Nitrogen-doped porous defective carbon nanometer fiber mesh and preparing method and application thereof

A carbon nanofiber, hole defect technology, applied in the field of nanomaterial chemistry and electrochemistry, to achieve the effect of simple post-processing, remarkable results, and little pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

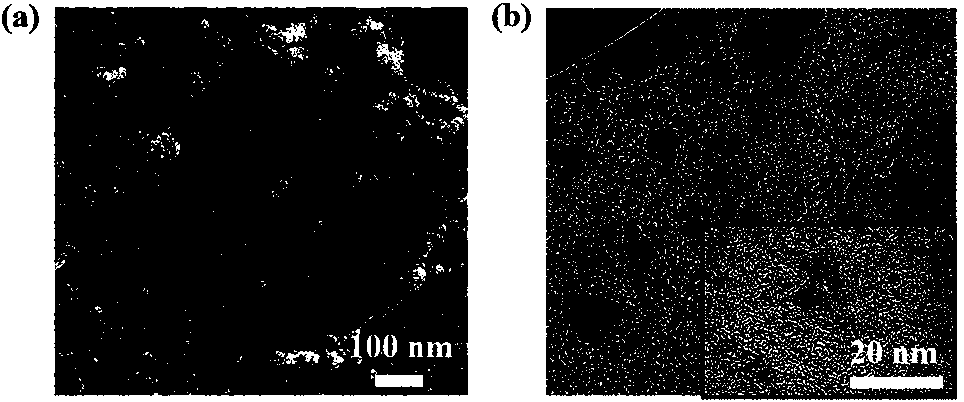

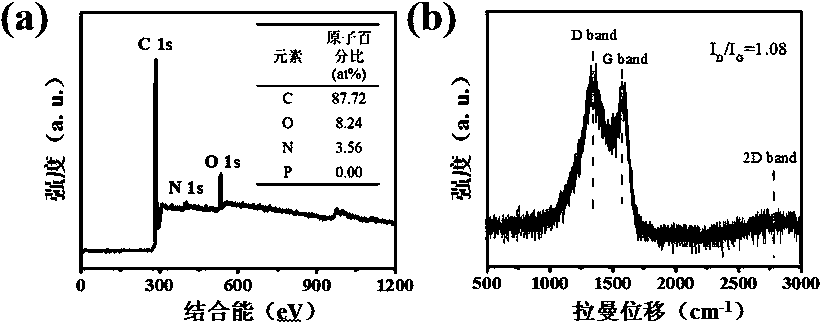

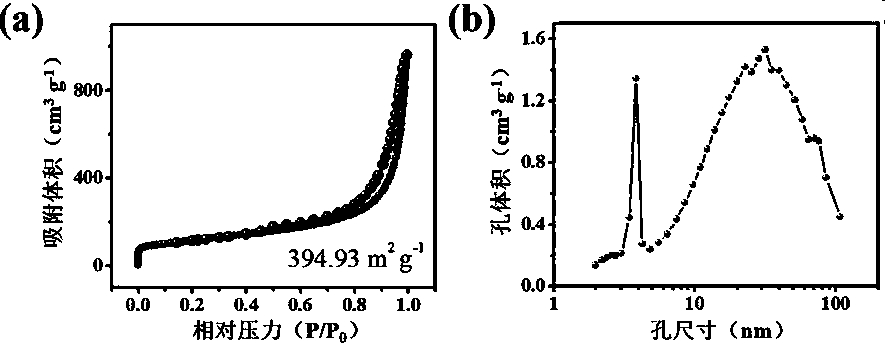

[0031] A method for preparing a nitrogen-doped porous defect carbon nanofiber network, comprising the steps of:

[0032] 1) In a 100mL beaker, add 5g melamine, 1g P123 and 0.85g triphenylphosphine, add 25mL deionized water, heat and stir at 60°C for 30min (heating power 100W, stirring speed 1080rpm) to form a suspension;

[0033] 2) Put the suspension obtained in step 1) into an electric heating constant temperature blast drying oven, and dry at 80°C for 72 hours;

[0034] 3) Carbonization: place the dried product obtained in step 2) on a porcelain boat and send it to a carbonization furnace, and heat it up to 1000°C at a rate of 10°C / min under high-purity argon (argon flow rate is about 60 sccm), After carbonization for 360 min, and then naturally cooled to room temperature, the obtained black blocky product is the nitrogen-doped porous defect carbon nanofiber network.

Embodiment 2

[0041] The difference from Example 1 is that in step 1), melamine is changed to urea; other steps are the same as in Example 1.

Embodiment 3-5

[0043] The difference from Example 1 is that in step 1), P123 is changed to F108, F127 and polyethylene glycol 2000 respectively in sequence; other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com