Patents

Literature

935results about How to "Avoid bad consequences" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

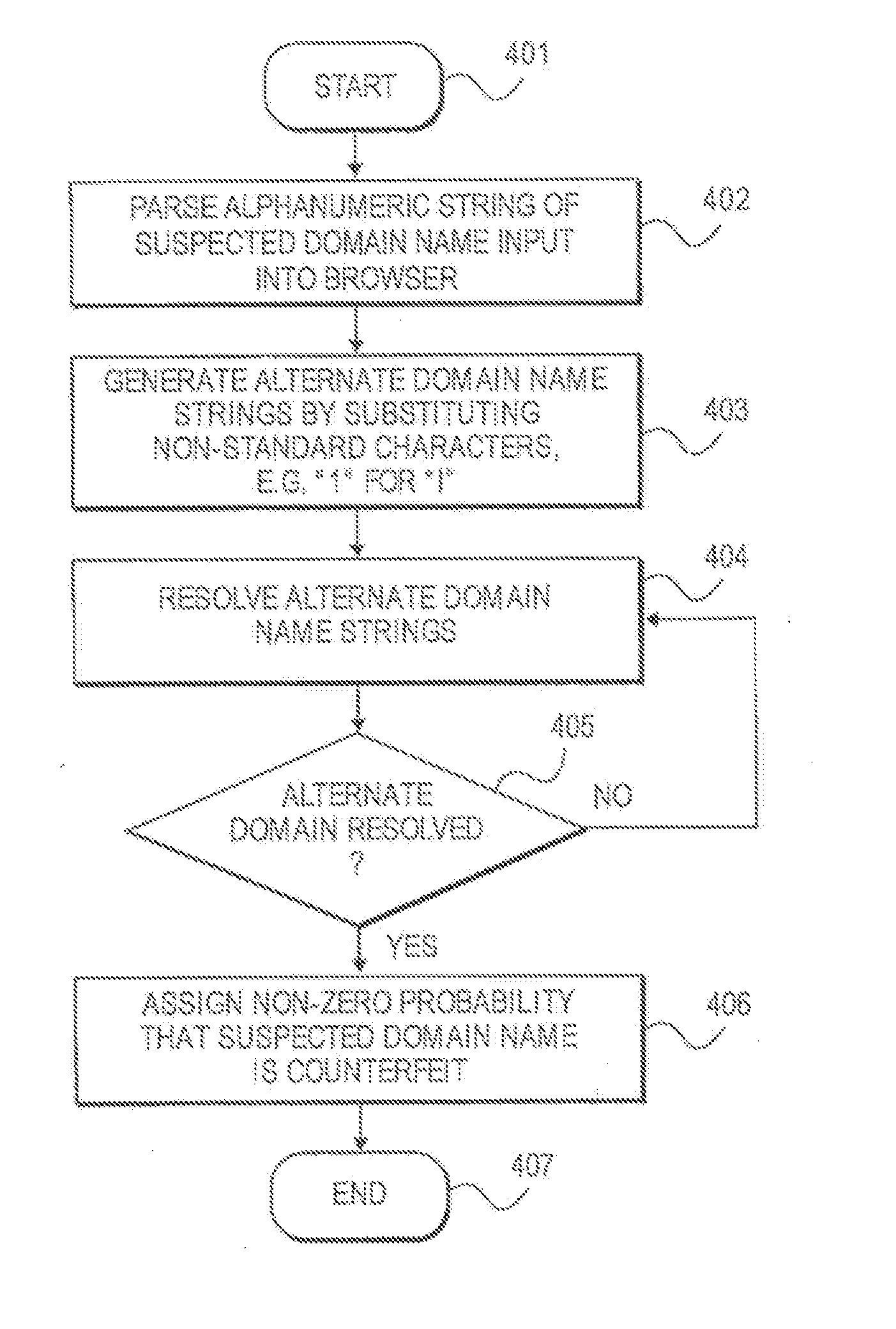

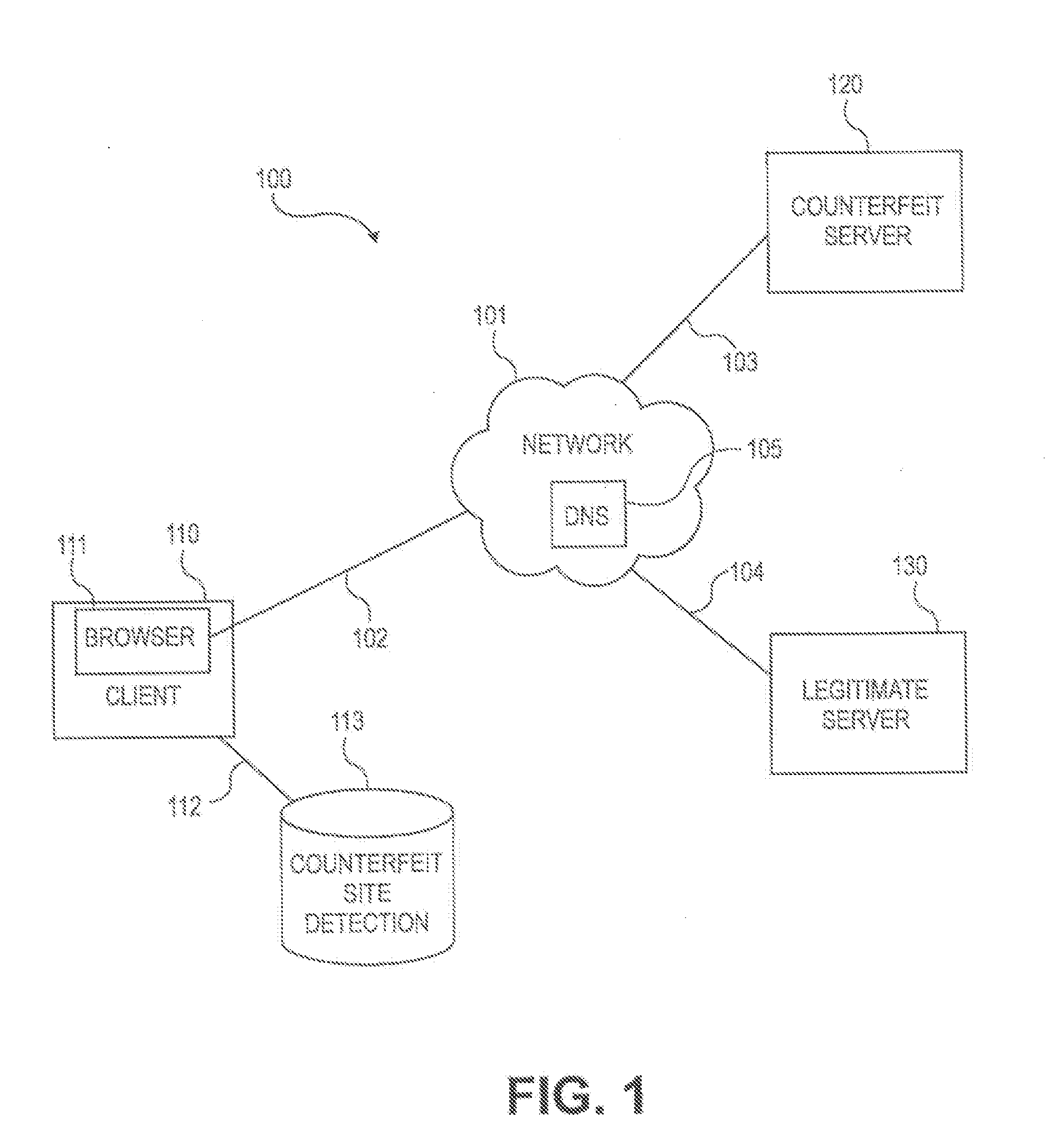

Method and system for determining a probability of entry of a counterfeit domain in a browser

ActiveUS20080092242A1Easy to useImprove security levelMemory loss protectionDigital data processing detailsDomain nameUniform resource locator

Embodiments of the present invention provide a method and system for determining a probability that a suspected domain name of a domain accessed using a universal resource locator (URL), which can be entered as a character string into a browser associated with a client in a net environment, is a counterfeit of a legitimate domain name. Characters in the suspected domain name can be identified as known as likely to be deceptively substituted for corresponding legitimate characters of a legitimate domain name. An alternate domain name is generated by substituting predetermined characters with the corresponding legitimate characters. An attempt can be made to resolve alternate domains of the alternate domain names. If the names are successfully resolved, a non-zero probability is assigned to the suspected domain name as being counterfeit.

Owner:RED HAT

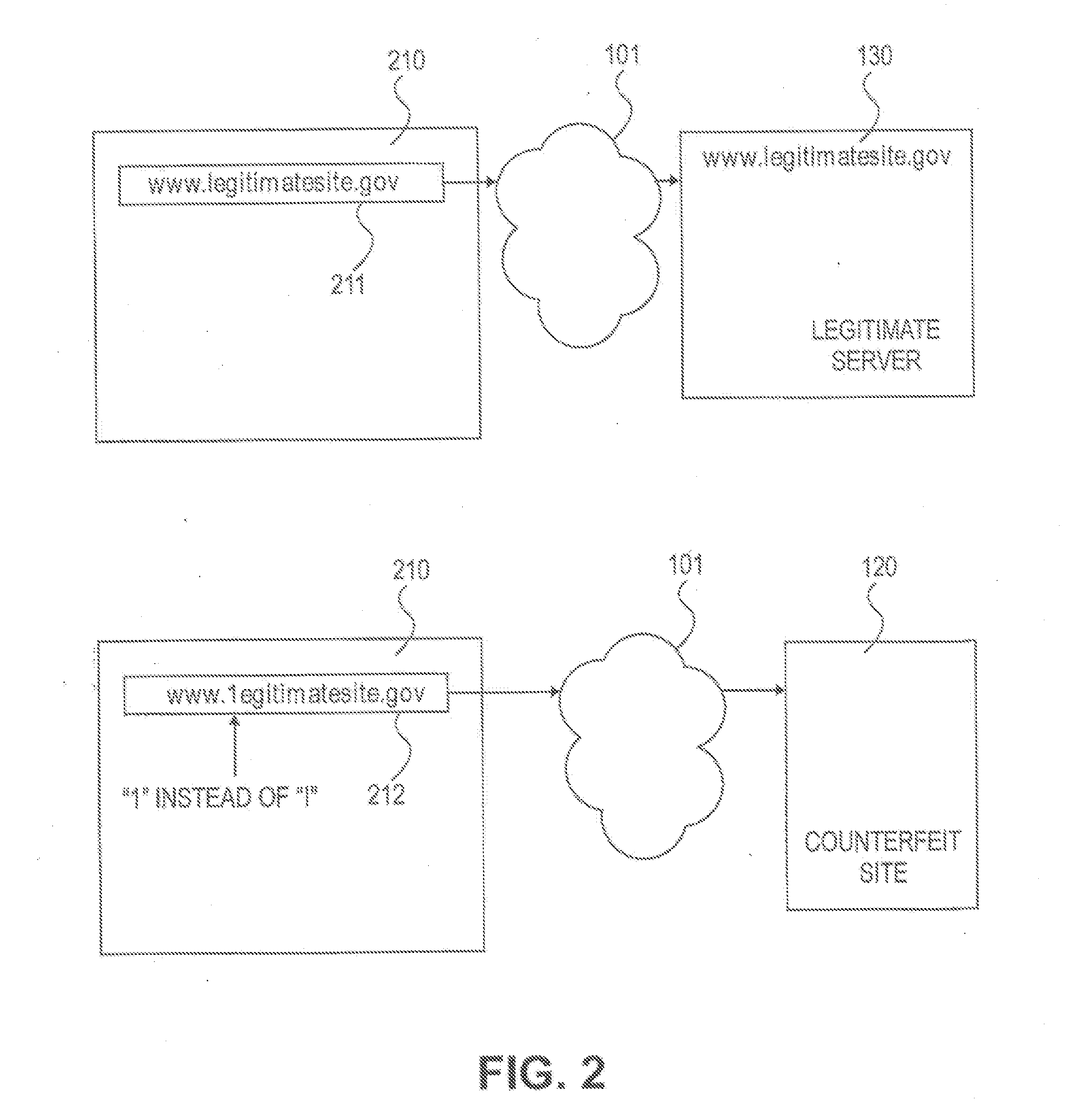

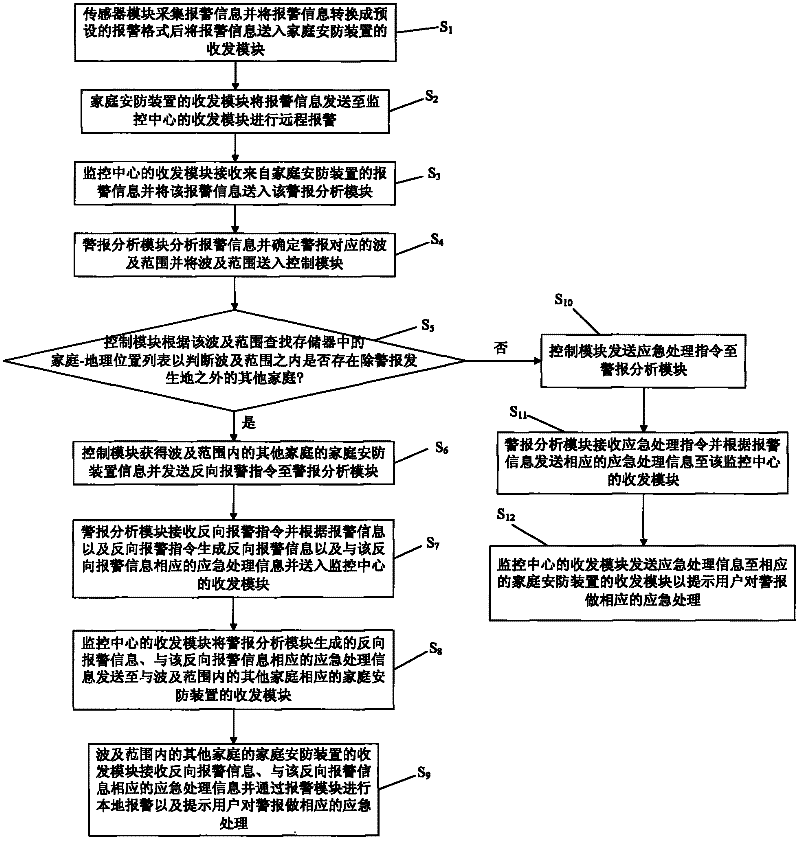

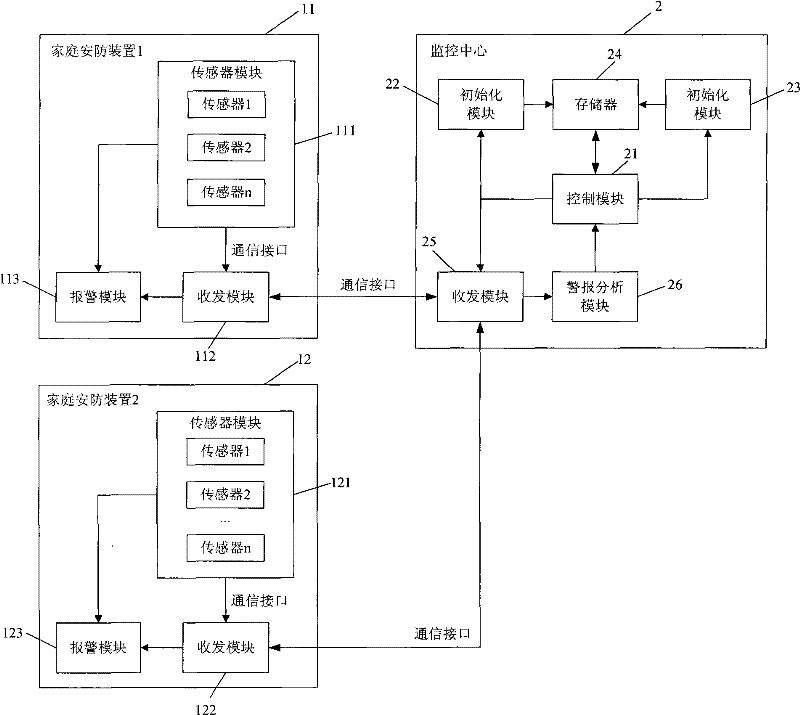

Home security device, monitoring center, two-way alarm system and two-way alarm method

The invention discloses a home security device. The home security device comprises a sensor module and an alarm module connected with the sensor module, as well as a transceiving module which is used for receiving alarm information collected by the sensor module, converting the alarm information to a preset alarm format, sending the alarm information to the alarm module for performing local alarm, sending the alarm information to a monitoring center connected with the home security device for performing remote alarm and receiving reverse alarm information and emergency processing information from the monitoring center, wherein the reverse alarm information and the emergency processing information are sent to the alarm module for performing the local alarm and prompting a user to perform emergency processing. The invention further discloses the monitoring center, a two-way alarm system and a two-way alarm method. The home security device disclosed by the invention can enable a family to perceive the occurrence of a disaster, alarm, simultaneously prompt the families in the range which can be affected by the disaster as soon as possible, further enable the users in the affected range but not trigger alarm conditions to prepare as soon as possible and reduce loss.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

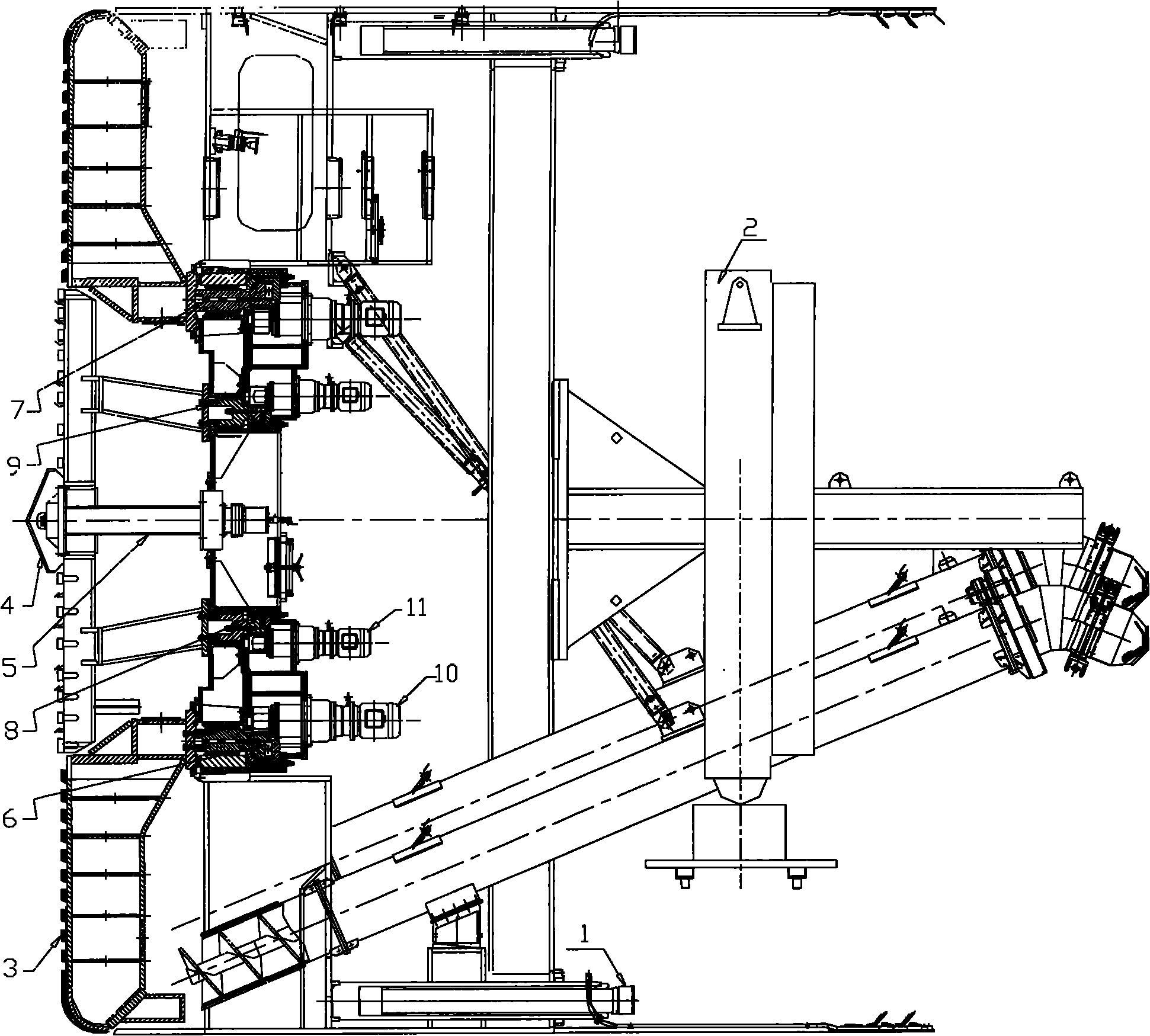

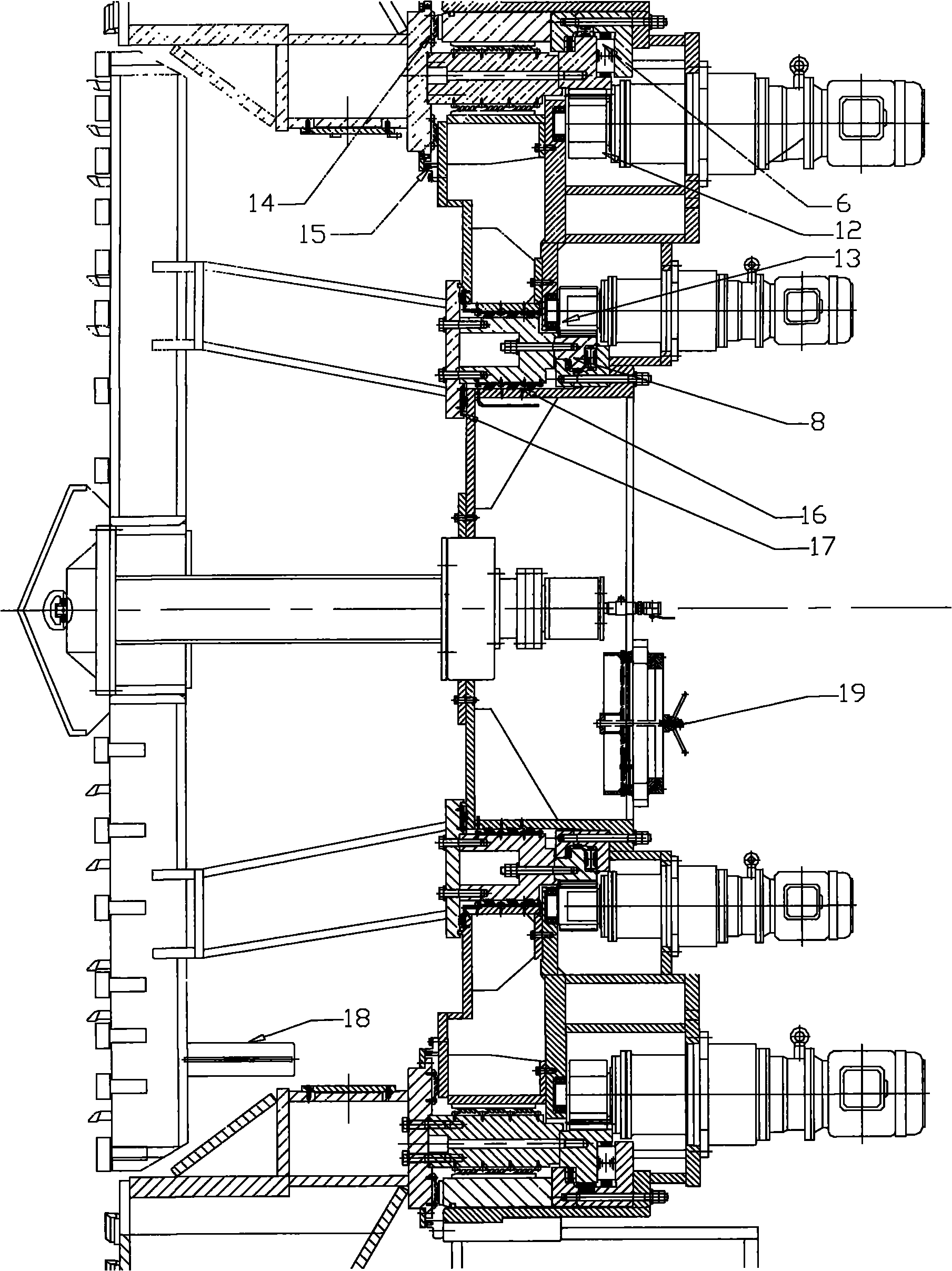

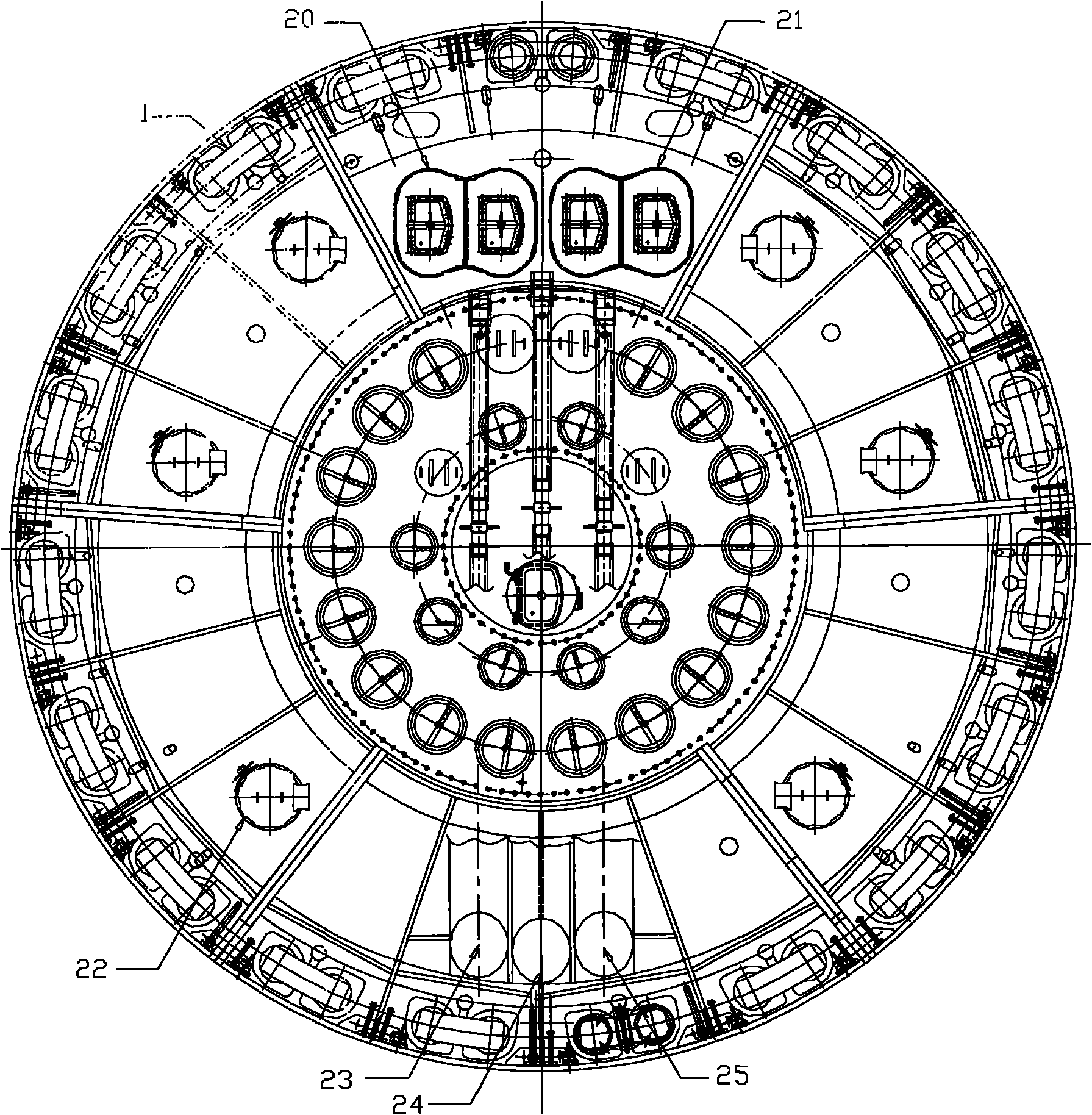

Large-diameter earth pressure balance shield machine

InactiveCN101798928AReduce wear rateChange the situation of uneven damageTunnelsControl theoryEarth pressure balance

The invention relates to a large-diameter earth pressure balance shield machine. The machine comprises a cutterhead, a cutterhead drive part, a propulsion oil cylinder, an erector, spiral conveyors and a frame; the cutterhead is a double-cutterhead which comprises a peripheral large cutterhead and an independent central cutterhead; the cutterhead drive part comprises two driving mechanisms which drive the peripheral large cutterhead and the independent central cutterhead respectively; and the peripheral large cutterhead and the independent central cutterhead rotate independently and bidirectionally. Compared with the prior art, the shield machine adopts the double-cutterhead design, greatly optimizes a cutting speed of the cutterhead on a soil body, further improves a propulsion speed of the shield, optimizes the disturbance effect of the cutterhead on the soil body, and prevents the rolling of a shield machine body; different opening rates are designed on the cutterhead and are suitable for different situations of a central part and a peripheral part when a tunnel is advanced; and three spiral conveyors discharge soil, effectively control the posture of the shield, and prevent the deviation of a tunnel axis.

Owner:SHANGHAI LIXING ENG TECH DEV

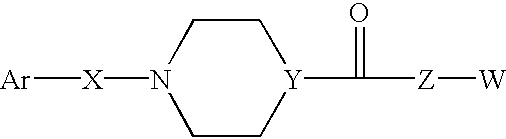

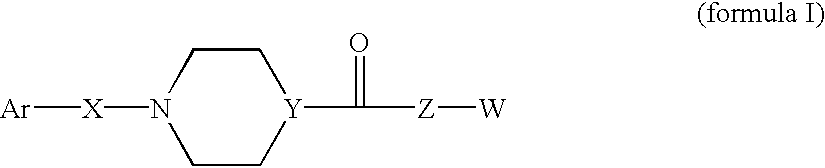

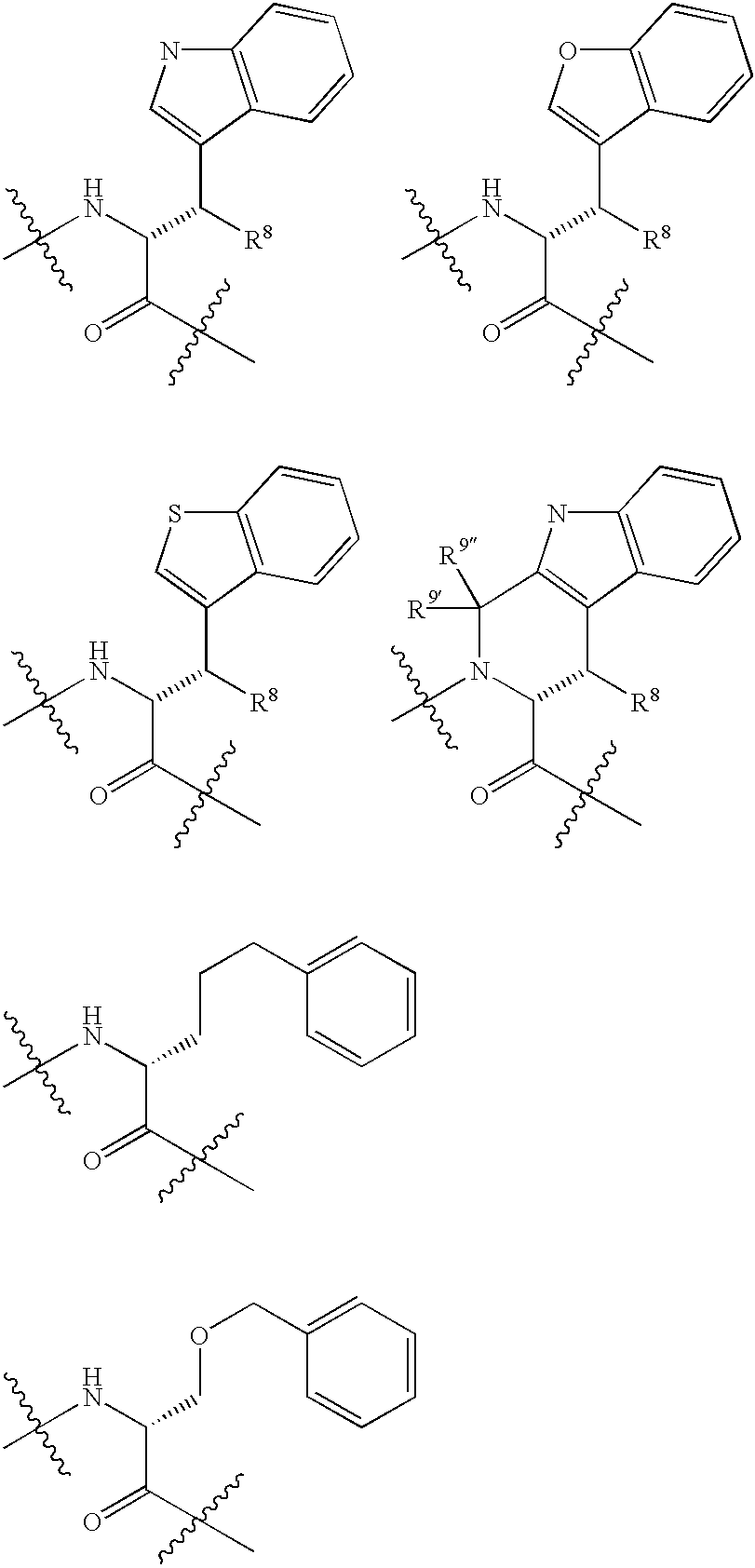

Somatostatin antagonists and agonists that act at the sst subtype 2 receptor

InactiveUS20020128206A1Ease of detectabilityEasy to prepareDipeptide ingredientsMetabolism disorderArylMammal

Compounds according to the formula: 1 and pharmaceutically acceptable salts, solvates or hydrates thereof, wherein group Ar is optionally substituted (C.sub.6-C.sub.10)aryl or (C.sub.1-C.sub.9)heteroaryl; X is a direct link, --CH.sub.2 --, --SO.sub.2 --, --CO--, --CHR.sup.1-- where R.sup.1 is(C.sub.1-C.sub.6) alkyl, or --CR.sup.1'R.sup.1"-where both R.sup.1' and R.sup.1" are, independently, (C.sub.1-C.sub.6)alkyl; Y is N or CH; and Z and W are as herein defined, and pharmaceutical compositions thereof, and methods useful to facilitate secretion of growth hormone(GH) in mammals.

Owner:HAY BRUCE A +2

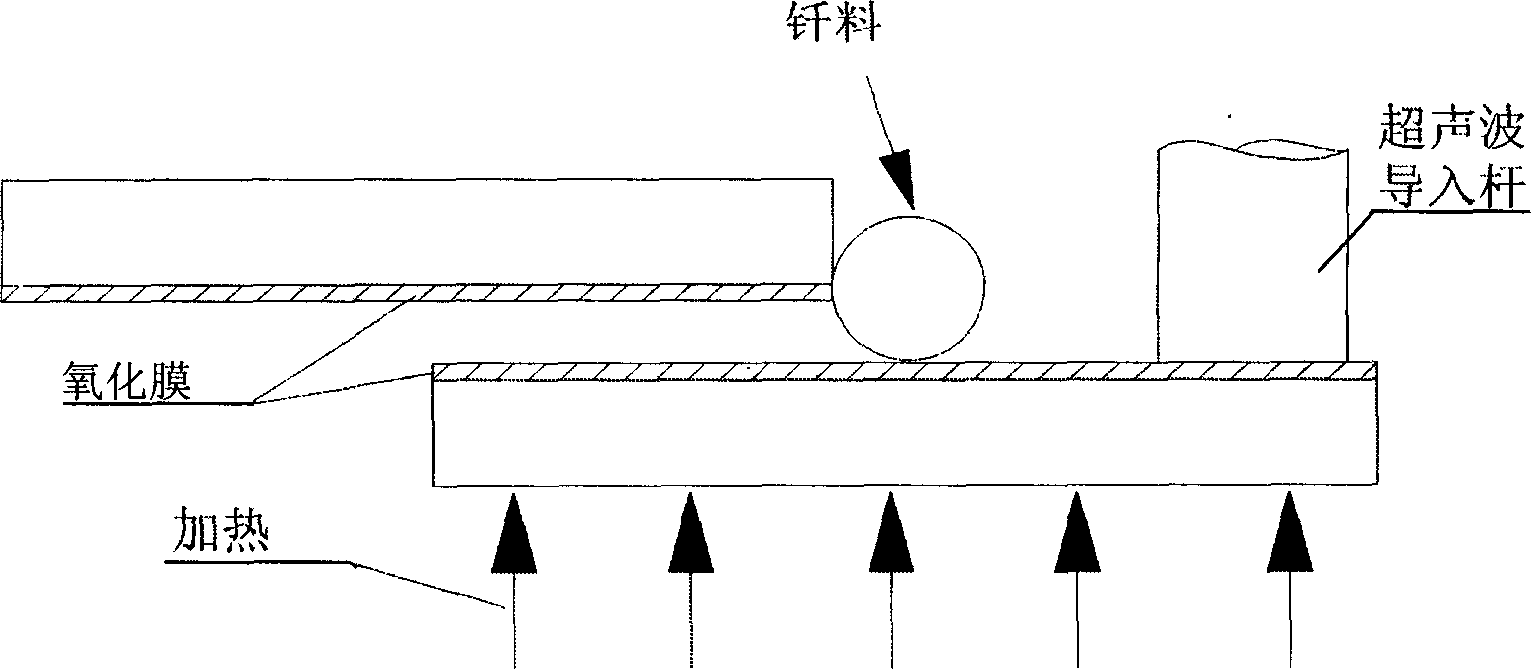

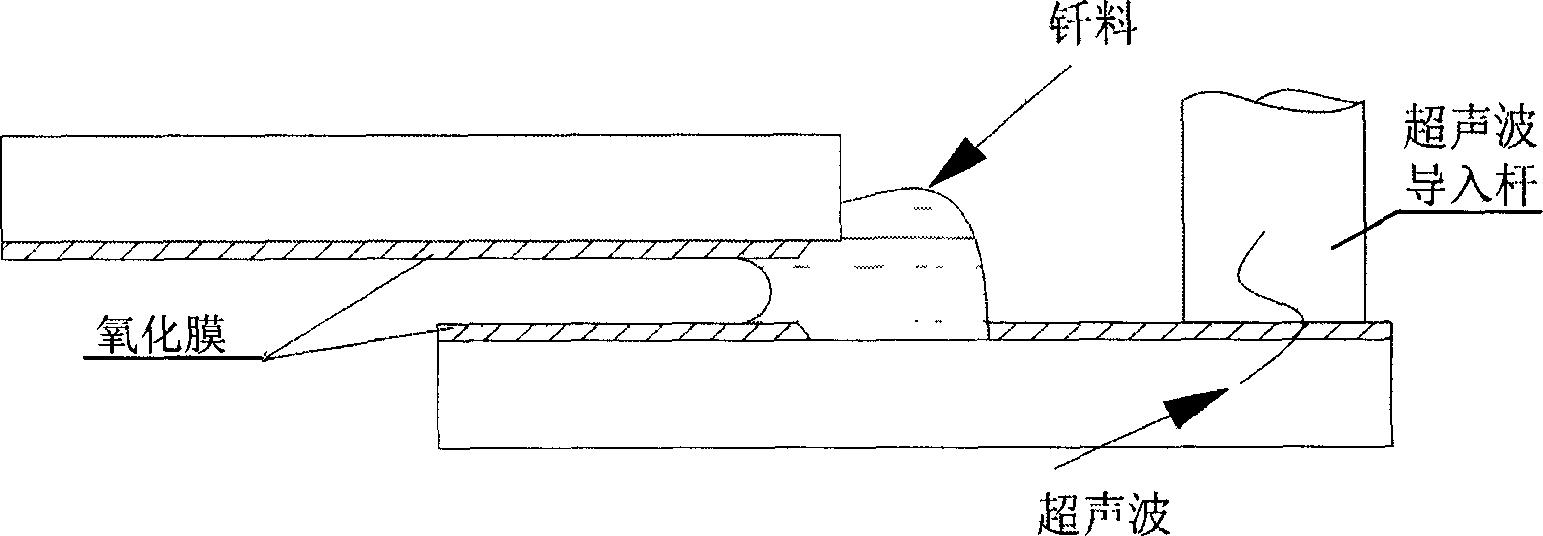

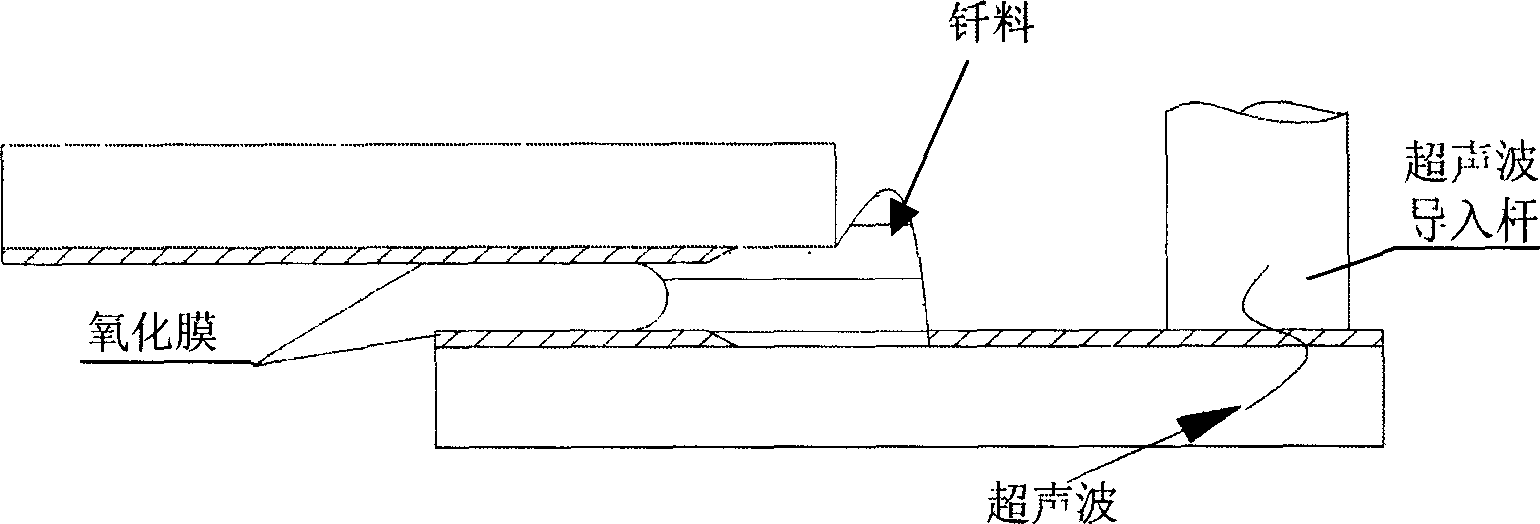

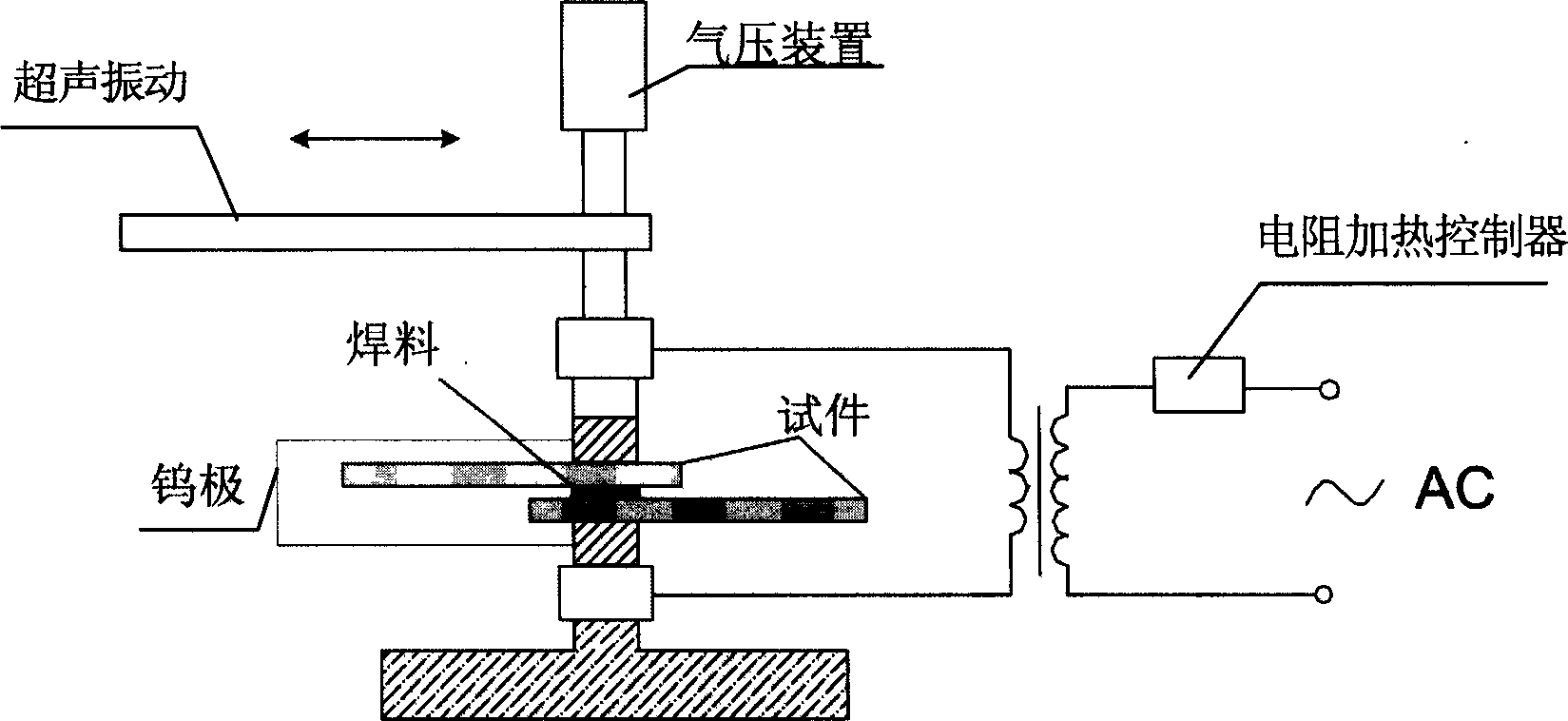

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1644291AAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

An ultrasonic capillary welding method for the Al-base composite material includes such steps as arranging upper and lower parts to be welded in such manner that the gap between them is 10-300 microns, putting the flux close to lap end, heating to smelt the flux, holding the temp, pressing the ultrasonic head onto surface of the part to be welded, and applying ultrasonic vibration for 0.5-15 S. Its advantages are high welding quality, low welding temp, and high speed.

Owner:HARBIN INST OF TECH

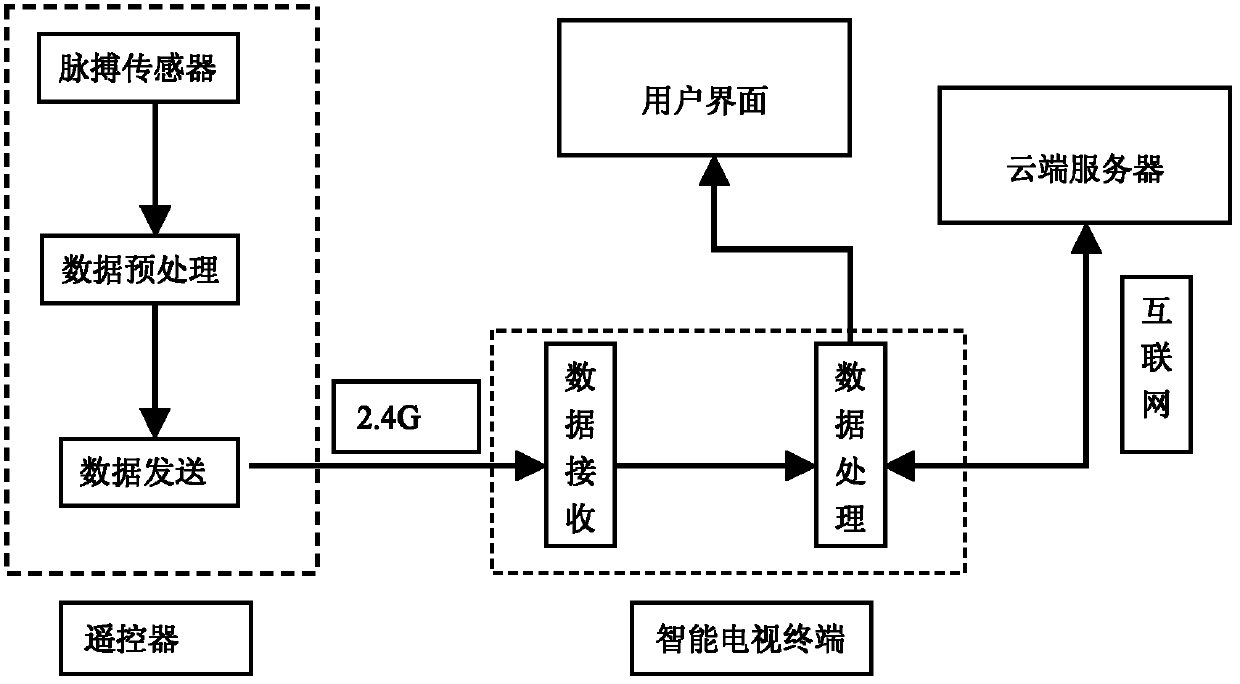

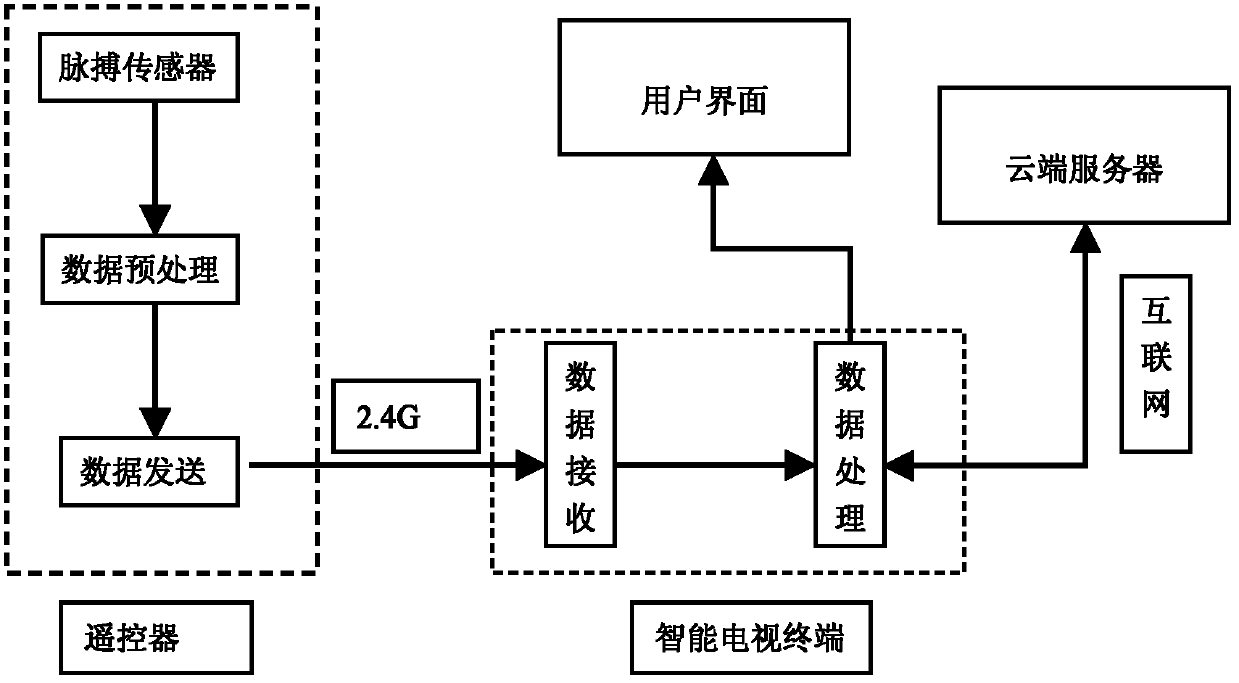

Autonomous remote health monitoring system

InactiveCN102609627ARealize health monitoringEasy to operateCatheterSpecial data processing applicationsTerminal equipmentMonitoring system

The invention relates to a human-machine interaction technique, in particular to a system achieving autonomous health monitoring by a health examination device and an internet; the system comprises the health examination device, a hand-held apparatus, a terminal apparatus and a cloud service platform; and a user autonomously exams the health by the health examination device, at the same time, the data of the user are transmitted to the cloud service end by the terminal apparatus connected with the Internet to analyze and process, finally, the health information suitable for the user is fed back to the user, so as to achieve the autonomous health management whenever and wherever possible. The autonomous remote health monitoring system provided by invention has the following beneficial effect: users can monitor own health autonomously at any time, the operation method is simple and convenient, and at the same time, the obtained health management information is real-time, efficient and accurate. The autonomous remote health monitoring system is suitable for health monitoring systems.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

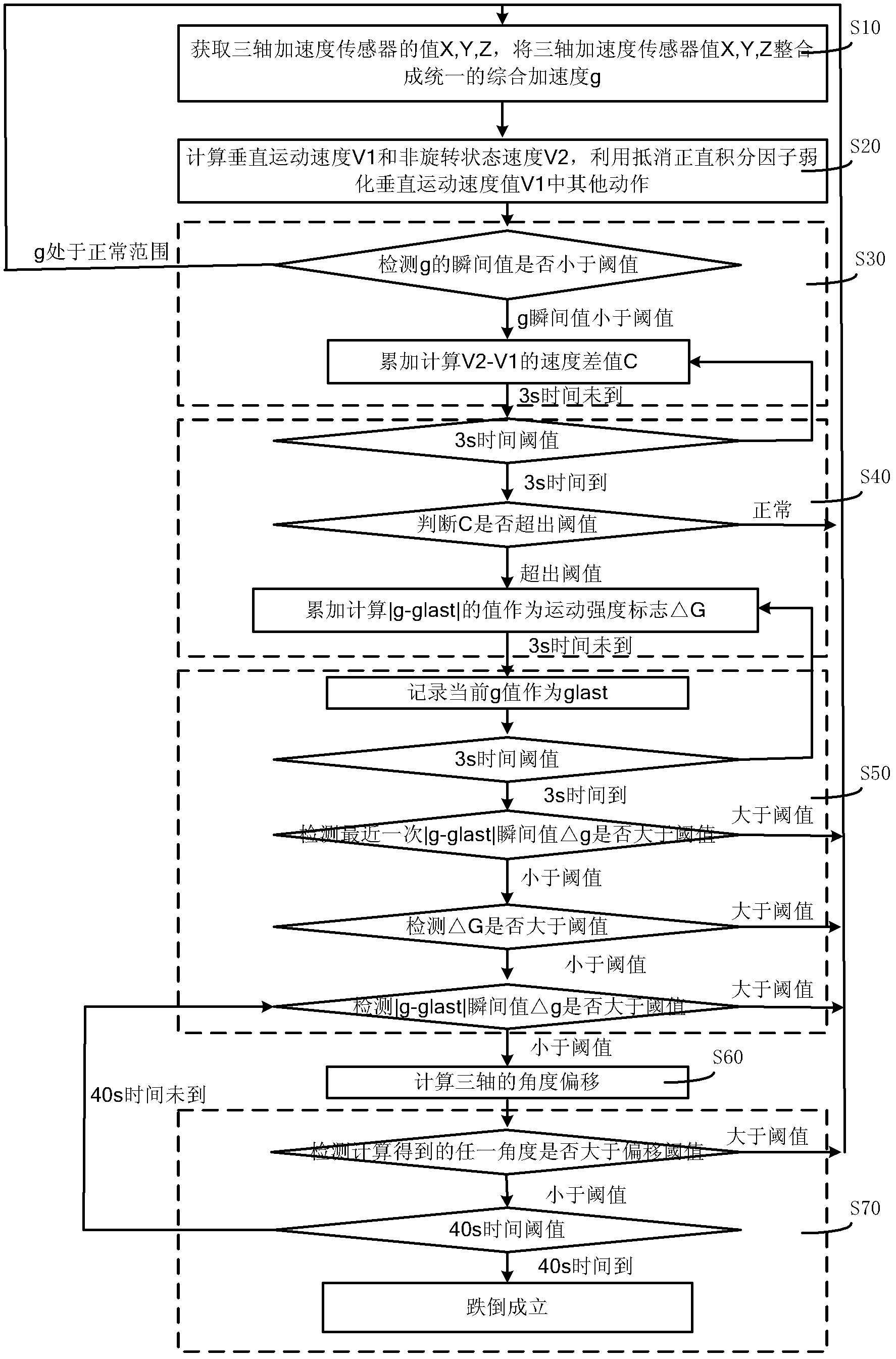

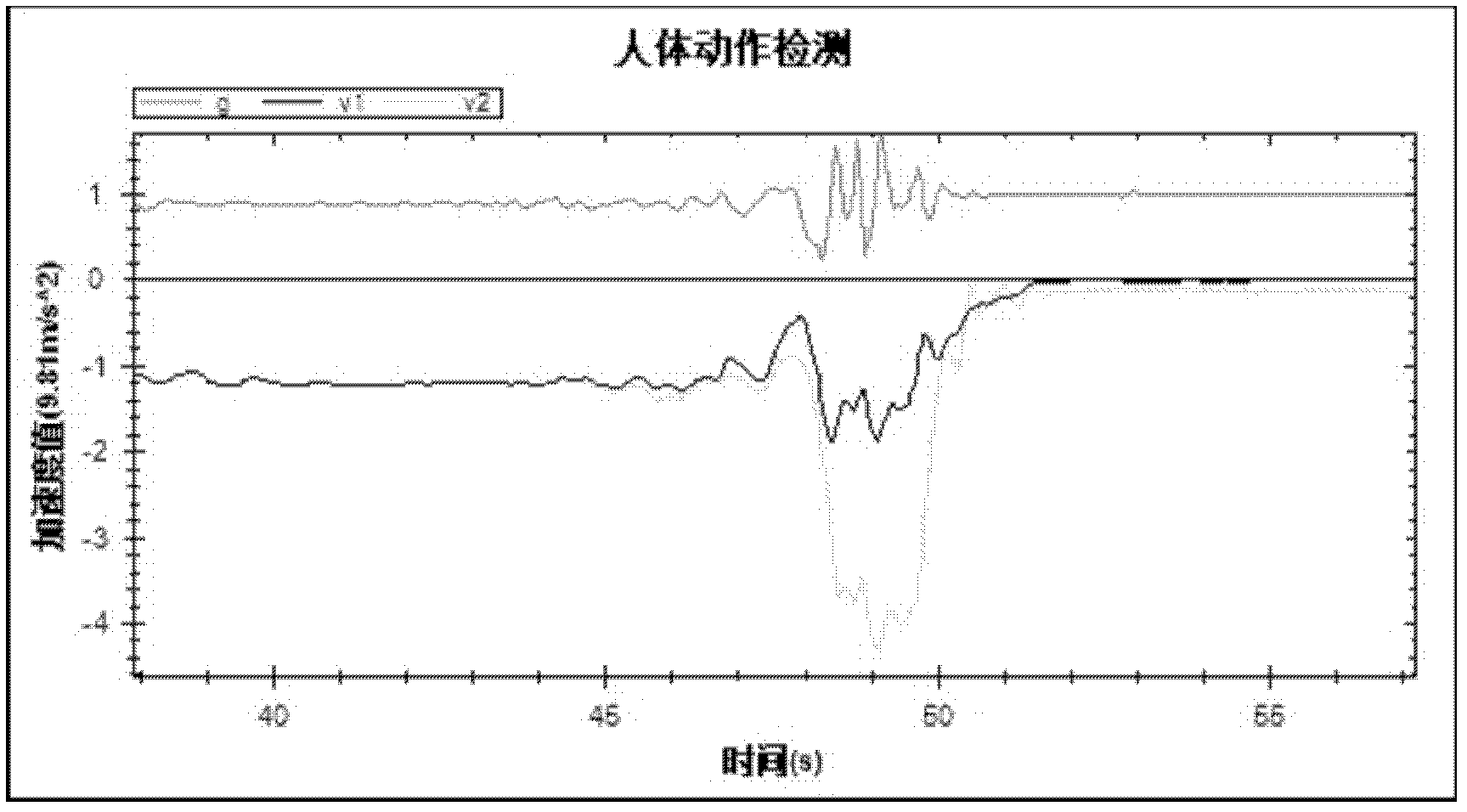

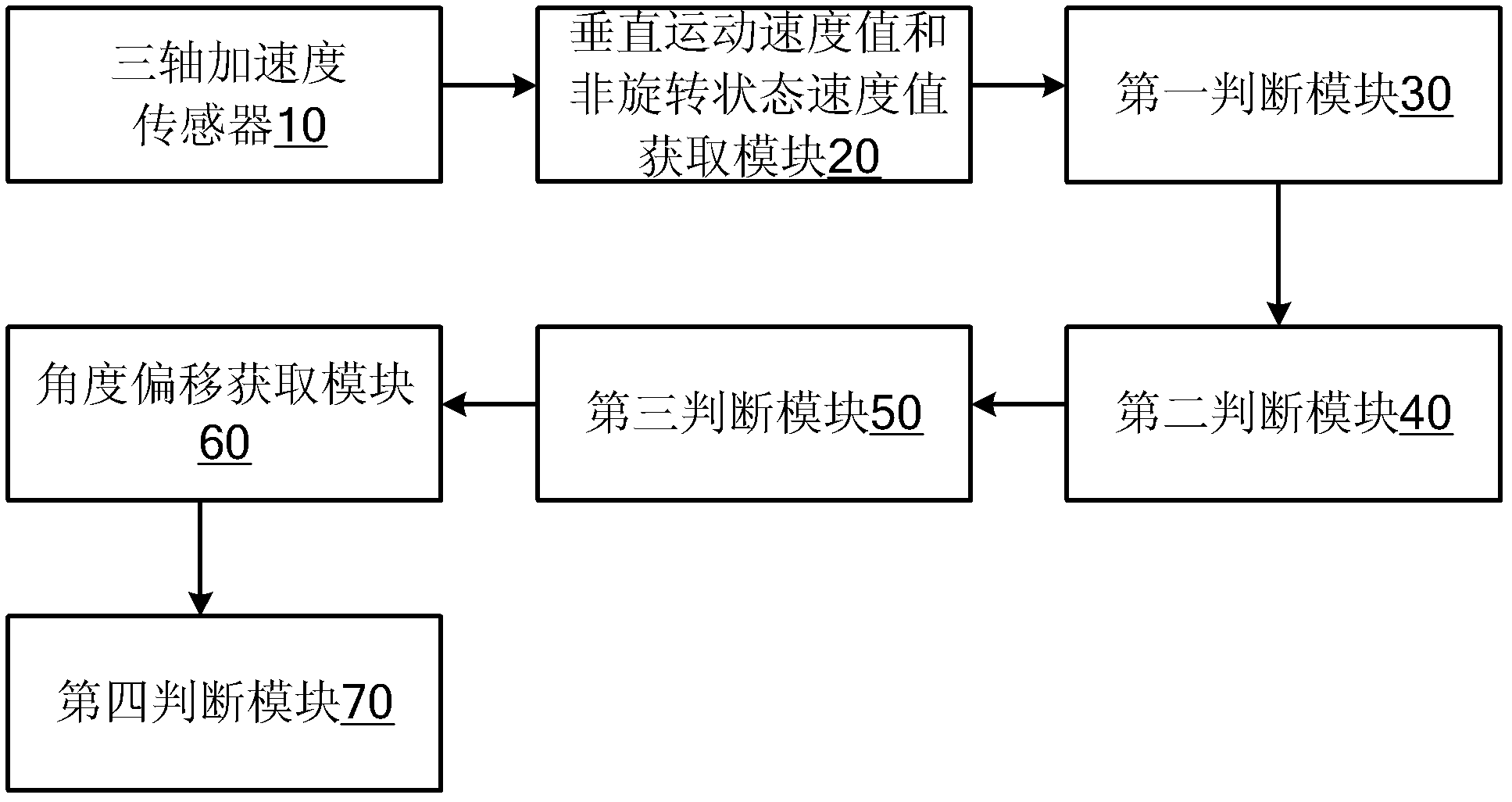

Falling detection method, falling detection device and wrist type device

The invention discloses a falling detection method, a falling detection device and a wrist type device. The falling detection device disclosed by the embodiment of the invention comprises a triaxial acceleration sensor, a vertical motion speed value and non-rotation state speed value acquisition module, a first judgment module, a second judgment module, a third judgment module, an angle deviation acquisition module and a fourth judgment module. According to the falling detection device disclosed by the invention, the acceleration sensor is adopted for setting different threshold standards according to different people groups, so that falling with different strengths can be detected, serious consequences caused by falling can be avoided, and the falling detection device is simple and convenient to use.

Owner:ZHEJIANG UNIV CITY COLLEGE

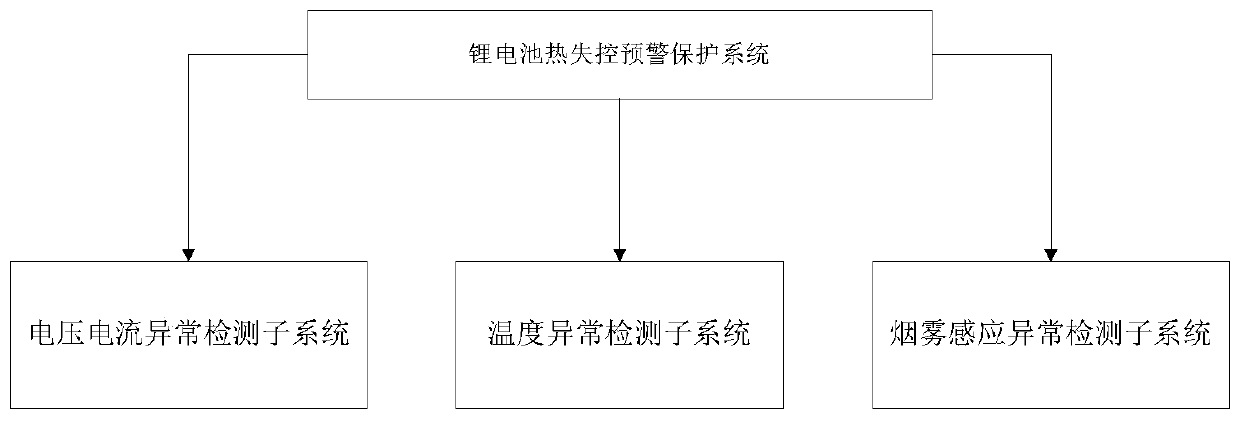

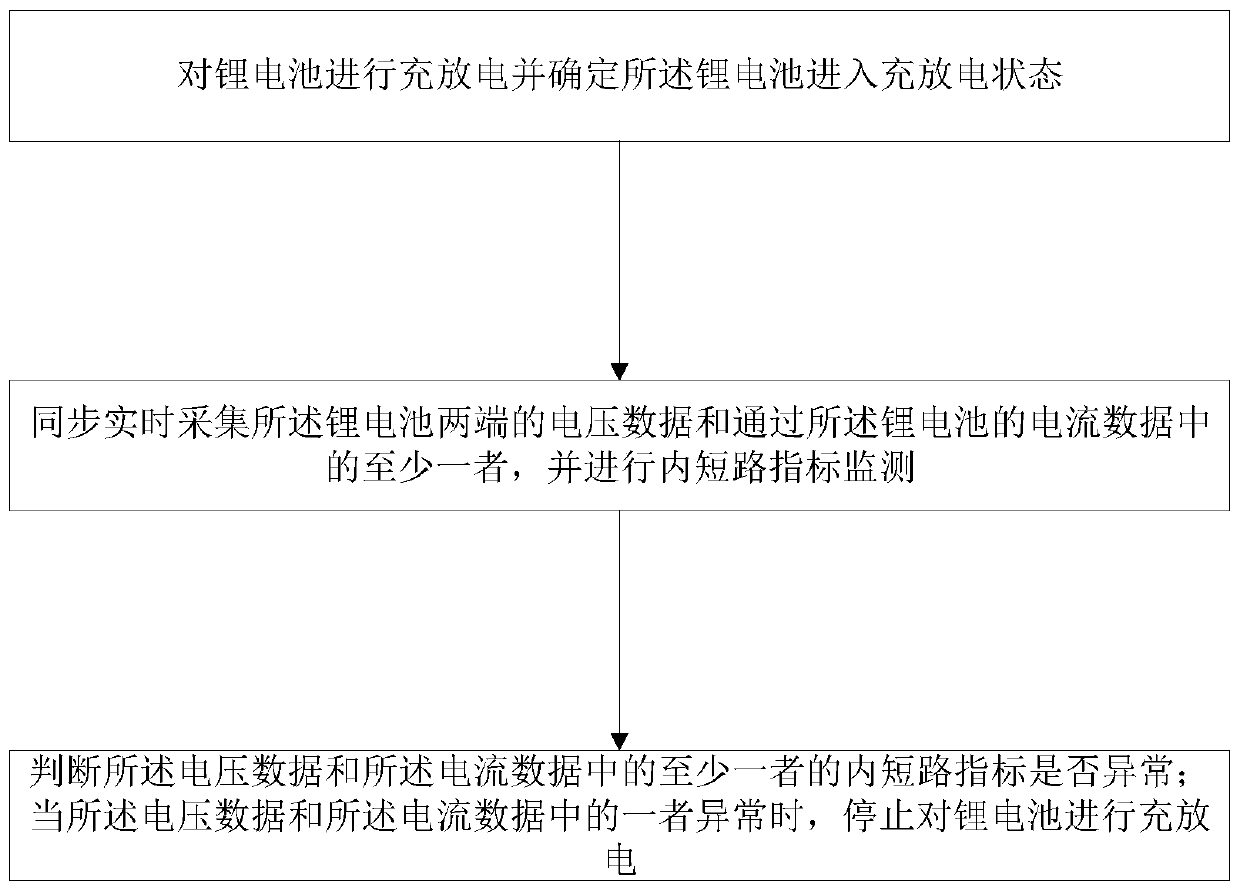

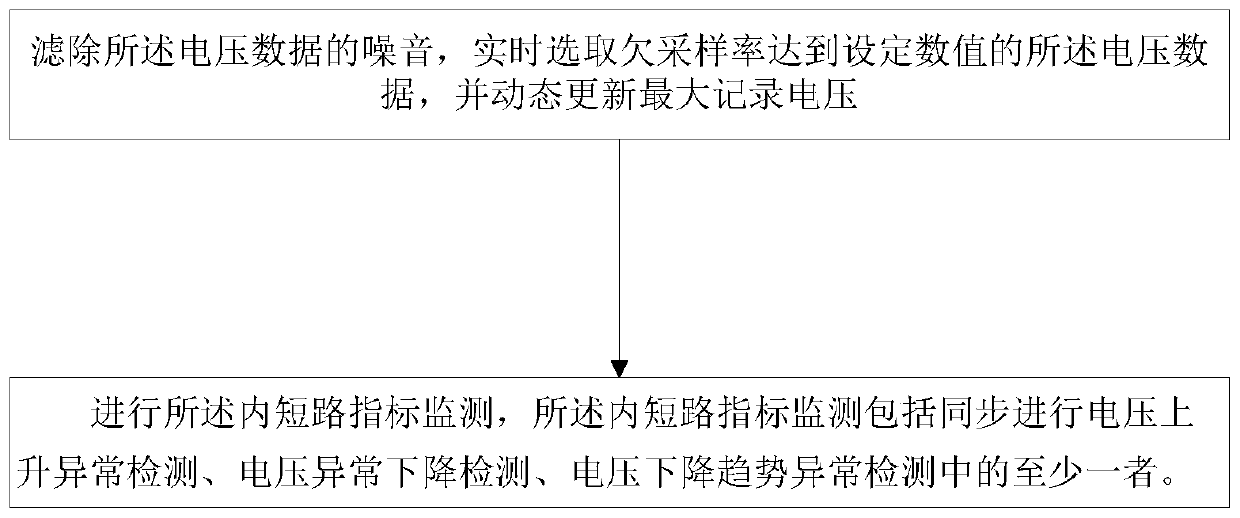

Thermal runaway early warning protection system and method for lithium battery

ActiveCN110350258ARealization of thermal runaway warningAvoid bad consequencesElectrical testingSecondary cells testingFire sprinklerAnomaly detection

The invention provides a thermal runaway early warning protection system for a lithium battery. The system comprises a voltage and current anomaly detection subsystem, a temperature anomaly detectionsubsystem and a smoke induction anomaly detection subsystem, wherein the voltage and current anomaly detection subsystem is used for collecting voltage data at two ends of the lithium battery and dataof current going through the lithium battery in real time in the charge and discharge processes of the lithium battery so as to judge whether the voltage data and the data of current are abnormal, and charging and discharging are stopped when voltage and / or current are / is abnormal; the temperature anomaly detection subsystem is used for collecting the temperature of the lithium battery in real time in the charge and discharge processes of the lithium battery so as to judge whether the temperature exceeds a preset temperature threshold value, and when the temperature exceeds the temperature threshold value, a temperature anomaly alarm is given; and the smoke induction anomaly detection subsystem is used for detecting whether smoke exists in real time in the charge and discharge processes of the lithium battery, and when the smoke is detected, an alarm and a fire sprinkler are started. Thermal runaway early warning for the lithium battery is realized through synergistic effect of the three subsystems, so that negative effects caused by thermal runaway are effectively avoided.

Owner:GUANGDONG HYNN TECH CO LTD

Aluminium base composite material ultra sonic electrical resistance welding method

InactiveCN1686659AEasy to operateStrong designWelding apparatusElectrical resistance and conductanceMegasonic cleaning

An ultrasonic-resistance welding method for the Al-based composition includes grinding the surfaces of Al-based compositions, ultrasonic cleaning, putting the flux between two surfaces to be welded, heating by electric resistance, decreasing the thickness of liquid film between two surfaces, ultrasonic vibrating, pressing and natural cooling.

Owner:HARBIN INST OF TECH

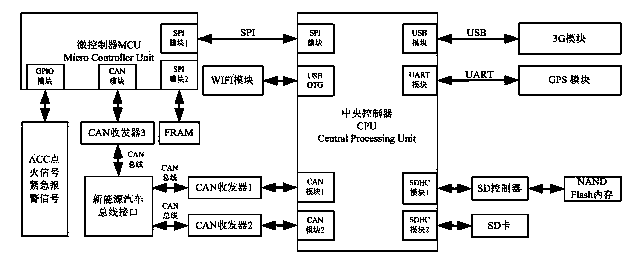

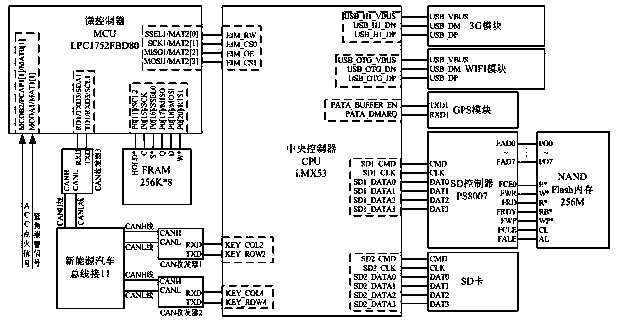

New energy automobile CAN bus data wireless transmission vehicle data recorder device

ActiveCN103489230AEasy to superviseEasy to controlRegistering/indicating working of vehiclesWireless transmissionNew energy

The invention provides a new energy automobile CAN bus data wireless transmission vehicle data recorder device. A double single chip microcomputer communication technology, an embedded Linux technology, a 3G technology, a GPS technology, a CAN bus collection technology, a USB technology and a WIFI technology are integrated, the new energy automobile CAN bus data wireless transmission vehicle data recorder device is used for collecting and monitoring new energy automobile data, enables CAN bus data, positioning information data and failure warning information data of a new energy automobile to be uploaded to a monitoring center in real time in a protocol format according with a national standard and a department standard through a 3G wireless communication network, and the monitoring center carries out storage and follow-up analysis on the received data. The new energy automobile CAN bus data wireless transmission vehicle data recorder device has a local storage function, can analyze control commands issued by the monitoring center, makes a corresponding response, and provides a basis for operation, supervision and data analysis of the new energy automobile.

Owner:QIMING INFORMATION TECH

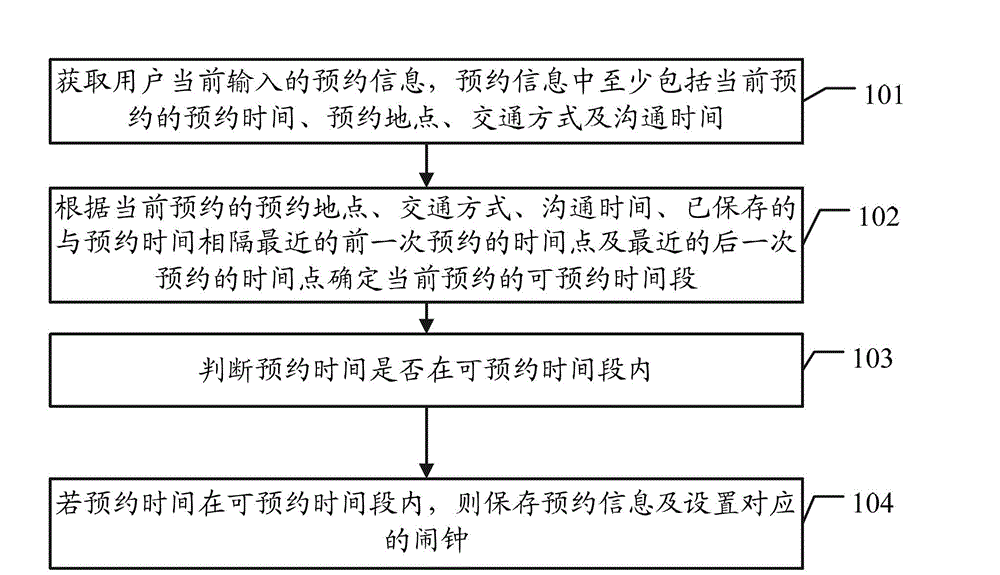

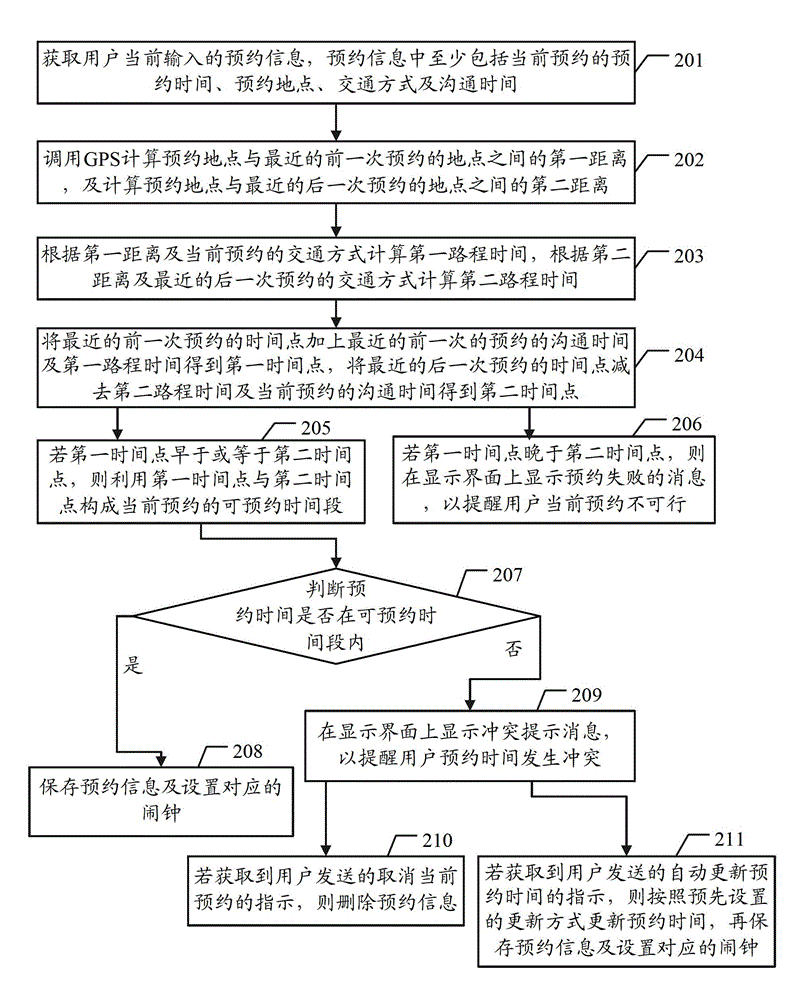

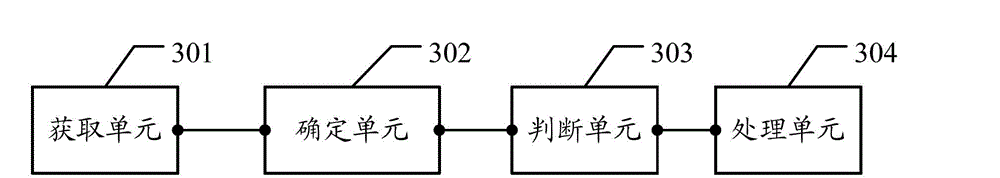

Appointment processing method and terminal

The embodiment of the invention discloses an appointment processing method and an appointment processing terminal, which are used for processing an appointment between a user and a client and avoiding conflict of appointment time. The method disclosed by the embodiment of the invention comprises the steps of: obtaining appointment information which is currently input by the user, wherein the appointment information at least comprises a currently-appointed appointment time, an appointed site, a traffic manner and communication time; determining a currently-appointed time period capable of being appointed according to the currently-appointed appointed site, the traffic manner, the communication time, the last time of the stored appointed time point which is the closest to the appointed time, and the currently-appointed time period capable of being appointed, which is the closest to the next time of the appointed time point; judging whether the appointed time is in the time period capable of being appointed or not; if so, storing the appointment information and setting a corresponding alarm clock. Therefore, a bad result caused by conflicting with the appointed time of the client can be effectively avoided, client management can be well realized by the user, and the user requirements are met.

Owner:SHENZHEN TINNO WIRELESS TECH

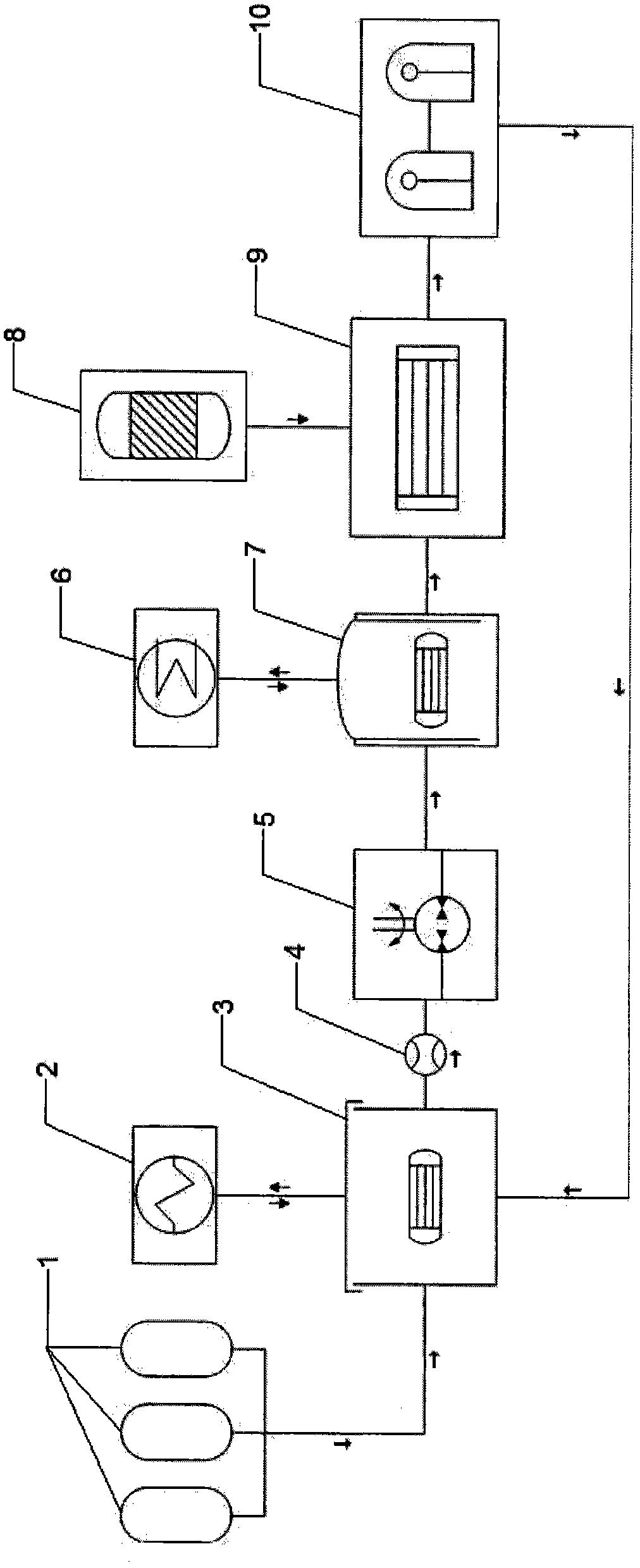

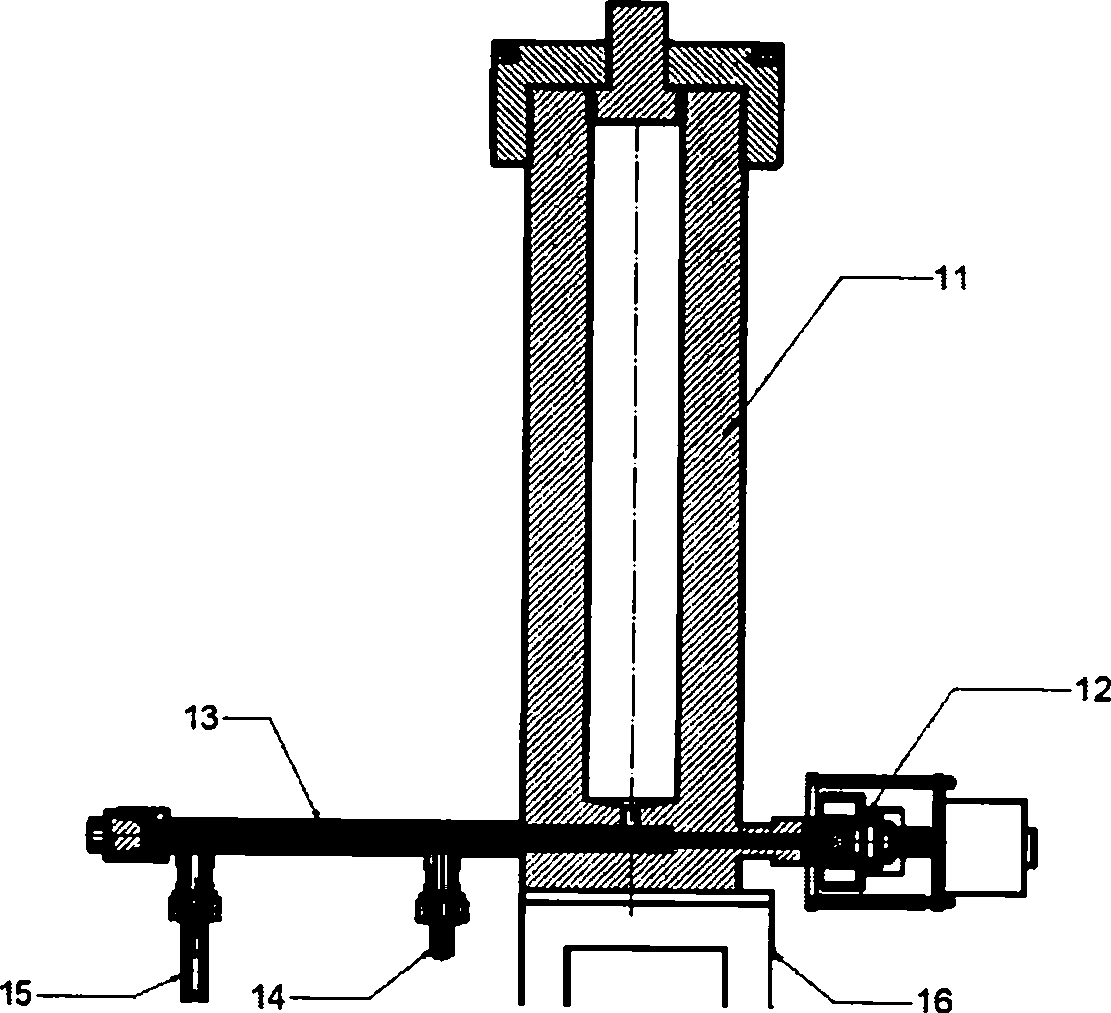

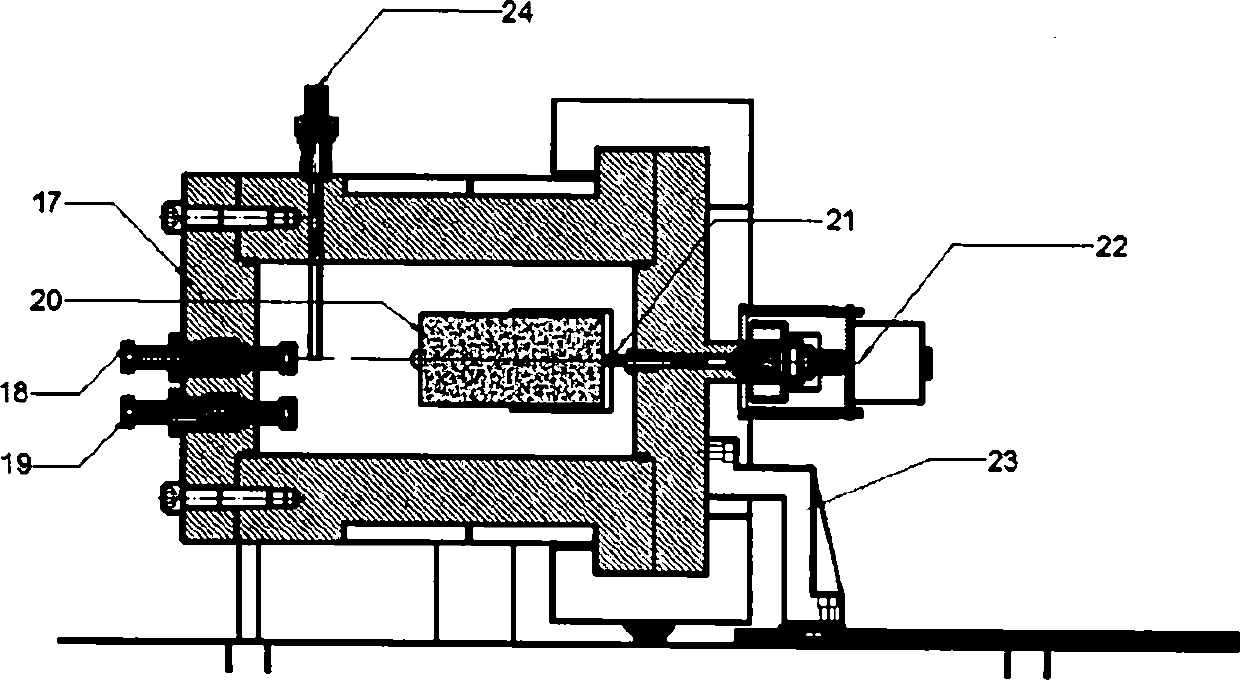

Supercritical carbon dioxide abrasive jet flow perforation simulation experiment system

ActiveCN103742075AEnhance investigation abilityStrong pressureLiquid/gas jet drillingFluid removalChemistryNozzle

The invention discloses a supercritical carbon dioxide abrasive jet flow perforation simulation experiment system used for simulating the processes that supercritical carbon dioxide abrasive jet flow scours broken rocks and damages a sleeve pipe, comparing and analyzing different jet flow experiment effects, revealing different factor influencing rules and the like. The supercritical carbon dioxide abrasive jet flow perforation simulation experiment system is composed of a carbon dioxide liquefying device, a supercritical carbon dioxide generating device, a supercritical carbon dioxide abrasive jet flow experiment device and a carbon dioxide recycling device, wherein the supercritical carbon dioxide abrasive jet flow experiment device is composed of a jet flow surrounding pressing barrel device and an abrasive adding device and is a kernel module of the system, supercritical carbon dioxide fluid forms jet flow when passing a sprayer, and abrasives are conveyed through a stranding cage and a sand adder to be mixed with the jet flow, so that the supercritical carbon dioxide abrasive jet flow is formed and carries out perforation inside the surrounding pressing barrel. The supercritical carbon dioxide abrasive jet flow perforation simulation experiment system is safe, simple and convenient to operate, high in efficiency and capable of simulating the perforation operation of the supercritical carbon dioxide abrasive jet flow in various work conditions and being applied to experiments of fluid like liquid nitrogen.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

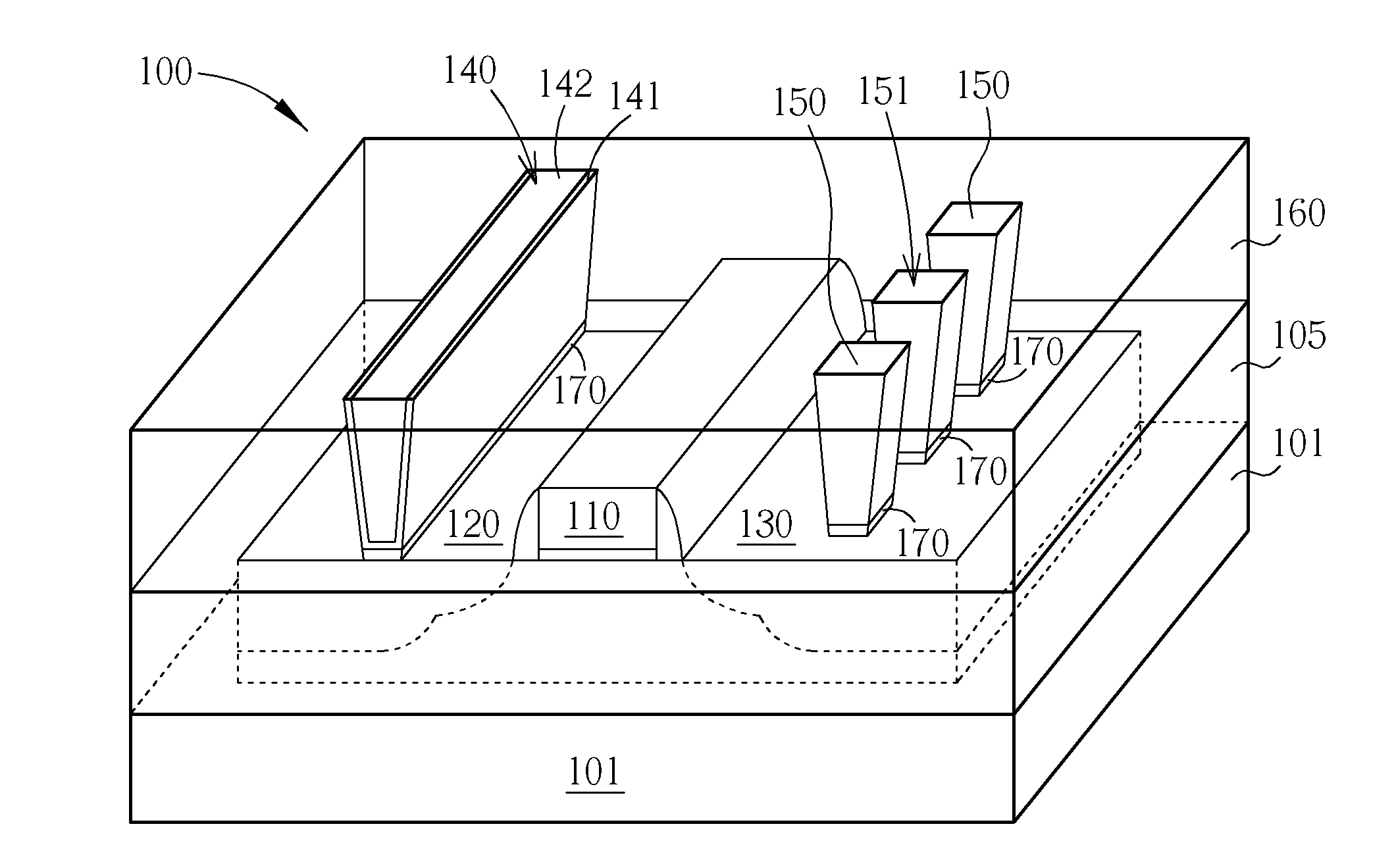

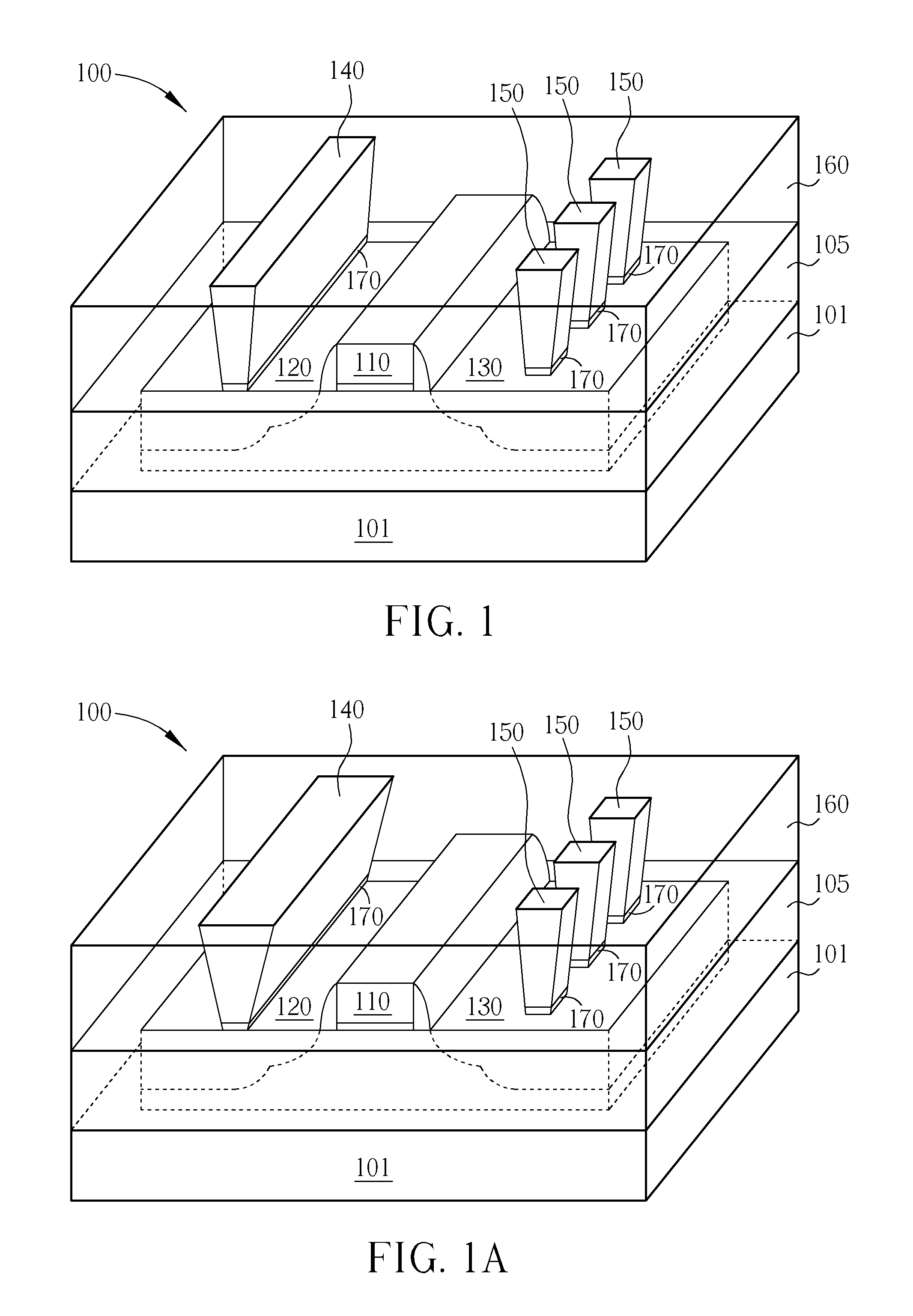

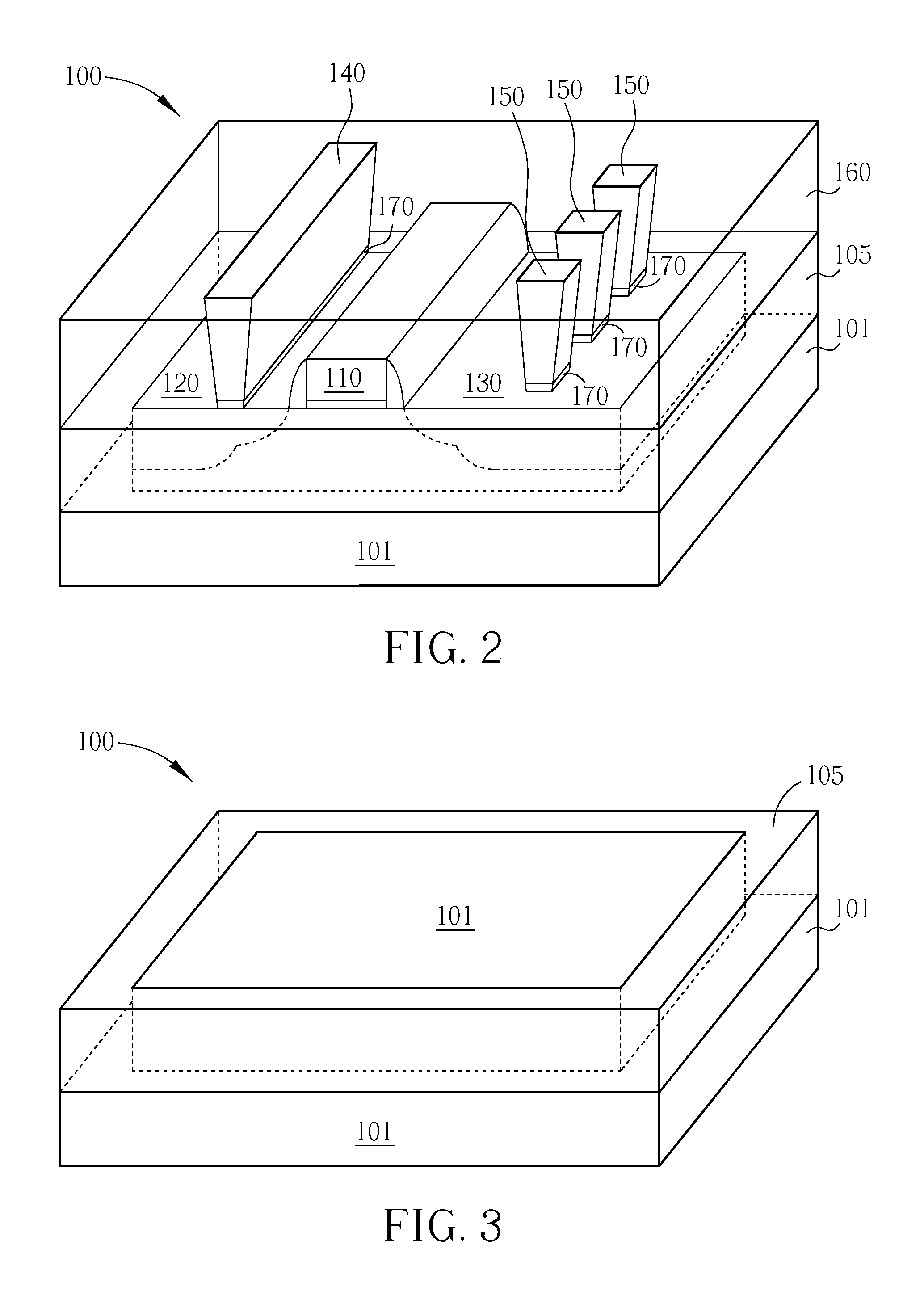

Semiconductor structure and method for making the same

InactiveUS20120086054A1Deteriorated operational performanceHigh currentSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

A semiconductor structure is disclosed. The semiconductor structure includes a gate structure disposed on a substrate, a source and a drain respectively disposed in the substrate at two sides of the gate structure, a source contact plug disposed above the source and electrically connected to the source and a drain contact plug disposed above the drain and electrically connected to the drain. The source contact plug and the drain contact plug have relatively asymmetric element properties.

Owner:UNITED MICROELECTRONICS CORP

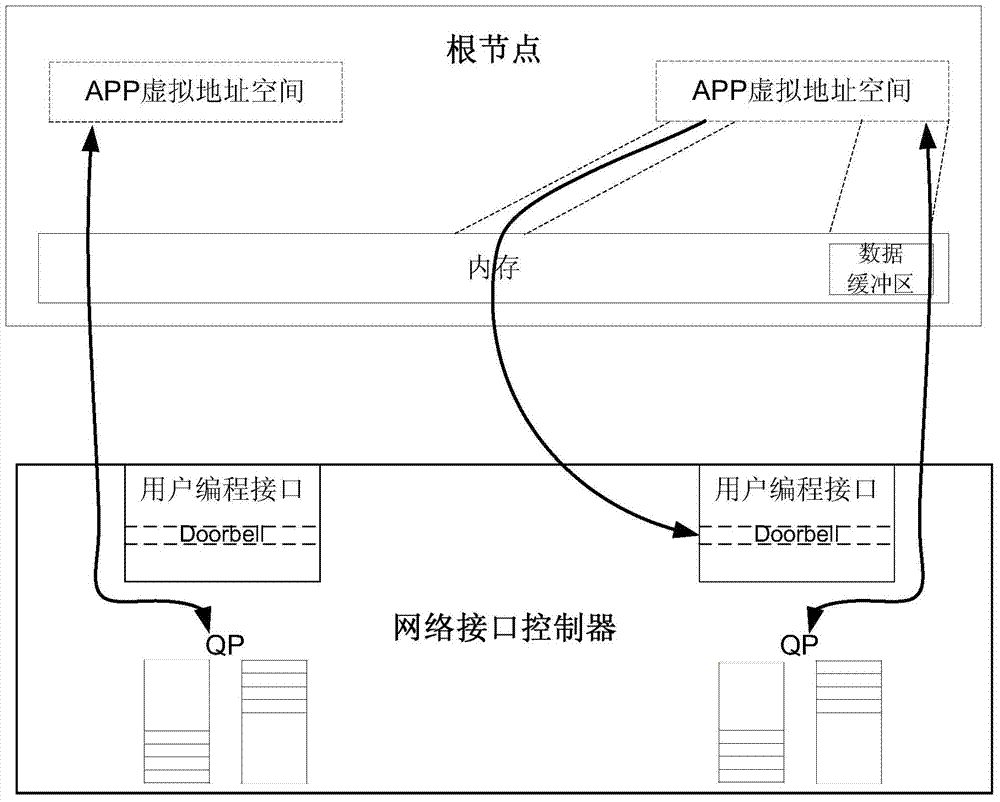

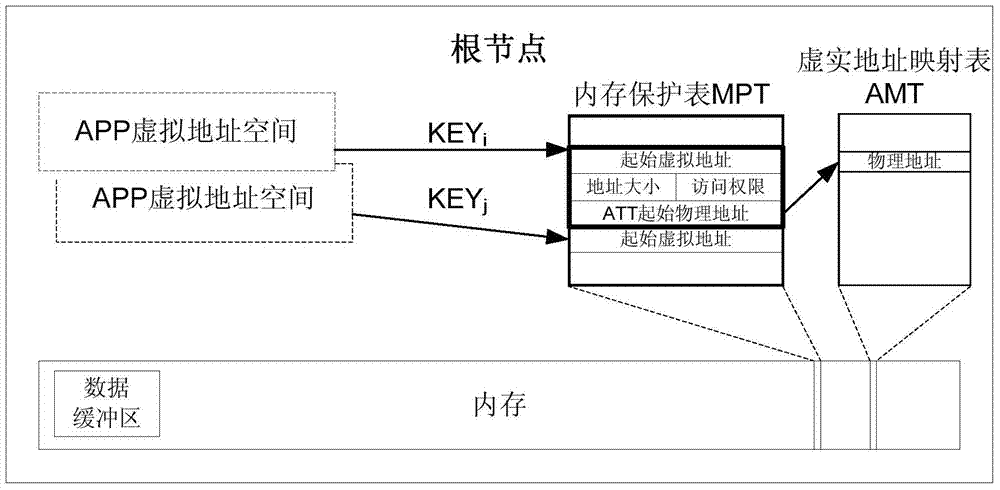

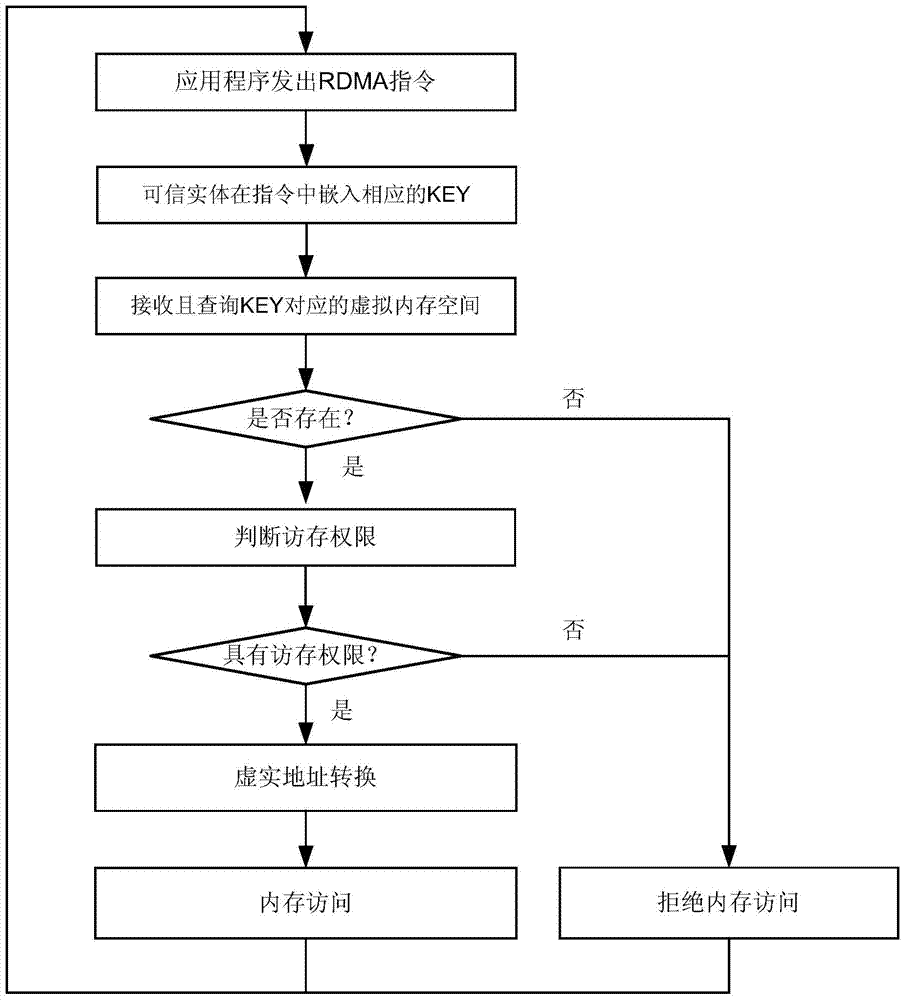

Memory protection method and system and network interface controller

InactiveCN103488588AEasy to operateAvoid bad consequencesUnauthorized memory use protectionVirtual memoryApplication software

The invention provides a memory protection method and system and a network interface controller. The memory protection method comprises the steps that a KEY is inserted into an access and storage command sent by a credible entity on an application program, wherein the KEY corresponds to the virtual memory space distributed to the application program; the fact that whether the access and storage command has an access right is judged by the network interface controller according to a memory protection table and then whether the access and storage command is allowed to be executed is judged. According to the memory protection method and system and the network interface controller, memory protection is provided for each node of a system with multiple computer nodes, and bad consequences caused by misoperation or malicious operation of the application program are prevented; in addition, performance of I / O operation is improved.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

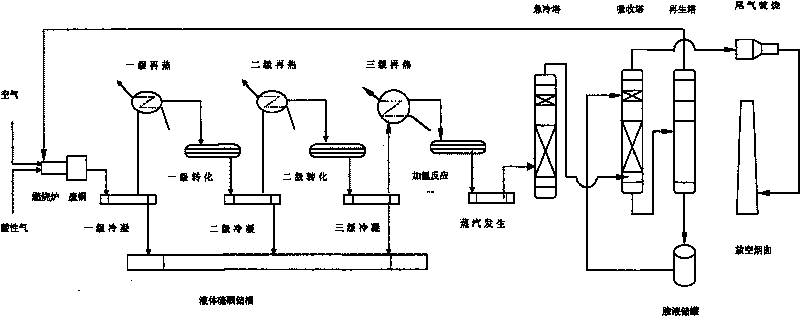

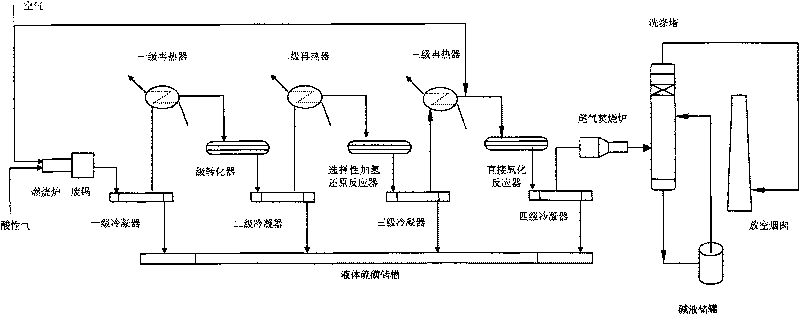

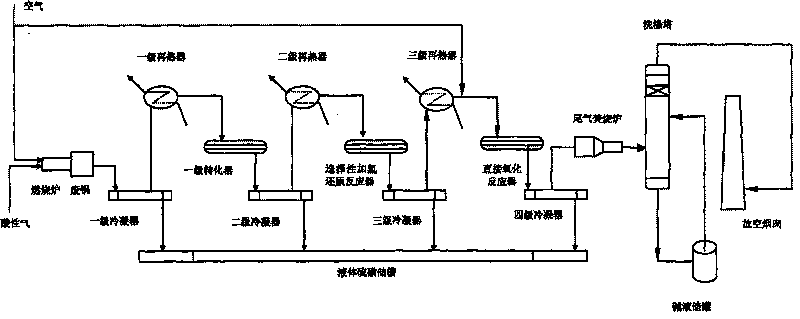

Method for obtaining high-purity sulphur from Claus reactive tail-gases

InactiveCN101693164AReduce design processReduce the amount of additional equipmentChemical industryDispersed particle separationManufacturing cost reductionSingle process

The invention relates to a method for obtaining high-purity sulphur from Claus reactive tail-gases, which belongs to the technical field of environmental protection. The method comprises steps as follows: (1) Claus tail-gas is preheated to reach the temperature between 160 DEG C to 300 DEG C; (2) the preheated gas enters a reduction reaction furnace filled with selective reaction catalysts to perform reduction reaction; (3) liquid sulphur is separated out of the reacted process gas via a condenser; (4) the process gas performs direct oxidization reaction inside a direct oxidizing reactor after being compensated with oxygen and preheated again; (5) liquid sulphur is separated out of gas on an outlet of the reactor via a sulphur condenser and a separator, tail gases after burned are cooled, washed by using an alkaline liquor and then discharged. The method overcomes the shortcoming that sulphur can not be produced by a traditional tail-gas hydrogenation reactor, improves total recovery efficiency of sulphur in a single process, and has the advantages of saving energy, lowering H2 consumption amount, reducing volume of absorption towers, decreasing arranged devices, lowering manufacturing cost and reducing operating load of the overall set of devices.

Owner:邵志辉

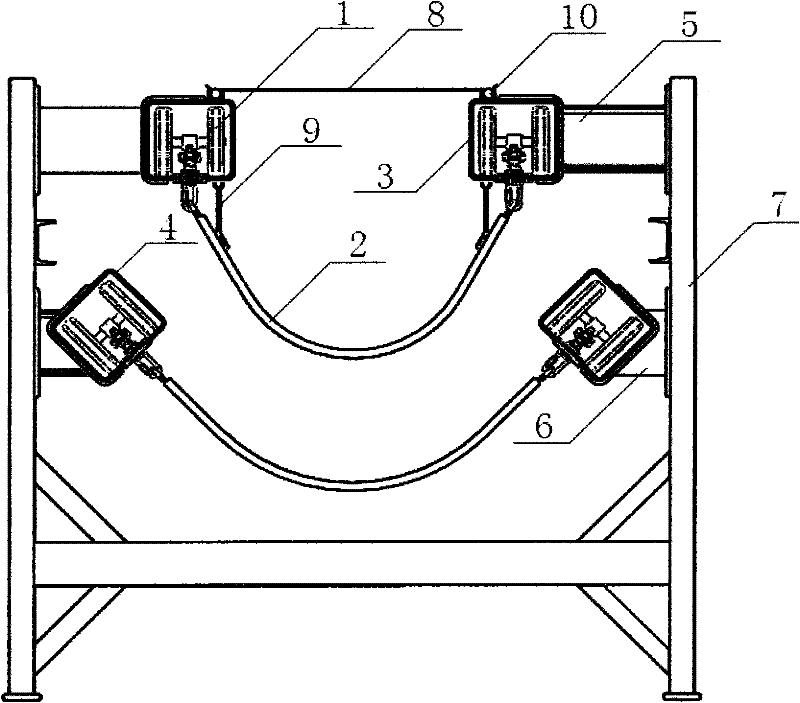

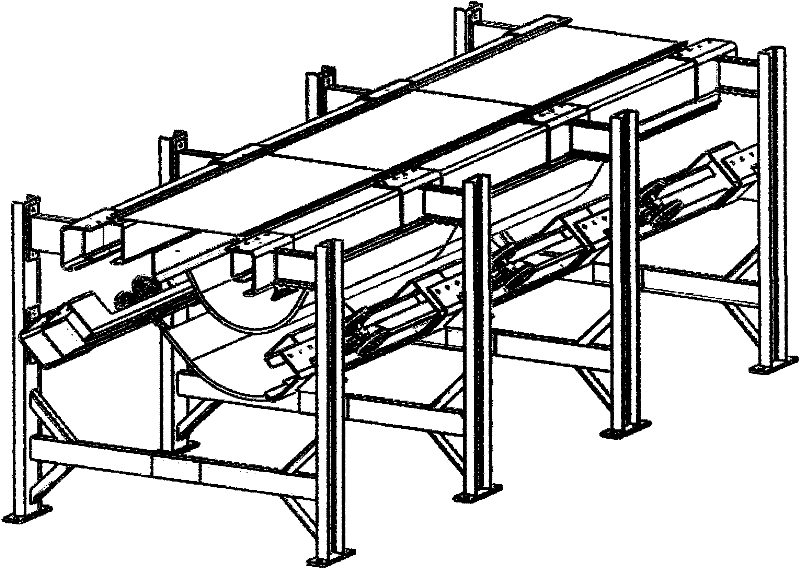

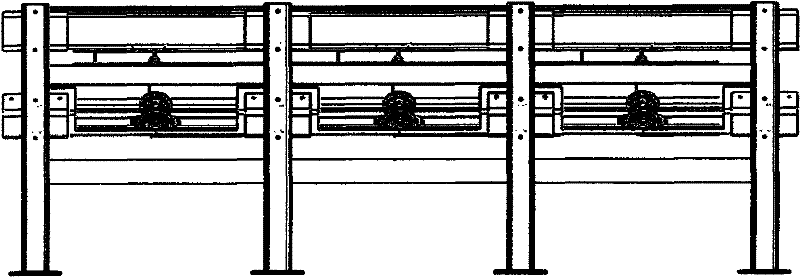

Track hanging conveyor

InactiveCN102295134AAchieve steeringSimple structureConveyorsSupporting framesBlock and tackleConveyor belt

The invention relates to a rail suspension type conveyor, which is the combination of a belt type material conveying system and a rail delivery technology, reflects the continuous conveying feature of belt type conveying and the low-energy consumption feature of the rail transport, and changes the form that carrier rollers are adopted to support a belt in the traditional belt type conveying system. In the rail suspension type conveyor, by utilizing the traditional conveying system driving and control technology, two sides of a conveying belt are respectively provided with a set of annular guide rail system, a suspension pulley block is used to suspend a suspension conveyor belt so as to provide the suspension support for the conveyor belt; a driving roller is used for driving the suspension conveyor belt to operate, and the suspension conveyor belt drags the suspension pulley block to roll and travel along an annular rail so as to realize the feeding, transshipping and unloading functions of the traditional belt type conveying system; meanwhile, the steering function of a single conveying system can be realized to improve the safety of the conveying system; all carrier rollers in the running section are cancelled, and the energy conservation effect is obvious; and the rail suspension type conveyor is particularly suitable for the long-distance transport and the conveying occasions, such as a mine laneway and the like, with greater conveying amount.

Owner:李超

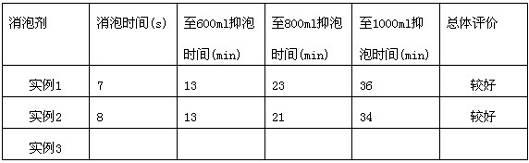

Self-emulsifying molecular antifoaming agent and preparation method thereof

InactiveCN102160939AStrong anti-foaming abilityReduce surface tensionFoam dispersion/preventionPolymer scienceFatty alcohol

The invention discloses a self-emulsifying molecular antifoaming agent and a preparation method thereof. The antifoaming agent comprises the following components in percent by mass: 20 to 60 percent of antifoaming active substance and 40 to 80 percent of dispersion medium, wherein the antifoaming active substance consists of higher fatty alcohol, alkynol, polyether and silicone oil in a mass ratio of 1:(0.8-1.5):(2-3):(2-4); and the dispersion medium is grafted star polymer. The preparation method comprises the following steps of: adding 50 to 150 parts of trichloromethane and 1 to 2 parts ofp-methyl benzene sulfonic chloride into 20 to 60 mass parts of active substance and 40 to 80 mass parts of star polymer, raising the temperature to between 40 and 70 DEG C, and reacting for 3 to 6 hours; and after the reaction is finished, washing sodium carbonate until the ph is 7, drying by using anhydrous sodium sulfate, and evaporating the solvent under reduced pressure to obtain the antifoaming agent. The extended arm of the star polymer in the antifoaming agent is grafted with the active substance, so that various components are synergistic, and the obtained antifoaming agent is high instability, low in surface tension, high in surface activity, high in antifoaming capacity, long in foam inhibition time and small in dosage.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

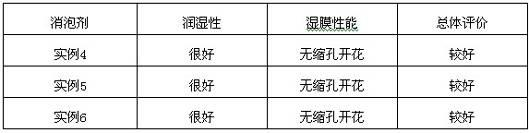

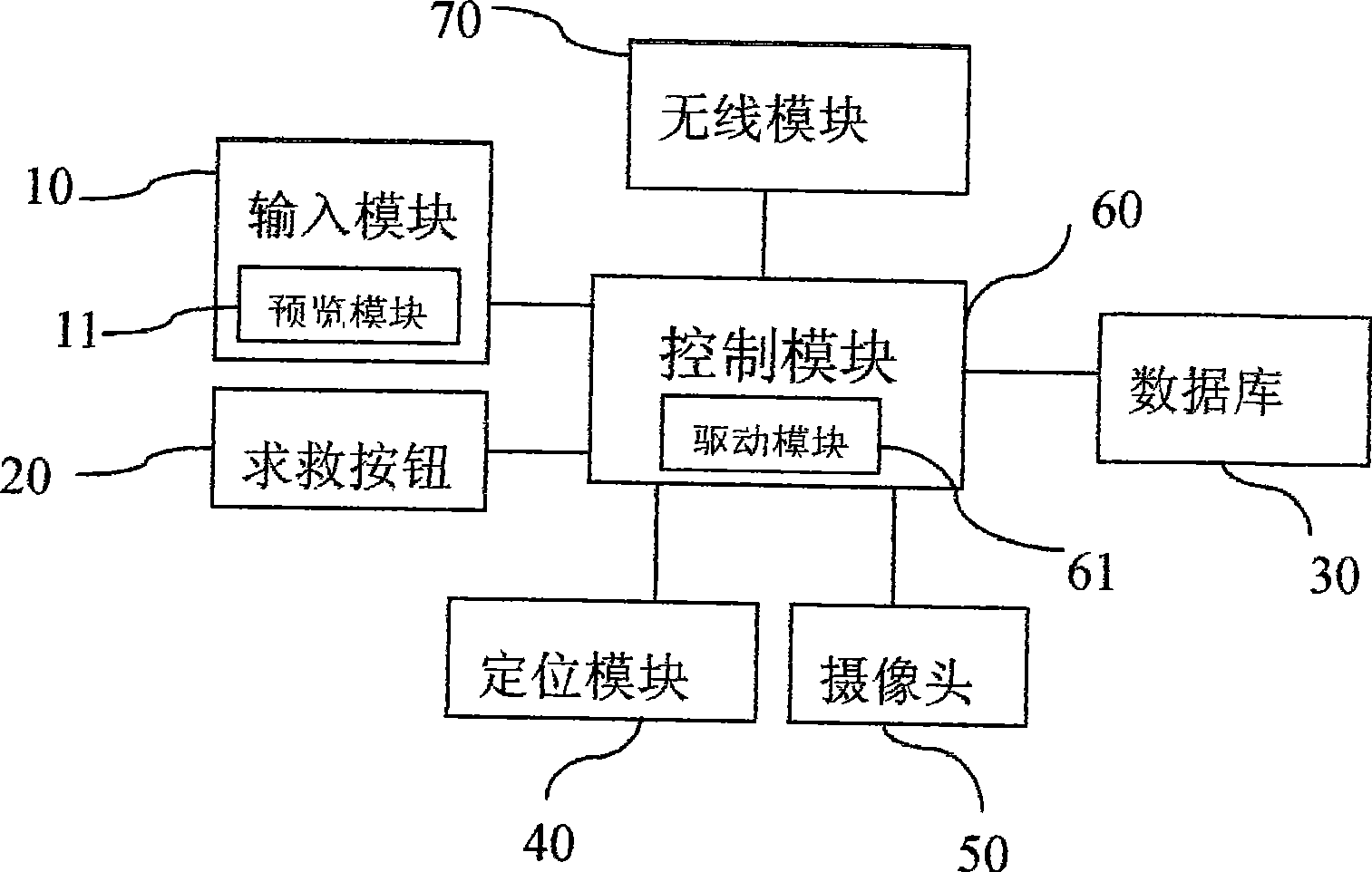

System for asking for help by pressing one key

InactiveCN101448206AUnderstand situationEasy to understandBroadcast service distributionWireless commuication servicesKey pressingComputer science

The invention provides a system for asking for help by pressing one key, which comprises a key for asking for help, an input module, a database, a locating module, a camera, a control module and a driving controller; wherein, the key is used for asking for help from the outside by the user; the input module is used for inputting and setting the information of the help seeker; the database is used for storing the information set by the input module; the locating module is used for positioning the exact position of the help seeker; the camera is used by the rescuer for looking over the image information of the environment where the help seeker is positioned; the control module is used for connecting the input module, the database and the camera, writing the information of the help seeker set by the input module into the database, and controlling the camera to look over the environment around the help seeker according to the command sent by the rescuer; and the driving controller is connected with the input module, the locating module and the control module, and the driving module executes the control command sent by the control module to control the camera to rotate, so as to better observe the environment around the help seeker. The system leads the user to effectively and quickly ask for help when in danger.

Owner:于显

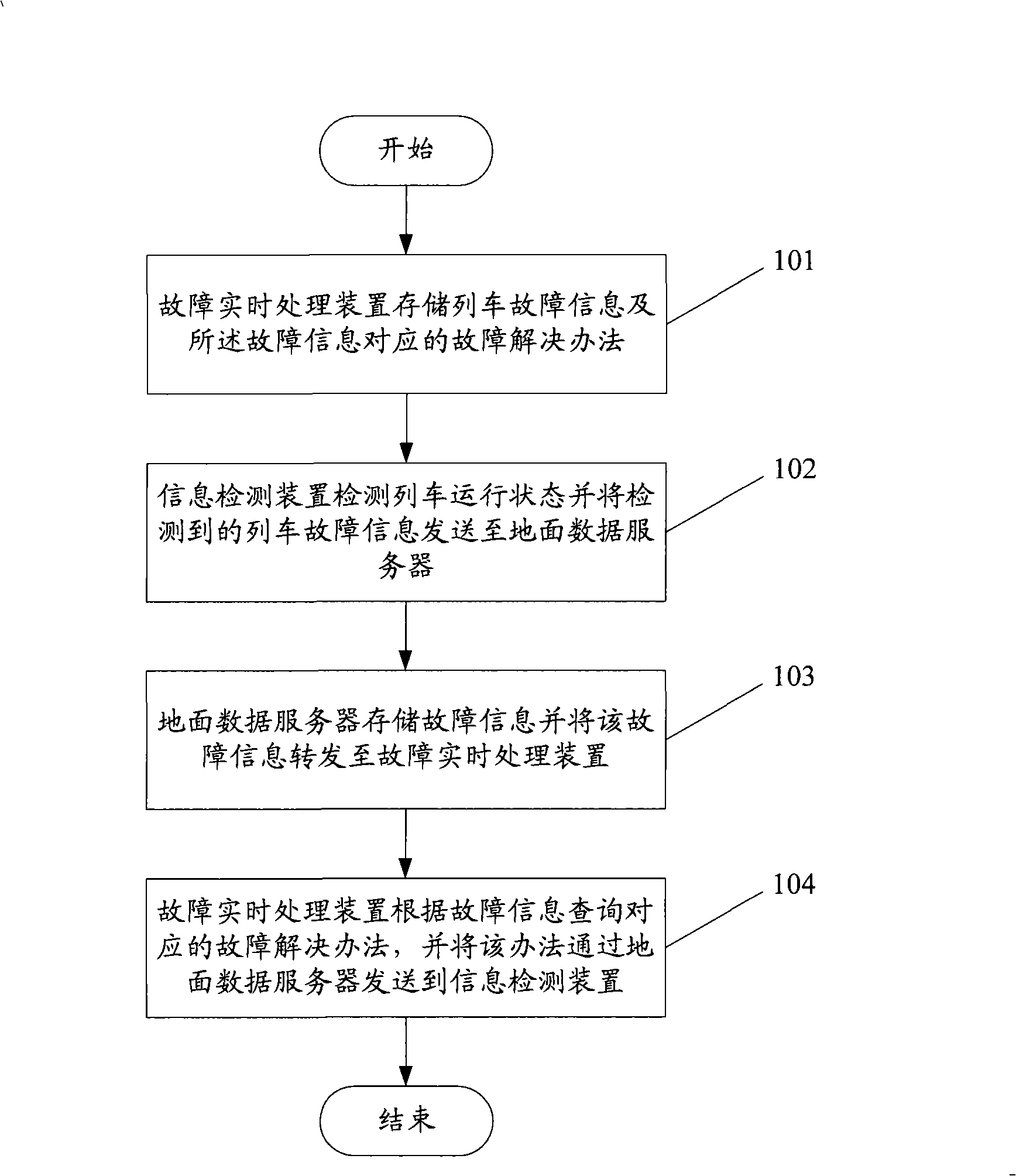

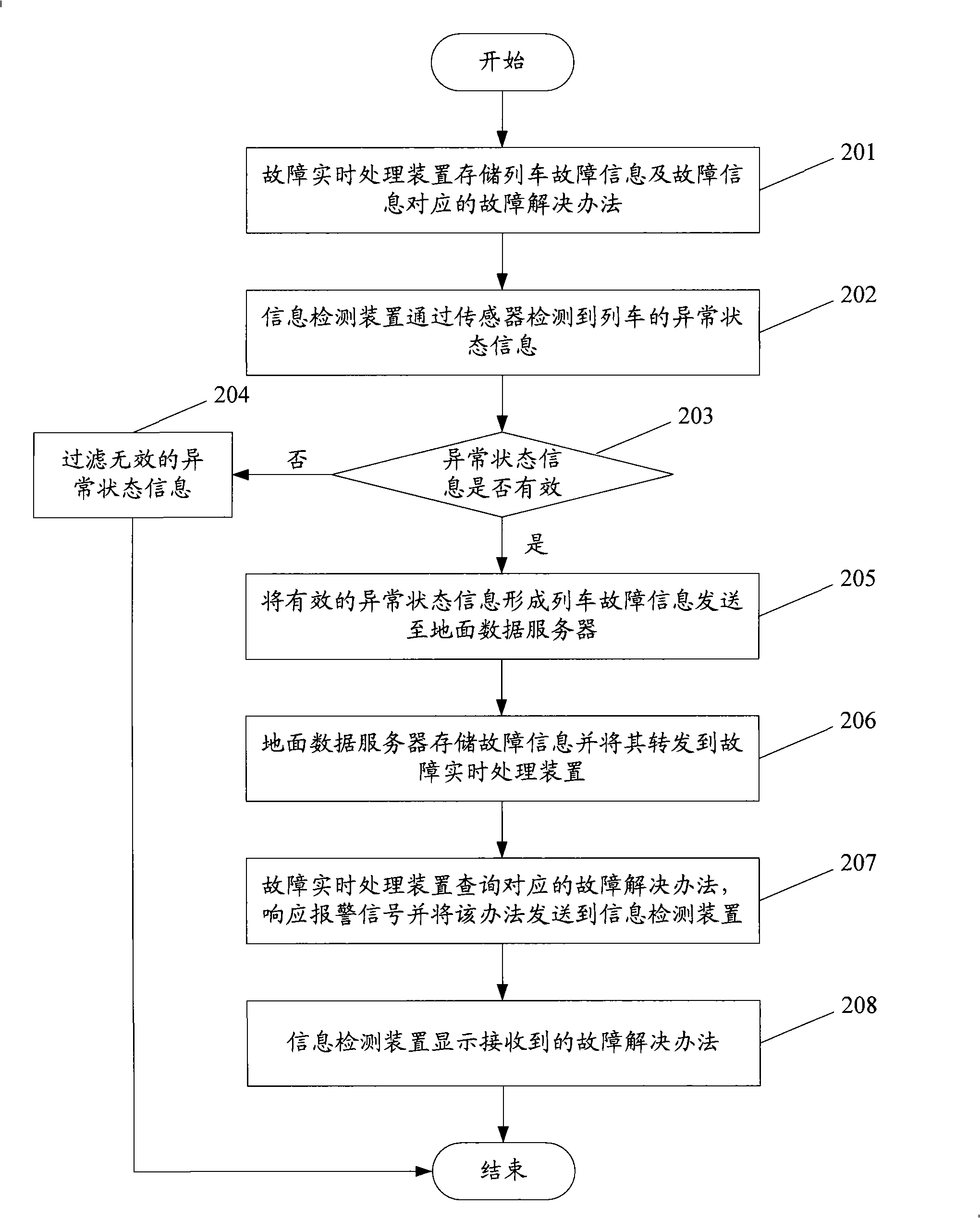

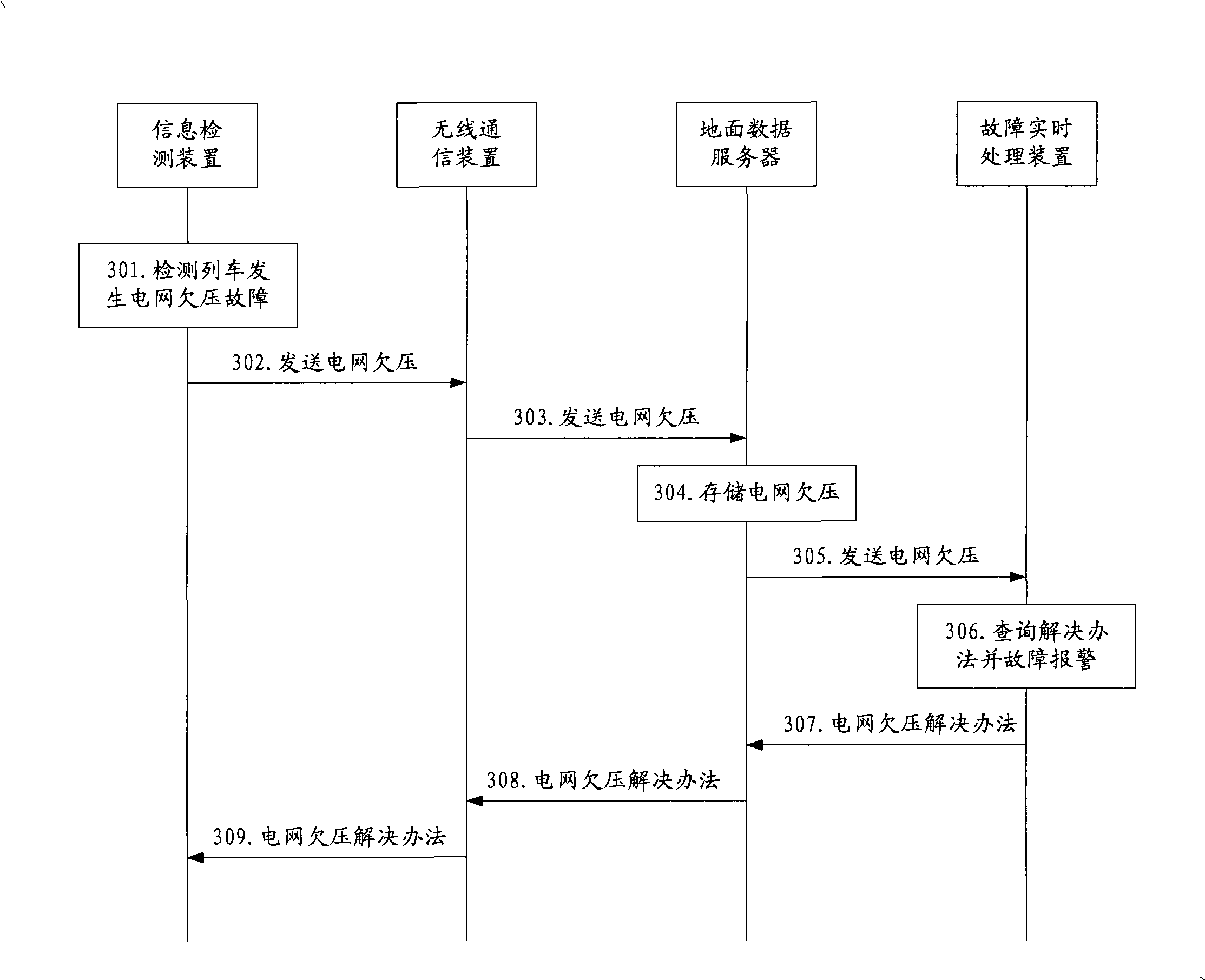

Real-time examination and repair method and system for train fault

InactiveCN101315651AReduce accident rateImprove securityRegistering/indicating working of vehiclesTesting/monitoring control systemsComputer scienceRepair method

The invention discloses a method for the real-time overhaul of train failure, a real-time failure processing device stores train failure information and corresponding failure solving methods of the failure information, and the method comprises the steps that: A. an information detecting device detects train running state and sends the detected train failure information to a ground data server; B. the ground data server stores the failure information and transmits the failure information to the real-time failure processing device; C. the real-time failure processing device inquires corresponding failure solving methods according to the failure information and sends the failure solving methods to the information detecting device by the ground data server. The invention also discloses a real-time train failure overhaul system which comprises the information detecting device, the ground data server and the real-time failure processing device. The adoption of the method and the system can effectively improve the timeliness of train failure overhaul, thus improving the safety and the stability of locomotive running and reducing the occurrence of the accident of locomotive defect.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Attribute-based encryption method and attribute-based encryption system capable of protecting privacy and supporting user Undo

ActiveCN105100083APrivacy protectionReduce total communication costsTransmissionAttribute-based encryptionCloud computing

The invention discloses an attribute-based encryption method and an attribute-based encryption system capable of protecting privacy and supporting user Undo. The attribute-based encryption system comprises eight modules including a Setup module, a KeyGen module, an Encrypt module, a Decrypt module, a ReKey module, a TKGen module, a TK-Encrypt module and a TK-Decrypt module. Moreover, the method provided by the invention can solve the problem of privacy protection in cloud computation, and support user Undo and safe outsourcing operations to a ciphertext. Meanwhile, a function of authentication to transformed ciphertext is provided, illegal substitution of the transformed ciphertext and adverse consequences caused by illegal substitution are prevented, and system flexibility is high.

Owner:HOHAI UNIV

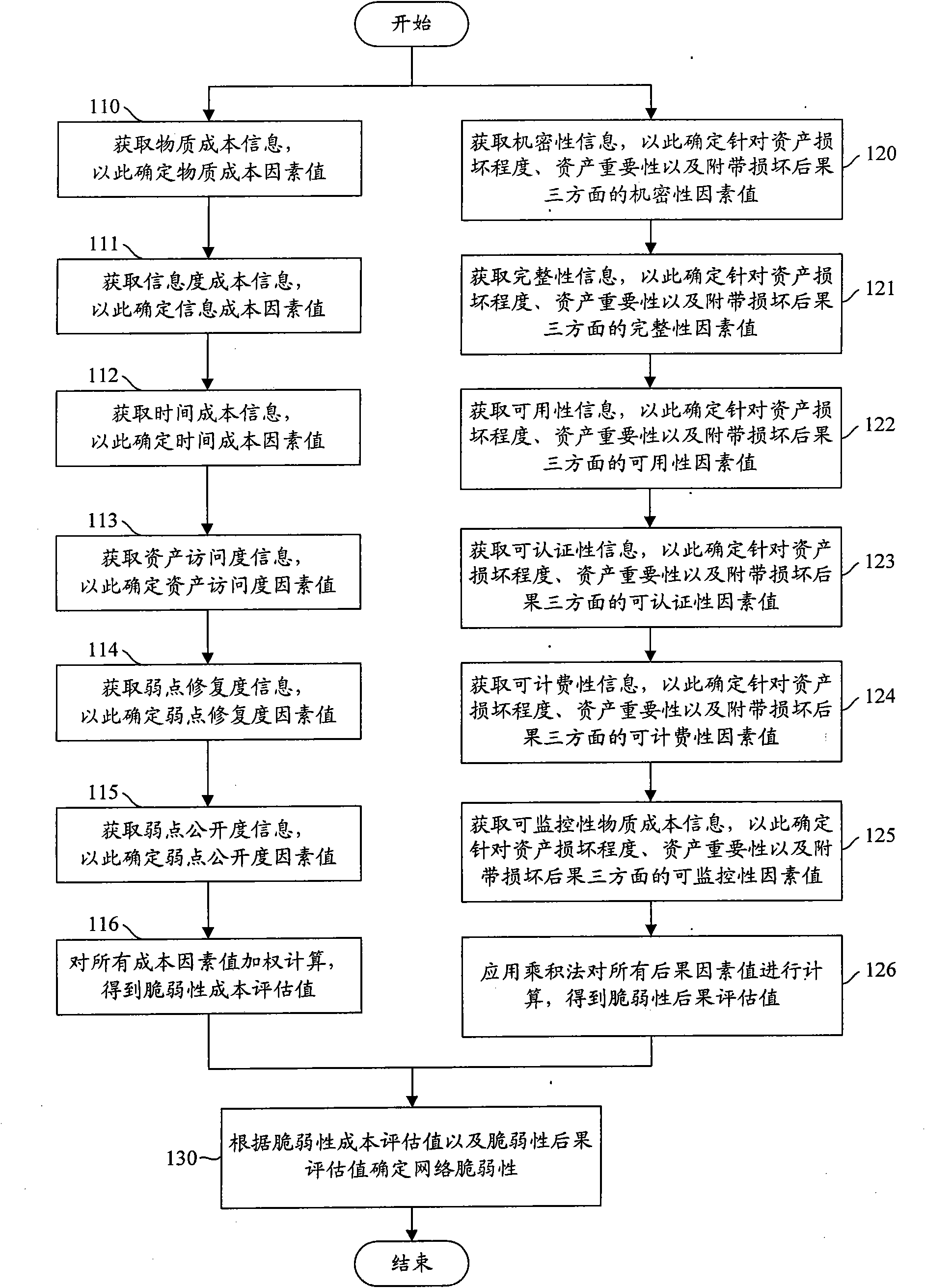

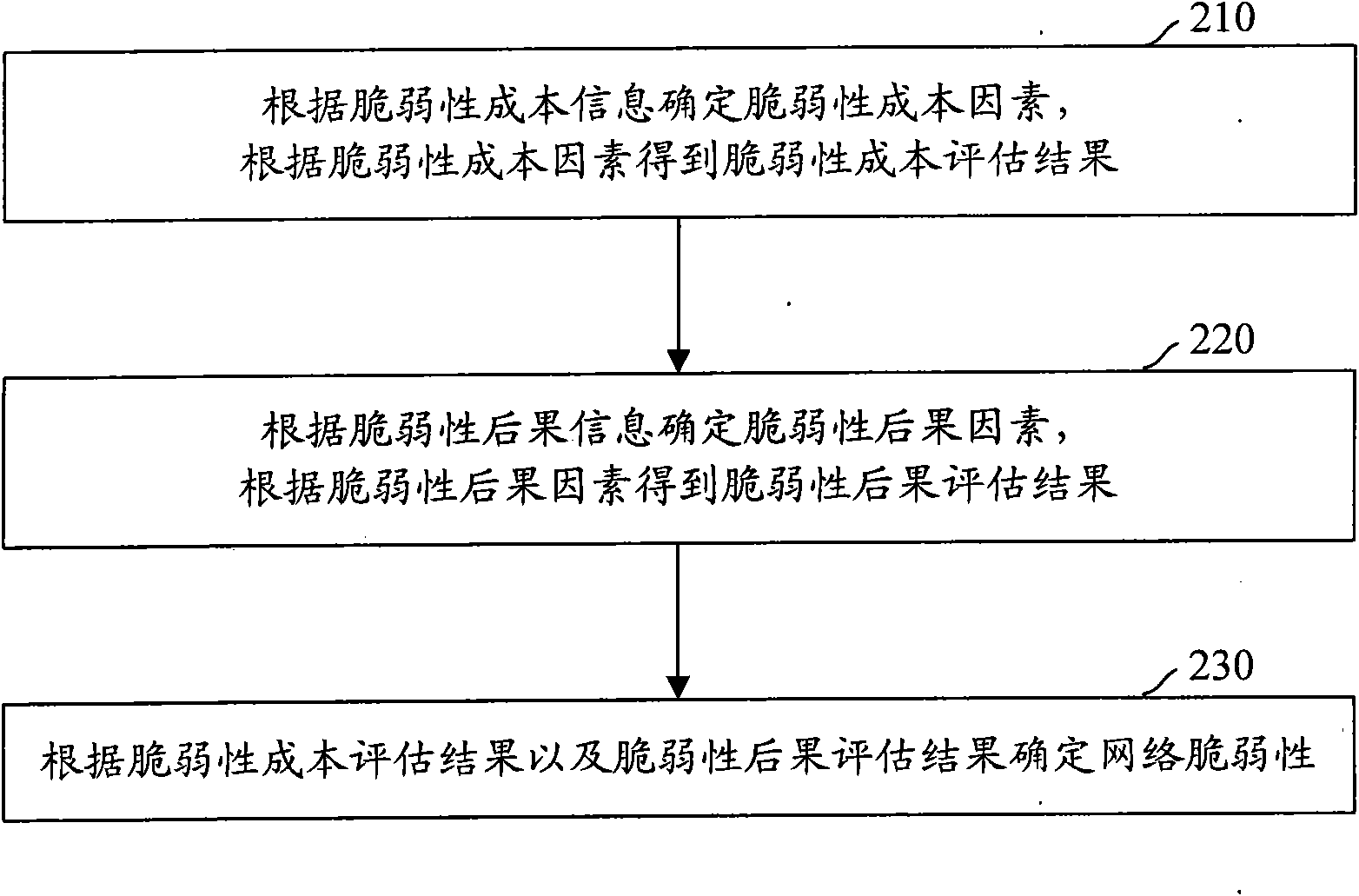

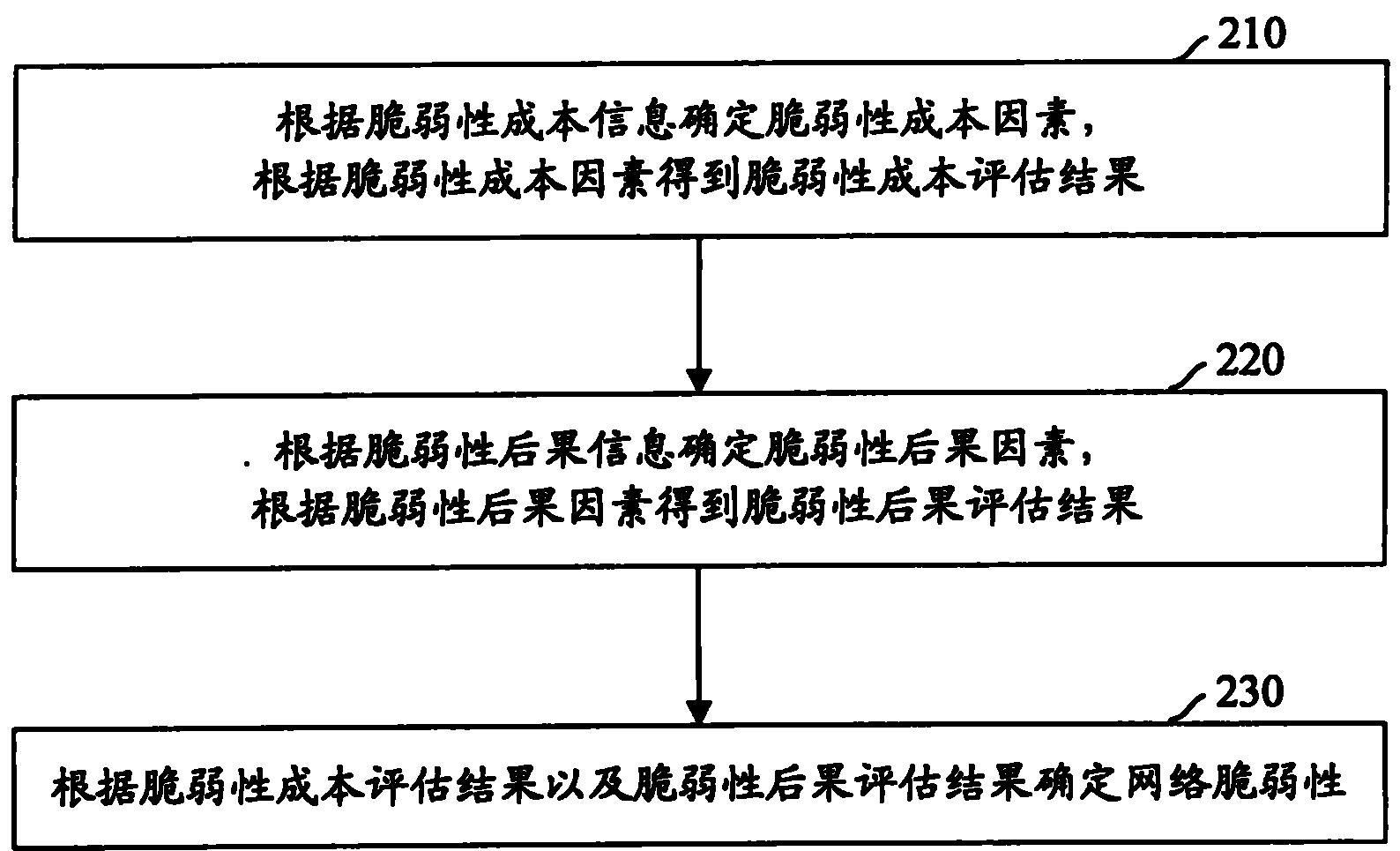

Network vulnerability evaluation method

InactiveCN101964730AImprove accuracyAvoid bad consequencesData switching networksCost evaluationEvaluation result

The invention discloses a network vulnerability evaluation method. The method comprises the following steps of: determining vulnerability cost factors according to vulnerability cost information; obtaining a vulnerability evaluation result according to the evaluation cost factors; determining vulnerability consequence factors according to vulnerability consequence information; obtaining a vulnerability consequence evaluation result according to the vulnerability consequence factors; and determining network vulnerability according to the vulnerability cost evaluation result and the vulnerability consequence evaluation result. Therefore, the method of the invention takes the vulnerability cost factors and the vulnerability consequence factors into consideration comprehensively when evaluates the network vulnerability, and enriches and perfects the basis for network vulnerability evaluation in a targeted way, so that the accurate performance of the network vulnerability evaluation is improved obviously. Moreover, the obtained improved network vulnerability evaluation accuracy can provide important reference for network safety management, ensures that corresponding safety measures can be implemented more targeted in a planned manner based on the reference, and avoids a serious result caused by utilizing the network vulnerability.

Owner:BEIJING UNIV OF POSTS & TELECOMM +1

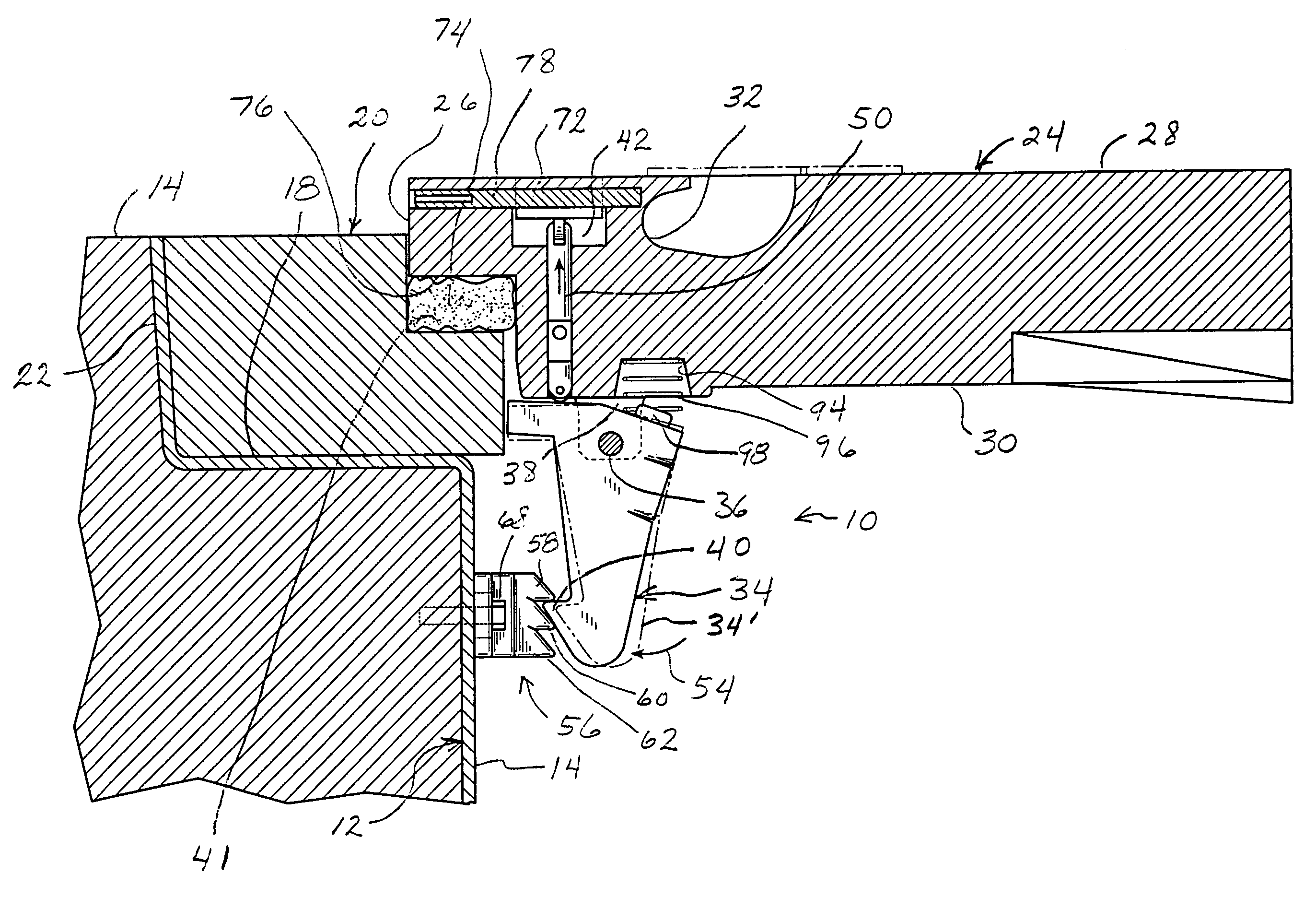

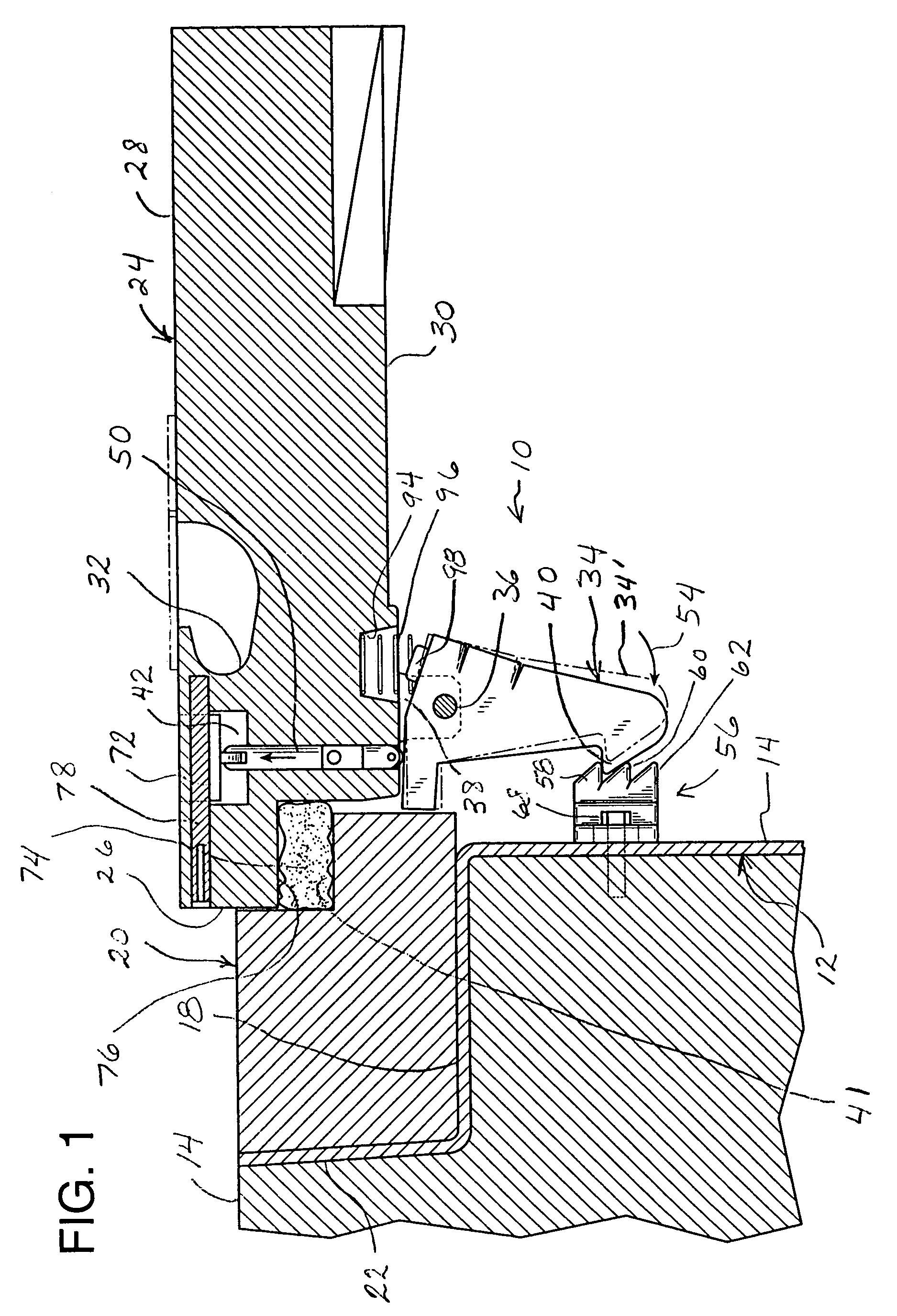

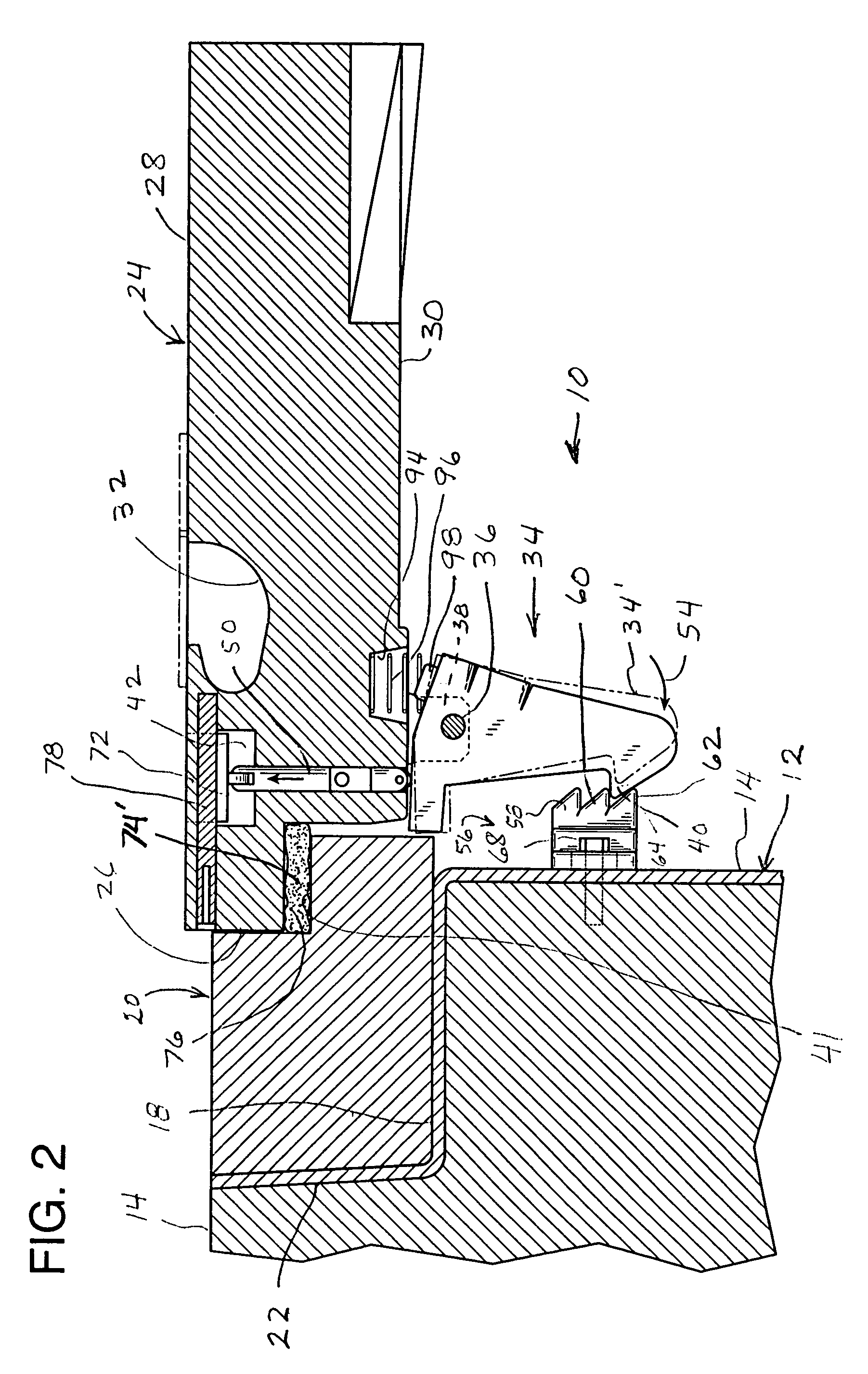

Multi-position aircraft servicing pit lid latch

InactiveUS7261332B1Avoid bad consequencesEasy to close and latchArtificial islandsBuilding locksSpacing toothEngineering

Owner:CAVOTEC ACQUISITION US INC

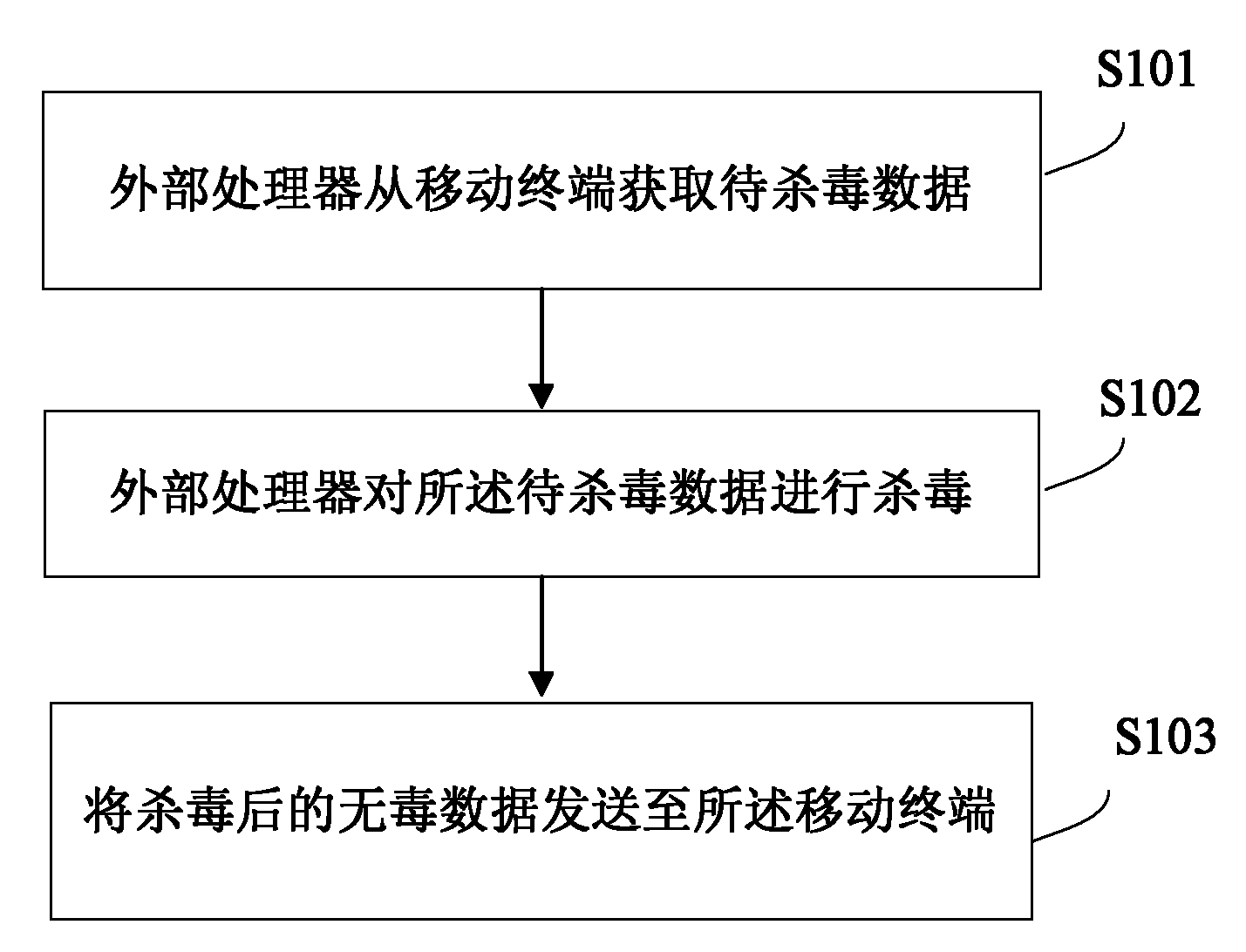

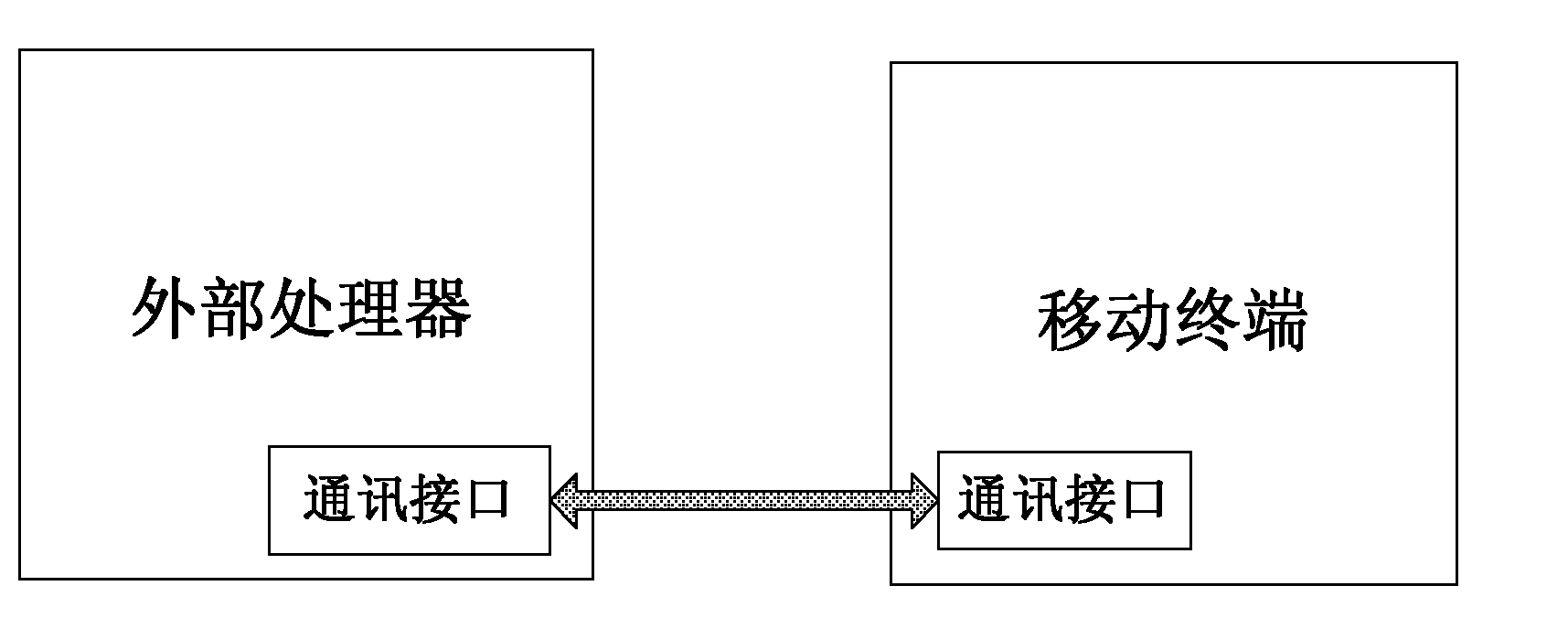

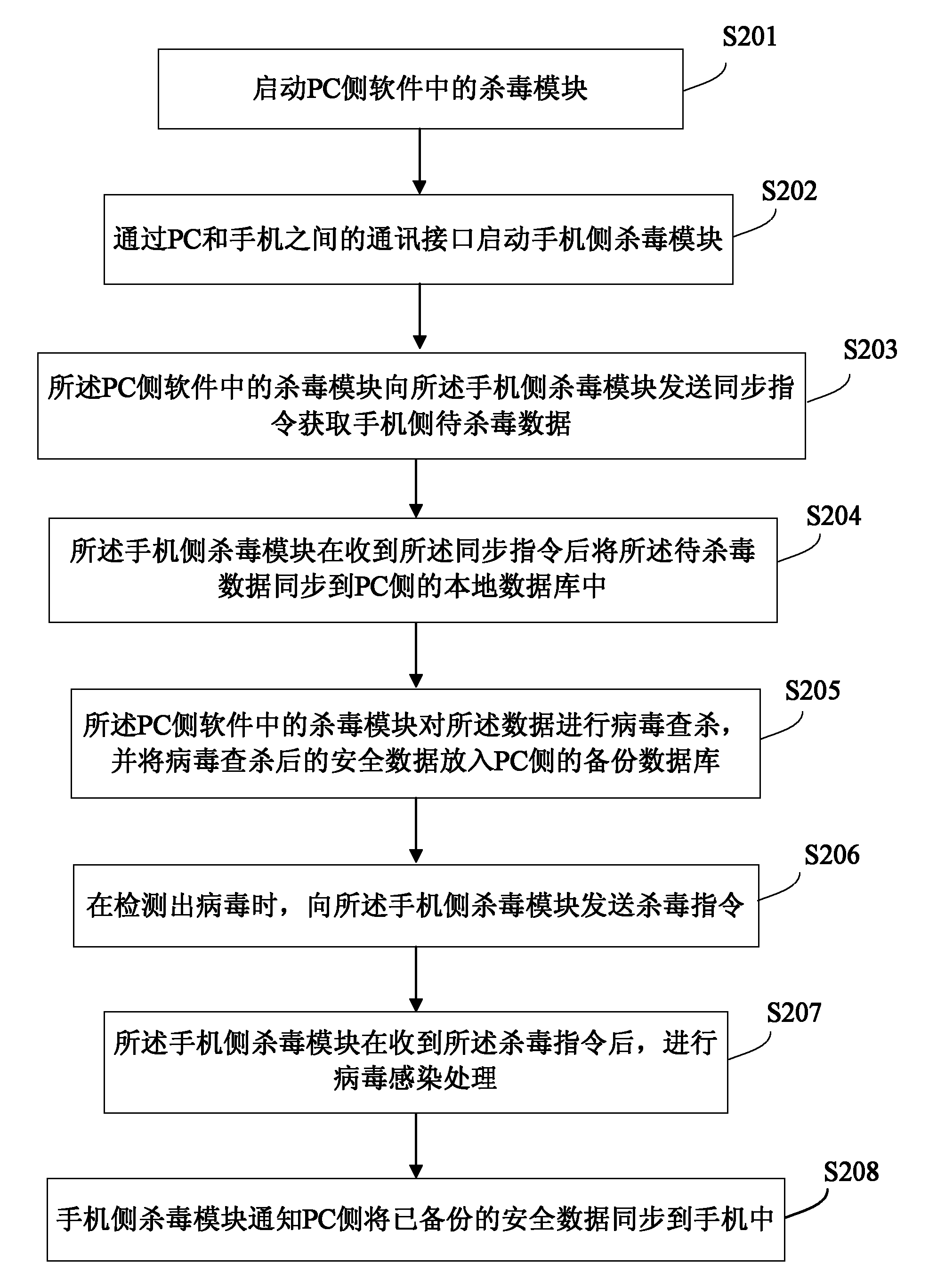

Method and system for killing mobile terminal viruses

InactiveCN102222184AGuarantee data securityAvoid bad consequencesPlatform integrity maintainanceCommunication interfaceVirus

The invention discloses a method and a system for killing mobile terminal viruses. The system comprises an external processor and a mobile terminal which are connected through communication interfaces. The method comprises the following steps that the external processor acquires data to be subject to virus killing from the mobile terminal; and after the data is subject to the virus killing, non-virus data after the virus killing is transmitted to the mobile terminal. The method and the system can make up the defect that mobile terminal virus-killing software has limit space and processing capability so that the virus check and killing is not complete, can avoid the serious consequences caused by virus check leakage to a user, improves the capability of killing viruses of the mobile terminal, and better protects the data safety of the mobile terminal.

Owner:ZTE CORP

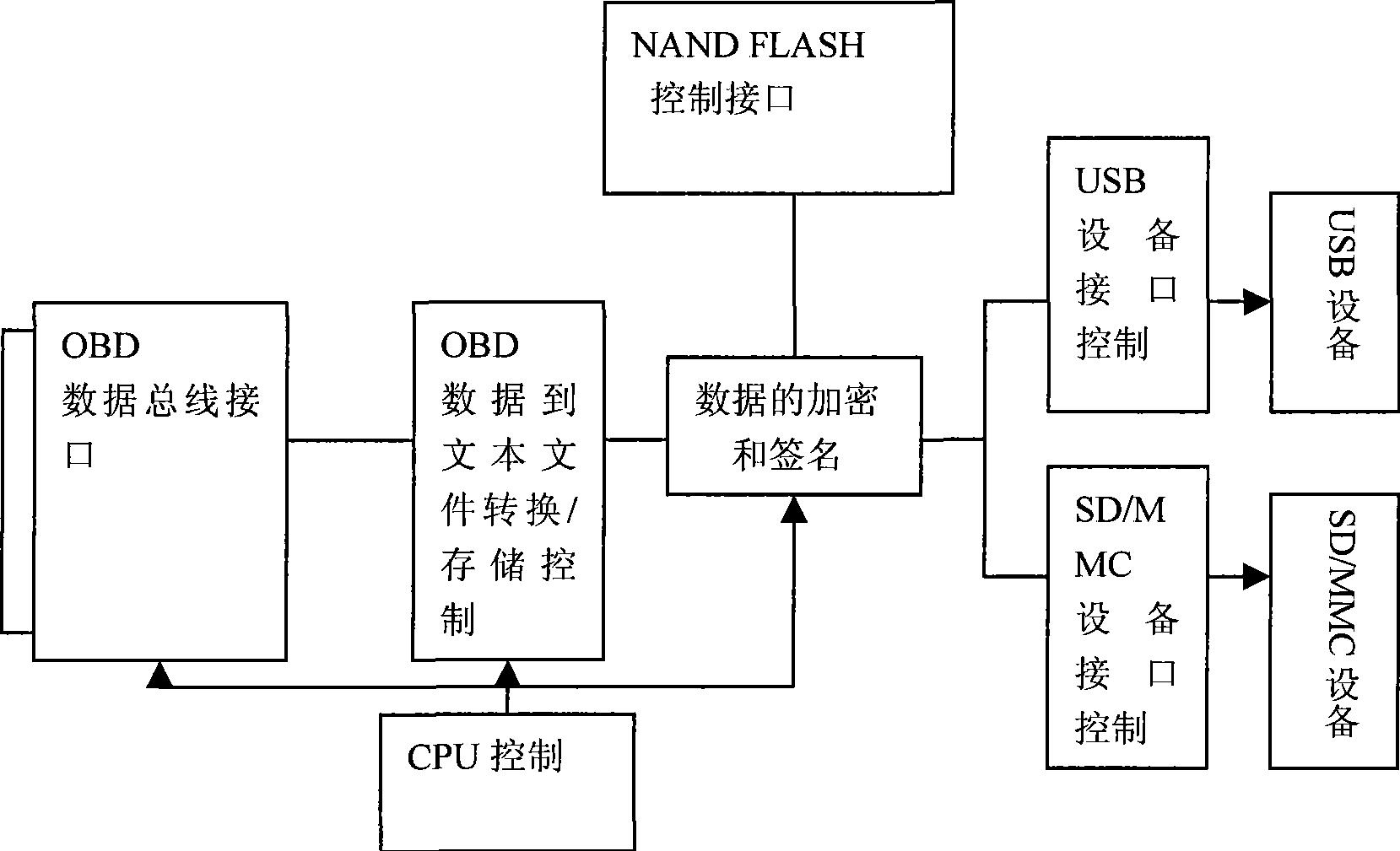

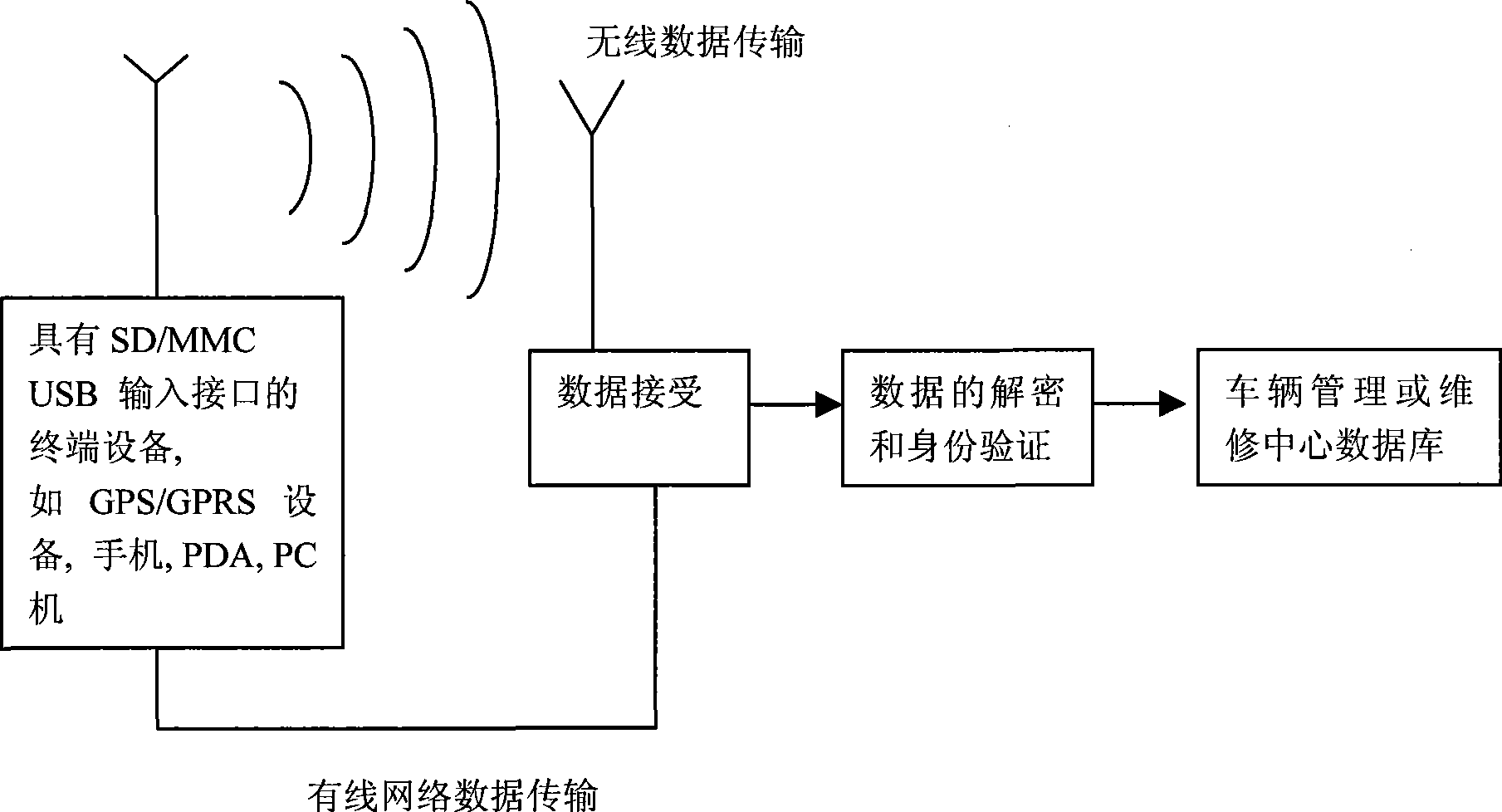

Automobile mounted automatic diagnosis method based on RSA ciphering and signature algorithm

ActiveCN101420306AImprove securityAccurate and Efficient Improvement MeasuresVehicle testingEngine testingDiagnosis methodsData information

Owner:苏州国芯科技股份有限公司

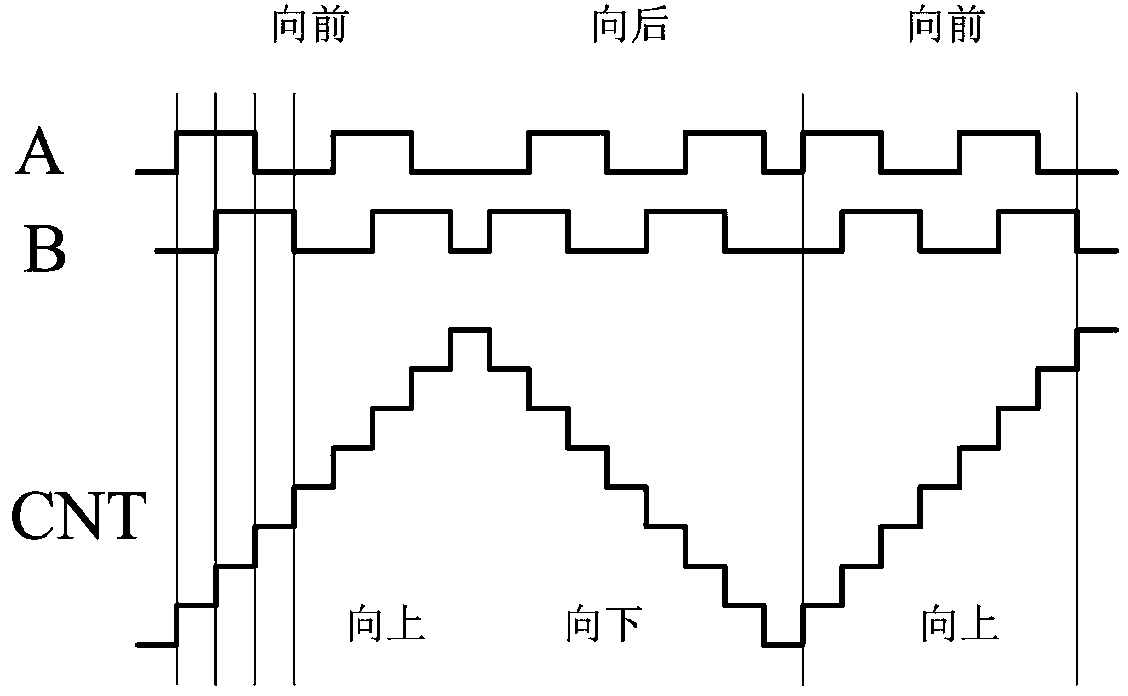

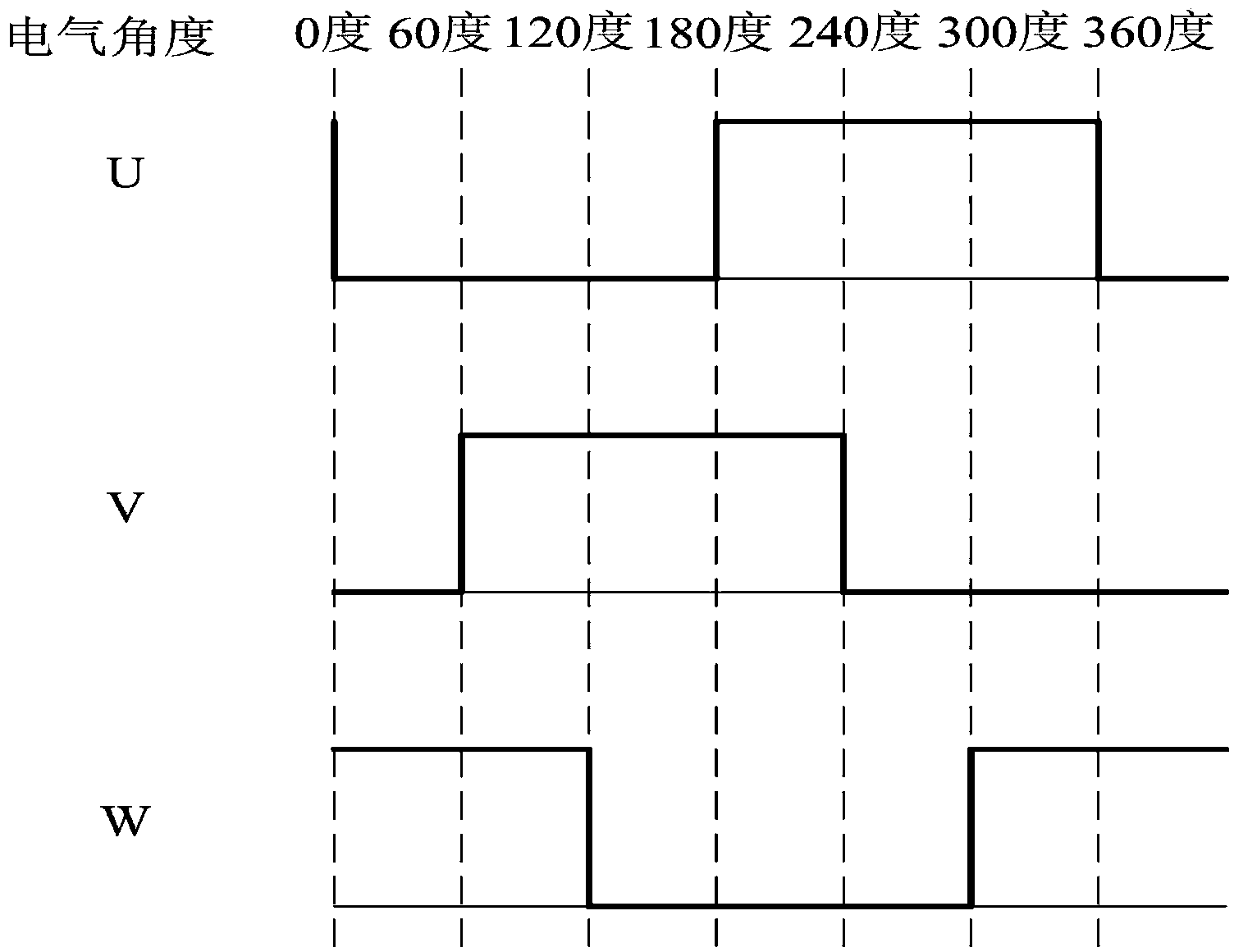

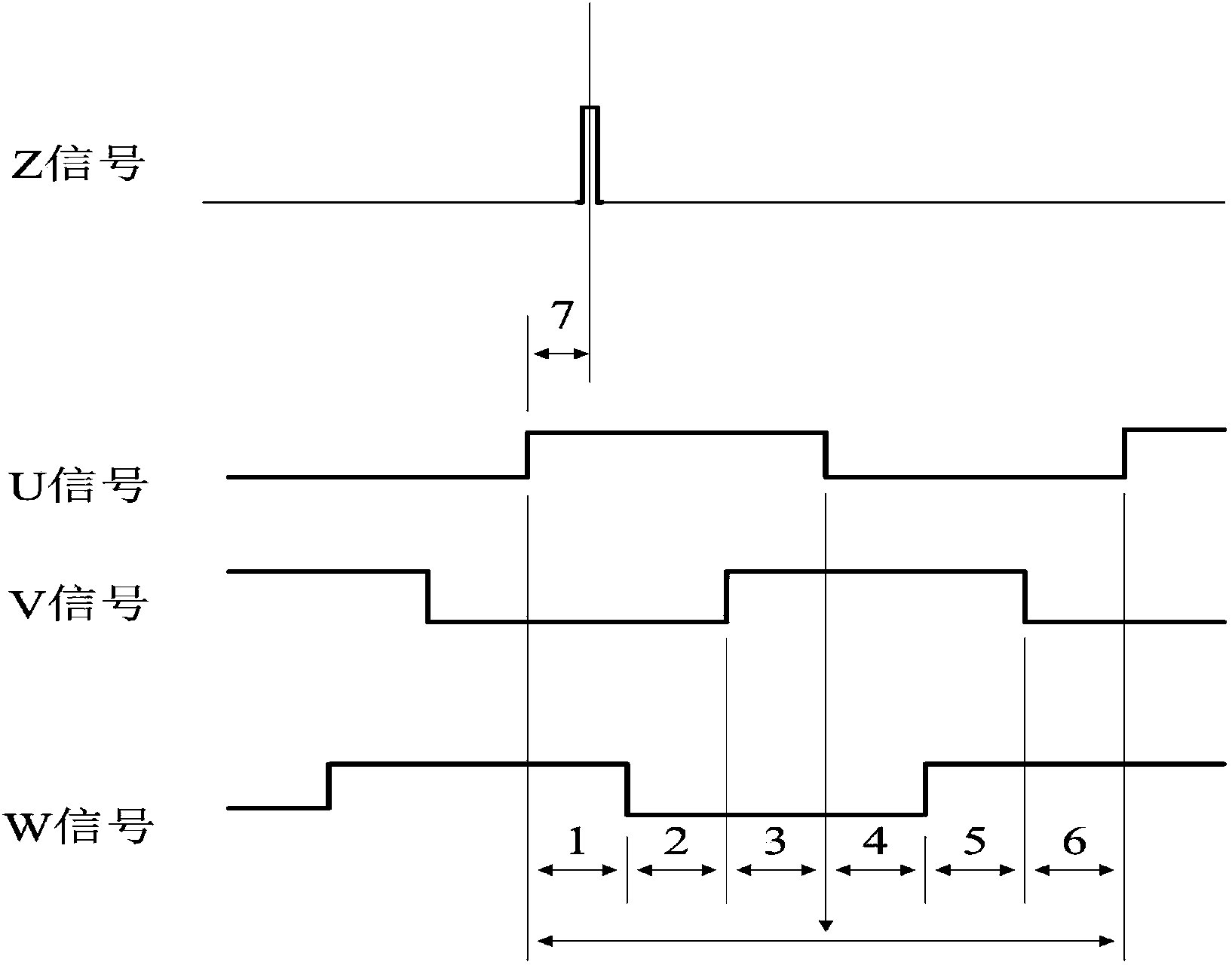

Fault self-diagnosis method for encoder in servo driving system

ActiveCN103441712ARealize real-time detectionConditions affecting operationElectronic commutation motor controlElectrical testingDiagnosis methodsClosed loop

The invention discloses a fault self-diagnosis method for an encoder in a servo driving system. Closed loop self-diagnosis and open loop self-diagnosis for encoder faults are achieved by detecting an output signal of the encoder in real time. A servo controller in the servo driving system receives a UVW signal and / or an ABZ signal output by the encoder in real time, the position information of a motor rotor is obtained through the UVW signal and / or the ABZ signal received in real time, and accordingly the operation state of the encoder is detected in real time. Once the encoder breaks down, the encoder is shut down and errors are reported, and the situation that the operation of a motor is affected due to the fact that the signals are lost because of the encoder faults and serious consequences caused by the encoder faults are avoided. In addition, closed loop self-diagnosis and open loop self-diagnosis can be achieved, real-time protection can be carried out under the situation of loading operation of the servo driving system, and the encoder can be detected when the motor has no load.

Owner:武汉迈信电气技术有限公司

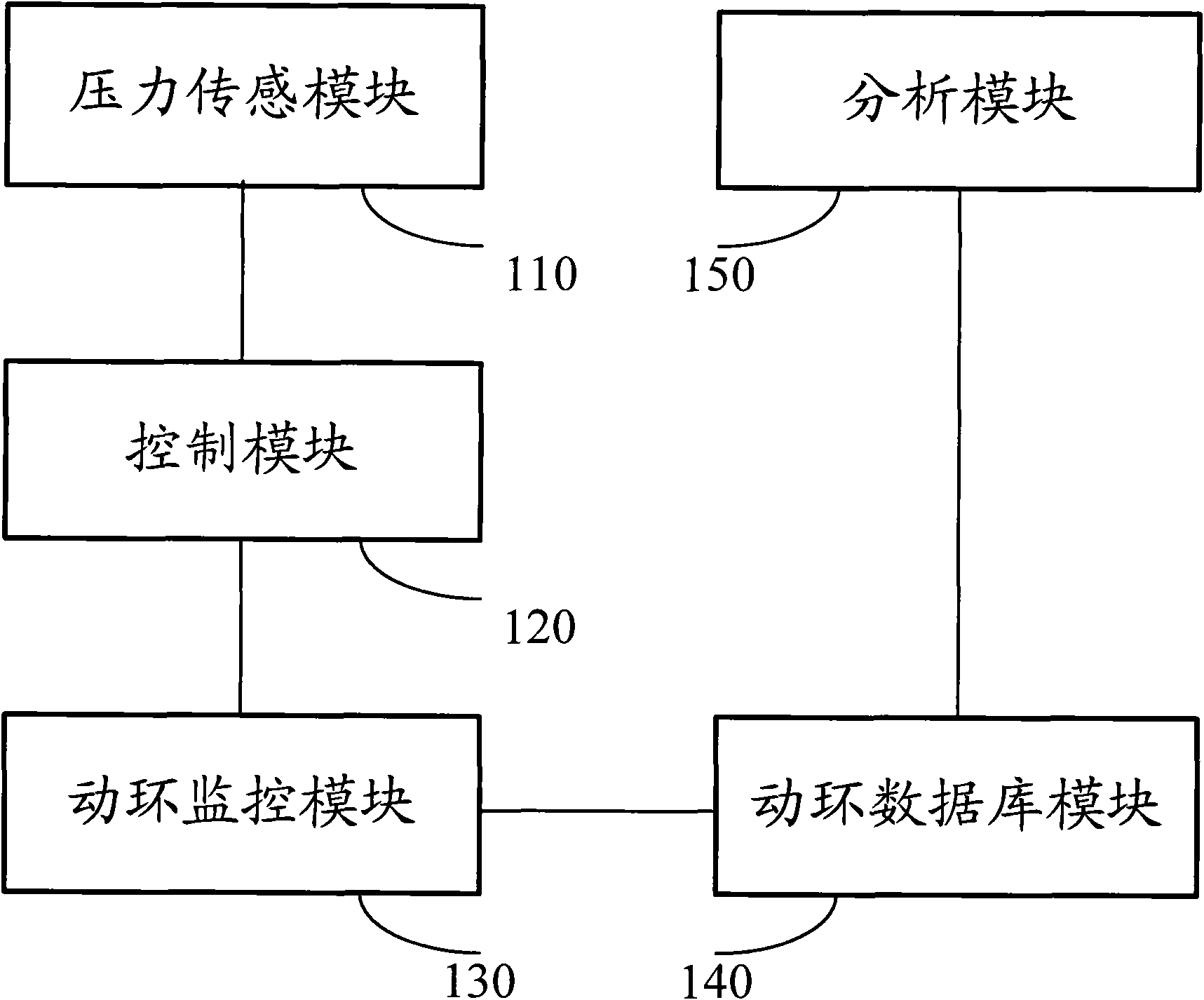

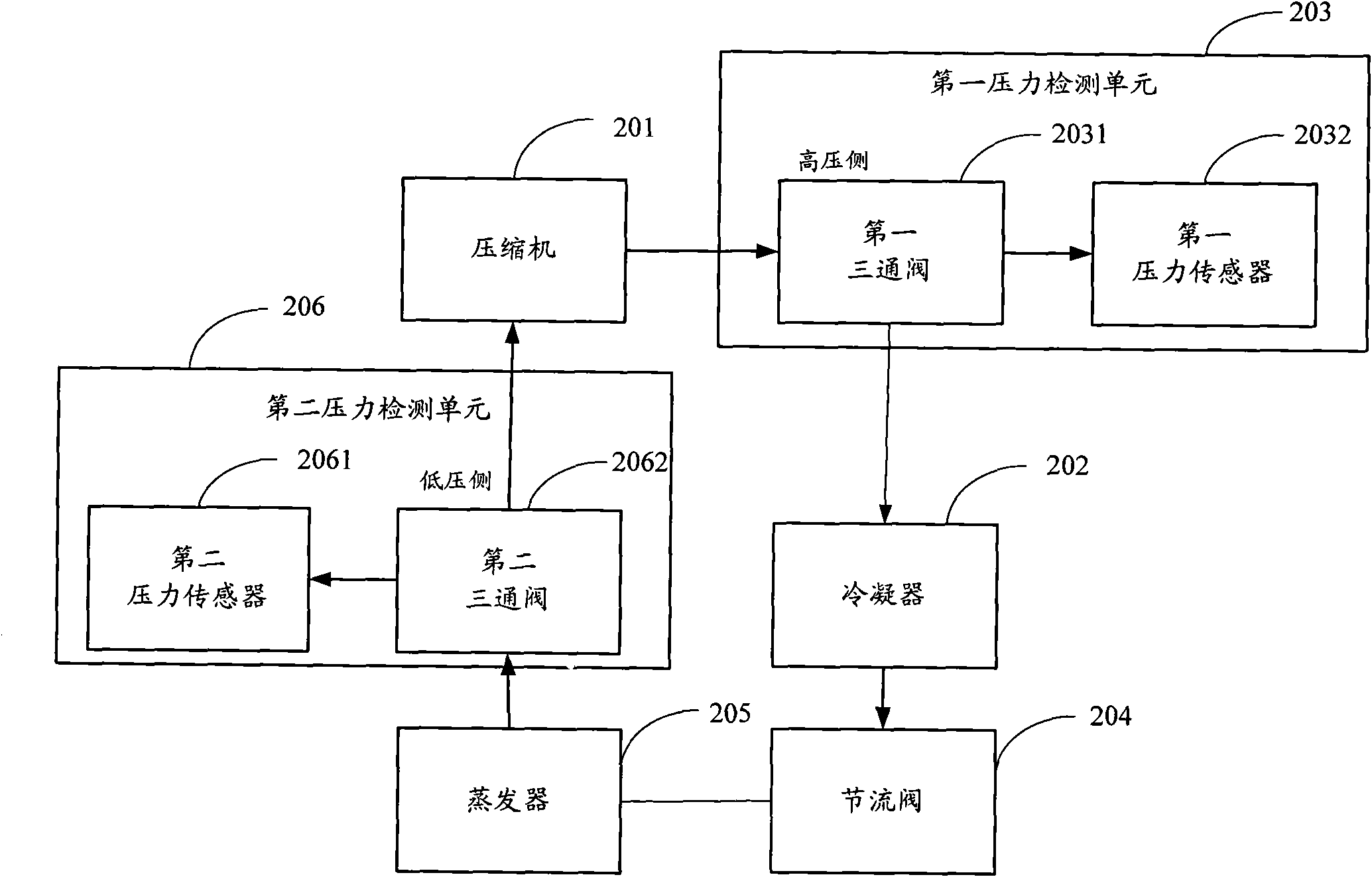

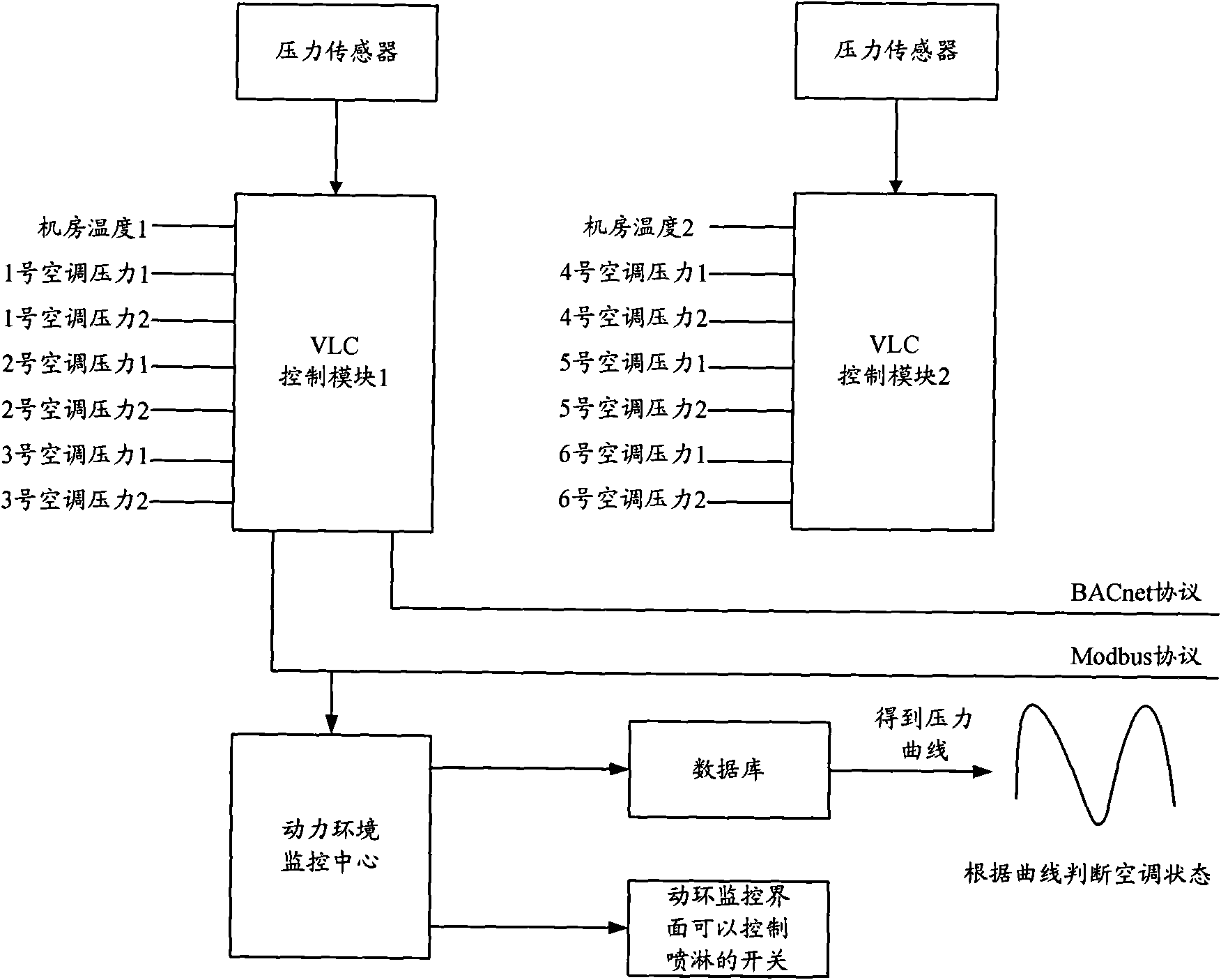

Method and device for monitoring pressure value of air conditioner in real time

ActiveCN102080864APrevent leakageImprove protectionSpace heating and ventilation safety systemsLighting and heating apparatusFreonEngineering

The embodiment of the invention discloses a device for monitoring the pressure value of an air conditioner in real time. The device comprises a pressure sensor, a control module and a moving ring monitoring module, wherein the pressure sensor is installed in a refrigerating circuit of the air-conditioner, and is used for detecting the variation of the pressure of the air conditioner and transmitting pressure data to the control module; the control module is connected with the pressure sensor and is used for receiving the pressure data sent by the pressure sensor and uploading the pressure data to the moving ring monitoring module; and the moving ring monitoring module is connected with the control module and is used for centralized monitoring of the pressure value of the air conditioner. In the device, the pressure sensor is adopted to replace a pressure switch so as to directly check the pressure value of the air conditioner in no need of hanging a pressure gage by man power to measure the pressure, thereby improving the efficiency, reducing the judgment time and maintenance time of faults and reducing the leakage of freon and refrigeration oil; simultaneously, the operation modeof the air conditioner can be traced, so that potential fault areas and potential energy-saving spaces of an air conditioning unit are found in advance; and in addition, the demand of a communicationmachine room on the refrigerating output of the air conditioner in future is correctly forecasted through analyzing historical data.

Owner:CHINA MOBILE GROUP JIANGSU

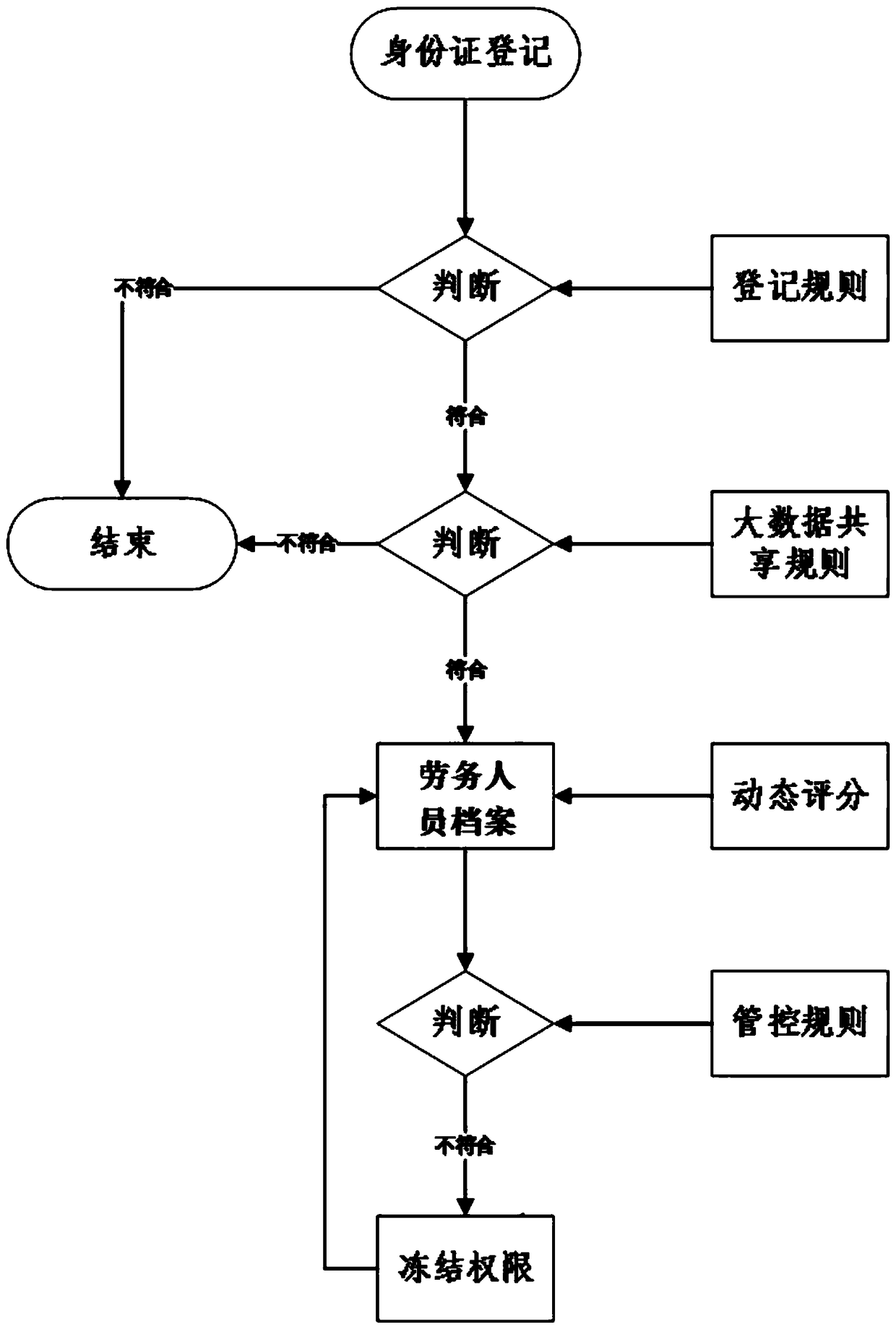

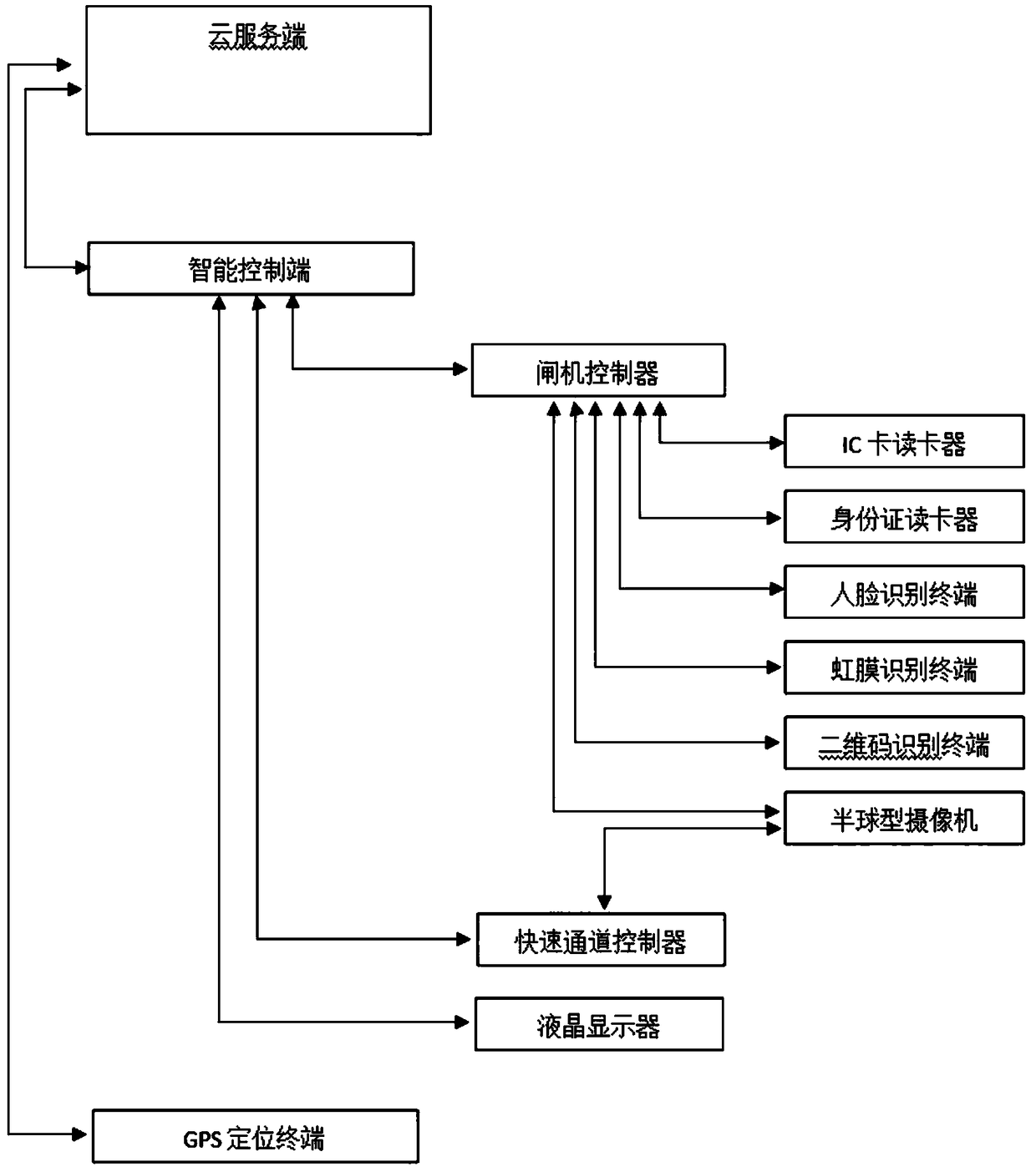

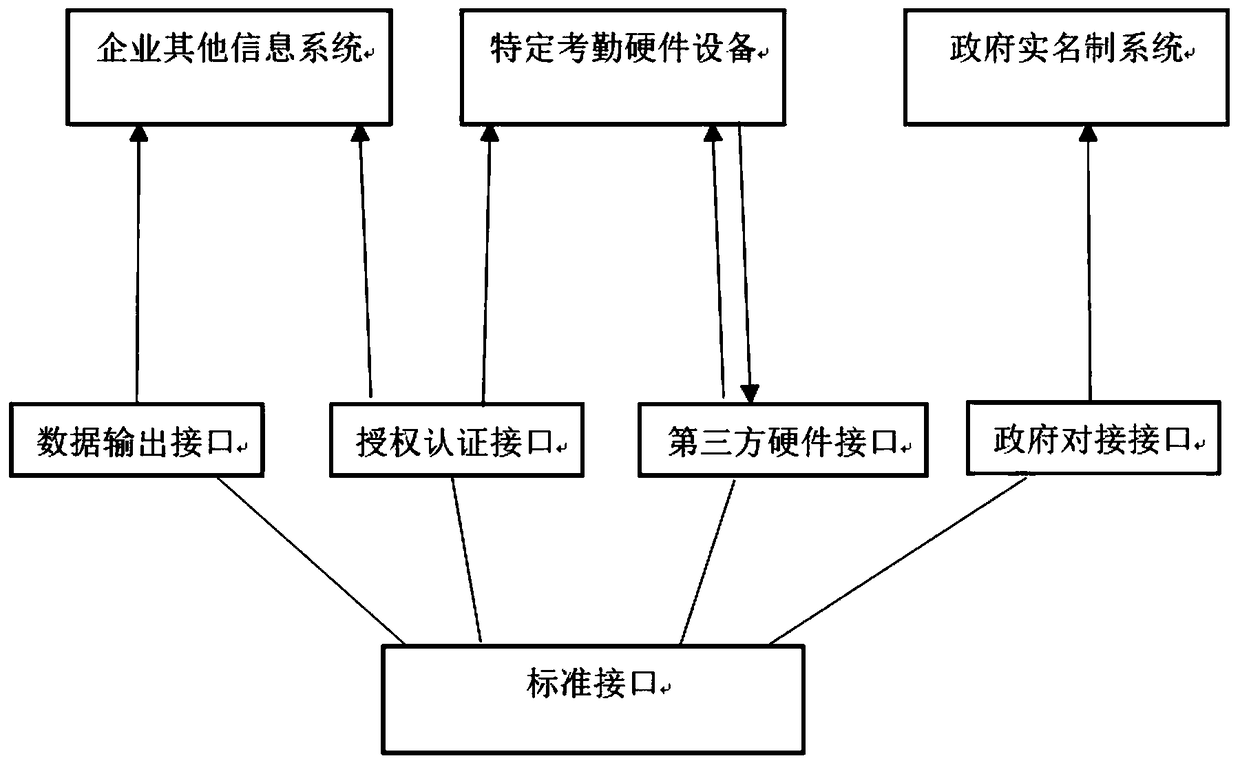

A management system and management method of a construction engineering labor service personnel

PendingCN109255731AReduce workloadAvoid enteringRegistering/indicating time of eventsData processing applicationsService personnelManagement system

The invention belongs to the field of engineering construction, in particular to a management system and a management method of a construction engineering labor service personnel. The current labor force management system on the market is applied independently by each enterprise or project, the information of the same labor personnel can not be shared, the labor team and labor personnel flow frequently, and the enterprise can not grasp the complete employment experience and performance evaluation of the past years, so there is an urgent need in the field of construction engineering labor personnel management system and management method to overcome the above problems. The invention provides the management system and the management method for the construction engineering labor service personnel, which can help to identify whether the labor service personnel conform to requirements, actively discover problems and implement predetermined measures to prevent employment risks. There are many kinds of attendance plans, and different types of projects choose the appropriate plan according to the needs; It has a standard interface to meet the needs of multiple data docking and help enterprises to improve the application value of real-name data. The invention is simple, easy to use and low in cost.

Owner:GLODON CO LTD

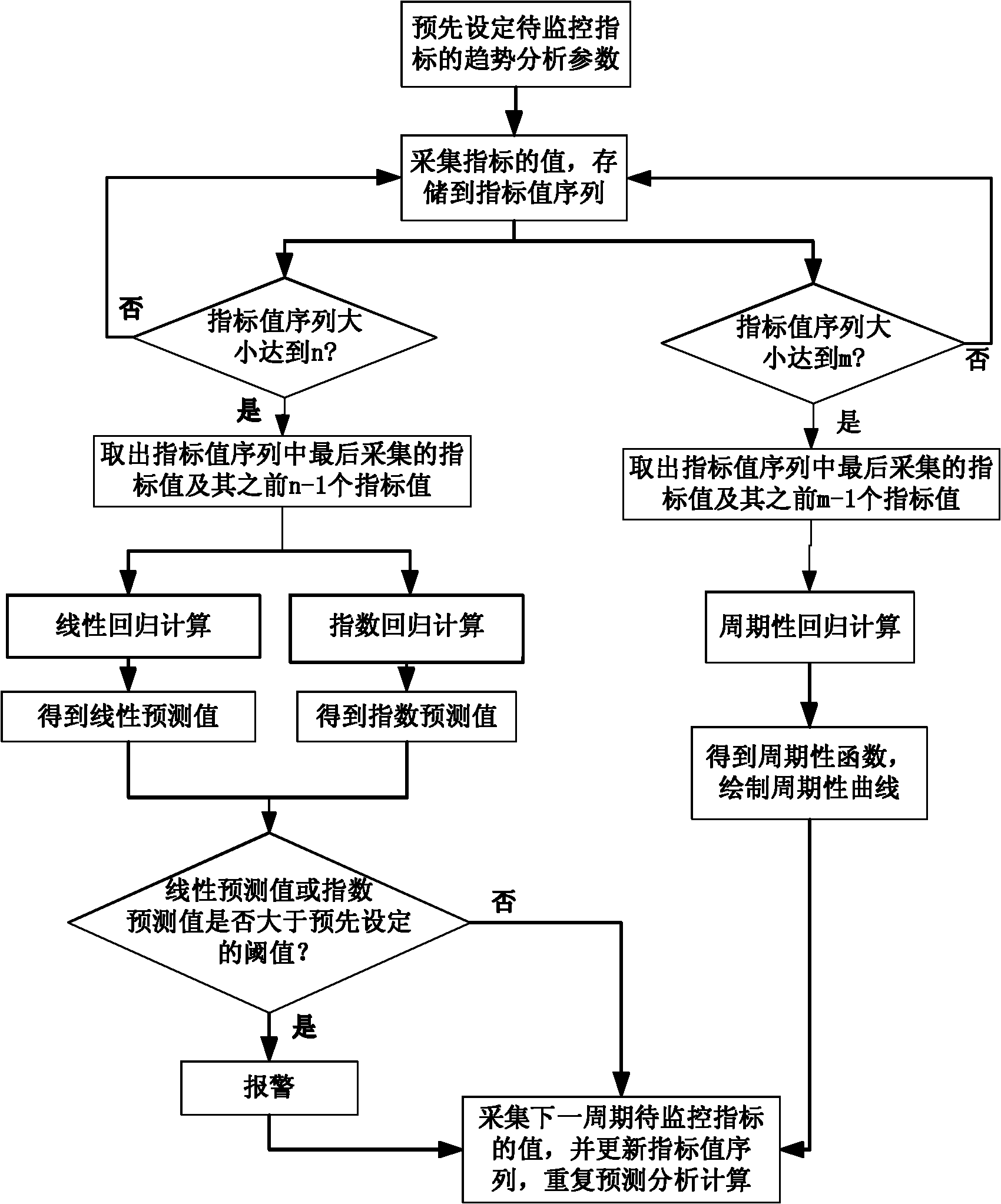

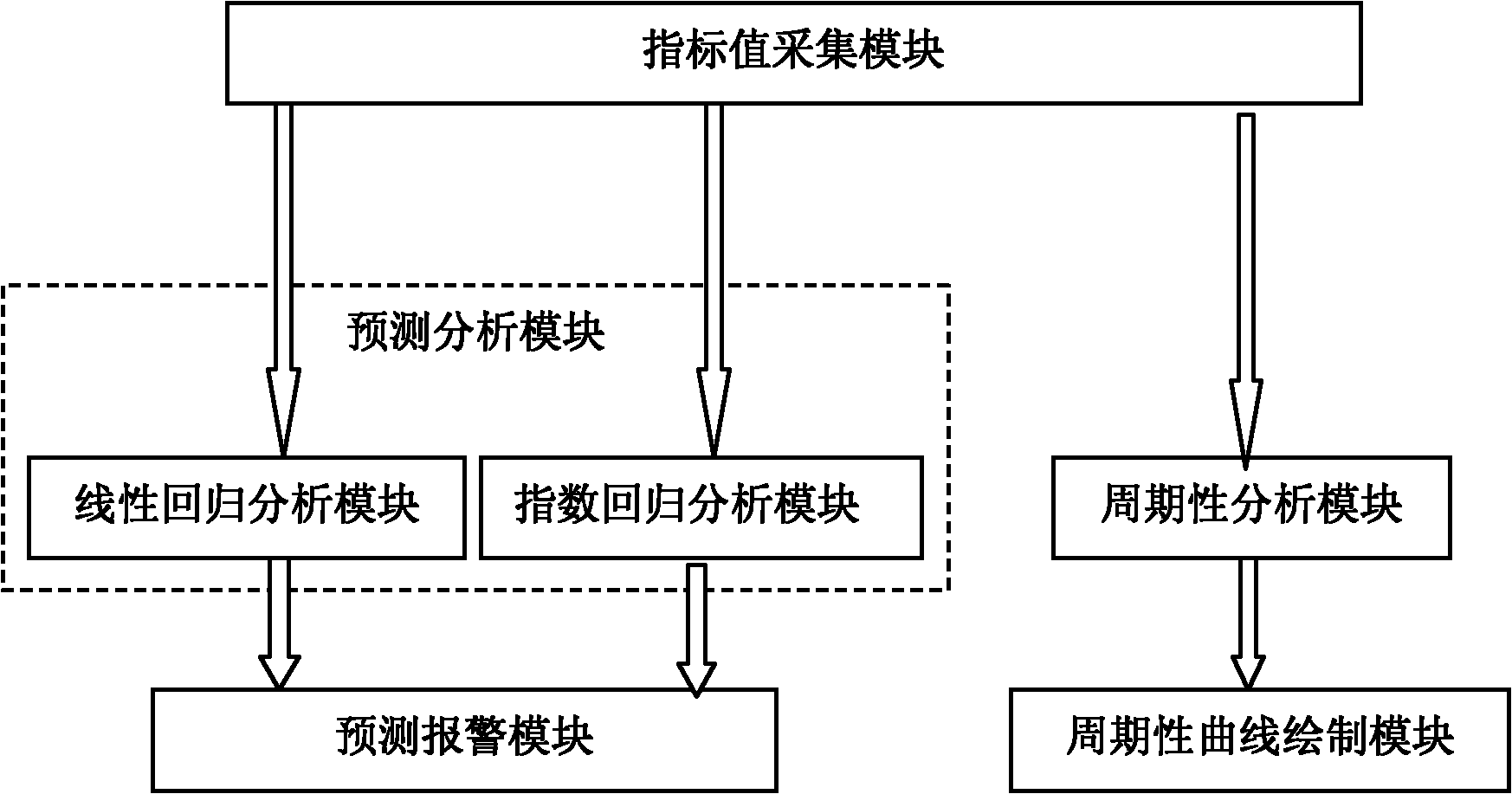

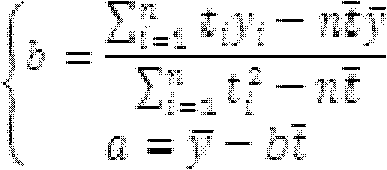

Trend analysis method and device for monitoring indexes in monitoring system

InactiveCN102148701AImprove accuracyAdd periodic analysis functionData switching networksRegression analysisControl signal

The invention discloses a trend analysis method and a trend analysis device for monitoring indexes in a monitoring system. The method comprises the following steps of: setting predictive analysis parameters of the indexes in advance; performing predictive analysis and periodical analysis by utilizing an acquired index value sequence respectively; in the predictive analysis, obtaining prediction results by comprehensively adopting a linear regression algorithm and an exponential regression algorithm, and externally outputting control signals according to the results of comparison between the prediction results and a preset threshold value; and in the periodical analysis, obtaining a periodical regression function according to acquired index values, and then drawing a periodical curve by using the periodical regression function. The device comprises an index value acquisition module, a predictive analysis module, a prediction alarming module, a periodical regression analysis module and a periodical curve drawing module. In the method and the device, the predictive analysis is performed by comprehensively adopting the linear regression algorithm and the exponential regression algorithm so as to achieve high accuracy; and an index variation periodical analysis function is added, so the index variation periodical curve can be obtained.

Owner:GUANGDONG UNIVERSITY OF BUSINESS STUDIES

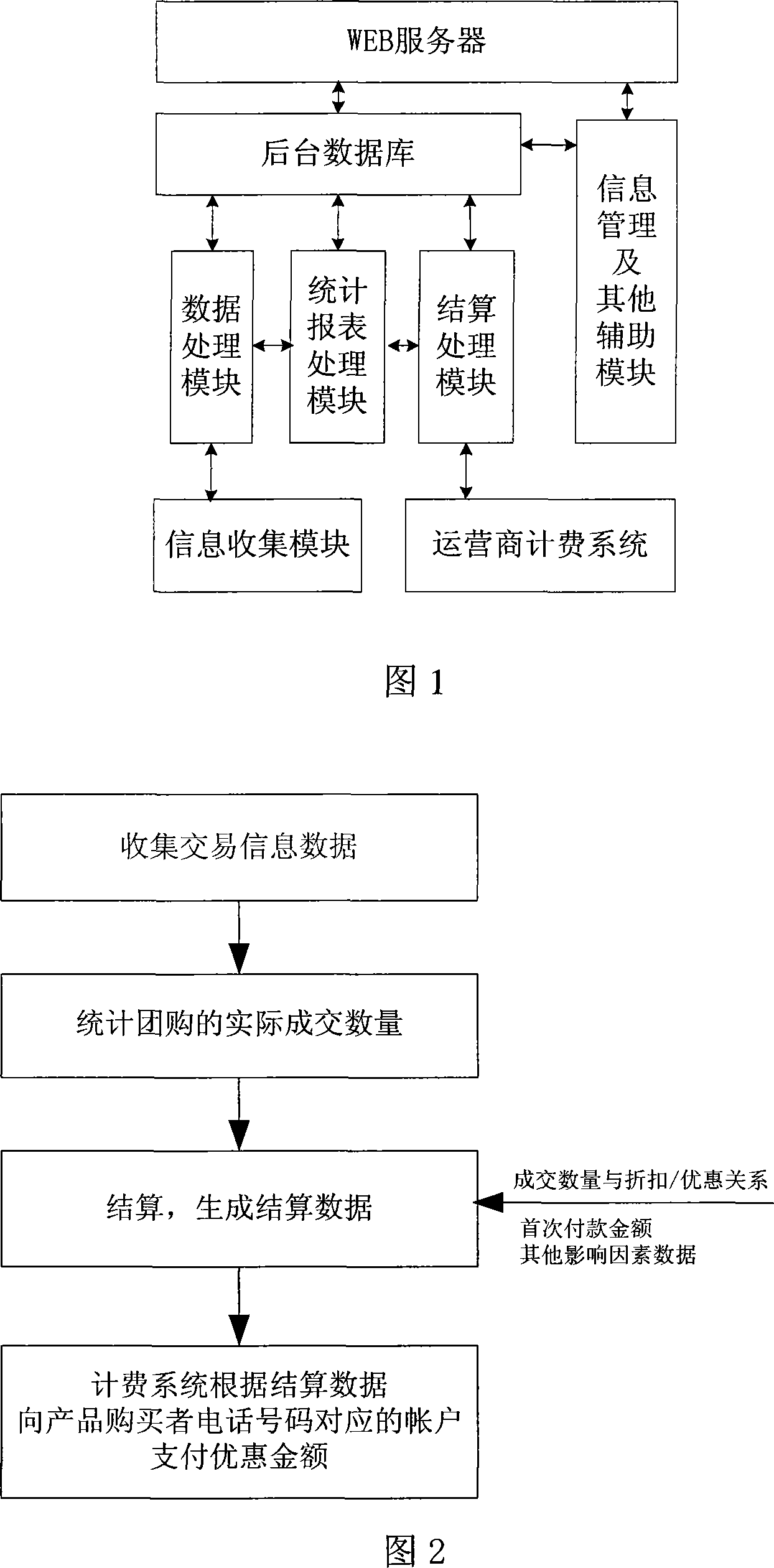

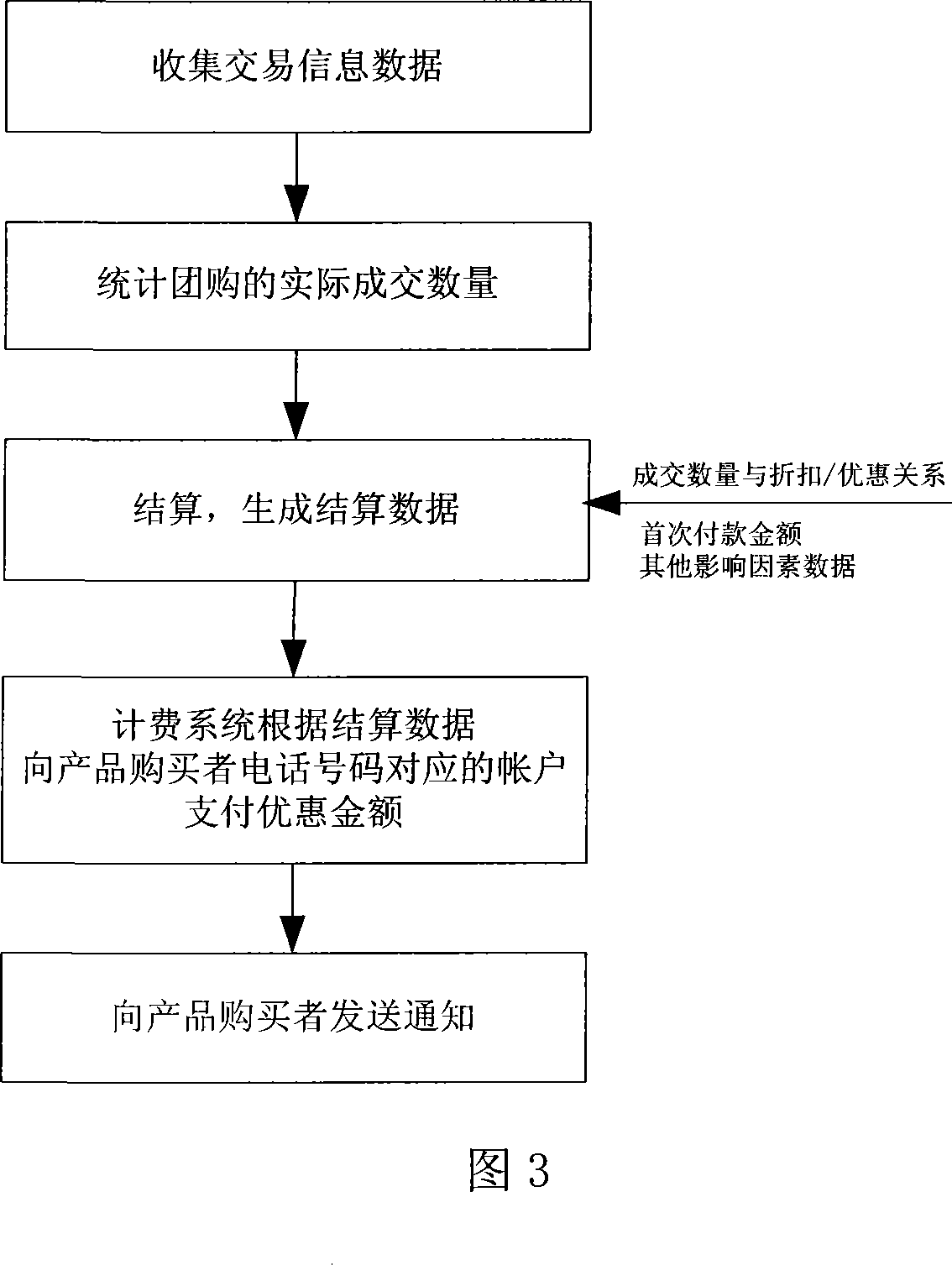

Group-buy settlement payments system and method with communicating technology

InactiveCN101114358ABest profit distributionAutomatically determinedPayment architectureCommerceGroup buyingComputer science

The invention discloses a system and method of group buying pattern balance and payment making use of the communication technique. The invention uses telephone numbers as marks of product buyers, adopts the transaction way of first payment plus preferential payment, and after the system gathers the first payment information, the statistics of practical transaction situations are made, and the preferential payment of network group buying is finished by making use of the accounting system of telecom operators based on the pattern balance situations. The invention has the advantages that the invention avoids the bad results caused by the inconsistency between the predicted transaction quantity and the practical transaction quantity in the network group buying, which achieves the best benefit distribution in network group buying between product buyers and product suppliers, and simplifies the process of network group buying, which is convenient for the participants of the group buying transaction and is beneficial to the development of network group buying, and can reduce the pattern balance and payment cost and efficiency of the group buying organizations and improve the efficiency of network group buying. The invention is particularly suitable for the network group buying websites and telecom operators.

Owner:徐世元

In-situ heat cross bonding process for preparing fluorine containing gel state electrolyte material and process for making polymeric lithium ion cell

The invention provides a method of making fluorine-containing gel state electrolyte material and polymeric lithium ion cells by employing in-situ thermal cross bonding process, wherein fluorine-containing acrylic ester material is used as monomer, and double functional group acrylic acid ester containing polyethylene glycol or triple functional group acrylic acid ester containing polyethylene glycol are used as cross linking agent, the making process comprises injecting the miscible liquid comprising monomer, cross linking agent, thermal initiation agent and lithium ion electrolyte salt solution into the core of lithium ion cells, heating the cell to result in-situ thermal chemical cross-linking for the two acrylic esters, whereby the acrylic ester copolymer network bundles the solution in the electrolyte, forming the gel state electrolyte material with stabilized physical and chemical properties.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com