Patents

Literature

95results about How to "Improve Platability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot-dip galvanized steel sheet and production thereof

InactiveUS6312536B1High strengthGood formabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

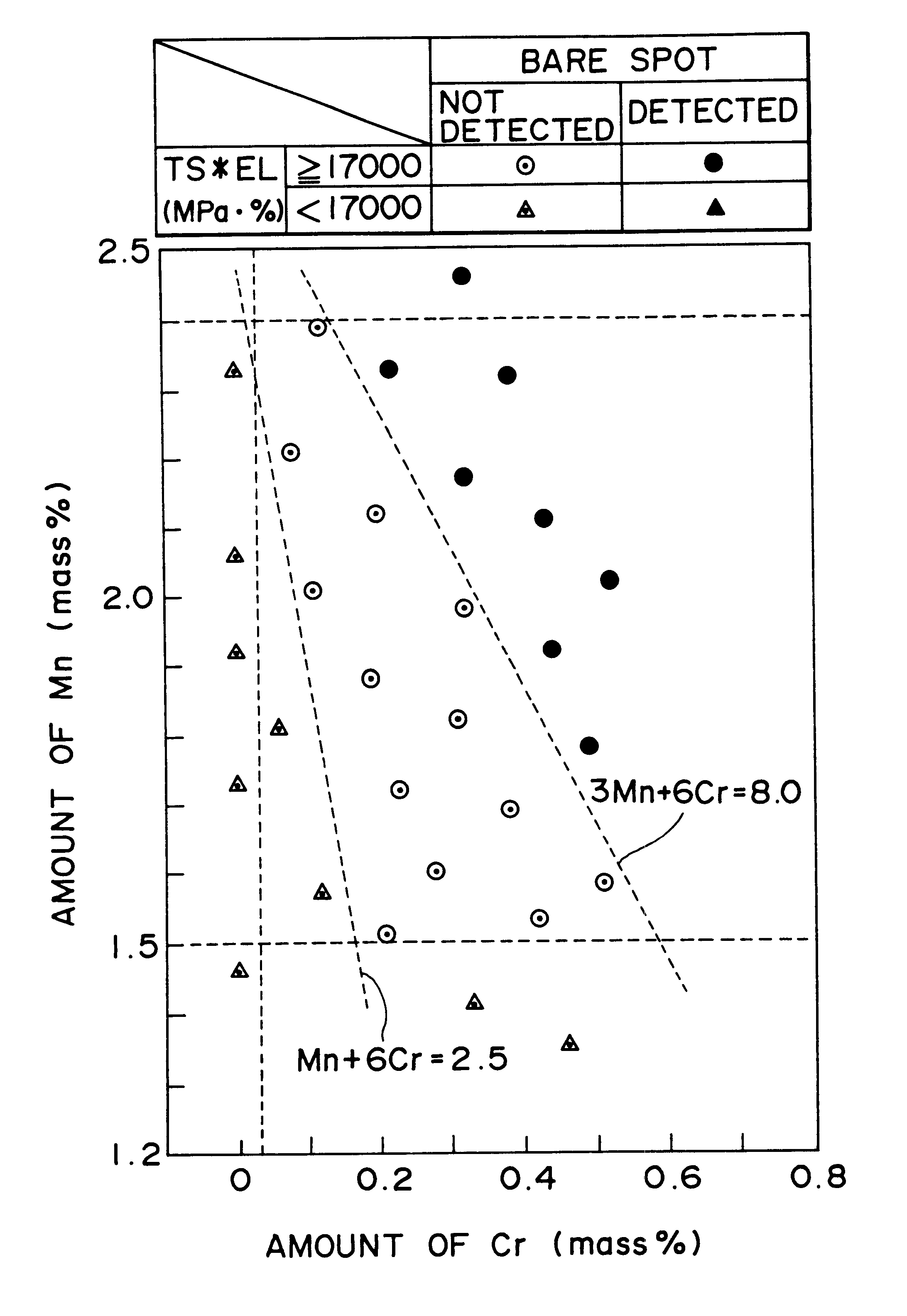

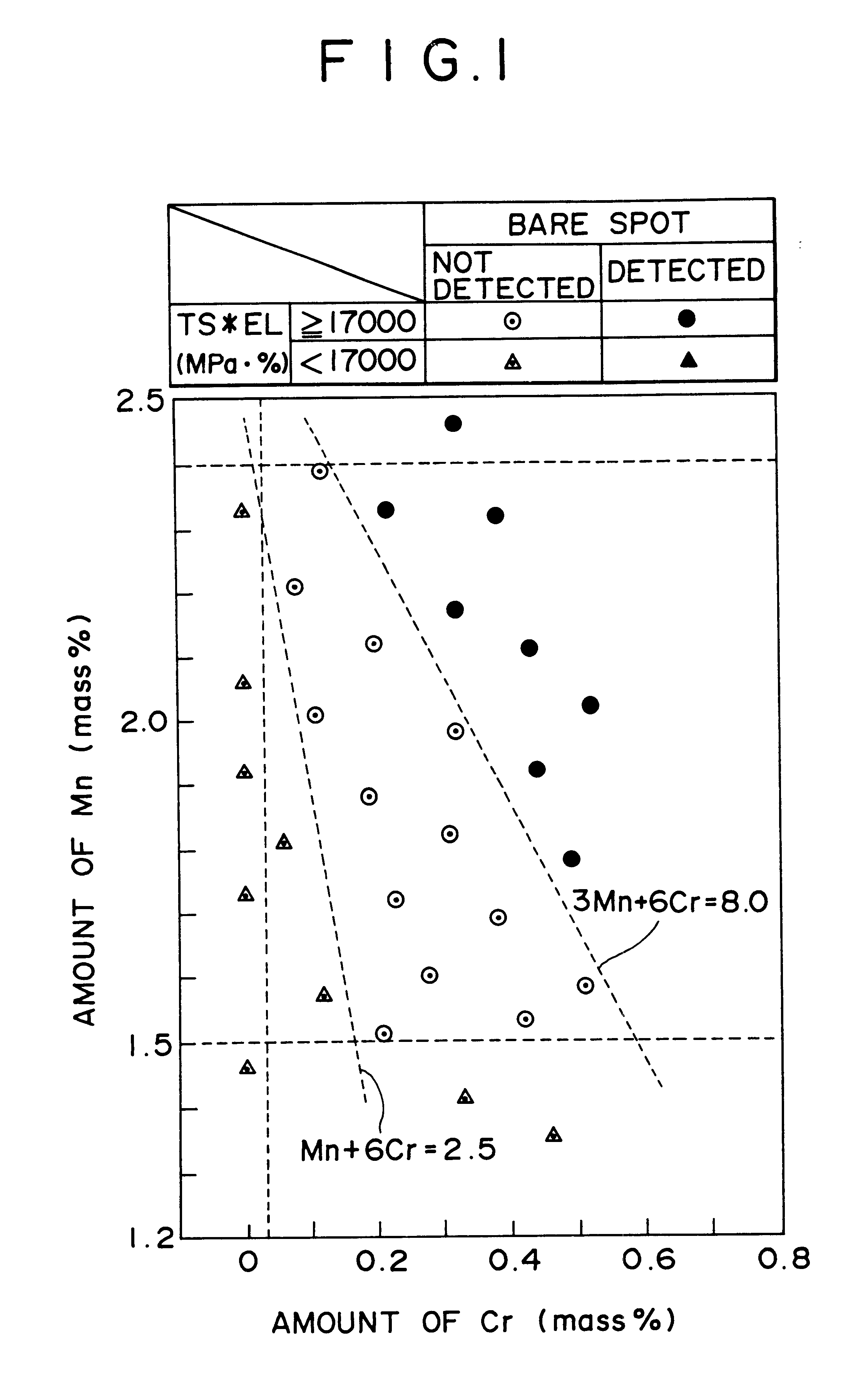

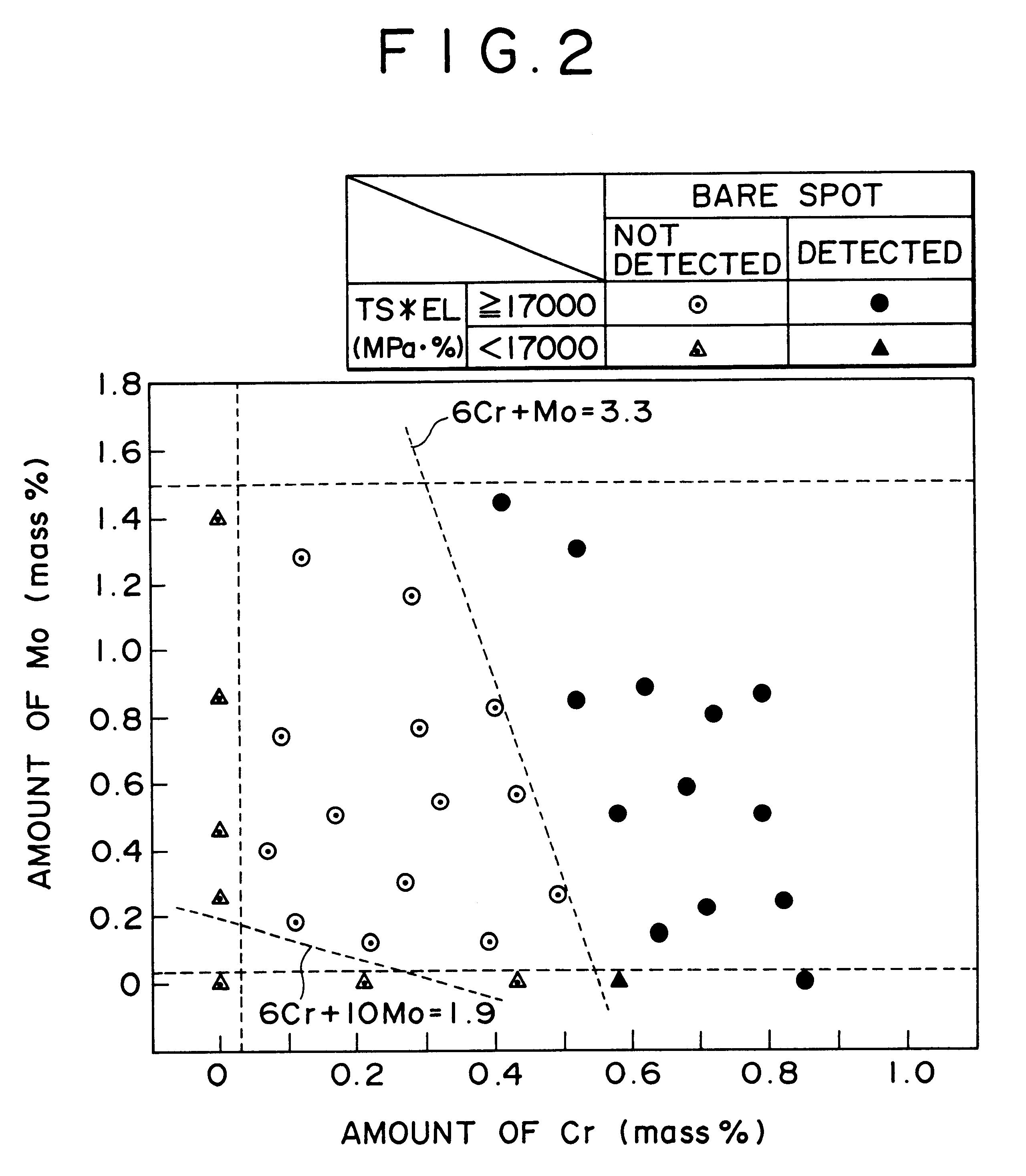

A hot-dip galvanized steel sheet having both high strength and good formability. A process for producing said hot-dip galvanized steel sheet without requiring additional steps of surface grinding and pre-plating.The hot-dip galvanized steel sheet is produced by forming a hot-dip galvanizing layer on a base cold-rolled steel sheet composed of C (0.02-0.20 mass %), Mn (1.50-2.40 mass %), Cr (0.03-1.50 mass %), Mo (0.03-1.50 mass %), 3Mn+6Cr+Mo (no more than 8.1 mass %), Mn+6Cr+10 Mo (no less than 3.5 mass %), Al (0.010-0.150 mass %), and Fe as the principal component, with Ti limited to 0.01 mass % or less, Si limited to 0.04 mass % or less, P limited to 0.060 mass % or less, and S limited to 0.030 mass % or less, and said base steel sheet having the composite microstructure composed mainly of ferrite and martensite.

Owner:KOBE STEEL LTD

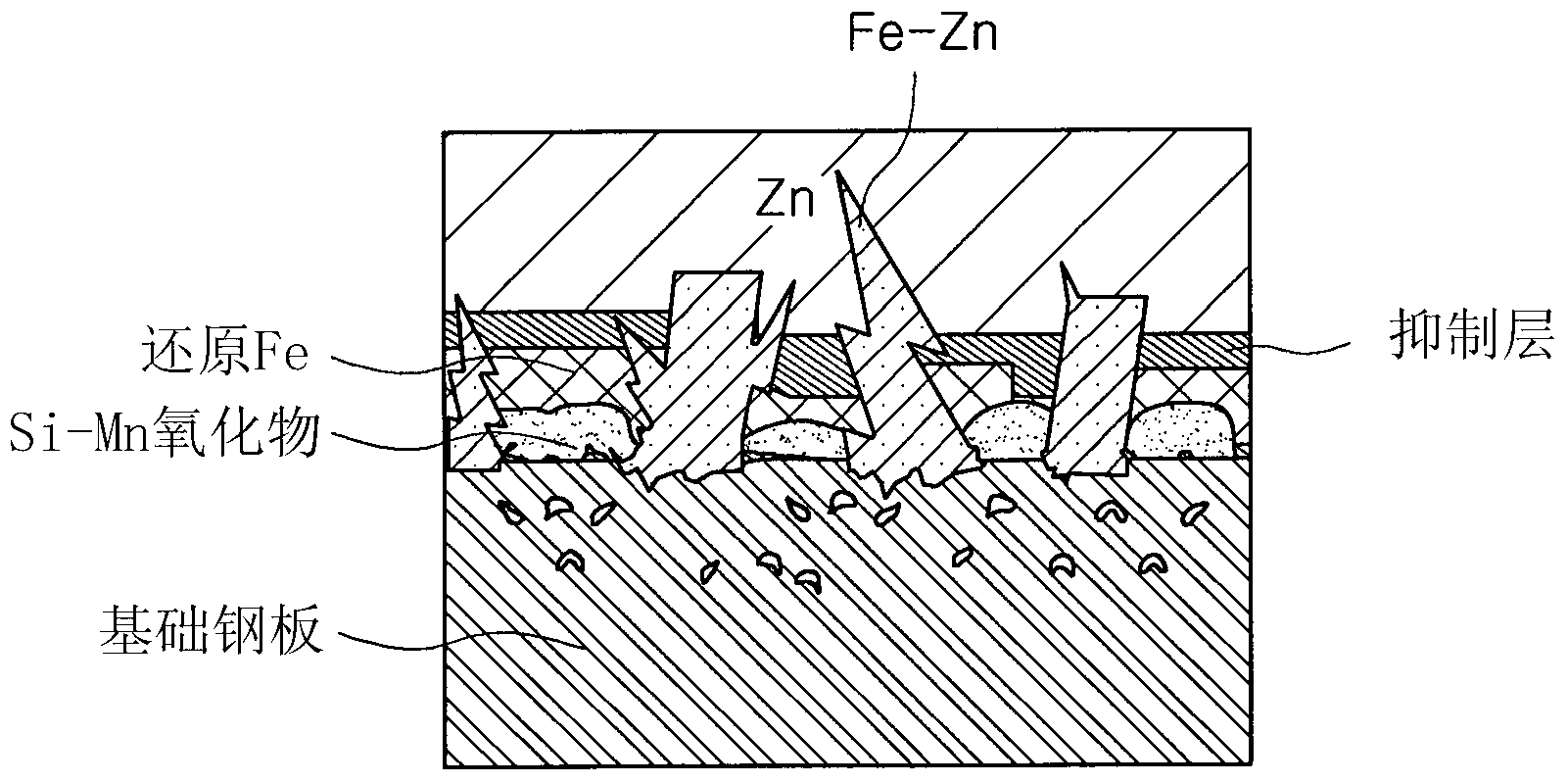

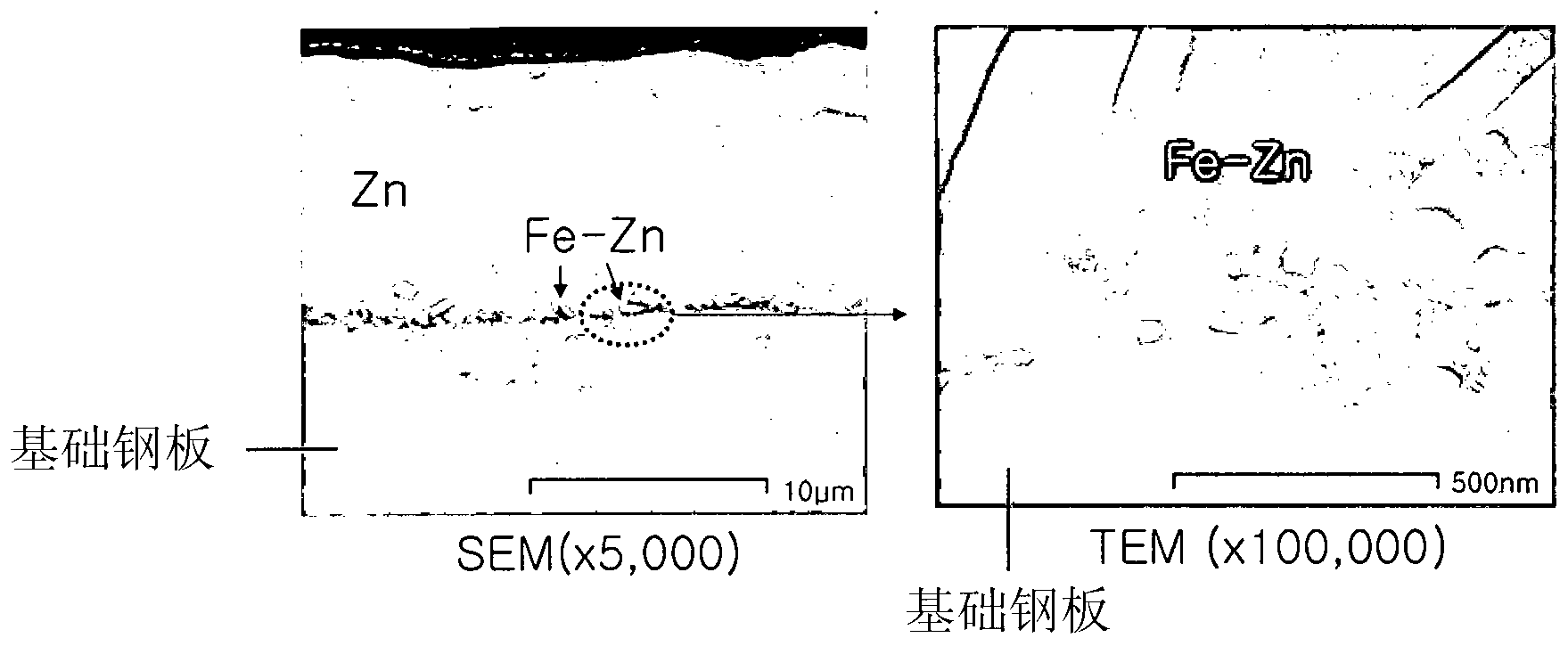

High strength hot dip galvanized steel sheet and high strength galvannealed steel sheet excellent in shapeability and plateability and methods of production and apparatuses for production of the same

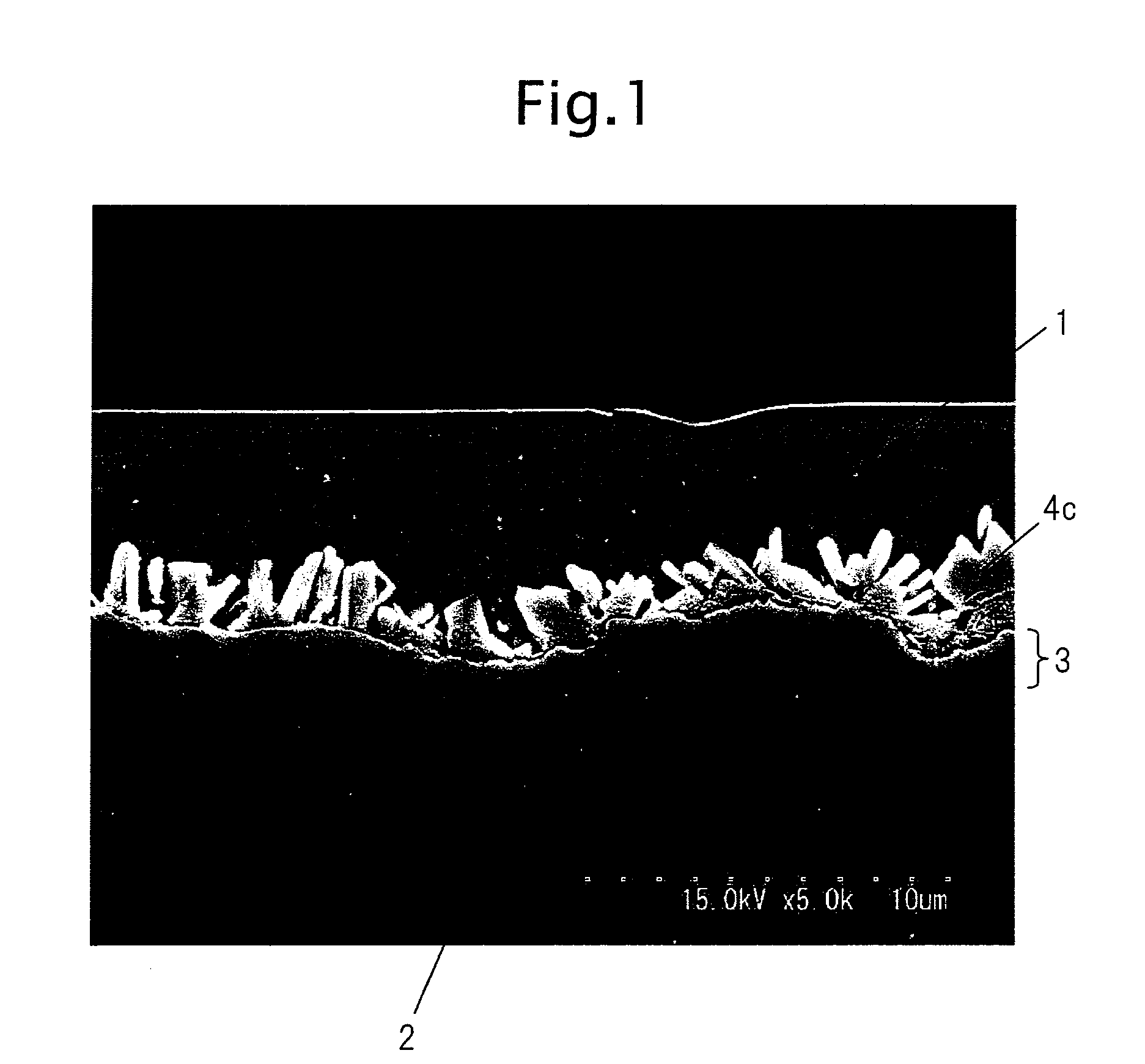

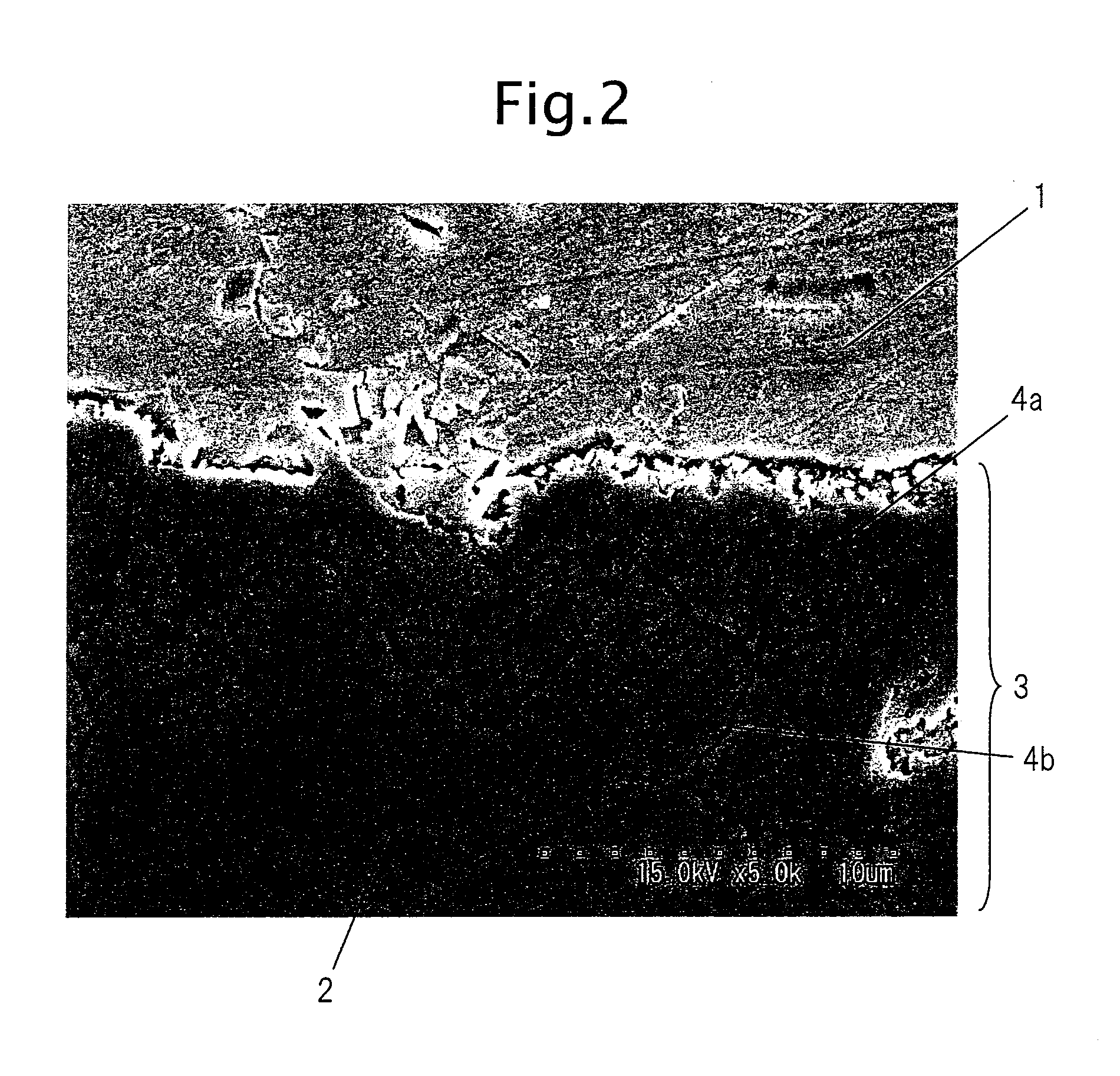

ActiveUS20100304183A1Excellent in shapeability and plateabilityHigh strengthHot-dipping/immersion processesPretreated surfacesOxideHigh intensity

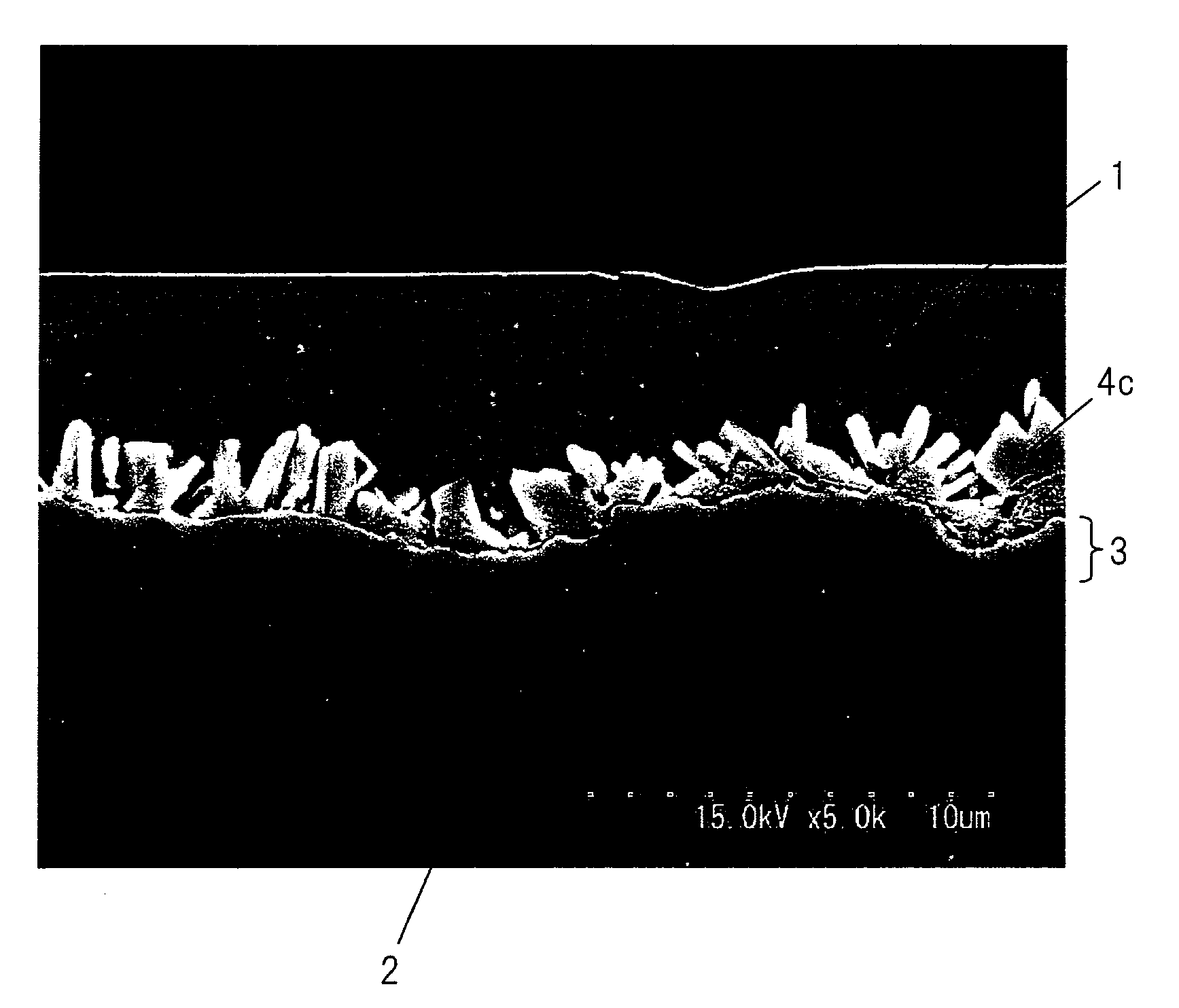

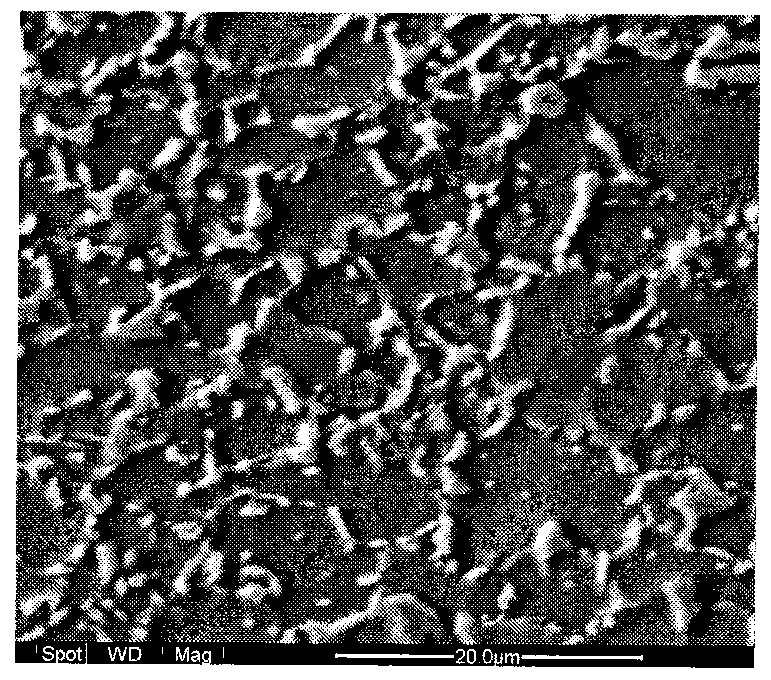

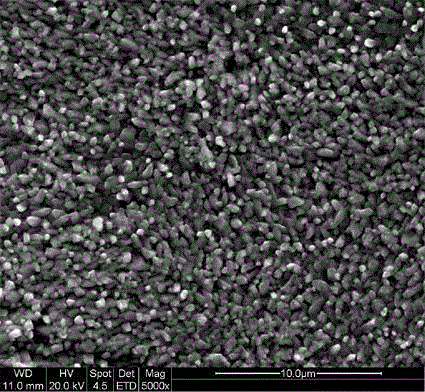

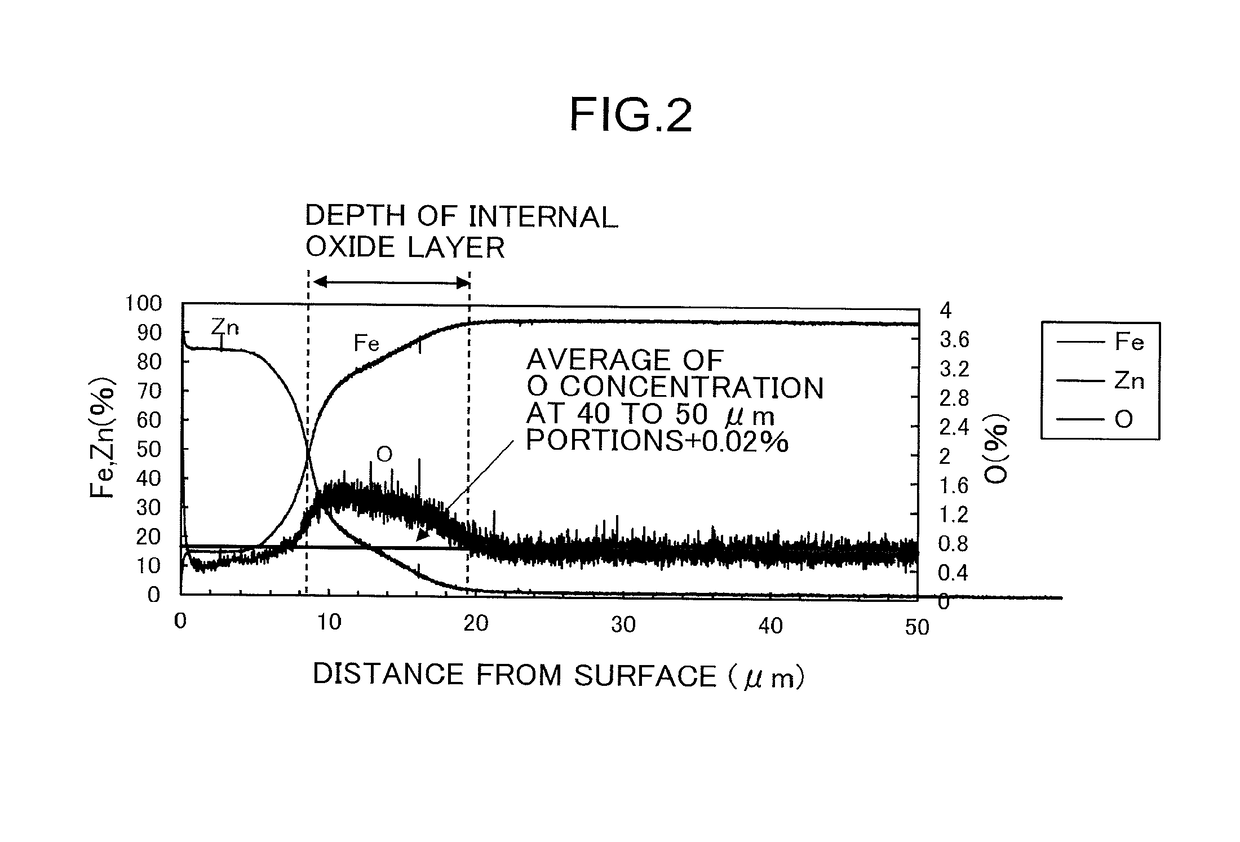

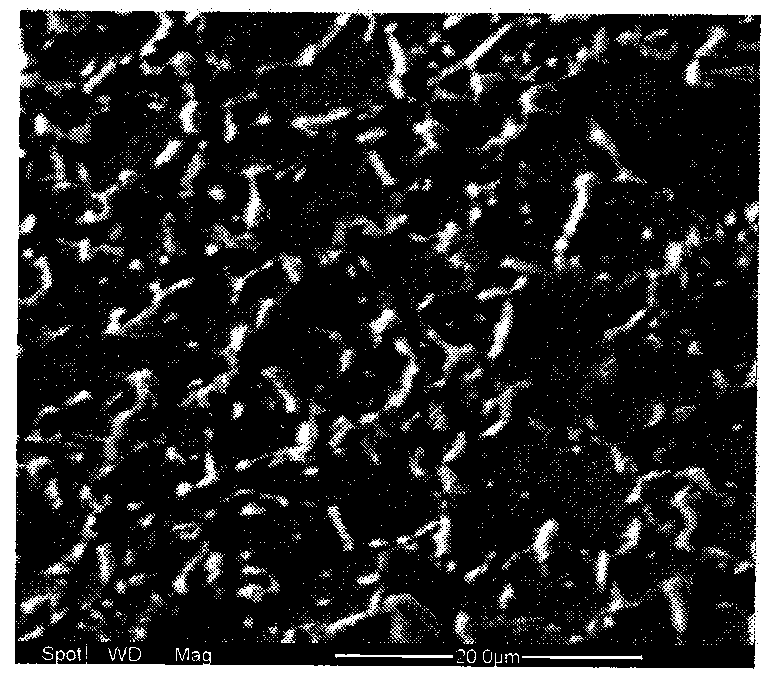

Hot dip galvanized steel sheet excellent in shapeability and plateability comprised of high strength steel sheet according to the present invention can be provided containing, by mass % about, C: 0.05 to 0.25%, Si: 0.3 to 2.5%, Mn: 1.5 to 2.8%, P: 0.03% or less, S: 0.02% or less, Al: 0.005 to 0.5%, N: 0.0060% or less and the balance of Fe and unavoidable impurities. The exemplary steel sheet can have thereon a galvanized layer containing, e.g., about Al: 0.05 to 10 mass % and Fe: 0.05 to 3 mass % and the balance of Zn and unavoidable impurities. Such exemplary hot dip galvanized steel sheet can have oxides containing Si in an average content of about 0.6 to 10 mass % at the crystal grain boundaries and in the crystal grains at the sheet steel side 5 μm or less from the interface between the high strength steel sheet and the plating layer and by the presence of Fe—Zn alloy with an average grain size of about 0.5 to 3 μm at the plating side.

Owner:NIPPON STEEL CORP

Alloyed hot galvanizing bake hardening steel and method for manufacturing same

ActiveCN101230437ANot easy to produceImprove PlatabilityHot-dipping/immersion processesTemperature control deviceCooking & bakingSheet steel

The invention relates to an alloyed hot-galvanized baking-hardened steel plate and the manufacturing method thereof, which solves the problems of the anti-pulverization of the galvanized layer, the surface quality and the baking-hardened value. The mass percentage for the chemical components of a baseplate is as follows: C 0.0015 to 0.0025 percent, Si less than or equal to 0.030 percent, Mn 0.50 to 0.60 percent, P 0.050 to 0.060 percent, S less than or equal to 0.015 percent, N less than or equal to 0.003 percent, sol.Al 0.030 to 0.055 percent, Nb 0.004 to 0.015 percent, O less than or equal to 0.0050 percent and the rest are Fe and unavoidable impurities. The weight of the galvanized layer (for a single side) is 30-60g / m2 and the mass percentage for the Fe component of the galvanized layer is 8 to 12 percent. The steel plate of the invention has excellent anti-pulverization performance of the galvanized layer, excellent surface quality and appropriate baking-hardened value.

Owner:BAOSHAN IRON & STEEL CO LTD

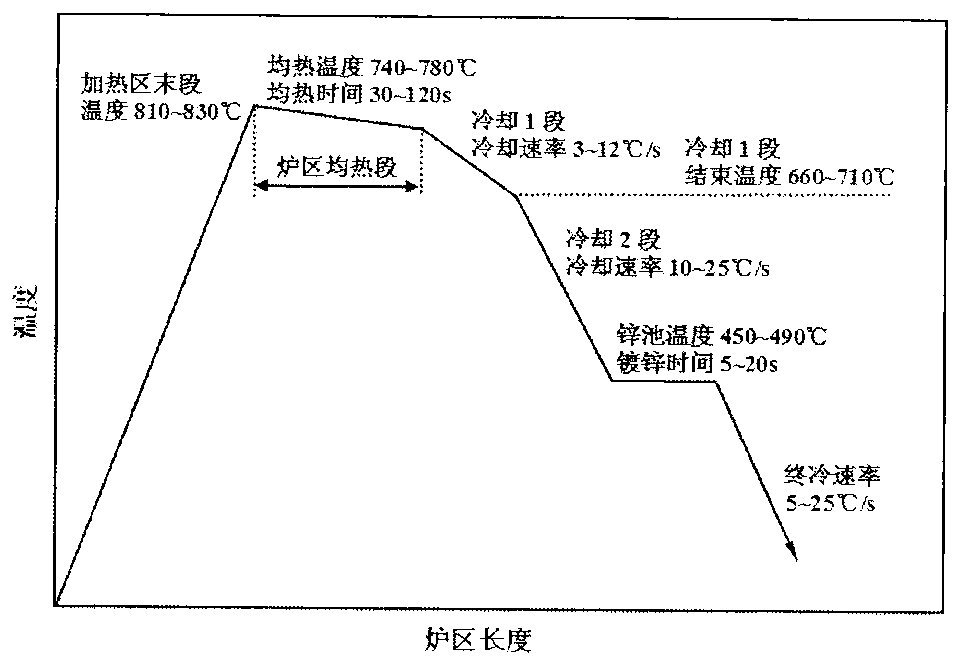

High-strength cold-rolled hot-galvanized dual-phase steel plate and manufacture method thereof

ActiveCN102719751AAdd lessReduce compositionTemperature control deviceContinuous annealingUltimate tensile strength

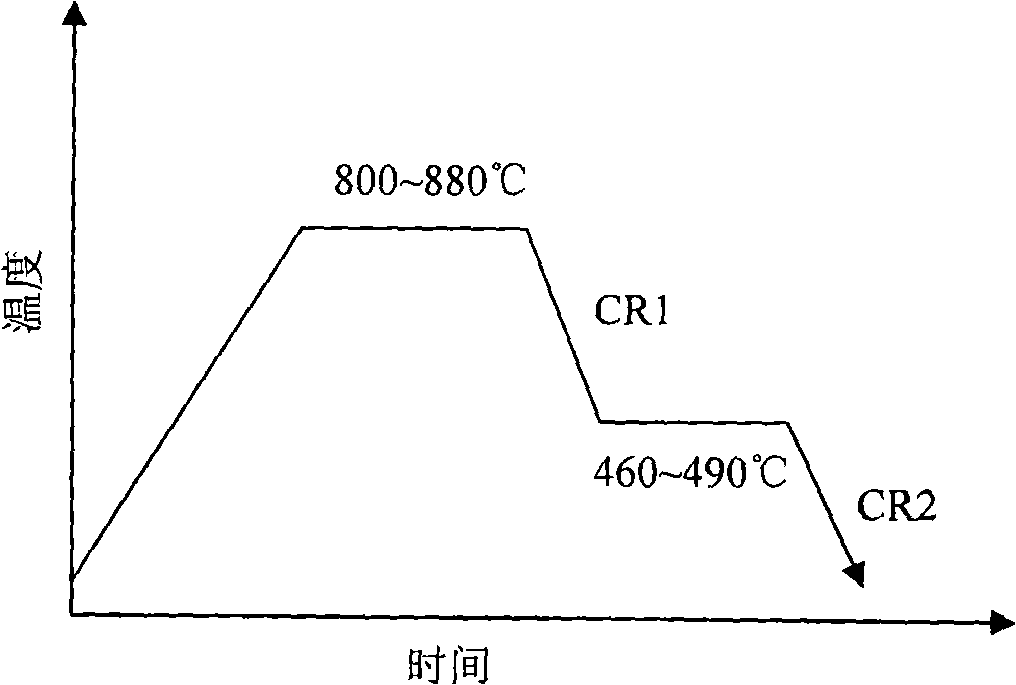

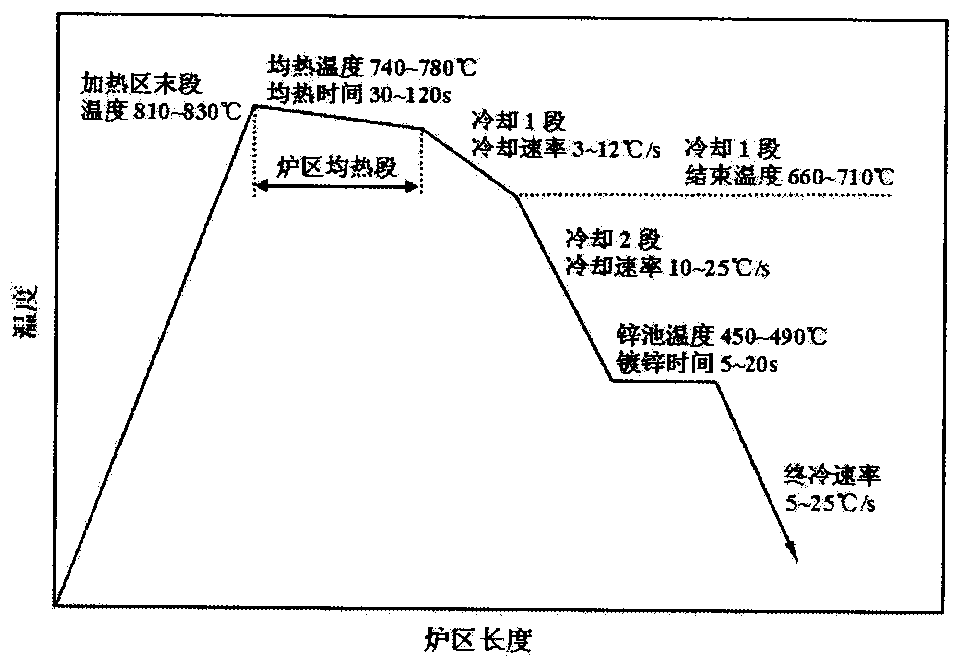

The invention discloses a high-strength cold-rolled hot-galvanized dual-phase steel plate, characterized in that components, in mass percentage, are: 0.03% to 0.15% of C, less than or equal to 0.15% of Si, 1.00% to 1.75% of Mn, less than or equal to 0.015% of P, less than or equal to 0.012% of S, 0.02% to 0.15% of Al, 0.35% to 0.75% of Cr, 0.02% to 0.15% of Cu, 0.010% to 0.035% of Ti, less than or equal to 0.005% of N, in addition meeting the requirement that the total percentage of Mn, 1.29Cr and 0.46Cu is not less than 1.5% and not more than 2.5%, and the balance being Fe and inevitable impurities. The manufacture method comprises converter smelting, secondary refining, continuous casting, hot continuous rolling, cold acid continuous rolling, annealing galvanizing and hot dipping, wherein a galvanized substrate with a reasonable organization and composition and an excellent plate shape is obtained through controlled rolling and controlled cooling while rolling; and through employing a micro-slowly cooling way for heating from an end segment to an isothermal segment and a secondary fast cooling way for a fast cooling segment during continuous annealing galvanizing, the cold-rolled hot-galvanized dual-phase steel plate is obtained, wherein the steel plate is advantageous by having a tensile strength between 490 to 700 MPa, well-matched strength and ductility, an excellent coating performance, and a thickness between 0.5 to 2.5 mm, and can be used as an automobile cover component, an inner plate, a structural component, etc.

Owner:ANGANG STEEL CO LTD

TRIP steel plate for high strength cold rolling hot dip galvanizing and preparation thereof

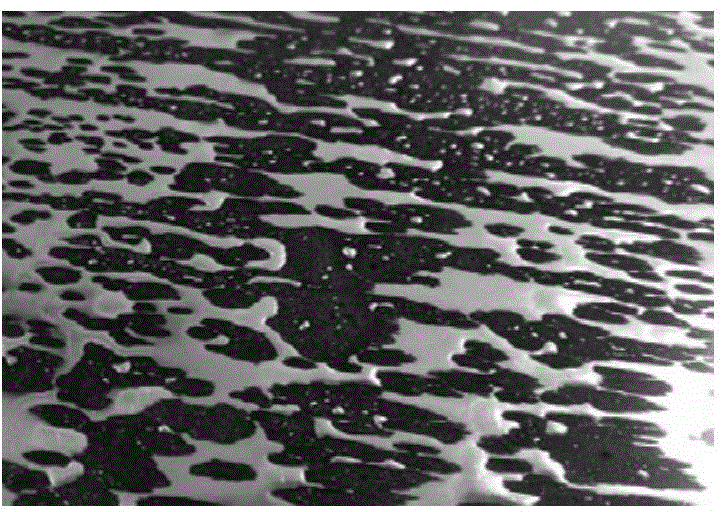

InactiveCN101353761AImprove PlatabilityGood coating performanceHot-dipping/immersion processesSheet steelTRIP steel

The invention pertains to the metal material processing field and particularly provides a TRIP steel sheet used for high-strength cold rolling and hot galvanizing and a manufacturing method thereof. The TRIP steel sheet comprises the following components: 0.1wt percent to 0.4wt percent of C, not more than 0.06wt percent of Si, 0.5wt percent to 2.5wt percent of Mn, 0.5wt percent to 2.0wt percent of Al, not more than 0.03wt percent of P, not more than 0.02wt percent of S, 0.01wt percent to 0.10wt percent of Nb, 0.01wt percent to 0.10wt percent of Ti, 0.1wt percent to 1.0wt percent of Cu, 0.1wt percent to 0.6wt percent of Ni and the rest is iron. Through the measures of controlling the content of the elements such as C, Mn, Nb and Ti in the steel, and the temperature and time of hot rolling, reeling, cold rolling, annealing and the like, the comprehensive performance of the TRIP steel sheet is improved. Compared with the traditional TRIP steel, the TRIP steel sheet has the following advantages of: 1) good platability: due to the low silicon adopted, the requirements of the plating layer of hot plated pure zinc and alloy plated zinc can be met to obtain the plating layer with good performance; and 2) good grain refining effect: due to Nb micro-alloying, grain can be effectively refined.

Owner:UNIV OF SCI & TECH BEIJING +1

Nb, Ti alloyed low-carbon high-intensity high-plasticity TWIP steel and preparation method thereof

ActiveCN102312158AExcellent overall performanceBroad application prospectsSteel platesManufacturing sector

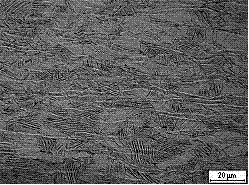

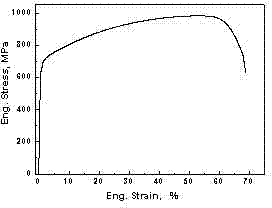

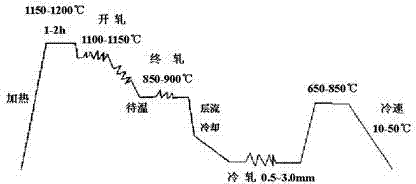

The invention, belonging to the field of high-intensity alloy steel, relates to a preparation method of a Nb, Ti alloyed low-carbon high-intensity high-plasticity twinning induced plasticity (TWIP) steel. The steel comprises the following ingredients: 0.05-0.10 wt% C, 23.5-27 wt% of Mn, 0.01-0.03wt% of Si, at most 1.0 wt% of Al, at most 0.01 wt% of P, at most 0.02 wt% of S, 1.0-2.5 wt% of Nb, 0.5-1.25 wt% of Ti, 0.02 -0.08 wt% of N, and the balance consisting of Fe and inevitable impurities. The preparation method comprises the following steps: melting the ingredients and then casting into a casting blank, heating the casting blank and then carrying out hot rolling at the opening rolling temperature of 1100-1150 DEG C with multiple passes and small press quantity to obtain the accumulated deformation degree of more than 60 % at the temperature of more than 950 DEG C, processing the casting blank in a finishing rolling mode at the temperature of 850-900 DEG C, after the hot rolling, rapidly cooling to 400-550 DEG C for reeling, carrying out cold rolling on the steel plate processed by hot rolling with the thickness of 0.5-3.0 mm, preserving the steel plate processed by cold rolling at the temperature of 650-850 DEG C for 3-30 min, and then rapidly cooling to room temperature with the cooling rate of 10-50 DEG C / s. The material prepared by the method can be applied in automobile manufacturing industry. The material has the yield strength of more than 550 MPa and the elongation rate of no less than 60 %, thereby obviously improving the ability of anti-collision and impact of automobile for the first time and greatly increasing the crashworthiness indexes.

Owner:SHANGHAI JIAO TONG UNIV

Copper alloy for electronic machinery and tools and method of producing the same

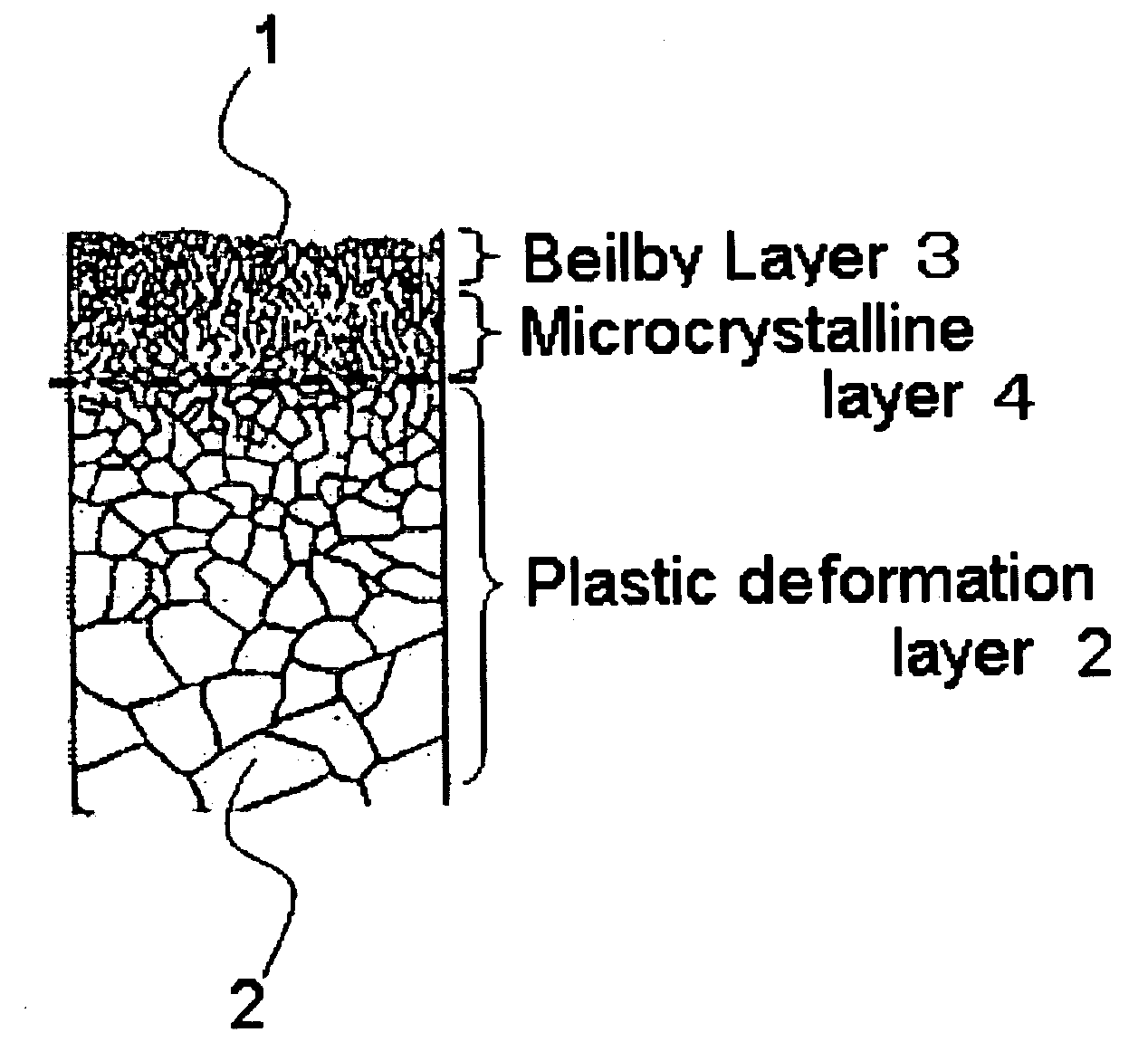

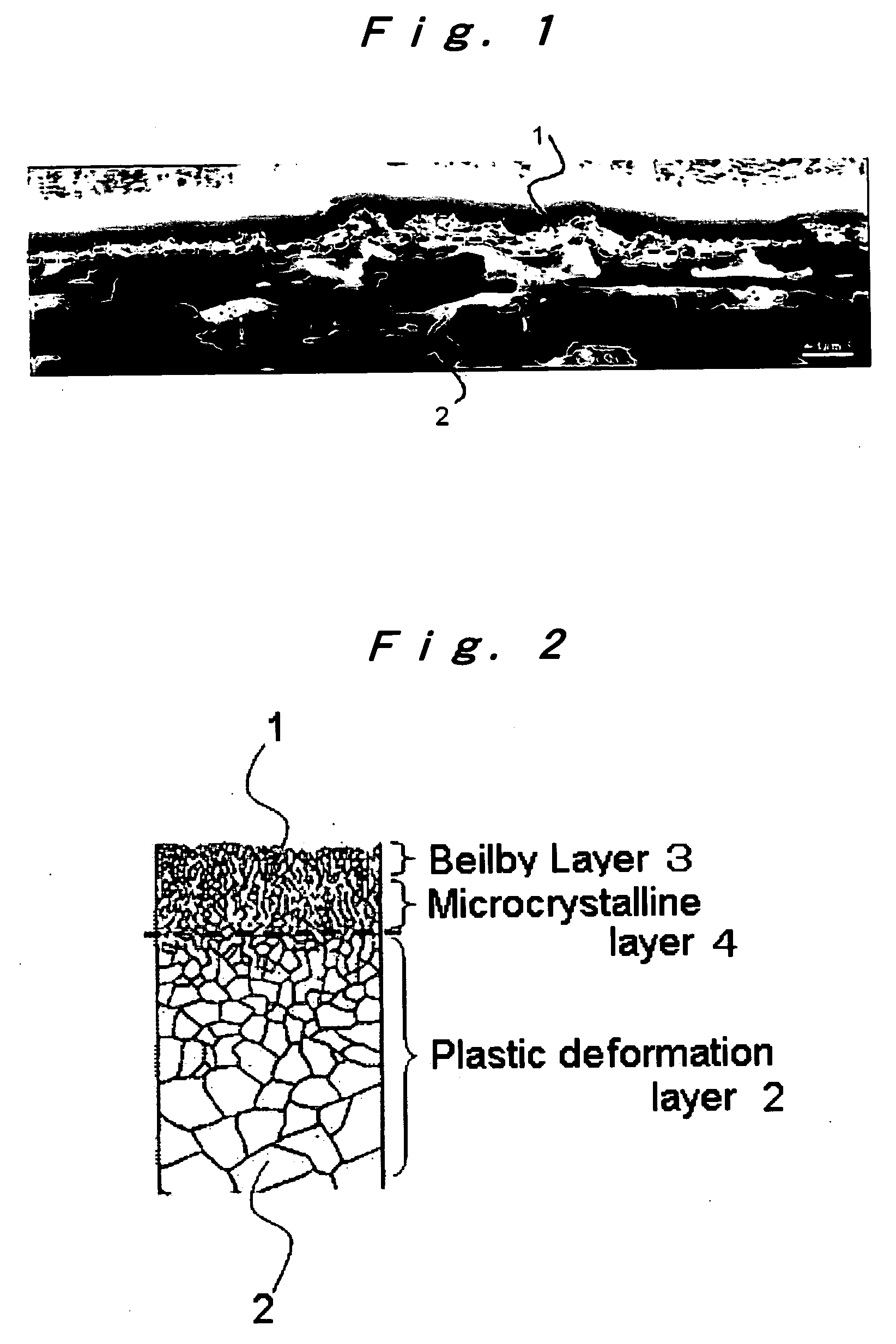

InactiveUS20070015001A1Improve PlatabilityReduce adhesionWave amplification devicesThermometers using material expansion/contactionSurface layerMetallurgy

A copper alloy for electronic machinery and tools, having a surface layer of a work affected layer whose thickness is 0.2 μm or below; and a method of producing the same.

Owner:FURUKAWA ELECTRIC CO LTD

450 MPa-level zinc-plated dual-phase steel for sedan and production method thereof

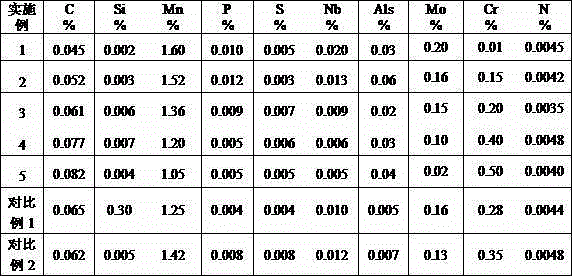

ActiveCN105369135AUniform surface color without defectsUniform color without defectsHot-dipping/immersion processesBall impactLevels zinc

450 MPa-level zinc-plated dual-phase steel for a sedan comprises components in percentage by weight as follows: 0.04%-0.09% of C, smaller than or equal to 0.01% of Si, 1.0%-2.0% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, 0.01%-0.08% of Als, 0.01%-0.30% of Mo, 0.01%-1.0% of Cr, 0.001%-0.03% of Nb and smaller than or equal to 0.005% of N. The production steps comprise heating of a casting blank after smelting, refining and continuous casting; finish rolling; reeling; cold rolling after acid pickling; hot galvanizing; finishing. The mechanical properties of a product are shown as follows: the yield strength is 260-320 MPa, the tensile strength is 470-510 MPa, the elongation percentage is 28%-33%, and the n value is 0.17-0.19; the product has good platability, the surface of a plating has uniform glossiness and doesn't have defects, an inhibition layer is continuous and compact, the adhesion of the zinc-plated layer reaches the first level of ball impacting, the bending test proves that the zinc-plated layer and base steel are qualified, and surface quality requirements of an intermediate car for a high-strength structural part and an outer covering part can be met.

Owner:武汉钢铁有限公司

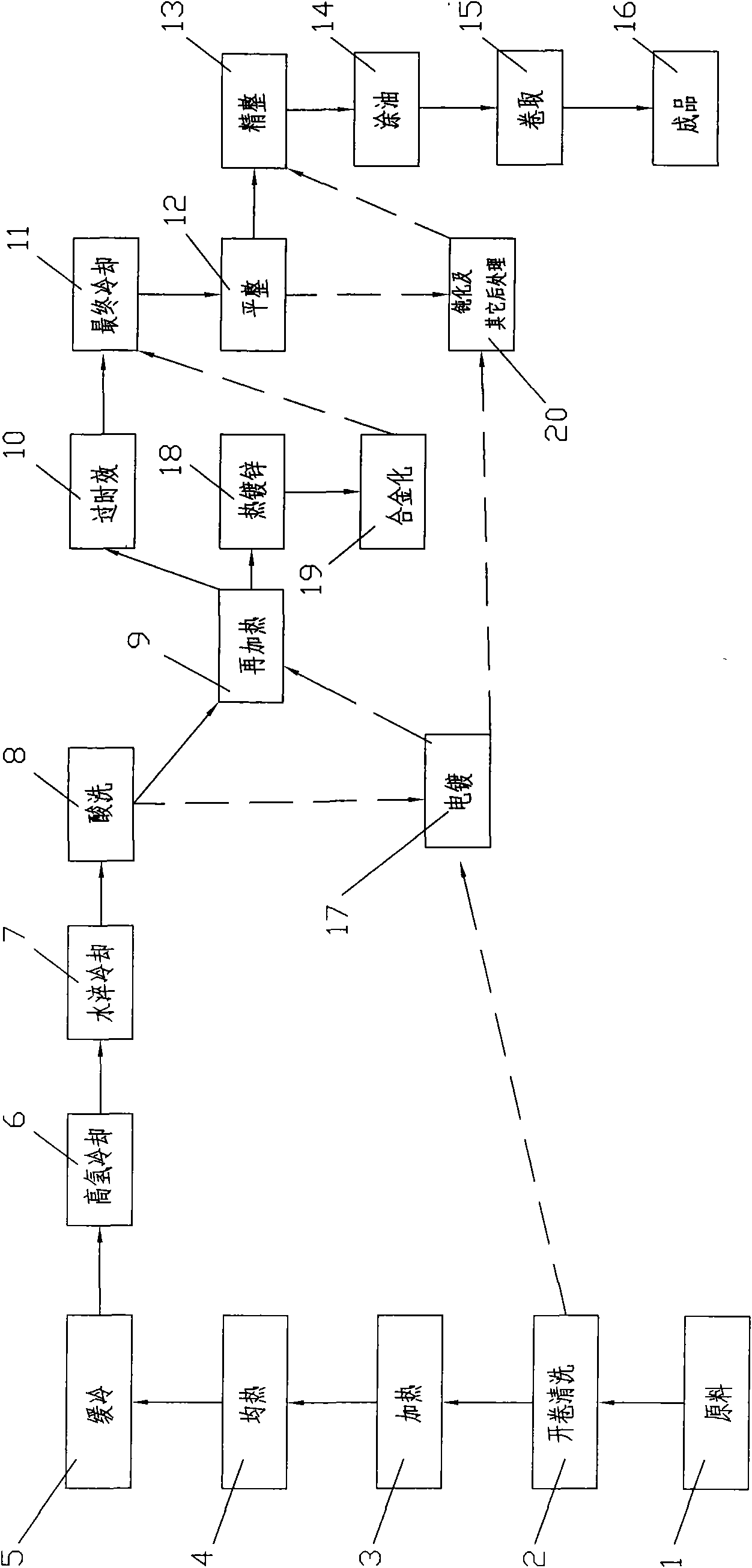

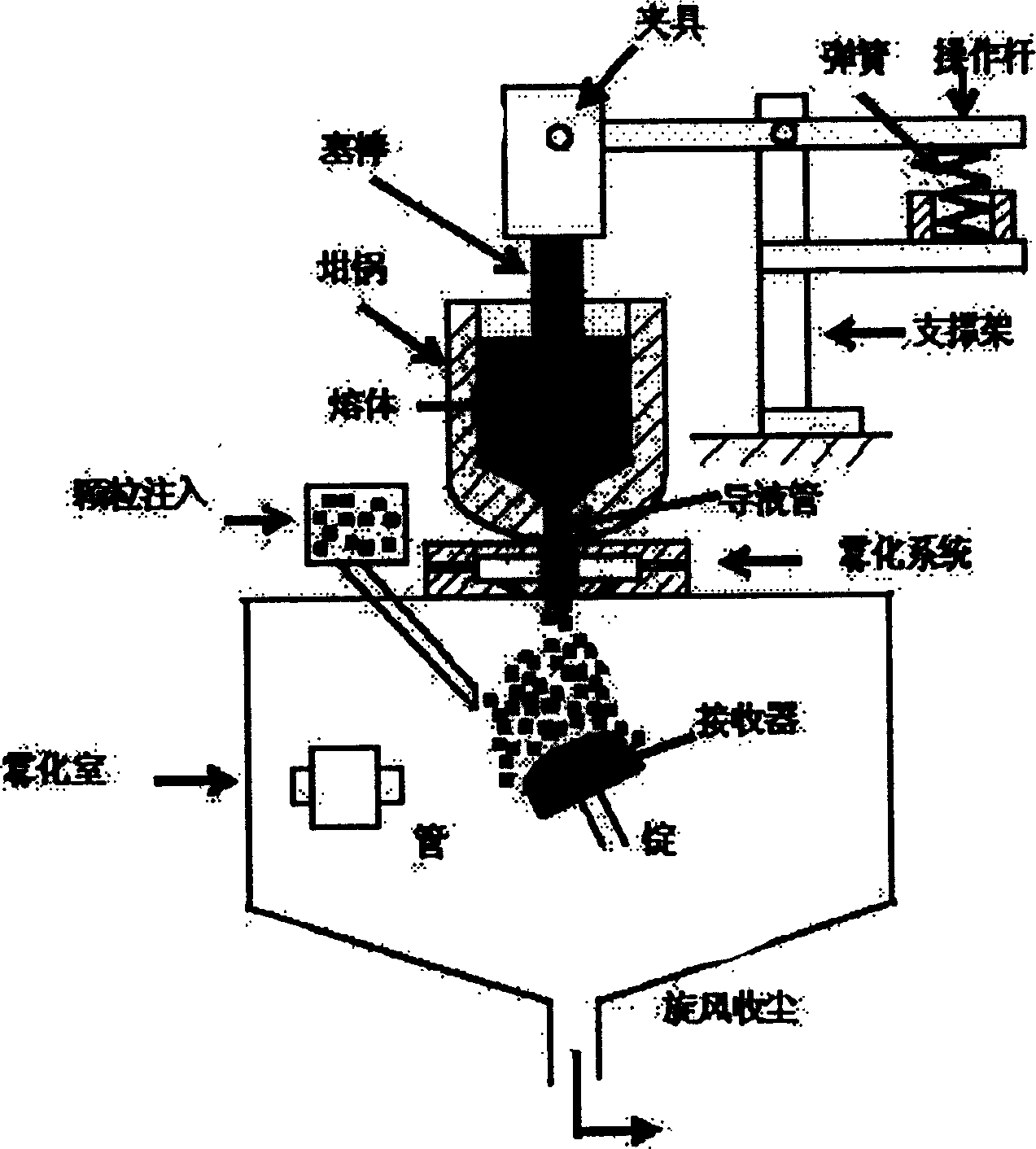

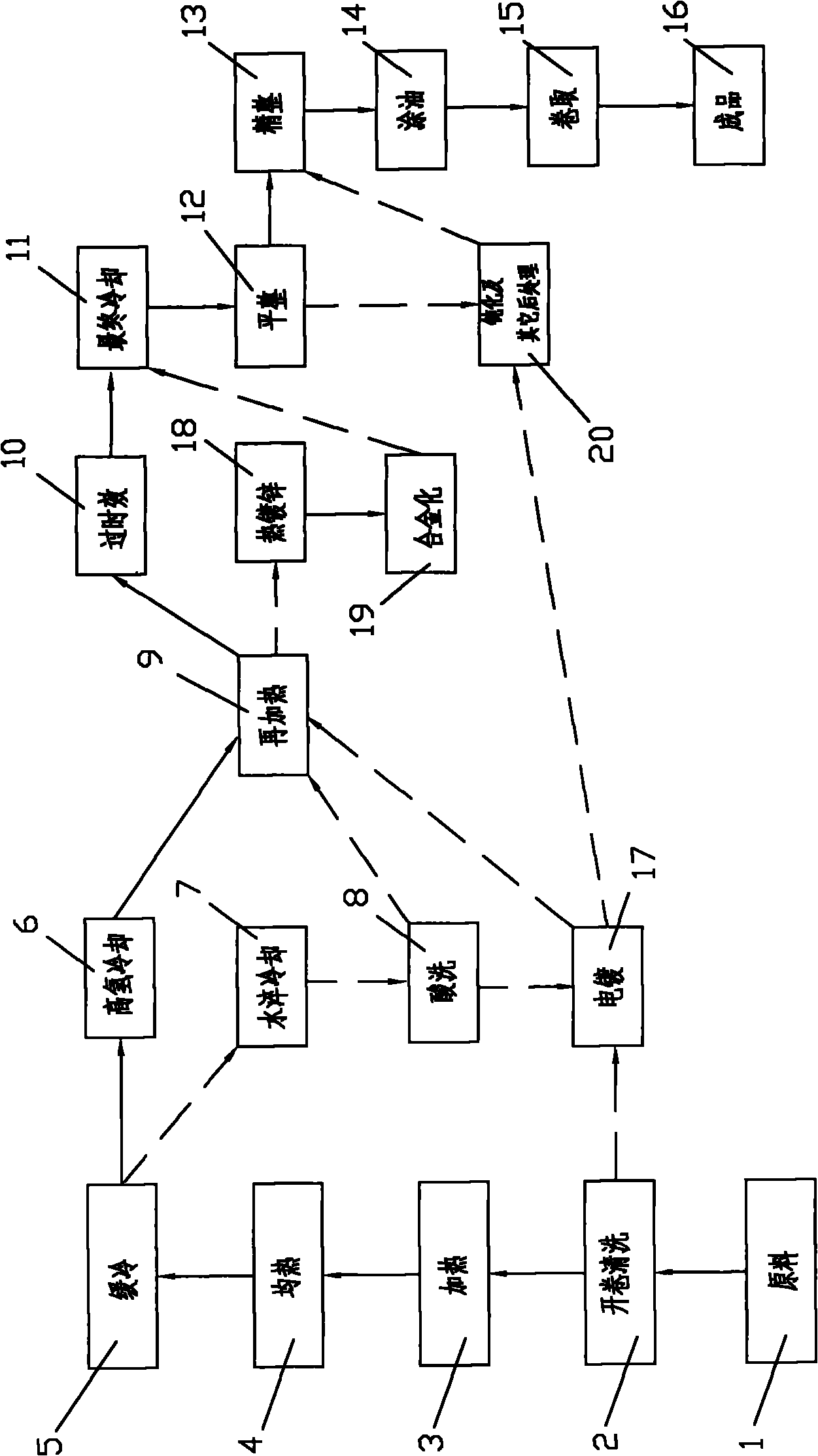

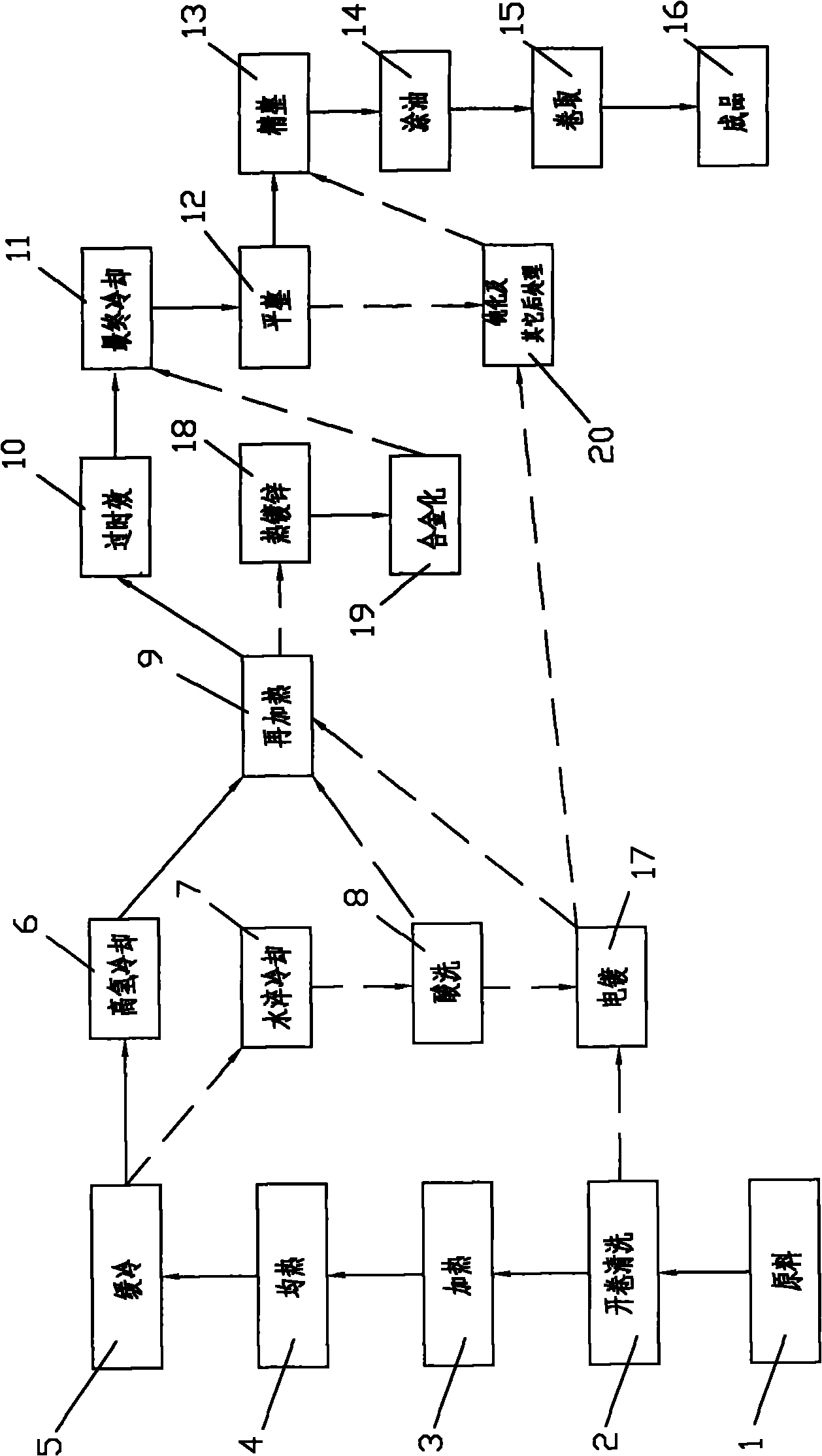

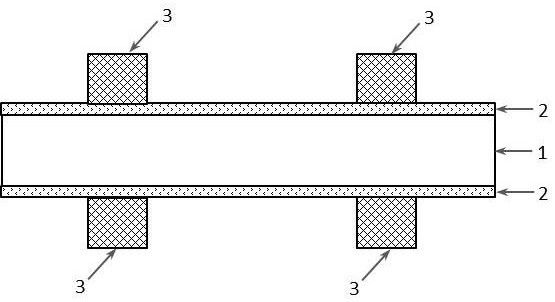

Flexible strip processing line suitable for producing various high-strength steel

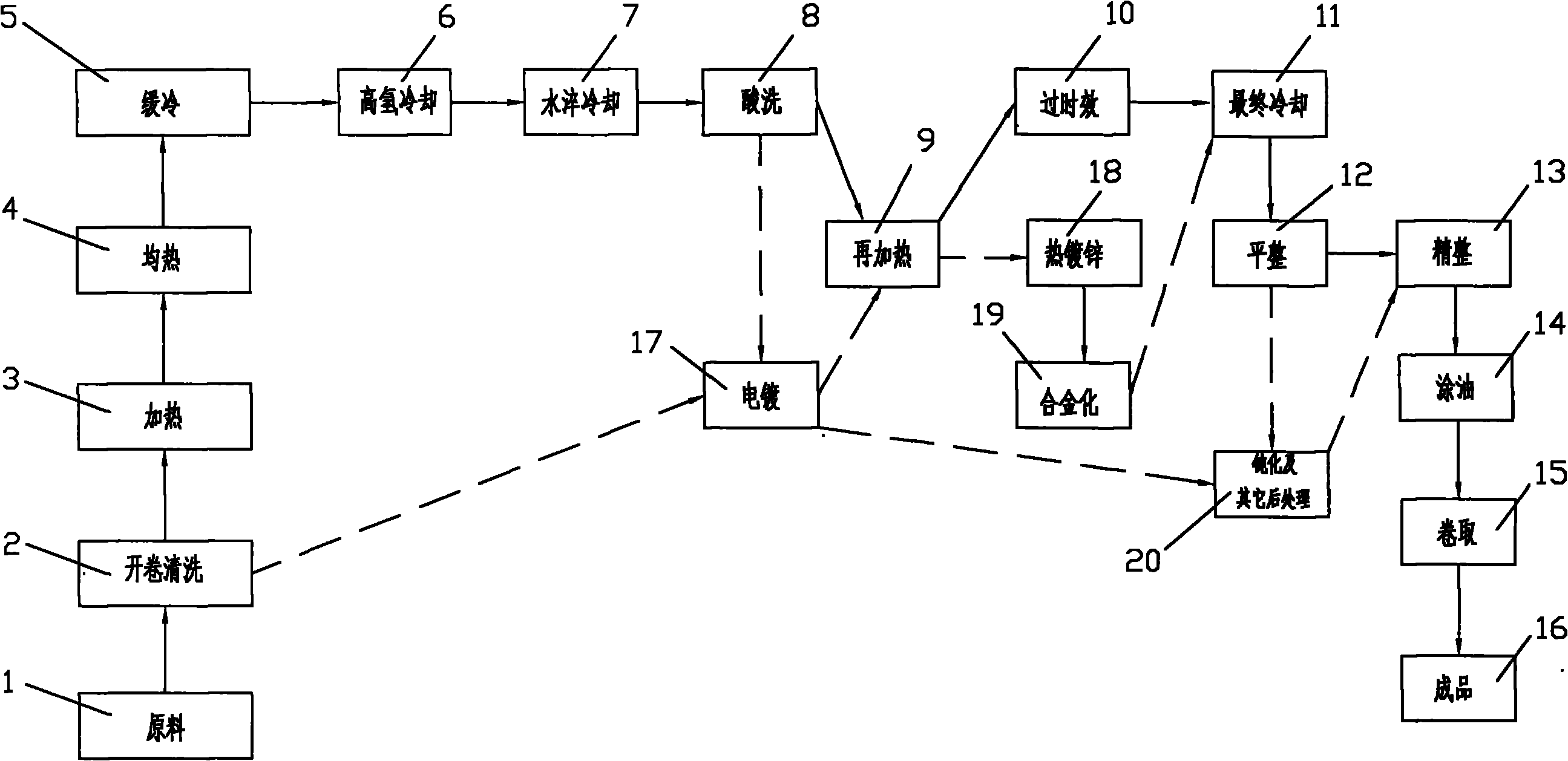

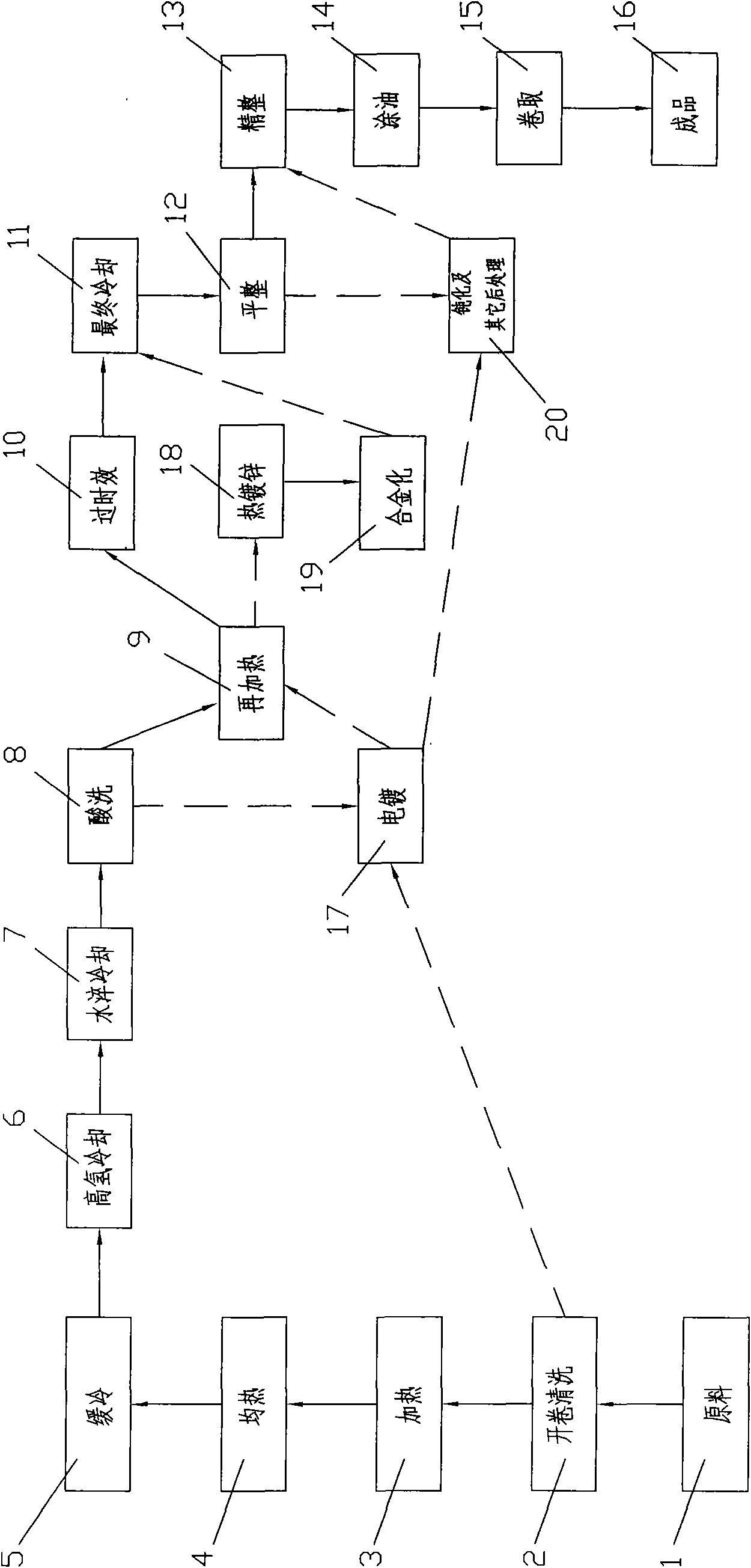

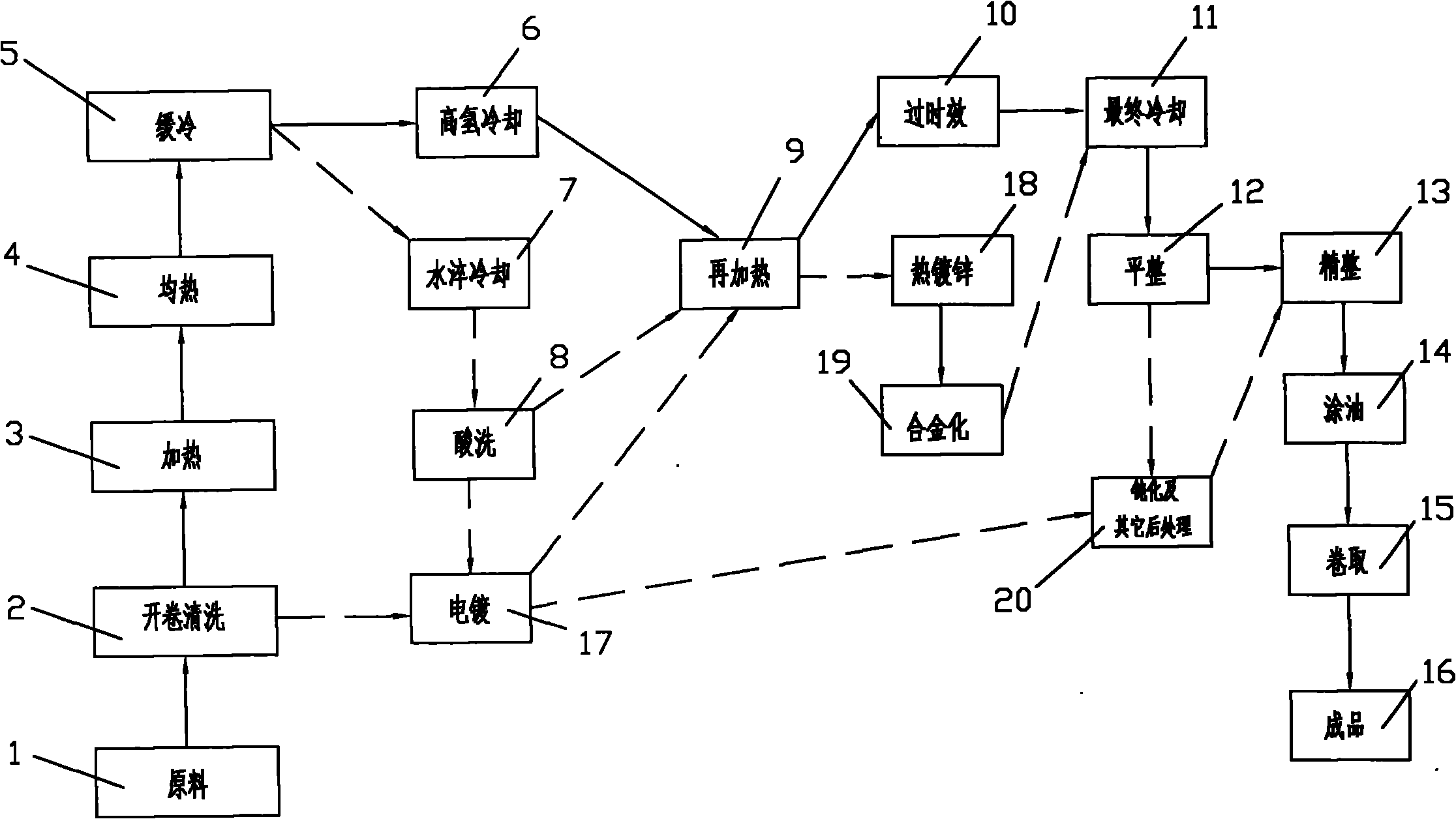

ActiveCN101812578ARich product varietyReduce manufacturing costHot-dipping/immersion processesFurnace typesElectroplatingSlow cooling

The invention discloses a flexible strip processing line suitable for producing various high-strength steel, which has the following configuration: decoiling, cleaning, heating, soaking and slow cooling stations are arranged sequentially to a gas jet cooling station and a water quenching cooling station; a reheating station is arranged on the rear of the gas jet cooling station; an overaging station or hot galvanizing station and coating normalizing and annealing station are arranged on the rear of the reheating station, and a movable bypass channel is connected with the reheating and overaging stations; then, final cooling and leveling stations are arranged, and oiling or passivating and other postreatment stations are connected to a coiling station so as to obtain finished products; an acid pickling and electroplating stations are arranged corresponding to the water quenching cooling station; and a connecting channel is arranged on the rear of the electroplating station, and is correspondingly connected with the reheating or directly connected with the passivating station and other posttreatment stations. The flexible strip processing line integrates production of common cold-rolled sheets, and hot dip galvanized and coating alloying annealed sheets and electroplating of Zn and Ni sheets, particularly superstrength cold-rolled sheets, galvanized sheets and hot dip galvanized and coating alloying annealed sheets to one machine set so as to realize flexible production.

Owner:BAOSHAN IRON & STEEL CO LTD

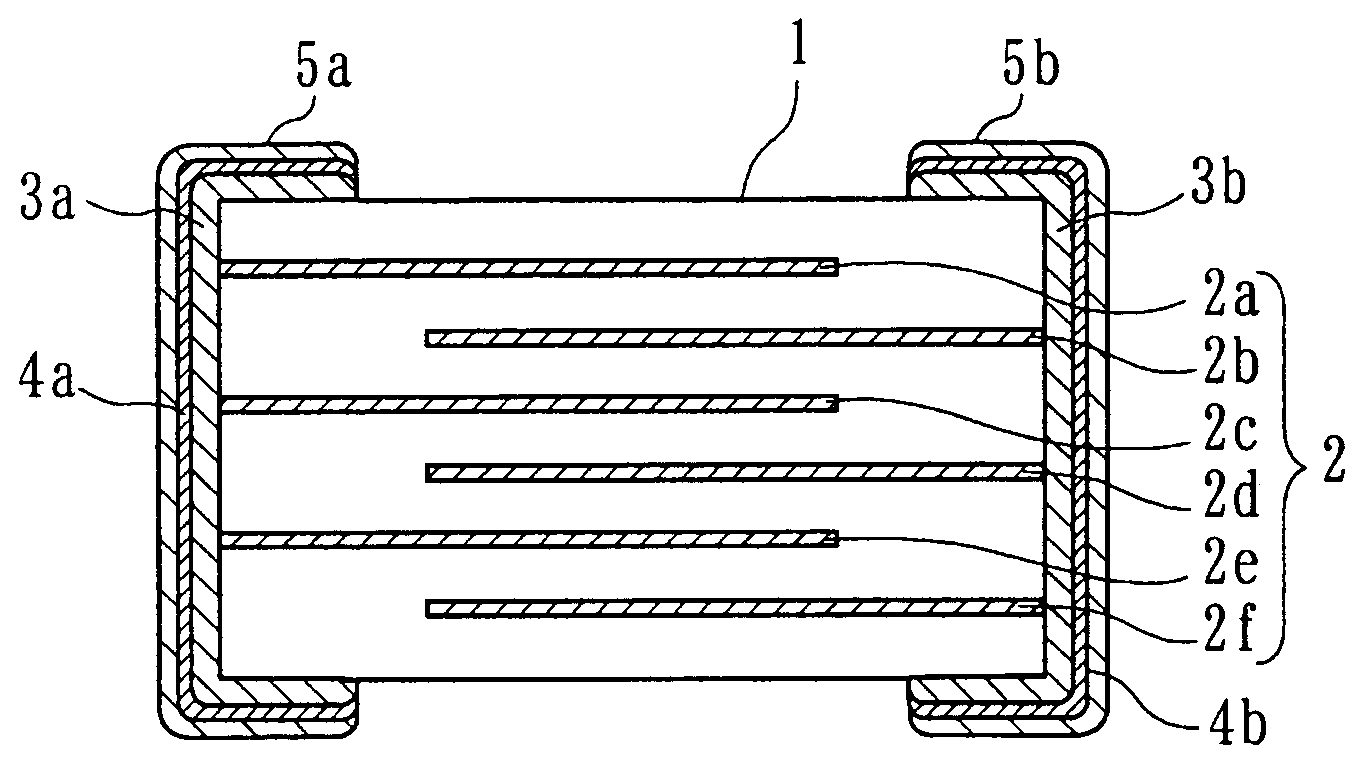

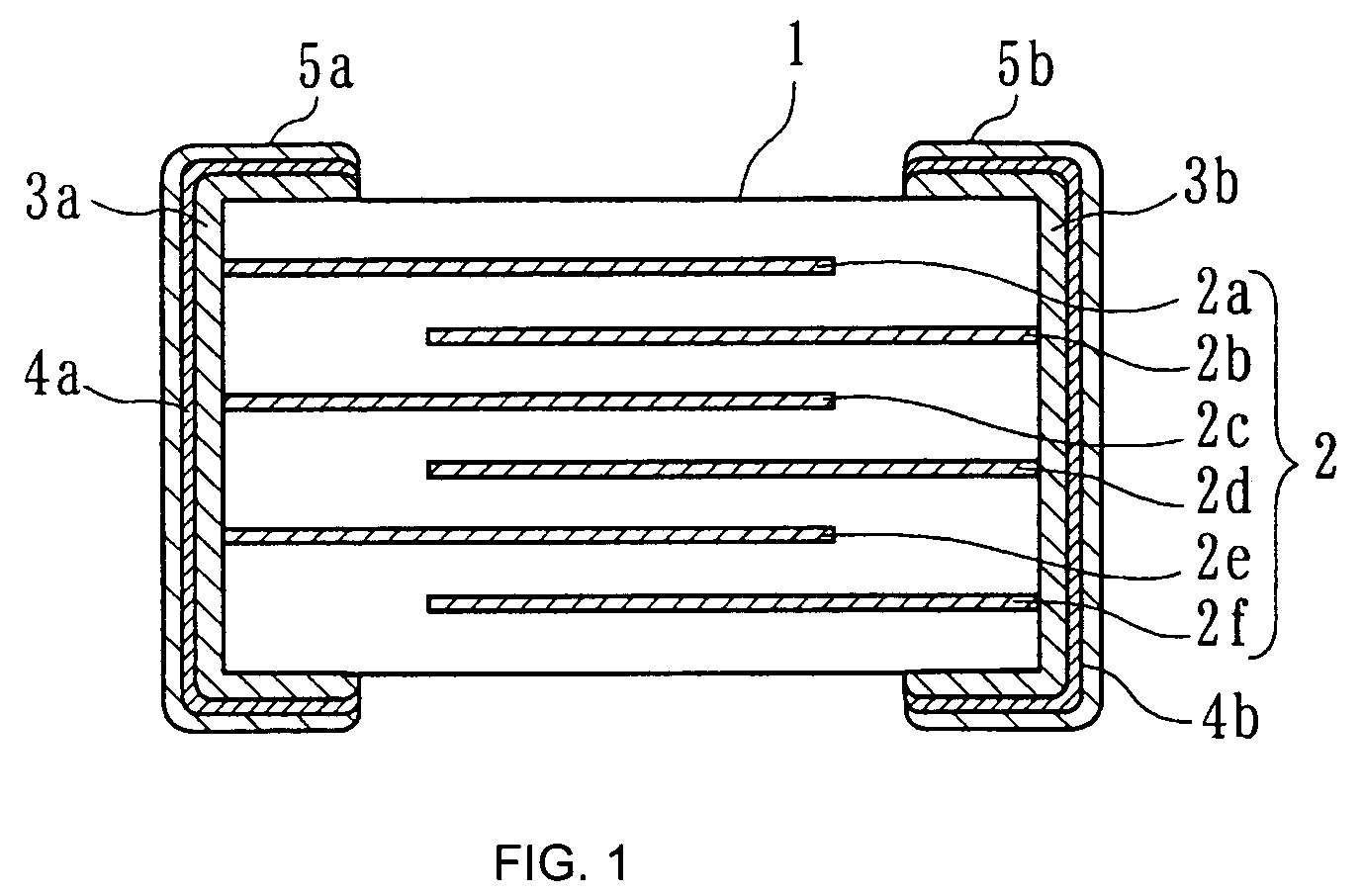

End-blocking slurry for flaky component

InactiveCN101728002AImprove process performanceAcid resistantConductive materialNon-conductive material with dispersed conductive materialElectrical conductorSlurry

The invention relates to an end-blocking slurry for a flaky component, which is prepared from the following raw materials in percentage by mass: 40 to 55 percent of silver powder, 4 to 15 percent of glass powder, 5 to 25 percent of inorganic filler and 20 to 40 percent of organic carrier, wherein the silver powder comprises the following silver powder in percentage by mass in the slurry: 25 to 40 percent of flaky silver powder and 15 to 30 percent of spherical silver powder. The end-blocking slurry has the advantages that: (1) the content of silver is low so as to reduce the cost of the slurry and improve the market competitiveness of the products, and 300 RMB can be saved in 1 kg of the slurry; (2) lead is not contained in the slurry, which is in favor of environmental protection; (3) a compact and flat conductor layer is formed at the end head of a substrate without pit and bulge after the processes of dipping the silver, drying and sintering, so the platability is good, the adhesive force is strong, and the glass is acid resistant. The slurry has good process use characteristics and is suitable to be used in the industries for generating the flaky components.

Owner:贵阳晶华电子材料有限公司

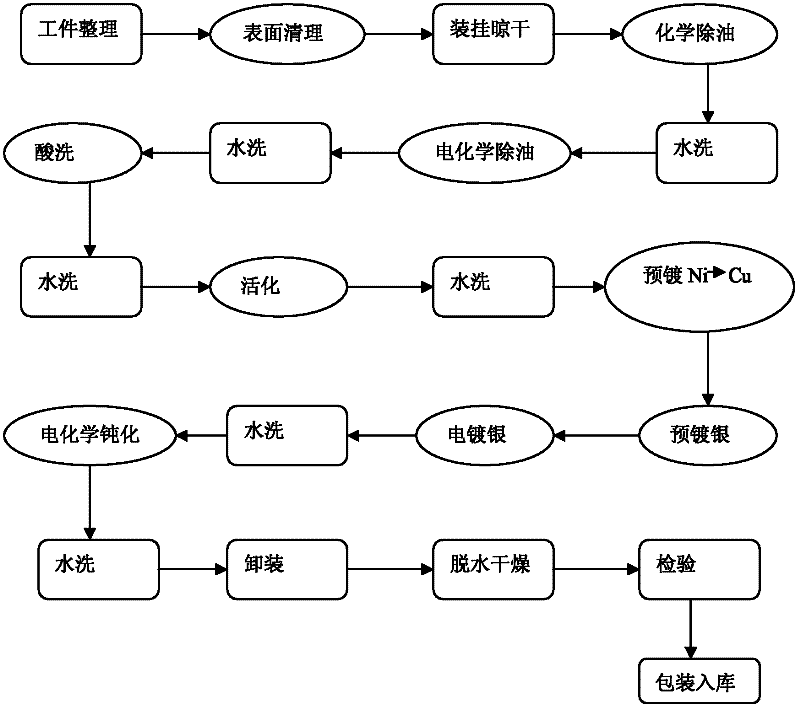

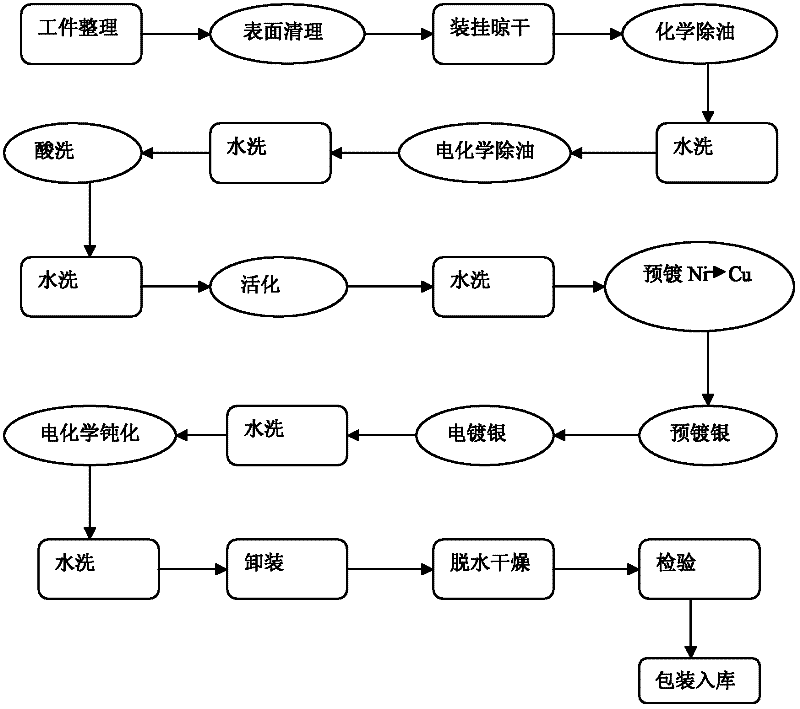

Method for silvering kovar alloy interconnection piece

The invention relates to a method for silvering a kovar alloy interconnection piece. The method comprises the following steps of 1, carrying out surface screening and wiping cleaning, 2, carrying out combined oil removal, 3, carrying out pickling and activation, 4, carrying out pre-plating treatment, 5, carrying out pre-silvering, 6, carrying out silver electroplating, and 7, carrying out electrochemical passivation. The method is characterized in that the step 3 is utilized for preparing pickle and an activation solution and carrying out pickling and activation; the step 4 is utilized for impacting nickel and plating copper on a bottom layer; and the step 7 is utilized for preparing a passivation aqueous solution and carrying out electrochemical passivation. The method has the advantages that 1, a kovar alloy is utilized as a base material of an interconnection piece for a cell array so that a production technology is simplified and a cost is reduced; and 2, on the basis of a cyaniding silver-electroplating technology, through further optimization of activation solution preparation, a pre-plating treatment method and passivation treatment, the requirements on atomic oxygen resistance, electrical conductivity and solderability of an interconnection piece are satisfied; after high / low temperature circulation, tensile strength is great than or equal to 0.83N / mm<2>; a yield is high; and the characteristics of mass production feasibility and cell array service life improvement are obtained.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

High manganese hot-dip galvanized steel sheet containing rare earth and manufacture method thereof

The invention relates to a high manganese hot-dip galvanized steel sheet containing rare earth and a manufacture method thereof. The high manganese hot-dip galvanized steel sheet comprises the following chemical components by chemical component: 0.4-0.8% of C, 14-20% of Mn, 0.05-0.15% of RE, less than or equal to 0.020% of P, less than or equal to 0.012% of S, 1.0-2.0% of Al, 0.01-0.03% of N, and the balance of Fe and unavoidable impurity, and Mn+20*C are greater than or equal to 30%, and Al+5*Re are greater than or equal to 1.8%. The method employs a cold rolling-continuous annealing for pickling-galvanizing technology, the steel plate yield strength is 450-650 MPa, the tensile strength is 980-1100 MPa, the elongation percentage is more than 50%, structure under room temperature is 100% of austenite, the recrystallization fraction is 80-95%, the delayed cracking performance is good, and the steel sheet has superhigh strength and high mouldability. The steel sheet is especially suitable for vehicle structural members and safety members with high shaping performance and corrosion resistance as well as complex shapes, such as side door beam, bumpers, floor tunnels, various beams and b columns.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel elastic conductive alloy and its preparing method

The present invention relates to one kind of elastic conductive alloy and its preparation process. The alloy consists of Cu, Ni, Sn and rare earth element Y in certain proportion, and its preparation process includes smelting mother alloy, spraying deposited blank, rolling to deform, ageing and other steps. The alloy of the present invention has not only high strength, high hardness, high elasticity, good weldability, good platability and other advantages, but also excellent heat stress relaxation resistance, good conducting stability and excellent technological performance. It may be used in electronic industry to replace beryllium bronze in making various precise instrument elements.

Owner:TONGJI UNIV

Conductive paste and ceramic electronic component

ActiveUS7285232B2Improve PlatabilityHigh densityThin/thick film capacitorCurrent responsive resistorsConductive pasteMetallurgy

A conductive paste contains conductive powder, glass powder and an organic vehicle. The glass powder contains about 10% to 31% of B2O3, about 65% to 86% of SiO2, and more than about 0.5% to less than about 5% of M2O on a weight basis, wherein M represents an alkali metal element. A ceramic electronic component includes a ceramic element and an external conductor placed on the component element. The external conductor contains a glass component containing about 10% to 31% of B2O3, about 65% to 86% of SiO2, and more than about 0.5% to less than about 5% of M2O on a weight basis, wherein M represents an alkali metal element.

Owner:MURATA MFG CO LTD

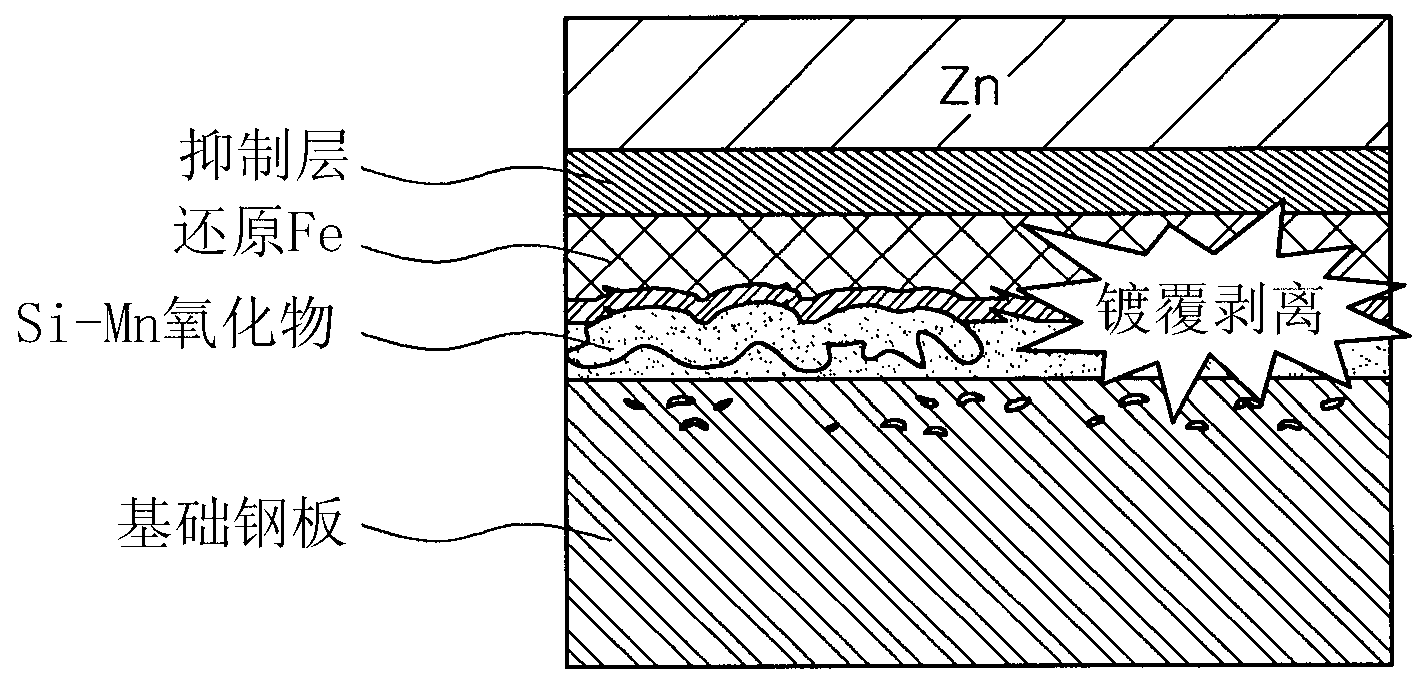

Hot dip plated steel sheet having excellent plating adhesiveness and method of manufacturing the same

InactiveCN103282532AImprove PlatabilityImprove adhesionHot-dipping/immersion processesThin material handlingSheet steelManganese

Provided is a hot dip plated steel sheet used in automotive materials and a method of manufacturing the same, and more particularly, to a hot dip plated steel sheet having excellent platability and plating adhesiveness in which a steel sheet containing alloying elements forming oxides on a surface of the steel sheet at high temperatures is used as an underlying steel sheet, and a method of manufacturing the same. According to the present invention, a hot dip plated steel sheet having excellent platability and plating adhesiveness is provided, in which a steel sheet containing alloying elements forming oxides on a surface of the steel sheet at high temperatures is used as an underlying steel sheet, and thus, limitations in added amounts of silicon (Si), manganese (Mn), or aluminum (Al) may be mitigated. Therefore, development of new steels may be accelerated.

Owner:POHANG IRON & STEEL CO LTD

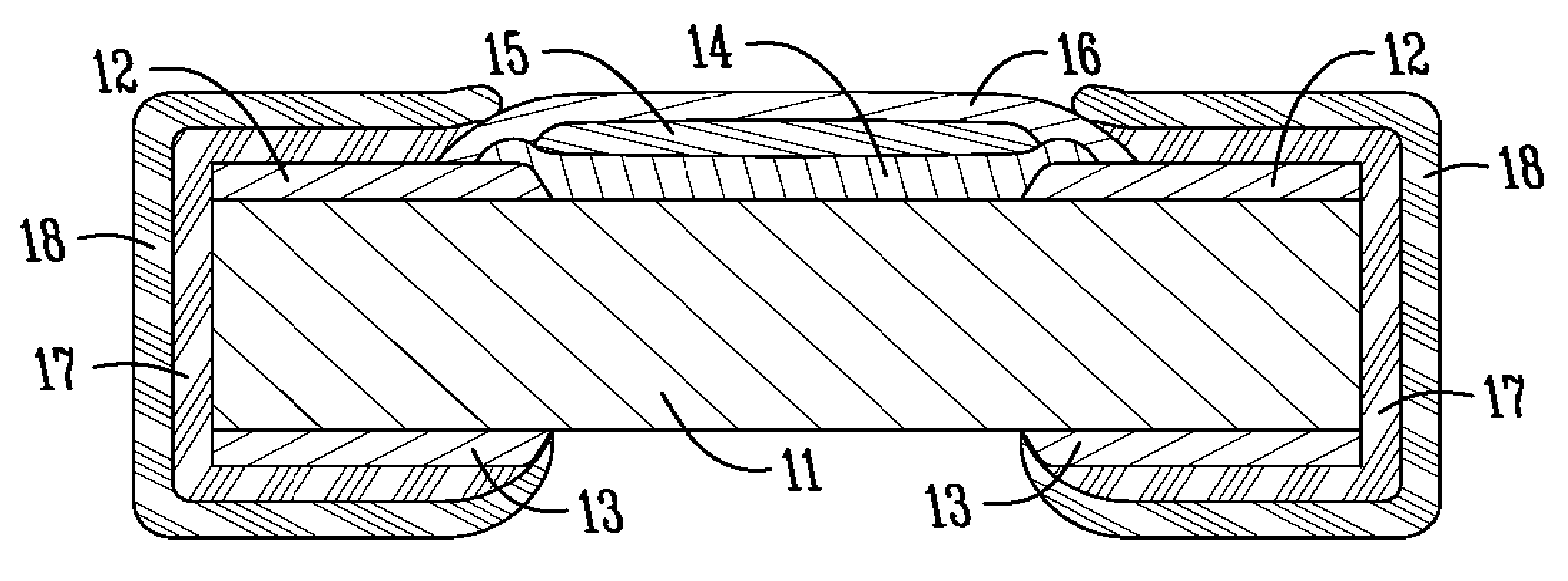

Sulfuration resistant chip resistor and method for making same

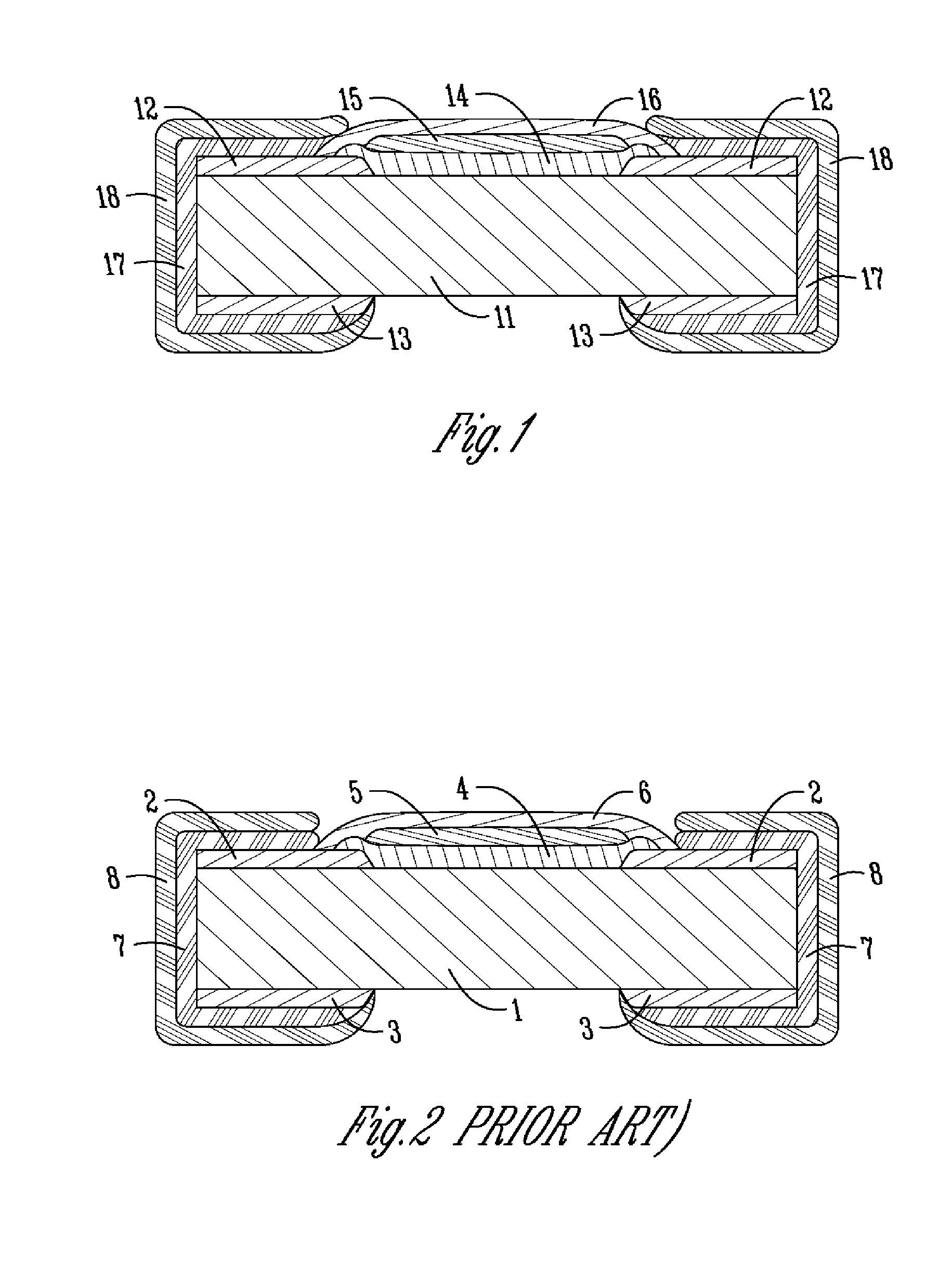

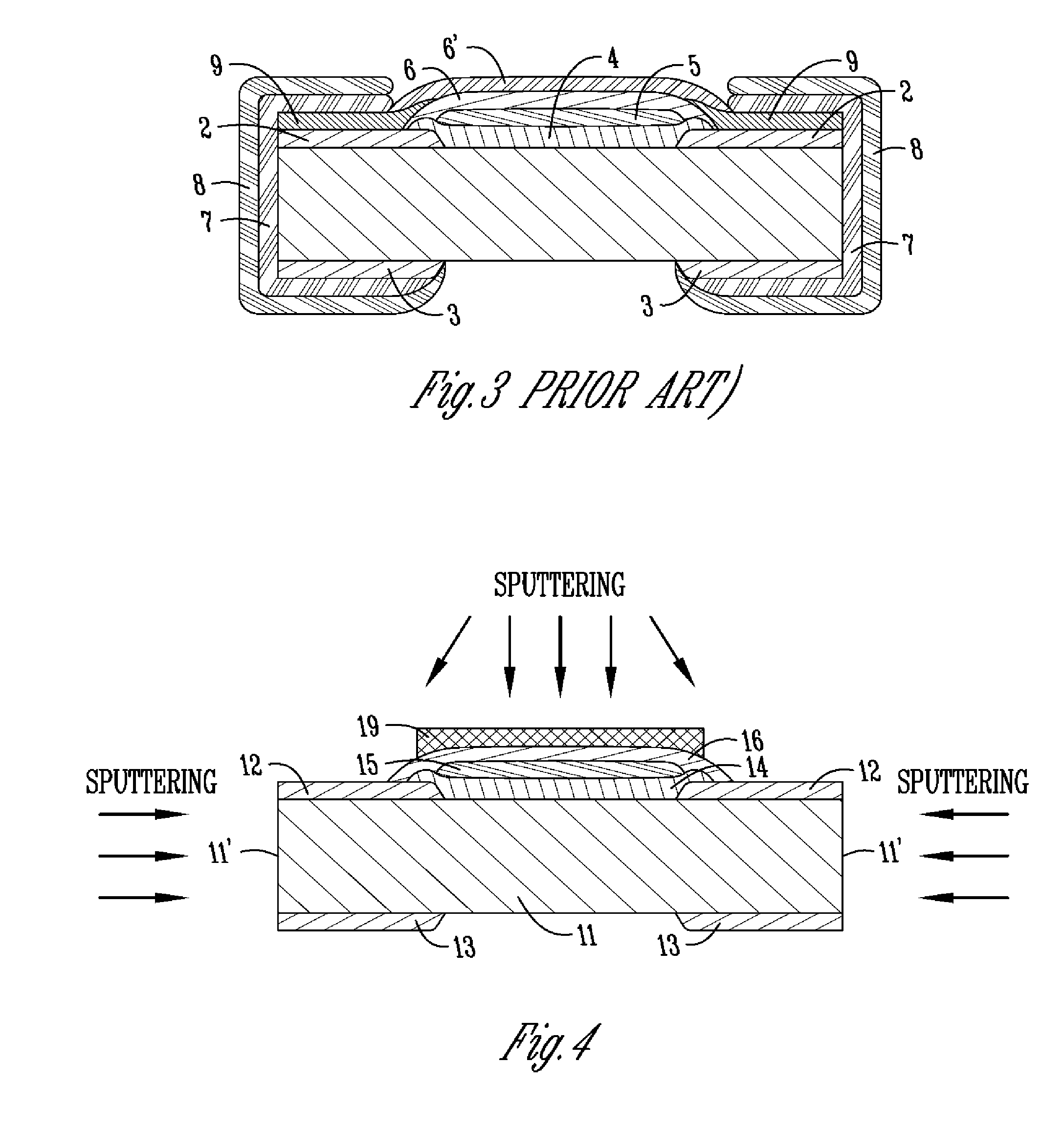

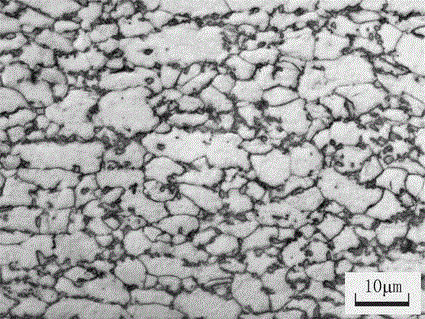

ActiveUS7982582B2Improve PlatabilityResistor manufactureResistor detailsProtection layerResistive element

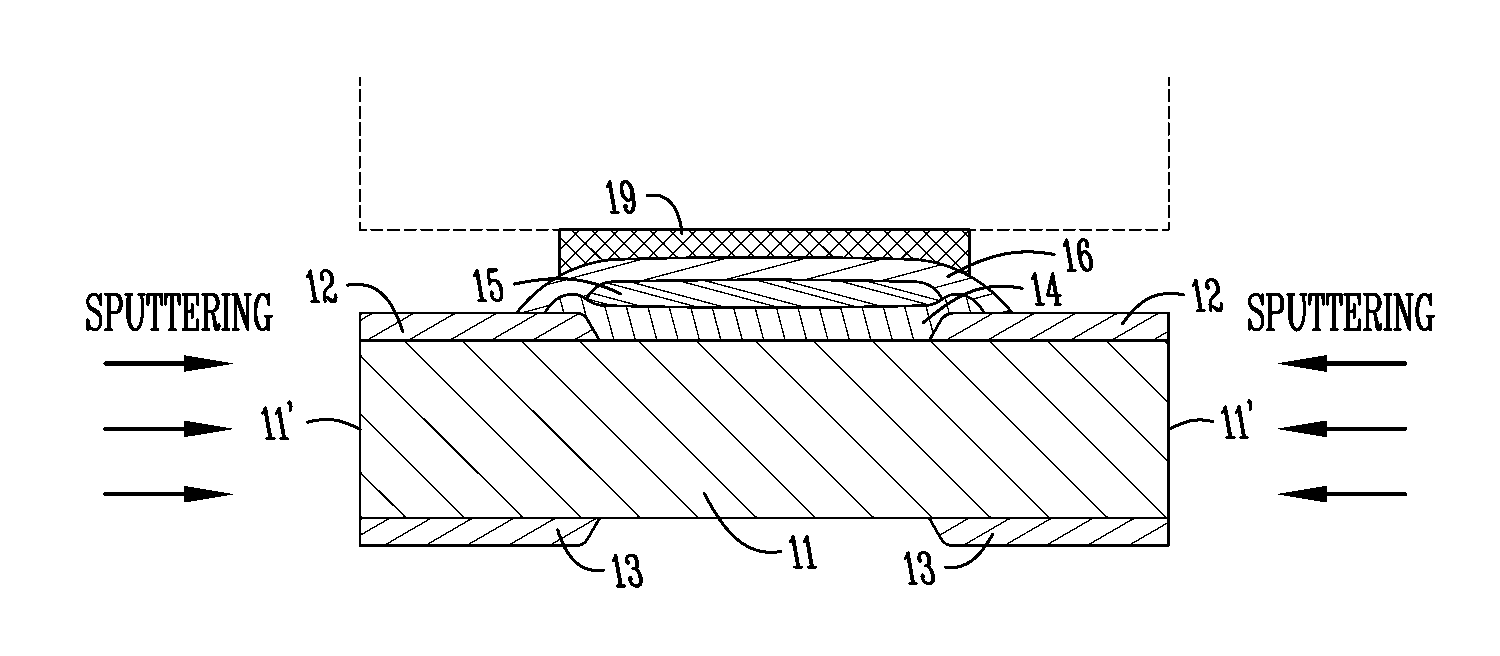

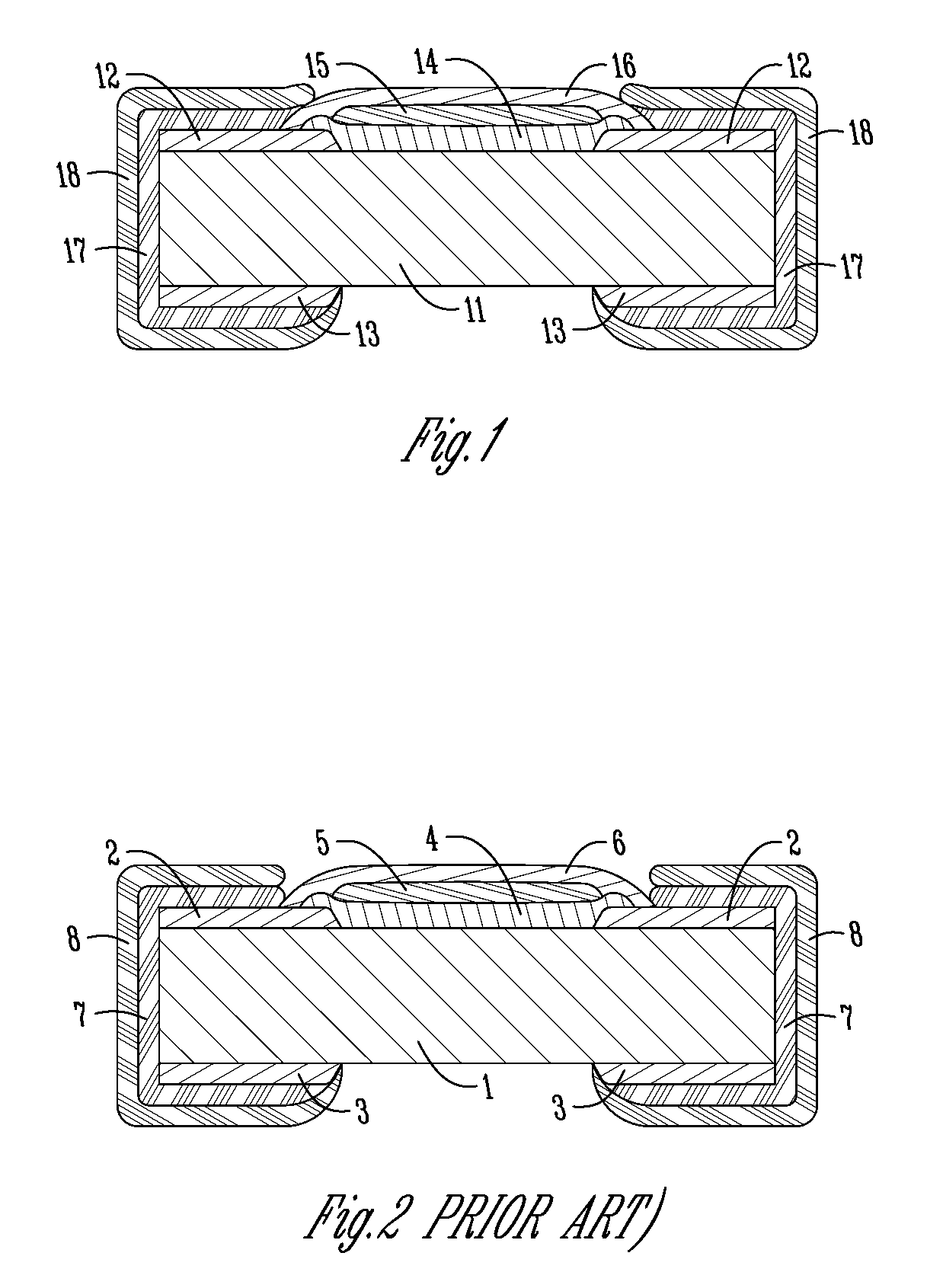

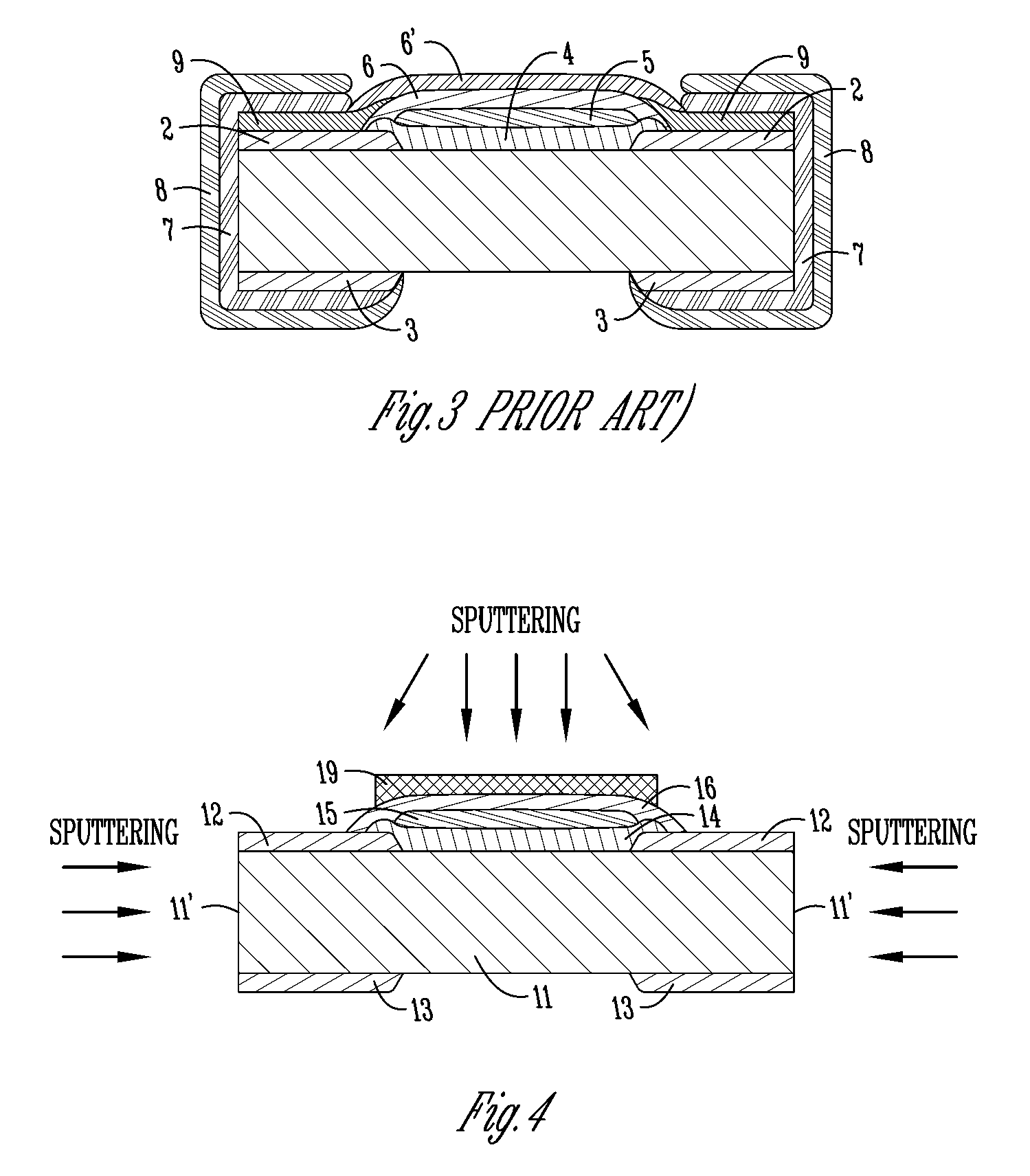

A chip resistor includes an insulating substrate 11, top terminal electrodes 12 formed on top surface of the substrate using silver-based cermet, bottom electrodes 13, resistive element 14 that is situated between the top terminal electrodes 12 and overlaps them partially, an optional internal protective coating 15 that covers resistive element 14 completely or partially, an external protective coating 16 that covers completely the internal protection coating 15 and partially covers top terminal electrodes 12, a plated layer of nickel 17 that covers face sides of the substrate, top 12 and bottom 13 electrodes, and overlaps partially external protective coating 16, finishing plated layer 18 that covers nickel layer 17. The overlap of nickel layer 17 and external protective layer 16 possesses a sealing property because of metallization of the edges of external protective layer 16 prior to the nickel plating process.

Owner:VISHAY INTERTECHNOLOGY INC

Flexible strip steel treating line suitable for producing various high-strength steel

ActiveCN101812579ARich varietyMeet actual needsHot-dipping/immersion processesElectrolysis componentsStrip steelSlow cooling

The invention discloses a flexible strip steel treating line suitable for producing various high-strength steel. The flexible strip steel treating line comprises an uncoiling working position, a washing working position, a heating working position, a soaking working position and a slow cooling working position, a jet cooling working position or a water quenching cooling working position in turn, wherein a reheating working position and then an overaging working position or a hot galvanizing working position and a cladding alloying and annealing working position are arranged after the jet cooling working position; a moveable bypass channel is arranged to connect the reheating working position and the overaging working position respectively; a final cooling working position and a flatting working position are connected after the overaging working position and the hot galvanizing working position; then, a finishing working position and an oil coating working position, or a passivating working position and other post-treatment working positions are connected; the finishing working position and the oil coating working position are connected to a coiling working position to finish a finished product; an acid cleaning working position and an electroplating working position are arranged corresponding to the water quenching and cooling working position; the reheating working position can be connected after the acid cleaning working position directly; an uncoiling and washing working position can be directly connected before the electroplating working position; and the bypass channel or a switching device is arranged after the electroplating working position to respectively and correspondingly connect the reheating working position or directly connect the passivating working position and the other post-treatment working positions.

Owner:BAOSHAN IRON & STEEL CO LTD

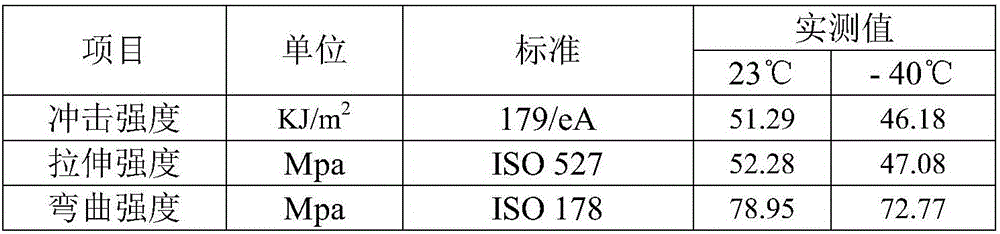

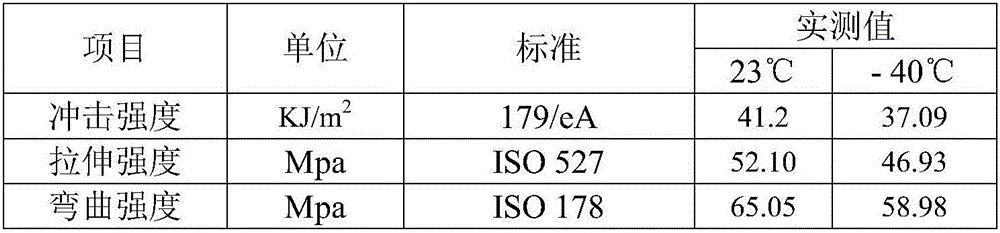

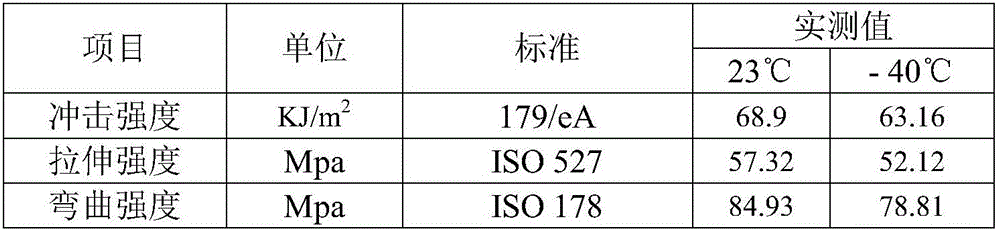

PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) blended material applicable to electroplating and preparation method thereof

InactiveCN106280367AUniform particle size distributionStrong impact resistanceProcedure AgentsUv absorber

The invention provides a PC / ABS (Polycarbonate / Acrylonitrile Butadiene Styrene) blended material applicable to electroplating. The PC / ABS blended material is prepared from the following raw materials in parts by weight: 40-80 parts of PC, 20-60 parts of ABS, 0.1-1 part of a lubricant, 1-10 parts of a compatilizer, 0.5-5 parts of a processing auxiliary agent, 1-10 parts of a toughening agent, 0.1-0.5 part of an antioxidant and 0.1-3 parts of an ultraviolet absorbent. The invention further provides a preparation method of the PC / ABS blended material applicable to electroplating. By adopting the PC / ABS blended material provided by the invention, the electroplating performance of the common PC can be effectively improved; meanwhile, the PC / ABS blended material has a good high temperature and low temperature keeping rate; and the PC / ABS blended material applicable to electroplating has the advantages of relatively low cost, simple synthetic method and convenience for operation.

Owner:太仓市华鼎塑料有限公司

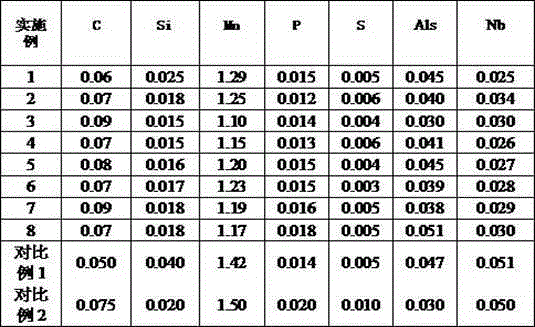

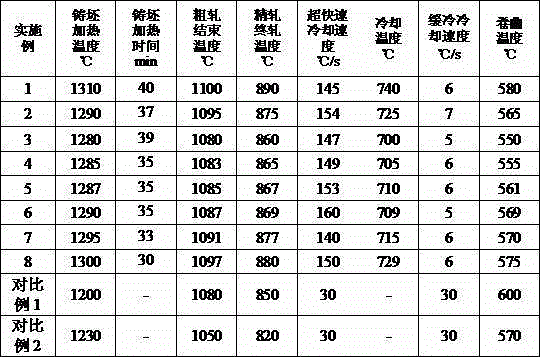

Coated steel used for 500 MPa grade automobile girder and ultrafast-cooling production method of coated steel

Coated steel used for a 500 MPa grade automobile girder comprises, by weight, 0.06-0.09% of C, not more than 0.025% of Si, 1.10%-1.29% of Mn, not more than 0.015% of P, not more than 0.006% of S, 0.020%-0.060% of Als and 0.025%-0.034% of Nb. The production method includes the steps that argon blowing is conducted in an argon station after converter smelting is conducted; casting blanks are heated after tapping is conducted and the blanks are formed through continuous casting; staged hot rolling is conducted; laminar cooling is conducted in a variable-speed cooling manner; reeling is conducted; and finishing and subsequence procedures are conducted. Under the design of low alloy components, ultrafast cooling and staged cooling are adopted, the produced coated steel used for the girder has excellent surface quality and platability, hot galvanizing production can be directly conducted, the denting resistance and coating adhesive force of steel plates are further improved, and good surface quality is achieved.

Owner:武汉钢铁有限公司

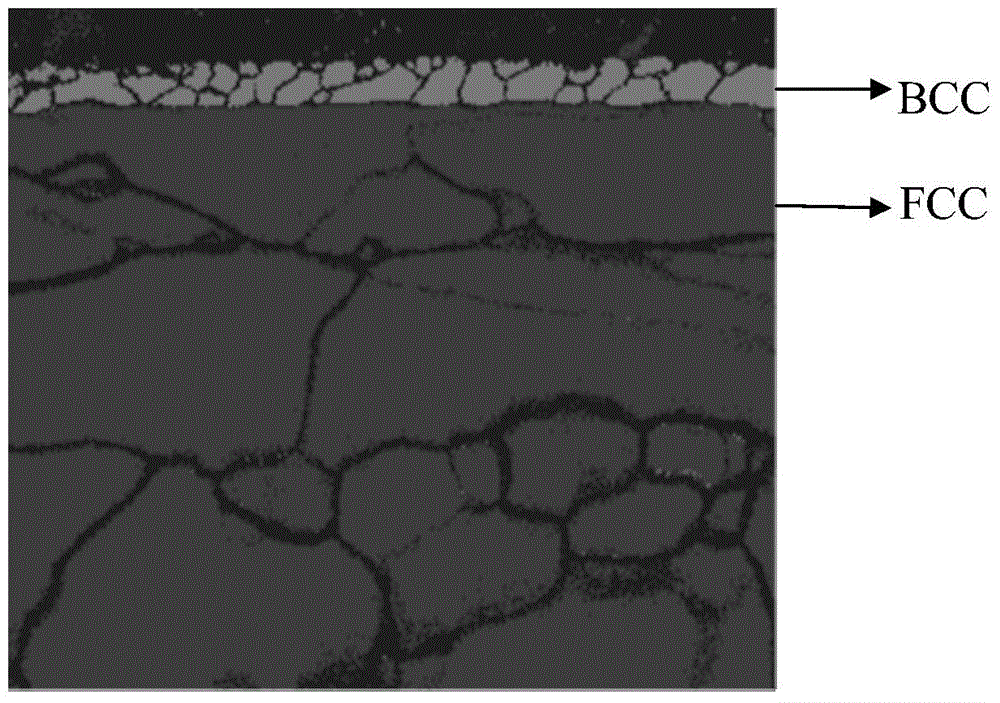

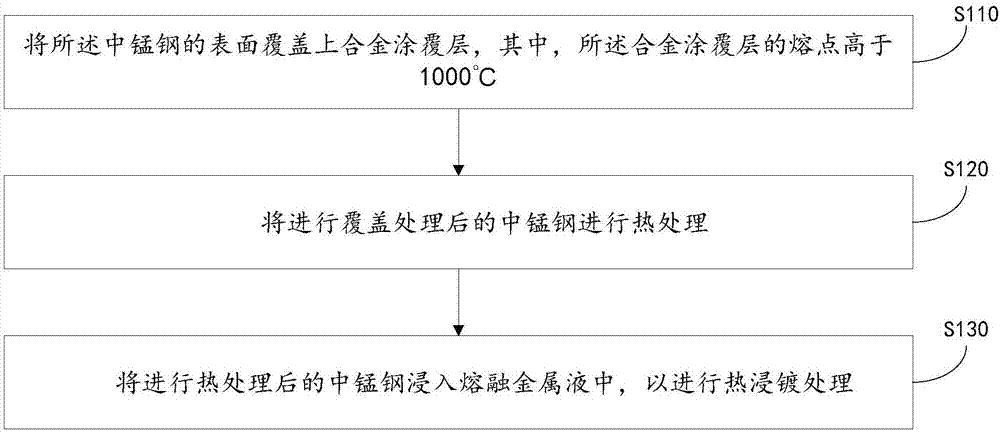

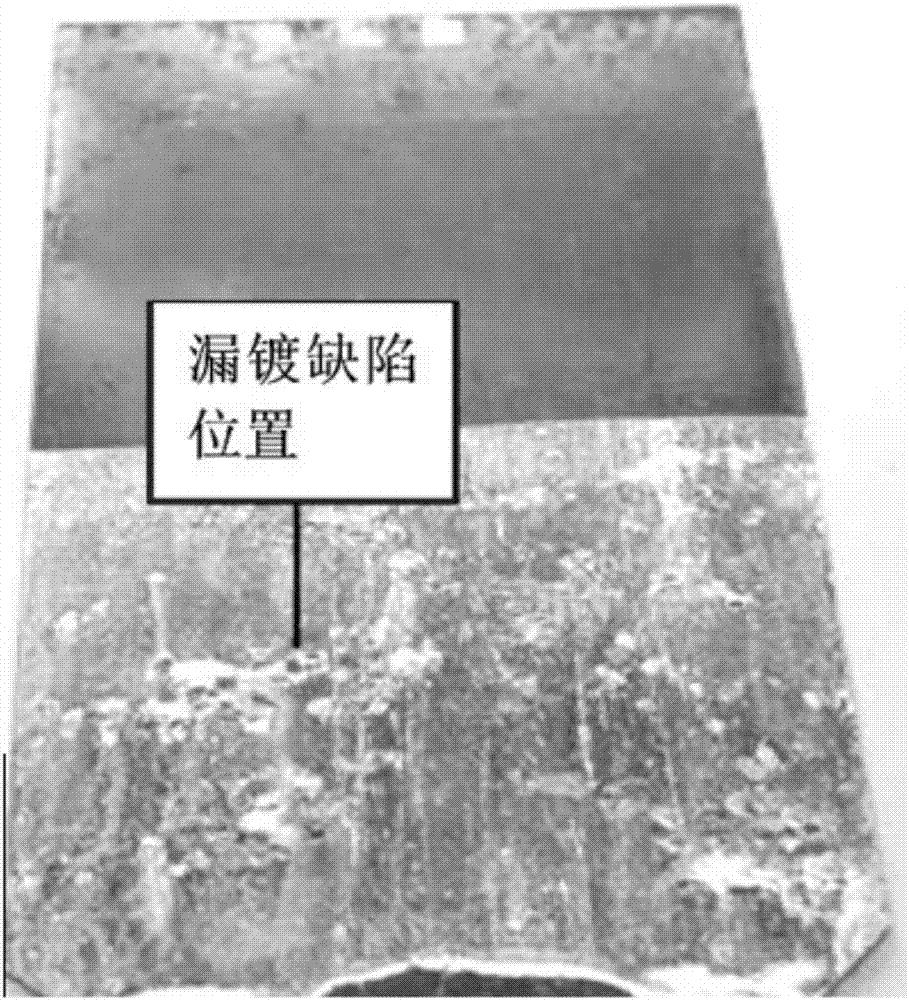

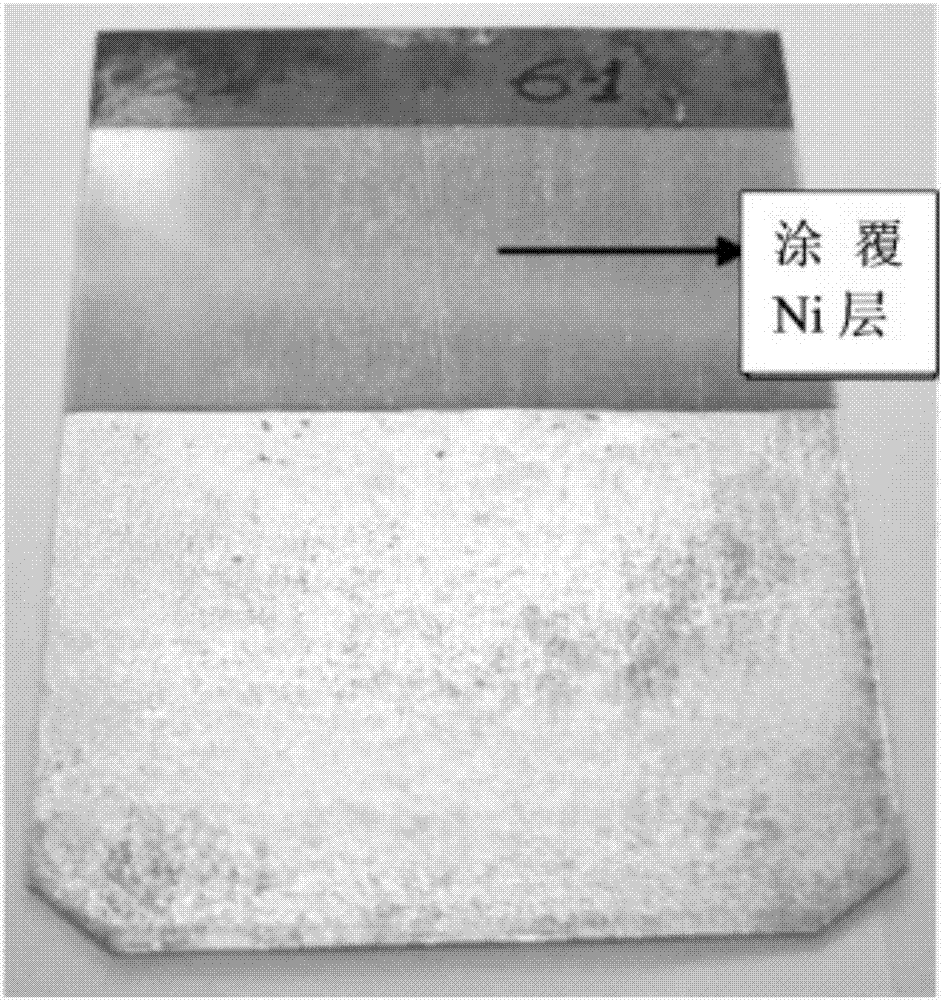

Medium manganese steel hot dipping method

ActiveCN107299306AImprove PlatabilityPrevent evaporationHot-dipping/immersion processesManganeseAlloy coating

The embodiment of the invention discloses a medium manganese steel hot dipping method. Medium manganese steel comprises the following elements in percentage by mass: less than or equal to 0.5% and more than or equal to 0.1% of [C], 2.0% and more than or equal to 0.2% of [Si], 10% and more than or equal to 4% of [Mn], and 2% and more than or equal to 0.2% of [Al], the method comprises the following steps: covering an alloy coating layer on the surface of the medium manganese steel, wherein the melting point of the alloy coating layer is higher than 1000DEG C; performing thermal treatment to the covered medium manganese steel; and dipping the medium manganese steel subjected to thermal treatment into molten metal for hot dipping treatment. By adopting the method, the technical problem that the quality of the plated layer is poor as oxides are easily formed during thermal treatment process by adopting the medium manganese steel hot dipping method in the prior art can be solved.

Owner:SHOUGANG CORPORATION

Sulfuration resistant chip resistor and method for making same

ActiveUS20120126934A1Improve PlatabilityVacuum evaporation coatingSputtering coatingMetallic NickelResistive element

A chip resistor includes an insulating substrate 11, top terminal electrodes 12 formed on top surface of the substrate using silver-based cermet, bottom electrodes 13, resistive element 14 that is situated between the top terminal electrodes 12 and overlaps them partially, an optional internal protective coating 15 that covers resistive element 14 completely or partially, an external protective coating 16 that covers completely the internal protection coating 15 and partially covers top terminal electrodes 12, a plated layer of nickel 17 that covers face sides of the substrate, top 12 and bottom 13 electrodes, and overlaps partially external protective coating 16, finishing plated layer 18 that covers nickel layer 17. The overlap of nickel layer 17 and external protective layer 16 possesses a sealing property because of metallization of the edges of external protective layer 16 prior to the nickel plating process.

Owner:VISHAY INTERTECHNOLOGY INC

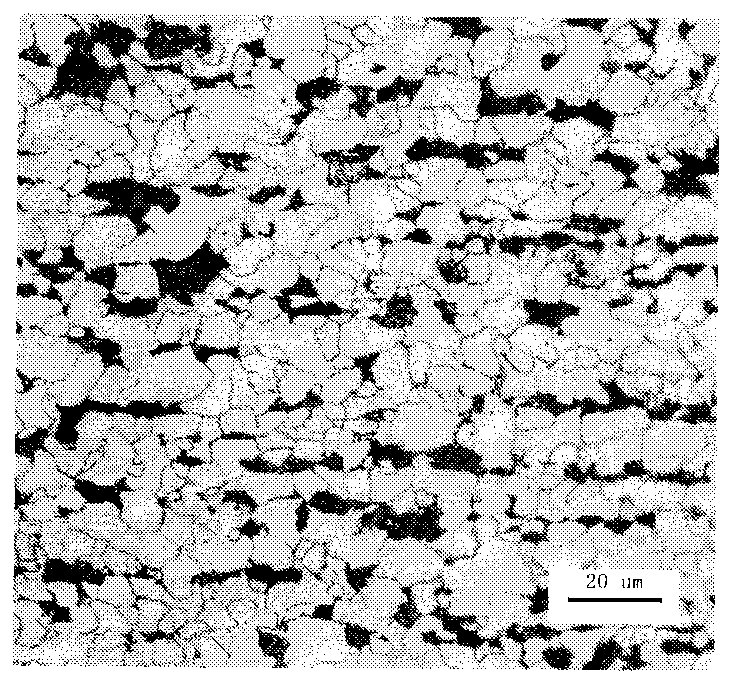

Galvanized dual-phase steel for 500 MPa class car and production method

ActiveCN105401071AUniform color without defectsSuppression of continuous densificationHot-dipping/immersion processesPunchingZinc

A galvanized dual-phase steel for a 500 MPa class car comprises the following components in percentage by weight: 0.04-0.09% of C, smaller than or equal to 0.01% of Si, 1.0-2.0% of Mn, smaller than or equal to 0.015 of P, smaller than or equal to 0.010% of S, 0.01-0.08% of Als, 0.01-0.30% of Mo or 0.02-0.9% of Cr, 0.001-0.03% of Nb and smaller than or equal to 0.005% of N. The production method comprises the following production steps: heating of casting blanks after smelting, refining and continuous casting, finish rolling, reeling, cold rolling after acid pickling, hot galvanizing, and finishing. According to the mechanical properties of the product, yield strength is 295-365 MPa, tensile strength is 515-558 MPa, ductility is 25-30%, and n value is 0.165-0.18; and platability of the product is good, the surface of a plating layer is uniform in color and does not have defects, an inhibition layer is continuous and compact, the adhesive force of a zinc layer reaches level-one standard of ball punching, bending test on the zinc layer and a steel base is qualified, and requirements of intermediate cars on surface quality of high-strength structures and outer covering parts can be met.

Owner:武汉钢铁有限公司

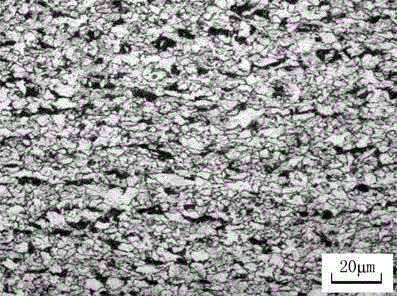

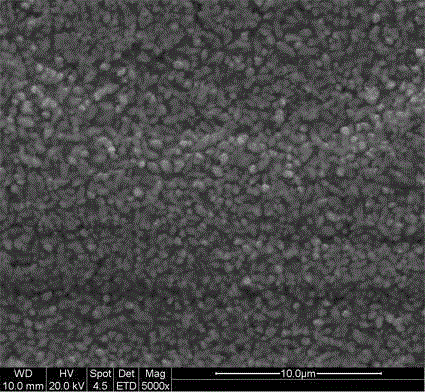

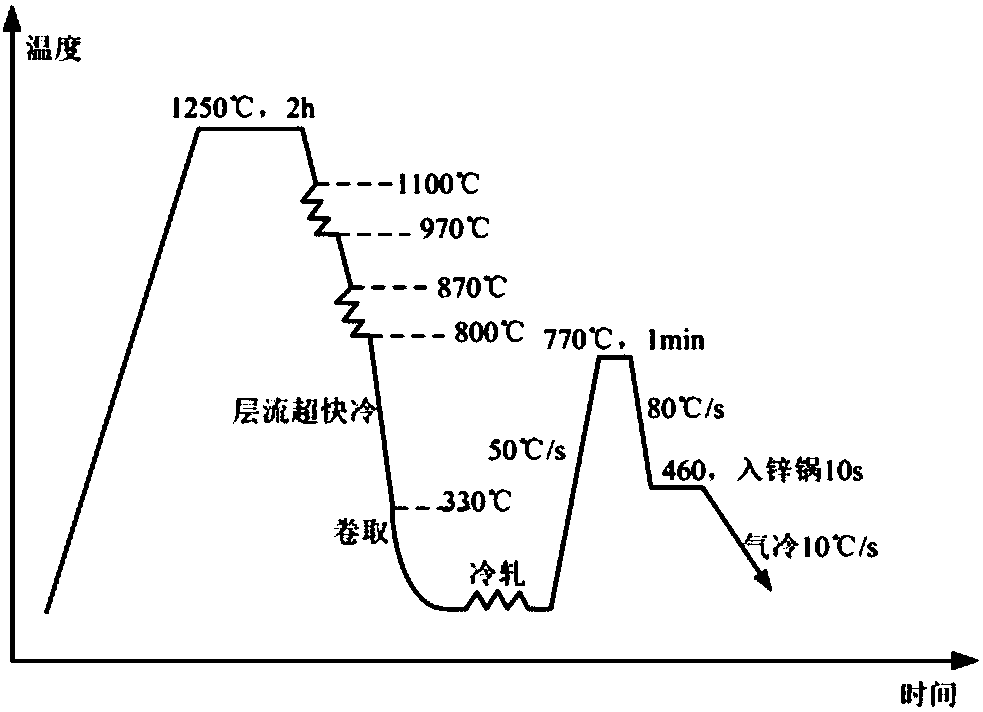

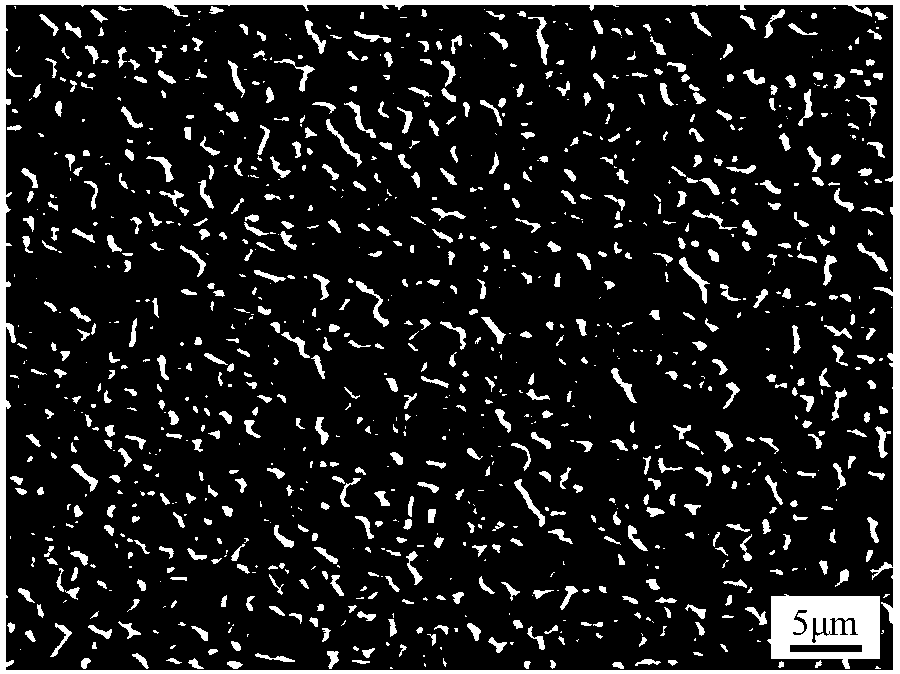

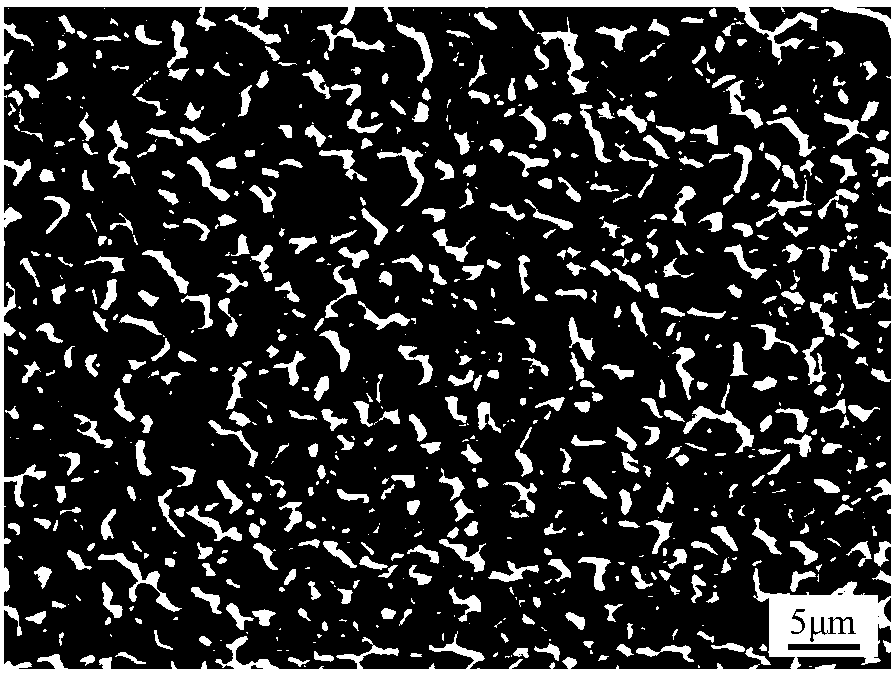

High-static toughness and high-platability fine-grain hot galvanizing dual-phase steel and production method thereof

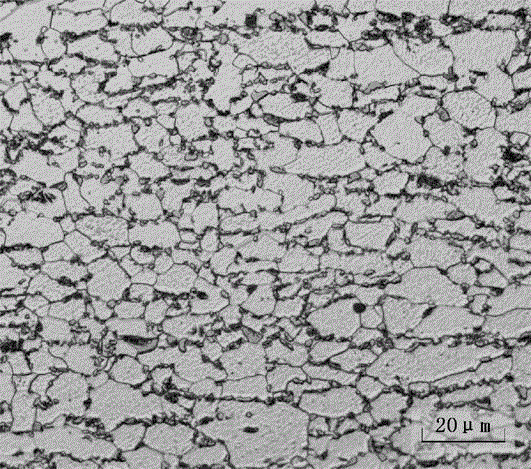

ActiveCN107829038ALow costReduce selective oxidationHot-dipping/immersion processesChemical compositionStrip steel

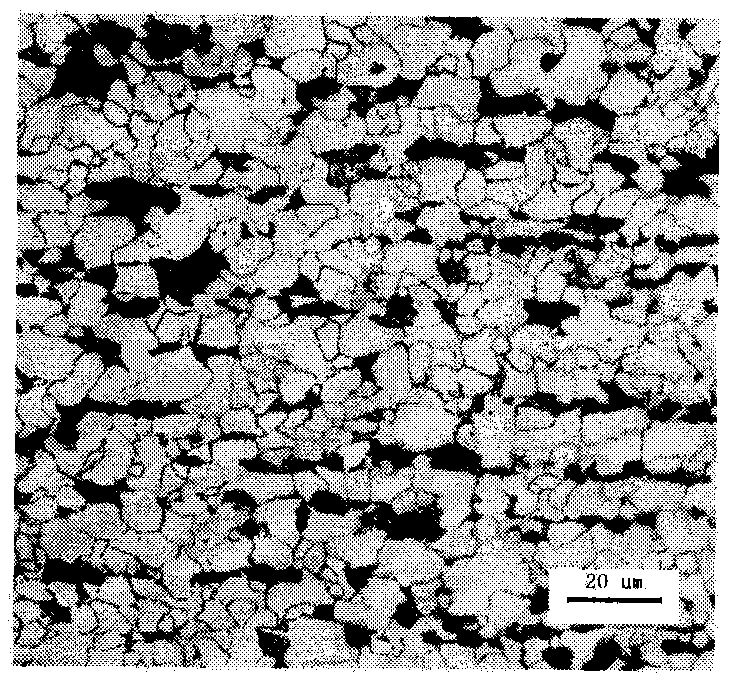

The invention discloses a high-static toughness and high-platability fine-grain hot galvanizing dual-phase steel and a production method thereof, and belongs to the field of metallurgy materials. Thechemical components of the high-static toughness and high-platability fine-grain hot galvanizing dual-phase steel are, by weight, 0.08%-0.12% of C, 1.8%-2.5% of Mn, less than 0.005% of Si, 0.3%-0.5% of Al, 0.04%-0.08% of P, 0.03%-0.06% of Nb, 0.02%-0.05% of Ni, less than 0.005% of S and the balance iron. The production method comprises the steps of vacuum smelting, blank forging, first-stage austenite recrystallization zone rolling, second-stage two-phase zone hot rolling, multi-pass cold rolling and rapid annealing. According to the high-static toughness and high-platability fine-grain hot galvanizing dual-phase steel and the production method thereof, the selective oxidation of alloy elements in the annealing process can be greatly reduced, platability of the steel is improved, and the structure and the performance of the strip steel are optimized.

Owner:NORTHEASTERN UNIV LIAONING

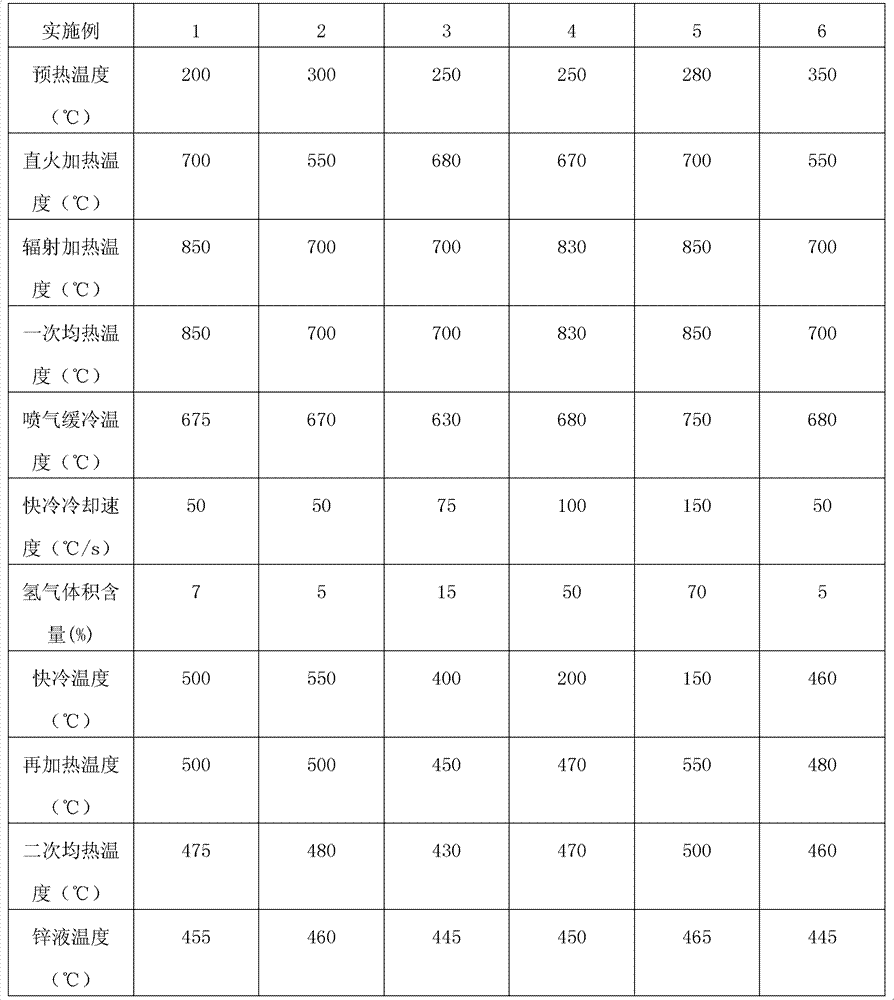

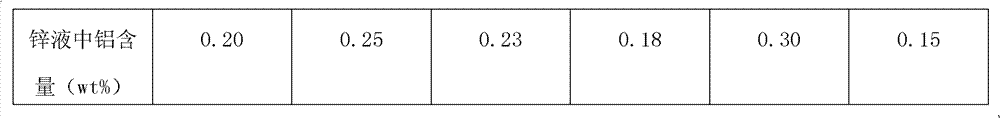

Strip steel continuous hot galvanizing method

InactiveCN102816986AImprove PlatabilityAchieve heat treatmentHot-dipping/immersion processesHydrogenStrip steel

The invention discloses a strip steel continuous hot galvanizing method. The strip steel continuous hot galvanizing method sequentially comprises the following steps of washing and pre-heating strip steel, adopting short flame to heat the strip steel to be at the temperature of 550-700 DEG C in a strip steel directly contacted mode, adopting a radiant tube heating method to continue to heat the strip steel to be at the temperature of 700-850 DEG C, sequentially soaking and slowly cooling the strip steel, adopting nitrogen and hydrogen mixed gas with 5-70% of hydrogen volume to quickly cool the strip steel to be at the temperature of 150-550 DEG C, heating the strip steel again to be at the temperature of 450-550 DEG C, performing secondary soaking to the strip steel and performing hot galvanizing treatment to the strip steel. By means of the method, the platability of ultrahigh strong steel can be obviously improved, various annealing curves can be achieved flexibly, and annealing processes which cannot be achieved by a traditional hot galvanizing unit can be achieved. In addition, the 'zinc scale' detect in starting of the unit can be obviously overcome.

Owner:BAOSHAN IRON & STEEL CO LTD

Heterojunction solar cell and preparation method and application thereof

ActiveCN114597270AIncrease the open circuit voltageImprove battery efficiencyPhotovoltaic energy generationSemiconductor devicesHeterojunctionManufacturing cost reduction

The invention provides a heterojunction solar cell and a preparation method and application thereof, and the preparation method comprises the steps: carrying out the polymerization of a combination of 3, 4-ethylenedioxythiophene and styrene sulfonic acid monomers on a silicon substrate provided with a transparent conductive layer as a monomer, and obtaining a high-molecular conductive film; and electrochemically depositing a tin-copper alloy layer on the polymer conductive film to form a metal grid line, thereby obtaining the heterojunction solar cell. According to the invention, the tin-copper alloy grid line is prepared by an electrochemical deposition process, so that the manufacturing cost is remarkably reduced, the metal grid line has better conductivity and stability, and an outer protective layer does not need to be arranged. According to the preparation method, a PEDOT: PSS polymer conductive film is formed in an in-situ polymerization mode, and the PEDOT: PSS polymer conductive film is used as a bonding layer of a transparent conductive layer and a metal grid line, so that the conductivity and the plating property can be effectively improved, the damage to TCO in laser etching is prevented, copper ions are prevented from migrating to the cell, and the comprehensive performance of the heterojunction solar cell is effectively improved.

Owner:SUZHOU KZONE EQUIP TECH

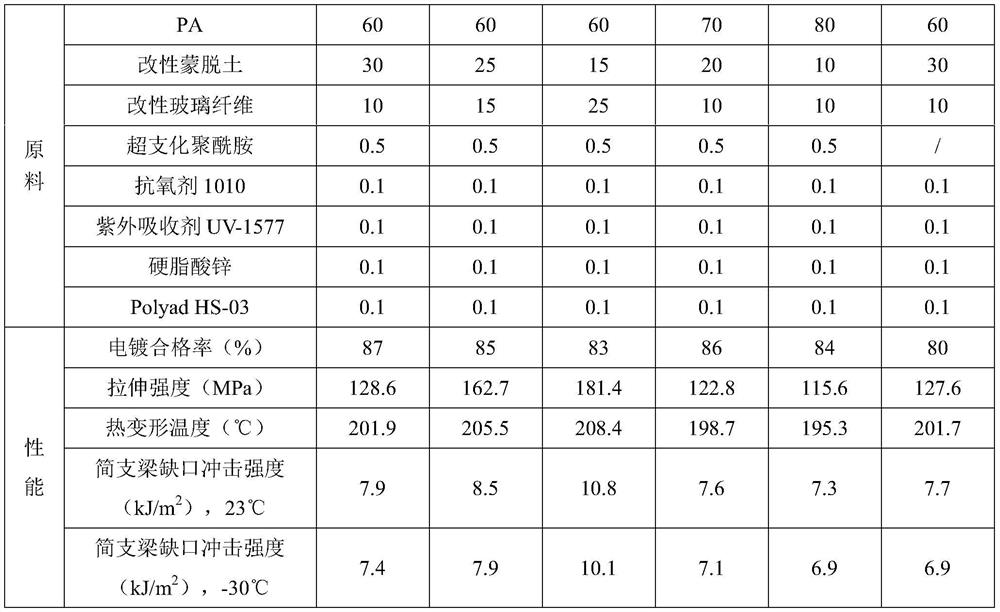

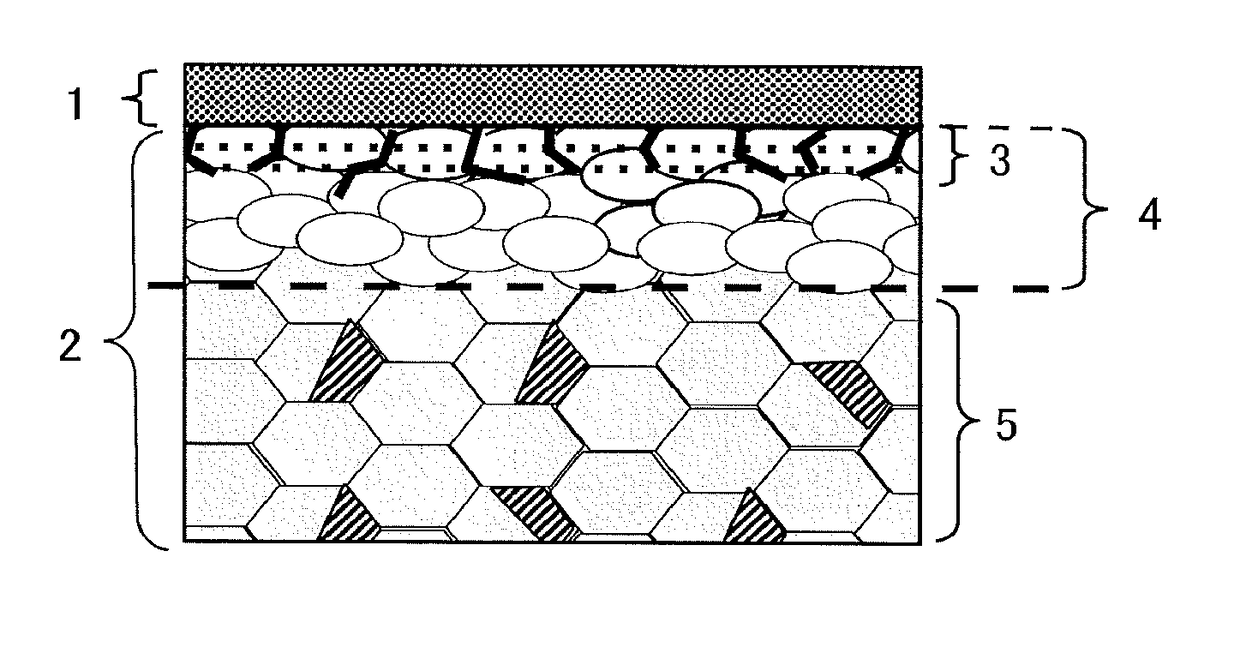

High-strength plated steel sheet having excellent plating properties, workability, and delayed fracture resistance, and method for producing same

InactiveUS20180010226A1Delayed fracture resistanceGood molding effectHot-dipping/immersion processesFurnace typesSoft layerSheet steel

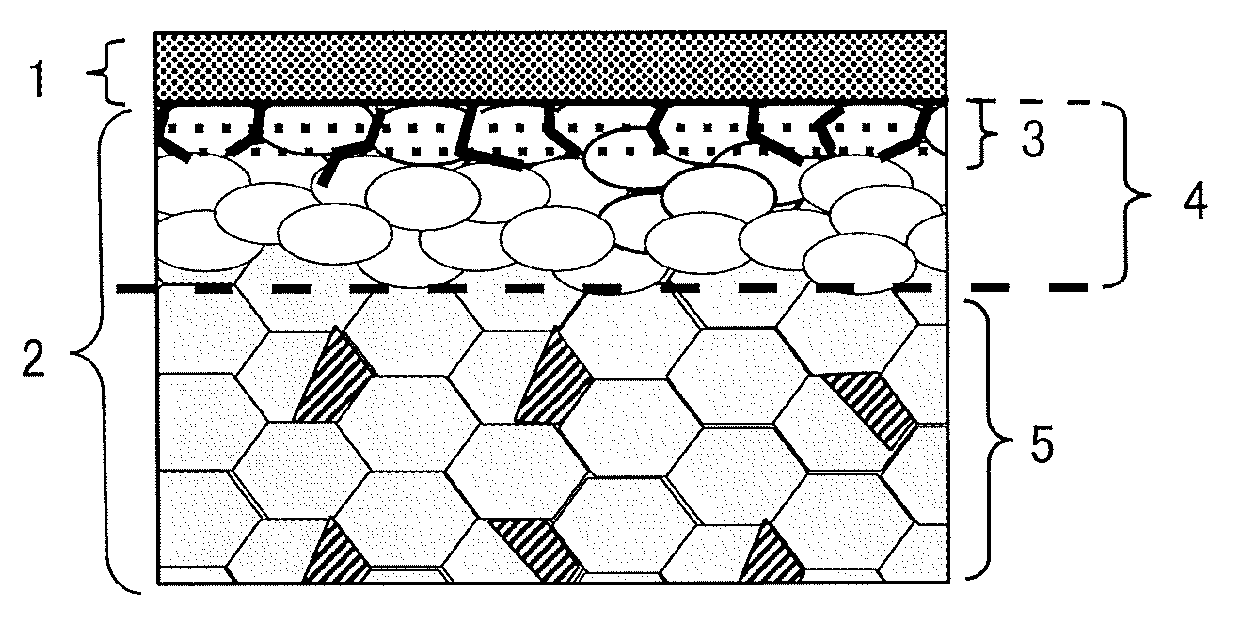

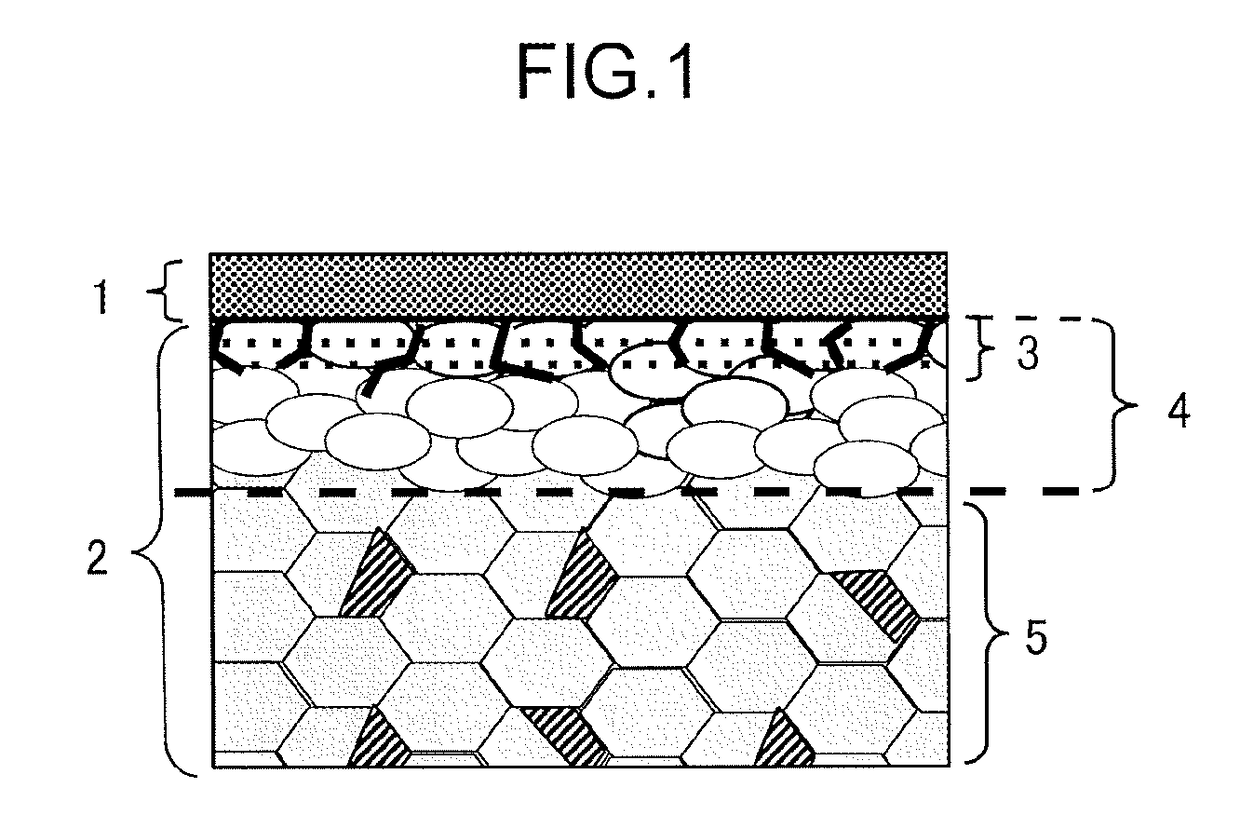

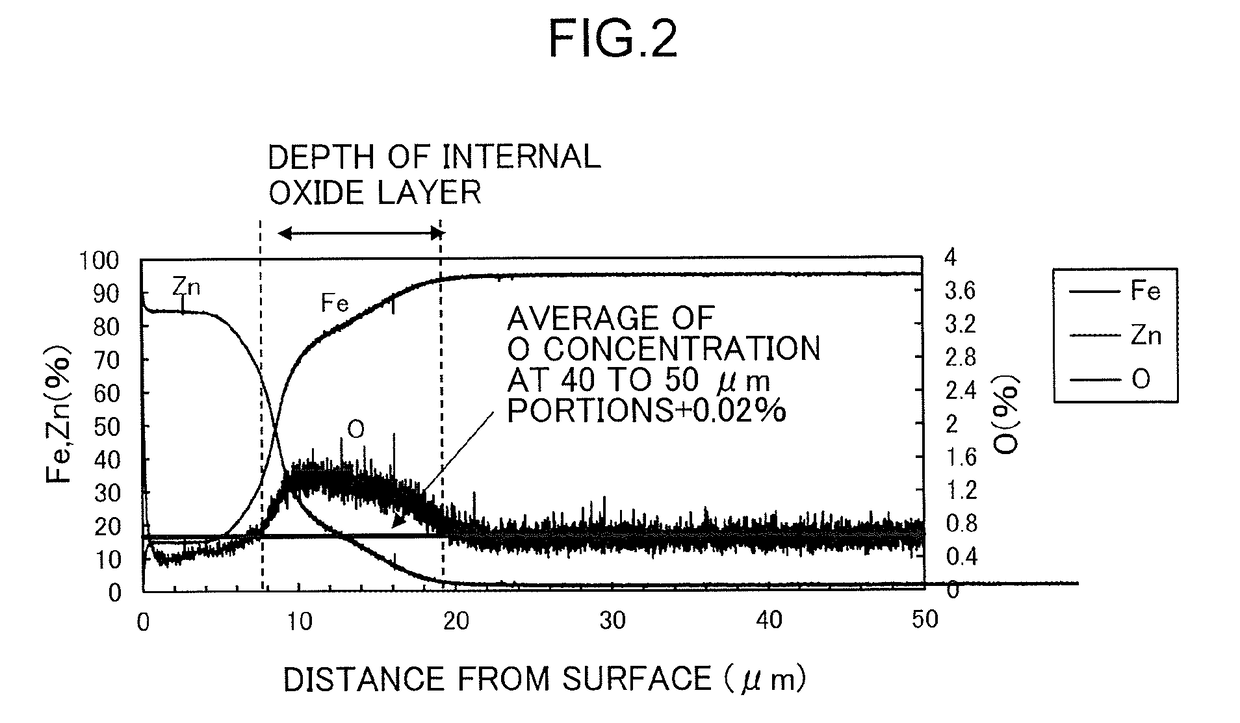

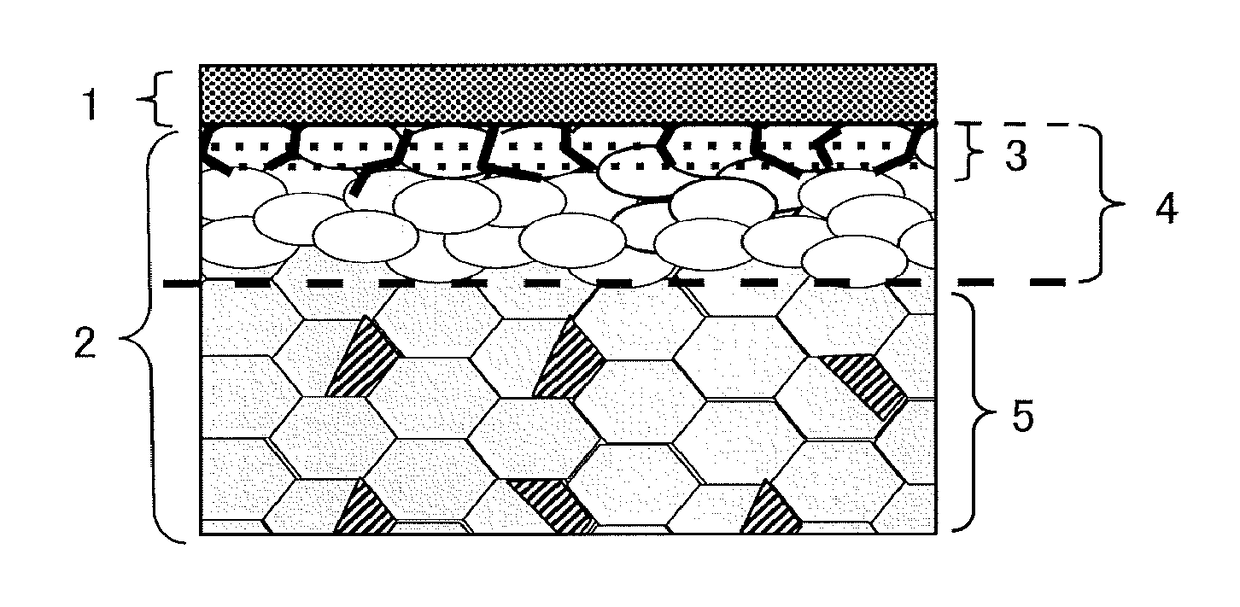

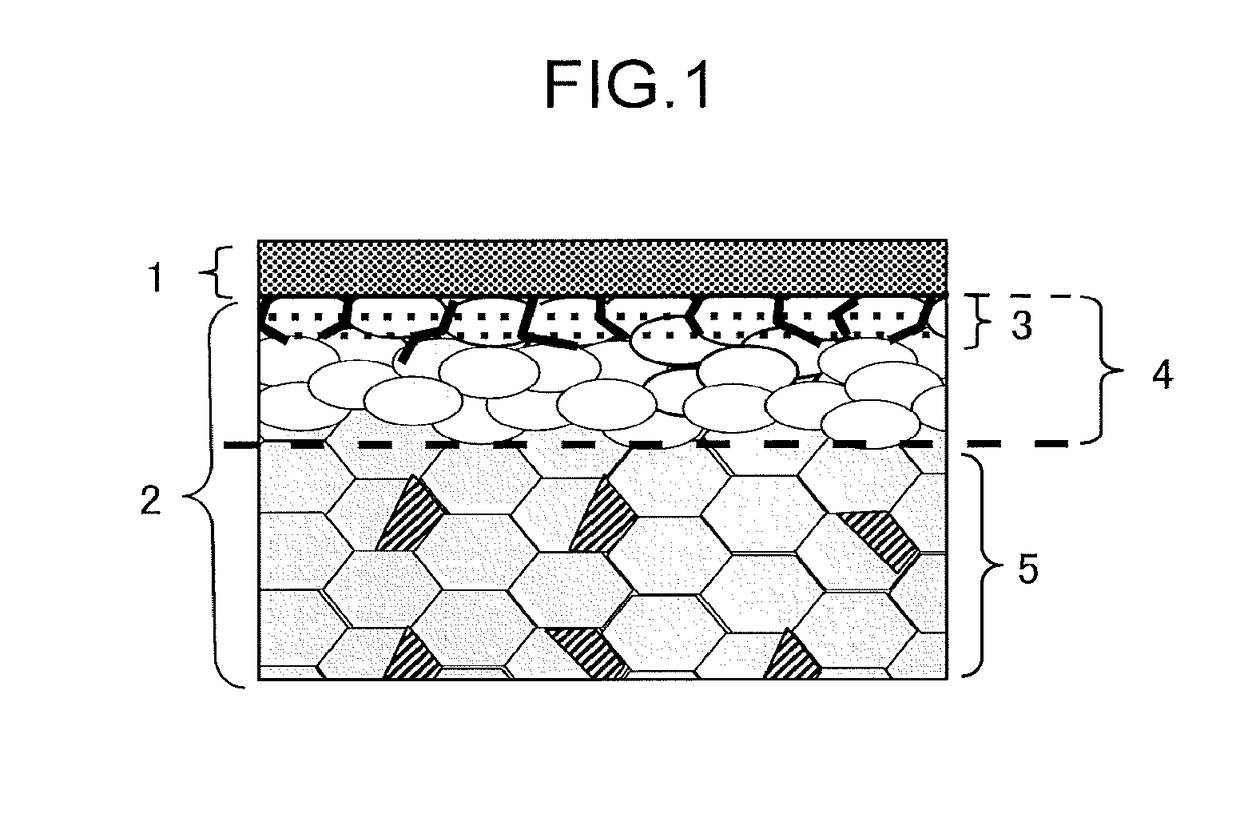

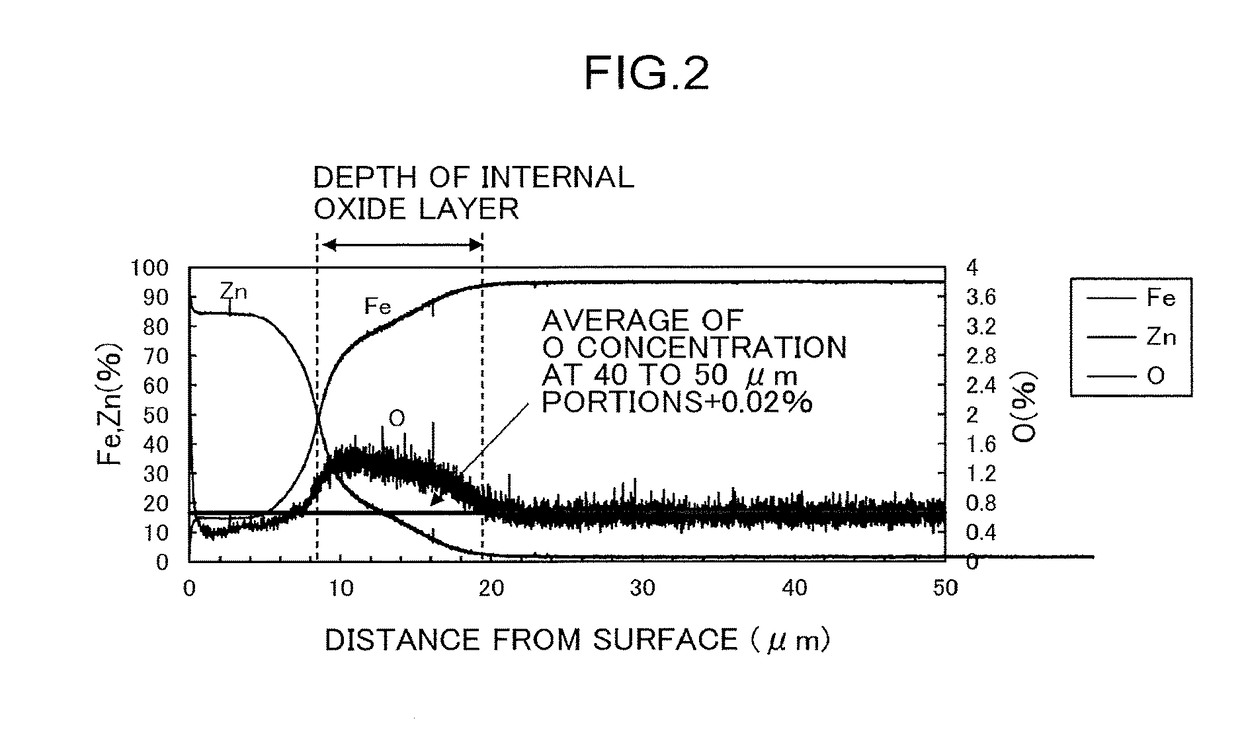

The high-strength plated steel sheet of the present invention has a plated layer on the surface of a base steel sheet and contains predetermined steel components. The steel sheet includes, in the order from the interface of the base steel sheet and the plated layer towards the base steel sheet: a soft layer having a Vickers hardness that is 90% or less of the Vickers hardness at a portion t / 4 of the base steel sheet, where t is a sheet thickness of the base steel sheet: and a hard layer containing martensite, bainite, and ferrite in predetermined ranges. The average depth D of the soft layer is 20 μm or greater, and the average depth d of an internal oxide layer is 4 μm or greater and smaller than D.

Owner:KOBE STEEL LTD

High-strength plated steel sheet having excellent plating properties, workability, and delayed fracture resistance, and method for producing same

InactiveUS20170369965A1Good molding effectDelayed fracture resistanceHot-dipping/immersion processesFurnace typesSheet steelOxide

A high-strength plated steel sheet has a plated layer on the surface of a base steel sheet and contains predetermined steel components. The steel sheet includes, in the order from the interface of the base steel sheet and the plated layer towards the base steel sheet: a soft layer having a Vickers hardness that is 90% or less of the Vickers hardness at a portion t / 4 of the base steel sheet, where t is a sheet thickness of the base steel sheet; and a hard layer containing martensite and bainite, and ferrite in predetermined ranges. The average depth D of the soft layer is 20 μm or greater, and the average depth d of an internal oxide layer is 4 μm or greater and smaller than D.

Owner:KOBE STEEL LTD

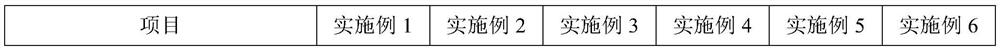

Electroplated nylon material and preparation method thereof

The invention provides an electroplated nylon material and a preparation method thereof. The electroplated nylon material comprises the following components in parts by weight: 40-80 parts of polyamide, 10-50 parts of modified minerals and 10-30 parts of modified glass fibers, wherein the total parts by weight of polyamide, modified minerals and modified glass fibers are 100 parts; the modified mineral is a mineral of which the surface is bonded with a silane coupling agent and adsorbs rare earth ions; the modified glass fiber is glass fiber of which the surface is bridged with maleic anhydride grafted ultra-high molecular weight polyethylene through a silane coupling agent and which adsorbs rare earth ions. The electroplated nylon material is prepared by mixing the components and then carrying out melt extrusion by using an extruder. The electroplating nylon material provided by the invention has good electroplating performance, rigidity, heat resistance and impact toughness through synergistic cooperation of the modified minerals and the modified glass fibers.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

High-strength plated steel sheet having excellent plating properties, workability, and delayed fracture resistance, and method for producing same

ActiveUS20180010227A1Good molding effectHigh strengthHot-dipping/immersion processesFurnace typesSoft layerSheet steel

Disclosed herein is a high-strength plated steel sheet having a plated layer on the surface of a base steel sheet and containing predetermined steel components. The steel sheet includes, in the order from the interface of the base steel sheet and the plated layer towards the base steel sheet: a soft layer having a Vickers hardness that is 90% or less of the Vickers hardness at a portion t / 4 of the base steel sheet, where t is a sheet thickness of the base steel sheet; and a hard layer consisting of a structure which is mainly composed of martensite and bainite and in which the average grain size of prior austenite is 20 μm or less. The average depth D of the soft layer is 20 μm or greater, and the average depth d of an internal oxide layer is 4 μm or greater and smaller than D.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com