Patents

Literature

40results about How to "Solve the bending problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

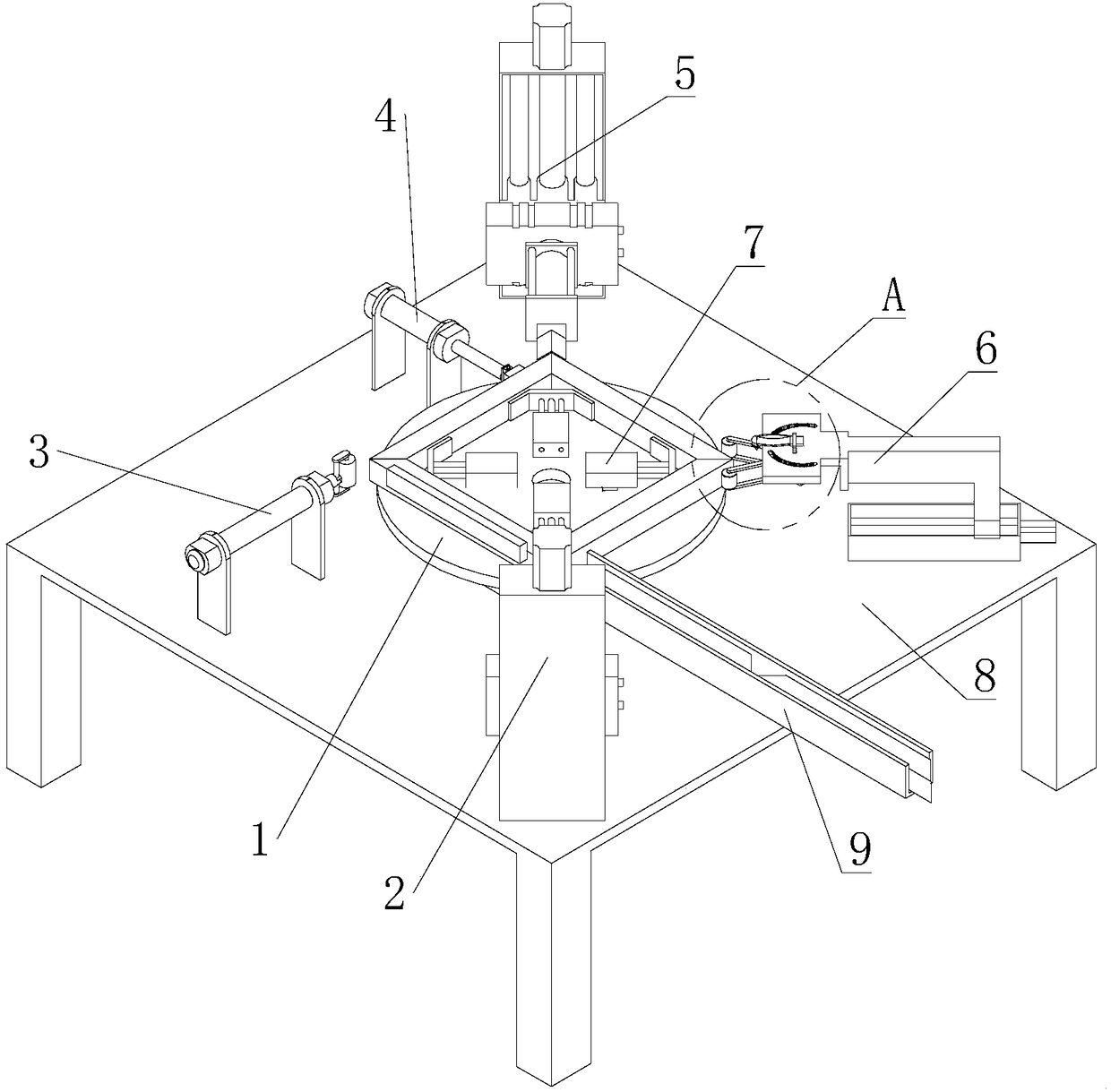

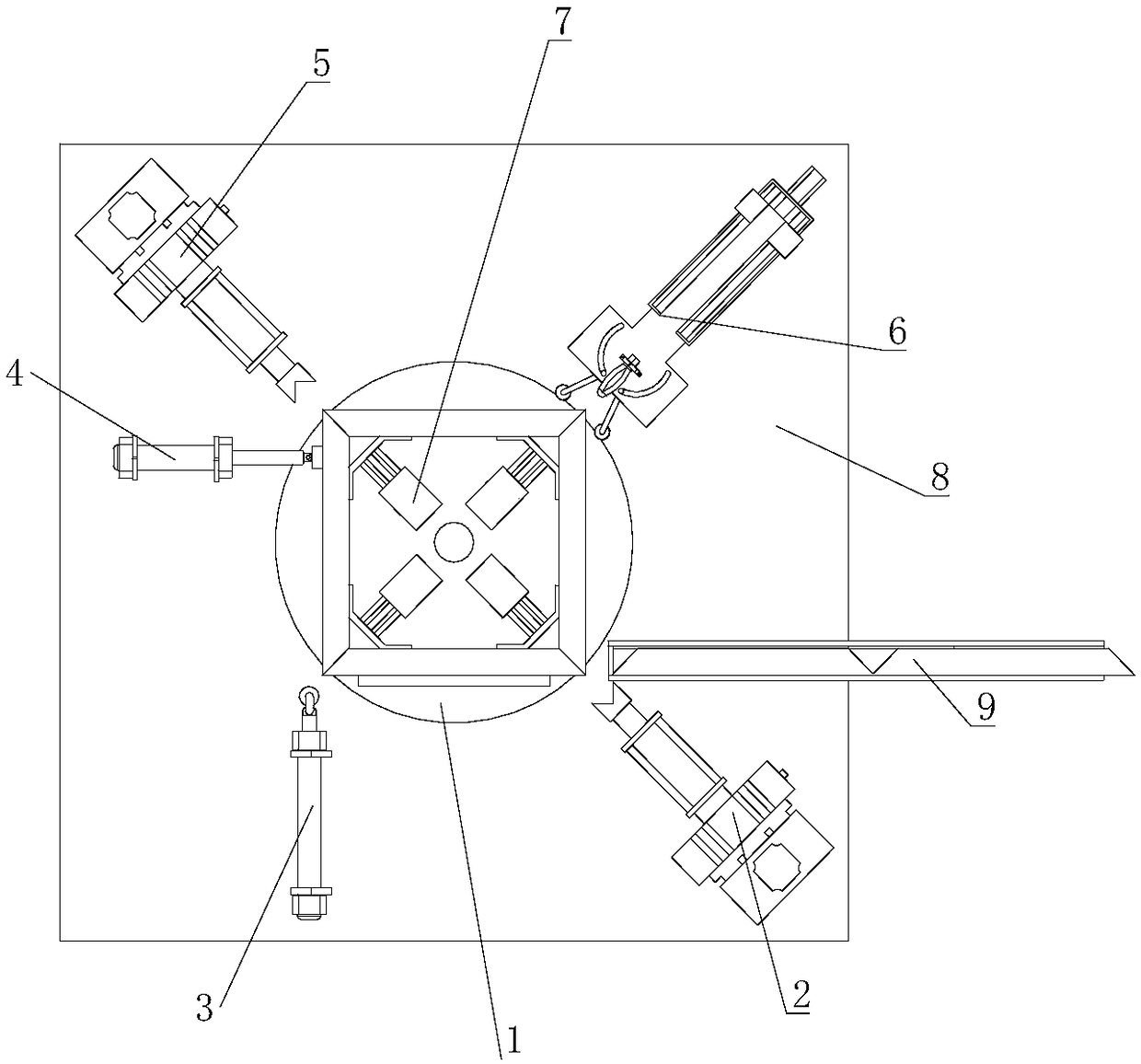

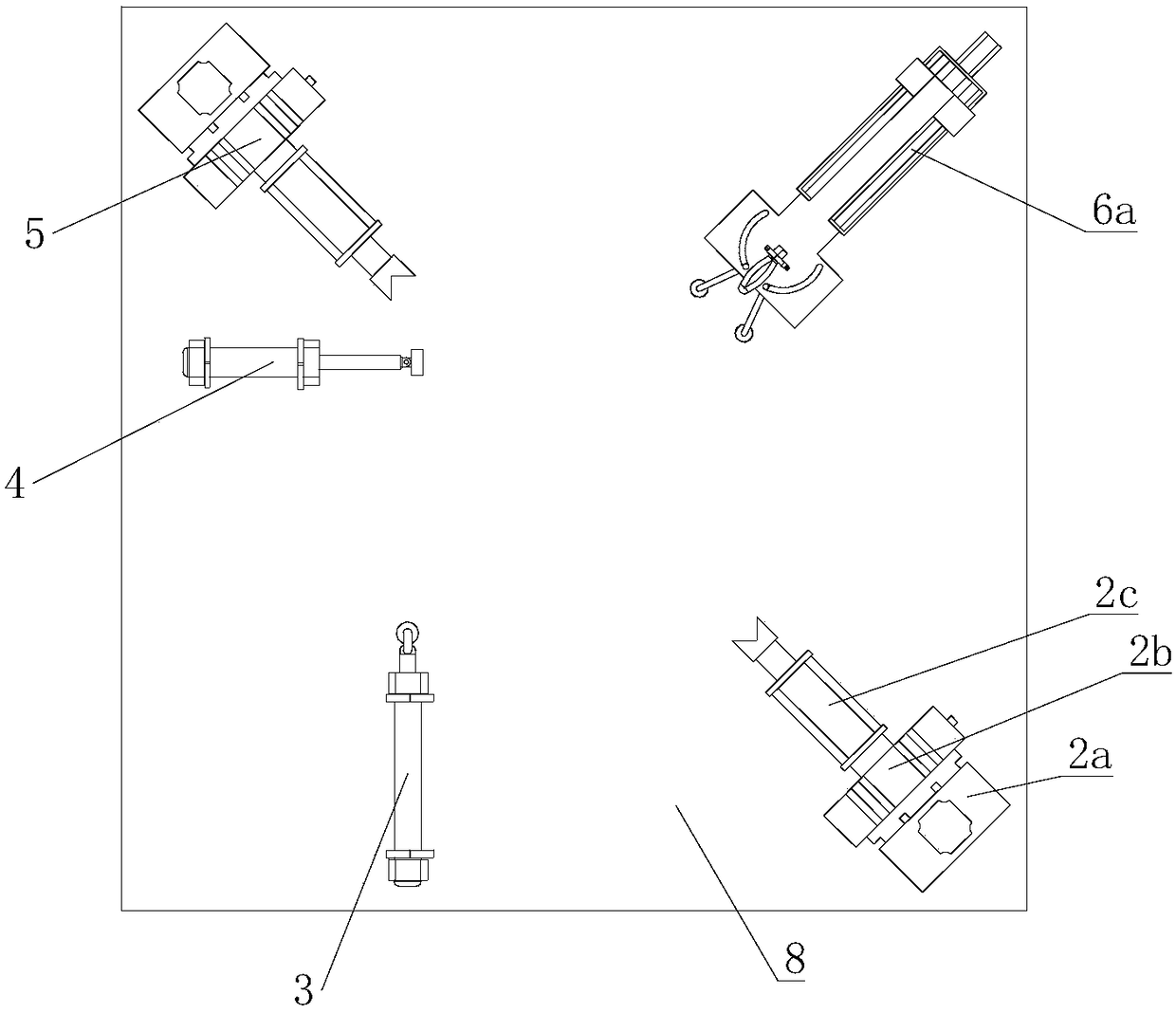

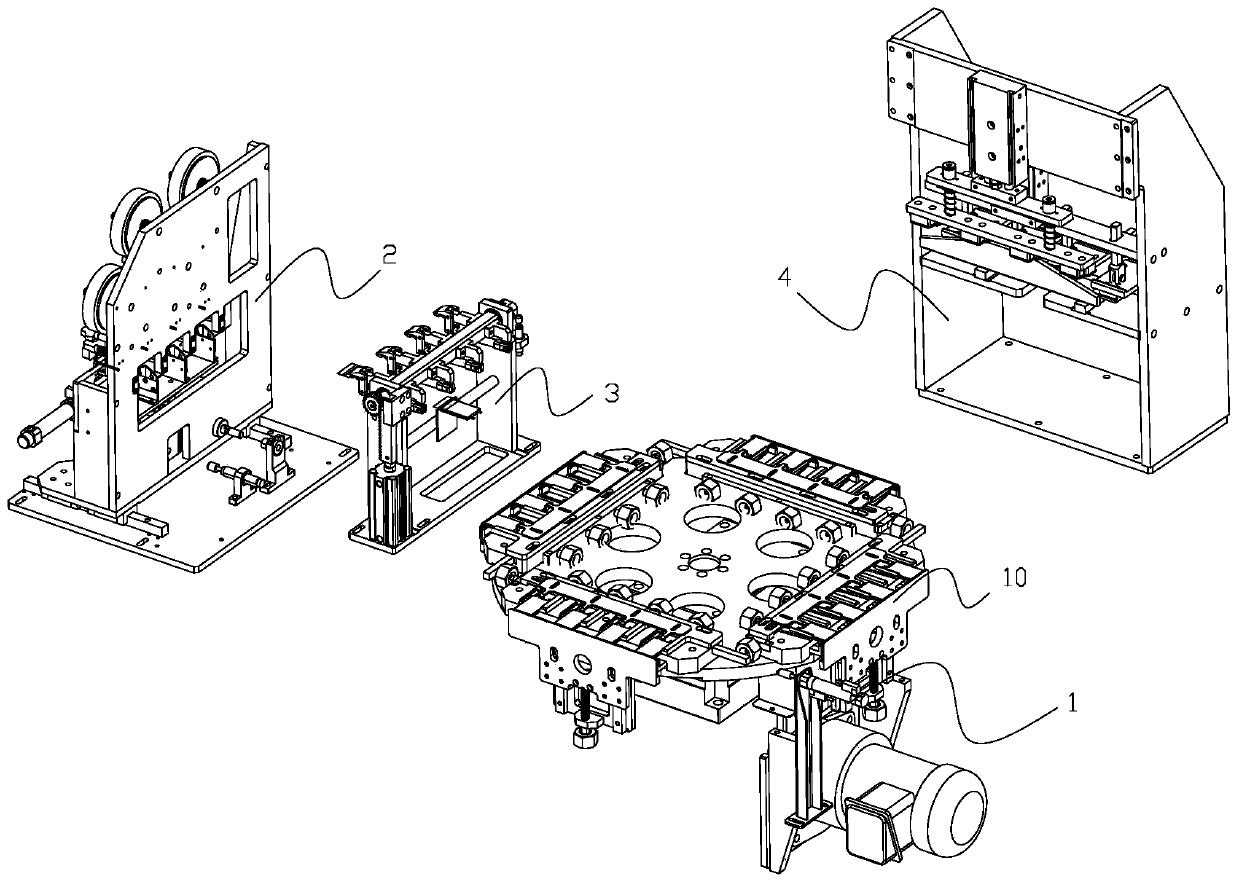

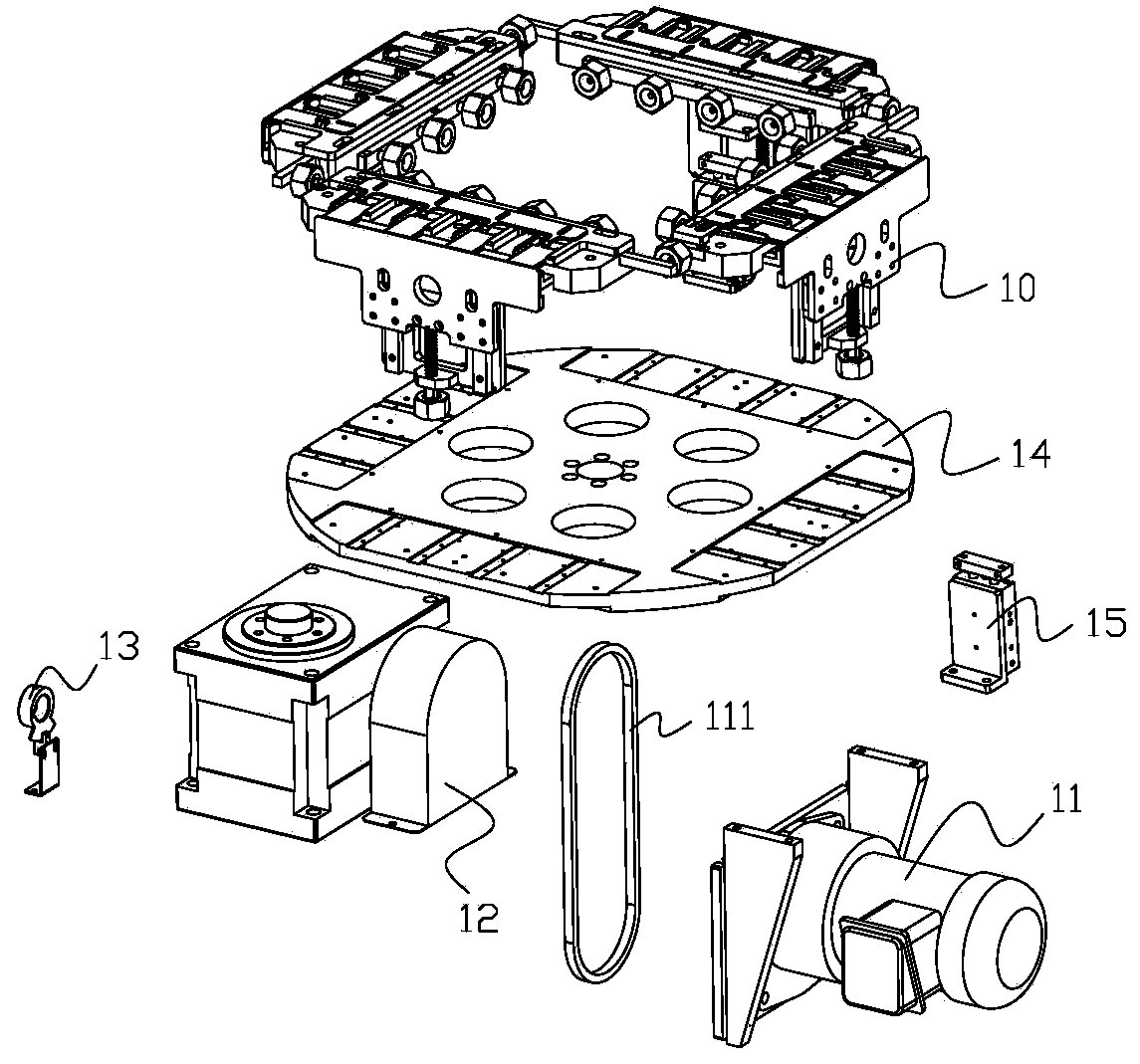

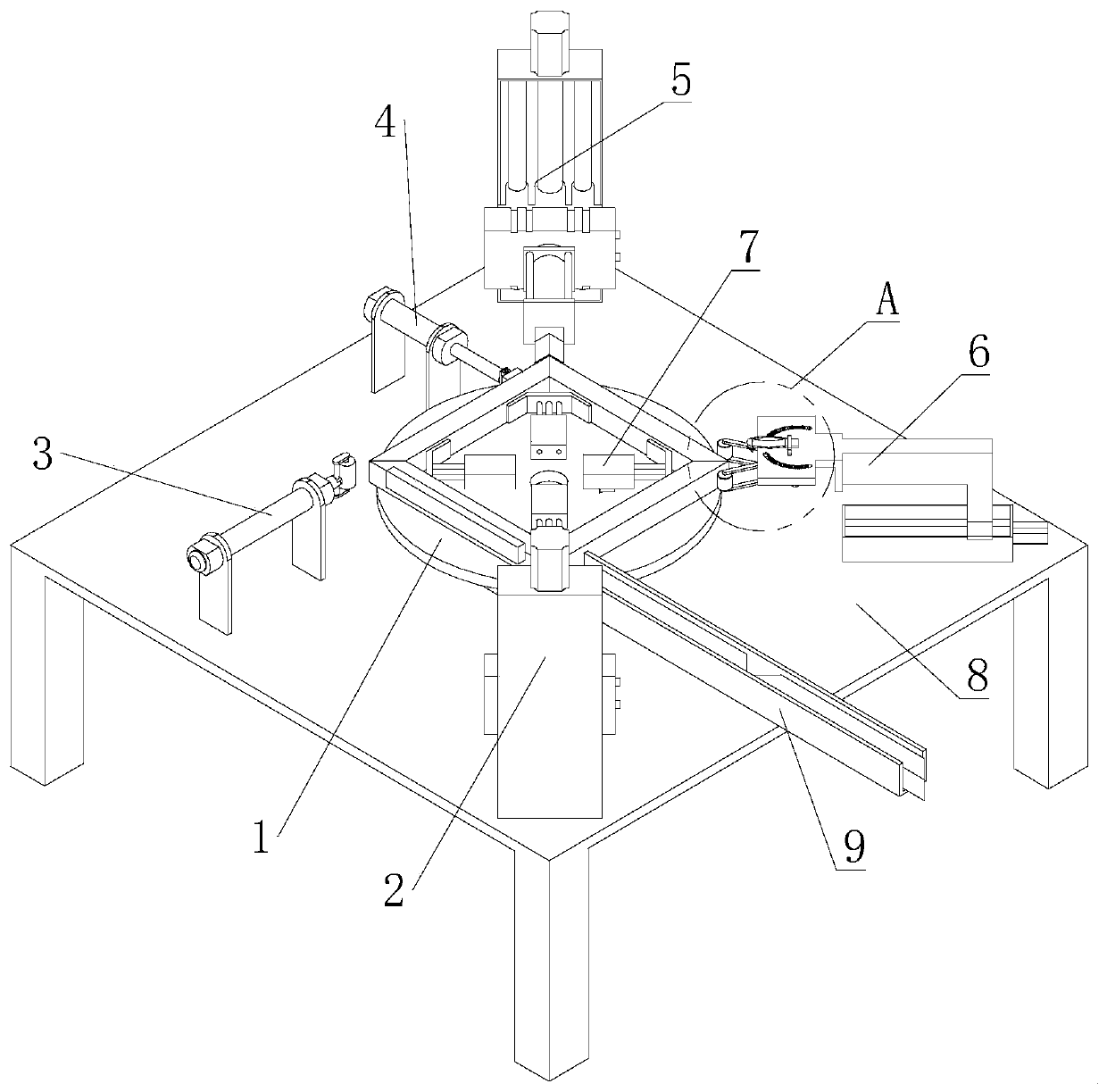

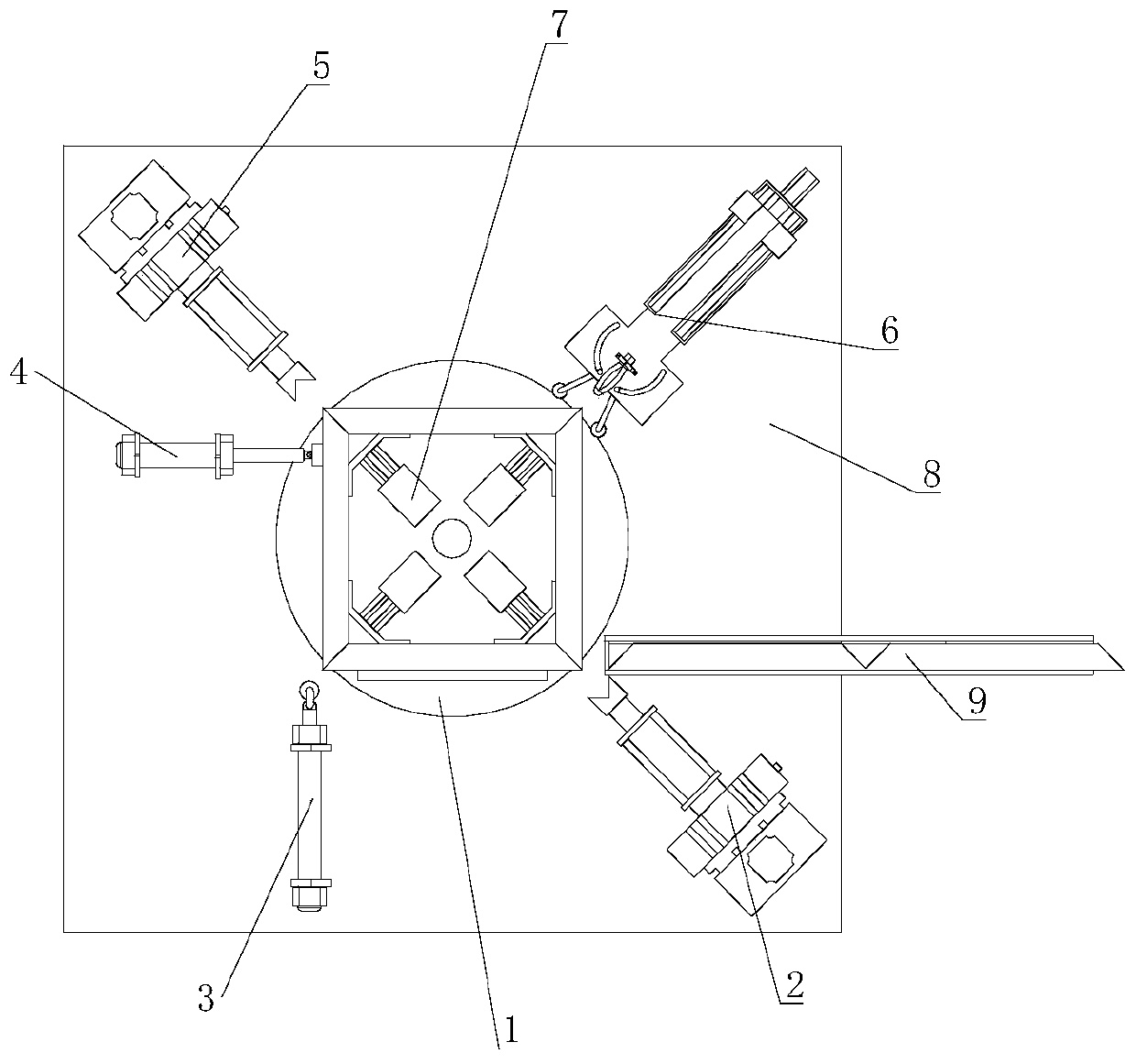

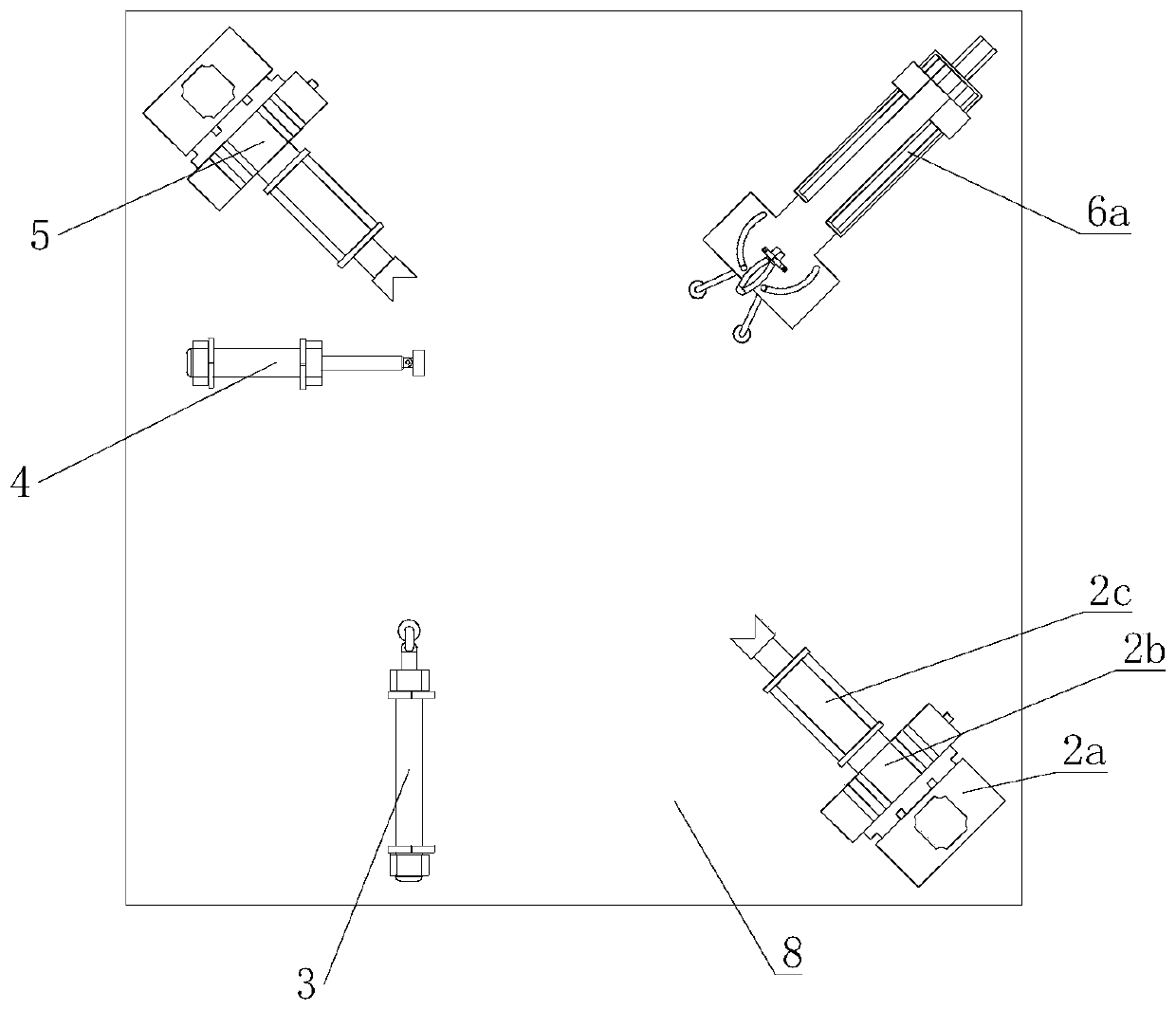

Automatic bending and welding equipment for door and window pipe materials

ActiveCN108581498AWill not deformWeld firmlyOther manufacturing equipments/toolsCircular discEngineering

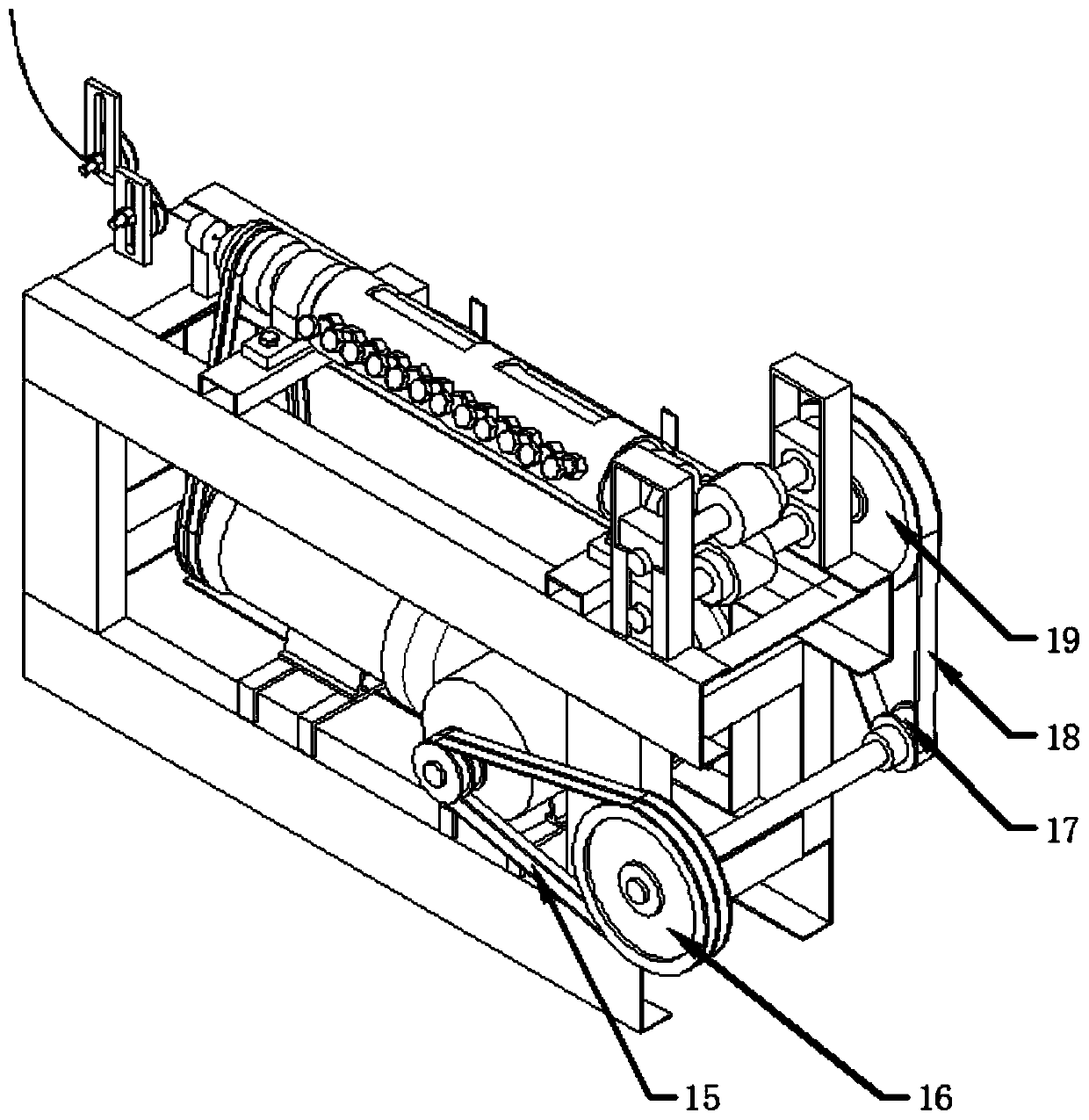

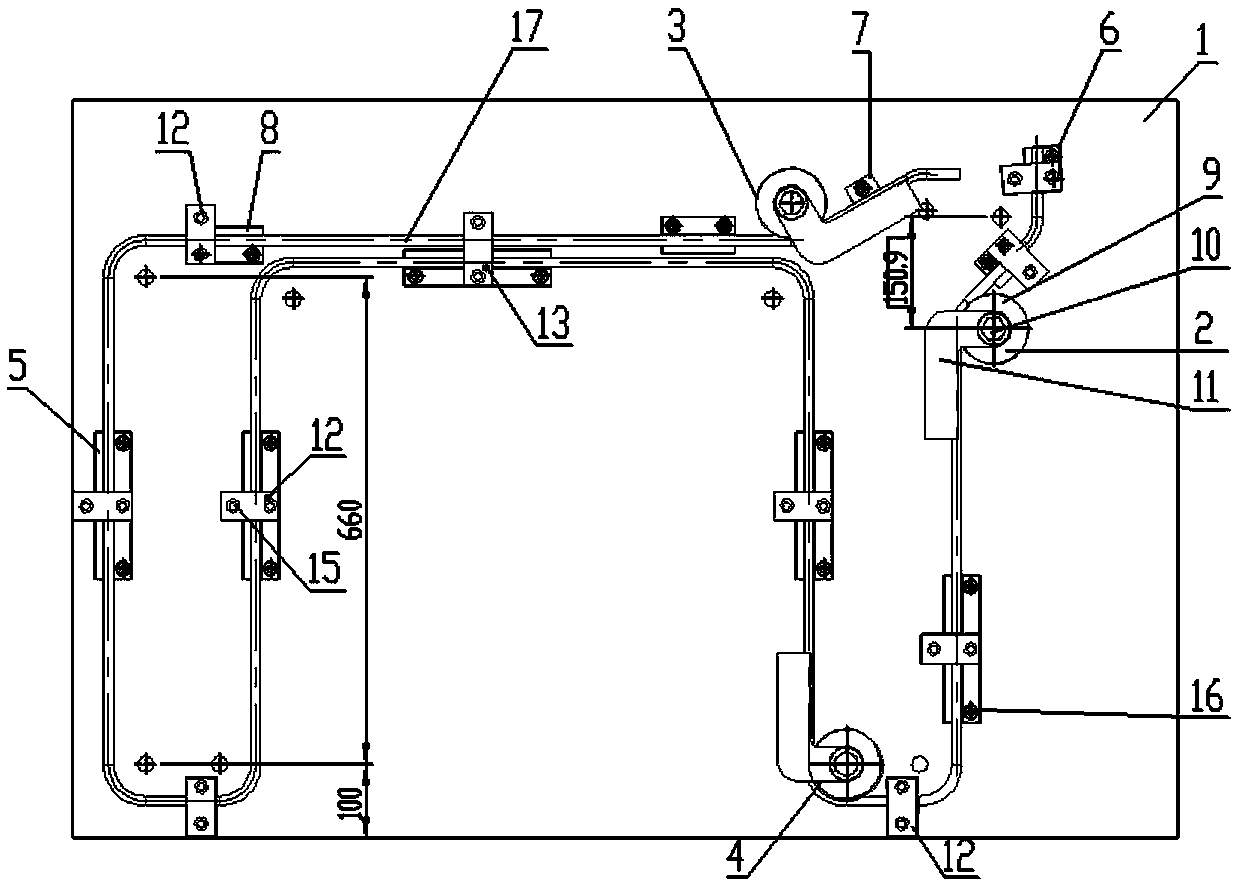

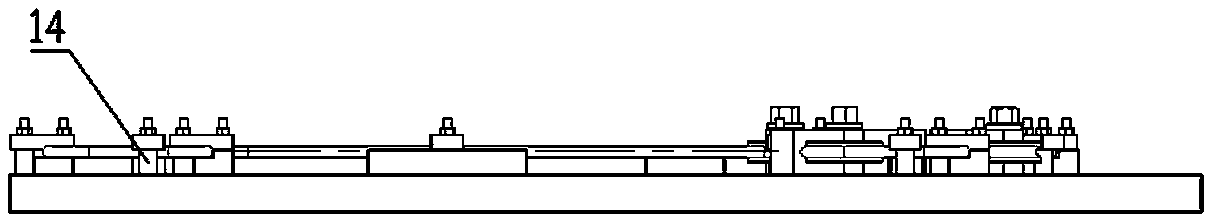

The invention relates to the field of automatic machining, in particular to automatic bending and welding equipment for door and window pipe materials. The automatic bending and welding equipment comprises a base and further comprises a rotary workbench, a first overturning mechanical arm, a first bending assembly, a second bending assembly, a second overturning mechanical arm and a welding assembly. The rotary workbench comprises a stepping type index plate and a rotary disc. The rotary disc is provided with a clamping assembly used for fixing a square pipe. The first overturning mechanical arm, the first bending assembly, the second bending assembly, the second overturning mechanical arm and the welding assembly are sequentially arranged in the output direction of the rotary disc, and the first overturning mechanical arm, the first bending assembly, the second bending assembly, the second overturning mechanical arm and the welding assembly are all arranged on the base. The output endof the first overturning mechanical arm and the output end of the second overturning mechanical arm are arranged oppositely and extend in the axis direction of the rotary disc. By means of the automatic bending and welding equipment, bending of the stainless steel square pipes and the right angle welding work are achieved.

Owner:济南萨博特种汽车有限公司

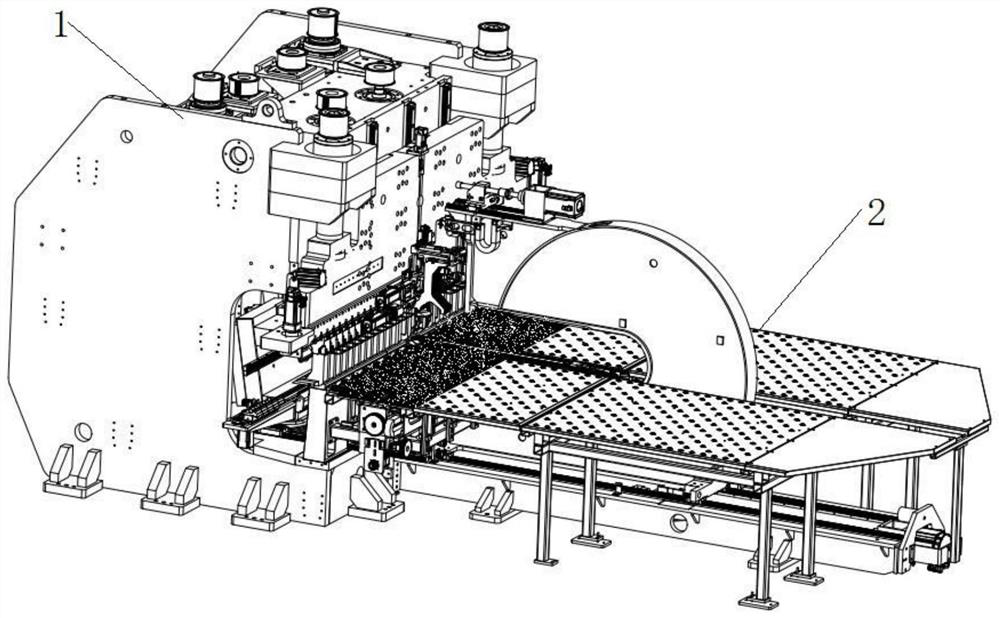

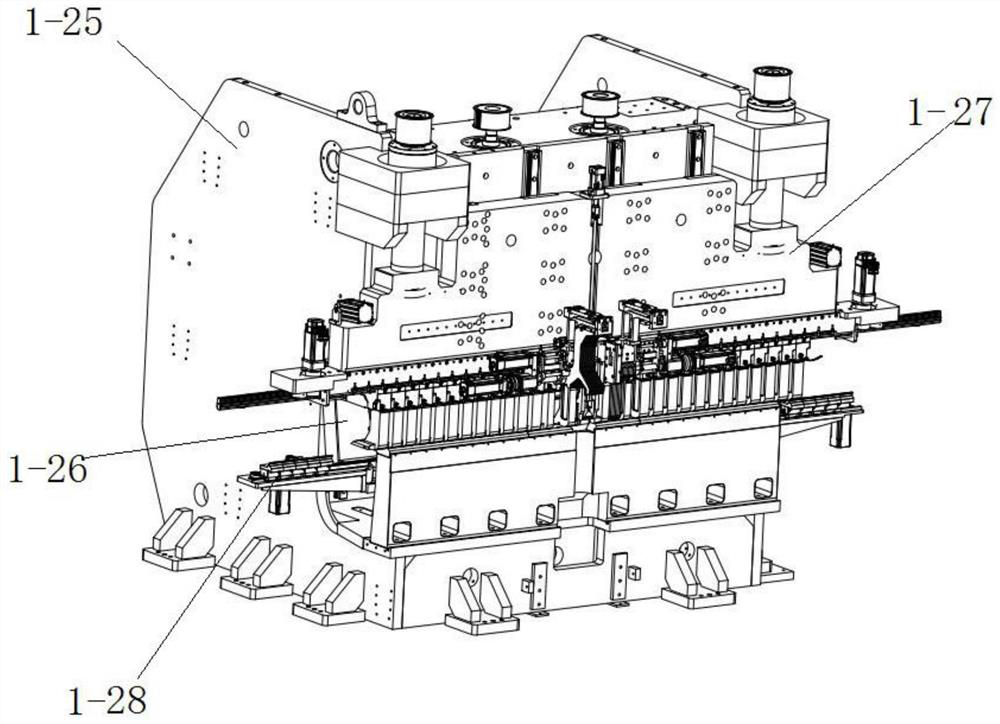

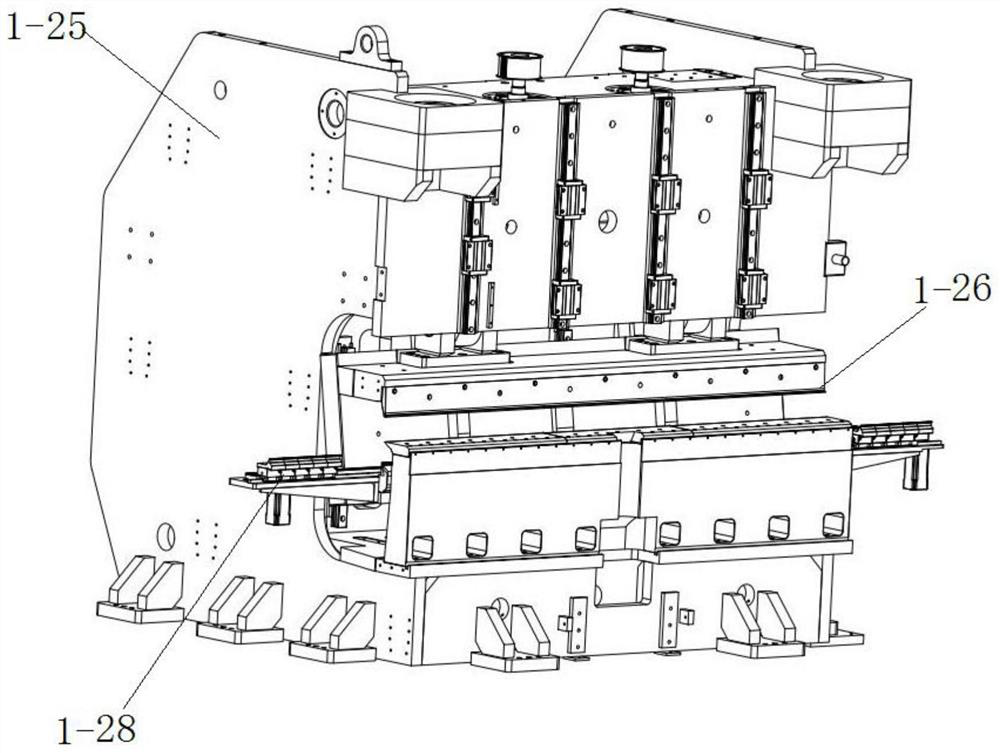

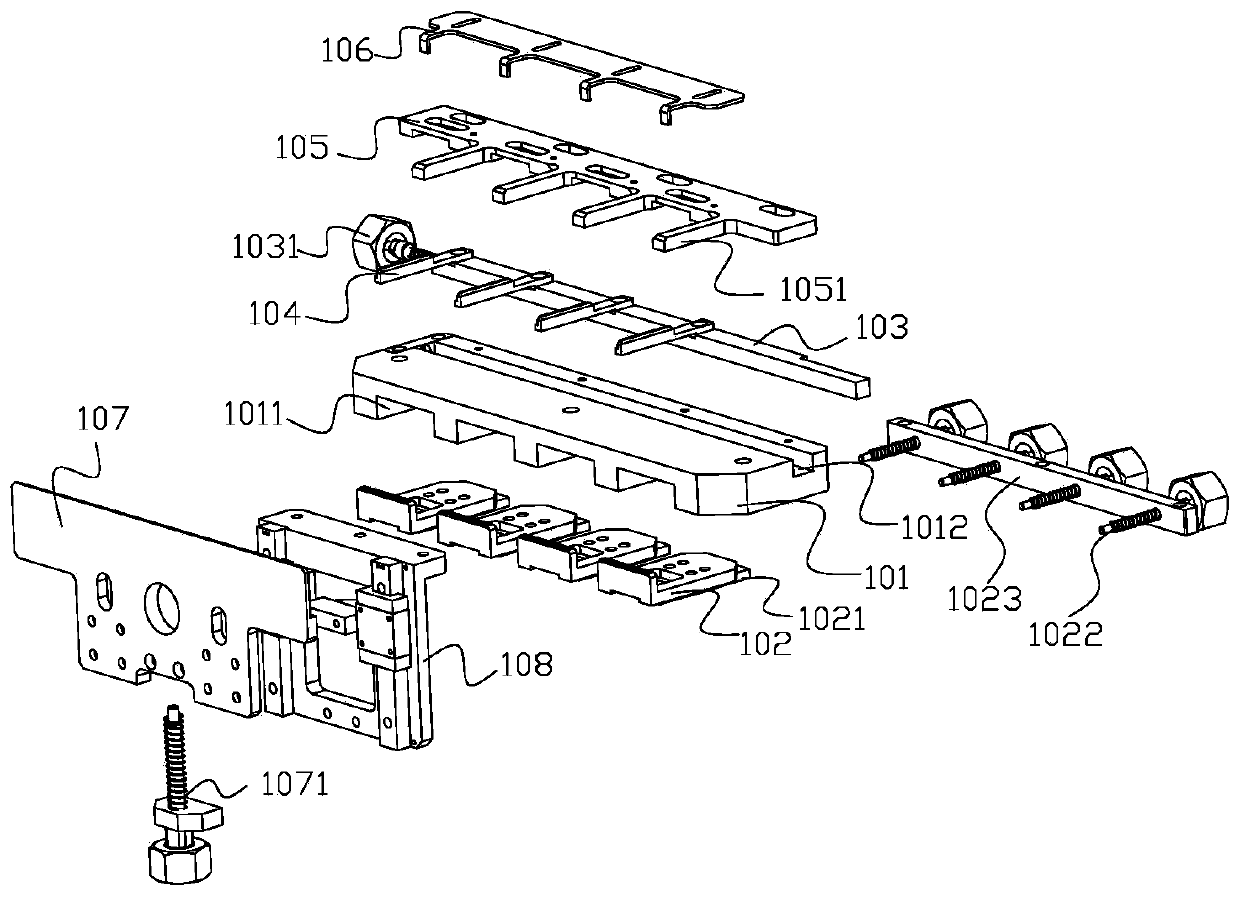

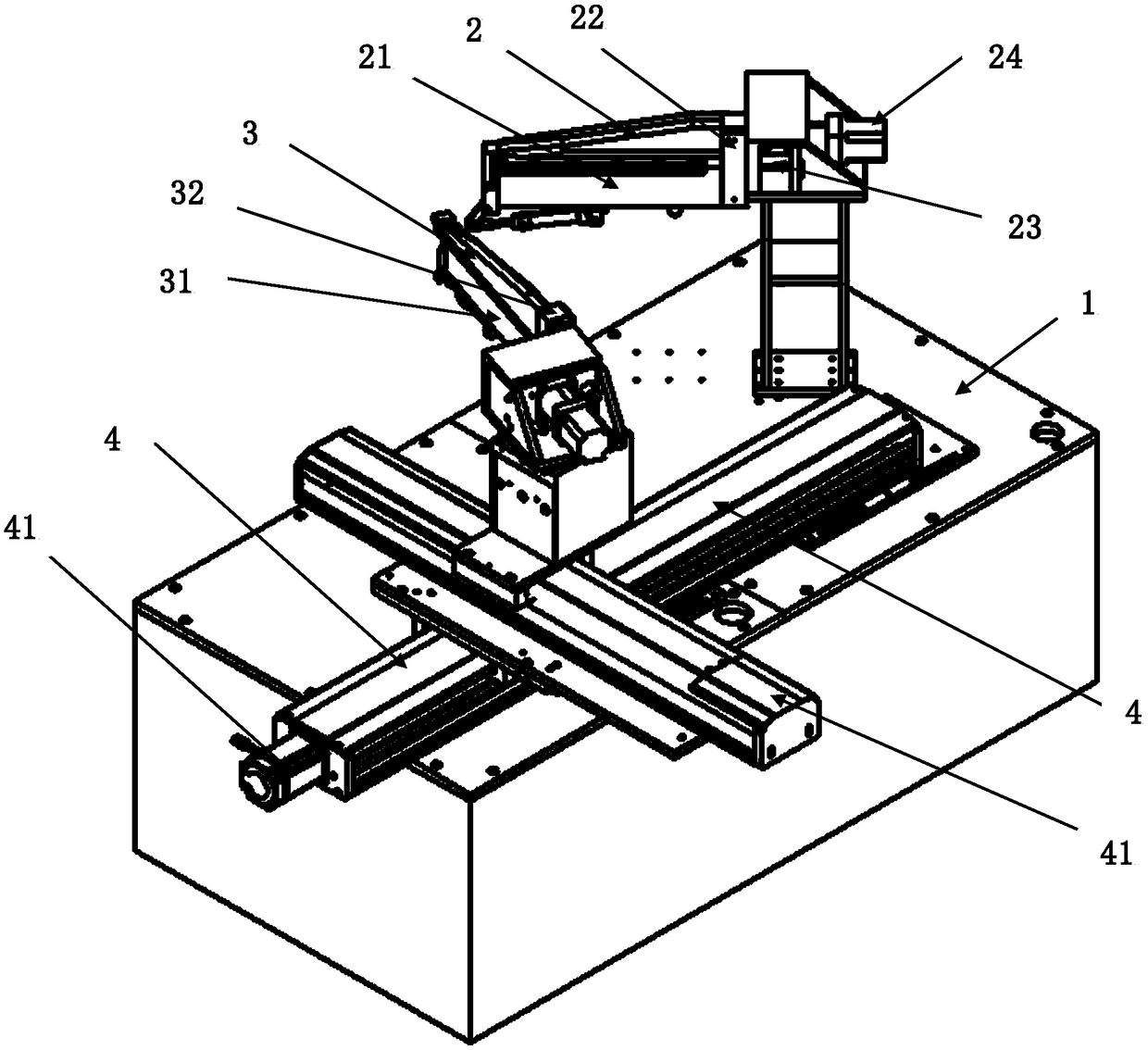

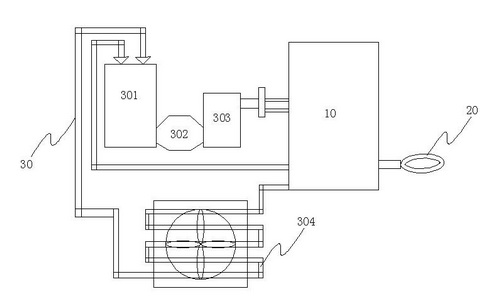

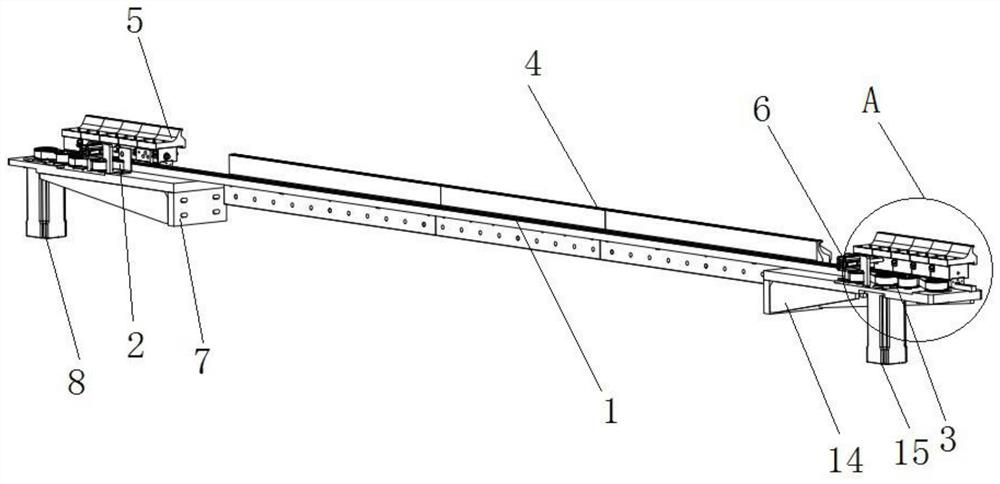

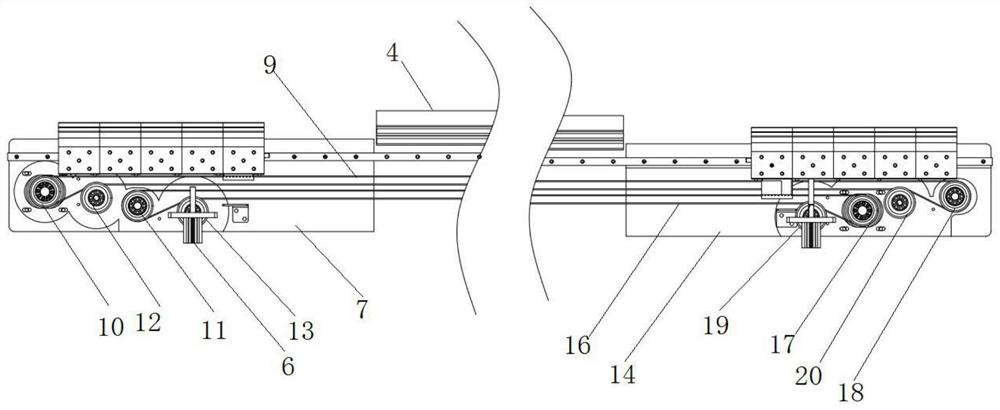

Full-automatic bending machine

PendingCN113649438ACompact structureSmall footprintShaping toolsMetal-working feeding devicesRobot handStructural engineering

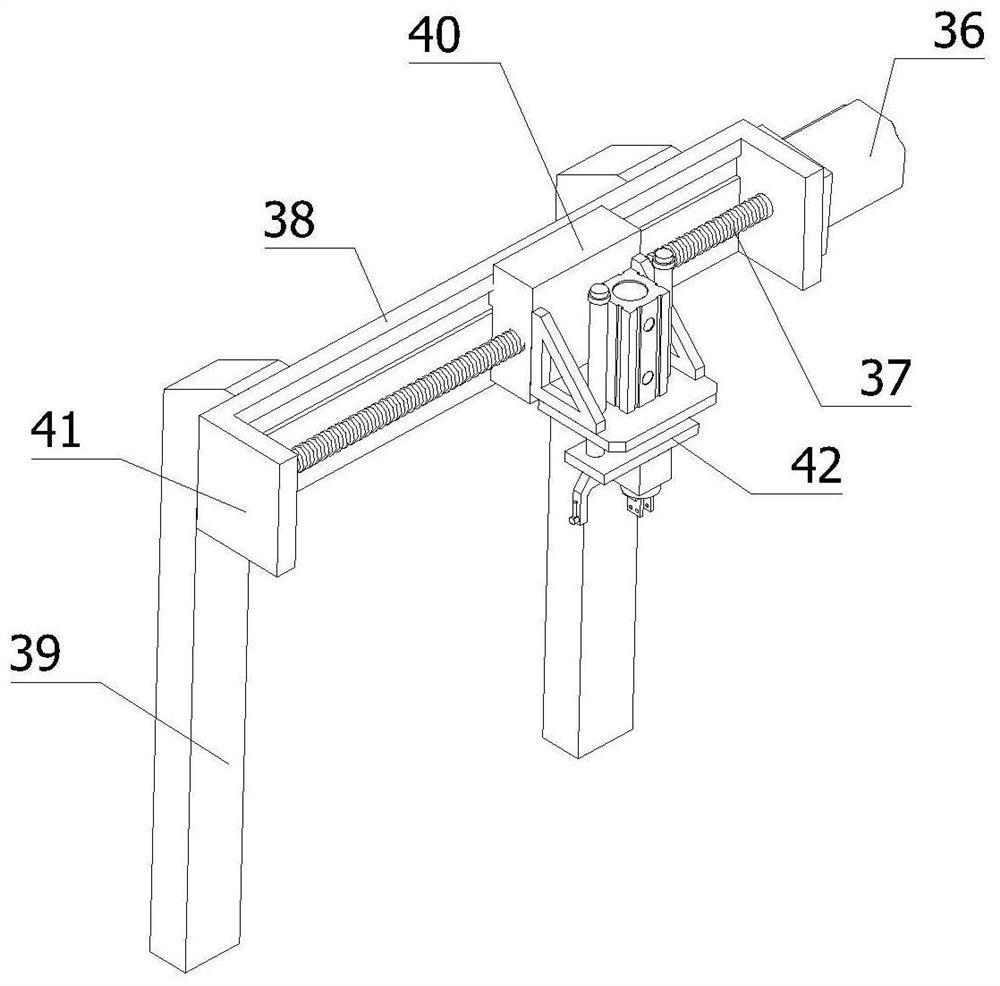

The invention discloses a full-automatic bending machine. The full-automatic bending machine comprises a bending machine main machine and a positioning and clamping workbench; the bending machine main machine comprises a main machine shell; an electric servo bending center tool driving mechanism is arranged in the main machine shell; an automatic tool changing device matched with the electric servo bending center tool driving mechanism is mounted on a bending operation opening of the main machine shell; a local bending mechanism is mounted on a lower tool of the electric servo bending center tool driving mechanism and comprises a local bending sliding rail, a left local bending assembly and a right local bending assembly; the left local bending assembly and the right local bending assembly are mounted on the local bending sliding rail in a sliding manner and symmetrically arranged at the two ends of the lower tool; the positioning and clamping workbench comprises a feeding rotary manipulator and a bearing table; and the bearing table comprises positioning equipment and a supporting rack. The positioning equipment and the supporting rack are connected into a whole. By means of the full-automatic bending machine, the bending efficiency can be remarkably improved, labor input is reduced, and the automation degree is improved.

Owner:HEBEI HANZHI CNC MASCH CO LTD

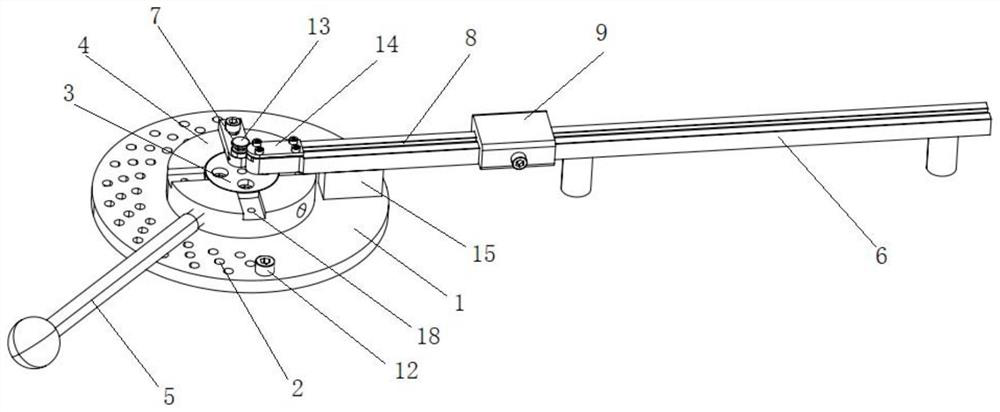

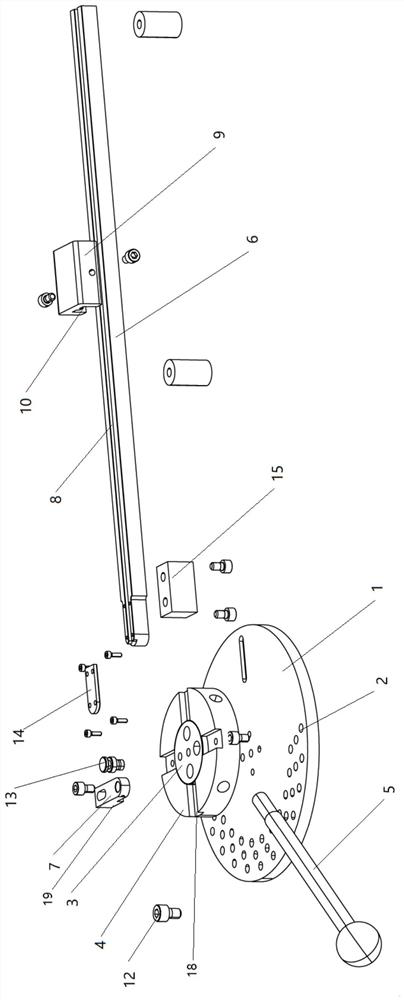

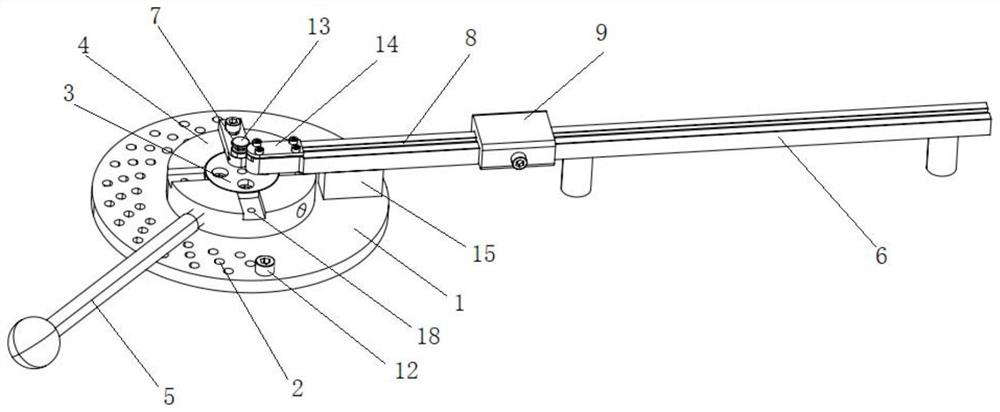

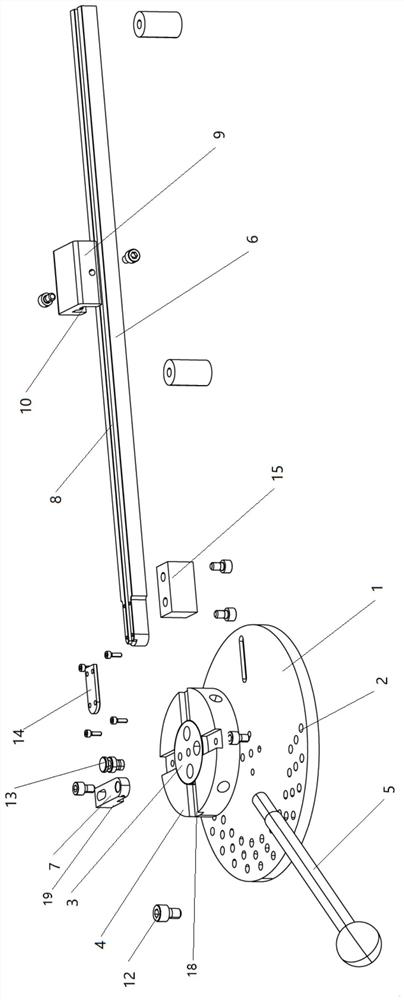

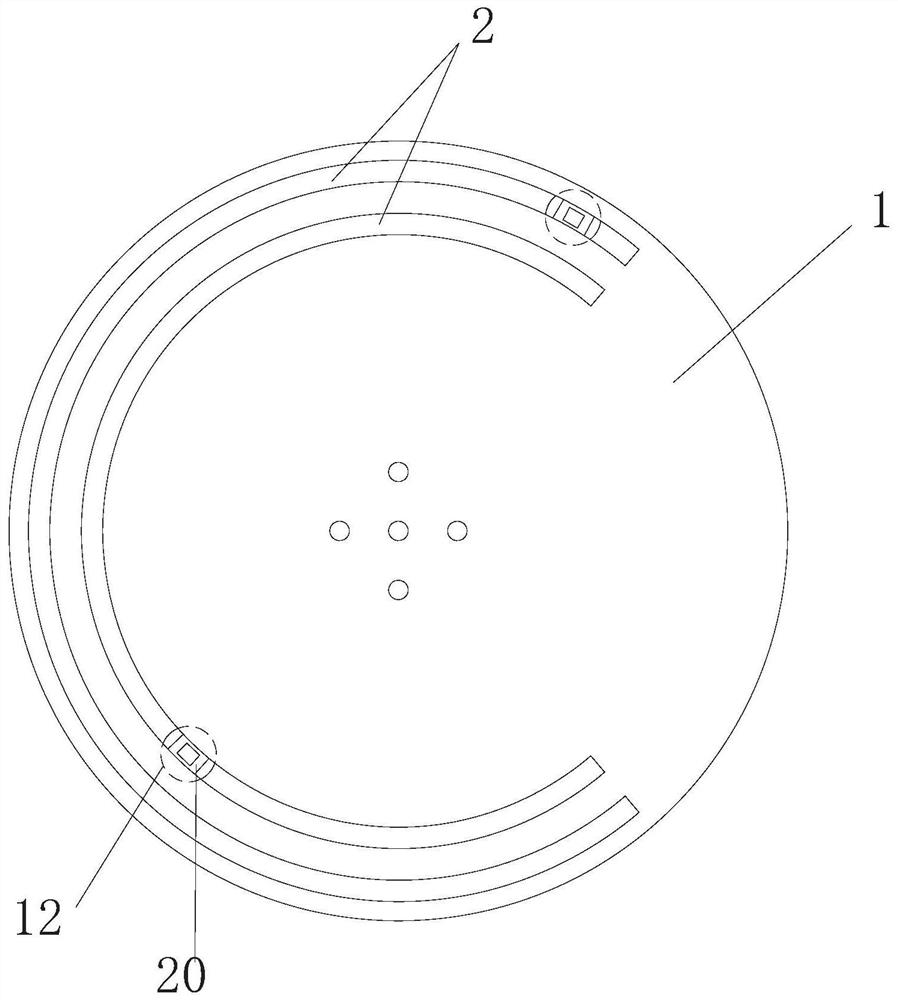

Hairpin motor copper wire 2D forming tool and process

The invention relates to a hairpin motor copper wire 2D forming tool. The hairpin motor copper wire 2D forming tool comprises a base plate, a plurality of positioning holes formed in the base plate, angle positioning pieces arranged on the base plate through the positioning holes and adjustable in position, a middle column fixedly arranged on the base plate, a rotating disc rotatably connected to the middle column, a handle connected to the outer side face of the rotating disc, a wire groove fixedly formed in the upper portion of the base plate, an adjusting block connected to the wire groove in a sliding mode and a blocking column detachably connected to the rotating disc, the blocking column and the wire groove are arranged in the radial direction of the middle column, the outer wall of the inner end of the blocking column is close to the inner end of a channel, the top ends of the angle positioning pieces are higher than the bottom end of the handle, and the contact faces of the handle and the angle positioning pieces are inclined faces. According to the hairpin motor copper wire 2D forming tool, flexible machining of a flat copper wire can be achieved, and the machining requirement for the shape of each layer of copper wire is met; and the hairpin motor copper wire 2D forming process is flexible in setting and convenient to operate.

Owner:跃科智能制造(无锡)有限公司

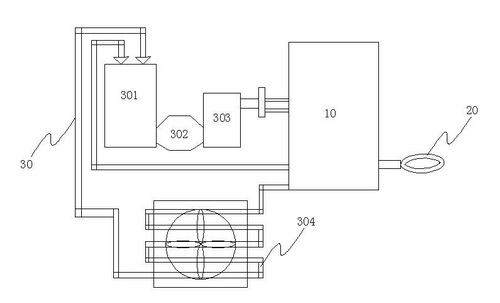

Automatic rubberizing method and equipment for lithium battery

InactiveCN110911758ASolve the loop problemImprove orderNon-aqueous electrolyte cellsFinal product manufactureAdhesive beltEngineering

The invention relates to the field of battery production mechanical automation, in particular to lithium battery automatic adhesive tape sticking equipment which comprises a conveying device, an adhesive tape preparation device, an adhesive tape sticking device and an adhesive tape pressing and wrapping device. The conveying device is of a rotary disc structure, jigs are arranged on the conveyingdevice, and the conveying device conveys a battery to be machined into the glue preparing device, the glue pasting device and the glue pressing and wrapping device through the jigs to be machined formachining. The adhesive tape preparation device is arranged in an adhesive tape pasting area of the conveying device and is used for feeding and cutting an adhesive tape; the adhesive tape sticking device is connected to the adhesive tape preparation device and is used for sticking the cut adhesive tape to the battery in the adhesive tape sticking area; the adhesive pressing and coating device isarranged in the adhesive pressing and coating area, and is used for pressing the front surface of the adhesive tape and coating the redundant adhesive tape on the back surface of the battery; and after the glue pressing and the glue coating are completed, the conveying device discharges the processed batteries. The battery gluing device has the technical effects that the battery is limited throughthe jig, so that the gluing accuracy is ensured; and the back surface of the battery is coated with rubber through the rubber folding mechanism and the rubber coating mechanism, so that equipment functions are enriched.

Owner:张俊

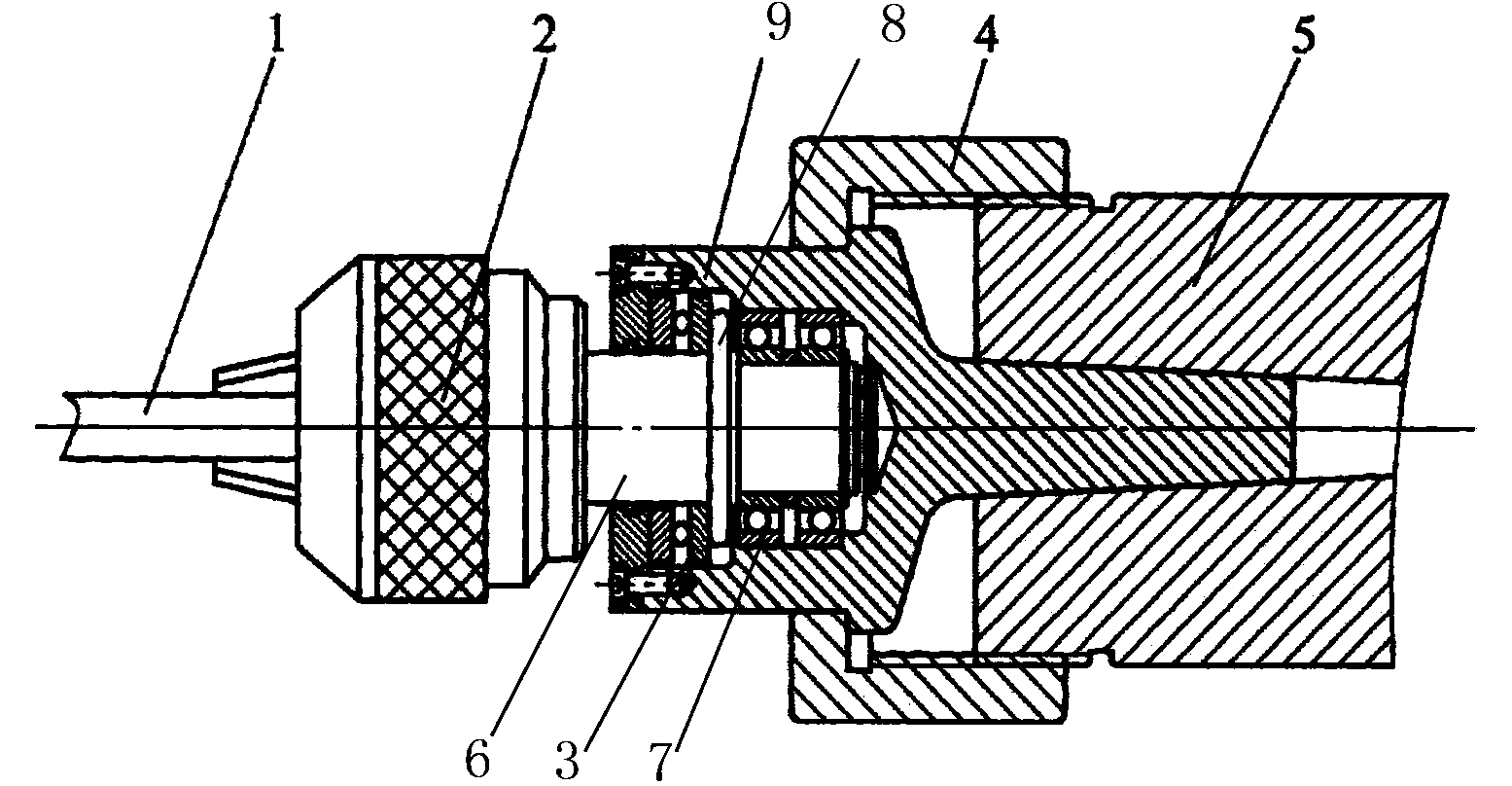

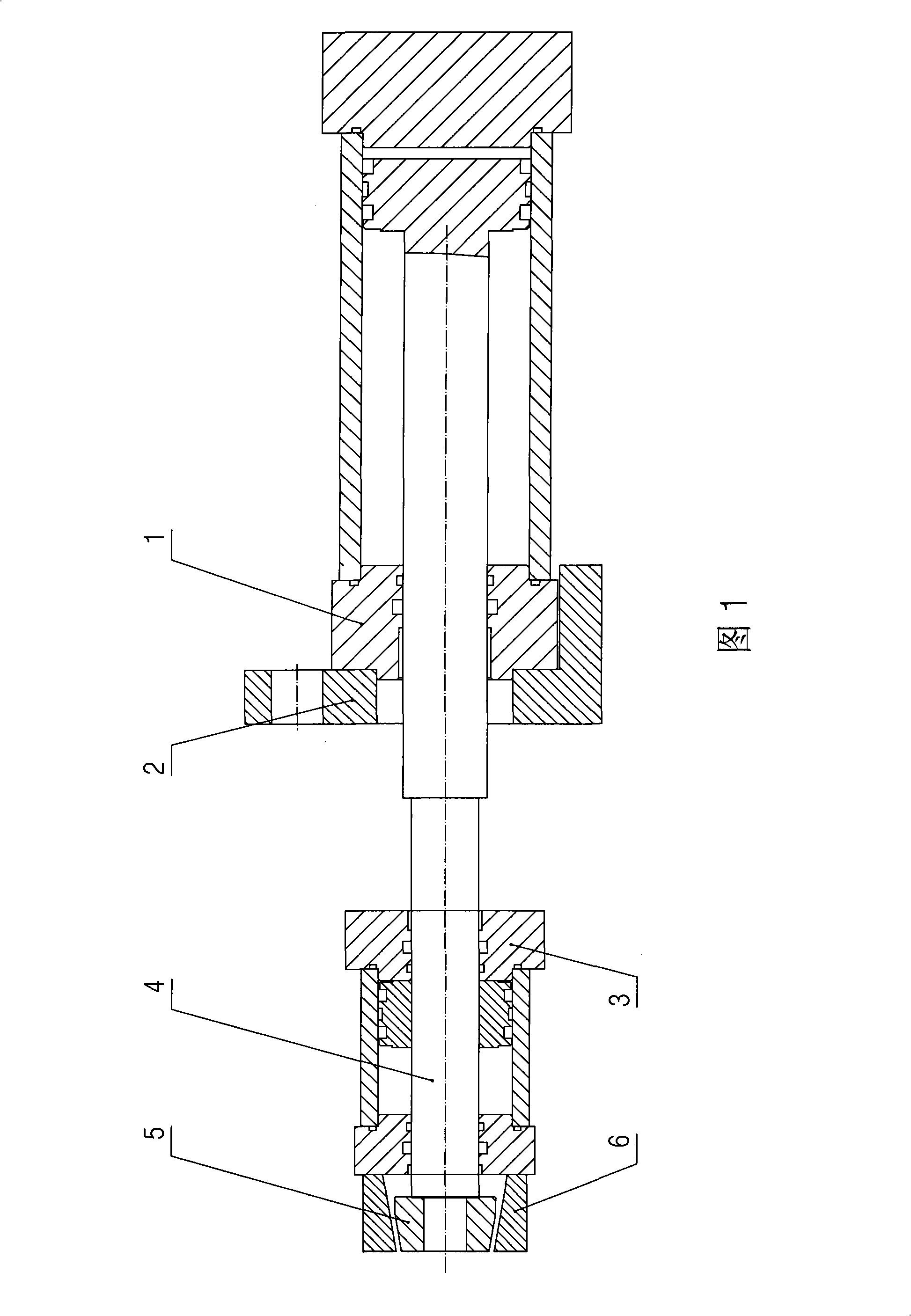

Post-tensioning chuck device

InactiveCN104384531ASolve the bending problemImprove rigidityPositioning apparatusTurning machinesPull forceCutting force

The invention provides a post-tensioning chuck device, relates to the field of a mechanical auxiliary device, and particularly relates to the post-tensioning chuck device. The post-tensioning chuck device comprises a connection handle and a connection nut, which are connected with a machine tool tailstock sleeve, and is characterized in that the tail part of the connection handle is a Mohs tapered handle and the head of the connection handle is a barrel with a groove; a plurality of lug bosses are arranged in the head of the connection handle and one lug boss is arranged on the outer side of the head of the connection handle; a rotary device is arranged in the head of the connection handle and is connected with an adjustable chuck assembly; a clamping claw is arranged at the front end of the adjustable chuck assembly. The post-tensioning chuck device is used for clamping mini-type and ultra-long type thin and long shaft workpieces when the external circles of the workpieces are turned; the workpieces are turned at a stretching state and the problem that thin and long shafts are bent by an axial cutting force can be solved; meanwhile, the bending and deformation degree, caused by a radial cutting force, is reduced under the action of the axial cutting force, and the rigidity and the machining precision of the thin and long shafts are improved.

Owner:SHAANXI QIYUAN TECH DEV

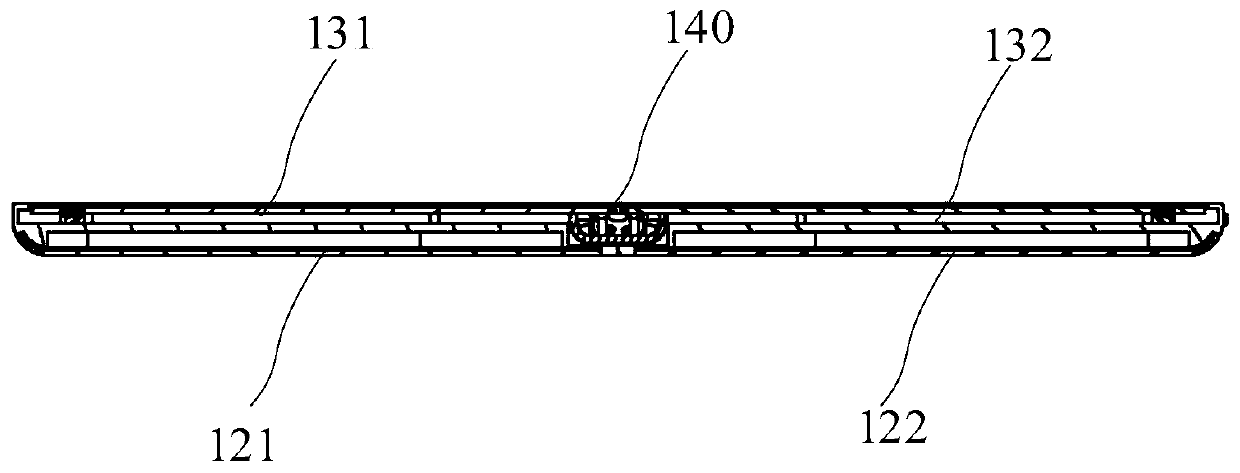

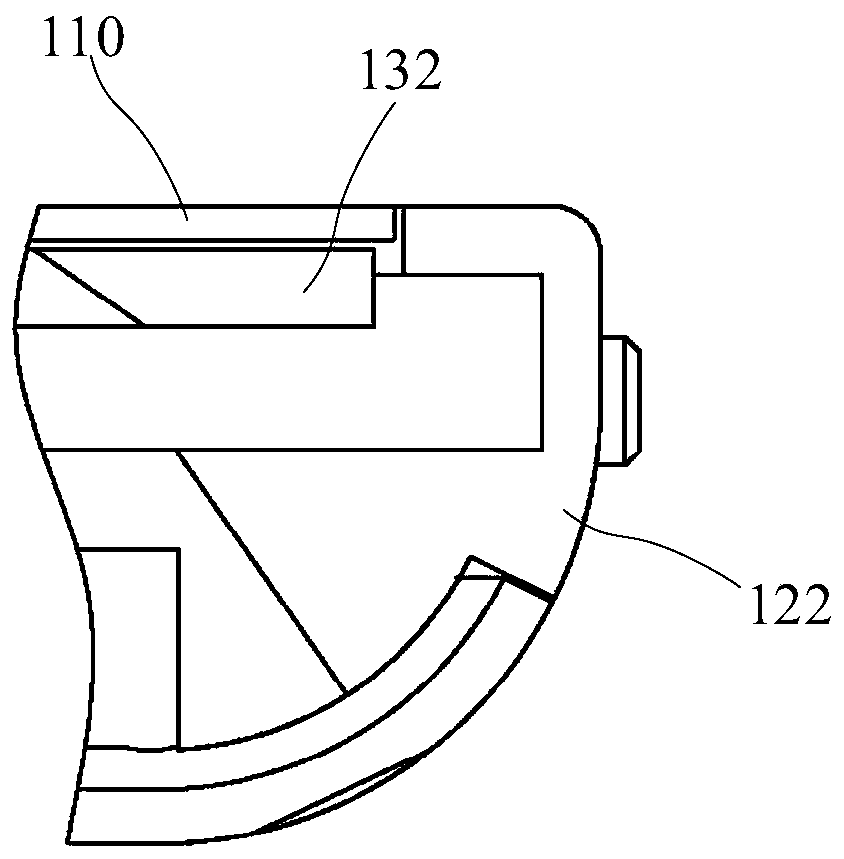

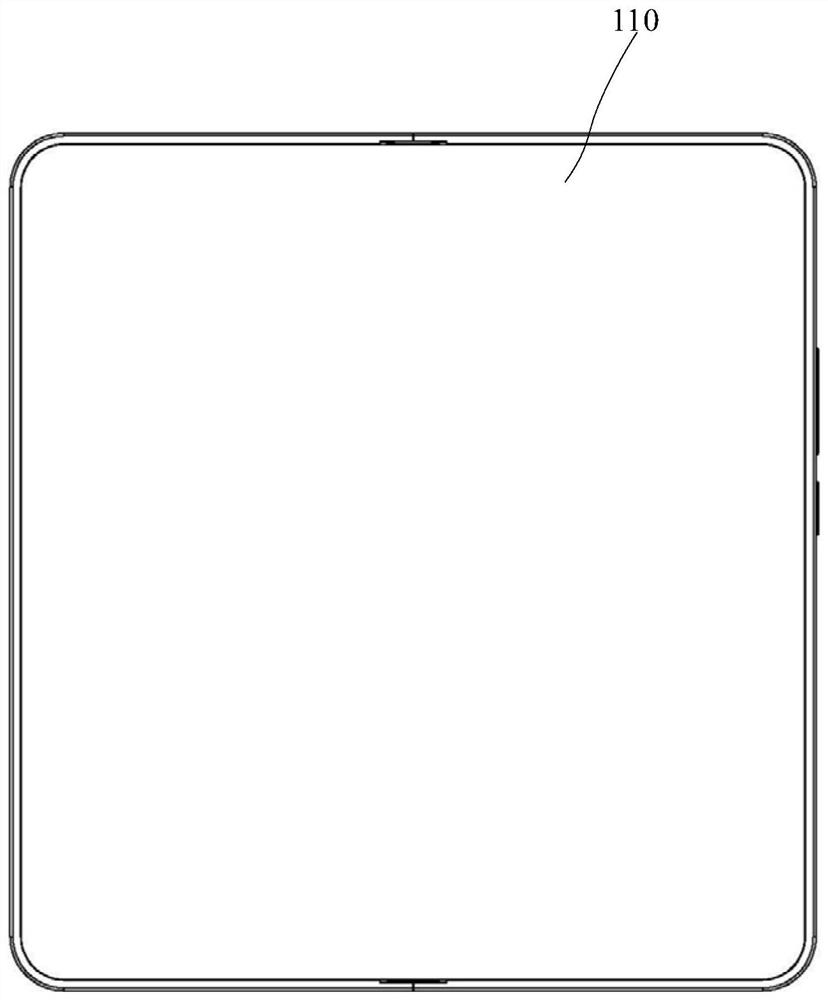

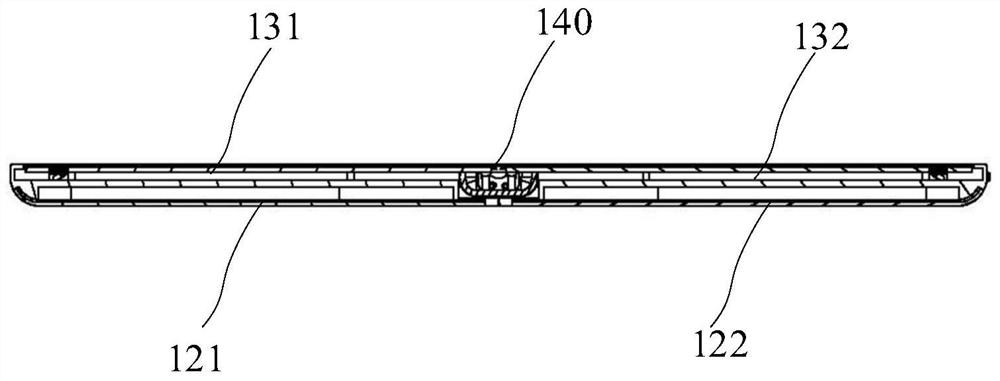

Terminal device

ActiveCN111405088AReduce thicknessSolve the bending problemDigital data processing detailsTelephone set constructionsTerminal equipmentStructural engineering

The invention discloses a terminal device. The terminal device moves through a rotating shaft mechanism, a screen of the terminal equipment can slowly sink along with rotation of a first rotating shaft part and a second rotating shaft part in the rotating shaft mechanism; and when the terminal equipment is folded to zero degree, a first shell and a second shell of the terminal equipment are completely closed, and the screen forms a U-shaped structure with an R angle, so that the problems of screen bending and screen protection are perfectly solved, and meanwhile, the thickness of the terminalequipment during folding is also reduced.

Owner:TCL COMM TECH NINGBO CO LTD

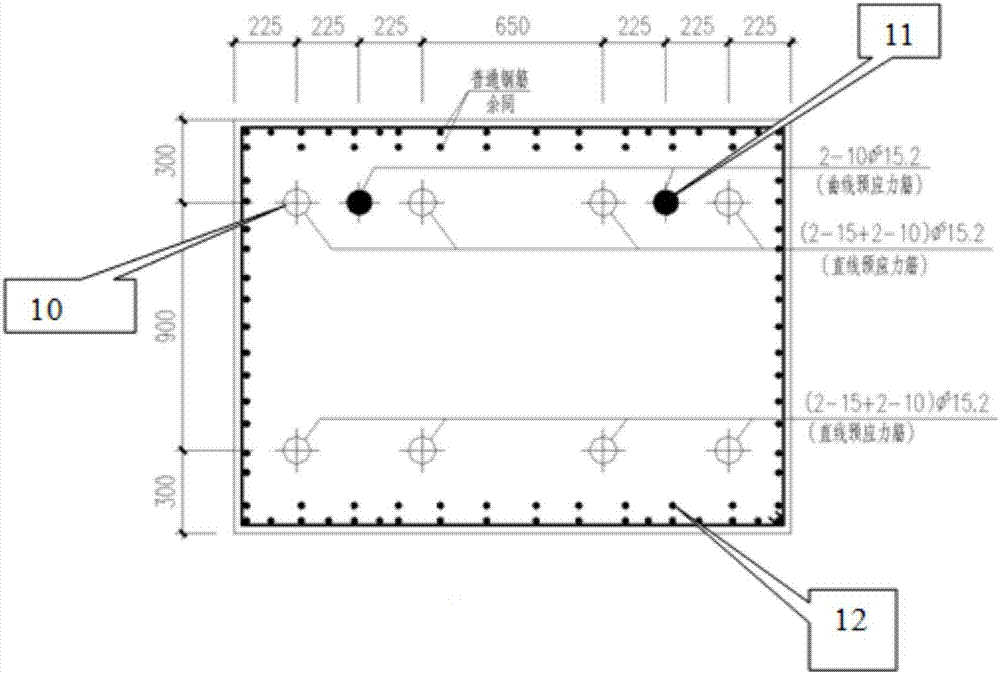

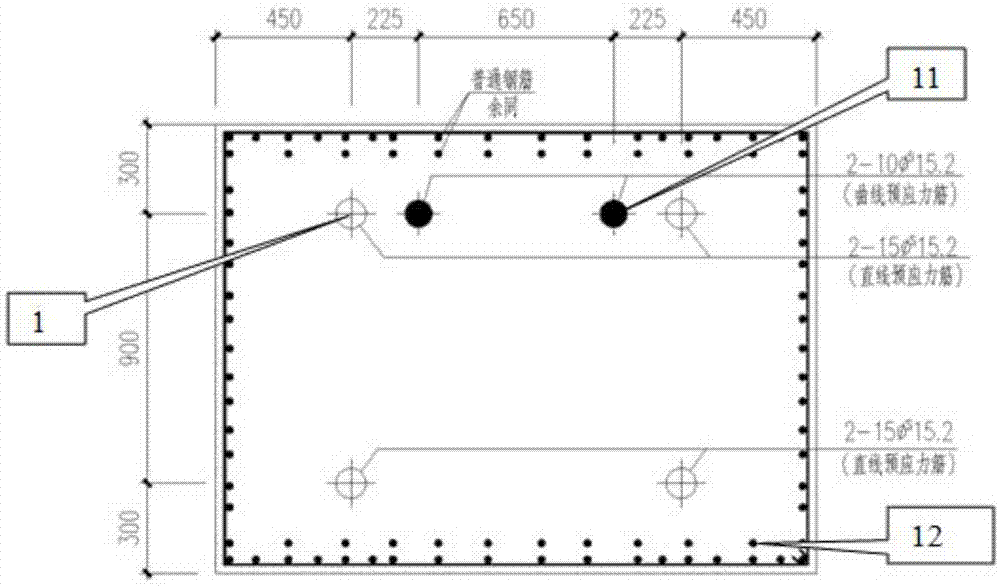

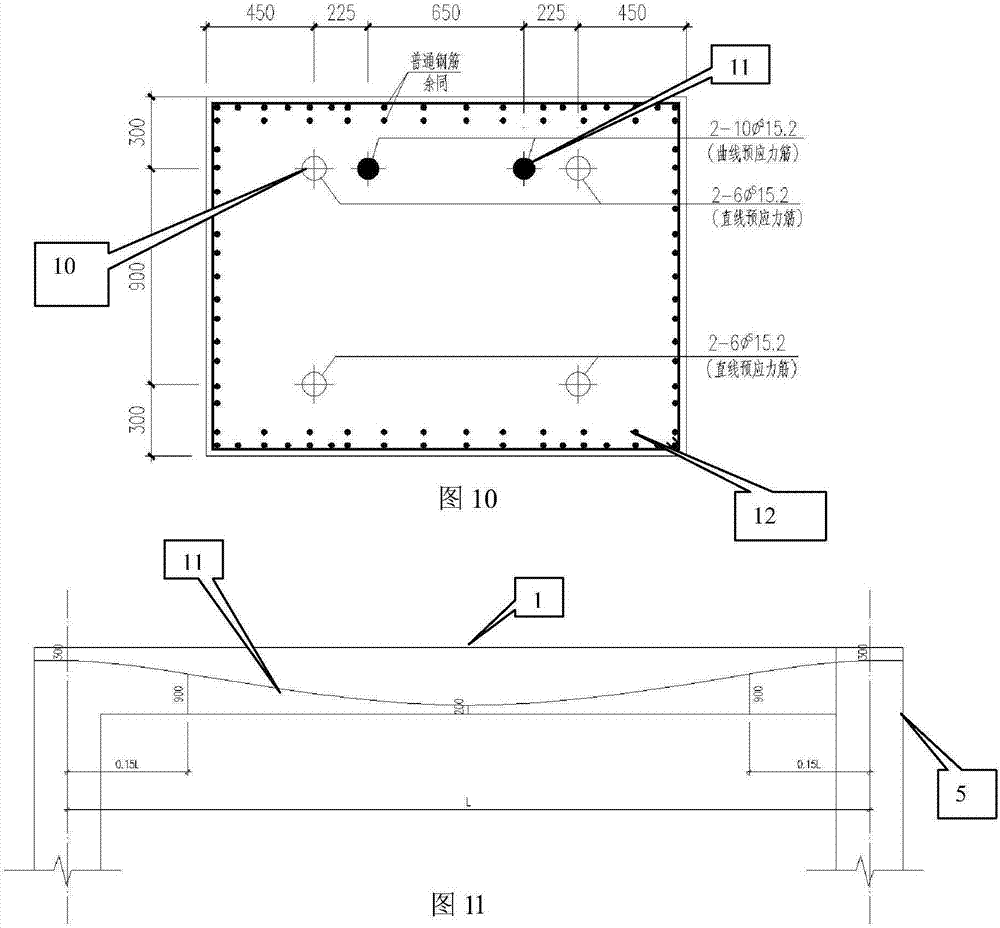

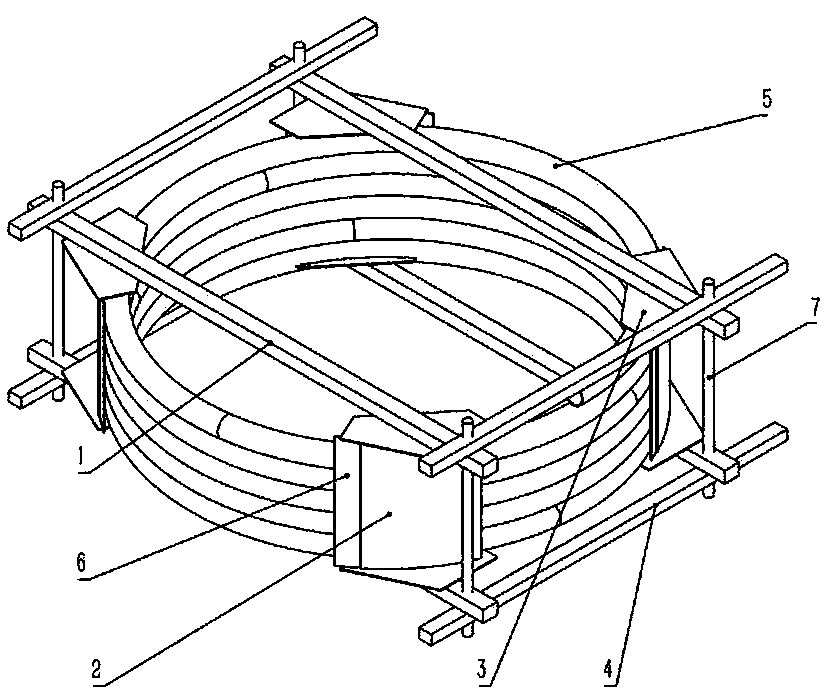

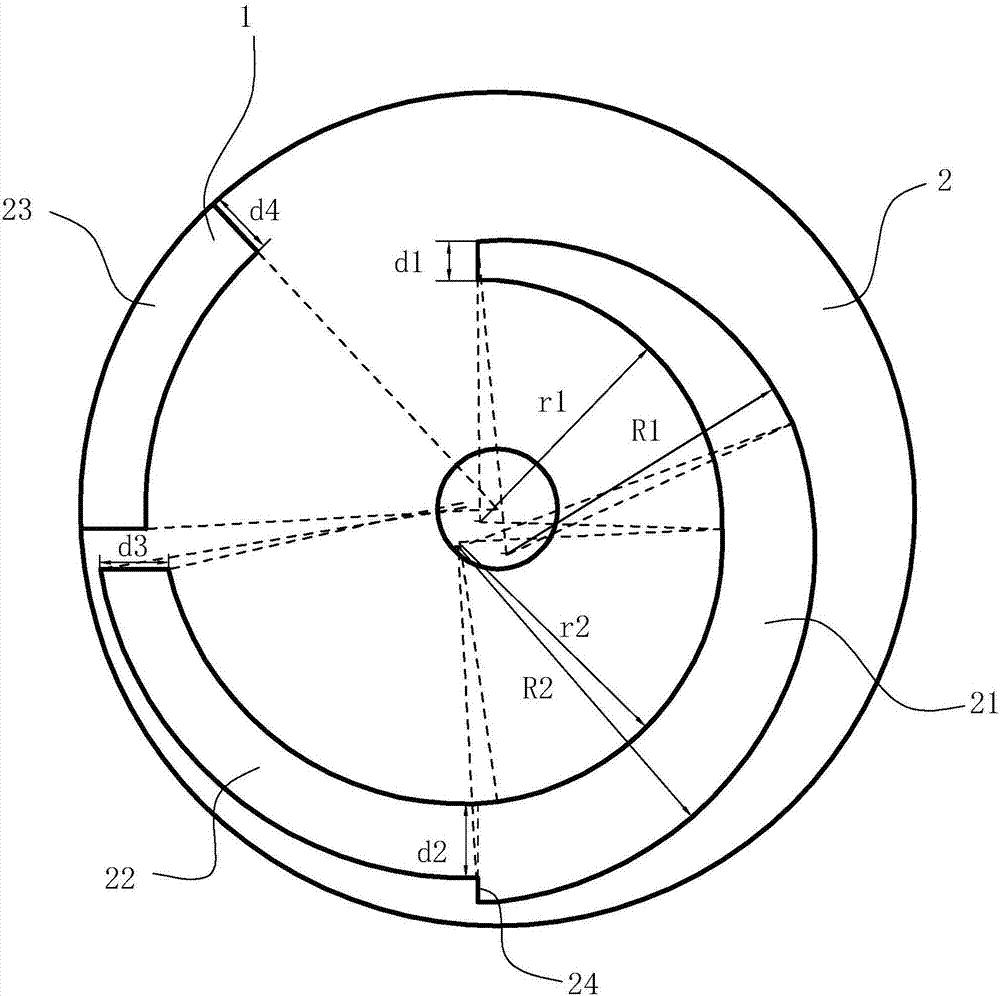

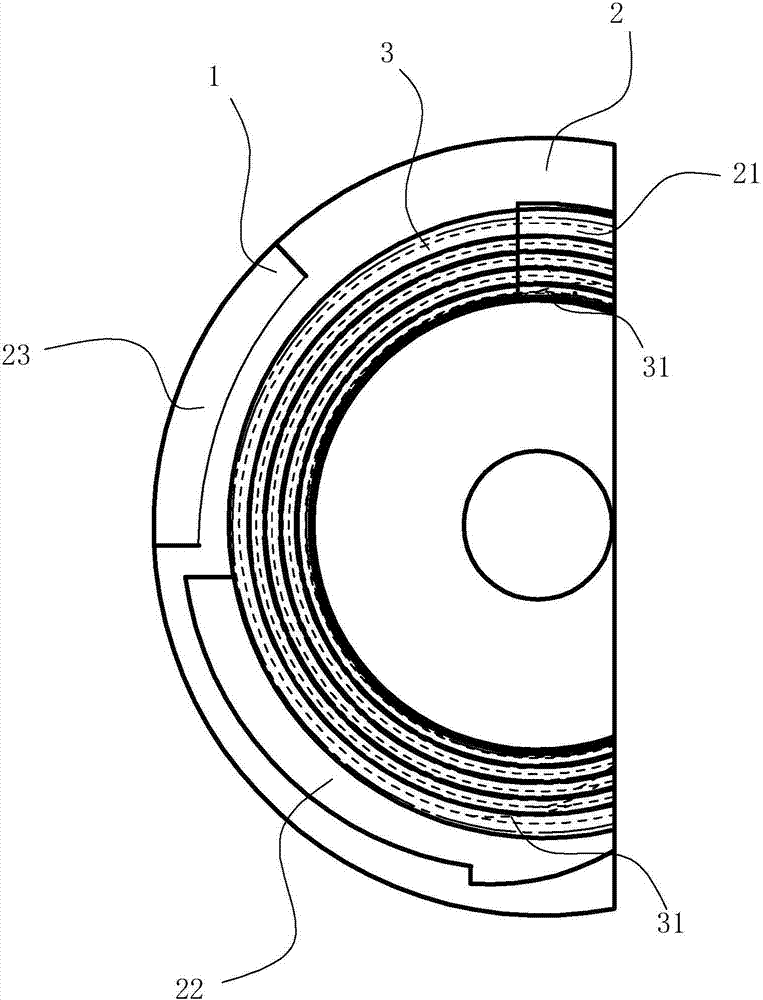

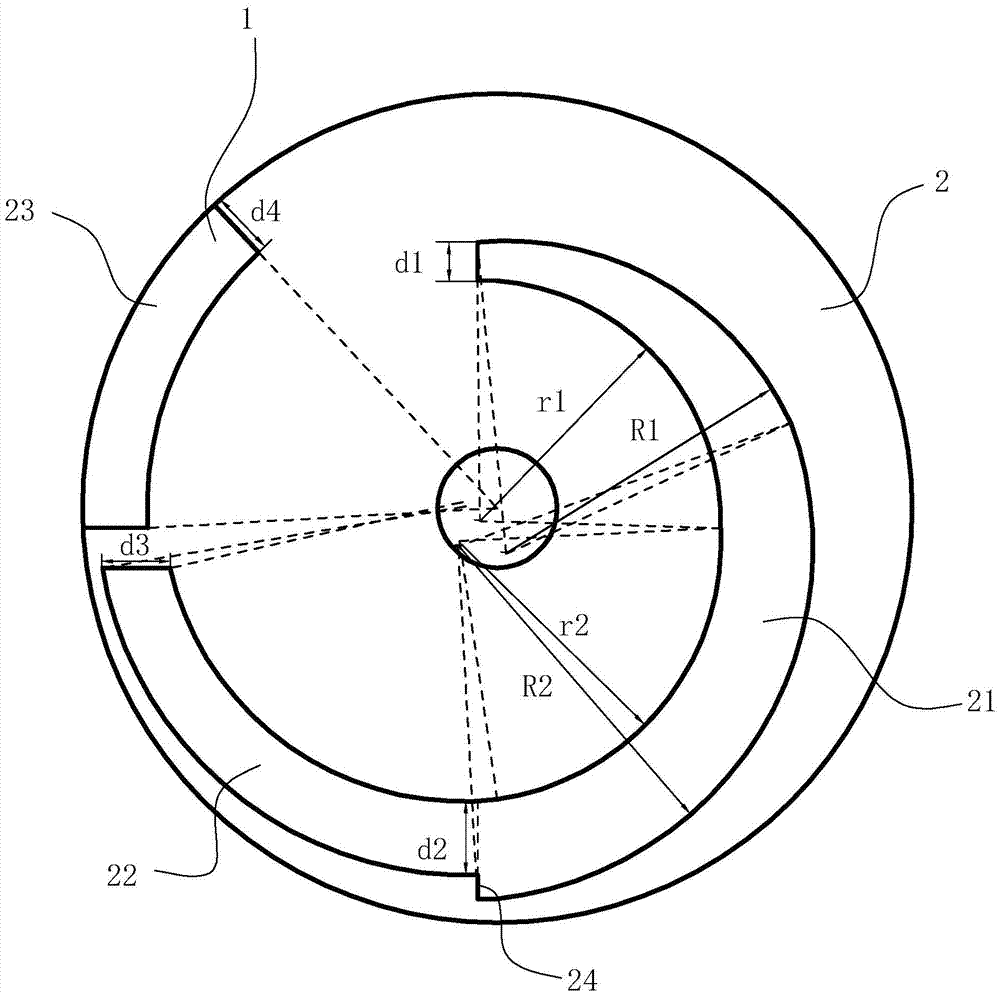

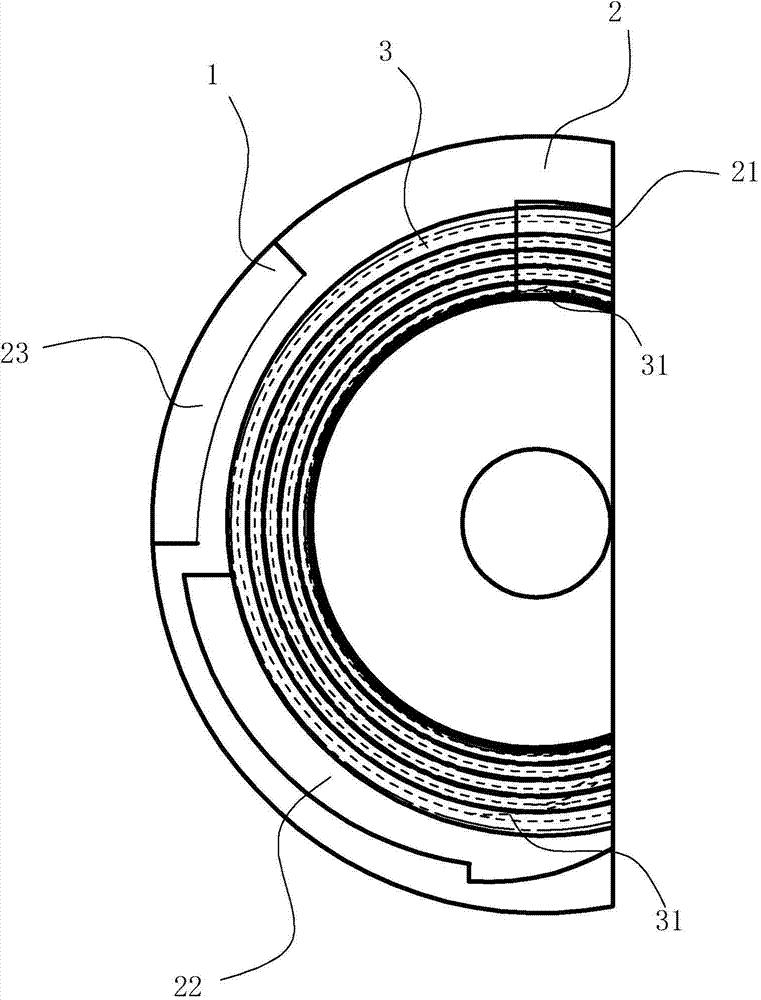

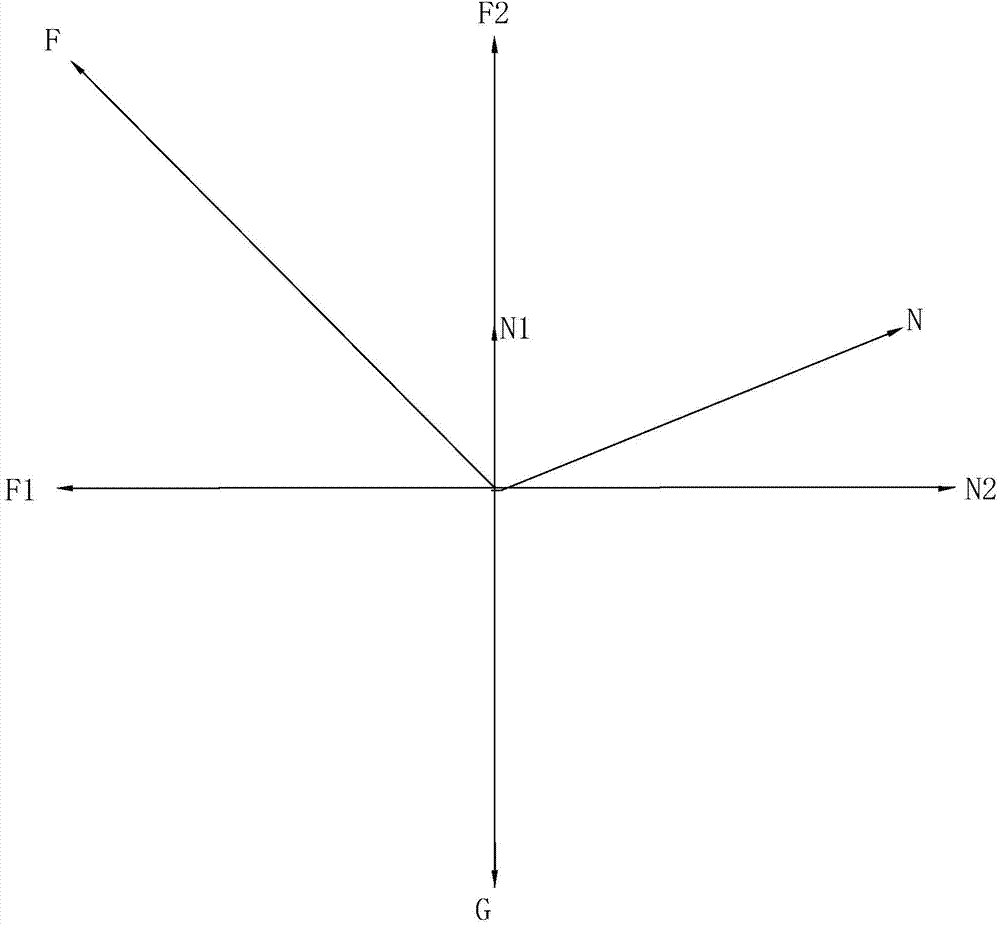

Saddle-shaped spatial pre-stressed ring beam

ActiveCN107419849AIncrease stiffnessPrevent buckling damageGirdersJoistsPrestressed concrete beamPre stress

The invention relates to a saddle-shaped spatial pre-stressed ring beam. The saddle-shaped spatial pre-stressed ring beam consists of an inner ring beam, an outer ring beam and radial beams, wherein the inner ring beam is connected with the outer ring beam through the radial beams; the inner ring beam is a multi-span uniform-section continuous variable-elevation pre-stressed concrete beam; the outer ring beam is a multi-span uniform-section continuous variable-elevation reinforced concrete beam; the radial beams are single-span uniform-section horizontal reinforced concrete beams; curve pre-stressed tendons, straight-line pre-stressed tendons and regular reinforcements are arranged in the inner ring beam in a ring-shaped manner; the pre-stressed tendons and the regular reinforcements of the inner ring beam are arranged in the way that after arrangement of the regular reinforcements, the straight-line pre-stressed tendons are uniformly arranged along the periphery of the beam section at first within the range of a reinforcement cage formed by the regular reinforcements, and then the curve pre-stressed tendons are arranged between the straight-line pre-stressed tendons at the top layer; the inner ring beam and the outer ring beam are connected with a lower concrete structure through cast-in-place reinforced concrete beam-column joints; a cable-membrane structure and a spatial saddle-shaped ring beam are connected through a sliding hinged support; and the sliding hinged support realizes radial horizontal constraint release and circumferential horizontal constraint preservation.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

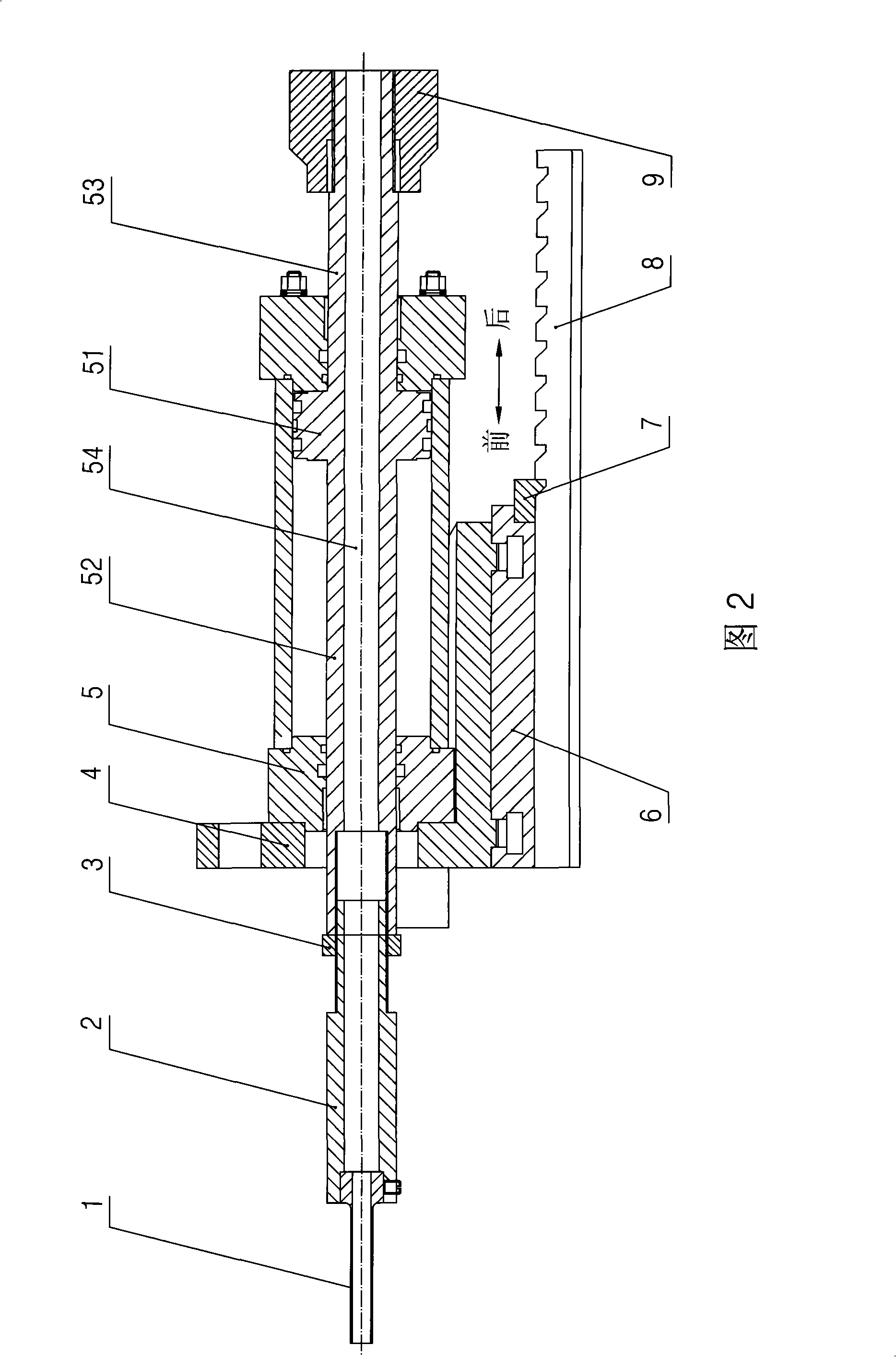

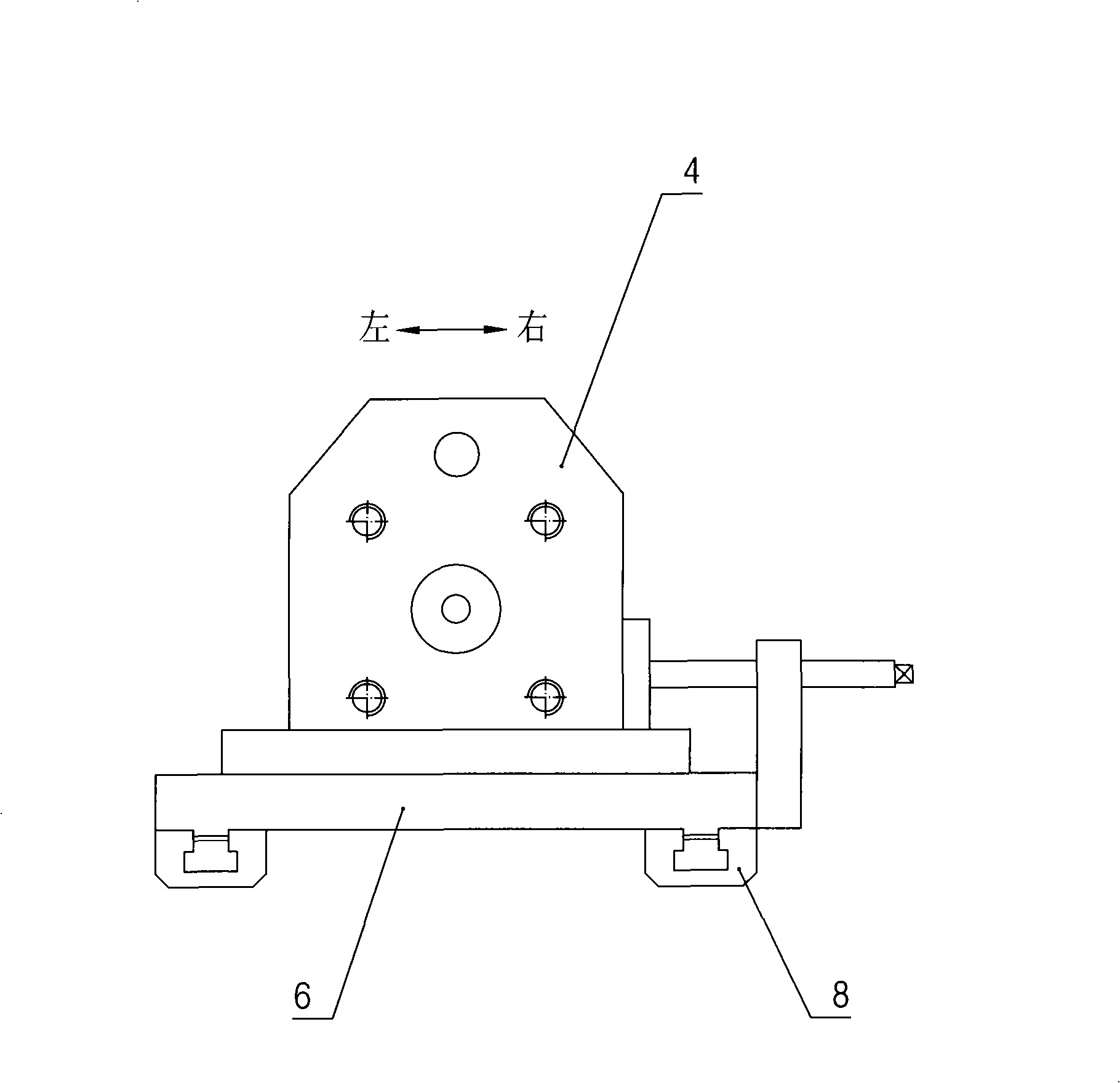

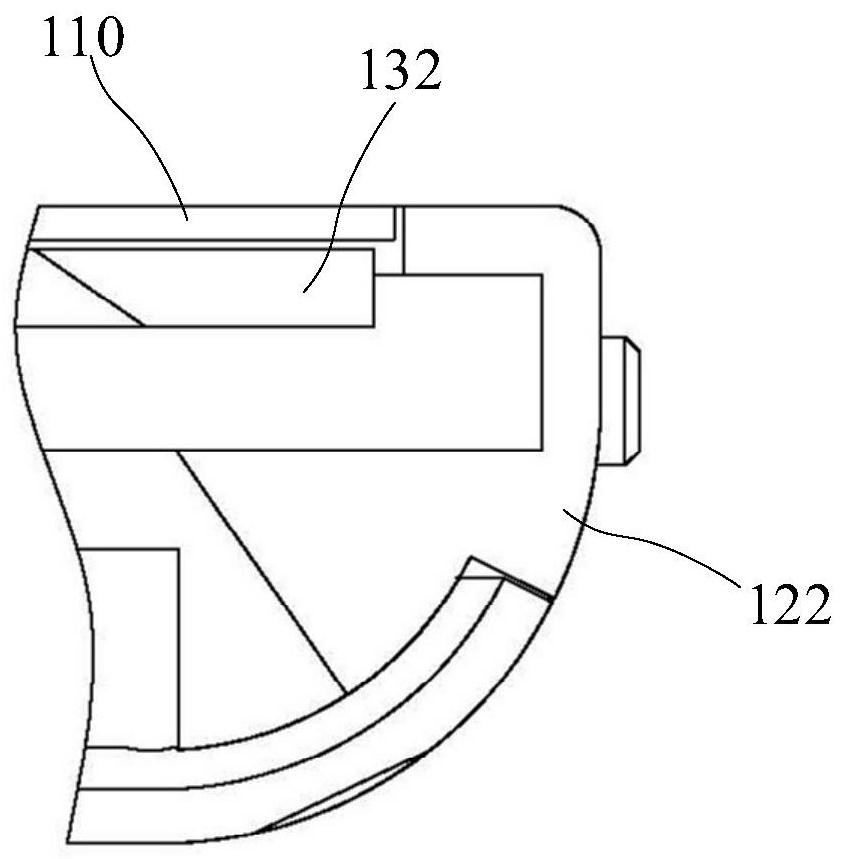

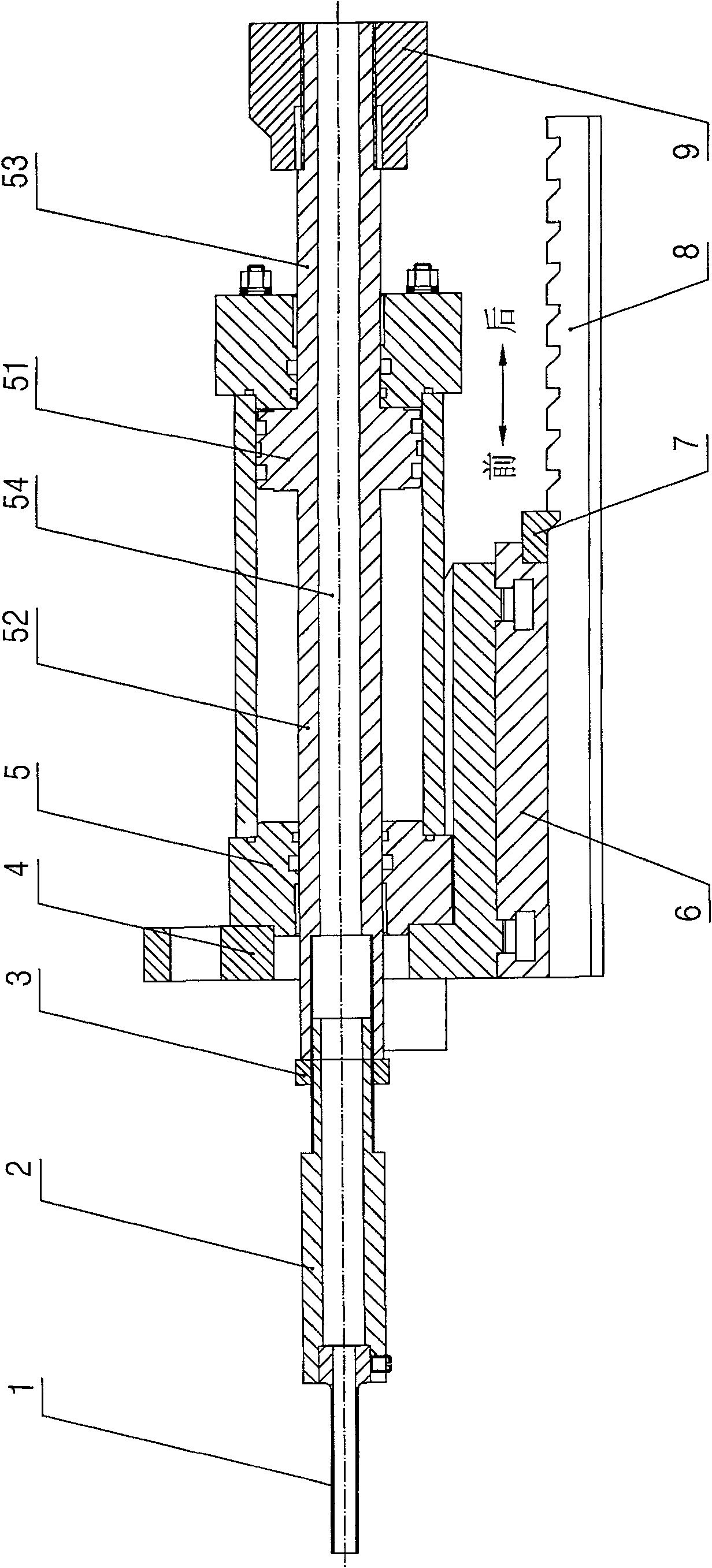

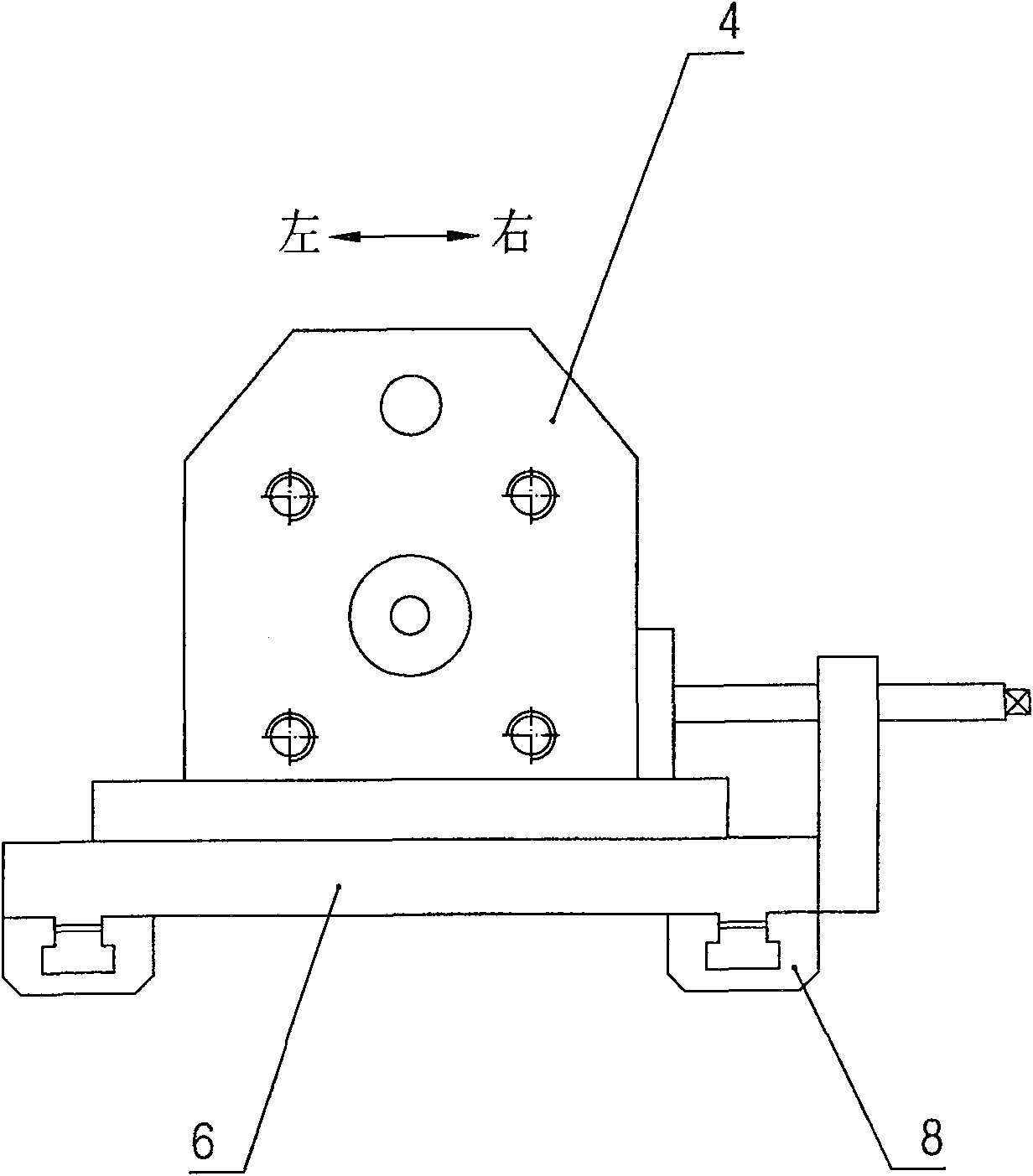

Top pulling device in pipe bender

The invention discloses a pushing device in a pipe bending machine, which can cause the pipe bending machine to bend short pipes; the pushing device comprises a pushing pipe, an oil cylinder base and a dual-outlet type pushing oil cylinder which is arranged on the oil cylinder base; a piston of the pushing oil cylinder and piston rods which are arranged at the left side and the right side of the piston are provided with perforated operation holes; the end part of the piston rod at the left side is provided with the pushing pipe; the internal hole of the pushing pipe is communicated with the operation hole; the end part of the piston rod at the right side is provided with a position limit nut by a thread; the oil cylinder base is movably arranged on a sliding plate which is movably arranged on a rack; the rack is provided with a positioning tooth; the side part of one side of the positioning tooth is embedded in the positioning concave trough of the sliding plate. A pushing connecting pipe with a hollow structure is also arranged between the pushing pipe and the piston rod. The pipe bending machine installed with the pushing device of the invention can be used for processing the short pipes, especially for the short pipes with the bending radius which is equal to or less than 1.5 times of the external diameter of the pipe.

Owner:JIANGSU HEFENG MECHANICAL MAKING

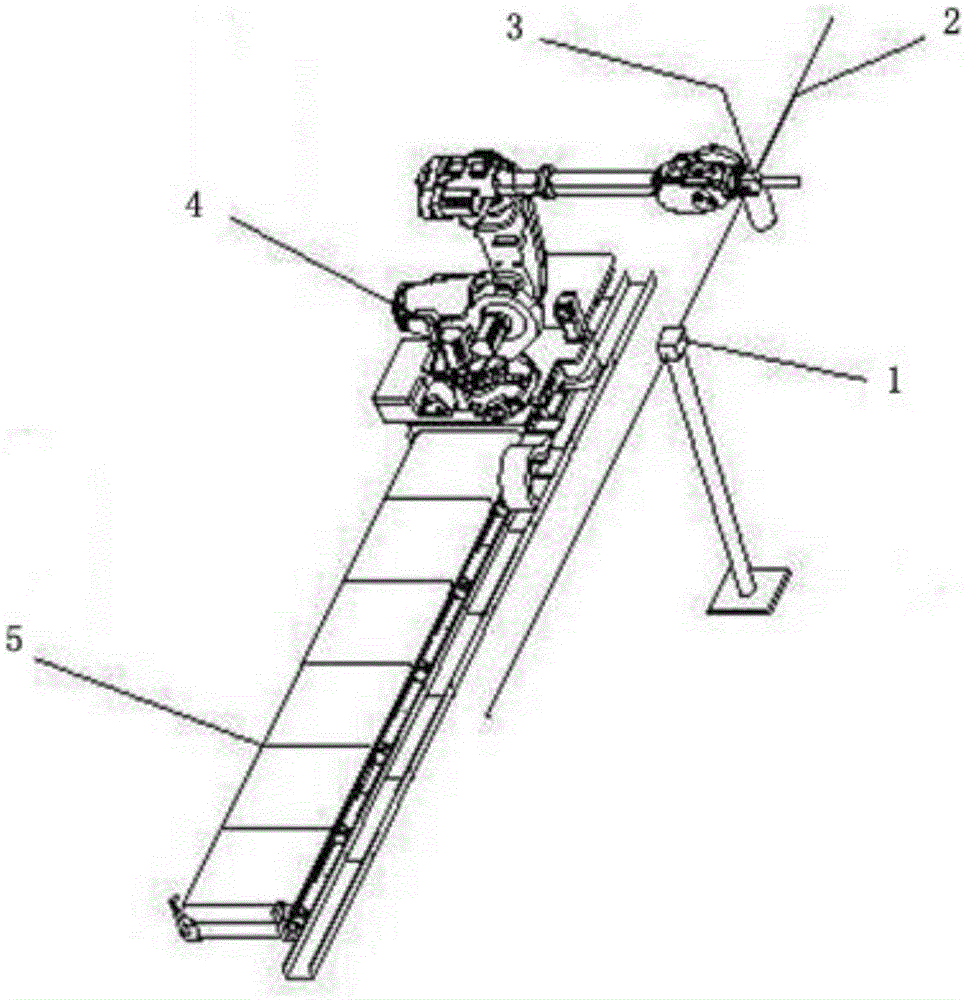

Seven axis pipe bending robot

The invention belongs to the technical field of industrial machinery and discloses a seven-shaft elbow robot which comprises a common six-shaft industrial robot, an elbow power device, a seven-shaft walking device, an automatic feeding device and a product fixing device. The elbow power device is mounted on a sixth shaft of the common six-shaft industrial robot which is mounted on the seven-shaft walking device, and the product fixing device is mounted on one side of the seven-shaft walking device. The seven-shaft elbow robot has the advantages that the problem of bending of elongate pipes is solved, and the seven-shaft elbow robot is obvious in economic benefit, high in efficiency, capable of realizing offline programming and online angle compensation, high in automation level, high in flexibility and small in needed workshop area relatively to conventional pipe benders, and integrates the advantages of a double-head pipe bender and the advantages of automatization.

Owner:HUBEI ROBOT TECH CO LTD

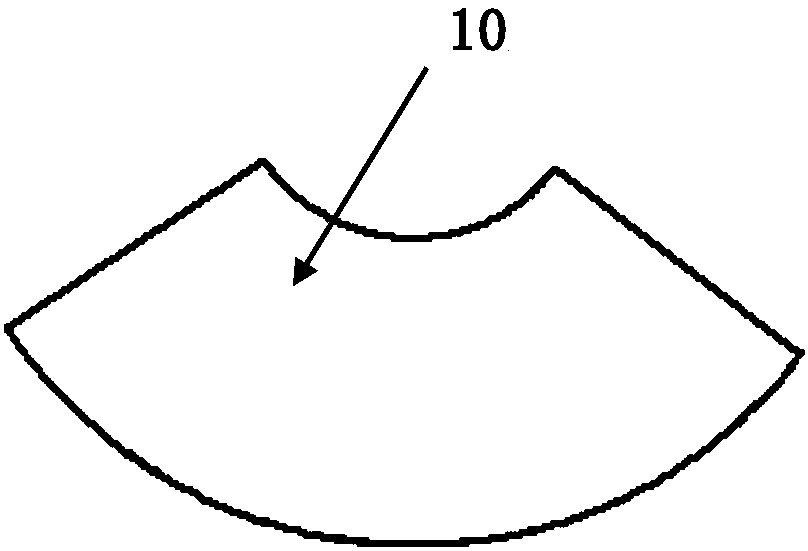

Small-diameter cylinder automatic forming device and process

The invention provides a small-diameter cylinder automatic forming device and process. The device comprises a machine base, clamping bases, fixing bases, a guide rail, a clamping arm, a hydraulic system and cooling systems, wherein the clamping arm is composed of a left clamping arm and a right clamping arm, the left clamping arm and the right clamping arm are symmetrical left and right, and are the same in structure, a hydraulic clamping mechanism is arranged in each clamping base, an F-shaped safety clamping jaw is arranged at the front end of the clamping arm, the tail part of the clampingjaw is connected with an air cylinder piston rod, a left clamping arm fixing base is installed on the machine base, a right clamping arm fixing base is installed on the guide rail, a stepping motor isarranged on the guide rail, the motor drives the guide rail, and the tail ends of the fixing bases are provided with gears, servo motors and cooling systems. A rounding process comprises the following steps of preparation, feeding, detection, clamping, rounding and the like. According to the small-diameter cylinder automatic forming device and process, the problems of bending and welding on original small size, small angle and small radius sector-shaped plate materials with diameters of the small ends are larger than 46 mm after being bent into a cylinder body are solved, the production costis reduced, the problem that the requirements of original pure manual operation on technology of operators are high is solved, so that the quality and the efficiency of products are improved.

Owner:SHANGHAI WANSHENG VACUUM FLASK & VESSEL

Automatic spark plug assembly line

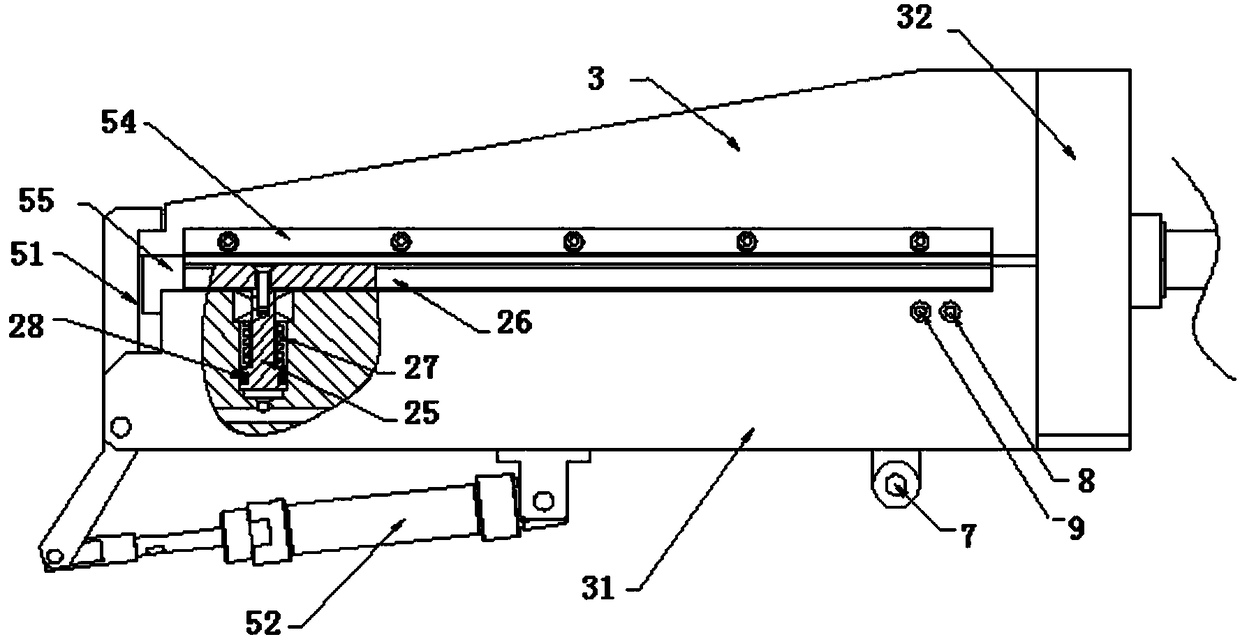

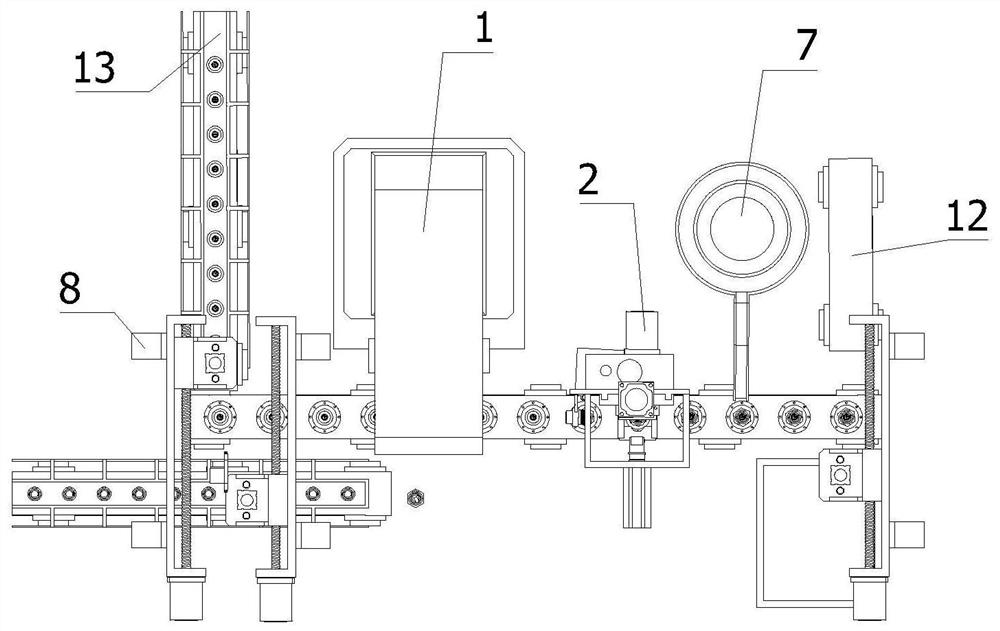

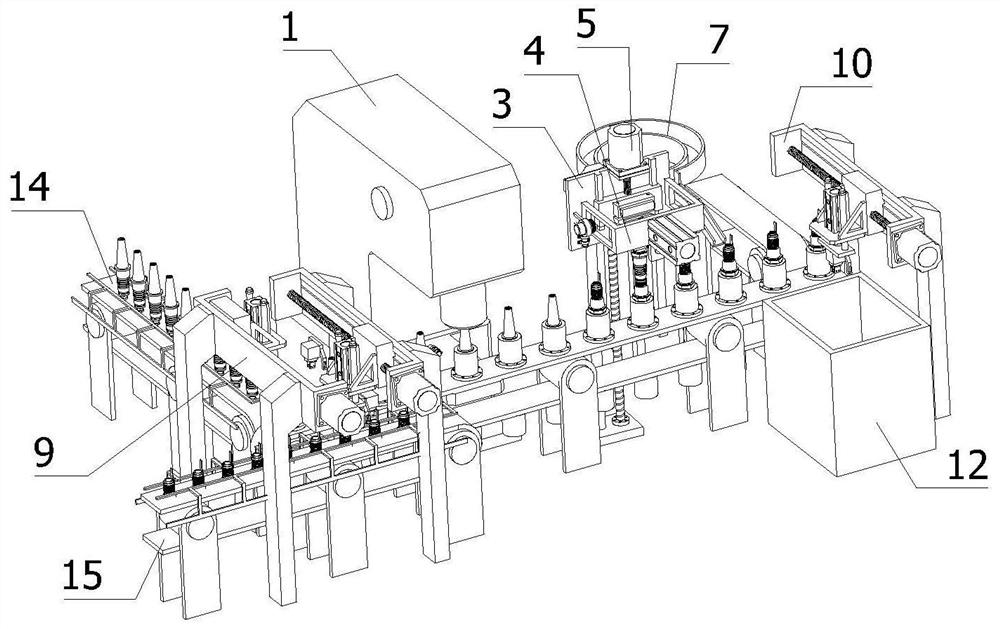

InactiveCN113305563ASolve the bending problemSolve manual feedingAssembly machinesMetal working apparatusTransmission beltAssembly line

The invention relates to the field of spark plug assembly, in particular to an automatic spark plug assembly line. The automatic spark plug assembly line involves a riveting machine, a bending mechanism, a sleeving assembly, a material moving mechanism and a feeding mechanism, wherein the bending mechanism located on the side of the riveting machine, the bending mechanism comprises a bending assembly, a bottom plate, a clamping assembly and a detection assembly, A sleeving assembly; the material moving mechanism is located on the side of the riveting machine, the material moving mechanism comprises a first material moving assembly, a second material moving assembly, a third conveying belt and a discharging assembly, the feeding mechanism is located on the side of the third conveying belt, and the feeding mechanism comprises a first conveying belt and a second conveying belt; According to the technical solution, the problem of bending spark plugs of different models is solved, and the problems of manual feeding and detection are solved through automatic feeding and discharging.

Owner:周小鹏

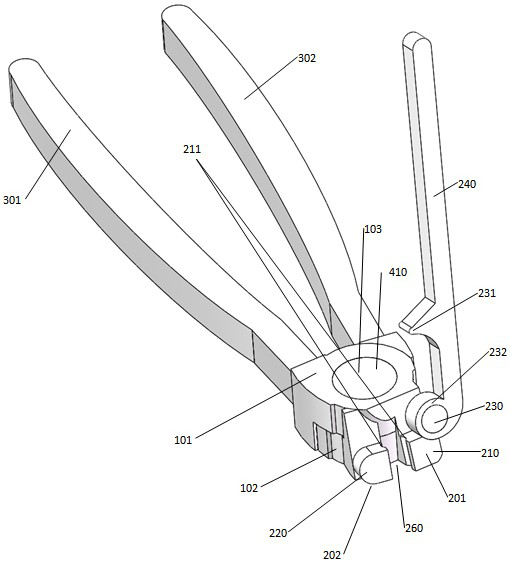

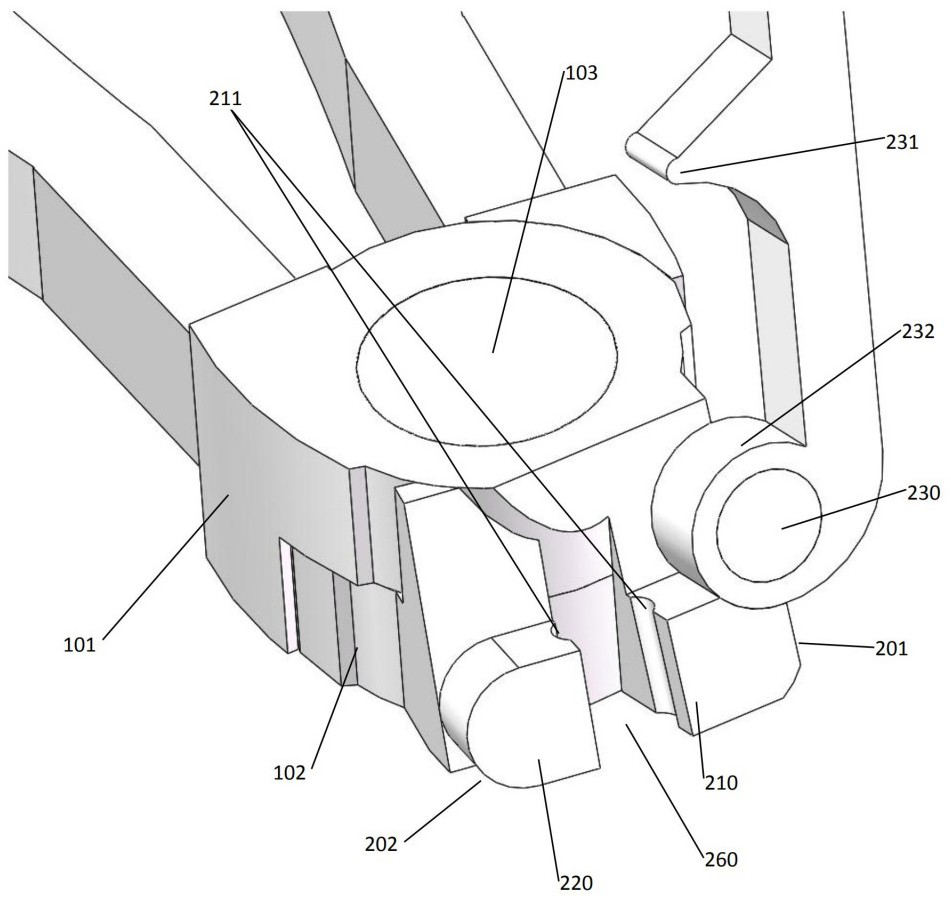

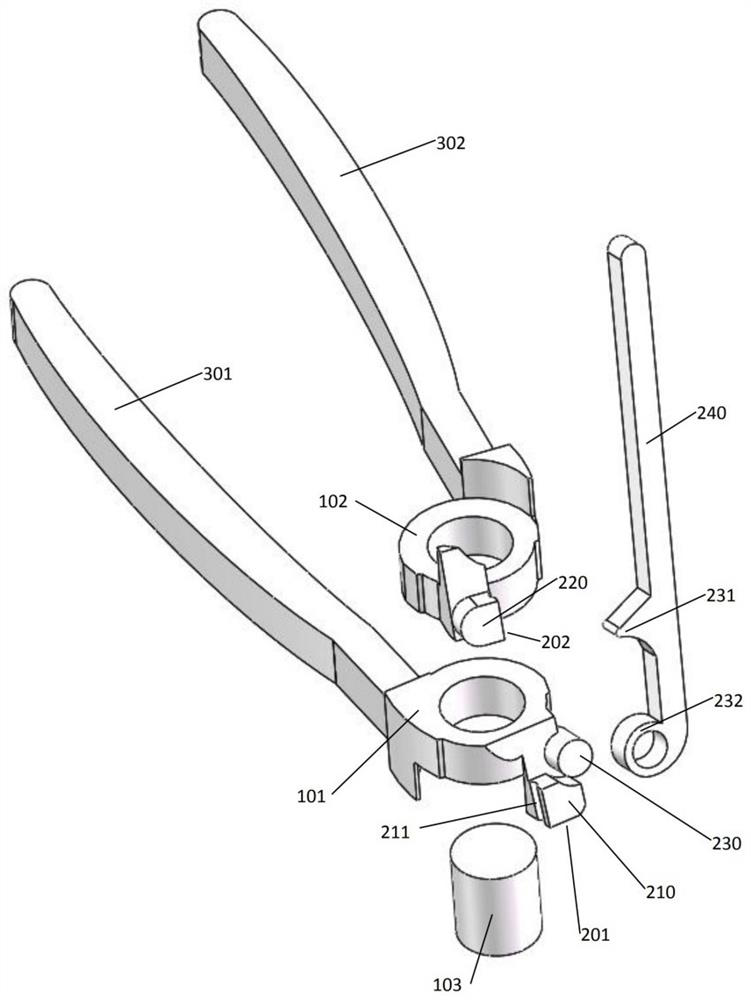

Kirschner wire operating forceps

PendingCN112869860ASolve the clampingSolve the bending problemOsteosynthesis devicesTransverse grooveOrthopedic department

The invention relates to a pair of kirschner wire operating forceps, which comprise two cheek rotating parts which rotate relatively, each cheek rotating part extends to one end to form a forceps head, and the two forceps heads form an opening and closing forceps mouth; and each cheek rotating part extends towards the other end to form a handle. The forceps are characterized in that the forceps head can be two clamping heads which are provided with transverse groove clamping surfaces which are matched with each other. The forceps is simple in structure and solves the problems of clamping, bending and cutting of orthopedic kirschner wires.

Owner:ZHENGZHOU ZEZHENG TECHN SERVICES

Intermediate frequency heating system

InactiveCN101909374AHeating evenlyImprove heating efficiencyCoil arrangementsInduction heating controlTemperature controlPower controller

The invention relates to a heating system, in particular to an intermediate frequency heating system, which mainly comprises an intermediate frequency power controller, an induction heating ring and a water cooling system, wherein the intermediate frequency power controller is connected with the induction heating ring; the water cooling system is connected with the induction heating ring; the intermediate frequency power controller adopts a serial resonant inverting circuit; and an electronic device IGBT is composed of a converting full bridge, and is matched with a power regulating circuit, a protection circuit and a display circuit. The intermediate frequency heating system takes the IGBT as a main converting element, has the characteristics of high heating efficiency, uniform heating, simple operation, controllable temperature, convenient movement and the like, and particularly solves the problem of bending a steel pipe with the major diameter phi of 1,016*18mm made of X70 pipeline steel in a bridge rib steel pipe process.

Owner:SINOHYDRO ENG BUREAU 15

Machining method of pedal shaft core

InactiveCN113441905ASolve the bending problemSolve the problem that although the locking is hard enough, the production cost is highStructural engineeringMachine

The invention relates to a machining method of a pedal shaft core. The machining method of the pedal shaft core comprises the following steps of blanking and wire drawing, forming, tool withdrawal groove machining, thread rolling, heat treatment, vibration discharging, automatic material taking, annealing, cooling and blackening. In the step, due to the fact that thread rolling is carried out before heat treatment, it is quite convenient to machine, and meanwhile, heat treatment is carried out on the shaft core, so that the shaft core reaches the high hardness, a requirement that a pedal is large in strength and cannot be bent can be met, the head of the shaft core is annealed, the material hardness is greatly reduced; after spin riveting, the head of the shaft core is plastically deformed into a mushroom-shaped protrusion, and therefore the pedal frame is buckled, and the pedal is very safe to use; in the whole set of step, the longest machining time of a single shaft core is the annealing process, the time is 5 seconds per shaft core, and 5760 shaft cores can be produced per shift according to eight hours per shift, so that the production efficiency is greatly improved.

Owner:彭灵敏

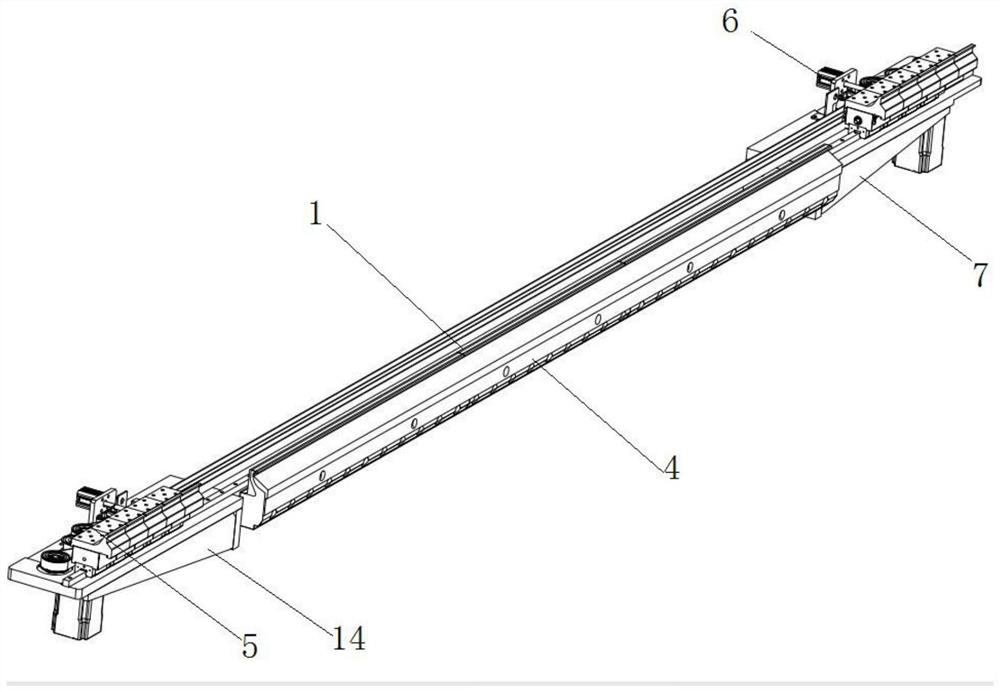

Local bending mechanism

PendingCN113714344ADemonstrate flexibilitySolve the bending problemStructural engineeringMechanical engineering

The invention discloses a local bending mechanism which comprises a local bending sliding rail, a left local bending assembly and a right local bending assembly. The left local bending assembly and the right local bending assembly are installed on the local bending sliding rail in a sliding mode and symmetrically arranged at the two ends of a bending machine lower tool; the left local bending assembly and the right local bending assembly are each provided with a local bending tool set and a tool selection air cylinder; the left local bending assembly comprises a left mounting frame and a left cutter driving mechanism; the right local bending assembly comprises a right mounting frame and a right cutter driving mechanism; and each local bending cutter set is formed by connecting a plurality of local bending cutters into a whole through a clamping pin mechanism, and the cutter selection air cylinders are installed on the left mounting frame and the right mounting frame. According to an automatic bending machine additionally provided with the local bending mechanism, the bending problem of a product needing bending at the two ends and needing no bending in the middle can be well solved, and the automatic bending machine can adapt to more products.

Owner:扬州汉智数控机械有限公司

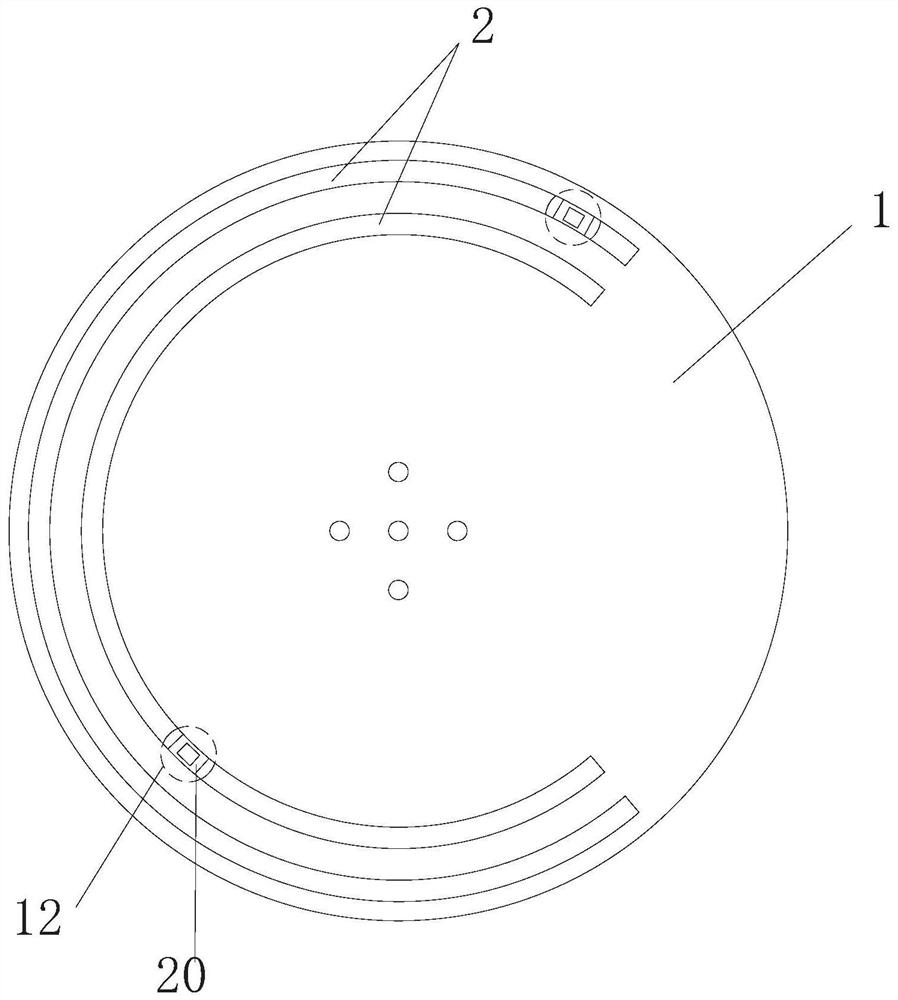

Packaging, transporting and storing technology of marine flexible pipe

InactiveCN111532884ASmall amount of deformationPerformance is not affectedContainers for annular articlesFilament handlingMarine engineeringStructure Collapse

The invention discloses a packaging, transporting and storing technology of a marine flexible pipe. According to the packaging, transporting and storing technology, by controlling the temperature in the coiling process and the elliptical ratio existing after coiling, the deformation amount of the marine flexible pipe is controlled, so that the deformation amount of the marine flexible pipe in thelater-period natural cooling and shaping process is greatly reduced, and therefore the performance of the marine flexible pipe is not influenced. The invention further provides a transportation fixingdevice. The transportation fixing device guarantees that the marine flexible pipe is free of damage in the bundling, piling, transporting and hoisting process. The invention further provides a long-term storage technology based on material performance and storage conditions. The long-term storage technology based on the material performance and the storage conditions effectively solves the problems of structure collapse and bending caused by environment temperature change in the long-term storage process of the marine flexible pipe.

Owner:杭州智海人工智能有限公司

Terminal Equipment

ActiveCN111405088BReduce thicknessSolve the bending problemDigital data processing detailsTelephone set constructionsTerminal equipmentStructural engineering

Owner:TCL COMM TECH NINGBO CO LTD

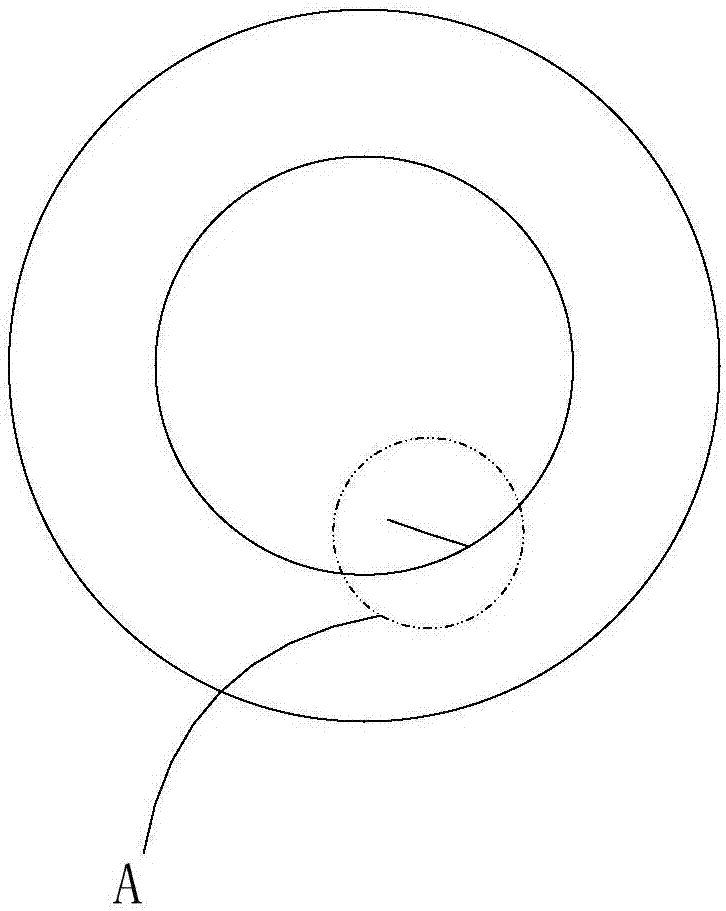

A wrapping paper pad for internally drawn copper coils

ActiveCN104843347BPlay an isolation rolePlay a functional roleContainers for annular articlesEngineeringCopper coil

A wrapping paper pad for internally drawn copper coils, characterized in that: the wrapping paper pad is formed by stacking circular first paper pads and second paper pads, and the second paper pad is superimposed on the first The top of the paper pad is in contact with the copper coil tube, and the second paper pad is surrounded by an arc-shaped hollow part for the interlaced layers of the copper coil tube to be inserted. The rotation direction of the hollow part is opposite to the extraction direction of the copper coil tube. The part is two continuous sections, wherein the first hollow part is an arc-shaped structure with a narrow front end and a wide rear end, the inner edge of the second hollow part is smoothly connected with the inner edge of the first hollow part, and the inner edge of the second hollow part The outer edge is connected to the outer edge of the first hollow part in a stepped diameter-reducing shape, and the second hollow part is in an arc-shaped structure with a wide front end and a narrow rear end. The invention is simple in structure, strong and wear-resistant, better solves the problem of bending or breaking of the interlaced layers at the bottom of the inner-drawing copper coil pipe, greatly improves production efficiency, and reduces production cost.

Owner:NINGBO JINTIAN COPPER TUBE +1

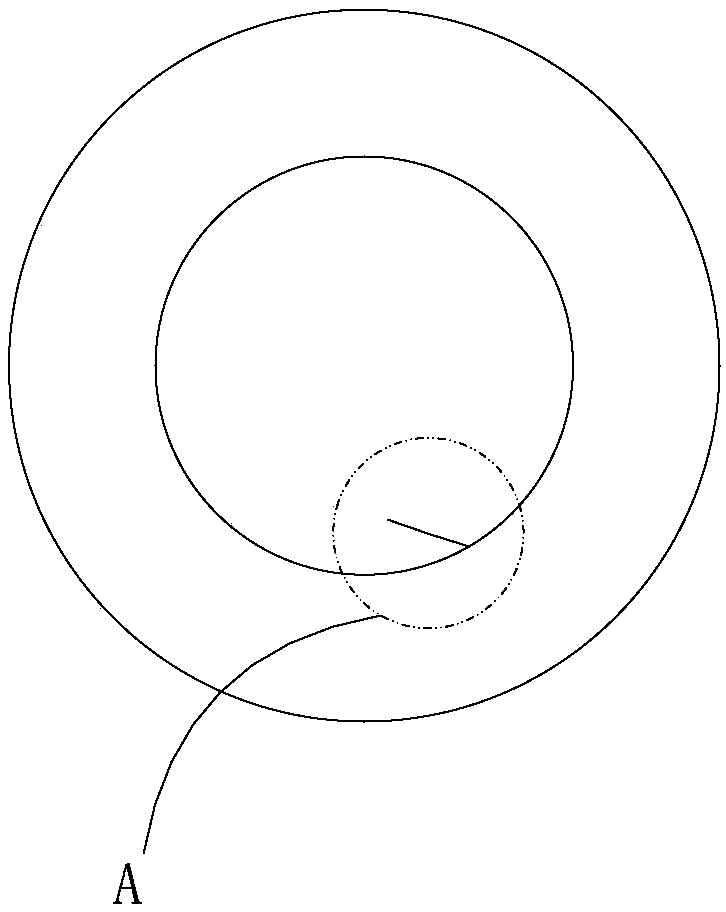

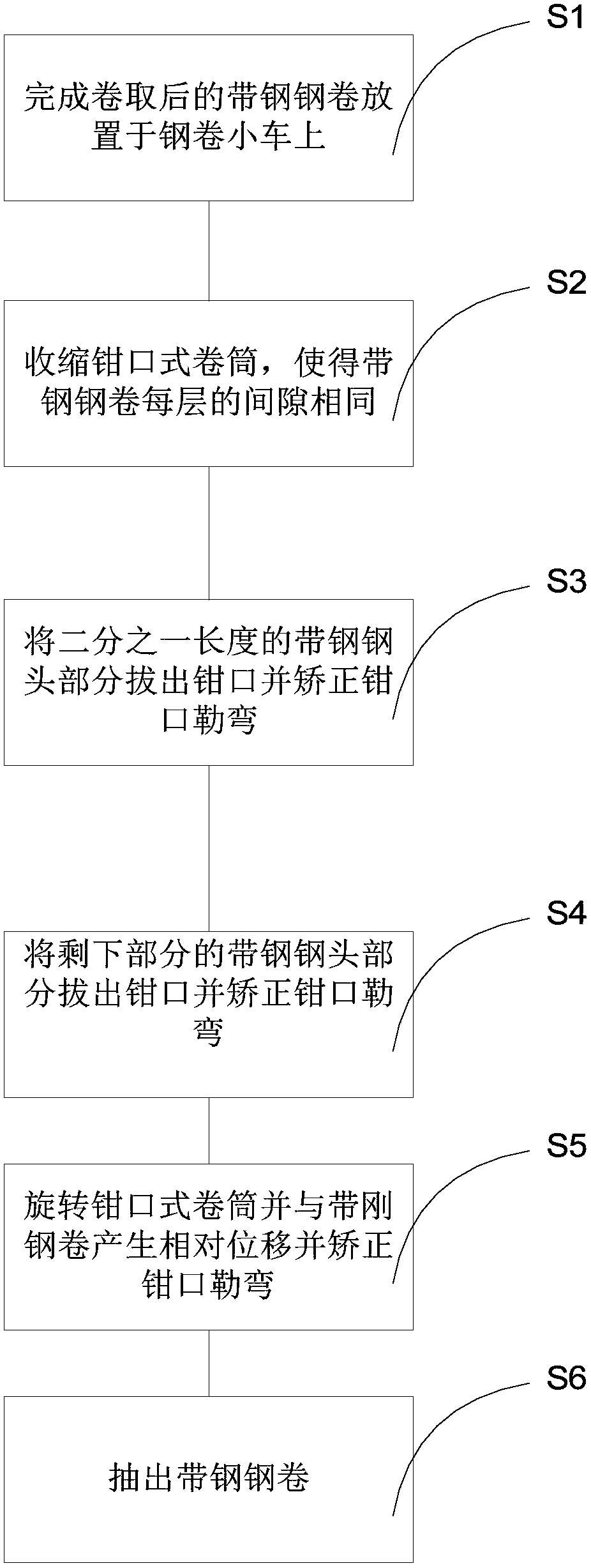

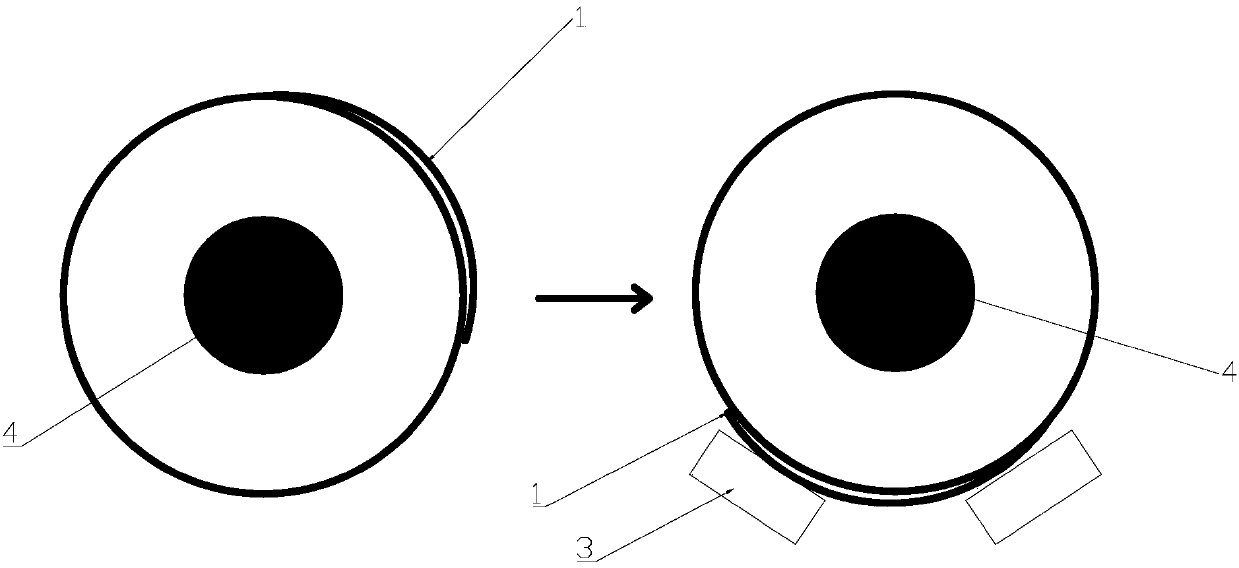

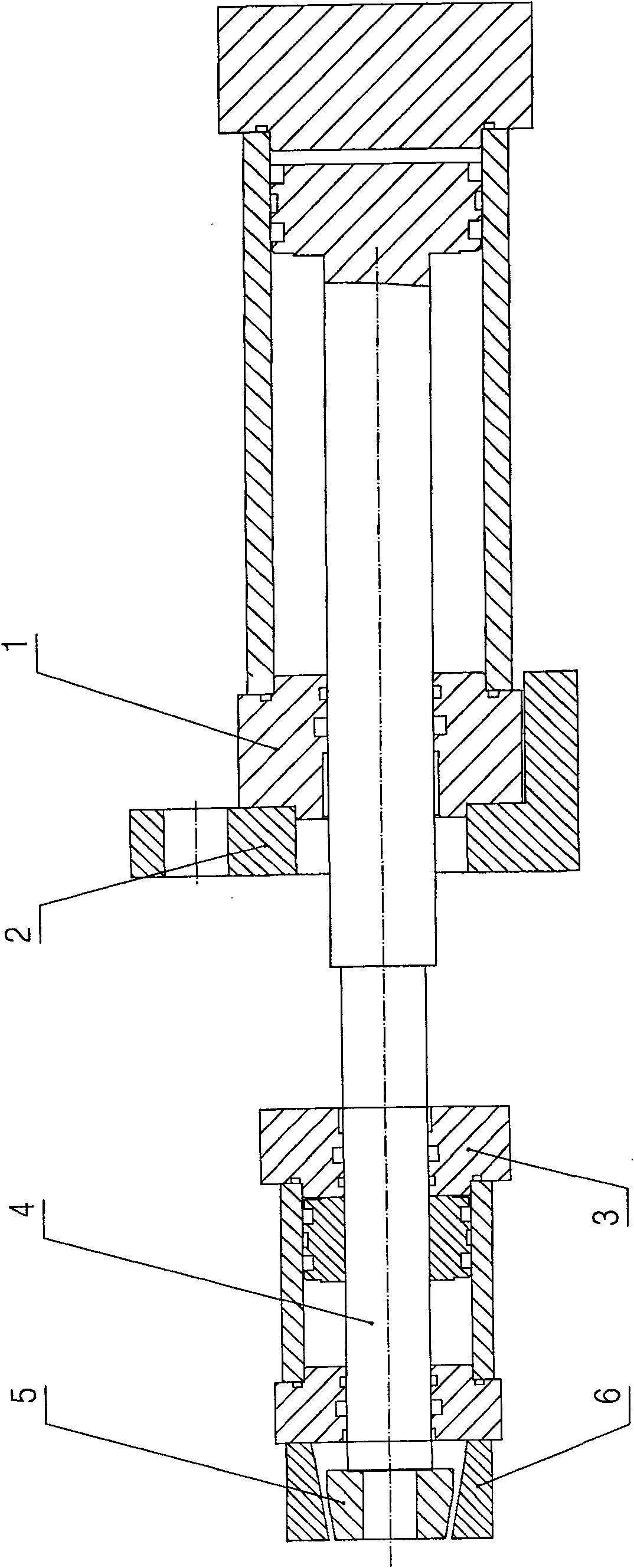

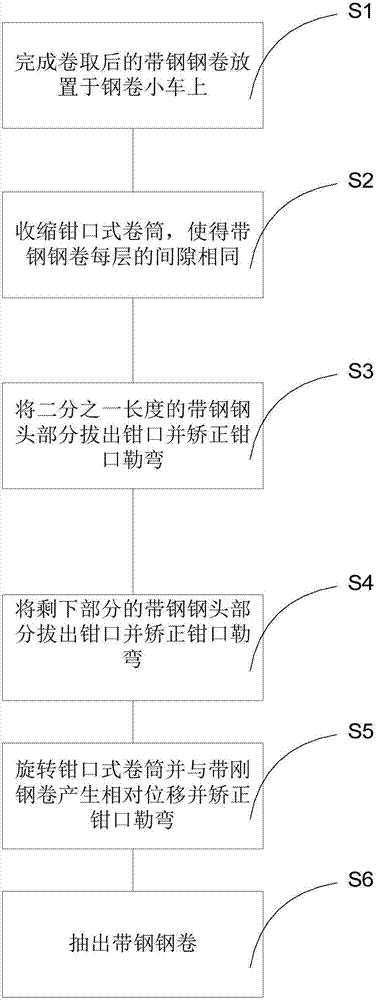

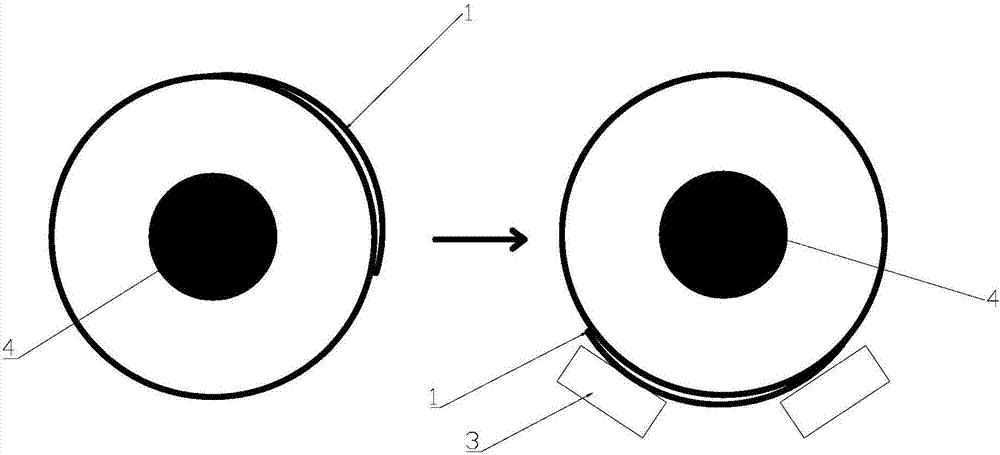

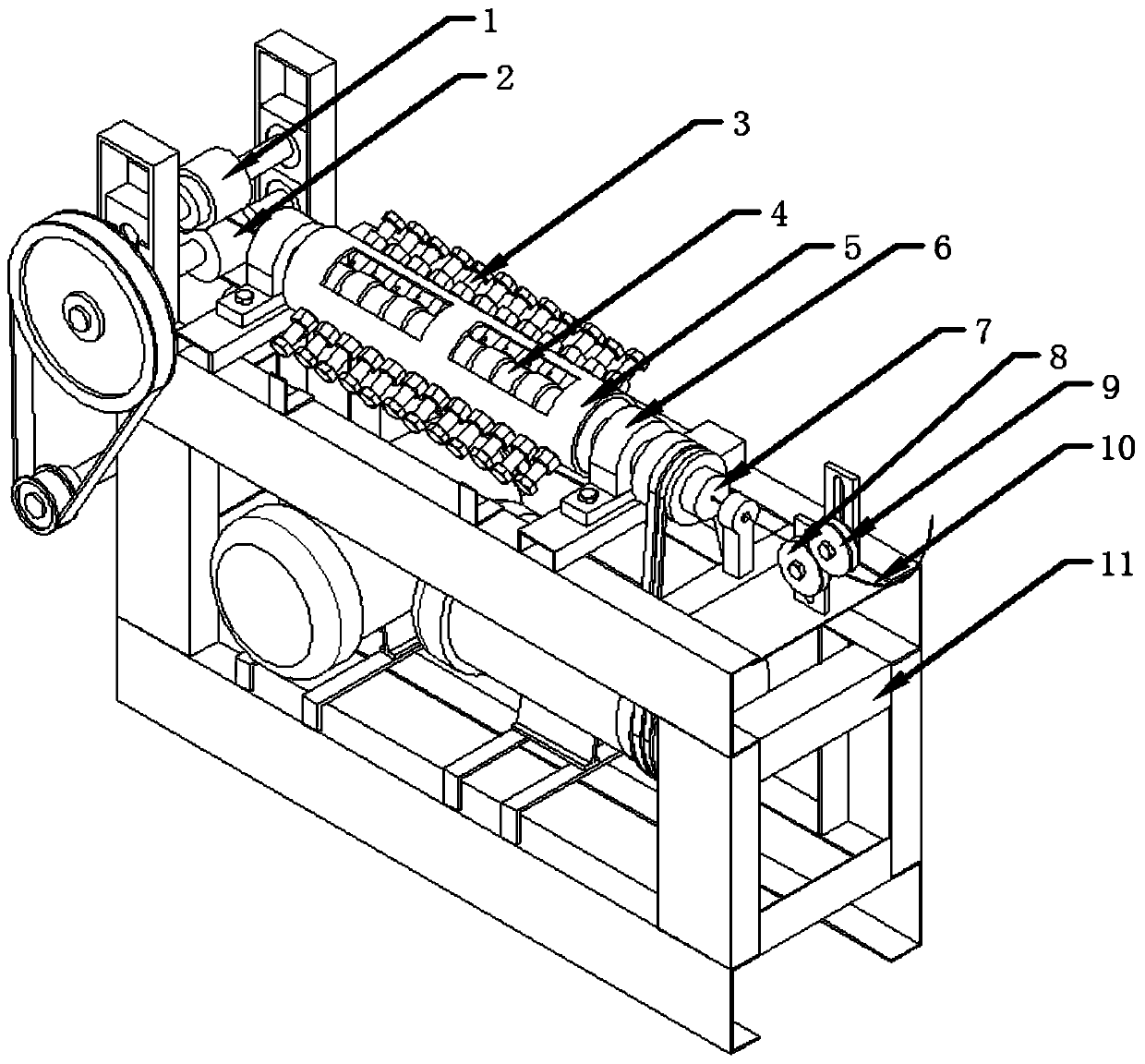

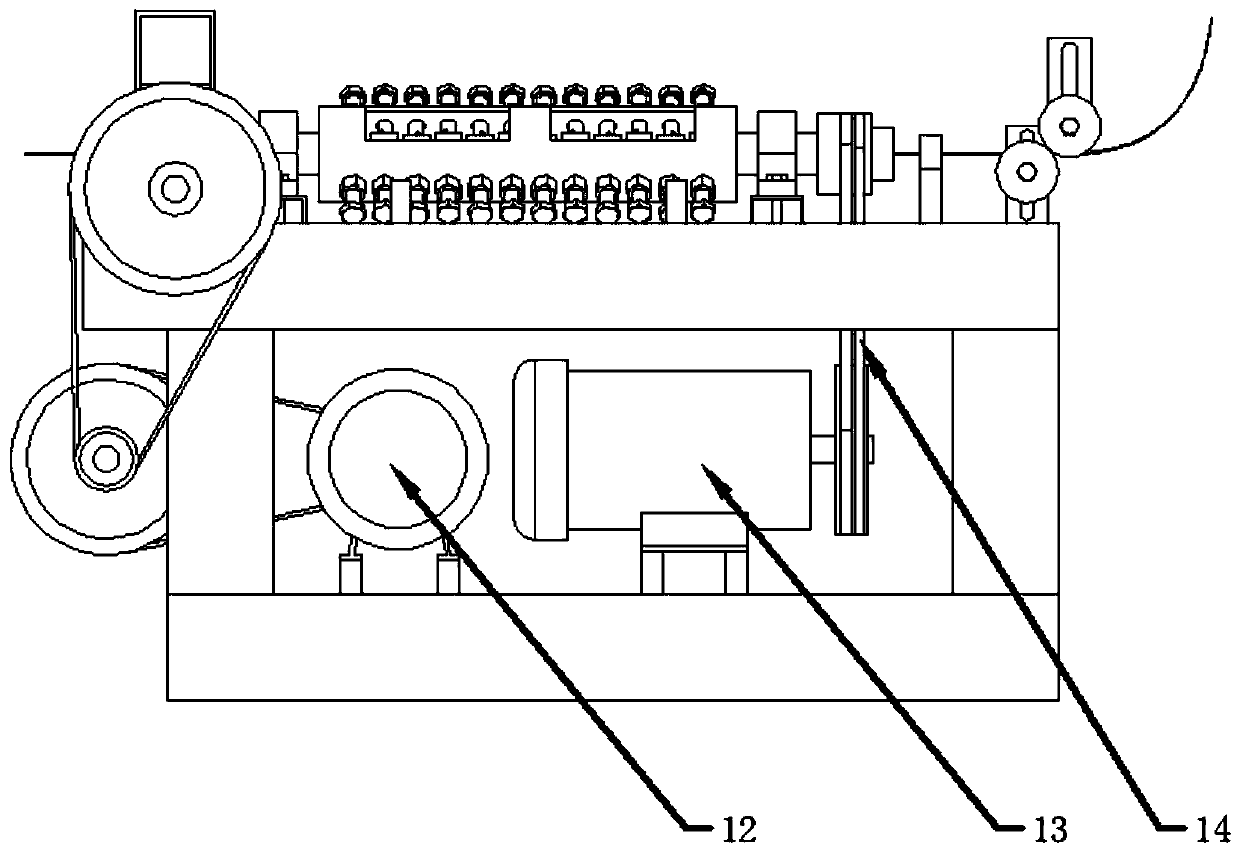

A Method for Eliminating Bending of Jaws of Inner Ring of Hot-rolled Finishing Coil

ActiveCN107537878BSolve the bending problemMeet quality requirementsRelative displacementStrip steel

The invention discloses a method for eliminating jaw bending of an inner ring of a hot-rolling finishing coil. The method comprises the steps that firstly, the head of strip steel is placed in a jaw of a jaw-type coil cylinder to be coiled, and the coiled strip steel coil is placed on a steel coil trolley, so that the tail of the outer ring of the strip steel coil is placed on a supporting plate of the steel coil trolley; secondly, the jaw-type coil cylinder is contracted, so that gaps of all layers of the strip steel coil are same; thirdly, half of the strip steel head in the jaw is pulled out of the jaw, and the pulled-out part is flattened; fourthly, an all-cotton fabric on the strip steel head in the jaw in the third step is pulled out of the jaw, and the pulled-out part is flattened;fifthly, the jaw-type coil cylinder is rotated to enable the jaw and the strip steel head to make relative displacement, the length of relative replacement is the same as the length of the pulled-outpart in the fourth step, and the relative displacement part is flattened; and sixthly, the strip steel coil is pulled out. Jaw bending caused by the jaw-type coil cylinder can be effectively eliminated.

Owner:BAOSHAN IRON & STEEL CO LTD

Top pulling device in pipe bender

The invention discloses a pushing device in a pipe bending machine, which can cause the pipe bending machine to bend short pipes; the pushing device comprises a pushing pipe, an oil cylinder base and a dual-outlet type pushing oil cylinder which is arranged on the oil cylinder base; a piston of the pushing oil cylinder and piston rods which are arranged at the left side and the right side of the piston are provided with perforated operation holes; the end part of the piston rod at the left side is provided with the pushing pipe; the internal hole of the pushing pipe is communicated with the operation hole; the end part of the piston rod at the right side is provided with a position limit nut by a thread; the oil cylinder base is movably arranged on a sliding plate which is movably arranged on a rack; the rack is provided with a positioning tooth; the side part of one side of the positioning tooth is embedded in the positioning concave trough of the sliding plate. A pushing connecting pipe with a hollow structure is also arranged between the pushing pipe and the piston rod. The pipe bending machine installed with the pushing device of the invention can be used for processing the short pipes, especially for the short pipes with the bending radius which is equal to or less than 1.5 times of the external diameter of the pipe.

Owner:JIANGSU HEFENG MECHANICAL MAKING

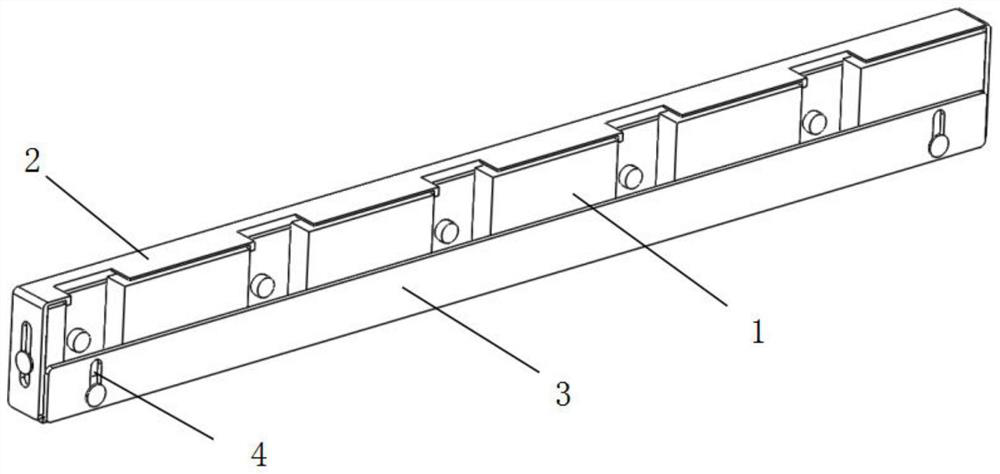

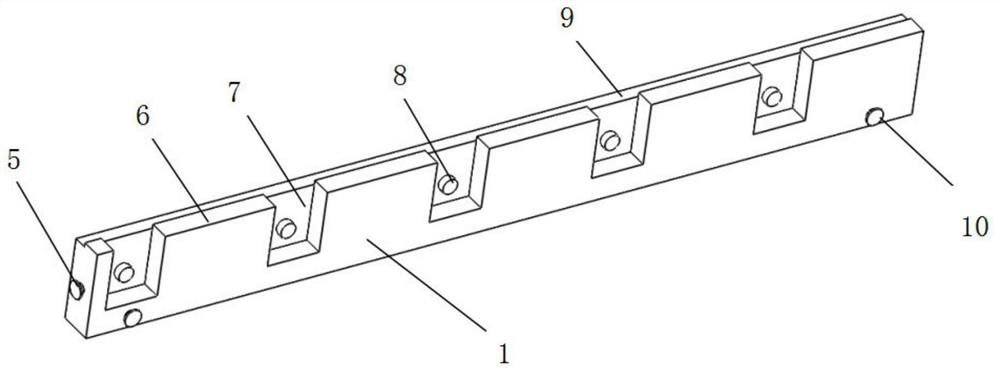

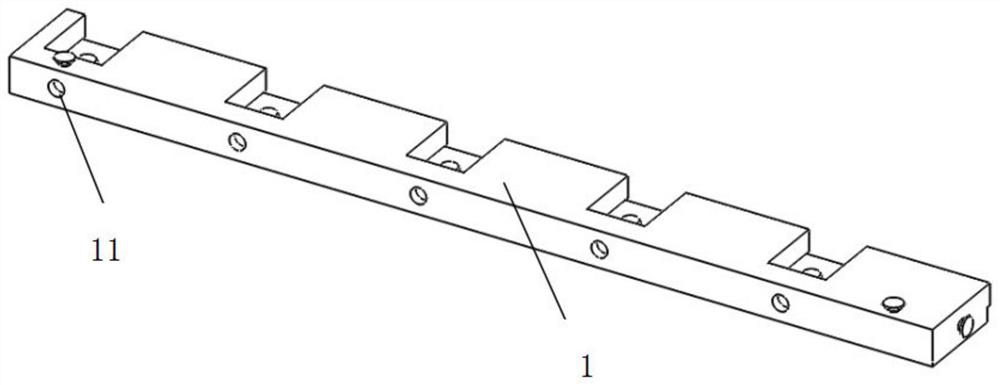

Laser fixing device and fixing method for c-mount laser welding line

ActiveCN113540961BIncrease productivitySimple structureLaser detailsSemiconductor lasersEngineeringErbium lasers

The invention relates to a laser fixing device and a fixing method for a C-mount laser welding line. The laser fixing device includes a fixing bar, a pressing piece and a retaining bar; There is a gap in the middle of the pressing sheet, which corresponds to the fixing groove, and the sides of the pressing sheet are provided with symmetrically structured sides, through which the pressing sheet is connected to the fixing bar; The laser fixing device used in the C-mount laser welding line of the present invention has the advantages of simple structure, low cost and convenient and reliable operation. The device of the present invention is small in volume, simple in structure and convenient in maintenance and repair. The device fixes 5 C-mount lasers at a time, and can realize the continuous welding line work of C-mount lasers. Compared with the previous single laser fixing welding line, the production efficiency of laser welding line is improved. ten times.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

A 2D forming tooling and forming process for copper wire of a card-sending motor

The invention relates to a copper wire 2D forming tool for a card generator, which includes a chassis, a number of positioning holes arranged on the chassis, an angle positioning member arranged on the chassis through the positioning holes and whose position can be adjusted, a central column on the chassis fixedly arranged, Rotate the turntable connected to the center column, the handle connected to the outer surface of the turntable, the wire groove fixedly arranged above the chassis, the adjustment block slidably connected to the wire groove and the stop post detachably connected to the turntable, the Both the retaining column and the wire groove are arranged radially along the center column, and the inner and outer walls of the retaining column are close to the inner end of the channel, the top of the angle positioning member is higher than the bottom end of the handle, and the handle and the inner end of the channel are close together. The contact surface of the angle positioning part is an inclined plane; the 2D forming tooling for the copper wire of the hairpin motor of the present invention can realize the flexible processing of the copper wire and meet the processing requirements of the shapes of the copper wires of each layer; Easy to operate.

Owner:跃科智能制造(无锡)有限公司

Packaging paper pad for inwards-drawing type copper coil pipe

ActiveCN104843347APlay an isolation rolePlay a functional roleContainers for annular articlesCopper coilElectrical and Electronics engineering

A packaging paper pad for an inwards-drawing type copper coil pipe is characterized by being formed by stacking a circular-ring-shaped first paper pad body and a circular-ring-shaped second paper pad body. The second paper pad body is stacked above the first paper pad body and is in contact with the copper coil pipe; arc-shaped hollow-out portions allowing a staggering layer of the copper coil pipe to be contained are circularly arranged in the second paper pad body, and the rotating direction of the hollow-out portions is opposite to the drawing direction of the copper coil pipe; the hollow-out portions are two continuous segments; the first hollow-out portion is of a gradually-wide arc-shaped structure with the narrow front end and the wide rear end, and the inner edge of the second hollow-out portion is in smooth connection with the inner edge of the first hollow-out portion; and the outer edge of the second hollow-out portion is in stepped reducing connection with the outer edge of the first hollow-out portion, and the second hollow-out portion is of a gradually-narrow arc-shaped structure with the wide front end and the narrow rear end. The packaging paper pad is simple in structure, firm and resistant to abrasion, and better solves the problem that the staggering layer of a bottom layer of the inwards-drawing type copper coil pipe is bent or broken; and the production efficiency is greatly improved, and the production cost is reduced.

Owner:NINGBO JINTIAN COPPER TUBE +1

Method for eliminating jaw bending of inner ring of hot-rolling finishing coil

ActiveCN107537878ASolve the bending problemMeet quality requirementsRelative displacementStrip steel

The invention discloses a method for eliminating jaw bending of an inner ring of a hot-rolling finishing coil. The method comprises the steps that firstly, the head of strip steel is placed in a jaw of a jaw-type coil cylinder to be coiled, and the coiled strip steel coil is placed on a steel coil trolley, so that the tail of the outer ring of the strip steel coil is placed on a supporting plate of the steel coil trolley; secondly, the jaw-type coil cylinder is contracted, so that gaps of all layers of the strip steel coil are same; thirdly, half of the strip steel head in the jaw is pulled out of the jaw, and the pulled-out part is flattened; fourthly, an all-cotton fabric on the strip steel head in the jaw in the third step is pulled out of the jaw, and the pulled-out part is flattened;fifthly, the jaw-type coil cylinder is rotated to enable the jaw and the strip steel head to make relative displacement, the length of relative replacement is the same as the length of the pulled-outpart in the fourth step, and the relative displacement part is flattened; and sixthly, the strip steel coil is pulled out. Jaw bending caused by the jaw-type coil cylinder can be effectively eliminated.

Owner:BAOSHAN IRON & STEEL CO LTD

Shape correction enhancement device for magnetostrictive waveguide wire

The invention provides a shape correction enhancement device for a magnetostrictive waveguide wire. The shape correction enhancement device comprises a support platform, a guide structure, a central shaft, a shape correction structure and an extrusion structure, wherein the guide structure, the central shaft, the shape correction structure and the extrusion structure which are sequentially arranged on the support platform according to the extension direction of the waveguide wire; the central shaft is of a hollow structure; the shape correction structure comprises shape correction blocks and ashape correction block fixing cover; the shape correction block fixing cover is cylindrical; one end of the shape correction block fixing cover is fixedly connected with the central shaft and the other end is arranged on the support platform through a bracket; a plurality of shape correction blocks are axially arranged at intervals and two adjacent shape correction blocks are arranged in a staggered manner up and down; and each shape correction block is fixed on the shape correction block fixing cover through a bolt. The shape correction enhancement device can be used for carrying out shape correction on the waveguide wire, the bending problem of the waveguide wire can be solved, the performance of the waveguide wire is improved, the magnetostrictive coefficient is improved, relatively large internal stress in the waveguide wire is reduced and the thermal expansion coefficient is basically not affected.

Owner:TIANJIN HENGLIYUANDA INSTR

Bending die for cooling pipe in poloidal field coil support and method of bending die

The invention discloses a bending die for a cooling pipe in a poloidal field coil support. Positioning shaft holes are formed in cooling pipe bending radius round points arranged on a bending bottom plate. Wheels and bending handles are fixedly arranged on the bending bottom plate through positioning shafts via the holes. Stress application bars are arranged in the threaded holes of the bending handles. Four baffles are arranged on the bending bottom plate through screw rods and nuts via gaskets. Two pressing plates are arranged on the bending bottom plate through hexagon socket head cap screws. The cooling pipe drawing is carved on the bending bottom plate, the bending radius round point positions are marked, the threaded holes containing the positioning shafts are drilled and tapped at the positions, where the bending radius round points are arranged, on the bending bottom plate, threaded holes used for installing the four baffles are drilled and tapped, the threaded holes are used for fixing the three bending dies and the four baffles, then one end of the bent cooling pipe penetrates the bending handles and the wheels, and one end of the cooling pipe is fixed to the bending bottom plate. The stress application bars are arranged in the threaded holes of the bending handles, the stress application bars are rotated according to the drawing orientation of the cooling pipe, the cooling pipe and the wheels can rotate, after the cooling pipe and the wheels rotate to positions, the stress application bars are loosened, and the cooling pipe is rebounded to the bending position.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Production process of two-time formed high-accuracy ceramic ferrule

The invention discloses a production process of a two-time formed high-accuracy ceramic ferrule. The production process includes the following steps of banburying, smashing, primary injection molding,secondary injection molding and after-treatment. A ceramic ferrule semi-finished product is subjected to thermal debinding and sintering treatment, and a ceramic ferrule finished product is obtained.According to the production process of the two-time formed high-accuracy ceramic ferrule, the primary injection molding procedure and the secondary injection molding procedure are designed particularly; a tubular intermediate body is obtained through primary injection molding; and during secondary injection molding, ceramic plastic materials in a thermal flow channel are injected into a through hole through injecting holes in the tubular intermediate body for cooperation with a second core rod in the through hole, an optical fiber injecting hole is obtained, the ceramic plastic materials areinjected from the two sides of the second core rod through the multiple injecting holes, balance of the impact force is achieved, thus the problem of bending of the second core rod is avoided, and theforming accuracy of the optical fiber inserting hole is guaranteed.

Owner:湖南中科光电有限公司

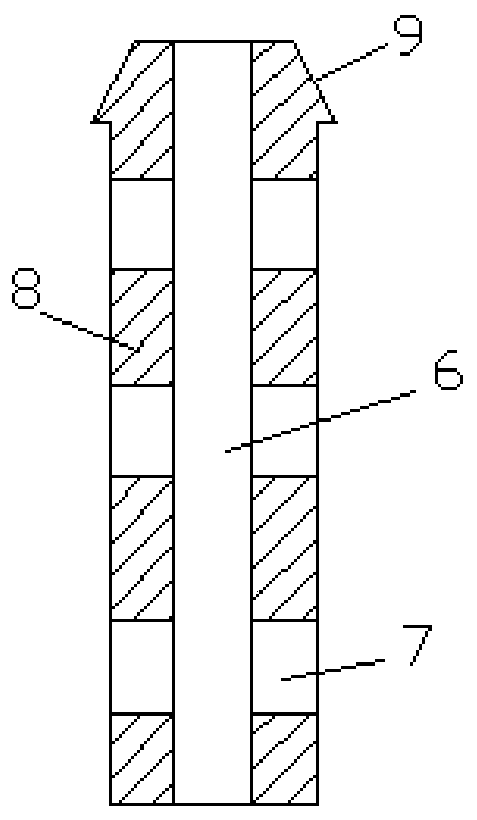

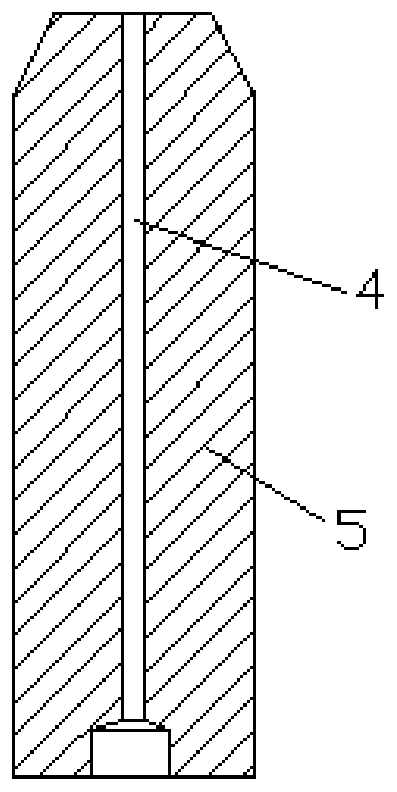

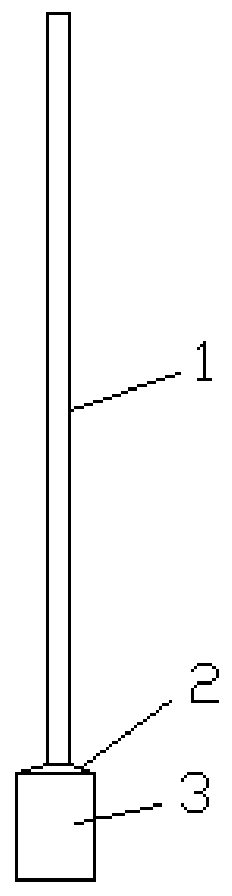

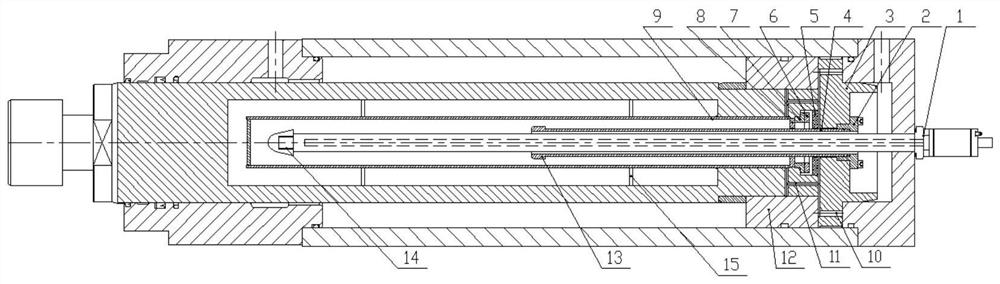

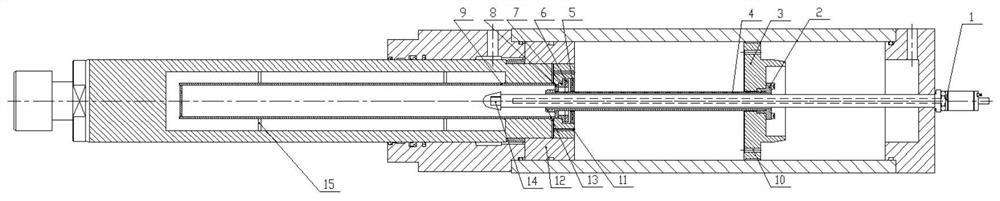

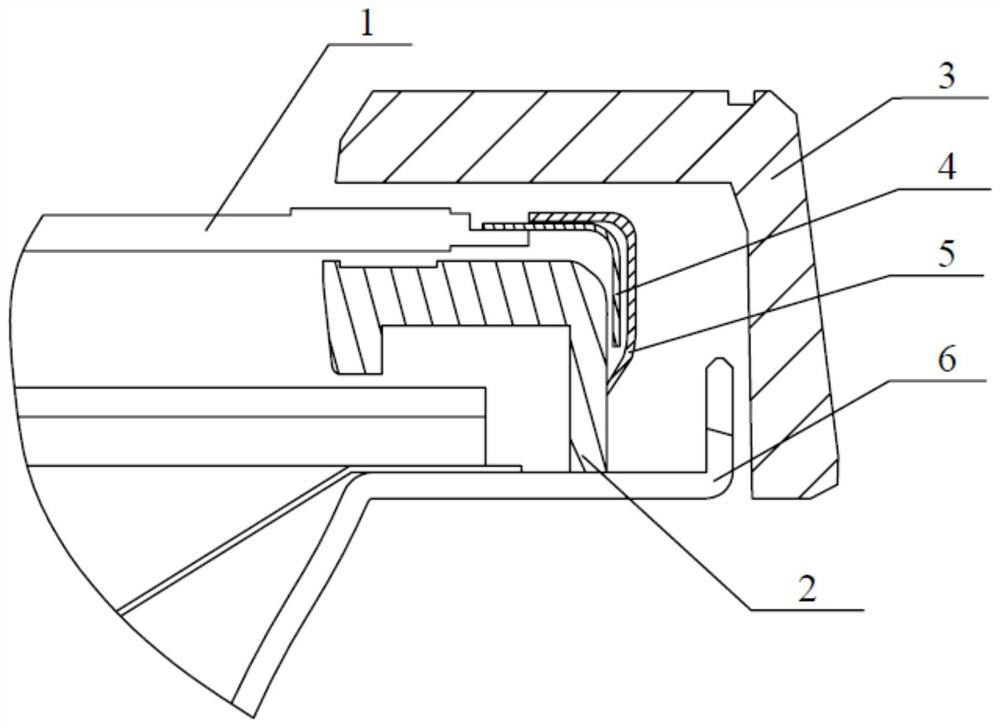

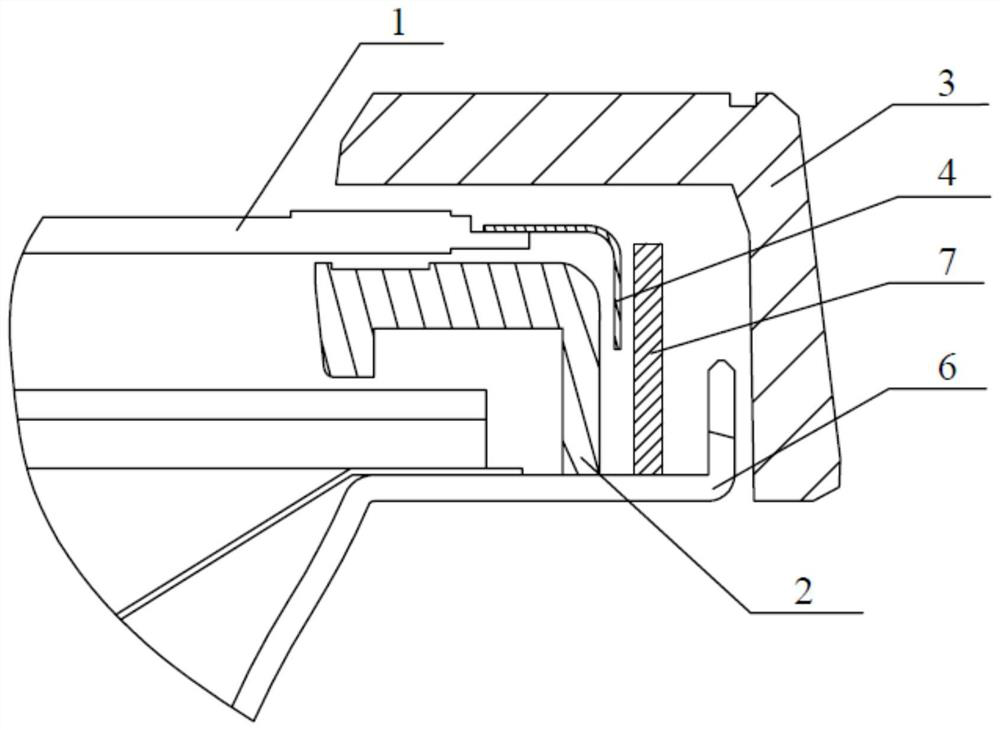

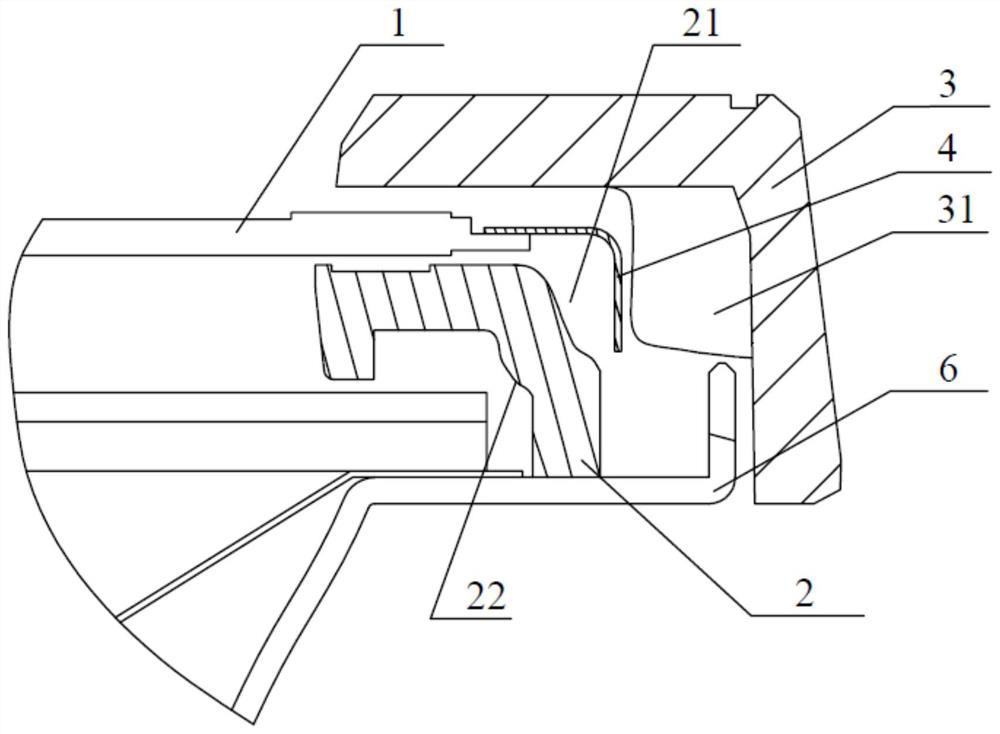

Ultra-long stroke hydraulic cylinder built-in sensor protection device

ActiveCN113027863BPrevent saggingSolve the bending problemFluid-pressure actuatorsPiston rodsHydraulic cylinderSupport point

The invention discloses a built-in sensor protection device for an ultra-long-stroke hydraulic cylinder, which includes an inner protective tube, an open flange, a supporting piston, an outer protective tube, a magnetic ring, a magnetic ring seat, a stopper, a main piston, a boss and a boss nut The present invention provides an end supporting point for the built-in sensor of the hydraulic cylinder through the main piston, and provides a middle supporting point for the built-in sensor of the hydraulic cylinder through the supporting piston. The support can better avoid the bending problem of the built-in sensor protection device of the ultra-long stroke hydraulic cylinder, and has the characteristics of simple structure and outstanding effect.

Owner:韶关液压件厂有限公司

A liquid crystal module

ActiveCN108287426BSolve the bending problemSolve protection problemsNon-linear opticsEngineeringMechanical engineering

The invention belongs to the technical field of liquid crystal televisions and discloses a liquid crystal module. The liquid crystal module includes a glass panel, a middle frame, a front frame and a COF, wherein the middle frame is arranged under the glass panel, and the outer wall of the middle frame is provided with grooves; the front frame covers the outside of the glass panel and the middle frame, and Ribs are provided on the inner wall of the surface frame; one end of the COF is set on the glass panel, and the other end presses against the ribs and bends toward the groove. In the present invention, ribs are provided on the inner wall of the surface frame corresponding to the COF, and grooves are provided on the outer wall of the middle frame corresponding to the COF, so that the liquid crystal module does not need to add any limiting materials when assembling, but only uses the ribs to adjust the COF. Pressure is applied to make the COF bend towards the inside of the groove, and the relative position of the groove and the rib is used to fix it, which efficiently and concisely solves the COF bending and positioning protection, thereby realizing the design of the ultra-narrow bezel LCD module.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

An automatic bending and welding equipment for door and window pipes

ActiveCN108581498BWill not deformWeld firmlyOther manufacturing equipments/toolsCircular discMachining

The invention relates to the field of automatic machining, in particular to automatic bending and welding equipment for door and window pipe materials. The automatic bending and welding equipment comprises a base and further comprises a rotary workbench, a first overturning mechanical arm, a first bending assembly, a second bending assembly, a second overturning mechanical arm and a welding assembly. The rotary workbench comprises a stepping type index plate and a rotary disc. The rotary disc is provided with a clamping assembly used for fixing a square pipe. The first overturning mechanical arm, the first bending assembly, the second bending assembly, the second overturning mechanical arm and the welding assembly are sequentially arranged in the output direction of the rotary disc, and the first overturning mechanical arm, the first bending assembly, the second bending assembly, the second overturning mechanical arm and the welding assembly are all arranged on the base. The output endof the first overturning mechanical arm and the output end of the second overturning mechanical arm are arranged oppositely and extend in the axis direction of the rotary disc. By means of the automatic bending and welding equipment, bending of the stainless steel square pipes and the right angle welding work are achieved.

Owner:济南萨博特种汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com