Polymer film applied to redox flow battery and preparation method and application thereof

A polymer membrane and liquid flow battery technology, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve problems such as complex processes and development limitations, and achieve the effects of simple preparation process, overall performance optimization, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

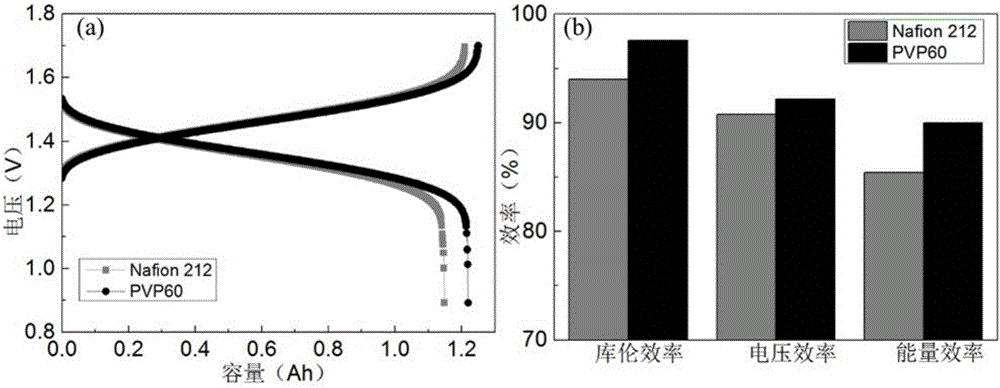

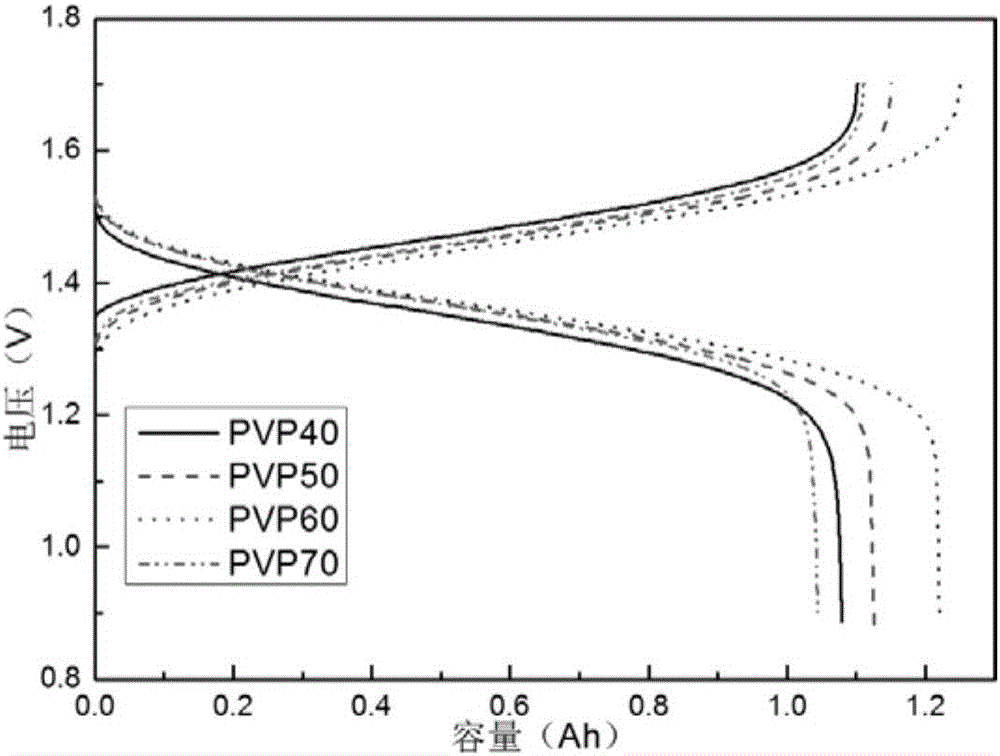

[0045] In an embodiment of the present invention, a polymer membrane applied to a flow battery includes a hydrophilic phase A and a hydrophobic phase B, the hydrophilic phase A is polyvinylpyrrolidone, the hydrophobic phase B is polysulfone, and the mass fraction of the hydrophilic phase A is 20-70%.

[0046] The preparation method comprises the steps of:

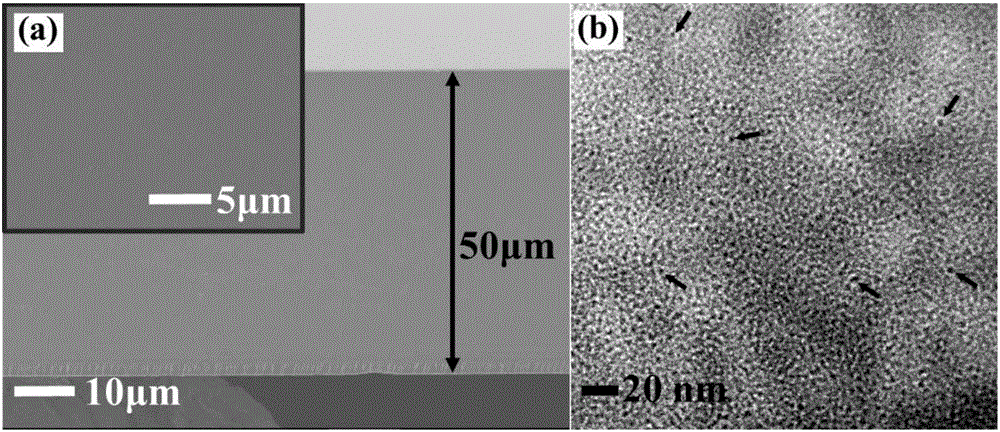

[0047] Mix the hydrophilic polymer A polyvinylpyrrolidone (molecular weight: 29-1300 kg / mol) and the hydrophobic polymer B polysulfone (molecular weight: 77-83 kg / mol) in proportion. The mixed polymer was dissolved in N,N-dimethylformamide (DMF), and stirred at room temperature for 12-24h. After the polymer is completely dissolved to form a homogeneous film solution, the film solution is placed on the surface of a clean glass plate, and the thickness of the liquid film is adjusted with an adjustable applicator. Place the film-coated glass plate in a strong convection oven and bake at 120-140°C for 6-20h. After the organi...

Embodiment 2

[0052] In an embodiment of the present invention, a polymer membrane applied to a flow battery includes a hydrophilic phase A and a hydrophobic phase B, the hydrophilic phase A is polyvinylpyrrolidone, the hydrophobic phase B is polysulfone, and the mass fraction of the hydrophilic phase A is 20-70%.

[0053] The preparation method comprises the steps of:

[0054] Mix the hydrophilic polymer A polyvinylpyrrolidone (molecular weight: 29-1300 kg / mol) and the hydrophobic polymer B polysulfone (molecular weight: 77-83 kg / mol) in proportion. Dissolve the mixed polymer in N,N-dimethylformamide (DMF), control the dissolution temperature between 20-80°C to obtain a polymer solution, and the mass percentage of organic solvent is 80-95% . A high-voltage electrospinning device was used to prepare the polymer film, the distance between the spinneret and the collecting plate was maintained at 10-20 cm, the spinning voltage was 10-20 kV, and the solution flow rate was 0.5-2 mL / min. Soak ...

Embodiment 3

[0059] In an embodiment of the present invention, a polymer membrane applied to a flow battery includes a hydrophilic phase A and a hydrophobic phase B, the hydrophilic phase A is polystyrene sulfonic acid, the hydrophobic phase B is chitosan, and the hydrophilic phase A The mass fraction is 20-70%.

[0060] The preparation method comprises the steps of:

[0061] Mix the hydrophilic polymer A polystyrene sulfonic acid and the hydrophobic polymer B chitosan in proportion. The mixed polymer was dissolved in N-methylpyrrolidone (NMP), and stirred at room temperature for 12-24h. After the polymer is completely dissolved to form a homogeneous film solution, the film solution is placed on the surface of a clean glass plate, and the thickness of the liquid film is adjusted with an adjustable applicator. Place the coated glass plate in a strong convection oven and bake at 60-80°C for 6-20h. After the organic solvent is completely volatilized, the temperature of the oven is slowly l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com