Patents

Literature

1175 results about "Thermal fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power semiconductor module

InactiveUS20070216013A1Minimize powerIncreased reliability against thermal fatigueSemiconductor/solid-state device detailsSolid-state devicesMetallic foilThermal fatigue

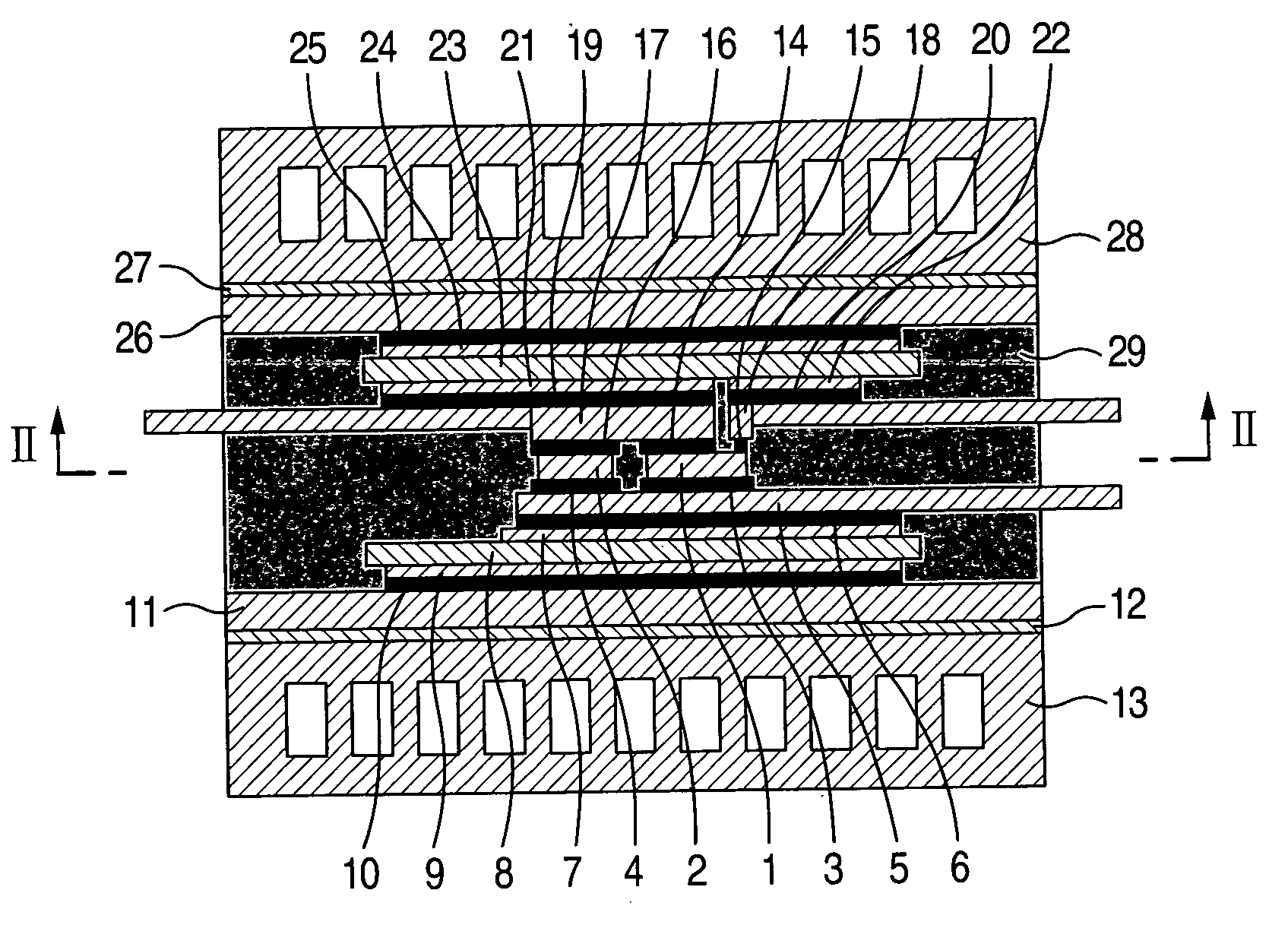

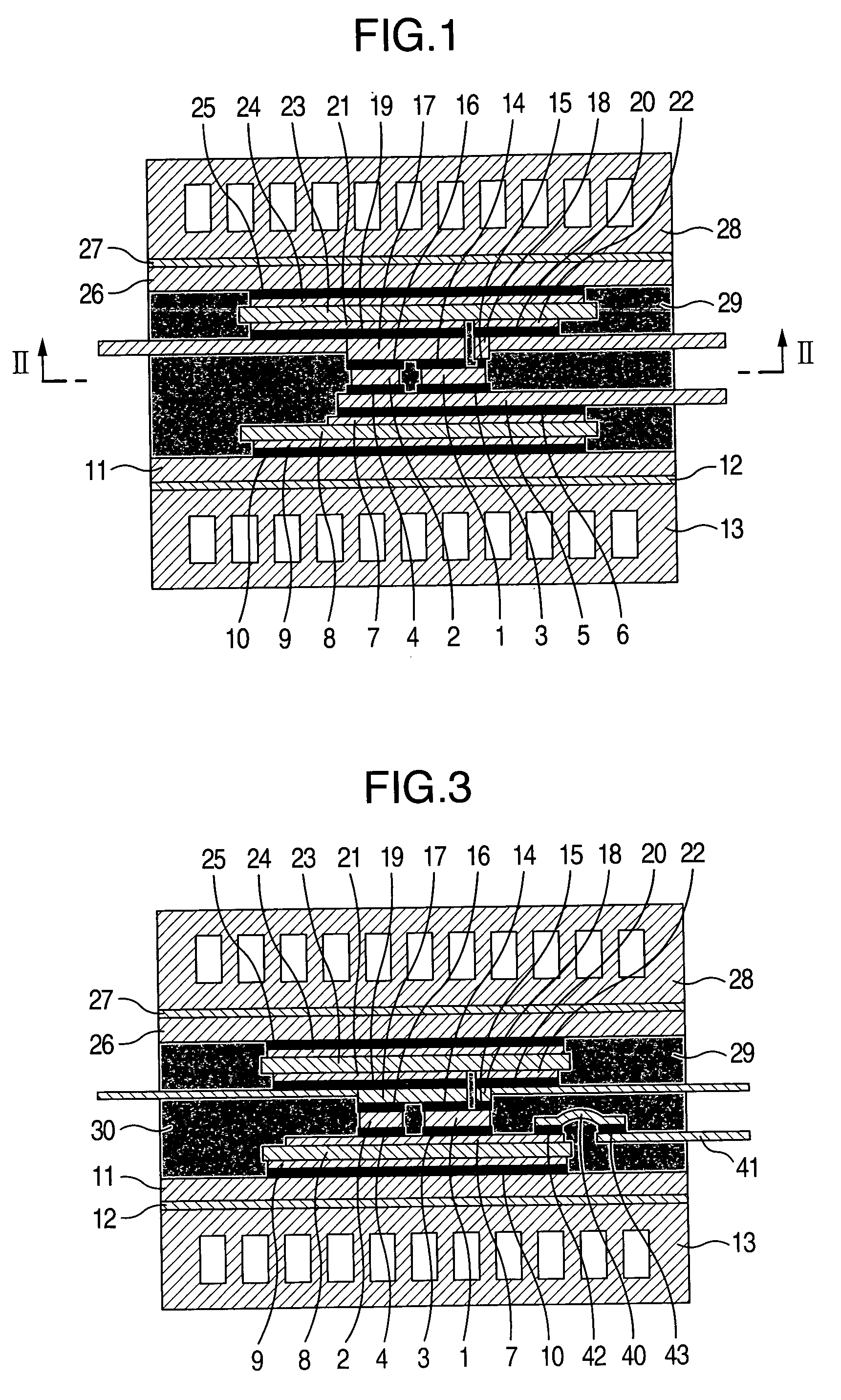

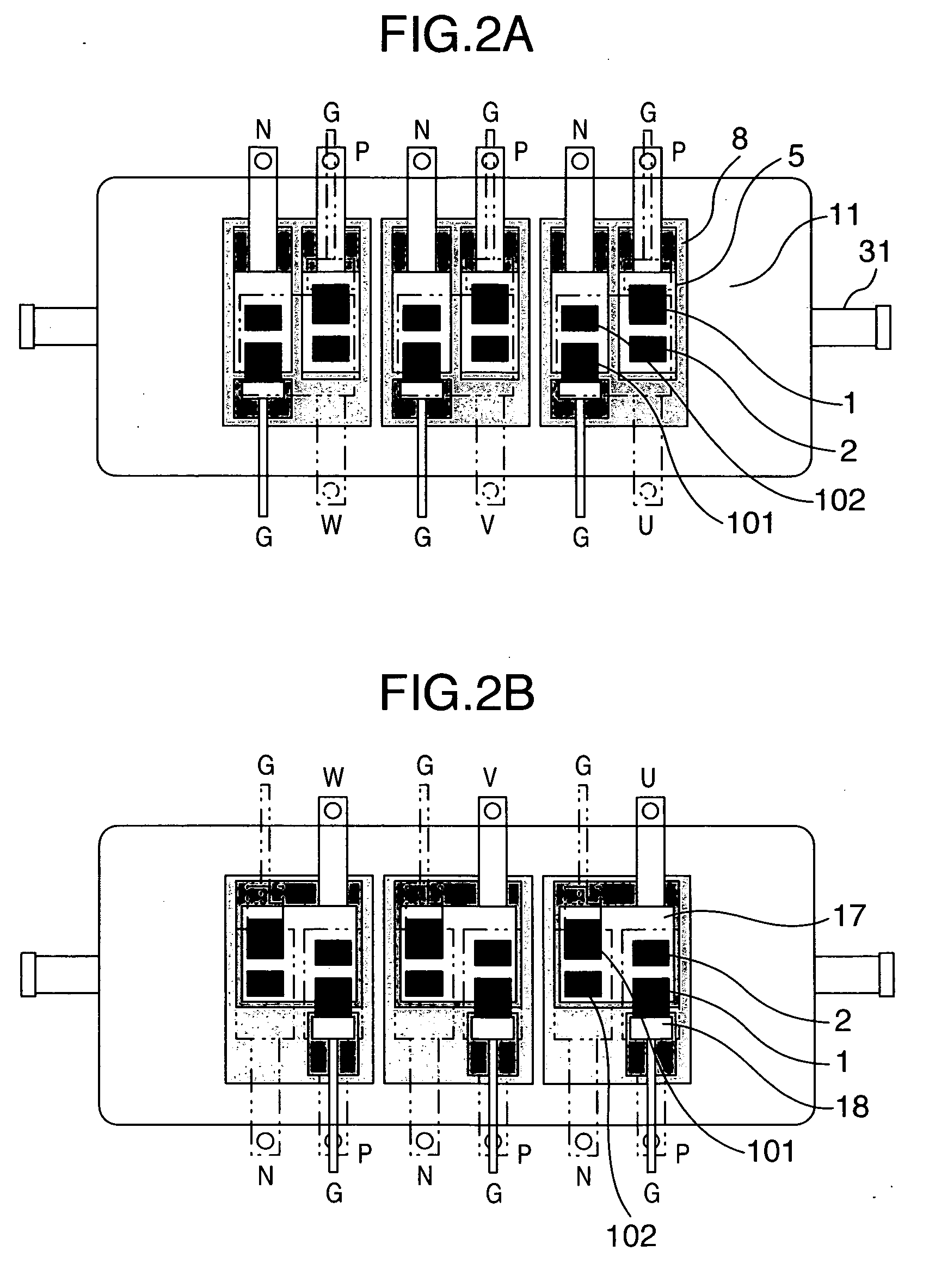

A power semiconductor module having an increased reliability against thermal fatigue includes a power semiconductor element, a lower-side electrode connected to the lower side of the element, a first insulating substrate connected to the upper side of the lower-side electrode and having metallic foils bonded on both surfaces thereof, an upper-side electrode connected to the upper side of the power semiconductor element, a second insulating substrate connected to the upper side of the upper-side electrode and having metallic foils bonded on both surfaces thereof, a first heat spreader connected to the lower side of the first insulating substrate, and a second heat spreader connected to the upper side of the second insulating substrate. The power semiconductor element and the first and second insulating substrates are sealed with a resin.

Owner:HITACHI LTD

Method for forming reflowed solder ball with low melting point metal cap

InactiveUS6344234B1Reduce the hole diameterMinimal diameterFinal product manufactureSemiconductor/solid-state device detailsTinningIndium

A method and structure for a solder interconnection, using solder balls for making a low temperature chip attachment directly to any of the higher levels of packaging substrate is disclosed. After a solder ball has been formed using standard methods it is reflowed to give the solder ball a smooth surface. A layer of low melting point metal, such as, bismuth, indium or tin, preferably, pure tin, is deposited on the top of the solder balls. This structure results in localizing of the eutectic alloy, formed upon subsequent low temperature joining cycle, to the top of the high melting solder ball even after multiple low temperature reflow cycles. This method does not need tinning of the substrate to which the chip is to be joined, which makes this method economical. It has also been noticed that whenever temperature is raised slightly above the eutectic temperature, the structure always forms a liquid fillet around the joint with copper wires. This liquid fillet formation results in substantial thermal fatigue life improvement for reduced stress at interface; and secondly, provides an easy means to remove chip for the purpose of chip burn-in, replacement or field repairs.

Owner:ULTRATECH INT INC

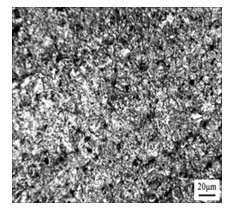

Vermicular graphite cast iron for producing brake drum of high-speed and heavy-load automobile

The invention discloses alloyed vermicular graphite cast iron produced by alloying the ordinary vermicular graphite cast iron. The cast iron comprises an alloy of two or more of elements such as Cu, Cr, Mo, Ni, Sn, Sb, B, Ti, Al, V and the like. The vermicular graphite cast iron comprises the following chemical ingredients in percentage by weight: 3.00-3.80 percent of C, 2.00-2.80 percent of Si, 0.45-0.95 percent of Mn, less than 0.06 percent of P, less than or equal to 0.02 percent of S, and 0.02-0.60 percent of alloy ingredient. The technical indexes of the vermicular graphite cast iron are that: VG is more than or equal to 80 percent, Rm is more than or equal to 380 MPa, hardness is between 180 HBW and 258 HBW, cast pearlite is more than or equal to 60 percent, and elongation rate is between 1 percent and 2 percent. The vermicular graphite cast iron has the advantages of high intensity, high heat conductivity, high wear resistance, high thermal fatigue resistance, small deformation, simple casting process and easiness in mechanical production. The service life of a produced brake drum for a high-speed and heavy-load automobile is remarkably prolonged, and safety is ensured.

Owner:罗云

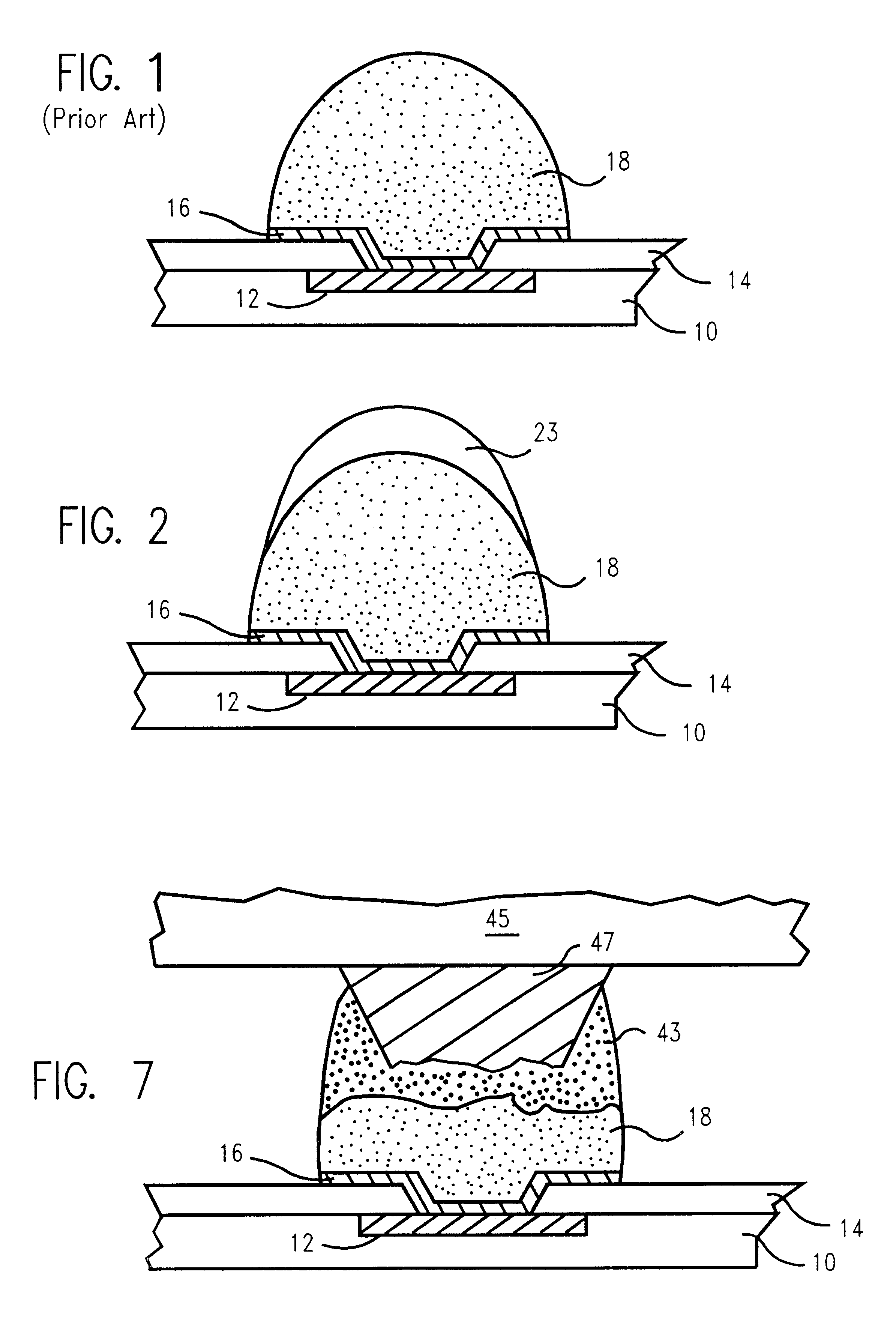

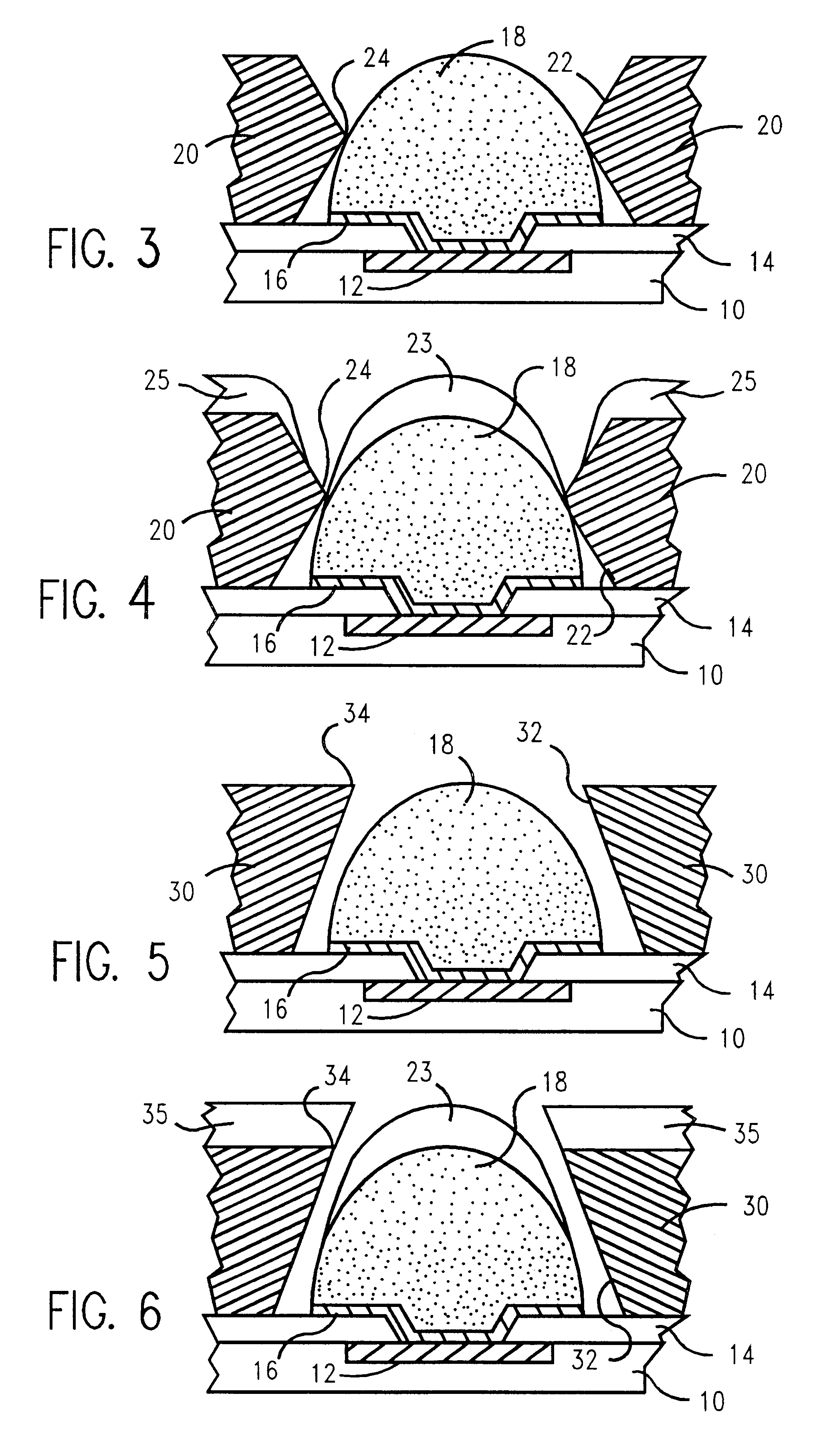

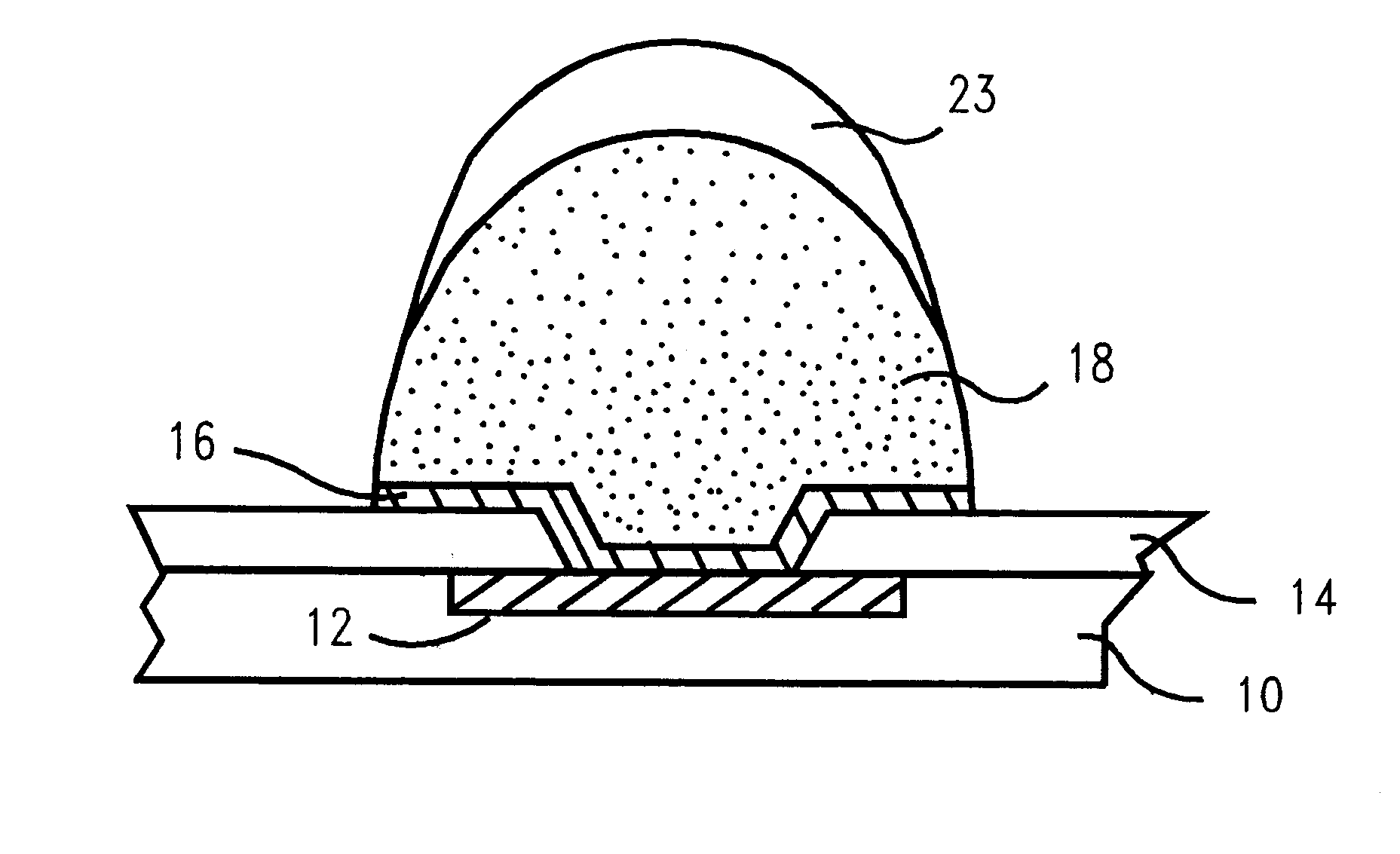

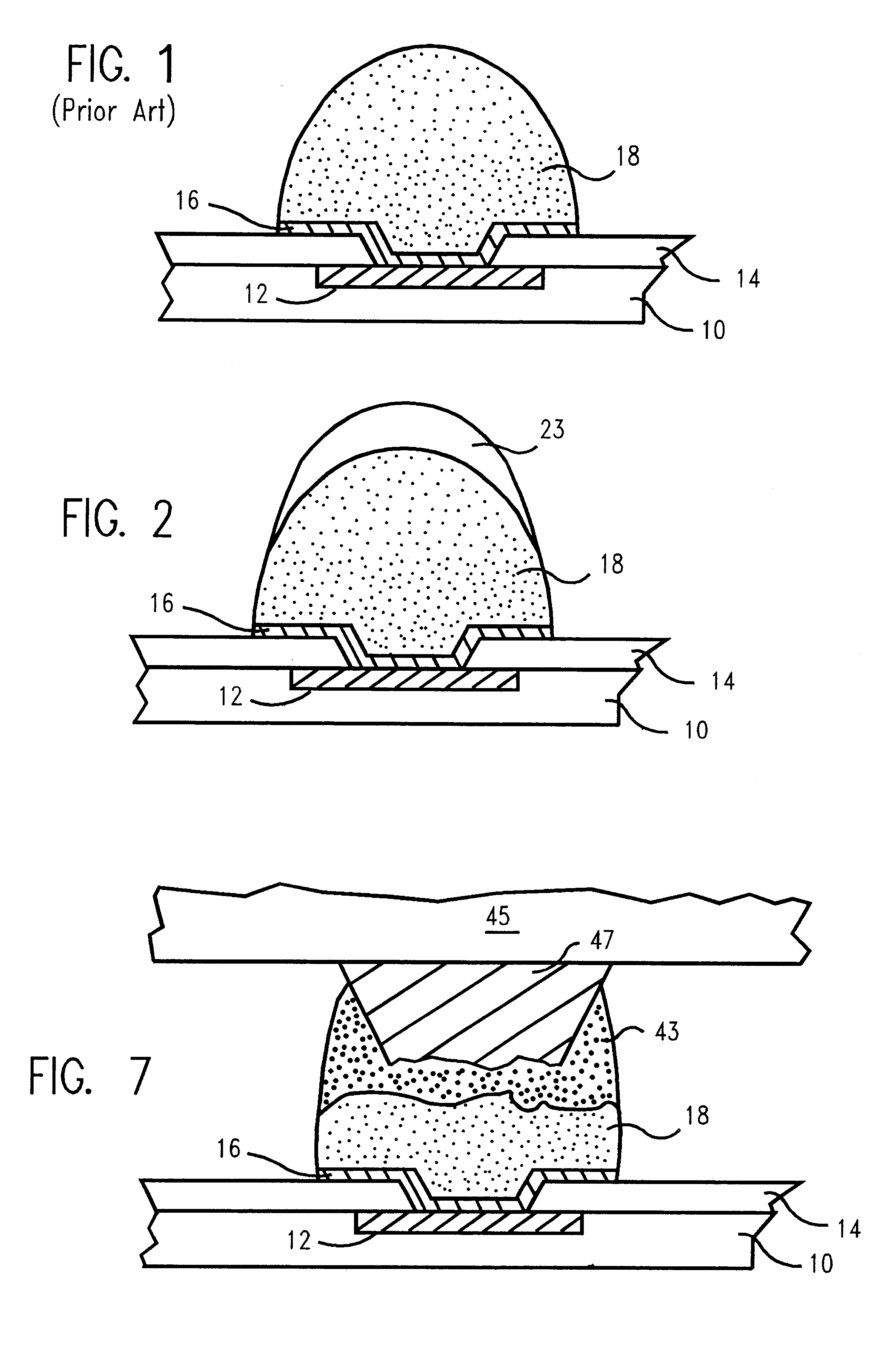

Reflowed solder ball with low melting point metal cap

InactiveUS6259159B1Low costEasy to buildPrinted circuit assemblingFinal product manufactureTinningIndium

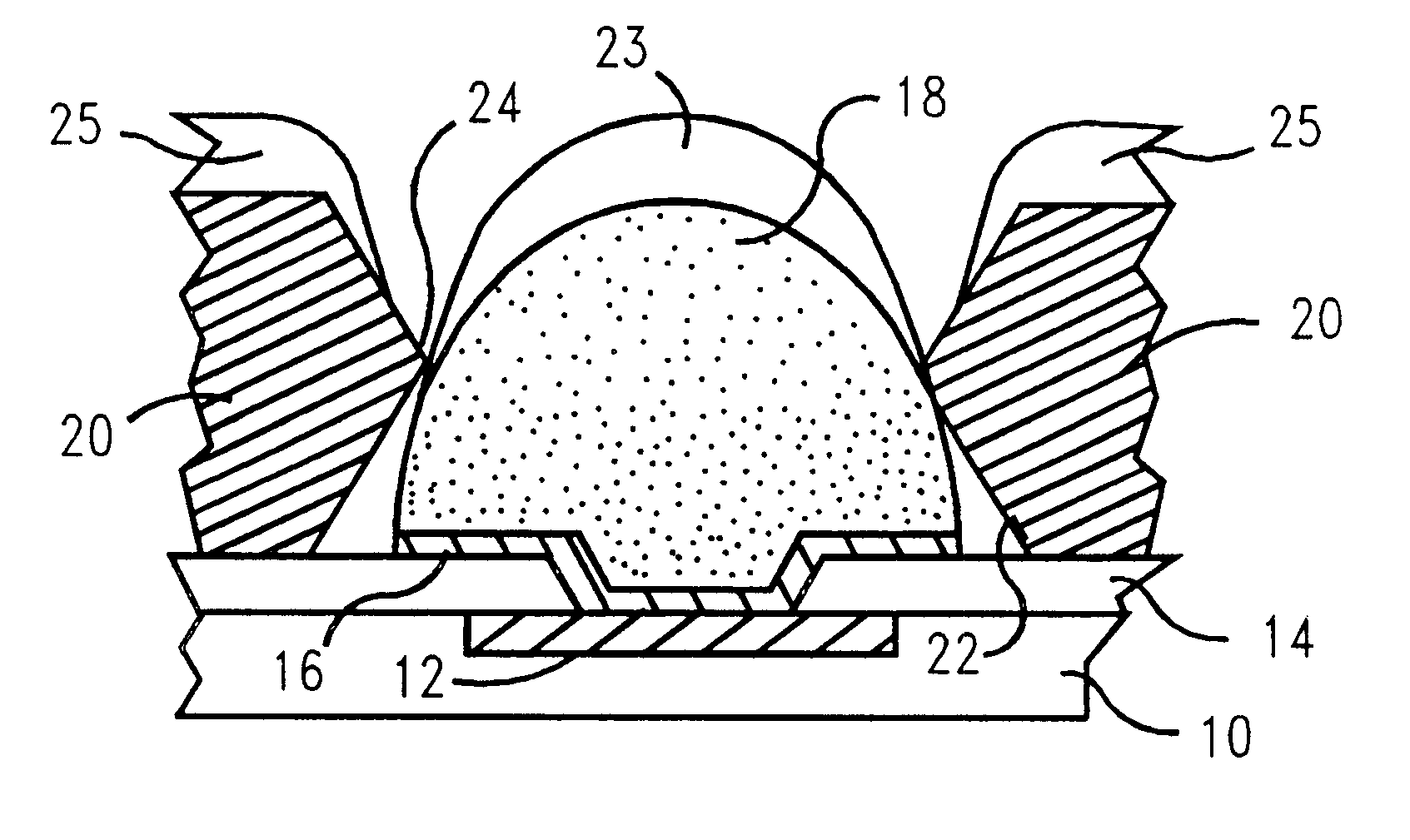

A method and structure for a solder interconnection, using solder balls for making a low temperature chip attachment directly to any of the higher levels of packaging substrate is disclosed. After a solder ball has been formed using standard methods it is reflowed to give the solder ball a smooth surface. A layer of low melting point metal, such as, bismuth, indium or tin, preferably, pure tin, is deposited on the top of the solder balls. This structure results in localizing of the eutectic alloy, formed upon subsequent low temperature joining cycle, to the top of the high melting solder ball even after multiple low temperature reflow cycles. This method does not need tinning of the substrate to which the chip is to be joined, which makes this method economical. It has also been noticed that whenever temperature is raised slightly above the eutectic temperature, the structure always forms a liquid fillet around the joint with copper wires. This liquid fillet formation results in substantial thermal fatigue life improvement for reduced stress at interface; and secondly, provides an easy means to remove chip for the purpose of chip burn-in, replacement or field repairs.

Owner:IBM CORP

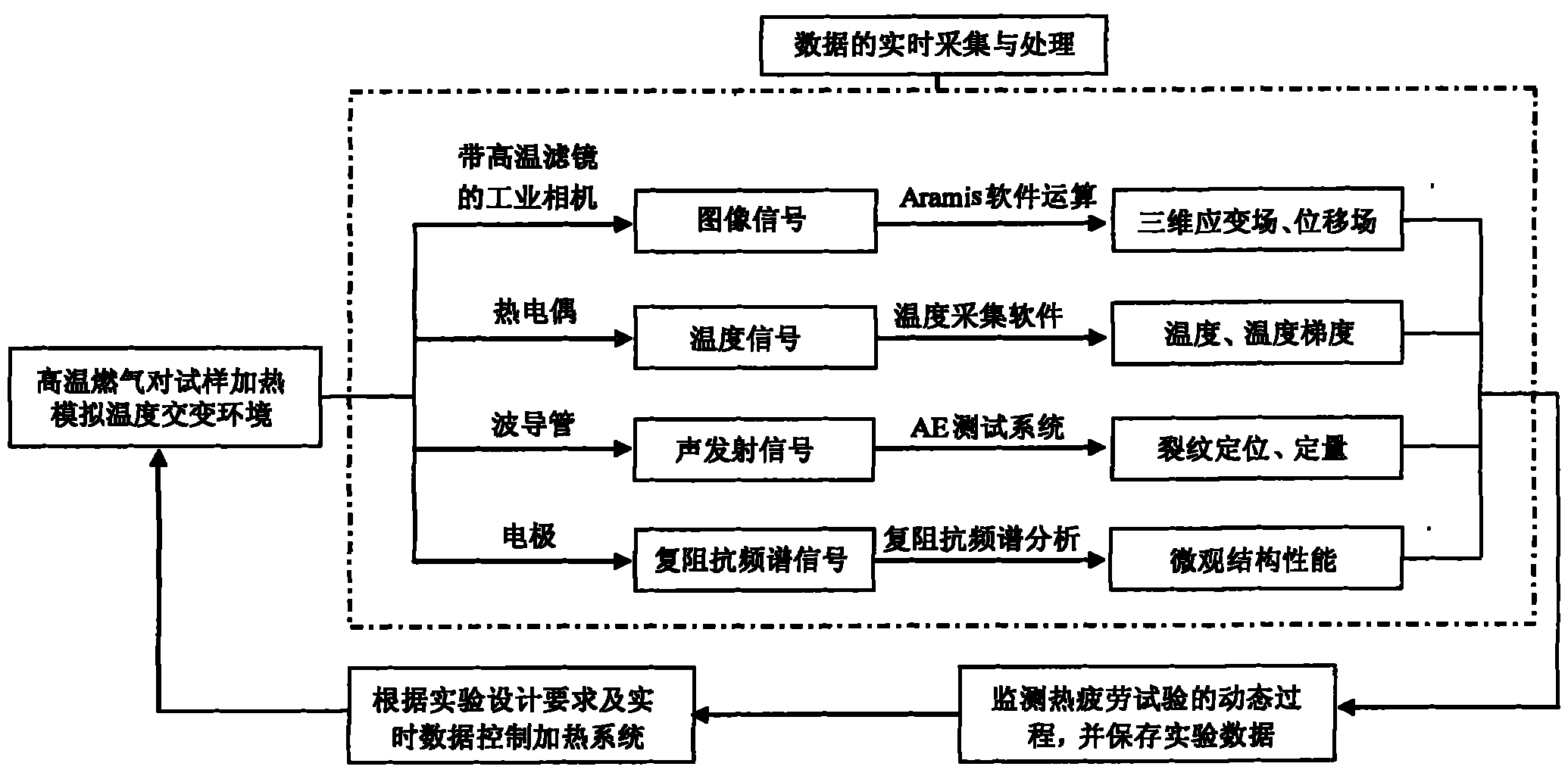

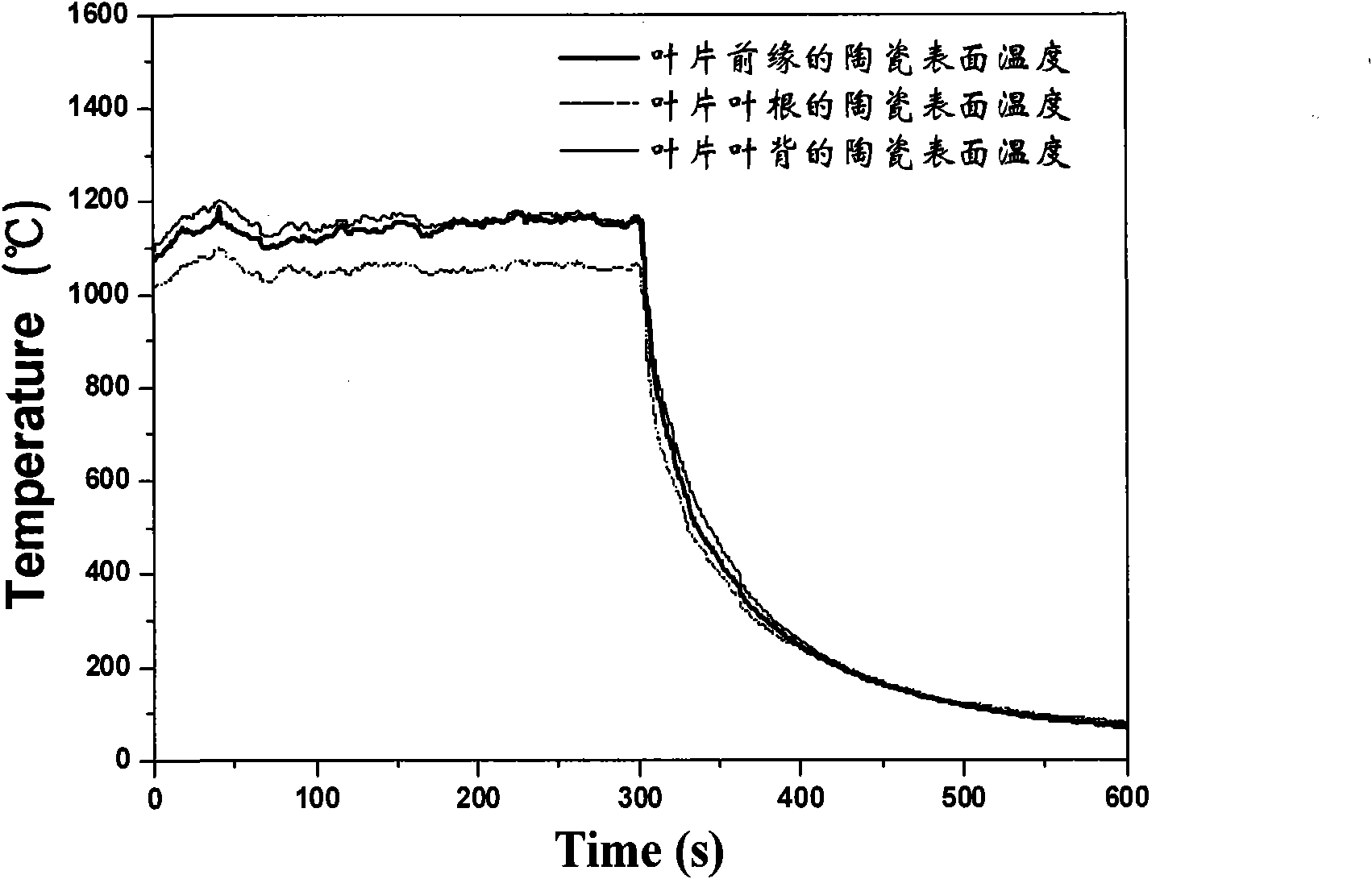

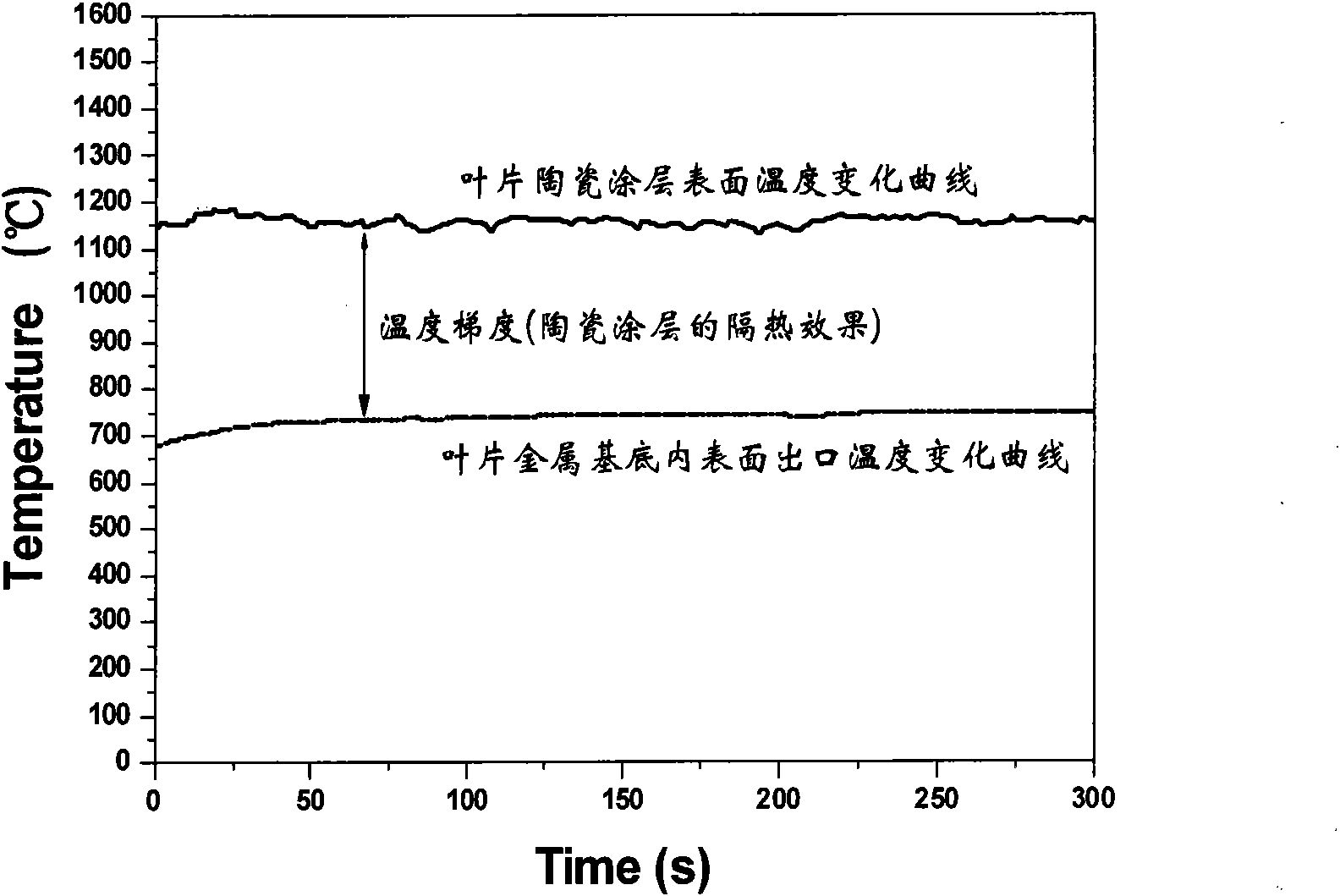

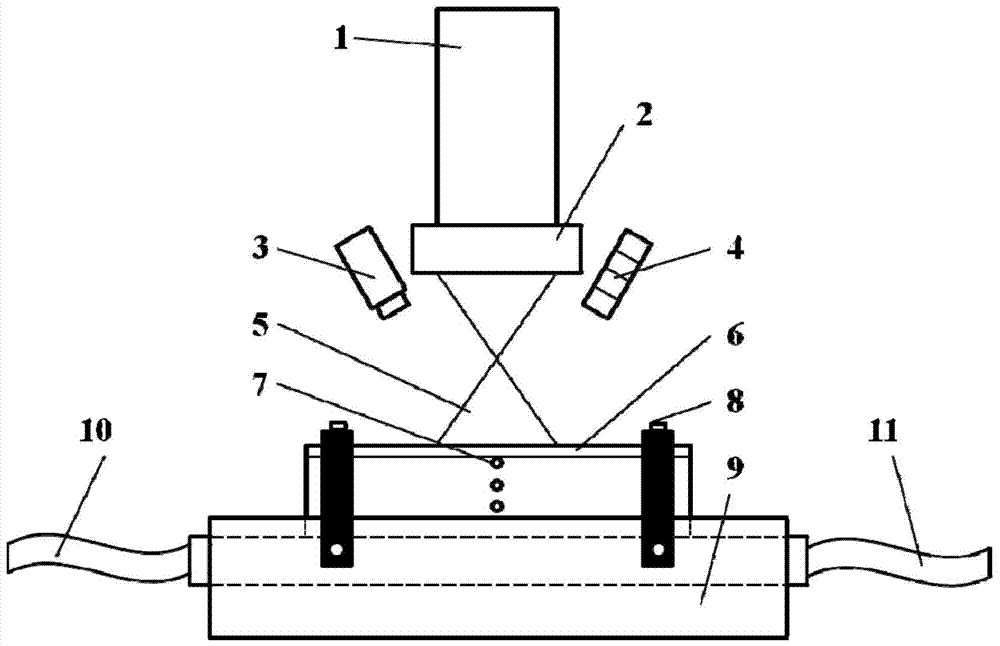

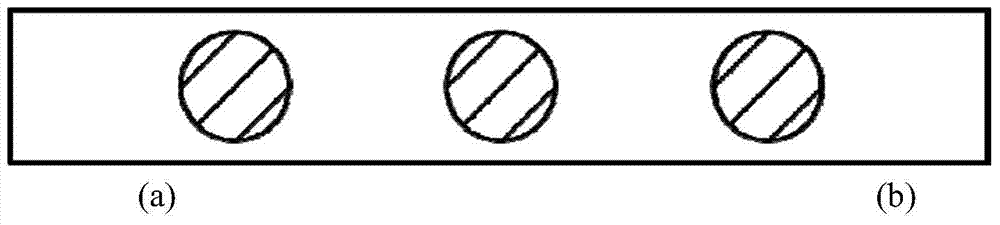

Simulation test method of thermal fatigue failure of blade with thermal barrier coating

ActiveCN101776645AMonitor temperature in real timeReal-time monitoring of temperature gradientsMaterial analysis using acoustic emission techniquesThermometers using electric/magnetic elementsAviationCeramic coating

The invention belongs to the technical field of turbine blade performance detection in the aviation industry, in particular to a simulation test method of thermal fatigue failure of a blade with thermal barrier coating. The method can simulate the thermal fatigue work environment of temperature alternating circulation of various blades in an aircraft engine with high performance, and simultaneously tests and analyzes data, such as temperature, temperature gradient, surface topography image evolution, three dimensional deformation field, three dimensional displacement field, interface oxidation layer and thickening rule thereof, thermal fatigue flaw initiation and expansion, cooling airflow and the like of a blade sample with a thermal barrier coating, thus realizing real-time monitoring of three dimensional thermal strain and stress of the blade in the process of thermal fatigue experiments, and providing an important means for predicting thermal fatigue damaging position and invalidation time of the blade. The experimental data obtained by the method can provide important experiment basis for effectively evaluating the failure mechanism of the aircraft engine blade in the environment of high-temperature gas and predicting ceramic coating dropping position, dropping time and service life.

Owner:XIANGTAN UNIV

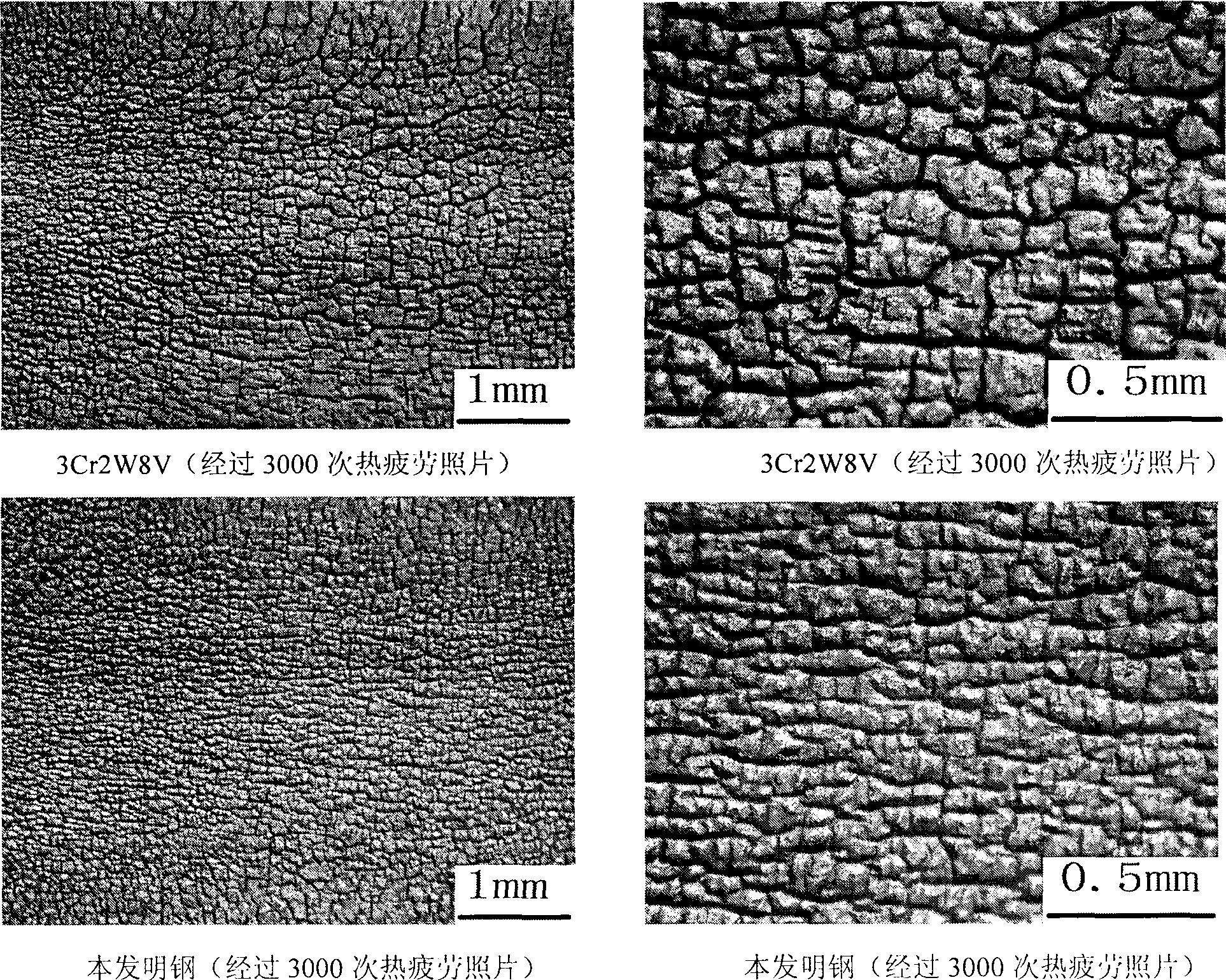

High manganese and low chromium type high strength and toughness hot-work die steel and preparation method thereof

The invention relates to a high-manganese and low chromium type high-obdurability hot-work die steel, pertaining to the technical field of alloy steel manufacturing process. The constituents of the steel and the weight percent are as follows: C: 0.3 percent to 0.6 percent, Si: 0.1 percent to 0.5 percent, Mn: 0.5 percent to 1.5 percent, Cr: 1.5 percent to 4.0 percent, Mo: 1.0 percent to 3.0 percent, V: 0.4 percent to 1.3 percent, W: 0.5 percent to 2.0 percent, P: less than 0.02 percent, S: less than 0.02 percent and Fe as the rest. The preparation process of the hot-work die steel is as follows: material distribution, induction smelting and molding, followed by electroslag remelting; at the temperature of 1,200 DEG C to 1,280 DEG C, homogenization treatment is carried out for 8h to 10h, then forging and annealing are carried out, the materials are heated to the temperature of 1,000 DEG C to 1,100 DEG C for austenization, and two times of tempering are carried out at the temperature of 580 DEG C to 640 DEG C after oil quenching or high-pressure air quenching. The hot-work die steel has high thermal stability, high heat resistance and good thermal fatigue property.

Owner:SHANGHAI UNIV

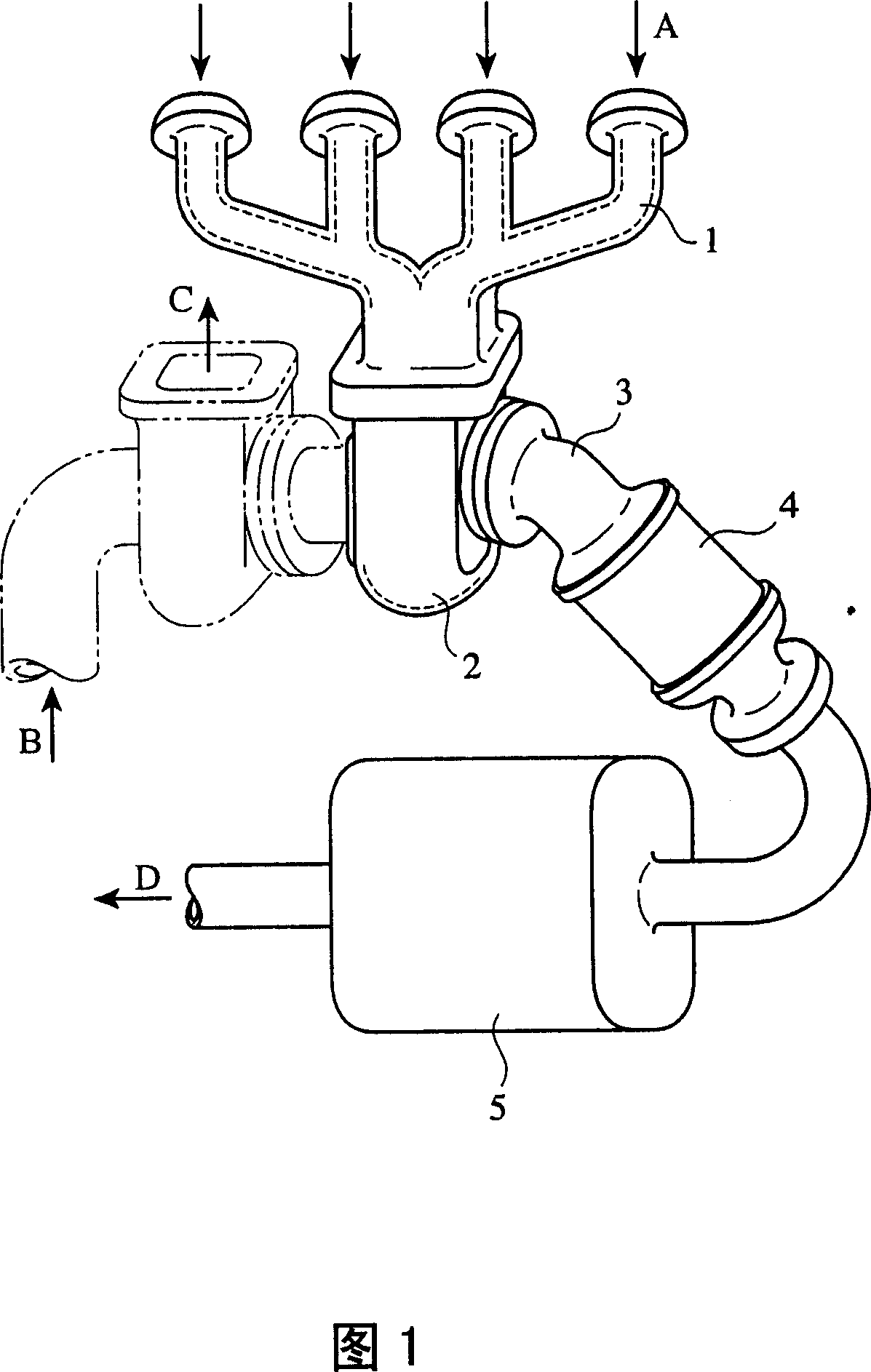

High-cr high-ni austenitic heat-resistant cast steel and exhaust system component produced from same

ActiveCN1942598AHigh temperature yield pointImprove oxidation resistanceSilencing apparatusMachines/enginesThermal fatigueImpurity

Disclosed is a high-Cr high-Ni austenitic heat-resistant cast steel having a composition mainly containing C, Si, Mn, Cr, Ni, W and / or Mo, and Nb, and further containing, in weight%, 0.01-0.5% of N, not more than 0.23% of Al, not more than 0.07% of O and the balance of Fe and unavoidable impurities. Since this high-Cr high-Ni austenitic heat-resistant cast steel is excellent in high-temperature resistance, oxidation resistance and thermal fatigue life, it is preferably used for exhaust system components.

Owner:PROTERIAL LTD

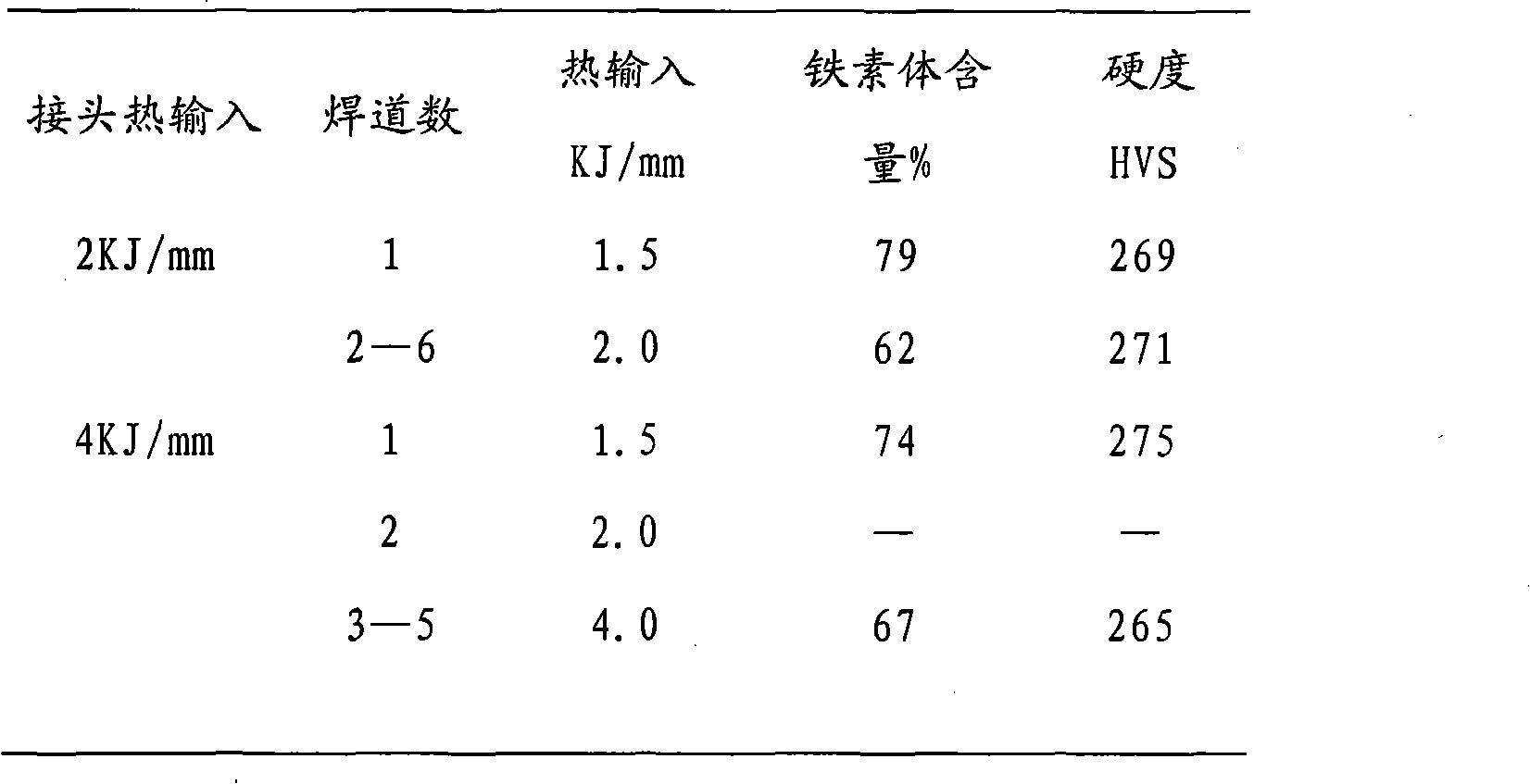

Process for welding duplex stainless steel

ActiveCN101972878AOvercome adverse defectsGood welding effectArc welding apparatusShielding gasPetrochemical

The invention relates to a process for welding duplex stainless steel, in particular to the process for welding the duplex stainless steel used for high-sulfur content refining equipment, highly-corrosive petrochemical equipment and pipelines, high-parameter power devices, and the chloridion-corroded environments of seawater and the like. In the process, a specific protective gas favorable for the welding of the duplex stainless steel is adopted, and simultaneously limited linear energy and inter-layer temperature are regulated in the welding process, so that the unfavorable defects of the conventional welding process can be overcome, and a metallographic structure with the ferrite content of 30 to 70 percent and a ferritic phase in percentage equivalent to that of an austenitic phase is obtained. A welding joint obtained by the welding process has high mechanical properties, high strength and hardness, particularly high yield strength which is about twice that of austenitic stainless steel, high thermal fatigue resistance, pitting corrosion resistance, crevice corrosion resistance, intercrystalline corrosion resistance and high weldability.

Owner:CHINA NAT CHEM ENG NO 7 CONSTR

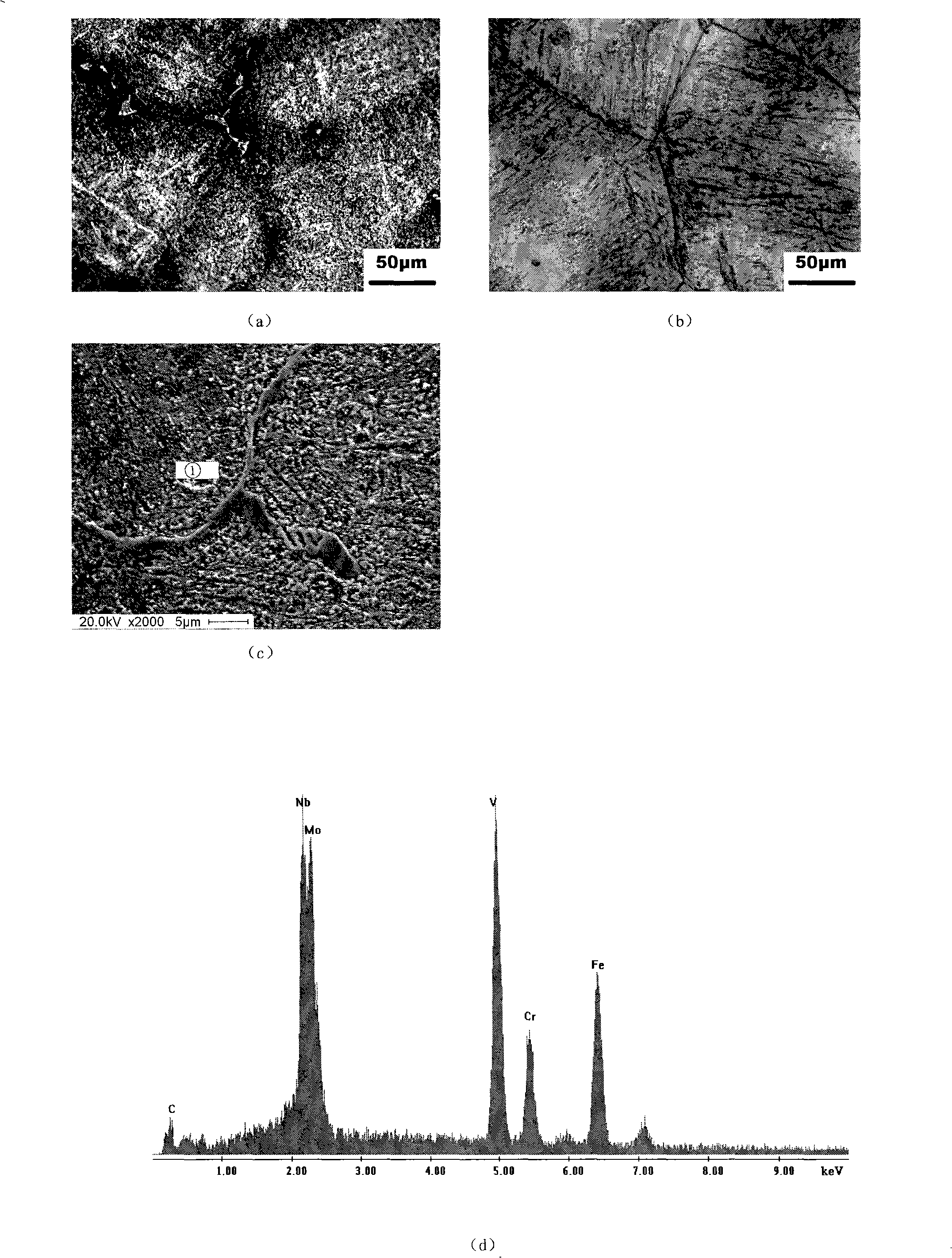

Niobium microalloyed high strength hot work die steel and preparation thereof

The invention relates to niobium microalloyed high-strength hot working die steel, belonging to the alloy steel manufacturing process technical field. The compositions by weight percentage of the steel are: 0.3 to 0.6 percent of C, 0.1 to 0.5 percent of Si, 0.1 to 0.5 percent of Mn, 4.0 to 6.5 percent of Cr, 1.0 to 3.5 percent of Mo, 0.4 to 1.4 percent of V, 0.02 to 0.10 percent of Nb, less than 0.03 percent of P, less than 0.03 percent of S, and the balance being Fe. The process for preparing the hot working die steel comprises the following steps of: batching, smelting, secondary refining and electroslag remelting; homogenizing the mixture for 5 to 10 hours at a temperature of between 1210 and 1300 DEG C, and forging, annealing, quenching and tempering the mixture; heating up the mixture to a temperature of between 1000 and 1100 DEG C for austenization, after performing 'step heating' at a temperature of 650 DEG C and at a temperature of 800 DEG C, then performing secondary tempering to the processed mixture, and finally acquiring the hot working die steel. The die steel has the advantages of good thermal resistance, good thermal stability and good thermal fatigue performance.

Owner:SHANGHAI UNIV

Method for estimating fatigue life of pipeline of nuclear power plant

ActiveCN103698236AImproving the Fatigue Life Estimation ProcessAvoid accidentsMaterial strength using repeated/pulsating forcesThermal fatigueNuclear engineering

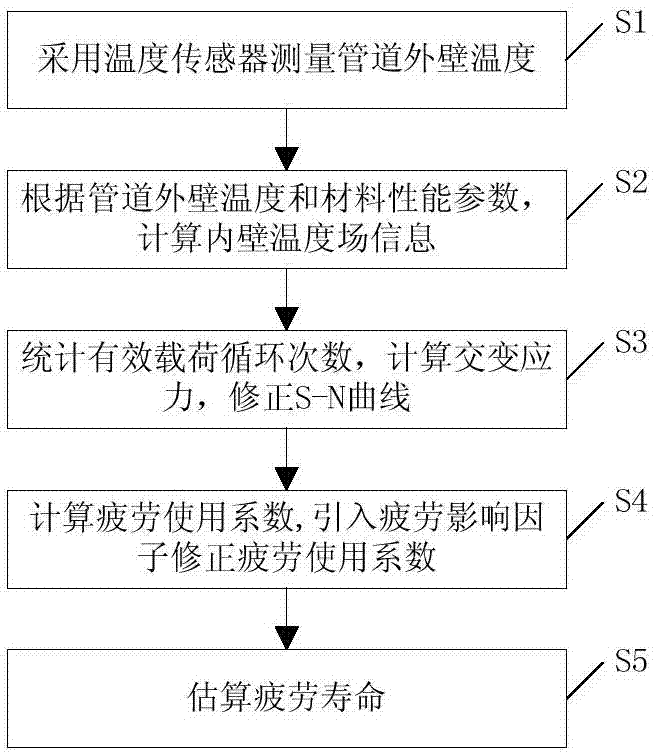

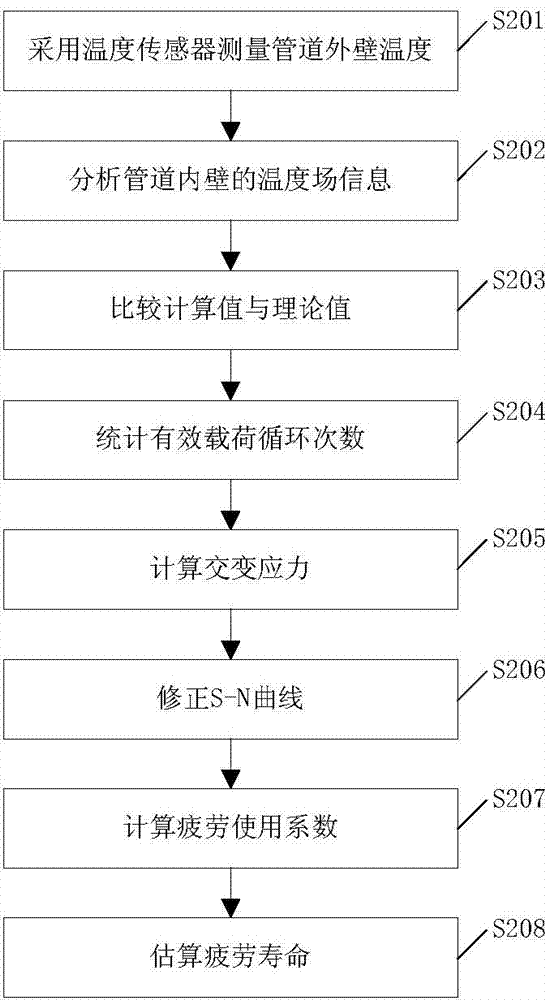

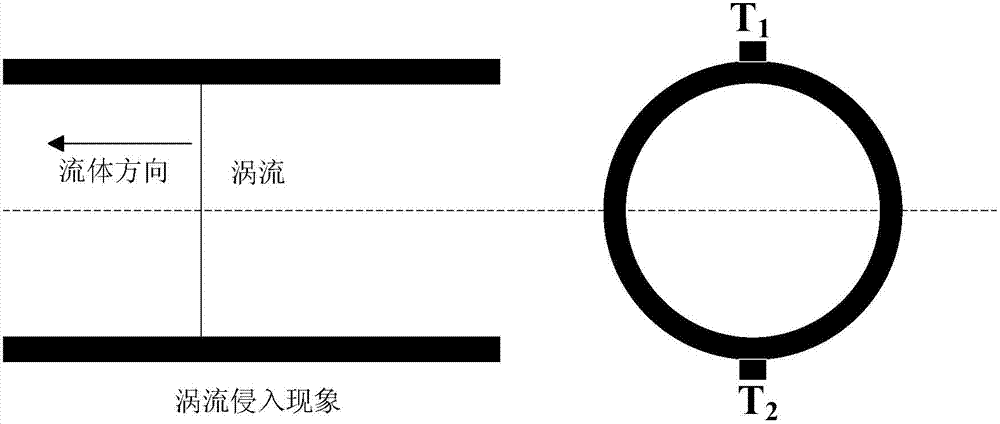

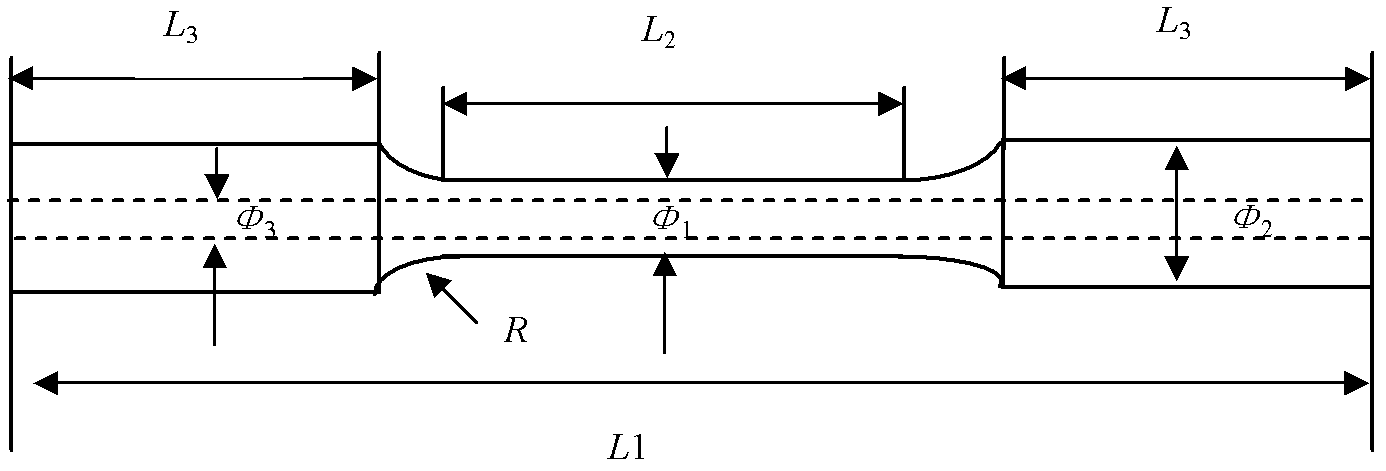

The invention discloses a method for estimating the fatigue life of a pipeline of a nuclear power plant. The method comprises the following steps: S1, measuring the temperature of the outer wall of the pipeline; S2, calculating information on a temperature field of the inner wall of the pipeline; S3, counting the cycle index of an effective load, determining alternating stress, and amending an S-N curve; S4, calculating a fatigue coefficient and amending the fatigue coefficient; and S5, estimating the fatigue life. The method has the beneficial effects of helping a designer master relevant data of the nuclear power plant under a thermal fatigue environment, optimizing an operating standard and an inspection outline according to the estimated fatigue life, developing the design safety margin of the pipeline of the nuclear power plant and providing data support for the regular audit or lifetime extension of the power plant.

Owner:中广核工程有限公司 +1

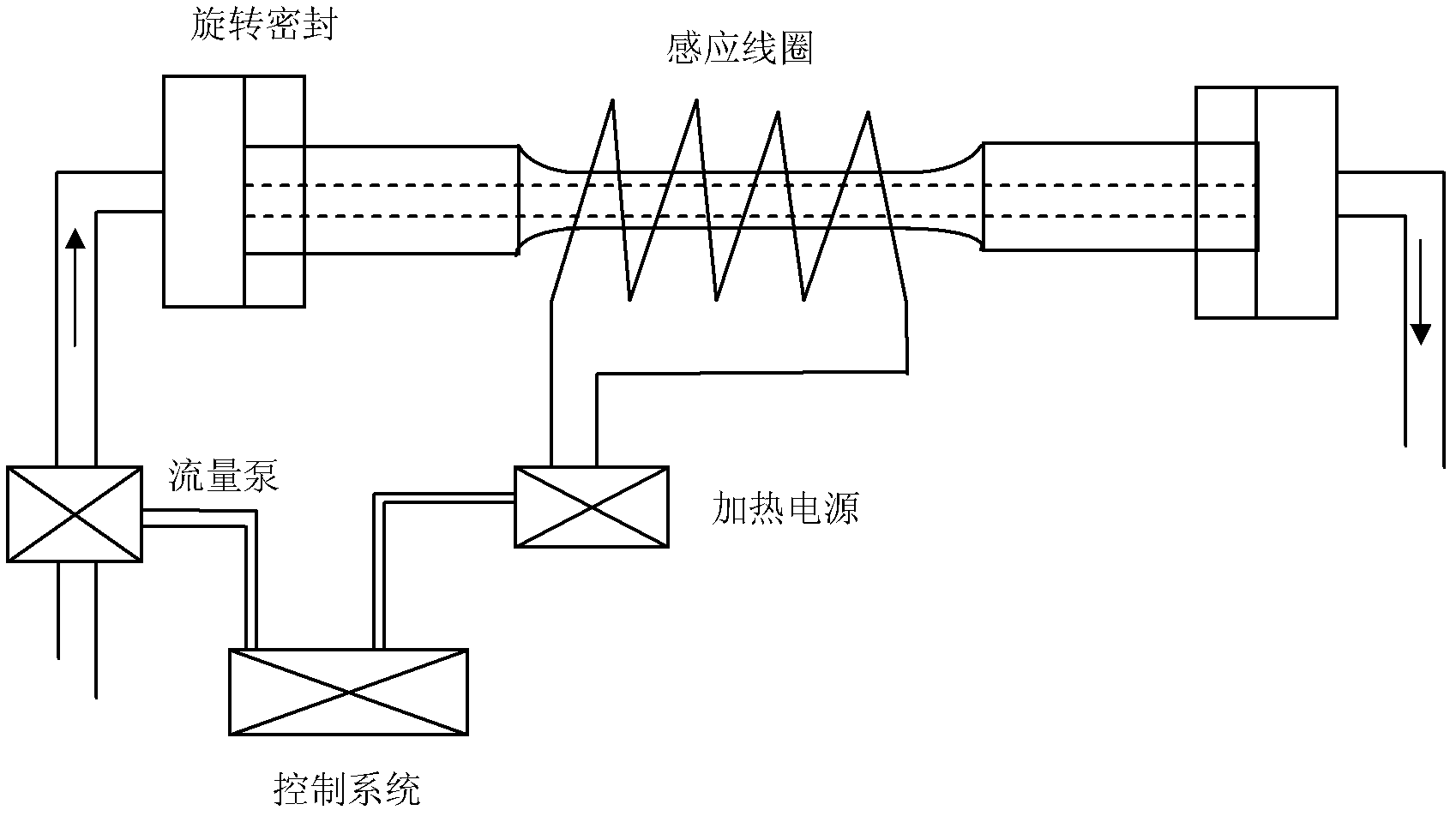

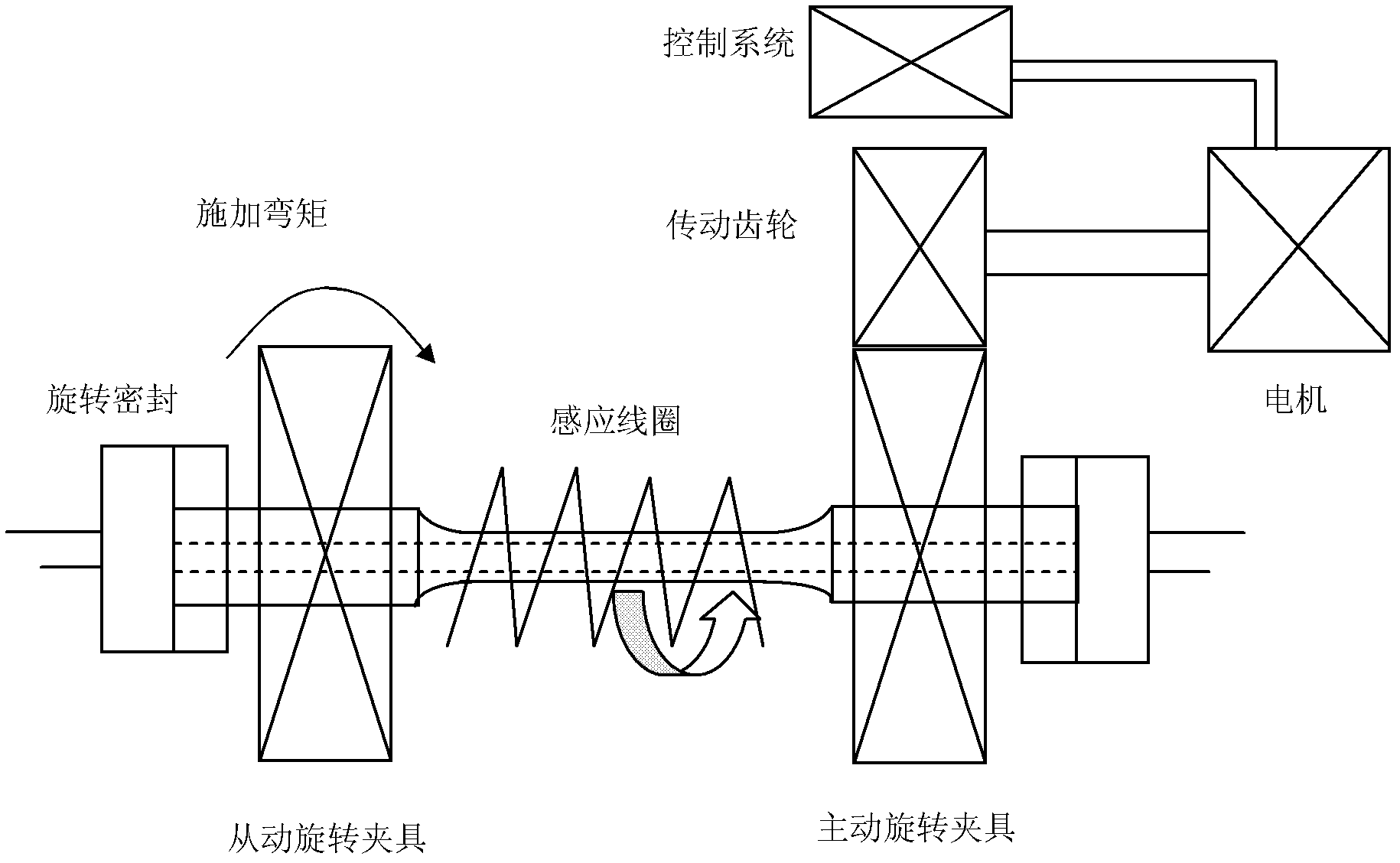

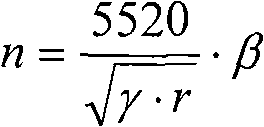

Thermal-force coupling fatigue test device and method

The invention relates to a thermal-force coupling fatigue test device and method, belonging to the field of metal material performance test and analysis. The device comprises a tested material test sample, a cold-thermal fatigue system and a stress fatigue system, wherein the test sample comprises a clamping section, a test section and a transition section; the cold-thermal fatigue system comprises a high frequency induction coil, a rotary seal device, a flow pump, a temperature sensor, a heating power supply, a cooling medium pipeline and a control system; and the stress fatigue system mainly comprises a driving rotating fixture, a driven rotating fixture, a transmission gear, a motor and a motor control system. The method comprises the following steps of: connecting and fixing the test sample with the cold-thermal fatigue system and the stress fatigue system, and carrying out cold-thermal fatigue while stress fatigues under different stresses are carried out to obtain a curve which shows variation of stress fatigue life along with cyclic stress; and adjusting parameters of the cold-thermal fatigue, thus influence of cold-thermal fatigue temperature to fatigue limit can be obtained.

Owner:UNIV OF SCI & TECH BEIJING

Welding flux core welding wire for continuous cast roller over laying welding

InactiveCN1597233AImprove wear resistanceGood thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaWear resistanceMaterials science

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof

The invention relates to a composite roll for centrifugally casting high-chromium cast iron and a preparation method thereof, belonging to the technical field of the steel rolling. The composite roll comprises a roll external layer and a roll core. The chemical components of the materials of the roll external layer in terms of the percentage by weight are as below: 25-28 of alloy scrap iron of a high-nickel-chromium infinite chilled iron roll, 28-30 of carbon ferrochrome, 1.5-2.5 of mid-carbon ferromanganese, 2.5-3.5 of ferroboron, 0.5-0.8 of silicon-calcium-barium alloy, 0.2-0.4 of aluminum, 0.3-0.5 of ferrotitanium, 0.2-0.4 of rare earth ferrosilicon, 0.10-0.15 of zinc, 0.15-0.18 of magnesium and the balance of low-carbon waste steel sheet. The roll core is high-strength alloy cast iron or low-alloy ductile cast iron. The roll external layer and the roll core are formed through centrifugal composite casting. The roll has low production cost, contains a small number of impurities and has high degree of purity; the hardenability, the mechanical performance and the thermal fatigue of the roll can be improved; and the roll has long service life and low production cost.

Owner:江苏环立板带轧辊有限公司

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

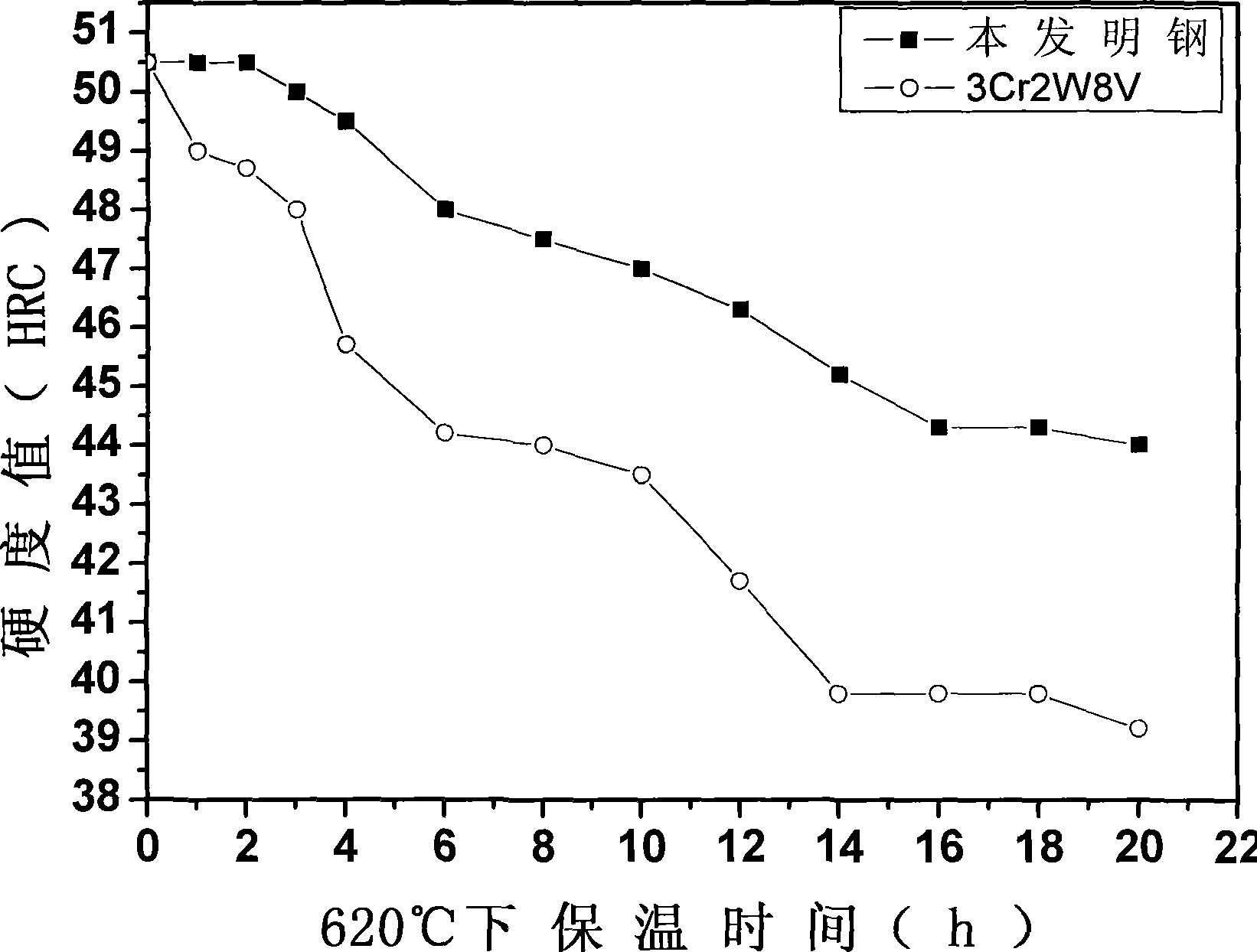

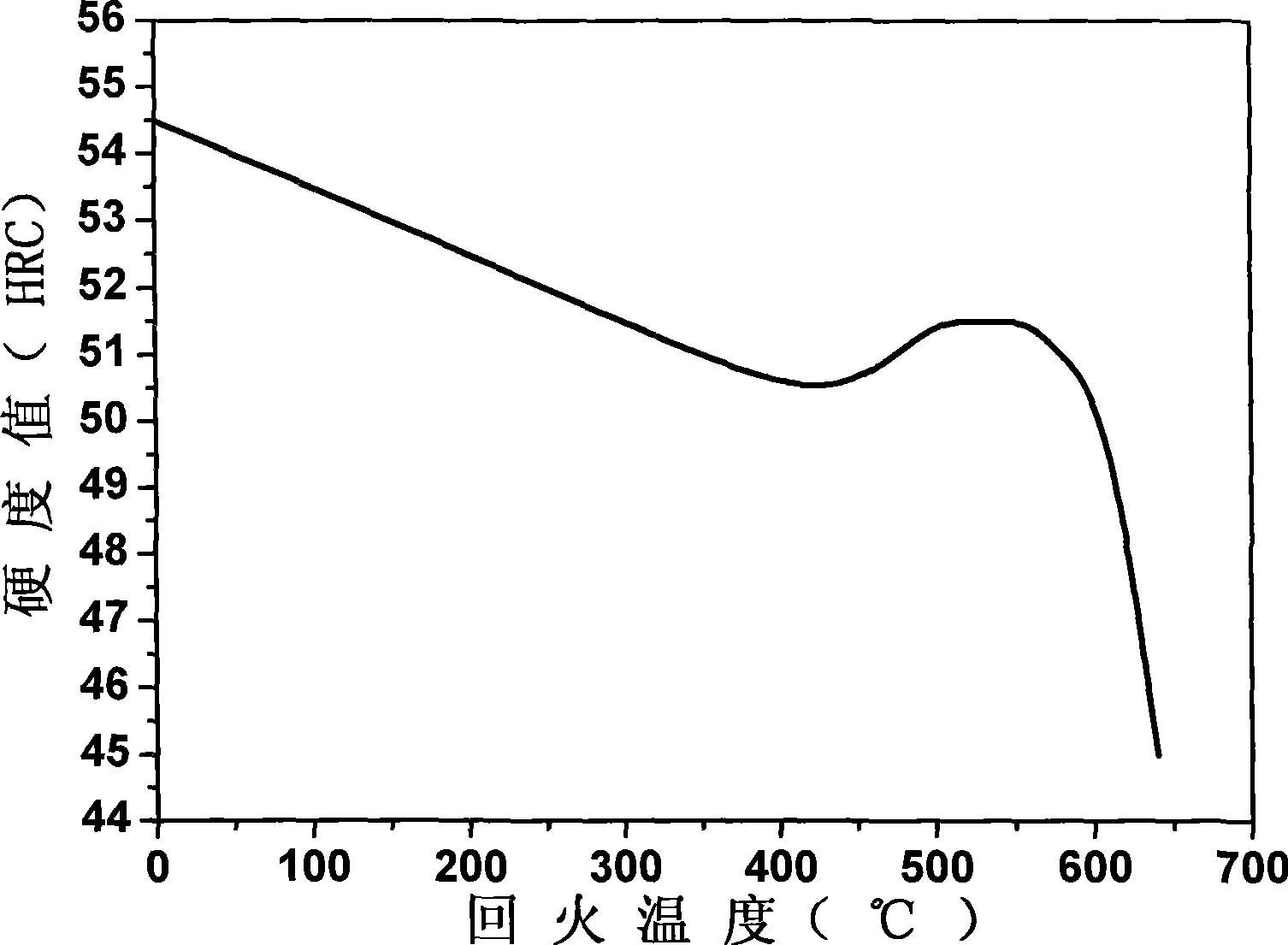

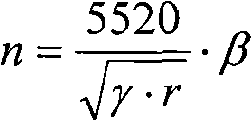

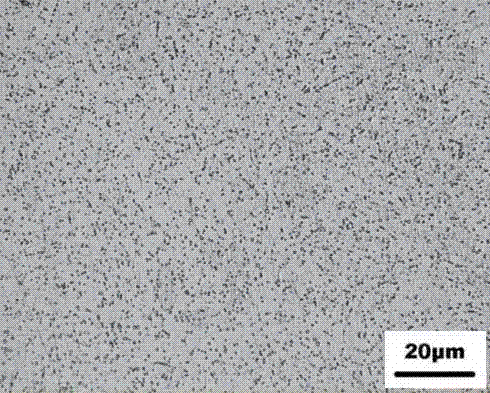

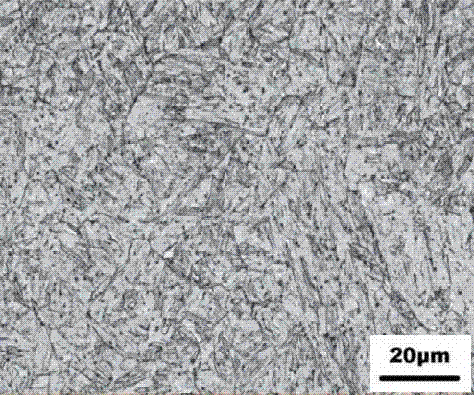

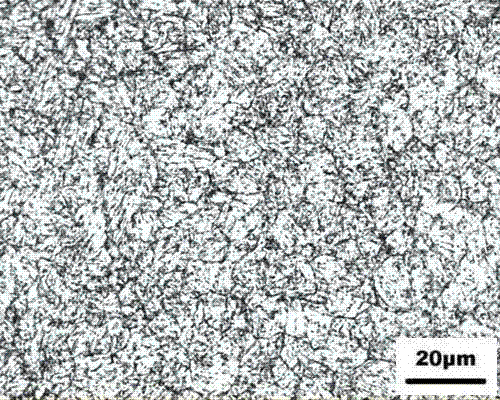

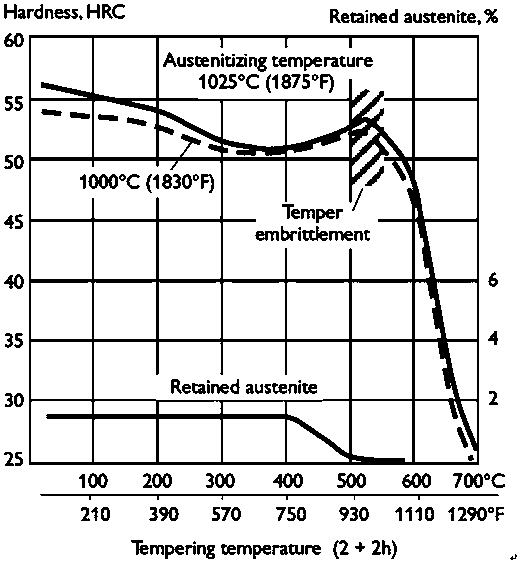

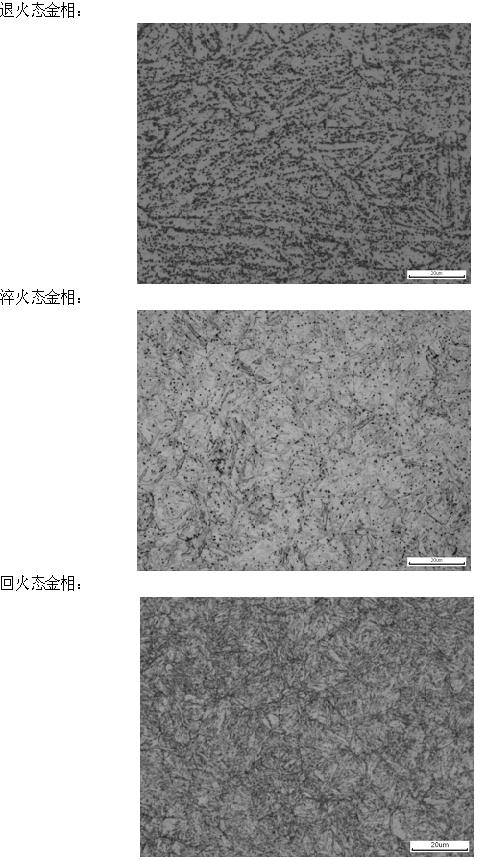

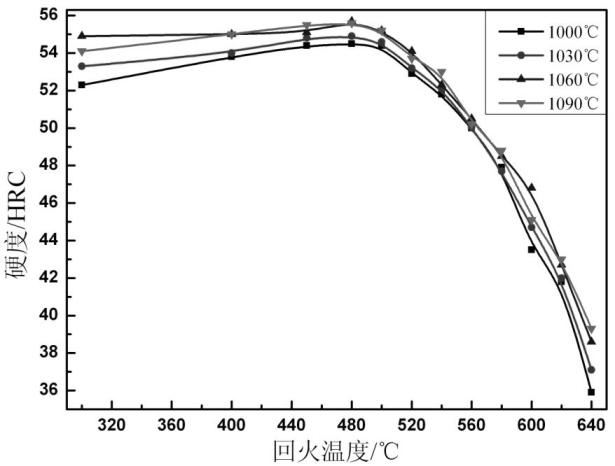

Chromium-molybdenum-vanadium hotwork tool-die steel and heat treatment process thereof

The invention relates to low-cost chromium-molybdenum-vanadium hotwork tool-die steel and a heat treatment process thereof and belongs to the technical field of alloy steel manufacturing processes. The steel comprises the following components by weight percent: 0.3-0.4% of C, 0.6-1.2% of Si, 0.6-1.2% of Mn, 3.5-4.5% of Cr, 0.8-1.2% of Mo, 0.4-0.8% of V, less than 0.02% of P, less than 0.02% of S and the balance of Fe. The preparation process of the hotwork tool-die steel is as follows: mixing, smelting, casting and then remelting electroslag; carrying out homogenization treatment at 1200-1280 DEG C for 8-10 hours, then forging, and carrying out ultrafining heat treatment and isothermal annealing treatment; and finally quenching and tempering, namely heating steel ingots to 1000-1100 DEG C to be austenitized and carrying out tempering two to three times at 560-620 DEG C after carrying out oil quenching or high pressure gas quenching. The hotwork tool-die steel has the advantages of high heat stability and roughness and good heat fatigue property.

Owner:SHANGHAI UNIV

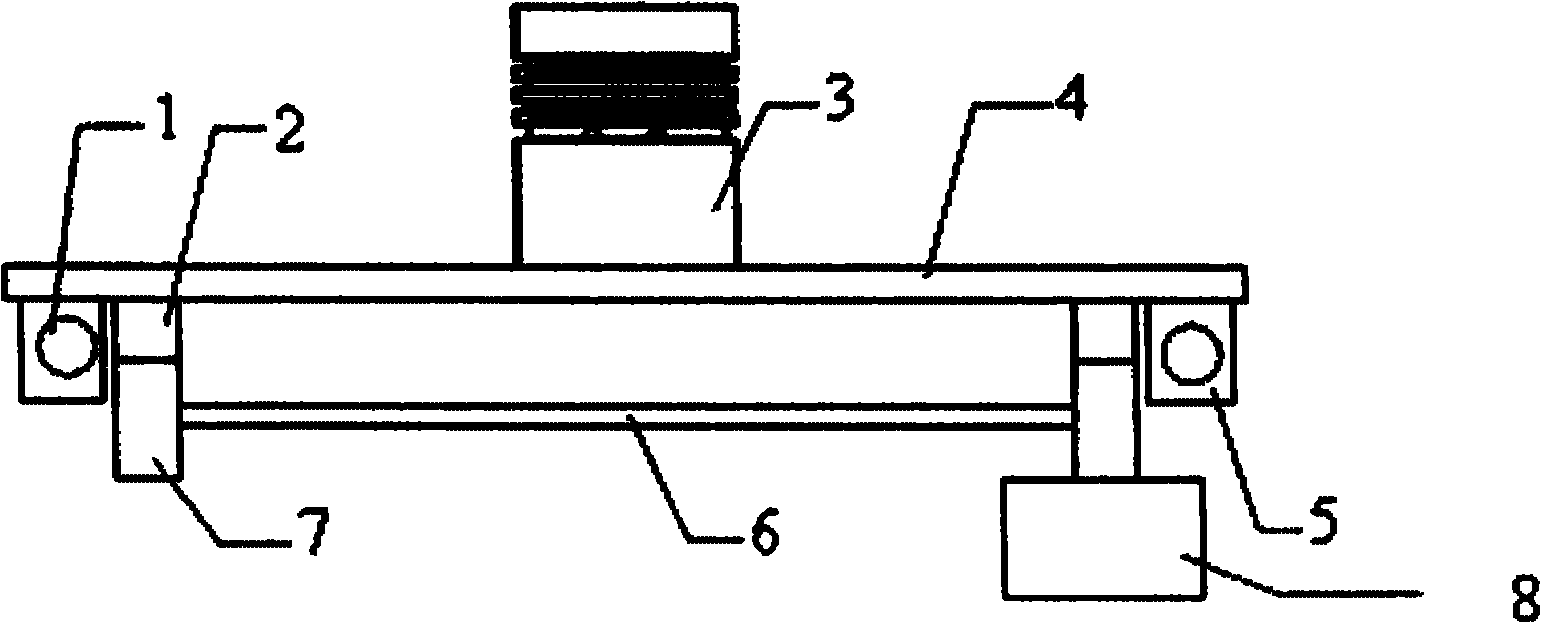

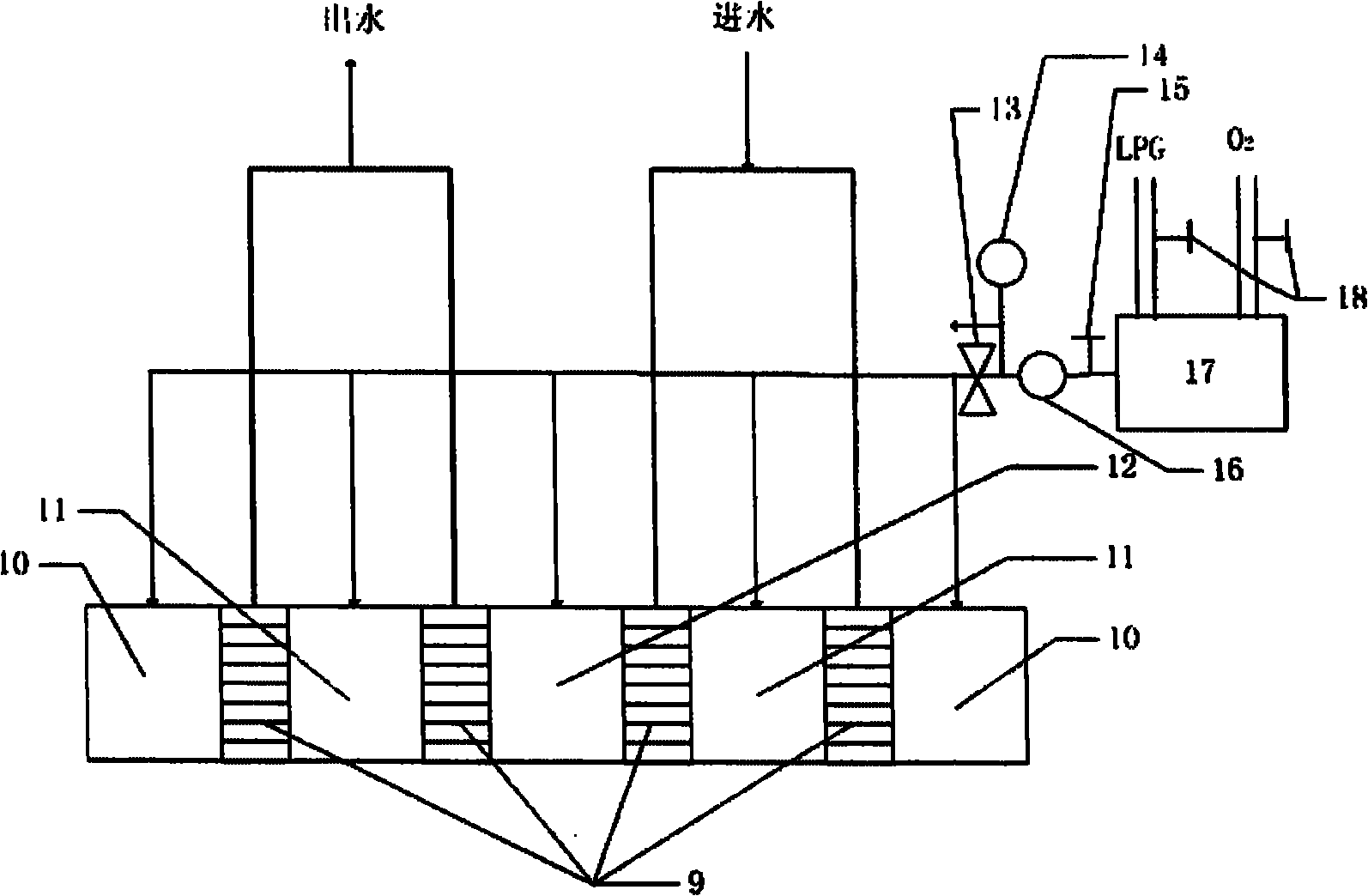

Heated structural member thermal shock and thermal fatigue test stand

InactiveCN101893536AReduce test costsShorten the development cycleThermometers using electric/magnetic elementsUsing electrical meansCombustorThermal fatigue

The invention relates to a structural member test unit, aiming at providing a heated structural member thermal shock and thermal fatigue test stand which comprises a movable test bench for a test piece erecting stage, wherein a travelling mechanism is arranged below the test piece erecting stage and comprises a sliding sleeve, a guide rail, a rack, a gear, a transmission shaft and a servo motor; the sliding sleeve and the rack are fixed below the test piece erecting stage, and the guide rail is sleeved in the sliding sleeve; a heating station is arranged on the test bench, and the two sides of the heating station are respectively and symmetrically provided with a cooling station; and a burner of a fuel gas heating system is arranged at the heating station, and each cooling station is provided with a compressed air or cooling water outlet. The invention provides a real machine assessment system which can replace the existing thermal fatigue / thermal shock tests of heated parts such as pistons, cylinder covers and the like; and under the condition of no engine model machine, the heated structural member thermal shock and thermal fatigue test stand can carry out hot strength assessment operation on the heated parts such as pistons, cylinder covers and the like, thus not only saving test expenses but also shortening development period.

Owner:ZHEJIANG UNIV

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

Low silver solder alloy and solder paste composition

InactiveUS20120175020A1Easy to stretchExcellent melting pointTransportation and packagingWelding/cutting media/materialsIndiumCobalt

A low silver solder alloy of the present invention comprises 0.05-2.0% by mass of silver; 1.0% by mass or less of copper; 3.0% by mass or less of antimony; 2.0% by mass or less of bismuth; 4.0% by mass or less of indium; 0.2% by mass or less of nickel; 0.1% by mass or less of germanium; 0.5% by mass or less of cobalt (provided that none of the copper, the antimony, the bismuth, the indium, the nickel, the germanium, and the cobalt is 0% by mass); and the residue is tin. According to the present invention, the long-term reliable low silver solder alloy is provided, wherein the low silver solder alloy permits the cost reduction by decreasing the Ag content, and has the excellent stretch, melting point, and strength, and also has the high fatigue resistance (thermal fatigue resistance).

Owner:HARIMA CHEM INC

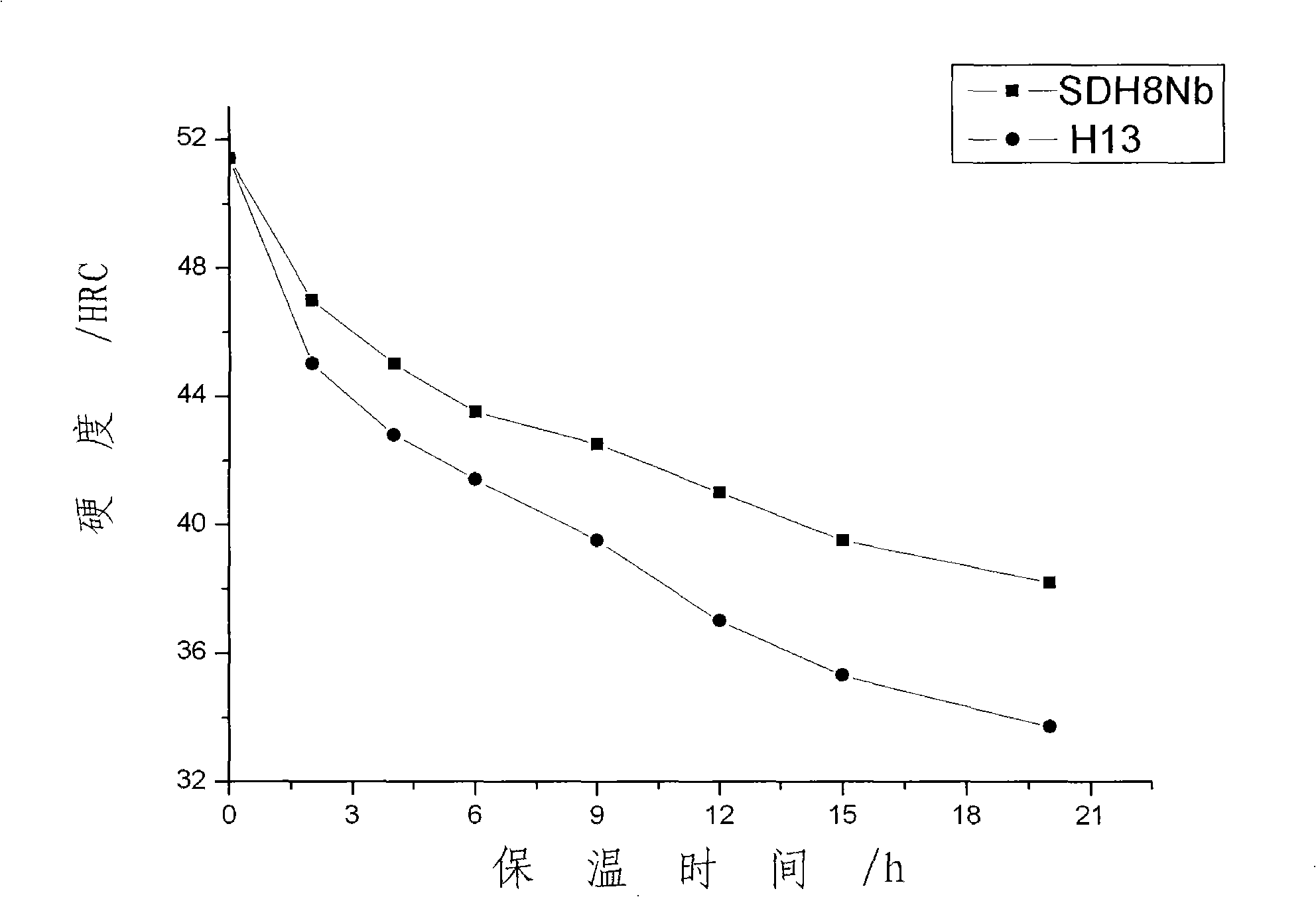

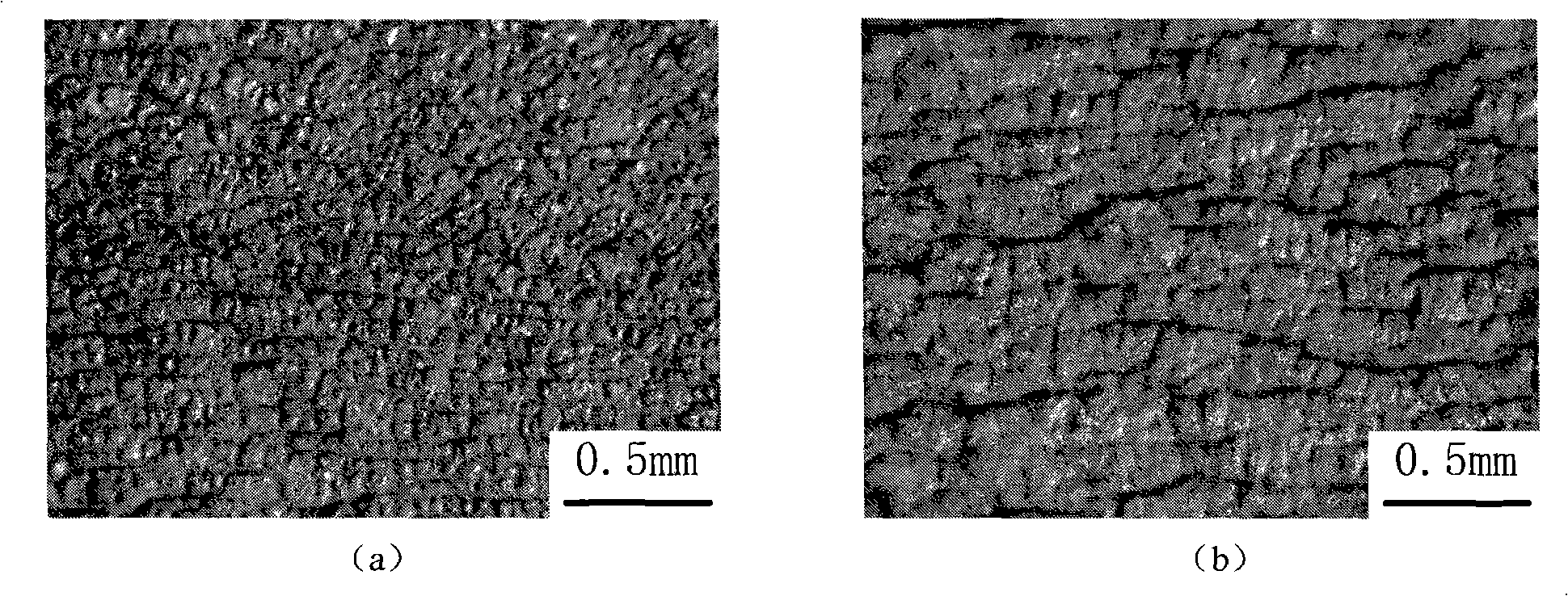

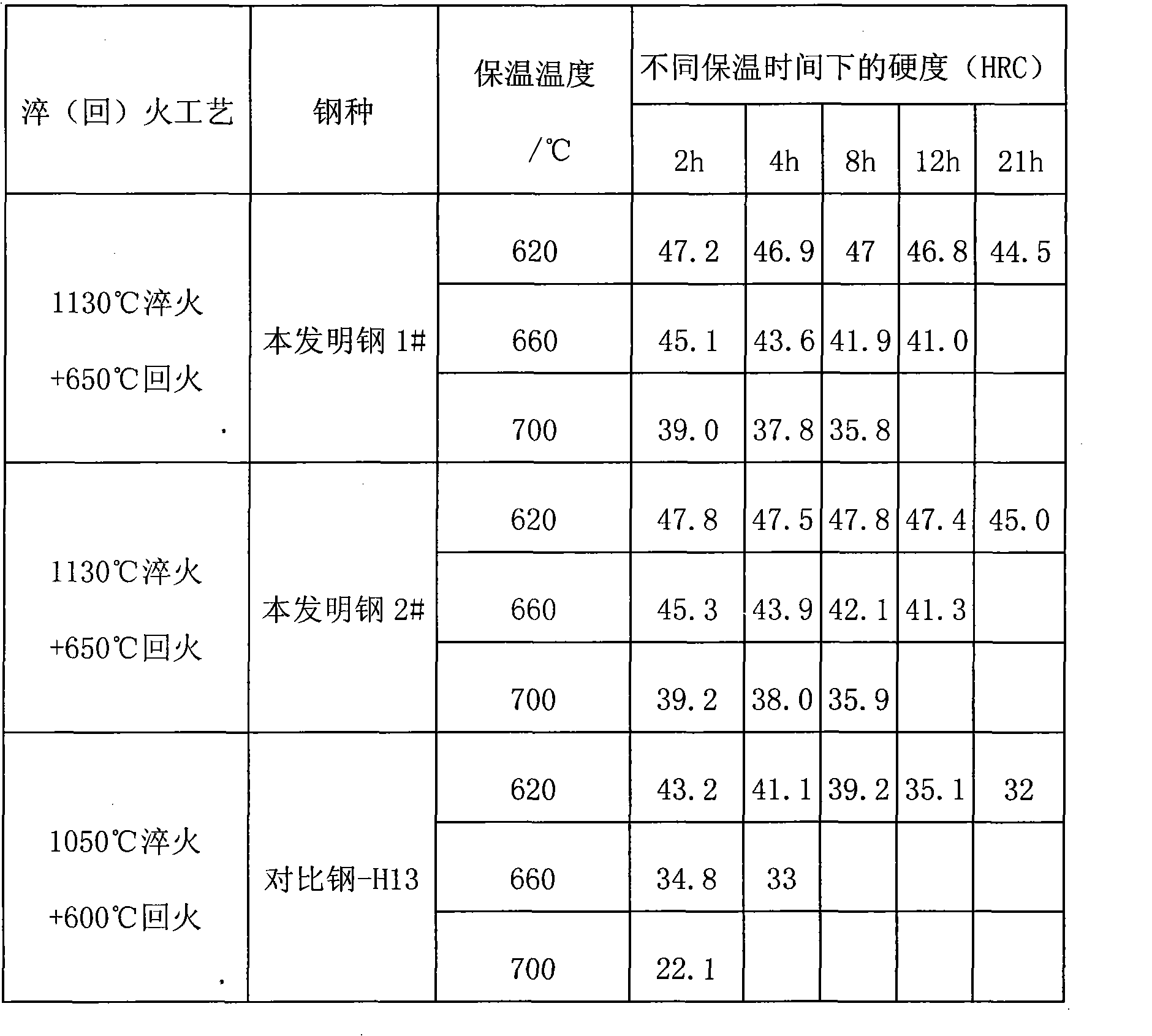

High-performance hot-working die steel for large die-casting die and manufacturing technology of high-performance hot-working die steel

The invention relates to high-performance hot-working die steel for a large die-casting die and a manufacturing technology of the high-performance hot-working die steel. The high-performance hot-working die steel is prepared from, by mass, 0.20%-0.30% of C, smaller than or equal to 0.40% of Si, 0.30%-0.60% of Mn, 4.10%-4.50% of Cr, 2.10%-2.30% of Mo, 0.10%-0.20% of W, 0.40%-0.80% of V, smaller than 0.01% of P, smaller than 0.005% of S, 0.02%-0.04% of Nb and the balance Fe. The manufacturing method of the die steel comprises the following manufacturing process that material mixing, smelting andcasting are conducted, and then electroslag remelting is conducted; high-temperature diffusion heat treatment is conducted, multi-directional forging hot working is conducted, and cooling controllingafter forging is conducted; secondary carbide refining heat treatment and isothermal annealing treatment are conducted; and finally quenching and tempering heat treatment is conducted. The hot-working die steel has the advantages that the hardenability, the heat stability, the impact toughness and the thermal fatigue property are superior to those of H13 steel, the hot-working die steel can be machined into a single large die-casting die with the weight reaching 5 tons or above, and the good using performance is achieved.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

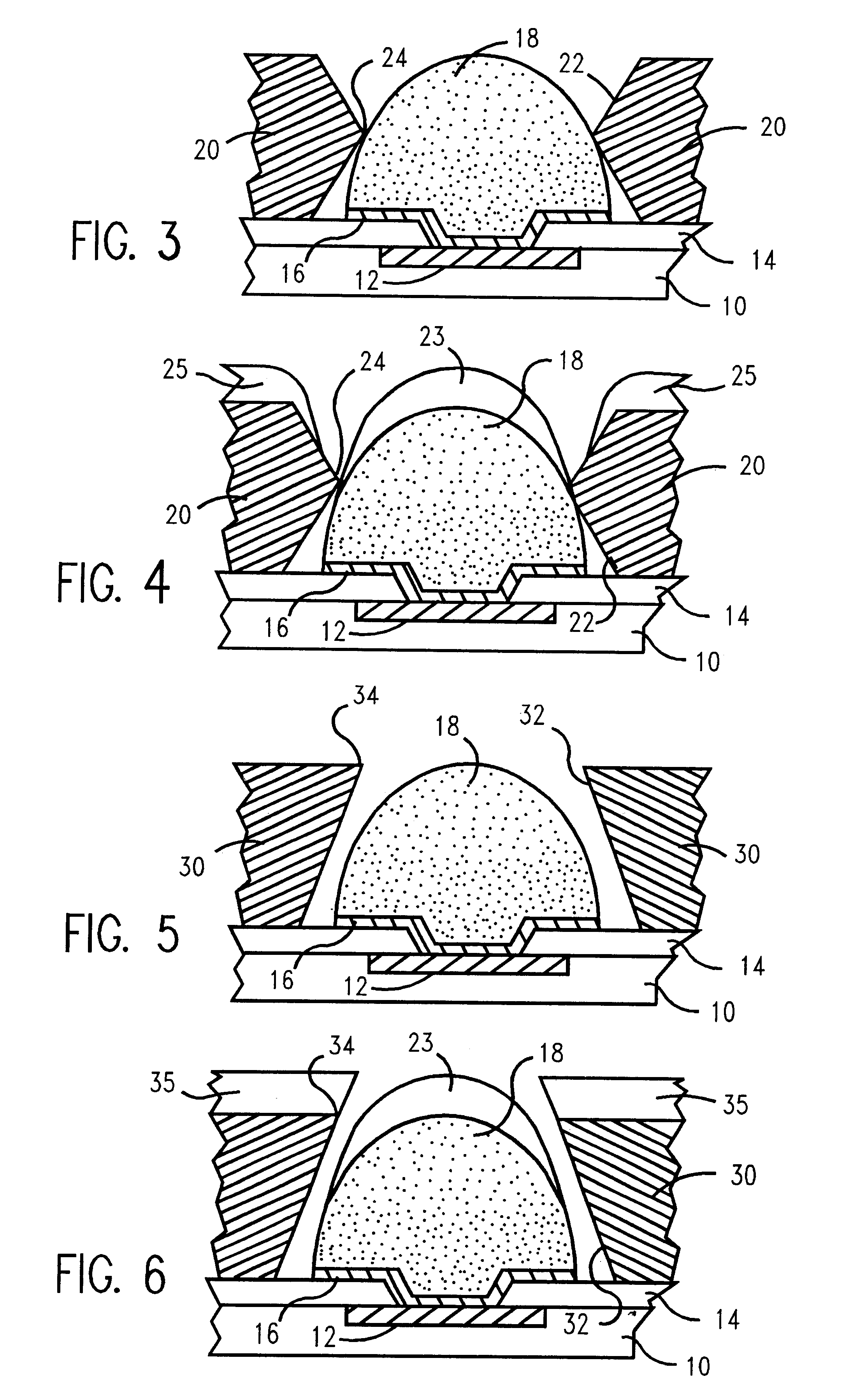

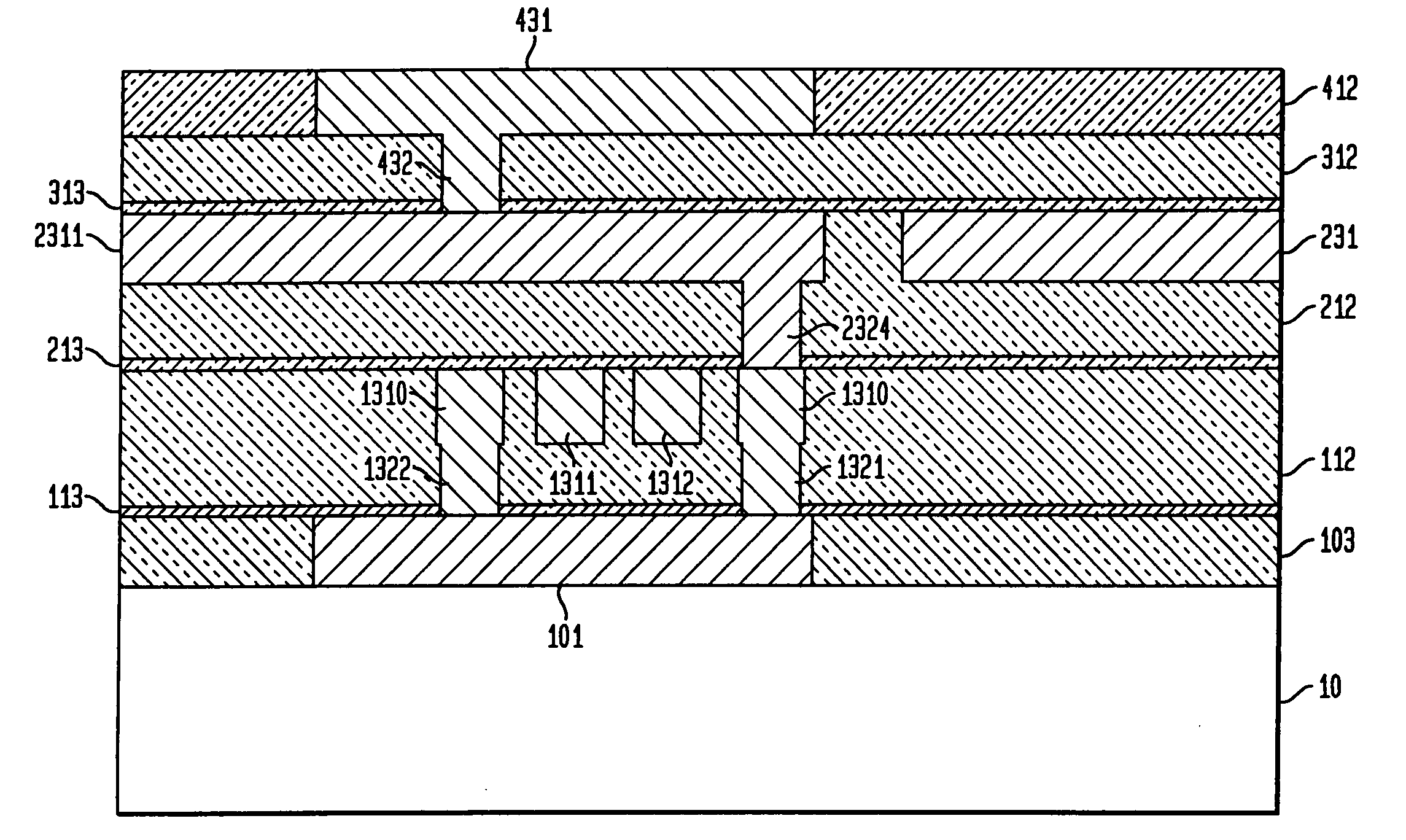

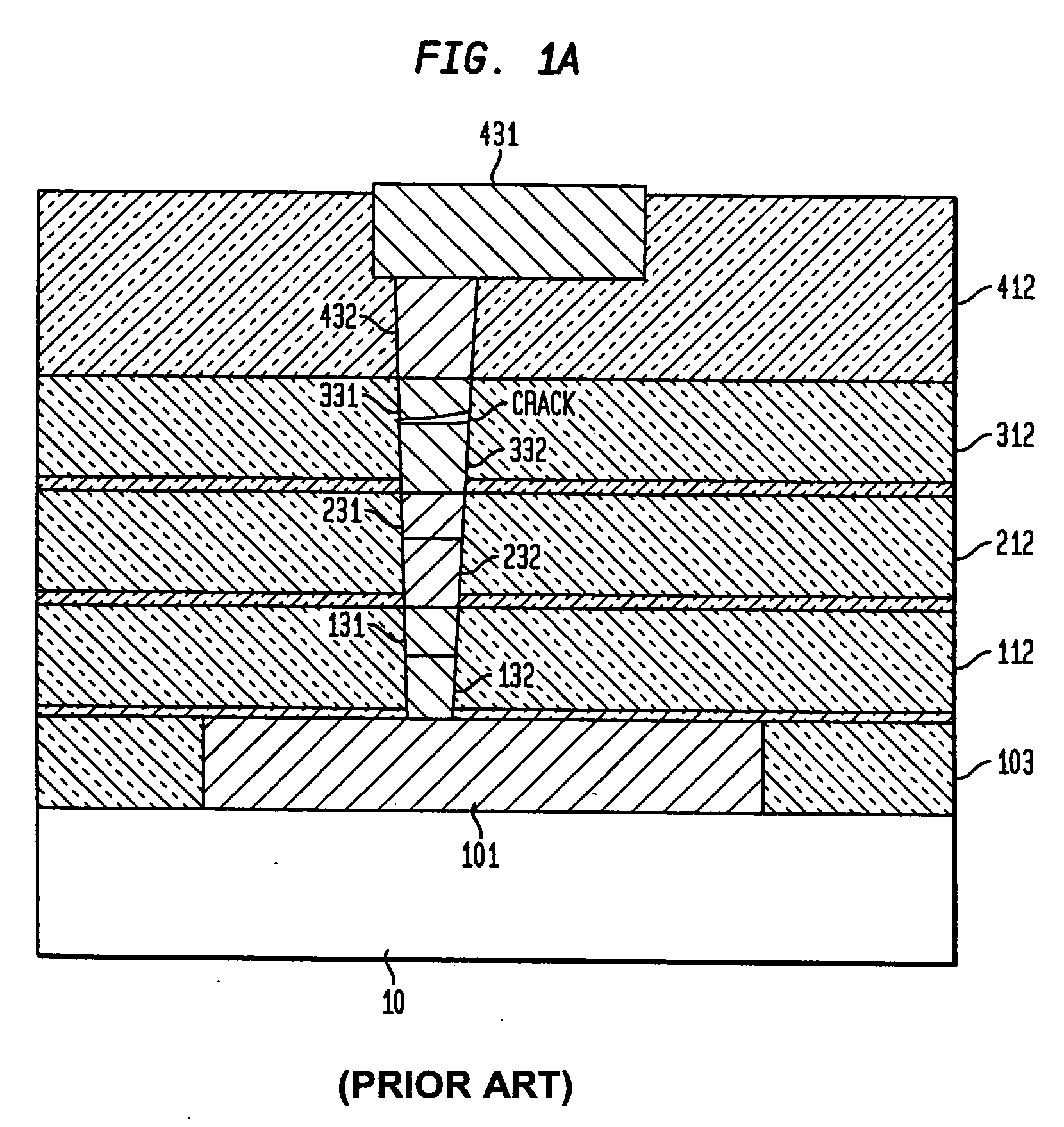

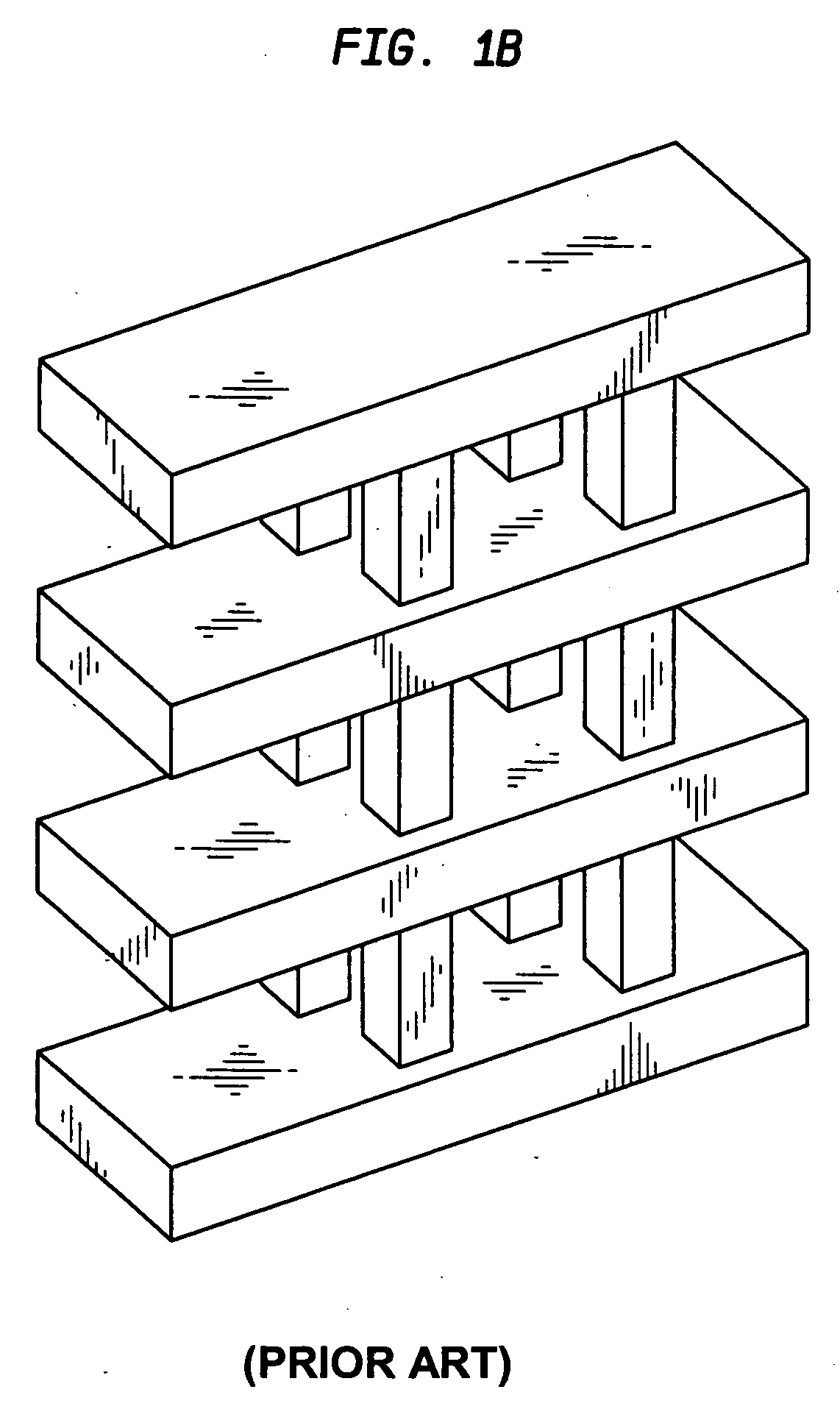

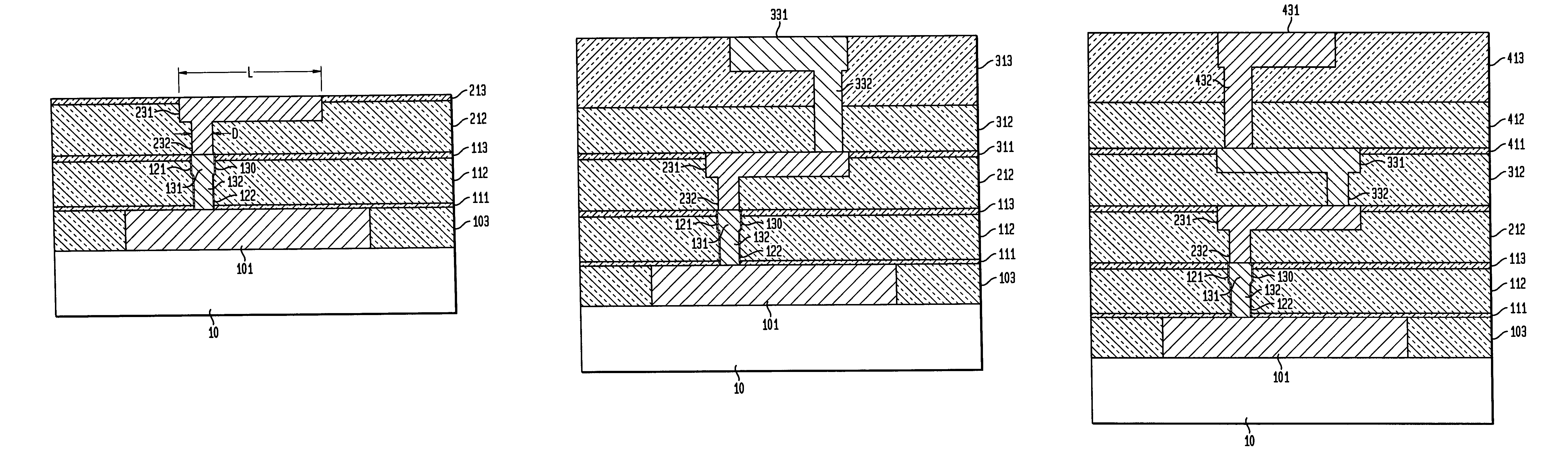

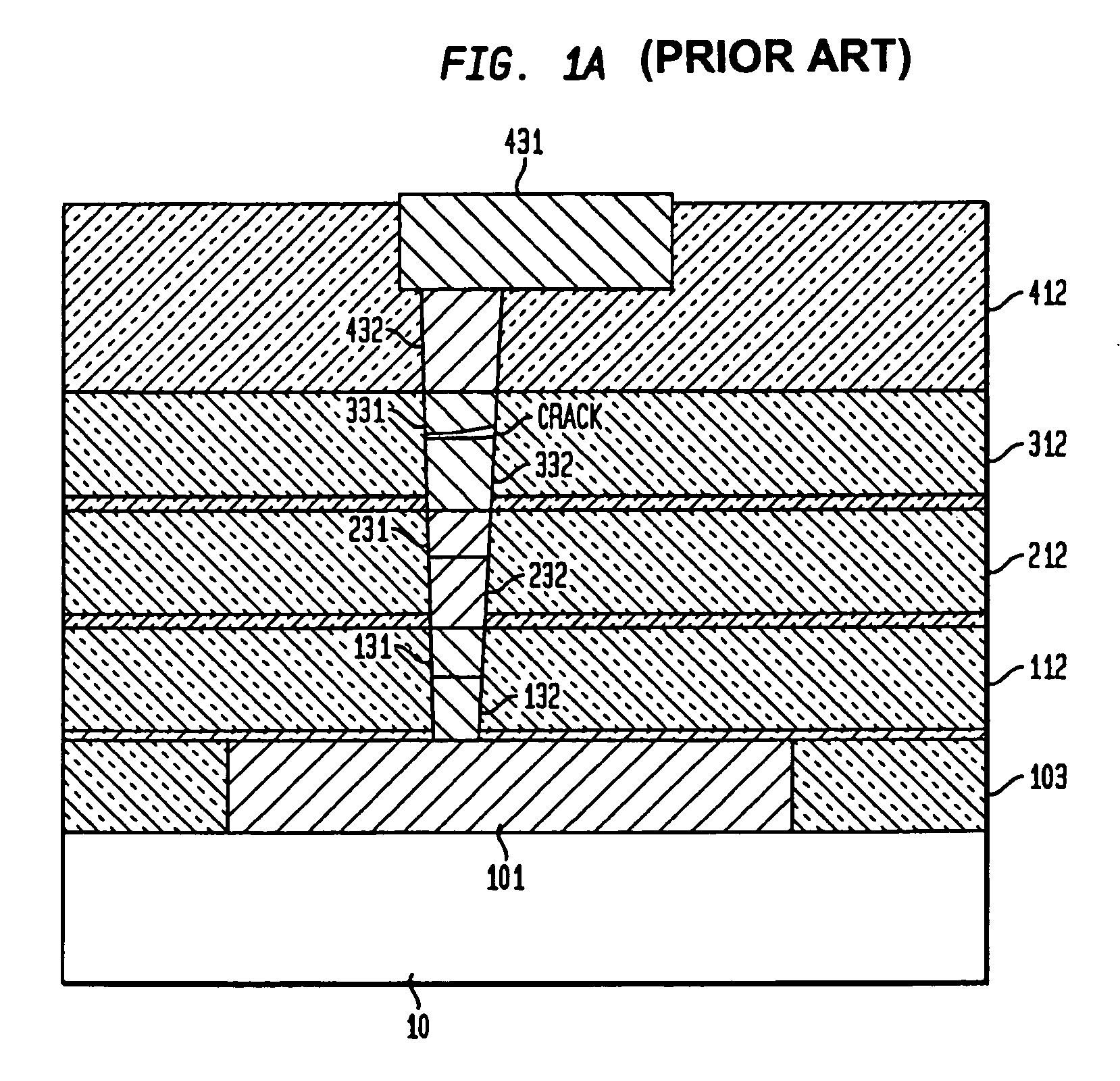

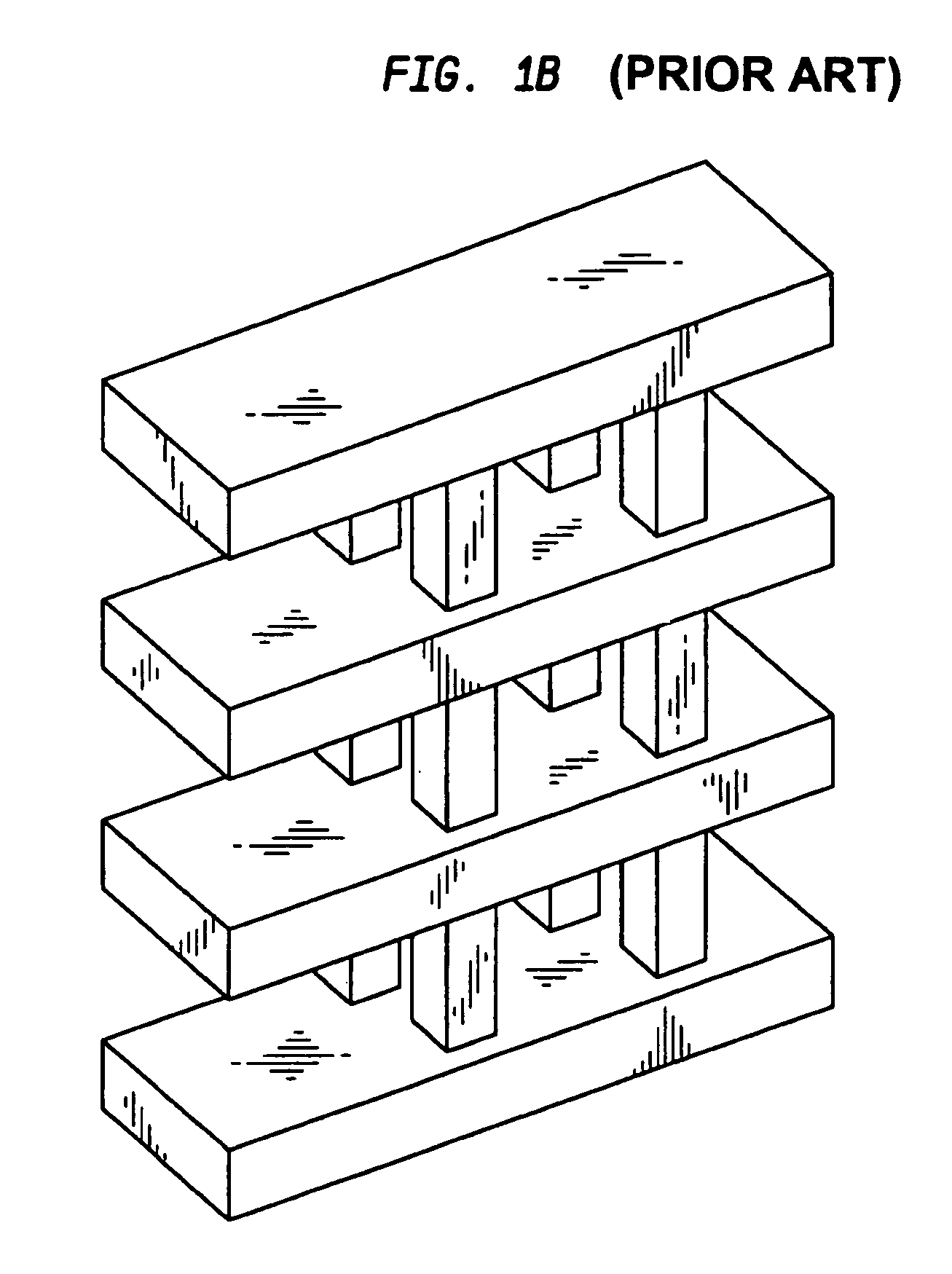

Stacked via-stud with improved reliability in copper metallurgy

InactiveUS20060014376A1Reduce intensityAllow flexibilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMaterials science

A multilevel semiconductor integrated circuit (IC) structure including a first interconnect level including a layer of dielectric material over a semiconductor substrate, the layer of dielectric material comprising a dense material for passivating semiconductor devices and local interconnects underneath; multiple interconnect layers of dielectric material formed above the layer of dense dielectric material, each layer of dielectric material including at least a layer of low-k dielectric material; and, a set of stacked via-studs in the low-k dielectric material layers, each of said set of stacked via studs interconnecting one or more patterned conductive structures, a conductive structure including a cantilever formed in the low-k dielectric material. The dielectric layer of each of the multiple interconnection levels includes a soft low-k dielectric material, wherein the cantilever and set of stacked via-studs are integrated within the soft low-k dielectric material to increase resistance to thermal fatigue crack formation. In one embodiment, each of the set of stacked via-studs in the low-k dielectric material layers is provided with a cantilever, such that the cantilevers are interwoven by connecting a cantilever on one level to a bulk portion of the conductor line on adjacent levels of interconnection, thereby increasing flexibility of stacked via-studs between interconnection levels.

Owner:GLOBALFOUNDRIES INC

Alloy steel for braking discs

ActiveCN101519754AImprove mechanical propertiesImprove thermal fatigue resistanceFriction liningNiobiumManganese

The invention relates to alloy steel for braking discs. Chemical compositions of the alloy steel comprise in percentage by weight: 0.21 to 0.26 percent of carbon, 0.8 to 1.0 percent of silicon, 0.5 to 1.0 percent of manganese, 1.2 to 1.55 percent of chromium, 1.95 to 1.99 percent of nickel, 0.34 to 0.41 percent of molybdenum, 0.1 to 0.2 percent of vanadium, 0.05 to 0.06 percent of niobium, less than 0.01 percent of tungsten, less than 0.02 percent of titanium, less than 0.02 percent of aluminum, 0.05 to 0.09 percent of copper, 0.02 to 0.03 percent of zirconium, and the balance of Fe and unavoidable impurities. The alloy steel provided by the invention is steel for casting, has higher mechanical strength and thermal fatigue resistance, also has better thermal cracking resistance, stable friction property and good thermal conductivity at the same time, and is particularly suitable for producing the braking discs used for rail transit vehicles such as city rail transit vehicles, railway locomotive vehicles, motor vehicles, high-speed trains, and the like.

Owner:BEIJING ZONGHENG ELECTROMECHANICAL TECH DEV

Special flux-cored wire for surfacing repair of BD roller

InactiveCN101804530AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaHigh carbonManganese

The invention discloses a special flux-cored wire for surfacing repair of a BD roller, which consists of a tube skin and a flux core, wherein the tube skin is an H08A steel strip, and the flux core comprises the following components by weight percent: 15-25% of high-carbon ferrochrome, 2-10% of micro-carbon ferrochrome, 5-7% of metal manganese, 6-12% of ferromolybdenum, 3-10% of ferrotungsten, 5-10% of ferrovanadium, 0.5-6% of ferrotitanium, 0.3-5% of yttrium-based rare-earth, 1-3% of ferrocolumbium, 4-10% of cryolite and 10-50% of ferrous powder, wherein the filling coefficient is 30-45%. The special flux-cored wire selects a Cr-Mo-W-V alloy system with optimal alloy matching and carries out Ti-Nb-Re micro-alloy grain refinement, thereby leading a surfacing repair layer to have the advantages of high hardness, high wear resistance, high toughness and high anti-cold and hot alternating thermal fatigue performance, and exponentially prolonging the service life of the BD roller after surfacing repair in comparison with the BD roller after the ordinary roller flux-cored wire repair.

Owner:邯郸市永固冶金备件有限公司

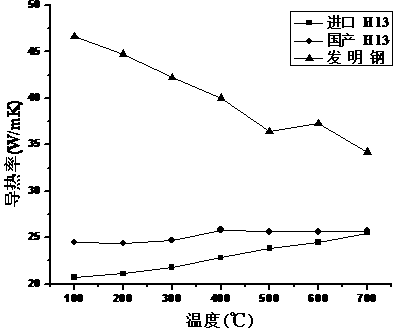

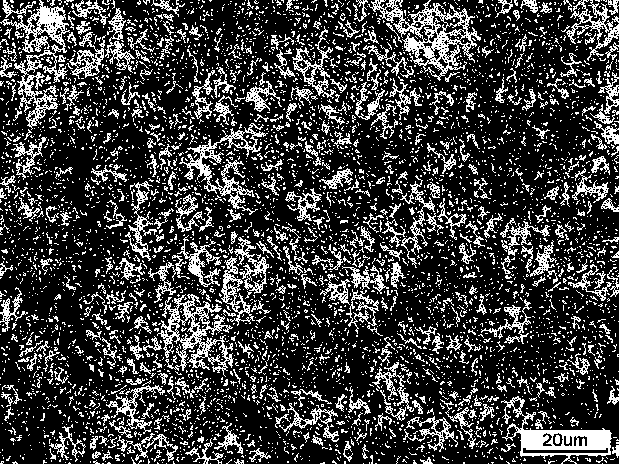

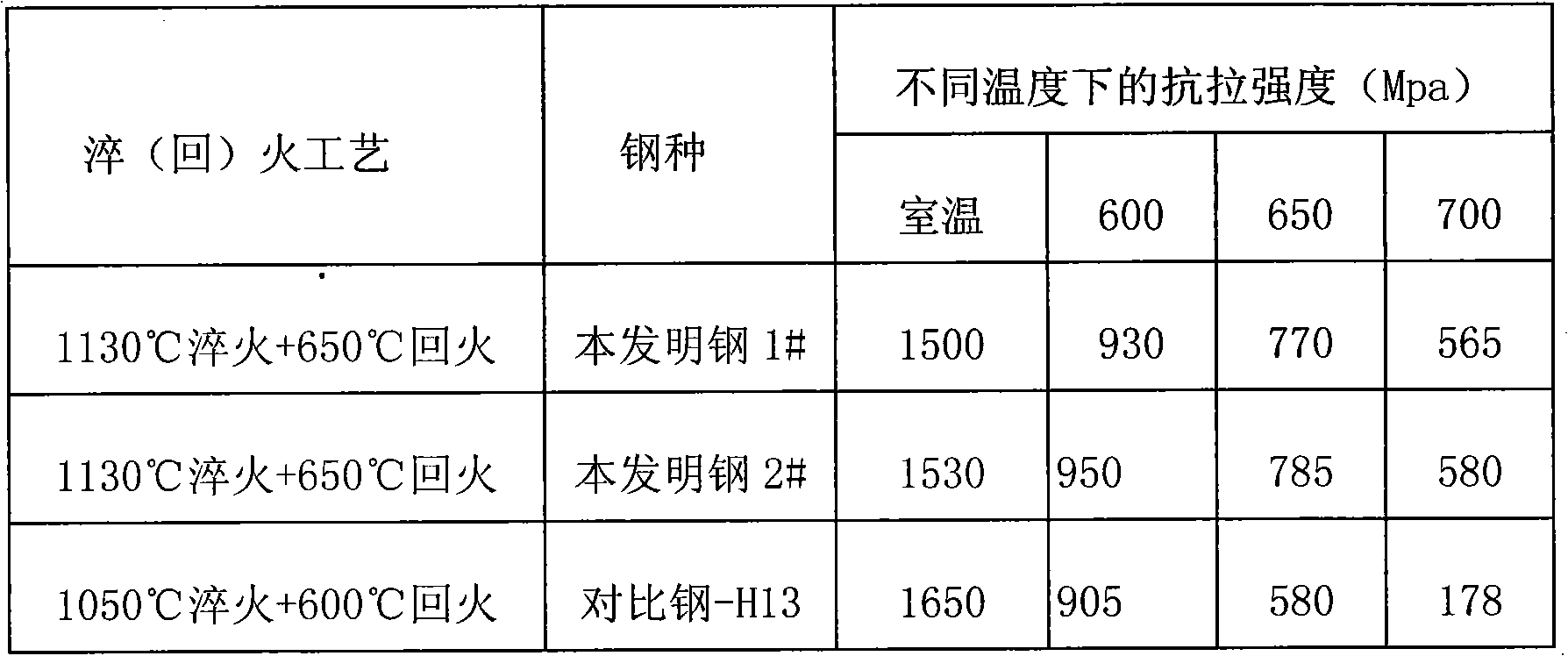

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

Borated low-alloy high-speed steel roller and manufacturing method thereof

InactiveCN103014516AReduce contentReduce manufacturing costRollsMetal rolling arrangementsBorideThermal fatigue

The invention belongs to the technical field of steel rolling, and relates to a roller, in particular to a borated low-alloy high-speed steel roller and a manufacturing method of the borated low-alloy high-speed steel roller. The roller comprises a roller body and a roller core, wherein the roller body comprises the following chemical components by weight percentage: 0.7-0.8% of C, 1.3-2.4% of Cr, 2.50-3.0% of B, 1.0-1.5% of W, 1.0-1.5% of V, less than or equal to 1.0% of Si, less than or equal to 0.4% of Mn, 0.09-0.12% of Ti, 0.16-0.19% of Mg, 0.10-0.12% of RE, less than or equal to 0.03% of P, less than or equal to 0.03% of S, and the balance of Fe and unavoidable trace impurities. The roller core is made of nodular cast iron. The manufacturing method of the roller comprises the steps of smelting, deoxidation and alloying, composite modification of RE-Mg, centrifugal casting and heat treatment, and then a finished product is processed. The roller and the manufacturing method have the major advantages that boride particles are major wear-proof particles; the addition amount of alloying elements is reduced, so that the production cost is lowered; and the roller is high in rigidity, good in wear resistance and thermal fatigue resistance, uniform in material, and high in accident resistance in the later period.

Owner:镇江市丹徒区环宇轧辊厂

Hot working die steel and preparation method thereof

InactiveCN101798661AExtended service lifeImprove performanceTemperature control deviceThermal fatigueCrack resistance

The invention belongs to the technical field of hot working die steel and particularly provides a hot working die steel and a preparation method thereof. The hot working die steel comprises the components in percentage by weight: 0.30-0.60% of C, 2.7-3.5% of Cr, 2.0-2.5% of Mo, 0.20-0.80% of Si, 0.50-1.0% of Mn, 0.60-1.2% of V, 0.60-1.5% of Ni, 0.05-0.15% of Nb, 0.002-0.006% of B, less than or equal to 0.030% of S, less than or equal to 0.030% of P and the balance of Fe. The preparation method comprises: EAF primary smelting, LF refining, VD degassing, electroslag remelting, forging and heat treatment process route. The hot working die steel has reasonable steel alloy element proportioning, high thermal fatigue resistance, thermal shock cracking resistance, high heat stability and favourable combination property and greatly improves the service life of a hot working die. The steel of the invention can be used for manufacturing extrusion dies, forging dies and the like with long service life.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

Stacked via-stud with improved reliability in copper metallurgy

InactiveUS6972209B2Facilitate redundant pathIncrease flexibilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMaterials science

A multilevel semiconductor integrated circuit (IC) structure including a first interconnect level including a layer of dielectric material over a semiconductor substrate, the layer of dielectric material comprising a dense material for passivating semiconductor devices and local interconnects underneath; multiple interconnect layers of dielectric material formed above the layer of dense dielectric material, each layer of dielectric material including at least a layer of low-k dielectric material; and, a set of stacked via-studs in the low-k dielectric material layers, each of said set of stacked via studs interconnecting one or more patterned conductive structures, a conductive structure including a cantilever formed in the low-k dielectric material. The dielectric layer of each of the multiple interconnection levels includes a soft low-k dielectric material, wherein the cantilever and set of stacked via-studs are integrated within the soft low-k dielectric material to increase resistance to thermal fatigue crack formation. In one embodiment, each of the set of stacked via-studs in the low-k dielectric material layers is provided with a cantilever, such that the cantilevers are interwoven by connecting a cantilever on one level to a bulk portion of the conductor line on adjacent levels of interconnection, thereby increasing flexibility of stacked via-studs between interconnection levels.

Owner:GLOBALFOUNDRIES INC

Ultra-thick hard alloy, and preparation method and application thereof

The invention discloses an ultra-thick hard alloy, a preparation method and application thereof. The raw material of the ultra-thick hard alloy comprises the following components in percentage by weight: 10.0-10.5% of Co and the balance of WC. The preparation method comprises the following steps of pretreatment, raw material preparation, wet grinding, spray drying, compression moulding and sintering. According to the invention, technical conditions of each component and technical conditions of each step are selected preferentially, and common technical problems in the preparation of ultra-thick ally in China, such as non-even grains, poor anti-impact toughness and thermal fatigue resistance and too many pores. The ultra-thick hard ally has excellent thermal conductivity, impact toughness and thermal fatigue resistance, cross breaking strength is larger than or equal to 3,100Mpa, the hardness is 86-87HRA, the coercive force is 3.0-4.0KA / m, and WC average grain size is 5-6 microns.

Owner:赣州海盛钨业股份有限公司

High-silicon high-manganese type high-thermal stability hot work die steel and thermal treatment process thereof

The invention relates to high-silicon high-manganese type high-thermal stability hot work die steel and a thermal treatment process thereof, and belongs to the technical field of alloy steel manufacturing process. The hot work die steel is characterized in that the ratio of high silicon to high manganese in chemical components is kept to be 1 to 1 and main alloy elements by mass percent comprise 0.25-0.45% of C, 0.8-2.0% of Si, 0.8-2.0% of Mn, 3.5-4.5% of Cr, 0.6-1.2% of Mo, 0.4-0.8% of V, less than 0.02% of P, less than 0.02% of S and Fe for the rest. A preparation process for the hot work die steel comprises the steps as follows: firstly, preparing materials, smelting and casting; secondly, carrying out electroslag remelting; carrying out high temperature homogenization thermal treatment, and carrying out multi-direction forging hot working; thirdly, carrying out superfine thermal treatment and isothermal annealing treatment; and lastly, carrying out quenching and tempering thermal treatment, namely heating to be 980-1100 DEG C for austenitizing, carrying out oil cooling or mist cooling, and tempering for two to three times at a temperature of 540-600 DEG C. The hot work die steel has the advantages of high thermal stability, high flexibility and good thermal fatigue performance.

Owner:SHANGHAI UNIV

Thermal protection coating surface performance test method

InactiveCN104713897AHighlight substantiveAccelerated thermal fatigueMaterial thermal analysisCoated surfaceThermal fatigue

The invention provides a thermal protection coating surface performance test method including following steps: a), processing a thermal protective coating sample, installing the sample on a cooling base, wherein the sample lower surface and the cooling base form a closed cooling medium channel; b), using a laser beam with variable intensity to heat the sample thermal protective coating surface, then cooling the sample; repeatedly performing the step b) for specified cycle times; measuring temperature values of every measuring point required in the experimental process; observing the change of the thermal protective coating surface state in the experimental process; and c) evaluating the sample thermal fatigue performance and heat insulation performance. The thermal protection coating surface performance test method improves the thermal stress, significantly accelerates the surface thermal fatigue, shortens the testing period, and saves the experimental cost. Movement is not needed in the hot and cold cycle, so that the test system is relatively simple. Two surface properties of thermal protective coating thermal fatigue performance and heat insulation performance can be simultaneously tested.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

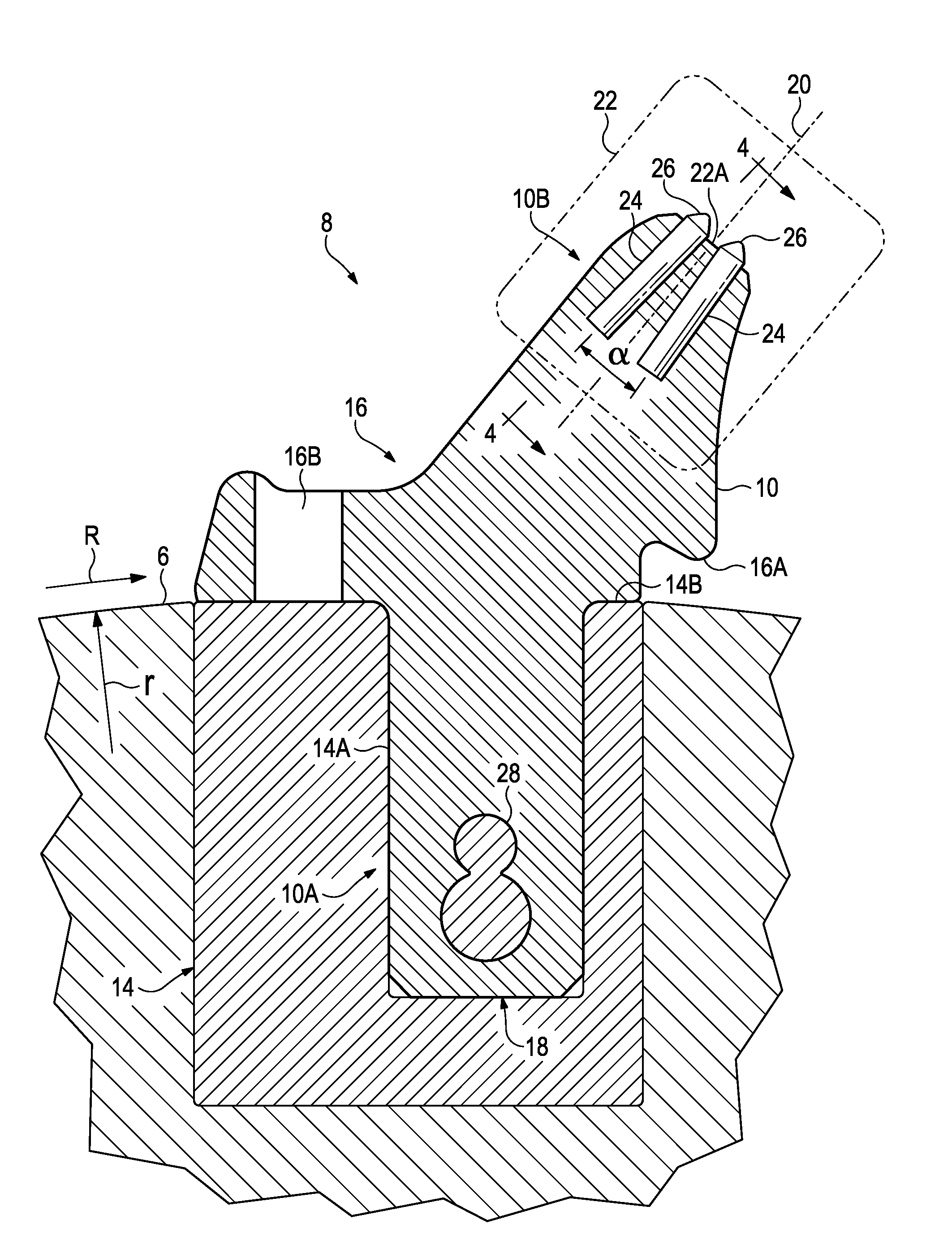

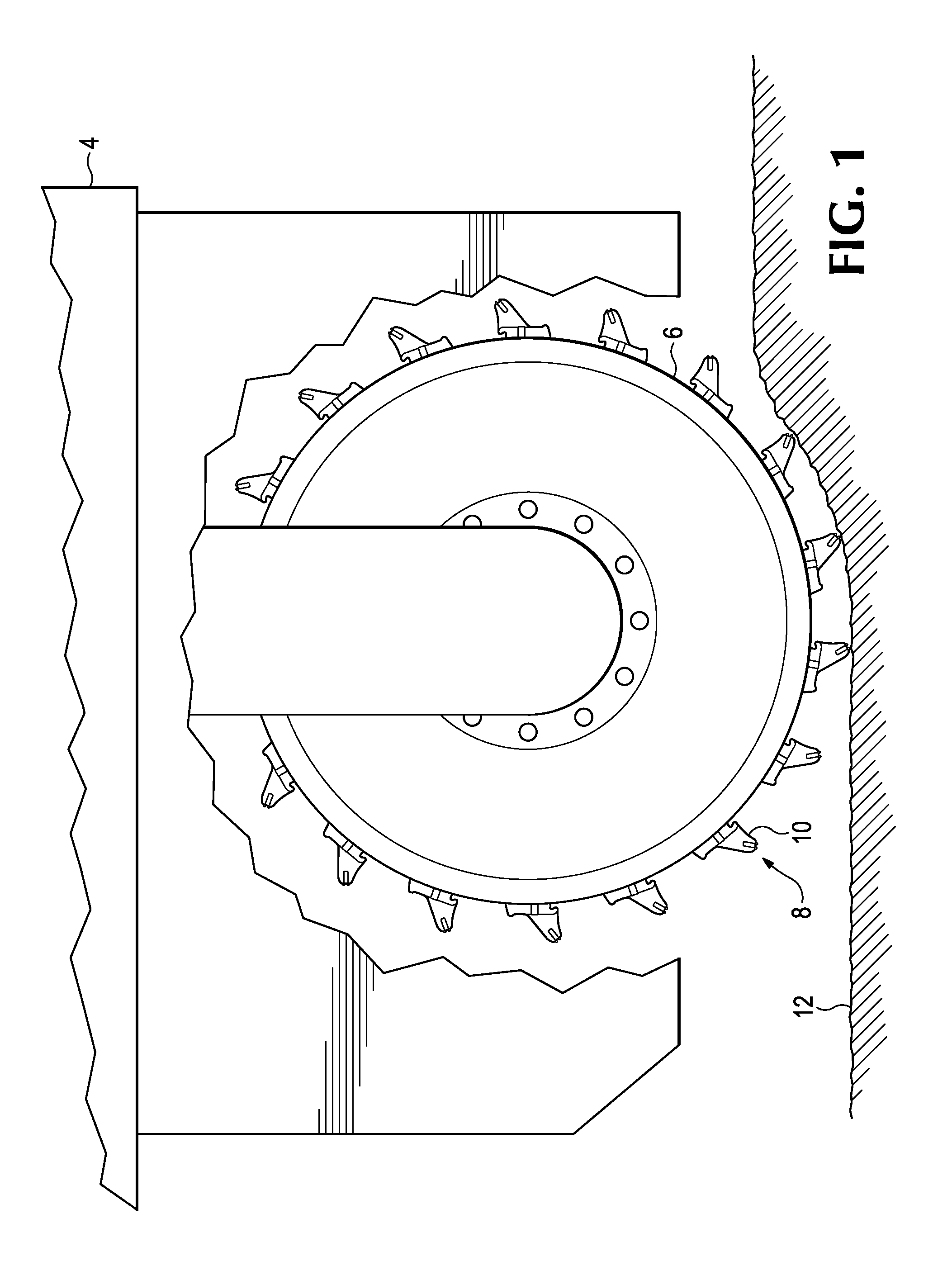

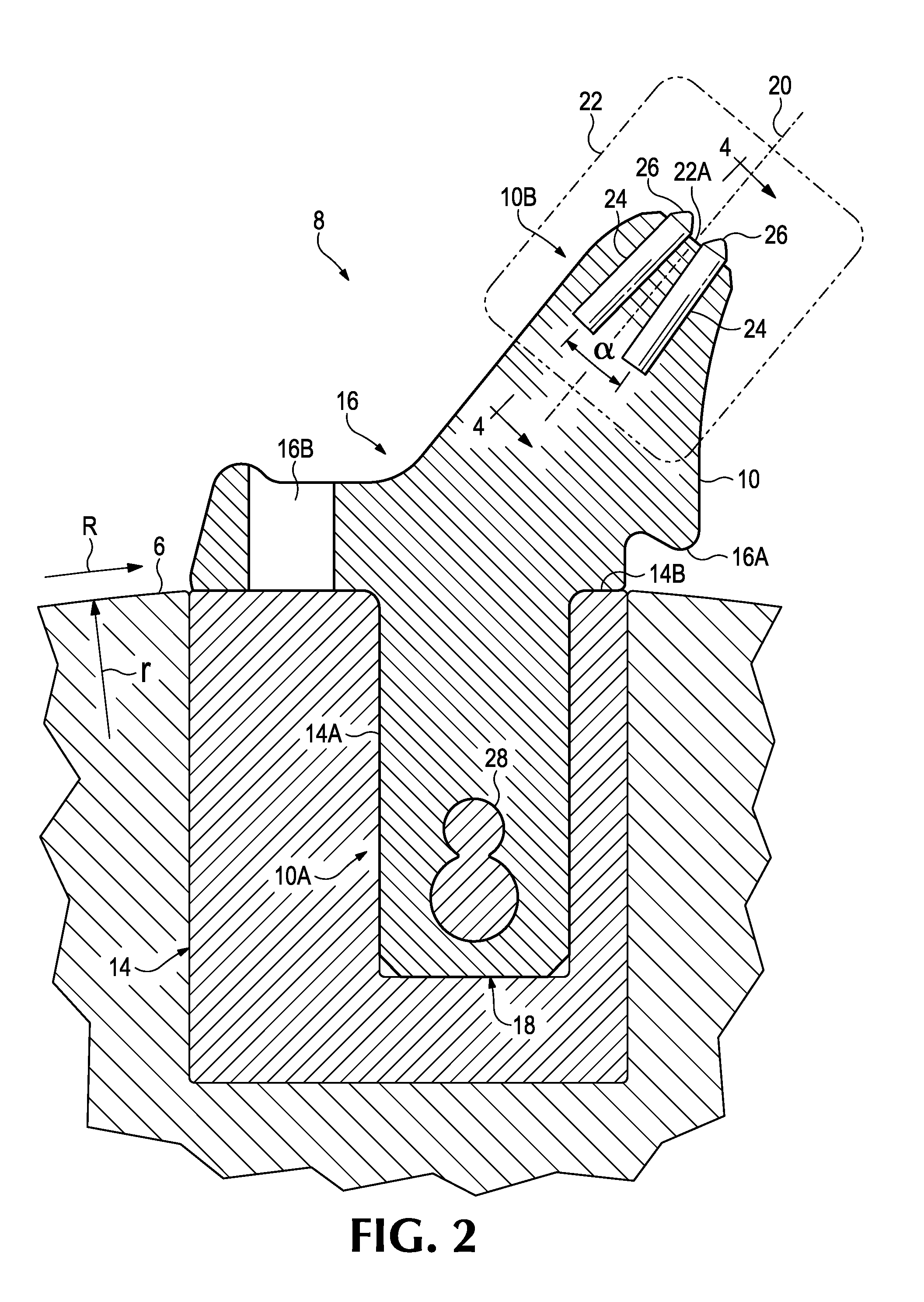

Pick For Earthworking Machine

A pick to be used on an earth working roll for mining, construction and public works machines such as crushers, surface miners, milling machines and the like. The pick includes a working end with holes that extend into the pick and inserts are received into the holes. The inserts during operation impact and fracture a consolidated material to separate the material. Impacting the material generates heat in the pick at the working end of the pick which must be dissipated and attenuated to limit thermal fatigue in the inserts that occurs at high temperatures. The inserts in the working end are configured to dissipate the generated thermal energy from the inserts to the body of the pick.

Owner:ESCO HYDRA UK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com