Patents

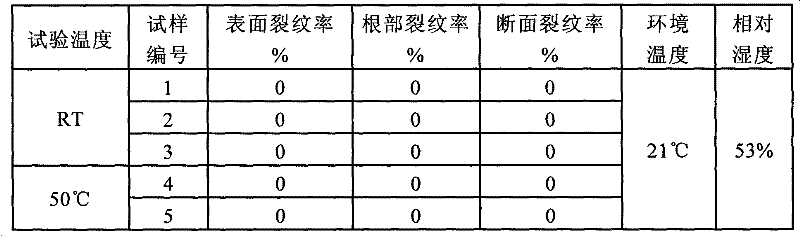

Literature

251results about How to "Low elemental content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and production method thereof

InactiveCN102251180ALow elemental contentReduce residual stressDrilling rodsProcess efficiency improvementRare earthFlame cutting

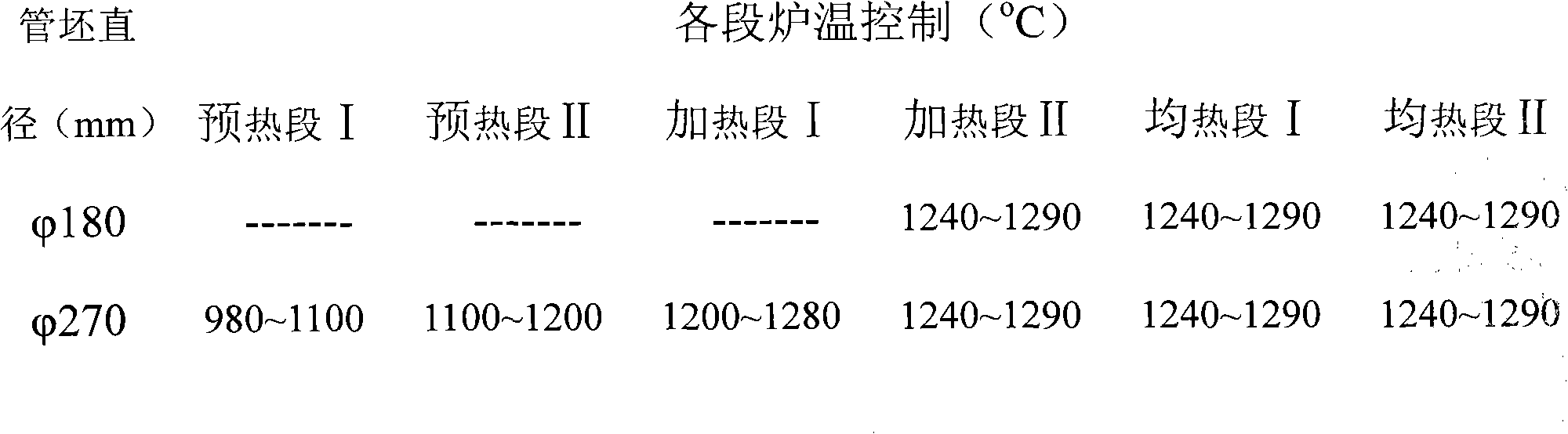

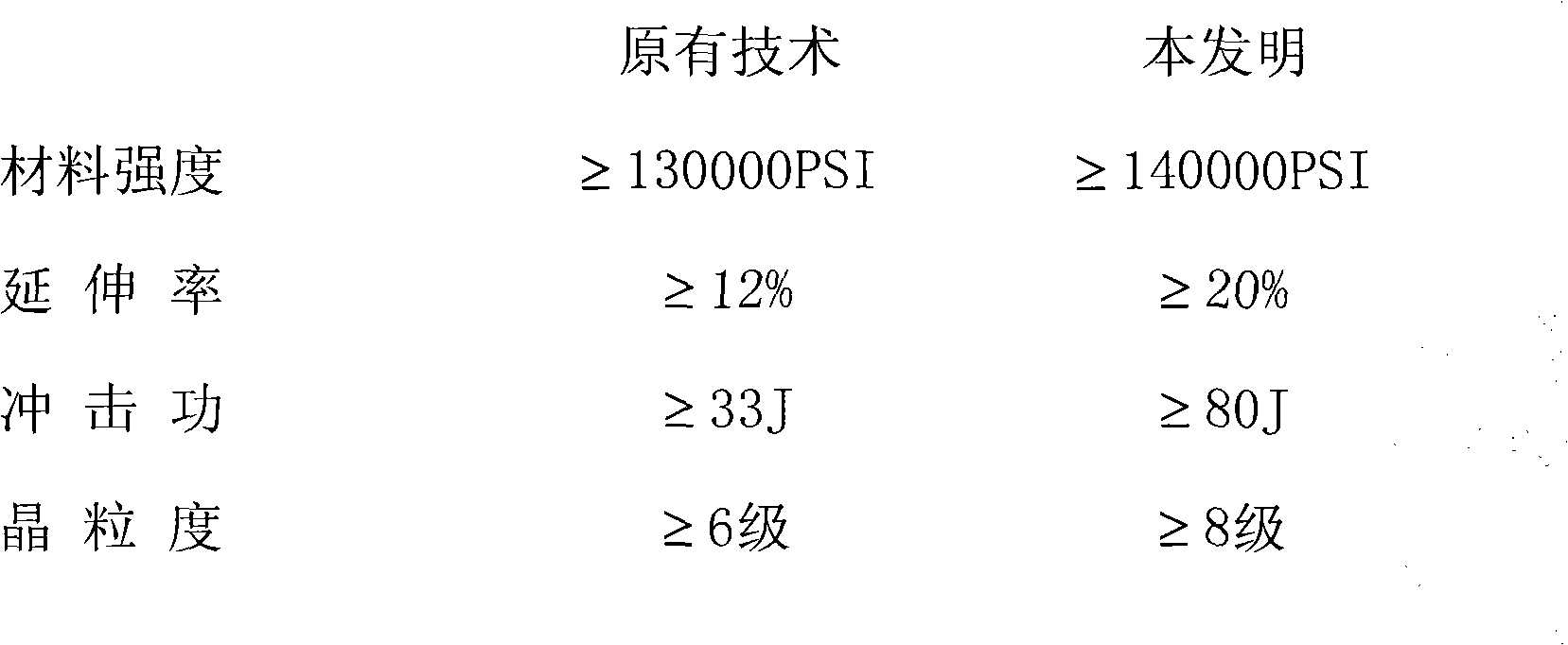

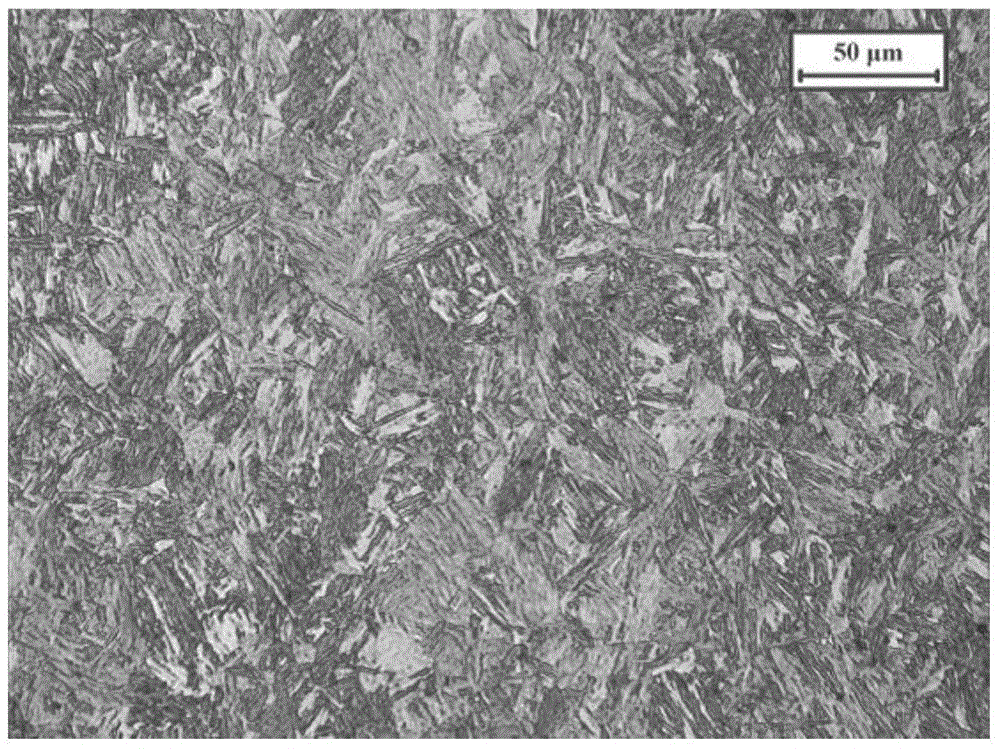

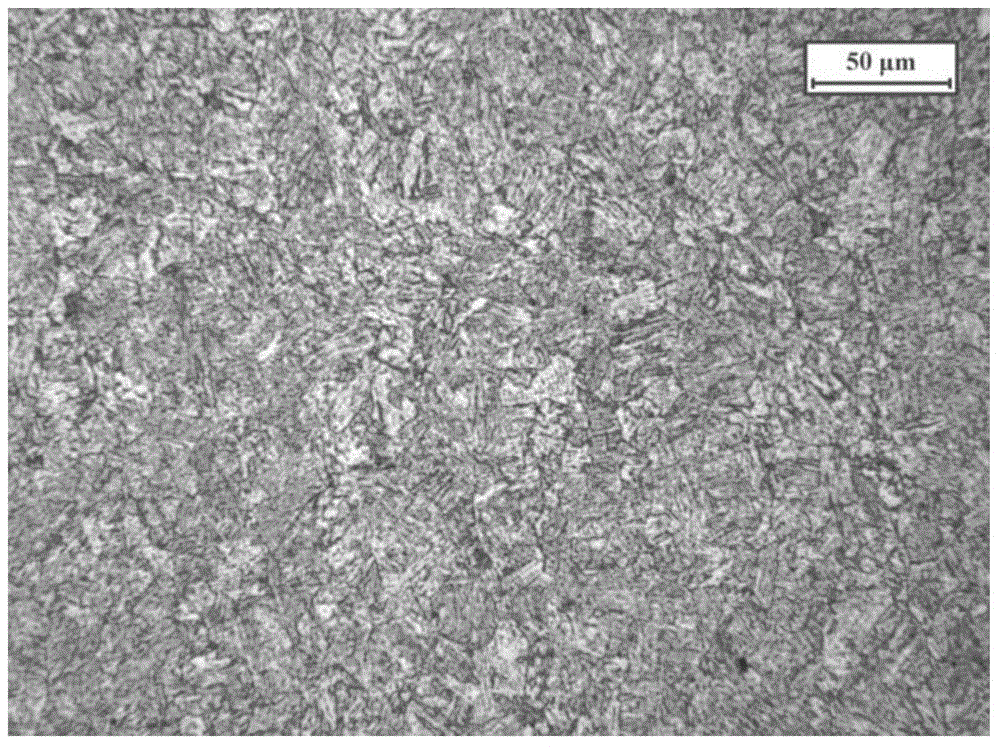

A rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and a production method thereof belong to the technical fields of ferrous metal smelting and metal press working. The petroleum casing comprises the following raw materials by weight percent: 90% of blast furnace molten iron and 10% of high quality steel scrap. The casing blank comprises the following chemical components by weight percent: 0.18-0.35% of C, 0.10-0.35% of Si, 0.55-1.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.60-1.10% of Cr, 0.15-0.50% of Mo, 0.01-0.03% of Al, 0.0005-0.0100% of RE ( RE is the mixed rare earth metals of Ce and La and the weight percents of Ce and La are 67% and 33% respectively), less than 0.10% of Cu, less than 0.10% of Ni and the balance of Fe and trace elements. The process flow of the production method is as follows: pretreating molten iron, smelting in a top-bottom blowing converter, refining in a ladle furnace (LF), performing VD vacuum treatment, performing continuous casting of round billets, performing flame cutting, heating the casing blanks, boring, performing continuous rolling, performing sizing and diameter reducing, cooling, performing saw cutting, performing heat treatment, straightening, performing flaw inspection and lathing screw threads. The mechanical properties of the petroleum casing are as follows: the strength is no less than 140000PSI, the residual stress is no more than 80MPa, the impact power is no less than 80J and the grain size is no less than the grade 8. The product is characterized in that the residual stress is low, the content of harmful elements is low, the impact toughness is high, the grains are small, and the product resists extrusion and is difficult to damage.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

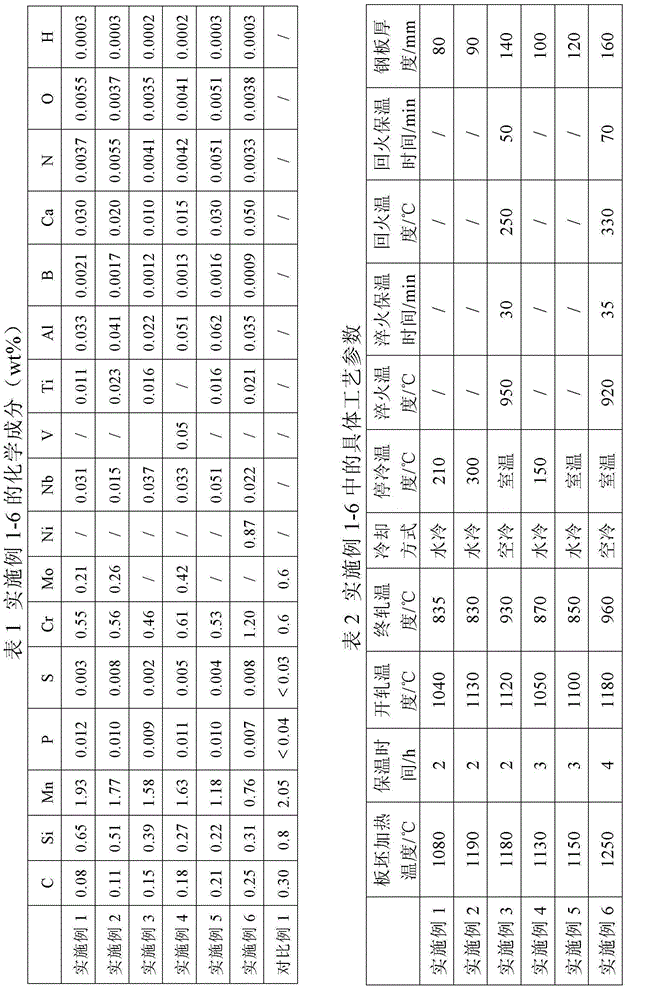

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

Fine crystal strengthen carbon constructional steel and manufacture process for hot-rolling thin slab thereof

InactiveCN101153367AHigh strengthHigh elongationShaping toolsHeat treatment process controlChemical compositionThin slab

The invention relates to a manufacture process of carbon steel and carbon steel hot rolling plate, in particular to a manufacture process of fine grain reinforcement carbon structural steel and hot rolling sheet plate of the steel. The invention mainly solves the technical problem that hot rolling plate of higher strength can not be produced on common completely continuous hot continuous rolling mill by use of common carbon structural steel at present. The fine grain reinforcement carbon structural steel adopts the following chemical composition (weight percent): 0.14 percent to 0.20 percent of C, 0.10 percent to 0.40 percent of Si, 0.65 percent to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S and the rest, Fe. The manufacture process of the hot rolling sheet plate is as follows: a continuous casting slab which meets the requirements of compositions is heated to 1,210 DEG C to 1,250 DEG C; a rough rolling stage comprises five-pass tandem rolling and the end temperature of the rough rolling stage is between 1,050 DEG C and 1,060 DEG C; in addition, the thickness of an intermediate slab ranges from 35 mm to 45 mm. When rough rolling is finished, the intermediate slab is curled through a hot coil box and then is unfolded for finish rolling; a finish rolling stage comprises six-pass tandem rolling with the start rolling temperature ranging between 920 DEG C and 940 DEG C and the end temperature ranging between 820 DEG C and 860 DEG C; after finish rolling, the thickness of a steel plate is between 2 mm to 8 mm; in addition, a laminar flow cooling stage adopts forepart intensive cooling with the coiling temperature ranging from 520 DEG C to 620 DEG C.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Low-alloy ultrahigh-strength wear-resistant steel and production method thereof

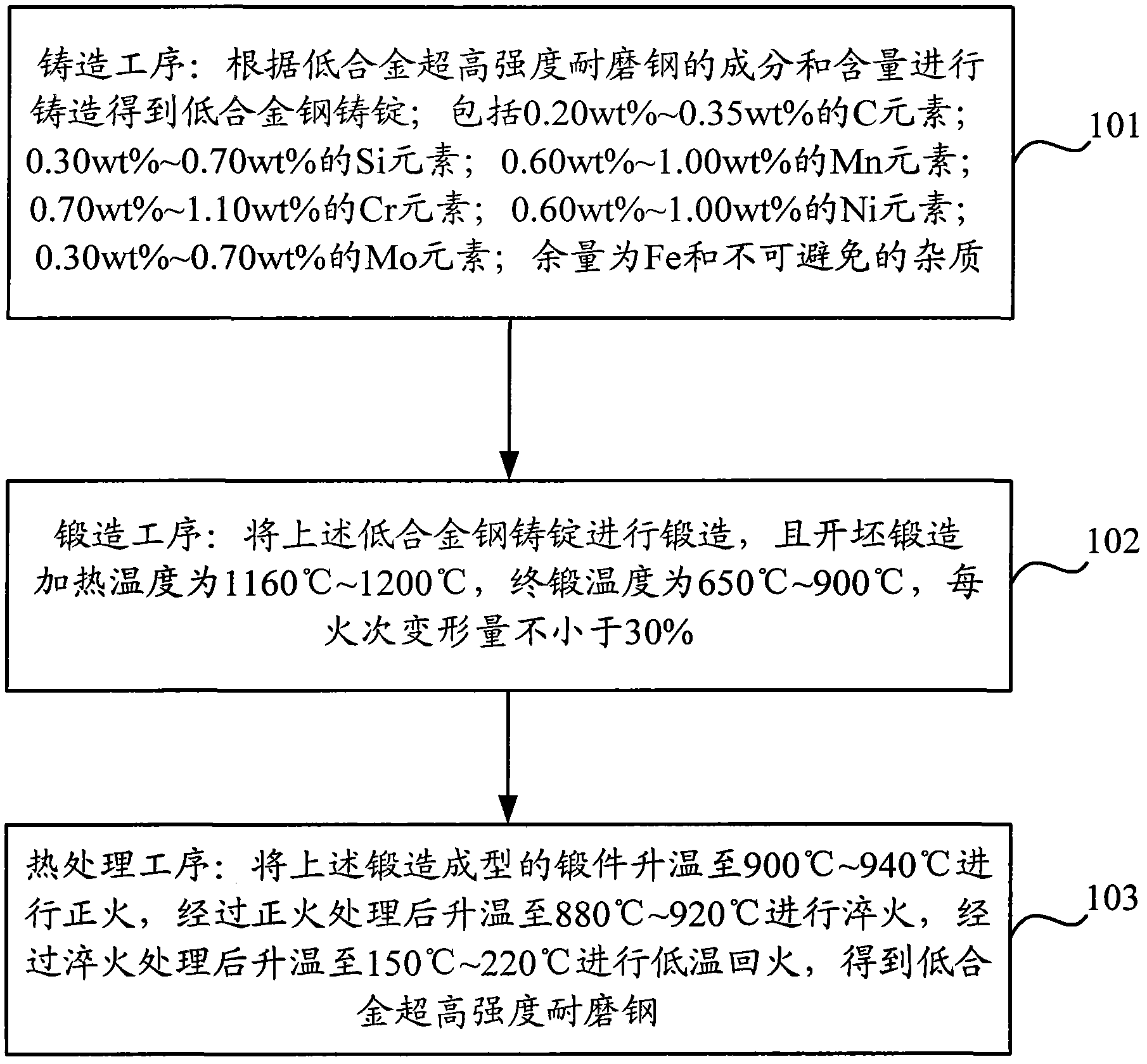

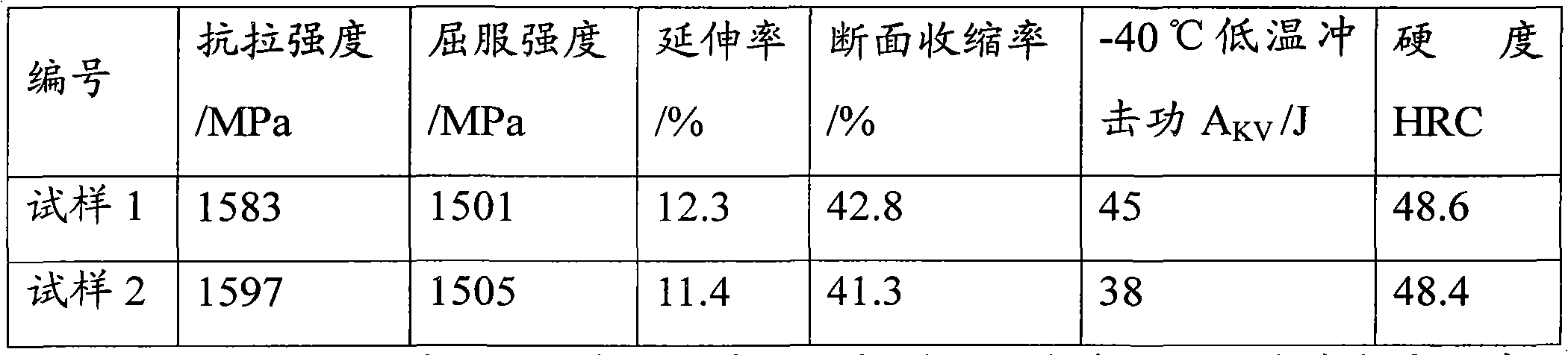

InactiveCN102605272ASimple manufacturing and handling processHigh toughness and wear resistanceQuenchingDuctility

The invention discloses low-alloy ultrahigh-strength wear-resistant steel and a production method of the wear-resistant steel, wherein the production method comprises a casting procedure of casting the following components by weight percentage to obtain ingots of low-alloy steel: 0.20-0.35wt% of C, 0.30-0.70wt% of Si, 0.60-1.00wt% of Mn, 0.70-1.10wt% of Cr, 0.60-1.00wt% of Ni, 0.30-0.70wt% of Mo, and the balance of Fe and other inevitable impurities; a forging procedure of forging the ingots of the low-alloy steel by controlling the cogging, forging and heating temperature to be 1160-1200 DEG C and the final forging temperature to be 650-900 DEG C while keeping the deformation at each heating number being not less than 30%; and a thermal processing procedure of heating the forged-formed forge piece to 900-940 DEG C for normalization, afterwards heating the forge piece to 880-920 DEG C for quenching, and heating to 150-220 DEG C to implement low-temperature tempering so as to obtain the low-alloy ultrahigh-strength wear-resistant steel. According to the embodiment of the invention, the low-alloy ultrahigh-strength wear-resistant steel has high strength, high ductility and high wear resistance.

Owner:SANY GRP

390 MPa class low-temperature hull steel having excellent toughness and manufacturing method thereof

ActiveCN103882297ALow elemental contentReduce contentTemperature control deviceReduction rateNiobium

The invention discloses 390 MPa class low-temperature hull steel having excellent toughness and a manufacturing method thereof. The hull steel comprises, by weight, 0.05-0.12% of carbon, 0.08-0.30% of silicon, 1.0-1.40% of manganese, not more than 0.01% of phosphorus, not more than 0.01% of sulphur, 0.01-0.05% of aluminum, 0.02-0.04% of niobium, 0.005-0.020% of titanium with the balance being ferrum and unavoidable impurities. A first stage rolling temperature is 1050-1100 DEG C, a total reduction rate is not less than 60% and a finish rolling temperature is 900-940 DEG C; a second stage rolling temperature is 850-900 DEG C, the total reduction rate is not less than 60% and the finish rolling temperature is 790-880 DEG C. The steel is the steel is subjected to ultra-rapid cooling at a cooling speed of larger than 30 DEG C per second and is cooled at a cooling speed of larger than 10 DEG C per second in a manner of laminar flow; a self-tempering temperature of the steel ranges from 580-640 DEG C and the final cooling temperature of the steel ranges from 500-630 DEG C; and the steel is air cooled to the room temperature.

Owner:ANGANG STEEL CO LTD

600MPa-level vanadium-containing hot-galvanizing dual-phase steel and preparation method thereof

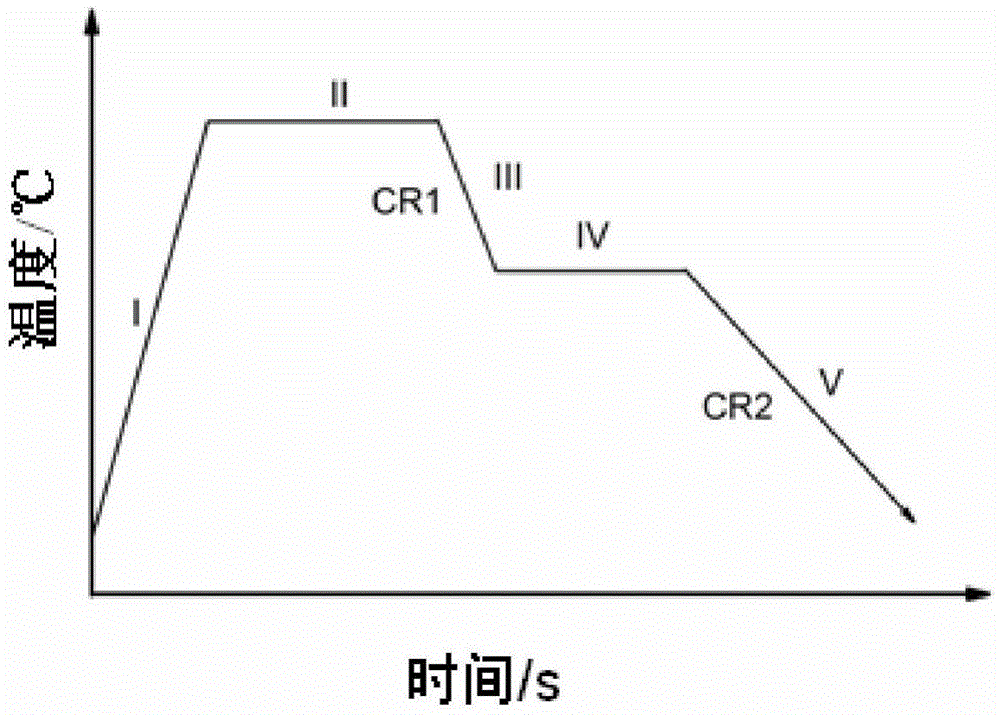

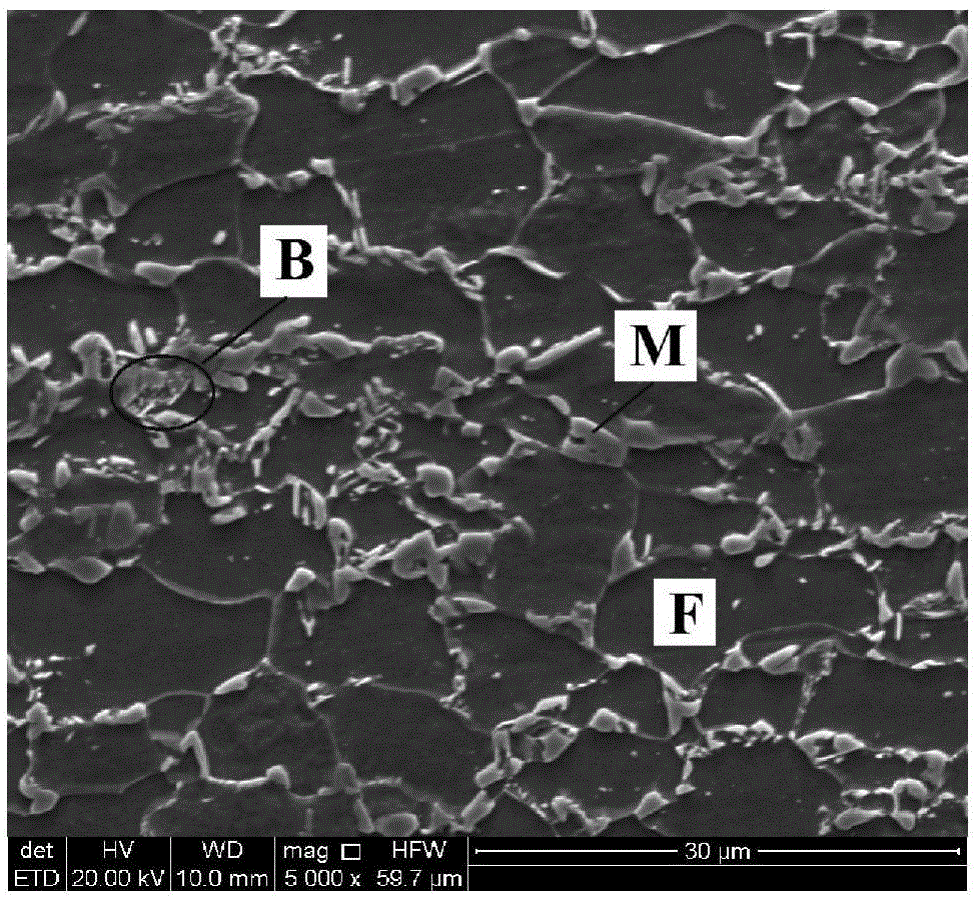

ActiveCN105603325AImprove hardenabilityHigh strengthHot-dipping/immersion processesSocial benefitsUltimate tensile strength

The invention belongs to the technical field of hot-galvanizing high-strength steel for automobiles and particularly relates to 600MPa-level vanadium-containing hot-galvanizing dual-phase steel and a preparation method thereof. The dual-phase steel comprises the following components in percentage by weight: 0.04%-0.10% of C, 0.10%-0.60% of Si, 1.30%-1.90% of Mn, 0.10%-0.50% of Cr, 0.05%-0.25% of Mo, 0.01%-0.06% of Al, 0.01%-0.05% of V, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.006% of N and the balance of Fe and inevitable impurities. According to the dual-phase steel, partial Cr and Mo are replaced with trace V and Si, so that the strength and hardenability of the dual-phase steel are improved, and meanwhile, the production cost is lowered; and by combining with a pre-oxidization reduction process, the surface galvanizing quality of the dual-phase steel is improved. The hot-galvanizing dual-phase steel prepared by virtue of the preparation method has excellent forming property, welding property and galvanizing property, oblivious cost advantage and remarkable economic and social benefits.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

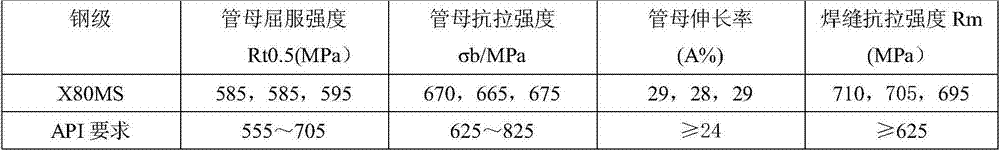

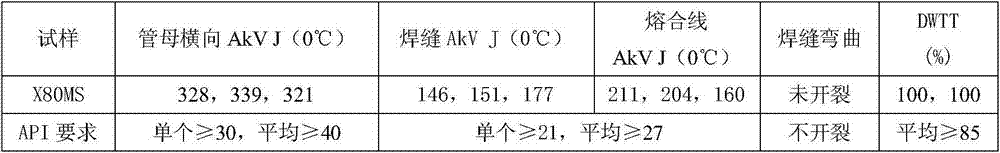

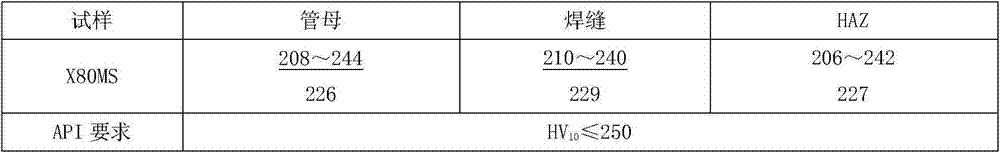

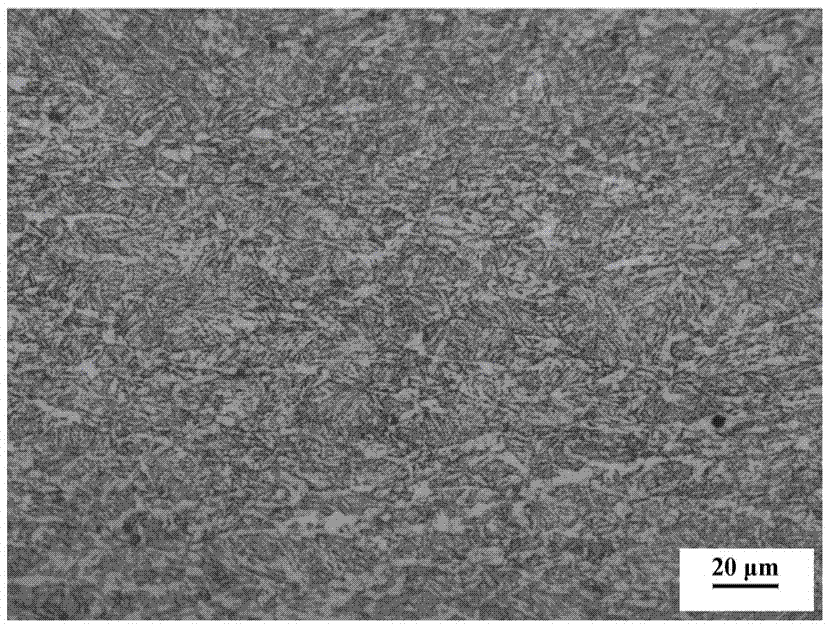

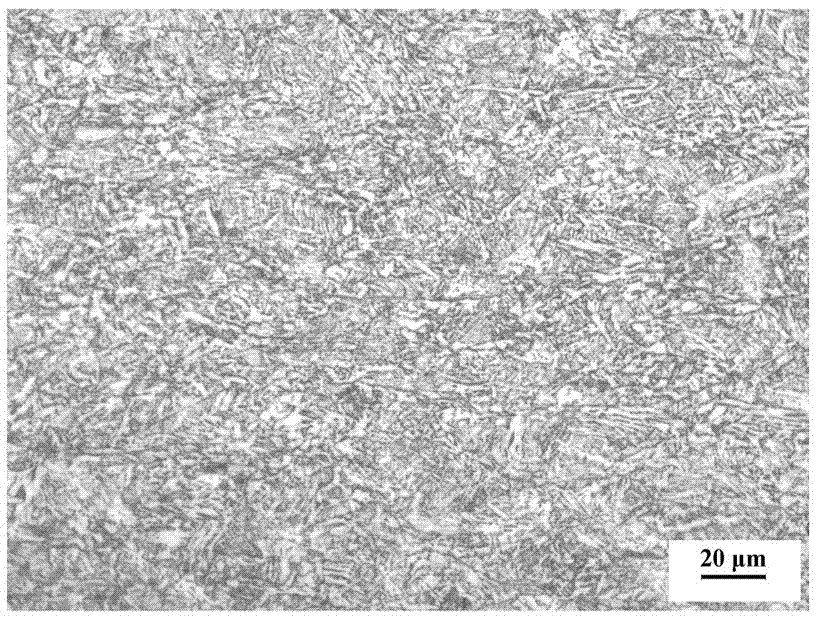

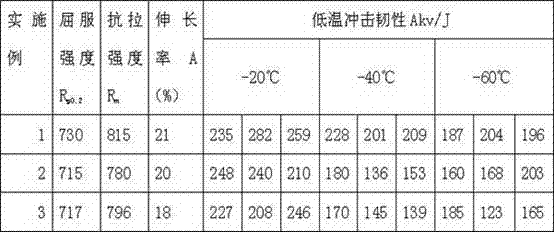

X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as manufacturing method thereof

The invention discloses an X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as a manufacturing method thereof. The straight seam submerged-arc welded pipe comprises a welding seam and a welded pipe body, and is characterized in that the welded pipe body consists of the following elements in percent by mass: not greater than 0.04% of C, 0.20%-0.40% of Si, 1.20%-1.80% of Mn, not greater than 0.008% of P, not greater than 0.002% of S, 0.10%-0.30% of Ni, not greater than 0.15% of Cr, not greater than 0.15% of Cu, 0.01%-0.10% of Nb, 0.01%-0.10% of Ti, 0.10%-0.30% of Mo, 0.04%-0.10% of Al, not greater than 0.0005% of B, not greater than 0.002% of Ca, and the balance of Fe and inevitable impurities. According to the X80-level straight seam submerged-arc welded pipe and the manufacturing method thereof disclosed by the invention, the X80 straight seam submerged-arc welded pipe disclosed by the invention has good strength, toughness, welding performance, ductility and corrosion resistance through reasonably deploying and controlling material components, a manufacturing process, a manufacturing technology and subsequent processing. Besides, high-pressure large-flow conveying requirements of oil gas under an acidic environment are satisfied.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Steel plate with low welding crack sensitivity and manufacturing method thereof

InactiveCN105441790AReduce manufacturing costGood welding performanceTemperingUltimate tensile strength

The invention relates to a steel plate with low welding crack sensitivity and a manufacturing method thereof. The steel plate is composed of, by weight, 0.03%-0.09% of C, 0.20%-0.60% of Si, 1.40%-1.80% of Mn, 0-0.020% of P, 0-0.005% of S, 0.15%-0.45% of Cr, 0.03%-0.06% of Nb, 0.006%-0.04% of Ti, 0.015%-0.04% of Als, 0.0008%-0.003% of B, 0-0.04% of As, 0-0.03% of Sn, 0-0.005% of N, 0-0.003% of O, 0-0.0002% of H, and the balance Fe and inevitable impurities. By the adoption of the technologies of controlled rolling, relaxation and quick cooling, the heat treatment procedure of quenching and tempering or the heat treatment procedure of tempering or the like is not needed, the ultrafine bainite plate is obtained, and working procedure cost is reduced while strength, toughness and welding performance are guaranteed.

Owner:SGIS SONGSHAN CO LTD

Weather-resistant hot rolled broad steel strip and method for manufacturing same

InactiveCN101139687ALow costEasy to industrializeTemperature control deviceMetal rolling arrangementsWeather resistanceChemical composition

The invention relates to a manufacturing method of a weathering resistance steel stripe, whose chemical components by weight are: C 0.06-0.12%, Si 0.25-0.50%, Mn 0.30-0.50%, P 0.07-0.15%, S 0.015% below, Cu 0.25-0.40%, Cr 0.30-1.2%, Ni 0.10-0.50%, and the remainder Fe and unavoidable foreign matters. The steel stripe is manufactured by converter smelting, continuous sheet blank casting, and rolling by a hot continuous rolling unit, etc., is of excellent anti-corrosion performance and weldability, even mechanical properties, and can be used for making a plurality of products with long service life. The weathering resistance steel stripe is specially suitable for manufacturing containers, and is of low cost and easy to industrialize.

Owner:LAIWU IRON & STEEL GRP

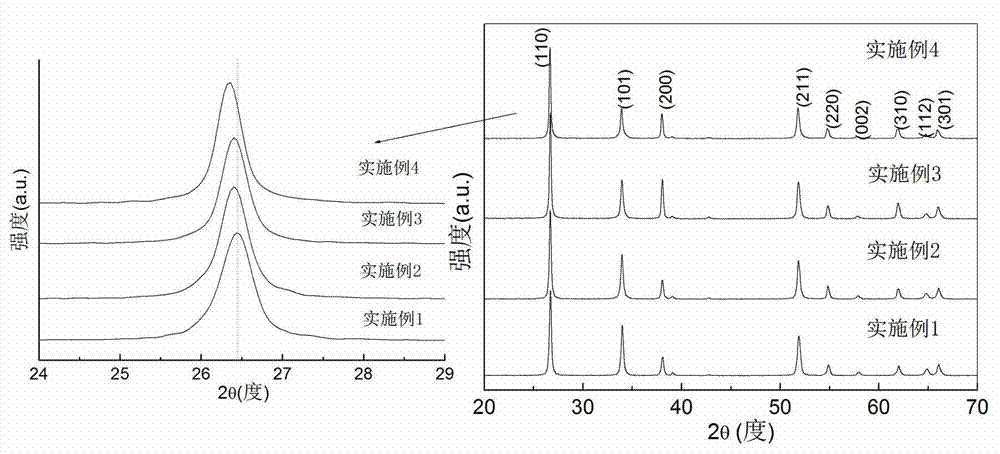

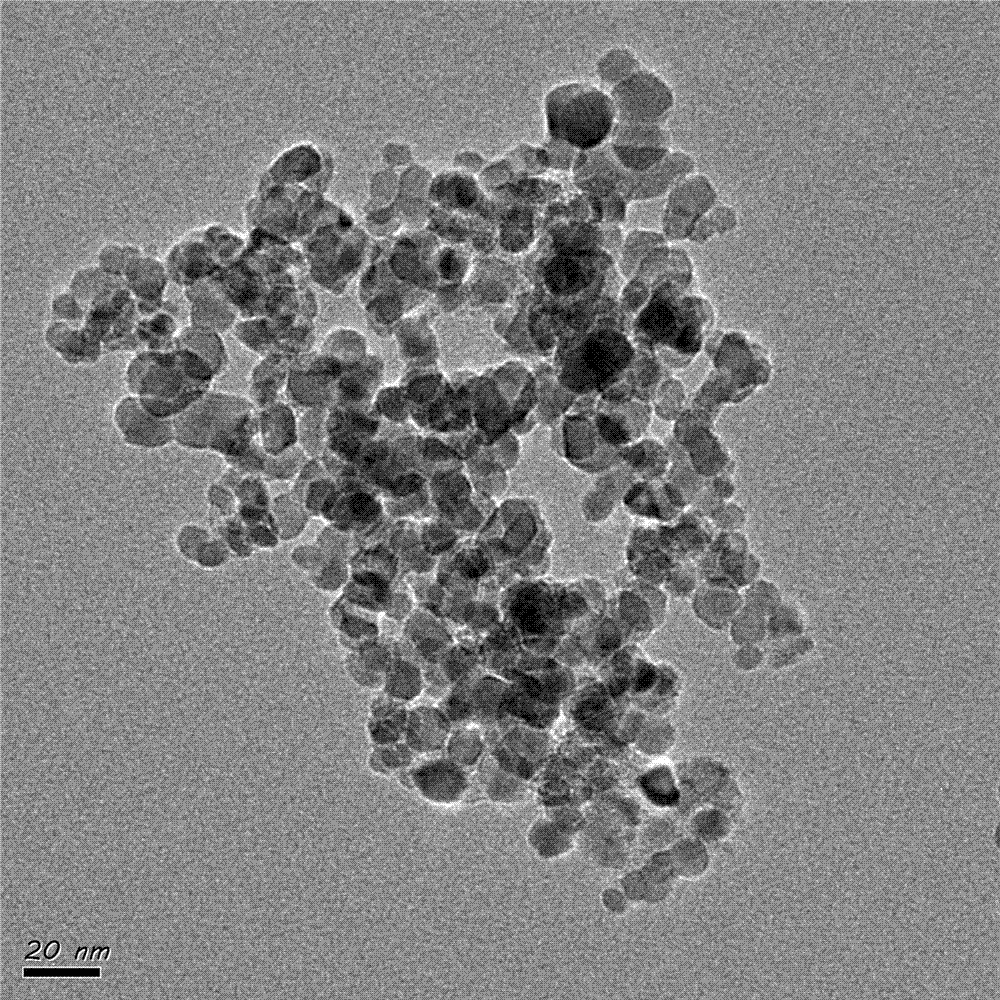

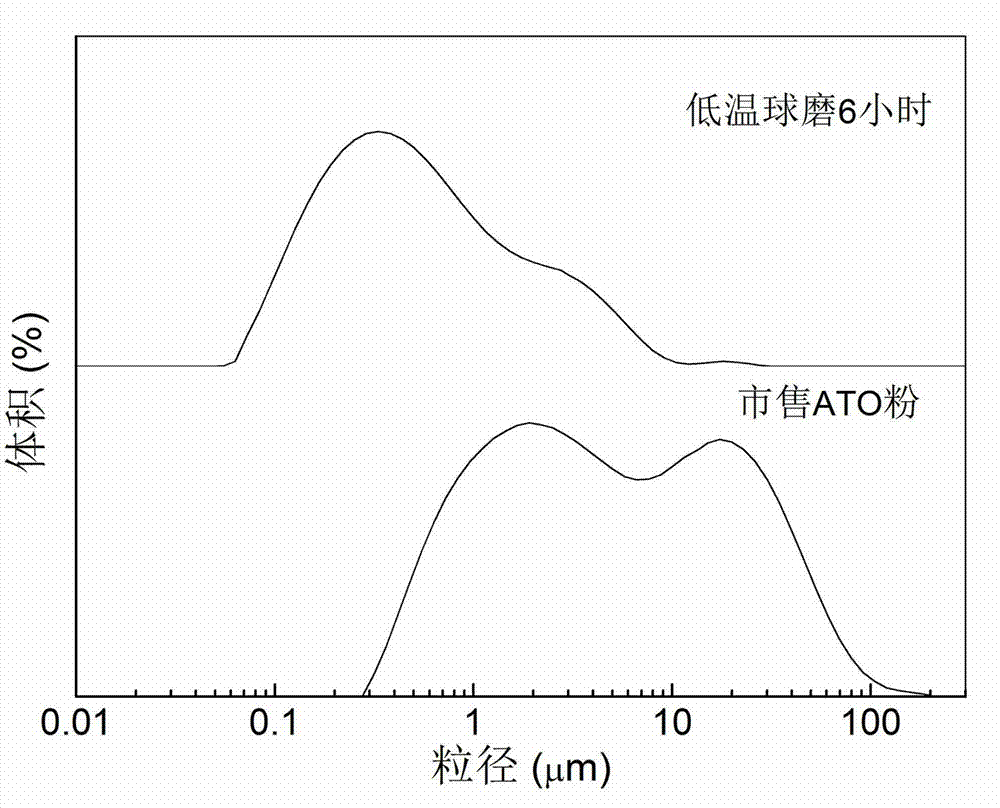

Method for preparing tin antimony oxide nanometer powder in low-temperature ball-milling way

InactiveCN103041896ANo pollution in the processSimple processMaterial nanotechnologyGrain treatmentsThermal insulationSolar cell

The invention relates to a method for preparing tin antimony oxide nanometer powder in a low-temperature ball-milling way. The method comprises the steps as follows: taking high-purity tin oxide powder and antimony oxide powder with purity of 99.9 and particle size of 50-500 meshes as initial raw materials; mixing the raw materials according to the condition that the atomic ratio of antimony to tin ranges from 1:99 to 30:70; adopting liquid nitrogen as a ball-milling medium and a zirconium oxide ball as a grinding ball; performing the low-temperature ball-milling operation; controlling the ball-milling time to be 1-48 h, the ball-milling rotation speed to be 100-1000 r / min and the ball-milling ratio to range from 10:1 to 100:1; and preparing the tin antimony oxide nanometer powder with high purity, low agglomeration rate and particle size of 10-100 nm, and the tin antimony oxide nanometer powder is uniformly doped with 1-30% of other elements by atom percent. The method is simple in process and low in cost, and can be used for industrial scale continuous production; and the prepared tin antimony oxide nanometer powder has the advantages of high purity, low agglomeration rate, uniformity and controllability for doping and the like, and can be widely applied to the fields of solar cells, infrared absorption thermal insulation materials and the like.

Owner:WUHAN UNIV OF TECH

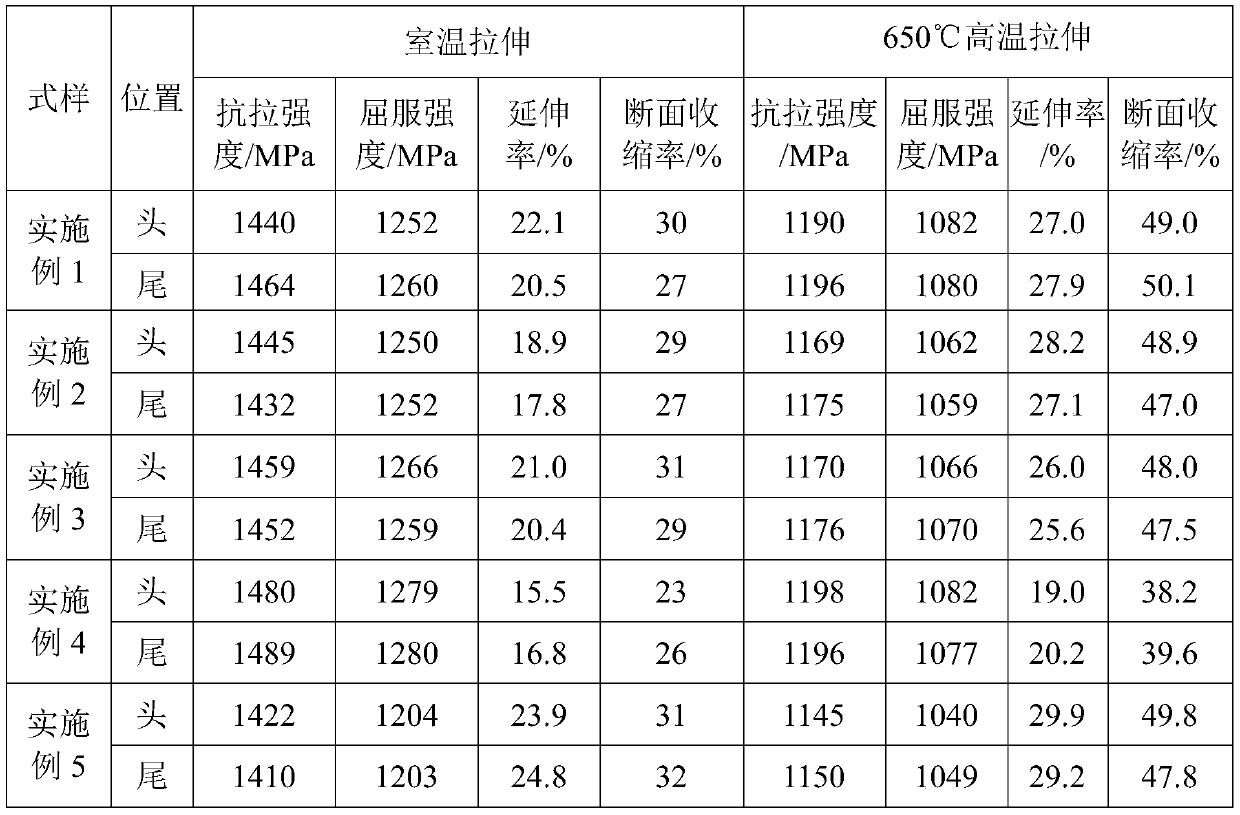

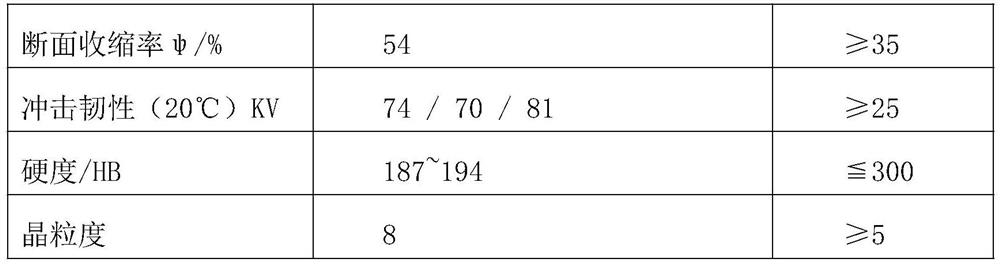

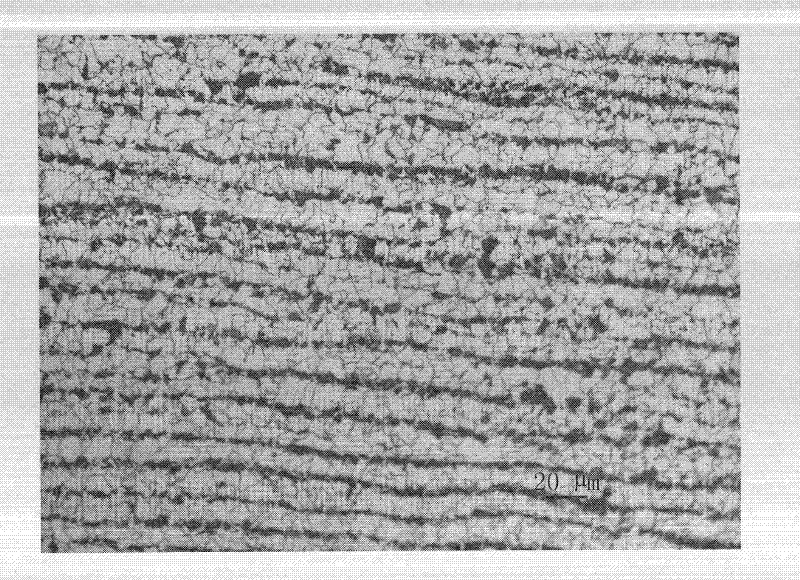

GH4169 high-temperature alloy free-forged bar billet and preparation method thereof

ActiveCN110449541ALow elemental contentImprove tissue uniformityMetal-working apparatusSmelting processIngot

The invention discloses a GH4169 high-temperature alloy free-forged bar billet. The GH4169 high-temperature alloy free-forged bar billet is characterized in that the specification is phi 250mm-350mm,the flaw detection level is not lower than phi 0.4dB-6dB, and the grain size is grade 8-9. The invention further discloses a preparation method of the bar billet. The preparation method comprises thefollowing steps that firstly, GH4169 high-temperature alloy cast ingots are smelted through a combined triple smelting process of vacuum induction smelting, electroslag remelting and vacuum self-consuming remelting, and high temperature homogenization treatment is carried out; secondly, upsetting, stretching, cogging and forging are carried out on the GH4169 high-temperature alloy cast ingots; then the billet materials obtained after cogging are deformed by upsetting and stretching, and the billet materials with the diameter of 400mm-500 mm are obtained; and finally, continuous remelting drawing forging is carried out on the billet materials obtained after upsetting and stretching at high-temperature to obtain the GH4169 high-temperature alloy free-forged bar billet with the diameter of 250mm-350mm. According to the preparation method , the grain size of the bar billet is controlled to be grade 8-9, the grain size grade difference from an edge part to a core part is controlled to be 1grade or within, and the structure uniformity of the large bar billet is improved.

Owner:西部超导材料科技股份有限公司

Pressure container steel plate resistant to hydrogen induced cracking and manufacturing method thereof

ActiveCN105886909AHigh strengthImprove low temperature impact toughnessFurnace typesHeat treatment furnacesNon-metallic inclusionsHardness

The invention relates to a pressure container steel plate resistant to hydrogen induced cracking. The steel plate comprises, by weight, 0.16%-0.20% of C, 0.15%-0.40% of Si, 1.05%-1.20% of Mn, less than or equal to 0.008% of P, less than or equal to 0.002% of S, less than or equal to 0.01% of Nb, less than or equal to 0.01% of V, less than or equal to 0.01% of Ti, less than or equal to 0.0005% of B, and the balance Fe and inevitable impurity elements. The carbon equivalent Ceq is less than or equal to 0.42%, and a calculation formula for the carbon equivalent Ceq is Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The steel plate is high in strength and low-temperature impact toughness, low in hardness and good in HIC resistance. The steel plate has fine grains and low nonmetal inclusion content, and obvious banded structures do not exist. After long-time simulation of postweld heat treatment at a high temperature, the strength and the low-temperature impact toughness of the steel plate are not obviously weakened.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

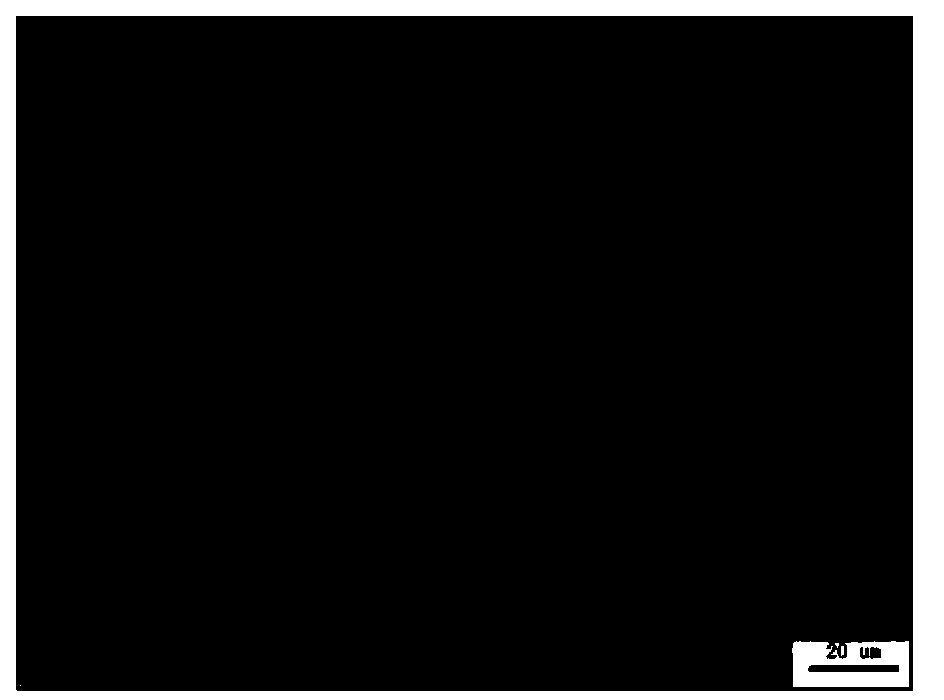

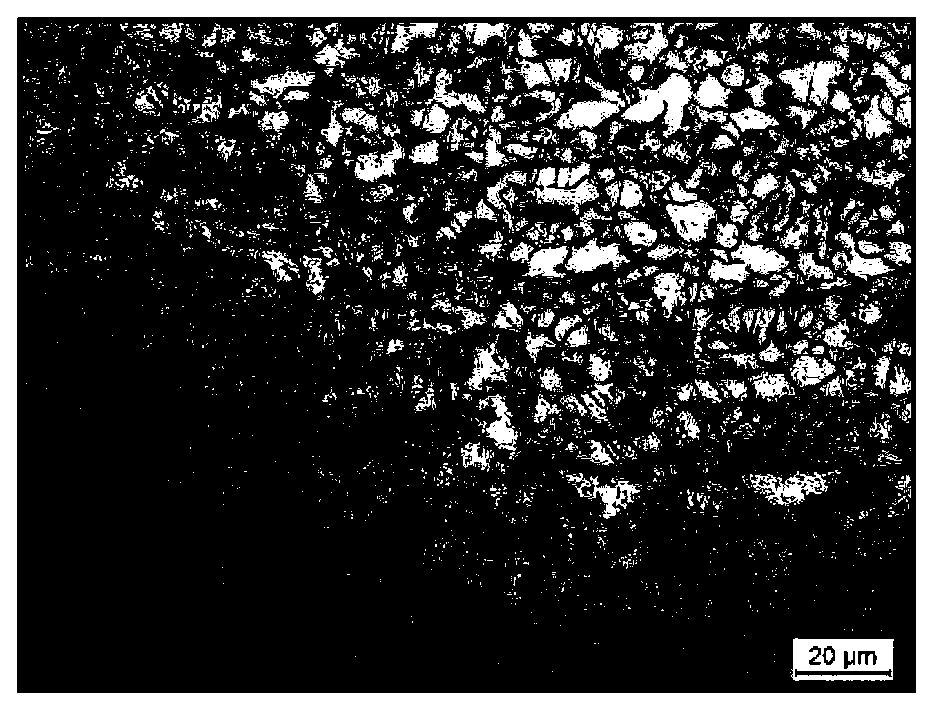

Preparation method of low-alloy manganese martensite wear resistant cast steel

InactiveCN101880828AExcellent strength and toughnessLow elemental contentAlloy elementRare-earth element

The invention relates to a preparation method of low-alloy manganese martensite wear resistant cast steel, which belongs to the technical field of low-alloy wear resistant cast steel preparation. The method adopts Mn as the main alloy element, and adds a small amount of Si, Cr, Cu, B and rare earth elements (La, Ce, Nb, Pr) and other alloy elements, and the balance of Fe. The method adopts a conventional steelmaking process to smelt, casts, forms, water quenches after austenitizing, heats, insulates heat and tempers at low temperature. The produced wear resistant cast steel is organized into tempered martensite after being water quenched and tempered. The tensile strength Rm of the cast steel is more than 1800MPa, the regulated non-proportional extension strength Rp0.2 is more than 1600MPa, the elongation after break A is more than 5 percent, the unnotched impact toughness aK is more than 150J / cm<2> and the U-shaped notch impact energy aKU is more than 20J / cm<2>. The wear resistant cast steel has the advantages of low alloy element content, strong toughness and wear resistance, simple process and low cost, and can be used for manufacturing bucket teeth, hammers, tooth plates, linings, crawler boards and other wear resistant cast steel.

Owner:TSINGHUA UNIV

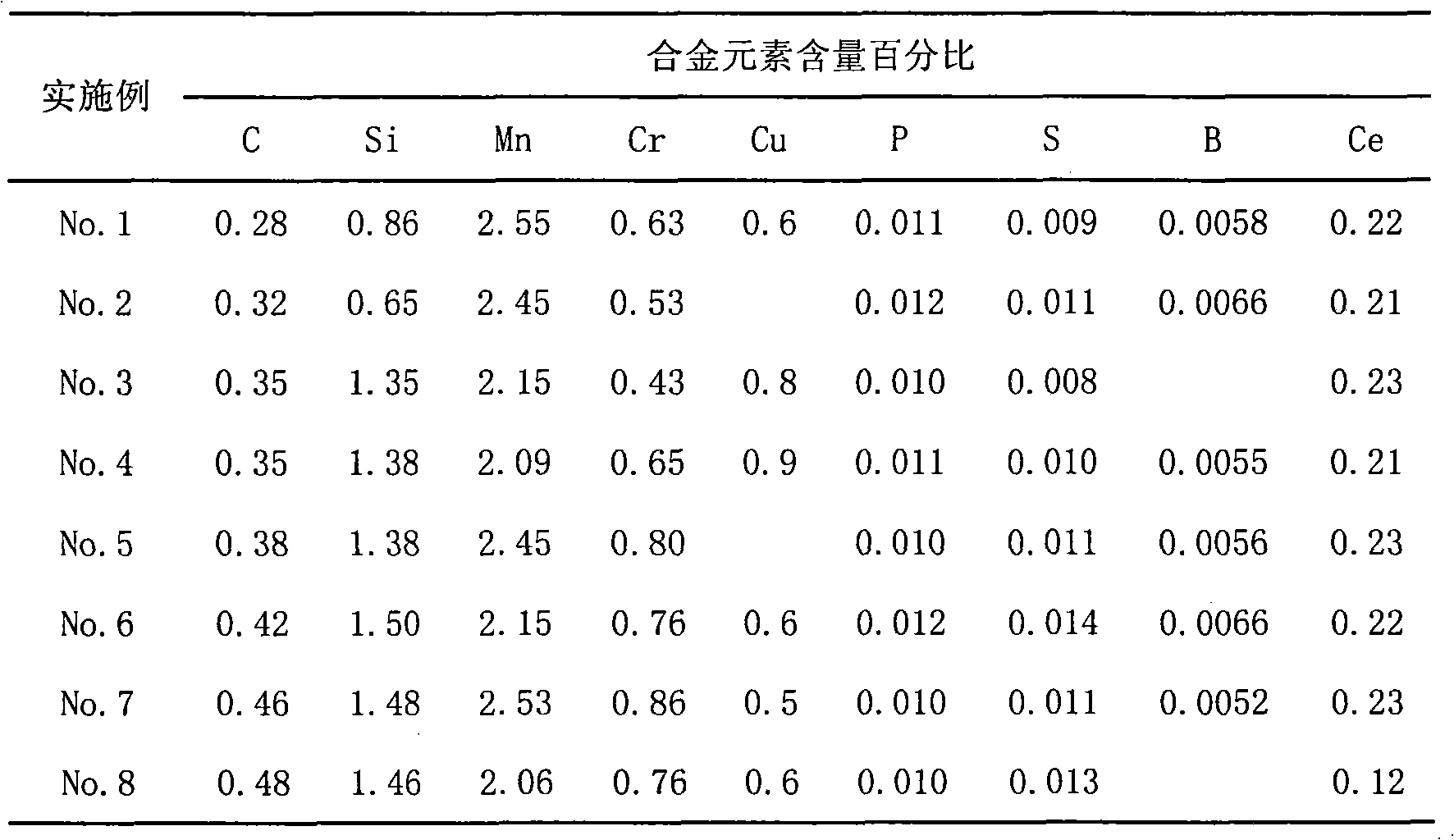

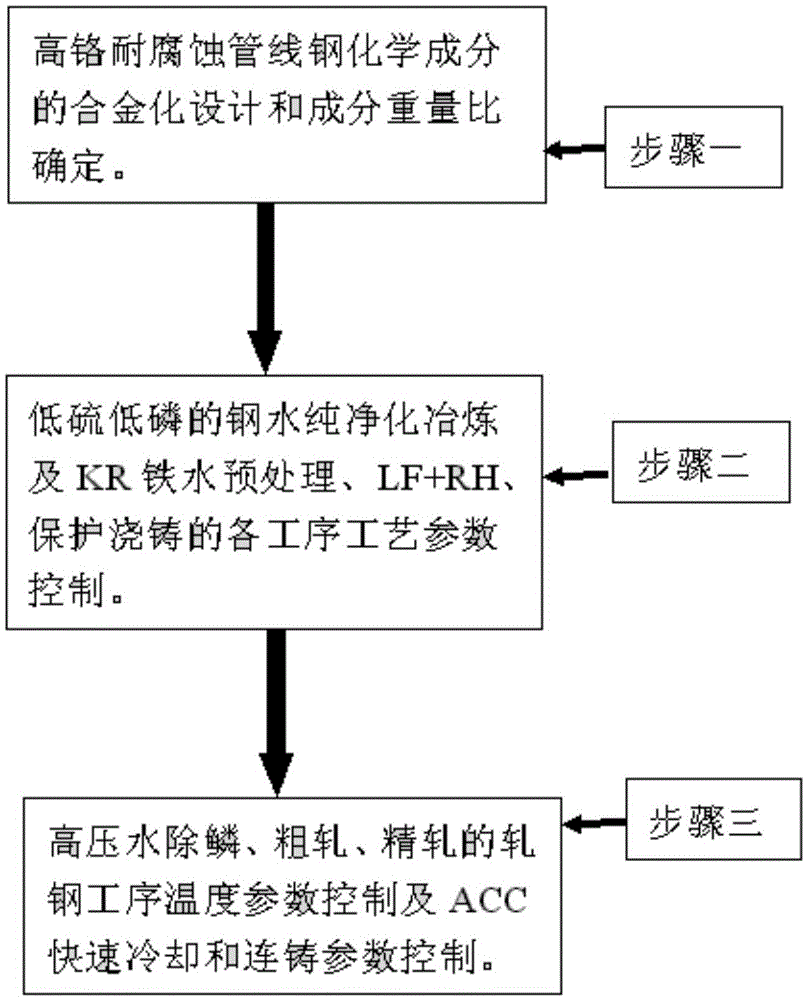

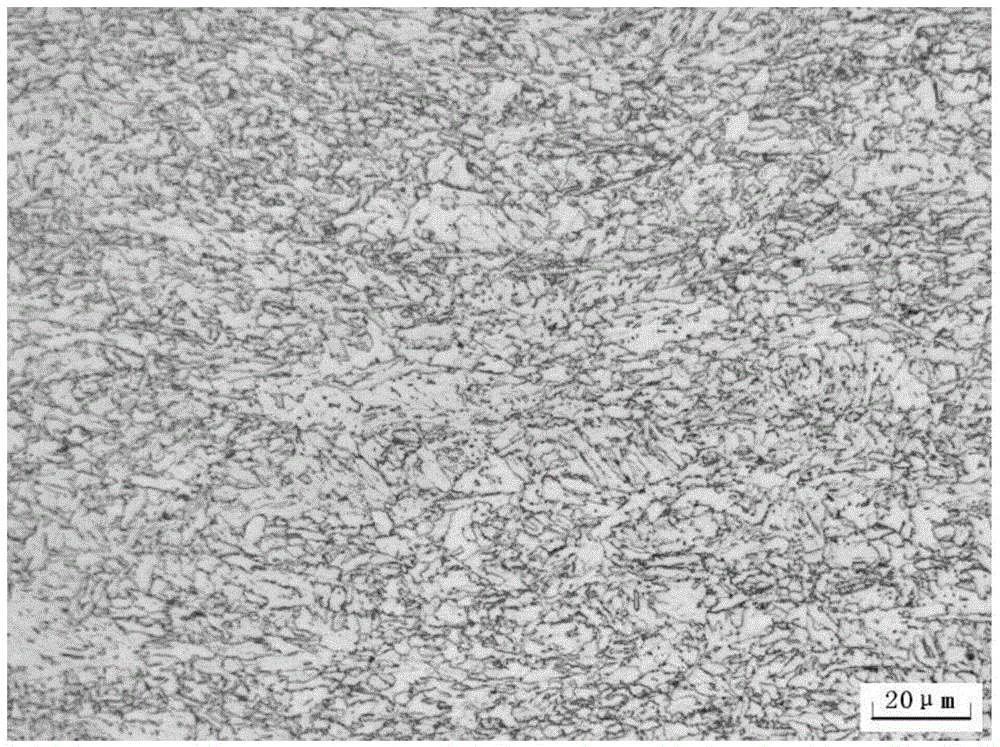

High-chrome corrosion-resisting high-strength pipeline steel and manufacturing method thereof

InactiveCN105483521AEliminate segregationAvoid formingManufacturing convertersProcess efficiency improvementAlloy elementCorrosion resistant

The invention discloses high-chrome corrosion-resisting high-strength pipeline steel and a manufacturing method thereof. The high-chrome corrosion-resisting high-strength pipeline steel is prepared from, by weight percent, 0.04%-0.08% of carbon, 0.15%-0.55% of silicon, 0.15%-0.95% of manganese, 0.030% of phosphorus or less, 0.006% of sulfur or less, 0.8%-2.0% of chrome, 0.15%-0.55% of copper, 0.020%-0.090% of niobium, 0.008%-0.035% of titanium, 0.010% of nitrogen or less and the balance iron and inevitable impurities. The high-chrome corrosion-resisting high-strength pipeline steel is different from universal low-carbon high-manganese composition design, a low-carbon, low-manganese and high-chrome alloying composition system is adopted, the manganese alloy element segregation problem caused by a high-manganese system is eliminated from compositions, and band segregation structure forming is avoided. During molten steel smelting, the refining means of KR molten iron pretreatment deep desulfuration, LF and RH refining and the like are adopted, a dual slag stopping method dephosphorization technology is adopted, a rolling control and cold control rolling process is adopted for controlling phase change temperature, the grain structure is refined, and toughness matching of the pipeline steel is guaranteed; and the produced pipeline steel has excellent corrosion resistance and higher strength and toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Rare earth containing H profile steel with high strength and high toughness and production method thereof

InactiveCN103266279ALow elemental contentReduce residual stressProcess efficiency improvementMetal rolling arrangementsRare-earth elementDistillation

The invention relates to rare earth containing H profile steel with high strength and high toughness and a production method thereof, and belongs to the technical field of metallurgy and moulding. The raw material comprises 90wt% of blast furnace molten iron and 10wt% of high quality steel scrap. The casting blank comprises the following components in percentage by weight: 0.07-0.12% of C, 0.10-0.30% of Si, 1.40-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.30-0.60% of Cr, 0.20-0.50% of Ni, 0.06-0.20% of V, 0.01-0.03% of Ti, 0.01-0.01% of Al, 0.0005-0.010% of rare earth element RE, less than 0.10% of Cu and the balance of Fe and microelements which cannot be detected. The process flow is as follows: molten iron pre-treatment; smelting by a top-bottom combined blowing converter; refining by an LF (Ladle Furnace); VD (Vapor Distillation) vacuum treatment; continuous casting of square billets; cutting; heating the casting blank; dephosphorization by high pressure water; BD1 cogging; BD2 central rolling; dephosphorization by high pressure water; CCS (Cold Crushing Strength) universal rolling; straightening; cooling; flaw detection; and saw cutting. The mechanical properties of the steel are as follows: the yield strength is 490-570MPa, the strength of extension is 660-750Mpa, the yield ratio is greater than or equal to 0.80, the ductility is greater than or equal to 25%, and the horizontal impact value: aKV is greater than or equal to 100J / cm<2> (minus 40 DEG C). The product provided by the invention has the characteristics of low content of impurity elements, high strength, good toughness and excellent welding performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Easy welding steel plate with yield strength of 550MPa and high toughness and manufacturing method thereof

The invention discloses an easy welding steel plate with yield strength of 550MPa and high toughness and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.05 to 0.08 percent of C, 0.25 to 0.50 percent of Si, 1.65 to 1.90 percent of Mn, 0.03 to 0.07 percent of Nb, 0.03 to 0.07 percent of V, 0.0006 to 0.002 percent of B, 0.01 to 0.04 percent of Al, 0.01 to 0.03 percent of Ti, and the balance of Al and inevitable impurities, wherein the content of Fe accords with the following relation that: Mn is more than or equal to 3.01Si +12.8Nb+6.65V-12.12C and less than or equal to 4.78Si+13.8Nb+12.72V-10.13C. A tissue with a bainite strip serving as a substrate is obtained by a control rolling and control cooling technology. The yield strength of the easy welding thick plate with yield strength is more than 550MPa, the tensile strength is more than 670MPa, the Charpy impact power Akv(-20 DEG C) is more than 150 J, and the sensitivity index Pcm of welding cracks is less than or equal to 0.19 percent. The steel plate has high welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

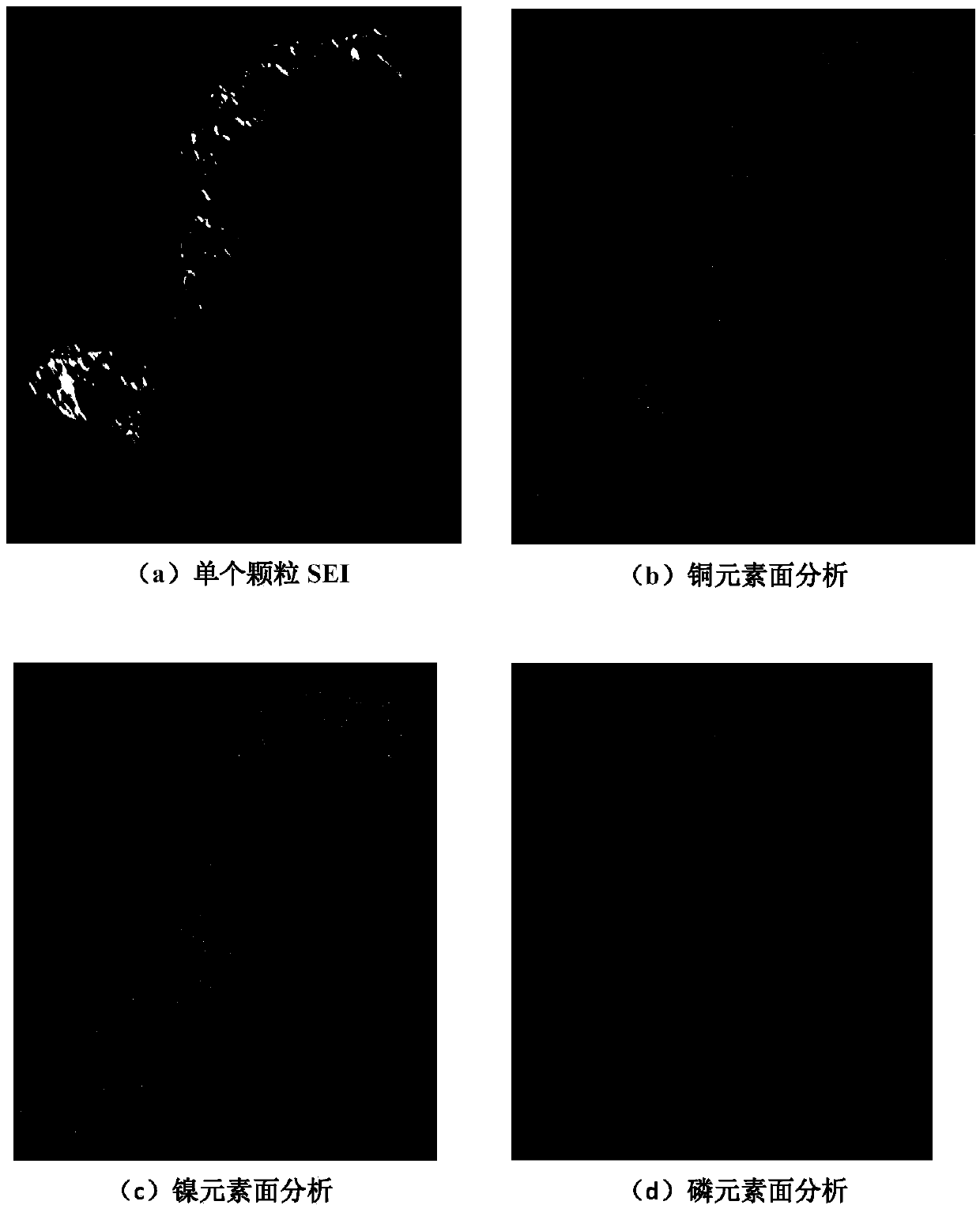

Sonochemistry preparation method allowing surface of copper powder to be coated with nickel and phosphorus alloy layer

The invention relates to metal-coated composite powder, in particular to a sonochemistry preparation method allowing the surface of copper powder to be coated with a nickel and phosphorus alloy layer. The method is characterized in that high-energy ultrasonic agitation is effectively added into a traditional process of chemical plating, and the cavitation effect, the oscillation effect and other effects of the high-energy ultrasonic agitation are utilized, so that the preparation efficiency of composite copper powder coated with nickel is improved, and the problems of powder accumulating and the like are solved. In addition, when the copper powder coated with the nickel and phosphorus is prepared, sodium hypophosphite is used as a reducing agent of an acidic chemical plating solution, and the plating solution is easy to prepare and high in stability; due to the fact that activating treatment is carried out on the copper powder through hydrochloric acid before plating, the defect that traditionally, when salt activation and sensibilization are carried out on the surface of the copper powder, precious metal palladium salt is brought into the plating solution, so that the plating solution is decomposed is overcome, and also the activation processes of the powder are simplified. Meanwhile, because the high-energy ultrasonic agitation is kept in the whole plating process, the prepared composite powder is excellent in dispersity, the coating layer of the powder is complete and uniform, the plating of the powder is compact, and the powder is in an amorphous state.

Owner:JIANGSU UNIV OF SCI & TECH

Steel for ball mill steel ball and preparation method thereof

The invention relates to steel for a ball mill steel ball and a preparation method thereof. The steel comprises the following components in percentage by weight: 0.75 to 0.85 percent of C, 0.17 to 0.35 percent of Si, 0.70 to 0.90 percent of Mn, 0.40 to 0.60 percent of Cr, 0.010 to 0.060 percent of Al, more than or equal to 0.20 percent of Cu, more than or equal to 0.20 percent of Ni, more than or equal to 0.030 percent of P, more than or equal to 0.030 percent of S, more than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The preparation method comprises steps of smelting, refining outdoors, continuous casting and continuous rolling. The steel has the characteristics of high rigidity, high strength, high wear resistance, short production period, low production cost and capability of substituting high-alloy wear-resistant steel serving as the ball mill steel ball.

Owner:SHANDONG IRON & STEEL CO LTD

High-heat-resistance hot work die steel and preparation method

ActiveCN105018854AGood comprehensive mechanical propertiesImprove thermal fatigue resistanceAlloy elementCompound (substance)

The invention provides high-heat-resistance hot work die steel and a preparation method. The high-heat-resistance hot work die steel comprises the following chemical components in percentage by mass: 0.38-0.44% of C, 3.8-4.4% of Cr, 1.8-2.4% of Mo, 0.2-0.6% of Si, 0.5-0.8% of Mn, 0.5-0.7% of V, 0.8-1.2% of Ni, 0.02-0.05% of Cu, 0.08-0.12% of Ta, 0.01-0.03% of Nb, 0.008-0.016% of W, 0.008-0.016% of Co, P and S both less than 0.030%, and the balance of Fe. The steel is tapped until the chemical components are accordant with the requirements through the steps of alloying, burdening, smelting and analysis of stokehole chemical components; and then, the treatments of annealing, quenching and tempering are performed. The steel is excellent in comprehensive mechanical performance, high in heat fatigue resistance and excellent in heat stability and high-temperature strength; meanwhile, the steel carbon and the alloy element are lower in content; the production cost is low; the preparation procedures are simple; and the application value is excellent.

Owner:HARBIN ENG UNIV

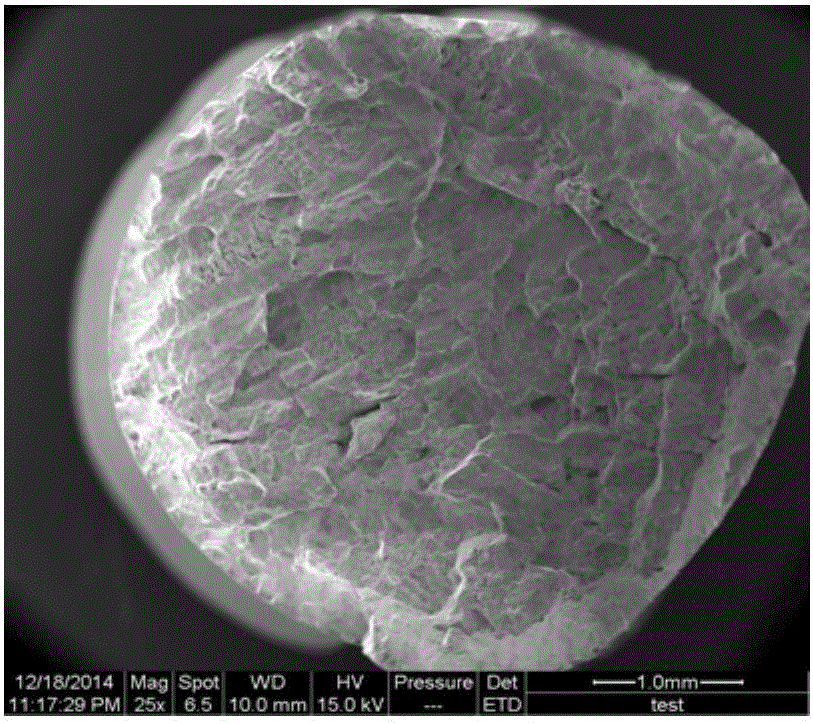

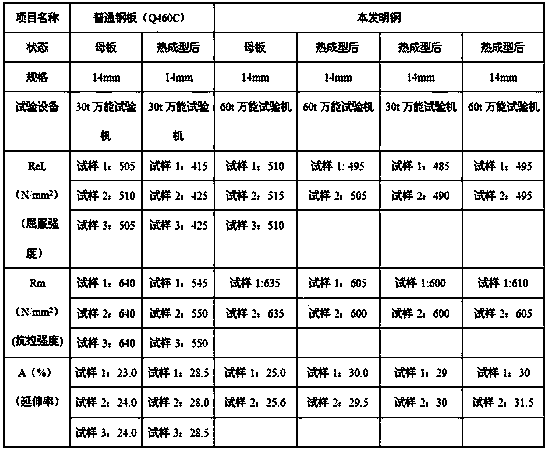

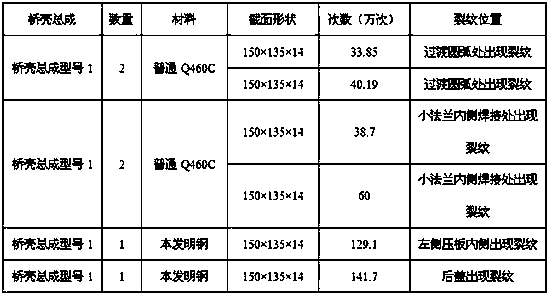

Steel plate for punching-welding axle housing and manufacturing method thereof

The invention relates to a 600MPa steel plate which is used for punching and welding an axle housing after being heated and is good in hot punching formability and a manufacturing method of the steel plate. Nb, V and other elements which guarantee the high temperature performance of steel are added, the content of C, Si and other elements which influence punching performance is lowered, Ti, Al and other nitrogen fixation elements are in cooperation, the steel plate is fundamentally guaranteed to have the good formability, meanwhile, high-temperature strength is improved, low-temperature toughness is excellent, welding performance is improved, fatigue strength is obviously improved, and the fatigue life of the component is prolonged by more than 50%. The steel plate can be widely applied to the production of medium plate rolling pieces in large structures of hot forming, a large air blower, a vibrating screen and the like under a high temperature condition, and the steel for the medium plate rolling pieces requires for high-temperature strength.

Owner:JIGANG GRP

Aluminum titanium boron carbon zirconium rare earth refiner, preparation method and application thereof

The invention discloses an aluminum titanium boron carbon zirconium rare earth refiner, a preparation method and application thereof. The aluminum titanium boron carbon zirconium rare earth refiner comprises the following components by mass percent: 3% to 5% of titanium, 0.3% to 0.5% of boron, 0.08% to 0.15% of carbon, 0.08% to 0.22% of zirconium, 0.8% to 1.2% of rare earth, 0.10% or less of impurity Fe, 0.03% or less of impurity V, 0.08% or less of impurity Si and 0.15% or less of other impurities, and the balance being aluminum, wherein the content of each of the other single impurity elements is smaller than 0.03%. According to the aluminum titanium boron carbon zirconium rare earth refiner, through control of the reasonable addition amount of the zirconium element and preparation conditions, cylindrical objects and needle-shaped objects of TiAl3 are effectively decreased, TiB2 aggregation is reduced, generated harmful Al4C3 phases are decreased, size and distribution problems of TiAl3 phase particles are solved, the internal air content of an alloy is decreased, the refining time of the obtained refiner is short (10s), and the refining duration is long (larger than 12 h).

Owner:NANJING YUNKAI ALLOY CO LTD

3004 aluminum foil and preparing method and application thereof

The invention discloses 3004 aluminum foil and a preparing method and application thereof. The aluminum foil comprises chemical elements: by mass, 0.15-0.25% of Si, smaller than or equal to 0.55% of Fe, 0.14-0.2% of Cu, 1.02-1.15% of Mn, 0.95-1.1% of Mg, smaller than or equal to 0.05% of Cr, smaller than or equal to 0.15% of Zn, 0.015-0.025% of Ti, smaller than 0.1% of other chemical elements andthe balance Al. The 3004 aluminum foil is obtained by performing 3004 aluminum alloy smelting, refining, standing, online degassing and deslagging, casting, face-milling, uniform heating treatment, hot rolling, cold rolling, intermediate annealing, cold foil rolling and finished product annealing. With the combination of the various elements and the preparing process, the prepared aluminum foil has high strength and toughness, the thickness is greatly reduced when the aluminum foil is used as a container, use is convenient, and the consumption of the raw materials is reduced; and waste ring-pull cans can be adopted as a raw material, the consumption of the raw material is reduced, resources are reutilized, the source of the raw materials for preparing the aluminum foil is widened, meanwhile the burdens on the environment are avoided, the production cost is reduced, and the 3004 aluminum foil has quite good social economic benefits.

Owner:河南明泰科技发展有限公司

Aluminum-free high-strength heat-resistant die-casting magnesium alloy and preparation method thereof

InactiveCN101613823AGood liquidityLow tendency to crater and porosityRare-earth elementChemical composition

The invention provides an aluminum-free high-strength heat-resistant die-casting magnesium alloy. The alloy comprises the following chemical compositions in percentage by weight: 7.5 to 12.5 percent of Gd, 2.5 to 3.5 percent of Y, 0.3 to 1 percent of Zr, 0.5 to 1.5 percent of Zn, less than or equal to 0.02 percent of Si, less than or equal to 0.003 percent of Fe, less than or equal to 0.003 percent of Ni, less than or equal to 0.003 percent of Cu, and the balance of Mg, wherein Si, Fe, Ni and Cu are impurity elements. By adding Gd, Y, Zr and Zn as rare earth elements to magnesium melt, the invention develops the magnesium alloy which is high in strength, high in heat resistance and suitable for die casting. Although the prices of the magnesium alloy is 2 to 3 times that of the common die-casting magnesium alloy, the magnesium alloy has the advantages of good die-casting forming performance, high mechanical properties and good heat resistance, can be used for parts requiring high heat resistance, and has great potential for development.

Owner:SHENYANG POLYTECHNIC UNIV

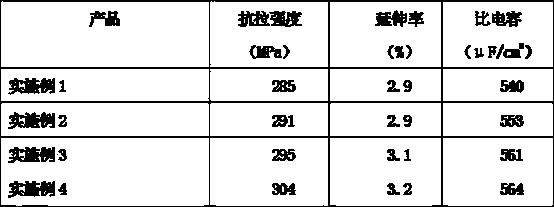

Low-manganese aluminum alloy for cathode foil and preparation method thereof

The invention relates to a low-manganese aluminum alloy for a cathode foil and a preparation method thereof. The low-manganese aluminum alloy is characterized by comprising the following chemical components in percentage by weight: 0.30-0.60% of Mn, 0.20-0.40% of Fe, 0.10-0.20% of Cu, Si not higher than 0.15%, Mg not higher than 0.08%, Zn not higher than 0.05%, Ti not higher than 0.15%, other impurity elements with single content not higher than 0.05%, other impurity elements with total content not higher than 0.15%, and the balance of Al. According to the low-manganese aluminum alloy of the present invention, the content of alloy elements is reduced, so that the alloy strength is reduced, the rolling force during rolling is reduced, the processing difficulty is reduced, and the energy is saved; and the cathode foil produced by the low-manganese aluminum alloy has the advantages of good surface quality, no dust, uniform structure and high specific capacitance.

Owner:广西南南铝加工有限公司

Rare earth containing, high strength and high toughness seamless steel pipe used for gas cylinder and production method thereof

InactiveCN103343293ALow elemental contentReduce residual stressManufacturing convertersProcess efficiency improvementRare-earth elementGas cylinder

The invention provides a rare earth containing, high strength and high toughness seamless steel pipe used for a gas cylinder and a production method thereof, belonging to the technical field of metallurgy and molding. Raw materials comprises, by weight percent, 90 % of blast furnace molten iron and 10 % of high-quality scrap steel. A pipe blank comprises the following chemical components by weight percent: 0.10-0.15 of C, 0.10-0.30 of Si, 0.90-1.20 of Mn, less than or equal to 0.020 of P, less than or equal to 0.010 of S, 0.90-1.20 of Cr, 0.10-0.30 of Mo, 0.40-0.70 of Ni, 0.06-0.20 of V, 0.01-0.03 of Ti, 0.005-0.030 of Al, 0.0005-0.0100 of rare earth element RE, and the balance being Fe and undetectable trace elements. A technology proves comprises steps of pretreatment of molten iron, combined blown converter smelting, LF furnace refine, VD vacuum treatment, round ingot continuous casting, cutting, pipe blank heating, perforation, pipe rolling, sizing, cooling, sawing, heat treatment, straightening, hydrostatic test and flaw detection. Mechanical properties comprises a yield strength of 860-930 MPa, a tensile strength of 1000-1100 MPa, a yield ratio of less than or equal to 0.90, an elongation percentage of more than or equal to 19 %, a transverse impact value aKV of more than or equal to 150 J / cm<2>(-40 DEG C), a grain size of more than 8.0 grade, and a residual stress of less than or equal to 30 MPa. The product provided by the invention has characteristics of low impurity element content, small residual stress, high intensity, good toughness and excellent technology performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

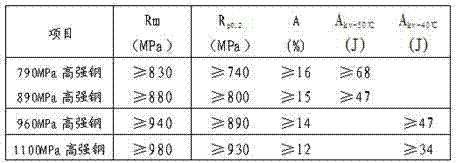

Non-preheating and non-copper-plating automatic low-alloy-steel welding wire for ships and production technology of wire

ActiveCN102922171ALow elemental contentImprove cleanlinessWelding/cutting media/materialsSoldering mediaChemical compositionCopper plating

The invention relates to a non-preheating and non-copper-plating automatic low-alloy-steel welding wire for ships. The welding wire comprises the following chemical compositions: 0.02%-0.1% of C, 2%-4% of Mn, 2%-4% of Ni, 0.5%-1% of Mo, 0.5%-0.8% of Si, 0-0.5% of Cu, 0-1.2% of Cr, 0-0.12% of V and 0-0.05% of Ti; and the drawing diameter of the welding wire ranges from phi 4.0mm to phi 1.0mm. The non-preheating and non-copper-plating automatic low-alloy-steel welding wire can be used for welding steel with high strength and high toughness without preheating, can avoid cold cracks during welding of a modern ship structure, can simplify a production technology, reduce the production cost and improve the production efficiency during the welding process, and can reduce the production cost and prevent impurities containing copper from being mixed to influence a welding effect since the welding wire does not need to be stored in a copper plating way.

Owner:JIANGSU TIANYE ALLOY MATERIAL

Fertilizing method for reducing cadmium content of leafy vegetables in overproof cadmium vegetable plot

ActiveCN103053255AIncrease productionImprove mineral nutrientsFertilising methodsOrganic fertilisersLeafy vegetablesHusk

The invention discloses a fertilizing method for reducing the cadmium content of leafy vegetables in an overproof cadmium vegetable plot, which comprises the following steps: (1) taking a carbonized rice husk as a base fertilizer, applying before the leafy vegetables are sowed and uniformly raking with soil or embedding the carbonized rice husk into a planting trench before the leafy vegetables are transplanted; and (2) taking an inorganic fertilizer as an additional fertilizer, and spray-applying the inorganic fertilizer rich in nitrogen, phosphorus and potassium taken as the additional fertilizer after the final singling or the survival of the leafy vegetables. In the step (1), 250-750 kg of carbonized rice husk is applied for each mu. In the step (2), the inorganic fertilizer is uniformly divided into 3 or 4 parts and is dissolved into water to be spray-applied, the inorganic fertilizer is sprayed for the first time after the final singling or the survival of the leafy vegetables, is sprayed once every 5-10 days and is totally sprayed for three or four times, and the inorganic fertilizer provides N5-15 kg, P2O51.6-4.0 kg and K2O55.0-15.0 kg for each mu. The fertilizing method has the benefit that as the carbonized rice husk and the inorganic fertilizer are applied together, the safe quality of the leafy vegetables is improved, and the content of Cd in the leafy vegetables is reduced.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

Titanium-zirconium-ferrum based solder for TiAl or Ti3Al alloy soldering

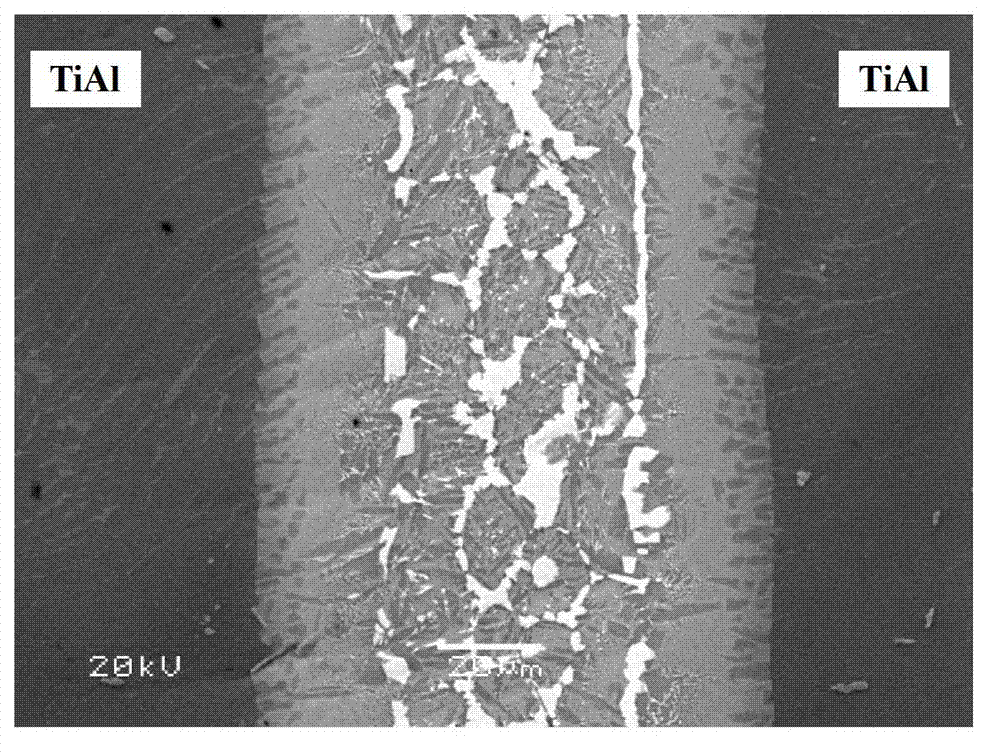

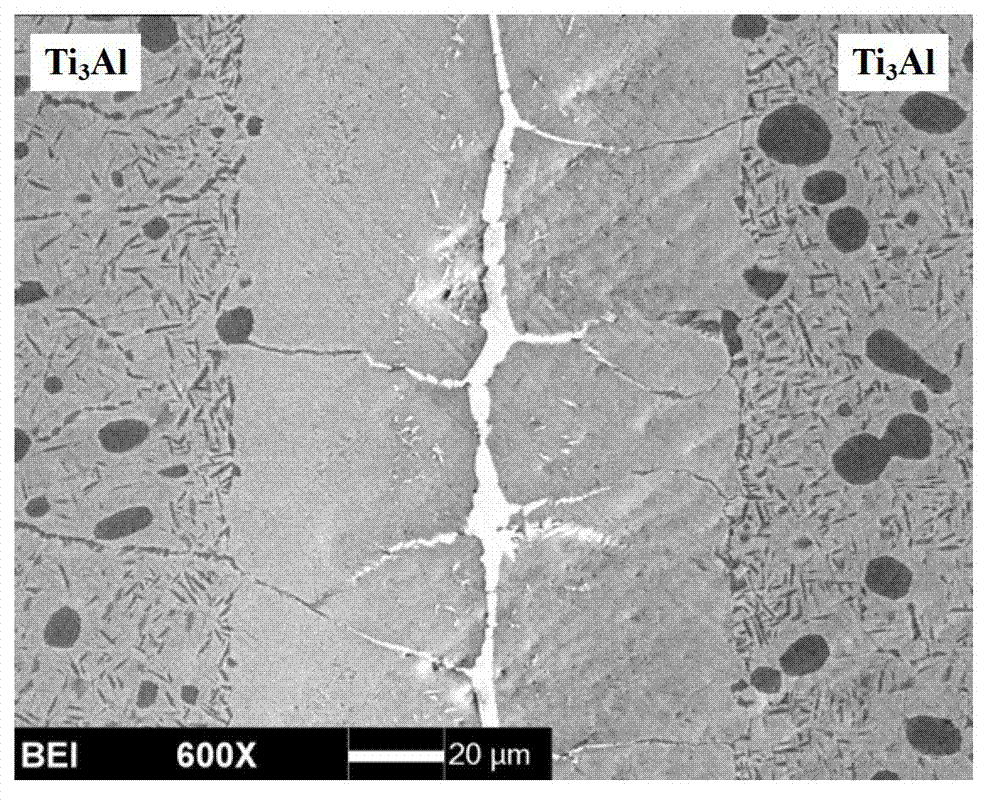

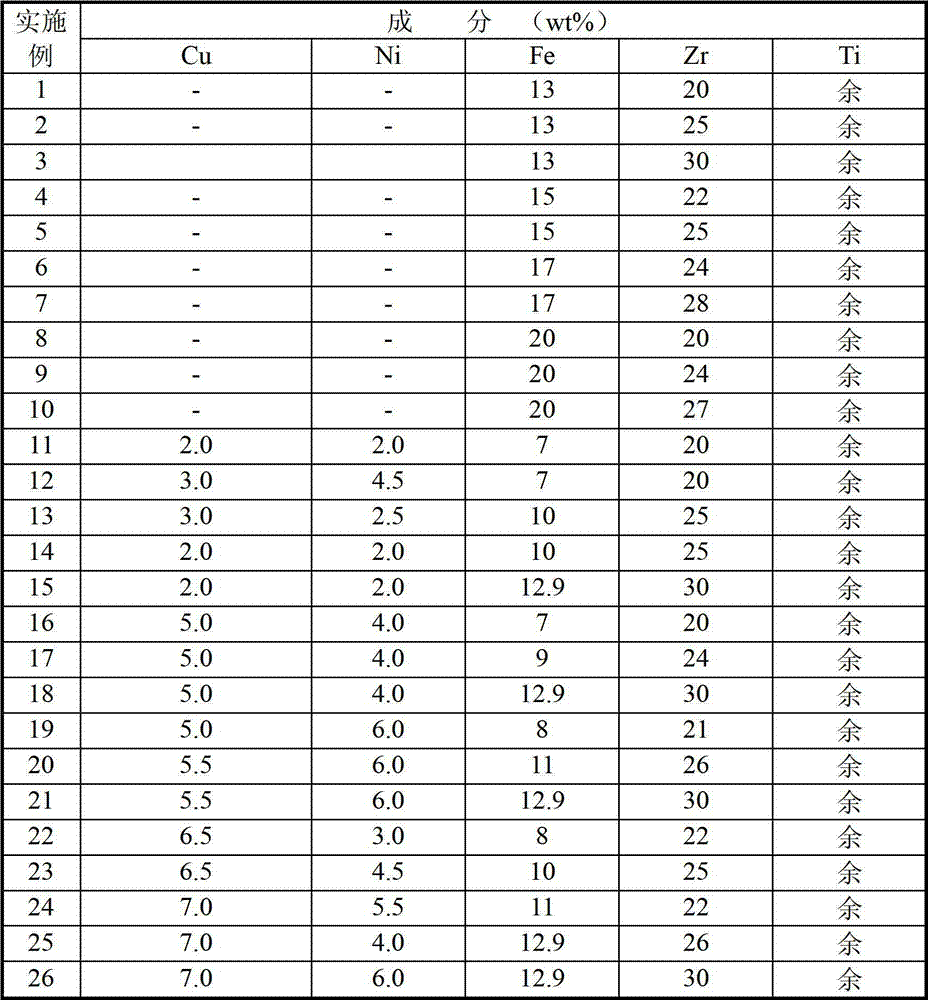

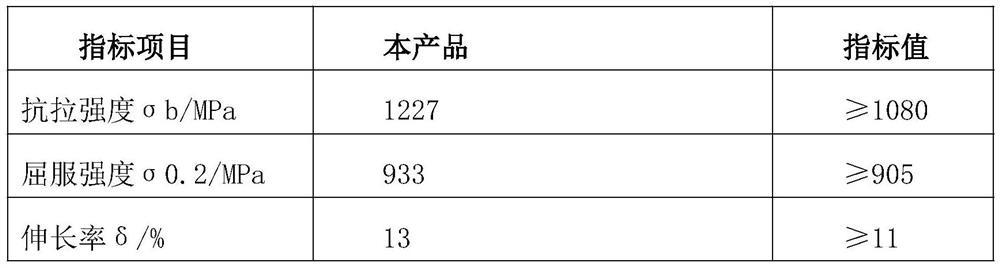

InactiveCN102922172AReduce formationImprove performanceWelding/cutting media/materialsSoldering mediaChemical compositionTitanium zirconium

The invention discloses a titanium-zirconium-ferrum based solder for TiAl or Ti3Al alloy soldering, which comprises chemical compositions in percent by weight: 20.0-30.0% of Zr, 13.0-20.0% of Fe and the balance of Ti or 20.0-30.0% of Zr, 7.0-12.9% of Fe, 2.0-8.0% of Cu, 2.0-6.0% of Ni and the balance of Ti. TiAl / TiAl and Ti3Al / Ti3Al alloy joints are obtained by using the solder at soldering temperature of between 1,030 and 1,070 DEG C, the shearing strength of a corresponding soldered joint at room temperature reaches 300 to 380MPa, the shearing strength of a soldered TiAl alloy joint at 760 DEG C reaches 210 to 250MPa, and the shearing strength of a Ti3Al alloy joint at 650 DEG C reaches 330 to 370MPa. The solder is suitable for self-connection of TiAl alloy or Ti3Al alloy.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

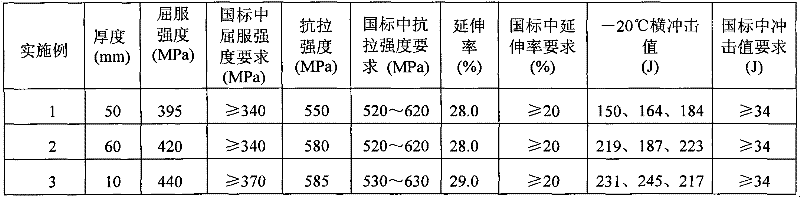

Production method of 18CrNiMo7-6 forging for wind power equipment gear

The invention discloses a production method of a 18CrNiMo7-6 forging for a wind power equipment gear. The production method includes the following steps of feeding, forging, normalizing, tempering, rough turning, UT flaw detecting and finish turning. In feeding, 18CrNiMo7-6 steel is taken and used as a raw materials steel ingot; in forging, a forging is formed after three times of upsetting and drawing, the sum of the forging ratios of three times of upsetting and drawing is larger than 7:1, the initial forging temperature is 1,220 DEG C, and the final forging temperature is 850 DEG C; in normalizing, the forging is heated to 710+ / -5 DEG C and heat-preserved for 2-2.5 h, then the forging is heated to 960+ / -5 DEG C at the heating rate being smaller than or equal to 150 DEG C / h and heat-preserved for 6-6.5 h, and then the forging is air-cooled below 300 DEG C; in tempering, the forging is heated to 680 DEG C at the heating rate being smaller than or equal to 150 DEG C / h and kept for 10-12 h, and then the forging is air-cooled to room temperature; and in finish turning, the forging is finish-turned into the wind power equipment gear meeting the dimension requirements.

Owner:ZHANGJIAGANG HAIGUO HEAVY FORGING

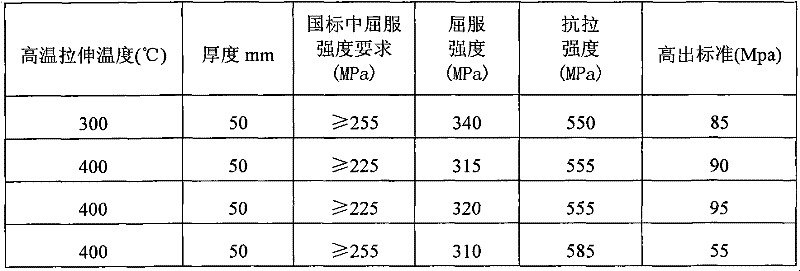

Ni-free normalized type Q370R pressure vessel steel plate and manufacturing method thereof

InactiveCN102605245ALow elemental contentLow costTemperature control deviceSteel platesLiquefied natural gas

The invention relates to a Ni-free normalized type Q370R pressure vessel steel plate and a manufacturing method of the Ni-free normalized type Q370R pressure vessel steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.15-0.18% of C,0.25-0.50% of Si, 1.4-1.6% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.02-0.03% of Nb, 0.07-0.08% of V, 0.006-0.010% of Ti, 0.024-0.034% of Als, and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps of: taking molten iron and waste steel subjected to desulfuration pretreatment as raw materials, and then performing the processes of smelting, continuous casting, heating, rolling and cooling, normalizing thermal treating, and the like, thereby obtaining the Ni-free normalized type Q370R pressure vessel steel plate. The Ni-free normalized type Q370R pressure vessel steel plate has the advantages of above 370MPa yield strength, excellent plasticity, low-temperature impact toughness, high-temperature tensile property, excellent Z directional tensile property, and wide application in the field of storing liquefied petroleum gas, liquefied natural gas, and the like.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com