Manufacturing method of adjustable FP (filter pass) optical filter based on MEMS (micro electro mechanical system) process

An optical filter and filter technology, which is applied in the process, optics, and optical components for producing decorative surface effects, can solve the problems of complex manufacturing process, high manufacturing difficulty and high price of high-quality micro-concave mirrors. Achieve the effect of simple structure, fast tuning speed and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

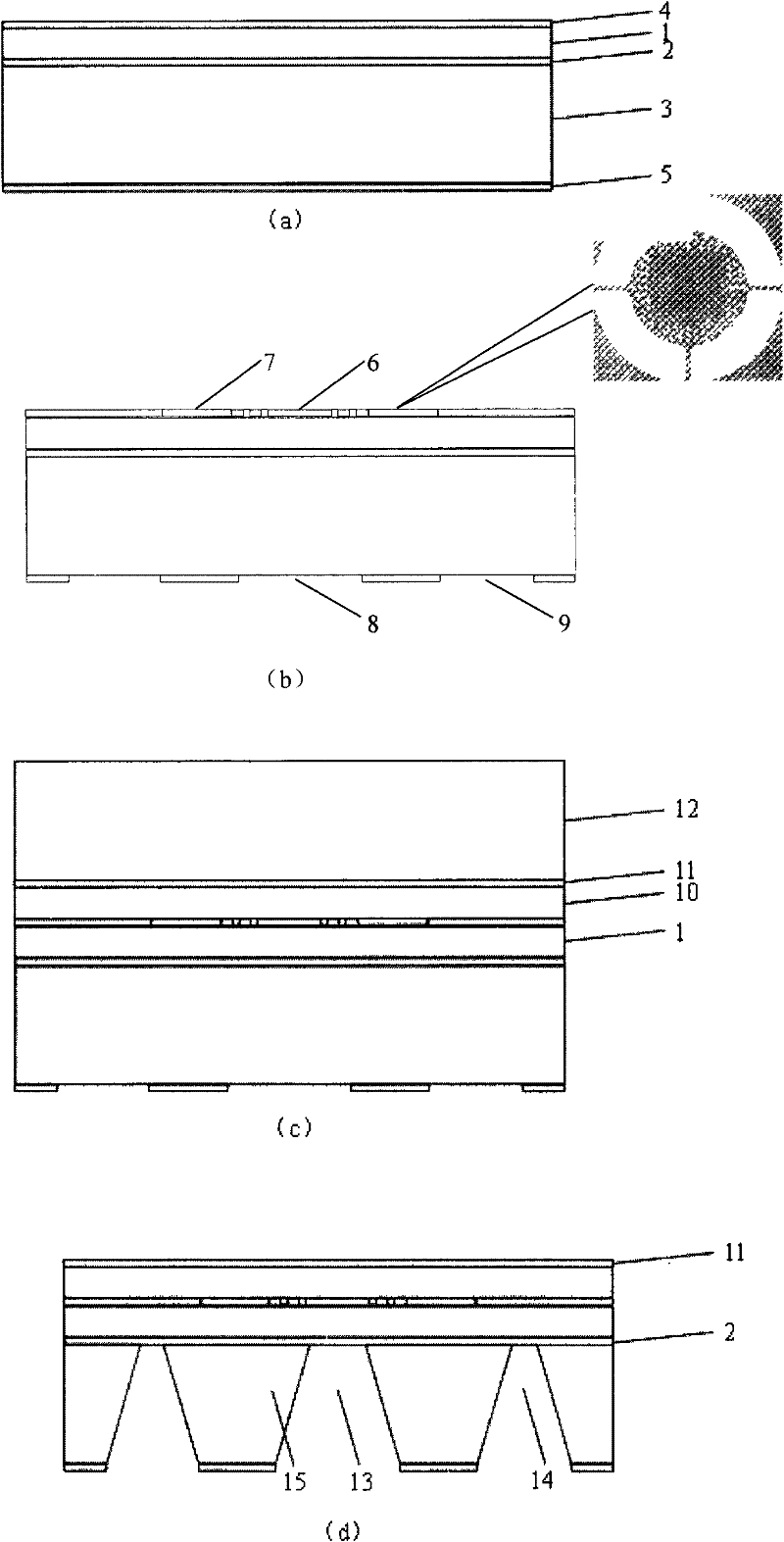

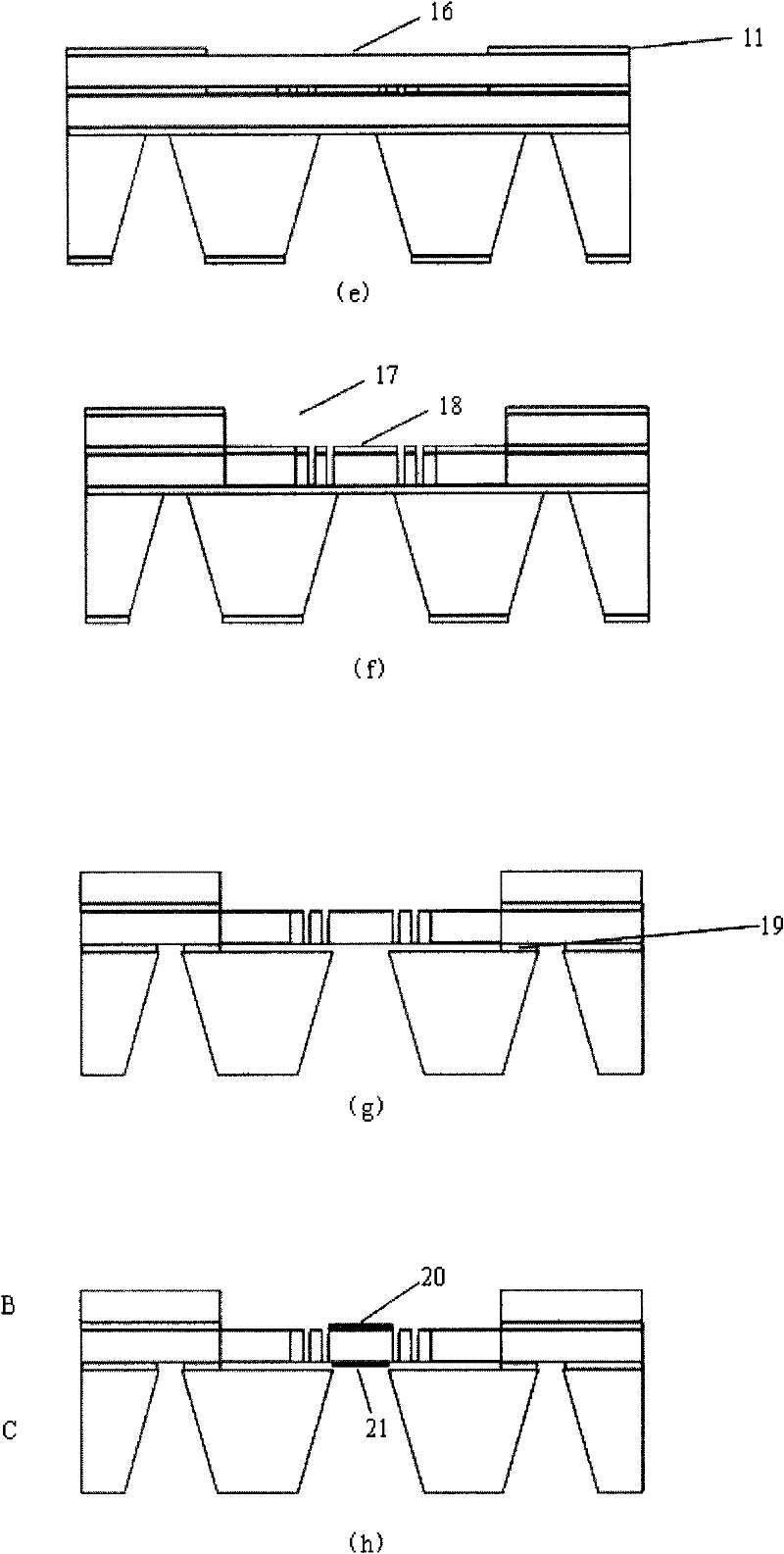

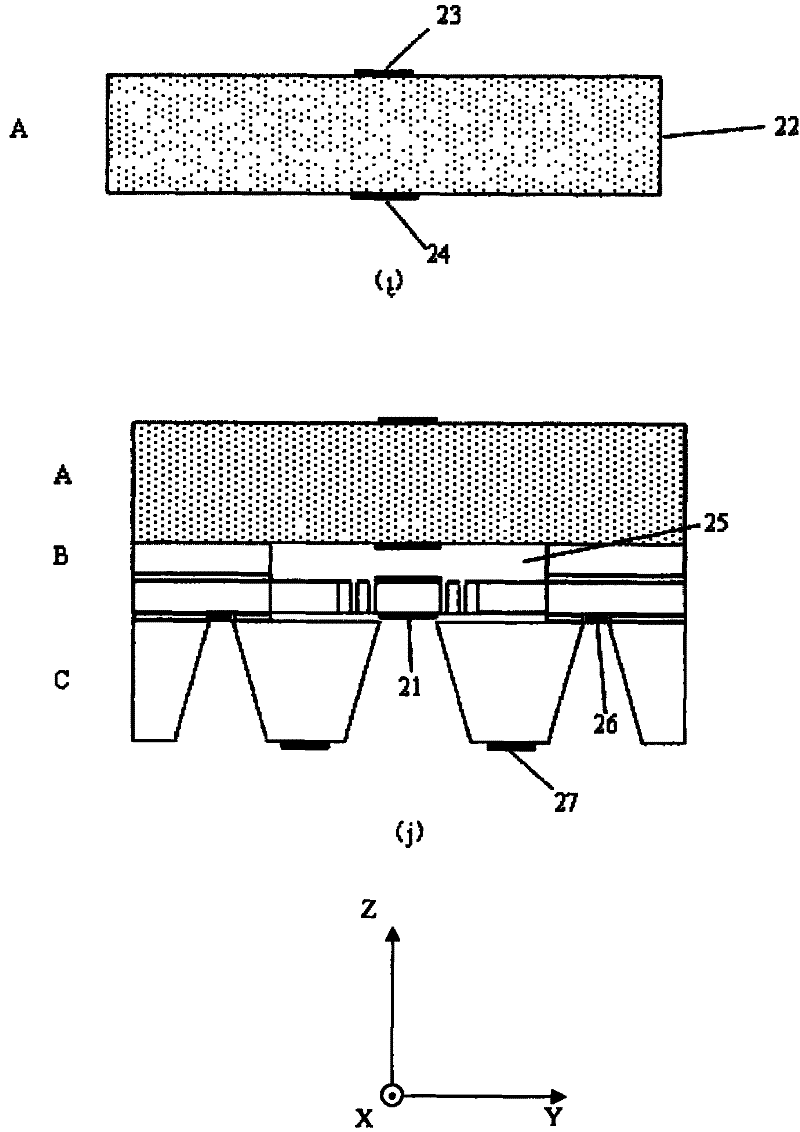

[0043] The various stages of manufacturing the FP cavity tunable filter provided by the present invention are further explained below with reference to the accompanying drawings. figure 2 An example of the FP tunable filter made. By referring to US patent 6373632B1, it is helpful to understand the manufacturing method and process of the present invention. The present invention is a practical and convenient method for manufacturing a MEMS flat-flat interference cavity FP tunable filter.

[0044] The detailed manufacturing process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] Step 1 realizes the manufacture of the cavity isolator B and the movable micromirror support structure C, and the process flow is as follows:

[0046] (a) Commercial low-resistance SOI used 1 The thickness of the silicon wafer is 30 μm for the top layer of silicon 1 , 2 μm for the thickness of the middle silicon dioxide layer 2 , and 38...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com