Patents

Literature

283results about How to "Good refinement effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

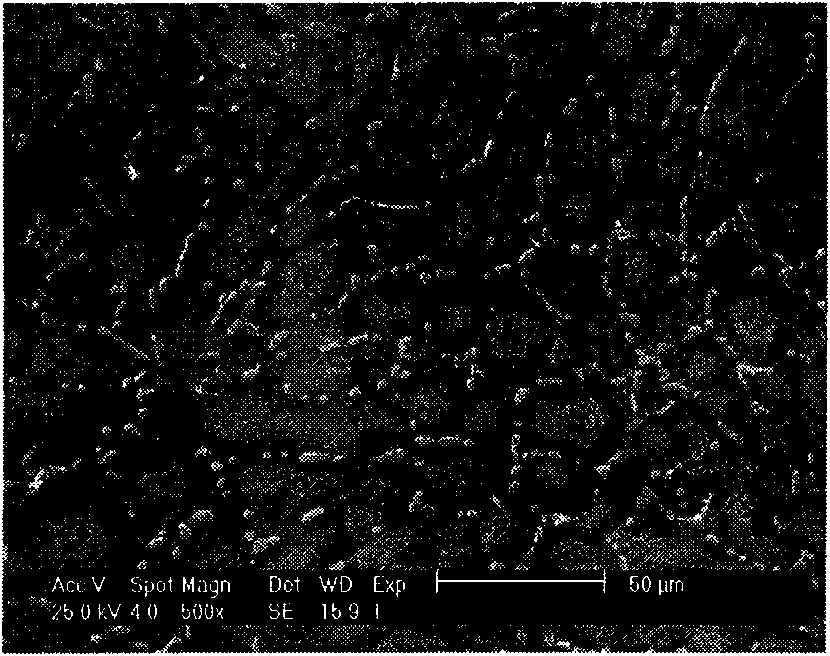

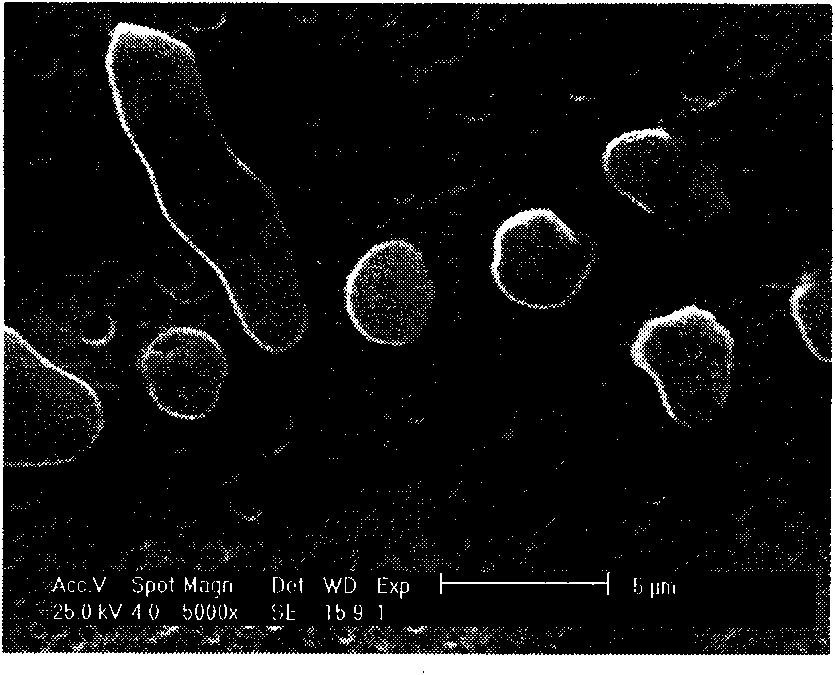

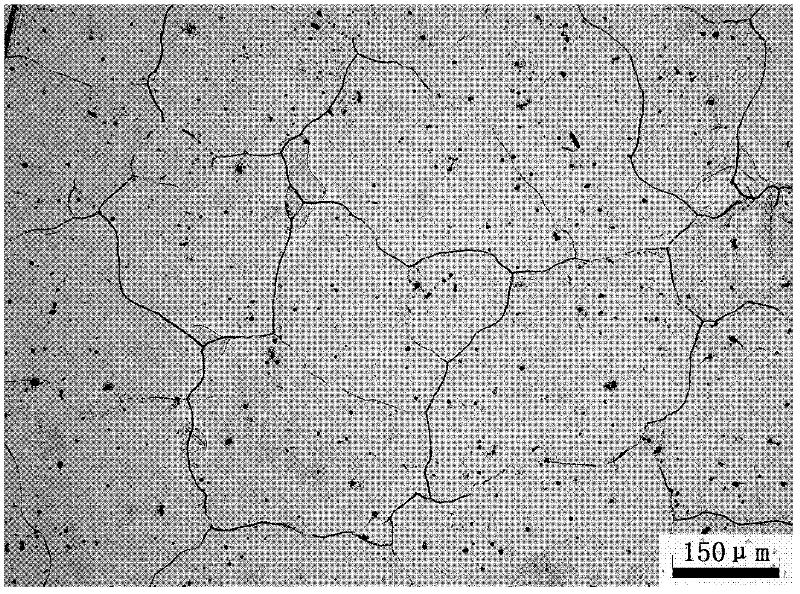

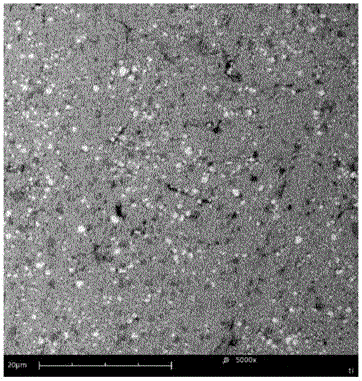

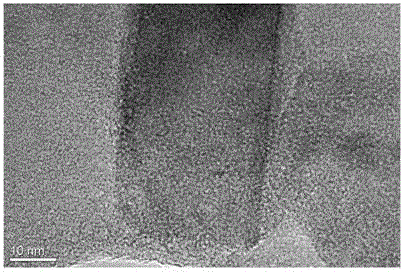

Method for preparing Al-Ti-B grain refiner

The Al-Ti-B crystal grain fining agent for metal material has the components including Ti 2-10 wt%, B 2 wt% and Al the rest. The preparation process includes the steps of: mixing industrial pure potassium fluorotitanate and potassium fluoroborate homogeneously, heating to melt industrial pure aluminum, adding the mixed salt into aluminum melt and covering the surface of the melt with KCl, introducing ultrasonic wave to over the melt, skimming slag, cooling the melt naturally while continuous ultrasonic treatment until the intermediate alloy solidifies completely to obtain the Al-Ti-B crystal grain fining agent. The present invention has short preparation period and less oxidation loss of aluminum melt, and the obtained casting structure has fine TiAl3 grains of homogeneous size below 20 microns and TiB2 grains with clear contour. The Al-Ti-B crystal grain fining agent is used in preparing industrial pure aluminum with crystal grains smaller than 120 microns.

Owner:SHANGHAI JIAO TONG UNIV

Three-dimensional structural description method of hepatic vascular system

ActiveCN102402796AAccurate divisionPrecise resectionImage enhancement3D modellingStructure analysisVoxel

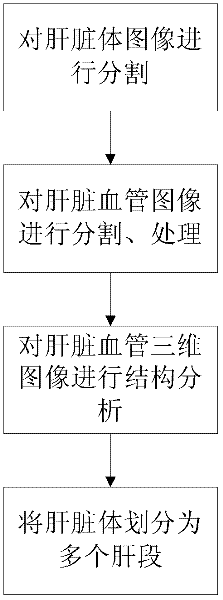

The invention discloses a three-dimensional structural description method of hepatic vascular system, which belongs to the field of medical liver division. The method comprises the following steps of: firstly, dividing a hepatic image and a hepatic vascular image, structurally analyzing the hepatic vascular three-dimensional image, skeletonizing the liver and the blood vessel, and marking the skeletonized voxel points; next, storing the marked voxel points to data structure of multi-branch tree; then, distinguishing main and branch blood vessels according to master slave relation of the voxelpoints in the multi-branch tree; finally, dividing the liver body into multiple liver segments according to relation between the blood vessels in the hepatic vascular system. By the three-dimensionalstructural description method of hepatic vascular system, accurate division of liver is realized so that guidance is provided for accurate removal of liver.

Owner:SHENZHEN YORATAL DMIT

TRIP steel plate for high strength cold rolling hot dip galvanizing and preparation thereof

InactiveCN101353761AImprove PlatabilityGood coating performanceHot-dipping/immersion processesSheet steelTRIP steel

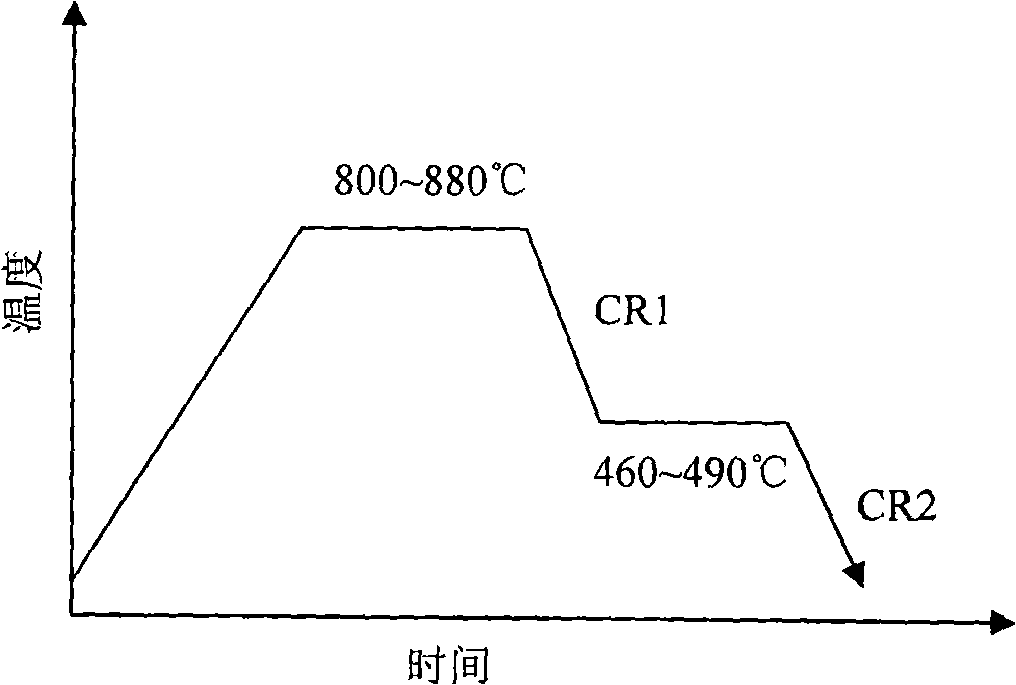

The invention pertains to the metal material processing field and particularly provides a TRIP steel sheet used for high-strength cold rolling and hot galvanizing and a manufacturing method thereof. The TRIP steel sheet comprises the following components: 0.1wt percent to 0.4wt percent of C, not more than 0.06wt percent of Si, 0.5wt percent to 2.5wt percent of Mn, 0.5wt percent to 2.0wt percent of Al, not more than 0.03wt percent of P, not more than 0.02wt percent of S, 0.01wt percent to 0.10wt percent of Nb, 0.01wt percent to 0.10wt percent of Ti, 0.1wt percent to 1.0wt percent of Cu, 0.1wt percent to 0.6wt percent of Ni and the rest is iron. Through the measures of controlling the content of the elements such as C, Mn, Nb and Ti in the steel, and the temperature and time of hot rolling, reeling, cold rolling, annealing and the like, the comprehensive performance of the TRIP steel sheet is improved. Compared with the traditional TRIP steel, the TRIP steel sheet has the following advantages of: 1) good platability: due to the low silicon adopted, the requirements of the plating layer of hot plated pure zinc and alloy plated zinc can be met to obtain the plating layer with good performance; and 2) good grain refining effect: due to Nb micro-alloying, grain can be effectively refined.

Owner:UNIV OF SCI & TECH BEIJING +1

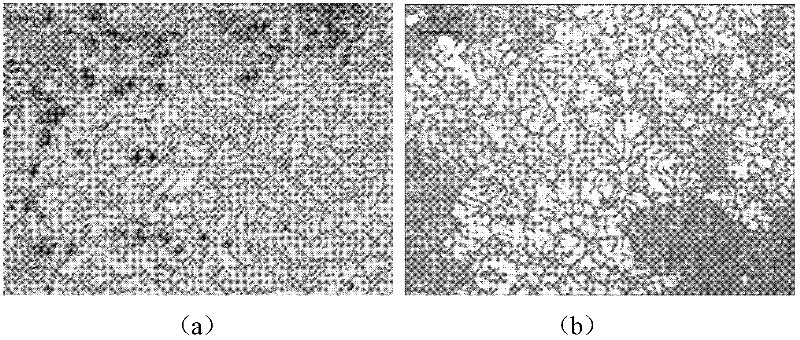

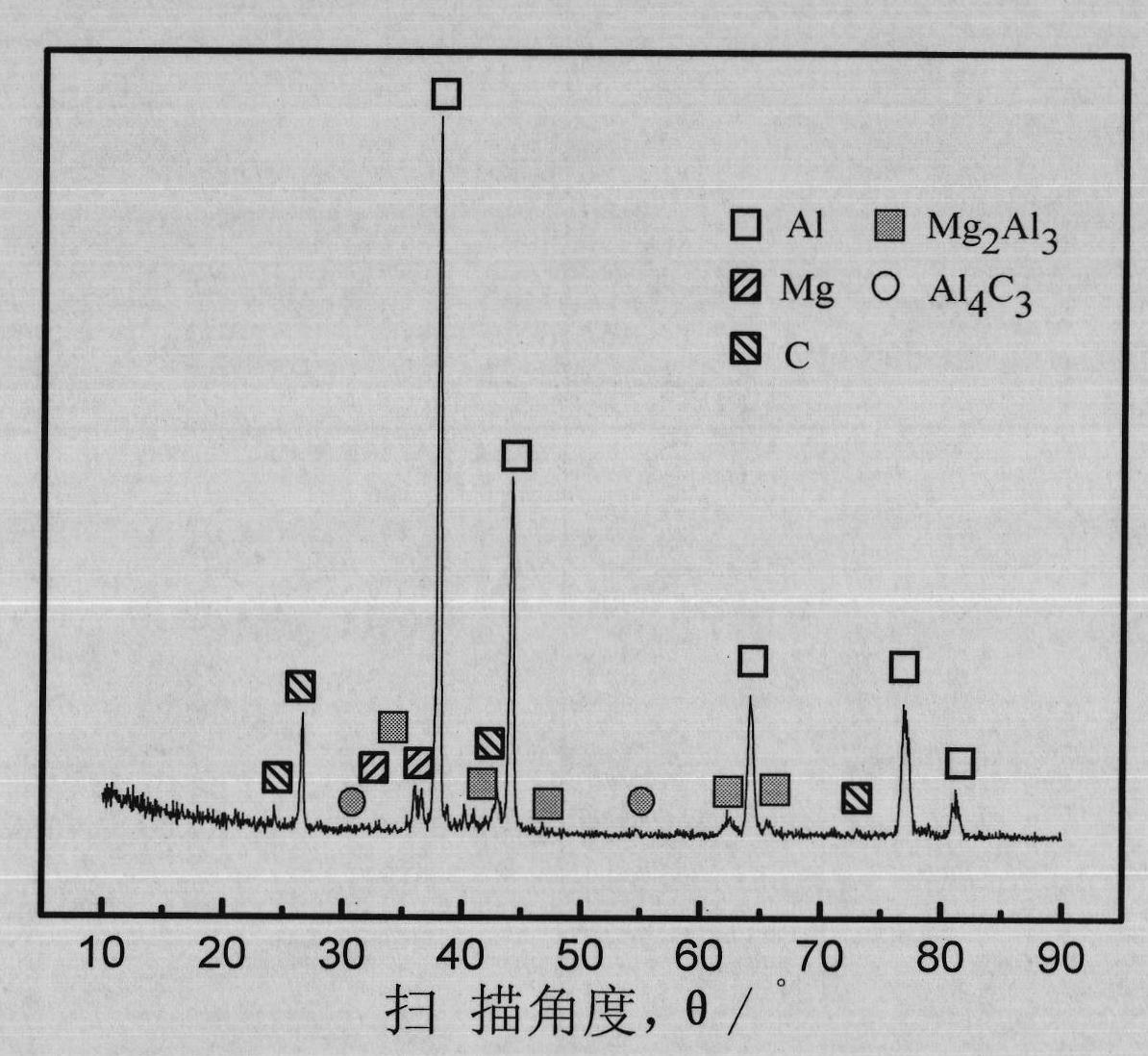

Method for modification and refinement of hypoeutectic and eutectic Al-Si alloy

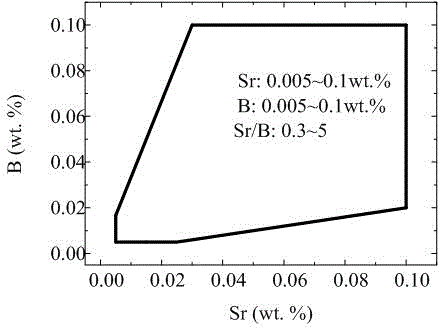

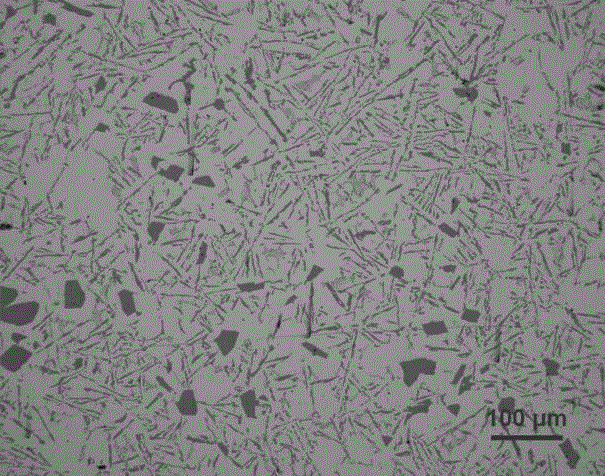

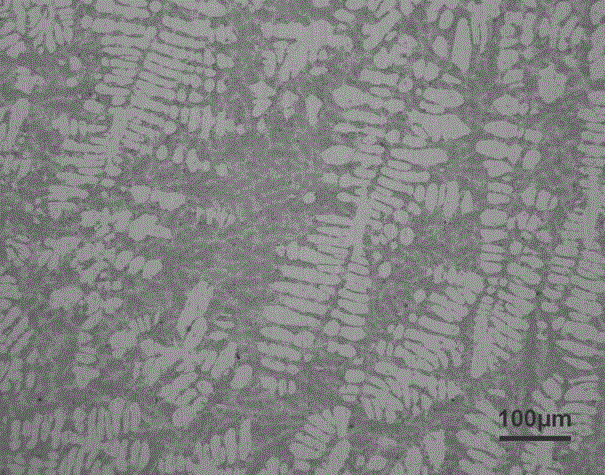

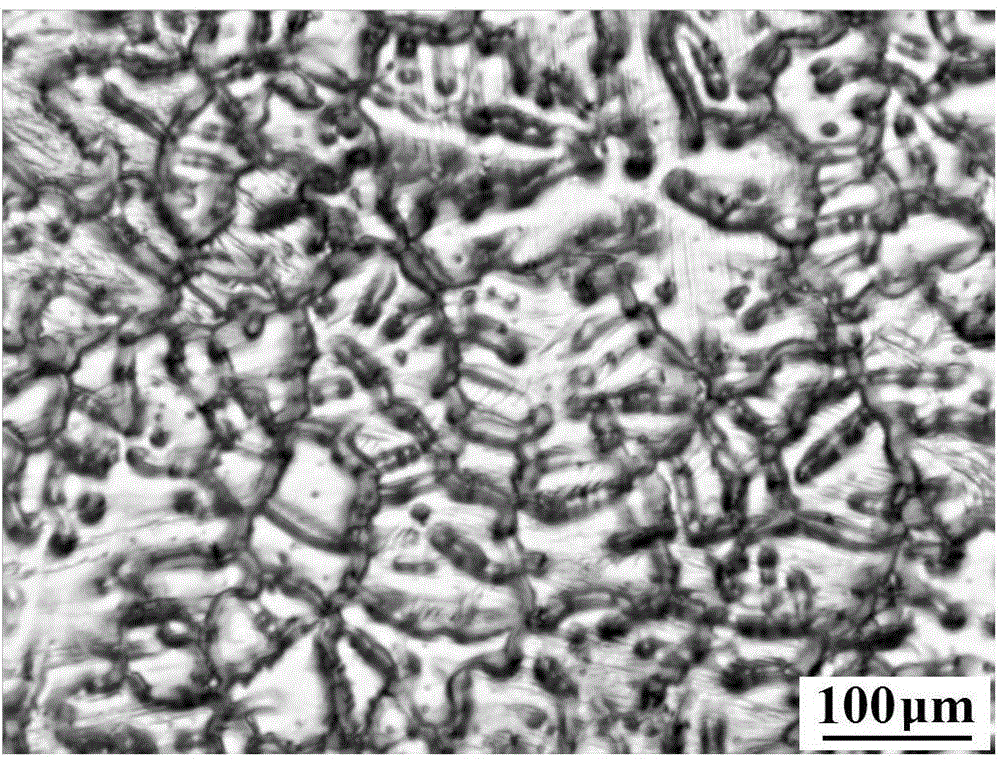

The invention relates to a method for modification and refinement of a hypoeutectic and eutectic Al-Si alloy. The hypoeutectic and eutectic Al-Si alloy with the Si content of 2-13.5 wt.% is subjected to modification and refinement treatment with Sr and B; after treatment, the Sr content in an alloy melt is 0.005-0.1%, the B content is 0.005-0.1%, and the mass ratio of Sr to B is 0.3-5. An Al-B intermediate alloy is used as a refiner, and has excellent grain refining effect on the Al-Si alloy; an Al-Sr intermediate alloy is used as a modifier, can effectively modify eutectic Si in the Al-Si alloy. By controlling melting, modification and refinement treatment processes, the grain refiner also has good refinement effect on alpha-Al while the added modifier has good modification effect on the eutectic Si, so that an ingot microstructure is simultaneously modified and refined, and a mutual poisoning effect between Sr and B can be effectively avoided.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

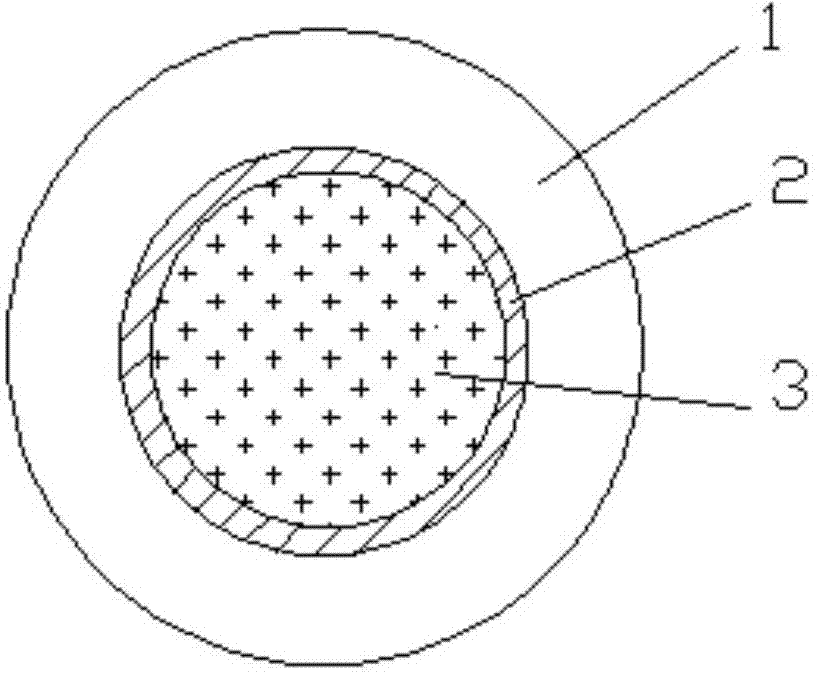

Titanium silicon nitride core-spun yarn

The invention discloses a titanium silicon nitride core-spun yarn which comprises a core layer and a steel sheet layer wrapped outside the core layer, wherein the core layer is a titanium silicon nitride alloy layer; a network support layer prepared from steel or iron is arranged between the core layer and steel sheet layer; and the titanium silicon nitride alloy layer is composed of titanium silicon nitride alloy particles with the particle size of less than 3mm. The Ti and the carbon or nitrogen in the steel form nano-size compounds which have favorable refinement effect on the structure, thereby enhancing the strength of the ferrous material, enhancing the TiN particle stability by nitridation and effectively preventing the austenite grains from growth. The titanium silicon nitride core-spun yarn sufficiently utilizes the cheap nitrogen element, and can save the titanium addition amount on the premise of ensuring certain strength level, thereby further lowering the cost of the non-quenched and tempered steel.

Owner:浙江宝信炉料股份有限公司

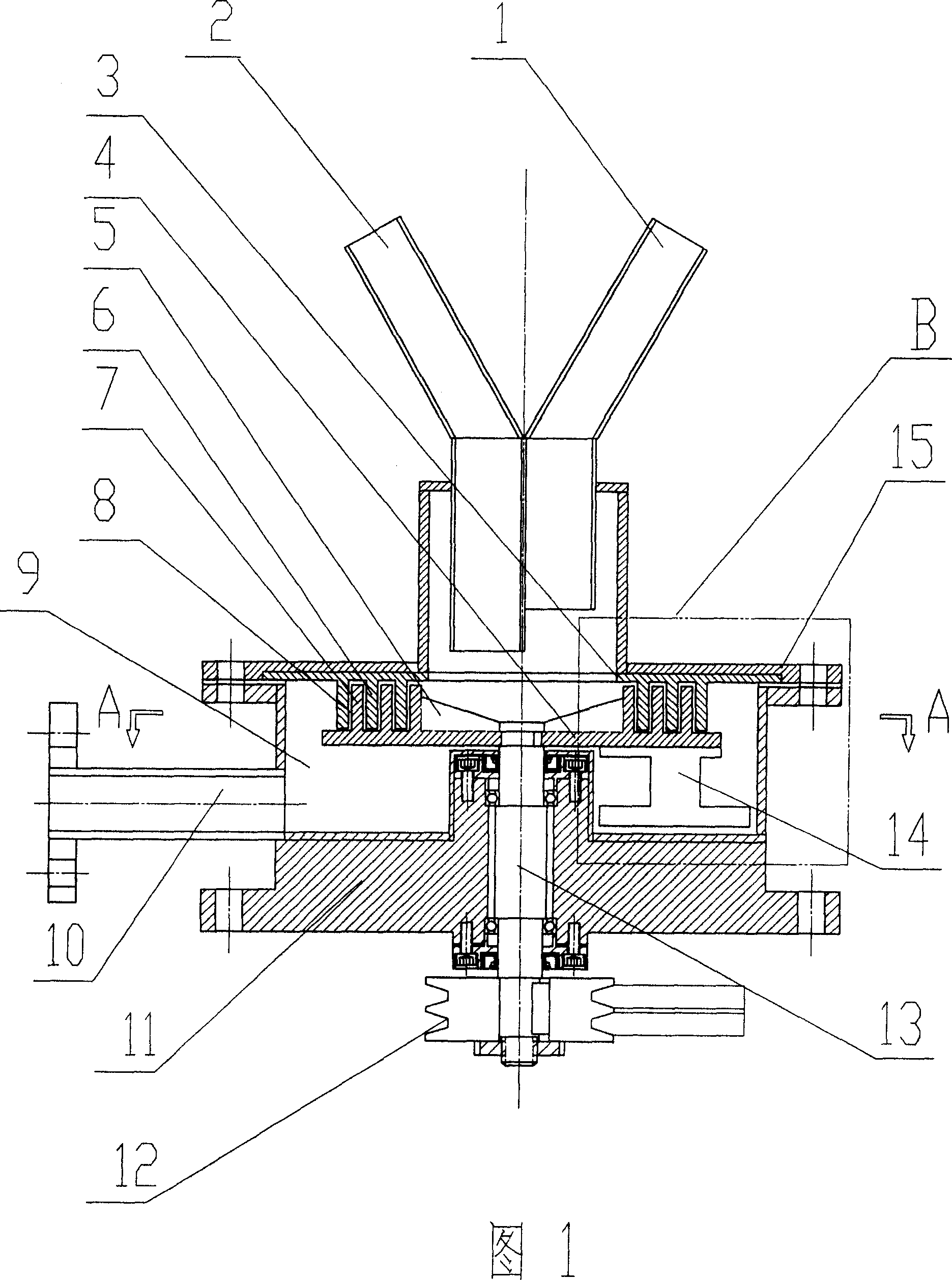

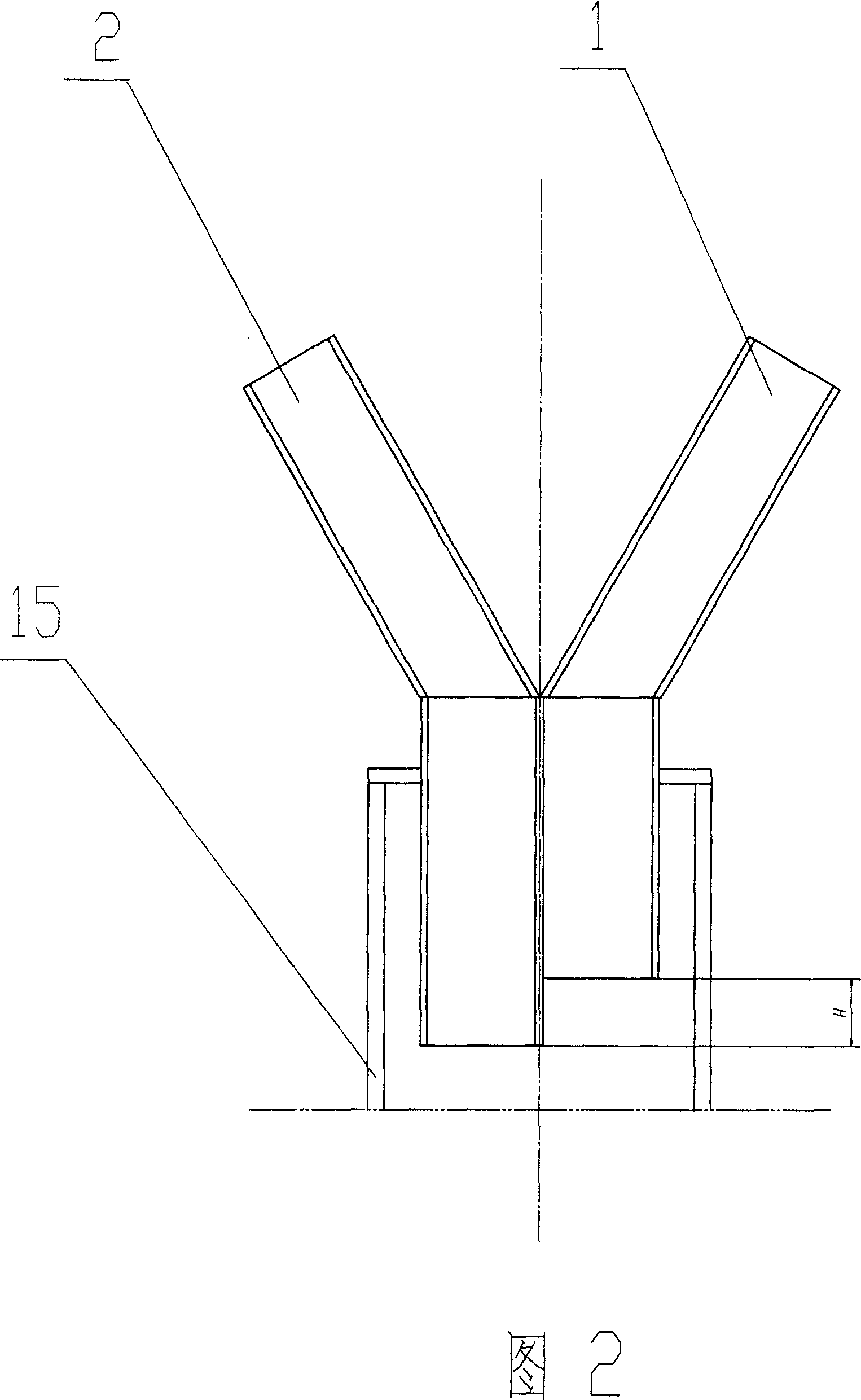

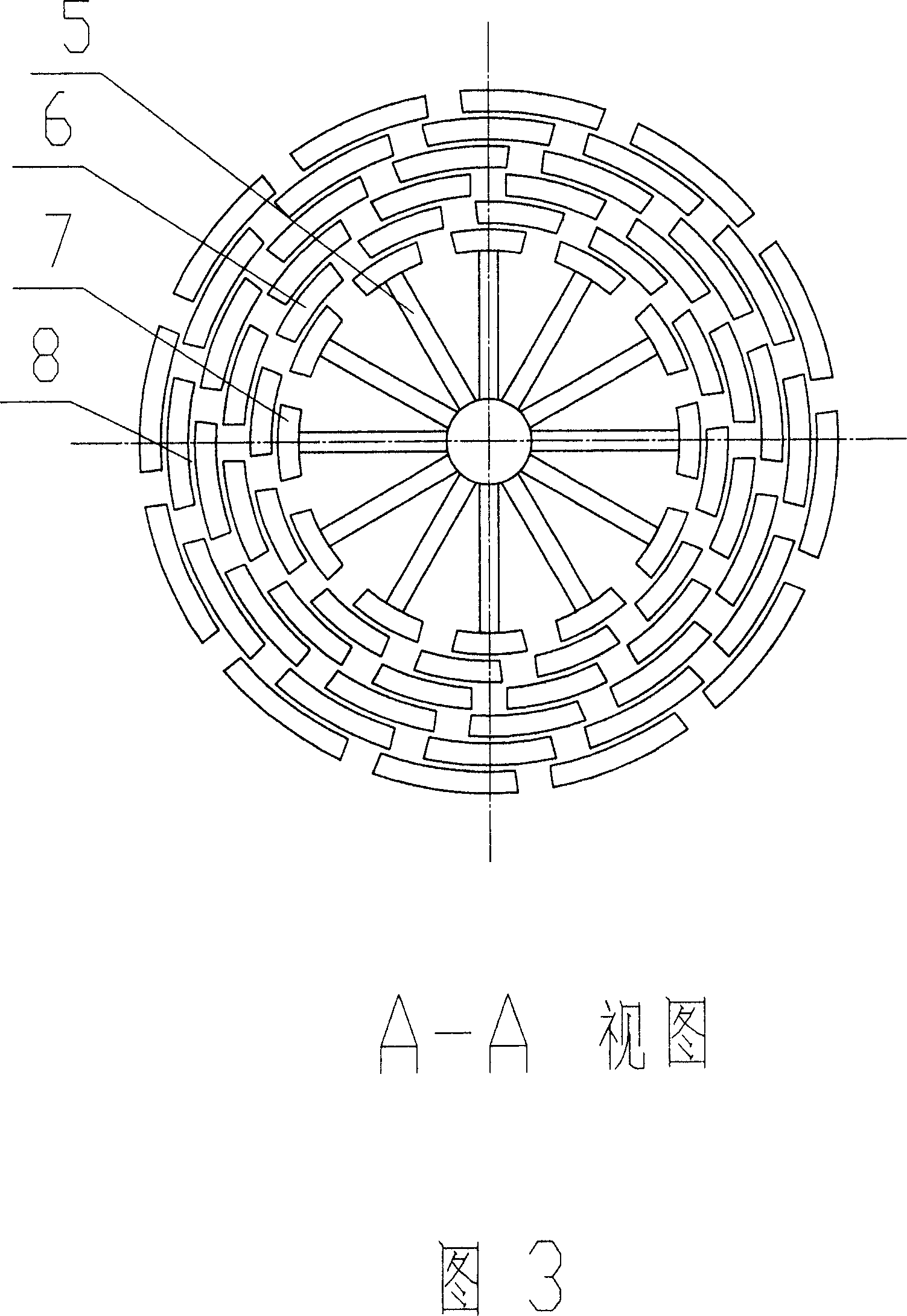

Continuous colloid mixer and its application

ActiveCN1986064ASolve the problem that continuous production cannot be realizedIncrease productivityRotary stirring mixersCocoaDrive shaftEngineering

The continuous colloid mixer includes the following members: solid feeding pipe, liquid feeding pipe, stator, rotor, pedestal, discharge port, rotating shaft and driving shaft. The continuous colloid mixer can mix solid powder and liquid to prepare colloid continuously in high production efficiency, and is used in the continuous production of cracking catalyst. Compared with available intermittent mixer, the present invention has lowered manufacture cost, continuous and stable production and improved product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

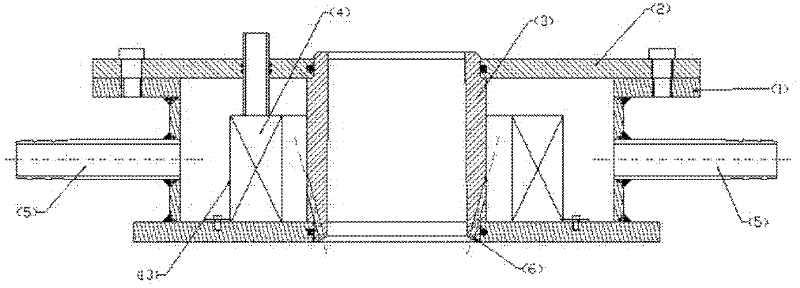

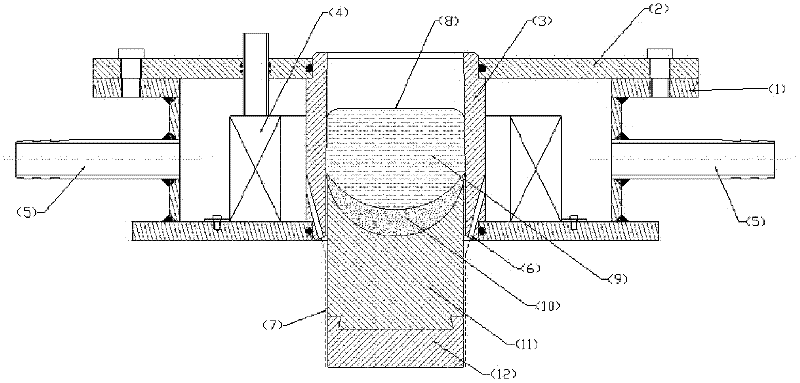

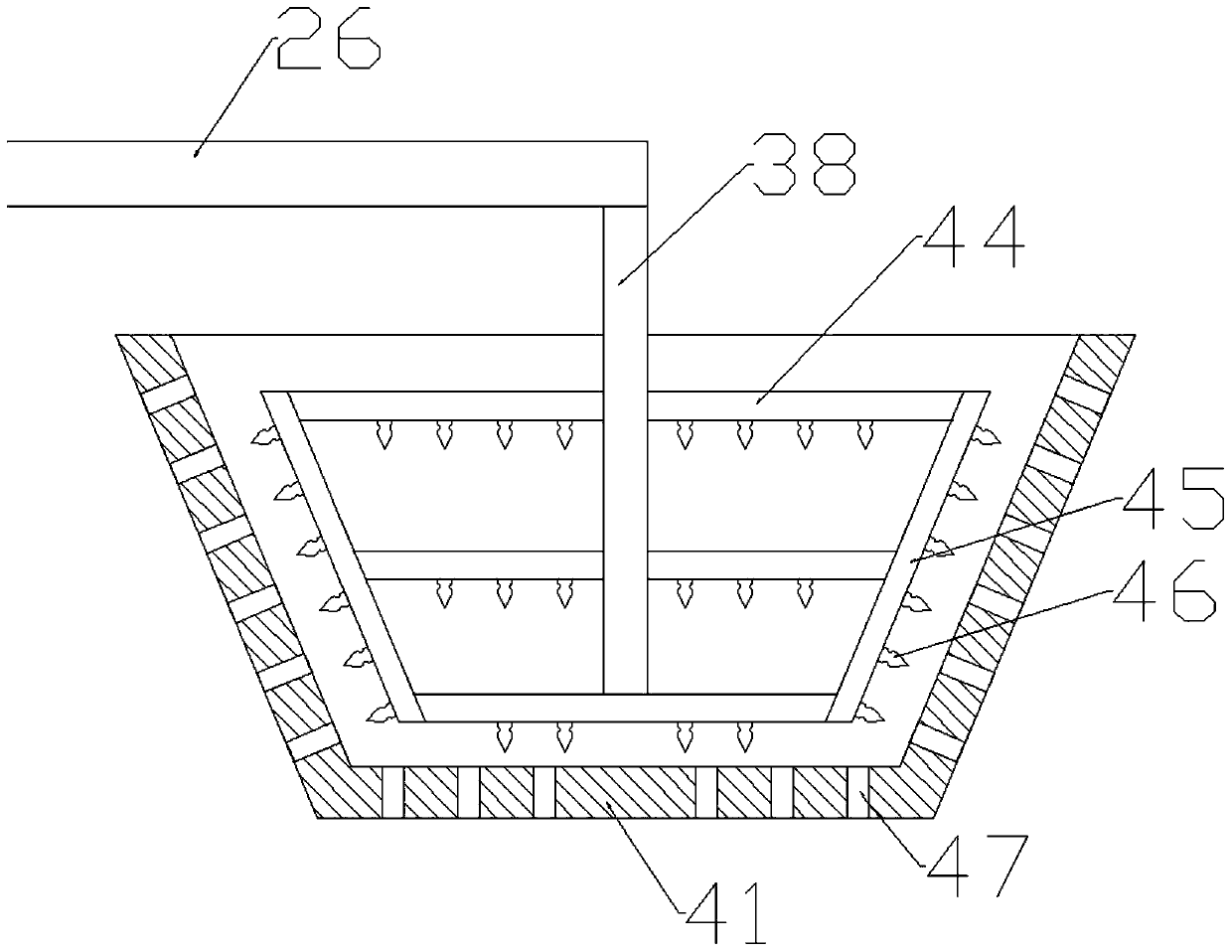

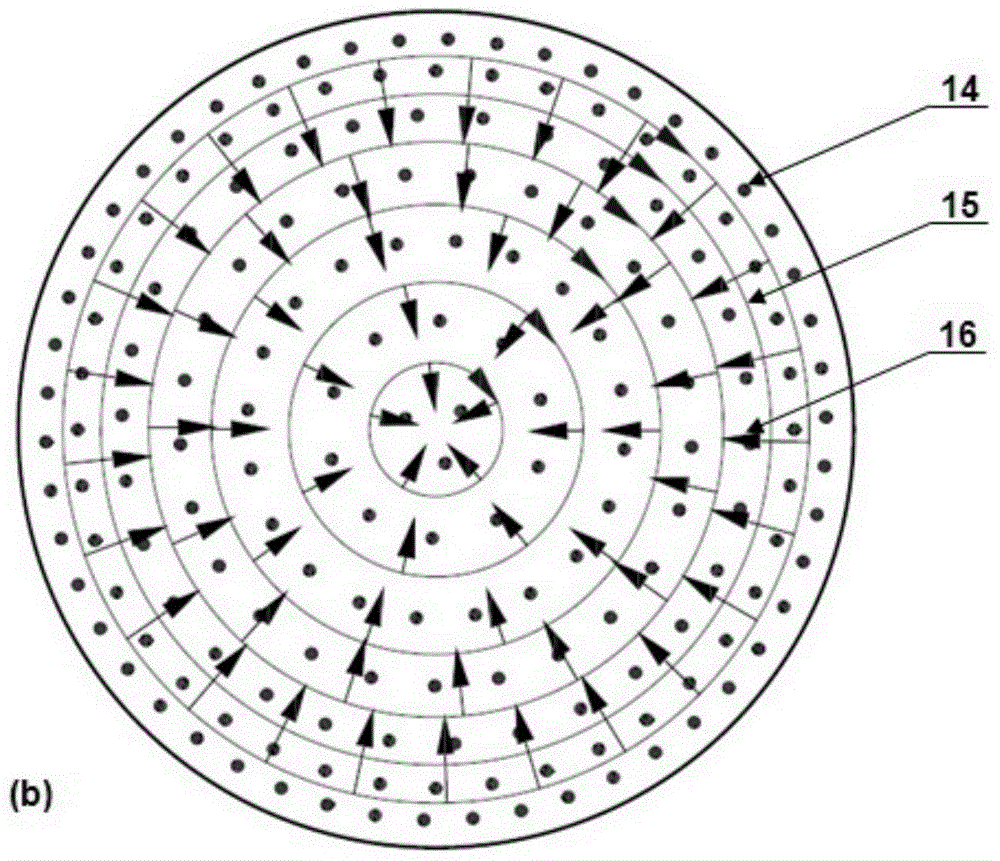

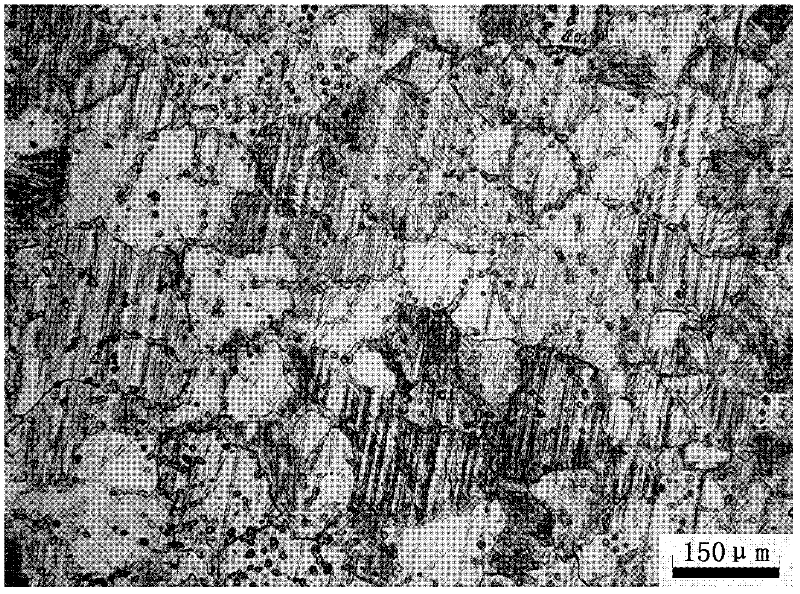

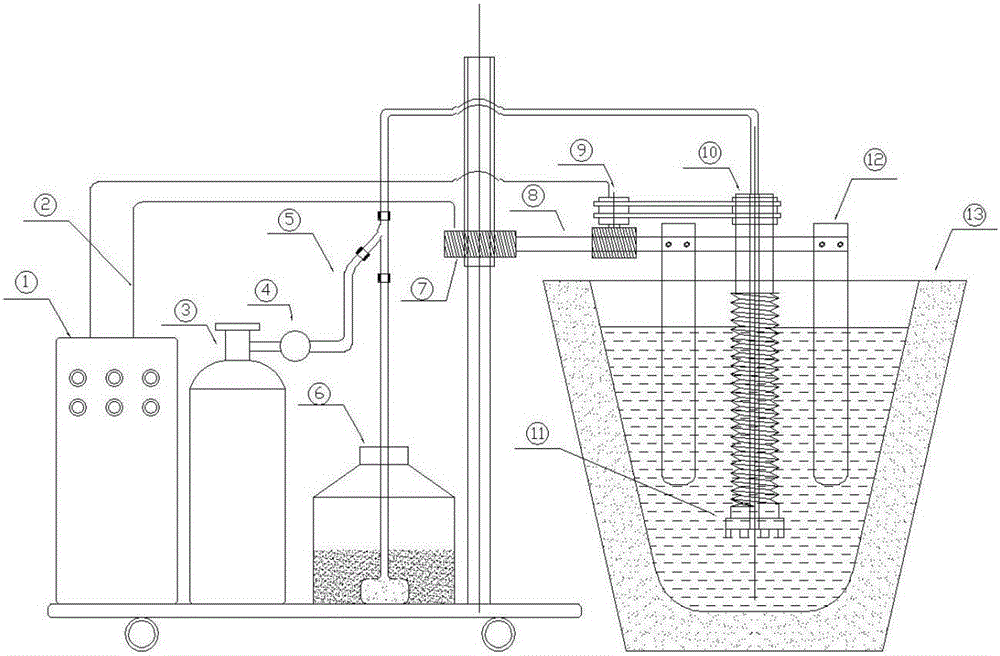

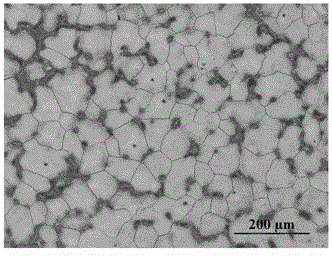

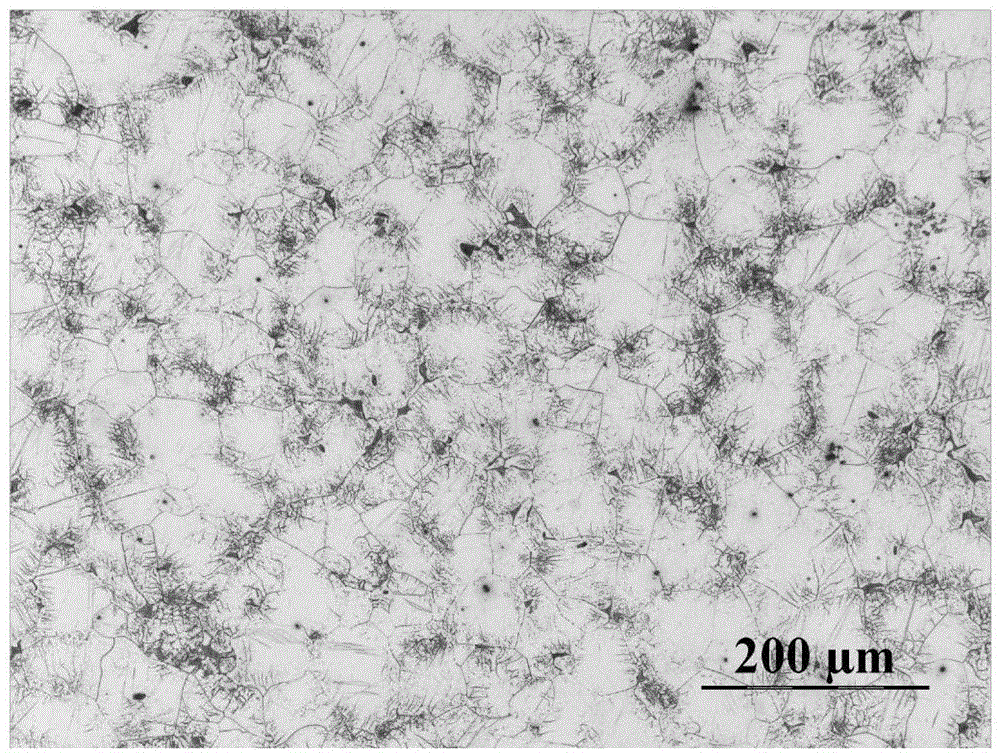

A magnesium alloy low-frequency pulsed magnetic field assisted semi-continuous casting mold and its application

The invention belongs to the field of the preparation of metal materials, and particularly relates to an auxiliary semi-continuous casting crystallizer for a low-frequency pulsed magnetic field of magnesium alloy and application thereof. The top of a casing of the crystallizer is provided with an upper cover of the crystallizer, the casing of the crystallizer and the position of a center hole of the upper cover of the crystallizer are provided with an inner sleeve of the crystallizer, a cooling water tank is formed between the casing of the crystallizer and the upper cover of the crystallizer, an excitation coil is arranged in the cooling water tank, the outer side of the casing of the crystallizer is provided with a water inlet communicated with the cooling water tank, and a secondary cooling water spraying hole communicated with the cooling water tank is arranged on the inner sleeve of the crystallizer. The casing and the upper cover of the crystallizer are made of stainless steel, and the inner sleeve of the crystallizer is made of a 4XXX family of aluminum alloy; and moreover, an upper opening of the inner sleeve of the crystallizer is higher than the upper surface of the upper cover, and a horn shape is formed between the upper opening and a lower opening. The auxiliary semi-continuous casting crystallizer for the low-frequency pulsed magnetic field of the magnesium alloyis used for the semi-continuous casting of the magnesium alloy, the forced convection of a melt is generated by utilizing pulsed electromagnetic force generated by the auxiliary semi-continuous casting crystallizer for the low-frequency pulsed magnetic field of the magnesium alloy to act on the melt of the magnesium alloy inside the crystallizer, bulky dendritic crystals are fragmented, the nucleation rate is increased, and the thinning effect of the crystal grains of a semi-continuous cast rod of the magnesium alloy is obvious.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

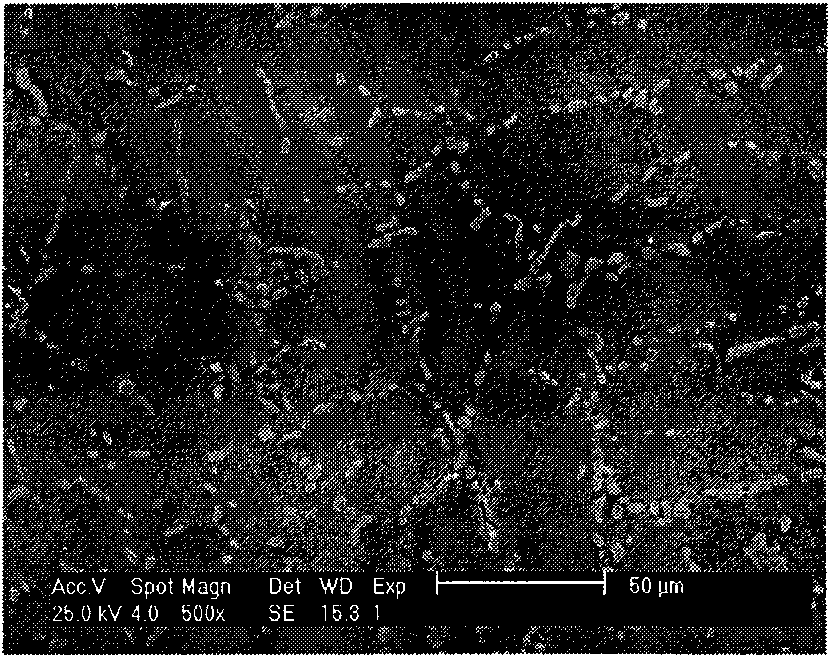

Prepn process of composite Al-Ti-C grain refining agent for aluminium and aluminium alloy

The present invention is preparation process of composite Al-Ti-C grain refining agent for aluminum and aluminum alloy with raised cooling speed, less Ti-C particle interface aggregation and raised Al-Ti-C grain refining performance. The preparation process includes: mixing material in certain weight proportion, pressing the mixture into cylindrical prefabricated block, stoving at 15-200 deg.c for 2 hr, pressing prefabricated block into aluminum melt at 760-820 deg.c to reach Ti content of 3-5%, hot-blast synthesis reaction and maintaining at 760-820 deg.c for 2 min, stirring the aluminum melt mechanically at 60-100 rpm for 5-10 min for the synthesized material to be diluted and dispersed well in the aluminum melt, standing for 5-10 min and casting in metal mold to obtain the product.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

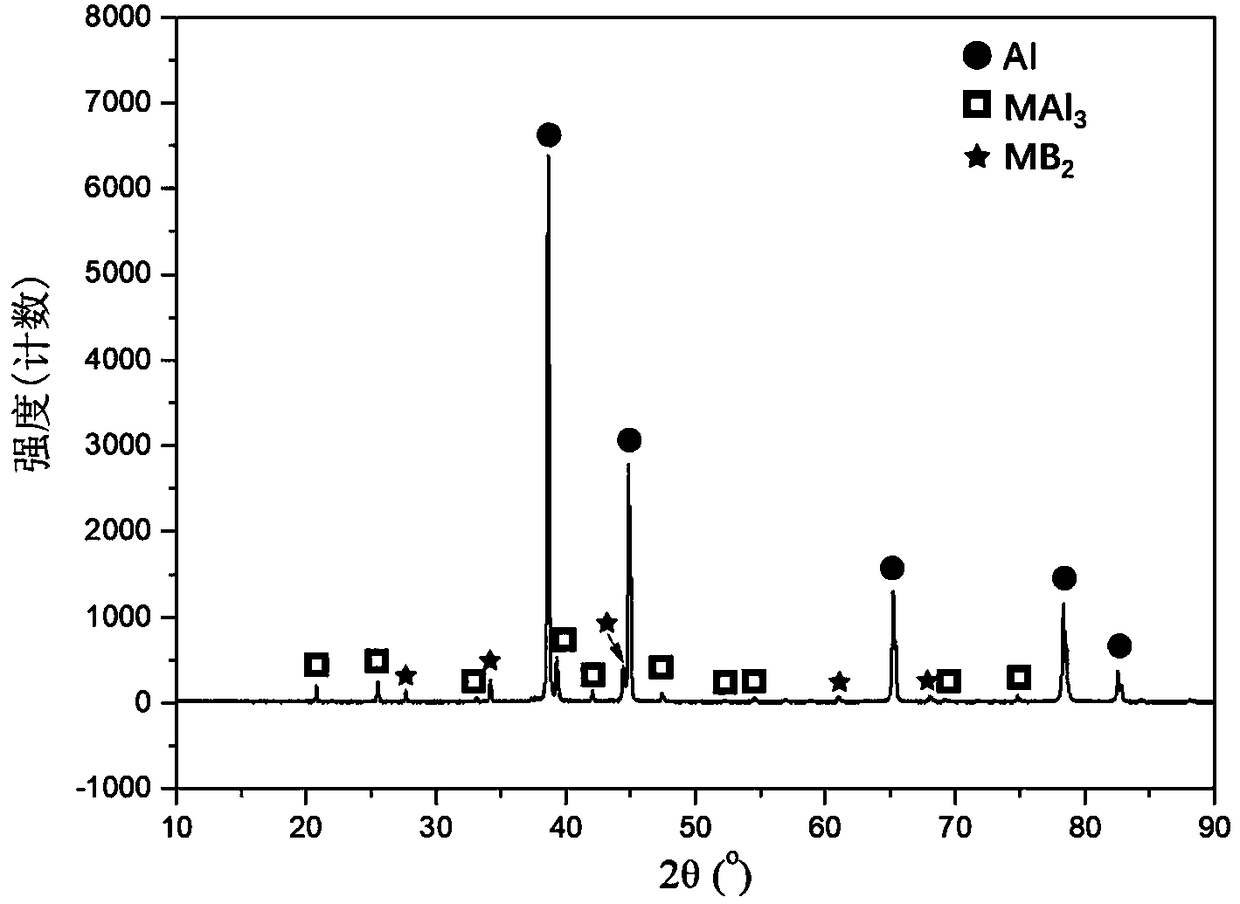

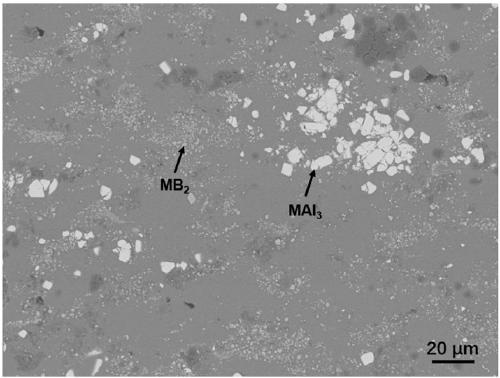

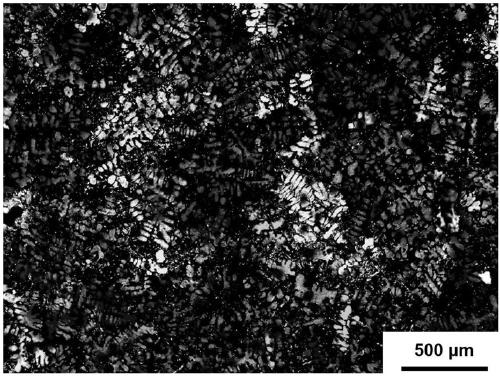

Al-M-B grain refiner for casting Al-Si alloy and preparation method thereof

The invention provides an Al-M-B grain refiner for casting an Al-Si alloy and a preparation method thereof. The Al-M-B refiner for casting the Al-Si alloy is composed of the components by mass: 85.0-96.0% of Al, 3.5-10.0% of M and 0.5-5.0% of B; the Al-M-B refiner contains refined particle phase MAl3 and MB2. The Al-M-B grain refiner is prepared by a fluoride salt method with Al blocks, K2TiF6 powder, Nb powder and KBF4 powder as raw materials. The Al-M-B alloy is prepared by melting. The prepared Al-M-B refiner can refine the grain size of alpha-Al in a high-silicon aluminum alloy to 700 microns or less, optimally to 200 microns or less; the amount of Nb is reduced and the cost of raw materials is reduced; the Al-M-B refiner has durable performance and is not easy to settle down and fail,and the refinement effect can still be less than 350 microns after heat preservation is performed for 2 h; the preparation method has the advantages of simple equipment conditions required for preparation and simple operation, and is suitable for industrial production.

Owner:SHANGHAI UNIV

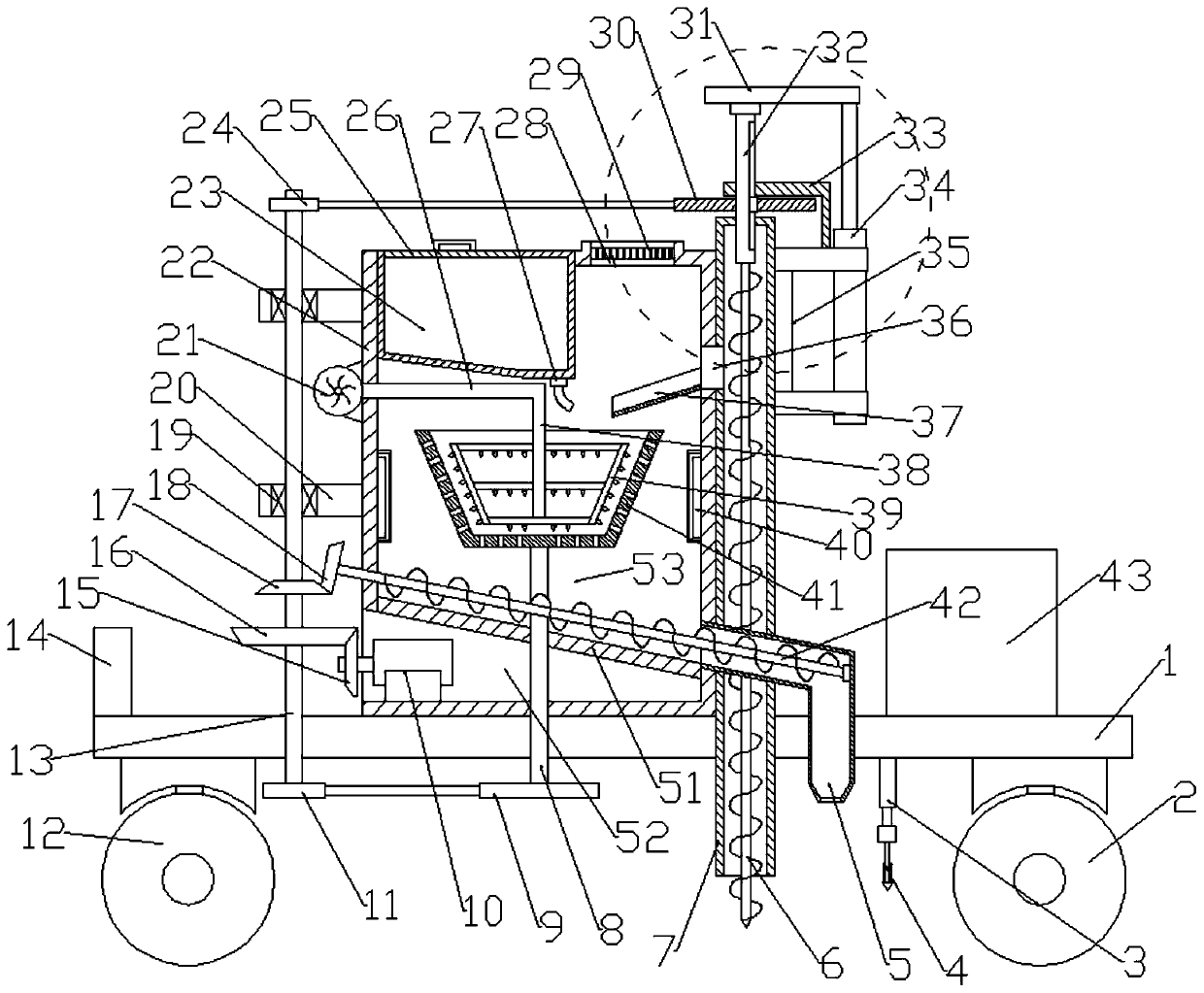

Soil remediation device used for municipal landscaping

InactiveCN109909288AFast backfillImprove repair effectSoil lifting machinesRotary stirring mixersSoil remediationLandscaping

The invention discloses a soil remediation device used for municipal landscaping. The soil remediation device comprises a loading platform, wherein a soil remediation box is arranged in the middle ofthe upper side of the loading platform; a vertically arranged material lifting barrel is arranged on the right side of the soil remediation box; a spiral soil auger is arranged in the material liftingbarrel; a vertical transmission shaft is arranged on the left side of the soil remediation box; a soil feeding hole is formed between the top of the right side wall of the soil remediation box and the material lifting barrel; the interior of the soil remediation box is divided into a soil remediation cavity at the upper part and a motor chamber at the lower part by a partition board; a rotary drum is arranged in the middle of the soil remediation cavity; discharging holes are uniformly distributed in the side surface and the bottom surface of the rotary drum; a vertical rod is arranged in thecenter of the rotary drum; a stirring and smashing head is arranged on the vertical rod; an agent box filled with a soil remediation agent is arranged on the left of the inner top of the soil remediation cavity, and a gas outlet used for discharging inside gas is formed in the right of the inner top of the soil remediation cavity. According to the soil remediation device, soil is fed automatically, is smashed efficiently, is remedied by heating and is backfilled accurately.

Owner:泰顺县刘志威家庭农场

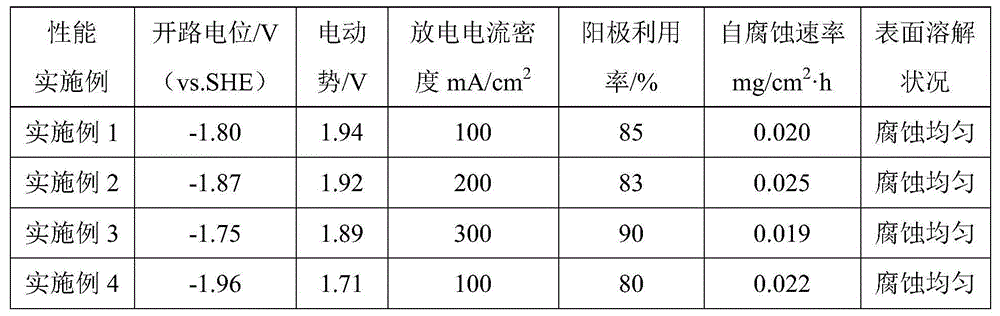

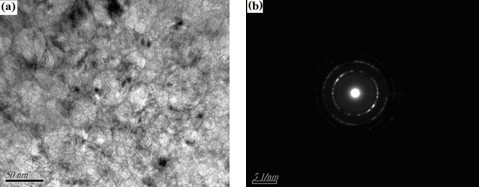

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

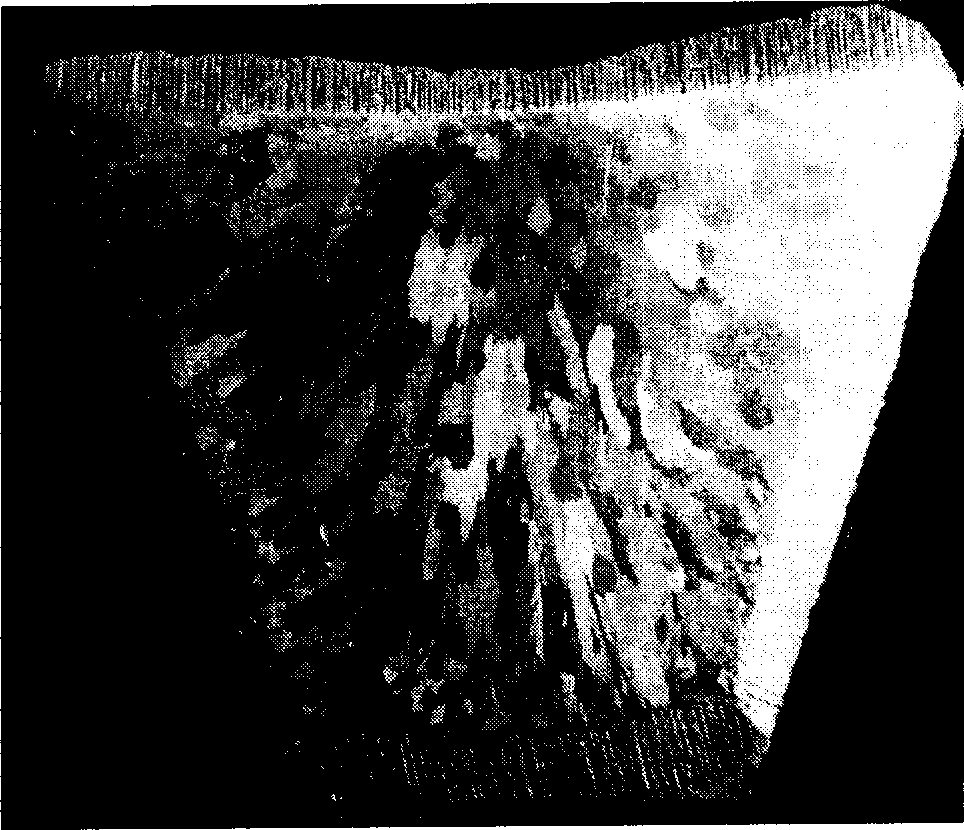

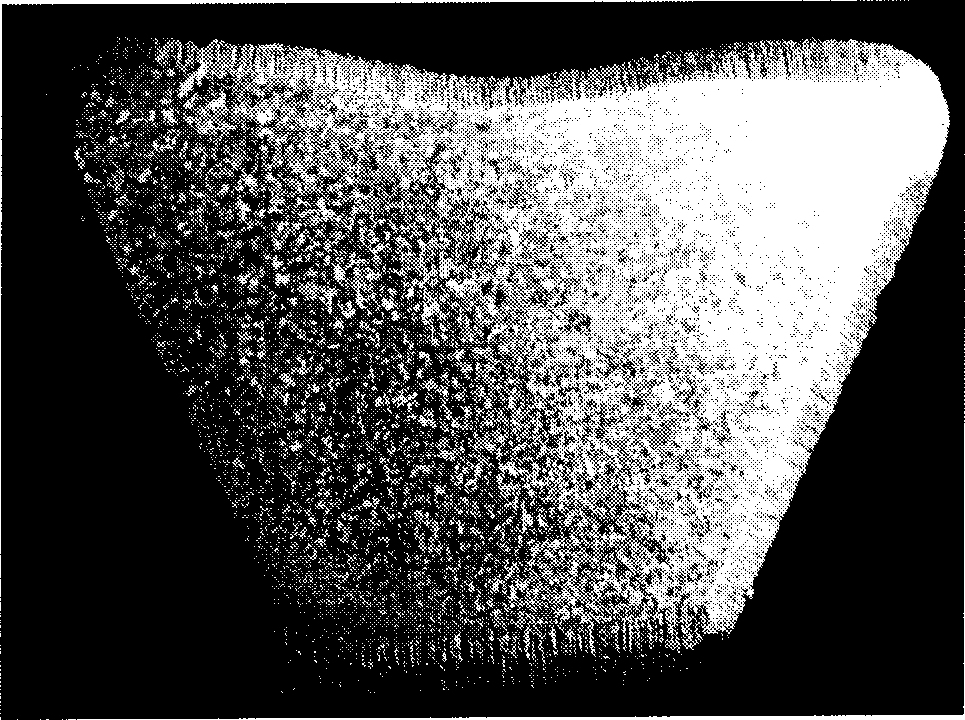

Grain refinement technology of silver-nickel electrical contact material and grain refinement technology of silver tin oxide electrical contact material

The invention discloses a grain refinement technology of a silver-nickel electrical contact material and a grain refinement technology of a silver tin oxide electrical contact material, belonging to the technical field of a metal-base composite material, which is characterized in that a uniform AgNi wire and a uniform AgSnO2 wire with a certain diameter specification are firstly drawn and thrust into short wires with the length of 1cm-5cm; the thrust wires are pressed into spindles after heat treatment; the spindles are made into the wire through sintering, upsetting and a plurality of hot extrusion, wherein, grain shearing deformation and grain refinement are realized by upsetting before extrusion, so tissue components in an extrusion material (110) are effectively reduced and oxide films on the boundary of powder grains are crushed and dispersed; and a plurality times of extrusion are adopted for extrusion deformation under large hydrostatic pressure, which is beneficial to elimination of tiny holes and combination of material points of the material so that the density and the shaping of the product are enhanced. In the course of extrusion, grain refinement is more obvious, the gross area of the grain boundary is increased, the capability for blocking crack expansion is enhanced, and the concentration of impurities on the grain boundary is reduced, thus avoiding brittle fracture along the grain boundary.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Grain refiner for synthesis of aluminium alloy by laser ignited self-propagation and method for preparing the same

InactiveCN1789448AHigh thermodynamic stabilityStrong resistance to grain refinement recession5052 aluminium alloyMetal

The invention relates grain refiner used for synthesizing aluminum alloy by laser firing and preparing method. The grain refiner comprises Al, Ti and B. The method comprises the following steps: mixing the Al, Ti, B and TiH2 powers with blending attachment, adding the powders into die and pressing them to preformed sample, after evacuating and filling argon gas, utilizing the laser to carry out self-propagating reaction of preformed sample and get grain refiner. The grain refiner possesses good refining effect and decline-resistant capability. The invention suits for aluminum alloy handling field.

Owner:DALIAN UNIV OF TECH

High-strength aluminum alloy material formed through metamorphism of salt hexafluorosilicate

The invention discloses a high-strength aluminum alloy material formed through metamorphism of salt hexafluorosilicate. The high-strength aluminum alloy material formed through the metamorphism of the salt hexafluorosilicate comprises, by weight, 2.6-3.2% of Cu, 0.45-0.7% of Mn, 2.0-2.4% of Mg, not more than 0.1% of Zn, not more than 0.15% of Ti, not more than 0.3% of Si, and not more than 0.3% of Fe. Salt hexafluorosilicate alterant accounts for 0.1-1.0% of the total furnace burden, and the rest is Al and unavoidable trace impurities, and the trace impurities comprise, by weight, not more than 0.05% of a single and not more than 0.10% of a total. The high-strength aluminum alloy material formed through the metamorphism of the salt hexafluorosilicate is good in metamorphism refining effect, can purify a furnace body, and is high in strength.

Owner:GUIZHOU ACAD OF SCI

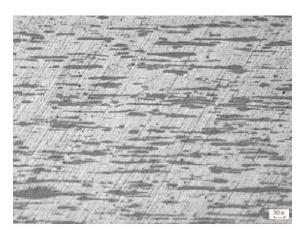

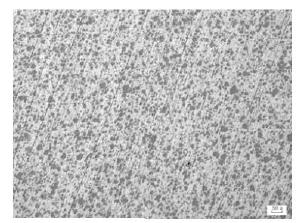

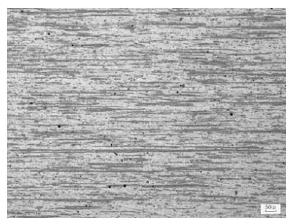

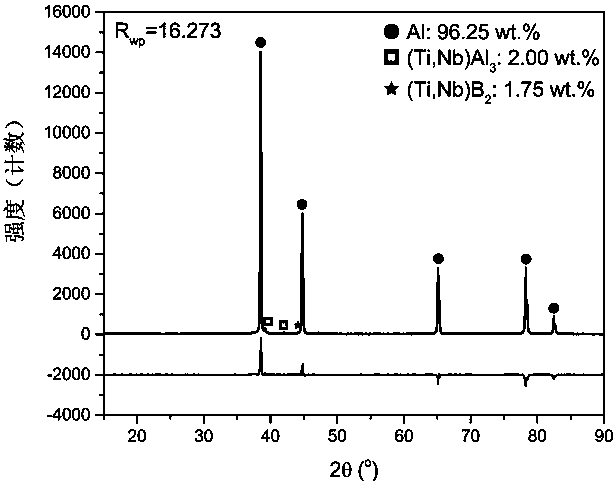

Al-Ti-Nb-B refiner for casting aluminum-silicon alloy as well as preparation method thereof and application thereof

The invention discloses an Al-Ti-Nb-B refiner for casting aluminum-silicon alloy as well as a preparation method thereof and application thereof. The Al-Ti-Nb-B refiner for casting aluminum-silicon alloy is prepared from the following components in percentage by weight: 96.20-98.90wt% of Al, 0.30-1.30wt% of Ti, 0.50-2.0wt% of Nb, and 0.30-0.50wt% of B. The Al-Ti-Nb-B refiner comprises a refining particle phase MA13 and MB2 with mass percentage of 2-4% and particle dimension smaller than 20 microns, wherein M is Ti or Nb. The preparation method for the Al-Ti-Nb-B refiner for casting aluminum-silicon alloy comprises the following steps of: a, weighing raw materials; b, smelting a Ti-Nb-B intermediate alloy; and c, smelting the Al-Ti-Nb-B refiner. A method of applying the Al-Ti-Nb-B refiner to casting aluminum-silicon alloy comprises the following steps of: a, melting the aluminum-silicon alloy; b, adding the Al-Ti-Nb-B refiner; and c, casting. The Al-Ti-Nb-B refiner prepared by the preparation method can be used for refining the crystalline grain size of alpha-Al in the aluminum-silicon alloy to be 150-450 microns, so that Nb content is greatly reduced, raw material cost is reduced,and components and structure uniformity of the prepared Al-Ti-Nb-B refiner are guaranteed.

Owner:SHANGHAI UNIV

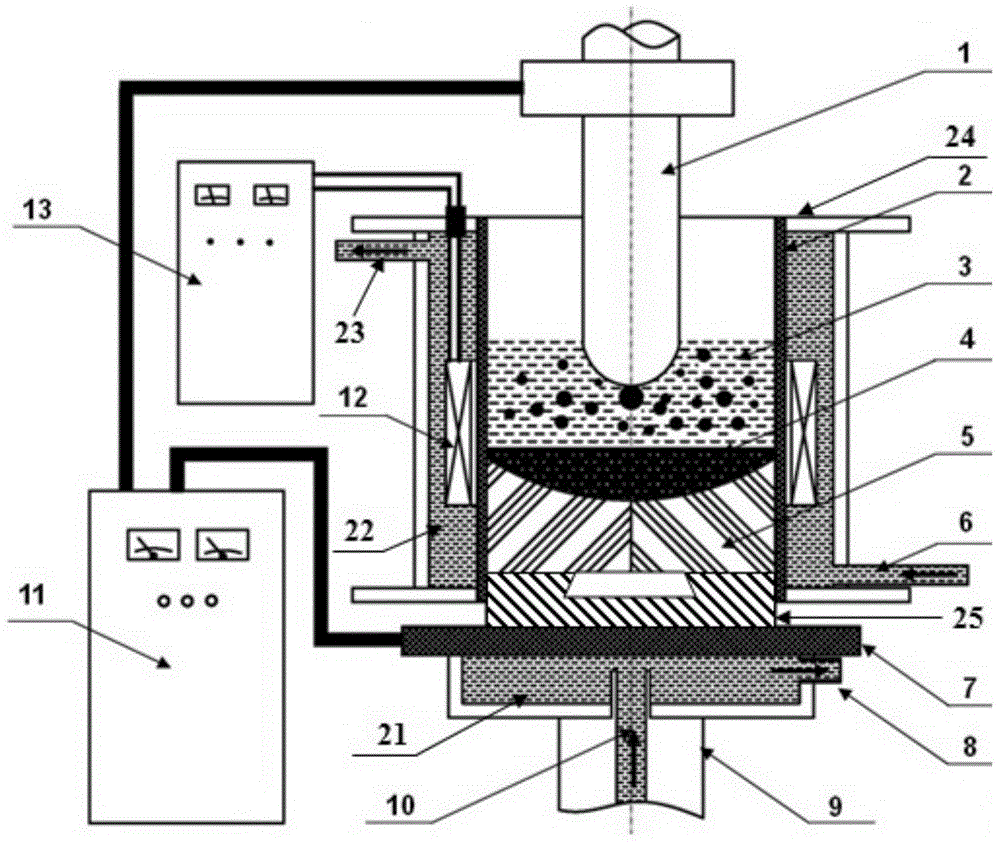

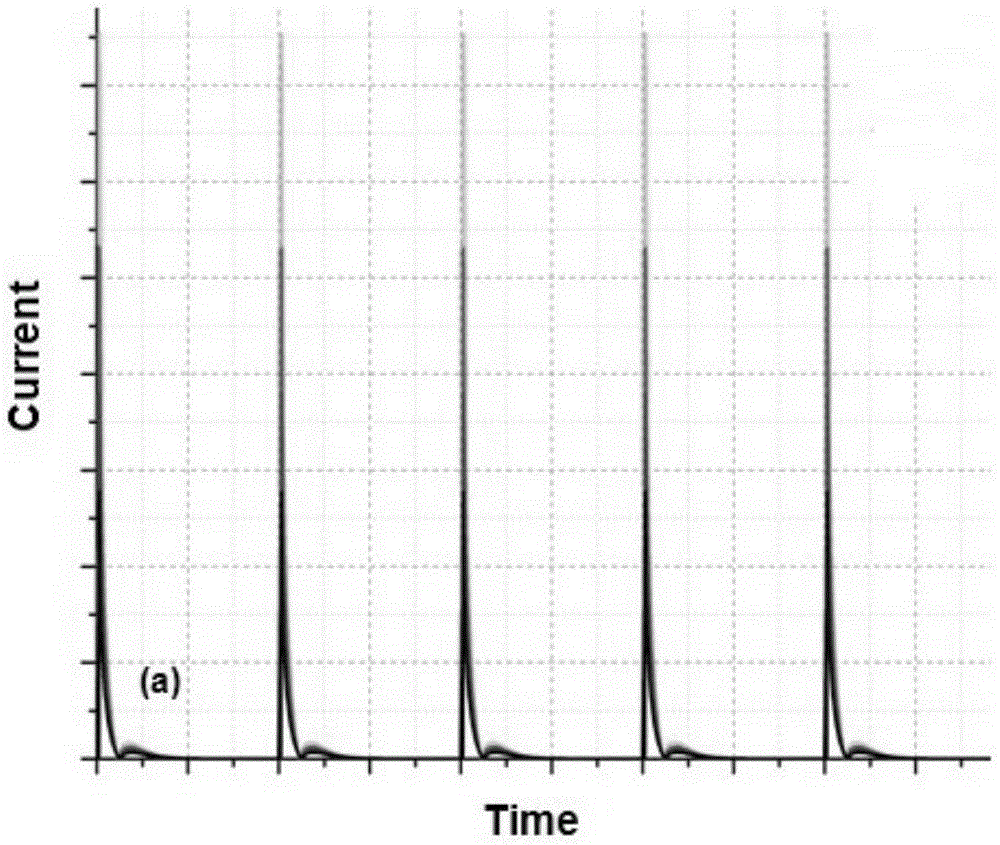

Method and device for casting electromagnetic compound control electroslag remelting fine grains

The invention relates to a method and a device for casting electromagnetic compound control electroslag remelting fine grains, and belongs to the field of preparation of metal materials. According to the method, metallic melt generates forced convection by using the action of exerted pulse magnetic field and periodic electromagnetic force which is generated by compounding of induced current in the melt and electroslag remelting current; a metal material solidification structure is fined; and composition segregation is reduced. Metal droplets can be crushed into fine liquid drops under the action of the electromagnetic force with direction and size in periodic change; the contact area and the contact time of the metal droplets and slag liquid are improved; and a good purification effect is achieved. The device comprises an electroslag remelting work power supply, a pulse power supply and an electromagnetic compound control electroslag remelting crystallizer, wherein the crystallizer is provided with a crystallizer red copper inner sleeve, a side cooling jacket, a bottom cooling jacket and a magnet exciting coil. The method and the device can be applied to electroslag remelting and refining of metal materials such as high-temperature alloy and high alloy steel; the alloy solidification structure can be fined; the segregation is reduced; the refining effect of the electroslag remelting process is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum-titanium-boron-strontium alloy refining and modifying agent

The invention relates to an aluminum-titanium-boron-strontium alloy refining and modifying agent, and belongs to a flux for casting. Aiming at the problem that an aluminum-titanium-boron alloy is used for refining and an aluminum-strontium intermediate alloy is used for modifying in turn to cause high labor and time consumption in the conventional process for treating a eutectic or hypoeutectic aluminum-silicon alloy melt, the invention provides the aluminum-titanium-boron-strontium alloy refining and modifying agent for refining and modifying simultaneously. The refining and modifying agent is characterized by comprising the following components in percentage by weight: 3 to 7 percent of titanium, 0.4 to 1.0 percent of boron, 7 to 11 percent of strontium and the balance of aluminum. During use, the refining and modifying agent is preheated, 0.4 weight percent of preheated refining and modifying agent is added into a 710 to 730 DEG C eutectic or hypo-eutectic aluminum-silicon alloy melt at one time, and melted after 3 to 5 minutes, the mixture is uniformly stirred, stood for 5 to 7 minutes and is subjected to slagging off, and casting operation is performed. Compared with the conventional two-time separate refining and modifying operation, the simultaneous refining and modifying operation has the advantages that: the labor and time consumption is low and the refining and modifying effects of the treated eutectic or hypoeutectic aluminum-silicon alloy are good through probation.

Owner:镇江市丹徒区振华熔剂厂

Refinement modifier for hypoeutectic aluminum-silicon cast alloy, and preparation method and application thereof

The invention discloses a refinement modifier for hypoeutectic aluminum-silicon cast alloy, and a preparation method and the application thereof. The refinement modifier for hypoeutectic aluminum-silicon cast alloy is characterized by comprising the chemical ingredients of Al-1Ti-3B-10RE which are, by weight, 0.9% to 1.1% of Ti, 2.8% to 3.2% of B, 10% to 12% of RE, and the balance Al. The RE comprises the ingredients of 40% of mixed light rare earth rich in La, and 60% of Y. The problem of (Al and Ti)B2 and AlB2 agglomeration in a refinement modifier is solved due to the active roles of rare earth elements in cooperation with fusion magnetic blending and quick solidification. Compared with the widely used refinement modifier Al-5Ti-1B and the widely used refinement modifier Al-10Sr, the refinement modifier for hypoeutectic aluminum-silicon cast alloy has the function of integrating refinement and modification, and is easy to apply; andthe titanium silicide poisoning refinement effect or the phenomenon that air intake of alloy melt is intensified by Sr or the phenomenon that Sr and B poison each other does not exist, and the effect of refining alpha-Al and the mechanical property ofalloy can be obviously improved.

Owner:JIANGXI ZHONGYAN METAL TECH CO LTD

Aluminum alloy welding wire and preparation method thereof

InactiveCN106238952AGood welding performanceImprove refinementWelding/cutting media/materialsSoldering mediaCrack resistanceWeld seam

The invention discloses an aluminum alloy welding wire and a preparation method thereof. The aluminum alloy welding wire consists of the following components in percentage by weight: 5.5-6% of Mg, 0.1-0.15% of Ti, 0.1-0.3% of Cr, 0.08-0.18% of Mn, 0.05-0.2% of Sc, 0.1-0.18% of Nd, 1-2% of Mo, 1-2% of W, 0.2-0.8% of V, 0.01-0.05% of Bi, 2-5% of Cu, 0.25-0.35% of Zr, 0.1-0.25% of Ag, less than or equal to 0.25% of Si, less than or equal to 0.2% of Fe, less than or equal to 0.20% of Zn, less than or equal to 0.15% of other impurity elements each being less than or equal to 0.05%, and the balance Al. The aluminum alloy welding wire disclosed by the invention is compact in tissue and is smooth in surface; and tensile strength, cracking resistance, wear resistance and corrosion resistance of a welding seam are good.

Owner:安徽飞弧焊业股份有限公司

Wet precoated sand

ActiveCN101934350AImprove bindingGood refinement effectFoundry mouldsFoundry coresCouplingMoisture absorption

The invention discloses wet precoated sand, which comprises raw sand, a binding agent, a curing agent, a coupling agent and a lubricating agent. The amounts of the curing agent and the coupling agent are respectively 50-70% and 0.5-1% of the amount of the binding agent; the amounts of the binding agent and the lubricating agent are respectively 3-5% and 0.2-0.8% of the amount of the raw sand; the binding agent comprises the following components in part by weight: 70-80 parts of phenolic resin, 10-20 parts of quartz powder and 5-15 parts of fire clay; the coupling agent is a silane coupling agent; and the wet precoated sand has the tensile strength not less than 4 MPa and the gas-generating amount not more than 19. The wet precoated sand not only has relatively small degree of roughness, relatively strong cohesive property, but also has relatively good density, difficult moisture absorption and difficult dryness absorption and can be stored for a long time in a daily environment.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Al-Sb-Y-Mg modifier for hypoeutectic Al-Si alloy and preparation process thereof

The invention discloses an Al-Sb-Y-Mg modifier for a hypoeutectic Al-Si alloy, which consists of the following elements according to weight percent: 82 percent to 92 percent of aluminum, 5 percent to 15 percent of antimony, 1 percent to 2 percent of yttrium, 1 percent to 2 percent of magnesium, and 1 percent to 2 percent of aluminum covering agent. The aluminum covering agent comprises 50 percent by weight of NaCl powder and 50 percent by weight of KCl powder. The invention also discloses a method for preparing the modifier, which comprises the steps of placing aluminum ingot accounting for 82 percent to 92 percent of the modifier in weight percentage into a graphite crucible with temperature of 450 to 550 DEG C and adding the aluminum covering agent accounting for 1 percent to 2 percent of the modifier in weight percentage; increasing the temperature to 760 to 800 DEG C; later adding antimony ingot accounting for 5 percent to 15 percent of the modifier in weight percentage, yttrium ingot accounting for 1 percent to 2 percent of the modifier in weight percentage, and magnesium ingot accounting for 1 percent to 2 percent of the modifier in weight percentage into molten aluminum liquid in sequence and keeping the temperature for 20-30min; then introducing argon gas at a place of 8-15mm away from a melt bottom at flow of 8-20ml / s and implementing refining for 2-5min on the melt; and finally removing the slag and pouring the melt into a metal type die, and cooling to room temperature.

Owner:CITIC DICASTAL +1

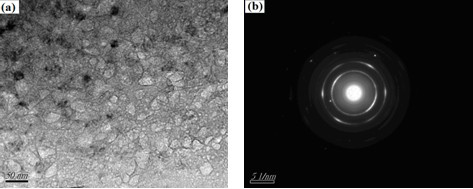

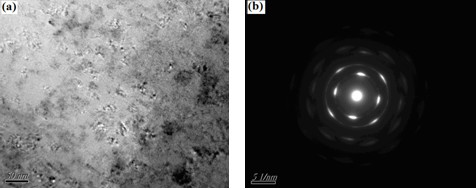

A kind of preparation method of nanocrystalline polycrystalline magnesium material

The invention relates to a high-performance magnesium alloy or magnesium-based composite material. The grain size of the prepared material matrix is in nano scale. The material has the characteristics of high strength and high toughness and belongs to the field of preparation of new materials. A cast state or deformation state magnesium alloy or magnesium-based composite material is subjected to cryogenic-low heat circulation treatment by controlling important parameters such as cryogenic temperature, cold treatment time, cold heat circulation times, low-heat temperature, heat treatment time and the like; the magnesium material after treatment has a nanocrystal microstructure and corresponds to the mechanical properties of high strength and high toughness. A preparation method of the high-performance magnesium material has the advantages of 'high performance, high efficiency, low cost and low pollution'.

Owner:JIANGSU UNIV

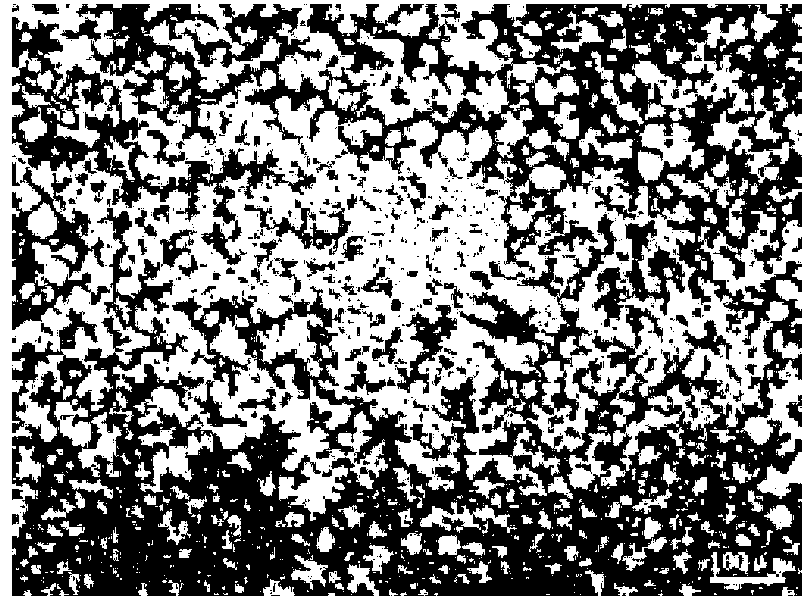

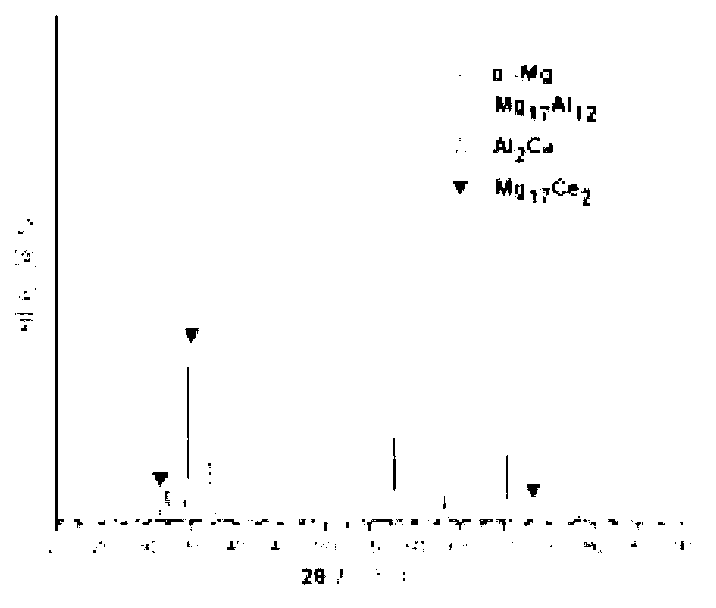

Calcium and cerium added flame-retardant magnesium alloy and preparation method thereof

The invention discloses a calcium and cerium added flame-retardant magnesium alloy and a preparation method thereof. The flame-retardant magnesium alloy comprises the following elements in percentage by mass: 85.90-88.03% of Mg, 8.18-9.15% of Al, 0.43-0.87% of Zn, 0.16-0.38% of Mn, 2.20-2.50% of Ca, 1.00-1.20% of Ce. The preparation method of the alloy is implemented through compositely adding Mg (29.9wt% of Ca)-Mg (30.8wt% of Ce) intermediate alloy into an AZ91D magnesium alloy melt, so that a dense protective oxide film is generated on the surface of the magnesium alloy melt, thereby preventing the alloying approach of magnesium alloy burning; the magnesium alloy can be smelted under the condition of no fusing agent or gas protection measures. Through carrying out an appropriate heat treatment process on a magnesium alloy sample, the cast magnesium alloy disclosed by the invention both has good flame retardant properties and good mechanical properties.

Owner:HEBEI UNIV OF TECH

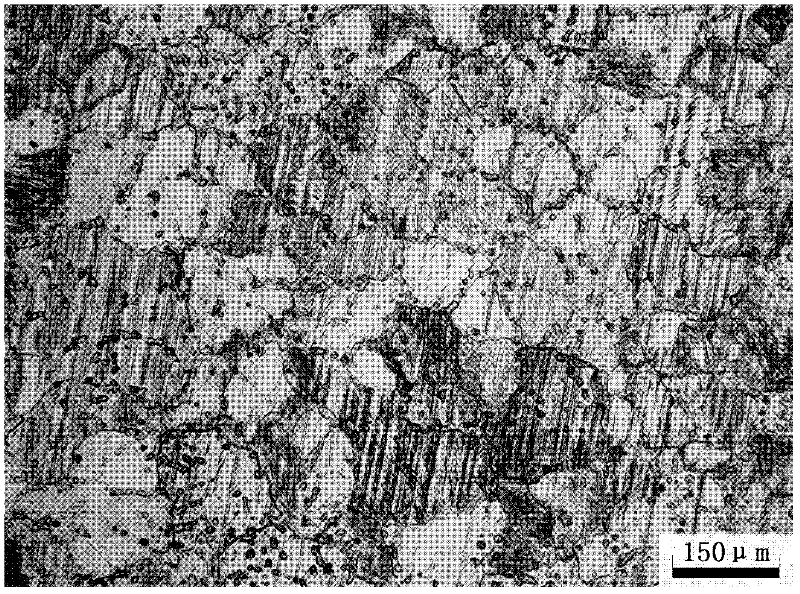

Method for compositely refining AZ31 magnesium alloy crystal particles by ultrasound field and refining agent

The invention provides a method for compositely refining AZ31 magnesium alloy crystal particles by an ultrasound field and a refining agent and belongs to the technical field of magnesium alloy casting. The method is characterized by comprising the following steps of: firstly, melting an AZ31 magnesium alloy under the protection of a magnesium alloy fusing agent; adding the refining agent consisting of SiC ceramic particles and magnesium powder when the temperature is raised to 780 DEG C, wherein the addition amount of the refining agent is 0.2%-1% by mass of magnesium alloy melt; after insulating for 20 minutes, stirring so that the refining agent is dispersed in the melt; after further insulating for 10 minutes, refining with argon; and applying the ultrasound field at the temperature of 680 DEG C-700 DEG C to process for 2 minutes and then pouring. The method has the beneficial effects of simple operation process, low production cost and good AZ31 magnesium alloy refining effect; and by using the method, the strength and toughness of the AZ31 magnesium alloy are obviously improved.

Owner:DALIAN UNIV OF TECH

Strong shearing and stirring aluminum alloy melt composite treatment device and technology

The invention relates to a strong shearing and stirring aluminum alloy melt composite treatment device and technology. The device comprises a control cabinet, a wire, a gas storage bottle, a gas flow control valve, a gas pipe, a powder storage tank, a lifting system drive motor, a supporting rod, a graphite rotor drive motor, a graphite rotor, a rotary spray head, scum boards and a transfer bag. A gas flow and powder adding channel is arranged in a middle hole of the graphite rotor. Powder in the powder storage tank is a refining agent and a grain refiner. The part, immersed in melt, of the graphite rotor is in a left screw type thread type. The scum boards are arranged on the two sides of the graphite rotor. An Al-Sr-RE intermediate alloy is added and preheated into the kermesinus transfer bag, 1.0 kg to 1.5 kg of a dry covering agent is uniformly spread on the surface, 1.0 kg to 1.5 kg of the dry refining agent and 1.0 kg to 1.5 kg of the dry grain refiner are added into a powder storage bottle, the graphite rotor is moved to the position 80-100 mm away from the bottom of the transfer bag, and refining and purifying are started. The device and technology have the better effects of degassing purification, refining and homogenization.

Owner:JIANGSU KAITE AUTO PARTS

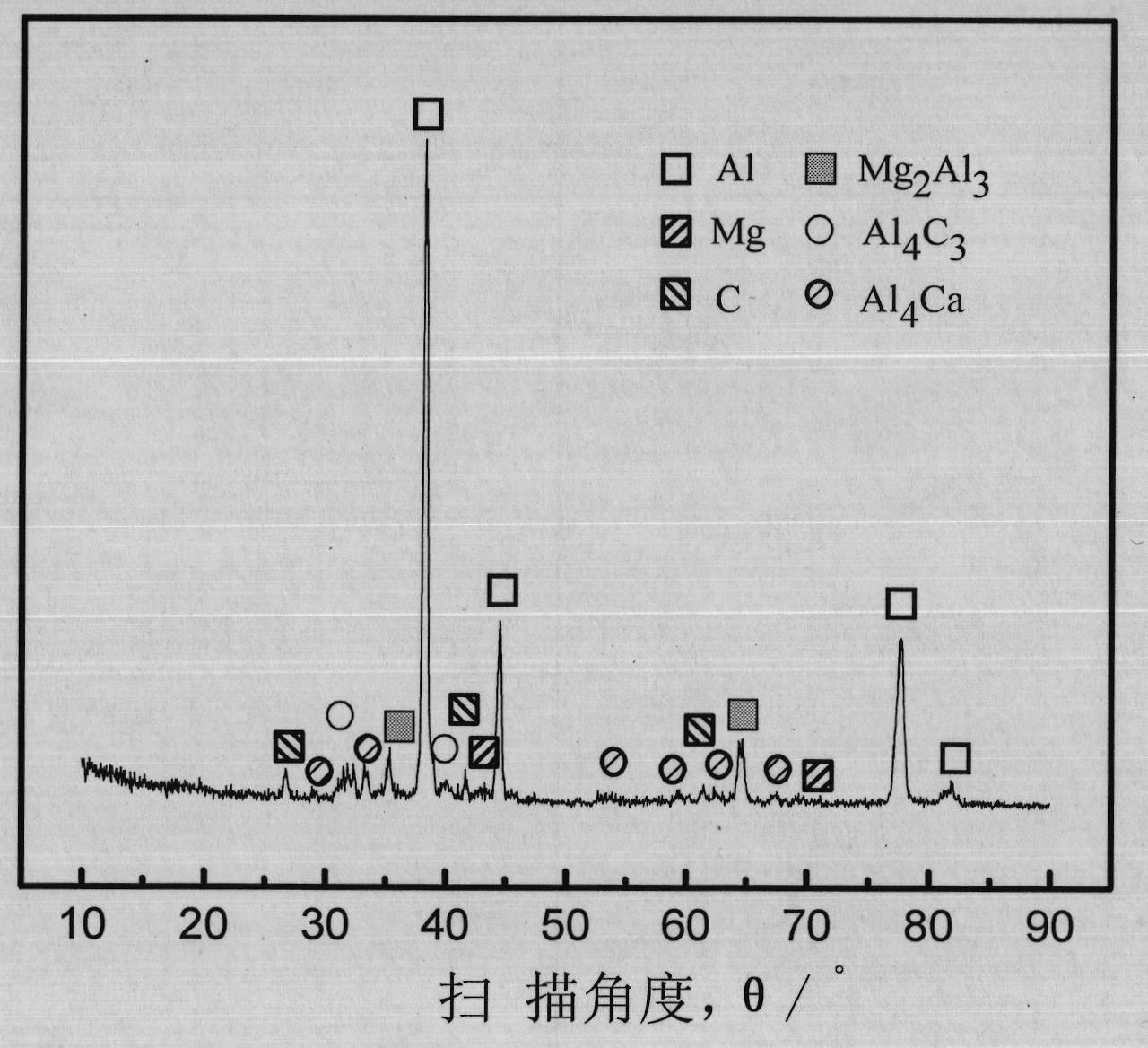

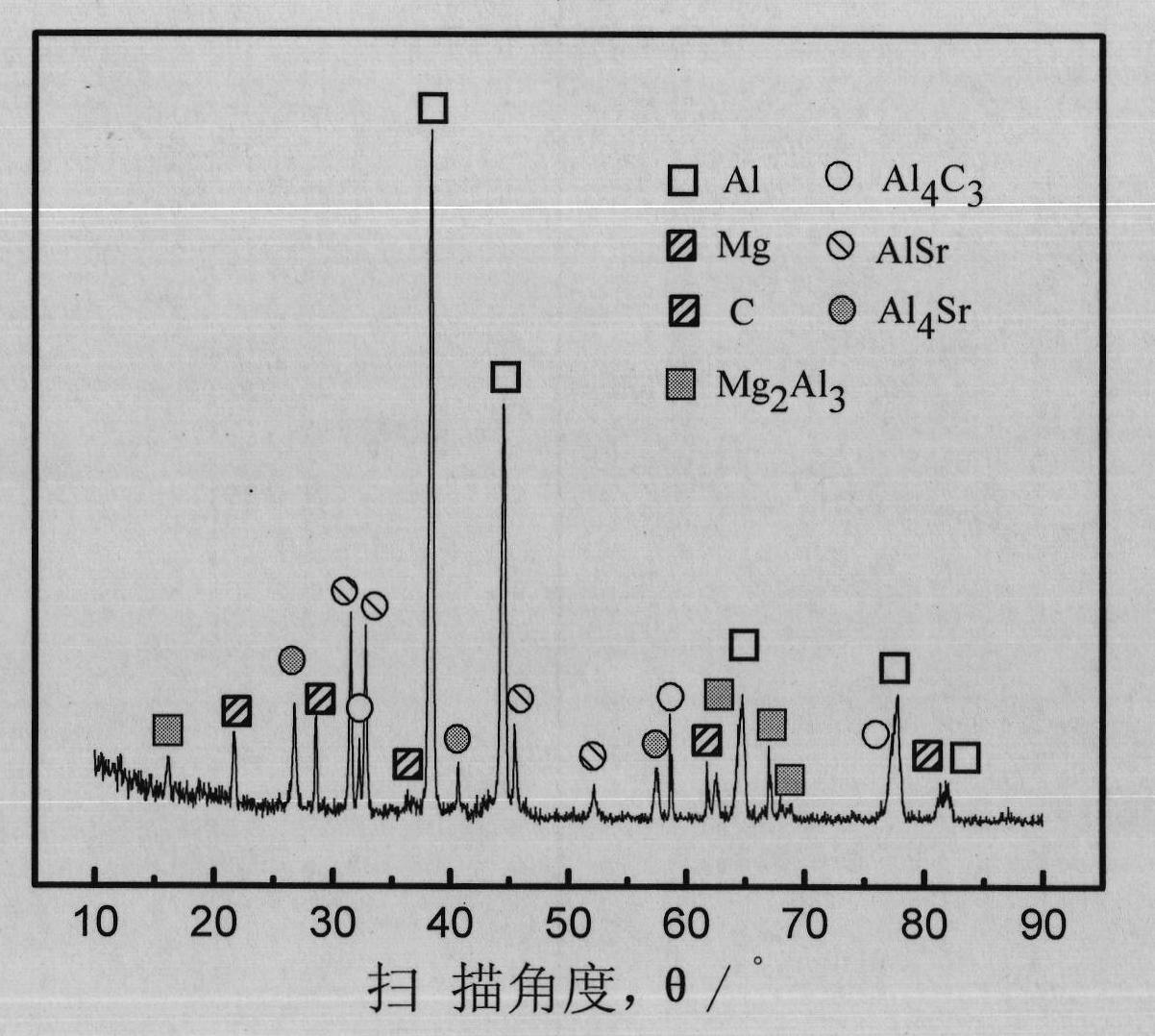

Composite grain finer for Mg-Al alloy and preparation method thereof

The invention discloses a composite grain finer for Mg-Al alloy and a preparation method thereof. The composite finer comprises the following components: 50-60 percent of Al, 1-5 percent of C, 5-10.5 percent of Ca or 5-10.5 percent of Sr, and the balance of Mg. The preparation method comprises the following steps of: melting pure Al under 700-800 DEG C, adding Mg-CA or Mg-Sr intermediate alloy according to the formula, and compensating the insufficient Mg with pure Mg to obtain Al-Mg-Ca or Al-Mg-Sr intermediate alloy melt, cooling the melt to 600-650 DEG C, uniformly dispersing graphite powder into the melt by using a semi-solid stirring method, and casting to obtain the composite grain finer. The finer has the advantages of simple preparation method, easy batch production, easy control of the addition amount, no discharge of pollutant and particularly remarkable fining effect for the Mg-Al alloy with low Al content.

Owner:SOUTH CHINA UNIV OF TECH

Machining method for aluminum alloy turbine blade of aero-engine

The invention discloses a machining method for an aluminum alloy turbine blade of an aero-engine, and belongs to the technical field of machining for turbine blades of aero-engines. The machining method comprises the following steps: casting the aluminum alloy turbine blade, carrying out film hole machining through a machining method of ultrafast laser annular cutting and spiral scanning, and removing a remelted layer through abrasive particle flow machining and a melted layer removal solution. According to the machining method disclosed by the invention, the film hole machining is carried outthrough the machining method of ultrafast laser annular cutting and spiral scanning, so that the heat effect can be greatly reduced and the surface integrity is improved, the machined film hole has few burrs, grooves and micro-cracks, and the maximum thickness of the remelted layer is not greater than 25[mu]m. Abrasive particles uniformly grind the surface or the corners of a channel under a pressure effect, so that allowance can be removed, the effects of deburring, chamfering and polishing can also be acted, the remelted layer can also be effectively reduced, a hole diameter increment is controlled to be 0.02mm to 0.04mm, and the remelted layer and the micro-cracks can be effectively controlled. The remelted layer is further removed through the remelted layer removal solution, so that no remelted layer residue at the inlet-outlet of the film hole can be achieved.

Owner:安徽恒利增材制造科技有限公司

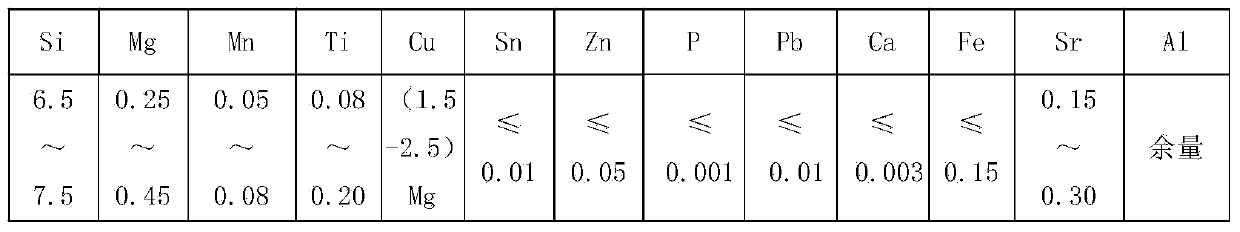

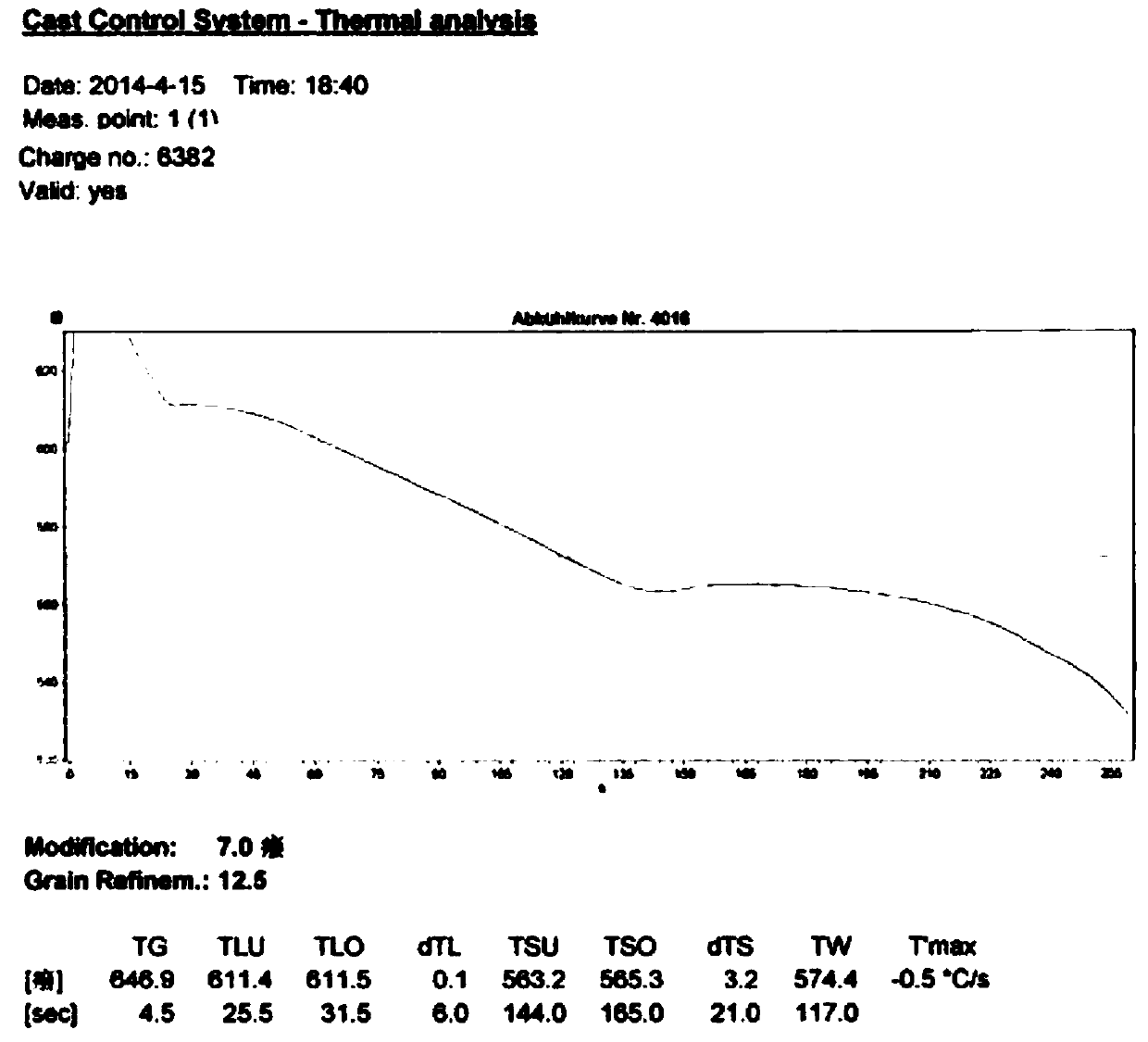

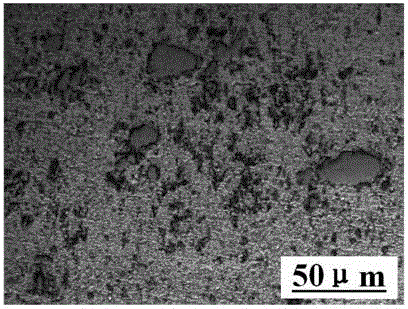

Hypoeutectic Al-Si alloy material for all-aluminum engine of high-grade car and preparation method of hypoeutectic Al-Si alloy material

The invention relates to a hypoeutectic Al-Si alloy material for an all-aluminum engine of a high-grade car and a preparation method of the hypoeutectic Al-Si alloy material. The hypoeutectic Al-Si alloy material with high strength and high toughness is researched by adding Cu and Mn strengthening elements and a Sr modification element, improving an industrial silicon melting process and adopting a process for removing gas and residues in a furnace and a casting process and a technology for detecting refinement and modification of alloy on line through thermal analysis. The hypoeutectic Al-Si alloy material has the tensile strength of 338-345Mpa and the elongation rate of 8.5-9.2% and can be completely applied to the all-aluminum engine of the high-grade car at home and abroad.

Owner:天津新立中合金集团有限公司

Aluminum alloy refiner, preparation method therefor and use thereof

Owner:CITIC DICASTAL +1

Zirconium refinement method for magnesium alloy crystalline grains

The invention provides a zirconium refinement method for magnesium alloy crystalline grains. The method includes the following steps that a, after potassium fluozirconate and a magnesium ingot are dried, under protection of a mixed fused salt system including NaCl and KCl, the potassium fluozirconate and the magnesium ingot are subjected to a reduction reaction for 35-45 min at the temperature of 900-1300 DEG C, casting is carried out for 4-5 min at the casting speed of 10-15kg / min at the temperature of 1040-1070 DEG C at the electromagnetic vibration frequency of 200-400 Hz, and a magnesia-zirconia master alloy ingot is obtained; b, pre-deformation treatment is carried out on the magnesia-zirconia master alloy ingot to obtain a magnesia-zirconia master alloy refiner; c, after a magnesium alloy raw material is smelted, the magnesia-zirconia master alloy refiner is added at the temperature of 750-780 DEG C, and after surface dross is removed, stirring, drossing and peeling are carried out. Compared with the prior art, the adopted refiner is magnesia-zirconia master alloy subjected to pre-deformation treatment, zirconium particles are fine and evenly distributed, the refining effect is good, a magnesium alloy structure is evenly distributed, the quality of a magnesium alloy product is improved, and the method is suitable for experimental and industrial application.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com