Patents

Literature

474 results about "Titanium zirconium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In its elemental form, zirconium has a silvery white appearance that is similar to titanium. Zirconium's principal mineral is zircon (zirconium silicate ). Zirconium is commercially produced as a byproduct of titanium and tin mining and has many applications as a opacifier and a refractory material.

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

Corrosion protective cleaning agent for tin-plated steel

InactiveUS6060122ASignificant positive effectGood effectOther chemical processesPretreated surfacesTitaniumNonionic surfactant

PCT No. PCT / EP96 / 01137 Sec. 371 Date Sep. 24, 1997 Sec. 102(e) Date Sep. 24, 1997 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 30558 PCT Pub. Date Oct. 3, 1996The invention concerns an aqueous corrosion-protective cleaning solution for tin-plated steel, in particular for tin-plated steel cans, the solution containing complex fluorides of the elements boron, titanium, zirconium, and hafnium; non-ionic surfactants; and corrosion inhibitors and having a pH within the range from 3 to 6. The invention also concerns an aqueous concentrate for preparing the solution by dilution with water and a method of cleaning tin-plated cans using the solution.

Owner:HENKEL KGAA

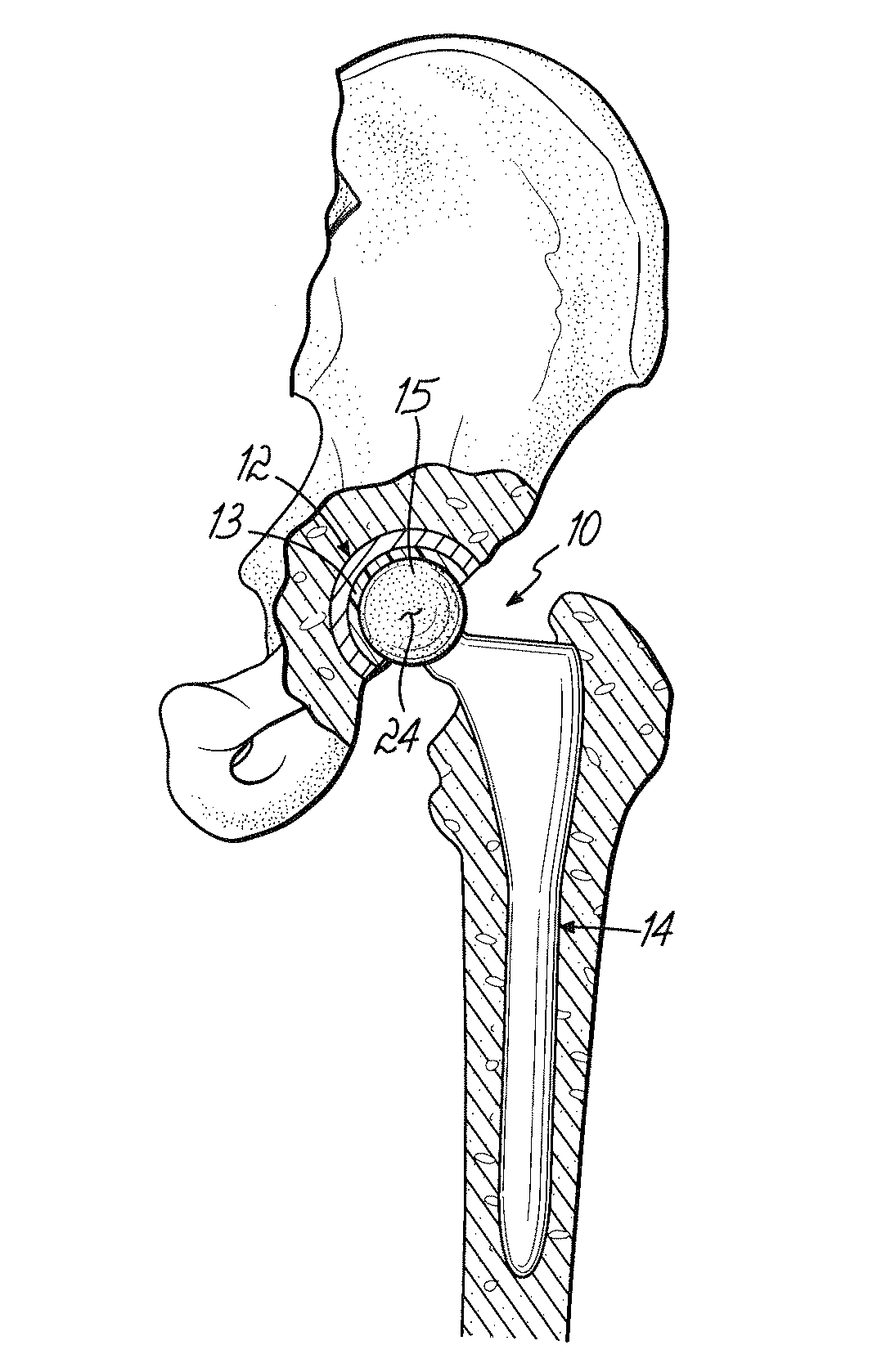

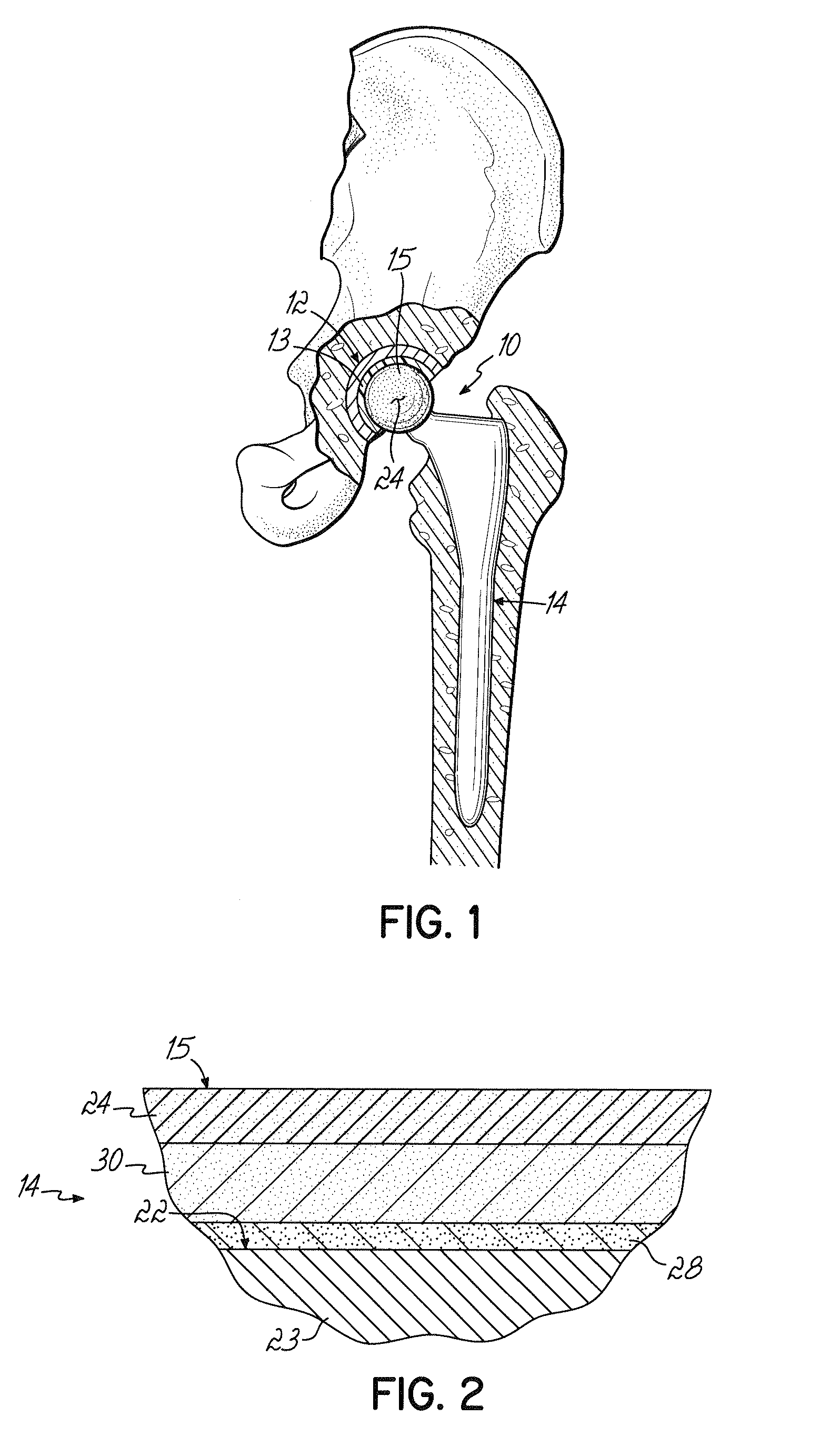

Titanium alloy with oxidized zirconium for a prosthetic implant

A prosthetic device having a generally fixed member formed from a low friction material such as ultra-high molecular weight polyethylene and an articulating titanium member, which includes an articular bearing surface. The articular surface is a zirconium oxide layer formed by applying a coating of zirconium onto the titanium member and heating this in an oxygen-containing environment. This causes the zirconium to oxidize and further causes the zirconium to migrate into the titanium member forming a titanium zirconium diffusion layer, which prevents delamination.

Owner:ZIMMER INC

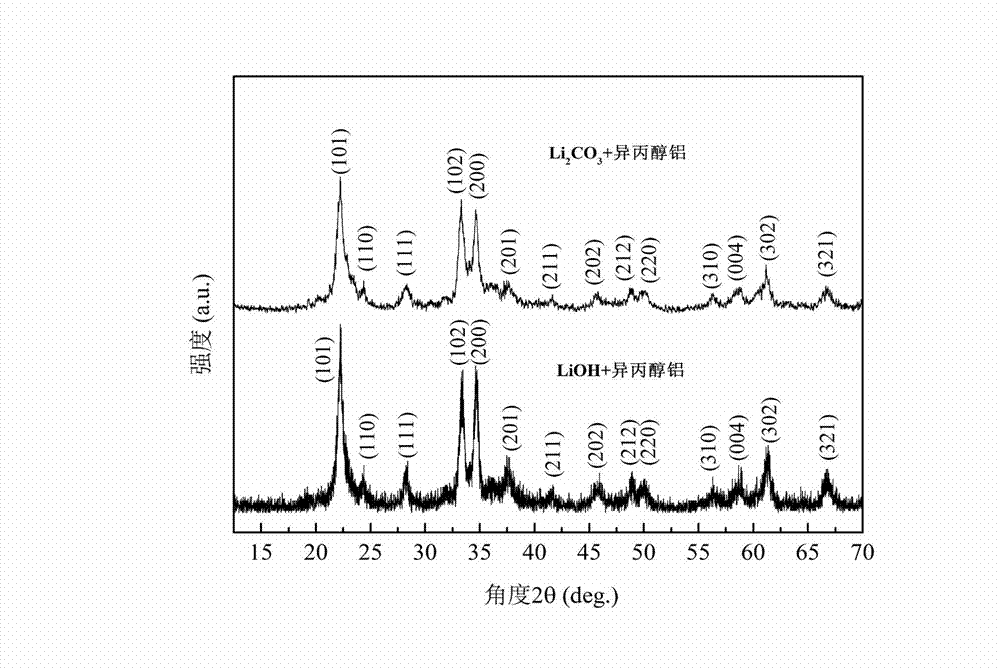

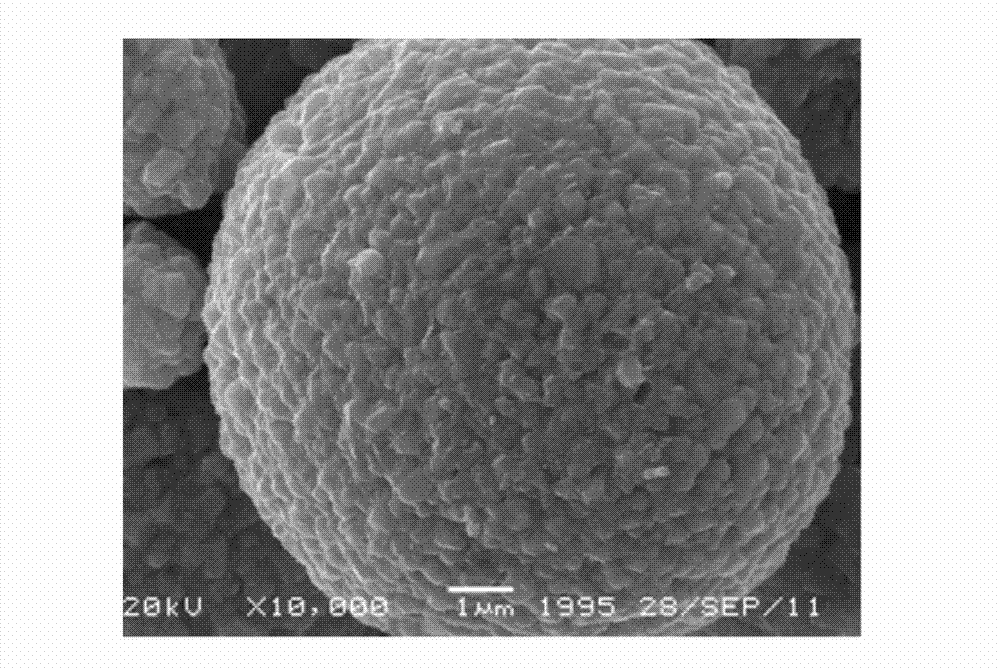

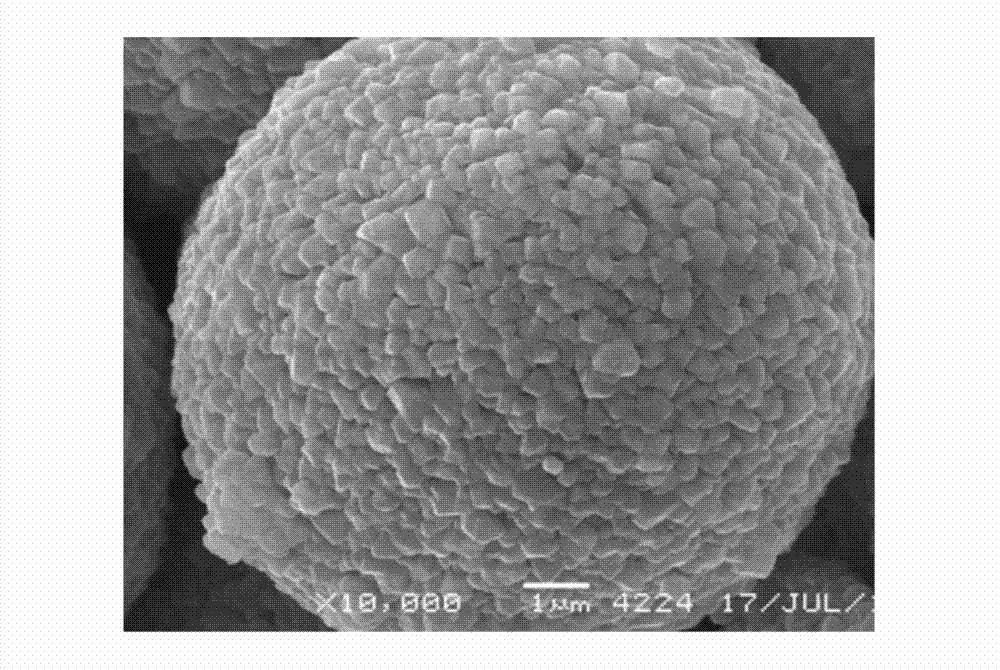

High-nickel positive active material of surface-modified lithium ion battery and preparation method of positive active material

ActiveCN102832389AEasy to processImprove electrochemical stabilityMaterial nanotechnologyCell electrodesElectrical conductorTitanium zirconium

The invention discloses a high-nickel positive active material of a surface-modified lithium ion battery. A matrix substance is the high-nickel positive active material LiNixCoyMzO2, the surface of the matrix substance is uniformly coated by a lithium-ion conductor compound which comprises at least one of LiAlO2, Li4Ti5O2 and Li2ZrO3; the content of the total impurity lithium in the positive active material is below 0.085%. The invention also discloses a preparation method of the positive active material. The preparation method comprises the following steps of: firstly mixing the matrix substance with an organic solution containing aluminum, an organic solution containing titanium or an organic suspension liquid containing aluminum / titanium / zirconium, drying, calcining the dried mixture, finally generating the lithium-ion conductor compound on the surface of the matrix substance, namely the high-nickel positive active material of the surface-modified lithium ion battery. The high-nickel positive active material disclosed by the invention has the advantages that the content of alkali substances is obviously reduced, the processing performance of the material is improved, and the electrochemical stability is improved.

Owner:HUNAN CHANGYUAN LICO CO LTD

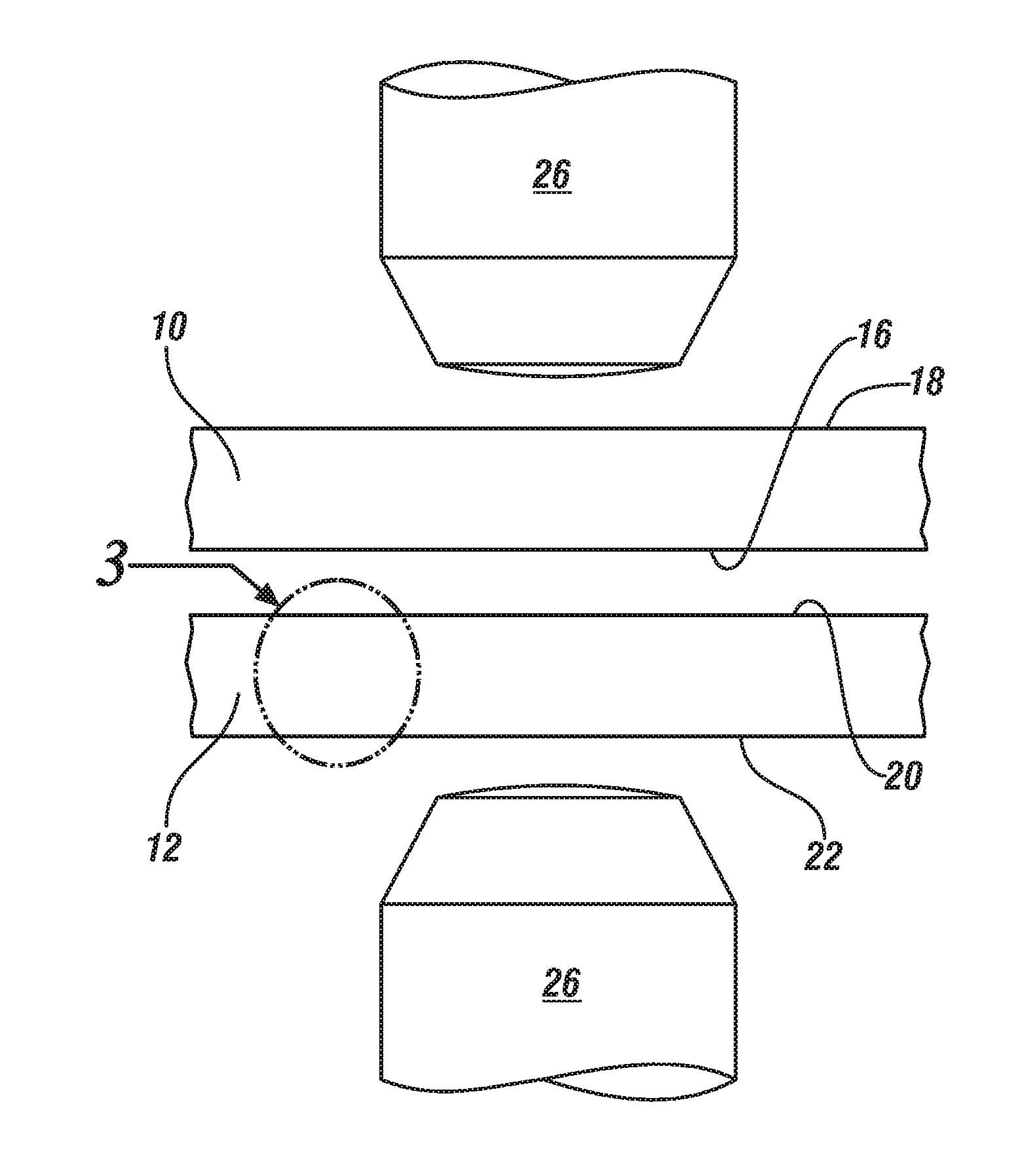

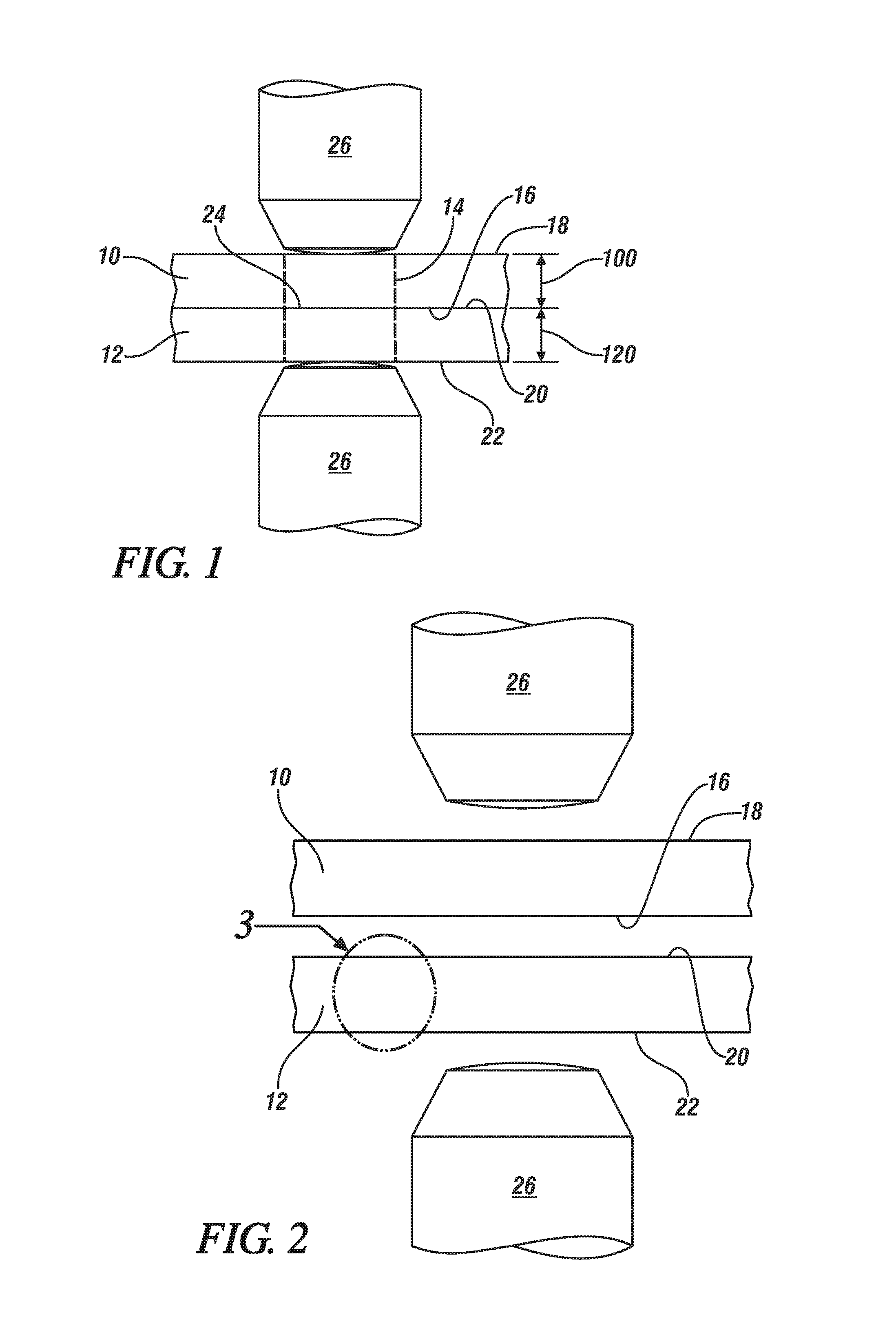

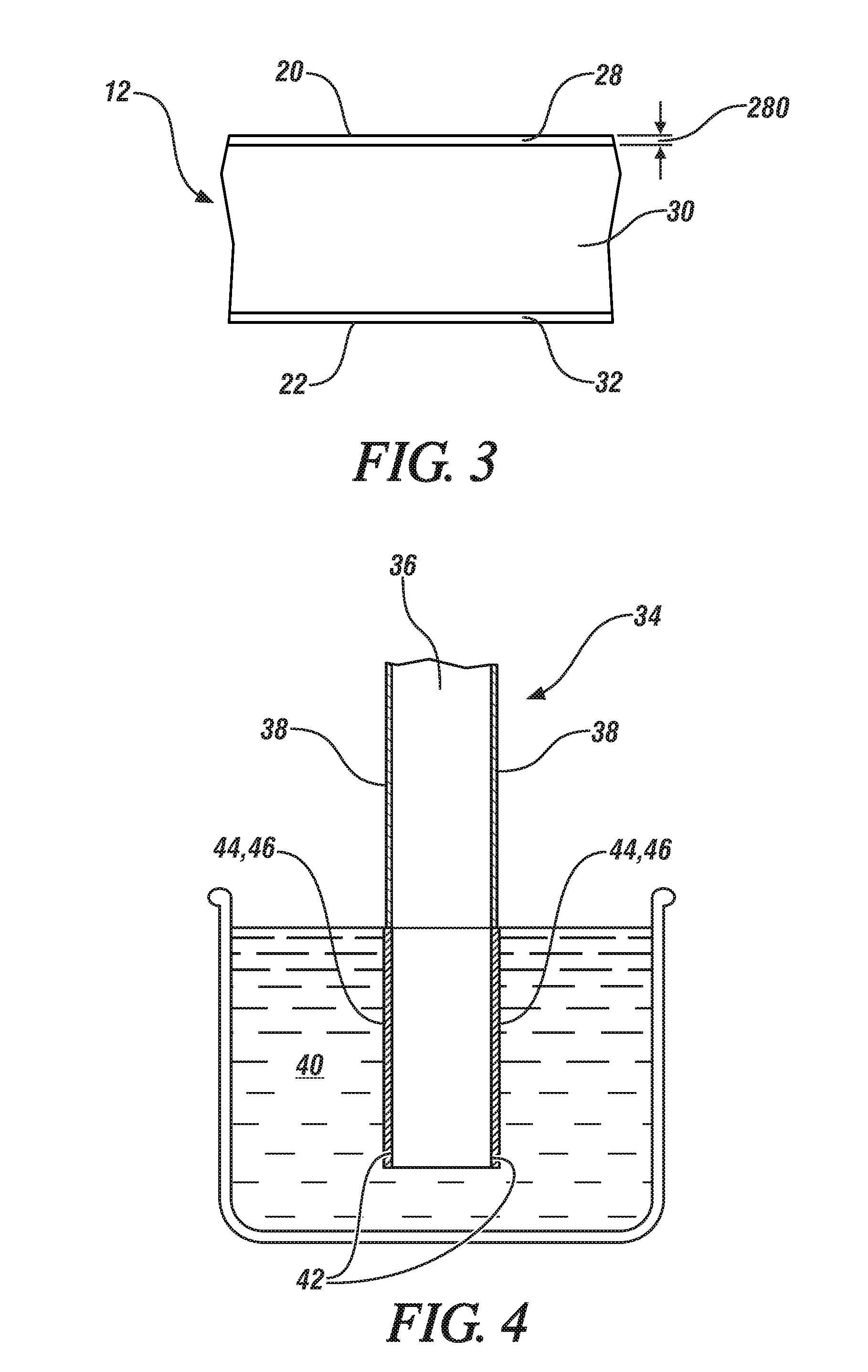

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

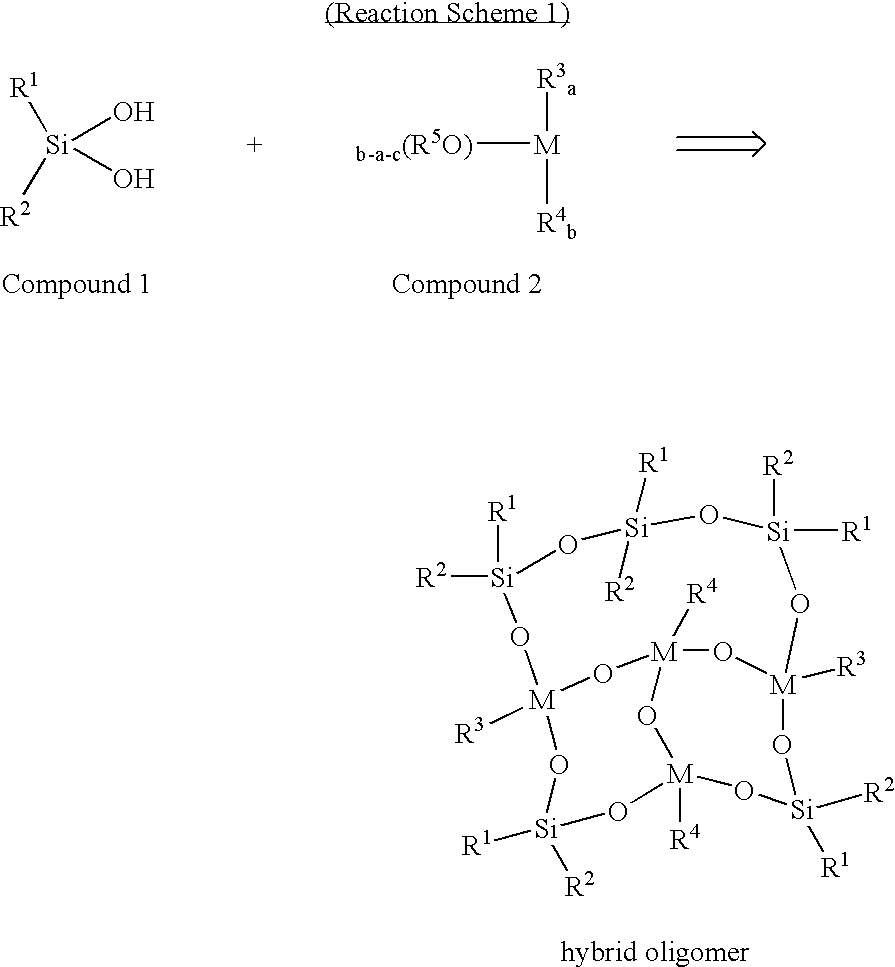

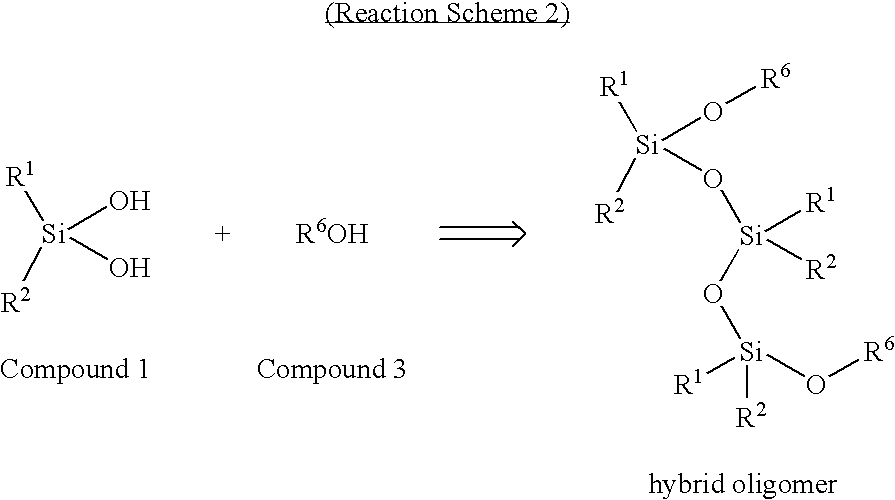

Inorganic/organic hybrid oligomer and nano hybrid polymer for use in optical devices and displays, and process for preparing the same

The present invention provides an inorganic / organic hybrid oligomer having silica or a complex of silica and a metal oxide present inside thereof and functional organic groups outside thereof, obtained by reacting: (i) Compound 1 and Compound 2; (ii) Compound 1 and Compound 3; or (iii) Compound 2 and Compound 3 with Compound 1; wherein Compound 1 is R1R2Si(OH)2, Compound 2 is (R3)a(R4)bM(OR5)(c-a-b), and Compound 3 is R6OH or R6COOH; a and b are each an integer between 0 and 3; c is an integer between 3 and 6; M is silicon, or a metal such as aluminum, titanium, zirconium, etc. that can be coordinated with ligands; provided that in the cases of (i), (ii) and (iii) at least one of R1, R2, R3, R4 and R6 has a polymerizable functional group; an inorganic / organic nano hybrid polymer prepared therefrom and a process for preparing the same.

Owner:KOREA ADVANCED INST OF SCI & TECH

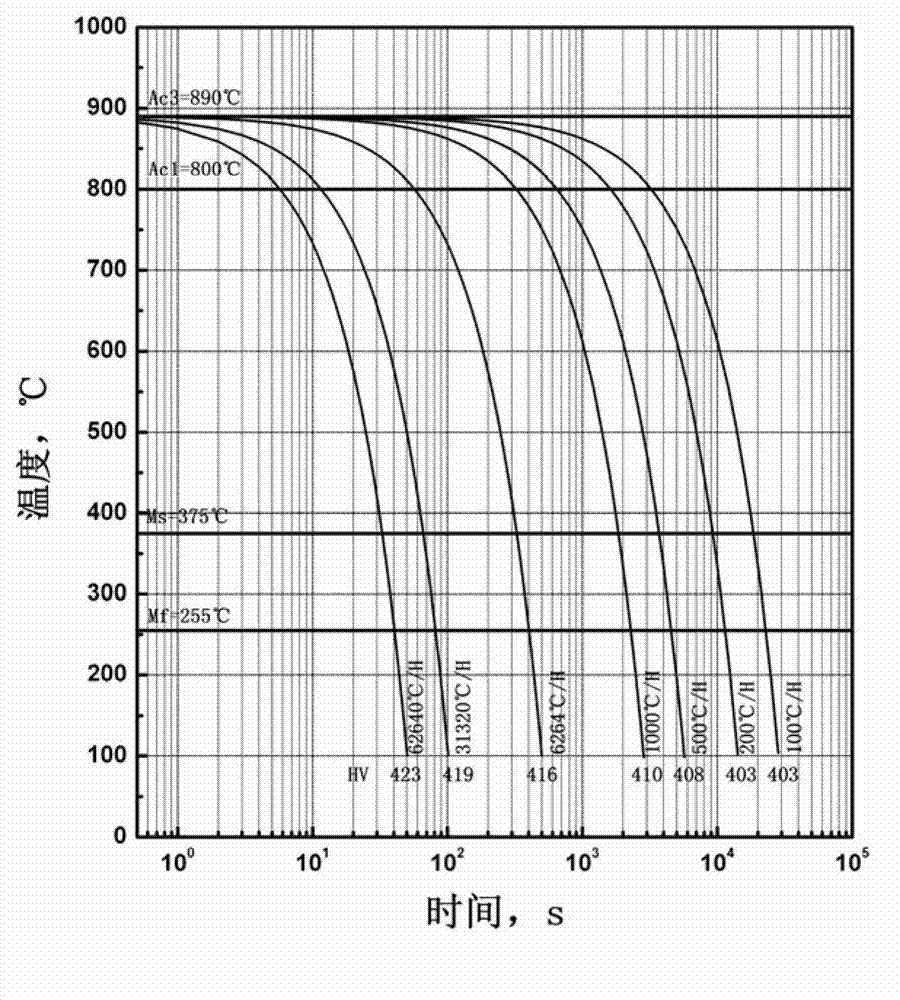

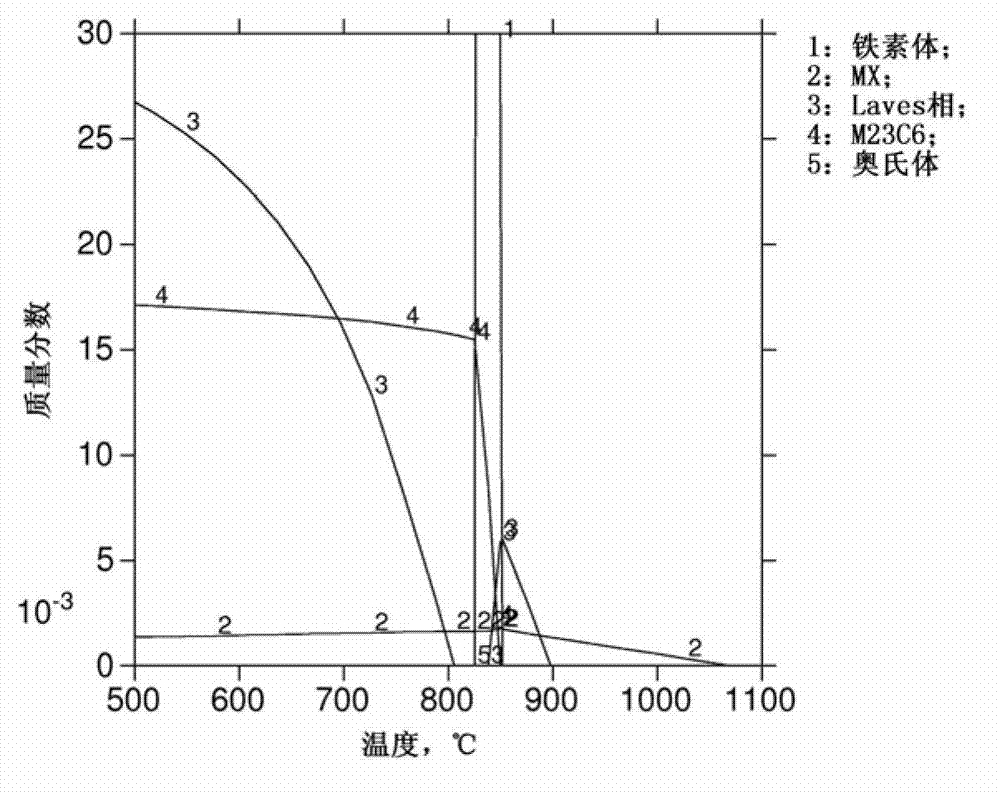

Steel for steam-temperature ultra-supercritical thermal power unit and preparation method thereof

The invention relates to steel for a steam-temperature ultra-supercritical thermal power unit and a preparation method thereof, belonging to the technical field of heat resistant steel. The steel comprises the following chemical compositions by weight percentage: 0.06-0.10 percent of carbon, 0.1-0.5 percent of silicon, 0.2-0.8 percent of manganese, not more than 0.004 percent of phosphorous, not more than 0.002 percent of sulfur, 8.0-9.5 percent of chromium, 2.5-3.5 percent of tungsten, 2.5-3.5 percent of cobalt, 0.03-0.07 percent of niobium, 0.10-0.30 percent of vanadium, 0.80-1.20 percent of copper, 0.006-0.010 percent of nitrogen, 0.010-0.016 percent of boron, 0.01-0.04 percent of rare-earth cerium, not more than 0.01 percent of nickel, not more than 0.005 percent of aluminum, not more than 0.01 percent of titanium, not more than 0.01 percent of zirconium and the balance of ferrum and inevitable impurity elements. The steel has the advantages that the steel can be used for preparing G115 steel of 650 DEG C of steam-parameter ultra-supercritical thermal power unit and a large-diameter boiler tube thereof, and the room-temperature mechanical property, the impact property, the high-temperature mechanical property and the permanence property of the steel are much higher than those of P92 steel in the Gb5310 and ASME standard.

Owner:CENT IRON & STEEL RES INST

Non-chromium deactivation liquid for processing aluminium alloy and method of use thereof

InactiveCN101161861AReduce pollutionMeet WEESMetallic material coating processesTitanium zirconiumPhosphoric acid

The present invention relates to a chrome-free passivating liquid for treating aluminum alloy and a method for using the same; the components of the passivating liquid and the weight concentration of the elements thereof consist of fluorin titanate comprising Ti (IV) between 0.05 wt percent and 0.15 wt percent, fluorin zirconate comprising Zr (IV) 0.01 wt percent and 0.05 wt percent and organic phosphate compound comprising 0.02 wt percent to saturated concentration. The use method of the passivating liquid of the invention has the following procedures: after grease on the surface of the aluminum alloy is removed, the aluminum alloy is treated by alkali cleaning, deoxidation and activation; when the temperature is between 25 DEG C and 60 DEG C and the PH value is between 3 and 3.5, the aluminum alloy is treated by impregnating or spraying for 2 min to 5 min. In the passivating liquid of the invention, organic phosphoric acid is directly added to a titanium zirconium system; the formed zirconium phosphate composite structure can obviously improve the corrosion resisting property of a passivating film and the adhesive capactiy of polymer coating (primer) on the surface of aluminum alloy.

Owner:NORTHEASTERN UNIV

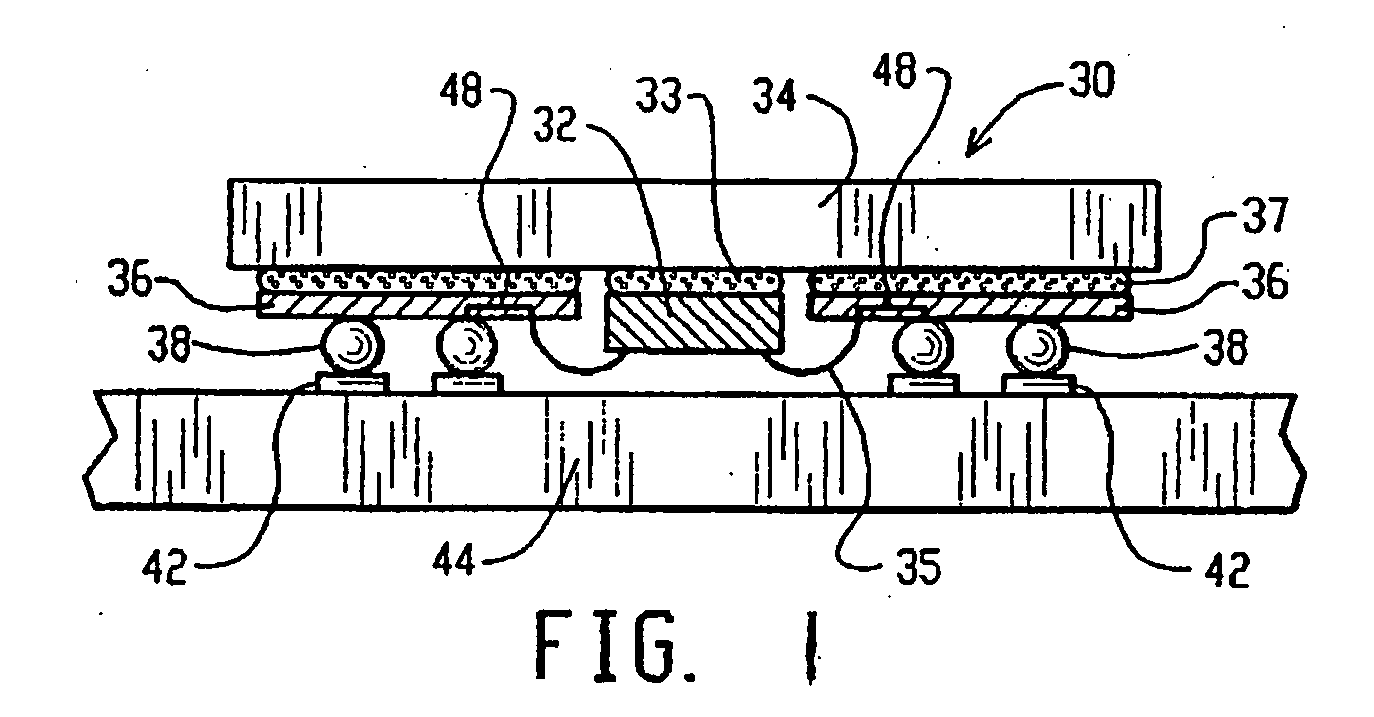

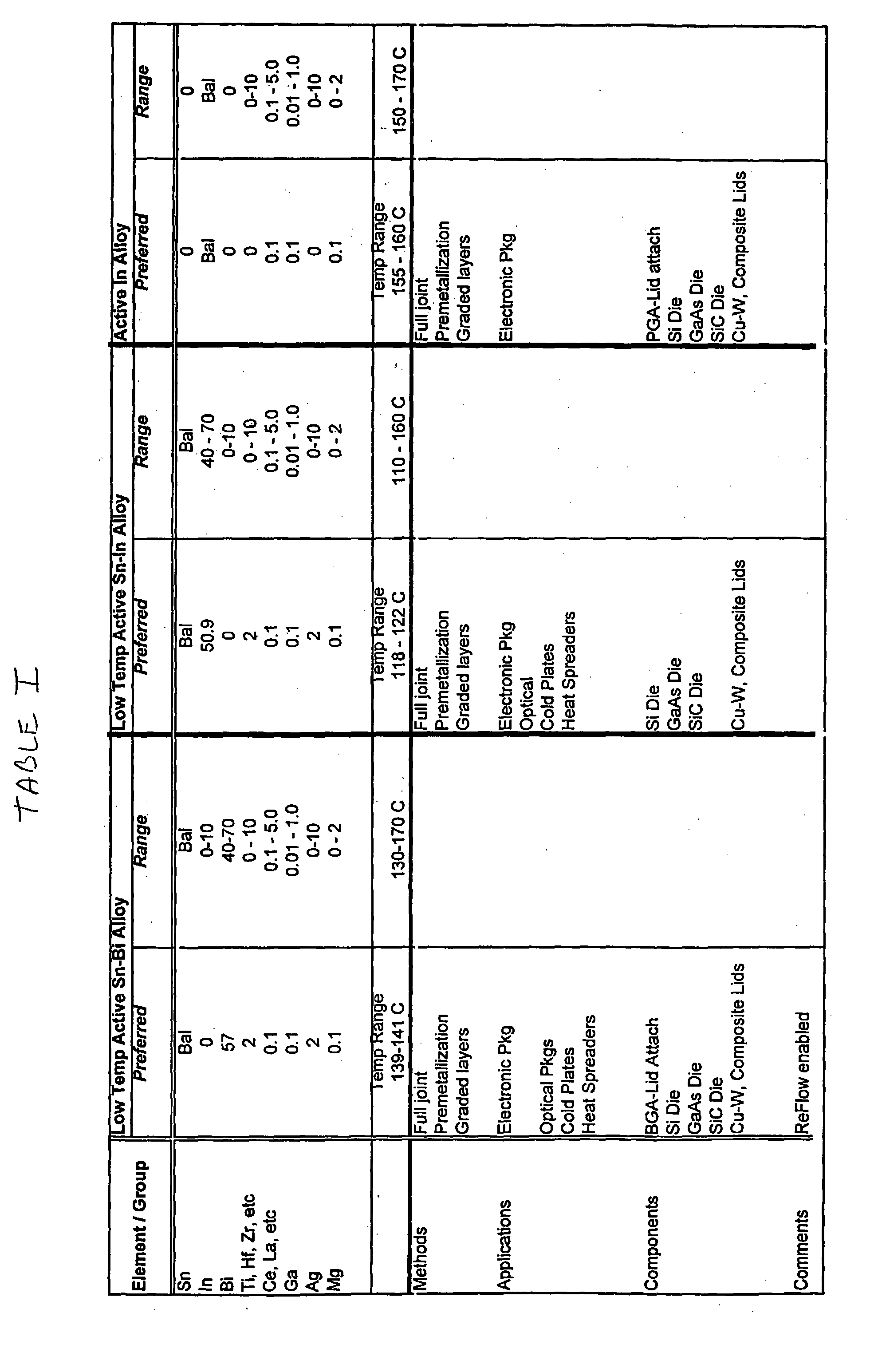

Electronic Package Formed Using Low-Temperature Active Solder Including Indium, Bismuth, and/or Cadmium

InactiveUS20070228109A1Increase concentrationHigh-strength, high-thermal conductivity jointsCooking-vessel materialsExhaust apparatusIndiumNiobium

An active solder alloy, an electronic device package including the active solder alloy bonding an electronic device to a substrate, and a method of forming high-strength joints by soldering using the solder alloy. The alloy contains up to about 10% by weight of an element or a mixture of elements selected from the group consisting of titanium, zirconium, hafnium, vanadium, niobium, or tantalum; between about 0.1 and 5% by weight of an element or a mixture of elements selected from the group of the lanthanides (rare earths); between about 0.01 and 1% by weight of gallium up to about 10% by weight of silver; up to about 2% by weight of magnesium; and a remainder consisting of tin, bismuth, indium, cadmium, or a mixture of two or more of these elements. The alloy enables low-temperature (less than about 180° C.) soldering within relatively narrow melting ranges (less than about 10° C.).

Owner:S BOND TECH

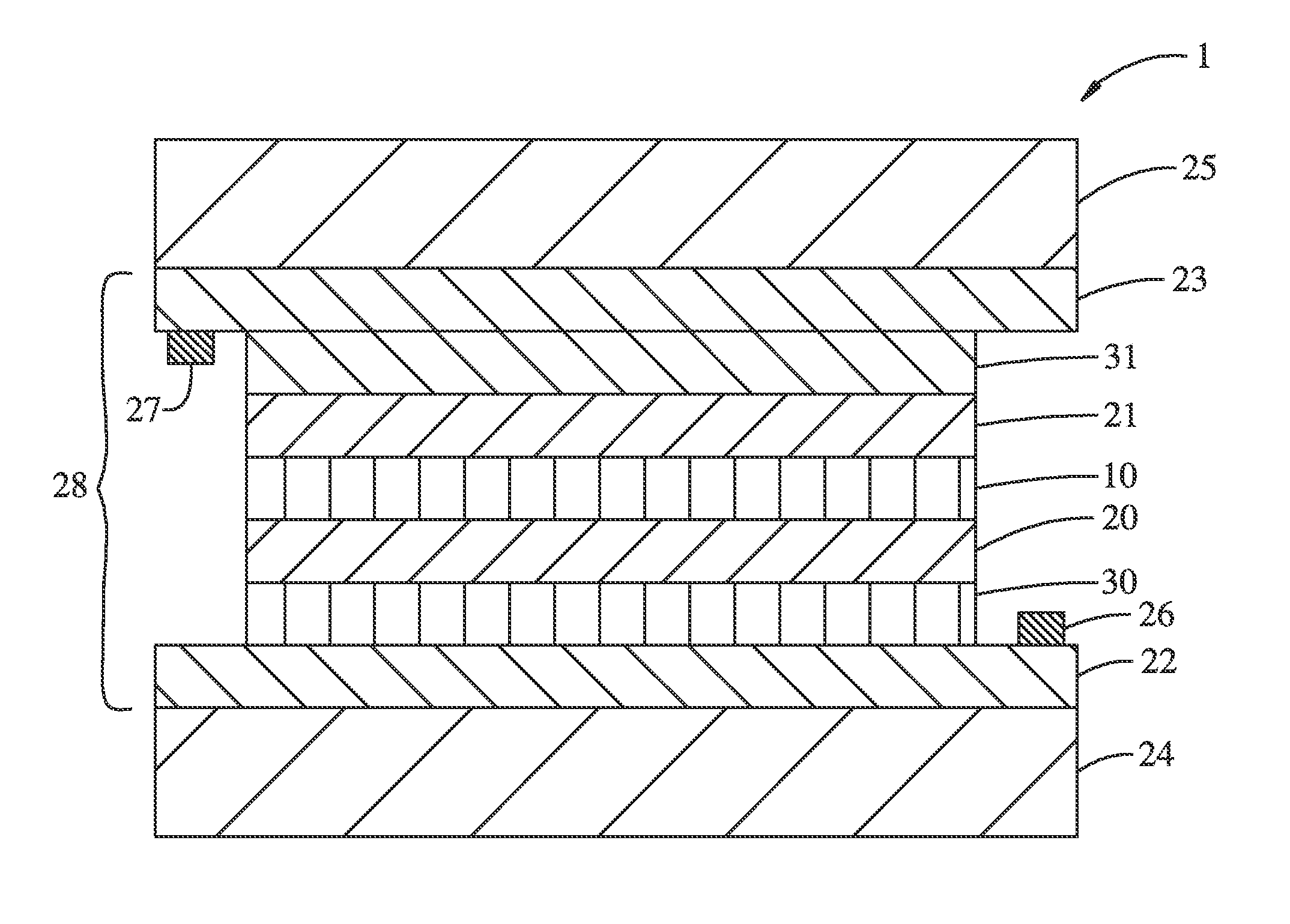

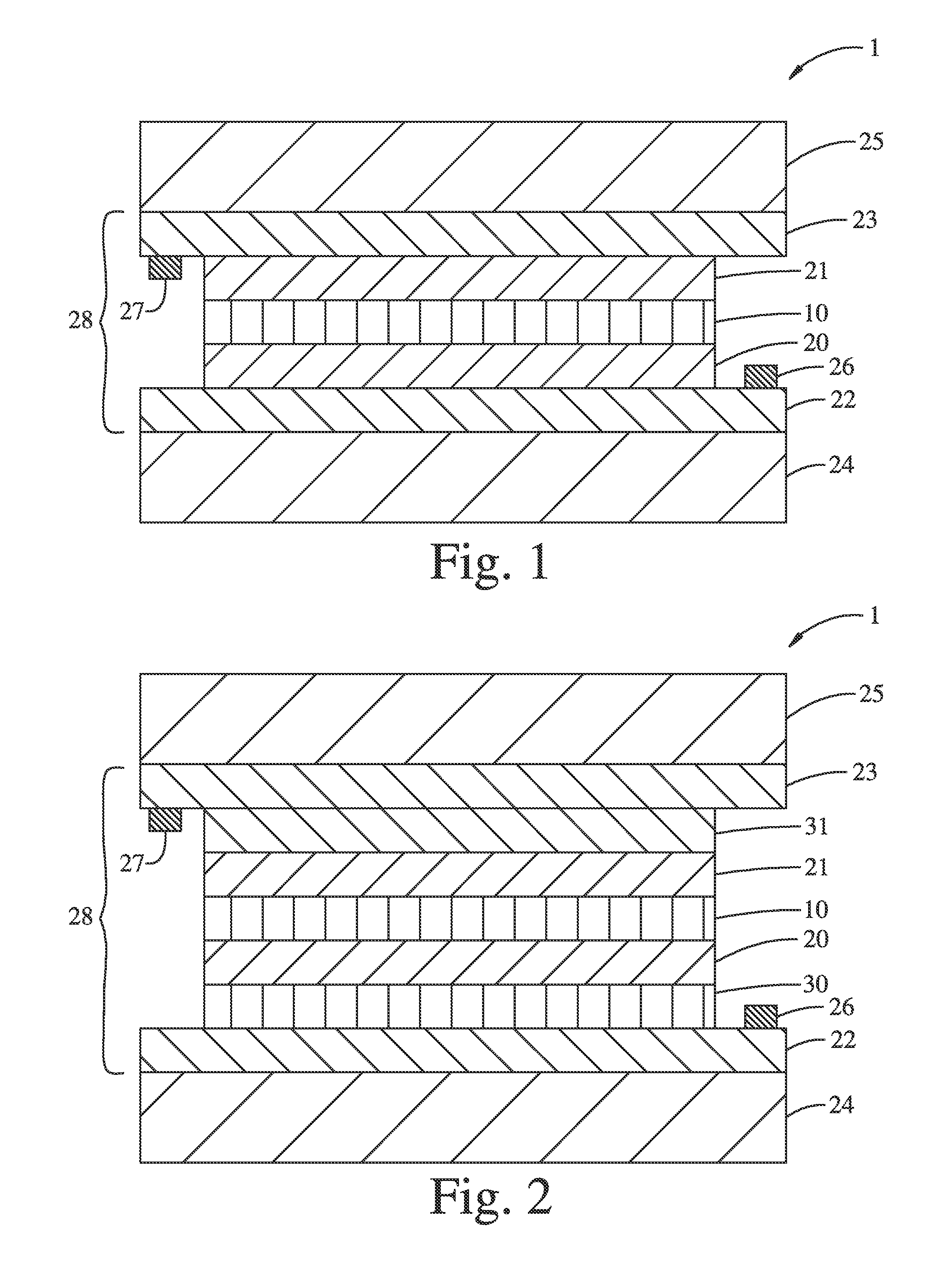

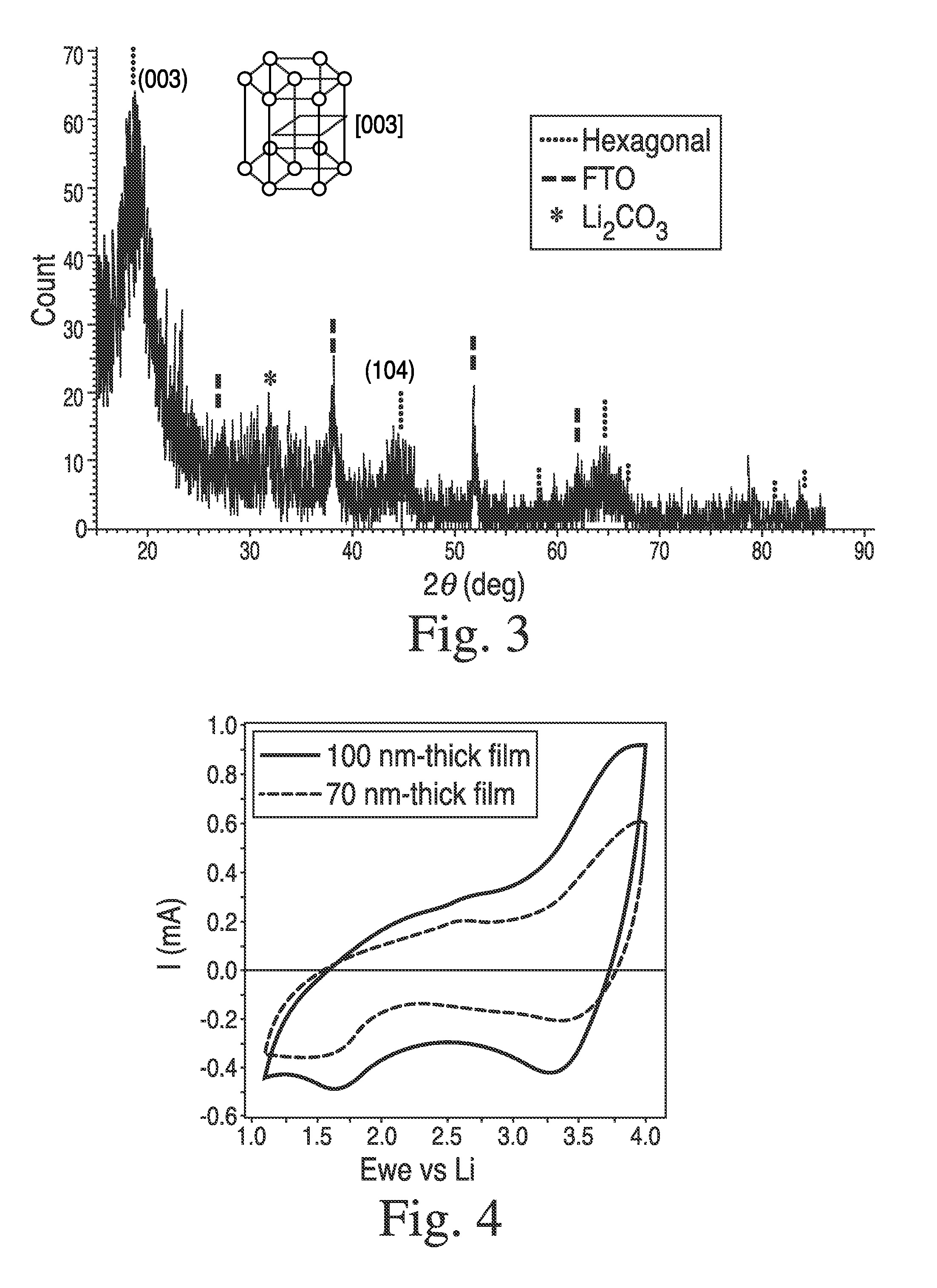

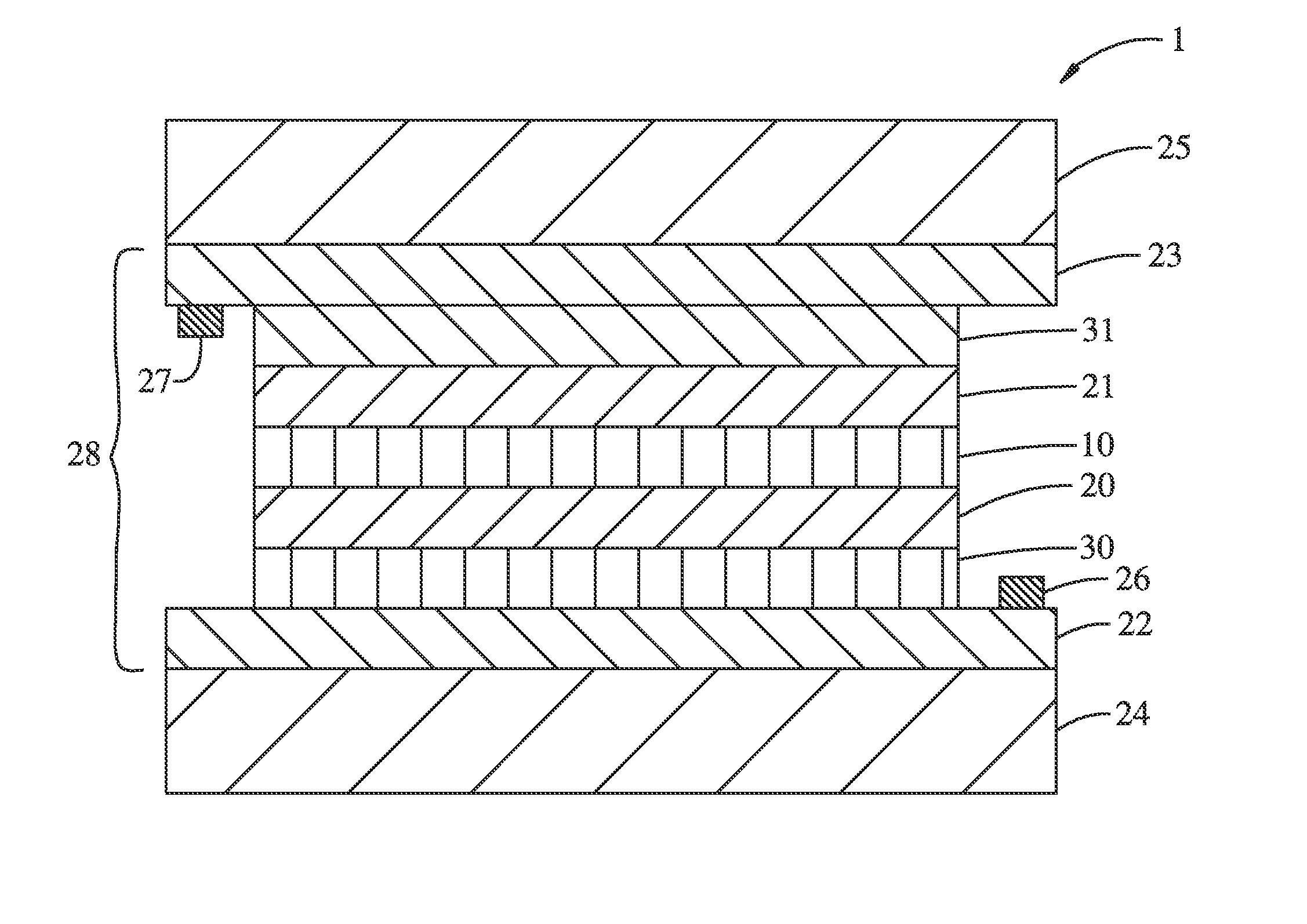

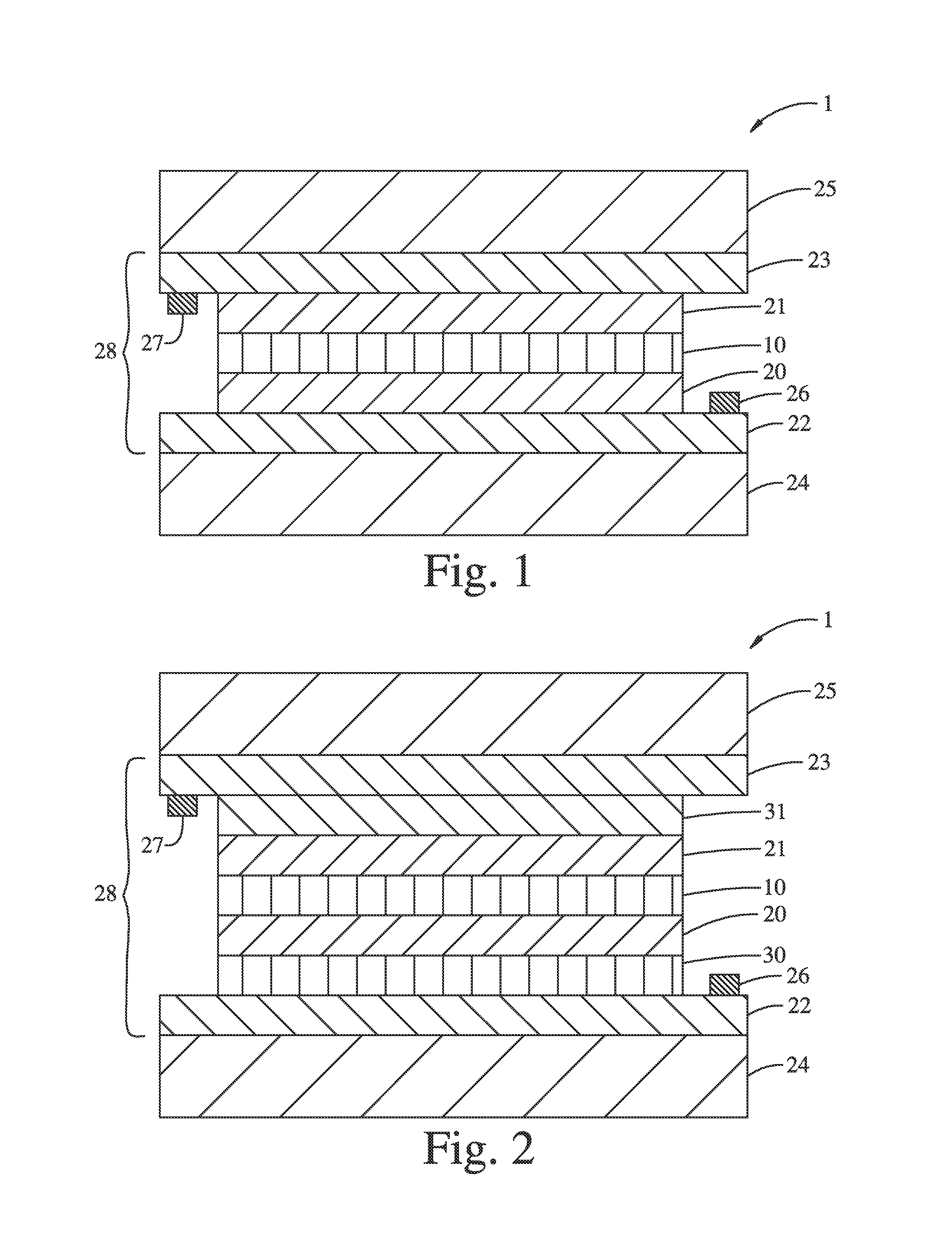

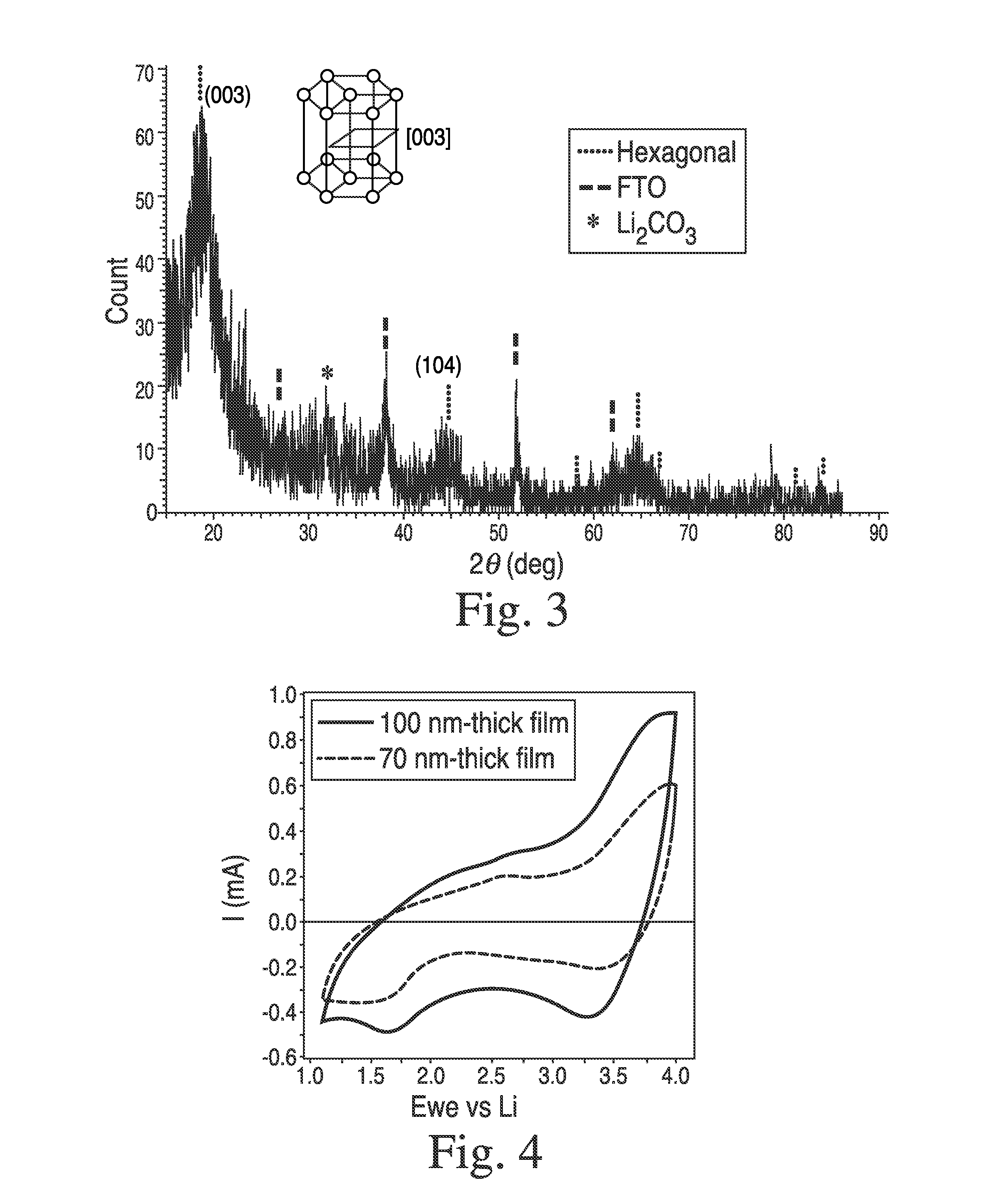

Electrochromic lithium nickel group 4 mixed metal oxides

Multi-layer electrochromic structures comprising an anodic electrochromic layer comprising a lithium nickel oxide composition on a first substrate, the anodic electrochromic layer comprising lithium, nickel and a Group 4 metal selected from titanium, zirconium, hafnium and a combination thereof, wherein (i) the atomic ratio of lithium to the combined amount of nickel and such Group 4 metal(s) in the anodic electrochromic layer is at least 0.4:1, respectively, (ii) the atomic ratio of the amount of such Group 4 metal(s) to the combined amount of nickel and such Group 4 metal(s) in the anodic electrochromic layer is at least about 0.025:1, respectively, and (iii) the anodic electrochromic layer exhibits an interplanar distance (d-spacing) of at least 2.5 Å as measured by X-ray diffraction (XRD), comprises at least 0.05 wt. % carbon, and / or has a coloration efficiency absolute value of at least 19 cm2 / C.

Owner:KINESTRAL TECH

Fischer-tropsch catalyst support and catalyst

A Fischer-Tropsch catalyst support comprising at least 15 wt % of a material having the formula XaYbOc wherein: X comprises an element selected from the group consisting of magnesium, calcium, barium, strontium, cerium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, zinc, niobium, ruthenium, rhodium, palladium, cadmium, osmium, iridium, platinum, gold, mercury, tin, lead, lanthanides, and mixtures thereof; Y comprises a different element to X, Y selected from the group consisting of silicon, aluminium, titanium, zirconium, cerium, hafnium, gallium, and mixtures of these, preferably silicon, aluminium and titanium and mixtures thereof, especially titanium; O is oxygen; a and b are, independently, in the range of 1-6; c is in the range of 1-15. Preferably a perovskite-type structure results which is more stable and resistant to degradation.

Owner:SHELL OIL CO

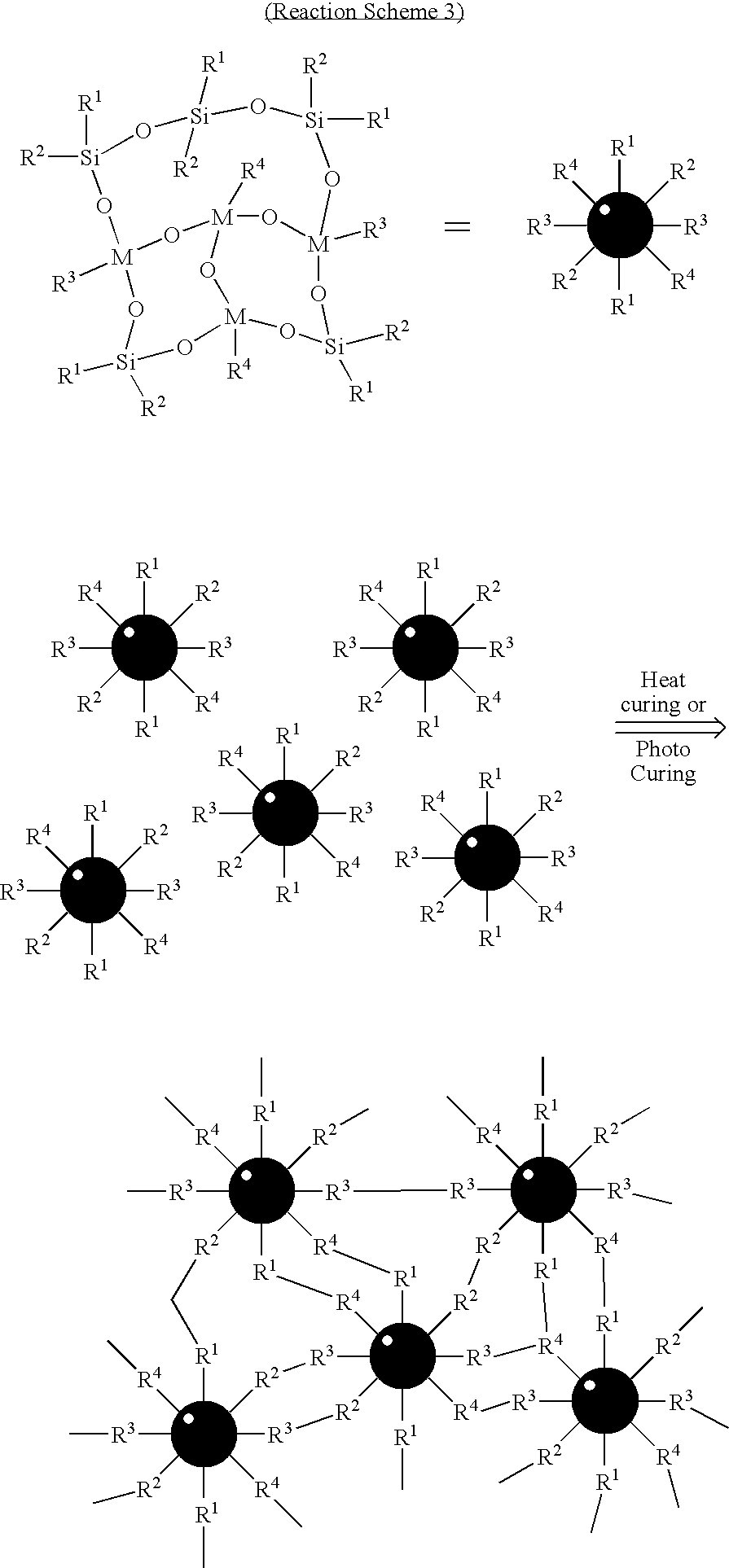

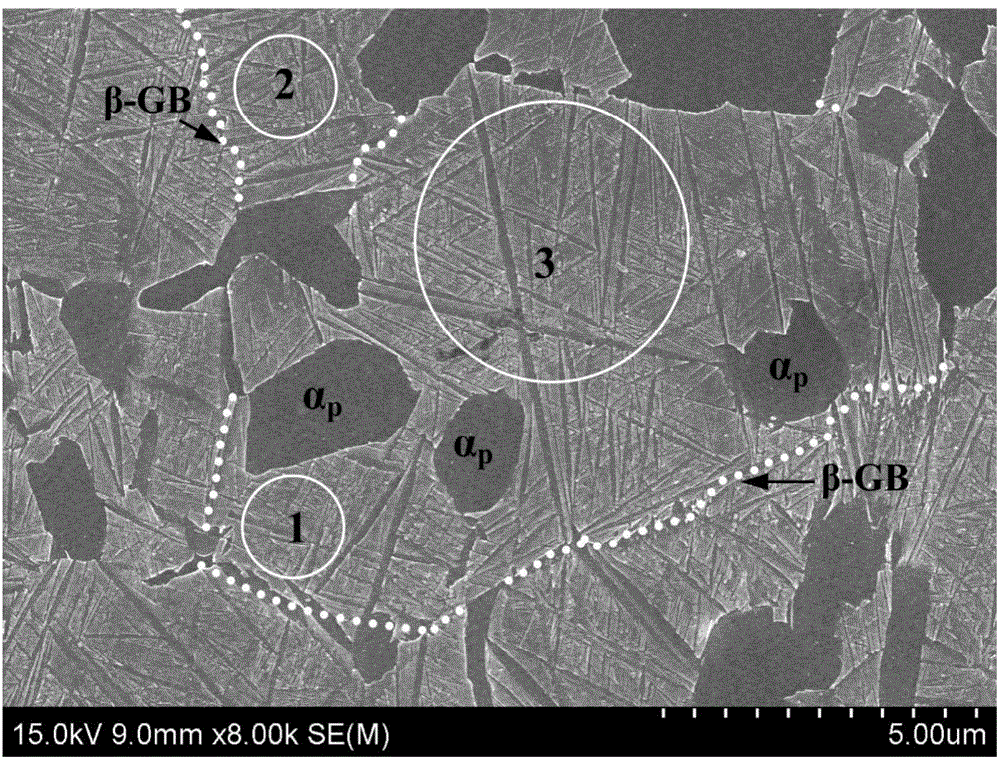

Preparation method of titanium zirconium base alloy

InactiveCN103602840AHigh strengthElongation at failure retentionElectric arc furnaceTitanium zirconium

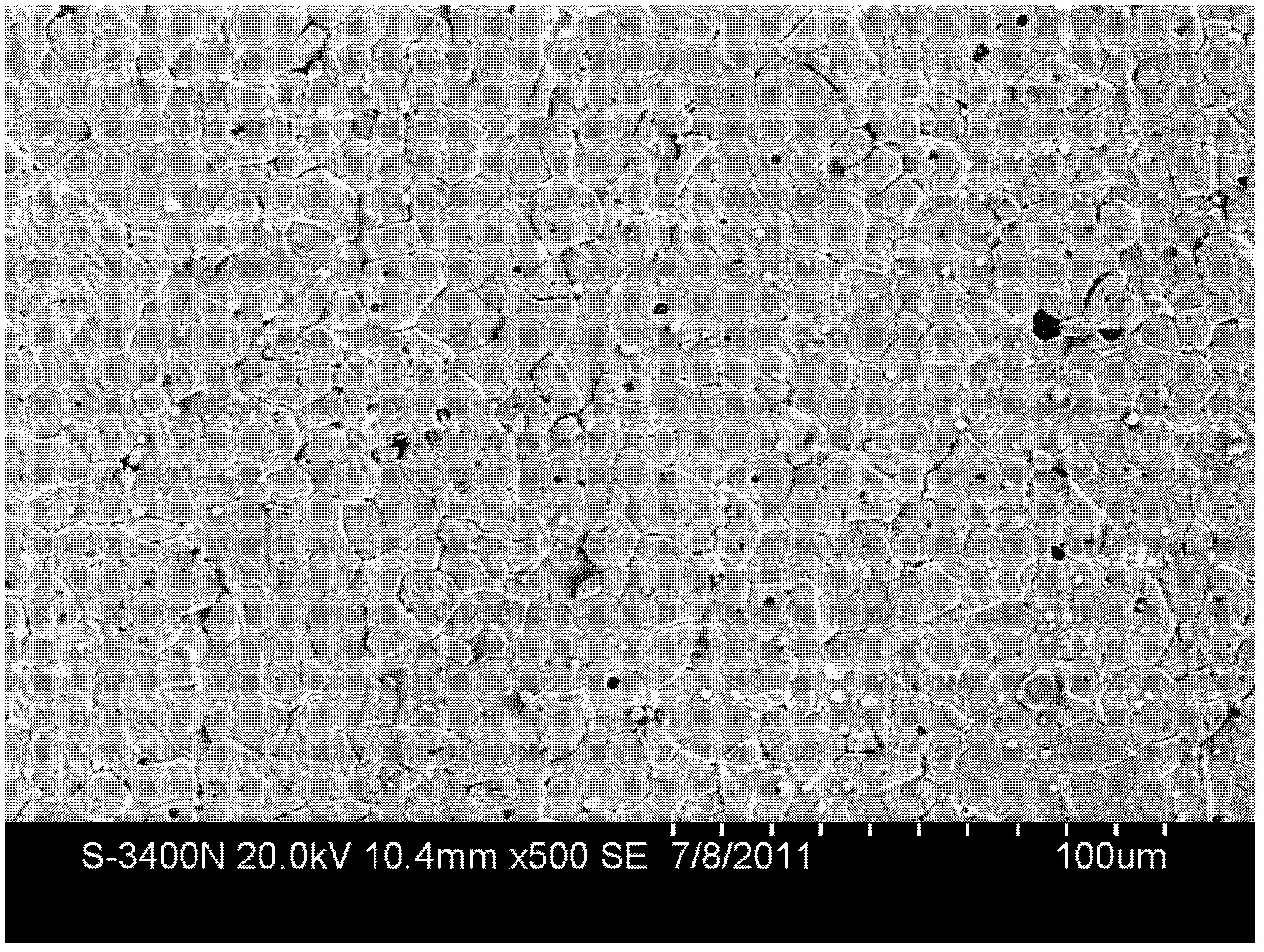

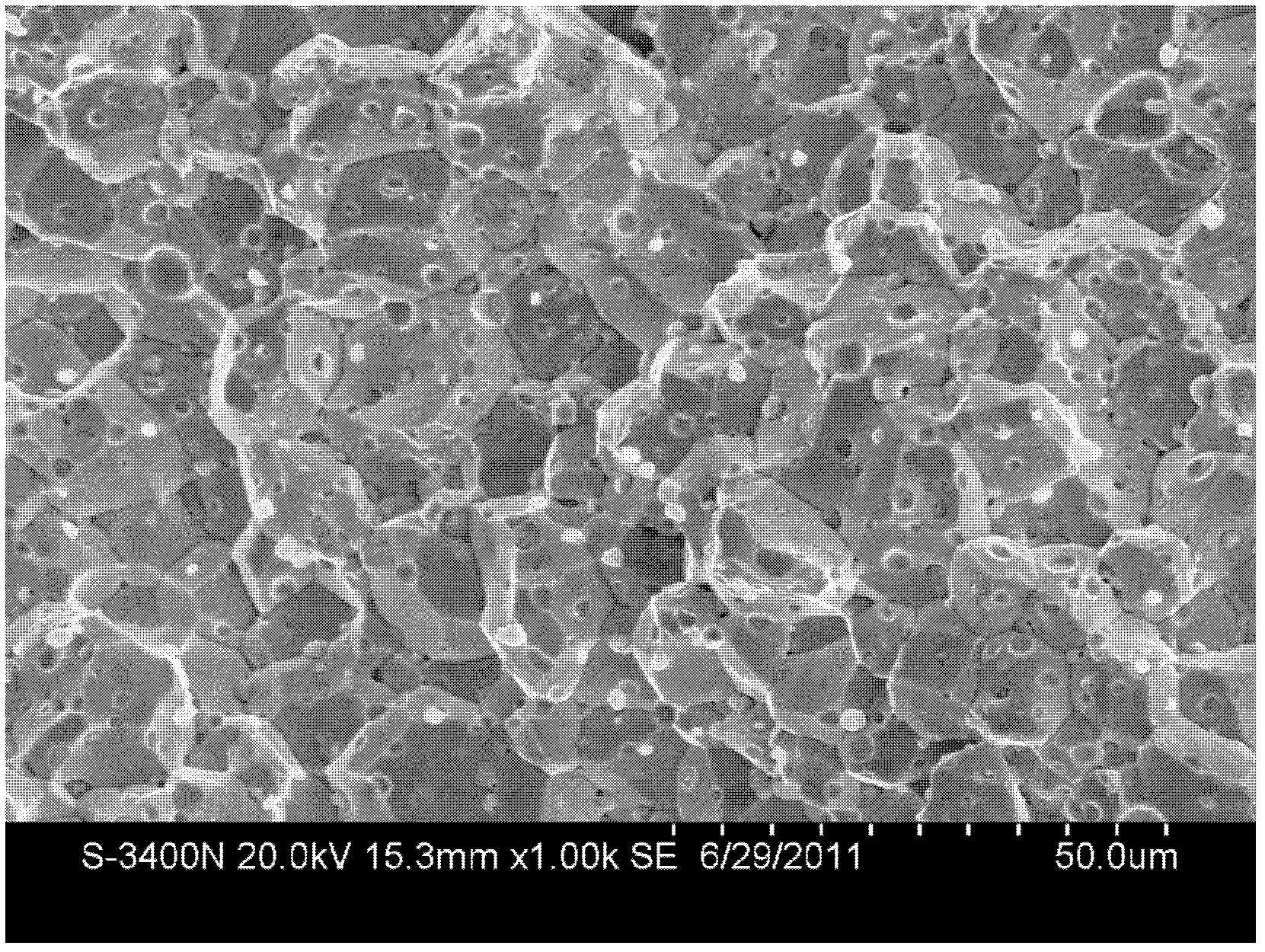

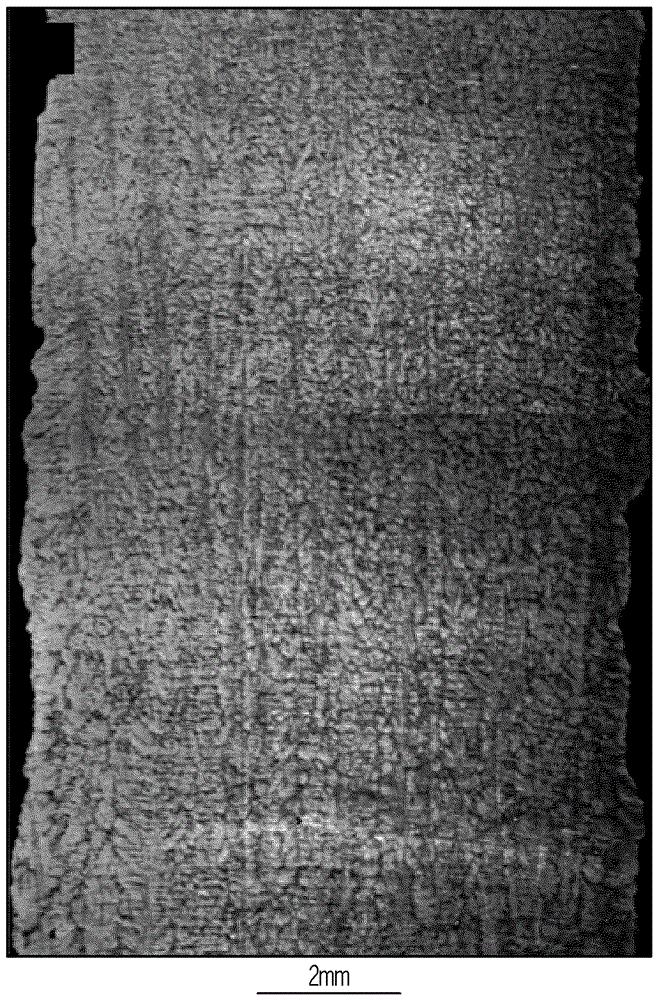

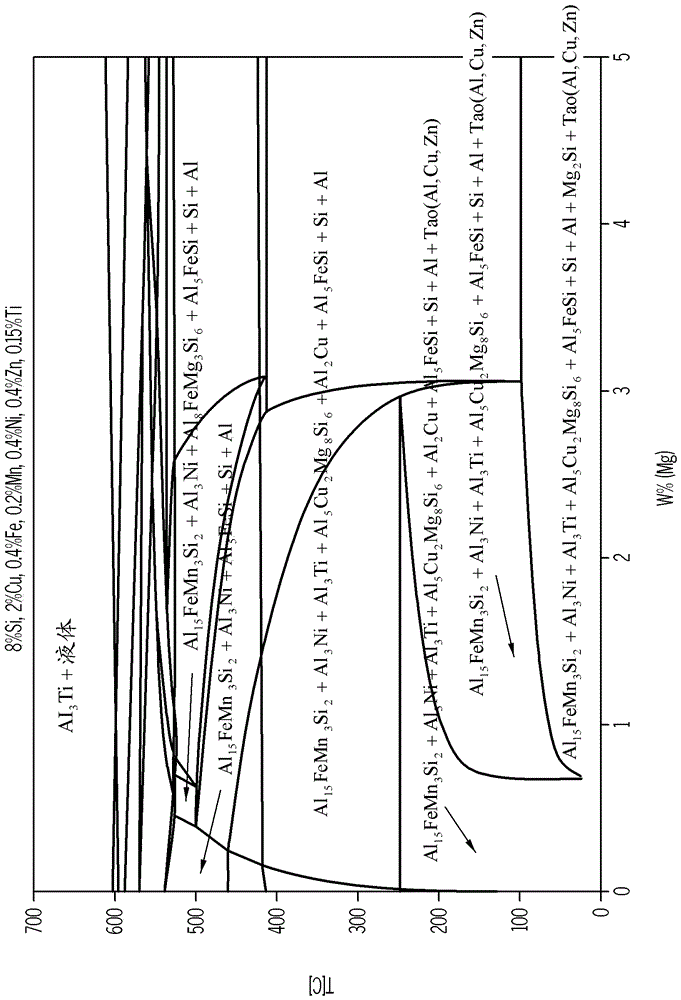

The invention relates to a preparation method of a titanium zirconium base alloy. The titanium zirconium base alloy comprises the following components in percentage by weight: 41-62% of Ti, 30-51% of Zr, 5% of Al and 3% of V. The preparation method comprises the following steps: adding the raw materials into a nonconsumable electric-arc furnace and melting the raw materials to obtain an alloy ingot; after coating a high-temperature antioxidant on the surface of the alloy ingot, heating and insulating in the furnace, and cogging and forging to obtain a platy alloy; after removing the antioxidant on the surface, heating in a thermal treatment furnace at 850-870 DEG C, insulating for 1 hour and performing water quenching and cooling; cutting the alloy plate to thin plates which are 3-4mm long for rolling and forming at room temperature, wherein the rolling strain rate is 2.2-3.1<-s> and the total deformation is over 80%; then, annealing, wherein the vacuum degree is 10<-4>-10<-5>Pa, the temperature is 740-760 DEG C; insulating for 1 hour; performing air cooling to room temperature. According to the preparation method provided by the invention, the titanium zirconium base alloy with the microstructure which is a special duplex microstructure is obtained, and the alloy strength is effectively improved while the plasticity of the alloy is maintained.

Owner:YANSHAN UNIV

Electrochromic lithium nickel group 4 mixed metal oxides

ActiveUS20140204444A1Record information storageAlkali metal oxidesTitanium zirconiumPhysical chemistry

Owner:KINESTRAL TECH

Process for producing lithium-containing composite oxide for positive electrode for lithium secondary battery

ActiveUS20060154146A1Improve featuresSolve the small densityMagnesium halidesCell electrodesAlkaline earth metalNiobium

It is to provide a positive electrode active material for a lithium secondary battery, which has a large volume capacity density and high safety, is excellent in uniform coating properties and is excellent in the charge and discharge cyclic durability and low temperature characteristics even at a high charge voltage. A process for producing a lithium-containing composite oxide represented by the formula LipQqNxMyOzFa (wherein Q is at least one element selected from the group consisting of titanium, zirconium, niobium and tantalum, N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, alkaline earth metal elements and transition metal elements other than the Q element and the N element, 0.9≦p≦1.1, 0<q≦0.03, 0.97≦x<1.00, 0≦y<0.03, 1.9≦z≦2.1, q+x+y=1 and 0≦a≦0.02) from a lithium source, an Q element source and an N element source, and if necessary, at least one source selected from the group consisting of an M element source and a fluorine source, characterized by using as the Q element source an Q element compound aqueous solution having a pH of from 0.5 to 11.

Owner:SUMITOMO CHEM CO LTD

Elastomeric urethane composition

An elastomeric urethane composition includes the reaction product of a resin composition, including a polyol, and an isocyanate. The resin composition and the isocyanate are reacted, in the presence of a first and a second catalyst, to form a polyurethane elastomer. The first catalyst includes a metal selected from the group of iron, titanium, zirconium and hafnium. The second catalyst includes an amine. The elastomeric urethane composition may be used in a method of making an article. The method includes reacting the resin composition and the isocyanate to form the elastomeric urethane composition, applying the elastomeric urethane composition to a mold cavity, and allowing the elastomeric urethane composition to cure to form a first layer. The method also includes applying a urethane composition, different from the elastomeric urethane composition, to the mold to form a second layer, curing the article in the mold, and de-molding the article from the mold.

Owner:BASF CORP

High thermal conductivity cast aluminium alloy and preparation method thereof

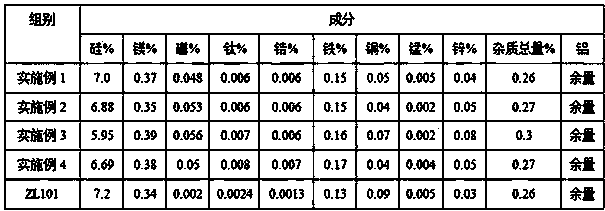

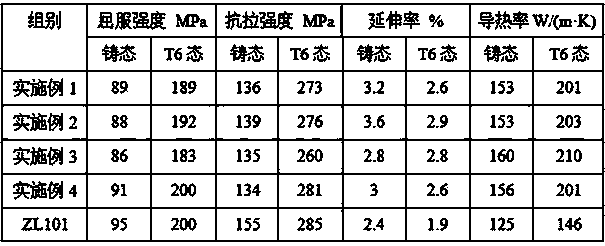

InactiveCN103526082AExpand the range of industrial applicationsImprove thermal conductivityTitanium zirconiumManganese

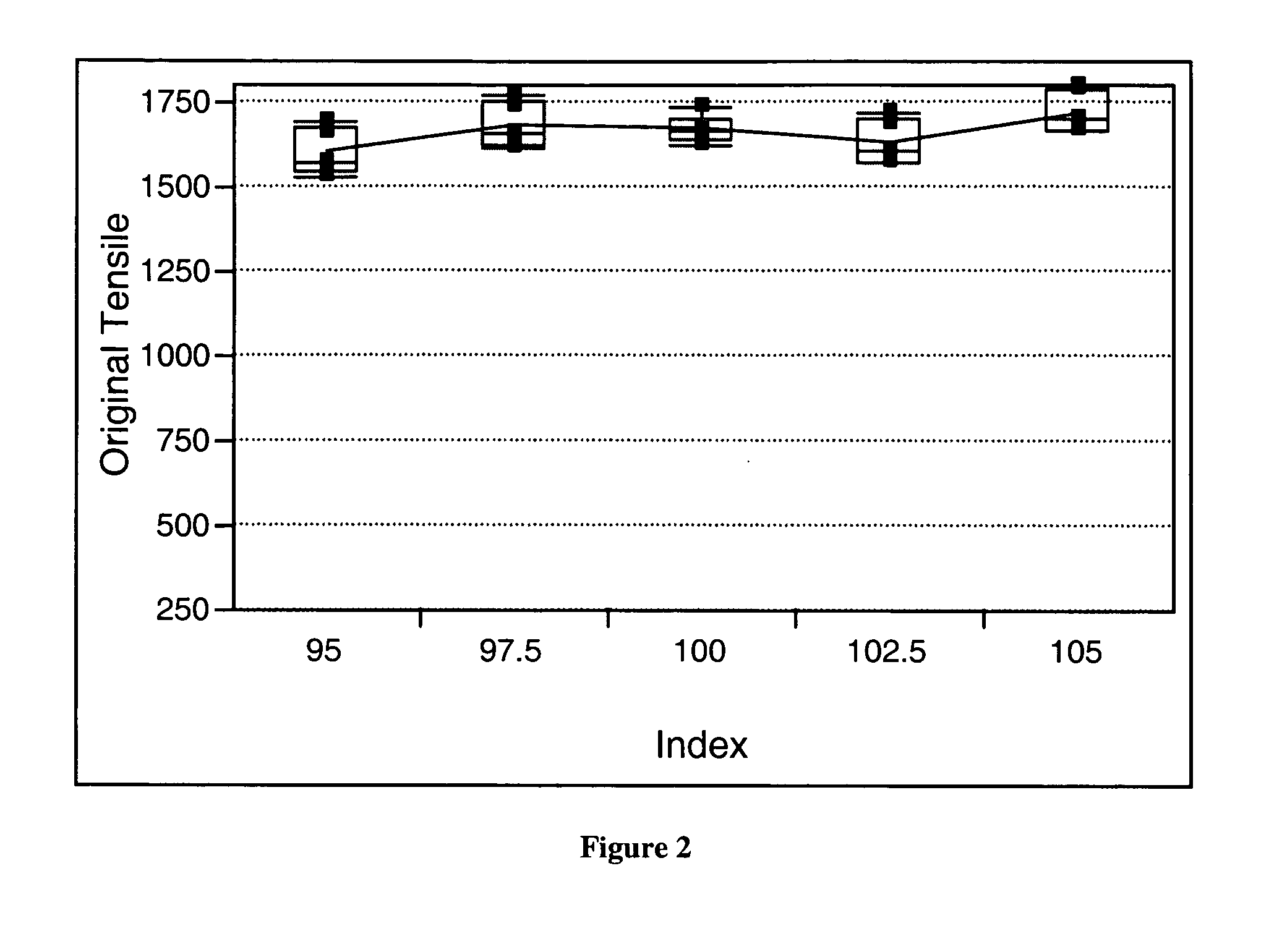

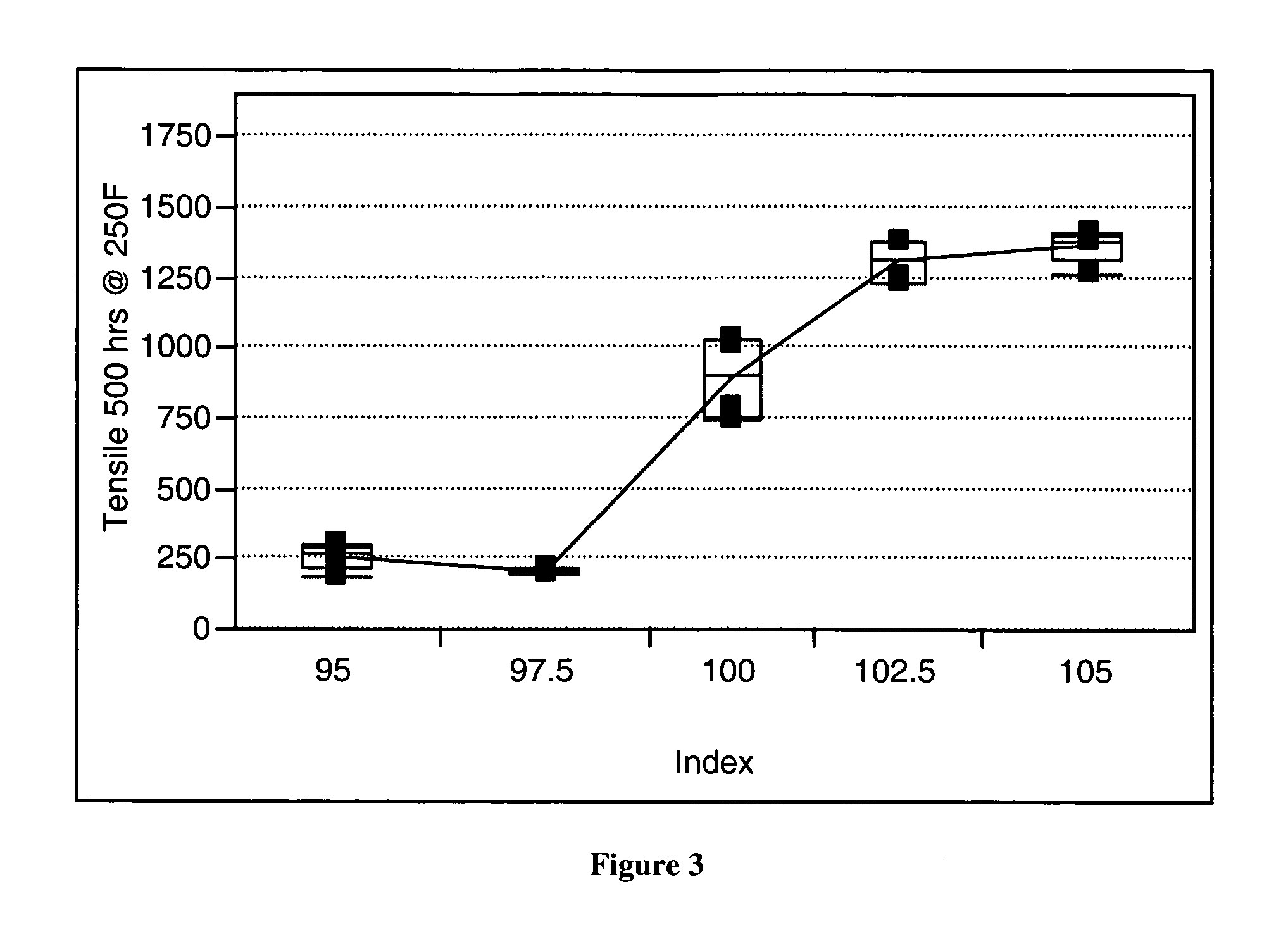

The invention discloses a high thermal conductivity cast aluminium alloy and a preparation method thereof. The high thermal conductivity cast aluminium alloy comprises the following components by weight percent: 5.0-7.5% of silicone, 0.25-0.5% of magnesium, 0.01-0.06% of boron, 0.005-0.02% of titanium, 0.005-0.02% of zirconium, less than 0.2% of iron, less than 0.2% of copper, less than 0.1% of manganese, less than 0.1% of zinc, no more than 0.3% of all the other impurities and the balance of aluminium. The preparation method comprises that boron oxide is taken as a modificator, and then titanium and zirconium elements are added, thus a cast aluminium alloy with thermal conductivity as high as 210W / (m.K) can be prepared. The high thermal conductivity cast aluminium alloy has the advantages that thermal conductivity of a Al7SiMg cast aluminium alloy is obviously improved on the basis of the existing good casting property, mechanical property and thermal treatment property, and an industrial application range of the Al7SiMg cast aluminium alloy is expanded.

Owner:GUANGZHOU KINBON NON FERROUS ALLOY METALS CO LTD

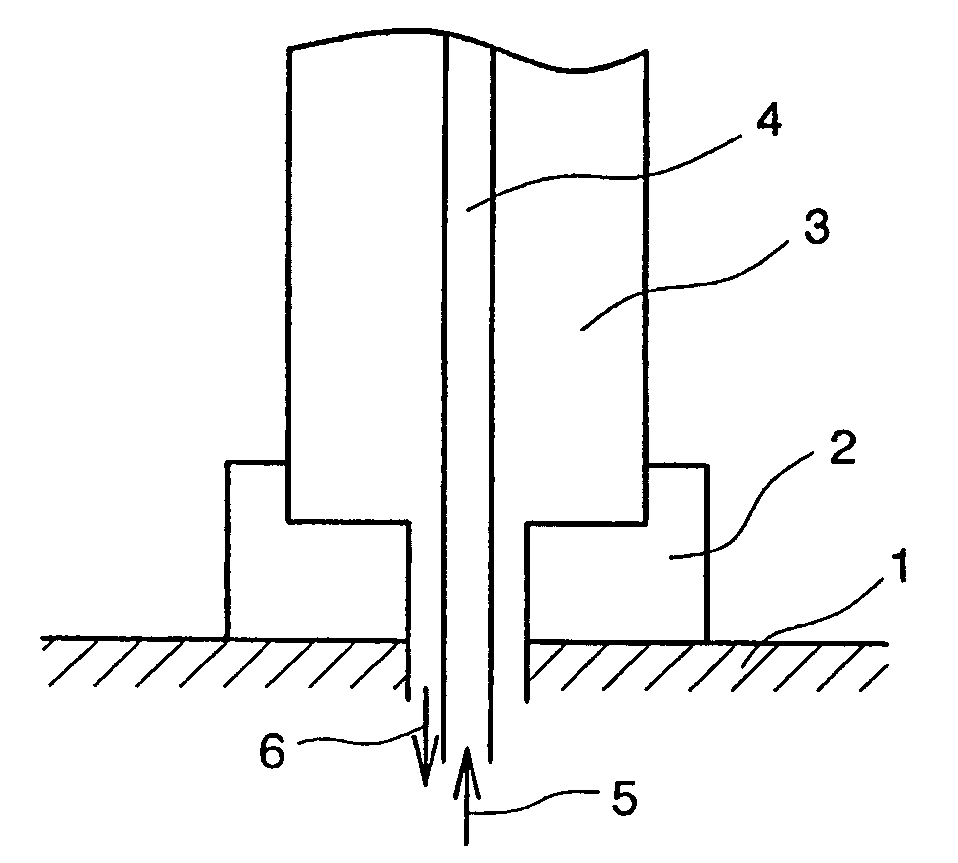

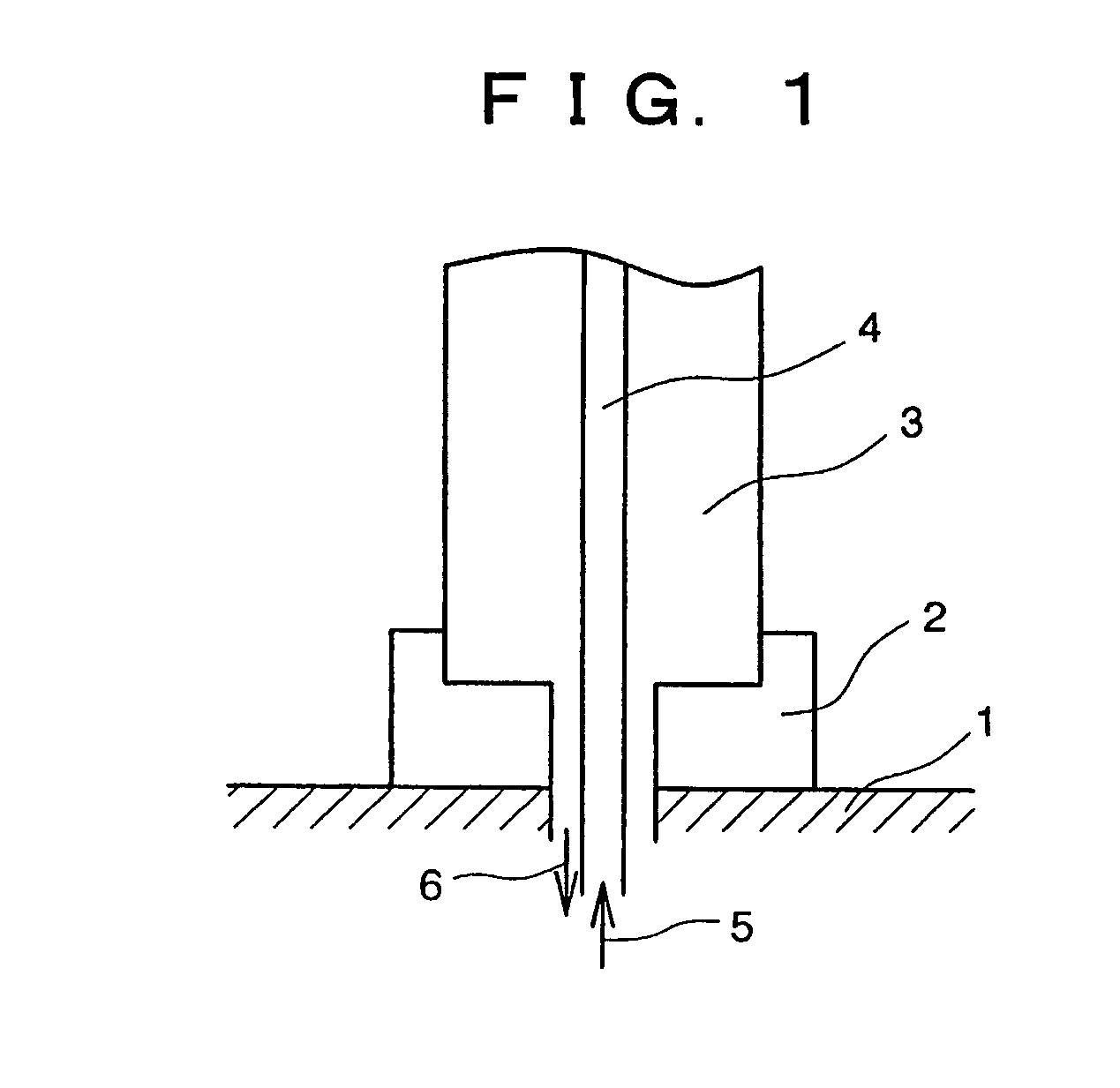

Method for manufacturing polycrystalline silicon, and polycrystalline silicon for solar cells manufactured by the method

InactiveUS7732012B2Low costIncrease deposition ratePolycrystalline material growthLiquid surface applicatorsTitanium zirconiumAlloy

Provided is a method for the preparation of polycrystalline silicon in which, in conducting preparation of polycrystalline silicon by the Siemens method or by the monosilane method, no outer heating means is necessitated for the core member (seed rod), onto which polycrystalline silicon is deposited, from the initial stage of heating, the deposition rate is high and the core member seed rod can be used repeatedly.The method for deposition of high-purity polycrystalline silicon, at a high temperature, onto a white-heated seed rod in a closed reaction furnace by pyrolysis or hydrogen reduction of a starting silane gas supplied thereto, is characterized in that the seed rod is a member made from an alloy having a recrystallization temperature of 1200° C. or higher. It is preferable that the alloy member is of an alloy of Re—W, W—Ta, Zr—Nb, titanium-zirconium, or a carbon-added molybdenum (TZM) in the form of a wire member having a diameter of at least 0.5 mm, a plate member having a thickness of at least 1 mm or a prismatic member, or a tubular member having a diameter of at least 1 mm, wall thickness of at least 0.2 mm with an inner diameter not exceeding 5 mm, that the plate member, wire member, prismatic member or tubular member has a tapered form and further that the tubular member is a tapered duplex tube.

Owner:SHIN ETSU FILM +1

Catalyst for producing epoxy compound and process for producing epoxy compounds with the same

InactiveUS20030171604A1High yieldImprove utilization efficiencyOrganic chemistryOther chemical processesIndiumHafnium

The present invention provides a catalyst capable of producing an epoxy compound in high yield and improving the utilization efficiency of the oxidizing agent as well as a method of producing an epoxy compound using that catalyst. A catalyst for producing an epoxy compound by oxidizing a compound having at least one ethylenic double bond with an oxidizing agent, comprising a polyatom-containing heteropolyoxometalate anion (A1) having two defective and / or three defective structure sites and containing silicon as the heteroatom, and an element (E1) being at least one element selected from the group consisting of vanadium, tantalum, niobium, antimony, bismuth, chromium, molybdenum, selenium, tellurium, rhenium, cobalt, nickel, ruthenium, rhodium, palladium, osmium, platinum, iridium, silver, gold, zinc, aluminum, gallium, indium, scandium, yttrium, titanium, zirconium, hafnium, germanium, tin and lanthanoids, and being different from the polyatom.

Owner:NIPPON SHOKUBAI CO LTD

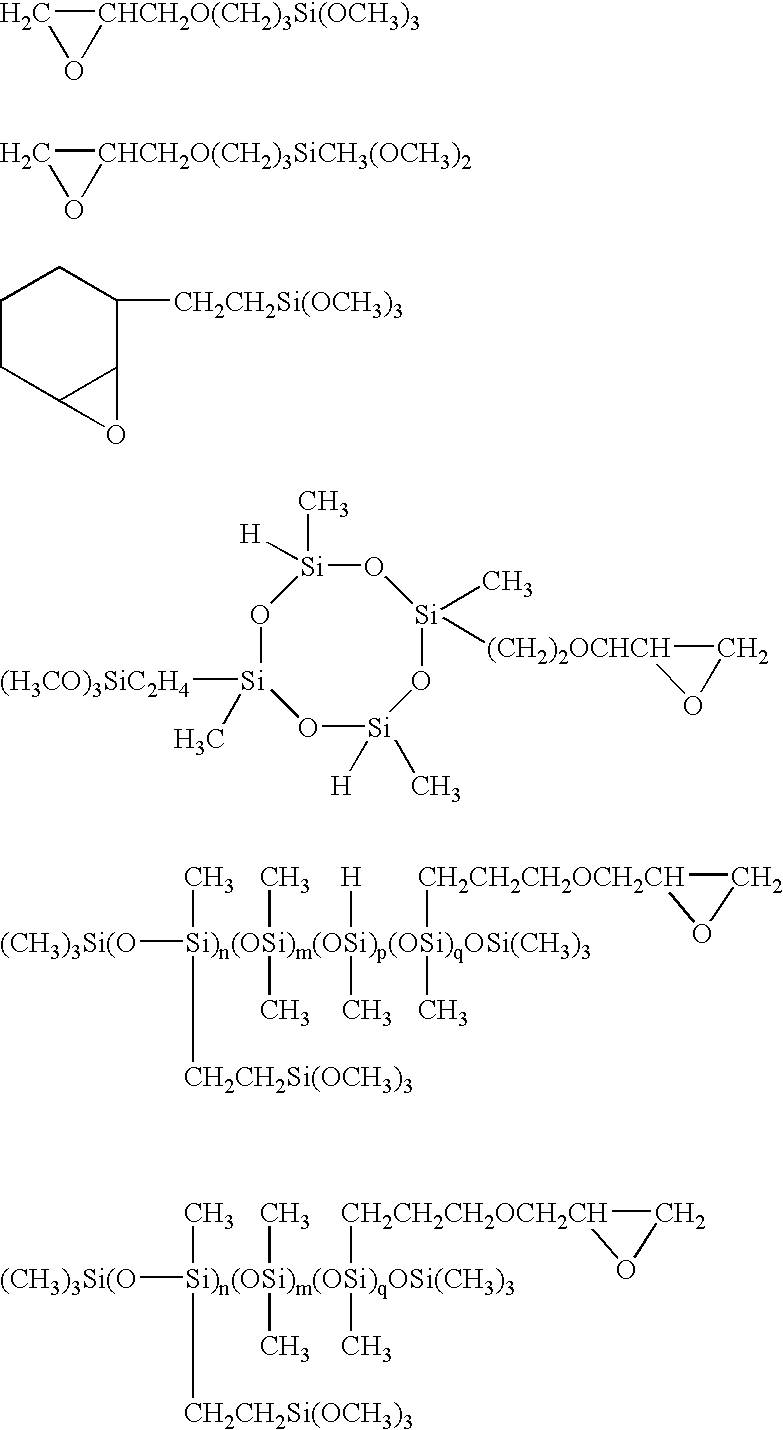

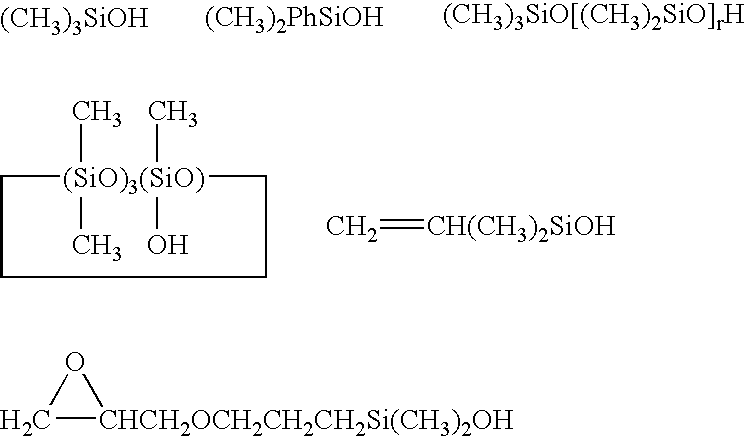

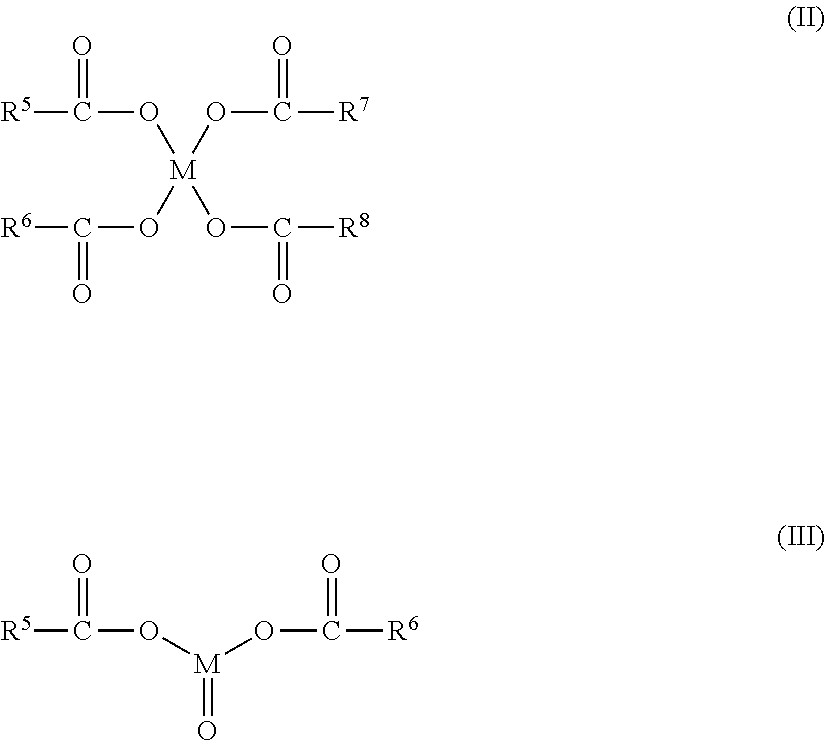

Liquid silicone rubber coating composition, curtain airbag and making method

ActiveUS20090001690A1Minimize viscosity changeFine and uniform coatingLayered productsFibre treatmentPolymer scienceSilanes

A liquid silicone rubber coating composition comprising (A) an organopolysiloxane containing silicon-bonded alkenyl radicals, (B) an organohydrogenpolysiloxane containing SiH radicals, (C) an addition reaction catalyst, (D) finely divided silica, (E) an organosilicon compound containing epoxy and alkoxy radicals, (F) an organic titanium, zirconium or aluminum compound, and (G) a silanol-containing silane or siloxane compound is coated on a surface of an airbag base fabric and cured to form a rubber coating layer thereon. The composition is suited for curtain airbags.

Owner:SHIN ETSU CHEM IND CO LTD

Iminooxadiazinedione polyisocyanates

The present invention relates to a process for producing polyisocyanates comprising reacting an isocyanate component in the presence of a mono- or multinuclear complex of titanium, zirconium and / or hafnium as catalyst to give polyisocyanates having a content of iminooxadiazinedione groups of ≧20 mol % based on the total amount of isocyanurate and iminooxadiazinedione groups. The present invention also provides polyisocyanates obtainable by the process according to the invention and both polyurethanes and polyureas obtainable by reacting the polyisocyanates with at least one hydroxy-functional or amino-functional component respectively.

Owner:COVESTRO DEUTSCHLAND AG

DeNOx catalyst preparation method

InactiveUS20080279740A1High NO conversionReduced activityNitrogen compoundsHeterogenous catalyst chemical elementsMixed oxideTitanium zirconium

A catalyst comprising iron and a titanium-zirconium mixed oxide gel, and a process for preparing the catalyst are disclosed. The process comprises combining an iron compound and a titanium-zirconium mixed oxide gel in water to form an iron-titanium-zirconium mixed oxide, and then removing water to produce the catalyst. The catalyst is particularly effective for DeNOx applications, demonstrating high activity and good thermal stability.

Owner:MILLENNIUM INORGANIC CHEM

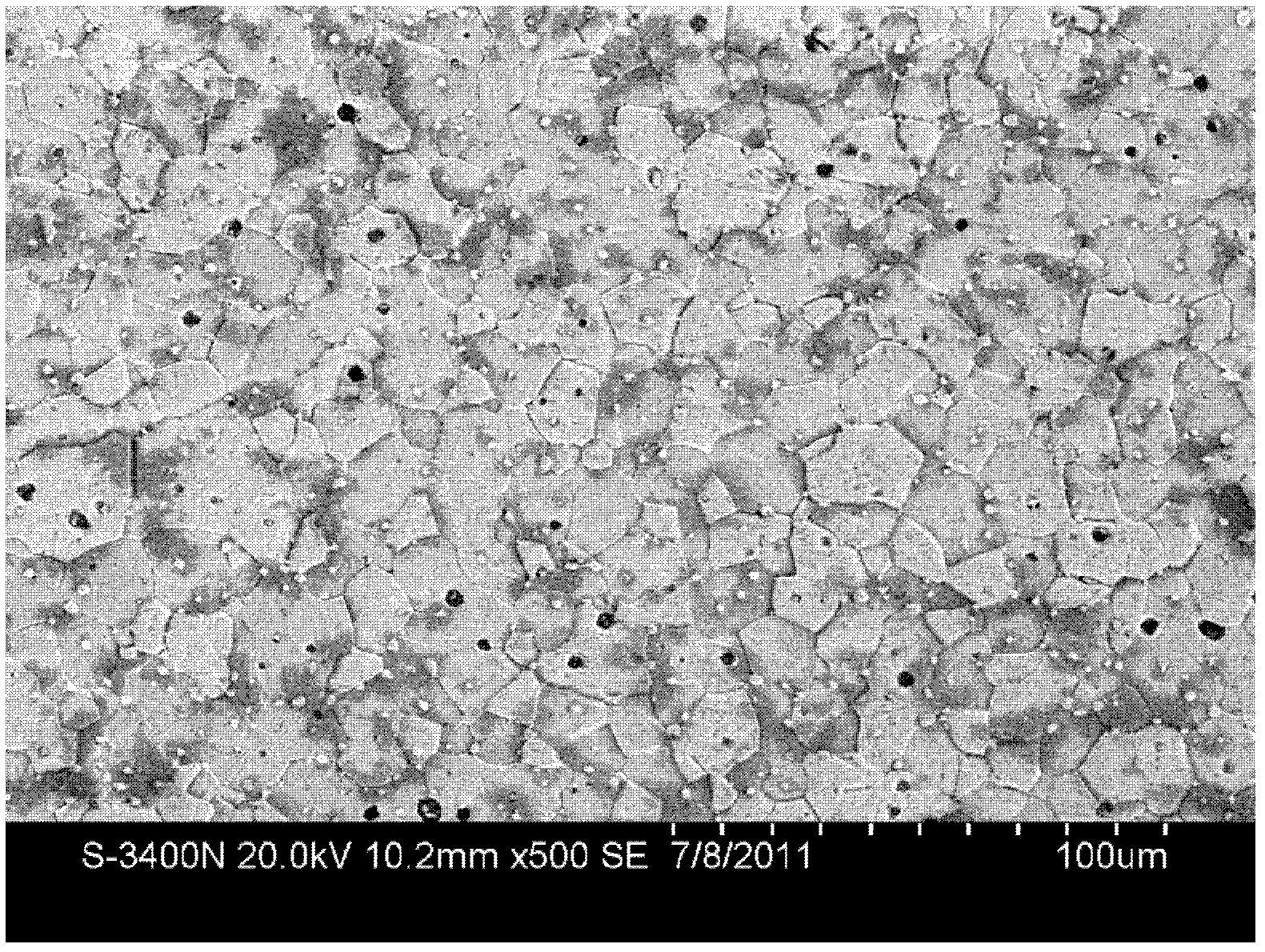

Method for preparing fine-grain high-density TZM (Titanium-Zirconium-Molybdenum Allo) alloy

The invention discloses a method for preparing a fine-grain high-density TZM (Titanium-Zirconium-Molybdenum Allo) alloy. The method disclosed by the invention comprises the following steps of: with pure molybdenum powder, ZrH2 powder, La2O3 powder and graphite powder as raw materials, mixing the raw materials, and carrying out ball milling, press molding, presintering and high-temperature sintering to obtain the TZM alloy. The TZM alloy prepared by using the method disclosed by the invention has the characteristics of fine crystal grains, distribution uniformity, low porosity, high compactness, simple preparation process and strong operability and controllability and has the most remarkable advantages that: on the basis of the traditional ZTM alloy preparation method, rare earth oxide La2O3 is solid-solid doped in the alloy powders, a mode of combining mixing and ball-milling of the alloy powders and a mode of sectional sintering during high-temperature sintering are adopted, crystal grains are fined, the alloy density is remarkably improved, the sintering temperature of the TZM alloy is reduced to 1800-2000 DEG C from 2100-2300 DEG C in the traditional method, therefore energy resources are saved and requirements of an enterprise on the fine-grain TZM alloy material with high density can be met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Catalyst composition and method of controlling PFC and HFC emissions

The present invention relates to a catalyst composition and a catalytic process for the destruction of PFC's and HFC's using a catalyst which comprises aluminum oxide that has preferably been stabilized through the addition of a stabilizing agent (such as titanium, zirconium, or cobalt, or mixtures of these elements). The addition of these elements to the aluminum oxide unexpectedly enhances the catalyst's stability without significantly altering the reactivity of the catalyst. The total amount of stabilizing agent added to the catalyst can be as low as 0.005 parts (by weight) stabilizing agent per part (by weight) aluminum oxide (Al2O3) or as great as 2 or more parts (by weight) stabilizing agent per part (by weight) aluminum oxide; so long as there is sufficient aluminum oxide available to effectively catalyze the destruction of the target PFC's and / or HFC±.

Owner:GUILD ASSOCS

Method for titanium-zirconium conversion film/silane film double-layer protection for aluminium alloy surface

InactiveCN106702382AGood storage stabilityGood resistance to salt spraySuperimposed coating processTitanium zirconiumSilanes

The invention relates to the field of surface protection for aluminium alloys, and specifically discloses a method for titanium-zirconium conversion film / silane film double-layer protection for an aluminium alloy surface. The method comprises the following steps: firstly, carrying out polishing, alkali cleaning and acid cleaning on an aluminium alloy, then soaking the aluminium alloy in a zirconium / titanium conversion solution for 1-60min to generate a layer of titanium / zirconium conversion film, naturally airing, then soaking a sample sheet in a silane hydrolysate for 1-30min, taking out, and then curing at 25-200 DEG C to form a silane film. According to the method disclosed by the invention, a surface treatment technology of titanium-zirconium conversion film / silane film double-layer protection is adopted, and the defects of low corrosion resistance of a single conversion film and the silane film, low wear resistance of the single conversion film, and the like are solved; and moreover, the treatment solution in the method disclosed by the invention is free from toxic substances and meets the requirement of environmental protection, and the process is simple and easy to form industrialization.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Novel regeneration cast aluminum alloy for structural application

The invention discloses a novel regeneration cast aluminum alloy for structural application. The aluminum alloy that can be cast into structural components wherein at least some of the raw materials used to produce the alloy are sourced from secondary production sources. In addition to aluminum as the primary constituent, such an alloy includes 5 to 14% silicon, 0 to 1.5% copper, 0.2 to 0.55% magnesium, 0.2 to 1.2% iron, 0.1 to 0.6% manganese, 0 to 0.5% nickel, 0 to 0.8% zinc, 0 to 0.2% of other trace elements selected from the group consisting essentially of titanium, zirconium, vanadium, molybdenum and cobalt. In a preferred form, most of the aluminum is from a secondary production source. Methods of analyzing a secondary production aluminum alloy to determine its constituent makeup is also disclosed, as is a method of adjusting the constituent makeup of such an alloy in situations where the alloy is out of tolerance when measured against its primary source counterpart.

Owner:GM GLOBAL TECH OPERATIONS LLC

Coating composition

A coating composition comprising an aqueous mixture containing acid-stable particles and one or more fluoroacids. The amount of the acid-stable particles in the coating composition is from 0.005% to 8% by weight on a dry weight basis. The acid-stable particles can be selected from aluminum-modified silica particles, nonaluminum-modified silica particles, and organic particles selected from anionically stabilized polymer dispersion particles. The invention is also directed to a coating on a metal substrate. The coating contains acid-stable particles attached to the metal substrate through a metal-oxide matrix. The metal-oxide matrix comprises a metal selected from titanium, zirconium, silicon, hafnium, boron, aluminum, germanium, or tin.

Owner:HENKEL KGAA

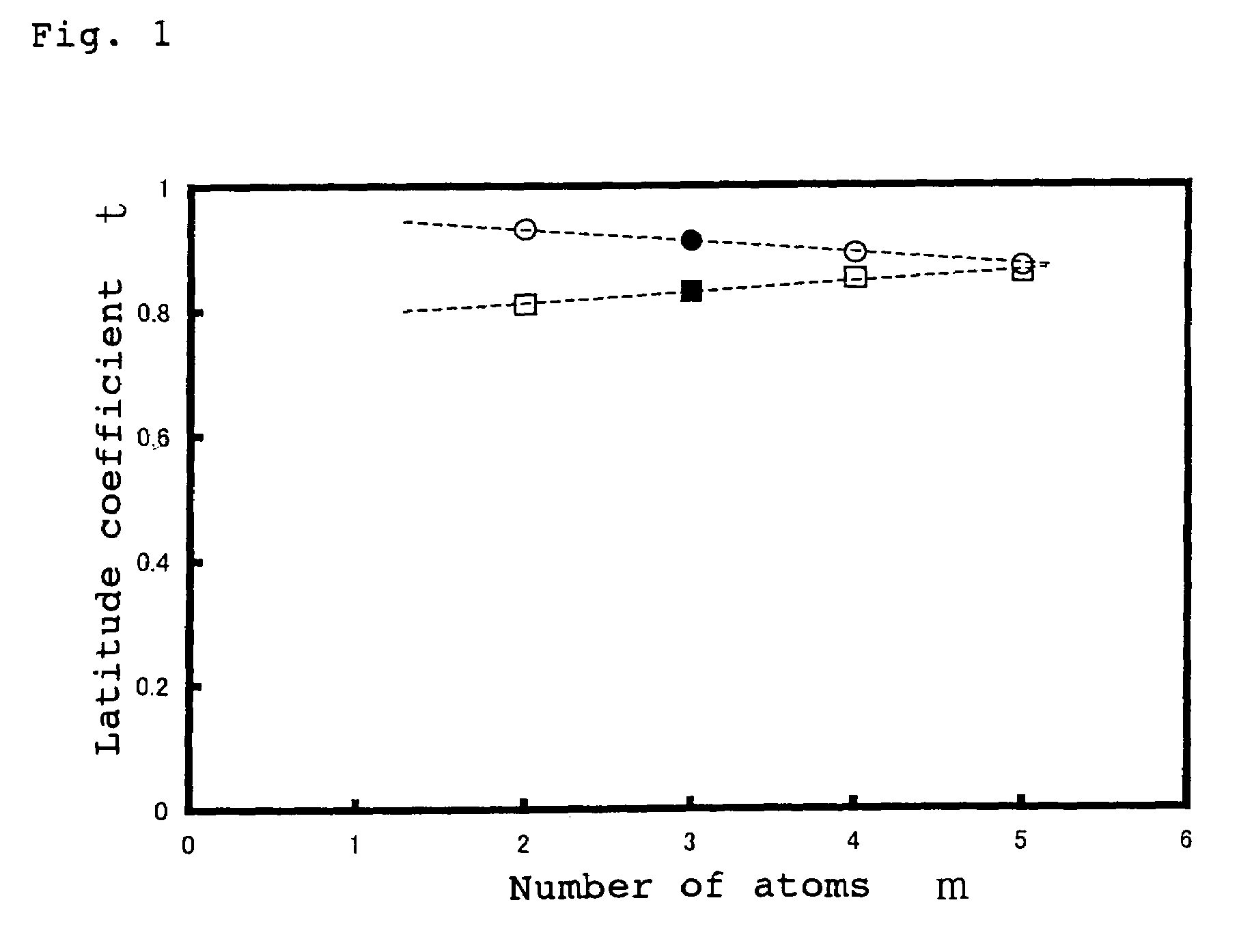

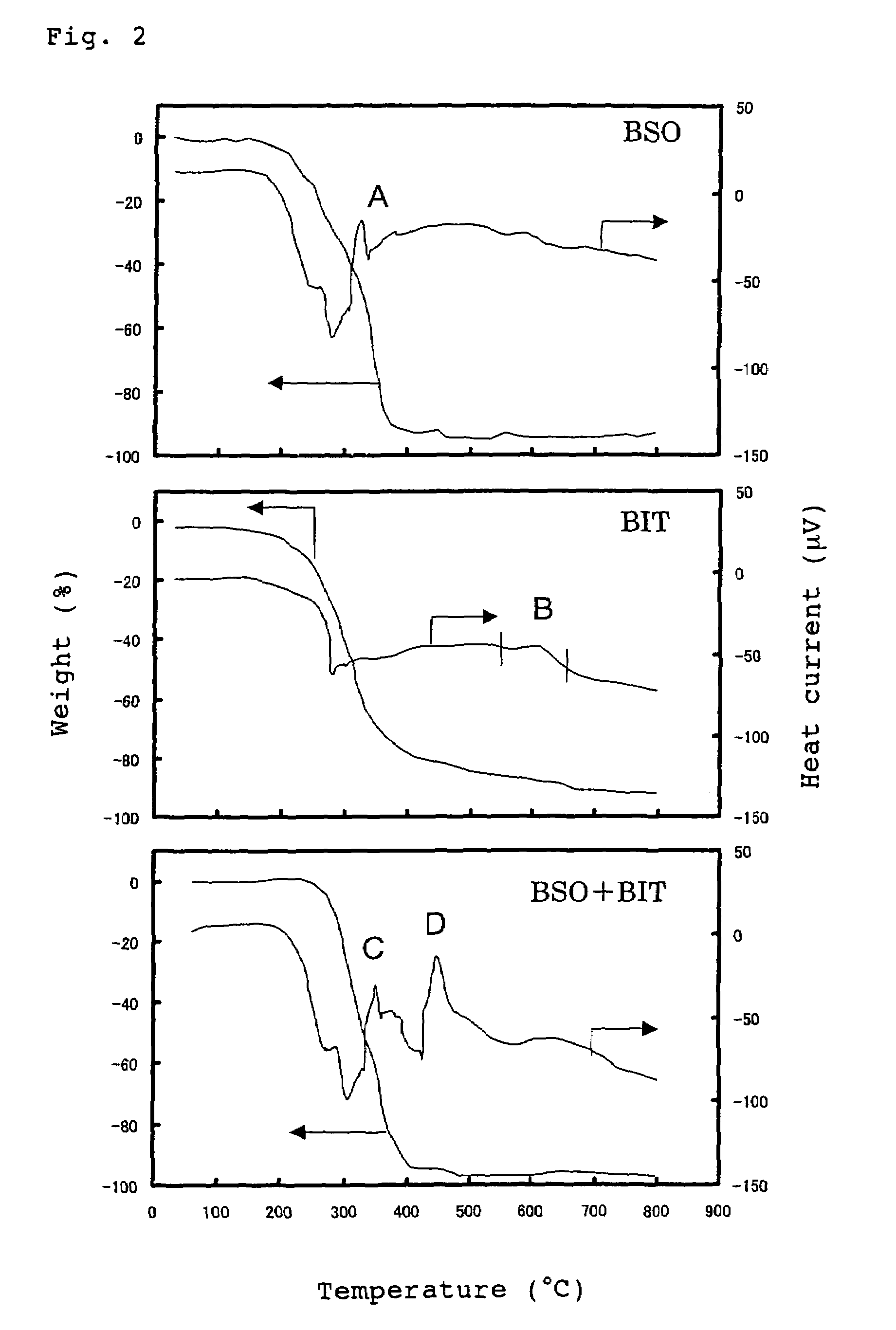

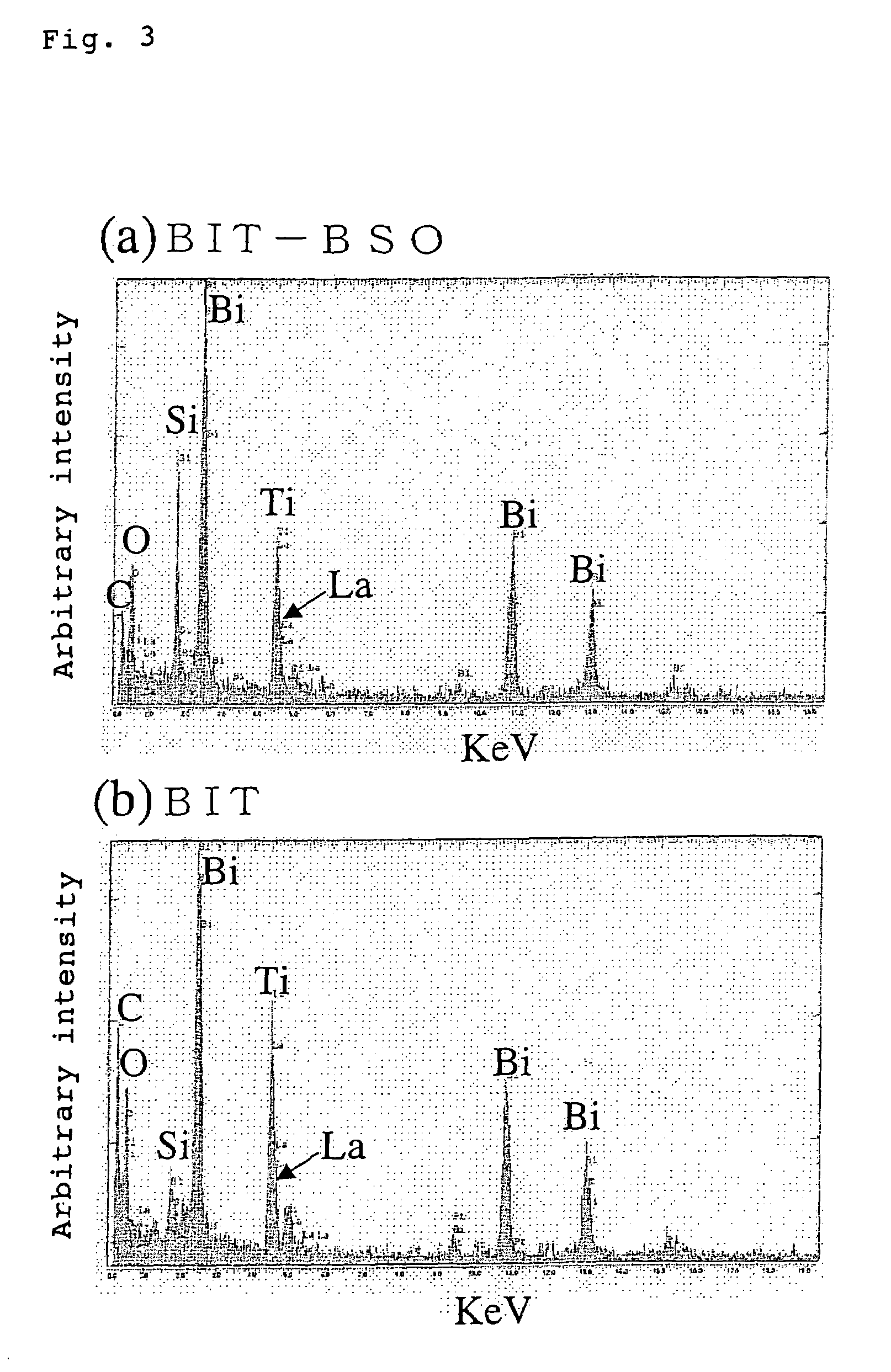

Oxide material, method for preparing oxide thin film and element using said material

An oxide material characterized by that it has a perovskite structure comprising an oxide represented by ABO3, (Bi2O2)2+ (Am−1BmO3m+1)2− wherein A represents one kind or two or more kinds of ions selected from the group consisting of Li+, Na+, K+, Pb2+, Ca2+, Sr2+, Ba2+, Bi3+, Y3+, Mn3+ and La3+, B represents one kind or two or more kinds of ions selected from the group consisting of Ru3+, Fe3+, Ti4+, Zr4+, Cu4+, Nb5+, Ta5+, V5+, W6+ and Mo6+, and m represents a natural number of 1 or more, LnBa2Cu3O7, Z2Ba2Can−1CunO2n+4 or ZBa2Can−1CunO2n+3, wherein Ln represents one kind or two or more kinds of ions selected from the group consisting of Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, Z represents one kind or two or more kinds of ions selected from the group consisting of Bi, Tl and Hg, and n represents a natural number of from 1 to 5; and a catalytic substance containing one or more kinds of elements selected from the group consisting of Si, Ge and Sn.

Owner:SHARP KK +1

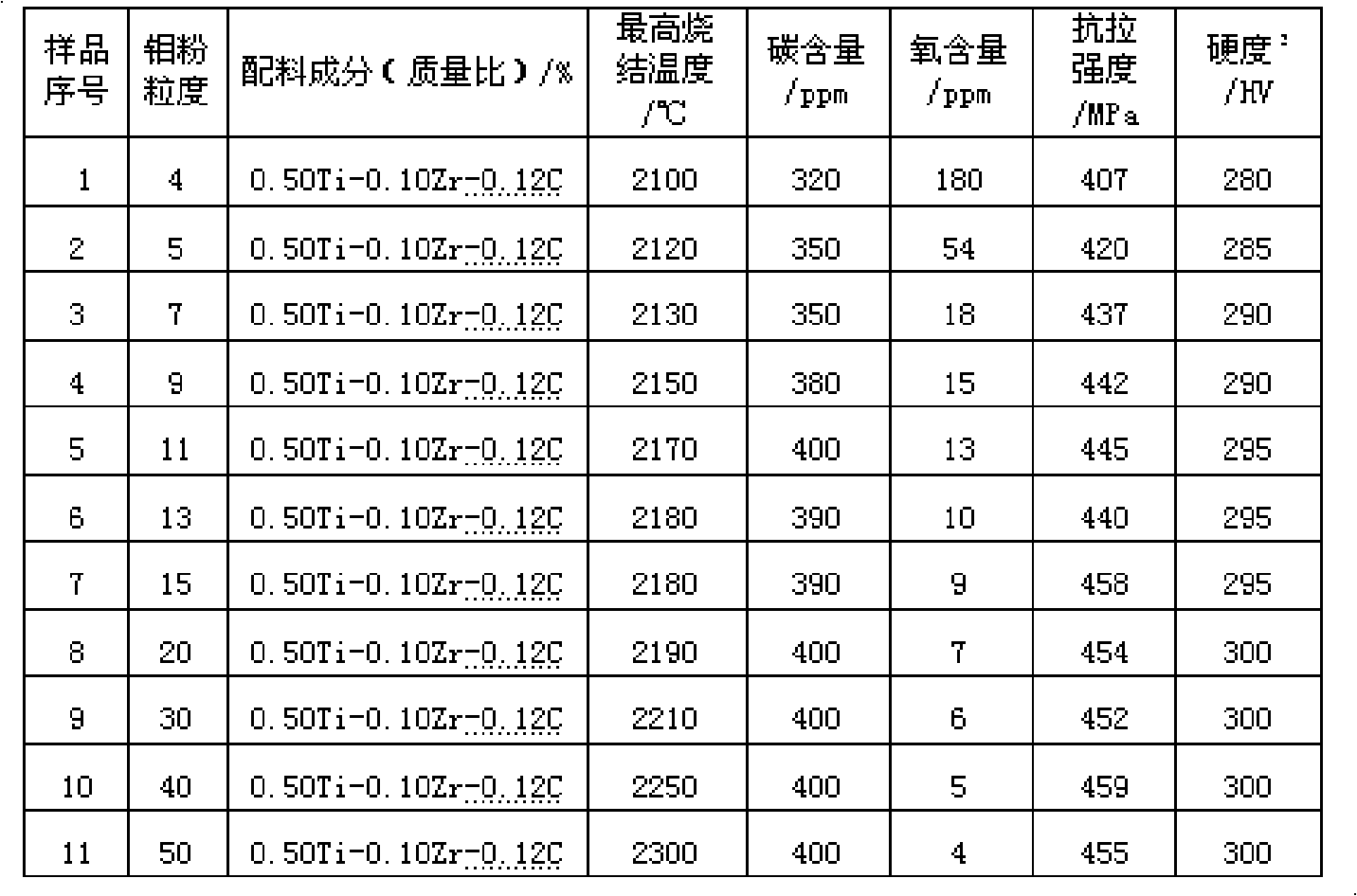

Method for preparing low-oxygen titanium-zirconium-molybdenum (TZM) alloy and application

ActiveCN102041404AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesTitanium zirconiumAlloy

The invention provides a method for preparing a low-oxygen titanium-zirconium-molybdenum (TZM) alloy, which comprises the following steps of: 1) selecting raw materials, namely, uniformly mixing industrial molybdenum powder with the Fisher particle size of 4 to 50 mu m, powder containing titanium and zirconium and with the Fisher particle size of 3 to 10 mu m, and simple substance carbon powder with the Fisher particle size of 0.1 to 3 mu m according to a certain mass ratio; 2) shaping the raw materials, namely, treating the mixed raw materials under the pressure of 100 to 300 Mpa to obtain a shaped blank; and 3) sintering the raw materials, namely, sintering the shaped blank in the environment of vacuum, hydrogen or inert gas at the temperature of 1,800 to 2,300 DEG C for 5 to 15h to obtain the low-oxygen TZM alloy. The method solves the problem of high oxygen content of the TZM alloy prepared by a powder metallurgy method. The low-oxygen TZM alloy prepared by the method can be used for the preparation of a rotating anode of an X-ray tube, a composite target substrate, a high-temperature crucible, a hot-forging die and a high-temperature ceramic pad.

Owner:XIAN GEMEI METAL MATERIAL

Catalyst for producing epoxy compounds and method of producing epoxy compounds using the same

InactiveUS6743748B2High yieldImprove utilization efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIridiumPtru catalyst

The present invention provides a catalyst capable of producing an epoxy compound in high yield and improving the utilization efficiency of the oxidizing agent as well as a method of producing an epoxy compound using that catalyst.A catalyst for producing an epoxy compound by oxidizing a compound having at least one ethylenic double bond with an oxidizing agent,comprising a polyatom-containing heteropolyoxometalate anion (A1) having two defective and / or three defective structure sites and containing silicon as the heteroatom, andan element (E1) being at least one element selected from the group consisting of vanadium, tantalum, niobium, antimony, bismuth, chromium, molybdenum, selenium, tellurium, rhenium, cobalt, nickel, ruthenium, rhodium, palladium, osmium, platinum, iridium, silver, gold, zinc, aluminum, gallium, indium, scandium, yttrium, titanium, zirconium, hafnium, germanium, tin and lanthanoids, and being different from the polyatom.

Owner:NIPPON SHOKUBAI CO LTD

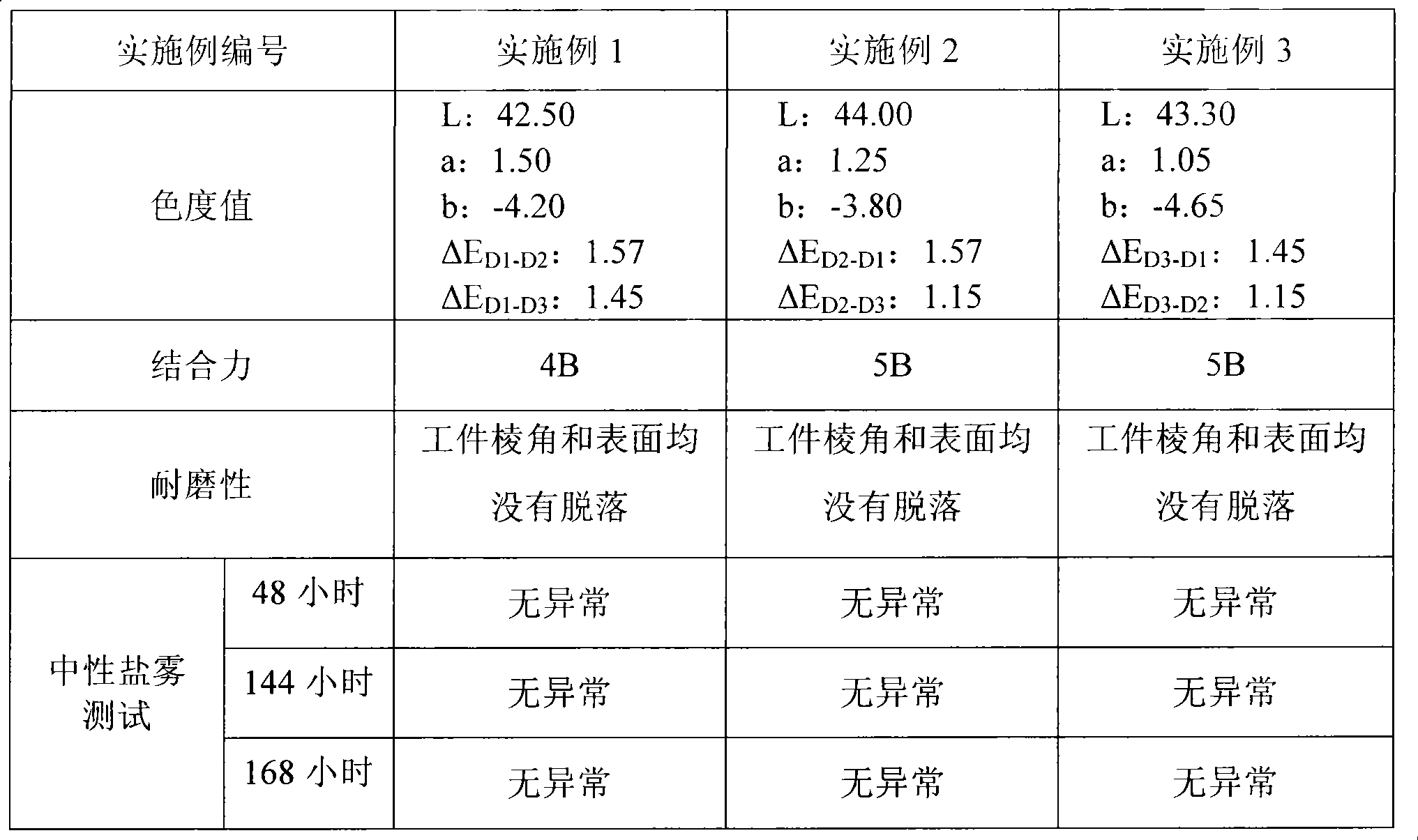

Coating material and preparation method thereof

ActiveCN101468538AStrong metal textureImprove bindingLayered productsVacuum evaporation coatingSputteringTitanium zirconium

The invention provides a film plating material, which comprises a base material and a film layer plated on the base material. The film layer comprises a titanium-zirconium film layer and a titanium-zirconium nitrification film layer which are plated on the base material sequentially. The invention also provides a method for preparing the film plating material. The method comprises: a power supply is applied onto a magnetron target to make target substances on the magnetron target spatter and deposit on the base material under the condition of forming magnetron spattering of the titanium-zirconium film layer and the condition of forming magnetron spattering of the titanium-zirconium nitrification film layer sequentially, so as to form the titanium-zirconium film layer and the titanium-zirconium nitrification film layer which are plated on the base material sequentially. The target is a titanium-zirconium embedding target. The film plating material has the advantages of blue film layer, small color difference, even colors, strong metal texture of the film layer, good bonding strength, and good abrasion resistance and corrosion resistance.

Owner:JIANGSU HAIYU MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com