Method for extracting lithium from electrolytic aluminum waste residues

A technology of electrolytic aluminum waste residue and extraction method, applied in the field of lithium extraction, can solve the problems of increasing the use of carbon dioxide, increasing the cost of equipment input, reducing the extraction rate of lithium carbonate, etc., to reduce pollution, reduce investment in production equipment, and low cost of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

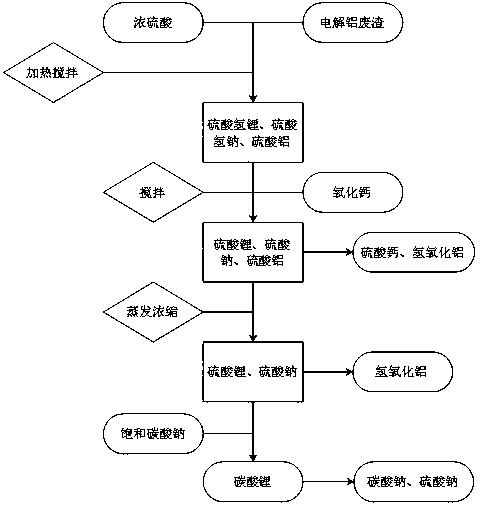

Image

Examples

Embodiment 1

[0039] A method for extracting lithium in electrolytic aluminum waste slag, the steps are as follows:

[0040] React 50kg of electrolytic aluminum waste slag from which carbon and iron have been removed with 100kg of concentrated sulfuric acid. The reaction temperature is 250°C. After 6 hours of reaction, mixture A is obtained. At the same time, water is used to absorb HF produced by the reaction. The obtained HF aqueous solution can be used to prepare cryolite ;

[0041] Dissolve the mixture A with 500kg of water and filter to obtain the filtrate B. Calcium oxide is slowly added to the filtrate B until the pH value of the solution reaches 7.5, and the resulting solution is filtered to obtain the filter residue C and the filtrate D. The main component of the obtained filter residue C is hydroxide Aluminum and calcium sulfate, aluminum hydroxide can be used to prepare by-products such as cryolite, and calcium sulfate can be used to prepare by-products such as gypsum powder.

...

Embodiment 2

[0046] A method for extracting lithium in electrolytic aluminum waste slag, the steps are as follows:

[0047] React 50kg of electrolytic aluminum waste slag from which carbon and iron have been removed with 125kg of concentrated sulfuric acid. The reaction temperature is 100°C. After 20 hours of reaction, a mixture A is obtained. At the same time, water is used to absorb the HF produced by the reaction. The obtained HF aqueous solution can be used to prepare cryolite ;

[0048] Dissolve the mixture A with 500kg of water and filter to obtain the filtrate B. Calcium oxide is slowly added to the filtrate B until the pH value of the solution reaches 7. The obtained solution is filtered to obtain the filter residue C and the filtrate D. The main component of the obtained filter residue C is hydroxide Aluminum and calcium sulfate, aluminum hydroxide can be used to prepare by-products such as cryolite, and calcium sulfate can be used to prepare by-products such as gypsum powder.

...

Embodiment 3

[0052] A method for extracting lithium in electrolytic aluminum waste slag, the steps are as follows:

[0053] React 50kg of electrolytic aluminum waste slag from which carbon and iron have been removed with 75kg of concentrated sulfuric acid. The reaction temperature is 300°C. After 6 hours of reaction, mixture A is obtained. At the same time, water is used to absorb HF produced by the reaction. The obtained HF aqueous solution can be used to prepare cryolite ;

[0054] Dissolve the mixture A with 500kg of water and filter to obtain the filtrate B. Calcium oxide is slowly added to the filtrate B until the pH value of the solution reaches 7.5, and the resulting solution is filtered to obtain the filter residue C and the filtrate D. The main component of the obtained filter residue C is hydroxide Aluminum and calcium sulfate, aluminum hydroxide can be used to prepare by-products such as cryolite, and calcium sulfate can be used to prepare by-products such as gypsum powder.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com