A method for smelting titanium-containing ferritic stainless steel

A smelting method and stainless steel technology are applied in the production field of titanium-containing ferritic stainless steel, which can solve the problems of affecting product quality, easy deposition of nozzles, and increasing the formation of core-containing TiN, so as to suppress harmful inclusions of magnesium-aluminum spinel. Form, ensure smooth progress, and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

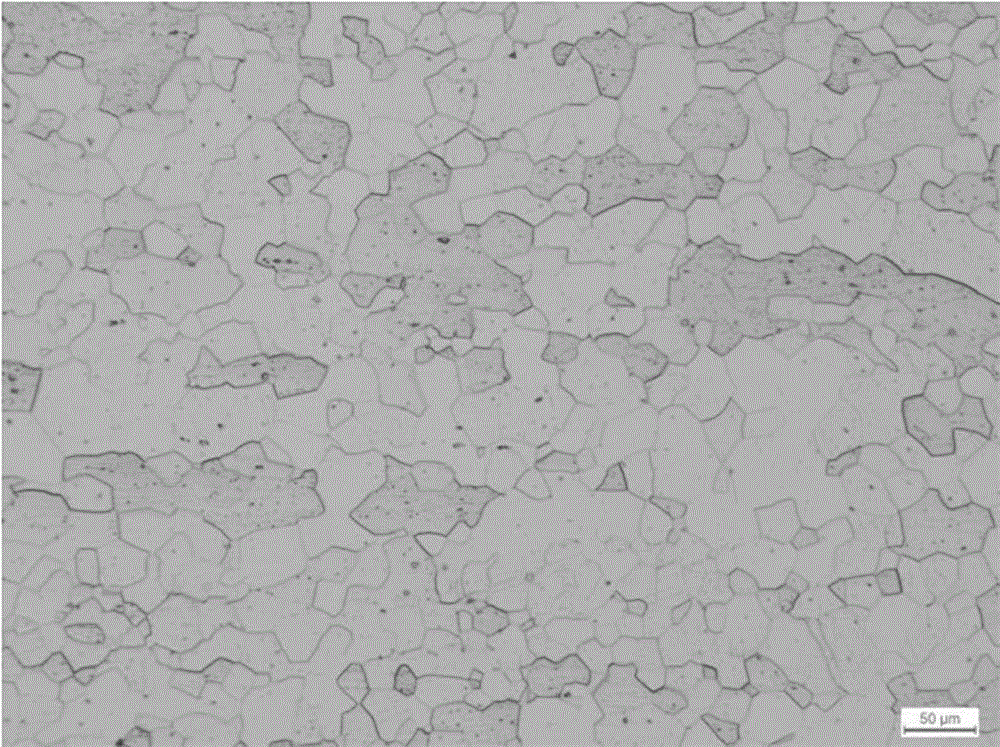

Embodiment 1

[0023] A method for smelting titanium-containing ferritic stainless steel, comprising the following steps:

[0024] 1. Dephosphorization treatment of molten iron in dephosphorization converter

[0025] The molten iron is mixed into the dephosphorization converter from the ordinary molten iron tank, and the dephosphorization treatment is carried out by the injection method, and the flow rate of the top blowing oxygen lance is 70Nm during the treatment process 3 / min, the gun position is 1.7m, add slagging material and dephosphorizing agent after 2min, the amount of slagging material added is 25.0kg / t per ton of molten iron, the amount of dephosphorizing agent added is 20.0kg / t per ton of molten iron, treatment In the process, the slag basicity is controlled at 2.0; the percentage by weight of the composition of the treated molten iron is:

[0026] C: 2.8%, Mn: 0.20%, P: 0.015%, S: 0.05%, the rest is Fe and unavoidable impurities, the temperature is 1380°C;

[0027] 2. The mol...

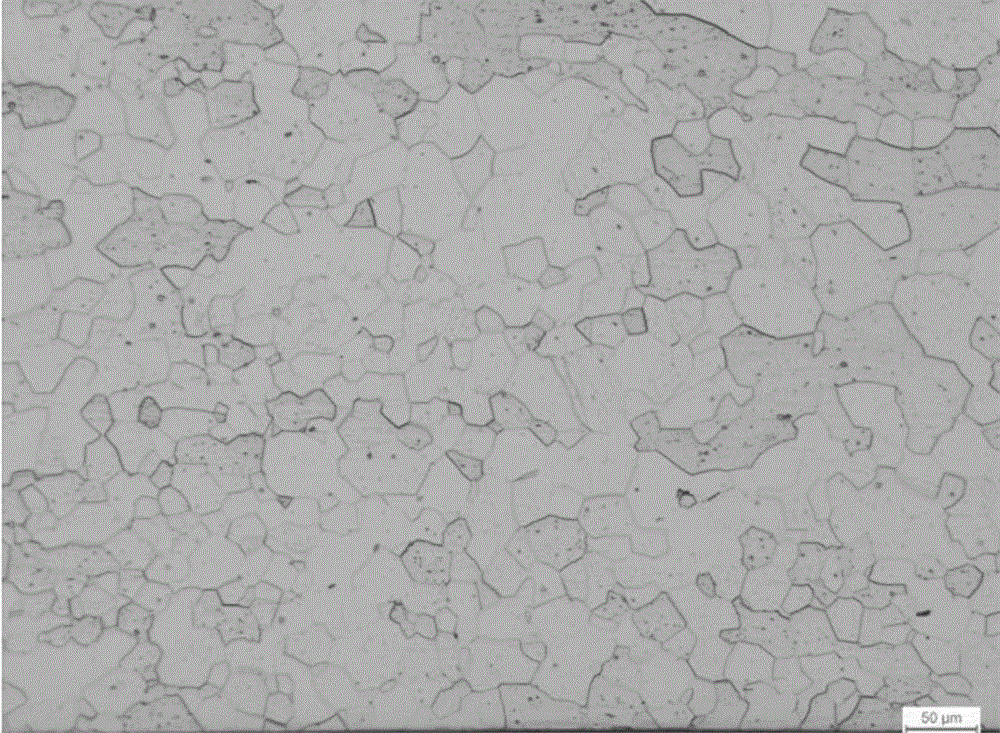

Embodiment 2

[0055] A method for smelting titanium-containing ferritic stainless steel, comprising the following steps:

[0056] 1. Dephosphorization treatment of molten iron in dephosphorization converter

[0057] The molten iron is mixed into the dephosphorization converter from the ordinary molten iron tank, and the dephosphorization treatment is carried out by spraying. Phosphorus agent, the amount of slagging material added is 30.0kg / t per ton of molten iron, the amount of dephosphorization agent added is 25.0kg / t per ton of molten iron, and the slag alkalinity is controlled at 2.5 during the treatment process; the weight percentage of the composition of the molten iron after treatment is :

[0058] C: 3.5%, Mn: 0.21%, P: 0.02%, S: 0.042%, the rest is Fe and unavoidable impurities, the temperature is 1460°C;

[0059] 2. The molten steel is decarburized, denitrified and reduced in the AOD converter

[0060] 96.8t of molten iron is injected into the AOD converter, and oxygen is blown...

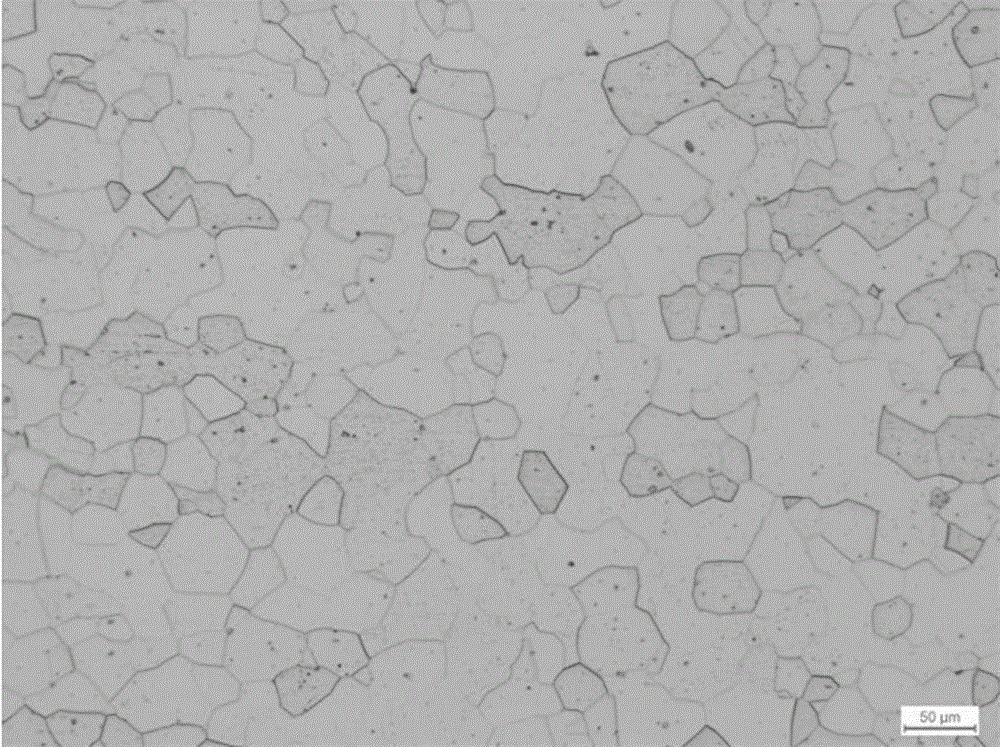

Embodiment 3

[0087] A method for smelting titanium-containing ferritic stainless steel, comprising the following steps:

[0088] 1. Dephosphorization treatment of molten iron in dephosphorization converter

[0089] The molten iron is mixed from the ordinary molten iron tank into the dephosphorization converter, and the dephosphorization treatment is carried out by the injection method. During the treatment process, the flow rate of the top blowing oxygen lance is 100Nm 3 / min, the gun position is 1.6m, add slagging material and dephosphorization agent 2min after the start, the amount of slagging material added is 26.0kg / t per ton of molten iron, the amount of dephosphorizing agent added is 23.0kg / t per ton of molten iron, treatment In the process, the slag basicity is controlled at 2.2; the percentage by weight of the composition of the treated molten iron is:

[0090] C: 3.0%, Mn: 0.25%, P: 0.017%, S: 0.040%, the rest is Fe and unavoidable impurities, the temperature is 1470°C;

[0091]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com