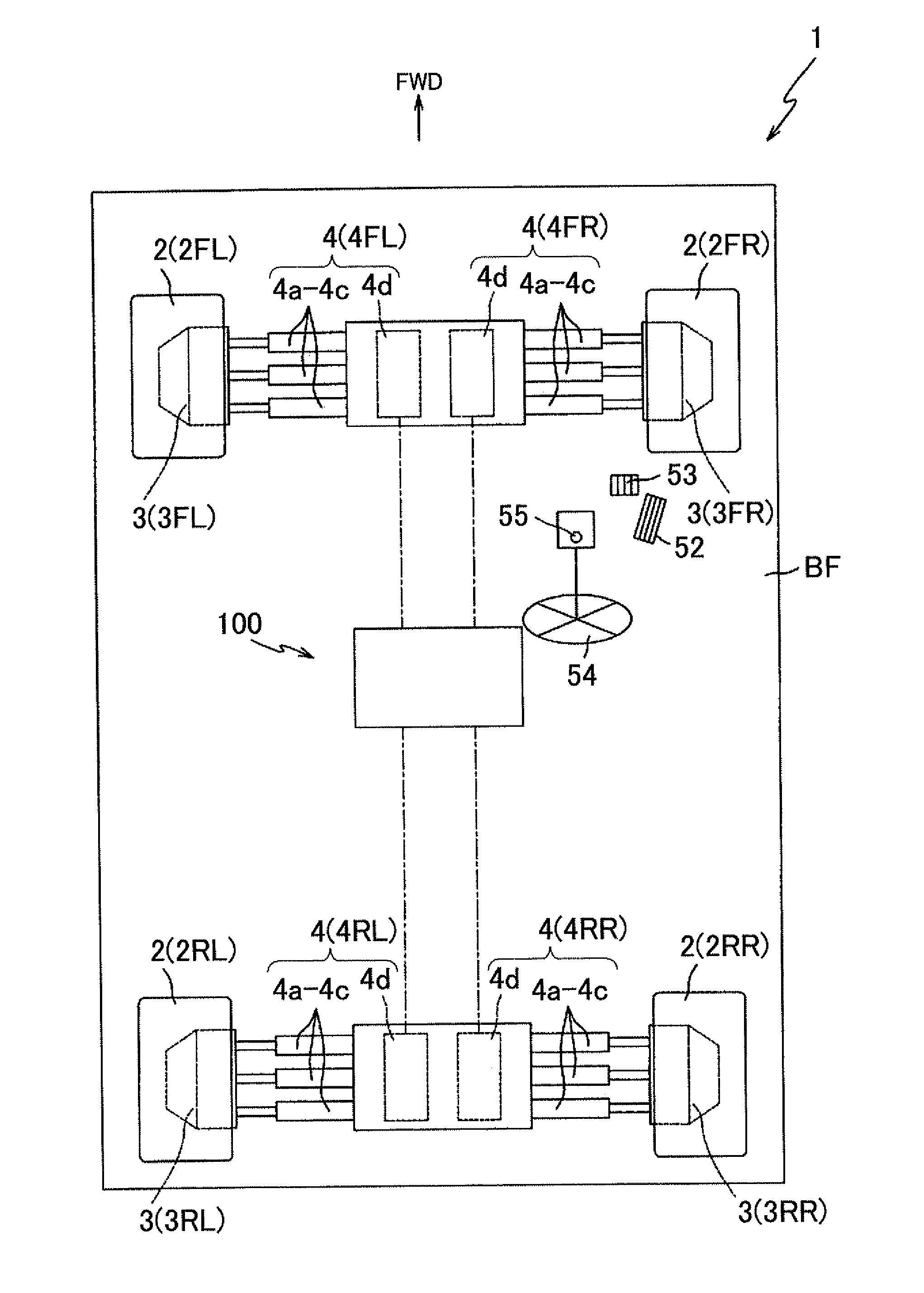

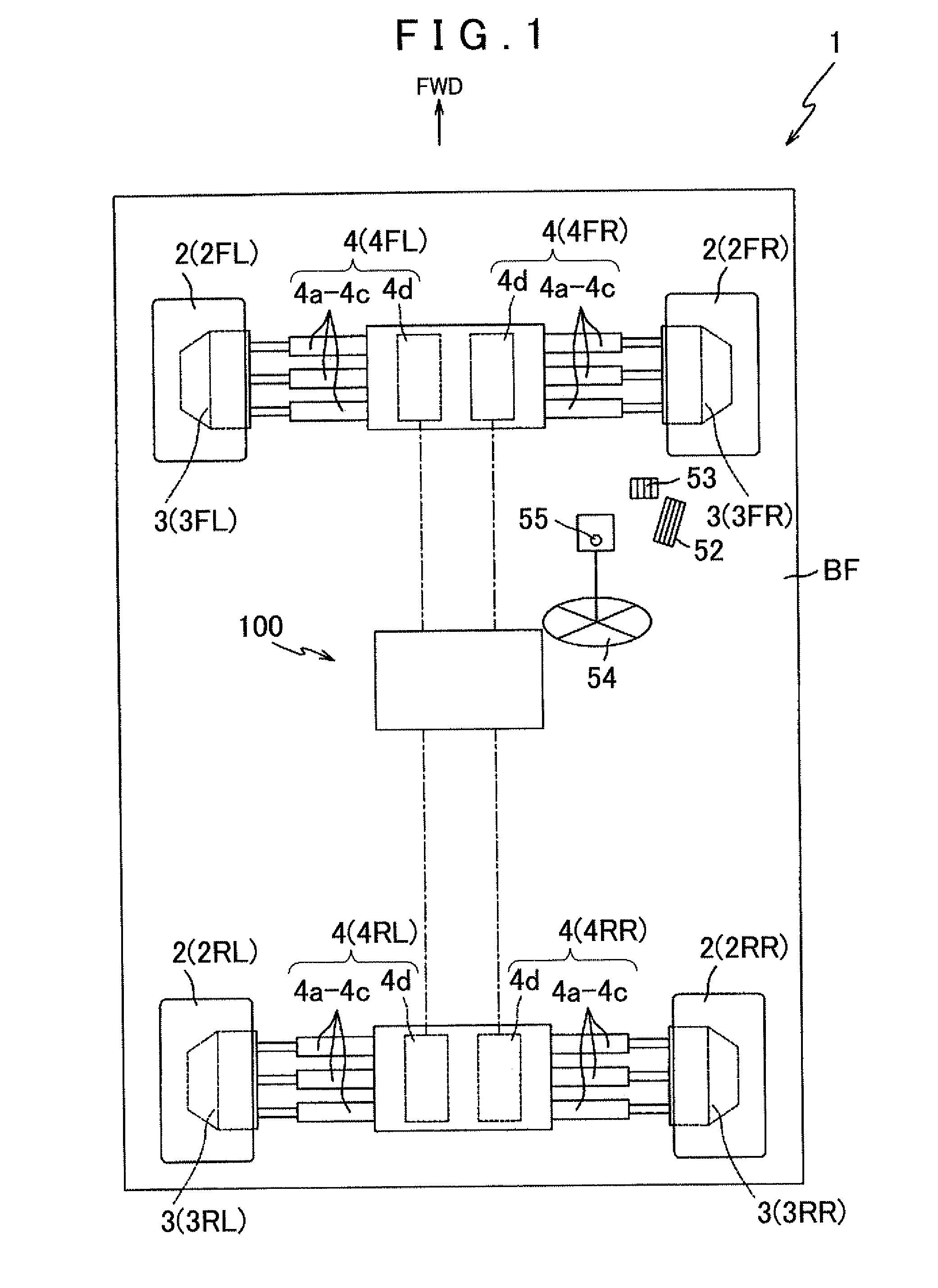

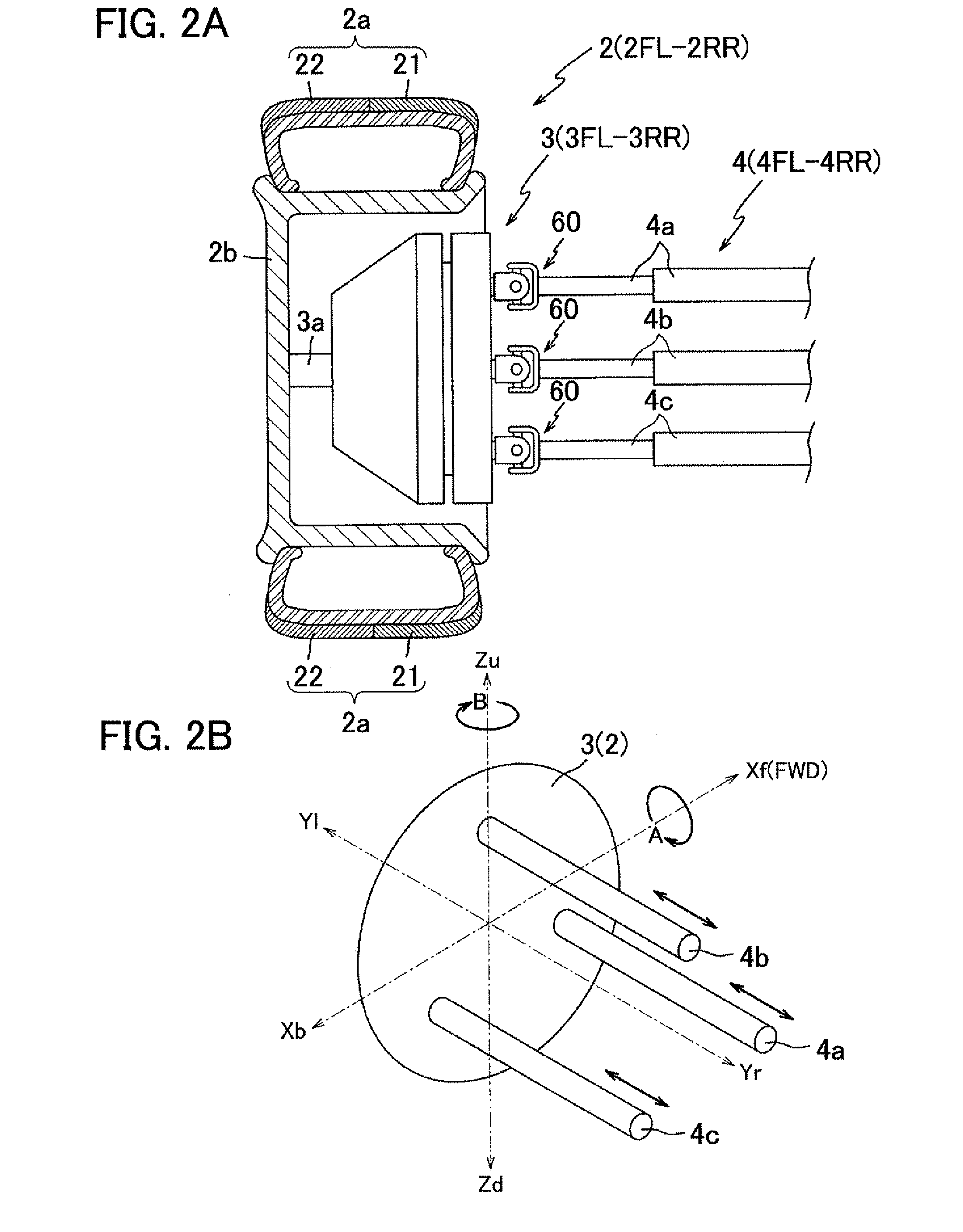

Camber angle controlling device

InactiveUS20100217491A1Improve gripIncrease clamping forceDigital data processing detailsSpecial tyresRolling resistanceCamber angle

A camber angle applying device is controlled to adjust the camber angle of wheels to a predetermined value. Therefore, the characteristics (or a high gripping property) of a high gripping force and the characteristic (or a low rolling resistance) of a small rolling resistance can be separately used as the performance of the wheels. By utilizing the high gripping property of the wheels, therefore, a vehicle is enabled to reduce its energy consumption, while retaining its running characteristics (such as a turning performance, an accelerating performance or a braking performance), by utilizing the rolling resistance of the wheels. Moreover, the camber angle applying device is controlled to reduce the rolling resistance of the wheels, so that the energy loss to occur in the wheels during running can be reduced to further reduce the energy consumption of the vehicle.

Owner:EQUOS RES

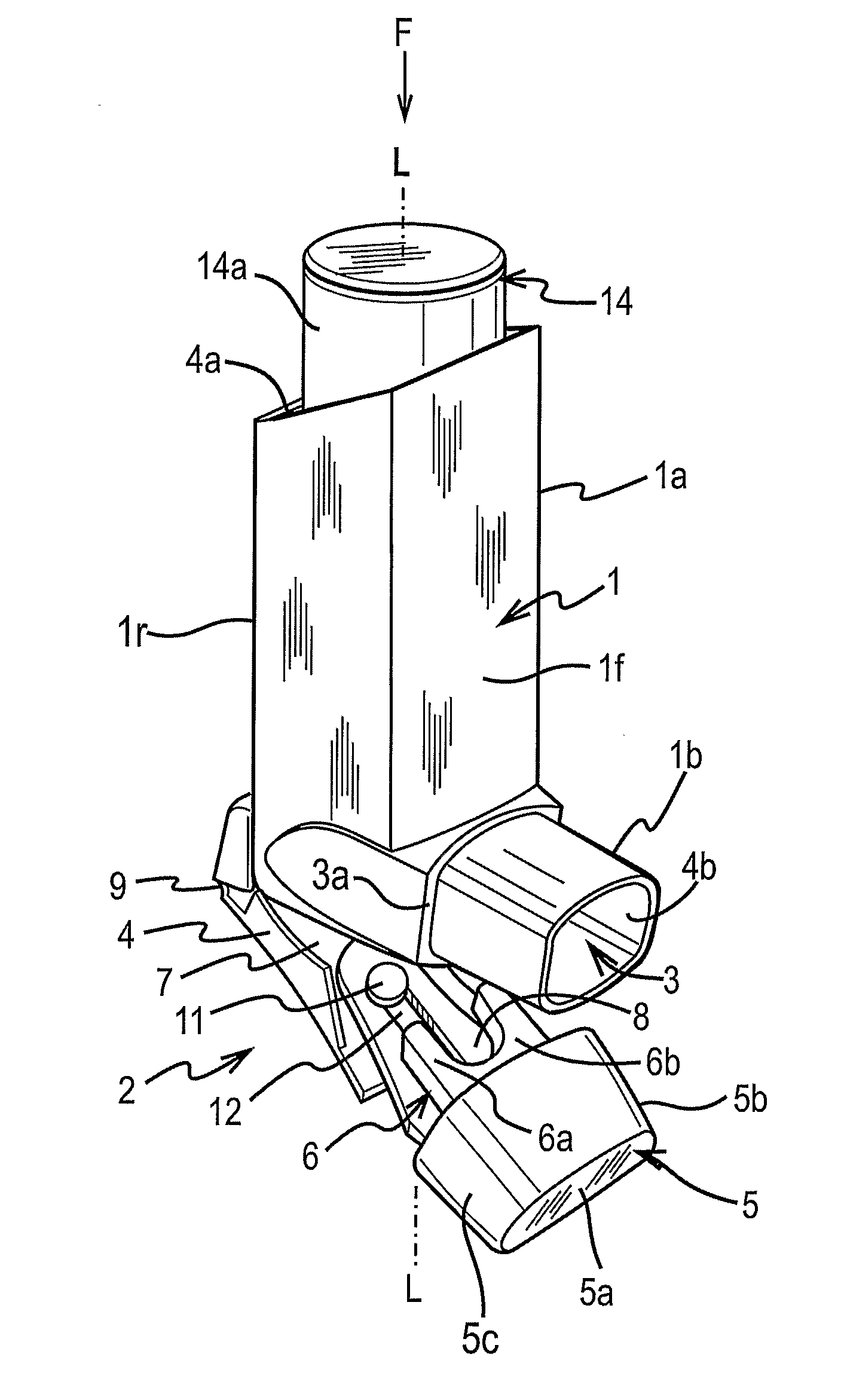

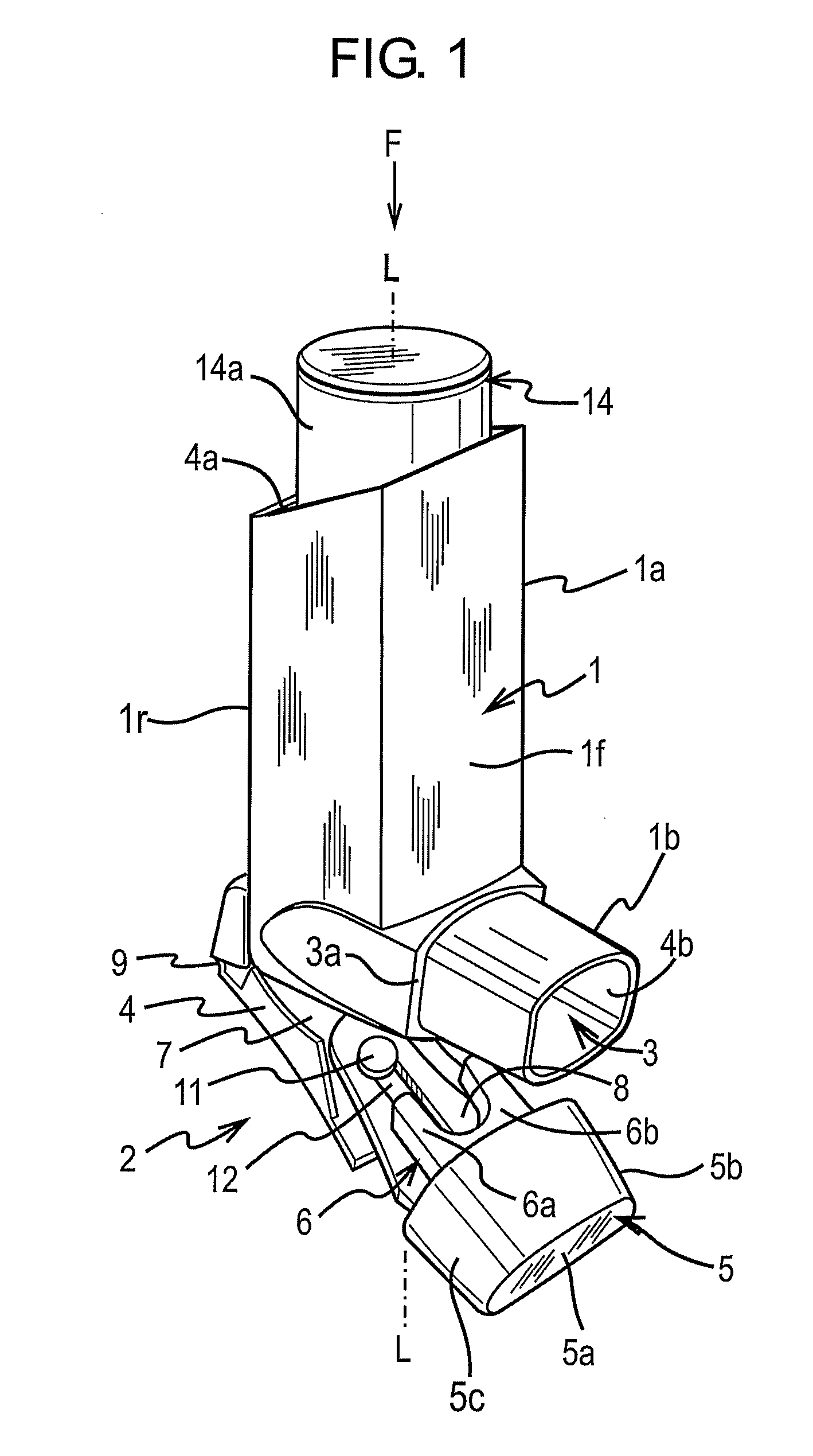

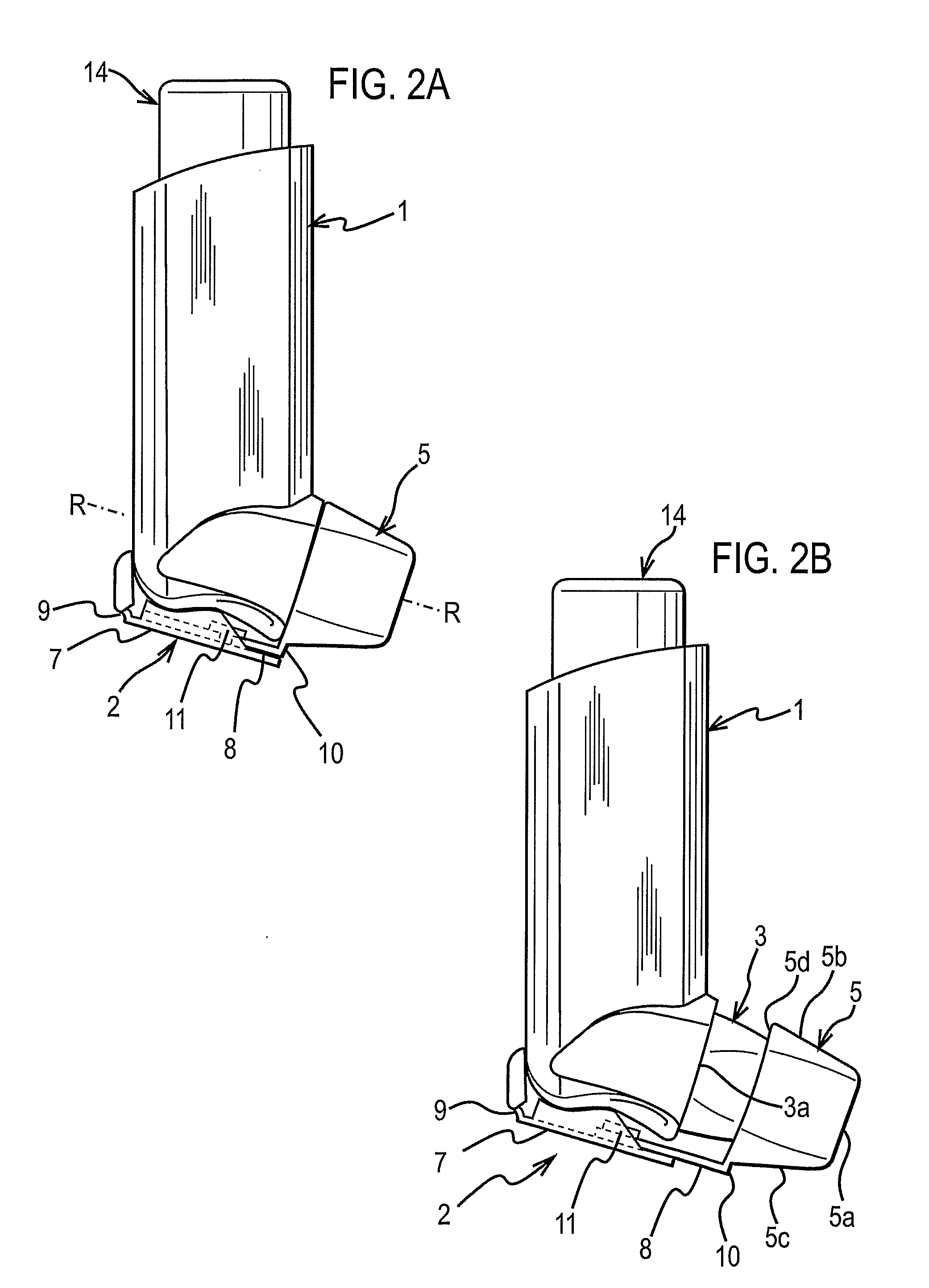

Dispensing Device

ActiveUS20080105253A1Improve fitSecure closureMedical devicesMedical atomisersGeneral surgeryInhaler

An inhaler is provided with a restricting member to prevent unintentional actuation of the inhaler. Also provided is an inhaler with an extensible strap joining a dust cap to the housing of an inhaler, the strap being particularly suited for use with inhalers that comprise a restricting member. The inhaler is useful, for example, in the treatment of asthma.

Owner:GLAXO GROUP LTD

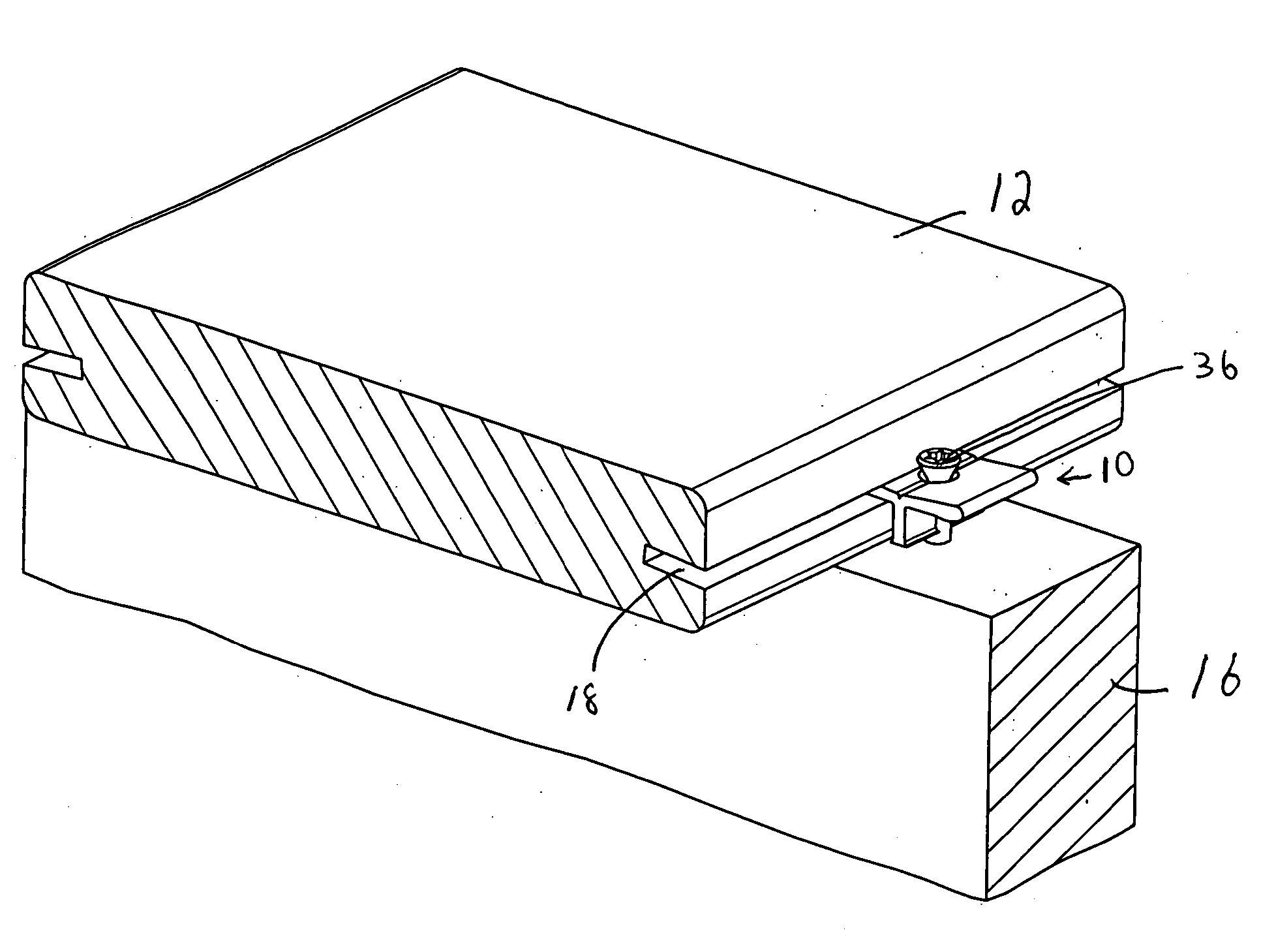

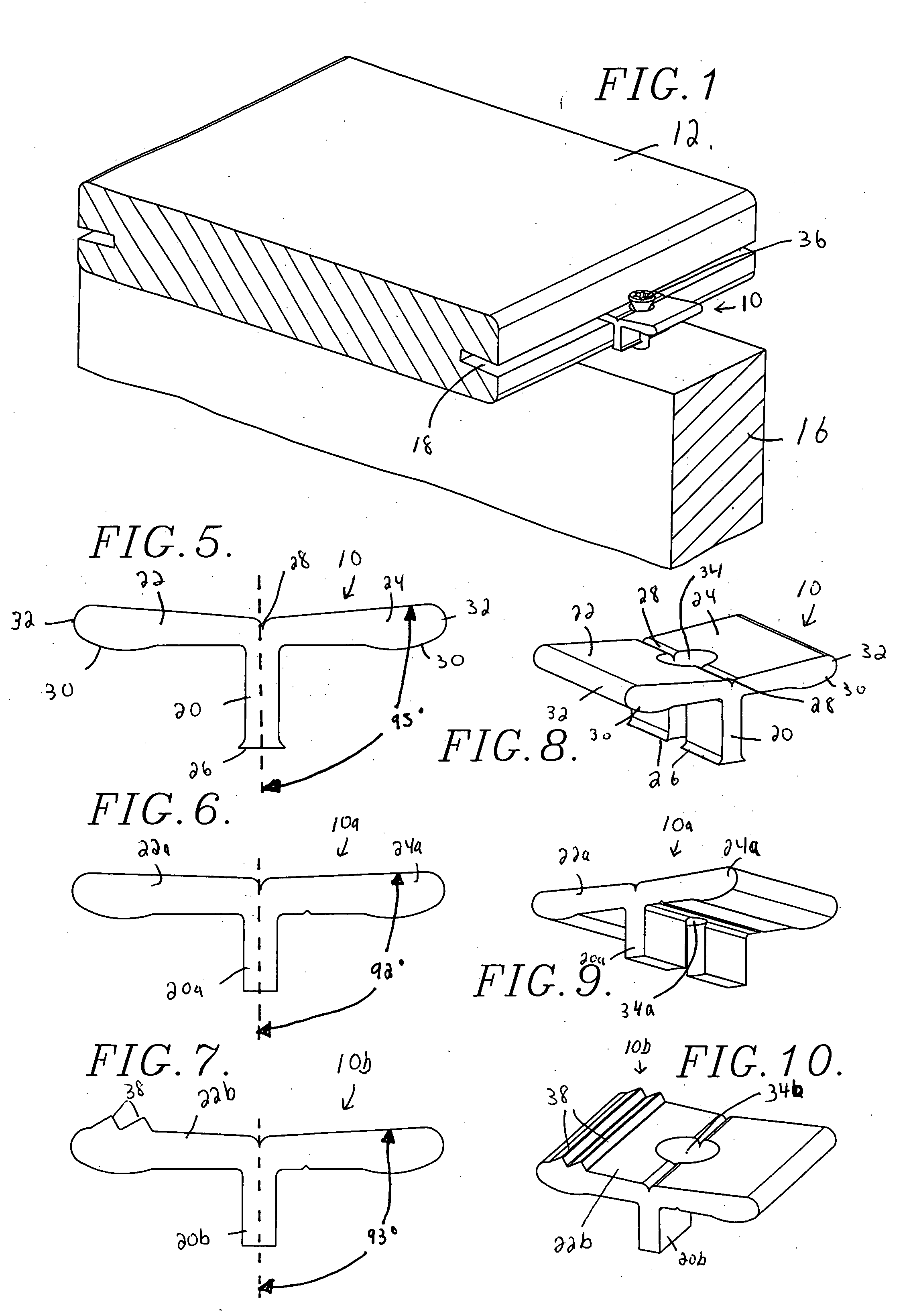

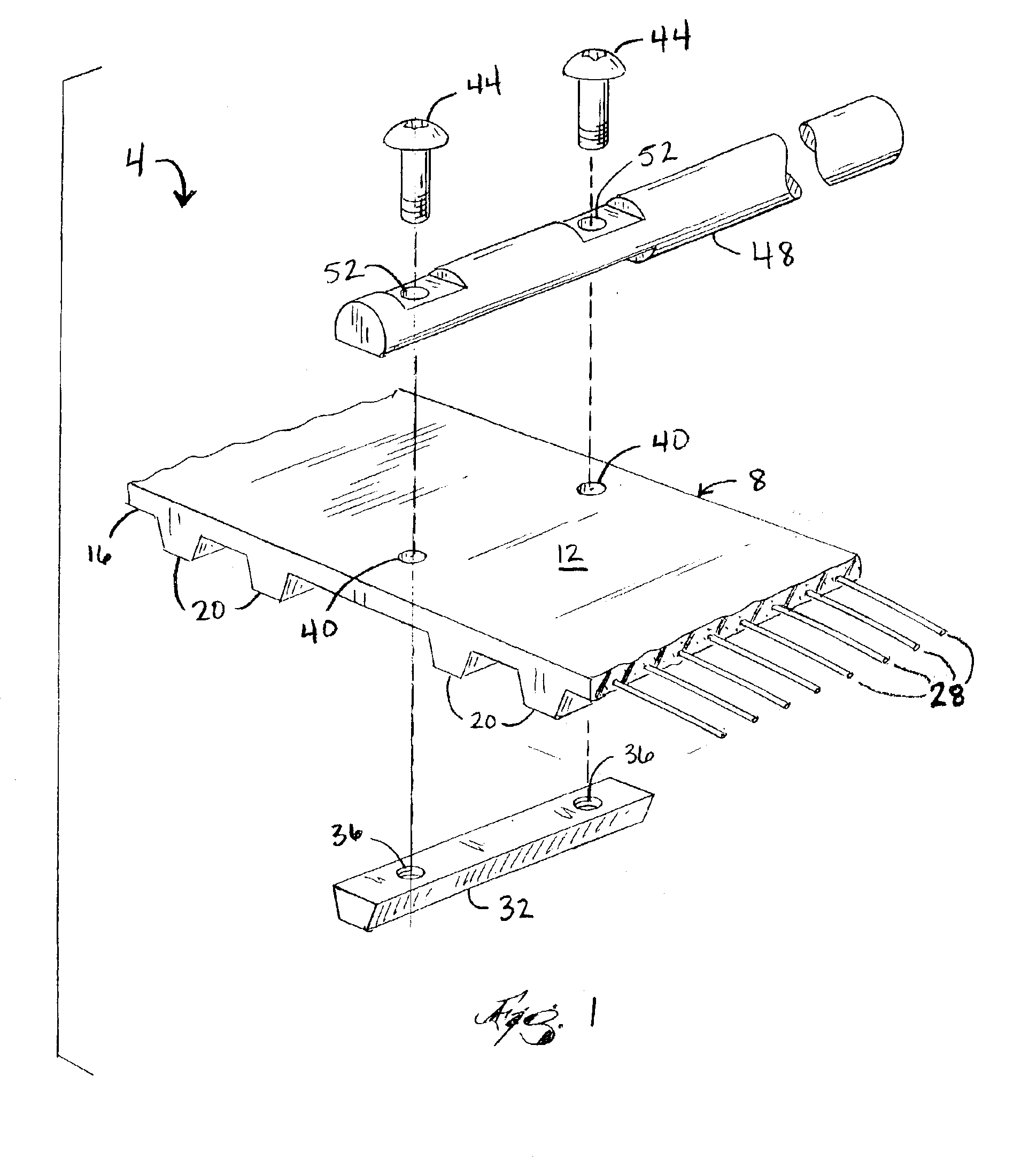

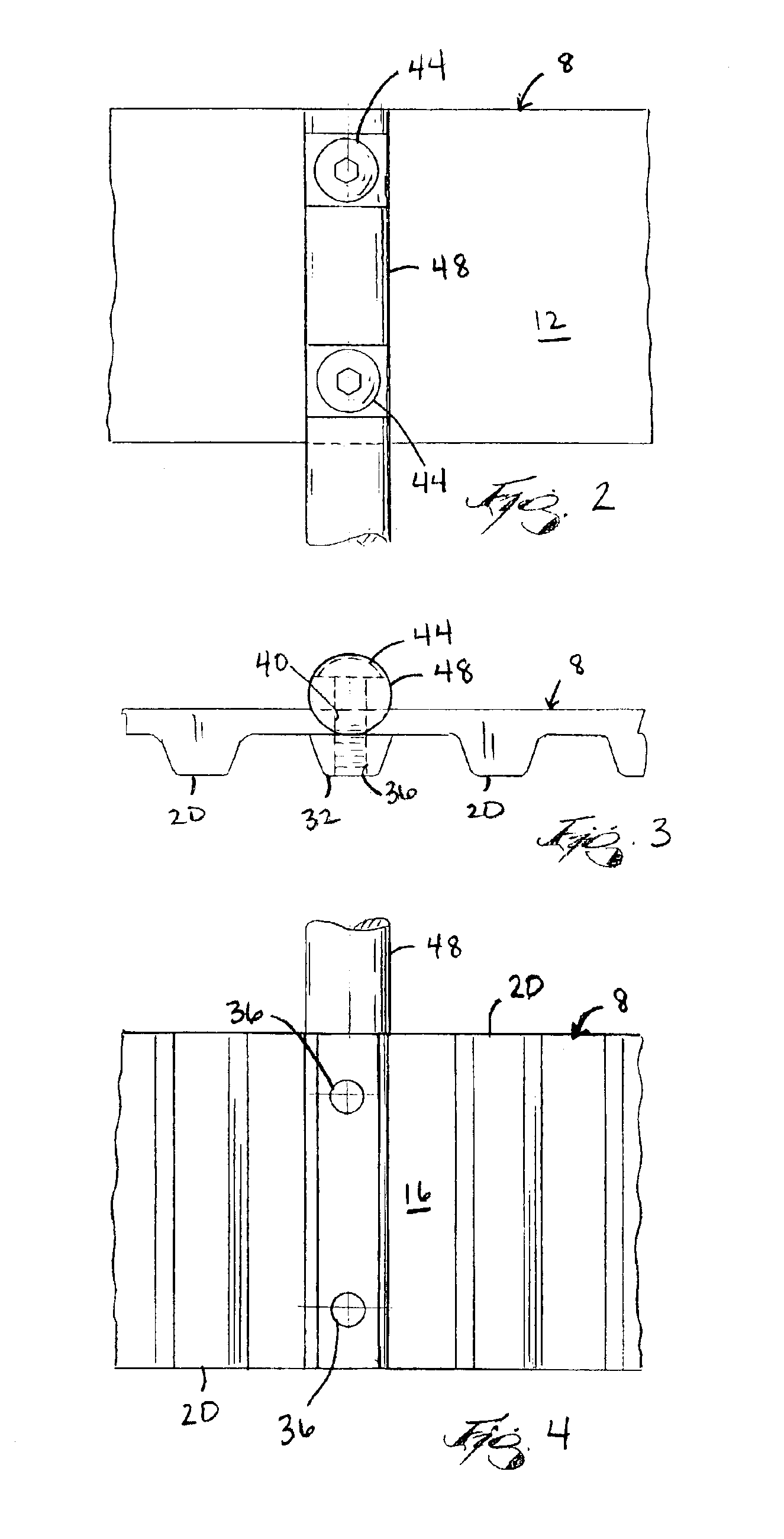

Deck clip

InactiveUS20060059822A1Effective movementEasy to installCeilingsSheet joiningJoistMarine engineering

A deck clip comprises a generally vertically extending leg; and a pair of arms extending from an upper edge of the leg. Each arm is configured for insertion into a slot of a deck board and presents an enlarged lobe. When the deck clip is screwed to a deck joist, the lobes grip the deck boards and hold them tight against the joist. The shape of the lobes increases the gripping force between the lobes and the deck boards as adjacent boards are hammered or otherwise pushed together. The lobes facilitate the gripping of the boards and help maintain the desired gap between adjacent boards for the life of the deck.

Owner:WOOD HAVEN

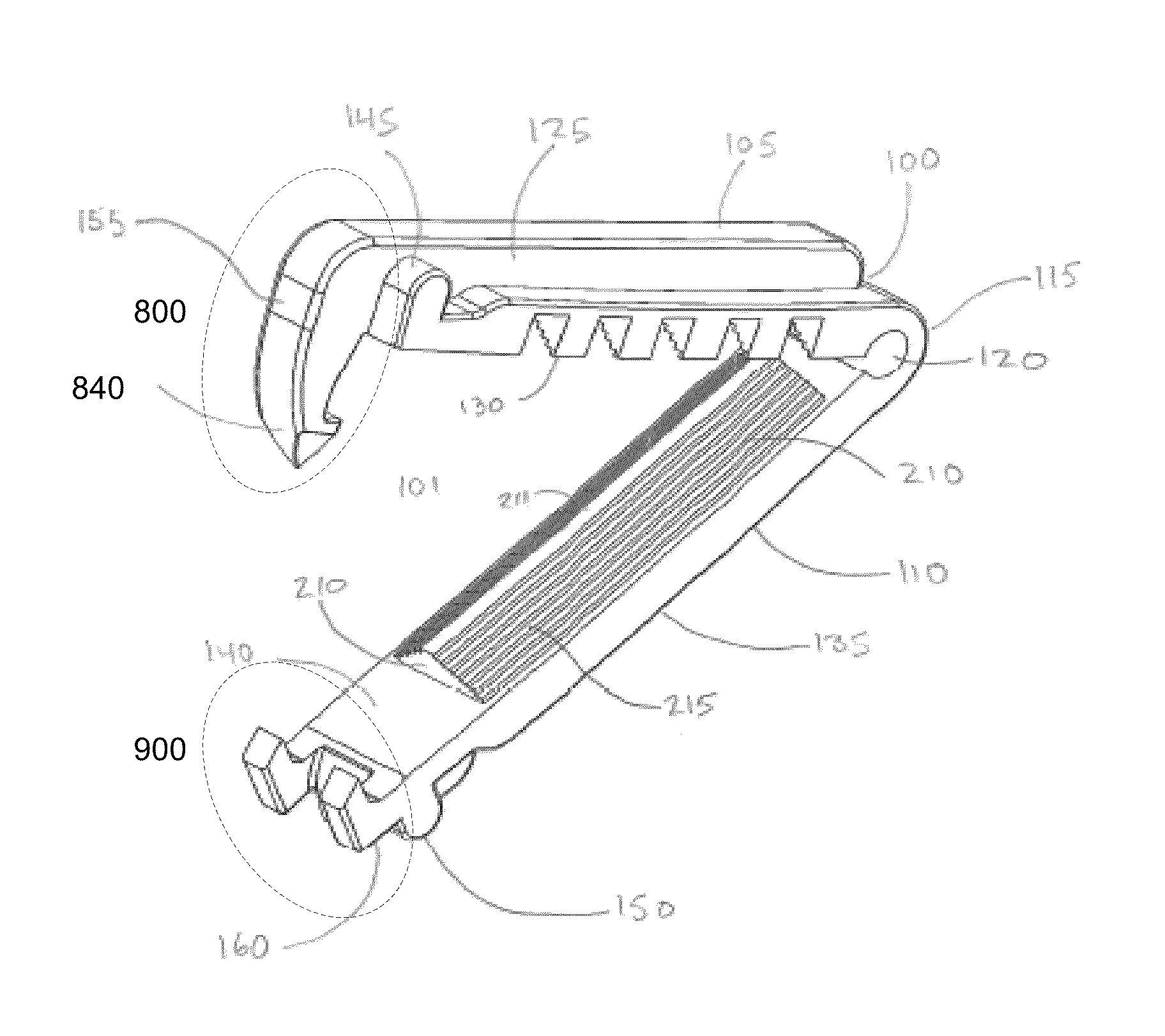

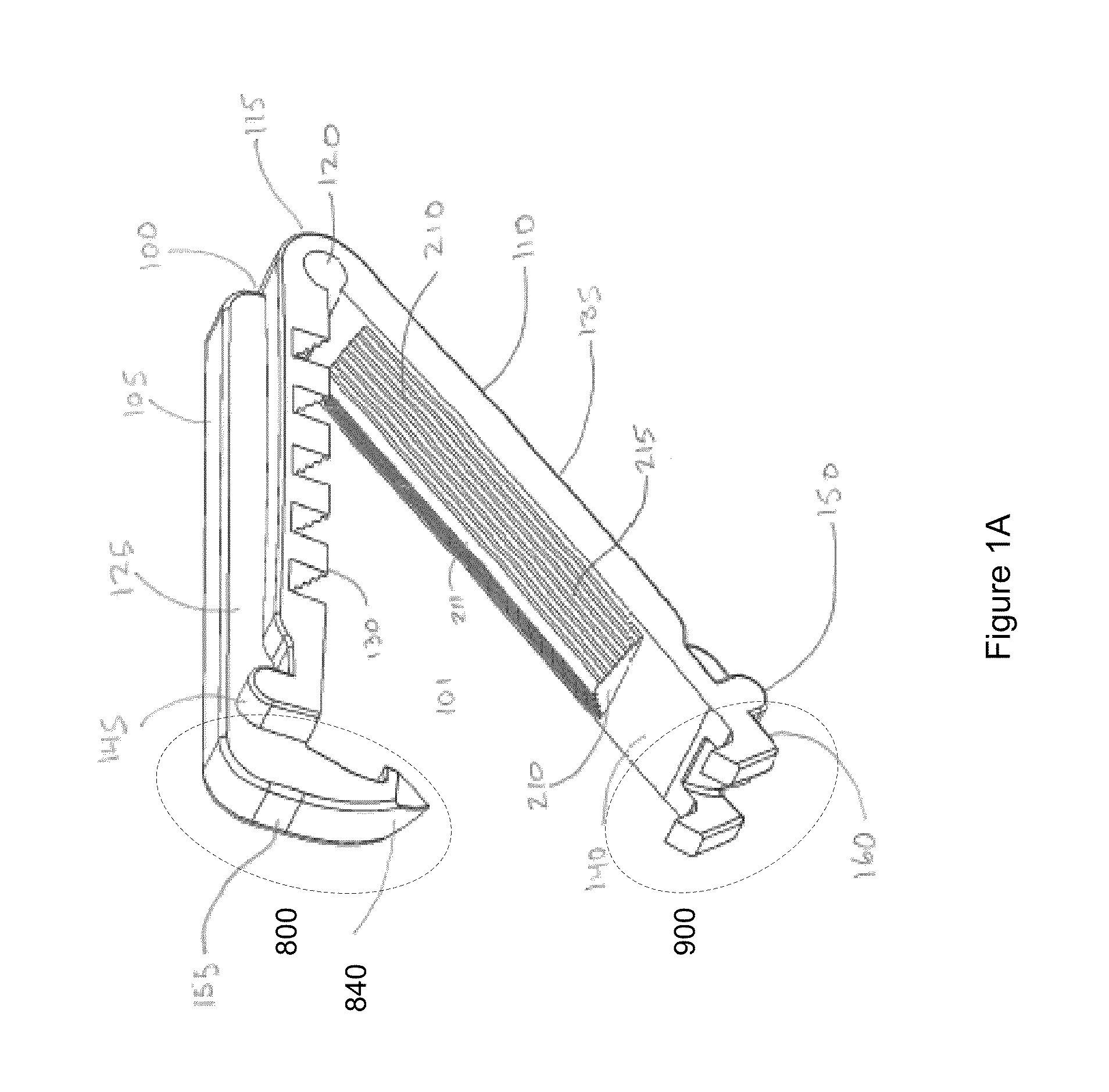

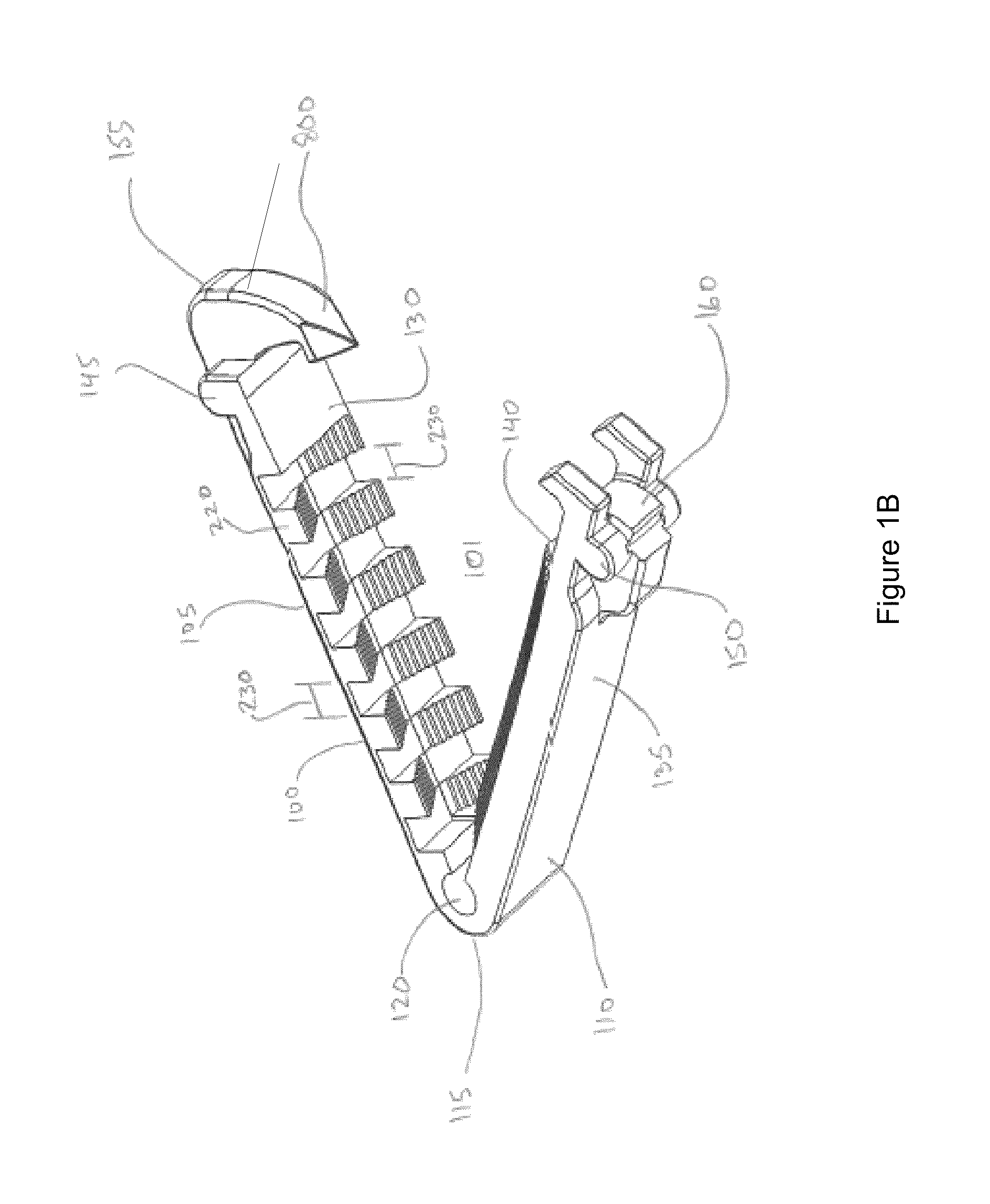

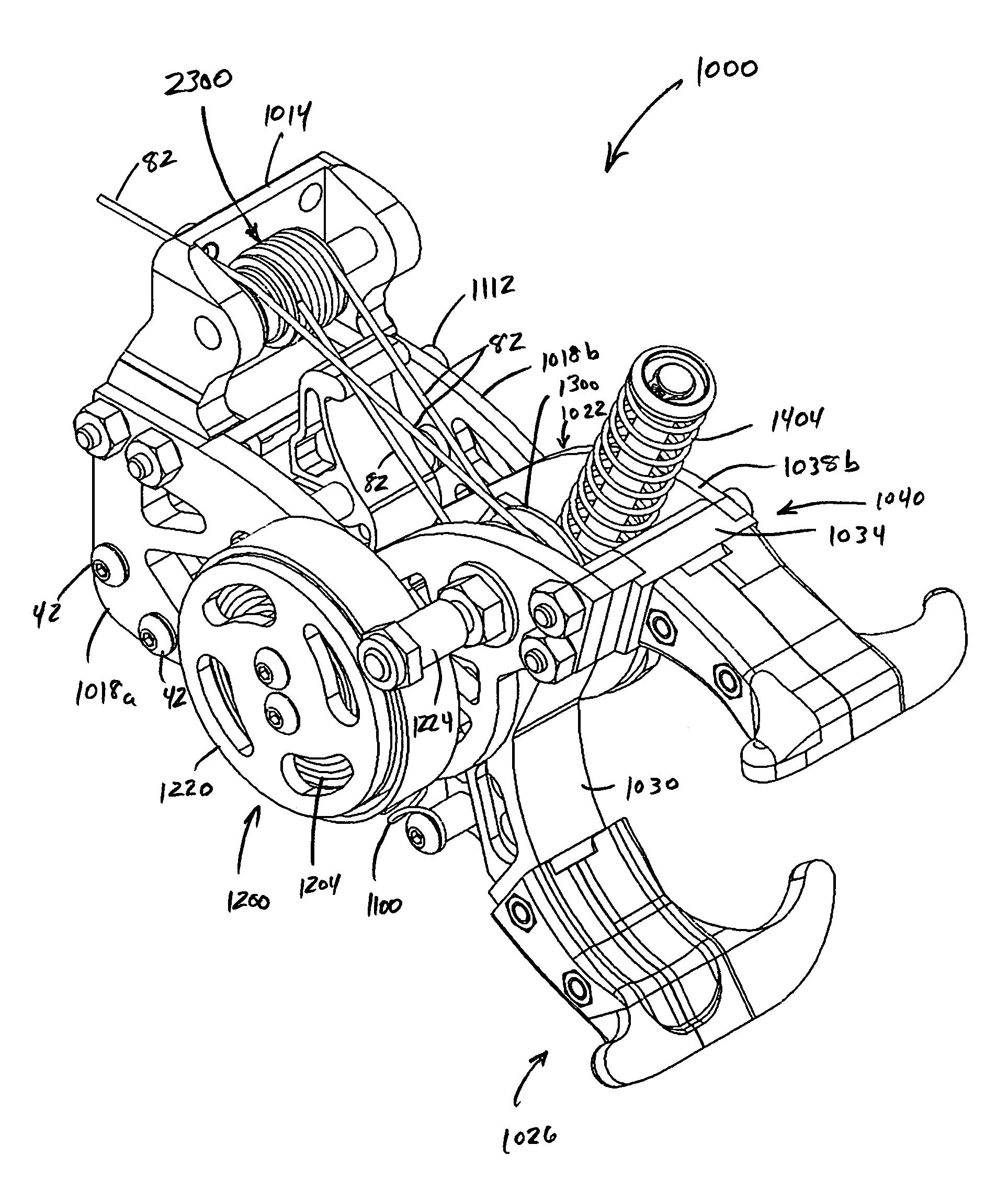

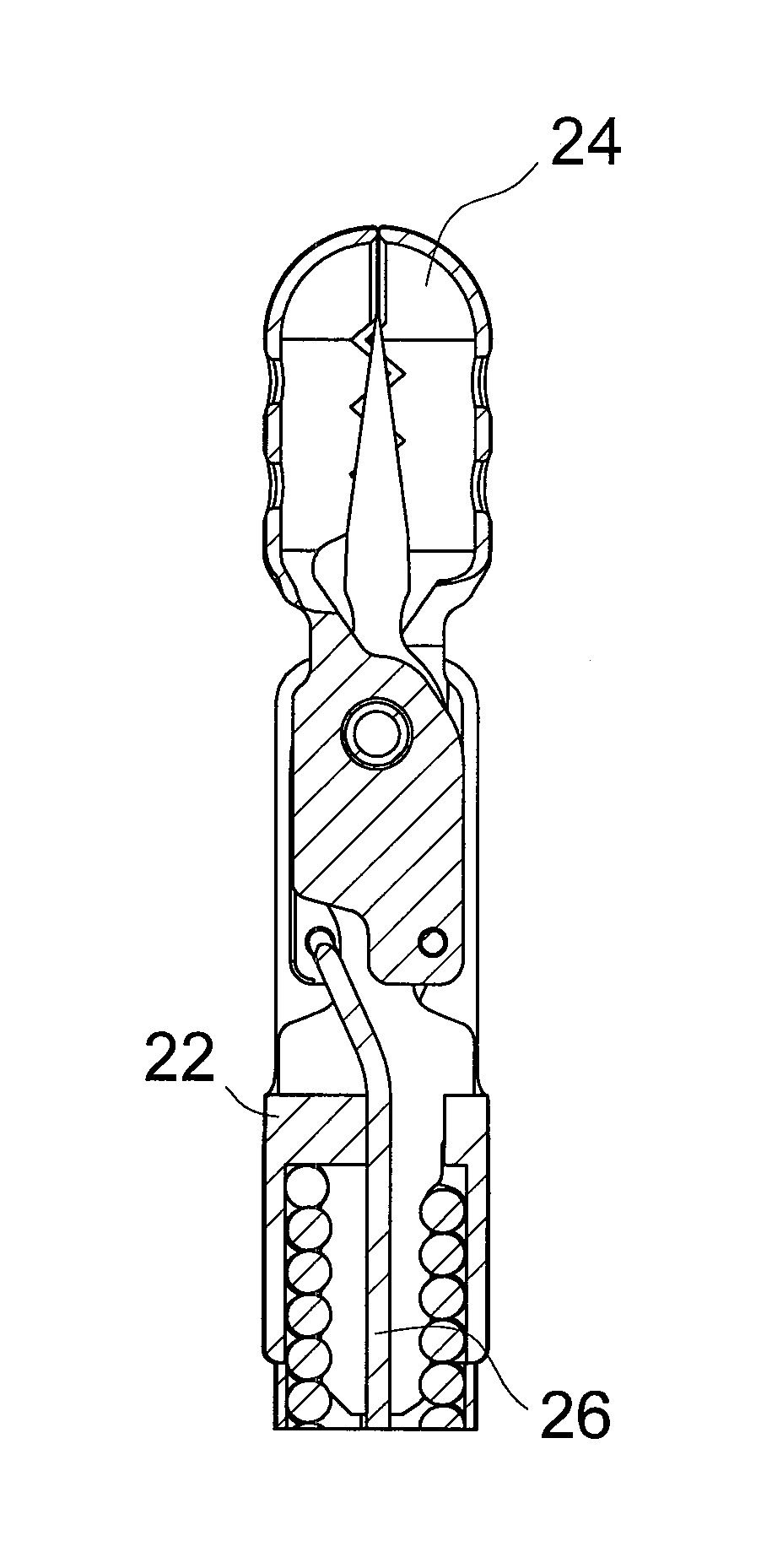

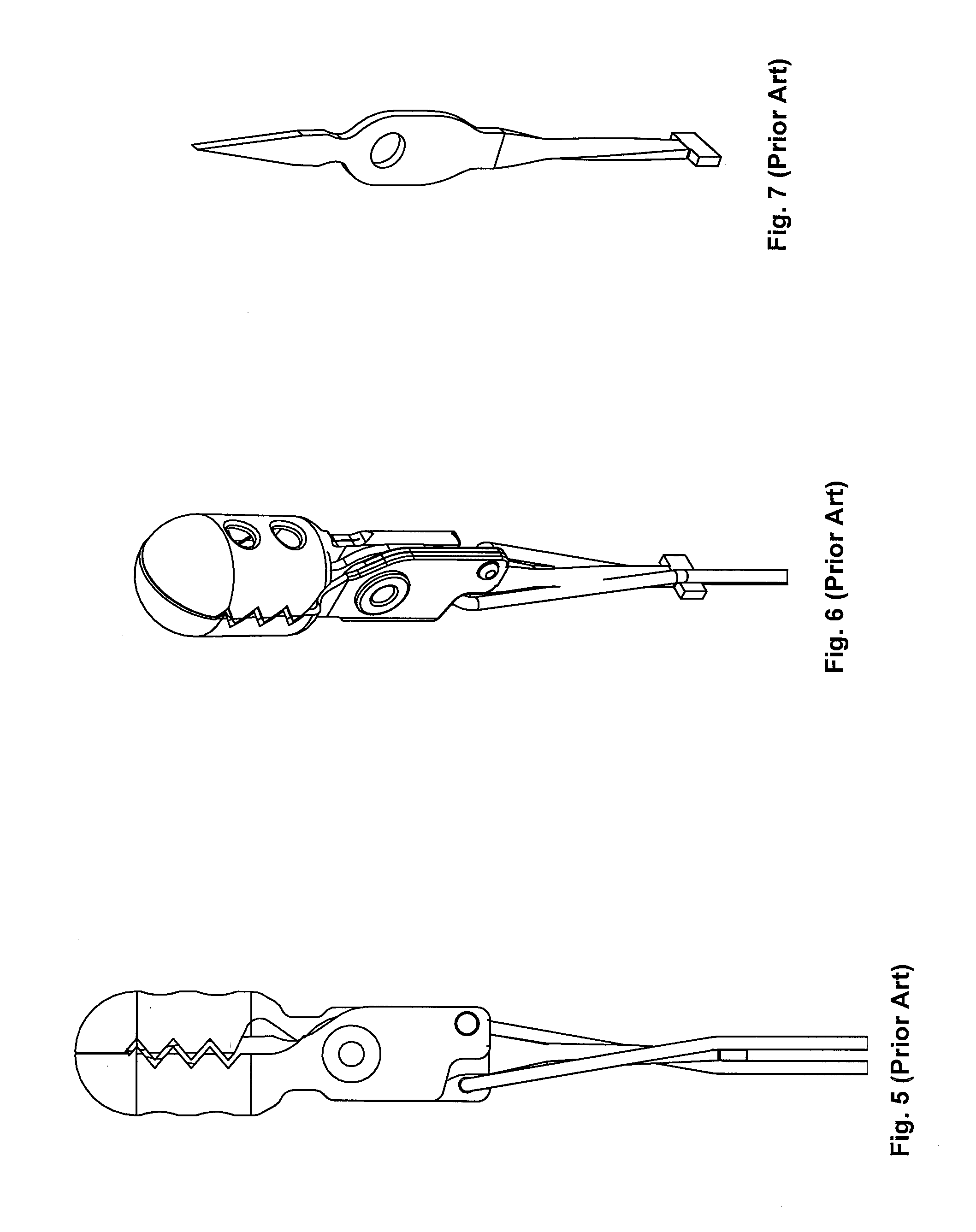

Prehensor device and improvements of same

InactiveUS7341295B1Great tractionIncrease clamping forceProgramme-controlled manipulatorGripping headsClutchEngineering

A prehensor is provided comprising embodiments of a variable mechanical advantage mechanism, the prehensor including a first mechanical advantage for sizing an object, and a second mechanical advantage for gripping the object. Embodiments of the variable mechanical advantage mechanism include a brake assembly and multiple embodiments of a brakeless assembly. Additionally, multiple embodiments of a selectable voluntary opening / voluntary closing mechanism are provided, whereby a single prehensor can be switched back and forth between a voluntary closing mode and a voluntary opening mode. Additional embodiments include a safety clutch, an improved prehensor tendon, replaceable digits, and self decontaminating digits.

Owner:INVISIBLE HAND ENTERPRISES LLC

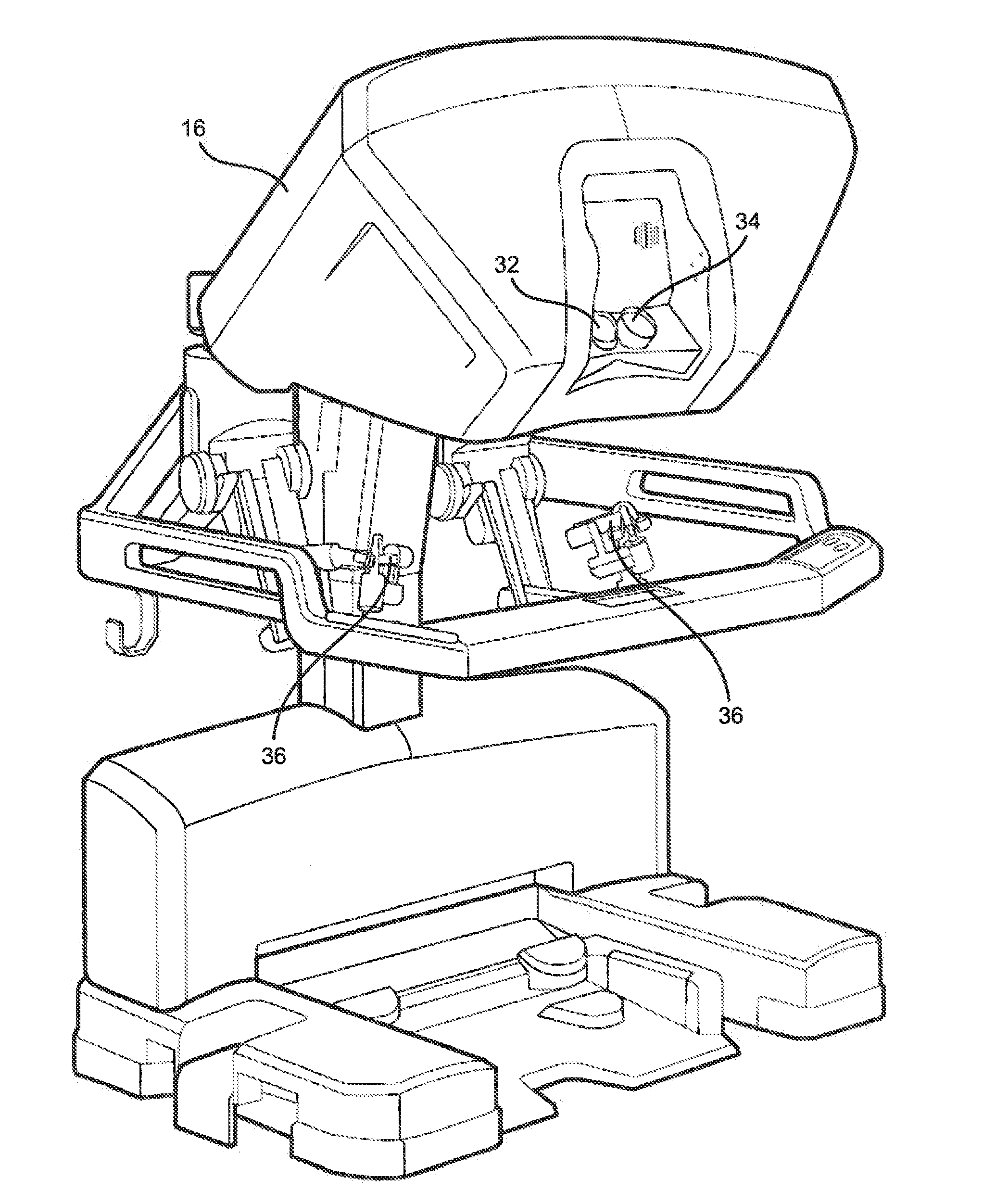

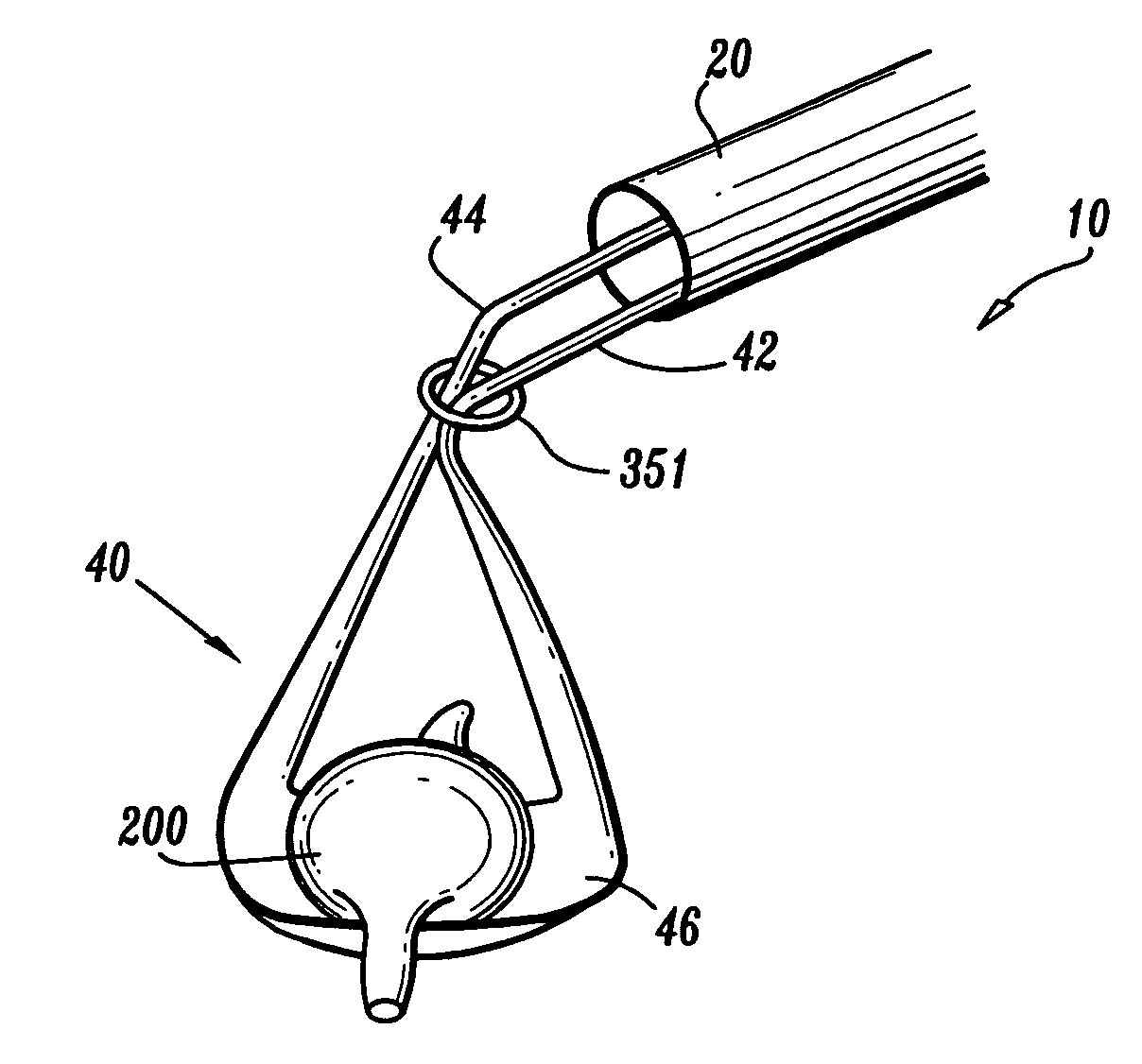

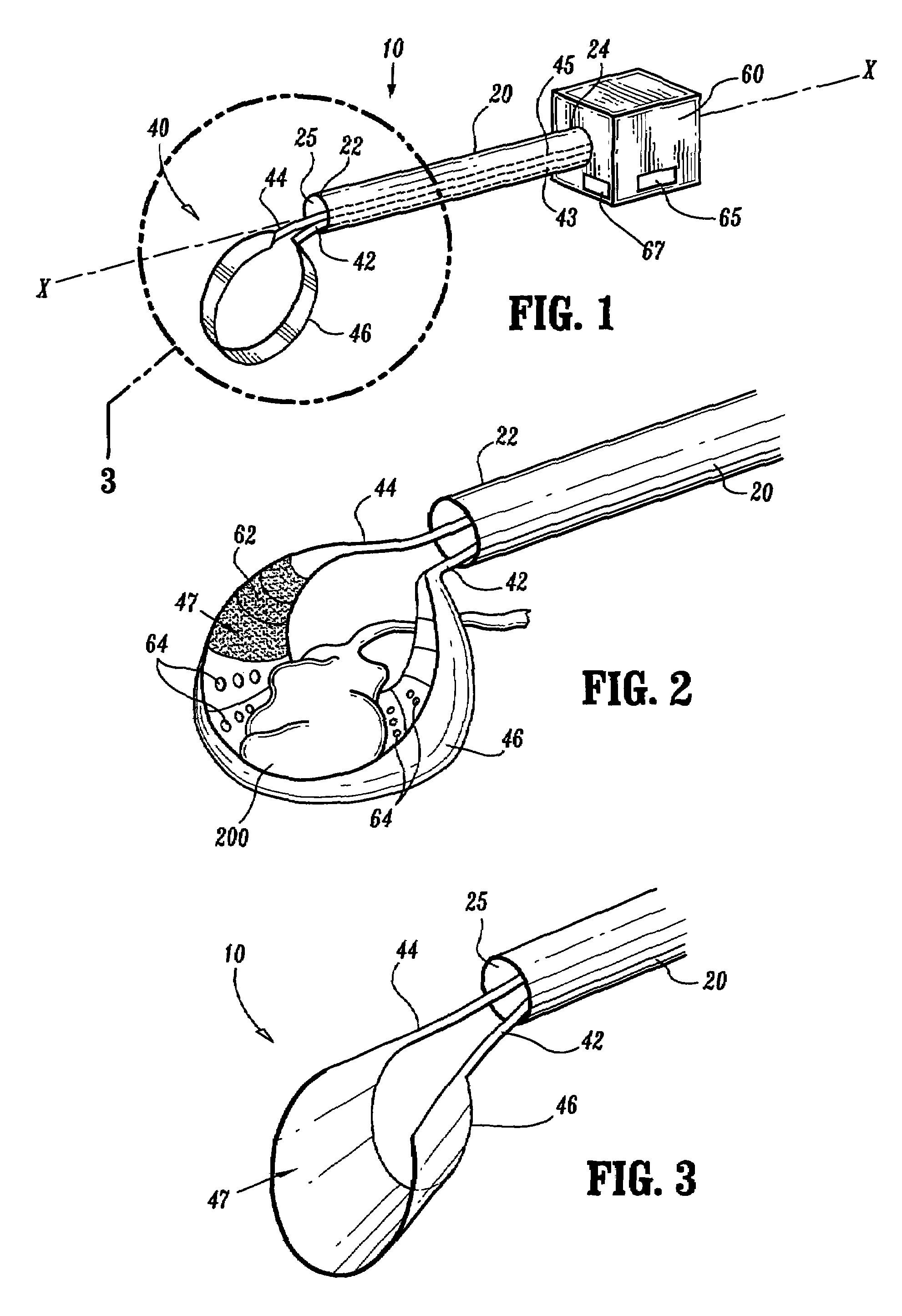

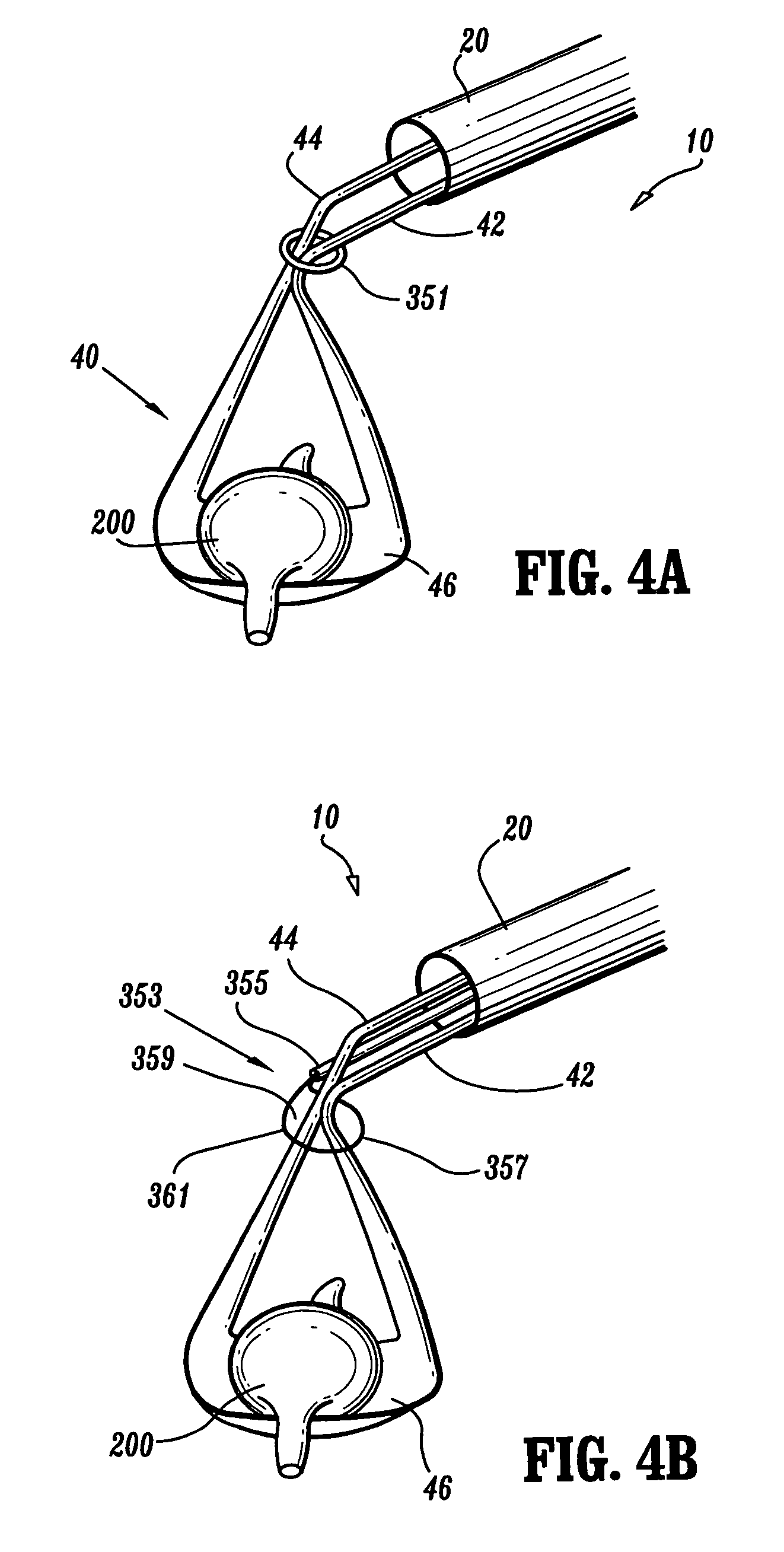

Organ retractor and method of using the same

InactiveUS7311661B2Increase clamping forceReduce morbiditySurgical pincettesProsthesisEndoscopeInvasive surgery

Owner:COVIDIEN LP

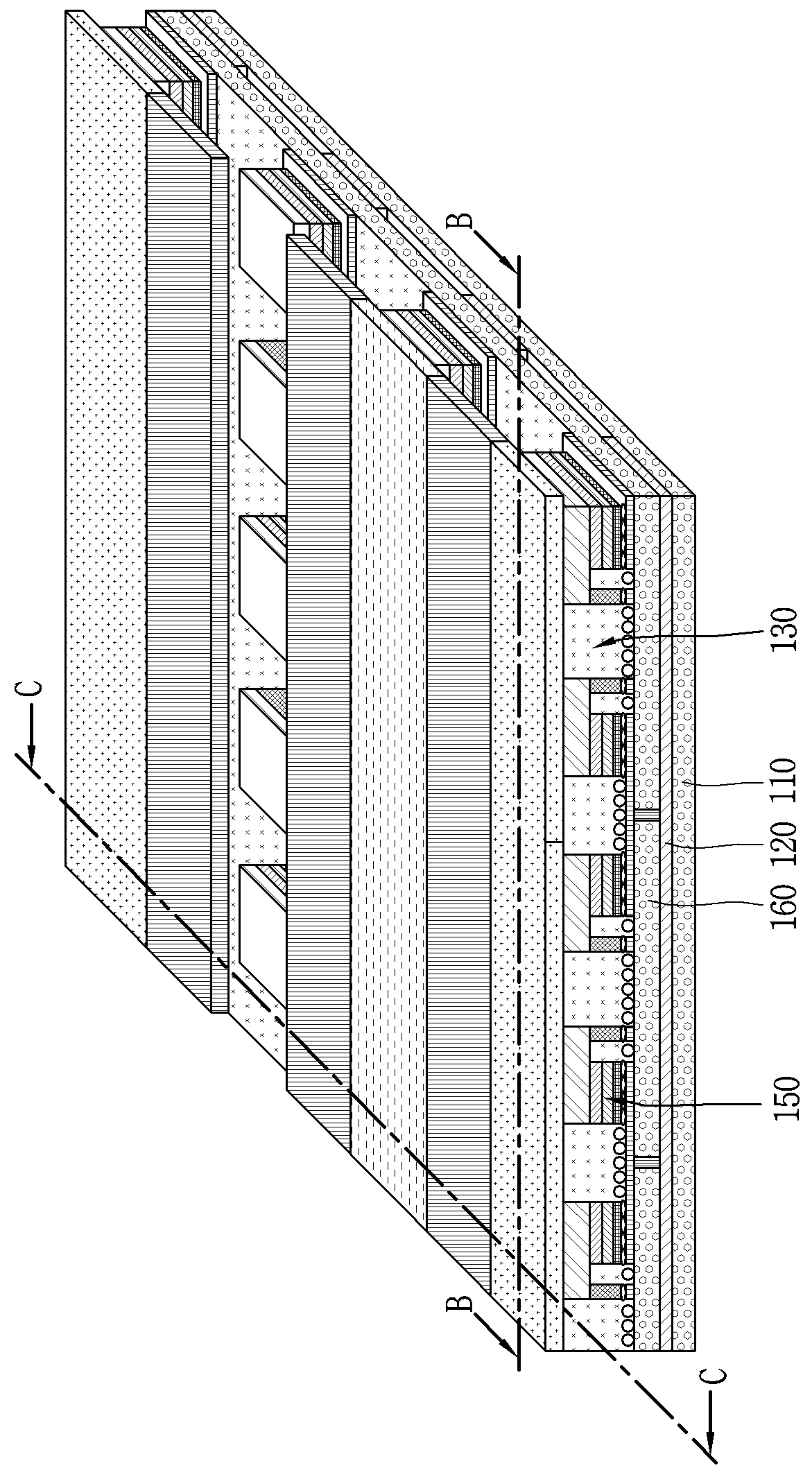

Transfer head and transfer system for semiconductor light-emitting device and method for transferring semiconductor light-emitting device

ActiveUS20180277524A1Increase clamping forcePrecise control for alignmentSolid-state devicesSemiconductor/solid-state device manufacturingTransfer systemDisplay device

The present invention relates to a display device and, more particularly, to a transfer head for a semiconductor light-emitting device applied to the display device and a method for transferring a semiconductor light-emitting device. The transfer head for a semiconductor light-emitting device, according to the present invention, comprises: a base substrate; and an electrode unit disposed on the base substrate to generate an electrostatic force by charging an un-doped semiconductor layer of the semiconductor light-emitting device with electric charges, wherein the base substrate and the electrode unit are formed of light-transmitting materials so that at least a part of the semiconductor light-emitting device is viewable through the base substrate and the electrode unit in sequence.

Owner:LG ELECTRONICS INC

Surgical stapling device with captive anvil

ActiveUS20110121050A1Precise maintenanceIncrease clamping forceSuture equipmentsStapling toolsDistal portionSurgery

A device for clamping tissue includes a first jaw having a distal portion for communicating with tissue and a proximal portion having a first wing and a second wing. The device also includes a second jaw having a distal portion for communicating with tissue and a proximal portion having a first slot and a second slot, the first slot disposed between a middle structure and a first lateral structure, the second slot disposed between the middle structure and a second lateral structure. The first jaw is rotatably coupleable to the second jaw with the first wing extending into the first slot and the second wing extending into the second slot.

Owner:TYCO HEALTHCARE GRP LP

Manipulator

InactiveUS7043338B2Easy constructionImprove reliabilityMicromanipulatorJointsWork unitRobot end effector

A manipulator comprises an operation command unit provided with an attitude adjusting unit and an end effector control unit, a connecting unit having one end connected to the operation command unit, a working unit connected to the other end of the connecting unit and provided with an end effector and a support unit supporting the end effector for motions, and a control unit that transmits an operation command provided by the attitude adjusting unit to the support unit to adjust the attitude of the end effector and transmits an operation command provided by the end effector control unit to the end effector to operate the end effector. The support unit includes a first joint capable of turning about a first axis perpendicular to the center axis of the connecting unit, and a second joint capable of turning about a second axis perpendicular to the first axis. The end effector can be turned for rolling about an axis substantially parallel to the second axis of the second joint. The attitude adjusting unit has a third joint having a third axis perpendicular to the center line of the connecting unit. The end effector control unit is formed such that the fingers of an operator gripping operating members included in the end effector control unit extend substantially in parallel to the fourth axis.

Owner:KARL STORZ GMBH & CO KG

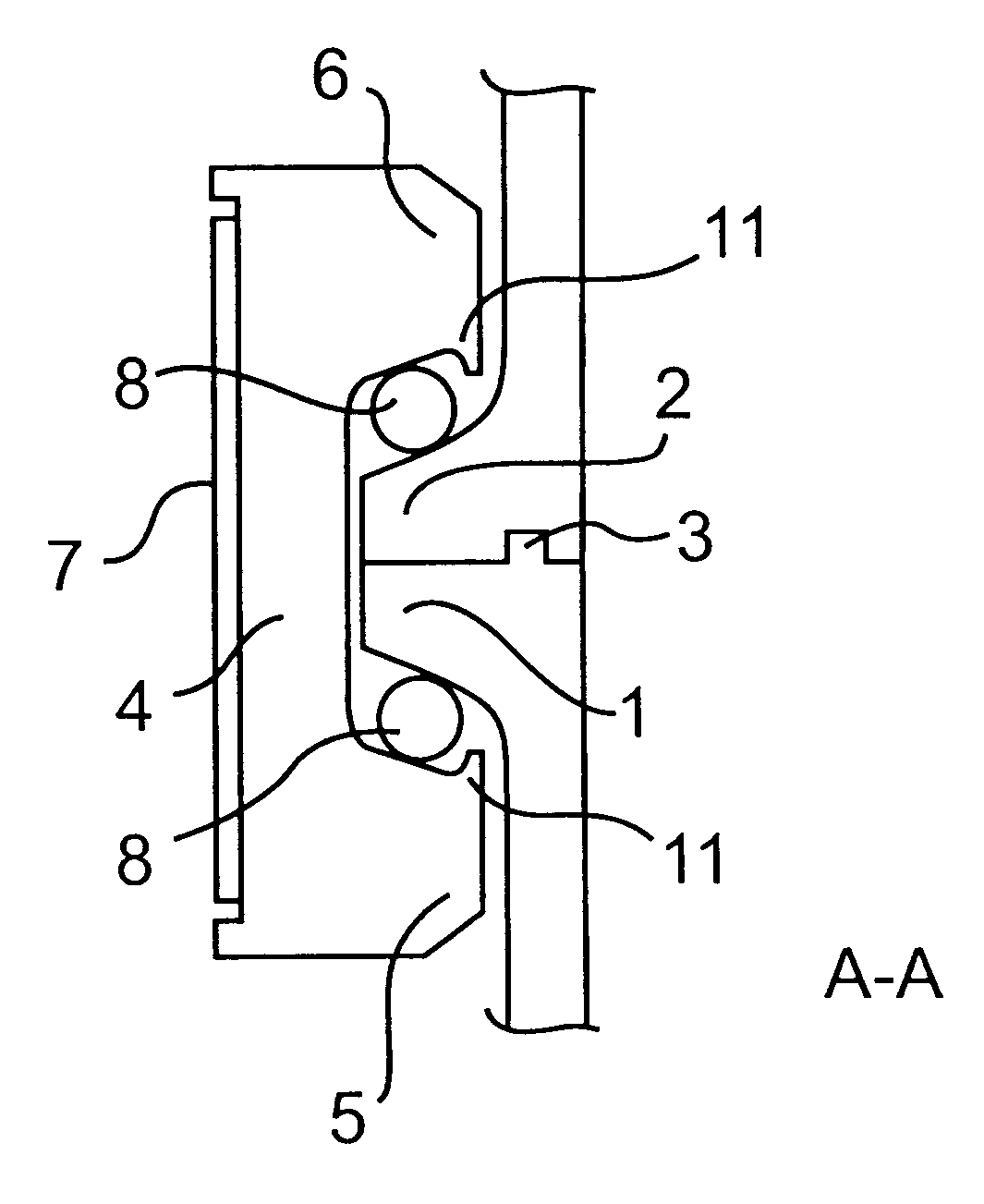

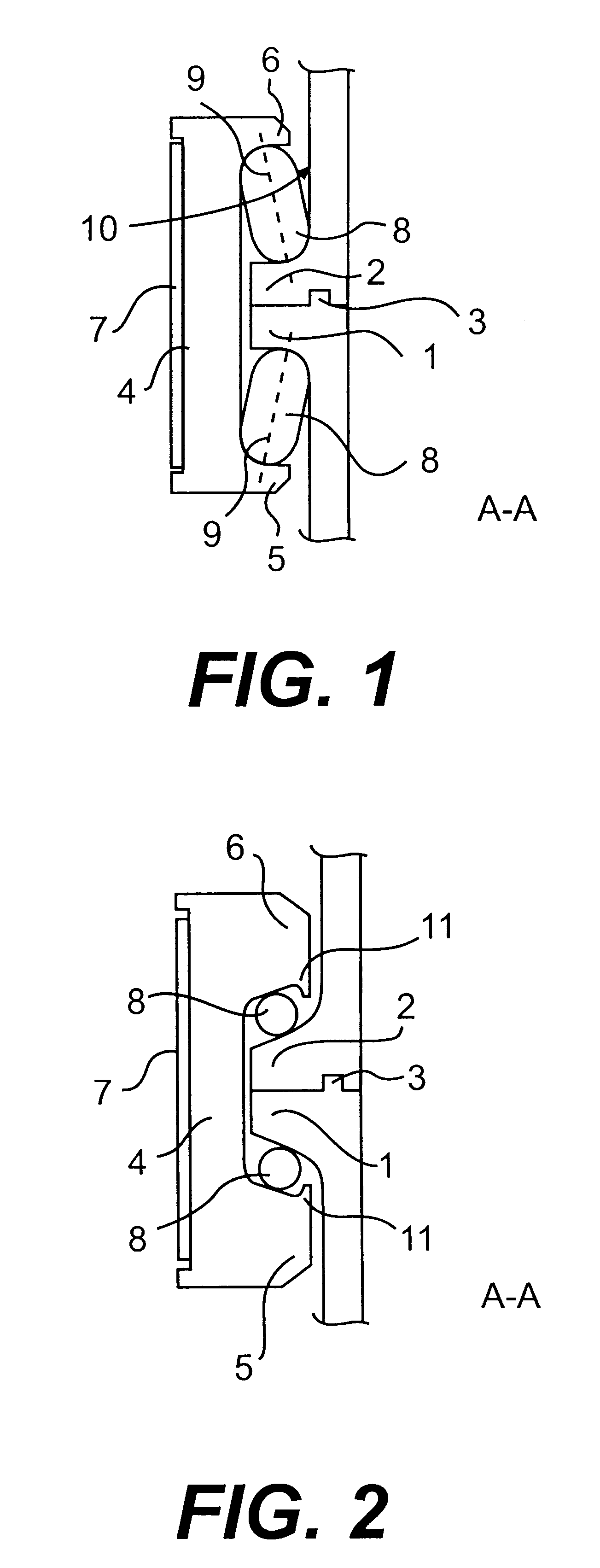

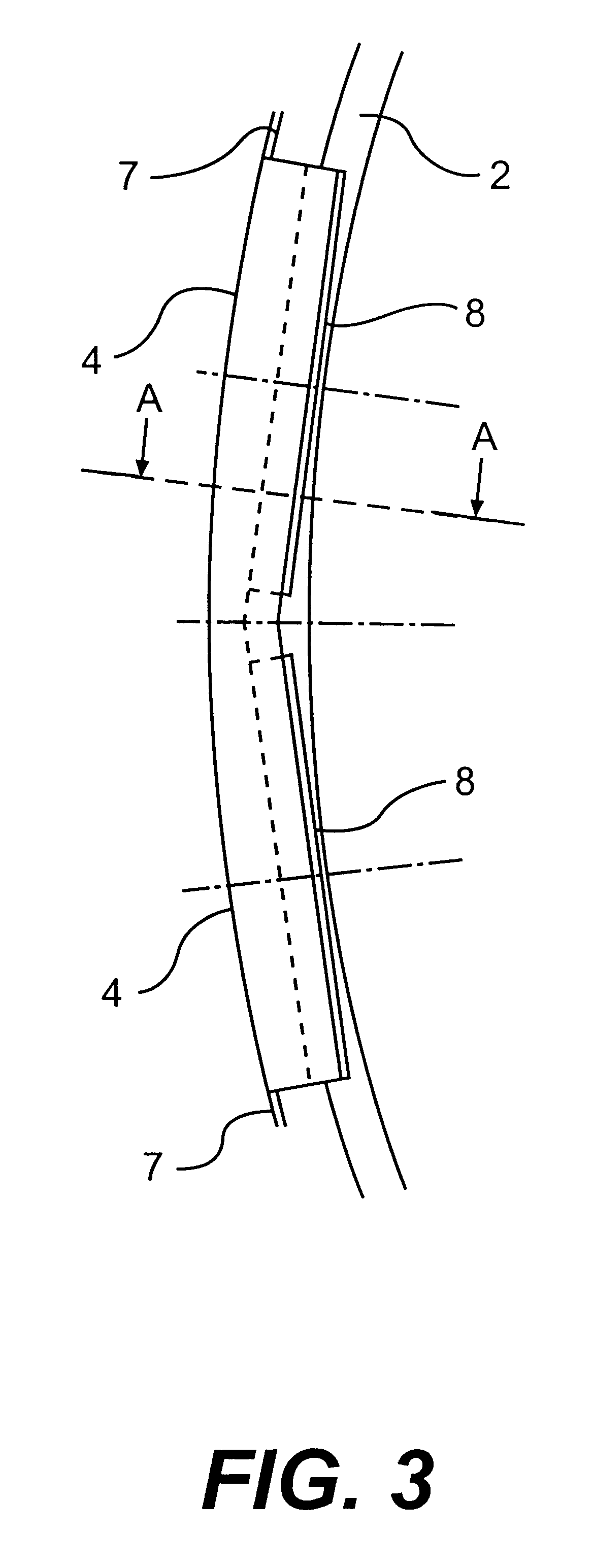

Joint for space vehicle

A joint in a space vehicle to hold together a first part of the vehicle and a second part of the vehicle that can be separated from the first part, in which the joint includes a first flange member (1) attached to the first part of the vehicle and a second flange member (2) attached to the second part of the vehicle. A number of clamps (4) equipped with two clamping lips (5, 6) are distributed around the perimeter of the flange members (1, 2) that transfer radial force from a tensioning means (7), arranged around the clamps (4), to both of the flange members (1, 2) in order to press these together, whereby rolling members (8) are arranged between at least one of the clamping lips (5, 6) of the respective clamps (4) and the adjacent first (1) or second (2) flange member.

Owner:SAAB ERICSON SPACE

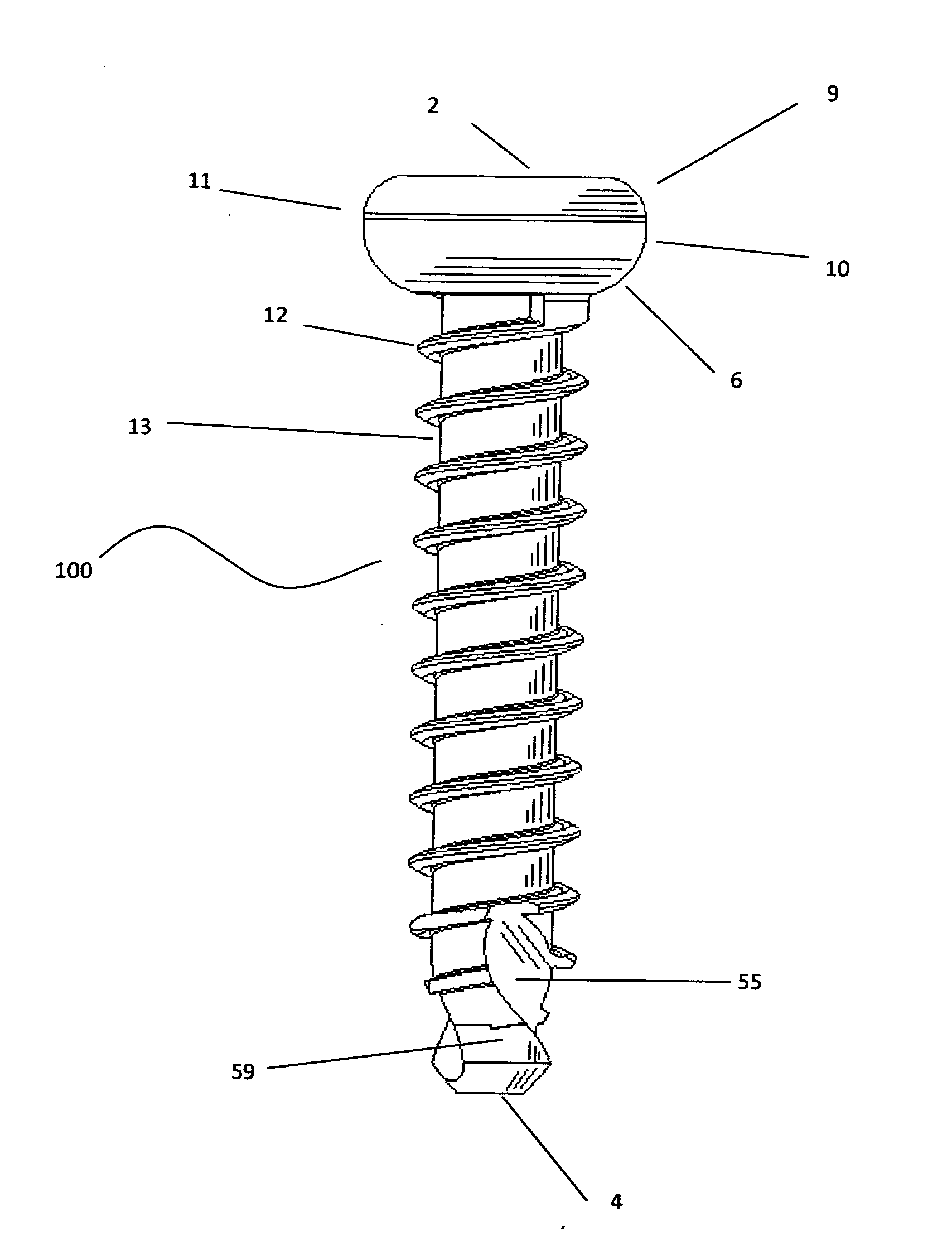

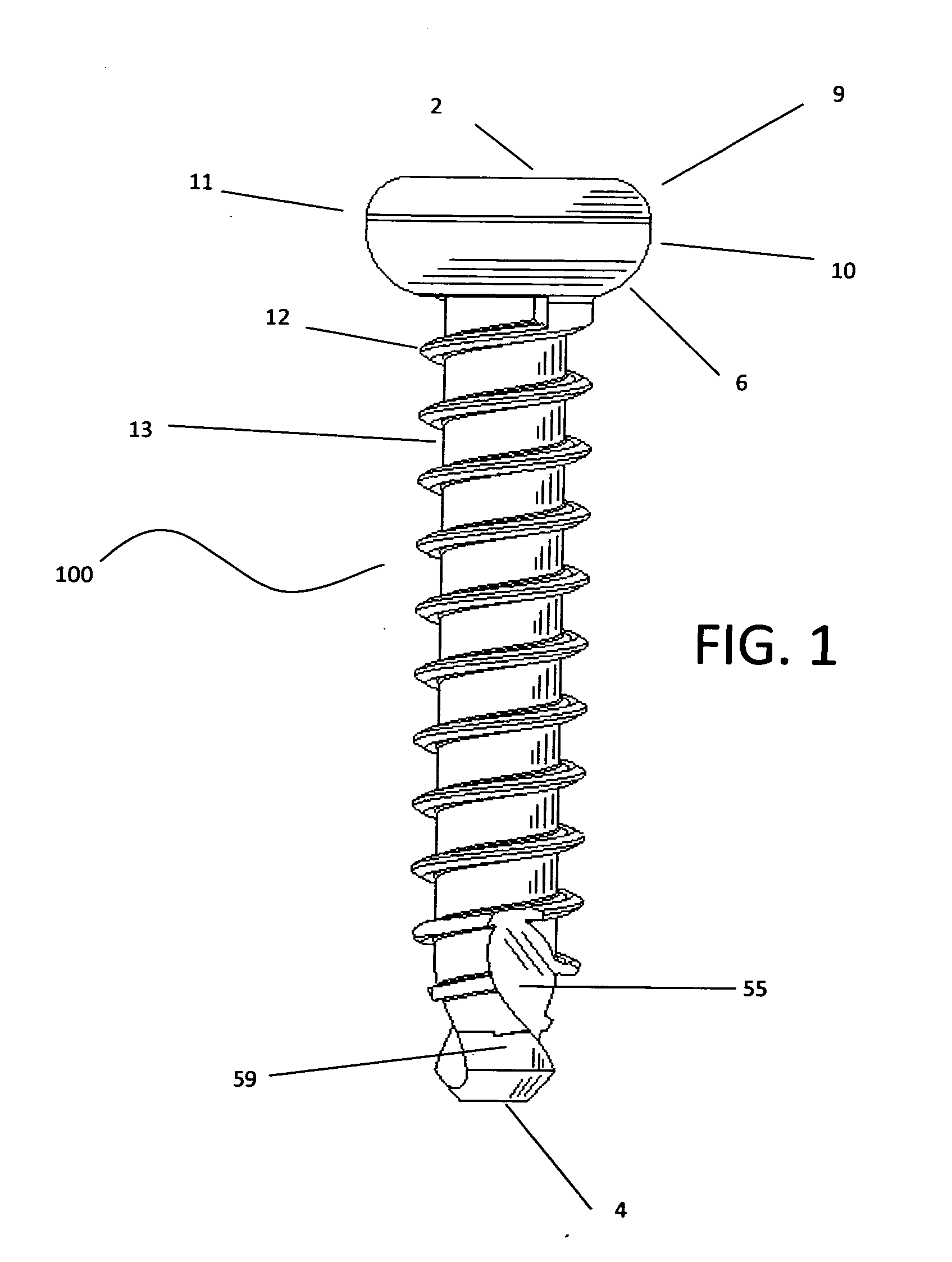

Orthopedic fastener device

ActiveUS20140058460A1Good retentionMinimal damageSuture equipmentsLigamentsThreaded fastenerPlastic surgery

An orthopedic structure includes a method for making a threaded fastener with thread geometry and leading edge geometry which provides greater precision during installation. Specifically, thread pitch and tooth profiles are independently variable. A leading portion of the fastener advances bone shards forward of the forward of the fastener to reduce insertion torque and prevent the shards from residing in the upstream tooth profile for better retention.

Owner:RTG SCI LLC

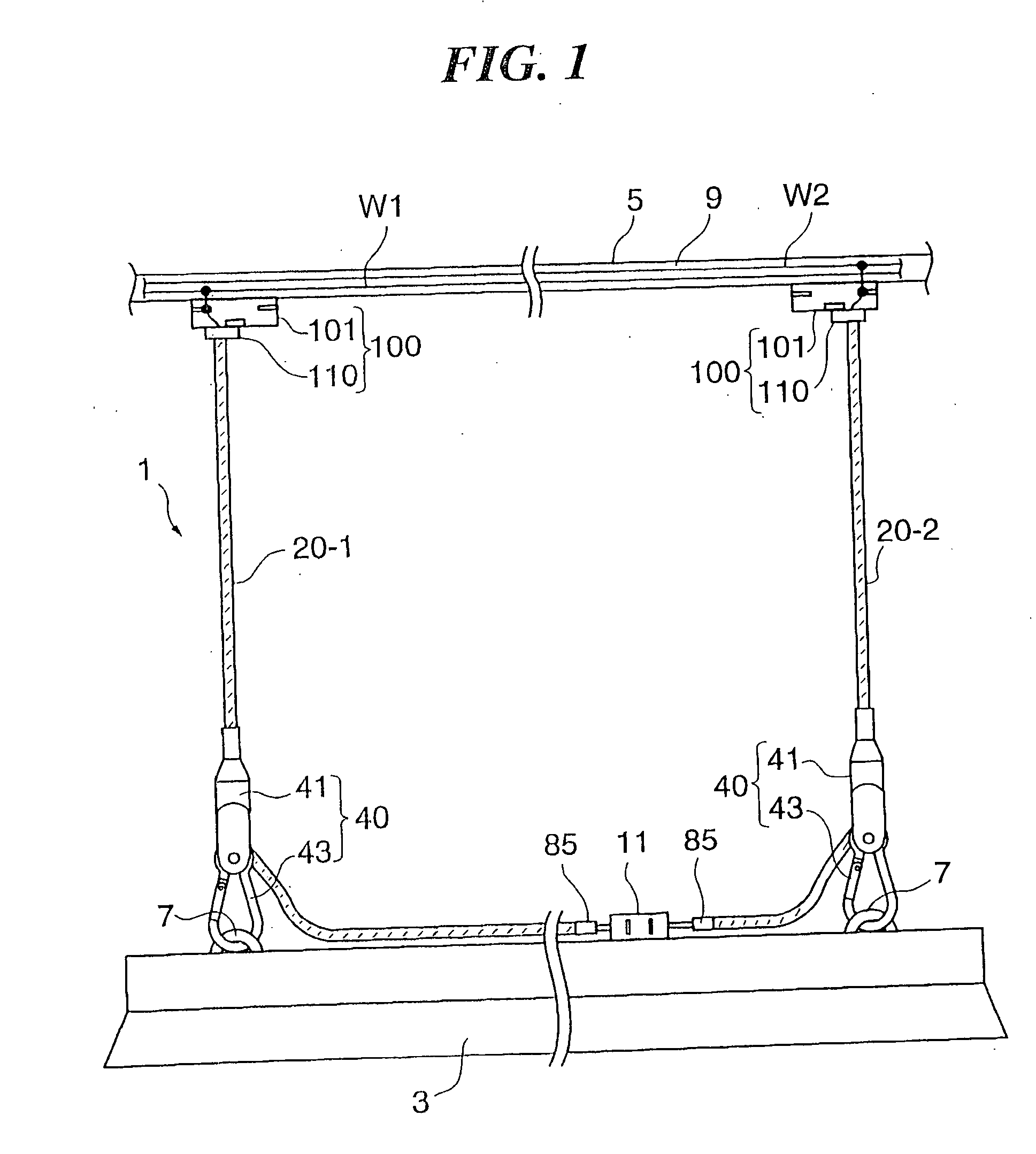

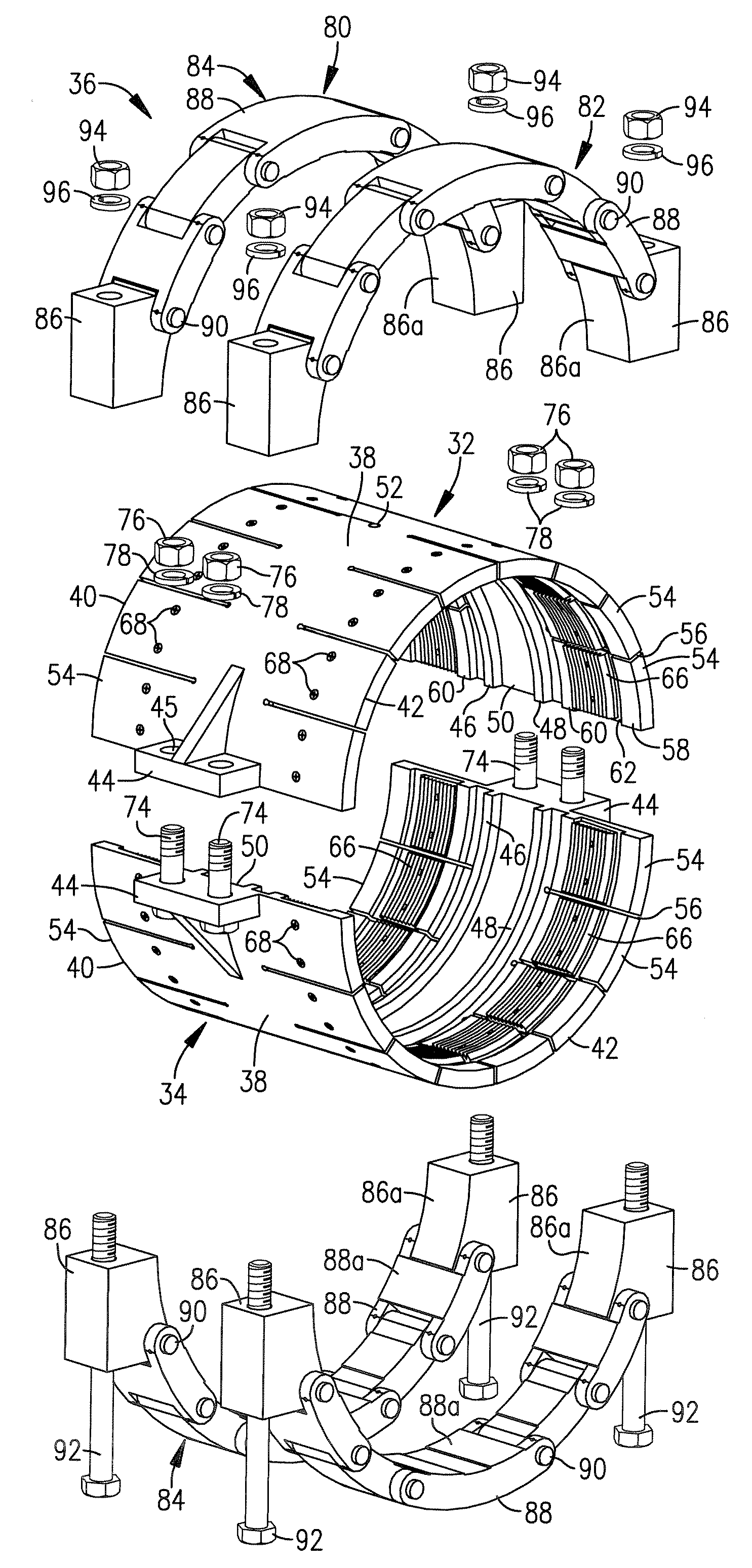

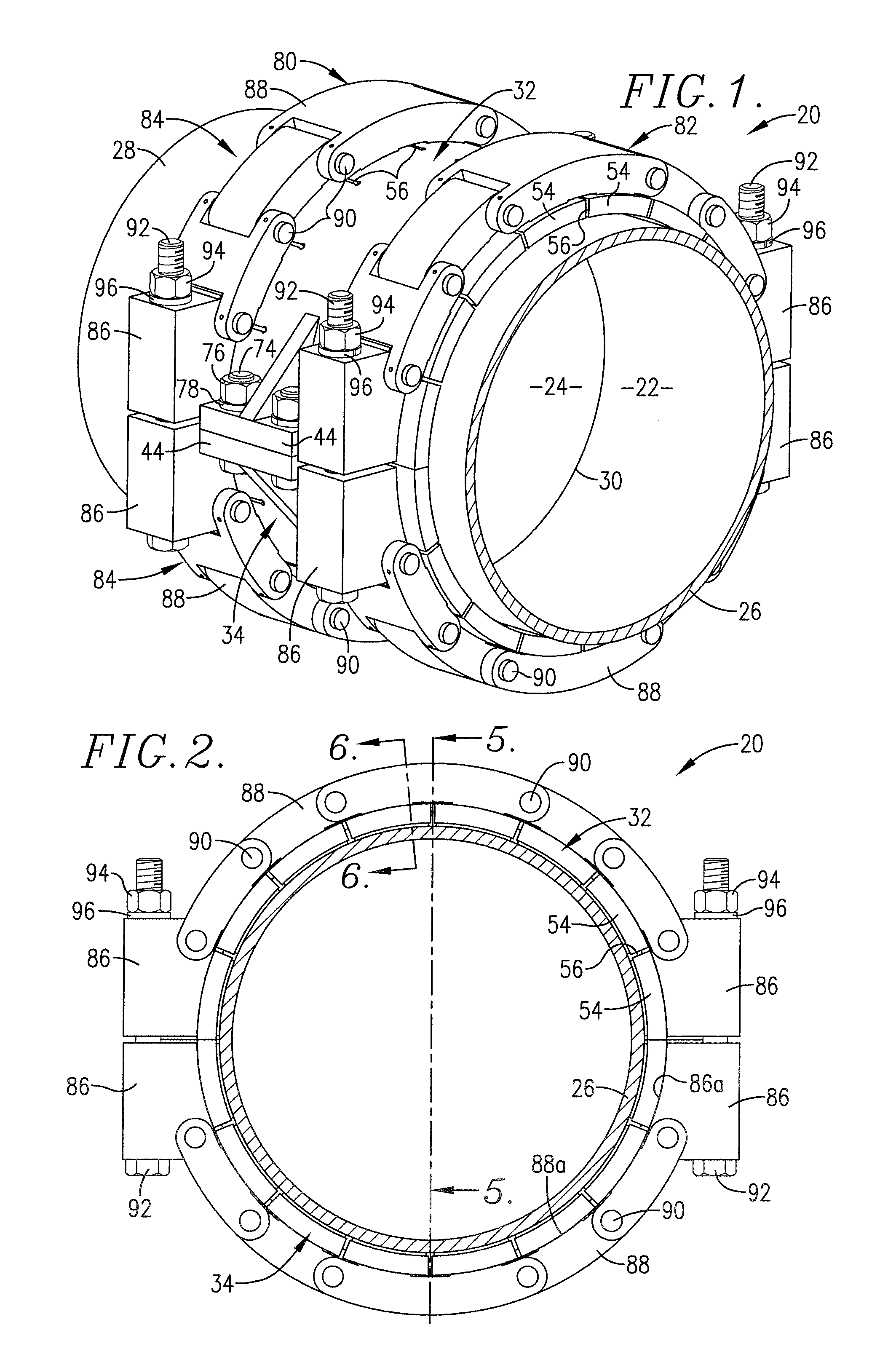

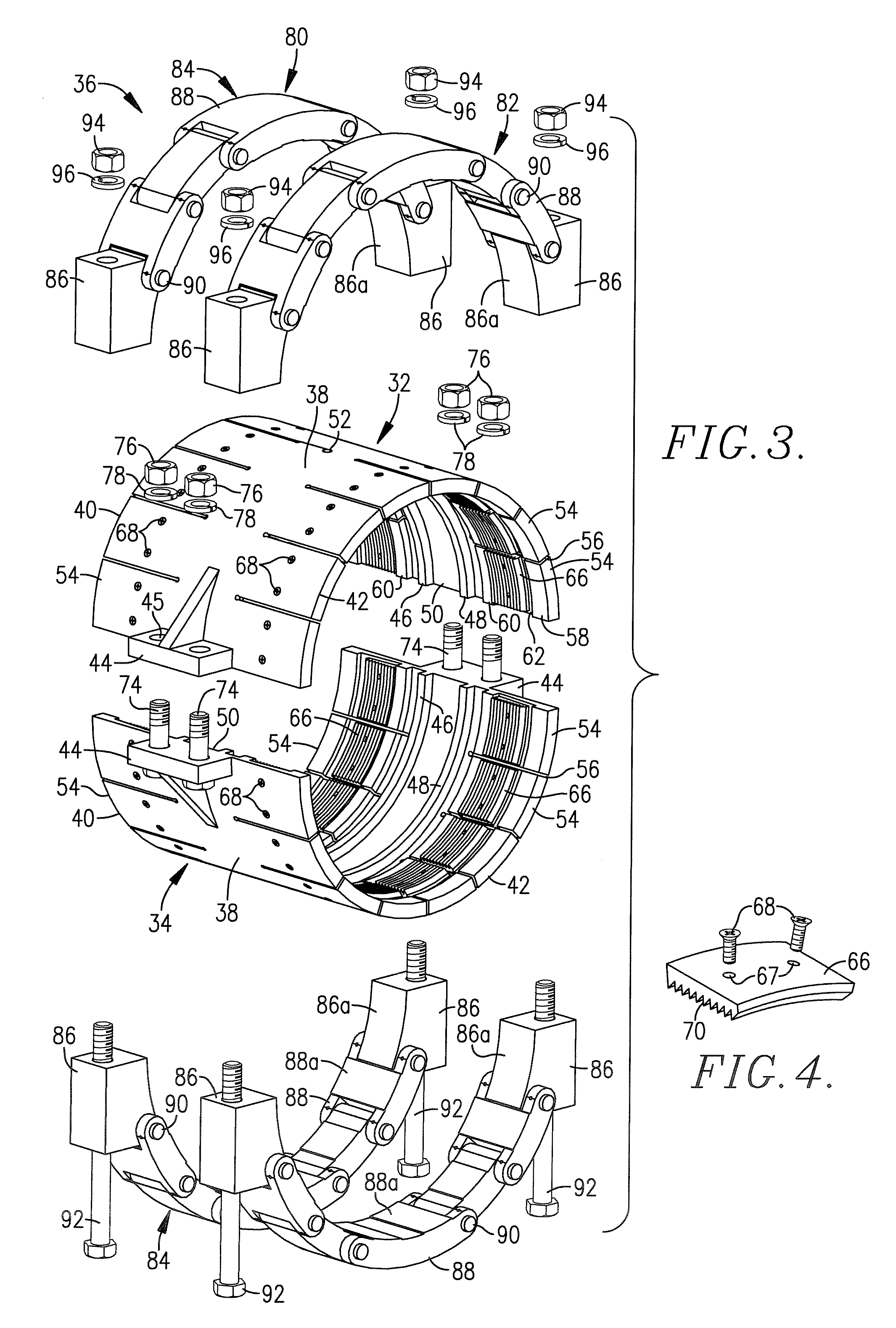

Self-tightening clamp assemblies for protection against full pipe separation

ActiveUS20070296213A1Efficient actionIncrease clamping forceSleeve/socket jointsFlanged jointsGrip forceEngineering

Improved self-tightening clamp assemblies are provided, which are designed for application to the adjacent ends of connected pipe sections in spanning relationship to the joint therebetween. The assemblies include a plurality of clamp bodies configured for placement about the adjacent pipe section ends and carrying a plurality of pipe-engaging teeth; a clamping mechanism is operably coupled with the clamp bodies to cause the teeth to grippingly engage the pipe section ends. The teeth are oriented so as to exert an increasing gripping force on the pipe sections ends in the event of relative separation movement between the ends.

Owner:PHILLIPS 66 CO

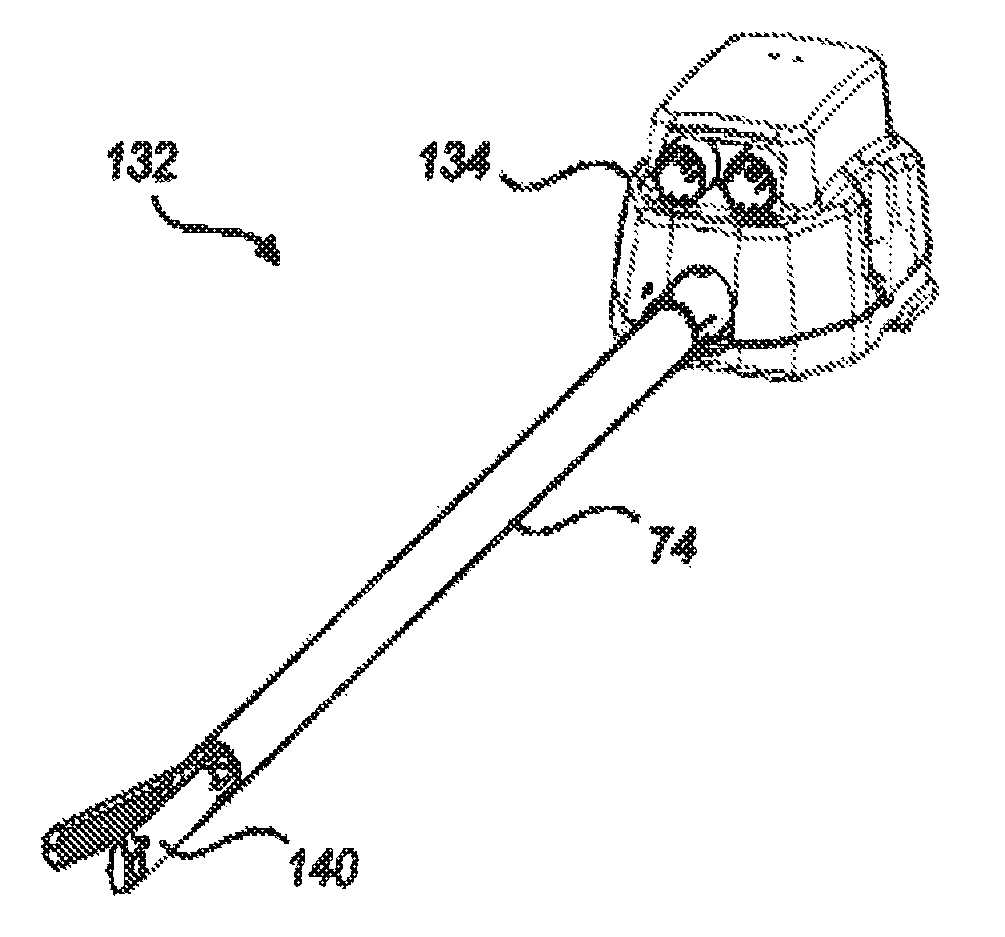

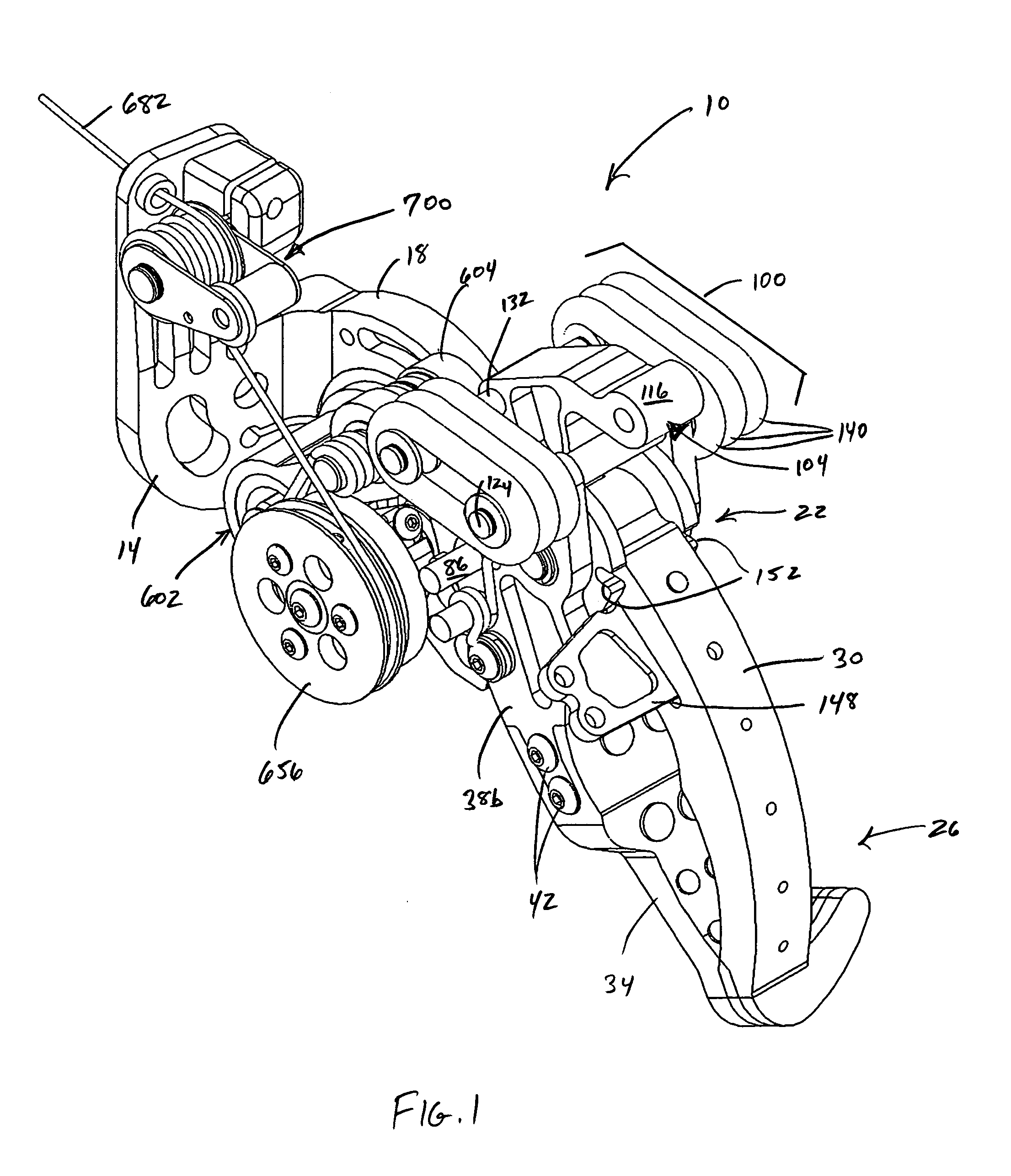

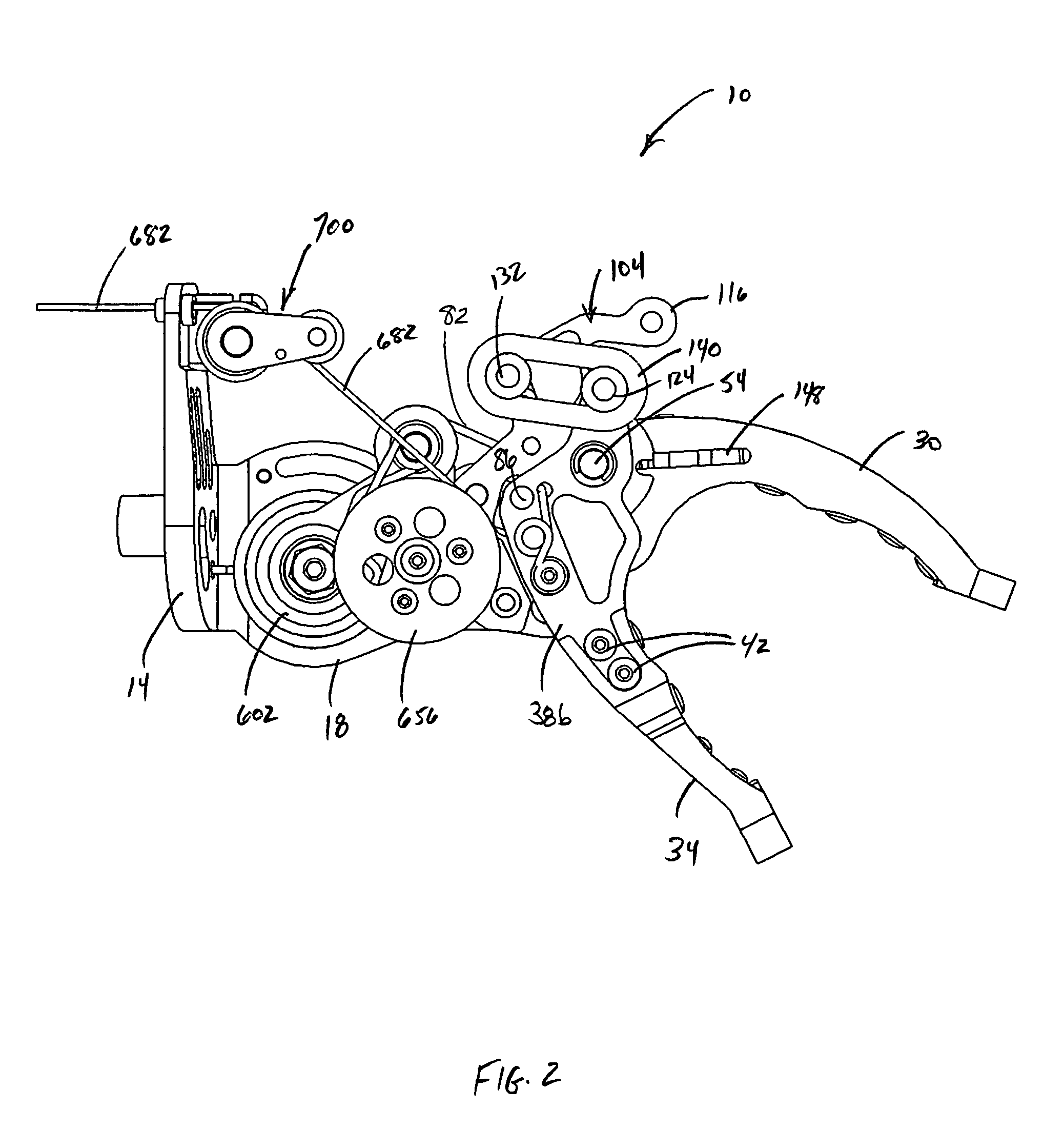

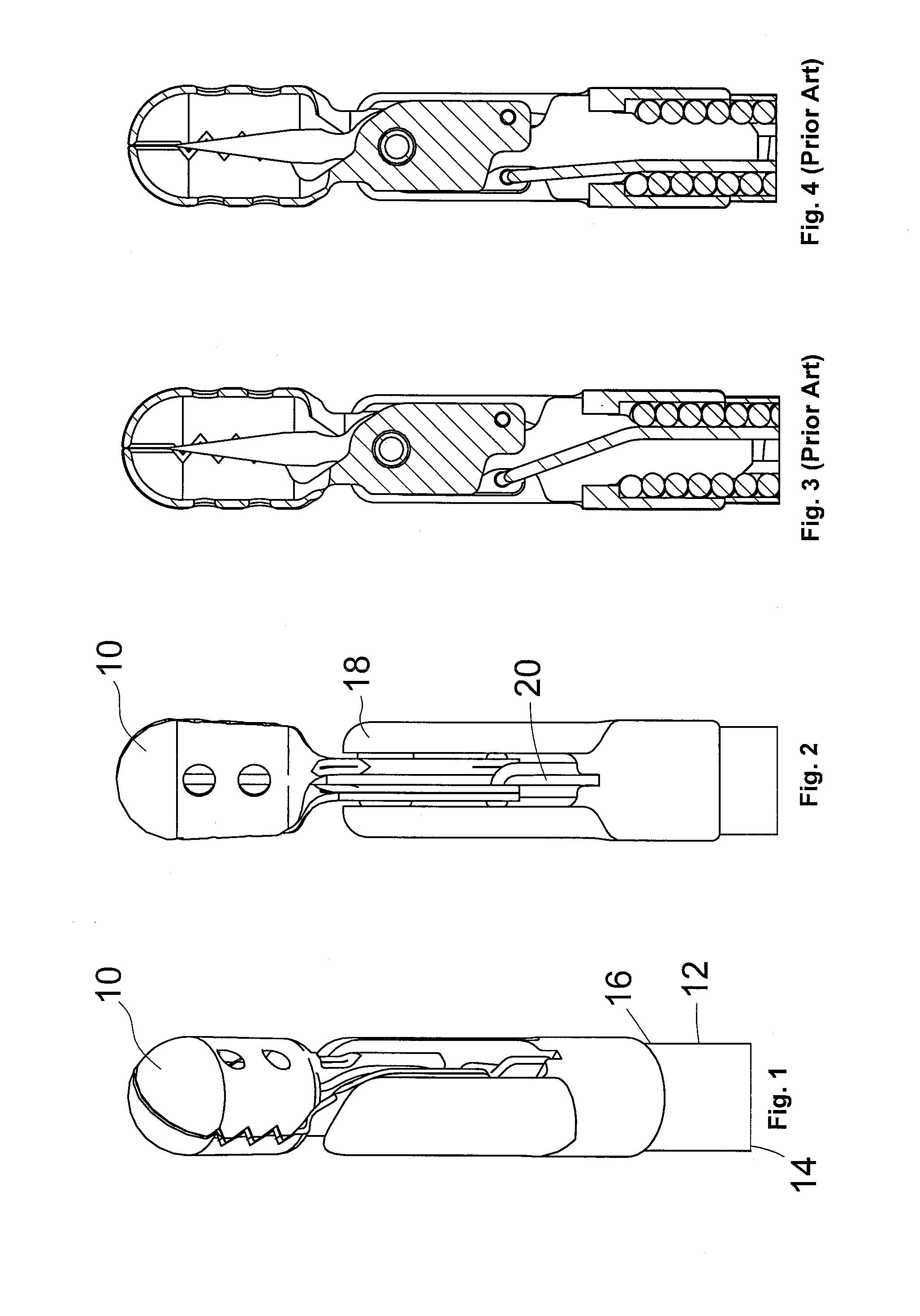

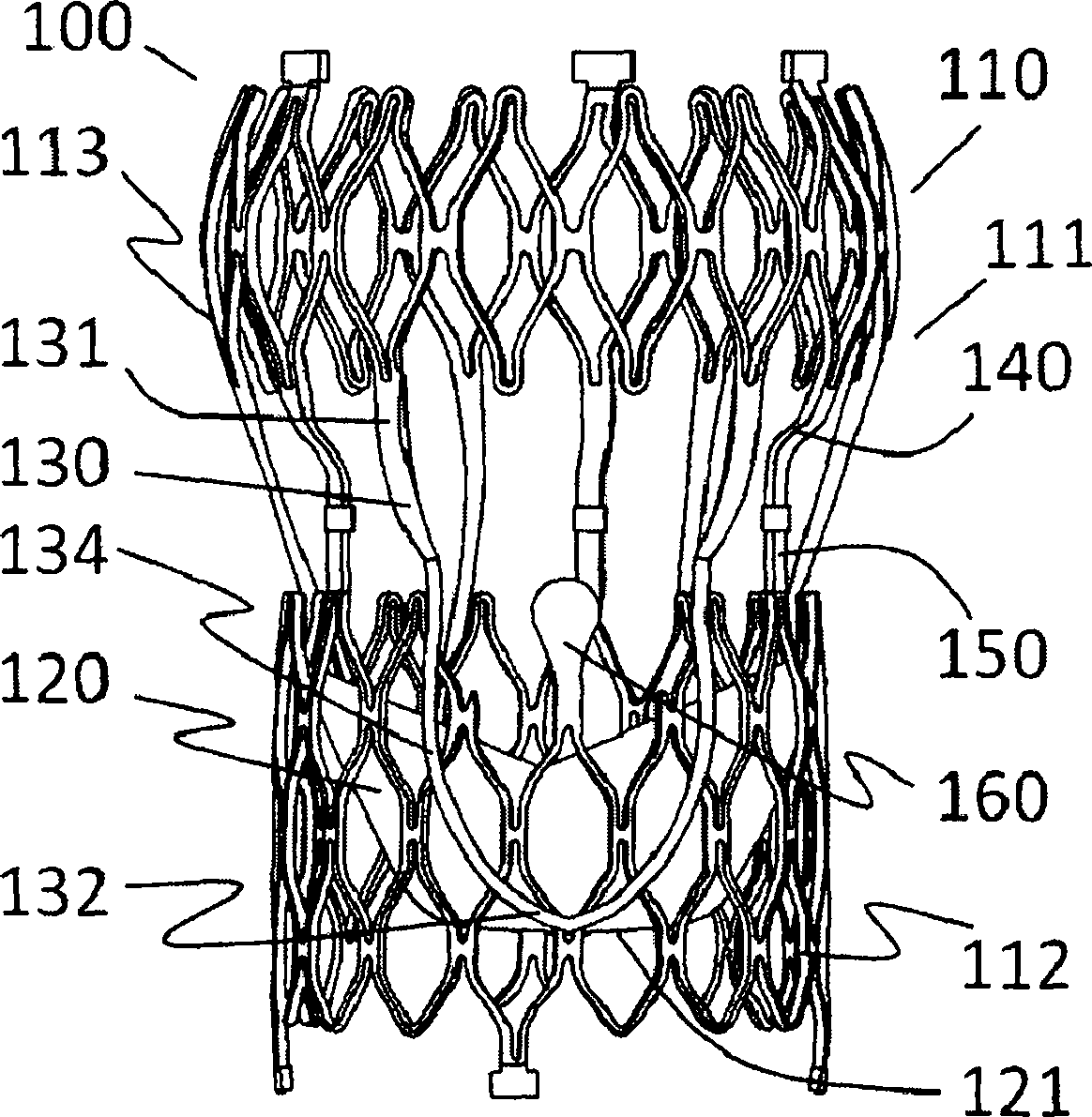

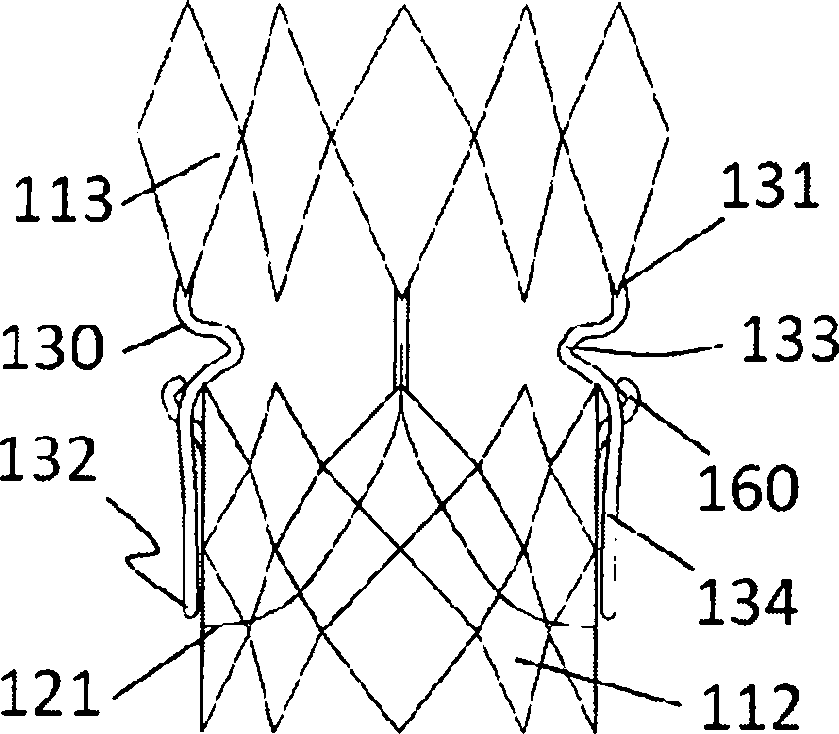

End effector assembly with increased clamping force for a surgical instrument

ActiveUS20110276085A1Increase clamping forceVaccination/ovulation diagnosticsSurgical forcepsSurgical instrumentEngineering

An end effector assembly with increased clamping force for a surgical instrument including a hollow shaft having a proximal end and a distal end, a clevis coupled to the distal end of the hollow shaft, a flat support coupled to the clevis, a deflection member, a procedural member assembly rotatably coupled to the flat support and a pair of actuation means attached to the procedural member assembly and slidable relative to the hollow shaft for rotationally moving the procedural member assembly between a closed and an open position wherein the deflection member engaged the actuation means. The deflection member may be integral with the clevis, coupled to the clevis and the flat support, coupled to just the flat support, may be adjustable or rotatable or coupled to hollow shaft.

Owner:KRZYZANOWSKI JACEK

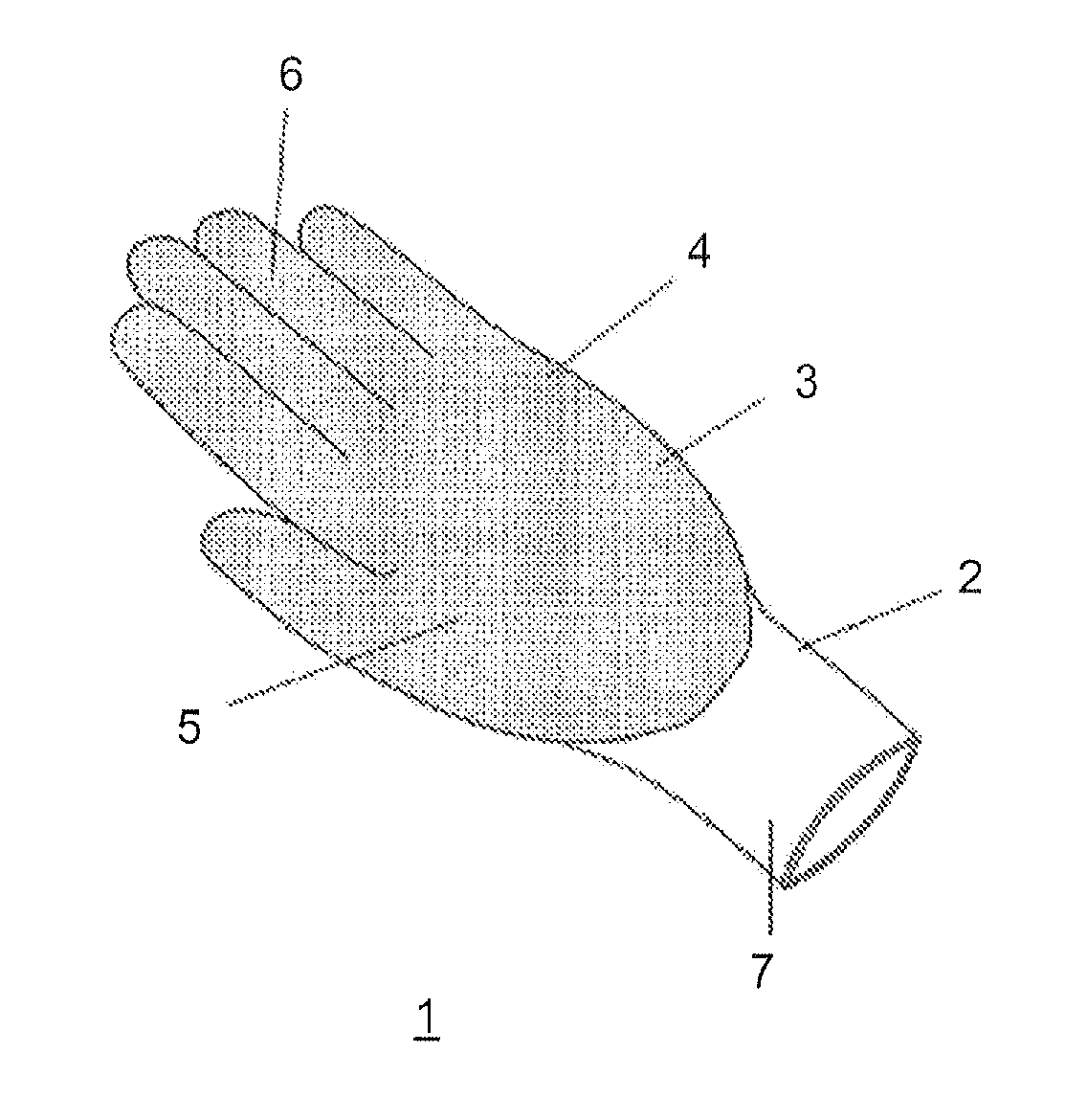

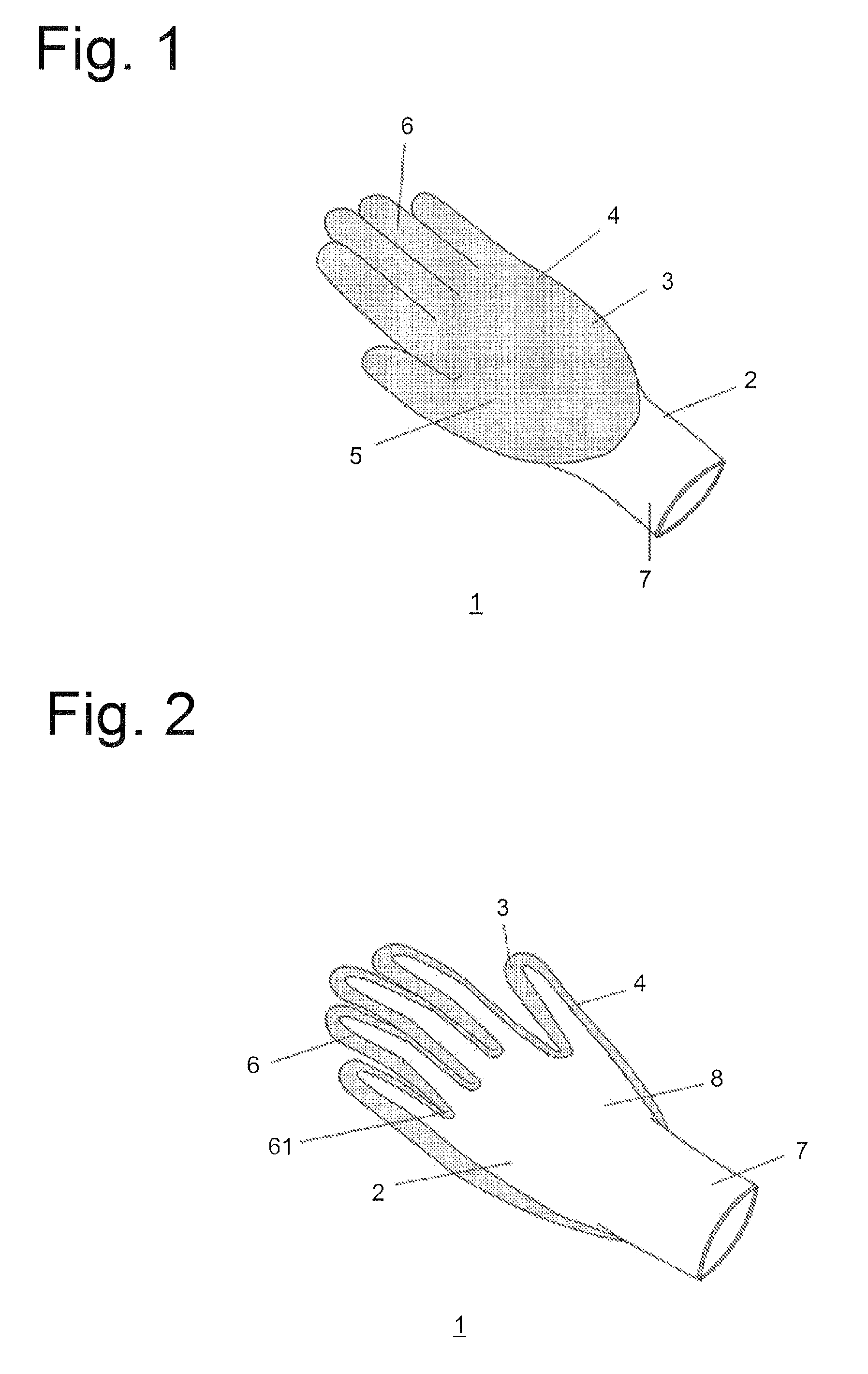

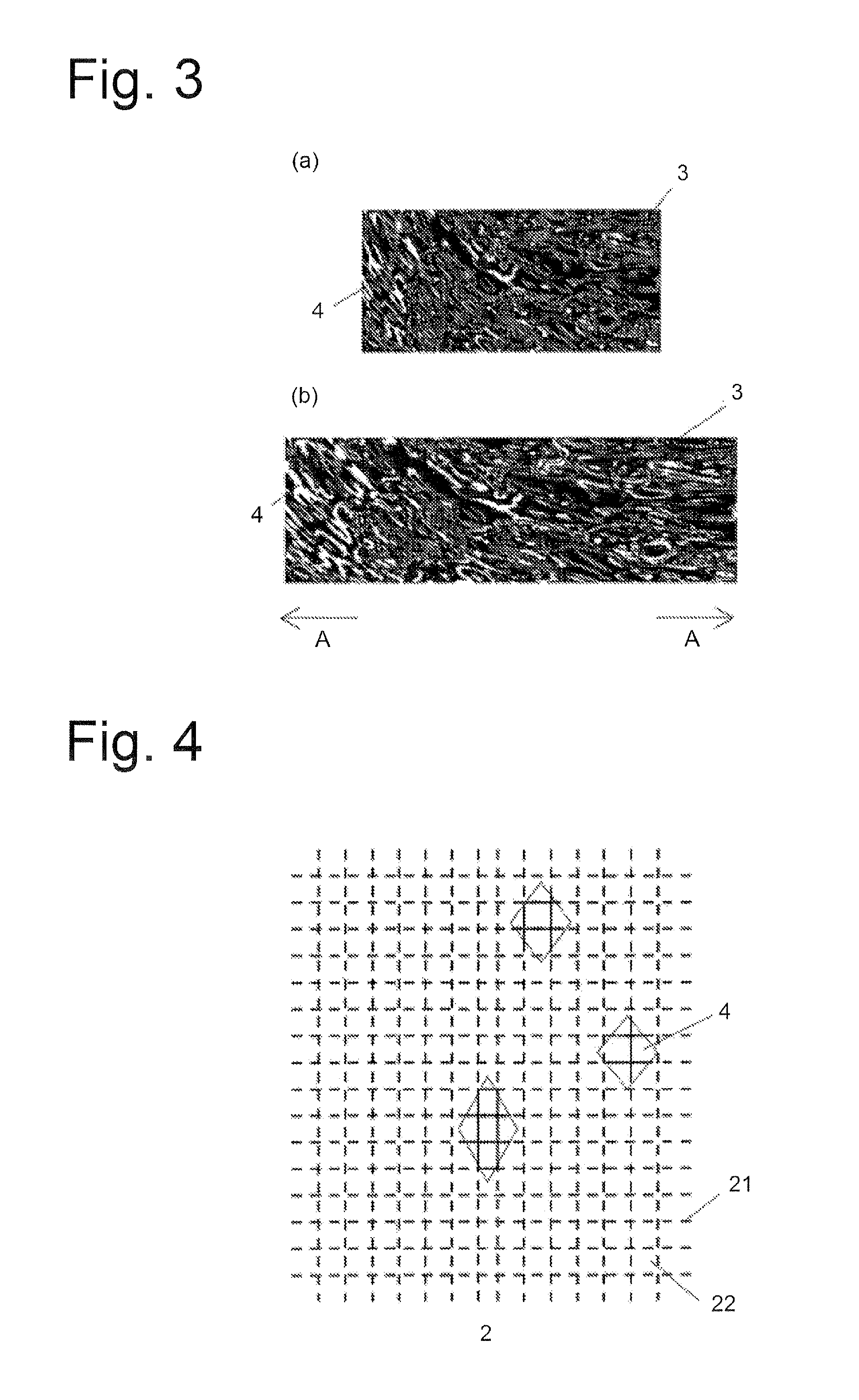

Glove

InactiveUS20130091618A1Improved object grip forceBreathability can be securedGarment special featuresGlovesBiomedical engineeringFiber

The present invention provides a glove that can reduce a humid feeling during usage while realizing a grip force, usability, workability, and breathability. The glove of the present invention includes a hand-shaped base layer (2a, 2b) made of fibers having a stretching property, a coating (3a, 3b) formed on the surface of the base layer (2a, 2b), at least on the surface of a palm of the base layer, and a plurality of breathing pores (4a, 4b) formed in the coating (3a, 3b), wherein the opening areas of the breathing pores (4b) when the glove is worn are larger than the opening areas of the breathing pores (4a) when the glove is not worn.

Owner:TOWA

Belt attachment device and method

InactiveUS6896125B2Facilitates mounting itemFacilitates attachment and detachmentConveyorsBelt fasteningsMechanical engineeringEngineering

A conveyor belt assembly including a flexible belt body with a plurality of spaced flexible teeth and at least one hardened tooth coupled to the belt body. The flexible belt body and flexible teeth comprise a resilient material. The hardened tooth comprises hardened plastic or metal. The flexible belt body also includes at least one reinforcing member within the belt body. A guide member is coupled to the flexible belt body and the hardened tooth to assist in transporting objects on the conveyor belt assembly. A pivotable clamping device clamps the ends of the belt body together to form a continuous belt. The clamping device clamps the reinforcing member to ensure a strong connection.

Owner:PFLOW INDS

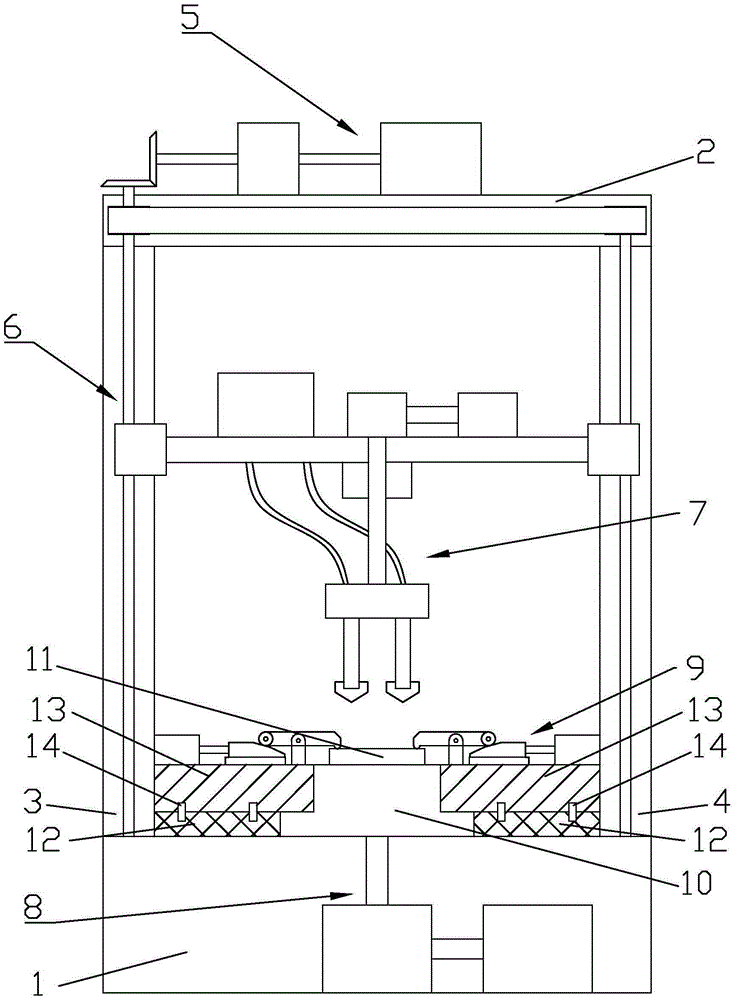

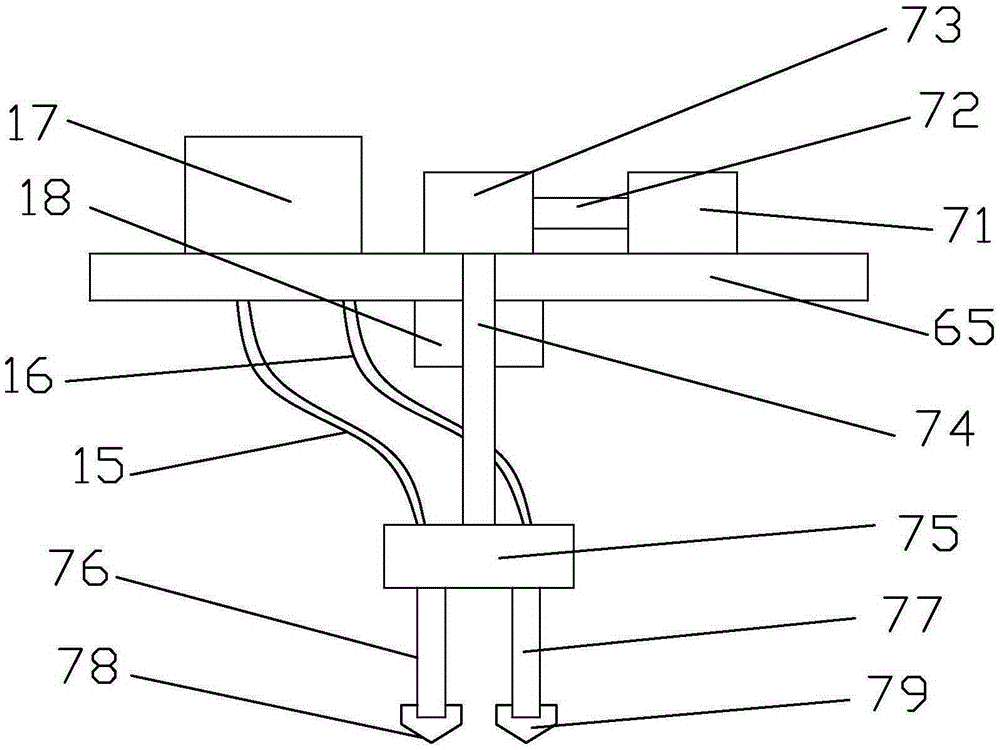

Drilling device applied to graphite mold production

InactiveCN105414599ASolving Drilling ProblemsStrong targetingWorkpiecesTurning toolsElectric machineryReducer

The invention discloses a drilling device applied to graphite mold production. The drilling device comprises a frame and a drilling table; drilling longitudinal frames and a drilling transverse frame are arranged on the frame; the drilling longitudinal frames are positioned at the two sides of the frame; the drilling transverse frame is positioned between the drilling longitudinal frames, and is provided with a lifting driving mechanism and a lifting mechanism; the lifting mechanism includes lifting platforms and lifting lead screws; the lifting lead screws are mounted in the drilling longitudinal frames, and are connected with lifting lead screw connecting bases; the lifting lead screw connecting bases are connected with the lifting platforms; drilling mechanisms are arranged on the lifting platforms, and include drilling motors and drilling lead screws; the drilling motors are connected with drilling motor output shafts; the drilling motor output shafts are connected with drilling speed reducers; the drilling speed reducers are connected with the drilling lead screws; the drilling lead screws are connected with drilling bases; and the drilling bases are connected with drill rods. The machine is simple in structure, strong in pertinency, precise in positioning and excellent in drilling effect, and preferably solves the drilling problem in the graphite mold production.

Owner:SHENGZHOU SIGMA TECH

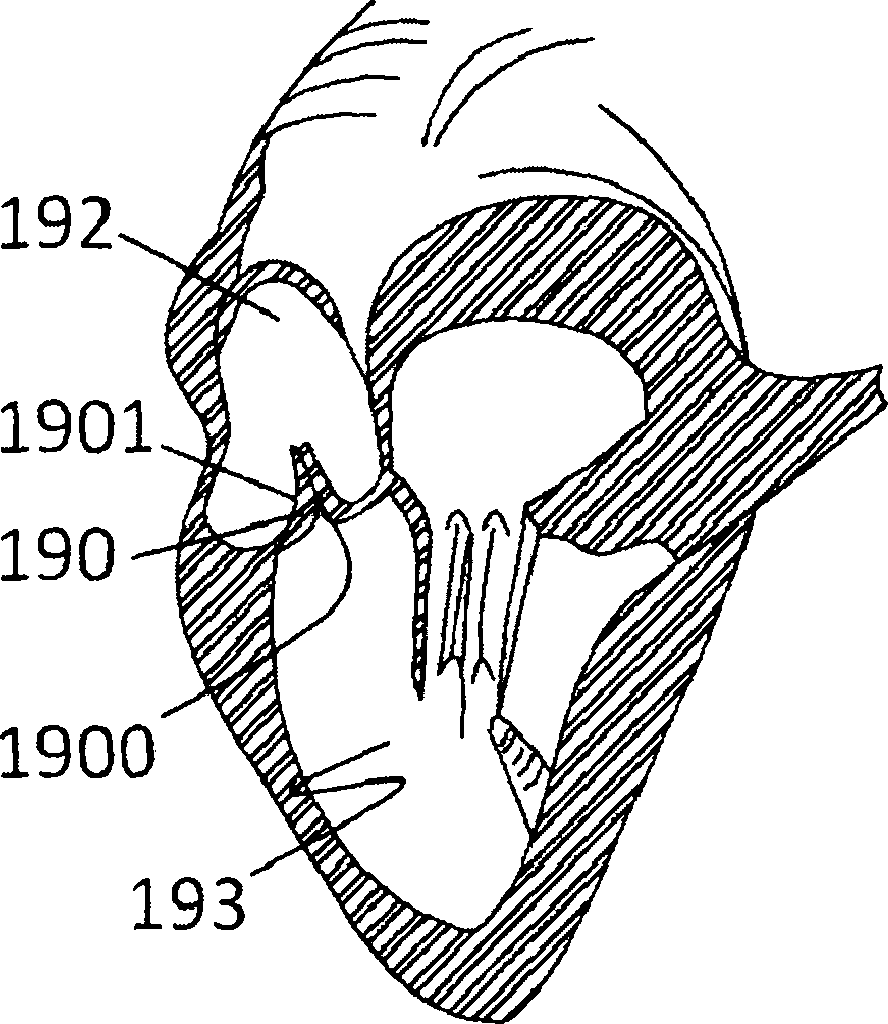

Artificial valve prosthesis with valve leaflet clamping device

The invention relates to artificial valve prosthesis with a valve leaflet clamping device. The manual valve prosthesis comprises a bracket and an artificial valve, wherein the bracket comprises an auxiliary support clamping section and a valve sewing section; the artificial valve is fixedly connected to the valve sewing section; the auxiliary support clamping section is composed of a support bracket, a valve leaflet clamping device and an upper connection fixing section; the leaflet clamping device, the support bracket and the upper connection fixing section are integrally cut; a lower connection fixing section matched with the upper connection fixing section is arranged on the valve sewing section; the bracket is embedded and connected with the lower connection fixing section into a whole through the upper connection fixing section; one part of the valve leaflet clamping device is overlapped with the valve sewing section; the overlapped part is tightly attached to the outer surface of the valve sewing section in a natural state; a bump which protrudes outwards along the radial direction is arranged on a skeleton structure of the valve sewing section in the overlapped region; and a bending section which bends towards the axis direction of the bracket along the radial direction of the bracket is arranged on the valve leaflet clamping device or the support bracket or the upper connection fixing section.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

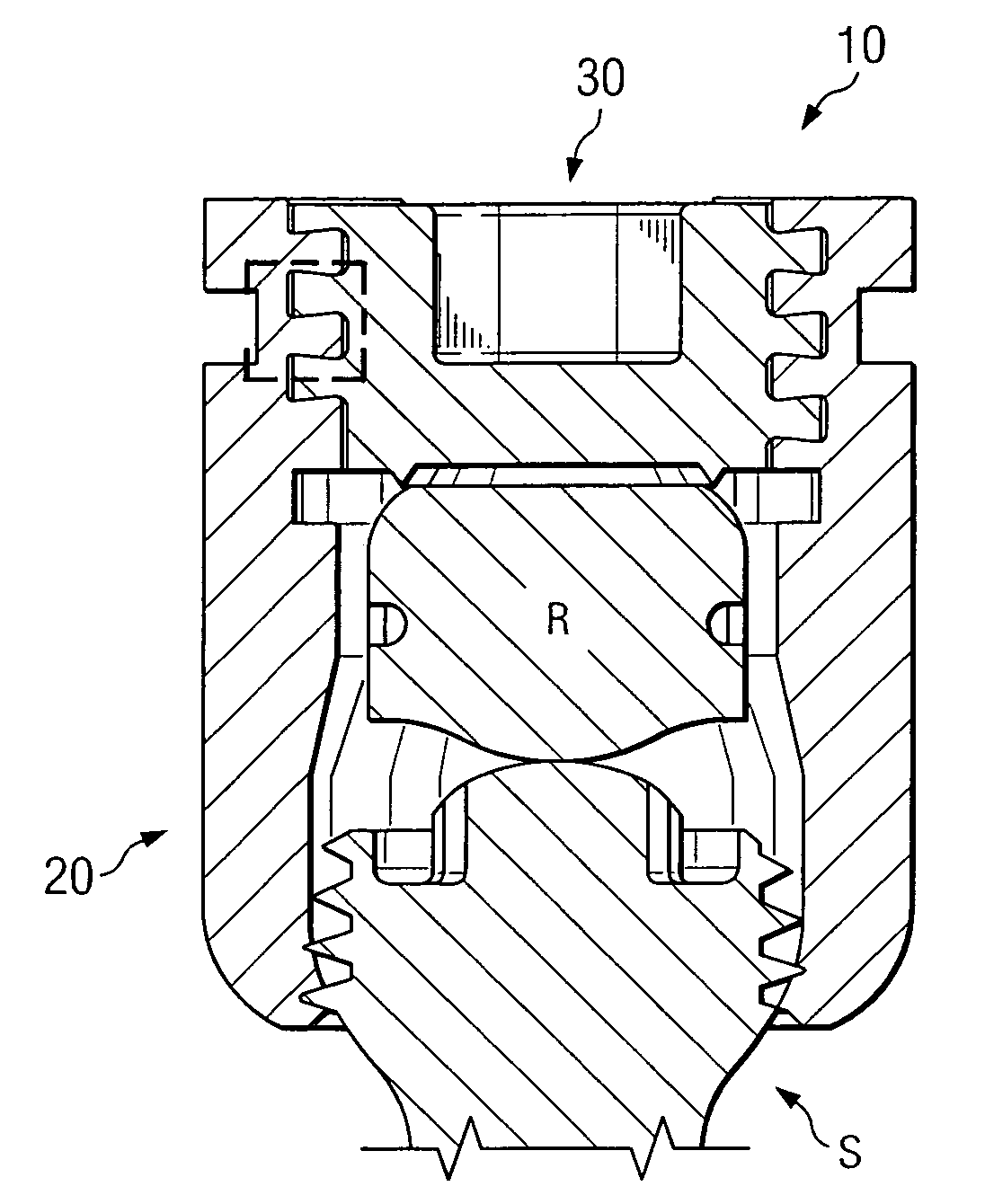

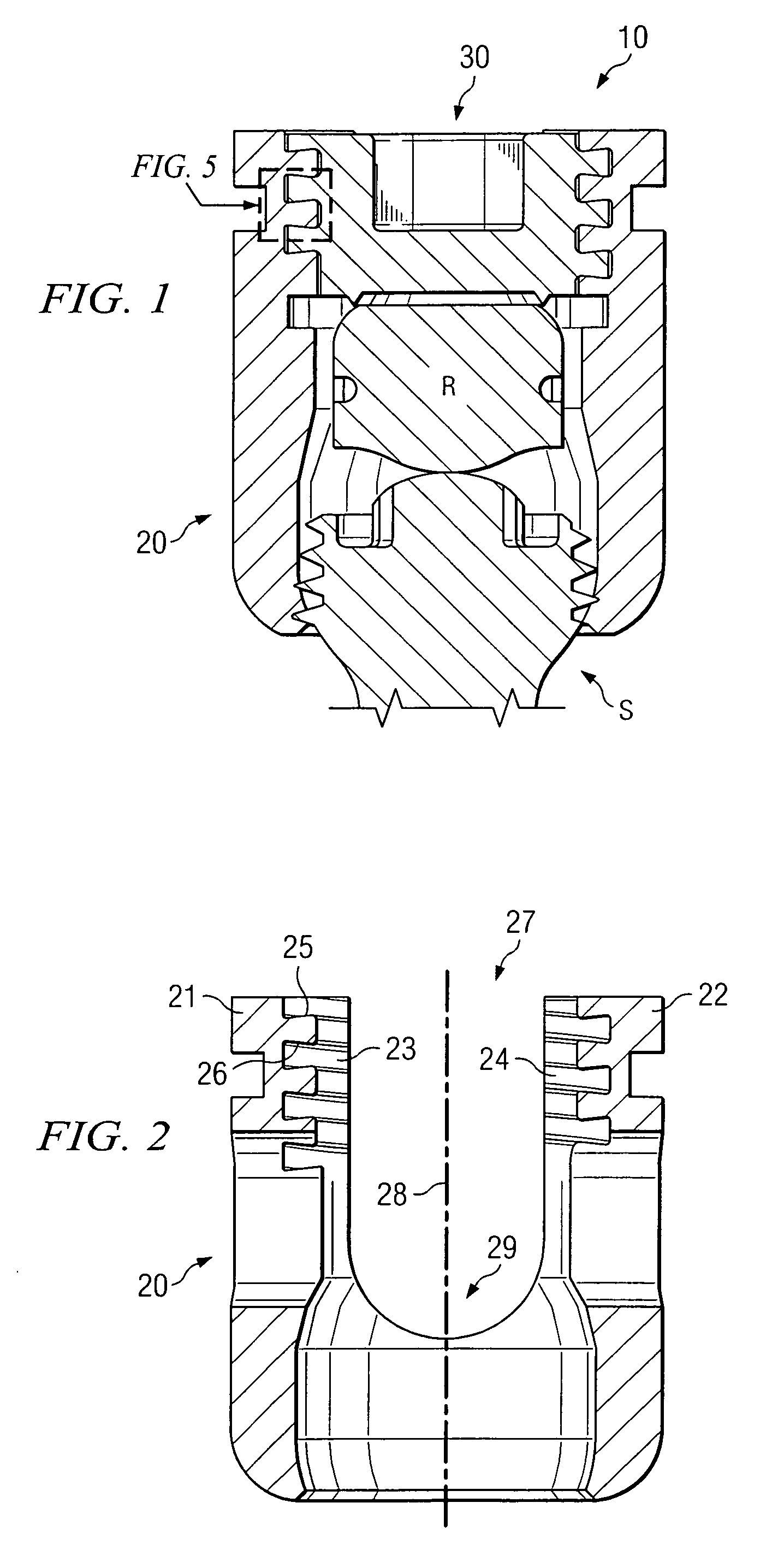

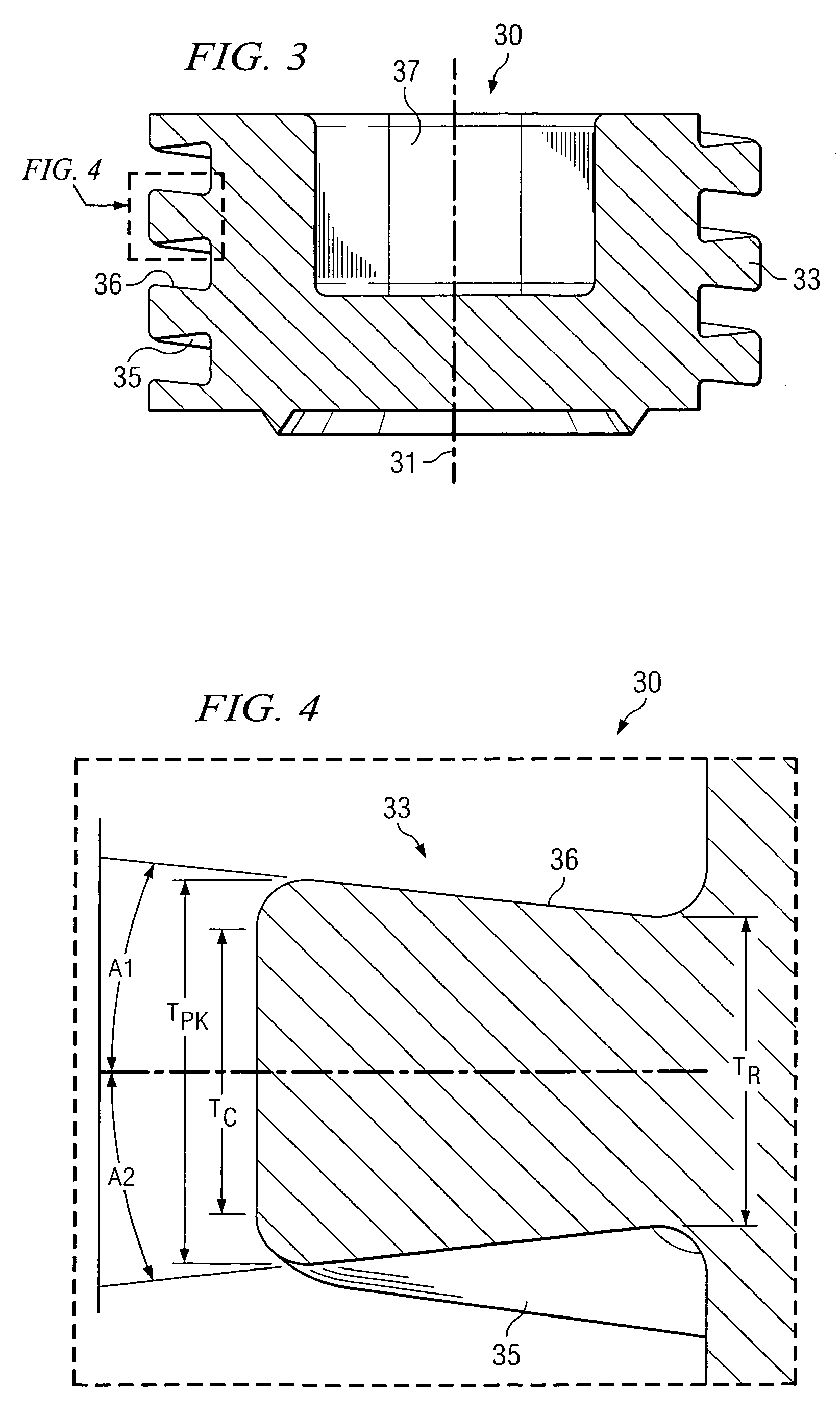

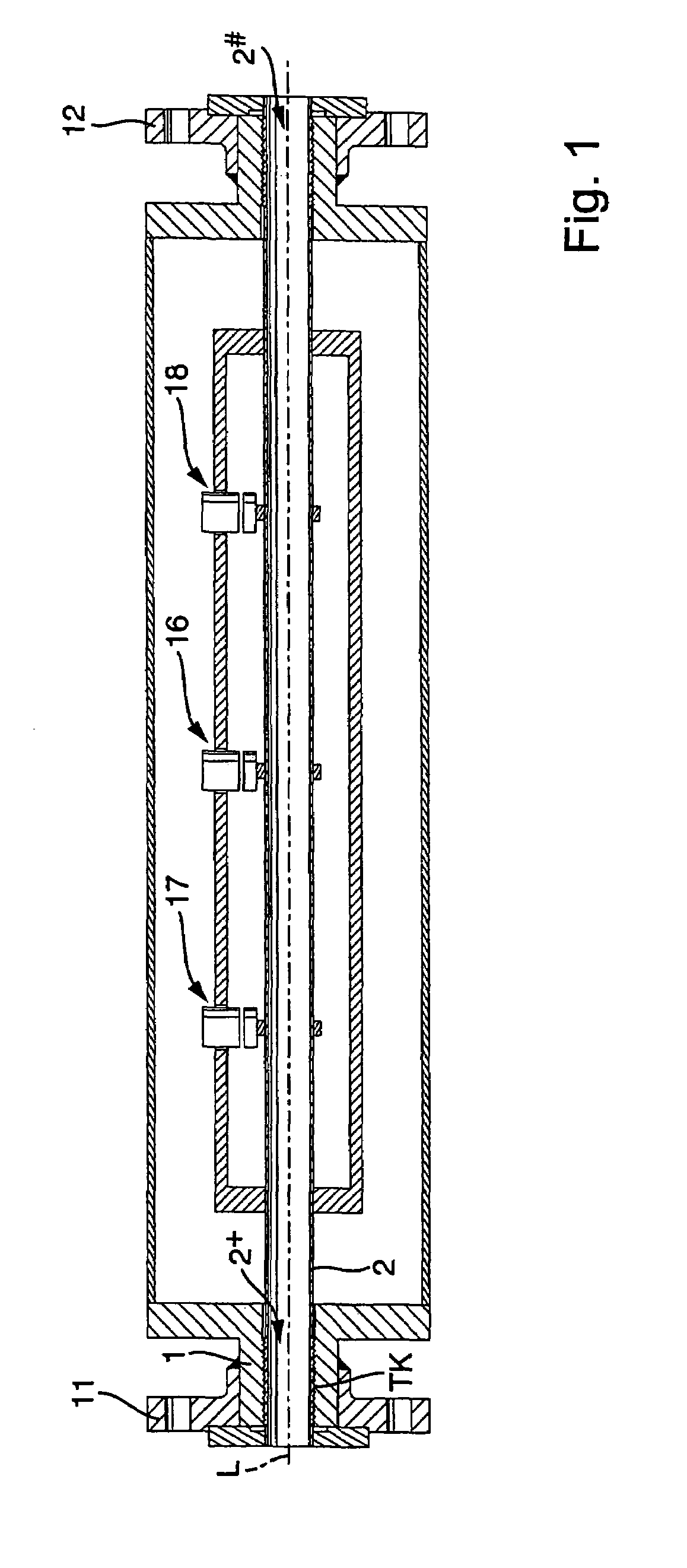

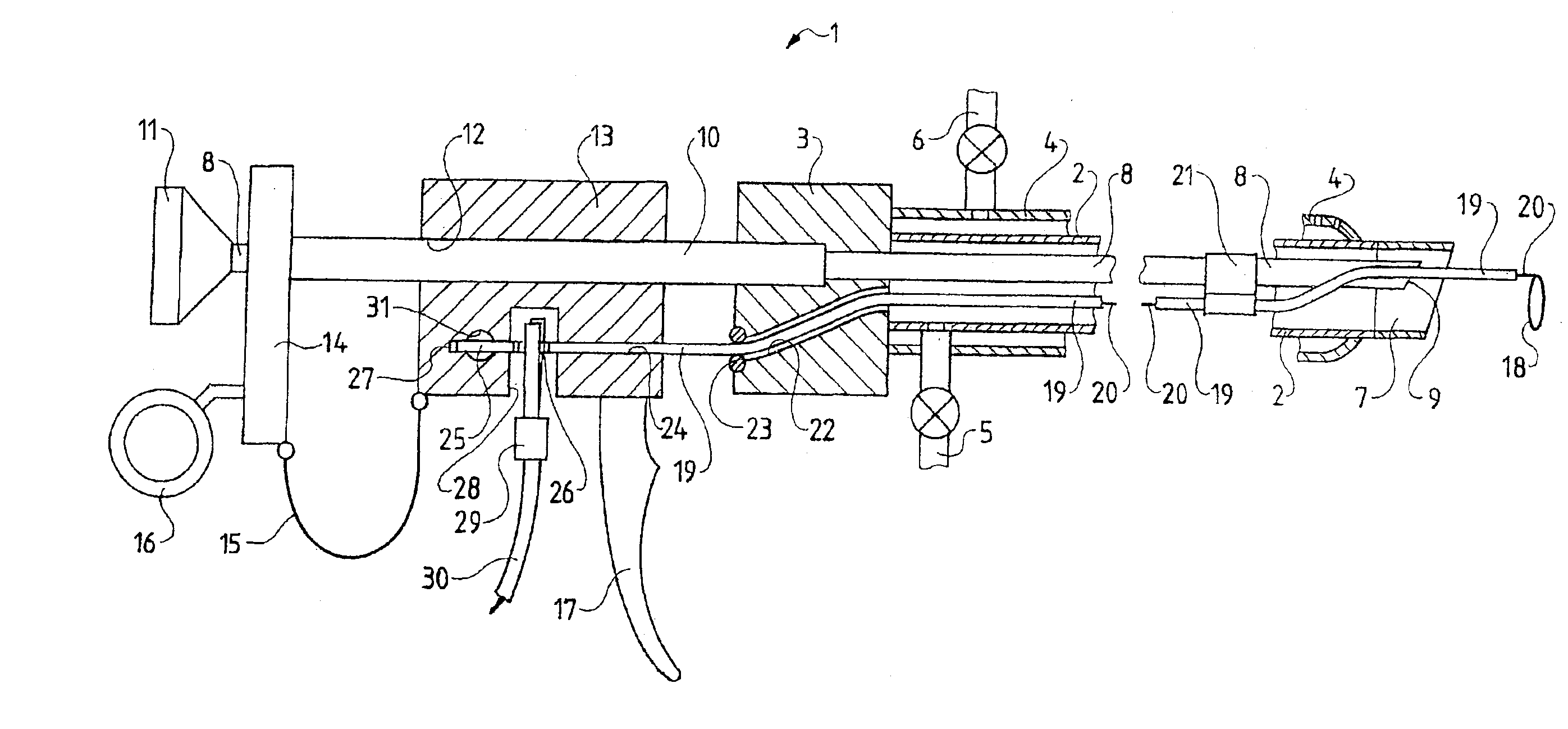

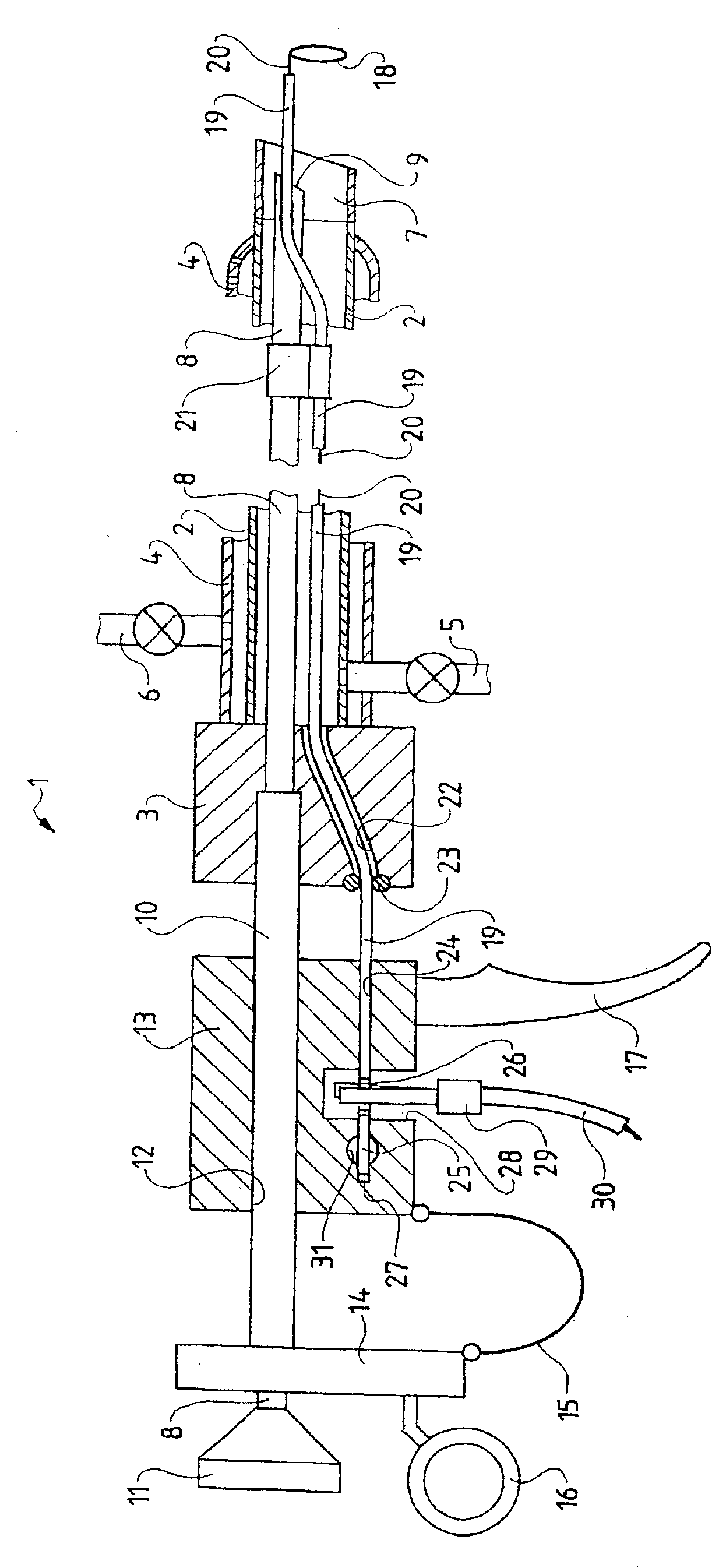

Urological electrosurgical resectoscope

InactiveUS6893441B2Increase clamping forceTighter pivotingSurgical instruments for heatingRESECTOSCOPEEngineering

A urological resectoscope having an axially extending shaft tube, the proximal end thereof being fixed to a main body. A sliding body is proximally positioned in relation to the main body, and can slide in a parallel manner in relation to the axis thereof. The sliding body includes a receiver, a fixing device and a contacting device. An electrode that can be subjected to a high frequency, including a rigid electrode carrier having one external, insulated conductive wire, can be positioned in the resectoscope such that it can axially slide beyond the distal end of the shaft tube. In the assembly position, the electrode carrier extends through the shaft tube and the main body into the receiver, and can be fixed by the fixing device and contacted by the contacting device. The fixing device is proximally arranged in relation to the contacting device on the sliding body.

Owner:OLYMPUS WINTER & IBE

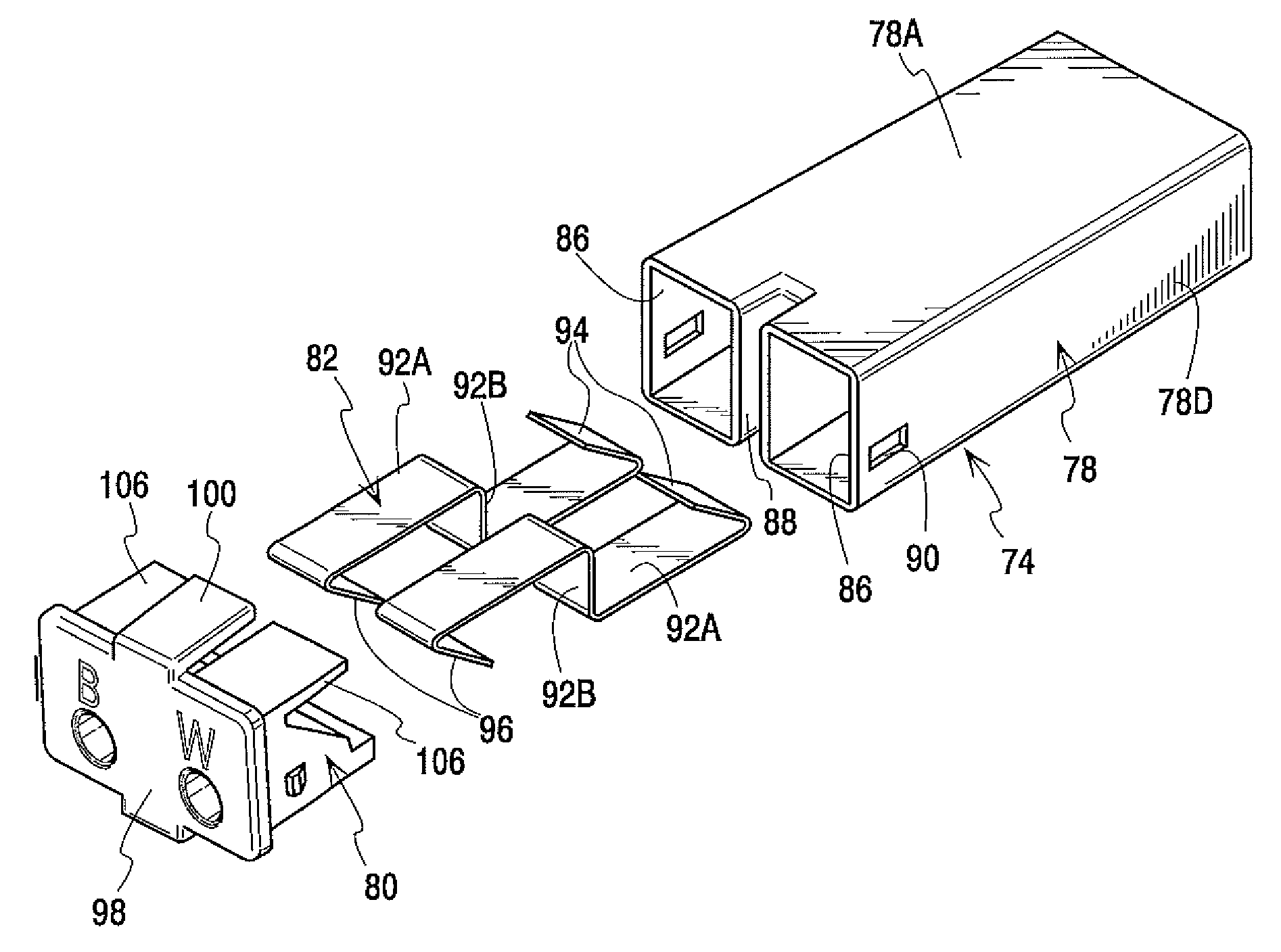

Releasable wire connector

ActiveUS7281942B2Avoid arcingIncrease clamping forceCompound screeningApoptosis detectionElectrical conductorEngineering

A releasable wire connector has a housing and a cap slidably engaging one another and enclosing an electrical contact. The contact has inner and outer flexible fingers disposed opposite wire ports in the housing and cap. The fingers engage conductors inserted into the connector to retain the connectors therein and electrically connect them. The cap carries a release block which will engage some of the fingers and urge them out of engagement with the conductors to allow disengagement of a wire from the connector. One of the fingers may be split into sacrificial and main tines which are arranged so that the sacrificial tine will always be the first to make and the last to break contact with a conductor. Any arcing that may occur will then always be on the sacrificial tine so the main tine will not be degraded by arcing.

Owner:IDEAL IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com