Low-melting-point metal cable continuation device

A low-melting-point metal and cable connection technology, applied in conductive connection, electrical component connection, welding/welding connection, etc., can solve the problems of core wire and insulating layer damage, affecting welding quality, secondary failure, etc. , the structure is simple, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

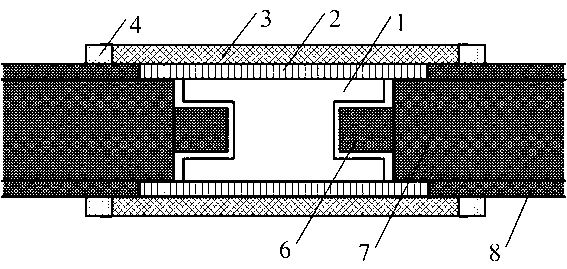

[0031] Embodiment 1 shows a typical application of the low melting point metal cable splicing device of the present invention. figure 1 It is a schematic diagram of the welding structure of the low-melting point metal cable connection device.

[0032] Such as figure 1 As shown, the low-melting-point metal cable connection device of this embodiment is composed of a low-melting-point metal inner ring 1 , an insulating sleeve 2 , a shielded copper mesh 3 with a low-melting-point metal coating 4 , and a heat gun 5 .

[0033] The structure of the cable to be connected is the core wire 6, the insulating sleeve 7 and the shielding net 8 in sequence from the inside to the outside.

[0034] In this embodiment, the cable core wire 6 is made of copper with a diameter of 3 mm, the cable shielding layer 8 is made of copper mesh, and the material of the insulating sleeve 7 is solid polyethylene.

[0035] In this embodiment, the low-melting-point metal is bismuth-indium-tin alloy (mass fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com