Titanium-zirconium-ferrum based solder for TiAl or Ti3Al alloy soldering

A brazing material and brazing technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of reducing the mechanical properties of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

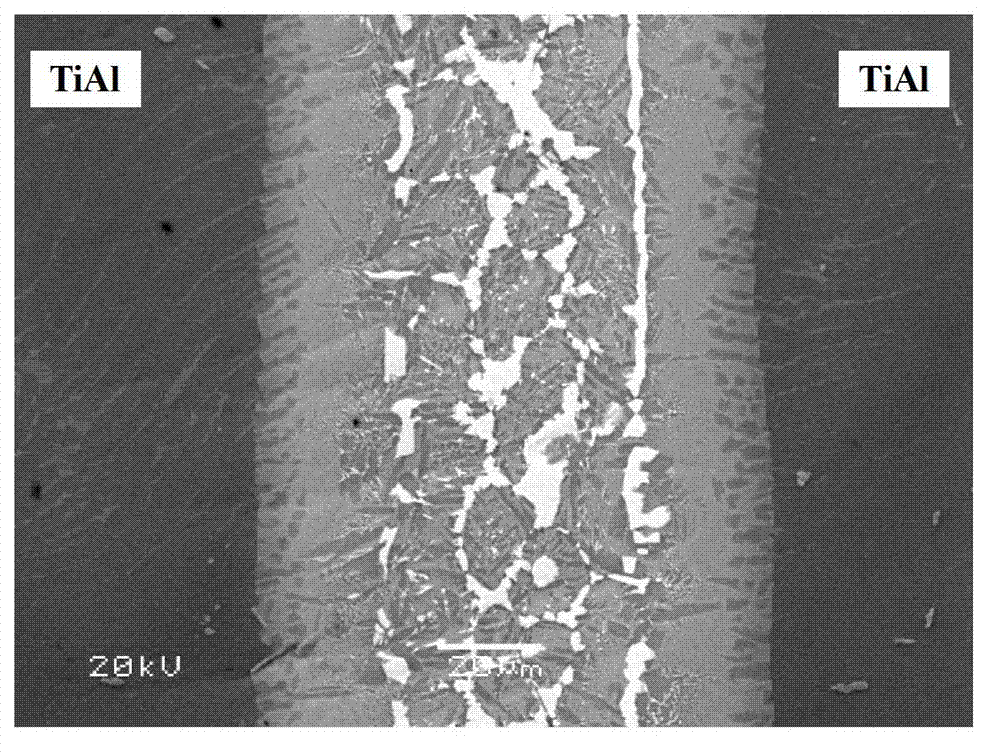

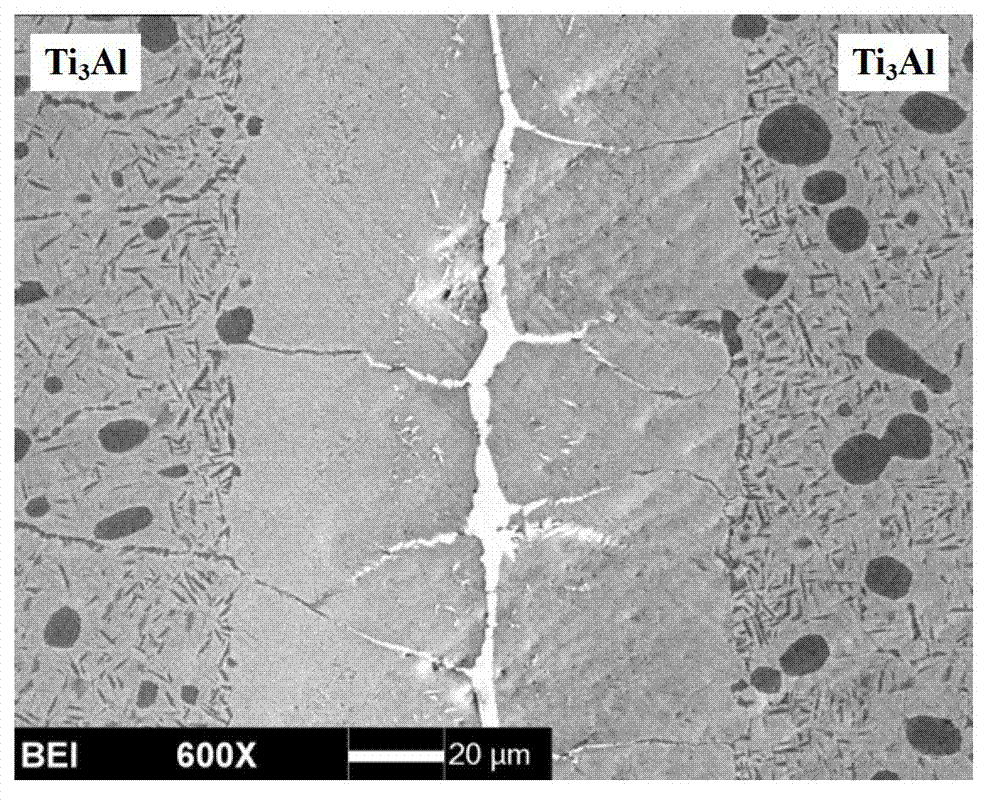

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

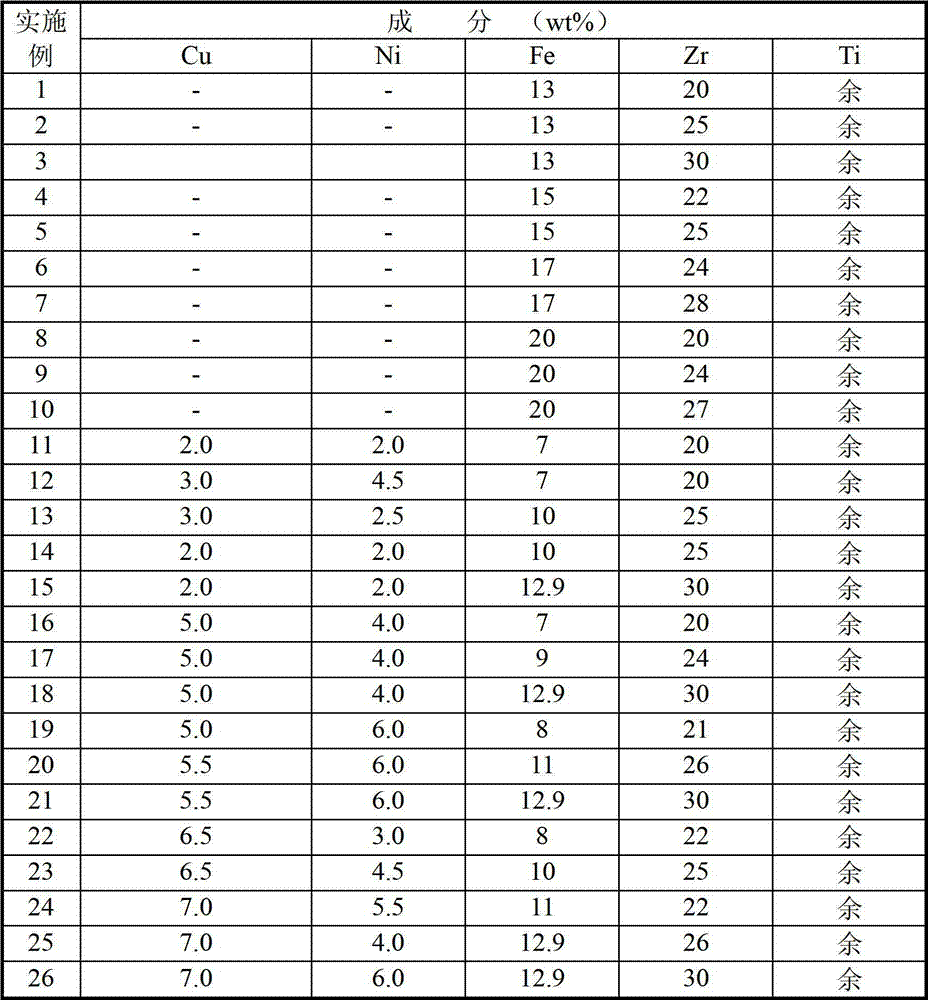

[0016] Table 1 shows the composition and weight percentage composition of the solder described in the technical solution of the present invention.

[0017] The composition and weight percent of brazing filler metal described in technical scheme of the present invention in table 1

[0018]

[0019]

[0020] The method for preparing the above brazing filler metal is: firstly, under the protection of argon gas, the brazing filler metal raw material is weighed according to the proportion and melted into an alloy ingot by using an arc melting method. The raw material is high-purity Ti, Zr, Ni , Cu, Fe, and then use one of the following methods to prepare solder:

[0021] (1) adopting argon atomization powder making equipment to prepare powdery solder;

[0022] (2) Under the protection of argon, the quenched foil strip solder is prepared by using the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com