Patents

Literature

41results about How to "Solve the clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

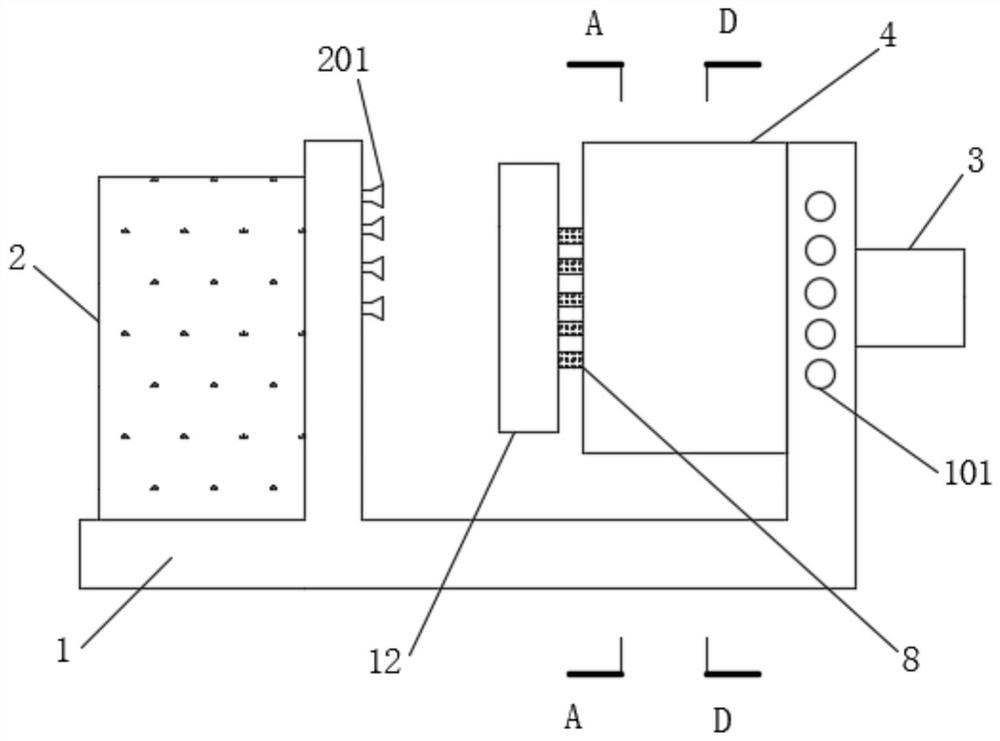

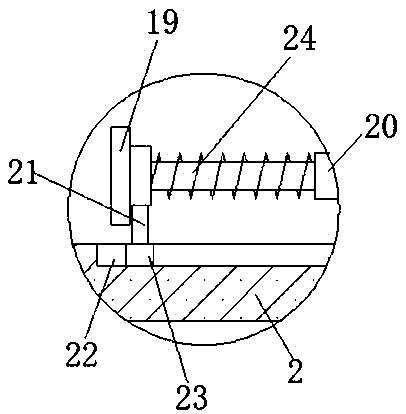

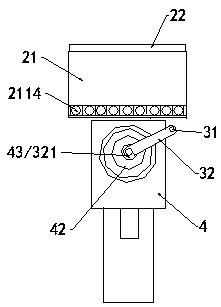

O-shaped sealing ring automatic assembly device and method

InactiveCN108655689AAssembly precisionAccurate assembly tasksMetal working apparatusEngineeringMechanical engineering

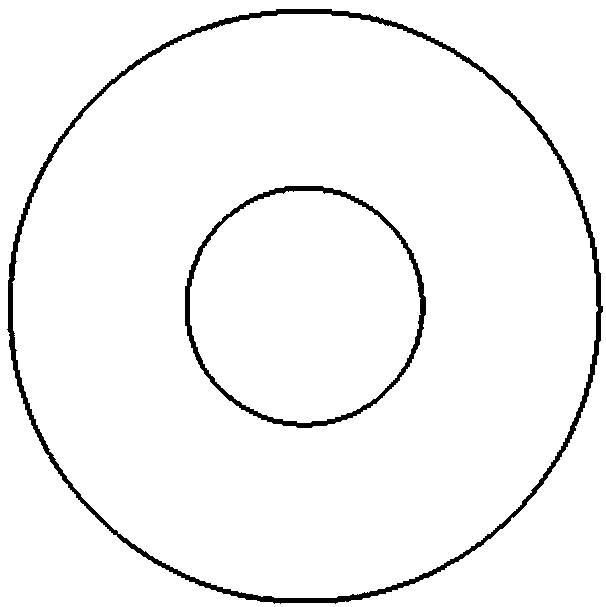

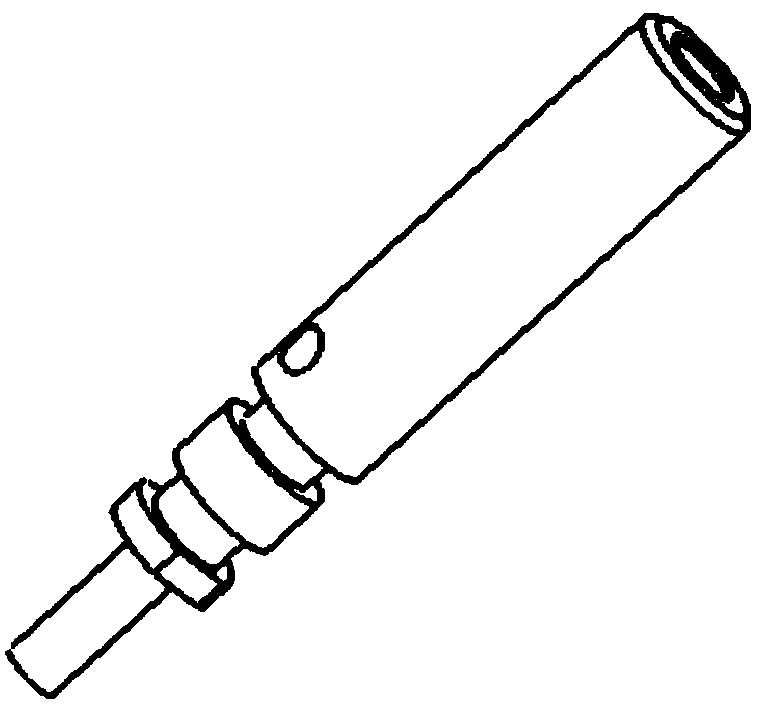

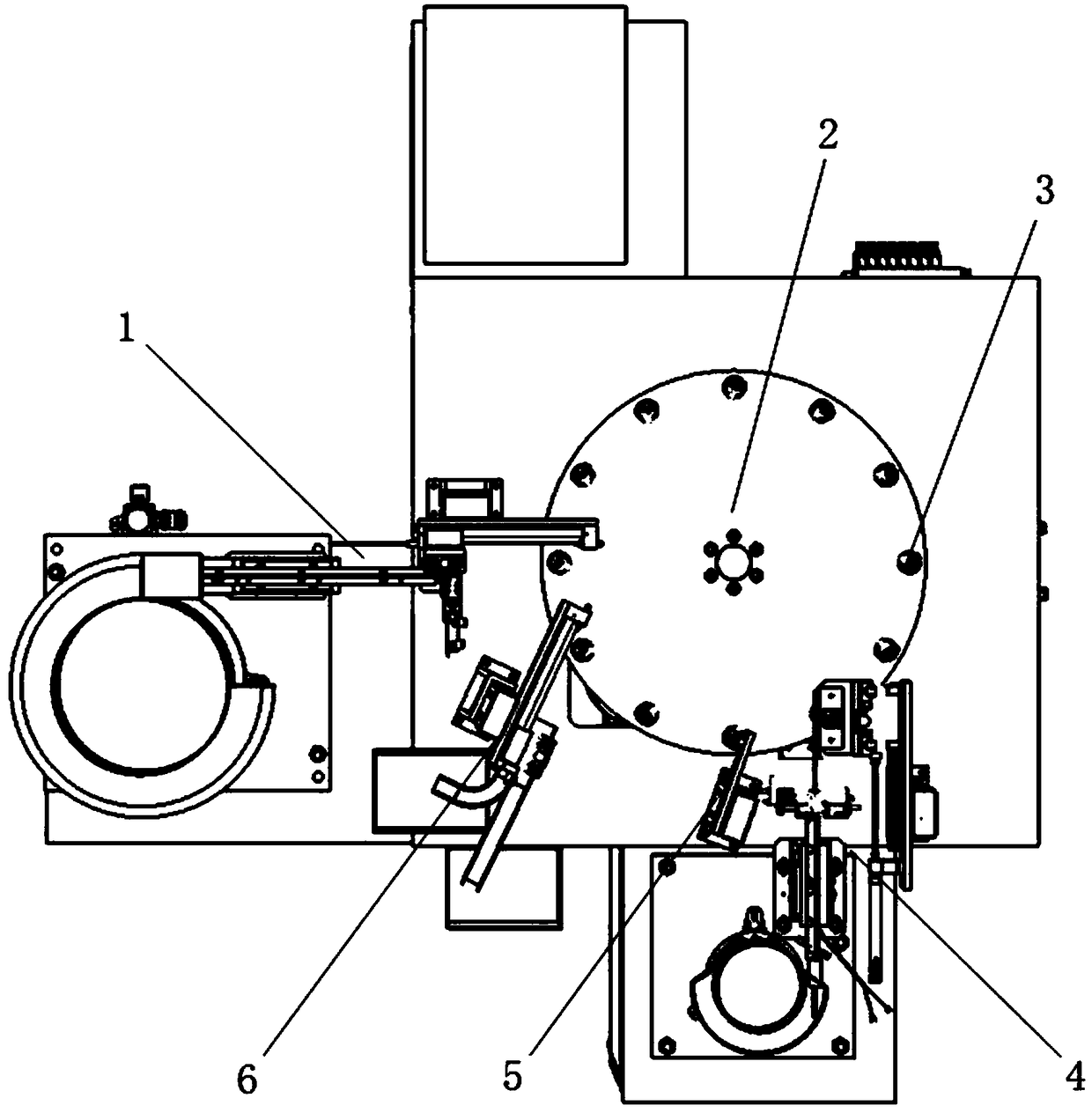

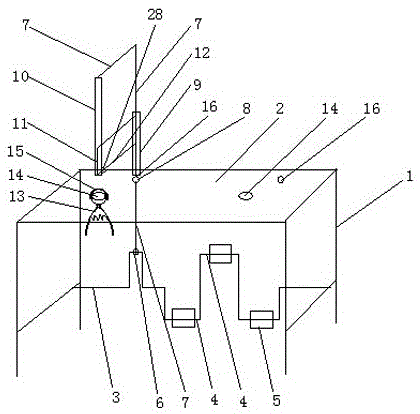

The invention discloses an O-shaped sealing ring automatic assembly device and method. The device comprises a sleeve automatic loading module, an O-shaped sealing ring automatic loading module, an automatic detecting module, a finished product sorting module, all of which are arranged on the outer side of a revolving worktable module in the peripheral direction in sequence; the sleeve automatic loading module and the O-shaped sealing ring automatic loading module are in supply connection with the revolving worktable module; the automatic detecting module detects the assembly effect of O-shapedrings on the revolving worktable module in real time; and the finished product sorting module is used for realizing sorting of qualified and unqualified products through chutes according to the detecting result of the automatic detecting module. The device is simple in structure and convenient to use; and through motions of three arc plates on clamping jaws of a three-jaw cylinder and pressing plates with the same apertures as the diameters of sleeves, the clamping and assembly of the O-shaped sealing rings are achieved, the automatic assembly task of the O-shaped sealing rings can be finished with high quality, a lot of manpower and costs are saved, the assembly efficiency is quickly accelerated, and the production demands are met.

Owner:NANJING KANGNI NEW ENERGY AUTO PARTS CO LTD +1

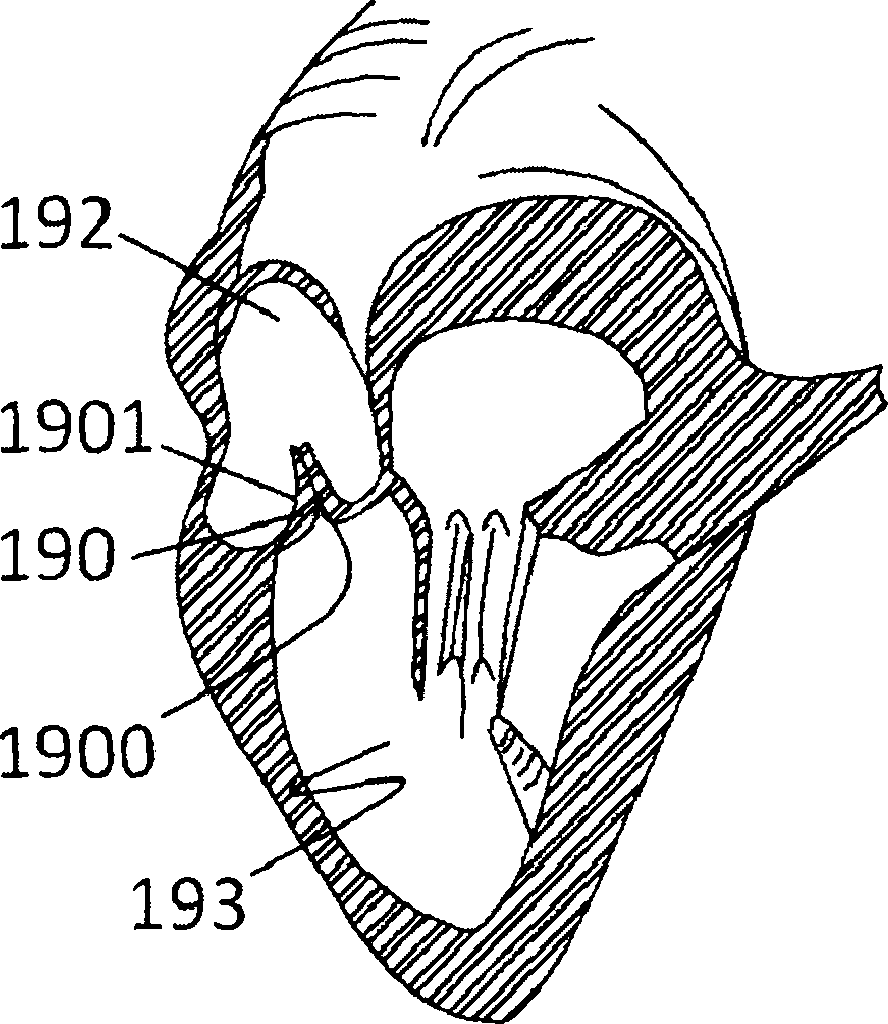

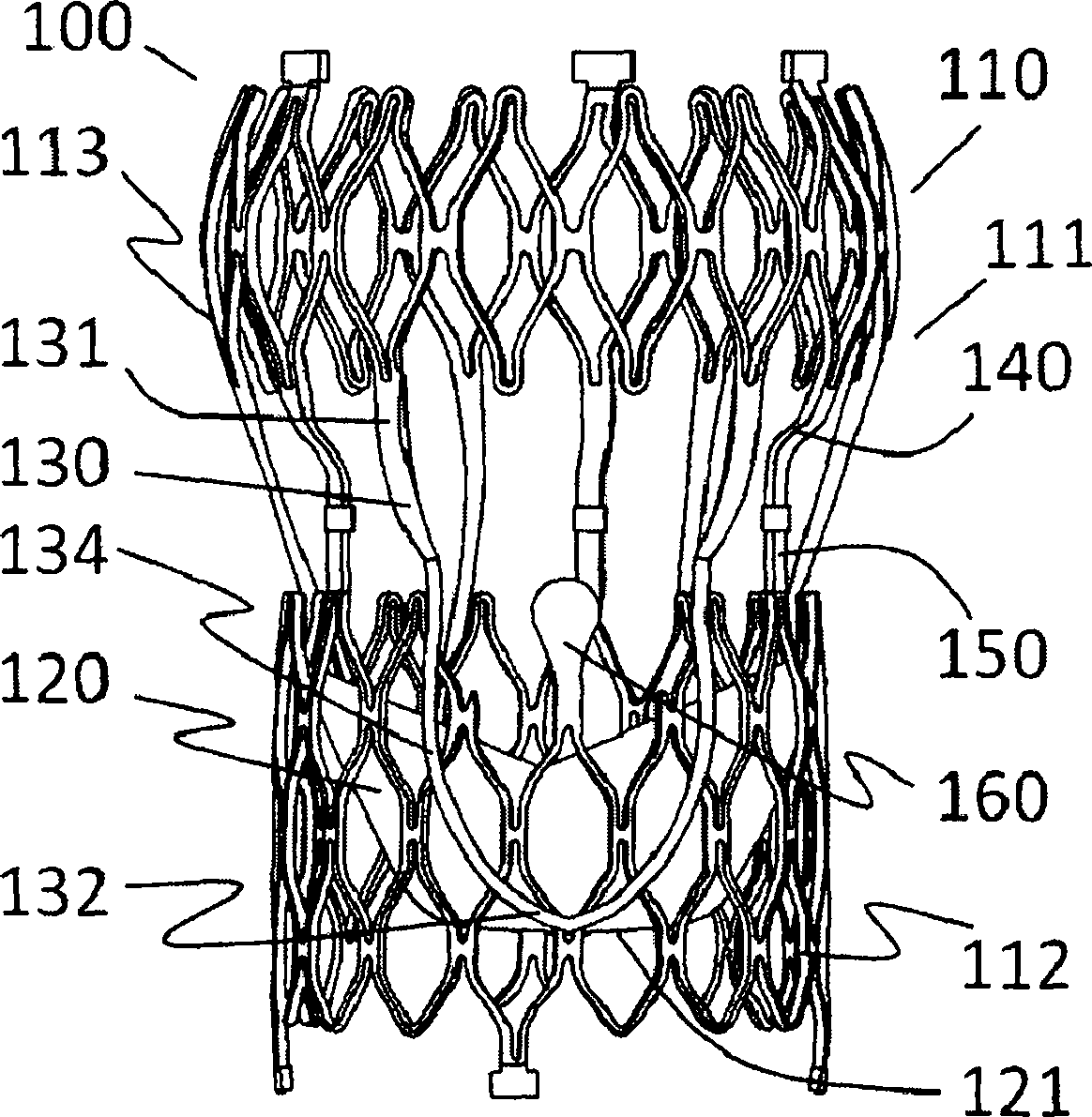

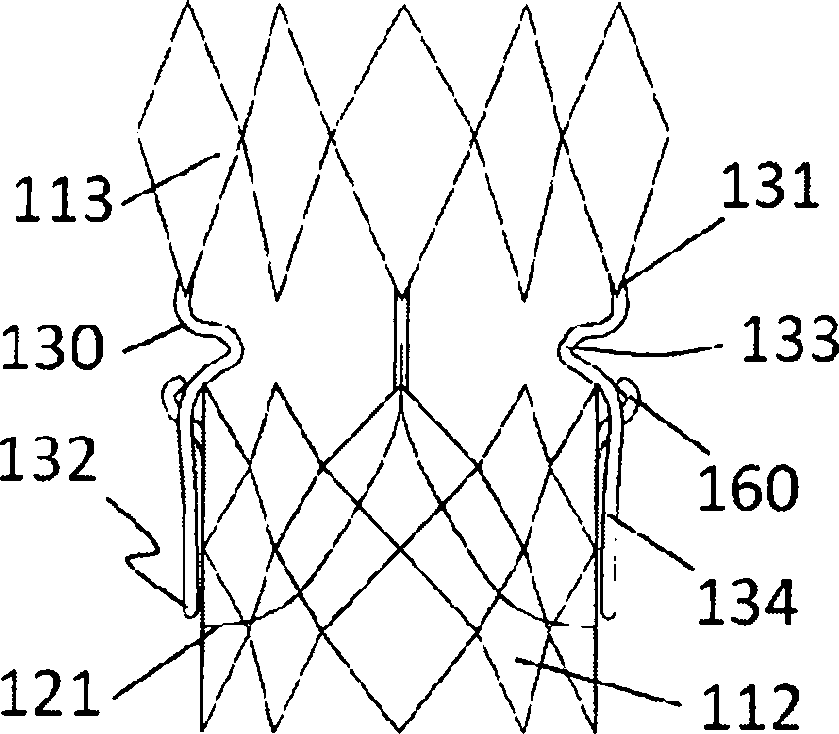

Artificial valve prosthesis with valve leaflet clamping device

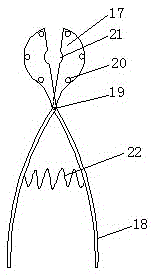

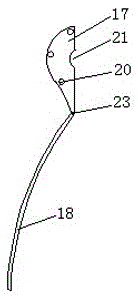

The invention relates to artificial valve prosthesis with a valve leaflet clamping device. The manual valve prosthesis comprises a bracket and an artificial valve, wherein the bracket comprises an auxiliary support clamping section and a valve sewing section; the artificial valve is fixedly connected to the valve sewing section; the auxiliary support clamping section is composed of a support bracket, a valve leaflet clamping device and an upper connection fixing section; the leaflet clamping device, the support bracket and the upper connection fixing section are integrally cut; a lower connection fixing section matched with the upper connection fixing section is arranged on the valve sewing section; the bracket is embedded and connected with the lower connection fixing section into a whole through the upper connection fixing section; one part of the valve leaflet clamping device is overlapped with the valve sewing section; the overlapped part is tightly attached to the outer surface of the valve sewing section in a natural state; a bump which protrudes outwards along the radial direction is arranged on a skeleton structure of the valve sewing section in the overlapped region; and a bending section which bends towards the axis direction of the bracket along the radial direction of the bracket is arranged on the valve leaflet clamping device or the support bracket or the upper connection fixing section.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

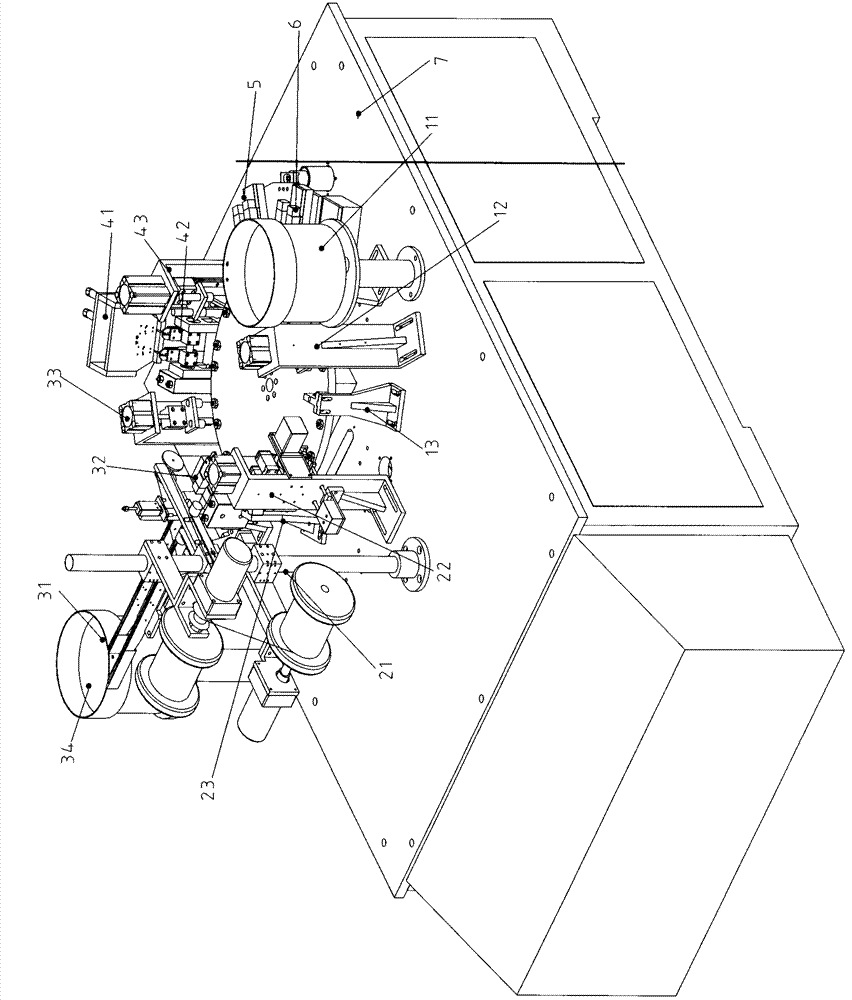

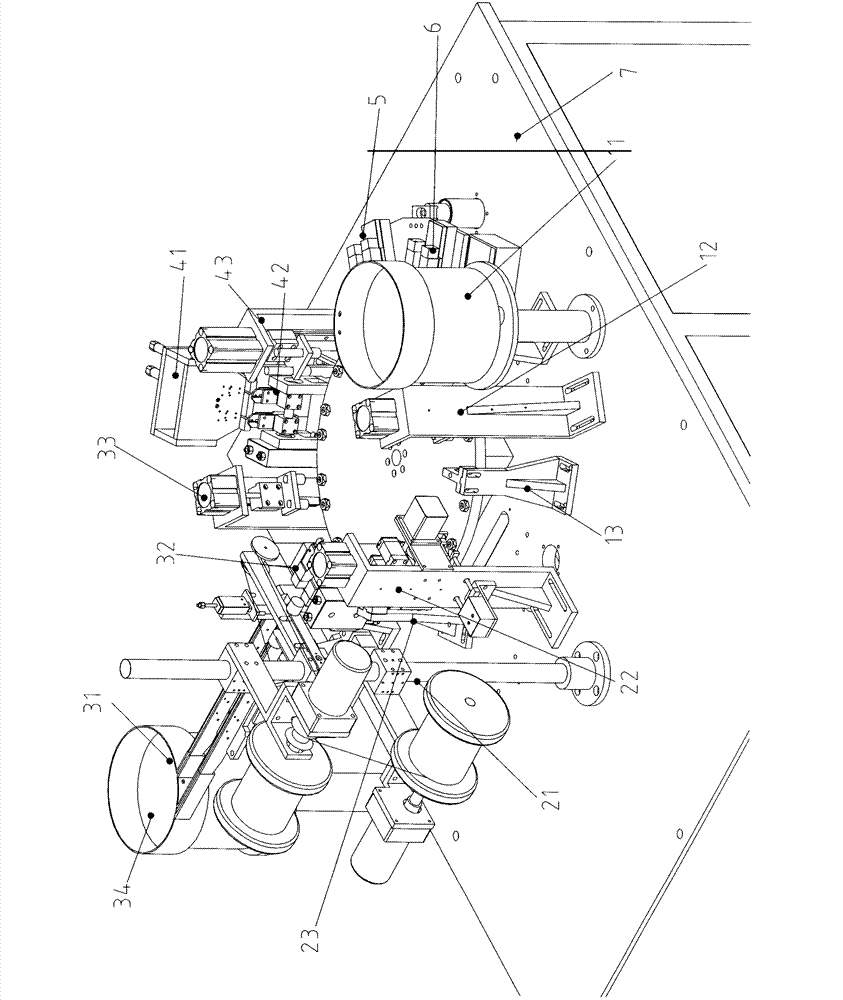

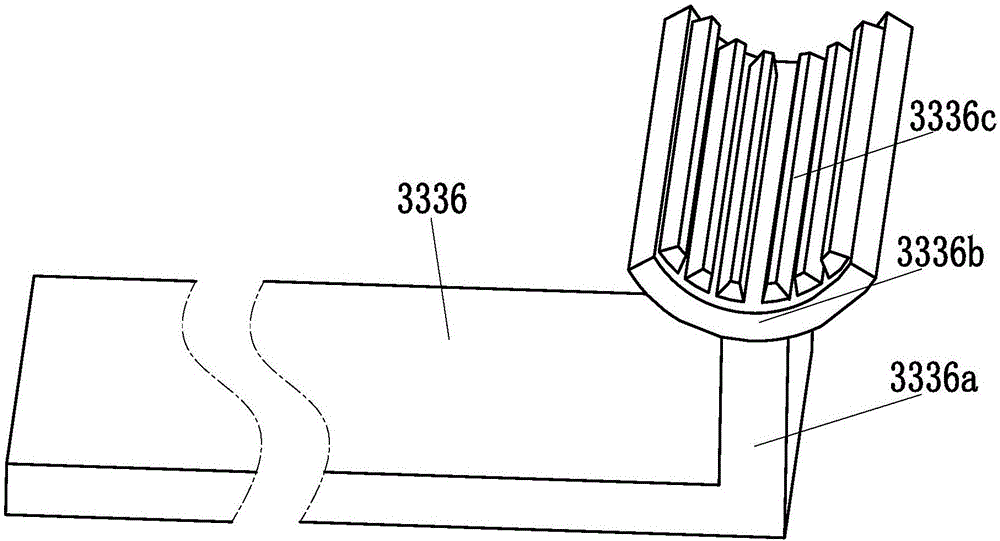

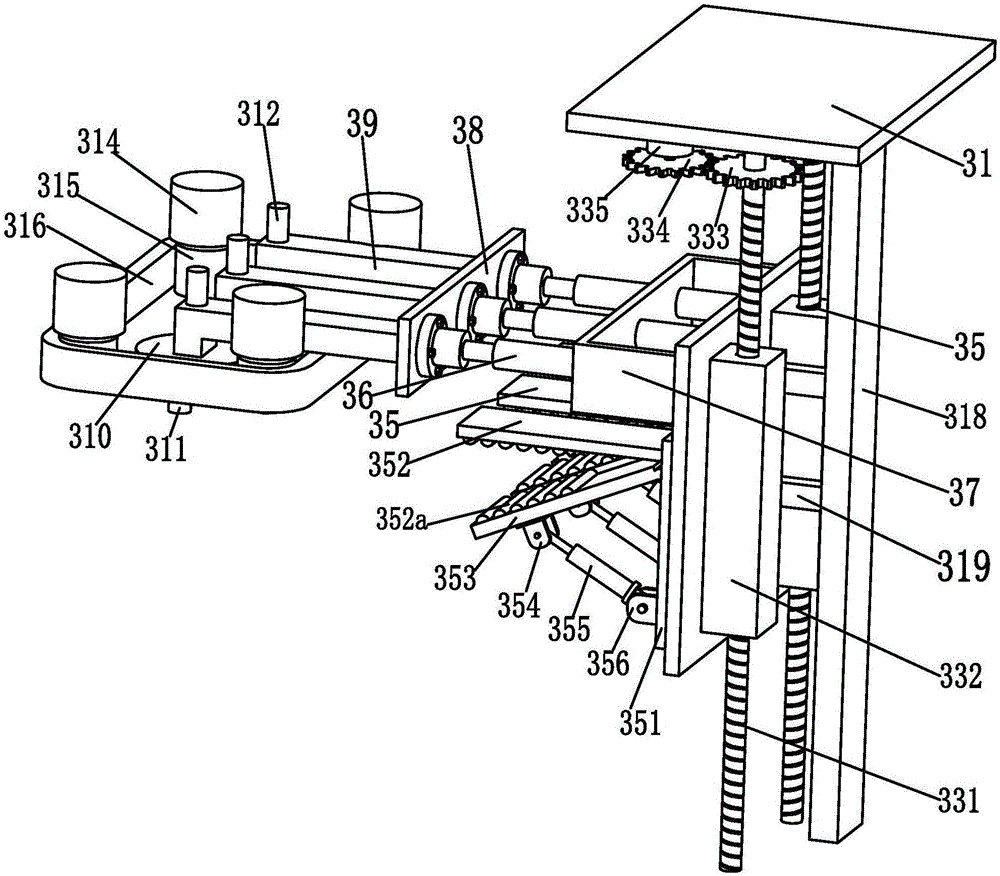

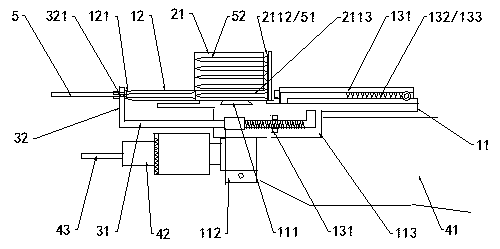

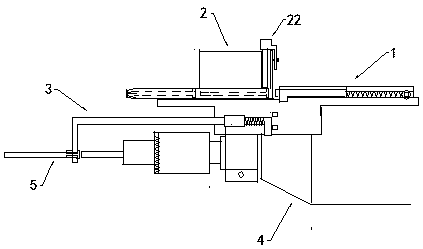

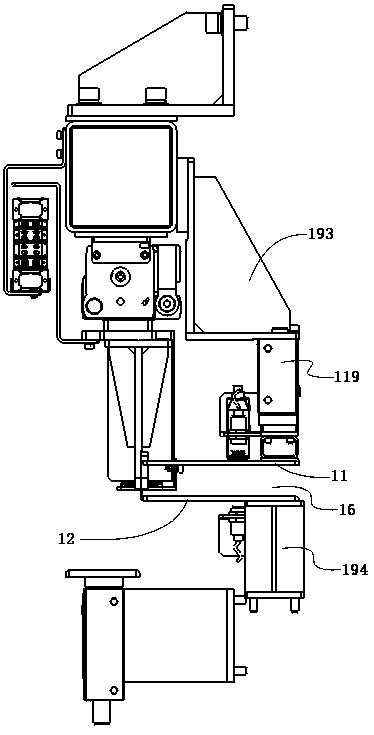

Automatic assembling system of pin type pen head component

InactiveCN102815127ASolve the softness problemSolve the clampingPen repairingFront loadingEngineering

The invention discloses an automatic assembling system of a pin type pen head component. The system comprises a machine frame, a power device and a part conveying system, wherein the machine frame forms an equipment support and a main body; the part conveying system is connected with the power device; and a pen head supplying mechanism, a pen head assembling mechanism, a pen head direction detection mechanism, an ink core supplying mechanism, an ink core cutting and assembling mechanism, an ink core assembly detecting mechanism, a front loading mechanism, a front assembling mechanism, a front assembly detecting mechanism, a relay core loading mechanism, a relay core assembling mechanism, a relay core assembly detecting mechanism, an unqualified product selecting mechanism and a finished product unloading mechanism are sequentially arranged in the movement direction of the part conveying system. By the automatic assembling system of the pin type pen head component, the problem that an ink core is not easy to clamp and cut because the ink core is relatively flexible and elastic is solved, and meanwhile, the technical scheme of automatic material supply, automatic assembly and automatic detection is adopted, so that each part is precisely assembled, and the stability in an assembling process is ensured.

Owner:QINGDAO CHANGLONG STATIONERY

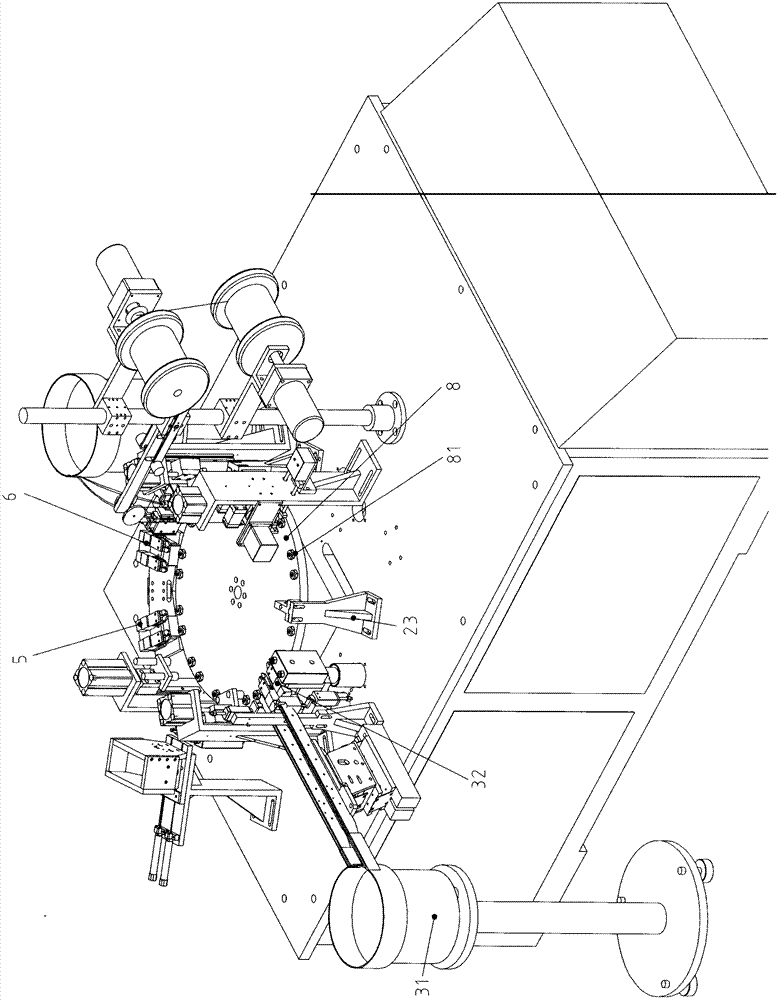

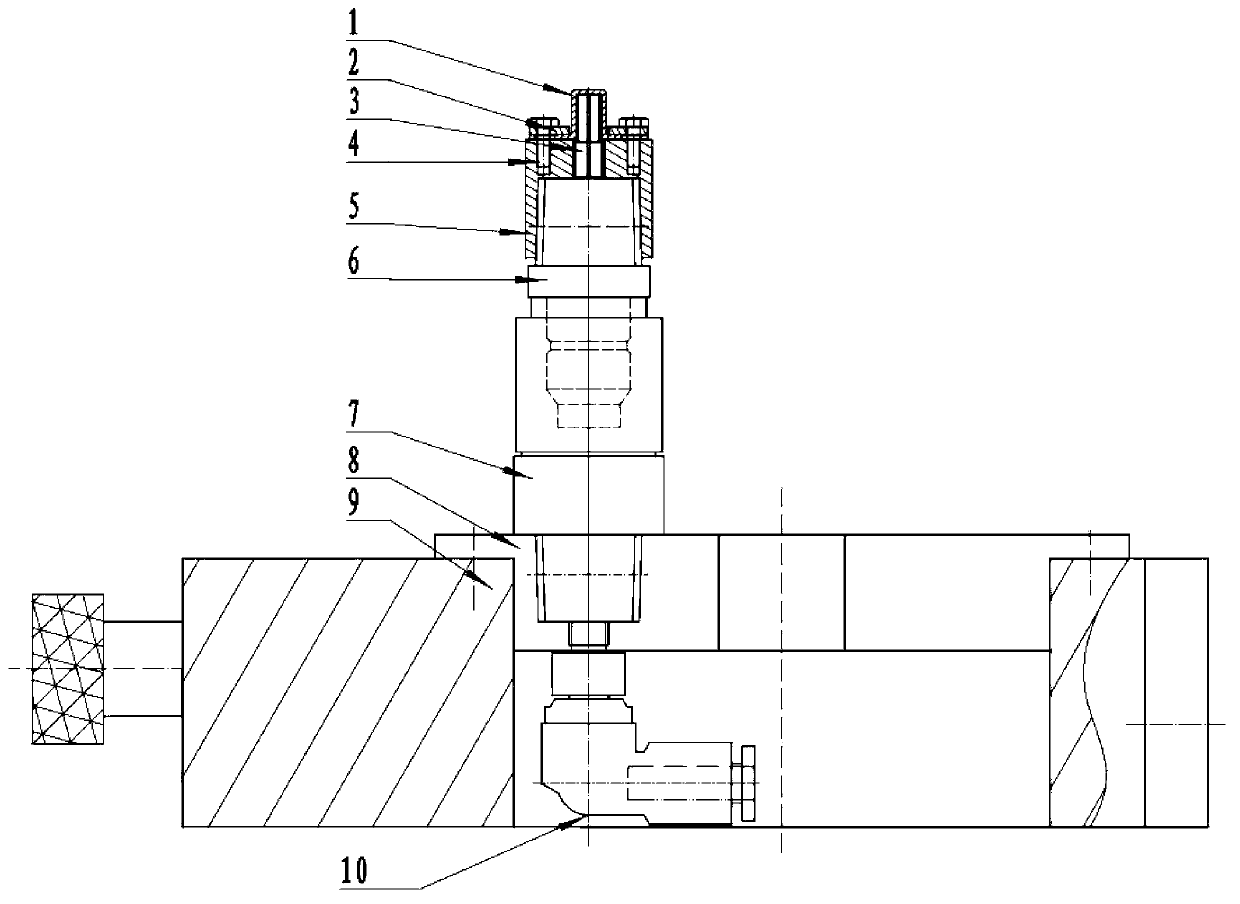

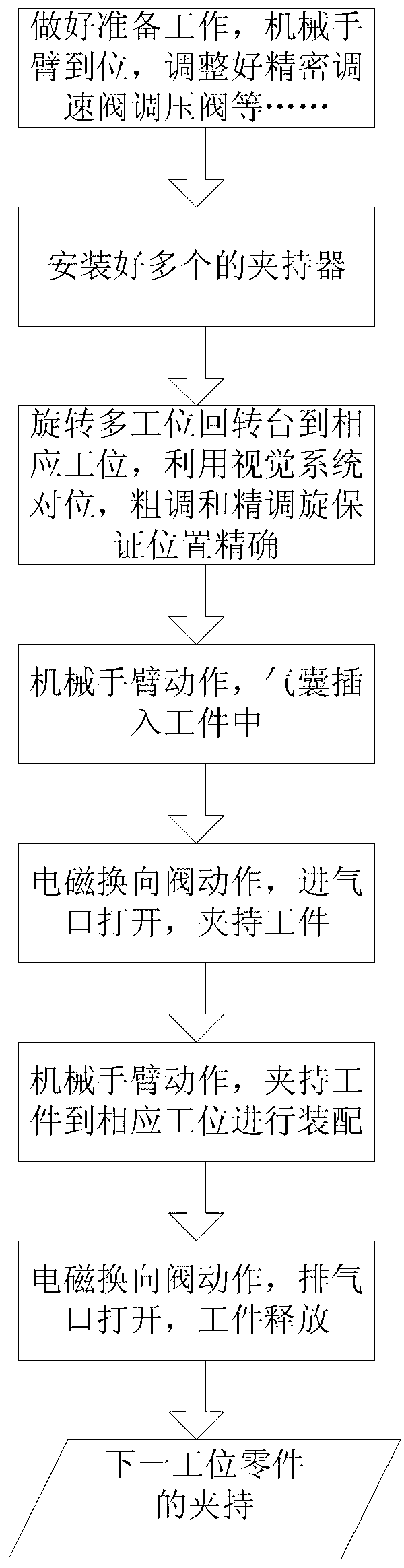

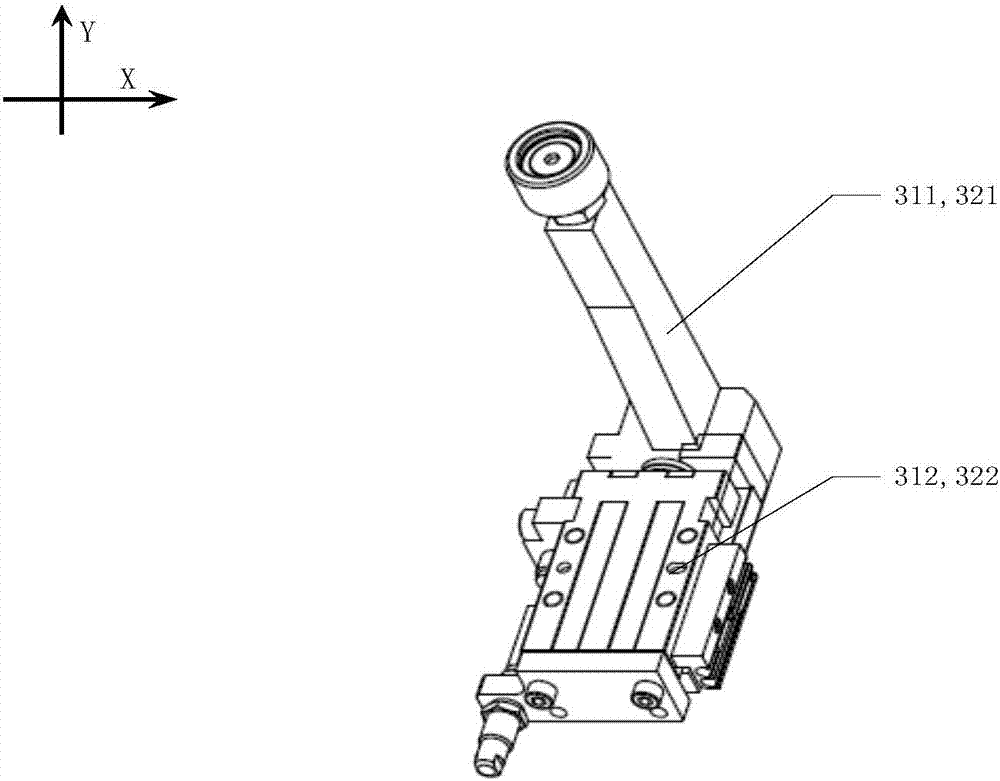

Multi-station silica gel air bag clamping device for clamping ultrathin wall deep cylinder part

ActiveCN103341861ARealize flexible clampingImprove clamping efficiencyGripping headsMetal working apparatusMagnetic exchangeEngineering

The invention relates to a multi-station silica gel air bag clamping device for clamping an ultrathin wall deep cylinder part and belongs to the field of microoperation and the micro electromechanical technology. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part particularly comprises an air bag clamping head, a conical surface quick-insertion connector, a multi-station rotary table and a gas circuit system. The air bag clamping head comprises an air bag, a center retainer, a ring fastening gasket and a connection transition part. The conical surface quick-insertion connector comprises a quick-change connector plug and a quick-change connector socket. The multi-station rotary table comprises a 360-degree manual rotary table and a pinboard. The gas circuit system comprises a gas source, a filter, a pressure regulating valve, a speed controlling valve, a magnetic exchange valve and a gas pipe connector. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part solves the problems that clamping of thin-wall parts is small in strength, poor in intensity, and deformation, invalidation and even damage are prone happening. Use of the quick-change connector and the multi-station rotary table can effectively achieve quick and flexible clamping and assembling of parts of different sizes and the same kind, facilitate operation and improve assembling precision and assembling efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Cucumber flexible picking manipulator end executor and picking method

ActiveCN107696047ASolve efficiency problemsSolve the clampingGripping headsHarvestersKey pressingCucumber family

The invention provides a cucumber flexible picking manipulator end executor and a picking method and relates to the field of agricultural picking robots. The cucumber flexible picking manipulator endexecutor is composed of a stepping motor, polished shafts, a lead screw, a mounting plate, a supporting plate, a nut slide block, an ejector plate, a visual sensor, a cutting cylinder, cutting fingers, a clamping cylinder, clamping fingers, springs, flexible clamping walls, silica gel keys, a laser sensor, a clamping arm rotating shaft and a rotary motor. The cucumber flexible picking manipulatorend executor is characterized in that the flexible clamping walls are installed on the two sides of the mounting plate through clamping wall rotary shafts, the silica gel keys are connected with the flexible clamping walls through the springs, and the working processes of aligning at cucumbers, moving close to the cucumbers, clamping the upper sections of the cucumbers, flexibly clamping the middle lower sections of the cucumbers and cutting off stems are completed. By adoption the picking manners that the flexible clamping walls clamp the middle sections and the lower sections of the cucumbers, the clamping fingers clamp the upper sections of the cucumbers, and the cutting fingers cut off the stems, the technical problems that the cucumber picking efficiency is low and cucumbers are proneto being damaged during clamping and are liable to break off due to shaking are solved.

Owner:新昌县大菠萝农业发展有限公司

Floating clamping jaw for lathe machining

The invention discloses a floating clamping jaw for lathe machining. The floating clamping jaw comprises a floating clamping jaw body, a floating clamping jaw base and a floating jaw T-shaped block which are sequentially connected through a floating jaw screw, the floating clamping jaw base and the floating jaw T-shaped block are fixed through a clamping screw, the floating clamping jaw is limited to the floating jaw screw in a rotating mode, the working face of the floating clamping jaw is fixedly provided with a plurality of floating jaw cushion blocks, the floating clamping jaw base is connected with the floating clamping jaw body through a positioning pin, and an elastic deformation body is further arranged between the positioning pin and the floating clamping jaw body in a sleeved mode. By means of the method, parts to be machined through a lathe can be positioned and clamped precisely and reliably, problems of inclined clamping, deformation of part clamping, clamping jaw wear and the like are avoided and clamping accuracy is improved.

Owner:CHANGSHU CHANGZHOU BEARING

Clamping mechanism for vehicle wire harness

InactiveCN106141946ARealize automatic clamping functionNo need to manually adjust the clamping forceClampsHydraulic cylinderEngineering

The invention relates to a clamping mechanism for a vehicle wire harness. The clamping mechanism comprises a clamping support plate; two linear slide rails 2 are symmetrically mounted on the side wall of the clamping support plate through screws; two clamping support chains are symmetrically mounted at the upper and lower two ends of the two linear slide rails 2; the vehicle wire harness is automatically clamped through the two clamping support chains symmetrically distributed up and down without manually adjusting the clamping force; the clamping support chains include arch frames respectively mounted on the two linear slide rails 2; clamping panels are welded at the middle parts of the arch frames; hydraulic cylinders 3 are mounted at the middle parts of the upper ends of the clamping panels; two extension rods are symmetrically mounted on two sides of the upper ends of the clamping panels; the two extension rods and the top ends of the hydraulic cylinders 3 are respectively mounted on top plates; the bottom ends of the top plates are mounted on the clamping support plate; and clamping heads are arranged at the top ends of the clamping panels. The clamping mechanism can realize automatic clamping function in machining of the vehicle wire harness, needs no manual adjustment of the clamping force, and has such advantages as good clamping effect and high working efficiency.

Owner:YJH ELECTRICAL EQUIP

Paint spraying clamping device for intelligent manufacturing of automobile hubs

ActiveCN112024199AFix stability issuesSolve the clampingSpraying apparatusStructural engineeringSmart manufacturing

The invention relates to the technical field of automobile hub paint spraying, and discloses a paint spraying clamping device for intelligent manufacturing of automobile hubs. The paint spraying clamping device comprises a base, arc-shaped blocks are connected into a rotary drum and in a sliding groove, arc-shaped magnetic blocks are arranged on the two sides of each arc-shaped block, rectangularmagnetic blocks corresponding to coils are arranged on the left portions of sliding rods, the outer side ends of fixing rods are connected with extrusion rods, and the left side in the rotary drum isconnected with annular air bags corresponding to the extrusion rods. The coils are energized to generate magnetic fields to attract the rectangular magnets, the arc-shaped blocks move rightwards on the sliding rods and extrude first springs, when the contracted arc-shaped blocks are completely separated from the arc-shaped magnet blocks on the left side and the right side, the other arc-shaped blocks are separated at equal intervals, the arc-shaped blocks drive the fixing rods to be separated again at equal intervals through the adjusting rods, and the annular air bags are inflated to expand to extrude the extrusion rods, the extrusion rods push the fixing rods to clamp the hubs. The structure solves the problems that existing paint spraying clamping equipment for automobile hubs is poor in stability and cannot applicable to clamping of different hubs.

Owner:大连万盛合机电设备有限公司

Distribution-box partition plate clamping and supporting device

InactiveCN106514089AAchieve stable clamping support functionThe stable clamping support function does not requireWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Owner:淄博凯越电气有限公司

Red date pitting machine for walnut-containing dates

The invention discloses a red date pitting machine for walnut-containing dates. The red date pitting machine comprises a frame, a platform, a driving shaft, a pedal crankshaft, a pedal plate, a driving rod crankshaft, a driving rod, a universal joint, a driving rod guide tube, a pitting tube, a pit-ejecting rod, a pit-ejecting rod fixing piece, a date clamping tool, a pit falling hole, a tightening component, a driving rod guide tube fixing hole, date clamping tool heads, date clamping tool handles, a fixing button, date clamping rods, pitting tube semicircular through holes, a compression spring, fixing holes, fixing rings, springs, an elastic sheet, a slot and a blade. According to the red date pitting machine, a principle of converting circular rotation of the crankshaft into upward-downward vertical motion is adopted, the continuous operation of putting dates to be pitted into the date clamping tool, driving the pits downwards, taking the date clamping tool out, discharging the pits and putting the dates to be pitted into the date clamping tool is designed in sequence during one rotation cycle of the pedal crankshaft, and the four continuous procedures are connected tightly; moreover, certain operation time is reserved among the four procedures, and simple repeated operation is performed by dual hands and dual feet.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

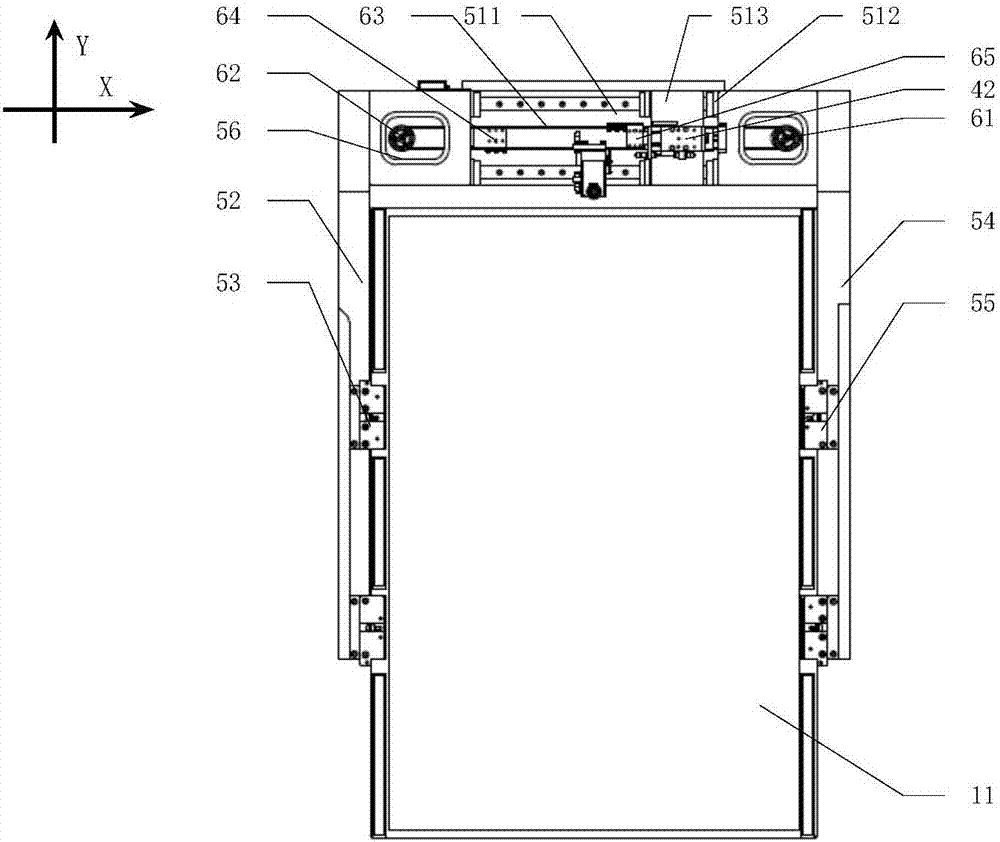

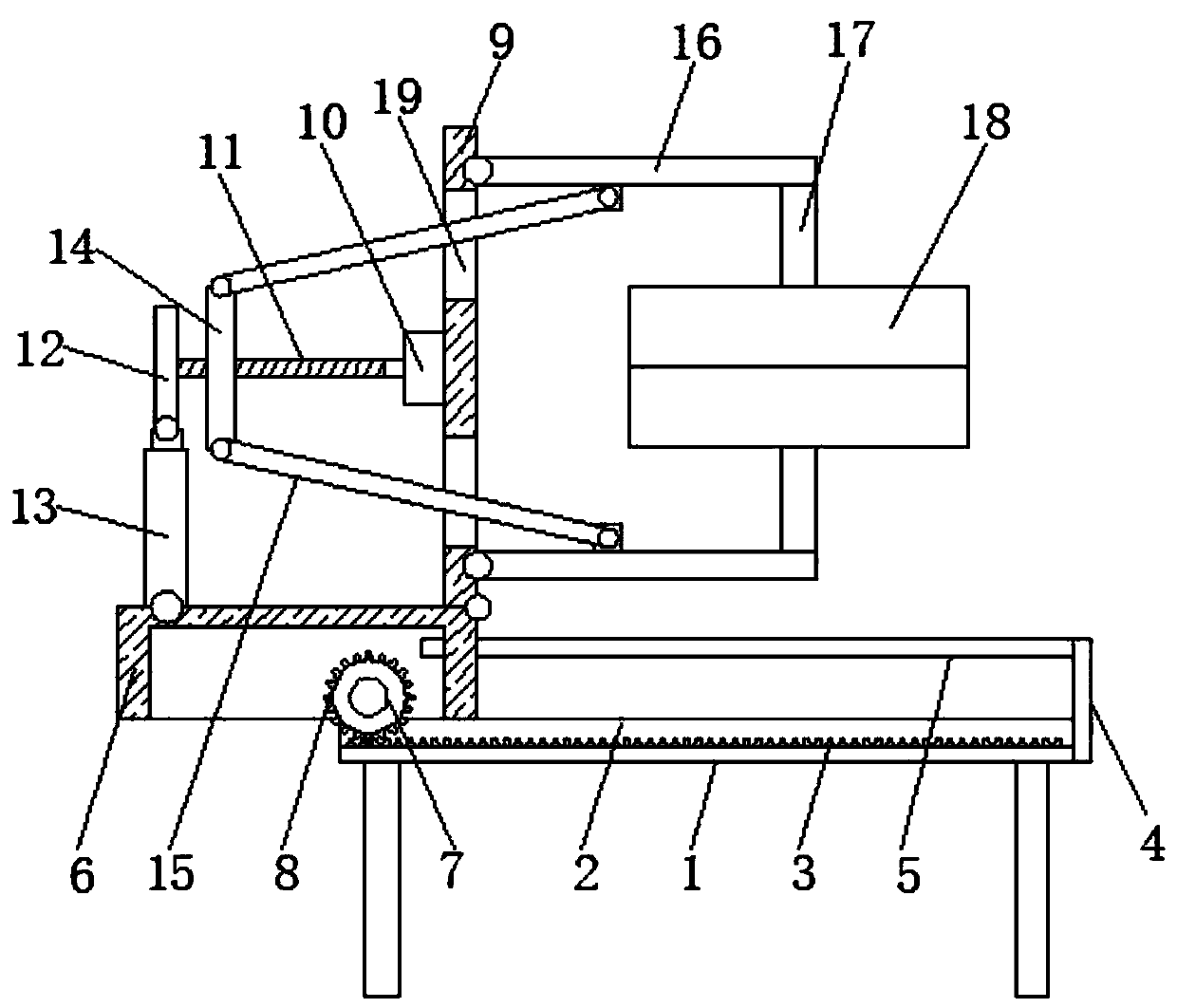

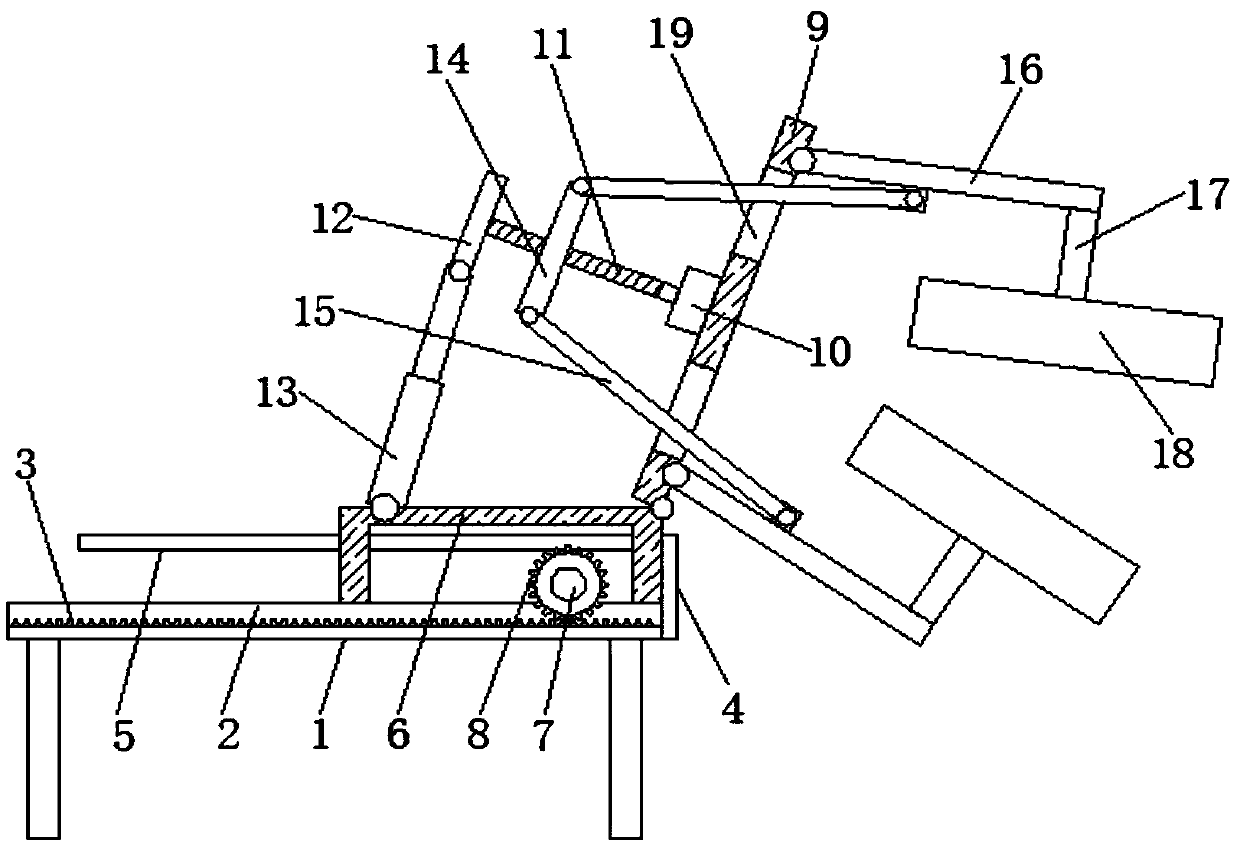

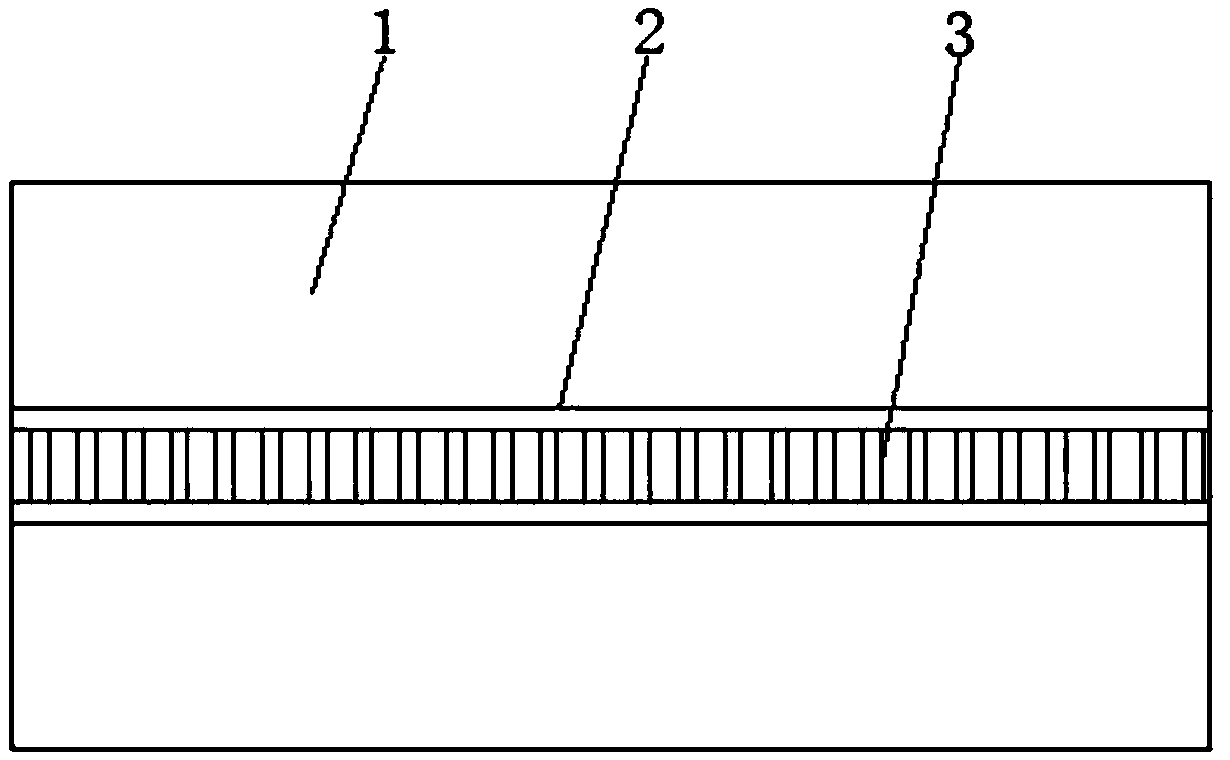

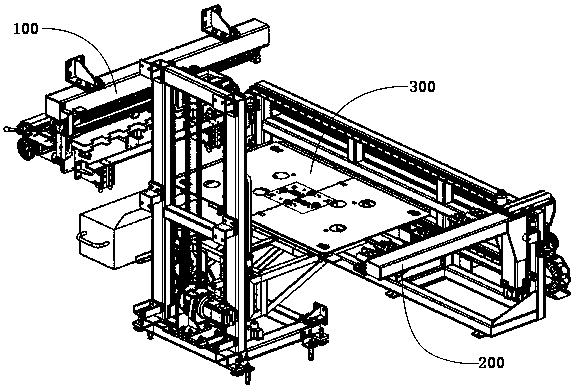

Metal pattern plate manipulator pre-aligning mechanism and metal pattern plate feeding method and application

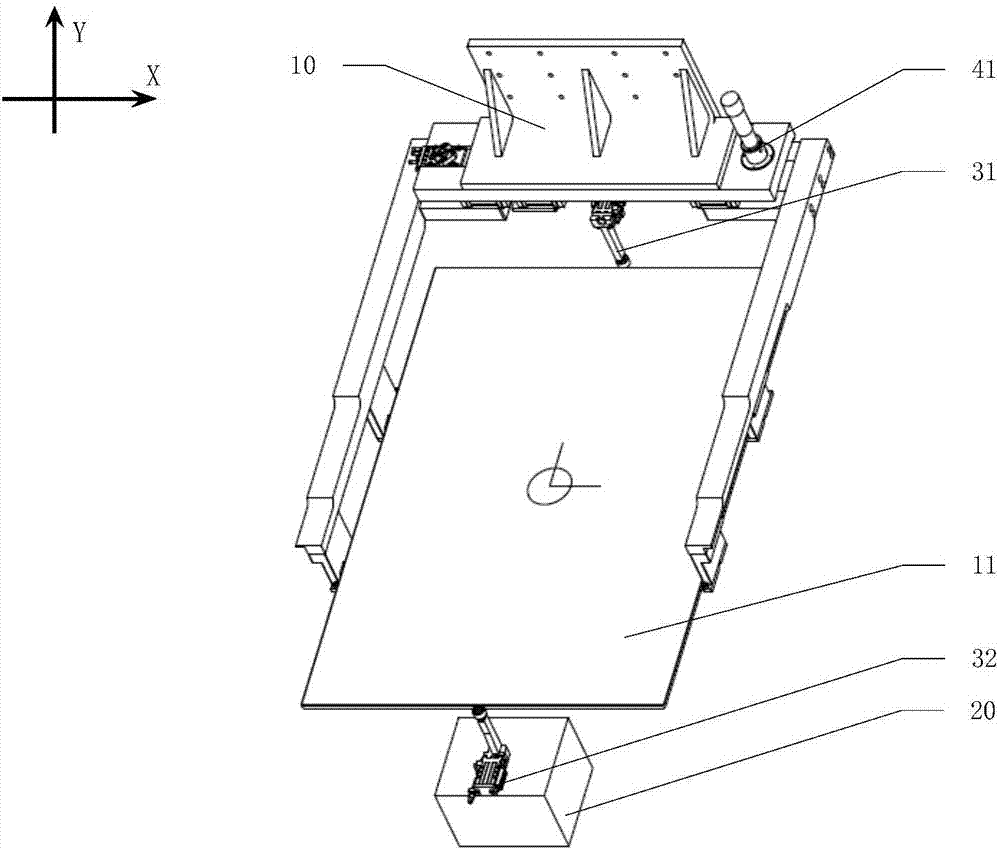

ActiveCN107285006APhenomenon that prevents damage to the maskEnsure safetyConveyorsConveyor partsTransfer procedureLarge size

Then invention discloses a metal pattern plate feeding method and discloses a metal pattern plate manipulator pre-aligning device adopting the method at the same time. The method comprises the steps that (a) X-direction primary positioning is conducted, specifically, a first X-direction driver drives X-direction movement assemblies to oppositely move in the X direction to enable the X-direction movement assemblies to hold a metal pattern plate located above; and (b) X-direction secondary positioning is conducted, specifically, after X-direction primary positioning is conducted, a second X-direction driver drives the X-direction movement assemblies to continue to oppositely move in the X direction to enable the X-direction movement assemblies to tightly clamp the metal pattern plate in the X direction. The metal pattern plate feeding method further comprises the steps that Y-direction positioning is conducted, specifically, before X-direction secondary positioning, at the same time of X-direction secondary positioning or after X-direction secondary positioning, a Y-direction driver drives a Y-direction movement assembly to move in the Y direction, and the Y-direction movement assembly acts on the metal pattern plate and conducts Y-direction positioning. According to the metal pattern plate feeding method, the speed and force of tight clamping for positioning in the feeding process of the large-size metal pattern plate can be flexibly controlled, and the safety of the metal pattern plate conveying process is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

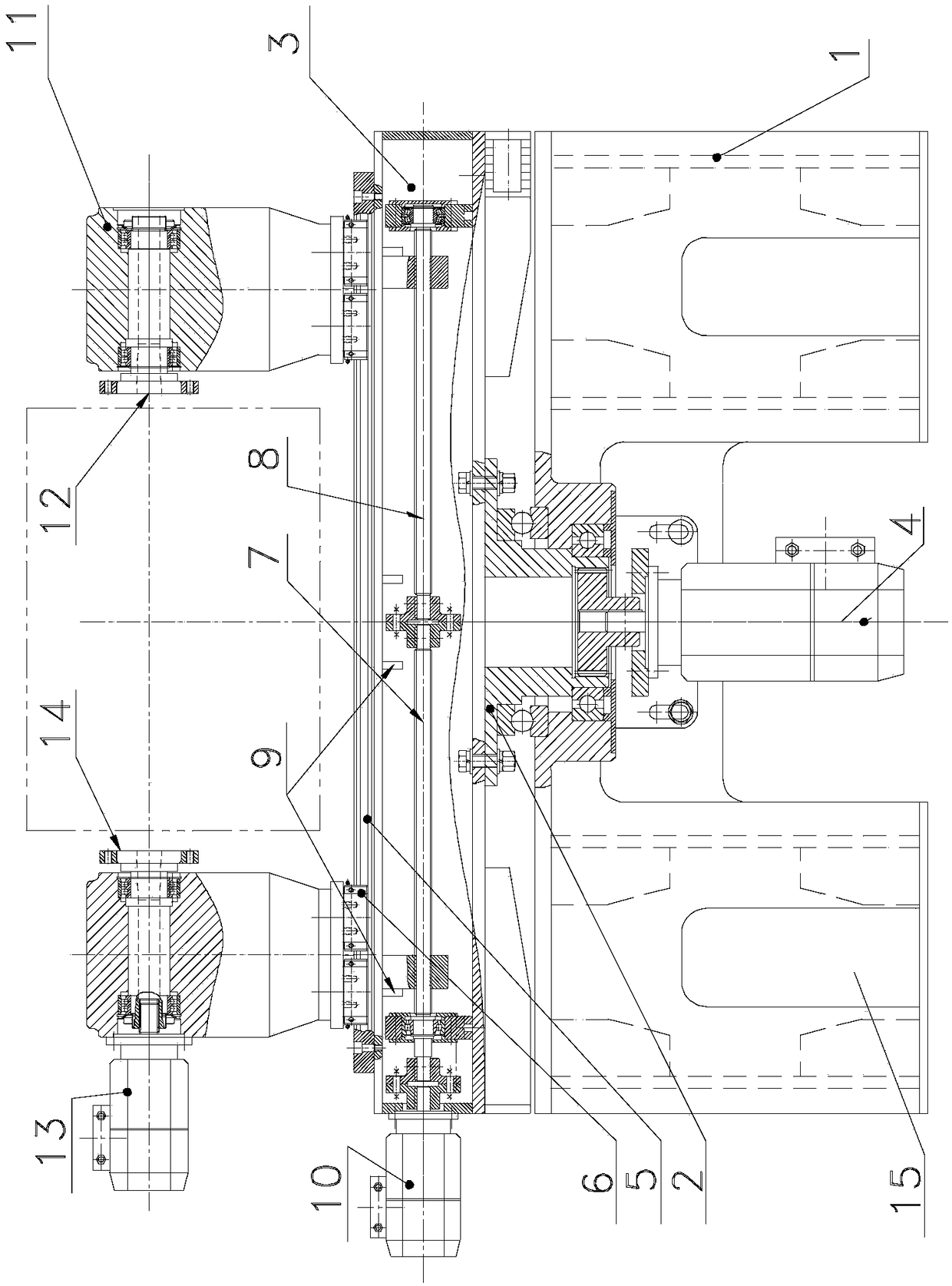

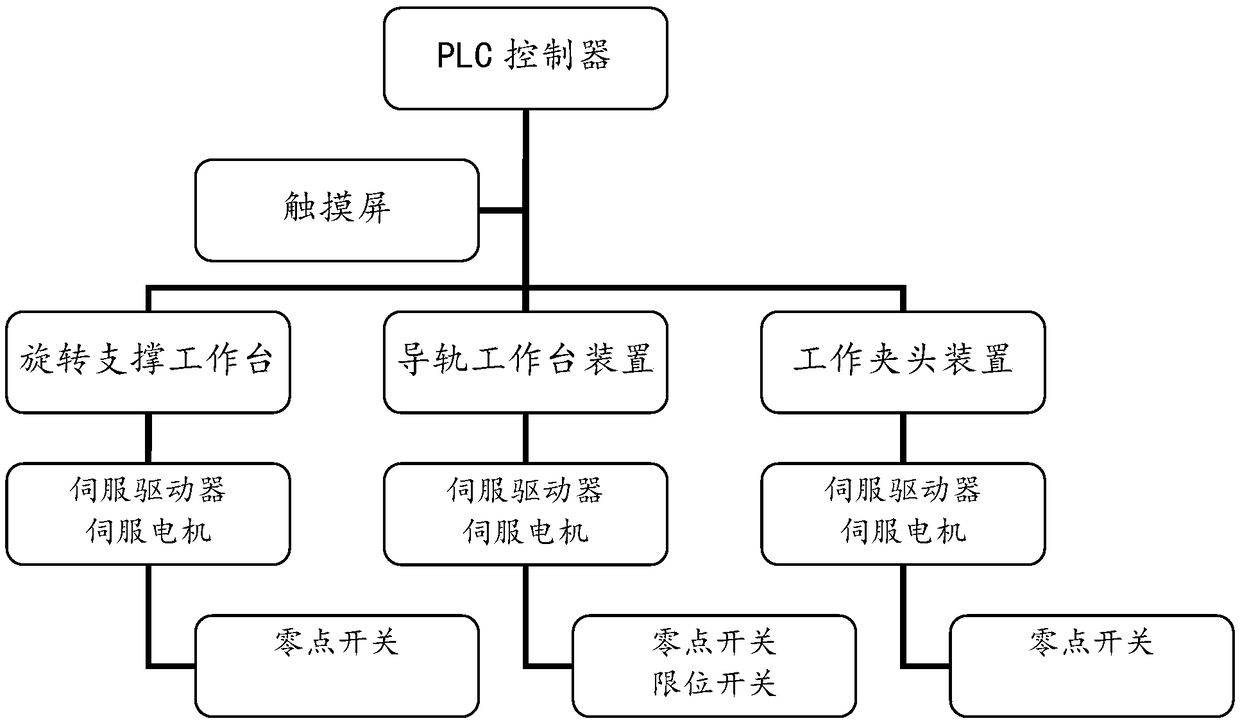

Rotary clamping turnover tool

PendingCN109202484ASolve the long-term dependence on manualSolve the clampingPositioning apparatusMetal-working holdersMotor driveEngineering

The invention provides a rotary clamping turnover tool which comprises a supporting table, a rotating fixing disc arranged on the supporting table and capable of circumferentially rotating around thecentral axis, a first servo motor which is positioned on the supporting table and can drive the rotating fixing disc to rotating around the central axis, a guide rail workbench fixed to the rotating fixing disc, a guide rail arranged on the guide rail workbench, two sliding blocks which are arranged on the guide rail and move oppositely or reversely by taking the central axis of the rotating fixing disc as the center, a screw rod mechanism driving the two sliding blocks to move in the opposite direction or the reverse direction, a second servo motor driving the screw rod mechanism to move, andtwo working clamping head bases which are correspondingly fixed on each sliding block, a first positioning part is arranged on one of the working clamping heads, and a second positioning part which is opposite to the first positioning part is arranged on the other of the working clamping heads, and a third servo motor for driving the second positioning part to rotate. According to the invention,the production efficiency and the production quality are improved.

Owner:CHONGQING NO 2 MACHINE TOOL WORKS

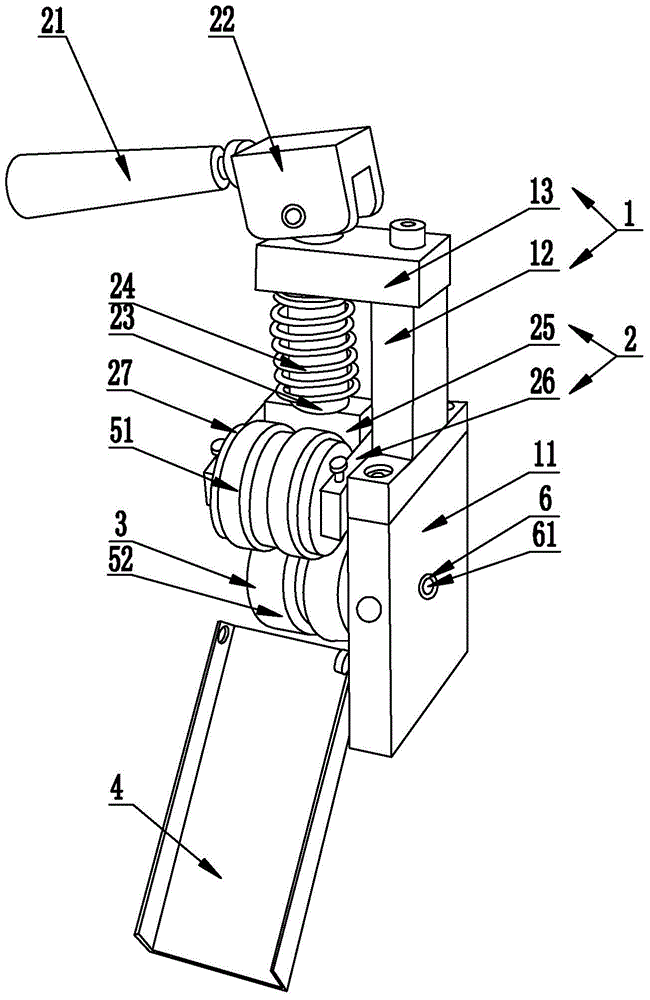

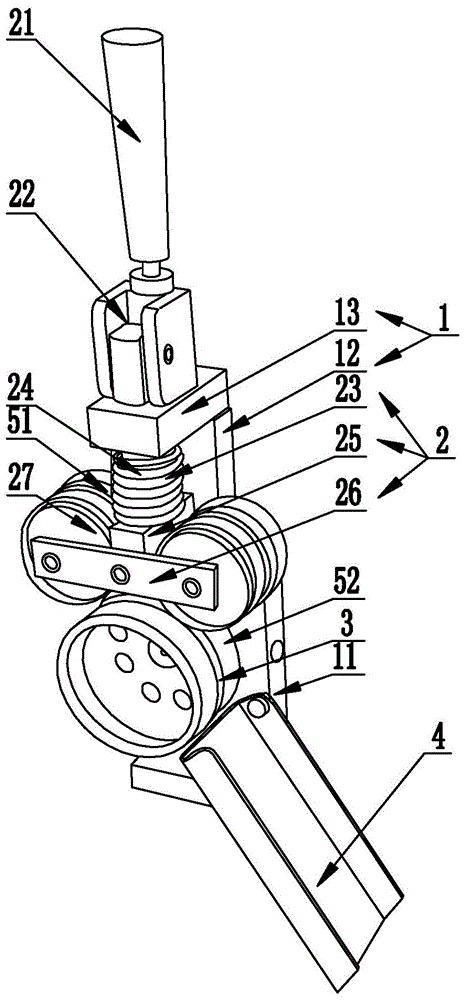

Clamping device and method for large-aperture diffraction grating

InactiveCN104062735ASolve the clampingSolve the problem of precise heartMountingsEngineeringDiffraction grating

The invention relates to a clamping tool and a clamping method on the basis of the tool. A clamping device of a large-aperture diffraction grating comprises a mirror frame, a main positioning frame arranged at the side edge of the mirror frame, and four compressing arm sets which are respectively arranged at four corners of the mirror frame; a large-aperture diffraction grating to be clamped is positioned into the mirror frame and stopped on the main positioning plate; the compressing arm sets compress the large-aperture diffraction grating to be clamped to connect with the mirror frame. With the adoption of the clamping device and method for the large-aperture diffraction grating, the installation and debugging are fast, and the precision is high.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

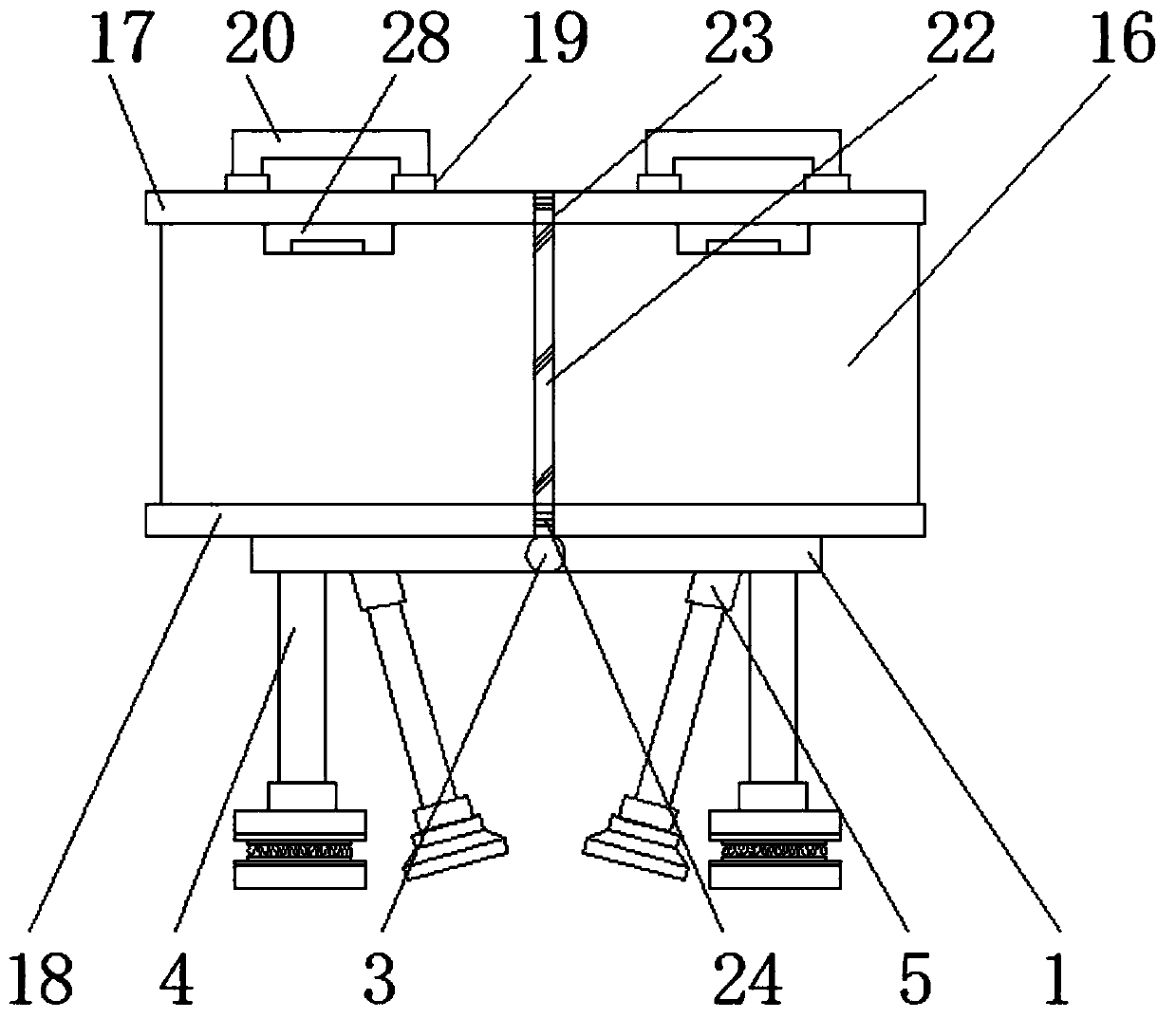

Clamping device for transverse deviation correction of ballastless track structure

ActiveCN109629353ASolve the cumbersome disassembly and assemblySolve the clampingRailway track constructionEngineeringCounterforce

The invention discloses a clamping device for transverse deviation correction of a ballastless track structure, belongs to the technical field of disease treatment for ballastless track structures ofrailways, and particularly relates to the clamping device for the transverse deviation correction of the ballastless track structure. The clamping device comprises a shedding-prevention holder and a clamping mandril, and the clamping mandril is composed of four parts including a length adjustment sleeve, a length adjustment lead screw, a connecting sleeve and a leveling end plate. The length adjustment of the clamping device is achieved through a sleeve-lead screw structure, and thus the change of spacing and clamping force of a counterforce structure (a limiting structure) and the track structure is adapted to. A spherical hinge structure is adopted for adjusting the clamping angle to a certain degree and the working condition that the structural stress surfaces at the two sides of the clamping device are not parallel can be adapted to. The shedding-prevention holder is adopted for solving the problems that detaching and installing are complicated, and the clamping mandril easily falls. Through the design of combination of multiple parts, the workload of spot operation is reduced. Through the light and compact structure, the weight is reduced on the premise of guaranteeing functions, and the operation convenience is improved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

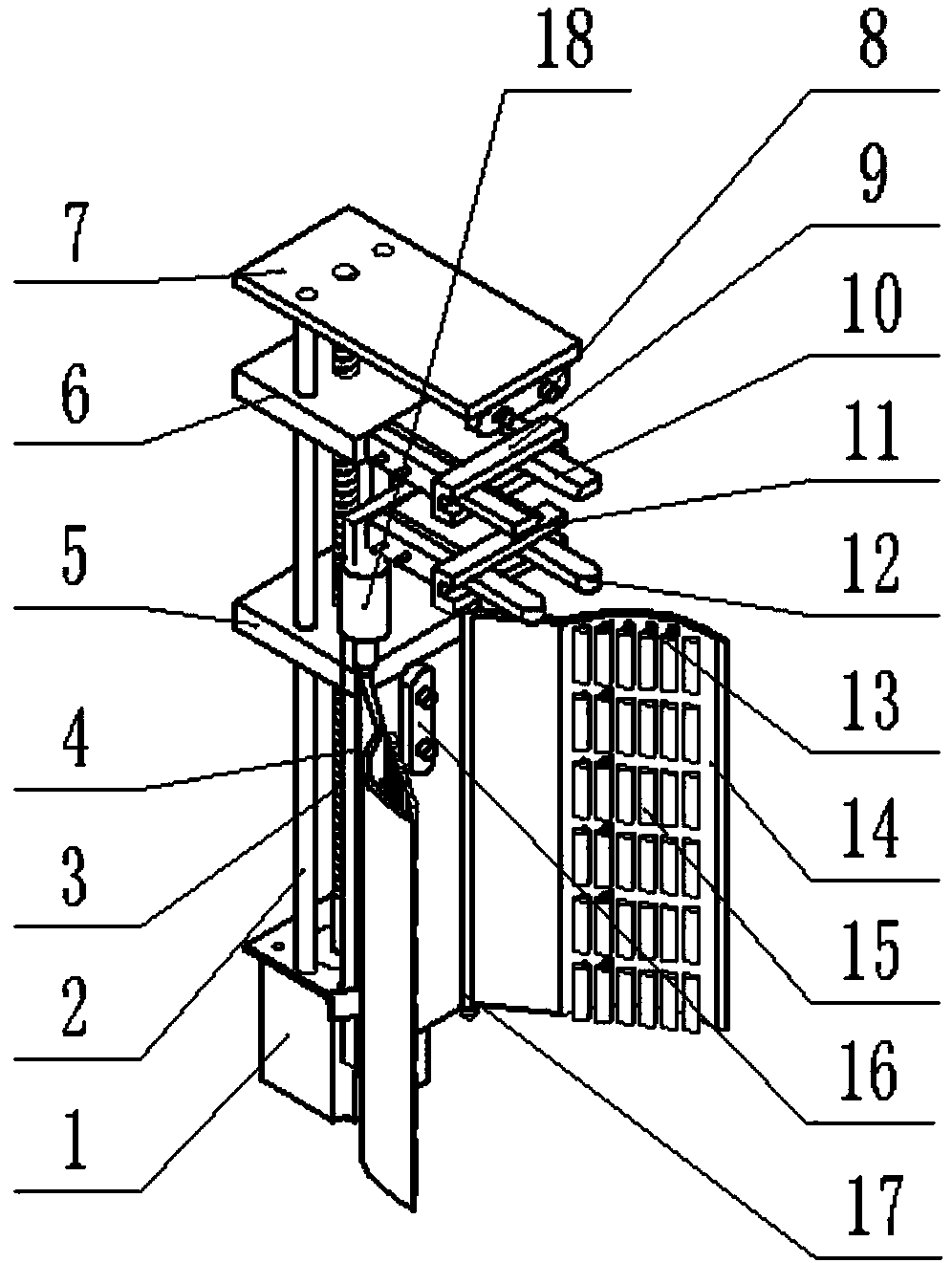

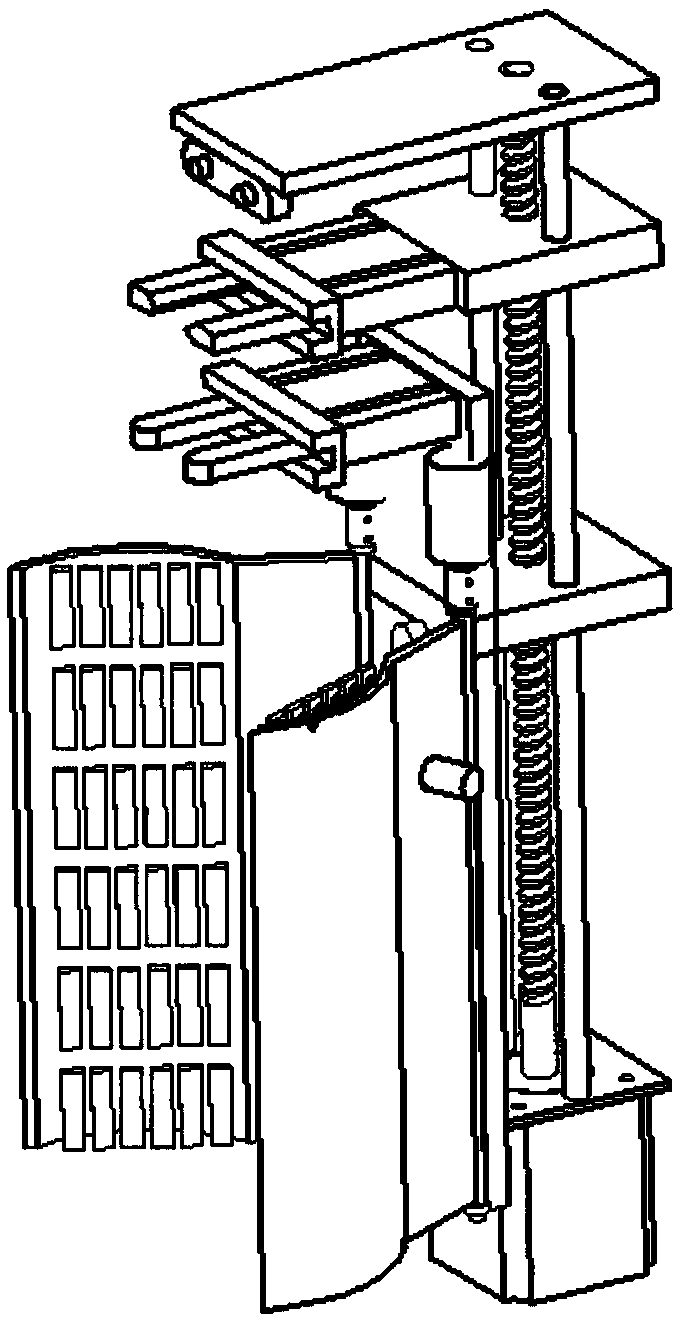

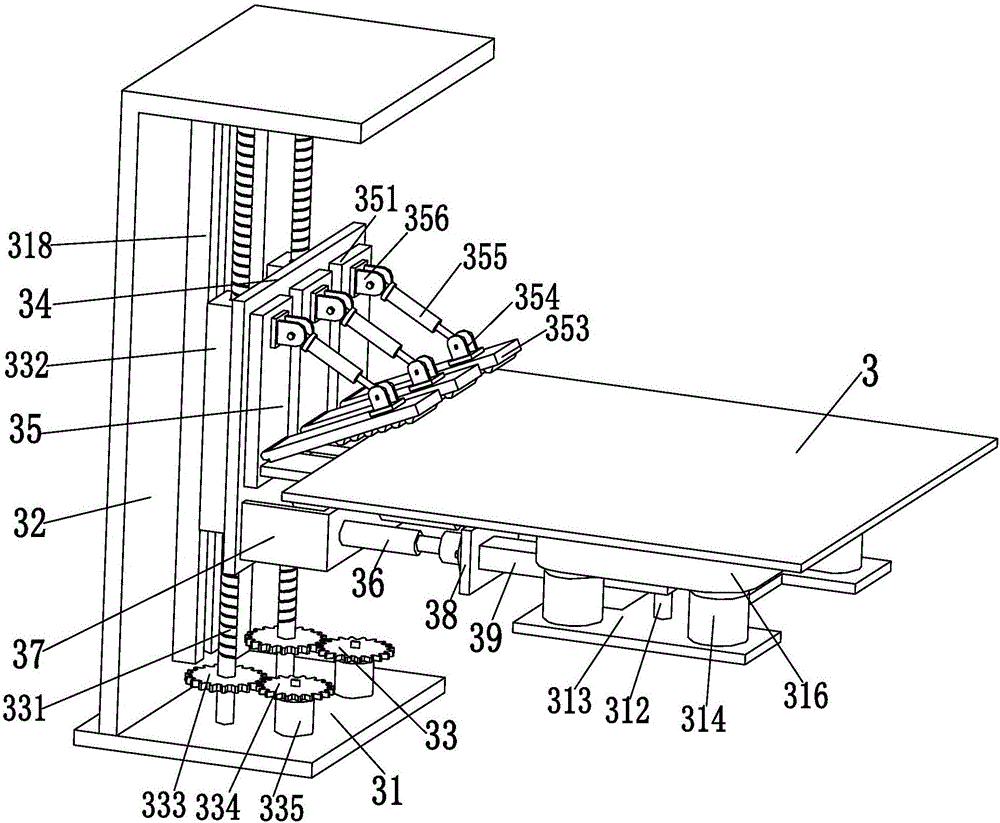

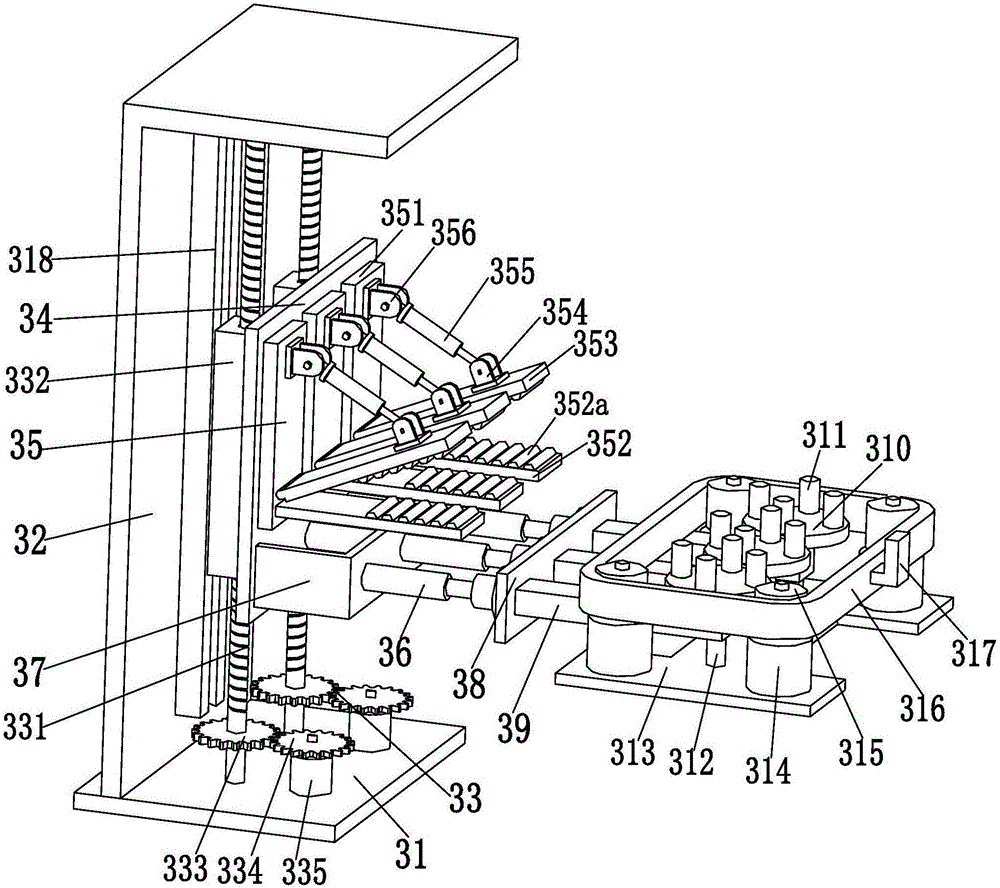

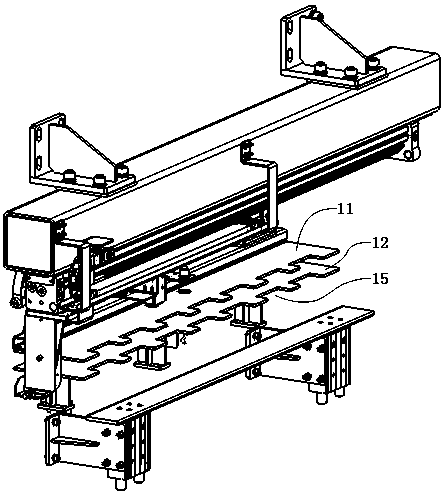

LFT-D composite material punching feeding and discharging industrial robot tooling

InactiveCN106945064ASolve the adsorption problemSolve the clampingMetal-working feeding devicesGripping headsArray data structureEngineering

The invention discloses an LFT-D composite material punching feeding and discharging industrial robot tooling. The LFT-D composite material punching feeding and discharging industrial robot tooling comprises a transverse beam support connected with an industrial robot arm, a longitudinal arm support is arranged on the transverse beam support, a plurality of discharging vacuum chuck assemblies are sequentially arranged at the upper end of the longitudinal arm support in the axial direction, and a plurality of feeding felting needle grabbing handle assemblies are sequentially arranged at the lower end of the longitudinal arm support in the axial direction; each feeding felting needle grabbing handle assembly comprises two clamping air cylinders, felting needles and a guide support, wherein the clamping air cylinders are fixedly positioned at the lower end of the longitudinal arm support and are arranged along the longitudinal arm support in the axial direction in a crossed and staggered manner, the felting needles are positioned to air cylinder rods of the two clamping air cylinders and extend in the axial direction of the air cylinder rods, and the guide support is connected between the two clamping air cylinders and conducts axial guide on the felting needles. By means of the LFT-D composite material punching feeding and discharging industrial robot tooling, the problem that an existing industrial robot tooling is hard to meet the requirement for absorption or clamping of the LFT-D composite material molten state through optimization structure.

Owner:CHONGQING JIANGDONG MACHINERY

Urea nozzle injection mold convenient for blanking

The invention discloses a urea nozzle injection mold convenient for blanking. Aiming at the problems of inconvenient blanking by the mold and manual mold clamping existing in the prior art, the urea nozzle injection mold comprises a table board, wherein the top of the table board is provided with a mounting groove in the length direction of the table board, the inner wall of the bottom of the mounting groove is welded with a rack, one side of the table board is welded with a fixing plate, a guide rod arranged horizontally is welded on the side, close to the table board, of the fixing plate, the guide rod is movably sleeved with a fixing cover, a driving mechanism is installed inside the fixing cover, a mounting plate is hinged on the side, close to the fixing plate, of the outer wall of the top of the fixing cover, a second driving motor arranged horizontally is fixedly connected to the side, far away from the fixing plate, of the mounting plate, and a screw rod is welded at the tail end of an output shaft of the second driving motor. The urea nozzle injection mold is novel in design, simple in operation, convenient for automatic clamping and fixing of a mold main body, convenientfor staff to perform blanking, time-saving and labor-saving, and high in working efficiency.

Owner:NINGBO ANCHUANG ELECTRONICS TECH CO LTD

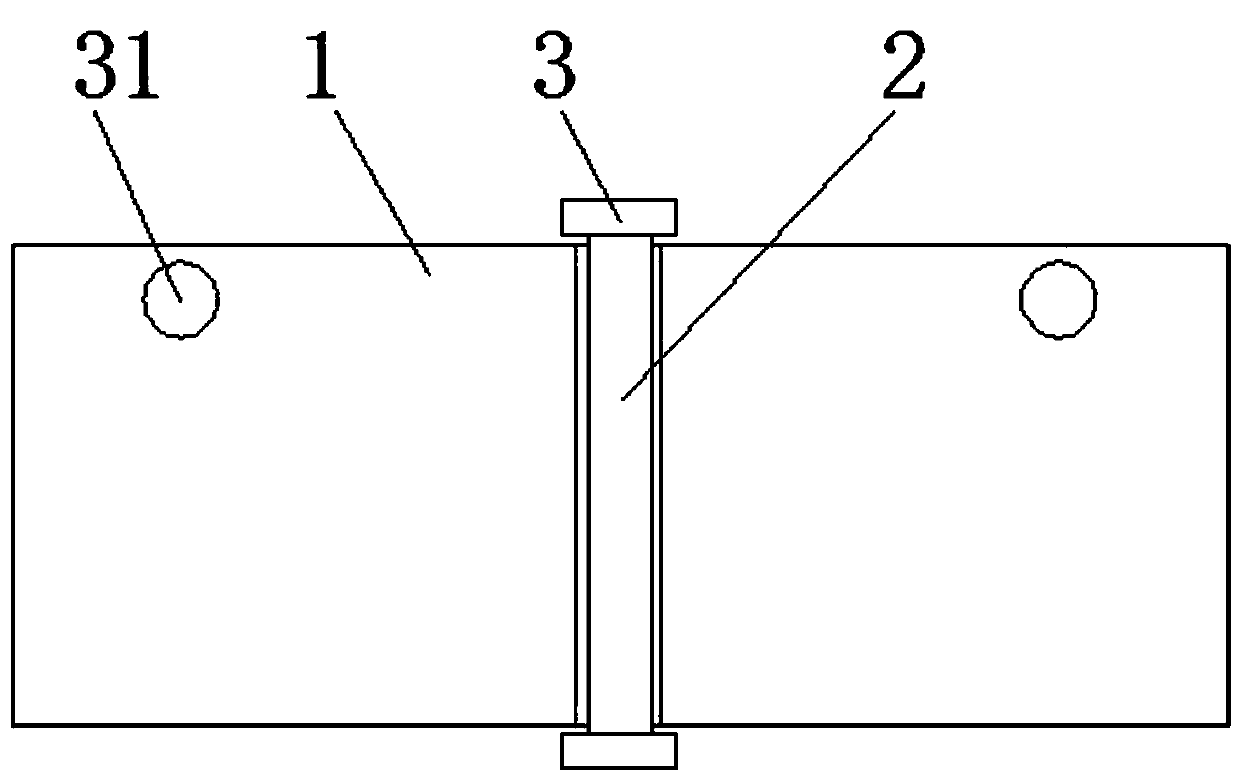

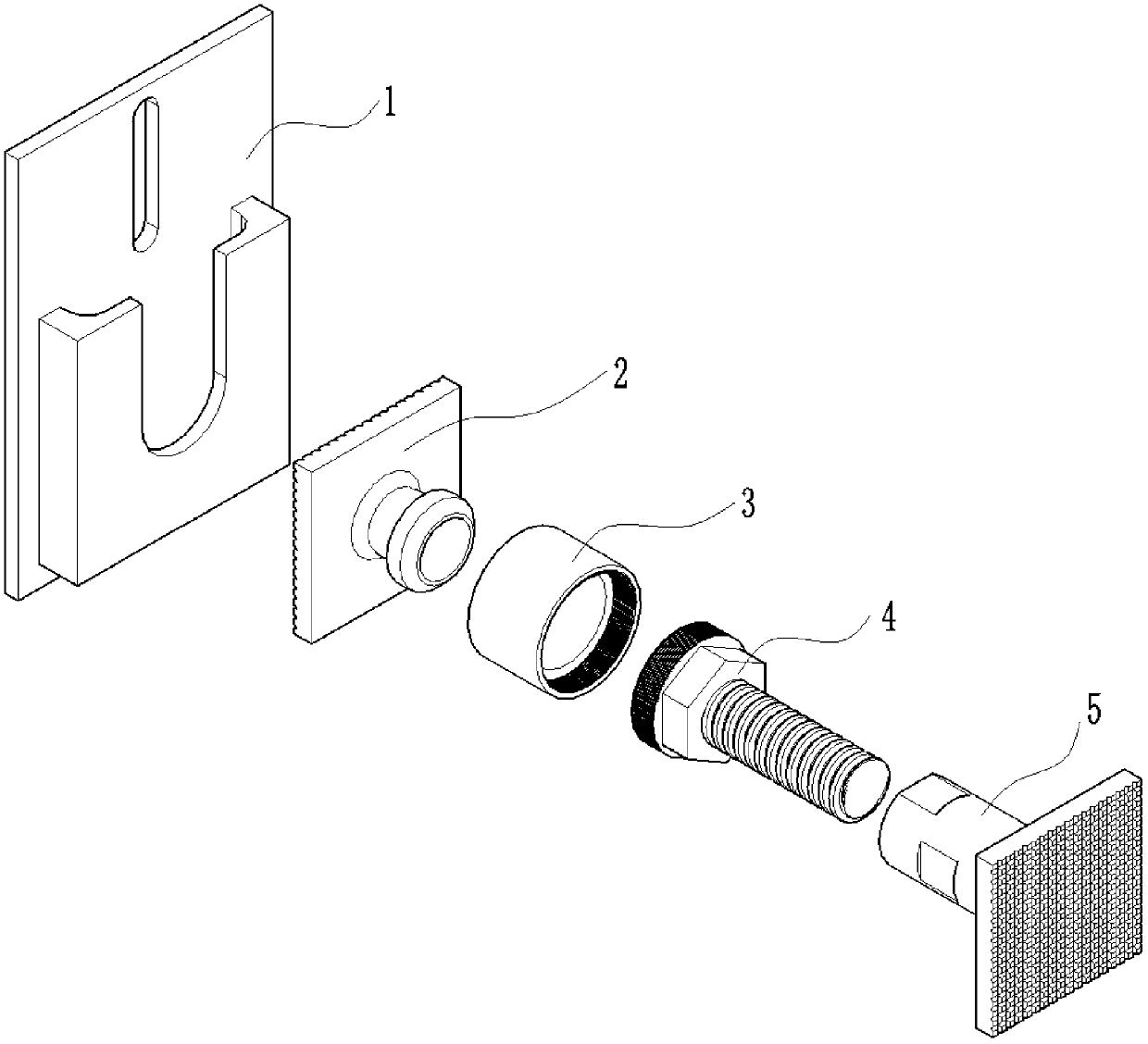

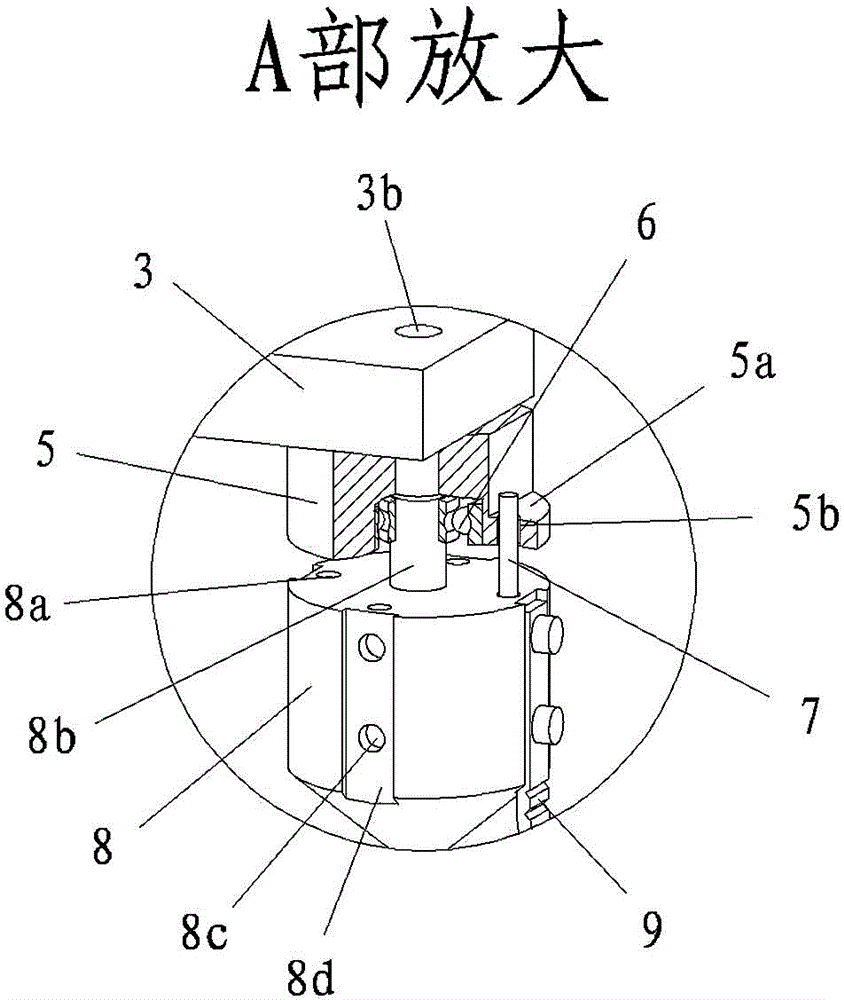

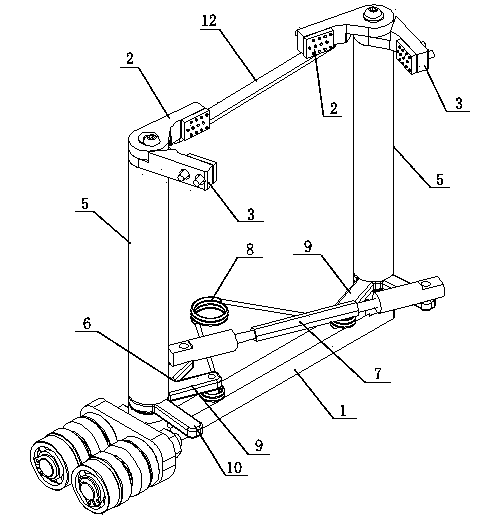

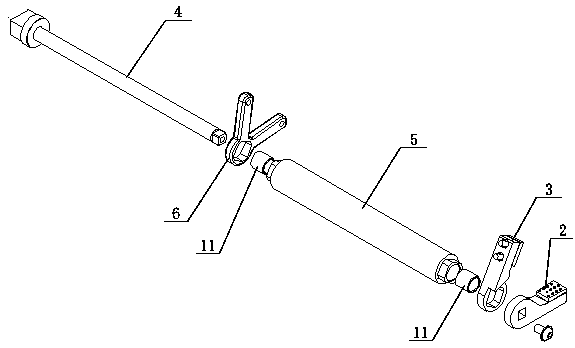

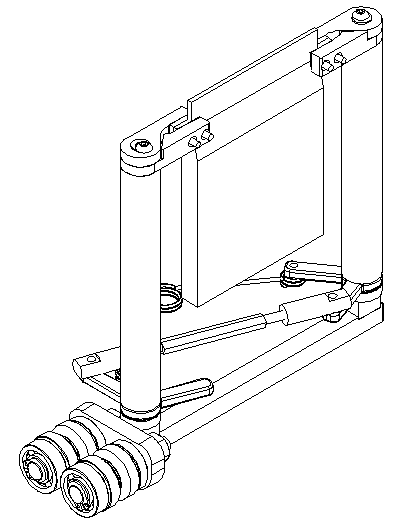

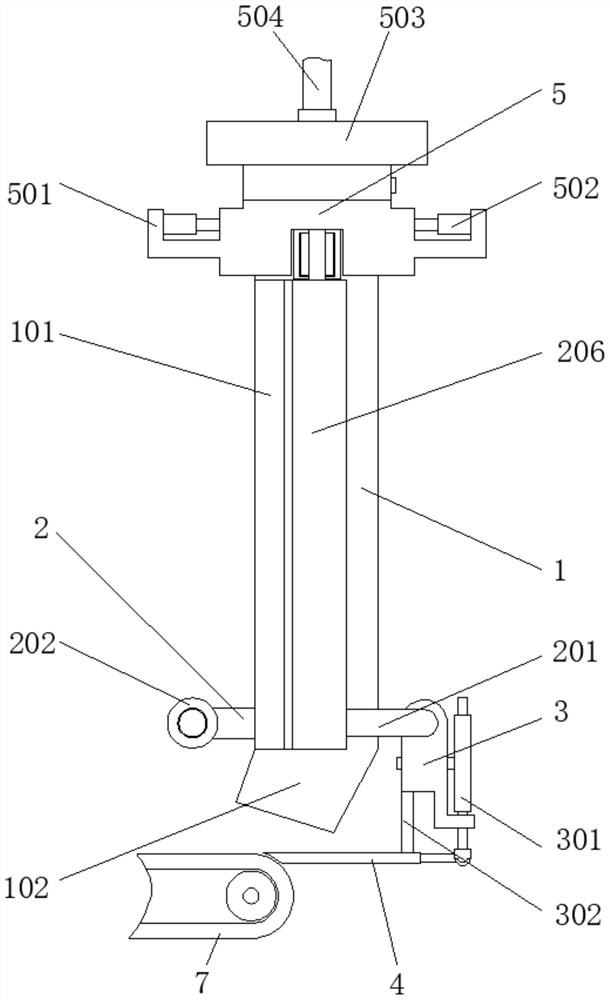

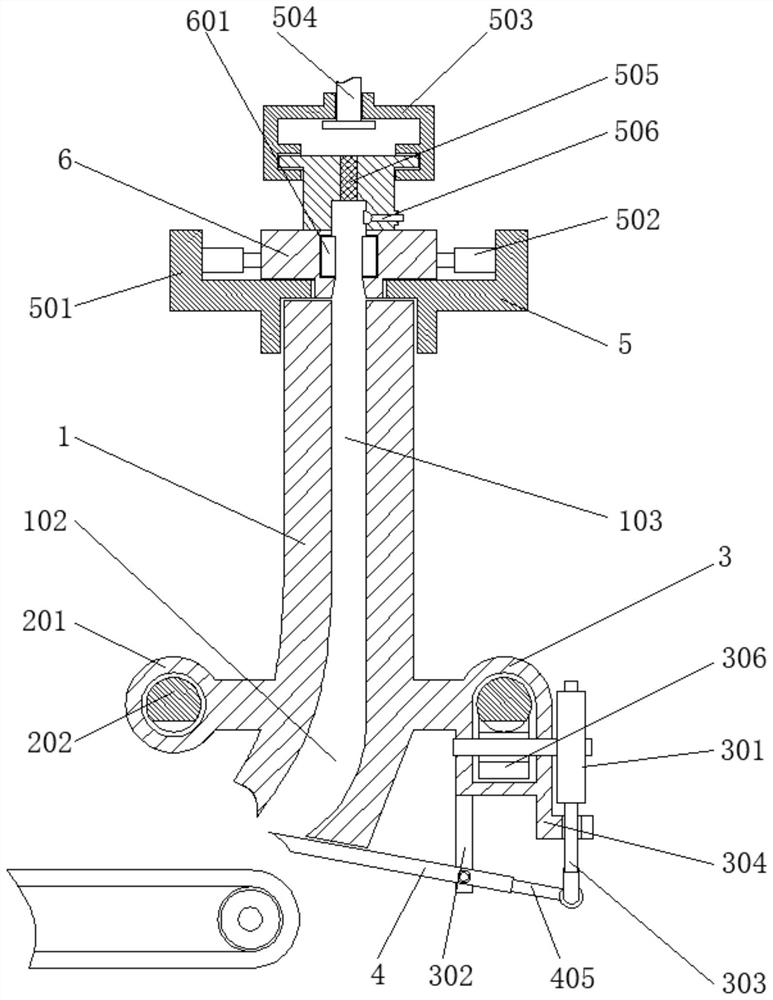

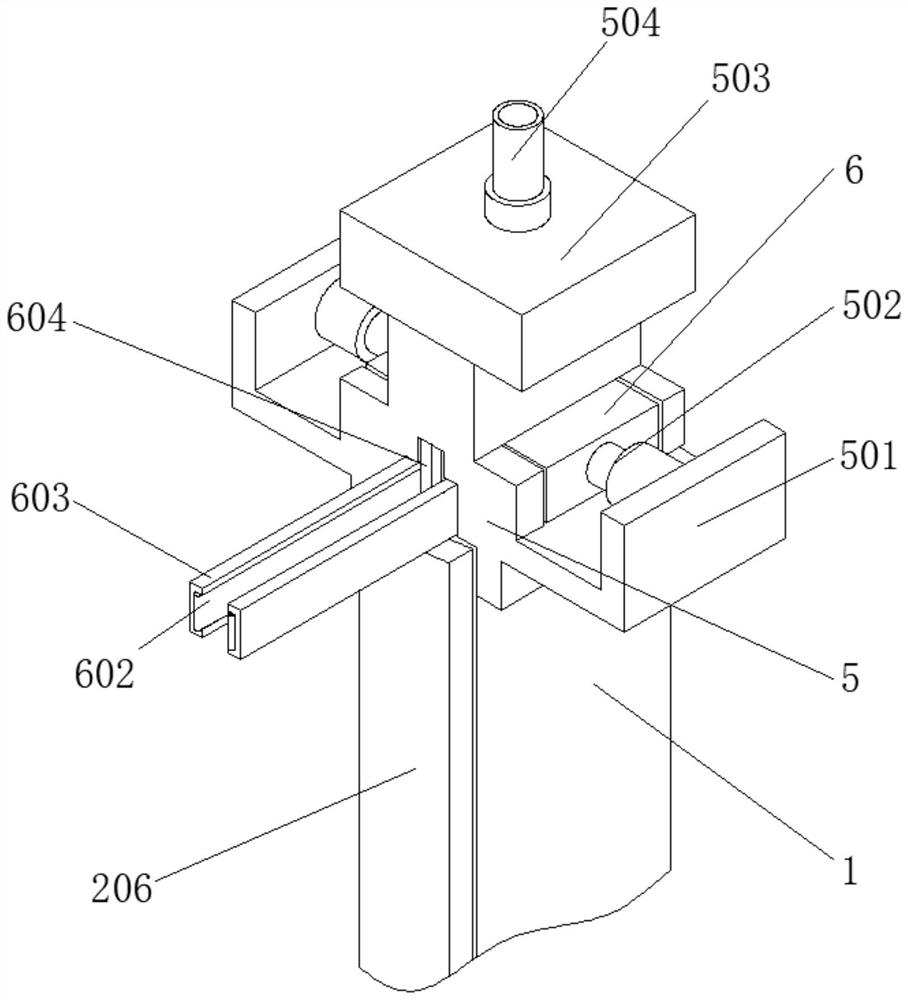

Pipeline fixing device for electrical and mechanical equipment

ActiveCN103600287ASolve the clampingFix fixityPipe supportsElectrical apparatusLine tubingMechanical equipment

A pipeline fixing device for electrical and mechanical equipment is characterized by comprising a base (1), a post (2), a beam (3), a locking nut (4), a rotor seat (5), a fixing pin (7), a rotor (8) and a hook (9). The lower end of the post is connected to the base, the upper side matches with the beam, the locking nut fixes and locks the post and the beam, the rotor seat is fixed on one side of the beam, the rotor matches with the rotor seat, and the hook is connected to the rotor. By means of the technical scheme, the device is simple in structure, the problem of influences caused by unfixed pipelines during machining is solved, and the device has the advantages of convenience for machining and operating, improvement on operating efficiency and the like.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Bag catching device

ActiveCN103466127AFast and accurate clampingFix stability issuesPackagingEngineeringElectrical and Electronics engineering

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

Clamp and mechanical arm

PendingCN107052842AStrengthen the role of clamping functionTo achieve the purpose of tight clampingWork clamping meansPositioning apparatusRobot handEngineering

The invention provides a clamp and a mechanical arm, and relates to the technical field of machining auxiliary equipment. The clamp comprises a clamping part and a sliding part, the clamping part comprises an upper clamping area and a lower clamping area which are oppositely arranged, the sliding part comprises an upper sliding area and a lower sliding area which are stacked, the upper sliding area is connected with the upper clamping area, the lower sliding area is connected with the lower clamping area, the upper sliding area is provided with an adjusting hole way, the lower sliding area is provided with a lower clamping block, the lower clamping block is connected with a connecting rod, the connecting rod penetrates the adjusting hole way to be connected with a locking component, the connecting rod can slide along the adjusting hole way, the locking component can rotate relative to the connecting rod, and rotation of the locking component relative to the connecting rod enables the connecting rod to begin to or stop sliding on the adjusting hole way. The aim of tightly clamping workpieces with different sizes to be machined is achieved, and the problems that in the prior art, the clamp cannot achieve clamping and low cost at the same time are solved.

Owner:NINGBO ZEE AUTOMATION EQUIP

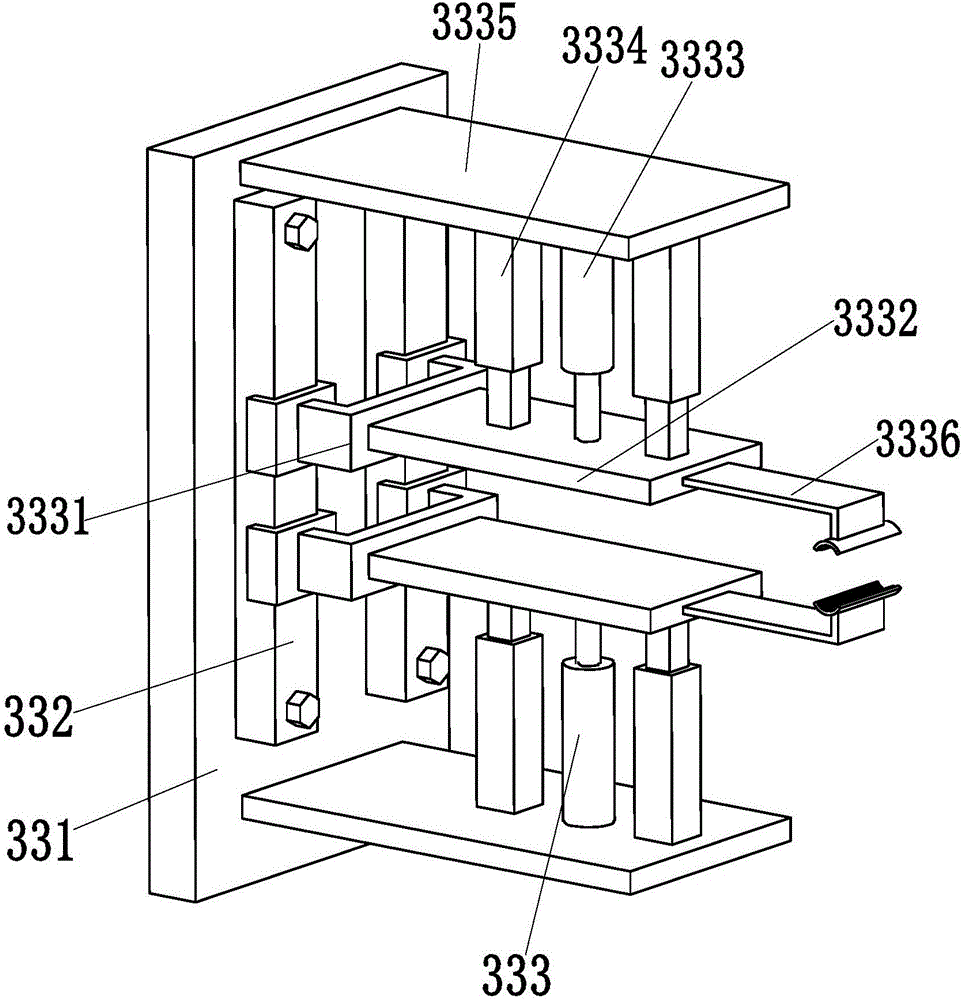

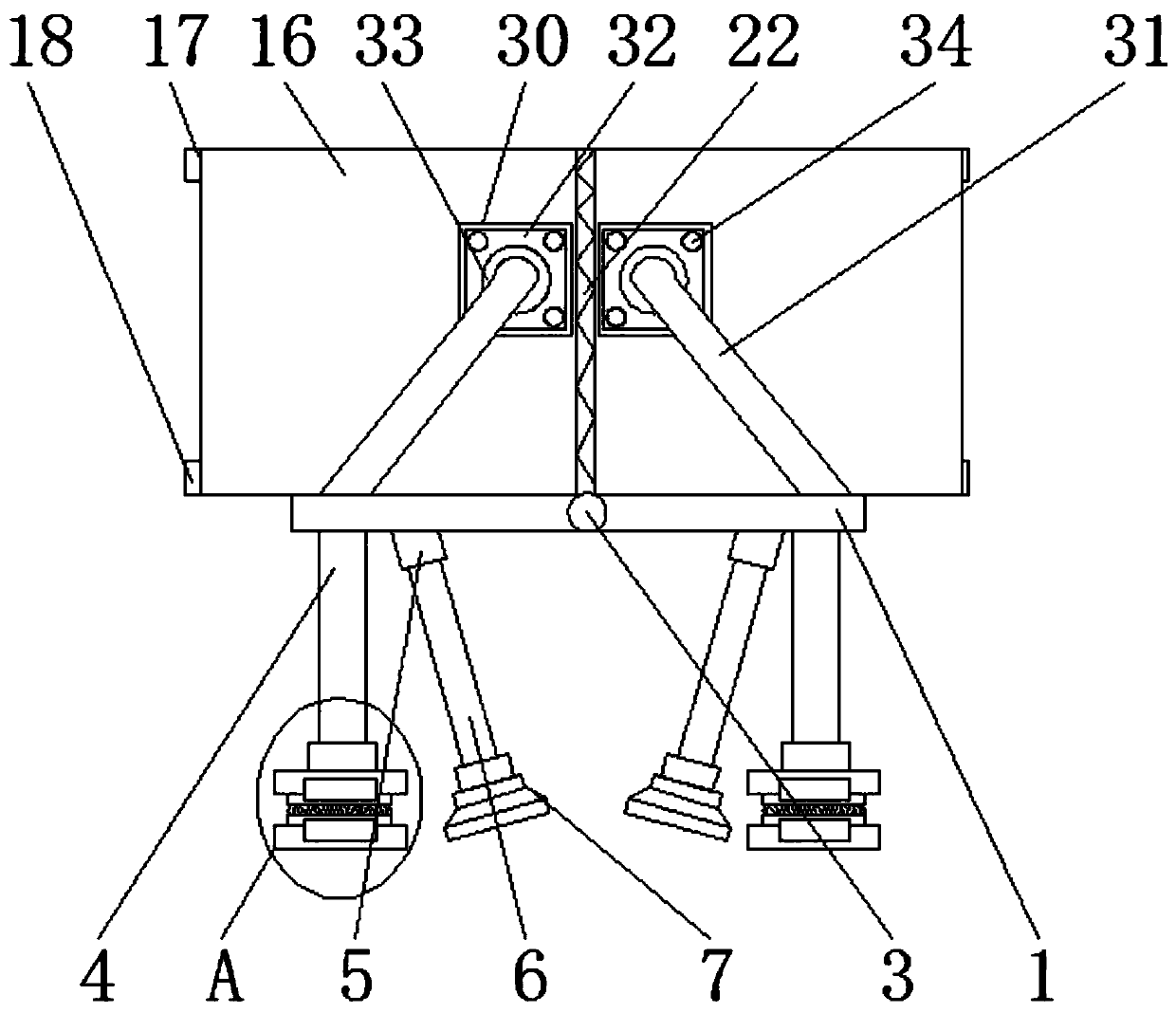

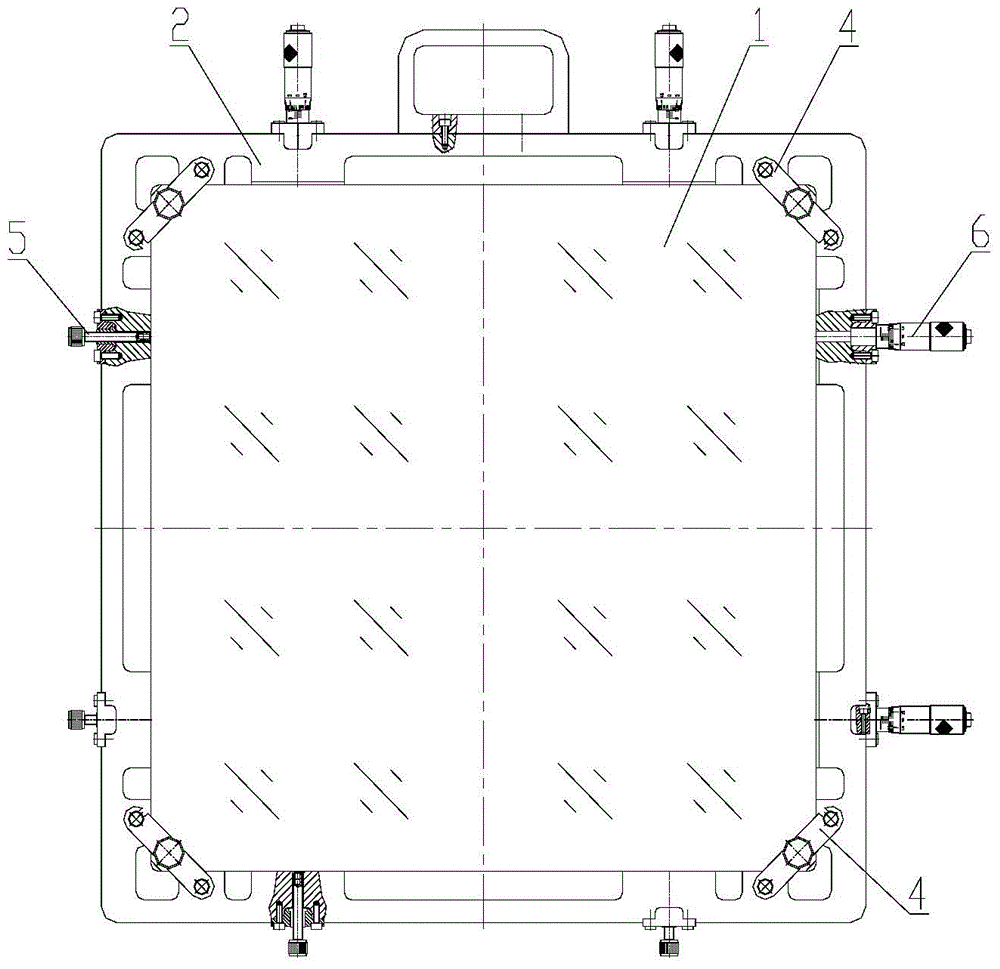

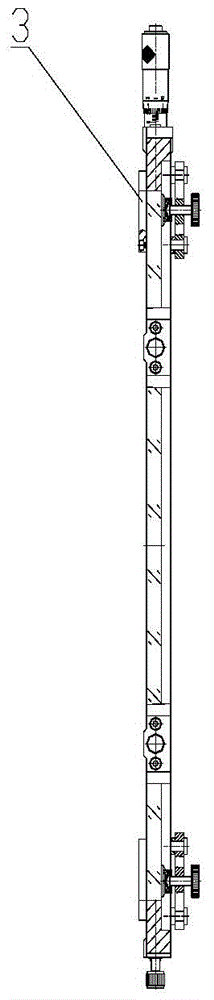

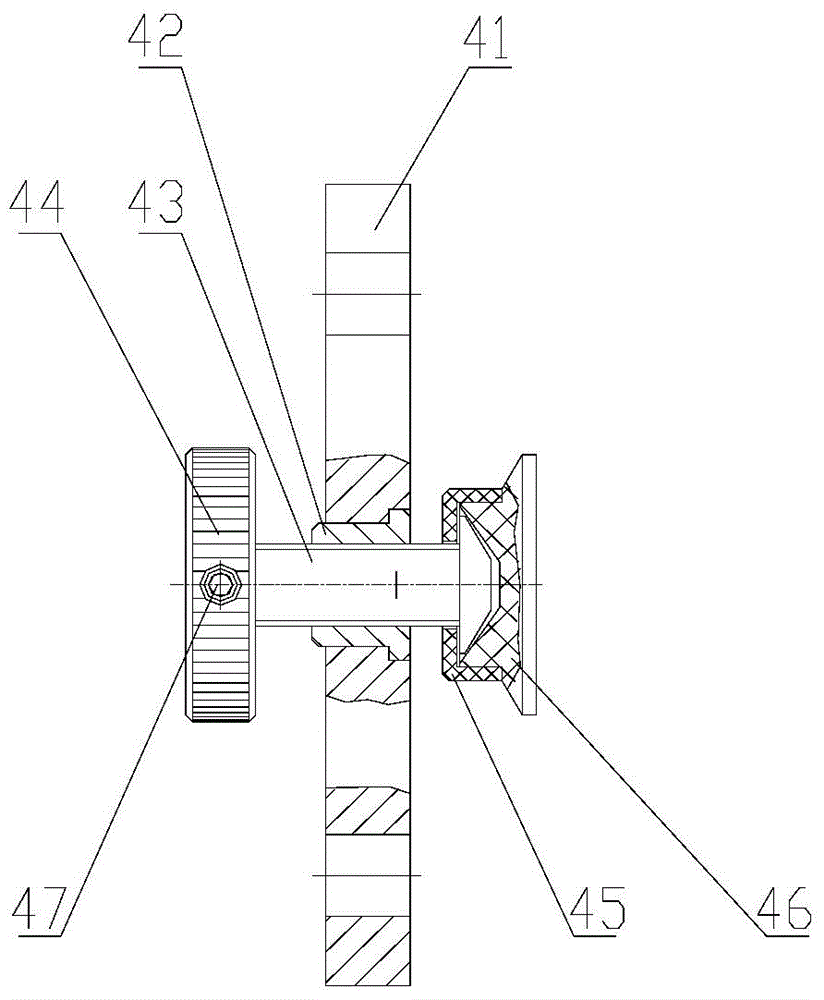

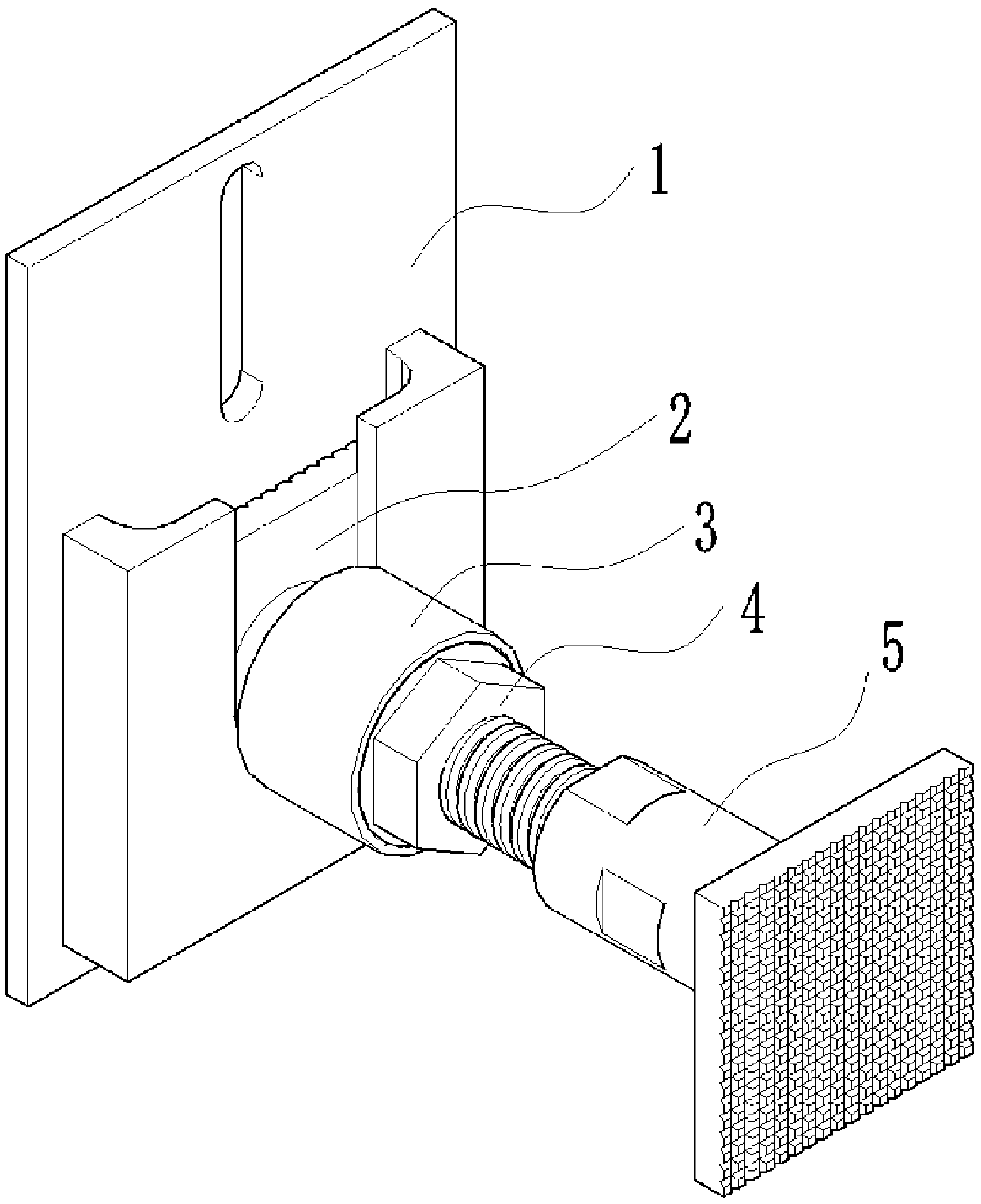

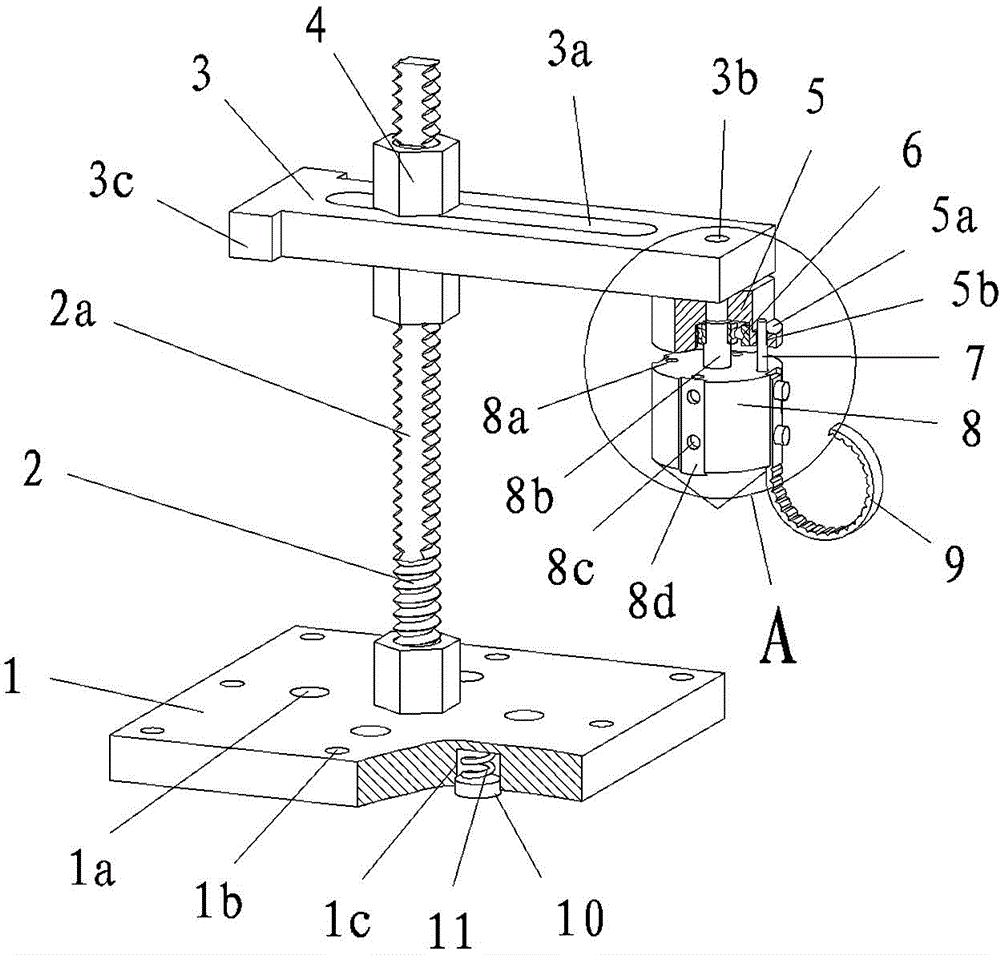

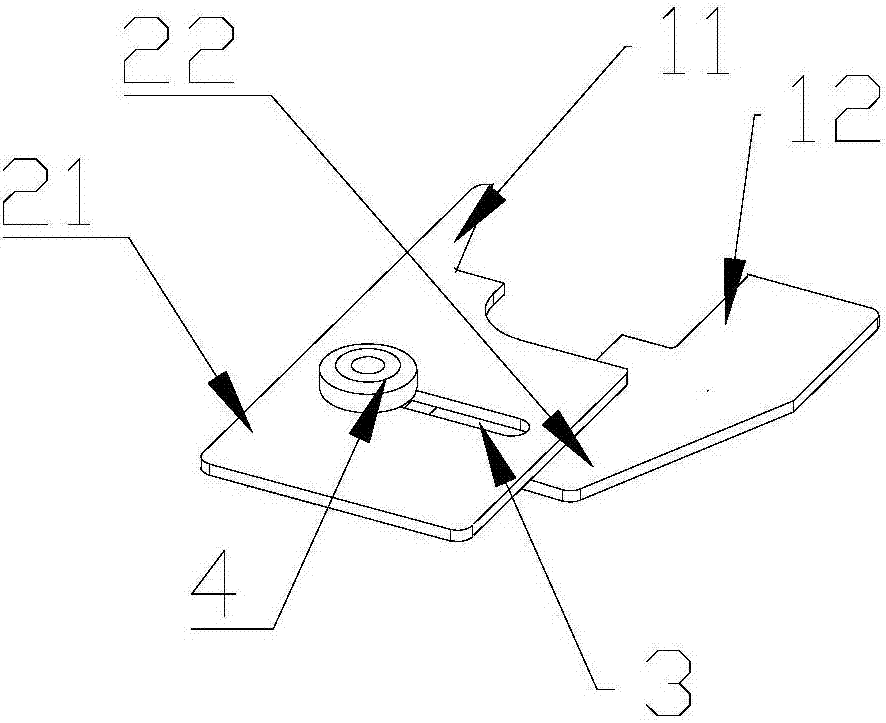

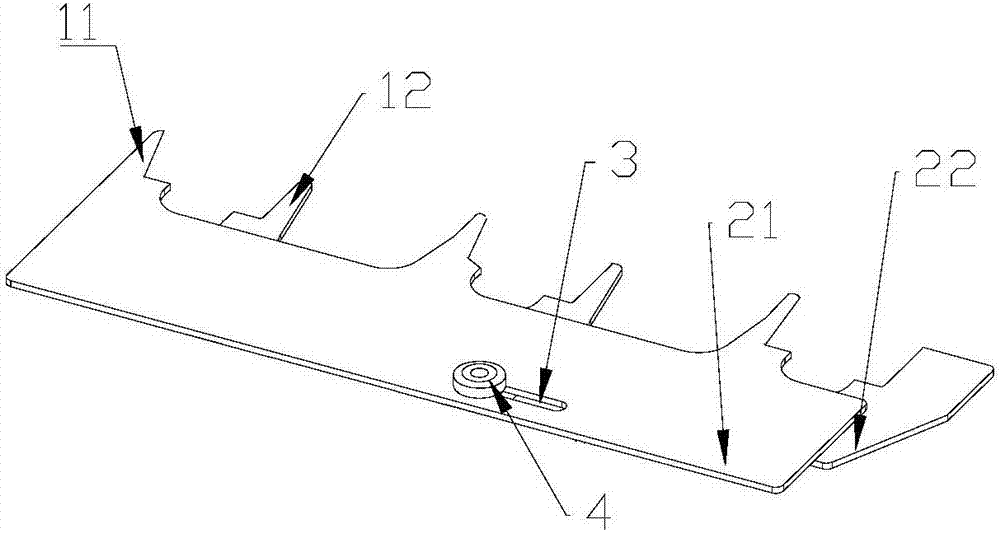

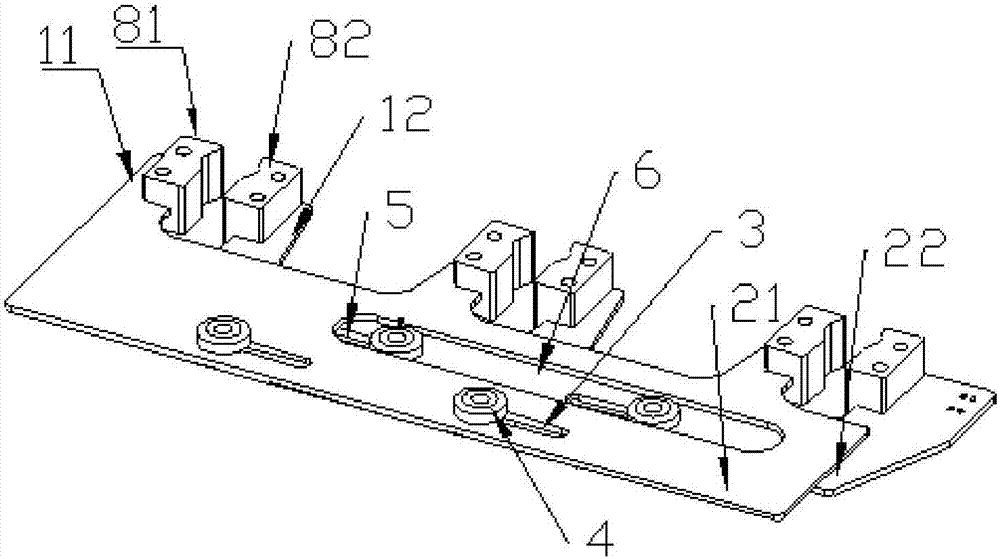

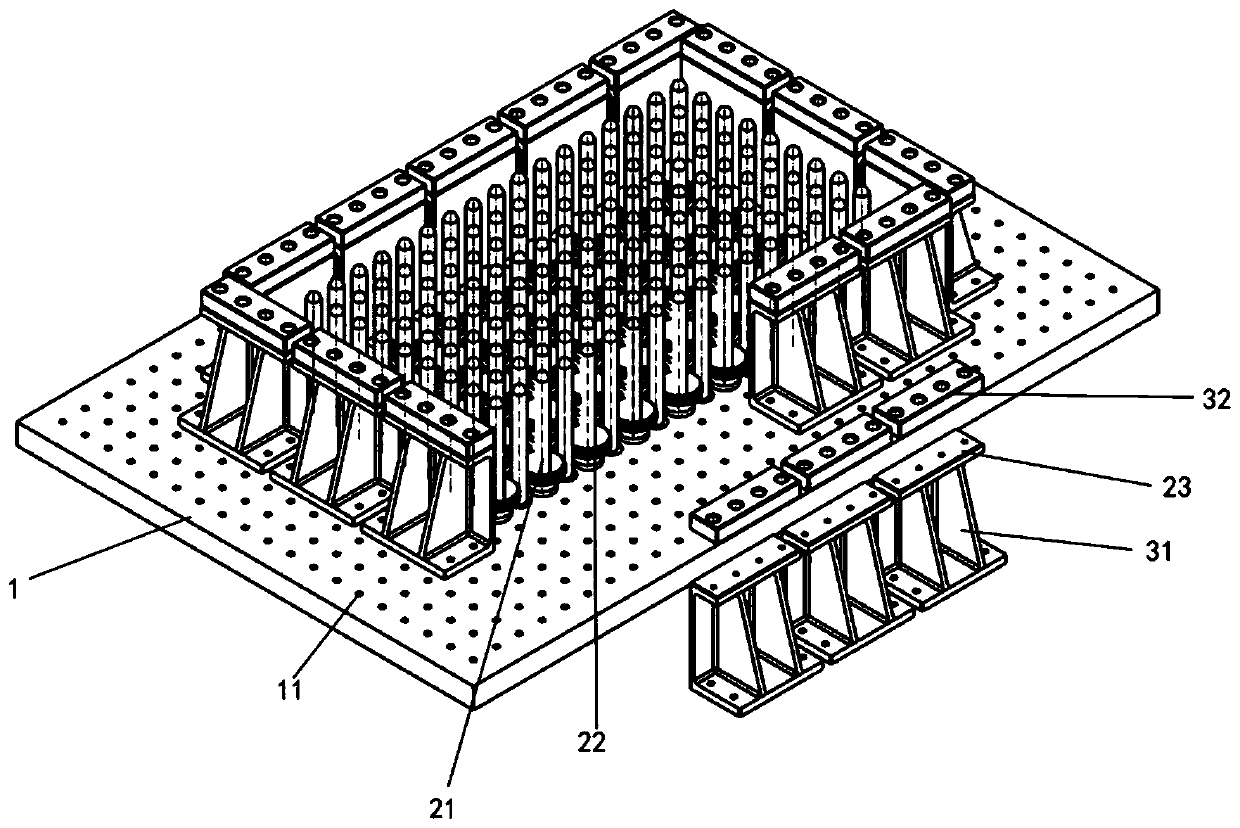

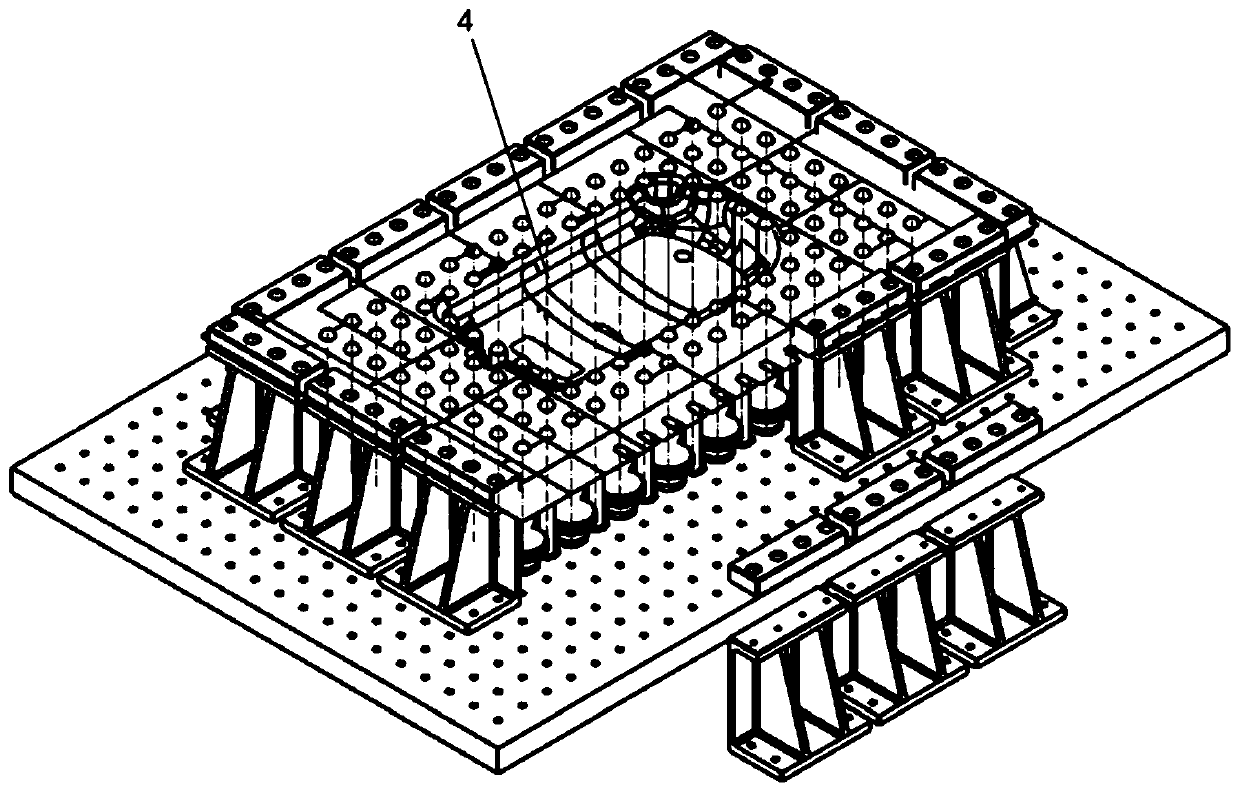

Flexible clamping device for single-point incremental forming of sheet metal and forming method

InactiveCN110722066ASolve poor design interchangeabilitySolve the clampingMetal-working feeding devicesPositioning devicesMechanical engineeringPhysics

The invention relates to a flexible clamping device for single-point incremental forming of sheet metal and a forming method. The flexible clamping device comprises a bottom plate, a plurality of clamping modules and a plurality of adjustable supporting modules, wherein the clamping modules and the adjustable supporting modules are detachably connected with the bottom plate. Mounting holes which are arranged in a matrix are formed in the bottom plate. The plurality of adjustable supporting modules are fixed on the upper surface of the bottom plate through the mounting holes and can be adjustedin height. The plurality of clamping modules are fixed on the upper surface of the bottom plate through the mounting holes and distributed at the peripheries of the adjustable supporting modules forclamping the sheet metal. Compared with the prior art, the flexible clamping device can be used for rapidly and accurately clamping the sheet metal and can be randomly combined according to the characteristics of a formed sheet metal part to generate a supporting structure for incremental forming; and the flexible clamping device has the functions of flexible clamping and flexible back mold.

Owner:SHANGHAI JIAO TONG UNIV +1

Clamping device

The invention discloses a clamping device which comprises an installation rack, a pressing mechanism, a driving rolling wheel and a conveying plate. The installation rack comprises an installation plate, a support vertical plate and a support transverse plate; the pressing mechanism comprises a handle, a lifting block, a pull rod, a spring, an installation block, a fixed plate and driven rolling wheels, and the driving rolling wheel is connected to a shaft on the right portion of the installation plate through a bearing. According to the clamping device, the structure is simple, operation is convenient, and the problems that for an existing zipper clamping device, operation and maintenance are not convenient, and the clamping effect is poor are solved.

Owner:CMZ ZIPPER ANHUI

Turning technology of thin-walled sealing piece for rail transit

The invention discloses a turning technology of a thin-walled sealing piece for rail transit. The thin-walled sealing piece for rail transit is formed in the mode that after a plurality of floating type jack catches are adopted on a numerical control lathe for one-time clamping, rough turning and finish turning are performed. In the rough turning process, an R0.4 circular bead blade is adopted, the back engagement of the cutting edge is 0.1-0.12 mm, the feeding amount is 0.04-0.05 mm / r, and 0.08-0.1 mm fine turning allowance is reserved on the outer circle and an inner hole; in the finish turning process, an R0.2 circular bead blade is selected, the back engagement of the cutting edge is 0.02-0.04 mm, and the feeding amount is 0.02-0.04 mm / r. Due to the mode, the problems that clamping of parts deflects and clamping deforms can be solved, and product precision and quality are improved.

Owner:CHANGSHU CHANGZHOU BEARING

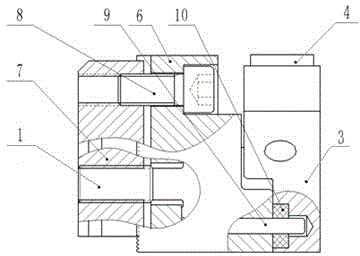

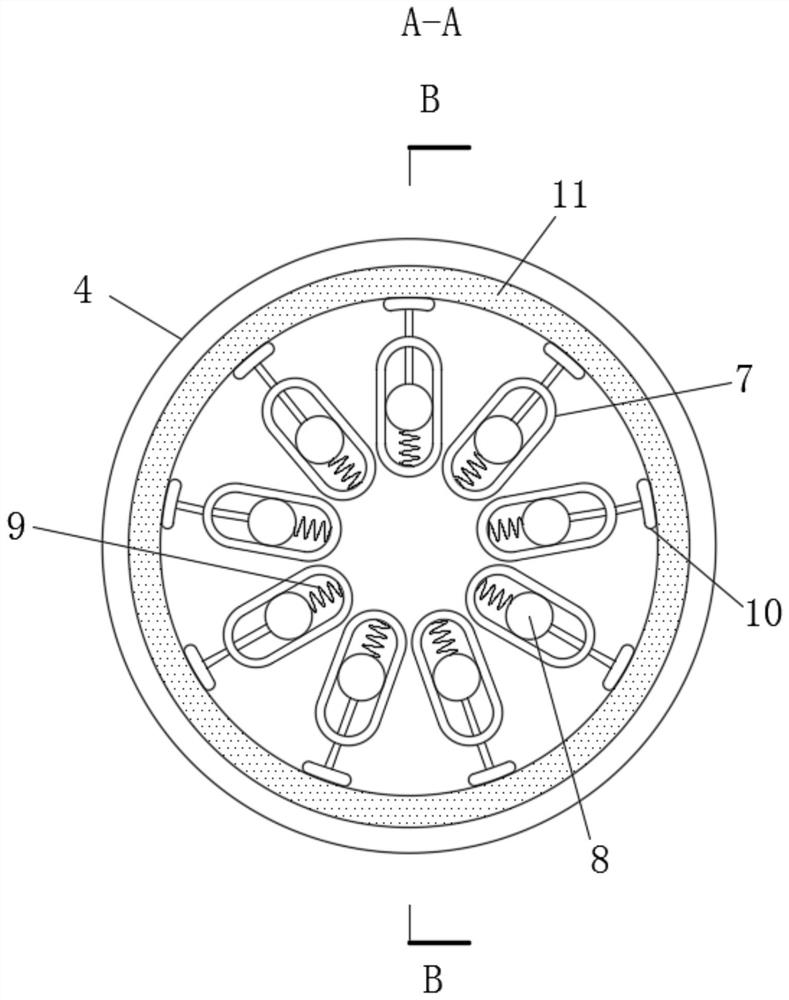

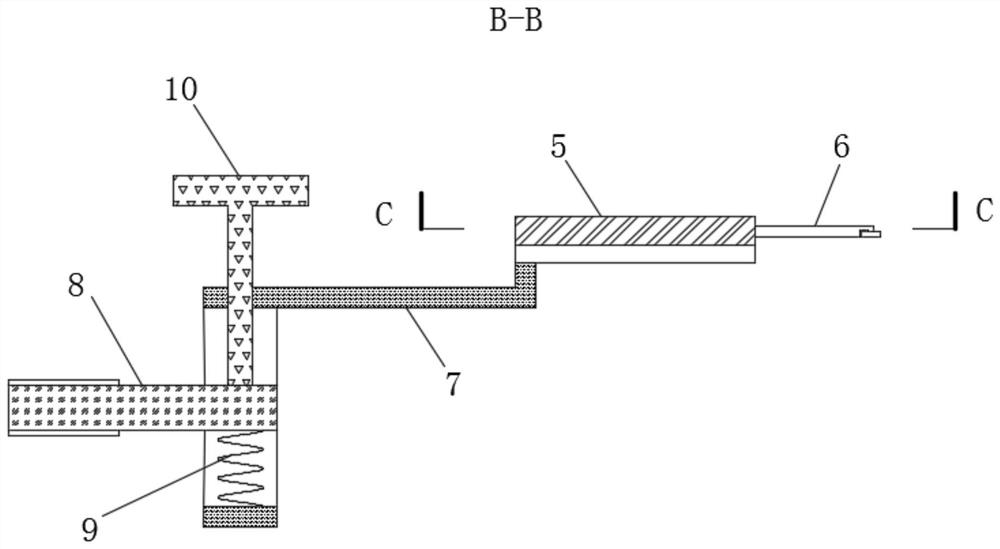

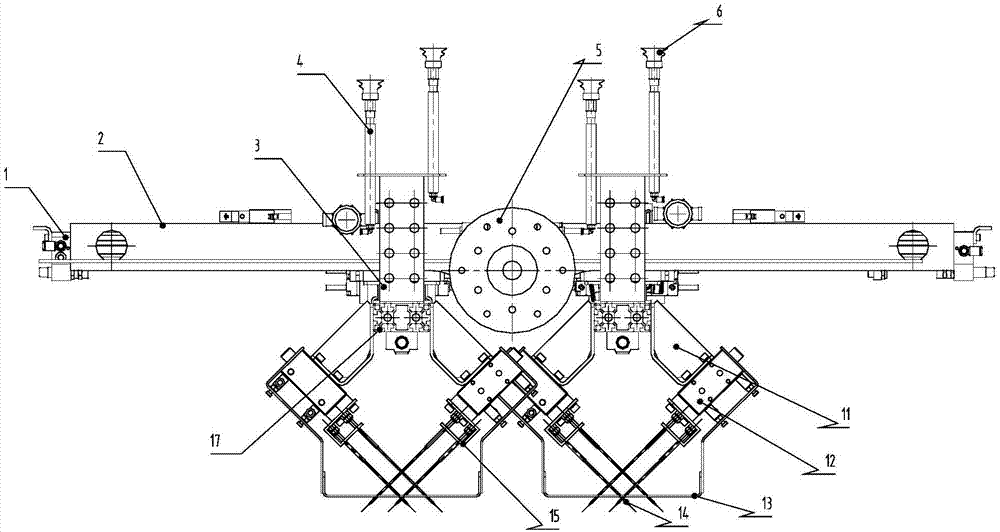

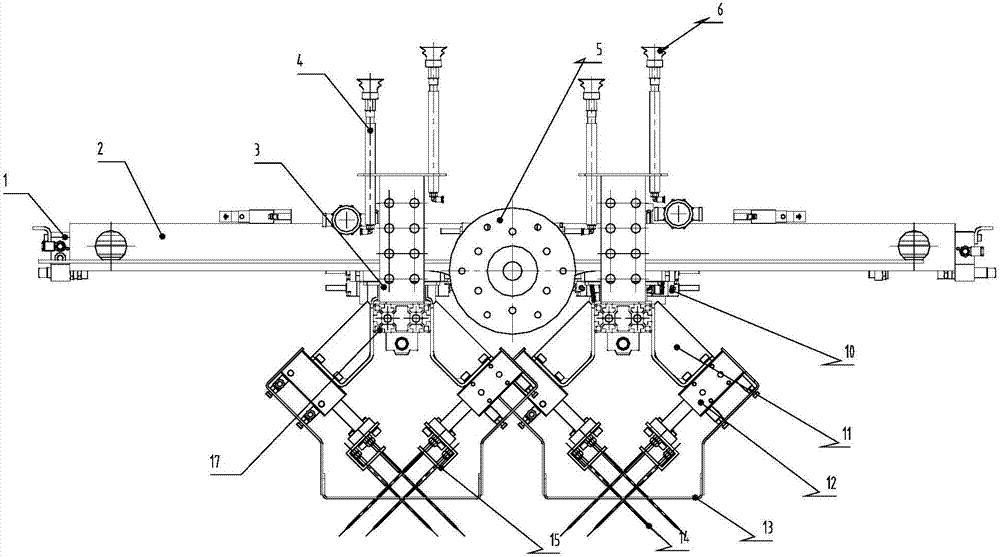

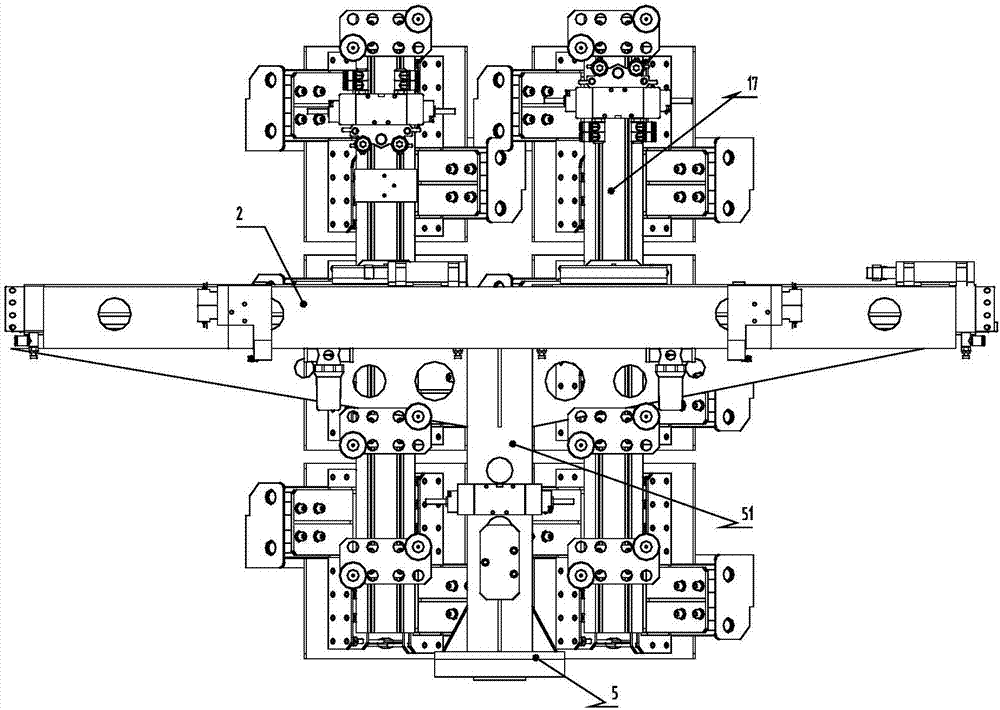

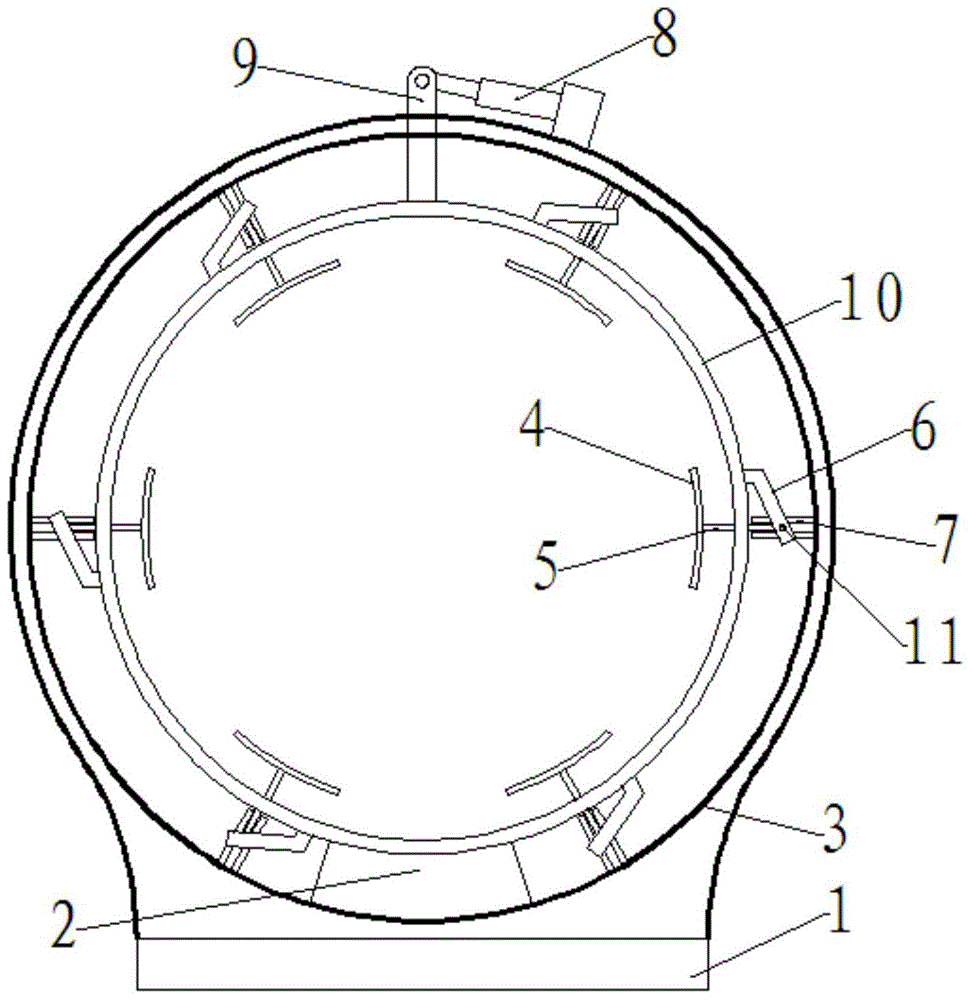

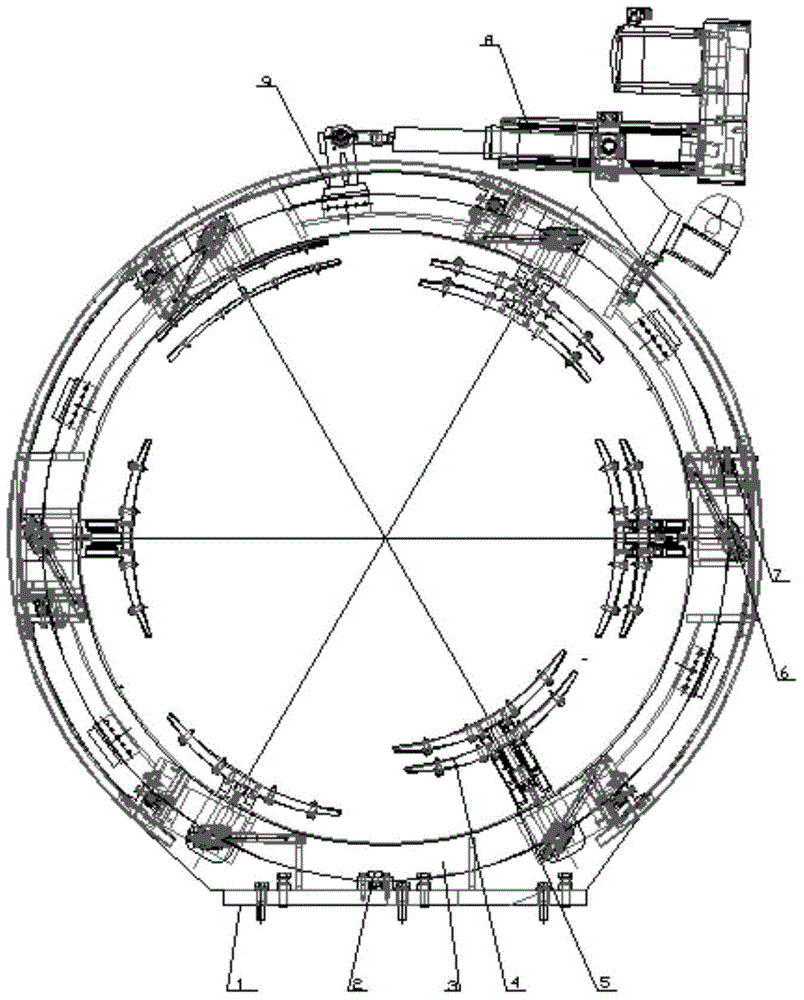

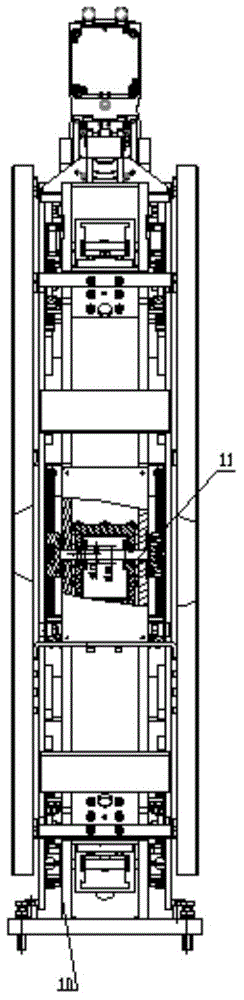

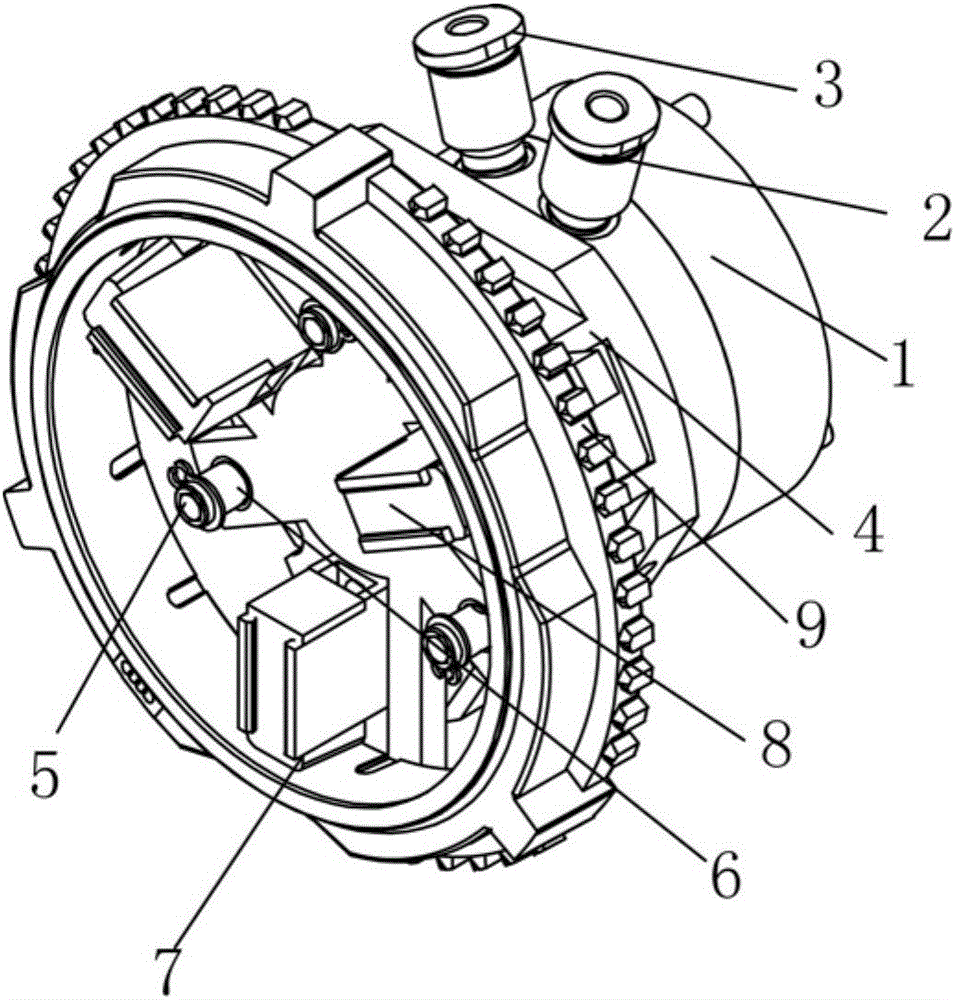

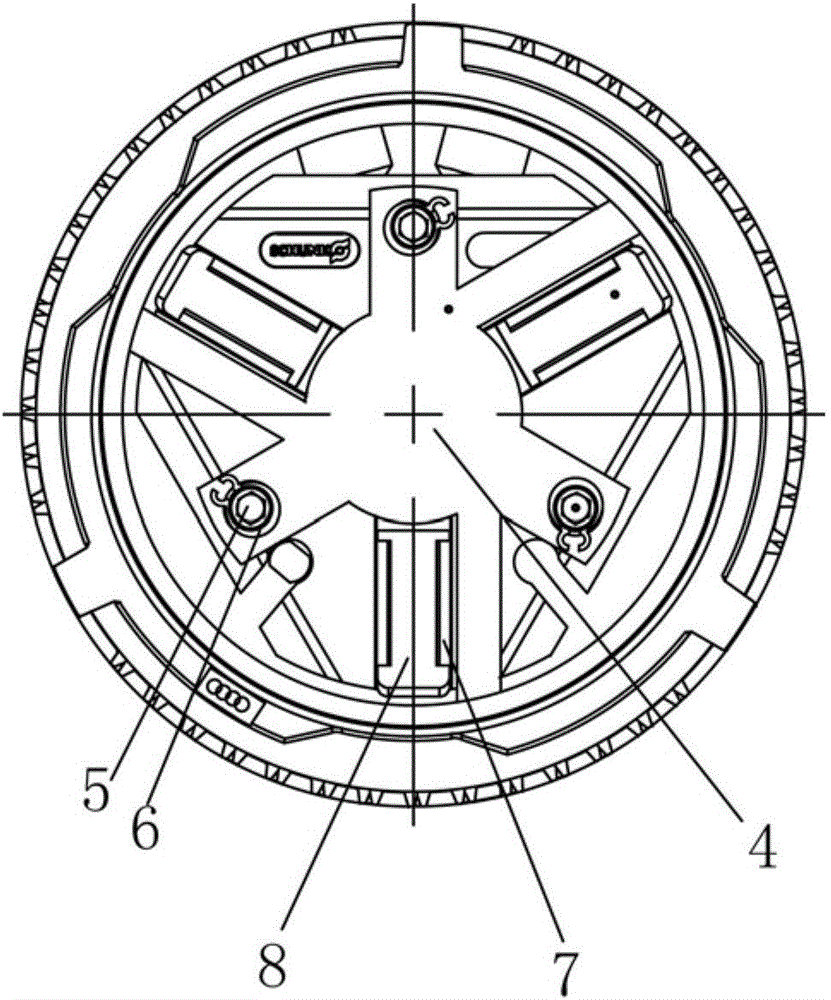

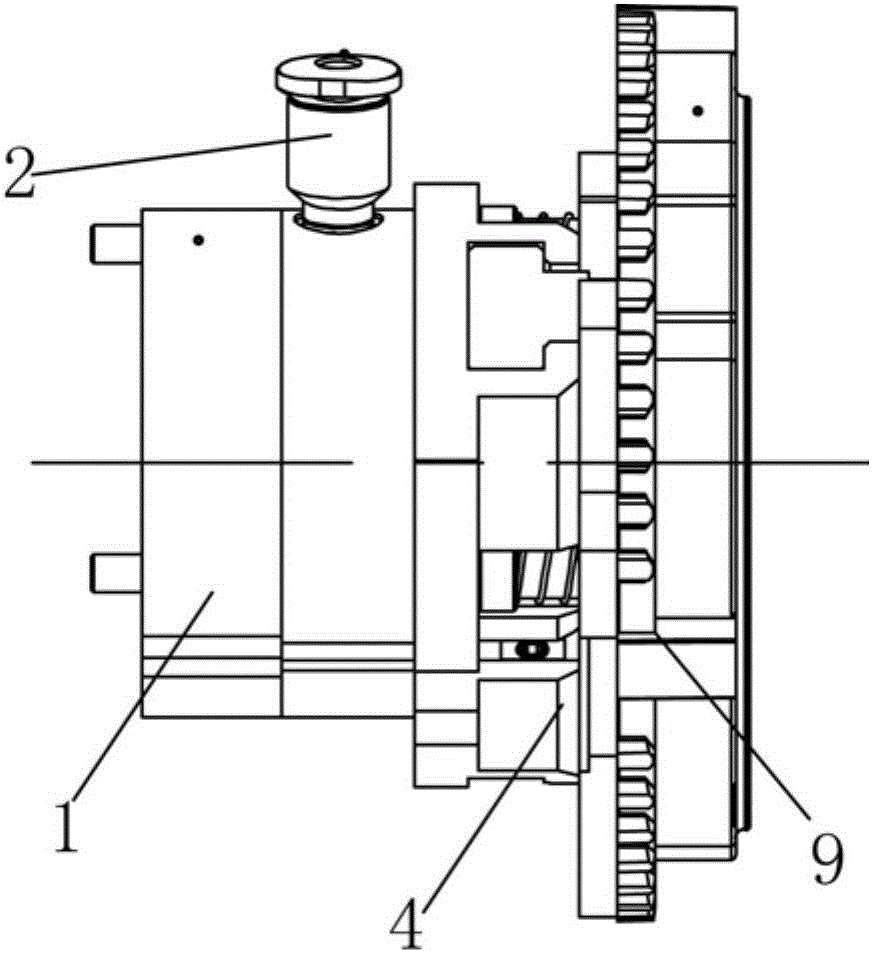

Tread transfer ring of tire building machine

The invention discloses a tread transfer ring of a tire building machine. The tread transfer ring comprises a base, a fixed disc and multiple clamping jaws, wherein a driving disc is connected into the fixed disc through a bearing, and is connected with an extension structure mounted outside the fixed disc through a bracket; the clamping jaws are mounted on the inner ring of the driving disc, and fit the disc wall of the driving disc through a clamping jaw bracket; the clamping jaw bracket penetrates through the disc wall of the driving disc, and is connected with a slide rail 1 mounted on the fixed disc through a shaft; and the shaft is connected with the driving disc through a slide rail 2. The tread transfer ring overcomes the defects in the prior art, and is reasonable in design structure; the driving disc capable of rotating is arranged in the fixed disc, and is driven to rotate through the extension structure; and when the driving disc rotates, the slide rail 2 is driven to move so as to drive the clamping jaw bracket and the clamping jaws to perform a radial motion along the slide rail 1. The extension and the shrinkage of a cylinder are controlled through a servo motor.

Owner:HANGZHOU CHAOYANG RUBBER

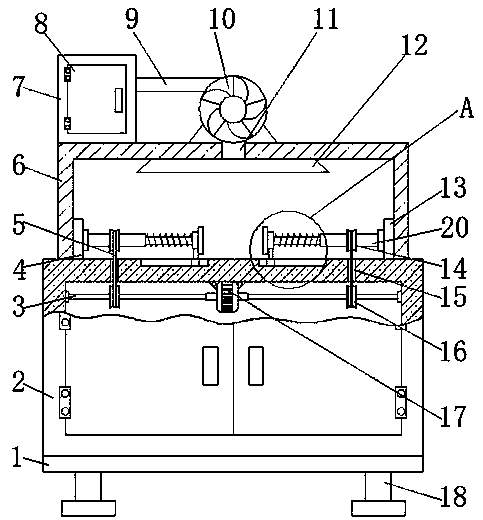

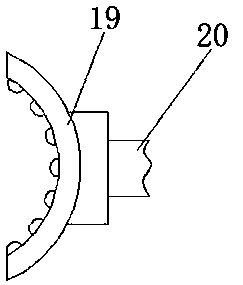

Clamping device for bearing machining

InactiveCN109128928ASolve the clampingSolve the problem of not having dust removalPositioning apparatusMaintainance and safety accessoriesEngineeringThreaded rod

The invention discloses a clamping device for bearing machining. The clamping device comprises a base, and the four corners of the bottom of the base are fixedly connected with supporting legs. The tops of the supporting legs are fixedly connected with a machining table, and the top of the machining table is fixedly connected with a connecting frame. The top of the connecting frame is fixedly connected with a dust removal mechanism. The top of the machining table is fixedly connected with a clamping mechanism, and the clamping mechanism comprises a double-shaft motor. The output end of the double-shaft motor is fixedly connected with a rotary rod. According to the clamping device, the base, the machining table, the rotary rod, the clamping mechanism, a belt body, a connecting frame, a duststorage box, a dust removal mechanism, a dust conveying pipe, a dust collector, a dust collecting pipe, a dust collecting plate, a fixed plate, a second belt disc, a through opening, a first belt disc, the double-shaft motor, the supporting legs, a clamping plate, a threaded sleeve, a fixed block, a sliding groove, a sliding block and a thread rod are arranged to be used in cooperation, the problem that an existing clamping device for bearing machining is poor in clamping effect and has no dust removal function.

Owner:LEIYANG XINDAWEI TECH

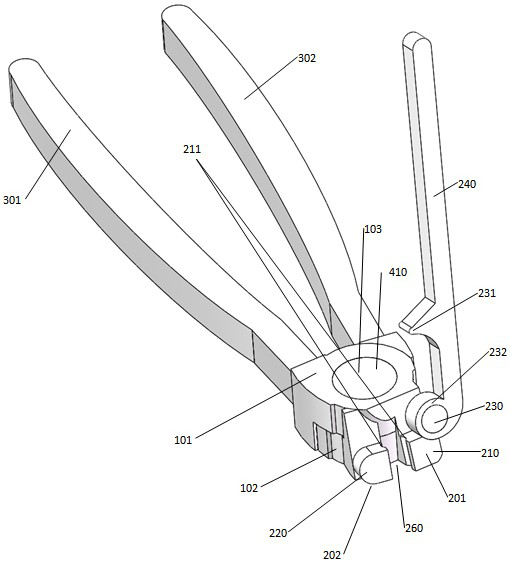

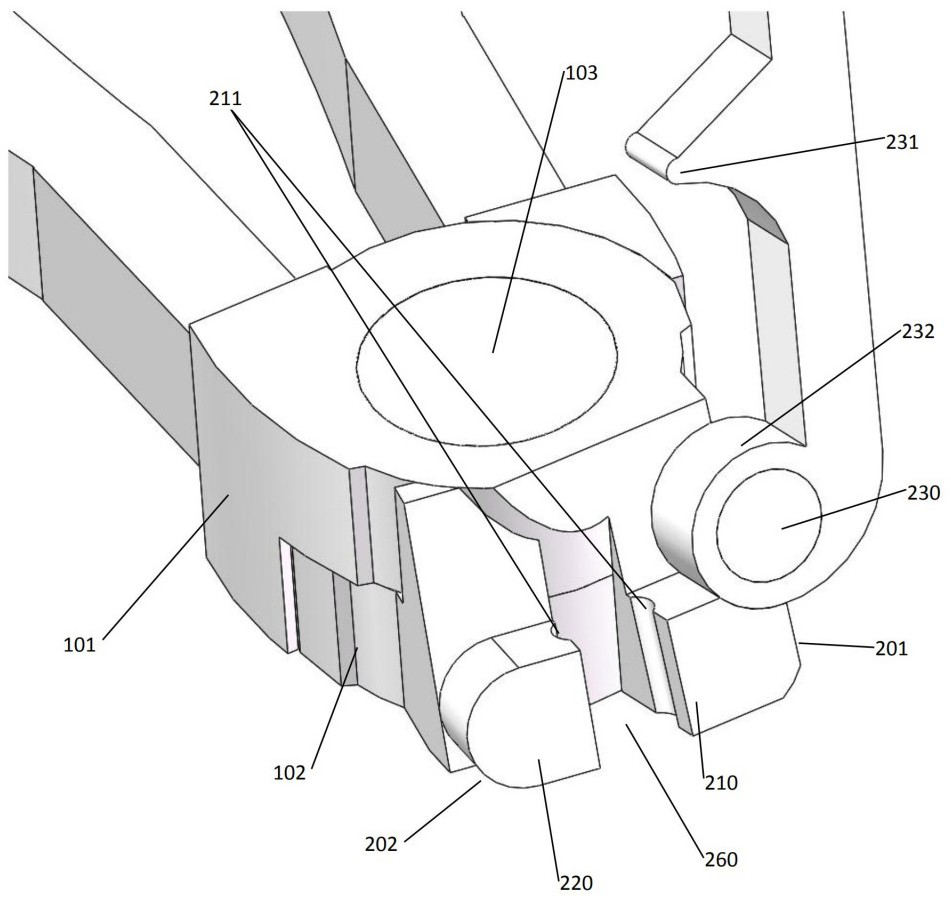

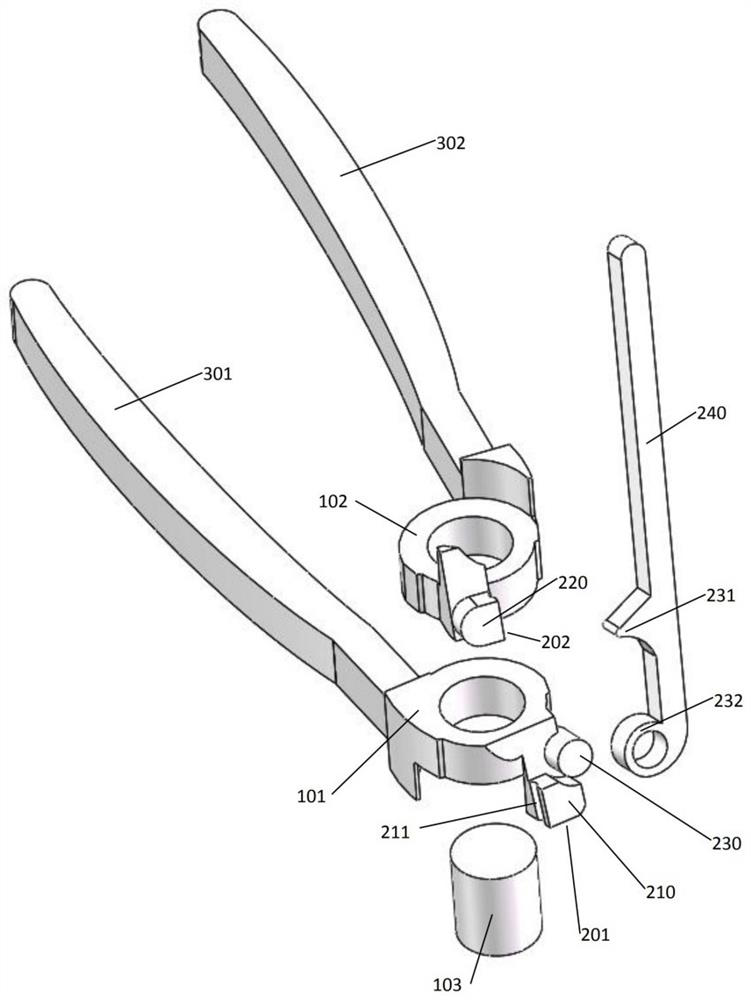

Kirschner wire operating forceps

PendingCN112869860ASolve the clampingSolve the bending problemOsteosynthesis devicesTransverse grooveOrthopedic department

The invention relates to a pair of kirschner wire operating forceps, which comprise two cheek rotating parts which rotate relatively, each cheek rotating part extends to one end to form a forceps head, and the two forceps heads form an opening and closing forceps mouth; and each cheek rotating part extends towards the other end to form a handle. The forceps are characterized in that the forceps head can be two clamping heads which are provided with transverse groove clamping surfaces which are matched with each other. The forceps is simple in structure and solves the problems of clamping, bending and cutting of orthopedic kirschner wires.

Owner:ZHENGZHOU ZEZHENG TECHN SERVICES

Automatic sealing and feeding mechanism of hosiery knitter and hosiery knitter

PendingCN114351363AReduce the impactSolve the problem of interfering with the sealing effectWork-feeding meansKnittingEngineeringOperation safety

The embodiment of the invention discloses an automatic sealing and feeding mechanism of a hosiery knitter and the hosiery knitter. The automatic sealing and feeding mechanism of the hosiery knitter comprises a guide cylinder, a rotating mechanism, a pressure regulating mechanism, a transmission mechanism, a control panel, a pressure regulating mechanism and a guide rail mechanism. By means of the guide cylinder, the pressure adjusting mechanism and the transmission mechanism, the sock legs can be conveniently fed, the sock legs do not need to be manually folded and moved, only the sock legs need to be horizontally placed on the conveying belt, contact between people and equipment is reduced, the operation safety of people is guaranteed, the use efficiency is improved, and the safety effect is improved; according to the sock leg sealing device, the influence of fuzzy balls on sock leg sealing is reduced, the sealing effect is improved, the use range of the mechanism is widened, the clamping mechanism can automatically adjust the distance, and different sock legs can be clamped.

Owner:上海东北亚新纺织科技有限公司

Screw delivery rack for electric drill

ActiveCN110549287ASolve the problem of spring pressure in separate warehouses and orderly deliverySolve the clampingPortable power-driven toolsPower driven toolsElectric driveCard holder

The invention discloses a screw delivery rack for an electric drill; the screw delivery rack comprises a screw pushing mechanism, a screw discharging mechanism and a screw turning mechanism, wherein the screw pushing mechanism comprises a rack plate, a through pipe and a pushing bolt, the rack plate is levelly arranged at the upper bottom end of the electric drill and fixed with the electric drillmachine body, the through pipe at the front end of the rack plate and the pushing bolt at the rear end of the rack plate are linearly arranged, a middle card holder moves and places a screw box of the screw discharging mechanism, each bin clamping bottom cavity, front and rear through holes in the box are respectively located and aligned with the through pipe and the pushing bolt; respectively, the rear end of the bolt of the screw turning mechanism is elastically moved and clamped in a bolt seat on one side of the rack plate, and a concave cone clamp of the folding plate at the top of a rotating rod is placed in front of a through pipe bundle opening, or the concave cone clamp of the front moving folding plate of the rotating rod rotates to the front of an electric drill driver rod. Thescrew delivery rack has a simple structure, low cost, and does not require electric drive to drive the screw; the current situation that the screw machine in the prior art is cumbersome to carry, complicated to operate, and has a small application range is changed; and the product has competitiveness and wide market prospect.

Owner:孙艳

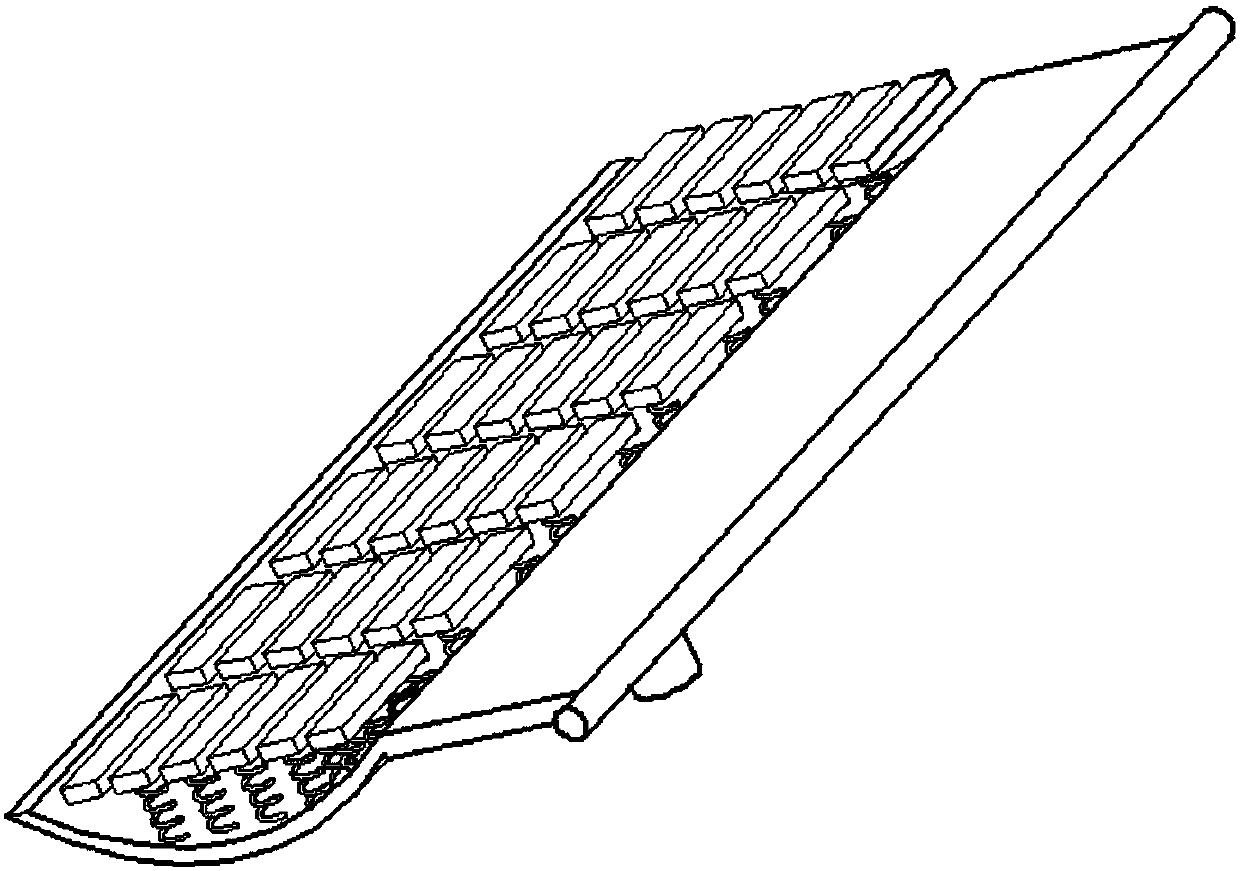

Leather fragmentation clamp pair

PendingCN108977591ASolve the clampingSolve the problem of drag and dropLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringMechanical engineering

The invention discloses a leather fragmentation clamp pair. The leather fragmentation clamp pair comprises a leather fixed clamp and a leather dragging clamp, wherein the leather fixed clamp comprisesa horizontal sheet pressing plate and a fixed plate; the sheet pressing plate is arranged just above the fixed plate and the action of clamping leather is realized under the driving of a sheet pressing driving mechanism. The sheet pressing plate and the fixed plate are provided with a plurality of tooth openings which are matched up and down. The leather dragging clamp comprises an upper clampingplate mechanism and a lower clamping plate mechanism. The upper clamping plate mechanism and the lower clamping plate mechanism are mounted on a translation dragging beam, which is horizontally arranged, through respective clamping plate driving mechanisms respectively, so that the upper clamping plate mechanism and the lower clamping plate mechanism can do up-down relative movement to realize leather clamping actions. The upper clamping plate mechanism and the lower clamping plate mechanism are provided with tooth bulges which are matched up and down. The tooth bulges are matched with the tooth openings, so that the tooth bulges can be inserted into the tooth openings. According to the leather fragmentation clamp pair, a design of the tooth openings and the tooth bulges between the leather fixed clamp and the leather dragging clamp is adopted, so that continuous work of unreeling and cutting off leather is realized.

Owner:江苏天辰智能装备有限公司

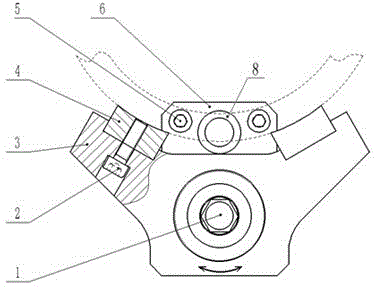

Grabbing technology and structure of feeding and discharging clamping claw special for automobile synchronization regulator

The invention discloses a grabbing technology and structure of a feeding and discharging clamping claw special for an automobile synchronization regulator. The grabbing structure of the feeding and discharging clamping claw special for the automobile synchronization regulator comprises a three-claw air cylinder, a clamping gas circuit connector, a loose gas circuit connector, a discharging push plate, push plate guideposts, reset springs, rubber soft claws and claw installing bases. The grabbing technology of the feeding and discharging clamping claw special for the automobile synchronization regulator is characterized in that the grabbing technology of the clamping claw aims at the automobile synchronization regulator, clamping and loosening of the clamping claw are controlled through the three-claw air cylinder, the inner surface of the automobile synchronization regulator is effectively protected against being scratched, and meanwhile, the friction coefficient is increased to improve clamping reliability; embedding structures are adopted between the rubber soft claws and the claw installing bases, and when rubber is worn, the rubber can be replaced quickly; meanwhile, the discharging push plate, the push plate guide plates and the reset springs are adopted to achieve quick discharge; and the defects of the prior art are overcome.

Owner:无锡市盛宝嘉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com