Patents

Literature

1018results about How to "Post-processing is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-lubricating type epoxide resin material and preparation thereof

InactiveCN101348600AImprove stabilityReduce pollutionMicroballoon preparationLubricant compositionFirming agentEpoxy resin composite

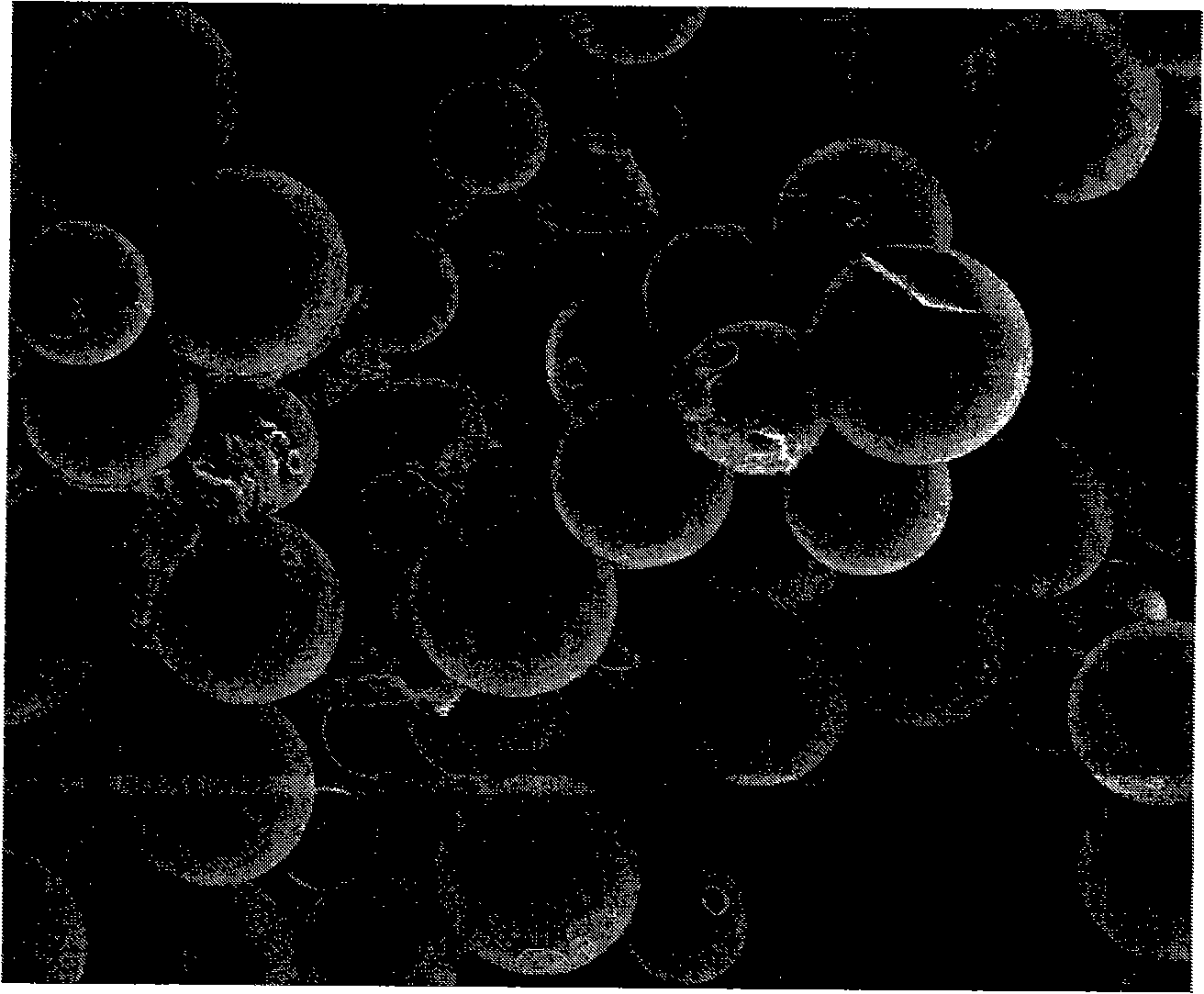

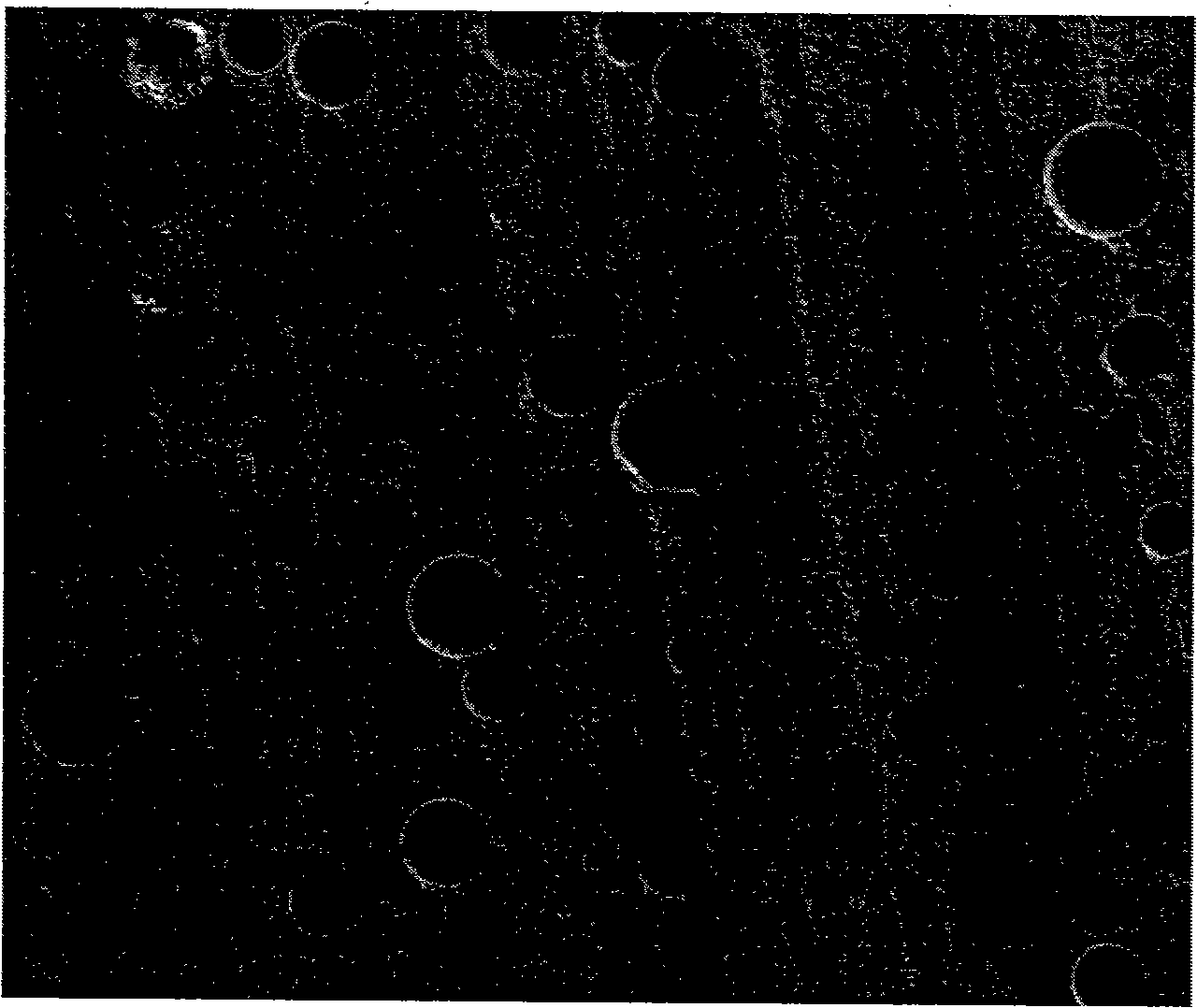

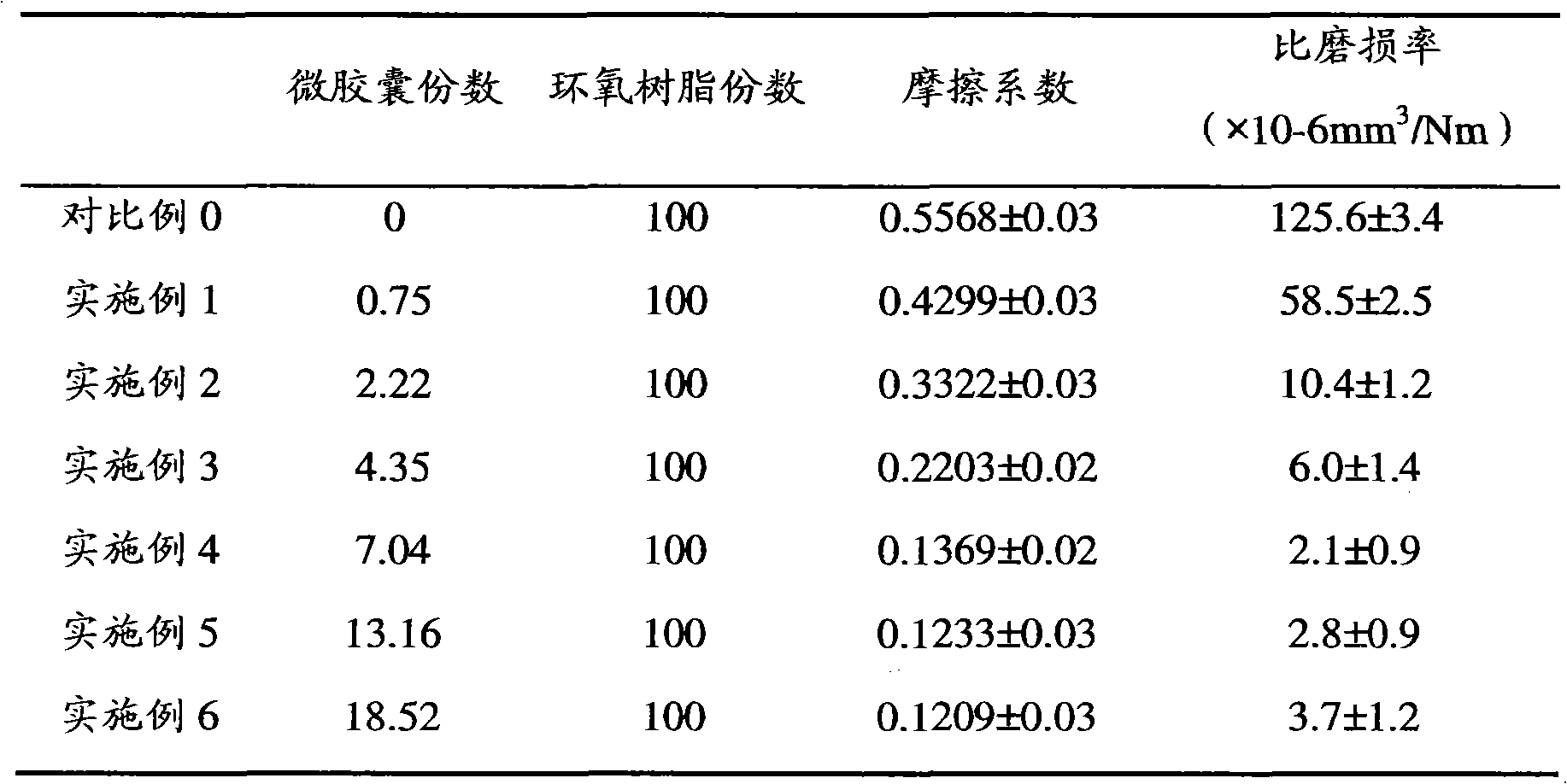

The invention discloses a self-lubricating type epoxy resin material and a preparation method thereof, belonging to the polymer material field. The self-lubricating type epoxy resin material comprises the following components in weight percentage: 60 to 80 percent of epoxy resin, 0.5 to 25 percent of lubricating oil microcapsules and 15 to 35 percent of curing agents. The preparation method for the self-lubricating type epoxy resin material comprises the following steps of well mixing the lubricating oil microcapsules, the epoxy resin with the curing agents and casting rapidly when to-be-mixed matter has gel phenomena, so as to obtain the self-lubricating type epoxy resin material. The invention also provides a lubricating oil microcapsule needed in the preparation of the epoxy resin material and a preparation method for the lubricating oil microcapsule. A technical proposal provided by the invention adds the lubricating oil microcapsules to the epoxy resin so as to prepare the epoxy resin compound material, which can remarkably improve the wear reducing-resisting performance of the epoxy resin material and has broad application prospects.

Owner:SUN YAT SEN UNIV

Method for preparing carbon quantum dots

InactiveCN103086356AEasy to operateEasy to handleNano-carbonLuminescent compositionsChemical compoundNanotechnology

The invention relates to a method for preparing carbon quantum dots. The method is mainly characterized by comprising the following steps of: adding hydrogen peroxide in natural compounds such as saccharides or proteins; and then, performing direct hydro-thermal treatment to obtain the carbon quantum dots with strong fluorescence. The shape of the natural compounds after hydro-thermal treatment can be greatly changed due to addition of hydrogen peroxide, so that the carbon quantum dots with strong fluorescence are formed. The method is wide in material source, very cheap in price, simple and convenient to operate, simple in post treatment and environment-friendly, and the yield of the carbon quantum dots is high. The property of the carbon quantum dots can be conveniently adjusted by content of added hydrogen peroxide, so that the method has large-scale preparation potential and a wide application prospect.

Owner:FUDAN UNIV

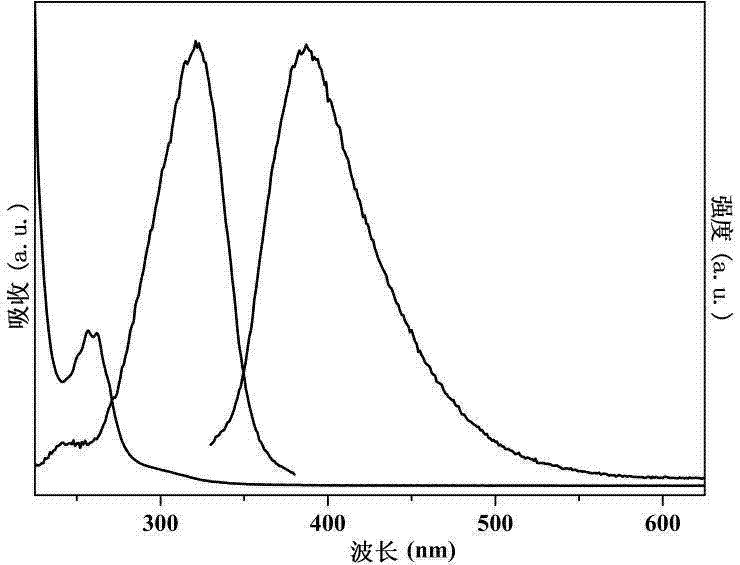

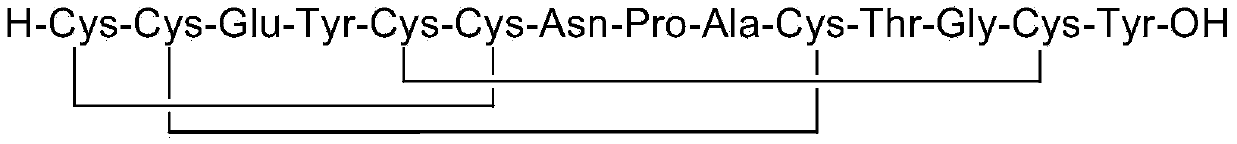

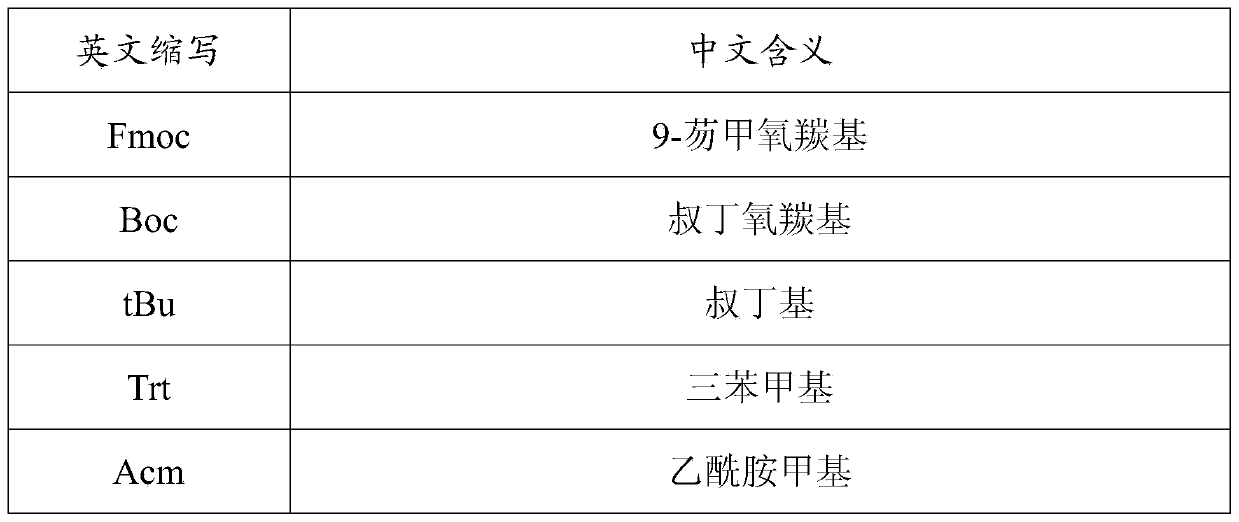

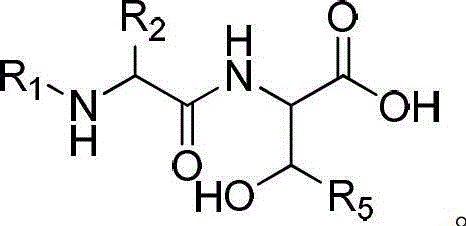

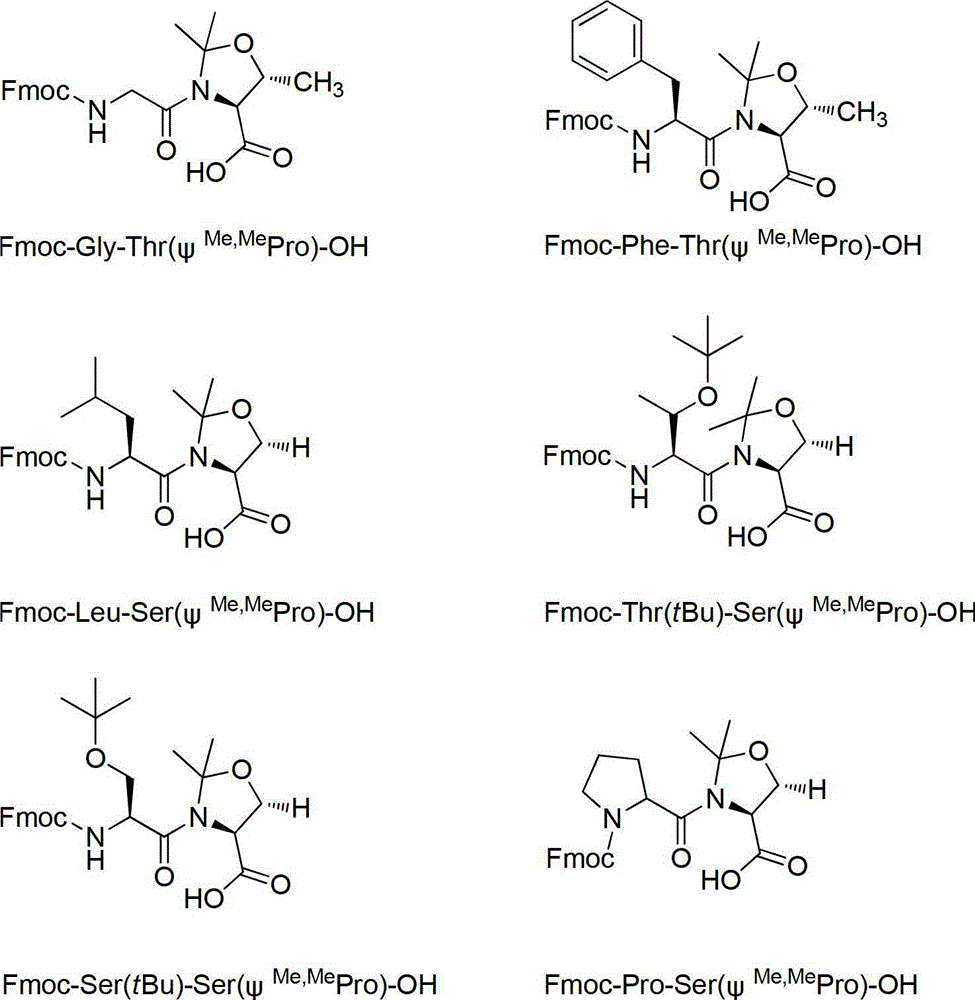

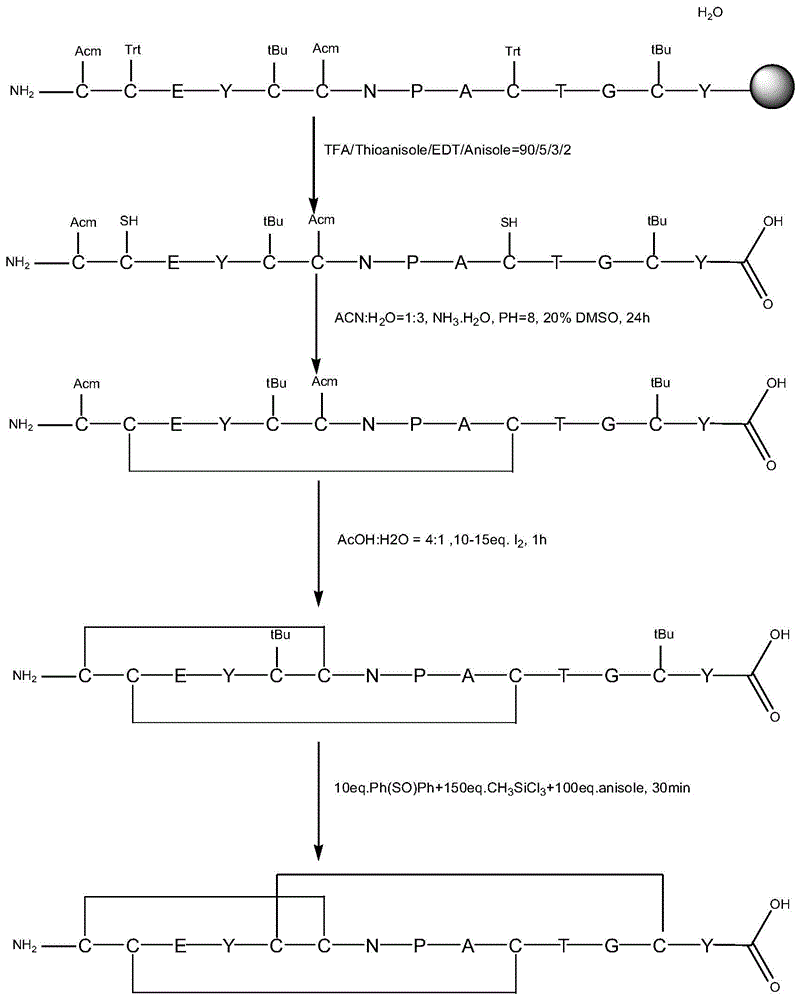

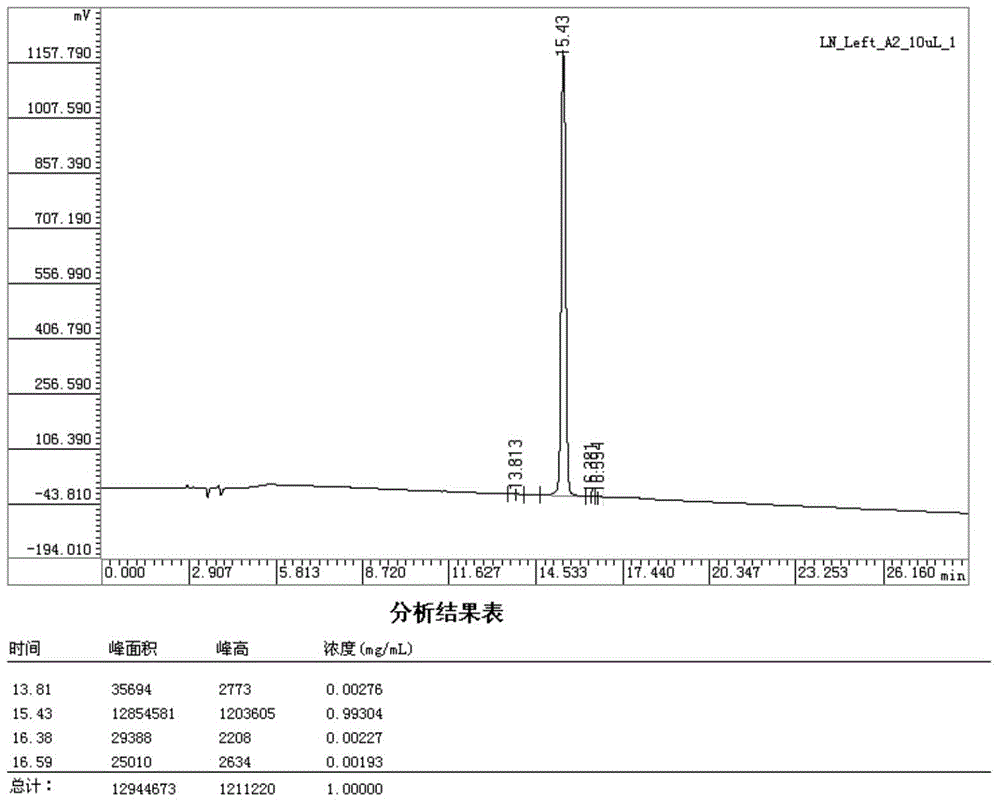

Method for preparing linaclotide

InactiveCN103626849AEasy to operatePost-processing is simplePeptide preparation methodsBulk chemical productionDisulfide bondPeptide

The invention belongs to the technical field of medicine synthesis, and discloses a method for synthesizing linaclotide by three pairs of total selectively formed disulfide bonds. By using the process, formation of three pairs of disulfide bonds in linaclotide can be sequentially completed in the same solution system, so that the operation method of the process is simple, the yield of final fine peptide of linaclotide can be greatly increased, and large-scale production can be realized.

Owner:HYBIO PHARMA

Preparation method of oxidized graphene and sodium alginate composite absorbing material capable of removing ciprofloxacin in aqueous solution

PendingCN105536726ARaw materials are easy to obtainLow costOther chemical processesAlkali metal oxides/hydroxidesPeristaltic pumpFreeze-drying

The invention provides a preparation method of an oxidized graphene and sodium alginate composite absorbing material capable of removing ciprofloxacin in an aqueous solution. The preparation method comprises the following steps: dispersing a certain amount of oxidized graphene samples in deionized water, putting the oxidized graphene samples into an ultrasonic cleaner, and performing ultrasonic treatment for 6-10 hours; dissolving a certain amount of sodium alginate into an oxidized graphene solution subjected to ultrasonic treatment, and performing ultrasonic treatment for 20 minutes; dropewise adding the mixed solution into a 0.2mol / L calcium chloride solution by virtue of a peristaltic pump, soaking for 1-3 days, and cleaning with deionized water for 3-4 times, thereby obtaining a sodium alginate and oxidized graphene sphere hydrogel material; and freeze-drying, thereby obtaining oxidized graphene and sodium alginate sphere aerogel. The preparation method is performed under a relatively mild condition, and oxidized graphene is packaged in a sodium alginate network structure by an ion bridge method, so that the nano toxicity of graphene powder is avoided, and a new nano material capable of efficiently absorbing ciprofloxacin antibiotics in the aqueous solution is prepared. The preparation process is simple, easily controllable in condition, low in cost and suitable for large-scale batch production.

Owner:SHANGHAI INST OF TECH

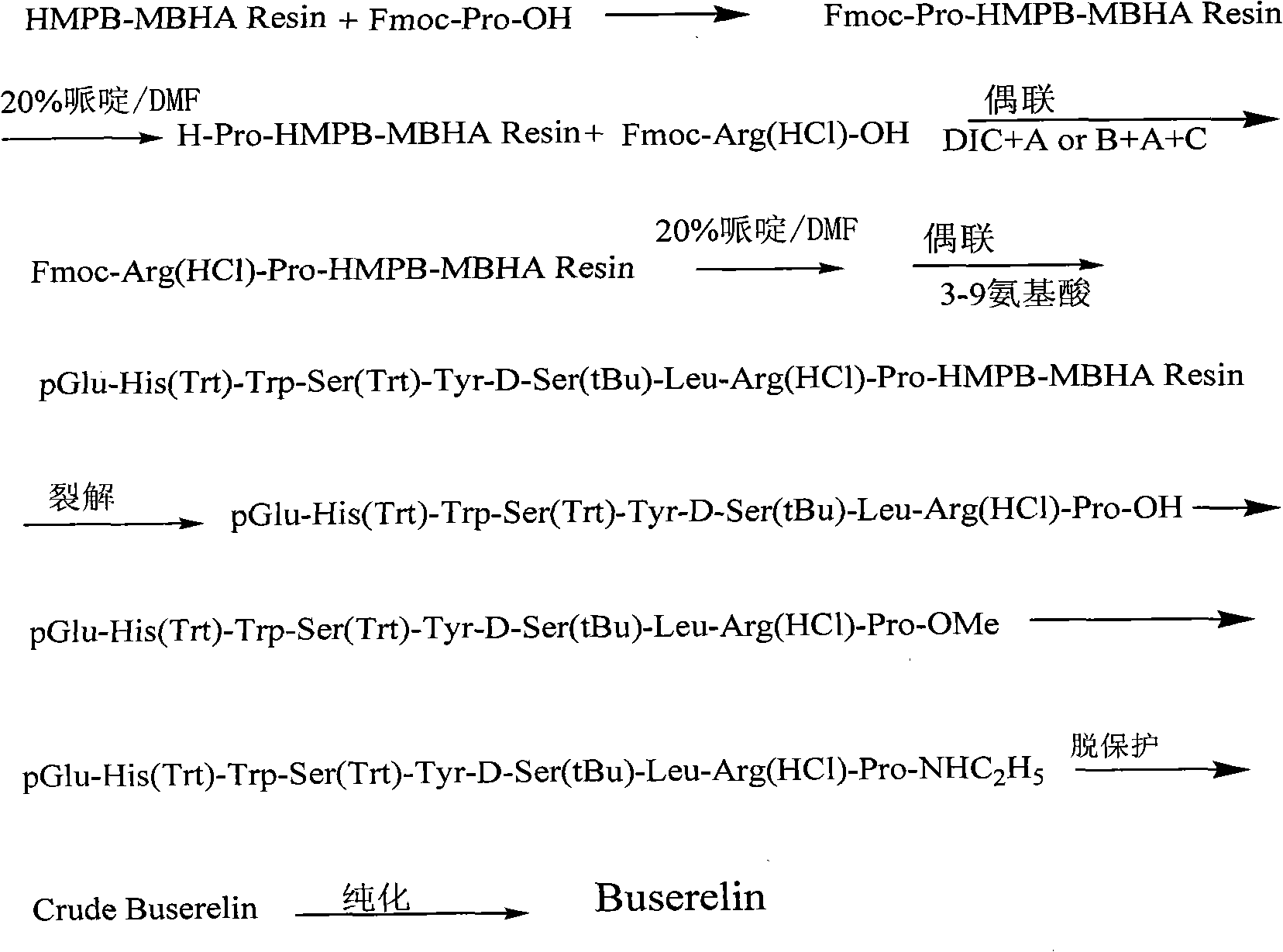

Solid-phase preparation method for buserelin

InactiveCN101935339AHigh yieldLow costLuteinising hormone-releasing hormonePeptide preparation methodsPeptide sequenceCombinatorial chemistry

The invention provides a solid-phase preparation method for buserelin. The method comprises the following steps of: 1) preparing a Fmoc-Pro-HMPB-MBHA resin with degree of substitution of between 0.15 and 0.80mmol / g from Fmoc-Pro-OH and a HMPB-MBHA resin with degree of substitution of between 0.2 and 0.9mmol / g by a solid-phase synthesis method; 2) gradually coupling remaining protected amino acid of the Fmoc-Pro-HMPB-MBHA resin according to a peptide sequence to obtain buserelin-HMPB-MBHA resin; 3) cracking the buserelin-HMPB-MBHA resin to obtain fully-protected peptide; and 4) performing ethyl amination, deprotection and purification on the obtained fully-protected peptide to obtain buserelin. The invention aims to provide a buserelin solid-phase synthesis method which has the advantages of high yield, low cost, mild reaction conditions, small environmental pollution and contribution to realizing industrialization.

Owner:HYBIO PHARMA

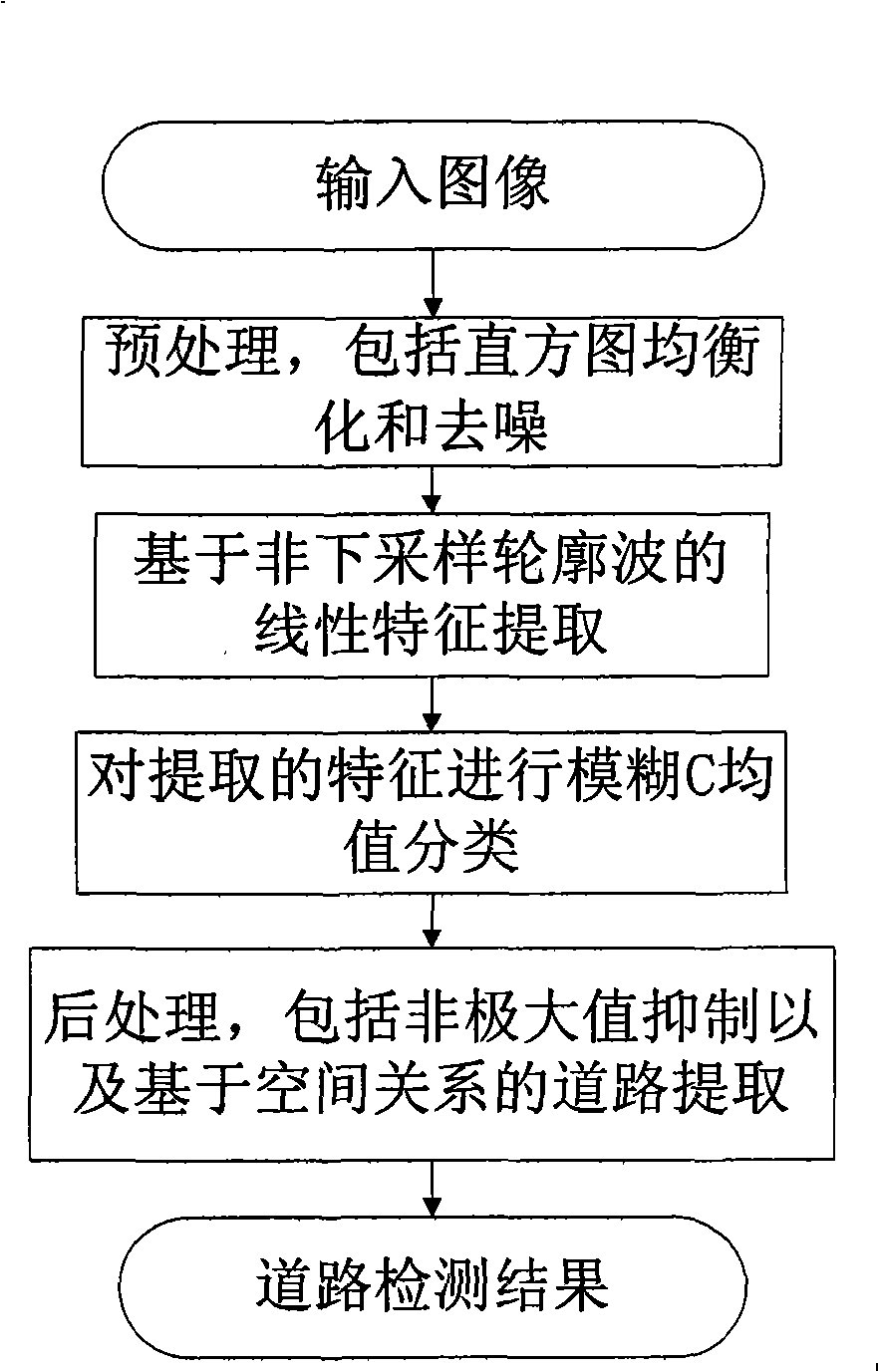

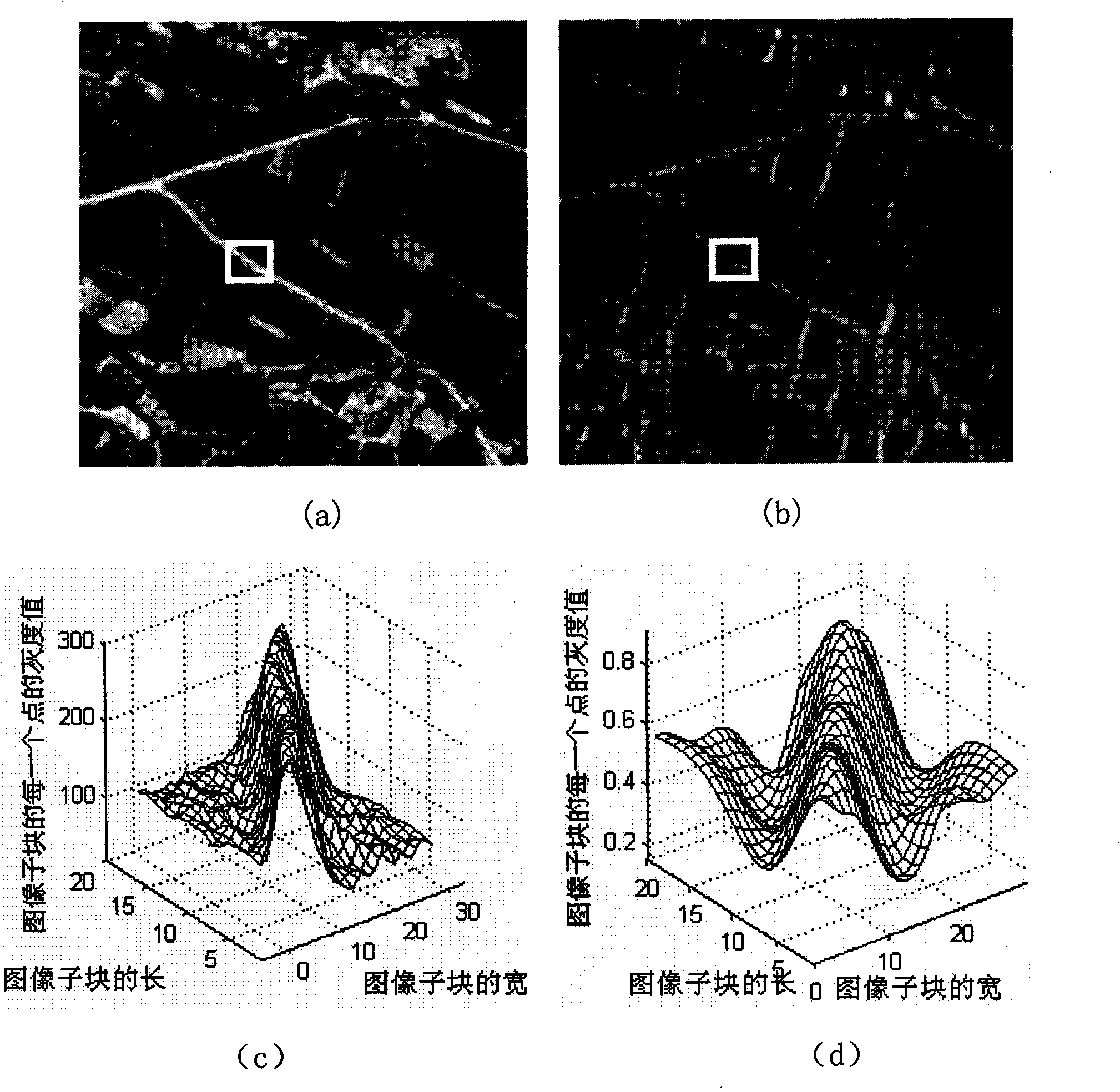

Method for extracting roads from remote sensing image based on non-sub-sampled contourlet transform

InactiveCN101551863AEasy extractionAccurate captureCharacter and pattern recognitionPicture interpretationComputation complexityContourlet

The invention discloses a method for extracting roads from a remote sensing image, which belongs to the technical field of image processing and solves the problem that the existing technology is not precise in detection and positioning of roads, and has a large number of false targets and bad continuity. The specific realization process comprises the following steps of: firstly implementing pretreatments including adaptive histogram equalization and Frost de-noising on the input images; then implementing three layers of non-sub-sampled contourlet transform thereon, decomposing each layer into eight directions, extracting the model maximum value of each direction sub-band of the first layer and the second layer as the linear characteristic vectors of roads; clustering the obtained characteristic vectors by using fuzzy C means clustering algorithm to obtain the initial extraction results of roads; and finally implementing non maximum value inhibition and road post treatment based on the spatial relationship to the initial extraction to obtain the final road extraction result. The invention has the advantages of accurate road positioning, good integrality, low calculation complexity and no need of training and learning, and is used for analysis and processing of the remote sensing image.

Owner:XIDIAN UNIV

Complete solid-phase synthesis method for liraglutide

InactiveCN103145828AImprove reaction efficiencyHigh purityPeptide preparation methodsBulk chemical productionFreeze-dryingSide chain

The invention discloses a complete solid-phase synthesis method for liraglutide. 2-Cl-TrtResin is enabled to serve as a solid-phase carrier. DIC / HOBt is enabled to serve as a condensation agent. After processing of microwave reaction technology, reaction time is shortened, and condensation efficiency is improved. According to side chain modification, novel ivDde side chain protected lysine is adopted and side chain modification synthesis is carried out. During the process, 20% piperidine is adopted to get rid of Fmoc protection until linear chain polypeptide synthesis is finished. Then, after hydrazine hydrate is adopted to get rid of ivDde protection, a side chain modification reaction is carried out. Obtained liraglutide with complete protection on the solid phase carrier is processed by trifluoroacetic acid, and crude liraglutide is obtained. After purification and freeze-drying by a C18 column, pure liraglutide is obtained. After strong negative ion salt conversion and free-drying, acetic acid liraglutide acetate is obtained. The complete solid-phase synthesis method for the liraglutide is simple in operation, short in synthesis cycle, low in production cost, few in accessory substance, high in product yield and beneficial for mass production.

Owner:宁波瑞达医药科技有限公司

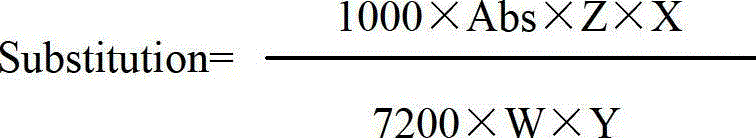

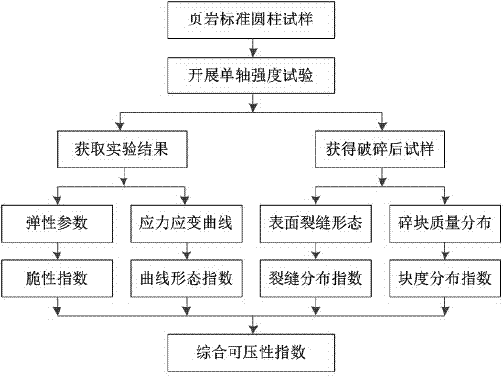

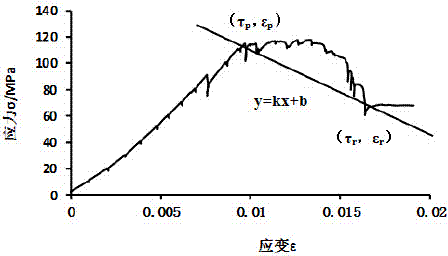

Shale compressibility comprehensive evaluation method based on uniaxial strength experiment

InactiveCN104777035AThe experimental process is simple and easyLow equipment requirementsMaterial strength using tensile/compressive forcesMass distributionElastic modulus

The invention provides a shale compressibility comprehensive evaluation method based on uniaxial strength experiment. The method comprises the steps of (1) taking a shale core sample for executing uniaxial compressive strength test, testing an elasticity parameter, and drawing a stress-strain curve diagram; (2) calculating normalized elasticity modulus and normalized poisson ratio to obtain a brittleness index; (3) obtaining key points on the stress-strain curve, and calculating the shape index of the stress-strain curve; (4) obtaining fracture distribution diagram of the side face of the fixed sample, and calculating a fracture distribution index through box-counting dimension method; (5) measuring spallation fragment mass distribution at different scales through a screen and a balance so as to obtain a block distribution index; and (6) calculating arithmetic mean value of the obtained brittleness index, shape index of the stress-strain curve, fracture distribution index and block distribution index of fragments to get the comprehensive compressibility index. The method provided by the invention is used for evaluating fracture net forming capability of the shale after being compressed, the experiment is simple and easy to carry out, and post treatment is visual and simple, so that the method is suitable for indoor evaluation and oilfield in-site application.

Owner:SOUTHWEST PETROLEUM UNIV

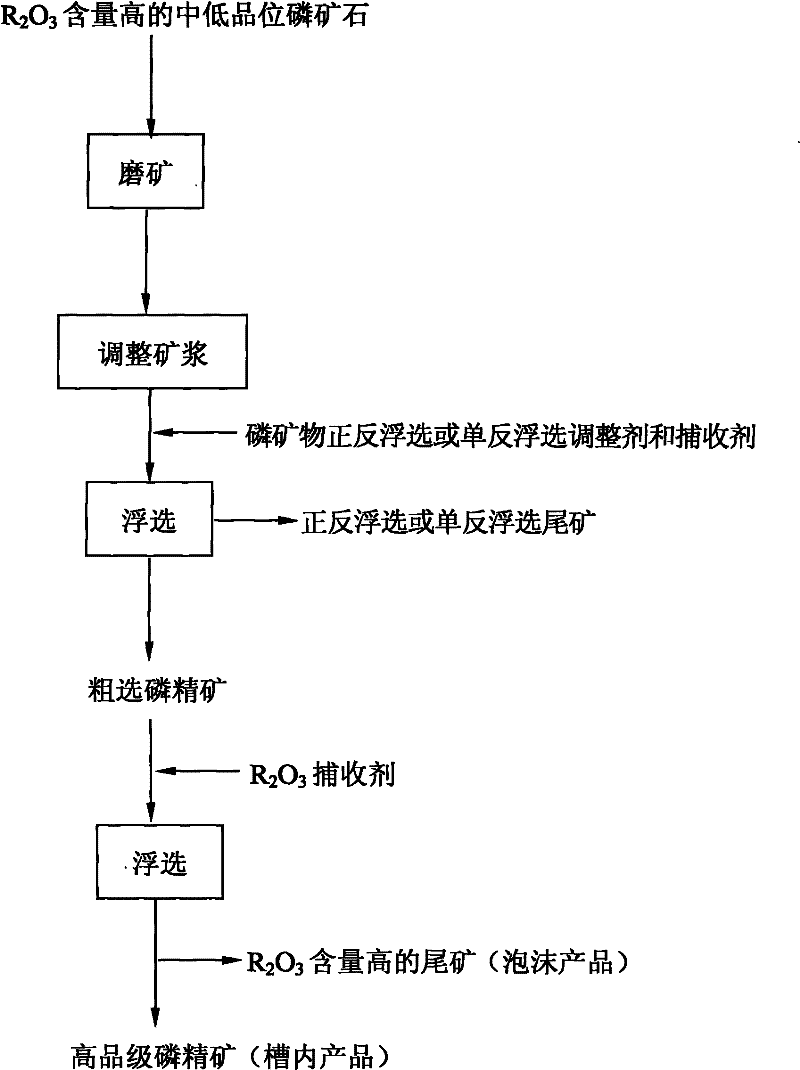

Oredressing method for removing sesquioxide of iron and aluminum

The invention relates to an oredressing method for pertinently reducing content of sesquioxide of iron and aluminum (R2O3) in the collophanite floatation process in advance. The process comprises the following steps of: (1) levigating raw collophanite until grains with the grain size of 0.038mm are more than or equal to 76 weight percent, and controlling the pulp mixing concentration to be 25-40 weight percent; (2) introducing ore pulp into a mineralizing agitation tank of a floatation machine, adding an agent for floating conventional mid-low grade collophanite for pneumatic flotation, ensuring that a spindle speed of the floatation machine is 1,800-2,100r / min, the floating aeration quantity is 0.05-0.10m<3> / h and the floating scraper speed is 20-30r / min, and obtaining phosphate concentrate subjected to rough concentration; and (3) controlling the pH of the phosphate concentrate subjected to rough concentration to be 4.5-5.5, adding a collector for removing R2O3, performing pneumatic flotation for 4 to 8 minutes, removing an impurity of R2O3 from foam, and obtaining base flow, namely a high grade phosphate concentrate product. By the method, the R2O3 content in the concentrate can be obviously reduced, the quality of the phosphate concentrate is improved, and production processes, flows and cost during purification in the subsequent acid making process can be reduced.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Synthesis process of 4, 4'-dichlorodiphenyl sulfone

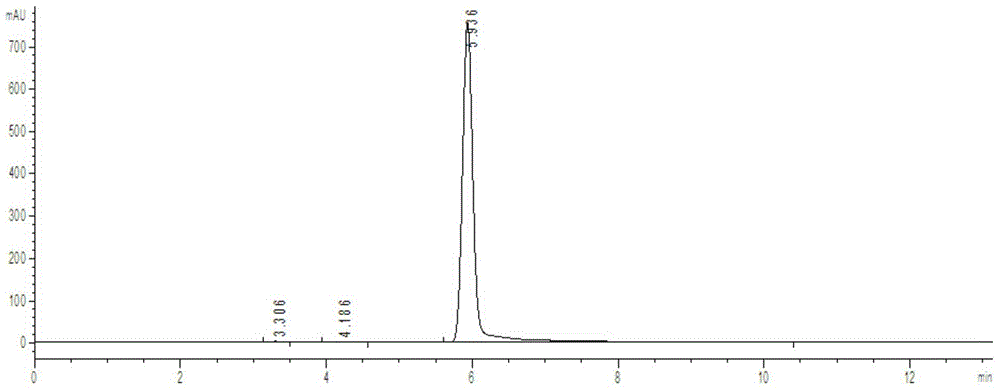

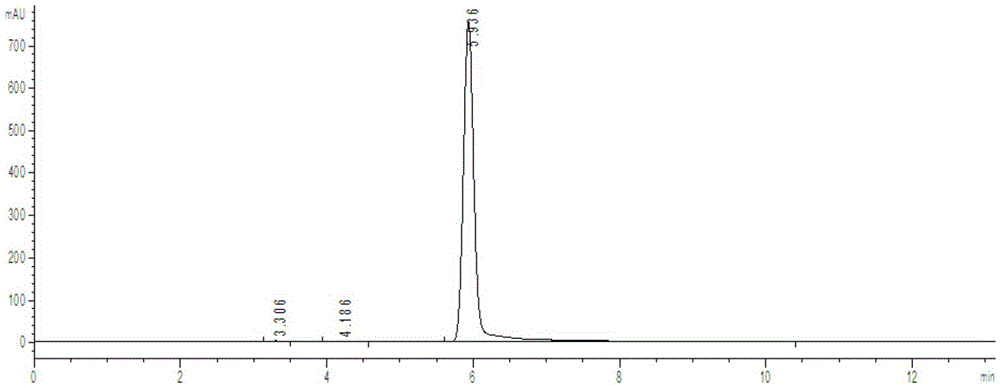

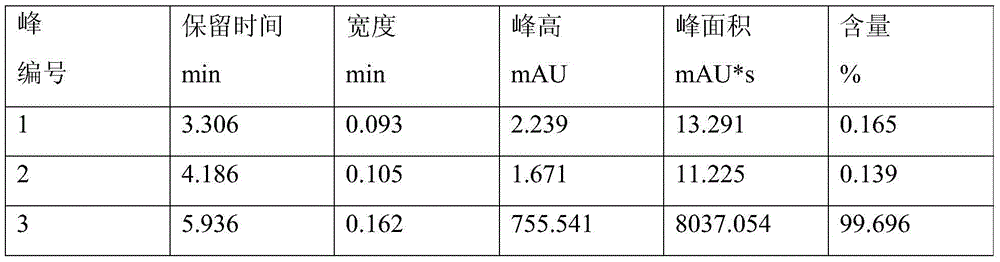

ActiveCN104402780ALow costPost-processing is simpleOrganic chemistryOrganic compound preparationSolventOrganic synthesis

The invention belongs to the field of organic synthesis, and in particular relates to a synthesis process of 4, 4'-dichlorodiphenyl sulfone. The synthesis process comprises the following steps: firstly, performing a Friedel-Crafts reaction on sulfoxide chloride and chlorobenzene under the action of a catalyst; cooling and hydrolyzing -after the reaction; heating and dissolving ; cooling, separating out crystals and filtering so as to obtain 4, 4'-dichlorodiphenyl sulfoxide; dissolving 4, 4'-dichlorodiphenyl sulfoxide in glacial acetic acid, adding hydrogen peroxide for an oxidizing reaction; lowering the temperature and cooling after the reaction is completed, and filtering so as to obtain 4, 4'-dichlorodiphenyl sulfone. Chlorobenzene is used both as a reaction material and a solvent, and other solvent impurities are not mixed in chlorobenzene, so that after-treatment is easier when the cost is saved, and the product is high in purity. The synthesis process has the advantages of simple process, low cost and few impurities. The obtained product has high purity and has the content of above 99.2% and the yield of above 90%, so that the product is good in economic benefit and is suitable for industrial production.

Owner:SHANDONG KAISHENG NEW MATERIALS

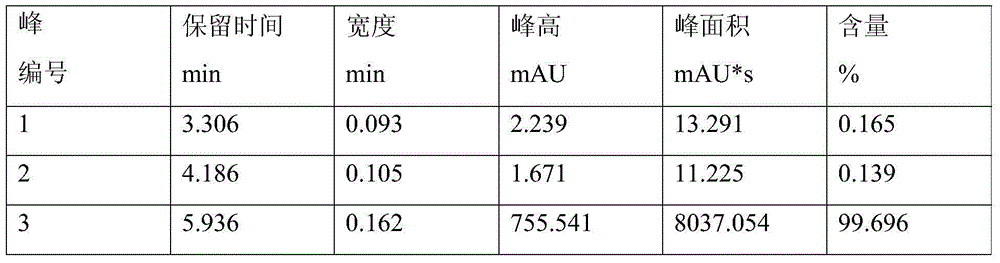

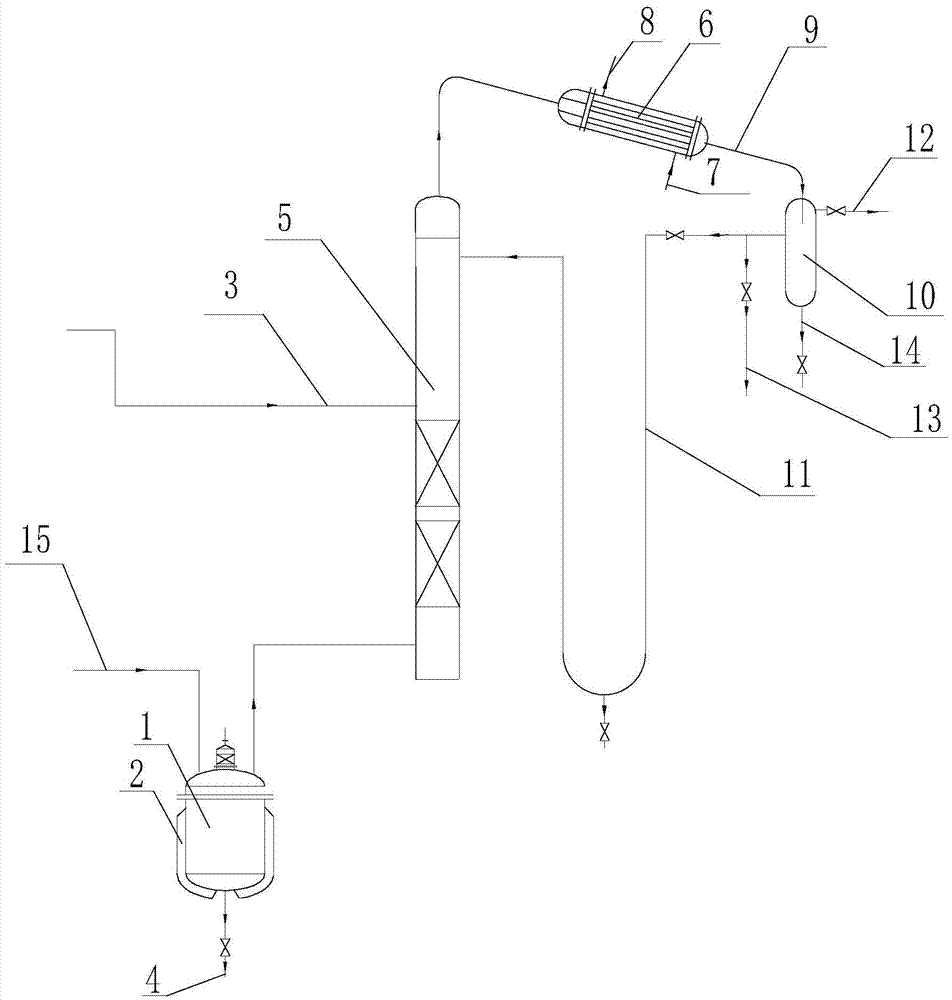

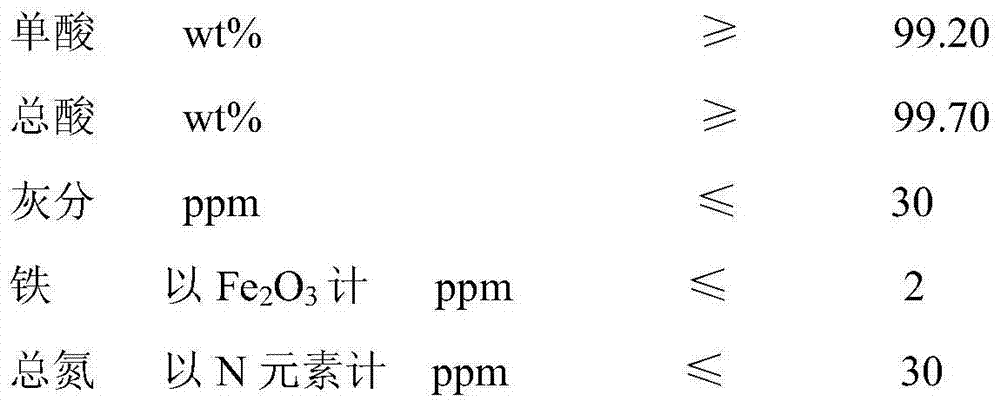

Method for refining long-carbon chain dicarboxylic acid

ActiveCN104496793AMeet the technical requirements of useLess investmentCarboxylic compound separation/purificationEngineeringCarboxylic acid

The invention relates to a method for refining long-carbon chain dicarboxylic acid. A long-chain dicarboxylic acid crude product prepared by a fermentation method is used as a raw material, acetic acid is used as a solvent, and the refining and purification are performed by recrystallization treatment. The method comprises the process steps of bleaching filtration, cooling crystallization, centrifugal separation, centrifugal material washing, secondary centrifugation and drying, and is characterized in that a. the long-chain dicarboxylic acid crude product to be refined does not need to be dried; b. the acetic acid solvent is recycled by an azeotropic distillation method, and isopropyl acetate is used as an azeotropic dehydrating agent; and c. the isopropyl acetate is used as a centrifugal material washing solvent for replacing the acetic acid. The purification method of the long-carbon chain dicarboxylic acid provided by the invention has the advantages of distillation equipment investment conservation, low operating power consumption, good product color, high purity, high refining yield and low production cost, the long-carbon chain dicarboxylic acid to be refined does not need to be dried and dehydrated, and the acetic acid solvent is completely recyclable. The quality of the refined product can meet the technical requirements of use of condensed monomer raw materials used by synthesis of high polymer materials.

Owner:山东广通新材料有限公司

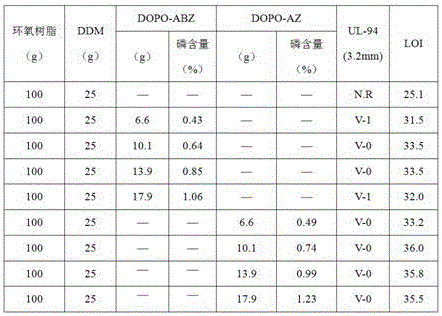

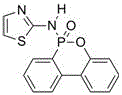

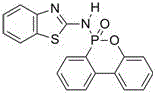

Flame retardant containing phosphorus, nitrogen and sulfur and used for epoxy resin and preparation method of flame retardant

InactiveCN106009040AThe synthesis process is simpleShort cycleGroup 5/15 element organic compoundsEpoxySulfur

The invention discloses a flame retardant containing phosphorus, nitrogen and sulfur and used for epoxy resin and a preparation method of the flame retardant. Firstly, DOPO and aminothiazole are taken as reaction raw materials and subjected to an Atherton-Todd reaction for preparation of the flame retardant containing phosphorus, nitrogen and sulfur. The process steps of the method are simple, the yield and the purity of the flame retardant are high, and the post-treatment process is simple and convenient. The flame retardant containing phosphorus, nitrogen and sulfur and prepared with the method is used for modifying cured epoxy resin and has good compatibility with epoxy resin, and the obtained cured flame-retardant epoxy resin has excellent flame retardancy; when the phosphorus content of the epoxy curing system reaches 0.43wt%-1.23wt%, the vertical burning grade can pass UL-94 V-0 level, and the limit oxygen index is as high as 36%.

Owner:FUJIAN NORMAL UNIV

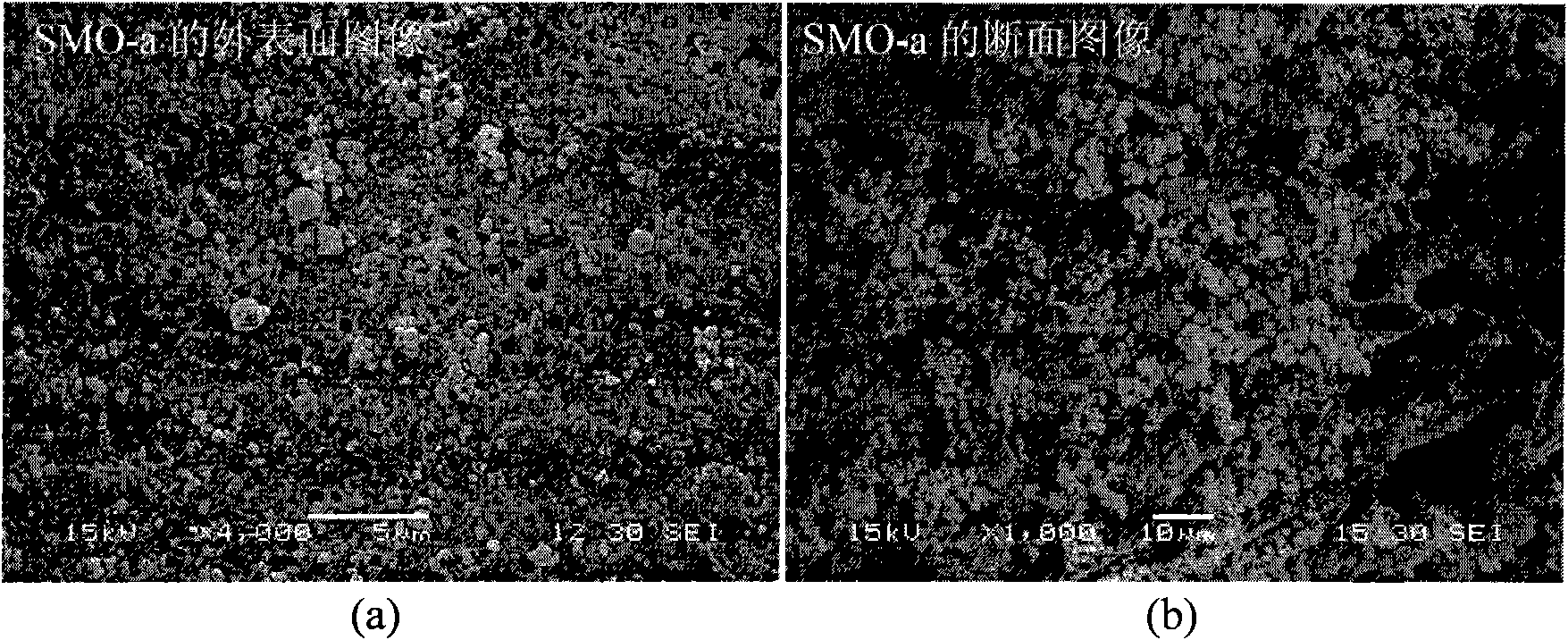

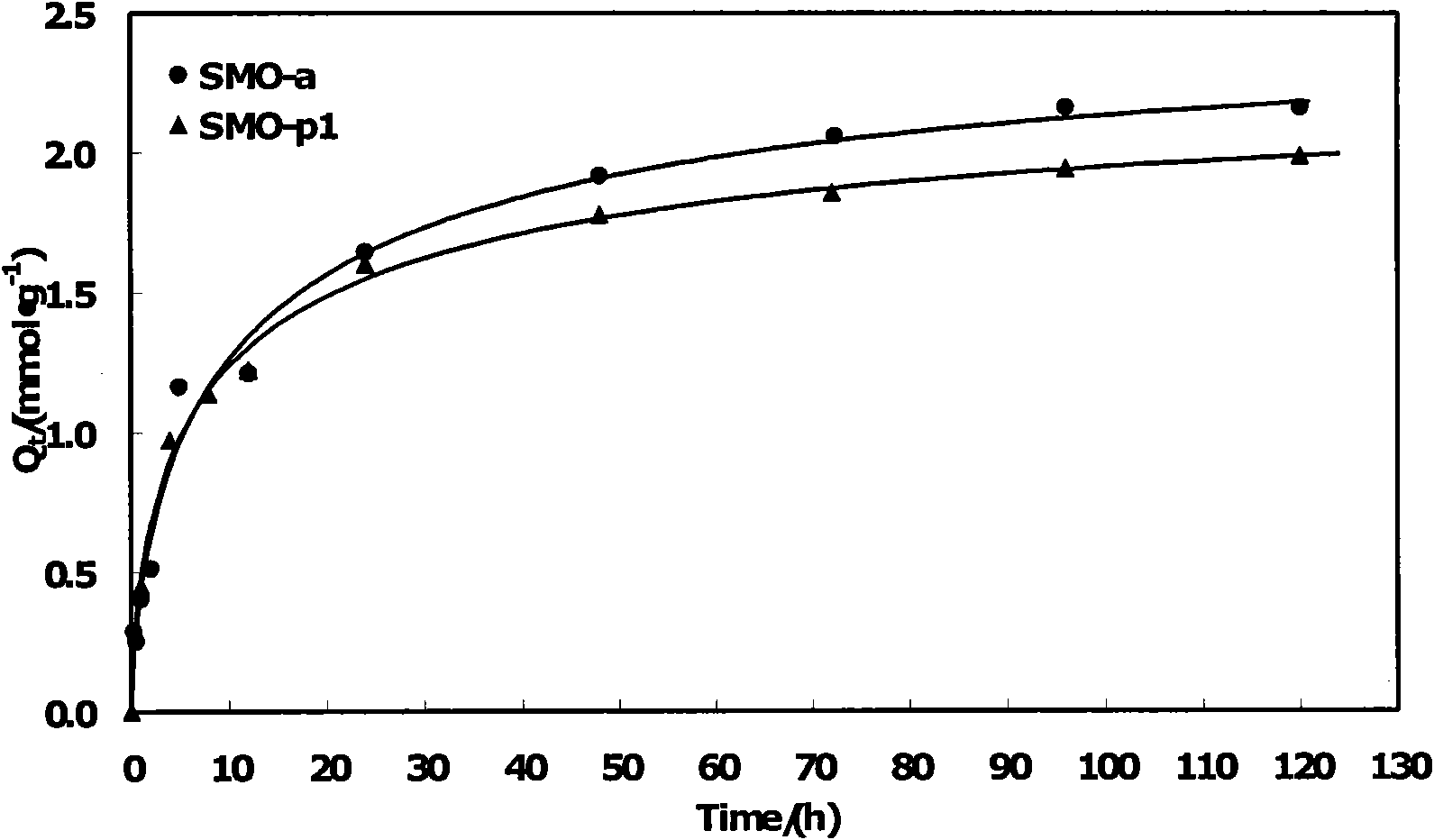

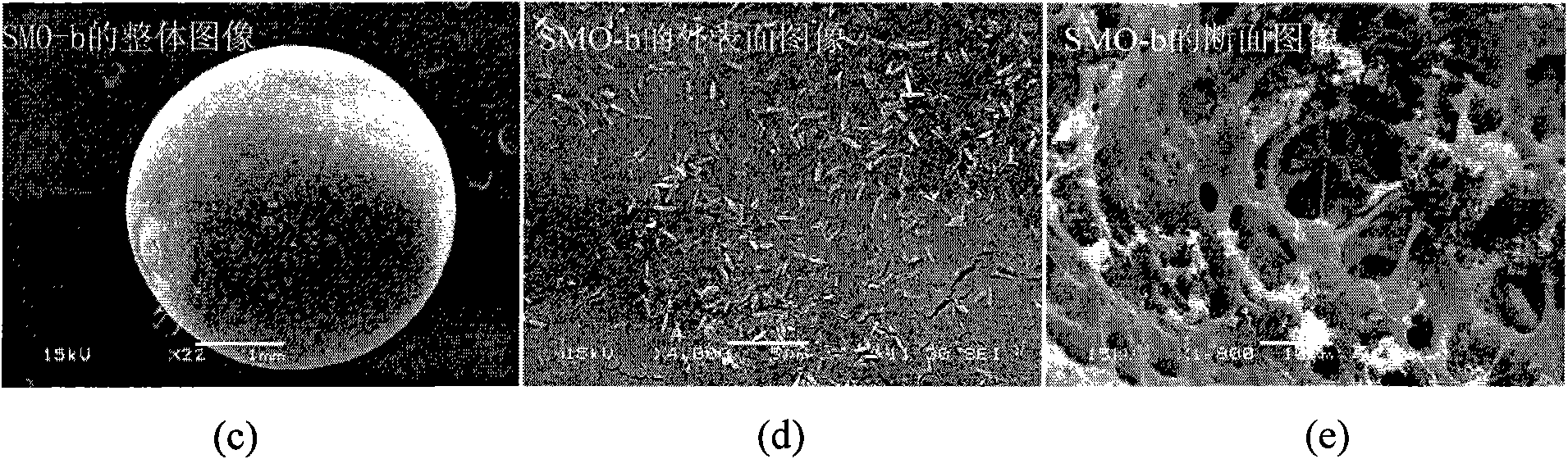

Spherical manganese dioxide type lithium ionic sieve

InactiveCN101898113APost-processing is simpleOvercome defectsOther chemical processesPelletizingSeawater

The invention relates to a spherical manganese dioxide type lithium ionic sieve used for adsorbing lithium in the lithium solutions such as salt lake brine, seawater, well brine and geothermal water. The preparation method of the spherical lithium ionic sieve is that the solubility difference of polyvinyl chloride in organic solvent and water and the characteristic that spheres are formed naturally under the action of different surface tensions are utilized, and shaping and granulation are performed to powder ionic sieve to obtain the spherical lithium ionic sieve, wherein the average diameter of the ionic sieve is 2.0mm-350mm. The adsorption performance of the millimeter-scale spherical manganese dioxide type lithium ionic sieve prepared by the invention is similar to that of the existing nanoscale ultrafine powder manganese dioxide type lithium ionic sieve, thus the lithium ionic sieve of the invention lays a foundation for the commercial application of the manganese dioxide type lithium ionic sieve.

Owner:EAST CHINA UNIV OF SCI & TECH

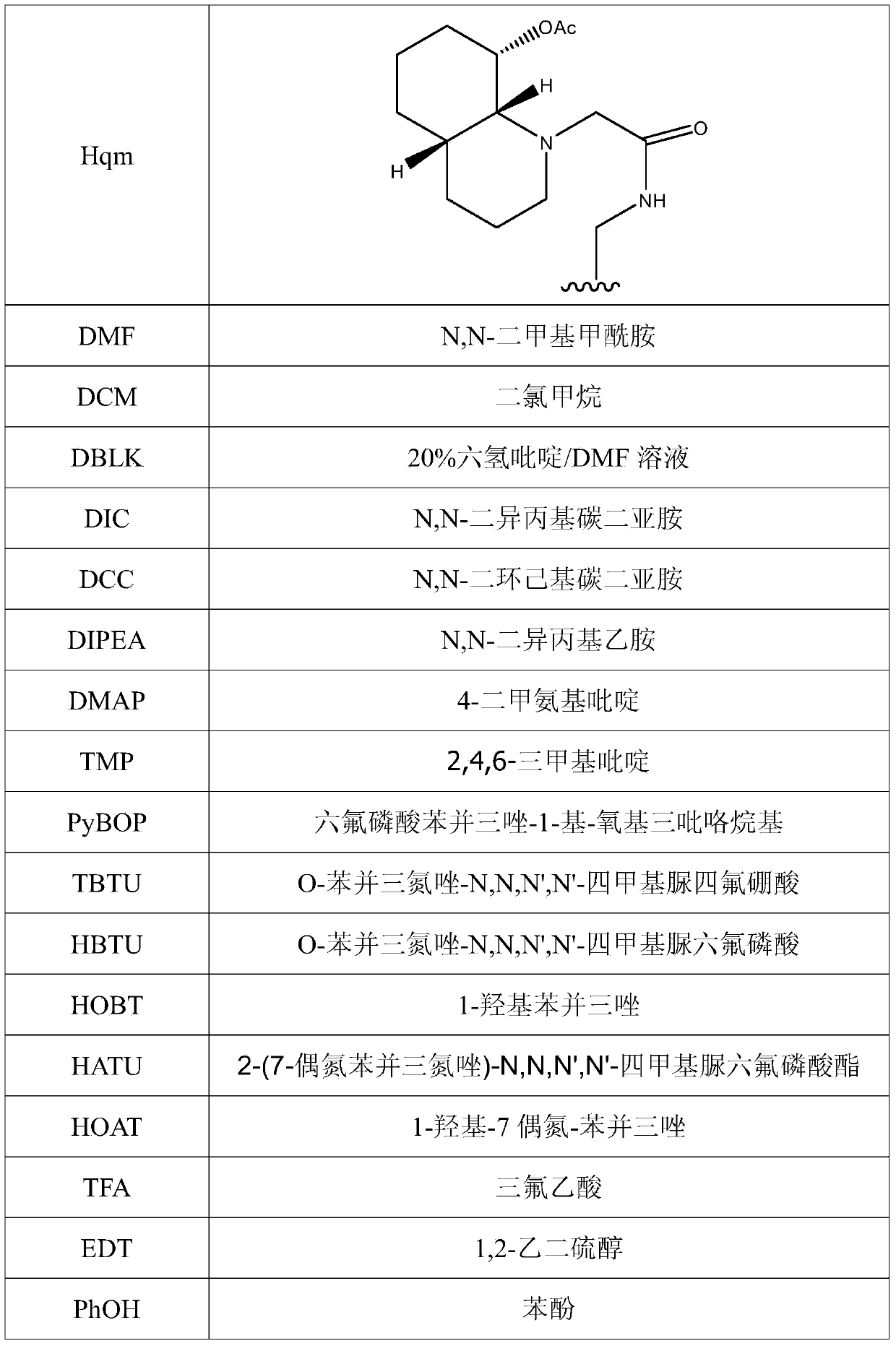

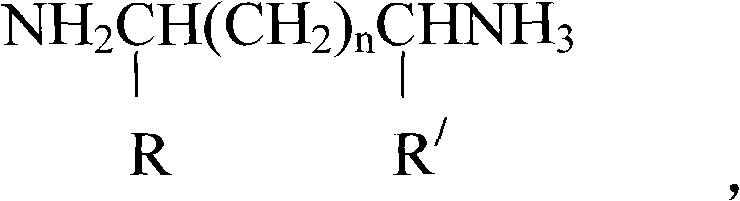

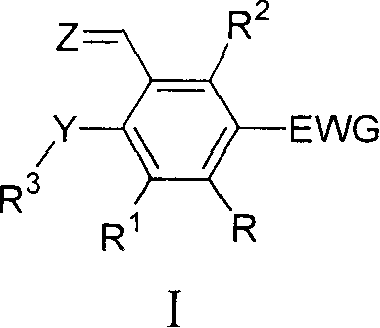

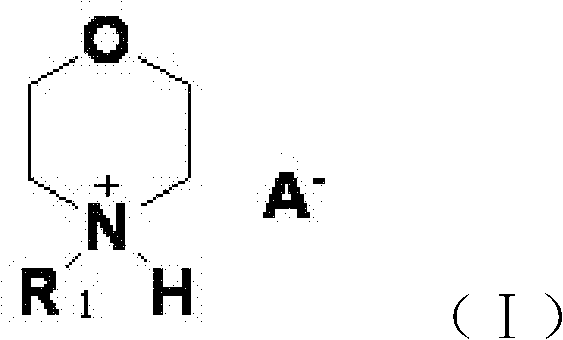

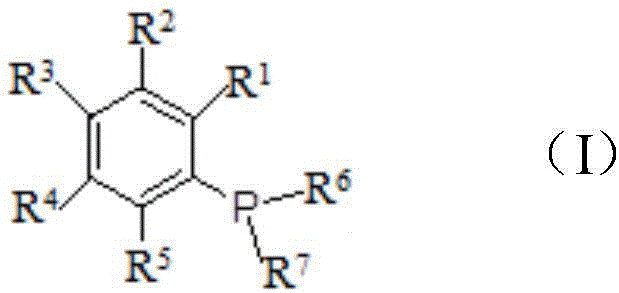

Ruthenium complex compound ligand, ruthenium complex compound, solid carrying ruthenium complex catalyst and preparation method and use thereof

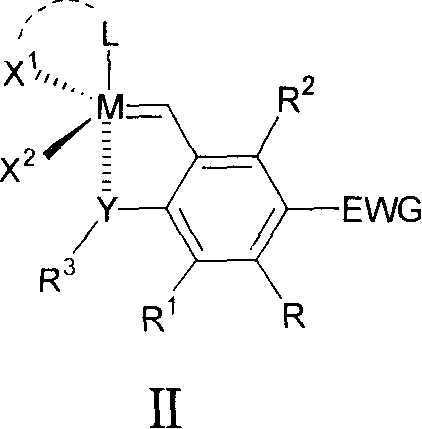

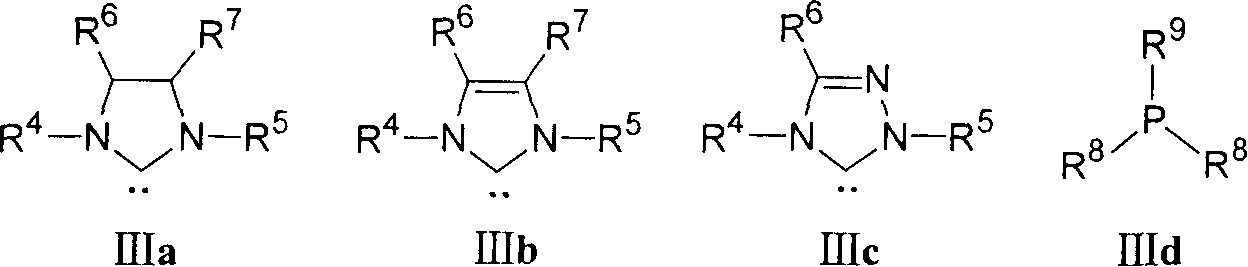

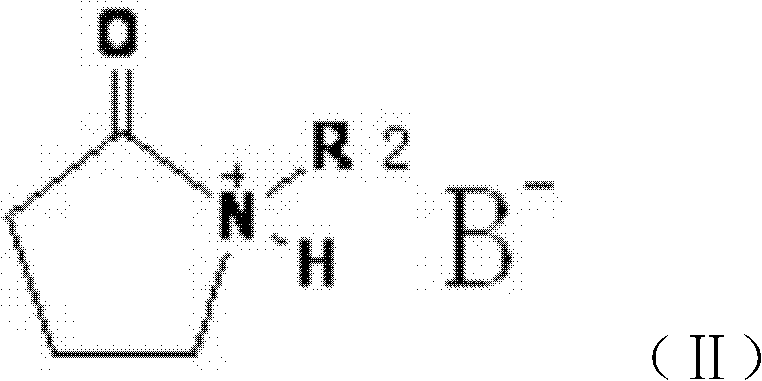

ActiveCN1907992AHigh catalytic activityImprove catalytic stabilityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsRutheniumStructural formula

The invention discloses a ruthenium complex compound ligand,fixed-carrying ruthenium complex compound catalyst and preparing method and utility, wherein the structural formula of ruthenium complex compound ligand I and II is displayed in the graph I and II; the structural formula of fixed-carrying ruthenium complex compound catalyst IV is as displayed in the right graph IVa-IVb.

Owner:ZANNAN SCITECH

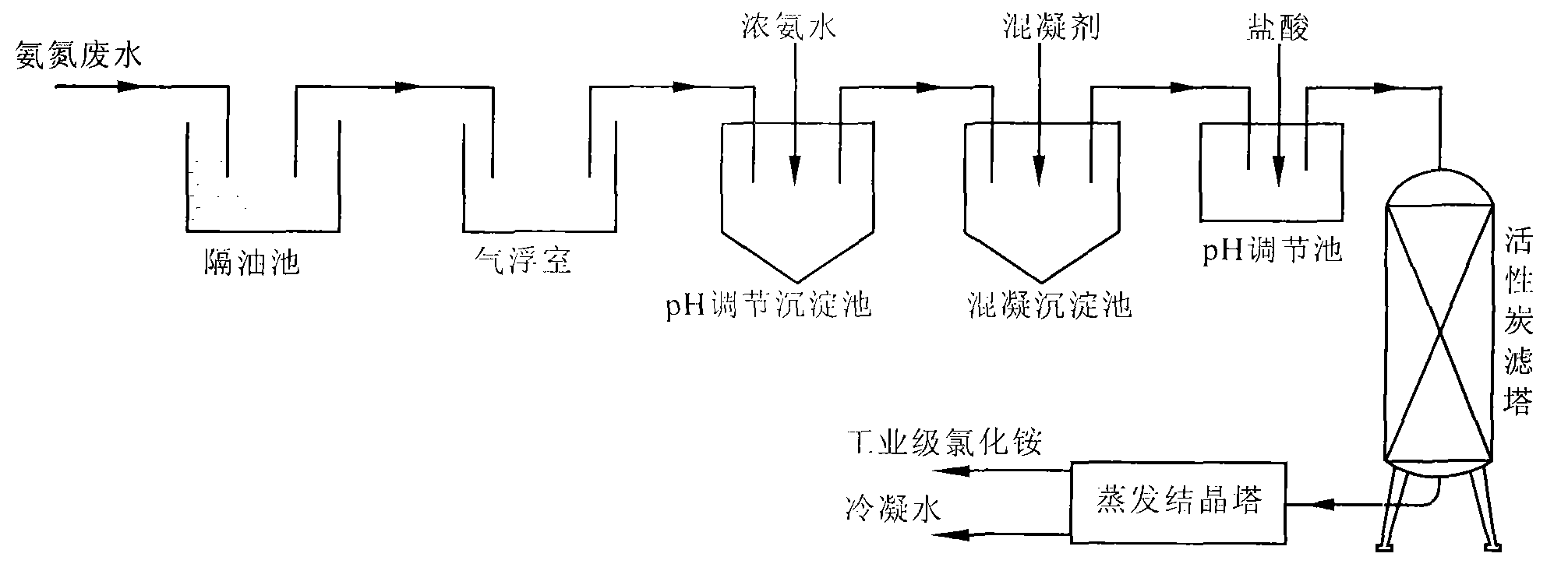

Compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and treatment method

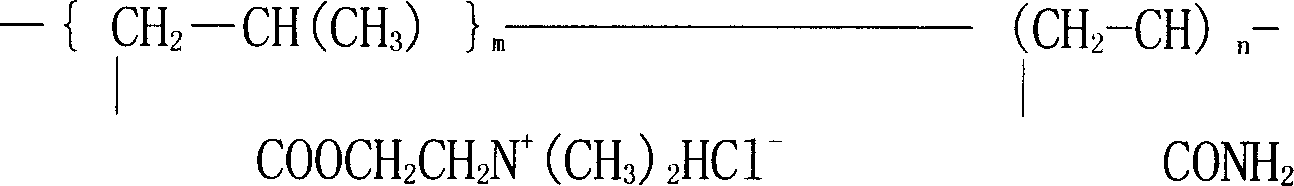

InactiveCN101555053ASimple processing methodLow costFatty/oily/floating substances removal devicesMultistage water/sewage treatmentRare earthPolyacrylamide

The invention provides a compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and a treatment method, belonging to the technical field of chemical environment protection and resource recovery. The compound coagulant is a mixed liquor of ammonium oxalate, ammonium sulphate, heavy metal precipitator DTCR and polyacrylamide (PAM). The treatment method for treating wastewater by using the compound coagulant comprises the following steps: firstly, oil substances in the wastewater are removed through a separation tank and an air floating chamber; secondly, the wastewater enters a pH adjusting precipitation tank to adjust the pH value to be 7.5-8.5; thirdly, the wastewater enters a coagulative precipitation tank, the compound coagulant is added, the wastewater after being coagulated and precipitated enters the pH adjusting precipitation tank to adjust the pH value to be 2.5-4, the wastewater after being adjusted the pH value enters an active carbon filter tower to be absorbed and filtered and then is evaporated and concentrated under the condition of negative pressure. The compound coagulant has simple treatment method, low cost and good effect. The treatment method has short process and simple and easy treatment, not only solves the problem of the pollution of the highly concentrated ammonian wastewater, but also achieves the purpose of recovering valuable materials.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Solid-phase synthesis method of exenatide

InactiveCN102942625AImprove efficiencyEasy to operateHormone peptidesPeptide preparation methodsAfter treatmentSynthesis methods

The invention provides a solid-phase synthesis method of exenatide, which comprises the following steps: 1) preparing Fmoc-Ser(tBu)-amino resin from initial raw materials Fmoc-Ser(tBu)-OH and amino resin with the substitution degree of 0.3-1.2mmol / g; 2) after removing Fmoc protecting group from the Fmoc-Ser(tBu)-amino resin, sequentially connecting Fmoc amino resins and at least one amino-protected Fmoc amino resin or dipeptide with temporarily substituted amide N in a peptide sequence, and removing Fmoc to obtain the exenatide amino resin of which the side chain is fully protected; and 3) removing the side chain protecting group from the resin, and precipitating with ice aether, thereby obtaining the exenatide. The synthesis method has the advantages of high efficiency, simple reaction operation and easy after-treatment, and is suitable for industrial production.

Owner:NANJING UNIV OF TECH +1

Linaclotide solid-phase synthesis method

InactiveCN104974229AGood effectPrecise positioningPeptide preparation methodsBulk chemical productionFreeze-dryingSolid-phase synthesis

The invention discloses a linaclotide solid-phase synthesis method, and belongs to the biochemical technical field. The method includes the following steps: (1) preparation of linaclotide resin; (2) cutting the linaclotide linear peptide resin obtained in the step (1), to obtain a protection group linear peptide containing Cys(Acm) and Cys(tBu); (3) oxidizing to form a first disulfide bond, to obtain a monodisulfide cyclopeptide; (4) removing an Acm protection group in the monodisulfide cyclopeptide, to obtain a dual disulfide cyclopeptide; (5) removing a tBu protection group of the dual disulfide cyclopeptide, to obtain a trisdisulfide cyclopeptide; and (6) purifying the trisdisulfide cyclopeptide by HPLC, and freeze-drying to obtain linaclotide. The process has the characteristics of simple reaction operation, easy post-processing, low cost, high yield, and considerable economic and practical values, and besides, has wide application prospect in the polypeptide drug design and synthesis field.

Owner:NANTONG SHIMEIKANG PHARMA CHEM

Method for preparing macromolecule material chain extender

The present invention relates to a high polymer material chain extender and a preparation method thereof, the components and the contents (weight parts) of the chain extender include: 50 to 75 parts of styrene monomer, 50 to 25 parts of acrylic acid glyceryl ester monomer, 0.1 to 1.2 parts of initiator, 0.1 to 1.0 part of dispersant and 0.1 to 0.3 part of other additives; the preparation method of the chain extender comprises that the reaction monomers and the additives are chosen, the monomers and the additives are added into a reactor according to a set sequence and a copolymerization reaction is carried out under the appropriate temperature and the stirring speed; the final product can be formed by washing and drying the reaction product. Compared with the prior art, the present invention is characterized by simple process, relative higher molecular weight, easy post-treatment, safety, reliability, broader usage and so on.

Owner:周小雯

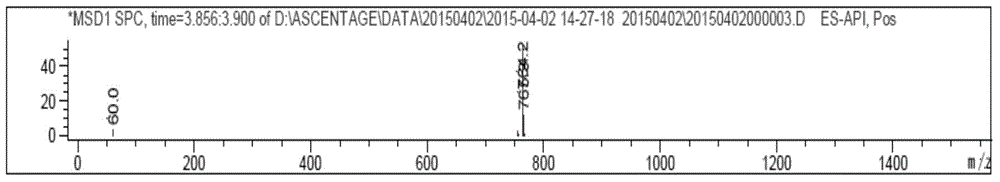

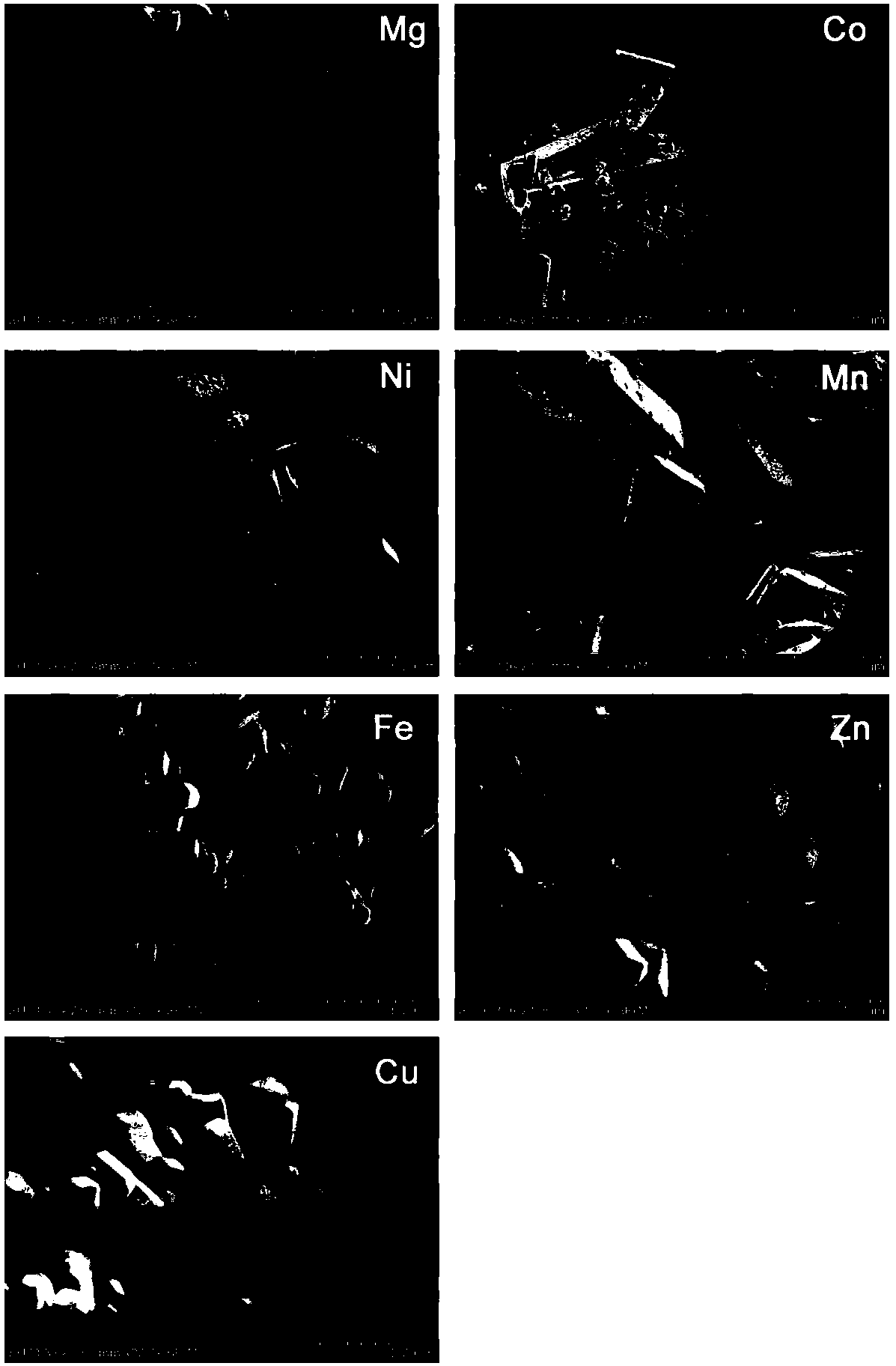

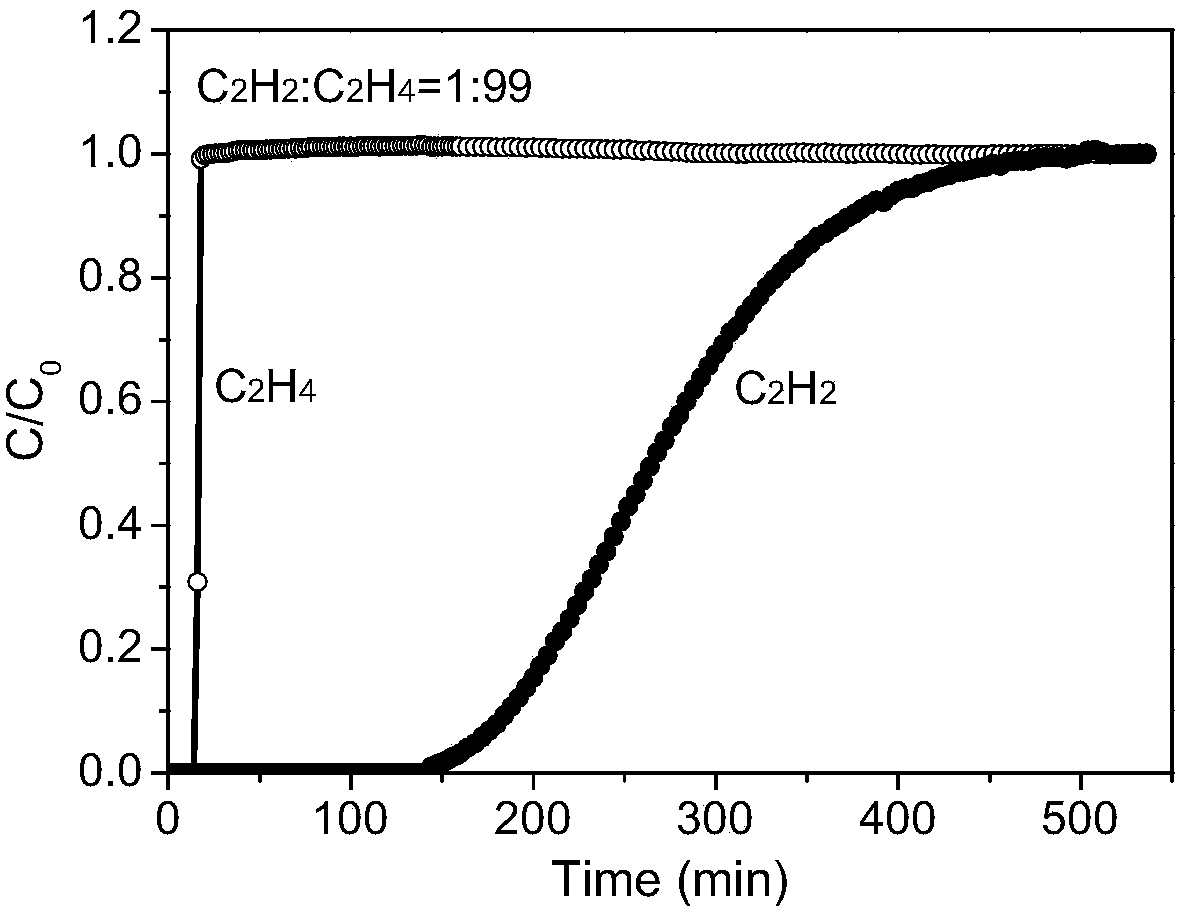

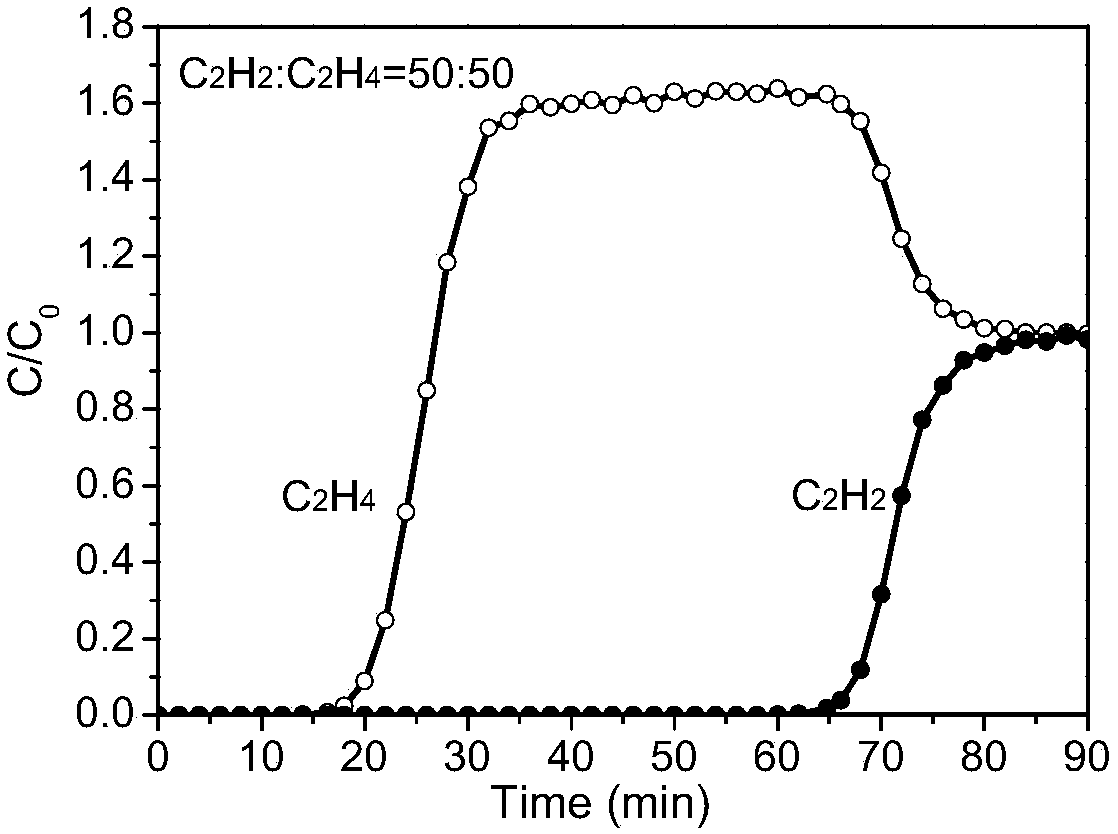

Method for separating ethylene and acetylene from mixed gas

ActiveCN108014751AEasy synthesis costLower synthesis costOther chemical processesAdsorption purification/separationAlkaline earth metalGallic acid ester

The invention discloses a method for separating ethylene and acetylene from a mixed gas. The method comprises the step of using a metal organic frame material as an adsorbent for separating the ethylene and the acetylene from the mixed gas containing the ethylene and the acetylene; the metal organic frame material has a structural formula of M(C7O5H4).2H2O, wherein M is a metal ion, and the metalorganic frame material is a three-dimensional network structure formed by coordination bonds or intermolecular forces from a transition metal ion or alkaline earth metal ion and gallic acid. The metalorganic frame material has a large adsorption capacity for the acetylene and an excellent selectivity for adsorption and separation of ethylene / acetylene. The materials for the synthesis of the material is cheap and easy to obtain, the material preparation process is simple, and the cost is low; and the material has good regeneration and repetition performance, can still maintain the original adsorption effect after vacuum or heating regeneration, and has broad industrial application prospects.

Owner:ZHEJIANG UNIV

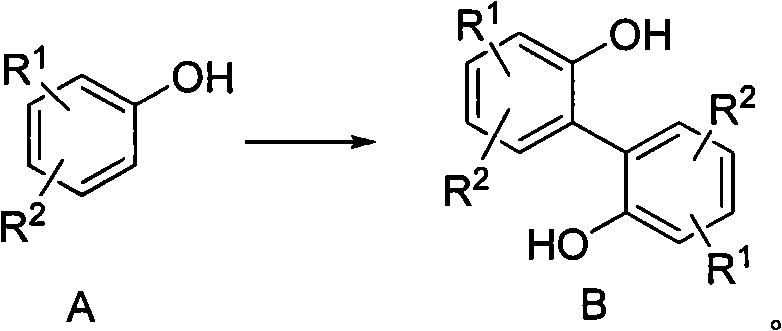

Preparation method of 2, 2'-biphenyl diphenol and derivatives thereof

ActiveCN101817713AImprove universalityPost-processing is simpleOrganic compound preparationOrganic chemistry methodsCompound aHydrogen atom

The invention provides a method for preparing 2, 2'-biphenyl diphenol derivatives, and the method comprises the step of carrying out oxidation coupling reaction on phenolic compound A with ortho-hydrogen atoms at 0-100DEG C with the help of peroxide, thus preparing 2, 2'-biphenyl diphenol compound B; and the method is simpler and more economical, the post processing is simple and easy to implement and has good universality, and the method can provide a series of 2, 2'-catechol derivatives.

Owner:合肥华纳生物医药科技有限公司

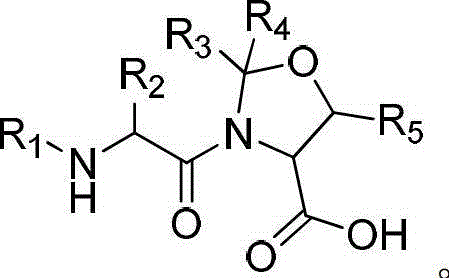

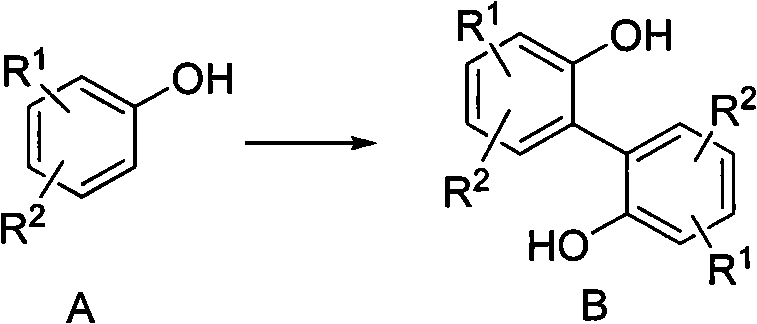

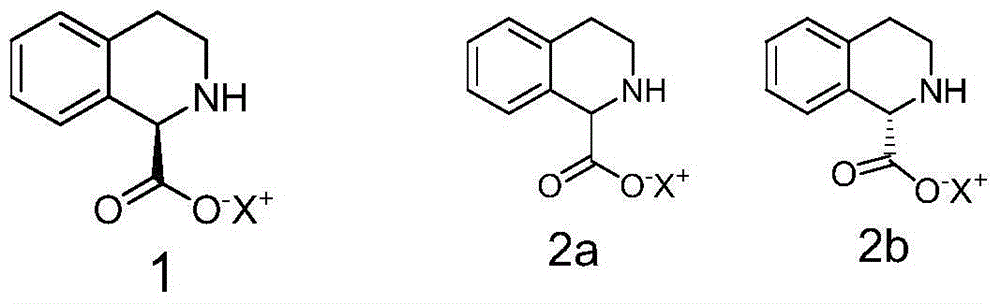

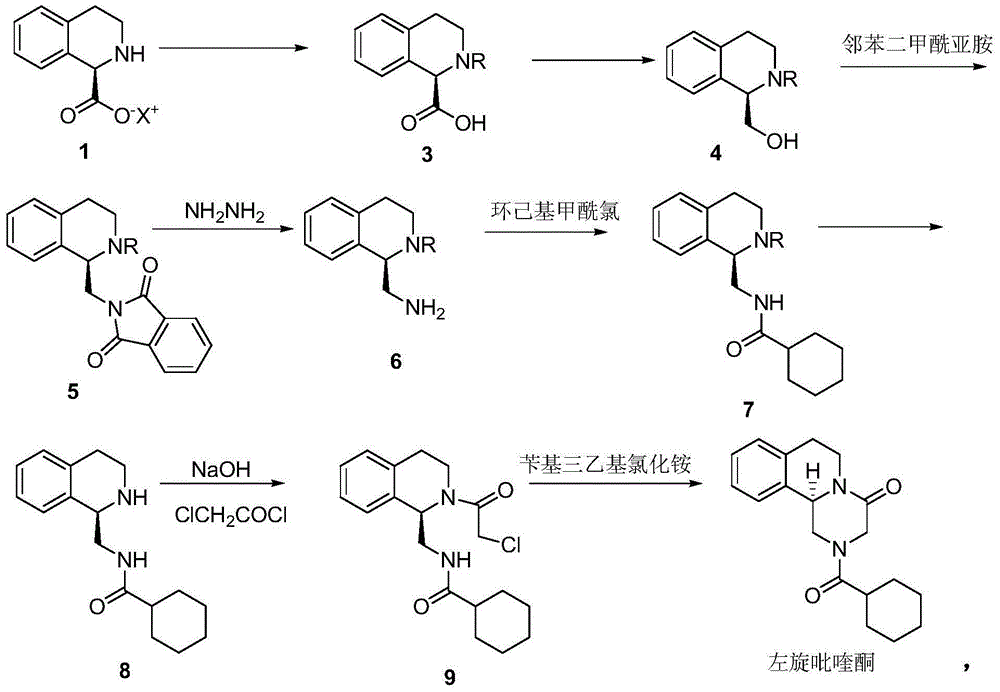

Preparation method of (R)-praziquantel

ActiveCN104557911AHigh optical purityLow costOrganic chemistryFermentationEnvironmental resistanceD-amino acid

The present invention relates to an (R)-praziquantel preparation method, comprising steps of using (R,S)-tetrahydroisoquinoline-1-formate or salts thereof, or 1-(S)-tetrahydroisoquinoline-1-formate or salts thereof as a raw material to prepare 1-(R)-tetrahydroisoquinoline-1-formate salts, and steps of preparing (R)-praziquantel from said 1-(R)-tetrahydroisoquinoline-1-formate salts. The preparation method for 1-(R)-tetrahydroisoquinoline-1-formate or salts thereof is as follows: perform an oxidation reaction between the raw material described above and oxygen in the presence of recombinant D-amino acid oxidase and catalase, then perform a reduction reaction on the resulting product under the effect of a borane-amine complex, thus successively converting 1-(S)-tetrahydroisoquinoline-1-formate or salts thereof into the 1-(R)-tetrahydroisoquinoline-1-formate or salts thereof isomer. The present method not only produces an (R)-praziquantel product with a high optical purity, but is also low-cost and environmentally friendly in terms of production.

Owner:TONGLI BIOMEDICAL

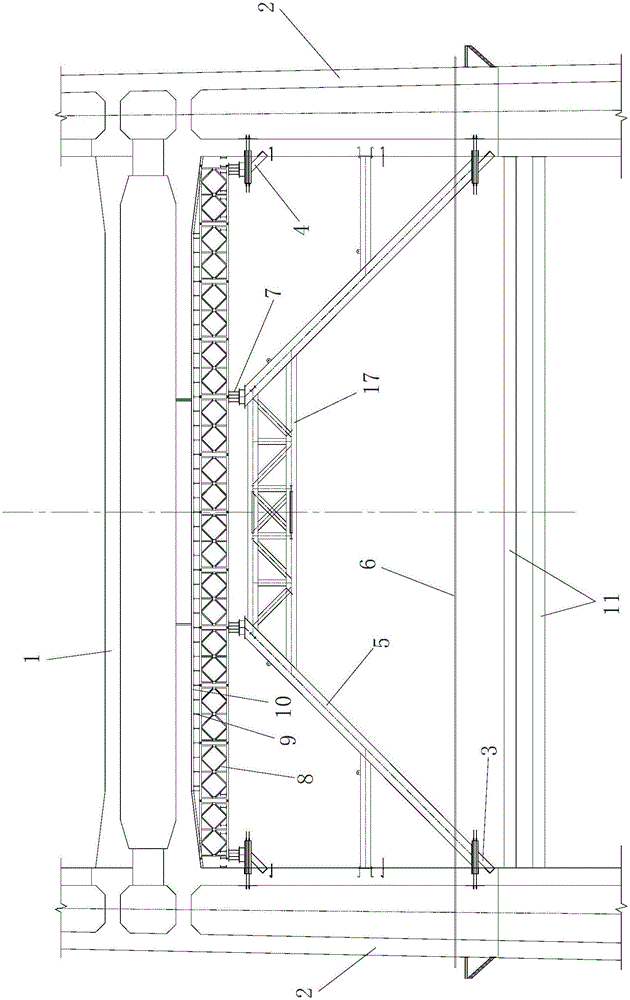

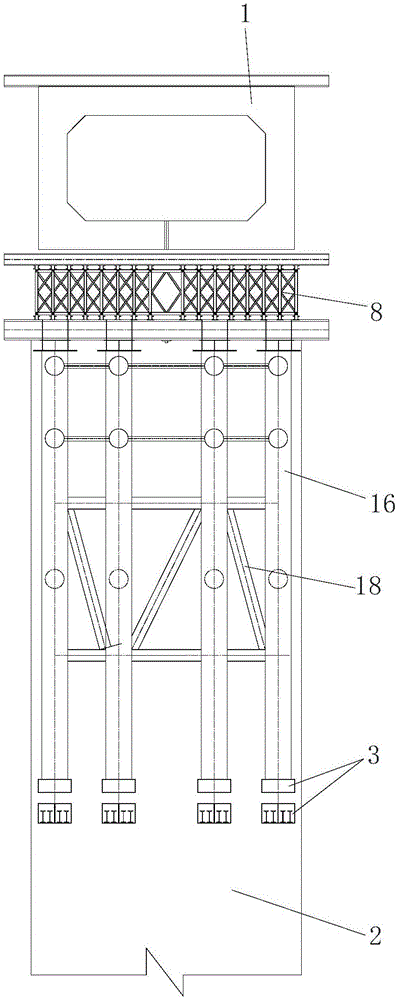

Construction support and method for overhead large-span heavy-duty cross beam

ActiveCN106677070ASimple structureEasy to processBridge erection/assemblySupporting systemPipe support

The invention discloses a construction support and method for an overhead large-span heavy-duty cross beam. The construction support comprises a lower bracket supporting structure, an upper bracket supporting structure located above the lower bracket supporting structure, and a middle supporting structure with the bottom supported on the lower bracket supporting structure. The top face of the upper bracket supporting structure is flush with the top face of the middle supporting structure, and the upper bracket supporting structure and the middle supporting structure form a temporary supporting platform for supporting the cross beam to be constructed. A load bearing structure is erected on the temporary supporting platform. The construction method comprises the steps that firstly, the lower bracket supporting structure is installed; secondly, the upper bracket supporting structure and the middle supporting structure are installed; thirdly, the load bearing structure is erected; fourthly, the support is prepressed; fifthly, the upper cross beam is constructed; and sixthly, the support is removed. According to the construction support and method, design is reasonable, construction is easy and convenient, the using effect is good, and the problems that as for an existing floor steel pipe supporting system, cost is high, the erection process is complex, the construction period is long, the construction risk is high, the requirement for supporting stability is high, and the construction progress of the upper cross beam is affected can be effectively solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

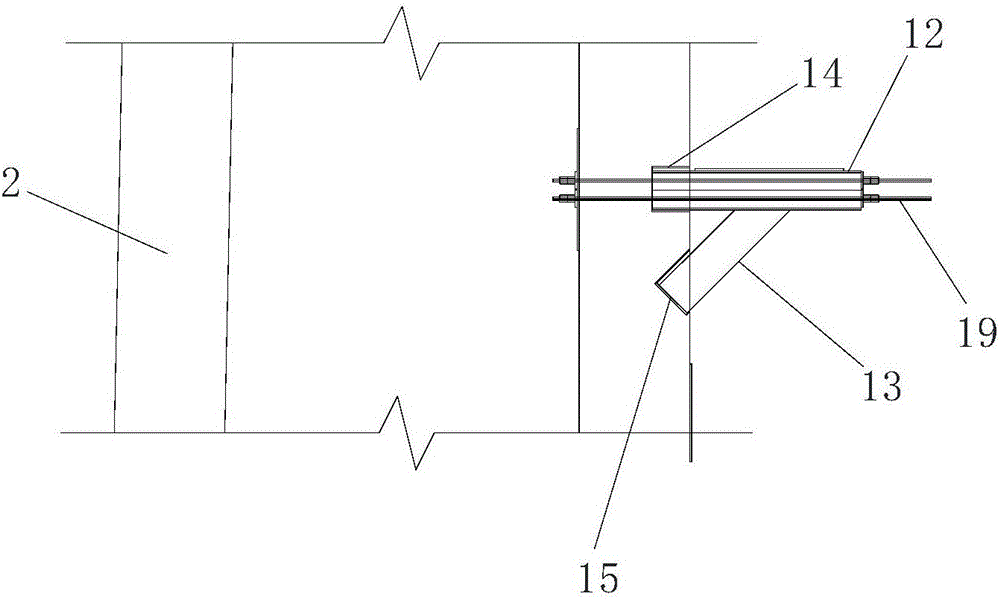

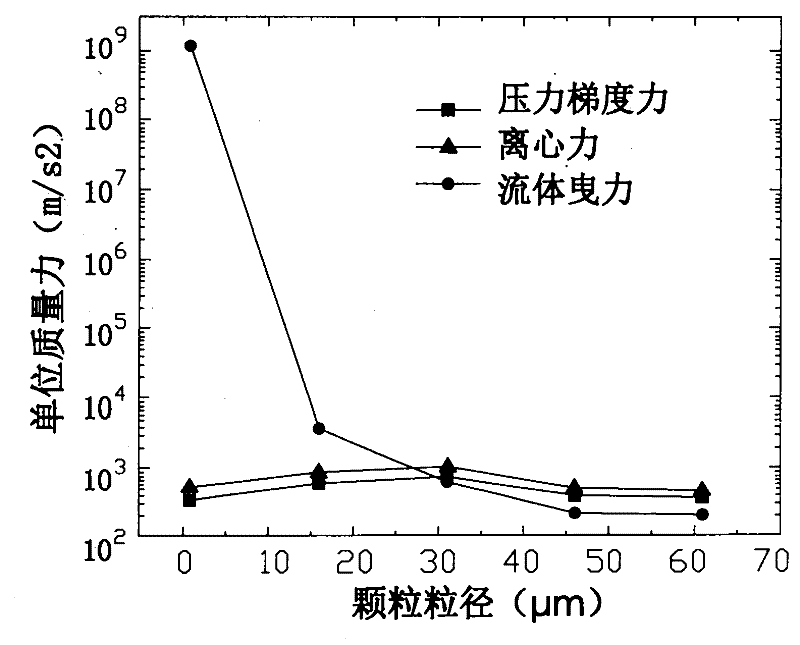

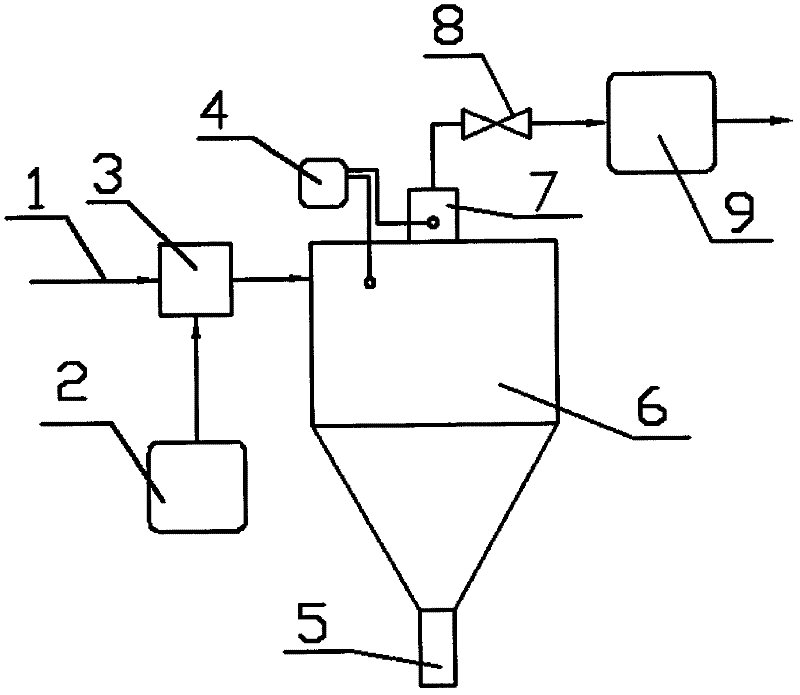

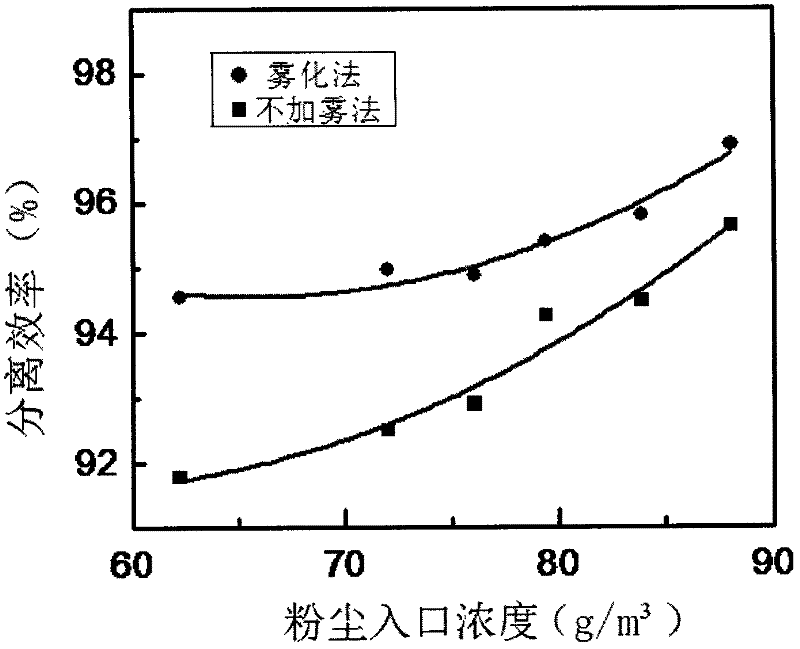

Dedusting device and dedusting method therefor

The invention discloses a dedusting device and a dedusting method therefor. The dedusting device is a cyclone dedusting device with a water atomization device. The dedusting device mainly comprises a cyclone dust collector and also comprises the water atomization device. A water mist outlet of the water atomization device is communicated with the interior of a mixing chamber. An upstream part of the mixing chamber is communicated with a waiting gas pipe. A downstream part of the mixing chamber is communicated with an air inlet of the cyclone dust collector. The water atomization device adopted by the invention is an electroacoustic transduction supersonic atomizing device, and sizes of liquid drops produced by the water atomization device are less than or equal to 5.0 micrometers.

Owner:LANZHOU UNIVERSITY

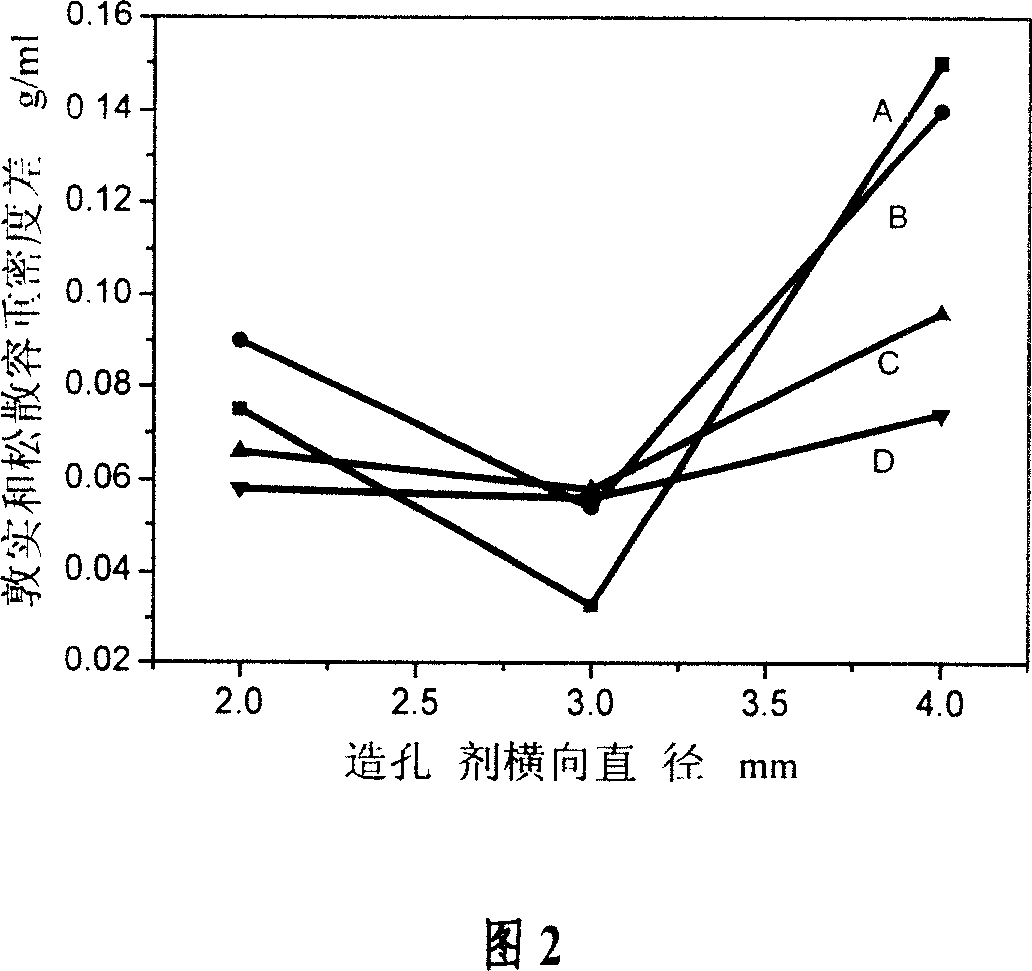

Prepn process of pore forming agent for porous magnesium alloy and porous aluminium and its pore forming method

The present invention relates to pore forming agent, and is especially pore forming agent for porous magnesium alloy and porous aluminum alloy and with controllable pore size, porosity and pore wall thickness and its preparation process and pore forming method. The pore forming agent is prepared with light calcium carbonate, RE carbonate, etc as material and through an extruding and pelletizing process. When it is used, the granular pore forming agent is used as the support and molten magnesium alloy or aluminum alloy is made to seepage flow into the pore forming agent so as to obtain porous magnesium alloy or aluminum alloy after treatment. The porous magnesium alloy and aluminum alloy preparing process can control the pore size, porosity and pore wall thickness effectively, and the alloy is used for sea water cell anode, metal rubber and other porous light metal product.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for generating 5-hydroxymethylfurfural by using ionic liquid catalysis

InactiveCN101812039AEasy to separateEasy to purifyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventHydroxymethylfurfural

The invention discloses a method for generating 5-hydroxymethylfurfural by using ionic liquid catalysis, which comprises the following steps: dissolving a reaction substrate into an organic solvent, and adding ionic liquid in an amount of 5 to 20 percent based on the total mole of the reaction substrate; and reacting the mixture for at least 2 hours at the temperature of between 70 and 120 DEG C under the protection of inert gas, namely neutralizing the reaction solution, and filtering, drying and distilling the reaction product to obtain the 5-hydroxymethylfurfural. The reaction system shows the characteristic of homogeneous reaction during catalytic dehydration, and has high catalytic activity and selectivity; and the using amount of a catalyst can be optimized to trace so as to improve the reaction conversion rate, reduce the use of other organic solvent and additive, reduce the cost and facilitate the separation and purification of the reaction product at the same time.

Owner:TIANJIN UNIV

Hdrogenation synthesis method for preparing 2-methyl allyl alcohol by using recyclable catalyst

InactiveCN102167657APost-processing is simpleReduce manufacturing costOrganic compound preparationHydroxy compound preparationSolventBoiling point

The invention discloses a method for synthesizing 2-methylacrolein into 2-methyl allyl alcohol by using a catalytic hydrogenation method, belonging to the technical field of synthesis of organic intermediates. A catalyst used in the method is recyclable. The synthesis method comprises the following steps of: (1) adding 2-methylacrolein, a catalyst, a polymerization inhibitor and a high-boiling-point solvent into a high-pressure kettle and introducing hydrogen for reacting; (2) after reacting, exhausting excessive hydrogen and rectifying reaction liquid to obtain 2-methylacrolein; and (3) adding the 2-methylacrolein and the solvent into residual liquid in a rectifying kettle, transferring into the high-pressure kettle and undergoing a reaction for preparing 2-methylacrolein through hydrogenation to realize the recycling of the catalyst. The method has the advantages of atom economy, environmental friendliness, high yield, simple post-treatment and the like.

Owner:武汉凯森化学有限公司

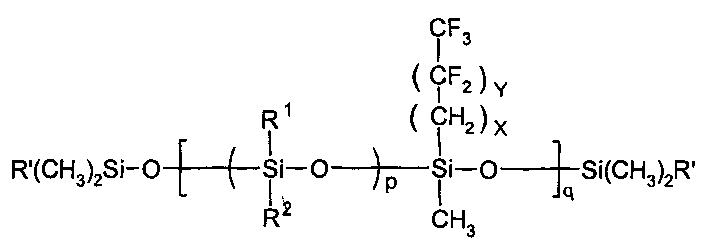

Fluorinated silicone lube oil synthetic method

A F-Si lubricating oil is prepared from the mixture of fluoric alkylmethyl dichlorosilane and dihydroxy dichlorosilane through dechlorimating by metallic oxide, synthesizing multiple elements mixed fluoric cyclosilane, and opening-loop polymerizing under trigger of strong acid. Its advantage is high performance.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

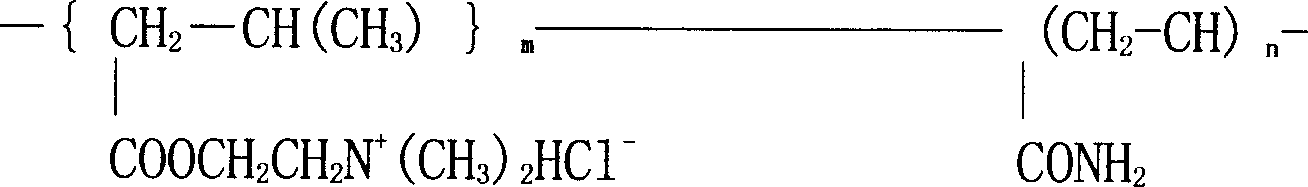

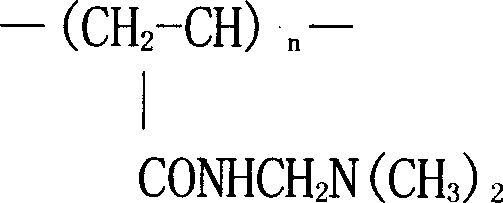

Processing method of urban sewage sludge reduction

ActiveCN101108751ALower zeta potentialImprove performanceWater/sewage treatment by centrifugal separationWater/sewage treatment by flocculation/precipitationBurn treatmentEmulsion

The invention relates to the processing method of the urban sewage and sludge reduction. The flocculating agent A is first added in the urban sewage and sludge and added with flocculating agent B to further react after emulsion breaking reaction. The flocculating agent A is a quaternary ammonium type cationic polymer and the flocculating agent B is a cationic polymer with aminomethyl polyacrylamide as the basis. The urban sludge processed by the method of the invention has volume greatly reduced, hard mud cake, low water ratio, which can meet the requirement of the subsequent landfill, composting and burning treatment and realize the comprehensive utilization of the sludge.

Owner:CHINA PETROLEUM & CHEM CORP +1

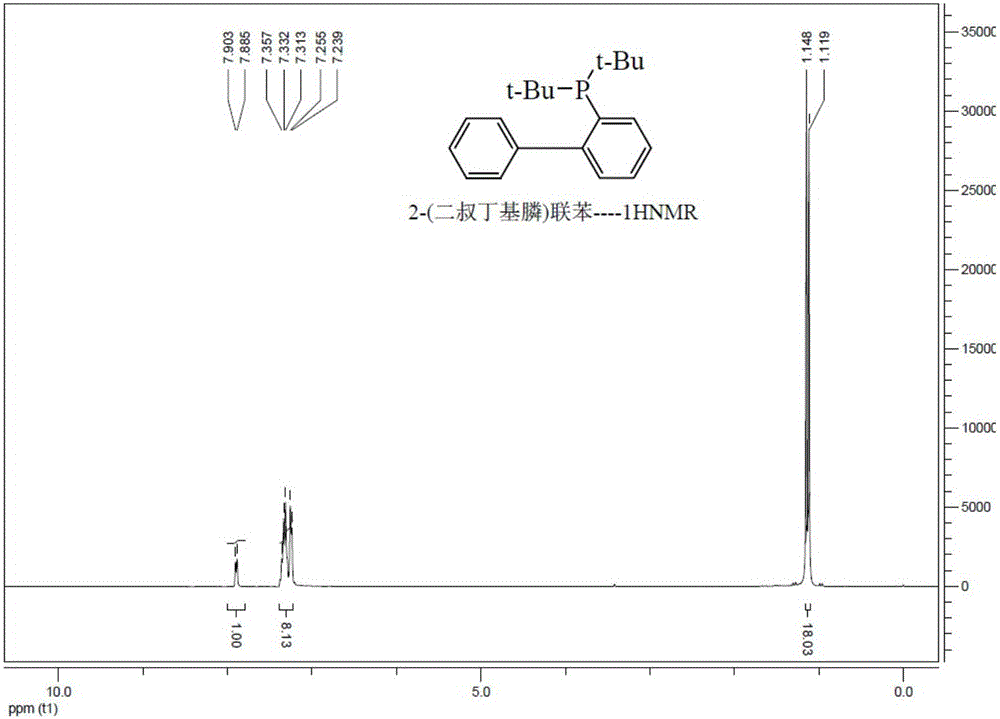

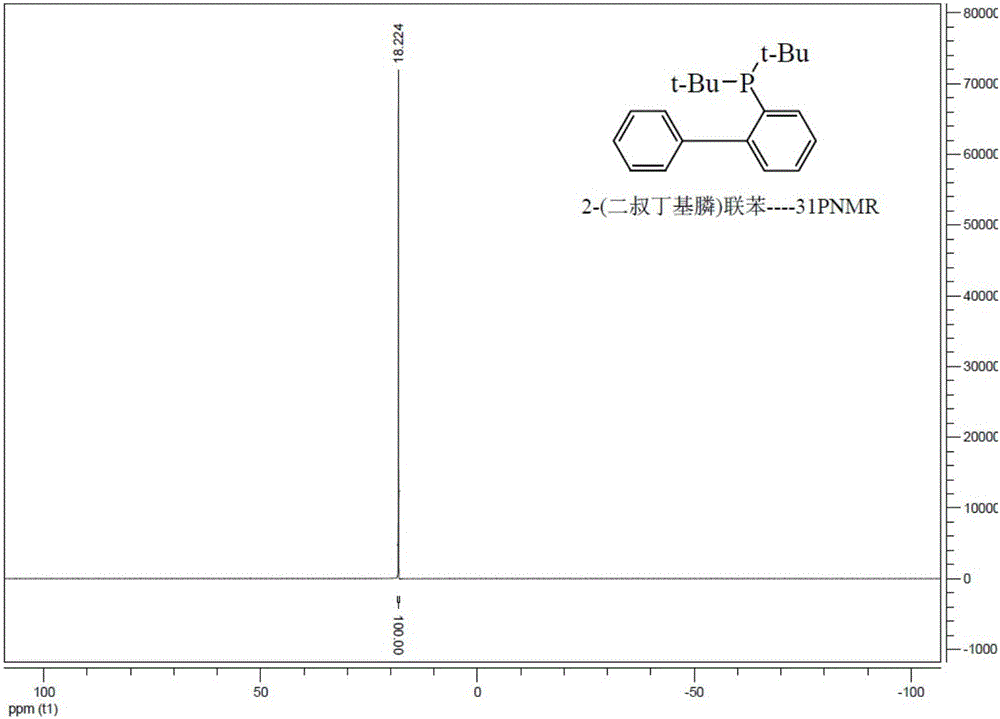

Preparation method of phosphinobenzene compound

ActiveCN105859774APost-processing is simplePurity and Quality GuaranteedGroup 5/15 element organic compoundsSolventChemistry

The invention relates to a preparation method of a phosphinobenzene compound. The method is characterized in that a bromobenzene compound reacts with magnesium to prepare a Grignard reagent, and the Grignard reagent reacts with a chlorophosphine compound under the catalysis of tetrakis(triphenylphosphine)palladium to obtain the phosphinobenzene compound. The method concretely comprises the following steps: preparing the Grignard reagent from the bromobenzene compound, magnesium chips and an organic solvent under the protection of insert gas, and refluxing for 2-10h; adding tetrakis(triphenylphosphine)palladium at room temperature, stirring for 10min-3h, adding the chlorophosphine compound at room temperature in a dropwise manner, and carrying out a refluxing reaction for 1-10h; and adding an aqueous solution of saturated weakly-acidic and weakly-alkaline salt to the above obtained reaction solution in a dropwise manner in ice-water bath, carrying out liquid separation, removing the solvent from the obtained organic phase, adding an alcohol solvent for crystallizing, and filtering obtained crystals to obtain the phosphinobenzene compound. The preparation method has the advantages of great increase of the preparation yield, simple post-treatment, omitting of the repeated ammonia water washing process, preparation process simplification, and facilitation of large-scale industrial production.

Owner:BEIJING GREENCHEM TECH

Synthetic process of 4,4'-dichlorodiphenyl sulfone

ActiveCN104402780BLow costPost-processing is simpleOrganic chemistryOrganic compound preparationChlorobenzeneOrganic synthesis

The invention belongs to the field of organic synthesis, and in particular relates to a synthesis process of 4, 4'-dichlorodiphenyl sulfone. The synthesis process comprises the following steps: firstly, performing a Friedel-Crafts reaction on sulfoxide chloride and chlorobenzene under the action of a catalyst; cooling and hydrolyzing -after the reaction; heating and dissolving ; cooling, separating out crystals and filtering so as to obtain 4, 4'-dichlorodiphenyl sulfoxide; dissolving 4, 4'-dichlorodiphenyl sulfoxide in glacial acetic acid, adding hydrogen peroxide for an oxidizing reaction; lowering the temperature and cooling after the reaction is completed, and filtering so as to obtain 4, 4'-dichlorodiphenyl sulfone. Chlorobenzene is used both as a reaction material and a solvent, and other solvent impurities are not mixed in chlorobenzene, so that after-treatment is easier when the cost is saved, and the product is high in purity. The synthesis process has the advantages of simple process, low cost and few impurities. The obtained product has high purity and has the content of above 99.2% and the yield of above 90%, so that the product is good in economic benefit and is suitable for industrial production.

Owner:SHANDONG KAISHENG NEW MATERIALS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com