Artificial valve prosthesis with valve leaflet clamping device

A technology of artificial valve and clamping device, which is applied in the field of medical devices, can solve problems such as postoperative stent falling off, artificial valve prosthesis displacement, and threats to the life safety of patients, so as to reduce the dependence on radial support force and avoid complications. disease effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0067] The distal end in this embodiment refers to the end away from the apex of the heart, and the proximal end refers to the end close to the apex of the heart.

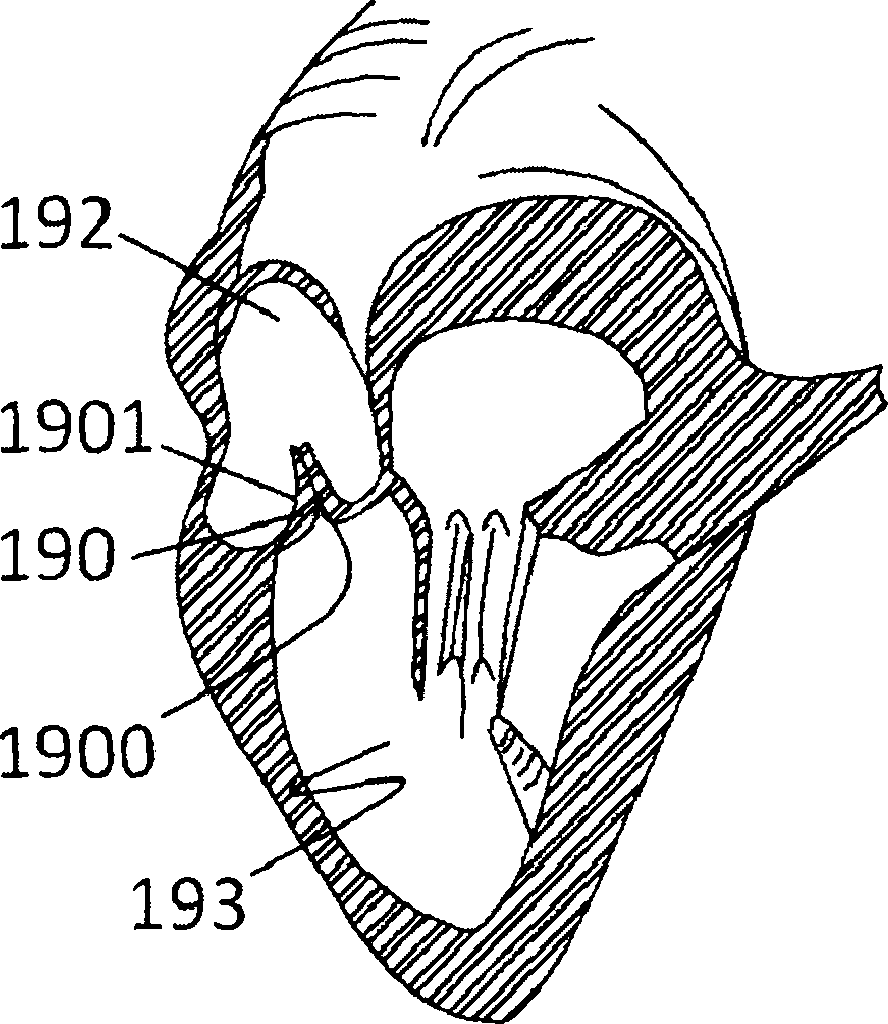

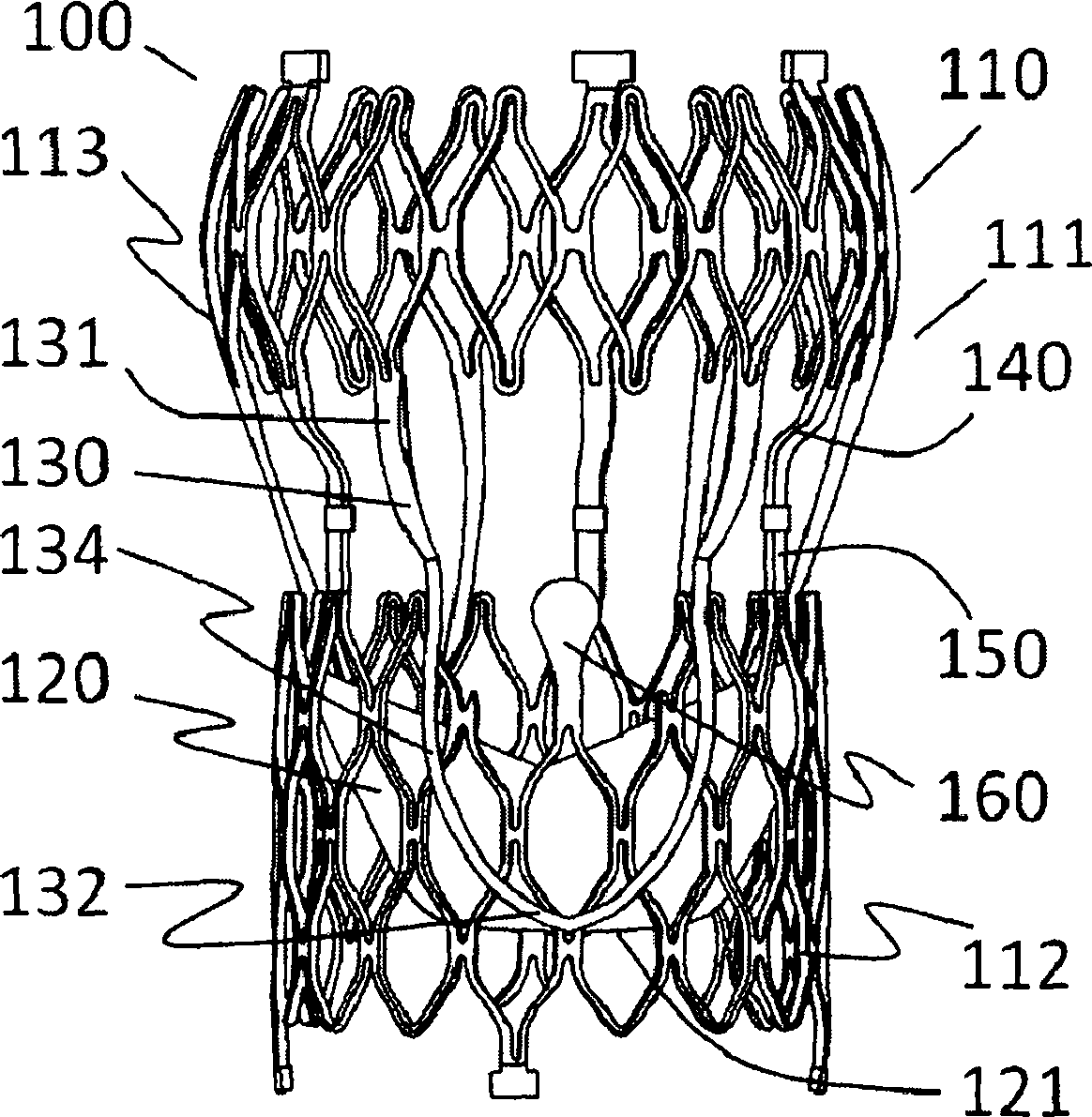

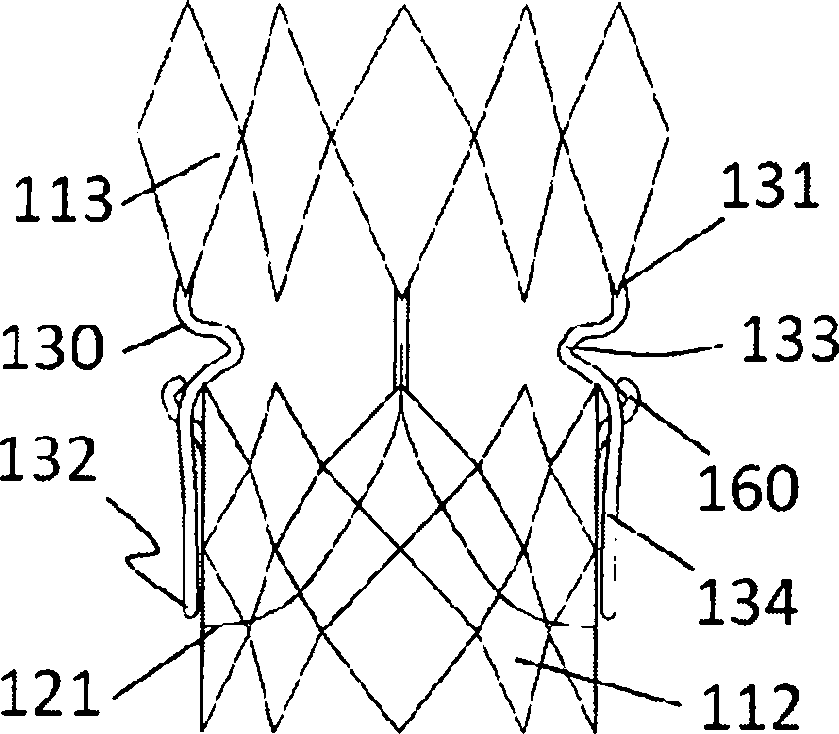

[0068] Such as Figure 1a As shown, when the left ventricle 193 contracts so that the blood pressure of the left ventricle 193 is higher than the blood pressure of the aorta 192, blood rushes from the left ventricle 193 through the aortic valve and enters the aorta 192, and when the left ventricle 193 relaxes, the blood pressure of the left ventricle 193 is lower than When the aorta 192 has blood pressure, the aortic valve closes, and at this moment, the contact of adjacent native valve leaflets 190 forms a closed surface 1900. At this time, the other surface 1901 of the valve leaflet 190 on one side of the aorta 192 is defined as the native valve leaflet. Opposite side of closed face. Such as Figure 1b with Figure 1c As shown, the artificial valve prosthesis 100 with leaflet clamping device of the present inve...

specific Embodiment 2

[0073] The distal end in this embodiment refers to the end away from the apex of the heart, and the proximal end refers to the end close to the apex of the heart.

[0074] In another embodiment of the present invention, as Figures 6a-6c As shown, the artificial valve prosthesis 200 with leaflet clamping device includes a stent 210 and an artificial valve 220, the stent 210 includes an auxiliary support clamping section 211 and a valve sewing section 212, and the artificial valve 220 It is fixedly connected to the valve sewing section 212, and the auxiliary support clamping section 211 is composed of a support bracket 213, a valve leaflet clamping device 230 and an upper connecting fixed section 240, and the valve leaflet clamping device 230 is connected with the valve leaflet clamping device 230. The supporting bracket 213 and the upper connecting and fixing section 240 are integrally cut, and the valve sewing section 212 is provided with a lower connecting and fixing section...

specific Embodiment 3

[0091] The distal end in this embodiment refers to the end away from the apex of the heart, and the proximal end refers to the end close to the apex of the heart.

[0092] In another embodiment of the present invention, as Figures 19a-19d As shown, the artificial valve prosthesis 300 with leaflet clamping device includes a stent 310 and an artificial valve (not shown), the stent 310 includes an auxiliary support clamping section 311 and a valve sewing section 312, the An artificial valve (not shown) is fixedly connected to the valve sewing section 312, and the auxiliary support clamping section 311 is composed of a support bracket 313, a leaflet clamping device 330 and an upper connecting fixed section 340, and the valve leaflet The clamping device 330 is cut integrally with the supporting bracket 313 and the upper connecting and fixing section 340 , and a lower connecting and fixing section 350 matching the upper connecting and fixing section 340 is provided on the valve sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com