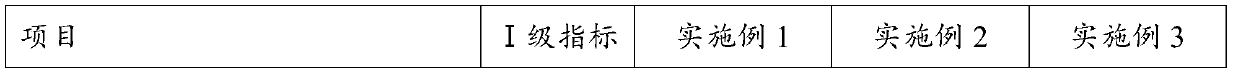

Patents

Literature

205results about How to "High film forming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal mine down-hole foam dedusting system

InactiveCN101251025AEvenly dispersedWill not cause accumulationMixing methodsDust removalFoaming agentCoal

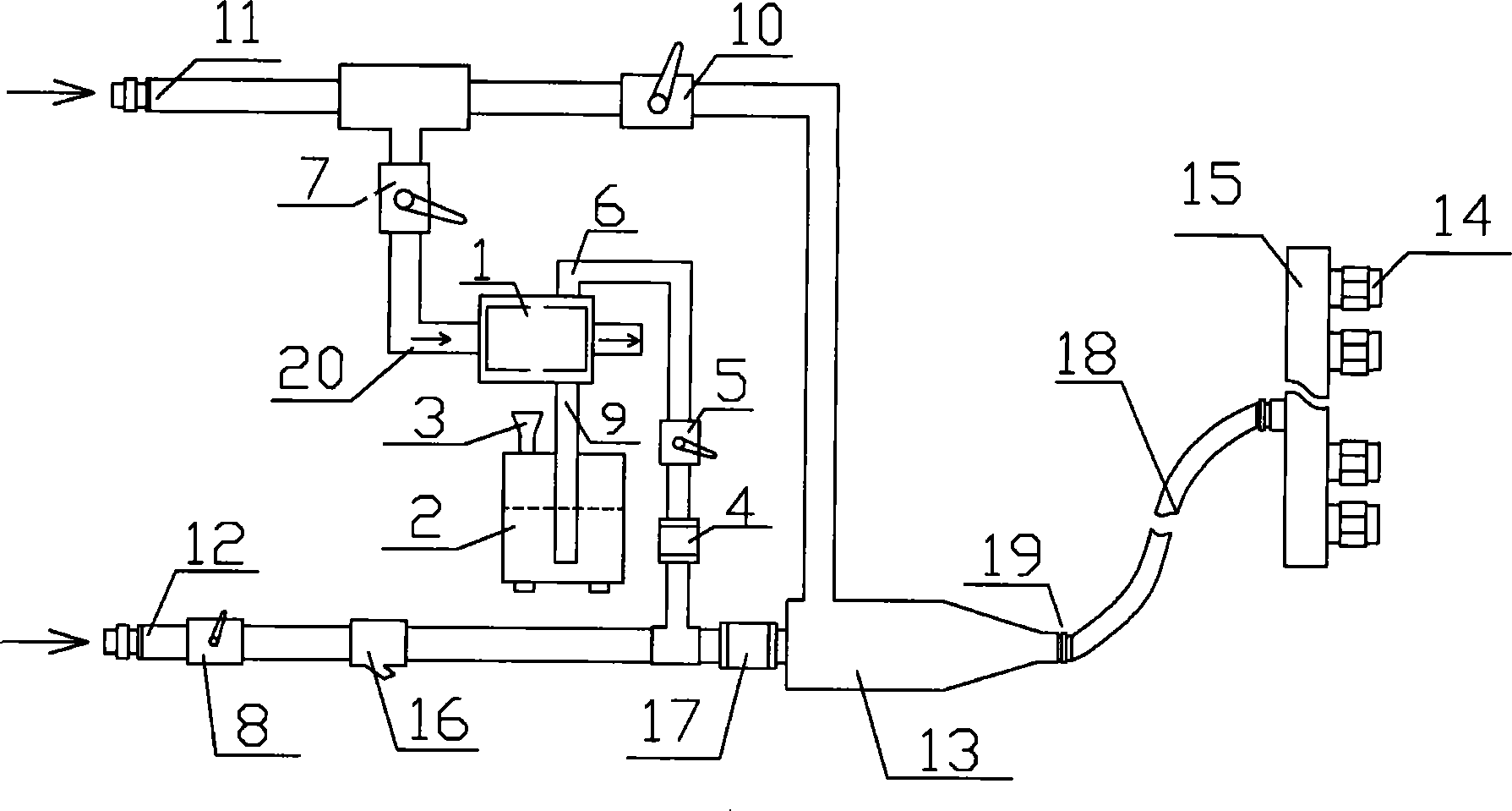

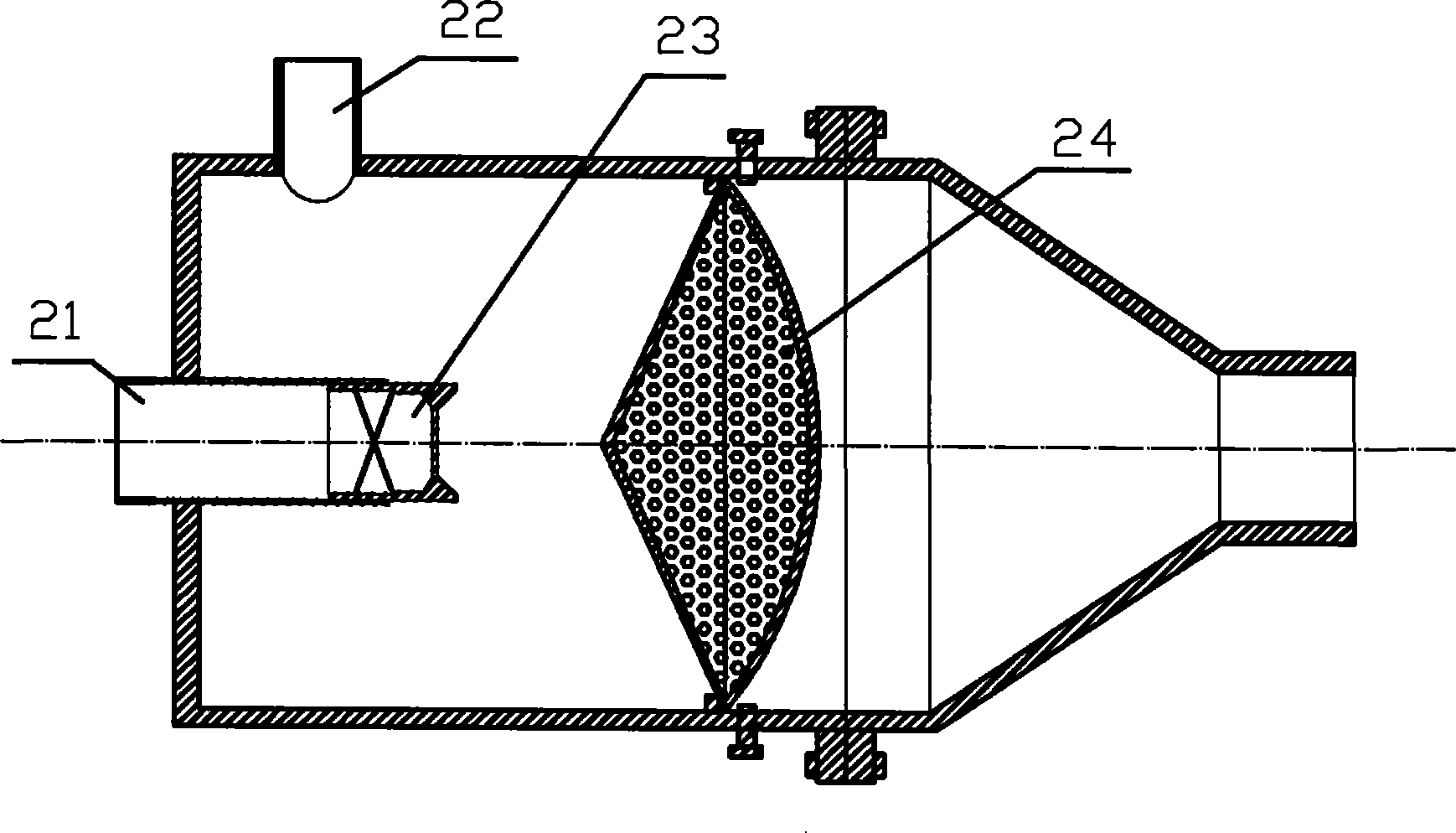

The invention relates to a foam dust removal system used for coal mine underground mining, mainly comprising a fixed quantity addition pump, a foaming agent reservoir, a compressed air pipeline, a clean water pipeline, a foam generator, a foam spray head and so on. By utilization of the prior water pipe in a dust removal place, foaming agents are added into the water pipe by the small-flow fixed quantity addition pump; mixed liquid and compressed air which contain the foaming agents pass through the foam generator simultaneously, and a great amount of foams are generated, conveyed to the foam spray head through a hose, ejected from the foam spray head in the form of an umbrella and cover dust producing points. The invention is particularly suitable for the coal mine underground mining work surface, traveling belt transfer points, a tunnel excavated section or other dust producing points with small space and effectively controls the dust producing sources. The foam dust removal system used has the advantages of simple structure, convenient operation, capability of operating continuously, high dust removal efficiency, no electric elements and safety and reliability.

Owner:CHINA UNIV OF MINING & TECH

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

Chromium-free treating liquid for preparing erosion-resisting oxide film on aluminum alloy surface, treating and using method thereof

ActiveCN101054664AImprove corrosion resistanceGolden colorMetallic material coating processesSodium acetateChromium free

The present invention discloses a chromium-free treatment liquid for preparing corrosion resistant oxidation film at aluminium alloy surface as well as the processing and use method thereof, characterized in that said treatment fluid utilizes a cobalt (III) salt as a main salt and a hypermanganate and a nitrate as a composite oxidizing compound to prepare a composite Co-Mn oxidation film having favorable corrosion resistance performances at aluminium alloy surface. The formula for said treatment liquid is that each litre solution contains cobalt salt of 5 g / L(-1)-20 g / L(-1), kalii permangana of 1 g / L(-1)-4 g / L(-1), sodium nitrate of 1 g / L(-1)-4 g / L(-1), promotor (chlorides and fluorides) of 1 g / L(-1)-4 g / L(-1), sodium acetate of 20 g / L(-1)-50 g / L(-1) and wetting agents (sodium dodecylbenzene sulfonate, OP-10) of 0.5 g / L(-1)-1 g / L(-1). Saic processing and use method comprises (1)sanding the aluminium alloy until its surface is smooth and even; (2) pretreating the aluminium alloy surface; (3) performing a conversion processing by using the treatment fluid; (4) cleaning-up using water and atmospheric-drying naturally. Said treatment fluid in accordance with the present invention possesses the advantages of environmental protection due to its hexavalent chromium-free, fast film-forming speed, simple process, uniform rete, strong corrosion resistance, few environment pollution, and the like.

Owner:GUANGYA ALUMINUM

Environmentally-friendly black chrome-silver-free zinc-plating passivation solution and preparation method thereof

InactiveCN101876071AReduce formulation costsHigh film forming efficiencyMetallic material coating processesSodium silicateCopper salt

The invention provides black passivation solution for zinc-plating post treatment. 1 liter of black passivation solution consists of 10 to 20g of sodium silicate, 20 to 30g of copper sulfate, 0.5 to 1.5g of nickel sulfate, 0.5 to 1.5g of ferrous sulfate, 1 to 3g of sodium acetate, 20 to 40mL of glacial acetic acid, 3 to 7mL of sulfuric acid (98 percent) and the balance of water. A zinc-plating material processed by the passivation solution has a uniform, bright and black appearance and high corrosion resistance, is free of rust for over 200h through a neutral salt spray test and can achieve the same effect as that achieved by the conventional black chrome-silver-contained passivation process in appearance and performance. The passivation solution has the advantages of thoroughly solving the problem of environment pollution caused by a chromium salt used by the conventional black zinc-plating passivation process, eliminating the use of a silver salt at the same time and greatly reducing the cost thereof by substituting silicate for the chromium salt as a main film-forming material and a copper salt, a nickel salt and a ferric salt for the silver salt as a blackening agent, along with stability and reliability and high film-forming efficiency.

Owner:KUNMING UNIV OF SCI & TECH

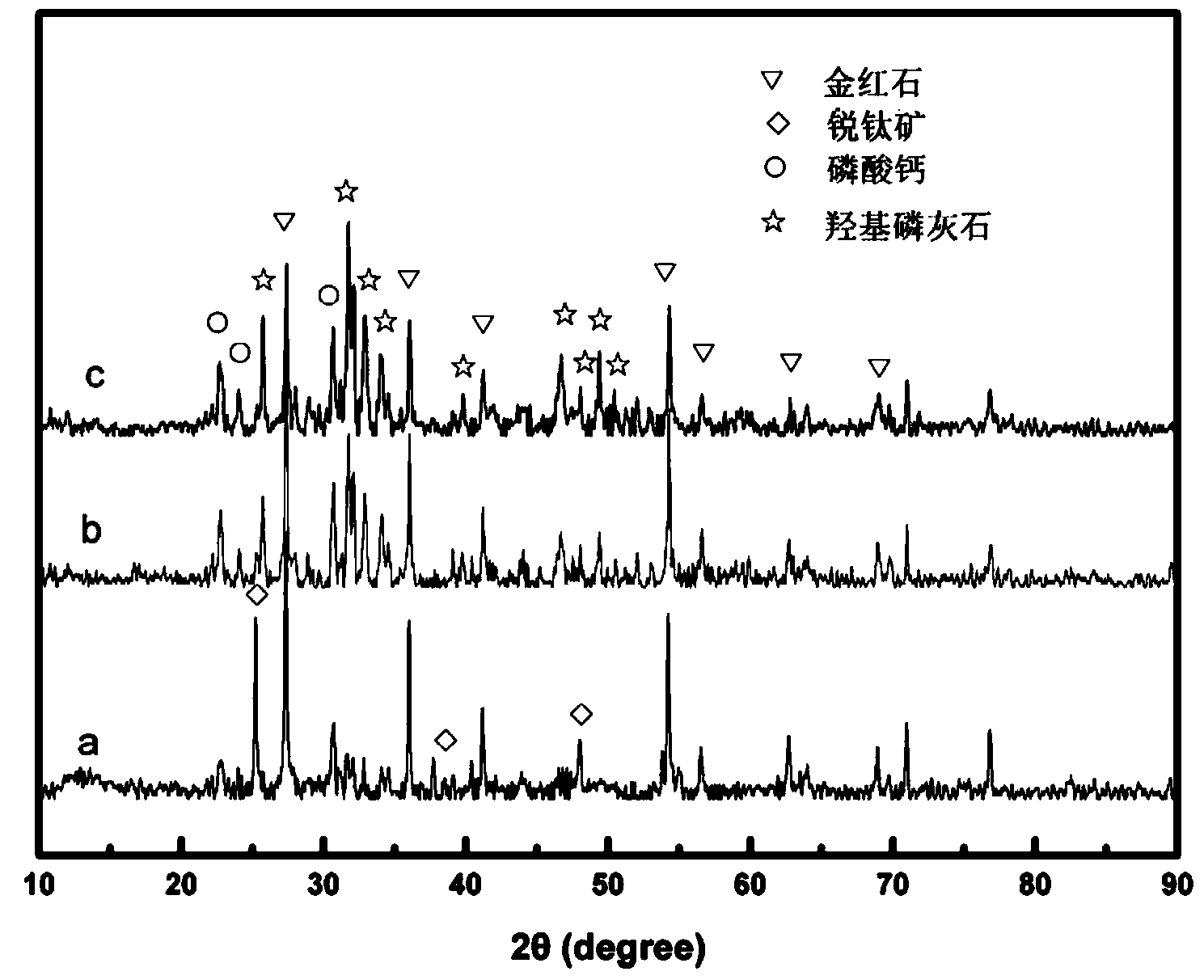

Preparation method for directly generating hydroxyapatite-containing biological ceramic membrane on surface of titanium

InactiveCN103451706AIncrease profitReduce solubilitySurface reaction electrolytic coatingSolubilityMicro arc oxidation

The invention discloses a preparation method for directly generating a hydroxyapatite-containing biological ceramic membrane on the surface of titanium, and aims to solve the practical problems that the prior art is complex in process, time-consuming, low in electrolyte utilization ratio, poor in membrane forming efficiency and the like. The preparation method adopts a basic method of micro-arc oxidation, and is characterized in that during the preparation of electrolyte, low-solubility calcium dihydrogen phosphate is used for providing phosphate anions and citric acid is used as a complexing agent. Compared with the prior art, although the solubility of the calcium dihydrogen phosphate used in the preparation method is low, the solubility of the calcium dihydrogen phosphate is improved after the calcium dihydrogen phosphate is complexed with the citric acid, calcium ions and phosphate anions are provided at the same time, the utilization ratio of the electrolyte is high, the reaction speed is high, the membrane forming efficiency is high, the preparation method is simple and easy to operate and low in cost, the hydroxyapatite-containing biological ceramic membrane prepared by the preparation method is stable in structure, uniform in distribution and high in effective matter content, and has a wide prospect in the fields of hard tissue implants, tooth planting and the like.

Owner:JILIN UNIV

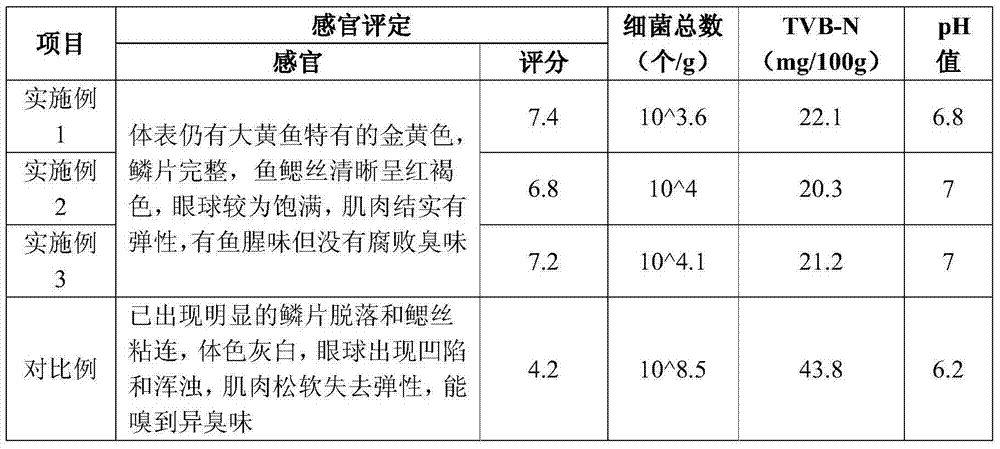

Coating preservation method of pseudosciaena crocea

ActiveCN104322650AGuaranteed food qualityGuaranteed sensory qualityMeat/fish preservation by coatingCold airComposite film

The invention dislcoses a coating preservation method of pseudosciaena crocea. The method includes following steps: (1) pre-treatment; (2) a soaking process; (3) a film-forming process; and (4) a packaging and refrigerating process. In the method, a sodium bicarbonate solution with a mass percentage concentration being 0.5-1% is employed for washing the pseudosciaena crocea, a composite film-forming preservative agent is developed on the basis of biochemical characteristics of the pseudosciaena crocea and an air-drying film-forming operation is carried out through cold air. The coating preservation method in operation process, is less in equipment investment, is environmentally-protective and safe, is suitable for industrialized production and can greatly prolong a preserving time of the pseudosciaena crocea on the premise of ensuring an edible quality and a sensory quality of the pseudosciaena crocea. The method is significant in preserving effect and is high in film-forming efficiency.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

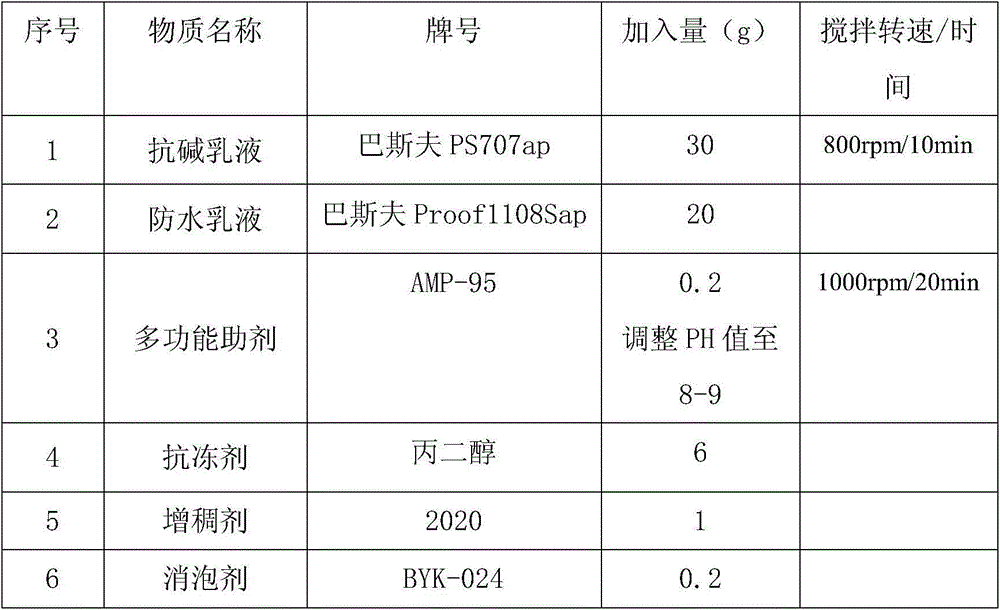

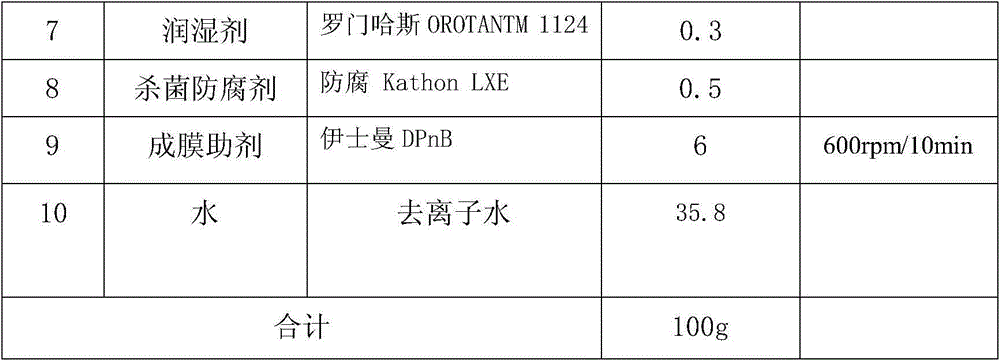

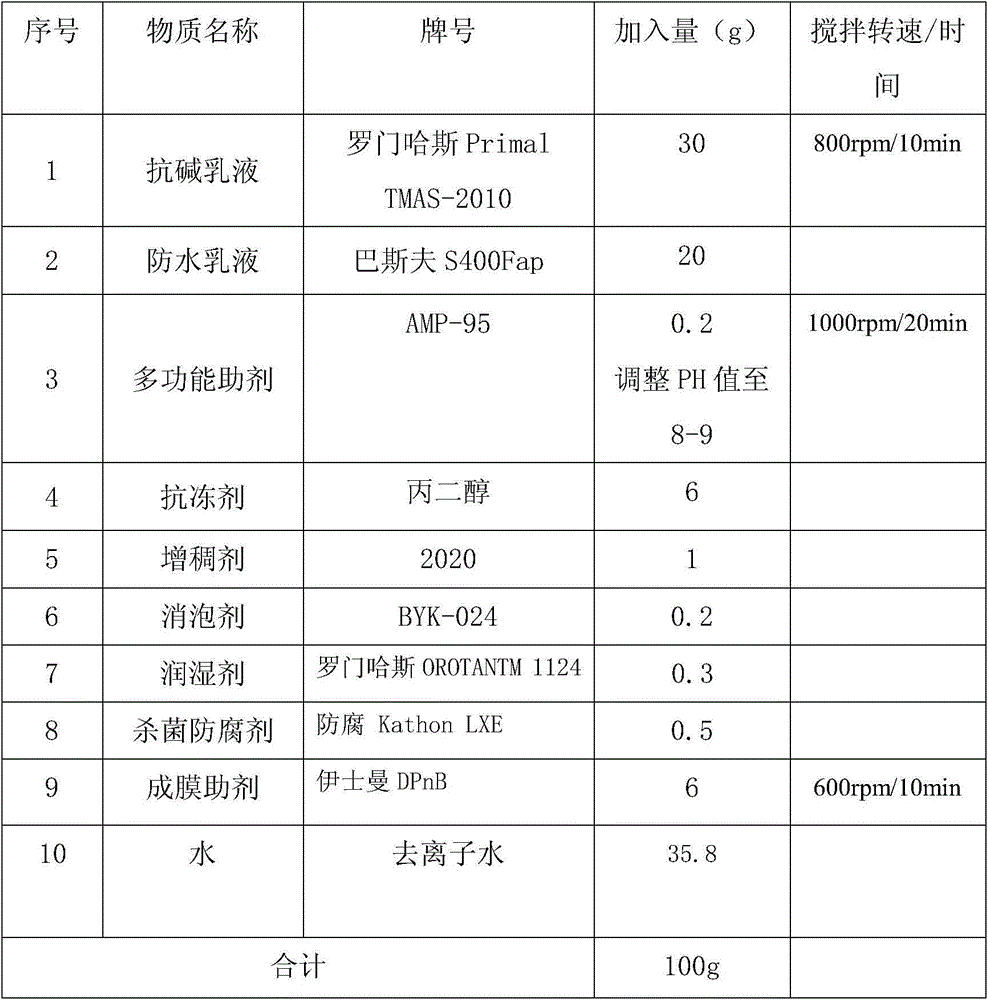

Waterproof alkali-resistant seal primer for external walls

A waterproof alkali-resistant seal primer for external walls comprises raw materials in percentage by mass as follows: 20-30% of an emulsion for an alkali-resistant primer and 20-30% of an emulsion for waterproof paint. The seal primer is high in finished product solid content, safe and environment-friendly; the seal primer has excellent waterproof, water-permeable, alkali-resistant seal performance and the large adhesive force, and compared with a product of the same quality, the seal primer has the larger construction area and the higher film forming efficiency. Experiments prove that the solid content of the waterproof alkali-resistant seal primer for the external walls is up to 25.2%, the water resistance is up to 168 h without abnormalities, the water permeability is up to 0.1 mL, the adhesive force is Grade 0, and the salting-out resistance is up to 120 h without abnormalities.

Owner:JIANGSU WONIUSHAN THERMAL INSULATION & WATERPROOF TEHNOLOGY

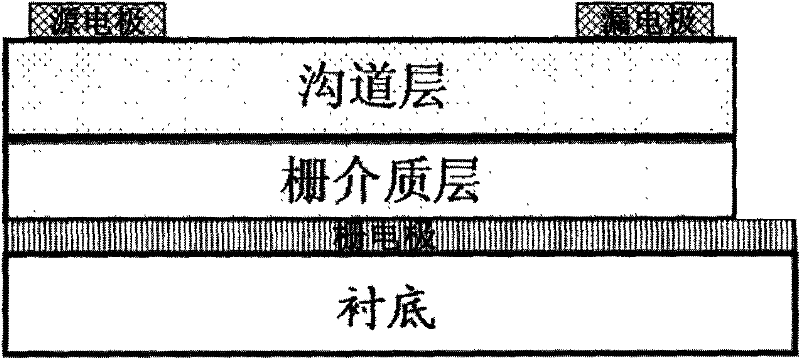

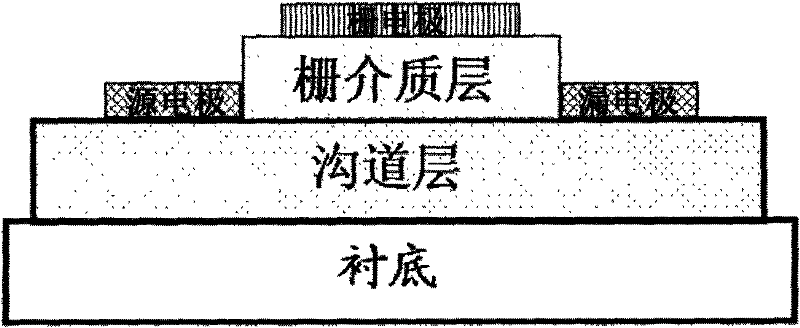

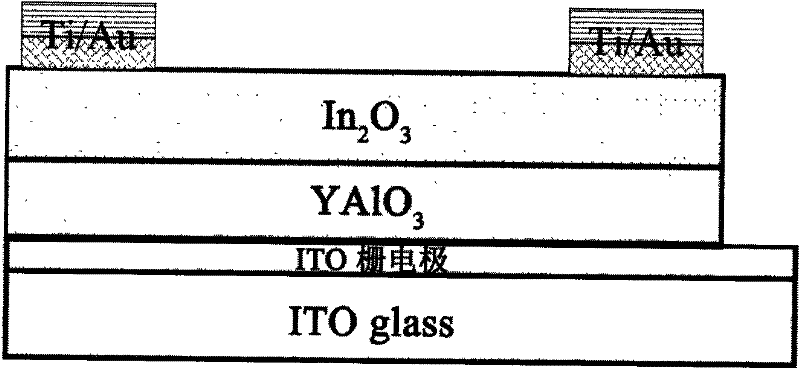

Preparation method of yttrium aluminum oxygen composite oxide high K medium thin film transistor

InactiveCN102683208AEasy to operateThe experimental process is precise and controllableSemiconductor/solid-state device manufacturingGate dielectricSource material

The invention discloses a preparation method of a YAIO3 composite oxide high K medium thin film transistor, which comprises the following steps of: taking a metal yttrium target (Y) and an aluminum target (A1) as source materials, preparing a gate dielectric layer material of a YAIO3 composite oxide high K medium as the thin film transistor by adopting a magnetron sputtering and rapid annealing technology, taking ITO (Indium Tin Oxide) glass as a substrate and taking source and drain electrodes as Ti / Au double-layered metal film electrodes; and the prepared thin film transistor can adopt a top gate structure or a bottom gate structure. The preparation method is simple and controllable, the low-temperature preparation can be realized, and the manufacturing cost is lower; and the prepared thin film transistor is excellent in performance, has smaller leakage current and larger capacitor, can be developed into a full-transparent thin film transistor and has very wide application prospect in the technical field of display devices.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

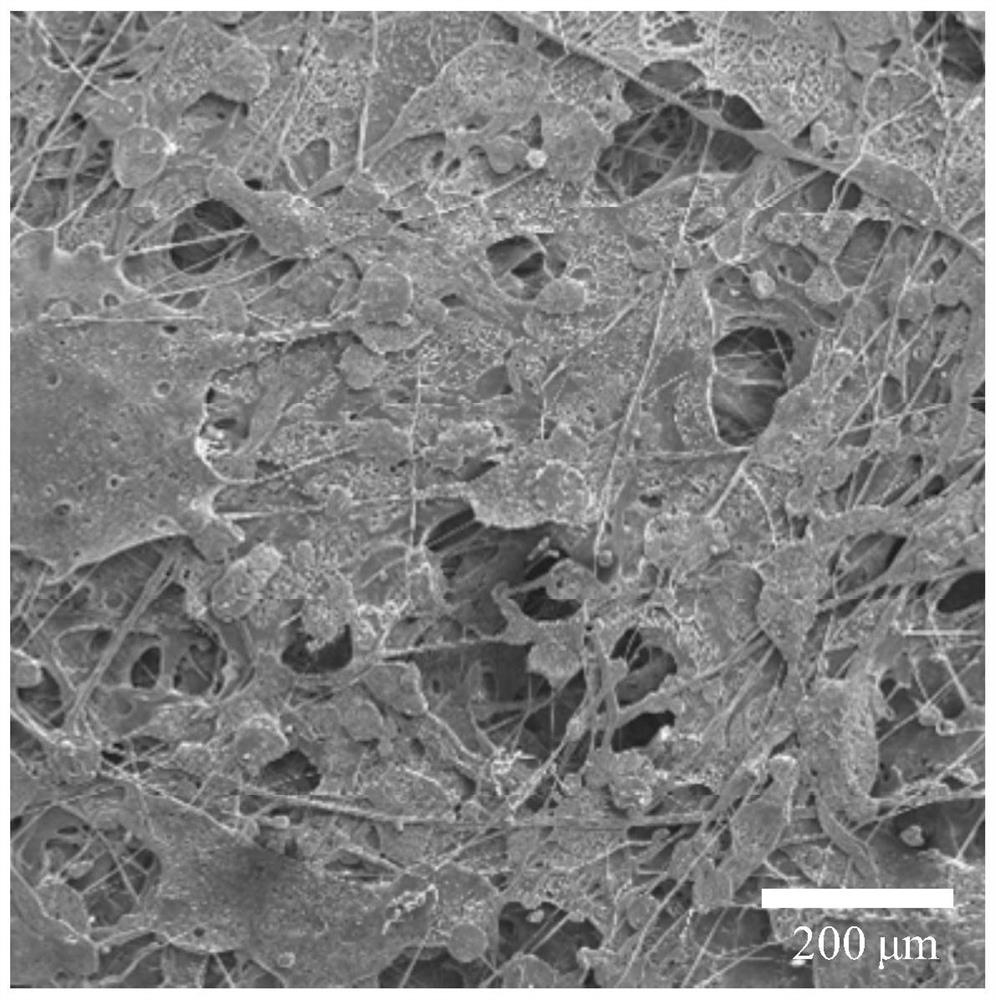

Nano filtering membrane containing silk fibroin and preparation method thereof

The invention relates to a nano filtering membrane containing silk fibroin consisting of complex fibers formed by silk fibroin and nano carbon, wherein the membrane contains 70-95wt% of silk fibroin and 3-30wt% of carbon nanospheres in unit area, the filtering membrane is 0.05-5 microns thick, has high specific area of fiber, strong adsorption effect and high strength, and is durable. The preparation method of the nano filtering membrane comprises the following steps: (1) putting silk into a sodium carbonate solution, boiling for degumming, and filtering to obtain coarse silk fibroin; (2) putting the obtained coarse silk fibroin into a calcium chloride solution for dissolution, thus obtaining an initial liquid of silk fibroin; (3) desalting the obtained initial liquid of silk fibroin to obtain a silk fibroin fluid; (4) adding carbon nanospheres into the obtained silk fibroin fluid, and performing ultrasonic dispersion uniformly to obtain a spinning solution; and (5) performing electrostatic spinning on the obtained spinning solution to obtain the nano filtering membrane.

Owner:汤氏(湖州)商业管理有限公司

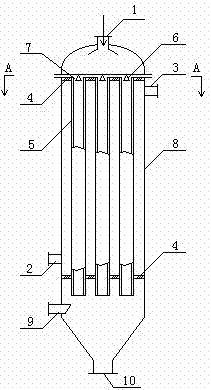

Tube alignment type condensation polymerization reaction kettle

The invention discloses a tube alignment type condensation polymerization reaction kettle. According to the kettle, tube plates (4) are arranged inside a vertical casing (8); the tube plates (4) are connected with a tube alignment (5); material distributors (6) are arranged on the upper end tube openings of the tube alignment (5); annular gaps (7) are arranged between the upper end tube openings of the tube alignment (5) and the material distributors (6); the top end of the vertical casing (8) is provided with a material inlet (1), and the lower end of the vertical casing (8) is provided witha material outlet (10); the lower part of the side surface of the vertical casing (8) is provided with a heating medium inlet tube (2), the upper part of the side surface of the vertical casing (8) is provided with a heating medium outlet tube (3), and the middle-lower part of the side surface of the vertical casing (8) is provided with a vacuum pumping port (9). According to the present invention, material naturally flows downward by gravity, if the tube alignment is large, the film forming of the inner wall of tube alignment is sufficient, such that the blocking problem can not be generated; the tube alignment type condensation polymerization reaction kettle of the present invention has characteristics of good film forming effect, reliable use, and high work efficiency, and can be used for productions of PET and other high viscosity polymers. In addition, a plurality of the tubes can be aligned in the tube alignment.

Owner:ZHEJIANG UNIFULL IND FIBER

Pretreatment liquid and pretreatment method before rare earth conversion

InactiveCN102011115AFast film formationHigh film forming efficiencyMetallic material coating processesPretreatment methodSorbent

Owner:SOUTH CHINA UNIV OF TECH

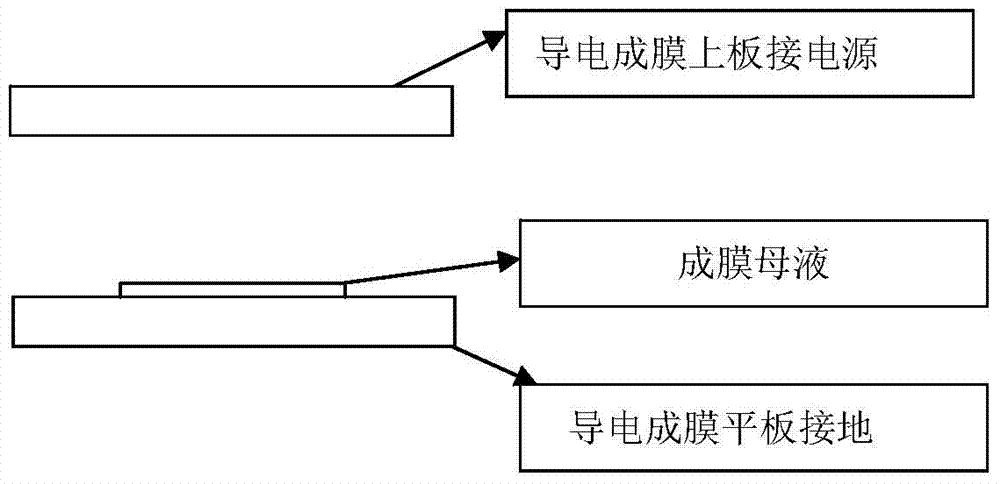

Method for preparing macromolecular nano composite membrane enriching inorganic filler on surface

The invention discloses a method for preparing a macromolecular nano composite membrane enriching inorganic filler on the surface, which is characterized by specifically comprising the following steps: (1) dissolving macromolecules and inorganic filler forming a membrane through phase inversion into a solvent to obtain mother liquid; (2) placing the mother liquid on a conductive membrane forming panel; (3) applying an electrostatic field vertical to the conductive membrane forming panel to the conductive membrane forming panel, wherein the electrostatic field promotes phase inversion of the mother liquid to obtain the macromolecular nano composite membrane enriching inorganic filler on the surface. After the inorganic filler is enriched on the surface, more properties of the macromolecular material can be obtained, and the method is particularly suitable for preparing materials with surface wear resistance, acid-alkali resistance, fire resistance, luminescence and the like.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Treating solution for preparing Al-Mo-Mn-Re quaternary composite passivation film on aluminum profile surface and its application method

ActiveCN102732870AImprove compactness and comprehensive performanceEfficient and fast film formation at low temperatureMetallic material coating processesChemistryLanthanum nitrate

The invention discloses a treating solution for preparing a corrosion resistant Al-Mo-Mn-Re quaternary composite passivation film on an aluminum alloy surface and its application method. The passivation solution is characterized by being a passivation treatment solution which is used for preparing a passivation film on an aluminum alloy surface by utilizing a molybdate, a rare earth salt and a permanganate oxidant. Per liter of the treating solution consists of: 8g.L<-1>-25g.L<-1> of sodium molybdate (or ammonium molybdate), 5g.L<-1>-10g.L<-1> of potassium permanganate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (or potassium fluoride), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (or ceric sulfate, lanthanum nitrate), 1g.L<-1>-5g.L<-1> of acetic acid, 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate (or OP-10) . The application method includes: (1) removing adhered dust and other dirt from the aluminum alloy; (2) then conducting pretreatment on the aluminum alloy surface; (3) using the treating solution for passivation treatment; and (4) carrying out water washing and drying. The treating solution of the invention has the advantages of fast film formation speed, simple process, uniform film, strong corrosion resistance, and less environmental pollution, etc.

Owner:GUANGDONG XINGFA ALUMINUM JIANGXI

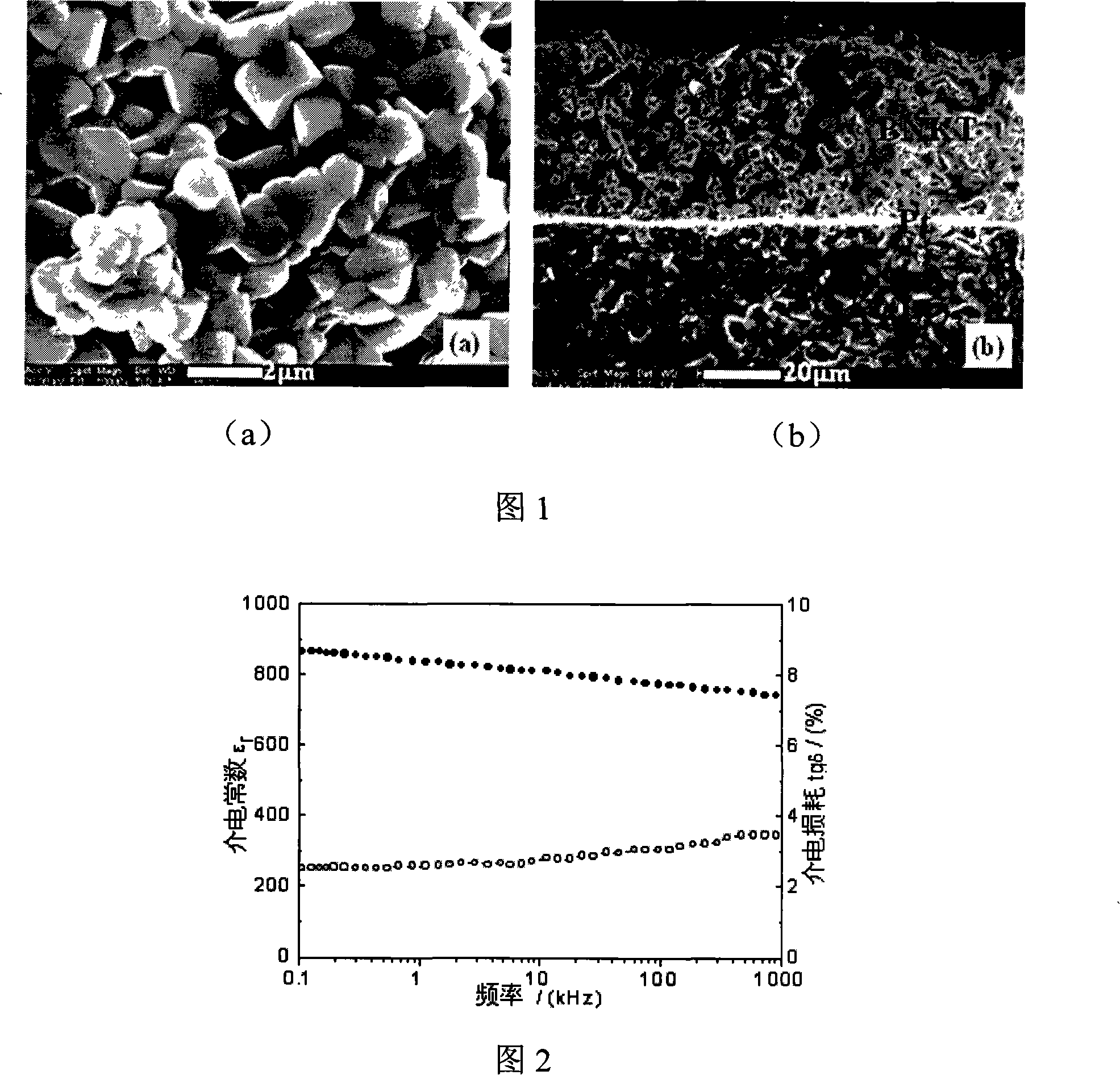

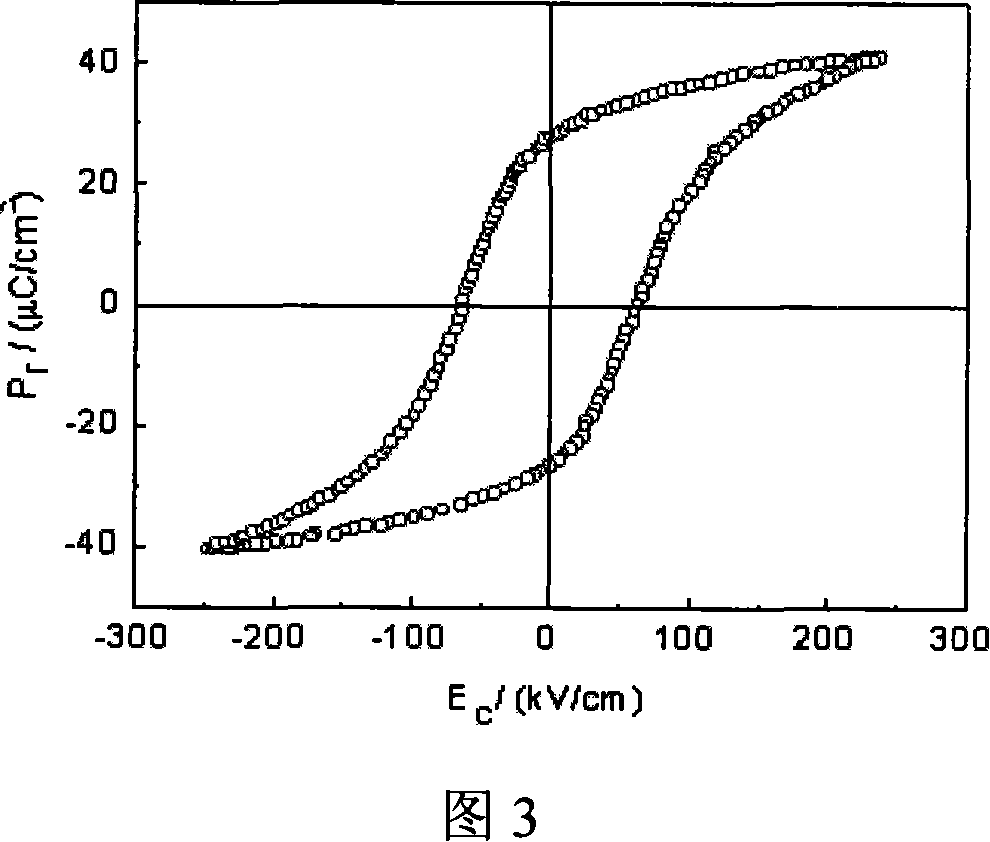

A preparation method for lead-free piezoelectricity thick film

InactiveCN101217180ASimple processHigh film forming efficiencyPiezoelectric/electrostrictive device manufacture/assemblySolid phasesMicro actuator

The invention discloses a silk screen printing preparation method of a lead-free piezoelectric thick-film, including: (1) the lead-free piezoelectric ceramic powder is prepared by adopting a solid phase method; (2) an adhesive is dissolved in terpineol according to the weight ratio of 3: 100 to 9: 100 so as to obtain an organic mixture; (3) the lead-free piezoelectric ceramic powder and the organic mixture are mixed according to the weight ratio of 15: 10 to 90: 10, a dispersant and a plasticizer are added for mixing, grinding and ball milling so as to obtain a paste which is ready to be printed; (4) the paste is printed on a substrate by adopting a silk screen printing technology, a thick-film blank with needed thickness is obtained by being placed flat, baking, preburning and repeated operation; (5) the blank is treated with sintering below 1050 to 1300 DEG C, and heat preservation is kept for 15 to 45 minutes. The invention has simple technology, environmental protection, high efficiency of film formation, good reproducibility, dense film formation and excellent electrical performances, the thickness can be controlled arbitrarily between 10 and 100Mum, various printing thick-film patterns can be obtained without a lithography technology; the invention is compatible with the MEMS technology and is applicable to the preparation of piezoelectric micro-motors, micro-fluid pumps, ultrasonic transducers and micro-actuators.

Owner:HUAZHONG UNIV OF SCI & TECH

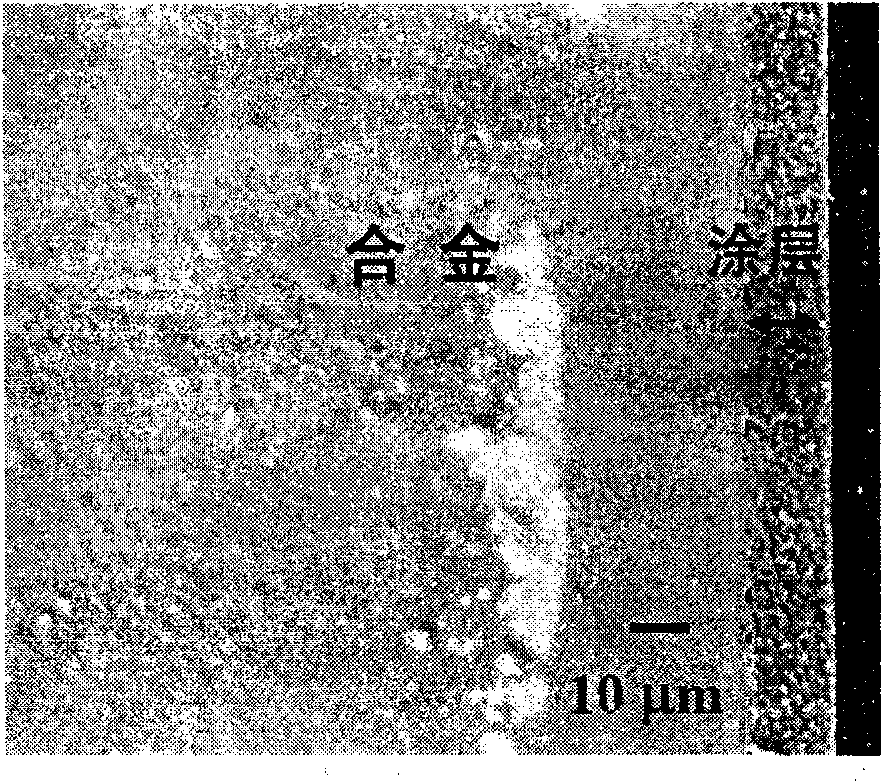

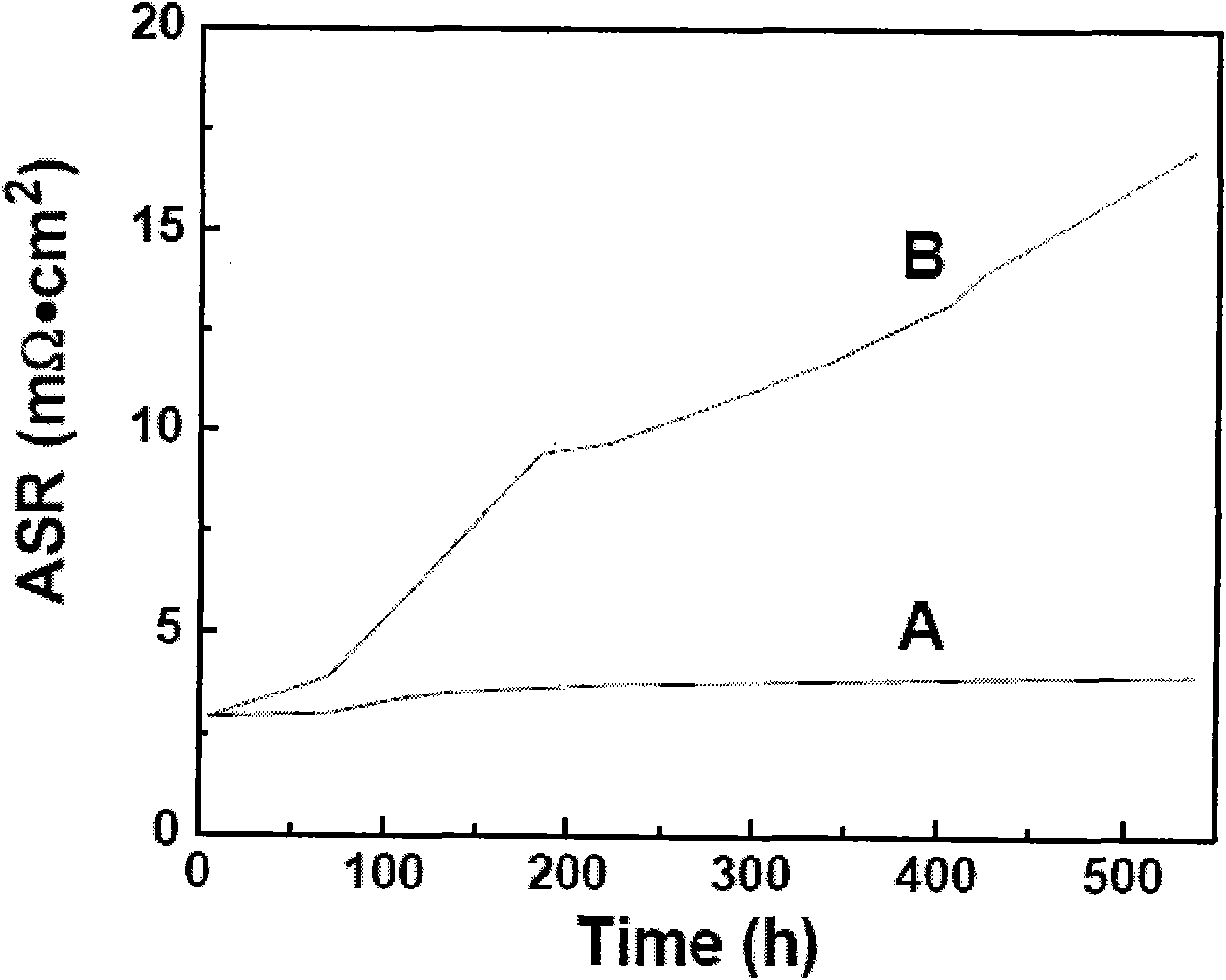

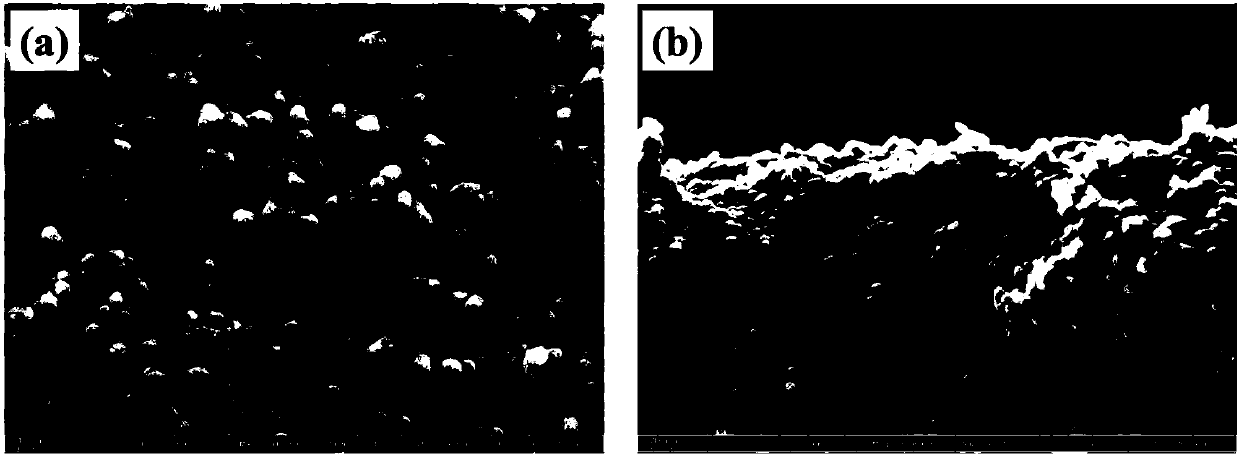

Alloy high temperature oxidation resisting nanostructure conductive coating prepared with spinel powder reduction method

InactiveCN101671829AImprove sinterabilityUniform and controllable thicknessConductive layers on insulating-supportsCable/conductor manufactureAlloy coatingNanostructure

The invention provides a preparing method of an alloy high temperature oxidation resisting nanostructure conductive coating, i.e. a spinel powder reduction coating method. On one hand, coating powdermaterial with favorable sintering performance is obtained by the regulation and control of the preparing process of coating powder material and effective reductive treatment; on the other hand, a nanometer microstructure film is prepared on the alloy surface by adopting silk screen assisted improved sizing agent coating technology. The film has controllable and even thickness and superior performance, and coating is tightly combined with the alloy; the coating alloy has lower area specific resistance (ASR) and higher long-time running stability under high temperature oxidation environment. Thespinel powder reduction coating method originated by the invention has simple film manufacturing method, low cost and strong repetitiveness, can be applied to coating preparation of alloy with different shapes or sizes, has superiority especially when preparing the large-area alloy coating in practical application, can greatly lower the preparing cost of the alloy coating and has strong applicability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Modified graphene oxide/hyperbranched polymer composite film as well as preparation method and application thereof

ActiveCN107737530AMild reaction conditionsImprove stabilityEther separation/purificationCarbon compoundsComposite filmAlcohol

The invention relates to a modified graphene oxide / hyperbranched polymer composite film as well as a preparation method and application thereof, and belongs to the field of film separation. An in-situpolymerization technology is used for performing decoration modification on the graphene oxide; meanwhile, a graphene oxide and hyperbranched polymer composite material is obtained through the preparation; the composite material is used as film casting liquid to prepare the modified graphene oxide / hyperbranched polymer composite film on a tubular base film under the pressure driving condition. The composite material is used for directly forming the film; the step of purifying and re-dispersing the modified graphene material is omitted; the film forming efficiency is greatly improved. The prepared composite can be used for the separation of methyl tert-butyl ether / methyl alcohol in the pervaporation field; good separation performance and stability can be shown; the potential application prospects are realized.

Owner:BEIJING UNIV OF TECH

Water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat

InactiveCN107312412AStrong adhesionImprove adhesionPolyurea/polyurethane coatingsWater basedAdhesive

The invention relates to a water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat, which is characterized by being prepared from the following composition materials: water-base resin, a coalescing agent, an other auxiliary agent, titanium white pulp, mill base and water. A preparation method of the water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat is characterized by comprising the following steps: sufficiently and evenly dispersing the water-base resin, the coalescing agent, the other auxiliary agent, the titanium white pulp, the mill base and the water, and packaging to form a finished product. The water-based woodware adhesive force-enhanced single-component matt modulation light-colored finishing coat has the advantages of good adhesive force on various primer base materials, good color stability after colour modulation, good water resistance and stain resistance, excellent coating effect, environment friendliness, safety, and simpleness and safety in use, and can be widely applied to coating of factory furniture.

Owner:上海展辰涂料有限公司 +4

Anodization method for improving protection performance of aluminum and aluminum alloy

InactiveCN102605405AReduce concentrationReduce pollutionSurface reaction electrolytic coatingAviationInorganic salts

The invention provides an anodization method for improving the protection performance of aluminum and aluminum alloy. Adopted anodization solution is prepared through proportionally mixing water and at least one kind of inorganic salt of sulfuric acid, sodium borate, malic acid and cerium, a voltage control mode is adopted for the anodization, and the aluminum or the aluminum alloy materials are subjected to anodization treatment. Anodization film layers prepared by adopting the method provided by the invention have the advantages that the corrosion resistance is good, the combination performance with organic paint films is excellent, and the influence on the substrate fatigue performance is low. The anodization method has the characteristics that the process is simple, the performance is stable, the film forming efficiency is high, and the environment pollution is low. The anodization method can be used for replacing the traditional chromic acid anodization and sulfuric acid anodization technology and can be applied to the surface protection of aluminum and aluminum alloy materials in all industries such as aviation and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

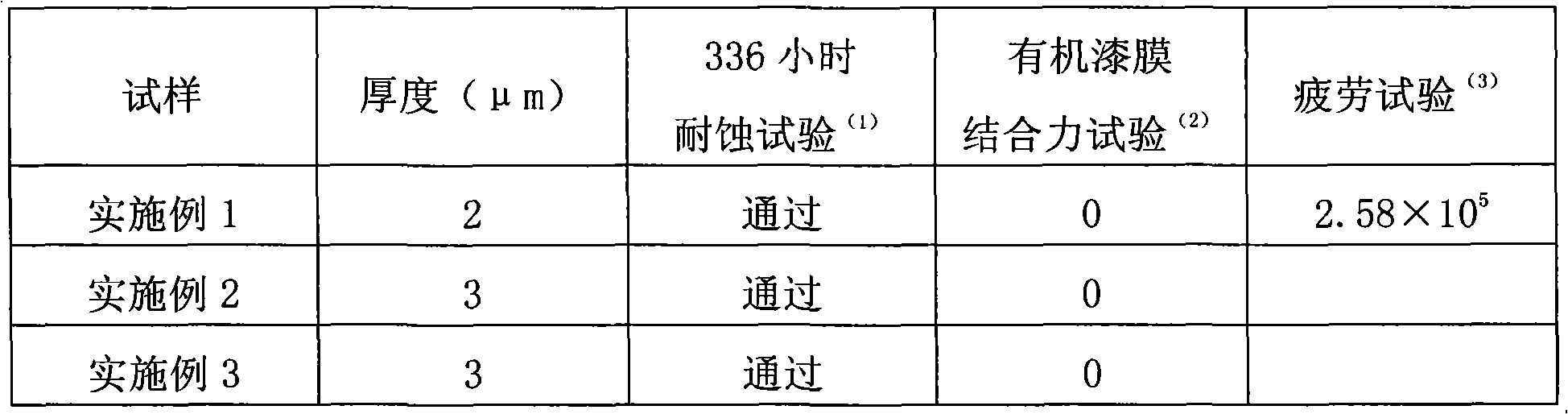

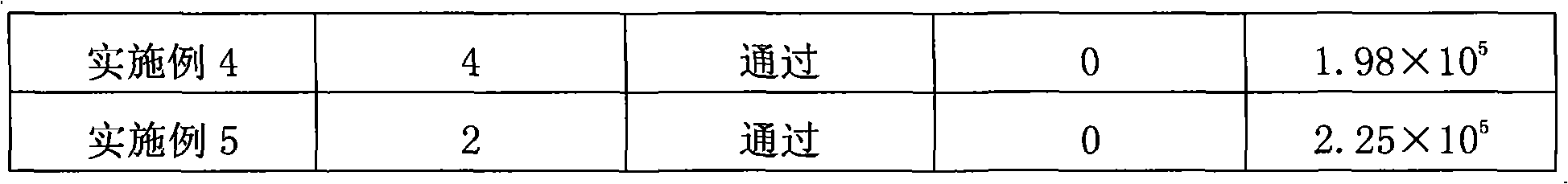

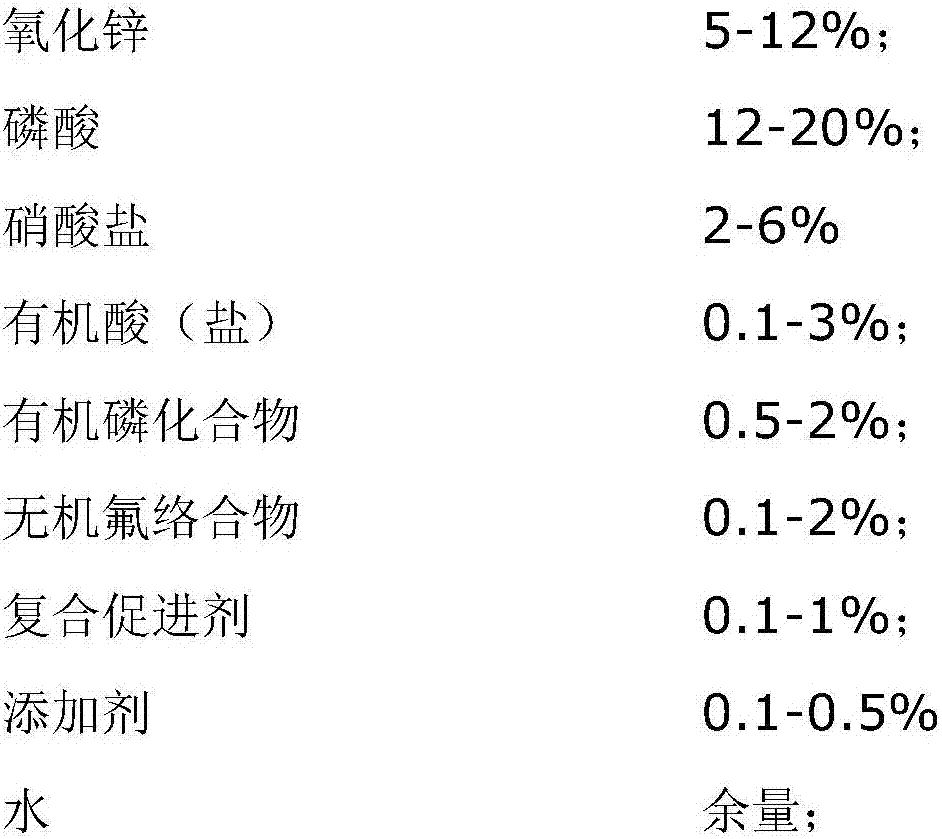

Rapid phosphating agent for galvanized steel sheets for color coating and application thereof

InactiveCN107326353AShort processing timeHigh film forming efficiencyMetallic material coating processesSalt spray testPhosphoric acid

The invention discloses a rapid phosphating agent for a galvanized steel sheets for color coating and application thereof. The rapid phosphating agent is mainly composed of zinc oxide, phosphoric acid, nitrate, organic acid (salt), an organic phosphorus compound, an inorganic fluorine complex, a compound accelerant, an additive, water, etc., and can be applied to rapid galvanized steel phosphating for color steel sheets before coating. The rapid phosphating agent has the advantages of short treatment time and high-efficiency film forming, can form a phosphating film on the surface of a galvanized based sheet within 5-15 seconds, conducts treatment at normal temperature without heating, and saves energy. A phosphating film layer is uniform, fine and smooth and has no show through, and the test time of resistance to neutral salt spray reaches above 48 hours.

Owner:杭州五源科技实业有限公司

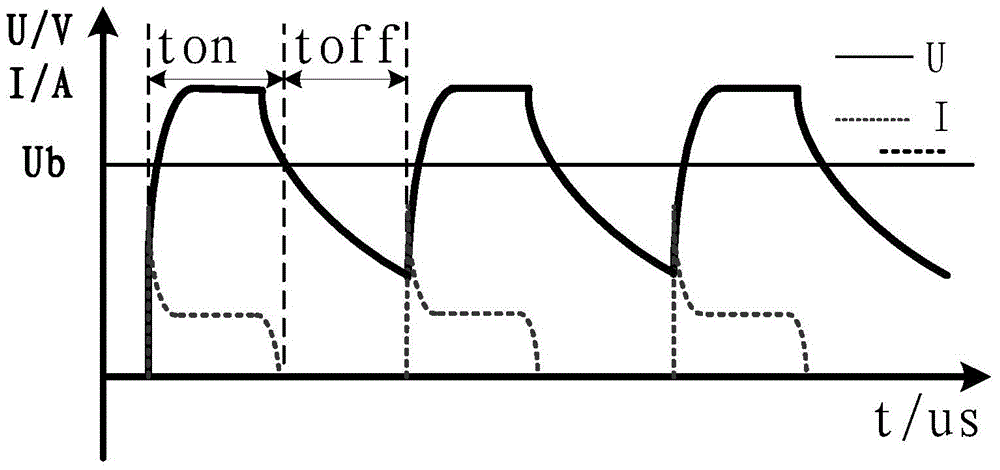

Method for controlling micro-arc oxidation electricity parameters under peak current output mode

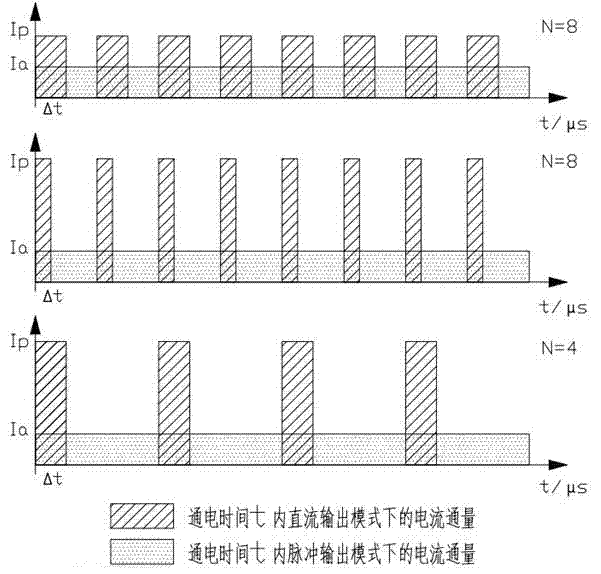

InactiveCN102212860AReduce heat lossImprove energy utilizationAnodisationMicro arc oxidationAverage current

The invention provides a method for controlling micro-arc oxidation electricity parameters under a peak current output mode, comprising the following steps of: respectively connecting a pre-treated piece as an anode and stainless steel as a cathode with an output port of a direct-current pulse power supply; immersing in micro-arc oxidation electrolyte; setting initial electricity parameters, wherein pulse peak current density is Ip1, pulse width delta is t1; pulse number is N1 and duration time is t1; undergoing an arc discharge phenomenon on the surface of the pre-treated piece within t1 andsimultaneously, forming a ceramic layer on the surface, and beginning to enter a growth thickening stage; in the event of not shutting off the power supply, under the conditions of ensuring that the average current Ia output is as low as possible and the growth of the ceramic layer can be kept, gradually reducing the value of Ip on the basis of Ip1, and gradually increasing the values of delta t and N on the basis of delta t1 and N1 to rapidly thickening the ceramic layer; and, when the ceramic layer achieves the pre-set thickness, taking out a work-piece; washing; and drying. The method disclosed by the invention has the benefits as follows: the heat loss can be reduced; and the smooth and uniform ceramic layer can be obtained.

Owner:NANJING HAORANG ENVIRONMENT SCI & TECH

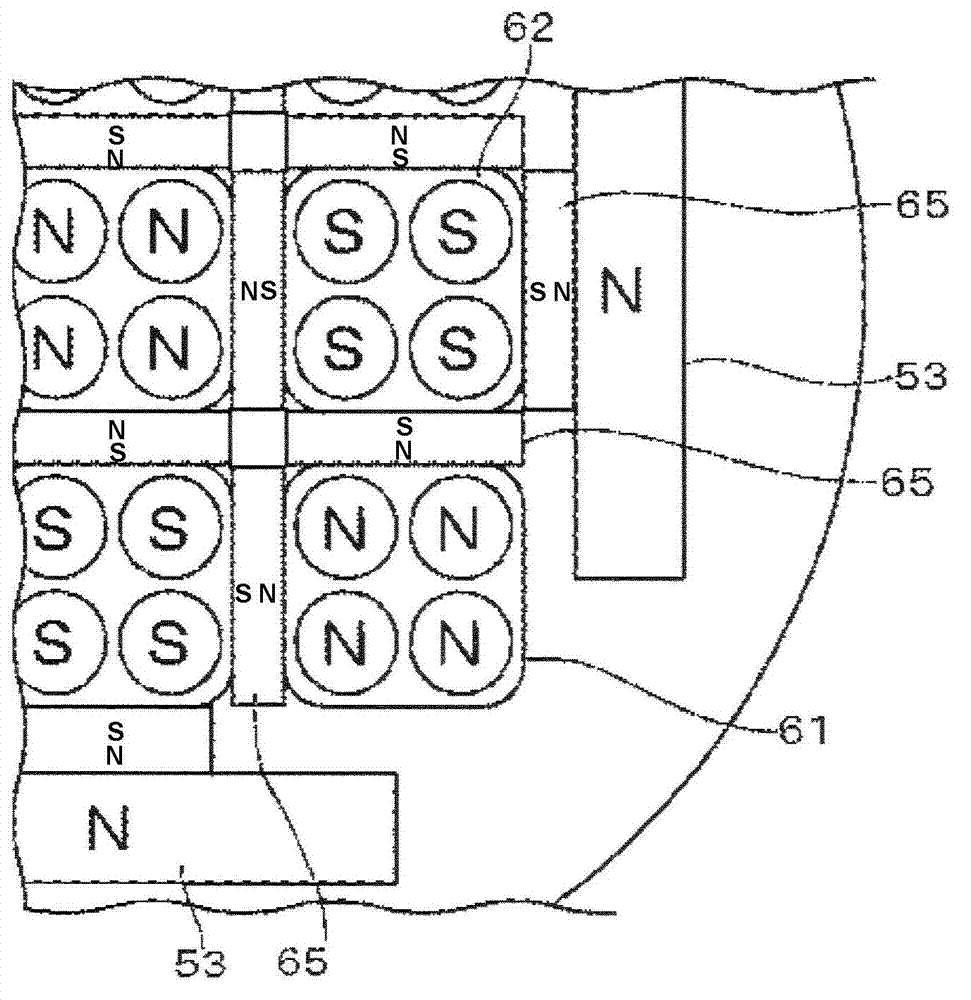

Magnetron sputtering apparatus and method

InactiveCN103031529ASolution to short lifeImprove efficiencyElectric discharge tubesVacuum evaporation coatingElectronAtomic physics

Owner:TOKYO ELECTRON LTD

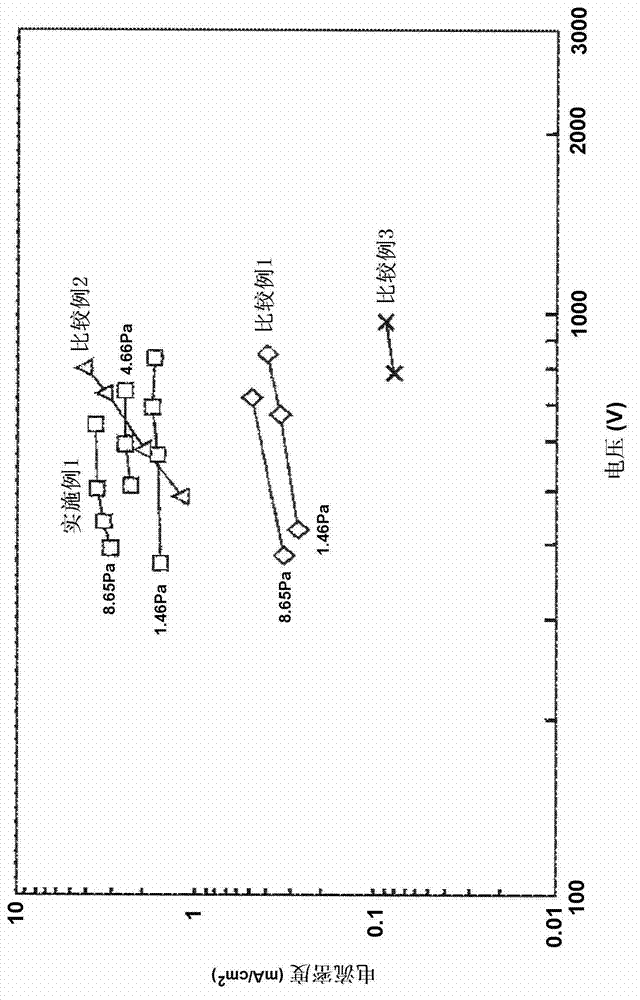

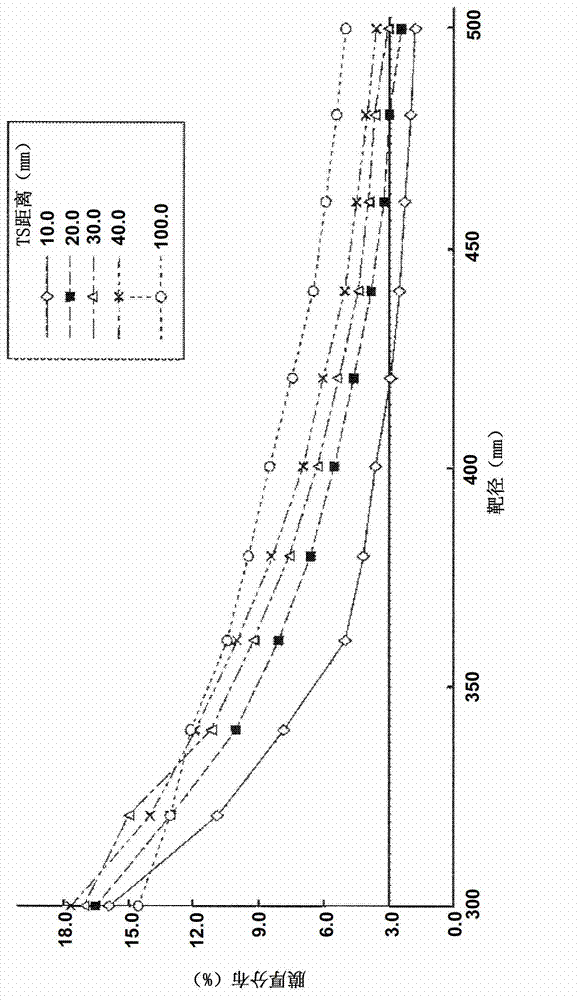

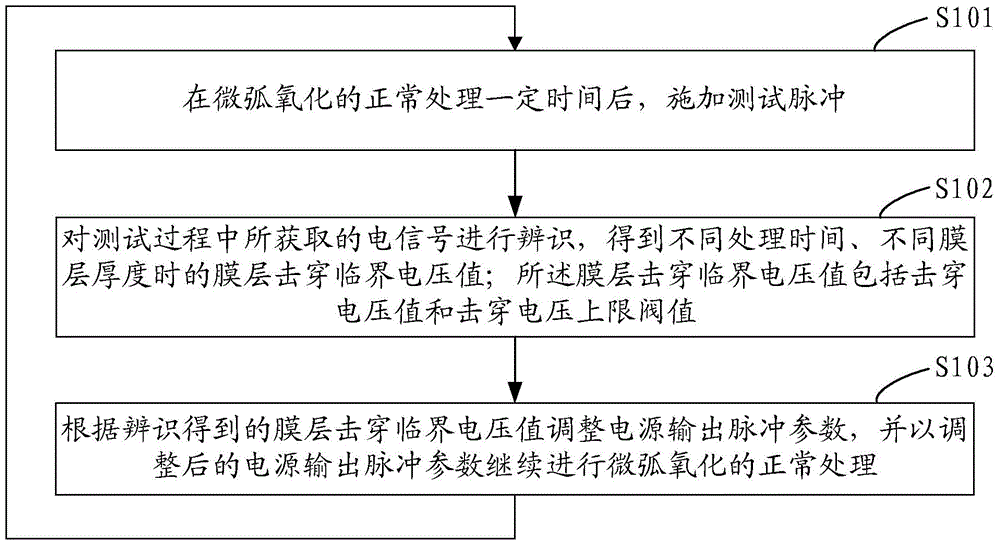

Self-adaptive control method for micro-arc oxidation process and system

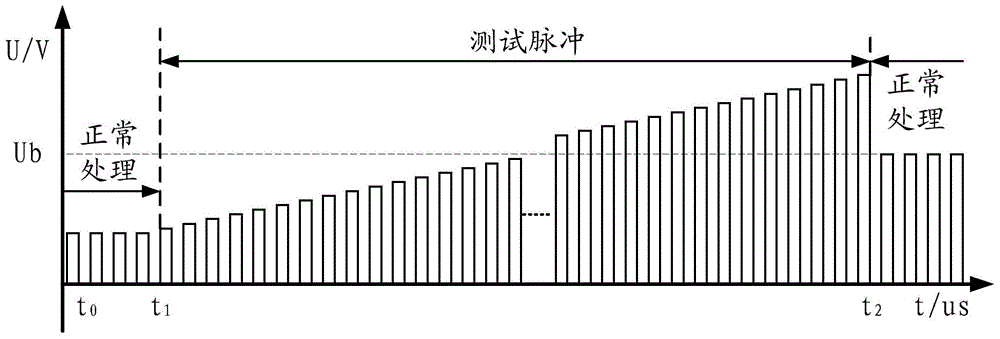

InactiveCN103823370AImprove film formationHigh film forming efficiencyAdaptive controlMicro arc oxidationSelf adaptive

The invention provides a self-adaptive control method for a micro-arc oxidation process and a system. The method comprises the following steps of applying test pulse after normal processing is carried out on micro-arc oxidation for a certain time, identifying electric signals acquired during the test process to obtain film?breakdown?critical voltage values in the case of different processing times and different film thicknesses, and adjusting power supply output?pulse parameters according to the film?breakdown?critical voltage values obtained after identification and continuing to carry out normal micro-arc oxidation processing according to the adjusted power supply output?pulse parameters, wherein the film?breakdown?critical voltage values comprise breakdown voltage values and breakdown voltage upper limit thresholds. According to the self-adaptive control method for the micro-arc oxidation process and the system, self-adaptive control on the micro-arc oxidation processing process can be realized, film forming effects are effectively improved, the film forming efficiency is enhanced, and a ceramic layer with excellent performances can be obtained.

Owner:广州市精源电子设备有限公司 +1

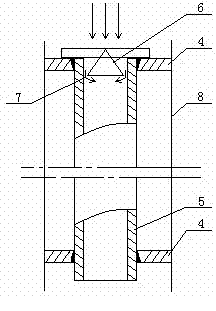

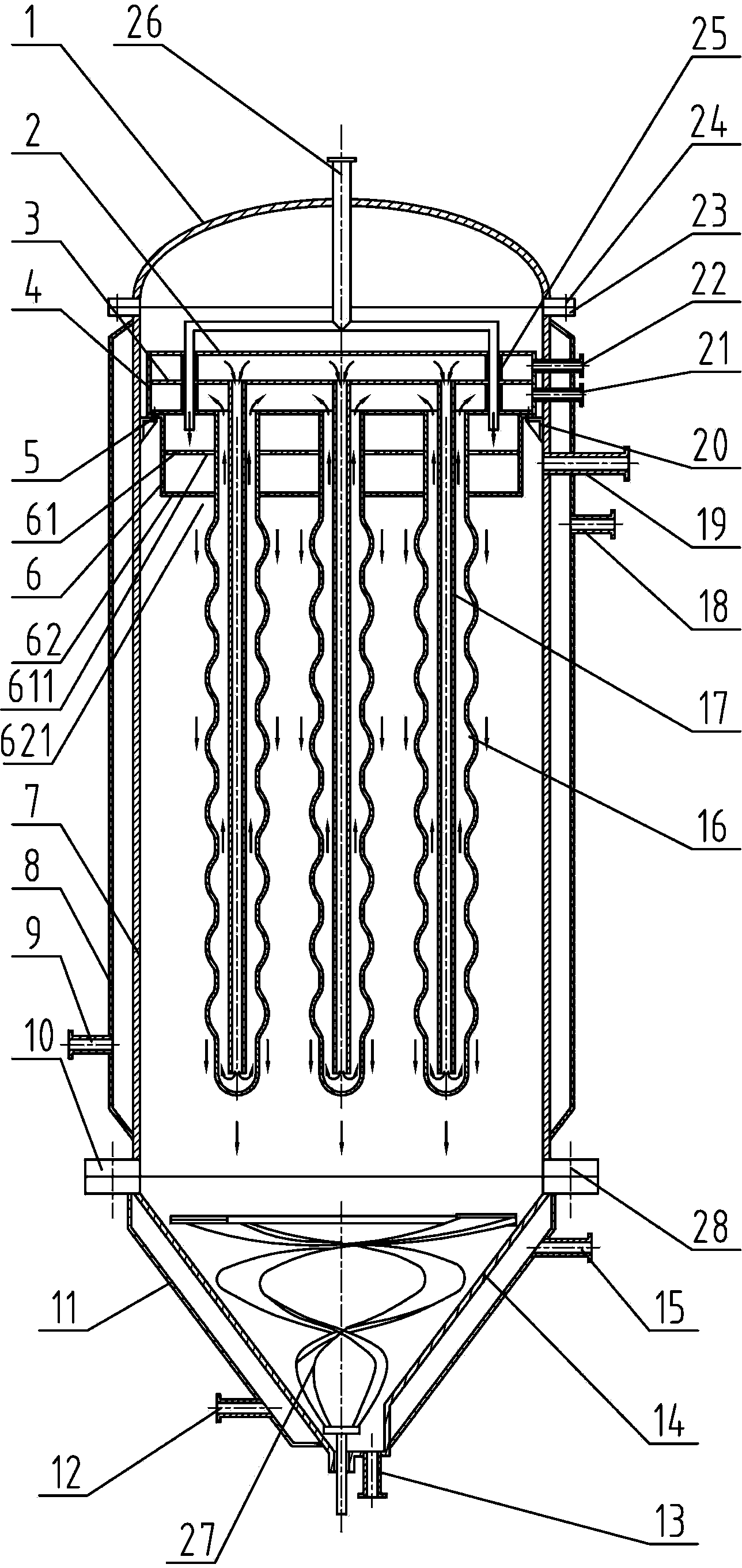

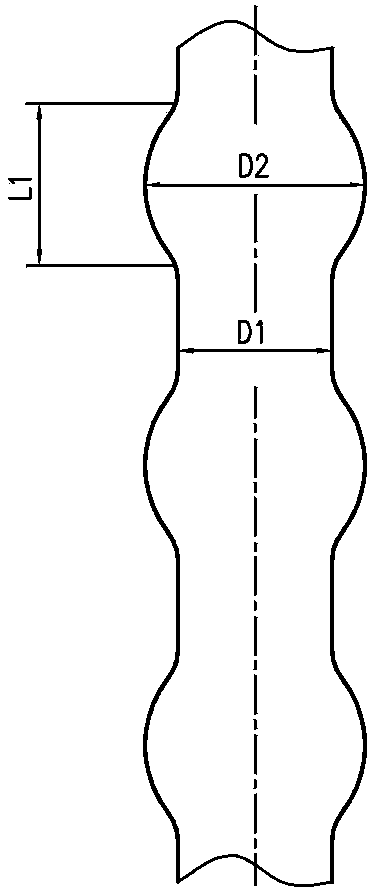

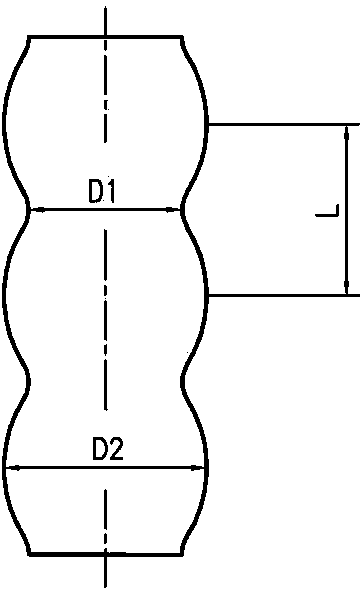

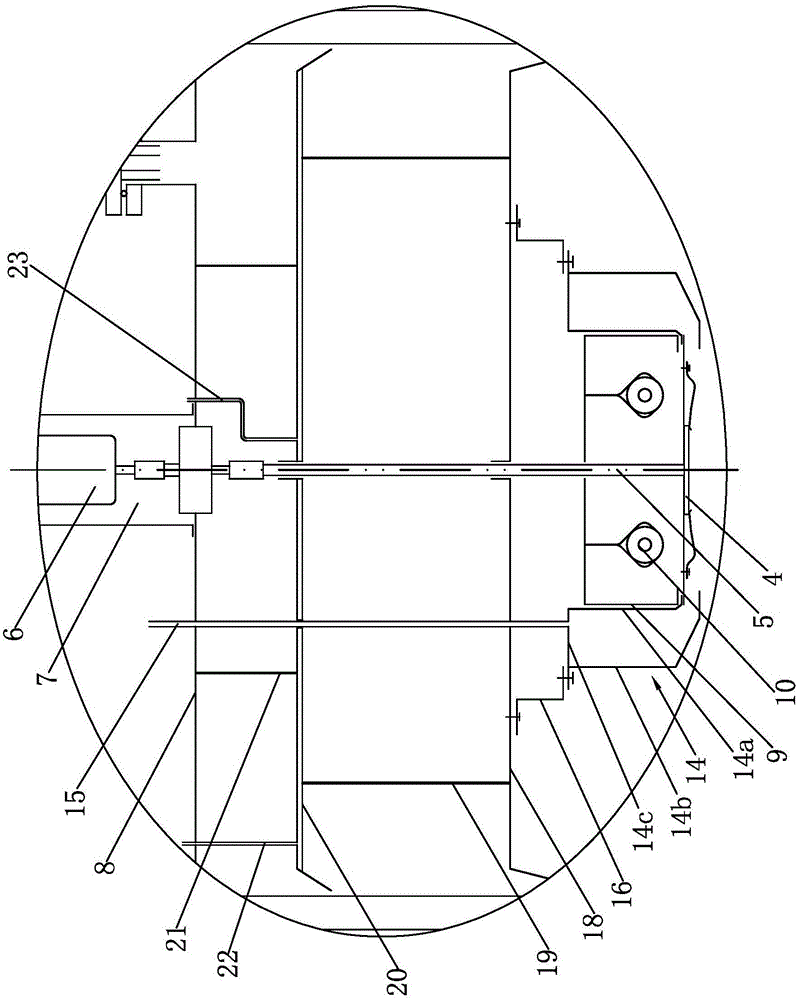

Melt polycondensation method, special reactor and falling-film elements

ActiveCN103360587AUniform melt residence timeNarrow molecular weight distributionChemical/physical/physico-chemical stationary reactorsPolytetramethylene terephthalateReaction temperature

The invention discloses a melt polycondensation method. Melted monomer blends or prepolymers slide down along the outer walls of tubular falling-film elements so as to be subjected to polycondensation, melts on all the falling-film elements gather at the bottom of a polycondensation reactor so as to be further stirred for reaction and mixed uniformly, and materials are discharged after the reaction finishes. The polycondensation reactor for implementing the method comprises a vertical shell, an end enclosure on the upper end, a bottom shell on the lower end, the falling-film elements, a heat transfer system, a film distributor and a helical ribbon stirrer, wherein the falling-film elements are corrugated pipes with optimized structural parameters. The polycondensation reactor has the advantages of simple structure, sufficient heat exchange, large film forming area, uniform reaction temperature and high polycondensation efficiency, guarantees the laminar flow in the process and can be used for the melt polycondensation of polyethylene glycol terephthalate, polytrimethylene terephthalate, polybutylene terephthalate, polyethylene naphthalate, polyamide and polycarbonate.

Owner:ZHEJIANG SCI-TECH UNIV

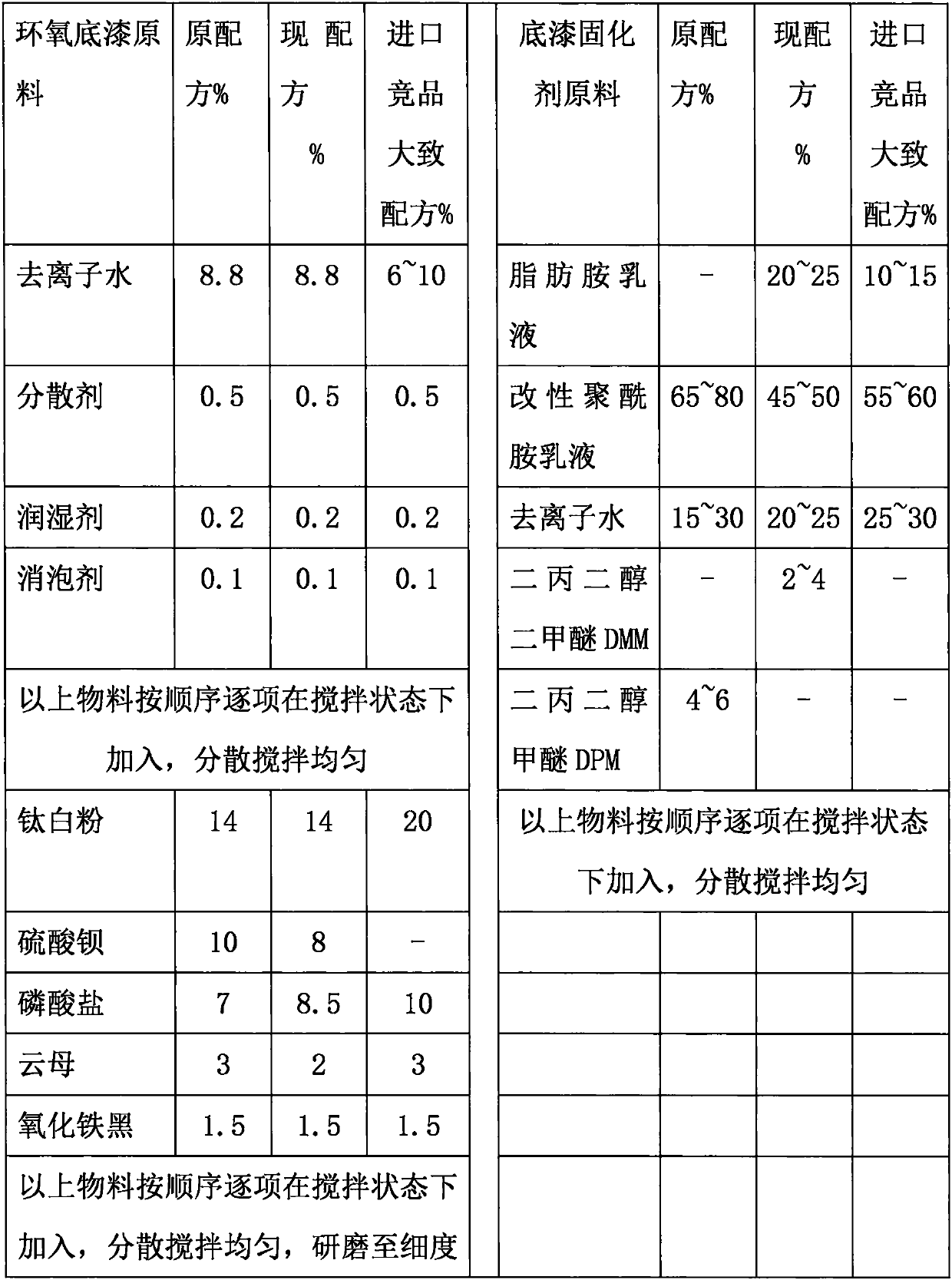

Special two-component water-based paint for buses and coating process of two-component water-based paint

InactiveCN110551437ALow VOCImprove film formationPretreated surfacesAnti-corrosive paintsWater basedEpoxy

The invention provides special two-component water-based paint for buses. The special two-component water-based paint comprises a two-component water-based epoxy primer, two-component water-based intermediate paint and two-component water-based finishing paint. While maintaining the original physical and chemical properties without reducing, compared with traditional solvent-based bus paint, the use of organic solvents can be significantly decreased, and VOC is lowered; compared with existing water-based bus paint on the market, the flash drying time can be shortened, the production pace is speeded up, and the more efficient coating efficiency can be obtained.

Owner:上海时佳涂料有限公司

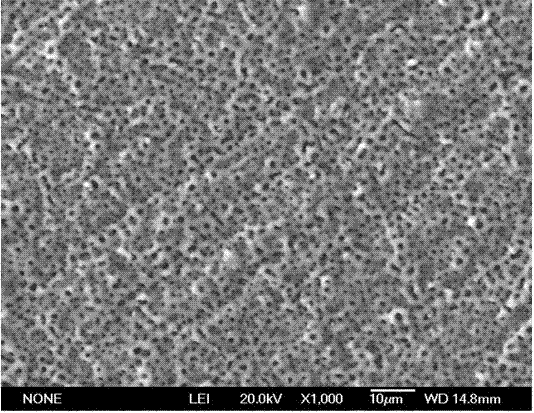

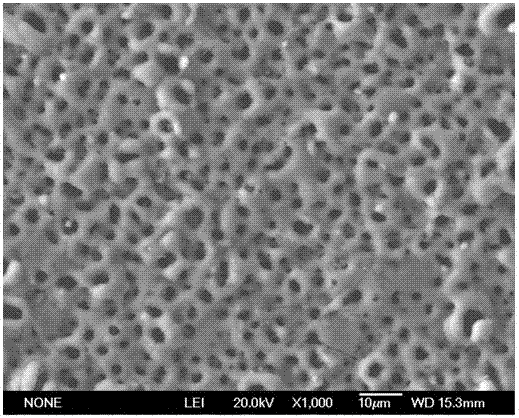

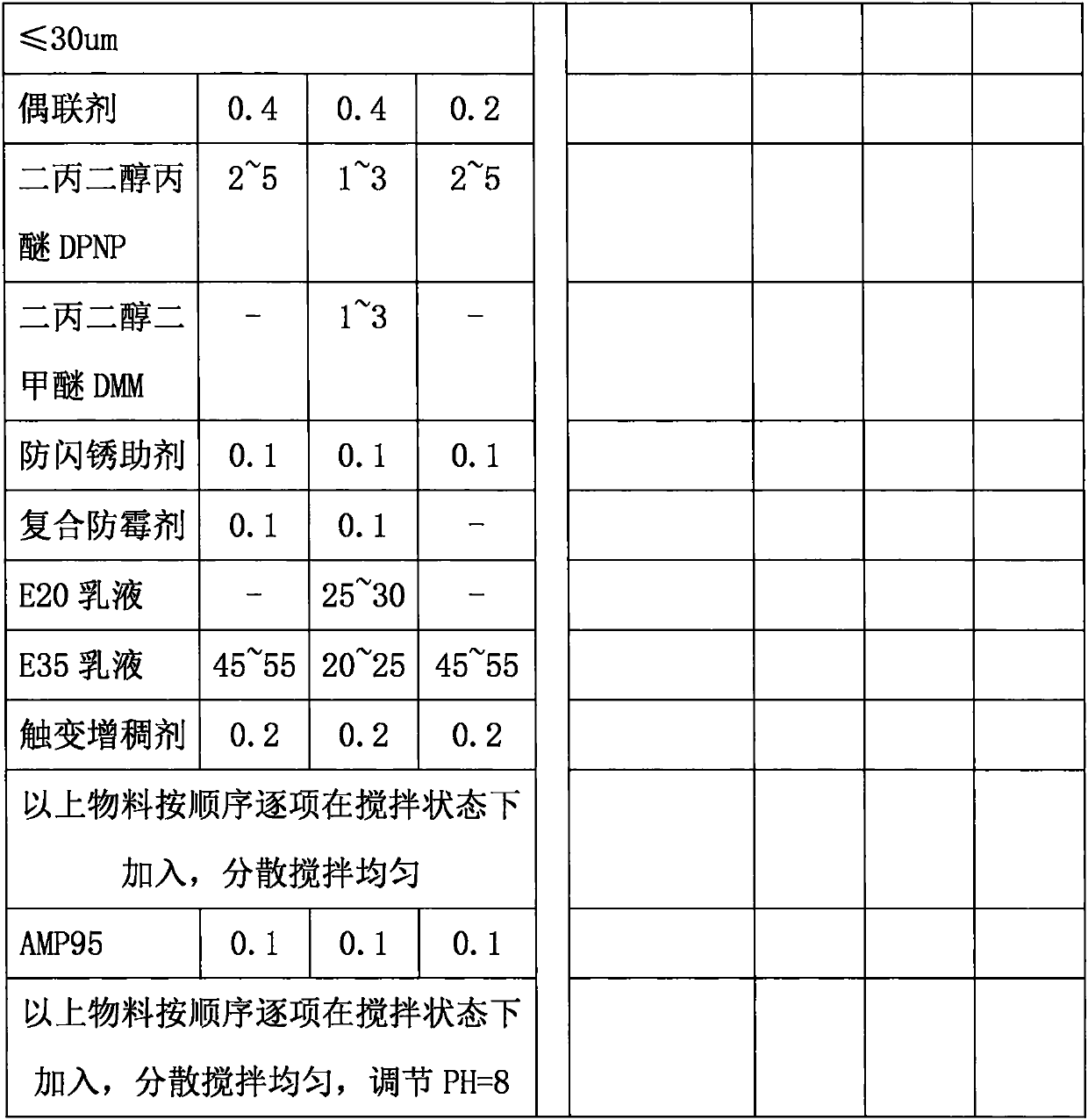

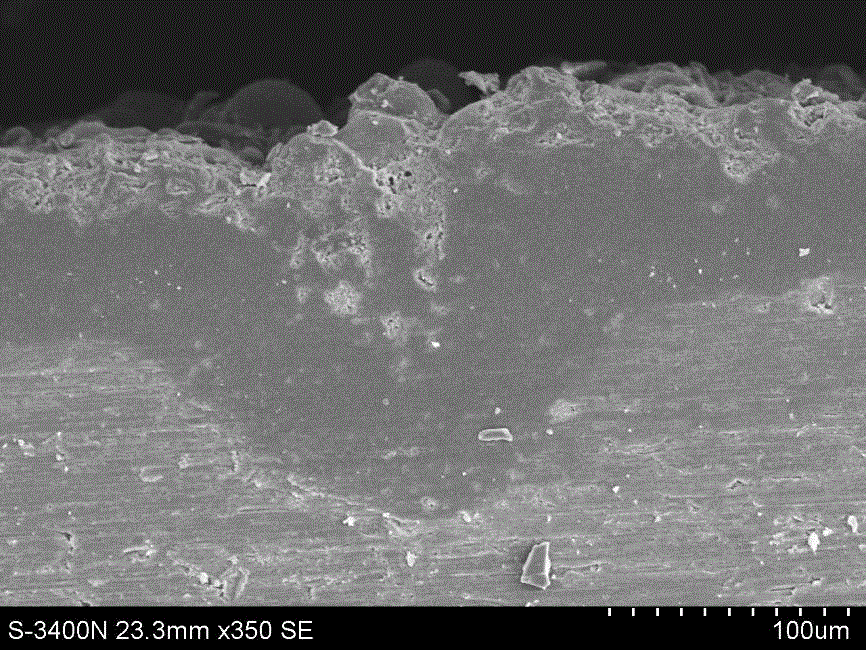

Aluminum alloy cylinder body inner surface ceramic layer and technique thereof

The invention provides an aluminum alloy cylinder body inner surface ceramic layer and a technique thereof. The technique comprises the following steps: firstly prefabricating a threaded spiral groove in the inner surface of an aluminum alloy cylinder body by machining; and then respectively growing two layers of Al2O3 ceramic films in situ on the inner surface and the outer surface of the spiral groove by micro-arc oxidation. The ceramic layer consists of two layers, the bottom layer is a threaded spiral layer under the inner surface of the cylinder body, the depth of the bottom layer is 30-400 mu m, the ceramic layer on the inner surface of the cylinder body is a surface layer, and the thickness of the surface layer is 0-10 mu m. The ceramic layer is combined to a base body firmly, is high in hardness and compactness, not only has wear resistance, impact resistance and corrosion resistance, but also has good thermal conductivity. The ceramic films are prepared simply, and are easy to control, low in cost and high in efficiency.

Owner:XIHUA UNIV

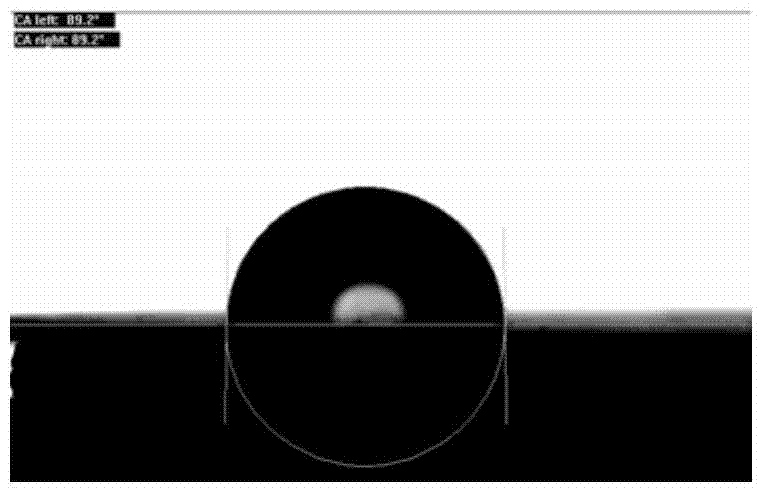

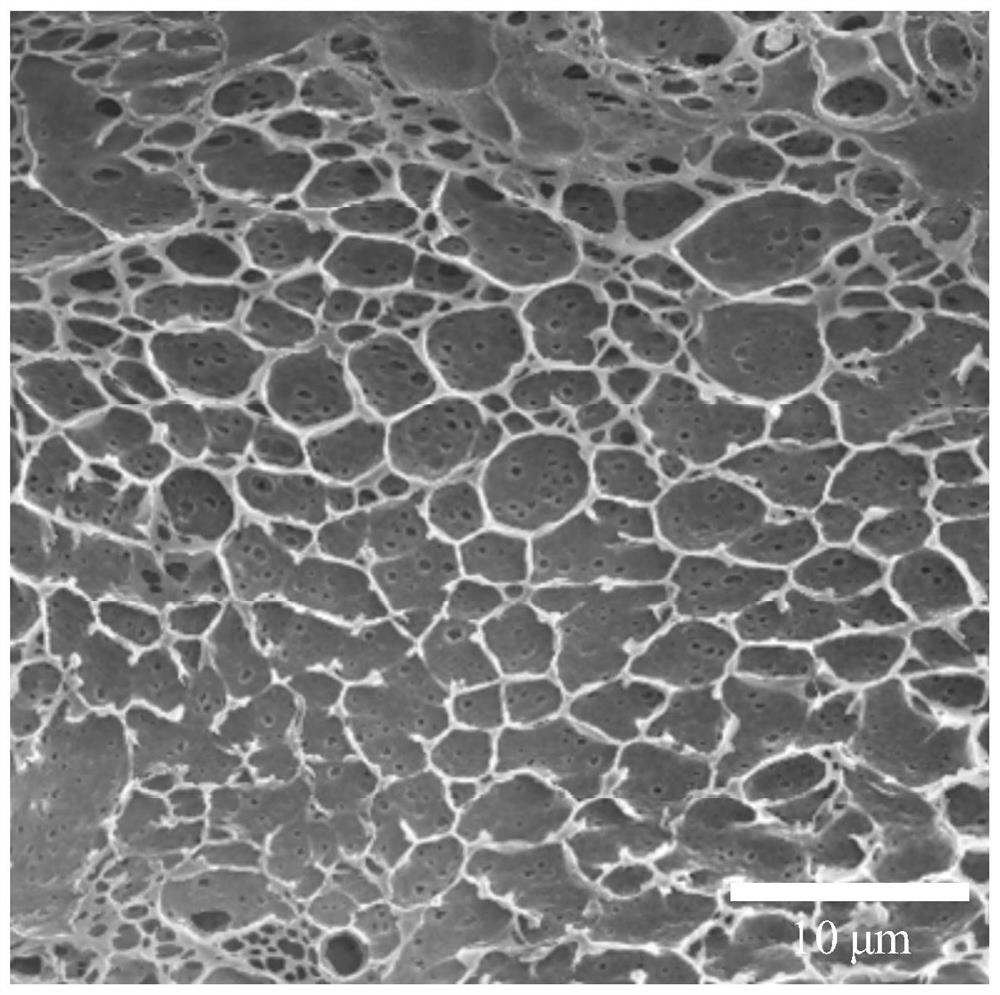

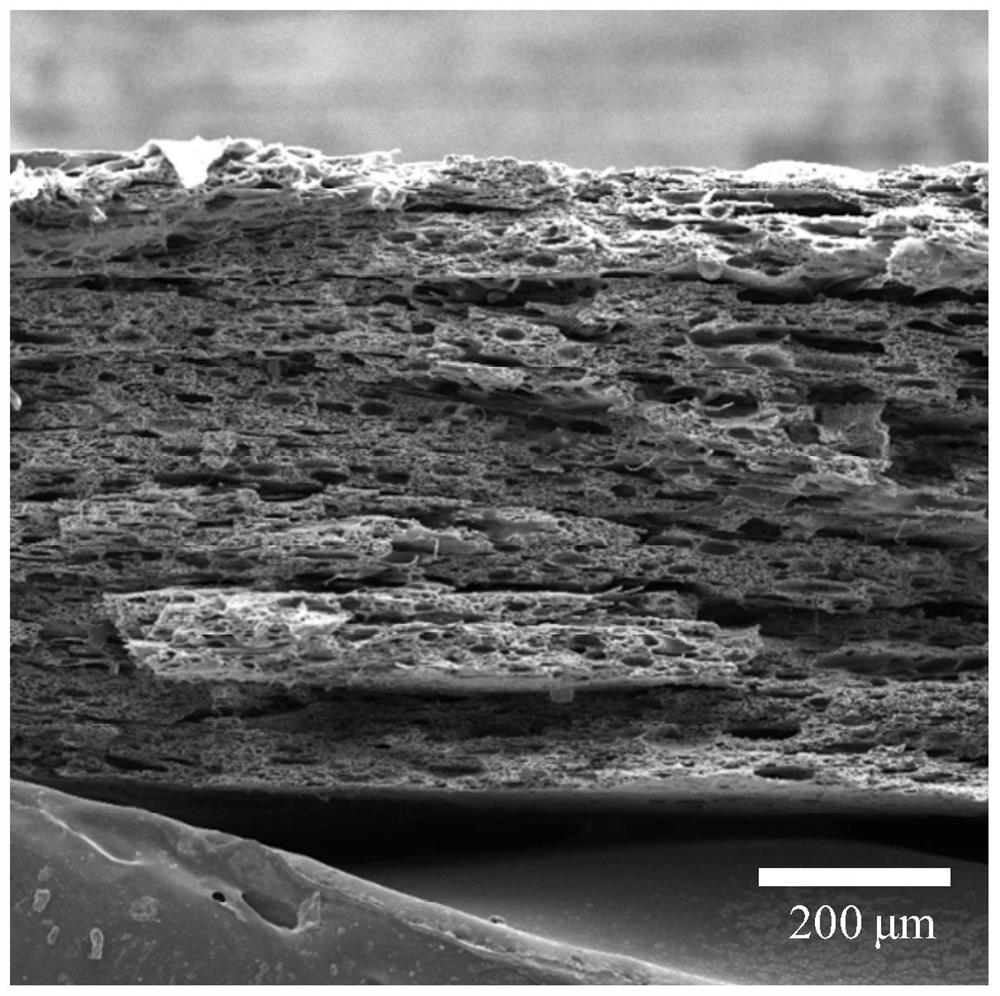

Hydrophobic heat insulation and cooling film and preparation method thereof

ActiveCN111910442AStrong absorption capacityGood cooling performanceConstructions elementsRoad vehiclesThin membranePolymer dissolution

The invention provides a hydrophobic heat insulation and cooling film and a preparation method thereof. The hydrophobic heat insulation and cooling film is a polymer porous film, the porosity is 30% -90%, the interior of the hydrophobic heat insulation and cooling film is of a spongy structure, the pore diameters of pores are distributed in a bimodal mode, and the width distribution of the poresis 0.2 micrometer - 0.6 micrometer and 1 micrometers - 5 micrometers respectively. The preparation method of the hydrophobic heat insulation and cooling film comprises the following steps of dissolving a polymer into an organic good solvent, adding a non-solvent to prepare a precursor solution, and spraying the precursor solution onto a substrate to obtain the hydrophobic heat insulation and cooling film. The hydrophobic heat insulation and cooling film is a flexible film material with good hydrophobicity, good heat insulation effect and good cooling effect, shows very excellent flexible performance, can be bent and curled at will, can be suitable for the surfaces of base bodies with different shapes, can achieve effective cooling and refrigeration inside the base bodies, and is good in application prospect and high in practicability; the preparation method of the hydrophobic heat insulation and cooling film has the advantages of simplicity, feasibility, low production cost, high filmforming efficiency and the like, is suitable for large-scale preparation and is beneficial to industrial application.

Owner:NAT UNIV OF DEFENSE TECH

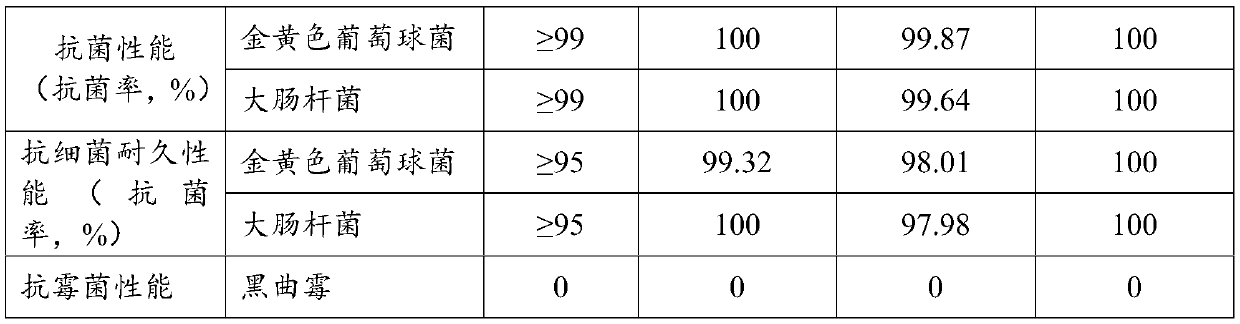

Antibacterial latex paint and preparation method thereof

PendingCN111500141AInhibition of agglomerationImprove antibacterial effectAntifouling/underwater paintsPaints with biocidesChemistryWeather resistance

The invention provides antibacterial latex paint. The latex paint is prepared from the following components, by weight: 100 parts of water, 8-13 parts of hydroxyethyl cellulose, 80-120 parts of modified acrylic emulsion, 25-40 parts of aluminum oxide modified nano titanium dioxide, 5-8 parts of a ZnOw nano antibacterial agent, 25-40 parts of nano silicon dioxide, 1-5 parts of a dispersing agent, 0.1-0.3 part of a defoaming agent and 0.5-3 parts of a coalescing agent. The antibacterial latex paint has the beneficial effects that (1), through the modification of the composite functional nano filler, the agglomeration of the nano antibacterial agent is effectively inhibited, and the antibacterial effect is improved; (2), due to the organic-fluorine-silicon-modified acrylic emulsion, the filmforming efficiency and quality are improved, and the stain resistance and weather resistance are improved; (3), an organic antibacterial agent is not used, so that the method is more environment-friendly; and (4), the emulsion paint prepared by the invention is simple to construct, smooth in paint surface, good in weather resistance and wide in application field.

Owner:黄俊

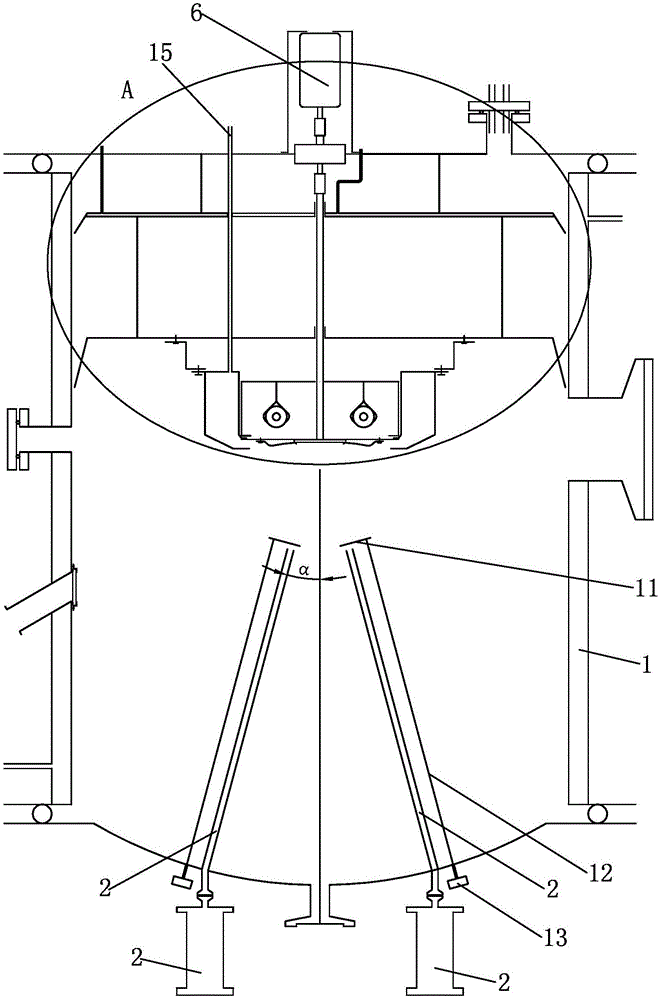

Independent-type multi-source confocal ultrasonic atomization pyrolysis spraying reaction chamber

ActiveCN105057154AFacilitate depositionPromote formationLiquid surface applicatorsLiquid spraying apparatusSpray nozzleEngineering

The invention discloses an independent-type multi-source confocal ultrasonic atomization pyrolysis spraying reaction chamber. A sample bearing table is arranged in the reaction chamber, a heating body shell is arranged on the upper portion of the sample bearing table, and heating bodies are arranged in the heating body shell; at least two atomization sources are mutually independent and are arranged in the circumferential direction of the reaction chamber, and a spraying nozzle on the upper portion of each atomization source is connected with a spraying pipe; the upper portions of the spraying pipes both face the axis line of the reaction chamber and both form a spraying angle alpha with the axis line of the reaction chamber; and a nozzle at the upper portion of each spraying pipe is provided with a baffle, and the baffles can block or open the spraying nozzles at the upper ends of the corresponding spraying pipes. By means of the independent-type multi-source confocal ultrasonic atomization pyrolysis spraying reaction chamber, a thin film containing required components can be obtained, and the defect of cross contamination caused by a traditional structure is overcome; and high-temperature reaction tail gas near the sample bearing table is hooded through a tail gas pumping hood, heat reflection can be achieved through a heat reflection hood, and cooling is further achieved through a water-cooling heat shield plate.

Owner:CHONGQING UNIV OF TECH

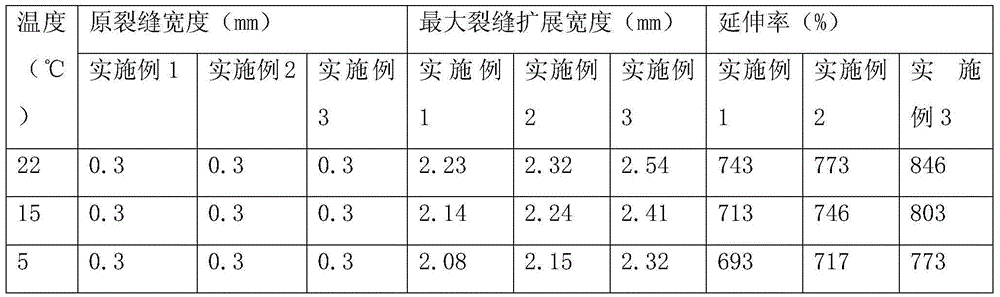

Exterior wall fluorocarbon paint and preparation method thereof

ActiveCN104987785AStrong crack resistanceHigh film forming efficiencyCoatingsCrack resistancePreservative

The invention discloses an exterior wall fluorocarbon paint. The exterior wall fluorocarbon paint comprises, by weight, 35-45 parts of aqueous fluorocarbon resin, 1-2 parts of a film forming assistant, 1-1.5 parts of diethylene diamine, 0.5-1 part of a thickener, 0.1-0.3 parts of a pH adjusting agent, 0.5-1 part of a dispersant, 10-16 parts of titanium dioxide, 5-10 parts of cellulose acetate pulp, 3-5 parts of butyl acetate, 0.5-1 part of an antiseptic, 3-4 parts of an antifoaming agent and 20-30 parts of pure water. The exterior wall fluorocarbon paint has strong crack resistance.

Owner:CHONGQING PINSHENG PAINT

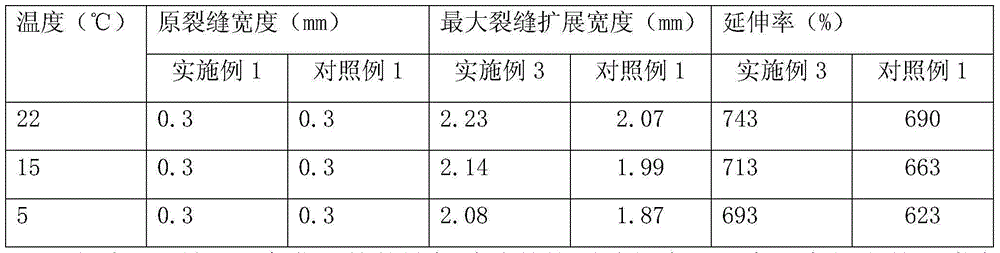

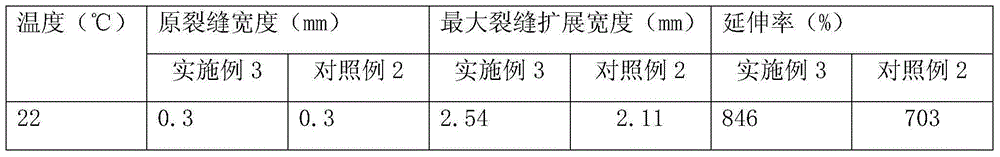

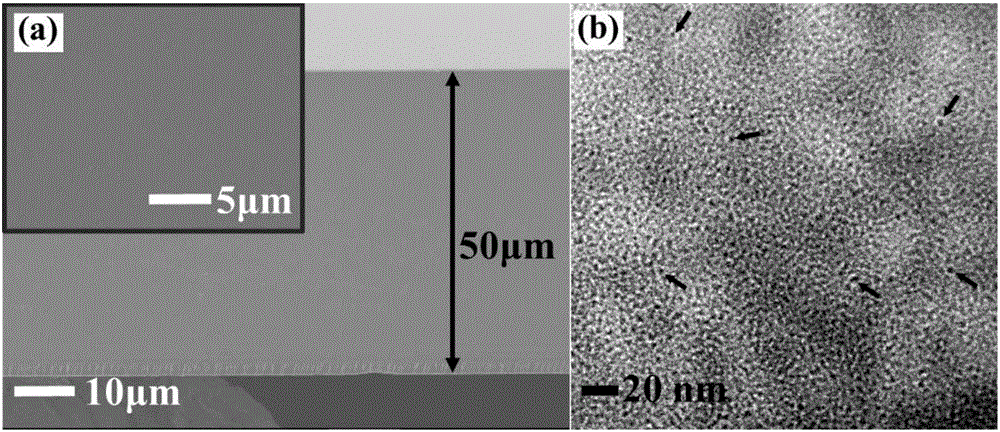

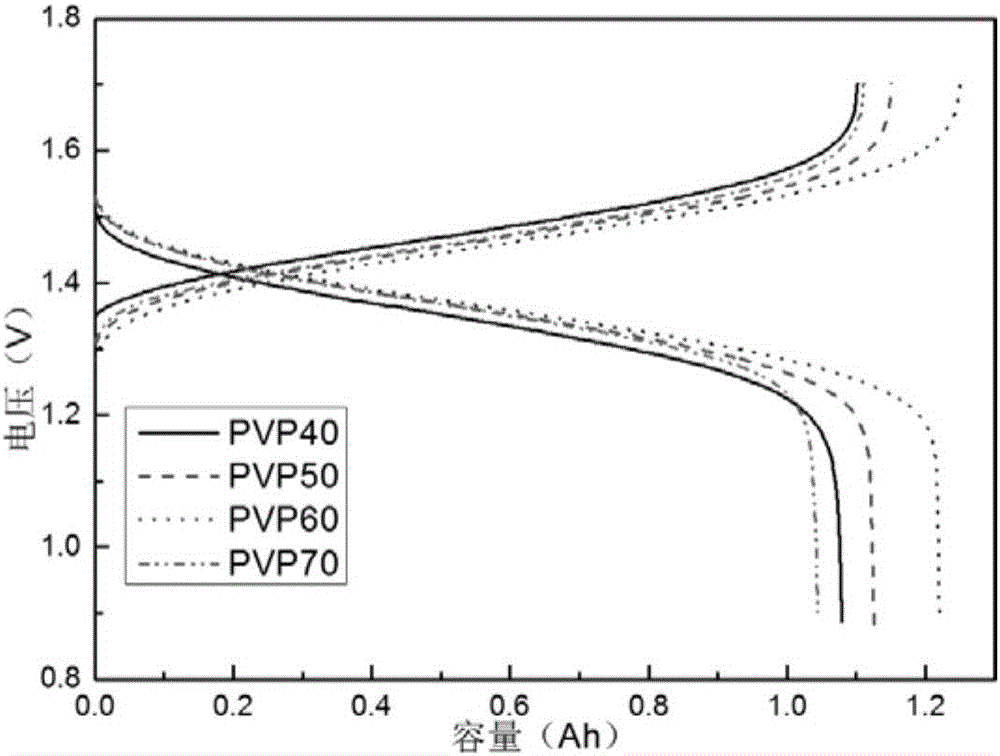

Polymer film applied to redox flow battery and preparation method and application thereof

InactiveCN105742678ASimple preparation processHigh film forming efficiencyRegenerative fuel cellsElectrolytic agentElectrical battery

The invention discloses a polymer film applied to a redox flow battery. The polymer film comprises a hydrophilic phase A and a hydrophobic phase B, wherein the mass percent of the hydrophilic phase A accounts for 10-80% of the polymer film, the hydrophilic phase A is arbitrary one of a hydrophilic macromolecule polymer, a cationic polymer and an anionic polymer, and the hydrophobic phase B is an aliphatic macromolecule polymer or an aromatic macromolecule polymer. The polymer film disclosed by the invention can be applied to the redox flow battery of an acidic electrolyte; and when the polymer film is applied to an all vanadium redox flow battery, the current efficiency of the battery reaches over 94%, the energy efficiency reaches over 75-90%, and the valid running time exceeds 2,000 hours.

Owner:THE HONG KONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com