Patents

Literature

327results about How to "Low soldering temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

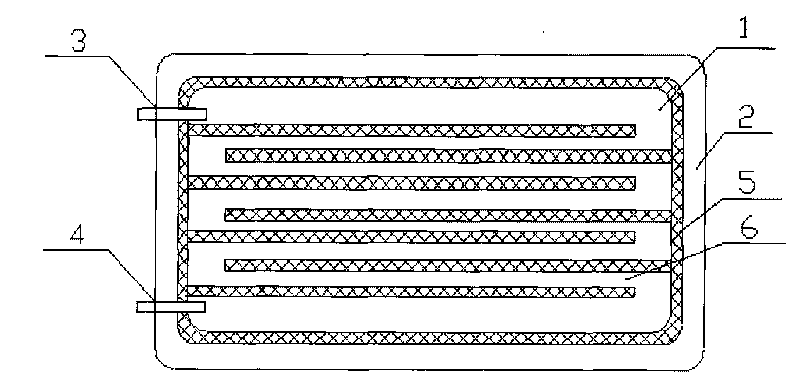

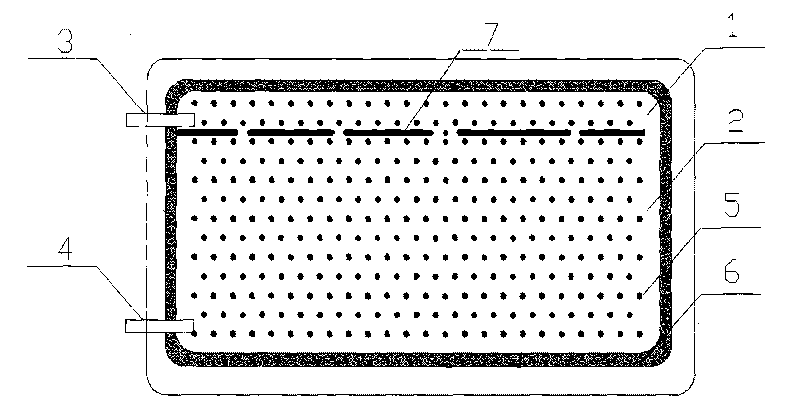

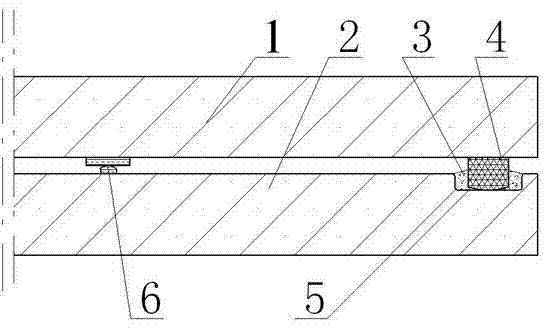

Stainless steel plate type heat exchanger and processing molding method thereof

InactiveCN101691961AUniform refrigerant flow pathLow flow resistanceShaping toolsEvaporators/condensersSteel platesHoneycomb

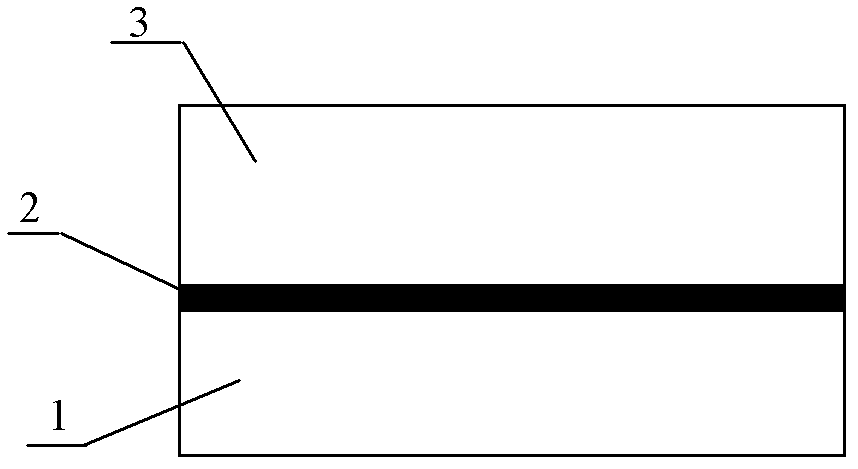

The invention discloses a stainless steel plate type heat exchanger and a processing molding method thereof. The plate type heat exchanger comprises a snakelike flow channel type and honeycomb flow channel type evaporation plate or a cold plate. The plate type heat exchanger adopts a stainless steel plate and consists of a stainless steel upper plate, a stainless steel lower plate, an inlet pipe and an outlet pipe, wherein the two stainless steel plates are overlapped and connected by a special welding method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two stainless steel plates and are connected with the stainless steel plate type heat exchanger body by using an electric arc welding method; and then the plate type heat exchanger is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

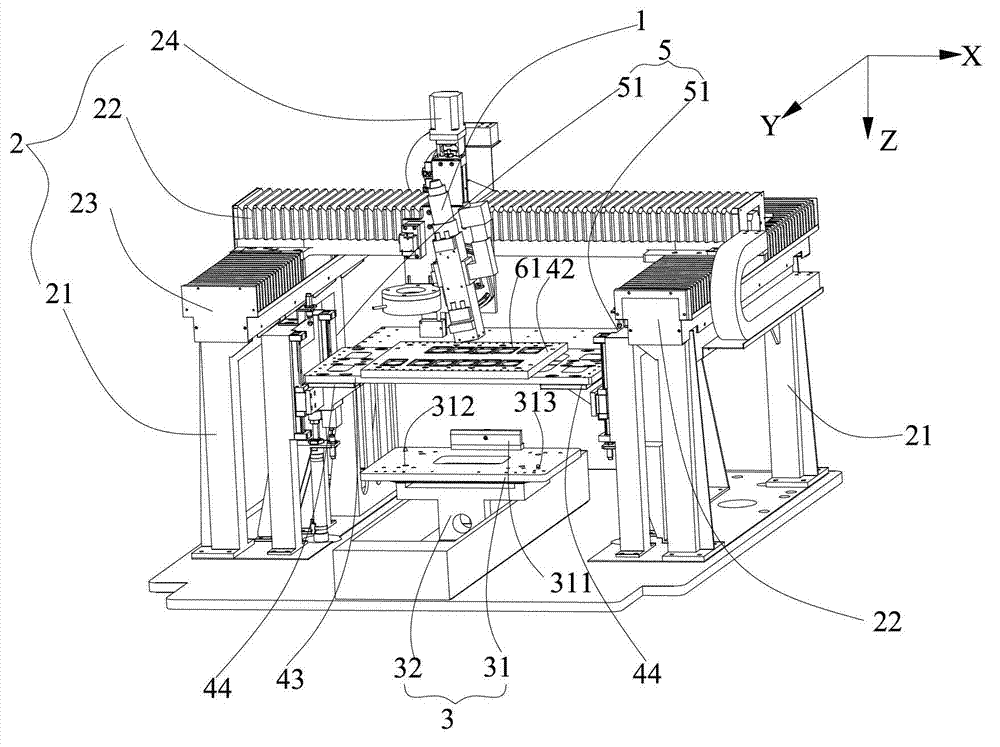

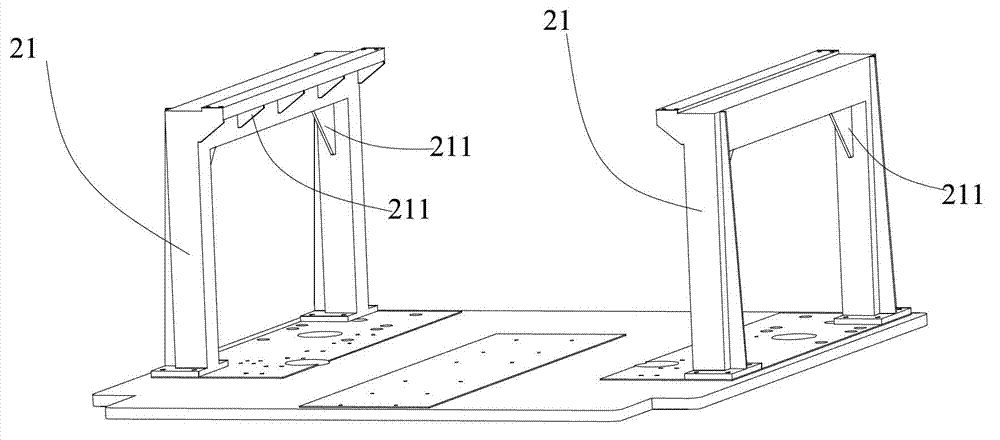

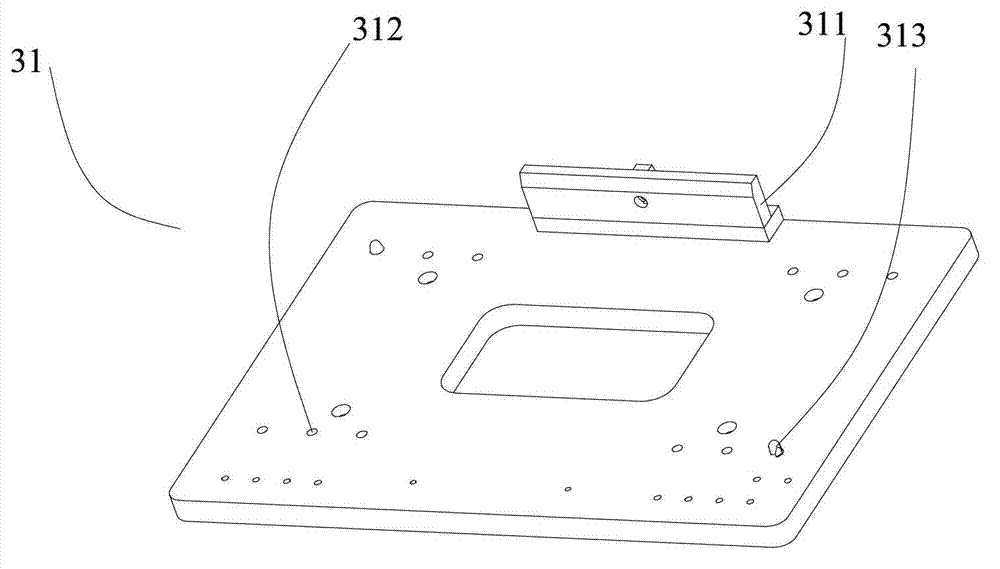

Full-automatic laser welder

ActiveCN103240527AGuaranteed compression effectSolving Automatic Laser Welding ProblemsLaser beam welding apparatusPortal frameLaser

The invention provides a full-automatic laser welder comprising a laser head, a laser head servo mechanism, a feeding and discharging device, a pressing mechanism and a transmission mechanism. The pressing mechanism comprises a plurality of pressing blocks and a pressing block support, wherein each pressing block is provided with a passage for laser emitted by the laser head to pass; and the pressing block support is elastically connected with each pressing block. The transmission mechanism is connected to the pressing block support to drive the pressing block support to move vertically so as to press or separate from corresponding connecting pieces. The laser head servo mechanism can further comprise two portal frames which are bilaterally and symmetrically arranged relative to the feeding and discharging mechanism along the X-direction, and each portable frame is provided with reinforcing ribs. The transmission mechanism can comprise a pair of transmission components which is bilaterally and symmetrically arranged relative to the feeding and discharging mechanism. The full-automatic laser welder can further comprise a gas cooling mechanism, a welding positioning unit and a controller. Therefore, pressing effects of welding spots of workpieces at different heights are guaranteed, welding temperature is lowered effectively, stability of a welding process is guaranteed, and welding optimal rate and efficiency are quite high.

Owner:CONTEMPORARY AMPEREX TECH CO

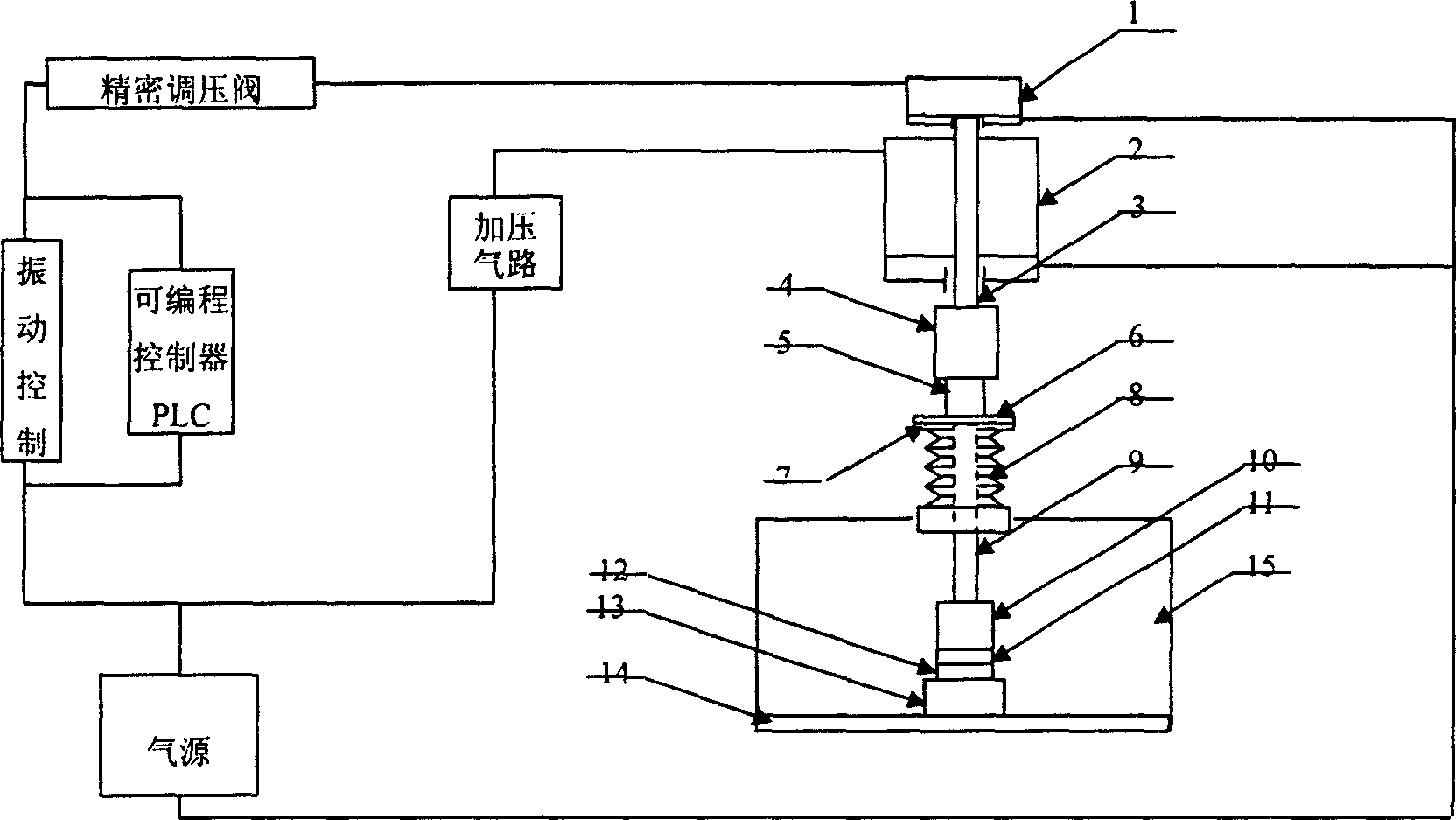

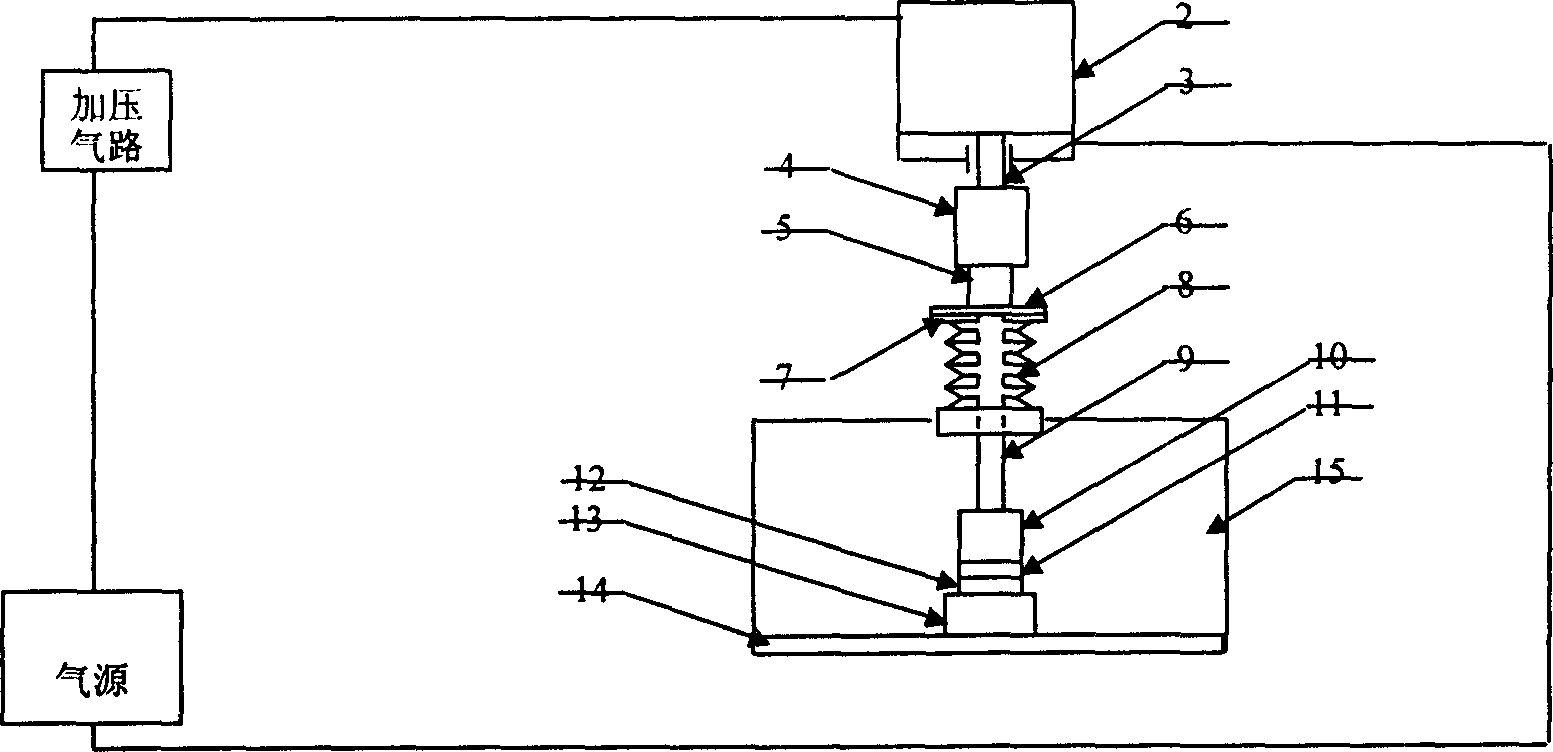

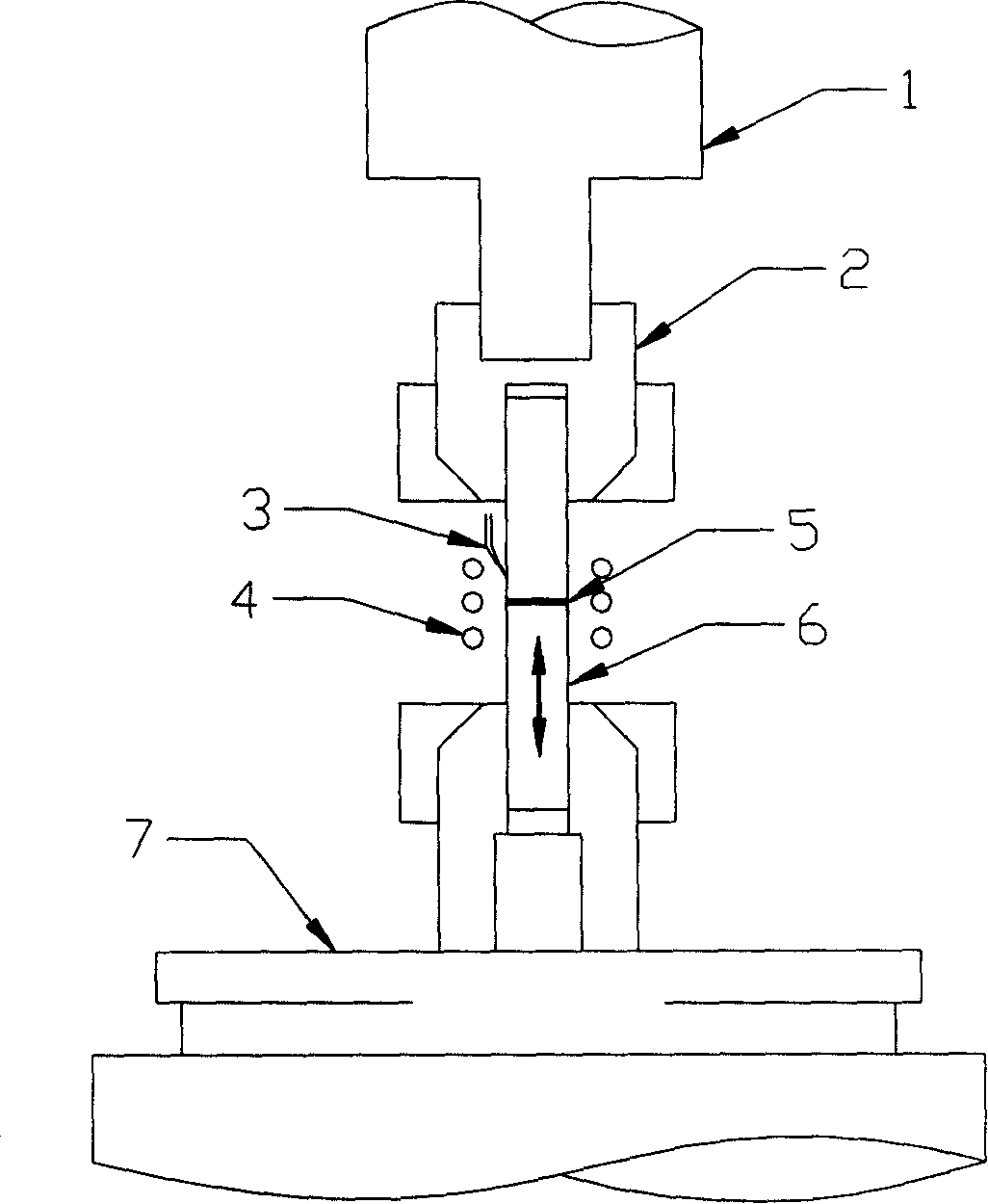

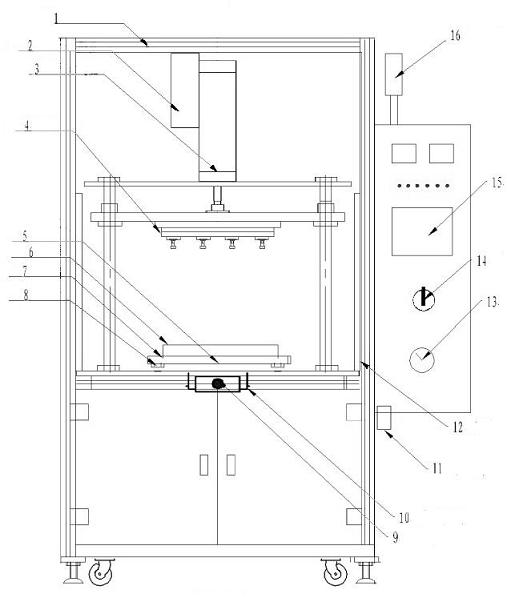

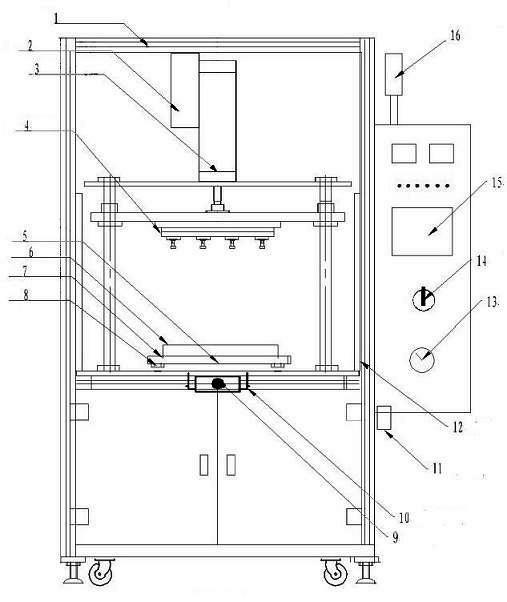

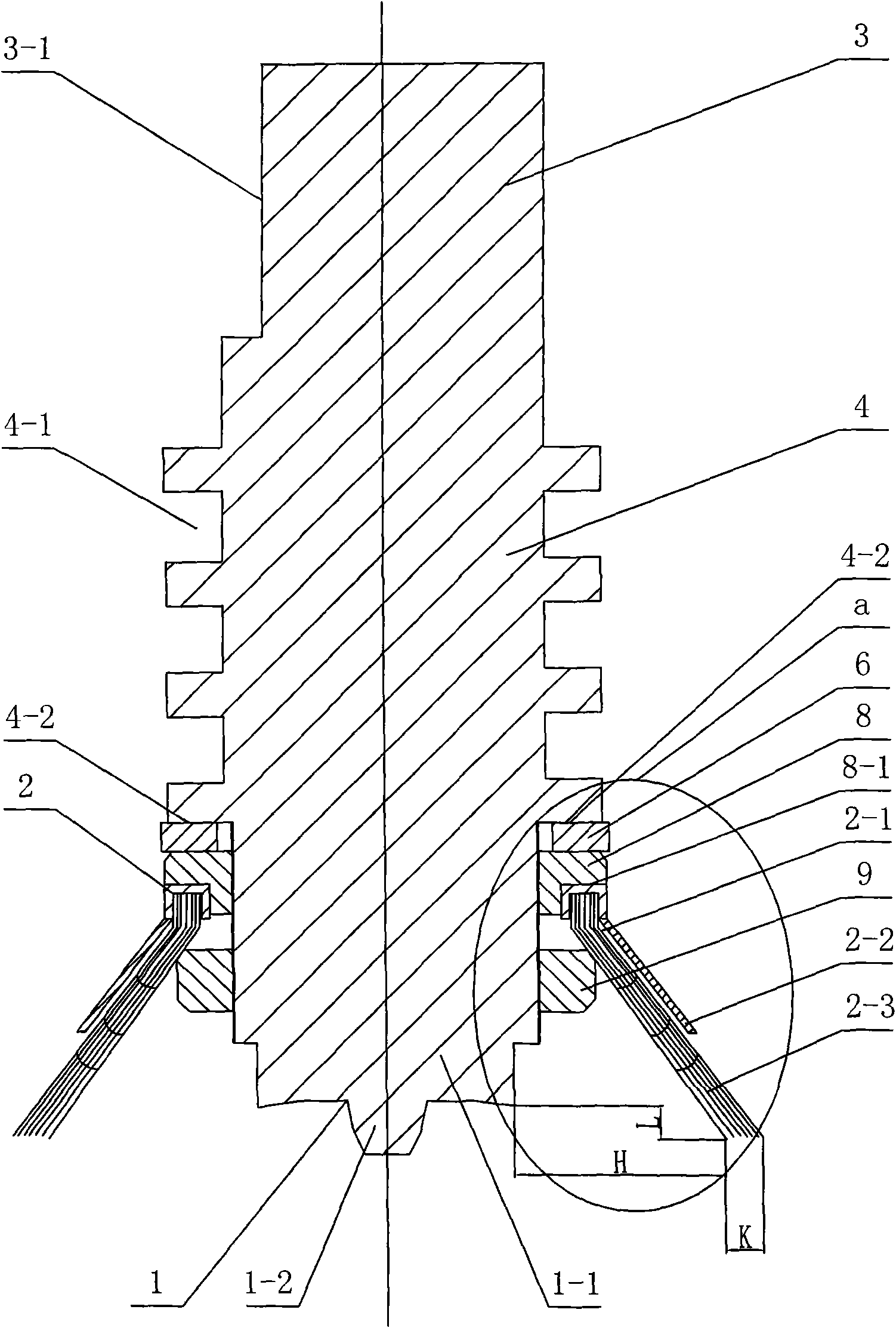

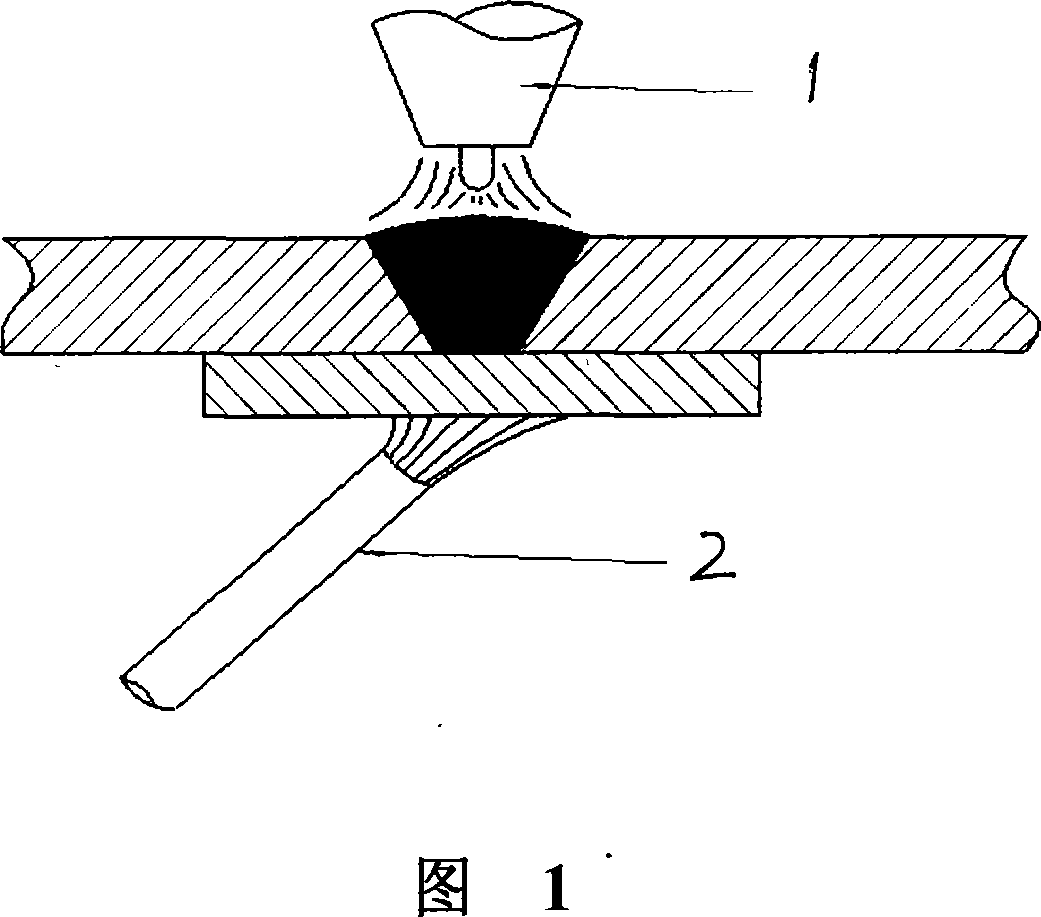

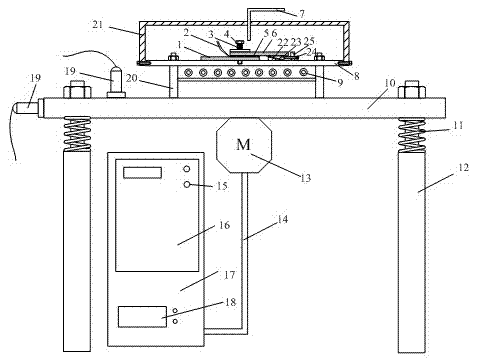

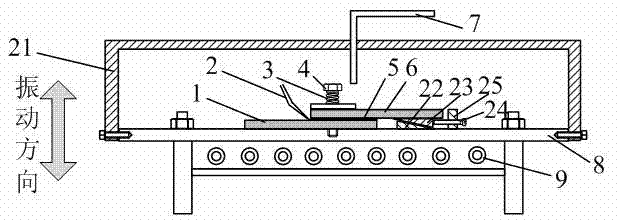

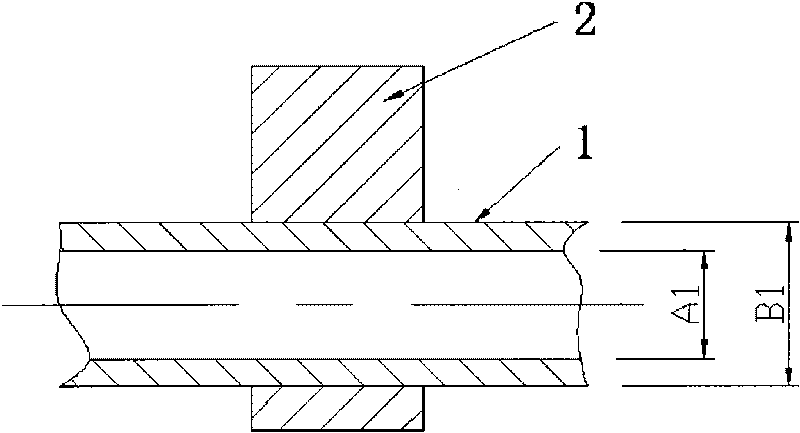

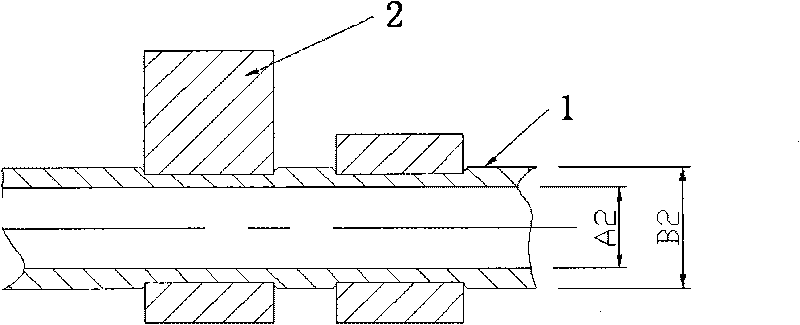

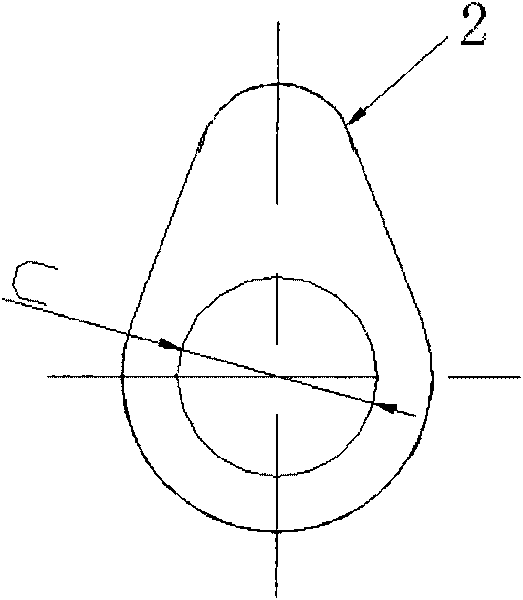

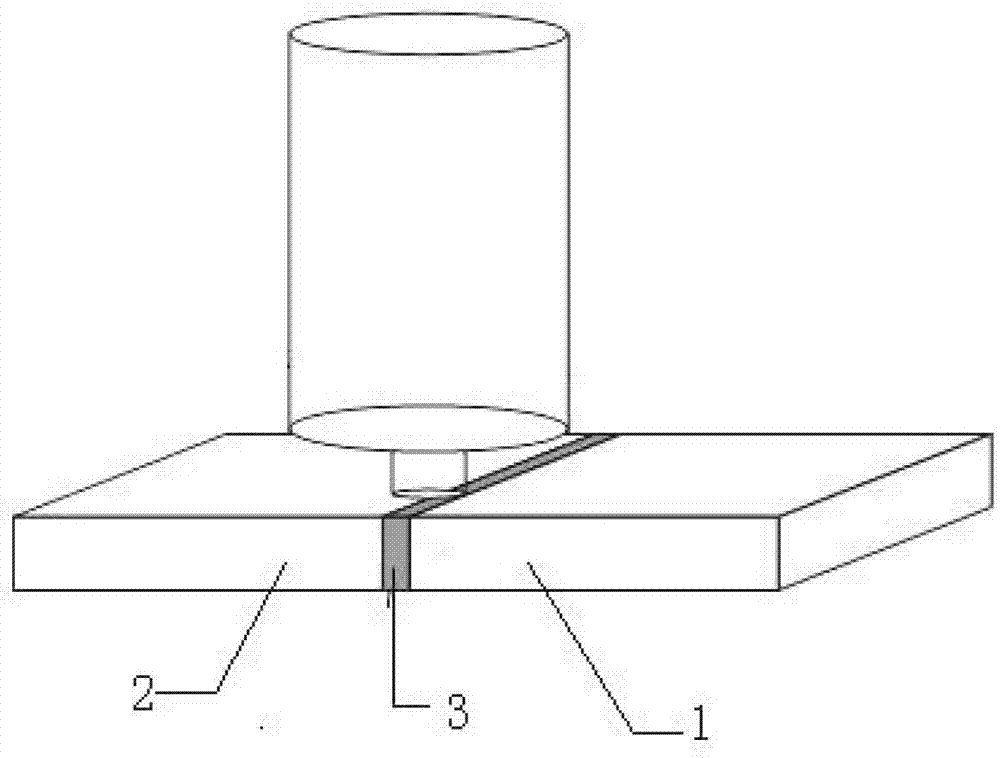

Pressurizing device and method for vacuum diffusion welding machine

InactiveCN1669718ALow soldering temperatureReduce welding soak timeNon-electric welding apparatusVibration controlEngineering

This invention disclose a pressure device for vacuum diffusion welding, with the purposes of solving problem of long time weld, too high temperature, which is characterized in adding a vibrating cylinder (1) to present device, precise pressure regulating valve, vibration controlling valve controlled by PLC and PLC matching with (1), wherein, vibrating cylinder (1) and pressure valve (2) share a pressure axis (3), other parts are all rigidly attached, vibrating cylinder (1) is attached to gas source circuit via precise regulating valve and vibration controlling valve and parallel to pressure circuit. The invention can lower welding temperature by 30-300Deg.C, reduce welding time by 20-50%, and improve efficiency of device by 1-3 times.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

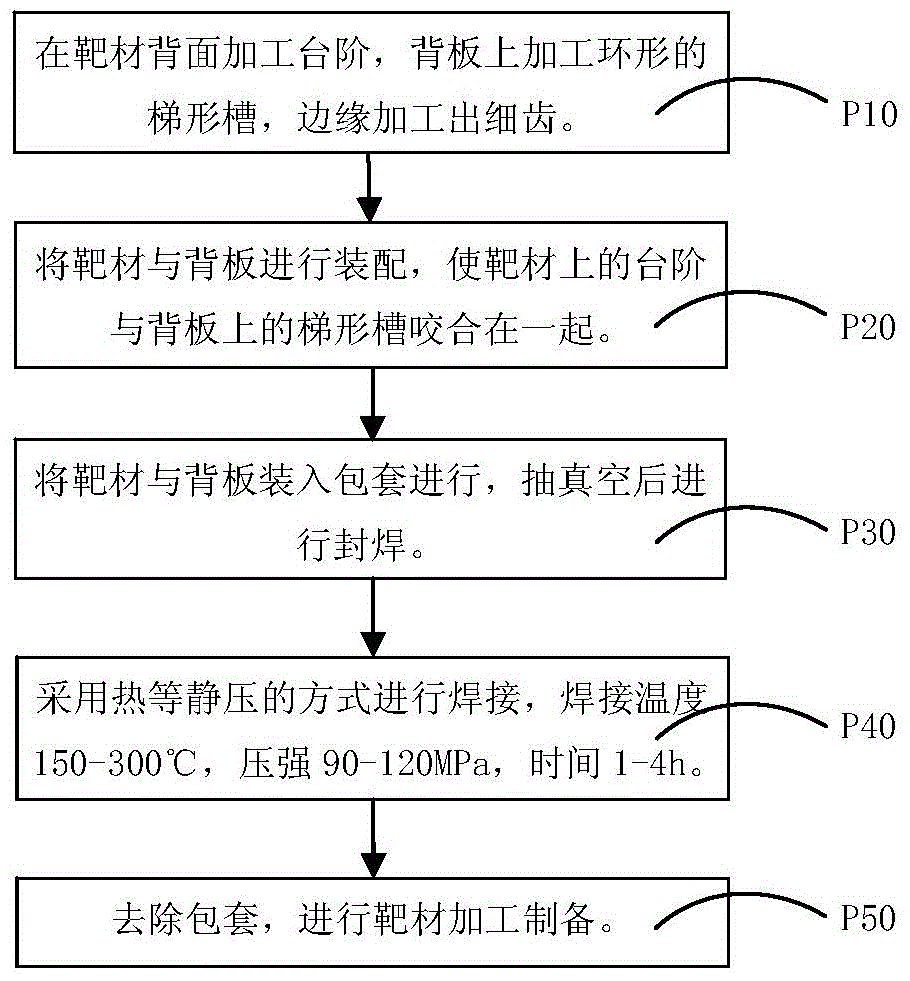

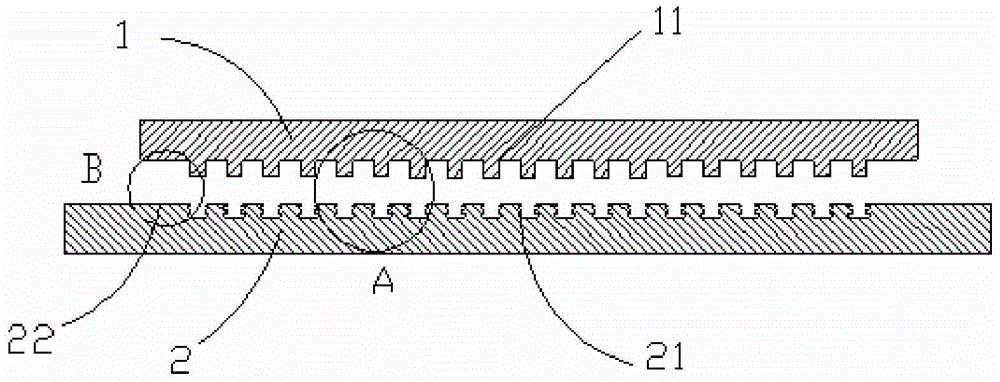

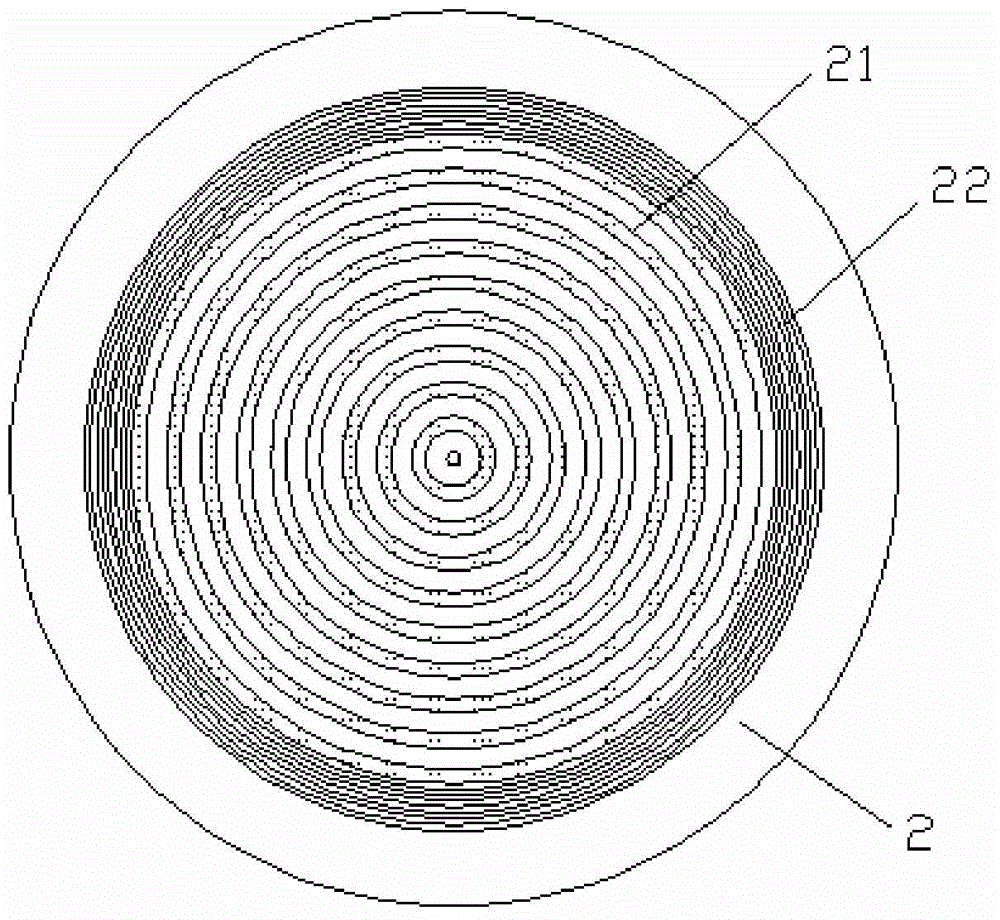

Welding method of aluminum alloy sputtering target material for integrated circuit package material

InactiveCN104625389AFine grainStrong reliabilityWelding/cutting auxillary devicesArc welding apparatusSputteringGrain growth

A welding method of an aluminum alloy sputtering target material for an integrated circuit package material comprises the steps that a protruding tooth of a certain shape and size is machined on the welding face of the target material, a corresponding groove is machined in a back plate, the target material and the back plate are put into a wrapping sleeve for carrying out vacuum seal welding after being assembled and combined, then a hot isostatic pressure method is adopted for enabling the groove to be completely filled with the material, and the target material is connected with the back plate. Due to the fact that welding temperature is low, aluminum alloy grain growth can be avoided, the welding intensity between the target material and the back plate is high, the target material is small in overall deformation, and subsequent machining is facilitated.

Owner:GRIKIN ADVANCED MATERIALS

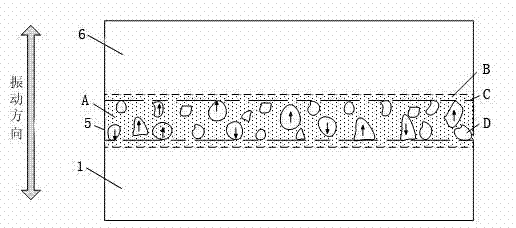

Aluminum alloy and its composite material non-vacuum semi-solid state vibration-rheological connection method

InactiveCN1876302AAchieve weldingShort welding cycleSoldering apparatusNon-electric welding apparatusForce constantSemi solid

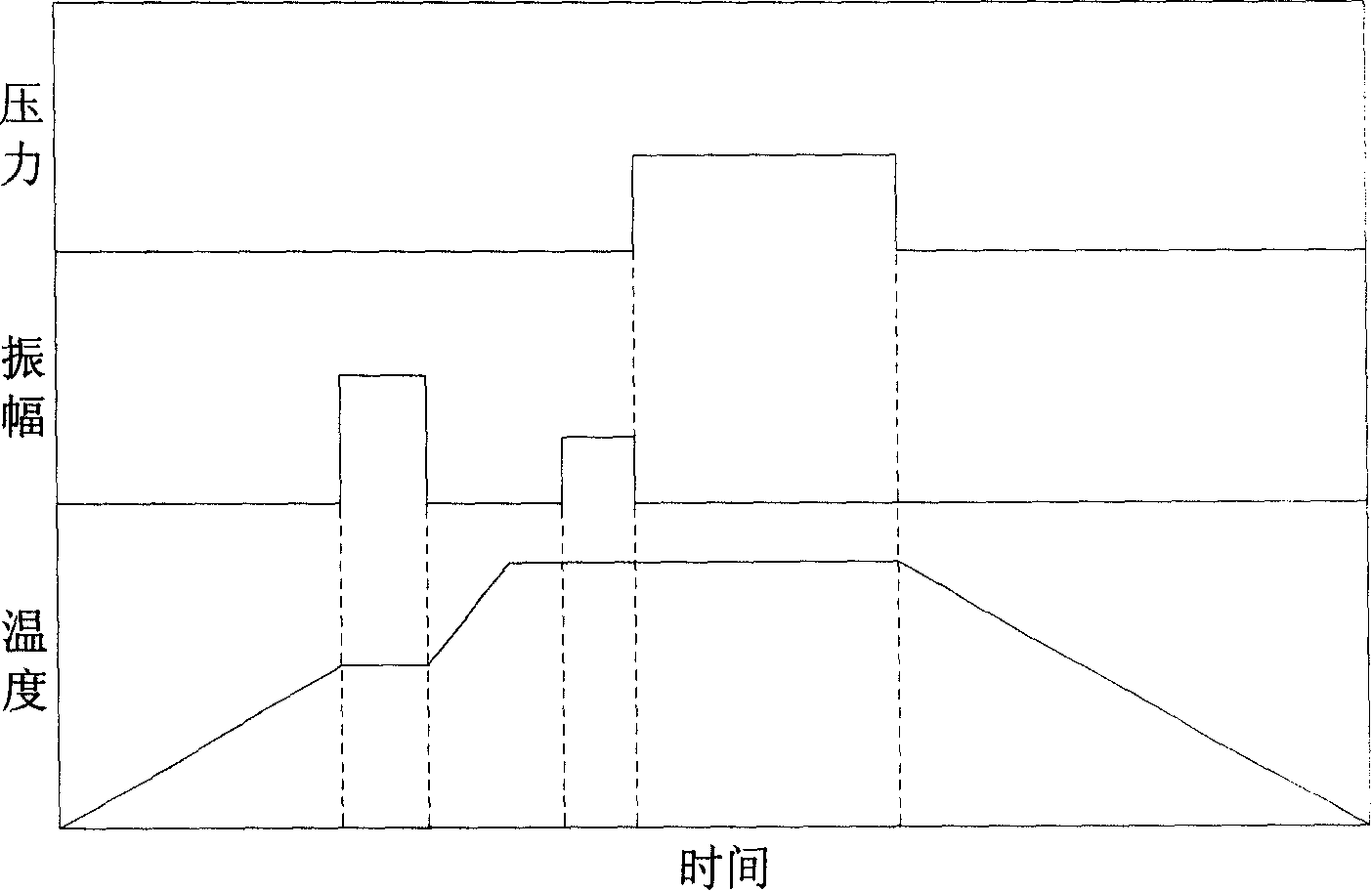

The invention provides a method for anti-vacuum vibrating theological connecting aluminum alloy and its complex material. The invention is characterized in that: clamping aluminum alloy or complex material weldment on chucking appliance and placing medium temperature welding material on two pre-welding surface, heating weldment with temperature being 380-400 Deg. C, starting vibrating device after welding material fusion, the amplitude is 0.1-0.5 mm. The temperature during vibrating process is the same, and the vibrating time is 10-300 seconds. The temperature is increased to 450-520 Deg. C after vibration, and it is kept for 1-5 minutes. Then starting vibrating device again, the amplitude is 0.1-1 mm, stopping after 3-60 seconds, forcing constant pressure with pressure range being between 0.1-2 Mpa, keeping temperature for 5-30 minutes, and cooling. The invention is characterized by low cost, high efficiency and quality.

Owner:HARBIN INST OF TECH

Hot melting device and hot melting method thereof

The invention relates to a hot melting device which comprises a stander and a cabinet, wherein the stander is arranged at the upper side of the cabinet, the side face of the stander is provided with a control box, the top surface of the cabinet is provided with a movable work table and a mould heating mould, the mould heating mould is fixedly connected with the top end of the stander by an upward / downward moving air cylinder, the mould heating mould is guided by stand columns arranged at two sides of the mould heating mould, the upper side of the movable work table is provided with a clamp, and the lower side of the movable work table is provided with a guide rail which moves the movable work table front and back and an air cylinder required for offering a frontward / backward motion. The hot melting device further comprises a pressurizing air cylinder, wherein the pressurizing air cylinder is arranged on the upward / downward moving air cylinder. Meanwhile, the invention further discloses a hot melting method of the hot melting device. Workpieces are connected with one another in a pressurizing way by means of hot melting, and a welding pressure is changed in the process of welding. Compared with the conventional hot melting welding mode, the pressure-variable welding mode is low in welding temperature, smooth in welding points, free from volatile smell during the conventional high-temperature hot melting welding of the plastic, and obvious in energy-saving effect, and the welding head and heating parts are long in service life.

Owner:太仓市皓荣化工科技有限公司

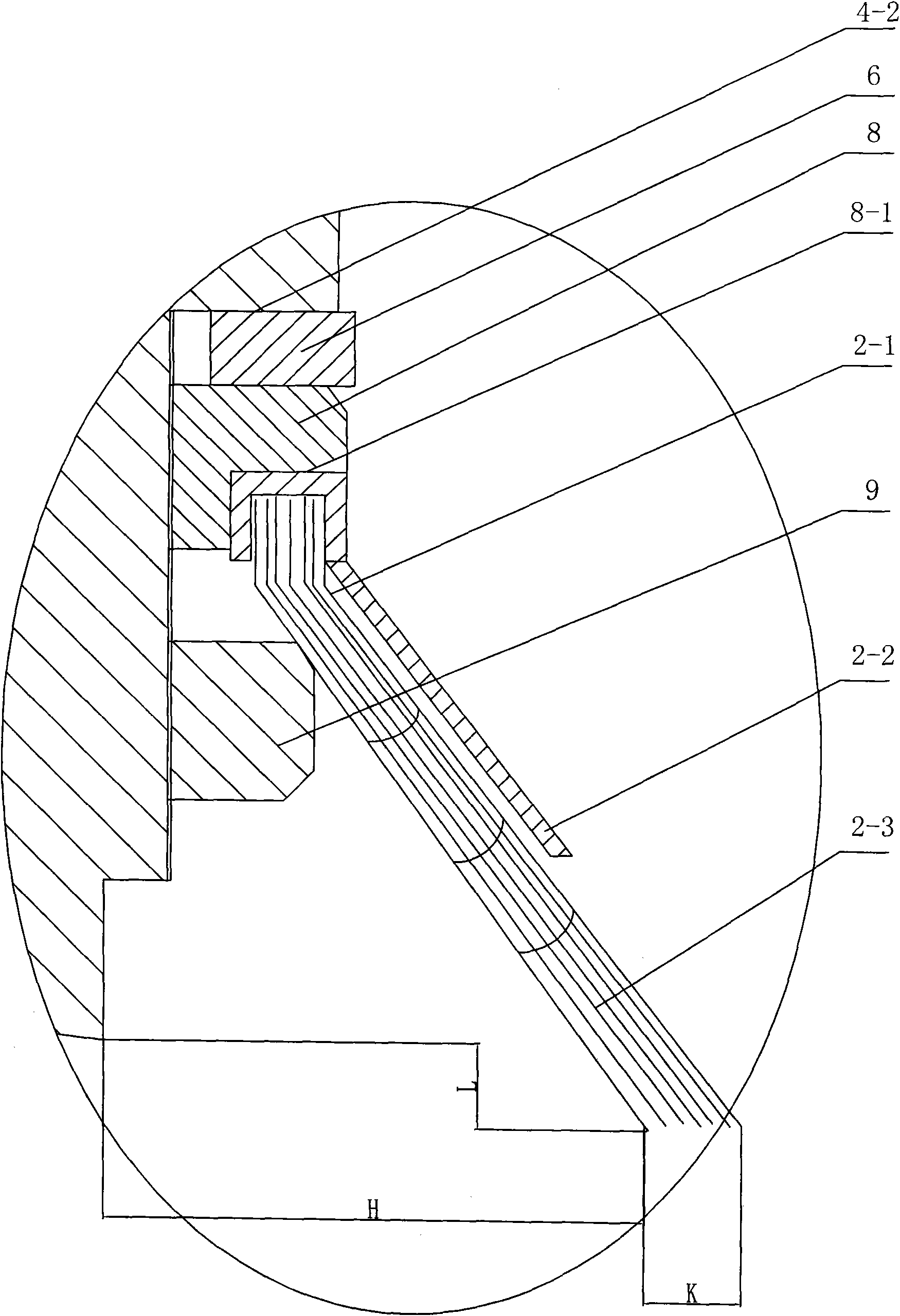

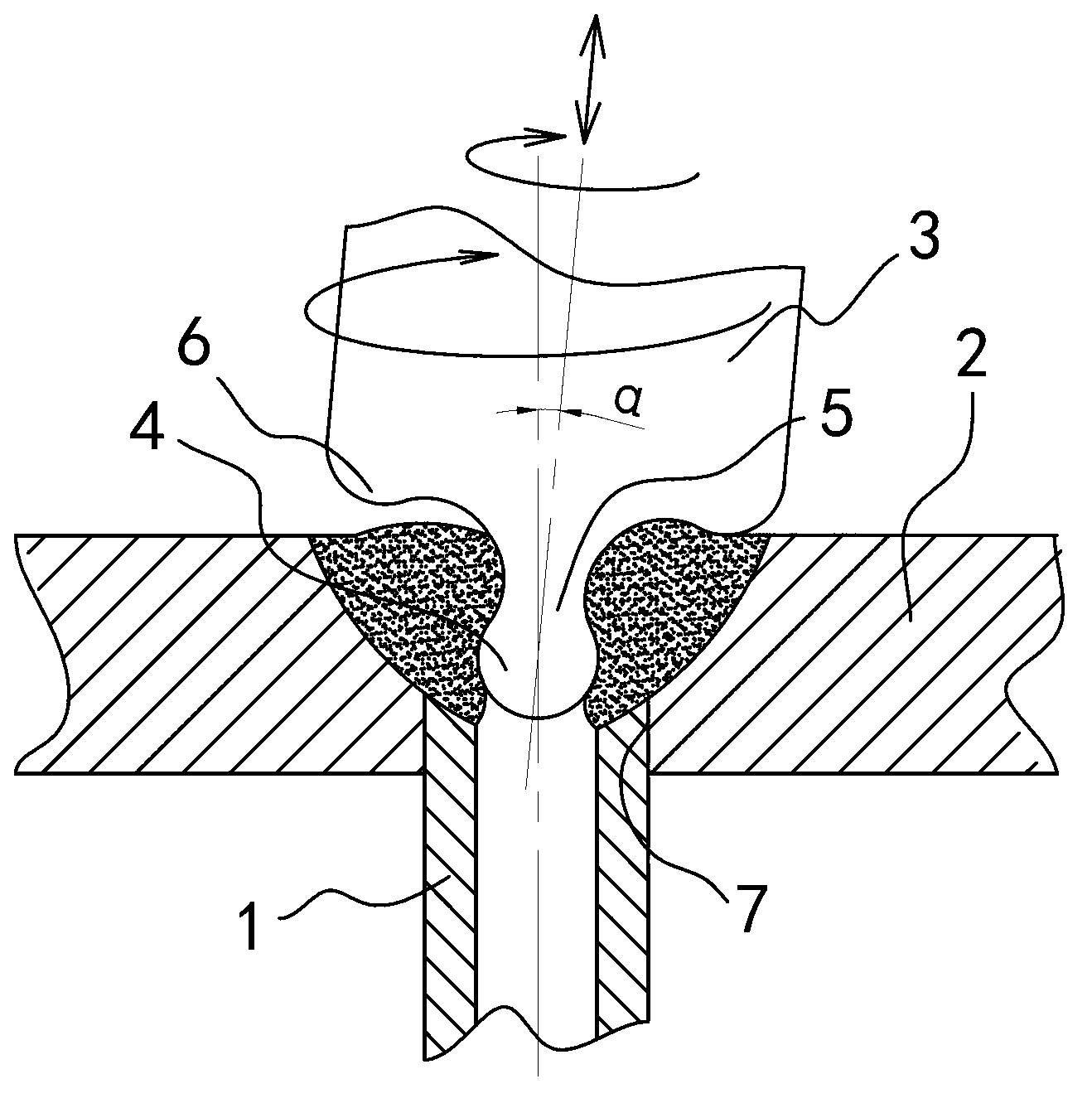

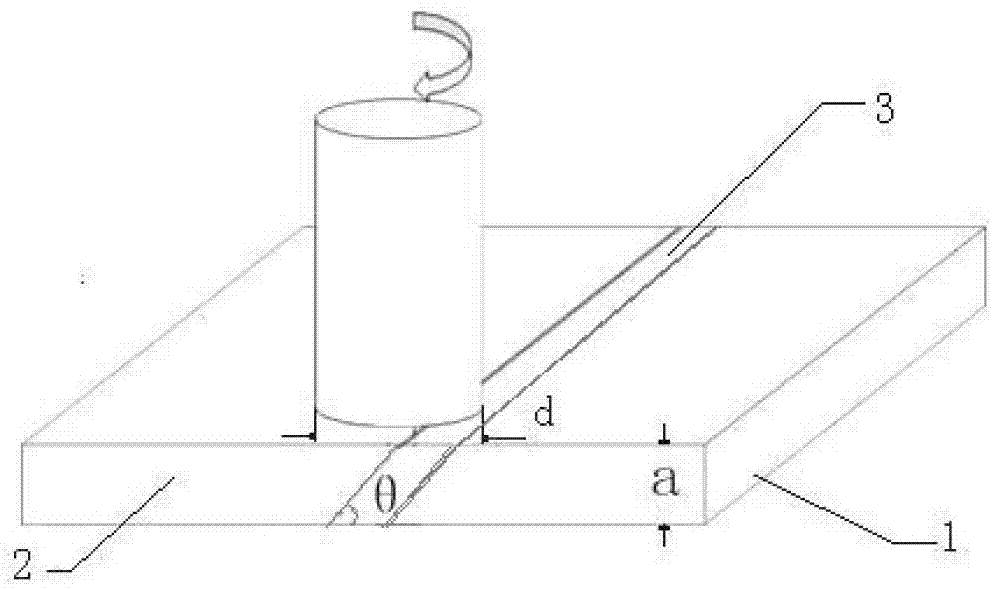

Pin tool suitable for local dry-type friction stir welding in water environment

InactiveCN101554681AAvoid enteringEntry will not happenNon-electric welding apparatusFriction weldingDecomposition

A pin tool suitable for local dry-type friction stir welding in water environment relates to a pin tool of friction stir welding. The invention solves the problems that the existing pin tool of friction stir welding is not applicable to the local dry-type welding in water environment; as underwater welding needs complicated supporting equipment and technical conditions, the difficulty of implementation is comparatively large; and the stability of an electric arc and drop transfer is poor and the decomposition of water at the high temperature of the electric arc can lead to seam hydrogenation so as to cause the deterioration of joint performance. A fitting nut is connected with the upper thread of a shaft shoulder and a positioning backing ring is arranged between the upper end face of the fitting nut and the end face of a shoulder. A U-shaped steel wire brush holder is fixedly installed on the shoulder. The upper ends of a plurality of stainless steel tendons are fixedly installed in the U-shaped steel wire bush holder and an inverted funnel-shaped shade covers the outside of the steel wire brush. The pin tool overcomes the defects of the existing pin tool of friction stir welding in welding under water environment, satisfies the requirements of local dry-type welding under water environment and also boosts the performance of joints.

Owner:HARBIN INST OF TECH

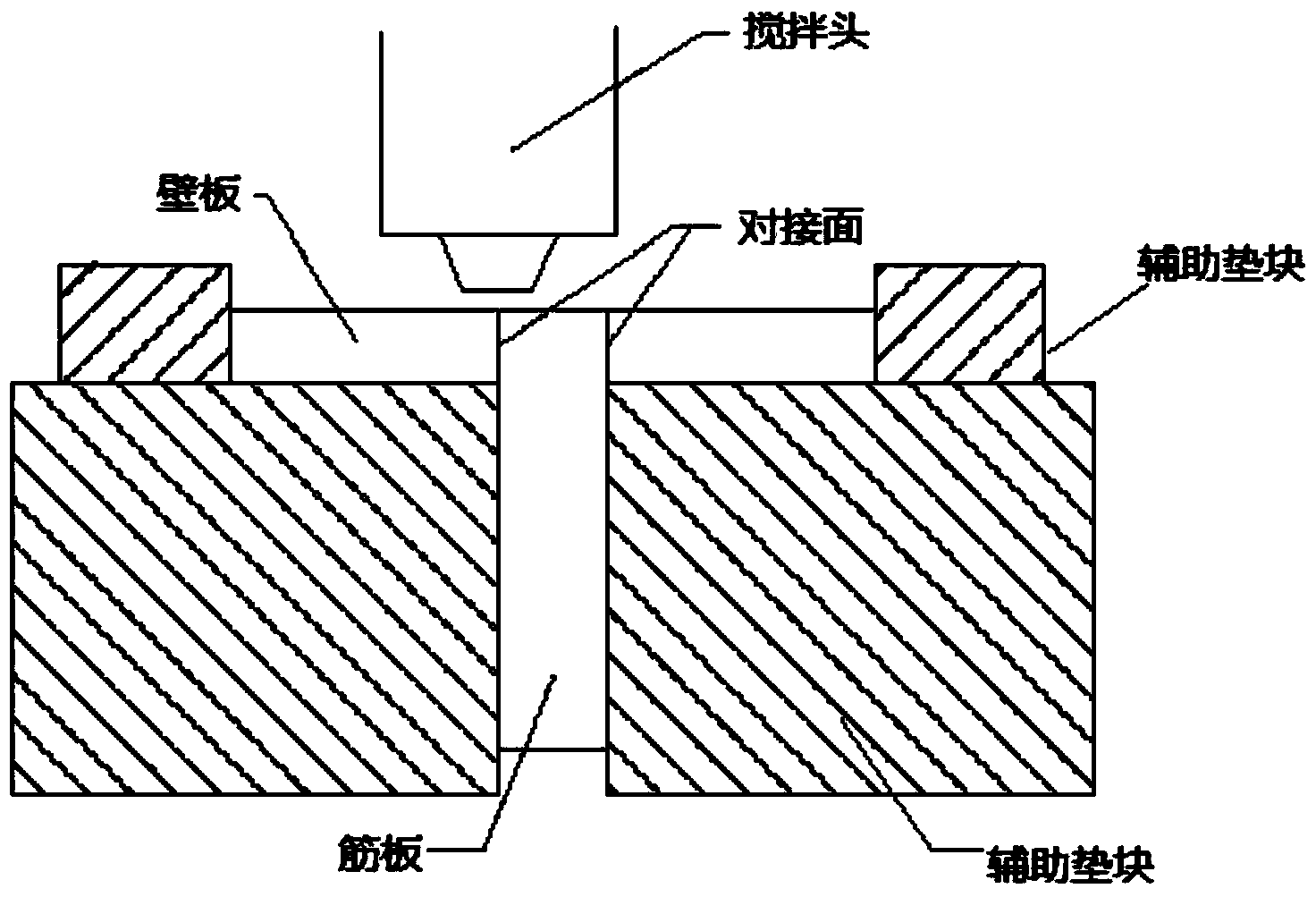

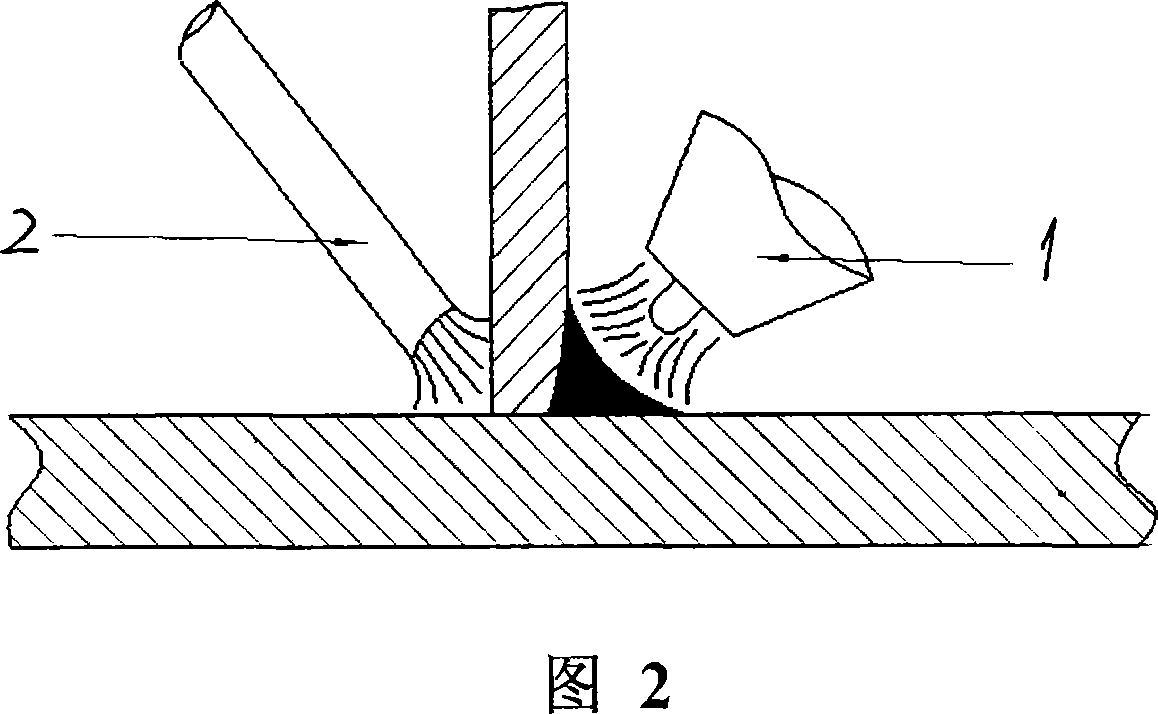

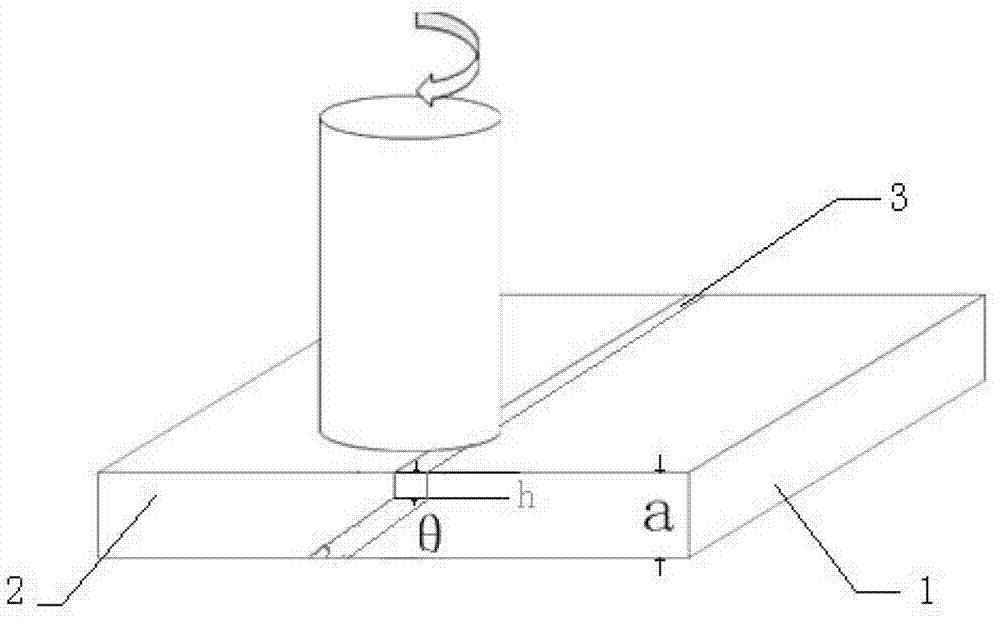

Method for T-shaped magnesium alloy section friction stir welding

InactiveCN104139239ASmall heat affected zoneSmall residual stress and deformationWelding/soldering/cutting articlesNon-electric welding apparatusCushionFriction stir welding

The invention provides a method for T-shaped magnesium alloy section friction stir welding. The method specifically comprises the following steps: alcohol is used for cleaning oil greasy dirt on alloy sections to be welded before welding; on the two sides of a magnesium alloy rib plate, a pair of auxiliary cushion blocks with a shape which is consistent with the shape of the plate is assembled; two magnesium alloy blocks with same geometric size are installed on the auxiliary cushion blocks of the rib plate as wallboards, and auxiliary cushion blocks are assembled on the two sides of the wallboards; by using a tooling, the auxiliary cushion blocks of the wallboards, three magnesium alloy sections to be welded and the auxiliary cushion blocks of the rib plates are transversely clamped on a welding bench; a main shaft of a friction stir welding machine rotates, is gradually inserted into one butting surface of the wallboards and the rib plate sections, is stopped for a while and horizontally moves to start welding, the welding is ended after the main shaft reaches an end point, and a stirring head is drawn out; parallel welding is conducted to the other butting surface, wherein the center spacing between the two weld seams is the thickness of the rib plate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

904L stainless steel welding method

InactiveCN101032780AExtended service lifeLow soldering temperatureWelding/cutting media/materialsWelding/soldering/cutting articlesWeld seamHigh-temperature corrosion

The 904L stainless steel welding process includes two steps, including manual tungsten pole argon arc welding and acid pickling and deactivating the weld seam surface. After being treated, the joints are welded with the welding wire of 904L and the weld seam is cooled with cold water, with the welding temperature being controlled below 80 deg.c, the welding speed being 45-50 cm / min, the weld seam depth / width ratio being kept in 1.5-2, and the welded workpiece having thickness not greater than 12 mm. The weld seam is then pickled and deactivated. The present invention has the advantages of low temperature welding, no molecule conversion inside 904L stainless steel, no generation of welding faults, less integrated deformation of the welded workpiece and long service life of the welded workpiece.

Owner:唐山三友集团化纤有限公司

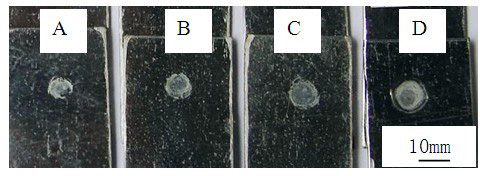

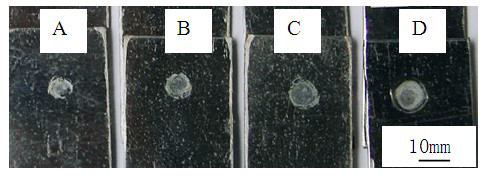

A resistance brazing method for galvanized steel sheets

InactiveCN102275046AFree from destructionExtended service lifeWelding apparatusMaterials scienceElectrical resistance and conductance

A resistance brazing method for galvanized steel sheets relates to the improvement of the resistance spot welding method for galvanized steel sheets. In the present invention, medium-temperature solder such as Zn-Al is placed on the two surfaces to be soldered. The solder can be sheet-like, foil-shaped, plated or sprayed on the surface to be soldered in advance, and the thickness of the solder is 0.05-0.5 mm. The electrode material can be an ordinary Cu-Cr-Zr electrode, and the electrode does not need special treatment. Set the resistance spot welding parameters, the welding current is 7000~14000A, the welding time is 10C~50C, the welding pressure is 0.7KN~5KN, start the resistance spot welding, and then let the weldment cool naturally. The invention can realize the connection without galvanized layer damage and copper pan under the premise that the galvanized steel sheet meets the strength, and improves the service life of the electrode.

Owner:CHONGQING UNIV OF TECH

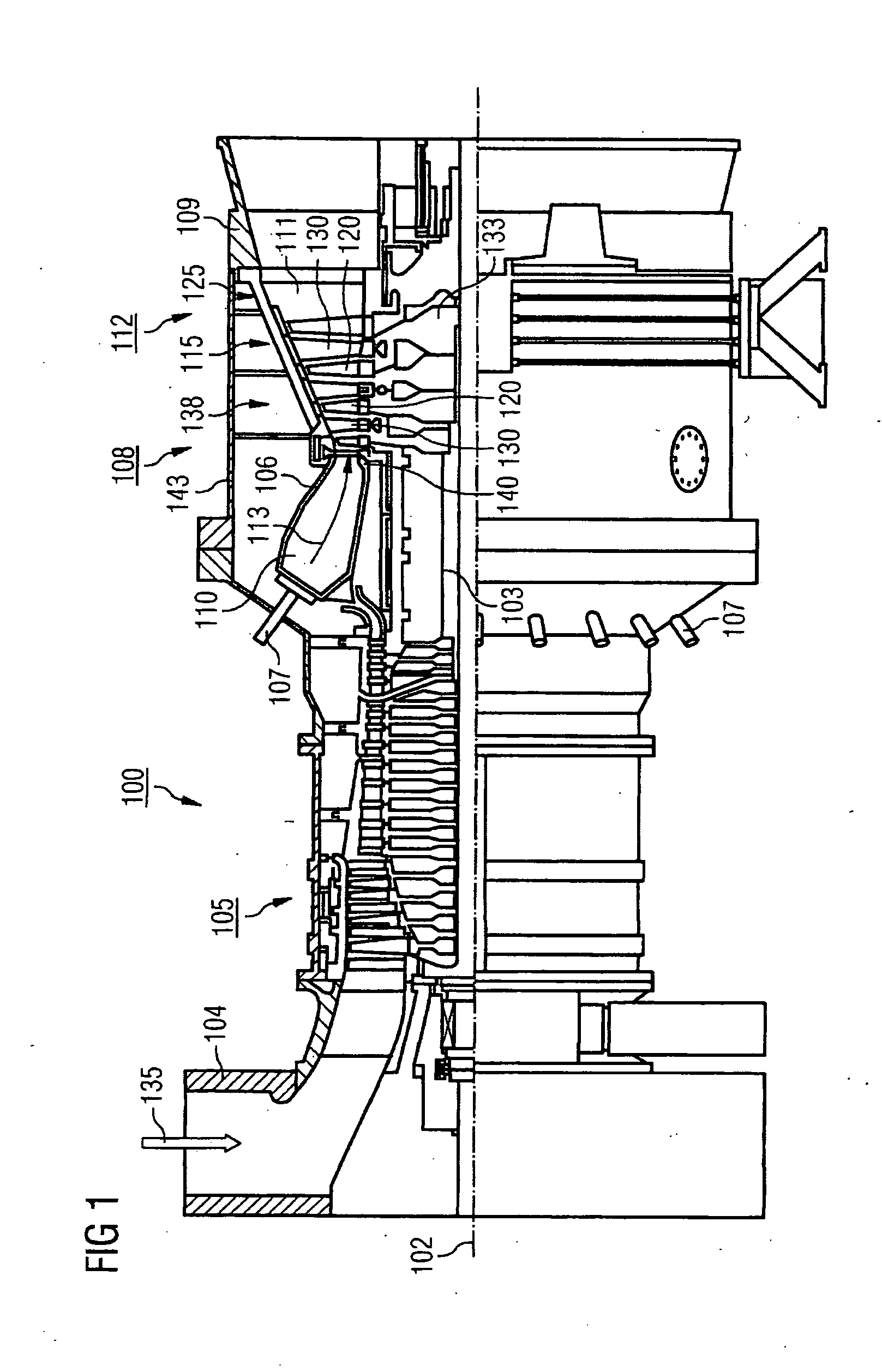

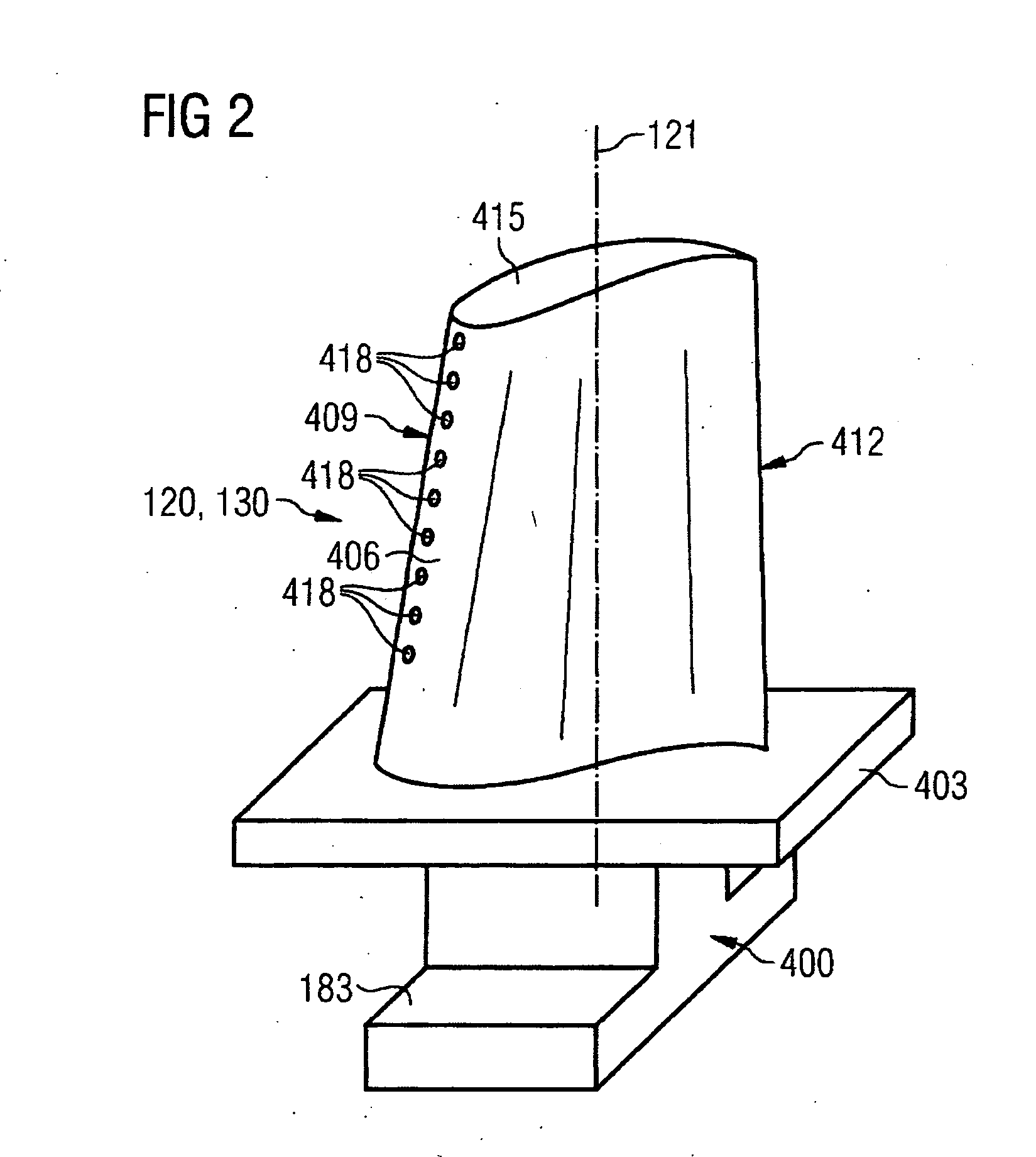

Method for Repairing Cracks in Components and Solder Material for Soldering Components

The invention relates to a method for repairing components that consist of superalloys, in particular for repairing components that consist of a superalloy with an aligned microstructure in such a way that the repaired site likewise has an aligned microstructure. The method comprises the following steps: a solder material is applied to the repair site; the repair site with the applied solder material is heated until the latter melts; and the melted solder material is left to solidify. The solder material is an alloy with the same alloy components as the component alloy. At least the fraction of one alloy component in the solder material composition is modified in relation to the fraction of that alloy component in the component alloy composition, in such a way that the melting temperature of the solder material is reduced in relation to the melting temperature of the component alloy.

Owner:MTU AERO ENGINES GMBH

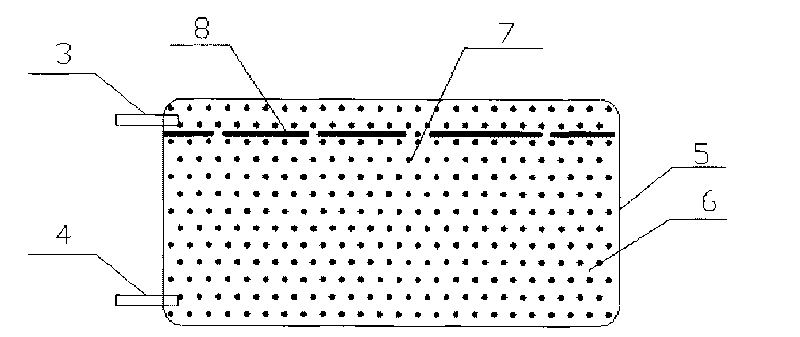

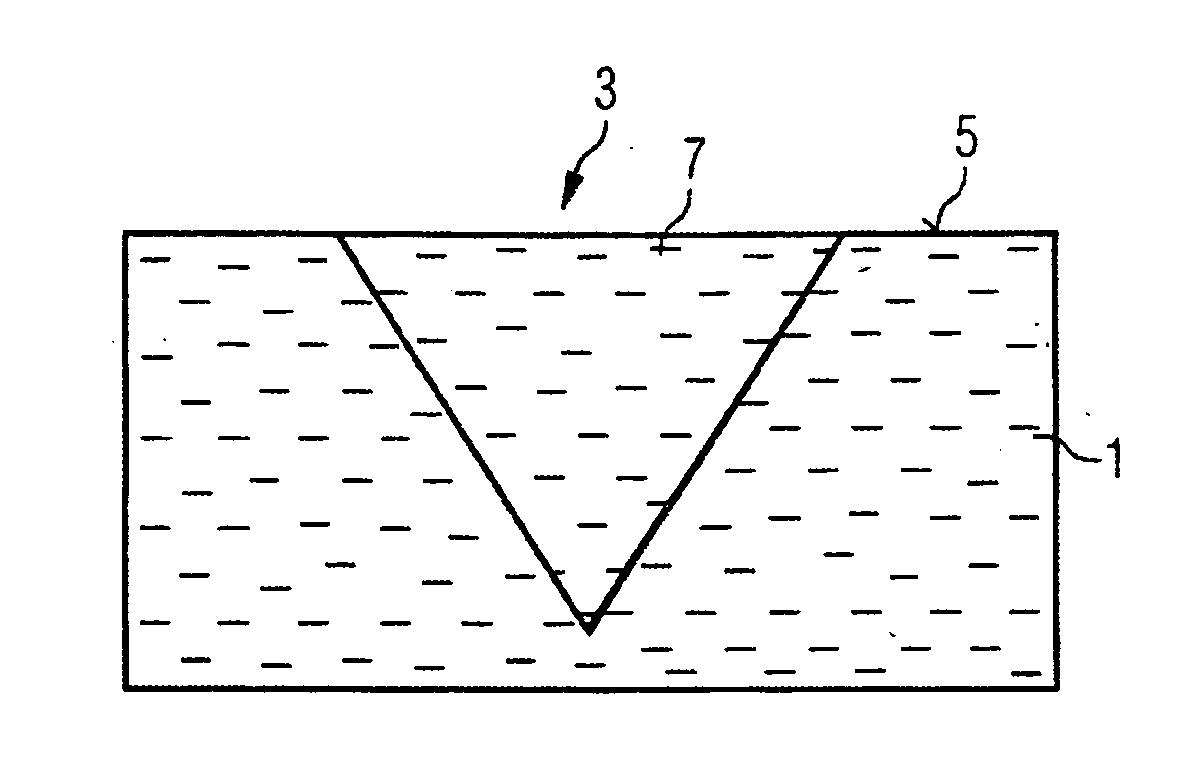

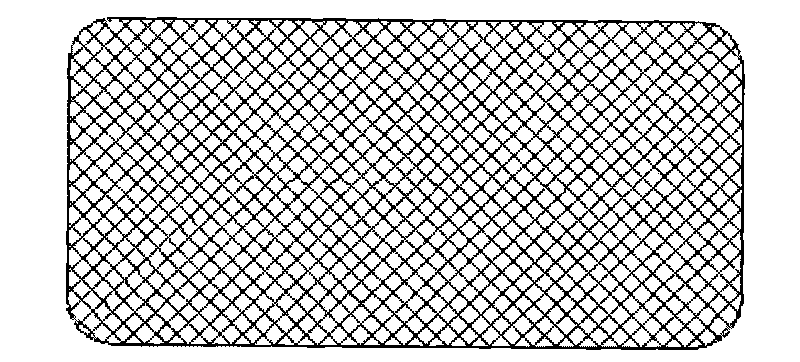

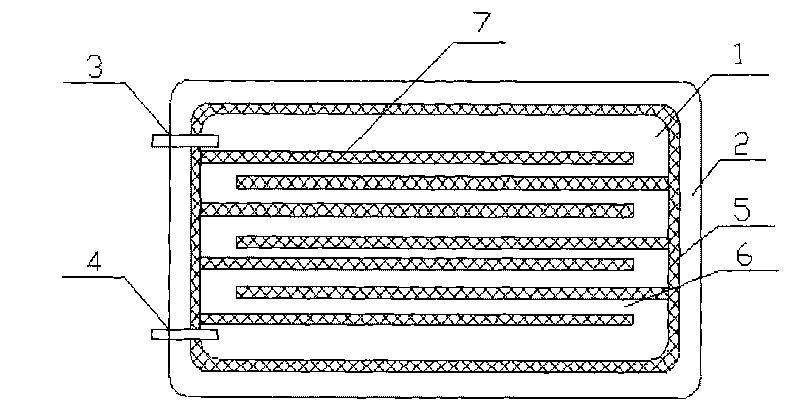

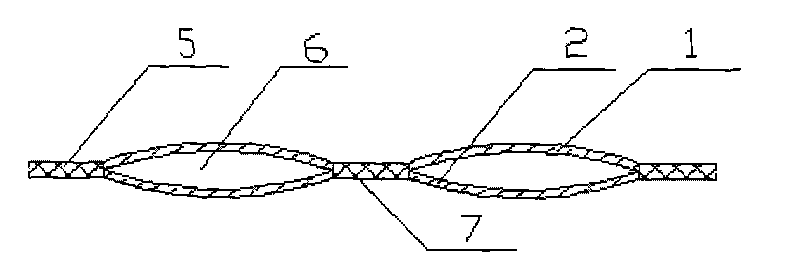

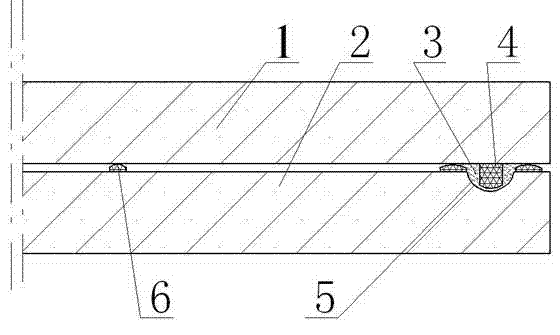

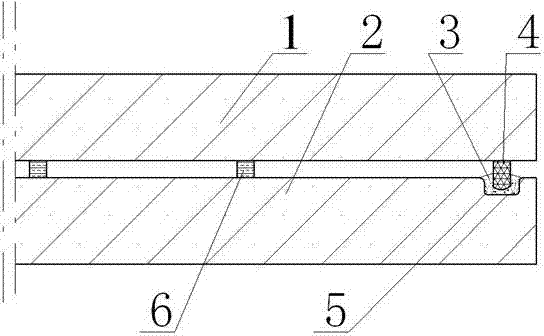

Aluminum honeycomb type evaporation plate and processing molding method thereof

InactiveCN101691978ANot easy to form dead angleLow flow resistanceShaping toolsArc welding apparatusAluminum honeycombEvaporation

The invention discloses an aluminum honeycomb type evaporation plate and a processing molding method thereof. The evaporation plate adopts a high strength aluminum alloy plate and consists of an upper plate, a lower plate, an inlet pipe and an outlet pipe, wherein the two high strength aluminum alloy plates are overlapped and welded together by a solid-phase stir friction connecting method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two high strength aluminum alloy plates and are connected with the high strength aluminum alloy evaporation plate body by using an electric arc welding method; and then the evaporation plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

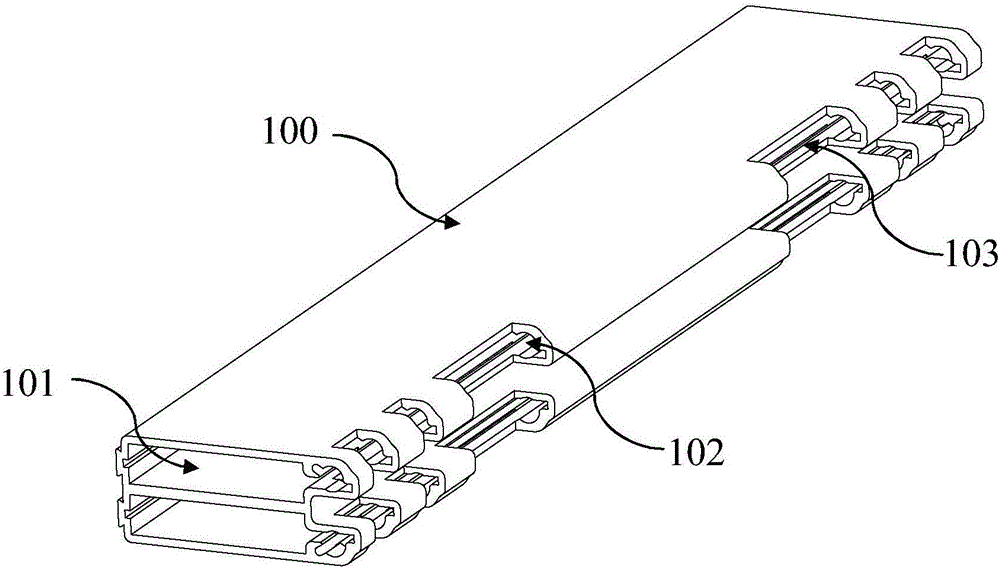

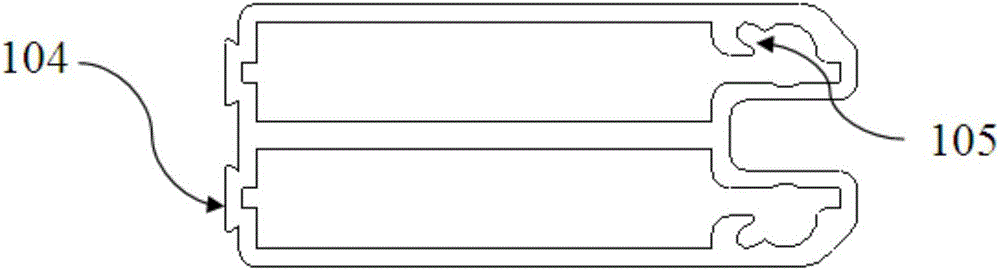

Low-melting-point metal cable continuation device

ActiveCN103326142AAvoid damageImprove conductivitySoldered/welded conductive connectionsElectric connection structural associationsMetal coatingEngineering

The invention relates to a low-melting-point metal cable continuation device. The low-melting-point metal cable continuation device is characterized by being composed of a low-melting-point metal inner ring, an insulating sleeve, a shielding copper mesh with low-melting-point metal coatings, and a heat gun. Grooves are formed in the two sides of the low-melting-point metal inner ring, and a cable core is connected to the grooves and welded. The insulating sleeve wraps the low-melting-point metal inner ring from the outer side for forming a welding spot outer insulating layer. The shielding copper mesh with the low-melting-point metal coatings is used for achieving welding of a cable metal shielding layer, and the two ends of the shielding copper mesh are coated with the low-melting-point metal coatings. In the use process, the heat gun is used for heating low-melting-point metal, so that the low-melting-point metal is melted for achieving the welding process. The low-melting-point metal cable continuation device is simple in structure, convenient to operate, safe and reliable, saves energy and protects environment, thereby being capable of being widely used in field of the cable continuation projects of rail transit, information communication and the like.

Owner:BEIJING EMIKON TECH DEV

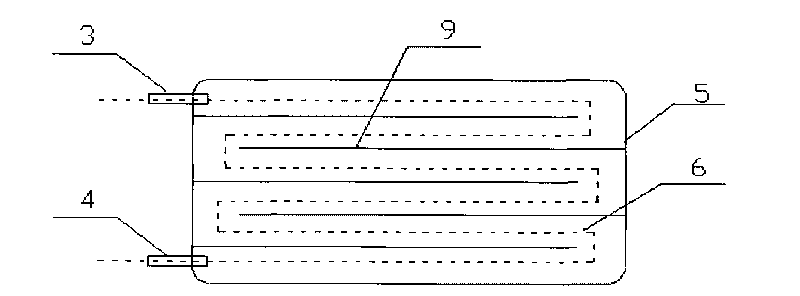

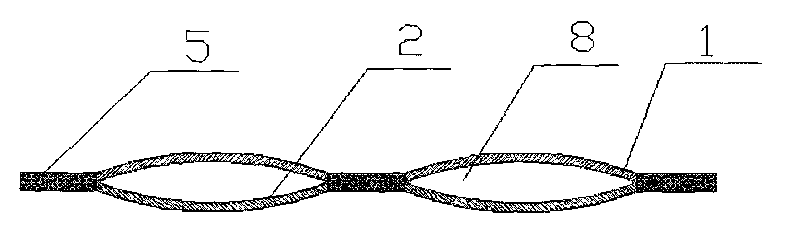

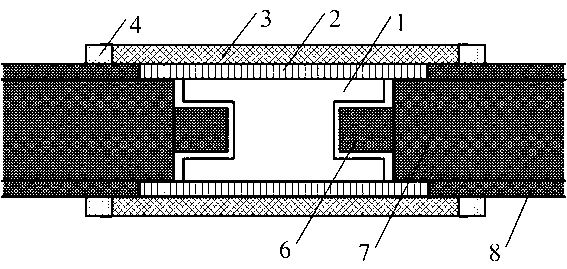

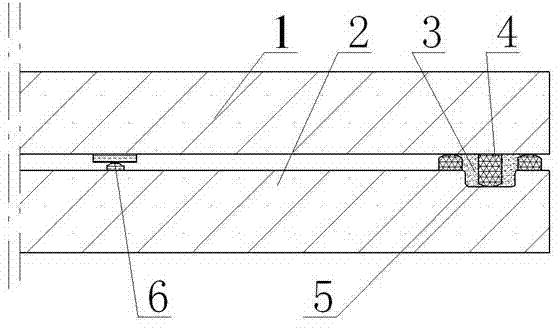

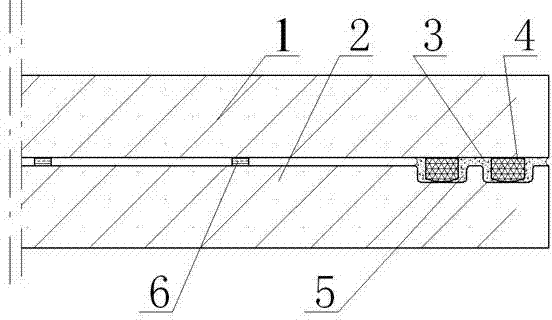

Stainless steel snakelike flow channel cold plate and processing molding method thereof

InactiveCN101691977AReduce pollutionLow soldering temperatureShaping toolsArc welding apparatusElectrical resistance and conductanceCold plate

The invention discloses a stainless steel snakelike flow channel cold plate and a processing molding method thereof. The snakelike flow channel cold plate adopts a stainless steel plate and consists of a stainless steel upper plate, a stainless steel lower plate, an inlet pipe and an outlet pipe, wherein the two stainless steel plates are overlapped and connected by a water-cooling resistance welding method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two stainless steel plates and are connected with the stainless steel snakelike flow channel cold plate by using an electric arc welding method; and then the snakelike flow channel cold plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

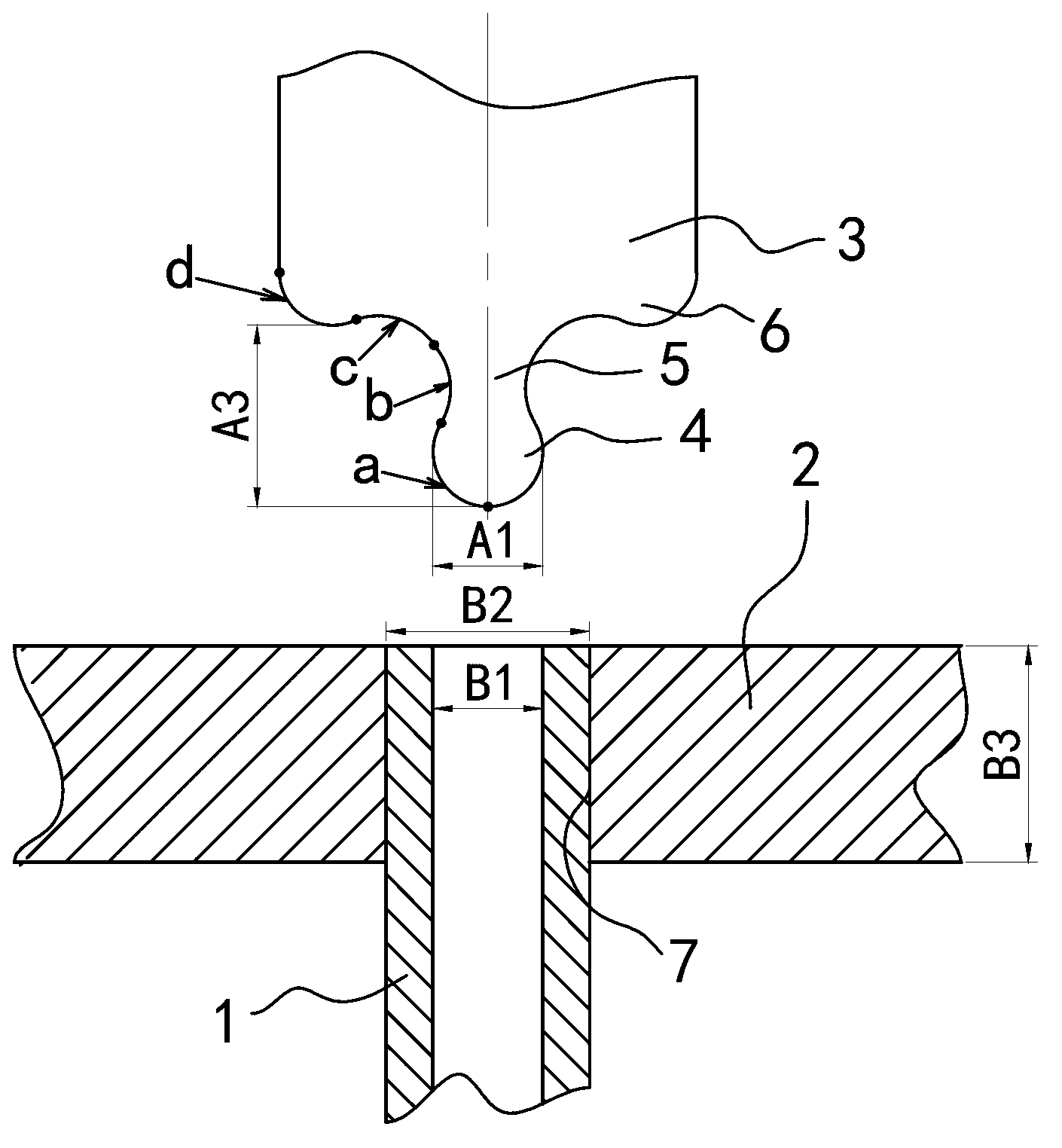

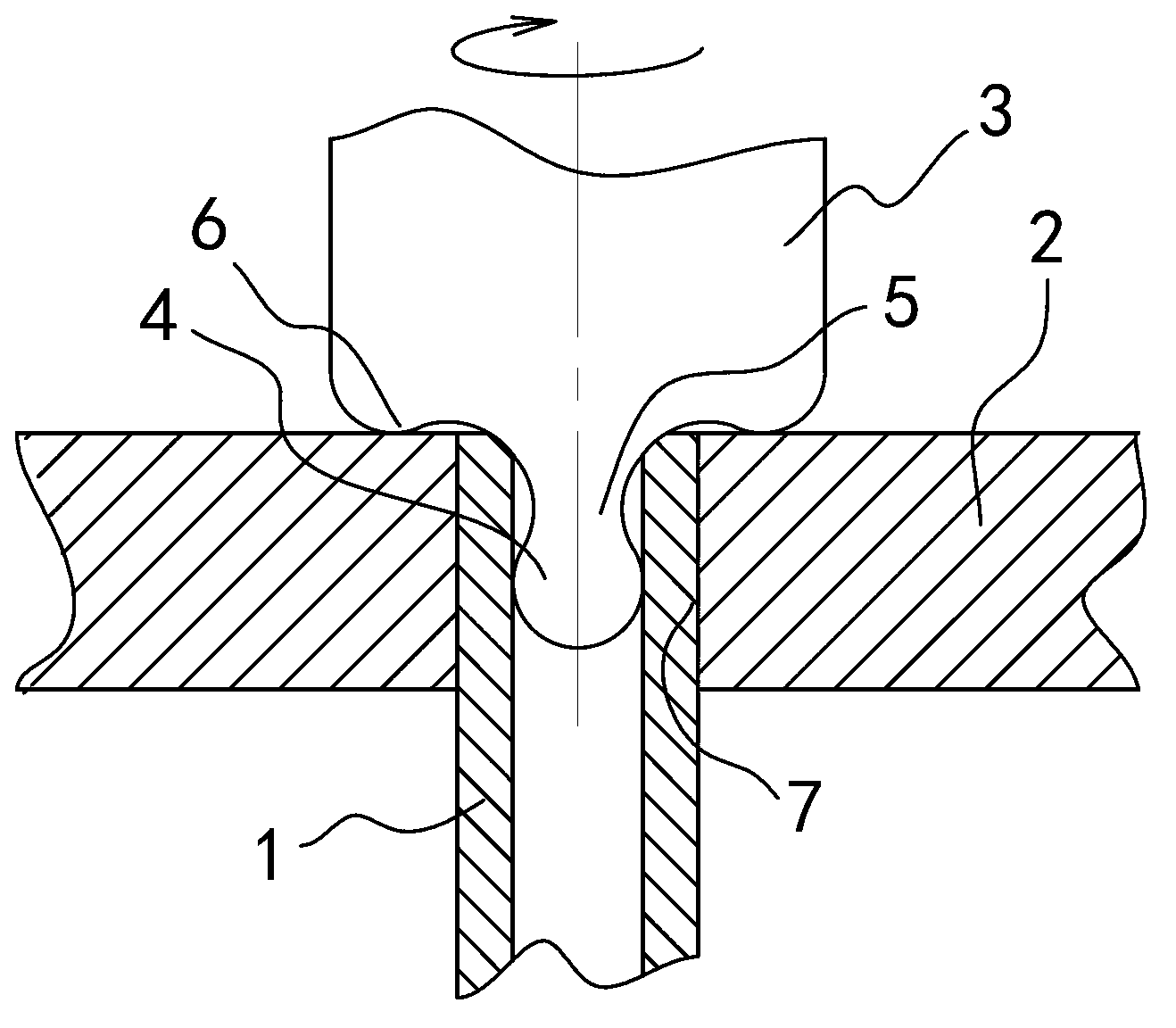

New tube plate welding method

InactiveCN103170724AHigh welding strength and environmental protectionLow soldering temperatureNon-electric welding apparatusInterference fitThick plate

Provided is a new tube plate welding method. The new tube plate welding method is characterized in that aiming at connecting objects which includes a tube and a plate, welding between the tube and the plate is achieved through adoption of a rotary welding set and modes of friction, stir and upsetting. According to the welding set, a working end of the welding set is composed of a ball head, a neck portion and shoulder portions in a connection mode in sequence, the diameter of the ball head is in interference fit with the inner diameter of the tube, the diameter of a peak of a fourth arc section on each shoulder portion is larger than the outer diameter of the tube, and a projection distance between the peak of the ball head and the peak of the fourth arc section on each shoulder portion in the axis direction is less than the thickness of the plate. The new tube plate welding method comprises the welding steps that (1) the tube is fixed with the plate in a support mode; (2) the ball head is inlaid into the tube; (3) the welding set rotates, and carries out circular pendulum motion and axial reciprocating motion at the same time, and therefore plastic deformation of materials of a combination portion between the plate and the tube is carried out; and (4) the welding set exits from the tube and the plate. The new tube plate welding method is applicable to welding between a thin wall tube and a thick plate, and has the advantages of being free from solder and scaling powder, high in welding intensity, environment-friendly, small in residual stress and deformation of a structure after welding, and the like.

Owner:苏州森光换热器有限公司

Heterogeneous semi-solid brazing method of aluminum alloy and magnesium alloy assisted by external vibration energy

InactiveCN102266994AAvoid serializationEfficient weldingSoldering apparatusRoom temperatureSemi solid

The invention provides a heterogeneous semi-solid brazing method for an aluminum alloy and a magnesium alloy under assistance of external vibration energy. According to the invention, the method comprises the following steps of: clamping an aluminum alloy weld member and a magnesium alloy weld member on a fixture and placing medium-temperature brazing filler metals of a Zn-Al or Al-Si series on two surfaces to be welded, wherein the brazing filler metals can be of flaky shapes or foil shapes, can be plating layers or can be sprayed on the surfaces to be welded in advance; heating the weld members so that the middle layer of brazing filler metal is in a semi-solid state; adjusting the pressure to be matched with the amplitude of the applied vibration; starting a vibrating device with amplitude of 0.01-2mm, wherein the brazing filler metals vibrate along with the two weld members, and the vibration time is 0.5-3 minutes according to actual requirements; stopping the vibration; and cooling the weld members to room temperature by air, wherein a certain pressure of 0.1-5 Mpa is always applied in the brazing process. According to the invention, high-efficiency, high-quality and economic connection between the aluminum alloy and the magnesium alloy can be realized.

Owner:CHONGQING UNIV OF TECH

Method for manufacturing combined cam shaft

InactiveCN101733632AAvoid displacementAvoid deformationMetal working apparatusLaser beam welding apparatusNumerical controlEngineering

The invention belongs to the technical field of machining, and relates to a method for manufacturing a combined cam shaft, in particular to the method for manufacturing the combined cam shaft with a hollow tube mandrel. The method comprises the following manufacturing processing steps: firstly, straightening the hollow tube mandrel; secondly, performing tight fit and cold assembled positioning on a cam, a shaft neck component and a mandrel by using a numerical controlled assembling machine, and then realizing close connection of the cam, a shaft neck and the mandrel by machining expanding, so that the mandrel which generates plastic deformation is firmly combined with the cam and the shaft neck which generate elastic deformation; and finally, fixing drive components at the two ends of the cam shaft by a laser welding method. The method for manufacturing the combined cam shaft has the advantages of simple overall process, obviously reduced weight compared with a cast iron cam shaft, low integrated cost and high assembly precision, and completely meets the using requirements on the cam shafts of various automobile engines.

Owner:CENT IRON & STEEL RES INST

Welding method for semiconductor ceramic shell sealing cap

ActiveCN103056500AReduce the maximum temperatureAvoid the problem of excessive local heating temperatureSemiconductor/solid-state device manufacturingWelding/cutting media/materialsMetal coatingCopper electrode

The invention relates to a welding method for a semiconductor ceramic shell sealing cap and belongs to the technical field of semiconductor ceramic packaging. The welding method comprises the steps of pre-arranging a metal coating layer on the surface of a metal cover plate, and pre-arranging a coated metal seal frame in a ceramic shell welding area; enabling a solder ring to undergo spot welding on the metal coating layer of the metal cover plate; enabling the metal cover plate to be aligned with the metal seal frame of a ceramic shell under the atmosphere of nitrogen, utilizing a parallel seam welding device and a small-angle (5-degree) copper electrode to perform low-power welding, and enabling the solder ring to be fully molten and respectively welded to the metal coating layer of the metal cover plate and the metal seal frame of the ceramic shell to finish melting seal of a circuit. According to the welding method, the problems that pulse is too large and the local central heating temperature is too high in the parallel seam welding process are solved, the problem that chips inside the circuit and bonding positions are in a high-temperature state in a melting seal process is solved, and the maximum temperature of parallel seam welding is reduced.

Owner:BEIJING MXTRONICS CORP +1

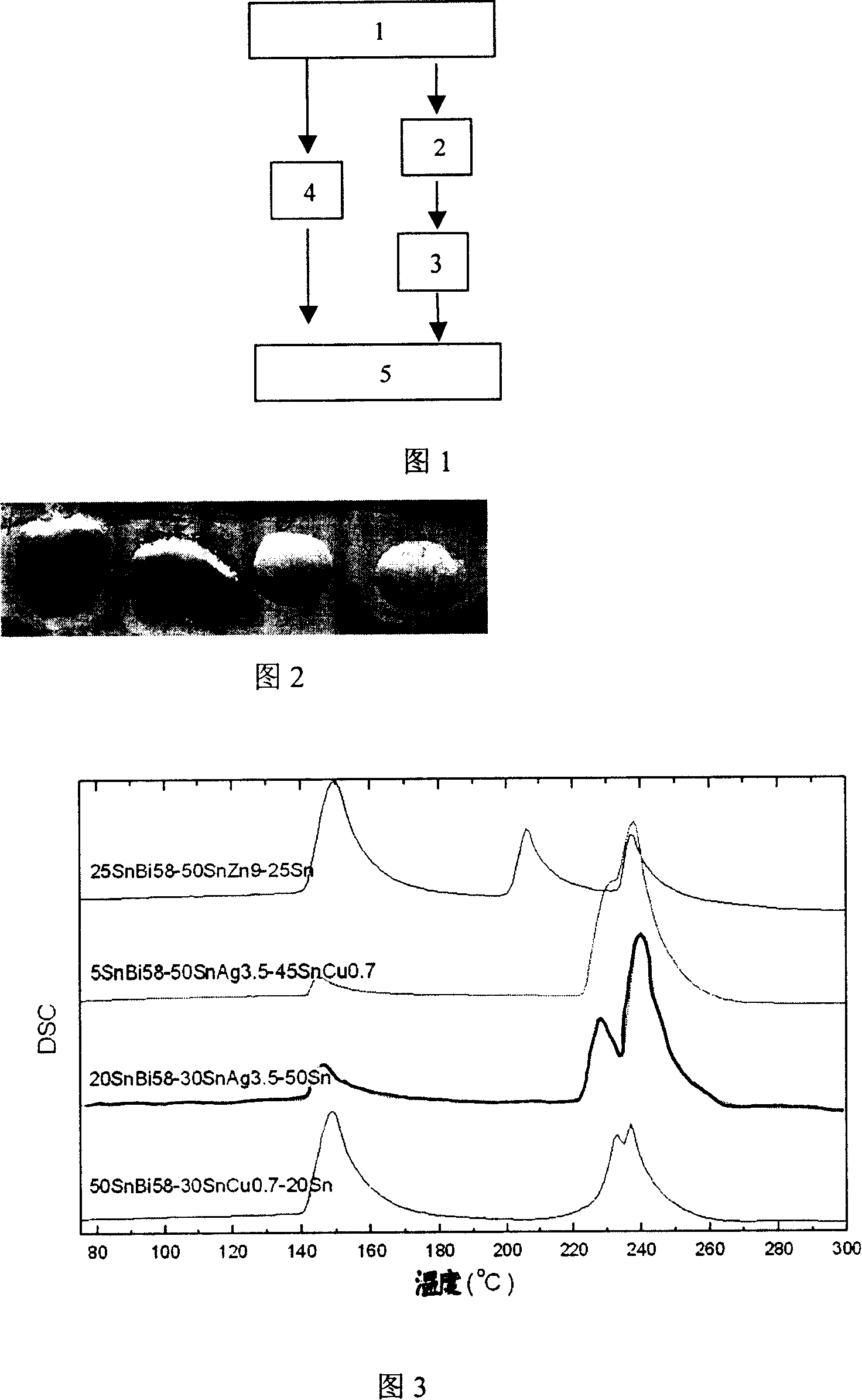

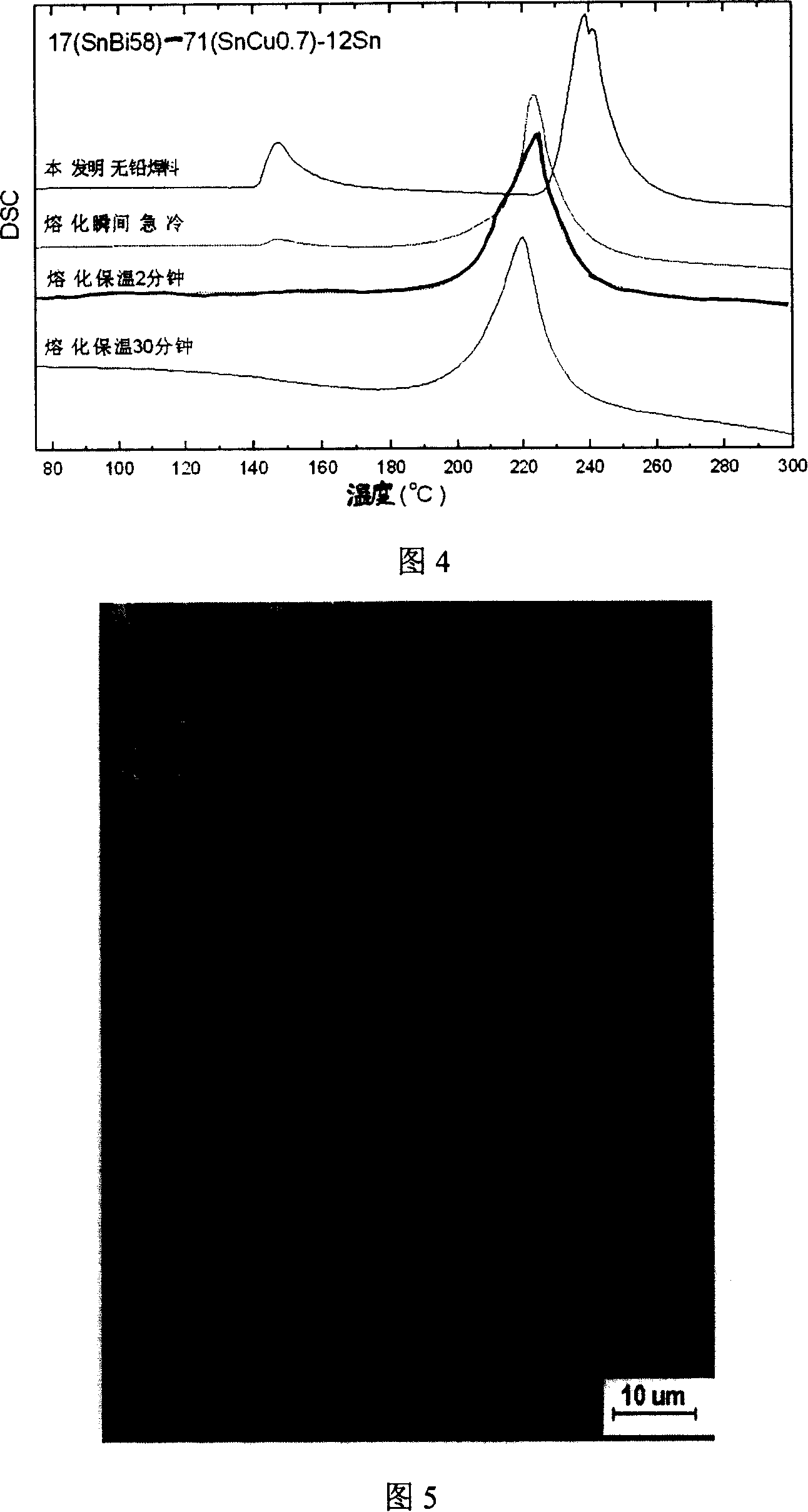

Home position alloying type lead-free solder and preparation method thereof

ActiveCN101138812AHas an occlusal effectReduce high temperature side effectsMixing methodsWelding/cutting media/materialsSingle substanceAlloy

The present invention, which belongs to the electronic soldering technology field, discloses an in-situ alloying lead-free solder and a preparation method thereof. The present solder consists of two or more alloy powders or single-substance metal powders, which are mixed mechanically and uniformly. In welding and application processes, the solder has the advantages of a strong anti-collapsing ability, a bright co-center circles of the solder joint, a good spreading effect, a simple preparation technique and low cost and the optimal advantages are that the welding with the use of a unified SMT welding technique and without changing the welding technique line and parameters of the previous solder is convenient. The medium / high temperature solder can be welded under a low temperature or gradient temperatures so that the medium / high temperature application of the low temperature solder is realized and the service life of the solder joint is prolonged.

Owner:BEIJING COMPO ADVANCED TECH

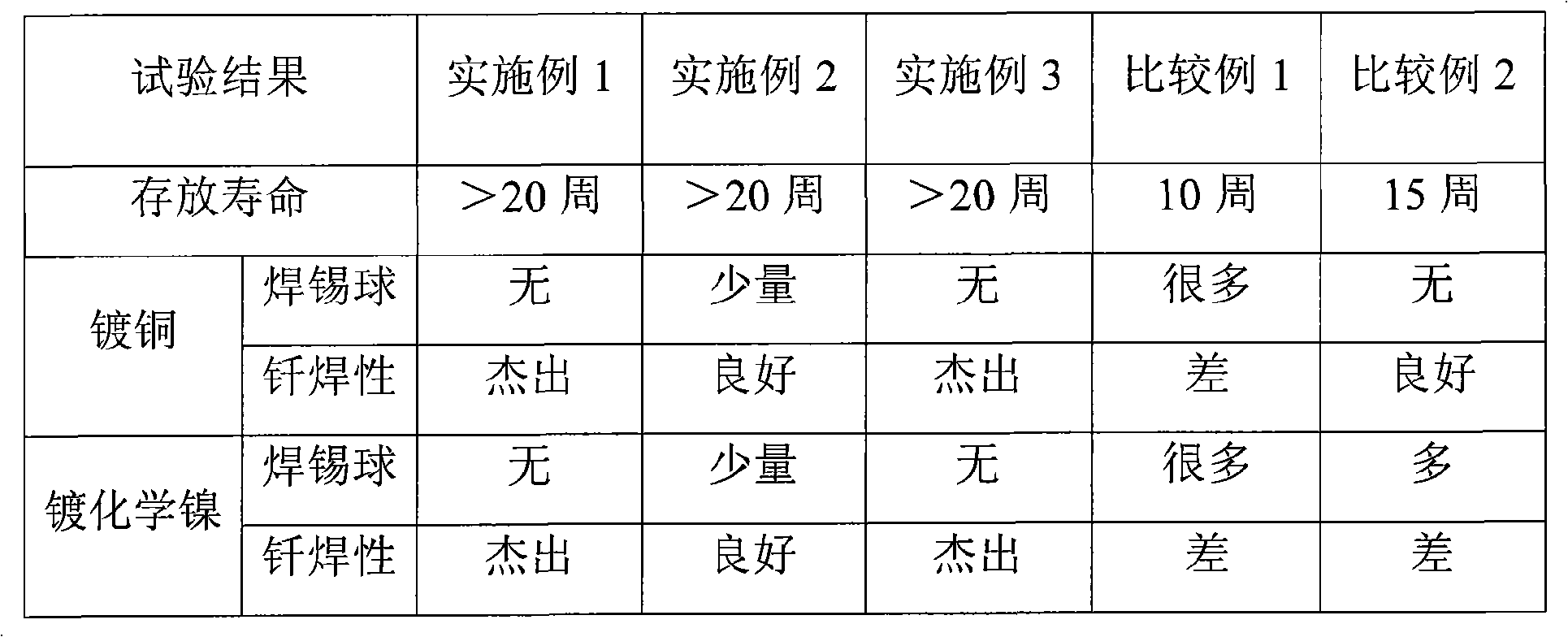

Lead-free halogen-free tin paste and production process thereof

InactiveCN104923952ALow melting pointLow soldering temperatureWelding/cutting media/materialsSoldering mediaOrganic acidSolvent

The invention relates to the technical field of electronic welding, in particular to lead-free halogen-free tin paste which comprises, in weight percent, 88%-90% of tin powder and 10%-12% of paste flux. The tin powder is made of alloys including 88-94.5% of Sn, 0.2-1.2% of Ag, 0.3-0.8% of Cu and 5-10% of Bi. The paste flux comprises rosin, solvents, corrosion inhibitors, activators, thixotropic agents and thickening agents, wherein the activators comprise organic acid and organic amine. The paste flux is prepared by an emulsion dispersion high-speed shearing process. A preparation method of the tin paste includes the steps: placing the tin powder and the paste flux into a sealed stirrer for stirring according to the proportion; pumping vacuum; releasing the vacuum; finishing preparation of the tin paste. The lead-free halogen-free tin paste is low in melting point, fine in weldability, full in welding spot and fine in reliability, achieves fine welding effects and meets environmental protection requirements, and the service life of the tin paste is prolonged.

Owner:广西南宁迈点装饰工程有限公司

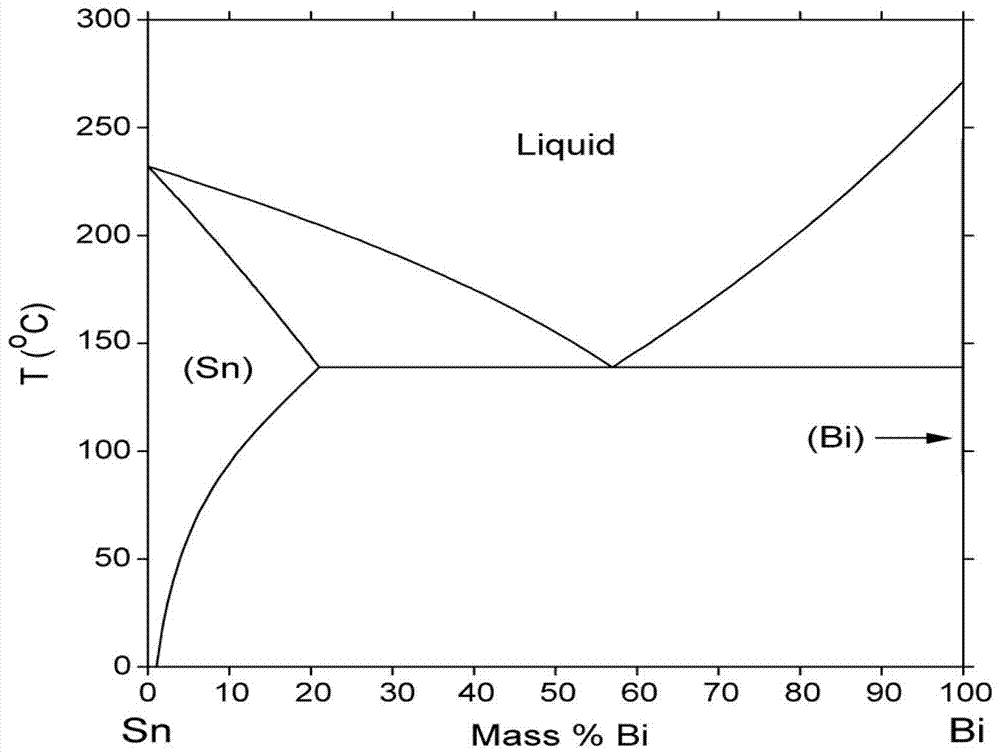

Low-temperature halogenide-free high-activity soldering tin paste

InactiveCN101327554ASuppresses viscosity changesExtended service lifeWelding/cutting media/materialsSoldering mediaSolderabilityHigh activity

The present invention relates to a low-temperature, halideless high-activity soldering paste, which contains a type of Sn-Bi-based leadless solder powder mixed with soldering flux, and wherein, the soldering flux contains at least one type of hydroxy alkylamine, the weight percentage of which is 0.5 percent to 20 percent. The soldering paste has the advantages of good viscosity stability, colorless and transparent residues and low corrosiveness and shows excellent solderability, and moreover, the soldering paste has good solderability on standard and hard-to-solder surfaces, particularly under a low soldering temperature. The soldering paste is applicable to the soldering of electronic elements with a bad thermal shock-resisting property.

Owner:DONGGUAN YONGAN TECH

Stirring friction and transient liquid phase diffusion welding method for connection of dissimilar materials

InactiveCN102825381ALower preparation quality requirementsAvoid (or reduce the formation ofNon-electric welding apparatusFriction weldingEngineering

The invention provides a stirring friction and transient liquid phase diffusion welding method for connection of dissimilar materials. Stirring friction welding and diffusion welding are combined, heat generated by stirring friction is used as a heat source of the diffusion welding, the heat source can move by continuously moving a stirring head in a welding process, so that different regions of a head to be welded is welded, other fixed equipment is not required in the welding process, heads to be welded in various shapes and sizes can be welded, and shortcomings that in the prior art, other fixed equipment is required to provide a heat source, so that cost is increased, the size and the shape of a head to be welded are easily limited by welding equipment are overcome. The stirring friction and transient liquid phase diffusion welding method has the advantages of low cost, wide application range and excellent mechanical property of welding joints.

Owner:UNIV OF SCI & TECH BEIJING

Glass solder-microwave welded and strip frame-groove-edge-sealed planar vacuum glass and manufacturing method thereof

InactiveCN102951828AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention relates to vacuum glass. The vacuum glass comprises upper glass and lower glass and is characterized in that an edge sealing strip frame is arranged at the welded periphery of the upper glass, an edge sealing strip frame and an edge sealing groove are arranged at the welded periphery of the lower glass, and the upper glass and the lower glass are welded together by utilizing glass solder in a microwave oven; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the edge sealing strip frames and the edge sealing groove can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology; and the method can be used for manufacturing both the ordinary vacuum glass and tempered vacuum glass.

Owner:戴长虹

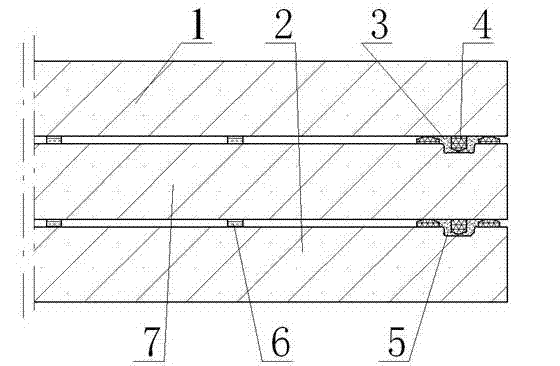

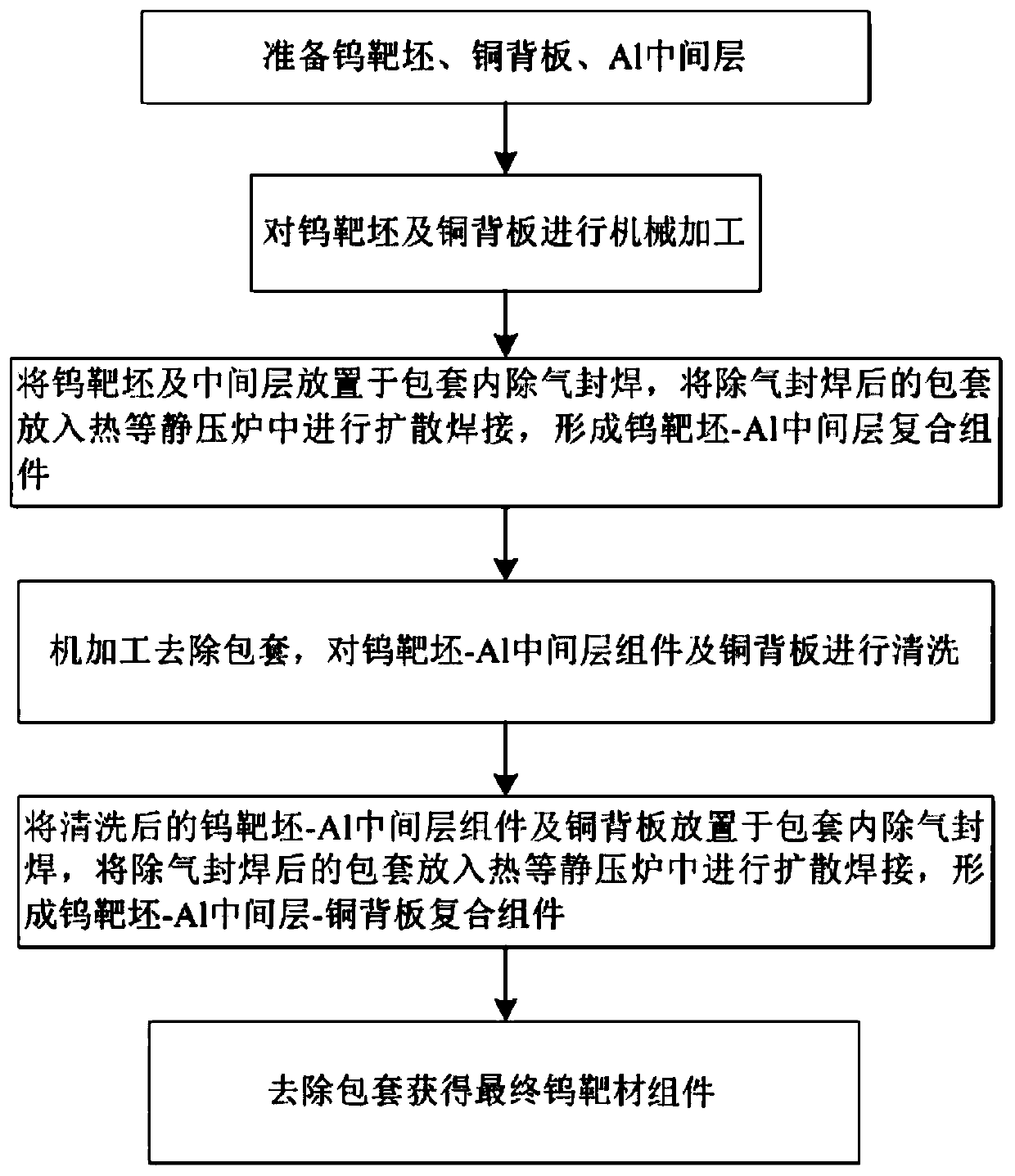

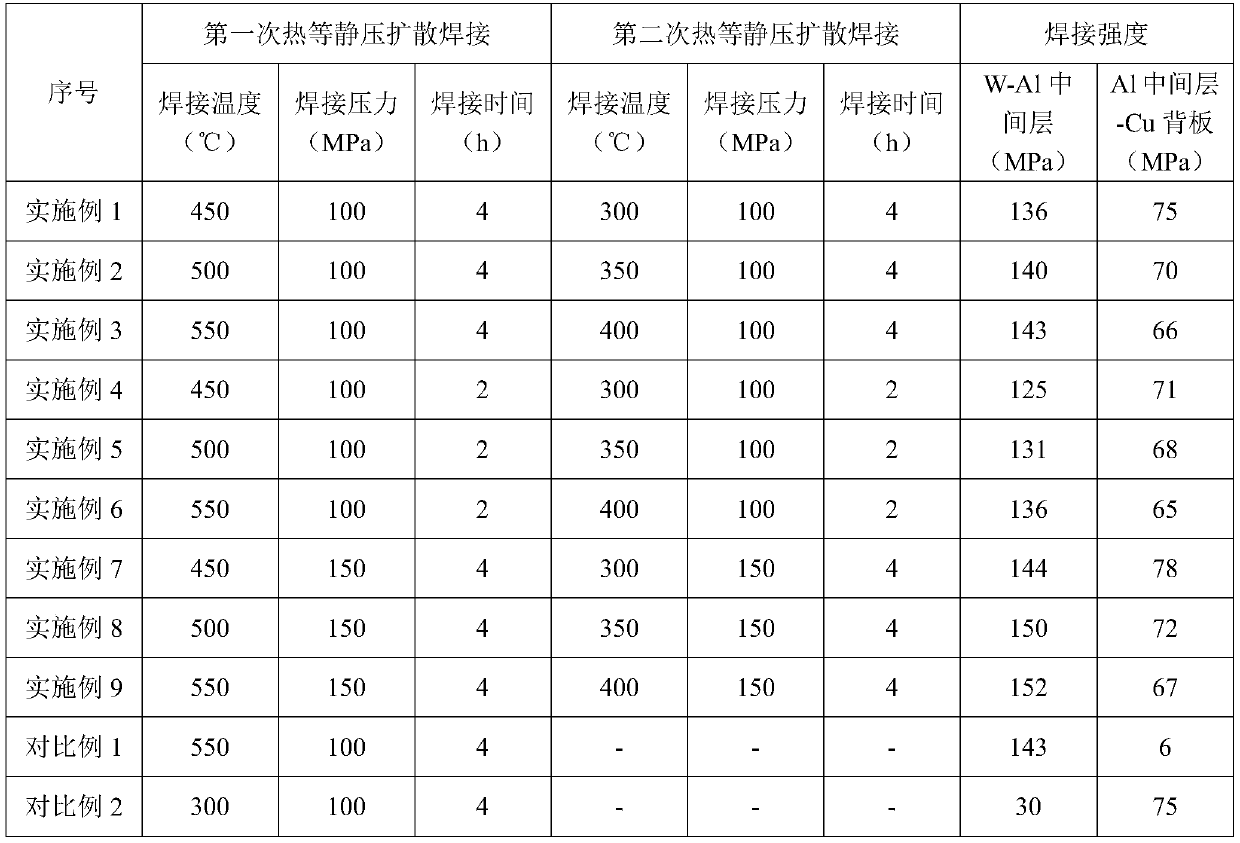

Two-step hot isostatic pressing diffusion welding method for tungsten target assembly

ActiveCN111014930AGuaranteed welding strengthImprove welding strengthNon-electric welding apparatusWeld strengthUltimate tensile strength

The invention discloses a two-step hot isostatic pressing diffusion welding method for a tungsten target assembly, and belongs to the technical field of magnetron sputtering target manufacturing. According to the welding method, hot isostatic pressing diffusion welding is carried out on a tungsten target blank and an Al intermediate layer, then secondary hot isostatic pressing diffusion welding iscarried out on the tungsten target blank and a copper back plate, finally, the tungsten target material assembly is obtained, and the welding strength of the tungsten target blank-Al intermediate layer welding face of the tungsten target material assembly is larger than or equal to 125 MPa, the welding strength of the Al intermediate layer-copper back plate welding face is larger than or equal to65 MPa, the welding-on rate of the two welding faces is larger than 99.5%, the overall deformation degree of the target material after welding is small, the target material is suitable for a high-power sputtering machine table, and it is guaranteed that desoldering and target falling are avoided in the sputtering process.

Owner:有研亿金新材料(山东)有限公司 +1

Method for low temperature brazing aluminium alloy to obtain brazed joint with high temperature use performance

ActiveCN101088690AHigh strengthSmall amount of deformationWelding/cutting media/materialsWelding/soldering/cutting articlesEtchingUltimate tensile strength

The method for low temperature brazed aluminum alloy to obtain brazed joint with high temperature use performance includes the following steps: 1. setting the brazing alloy inside the brazed gap; 2. primary brazing; and 3. ultrasonic treatment. The said brazing process has no any etching on the aluminum alloy workpiece, short brazing period, low brazing temperature, low operation cost, and capacity of obtaining brazed joint with high strength and high temperature use performance.

Owner:哈尔滨工大光电科技有限公司

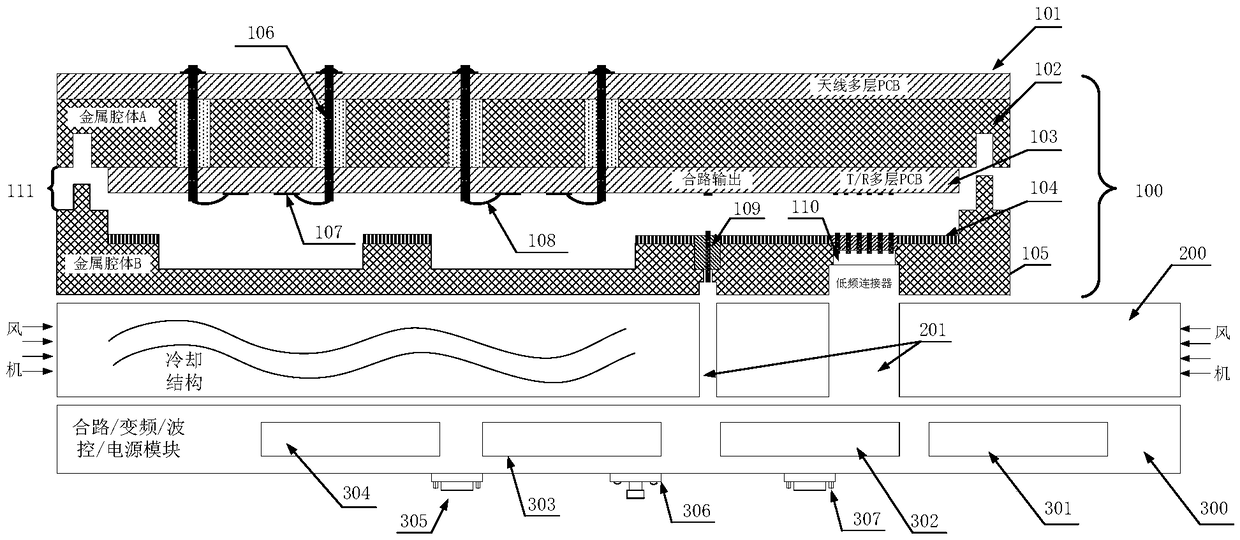

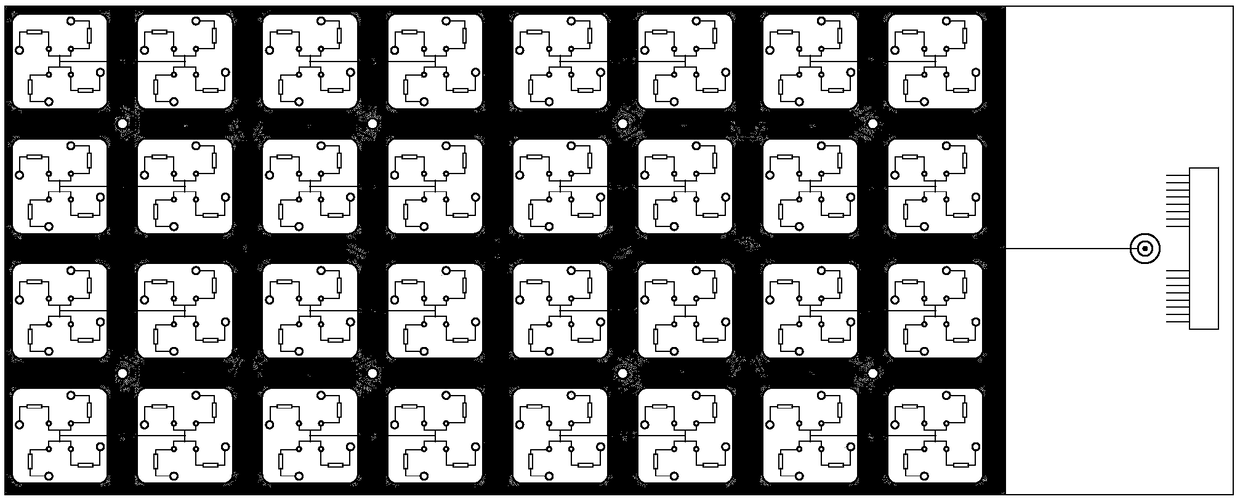

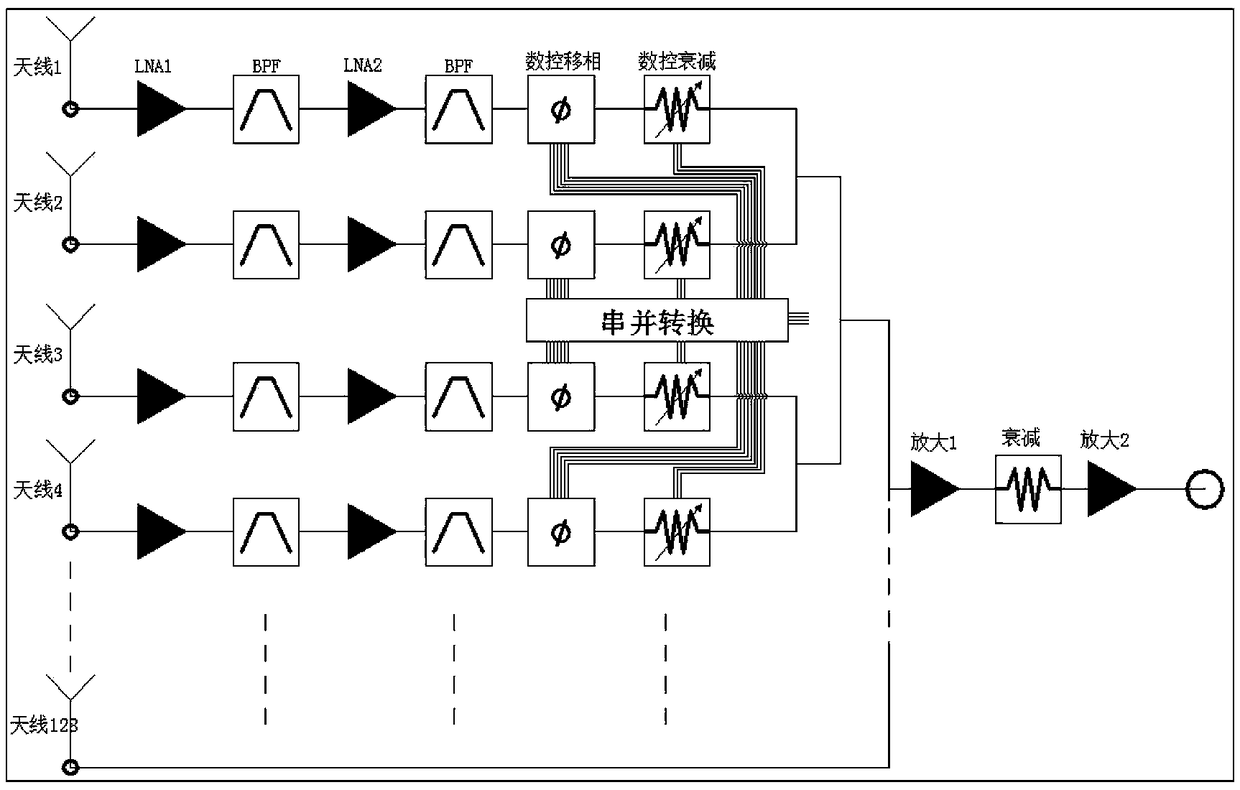

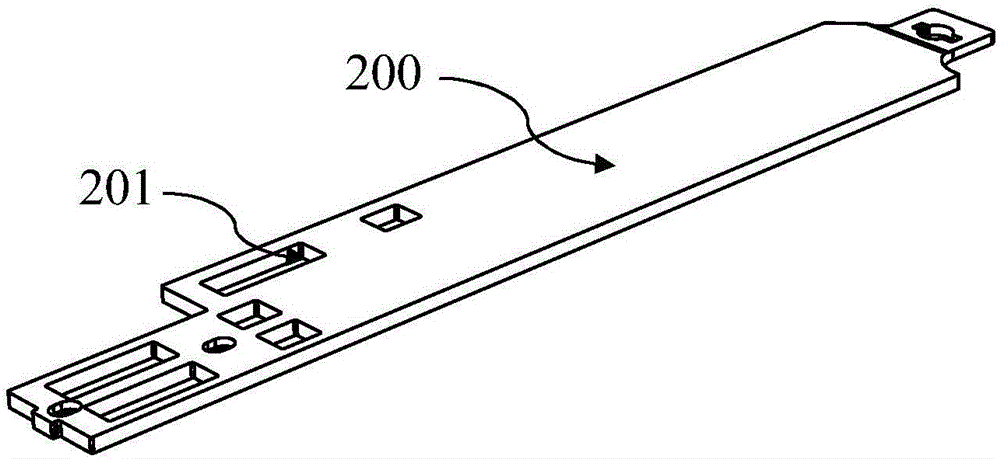

Multi-channel tile-type phased-array transceiver array and manufacturing method thereof

The invention discloses a multi-channel tile-type phased-array transceiver array and a manufacturing method thereof, and belongs to the technical field of phased arrays. The array of the invention comprises a sub-array module layer, a heat dissipation layer and a functional circuit layer, and the sub-array module layer comprises a sub-array module. The sub-array module comprises an upper metal shell and a lower metal shell, wherein a closed cavity is formed between the upper metal shell and the lower metal shell. The upper surface of the upper metal shell is provided with an antenna circuit board, and a lower surface of the upper metal shell is provided with a transceiver circuit board. A power distribution / synthesis network and a power supply control interface are disposed on the transceiver circuit board. The lower metal shell is provided with a second RF connector and a low-frequency connector, and the low-frequency connector is mutually connected with the power control interface. The array has the advantages of good heat dissipation and airtightness, high degree of integration, small size, light weight and convenient use, can effectively reduce the profile height of the array,and is beneficial to realize integration and miniaturization of the array.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

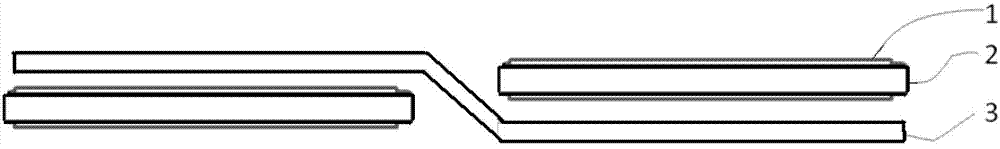

Welding method of copper and copper alloy

InactiveCN102489871ALow soldering temperatureTightly boundWelding/cutting media/materialsSoldering mediaRoom temperatureMechanical property

The invention relates to a welding method of copper and copper alloy, which is characterized in that: by adopting a room-temperature solid phase rolling-bonding mode, an uniform and dense silver-copper alloy layer (2) is bonded to the surface of a metal part (1), and then one surface of the metal part (1) to which the silver-copper alloy layer (2) is bonded is connected with a metal part (3) to be welded; and by heating, when the temperature reaches to the melting point of the silver-copper alloy layer (2), the alloy layer (2) is melted and is adhered to the contacted metal part (3) to complete the welding between the metal part (1) and the metal part (3). According to the welding method, the welding pieces are tightly combined, the defects of missing weld, unsmooth welding surfaces and the like can be overcome, the welding temperature of 200 to 500 DEG C of copper and copper alloy is reduced, and a matrix material still keeps higher physical and mechanical properties. The welding method can be applied to the welding between copper and copper, copper alloy and copper alloy, or copper and copper alloy.

Owner:SINO PLATINUM METALS CO LTD

Dielectric phase shifter with novel conducting cavities

ActiveCN106067577AReduce the number of partsSave assembly timeWaveguide type devicesAntennasDistortionEngineering

The invention discloses a dielectric phase shifter with novel conducting cavities. The dielectric phase shifter includes an outer shell, dielectric sheets, a circuit board and coaxial cables; two rectangular cavities are formed in the outer shell; one conducting cavity is formed at one side of each cavity, wherein the conducting cavity is connected with the cavity; each conducting cavity is hollow and is a circular hole of which the diameter is 3.6 mm, and a small groove of which the width is 1.2 mm formed at one side of the hole; in each conducting cavity 4, a portion with a reserved width is maintained to be original at a position where the outer conductor of a corresponding coaxial cable is welded to the conducting cavity 4, and a portion of which the width is 15mm is machined downwards so as to be removed, and therefore, the coaxial cable can extend into the conducting cavity so as to be welded to the conducting cavity; the circuit board is designed into a rectangle with four grooves formed at one side; and the four grooves are corresponding to the edges of circuit board pads for welding the inner conductors of the coaxial cables. When welding is carried out, only one-time clamping is required, and therefore, a welding technique is better, and the economical efficiency of welding is improved; and the conducting cavities are utilized to excellently wrap the outer conductors of the coaxial cables, distortion can be avoided, bending stress of the coaxial cables can be avoided, the risk that welding spots and the circuit board are damaged can be lowered, and hidden hazard points in intermodulation can be decreased.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Planar vacuum glass welded by metal solders in microwave manner and subjected to edge sealing by groove, and manufacturing method of glass

InactiveCN102951809AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionMicrowave ovenMetal

The invention discloses vacuum glass. The vacuum glass consists of upper glass and lower glass and is characterized in that the welding periphery of the upper glass is provided with an edge sealing strip frame, and the welding periphery of the lower glass is provided with an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a microwave oven, so that the vacuum glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the vacuum glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing vacuum glass without extraction openings in mass by virtue of a one-step method, and can be used for manufacturing not only common vacuum glass but also tempered vacuum glass.

Owner:戴长虹

Welding strip used in low-temperature welding mode and used for solar photovoltaic module

InactiveCN103199137ALow soldering temperatureReduce warpagePhotovoltaic energy generationSemiconductor devicesHigh conductivitySolar cell

The invention relates to a welding strip used in a low-temperature welding mode and used for a solar photovoltaic module. The welding strip structurally comprises a high-conductivity base material and a low-melting-point alloy layer which is arranged on at least one of surfaces of the base material, and the melting point of the low-melting-point alloy layer is 70-230 DEG C. Compared with the prior art, the welding strip not only guarantees welding reliability in a welding process, but also reduces the situation that due to a high-temperature welding mode, battery slices of a solar cell are broken.

Owner:袁奇英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com