Production method of ultralow-oxygen titanium-containing ferrite stainless steel

A production method, ultra-low oxygen technology, applied in the field of stainless steel smelting, can solve problems such as insufficient consideration, and achieve the effects of inhibiting magnesia-aluminum spinel, low oxygen content, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Requirements for VOD of the refining equipment in this embodiment: the equipment can handle 120t of molten steel, the ultimate vacuum is less than 100Pa, and the total blowing capacity of argon blowing at the bottom is higher than 60Nm 3 / h, the ladle refractory material is magnesium calcium brick. The type of steel is 430L, the amount of molten steel is 104000kg, and the initial composition of molten steel before VOD smelting is:

[0057] C: 0.4%, Si: 0.17%, Cr: 16.4%, S: 0.005%, N: 0.017%, Mn: 0.56%, P: 0.015%, all O: 0.02%, Ti: 0.01%, Al: 0.001% , and the rest are Fe and trace impurity elements.

[0058] Initial temperature: 1600°C.

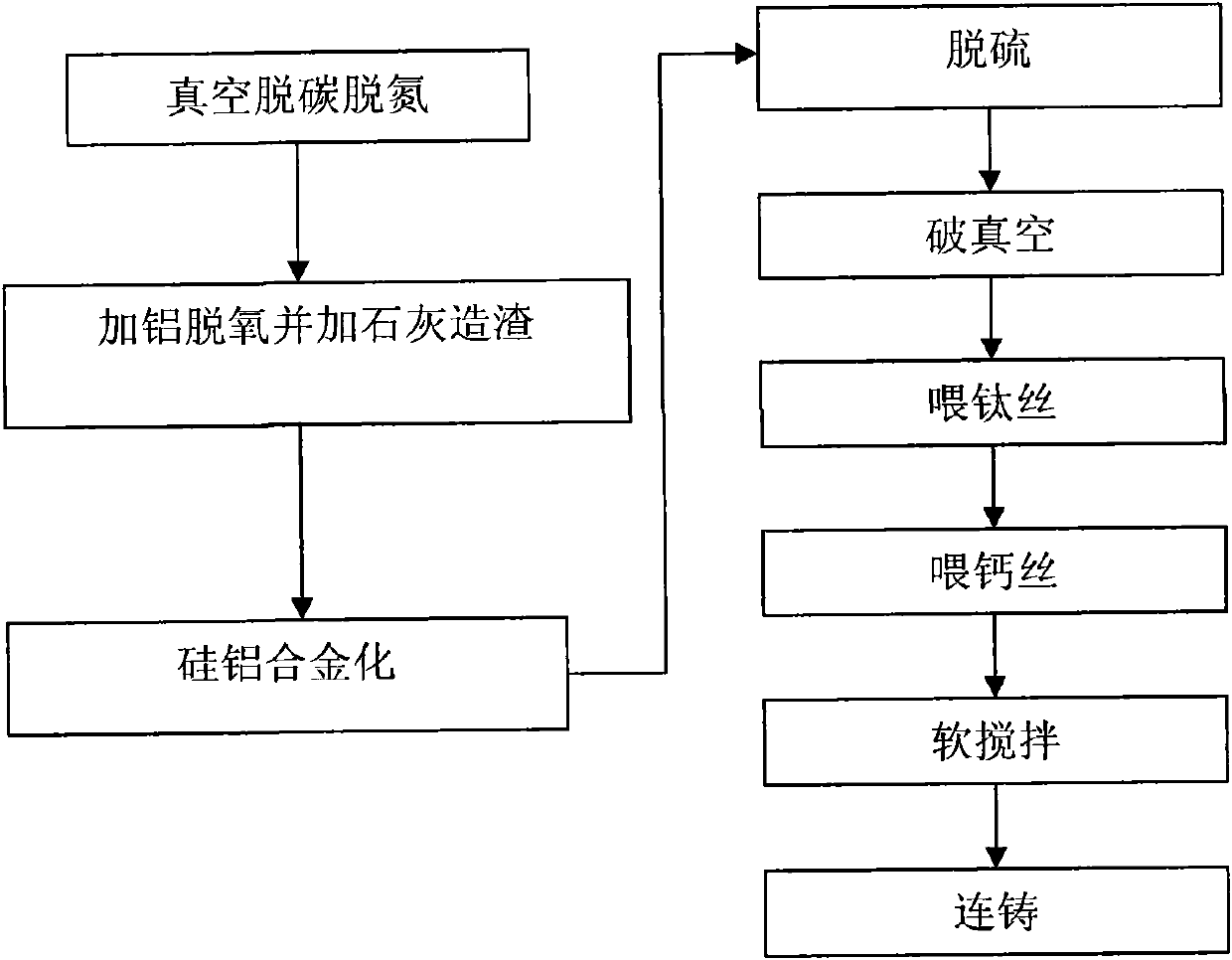

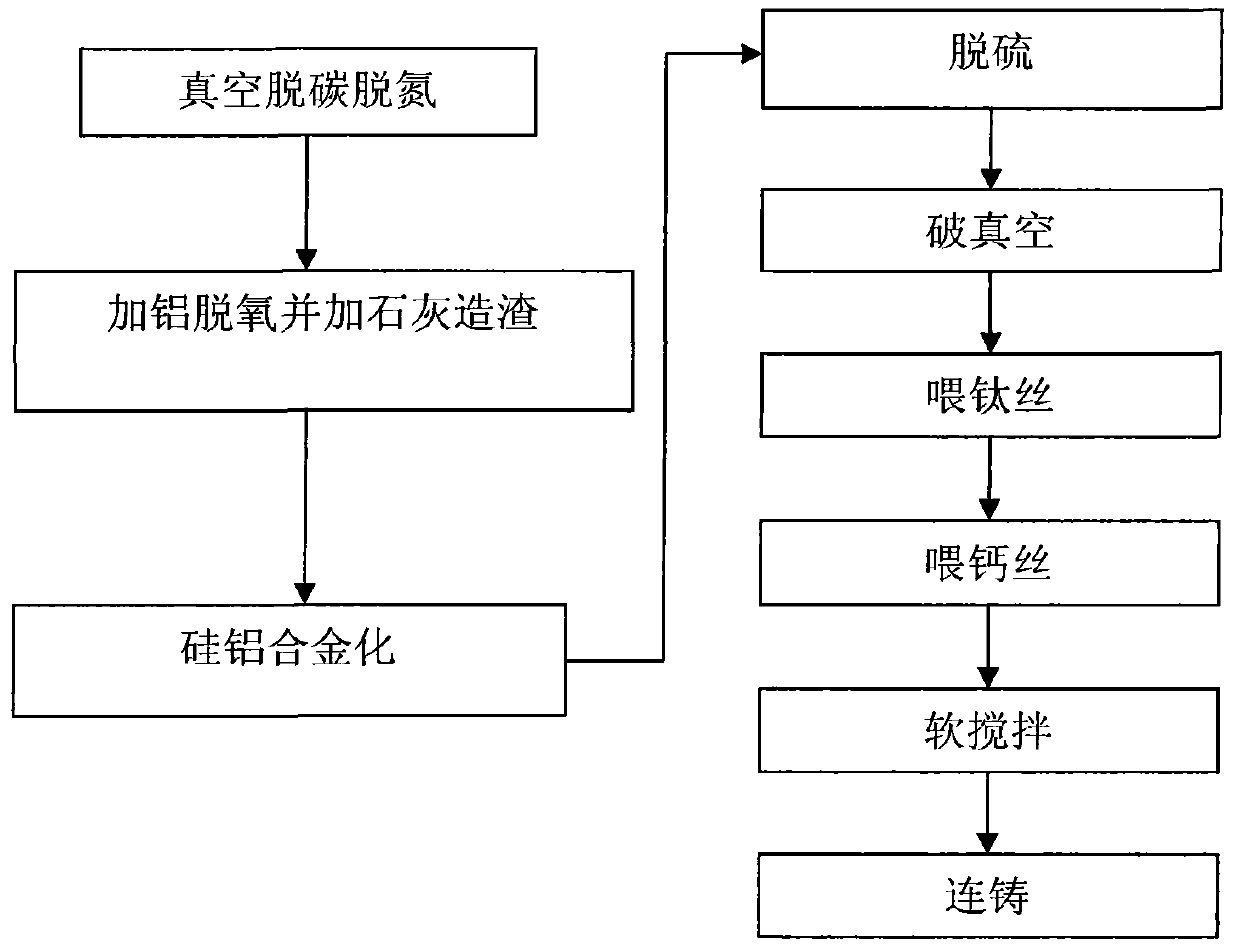

[0059] The implementation steps of this embodiment are as follows (see figure 2 ):

[0060] (1) The molten steel has undergone vacuum oxygen blowing decarburization and free decarburization treatment, and the total oxygen blowing volume is 1350Nm 3 After the treatment, the main components of molten steel are:

[0061] C: 0.009%, ...

Embodiment 2

[0083] Requirements for VOD of the refining equipment in this embodiment: the equipment can handle 120t of molten steel, the ultimate vacuum is less than 100Pa, and the total blowing capacity of argon blowing at the bottom is higher than 60Nm 3 / h, the ladle refractory material is magnesium calcium brick. The type of steel is 439, the amount of molten steel is 110,000kg, and the initial composition of molten steel before VOD smelting is:

[0084] C: 0.35%, Si: 0.04%, Cr: 17.6%, S: 0.005%, N: 0.011%, Mn: 0.22%, P: 0.013%, all O: 0.02%, Ti: 0.01%, Al: 0.001% , and the rest are Fe and trace impurity elements.

[0085] Initial temperature: 1600°C.

[0086] The implementation steps of this embodiment are as follows:

[0087] (1) The molten steel has undergone vacuum oxygen blowing decarburization and free decarburization treatment, and the total oxygen blowing volume is 1094Nm 3 After the treatment, the main components of molten steel are:

[0088] C: 0.005%, Si: 0.01%, Cr: 16...

Embodiment 3

[0111] Requirements for VOD of the refining equipment in this embodiment: the equipment can handle 120t of molten steel, the ultimate vacuum is less than 100Pa, and the total blowing capacity of argon blowing at the bottom is higher than 60Nm 3 / h, the ladle refractory material is magnesia carbon brick. The steel type is 409L, the amount of molten steel is 107000kg, and the initial composition of the molten steel before VOD smelting is:

[0112] C: 0.26%, Si: 0.15%, Cr: 11.5%, S: 0.004%, N: 0.013%, Mn: 0.3%, P: 0.013%, all O: 0.025%, Ti: 0.02%, Al: 0.001% , and the rest are Fe and trace impurity elements.

[0113] Initial temperature: 1620°C.

[0114] The implementation steps of this embodiment are as follows:

[0115] (1) The molten steel has undergone vacuum oxygen blowing decarburization and free decarburization treatment, and the total oxygen blowing volume is 938Nm 3 After the treatment, the main components of molten steel are:

[0116] C: 0.006%, Si: 0.01%, Cr: 10.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com