Patents

Literature

1055results about How to "Guaranteed parallelism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data stream processing apparatus and method using query partitioning

InactiveUS20140229506A1Short response timeImprove abilitiesDigital data information retrievalDigital data processing detailsComputer hardwareData stream processing

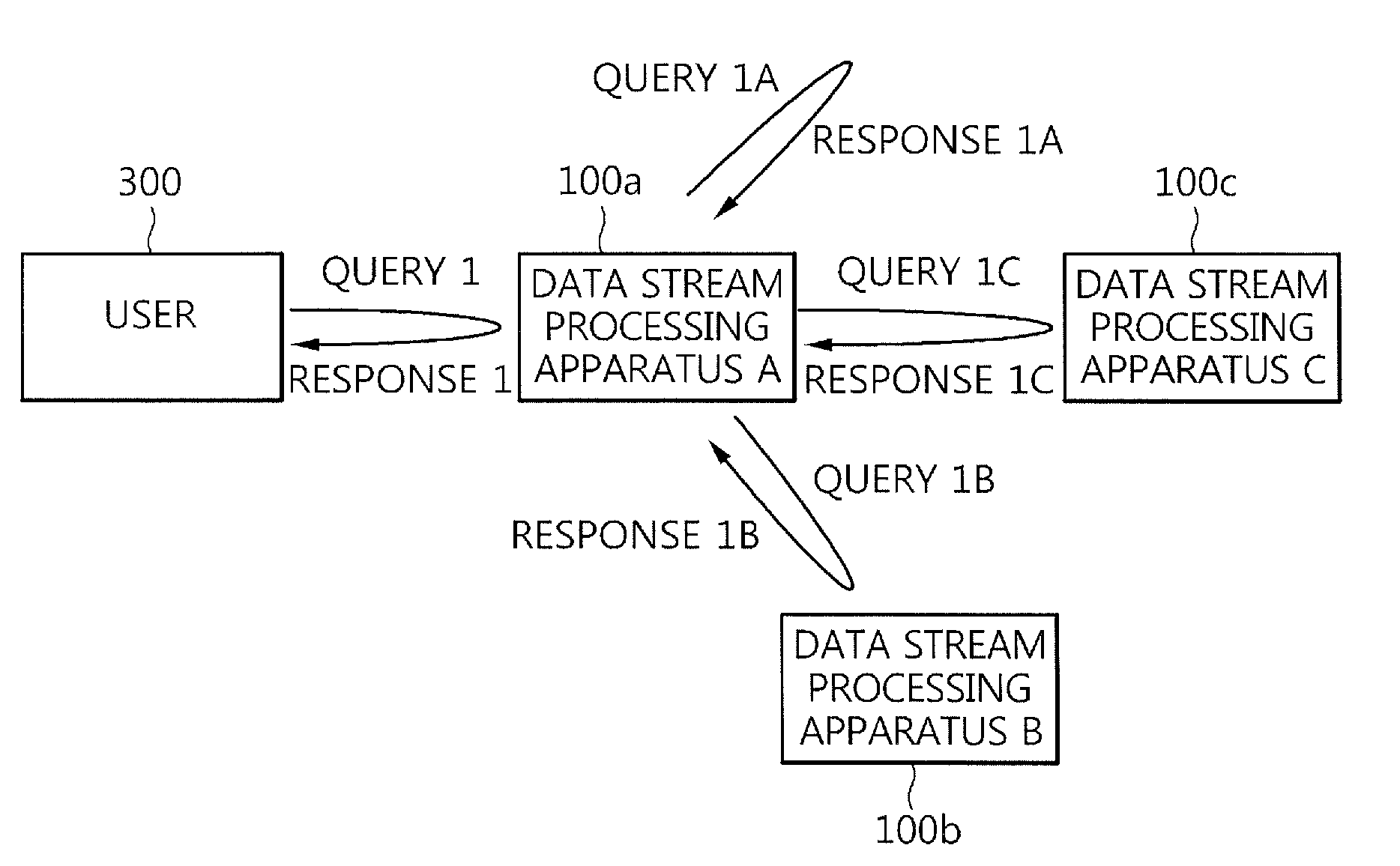

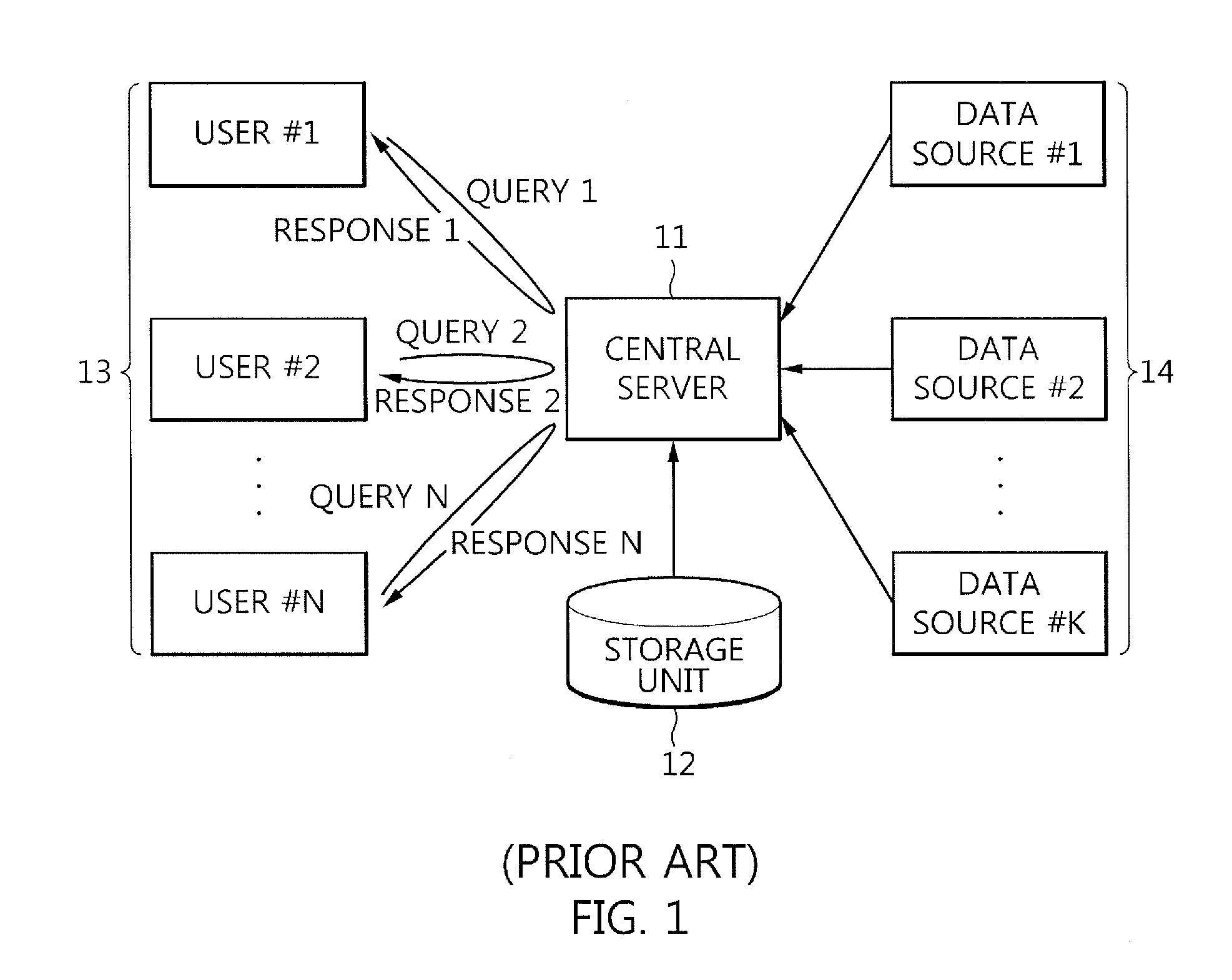

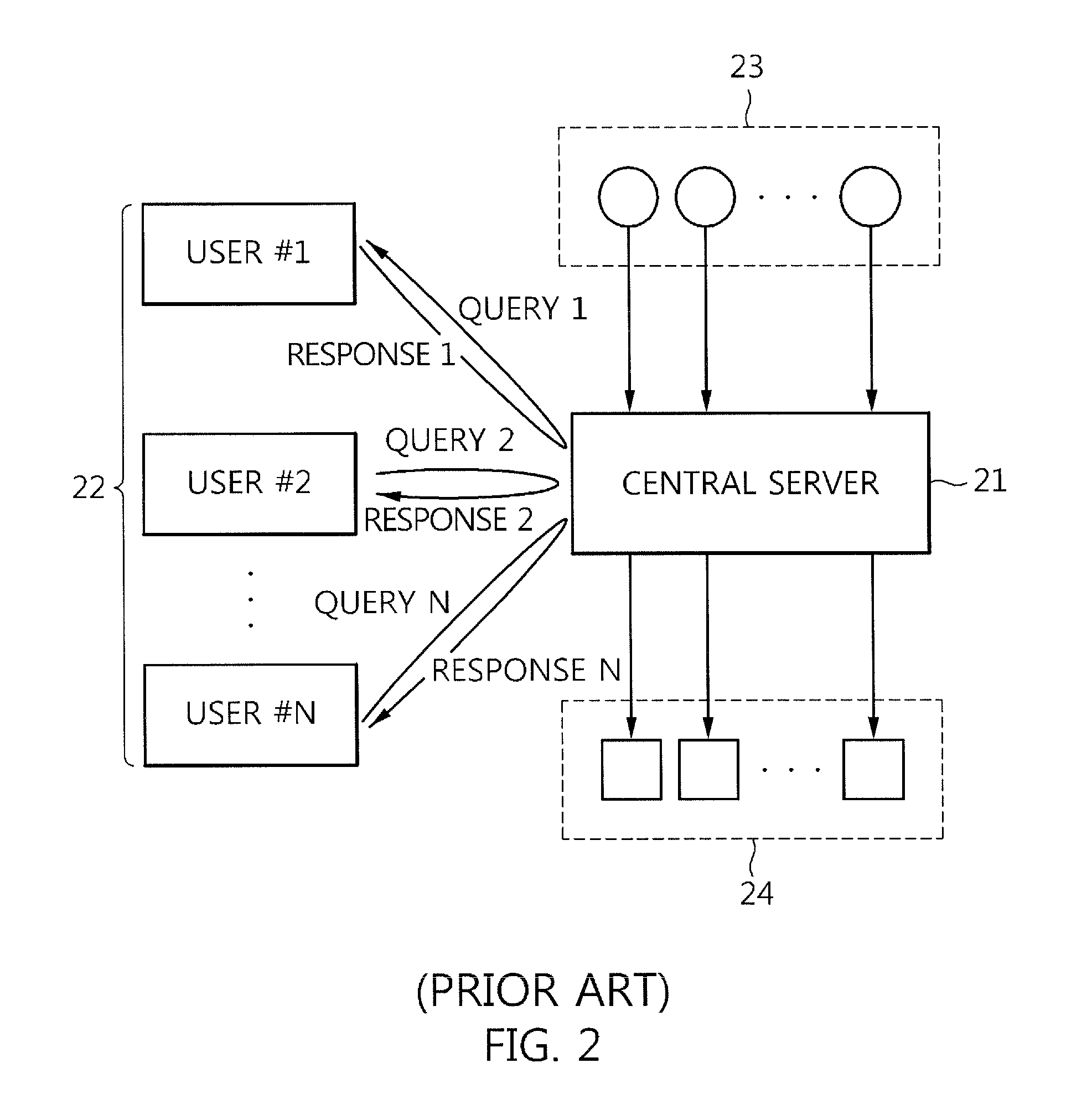

Disclosed herein is a data stream processing apparatus and method using query partitioning, which allow data stream processing apparatuses to perform partitioned processing / parallel processing on partitioned sub-queries. The proposed data stream processing apparatus using query partitioning receives a query from a user, partitions the query into a plurality of sub-queries, transmits the partitioned sub-queries to another data stream processing apparatus or a sub-query processing unit, integrates the results of the processing of sub-queries processed by the other data stream processing apparatus and the sub-query processing unit with each other, generates a response to the query, and transmits the generated response to the user.

Owner:ELECTRONICS & TELECOMM RES INST

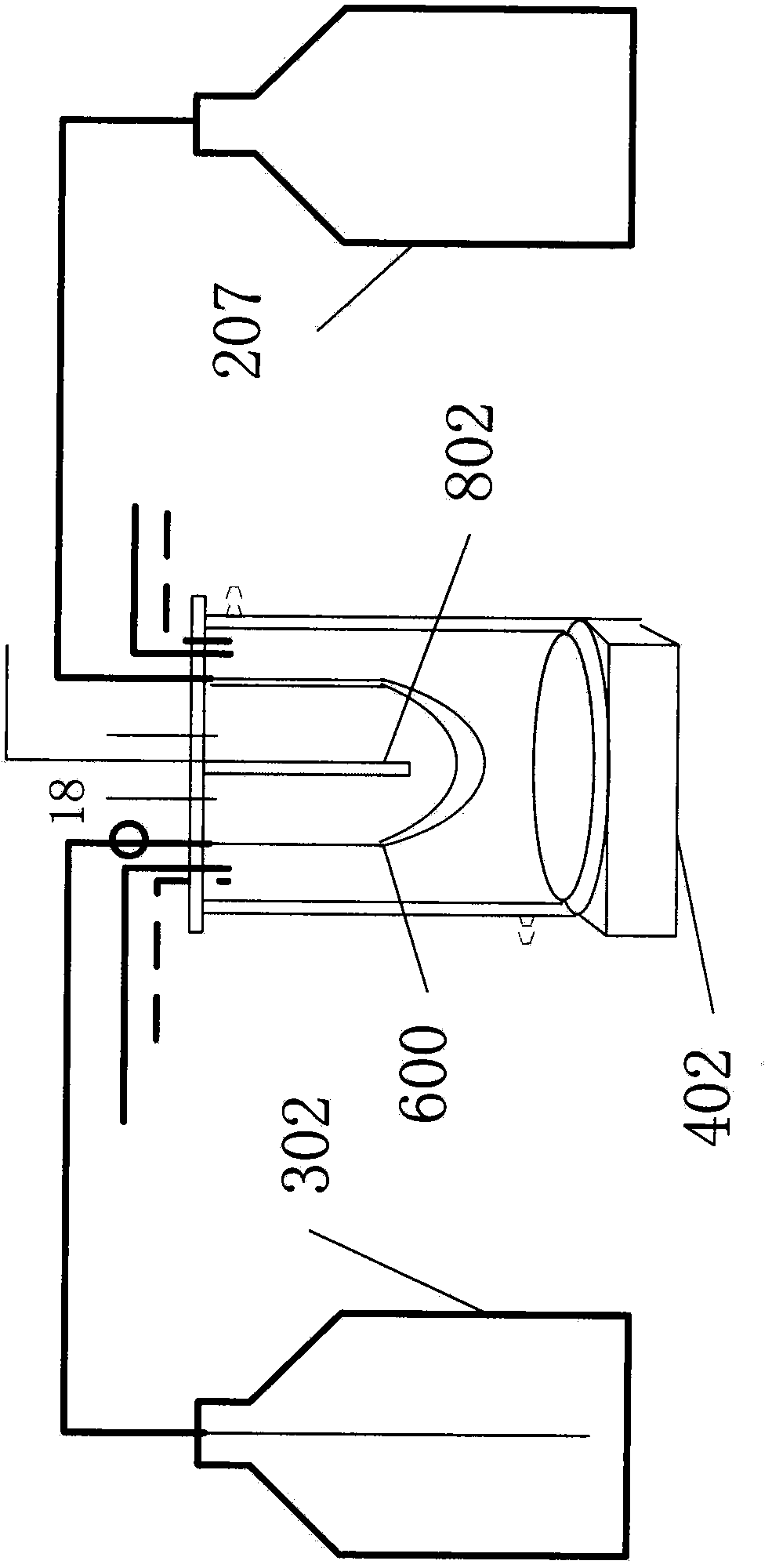

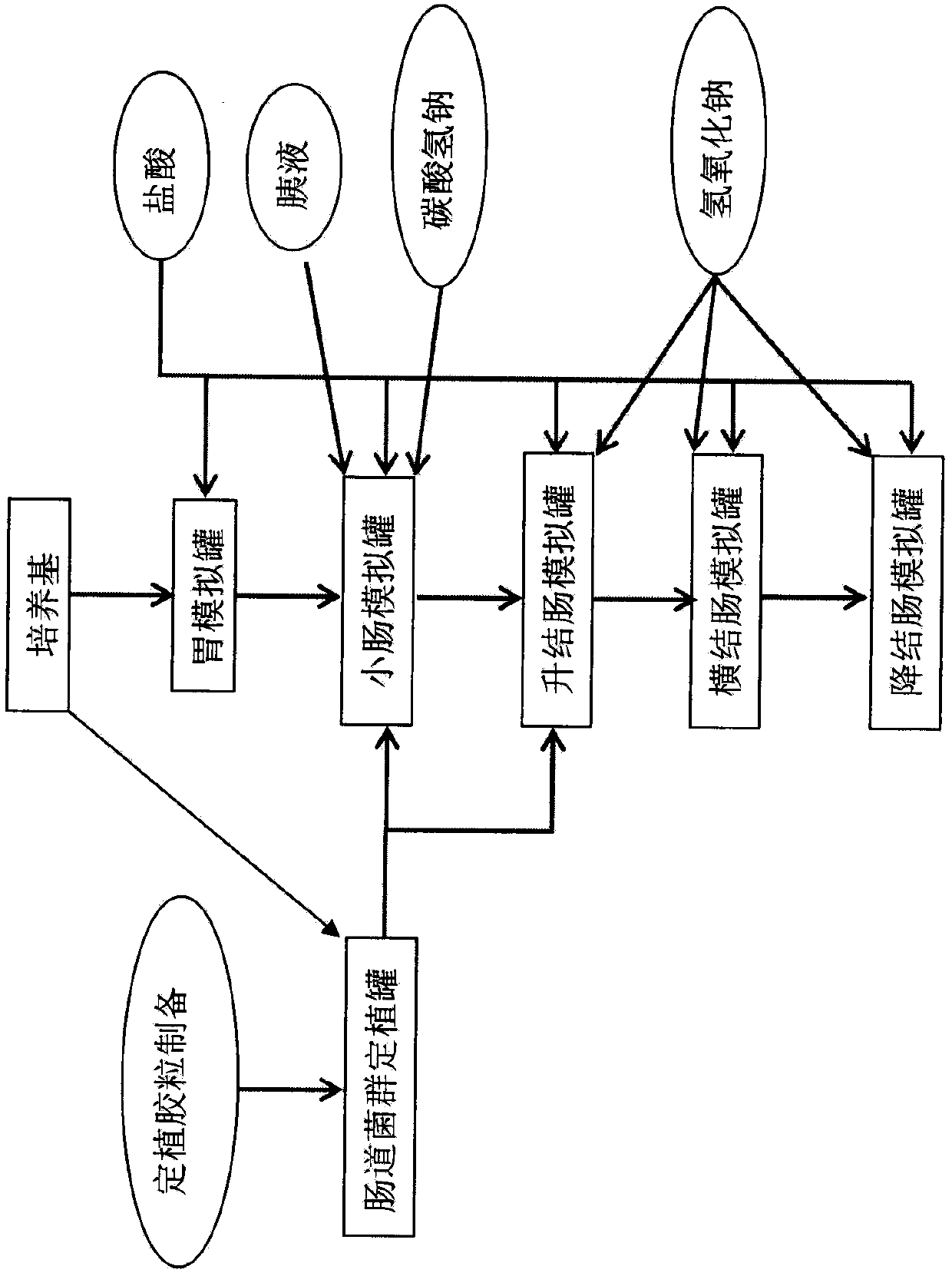

Human body gastrointestinal tract bionic system and simulation experiment method based on system

ActiveCN103740589AEliminate distractionsSimulate the realBioreactor/fermenter combinationsBiological substance pretreatmentsHuman bodyHuman gastrointestinal tract

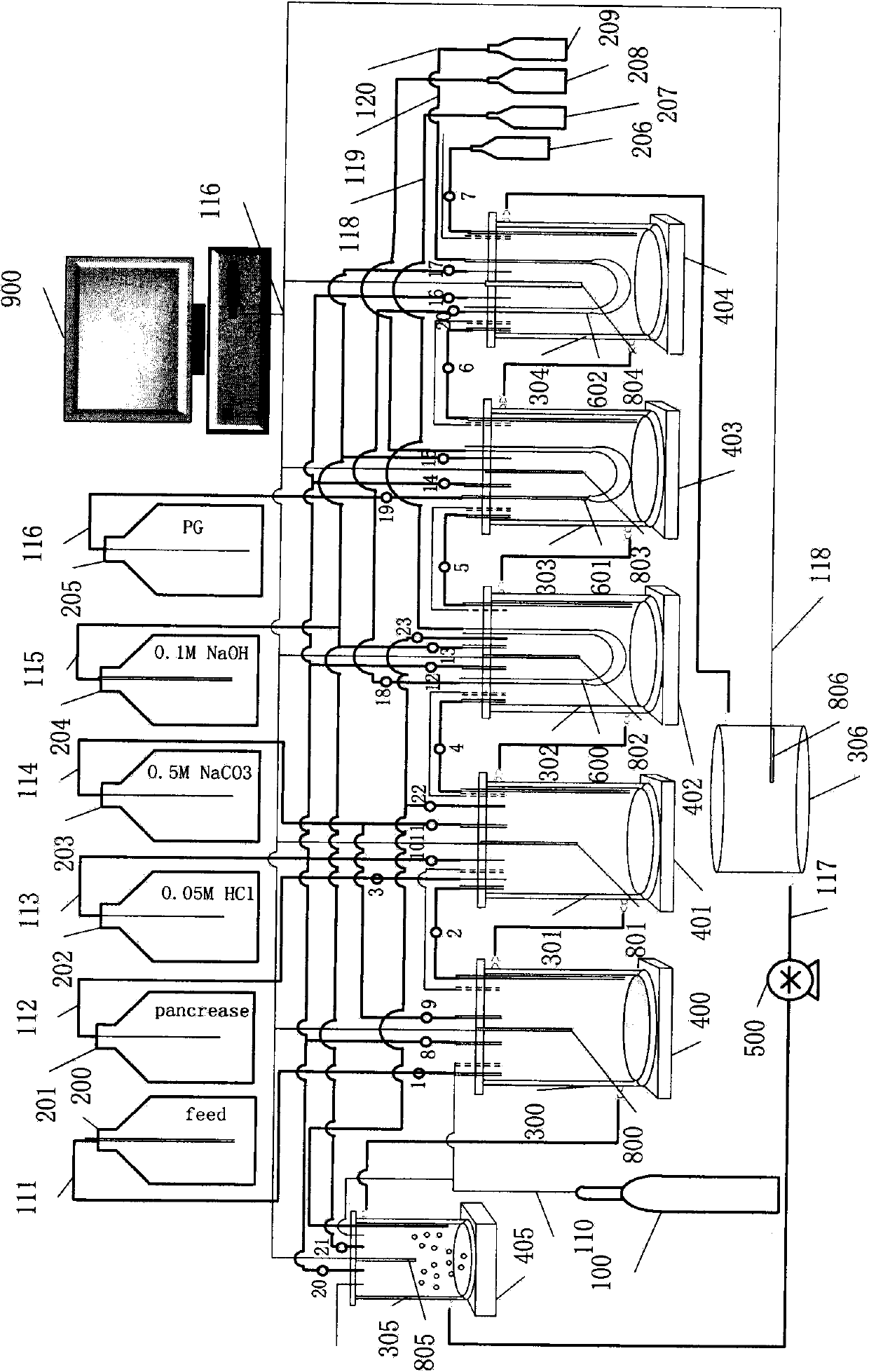

The invention relates to a human body gastrointestinal tract bionic system and a simulation experiment method based on the system. The system comprises a system controller, an intestinal flora planting system, a simulation digestion system, a simulation absorption system, a stirring system, a rate control system, a gas path system, a temperature adjusting system, a pH adjusting system, a digestion liquid reagent bottle, an absorbing liquid reagent bottle and a collector. The method comprises the following steps: setting parameters of the control system, preparing planting colloidal particles, planting the intestinal flora, simulating digestion and the like. The system simulates gastrointestinal tract digestion, absorption and intestinal microecology of human bodies under in-vitro conditions, is real in simulation and good in reproducibility, and us applicable to study on the fields of nutriology, toxicology, physiology, microbiology and the like as intelligent control is adopted.

Owner:马爱国 +1

Manufacturing technique and device for composite board

ActiveCN103231216AQuality assuranceAchieve mass productionOther manufacturing equipments/toolsVacuum pumpingComposite slab

The invention discloses a manufacturing technique for a composite board and belongs to the technical field of composite metal strip rolling. The manufacturing technique comprises the following steps implemented successively: joint surface machining, end surface machining, press fit, blank assembly, vacuum pumping and inert gases filling, heating, hot rolling and verifying. By means of the manufacturing technique, the machining accuracy is improved, and volume production of carbon steel-stainless steel composite boards is achieved; simultaneously, air in a combination blank is replaced through vacuum pumping and inert gases filling, oxidization of interfaces of the combination blank is prevented in a subsequent heating process, a little of residual air between the composite interface and two layers of stainless steel interfaces can be squeezed into an air storage bag gradually along with the moving of a roller and the composite blank simultaneously, and the residual air is prevented from expelling a separating agent or oxidizing the composite interfaces, accordingly, the joint of the finished composite slab is improved effectively, and the quality of the composite slab is further improved.

Owner:山东易川新材料科技股份有限公司

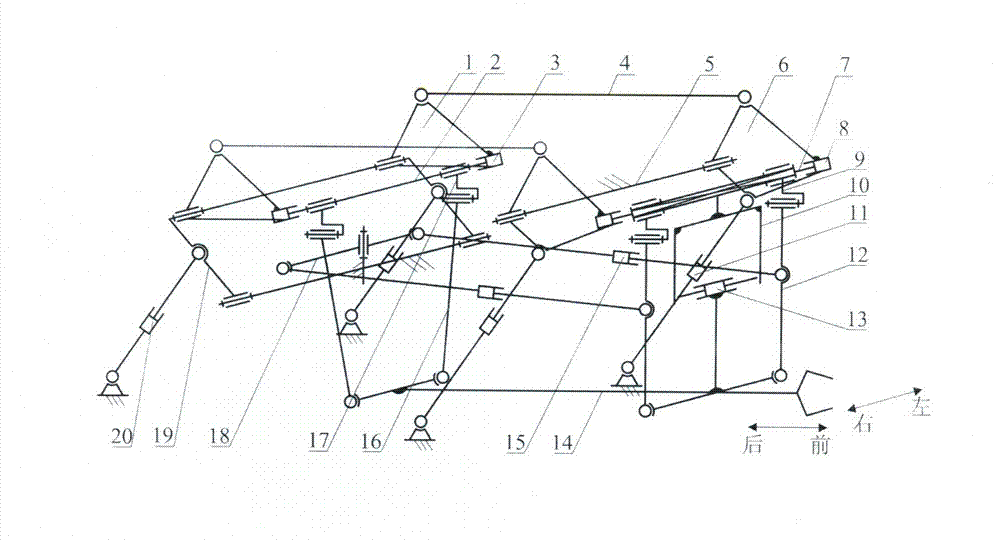

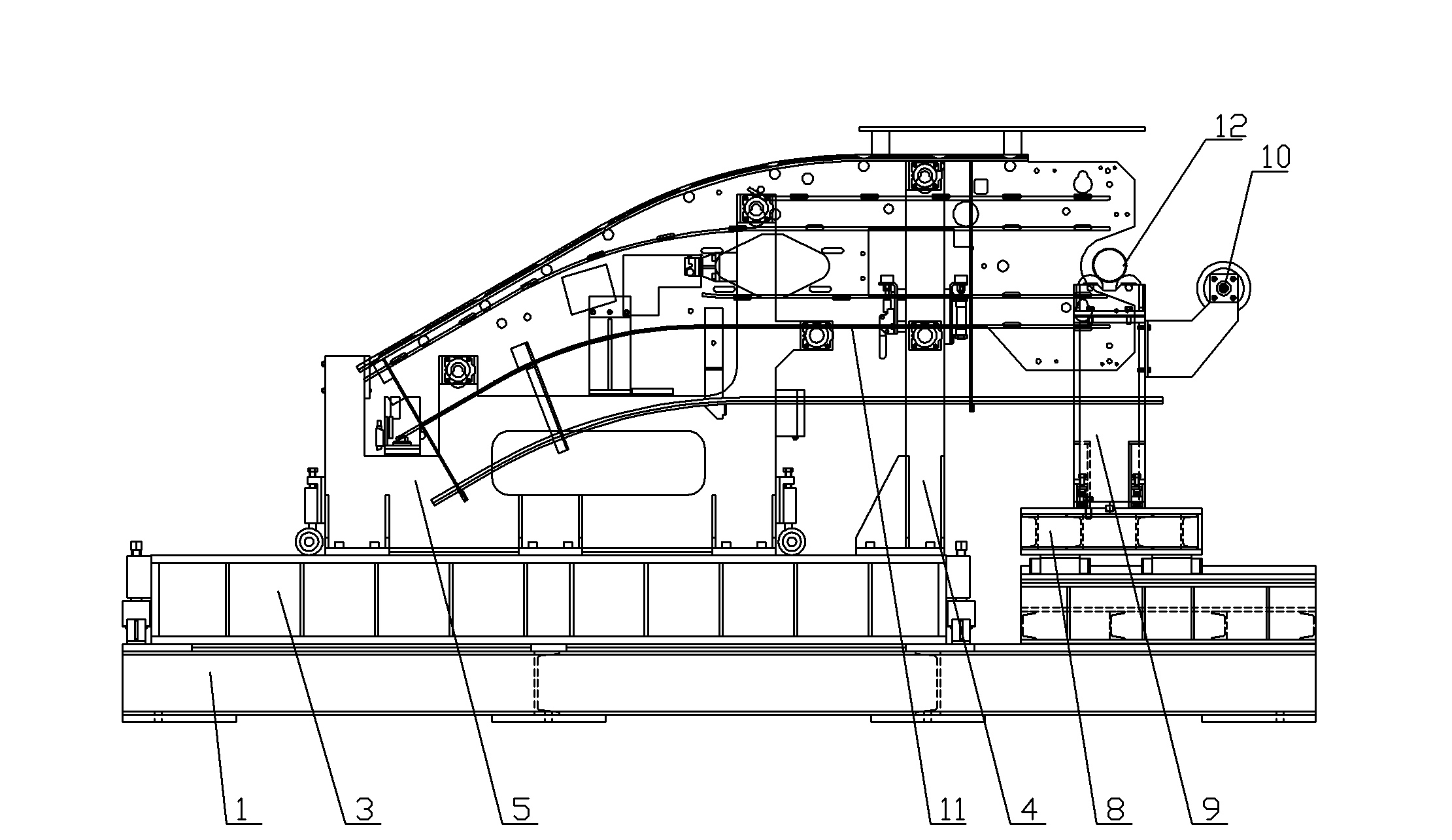

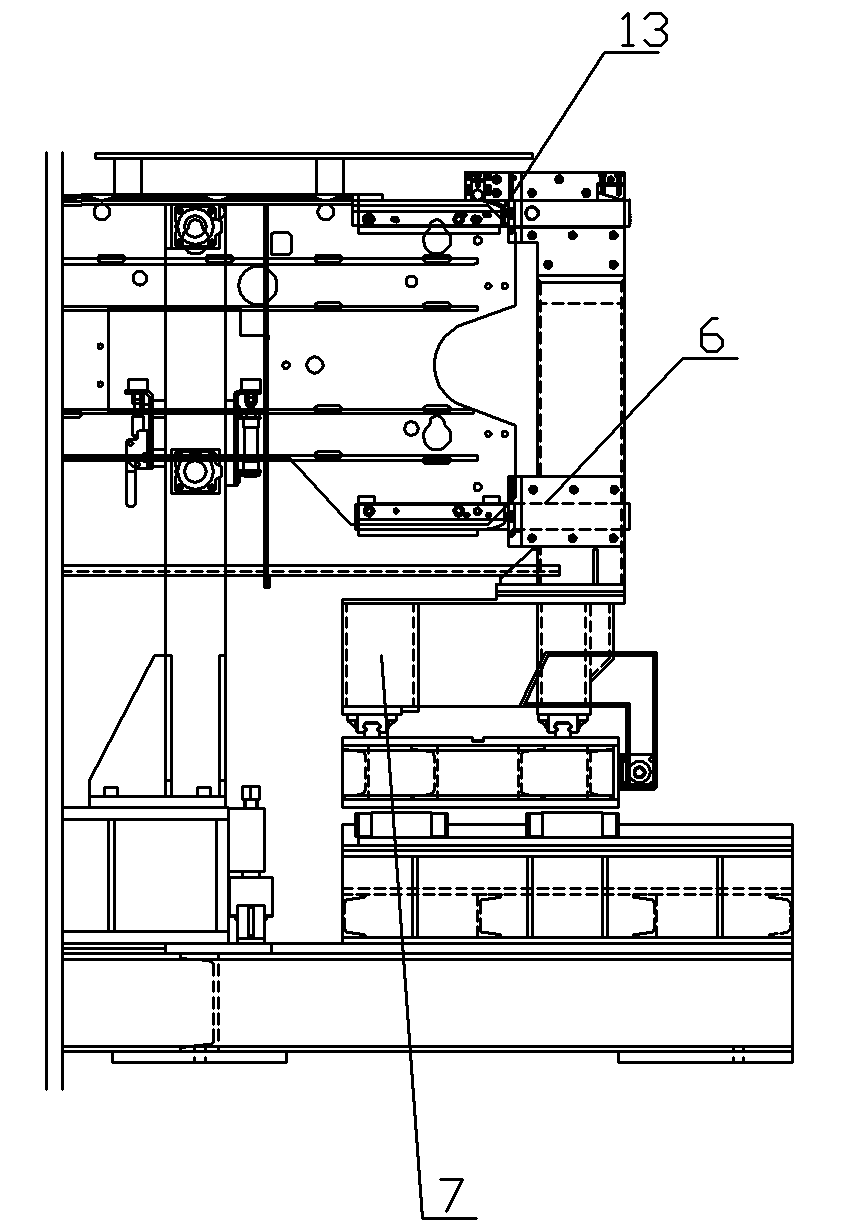

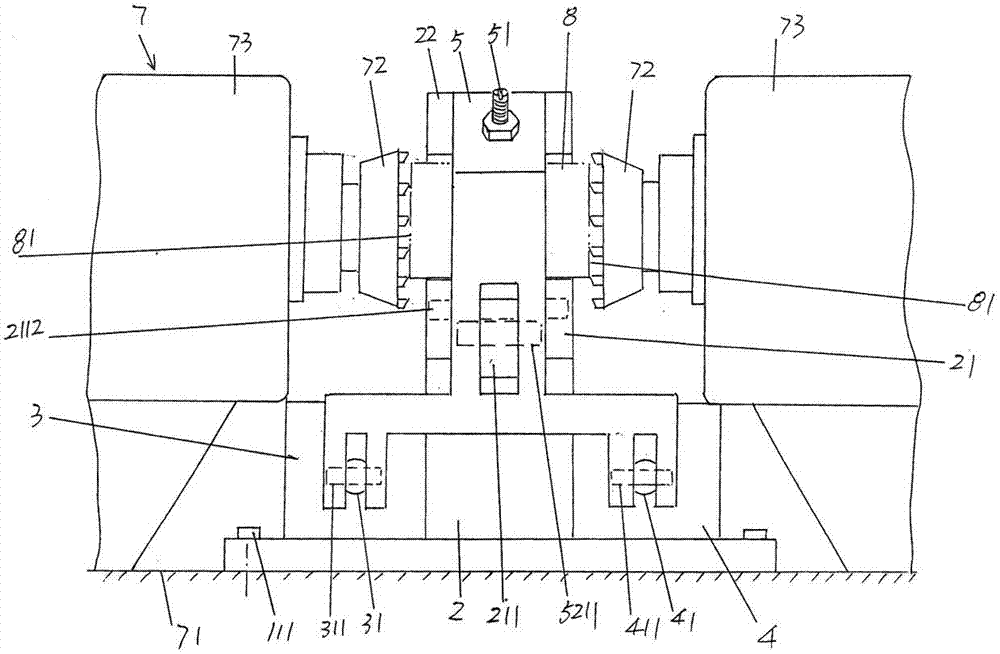

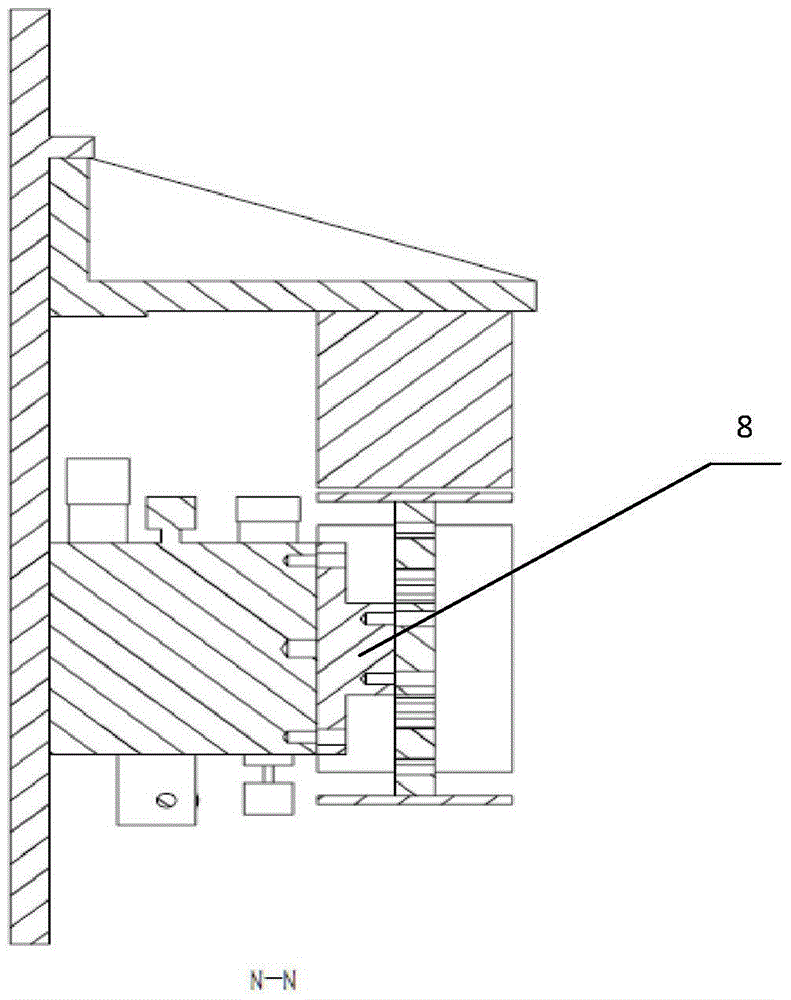

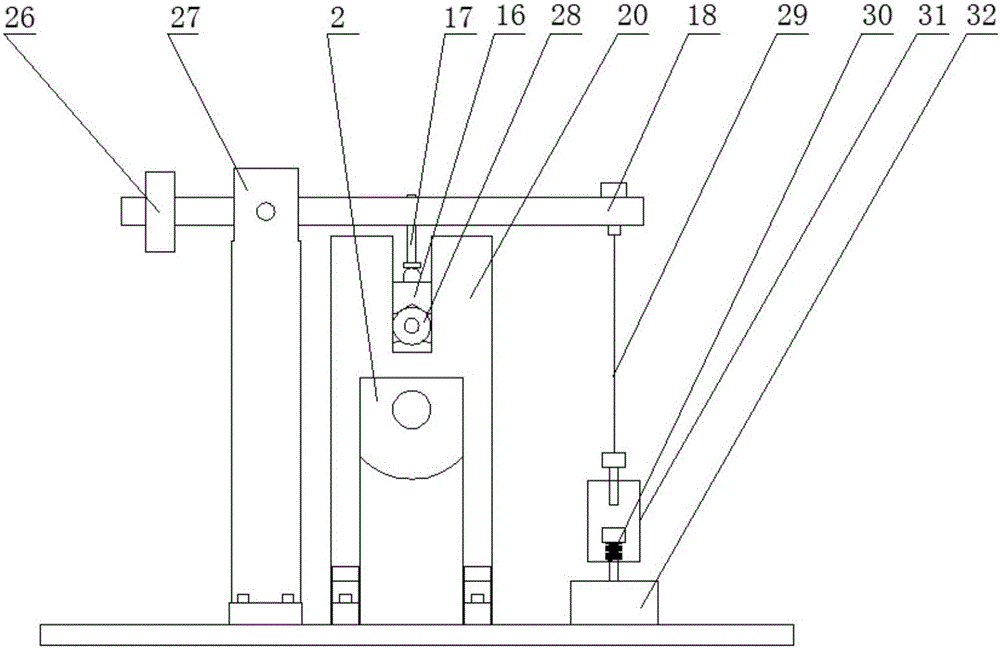

Lifting mechanism of parallel connecting lever type large-tonnage forging manipulator

InactiveCN102728764AImprove carrying capacityReduce stressForging/hammering/pressing machinesForging manipulatorEngineering

A lifting mechanism of a parallel connecting lever type large-tonnage forging manipulator is mainly characterized in that the front part and the rear part of a nipping lever are respectively connected with the lower ends of a front suspension lever and a rear suspension lever, the upper ends of the front and rear suspension levers are respectively connected on front and rear sliding levers by connecting pieces, left and right linear drivers are arranged at two ends of the front and rear sliding levers and are connected with front and rear lifting arms, and the other end of the lifting arm is connected with a rack. The lower arms of the two front lifting arms are connected with the upper ends of the two linear lifting drivers, the upper arms of the front lifting arms are connected with the front end of a horizontal synchronous lever, the rear end of the synchronous lever is connected with the upper arms of the rear lifting arms, the other ends of the two rear lifting arms are connected with one end of a pitching arm, and the other end of the pitching arm is connected with the rack. The middle parts of the two pitching arms are also connected with the upper ends of linear pitching drivers. The lifting mechanism reduces the stress at the connection part of the rack hinges, greatly improves the whole bearing capacity and transmission efficiency of the manipulator, is applicable to forging operation of large-tonnage forged pieces, and can also ensure the lifting parallelism of the nipping lever.

Owner:YANSHAN UNIV

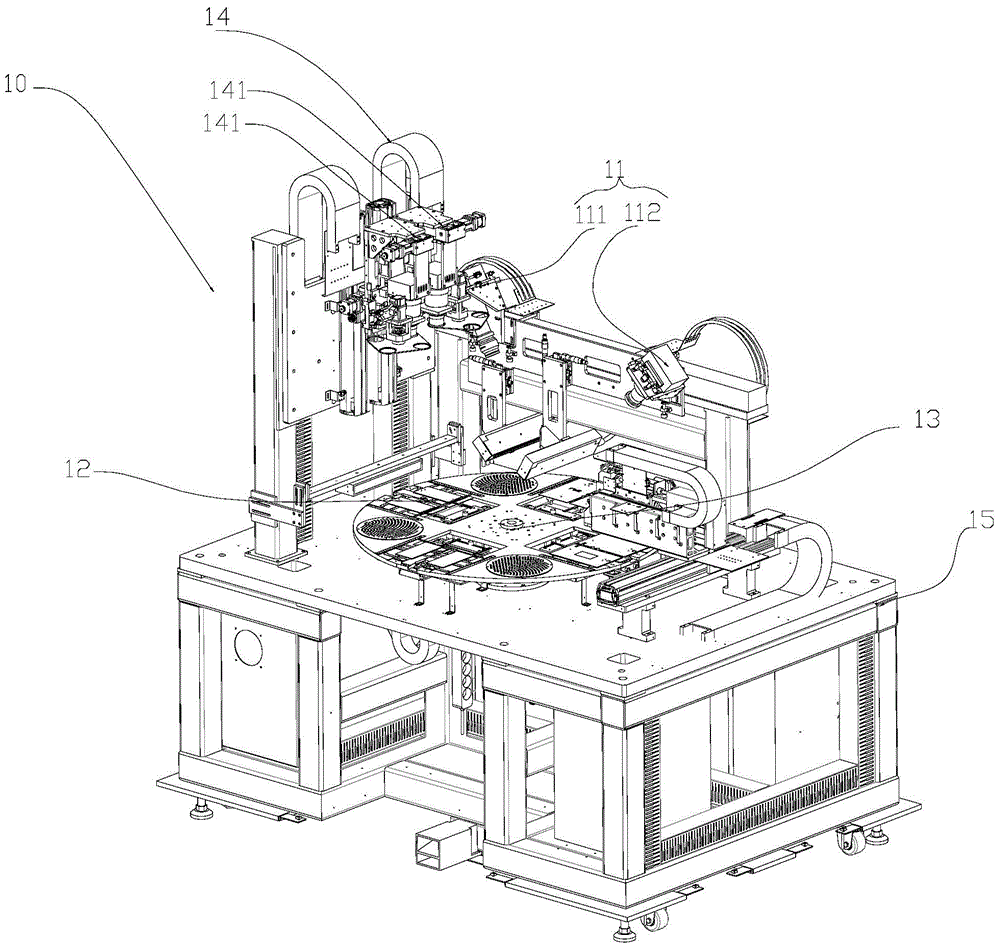

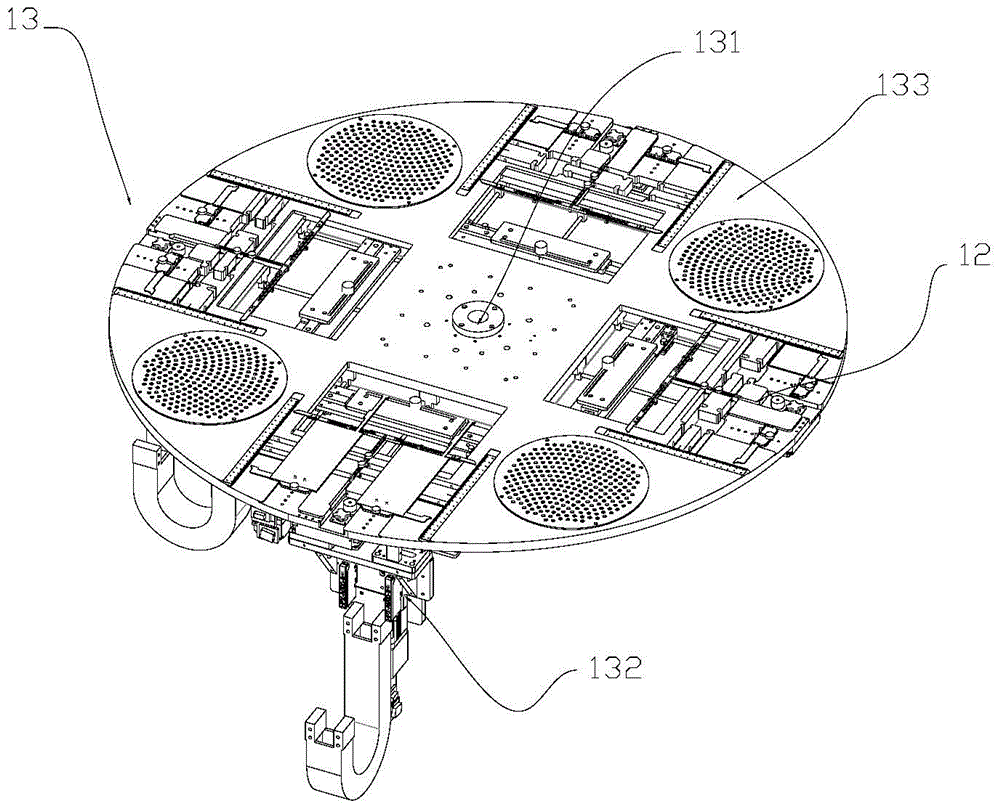

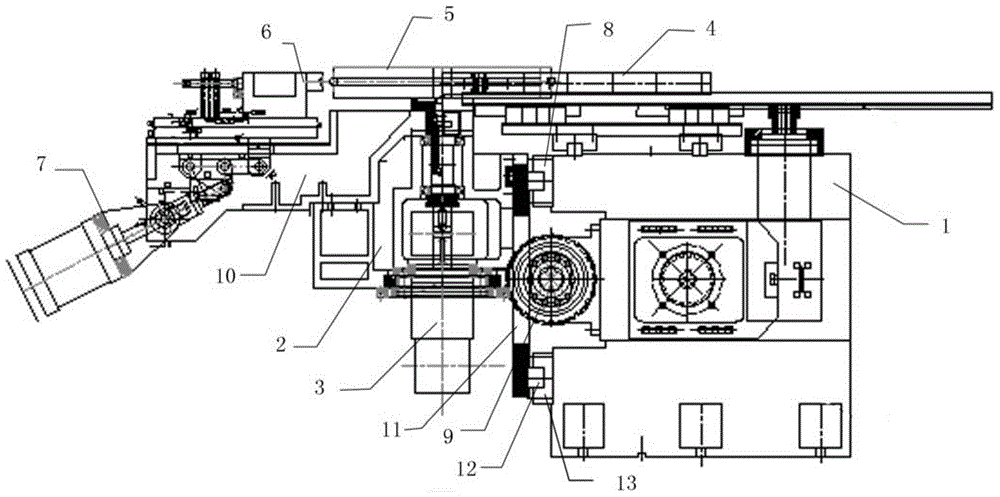

Optical detection equipment and method for liquid crystal display modules

ActiveCN104460060AImprove detection efficiencyGuaranteed parallelismOptically investigating flaws/contaminationNon-linear opticsCamera lensLiquid-crystal display

The invention discloses optical detection equipment for liquid crystal display modules. The optical detection equipment comprises an equipment body, a four-station rotary device, a double line scanning camera mechanism and a plane scanning camera mechanism, wherein the four-station rotary device comprises a rotary plate; a line scanning detection station, a feeding station, a plane scanning detection station and a plane scanning detection code spraying station are arranged on the four-station rotary device and circumferentially distributed along the center of the rotary plate; synchronous adjustment mechanisms used for simultaneously detecting the two liquid crystal display modules are correspondingly mounted on the stations of the four-station rotary device respectively. According to the optical detection equipment, the detection efficiency of the liquid crystal display modules can be improved, the liquid crystal display modules can be simultaneously detected, the detection rate is high, the parallelism of the liquid crystal display modules and camera lenses can be guaranteed, and the image quality requirements of camera detection and shooting can be met.

Owner:深圳鼎晶光电有限公司

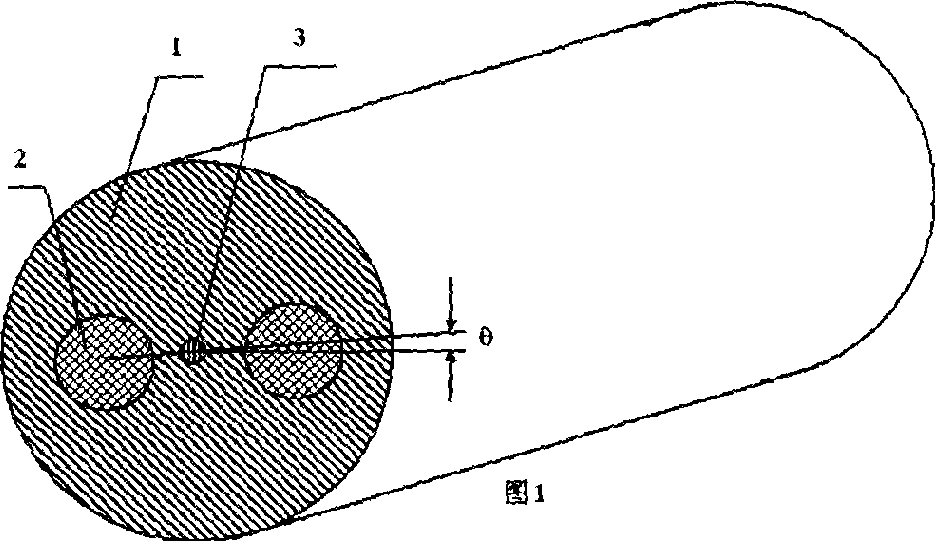

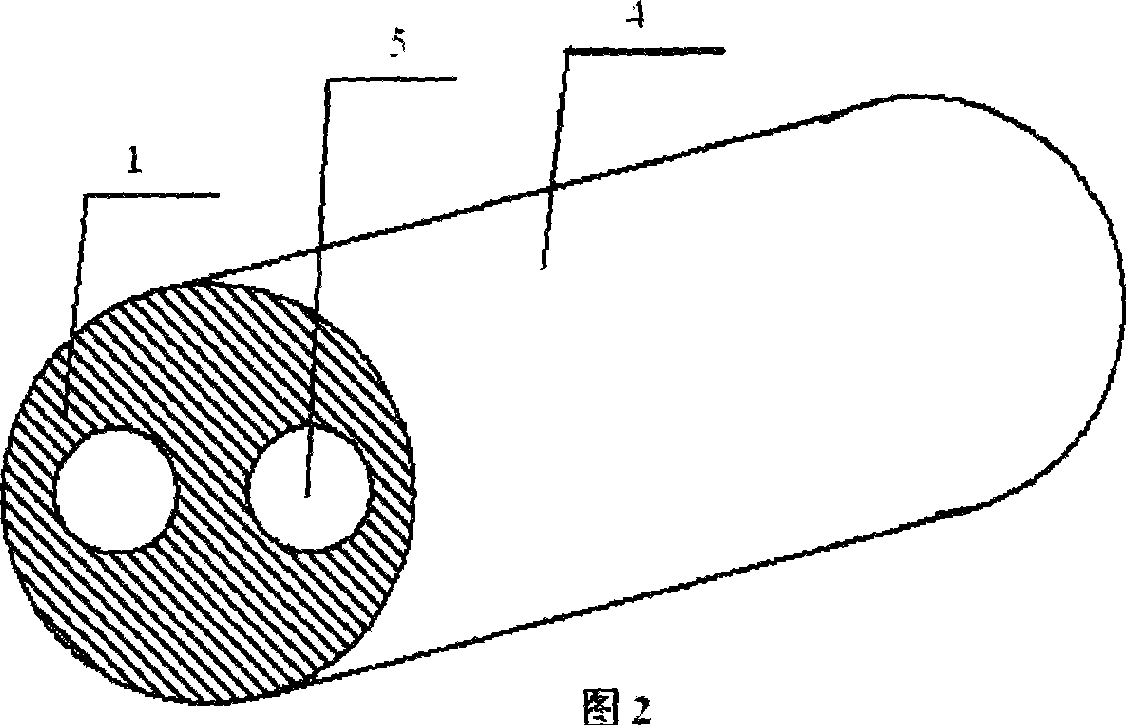

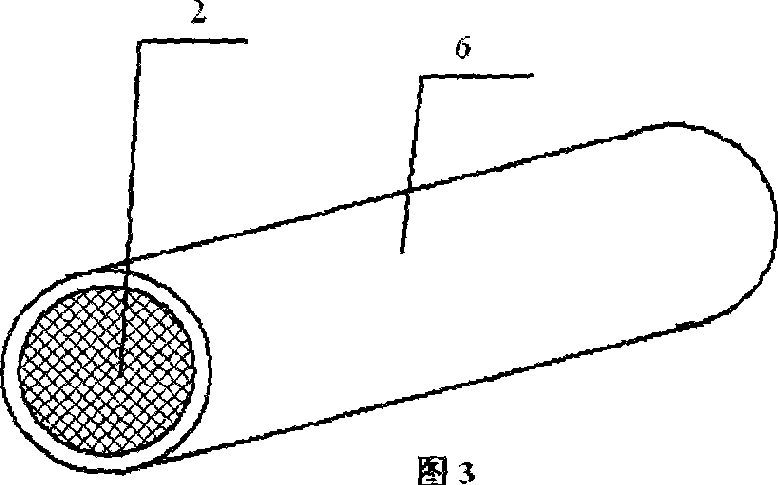

Large size combined optical fibre perform of polarization maintaining fiber and production method thereof

ActiveCN101391861AEasy to moveEvenly heatedGlass making apparatusGlass fibre productsStructural symmetryPolarization-maintaining optical fiber

The invention relates to a polarization maintaining optical fibre large-size composite optical fibre preform and a preparation technological method, and comprises the optical fibre preform with a fibre core and cladding layers; the areas of the cladding layers of the two sides of the fibre core of the optical fibre perform are provided with two holes which run through lengthways and are parallel to the fibre core; the two holes are provided with stress rods so as to form the composite optical fibre preform; the invention is characterized in that the optical fibre preform has the diameter of 30 to 80mm and the length of 200 to 800mm, the diameter range of the two side holes is 12 to 27mm and the diameter range of the stress area of the stress rod is 10 to 25mm. The polarization maintaining optical fibre large-size composite optical fibre preform and the preparation technological method lead the wire-drawing condition to be stable and controllable, and the drawn polarization maintaining optical fibre has excellent mechanical property and can pass the tension screening of 1 percent, even 2 percent; the preform with large diameter and large length is used for producing the polarization maintaining optical fibre; the wire-drawing length of a single preform reaches to be more than 200km, even more than 100km; and the production efficiency of the optical fibre is high. The drawn optical fibre structure has good symmetry and lengthwise uniformity and is easy to control.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

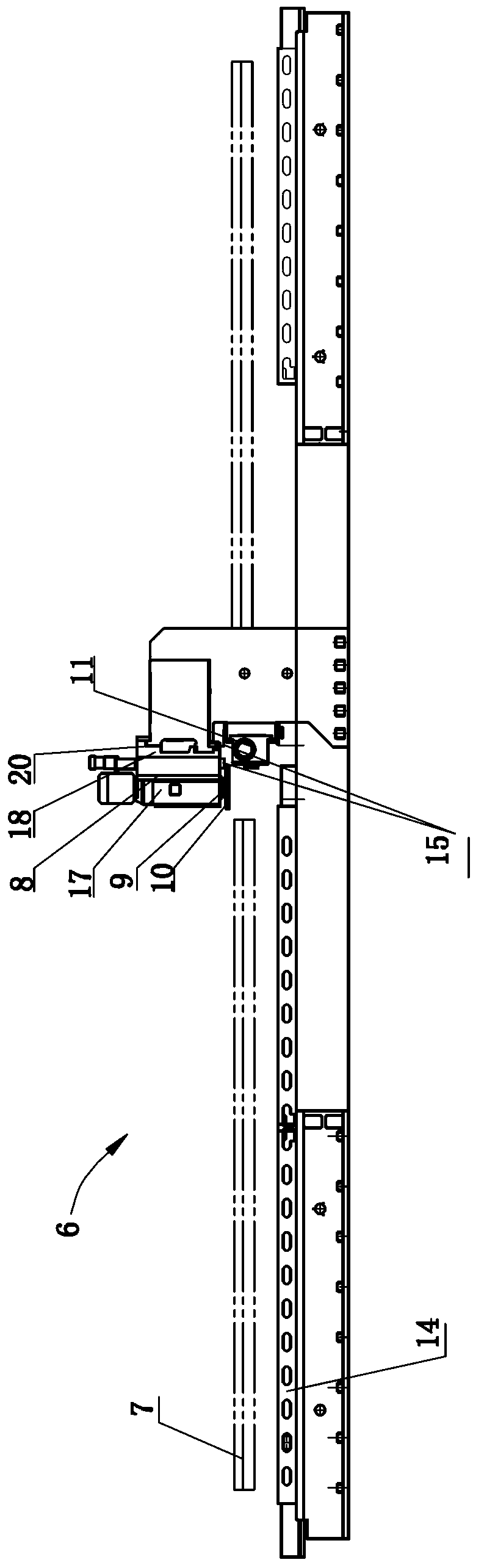

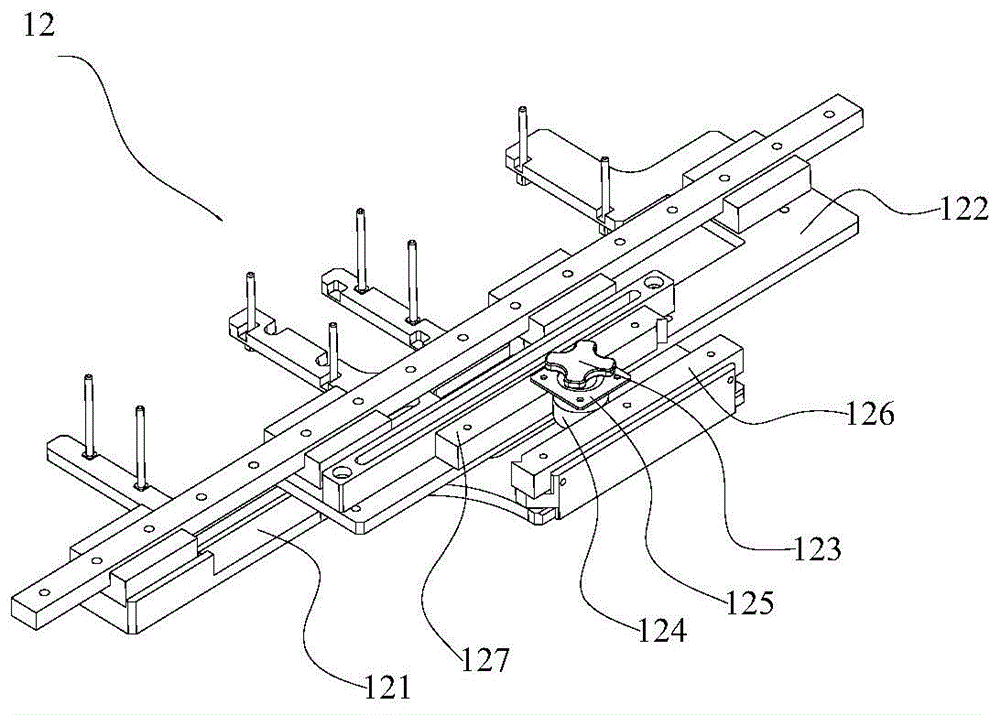

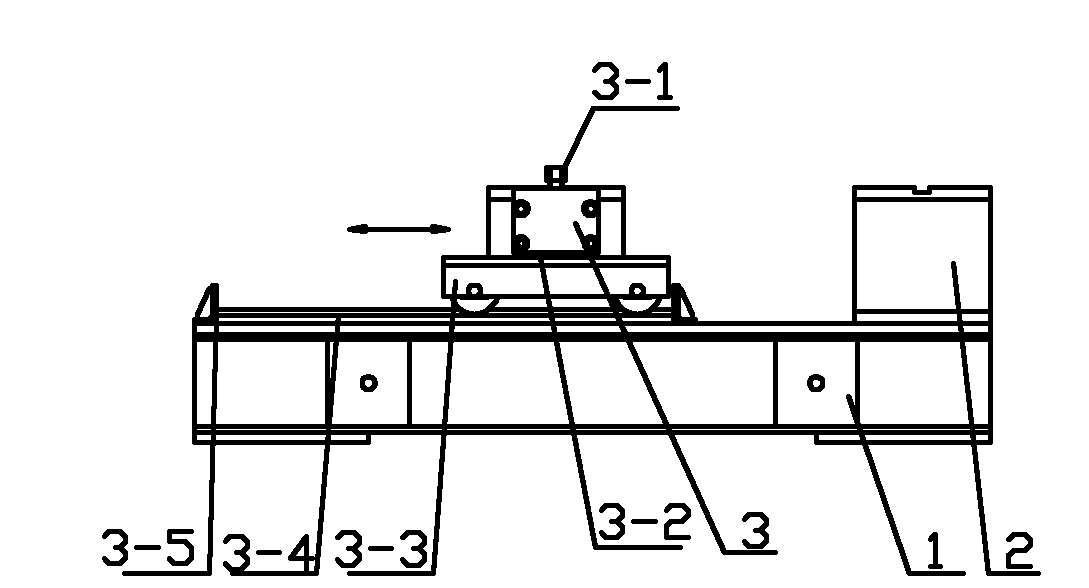

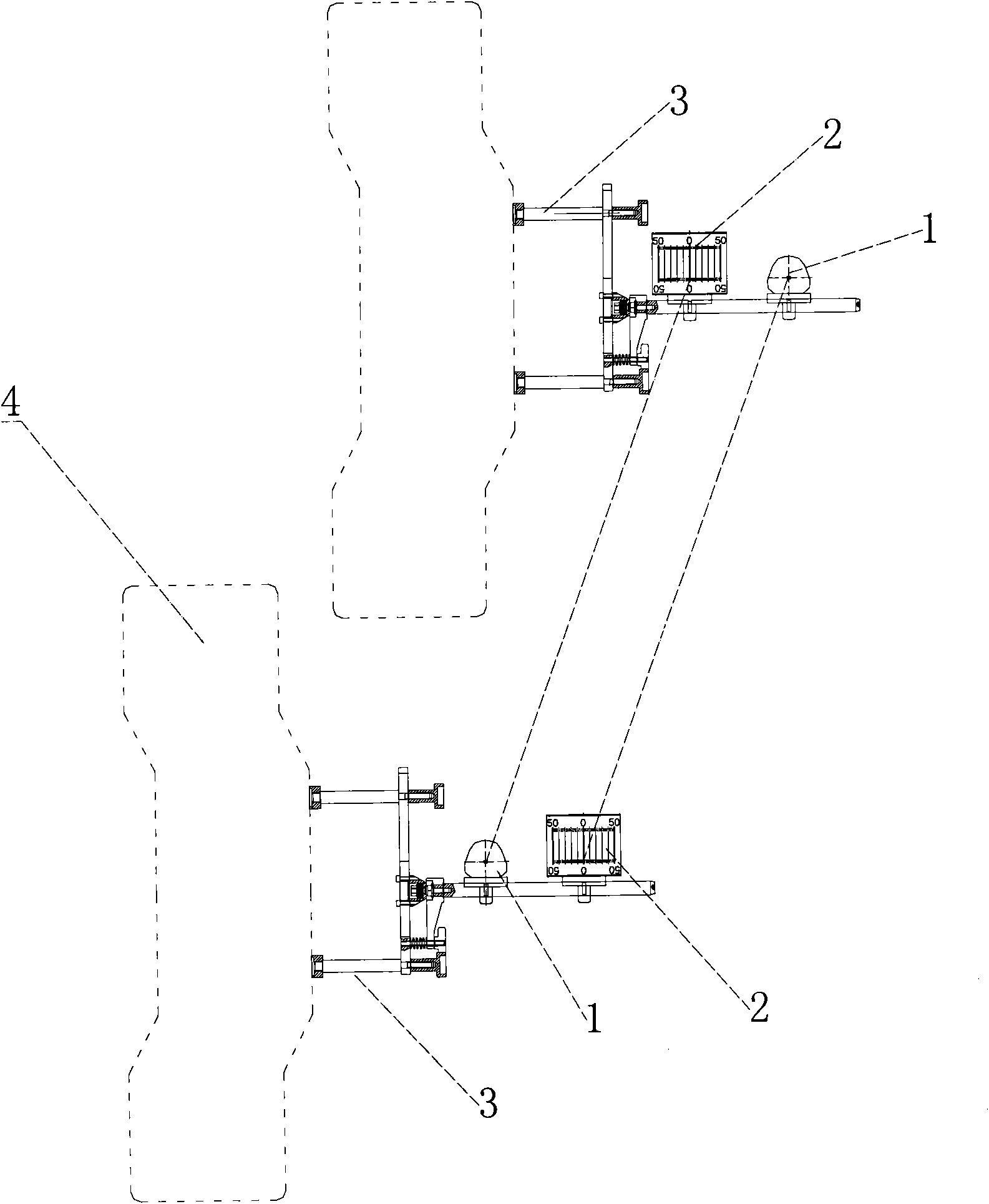

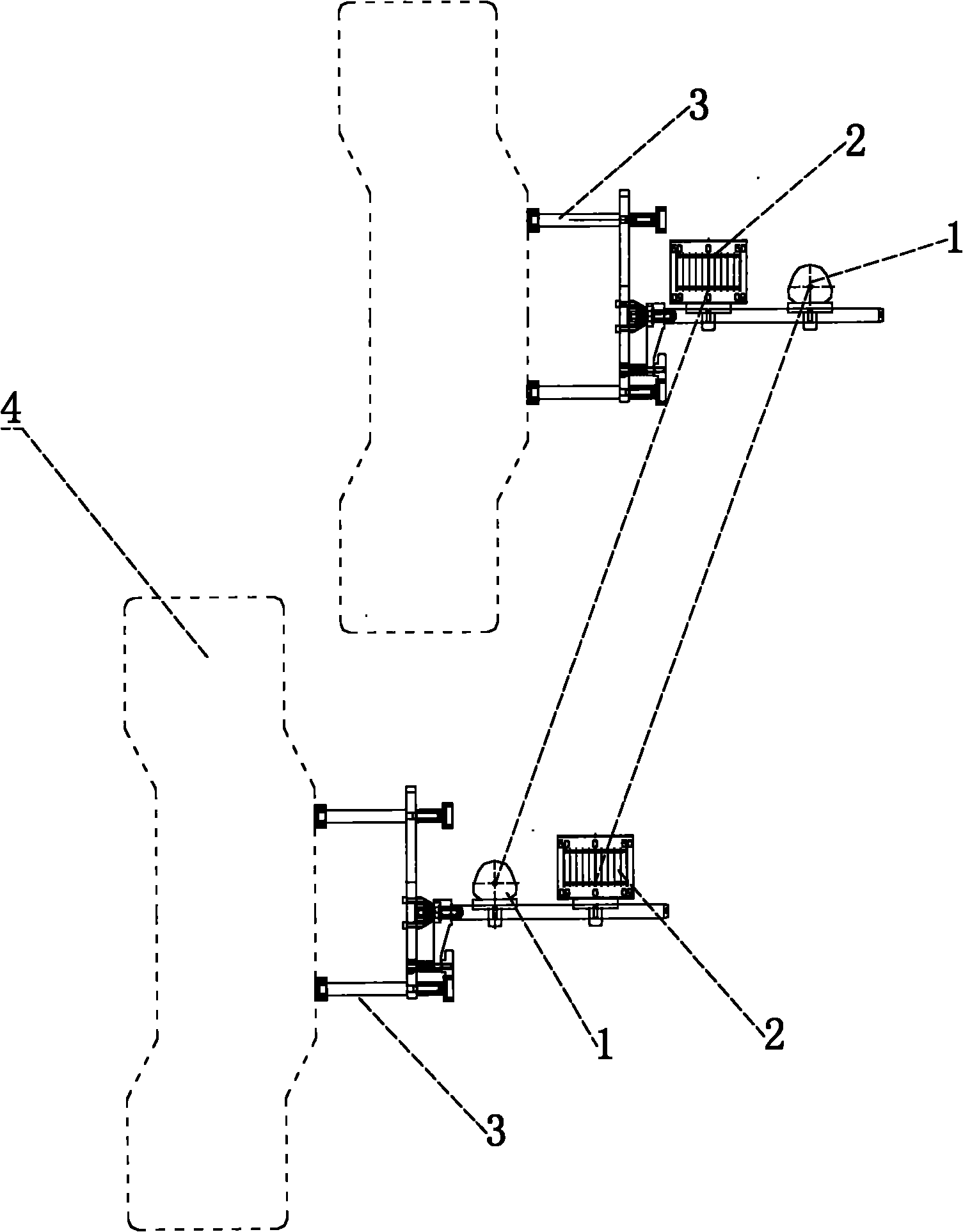

Assembly tooling for double assembly and main drive of head side plate on staircase and assembly method

ActiveCN102632382AReduce spacingLow costWelding/cutting auxillary devicesAssembly machinesAssembly lineEngineering

The invention discloses an assembly tooling for the double assembly and the main drive of a head side plate on a staircase and an assembly method. The tooling comprises a work platform, wherein a fixed reference beam, a beam capable of transversely moving, a main drive lengthways moving dolly are arranged on the work platform, and the two beams are in parallel with each other by moving the beam capable of transversely moving; and a positioning stand column and a positioning wall plate capable of lengthways moving the side plate of the staircase are respectively arranged on the two beams, gaps are remained between the corresponding positioning stand columns and positioning wall plates, and the corresponding positioning wall plates can respectively move along the beams, so that the distances between the corresponding positioning wall plates and the corresponding positioning stand columns are changed; a pair of tangential guide rail arranging seat transverse moving trolleys are distributed on the main drive lengthways moving dolly, and the tangential guide rail is transported to the installing position of the tangential guide rail on the side plate by the dolly; a left / right main drive height positioning device is further arranged on the main drive lengthways moving dolly, and the device is used for positioning the double assembly height position of the center and the side plate of the main drive axis; and a pair of driving axial centering devices is arranged on the main drive height positioning device.

Owner:HANGZHOU XO ELEVATOR

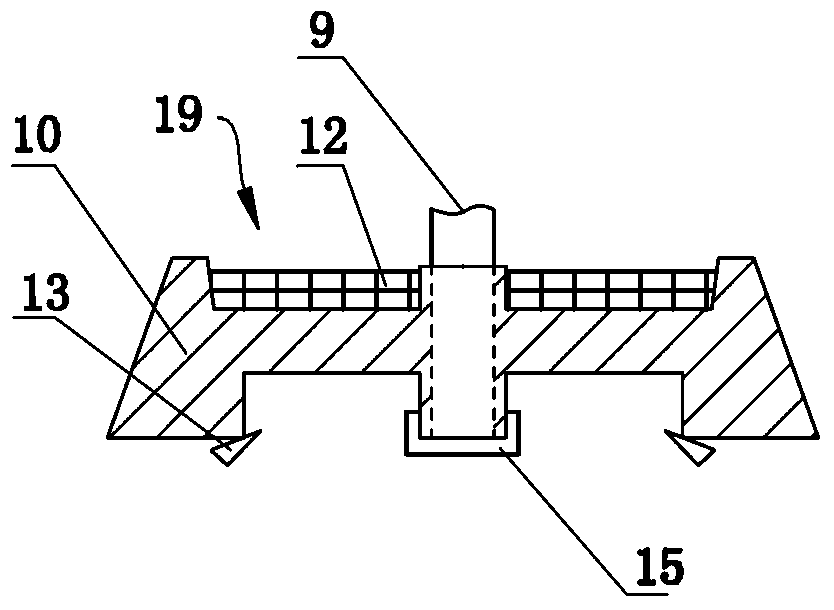

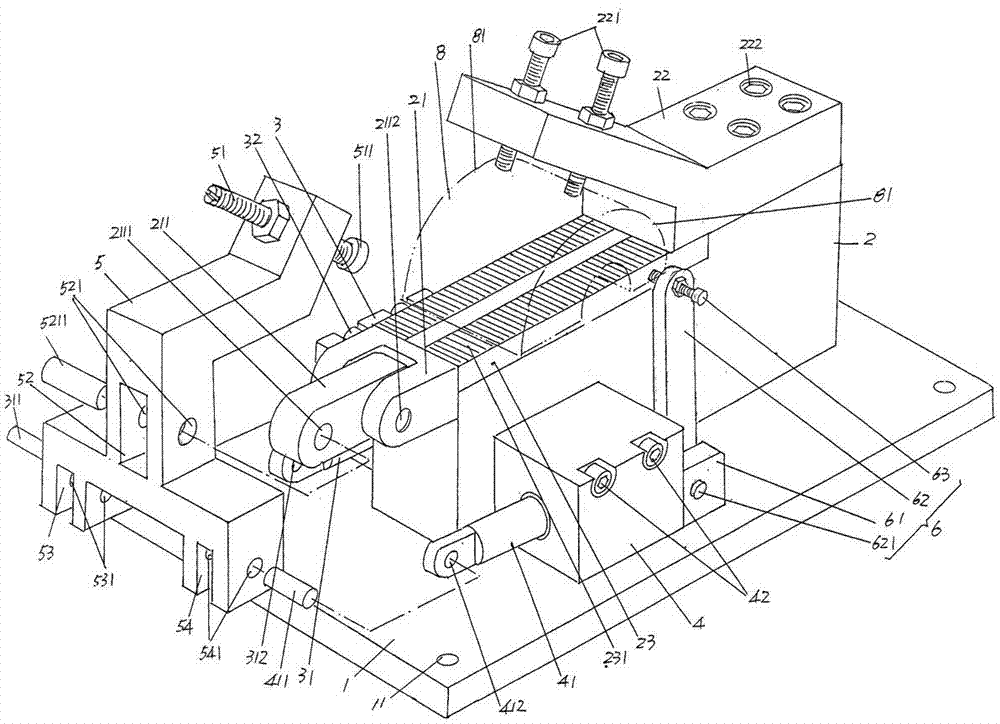

Clamp structure used for parallel face milling of glass mold

ActiveCN103273350BGuaranteed parallelismImprove milling efficiencyPositioning apparatusMetal-working holdersFixed bearingEngineering

The invention provides a clamp structure used for parallel face milling of a glass mold, and belongs to the technical field of tool clamps used for manufacture of the glass mold. The clamp structure comprises a bottom plate, a base, a first action cylinder, a second action cylinder, and a movable bearing base. The base is fixed on the upward side of the bottom plate, a connection shaft plate connecting base is formed on the upper portion of one end of the base, a fixed bearing base is fixed on the upper portion of the other end of the base, and a glass mold base plate is fixed in the middle of the base. The first action cylinder and the second action cylinder are located on two sides of the base respectively and fixed on the base. The upper portion of the movable bearing base corresponds to the fixed bearing base, the middle of the movable bearing base is connected with the connection shaft plate connecting base, one end of the lower portion of the movable bearing base is connected with the first action cylinder, the other end of the lower portion of the movable bearing base is connected with the second action cylinder, the upper portion of the movable bearing base corresponds to the upper portion of one end of the glass mold base plate in a vacant state, and the fixed bearing base faces one end of the movable bearing base and corresponds to the upper portion of the other end of the glass mold base plate. Milling efficiency is high, industrialization widened production requirements are met, operation intensity of workers is reduced, the parallelism of parallel faces of the glass mold can be guaranteed, and energy-saving effects are ideal.

Owner:ORI MOLD TECH SUZHOU

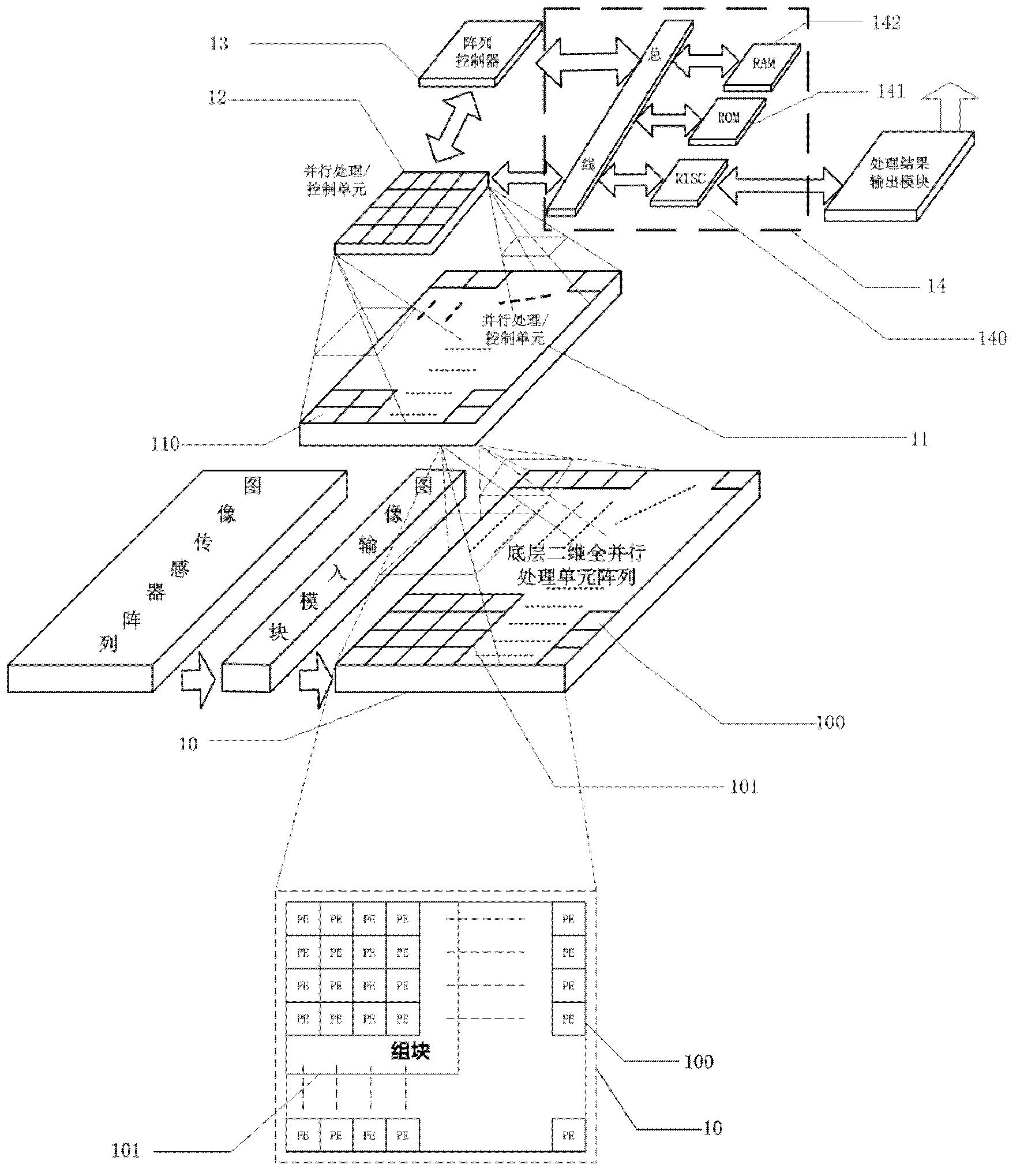

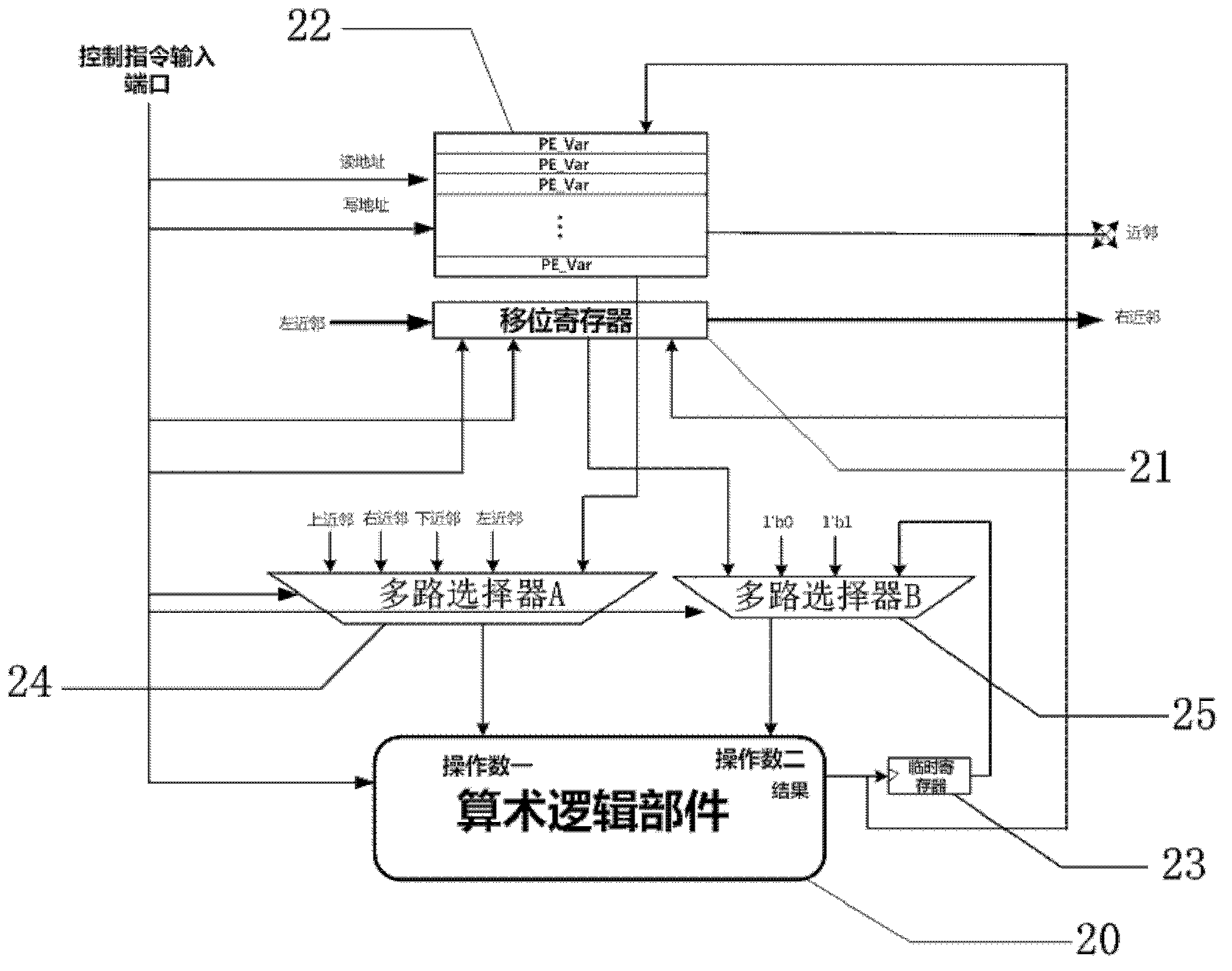

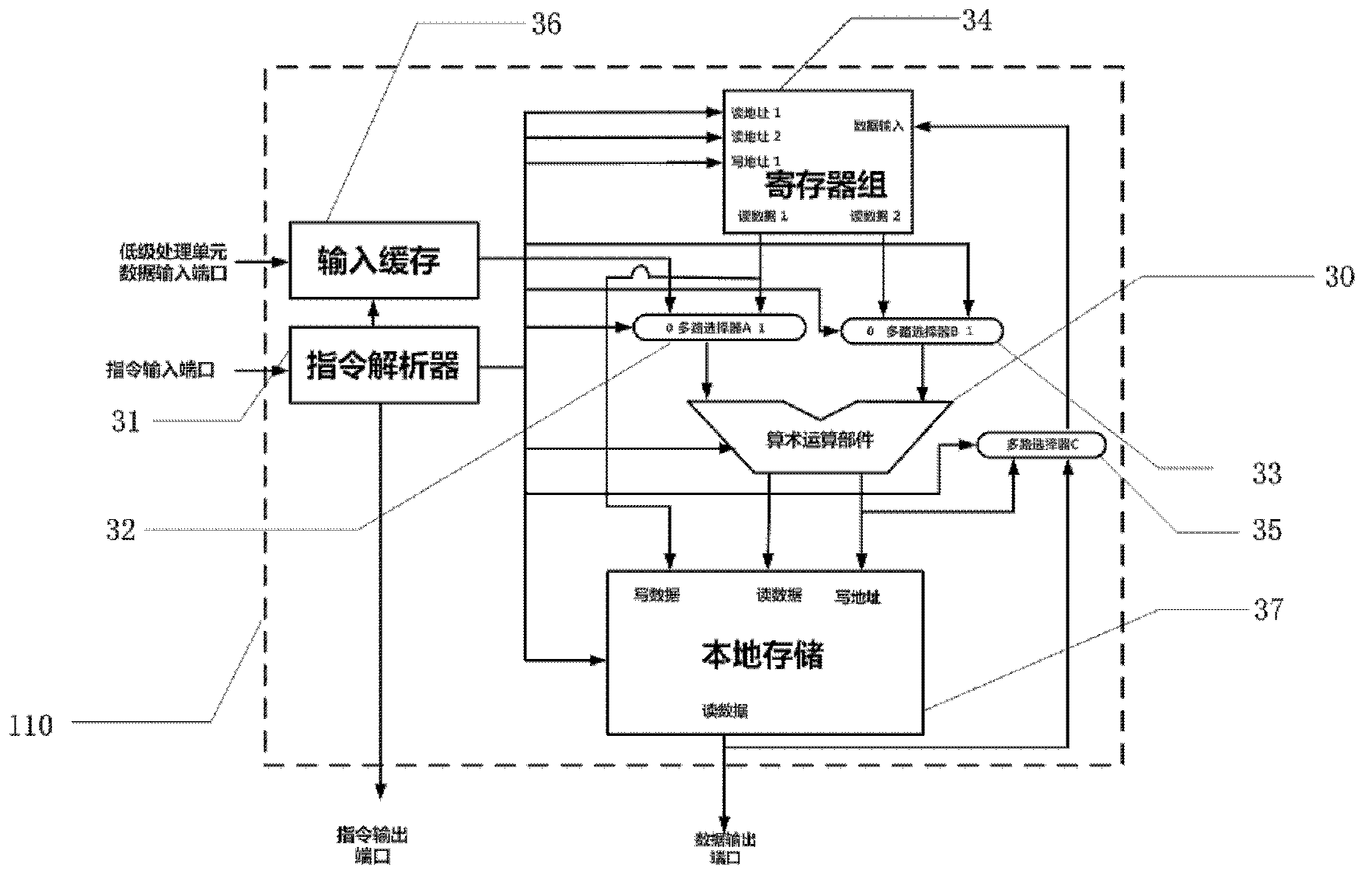

Visual processing device based on multi-layer parallel processing

ActiveCN103020890AEnhanced couplingIncrease flexibilityProcessor architectures/configurationImage sensorAlgorithm complexity

The invention discloses a visual processing device based on multi-layer parallel processing. The device comprises a high speed image sensor array, multiple layers of processor unit arrays and a reduced instruction-set computer (RISC) microprocessor subsystem. An image sensor is used for acquiring images of an actual world, a bottommost low-level processor unit array has a highest degree of parallelism and a relatively weak operational capability, and the degree of parallelism of the processor arrays is gradually lowered and the operational capability of the processor arrays is gradually improved with increasing of layers. A tight coupling between a hardware structure and various image processing algorithms with different degrees of parallelism and algorithm complexity is facilitated by the aid of the layered architecture. A RISC processor is used for performing system control and scheduling of image processing threads. By means of the visual processing device based on the multi-layer parallel processing, the system has high flexibility and high data throughput rate, a multi-thread concurrent working mode is achieved, image processing capacity is greatly improved, and speeds are greatly increased.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

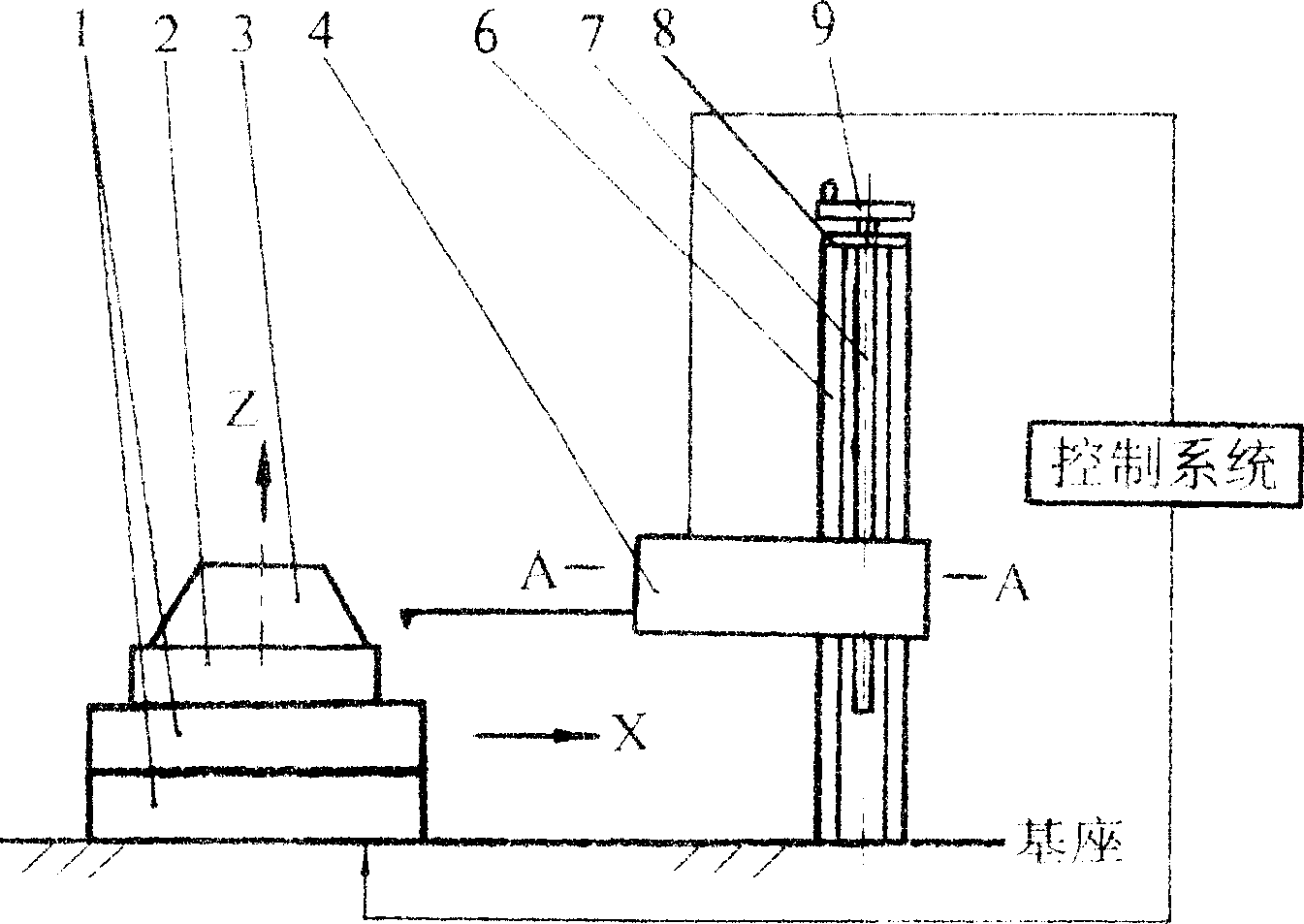

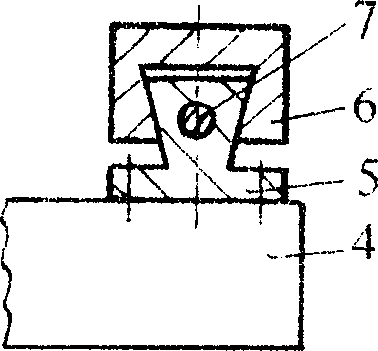

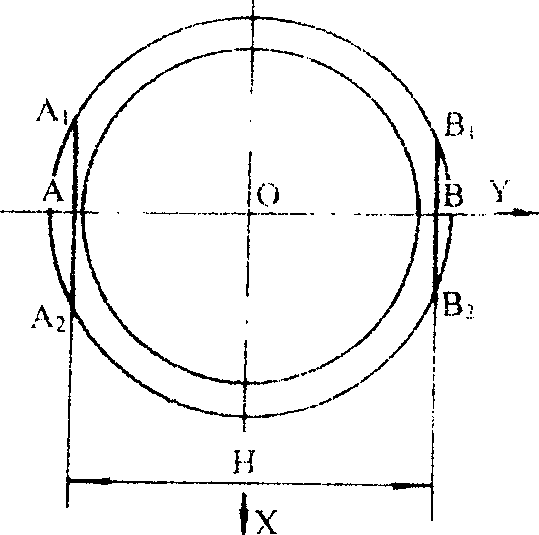

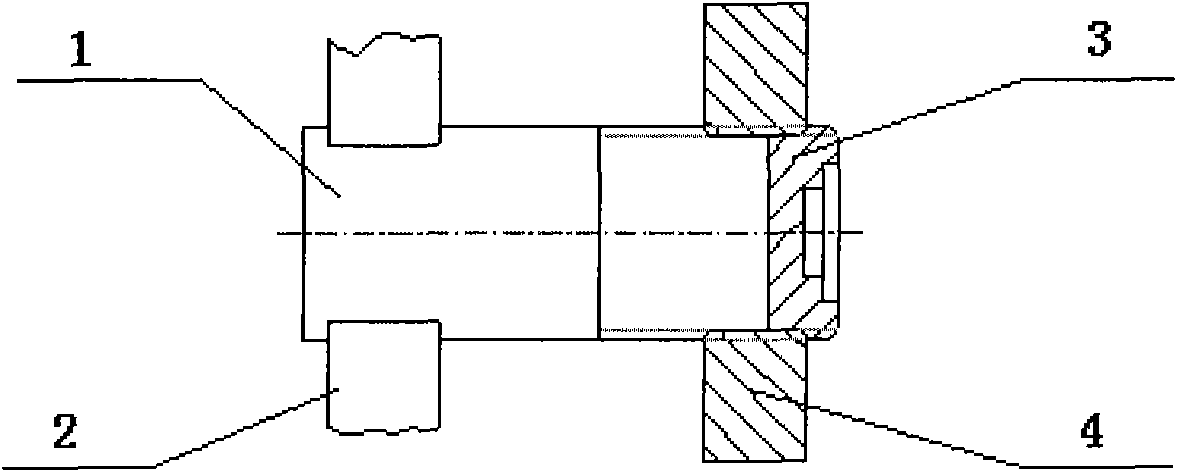

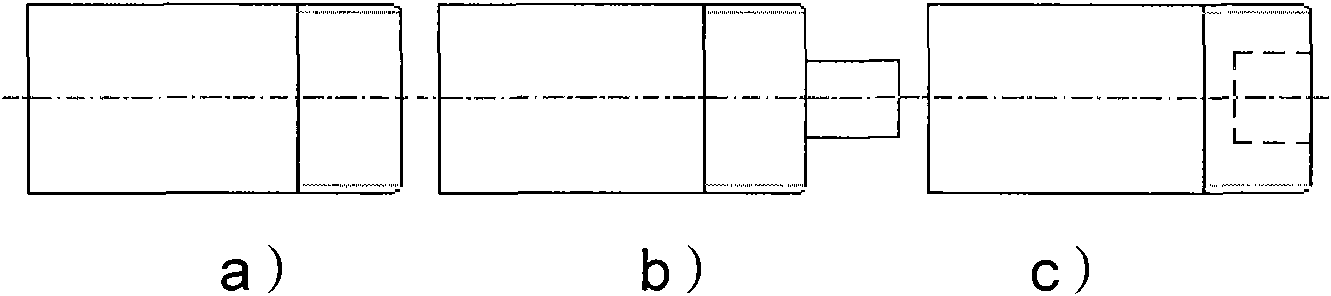

Measuring device for inner-rim large-flange spherical radius of taper roll bearing and measuring method

InactiveCN1892176AAids in quantitative analysisIncrease the measurable lengthMeasurement devicesComputer control systemCircular cone

The present invention relates to improvement of taper roller bearing inside track large capped edge sphere radius metering equipment and measuring method, belonging to measuring technology. It consists of base, x-double coordinates precision workbench, inner bore clamp, outline measurement used contacting type displacement sensor, dovetail groove guideway pair, end cover board, lifting / lowering hand wheel and computer control system. Said invention increases large capped edge sphere arc measurement length to ensure survey accuracy.

Owner:BEIHANG UNIV

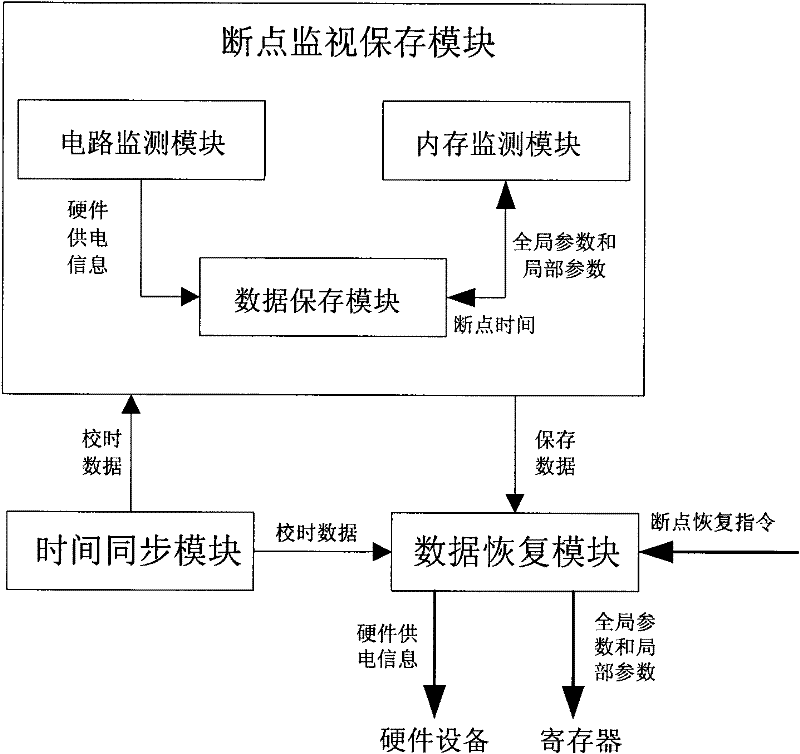

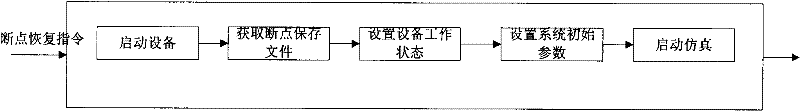

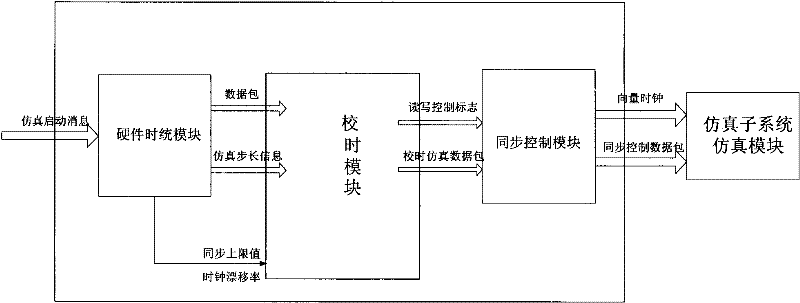

Breakpoint simulation controller and control method for ground simulation system

ActiveCN102298334AImprove Simulation EfficiencyImprove the simulation effectSimulator controlContinuationComputer module

The invention relates to a breakpoint simulation controller and a breakpoint simulation control method for a ground simulation system. The controller comprises a breakpoint monitoring storage module, a data recovery module and a time synchronizing module; under the semi-physical simulation condition, the breakpoint monitoring storage module records the global variable of the simulation system; when the simulation restarts, the data recovery module takes the data as input, so that continuation of system simulation is realized, the simulation efficiency and the simulation effect are greatly improved, and massive time, energy and cost are saved; meanwhile, the controller comprises the time synchronizing module, so that synchronization of accuracy record and recovery time of the system operating breakpoint is ensured; and by using the controller and the method, judgment of multi-process breakpoints of the complex simulation system is solved, the process data are stored in time, and data and means are provided for recovering the operation of the system.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

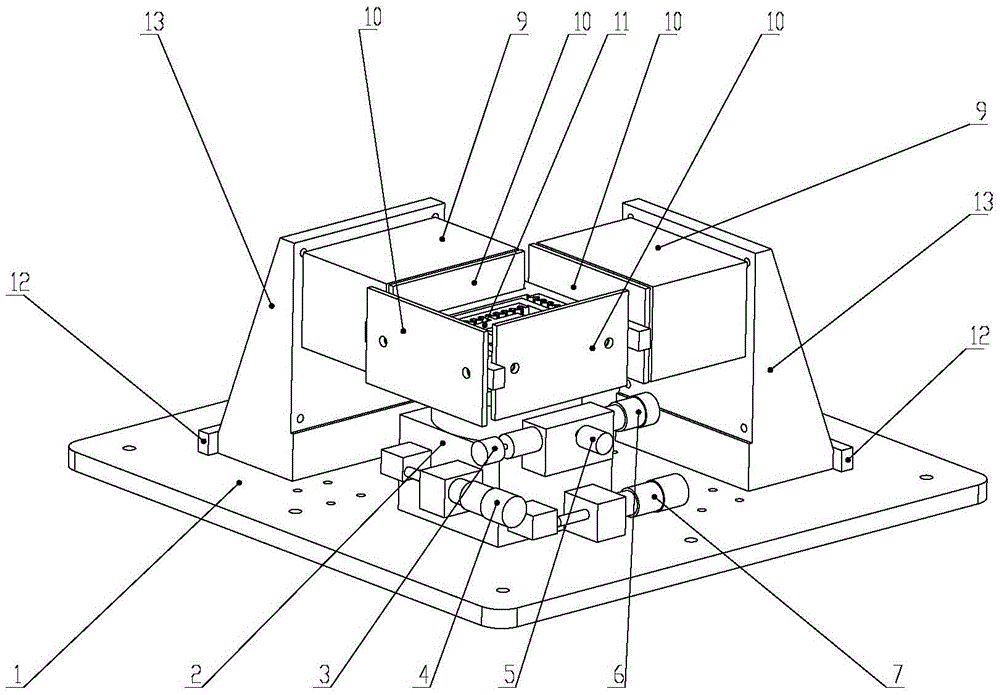

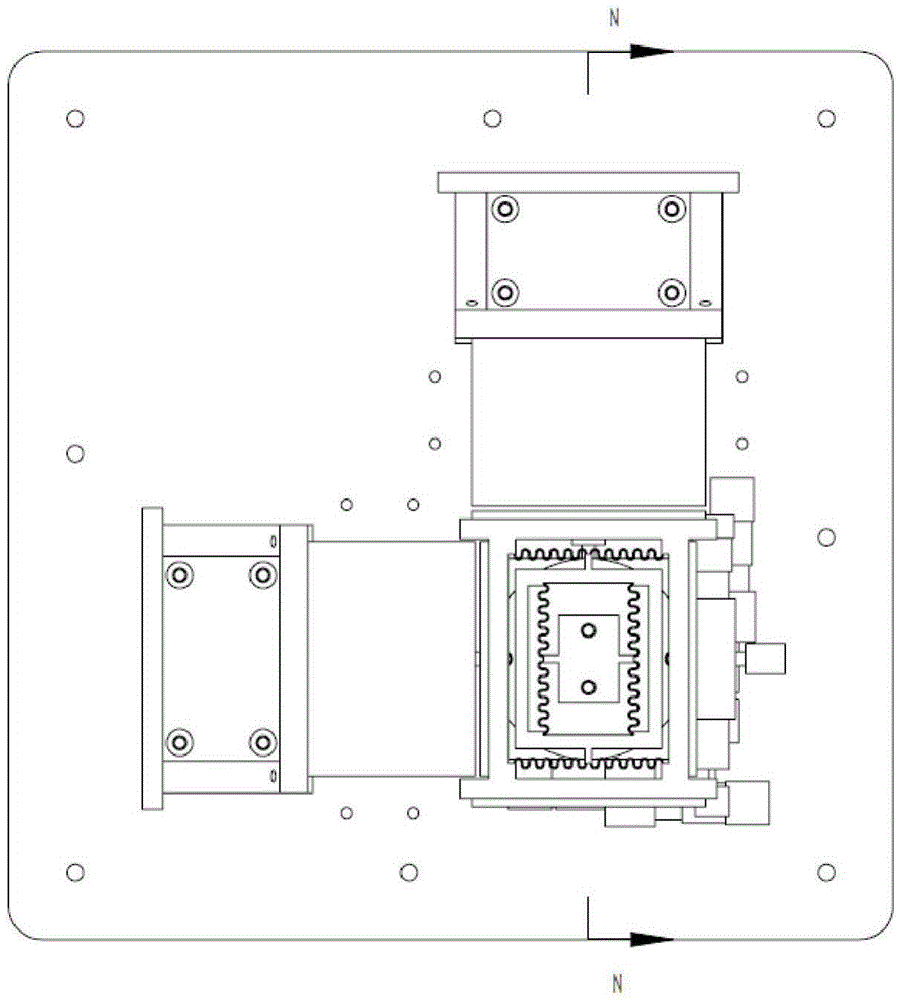

Displacement-adjustable precision locating platform

The invention discloses a displacement-adjustable precision locating platform. The displacement-adjustable precision locating platform comprises a base, a manual adjustable frame sliding table platform, a platform cushion block, a compliant hinge precision locating platform body, four electromagnetic armatures, two Z-axis right-angle junction plates and electromagnetic drivers. The manual adjustable frame sliding table platform can achieve three-freedom-degree precision locating adjustment through a cross rotating guide rail. The platform cushion block is arranged on a sliding table through four evenly-distributed threaded holes. The middle of the compliant hinge precision locating platform body is fixed to the platform cushion block through two threaded holes, and therefore the platform can achieve displacement in the X-axis direction and Y-axis direction along with the manual adjustable frame sliding table platform. The four electromagnetic armatures are fixed in the four directions of the compliant hinge precision locating platform body in a threaded connection manner. The two Z-axis right-angle junction plates are in threaded connection with the base of the platform. The electromagnetic drivers serve as drive equipment of the platform and are in threaded connection with the Z-axis right-angle junction plates to be connected with the base of the platform. The displacement-adjustable precision locating platform is simple in structure, small in overall size, low in cost and convenient to operate, and the high-precision locating requirement can be met.

Owner:SOUTH CHINA UNIV OF TECH +1

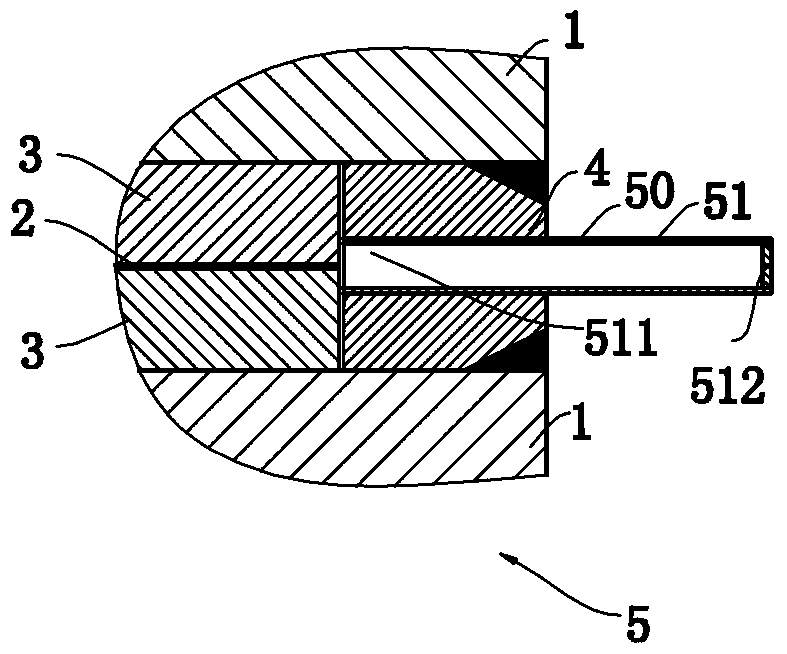

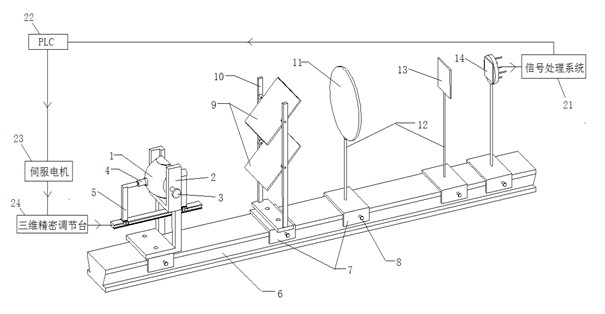

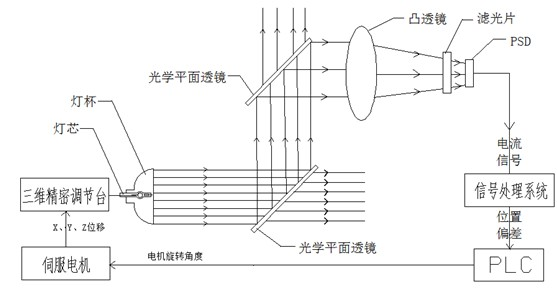

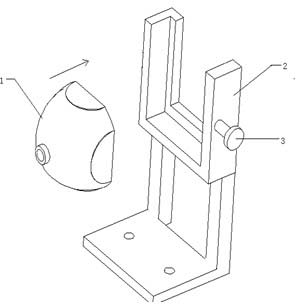

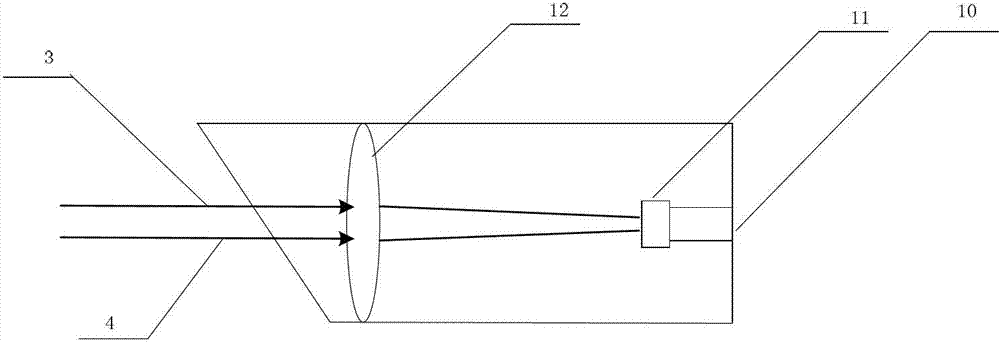

Automatic focusing device for projective bulb based on light spot detection and use method thereof

InactiveCN102305988AEasy to operateImprove efficiencyElectric circuit arrangementsProjectorsProgrammable logic controllerLight spot

The invention discloses an automatic focusing device for a projective bulb based on light spot detection and a use method thereof. The automatic focusing device comprises a lamp cup, a lamp cup clamping table, a screw I, a lampwick, a lampwick clamping frame, a large guide rail, a large slider, a screw II, an optical planar lens, a clamping holder, a convex lens, a supporting column, an optical filter, a two-dimensional photoelectric position sensor (PSD), a signal processing system, a PLC (programmable logic controller), a servo motor and a three-dimensional precise adjusting table, wherein light emitted from the lampwick can be reflected by the inner surface of the lamp cup to form parallel light beams, the parallel light beams can be transmitted and reflected twice by the optical planar lens, small parts of the light can be reflected to the convex lens, and then the light irradiates on the PSD by the optical filter after being gathered; a signal output by the PSD can be subjected to a series of conversion by the signal processing system, the PLC, the servo motor and the three-dimensional precise adjusting table; and finally the signal is used to control the position of the lampwick in the lamp cup. The device provided by the invention has the advantages of simple use method, low cost, high efficiency, high focusing precision and the like.

Owner:江苏森莱浦光电科技有限公司

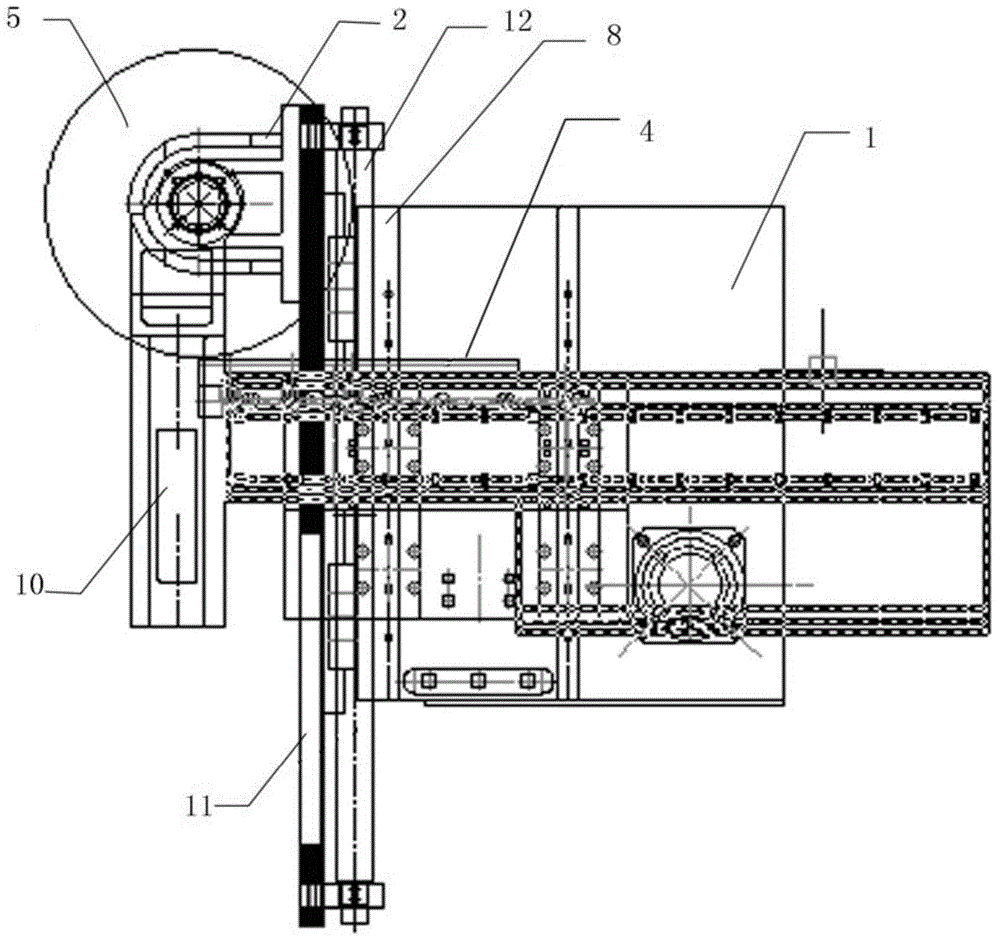

Pipe bending device of pipe bending machine applied for molding heat transferring tube of nuclear power evaporator

ActiveCN104475515AGuaranteed coaxialityGuaranteed parallelismMetal-working feeding devicesPositioning devicesNuclear powerEngineering

The invention discloses a pipe bending device of pipe bending machine applied for molding heat transferring tube of nuclear power evaporator; the pipe bending device of pipe bending machine applied for molding heat transferring tube of nuclear power evaporator comprises a machine head, and an auxiliary pushing device; the auxiliary pushing device is slidably mounted on the machine head along the axial direction of the bending steel pipe; the pipe bending device further comprises a machine seat which is slidably mounted on the machine head; the sliding direction of the machine seat is perpendicular to the axial direction of the steel pipe; the machine seat is connected with a machine seat drive device; a main shaft is mounted on the machine seat; a bending die is mounted on the upper end of the main shaft; a pipe bending arm is rotatably mounted on the machine seat; an arm driving device drives the pipe bending arm to rotate around the main shaft; a clamping device is movably mounted on the pipe bending arm; and the clamping device clamps the steel pipe when bending the pipe. The pipe bending device uses the auxiliary pushing device to position the steel pipe, thus ensuring the levelness on two ends of the steel pipe; then uses the movable bending die to approach the auxiliary pushing device for achieving bending the pipe, thereby the parallelism and the perpendicularity of the bent steel pipe can meet the requirements.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST

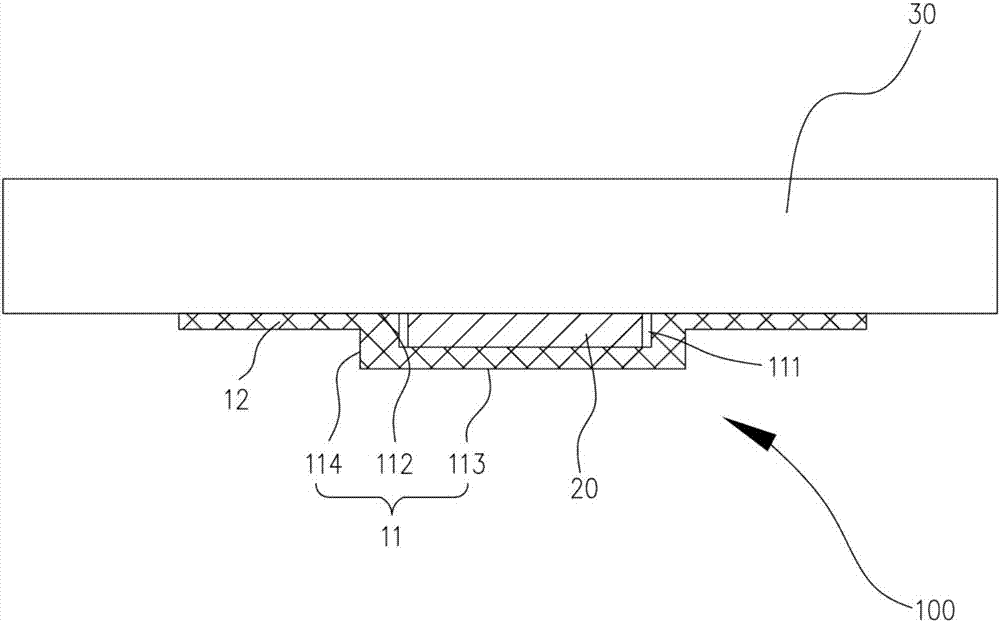

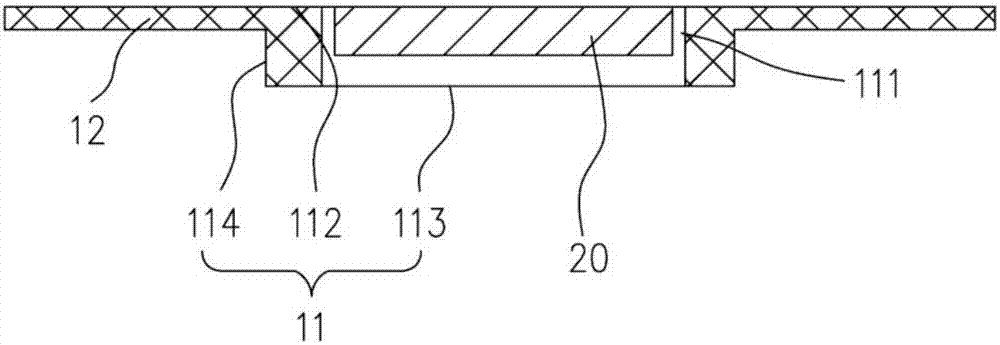

Fingerprint module, display device and mobile terminal

ActiveCN107169452AIncrease the bonding areaGuaranteed parallelismAcquiring/reconising fingerprints/palmprintsFingerprintEngineering

The invention discloses a fingerprint module, a display device and a mobile terminal. The fingerprint module comprises a supporting piece and a fingerprint chip, wherein the supporting piece comprises a main body and an extending piece extending from the peripheral side of the main body; the main body is provided with an accommodating groove; the extending direction of the extending piece is vertical to the opening direction of the accommodating groove; the extending piece is used for being attached to the back surface of a display screen; the fingerprint chip is fixed in the accommodating groove; and the fingerprint chip is parallel with the extending piece. Through extending the extending piece from the peripheral side of the main body of the supporting piece and enabling the extending piece to be attached to the back surface of the display screen, the attaching area between the fingerprint module and the display screen can be expanded; as the extending piece is parallel with the fingerprint chip, the parallelism between the fingerprint chip of the fingerprint module and the display screen is further ensured; the fingerprint chip sensing signal transmitting and receiving accuracy is improved, the fingerprint acquisition efficiency is enhanced, and the user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

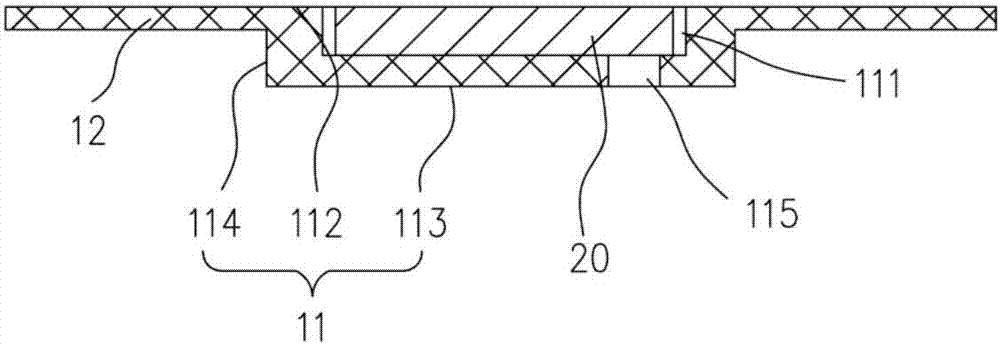

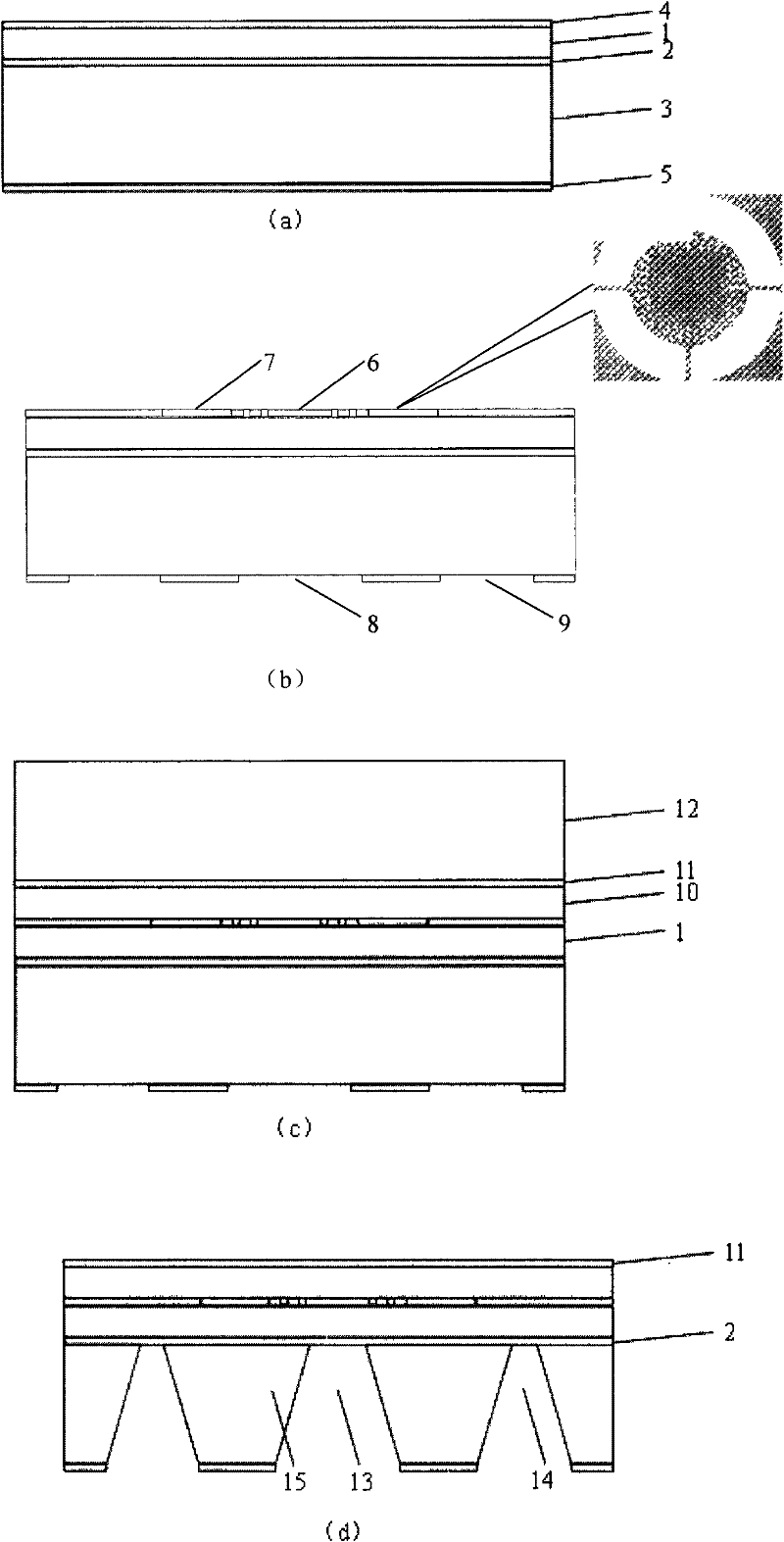

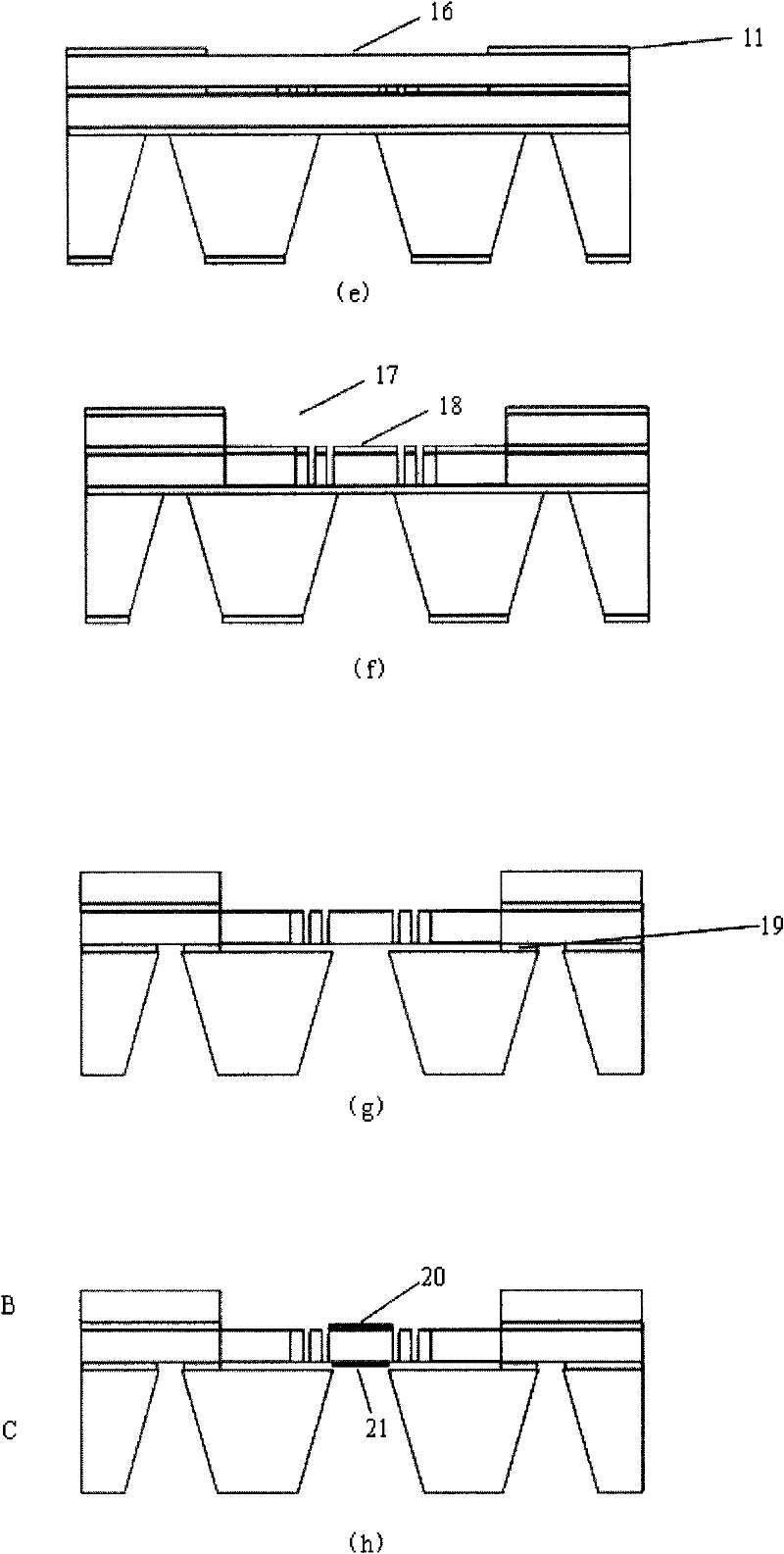

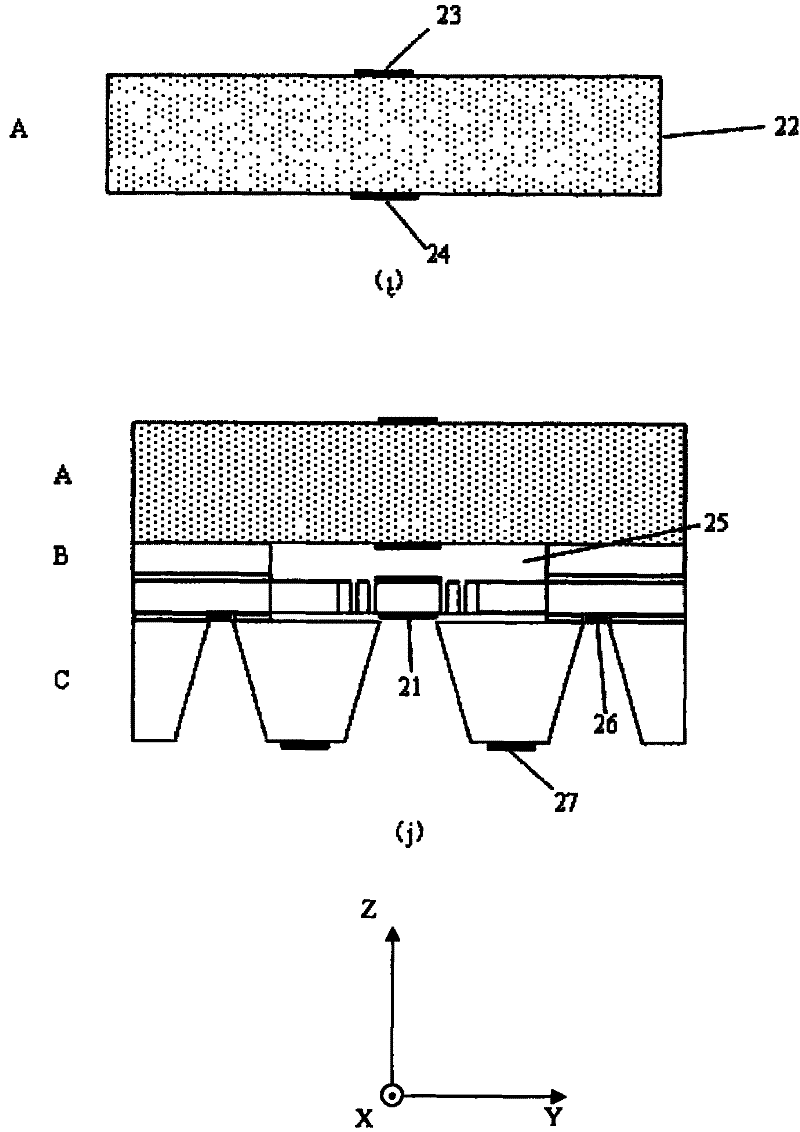

Manufacturing method of adjustable FP (filter pass) optical filter based on MEMS (micro electro mechanical system) process

InactiveCN102225739AImprove yieldGood process compatibilityDecorative surface effectsChemical vapor deposition coatingAcid etchingEvaporation

The invention relates to a manufacturing method of an adjustable FP (filter pass) optical filter based on an MEMS (micro electro mechanical system) process, which is characterized in that the etching window of all graphs is manufactured by adopting the etching twice; the manufacturing of a middle FP air cavity and a movable reflector surface structure is finished by adopting the plasma silicon etching once; a movable silicon membrane reflector is manufactured by adopting the processes such as the silicon-silicon bonding, the plasma dry etching, the HF (hydrogen fluoride) acid etching and the silicon oxide layer releasing once; the high-reflection membrane and anti-reflection membrane of the two reflectors in the FP cavity are manufactured by adopting a method for selecting evaporation through a hard template; and a final FP cavity filter is formed by adopting the silicon-glass bonding once. In the manufacturing method provided by the invention, the process procedures are greatly simplified; the mirror finish and parallelism of the FP cavity are guaranteed; and the optical technical index and chip yield of the manufactured FP filter are improved. Compared with the existing like product manufacturing process, the manufacturing method provided by the invention has the advantages of good process compatibility and maneuverability, low driving voltage and good optical tuning repeatability and stability and can be widely applied to an optical communication WDM (wavelength division multiplex) system.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

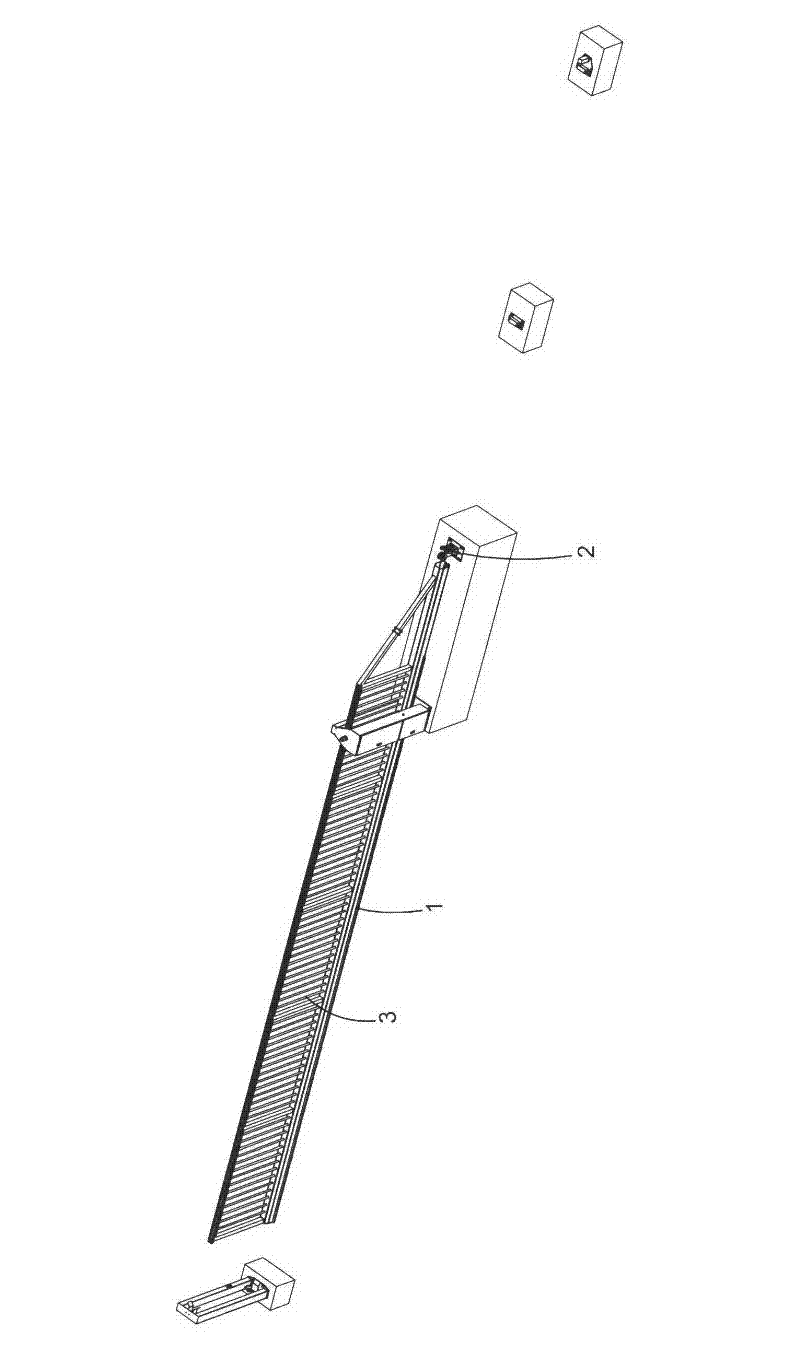

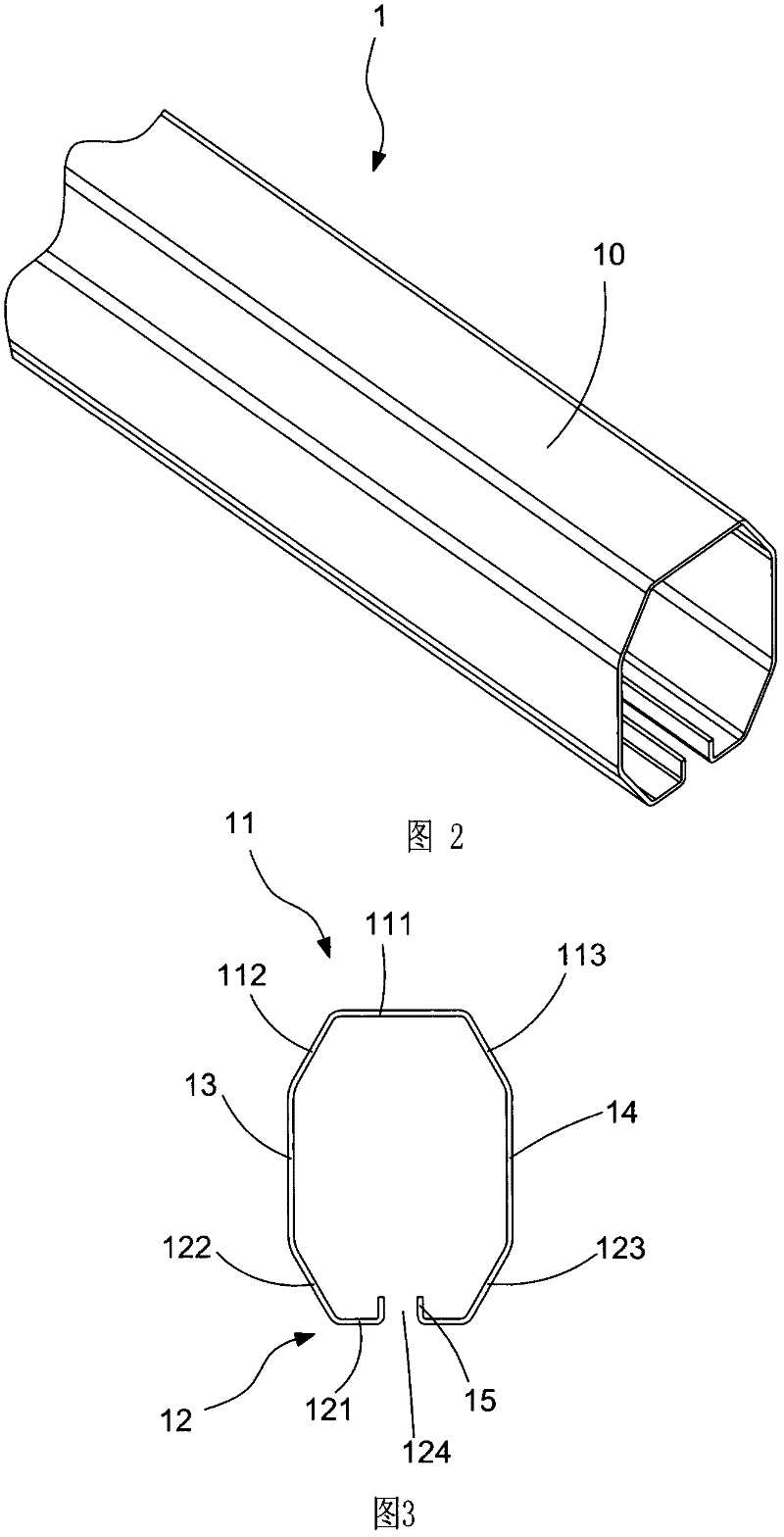

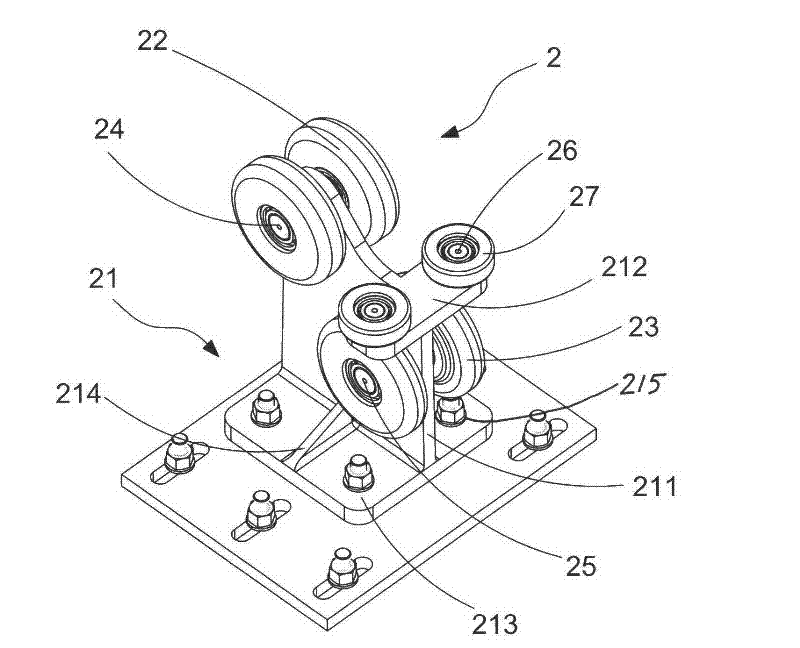

Railless sliding door

ActiveCN102418463AGuaranteed uptimeAvoid bending deformationWing arrangementsRolling resistanceEngineering

Owner:ZHANGJIAGANG GOLDNET FENCING SYST

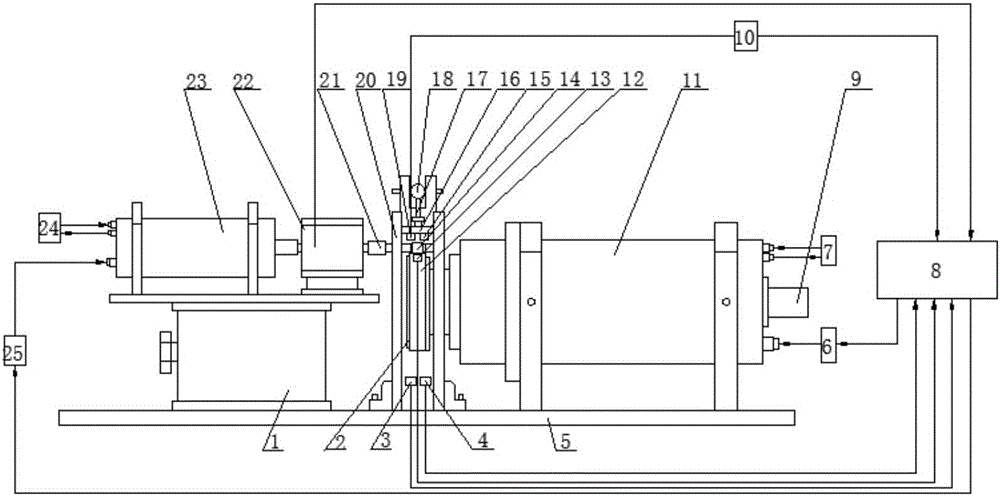

Interface friction property monitoring-based rolling-sliding friction life cycle test device

ActiveCN106198019ALive frictionReal-time film thicknessMachine bearings testingInvestigating abrasion/wear resistanceLow speedRolling-element bearing

The invention relates to an interface friction property monitoring-based rolling-sliding friction life cycle test device. A high-speed electric spindle on a support lifting platform is connected with a torque sensor; one end of the torque sensor is connected with an exchangeable rolling body in a measured object; two ends of the rolling body are provided with rolling bearings; the rolling bearings area arranged in a vertical guide rail; a pressing plate is arranged above the rolling bearings; a groove for accommodating a ball is arranged on the upper surface of the pressing plate; the upper part of the ball contacts with the fulcrum plane of a pressing rod; a lever is arranged on an upright column; the tail end of the lever is connected with the nut of a sensor on a support through a steel wire rope; one end of the support is provided with a low-speed motorized spindle; and the front end of the low-speed motorized spindle is equipped with the bearing inner ring of the measured object. With the test device of the invention adopted, the actual working condition of each roller and a bearing inner ring in the operation process of a cylindrical roller bearing can be simulated; the cause of abrasion caused by the change of interface contact is obtained; and a reliable data guarantee and technical support can be provided for the life cycle health condition monitoring and condition-based repair of the key friction pair of a rolling bearing.

Owner:XI AN JIAOTONG UNIV

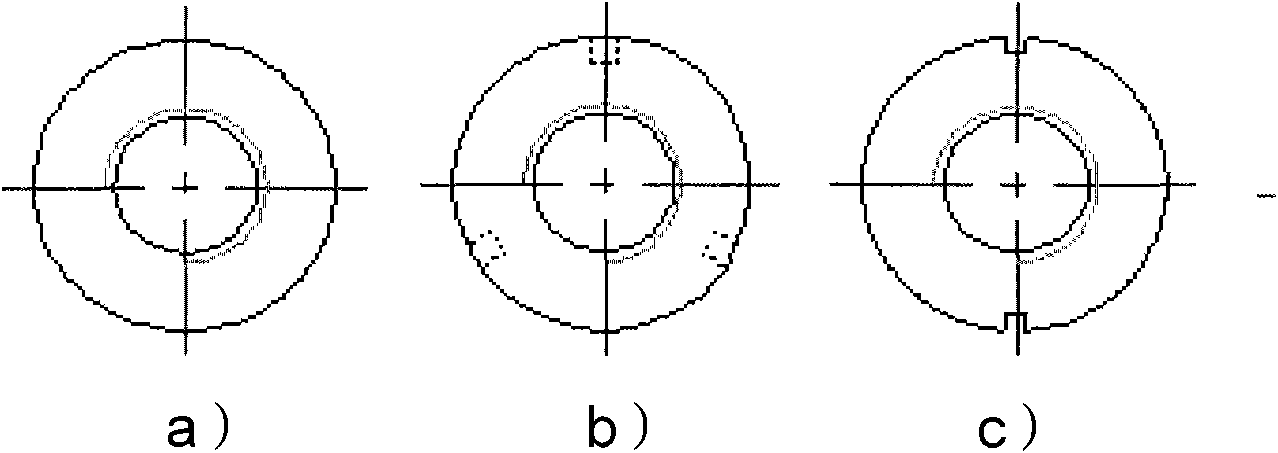

Stack-type multi-gap gas switch

InactiveCN101924328ASimplify the installation processGuaranteed parallelismSpark gap detailsCushionMetal

The invention relates to a stack-type multi-gap gas switch comprising a cylindrical outer insulation barrel, a disc-shaped upper cover plate, a disc-shaped lower cover plate, at least three ring electrodes, a triggering connector, an air tap and a plurality of ring-shaped insulation cushion blocks. The disc-shaped upper cover plate is fixed at the upper end of the outer insulation barrel; the disc-shaped lower cover plate is fixed at the lower end of the outer insulation barrel; the triggering connector is arranged in a plane of the outer insulation barrel; the upper cover plate and the outer insulation barrel as well as the lower cover plate and the outer insulation are sealed; the plurality of ring-shaped insulation cushion blocks with the same amount as the ring electrodes are arranged in the outer insulation barrel; a plurality of evenly distributed air holes are arranged on the outer side of the insulation cushion block; and a circular groove is arranged on the lower surface of the upper cover plate and is internally provided with an elastic metal ring contacted with an electrode of an uppermost stack assembly. The invention solves the technical problems of poor installation precision and complex installation process of the traditional multi-gap gas discharge switch and has the advantages of simple structure of the switch, convenient installation and operation process and high assembling precision.

Owner:NORTHWEST INST OF NUCLEAR TECH

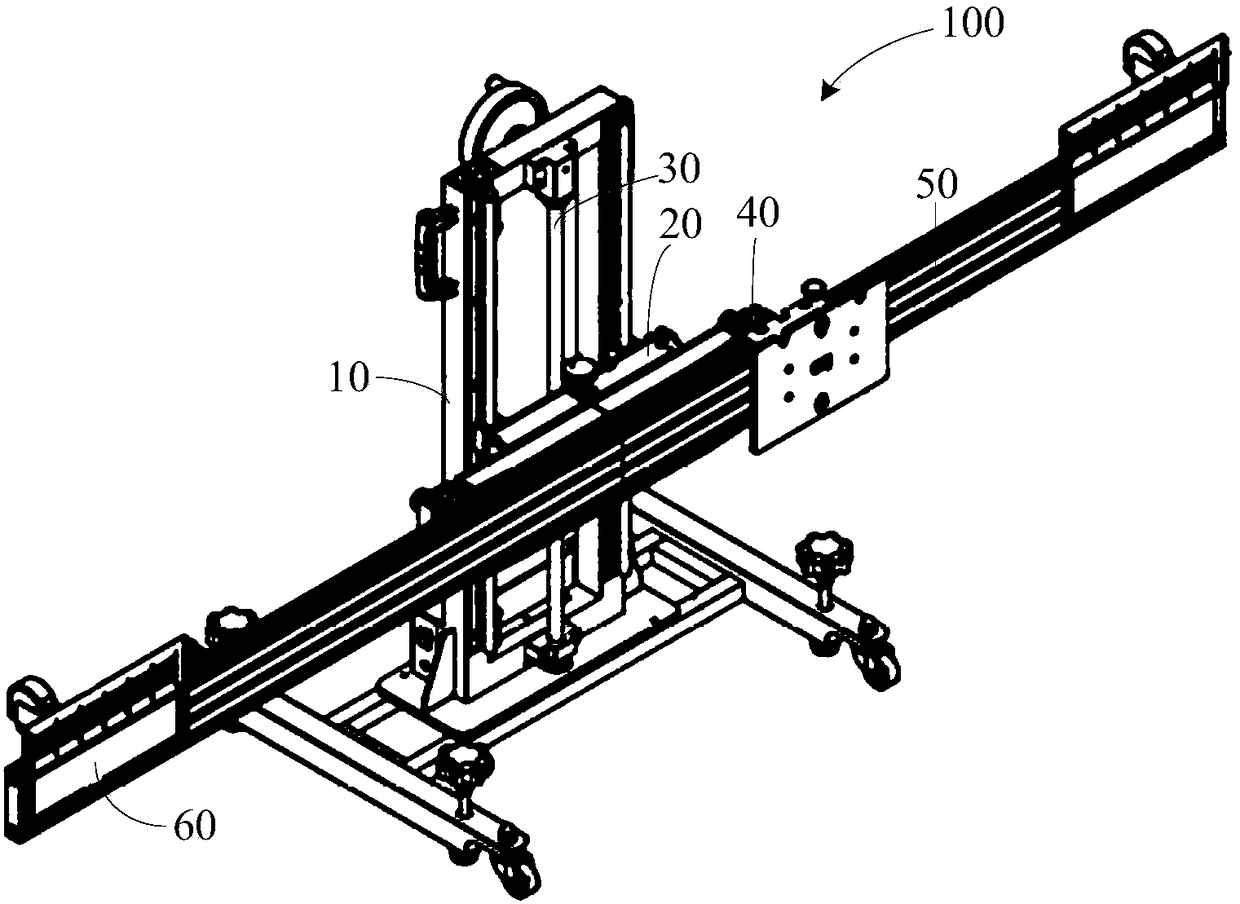

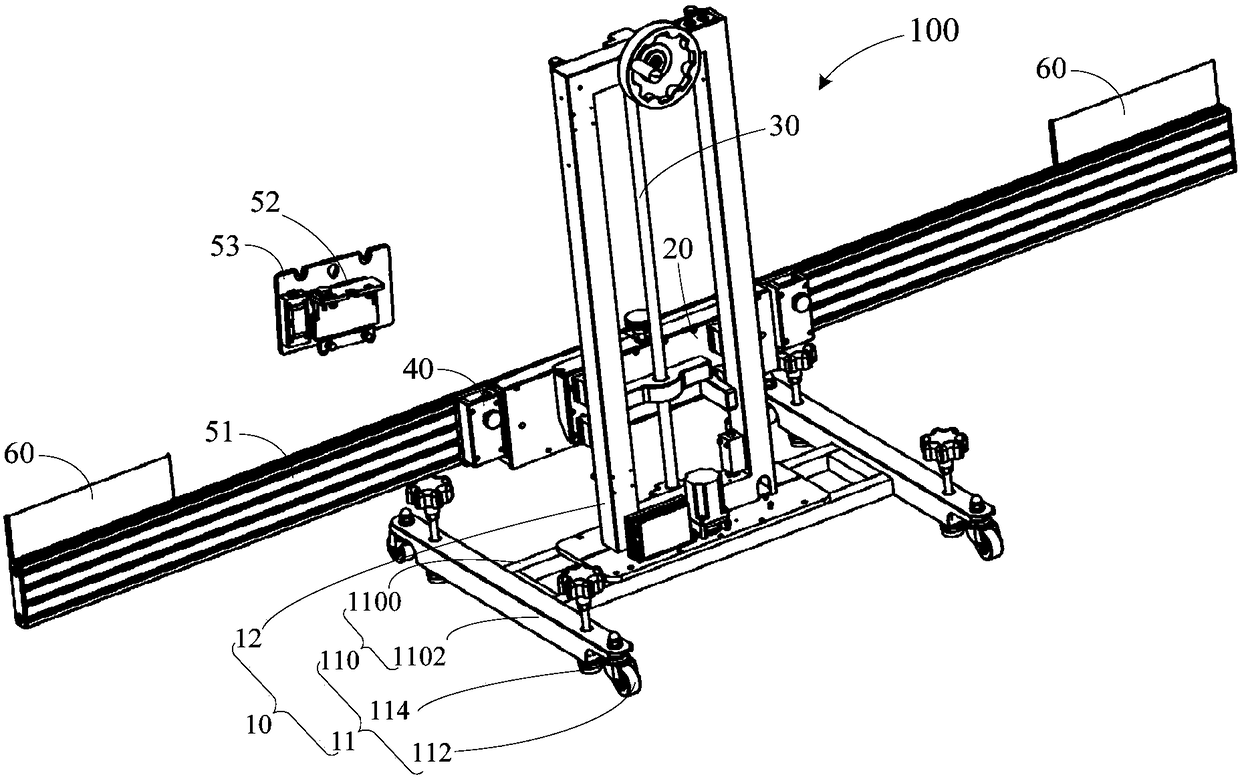

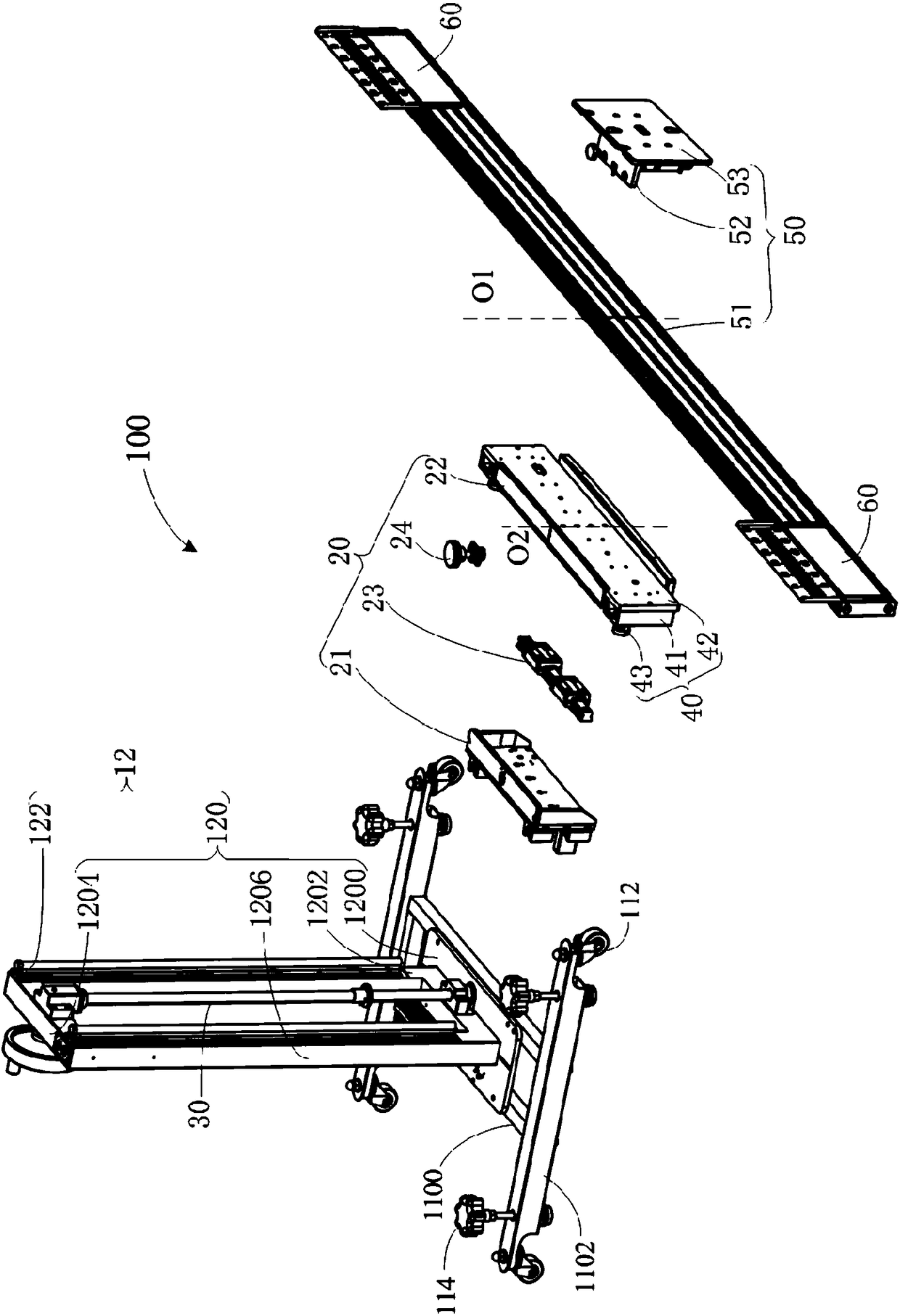

Sliding device and car calibration equipment

PendingCN108581982ASmooth slidingGuaranteed parallelismWork benchesOther workshop equipmentEngineeringMechanical engineering

Owner:AUTEL INTELLIGENT TECHNOLOGY CORP LTD

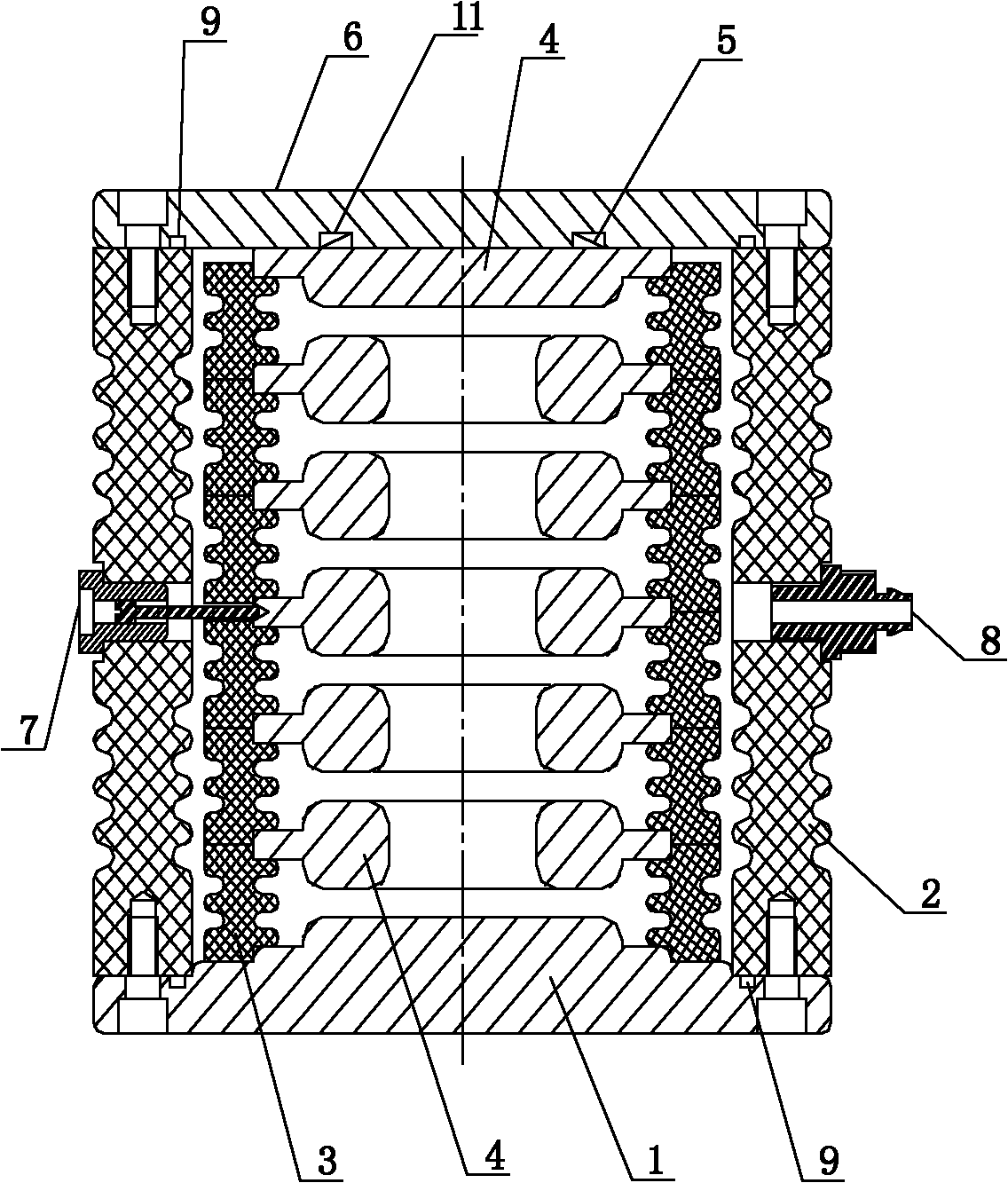

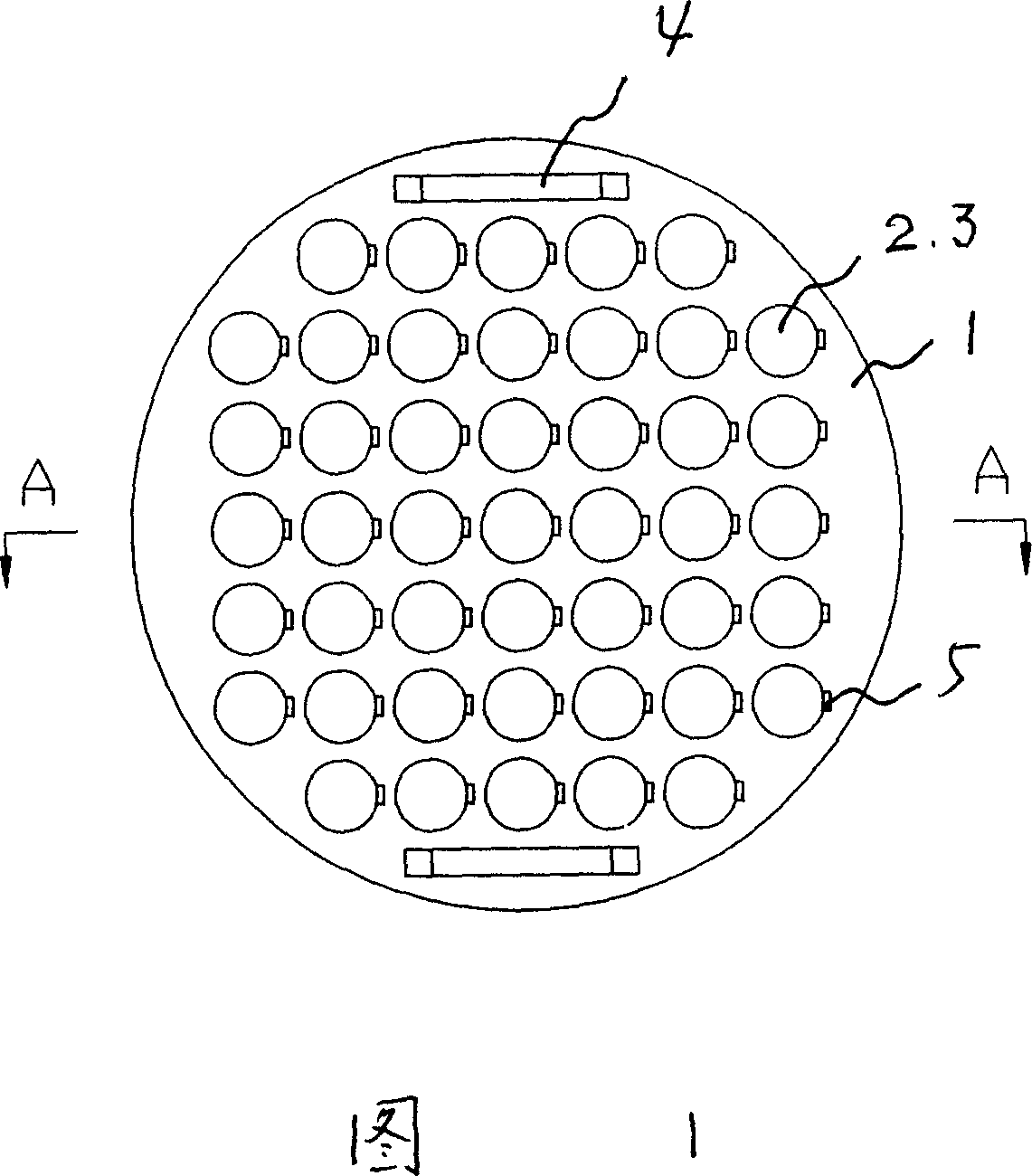

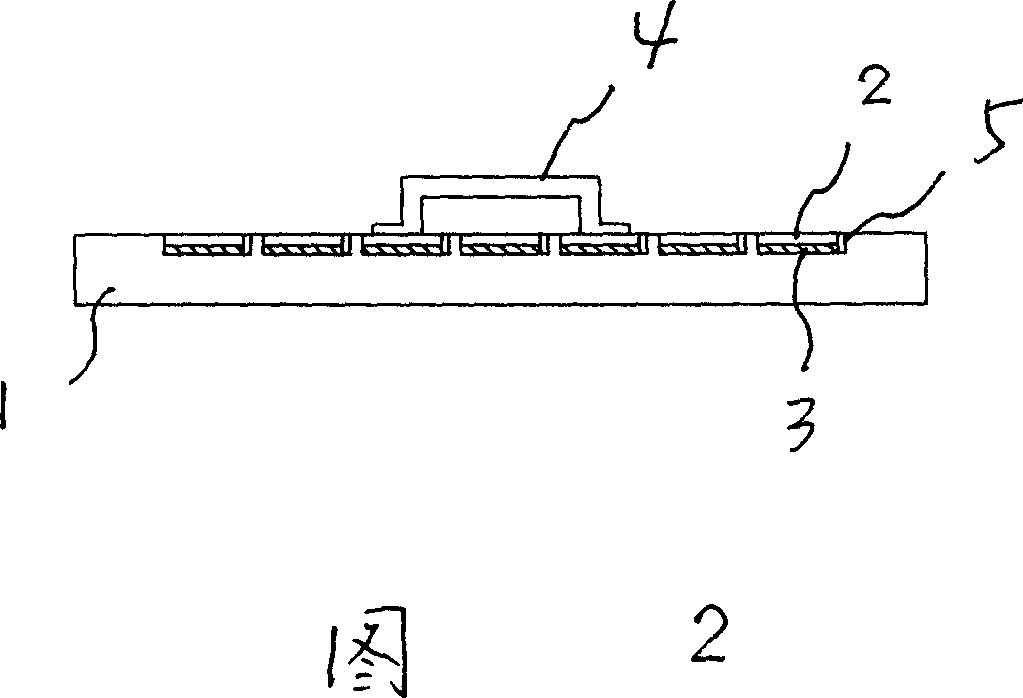

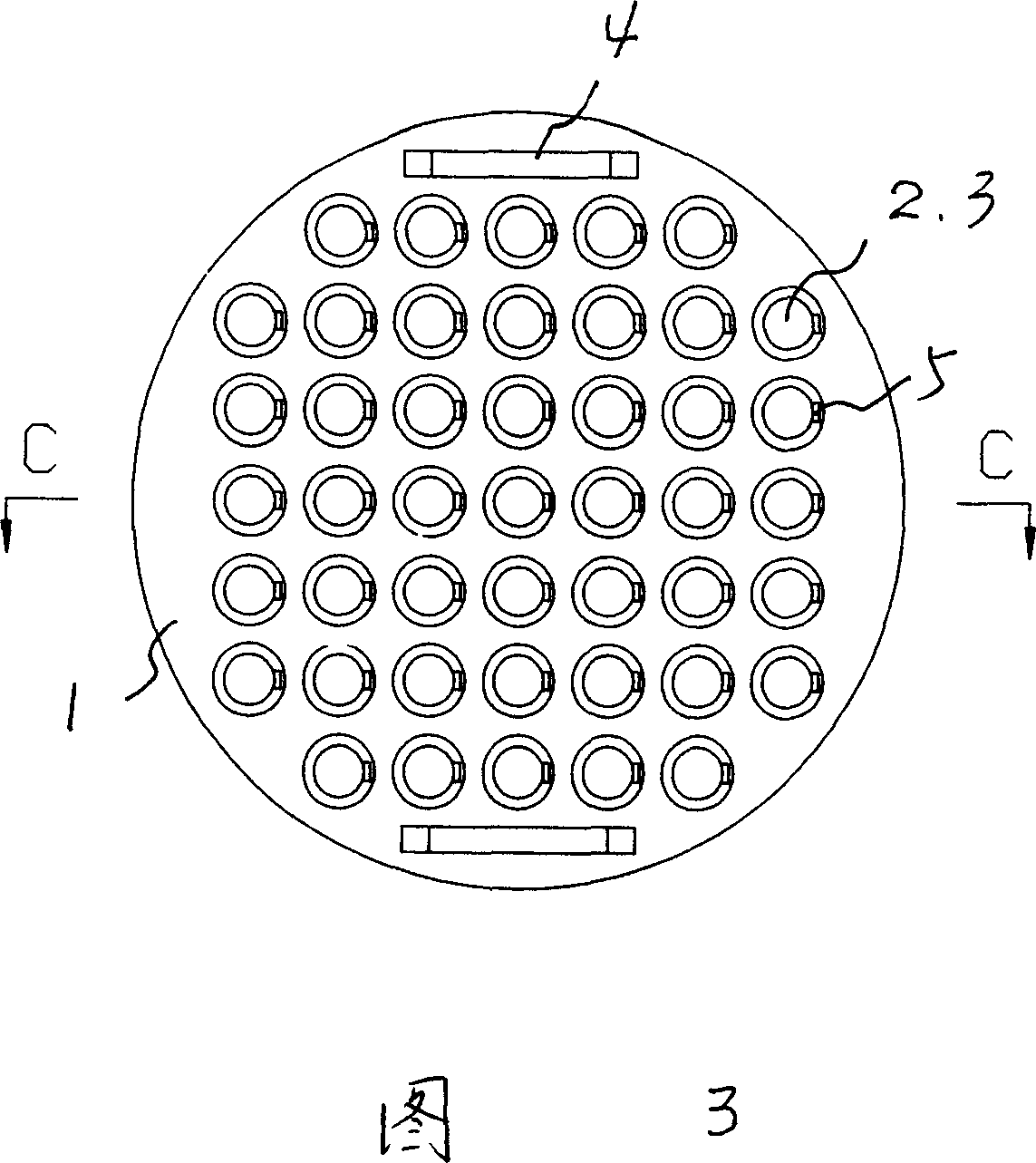

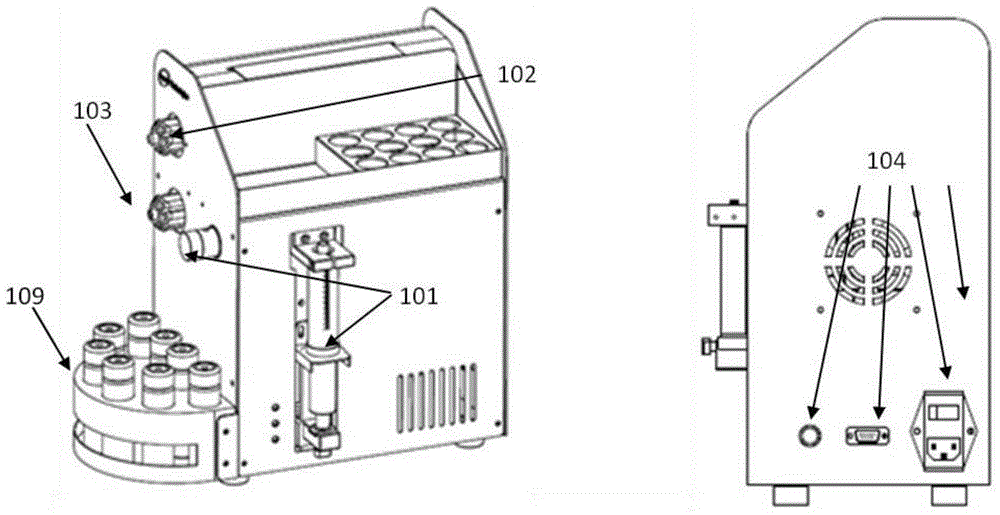

High-density array type cell slide culture apparatus, storage apparatus and experimental apparatus

ActiveCN1928063APromote growthImprove cultivation efficiencyTissue/virus culture apparatusHigh densityShape matching

The present invention discloses one kind of high density array type cell culturing device, storing device and experiment device. The cell culturing device includes carrier plate with ordered arranged slots of 0.3-0.4 mm depth and glass slides inside the slots. The storing device has one holder with ordered arranged openings for the circular sheets to be set in, and the openings have length smaller than the diameter of the circular glass slide, end width of 0.15-0.18 mm and middle width greater than the end width. The experiment device has experiment plate with ordered arranged notches for the sheets to be set in, and the notches have cross section shape matching the glass slides and depth of 4-6 mm. The present invention has the advantages of convenient use, high efficiency, high identity, etc.

Owner:李宏 +5

Turning positioning fixture for thin-wall rotational parts and clamping method

ActiveCN101972943AReduce distortionNot easy to damagePositioning apparatusMetal-working holdersEngineeringAxial force

The invention relates to a turning positioning fixture for thin-wall rotational parts and a clamping method. The fixture comprises a cylindrical positioning body and threaded rings, wherein an external thread is lathed on the external surface of the positioning end; the threaded rings are circular rings with internal diameter the same as the external diameter of the positioning body; the internal surfaces of the threaded rings are provided with internal threads matched with the external thread on the positioning body; and during positioning, one end of the positioning body is clamped on a machine tool and the positioning end is closely contacted with the part, and the positioning body is closely matched with the part through the external thread on the external surface and the internal threads on the threaded rings. In the embodiment, the clamp force on the part is mainly axial force, thus overcoming the negative effect that radial force leads to workpiece deformation during traditional machining; and the positioning body is clamped and lathed at the site, and during positioning and clamping, firstly the positioning body is ensured to be fit with the end face of the part and the end face runout of the part is ensured to be identical with that of the spindle of the machine tool, thus ensuring the flatness and the parallelism of the part. The fixture can carry out automatic alignment and positioning while screwing the threaded rings, is convenient to operate and reduces artificial operation errors.

Owner:BEIJING RES INST OF TELEMETRY

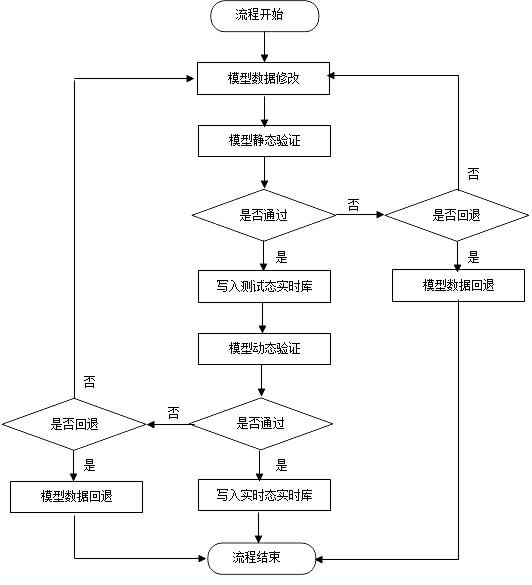

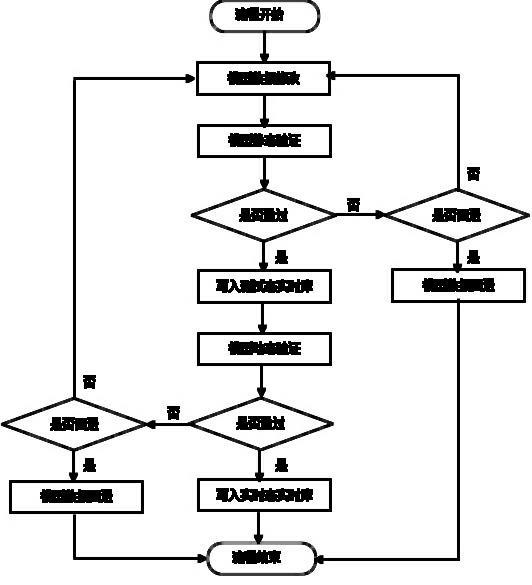

Dynamic verification and soft handover method for online state entering of power grid model

ActiveCN102117449ARealize seamless soft handoverGuaranteed parallelismData processing applicationsUser verificationDynamic models

The invention discloses a dynamic verification and soft handover method for the online state entering of a power grid model, which belongs to the technical field of power grid model management of a power system. The method is characterized in that: the updated data of the power grid model in a scheduling system may not directly enter an online state in an operation system, and can be downloaded into a real-time database of the operation system only after static model verification and dynamic model verification; when the verified model enters the online state, only incremental model data is downloaded by adopting a real-time database row-level dynamic downloading technology, thereby realizing the seamless soft handover of the power grid model; and a model returning mechanism is provided, and the by-the-user verification and enabling of the model is supported, so the parallelism of operations of a plurality of users is ensured, and the consistency of the data of the model is also ensured. By the method provided by the invention, the accuracy of the model can be maximally ensured, the model is ensured not to influence the real-time operation system in the online state entering process to realize disturbance-free online state entering, and the operation reliability and continuity of an online system are ensured.

Owner:NARI TECH CO LTD +1

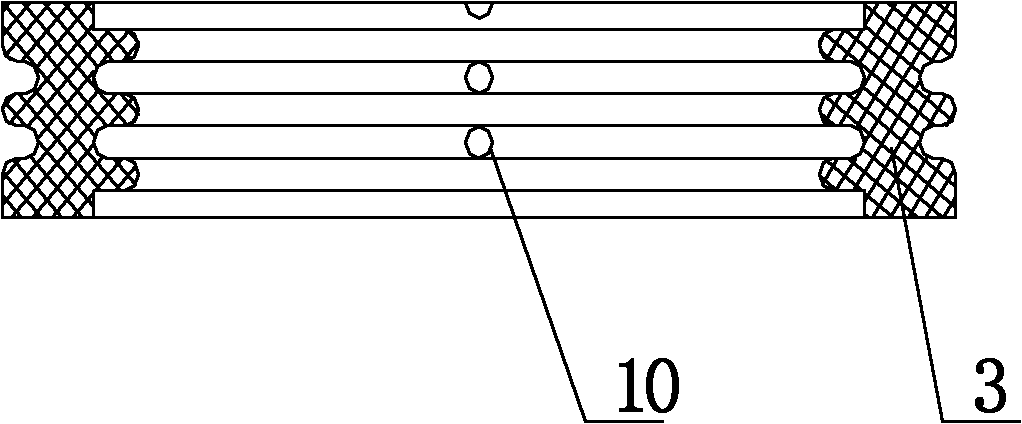

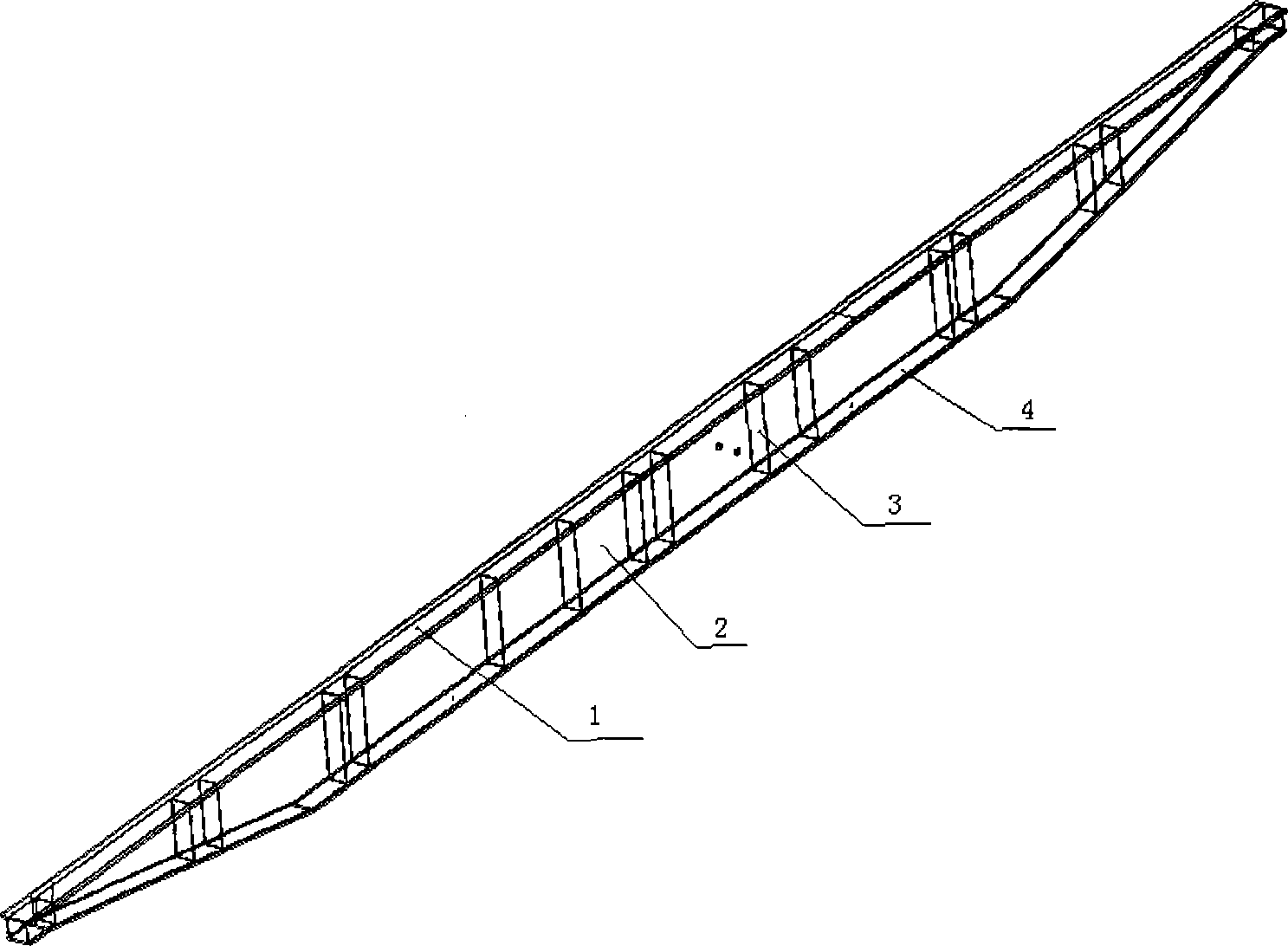

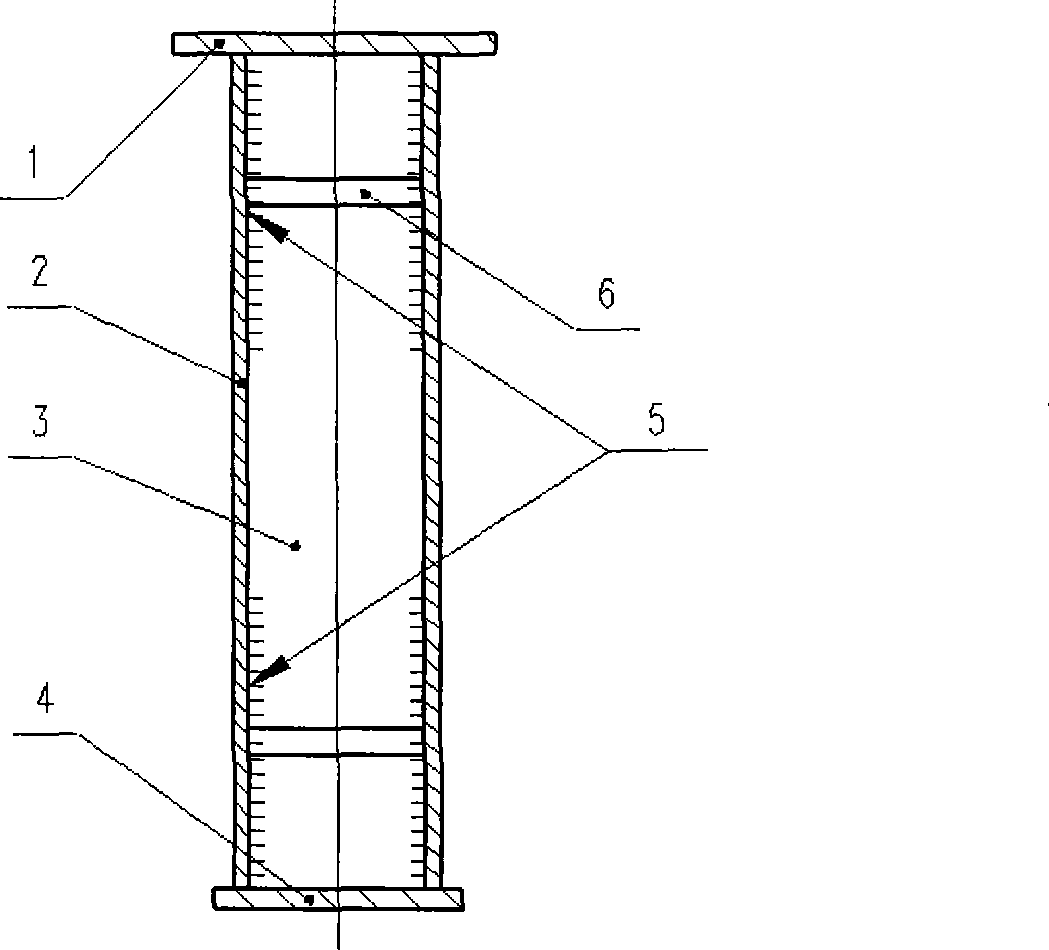

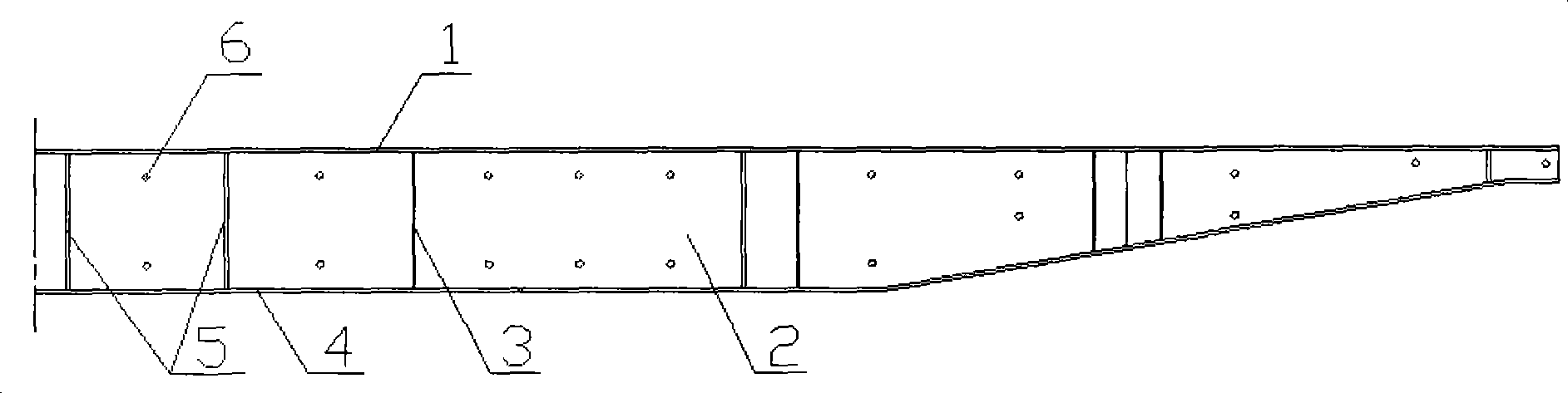

Method for assembling vertical rectangle box type structure girder

ActiveCN101434243AGuaranteed lumen sizeIncreased stiffness in all directionsWagons/vansWelding/soldering/cutting articlesProcess supportWeld seam

The invention provides a narrow-high long-big box style structural beam, comprising upper cover plates (1), web plates (2), inner-cavity clapboards of the structural beam (3) and lower cover plates (4). A plurality of process support rods (6) are arranged inside the inner cavity of the structural beam and connected with the web plates through spot welding. The assembling method of the structural beam is as follows: the clapboards and the web plates are fixed by spot welding as well as the web plates and the process support rods; the gaps caused by the spot welding between the clapboards and web plates are filled through welding; the symmetric welding is carried out from the middle part to two ends of the structural beam on the vertical direction and the multi-layer and multi-strip welding is adopted according to the size of welding angles; then the upper cover plates and lower cover plates are respectively fixed on the upper and lower ends of the web plates and clapboards through spot welding; and then welding seams are filled and the multi-layer and multi-strip welding is adopted according to the size of welding angles. The structural beam can avoid the falling or rising of the web plates so as to guarantee the inner cavity size of the structural beam, the parallelism of the web plates and the rigid on each direction and the assembling method is simple.

Owner:CRRC YANGTZE CO LTD

Machining method for axial step deep hole system of thin-wall ring

The invention relates to a machining method for an axial step deep hole system of a thin-wall ring and belongs to the technical field of axial step deep hole machining of the thin-wall ring. The machining method for the axial step deep hole system of the thin-wall ring is easy to operate, high in machining accuracy and capable of remarkably improving the working efficiency. According to the adopted technical scheme, a thin-wall ring body is horizontally fixed to an operating table and clamped through a clamp on the operating table; a center drill is adopted for drilling a locating center hole of step deep holes in the end face of the thin-wall ring; a hard alloy inner-cooling drill bit is adopted for drilling pre-drilled holes of large holes in the step deep holes in the locating center hole; a guide drill is adopted for drilling guide holes of small holes in the step deep holes in the locating center hole; the hard alloy inner-cooling drill bit is adopted again for drilling pre-drilled holes of the small holes in the step deep holes in the guide holes; and finally, a hard alloy inner-cooling spiral cutting blade step compound-forming reamer is adopted for forming hole walls and steps of the step deep holes through one-time locating cutting, and machining is finished. The method is widely used for machining of the axial step deep holes of the thin-wall ring.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

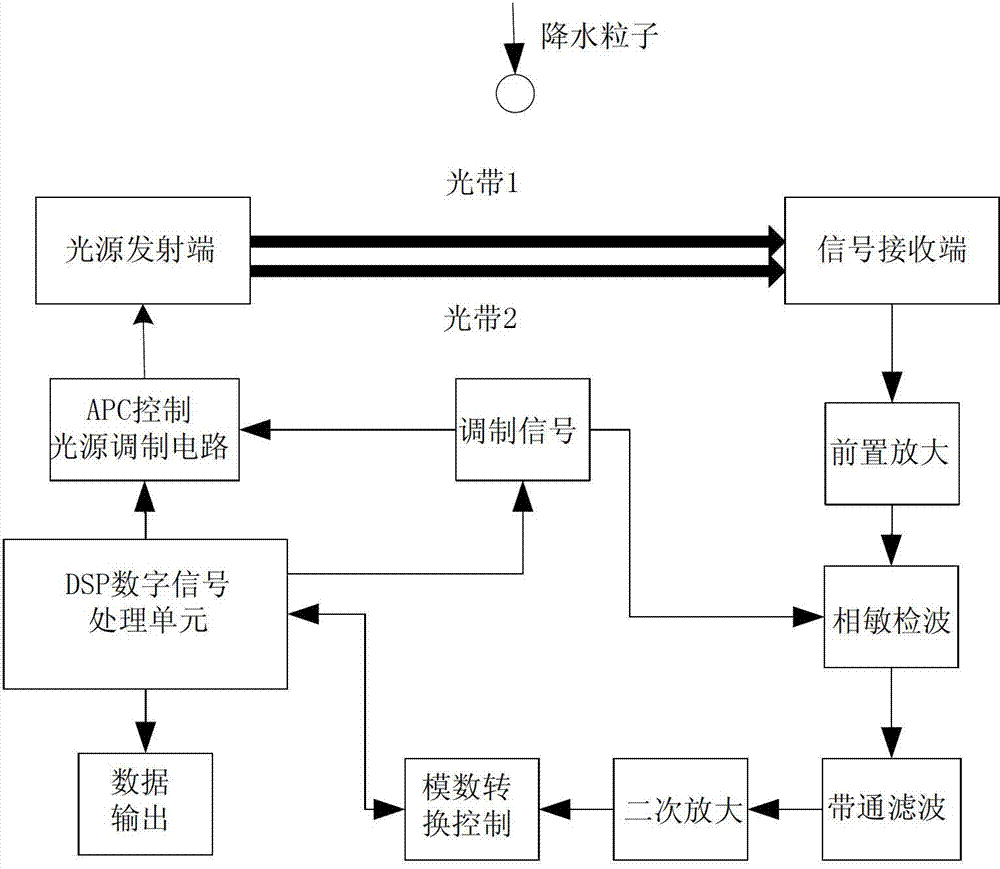

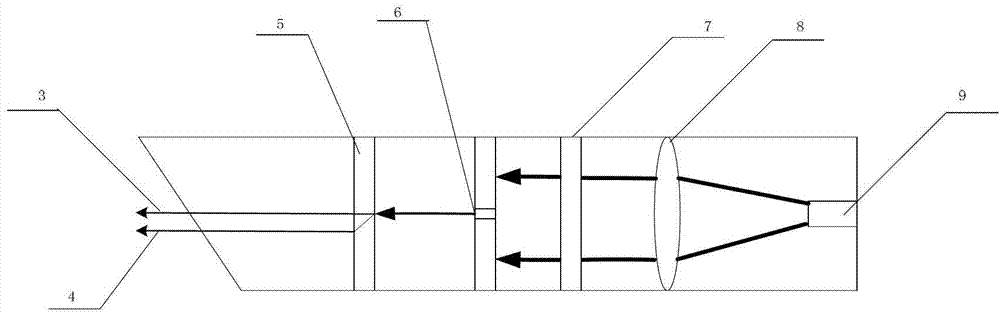

Method for measuring laser rainfall weather phenomenon and laser rainfall weather phenomenon instrument

ActiveCN102879835AAvoid errorsGuaranteed parallelismRainfall/precipitation gaugesPhotovoltaic detectorsAtmospheric sciences

The invention relates to a method for measuring a laser rainfall weather phenomenon and a laser rainfall weather phenomenon instrument. A calcite crystal with the birefringent characteristic is arranged at a light source transmitting end, so that two accurate parallel horizontal measurement light strips generated by the light source transmitting end take stopping and attenuating effects on light when falling rainfall particles pass through the measurement light strips; a double peak-shaped measurement signal is generated on a receiving end photoelectric detector; and by measuring a peak-peak interval and an integral value of the double peak signal, the falling speed of the rainfall particles and information of the particle size can be obtained, the judgment on the rainfall weather phenomenon is implemented and data such as a rainfall strength, a rain droplet size spectrum and the like can be provided.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

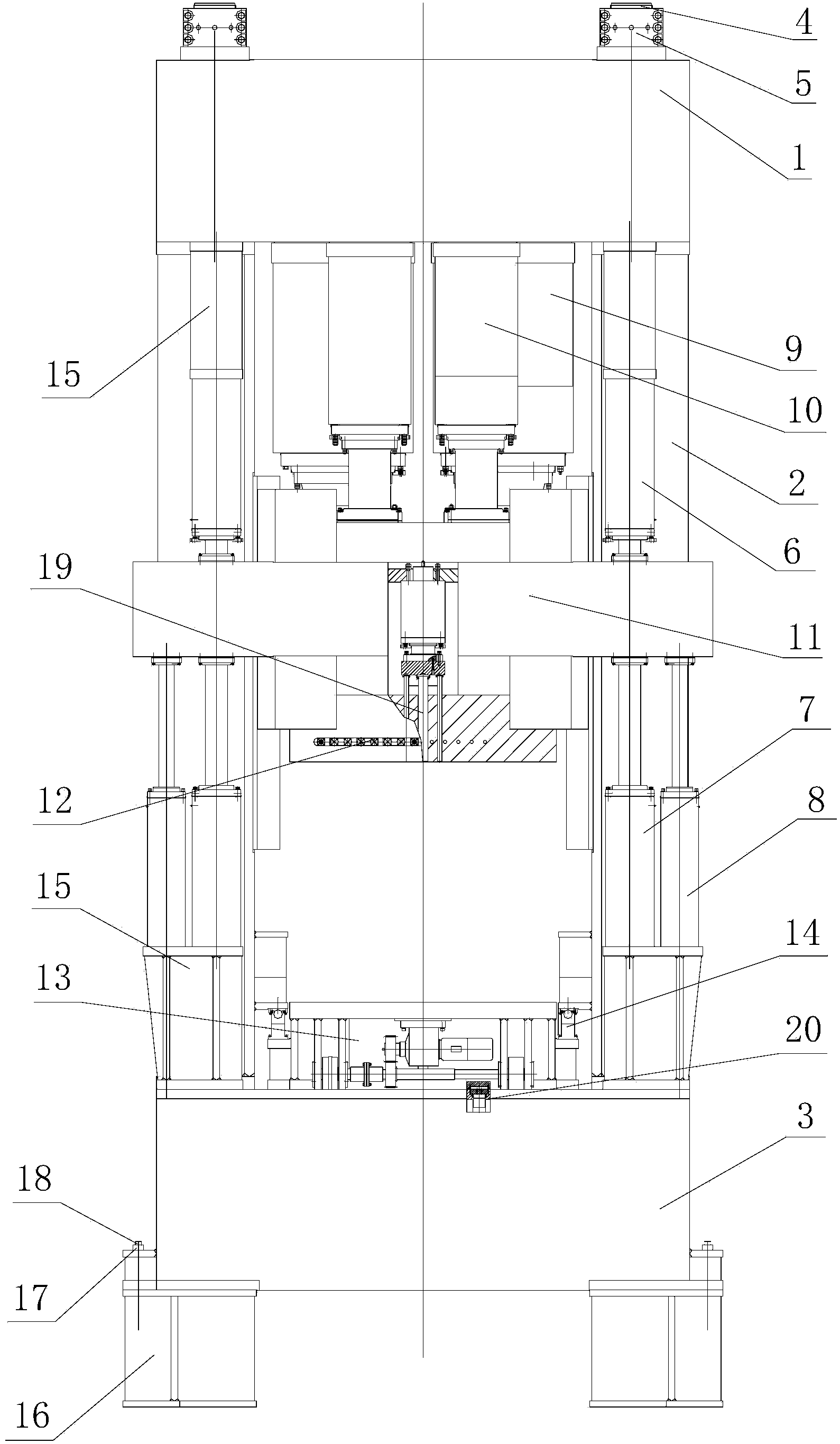

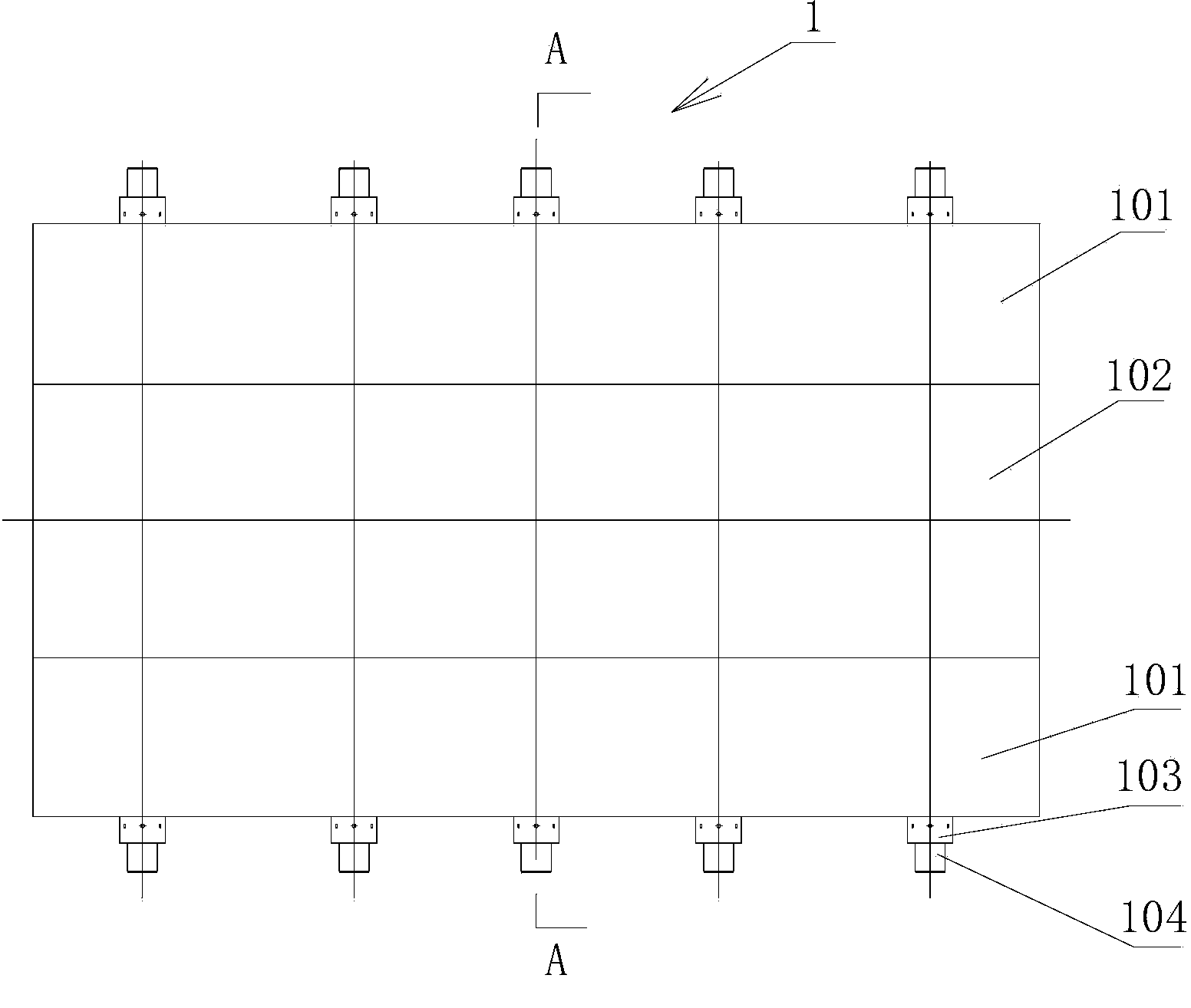

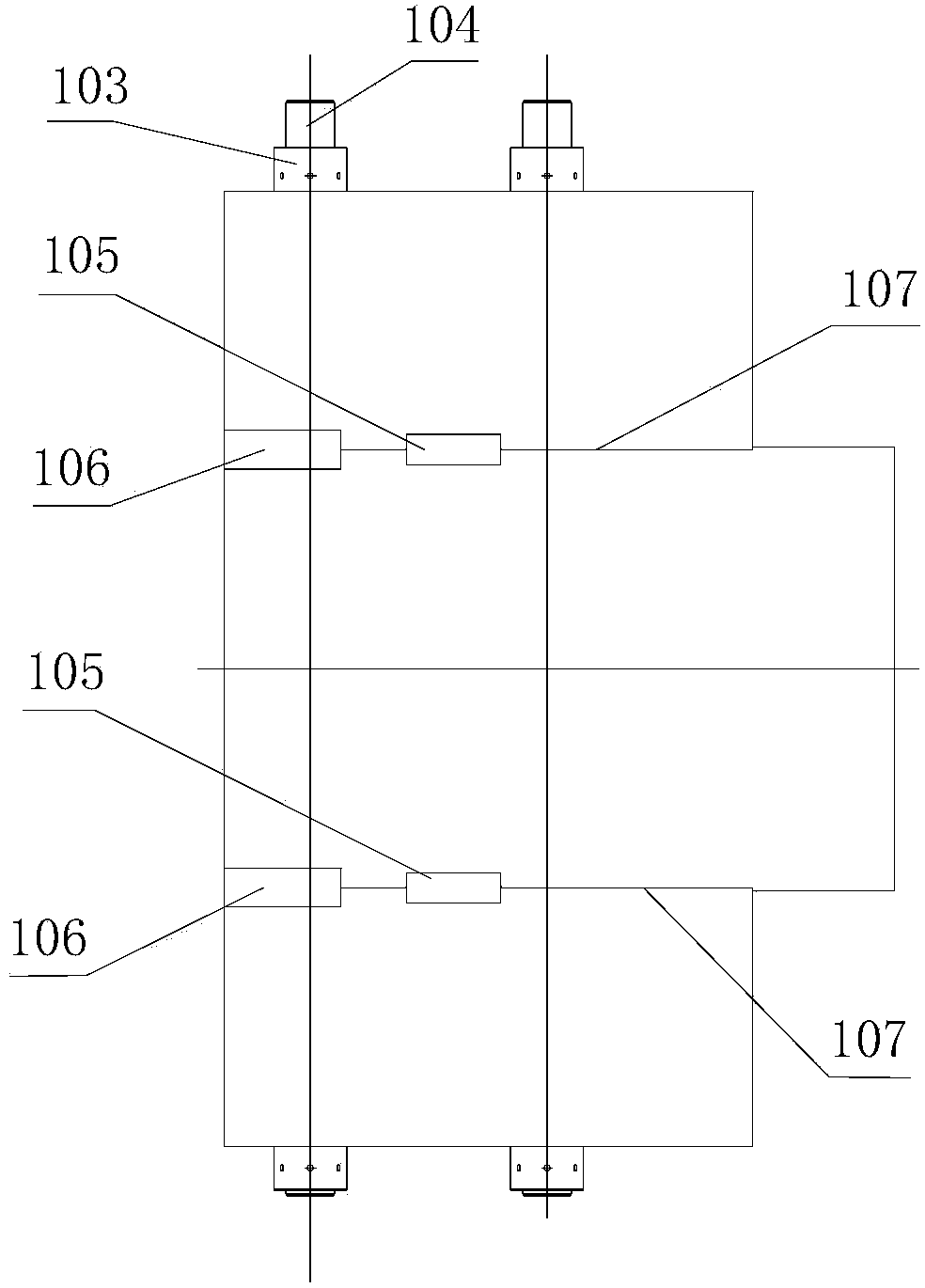

Heavy-duty isothermal forging hydraulic press

ActiveCN103447434AReduce manufacturing costHigh leveling accuracyForging/hammering/pressing machinesForging press detailsAviationLeveling effect

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

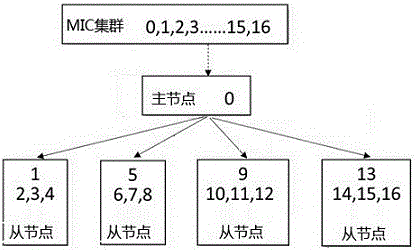

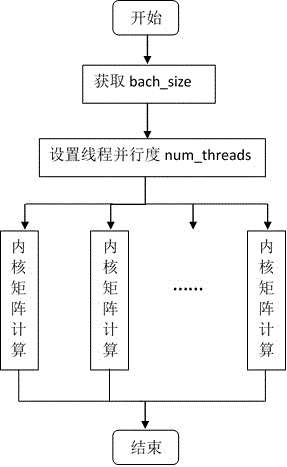

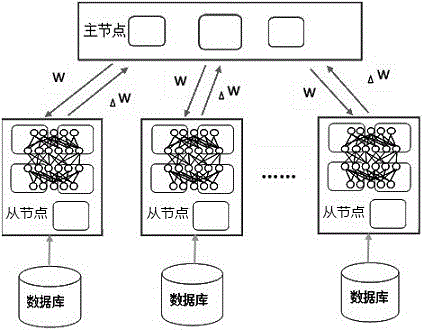

Deep learning framework Caffe system and algorithm based on MIC cluster

InactiveCN106650925AGuaranteed parallelismGuaranteed scalabilityProgram initiation/switchingResource allocationNODALAlgorithm

The invention discloses a deep learning framework Caffe system and algorithm based on an MIC cluster. The deep learning framework Caffe algorithm runs on multiple nodes of the MIC cluster according to an MPI technology; the nodes share a task and data equally via MPI communication; different nodes parallelly execute subtasks and process subdata, perform ForwardBackward calculation in Caffe, and feed back execution results to a master node; the master node calculates and tabulates weight information fed back by each node, and distributes updated parameters to the nodes; and each slave node performs next iterative computation according to the new parameters. Therefore, multithread-based parallel computing in a same process is realized; and as a large quantity of matrix calculations are involved in a convolutional neural network, while multithread-based parallel computing is mainly applied to matrix calculations, the performance of an MIC processor can be played to the most extent by setting a quantity of parallel threads, and the runtime performance of the Caffe is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

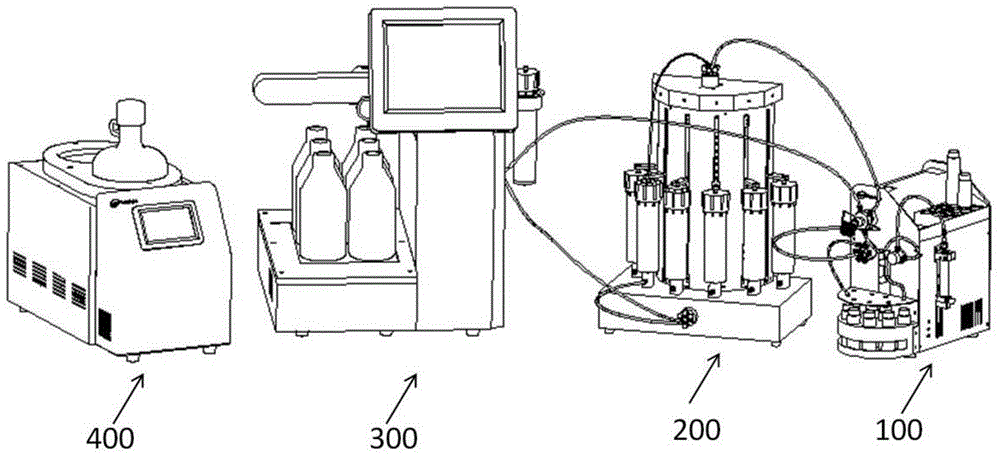

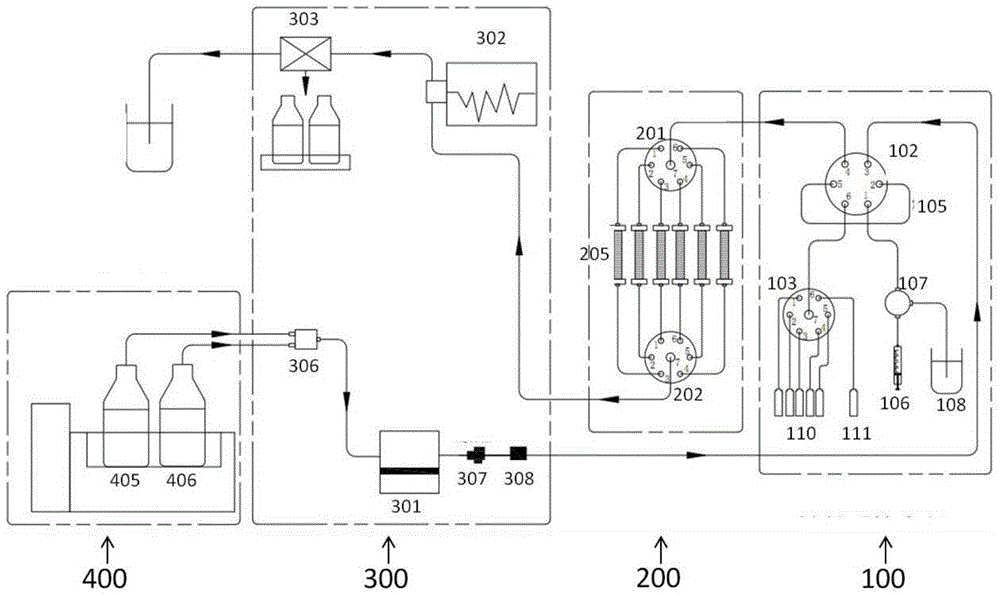

Full-automatic separation system and application of full-automatic separation system in separation of polar components in edible oil

ActiveCN104407083AEnsure process stability and result accuracySolving Validation LagsComponent separationColumn switchingChemistry

The invention provides a full-automatic separation system and application of the full-automatic separation system in separation of polar components in edible oil. The full-automatic separation system comprises an automatic sample injection system 100, a column switching system 200, an automatic separation system 300 and a temperature control system 400. When the device disclosed by the invention is used for separating the polar components in the edible oil, automatic sample injection and automatic chromatographic column switching can be realized; multiple samples can be continuously treated, and high-flux quick separation is realized; meanwhile, full mechanical control is performed on sample injection, column switching and separated component collection, so that influence on an experiment due to manmade factors is avoided; by ultraviolet online monitoring and automatic flowing speed correction, a detection result is accurate and stable.

Owner:天津博纳艾杰尔科技有限公司

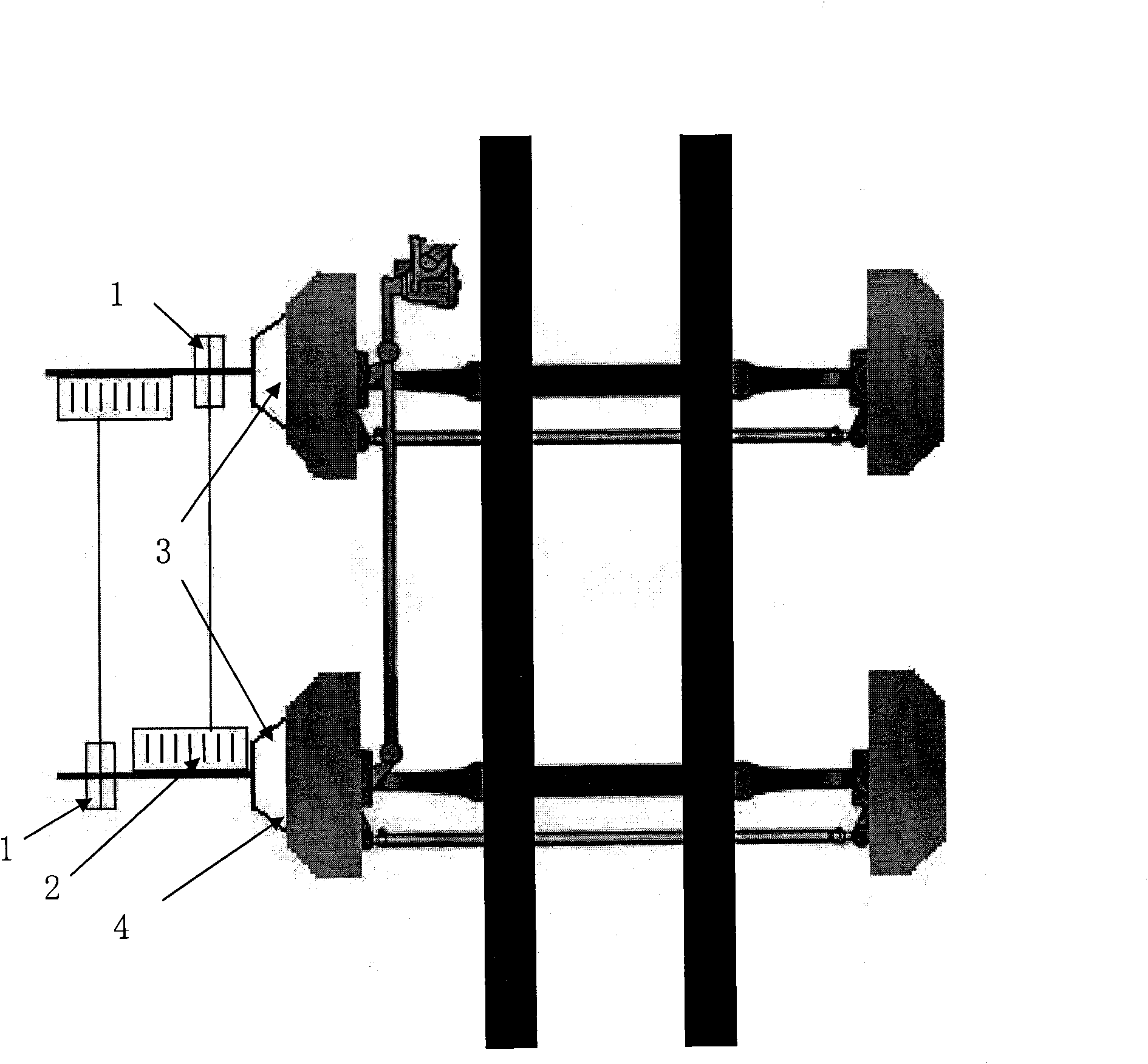

Dual-front axle wheel axle parallel position adjustment method

InactiveCN101886910AGuaranteed parallelismReduce abnormal wear and tearUsing optical meansLaser transmitterSteering wheel

The invention provides a dual-front axle wheel axle parallel position adjustment method. The invention comprises the following steps: concentrically clamping on the wheel hub of the dual front axles of a vehicle by a special clamp, fully utilizing the span between the dual front axles, setting operation manners of a laser emitter and a corresponding target respectively, regulating a drag link between two wheel axles, and carrying out precise position on the wheel axles of the vehicle to be positioned by corresponding position manners of laser and the target. After the adjustment, parallelism of the dual-front axle wheel is secured, and all steering wheels upwards roll right ahead when the vehicle runs along a straight line, thereby effectively reducing abnormal wear and fuel consumption of tires, improving driving comfortableness, reducing waste of social resources and strengthening traffic safety.

Owner:深圳市东智科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com