Patents

Literature

96results about How to "The process is green and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous capsule for cigarette and preparation method of aqueous capsule

ActiveCN106047485AImprove sealingWide range of optionsTobacco treatmentEssential-oils/perfumesWater solubleSolvent

The invention relates to an aqueous capsule for cigarette and a preparation method of the aqueous capsule. The aqueous capsule for cigarette consists of a capsule wall material and water-soluble core liquid, wherein the water-soluble core liquid is positioned inside the capsule wall material; the strength of the capsule wall material is 0.5-2.2kg; the density of the capsule wall material is 1.0-1.3g / cm<3>; and the density of the water-soluble core liquid is 0.9-1.3g / cm<3>. The aqueous capsule is simple in dripping method process, low in cost, uniform in particle size of a finished capsule product, wide in core liquid solvent optional range, stable in core liquid sealing, high in yield, green and environment-friendly in raw material and whole process procedure, safe and reliable, and applicable to industrial popularization.

Owner:YUNNAN XINYUN TECH DEV CO LTD

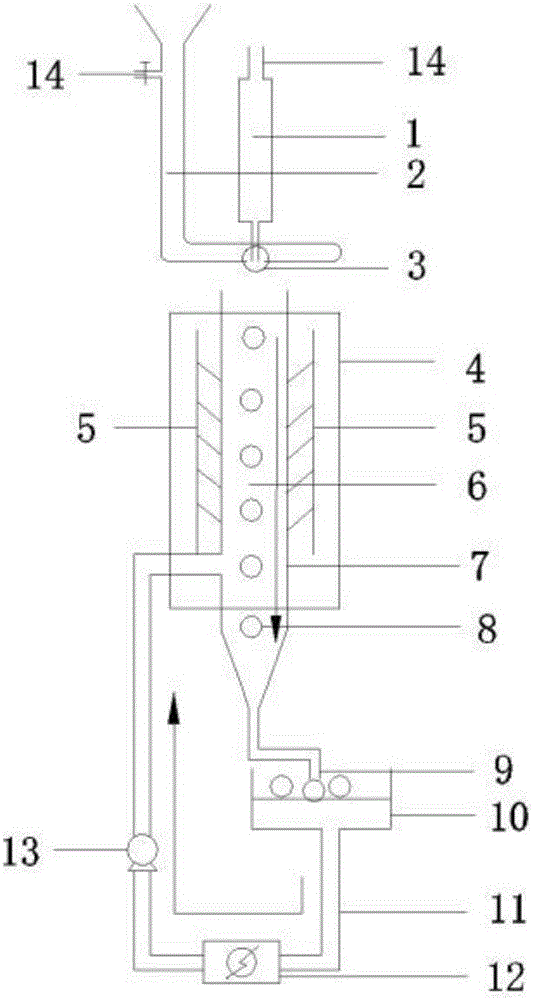

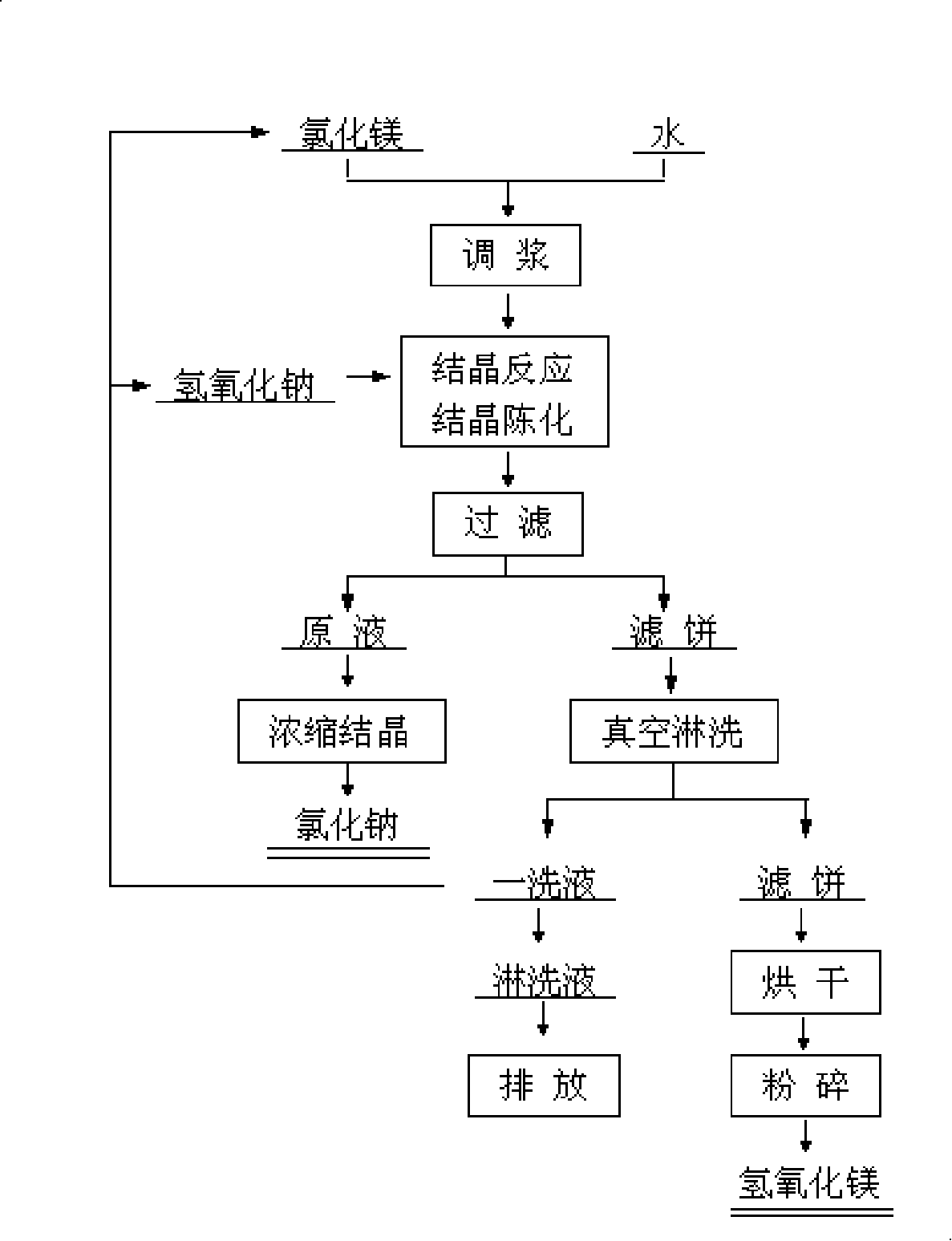

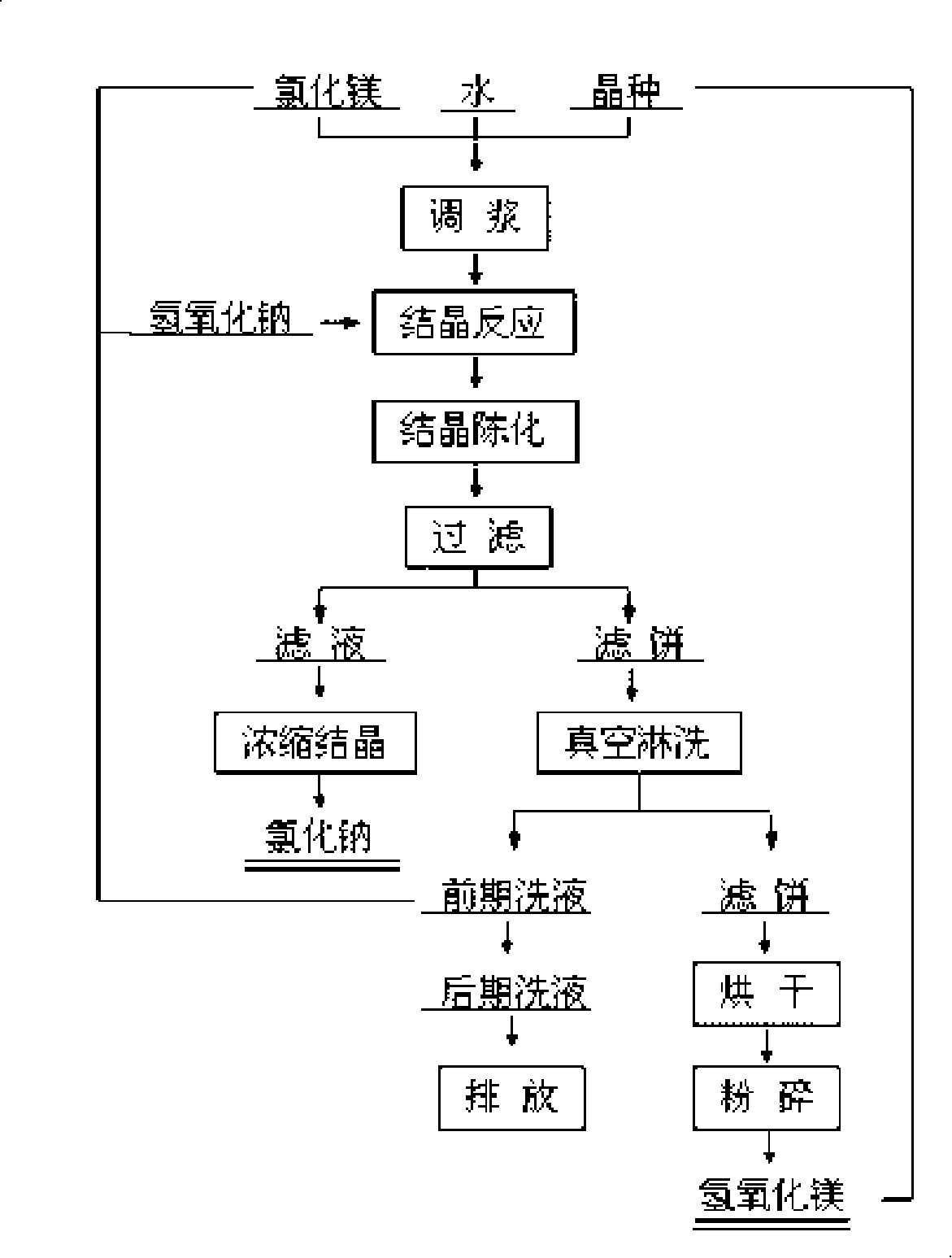

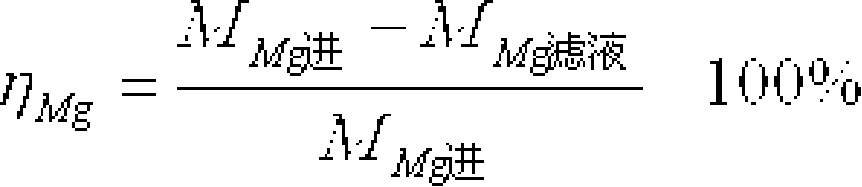

Technique for preparing high purity ultra-fine magnesium hydroxide by sodium hydroxide method

InactiveCN101234769ASpeed up the distribution balance stateHigh purityMagnesium hydroxideDecompositionSlurry

The invention discloses a process for preparing high-purity ultrafine magnesium hydroxide by a sodium hydroxide method; by using a crystal seed decomposition method, purified brine and crystal seed of the magnesium hydroxide are added to a reaction pool to be mixed and temperature is kept at 60-80 DEG C; then solution of the sodium hydroxide is added to the reaction pool to carry out the precipitation reaction, crystallization and aging; after the reaction is finished, slurry of the magnesium hydroxide is filtered and washed; cake after filter is dried and crashed, the crystal product of the magnesium hydroxide is obtained. Compared with the prior art, the process for preparing the high-purity ultrafine magnesium hydroxide accelerates agglomeration and growth of the magnesium hydroxide crystal by adding the crystal seed, solves the problem of the difficulty for filtering and washing the filter cake by using the prior sodium hydroxide method to produce the magnesium hydroxide, and directly utilizes the slurry of the magnesium hydroxide generated by the reaction as the crystal seed to carry out cyclic decomposition. The process flow is simple and the process parameter can be easily controlled. The production process is pro-environment without producing pollutant. At the same time, the purity of the magnesium hydroxide obtained by the process and the recovery rate of the magnesium are very high; furthermore, the purity of the by-product sodium chloride is high. The process for producing the magnesium hydroxide has great development prospect.

Owner:GUIZHOU UNIV

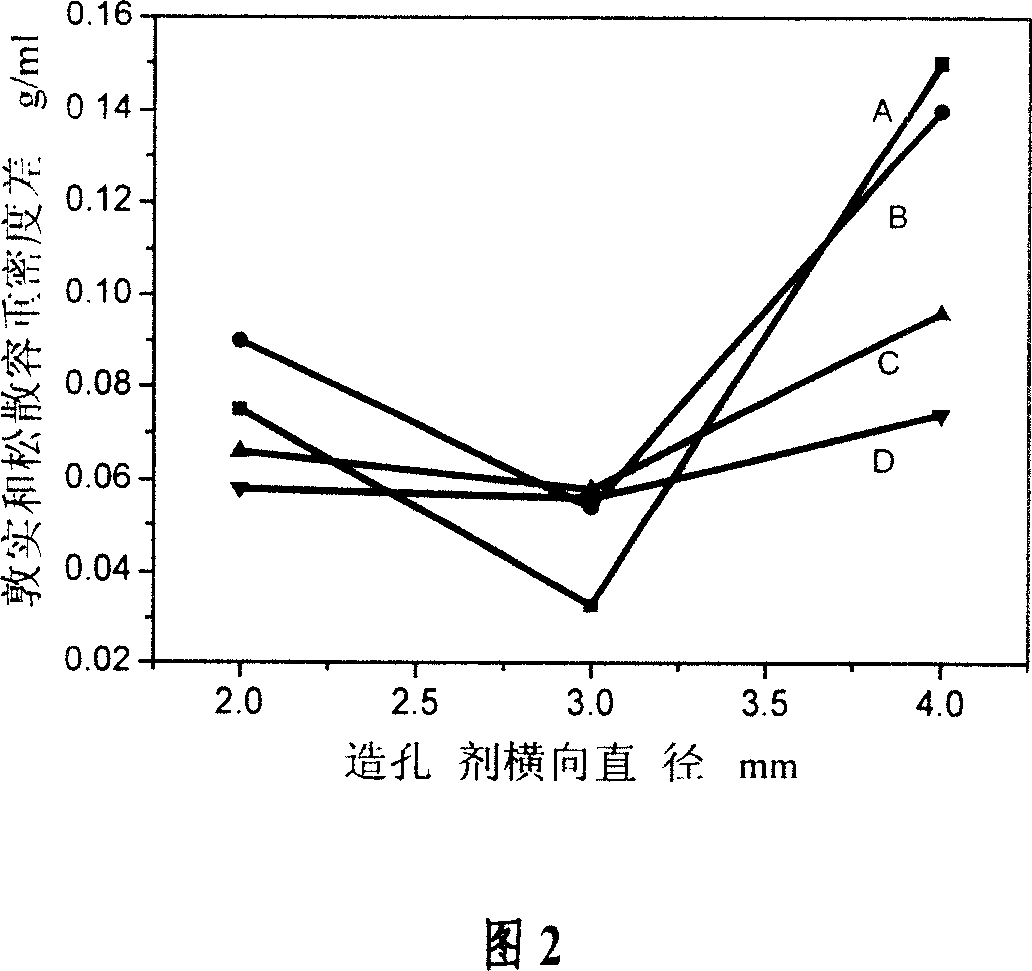

Prepn process of pore forming agent for porous magnesium alloy and porous aluminium and its pore forming method

The present invention relates to pore forming agent, and is especially pore forming agent for porous magnesium alloy and porous aluminum alloy and with controllable pore size, porosity and pore wall thickness and its preparation process and pore forming method. The pore forming agent is prepared with light calcium carbonate, RE carbonate, etc as material and through an extruding and pelletizing process. When it is used, the granular pore forming agent is used as the support and molten magnesium alloy or aluminum alloy is made to seepage flow into the pore forming agent so as to obtain porous magnesium alloy or aluminum alloy after treatment. The porous magnesium alloy and aluminum alloy preparing process can control the pore size, porosity and pore wall thickness effectively, and the alloy is used for sea water cell anode, metal rubber and other porous light metal product.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

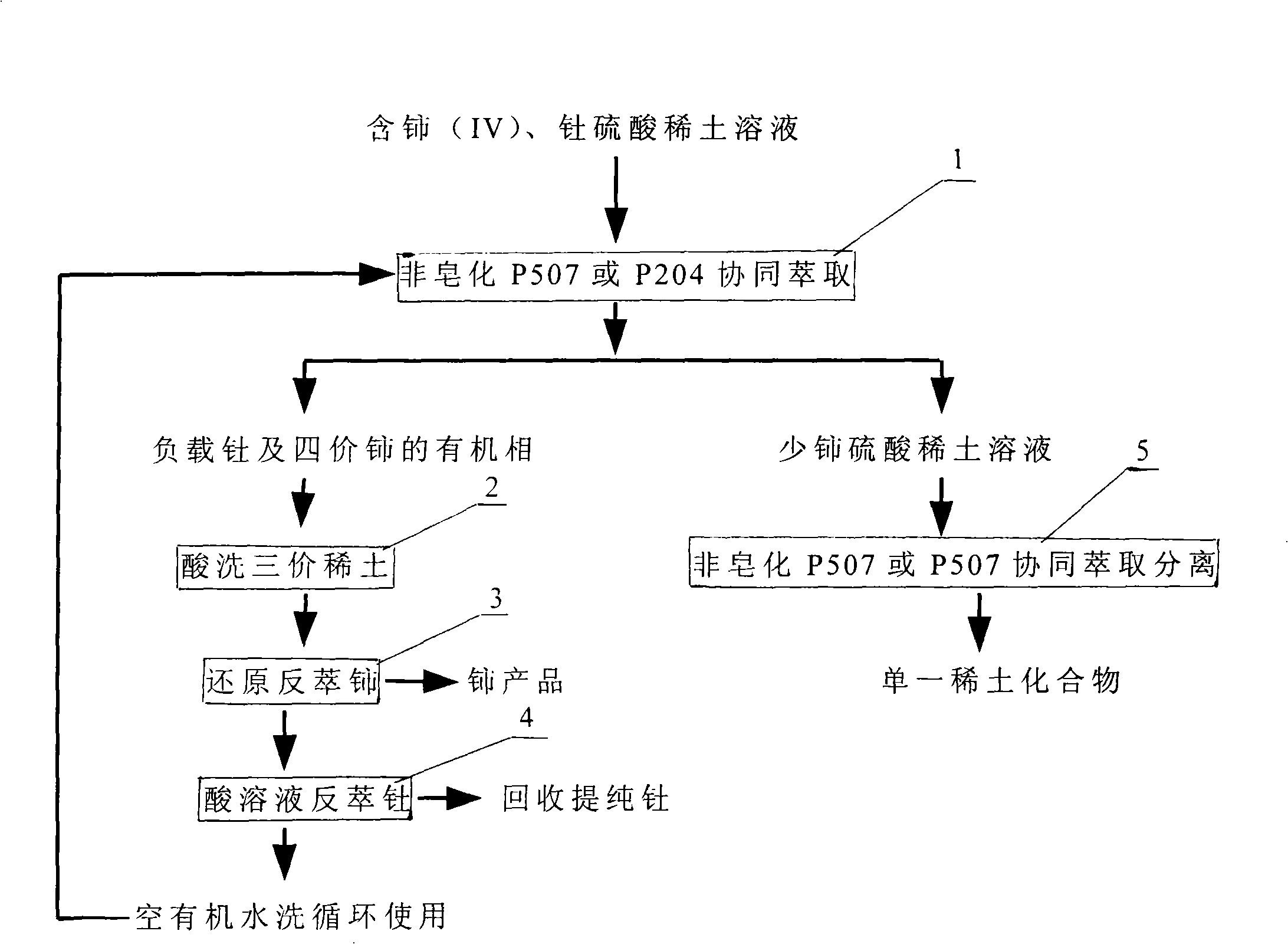

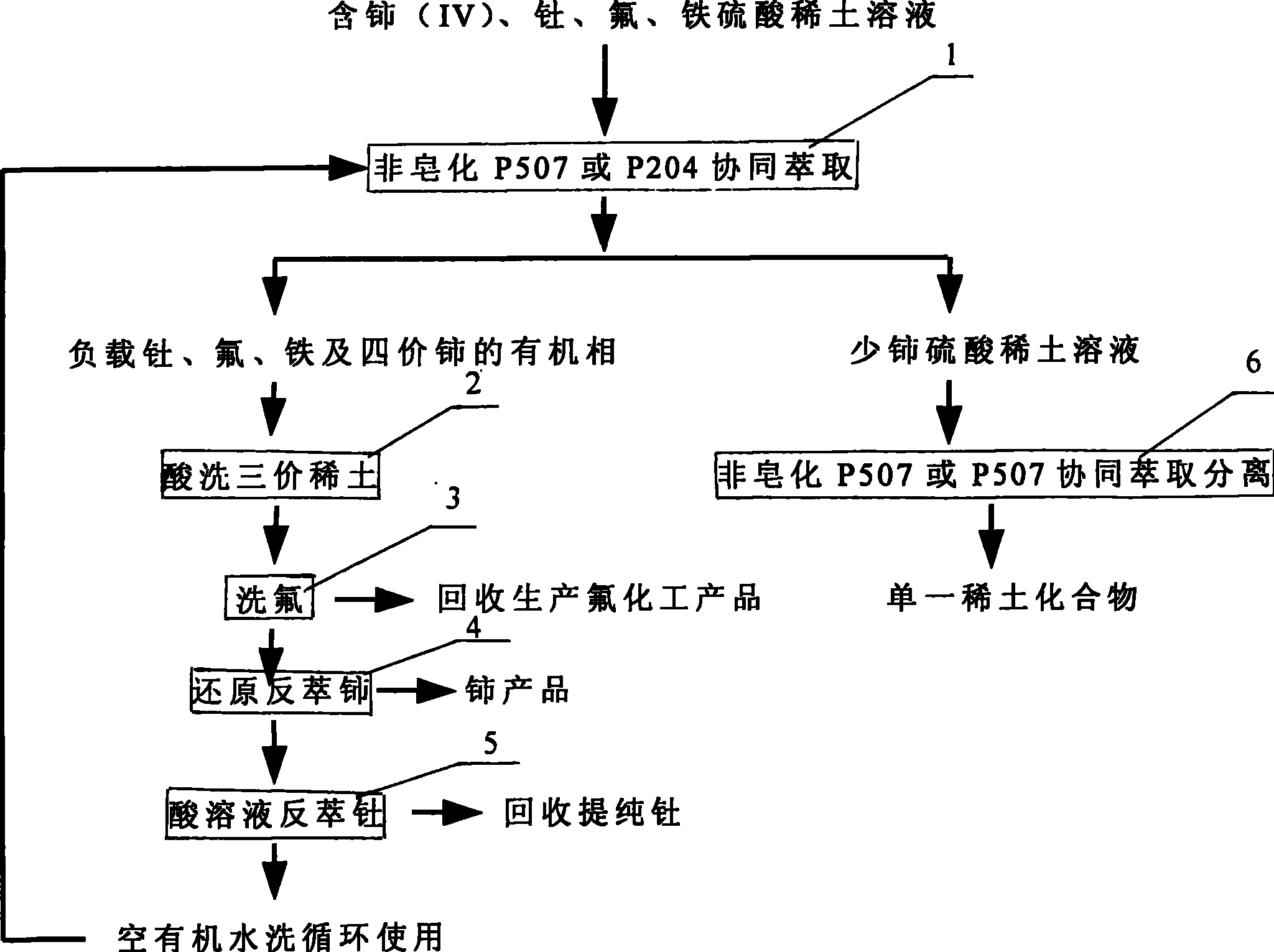

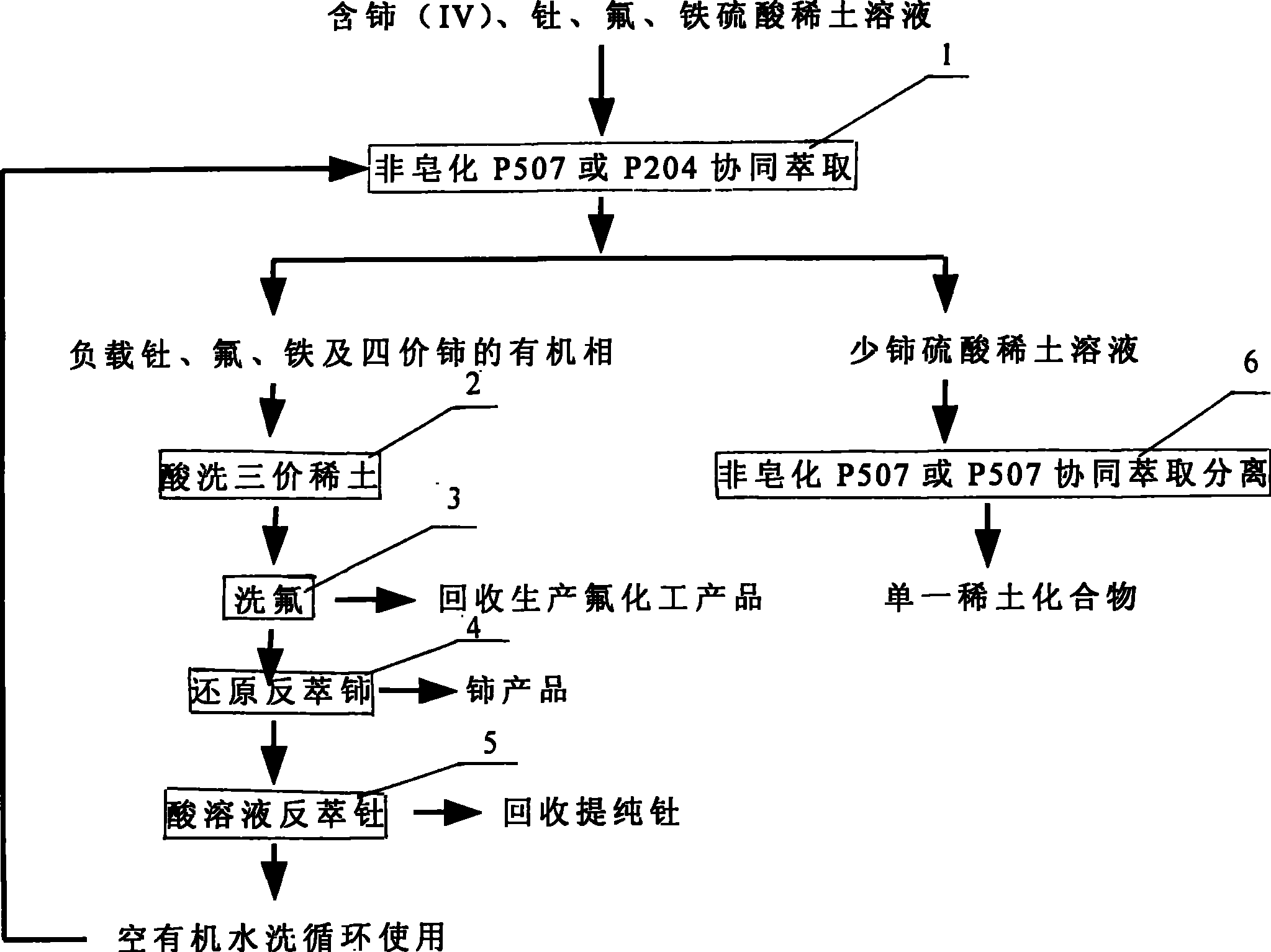

Technique for extraction separation of quadravalence cerium, thorium and cerium less tervalence rare earth from sulphuric acid rare earth solution

InactiveCN101294245ANo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementSulfate

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains the thorium and high-valence cerium, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (4) and the thorium are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain the products including pure cerium and pure thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or the synergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements after impurity removal. The technological methodn has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (4), the thorium and trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium is recovered as products, and the pollutions caused by thorium-containing waste residue and the ammonia-nitrogen containing wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, green environmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

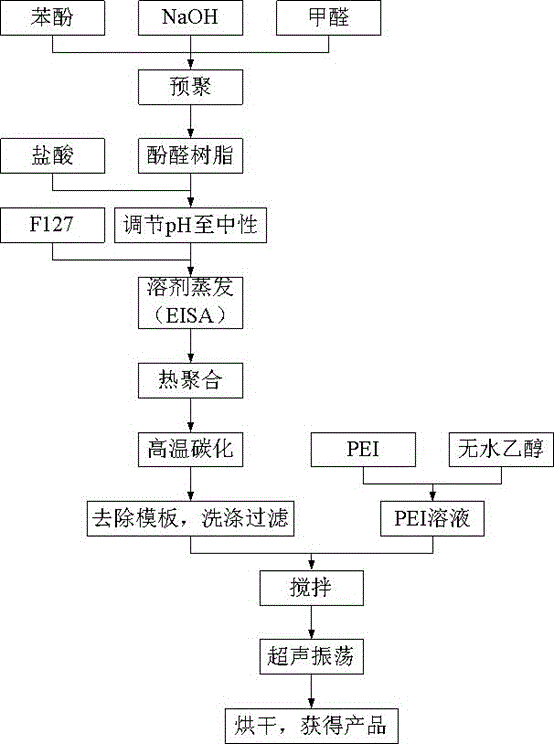

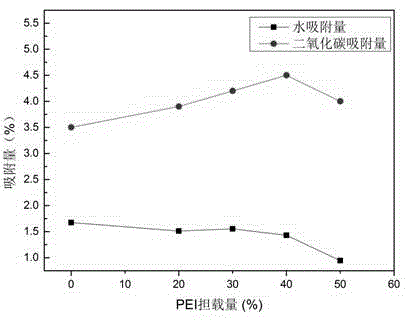

Carbon dioxide sorbent based on ordered mesoporous carbon and preparation method

InactiveCN105289530ALow renewableGood renewabilityOther chemical processesDispersed particle separationSorbentMaterials science

The invention provides a carbon dioxide sorbent based on ordered mesoporous carbon and a preparation method. According to the preparation method, ordered mesoporous carbon is synthesized according to a solvent evaporation-induced self assembly (EISA) method, and supported polyethylene imine (PEI) modification is performed on ordered mesoporous carbon according to an impregnation method, so as to improve the hydrophobicity of the novel sorbent. The sorbent obtained according to the preparation method is uniform in pore size distribution and very high in orderliness; the sorbent adopts the structure of ordered mesoporous carbon, so that the heat stability is relatively high; the carbon dioxide adsorbing capacity of the sorbent and the hydrophobicity are relatively high. Therefore, based on such properties, the sorbent not only can adapt to a high-humidity environment, but also can be applied to an adsorbing process of which the temperature is above normal; meanwhile, the renewability is high, no pollutant is generated in the preparation process, and the technological process is environmentally friendly.

Owner:NORTHEASTERN UNIV

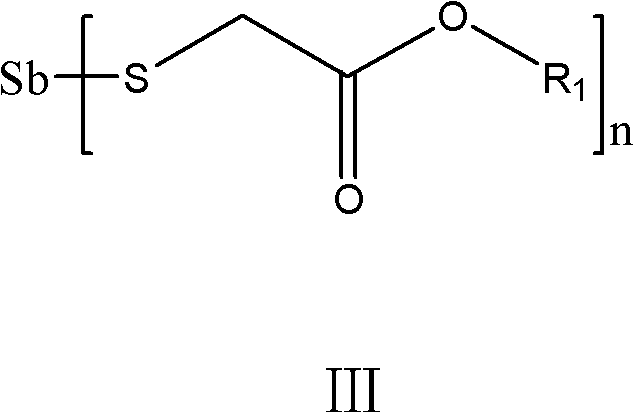

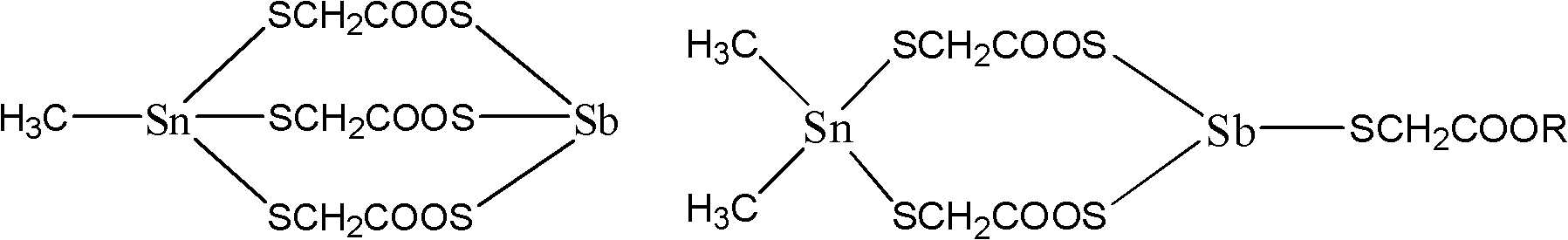

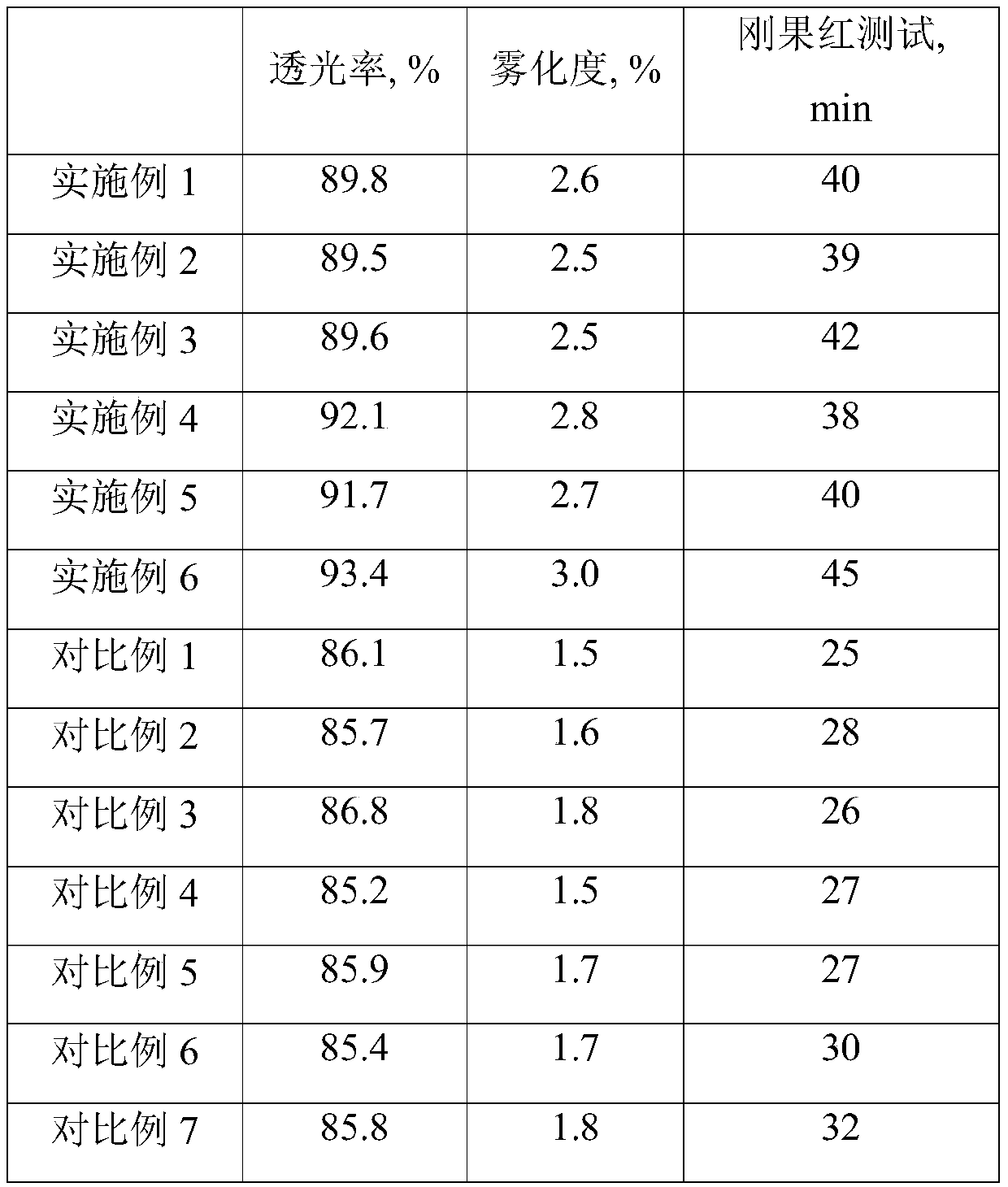

Sn-Sb-Zn composite heat stabilizer for polyvinyl chloride (PVC) sheets and preparation method and application thereof

InactiveCN102675770AReduce consumptionImproves initial and long-term thermal stabilityOrganic acidChemistry

The invention discloses a Sn-Sb-Zn composite heat stabilizer for polyvinyl chloride (PVC) sheets. The Sn-Sb-Zn composite heat stabilizer comprises, by weight, 10-20 parts of thioglycolic acid methyl tin, 40-60 parts of thioglycolic acetic ester antimony and 5-15 parts of organic acid zinc salt. The invention further discloses the preparation method of the Sn-Sb-Zn composite heat stabilizer and application of the Sn-Sb-Zn composite heat stabilizer as a PVC stabilizer. The composite heat stabilizer is high in product quality, low in toxicity, environment-friendly, less in tin content in a formula and applicable to various PVC hard sheet materials, has good initial and long-term heat stability, and is high in product transparency.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

Liquid rare earth calcium zinc stabilizer and preparation method thereof

The present invention provides liquid rare-earth calcium-zinc stabilizer and the preparation method. The liquid rare-earth calcium-zinc stabilizer is compound made of rare-earth calcium-zinc compound and effectively cooperative material. The beneficial effects of the liquid rare-earth calcium-zinc stabilizer and the preparation method provided by the present invention is mainly shown in that (1) the liquid rare-earth calcium-zinc stabilizer has the advantages of high product quality, no toxin, environmental protection, no toxic heavy metal component in recipe, strong practicability and wide application range, which is particularly applicable to the transparent packaging material of food, candy and medicine, as well as the advantages of good processing performance, no precipitation, excellent lubricating performance, superior transparency, thermal stability and oxidation resistance; (2) the process condition is stable and easy to control, thus being applicable to industrialized mass production; the process flow has the advantages of simplicity, environment friendliness, easy access to raw materials and less energy consumption, thus greatly decreasing the production cost; in addition, the whole production process has anhydrous operation, safety and convenience, no discharge of three wastes and less environmental pollution.

Owner:高春福

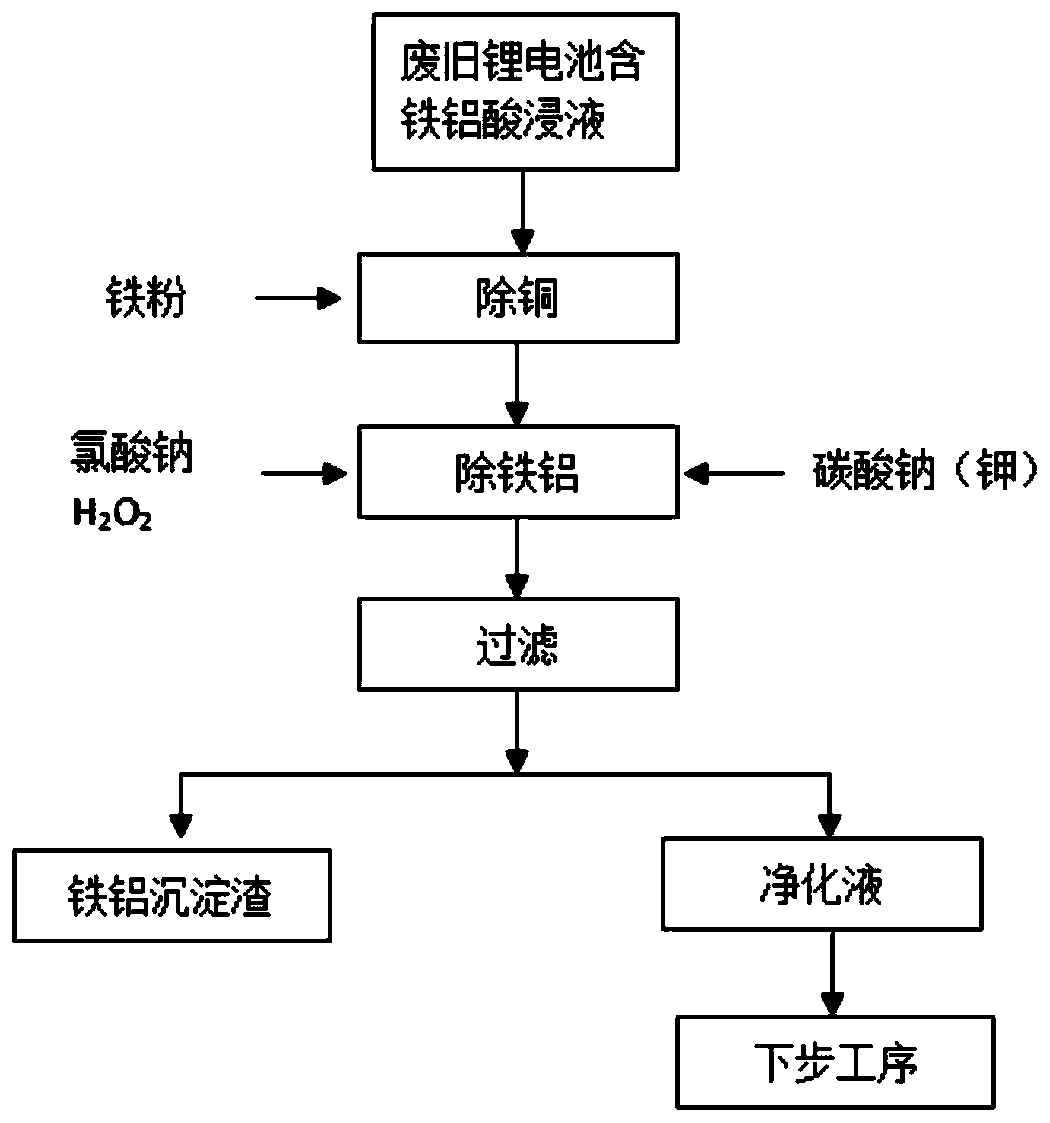

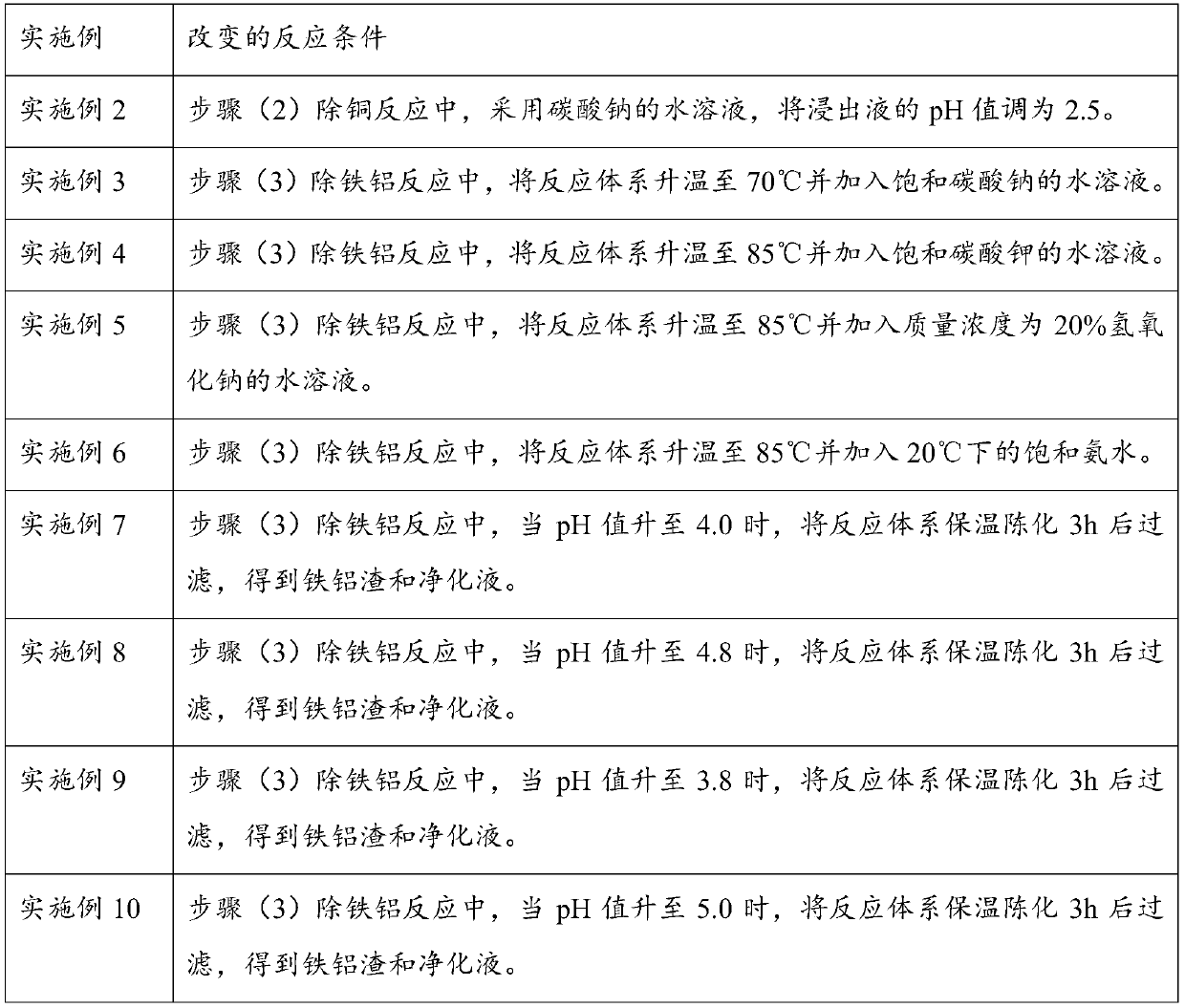

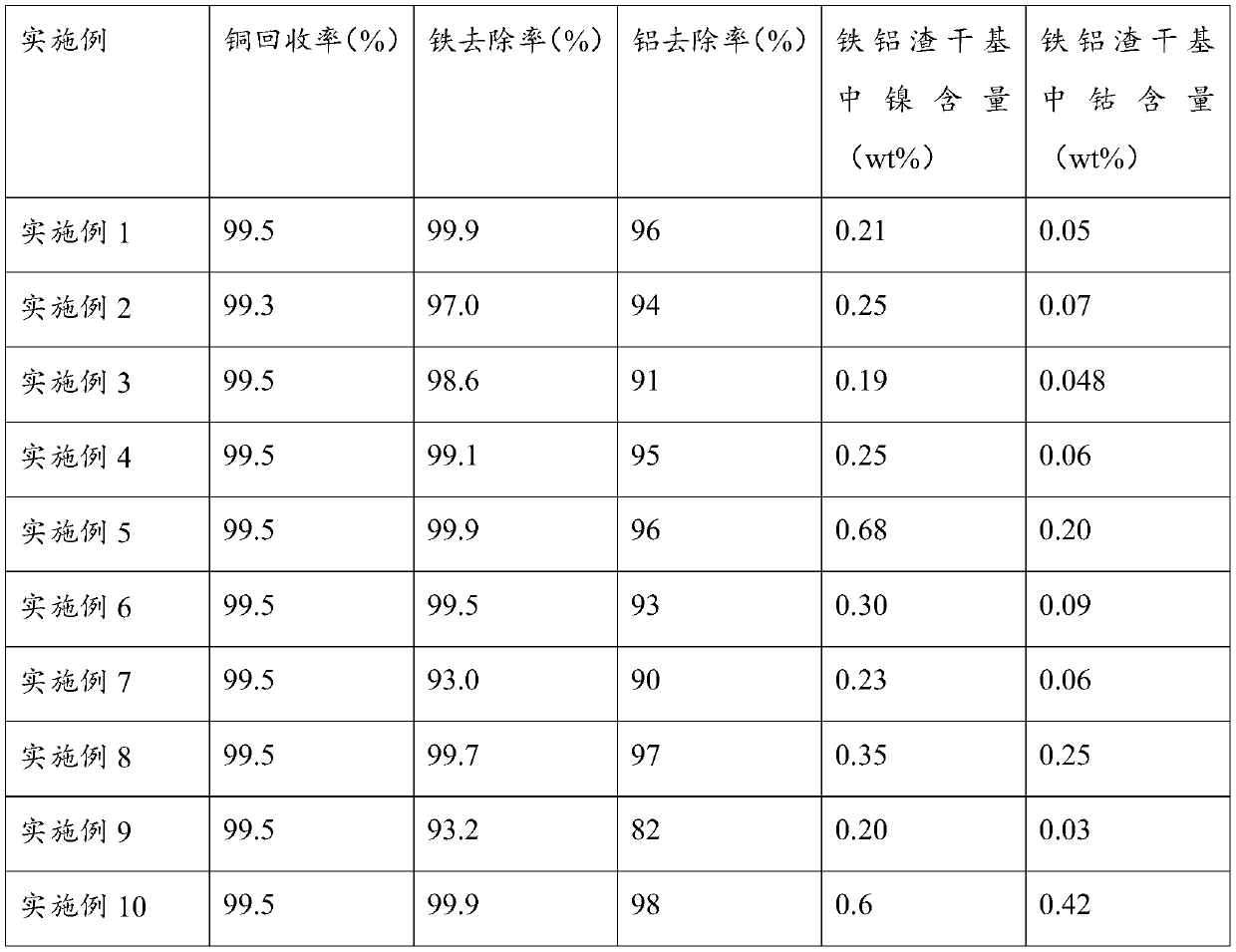

Method for recovering iron and aluminum from waste ternary lithium ion battery

InactiveCN110492193AImprove aggregation effectHigh removal rateWaste accumulators reclaimingProcess efficiency improvementElectrical batteryFiltration

The invention provides a method for recovering iron and aluminum from a waste ternary lithium ion battery, which comprises the following steps: crushing the waste ternary lithium ion battery, adding sulfuric acid and hydrogen peroxide into the crushed waste ternary lithium ion battery, and stirring to react to obtain a leachate; adding iron powder into the leachate, performing a stirring reaction,and filtering to obtain crude copper powder and copper removal liquid; successively adding an oxidizing agent and alkali carbonate into the copper removal liquid, and performing heat-preservation aging and filtration to obtain iron-aluminum slag and purified liquid. The iron-aluminum slag obtained through the method is good in gathering effect, and the removal rate of iron and aluminum is high.In addition, alkali carbonate is used for replacing alkali in the prior art in the iron and aluminum removing process, the technological process is environmentally friendly, and the recycling cost islow.

Owner:GREE ELECTRIC APPLIANCES INC

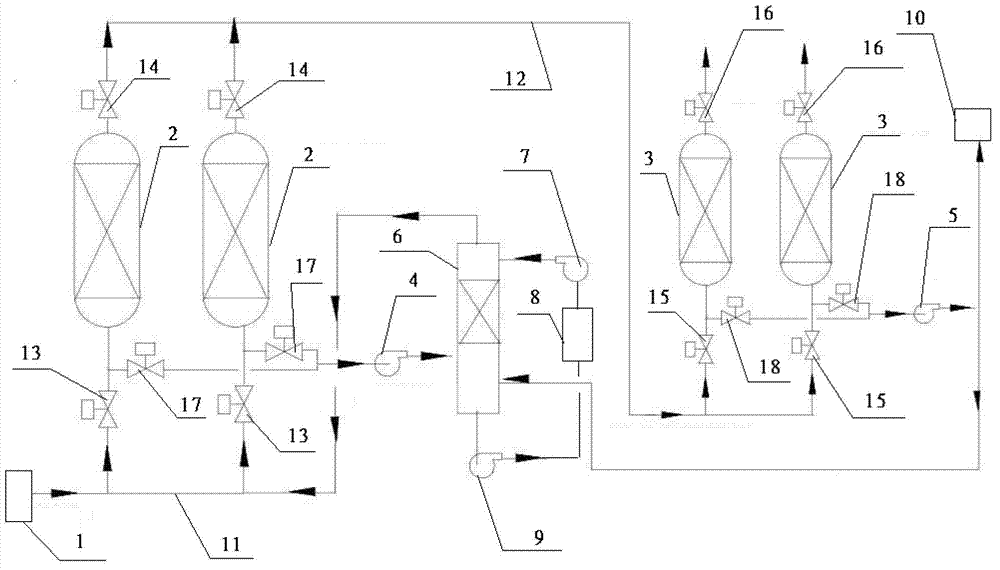

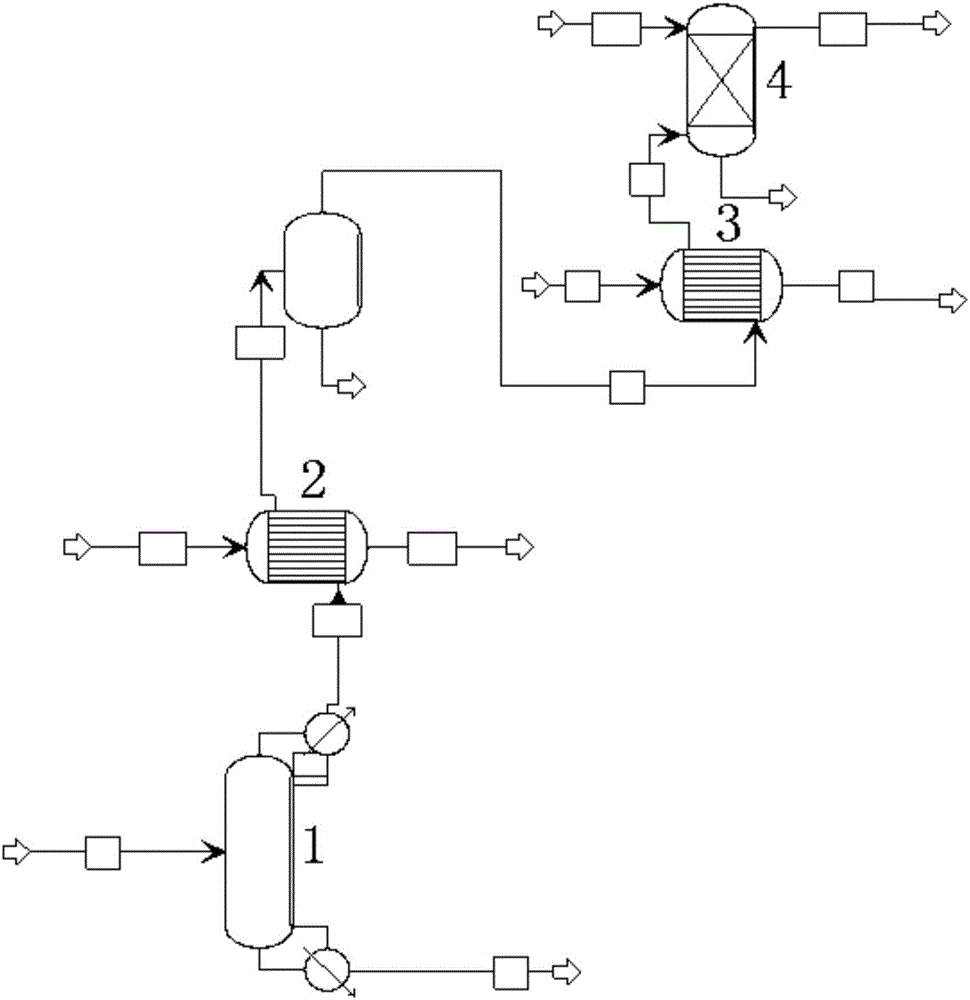

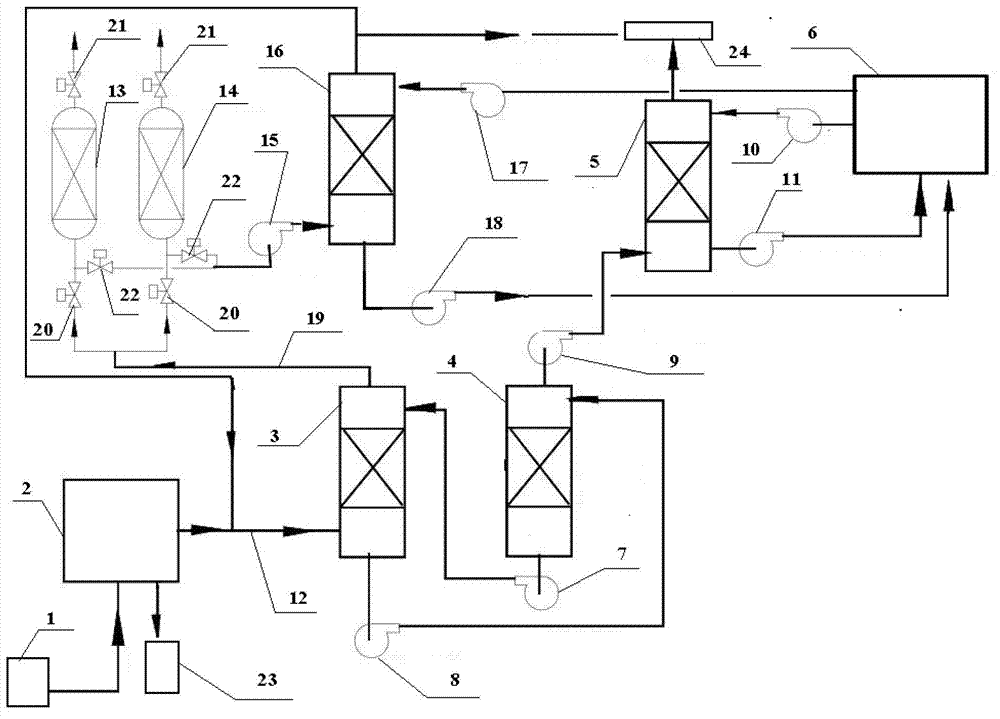

Absorption oil-gas recycling system and absorption oil-gas recycling process

The invention relates to an absorption oil-gas recycling system and an absorption oil-gas recycling process. The system comprises an absorption device, a desorption device, an intake device and a storage device, which are connected with one another. The absorption device and the desorption device are more first-staged. By the absorption oil-gas recycling system, the recycling process by combining multistage absorption and desorption is achieved, the problems of pollution and waste of hydrocarbon components in oil and gas are solved, external environment is protected effectively, and energy is utilized efficiently and economically. The absorption oil-gas recycling system is suitable for popularization and application in related oil-gas recycling fields, especially suitable for fields such as lean oil recycling and reusing and crude oil-gas recycling and reusing.

Owner:BAY ENVIRONMENTAL TECH BEIJING

Process for storing carbon dioxide in flue gas by utilizing brucite

InactiveCN102247753ALow cost of industrializationPermanent storageProductsReagentsEnvironmental resistanceResource utilization

The invention provides a process for storing carbon dioxide in flue gas by utilizing brucite. By the process, the release of magnesium ions and the carbonatization process of carbon dioxide are separated; and corresponding improvement measures are taken for each process, so that the process is higher in efficiency and lower in energy consumption. NH4Cl solution for digesting the brucite can be repeatedly used, so that the recycling of a raw material and the resource utilization of a product are realized. The whole process is environment-friendly and efficient, and low in energy consumption, and has the potential of industrial scale application.

Owner:NANJING UNIV

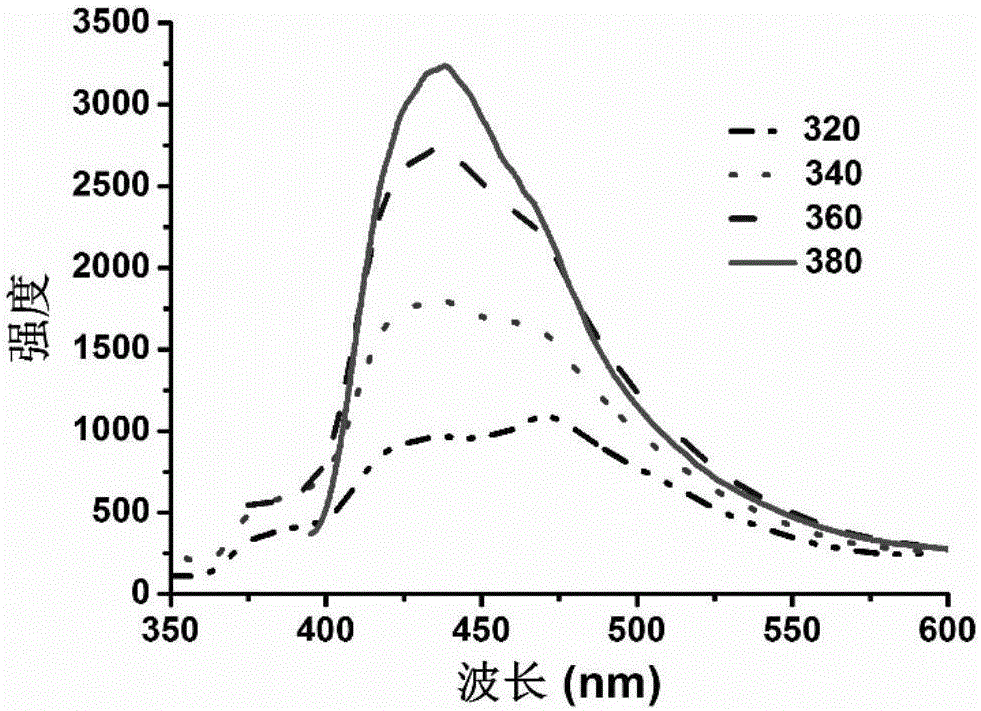

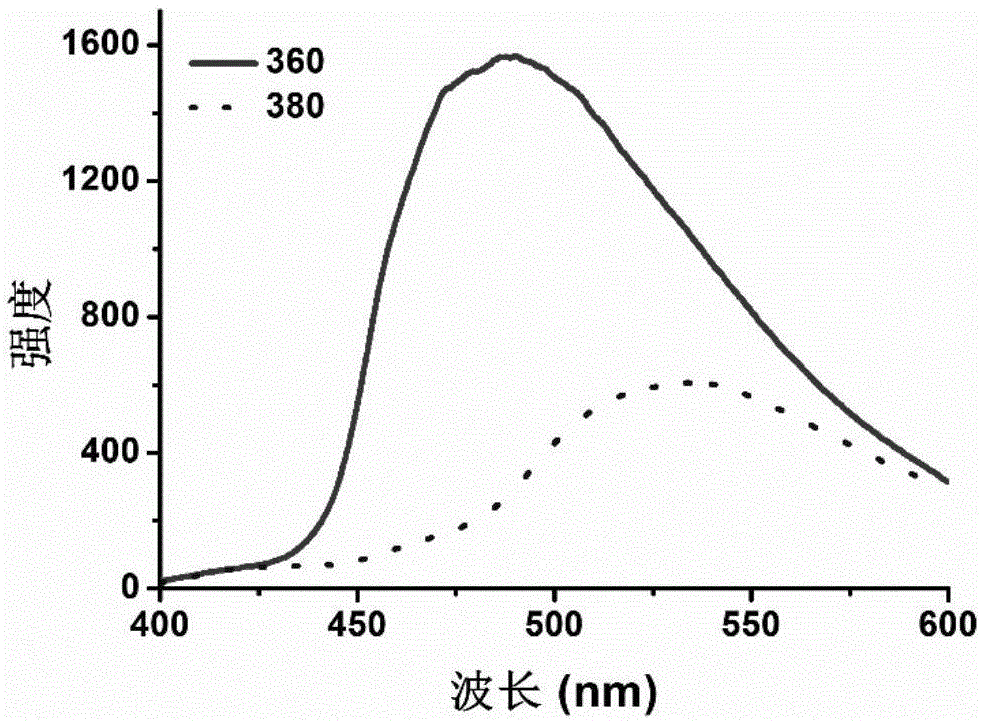

Carbon dot based composite nano-material with controllable luminescent properties, preparation method and application thereof

ActiveCN106497560AControllable LuminescenceIncrease dosageLuminescent compositionsFreeze-dryingSurface modification

The invention provides a carbon dot based composite nano-material with controllable luminescent properties, a preparation method and application thereof. The preparation method includes: adding cyanuric acid into a carbon quantum dot aqueous solution with a surface modified by carboxyl groups, or adding alkali metal hydroxide and cyanuric acid, stirring the obtained mixed solution, conducting centrifugation, collecting the precipitate, and performing freeze drying so as to obtain the carbon dot based composite nano-material with controllable luminescent properties. The preparation process provided by the invention is simple, low in cost, non-toxic and environment-friendly. By adjusting the pH value, the fluorescence luminous efficiency of the material can be greatly improved, and also the afterglow color and lifetime of the material can be changed. The carbon dot based composite nano-material with controllable luminescent properties provided by the invention has important application value in counterfeiting prevention, biosensing, display and lighting and other fields.

Owner:BEIJING UNIV OF CHEM TECH

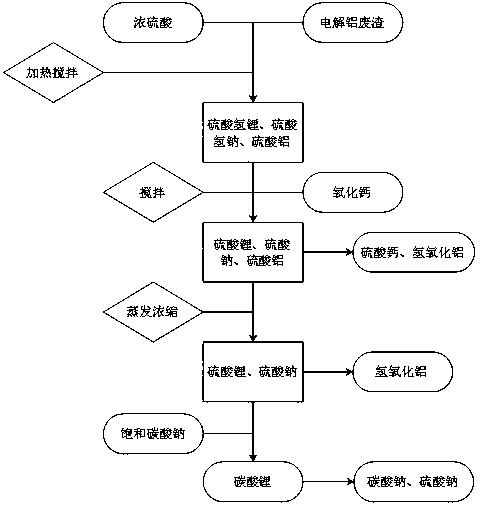

Method for extracting lithium from electrolytic aluminum waste residues

ActiveCN109179457AImprove the efficiency of lithium extractionReduce process stepsCalcium/strontium/barium sulfatesHydrogen fluorideLithium carbonateAluminum industry

The invention discloses a method for extracting lithium from electrolytic aluminum waste residues. The method comprises the following steps: (1) reacting the electrolytic aluminum waste residues withconcentrated sulfuric acid to obtain a mixture A; (2) adding water to dissolve the mixture A, filtering the obtained solution to obtain a filtrate B, slowly adding calcium oxide to the filtrate B, andfiltering the obtained solution to obtain a filter residue C and a filtrate D; (3) heating the filtrate D, carrying out evaporative concentrating, filtering the obtained concentrate, further carryingout evaporative concentrating on the obtained filtrate to obtain a filtrate E, and maintaining the filtrate E in a heated state; and 4) adding a saturated sodium carbonate solution to the filtrate Ein order to obtain a suspension F, filtering the suspension F to obtain a filter cake, and washing and drying the filter cake to obtain a lithium carbonate product. The method adopts the waste residueof the electrolytic aluminum industry as raw material, the raw material has a wide source, and has a lower cost than a lithium ore raw material, the method has the characteristics of easiness in extraction and high yield, other raw materials used in the extraction method have a low price and low cost, and obtained byproducts can be recycled.

Owner:台州闪能科技有限公司

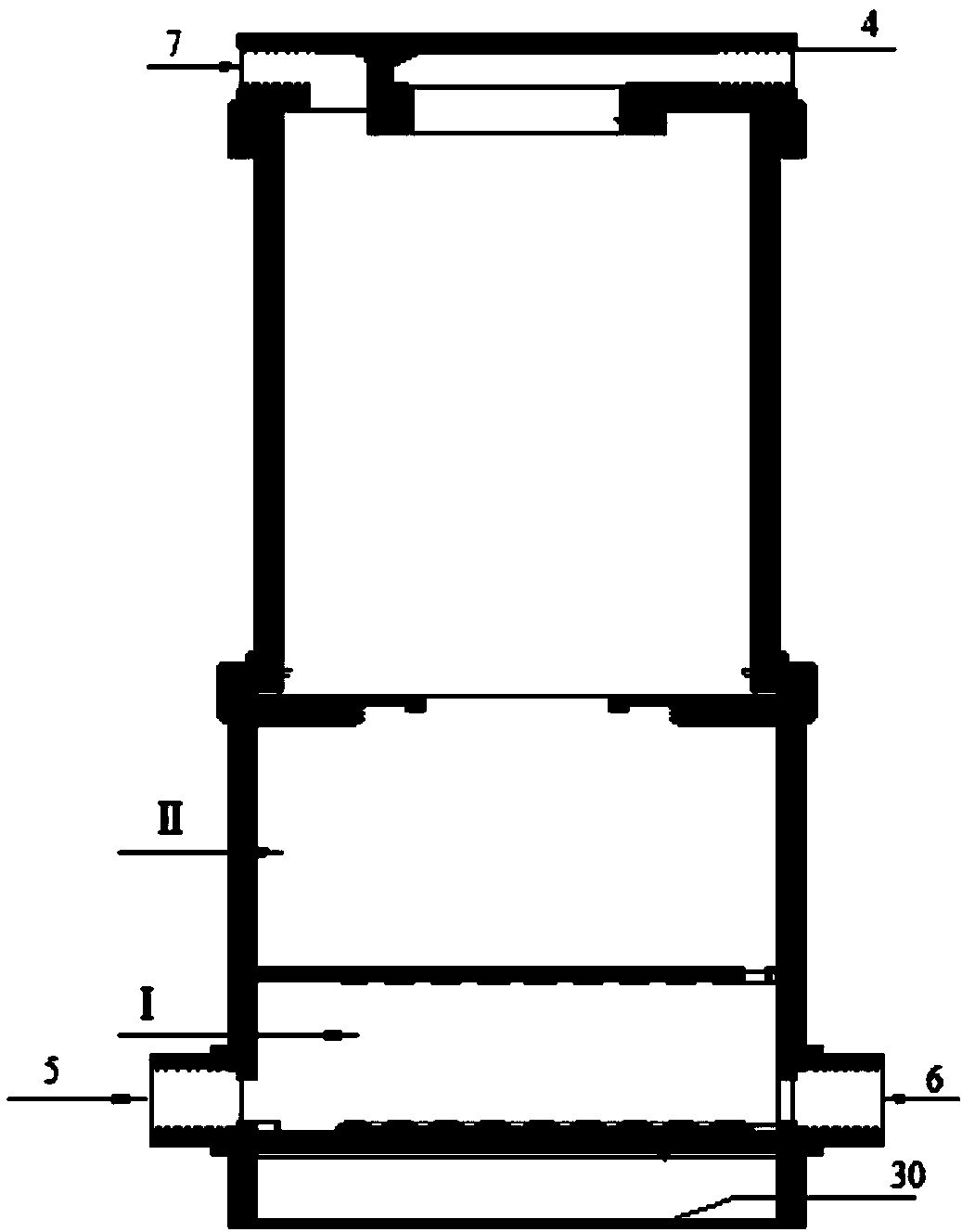

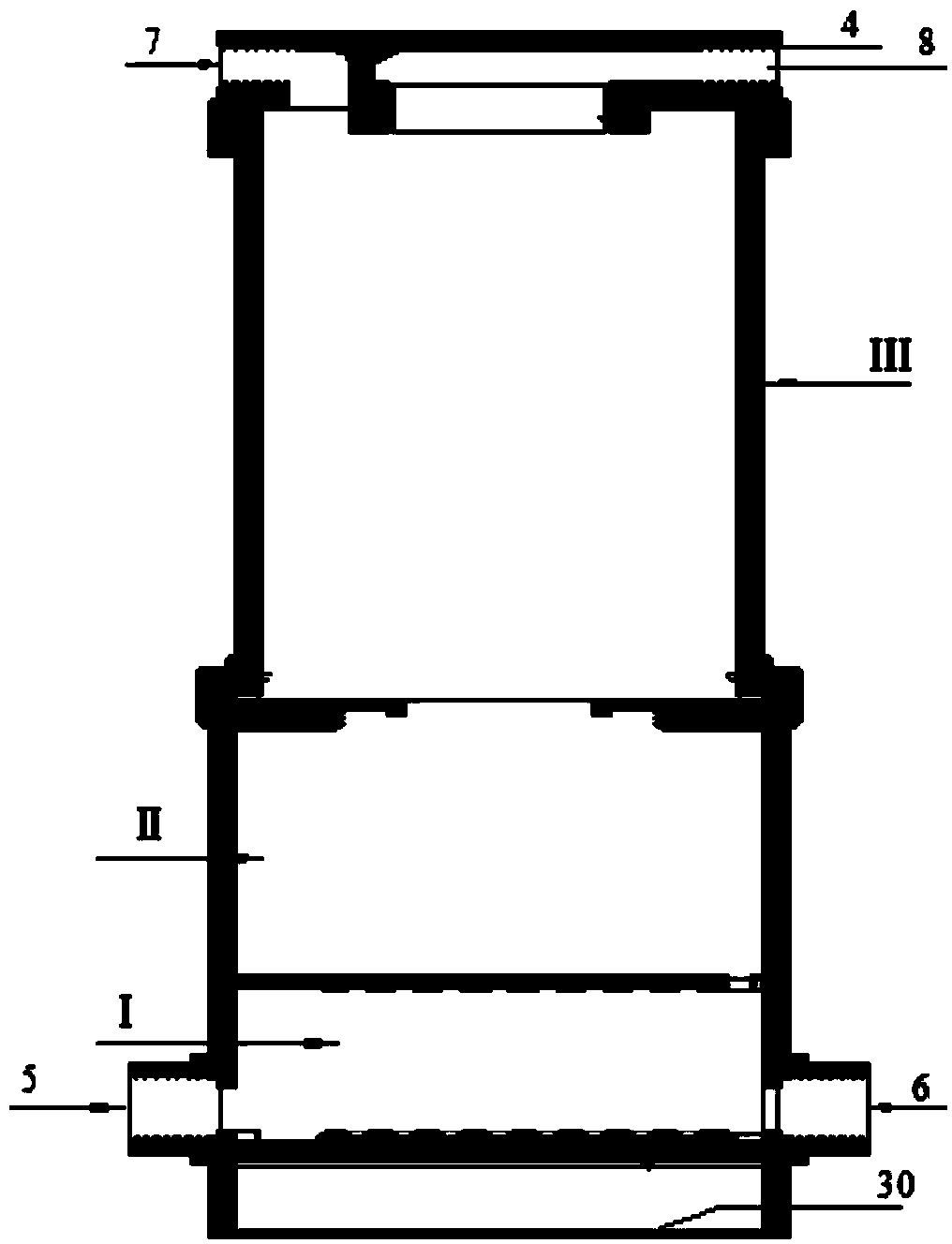

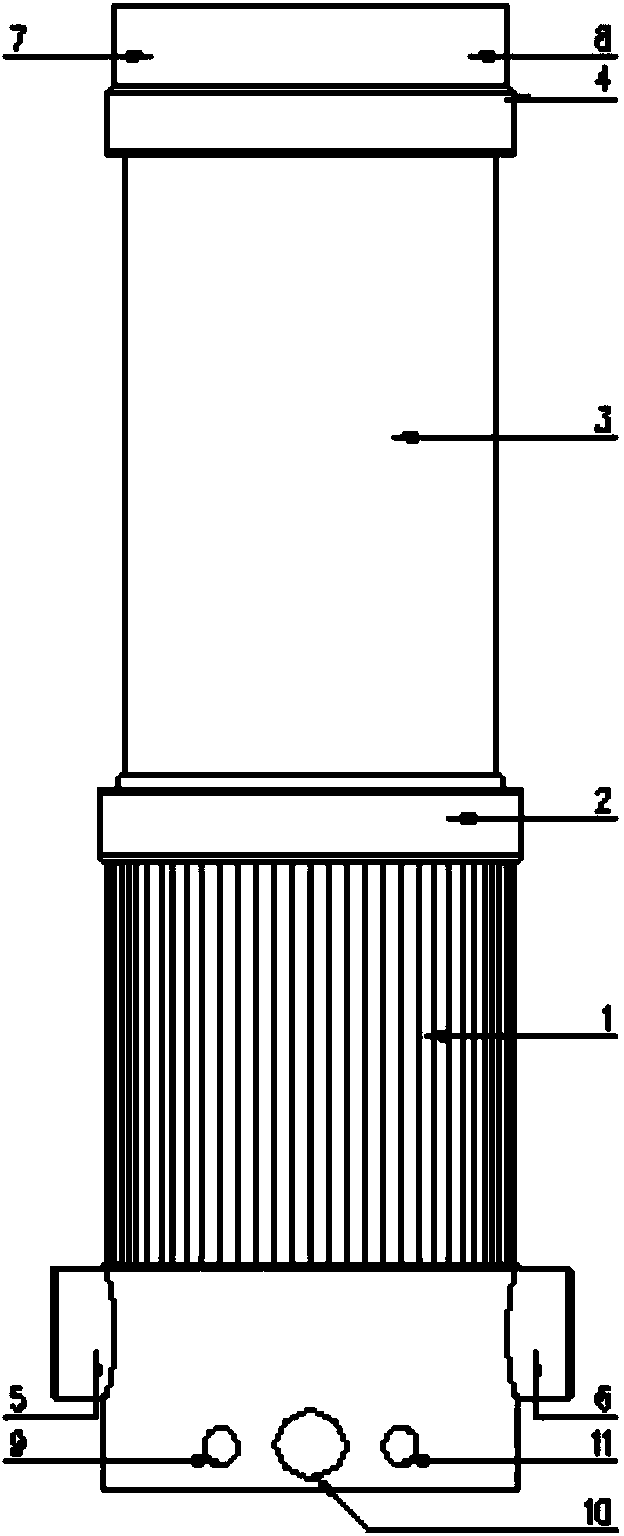

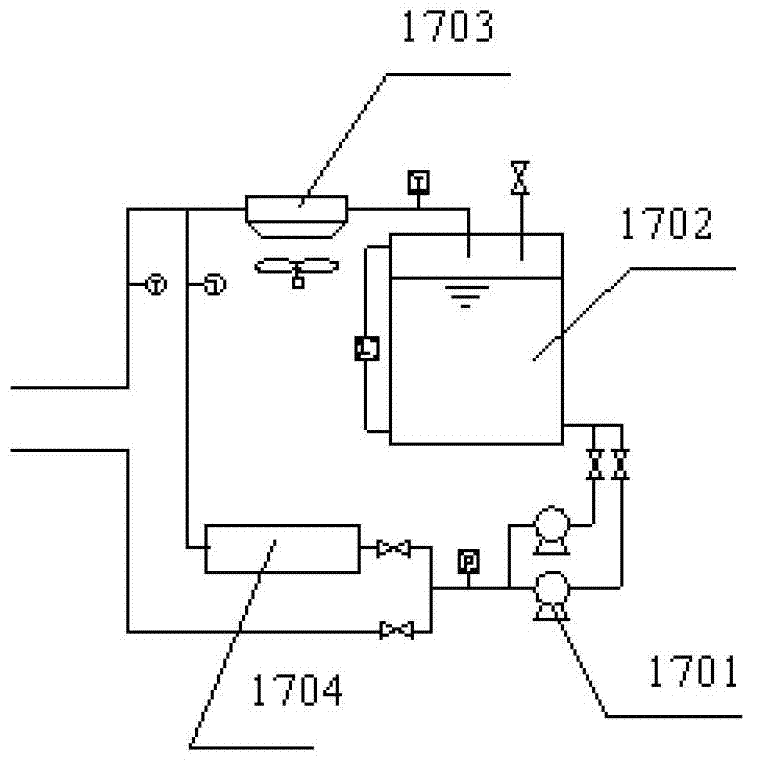

Water-purifying process and water-purifying equipment thereof

InactiveCN104098218ARealize integrated processingRealize water conservation and environmental protectionMultistage water/sewage treatmentWater savingTap water

The invention relates to a water-purifying process and water-purifying equipment thereof. Tap water is treated into flushing water, clean water and direct drinking water in a grading and classifying manner as required through a first-stage purification treatment device, a second-stage purification treatment device and a third-stage purification treatment device which are connected in sequence from bottom to top. By adopting the water-purifying process and the water-purifying equipment, water resources are utilized more optionally and reasonably, the problems of secondary pollution and the like since heavy metal pollutants in tap water cannot be removed in an efficient and environment-friendly way in the prior art are solved effectively, heavy metal ions, residual chlorine and other harmful particles in tap water are removed efficiently, bacteria are killed, the water quality is improved, sewage is disposed automatically, and the water yield and the utilization ratio of water are increased greatly; the health of a user is ensured; tap water is classified and treated effectively and is utilized in a shunting way according to the water quality, water amount and water pressure requirements of household water, and water is saved; energy is saved efficiently, space is saved, and remarkable energy-saving and environmental protection effects are achieved. The water-purifying process and the water-purifying equipment are suitable to be popularized and applied in relevant tap water treatment field.

Owner:合肥一言科技发展有限公司

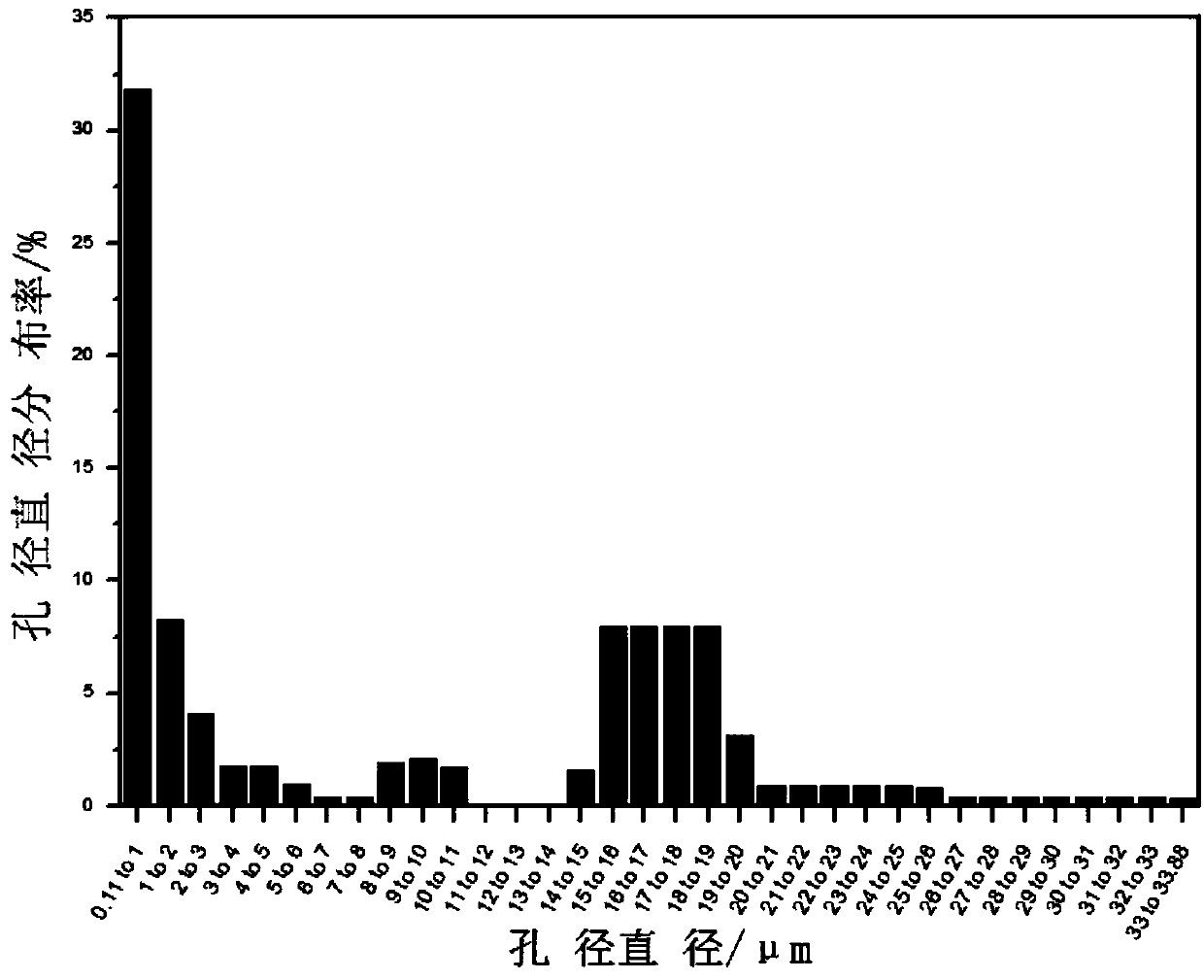

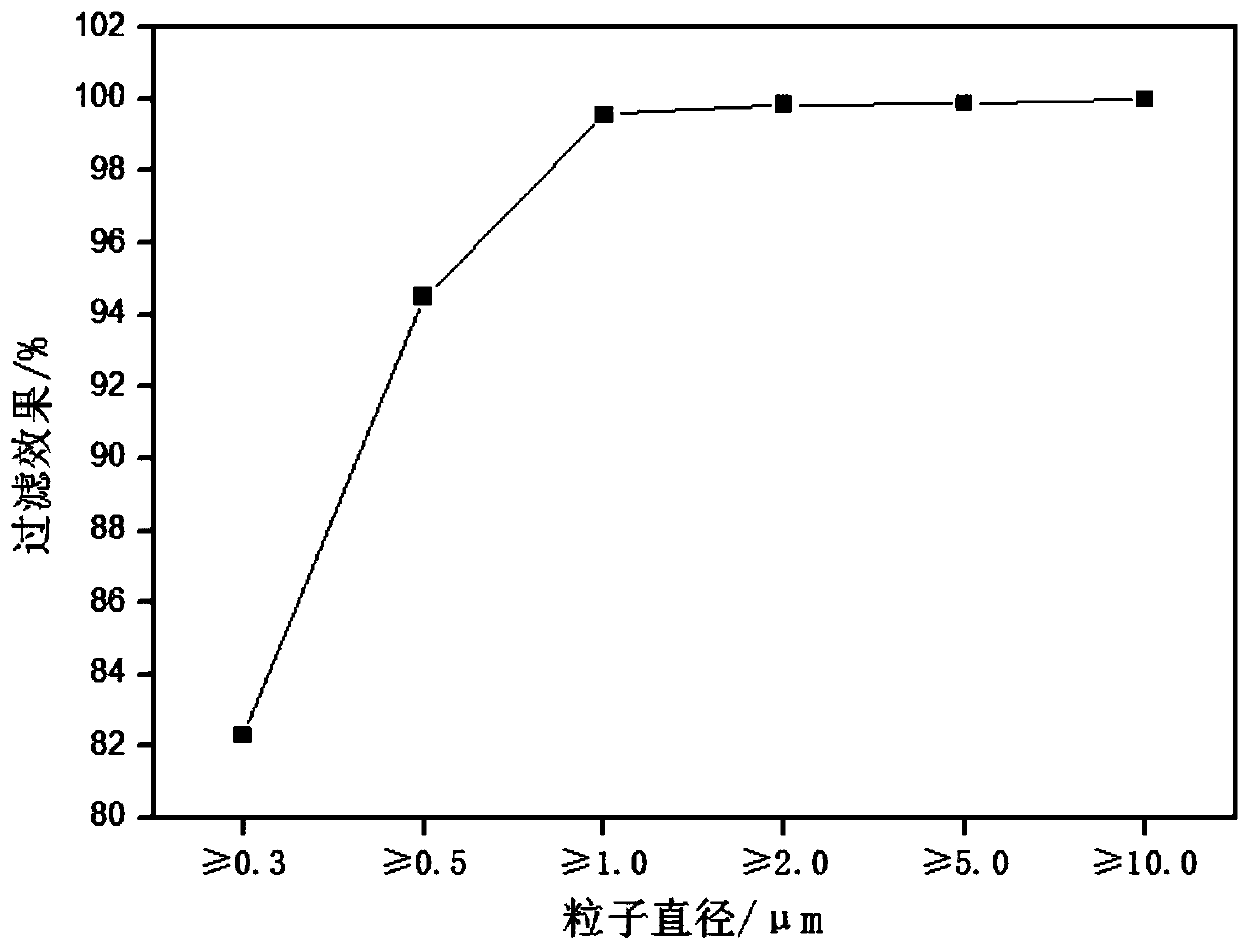

Preparation method of cotton bast fiber and chitosan composite nonwoven fabric for filtering

ActiveCN107604739AAvoid damageEasy to separatePulp beating methodsReinforcing agents additionHigh volume manufacturingElectrospinning

The invention discloses a preparation method of cotton bast fiber and chitosan composite nonwoven fabric for filtering, and belongs to the technical field of fiber materials. Cotton bast is separatedthrough steam flash-explosion pretreatment, formation is conducted by a papermaking method, and chitosan is added to enhance the mechanical property and the filtering efficiency. The preparation method is simple, convenient and environment-friendly in process flow and adapts to industrialized production. The nonwoven fabric adopts lignin-enriched cotton bast fiber and chitosan as raw materials, sothat the nonwoven fabric has high antibacterial property. The cotton bast and the chitosan are biology-based materials and can be degraded in the natural environment after use, so that environmentalburden is reduced and the problem that the electrostatic spinning method is difficult in industrialized and mass production is solved.

Owner:JIANGNAN UNIV

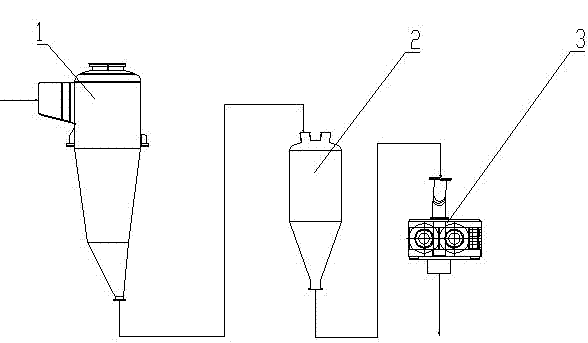

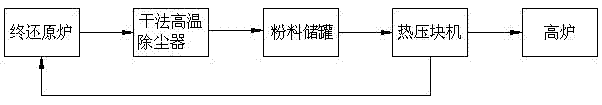

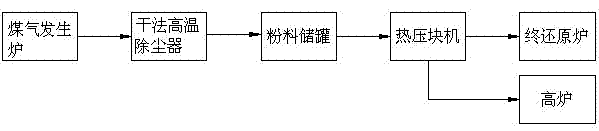

Comprehensive treatment process for high-temperature removed dust

The invention discloses a comprehensive treatment process for high-temperature removed dust. The process is used for thermally pressing the high-temperature removed dust to form hot removed dust press blocks by effectively using massive physical heat of dry high-temperature removed dust and easy forming property of a high-temperature material. The hot removed dust press block product provides a hot raw material for the subsequent process, and is added into a final reduction furnace or a pre-reduction furnace in a two-step smelting reduction process or added into a blast furnace after being cooled in use, so that the energy consumption of the subsequent process is effectively reduced. Meanwhile, the process links of cooling the hot removed dust, mixing, adding adhesive, pelletizing and the like in the conventional dust treatment flow are canceled in the hot removed dust press block process, so the process flow has predominant effects of saving energy, protecting environment, reducing cost, increasing comprehensive benefit and the like.

Owner:CISDI SHANGHAI ENG CO LTD +1

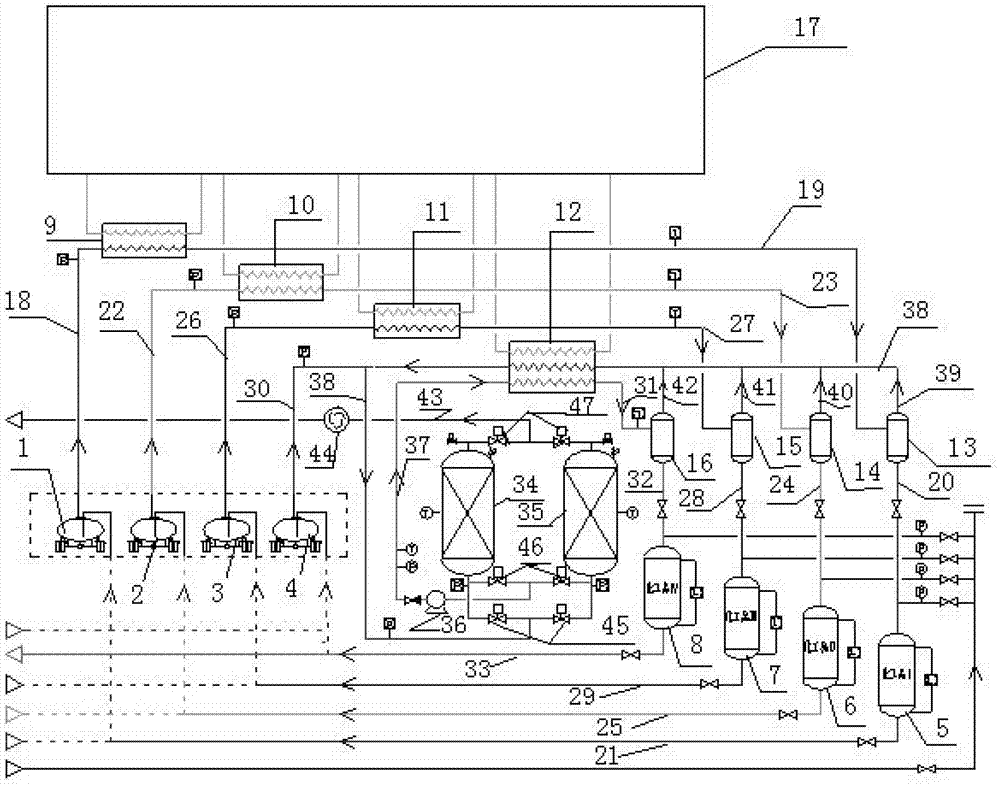

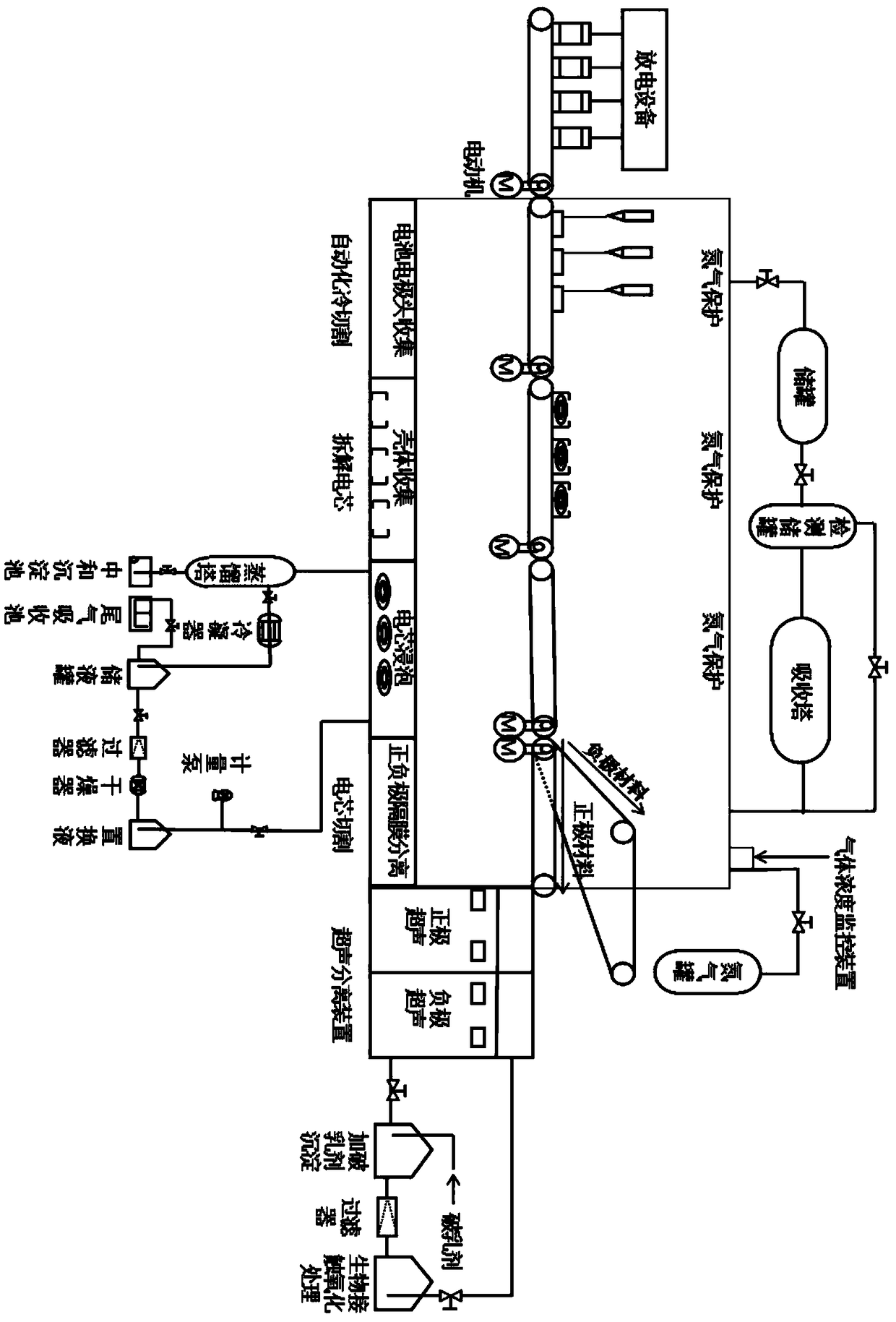

Waste gas recovery processing system and recovery processing technique used in chemical car loading

ActiveCN102764517ARealize recyclingAvoid pollutionDispersed particle separationVapor condensationChemical storageVapor–liquid separator

The invention relates to a waste gas recovery processing system and recovery processing technique used in chemical car loading. The system comprises a storage tank, a tank car, a pipeline, a condensation separation device and an adsorptive separation device, wherein chemicals are delivered from the storage tank to the tank car through the pipeline; the condensation separation device and the adsorptive separation device are connected with each other; the condensation separation device comprises a refrigerating unit, a condenser and a gas-liquid separator which are connected with each other; the adsorptive separation device an adsorption device and a desorption device which are connected with each other; the adsorption device is connected with the gas-liquid separator; and the desorption device is connected with the condenser. By using the system, the adsorption / condensation combined circular recovery processing technique is implemented. The invention can sufficiently implement classified recovery processing of organic chemical products and other components in waste gas, and effectively avoid pollution in the chemical storage tank region and the surrounding environment of the chemical storage tank region due to exhaust emission in the chemical car loading; and the invention is applicable to various chemical storage tank regions and related fields.

Owner:BAY ENVIRONMENTAL TECH BEIJING +1

Distillation extraction process of Chinese fir oil

InactiveCN106190526AImprove aroma qualityWill not polluteFatty-oils/fats productionDistillationWater soluble

The invention relates to a distillation extraction process of Chinese fir oil, particularly comprising the steps of: 1) placing Chinese fir wood chip being less than 0.1 cm in diameter into a distillation tank, and at the same time, uniformly adding a quick penetrating agent by 0.8-1.2 kg per 1.6 ton of the Chinese fir wood chip, stirring the Chinese fir wood chip, and when the distillation tank is full, sealing the distillation tank; and 2) performing distillation, wherein the production time of the distillation tank is 16 h and is divided into four steps: a) a first step, wherein vapor temperature is 80 DEG C, pressure is 0.5 kg and distillation time is 4 h; b) a second step, wherein the pressure is gradually increased to 8 kg, temperature is increased to 170 DEG C, and a water-soluble weak-alkaline penetrating agent is added through a pressure-reduced valve, and distillation time is 3 h; c) a third step: the pressure is gradually reduced to 3 kg, temperature is 132 DEG C and distillation time is 6 h; and d) a fourth step: quickly increasing the pressure to 10 kg, the temperature is 180 DEG C, and a water-soluble high-temperature penetrating agent is added through the pressure-reduced valve, and distillation time is 3 h. The Chinese fir oil is a colorless or slight-yellow transparent liquid, has good fragrance quality and can be directly used for flavor blending.

Owner:福建省建瓯市金路实业有限公司

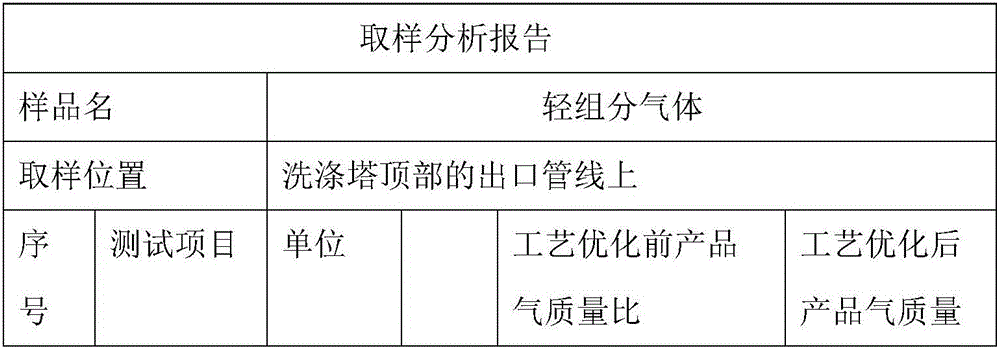

Improved method for recovering methanol from methanol rectification purge gas

InactiveCN106478370ALess investmentReduce circulationOrganic compound preparationHydroxy compound separation/purificationChemistryMethanol

The invention discloses an improved method for recovering methanol from methanol rectification purge gas. According to the invention, a purge gas washing tower and a pre-tower reflux tank are employed, gas at top of a pre-tower at a rectification section passes through two-stage condensation, a light component purge gas after condensation is introduced into the purge gas washing tower; deionized water is introduced as an extraction washing agent for circularly extracting and washing, and centrifugation and gravity self-separating auxiliary equipment and a separator plate are employed at a column reactor segment for standing, extracting, separating light oil and methanol. The method can extract and recover methanol, solves the problem of discharge of noncondensable gas after the environmental protection standard is increased, and has the advantages of concise process, less equipment investment, and easy operation.

Owner:EAST CHINA ENG SCI & TECH

Manufacturing process for bamboo weaved and knitted product

InactiveCN107234694AReduce crackingReduce riskWood treatment detailsReed/straw treatmentWater useWax

The invention provides a manufacturing process of bamboo woven products, comprising the following steps: preparing a plant dyeing agent; S2: soaking the bamboo to be dyed in the plant dyeing agent; ‑48 hours; take out the bamboo to be dyed after step S2, and wash it with 22°C water; place the bamboo to be dyed after step S3 to dry in the shade at 22°C for 24‑48 hours; repeat step S2‑S4, at least More than two times, a semi-finished product is obtained; the surface of the semi-finished product is evenly brushed with wood wax oil to obtain a finished product. The manufacturing process of a bamboo woven product provided by the present invention does not destroy the internal fiber structure of bamboo through low-temperature production, reduces the risk of cracking and deformation of bamboo, is more conducive to dyeing fastness, and dyes and fades more uniformly. Then use wood wax oil to protect the outer surface of bamboo to reduce the problem of dye fading. And the use of plant dyeing, the entire process is environmentally friendly and will not produce harmful substances to the human body.

Owner:李超

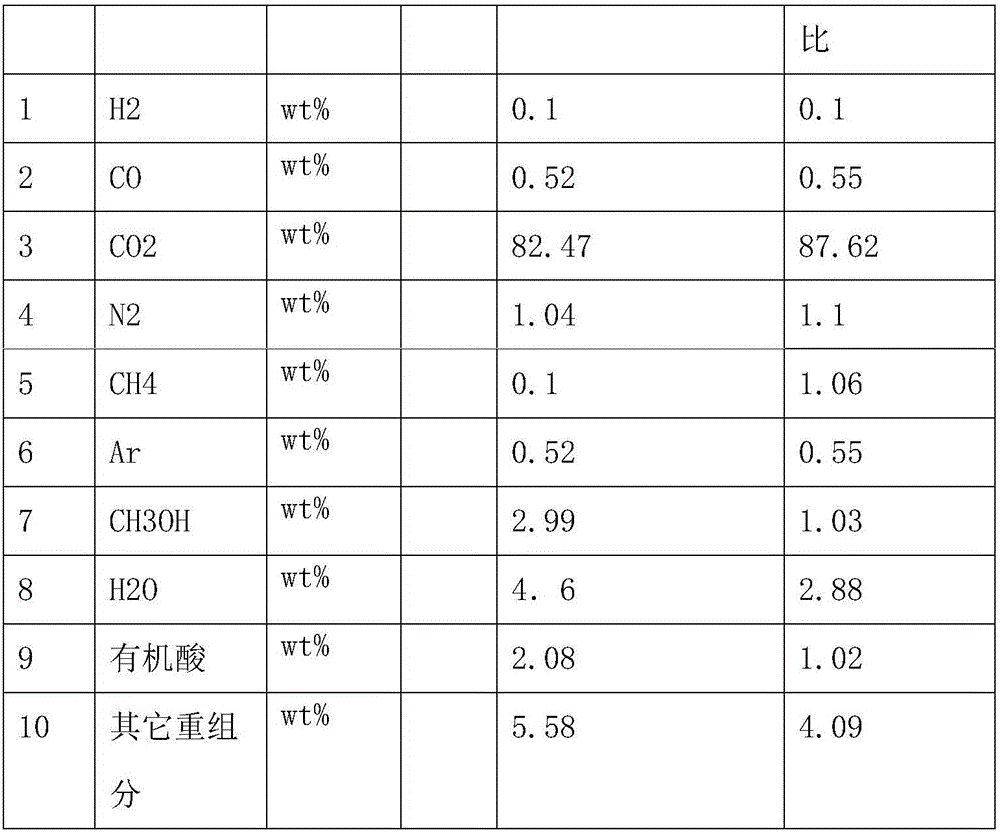

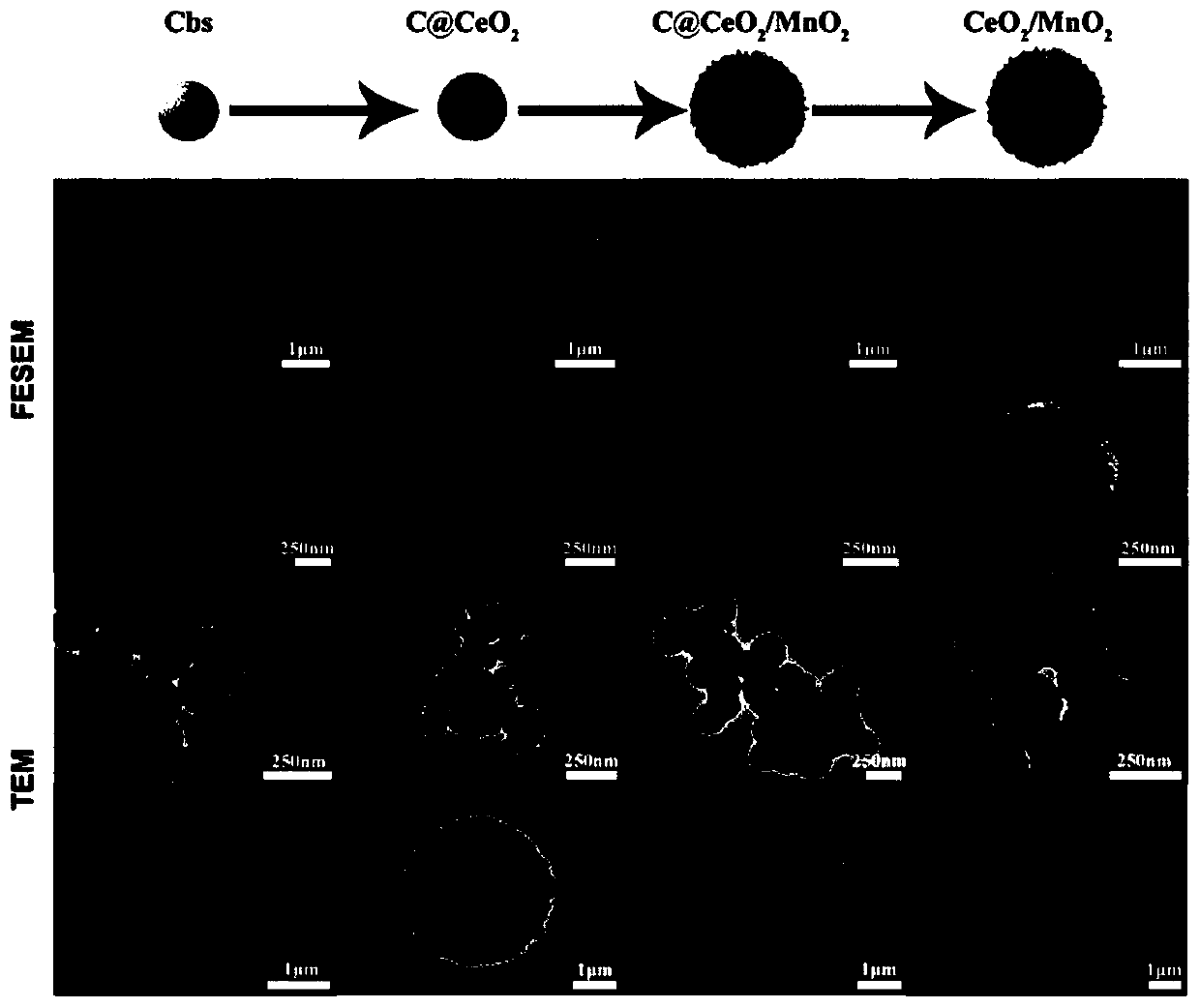

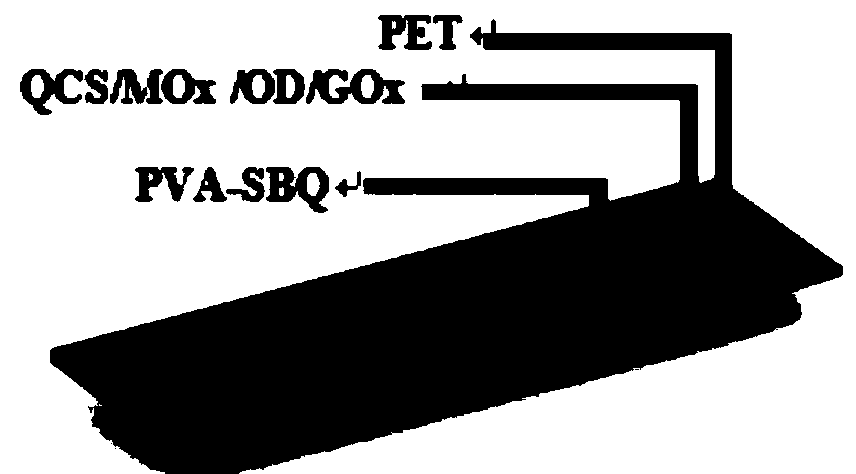

Flexible electrochemical glucose sensor and preparation method thereof

ActiveCN110887884APrevent leakageQuick responseMaterial analysis by electric/magnetic meansGlucose sensorsGlucose detection

The invention discloses a flexible electrochemical glucose sensor and a preparation method thereof, and belongs to the technical field of sensors. According to the invention, CeO2 / MnO2 hollow nanospheres are used as an electrocatalytic medium, and quaternary ammonium salt chitosan is used as a hydrogel matrix material; carboxyl modification is carried out on the surfaces of CeO2 / MnO2 hollow nanospheres, and the CeO2 / MnO2 hollow nanospheres are connected to self-healing conductive hydrogel through covalent bonds; meanwhile, GOx is loaded into the hydrogel through electrostatic interaction; andfinally, the hydrogel is externally wrapped by a layer of polymer. The method can prevent leakage of GOx and an electro-catalytic medium effectively; the prepared hydrogel sensor has the characteristics of wide linear range, quick response and high sensitivity for glucose detection; and meanwhile, the problems that a coating body of an existing glucose sensor is easy to lose, the coating is compact, and the adhesive force between the coating and an electrode is poor and the like are solved.

Owner:江苏跃凯生物技术有限公司 +2

A method for environmentally friendly recycle and reusing waste pow battery

ActiveCN109244586ASolve the safety problem of being volatile and easily decomposed into toxic and harmful gasesHarm reductionWaste accumulators reclaimingBattery recyclingFiltrationHazardous substance

A method for recycling and reusing waste power battery belongs to that field of recycling waste battery. The battery is completely discharged and placed under a sealed and protective gas atmosphere, and the battery pole head, the shell and the battery cell are collected by cold cutting; the obtained cell is immersed and cleaned in the replacement solution. And the positive electrode, the negativeelectrode and the diaphragm are separated by unwinding; The positive and negative electrode pieces are respectively soaked in distilled water and ultrasonicated to obtain positive and negative electrode materials, aluminum foil and copper foil; The electrolyte volatile in the process of cell disassembly is absorbed by absorption tower. Distillation, condensation, filtration and drying are used forrecycling of the replacement liquid used in the cell immersion process, and the harmful substances are recovered through a neutralization sedimentation tank and a tail gas absorption tank. The ultrasonic liquid is recycled after being precipitated by adding demulsifier, filtered and treated by biological contact oxidation. The invention realizes the recovery and regeneration of the waste lithiumion battery, the process is safe, harmless, the automation degree is high, the treatment is efficient and convenient, and the secondary pollution to the environment is not generated.

Owner:BEIJING UNIV OF TECH

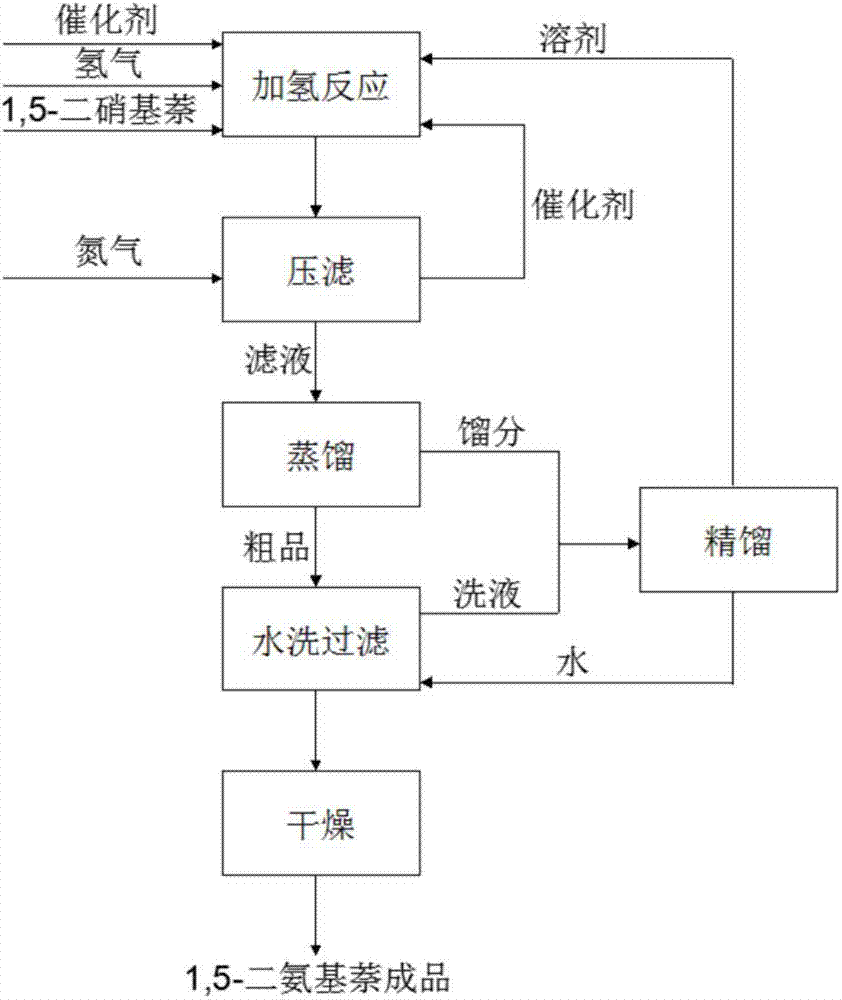

Environment-friendly 1, 5-diamido-naphthlamine production technique

ActiveCN103497113ASimple processSimple reaction conditionsOrganic compound preparationChemical recyclingN dimethylformamideDistillation

The invention discloses an environment-friendly 1, 5-diamido-naphthlamine production technique. The environment-friendly 1, 5-diamido-naphthlamine production technique sequentially includes (A), adding raw materials including 1,5-dinitronaphthalene, reaction solvent N, N-dimethylformamide (DMF) and a Pd / C (palladium / carbon) catalyst into a reaction kettle, and performing catalytic hydrogenation reaction at the reaction temperature of 25-50 DEG C and under the reaction pressure of 0.1-0.5 MPa; (B), after reaction, recycling a solid catalyst in reaction liquor by a nitrogen filter pressing method, obtaining a solid crude product after distilling of filter liquor, and obtaining a high-purity 1, 5-diamido-naphthlamine product after washing and filtering of the crude product; (C), mixing distillation cut obtained by distillation and washing liquor after washing, recycling DMF and water by a vacuum rectification method. The 1, 5-diamido-naphthlamine production technique is mild in reaction condition, high in reaction yield, high in purity of the obtained 1, 5-diamido-naphthlamine product, low in production energy consumption and simple and efficient in recycling process of catalyst and solvent; recycled catalyst, solvent and water can be utilized cyclically, so that the production technique is environment friendly.

Owner:XIANGTAN UNIV

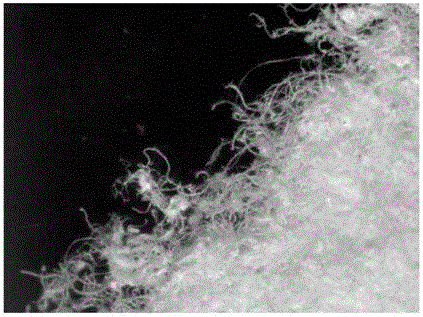

Modified aramid fiber pulp and preparation method thereof, and brake lining manufactured from modified aramid fiber pulp

ActiveCN106087411AAverage length longLarge specific surface areaPhysical treatmentFriction liningFibrillationSolvent

The invention provides a modified aramid fiber pulp with an average length of 5-8 mm, wherein the modified aramid fiber pulp is a modified aramid fiber pulp containing an imidazole ionic liquid. The invention further provides a preparation method of the modified aramid fiber pulp, wherein mainly steam blasting treatment, imidazole ionic liquid spraying treatment, fluidized bed airflow mill dry grinding and other processes are performed to prepare the modified aramid fiber pulp, the method has characteristics of short process, low energy consumption, no solvent and environment protection, and the prepared modified aramid fiber pulp has characteristics of high fibrillation degree, rich hairiness and large specific surface area. According to the present invention, with the application of the modified aramid fiber pulp as the reinforcing material to produce the brake lining and other friction materials, the strength, the toughness and the heat resistance of the brake lining are improved, the preparation formula does not contain asbestos, and the green environment protection advantage is provided.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

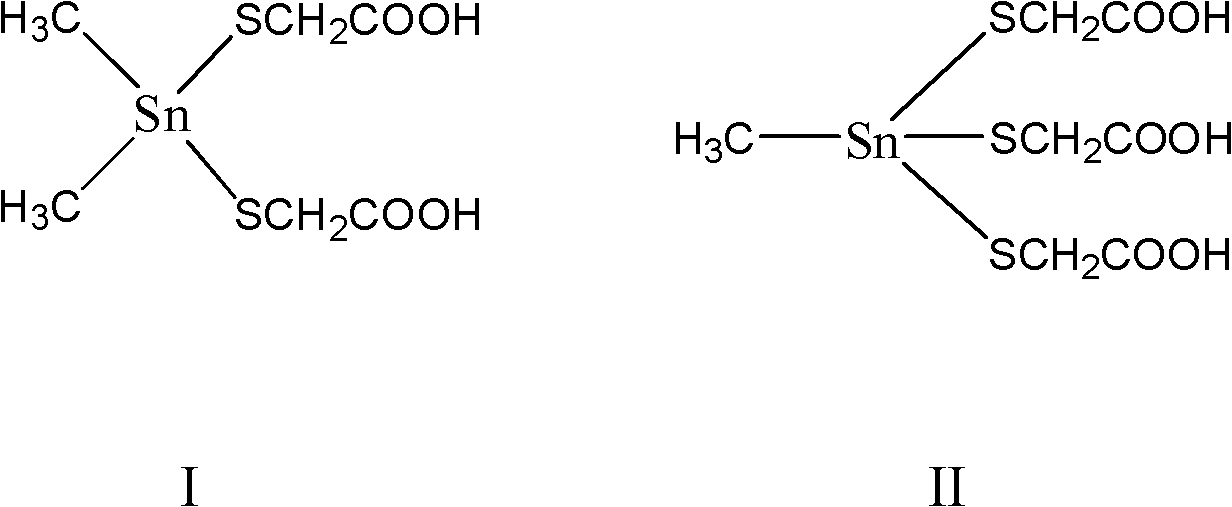

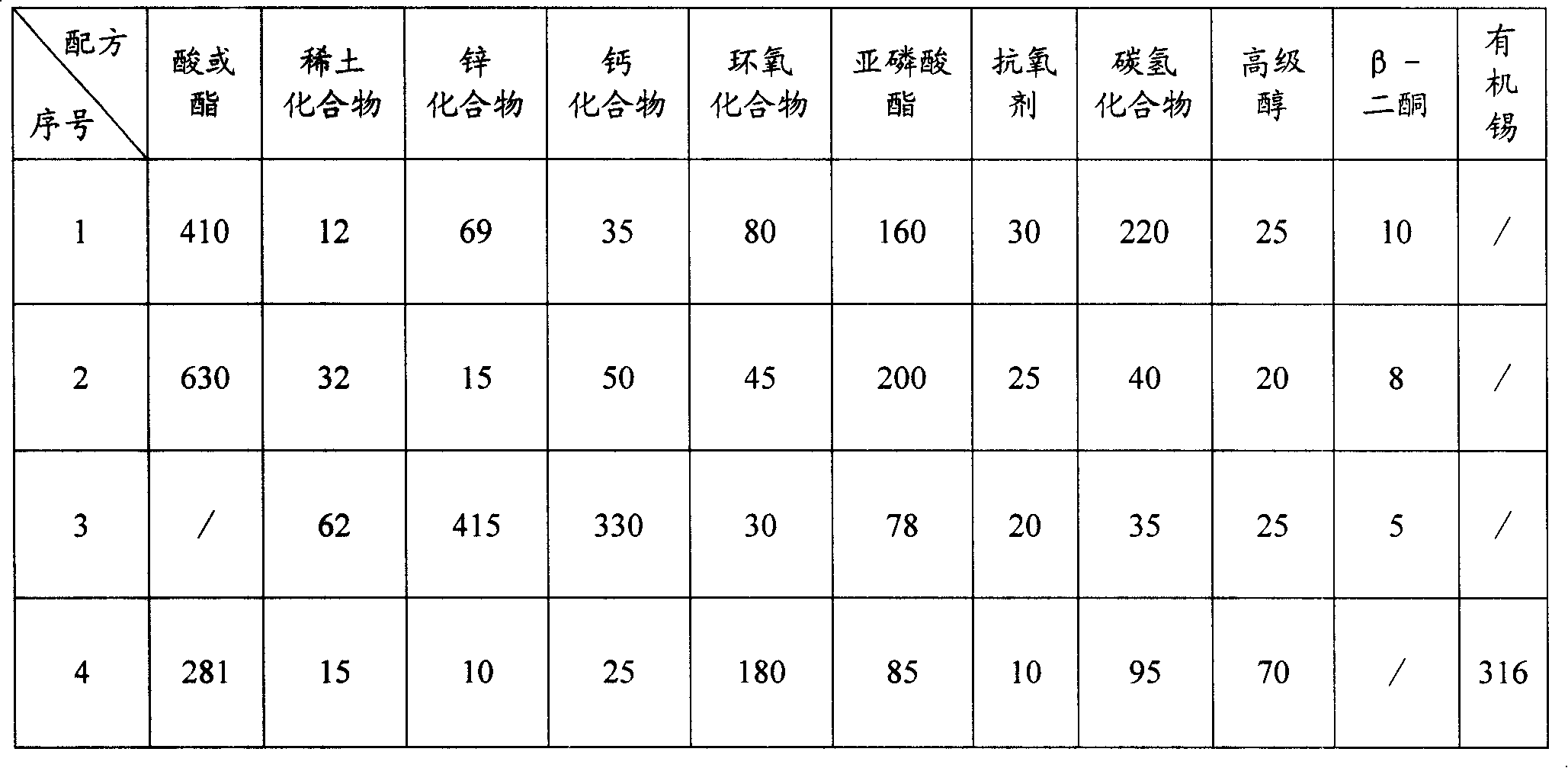

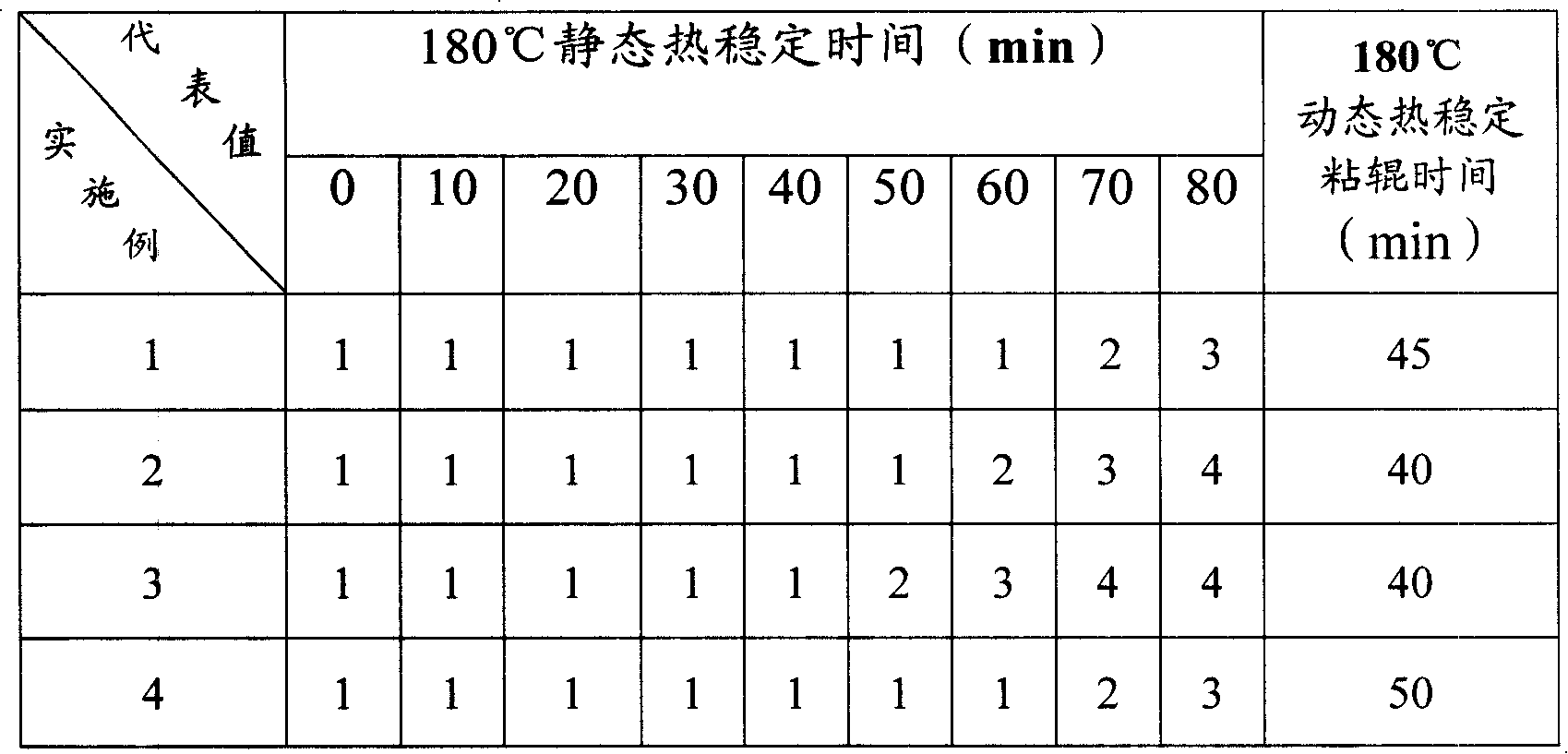

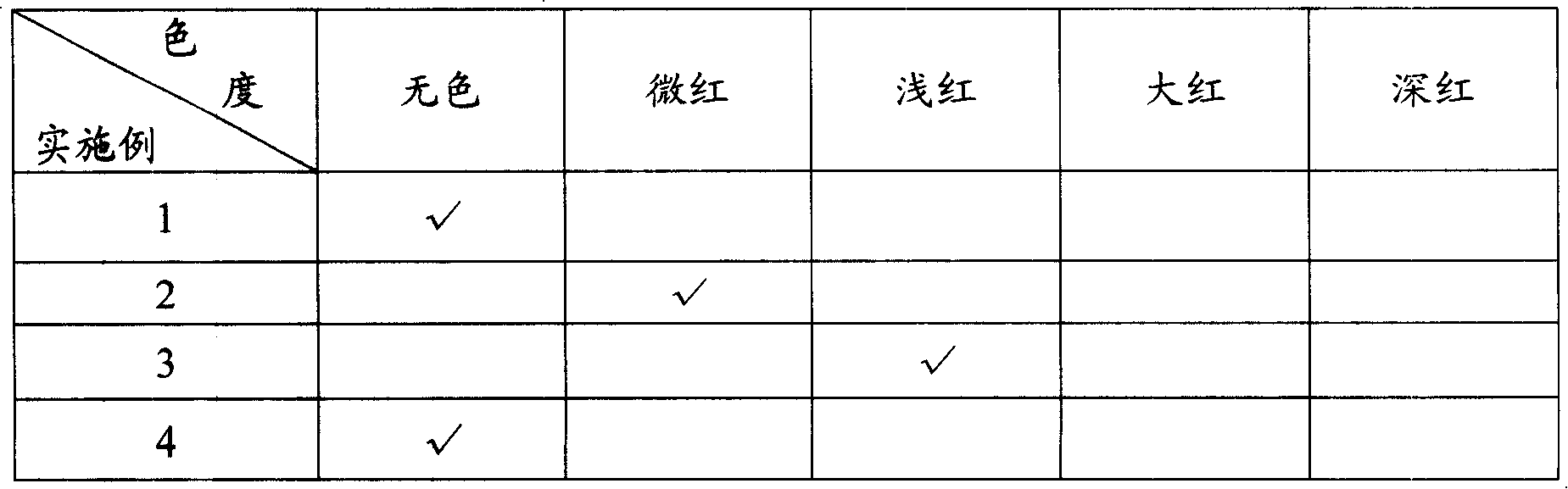

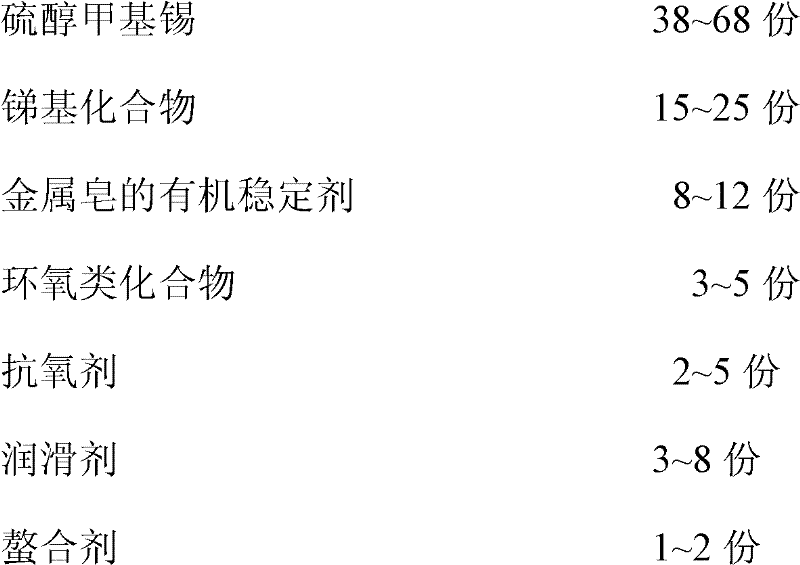

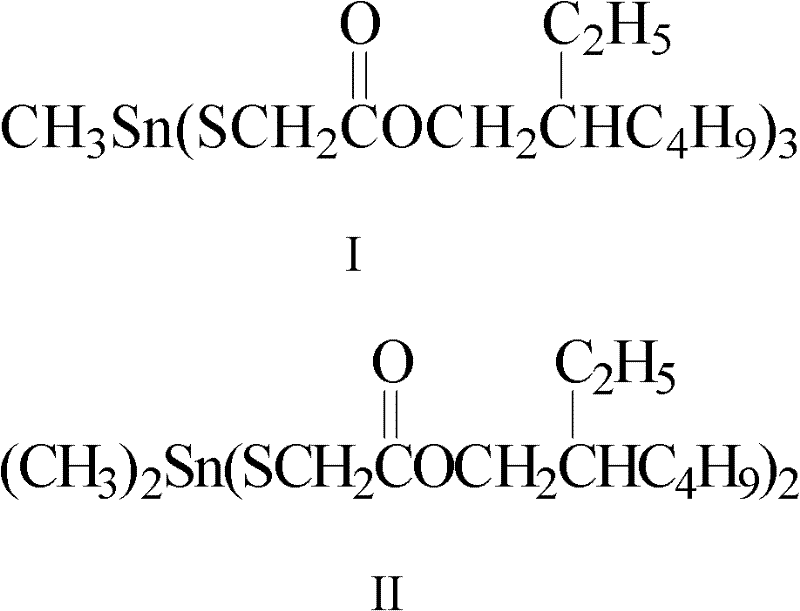

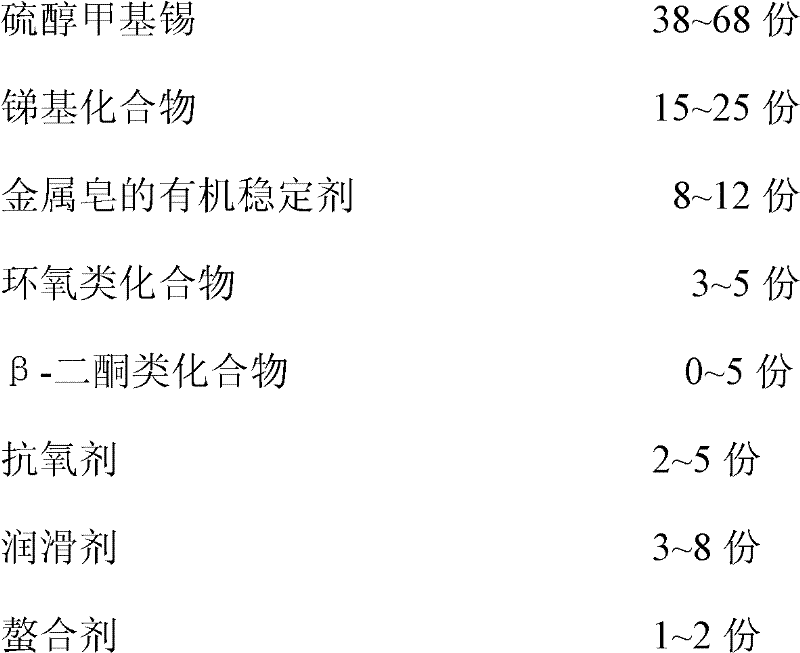

Methyltin composite heat stabilizer and preparation method thereof

The invention discloses a methyltin composite heat stabilizer, which comprises the following components in part by weight: 38 to 68 parts of methyl tin mercaptide, 15 to 25 parts of antimonide based compound, 8 to 12 parts of organic stabilizer of metallic soap, 3 to 5 parts of epoxy compound, 2 to 5 parts of antioxidant, 3 to 8 parts of lubricating agent and 1 to 2 parts of chelant, wherein the methyl tin mercaptide is a composite in which the mass ratio of S,S',S''-tris(isooctyl thioglycollate)-methyltin to S,S'-bis(isooctyl thioglycolate) dimethyltin is 20:80. The methyltin composite heat stabilizer has the advantages of high quality, low toxin, environmental protection, low tin content in the formula, strong practicability and wide application range; and materials prepared from the methyltin composite heat stabilizer, such as PVC sheets, pipes and blown films have the advantages of excellent initial and long-term heat stability, good lubrication system, no precipitation and good oxidation resistance, wherein the sheets and the blown films have good transparency.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

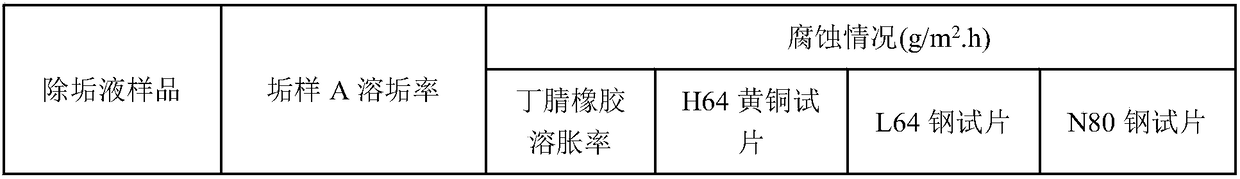

Combined integrated water injection well plug removal process method

InactiveCN108590587ACorrosiveReduced compatibilityCleaning apparatusDrilling compositionEnvironmental engineeringOil production

The invention discloses a combined integrated water injection well plug removal process method, and relates to the technical field of oil production engineering. The technical problem that the existing well washing method can not guarantee the unblocking of a shaft and is prone to causing secondary plugging due to corrosion. The process method comprises the following steps that S1, inorganic plugremoval agents are pumped into the well, and the well is shut for 12-24 hours; S2, a rotary scraper is used for scraping from a wellhead to the bottom of the well; S3, a skid-mounted filter well-washing truck on the ground is used for circularly washing the well, and fine particles after dispersing and dissolving are filtered into the skid-mounted filter well-washing truck; S4, the inorganic plugremover agents are circulated into the well; and S5: the well is opened, water is injected, and a water injection system is used for removing the plug of a stratum. The process is safe, environment friendly and reasonable, and does not produce waste liquids, no corrosion exists, the compatibility is good, and the plug of the shaft is removed while the plug of the stratum is removed.

Owner:长春市华泰石油科技开发有限公司

Calcium-zinc compound stabilizer as well as preparation method and application thereof

The invention belongs to the technical field of chemical stabilizers and discloses a calcium-zinc compound stabilizer as well as a preparation method and application thereof. The calcium-zinc compoundstabilizer is prepared from the following raw materials in percentage by mass: 10 to 30 percent of 2-ethylcaproic acid, 2 to 10 percent of benzoic acid, 0.5 to 4.2 percent of zinc oxide, 1.2 to 6.5 percent of calcium oxide, 8 to 15 percent of non-toxic phosphite, 20 to 35 percent of DINCH, 1 to 5 percent of ATBC, 0.1 to 3 percent of TXIB and 8 to 32 percent of chloromethyl ester. The novel calcium-zinc compound stabilizer disclosed by the invention, under the specific calcium-zinc salt ratio, creatively uses a novel non-toxic environment-friendly compound plastifier to obtain a colorless transparent liquid calcium-zinc stabilizer; and in addition, the method disclosed by the invention is simple in production technology and is easy to realize.

Owner:郴州万墨环保科技有限公司

Nickel-containing electroplating wastewater treatment method

InactiveCN107487892AEasy to recycleWide variety of sourcesSludge treatment by de-watering/drying/thickeningWater contaminantsSludgeElectroplating wastewater

The invention discloses a nickel-containing electroplating wastewater treatment method which comprises the following steps: putting nickel-containing electroplating wastewater into a stirring tank, and stirring with an electric stirring machine; putting a precipitator into the stirring tank; further putting a settling agent into the stirring tank; further putting a composite water purifier into the stirring tank, and increasing a stirring speed for a certain time; further putting a polymeric flocculant into the stirring tank, and reducing the stirring speed for a certain time; introducing obtained wastewater into the settling tank, and performing precipitation so as to obtain precipitated sludge; filtering and drying the precipitated sludge; dissolving the dried sludge into dilute sulfuric acid so as to obtain a primary solution; extracting the primary solution so as to obtain an extract; performing reverse extraction on the extract so as to obtain a reverse extract; electrolyzing the reverse extract, thereby obtaining metal nickel. The method is environmentally friendly in process procedure, low in energy consumption, high in heavy metal recycling rate, low in overall production cost and easy in industrial on-scale production.

Owner:长沙埃比林环保科技有限公司

Technique for extraction separation of quadravalence cerium, thorium, fluorine and cerium less tervalence rare earth from sulphuric acid rare earth solution

ActiveCN101294244BNo pollution in the processReduce consumptionProcess efficiency improvementRare-earth elementAmmoniacal nitrogen

The invention relates to a technological method for extracting and separating quadrivalent cerium, thorium, fluorine and less-cerium trivalent rare-earth from rare earth sulfate solution. The rare earth sulfate solution, which is obtained through processing the rare-earth ores and contains high-valence cerium, the fluorine, the thorium and ferrum, is used as raw material; synergistic extraction agent basing on P507 and P204 is adopted for extracting and separating; the cerium (1V), the thorium, the fluorine, and the ferrum are extracted into an organic phase, then selective washing and back extraction are performed step by step to obtain three products that are the cerium, the fluorine, and the thorium, the trivalent rare-earth is left in a water phase, and then unsaponifiable P507 or thesynergistic extraction agent basing on P507 is adopted to perform multistage fractional extraction to separate single rare earth elements. The technological method has the characteristics that the synergistic extraction agent basing on P507 and P204 is adopted, the thorium is easy to perform the back extraction, and extraction capacity is large, and the emulsification is not generated during the extraction process; the cerium (1V), the thorium, the fluorine, the ferrum and the trivalent rare-earth are extracted and separated in the same extraction system; both extraction and the separation adopt unsaponifiable extraction agent, and ammonia-nitrogen wastewater is not generated; in addition, the thorium and the fluorine are recovered as products, and the pollutions caused by thorium-containing waste residue, fluoride-containing wastewater and the ammonia-nitrogen wastewater are eliminated from headstream. Therefore, the technological method has the advantages of simple procedures, greenenvironmental protection, and low manufacturing cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Oil-gas recycling system and oil-gas recycling process

ActiveCN102764561ARecycle thoroughlyGuaranteed purification effectDispersed particle separationHydrocarbonWaste management

The invention relates to an oil-gas recycling system and an oil-gas recycling process. The system comprises a gas-liquid separation device, an absorption intake separation device, an intake separation device and a storage device. The storage device is connected with the gas-liquid separation device and the intake separation device respectively. The gas-liquid separation device is connected with the intake separation device which is connected with the absorption intake separation device. The absorption intake separation device is above first stage. The intake separation device is also above first stage. By the oil-gas recycling system, combination of multiple separation techniques is achieved, the recycling process by combining multistage intake and absorption intake is achieved, hydrocarbon components in oil and gas can be recycled completely and thoroughly, and energy waste is avoided. The oil-gas recycling system is evident in environment protection effect, low in economic cost, convenient and safe to operate, and suitable for popularization and application in related hydrocarbon-contained oil-gas recycling fields.

Owner:BAY ENVIRONMENTAL TECH BEIJING

A kind of method directly preparing pure 8-hydroxyquinolate calcium

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com