Patents

Literature

47 results about "Twip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A twip (abbreviating "twentieth of a point", "twentieth of an inch point", or "twentieth of an Imperial point") is a typographical measurement, defined as 1/20 of a typographical point. One twip is 1/1440 inch, 1/567 cm, 0.001764 cm, or 17.64 μm.

High entropy alloy having twip/trip property and manufacturing method for the same

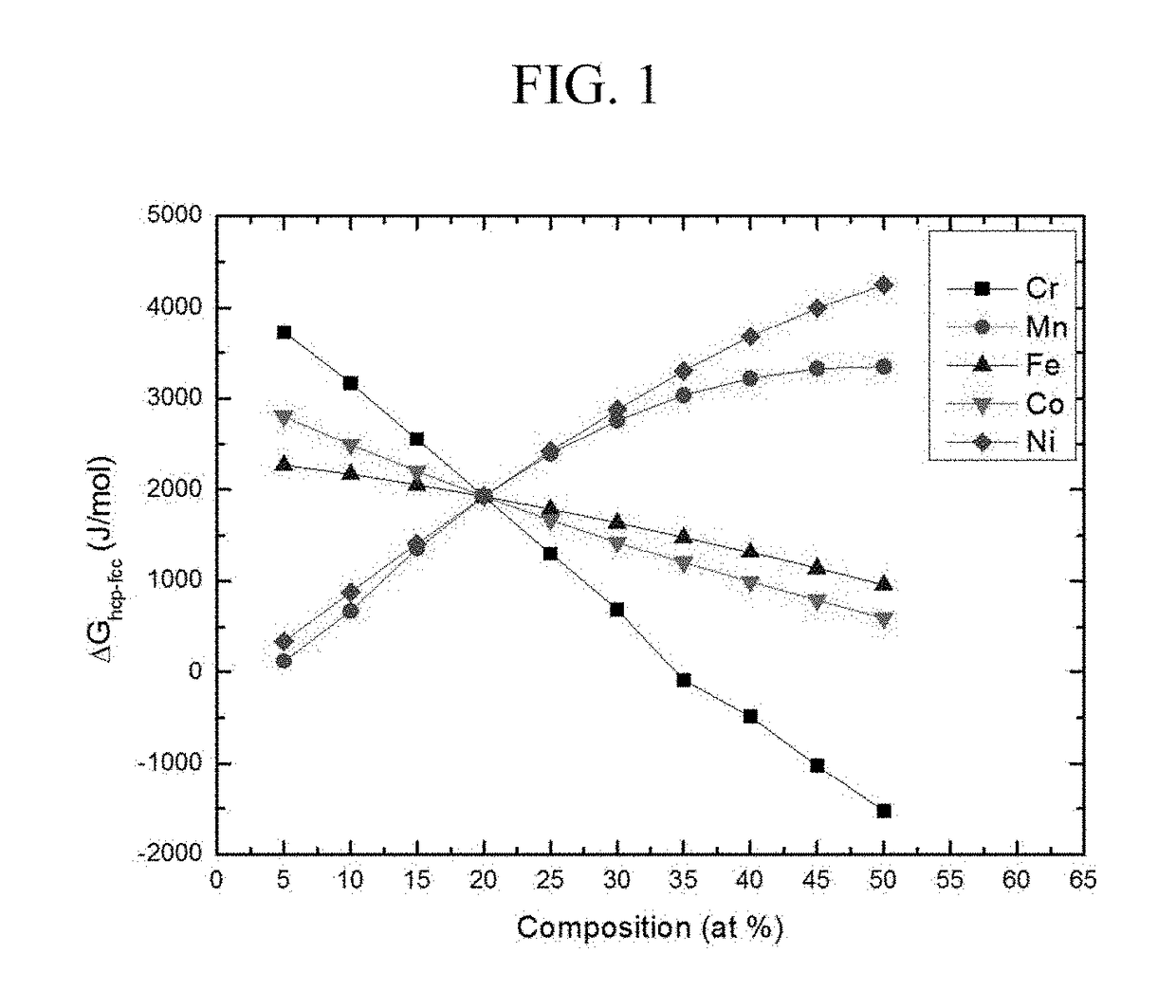

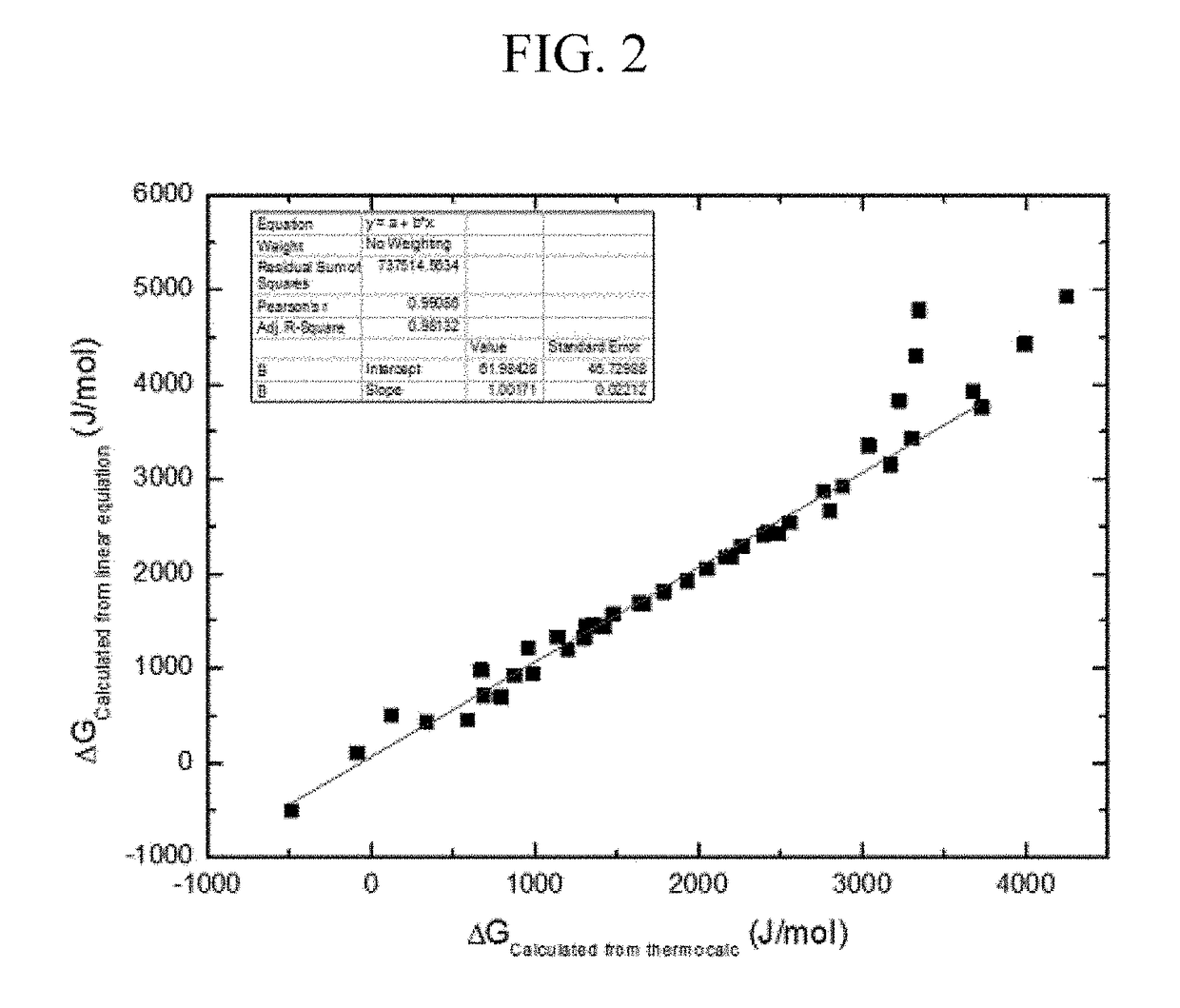

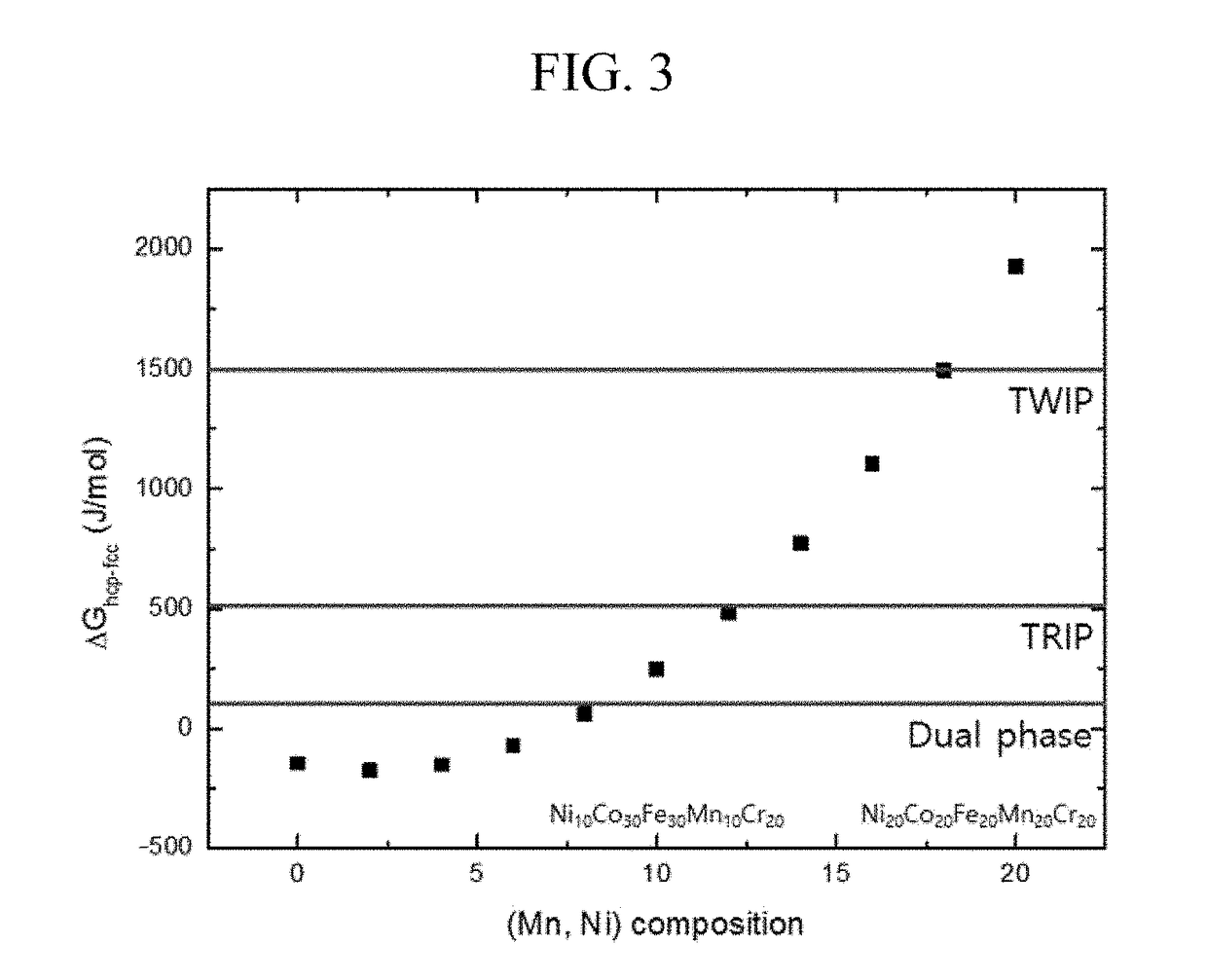

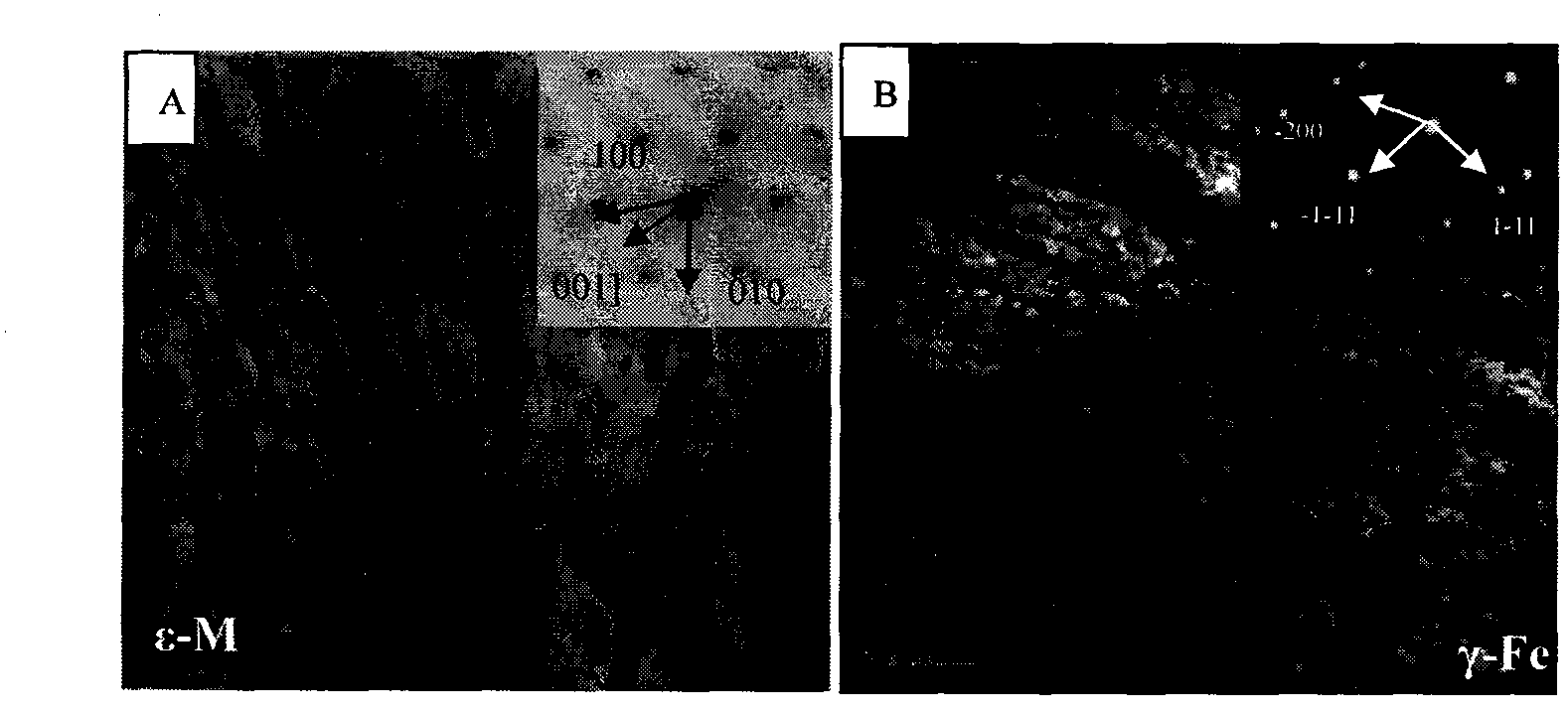

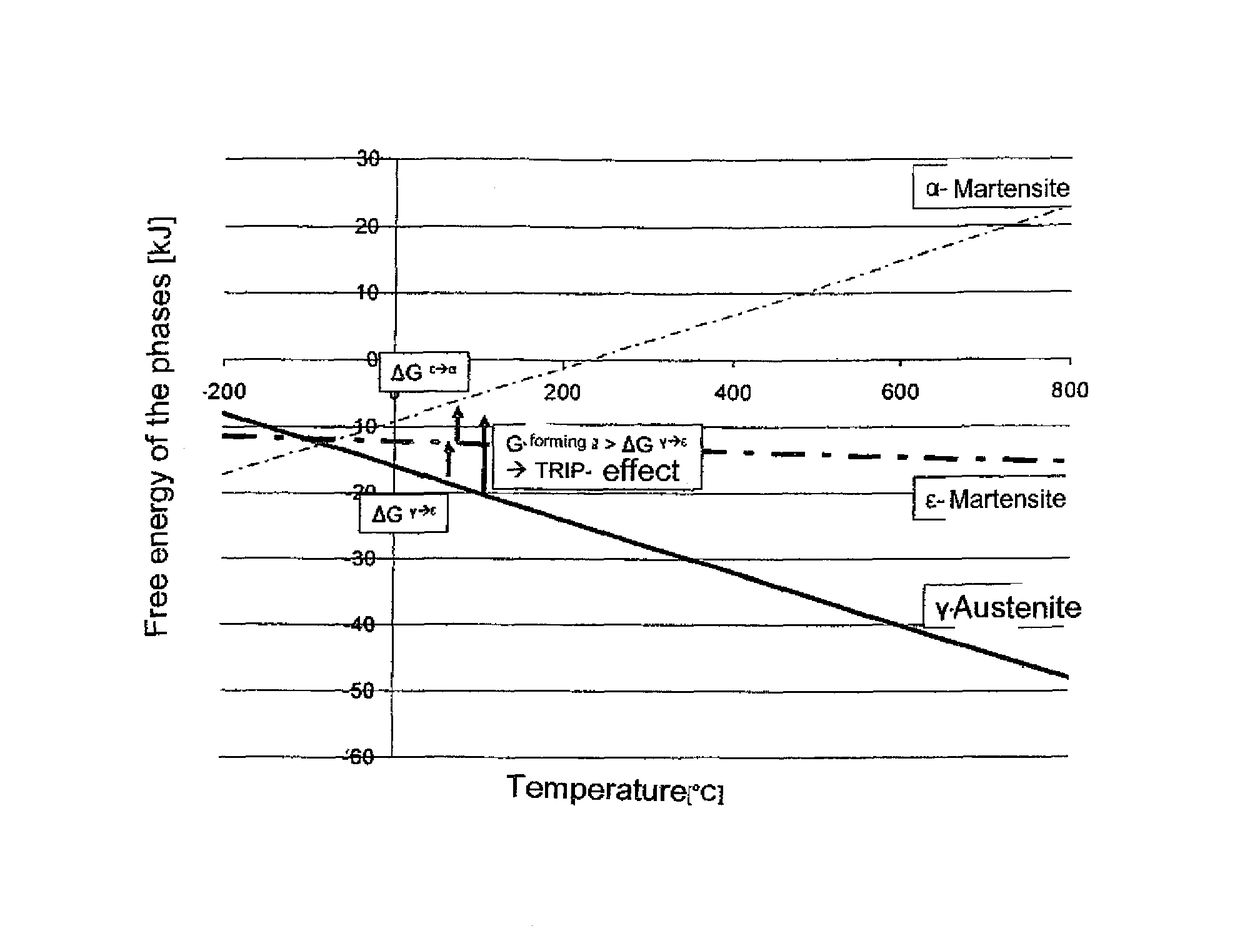

The present invention relates to a high entropy alloy having more improved mechanical properties by controlling contents of additive elements in a NiCoFeMnCr 5-element alloy to control stacking fault energy, thereby controlling stability of a γ austenite phase to control a transformation mechanism, wherein the stacking fault energy is controlled in a composition range of NiaCobFecMndCre (a+b+c+d+e=100, 1≦a≦50, 1≦b≦50, 1≦c≦50, 1≦d≦50, 10≦e≦25, and 77a−42b−22c+73d−100e+2186≦1500), and thus, the γ austenite phase exhibits a twin-induced plasticity (TWIP) property or a transformation induced-plasticity (TRIP) property in which the γ austenite phase is subjected to phase transformation into an ε martensite phase or an α′ martensite phase, under stress, thereby having improved strength and elongation at the same time to have excellent mechanical properties.

Owner:SEOUL NAT UNIV R&DB FOUND

Light and high-performance twin crystal inducing plasticity steel and preparation method thereof

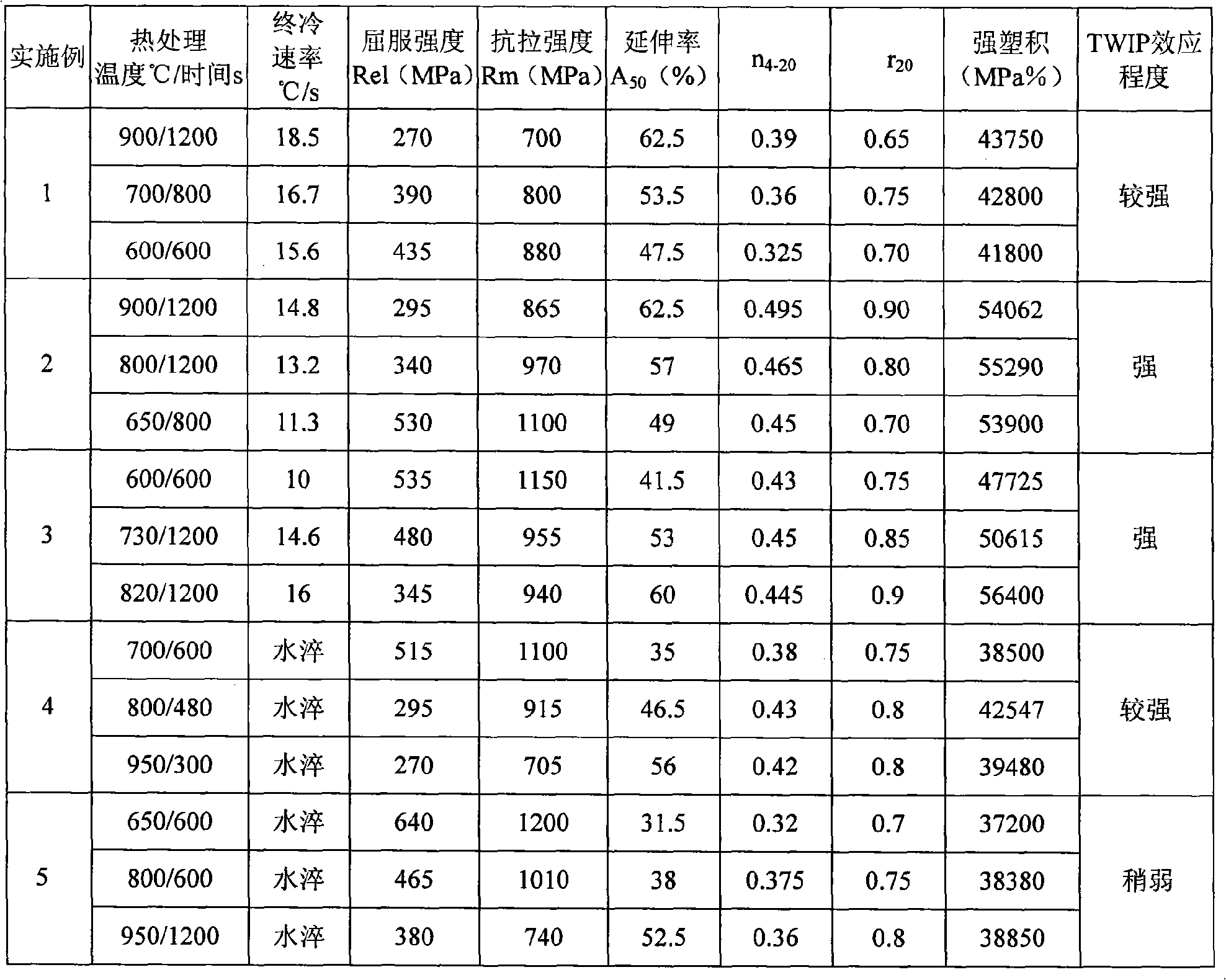

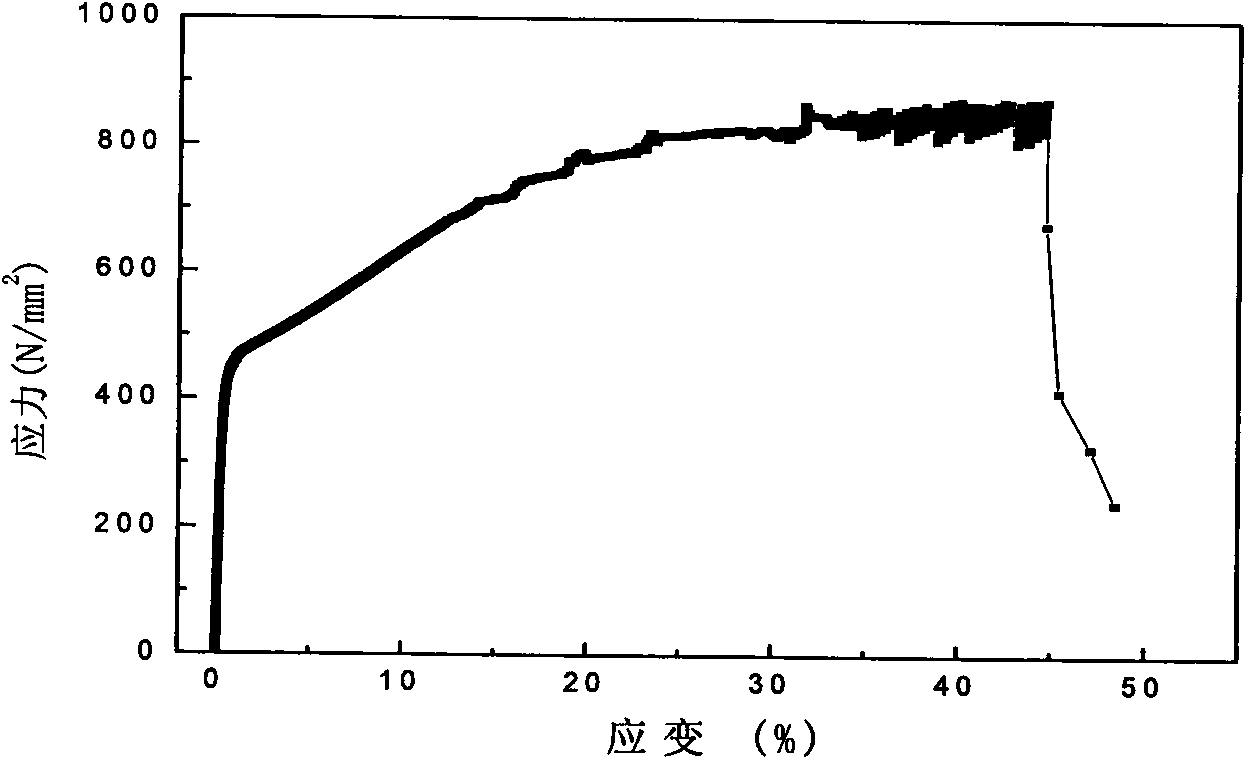

The invention provides light and high-performance twin crystal inducing plasticity steel, which comprises the following chemical compositions: 0.30 to 0.80 percent of C, less than or equal to 0.4 percent of Si, 15 to 25 percent of Mn, less than or equal to 0.05 percent of Al, 0.04 to 0.16 percent of P, 0.10 to 0.30 percent of Re, 0.01 to 0.02 percent of N and the balance of Fe. A preparation method comprises that: 1) vacuum melting is adopted and the tapping temperature is between 1,450 and 1,550DEG C; 2) a cast ingot is subjected to hot rolling, the initial temperature is between 1,150 and 700DEG C, the finishing temperature is more than or equal to 550 DEG C, and the cold rolled reduction ratio is between 40 and 80 percent; and 3) the annealing is performed at a temperature of between 600 and 1,000DEG C, and the steel is kept at a constant temperature for 0.5 to 20 minutes and then cooled to room temperature in a rate of 5 to 20 DEG C / s. Through composition design, the preparation method controls the casting, directly performs hot rolling and cold rolling for forming, and combines a heat treatment process to prepare the high-performance TWIP steel of which the strength and toughness balance is more than 40,000MPa percent. The light and high-performance twin crystal inducing plasticity steel is not added with silicon, aluminum and precious alloys, has low cost and high purity,and can avoid the defects of hot rolled billets; and the TWIP steel with different strength and plasticity can be prepared through different heat treatment systems, and the effective utilization of energy and resource can be achieved.

Owner:ANGANG STEEL CO LTD

TRIP/TWIP high strength plastic automotive steel with excellent processability and preparation method thereof

ActiveCN101928876AControl rest timeControl the tapping temperatureTemperature control deviceQuenching agentsChemical compositionSheet steel

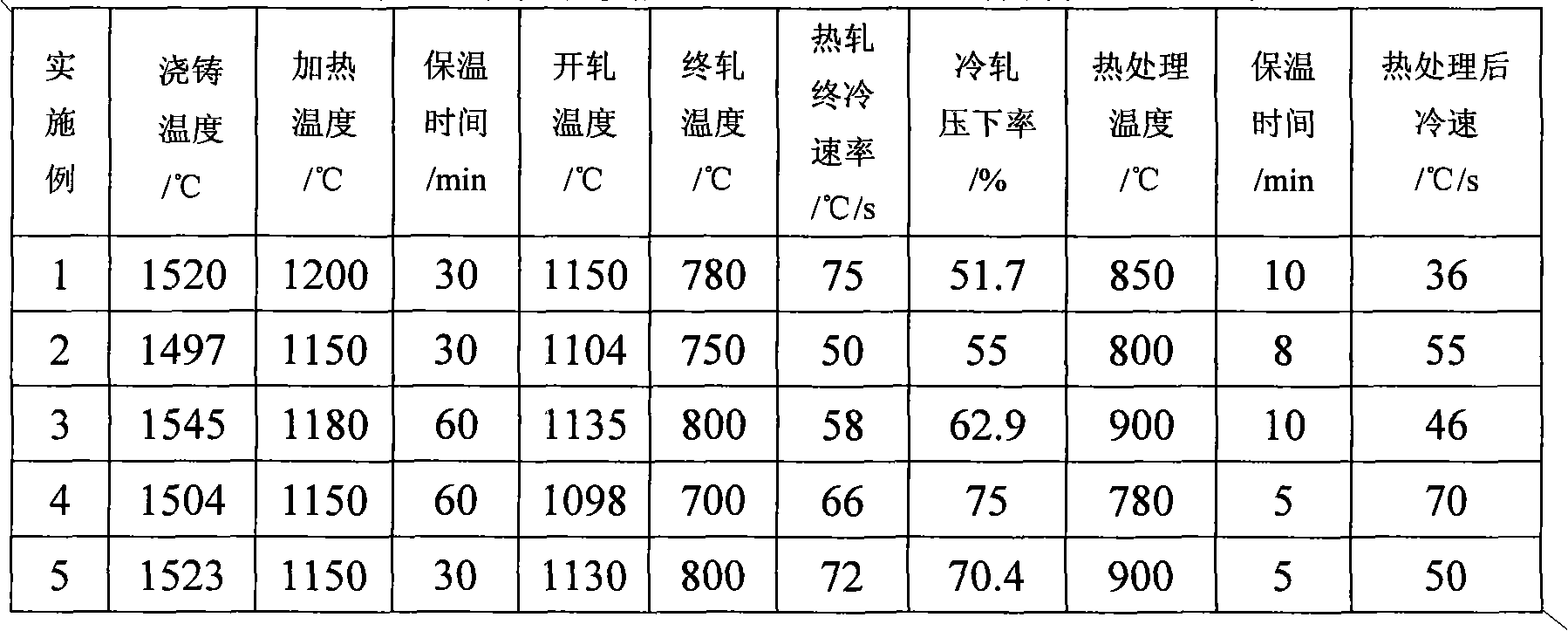

The invention discloses a TRIP / TWIP high strength plastic automotive steel with excellent processability and a preparation method thereof. The TRIP / TWIP high-strength plastic automotive steel comprises the following chemical components in percentage by weight: 0.10%-0.45% of C, 0.6% of Si or less, 10%-20% of Mn, 0.30% of Al or less, 0.20% of P or less, 0.005% of S or less, 0.05%-0.30% of Re, 0.004%-0.05% of N, 0.1% of Nb or less, and the balance of Fe and inevitable impurities. The method comprises the following steps of: carrying out vacuum smelting and casting at the casting temperature of 1,450-1,550 DEG C to obtain a billet; heating the cast billet at the temperature of 1150-1,250 DEG C, and keeping the temperature for 30-60 minutes; rolling the cast billet at the starting rolling temperature of 700-1,150 DEG C and the final rolling temperature of 600-850 DEG C, and carrying out water quenching on a rolled steel plate at the cooling rate of not less than 30 DEG C / s; carrying out cold rolling on a hot rolled plate at the reduction ratio of 40%-80% to obtain a steel plate with the thickness of 0.8mm to 2.0mm; carrying out thermal treatment on a cold rolled belt in a static furnace at the temperature of 600-1,000 DEG C, keeping the temperature for 3-10 minutes, and fast cooling at cooling rate of not less than 20 DEG C or carrying out water quenching to room temperature. The invention can obtain an organizational structure with certain component proportion by hot rolling control and thermal treating processes with preferable components, sufficiently utilizes the high strength of TRIP effect and the high plasticity of TWIP effect and organically combines the two effects to obtain the steel plate which has TRIP and TWIP effects and excellent comprehensive performances.

Owner:ANGANG STEEL CO LTD

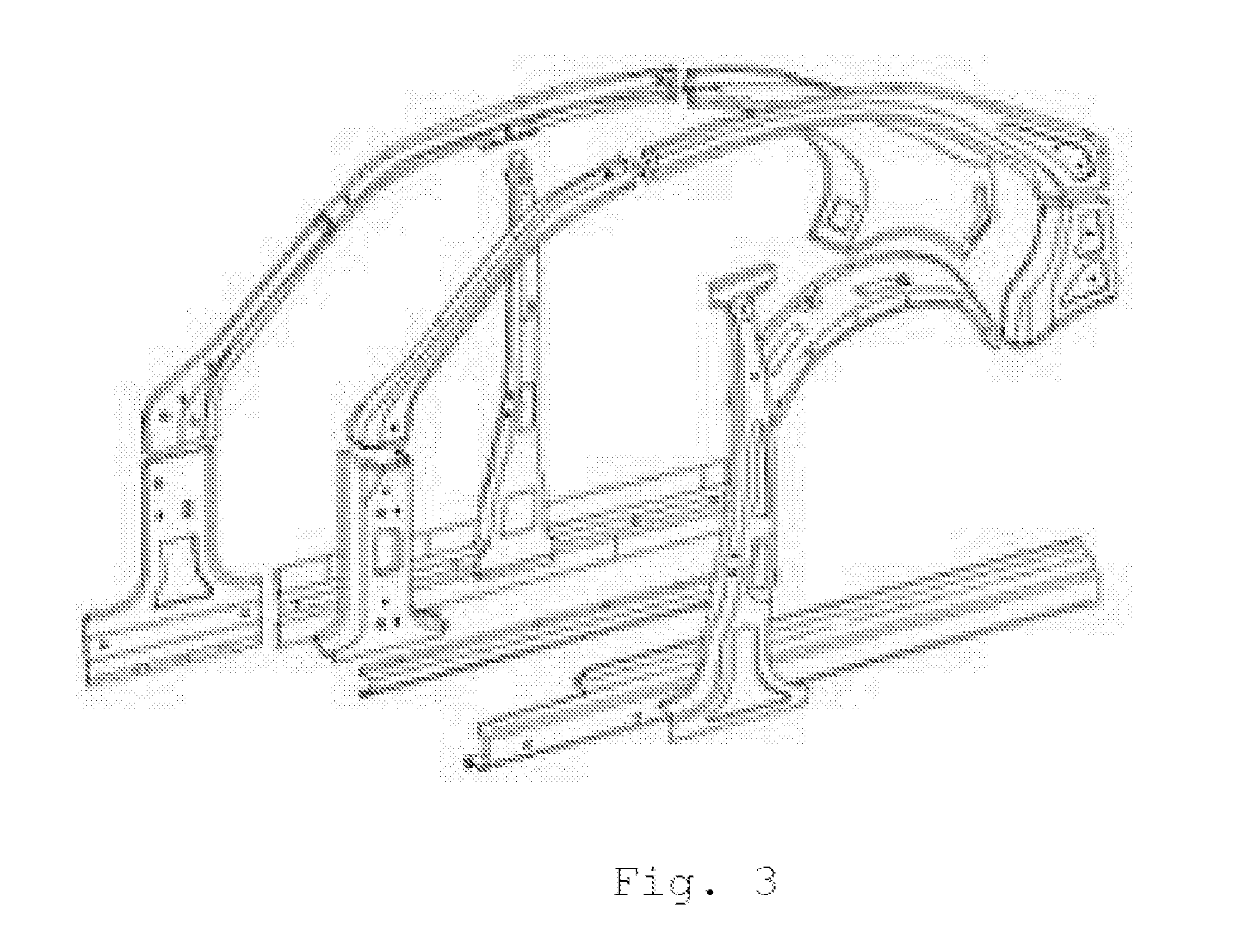

High-strength twip steel sheet and method of manufacturing the same

The present invention features a high-strength and light TWIP steel sheet which can be used to manufacture vehicle body parts, and a method of manufacturing the same.

Owner:HYUNDAI MOTOR CO LTD +1

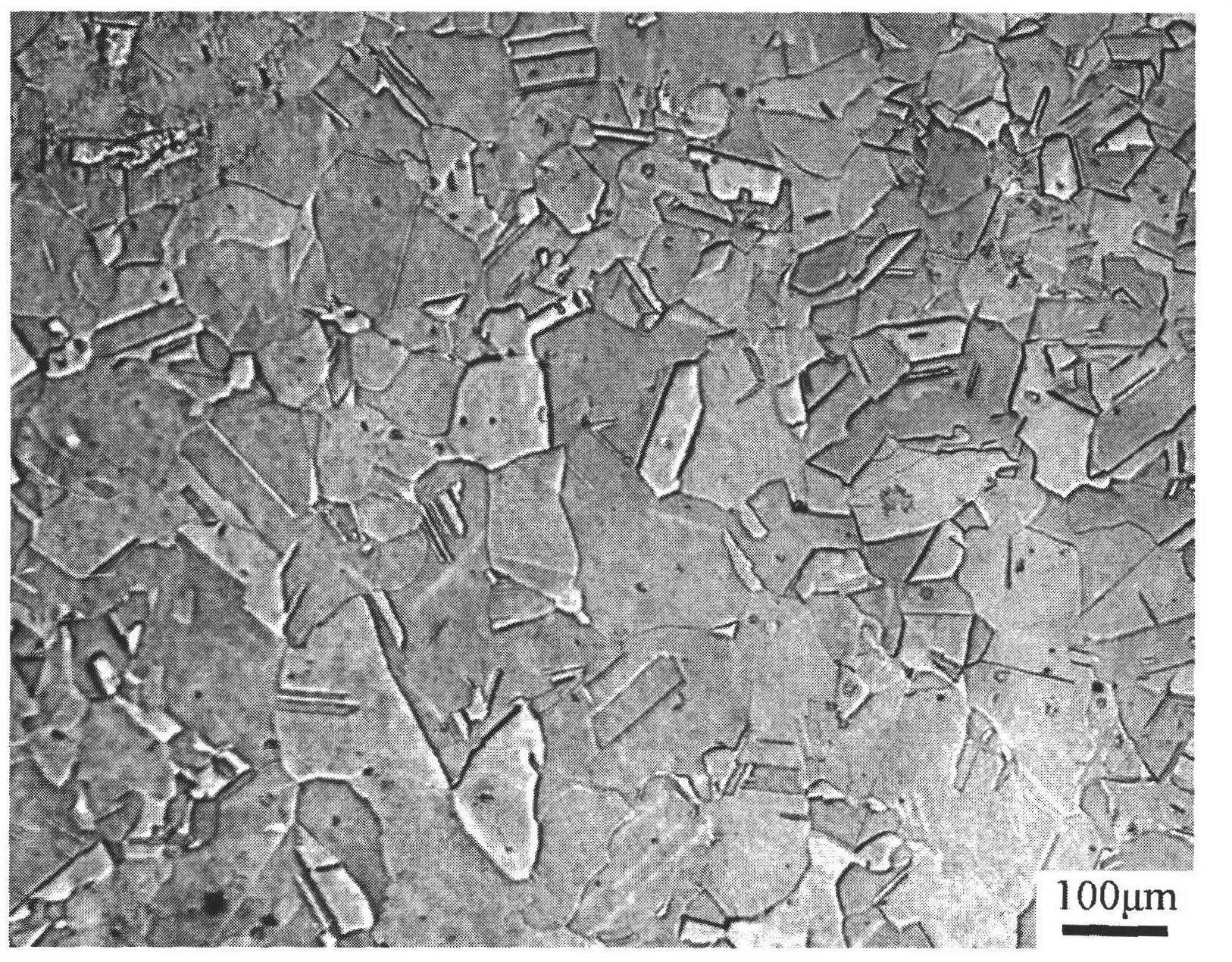

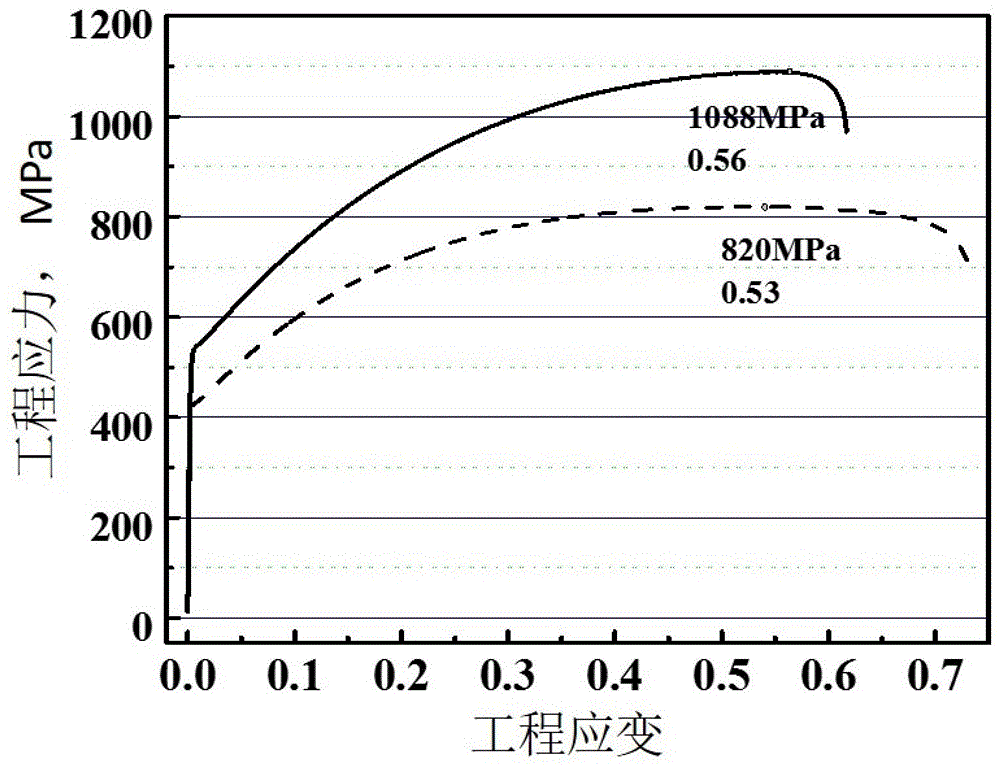

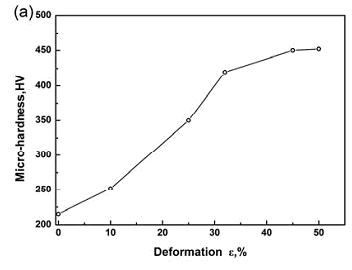

High strength and ductility alloy steel and heat treatment technology thereof

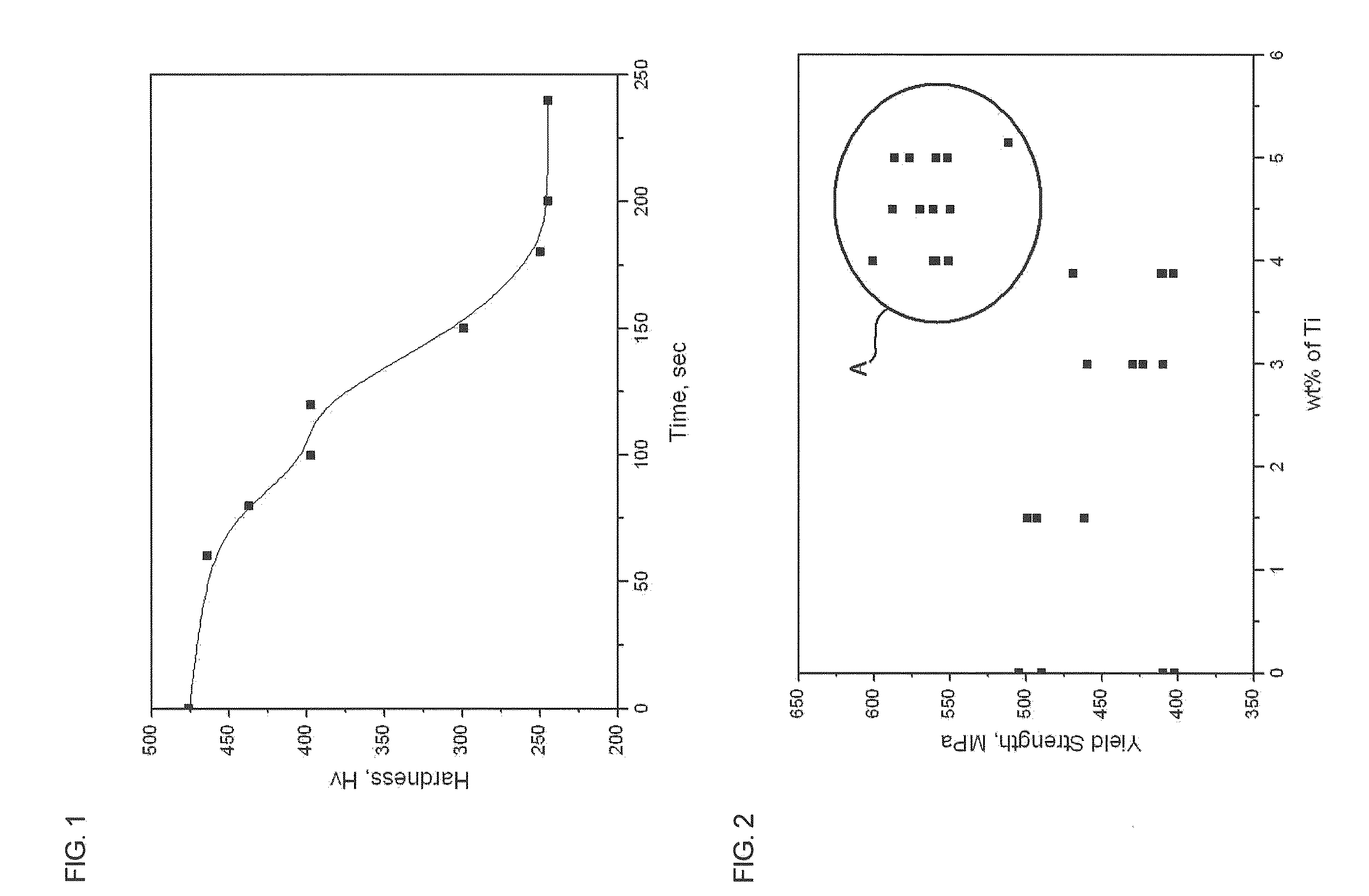

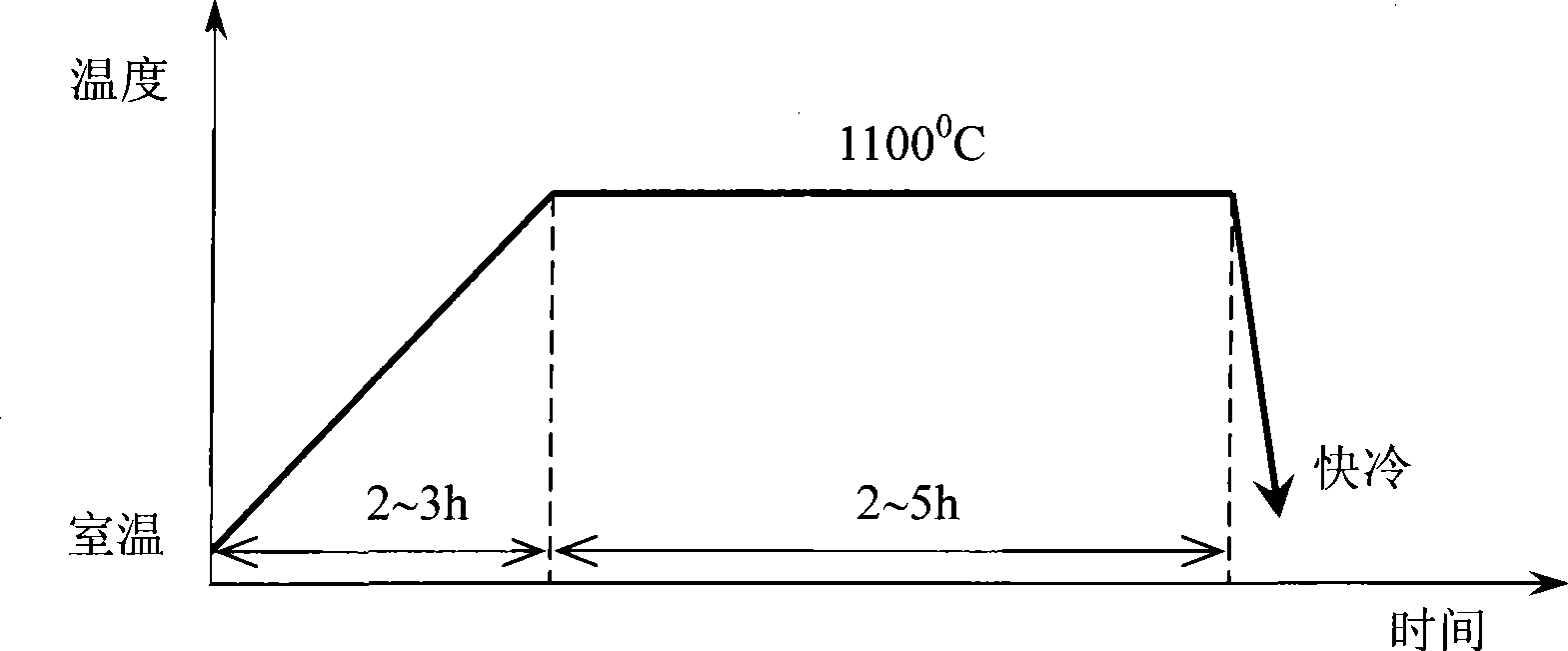

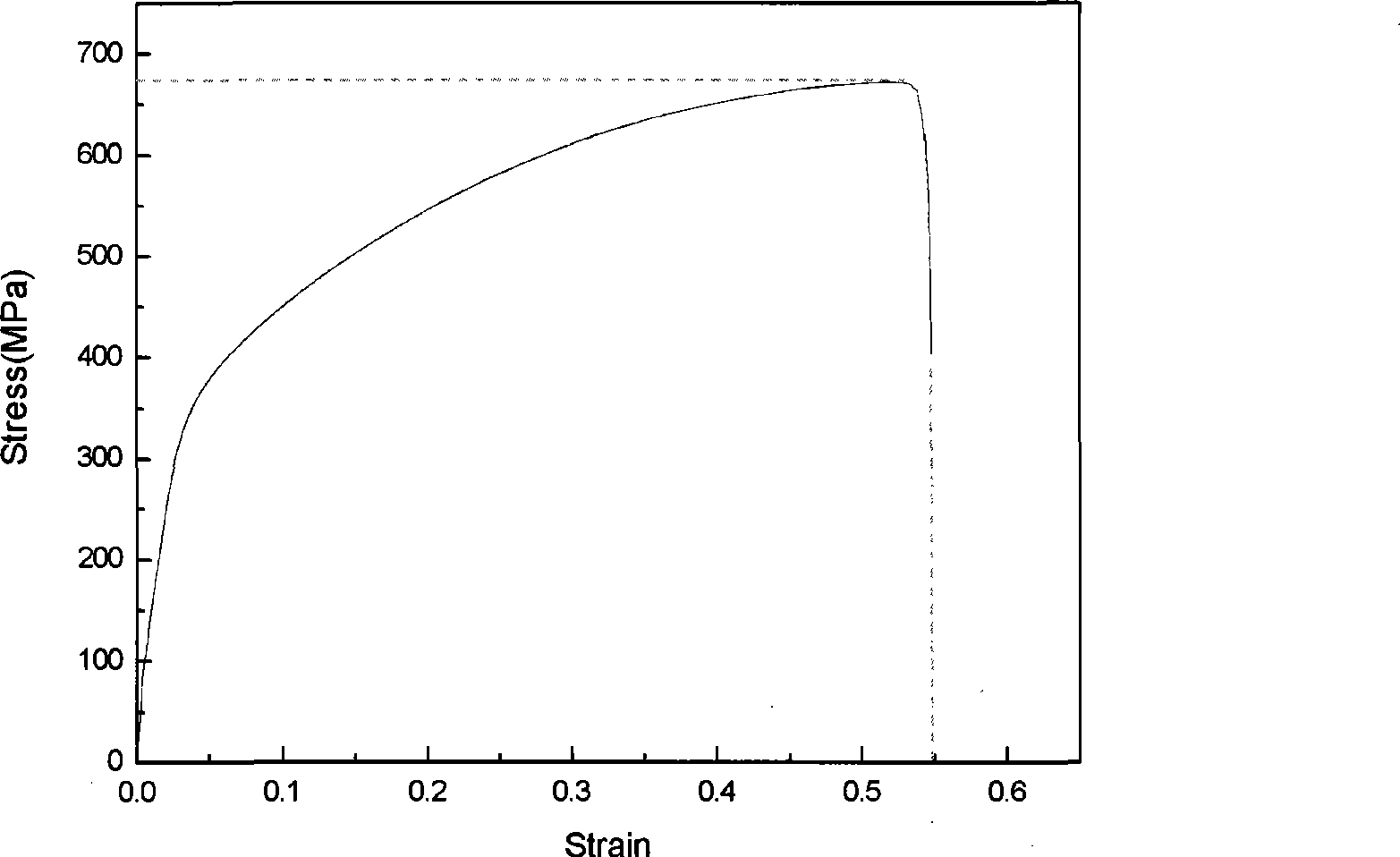

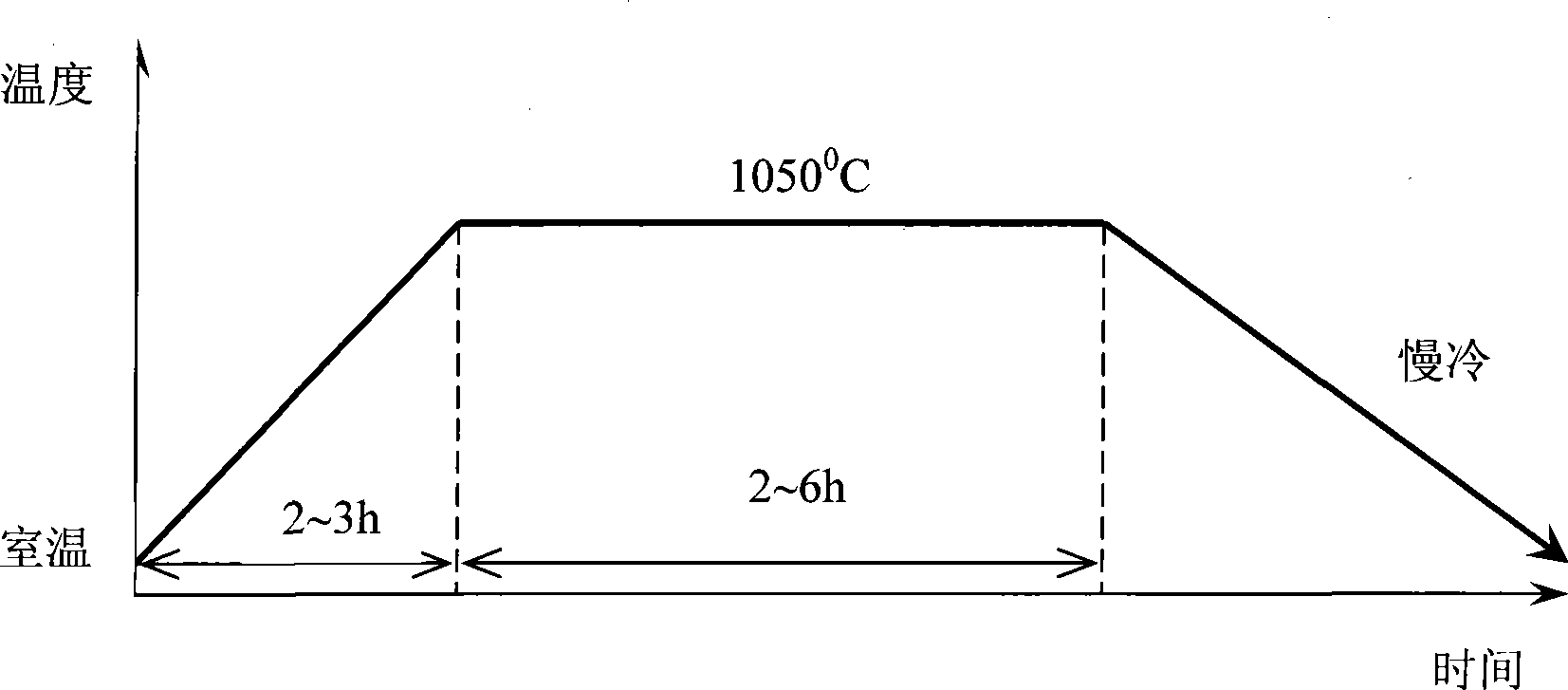

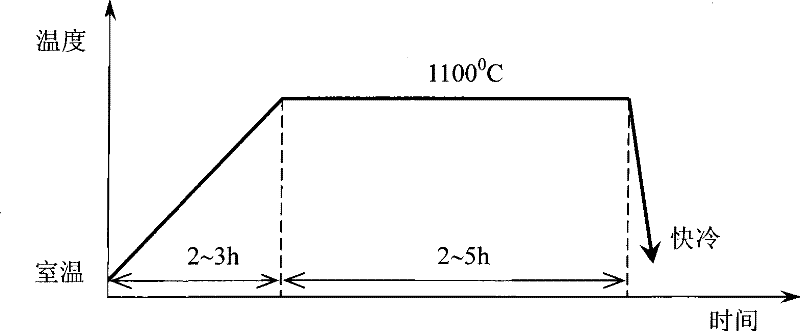

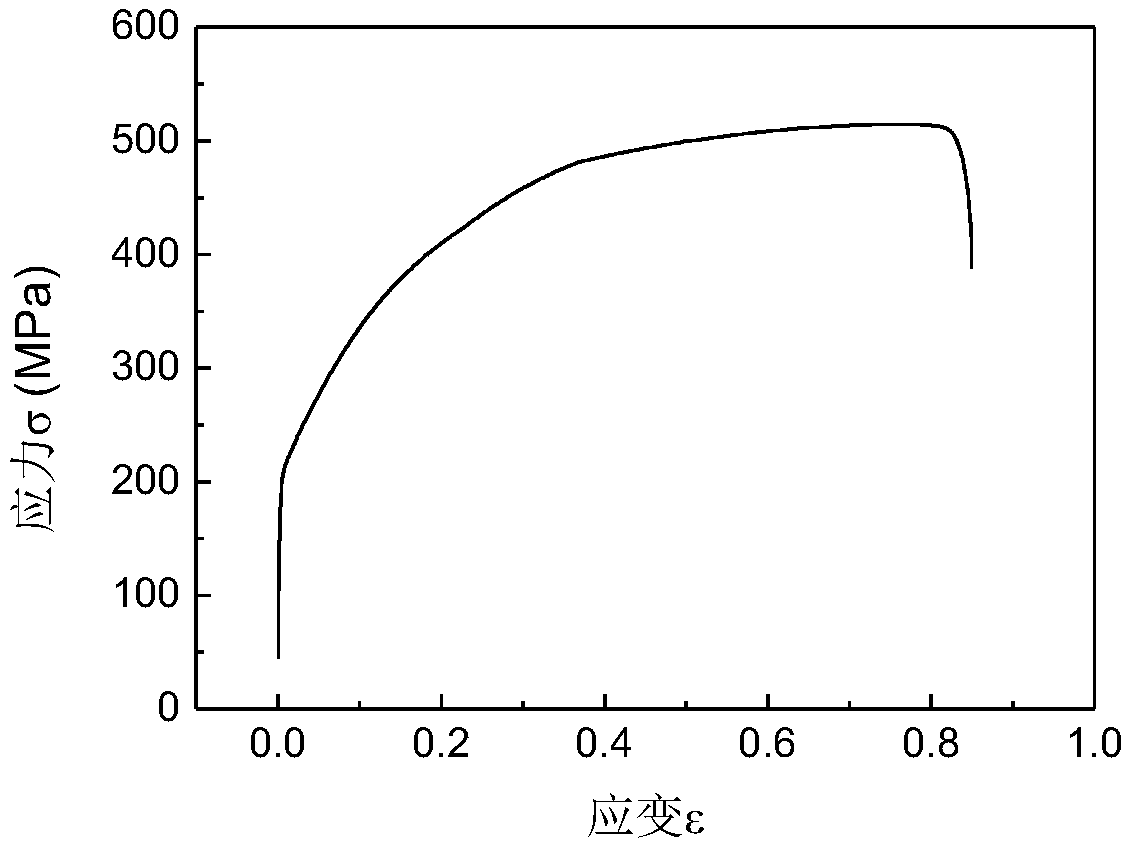

The invention discloses a high product of strength and ductility alloy steel and the thermal processing process of the same. The chemical compositions in percentage by weight of the steel are: 0.03 to 0.05 percent of carbon, thirty minus and plus 0.5 percent of manganese, three minus and plus 0.5 percent of aluminum, three minus and plus 0.5 percent of silicon and the balance being Fe. The process comprises the following of: a step of arranging work pieces in a resistance heating oven with appropriate clearance between work pieces; a step of powering up and heating with the speed rate of temperature rise of 6 to 9 DEG C per minute; a step of preserving temperature when the temperature reaches 11000 DEG C, the temperature fluctuation is less than or equal to minus and plus 5 DEG C and the preservation time is 2 to five hours according to the size of the work piece; after temperature preservation is completed, taking the work pieces out of the resistance heating oven and throwing the work pieces into a water pond with the water temperature less than or equal to 30 DEG C and swinging; when the surfaces of the work pieces have no obvious steam, the work pieces an be taken out of the water pond. The high product of strength and ductility alloy steel and the thermal processing technology, can regulate and control the steel microstructure and property of high product of strength and ductility TWIP steel and can regulate and control the strength and ductility of materials according to the application conditions at a higher level.

Owner:INST OF SOLID PHYSICS ACAD SINICA

Manganese-containing steel and production method therefor

The invention discloses manganese-containing steel and a production method therefor. The manganese-containing steel comprises the following components, by weight, 0.2-1.0% of carbon, 5-15% of manganese, 0.02-1.0% of aluminum, phosphorus of being less than 0.025%, sulphur of being less than 0.025%, nitrogen of being less than 0.03% and 0.03%-2% of silicon. The manganese-containing steel also comprises at least one of the following alloy elements: 0.01-1.2% of titanium, 0.01-1.2% of niobium, 0.01-1.2% of vanadium, and the balance being iron element. The above scheme is employed, the steel material with TWI and TRIP effects is provided. Compared with present TWIP steel, the manganese-containing steel has a low manganese content, has advantages of high intensity, high plasticity and low cost, and has high market application values.

Owner:邹平县永通金属材料有限公司

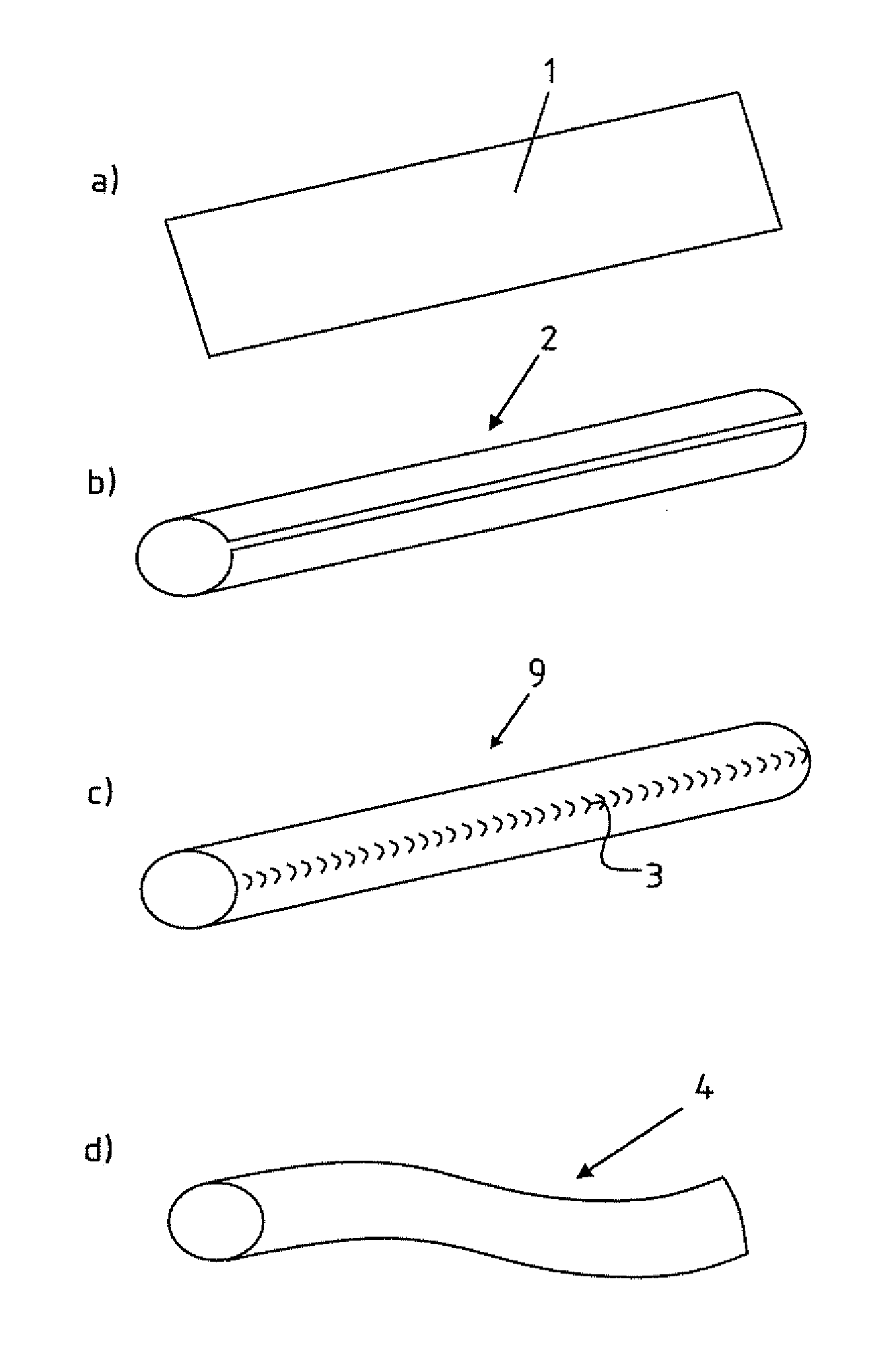

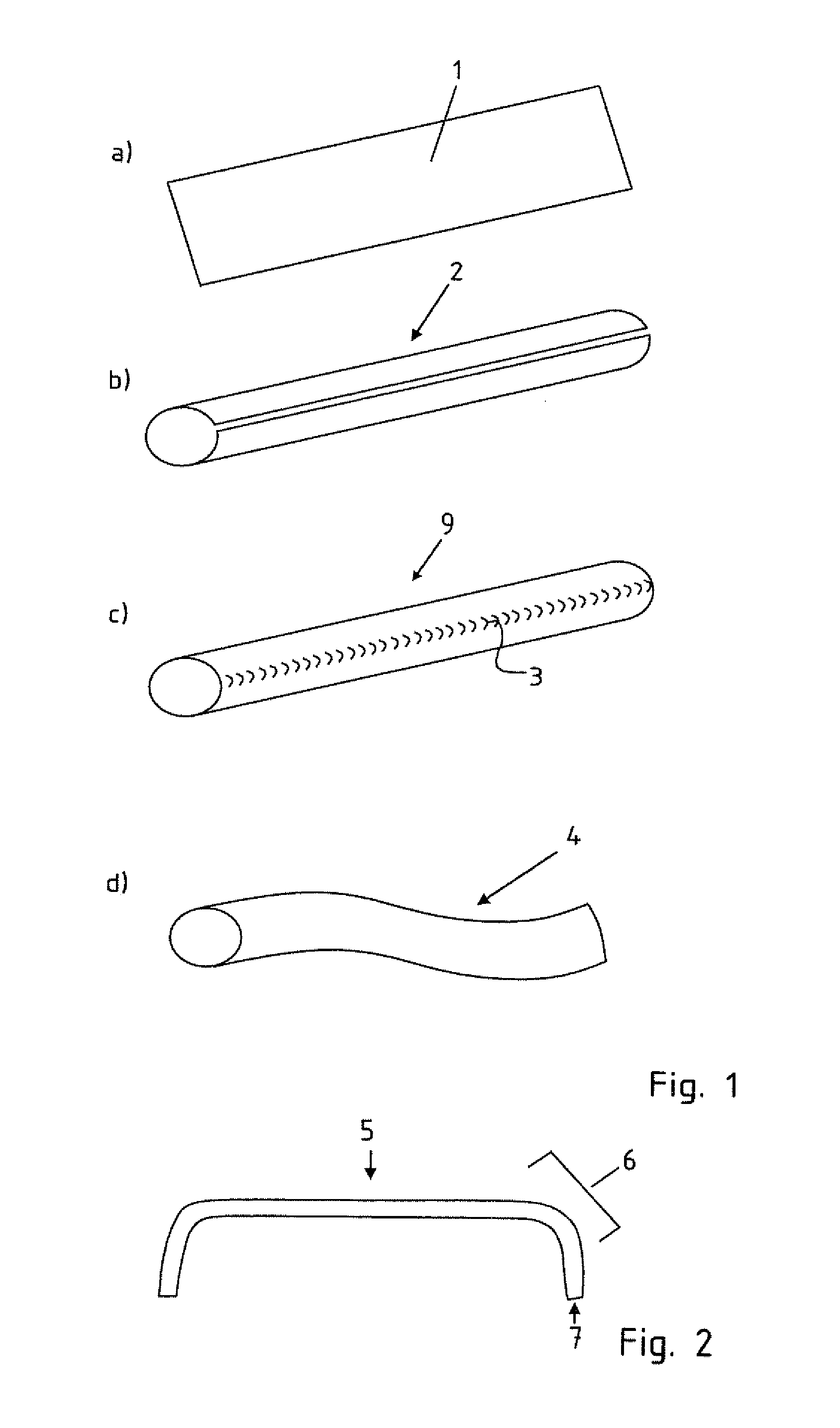

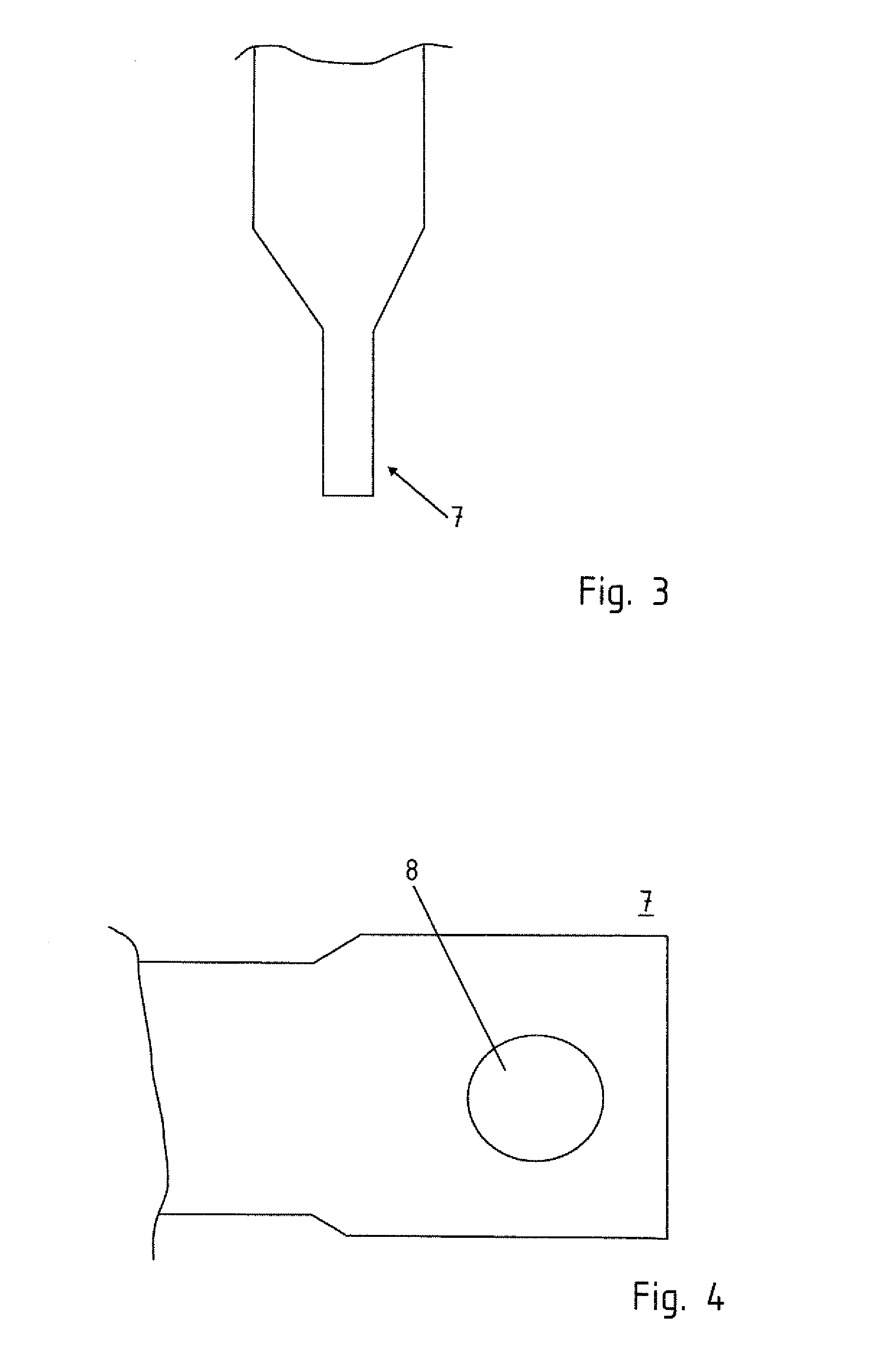

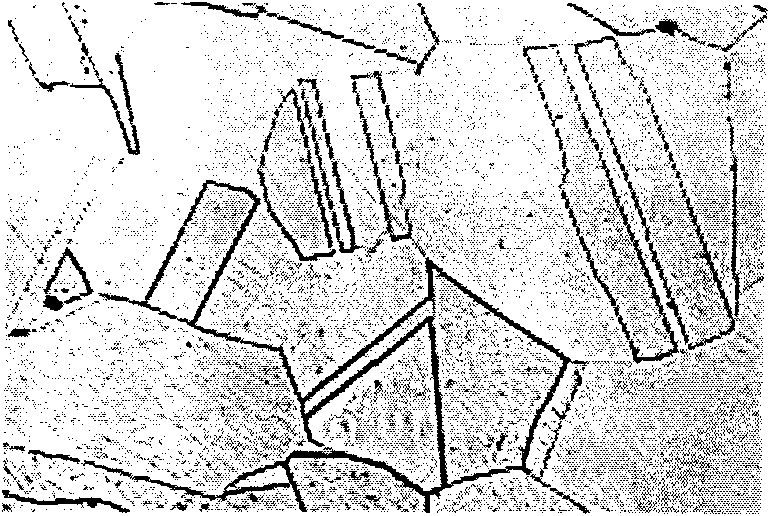

Method for producing a motor vehicle stabilizer

A method for producing a motor vehicle stabilizer, configured as a hollow tubular component, includes the steps of method steps of providing a steel strip made of a high-manganese-content steel alloy having TWIP and / or TRIP properties, forming a tubular profile from the steel strip, longitudinal seam welding of the tubular profile to form a tube, and bending the tube into the stabilizer rod.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

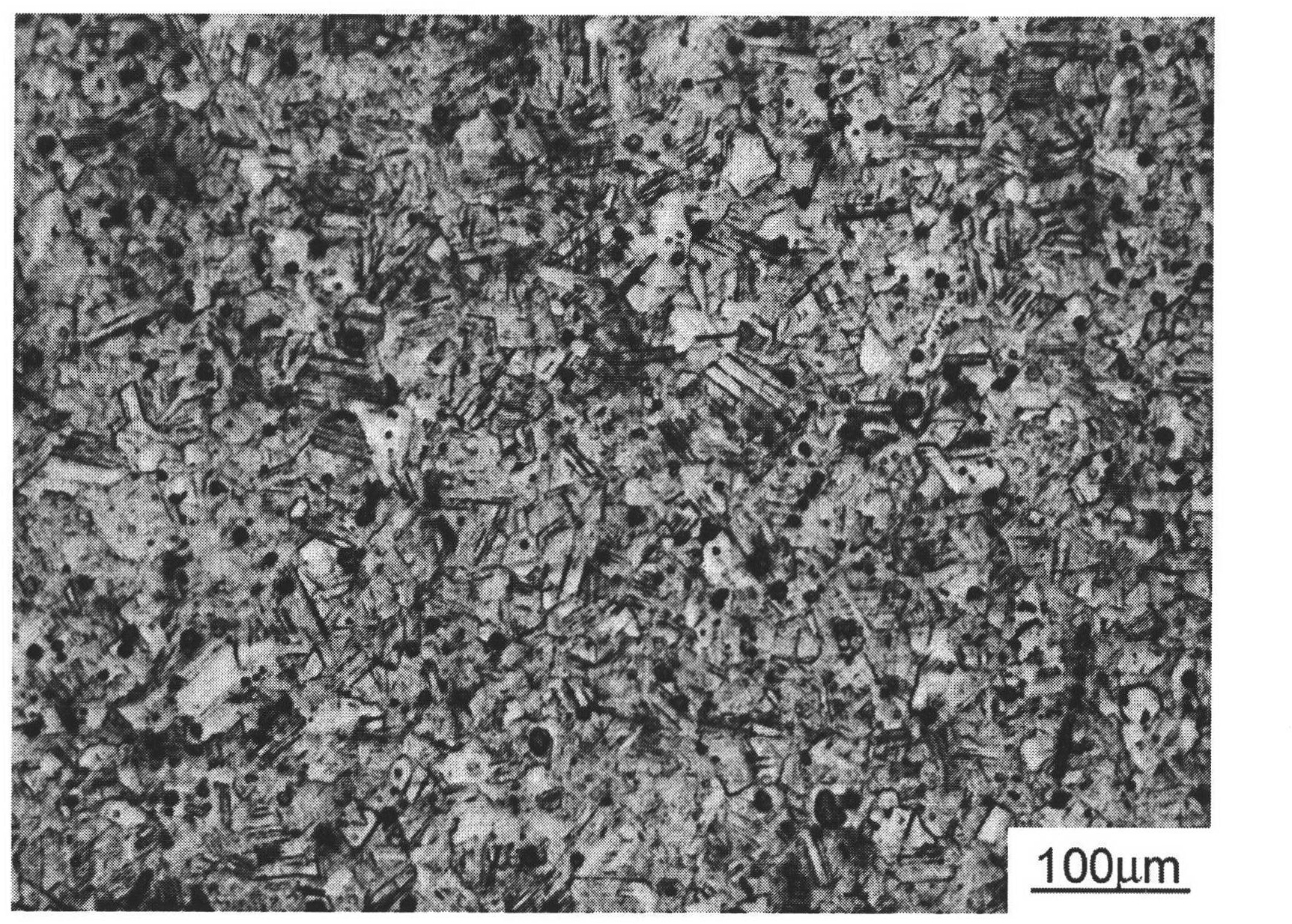

Electrolytic polishing method for high-strength hot rolling low carbon twinning induced plasticity (TWIP) steel

The invention relates to an electrolytic polishing method for a high-strength hot rolling low carbon twinning induced plasticity (TWIP) steel (comprising 25-33 percent of Mn, 2.3-2.55 percent of Si, 2-4 percent of Al, 0.005-0.02 percent of C and the balance of Fe). According to the method, an electrolytic polishing solution is a sand extracting solution (comprising the following components in percentage by mass: 20 percent of perchloric acid, 10 percent of glycerin and 70 percent of alcohol), and the voltage is 18-28V, the current density is 0.9-1.9A / cm2, the polishing time is 50-150S and the polishing solution temperature is 25-40 DEG C. The method does not generate a deformed twin crystal caused by stress strain in the electrolytically polished texture, the electrolytically polished metal surface is smooth and bright like a mirror face, and the method is widely applied to various occasions needing electrolytic polishing, such as low carbon TWIP steel metallographic phases in different dimensions, texture, stress tests, and the like in a laboratory. The invention belongs to the field of electrolytic polishing of high-strength steel.

Owner:SHANGHAI UNIV OF ENG SCI

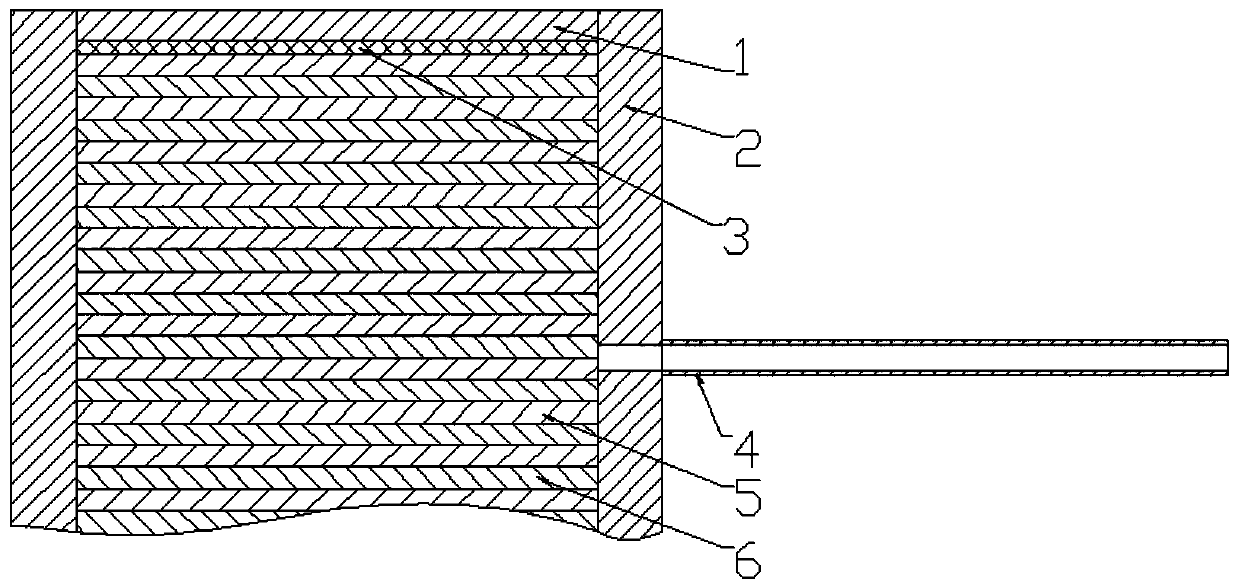

Electroslag remelting production method of high-strength high-plasticity TWIP (Twinning Induced Plasticity) steel

The invention provides a production method of high-strength high-plasticity TWIP (Twinning Induced Plasticity) steel, and belongs to the technical field of metallurgy. The TWIP steel comprises 0.03%-0.08% of C, 2.0%-3.0% of Si, 20%-30% of Mn, 2.5%-3.5% of Al, the balance of Fe and a small amount of other alloying elements. The TWIP steel is smelted by adopting a slag system comprising 60-70% of CaF2, 20-30% of Al2O3 and 5-15% of CaO; a right amount of manganese metal or electrolytic manganese and aluminium powder are added to slag so as to solve the problems of easy oxidization and burning loss of volatile elements in the TWIP steel. Argon is used for protecting remelting at a flow rate of 20-40Nm<3> / h, so that the burning loss of aluminium is reduced; the refinement is carried out at a low melting rate, and the melting rate is controlled at 700-950kg steel / hour. In a feeding period, electric currents gradually decline, and the feeding time is greater than 1.5 hours. The production method has the advantages that by adopting the electroslag remelting method, cracks are prevented from occurring in a TWIP solidification process, the solidification structure and the segregation condition of the TWIP steel can be improved, and meanwhile, the cleanliness of the TWIP steel can also be obviously improved.

Owner:UNIV OF SCI & TECH BEIJING

Twip steel sheet having an austenitic matrix

PendingUS20190218639A1High strengthGood formabilityHot-dipping/immersion processesFurnace typesMetallurgyTwip

A cold rolled and recovered TWIP steel sheet is provided having an austenitic matrix including by weight: 0.71<C<1.2%, 13.0≤Mn<25.0%, S≤0.030%, P≤0.080%, N≤0.1%, 0.1≤Si≤3.0%, 0.1≤V≤2.50%, and on a purely optional basis, one or more elements such as Cu≤5.0%, Al≤4.0%, Nb≤0.5%, B≤0.005%, Cr≤1.0%, Mo≤0.40%, Ni≤1.0%, Ti≤0.5%, 0.06≤Sn≤0.2%, the remainder of the composition being made of iron and inevitable impurities resulting from elaboration.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Preparation method of TWIP (Twinning Induced Plasticity) steel with high strength and high plasticity

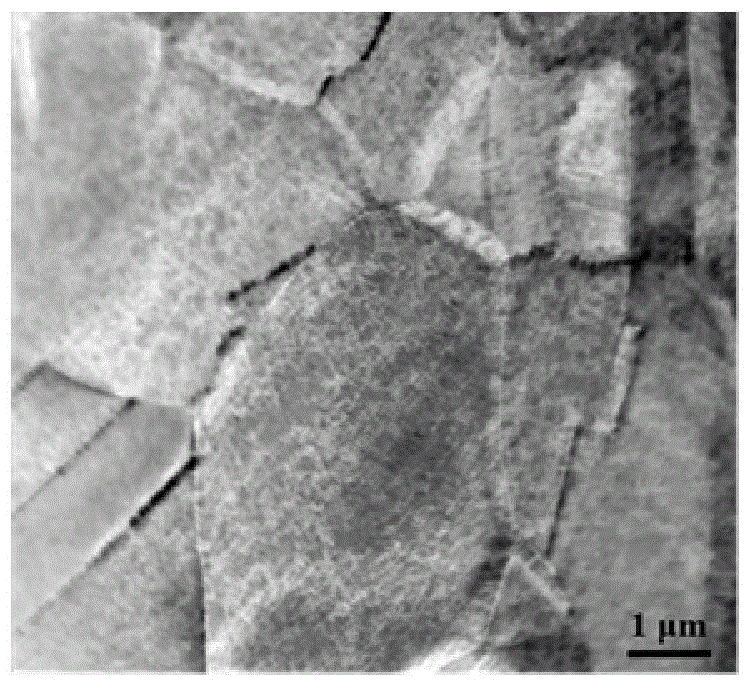

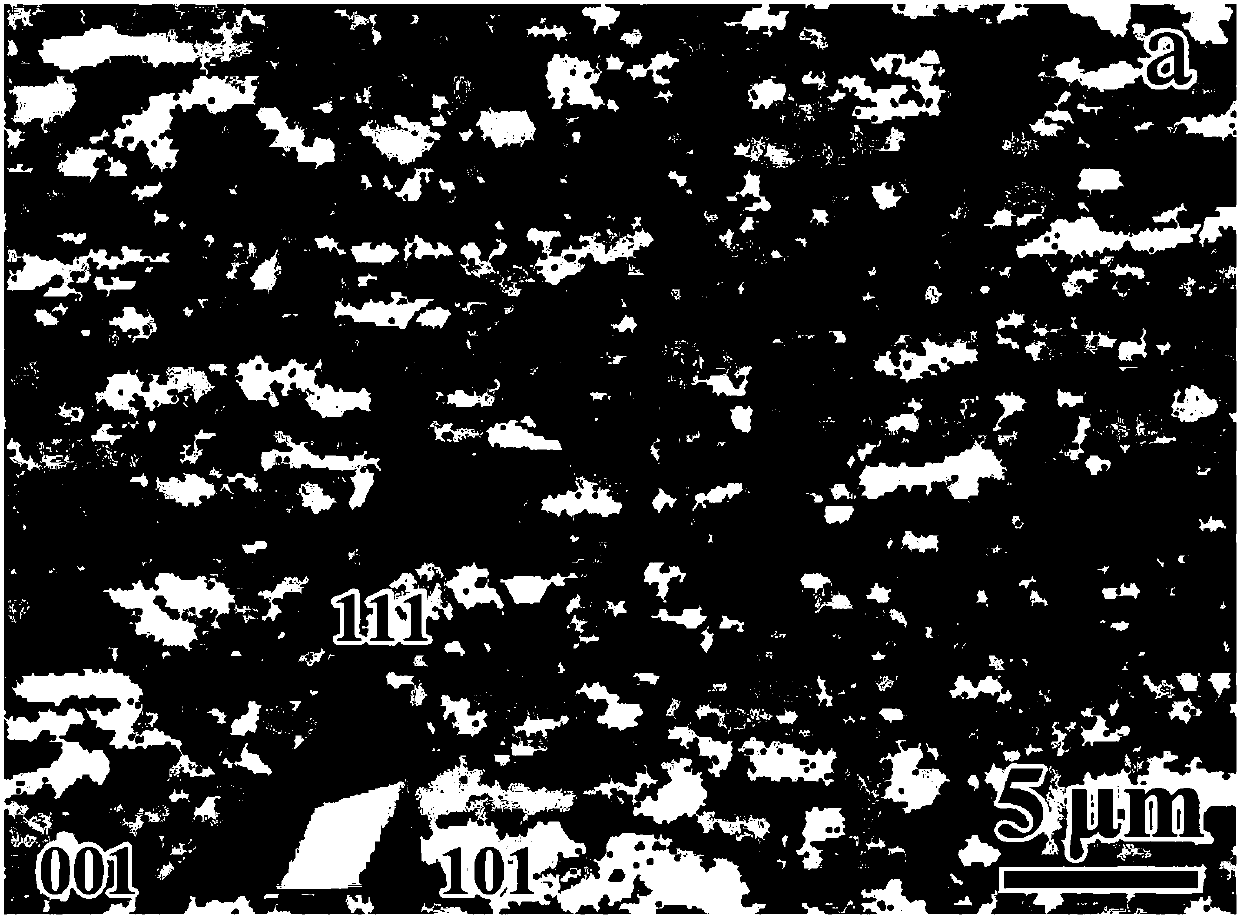

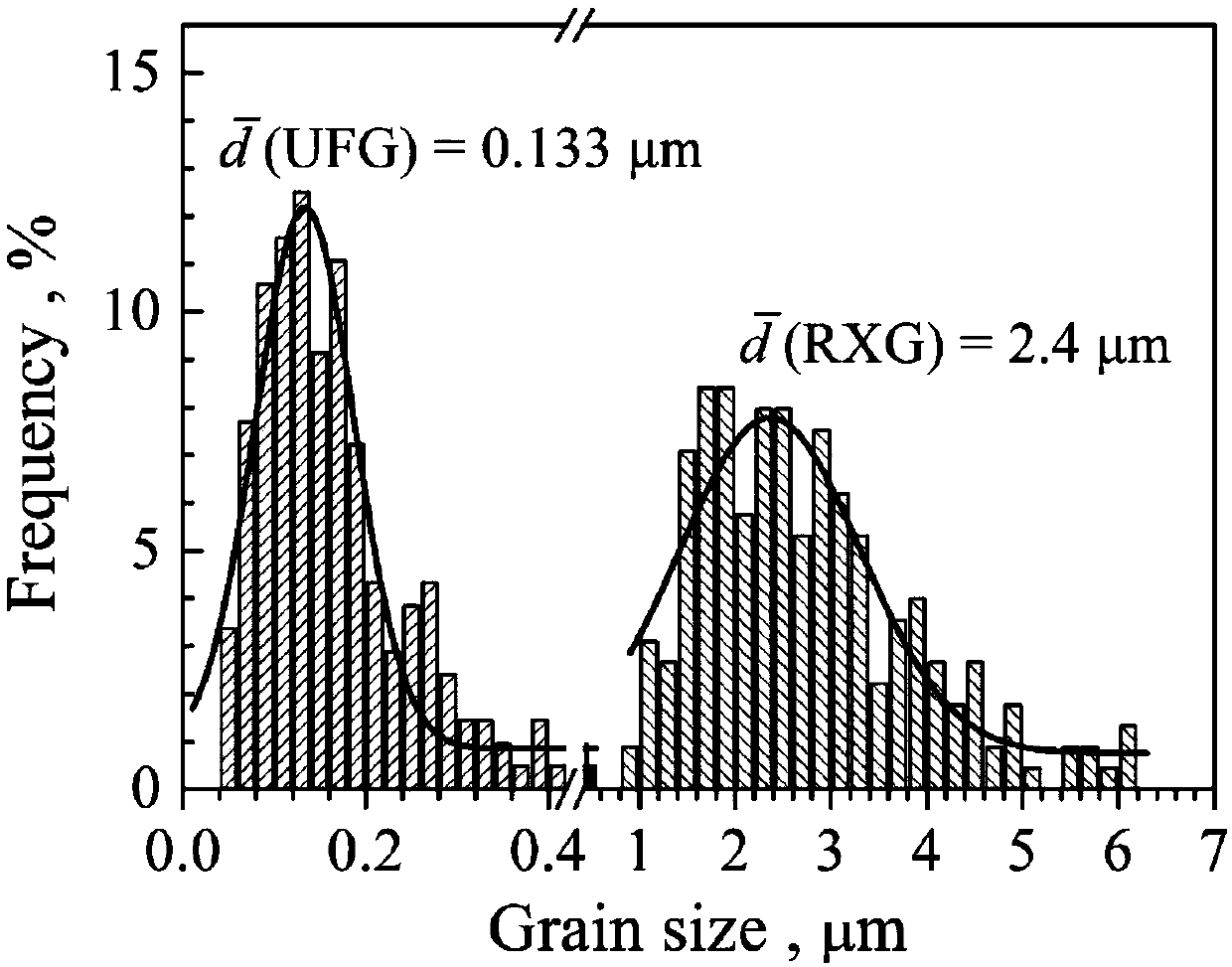

The invention relates to an ultra-fine grain metal material, and particularly provides a preparation method of TWIP (Twinning Induced Plasticity) steel with high strength and high plasticity. The TWIP steel is formed by nearly equiaxed-shaped perfect recrystallization grains and large annealing twins in recrystallized layer sheets. The invention further discloses the preparation method. The TWIP steel with high strength and high plasticity provided by the invention has excellent performances, and the preparation method is simple.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

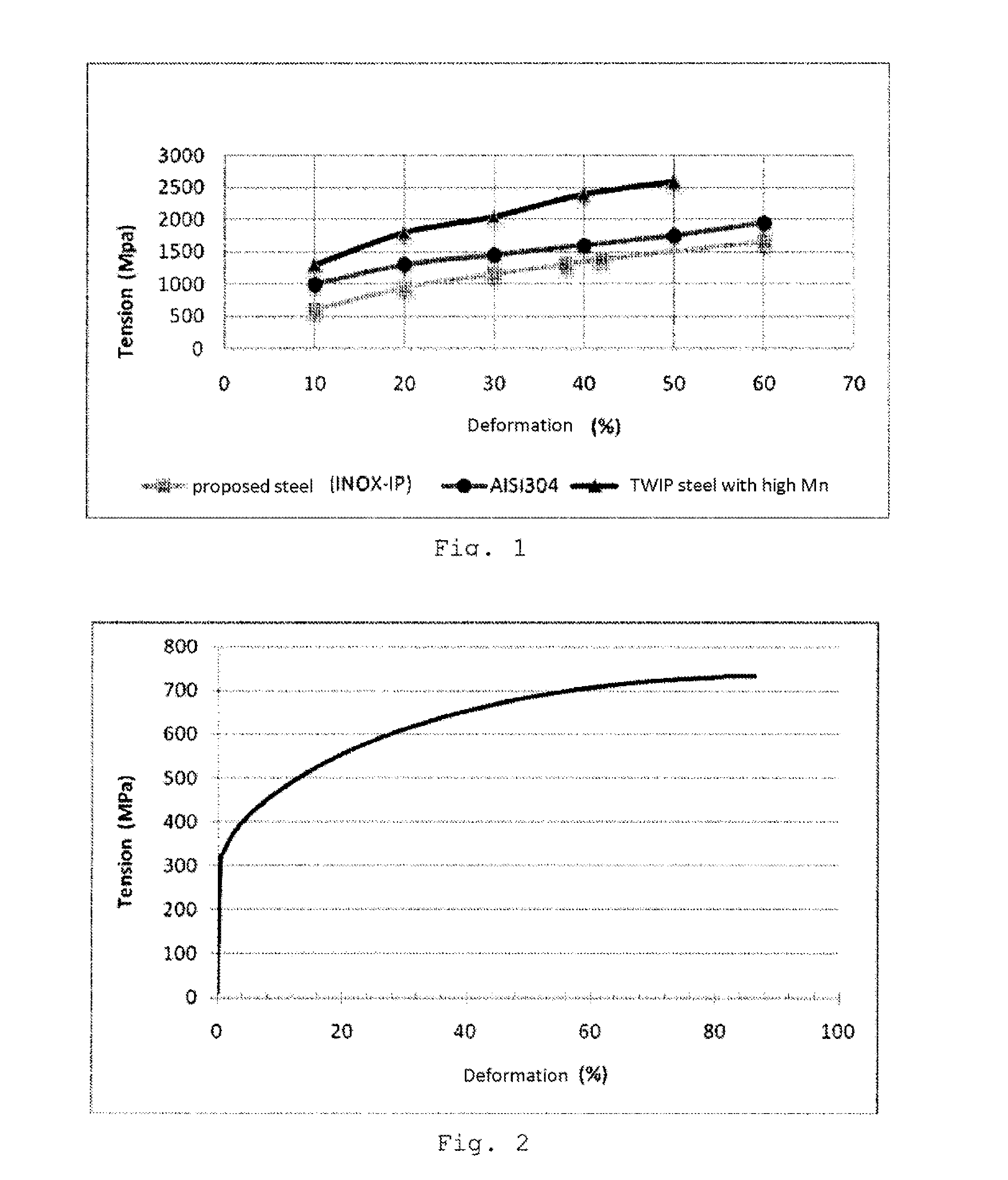

Austenitic twip stainless steel, its production and use

ActiveUS20150329947A1Increase resistanceIncreasing energy of stacking faultHigh resistanceChemical composition

The object of the invention is an austenitic stainless steel with high plasticity induced by twinning with innovative chemical composition, and the use thereof in the automobile industry and in all applications wherein both a high resistance to corrosion and a high formability is requested, together with mechanical features of high-resistant steels. The invention also concerns a process for the production of this austenitic stainless steel with high twinning-induced plasticity.

Owner:CENT SVILUPPO MATERIALI SPA

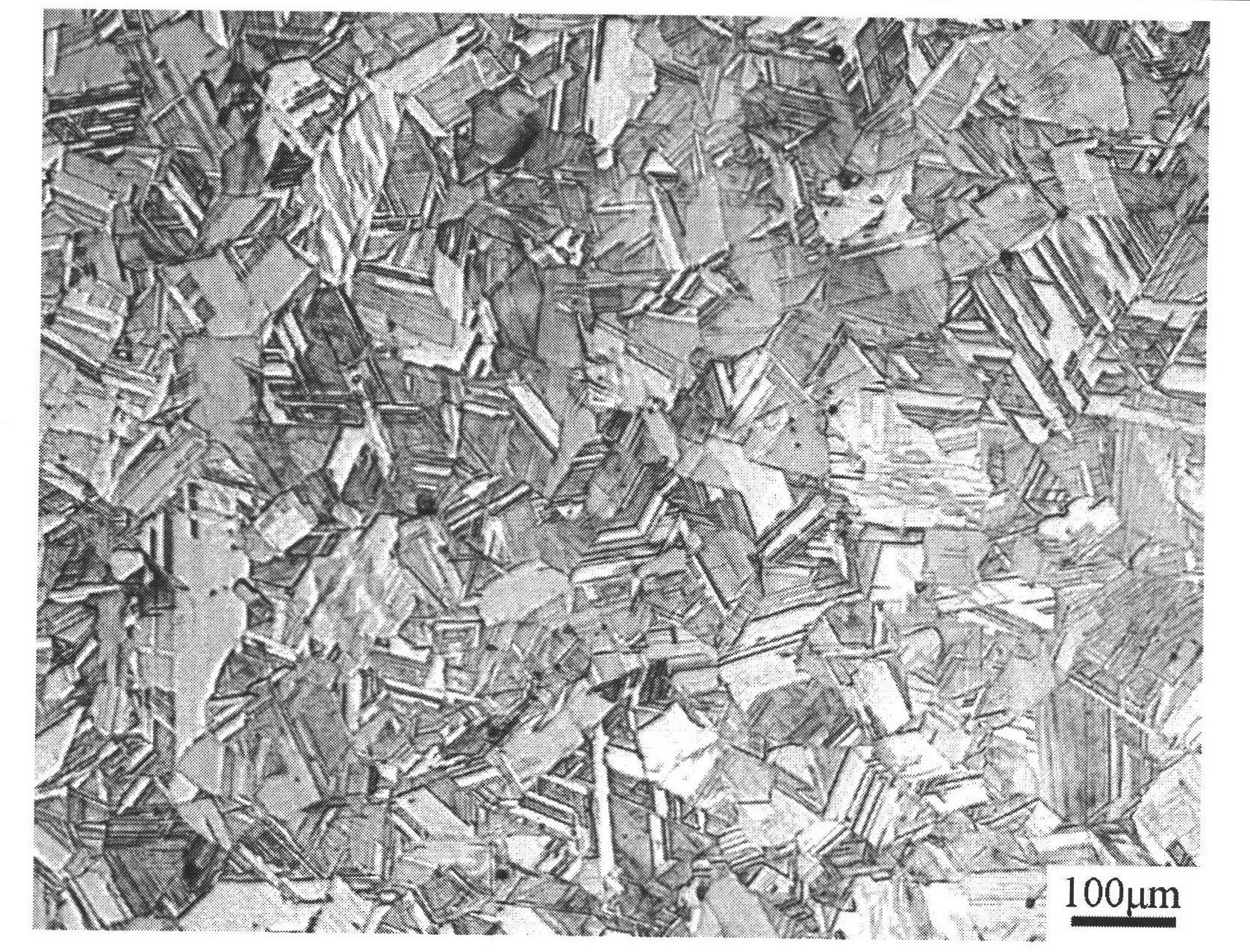

Electrolytic corrosion method of high strength and high toughness Fe-Mn-C series twinning induced plasticity steel

The invention discloses an electrolytic corrosion method of high strength and high toughness Fe-Mn-C series twinning induced plasticity (TWIP) steel. The steel is the second generation of the TWIP steel and is suitably used in the car impact resistant structural component and in other fields. The steel contains the following chemical components by weight percent: 0.2-0.7% of C, 17-24% of Mn and the balance Fe and inevitable impurities generated by the smelting process. The electrolytic corrosion method is characterized in that the electrolytic corrosion liquid is the mixed solution of 10% of perchloric acid, 80%-90% of glacial acetic acid and 0-10% of glycerol by volume, the working voltage is 30-45V; the current density is 0.5-1.5A / cm<2>, the corrosion time is 30-120s, the temperature of the corrosion liquid is 10-50 DEG C and the distance between the cathode and the anode is 1-5cm. The method of the invention is simple and practical and has good repeatability; the surface of the prepared TWIP steel does not have scratches and the surface deformations caused by polishing deformation such as the disturbing layer and the deformation twin, and the TWIP steel of the invention can satisfy the experimental requirements of the metallurgical phase, the type analysis of grain boundary, the strain test and the texture measurement on different sizes of Fe-Mn-C series TWIP steel samples.

Owner:CHINA JILIANG UNIV

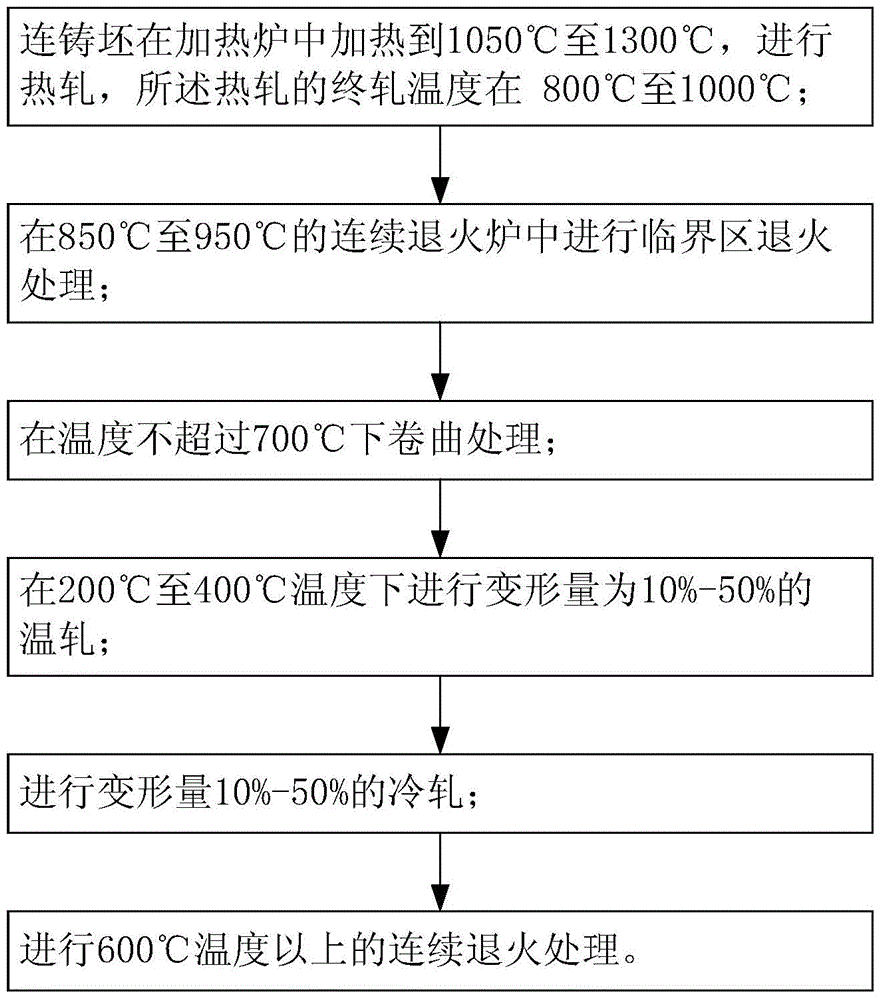

Twinning induced plasticity steel and production method thereof

The invention discloses twinning induced plasticity steel and a production method thereof. The production process comprises a steelmaking step, a continuous casting step and a rolling step; performing the continuous casting step is performed under a cast protective condition; the cast protective condition is that the casting powder is used for low superheat casting at a temperature of 5-10 DEG C, with the casting speed of 0.5 to 1.5 m / min; and in the rolling step, cold rolling pre deformation is adopted, and annealing treatment is performed when the temperature is near complete recrystallization. With the above scheme, the invention can provide the TWIP steel with a yield strength exceeding 1000MPa and a uniform elongation rate of more than 10%, is particularly suitable for special steel applications in automotive and the like, and has a very high market value.

Owner:嘉善县魏塘资产管理有限公司

High-strength-and-elongation cold-rolling medium manganese TRIP steel with multi-morphology and multi-size austenite structure and preparation method of high-strength-and-elongation cold-rolling medium manganese TRIP steel

ActiveCN109868345ALow C contentLow Al contentFurnace typesHeat treatment furnacesTRIP steelSheet steel

The invention relates to a preparation method of high-strength-and-elongation cold-rolling medium manganese TRIP steel with a multi-morphology and multi-size austenite structure. The preparation method includes the steps that S1, smelting and forging are conducted, specifically, smelting is conducted to obtain a steel ingot prepared from the components: 0.15-0.20% of C, 7-9% of Mn, 1.0-1.8% of Al,0.03-0.08% of Ce, P is less than 0.008%, S is less than 0.008%, and the balances of Fe and impurities, after the steel ingot is heated to 1200 DEG C and subjected to heat preservation for 1.5-3 h, asteel billet of 30-40 mm is forged, the temperature of finish forging is no less than 850 DEG C, and air cooling is conducted after forging; S2, hot rolling is conducted, specifically, the steel billet is heated to 1200-1250 DEG C and subjected to heat preservation for 1.5-2.5 h, then a steel plate is rolled through multi-pass, and air cooling is conducted; S3, annealing is conducted in a two-phase region, specifically, the steel plate is annealed at 660-690 DEG C for 40-70 min, then air cooling is conducted, and acid pickling is conducted; S4, small deformation cold rolling is conducted, specifically, cold rolling is conducted on the steel plate, and the overall reduction is controlled at 40-55%; and S5, annealing and low tempering are conducted, specifically, the steel plate is heated to660-690 DEG C and subjected to heat preservation for 6-12 min, annealing is conducted, then air cooling is conducted, and tempering is conducted at 180-230 DEG C for 15-25 min. According to the prepared cold-rolling medium manganese TRIP steel, tensile strength is larger than 1250 MPa, yield strength is 920-1060MPa, high-strength-and-elongation is larger than 65GPa.%, and the cold-rolling mediummanganese TRIP steel is close to or better than second-generation TWIP steel.

Owner:HEBEI UNIV OF ENG

High strength and ductility alloy steel and heat treatment technology thereof

Owner:INST OF SOLID PHYSICS ACAD SINICA

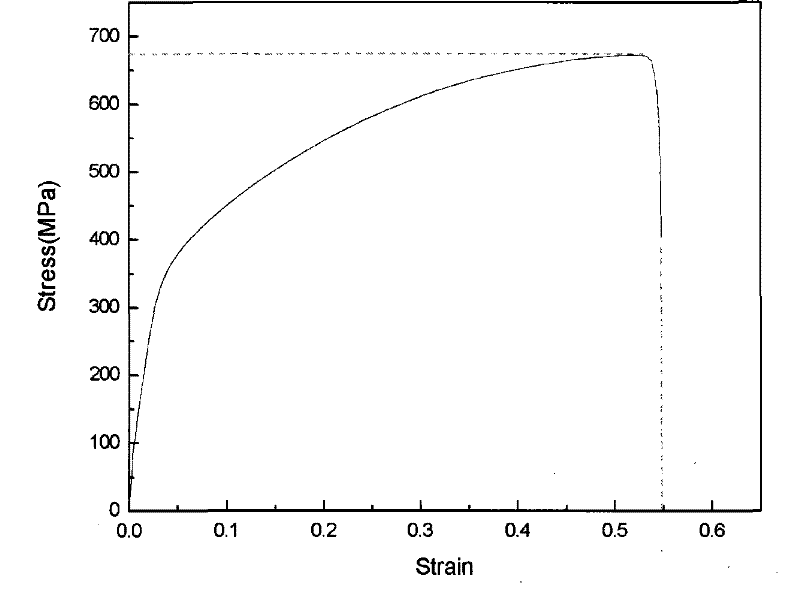

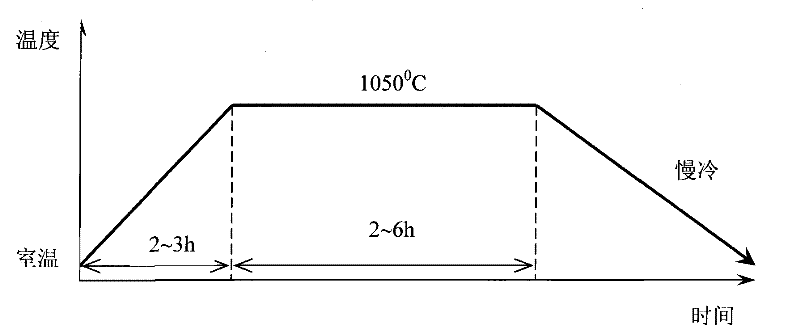

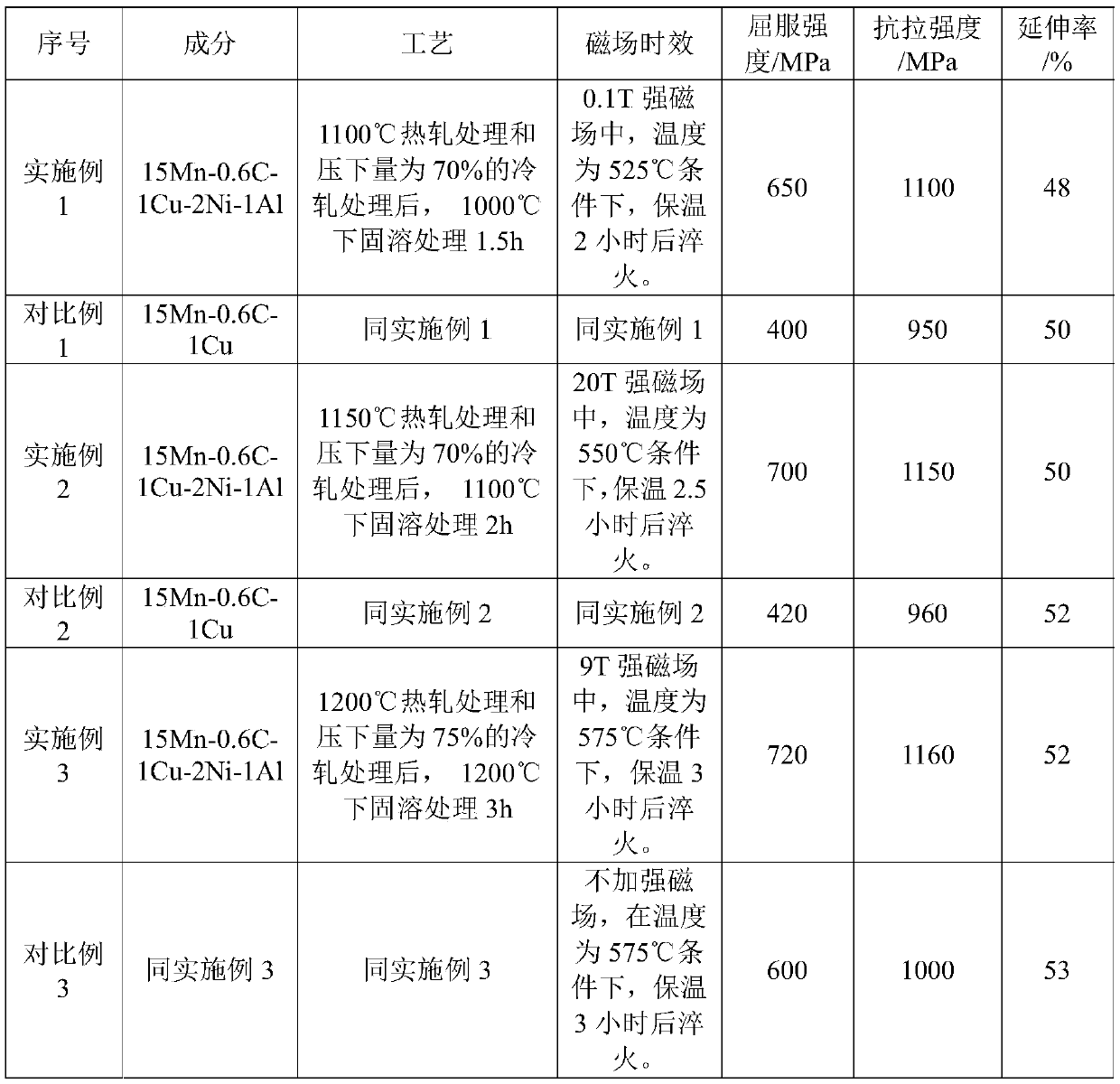

TWIP steel and preparation method thereof

The invention provides high-strength high-plasticity TWIP steel and a preparation method thereof. The technical scheme is that: aimed at the defects that higher strength and higher plasticity are notliable to achieve through single of twinning strengthening and nano precipitation strengthening in steel, the invention provides the preparation method of utilizing alloy elements like Cu, Ni and Al to replace a part of Mn to improve stacking fault energy, promote the TWIP effect, stabilize austenite, inhibit martensite phase transformation and refine twining structure on the basis that smelting,homogenization and delayed cracking problems due to high Mn content in TWIP steel are comparatively studied; and size, density and distribution of nano rich Cu particles and NiAl particles generated in steel are controlled through a strong magnetic field, and strength of TWIP steel is improved under the precondition that plasticity and toughness are not reduced.

Owner:NORTHEASTERN UNIV

Twin crystal induction plastic steel drug-shaped cover

InactiveCN101824524AAbundant resourcesLow costFurnace typesHeat treatment furnacesSolution treatmentRoom temperature

The invention relates to a twin crystal induction plastic steel drug-shaped cover which belongs to the field of metal materials. The composition range of the material is as follows: C:<=0.08 percent, Mn: 25 to 35 percent; Al: 2 to 4 percent; Si: 2 to 3 percent, S:<=0.01 percent, P:<=0.01 percent, and the balance Fe. The invention carries out double-solution treatment to the drug-shaped cover material: the thickness of a rolled board is 4 to 7mm, first time of solution treatment: the solution is carried out for 30min at 900DEG C, and the cooling speed is 20DEG C / s; and then the board is processed into the drug-shaped cover through a formation process, the wall thickness is 3 to 5mm, and solution is carried out again; and the solution is carried out for 45 to 90min at 1000 to 1100DEG C, and the cooling speed is 20 to 50DEG C / s. The elongation rate at room temperature after heat treatment is more than or equal to 80 percent. TWIP steel is applied to the field of drug-shaped cover material, thereby preventing cracks and other defects in the drug-shaped cover forming process on the one hand so as to improve the finished material rate, and forming the drug-shaped cover into complete bullets with large slenderness ratio during a bullet forming process through explosion on the other hand, so as to improve the penetration capability of the bullets; and therefore, the twin crystal induction plastic steel drug-shaped cover is a high-grade drug-shaped cover material.

Owner:UNIV OF SCI & TECH BEIJING

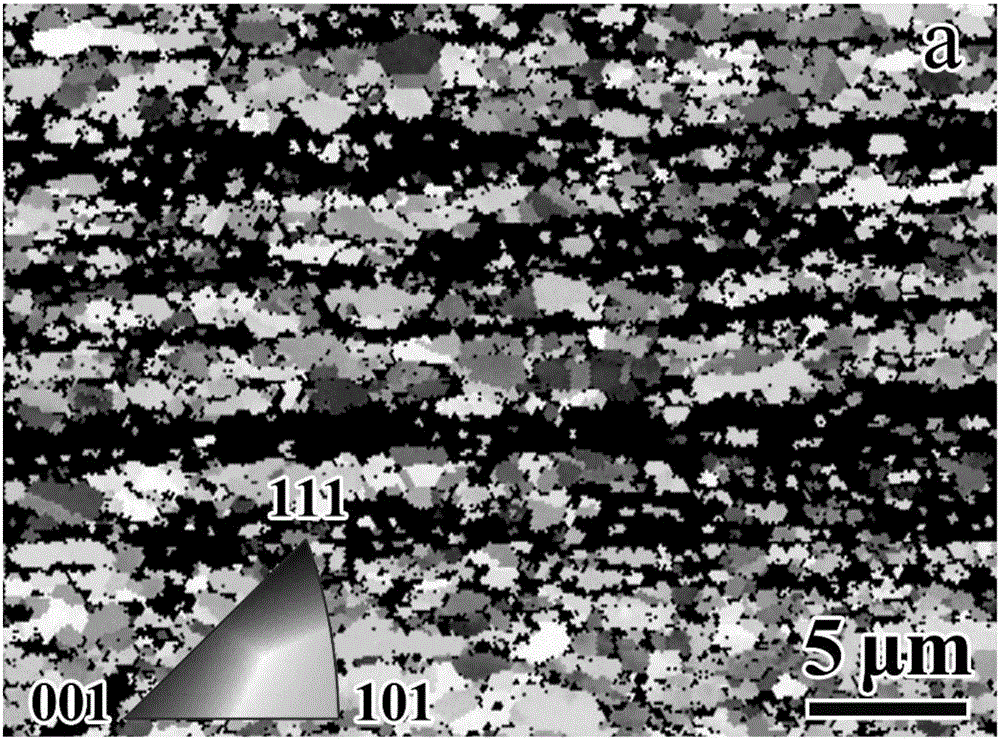

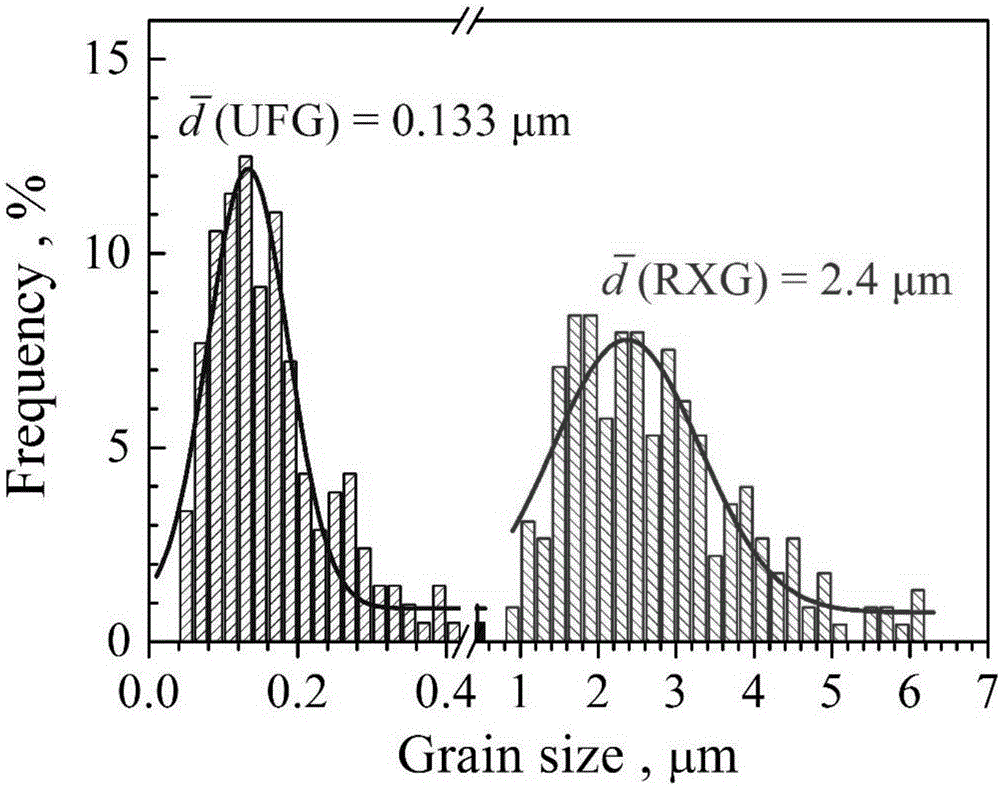

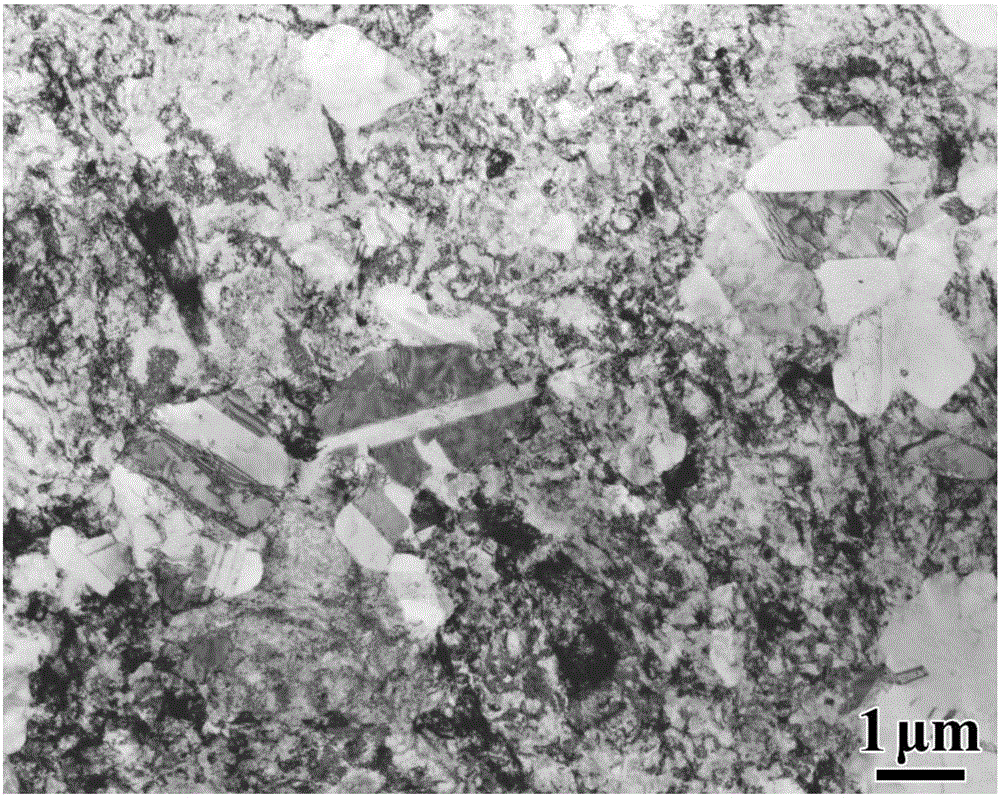

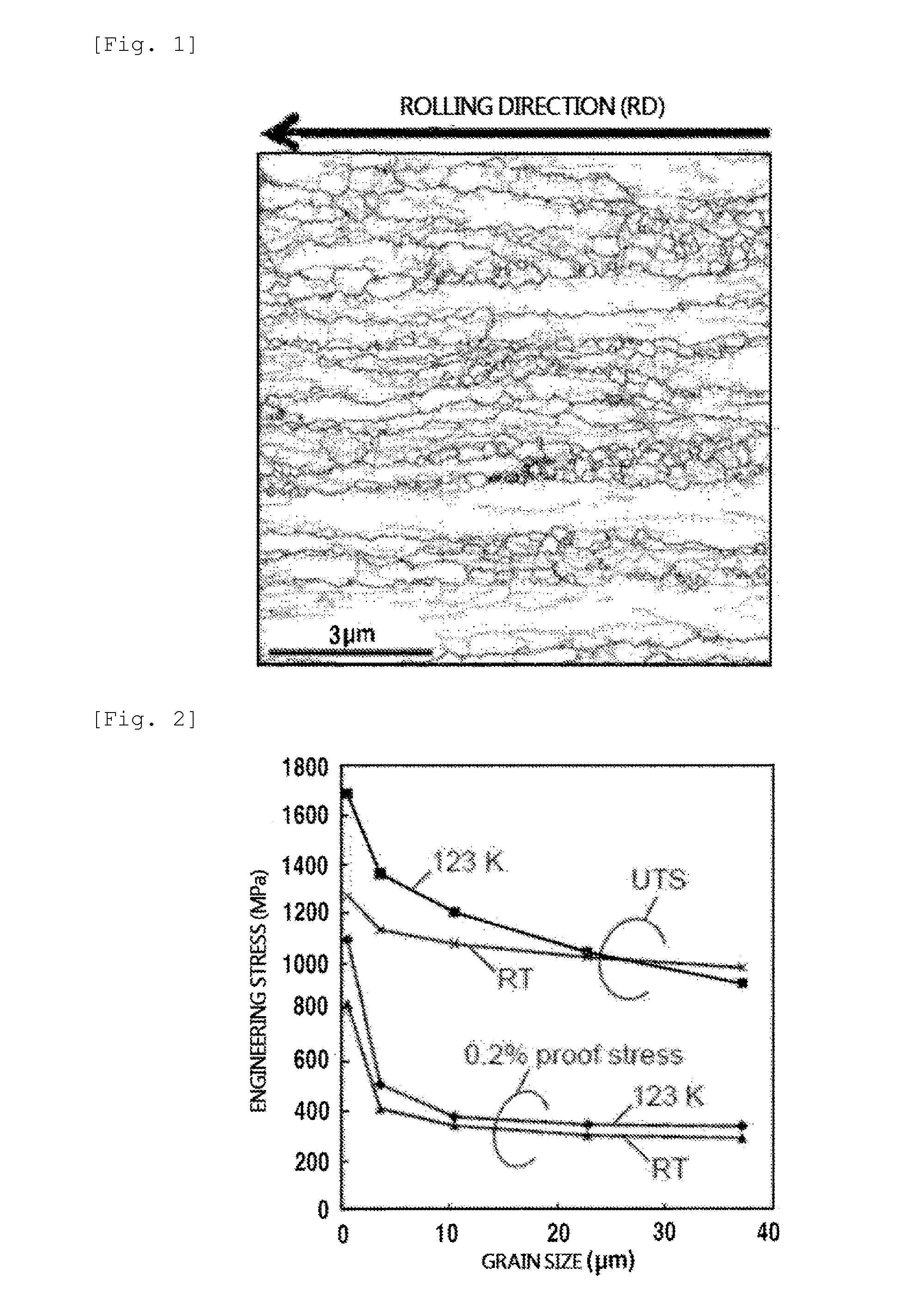

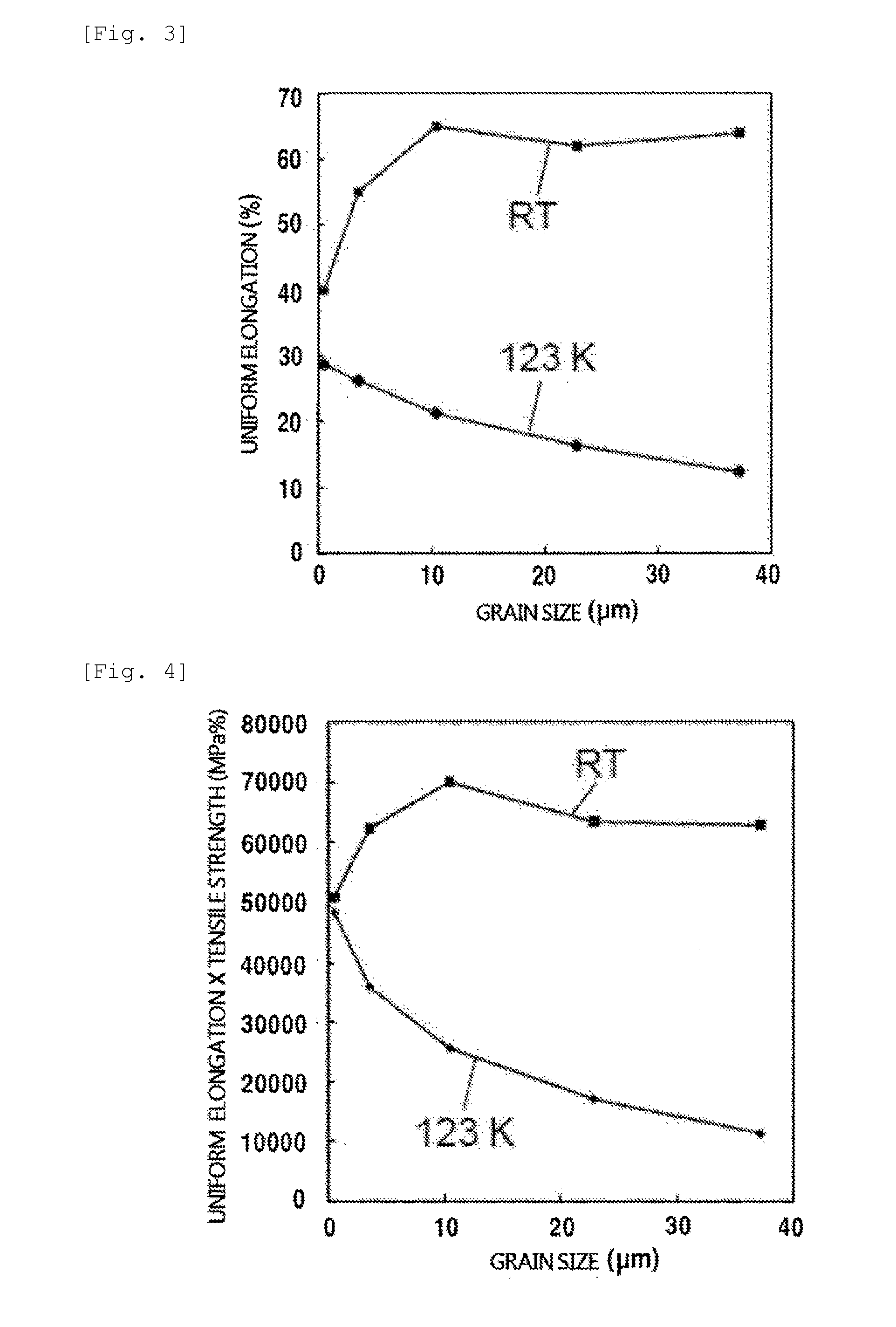

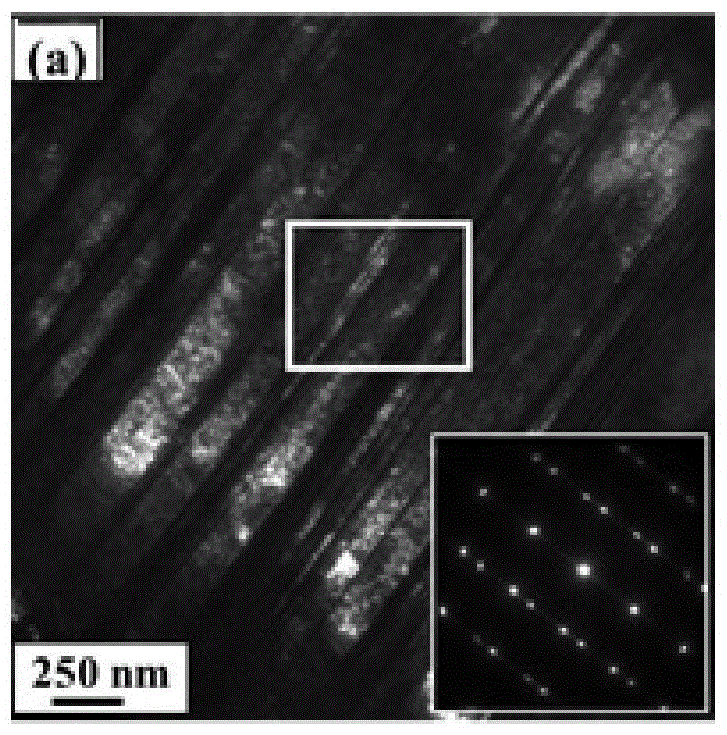

Fe-mn-c-based twip steel having remarkable mechanical performance at very low temperature, and preparation method thereof

Provided is a Fe—Mn—C-based twinning-induced plasticity (TWIP) steel which includes 13 wt % to 24 wt % of manganese (Mn), 0.4 wt % to 1.2 wt % of carbon (C), and iron (Fe) as well as other unavoidable impurities as a remainder, is manufactured by caliber rolling, has a microstructure including elongated grains that are elongated in a rolling direction, and has an average grain size of the elongated grains in a direction perpendicular to the rolling direction of 1 μm or less.

Owner:POSTECH ACAD IND FOUND

Steel forming method and forming component

ActiveCN105665576AReduce the number of twinsReduce the number of twins or even orders of magnitudeVehicle componentsMetallurgyTwip

The invention relates to a steel forming method and forming component. The steel forming method comprises steps as follows: (A) steel for forming is provided; (B) the steel is heated to the temperature of 150-500 DEG C; (C) heated steel is conveyed to steel forming equipment; (D) the steel is formed in the temperature range of 100-450 DEG C in the steel forming equipment. The steel forming method and forming component can reduce the number and even the order of magnitude of twin crystals formed during formation of the steel, particularly TWIP (twinning induced plasticity) steel and can inhibit formation of martensite, so that the technical scheme for solving the delayed cracking problem at the lower cost and under the lower energy consumption is provided.

Owner:EASYFORMING STEEL TECH CO LTD

Method for smelting high-manganese TWIP steel by adopting argon-oxygen decarburization furnace

The invention discloses a method for smelting high-manganese TWIP steel by adopting an argon-oxygen decarburization furnace. The method comprises the following steps: putting a raw material in the argon-oxygen decarburization furnace, then performing an oxygen blowing decarburization step, performing a reduction step, performing a desulphurization step and performing a component and temperature adjusting step to obtain qualified high-manganese TWIP steel; the oxygen blowing decarburization step adopts an oxygen and nitrogen mixed gas blowing method to smelt, and consists of multiple phases; in each phase, oxygen and nitrogen mixed gas is blown into molten steel in the argon-oxygen decarburization furnace from a bottom blowing or side blowing wind port; in the oxygen and nitrogen mixed gas, the oxygen-nitrogen volume ratio is within 3: 1-1: 10; and in the high-manganese TWIP steel, the carbon content is 0.35-1.2%, the manganese content is 15-33%, and the nitrogen content is lower than or equal to 0.1%. The method is low in smelting cost, convenient for operation and convenient for large-scale industrial production.

Owner:SHANGHAI INST OF TECH

Technology for smelting TWIP steel used in expansion pipe and manufacturing steel pipe

The invention relates to the field of metal material and petroleum natural gas industries, and particularly relates to a technology for smelting TWIP steel used in an expansion pipe and manufacturinga steel pipe. The technology is characterized in that materials comprise the following components in percentage by mass: 0.05-0.07% of C, 24-26% of Mn, 2% of Al, 0.5-1.5% of Si, not greater than 0.015% of P, not greater than 0.15% of S, and the balance Fe. According to the technology, the processes of component designing, smelting, electroslag remelting, forging, perforating, pipe rolling, sizingand annealing heat treatment are carried out to obtain the TWIP steel pipe used in the expansion pipe, and the obtained TWIP steel pipe has the advantages that the carbon content is low; the stable austenite structure is beyond 95%, so that the TRIP effect can be inhibited after expansion deformation; the deformation twin is produced; the mechanical performances are outstanding; and the weldability is high. The whole TWIP smelting and steel pipe manufacturing technology is simple, reliable, and low in cost, and has a good market application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

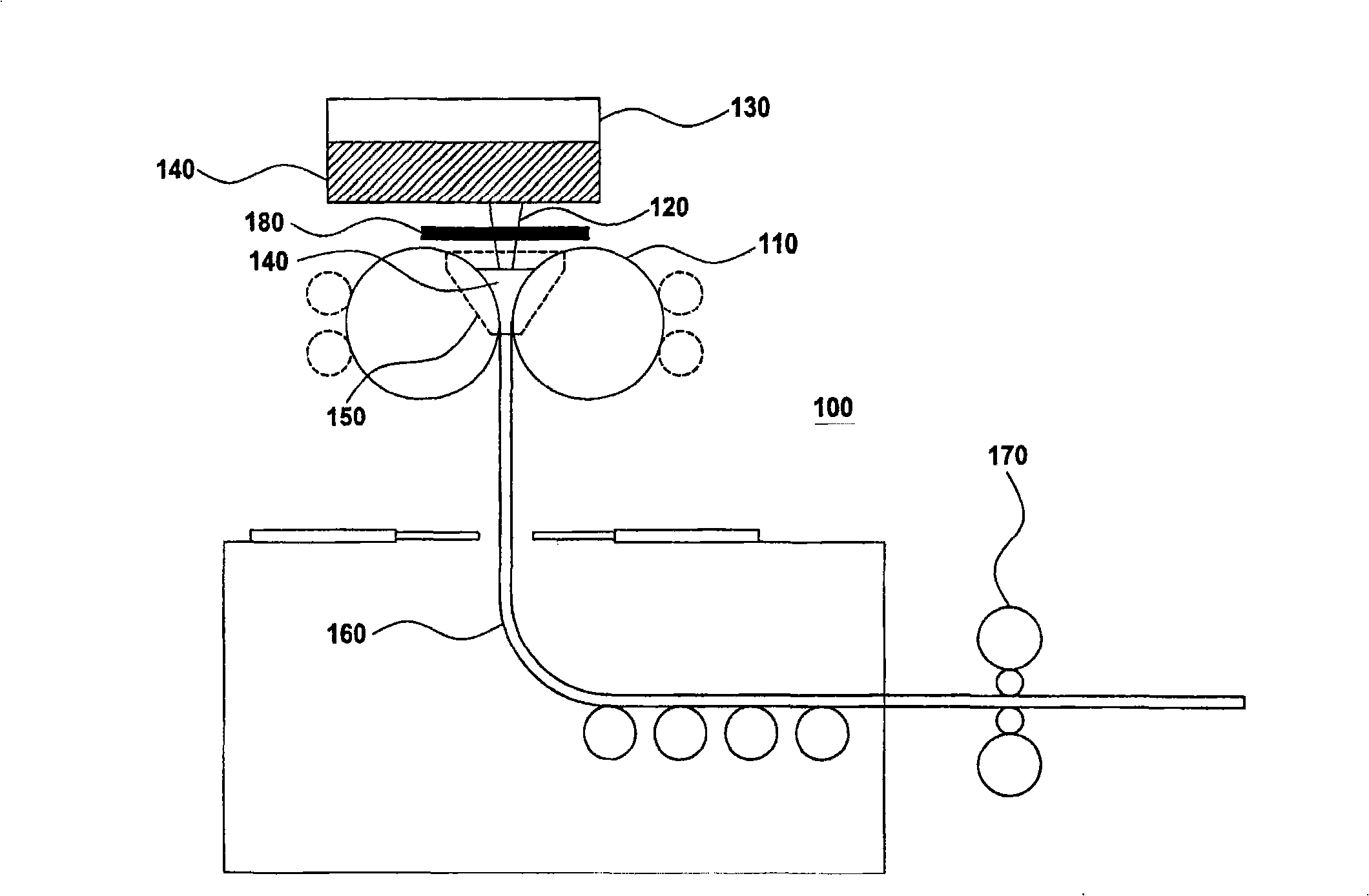

Casting roll for twin roll strip caster

Disclosed is a casting roll for a twin roll strip caster, and particularly, a casting roll for a twin roll strip caster, in which a continuous gas channel, for preventing the generation of dents in the surface of a strip when casting TWIP steel in order to improve the mechanical properties of the strip, including increasing the tensile strength and elongation, is formed in the surface of the casting roll, thus discharging gas mixed when the strip is cast, thereby preventing the generation of dents in the surface of the strip when casting the TWIP steel, in particular, a continuous gas channelis formed, thereby decreasing a conventional dent index and discouraging the generation of dents.

Owner:POHANG IRON & STEEL CO LTD

High-performance anti-corrosion TWIP/stainless steel multi-layer composite material and preparation method

ActiveCN110103530AHighlight substantive featuresHigh strengthLaminationLamination apparatusSurface layerStrength of materials

The invention discloses a high-performance anti-corrosion TWIP / stainless steel multi-layer composite material and a preparation method. The composite material comprises multiple TWIP steel material layers and multiple stainless steel material layers, the TWIP steel material layers and the stainless steel material layers are laminated alternately and rolled together, and the surface layers of the composite material are all stainless steel layers; the thickness of each material layer in the multi-layer composite material is less than or equal to 0.05 millimeter, and the number of the TWIP steelmaterial layers is one less than that of the stainless steel material layers. According to the preparation method, based on the requirements for the mechanical properties of the material, subsequent process adjustment and control such as thermal treatment or cold rolling or annealing treatment and the like are conducted, and therefore the TWIP / stainless steel multi-layer composite steel with the high yield strength and the high product of strength and elongation is obtained. The composite material is composed of thin stainless steel and TWIP steel plate materials through multi-layer lamination, the advantages of the TWIP steel can be exerted, and the corrosion resistance performance and strength requirement of the material can be ensured.

Owner:HEBEI UNIV OF TECH

A kind of preparation method of high-strength high-plasticity twip steel

The invention relates to an ultra-fine grain metal material, and particularly provides a preparation method of TWIP (Twinning Induced Plasticity) steel with high strength and high plasticity. The TWIP steel is formed by nearly equiaxed-shaped perfect recrystallization grains and large annealing twins in recrystallized layer sheets. The invention further discloses the preparation method. The TWIP steel with high strength and high plasticity provided by the invention has excellent performances, and the preparation method is simple.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

Method for producing a twip steel sheet having an austenitic microstructure

ActiveUS20190292617A1High strengthGood formabilityHot-dipping/immersion processesFurnace typesTwipDip-coating

A method for the manufacture of a cold rolled, recovered TWIP steel sheet coated with a metallic coating is provided including the following steps: (A) the feeding of a slab having the following composition : 0.1<C<1.2%, 13.0≤Mn<25.0%, S≤0.030%, P≤0.080%, N≤0.1%, Si≤3.0%, and on a purely optional basis, one or more elements such as Nb≤0.5%, B≤0.005%, Cr≤1.0%, Mo≤0.40%, Ni≤1.0%, Cu≤5.0%, Ti≤0.5%, V≤2.5%, Al≤4.0%, 0.06≤Sn≤0.2%, the remainder of the composition making up of iron and inevitable impurities resulting from elaboration; (B) Reheating such slab and hot rolling it; (C) A coiling step; (D) A first cold-rolling; (E) A recrystallization annealing; (F) A second cold-rolling; and (G) A recovery heat treatment performed by hot-dip coating.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Molybdenum-chromium-alloyed high-strength, high-ductility and high-carbon TWIP steel and preparation method thereof

The invention discloses molybdenum-chromium-alloyed high-strength, high-ductility and high-carbon TWIP steel and a preparation method thereof. According to the preparation method, few carbides are generated in the casting-state structure of the high-carbon TWIP steel by increasing a carbon content on the basis of Fe-Mn-C series of TWIP steel and adding Mo and Cr in the steel as alloy elements, and only a short-time solution treatment is needed before hot-rolling or cold-rolling, thus greatly simplifying the production process.

Owner:FUJIAN UNIV OF TECH

High-toughness twinning induced plasticity (TWIP) nodular cast iron alloy and preparation method thereof

The invention provides a novel high-toughness austenitic matrix nodular cast iron material which can be cold-rolled and hot-rolled and forged and a preparation method thereof. The high-toughness austenitic matrix nodular cast iron material comprises the following chemical components in percentage by mass: 3.5 to 4.0 percent of C, 8 to 15 percent of Mn, 8 to 15 percent of Ni, 2.0 to 2.8 percent of Si, less than or equal to 0.03 percent of S, less than or equal to 0.05 percent of P, 1.5 to 2.5 percent of rare earth Mg and the balance of Fe. The alloy is prepared through the steps of: smelting, spheroidizing and preparing by adopting a high-frequency induction heating smelting furnace in the air environment; casting and pouring by using graphite; and performing heat treatment, rolling and recrystallization. A finished product can be plastically deformed, and has high toughness.

Owner:FUZHOU UNIVERSITY

A method for smelting high-manganese twip steel using an argon-oxygen decarburization furnace

The invention discloses a method for smelting high-manganese TWIP steel by adopting an argon-oxygen decarburization furnace. The method comprises the following steps: putting a raw material in the argon-oxygen decarburization furnace, then performing an oxygen blowing decarburization step, performing a reduction step, performing a desulphurization step and performing a component and temperature adjusting step to obtain qualified high-manganese TWIP steel; the oxygen blowing decarburization step adopts an oxygen and nitrogen mixed gas blowing method to smelt, and consists of multiple phases; in each phase, oxygen and nitrogen mixed gas is blown into molten steel in the argon-oxygen decarburization furnace from a bottom blowing or side blowing wind port; in the oxygen and nitrogen mixed gas, the oxygen-nitrogen volume ratio is within 3: 1-1: 10; and in the high-manganese TWIP steel, the carbon content is 0.35-1.2%, the manganese content is 15-33%, and the nitrogen content is lower than or equal to 0.1%. The method is low in smelting cost, convenient for operation and convenient for large-scale industrial production.

Owner:SHANGHAI INST OF TECH

Method for producing components from lightweight steel

ActiveUS10214790B2Increased TRIP effectHigh yield strengthFurnace typesHeat treatment furnacesRoom temperatureTwip

A method is disclosed for producing components from an austenitic lightweight steel which is metastable in its initial state, by forming of a sheet, a circuit board or a pipe in one or more steps, exhibiting a temperature-dependent TRIP and / or TWIP effect during forming. To obtain a component with, in particular, high toughness, the forming is carried out at a temperature above room temperature, at 40 to 160° C., which avoids the TRIP / TWIP effect, and to achieve in particular high component strength, the forming is carried out at a temperature below room temperature, at −65 to 0° C., which enhances the TRIP / TWIP effect.

Owner:SALZGITTER FLASHSTAHL GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com