Patents

Literature

428results about How to "Easy to mass manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

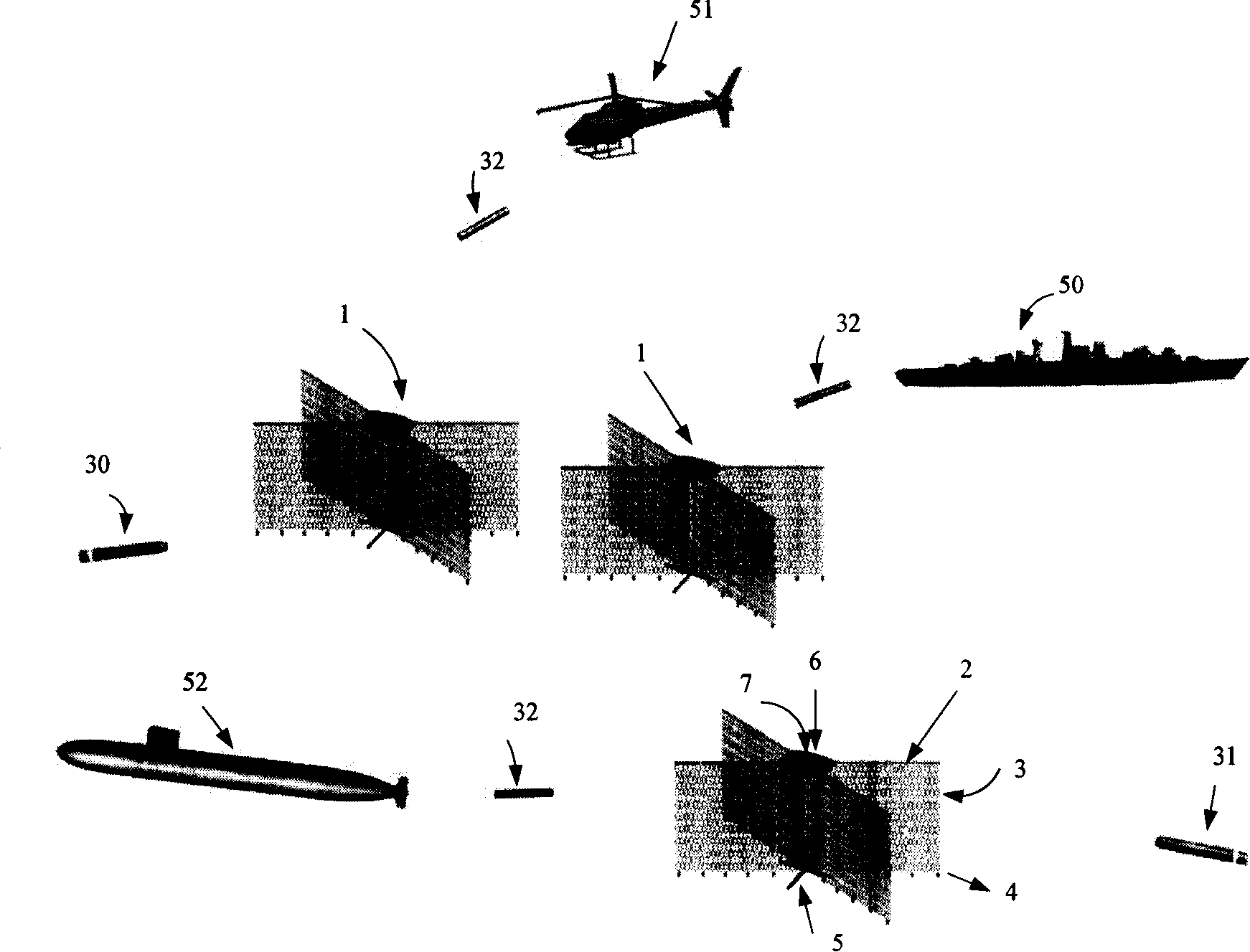

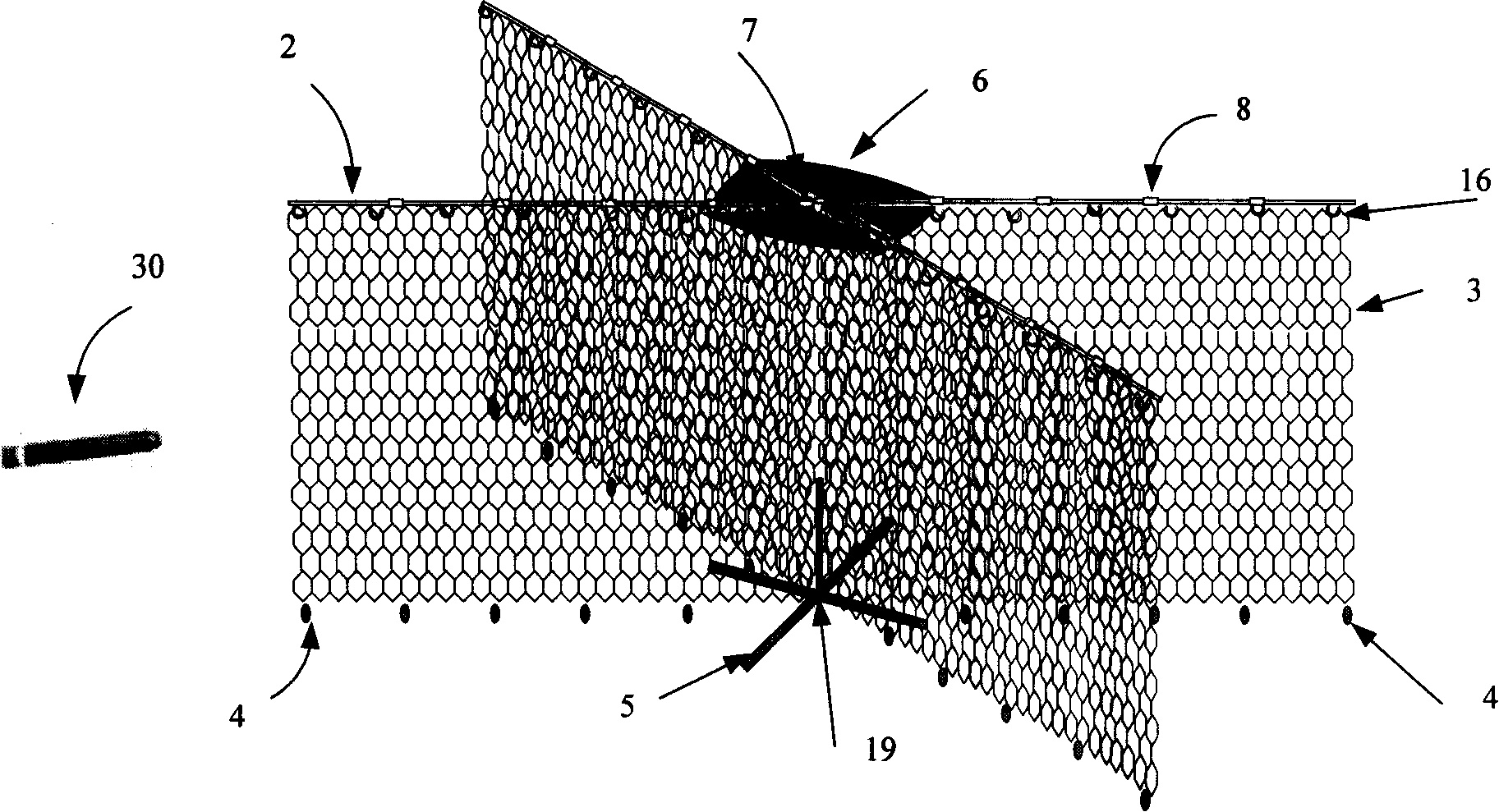

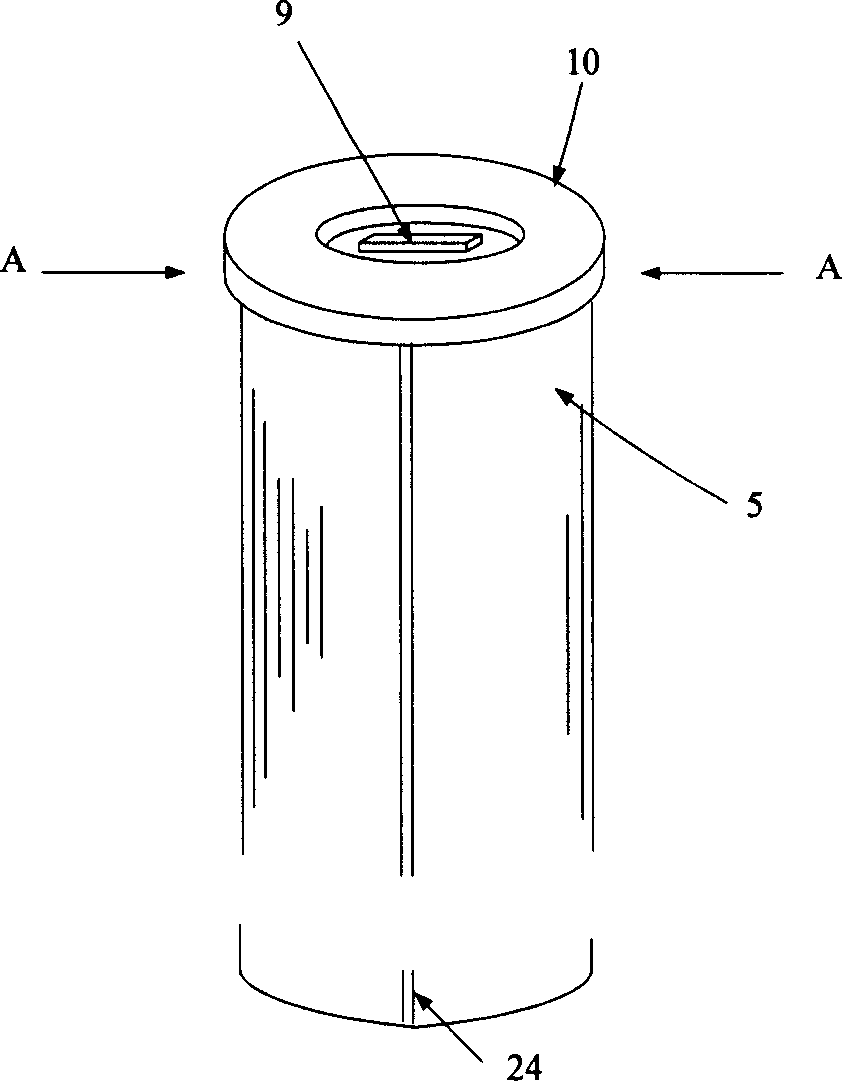

Decussation stereo torpedo catching net

InactiveCN101226043ADoes not affect mobilityLarge effective interception areaDefence devicesPull forceDecussation

The invention relates to a crossed three-dimensional torpedo interception net capable of intercepting torpedoes, especially a torpedo interception net which can be projected or cast and can outspread automatically when entering into the water to form a decussate three-dimensional torpedo interception net. The appearance is column-shaped, a top cover is arranged at the top part and is fixed and sleeved by bayonet locks on the casing which is divided into four sections, the specific density of the top part is lighter than the seawater and the specific density of the bottom part is heavier than the seawater. A decussate bracket is arranged inside, a telescopic link is connected on the lateral side, and a suspended net is connected with the telescopic link via a hanger. When the torpedo interception net is projected or cast into sea via a surface ship, a submarine or a helicopter, the top cover is ejected via a spring, the casing is opened, a going barren dives the telescopic link to expand and the suspended net is dragged to outspread in horizontally. Under the upward pulling force of the telescopic link and the downward pulling force of the weight of the connector of the suspended net, the suspended net is outspreaded along vertical direction; a stabilization membrane connected with the inner side of the suspended net control the stability of the torpedo interception net along the vertical direction.

Owner:孙珠峰

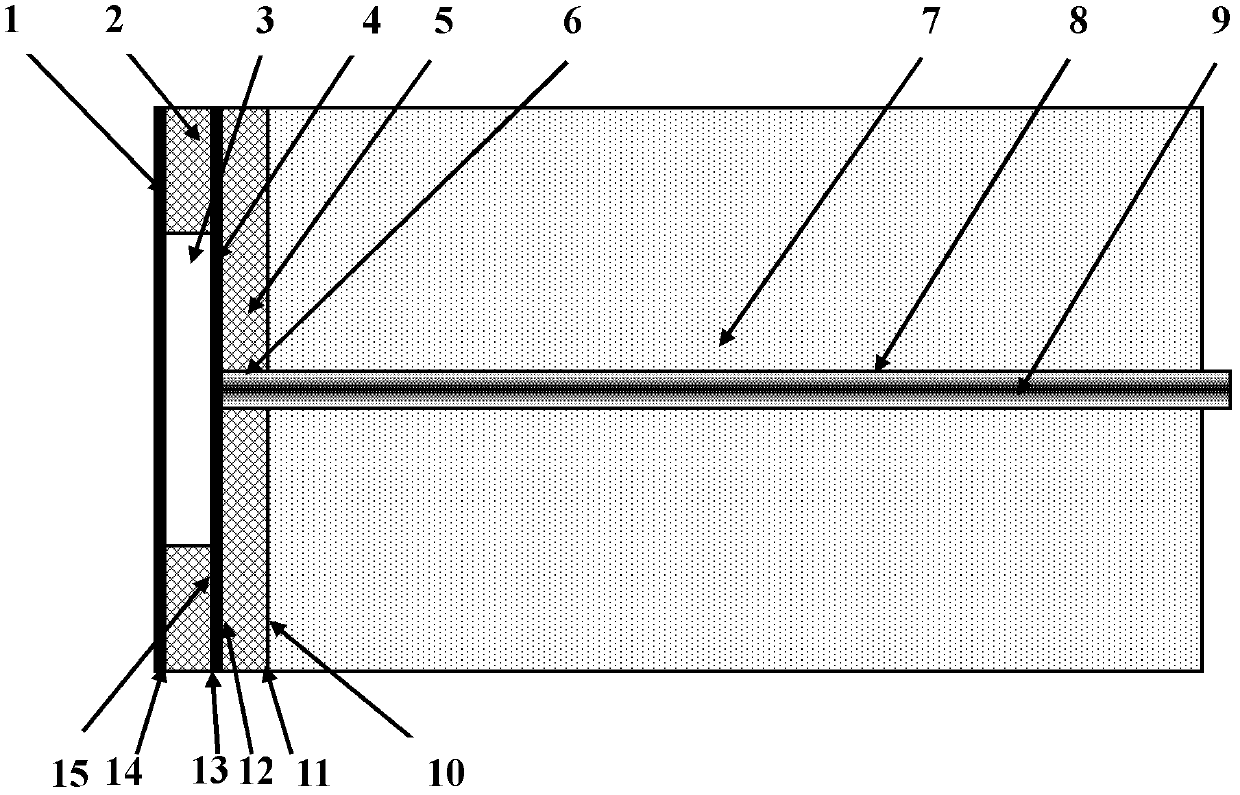

High-stability optical fiber Fabry-Perot pressure sensor packaged without glue and manufacturing method

ActiveCN102384809AEliminate the effects ofEasy to achieve airtightFluid pressure measurement by electric/magnetic elementsOptical light guidesEngineeringCo2 laser

The invention provides a high-stability optical fiber Fabry-Perot pressure sensor packaged without glue and a manufacturing method. The sensor comprises a sensor head, a sensor body with a through-hole in middle, and an optical fiber, wherein a four-layer structure (comprising a first monocrystalline silicon piece, a first Pyrex sheet glass, a second monocrystalline silicon piece and a second Pyrex sheet glass) is adopted by the sensor head; a first reflecting surface of a Fabry-Perot cavity is formed by the back surface of the first monocrystalline silicon piece; the second monocrystalline silicon piece is used for providing a second reflecting surface of the Fabry-Perot cavity; the second Pyrex sheet glass is in butt fusion with the sensor body; and the optical fiber is fixedly arrangedin the sensor body by adopting a CO2 laser, and thereby non-glue packaging is realized. When the first layer of monocrystalline silicon piece is deformed by external pressure changes, the length of the optical fiber Fabry-Perot cavity is changed; and after a broadband light source is accessed to the sensor, the change of the cavity length can be extracted through collecting a reflection spectrum of the sensor or extracting low-coherence interference fringes of the sensor, and thereby pressure information is obtained. By adopting the structure, the influences of environmental changes such as the temperature, the humidity, and the like can be effectively eliminated, and the measurement accuracy can be greatly improved.

Owner:TIANJIN UNIV

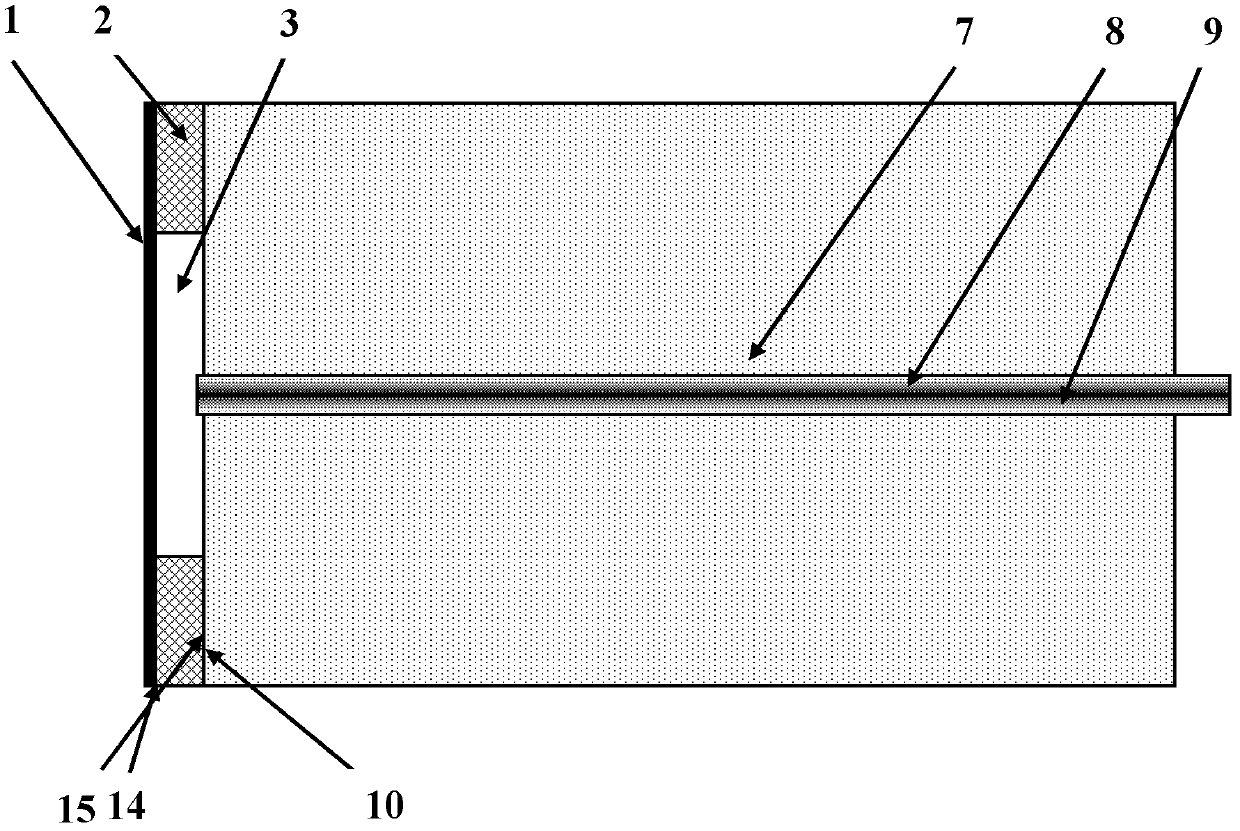

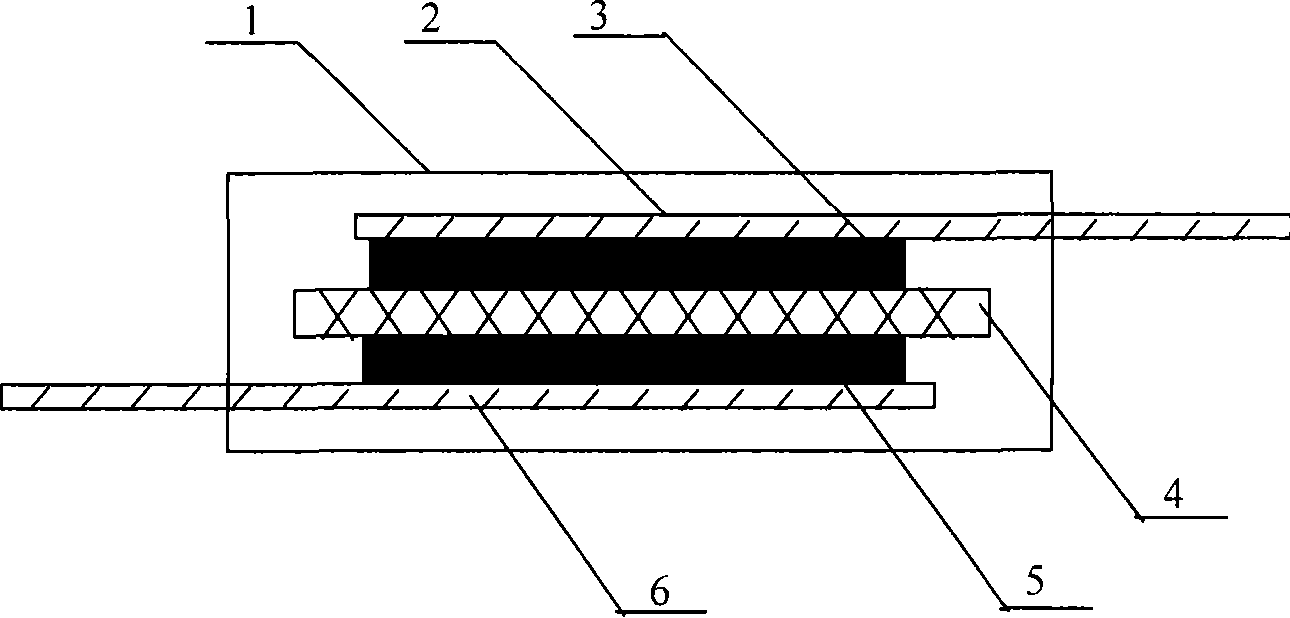

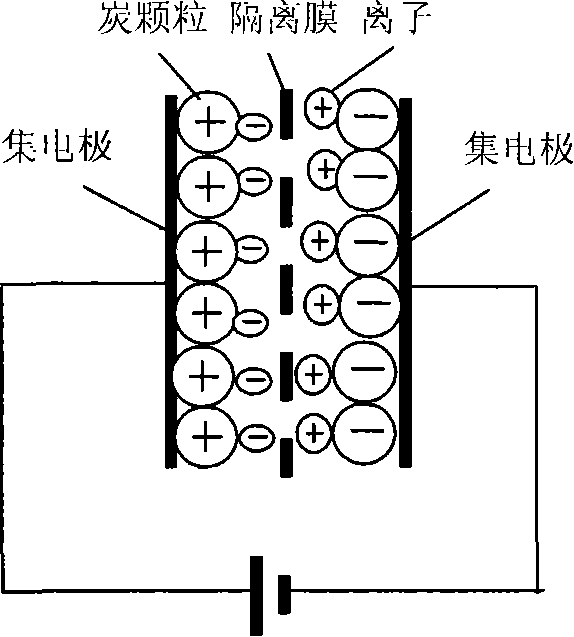

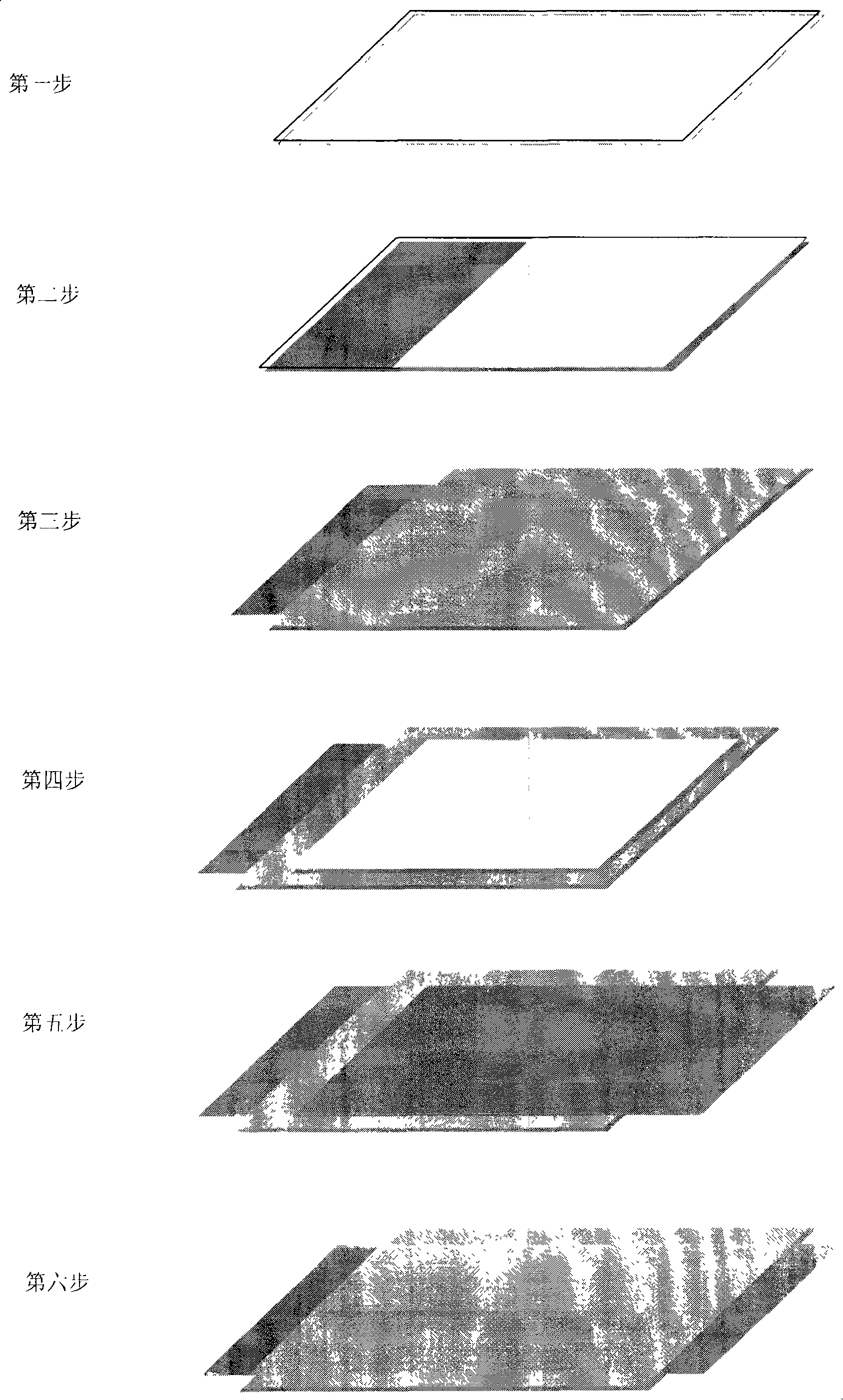

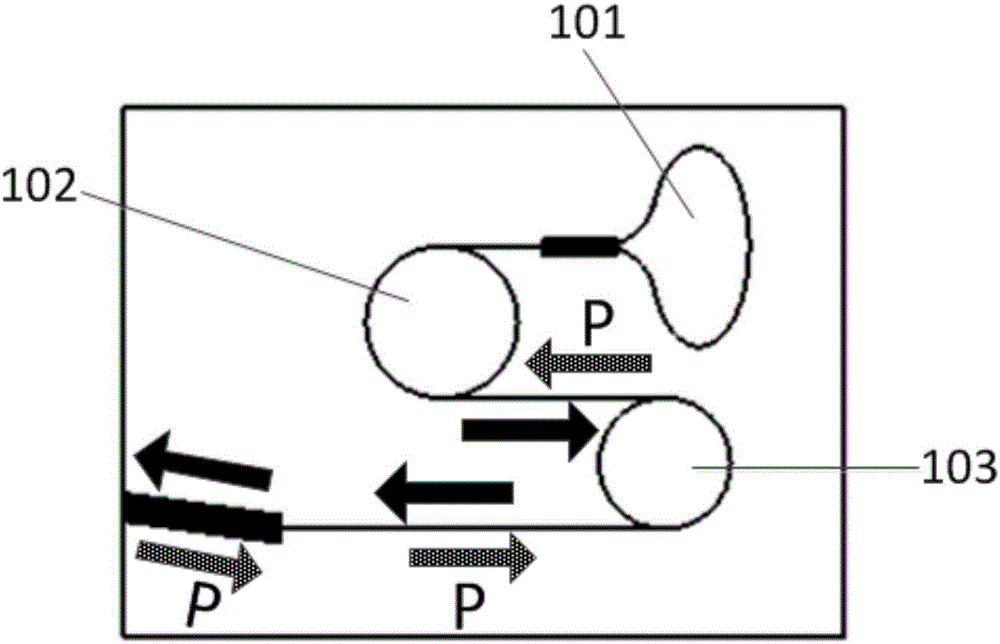

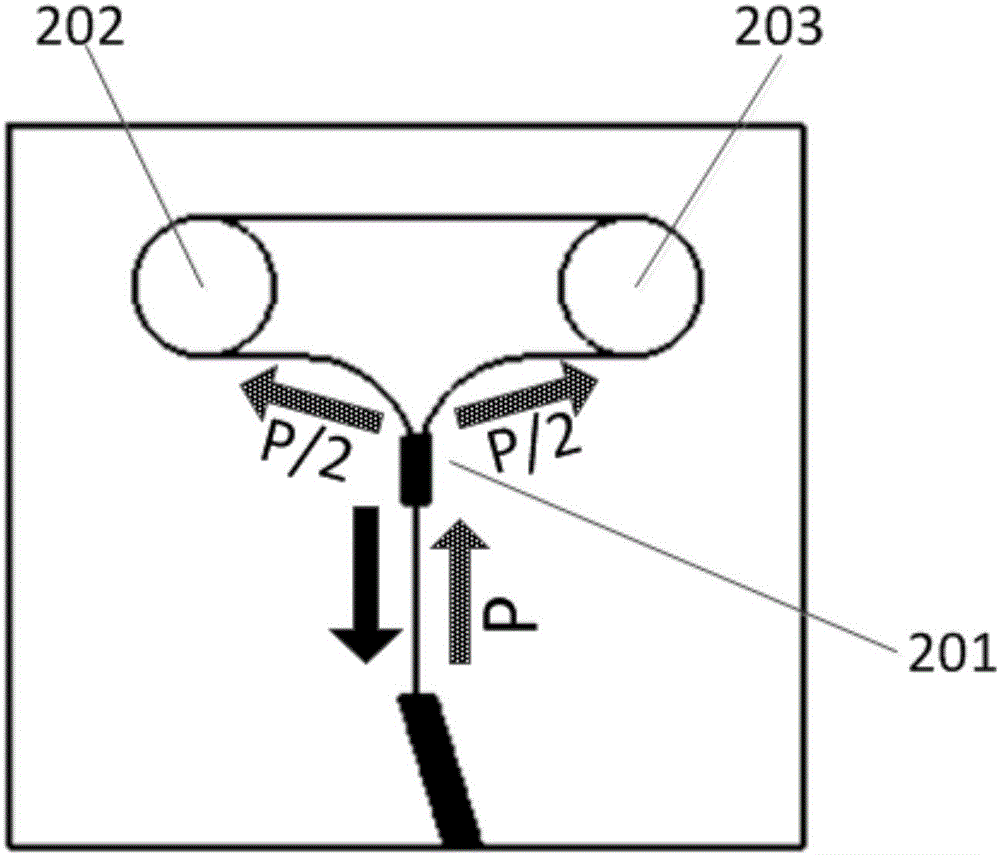

Flexible thin film type solid-state super capacitor and its manufacture process

ActiveCN101162650ALower internal resistanceGood power characteristicsSolid electrolytic capacitorsHybrid capacitor electrodesSolid-stateEngineering

The invention discloses a flexible film type solid state super capacitor and a method for manufacturing the same; the flexible film type solid state super capacitor comprises a positive electrode, a negative electrode, an outer electrode and an encapsulation film, wherein a flexibility solid state electrolyte membrane is arranged between the positive and the negative electrodes. The manufacturing method is as follows: the outer electrode pasting, the electrode pasting, the flexibility solid state electrolyte pasting, the electrode pasting, the outer electrode pasting and the encapsulation pasting are orderly and precisely coated on a basal body by the printing technique; by fitting the corresponding pressing, drying, cutting and packaging techniques, the flexible film type solid state super capacitor with electrode-membrane-electrode structure is finally formed. The flexible film type solid state super capacitor has the advantages of low product internal resistance and good power characteristic, and is suitable for the large scale production and particularly applied to flexible electric products such as electric papers, intelligent name cards and plastics electric products, etc.

Owner:CENT SOUTH UNIV

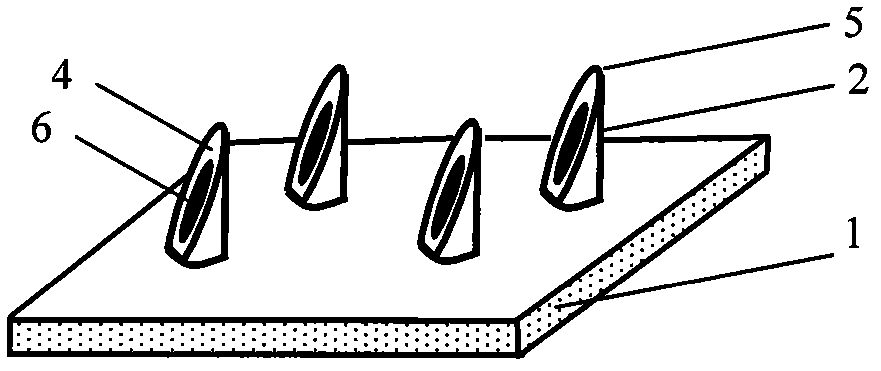

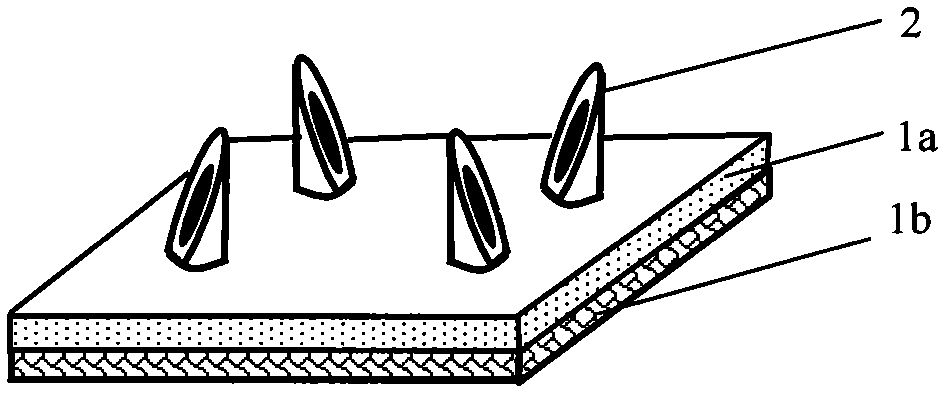

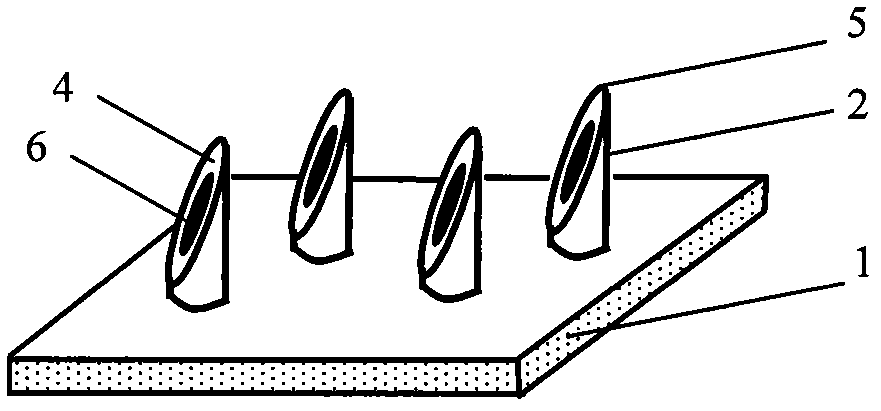

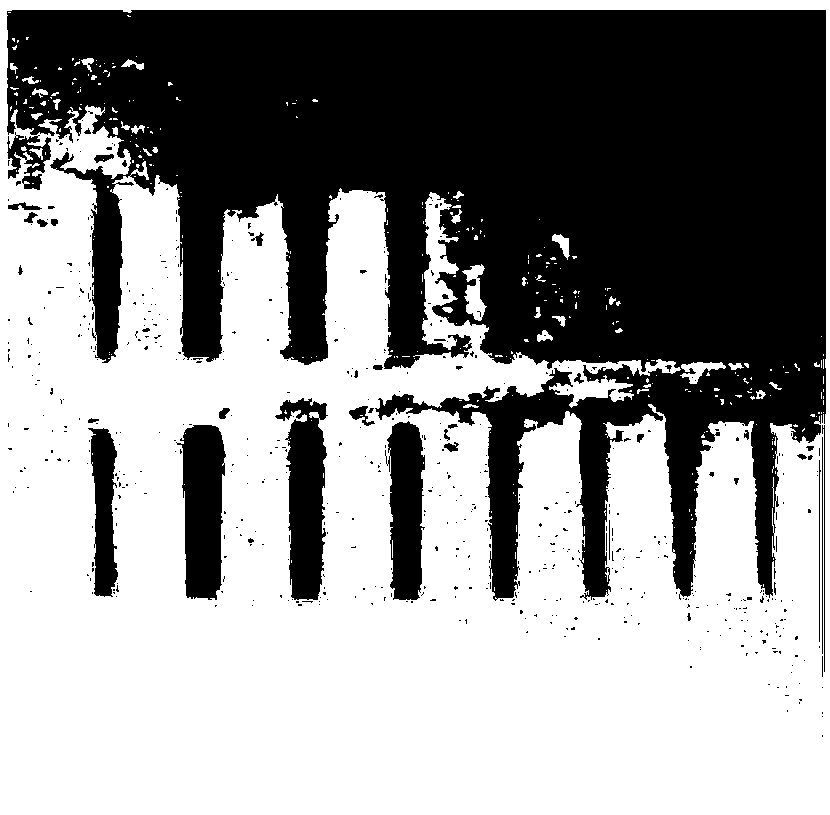

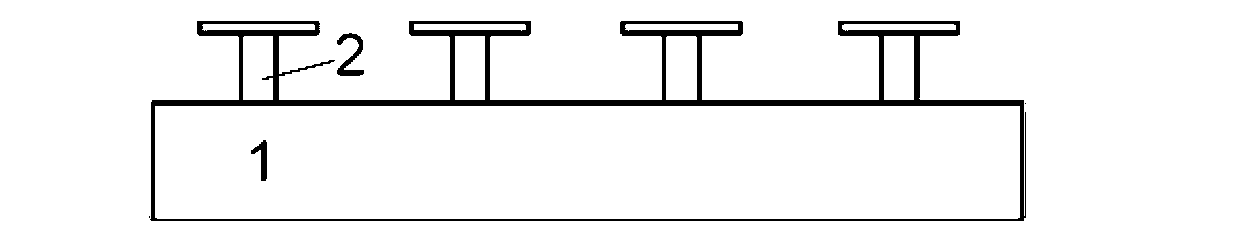

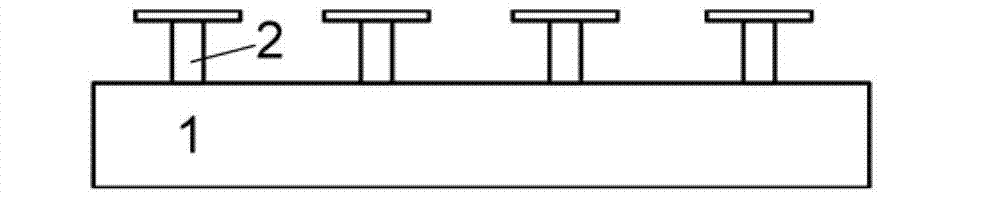

Empty micropin array chip, percutaneous dosing paster, device and manufacture method thereof

ActiveCN101912663AStable structureEasy to punctureMicroneedlesMedical devicesSyringe needleMicro-needle

The invention discloses an empty micropin array chip which comprises a substrate and an empty micropin, wherein the empty micropin comprises a pin head and a pin rod, the empty micropin is fixed on the substrate through the pin rod and is inclined to the substrate at a certain angle, the pin head is provided with an oval-shaped annular plane, one end of the pin head is a pinpoint, one part of the oval-shaped annular plane is embedded into the substrate, the pin rod is an empty circular pipe which is embedded into the substrate or is penetrated through the substrate, the bottom of the pin rod is parallel with the lower surface of the substrate or is convex or concave, and the empty micropin penetrates through the two sides of the substrate to be formed into the hole-shaped micropin or the bottom of the pin rod is sealed to be formed into a blind hole type micropin. The empty micropin array chip is firm in structure, sharp in pinpoint, convenient in puncture, low in cost, high in yield, and suitable for manufacture in bulk. The micropin in the array has good consistency, is free of pain feel and blooding when in use, and is safe and reliable since the minimally-invasive skin can fast heal after in use.

Owner:TSINGHUA UNIV

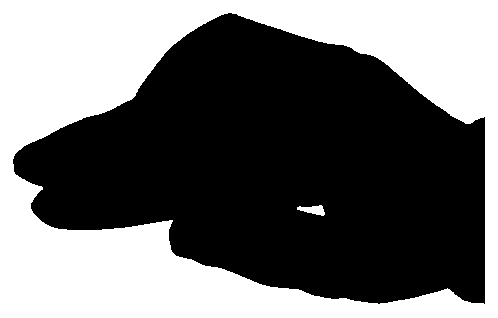

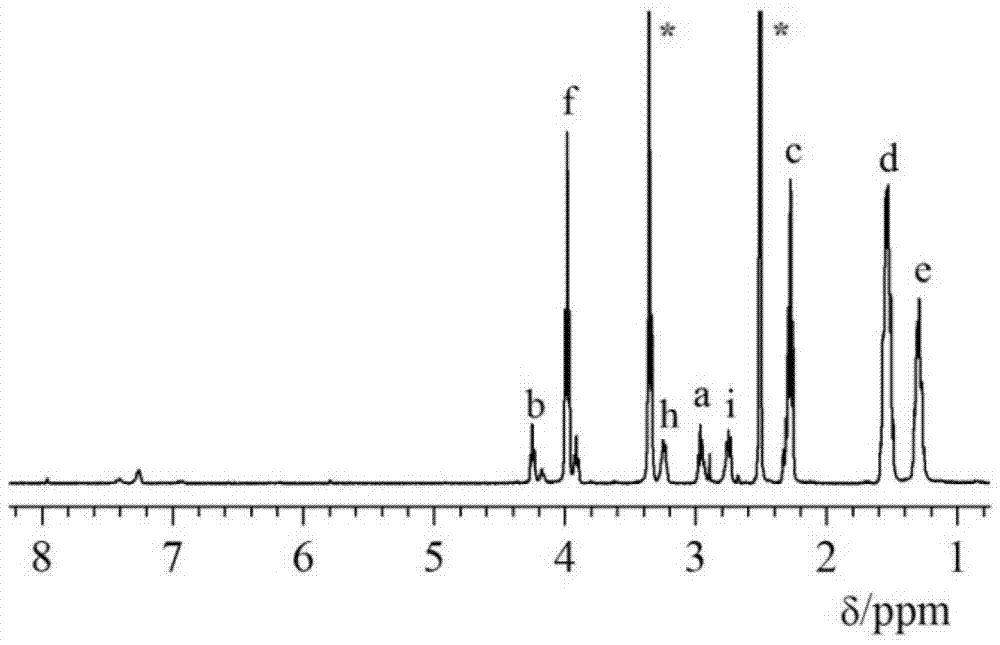

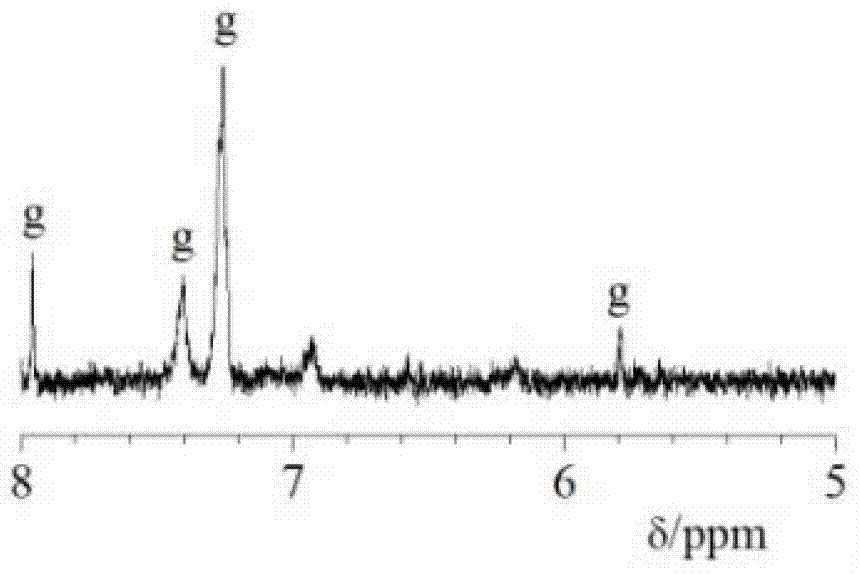

Wearable flexible stress sensor and preparation method and application thereof

The invention relates to a wearable flexible stress sensor and a preparation method and application thereof. Firstly, functional ink suitable for screen printing is prepared, and is printed on a wearable substrate through a screen printing method, and the stress sensor of a desired specification is produced. The stress sensor is used for monitoring physical deformation of stretching, bending, touching and the like from small ranges to large ranges, and has multiple application in the electronic skin fields and the biomedical application fields of human skins, expressions, pulses, heartbeats and the like, the human-computer interaction fields and the fields of virtual reality, entertainment technology and the like. The flexible stress sensor of the invention has the following advantages that the sensor has excellent stretching elasticity, and stretching strain can reach 100%; sensitivity is extremely high, and a sensitivity parameter (Gauge Factor) can be up to 8000 or more; linear relationships of working curves are excellent, stretching repeatability is good, and a stretching cycle lag is small; and a preparation process is simple, costs are low, massive integrated-device preparation is suitable, and application prospects are wide.

Owner:NANKAI UNIV

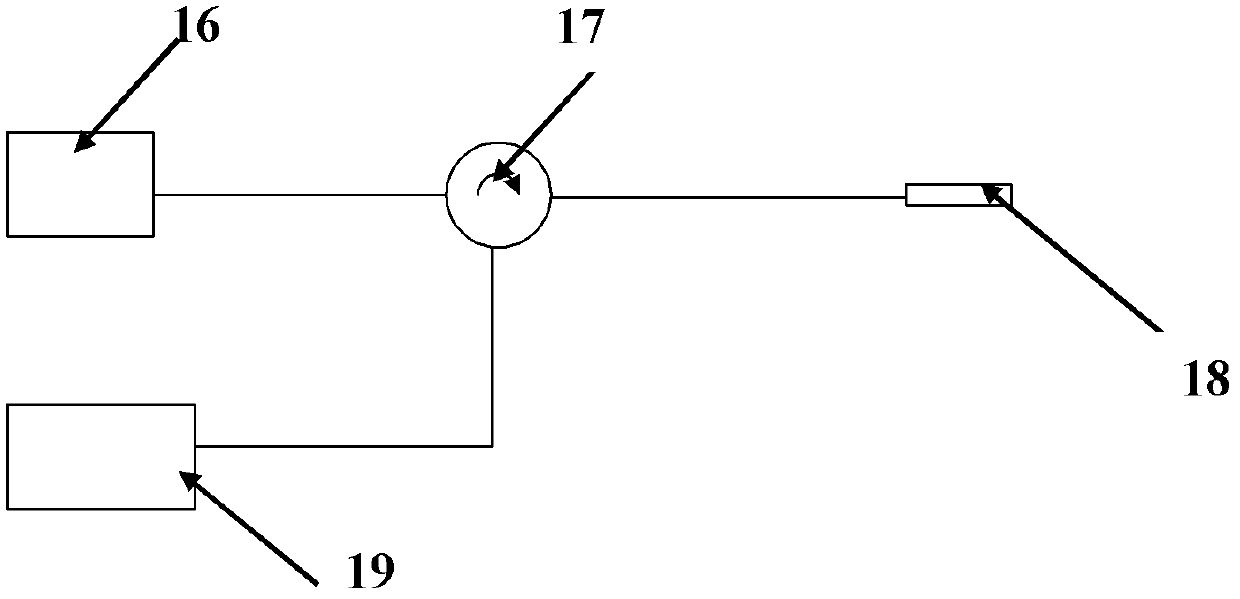

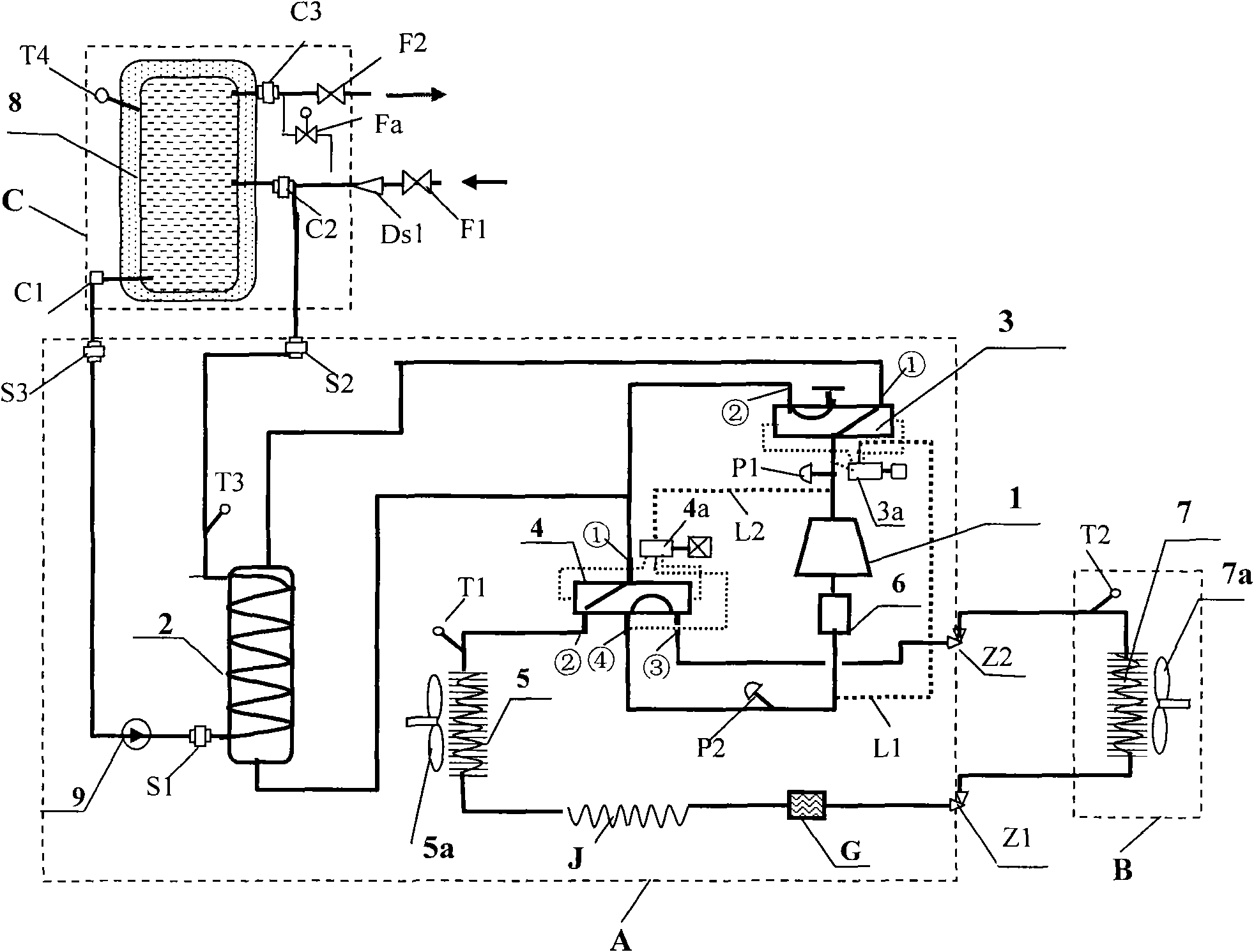

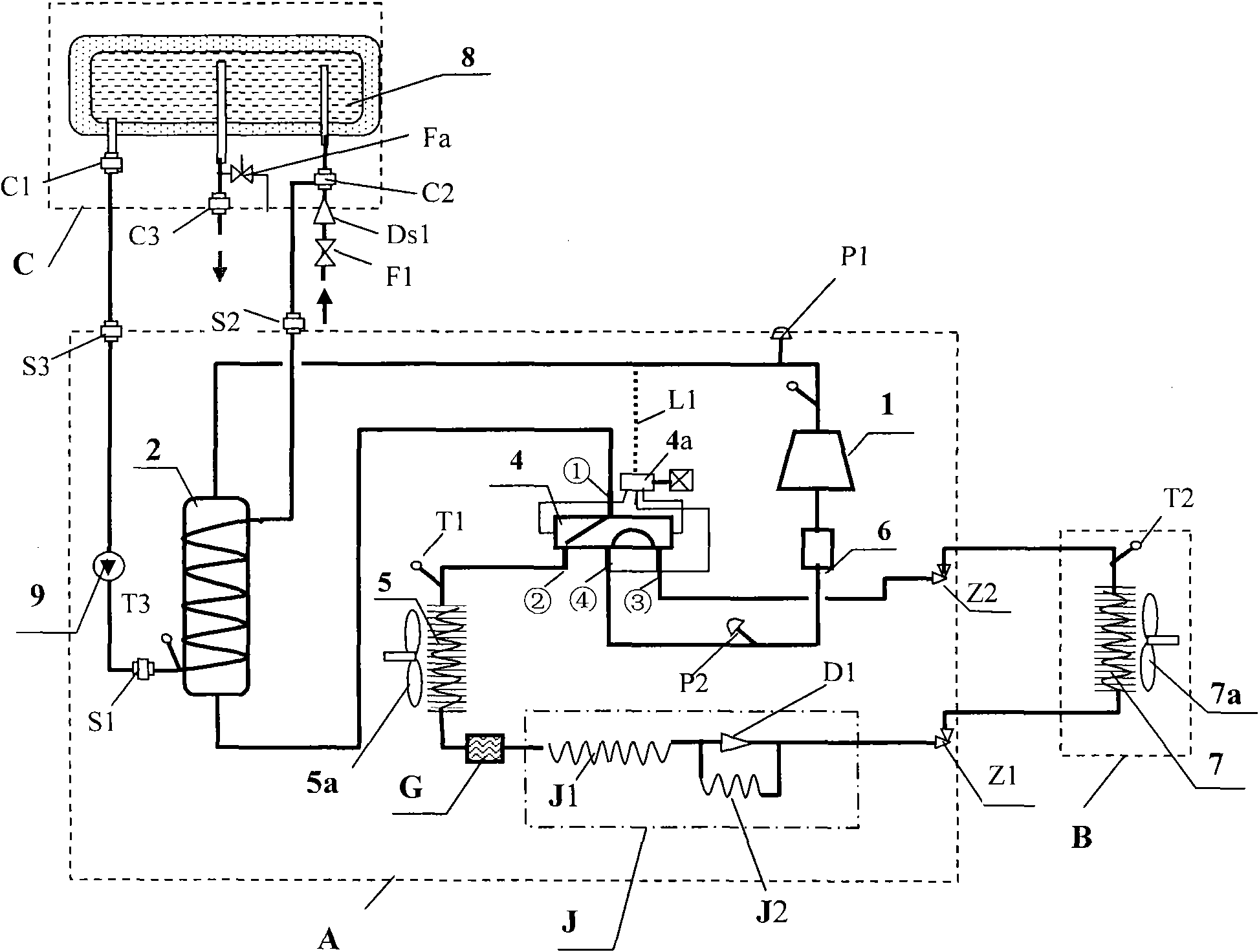

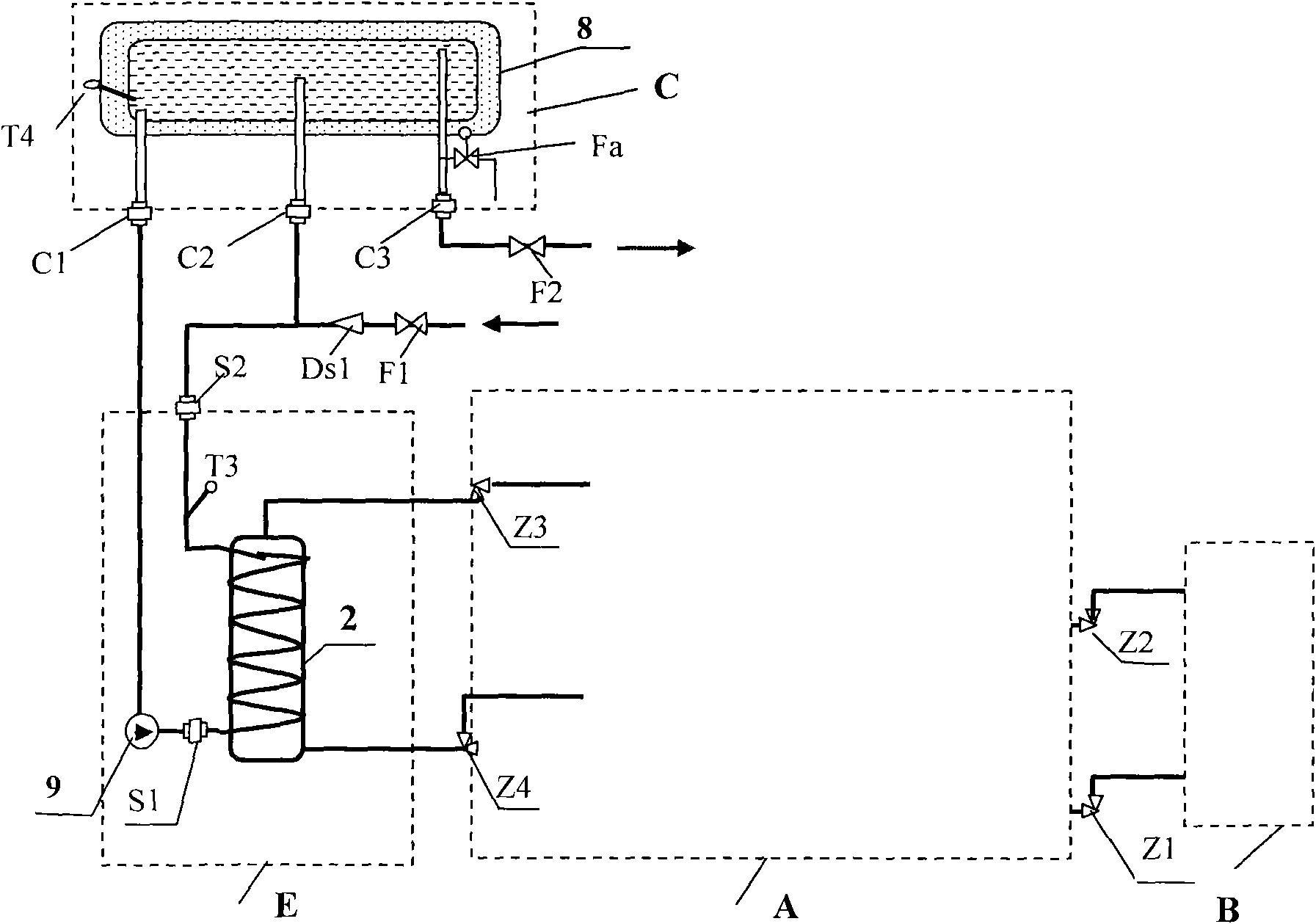

Simple, high-efficiency and reliable cold-warm air-conditioning water heater

InactiveCN102313326ASimple structureEasy to switchFluid heatersSpace heating and ventilation safety systemsFour-way valveLow voltage

The invention relates to a simple, high-efficiency and reliable cold-warm air-conditioning water heater, which comprises a refrigerant loop, a hot-water condensing heat exchanger, a hot-water storing box and a signal acquisition and circuit control system. A scheme I of the invention is characterized in that: an exhaust opening of a compressor is connected with an air inlet of a three-way valve; a first air outlet of the three-way valve is connected with a refrigerant inlet of the hot-water condensing heat exchanger, and a second air outlet is connected and communicated with a first interfaceof a four-way valve and a refrigerant outlet of the hot-water condensing heat exchanger; a second interface, a third interface and a fourth interface of the four-way valve are respectively connected with the upper ports of an outdoor-wind heat exchanger and an indoor-wind heat exchanger and an air inlet of an air-liquid separator, and a capillary is connected in series between the lower ports of the outdoor-wind heat exchanger and the indoor-wind heat exchanger; an air outlet of the air-liquid separator is connected with an air inlet of the compressor; and an electromagnetic guide-valve low-voltage air-outlet pipe of the three-way valve is communicated with an air-sucking pipe of the compressor, and an electromagnetic guide-valve high-voltage air-inlet pipe of the four-way valve is communicated with an exhaust pipe of the compressor. A scheme II of the invention is characterized in that: the hot-water condensing heat exchanger is added between the exhaust opening of the compressor of a refrigerant-circulating loop of a cold and warm air conditioner and an air inlet of the four-way valve, and the electromagnetic guide-valve high-voltage air-inlet pipe of the four-way valve is communicated with the exhaust pipe of the compressor; and the two technical schemes both have four functions of hot-water making and refrigerating, hot-water making, refrigerating and heating.

Owner:JIASHAN YONGNING PLASTICS

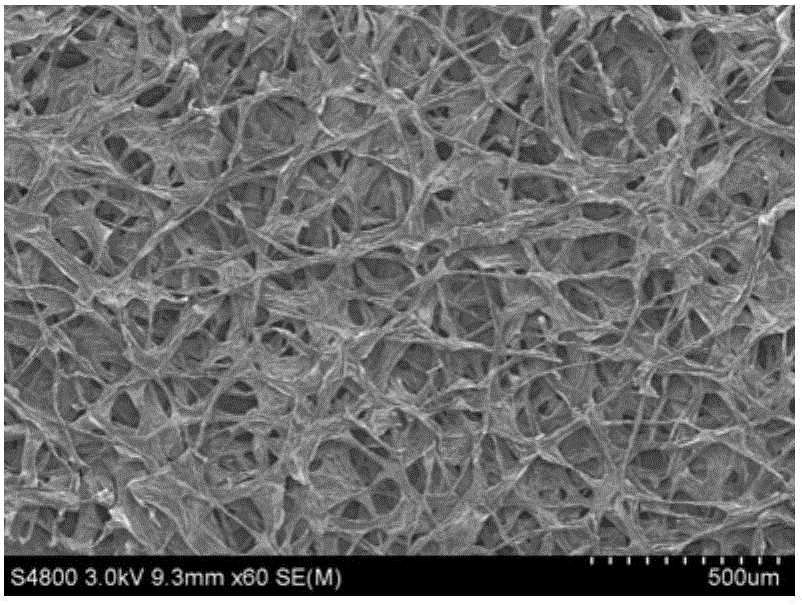

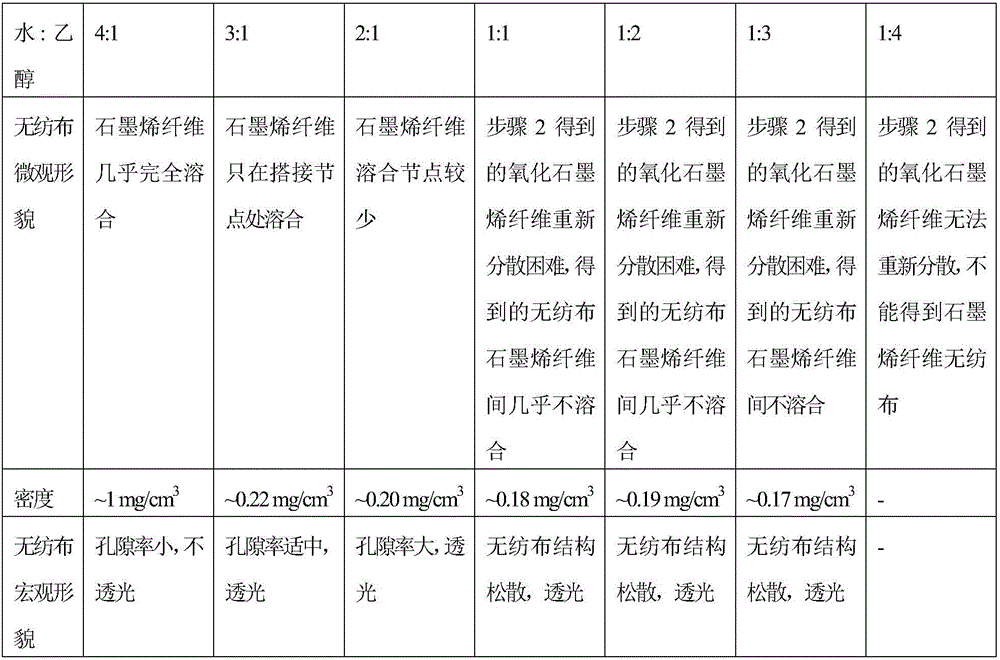

Graphene fiber non-woven fabric and preparation method thereof

ActiveCN106192201AGood electrical and thermal conductivitySimple methodNew-spun product collectionGrapheneElectricityPolymer science

The invention discloses a graphene fiber non-woven fabric and a preparation method thereof. The non-woven fabric is obtained by filtering and depositing a graphene short-fiber dispersion solution through a filter net and performing drying and reduction, so that the structural unit of the non-woven fabric is disorderly-stacked and bonded graphene short fiber, and fiber is overlapped to form a large number of holes through which liquid of gas can pass. The graphene fiber non-woven fabric has the good mechanical strength and tenacity, is completely composed of graphene fiber, does not contain high polymer materials as a skeleton or adhesives, the electricity and heat conducting performance of the reduced network structure overlapped by the graphene fiber is excellent, and the non-woven fabric can be used as a multifunctional high-performance fabric.

Owner:杭州德烯科技集团有限公司

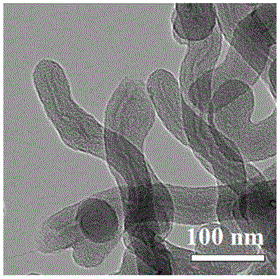

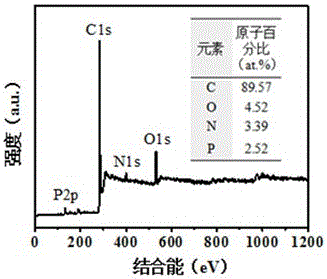

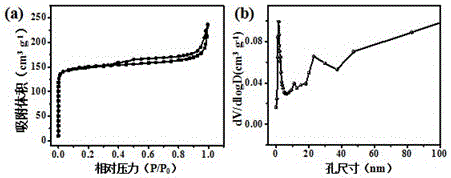

Nitrogen and phosphor co-doped porous carbon nanotube, and preparation method and application thereof

InactiveCN105006375AThe content is easy to controlQuantity is easy to controlMaterial nanotechnologyHybrid capacitor electrodesPorous carbonHigh capacitance

The invention relates to a preparation method of a nitrogen and phosphor co-doped porous carbon nanotube. The method includes the following steps: 1) preparing a carboxylation carbon nanotube; 2) preparing a melamine-phenolic resin wrapped carbon nanotube by taking melamine-resorcinol-presence of formaldehyde resin as a precursor; and 3) conducting phosphatization: mixing the melamine-phenolic resin wrapped carbon nanotube obtained from the step 2) with a phosphatization agent, dispersing the mixture in deionized water in an ultrasonic manner, drying the mixture, enabling a dried product to rise to 600-900 DEG C in an inert atmosphere and to be phosphatized for 120-180min, naturally cooling the product to a room temperature, washing obtained black powder with water, performing pumping filtration until the powder is neutral, drying and finally obtaining the nanotube. The prepared nitrogen and phosphor co-doped porous carbon nanotube enables the specific capacitance of a capacitor to be substantially increased.

Owner:ZHENGZHOU UNIV

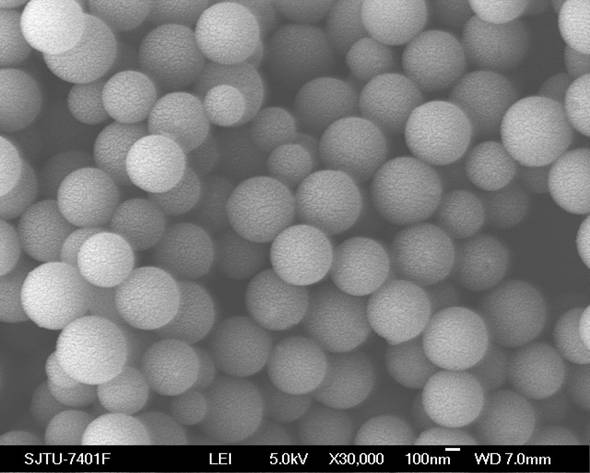

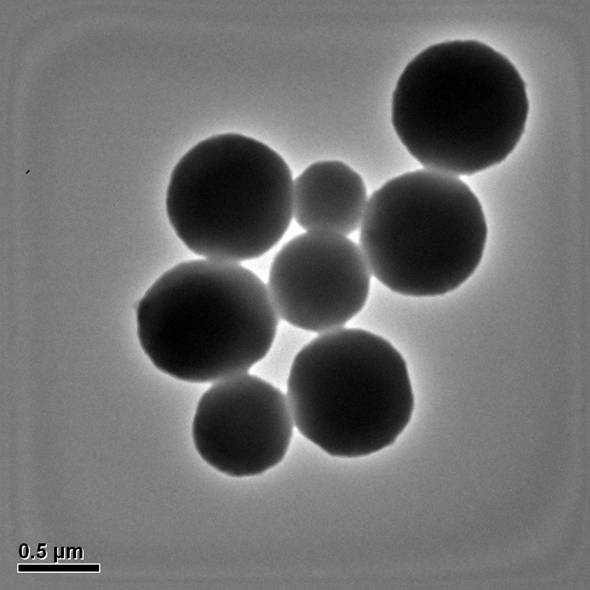

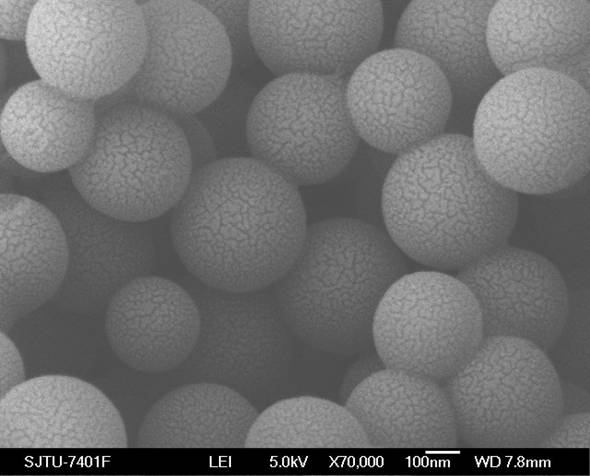

Method for preparing porous carbon spheres doped with nitrogen and phosphorus and application

The invention belongs to the technical fields of inorganic material chemistry and new energy, and discloses a method for preparing porous carbon spheres doped with nitrogen and phosphorus and an application. Water serves as a solvent, polyphosphazenes microspheres and activating agents are mixed in a mass ratio of (0.2-2):1, concentration of the polyphosphazenes microspheres is maintained at a level of 10-30wt%, stirring is performed completely, the mixture of the polyphosphazenes microspheres and the activating agents is obtained through centrifugal separation, the mixture of the polyphosphazenes microspheres and the activating agents is subjected to carbonization, and finally the porous carbon spheres doped with the nitrogen and the phosphorus are obtained. The activating agents are potassium hydroxide, sodium hydroxide, calcium chloride or zinc chloride. The polyphosphazenes microspheres serve as a carbon precursor in the method, are synthesized directly under the room temperature condition, and has a simple art process and high productivity. Simultaneously, the activating agents are used for processing polyphosphazenes so as to improve specific surface areas and pore structures of the porous carbon spheres greatly and be beneficial to improve hydrogen storage capacity.

Owner:ZHENGZHOU UNIV

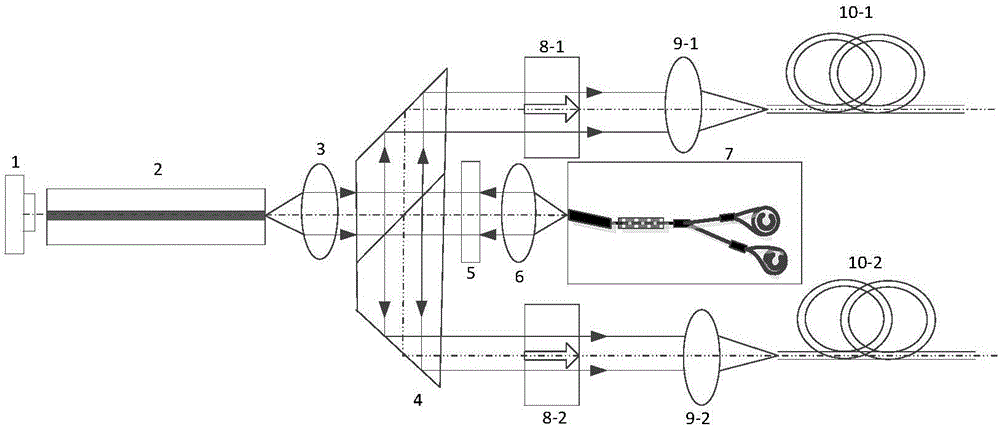

High-power dual-port output silicon-based tunable external cavity laser

ActiveCN106785882ASimple structural designExpand limit optical powerLaser detailsLaser optical resonator constructionExternal cavity laserBand-pass filter

The invention relates to a high-power dual-port output silicon-based tunable external cavity laser. A hybrid integration scheme is adopted, a low-cost low-loss silicon-based microring waveguide chip is used as an external cavity medium wavelength adjustment unit, end surface coupling with an III-V group reflective semiconductor gain tube core is realized through two collimating lenses, the structure is simple, the complex process limitations of a monolithic integrated semiconductor laser are overcome, no moving part exists in the external cavity, and the reliability and the stability can be effectively improved. Through optimal design of the silicon-based microring waveguide chip structure, the nonlinear optical effect generation probability of laser in a silicon-based waveguide microring resonator is greatly reduced, and the maximum optical power which is allowed to be outputted by the laser of the structure is improved. Due to addition of a band pass filter in the external cavity collimating light path, technical requirements on the silicon-based microring waveguide chip can be effectively reduced, the coupling packaging efficiency can be improved, and low-cost batch production is facilitated.

Owner:GUANGXUN SCI & TECH WUHAN

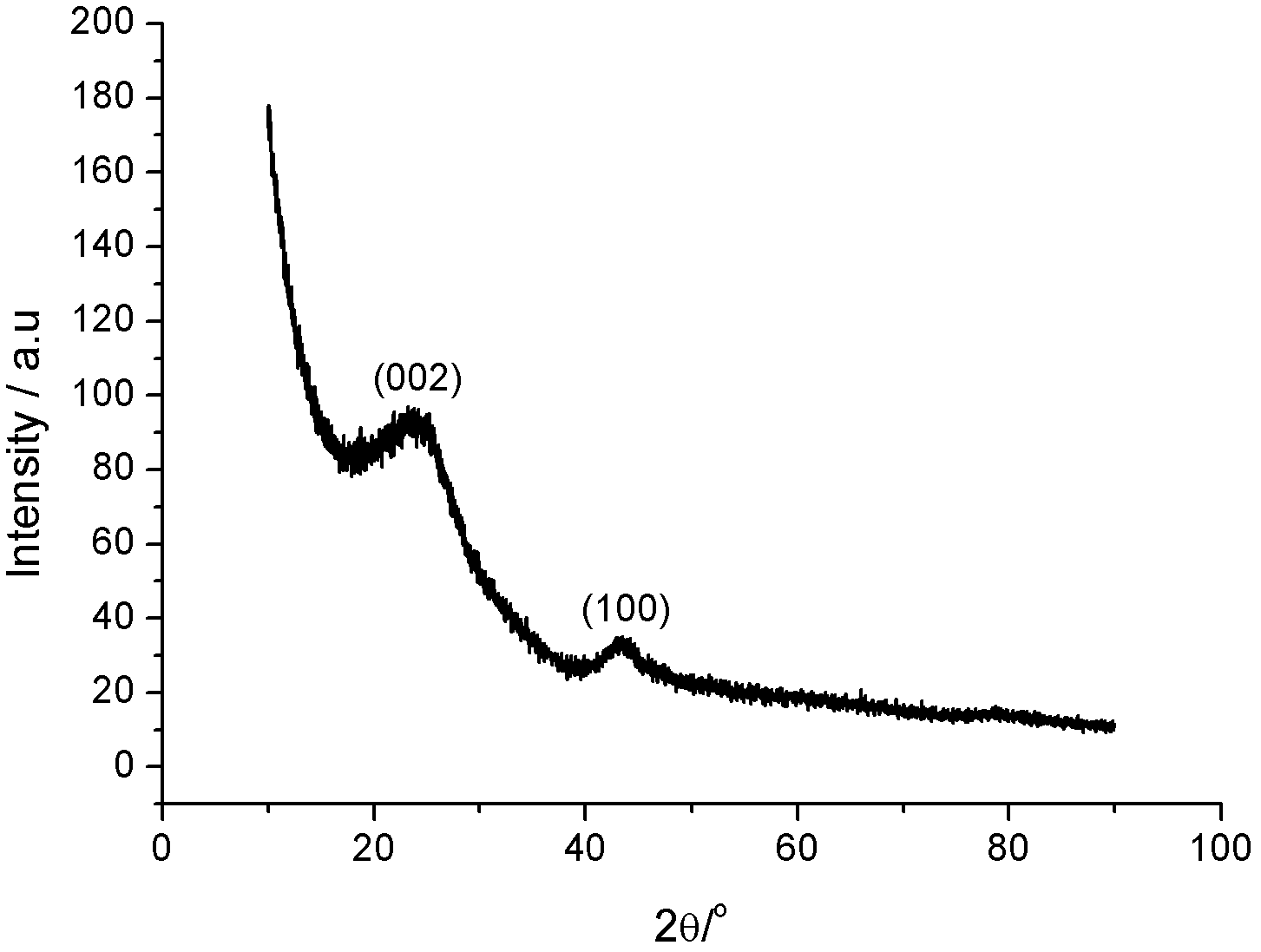

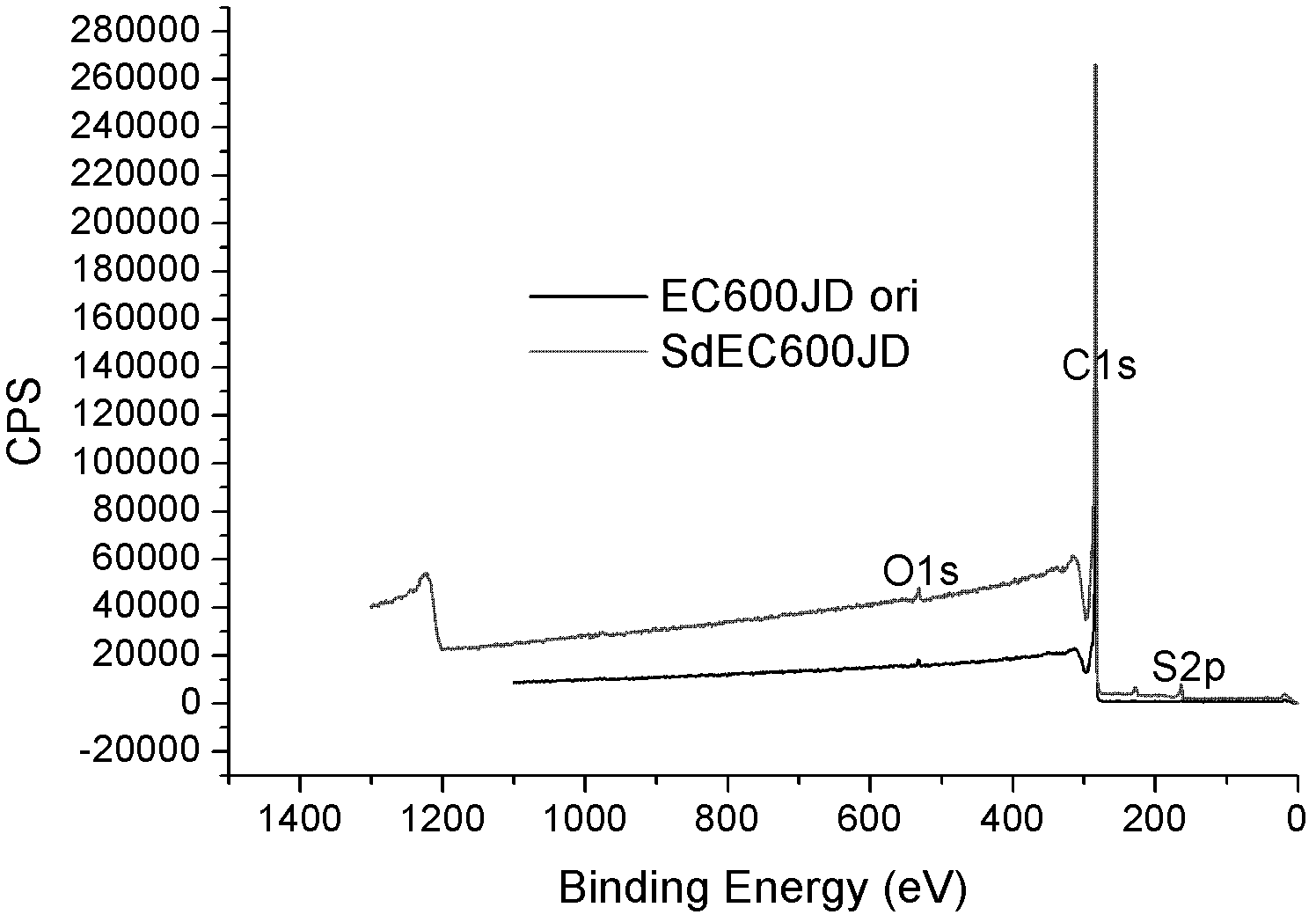

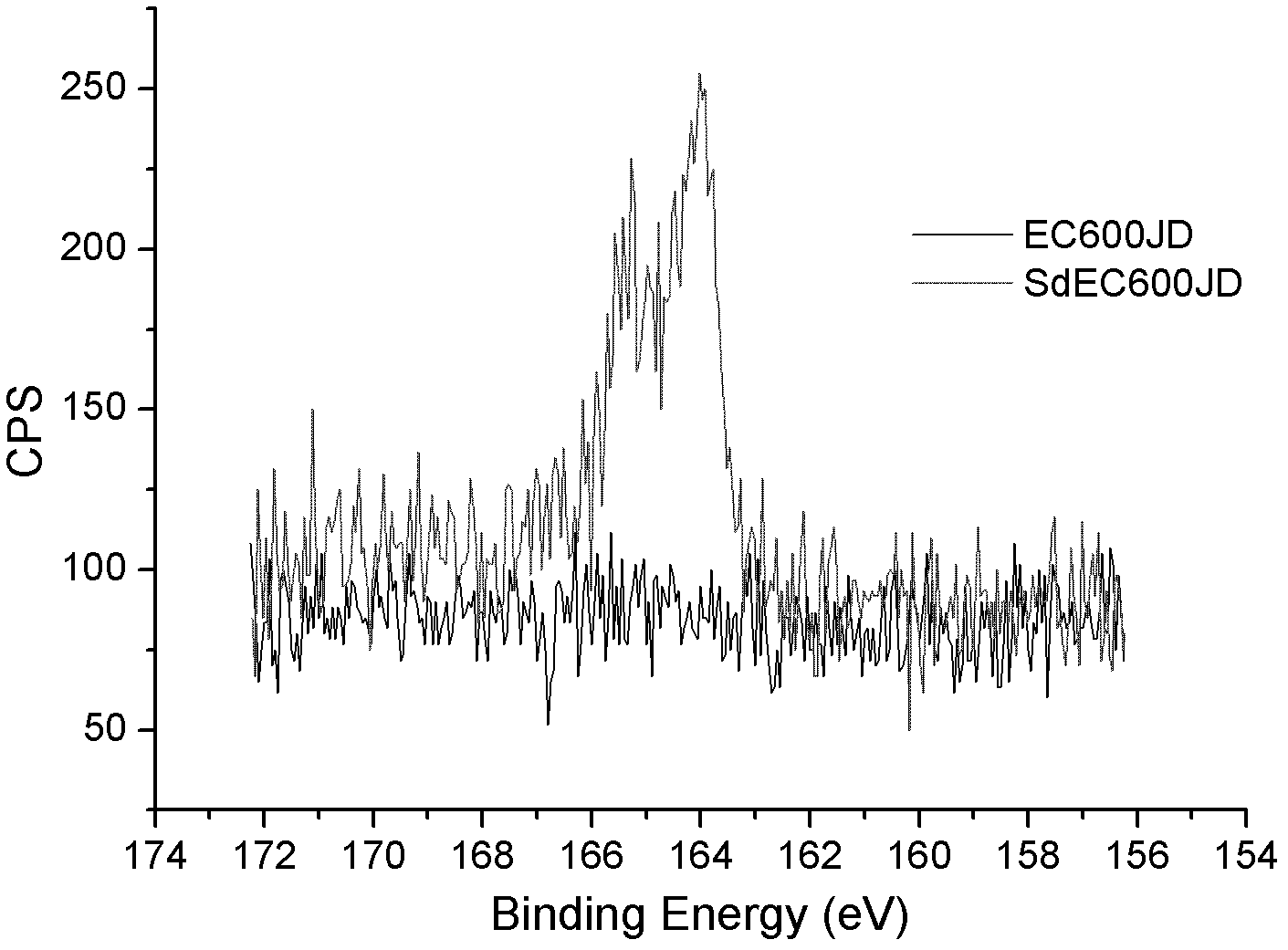

Sulfur-doped carbon material or sulfur-nitrogen-doped carbon material and preparation method and application thereof

InactiveCN102544521AImprove electrochemical performanceExcellent first discharge performanceFuel and primary cellsActive material electrodesNitrogen dopedRaw material

The invention discloses a sulfur-doped carbon material or a sulfur-nitrogen-doped carbon material. The sulfur-doped carbon material is formed by doping sulfur into a carbon material, or the sulfur-nitrogen-doped carbon material is formed by doping the sulfur and nitrogen into the carbon material, wherein the carbon material is carbon black. The material can be used as or in an electrode material for manufacturing a battery and has excellent electrochemical performance. The invention further discloses a preparation method of the sulfur-doped carbon material or the sulfur-nitrogen-doped carbon material, and the preparation method comprises the following steps of: evenly mixing a sulfur doping raw material or the sulfur doping raw material and a nitrogen doping raw material with the carbon material, to form a mixture, then, pouring the mixture into water to form a uniformly-dispersed suspension; and drying the suspension to obtain a substance, grinding the substance, and then, calcining the substance in an inert gas atmosphere to obtain the sulfur-doped carbon material or the sulfur-nitrogen-doped carbon material. The preparation method is simple in operation and easy in mass production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

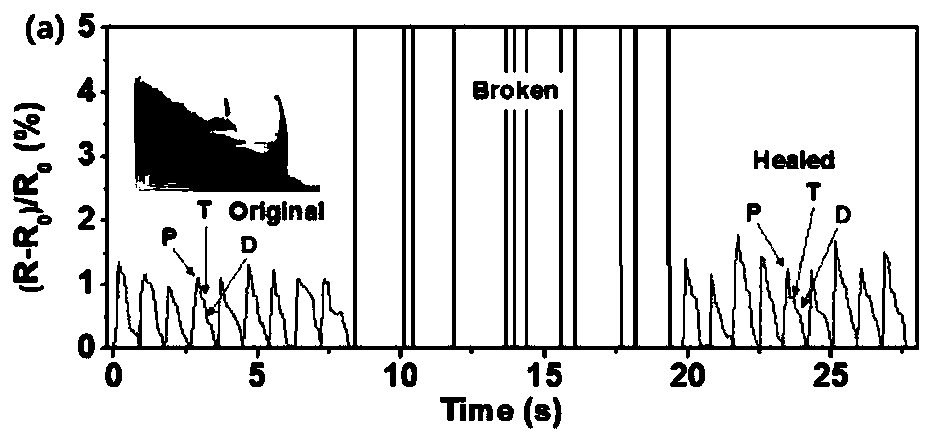

Stress sensor with self-repairing ability and preparation method thereof

InactiveCN109974905AWide range of workHigh sensitivityMaterial nanotechnologyNanosensorsScreen printingElectrical resistance and conductance

The invention discloses a stress sensor with a self-repairing ability and a preparation method thereof. according to the preparation method, a one-dimensional metal nanowire, a two-dimensional inorganic nanosheet, hydrogel functional polymers, an additive and the like are compounded to prepare a nanocomposite colloidal printing ink with rheological characteristics, and the colloidal printing ink is printed on a wearable substrate through screen printing to prepare the repairable stress sensor having a shell-like bionic structure, wherein the one-dimensional metal nanowire provides a conductivenetwork structure for reducing resistance of the sensor; the two-dimensional inorganic nanosheet forms a layered strcture for improving sensitivity of the sensor; and a reversible dynamic cross-linking point is formed among the repairable hydrogel functional polymers, the two-dimensional inorganic nanosheet and the additive, so that the device has repairable performance. The prepared stress sensor has the advantages of large operating strain range, high sensitivity, repairable property after overload damage and the like, and has great application prospects in the fields of artificial electronic skin and biomimetic robots.

Owner:NANKAI UNIV

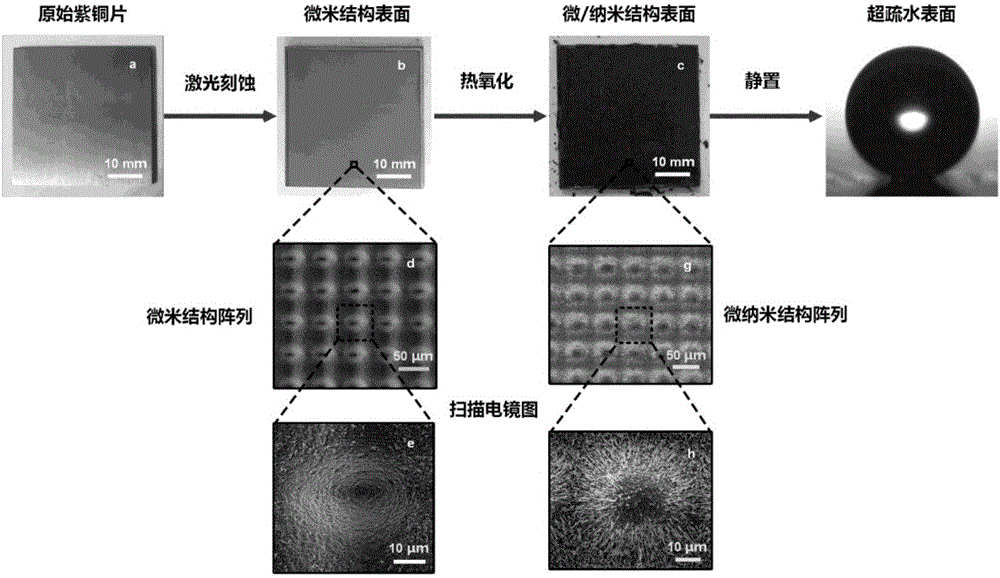

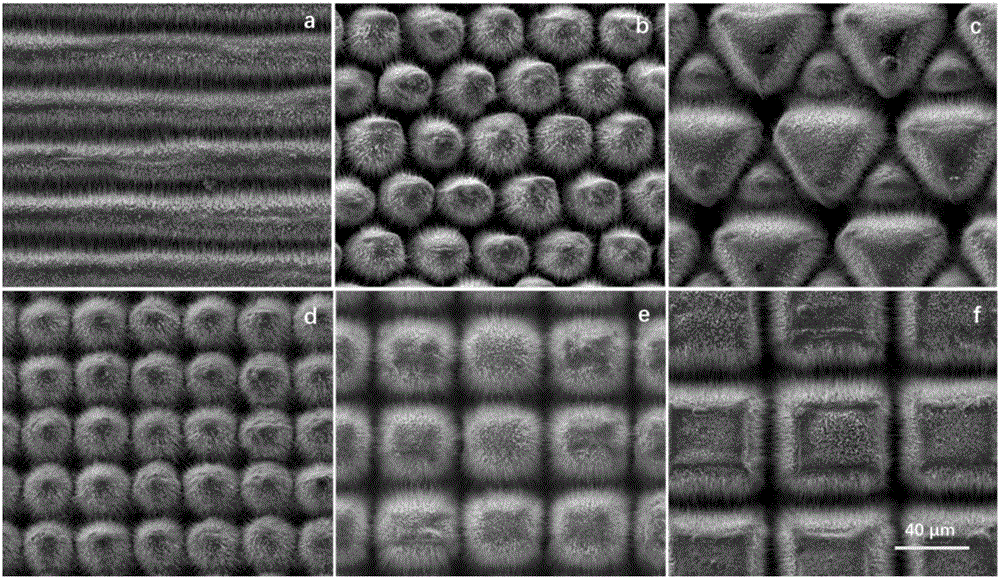

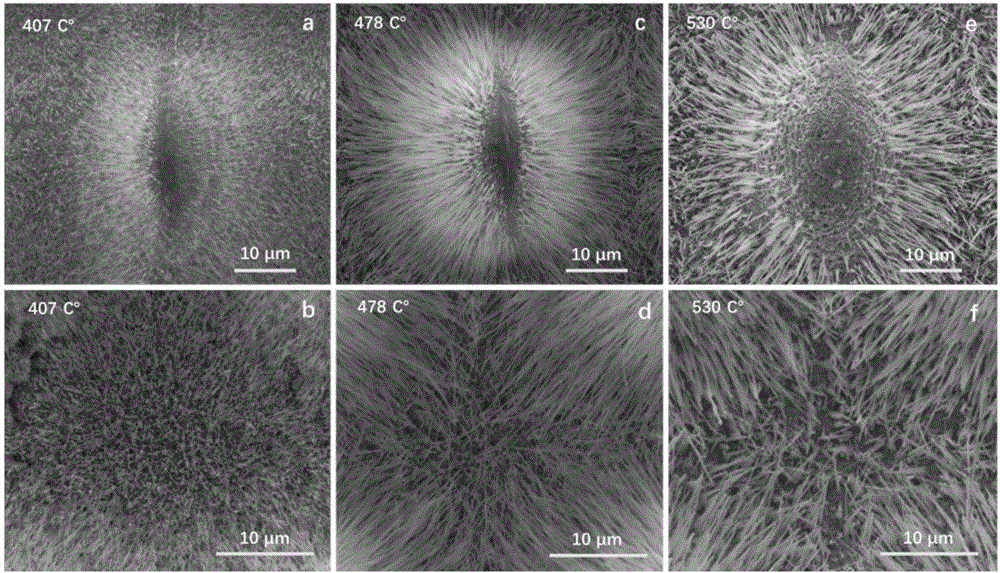

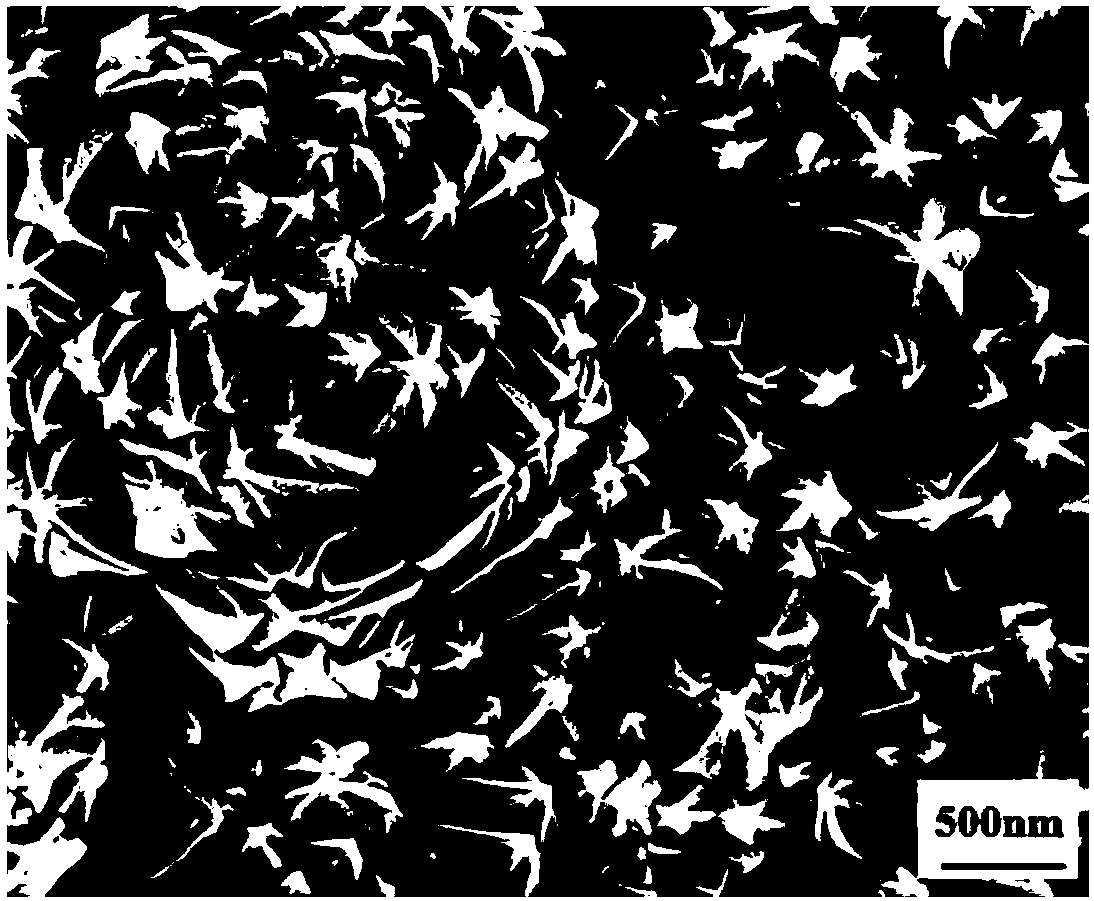

Micro-nanostructure controlled copper-based superhydrophobic surface and preparation method and application thereof

InactiveCN107522161AReduce pollutionEasy to mass manufactureSemi-permeable membranesVolume/mass flow by thermal effectsMicro structureNanowire

The invention discloses a micro-nanostructure controlled copper-based superhydrophobic surface and a preparation method and application thereof. The copper-based superhydrophobic surface comprises micro structure arrays and nanowires, wherein center spacing of the micro structure arrays is 10 to 500[mu]m, the height of each micro structure array is 5 to 500[mu]m; the nanowires have the diameter of 40 to 200nm, the length of 2 to 50[mu]m and average spacing of 0.1 to 3[mu]m; and the nanowires grow in parallel to the direction of a local normal of the copper-based superhydrophobic surface and has the ingredient being copper oxide. The copper-based superhydrophobic surface can implement liquid droplet bouncing heat exchange of water vapor condensation and can also promote classical droplet condensation so as to reinforce heat exchange. Moreover, the micro-nanostructure controlled copper-based superhydrophobic surface can also be used for the fields of self-cleaning, corrosion resistance, ice prevention, frosting resistance and the like.

Owner:TSINGHUA UNIV

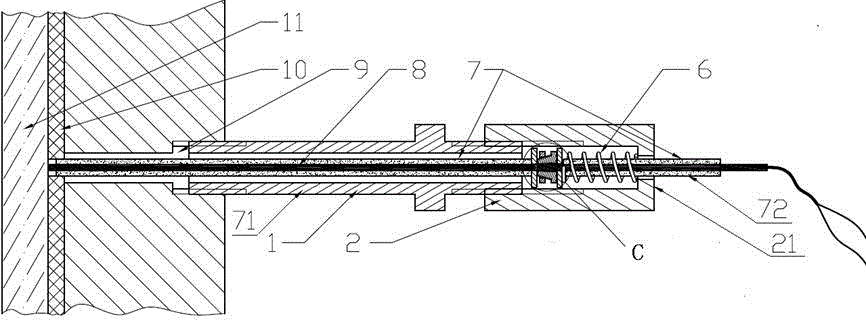

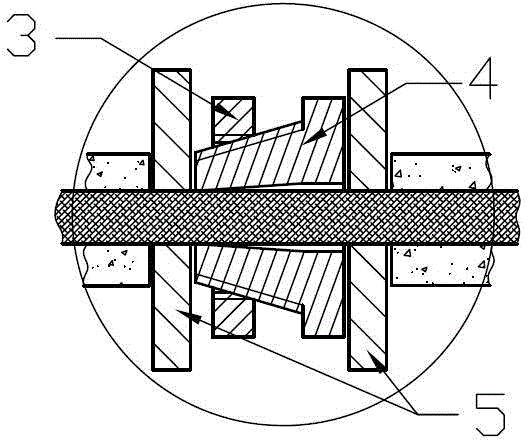

Thermocouple insulation locator, mounting method thereof and wall temperature measuring device

InactiveCN104089715AAvoid damagePrecise positioningThermometer detailsThermometers using electric/magnetic elementsMeasurement deviceArchitectural engineering

The invention discloses a thermocouple insulation locator, a mounting method of the locator and a wall temperature measuring device. The thermocouple insulation locator comprises a self-tightness locating bolt fixed to a thermal coupler, a locating nut connected to the self-tightness locating bolt, a first insulation casing pipe, a second insulation casing pipe, a locating guide pipe and a pushing and pressing nut, wherein the first insulation casing pipe and the second insulation casing pipe are arranged on the two sides of the self-tightness locating bolt and are arranged on the thermal coupler in a sleeved mode, the first insulation casing pipe is sleeved with the locating guide pipe, and the pushing and pressing nut is arranged on the second insulation casing pipe in a sleeved mode and is in threaded connection with the rear end of the locating guide pipe. An end cover is arranged at the rear end of the pushing and pressing nut, and insulation blocking pieces are arranged between the self-tightness locating bolt and the two insulation casing pipes, a pushing and pressing spring is arranged between the insulation blocking piece at the rear end of the self-tightness locating bolt and the end cover arranged at the rear end of the self-tightness locating bolt in a sleeved mode, and the second insulation casing pipe is sleeved with the pushing and pressing spring. According to the thermocouple insulation locator, the thermal coupler can be precisely located to the measuring point, it is ensured that the thermal coupler is insulated from other components except a measured device, and small vibration and migration of the measured device in the channel direction of the thermal coupler can be borne.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

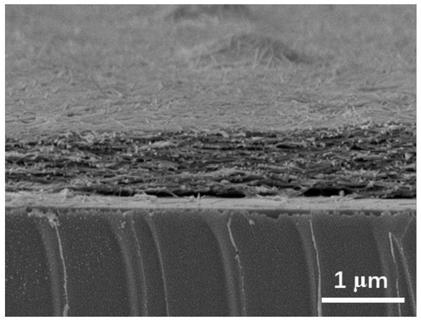

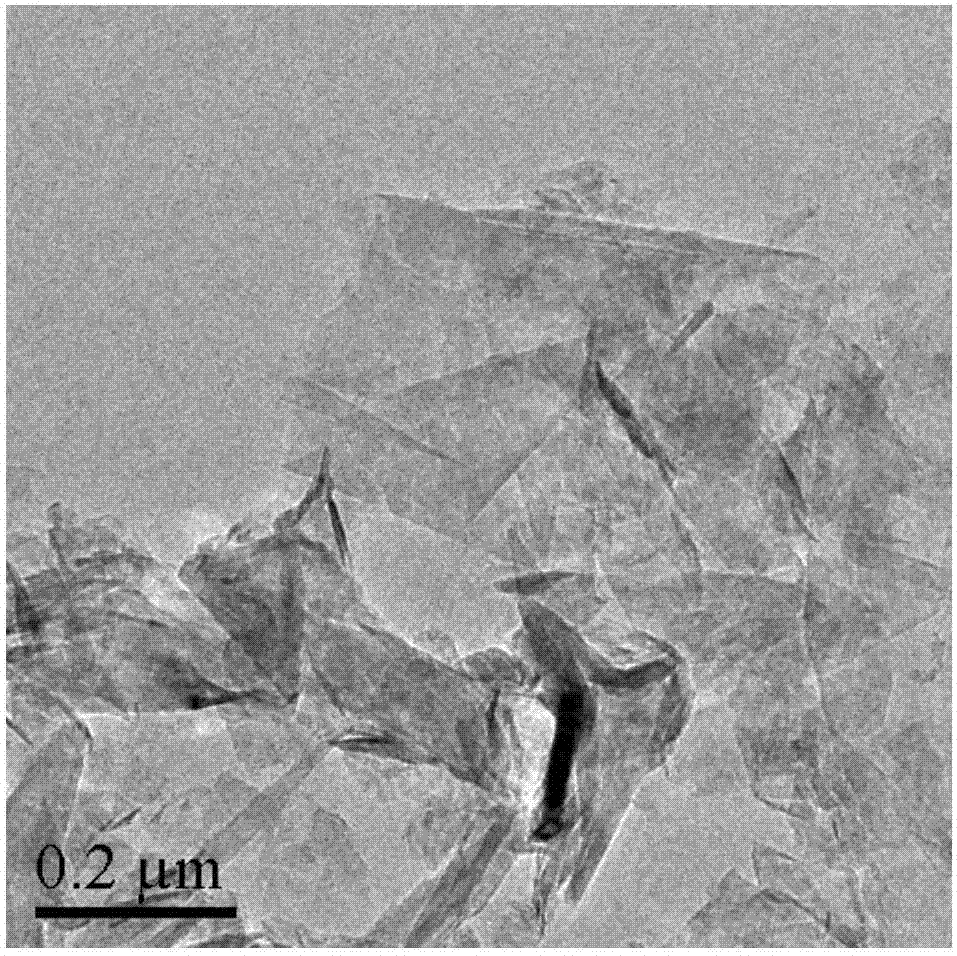

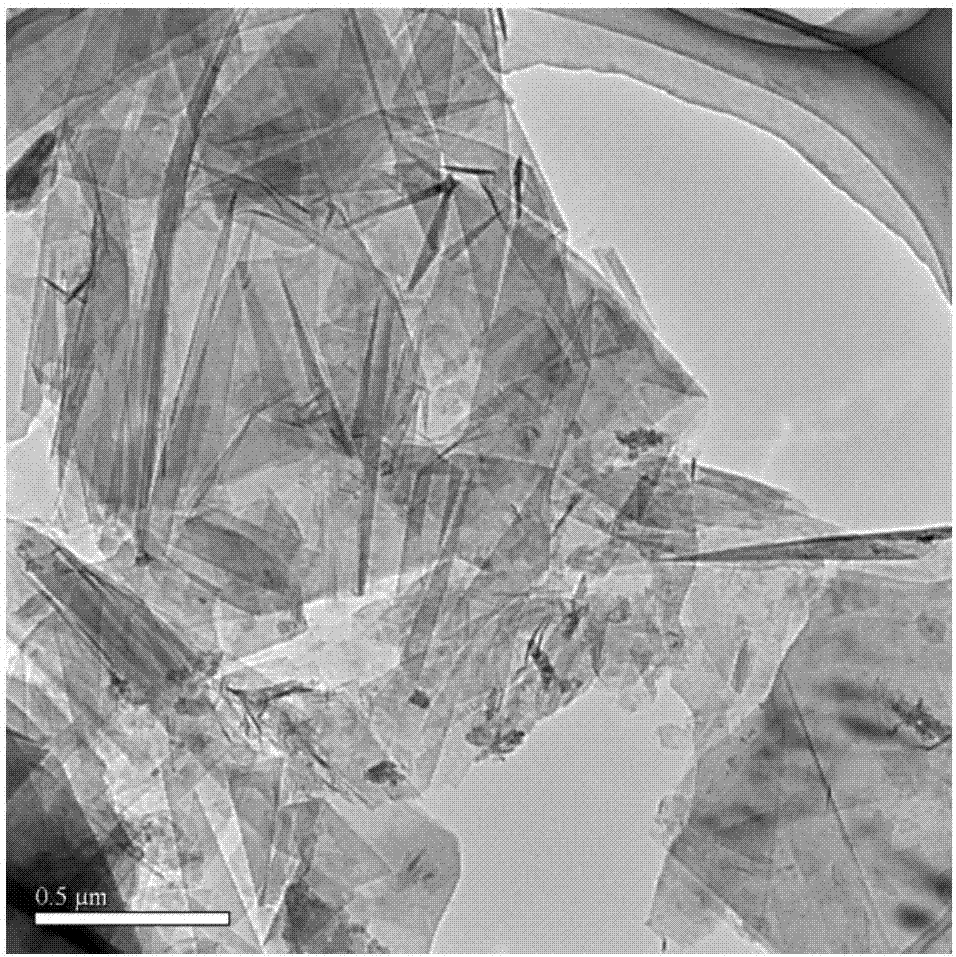

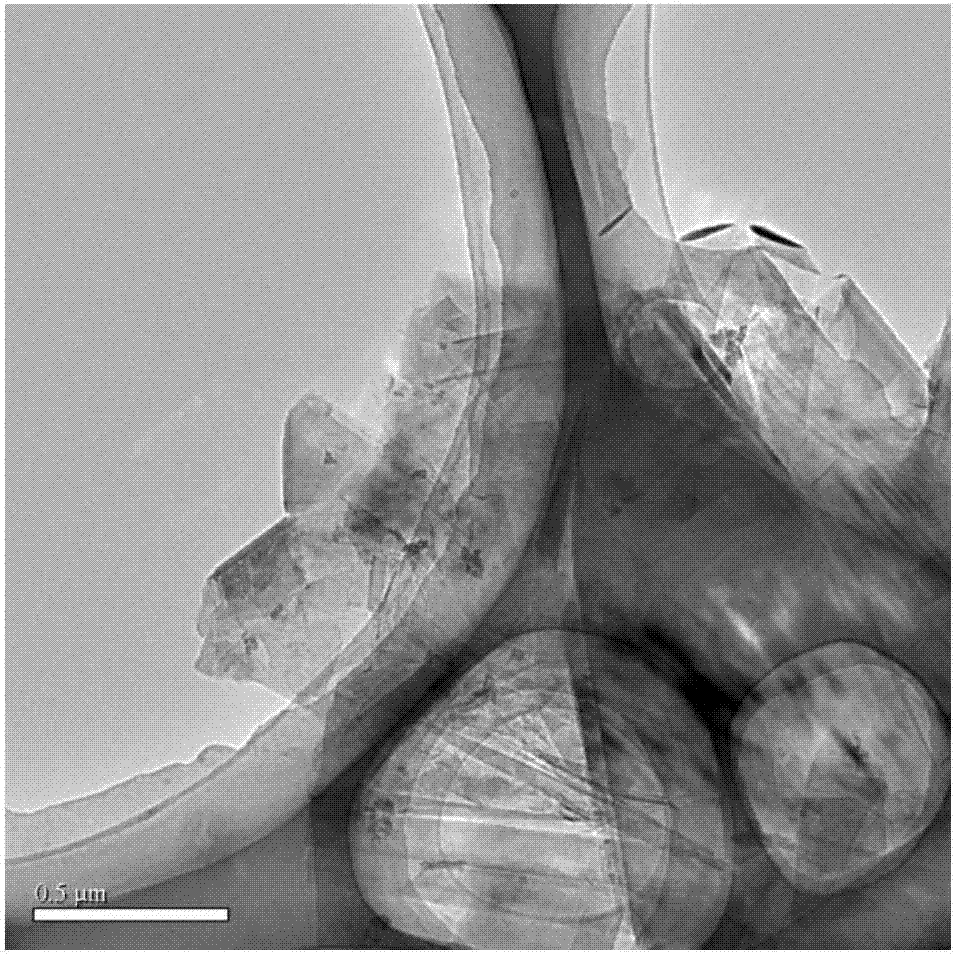

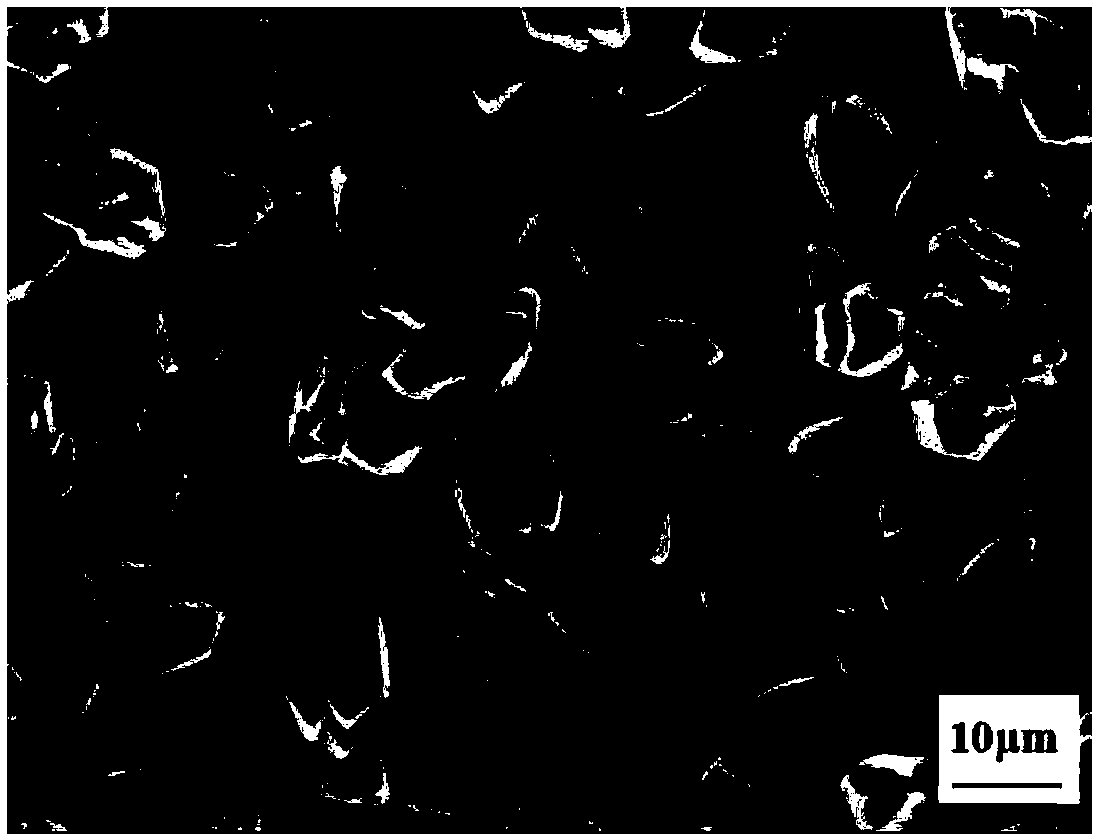

In-situ method for preparing graphene/carbon nanotube composite film

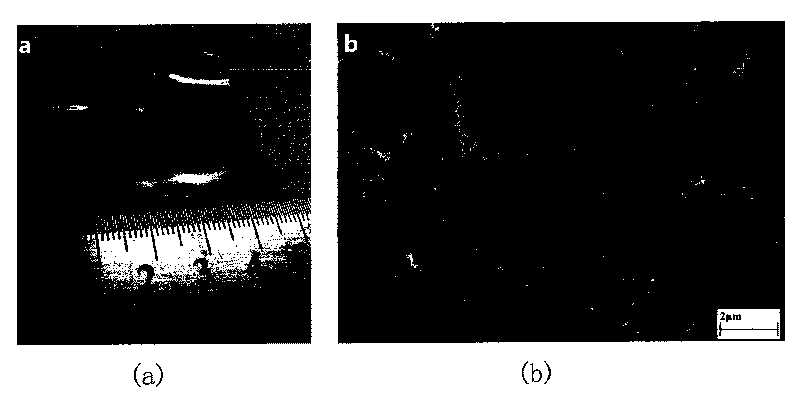

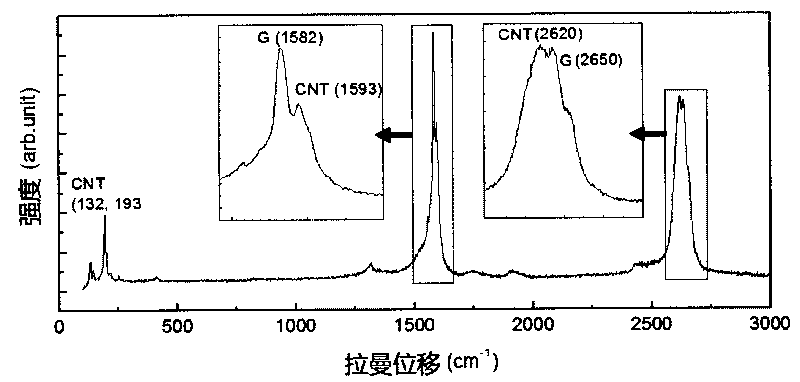

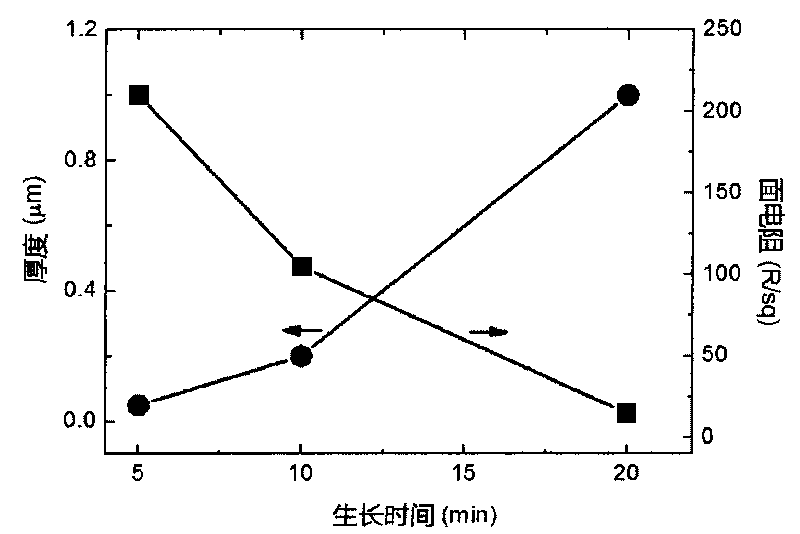

InactiveCN101696491AIncreasing the thicknessThickness is easy to controlChemical vapor deposition coatingComposite filmHydrogen

The invention relates to an in-situ method for preparing a graphene / carbon nanotube composite film, which comprises the following steps of: 1. weighing ferrocene and sulfur, uniformly mixing and placing the mixture at the front end of a reaction vessel; placing a polycrystal nickel piece in the center of the reaction vessel and sealing the reaction vessel; 2. introducing a hydrogen / argon mixed gas into the reaction vessel, heating the center of the reaction vessel to 1100-1150 DEG C and adjusting the flow of the hydrogen / argon; 3. heating the ferrocene and the sulfur at the front end of the reaction vessel so as to enable the ferrocene and the sulfur to be volatilized and carrying a volatilized gas into the reaction vessel to react by the adjusted hydrogen / argon mixed gas in the step 2; 4. stopping heating the center of the reaction vessel, shutting off the hydrogen, adjusting the flow of the argon, drawing the nickel piece out of the center of the reaction vessel and cooling to room temperature; and obtaining the graphene / carbon nanotube composite film on the nickel piece. The invention realizes the batch production of the graphene / carbon nanotube composite film and has the characteristics of large area, controllable thickness, high electrical conductivity and continuation.

Owner:TSINGHUA UNIV

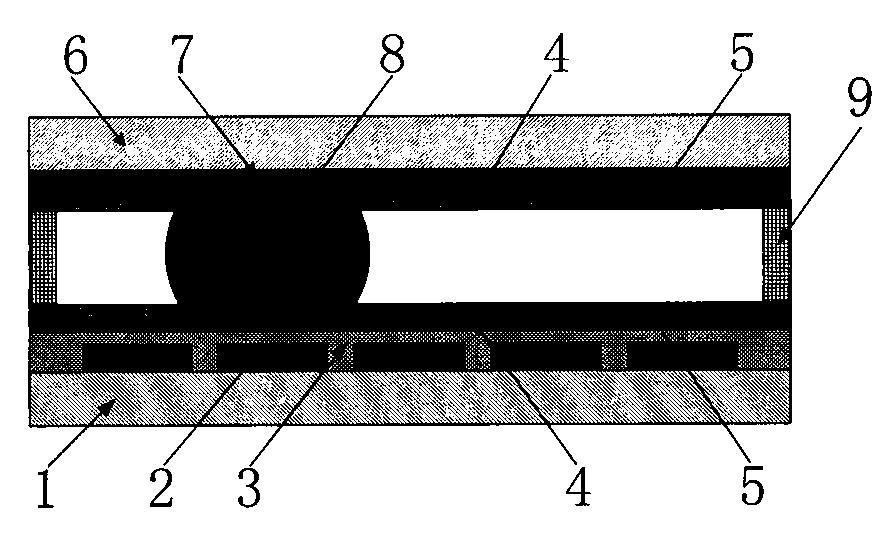

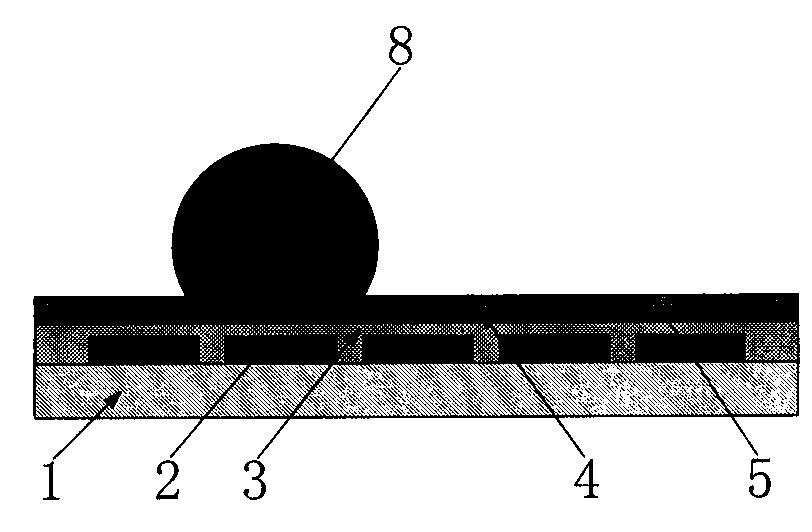

Digital micro-droplet drive with deep submicron pore structure and manufacturing method thereof

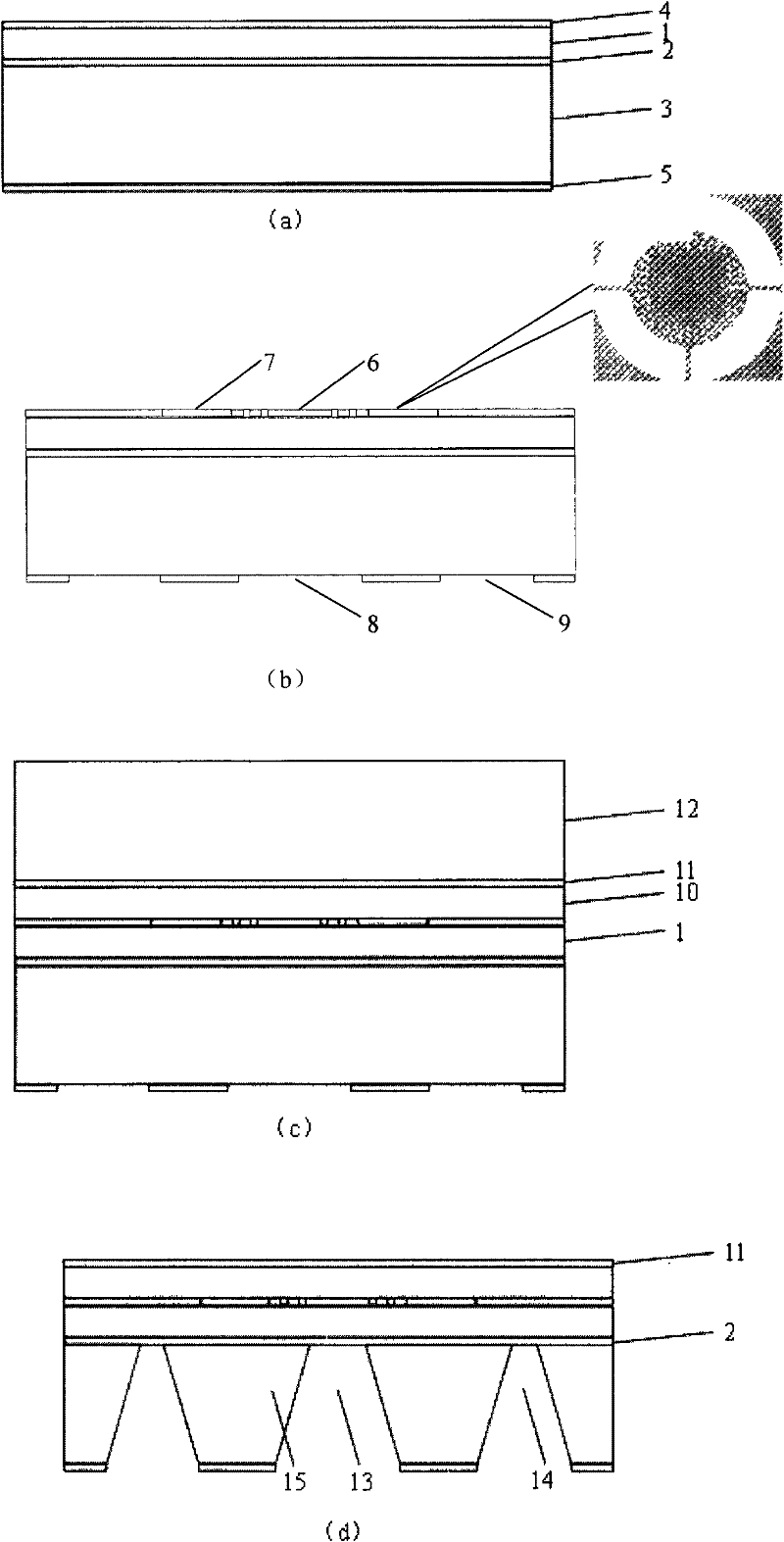

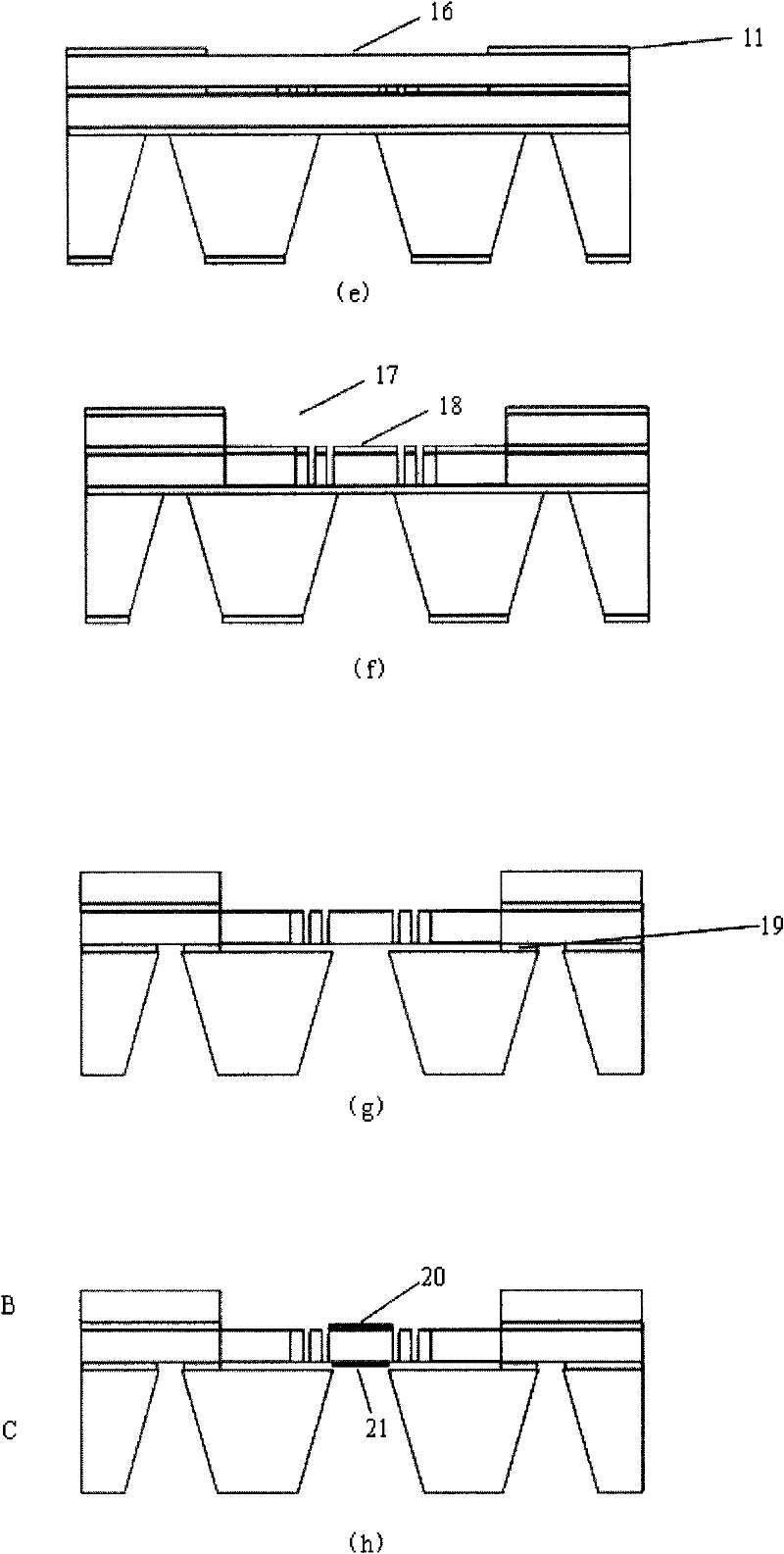

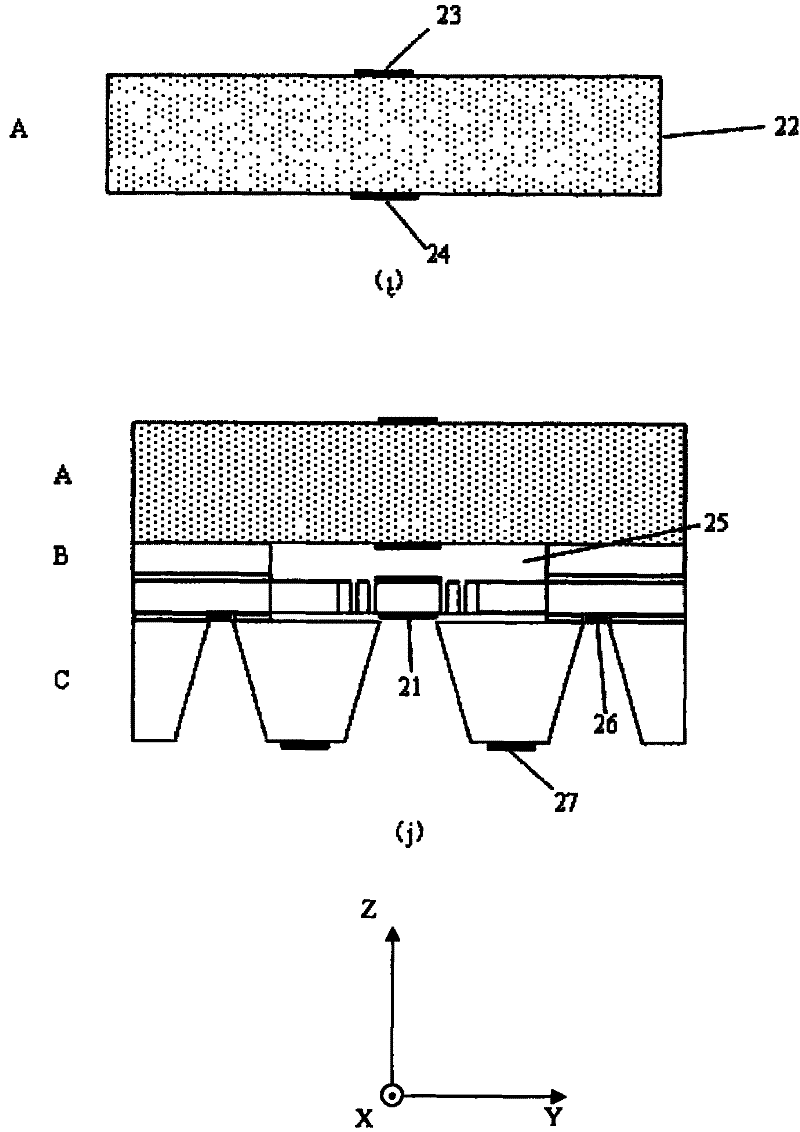

InactiveCN101559914AImprove hydrophobicityReduce thicknessTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectrode array

The invention relates to a digital micro-droplet drive with deep submicron pore structure and a manufacturing method thereof. The invention is characterized in that the digital droplet drive comprises two structures of a bipolar plate and a monopolar plate. The lower polar plate of the structure of the bipolar plate is composed of an insulating substrate, a driving electrode array, a dielectric layer, a deep submicron pore structure and a hydrophobic film layer. The upper polar plate comprises an insulating base plate, a reference electrode layer, a deep submicron pore structure and a hydrophobic film layer. The upper polar plate and the lower polar plate are connected by a supporting structure. The driving electrodes are uniformly distributed on the insulating substrate in the shape of an array, the dielectric layer is coated on the driving electrode array, and the deep submicron pore structures and the hydrophobic film layers form a super-hydrophobic film layer that is coated on the dielectric layer. The structures of the lower polar plates in the monopolar plate structure and the bipolar plate structure are the same. The invention uses the deep submicron pore structures to effectively enhance the hydrophobic properties of the hydrophobic film layers, effectively reducing the thickness of the structure and reducing driving voltage.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

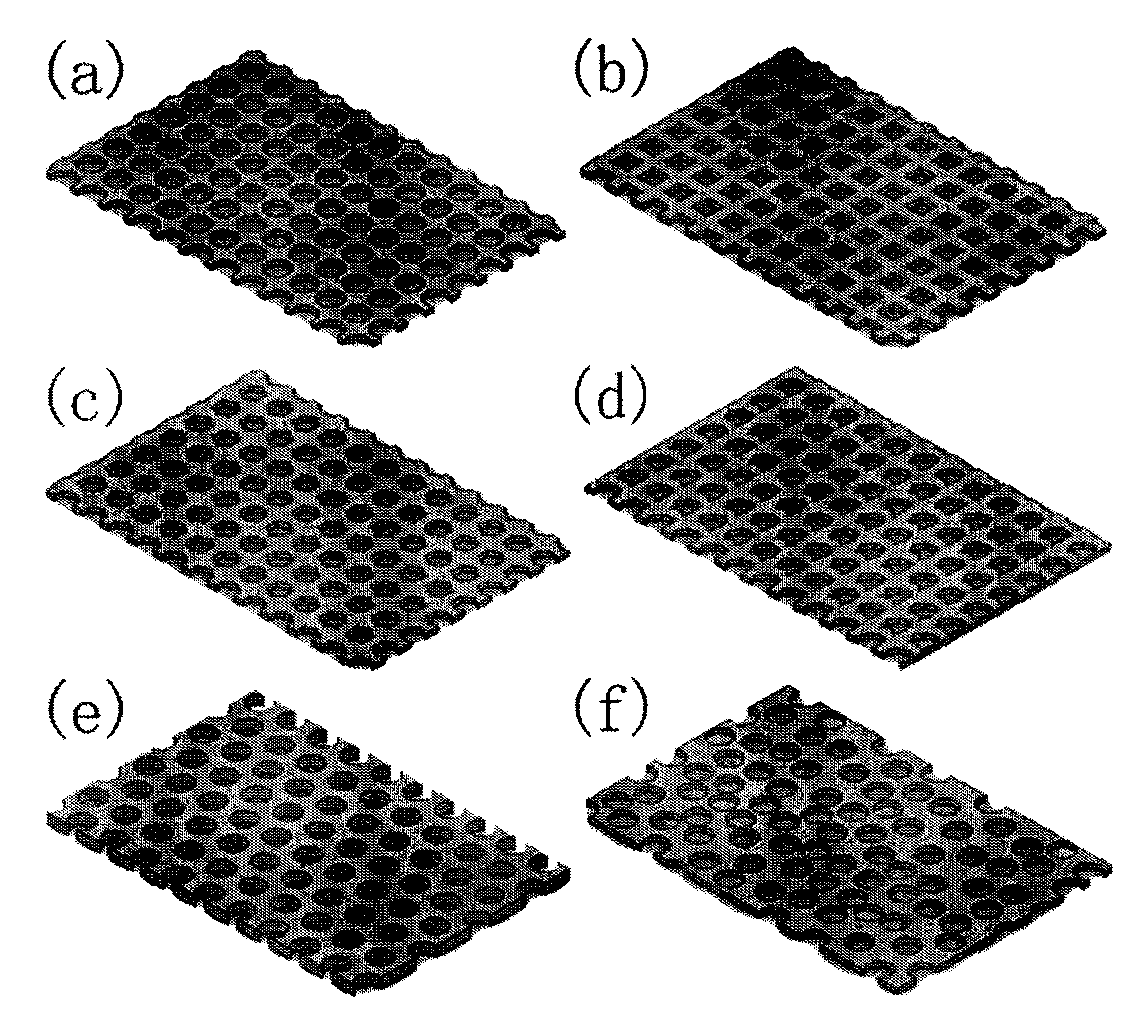

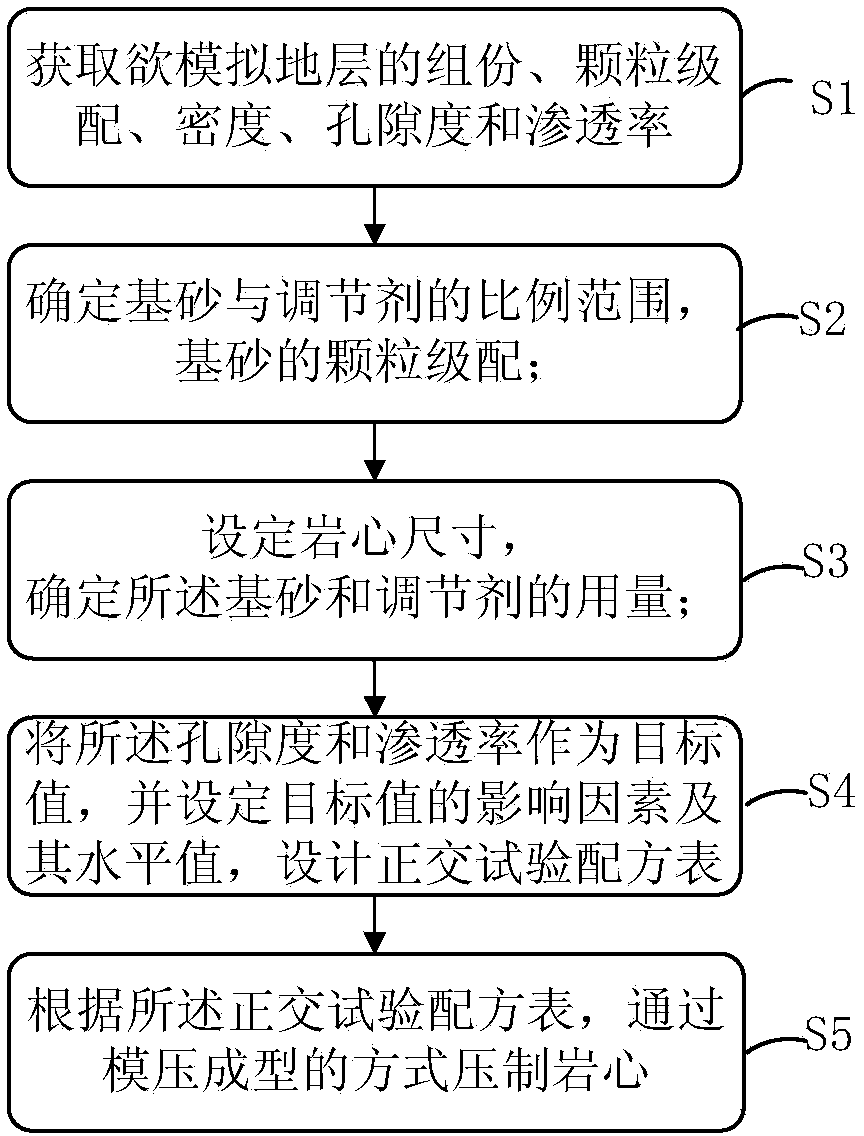

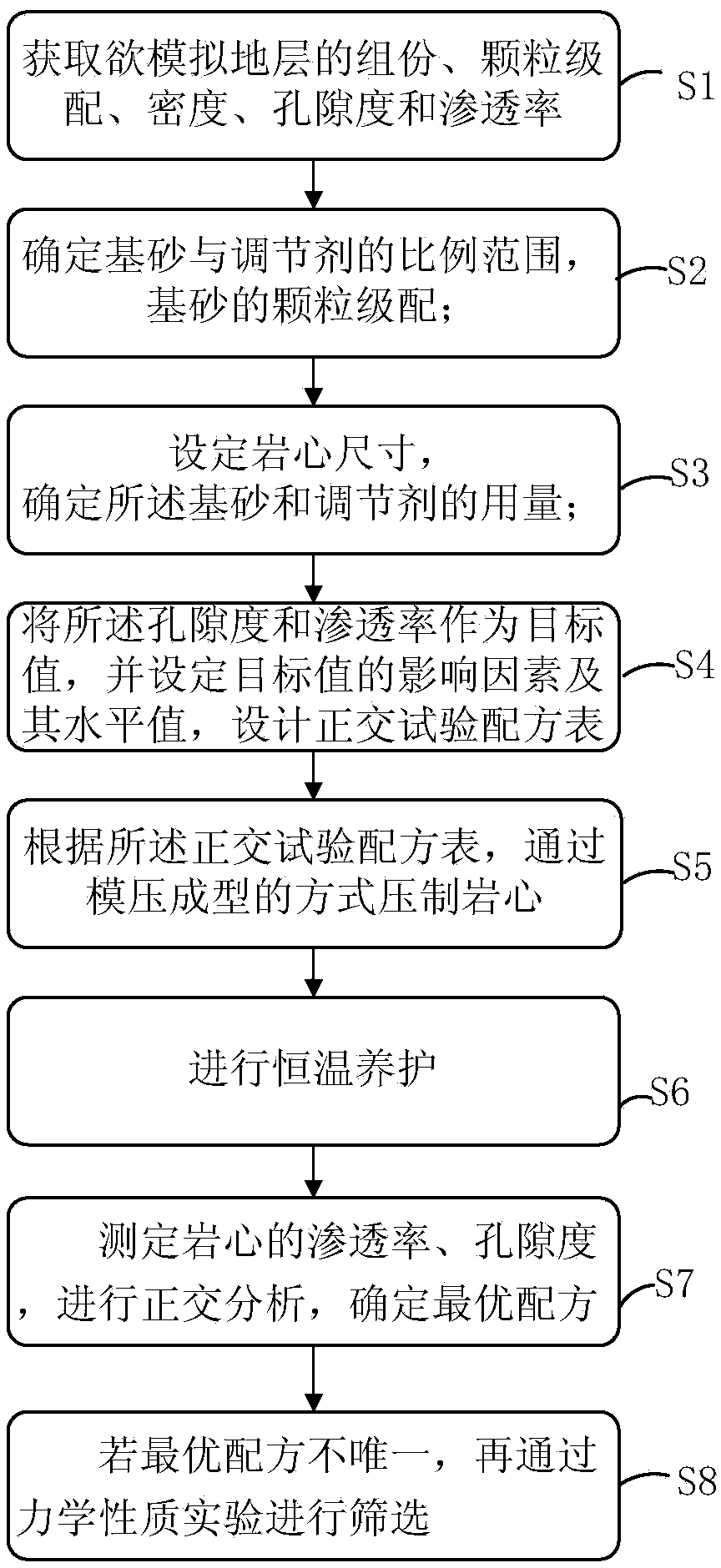

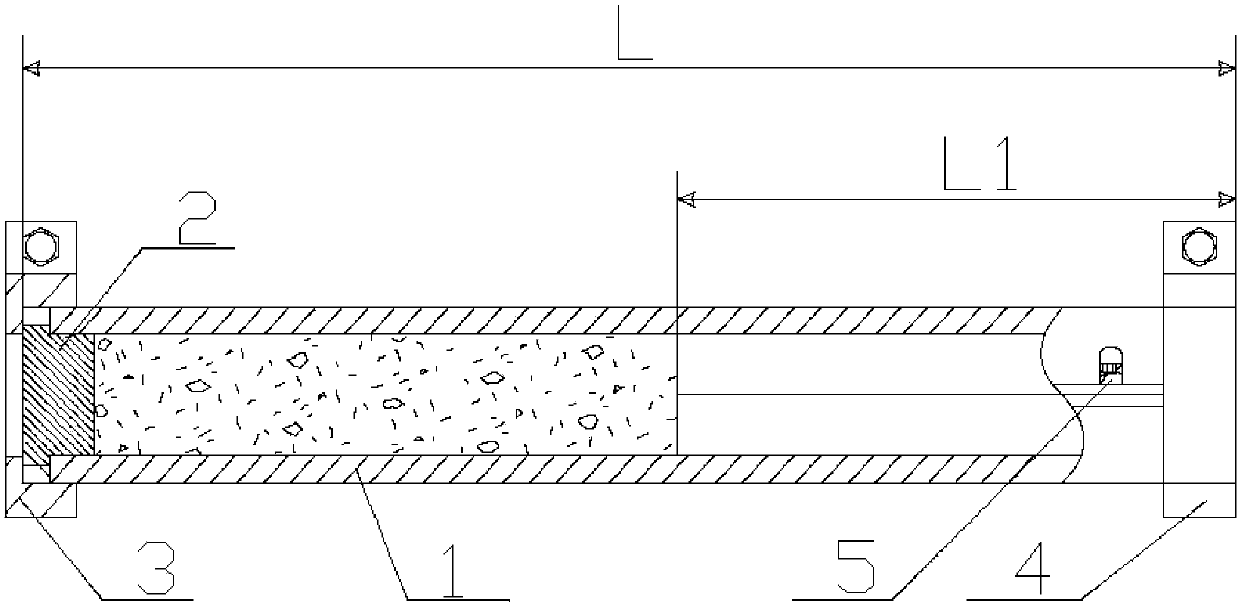

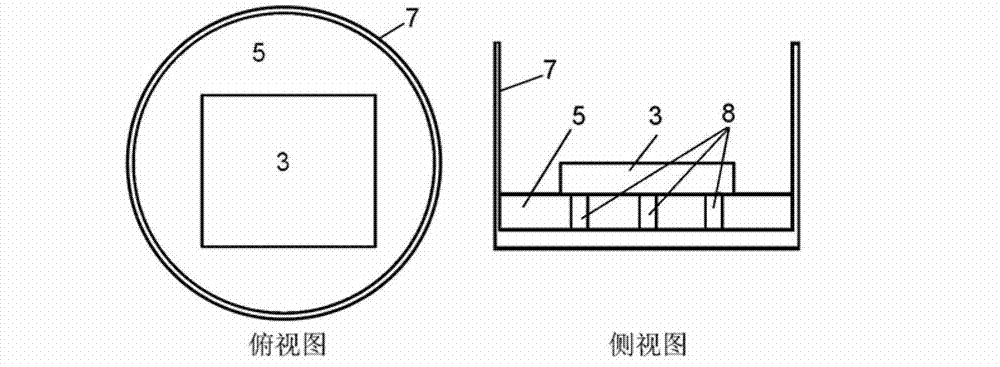

Preparation method of artificial rock core for simulating permafrost region hydrate stratum skeleton

InactiveCN104198243AHigh mechanical strengthEasy to mass manufacturePreparing sample for investigationCompression moldingRock core

The invention discloses a preparation method of an artificial rock core for simulating a permafrost region hydrate stratum skeleton. The method comprises the following steps: S1: acquiring the components, grain composition, density, porosity and permeability of a stratum to be simulated; S2: determining the range of the proportion of base sand to a conditioning agent according to the components of the stratum to be simulated, and determining the grain composition of the base sand according to the grain composition of the stratum; S3: setting a rock core size, and determining the use amount of the base sand and the conditioning agent according to the set rock core size and the density of the stratum to be simulated; S4: with the porosity and the permeability as target values, setting the influence factors and the level values of the target values, and designing an orthogonal test formula graph; and S5: according to the orthogonal test formula graph, pressing the rock core in a compression molding way. The rock core prepared by the preparation method approaches the real permafrost region natural gas hydrate stratum in basic physical parameters, and the pore distribution approaches the normal distribution characteristics of the real stratum, therefore, the method is conductive to large-batch production for comparison and repeated test.

Owner:PETROCHINA CO LTD

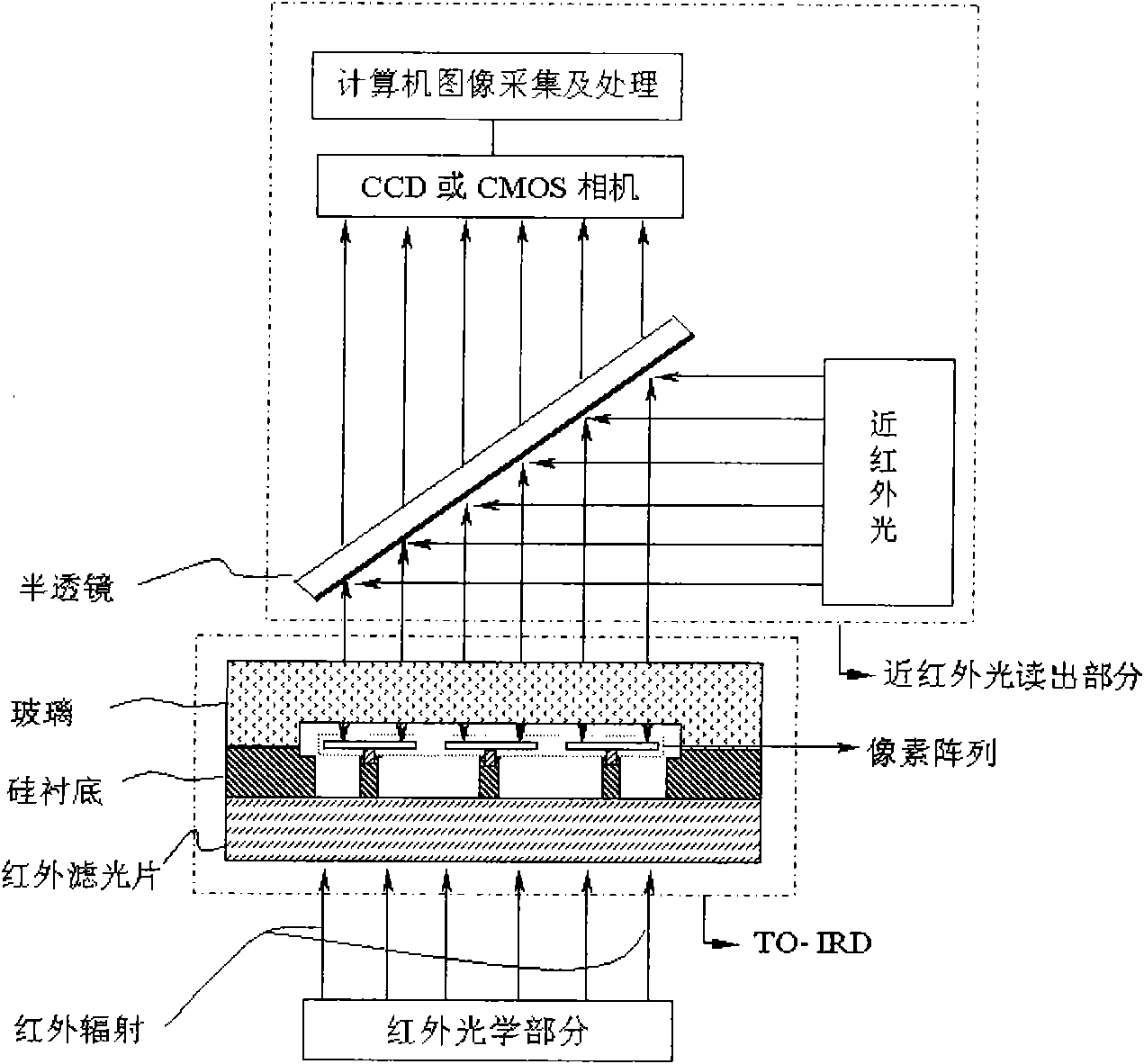

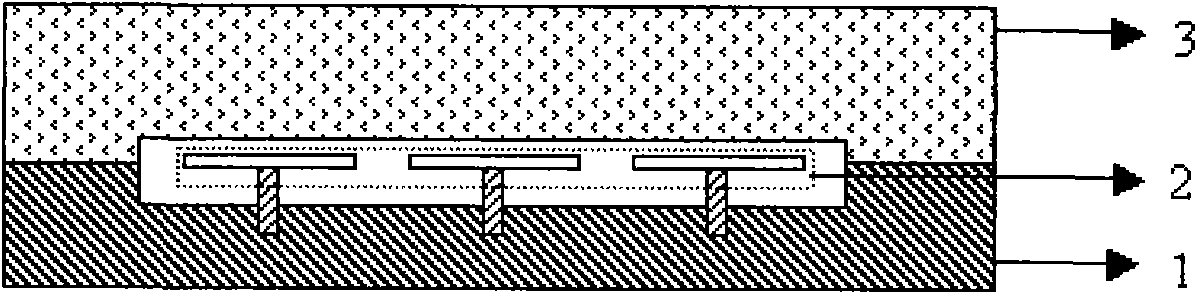

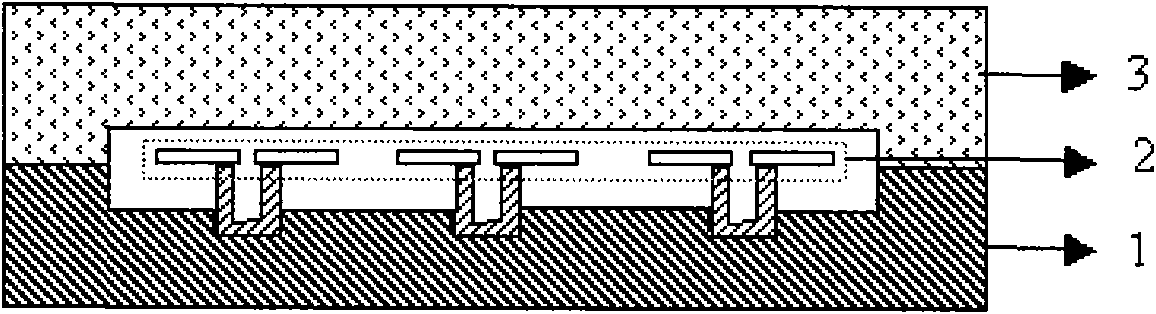

Thermo-optical infrared detector and preparation method thereof

ActiveCN101566502ASimple structureReduce manufacturing difficultyTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesModulation functionAbsorption rate

The invention relates to a thermo-optical infrared detector and a preparation method thereof, and is characterized in that the infrared detector consists of a silicon substrate, a pixel array arranged on the silicon substrate and a glass bonded with the silicon substrate; alternatively, the infrared detector consists of a silicon substrate, a pixel array arranged on the silicon substrate, a glass bonded with the silicon substrate and an infrared filter bonded with the silicon substrate. In the TO-IRD, a special heat-insulation structure and a process design are used for preparing a heat insulation column with high height standing on the silicon substrate, thus improving the heat insulation performance of the TO-IRD; in a pixel film system, by designing and preparing a special infrared absorbing layer, the absorption rate of the TO-IRD to the infrared radiation is improved; furthermore, the modulation function of the TO-IRD to the readout beam is not affected; and the vacuum encapsulation of the device is realized by the bonding of silicon glass or bonding of infrared filter in vacuum.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

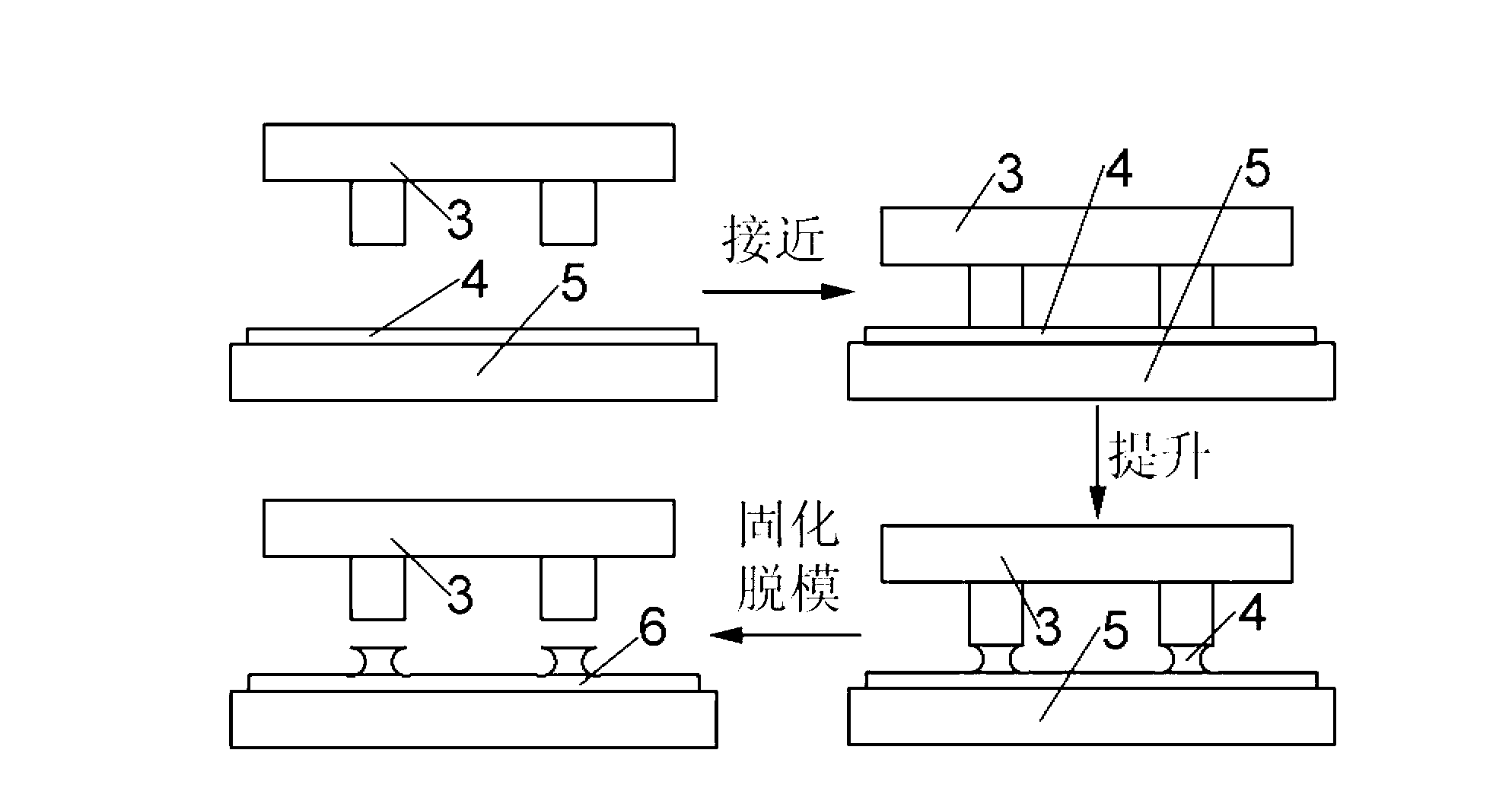

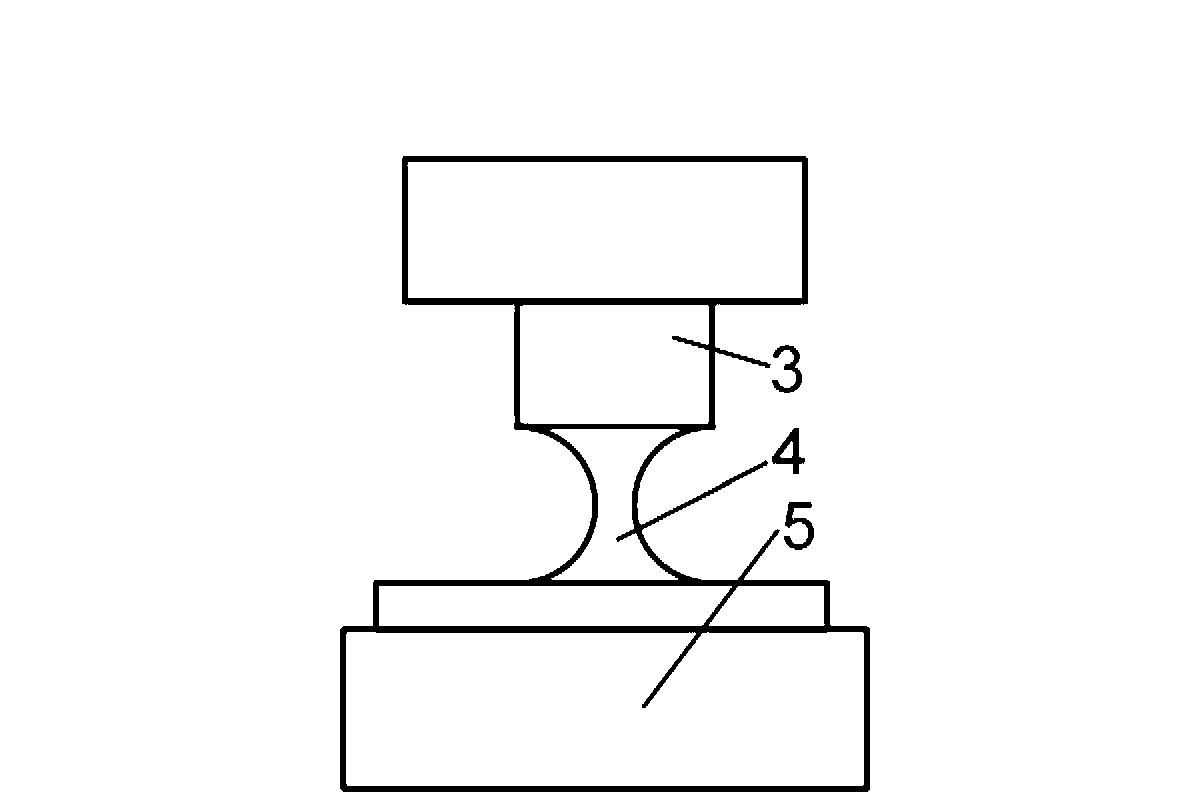

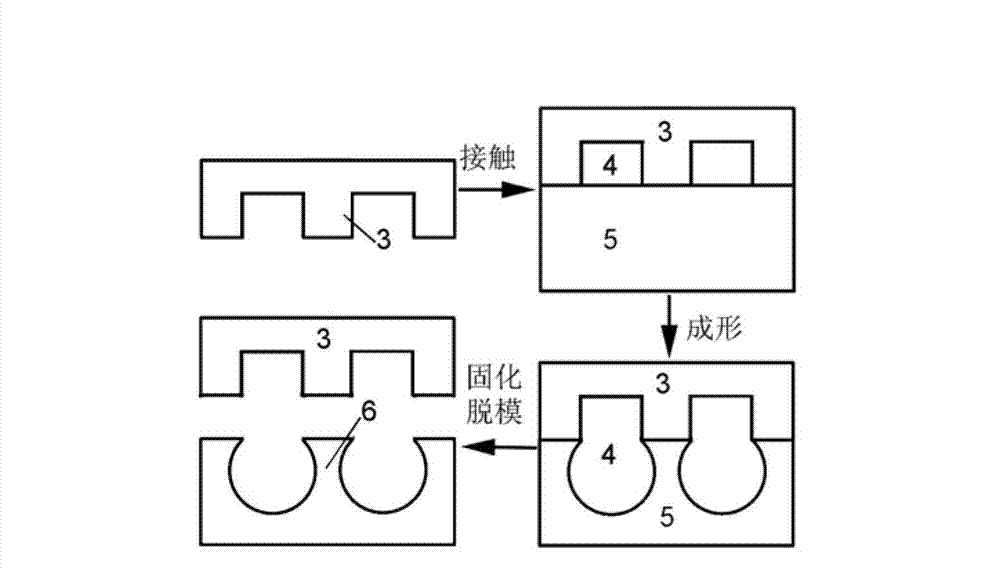

Capillary forming method for preparing super oleophobic surface

InactiveCN103011063AAchieve preparationEasy to mass manufactureDecorative surface effectsChemical vapor deposition coatingMicro nanoLiquid state

The invention relates to the field of functional surface preparation technology, and particularly relates to a capillary forming method for a preparing super oleophobic surface. The capillary forming method is suitable for preparation of a polymer super oleophobic surface, particularly suitable for the preparation of the super oleophobic surface under a simple condition. A pre-prepared micro-nano structure surface is employed as a template by the method; the template is put on a smooth and flat substrate which is coated by a liquid state polymer film; the template is separated 5-50 [mu]m from the substrate after contact with the separate speed ranging from 0.1 [mu]m / s to 5 [mu]m / s; the liquid state polymer is aggregated in a gap between the micro-nano structure and the substrate under the action of a capillary force; and at the time, the liquid state polymer is cured, so that a preparation of a secondary groove structure. Equipment required by the method is simple, preparation of the super oleophobic surface can be realized under a simple condition, preparation cost is low, and batch preparation can be easily realized.

Owner:JIANGSU UNIV

Manufacturing method of adjustable FP (filter pass) optical filter based on MEMS (micro electro mechanical system) process

InactiveCN102225739AImprove yieldGood process compatibilityDecorative surface effectsChemical vapor deposition coatingAcid etchingEvaporation

The invention relates to a manufacturing method of an adjustable FP (filter pass) optical filter based on an MEMS (micro electro mechanical system) process, which is characterized in that the etching window of all graphs is manufactured by adopting the etching twice; the manufacturing of a middle FP air cavity and a movable reflector surface structure is finished by adopting the plasma silicon etching once; a movable silicon membrane reflector is manufactured by adopting the processes such as the silicon-silicon bonding, the plasma dry etching, the HF (hydrogen fluoride) acid etching and the silicon oxide layer releasing once; the high-reflection membrane and anti-reflection membrane of the two reflectors in the FP cavity are manufactured by adopting a method for selecting evaporation through a hard template; and a final FP cavity filter is formed by adopting the silicon-glass bonding once. In the manufacturing method provided by the invention, the process procedures are greatly simplified; the mirror finish and parallelism of the FP cavity are guaranteed; and the optical technical index and chip yield of the manufactured FP filter are improved. Compared with the existing like product manufacturing process, the manufacturing method provided by the invention has the advantages of good process compatibility and maneuverability, low driving voltage and good optical tuning repeatability and stability and can be widely applied to an optical communication WDM (wavelength division multiplex) system.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

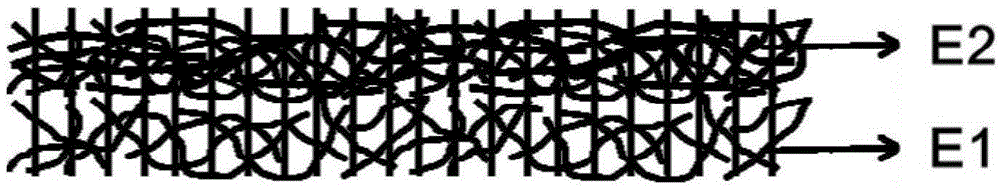

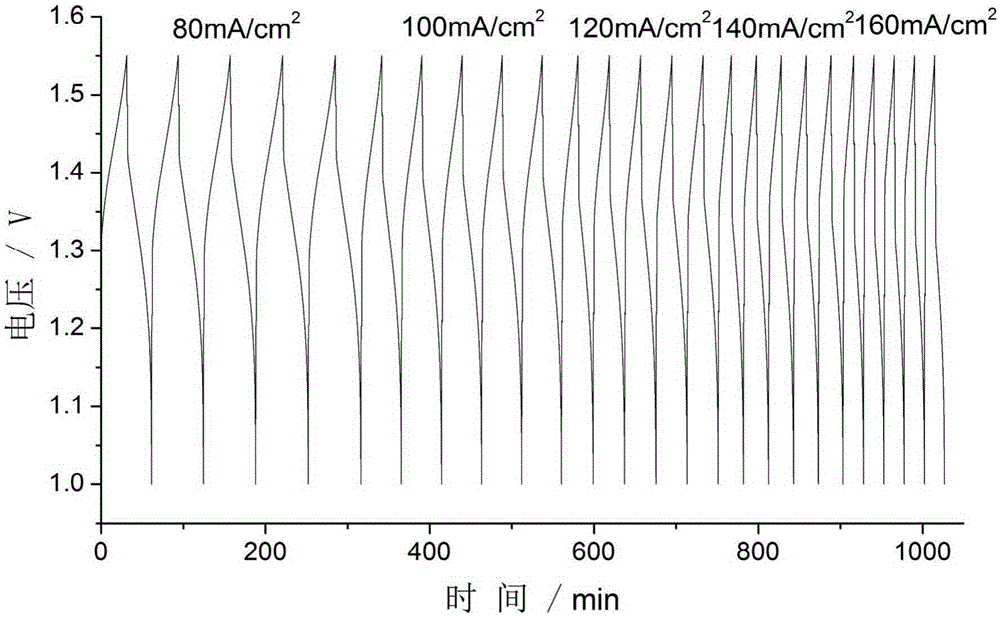

Gradient electrode for flow batteries and application thereof

The invention relates to a gradient electrode for flow batteries. The gradient electrode is formed by: stacking at least two layers of graphite fiber or carbon fiber felt with different bulk densities in an order from low bulk density to high bulk density, and making the materials into a whole by longitudinal needling perpendicular to an electrode surface. The electrode can effectively reduce the resistance of the electrode body, and lower the flow resistance of an electrolyte solution and provide more reaction sites, thus finally reducing ohmic polarization, electrochemical polarization and concentration polarization of flow batteries. The gradient electrode provided by the invention improves the energy efficiency and voltage efficiency of flow batteries so as to improve the working current density, thus greatly reducing the weight, volume and cost of batteries with similar output power.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

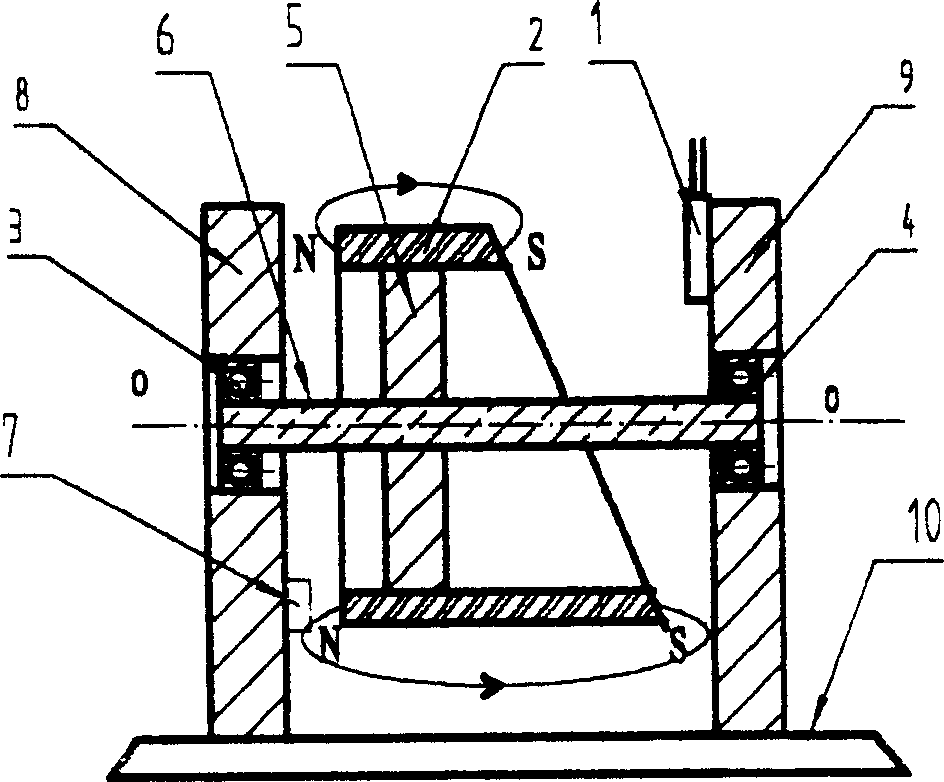

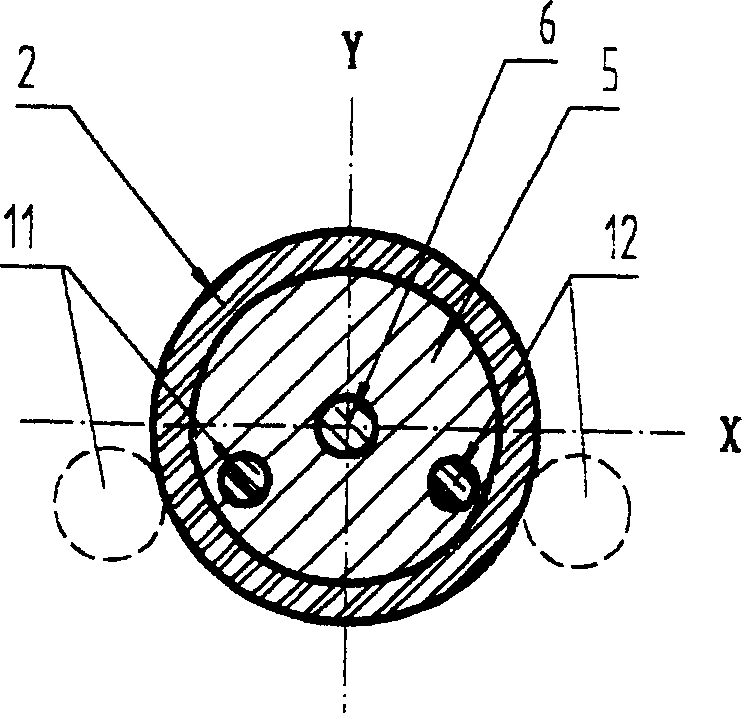

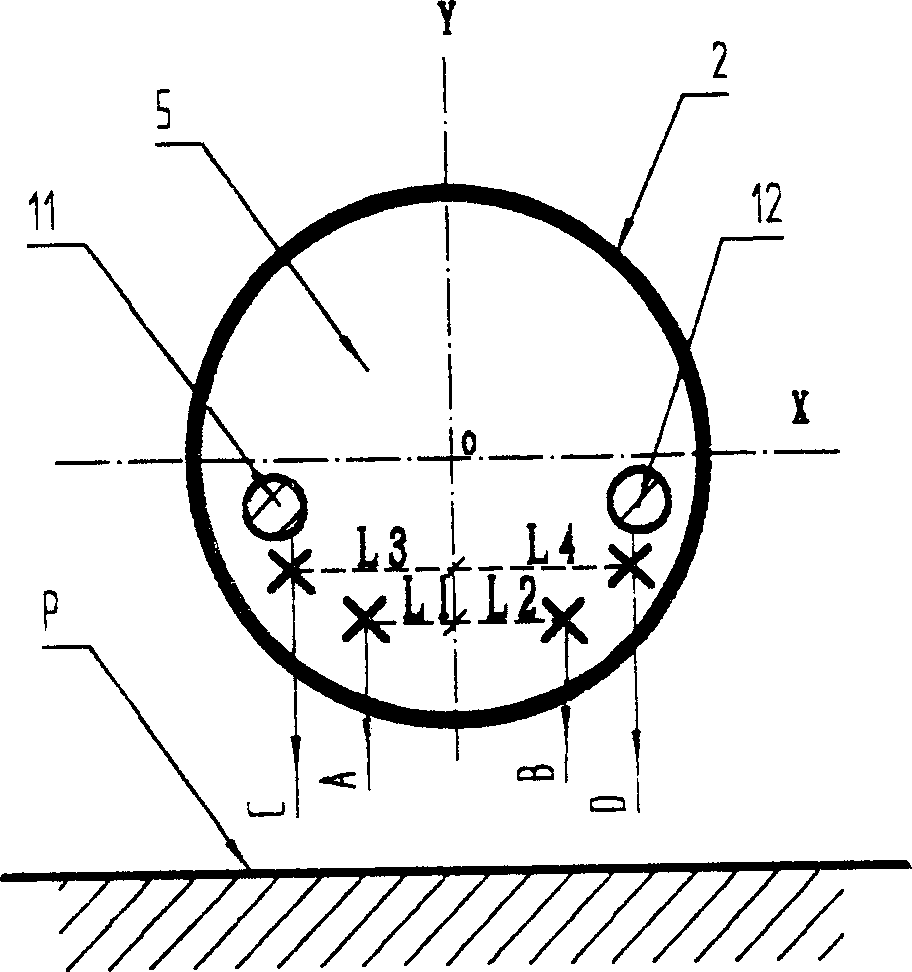

Magnetic induction angular shift sensor

The magnetic induction angular shift sensor for detecting rotating, inclined and vertical angular shift consists of permanent magnet, and magnetic induction sensor fixed to the frame. The permanent magnet has one axial end plane inclined to the rotating shaft and produces magnetic field, and with the coaxial rotation of the magnetic induction sensor relative to the permanent magnet, the distance between the axial end plane and the magnetic induction sensor changes gradually and the sensing area of the magnetic induction sensor senses gradually changed magnetic field representing the detected angular shift. The present invention has higher sensitivity when the rotating shaft, permanent magnet, etc. is regulated.

Owner:许建平

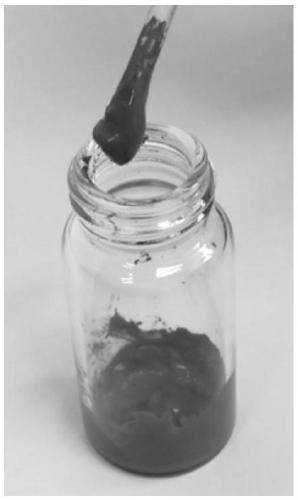

Method of producing graphene by stripping graphite via time-space-synchronous ultrasonic treatment and ball-milling process

The invention discloses a method of producing graphene by stripping graphite via time-space-synchronous ultrasonic treatment and a ball-milling process. The method includes the steps of: adding a graphite raw material and a stripping reagent into an ultrasonic ball milling device and performing ball milling for 2-96 h under an ultrasonic environment; and separating, washing and drying the mixtureto obtain graphene powder. Through the time-space-synchronous ultrasonic treatment and the ball-milling process, the graphite is stripped; due to the synergistic effect of the two methods, interlayerin-situ expansion of the graphite is formed and meanwhile a strong shear force is applied to the graphite during ball milling. The method is high in efficiency and yield and is suitable for large-scale production of graphene.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Preparation of array-structure transition metal selenide electrode and application of array-structure transition metal selenide electrode to electrolyzed water

The invention provides preparation of an array-structure transition metal selenide electrode and application of the array-structure transition metal selenide electrode to electrolyzed water and belongs to the technical field of electrodes. The preparation comprises the following steps: step 1, optimizing a nickel sheet (NF) substrate through simple pre-treatment; step 2, uniformly forming a metalorganic framework material (Mn / Fe / Co / Ni / Cu-MOF) nano-array on the surface of the nickel sheet substrate in situ, so as to obtain an NF-MOFs material; step 3, carrying out selenation on the surface ofan MOFs nano-array in situ to finally prepare an NF-MxSey nano-array electrode material. The NF-MxSey is used as an electrolyzed water electrode, has a relatively low starting site, relatively large current density, excellent electro-catalytic water decomposition performance and relatively high stability, and can be applied to new energy source storage and conversion devices for the electrolyzed water and the like.

Owner:BEIJING UNIV OF TECH

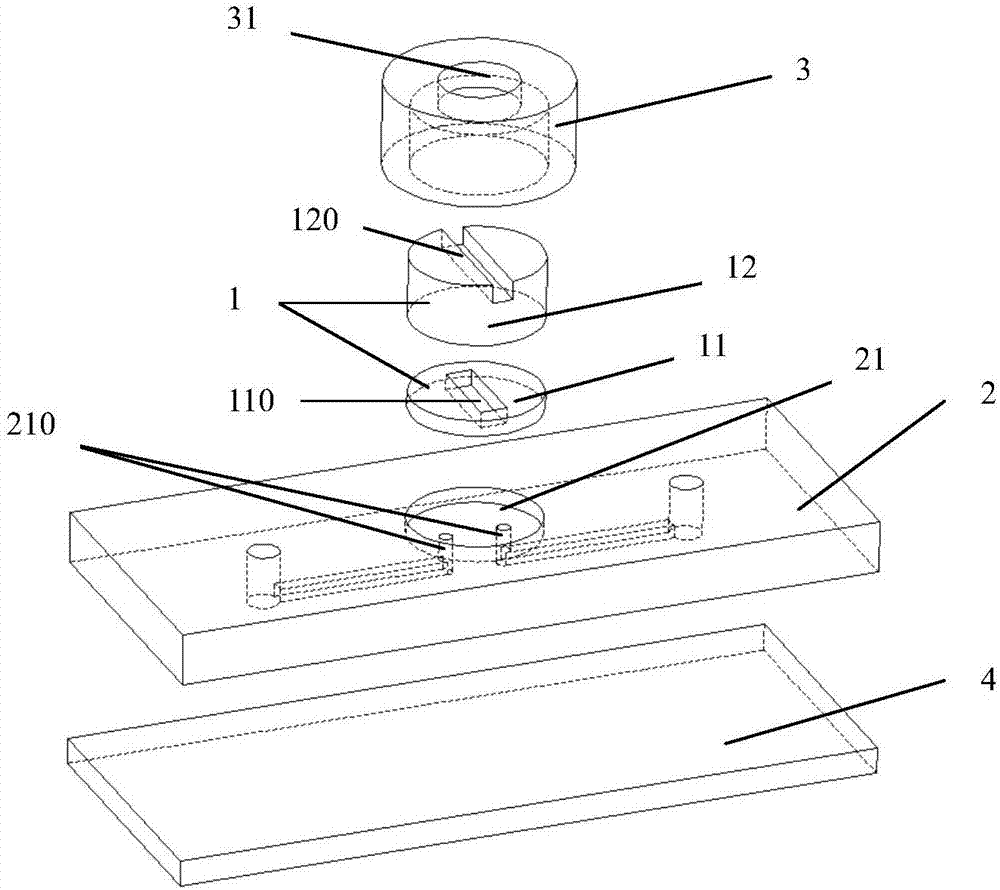

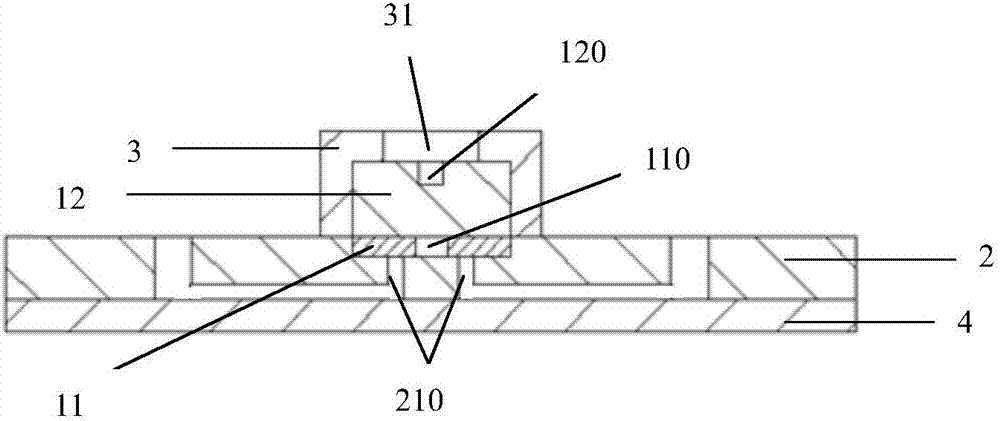

Microfluidic chip with rotary valve structure

PendingCN107096580ARealize free conversionAchieve clearanceLaboratory glasswaresFluid controllersRotary valveEngineering

A microfluidic chip with a rotary valve structure includes a valve core, a substrate and a base plate, one surface of the substrate is attached to the base plate, the other surface of the substrate is provided with a valve chamber and a flow passage, the valve chamber is provided with at least two valve chamber through holes, each valve chamber through hole is respectively connected with the flow passage, the substrate is also provided with an inlet and an outlet respectively connected the flow passage, the valve core comprises a sealing layer and a support layer, the sealing layer is arranged in the valve chamber, the support layer is arranged on the sealing layer, the sealing layer is provided with a switching channel; and the support layer rotates to drive the rotation of the sealing layer for communication of the switching channel with the at least two valve chamber through holes. Free conversion and opening and closing of different flow paths can be realized only by use of one valve core, the control requirements of various flow paths can be met, production efficiency is improved; the control of the flow paths can be realized only by rotating of the valve core, and the control method is simple and efficient.

Owner:BEIJING BAIKANGXIN BIOLOGICAL SCI & TECH

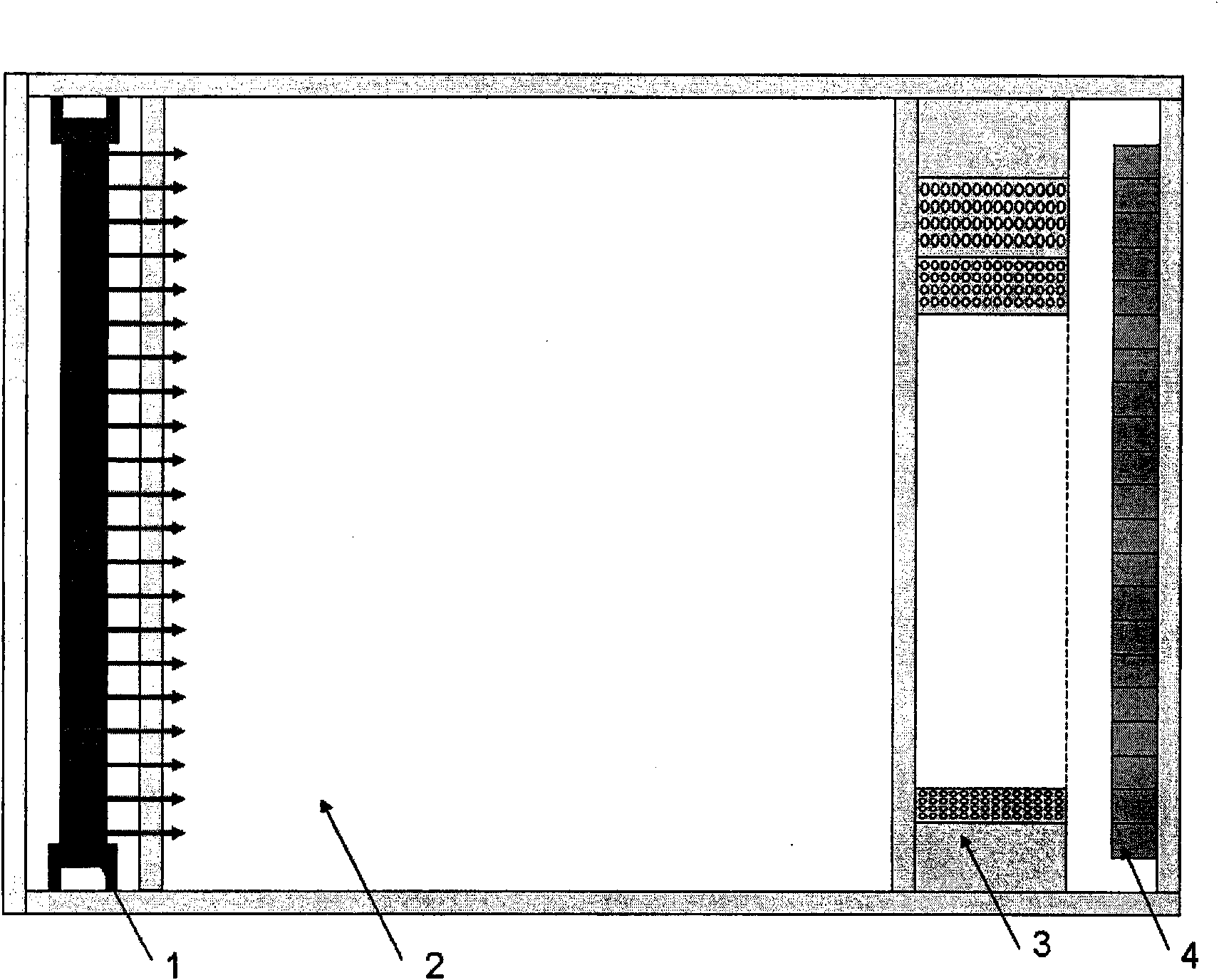

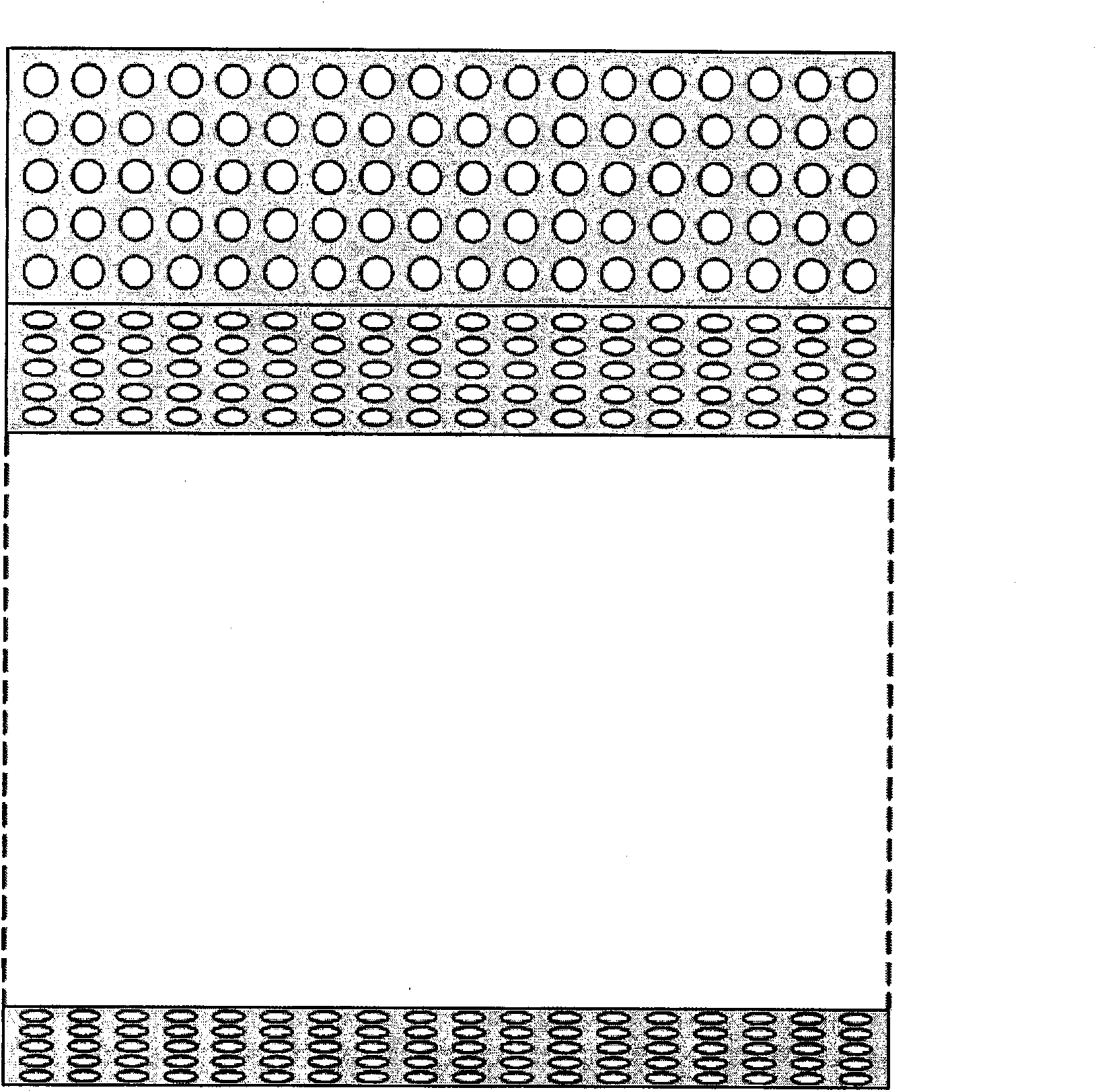

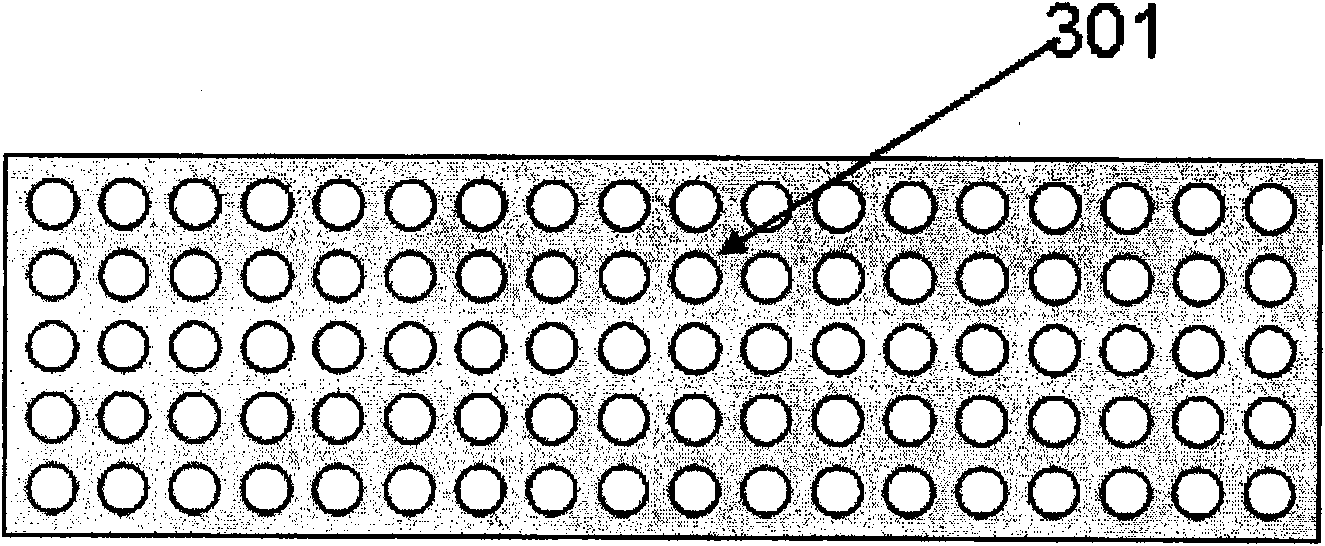

Infrared spectrum type MEMES gas sensitive sensor based on filter structure light splitting

ActiveCN101923052AHigh sensitivityGood repeatabilityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesInfraredGas detector

The invention discloses an infrared spectrum type MEMES gas sensitive sensor based on filter structure light splitting which analyzes the infrared absorption spectrum of a gas to determine the component and concentration of the gas. The gas sensitive sensor comprises an infrared light supply (1), an analysis air chamber (2), a photonic crystal filter (3) and an infrared light intensity detection array (4) which are integrated on a silicon substrate. The sensor utilizes the infrared transmittance information of gas to detect gas, the positions of characteristic peaks to judge the category of gas and the absorbances of the specific wavelengths to determine the content of gas, thus effectively solving the problems that the existing gas sensitive sensor has low sensitivity, the categories of the detected gas are limited and the anti-interference ability of the gas sensitive sensor is low. In addition, the preparation method of the sensor of the invention and the CMOS technology are compatible, thus the sensor is easy to integrate, the cost is reduced and the promotion and application of the sensor are facilitated.

Owner:新疆中科丝路物联科技有限公司

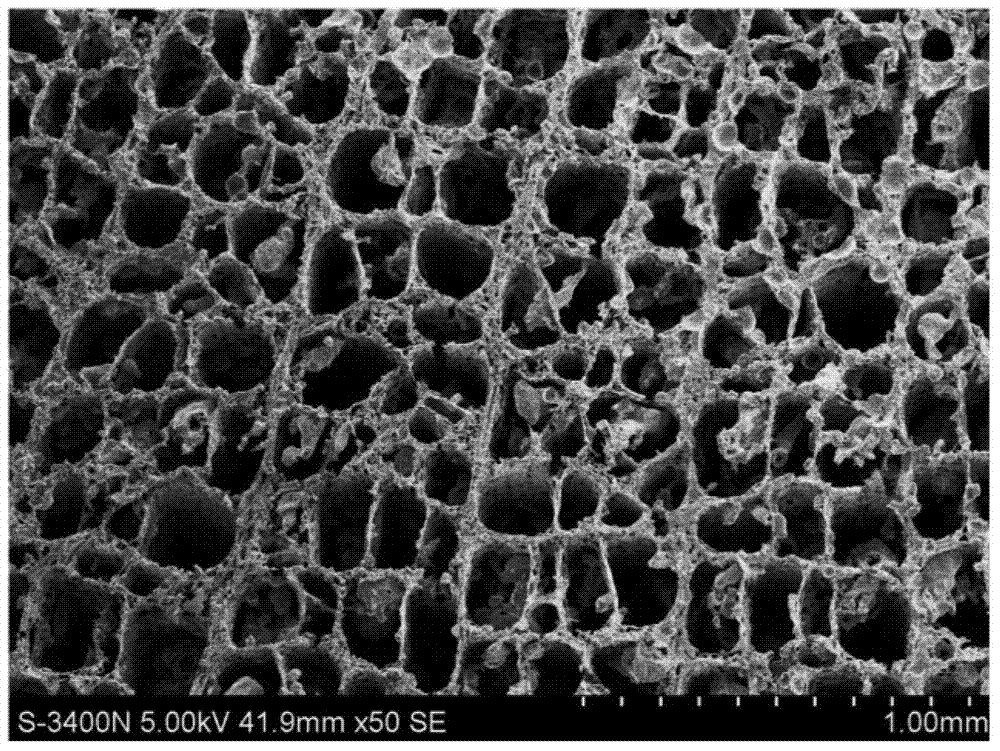

Reductively biodegradable type honeycomb polyurethane support, and preparation method and application thereof

InactiveCN103495203AEffectively regulates degradabilityStrong controllability of biodegradationProsthesisPolyesterStructural formula

The invention discloses a reductively biodegradable type honeycomb polyurethane support, and a preparation method and application thereof. The preparation method comprises: taking 2,2'-dithiodiethanol as an initiator, employing a ring-opening polymerization method to synthesize double-hydroxy-terminated polycaprolactone containing disulfide bonds; reacting with diisocyanate containing a disulfide bond to form polyester type polyurethane containing disulfide bonds; then dipping a biological template wisteria sinensis with a sodium chloride solution and calcining to obtain a negative template porous sodium chloride of wisteria sinensis; and finally immersing the negative template porous sodium chloride of wisteria sinensis with a waterless organic solution of the polyester type polyurethane containing disulfide bonds, drying and removing the negative template to obtain the honeycomb polyurethane support, wherein the molecular structural formula of the polyurethane is shown in the description. The reductively biodegradable type honeycomb polyurethane support has the advantages of simple technology, easy batch preparation, and strong biodegradation controllability; and the honeycomb structure is beneficial to transportation of substances inside or outside the support, the support can be used as a porous support for tissue regeneration repair, and belongs to a tissue engineering support material with excellent comprehensive performances.

Owner:XI AN JIAOTONG UNIV

Gas-assisted forming method for producing ultra-oleophobic surface

InactiveCN103030099AAchieve preparationEasy to mass manufactureDecorative surface effectsChemical vapor deposition coatingPressure differenceVacuum drying

The invention relates to the technical field of production of functional surfaces, in particular to a gas-assisted forming method for producing an ultra-oleophobic surface, which is applicable to production of the ultra-oleophobic surface of a polymer, in particular to production of the ultra-oleophobic surface under a simple condition. The gas-assisted forming method for producing the ultra-oleophobic surface comprises the following steps: putting a liquid polymer into a container; covering a porous template on the surface of the liquid polymer, and fixing the position of the porous template so as to expose a part of the surface of the liquid polymer; sending the container into a vacuum drying box, vacuumizing, and expanding air confined between the liquid polymer and template pores under the action of pressure difference to form a spherical crown-shaped pore array; and curing the polymer so as to produce a secondary groove structure. Less equipment is required in the two-step forming method; by the two-step forming method, the ultra-oleophobic surface can be produced under the simple condition; the production cost is low; and batch production is easy.

Owner:JIANGSU UNIV

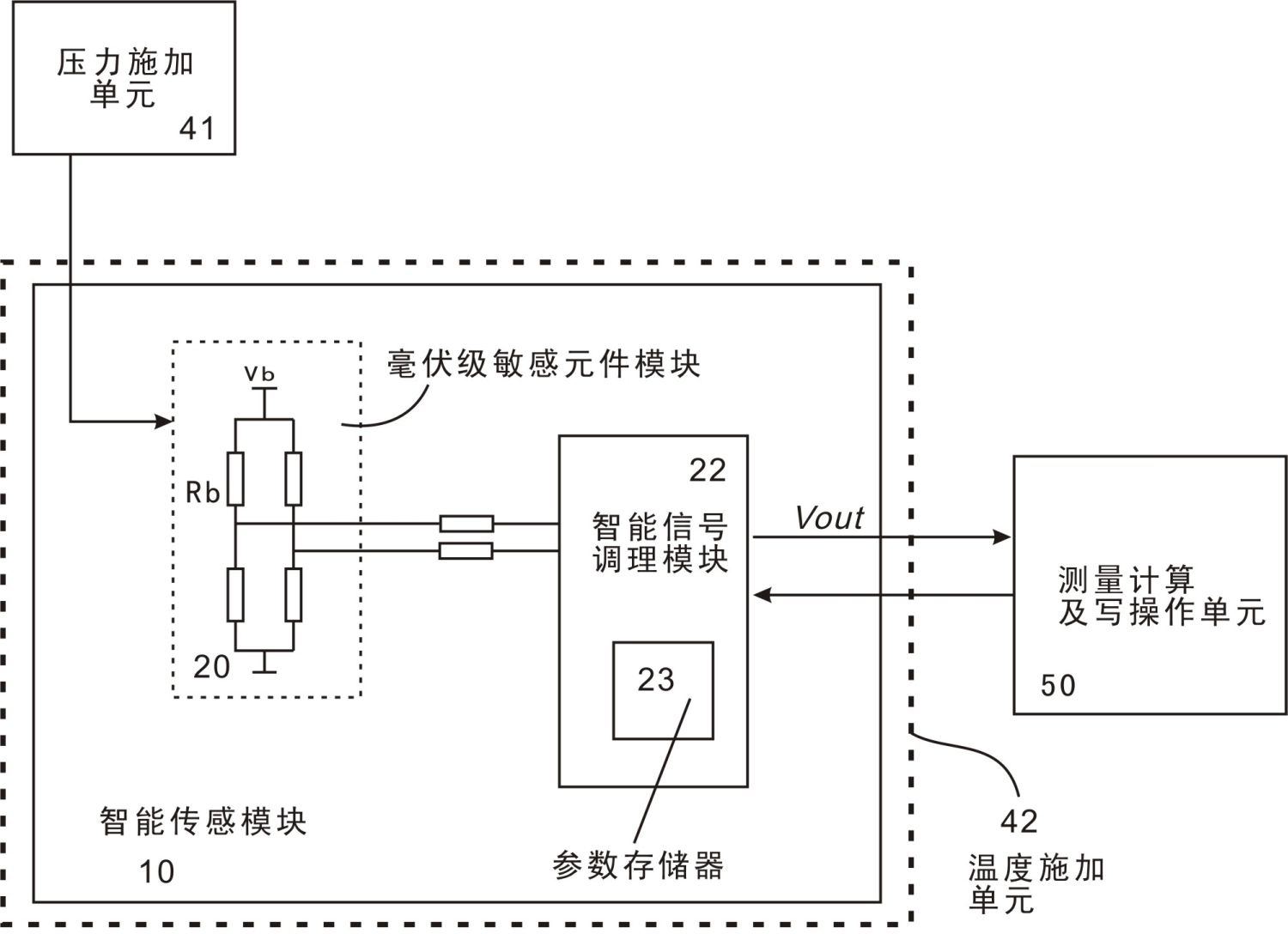

Method for setting temperature compensation factor of pressure sensor

ActiveCN102052991AGuaranteed temperature errorCalibration test process optimization and convenienceFluid pressure measurementSignal conditioningControl engineering

The invention relates to a method for setting a temperature compensation factor of a pressure sensor. An intelligent sensing module in the pressure sensor comprises a millivolt-level sensitive element module, an intelligent signal conditioning module and an internal parameter storage device in the intelligent signal conditioning module. The setting method comprises the following steps: providing a working environment for the intelligent sensing module by means of a pressure application unit and a temperature application unit; and connecting a measuring calculation and writing operation unit to the intelligent signal conditioning module for setting. In the method provided by the invention, two concise functions are used to express the relationship between the zero-point temperature drift compensation factor and the zero point as well as the relationship between the full-scale temperature drift compensation factor and the full scale, and the operating procedure is designed accordingly. By using the method, the required zero-point and full-scale temperature drift compensation factors can be calculated and written in the sensor to implement temperature compensation by simply measuring zero-point and full-scale output data at two temperature points. The method in the invention is very easy to implement in the actual production process, obviously simplifies the operation, optimizes the procedure and improves the production efficiency.

Owner:东莞市百赛仪器有限公司

Nitrogen-doped porous defective carbon nanometer fiber mesh and preparing method and application thereof

ActiveCN109286025ASimple preparation processReduce environmental pollutionMaterial nanotechnologyCell electrodesChemistryUrea

The invention belongs to the technical field of nanometer material chemistry and electrochemistry, and particularly discloses nitrogen-doped porous defective carbon nanometer fiber mesh and a preparing method and application thereof. A nitrogen source, a surfactant and a phosphorus source are added to water to be heated and stirred to form suspension liquid; the nitrogen source is melamine or urea, the surfactant is P123, F108, F127 or polyethylene glycol 2000, and the phosphorus source is triphenylphosphine or phytic acid; the obtained suspension liquid is dried; an obtained dried product isheated to 500-1150 DEG C under the inert atmosphere, carbonized for 120-360 min and then naturally cooled to the room temperature, and the obtained black blocky product is the nitrogen-doped porous defective carbon nanometer fiber mesh. The nitrogen-doped porous defective carbon nanometer fiber mesh is applied as an electrode material in electrochemical oxygen reduction and / or oxygen evolution. The nitrogen-doped porous defective carbon nanometer fiber mesh can remarkably improve the oxygen reduction (ORR) and oxygen evolution (OER) performance of a catalyst.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com