Method for preparing low-oxygen titanium-zirconium-molybdenum (TZM) alloy and application

A technology of alloy and mixed raw materials, which is applied in metal processing equipment, manufacturing tools, non-luminescent electrode manufacturing, etc., can solve the problems of high oxygen content in TZM alloys, and achieve the effects of strong toughness at room temperature, uniform dispersion, and high recrystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

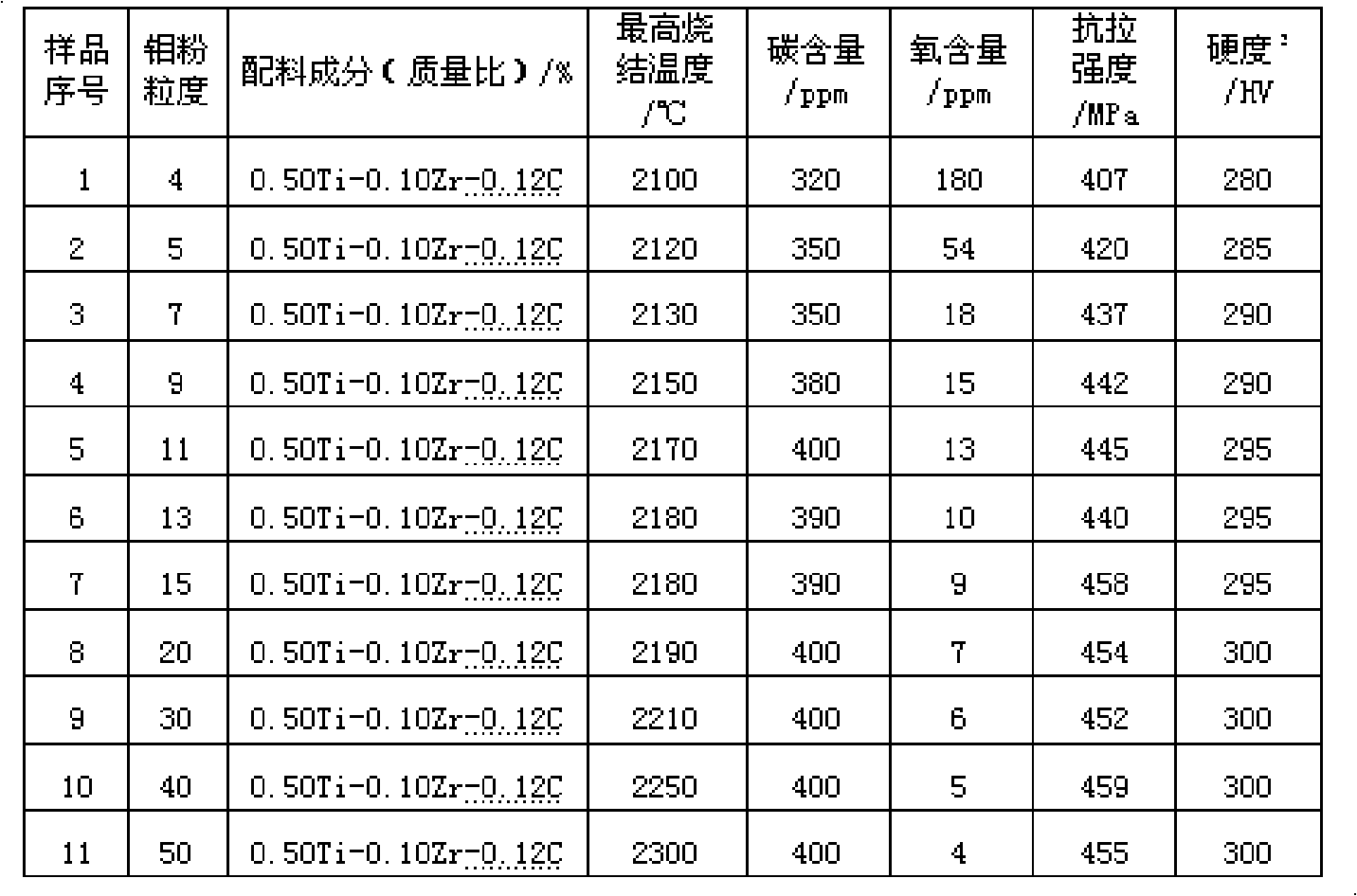

[0023] 1) Take industrial molybdenum powder with a Fisherley particle size of 4 μm, 5 μm, 7 μm, 9 μm, 11 μm, 13 μm, 15 μm, 20 μm, 30 μm, 40 μm, and 50 μm, and titanium hydride powder with a Fisher’s particle size of 3 μm to 10 μm. Zirconium hydride powder of 3 μm to 10 μm, and carbon black with a Fischer particle size of 0.1 μm to 3 μm. The added mass of titanium hydride powder is 0.50%, the added mass of zirconium hydride powder is 0.10%, the added mass of carbon black powder is 0.12%, and the rest is molybdenum powder. Mix the selected molybdenum powder, titanium hydride, zirconium hydride powder and carbon black powder evenly.

[0024] 2) Raw material forming

[0025] The raw materials uniformly mixed in step 1) are subjected to static pressure molding under a pressure of 200 MPa to obtain a billet, the size of which is Φ120mm×130mm.

[0026] 3) Raw material sintering

[0027] Sinter the shaped billet in a hydrogen protective atmosphere. The sintering temperature is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com