Small-diameter cylinder automatic forming device and process

An automatic forming, small-diameter technology, applied in other home appliances, home appliances, applications, etc., can solve the problem of not meeting the bending of fan-shaped sheets, and achieve the goal of controlling thermal deformation, reducing production costs, and improving quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

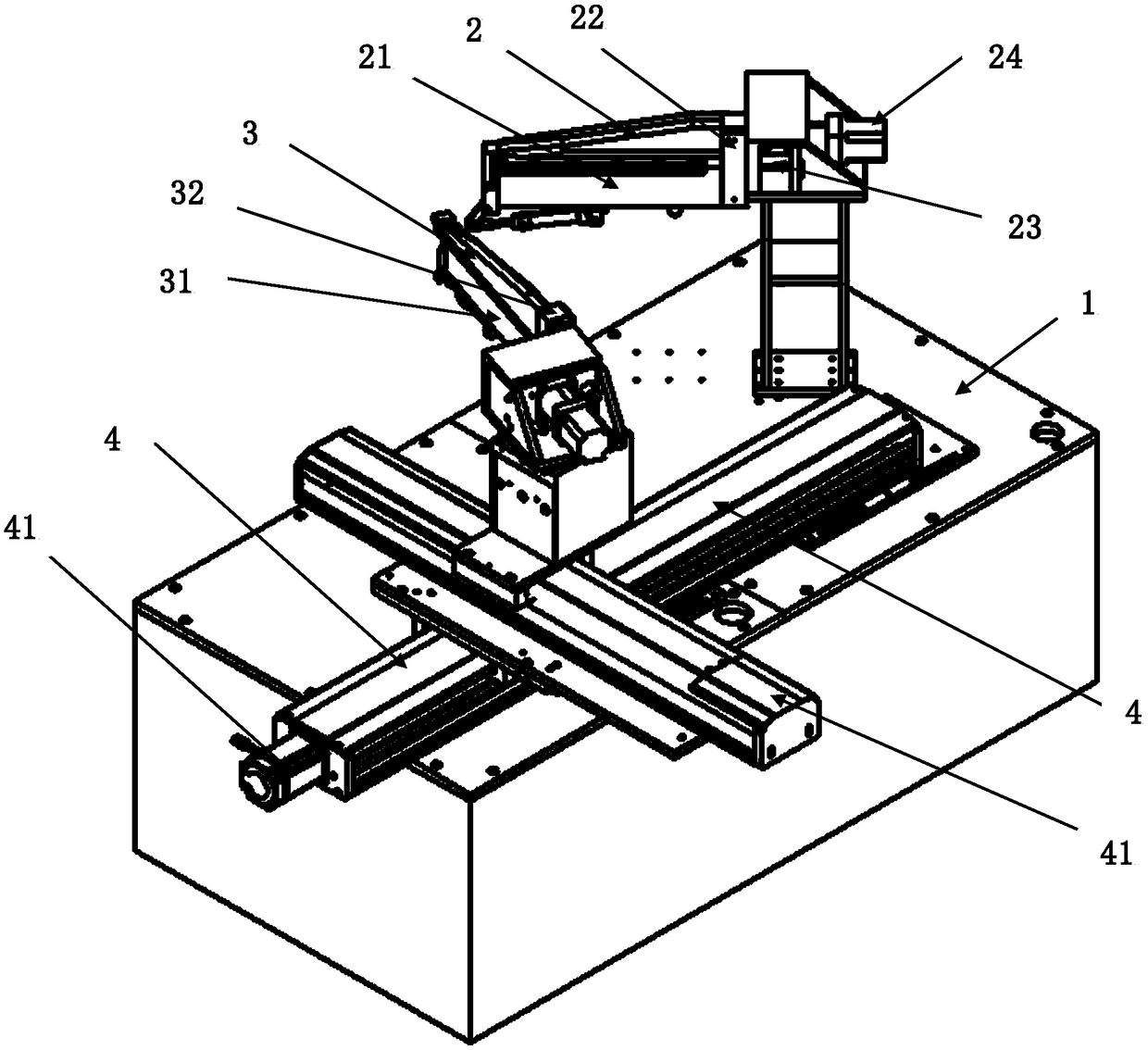

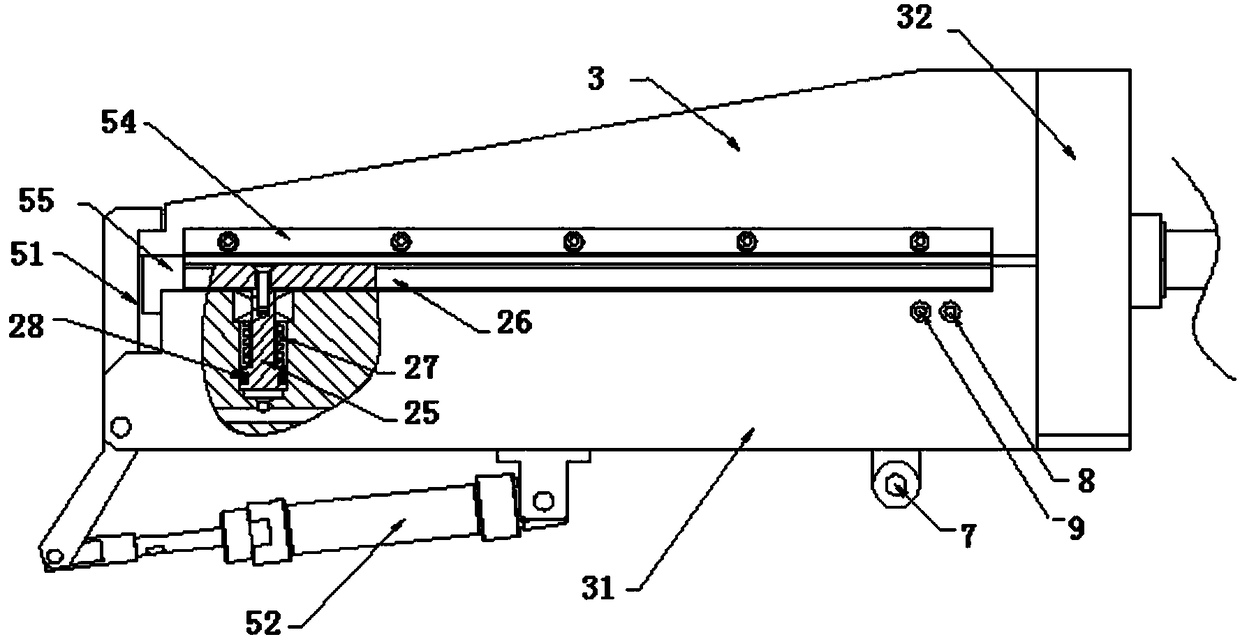

[0022] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0023] see Figure 1 ~ Figure 4 , this embodiment consists of machine base 1, left clamping arm 2, left clamping seat 21, left fixed seat 22, right clamping arm 3, right clamping seat 31, right fixed seat 32, guide rail 4, hydraulic system and cooling system composition. In this embodiment, the device for automatically bending the sheet metal 10 into a conical barrel 11 through the control system. The clamping arm of this embodiment is composed of a left clamping arm 2 and a right clamping arm 3 , the left clamping arm 2 is installed on the left clamping seat 21 , and the right clamping arm 3 is installed on the right clamping seat 31 . The left clamping arm 2 and the right clamping arm 3 are bilaterally symmetrical and have the same structure. Only the left clamping arm 2 and the left clamping seat 21 are described here, and the situation of the right cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com