Patents

Literature

117 results about "Aluminium industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

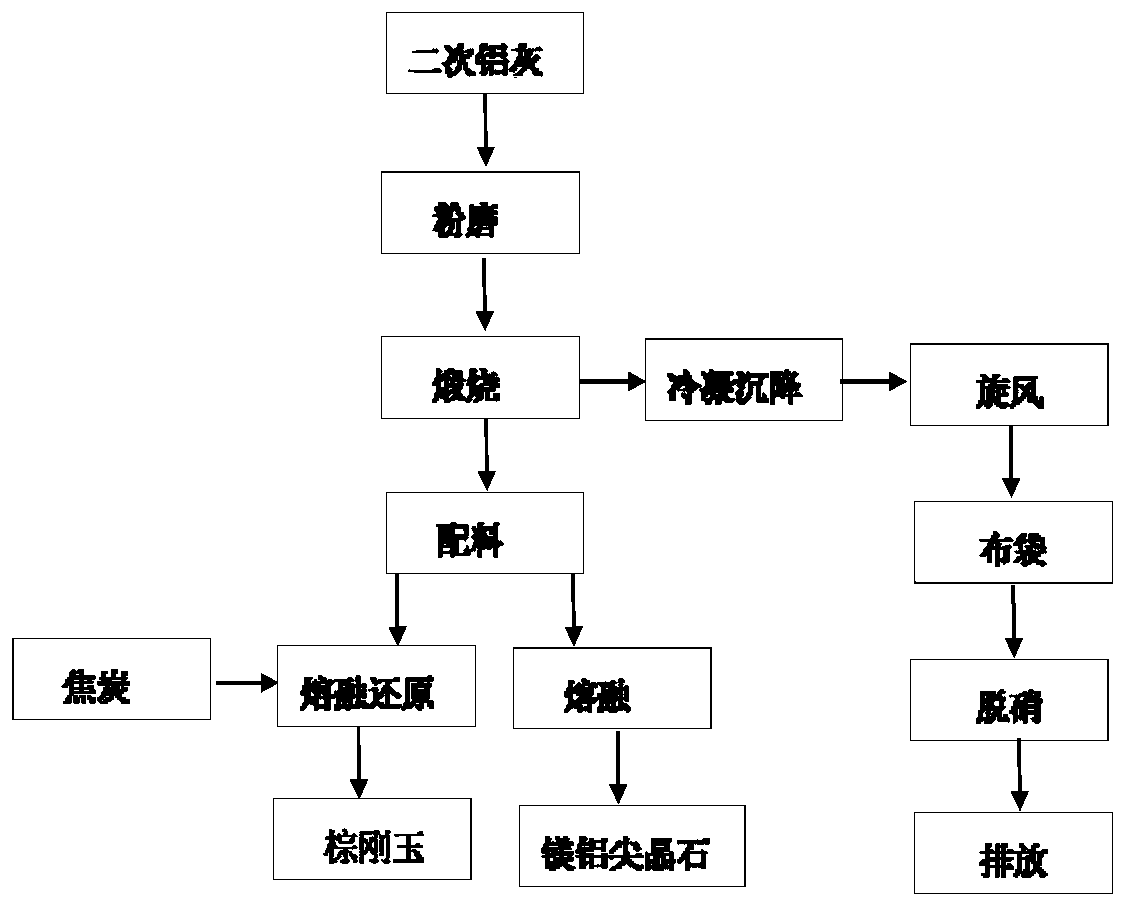

Method of manufacturing refractory material by innocent treatment of secondary aluminum ash

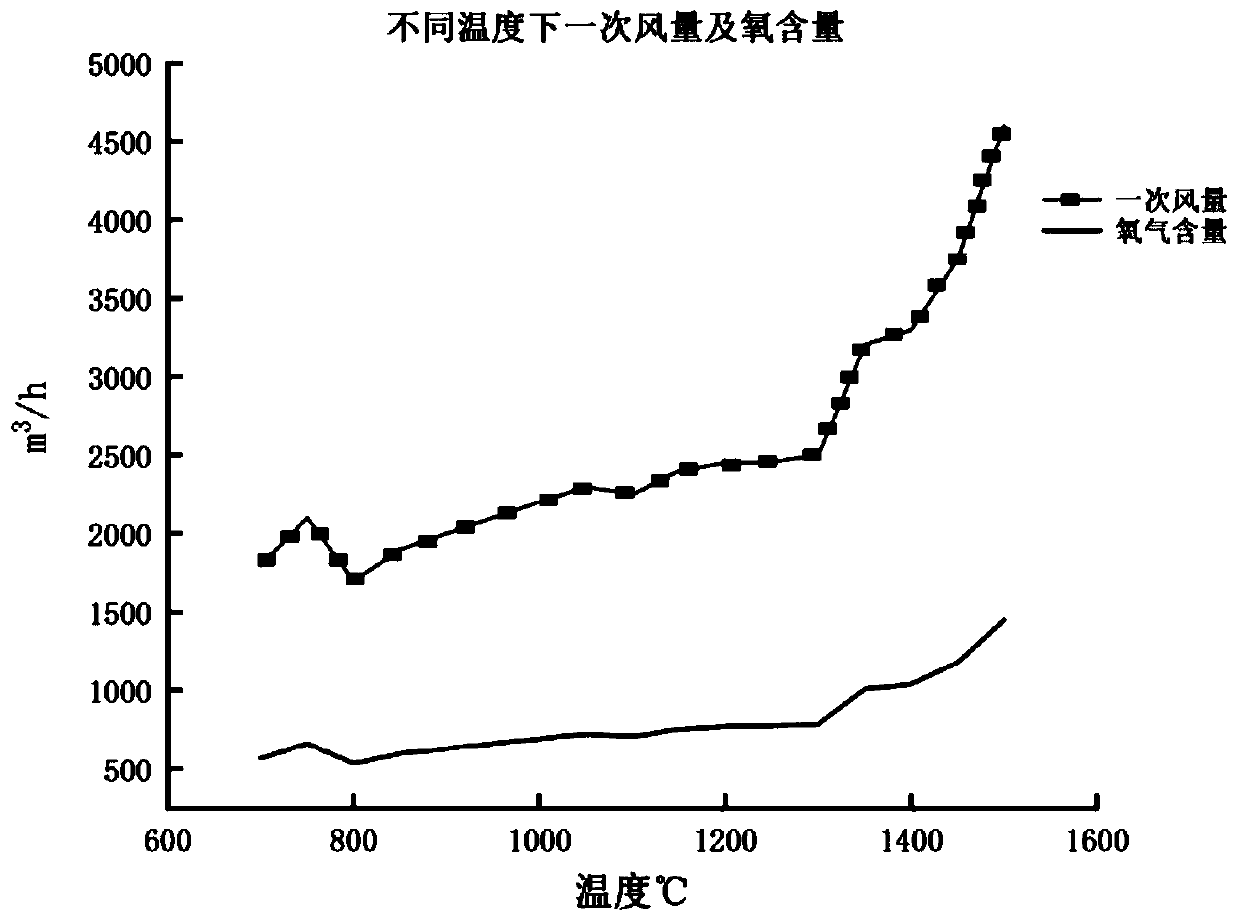

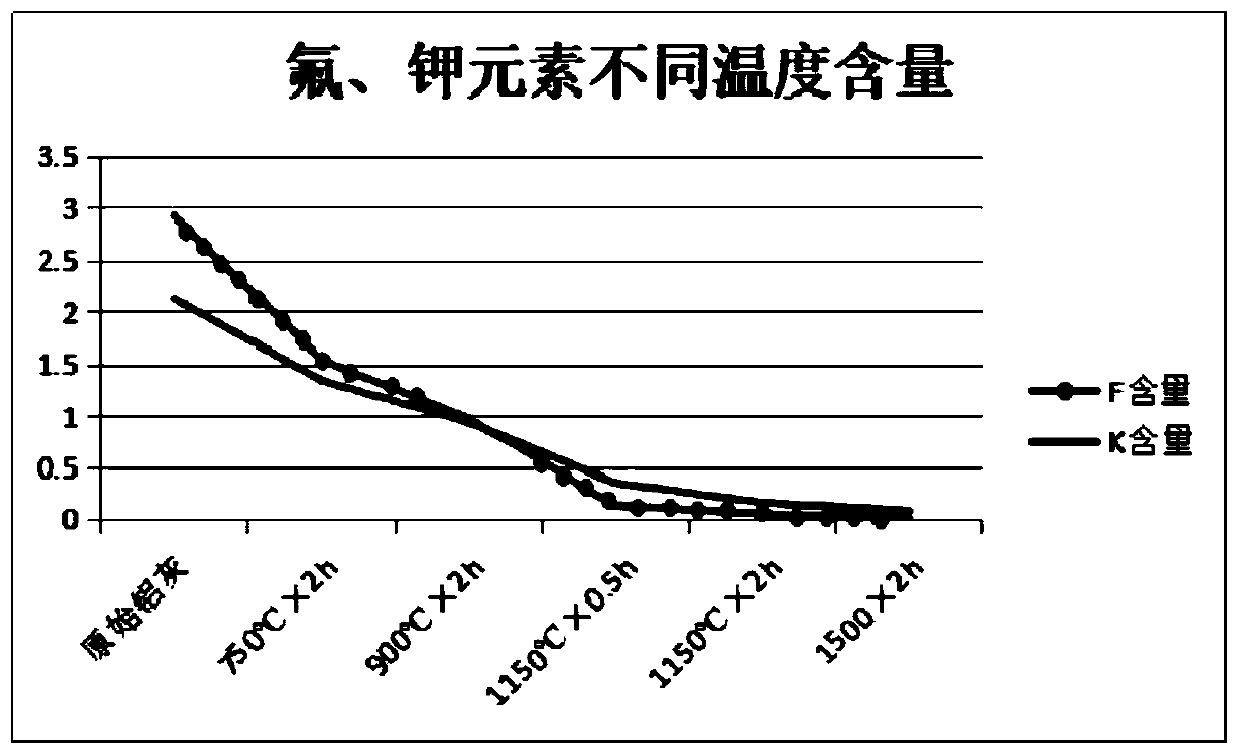

The invention discloses a method for manufacturing a refractory material by innocent treatment of secondary aluminum ash, and belongs to the field of aluminum industry. The method comprises the following steps: further grinding the secondary aluminum ash until 80% of the secondary aluminum ash passes through a screen with the pore diameter of 74 microns; and calcining the secondary aluminum ash for 0.5-4 hours at the temperature of 1150-1550 DEG C in an oxidizing atmosphere with the oxygen content of 12%-18% to convert metal aluminum, aluminum nitride and aluminum carbide in the secondary aluminum ash into aluminum oxide and volatilize the fluoride salt and chloride salt in the secondary aluminum ash, thereby producing a calcined oxide; cooling the waste flue gas containing fluoride salt and chlorate produced in the calcining process for recovery, and denitrifying and discharging the flue gas. The calcined oxide is independently prepared or mixed with an additive, and the aluminum-magnesium refractory material is prepared after electric arc melting. The preparation method can be used for preparing the refractory material with high purity.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Ca and heavy rare earth Gd-containing die-casting heat resisting magnesium alloy and preparation thereof

The invention relates to a die-casting heat resistant magnesium alloy containing Ca and heavy rare earth element Gd and a preparation method thereof, pertaining to the metal material technical field. The components and weight percentage thereof of the alloy are: 3.0 to 8.0 percent of Al, 0.1 to 3.0 percent of Ca, 0.1 to 3.0 percent of Gd, 0 to 0.5 percent of Mn, lower than 0.02 percent of impurity elements and the rest is Mg. The preparation method of the alloy comprises the following steps: the materials are weighed, and industrial pure Mg is heated under the protection of the mixed gas of N2 and 0.2 percent of SF6; after Mg is wholly melted, industrial pure Al, industrial pure Ca and Al-Mn interalloy are added at the temperature of 650 to 680 DEG C, Mg-Gd interalloy is added at the temperature of 660 to 680 DEG C, the temperature is increased to 740 to 760 DEG C, and when the Mg liquid is cooled to 670 to 690 DEG C, the mixture carries out die casting. The preparation method of the invention has the advantages of low cost and high production efficiency, obviously increases the tensile strength, the yield strength, the elongation percentage and the creep resistance of the alloy at room temperature, and has excellent die-casting performance.

Owner:SHANGHAI JIAO TONG UNIV

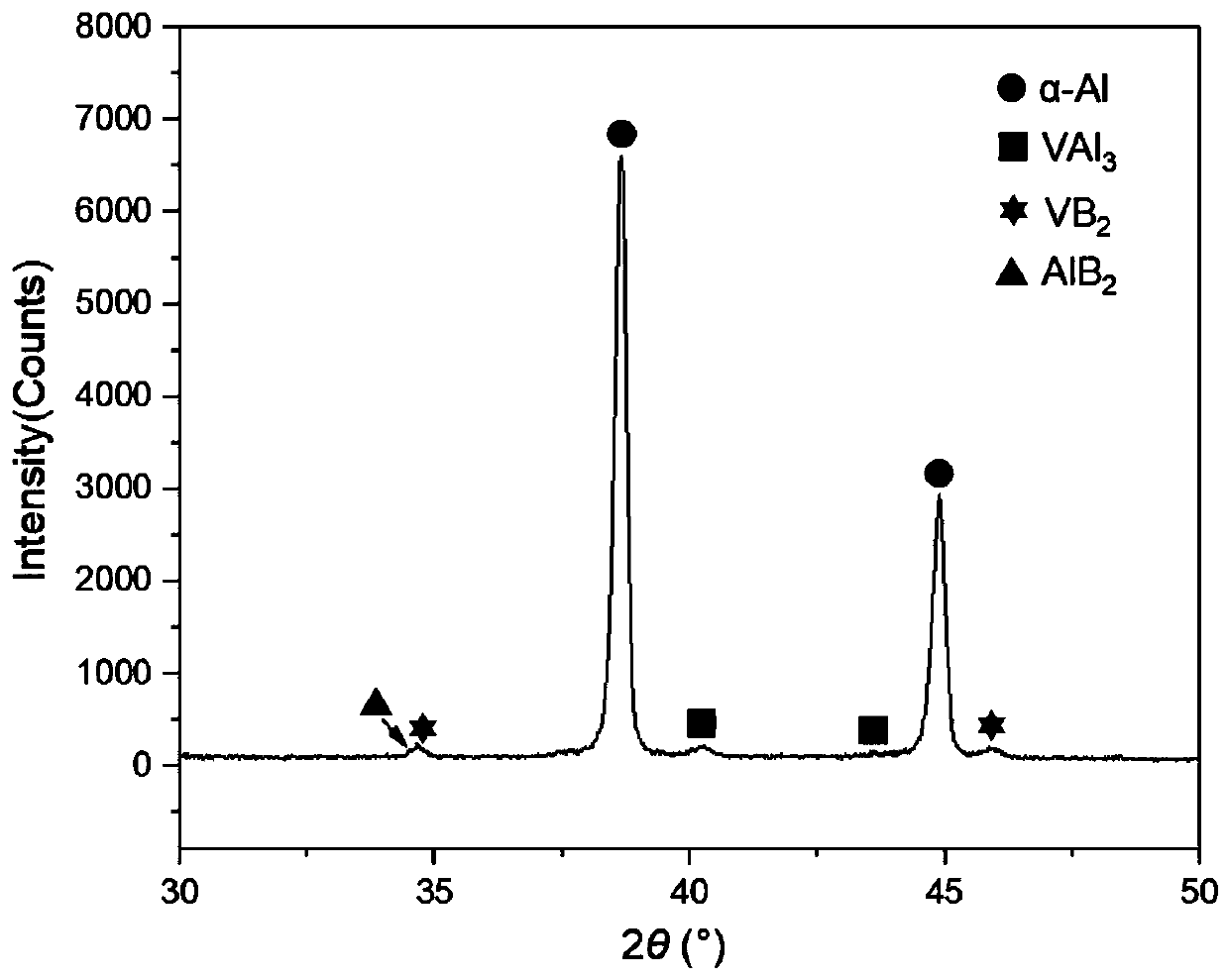

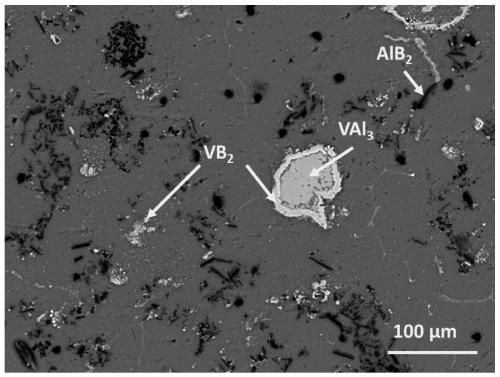

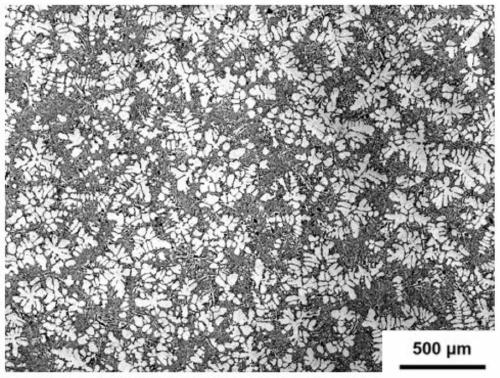

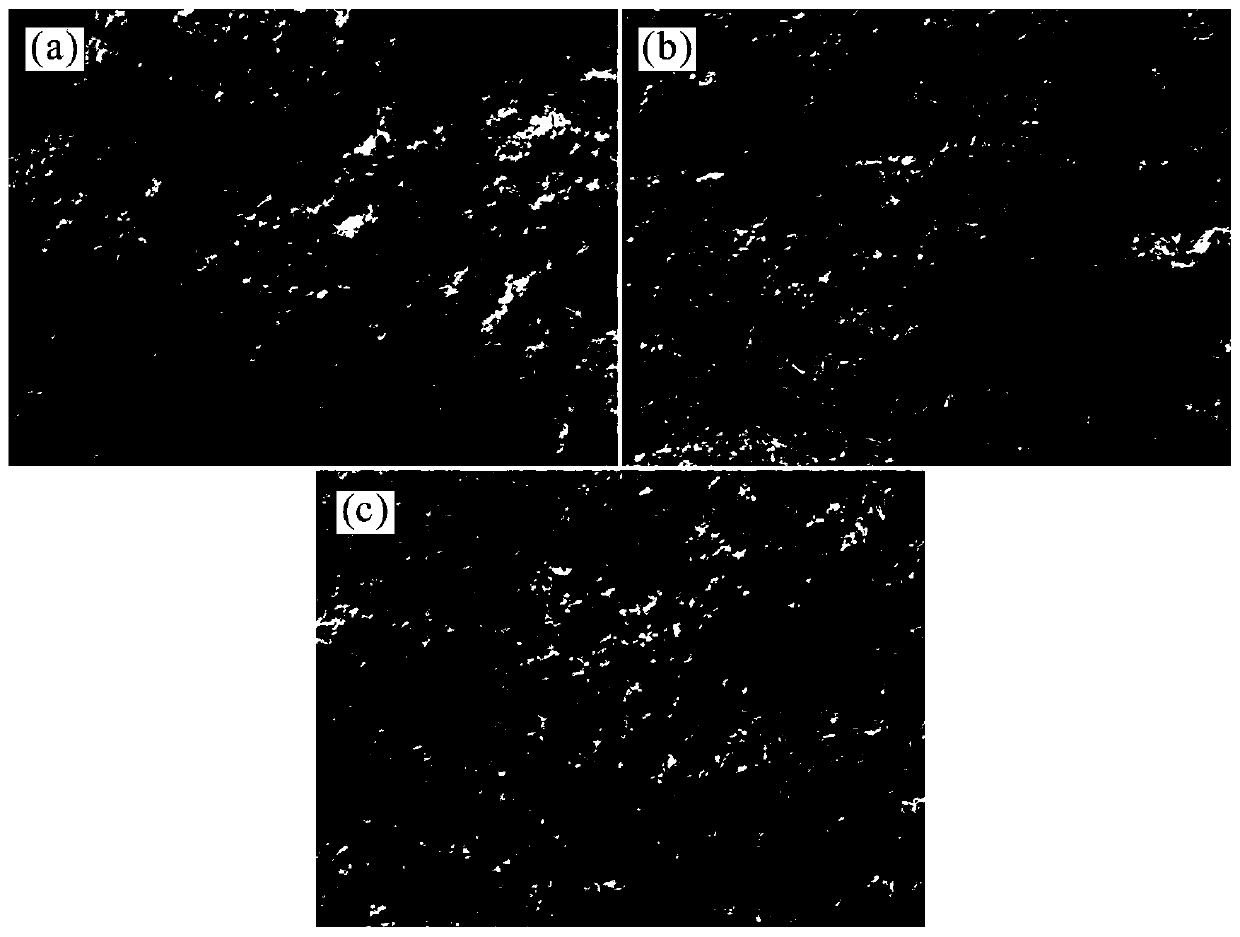

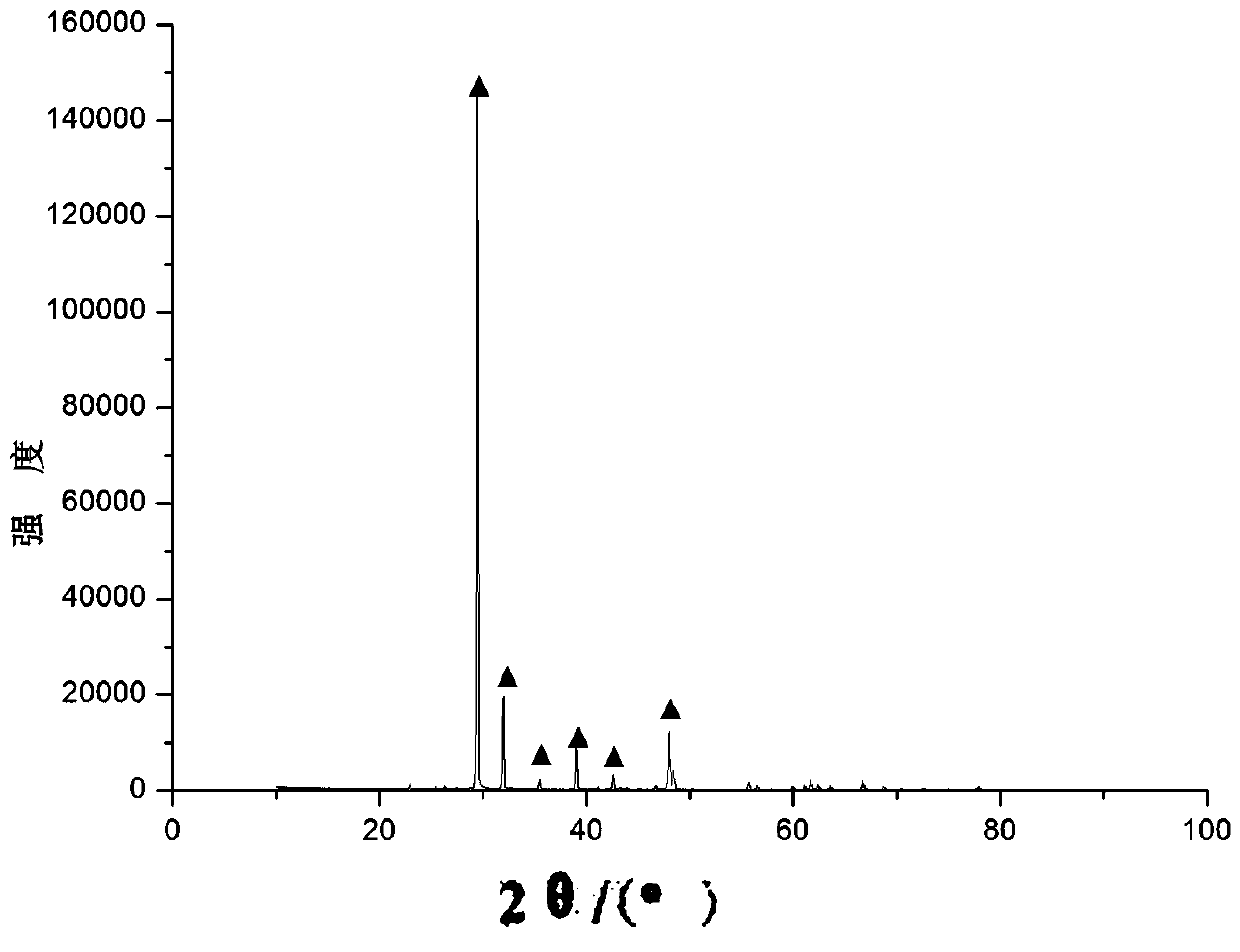

Al-V-B refining agent for cast aluminum-silicon alloy, preparation method and application thereof

ActiveCN110157935AImprove refinementMeets Aluminum Industry Acceptance StandardsSilicon alloyChemical element

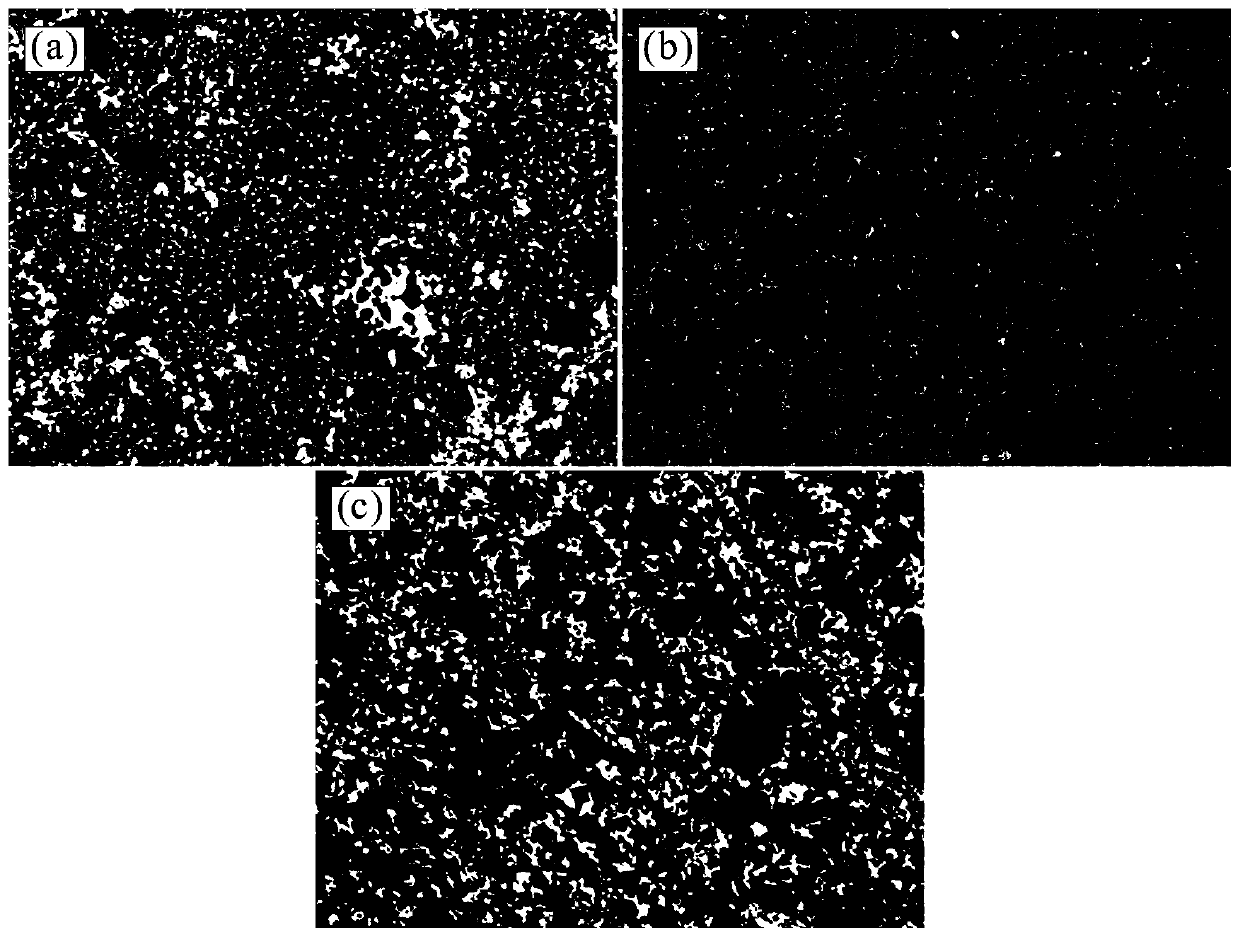

The invention discloses an Al-V-B refining agent for cast aluminum-silicon alloy, a preparation method and application thereof. The Al-V-B refining agent comprises the following chemical elements of,in percentage by mass, 80.0%-95.8% of aluminum, 2.1%-10.0% of vanadium and 2.1%-10.0% of boron; the phase composition of the refining agent is composed of an aluminum solid solution alpha-Al acting asa matrix and particle particles with the particle size of 2-100 microns. The phase of each particle particle comprises a VAl3 phase, a VB2 phase and an AlB2 phase at the same time. In the casting aluminum-silicon alloy application, the grain size of the alpha-Al in the cast aluminum-silicon alloy is refined to be 220 microns or below. The preparation method of the refining agent adopts a villiaumite method and comprises the following steps of weighing raw materials; and smelting the Al-V-B alloy. According to the Al-V-B refining agent, the refining effect can reach 184 microns, and the requirement of the aluminum industry approved standard of less than or equal to 220 microns are met; and the preparation method is simple and convenient, and is suitable for large-scale industrial production.

Owner:SHANGHAI UNIV

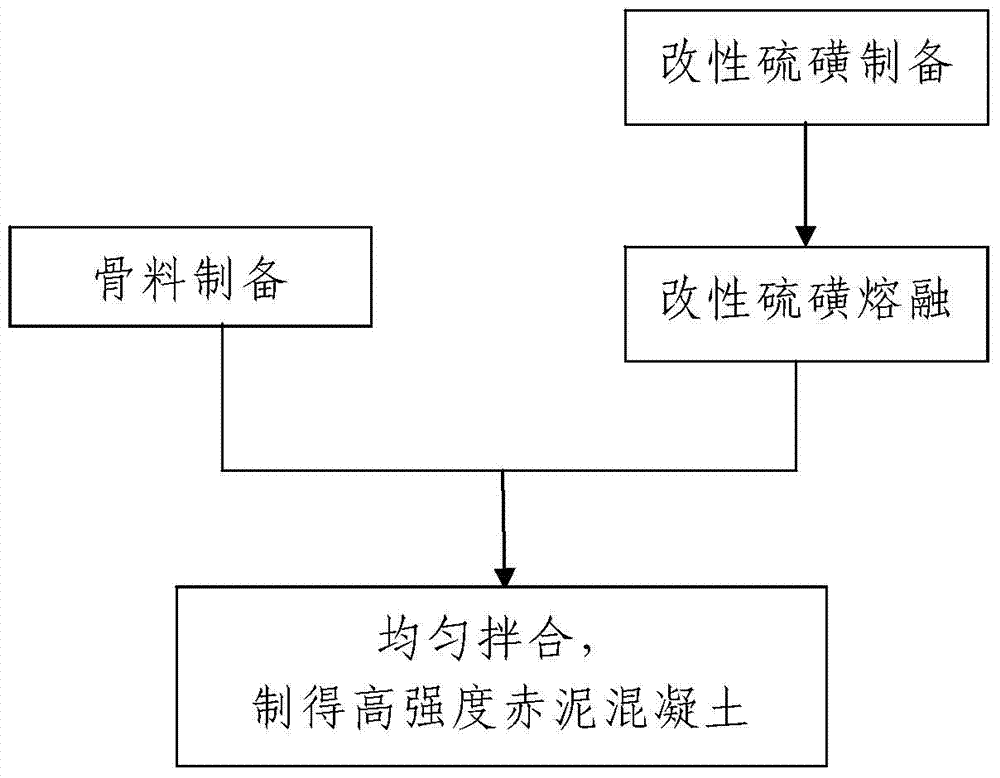

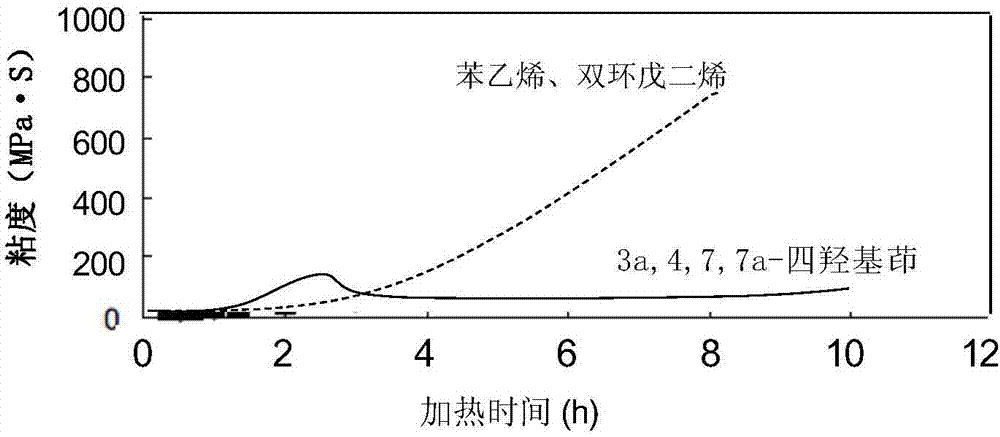

Low-emission high-strength red-mud concrete, and industrial production method and application thereof

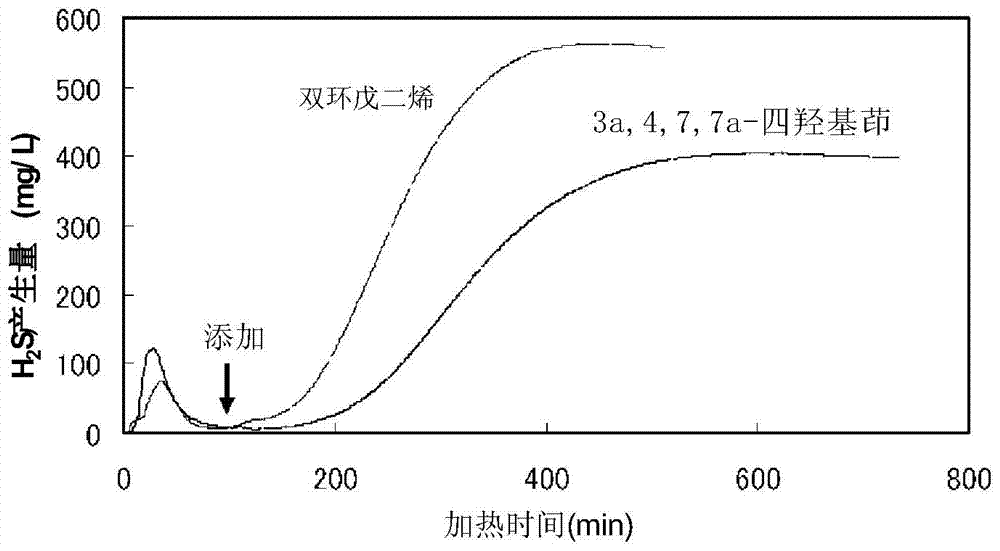

The invention discloses a low-emission high-strength red-mud concrete and an industrial production method and application thereof. The high-strength red-mud concrete comprises, by weight, 21 to 40% of modified sulphur, 25 to 60% of red mud particles and 54 to 0% of steel slag, is prepared through uniform blending of the modified sulphur, the red mud particles and steel slag particles and has compressive strength of no less than 50 MPa. The industrial production method comprises the following steps: 1, preparation of the modified sulphur; 2, preparation of aggregate and fusion with the modified sulphur; and 3, uniform blending. Application of the high-strength red-mud concrete is as follows: the high-strength red-mud concrete is poured into a casting molding die so as to obtain molded red mud stone. The industrial production method has the advantages of simple process steps, short production flow, low investment cost, easy operation, convenient implementation, capacity of effective utilization of the waste material red mud in the aluminum industry and discharge of low concentration sulfur-containing gas during production and casting; and a produced red mud concrete structural member has excellent performance.

Owner:嘉兴如运建筑科技有限公司

Method for preparing high-strength foam glass by utilizing red mud and waste glass

The invention relates to foam glass manufacturing method, in particular to a method for preparing high-strength foam glass by utilizing red mud and waste glass. The invention aims at providing a preparation method for high-strength red mud foam glass which utilizes solid wastes and reduces the foam glass production cost. According to the technical scheme, the method for preparing high-strength foam glass by utilizing red mud and waste glass comprises the steps: firstly mixing red mud, waste glass and foam agent, carrying out ball milling to obtain powder batch mixture, and then conducting foaming and annealing treatment to obtain high-strength red mud foam glass product, wherein the red mud is polluting waste slag exhausted when the aluminum oxide is extracted in aluminum industry. The method has the beneficial effects of massively applying solid wastes red mud and waste glass, being environment-friendly and energy-saving, and changing wastes into valuables, thereby having good social benefits and economic benefits.

Owner:刘立强

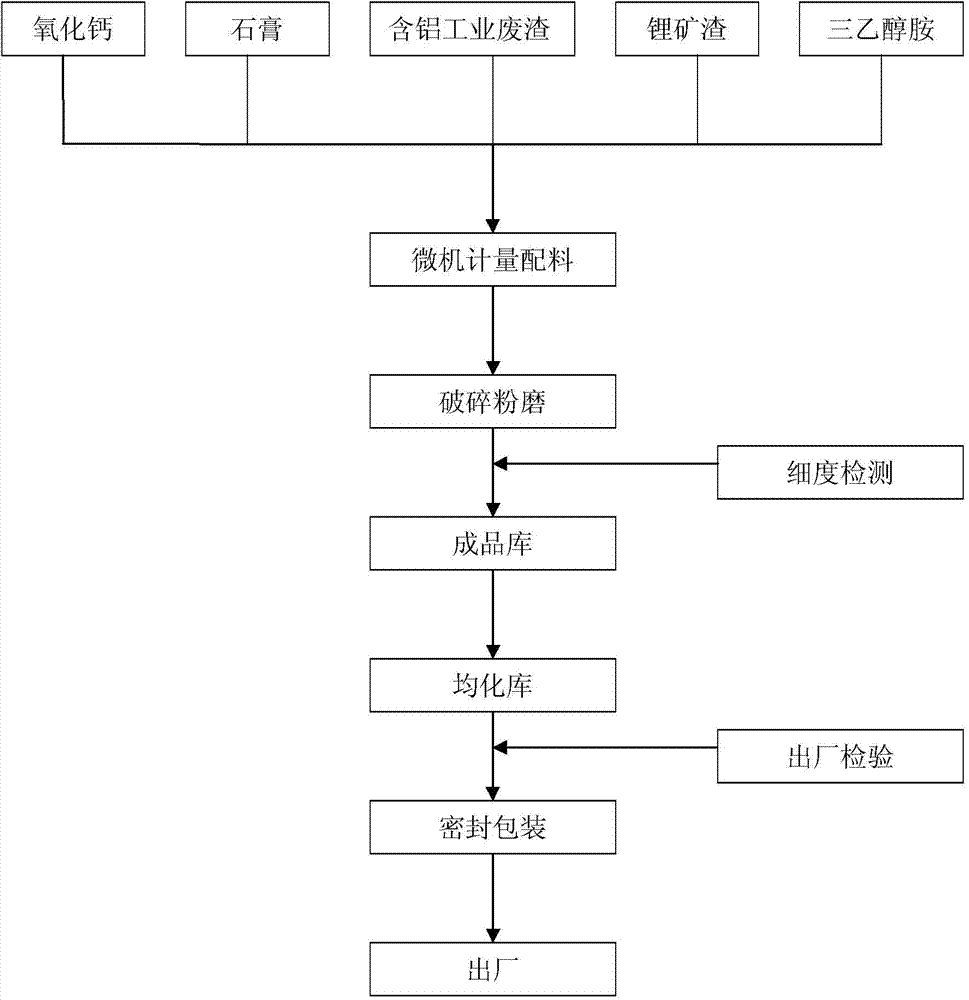

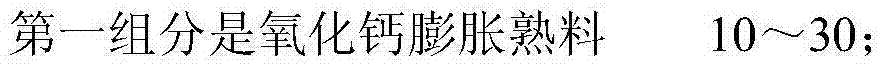

Concrete efficient expending agent employing aluminum-containing industrial waste residues as well as preparation method and application of concrete efficient expending agent

ActiveCN104761172ALarge limit expansion rateHigh compressive and flexural strengthIndustrial wasteSolubility

The invention provides a concrete efficient expending agent employing aluminum-containing industrial waste residues as well as a preparation method and an application of the concrete efficient expending agent. According to the concrete efficient expending agent employing the aluminum-containing industrial waste residues, the solubility of active Al2O3 in the aluminum-containing industrial waste residues is increased by employing multiple excitation effects of calcium oxide, gypsum, lithium slag and triethanolamine; and the obtained expending agent can generate two expending sources, namely calcium hydroxide and ettringite through hydration reaction. The expending agent has the characteristics of calcium oxide expending agents and calcium sulphoaluminate expending agents, and has relatively large restrained expansion rate, relatively high compression resistance and breaking strength.

Owner:JIANGSU SOBUTE NEW MATERIALS

Method for preparing foam glass ceramics by utilizing red mud and waste glass

The invention relates to foam glass ceramic manufacturing method, in particular to a method for preparing foam glass ceramics by utilizing red mud and waste glass. The invention aims at providing a preparation method for preparing environment-friendly and energy-saving foam glass ceramics. According to the technical scheme, the method for preparing foam glass ceramics by utilizing red mud and waste glass comprises the steps: firstly mixing red mud and waste glass, carrying out ball milling to obtain powder batch mixture, and then conducting foaming and annealing treatment to obtain foam glass ceramics, wherein the red mud is polluting waste slag exhausted when the aluminum oxide is extracted in aluminum industry. The method has the beneficial effects of being simple in preparation technique and low in sintering temperature, lowering the production cost of foam glass ceramics, and obtaining higher economic benefits while solving the environment-friendly problem.

Owner:SHANDONG JIANZHU UNIV

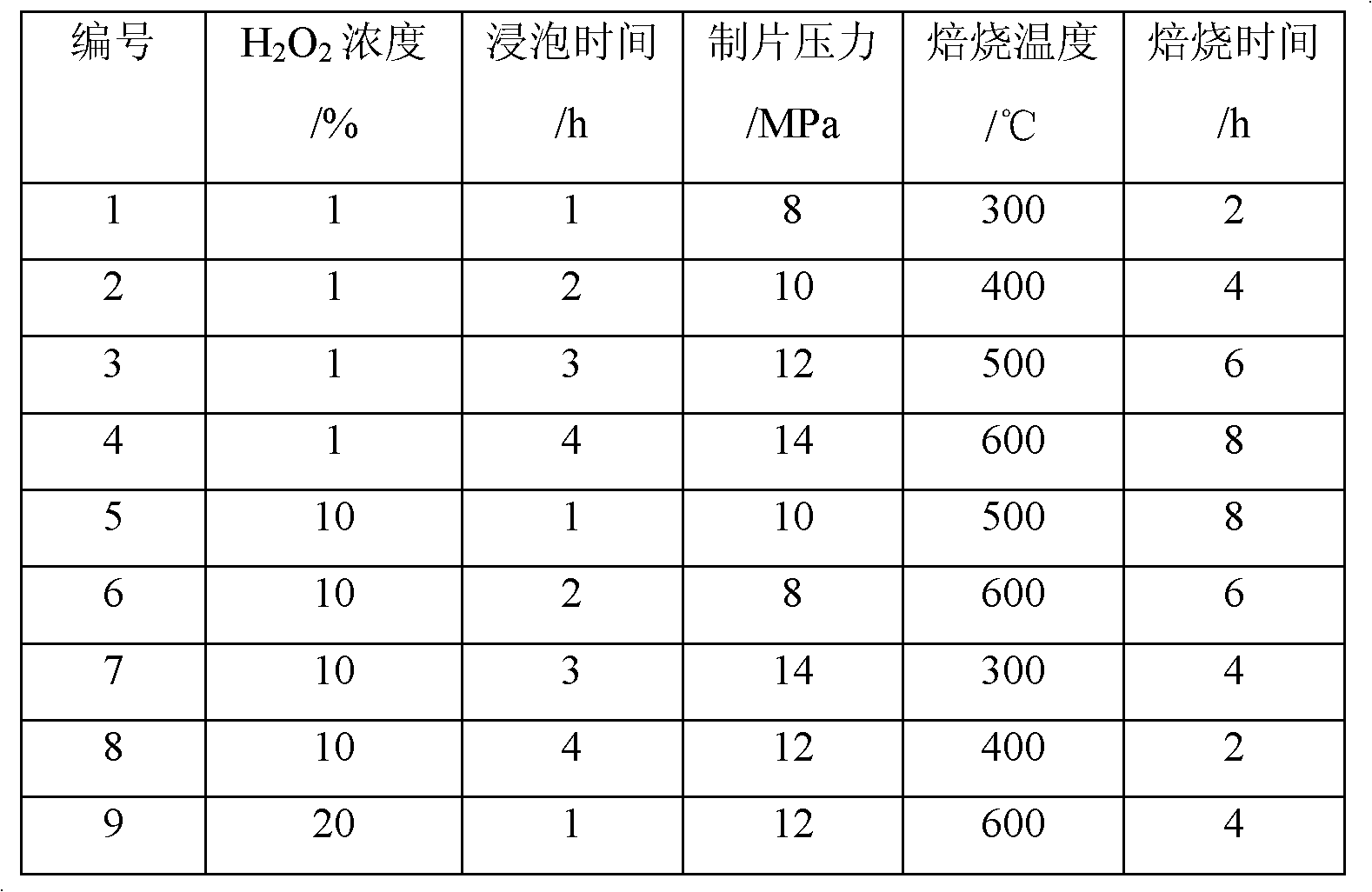

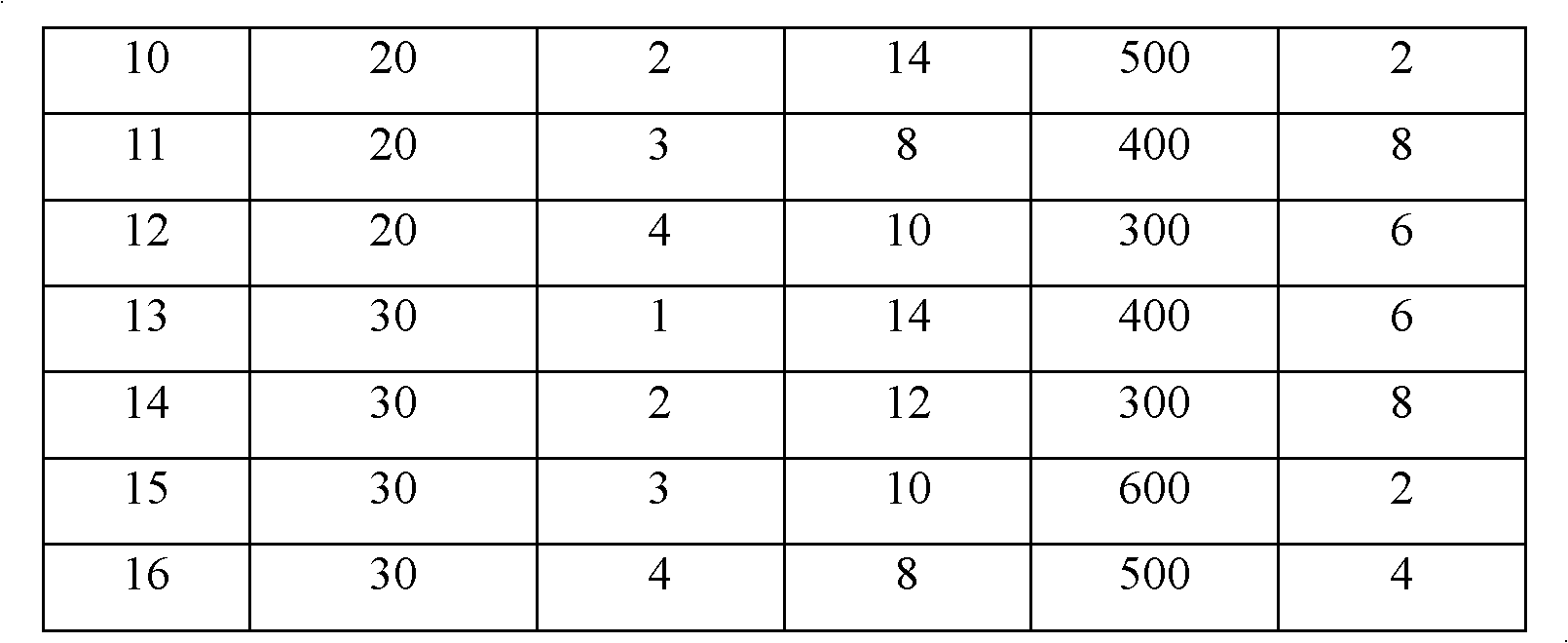

Ceramic catalyst taking red mud waste residues as carrier as well as preparation method and application thereof

ActiveCN111138167AAvoid secondary pollutionSolve the shortageCatalyst carriersHydrogenAluminium industryPtru catalyst

The invention discloses a ceramic catalyst taking red mud waste residues as a carrier as well as a preparation method and an application thereof. According to the catalyst, ceramic spherical particlesprepared from polluting red mud waste residues discharged when aluminum oxide is extracted in the aluminum production industry, aluminum source powder and a forming agent solution are used as carriers, molybdenum oxide is used as a catalytic active component, and zirconium oxide is used as a cocatalyst. The preparation method comprises the following steps: preparing a ceramic spherical particle carrier from red mud waste residues, aluminum source powder and a forming agent solution through crushing, burdening, granulating, forming, calcining and other processes; dipping the ceramic sphericalparticle carrier in an active component and co-catalytic ion precursor composite solution; drying the carrier, and roasting the carrier to obtain the ceramic-based reforming hydrogen production catalyst. The reforming hydrogen production catalyst not only can realize resource utilization of industrial waste residue red mud, but also is high in H2 selectivity of reforming formaldehyde to produce hydrogen at a low temperature, is simple in preparation process, and has a wide market application prospect.

Owner:南京环福新材料科技有限公司

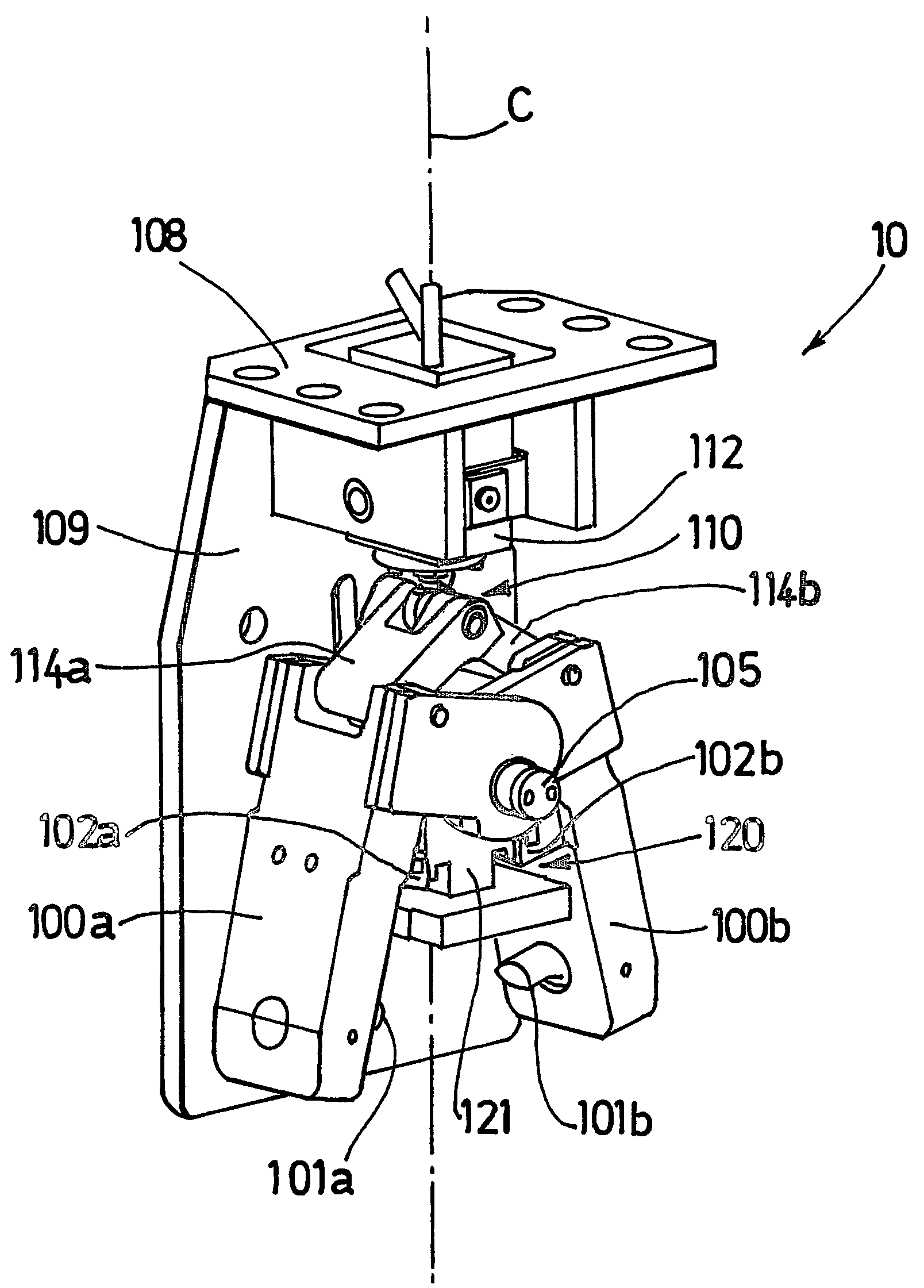

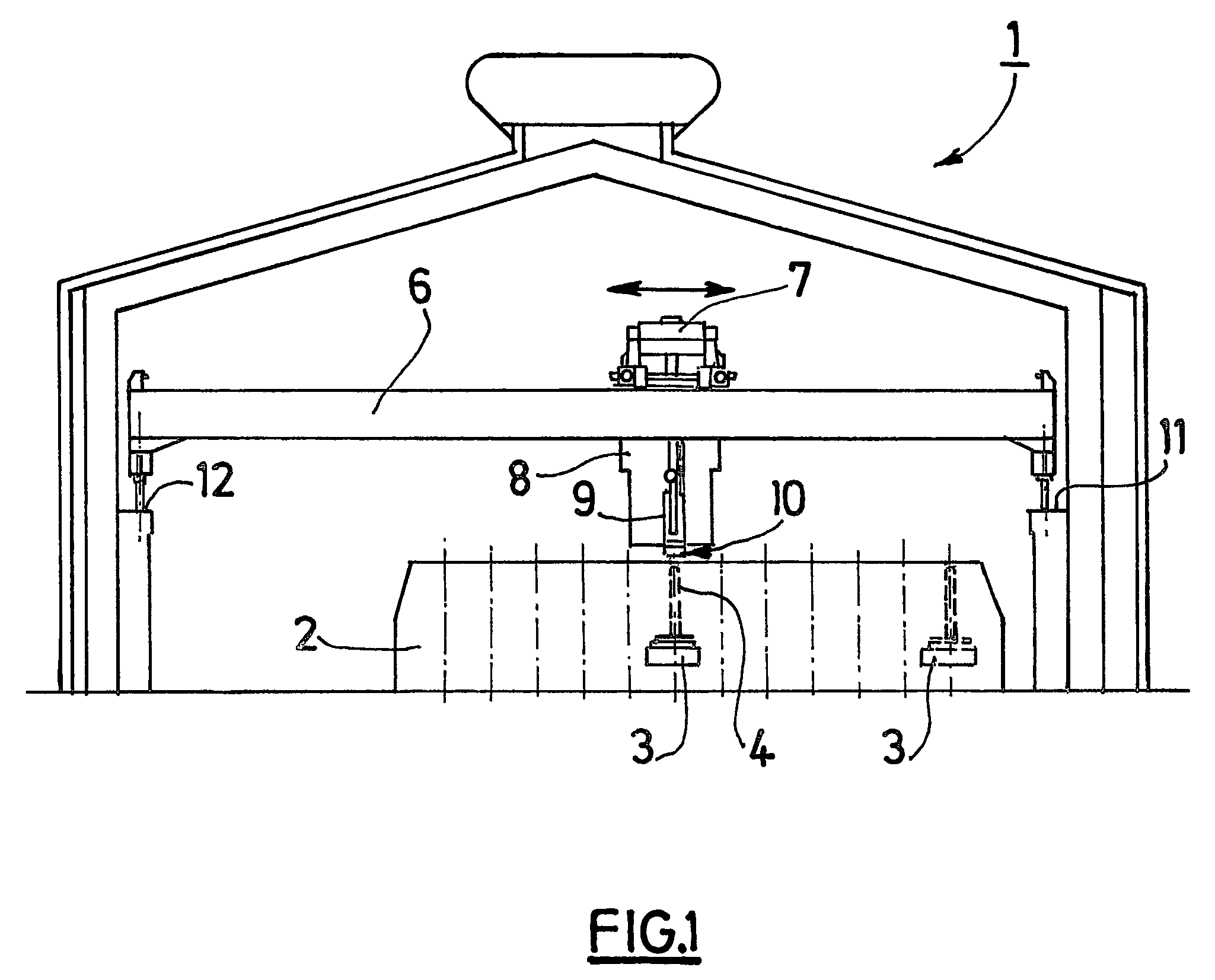

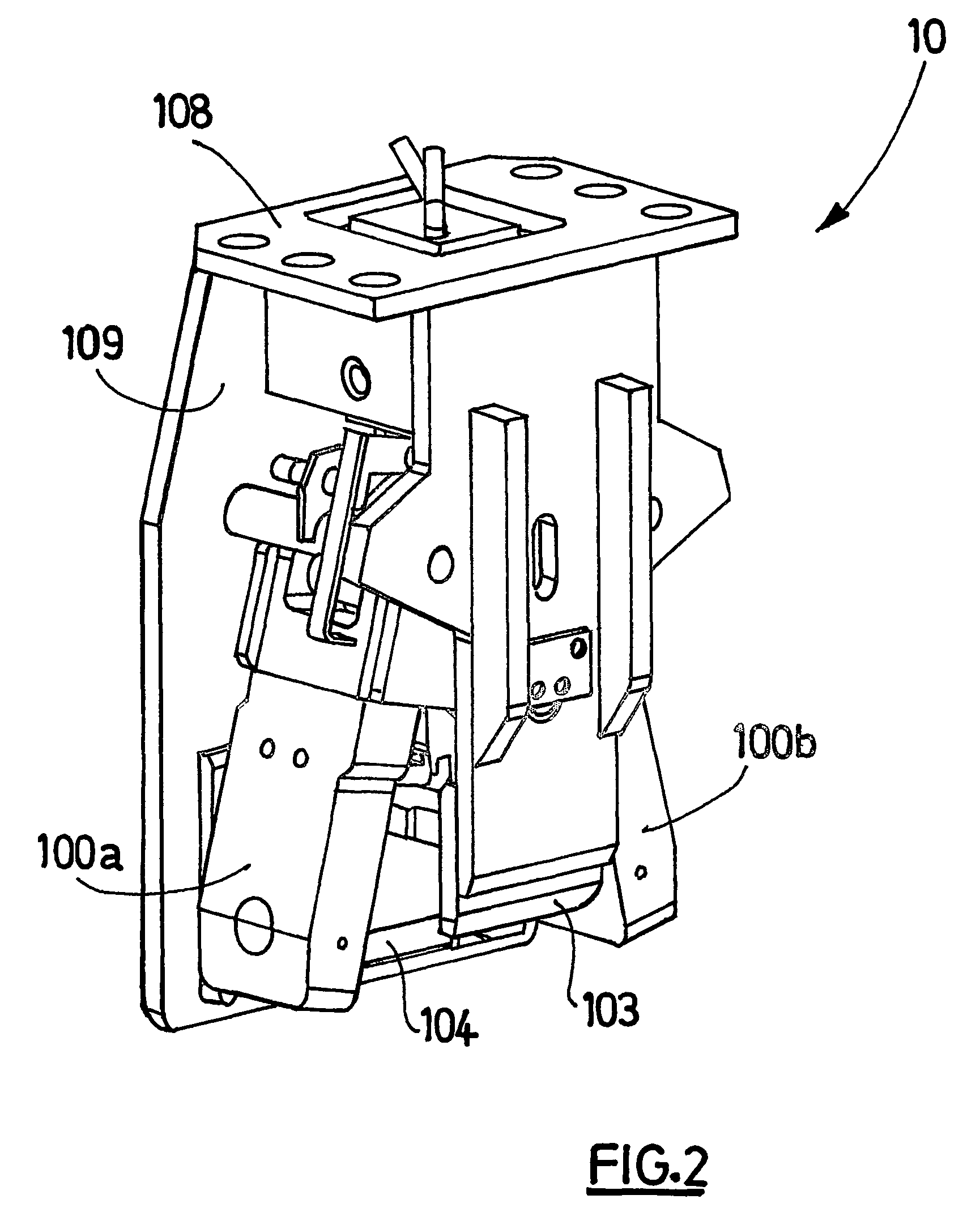

Handling clamp for a machine designed for tending an electrolytic cell used for the production of aluminium

InactiveUS7850218B2Inhibition releaseGripping headsMetal-working hand toolsAluminium industryMachine design

The present invention relates to a handling clamp, designed to grasp a stem fixed to a load and equipped with at least one attachment means. The stem is capable of moving between a lower position in the handling clamp and an upper position in the handling clamp when the handling clamp is closed on the stem. When the stem is in the lower position, the handling clamp is capable of being locked closed. When the stem is in the upper position, the handling clamp is capable of being unlocked. The handling clamp of the present invention is particularly adapted for use in the aluminium industry.

Owner:E-CL

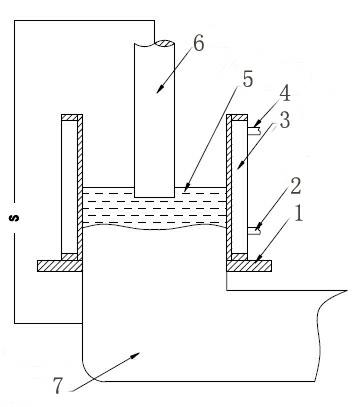

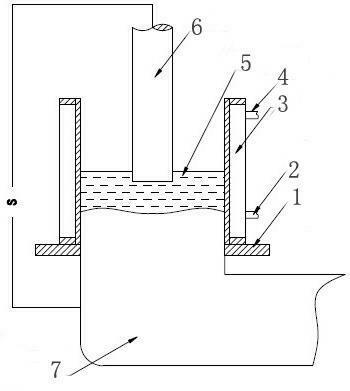

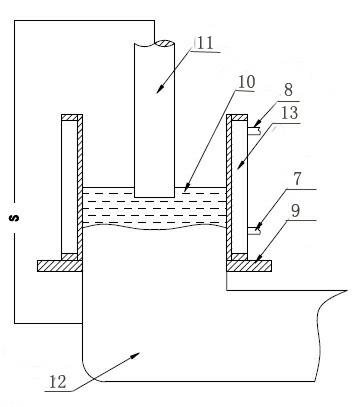

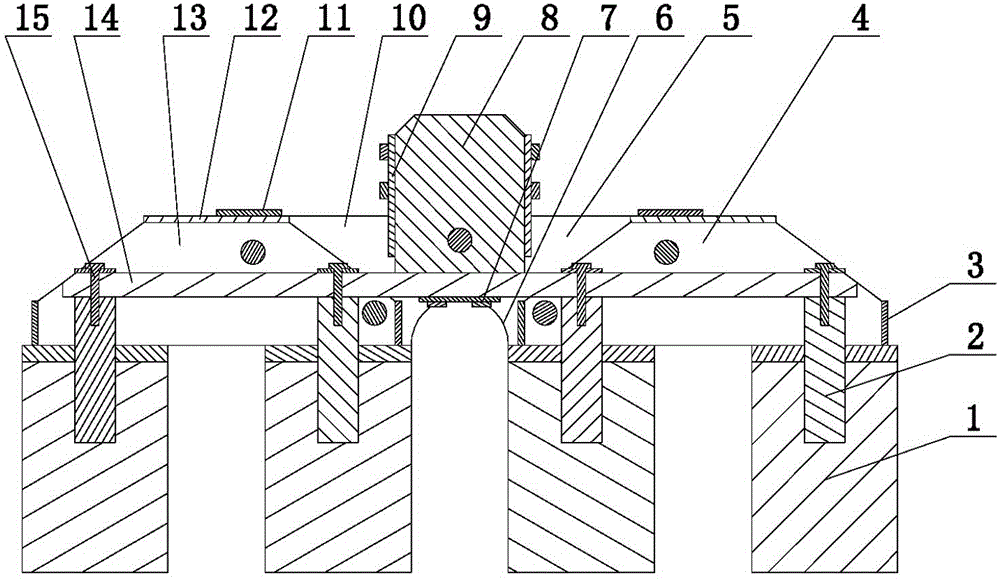

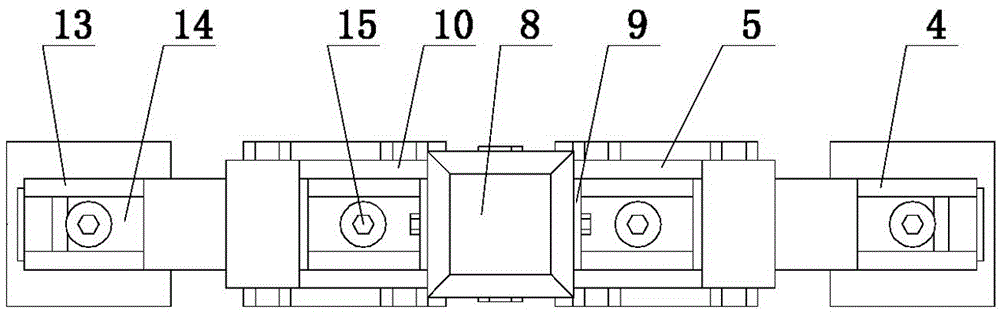

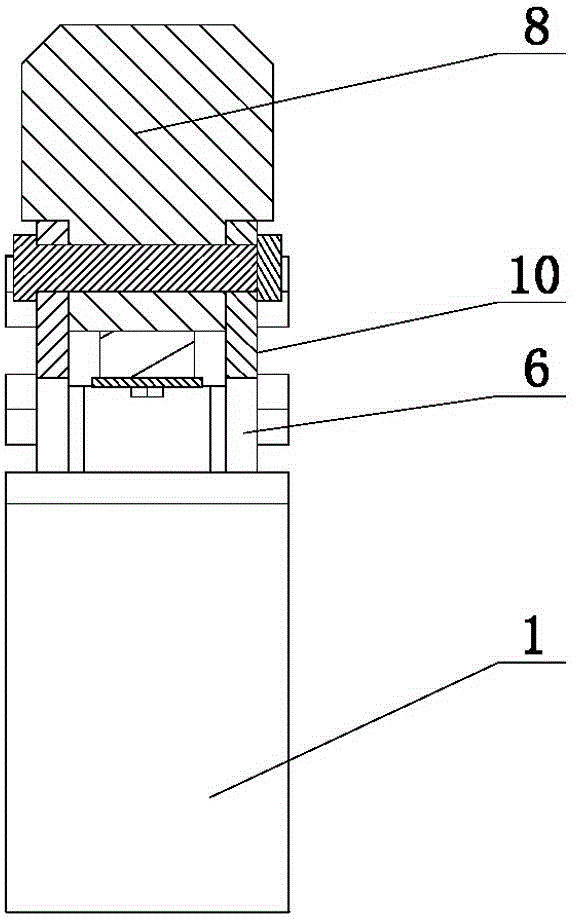

Device for repairing electrolytic aluminium anode steel claw by total cross-section fusion welding

The invention relates to a repairing device for an anode steel claw which is a consumptive part in the field of electrolytic aluminium, belonging to the electrolytic aluminium industry. The invention has the technical scheme that in a device for repairing an electrolytic aluminium anode steel claw by total cross-section fusion welding, a slag pool is formed by metal pallets and a cavity formed by moulds and a residual steel claw leg; the metal pallets are respectively arranged at the two opposite sides of the residual steel claw leg; the moulds are respectively positioned on the metal pallets and are closely jointed with the residual steel claw leg; the upper part and the lower part of each mould are respectively connected with a water outlet pipe and a water inlet pipe, and the interiors of the moulds are cavities; fluxing agent is arranged in the slag pool; an electrode is inserted into the slag pool, and a certain distance is maintained between the electrode and the residual steel claw leg; and the electrode and the residual steel claw leg are connected with a transformer by leads. The steel claw leg repaired by the device is high in strength and utilization rate; and meanwhile, the energy is saved, the consumption is reduced, and the problems caused by artificial repairing can be solved.

Owner:饶云福

Innocent treatment process for industrial heavy metal waste residue by utilizing treating waste with waste

The invention relates to an innocent treatment process for industrial heavy metal waste residue by utilizing treating waste with waste. In the process provided by the invention, a novel cement curing matrix taking the urban trash firing fly ash as a main component is utilized, wherein the curing matrix comprises following the components in percentage by weight: 60-70% of the urban trash firing fly ash, 10-20% of aluminum-containing additive (aluminum-containing industrial waste residue powder) and 6-20% of calcium controlling agent (lime powder). The process provided by the invention comprises the following components: mixing the trash firing fly ash curing matrix prepared from the components with the industrial heavy metal solid waste residue or sludge to be treated together; adding a proper amount of water, and stirring uniformly; and then preparing a cement curing body; after conserving for five days at normal temperature, embedding in a landfill site. The process provided by the invention is an innocent treatment method of treating waste with waste.

Owner:湖南布鲁斯凯碳资产管理有限公司

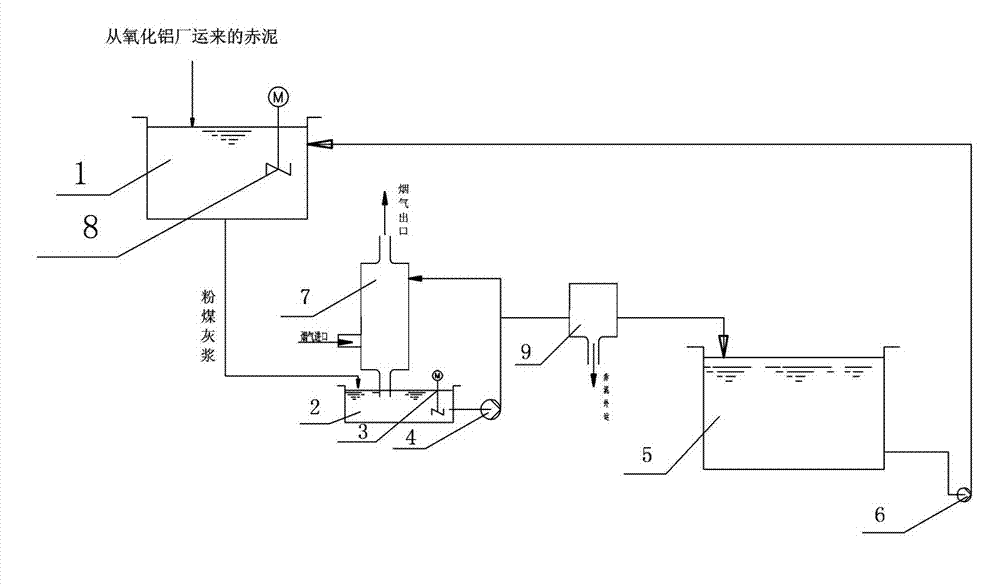

Method for desulfurization of flue gas in boiler by using red mud

ActiveCN103028324ALow costTo achieve the purpose of desulfurizationDispersed particle separationAluminium industryFlue gas

The invention discloses a method for desulfurization of flue gas in a boiler by using red mud. The red mud adopted by the method is the red mud which is prepared by adding water in pollutant waste residue-red mud discharged when aluminum oxide is extracted in the aluminum making industry. The method comprises the following steps: injecting the red mud into a red mud pool and continuously stirring the red mud; conveying the red mud to a desulfurization tower through a desulfurization circulating pump; carrying out desulfurization reaction on the red mud and the flue gas introduced to the middle lower part of the desulfurization tower; discharging desulfurized flue gas from the top of the desulfurization tower; discharging mud products containing sulfate generated by desulfurization from the bottom of the desulfurization tower; conveying the mud products containing sulfate discharged to a mud-water separation device; separating out the red mud and water after desulfurization; pumping separated clean water to a red mud preparation tank for recycling; and conveying separated desulfurized red mud. The flue gas generated by the boiler is desulfurated, so that the method is simple to operate and low in cost. Wastes are treated by wastes to the benefit of environmental protection, so that the method has remarkable economic and social benefits.

Owner:安阳化学工业集团有限责任公司

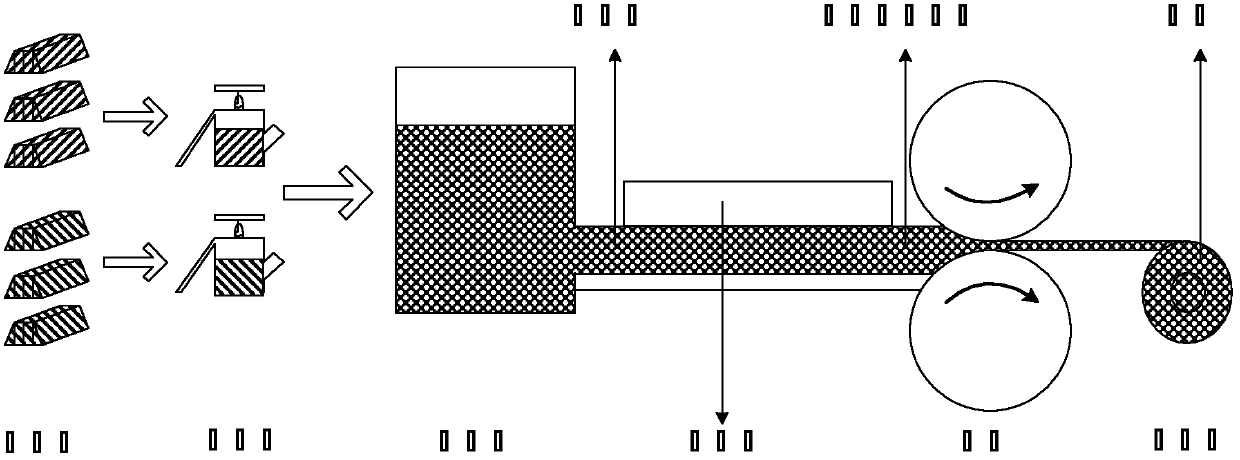

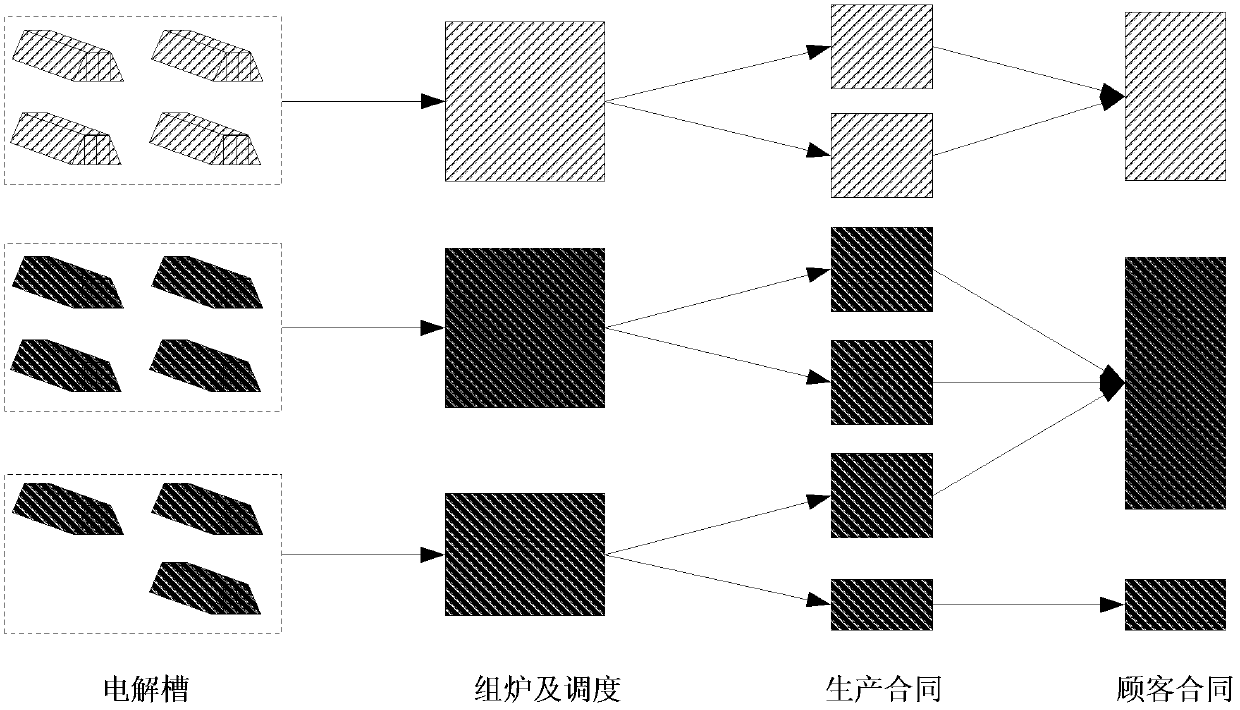

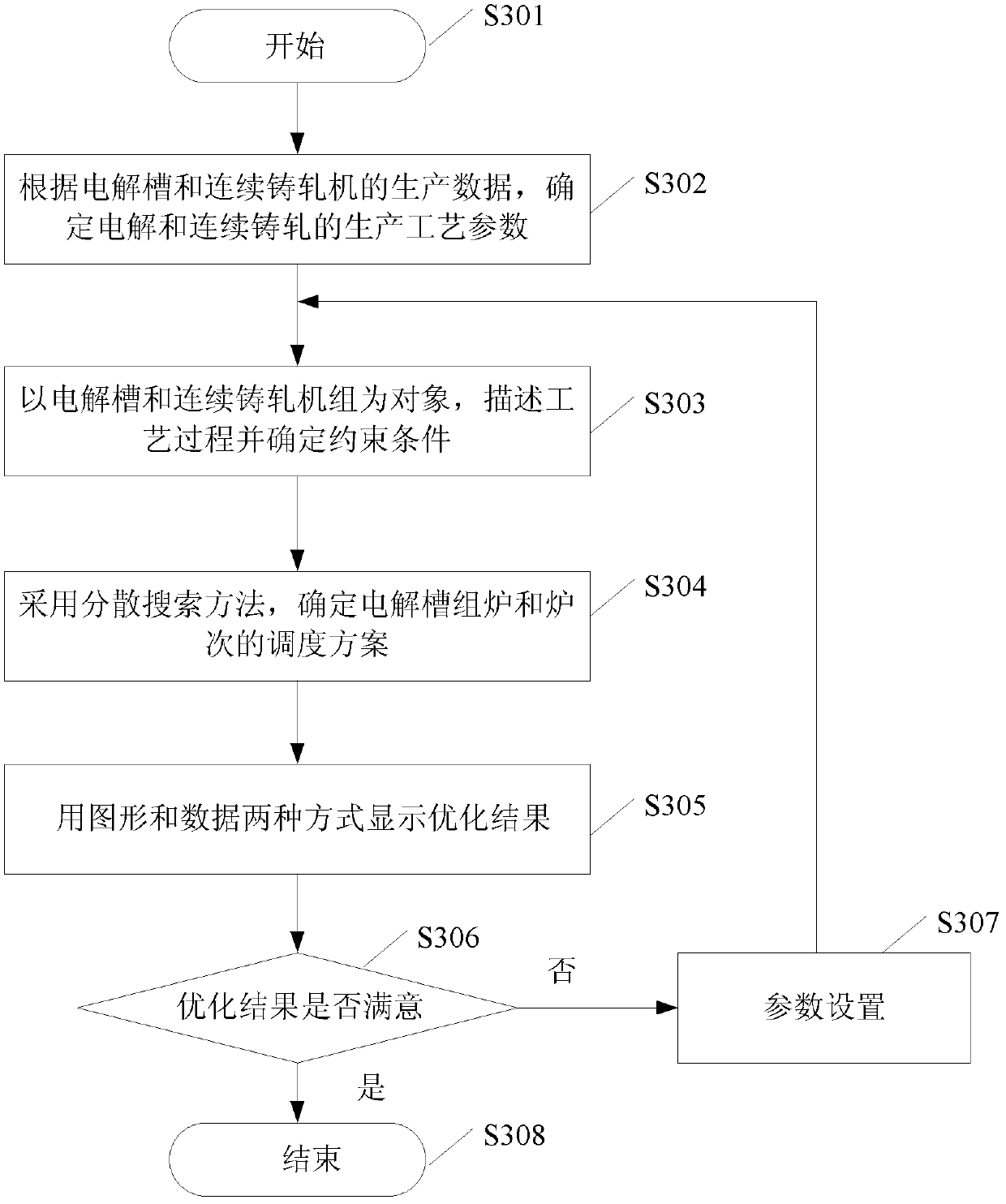

Furnace, dispatching method and device for aluminum continuous cast-rolling production

ActiveCN102699027AEasy to use and maintainReduce mixingRoll mill control devicesMetal rolling arrangementsAluminium industryProcess engineering

The invention relates to a furnace, a dispatching method and a device for aluminum continuous cast-rolling production and belongs to the technical field of aluminum industrial plate processing information. Manufacturing processes are described and constraint conditions are determined by utilizing production process parameters, taking electrolytic tanks and a continuous cast-rolling unit as objects and taking minimization of the electrolytic tanks, purity difference among furnace orders distributed by the electrolytic tanks, purity and position difference among the electrolytic tanks with the same distributed furnace order, manufacturing period and idle production capacity of the furnace orders in the whole plan as objectives, and furnaces and furnace order dispatching of the electrolytic tanks are determined by adopting the scatter search. Established product tasks are completed while production time of an aluminum continuous cast-rolling process is reduced, so that operation efficiency of the machine is improved; operations of furnace cleaning caused by different purities of adjacent furnace orders and halt for adjusting a crystallizer caused by different widths and thicknesses of the adjacent furnace orders are reduced, so that loss of materials can be reduced; and production task planning of the unit is more rational, so that production quality of aluminum coils can be improved.

Owner:NORTHEASTERN UNIV

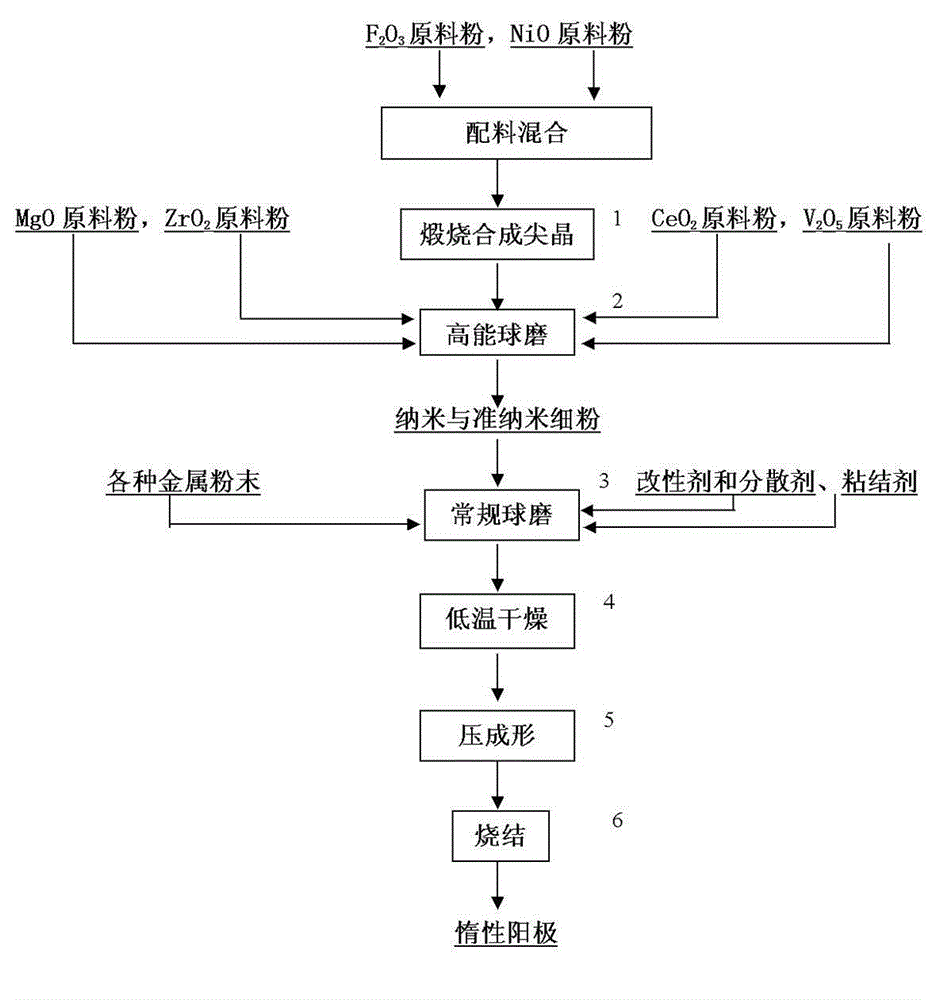

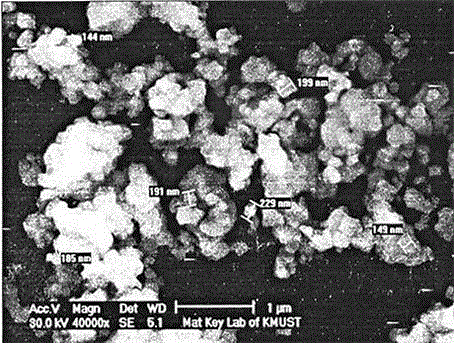

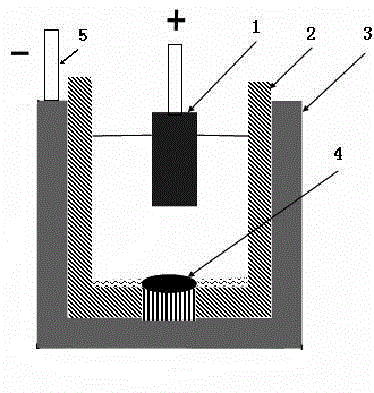

Metal oxide ceramic inert anode and preparation method and application thereof

The invention relates to a fused salt electrolytic aluminum inert anode and a preparation method and application thereof, and belongs to the technical field of ceramic-metal composite materials. The inert anode is composed of an oxide ceramic primary phase and a metal secondary phase. The oxide ceramic primary phase is composed of a nano and quasi-nanoparticle level NiFe2O4 spinel principal component and a ZrO2, V2O5, CeO2 ad MgO modified adding component. The metal secondary phase is formed by selecting five to six of micron order Ni, Cu, Co, Zn, Cr, Ag, Ti, Al, Sc, Zr, No, V, Mn, Y and La. The inert anode is compounded through spinel, nano and quasi nano oxide is obtained by milling through a high energy ball, and the inert anode can be prepared through the steps of common ball milling, compression molding and metal or protective atmosphere sintering, machining and the like of oxide and metal powder. The fused salt electrolytic aluminum inert anode has the advantages of being good in electrical conductivity, high in high-temperature salt corrosion resistance and antioxidation, good in thermal shock resistance and capable of not polluting aluminum electrolysis products. The fused salt electrolytic aluminum inert anode is used in fused salt electrolytic aluminum and is used as a substitution of a carbon anode, and the problems of high consumption and high pollution in the aluminum industry at present can be solved.

Owner:王宇栋

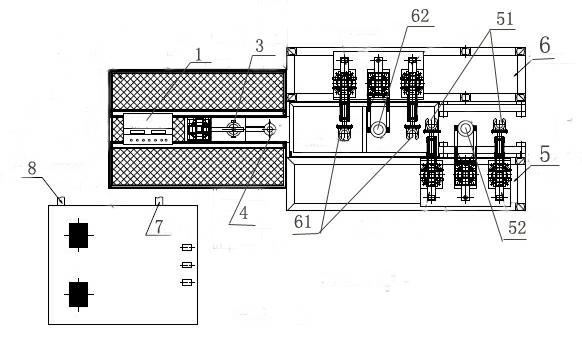

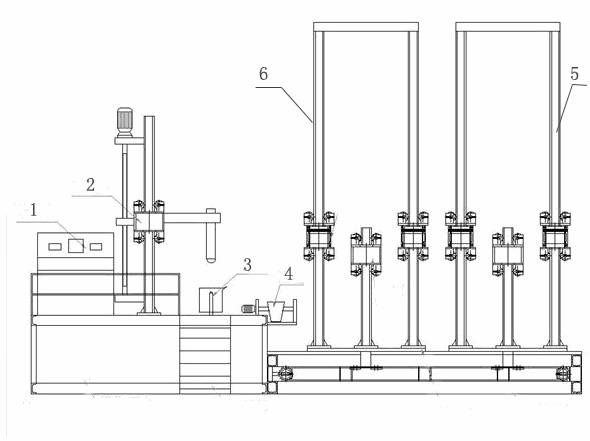

Electrolytic aluminum anodic steel claw repairing equipment

ActiveCN102560551AReduce labor intensityImprove labor efficiencyAluminium industryRestoration device

The invention relates to an electrolytic aluminium anodic steel claw repairing equipment and belongs to the electrolytic aluminium industry, which aims at solving the existing problems of artificial repairing by the usage of the electrolytic aluminium anodic steel claw repairing equipment, reducing intensity of work and increasing efficiency of work. The technical scheme that the electrolytic aluminium anodic steel claw repairing equipment comprises an operating platform and stand column platforms, wherein the operating platform is provided with a control panel, a slagging furnace, a crucible and a slag box, the programmable control panel has a control to the slagging furnace, the crucible, the slag box and the stand column platforms through program settings. The electrolytic aluminium anodic steel claw repairing equipment has the advantages of reducing work intensity of users, increasing work efficiency; simultaneously, being capable of repairing different types of steel claws and having a great applicability.

Owner:内蒙古世星新材料科技有限公司

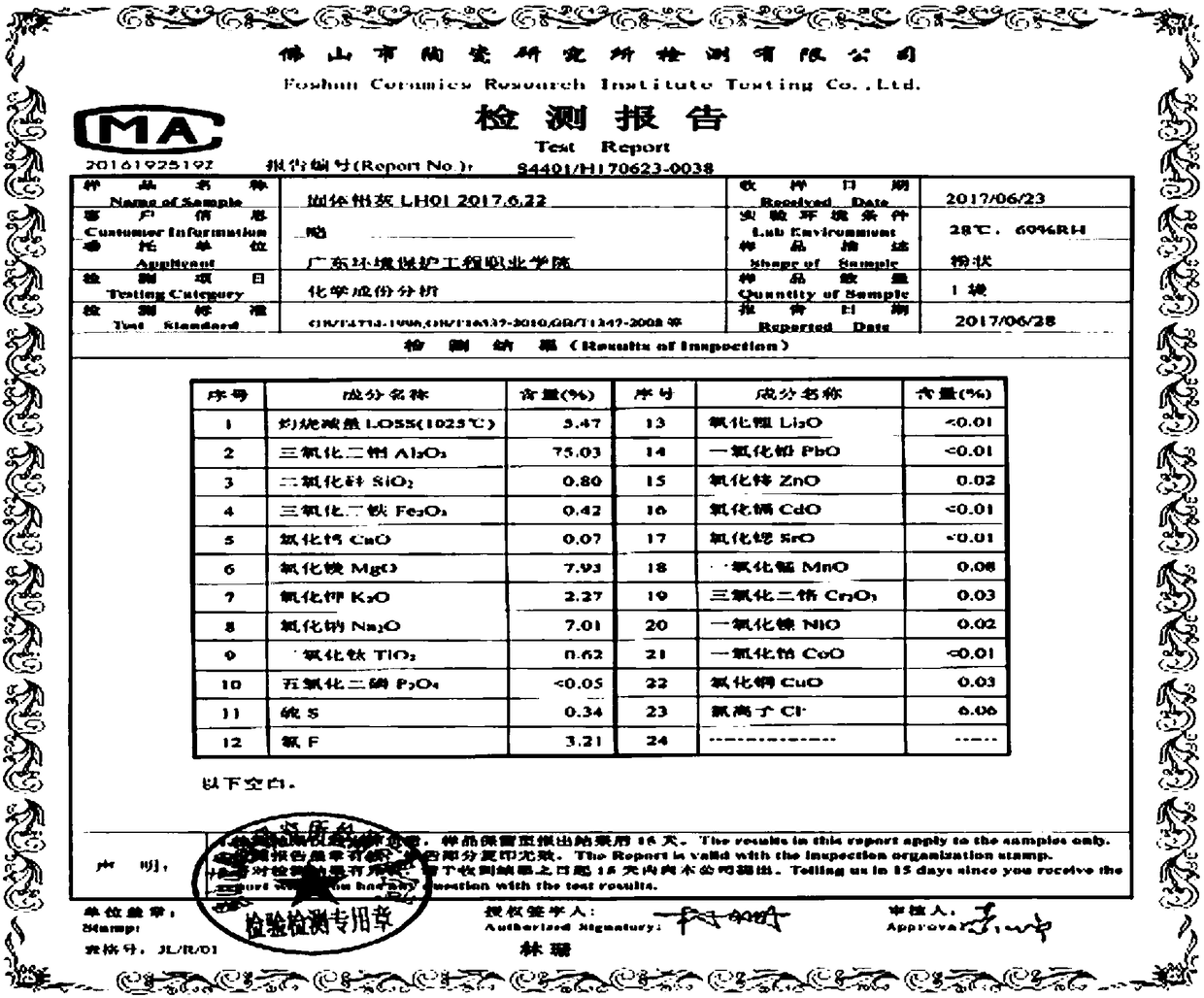

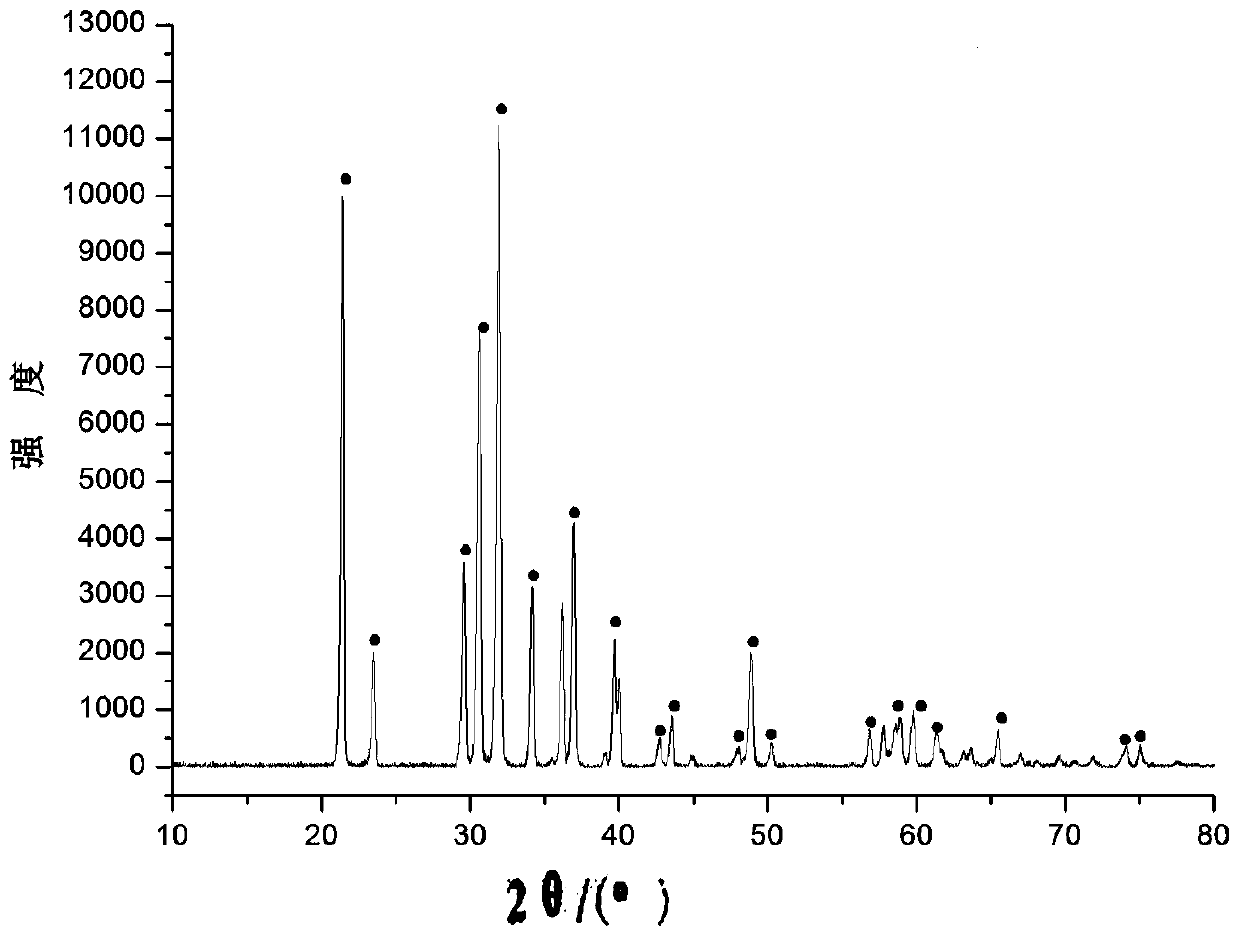

Metal ceramic material resistant to molten aluminum corrosion, and preparation method and application thereof

The invention provides a metal ceramic material resistant to molten aluminum corrosion, and a preparation method and an application thereof, and relates to the technical field of metal material corrosion and protection. The chemical composition of the metal ceramic material provided by the invention is Ti(C0.3,N0.7)-Al0.25FeNiCoCr, raw materials for preparing the metal ceramic material comprise Ti(C0.3,N0.7) and an Al0.25FeNiCoCr high-entropy alloy; the mass percentage of the Al0.25FeNiCoCr high-entropy alloy in the metal ceramic material is 8-30%; the microscopic Vickers hardness of the metalceramic material ranges from 779.4 HV[0.2] to 1237.1 HV[0.2]. The metal ceramic material provided by the invention has excellent molten aluminum corrosion resistance and good hardness and toughness,and can be applied to the aluminum industry. The preparation method of the metal ceramic material is simple in process and beneficial to large-scale production.

Owner:XIANGTAN UNIV

Method for producing cryolite by wast liquid of vacuum residues in aluminium industry

InactiveCN108059178AFull recoveryRealize high-value resource utilizationAluminium fluoridesAluminium industryResource utilization

The invention discloses a method for producing cryolite by wast liquid of vacuum residues in the aluminium industry. The waste liquid is alkali bath solution which is generated by utilizing sodium hydroxide to dissolve aluminium and contains sodium metaaluminate; a fluorine-containing acid compound and sodium carbonate are added in the waste liquid to produce the cryolite. According to the methoddisclosed by the invention, aluminium ions in the waste liquid can be sufficiently recycled and converted into the industrial cryolite, wastes are changed into treasure and high-value resource utilization of waste aluminium is implemented; sodion in the waste liquid is sufficiently utilized so as to greatly reduce cost of sodium hydroxide; aluminium and alkali in the waste liquid are sufficientlyrecycled, and zero discharge of wastewater and waste residues in a die repairing workshop is implemented.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

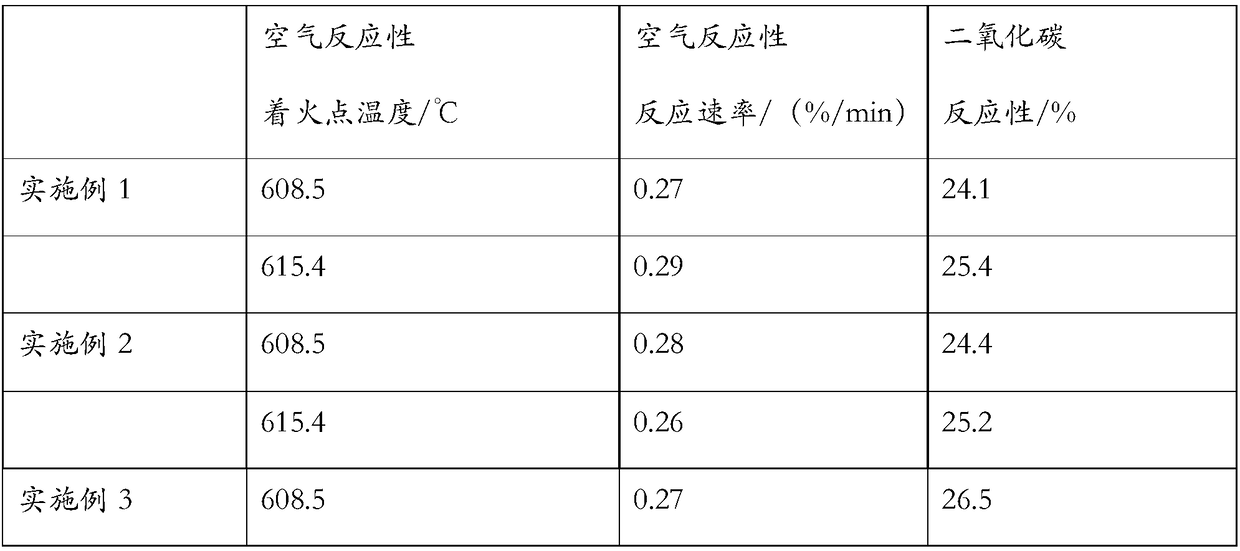

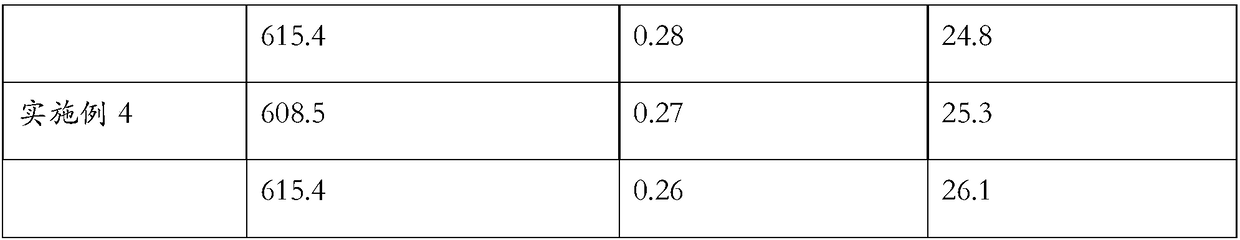

Preparation method of graphene composite protective layer for pre-baked carbon anode

The invention belongs to the field of carbon anode new materials for the electrolytic aluminium industry, and particularly relates to a preparation method of a graphene composite protective layer fora pre-baked carbon anode. The preparation method includes the steps of (1), adding graphene oxide in distilled water, stirring uniformly ultrasonically, adding phenolic resin with heating and stirring, performing redox reaction to obtain aqueous dispersion solution of graphene phenolic resin; (2) weighing a certain quantity of aqueous dispersion solution of graphene phenolic resin, sequentially adding graphite powder emulsion and nanometer aluminium oxide into the aqueous dispersion solution of graphene phenolic resin, and performing ultrasonic dispersion to obtain a graphene composite coating; (3), taking the graphene composite coating obtained the step (2), adding distilled water to dilute the graphene composite coating, covering the surface of the pre-baked carbon anode with the dilutedgraphene composite coating, and then drying naturally to obtain the graphene composite protective layer. The protective layer can effectively isolate oxidation action of air and carbon dioxide to carbon blocks; the carbon yield ratio in the air reactivity test is greater than 95%, and particularly the carbon yield ratio is greater than 96% after the CO2 reactivity test.

Owner:SUNSTONE DEV

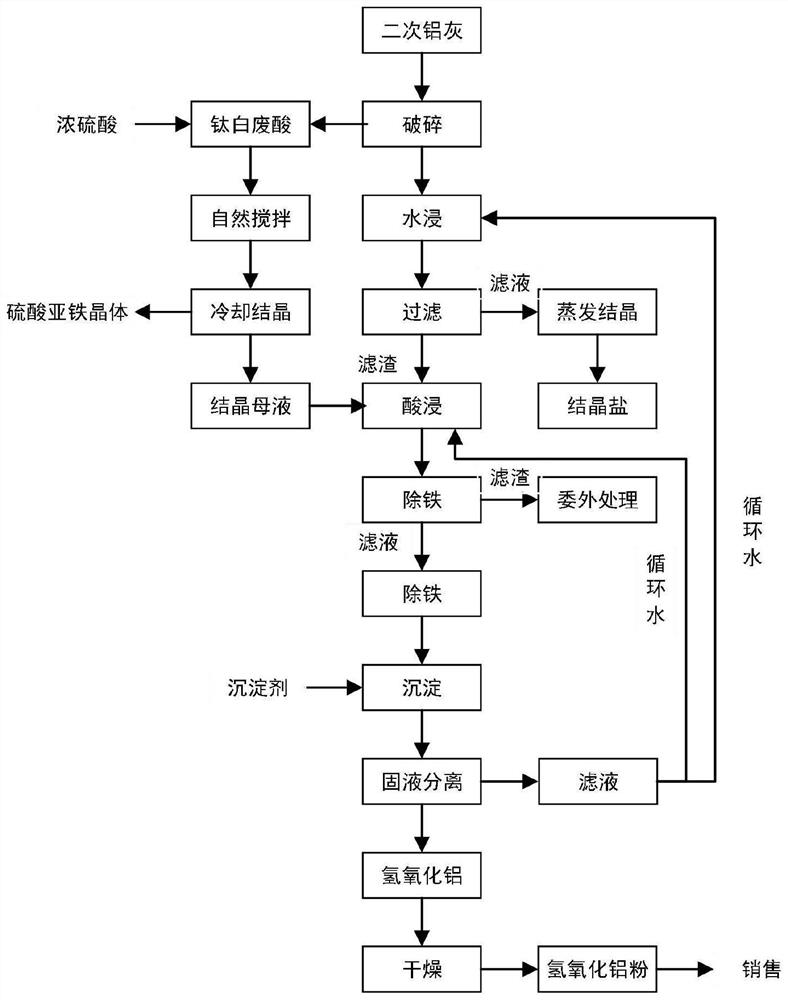

Method for recycling aluminum hydroxide powder by using titanium dioxide waste acid and secondary aluminum ash

ActiveCN112553470ALow utilization of valuable resourcesLow costAluminium compoundsProcess efficiency improvementAluminium industryAluminium hydroxide

The invention discloses a method for recycling aluminum hydroxide powder by using titanium dioxide waste acid and secondary aluminum ash, and belongs to the field of aluminum industrial waste treatment. The method comprises the steps of crushing, water leaching denitrification and desalination, waste acid pretreatment, acid leaching, impurity removal, precipitation and drying. The method for recycling the aluminum hydroxide powder by using the titanium dioxide waste acid and the secondary aluminum ash has the beneficial effects that the secondary aluminum ash is subjected to acid leaching after the titanium dioxide waste acid is pretreated, and the aluminum hydroxide powder is recycled; compared with a traditional process, the method has the advantages of being low in material consumption,low in treatment cost, good in economic benefit and the like; and valuable resources are recycled through a method of using waste to treat waste, the concept of circular economy, energy conservationand emission reduction is met, and the method can be widely applied to treatment of aluminum industrial waste.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

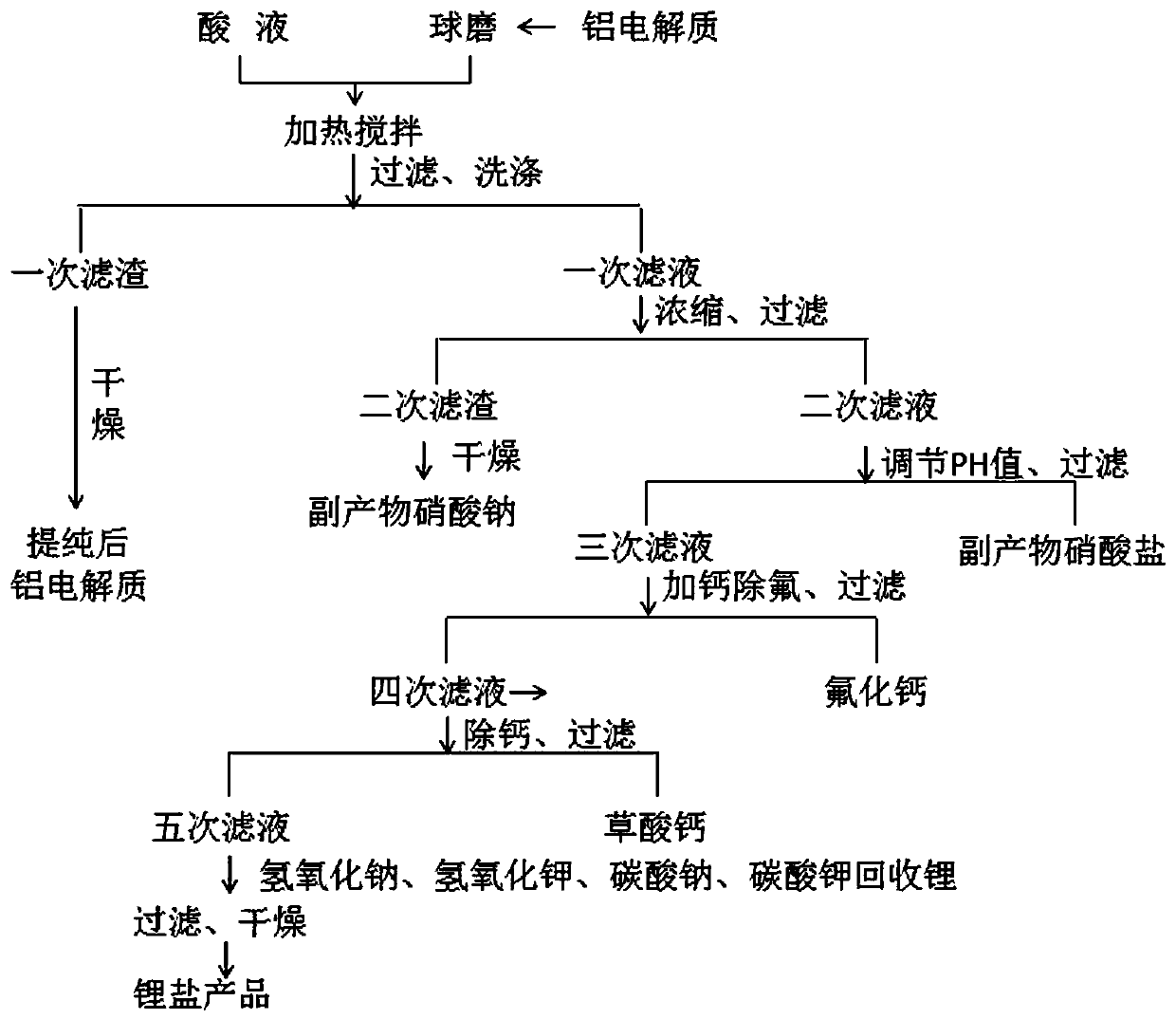

Method for delithiation, purification and recovery of lithium from aluminum electrolyte

ActiveCN109930174BImprove labor efficiencyRunning balance and stabilityCalcium/strontium/barium fluoridesAlkali metal nitrate preparationAluminium industrySocial benefits

Owner:ZHENGZHOU JINGWEI TECH & IND

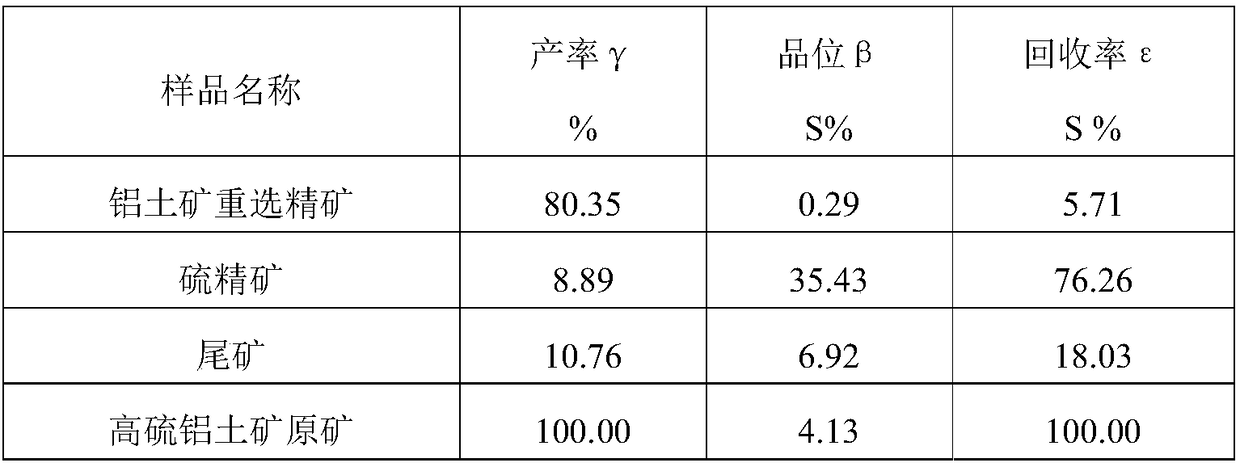

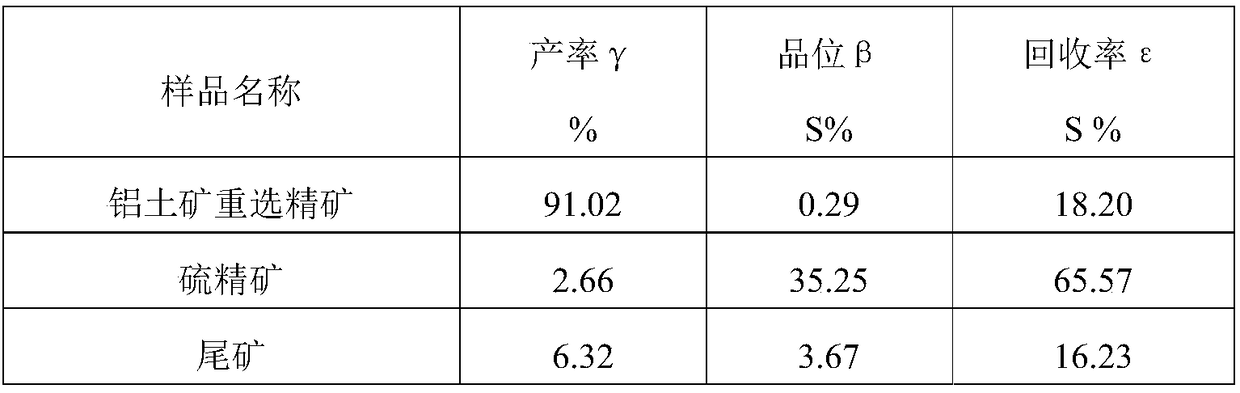

Sulphur-containing bauxite gravity concentration and desulphurization method

InactiveCN109317305AReduce manufacturing costImprove technical index of aluminum industrySolid separationAluminium industryLiquid medium

The invention belongs to the technical field of mineral process engineering, and specifically discloses a sulphur-containing bauxite gravity concentration and desulphurization method. The sulphur-containing bauxite gravity concentration and desulphurization method comprises the following steps of: modulating water for sulphur-containing bauxite mineral powder and / or a liquid caustic soda solutionand / or seeded precipitation spent liquor into ore pulp, adopting gravity concentration equipment to perform gravity concentration on the sulphur-containing bauxite ore pulp, and performing gravity concentration to separate and remove sulphur-containing minerals from the sulphur-containing bauxite ore pulp, wherein gravity-concentration operation is any one or two or more of roughing operation, selection operation and scavenging operation. The sulphur-containing bauxite gravity concentration and desulphurization method adopts a low-cost gravity concentration method to treat sulphur-containing bauxite, and a separation liquid medium needed in the gravity concentration process is water, liquid caustic soda solution and the seeded precipitation spent liquor, which is in common use with a solution in an aluminium oxide production process, and therefore, the generated bauxite concentrate does not need high-cost filtration operation, only needs simple concentration, and can be directly fed into an aluminium oxide production process, the production cost of producing bauxite concentrate and an aluminium oxide product is reduced, and the technical indexes of the aluminium industry are improved.

Owner:湖南绿脉环保科技股份有限公司

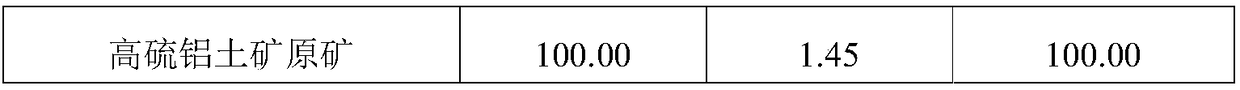

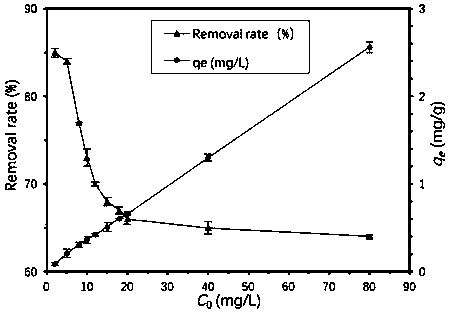

Absorbing agent for separating formaldehyde from air and preparation method thereof

InactiveCN102179231AImprove adsorption capacityLarge adsorption capacityOther chemical processesDispersed particle separationParticulatesAbsorption capacity

The invention provides an absorbing agent for separating formaldehyde from air and a preparation method thereof. The absorbing agent is obtained by taking red mud produced by the Bayer-process aluminium-smelting technique as a precursor and carrying out chemical modification and high-temperature roasting. The absorbing agent is red particles, the distribution range of internal micropore diameter of the absorbing agent is 0.9-2.7nm, and the appearance size is 0.45-0.9mm, so that the absorbing agent is beneficial to catching and removing trace formaldehyde in the air. In the absorbing agent provided by the invention, compared with the existing material for formaldehyde absorption, catalysis and purification, under a high air speed, the gas-phase low concentration formaldehyde can be absorbed in a high-efficiency manner, the absorption capacity is large, the service life is long, the used raw materials are from solid slag, namely red mud produced in the aluminium-smelting process in the aluminium industry, the source is wide, the cost is low, the prepared absorbing agent can achieve the purpose of using waste to treat harm and is beneficial to realizing clean production.

Owner:BEIHANG UNIV

Ceramsite matrix for constructed wetland, preparation method and application thereof

PendingCN110194652ARelieve stressHigh mechanical strengthCeramic materials productionCeramicwareConstructed wetlandSodium Bentonite

The invention provides a ceramsite matrix for constructed wetland and a preparation method thereof. Polluting slag red mud discharged during extraction of alumina in aluminum industry is utilized, andat the same time, the prepared ceramsite matrix can efficiently remove pharmaceutical wastewater and has certain effect of removing nutrient salts. The matrix is prepared from the following raw materials: bentonite, red mud and biomass in a mass ratio of (4-6):1:(0.1-0.9). The invention also provides application of red mud in preparation of ceramsite matrix for constructed wetland.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Method for controlling phosphorus and heavy metal release in pig manure

The invention provides a method for controlling phosphorus and heavy metal release in pig manure. In the method, a novel modified red mud fixative is prepared by roasting basic material waste slag red mud generated in the production process of the aluminum industry; and the red mud fixative is blended with a proper amount of the pig manure so as to effectively control the dissolution release of phosphorus and heavy metals in the pig manure and reduce the serious environmental pollution caused by the dissolution of the phosphorus and the heavy metal in the pig manure through the fixation of the fixative to the phosphorus and the heavy metals in the pig manure. The method realizes the recycling of waste resources, and has wide application prospect for area source pollution control.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

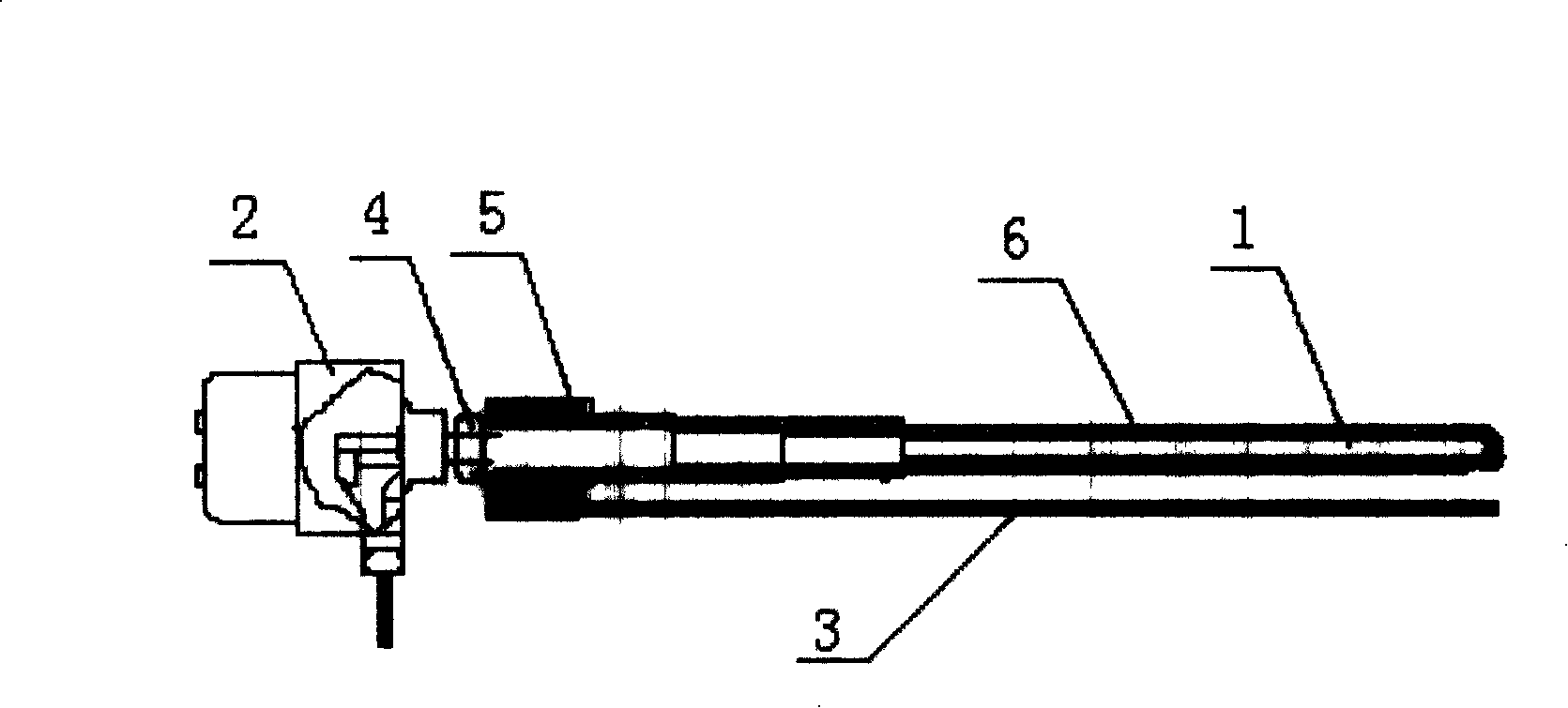

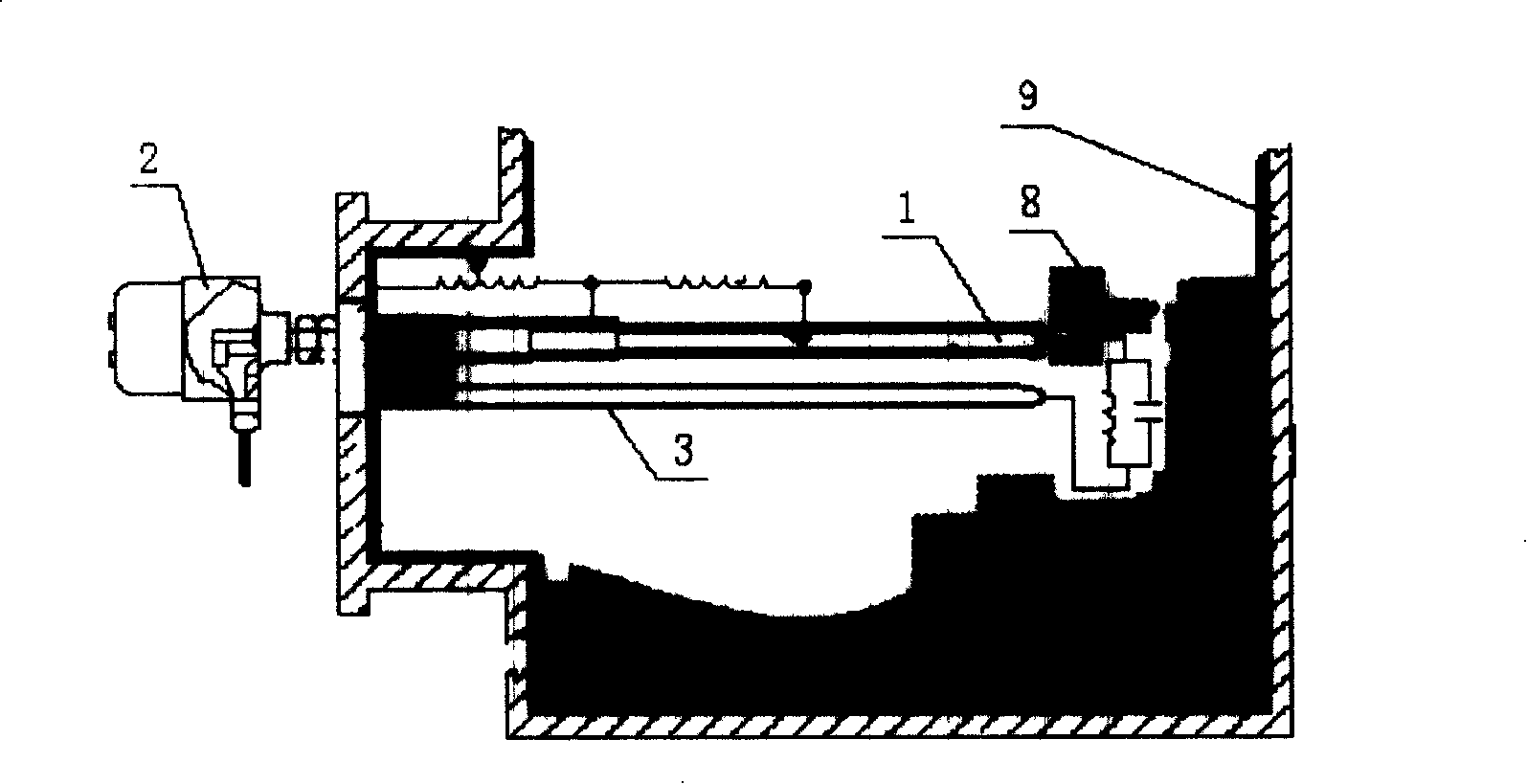

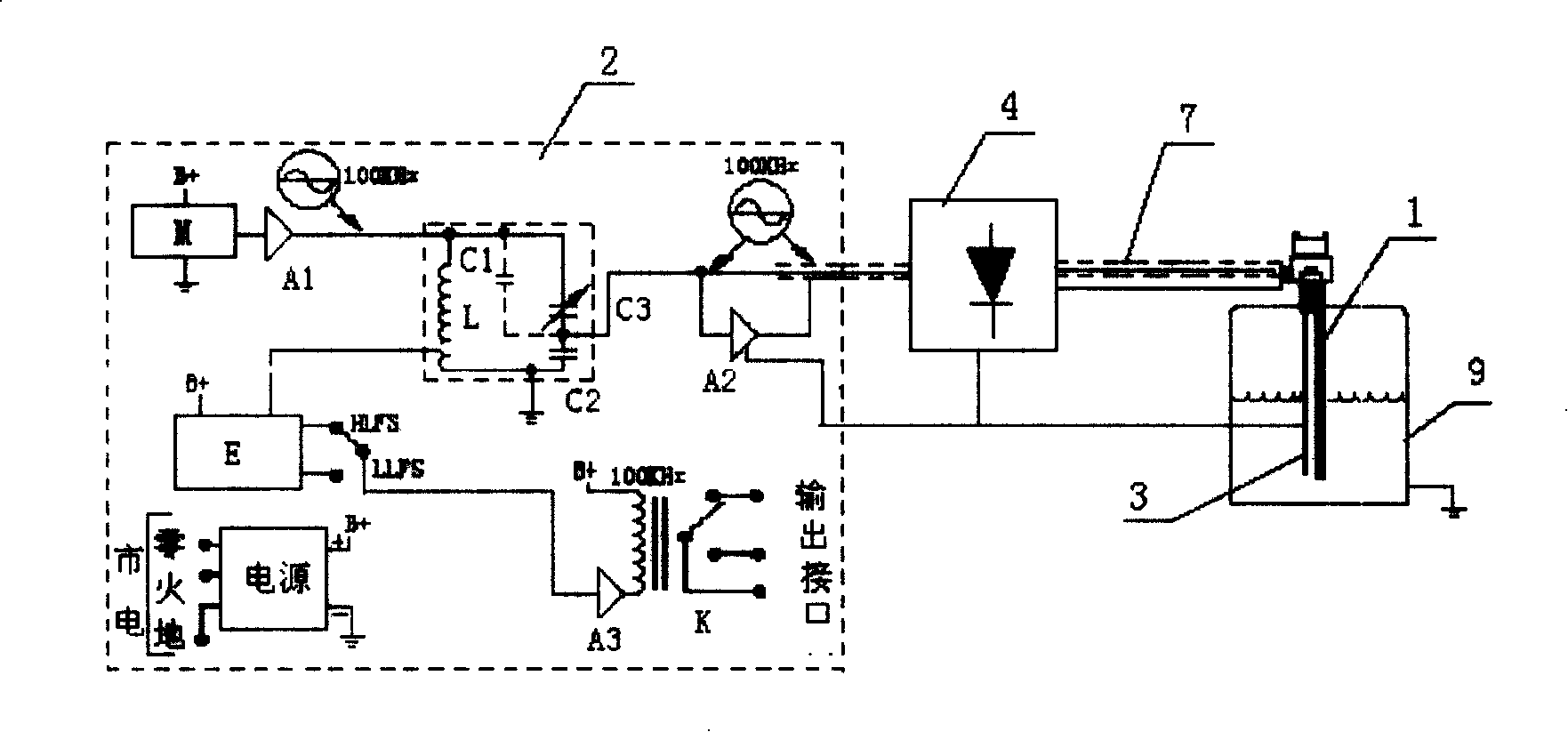

Two polar radio frequency admittance material level indicator

The invention discloses a bipolar radio-frequency admittance material level switch, comprising a main measuring staff 1, an electronic unit 2 and an auxiliary measuring staff 3 arranged on the main measuring staff 1, wherein, the auxiliary measuring staff 1 and the main measuring staff 3 are connected with the electronic unit 2. The bipolar radio-frequency admittance material level switch has the characteristics of HF corrosion resistance, high temperature resistance, scouring resistance, electromagnetic interference resistance, static electricity prevention, hanging prevention, anti-strong vibration effect, etc. The invention has stable and reliable operation, low failure rate and long service life, thereby greatly reducing expenses for repairing and maintaining spare parts and reducing cost for manufacturing electrolytic aluminium. The invention saves expenses of spare parts over 500,000 Yuan annually according to a calculation that consumption of material level switches are reduced by 100 per year, thereby providing a considerable economic benefit. The product not only can be applied to material measurement in the aluminium industry, but also can be popularized and applied in the petrochemical industry, the metallurgy industry, the electrical power industry, the energy industry, the cement industry and other industries.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

High-electric-conductive anode assembly effectively solving inward-bending deformation

ActiveCN105316704ASolve the problem of bending deformationReduce recycle cyclesAluminium industryAnode

A high-electric-conductive anode assembly effectively solving inward-bending deformation belongs to the technical field of anode electric-conductive devices in electrolytic aluminium industry. The invention particularly relates to a high-effective anode assembly effectively solving the inward-bending deformation, which not only solves a problem of inward bending of a steel claw, but also reduces welding quantity, is excellent in replaceability and is significantly higher than a cast steel claw in electric conductivity. The anode assembly includes a supporting cross beam which is characterized by including a first U-shaped steel board. An aluminum boss is disposed internally in the middle of the first U-shaped steel board through a bolt assembly. The upper end of the aluminum boss is stretched out from the upper part of the supporting cross beam. Two movable cross beams are respectively disposed in both the two ends of the first U-shaped steel board. Each movable cross beam includes a second U-shaped steel board which is connected to each end of the first U-shaped steel board in a sleeving manner. The second U-shaped steel boards are connected to the first U-shaped steel board through the bolt assembly in a long bar hole in the first U-shaped steel board. Two steel claw heads are respectively disposed on two ends of the bottom of the first U-shaped steel board.

Owner:NFC (SHENYANG) METALLURGICAL MACHINERY CO LTD

Ferro-aluminium-boron alloy and its production method

An AlFeB alloy used for preparing NdFeB material with high quality and output contains B (12-23 wt.%), Fe (60-84) and Al (4-21), and is prepared from industrial pure aluminium, industrial pure iron, low-carbon steel, and borax or industrial pure boric acid. Its preparing process is also disclosed.

Owner:黄湛良

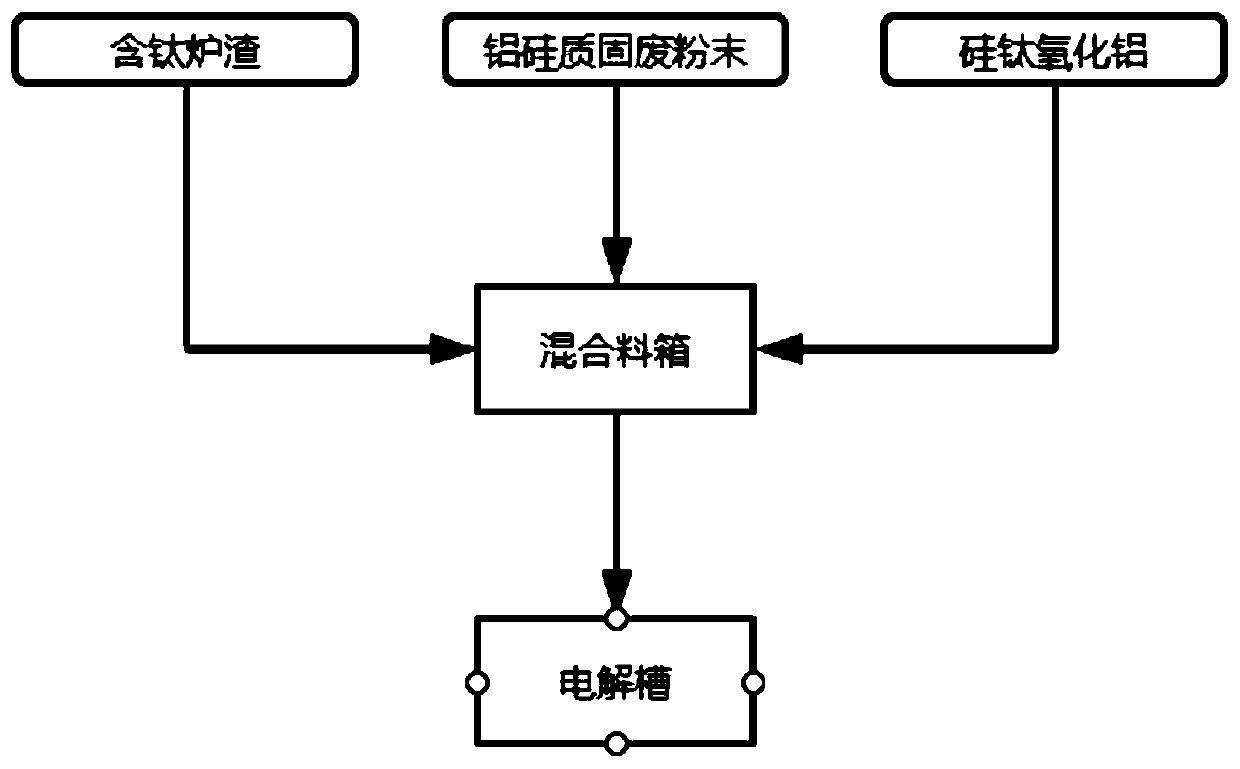

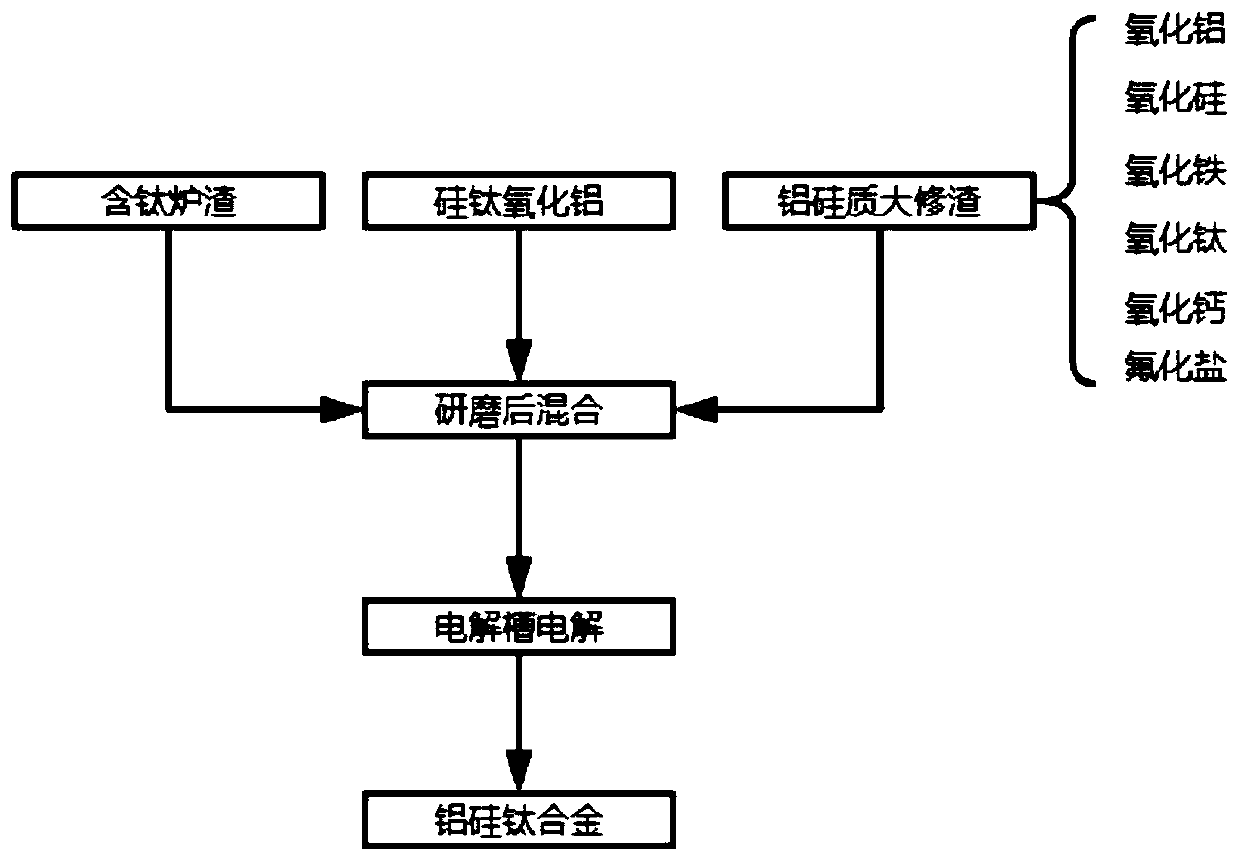

Preparation method of aluminum-silicon-titanium alloy

The invention provides a preparation method of an aluminum-silicon-titanium alloy. The preparation method comprises the following steps that (A) aluminum silicon overhaul slags are crushed to obtain crushed materials, in the crushed materials, the aluminum content is 15 wt% to 20 wt%, the silicon content is 10-15 wt%, the iron content is less than or equal to 5 wt%, and the titanium content is 1-3wt%; and (B) slags containing titanium, silicon-titanium alumina and the crushed materials are mixed into an electrolytic cell for electrolysis to obtain the aluminum-silicon-titanium alloy, and theelectrolyte superheat degree of electrolysis is 12-16 DEG C. According to the preparation method, the aluminum-silicon-titanium alloy is prepared by using an electrolytic method, the aluminum-silicon-titanium alloy with more stable chemical property and higher purity is obtained, the aluminum-silicon-titanium alloy is prepared by using the overhaul slag solid wastes harmful to the environment andproduced by electrolytic aluminum industry, the environmental problem of solid waste storage is solved, the solid wastes can be reused, and direct economic value is brought.

Owner:CENT SOUTH UNIV

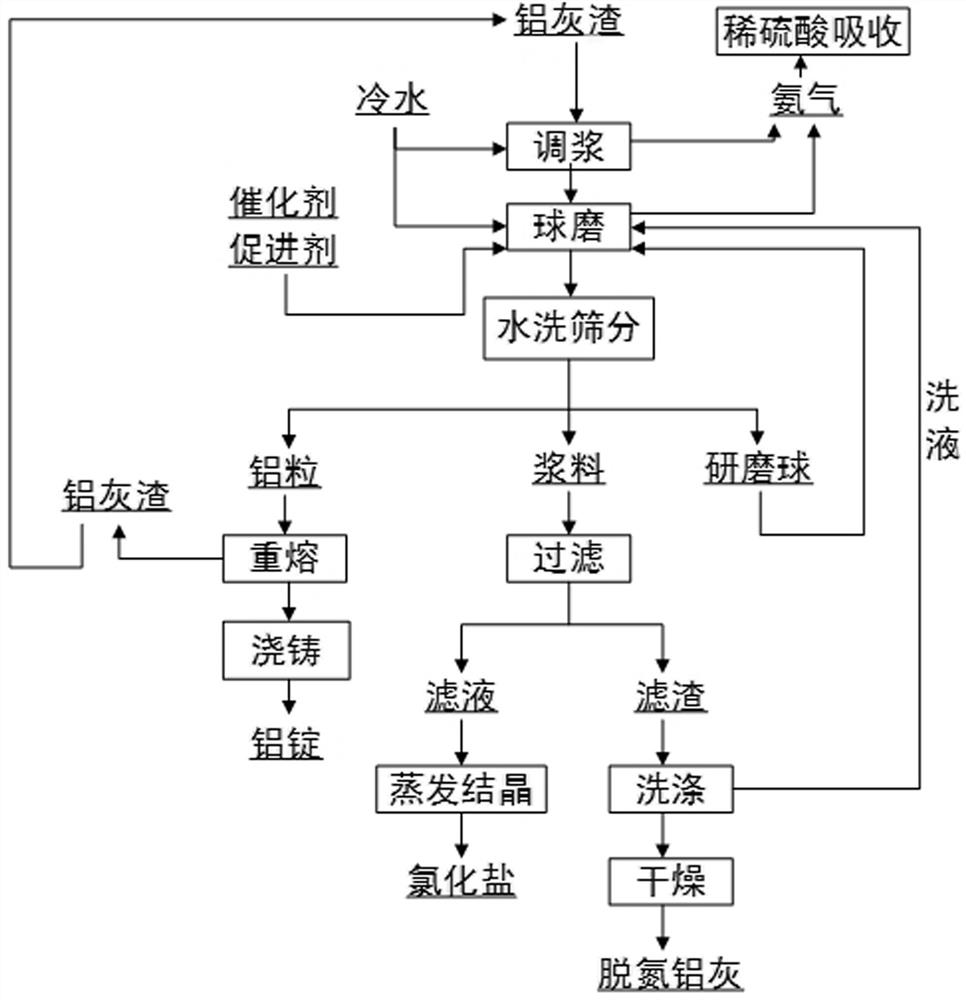

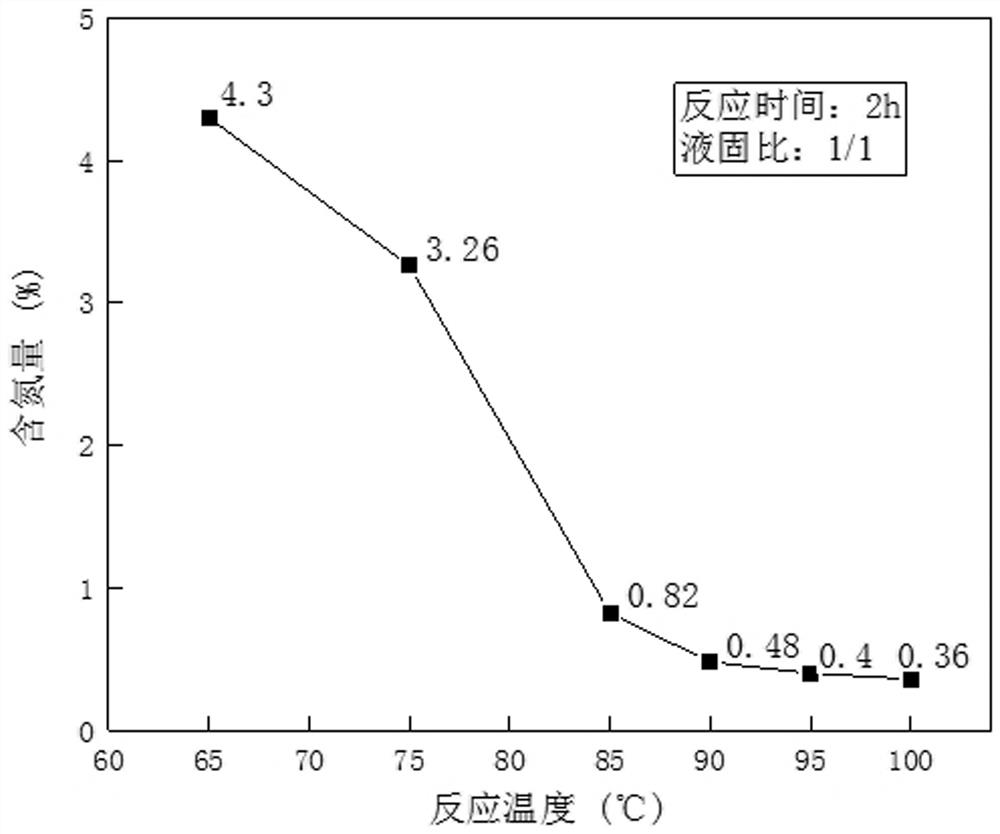

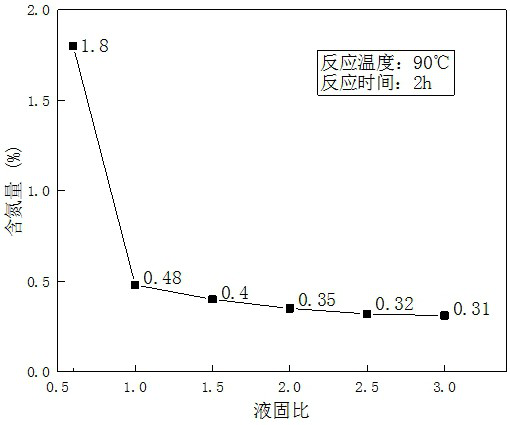

Method for treating aluminum ash in aluminum industrial production

ActiveCN112142353AAvoid flammable and explosive hazardsRapid responseSolid waste managementProcess efficiency improvementAluminium industryNonferrous metal

The invention belongs to the technical field of environment-friendly materials and non-ferrous metal smelting, and particularly relates to a method for treating aluminum ash in aluminum industrial production. According to the method, a wet chemical ball milling process is mainly used for strengthening an aluminum ash reaction, and a catalyst, an accelerant and the like are added to strengthen thehydrolysis reaction effect of the aluminum ash, so that the purpose of removing nitrogen in the aluminum ash is achieved, and the aluminum ash is changed into an available harmless powder material after harmless treatment. According to the harmless aluminum ash treatment method provided by the invention, the aluminum ash is treated by adopting a wet method, so that the risks of flammability, explosiveness and the like of the aluminum ash are avoided, and the operation safety coefficient is improved; mechanical stirring is replaced with a wet ball milling mode, and in the stirring process, thehydrolysis effect of the aluminum ash is enhanced by utilizing the mechanical force of ball milling; and according to the method, the technological process is shortened, the aluminum ash can be further refined while ball-milling aluminum separation is conducted, the reaction is more sufficient, the denitrification effect of the aluminum ash is improved, the reaction time is shortened, and energy can be greatly saved in industrial production.

Owner:NORTHEASTERN UNIV

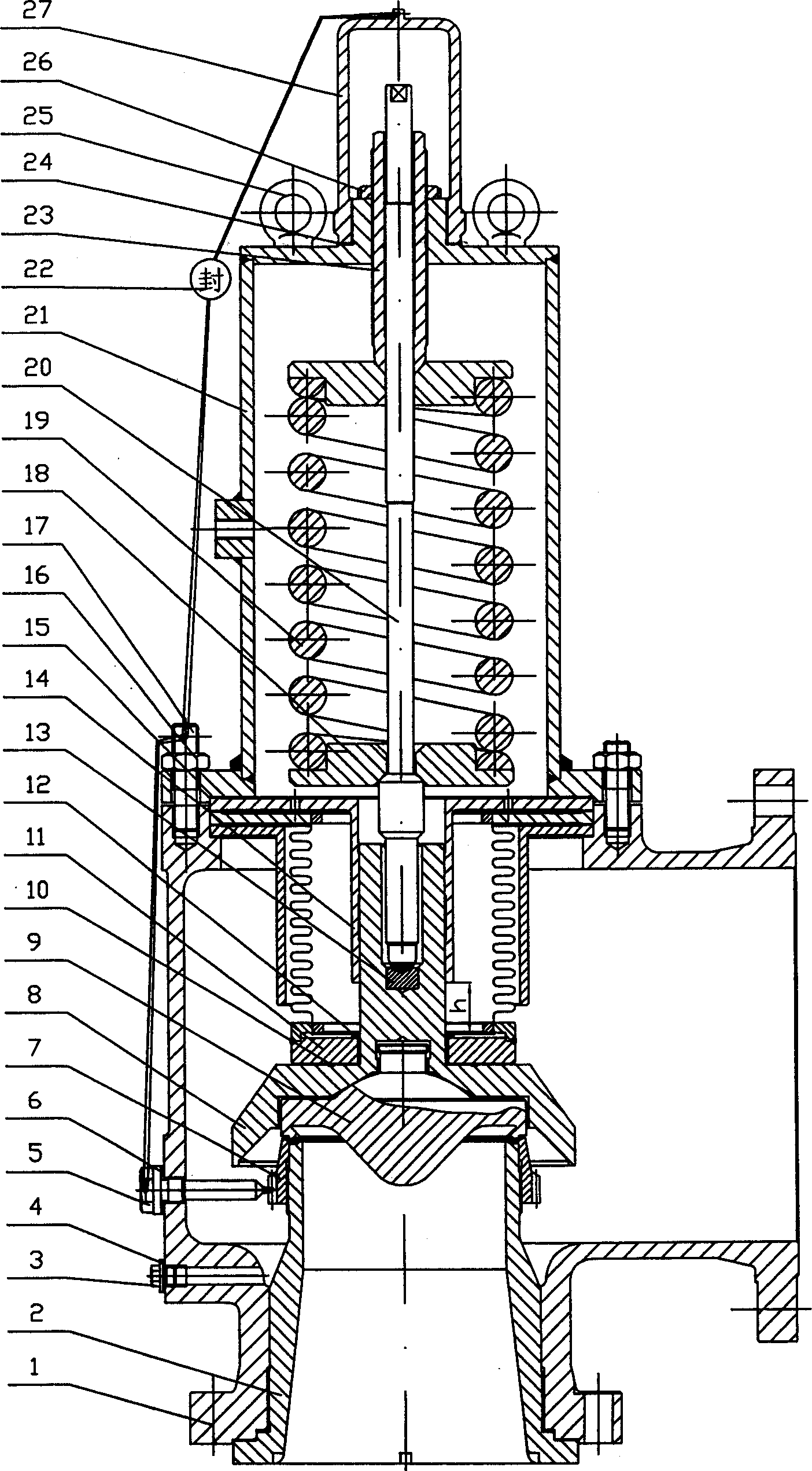

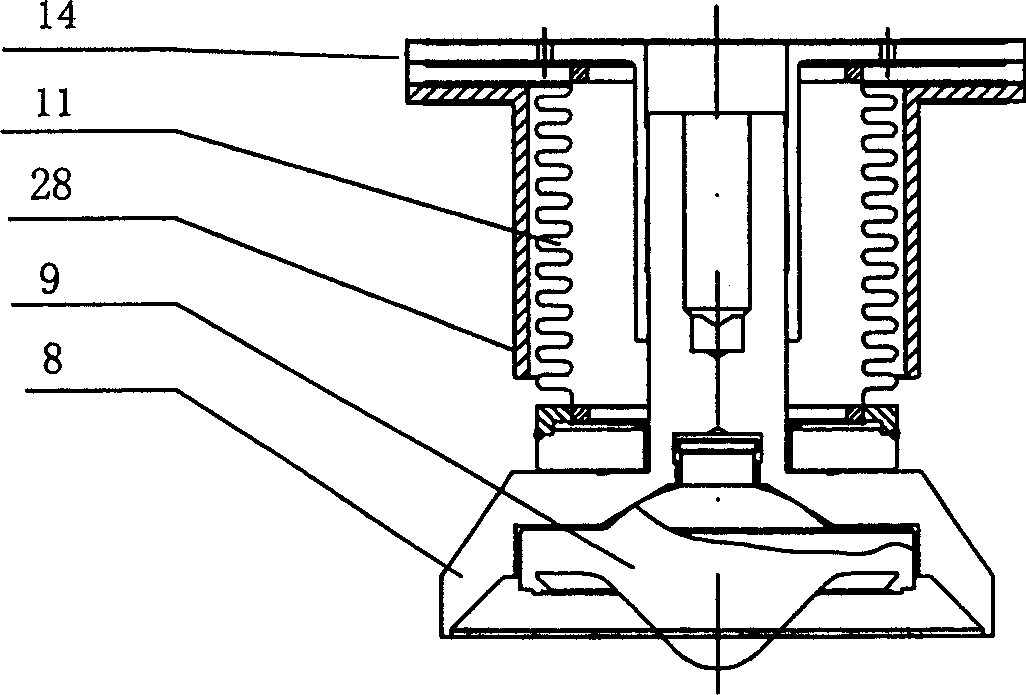

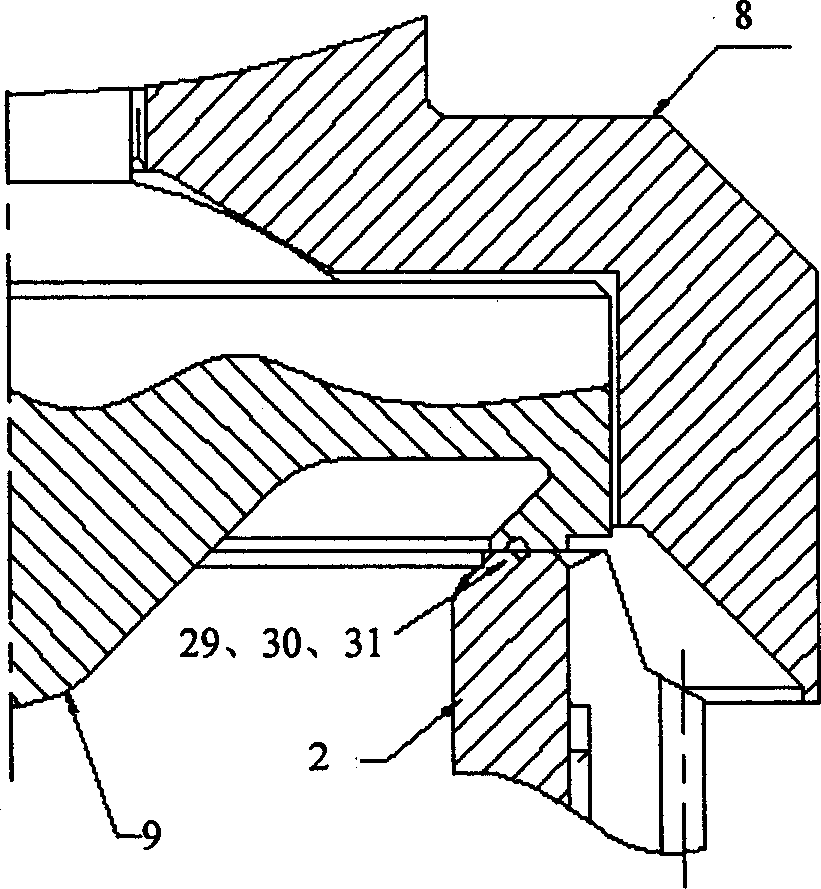

Safety valve specially for aluminium industry

InactiveCN1847709AEliminate the impact of motion performanceGuaranteed uptimeEqualizing valvesSafety valvesAluminium industryAluminum industry

The safety valve specially for aluminum industry includes a valve clack, a valve seat and a corrugated pipe assembly. It features the valve clack with elastic chute type upper sealing surface; an inner sealing ring and an elastically supporting outer ring in the sealing surface between the valve seat and the valve clack and with one semi-circular releasing slot in between; and welded high hardness Co-base alloy in the sealing surface between the valve seat and the valve clack. The corrugated pipe assembly has outside protecting sheath, the valve seat is made of F304 stainless steel and high hardness Co-base alloy, and the valve clack is made of 17-4PH precipitation hardening stainless steel. The present invention has improved performance, high alumina grain impact resistance and high sealing performance.

Owner:SHANGHAI KAITE VALVE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com