Heterogeneous semi-solid brazing method of aluminum alloy and magnesium alloy assisted by external vibration energy

A brazing method and vibration energy technology, which can be used in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of Mg/Al dissimilar metal joints, such as plastic toughness and unfavorable application, difficult to control the joining process, and limited welding flexibility. , to achieve the effect of overcoming poor forming, ideal engineering significance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

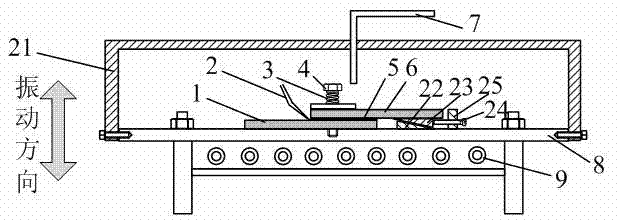

[0036] Further illustrate the implementation process of this method below in conjunction with accompanying drawing:

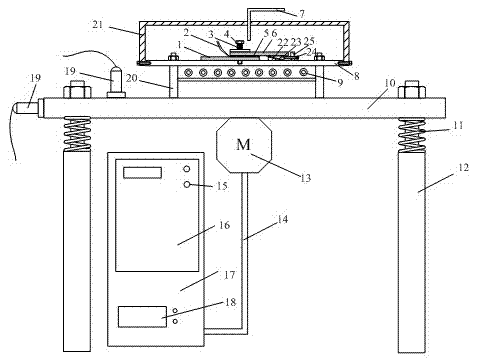

[0037] The method of the present invention can adopt figure 2 and image 3 The shown device is realized, and the device includes a welding part, a vibrating part, a control part and a fixture part. in:

[0038] The welding part includes a welding platform 8, a shielding gas cover 21, a thermocouple 2, a heating pipe 9 and a ventilation pipe 7; the weldment is placed on the welding platform 8, the shielding gas cover 21 is covered on the welding platform 8, and the thermocouple 2 is arranged on the shielding gas Inside the cover 21, one end is connected with the weldment, and the other end is connected with the temperature control module of the control part. A ventilation pipe 7 is connected to the shielding gas cover 21 . A heating pipe 9 is arranged under the welding platform 8 .

[0039] The vibration part includes a vibration platform 10 , a spring 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com