Method for modification and refinement of hypoeutectic and eutectic Al-Si alloy

A eutectic aluminum-silicon and aluminum-silicon alloy technology, which is applied in the field of aluminum alloy smelting and casting, can solve the problems of immaturity, deterioration and accelerated decline of refinement, and difficulty in obtaining fine fibrous eutectic structure at the same time, so as to achieve easy operation , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

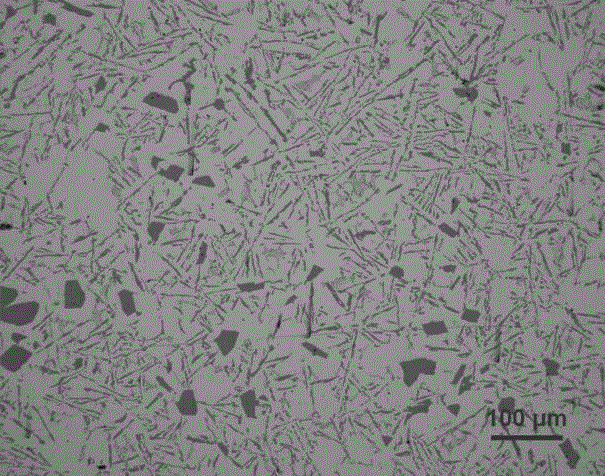

[0053] Example 1: Modification and refinement of hypoeutectic Al-Si alloys. Hypoeutectic aluminum-silicon alloy, silicon content 6.5~7.5wt.%, detailed chemical composition as alloy A in Table 1.

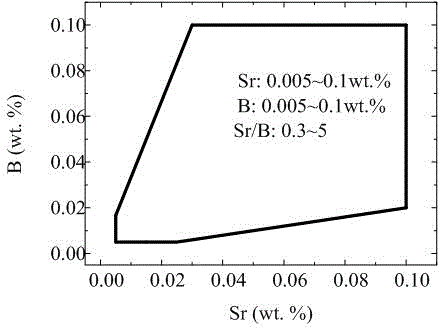

[0054] The smelting equipment adopts a 15kg resistance furnace. Electrolytic aluminum and aluminum-silicon intermediate alloys are put into the melting furnace first. After the furnace material is completely melted, other alloying elements are added in the form of intermediate alloys or pure metals to control the composition of each alloying element. Keep the temperature of the melt at 650~850℃, add Al-Sr master alloy so that the mass of strontium in the melt is 0.005~0.1% of the total mass of the melt; add Al-Sr master alloy and stir evenly; Inject high-purity inert gas for refining and degassing treatment, keep the melt temperature at 650~850°C during aeration, and aeration time for 10~40 minutes; after degassing treatment, let it stand for 10~30 minutes, remove scum; add Al-B in...

Embodiment 2

[0056] Example 2: Modification and refinement of hypoeutectic Al-Si alloys. Hypoeutectic aluminum-silicon alloy, silicon content 9~10wt.%, detailed chemical composition as alloy C in Table 1.

[0057] The smelting equipment adopts a 15kg resistance furnace. First, electrolytic aluminum and aluminum-silicon intermediate alloy are put into the smelting furnace in proportion, and the composition of each alloy element is controlled after the furnace charge is completely melted. Keep the temperature of the melt at 650~850℃, add Al-Sr master alloy so that the mass of strontium in the melt is 0.005~0.1% of the total mass of the melt; add Al-Sr master alloy and stir evenly; Inject high-purity inert gas for refining and degassing treatment, keep the melt temperature at 650~850°C during aeration, and aeration time for 10~40 minutes; after degassing treatment, let it stand for 10~30 minutes, remove scum; add Al-B in the middle Alloy, so that the mass of boron in the melt is 0.005~0.1%...

Embodiment 3

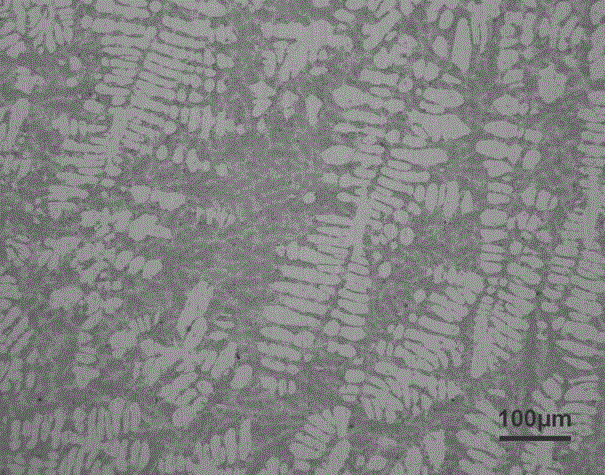

[0064] Example 3: Modification and refinement of eutectic Al-Si alloy ingots. The content of the eutectic aluminum-silicon alloy is 11.0~13.5wt.%, and the detailed chemical composition is as alloy D in Table 1. The specific implementation method of the present invention will be described below by taking the modification and refinement treatment in the semi-continuous casting production process of the Φ300mm ingot of alloy D as an example.

[0065] The smelting equipment adopts a 500kg resistance furnace. Electrolytic aluminum and polysilicon or aluminum-silicon intermediate alloys are put into the melting furnace first. After the furnace material is completely melted, other alloying elements are added in the form of intermediate alloys or pure metals to control the composition of each alloying element. Keep the melt temperature at 650~850℃, add Al-Sr master alloy so that the mass of strontium in the melt is 0.005~0.1% of the total mass of the melt; add Al-Sr master alloy and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com