Patents

Literature

139results about How to "Good welding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

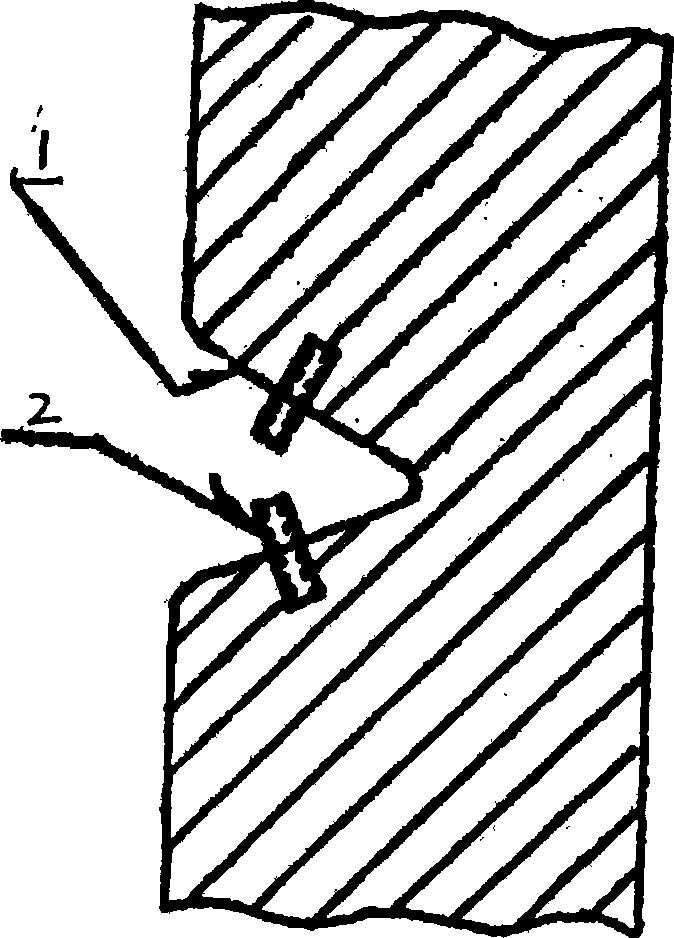

Large-sized iron casting fracture arc cold-welding repair method

InactiveCN101362243ASimple processGood welding effectArc welding apparatusWelding/cutting media/materialsCrazingCast iron

The invention provides a cold welding fracture recovery method for a large-scale cast iron piece. Non cast iron welding material is selected, a layer of metal is scraped off on the fracture surface along the crack direction, so as to form a V-shaped groove; steel screws are screwed in the two sides of the groove, and a direct current welder is used for multi-layer welding. The technique of the invention carries out welding repair to the fracture of the large-scale cast iron piece under the condition of not being influenced by climate, the technique is simple, and the welding effect is good.

Owner:JIANGXI COPPER CORP

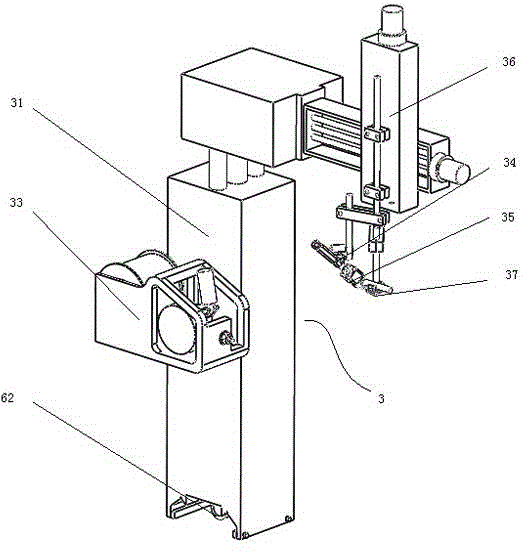

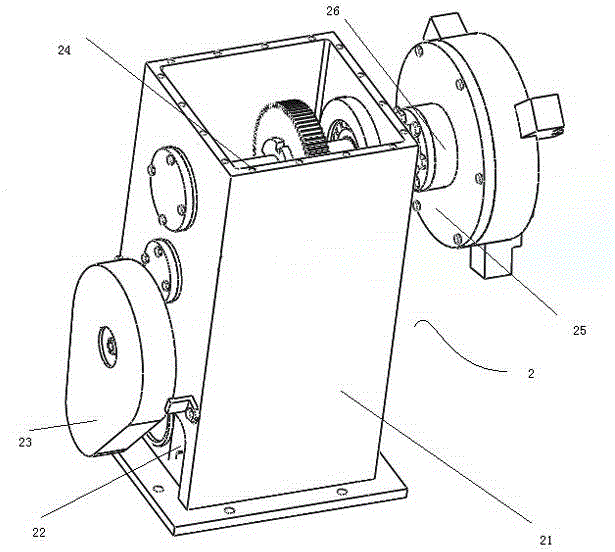

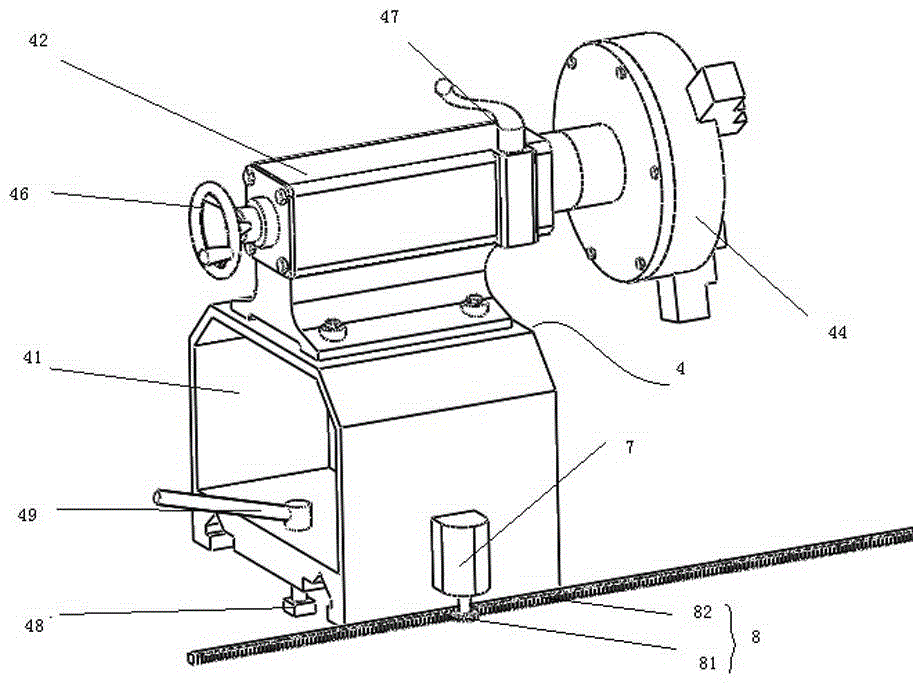

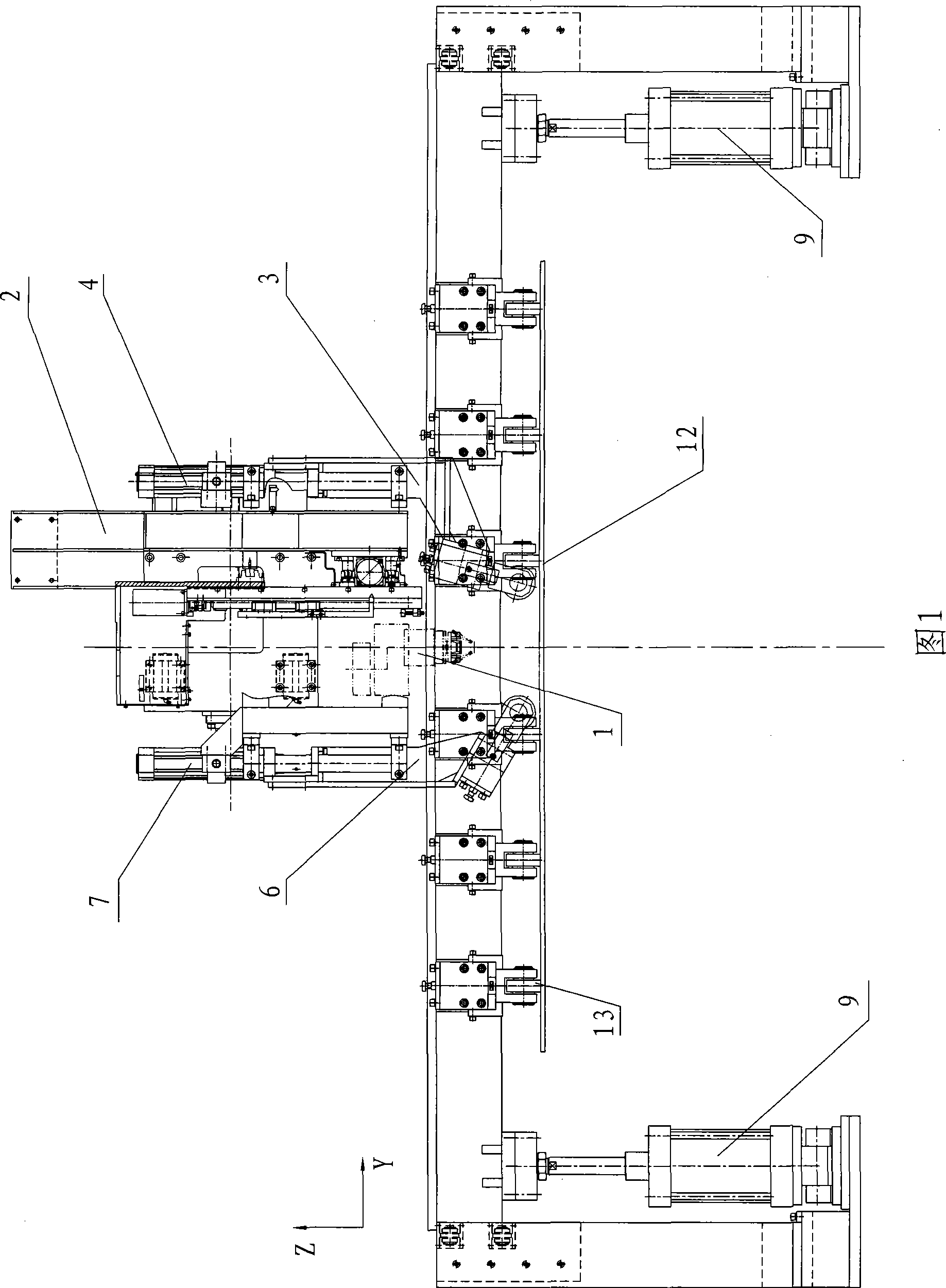

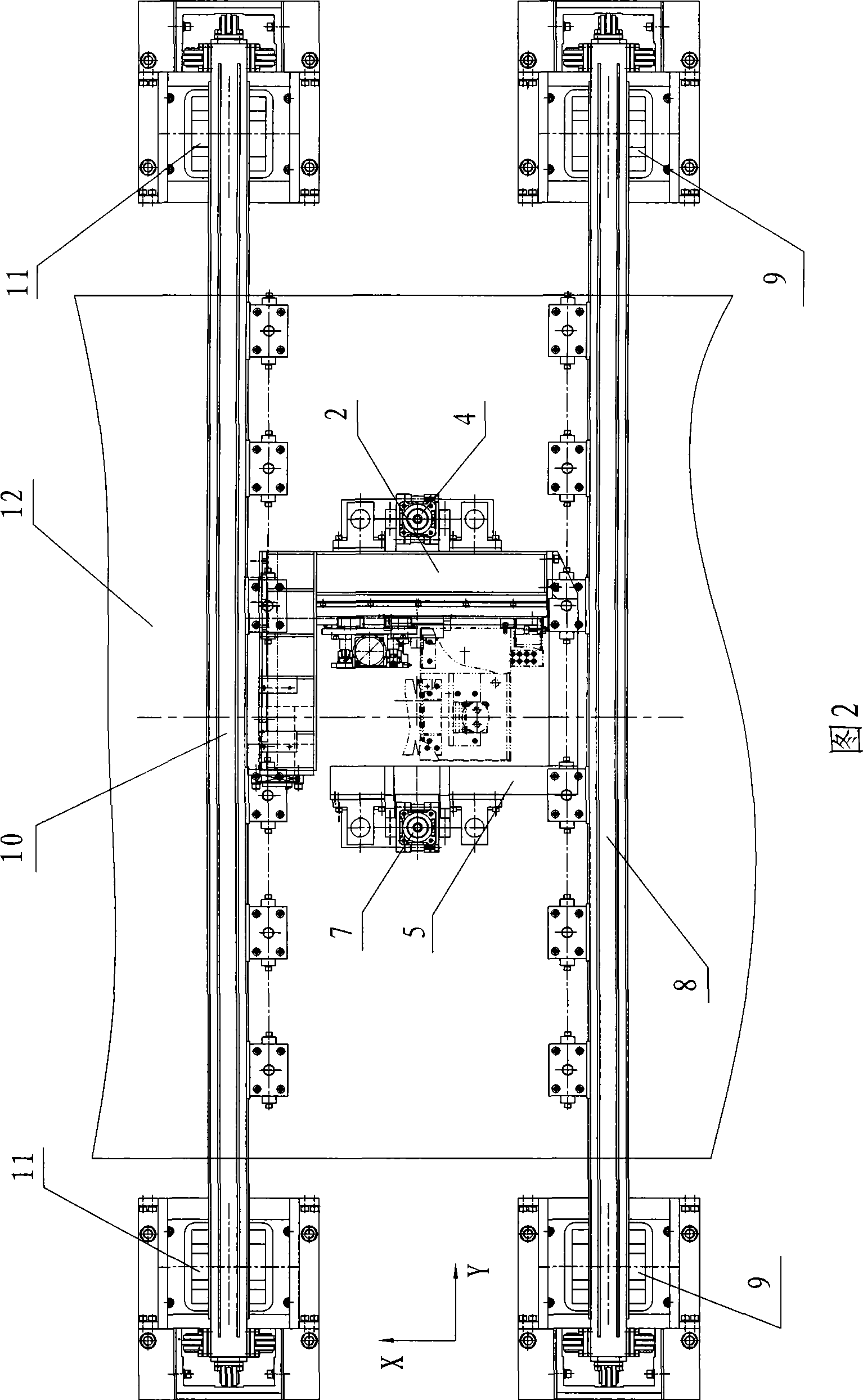

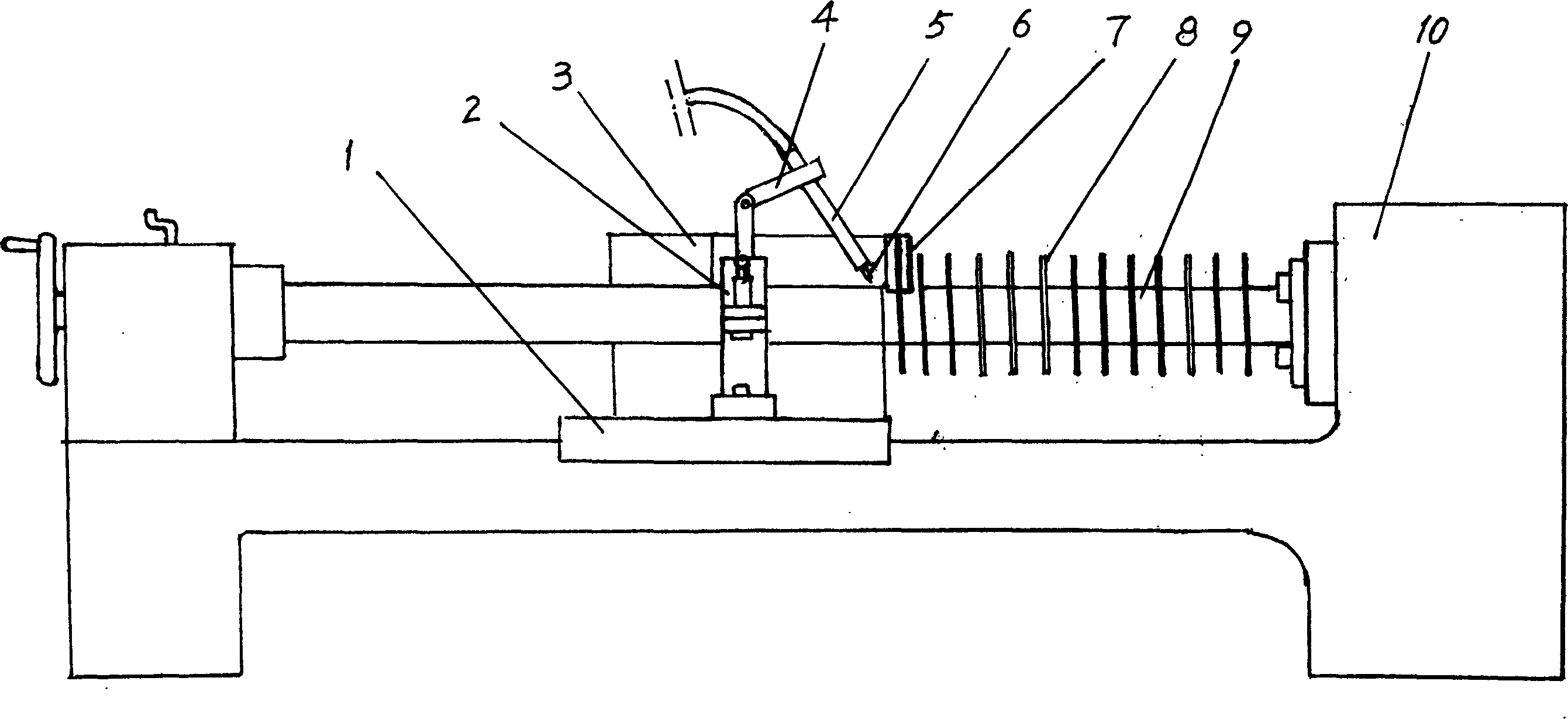

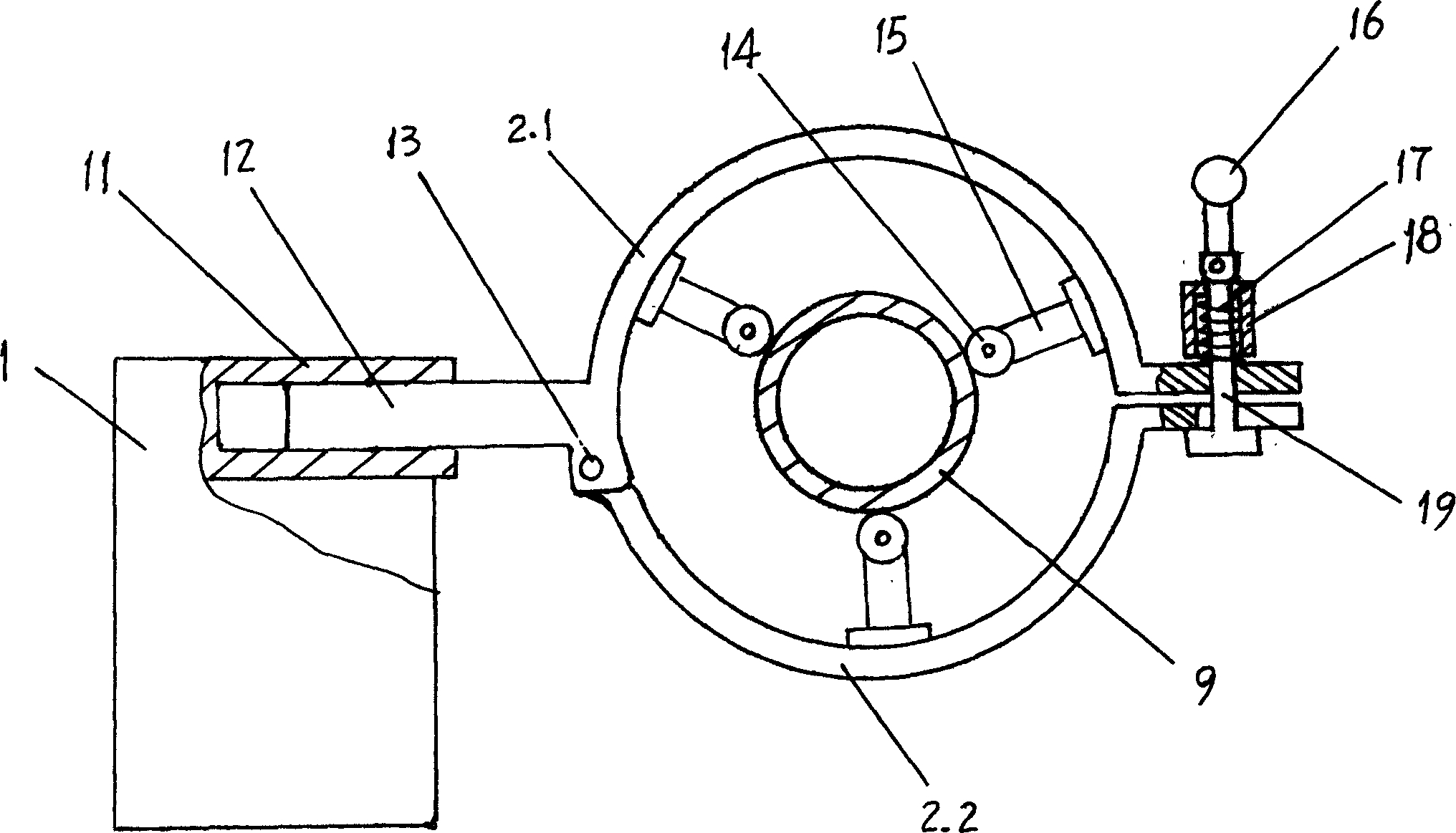

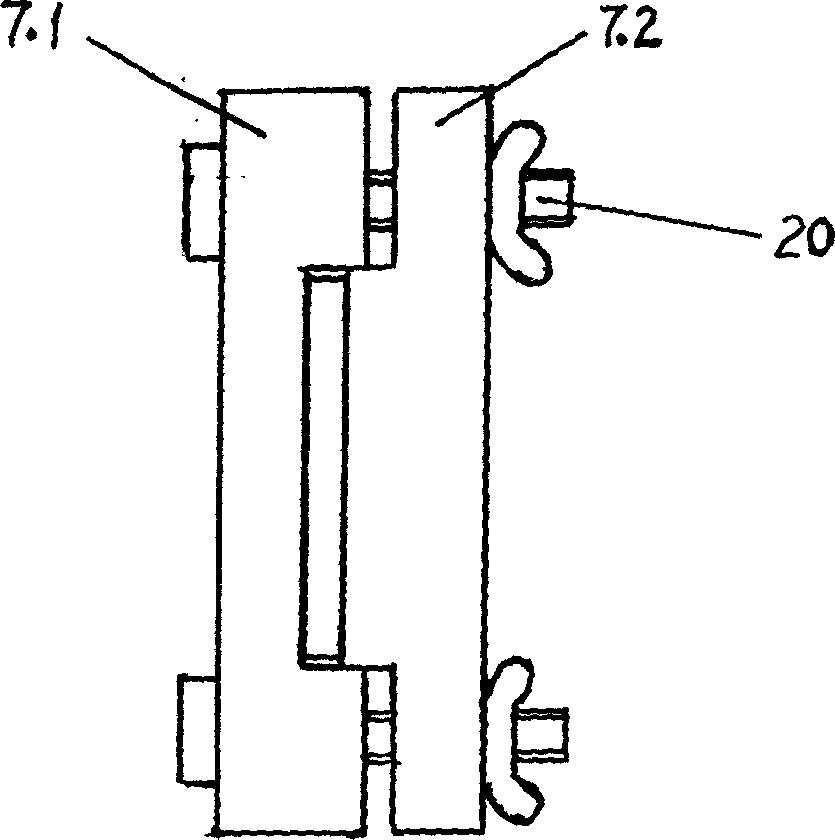

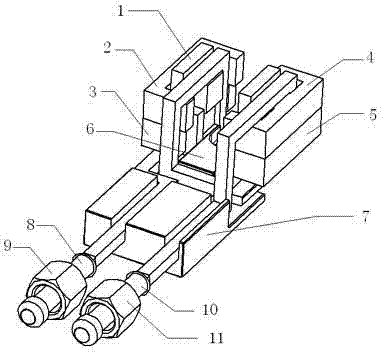

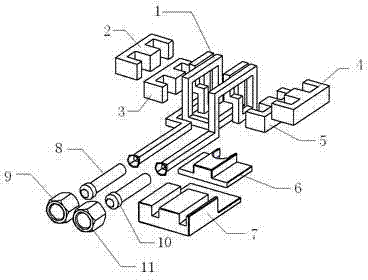

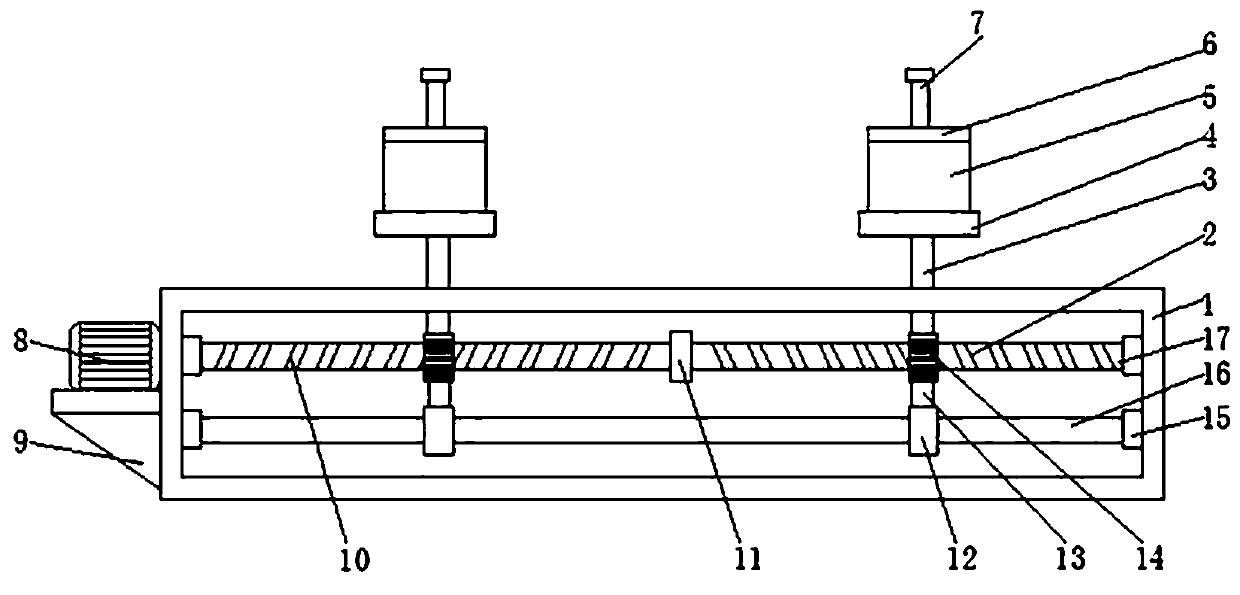

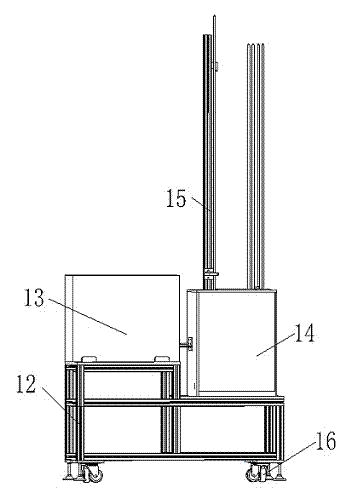

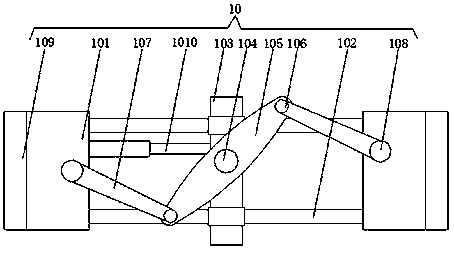

Welding machine tool

ActiveCN104690458AUniform supportGuaranteed stabilityWelding/cutting auxillary devicesArc welding apparatusControl systemEconomic benefits

The invention discloses a welding machine tool. The welding machine tool comprises a machine tool body and a control system; a main spindle box, a tail base mechanism and a welding mechanism for performing the welding operation are arranged on the machine tool body; the control system is connected with the main spindle box, the welding mechanism and the tail base mechanism, the welding mechanism is arranged between the main spindle box and the tail base mechanism; the main spindle box is fixed on the machine tool body, and the welding mechanism and the tail base mechanism are glided along the length direction of the machine tool body. The welding machine tool has variable functions, and not only can satisfy spot welding, simple linear welding and simple arc welding but also the welding of spiral vanes with different length requirements; the welding machine tool is simple in mechanism, convenient to operate, and high in efficiency; the welding machine tool has very big economic benefit and is worth to be popularized.

Owner:HOHAI UNIV CHANGZHOU

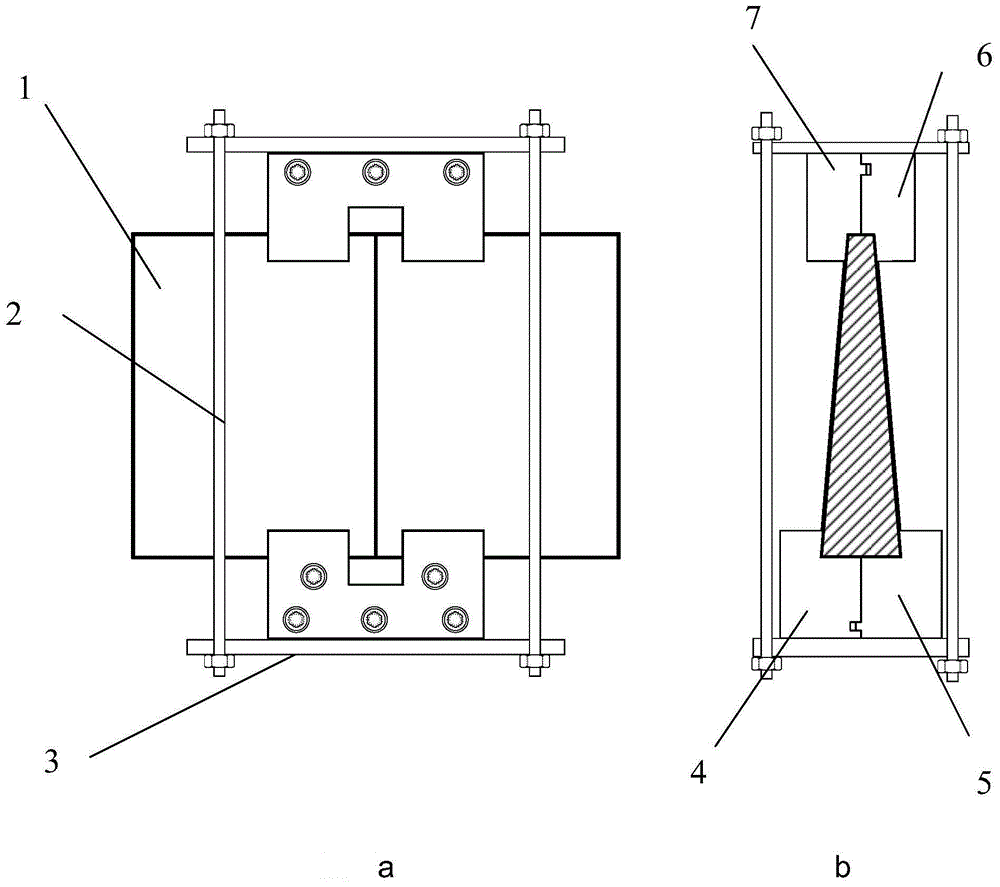

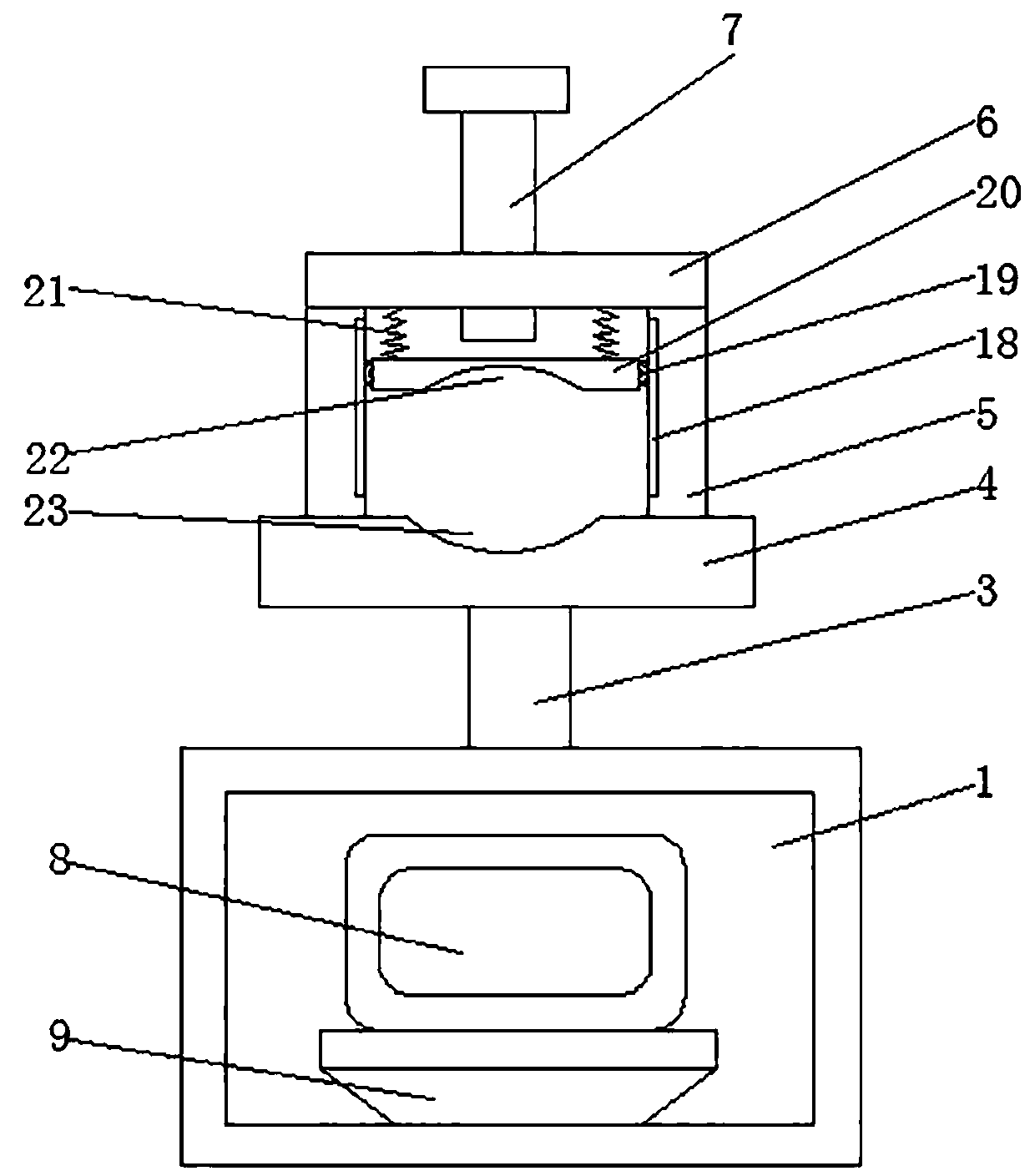

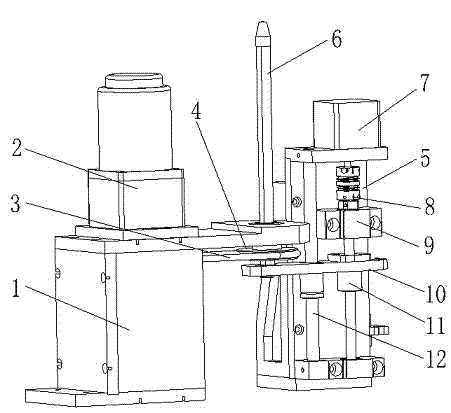

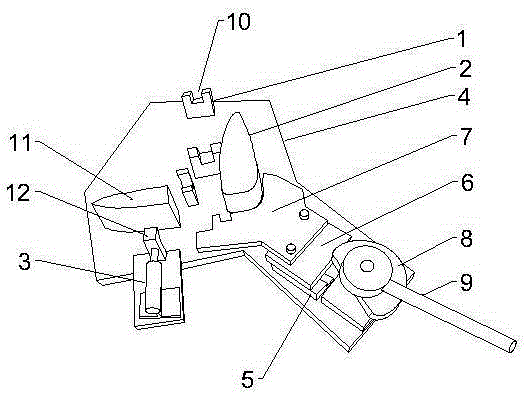

Compressing apparatus for laser beam welding

InactiveCN101376195AGood welding effectQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesMechanical pressLaser beam welding

The invention relates to a mechanical pressing device, particularly a novel laser welding pressing device for pressing and leveling plate materials during the laser stitch welding process. The device is arranged on a gantry and comprises a laser head, a Y-directional slipway, and a front and a rear pressing beams, wherein the front and the rear pressing beams are arranged at the upper part of a gantry worktable in a vertical reciprocating manner; a plurality of pressing wheels are respectively arranged on the front and the rear pressing beams; the Y-directional slipway mounted on the gantry beam is positioned between the front and the rear pressing beams and can carry out a reciprocating movement along the Y direction; a right press roll which can move up and down is arranged on one side of the Y-directional slipway, and the laser head and a installation base are arranged on the other side, and a left press roll which can move up and down is arranged on the installation base; the laser head and the left and the right press rolls are coupled with the Y-directional slipway; the laser head is positioned between the left and the right press rolls, and the laser head can carry out a reciprocating movement along the X direction and the Z direction; and the laser head work area is surrounded by the left and the right press rolls and the front and the rear pressing wheels. The device has the advantages that the gap and the flatness between a thin plate and a thick plate can be guaranteed and the welding effect is good.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

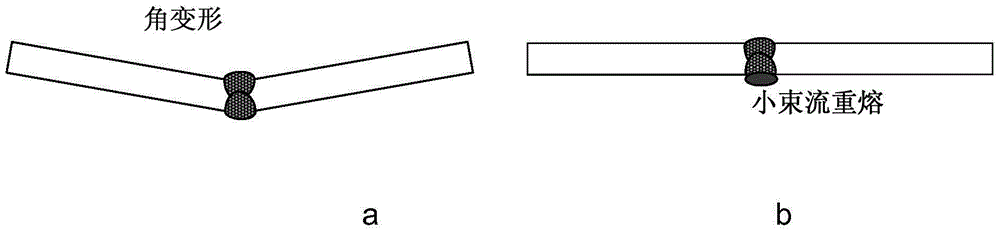

Electron beam welding deformation control method of large variable-thickness component

ActiveCN104959725AHigh precision and accurate positioningReduce accumulationWelding/cutting auxillary devicesAuxillary welding devicesVariable thicknessSpecial design

The invention relates to an electron beam welding deformation control method of a large variable-thickness component; a workpiece is clamped and positioned through a deformation preventing tool with a special design structure; the clamped workpiece is placed on a console of a vacuum electron beam welder for fixing; a weld line is prepositioned by a small beam flow of an electron beam; the positioning mode is weld line double-surface positioning; then, the workpiece is welded by electron beam welding process parameters with optimized design; the welding mold is double-surface welding; the structure deformation is measured after the welding; if the structure is deformed, the structure is corrected by the small beam flow correction process of the electron beam; and the method can effectively solve the connecting problem of large structural parts to improve the welding quality, and has excellent effect on whole structure deformation control.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Soldering flux and preparation method thereof

InactiveCN101983828AHigh activityGood welding effectWelding/cutting media/materialsSoldering mediaOrganic acidFilm-forming agent

The invention discloses a soldering flux, prepared by the following components by weight percent: 0.1-3% of organic acid activator, 0.01-2% of surfactant, 1-4% of wetting agent, 0.01-0.1% of corrosion inhibitor and 90.9-98.88% of film-forming agent. The preparation method thereof includes: (1) in weight percent, organic acid activator, surfactant, wetting agent, corrosion inhibitor and film-forming agent are accurately weighed; (2) the film-forming agent is added into a kettle with heating function and is heated to 110 DEG C, and mixing to be uniform is carried out; (3) slaw warming to 140 DEG C is carried out, the organic acid activator, surfactant, wetting agent and corrosion inhibitor are added once in ratio at 140 DEG C, and stirring is carried out for 0.5h; (4) cooling is carried out, thus obtaining the soldering flux finished product. The invention is mainly used in air conditioning and refrigeration industries, and the soldering flux can cause a welding ring to completely meet the welding requirement of the existing copper aluminium composite tube.

Owner:LICHUANG TAISHAN ELECTRONICS TECH

Welding method for heat radiating fin of heat exchanger and equipment thereof

InactiveCN1544193AGood welding effectImprove heat conduction and heat transfer performanceArc welding apparatusTubular elementsSteel tubeArc welding

The invention is a method of welding cooling fins of a transducer, and its character: the end head of the stainless steel band is welt upright on the steel pine wall, then the steel pipes rotates at uniform speed to apply stretching prestress on the stainless steel band, the steel band is driven by the rotating steel pipe to be wound upright on the steel pipe, at the time of winding, the Wu electrode of an argon-arc welding gun aligns with the horizontal point of tangency between the stainless steel band and the steel pipe and at the time of welding, outputs current to stabilize the arc to weld the roots of the cooling fins. Its advantages: it can continuously weld 1.0 -1.5mm thick, 10-15mm wide steel bands upright on to a stainless steel pipe with a 40-60 mm diameter, and it has good welding effect and enhances heat conducting and transferring performances and prolongs service life of the transducer.

Owner:温振武

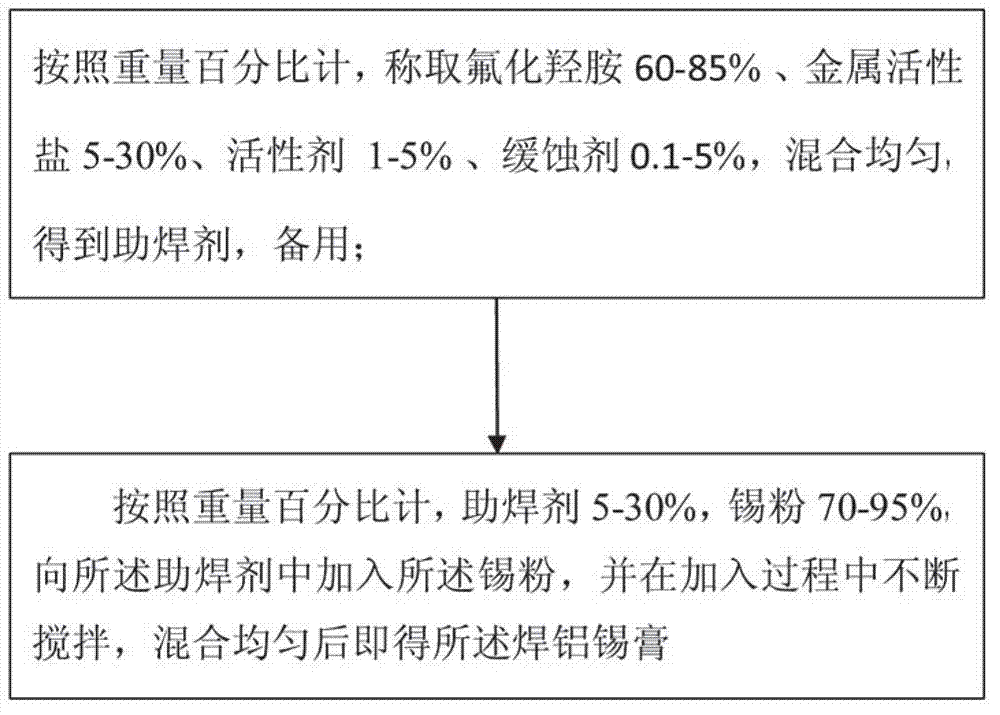

Aluminum welding tin paste and preparation method thereof

ActiveCN102922162AGood effectGood welding effectWelding/cutting media/materialsSoldering mediaHydroxylamineActive agent

The invention relates to an aluminum welding tin paste and a preparation method of the aluminum welding tin paste. The preparation method comprises steps of: 1) weighing 60 to 85% of fluorate hydroxylamine, 5 to 30% of metal active salt, 1 to 5% of active agent, and 0.1 to 5% of corrosion inhibitor by weight, and uniformly mixing to obtain a flux for later use; and 2) weighing 5 to 30% of flux, and 70 to 95% of tin powder by weight, adding the tin powder to the flux along with continuous agitating, and uniformly mixing, so as to obtain the aluminum welding tin paste. The aluminum welding tin paste has the following advantage that 1, a good effect is brought to an object which needs to be pre-coated by the welding flux before welding or the object which is relatively complex in welding shape, and the rate of spread of welding reaches 70 to 90%; and 2, a good welding effect is brought to some metals which are hardly welded relative to copper, such as stainless steel and aluminum.

Owner:青岛英太克锡业科技有限公司

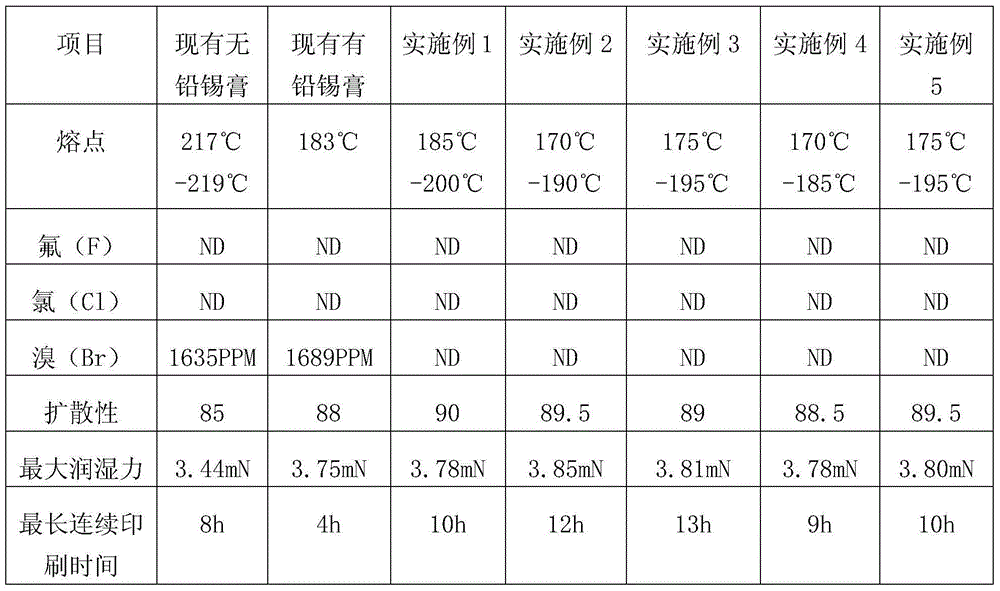

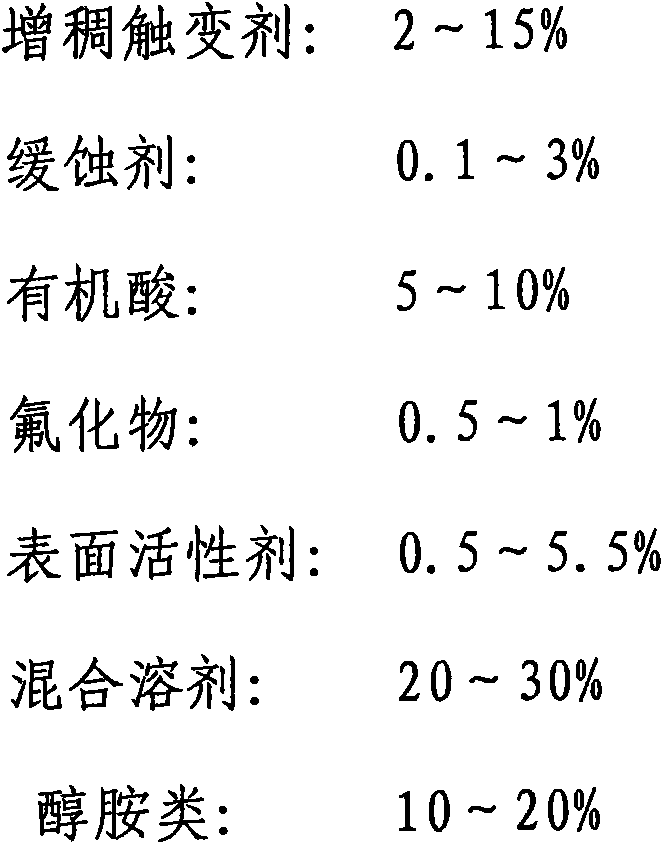

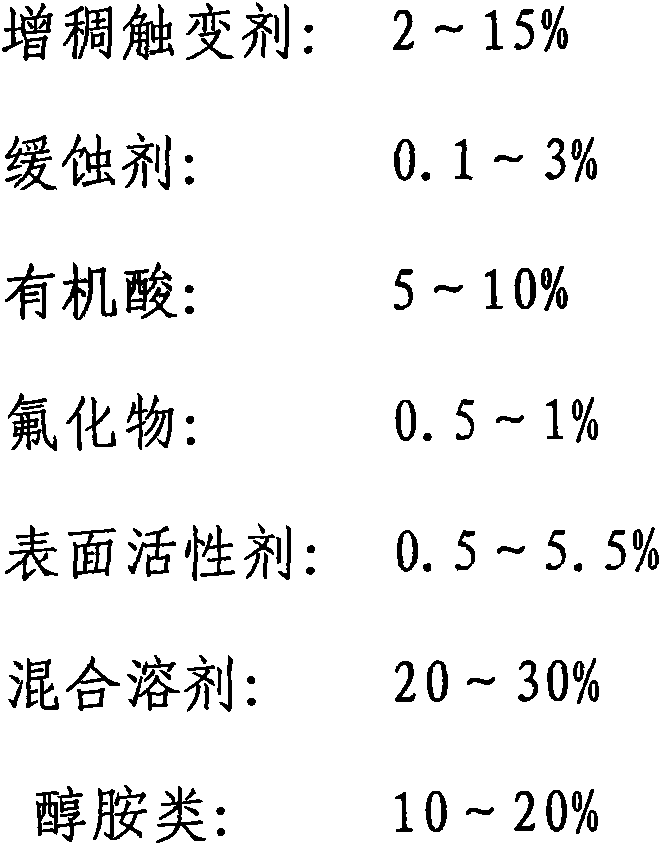

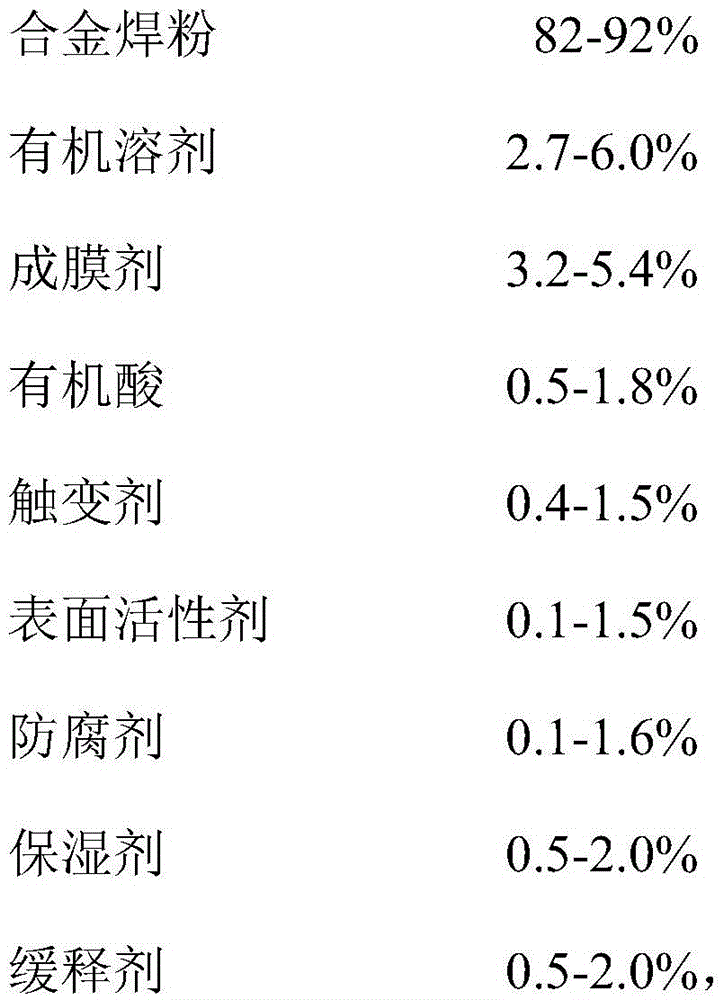

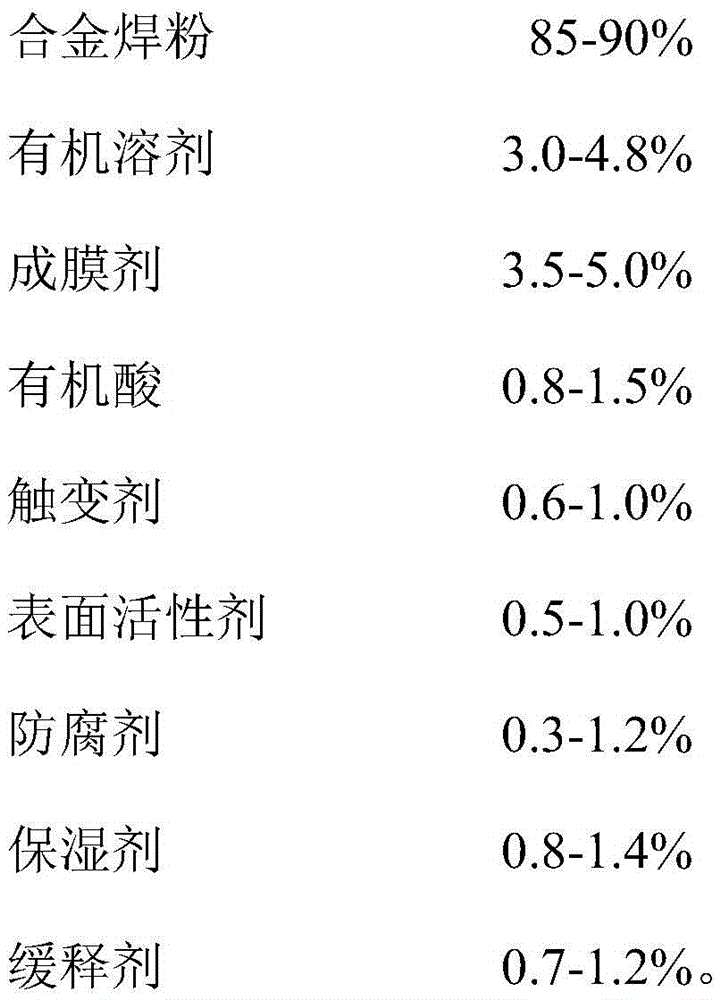

Lead-free halogen-free tin paste and production process thereof

InactiveCN104923952ALow melting pointLow soldering temperatureWelding/cutting media/materialsSoldering mediaOrganic acidSolvent

The invention relates to the technical field of electronic welding, in particular to lead-free halogen-free tin paste which comprises, in weight percent, 88%-90% of tin powder and 10%-12% of paste flux. The tin powder is made of alloys including 88-94.5% of Sn, 0.2-1.2% of Ag, 0.3-0.8% of Cu and 5-10% of Bi. The paste flux comprises rosin, solvents, corrosion inhibitors, activators, thixotropic agents and thickening agents, wherein the activators comprise organic acid and organic amine. The paste flux is prepared by an emulsion dispersion high-speed shearing process. A preparation method of the tin paste includes the steps: placing the tin powder and the paste flux into a sealed stirrer for stirring according to the proportion; pumping vacuum; releasing the vacuum; finishing preparation of the tin paste. The lead-free halogen-free tin paste is low in melting point, fine in weldability, full in welding spot and fine in reliability, achieves fine welding effects and meets environmental protection requirements, and the service life of the tin paste is prolonged.

Owner:广西南宁迈点装饰工程有限公司

Brazing filler metal for connecting copper and stainless steel, application of brazing filler metal and method for welding silencer

InactiveCN103252595AImprove the noise reduction effectReduce manufacturing costWelding/cutting media/materialsSoldering mediaMischmetalRare earth

The invention relates to brazing filler metal for connecting copper and stainless steel, application of the brazing filler metal and a method for welding a silencer and belongs to the field of brazing filler metal and silencer welding methods. The brazing filler metal comprises, by weight, 26-34 percent of Cu, 34-35 percent of Ag, 5-8 percent of Co, 2-4.5 percent of Li, 1-1.5 percent of Sn, 0.2-1.8 percent of Ni, 1.8-2 percent of B, 0.5-1.3 percent of Mn, 0.1-1.4 percent of Si, 0.03-0.16 percent of mischmetal and the balance of Zn. The mischmetal is composed of La and Pr, the mass ratio of La and Pr is equal to the mass ratio of Cu and Ag. When the brazing filler metal for connecting the copper and the stainless steel is applied to welding of the silencer, flames are utilized for welding, the requirement for welding is met, meanwhile, welding efficiency is high, production cost is low, a noise reduction effect after the silencer is welded is good, and the service life of the silencer is prolonged.

Owner:ANHUI ZHONGHUI REFRIGERATION

High-frequency inductive welding joint

ActiveCN102962577AGuaranteed uniformityGood welding effectHigh frequency current welding apparatusEngineeringElectrical and Electronics engineering

The invention discloses a high-frequency inductive welding joint, which comprises a square copper tube induction coil, a left upper ferrite magnetic core, a left lower ferrite magnetic core, a right upper ferrite magnetic core, a right lower ferrite magnetic core, a positioning block, a welding head bracket, a left connecting tube and a right connecting tube, wherein the left upper ferrite magnetic core, the left lower ferrite magnetic core, the right upper ferrite magnetic core and the right lower ferrite magnetic core are arranged on the square copper tube induction coil; unequal structures are adopted for the left upper ferrite magnetic core and the left lower ferrite magnetic core as well as the right upper ferrite magnetic core and the right lower ferrite magnetic core; the positioning block is arranged below the square copper tube induction coil, and is arranged on the welding head bracket; and the left connecting tube and the right connecting tube are connected to the square copper tube induction coil, and are fixedly arranged on the welding head bracket. Due to the adoption of the high-frequency inductive welding joint, the welding uniformity can be ensured effectively, and a very ideal welding effect is achieved.

Owner:青岛同日智能技术有限公司 +1

Preformed solder containing soldering flux and preparation method thereof

ActiveCN107433400AWon't hurtWon't scatterWelding/cutting media/materialsSoldering mediaThermal bridgeIngot

The invention relates to the technical field of materials for electronic device welding and specifically discloses a kind of performed solder containing soldering flux and a preparation method thereof. The performed solder containing the soldering flux comprises a soldering material and the soldering flux wrapped in the soldering material; the mass percent of the soldering material is 95%-99.9%, and the mass percent of the soldering flux is 0.1%-5%. The preparation method of the performed solder containing the soldering flux comprises the steps of preparing the soldering flux; smelting and casting an ingot of the soldering material; conducting charging and extruding the ingot of the soldering material into a preform body; rolling the perform body into a material strap; and cutting the material strap. By adopting the performed solder provided by the invention, the deficiencies of dipping the liquid soldering flux and externally applying the solid soldering flux are made up; the soldering flux can reduce the surface tension of the molten soldering material, facilitates wetting and spreading of the performed solder, promotes welding, prevents secondary oxidation of the performed solder and has an auxiliary heat conduction effect as a thermal bridge. By means of the performed solder containing the soldering flux, the welding quality is effectively improved, the good welding effect is achieved, the stability of the welding process can be guaranteed, and the production efficiency can be improved.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

Ceramic welding materials for high temperature kiln and a method

ActiveCN102086128ARemarkable effect of energy saving and consumption reductionExtended service lifeMicroparticleOxygen delivery

The invention discloses a method and corresponding ceramic welding materials for restoring damaged high temperature industrial kiln by ceramic welding technology, and the method comprises the following steps of: selecting materials the same as or similar torefractory materials at the kiln damaged position as base materials; selectively adding metal inflammable microparticles accounting for 10% to18% by weight of the base materials, such as aluminium, magnesium, silicon, zirconium and the like, and selecting chloride accounting for no more than 2% by weight of the base materials as additive; after mixing well under conveying of oxygen jetting the prepared welding material to a position of the kiln to be repaired; reacting the inflammable microparticles with the oxygen to produce a high temperature to allow the refractory materials rapid softening and fusion; combining together very tightly the refractory materials at the position to be prepared and the welding material; fully filling holes, junctions and slits with fused substance; and continuously filling on the heat repairing surface to achieve the purpose of kiln restoration.

Owner:山西高科耐火材料股份有限公司

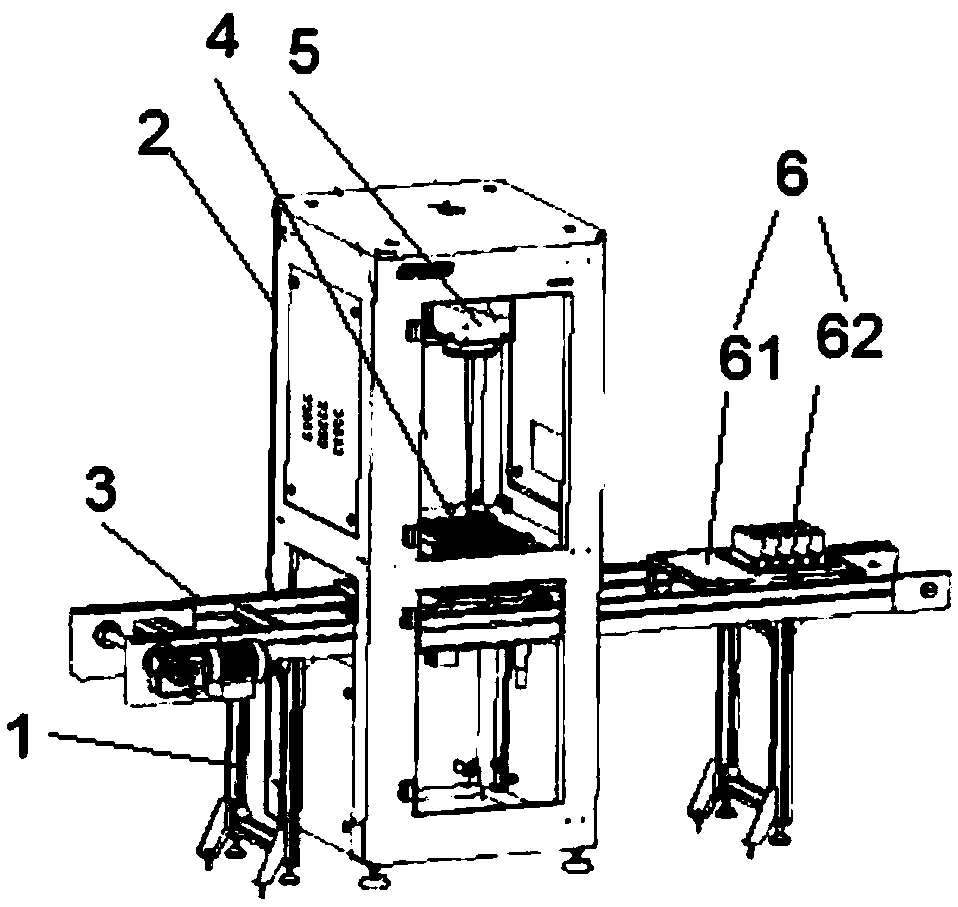

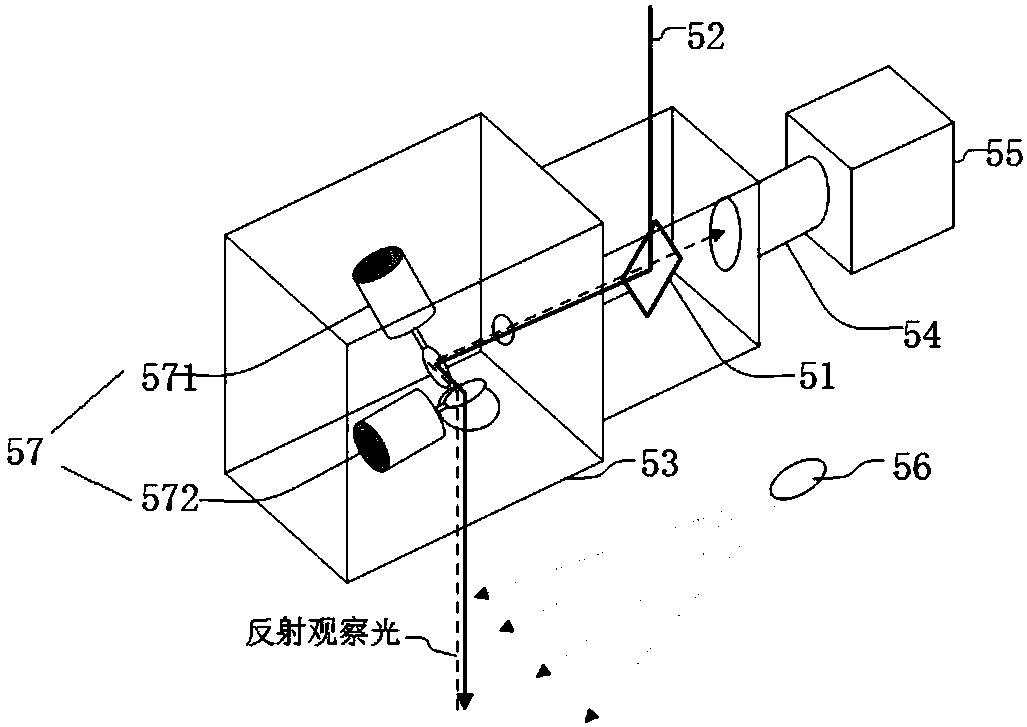

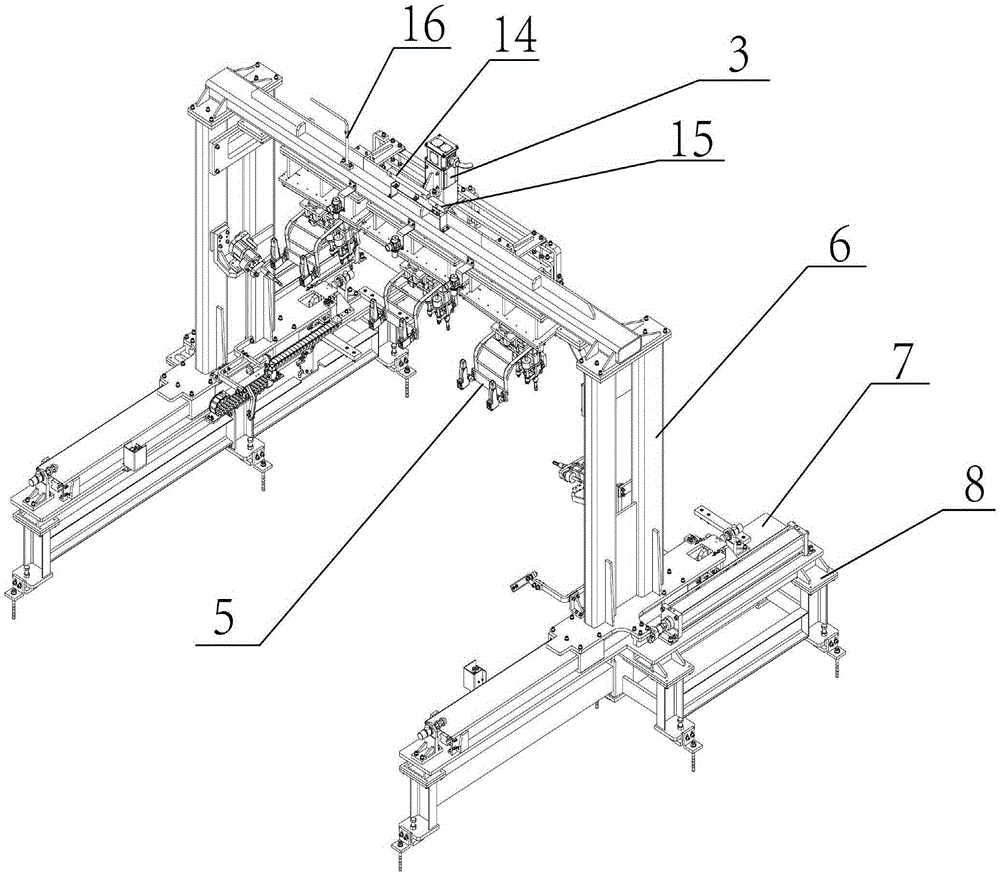

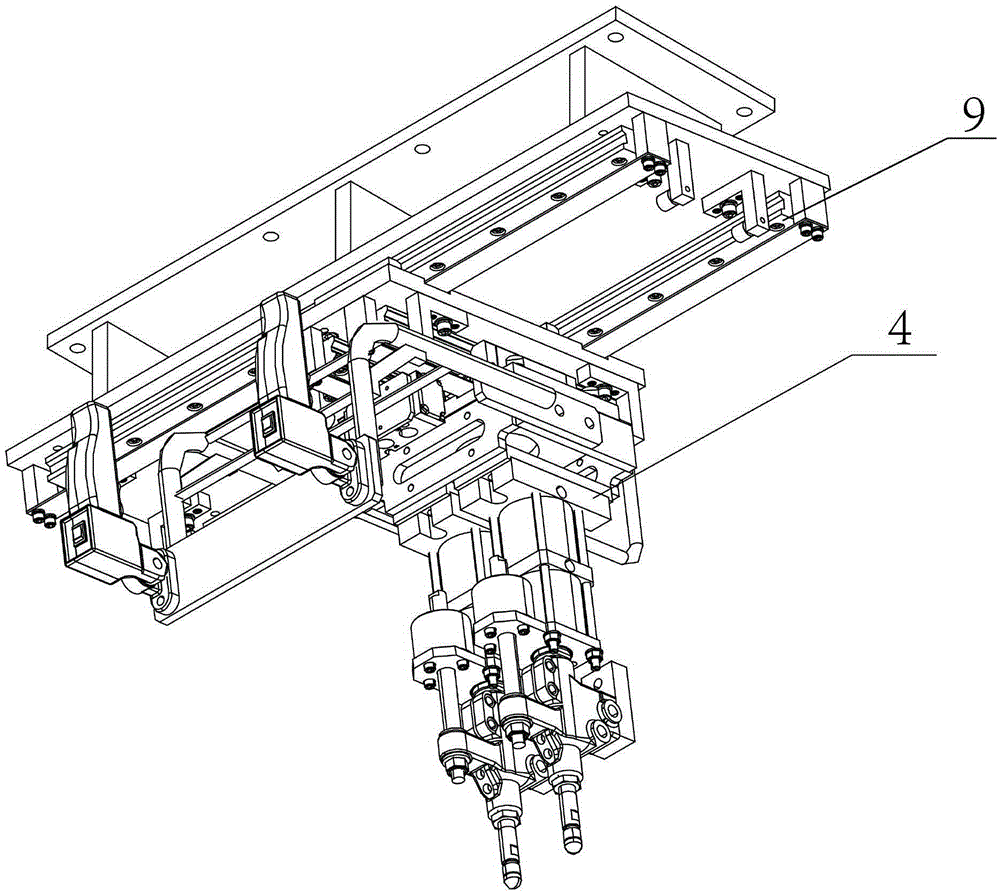

Laser high-speed scanning and welding system based on galvanometer for battery box, and working method

PendingCN107824970AFast welding speedGood welding effectLaser beam welding apparatusElectrical batteryGalvanometer

The invention discloses a laser high-speed scanning and welding system based on a galvanometer for a battery box. The laser high-speed scanning and welding system comprises a rack and a laser weldingprotection cabin, wherein a transport line used for workpiece transport is arranged on the rack; the laser welding protection cabin is arranged on the transport line; a fixture and a special long-distance laser welding machine based on the galvanometer are arranged in the laser welding protection cabin; a conveying mechanism used for conveying workpieces is arranged on the transport line; the fixture is arranged on the conveying mechanism; the special long-distance laser welding machine is arranged at the top of the laser welding protection cabin; and the transport line, the fixture, the special long-distance laser welding machine, a tray and a follow-up fixture are all connected with a control centre. According to the laser high-speed scanning and welding system disclosed by the invention, the battery box is scanned and welded through the special long-distance laser welding machine; a laser welding process can be efficiently and stably carried out through the rapid rotation of the galvanometer; and a facular movement track can be set to carry out waveform control, so that an ideal welding effect is achieved. The device is high in welding speed, and generates small thermal deformation, thereby greatly increasing the production efficiency, and also effectively improving the welding accuracy and welding quality.

Owner:TONGGAO ADVANCED MFG TECH TAICANG

Water cleaning type tin soldering paste soldering flux

ActiveCN104416299AHigh impedanceNo corrosionWelding/cutting media/materialsSoldering mediaOrganic acidRosin

The invention discloses water cleaning type tin soldering paste soldering flux. The invention has the key points that the water cleaning type tin soldering paste soldering flux comprises the components in percentage by weight: 2%-15% of thickening thixotropic agent, 0.1%-3% of corrosion inhibitor, 5%-10% of organic acid, 0.5%-1% of fluoride, 0.5%-5.5% of surface active agent, 20%-30% of mixed solvent, 10%-20% of alcamines, and the balance of rosin (modified rosin). The water cleaning type tin soldering paste soldering flux disclosed by the invention has the advantages that the soldering performance is excellent, the soldering reliability is high, and prepared tin soldering paste has the basic using characteristics of common rosin type tin soldering paste.

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

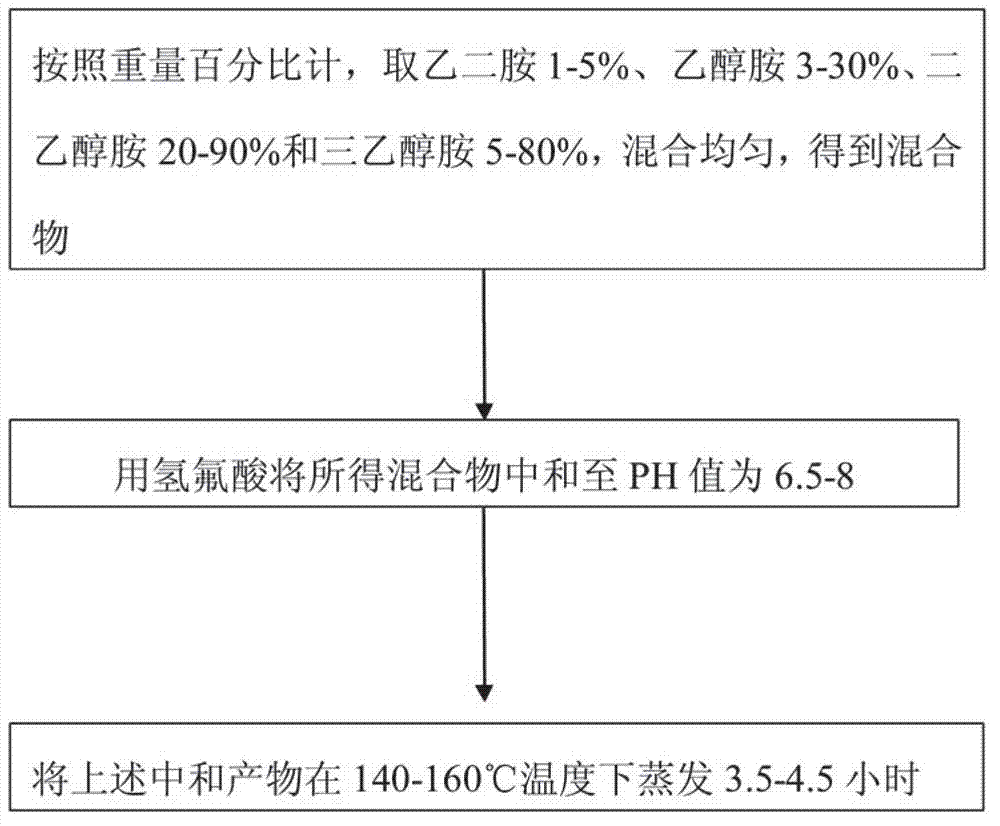

Cleaning-free water-soluble welding flux for lead-free welding and preparation method thereof

InactiveCN101524791AOperational securityAdapt to welding humidity requirementsWelding/cutting media/materialsSoldering mediaActive agentSurface-active agents

The invention discloses a cleaning-free water-soluble welding flux for lead-free welding, which comprises the following components of water-soluble modified rosin, organic acid active agent, halide active agent, nonionic surface active agent, flux and solvent deionized water. The invention also discloses a preparation method of the cleaning-free water-soluble welding flux for lead-free welding, which comprises the following steps: firstly, adding the flux and the deionized water in a reaction vessel with a stirrer according to a certain weight percentage for stirring; adding the water-soluble modified rosin according to the weight percentage in the stirring process; and secondly, adding the nonionic surface active agent, the organic acid active agent and the halide active agent for stirring continuously after dissolving the water-soluble modified rosin, and obtaining the cleaning-free water-soluble welding flux for lead-free welding after uniform stirring. The invention ensures high reliability of electronic information products, causes lead-free welding operating environment to be safe and reliable, conforms to the environmental protection requirements and saves energy resources simultaneously.

Owner:TAIZHOU ZHONGYI COMM DEVICE

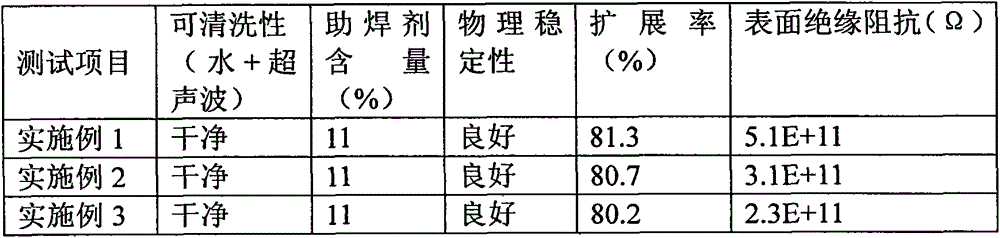

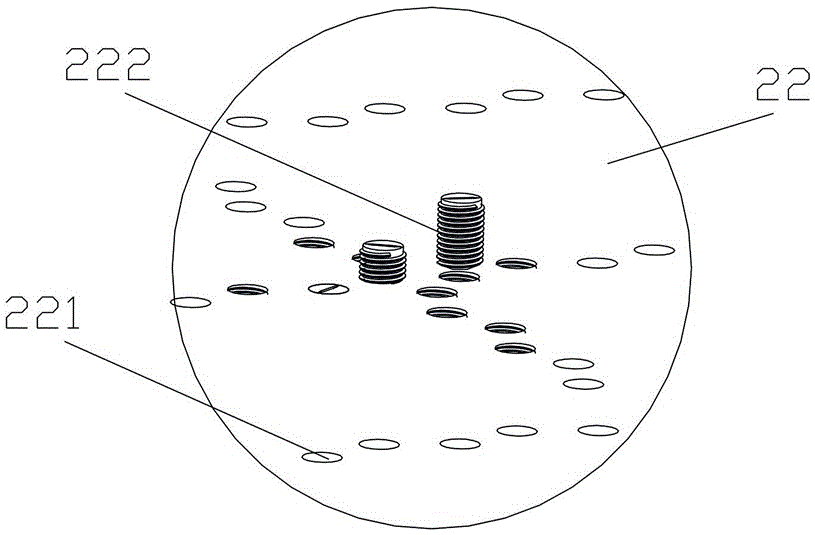

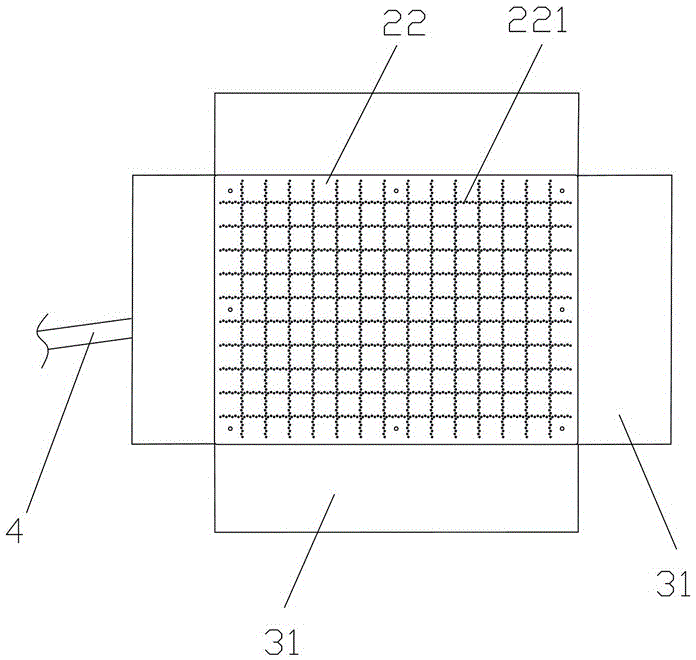

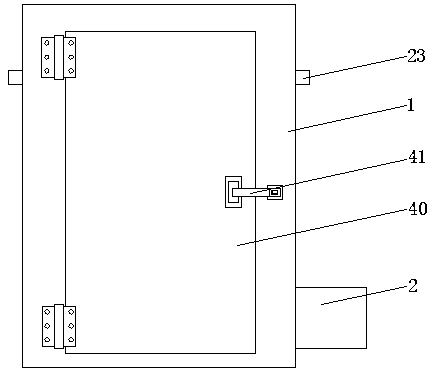

Negative-pressure adsorption welding device and negative-pressure adsorption welding method

InactiveCN106141519ANot prone to distortionImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a negative-pressure adsorption welding device which comprises a negative-pressure producing assembly and negative-pressure adsorption plate assemblies; the negative-pressure adsorption plate assemblies comprise a bottom negative-pressure adsorption plate assembly and a top negative-pressure adsorption plate assembly; negative-pressure adsorption chambers are formed between the negative-pressure plate assemblies and the adsorption plate assemblies; the negative-pressure production assembly communicates with the negative-pressure adsorption chambers for extracting air in the negative-pressure adsorption chambers to form vacuum negative pressure; a plurality of negative-pressure adsorption holes are formed in the adsorption plate assemblies for fixing to-be-welded parts onto the adsorption plate assemblies in a negative-pressure adsorption manner to carry out welding operation when vacuum negative pressure is formed in the negative-pressure adsorption chambers. The invention further discloses a negative-pressure adsorption welding method. The negative-pressure adsorption welding device is reasonable in design, is convenient and quick to operate, is small in welding deformation and is capable of reducing working cost and improving working efficiency.

Owner:株洲天瑞精密钣金有限公司

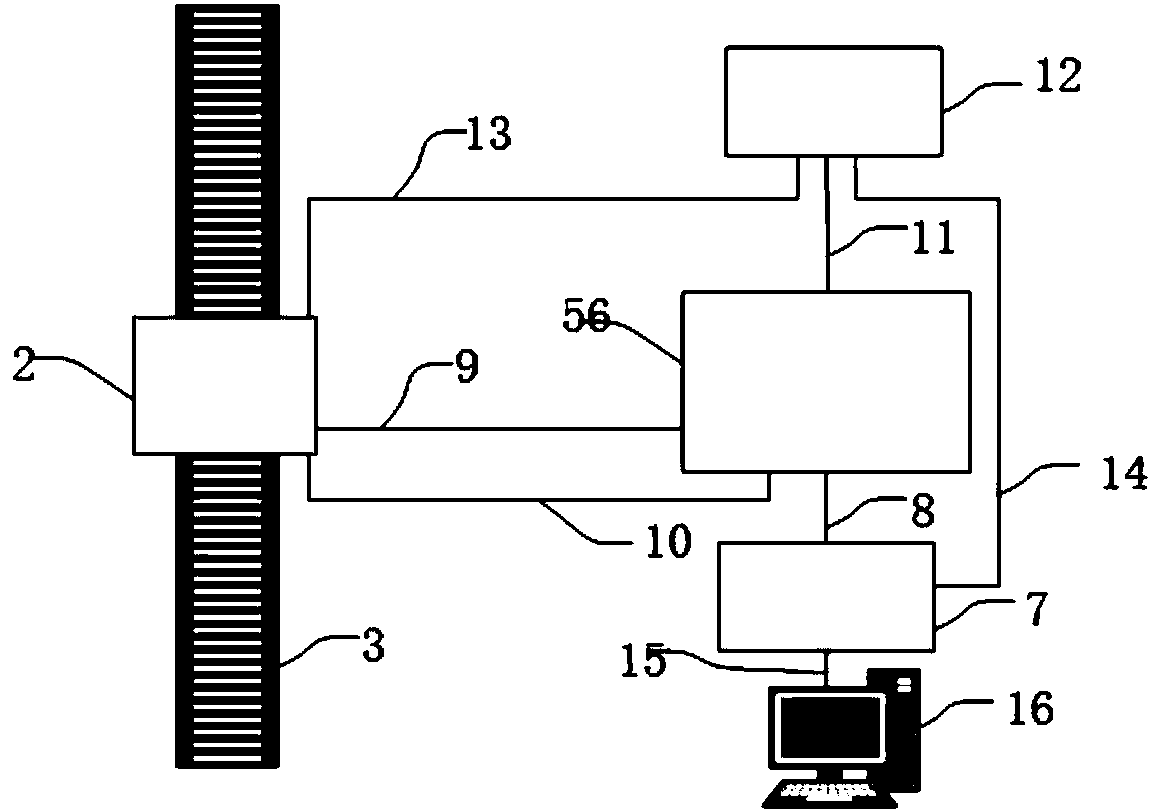

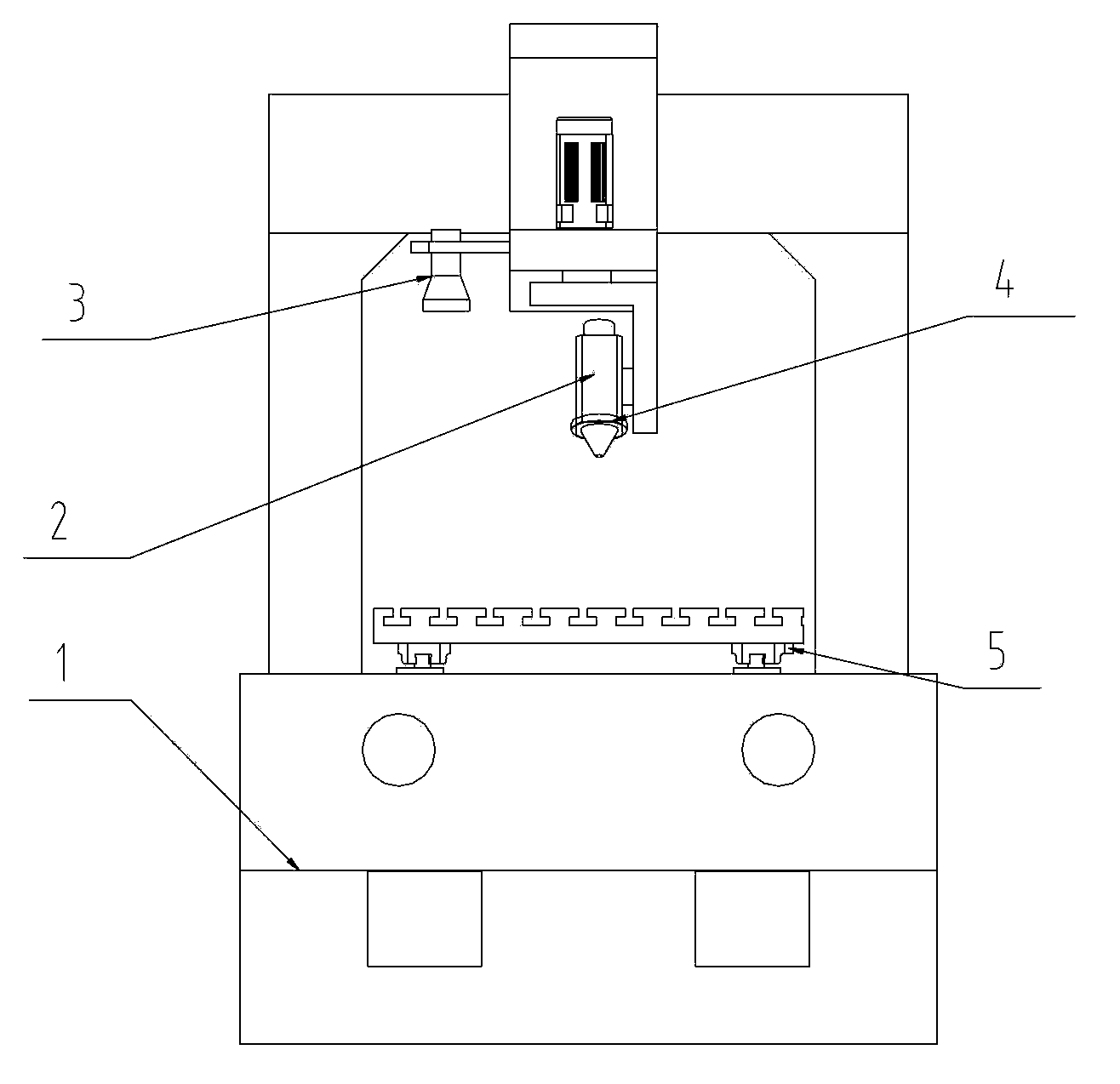

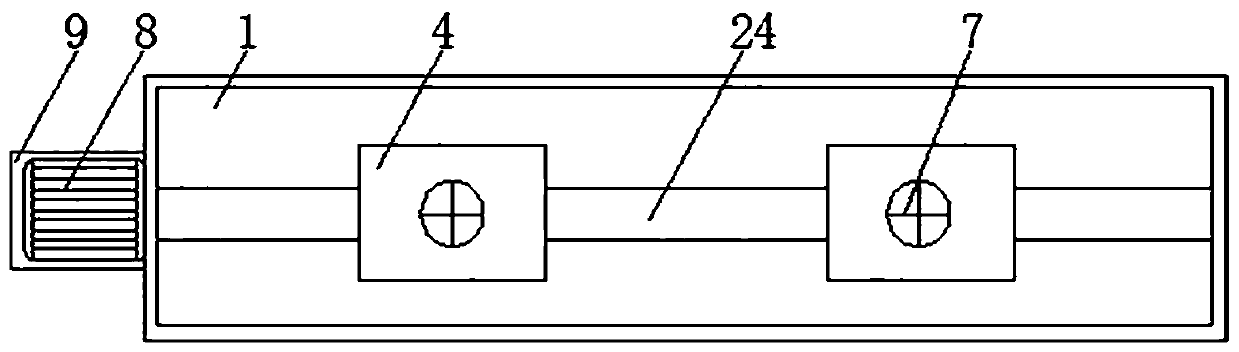

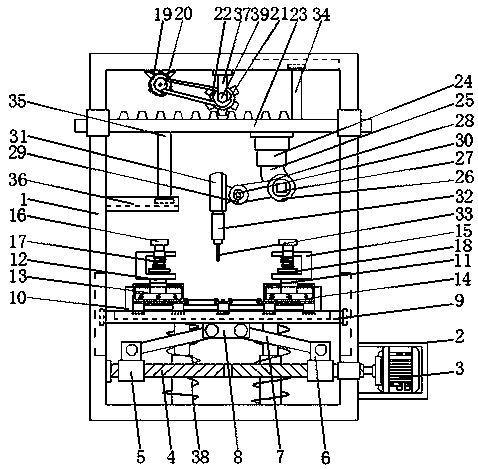

Micro stirring welding system integrating laser and mechanical sensors and welding method

ActiveCN103464888AAdjust control parameters in timeGood welding effectNon-electric welding apparatusControl systemCopper

The invention discloses a micro stirring welding system integrating laser and mechanical sensors and a welding method. The micro stirring welding system integrating laser comprises a five-axis machine tool platform, a welding spindle, a laser system, the mechanical sensor, a displacement sensor and a control system, wherein the mechanical sensor is arranged on the welding spindle; the displacement sensor is arranged near a guide rail on the five-axis machine tool platform; the laser system is arranged on the five-axis machine tool platform; the control system is respectively connected with the five-axis machine tool platform, the laser system, the mechanical sensor and the displacement sensor and is used for controlling regulation on the five-axis machine tool platform, the laser system, the mechanical sensor and the displacement sensor. The micro stirring welding system completes butt and overlapping welding of an ultrathin aluminium sheet with a thickness of 0.2 to 1mm, a copper plate and other metals suitable for stirring welding, implements a mechanical and displacement dual-control motion system and functions of laser positioning, parameter fine adjustment and the like and can be used for welding a pin of a microchip and an ultrathin part.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Butted bracket for pipeline welding

PendingCN110682049AEffectively fixedQuick fixWelding/cutting auxillary devicesAuxillary welding devicesButt jointScrew thread

The invention discloses a butted bracket for pipeline welding. The butted bracket comprises a base, bottom plates and press plates, wherein two bearings are arranged in the central positions of the two side walls in the base, a moving rod and a threaded rotating shaft are movably mounted in the base through the bearings, the moving rod is located under the threaded rotating shaft, a limiting blockis arranged in the central position of the threaded rotating shaft, a first thread and a second thread are formed on the surface of the threaded rotating shaft, are mutually opposite and are mutuallysymmetric with the limiting block serving as a symmetry point, internal thread sleeves are arranged at the first thread and the second thread in a sleeving manner, stand columns are fixedly mounted at the tops of the two internal thread sleeves, and an opening is formed in the central position of the top of the base. By means a series of structures, the butted bracket has the characteristics of facilitating rapid fixation and rapid butt joint of pipe orifices.

Owner:CHINA THIRD METALLURGICAL GRP

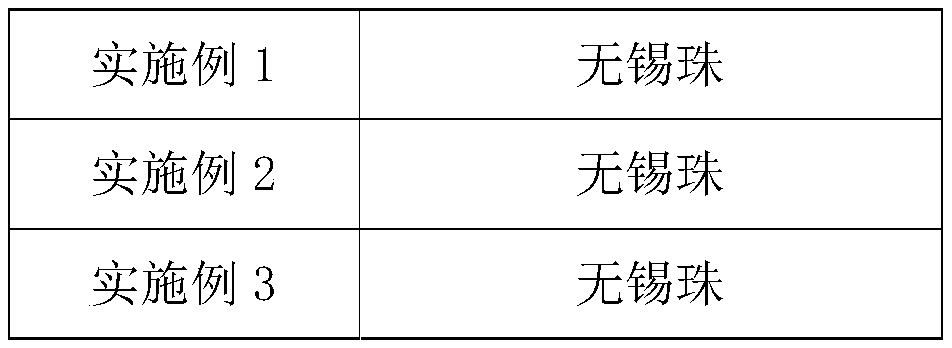

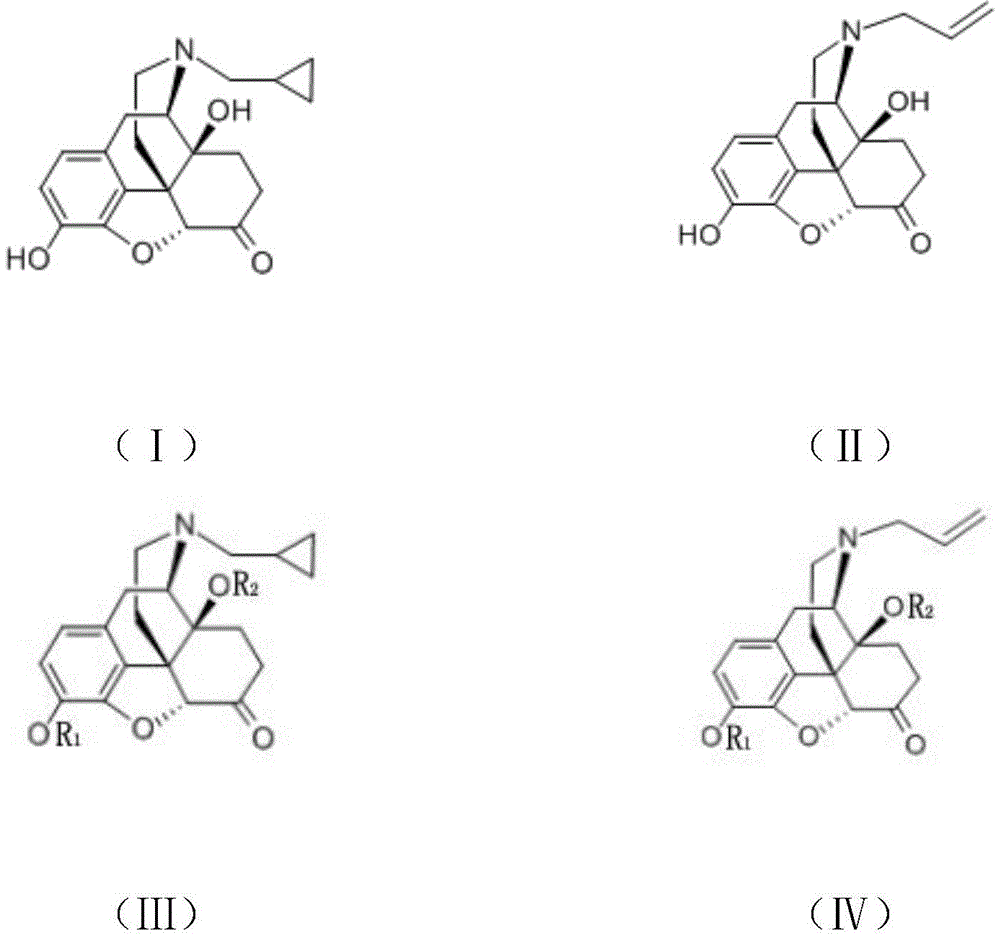

Anti-splashing laser soldering paste and preparation method thereof

ActiveCN111571064AIncrease moistureReduce oxidationWelding/cutting media/materialsSoldering mediaOrganic acidAlloy

The invention provides anti-splashing laser soldering paste. The anti-splashing laser soldering paste is prepared from raw materials in percent by weight: 87%-90% of alloy powder and 10%-13% of scaling powder. The alloy powder is formed by mixing one or more kinds of tin-based alloy powder and has a eutectic composition. The scaling powder is prepared from components in percent by weight: 35%-55%of rosin, 4%-9% of a thixotropic agent, 3%-9% of organic acid, 2%-8% of organic amine, 2%-6% of a high-boiling-point additive, 1%-2% of a compound X and the balance being a solvent. The invention further provides a preparation method of the anti-splashing laser soldering paste. The anti-splashing laser soldering paste can achieve instant welding, and has good wettability, and the problems of tin blasting, splashing, tin balls, non-tin-melting and the like are avoided.

Owner:深圳市唯特偶新材料股份有限公司 +1

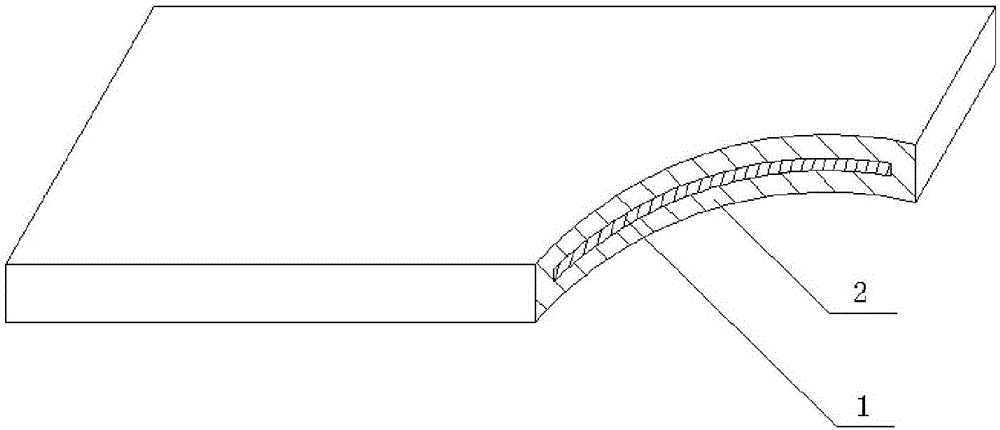

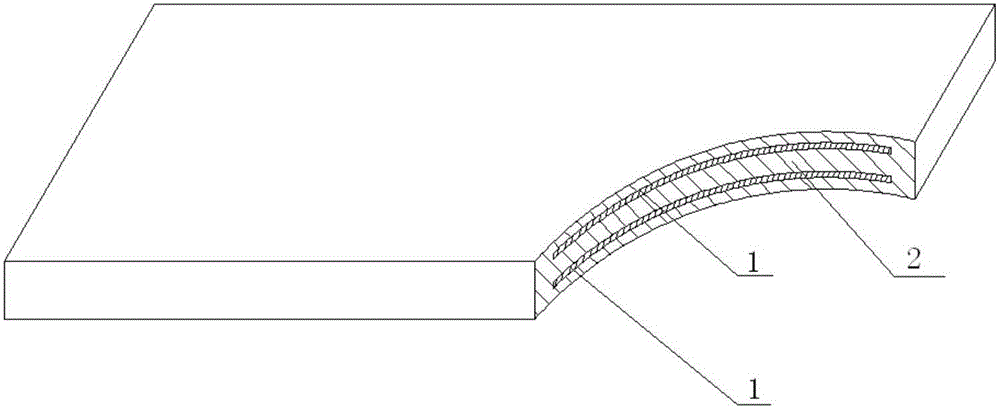

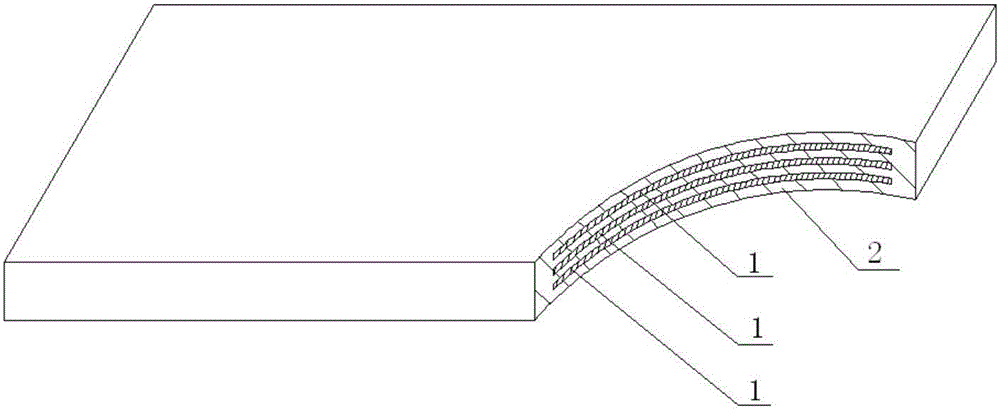

Waterproof roll free of folds and easy to weld

ActiveCN104531000AIncrease elasticityIncreased tensile strength at breakFilm/foil adhesivesMarine site engineeringPolyolefinEngineering

The invention belongs to the technical field of waterproof materials used in water conservancy projects and building projects and particularly discloses a waterproof roll free of folds and easy to weld. According to the technical scheme, the waterproof roll free of folds and easy to weld comprises a sheet, non-asphalt self-adhesive flue layers and isolating films, wherein the non-asphalt self-adhesive flue layers are attached to one side face or two side faces of the sheet, and the self-adhesive flue layers are coated with the isolating films. The sheet comprises, by weight, 65-70 parts of polyethylene, 15-18 parts of POE, 10-12 parts of EVA, 5-7 parts of polyethylene flexibilizer, 4-6 parts of maleic anhydride compatilizer and 1-2 parts of polyolefin aging-proof agent. The waterproof roll free of folds and easy to weld has the advantages that the hot melting temperature is low, both welding and construction are easy, and compared with ordinary materials, on the premise that the excellent welding effect is guaranteed, the welding temperature is lowered by 50-80 DEG C, and power consumption of a welding device is greatly reduced; meanwhile, the tensile strength at break is high, the elongation at break is high, the tearing strength is high, and chemical corrosion resistance is achieved, and the requirement for conduction in a low-temperature environment is met.

Owner:河北创隆工程橡塑有限公司

High-activity rosin soldering flux

InactiveCN104551451AImprove reliabilityGood electrical performanceWelding/cutting media/materialsSoldering mediaSalicylic acidStearic acid

The invention discloses high-activity rosin soldering flux. The high-activity rosin soldering flux is prepared from the following raw materials in parts by weight: 20-30 parts of rosin, 10-15 parts of phenolic resin, 5-10 parts of lactic acid, 5-10 parts of salicylic acid, 2-5 parts of citric acid, 2-3 parts of malonic acid, 10-15 parts of stearic acid, 5-10 parts of octaphenyl polyoxyethyiene, 2-5 parts of lauryl sodium sulfate, 0.5-1 part of aniline hydrochloride, 0.5-1.5 parts of zinc chloride, 1-1.5 parts of tin chloride, 0.2-0.5 part of aluminum chloride, 0.5-1 part of catechol, 1-3 parts of mercaptobenzothiazole, 5-10 parts of water, 2-5 parts of alcohol and 3-4 parts of acetone. The high-activity rosin soldering flux disclosed by the invention is not only environment-friendly in a using process, but also capable of improving the welding effect to the greatest extent.

Owner:TIANCHANG FEILONG BRAND STEEL GRID

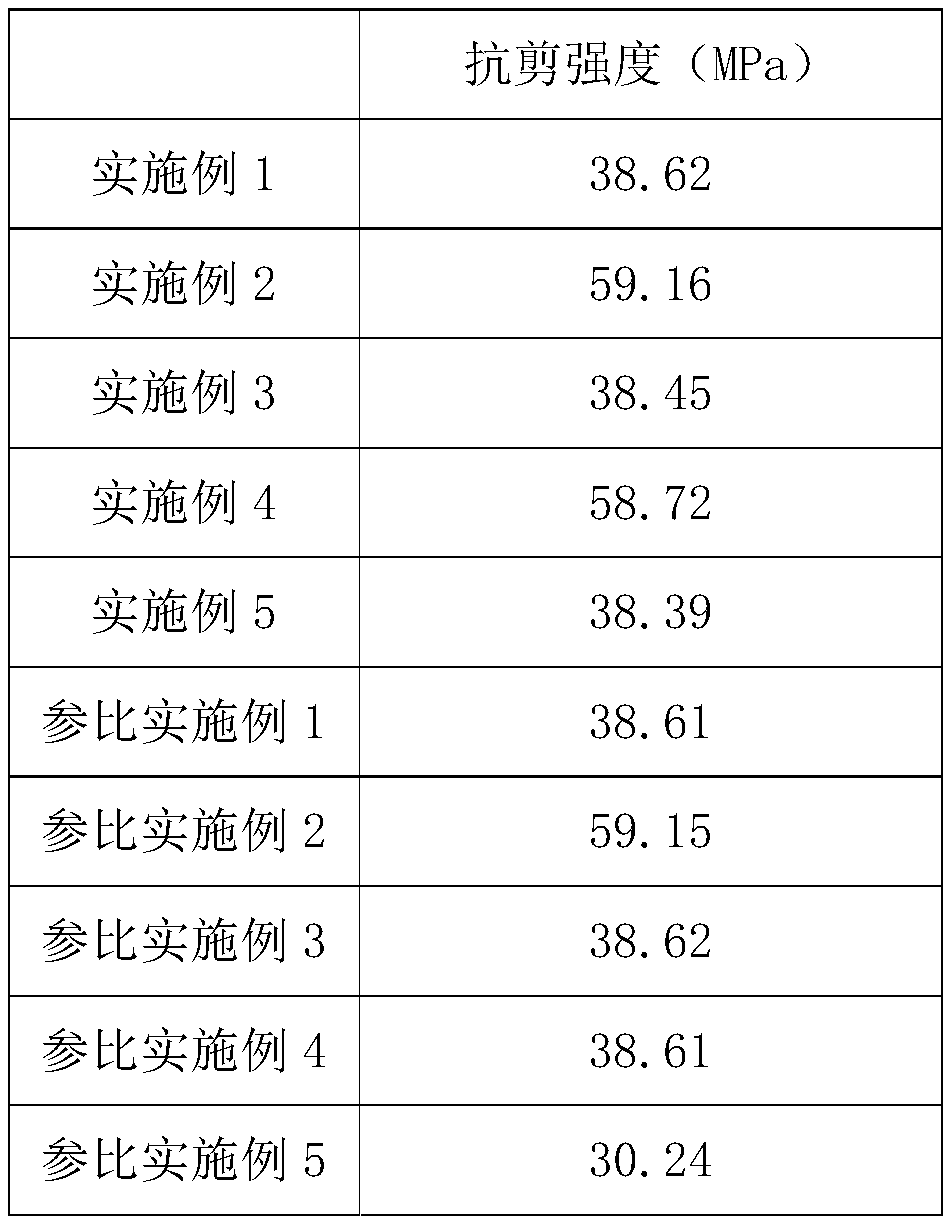

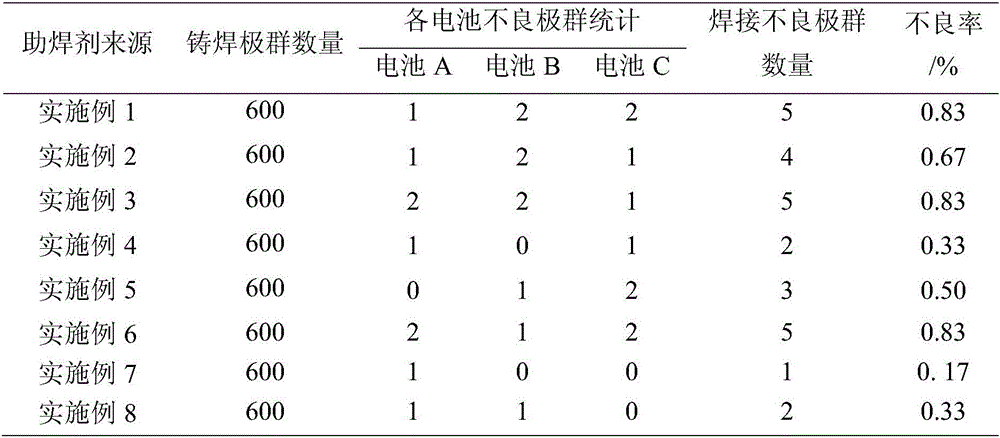

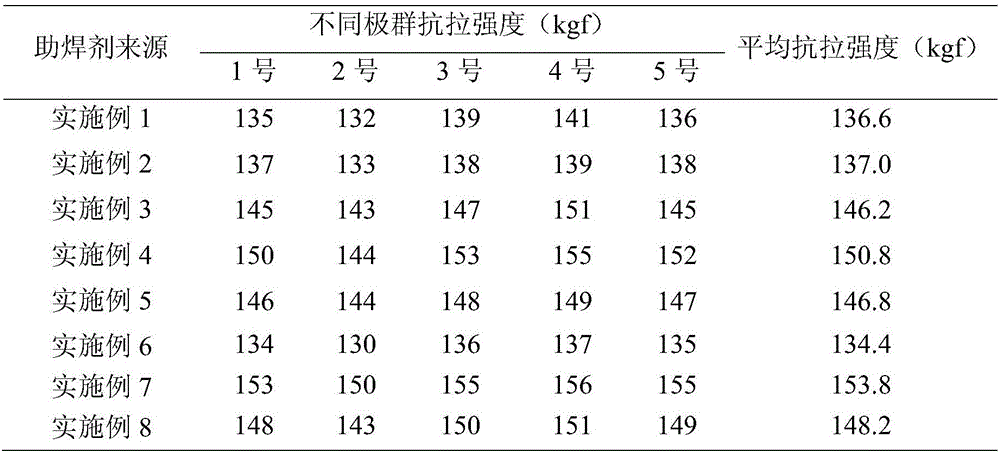

Lead acid battery flux and preparation method and application thereof

InactiveCN105945452AEfficient removalGood welding effectWelding/cutting media/materialsSoldering mediaAlcoholPhosphoric acid

The invention discloses a lead acid battery flux. The lead acid battery flux comprises the following components by mass percent: 5 to 20% of alcohol and 50 to 80% of phosphoric acid, and the balance being water. According to the lead acid battery flux, oxides on a tap can be effectively removed, the battery has a good busbar welding effect, the battery welding quality is improved, the defective problems of false welding, wrap welding and scaling of a product are improved, the welding defect rate is effectively decreased, residues after welding are less, the phenomenon that a battery is scrapped due to the situation that the flux adheres to a polar plate and a partition plate is eliminated, raw materials are convenient to obtain and prepare, and compared with a flux which can be purchased in the market, the flux has the advantage that the production cost is relatively low.

Owner:ZHEJIANG TIANNENG POWER ENERGY

Automatic brazing device of connection between copper and stainless steel

InactiveCN103111697AGood welding effectImprove welding qualitySoldering apparatusInduction weldingTemperature sense

The invention discloses an automatic brazing device of connection between copper and stainless steel. The automatic brazing device of the connection between the copper and the stainless steel comprises an operating platform and is characterized by further comprising a high-frequency induction welding machine, a sealing box and a brazing clamp. The high-frequency induction welding machine and the sealing box are arranged on the operating platform, argon is aerated into the sealing box, the brazing clamp is arranged in the sealing box, and a welding joint of the high-frequency induction welding machine stretches to a welding post on the brazing clamp inside the sealing box. The problems that in the prior art, when the copper and the stainless steel are welded, the stainless steel is relatively fast in temperature rising and the copper is relatively slow in temperature rising due to the fact that temperature sensing coefficients have a big difference, therefore, in the process of welding, the copper and the stainless steel are heated for same time, but the reached temperature is different so that the welding effect is relatively poor, and the product quality is influenced are solved. The automatic brazing device of the copper and the stainless steel is simple in structure, convenient to use and has relatively good welding quality.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

Lead-free and halogen-free roll coating solder paste and preparation method thereof

ActiveCN105618953AGood antioxidant propertiesGood welding effectWelding/cutting media/materialsPrinted circuitsOrganic acidSurface-active agents

Owner:DONGGUAN XIANFEI ELECTRONICS MATERIAL CO LTD

Welding clamp for aviation chair handrail

ActiveCN105290673AGood welding effectPrecise sizeWelding/cutting auxillary devicesAuxillary welding devicesHandrailEngineering

The invention provides a welding clamp for aviation chair handrail. The welding clamp for aviation chair handrail comprises a supporting block and a limiting block. One end of a base extends to form a pressing seat, a sliding groove is formed in the top of the pressing seat, and a sliding seat is movably assembled on the sliding groove. A pressing block is arranged at one end of the top of the sliding seat, a cam disc is arranged on the pressing seat at the other end of the sliding seat, and a control handle is arranged on the cam disc. The base is provided with the limiting block matched with the pressing block, the supporting block is arranged on one side of the limiting block, and a U-shaped clamping groove is formed in the top of the supporting block. A positioning block is arranged on one side of the supporting block, press pincers are arranged on one side of the positioning block, a pressing plate is arranged on a telescopic rod of the press pincers and provided with an inwards concaved arc surface, and the arc surface is located on one side of the positioning block. After the scheme is adopted, manual positioning is not needed, the welding effect is good, the size is accurate, a skewing phenomenon is avoided, the labor intensity of workers is greatly relieved, and the quality of products is improved.

Owner:HUZHOU MEISHENG MACHINERY

Automobile welding equipment for improving welding stability

InactiveCN108994504AImprove stabilityEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringThreaded rod

The invention discloses automobile welding equipment for improving welding stability and relates to the technical field of welding. The automobile welding equipment comprises a box body, one side of the box body is fixedly connected with a motor box, a first motor is fixedly connected to the bottom of the inner wall of the motor box, an output shaft of the first motor is fixedly connected with a threaded rod, the two sides of the surface of the threaded rod are both in threaded connection with sliding blocks, the tops of the sliding blocks are fixedly connected with first rotating bases, the surfaces of the first rotating bases are rotationally connected with rotating rods, and one ends of the rotating rods are rotationally connected with a second rotating base. Through the automobile welding equipment for improving the welding stability, parts are fixed conveniently, the welding stability of automobile parts is improved, welding quality is improved, clamp operation is simple, the equipment can be adapted to automobile parts in different sizes, there is no need to carry out welding through multiple types of welding tools, welding cost is reduced, and the equipment is suitable for being applied and popularized.

Owner:WUHU RUITAI PRECISION MACHINERY

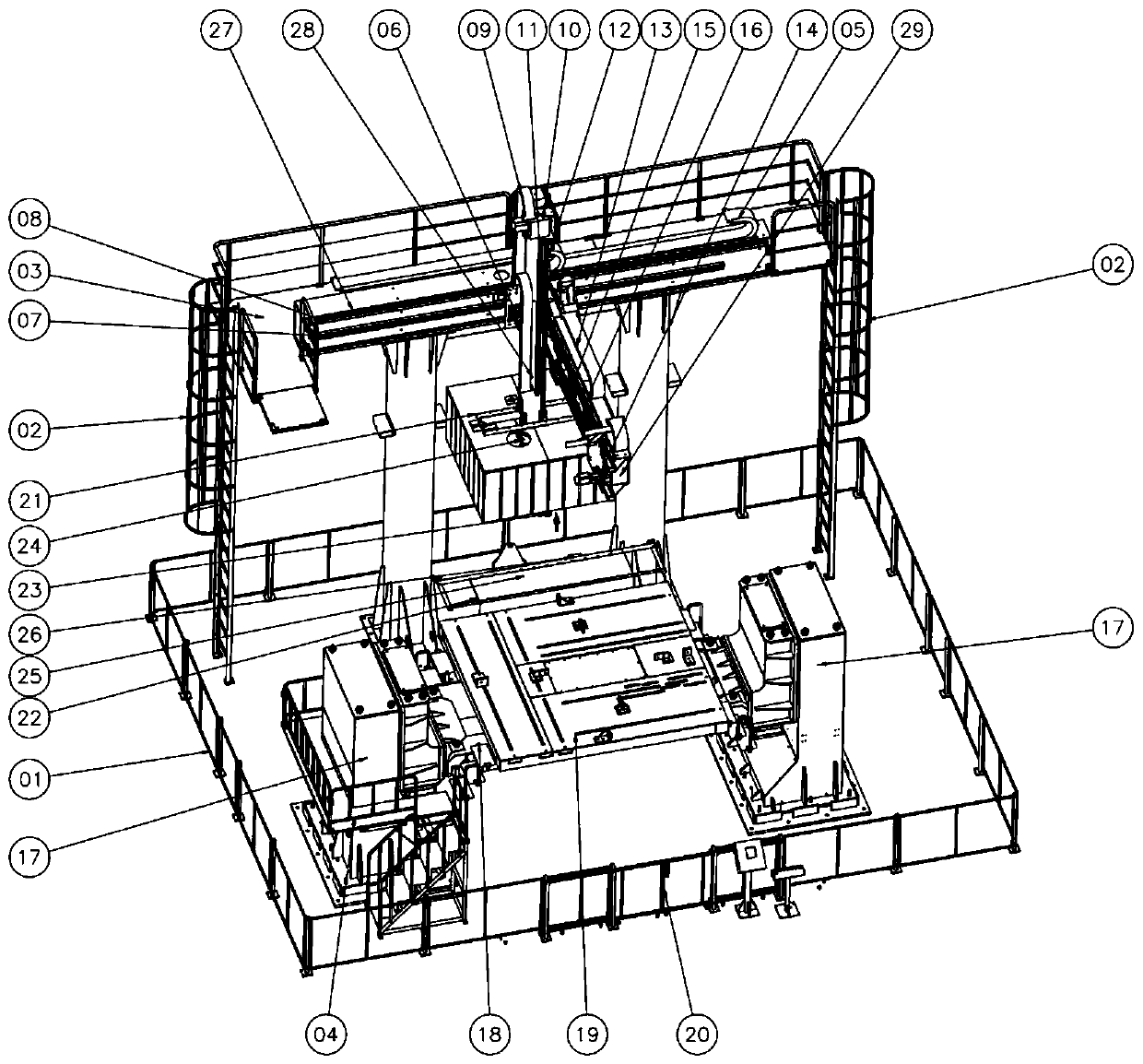

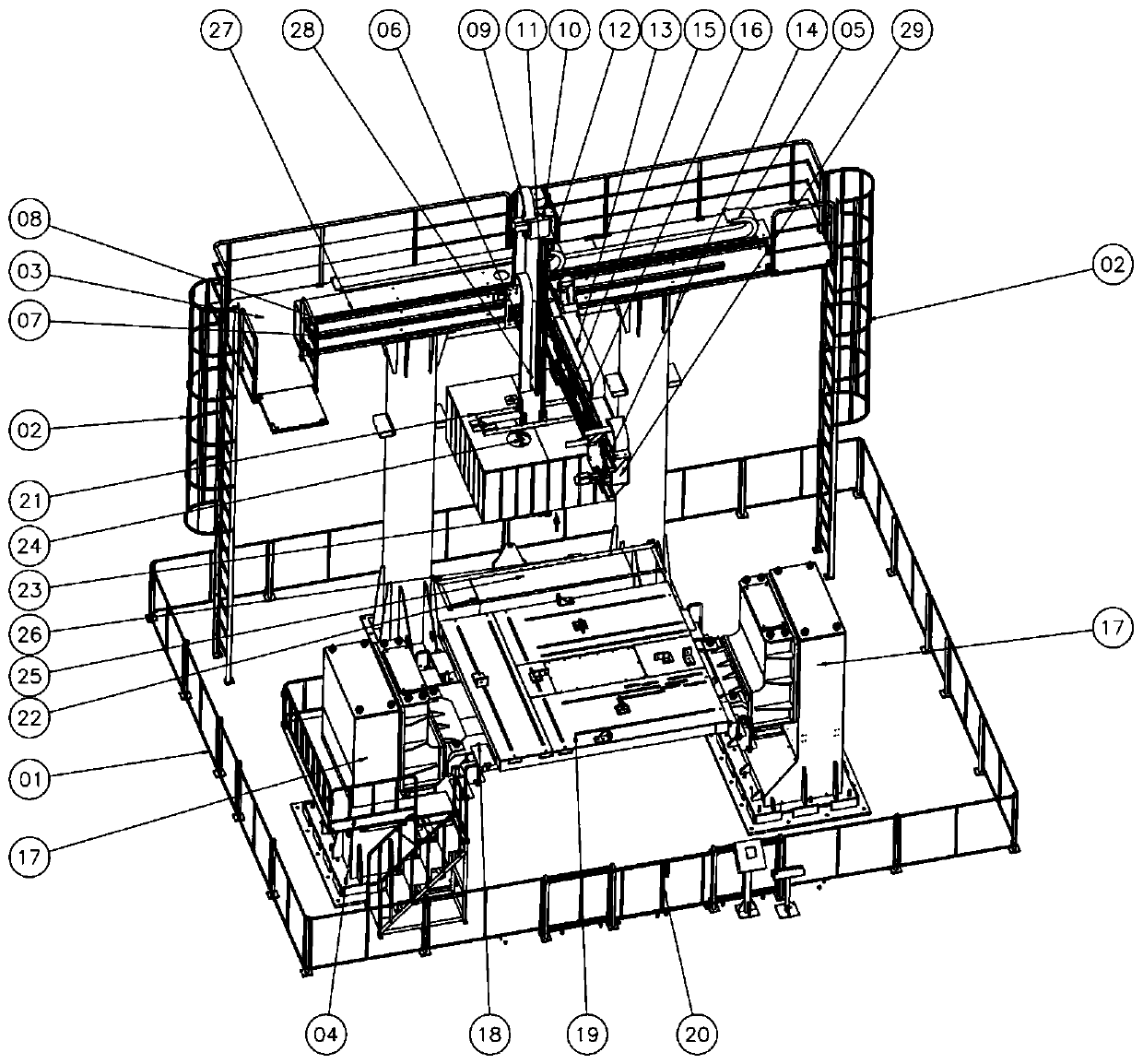

Large-sized robot welding workstation with flue dust treatment function

PendingCN109702291AExpand the welding rangeIncrease freedomWelding/cutting auxillary devicesAuxillary welding devicesControl systemDegrees of freedom

The invention discloses a large-sized robot welding workstation with a flue dust treatment function. The large-sized robot welding workstation comprises a safe enclosure of a welding workshop, a welding location control system, a workpiece turnover platform, a flue dust treatment robot welding system and a workstation controller, wherein the workpiece turnover platform and the flue dust treatmentrobot welding system are arranged in the safe enclosure of the welding workshop; the welding location control system is arranged above the flue dust treatment robot welding system; and the welding location control system, the workpiece turnover platform, the flue dust treatment robot welding system and the workstation controller are electrically connected. With the welding location control systemand the workpiece turnover platform, the welding range and the degree of freedom are extended, and the problem of small welding operation range of the welding robot is effectively solved; a high-pressure contact sensor is adopted for the welding robot, so that the actual weld joint position is determined automatically according to deformation in the welding process, and the optimal welding effectis achieved; and a flue dust treatment device improves the environment friendliness performance.

Owner:GUANGZHOU RUISONG INTELLIGENT TECH CO LTD

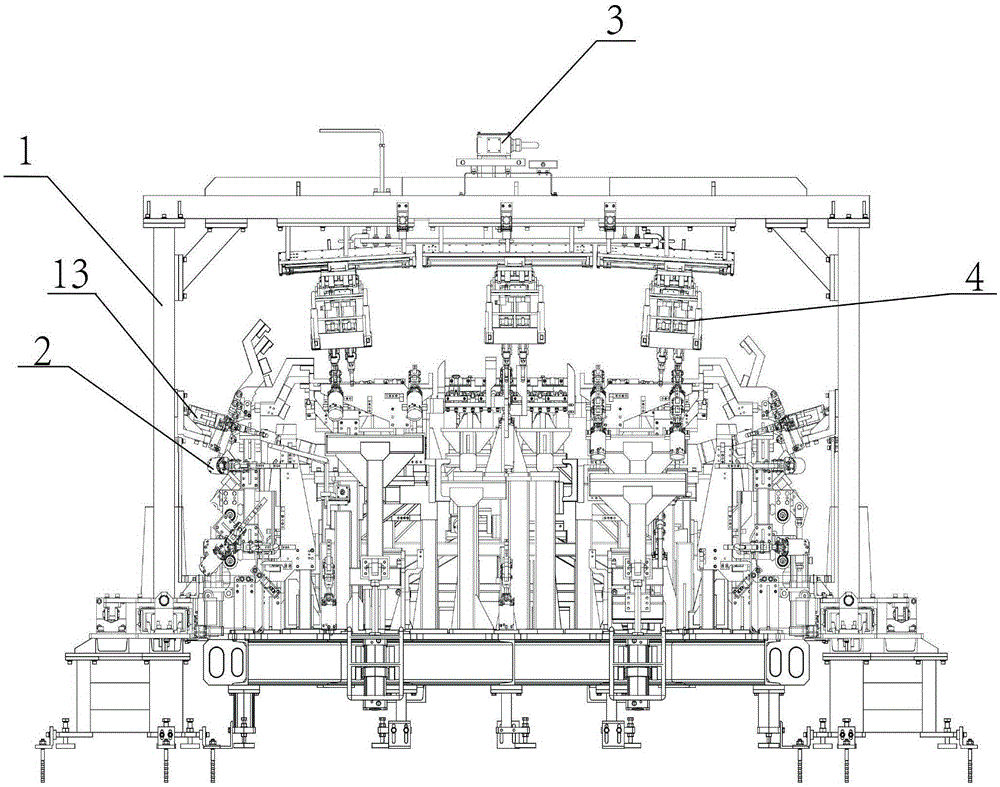

Single-face double-point welding process for automobile

InactiveCN105382393AReduce the difficulty of operationGood welding effectResistance electrode holdersVehicle componentsTransformerFunctional requirement

The invention aims at providing a single-face double-point welding process for an automobile. The process is characterized in that the process involves a special welding machine, automobile welding special clamps, a transformer, single-face double-point welding tongs, single-face double-point welding mechanisms, a gantry steel structure, gantry sliding-out mechanisms, gantry bases, a welding tong welding plane moving structure, upper electrodes, lower electrode islands, conductive bridges and locating connection parts; the transformer and the single-face double-point welding tongs are carried on the special welding machine, single-side double-electrode welding is adopted by the special welding machine, and the transformer is mounted on the top of the special welding machine. The process has the beneficial effects that full manual operation for welding can be achieved, only two workers are needed, and large heavy welding tongs are not used; the welding tongs are fixed to the special welding machine and are light, easy to operate and good in welding effect; on the basis that the functional requirement is met, the investment cost is lowered to a great extent, the operation difficulty of the workers is lowered, and the stability and multi-vehicle-type adapting capacity of equipment are greatly improved.

Owner:天津七所高科技有限公司

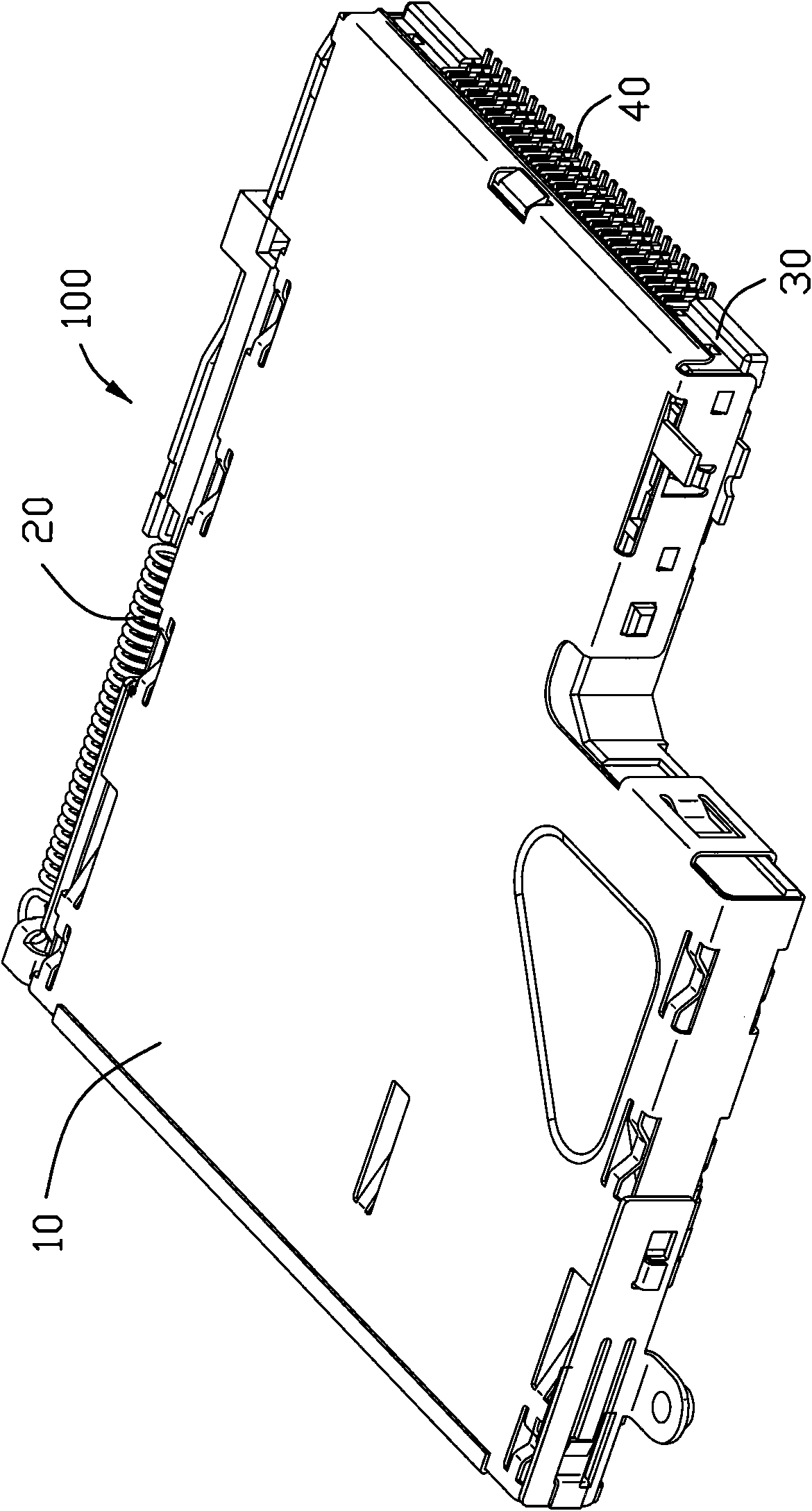

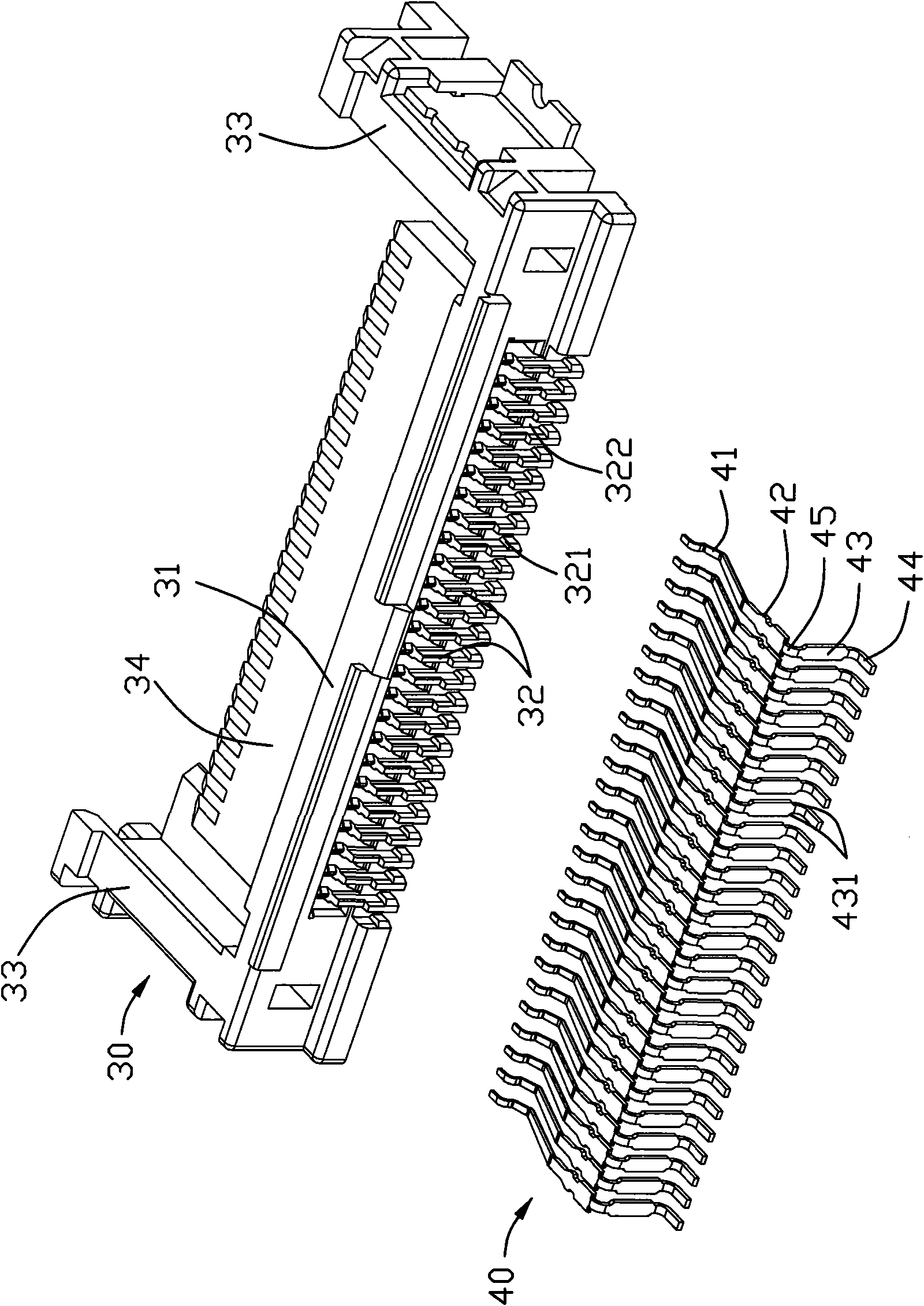

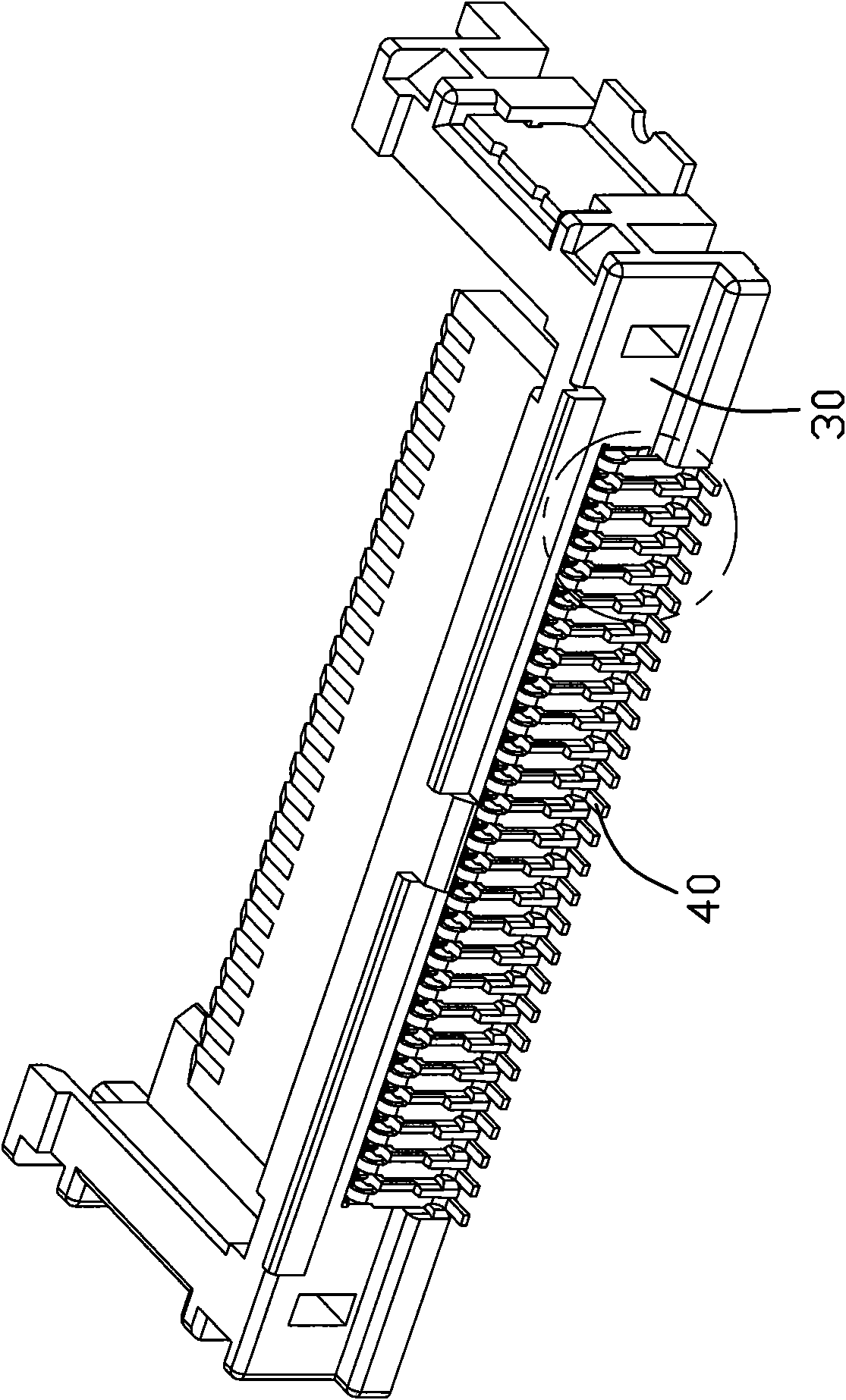

Electronic card connector

InactiveCN101651264AAvoid deformationIncreased requirements for coplanaritySecuring/insulating coupling contact membersCouplings bases/casesEngineering

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

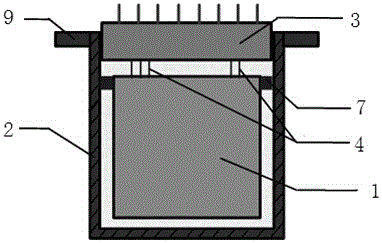

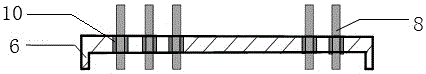

Airtight packaging structure of quartz flexible accelerometer

InactiveCN106066405AStable dynamic performance parametersRealize fully hermetic packageSpeed/acceleration/shock instrument detailsEpoxyAccelerometer

The invention discloses an airtight packaging structure of a quartz flexible accelerometer. The airtight packaging structure comprises a sensitive device, a shell, a servo circuit, a sealing cover and a glass insulator tube shell. The sensitive device is arranged in the sealing cover through epoxy glue. The opening part of the sealing cover is sealed by the glass insulator tube shell. The sealing cover, the glass insulator tube shell and the sensitive device jointly form a sensitive meter head. The sensitive device is fixedly arranged in the shell in the form of the sensitive meter head based on the gelatinization joint technology. The output lead of the sensitive device is connected with a servo circuit through pins on the glass insulator tube shell. Based on the packaging structure, the reliable and stable operation of an accelerometer in the low-pressure (or vacuum) environment and in the electromagnetic radiation environment for a long time can be ensured. Meanwhile, the structure is simple to manufacture and mature in process. The precision and the reliability of the accelerometer in satellite or other space application environments are effectively improved.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com