Al-V-B refining agent for cast aluminum-silicon alloy, preparation method and application thereof

A casting aluminum-silicon alloy and refining agent technology, which is applied in the field of casting aluminum-silicon alloy refining agent and Al-V-B refining agent for casting aluminum-silicon alloy, which can solve cumbersome operation, unsatisfactory application requirements, long time, etc. problems, to achieve the effect of simple preparation conditions, excellent refinement effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

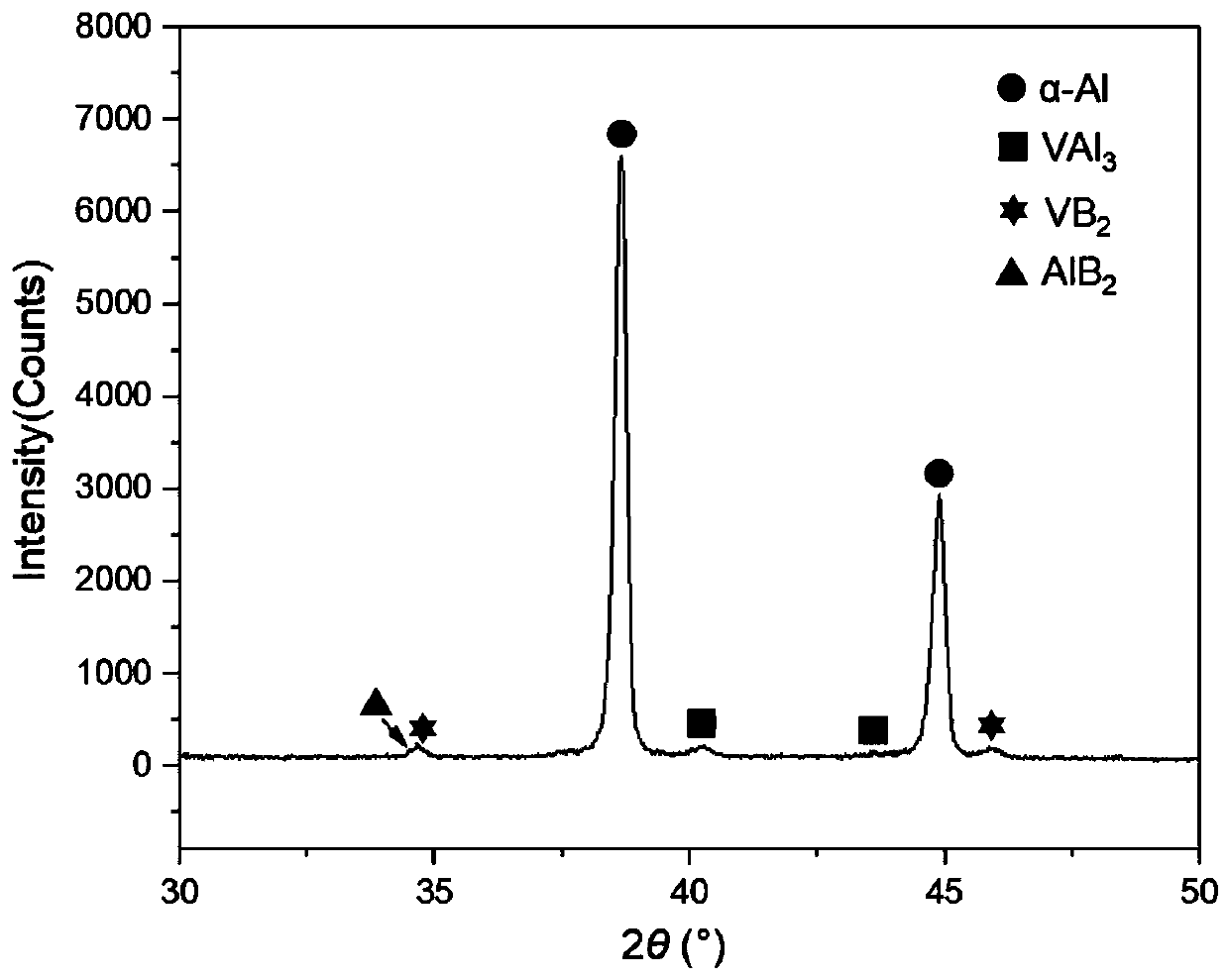

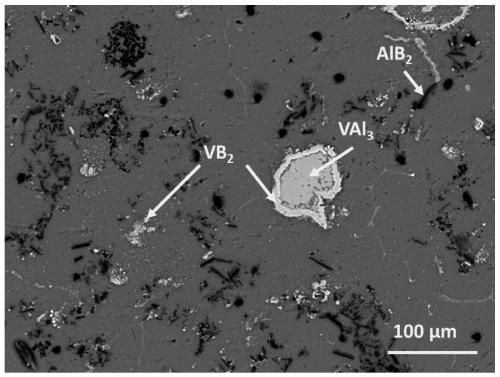

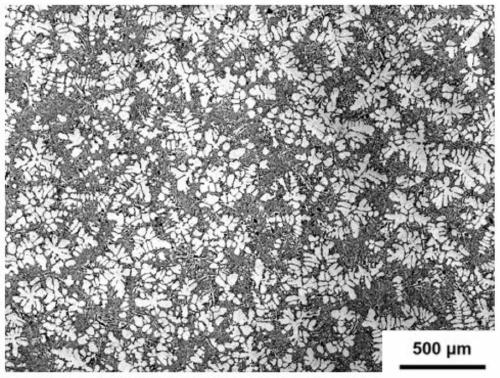

Embodiment 1

[0042] In this embodiment, an Al-V-B refining agent for casting aluminum-silicon alloy, its chemical element composition and mass percentage are: aluminum: 94%; vanadium: 3.0%; boron: 3.0%; the casting aluminum-silicon alloy The Al-V-B refiner is used as the alloy material, and its phase composition is composed of α-Al aluminum solid solution as a matrix and particle particles for refining, and the particle particles are dispersed in the α-Al matrix. The mass percent of pure vanadium in the Al-V-B refining agent for casting aluminum-silicon alloy in this embodiment is 3%, the mass percent of pure boron is 3%, and the balance is pure aluminum, which is Al-3V-3B as the refining agent .

[0043] In this embodiment, a method for preparing an Al-V-B refiner for casting aluminum-silicon alloys, the specific preparation method includes the following steps:

[0044] (1) Preparation of raw materials:

[0045] Using KBF 4 Powder is as B source, adopts Al block and V powder as metal r...

Embodiment 2

[0098] This embodiment is basically the same as Embodiment 1, especially in that:

[0099] In this embodiment, an Al-V-B refining agent for casting aluminum-silicon alloy, its chemical element composition and mass percentage are: aluminum: 95.8%; vanadium: 2.1%; boron: 2.1%; the casting aluminum-silicon alloy The Al-V-B refiner is used as the alloy material, and its phase composition is composed of α-Al aluminum solid solution as a matrix and particle particles for refining, and the particle particles are dispersed in the α-Al matrix.

[0100] In this embodiment, a method for preparing an Al-V-B refiner for casting aluminum-silicon alloys, the specific preparation method includes the following steps:

[0101] (1) Preparation of raw materials:

[0102] Using KBF 4 Powder is as B source, adopts Al block and V powder as metal raw material, is 95.8% according to aluminum, vanadium is 2.1%; Boron is 2.1% chemical element composition and mass percentage, takes by weighing 140.6 gr...

Embodiment 3

[0109] This embodiment is basically the same as the previous embodiment, and the special features are:

[0110] In this embodiment, an Al-10V-10B refining agent for casting aluminum-silicon alloy, its chemical element composition and mass percentage are: aluminum: 80.0%; vanadium: 10.0%; boron: 10.0%; Al-10V-10B refiner for silicon alloy is the alloy material, and its phase composition is composed of α-Al aluminum solid solution as the matrix and particle particles that act as a refiner, and the particle particles are dispersed in the α-Al matrix .

[0111] In this embodiment, a preparation method of Al-10V-10B refiner for casting aluminum-silicon alloy, the specific preparation method includes the following steps:

[0112] (1) Preparation of raw materials:

[0113] Using KBF 4 Powder is used as B source, adopts Al lump and V powder as metal raw material, is 80.0% according to aluminum, vanadium is 10.0%; Boron is 10.0% chemical element composition and mass percentage, take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com