Patents

Literature

43results about How to "Strong anti-foaming ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-emulsifying molecular antifoaming agent and preparation method thereof

InactiveCN102160939AStrong anti-foaming abilityReduce surface tensionFoam dispersion/preventionPolymer scienceFatty alcohol

The invention discloses a self-emulsifying molecular antifoaming agent and a preparation method thereof. The antifoaming agent comprises the following components in percent by mass: 20 to 60 percent of antifoaming active substance and 40 to 80 percent of dispersion medium, wherein the antifoaming active substance consists of higher fatty alcohol, alkynol, polyether and silicone oil in a mass ratio of 1:(0.8-1.5):(2-3):(2-4); and the dispersion medium is grafted star polymer. The preparation method comprises the following steps of: adding 50 to 150 parts of trichloromethane and 1 to 2 parts ofp-methyl benzene sulfonic chloride into 20 to 60 mass parts of active substance and 40 to 80 mass parts of star polymer, raising the temperature to between 40 and 70 DEG C, and reacting for 3 to 6 hours; and after the reaction is finished, washing sodium carbonate until the ph is 7, drying by using anhydrous sodium sulfate, and evaporating the solvent under reduced pressure to obtain the antifoaming agent. The extended arm of the star polymer in the antifoaming agent is grafted with the active substance, so that various components are synergistic, and the obtained antifoaming agent is high instability, low in surface tension, high in surface activity, high in antifoaming capacity, long in foam inhibition time and small in dosage.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

Defoaming agent

InactiveCN1426827APerformance is not affectedFast defoaming speedFoam dispersion/preventionAlcoholFoaming agent

A defoaming agent for anionic or non-ionic foaming agent used in production of rubber and plastics is prepared from hydrocarbonylated oil 40-60 wt portions, C4-C8 alcohol amine 3-29 portions, C10-C18 fatty acid 2-30 portions, alcohol amine ester of C10-C18 fatty acid 3-15 portions, codefoaming agent 5-15 portions, and disperser 3-8 portions through emulsifying with water. Its advantages are high defoaming speed and strong power on suppressing foams.

Owner:BC P INC CHINA NAT PETROLEUM CORP

Aqueous emulsion non-silicon defoamer and preparation method thereof

ActiveCN101780383BImprove surface activityEnhanced defoamingTransportation and packagingMixingWater basedEmulsion

The invention discloses an aqueous emulsion non-silicon defoamer and a preparation method thereof. The defoamer consists of a material with defoaming activity, an emulsifying material and a dispersion medium, wherein the material with defoaming activity consist of alkynol, higher aliphatic alcohol and glyceryl polyether; the emulsifying material consists of anionic emulsifier and non-ionic emulsifier; and the dispersion medium consists of water and glycol. The defoamer of the invention has excellent defoaming and anti-foaming functions and high wettability and stability and is particular suitable for water-based paint, oil ink and other systems.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

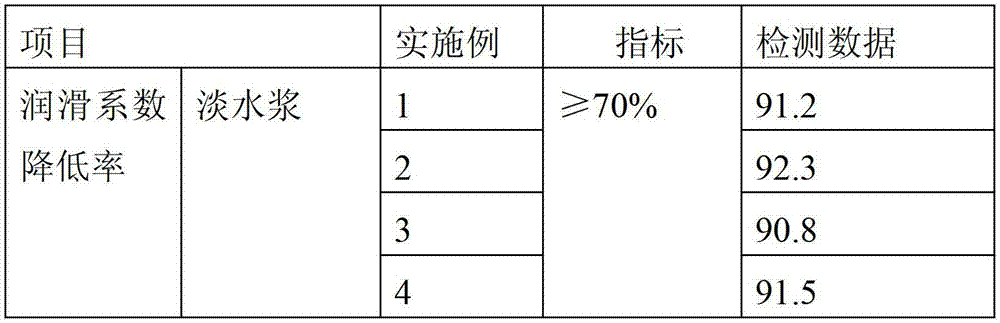

Lubricating defoamer for drilling fluid and preparation method thereof

ActiveCN103160258AEasily brokenImprove the lubrication effectDrilling compositionEngineeringBase oil

The invention provides a lubricating defoamer for a drilling fluid and a preparation method thereof. The lubricating defoamer for the drilling fluid is prepared from the following raw materials by weight percent: 30-43% of fatty acid, 15-25% of organic amine, 30-40% of base oil, 2-6% of penetrating agent and 10-15% of defoamer. Compared with the prior art, the lubricating defoamer for the drilling fluid is capable of functioning as the lubricant and the defoamer at the same time; the field operation steps are simple and the production cost is reduced.

Owner:成都西油华巍科技有限公司

Organosilicon defoamer with bactericidal action

InactiveCN106390533AFast defoaming speedStrong anti-foaming abilityFoam dispersion/preventionChemistryActivated carbon

The invention discloses an organosilicon defoamer with a bactericidal action. The organosilicon defoamer is prepared from the following raw materials in parts by weight: 40-60 parts of simethicone, 20-30 parts of silicon dioxide, 0.3-0.5 part of stearamide, 0.3-0.5 part of potassium iodide, 0.3-0.5 part of sodium carbonate, 0.4-0.6 part of tributyl phosphate, 4-6 parts of clinoptilolite powder, 0.3-0.4 part of sodium tripolyphosphate, 0.3-0.5 part of mannitol, 2-3 parts of common salt, 0.3-0.6 part of barium stearate, 1-3 parts of glycerine, 0.4-0.6 part of copper sulfate, 0.5-0.7 part of activated carbon and 10-20 parts of water.

Owner:合肥新万成环保科技有限公司

Exterior wall fluorocarbon paint and preparation method thereof

ActiveCN104987785AStrong crack resistanceHigh film forming efficiencyCoatingsCrack resistancePreservative

The invention discloses an exterior wall fluorocarbon paint. The exterior wall fluorocarbon paint comprises, by weight, 35-45 parts of aqueous fluorocarbon resin, 1-2 parts of a film forming assistant, 1-1.5 parts of diethylene diamine, 0.5-1 part of a thickener, 0.1-0.3 parts of a pH adjusting agent, 0.5-1 part of a dispersant, 10-16 parts of titanium dioxide, 5-10 parts of cellulose acetate pulp, 3-5 parts of butyl acetate, 0.5-1 part of an antiseptic, 3-4 parts of an antifoaming agent and 20-30 parts of pure water. The exterior wall fluorocarbon paint has strong crack resistance.

Owner:CHONGQING PINSHENG PAINT

Special defoaming agent for high-interface fluorocarbon resin emulsion and preparation method of special defoaming agent

The invention discloses a special defoaming agent for a high-interface fluorocarbon resin emulsion. The special defoaming agent is characterized in that the special defoaming agent comprises the following components in percentage by mass: 3-10% of fluorine-containing polyether modified polysiloxane, 2-7% of white carbon black, 40-60% of methylsilicone oil, 0.27-0.45% of a thickener, 0.22-0.33% of polyoxyethylene ether, 0.016-0.21% of cellulose and 30-45% of water. The special defoaming agent disclosed by the invention has the advantages of strong defoaming and foam-inhibiting efficacy, low surface tension, no volatility, excellent thermal stability and good compatibility with the fluorocarbon resin emulsion, and can effectively solve the problem that the fluorocarbon resin emulsion is liable to foaming in construction process.

Owner:安徽柏晨新材料科技有限公司

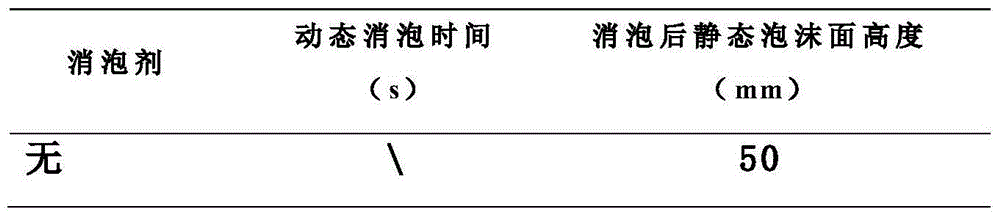

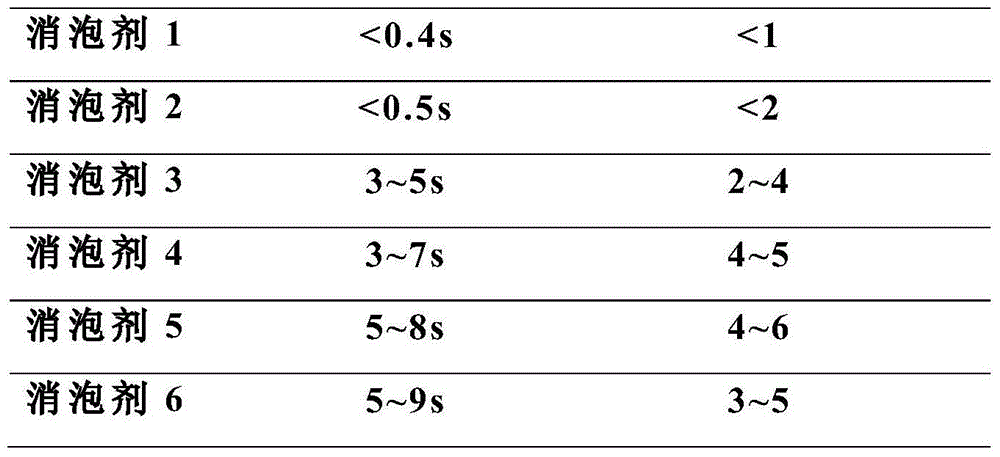

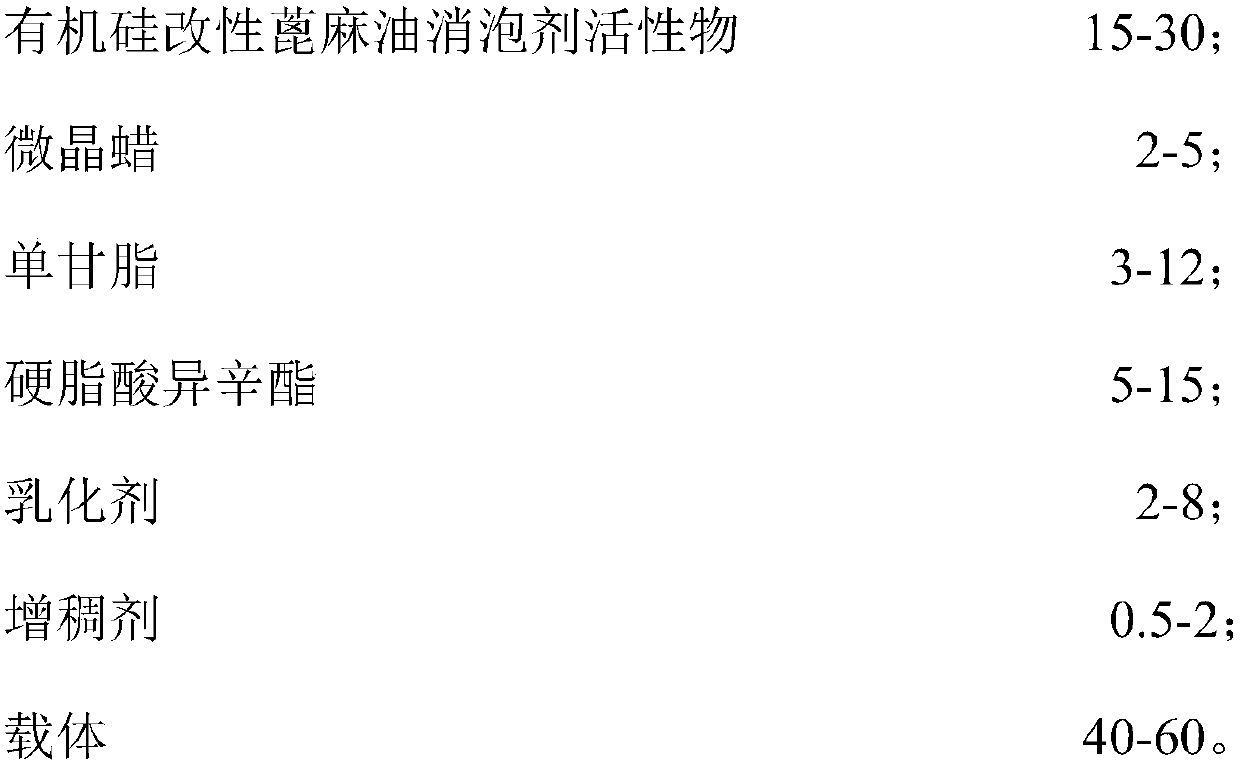

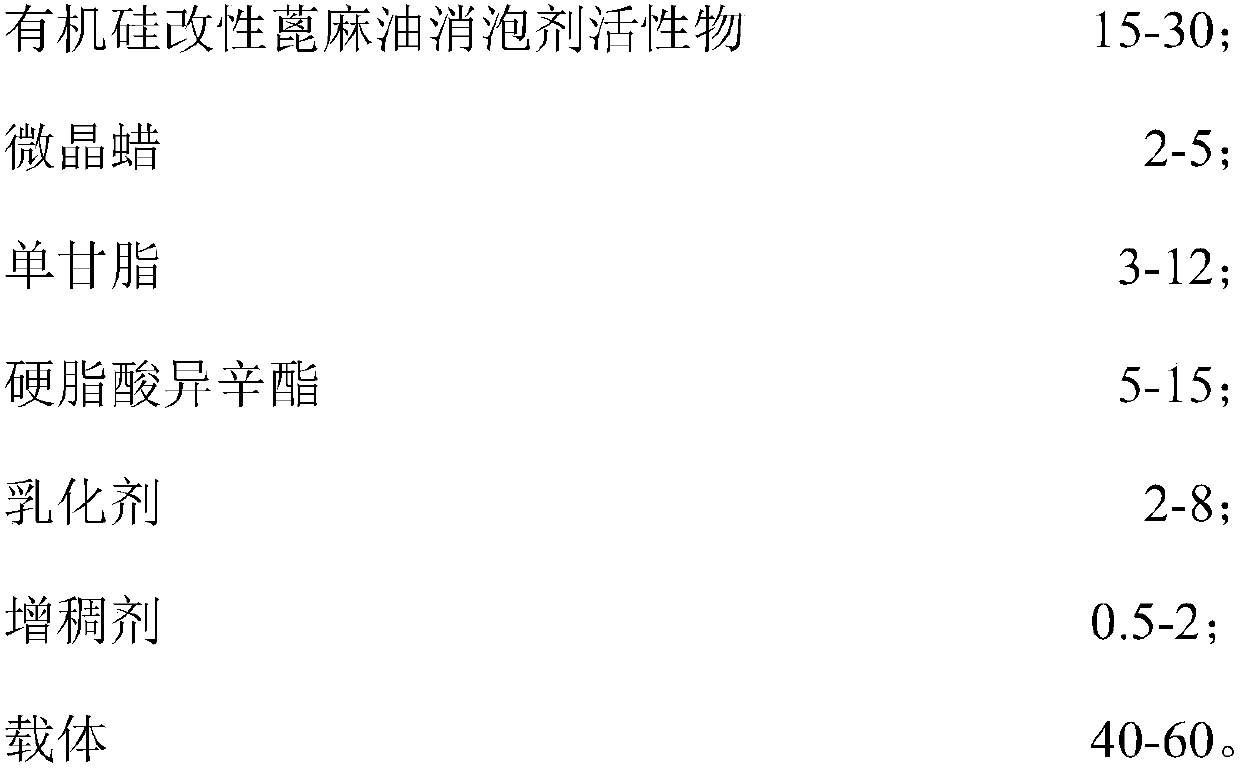

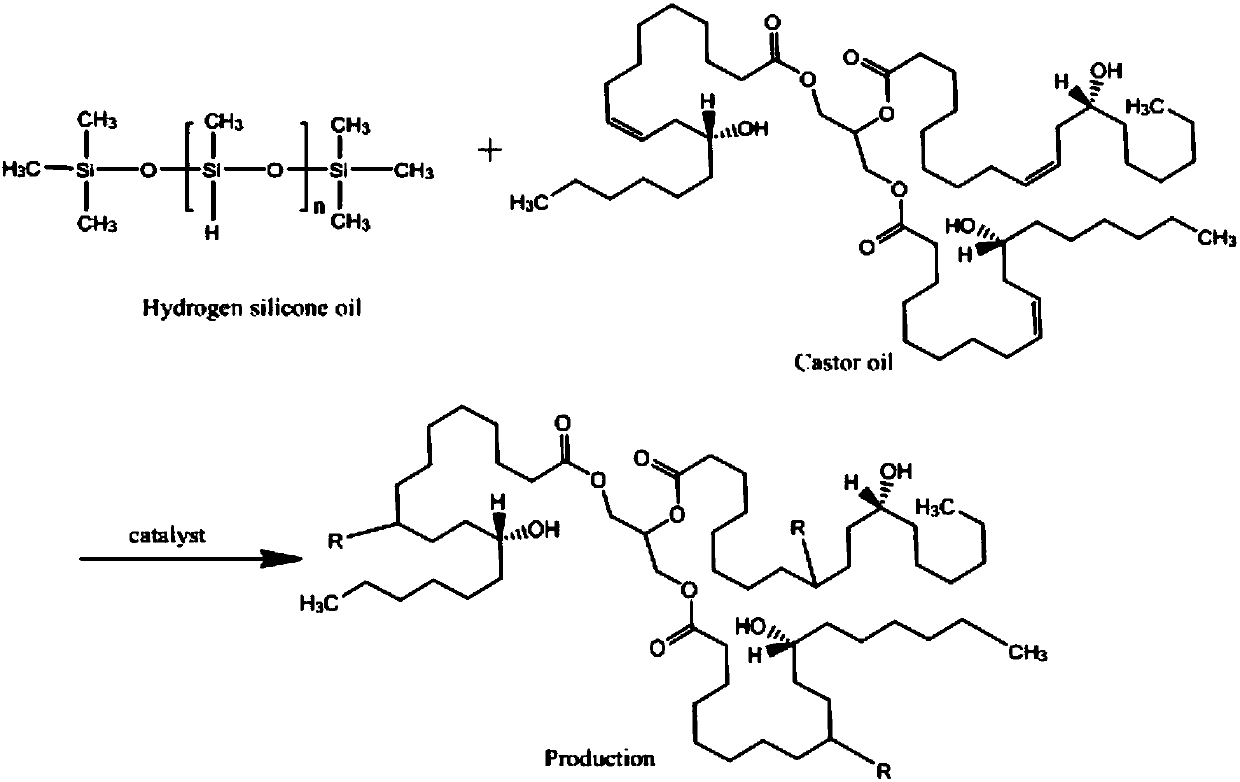

Antifoaming agent containing organosilicone modified castor oil for PVA (Polyvinyl Alcohol) production and preparation method of antifoaming agent

ActiveCN107551609AReduce adhesionReduce negative impactFoam dispersion/preventionMicrocrystalline waxMonoglyceride

The invention discloses an antifoaming agent containing organosilicone modified castor oil for PVA (Polyvinyl Alcohol) production and a preparation method of the antifoaming agent and belongs to the field of organosilicone modified antifoaming agents. The preparation method comprises the following steps: carrying out an addition reaction between hydrogen containing silicone oil and castor oil in an N2 protective catalyst system so as to obtain an organosilicone modified castor oil antifoaming agent active matter; and by utilizing the modified antifoaming agent active matter as well as microcrystalline wax, monoglyceride, isooctyl stearate, an emulsifier, a thickening agent and a carrier, thereby obtaining the antifoaming agent containing organosilicone modified castor oil. The antifoamingagent containing organosilicone modified castor oil produced according to the method disclosed by the invention is applied to eliminating foam produced in PVA production, has tiny negative effects onadhesiveness of slurry and mechanical property of slurry membranes, and has the characteristics of being small in dose, high in antifoaming speed, high in foam inhibition ability, nontoxic, harmless,simple in process and the like.

Owner:XIAN SUNY FINE CHEM

Antifoam agent and production technique thereof

InactiveCN101310813AStrong anti-foaming abilityImprove permeabilityTransportation and packagingMixingParaffin waxEmulsion

The invention relates to a defoaming agent and a production process, and the defoaming agent is composed of components with the following parts by weight: 60 parts of dimethyl silicone oil, 15 parts of glyceryl polyether 3050, 15 parts of liquid paraffin and 10 parts of water. The production process comprises the following steps: 10 parts by weight of water is added in a reactor; 60 parts by weight of dimethyl silicone oil is slowly added in the reactor to be stirred at the normal temperature, thus forming emulsion-like solution; 15 parts by weight of glyceryl polyether 3050 is added to be continuously stirred at the normal temperature till the glyceryl polyether 3050 is fully dissolved in the emulsion-like solution; 15 parts by weight of liquid paraffin is further added to be continuously stirred at the normal temperature till the liquid paraffin is fully dissolved in the emulsion-like solution; the low-speed stirring is carried out for 30 minutes, the solution is kept at 18 DEG C to 22 DEG C, and the defoaming agent is prepared by carrying out the reactor for 24 hours. The defoaming agent and the production process have the advantages that: the production process has no waste gas, no waste water and no noise to be discharged to the outside; the product is fully dissolved in the water and non-toxic, thus not producing secondary environmental pollution, the product is used in a big water region, the defoaming speed is fast, the using amount is small and the cost is low.

Owner:闫承慧

Organic silicon defoaming agent with anti-cracking function

InactiveCN106362443AHas anti-crack effectGood compatibilityFoam dispersion/preventionKerosenePotassium iodine

The invention discloses an organic silicon defoaming agent with an anti-cracking function. The defoaming agent is prepared from, by weight, 40-70 parts of simethicone, 20-30 parts of silicon dioxide, 10-20 parts of water, 1-2 parts of acrylic acid emulsion, 0.3-0.5 part of potassium iodide, 0.2-0.4 part of prenyl alcohol, 0.5-1 part of oxidized polyethlene wax, 0.3-0.5 part of kerosene, 0.4-0.8 part of tributyl citrate, 2-4 parts of calcium stearate, 0.4-0.8 part of nonylphenol polyoxyethylene ether, 2-4 parts of bentonite, 1-2 parts of stearamide, 1-2 parts of fatty acid and 0.2-0.4 part of butyl stearate.

Owner:合肥新万成环保科技有限公司

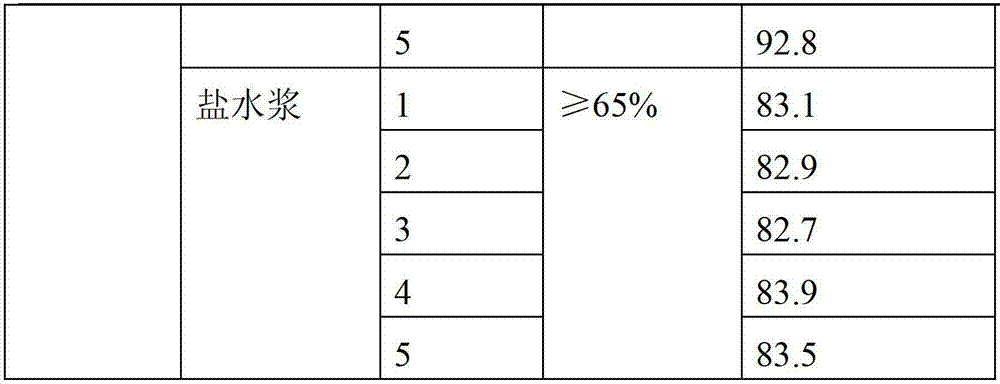

Anti-oxidation emulsion and anti-oxidation waterborne coating varnish prepared from same

ActiveCN107033288AImprove defoaming abilityStrong anti-foaming abilityPaper coatingCorrosion-inhibiting/anti-oxidant agent additionCardboardHot stamping

The invention relates to the technical field of coating varnish, in particular to anti-oxidation emulsion and anti-oxidation waterborne coating varnish prepared from the same. The anti-oxidation emulsion is prepared from raw materials in percentage by weight as follows: 30%-50% of an acrylic resin solution with neutral pH, 29%-41% of mixed monomers, 0.5%-1% of an emulsifier, 0.3%-0.8% of an initiator, 0.01%-0.05% of an oxidizing agent, 0.01%-0.05% of a reducing agent and 10%-25% of deionized water, and the sum of the raw materials in percentage by mass is 100%. According to the anti-oxidation emulsion, possibly existing acid-base substances can be reduced, the probability of oxidation is reduced, and hot stamping foil is not prone to oxidation; the anti-oxidation waterborne coating varnish prepared from the anti-oxidation emulsion contains no organic solvents, is low in content of VOCs (volatile organic chemicals) or free of VOCs, is environment-friendly, non-toxic and anti-oxidation, and is suitable for surface lustering of substrates, prone to hot stamping oxidation, of black cardboards, blackened paper, coated black paper and the like.

Owner:GUANGDONG YINGKE GRP CO LTD

High-efficiency antifoaming agent

InactiveCN105289050AFast defoaming speedStrong anti-foaming abilityFoam dispersion/preventionSolubilityDefoamer

The invention discloses a high-efficiency antifoaming agent. The high-efficiency antifoaming agent is prepared from low-hydrogen silicone oil, n-amyl alcohol, white carbon black, malonic acid, amino silicon oil, 1.5% concentrated sulfuric acid, octamethylcyclotetrasiloxane, trifluoropropionic acid, polyether silicone oil, carboxymethyl cellulose sodium, and sorbitol. According to a preparation method, low-hydrogen silicone oil is subjected to chemical modification so as to obtain the high-efficiency antifoaming agent, defoaming speed of the high-efficiency antifoaming agent is increased greatly, foam inhibition performance is improved, using amount is one third less than that of common antifoaming agents, and the high-efficiency antifoaming agent possesses excellent water solubility.

Owner:宣城市聚源精细化工有限公司

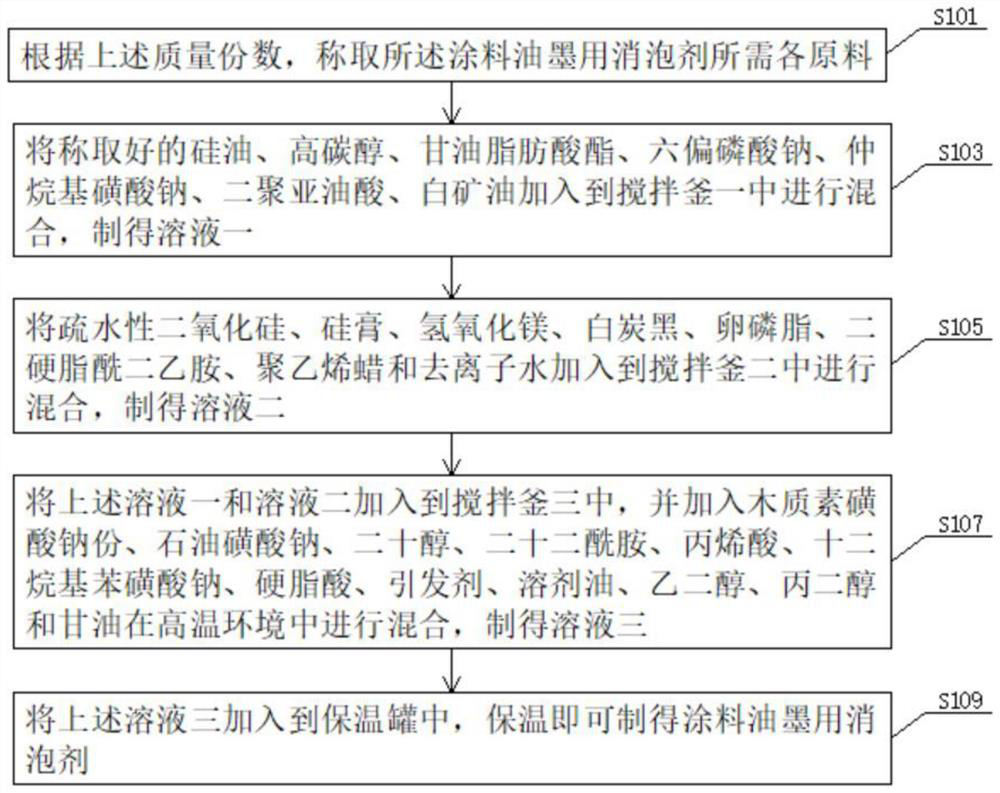

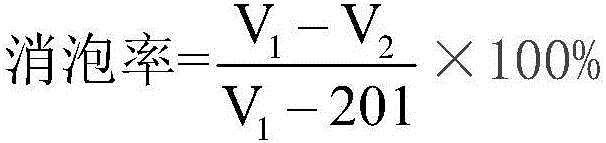

Defoaming agent for paint and ink and preparation method thereof

The invention discloses a defoaming agent for paint and ink and a preparation method of the defoaming agent. The defoaming agent for the paint and the ink is prepared from the following raw materialsin parts by mass: 42-48 parts of silicone oil, 14 -20 parts of hydrophobic silicon dioxide, 14-18 parts of silicon paste, 10-20 parts of higher alcohol, 1-3 parts of glycerin fatty acid ester, 3-5 parts of sodium hexametaphosphate, 1-2 parts of sodium secondary alkyl sulfonate, 4-10 parts of magnesium hydroxide, 5-11 parts of dimer linoleic acid, 5-7 parts of white carbon black, 4-8 parts of whitemineral oil, 8-14 parts of a surfactant, 20-30 parts of polyethylene wax, 10-12 parts of lecithin, 7-18 parts of a thickener, 4-14 parts of a co-emulsifier, 16-20 parts of distearoyl diethylamine and90-110 parts of deionized water. The defoaming agent of the invention has the beneficial effects of good dispersibility, strong affinity, strong foam inhibition capability, fast foam inhibition speed, lasting action time, capacity of realizing difficult generation of fine pinhole foams in the paint, strong high temperature resistance and stability and good compatibility with the paint and enablesthe surface of the paint to not prone to skinning and to have gloss, and a mixed solution of the defoaming agent with the paint has no layering phenomenon .

Owner:安徽銮威化工科技开发有限公司

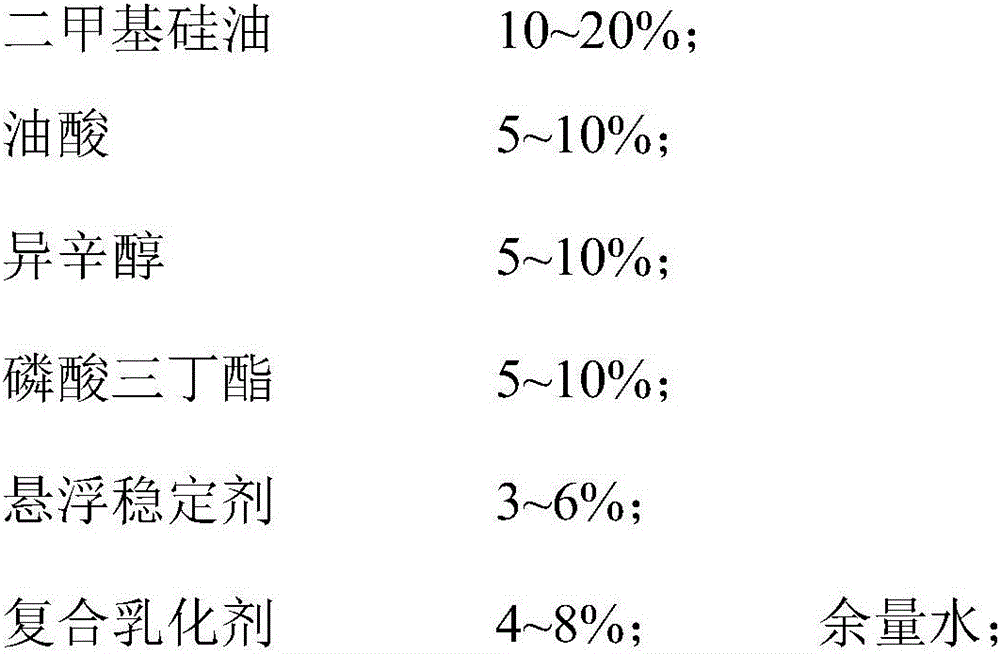

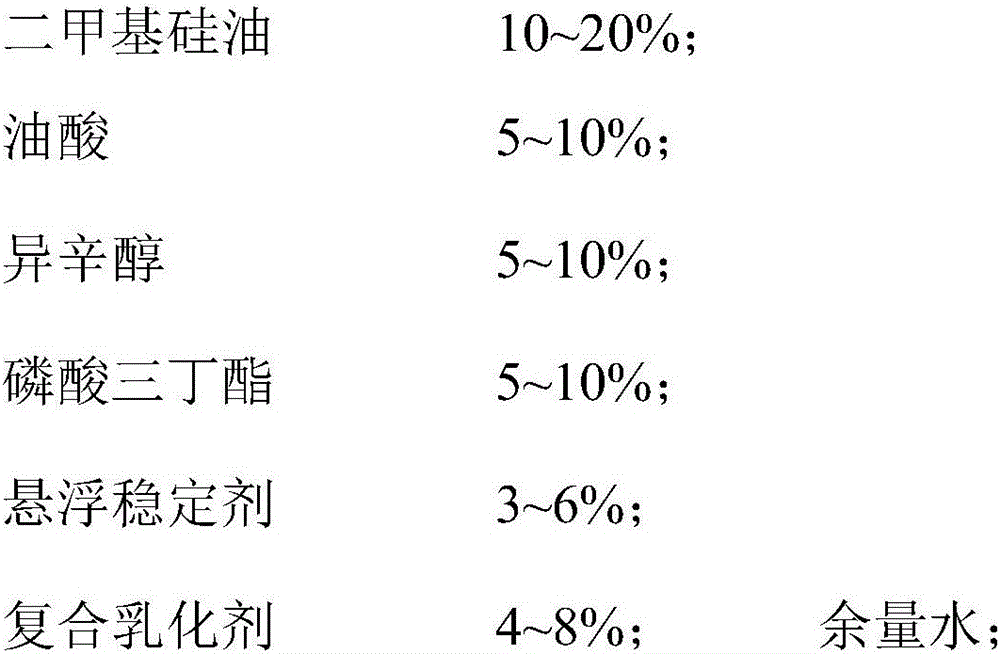

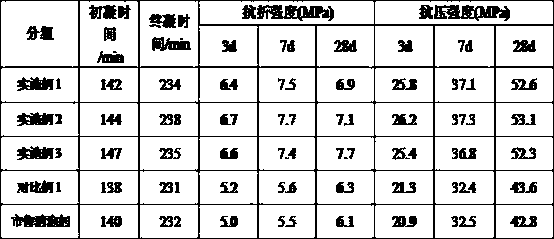

Latex cement defoaming agent and preparation method thereof

The invention discloses a latex cement defoaming agent and a preparation method thereof. The latex cement defoaming agent is prepared from the following components by mass percentage: 10-20% of dimethicone, 5-10% of oleic acid, 5-10% of isooctyl alcohol, 5-10% of tributyl phosphate, 3-6% of a suspension stabilizer, 4-8% of a composite emulsifier and the balance water. The composite emulsifier is a mixture of ester and ether, and after mixing, the theoretical HLB value of the emulsifier is 12.0-14.0. The preparation method of the latex cement defoaming agent consists of: firstly mixing the raw materials except the suspension stabilizer at 70-80DEG C, then adding the suspension stabilizer, further conducting constant temperature stirring for 10-60min, and performing discharging under stirring, thus obtaining the product. The latex cement defoaming agent does not undergo chemical reaction with other admixtures, can significantly increase the compressive strength of conventional density cement stones and low density cement stones, and also can increase the fluidity of cement slurry.

Owner:CNPC BOHAI DRILLING ENG

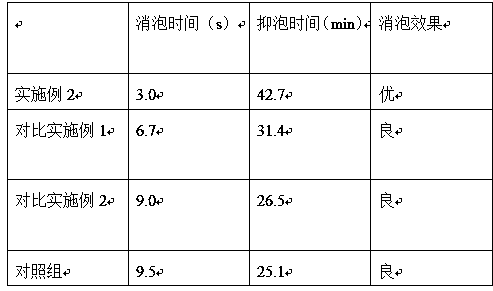

Defoaming agent suitable for polymer cement waterproof mortar and preparation method thereof

The invention relates to a defoaming agent suitable for polymer cement waterproof mortar and a preparation method thereof. The adaptability of the existing defoaming agent and the polymer cement-basedmortarareis poor in adaptabilityto the polymer cement-based mortar, so that thelikely to cause defects such as sinkhole, micro cracksof the mortar are easily causedsuch as sinkhole, micro cracks andthe like, andlikely to cause the decrease of mechanical performance and waterproof performance of the mortarare further easilycaused. The organic silicone defoaming agent is modified by virtue of acrylate monomers, so that the defoaming agent is better suitable for the alkaline condition of the polymer cement-based mortar, and the compatibility between the polymer cement-based mortar and the defoaming agent can be effectively optimized; and moreover, the defoaming agent is small in solubility and good in laying performance, high in foam inhibiting and foam eliminating performance, and capableof significantly improving the defoaming efficiency. Meanwhile, the defoaming agent is stable in performance, easy in storage and transportation and wide in application prospect.

Owner:广东南辉新材料有限公司

Preparation method of defoaming agent with good stability

InactiveCN109224536AEasy to prepareImprove the quality of useWater/sewage treatment by degassingFoam dispersion/preventionDefoaming AgentsRaw material

Owner:宣城市聚源精细化工有限公司

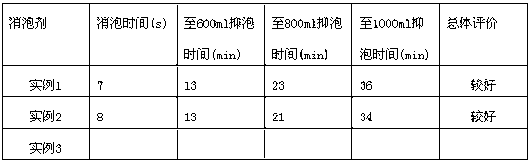

Novel defoaming agent with strong foam-inhibiting capacity

InactiveCN107200503AGood anti-foam performanceEasy to useDrilling compositionSodium BentonitePhosphate

The invention discloses a novel defoaming agent with strong foam-inhibiting capacity. The novel defoaming agent is prepared from the following ingredients in parts by weight: 11 to 18 parts of mineral oil, 16 to 21 parts of methyl cyclohexane, 4 to 9 parts of white carbon black, 7 to 16 parts of tributyl phosphate, 11 to 19 parts of compound emulsifier, 13 to 21 parts of organic bentonite, 13 to 23 parts of glycerol triacetate, 23 to 31 parts of water and 3 to 9 parts of tri-isobutyl phosphate.

Owner:四川宏升石油技术开发有限责任公司

Self-emulsifying molecular antifoaming agent and preparation method thereof

InactiveCN102160939BStrong anti-foaming abilityReduce surface tensionFoam dispersion/preventionPolymer scienceFatty alcohol

The invention discloses a self-emulsifying molecular antifoaming agent and a preparation method thereof. The antifoaming agent comprises the following components in percent by mass: 20 to 60 percent of antifoaming active substance and 40 to 80 percent of dispersion medium, wherein the antifoaming active substance consists of higher fatty alcohol, alkynol, polyether and silicone oil in a mass ratio of 1:(0.8-1.5):(2-3):(2-4); and the dispersion medium is grafted star polymer. The preparation method comprises the following steps of: adding 50 to 150 parts of trichloromethane and 1 to 2 parts ofp-methyl benzene sulfonic chloride into 20 to 60 mass parts of active substance and 40 to 80 mass parts of star polymer, raising the temperature to between 40 and 70 DEG C, and reacting for 3 to 6 hours; and after the reaction is finished, washing sodium carbonate until the ph is 7, drying by using anhydrous sodium sulfate, and evaporating the solvent under reduced pressure to obtain the antifoaming agent. The extended arm of the star polymer in the antifoaming agent is grafted with the active substance, so that various components are synergistic, and the obtained antifoaming agent is high instability, low in surface tension, high in surface activity, high in antifoaming capacity, long in foam inhibition time and small in dosage.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

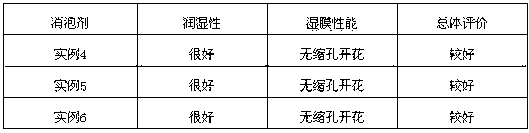

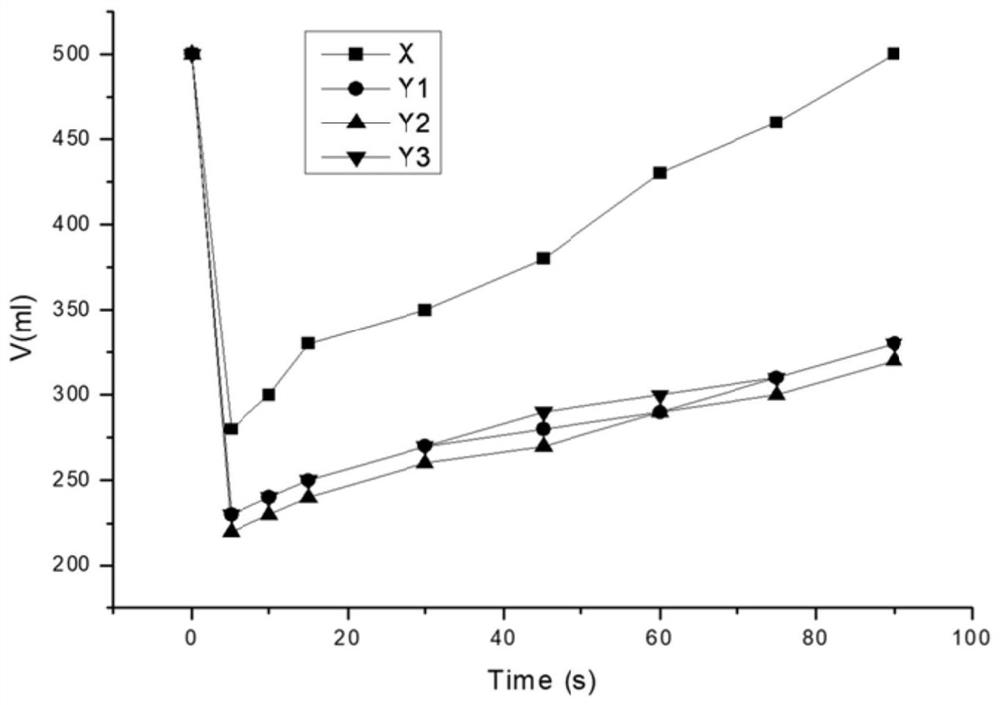

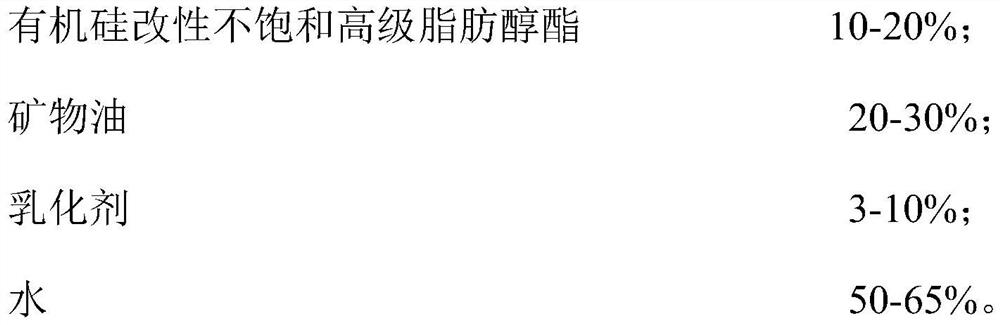

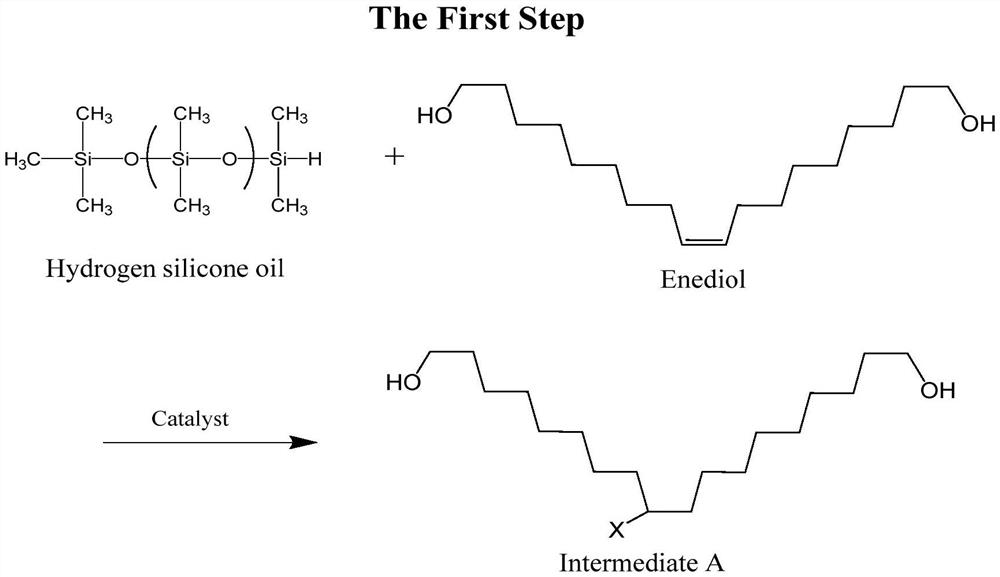

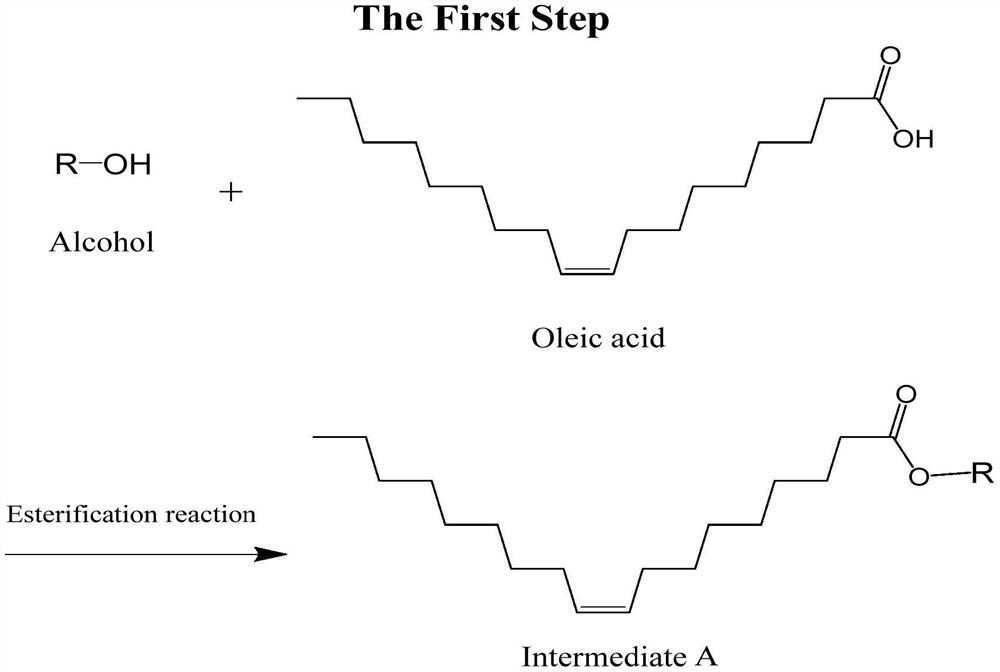

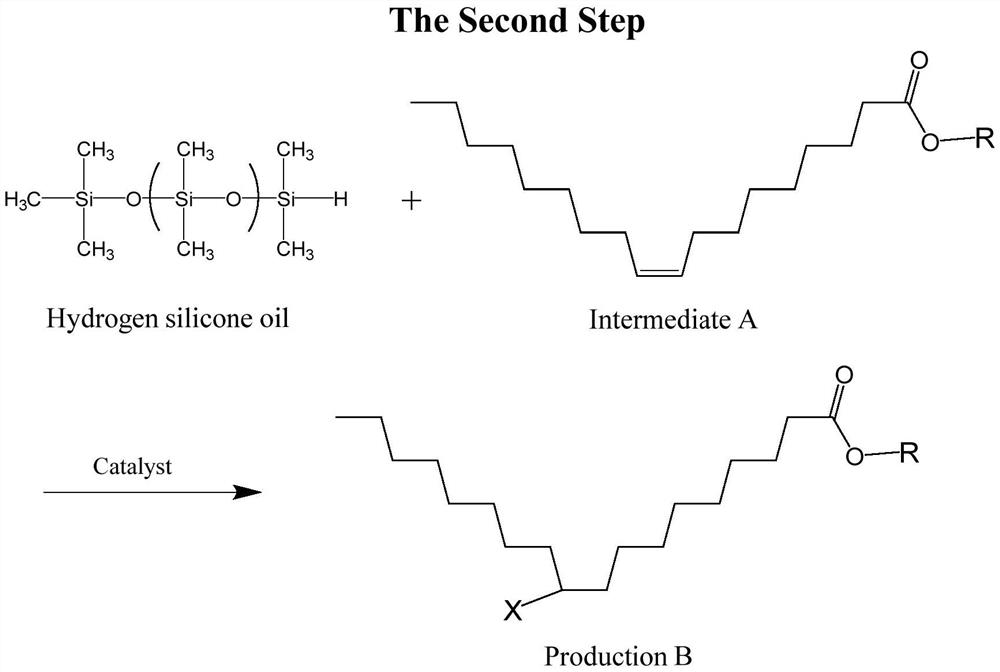

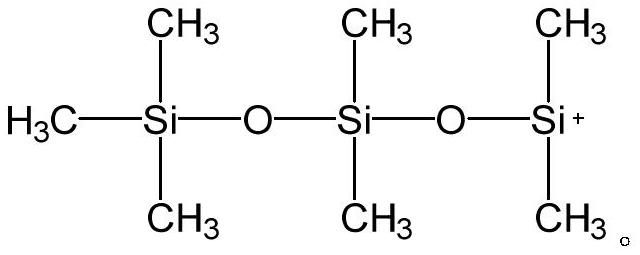

Organic silicon modified unsaturated higher aliphatic alcohol ester defoamer and preparation method thereof

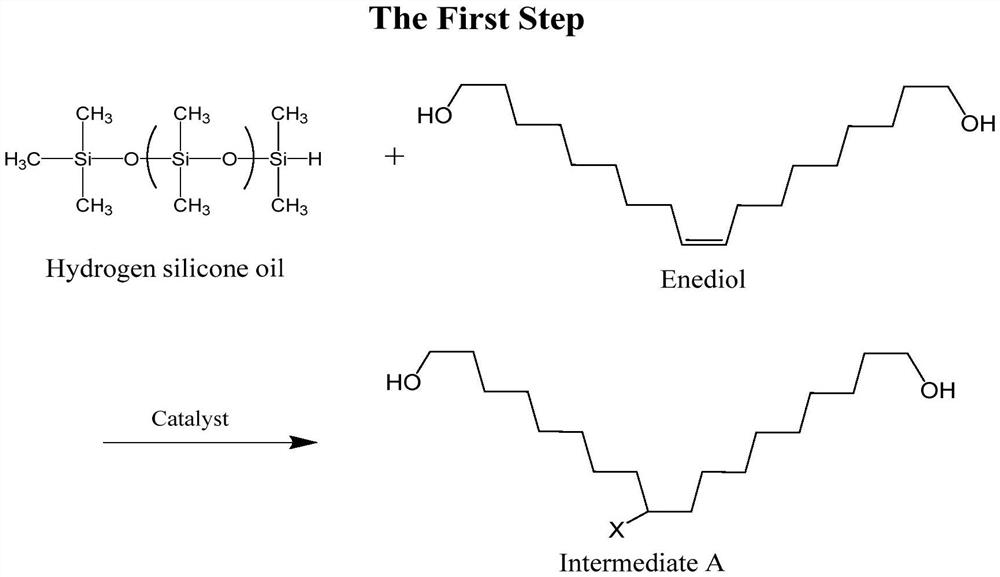

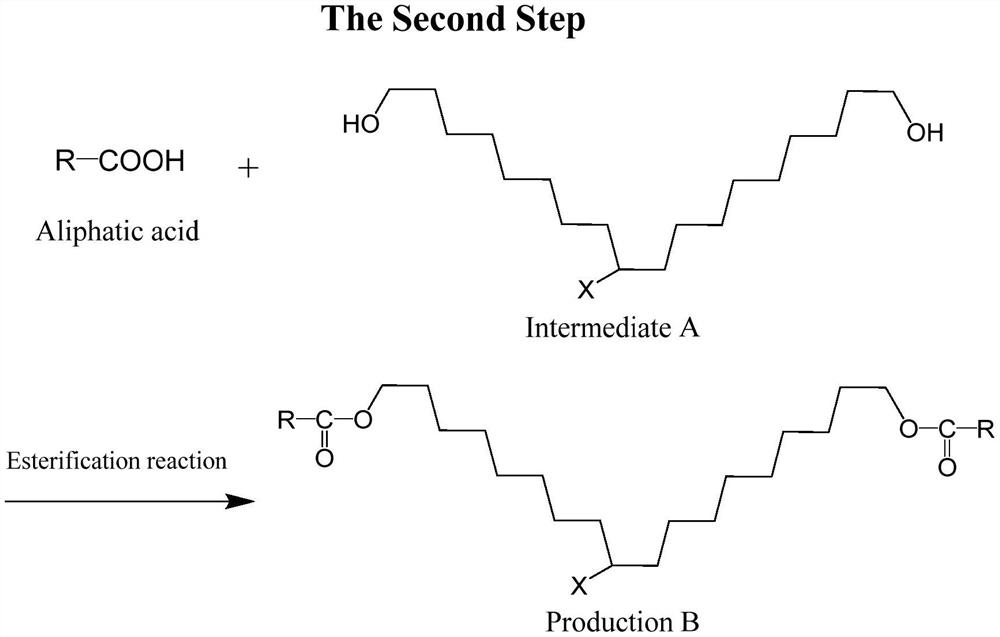

ActiveCN112604325ALow melting pointEmulsified high carbon alcoholFoam dispersion/preventionSaturated fatty acid esterPtru catalyst

The invention discloses an organic silicon modified unsaturated higher aliphatic alcohol ester defoamer and a preparation method thereof. The technical scheme adopted by the invention is as follows: the preparation method comprises the following steps: firstly, carrying out addition reaction on hydrogen-containing silicone oil and unsaturated higher aliphatic alcohol in an N2-protected catalyst system to obtain an intermediate, esterifying the intermediate and saturated fatty acid to obtain organic silicon modified unsaturated higher aliphatic alcohol ester, and finally, emulsifying the organic silicon modified unsaturated higher aliphatic alcohol ester, mineral oil and an emulsifier to prepare the organic silicon modified unsaturated higher aliphatic alcohol ester defoamer. The defoamer prepared by the invention not only improves the emulsion stability of the defoamer, but also is applied to papermaking wet cloth to enhance the water filtering performance of a paper machine, has very small negative influence on the surface mechanical properties of papermaking pulp and paper, and has the characteristics of high defoaming speed, strong foam inhibition capability, good degassing performance, no toxicity, no harm, simple preparation process and the like.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

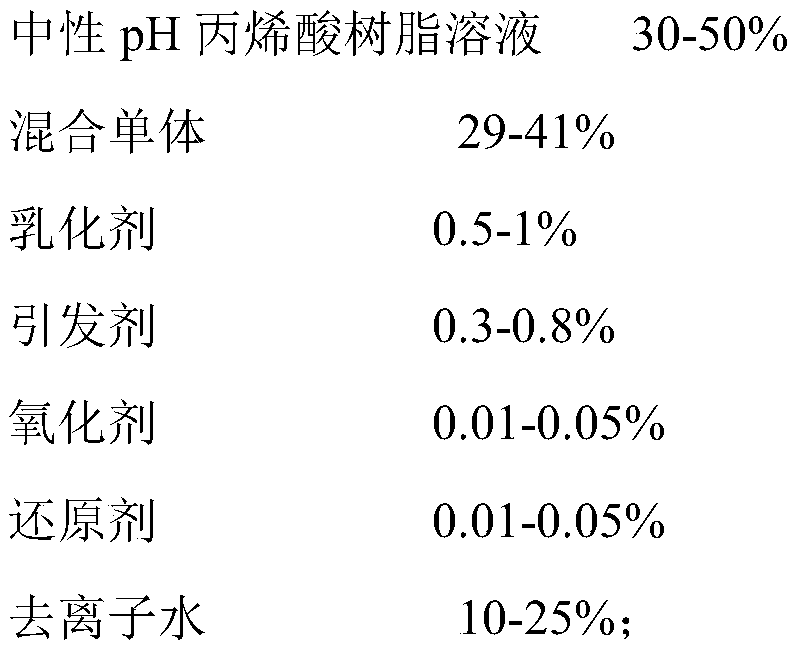

Low-viscosity high-efficiency emulsion type defoaming agent for offshore oilfield and preparation method thereof

ActiveCN112892003AGood spreading and spreadingGood defoaming effectFoam dispersion/preventionEtherPentaerithrityl

The invention discloses a low-viscosity high-efficiency emulsion type defoaming agent for an offshore oilfield and a preparation method thereof. Long-chain alkyl polydimethylsiloxane with a mixed structure, high-molecular-weight polydimethylsiloxane alcohol and polyether alkyl modified silicone oil are used as raw materials, a hydrophilic gas-phase white carbon black reinforcing agent react to prepare active silicon paste A; mixed polyether silicone oil B, propylene glycol polyether C and active silicon paste A with specific structures are mixed and react under the catalysis of reusable solid complex platinum to prepare a main agent of the defoaming agent, and a low-viscosity and high-efficiency emulsion type defoaming agent product is prepared by taking isomeric alcohol ether as a co-emulsifier, deionized water as a dispersing agent and pentaerythritol allyl ether polymer as a stabilizer. The product is low in viscosity and good in stability, has a better foam breaking effect on crude oil foams of offshore oilfields, and better meets the application requirements of offshore platforms.

Owner:中海油(天津)油田化工有限公司 +1

Emulsion-type antifoaming agent used for rubber and plastic

The invention discloses an emulsion-type antifoaming agent used for rubber and plastic, which belongs to the chemical preparation field. The emulsion-type antifoaming agent used for rubber and plastic comprises the following components by weight part: 13-20 parts of alkylol amine, 40-50 parts of alkymer, 25-30 parts of aliphatic acid, 5-10 parts of assisted antifoaming agent, 4-10 parts of dispersant and a proper amount of water. The emulsion-type antifoaming agent is capable of eliminating foams, and has the advantages of simple preparation, easy operation, fast defoaming speed and strong foam inhibition capability, the emulsion-type antifoaming agent has no adverse influence on rubber and plastic polymers, no by-product, waste water, exhaust gas and solid waste materials can be generated during a reaction process, and no pollution is generated on environment.

Owner:QINGDAO HAOTAI WATER

High-efficient water reducing agent

The invention provides a high-efficiency water reducer, which relates to the technical field of concrete admixtures in building materials, including polyethylene glycol monomethyl ether, malein rosin, phthalic anhydride, sodium p-styrenesulfonate, concentrated sulfuric acid, and sodium hydroxide solution , vitamin c, vitamin e, vitamin b, azobisisoheptanonitrile, dimethyl azobisisobutyrate, ammonium persulfate, foaming agent, defoaming agent, ultrapure water. The present invention takes polyethylene glycol monomethyl ether and maleic rosin as main raw materials, vitamin C and vitamin E as reducing agents; azobisisoheptanonitrile, dimethyl azobisisobutyrate and ammonium persulfate as Initiator, adding modified silicone defoamer, the high-efficiency water reducer made of good stability, used in concrete, can increase its workability, and this water reducer can be mixed with other water reducers to make The process is simple, the cost is low, and the practicability is high.

Owner:合肥华福土工合成材料有限公司

A kind of exterior wall fluorocarbon paint and preparation method thereof

ActiveCN104987785BHigh film forming efficiencyHigh mechanical strengthCoatingsButyl acetateCellulose acetate

The invention discloses a fluorocarbon paint for exterior walls, which comprises the following components by weight fraction: 35-45 parts of water-based fluorocarbon resin; 1-2 parts of film-forming aid; 1-1.5 parts of diethylenediamine; thickener 0.5-1 part; pH adjuster 0.1-0.3 part; dispersant 0.5-1 part; titanium dioxide 10-16 part; cellulose acetate paddle 5-10 part; butyl acetate 3-5 part; preservative 0.5-1 part ; 3‑4 parts of defoamer; 20‑30 parts of pure water. The fluorocarbon paint for exterior walls of the invention has the advantage of strong crack resistance.

Owner:CHONGQING PINSHENG PAINT

Oily defoamer

The invention relates to an oily defoamer capable of being used as a black liquor defoamer. The oily defoamer is prepared from the following compositions: kerosene, paraffin, octyl and sulfonated castor oil of which the weight ratio is 100-240:70-150:50-130:80-120. The oily defoamer has weak foam inhibiting capacity but strong defoaming capacity, can be combined with other defoamers for use to reduce cost, and has wide application.

Owner:尹玉娟

Antifoaming agent

InactiveCN105289049AFast defoaming speedStrong anti-foaming abilityFoam dispersion/preventionSolubilityCarboxymethyl cellulose

The invention discloses an antifoaming agent. The antifoaming agent is prepared from low-hydrogen silicone oil, amino silicon oil, 1.5% concentrated sulfuric acid, octamethylcyclotetrasiloxane, trifluoropropionic acid, polyether silicone oil, carboxymethyl cellulose sodium, and sorbitol. According to a preparation method, low-hydrogen silicone oil is subjected to chemical modification so as to obtain the antifoaming agent, defoaming speed of the antifoaming agent is increased greatly, foam inhibition performance is improved, using amount is one third less than that of common antifoaming agents, and the antifoaming agent possesses excellent water solubility.

Owner:宣城市聚源精细化工有限公司

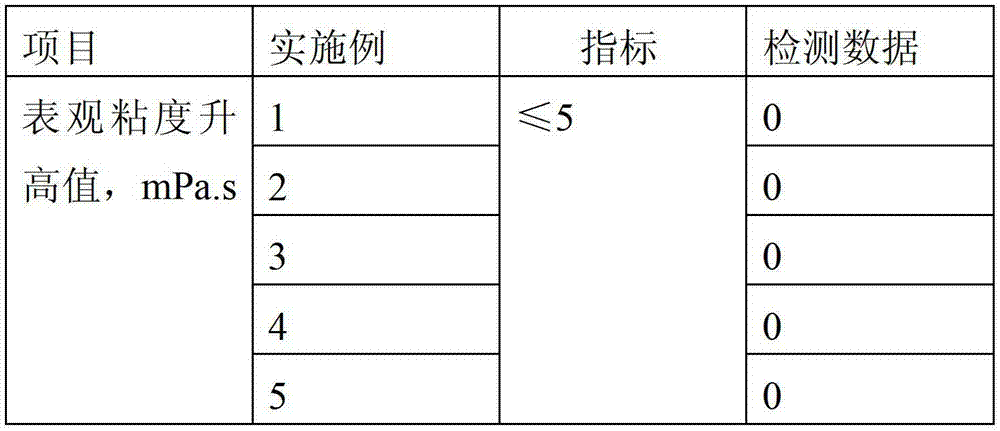

A kind of oleate modified silicone defoamer for coating and preparation method thereof

ActiveCN111888803BLow melting pointWide storage temperatureFoam dispersion/preventionPtru catalystOleic Acid Triglyceride

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Lubricating defoamer for drilling fluid and preparation method thereof

ActiveCN103160258BEasily brokenImprove the lubrication effectDrilling compositionEngineeringBase oil

The invention provides a lubricating defoamer for a drilling fluid and a preparation method thereof. The lubricating defoamer for the drilling fluid is prepared from the following raw materials by weight percent: 30-43% of fatty acid, 15-25% of organic amine, 30-40% of base oil, 2-6% of penetrating agent and 10-15% of defoamer. Compared with the prior art, the lubricating defoamer for the drilling fluid is capable of functioning as the lubricant and the defoamer at the same time; the field operation steps are simple and the production cost is reduced.

Owner:成都西油华巍科技有限公司

A kind of anti-oxidation emulsion and the anti-oxidation water-based coating varnish prepared by using it

ActiveCN107033288BImprove defoaming abilityStrong anti-foaming abilityPaper coatingCorrosion-inhibiting/anti-oxidant agent additionWater basedCardboard

The invention relates to the technical field of coating varnish, in particular to anti-oxidation emulsion and anti-oxidation waterborne coating varnish prepared from the same. The anti-oxidation emulsion is prepared from raw materials in percentage by weight as follows: 30%-50% of an acrylic resin solution with neutral pH, 29%-41% of mixed monomers, 0.5%-1% of an emulsifier, 0.3%-0.8% of an initiator, 0.01%-0.05% of an oxidizing agent, 0.01%-0.05% of a reducing agent and 10%-25% of deionized water, and the sum of the raw materials in percentage by mass is 100%. According to the anti-oxidation emulsion, possibly existing acid-base substances can be reduced, the probability of oxidation is reduced, and hot stamping foil is not prone to oxidation; the anti-oxidation waterborne coating varnish prepared from the anti-oxidation emulsion contains no organic solvents, is low in content of VOCs (volatile organic chemicals) or free of VOCs, is environment-friendly, non-toxic and anti-oxidation, and is suitable for surface lustering of substrates, prone to hot stamping oxidation, of black cardboards, blackened paper, coated black paper and the like.

Owner:GUANGDONG YINGKE GRP CO LTD

Defoaming agent and preparation method thereof

InactiveCN110694305AExcellent defoaming and anti-foaming propertiesFast defoaming speedFoam dispersion/preventionAlcoholEther

The invention discloses a defoaming agent and a preparation method thereof. The defoaming agent comprises water-soluble silicone oil, silicone grease, Span-80, Tween-80, tetradecyl alcohol ether MOA-4, an anti-static agent SE-10, water, stearic acid, propylene glycol, 201-500 CS silicone oil and 201-1000 CS silicone oil. The preparation method comprises following steps: preparing an organic silicon mixture from water-soluble silicone oil, 201-500 CS silicone oil and 201-1000 CS silicone oil; preparing an emulsifier mixture from silicone grease, span-80, Tween-80, tetradecyl alcohol ether MOA-4and antistatic agent SE-10, wherein adding 6.5 kg of water into a heating kettle, adding 1.1 kg of stearic acid, heating, and stirring for later use; preparing 100kg of the organic silicon mixture from water-soluble silicone oil, 201-500CS silicone oil and 201-1000CS silicone oil; adding the emulsifier mixture composed of 2 kg of silicone grease, 4.2 kg of Span S-80, 2 kg of Tween T-80, 1.3 kg oftetradecyl alcohol ether MOA-4 and 1.5kg of the antistatic agent SE-10 into an emulsifying machine to be uniformly stirred; adding the solution obtained in the step (1), stirring, and emulsifying; adding 120ml of propylene glycol; introducing cooling water into an interlayer of the emulsifying machine, and cooling to normal temperature to obtain a finished product.

Owner:青岛中宝硅材料科技有限公司

A kind of organosilicon modified unsaturated higher fatty alcohol ester defoamer and preparation method thereof

ActiveCN112604325BLow melting pointEmulsified high carbon alcoholFoam dispersion/preventionSaturated fatty acid esterPolymer science

The invention discloses a silicone-modified unsaturated higher fatty alcohol ester defoamer and a preparation method thereof. The technical scheme adopted in the present invention is: first, in N 2 In the protected catalyst system, hydrogen-containing silicone oil and unsaturated higher aliphatic alcohol are added to obtain an intermediate, and then the intermediate and saturated fatty acid are esterified to obtain a silicone-modified unsaturated higher aliphatic alcohol ester. Emulsifying unsaturated higher fatty alcohol ester with mineral oil and emulsifier to prepare silicone modified unsaturated higher fatty alcohol ester defoamer. The defoamer prepared by the invention not only improves the emulsion stability of the defoamer itself, but also can be applied to papermaking wet cloth to enhance the water drainage performance of the paper machine, and has little negative impact on the mechanical properties of papermaking pulp and paper surface. It has the characteristics of fast defoaming speed, strong antifoaming ability, good degassing performance, non-toxic and harmless, and simple preparation process.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com