Technology for smelting TWIP steel used in expansion pipe and manufacturing steel pipe

A preparation process and steel pipe technology, which is applied in the field of smelting TWIP steel for expansion pipes and steel pipe preparation technology, can solve the problems of unfavorable casting and forming, affect the surface quality of steel plates, and inhibit the TWIP effect, etc., and achieve the effect of inhibiting the TRIP effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation process of the present invention will be described in detail with reference to the accompanying drawings.

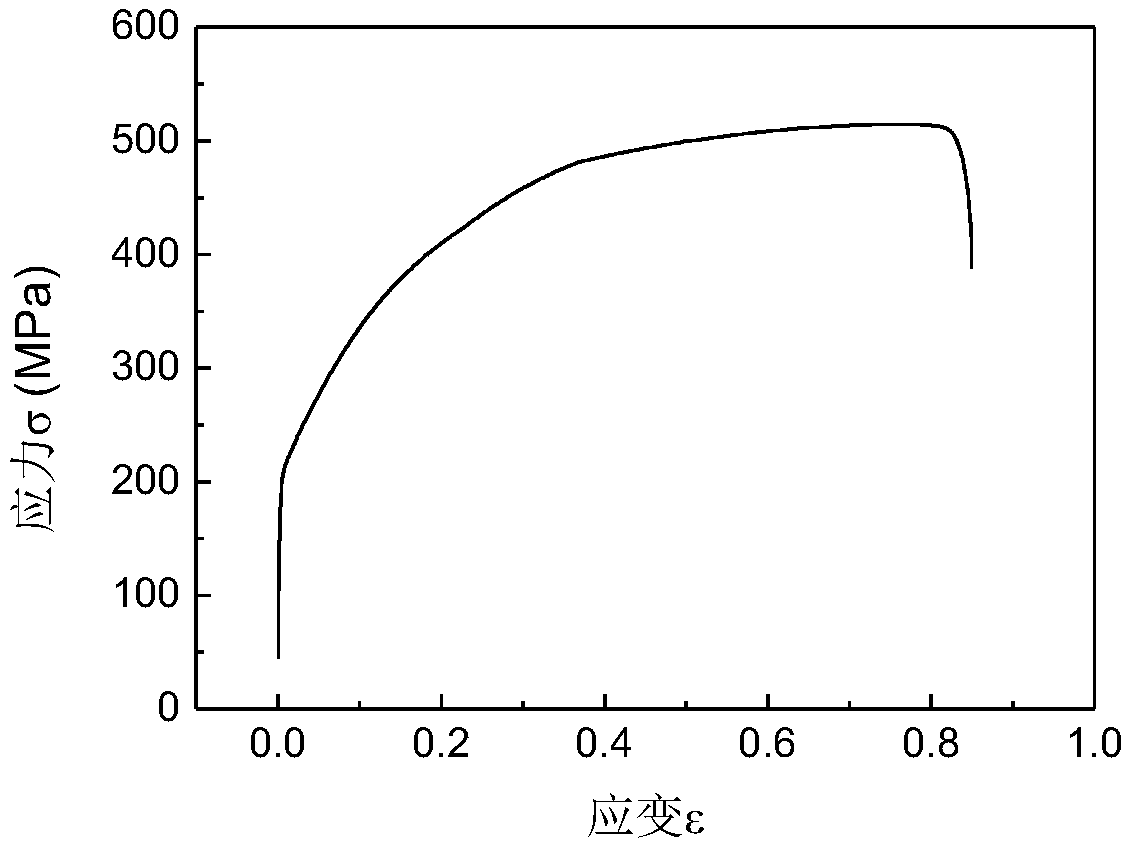

[0022] The mass percentage of TWIP steel material composition is: C: 0.064%, Mn: 25.17%, Al: 2.03%, Si: 0.589%, P: 0.014%, S: 0.013%, and Fe is the balance.

[0023] TWIP steel smelting and steel pipe preparation process steps:

[0024] (1) After weighing pure iron, electrolytic manganese, aluminum pellets and ferrosilicon according to the mass ratio of the above element components, put them in an intermediate frequency induction furnace for smelting, the tapping temperature range is 1500-1650 °C, and the casting temperature range is 1400 °C ~1500℃, electroslag remelting of the cast steel ingot;

[0025] (2) Then place the steel ingot on a forging machine for forging, the forging ratio is 3:1, the initial forging temperature is 1100-1200°C, the final forging temperature is 800°C, after forging, annealing heat treatment is carried out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com