Prepn process of pore forming agent for porous magnesium alloy and porous aluminium and its pore forming method

A technology of porous magnesium and porous aluminum, which is applied in the preparation of porous magnesium alloy and porous aluminum pore-forming agent and the field of pore-making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The particle size of the calcium carbonate powder used is above 150 mesh. At the same time, the decomposition temperature range of the powder raw material is analyzed with a thermal analyzer. The starting point and the end point of the thermal decomposition temperature of the calcium carbonate powder raw material should be 650°C and 780°C. The particle size of the yttrium-rich mixed rare earth carbonate powder used is also above 150 mesh. At the same time, the weight percentage of the yttrium-rich mixed rare earth carbonate powder in the yttrium-rich mixed rare earth carbonate powder is: Y is 58.01%, La is 2.17%, and Ce is 0.69%, Pr is 1.10%, Nd is 5.44%, Sm is 3.68%, Eu is 0.20%, Gd is 6.8%, Tb is 1.41%, Dy is 9.08%, Ho is 1.86%, Er is 5.03%, Tm is 0.62%, Yb is 3.63%, Lu is 0.48%; the sum of the percentages of each single rare earth in the mixed rare earth is 100%.

[0039] Mix the purchased calcium carbonate powder and yttrium-rich mixed rare earth carbonate powder thorou...

Embodiment 2

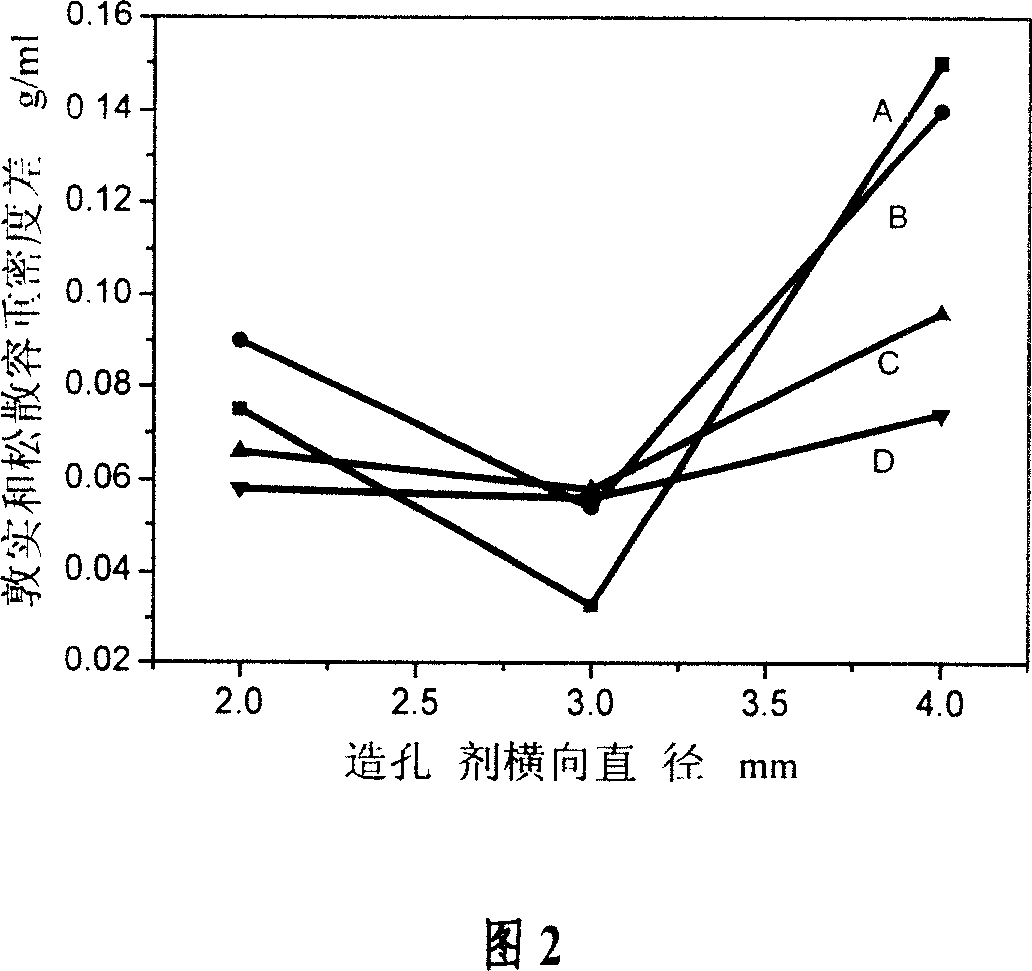

[0049] The rest is the same as in Example 1. The difference is: ①The formula of the pore former, as shown in the specific data in Table 1. ②The preparation conditions of the pore former are shown in the specific data in Table 2. ③The pore-forming conditions of the porous magnesium alloy are as shown in the specific data in Table 3. ④ The density of the synthesized pore former particles and the density of the porous magnesium alloy intermediate material containing the particles are shown in Table 4 for the specific data. ⑤ The main indicators of the obtained porous magnesium alloy material are shown in the specific data in Table 5.

Embodiment 3

[0051] The rest is the same as in Example 1. The difference is: ①The formula of the pore former, as shown in the specific data in Table 1. ②The preparation conditions of the pore former are shown in the specific data in Table 2. ③The pore-forming conditions of the porous magnesium alloy are as shown in the specific data in Table 3. ④ The density of the synthesized pore former particles and the density of the porous magnesium alloy intermediate material containing the particles are shown in Table 4 for the specific data. ⑤ The main indicators of the obtained porous magnesium alloy material are shown in the specific data in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Loose density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com