Empty micropin array chip, percutaneous dosing paster, device and manufacture method thereof

A hollow micro-needle array technology, which is applied in the field of medicine, medical and beauty equipment, can solve the problems of short effective treatment time, small dosage, unsuitable for liquid and ointment drugs, etc., to improve drug efficacy or beauty and beauty effects , Increased storage capacity, effective treatment time and improved cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

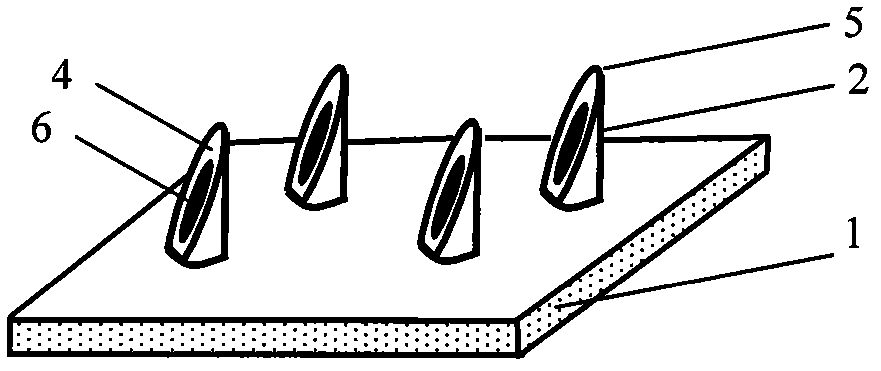

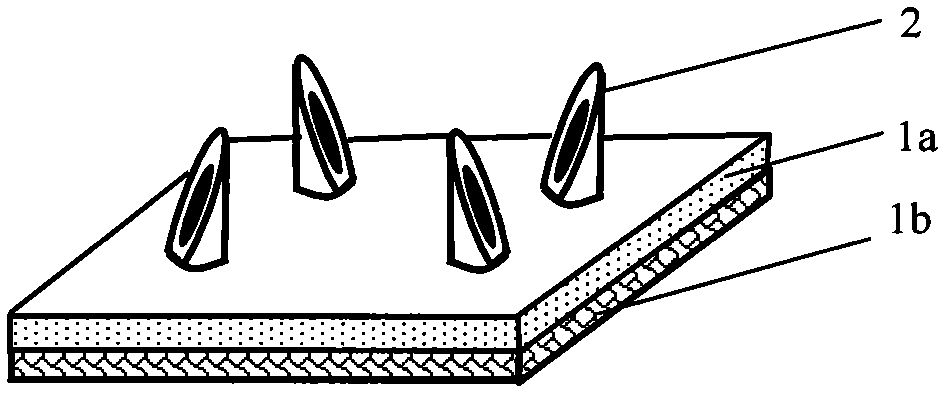

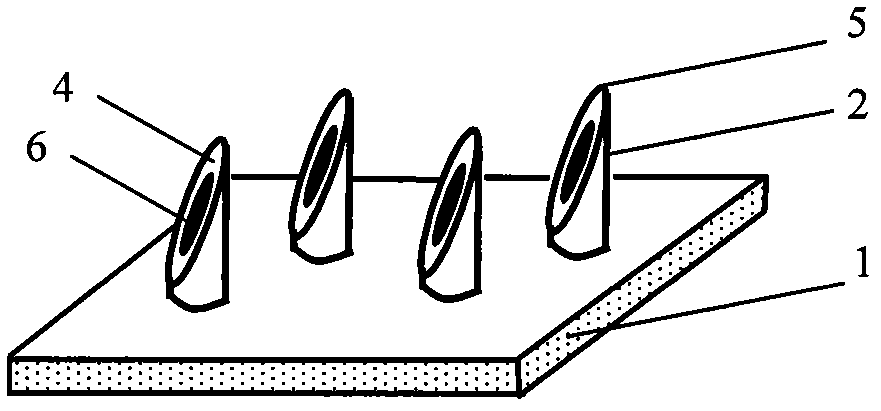

[0079] Figure 1-Figure 12 Shows the hollow microneedle array chip provided by the present invention, the hollow microneedle array chip includes a substrate 1 and a number of hollow microneedles arranged on the substrate 1, the number of hollow microneedles are formed at a certain interval Hollow microneedle array, the hollow microneedles include needles 2 exposed on the surface of the substrate and needle shafts 3 embedded in the substrate, the needles 2 have an elliptical annular plane 4 and one end is a needle tip 5, each of the hollow microneedles The elliptical annular planes 4 of the needles are parallel to each other or arranged at a certain angle or at any angle. The hollow microneedles penetrate both sides of the substrate to form a through hole 6 or are closed at the bottom of the needle shaft to form a blind hole 6 . The substrate 1 may include an upper substrate 1a and a lower substrate 1b stacked together, and the needle bar 3 at least penetrates the upper substra...

Embodiment 2

[0094] Manufacturing method of hollow stainless steel microneedle array chip

[0095] Insert a hollow stainless steel needle tube with an outer diameter of 250 microns and a length of 2 mm in each hole of the through-hole array mold. The needle 2 has an elliptical annular plane 4, or the plane is cut off at least a section of arc surface to make it exist more edges and corners, and then insert the needle bar 3 vertically or inclined at a certain angle into the epoxy resin prepolymer solution used to prepare the epoxy resin substrate, and form the prototype of the microneedle array chip after heating, polymerization and curing. The substrate bottom side of the chip is ground and polished to the desired thickness, thus forming a figure 1 with Figure 3-9 A hollow stainless steel microneedle array chip on a single-layer rigid substrate is shown.

Embodiment 3

[0097] Manufacturing method of hollow stainless steel microneedle array chip

[0098] Insert a hollow stainless steel needle tube with an outer diameter of 250 microns and a length of 1.5 mm in each hole of the through-hole array mold, and the needle 2 has an elliptical annular plane 4, or the plane is at least cut off a section of arc surface to make it There are more edges and corners, and then the needle 2 is vertically or obliquely penetrated a piece of non-woven fabric 1a and protrudes 0.5 mm, and finally a piece of polyethylene plastic film 1b with a thickness of about 1 mm and coated with adhesive is combined with the above-mentioned non-woven fabric 1b. The spun cloth 1a is bonded to form a Figure 10 A hollow stainless steel microneedle array chip on a double-layer flexible substrate is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com