Patents

Literature

5713results about How to "Good mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing heat-resisting alumina-silox aerogel thermal-protective composite material

The invention discloses a method for preparing a heat-resisting alumina-silox aerogel thermal-protective composite material, which comprises the following steps: (1) preparing Al2O3 sol; (2) preparing SiO2 sol; (3) preparing Al2O3-SiO2 sol, (4) preparing SiC coating-containing reinforcing fibers; (5) mixing the SiC coating-containing reinforcing fiber felts or fiber prefabricated members and the Al2O3-SiO2 sol; (6) aging; and (7) carrying out drying treatment by using supercritical fluid. The operating temperature of the Al2O3-SiO2 aerogel composite material prepared by the method can reach 1,200 DEG C; and therefore, the Al2O3-SiO2 aerogel composite material has good heat-insulating property and good mechanical property.

Owner:NAT UNIV OF DEFENSE TECH

Polyethylene rubber and processing method thereof

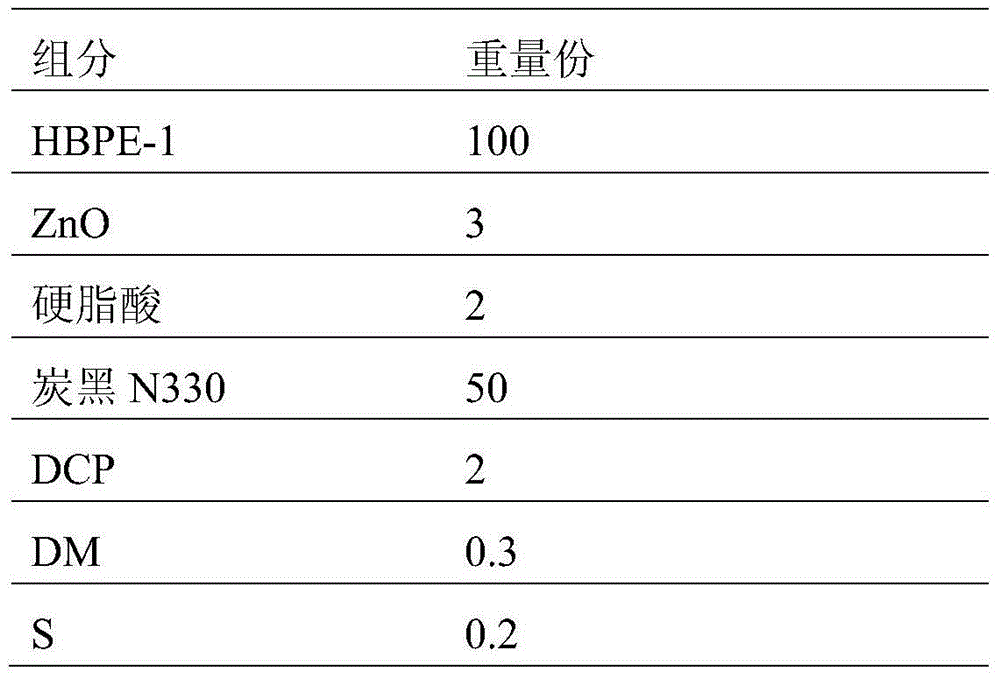

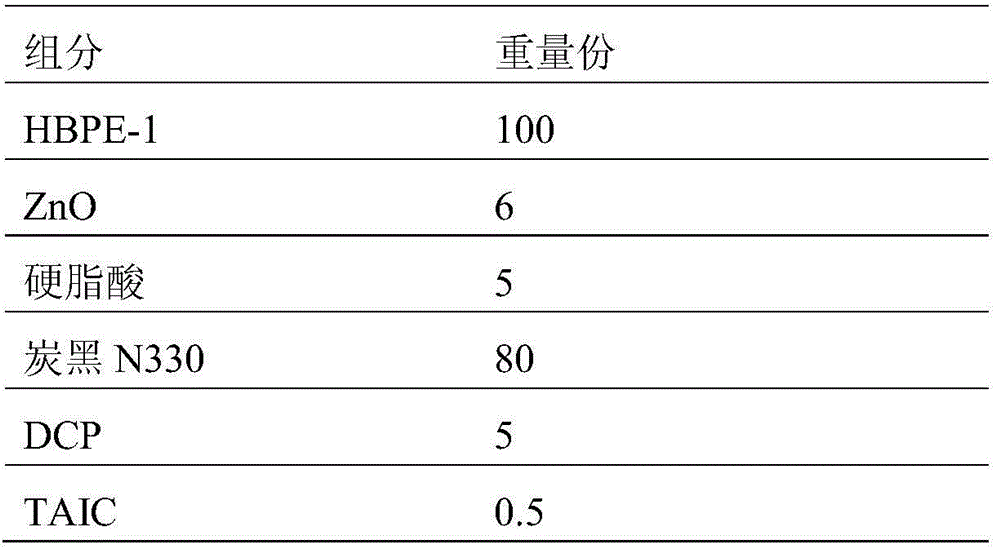

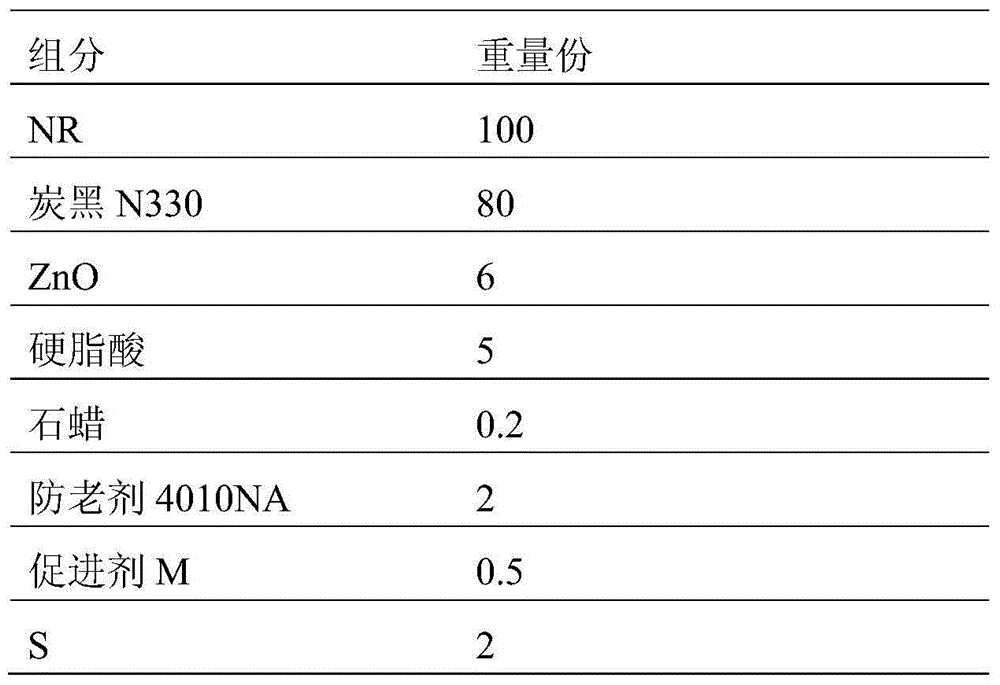

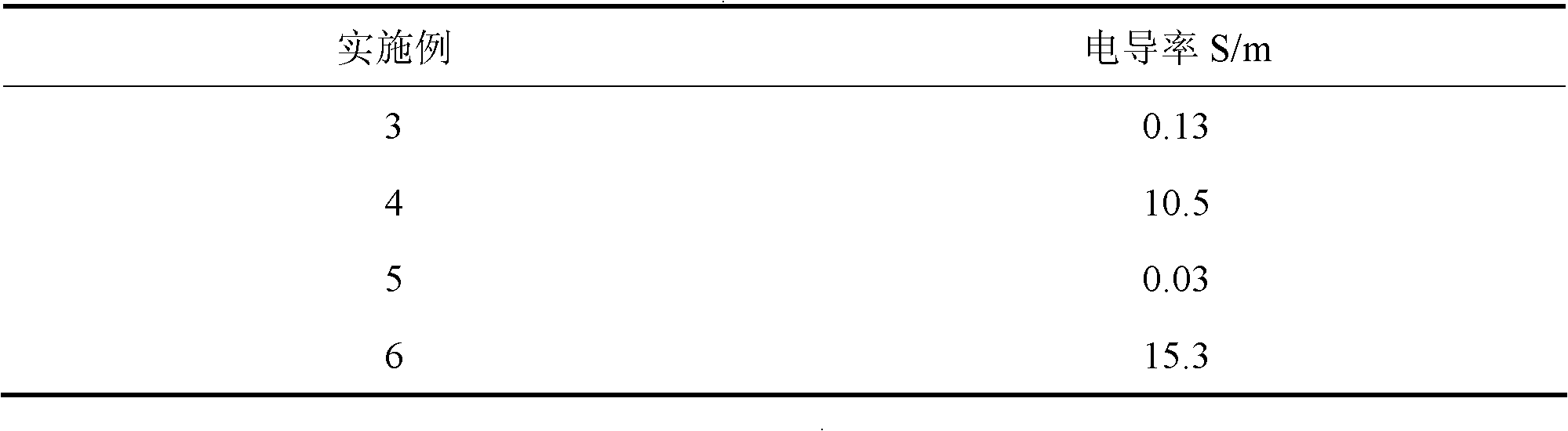

The invention belongs to the technical field of rubber, and particularly relates to polyethylene rubber and a processing method thereof. The polyethylene rubber comprises following raw materials by weight: 100 parts of hyper branched polyethylene, 50-80 parts of carbon black, 2-5 parts of a peroxide crosslinking agent, 0-6 parts of zinc oxide, 0-5 parts of a lubricant, 0.3-0.5 part of an accelerant, and 0-0.2 part of sulfur. Beneficial effects of the polyethylene rubber and the processing method thereof are that: the hyper branched polyethylene (HBPE) is sulfurized by utilization of a peroxide sulfurization system, has good mechanical performances through stress-strain performance tests, and has a characteristic of high elasticity of rubber. The processing method of the polyethylene rubber is totally different from preparation methods of chlorinated polyethylene rubber and chlorosulfonated polyethylene rubber at present. The polyethylene rubber and the processing method thereof break the limit that polyethylene can be only used for making plastic products, expand the application scope of the polyethylene, and largely increase the additional value of polyethylene homopolymers.

Owner:ZHEJIANG UNIV

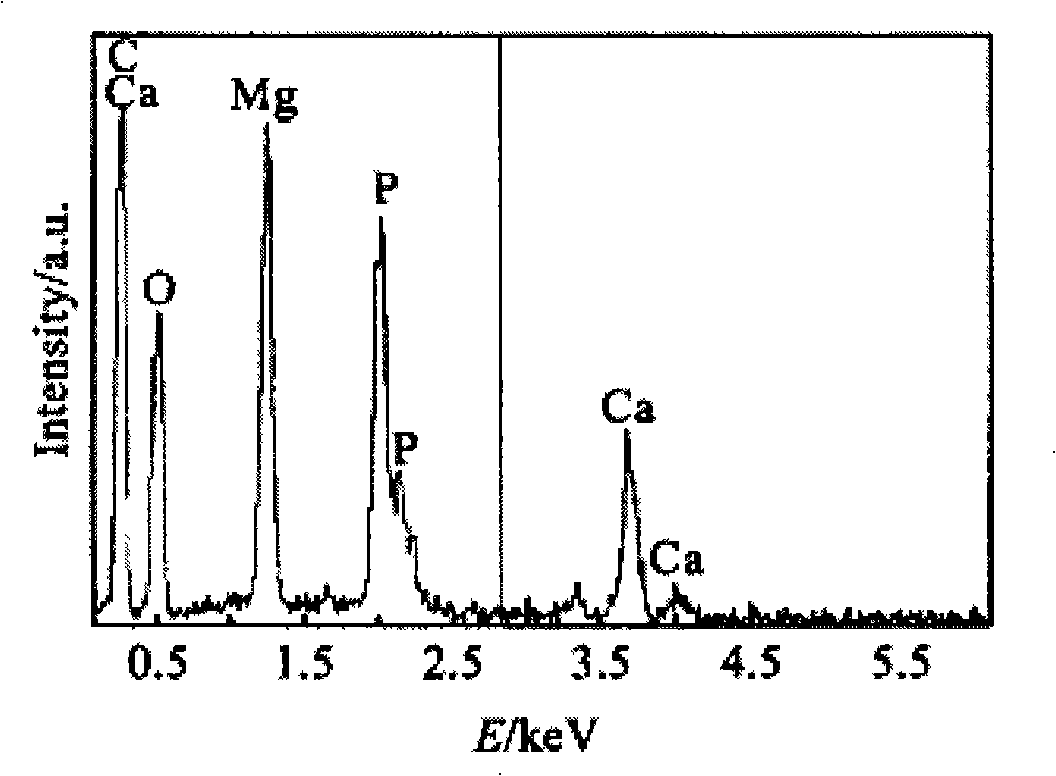

Metallic implant which is degradable in vivo

InactiveUS7879367B2Good mechanical propertiesProvide goodBiocideHeavy metal active ingredientsCorrosionBiomedical engineering

Owner:JORG MEYER

Preparation method of graphene/polymer nano composite material

ActiveCN102161785AEvenly dispersedGood mechanical propertiesOther chemical processesMagnetic/electric field screeningUltrasonic dispersionVacuum drying

The invention discloses a preparation method of a graphene / polymer nano composite material, which is characterized by comprising the following steps: adding 0.1-30 parts by weight of graphite oxide into 10-3000 parts by weight of water, and dispersing and exfoliating by carrying out ultrasonic dispersion (the power is 50-500W, and the frequency is 10-100000Hz) at 10-100 DEG C for 15 minutes-5 hours or mechanical lapping for 15 minutes-5 hours or mechanical stirring for 1-48 hours to obtain a graphene oxide water solution; adding the graphene oxide water solution into 100 parts by weight of polymer emulsion of which the solid content is 10-70%; continuing the ultrasonic or mechanical stirring to carry out uniform mixing; demulsifying by adding 1-100 parts by weight of 5-100% demulsifier toobtain a graphene oxide / polymer granular suspension; adding 0.1-100 parts by weight of reducer into the graphene oxide / polymer granular suspension, reducing at 20-100 DEG C for 1-72 hours, filtering,and drying in a drying oven at 20-100 DEG C for 2-72 hours or drying in a vacuum drying oven at 20-120 DEG C under a vacuum degree of 0.1-0.01 MPa for 2-48 hours, thereby obtaining the graphene / polymer nano composite material.

Owner:SICHUAN UNIV

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Controlled degradation magnesium alloy coating bracket and preparation thereof

InactiveCN101214396AImprove mechanical propertiesExcellent pharmacological propertiesAnodisationStentsSurface cleaningPolymer chemistry

The invention relates to a controlled degradation magnesium alloy coating stent and a preparation method. The stent body is made of medical high purity magnesium or magnesium alloy by mechanical processing or laser carving; the stent body is provided with a drug-loading coating which bears curative drug; the surface of the stent body is provided with an anti-corrosive coating; the surface of the anti-corrosive coating is provided with a degradable polymer film drug-loading coating; the preparation method includes surface cleaning, preparation of the degradable polymer film drug-loading coating, and application of curative drug; through (1)surface cleaning, (2)preparation of the degradable polymer film drug-loading coating, and (3)application of curative drug, an oxide film is formed on the surface; different drugs and dosage can be fixed by regulating the molecular weight and the thickness of the polymer layer, the drug-loading quantity is more than 30 percent, which improves the fixed stability of the drug, greatly reduces the degradation speed of the magnesium alloy and controls release of the drug, delays corrosion of the magnesium alloy, extends the service life of the stent, is safe in use, and meets the clinical requirement.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Flame-retardant polyester material with high glow wire ignition temperature and preparation method thereof

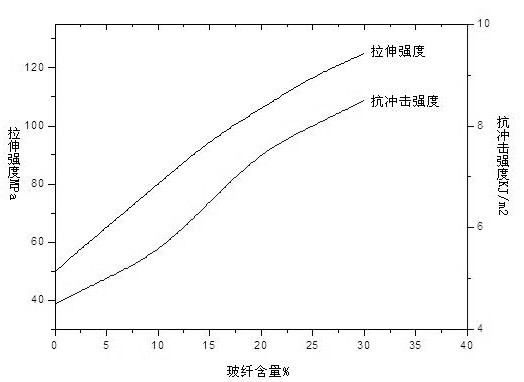

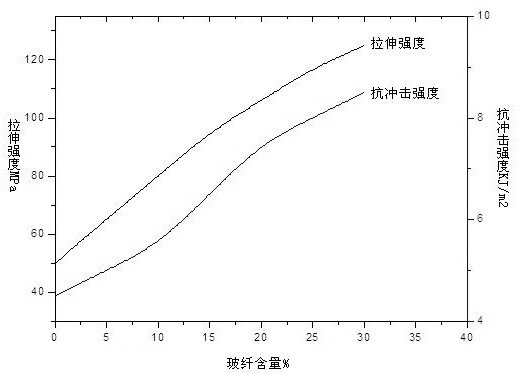

ActiveCN102250450AGWIT performance improvementsMeet performance requirementsPolyester resinUltimate tensile strength

The invention discloses a fame-retardant polyester material with a high glow wire ignition temperature and a preparation method thereof. The flame-retardant polyester material with a high glow wire ignition temperature is composed of the following components in parts by weight: 100 parts of polyester resins, 15-50 parts of bromine-series flame retardant, 5-20 parts of synergistic flame retardant, 0-20 parts of toughening agent, 0-80 parts of carbon forming agent, 5-40 parts of hot oxygen barrier agent, 0-120 parts of fibrous reinforcing agent and 0-10 parts of processing aid. The preparation method of the flame-retardant polyester material with a high glow wire ignition temperature comprises: drying the polyester resins, mixing with other components to obtain a premixed material, then feeding the premixed material into a twin-screw extruder, melting and plasticizing, kneading and mixing, extruding, drawing, cooling, pelletizing, drying and finally packaging. The flame-retardant polyester material with a high glow wire ignition temperature has the advantages of low cost, high glow wire ignition temperature, similar mechanical strength to ordinary flame-retardant polyester and wide application range.

Owner:KINGFA SCI & TECH CO LTD +1

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

Heat-conductive and anti-corrosion coating based on graphene functional material and preparation method of same

InactiveCN104817930AGood heat and corrosion resistanceGood mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsGraphene

The invention discloses a heat-conductive and anti-corrosion coating based on a graphene functional material, which includes following components: 0.05-6 parts of the graphene functional material, 60-80 parts of resin, 6-16 parts of a pigment, 8-18 parts of a filling material, 10-20 parts of a diluent, 0.1-0.3 parts of a defoaming agent and 10-30 parts of a curing agent. The invention provides the coating which is excellent in heat conductivity and anti-corrosion property and is based on the graphene functional material, wherein the graphene functional material has the excellent performances of various materials, so that the coating is enhanced in heat conductivity and further is enhanced in compactness and improved in anti-corrosion property.

Owner:山东利特纳米新材料有限公司

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

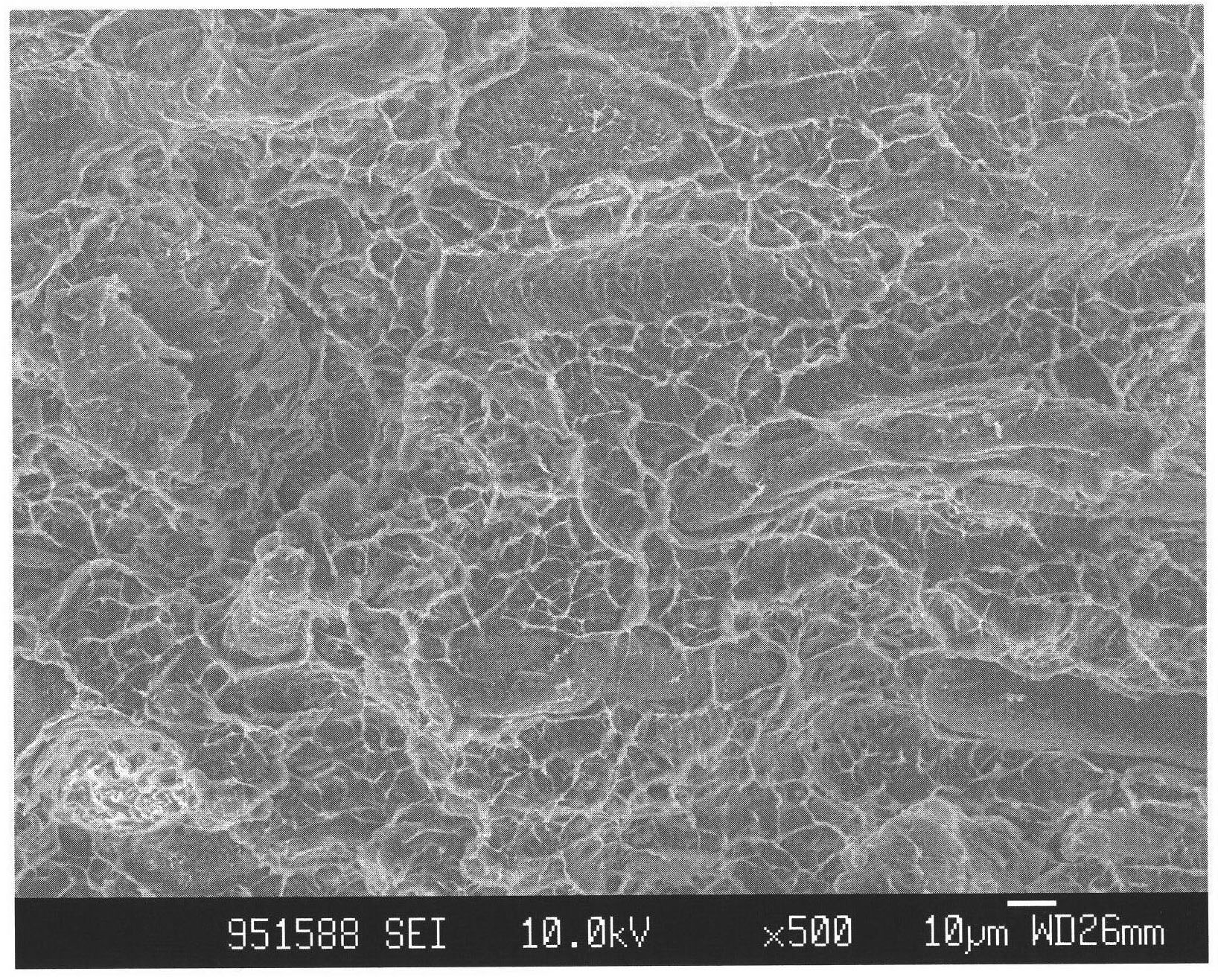

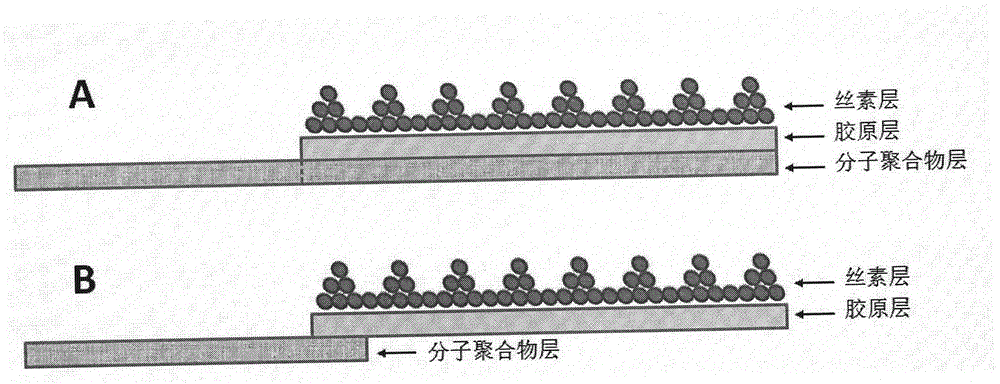

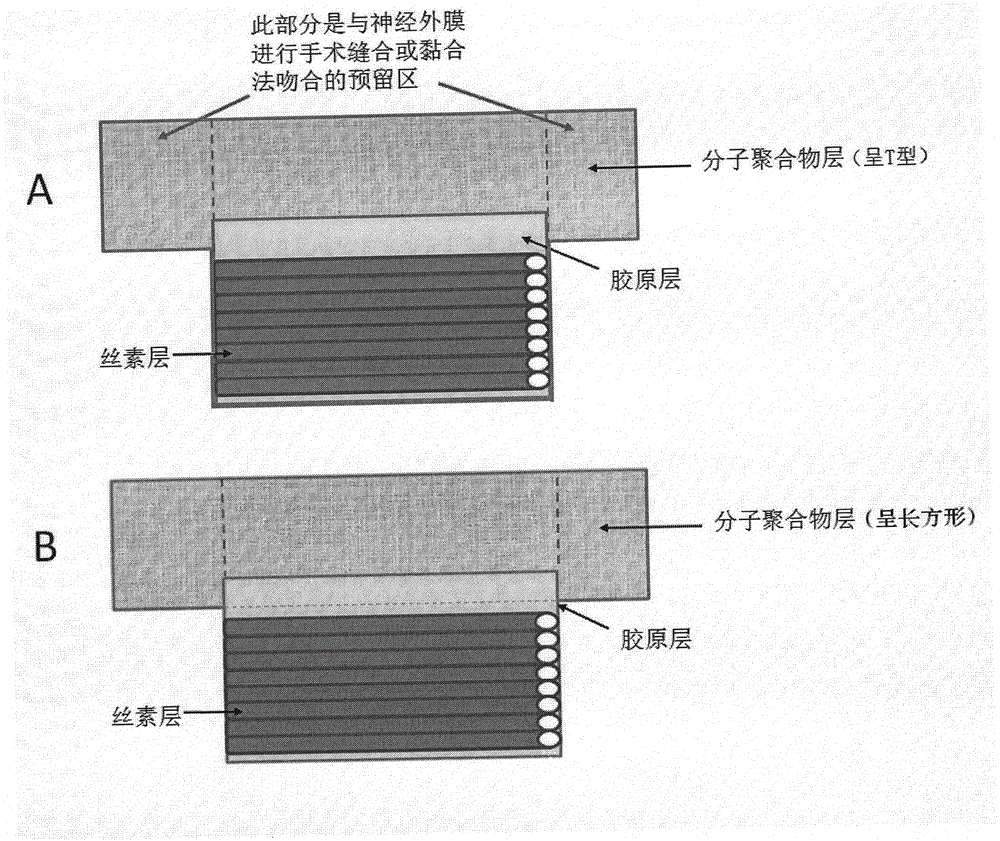

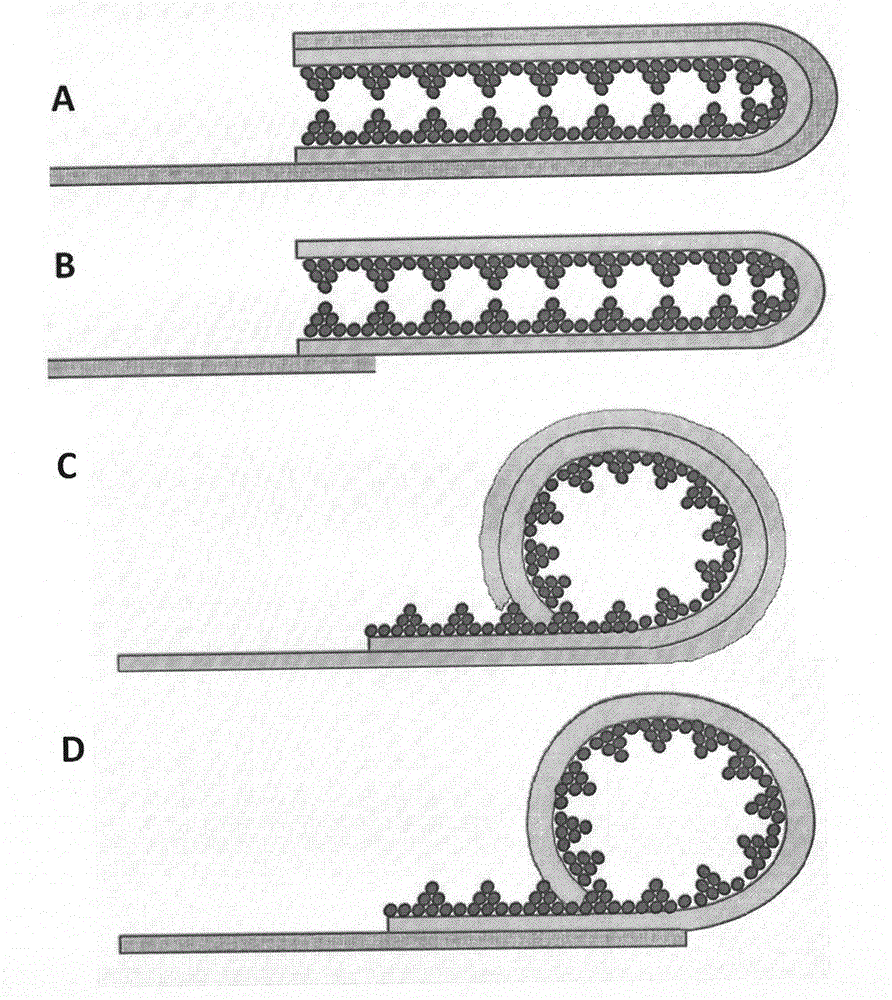

Composite repair material for bridging defect nerves and stent made of composite repair material

The invention provides a composite repair material which facilitates surgical operation and realizes quick defect nerve bridging and composition, preparation and application of a stent made of the composite repair material. The composite repair material consists of a fibroin layer, a collagen layer and a high-molecular polymer layer which are sequentially arranged, and during application, the composite repair material is folded or wound to form the nerve bridging stent taking the fibroin layer as the inner layer, the collagen layer as the middle layer and the high-molecular polymer as the outer layer. The composite repair material and the stent made of the composite repair material adopt the layered arrangement and a specific three-dimensional design to bring the advantages of various repair materials into full play, and meanwhile, make up for the deficiencies of the various repair materials. During surgical operation, only suturing or bonding anastomosis of epineurium is required but not suturing of perineurium, so that the operation time of a defect nerve bridging operation is greatly shortened, the operation technical difficulty is lowered, and the security is improved.

Owner:WENZHOU MEDICAL UNIV

Low smoke halogen-free flame retardant ethylene-propylene-diene rubber and preparation method by extrusion molding thereof

ActiveCN101704976AGood mechanical propertiesEasy extrusionEngine sealsVehicle sealing arrangementsPolymer scienceMechanical property

The invention relates to a low smoke halogen-free flame retardant ethylene-propylene-diene rubber and a preparation method by extrusion molding thereof; the preparation method comprises the following steps: firstly, raw rubber matrix is evenly mixed at 80-100 DEG C by an open mill or a banbury mixer, and then cooled down to the room temperature; carbon black, modified nanometer / micrometer hydroxide, plasticizer, flame retardant synergist, vulcanization accelerator and vulcanizing agent are added in sequence according to the proportion and evenly mixed. Mixed rubber is added into a single screw extrusion machine; the temperature of a machine body, a screw and a machine head is controlled to be 50-90 DEG C; the rotating speed of the screw is within 15-40 r / min to cause that glue stock is continuously squeezed out; and hot air (175-200 DEG C) or microwave (915-2450 MHz) is adopted to cause that the glue stock is continuously vulcanized and molded. The flame retardant ethylene-propylene-diene rubber has excellent mechanical property, low smoke halogen-free flame retardant performance and good extrusion performance, and is applicable to manufacturing of flame retardant gland strips used in doors and windows for building and vehicles.

Owner:BEIJING UNIV OF CHEM TECH +1

Halogen free flame retardant nylon 6 composite with high CTI value and preparation method thereof

InactiveCN101812231AHigh CTI valueImprove flame retardant performancePolymer scienceFlexural strength

The invention discloses a halogen free flame retardant nylon 6 composite with high CTI value and a preparation method thereof. The composite comprises the following components by mass percent: 643.5-68.8wt.% of nylon, 10-12wt.% of fire retardant, 7-19wt.% of fire retardant synergetic inorganic packing, 8-12% wt.% of toughening agent, 1-3wt.% of bulking agent, 5-10% wt.% of enhance inorganic filler and 0.2-0.5wt.% of anti-oxygen which are prepared into the compound by a high speed premixing dispersing primary extrusion processing. The disclosed composite has as high as 550V CTI value and UL 94V-0 level excellent fire resistance; simultaneously, the polymer has good mechanical property by a comprehensive modified technique, wherein the tensile strength reaches 70.5Mpa, the bending strength reaches 90.7MPa and the impacting strength of a gap reaches 28.1kJ / m2. The invention solves the problem that the flaming resistant and high CTI value are difficult to satisfy simultaneously; the inventive 6 nylon compound is very suitable for preparing a low-pressure vacuum contactor, a transformer coil framework, a high-temperature resistant relay, a breaker, a high voltage electrical apparatus, a handle and a thin wall electronic and electrical appliance elements, and the like.

Owner:BEIJING UNIV OF CHEM TECH

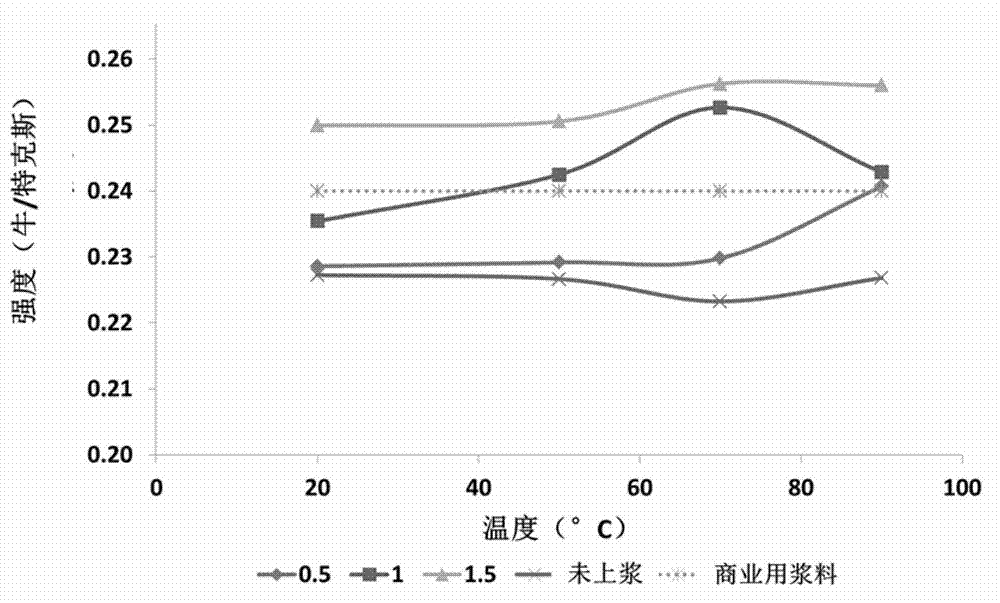

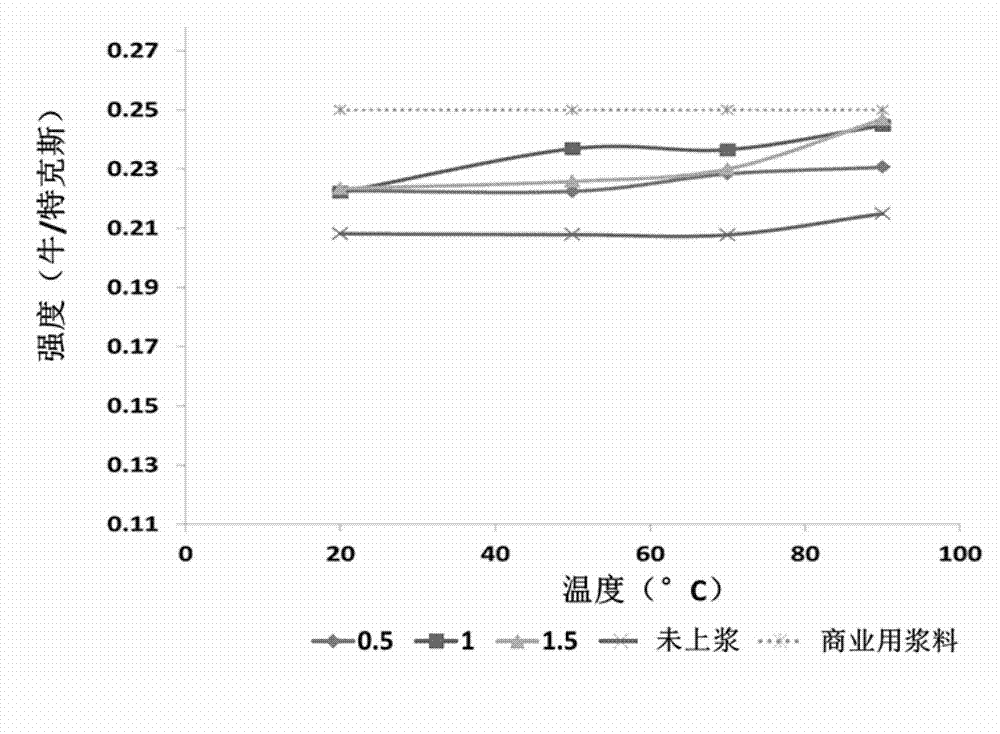

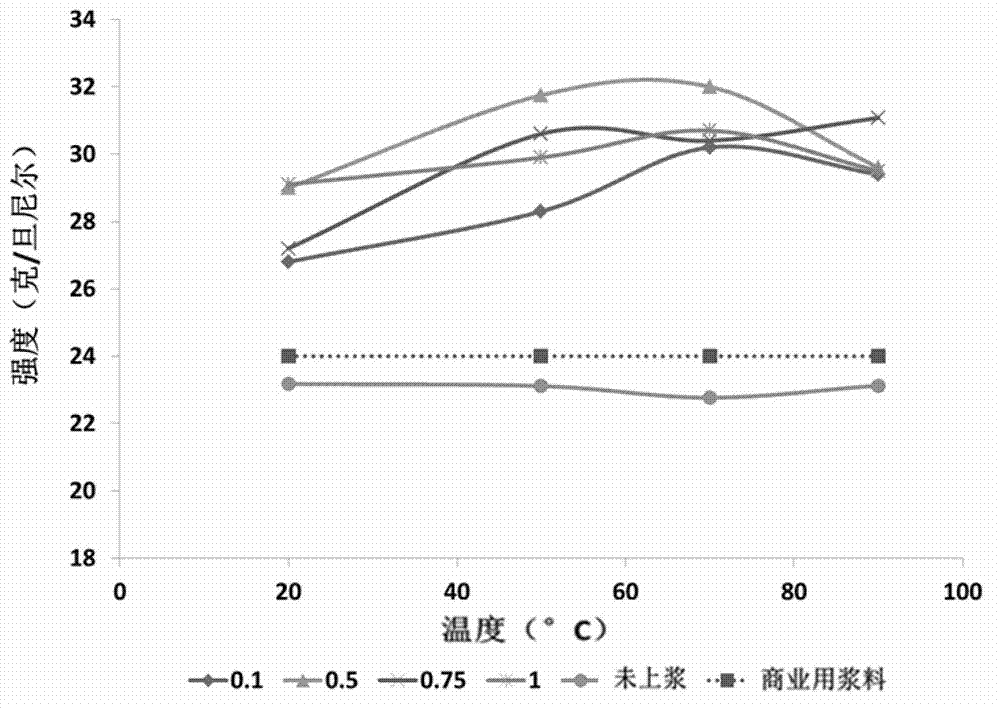

Preparation method of proteins and protein-based sizes for warp sizing

InactiveCN103087332AGood film formingGood mechanical propertiesFibre treatmentProtein proteinChemistry

The invention relates to a preparation method of proteins and protein-based sizes for warp sizing. The method comprises the following steps: (1) taking, putting the protein raw materials, such as plant proteins, animal proteins or animal-protein-based-materials, which are taken as size raw materials, into a sodium hydroxide solution or an alcohol solution, heating the obtained mixture for 30-60 minutes under the constant temperature condition of 20-90 DEG C, adjusting the pH value of the obtained mixture to be 7-8, removing undissolved precipitates through centrifugation or suction filtration, and eventually producing proteins or protein-based sizes; and (2) soaking thick yarns, spun yarns, fabrics or other textile materials into the sizes for 5-10 minutes at 20-90 DEG C, and after fabrics are soaked in the sizes, carrying out constant-speed rolling in the thickness direction of the fabrics. The proteins and the protein-based sizes prepared by using the method disclosed by the invention have good biodegradable properties, and can be directly applied to the sizing of cotton yarns, polyesters, polyester cotton blended yarns and other blended yarns, and the size preparation is low in cost and does not pollute the environment.

Owner:DONGHUA UNIV

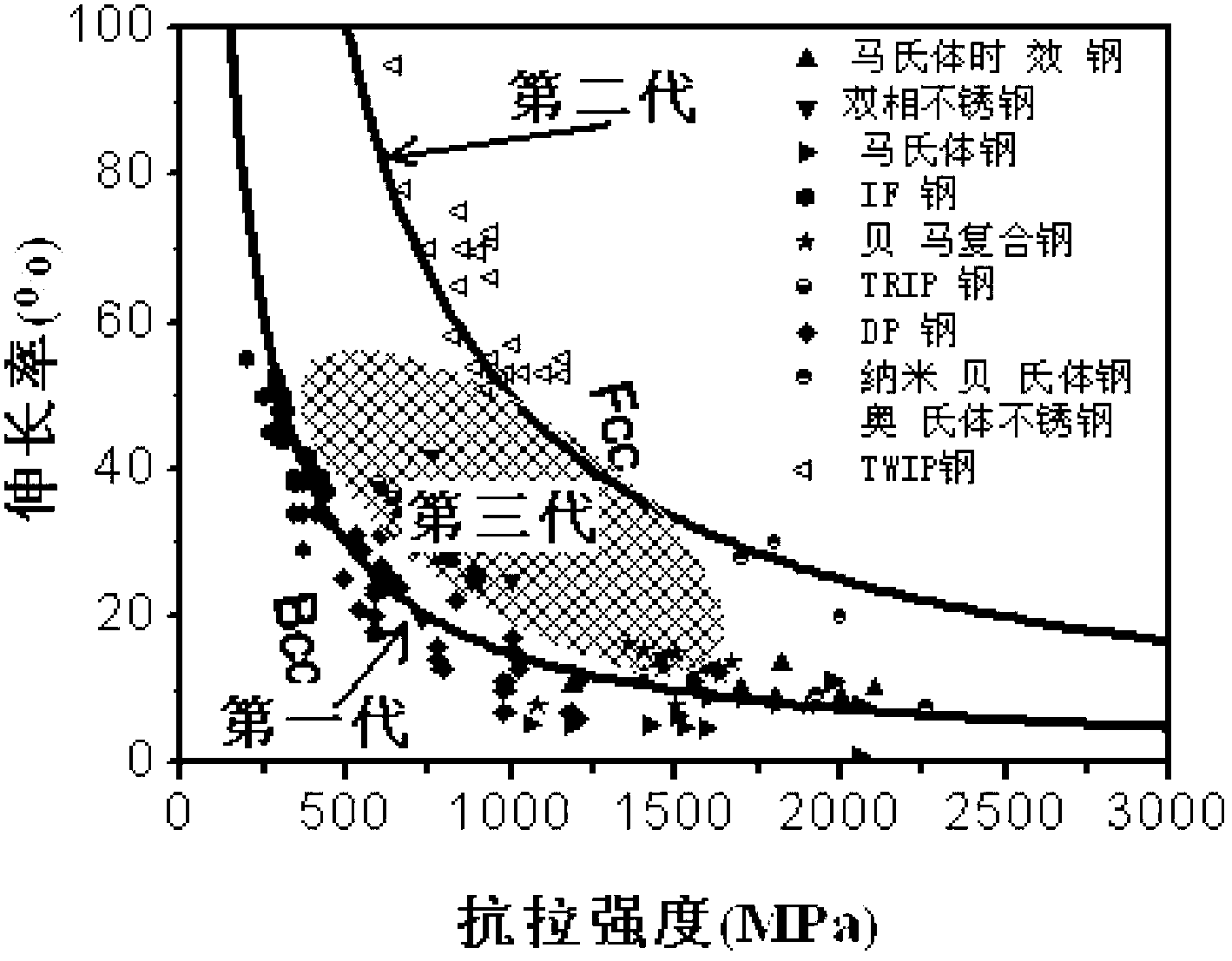

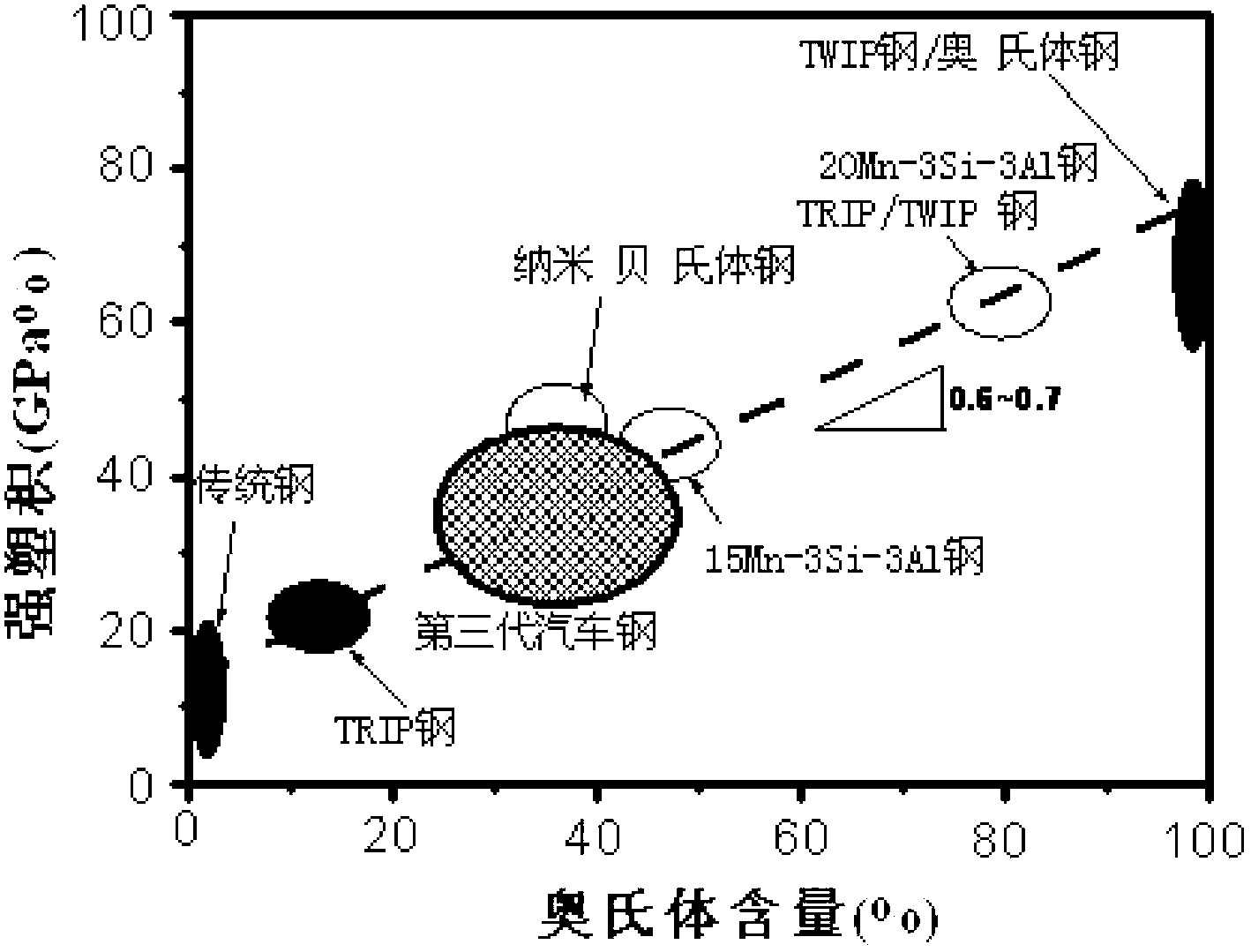

Medium temperature deformation nanometer austenite enhanced plasticized steel and preparation method thereof

The invention provides a medium temperature deformation nanometer austenite enhanced plasticized steel and a preparation method thereof, belonging to the technical field of high-strength high-plasticity automobile steel sheet materials, section bars and rods and wires. The steel comprises the following chemical components by mass: 0.03 to 0.39 wt% of C, 2.0 to 9.0 wt% of Mn, 0 to 2.0 wt% of Al, 0 to 2.0 wt% of Si, 0 to 2.0 wt% of Cr, no more than 0.020 wt% of P and no more than 0.02 wt% of S, with the balance being Fe and unavoidable impurities. The steel may further comprise one or more elements selected from the group consisting of 0.1 to 3.0 wt% of Ni, 0.1 to 0.8 wt% of Mo, 0.5 to 2.0 wt% of Cu, 0.0005 to 0.005 wt% of B, 0.02 to 0.10 wt% of Nb, 0.002 to 0.25 wt% of N, 0.05 to 0.25 wt% of Ti, 0.02 to 0.25 wt% of V, 0.002 to 0.005 wt% of RE and 0.005 to 0.03 wt% of Ca. The invention has the following advantages: sizes of austenite and ferrite of the steel are in a range of 50 to 250 nm; low cost, easy production, high strength and high plasticity are realized; the steel has yield strength of 0.6 to 1.3 GPa, tensile strength of 1.0 to 1.5 GPa and plasticity of 20 to 50% and has good low-temperature toughness.

Owner:CENT IRON & STEEL RES INST

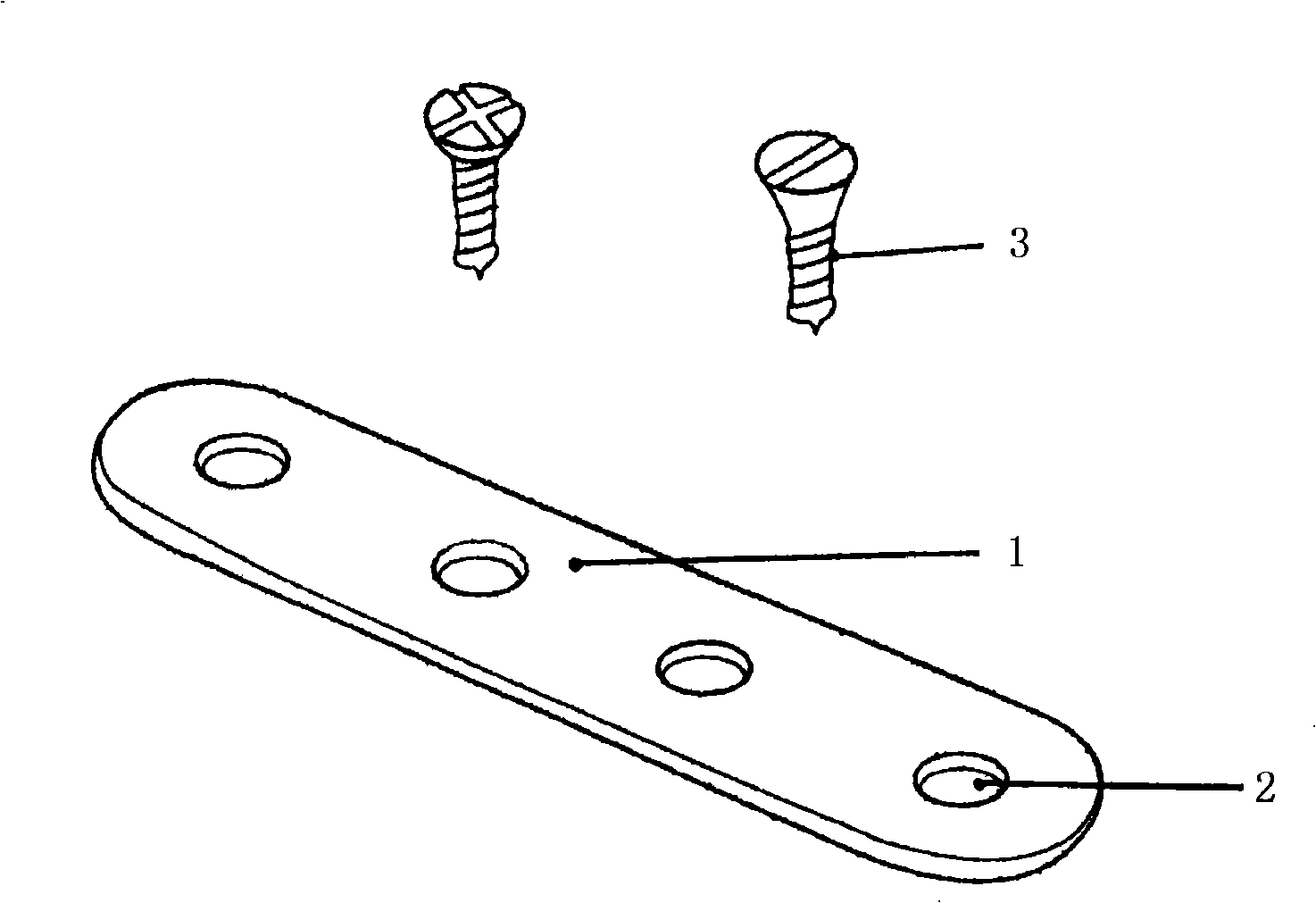

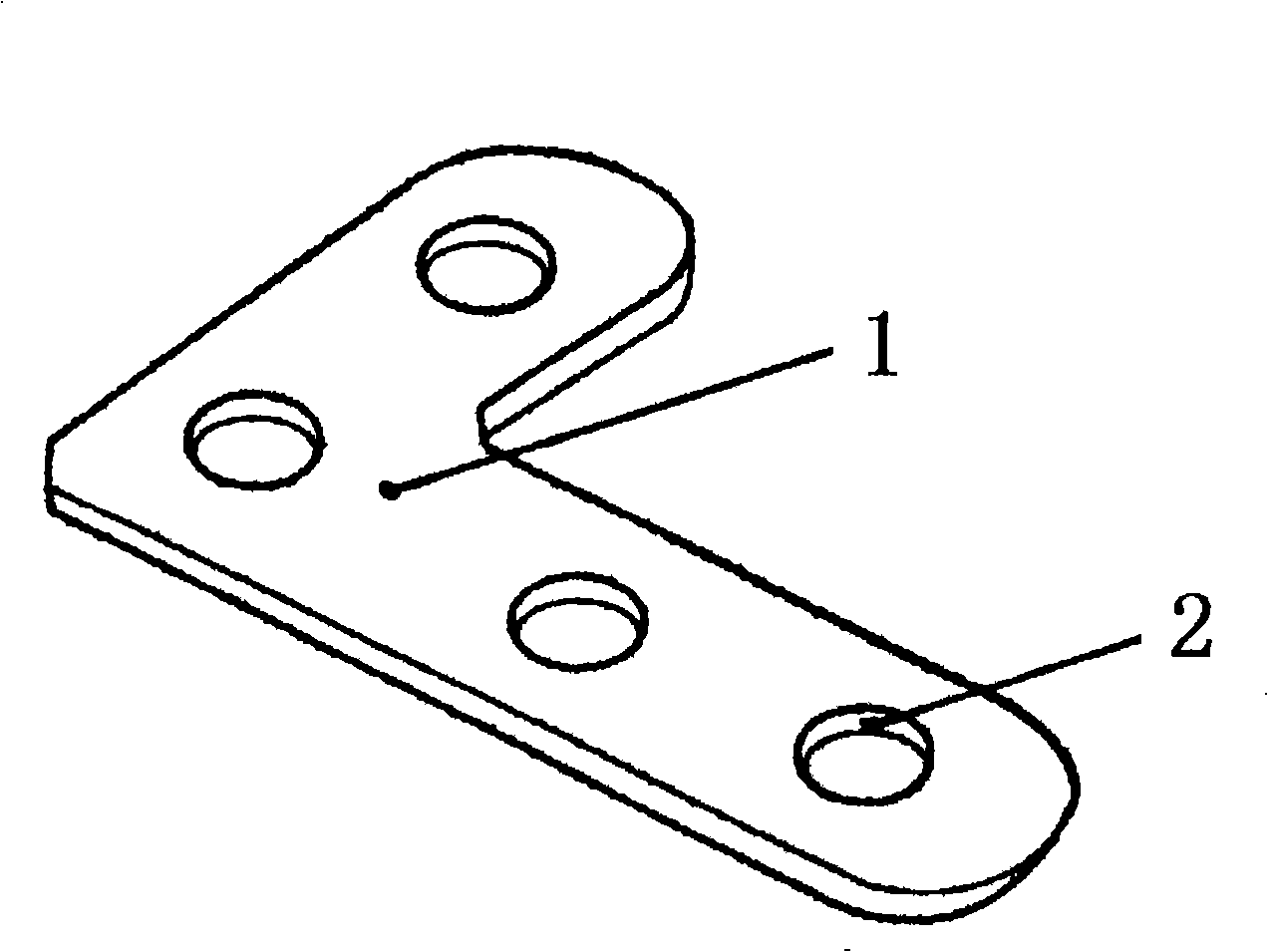

Biological and adsorbable bone internal fixation implantation instrument

InactiveCN101283922APromote healingUniform corrosion degradationInternal osteosythesisProsthesisInternal bone fixationReconstructive surgery

The invention relates to a bone implanting and internal fixation appliance with bioactivity and absorbability, which belongs to the field of bio-medical appliances, particularly to the field of medical appliances used for bone wound surgery, reparative and reconstructive surgery and plastic and cosmetic surgery. The appliance includes bone nails and a bone plate made of magnesium and the alloy thereof with bioactivity and absorbability. The bone implanting and internal fixation appliance is a bone internal fixation device, which comprises a blade plate and matched screws, intramedullary nails, a fracture and dislocation fixing device of vertebral column, bone nails or screws having individual fixation effect, wherein the bone internal fixation device is made of magnesium and the alloy thereof with bioactivity and absorbability. The bone internal fixation device can solve the problem in bioactivity of prior bone internal fixation device and promote healing the tissue where the device in implanted. The device also includes a protection layer prepared on the surface of the internal fixation device for controlling the degradation rate of magnesium alloy and the dissolution rate of magnesium ions, thus controlling the bioactivity and the absorption speed of the magnesium alloy device in an organism.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

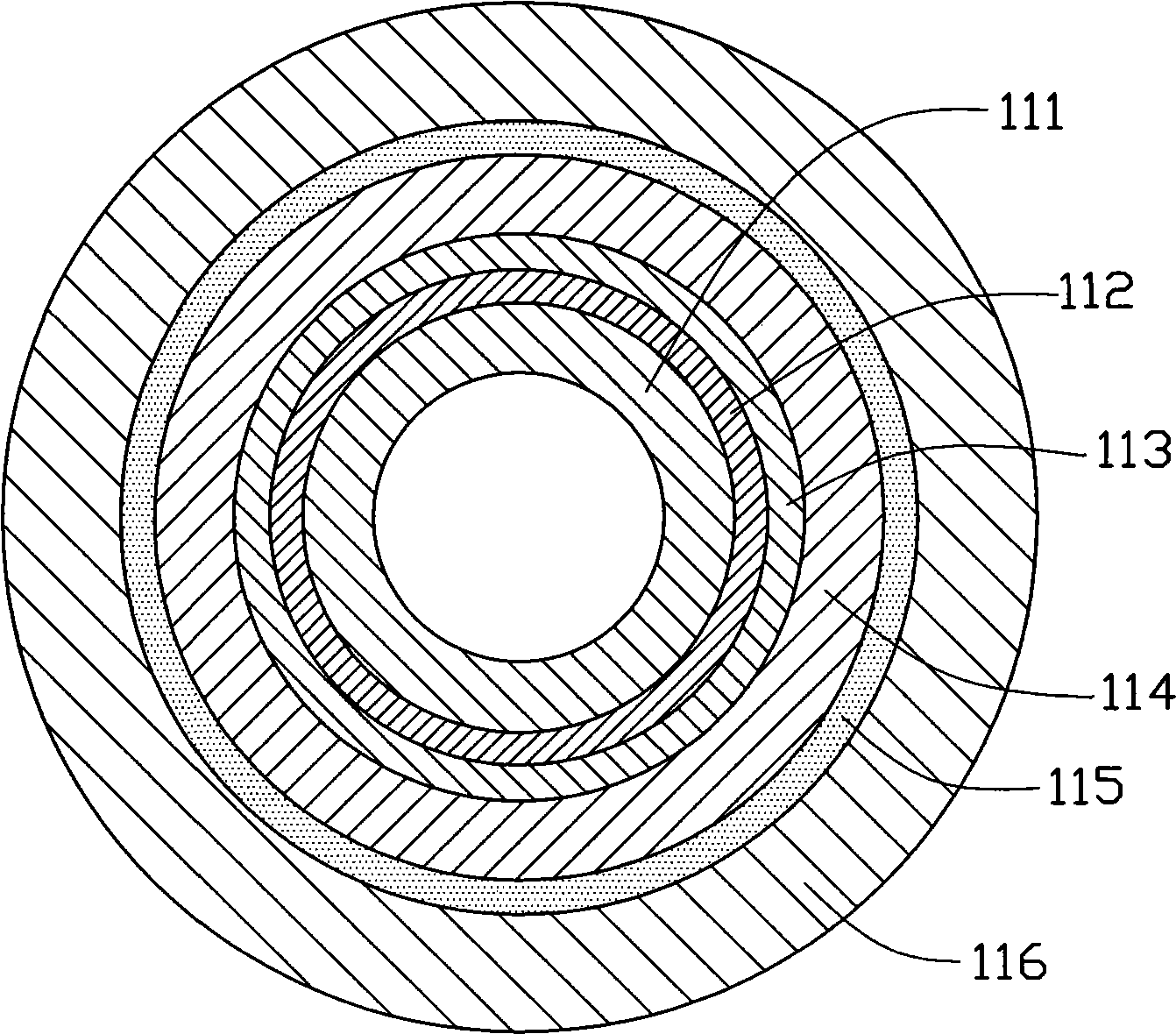

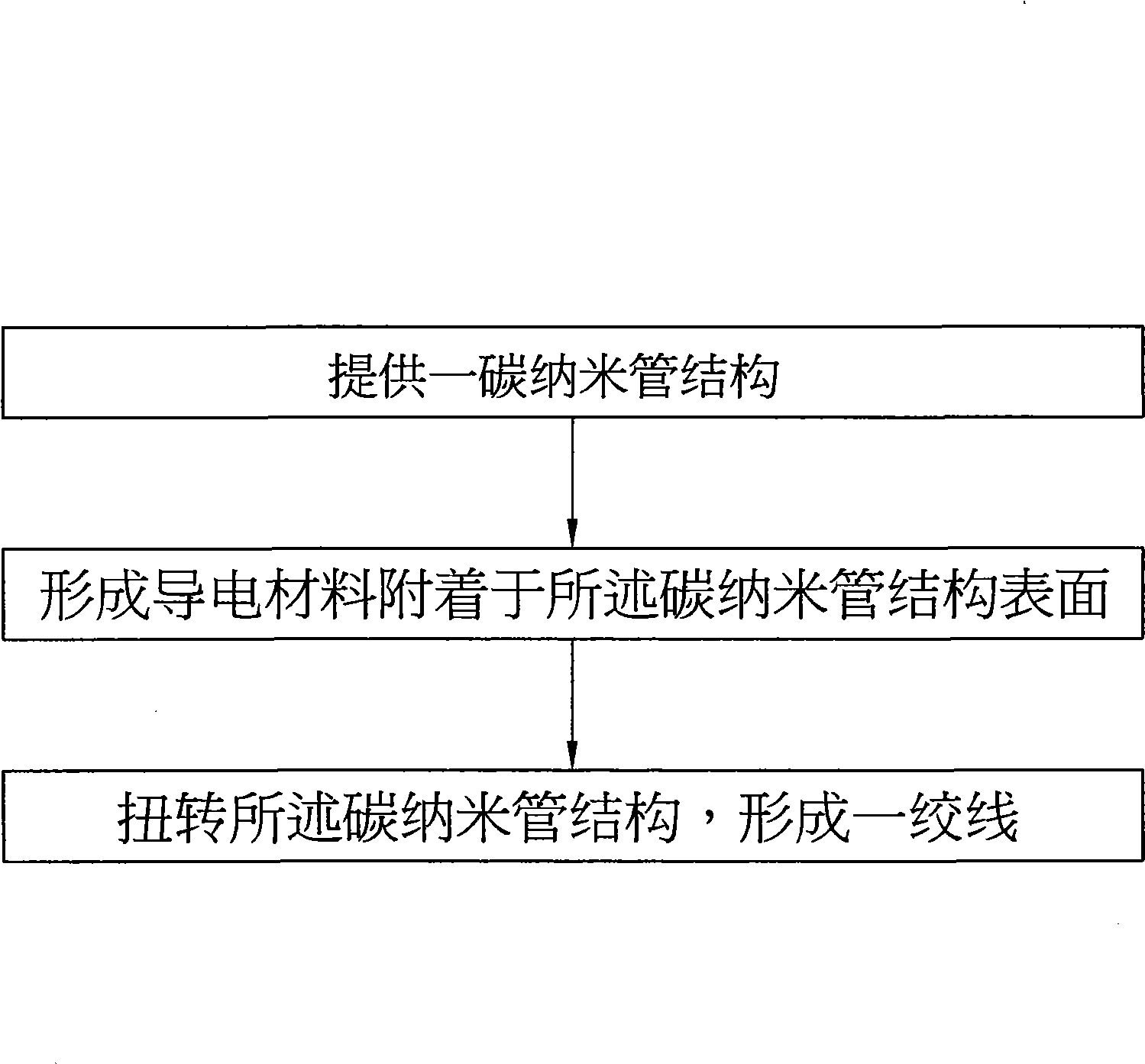

Stranded wire

ActiveCN101499328ALight in massHigh mechanical strengthNon-insulated conductorsIndividual molecule manipulationCarbon nanotubeConductive materials

The invention relates to a twisted line which comprises a plurality of carbon nano tubes that are connected with each other end to end by van der waals force, wherein the twisted line further comprises conducting materials covering on the surfaces of the carbon nano tubes.

Owner:TSINGHUA UNIV +1

Super-strength high-toughness wear resistant steel plate and production method thereof

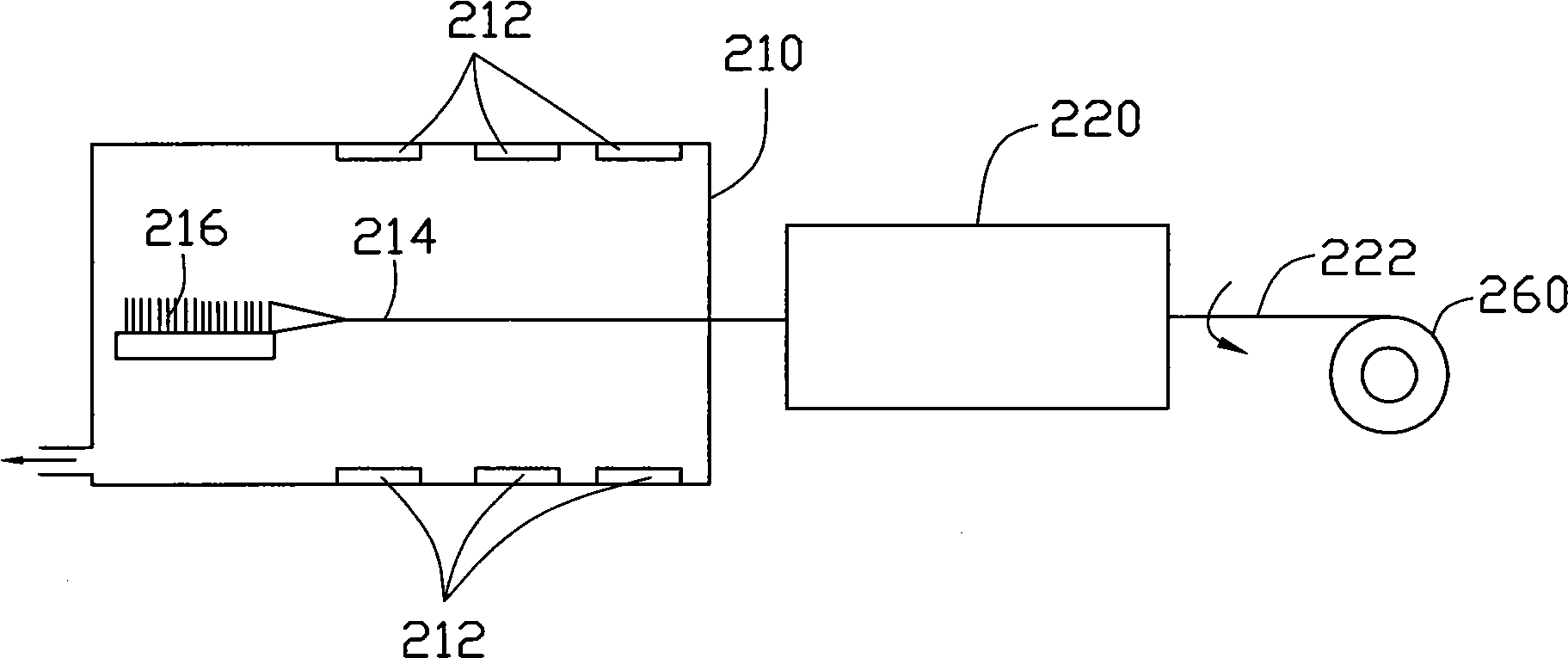

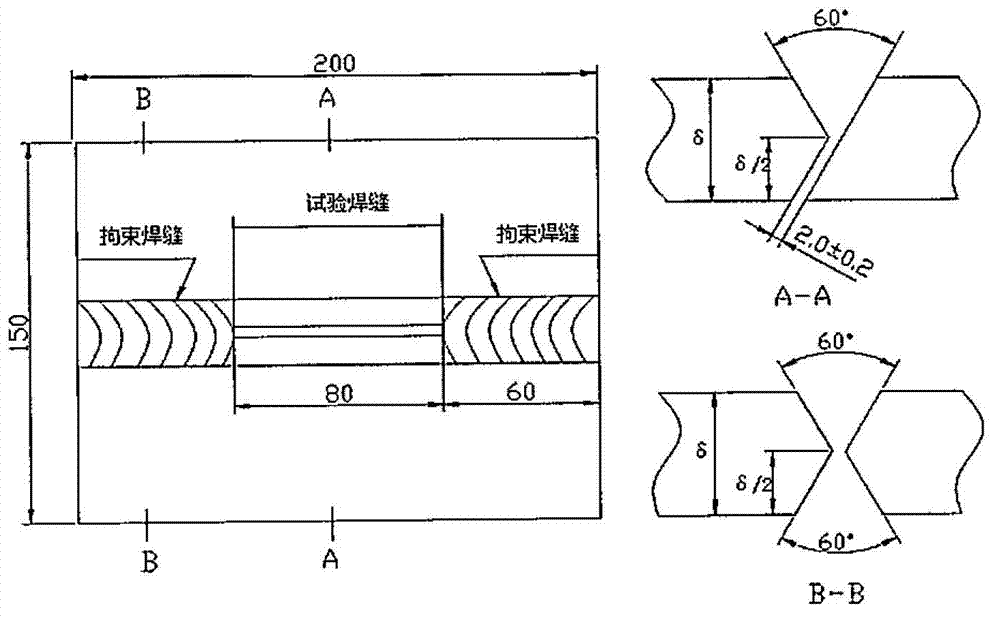

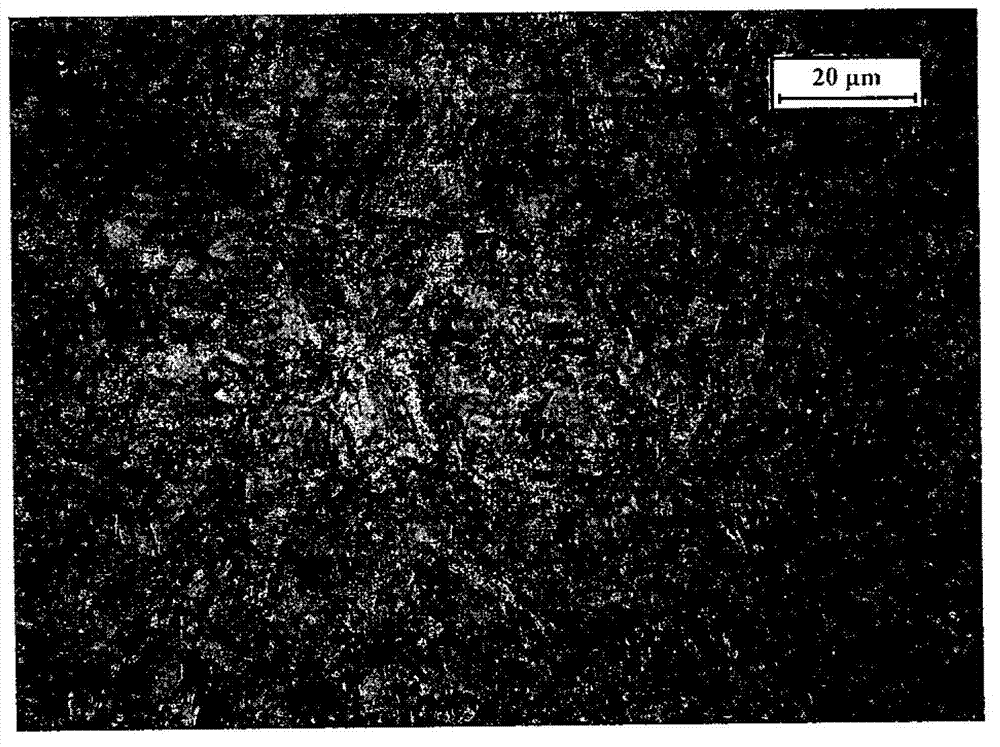

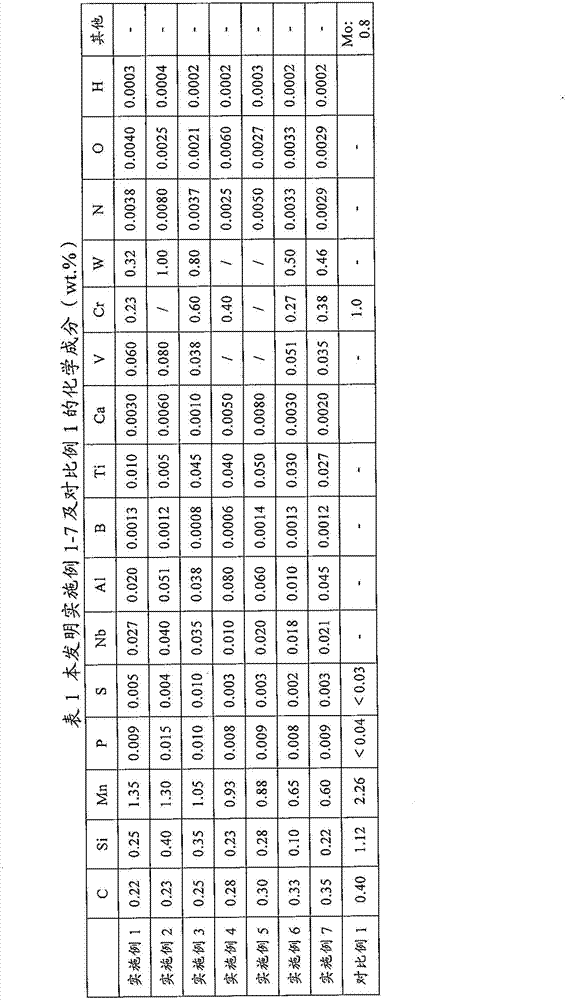

ActiveCN102876969AStrong mechanical propertiesGood mechanical propertiesFurnace typesQuenching agentsWear resistantHigh intensity

The invention provides a wear resistant steel plate, comprising the following chemical components (wt%): 0.22-0.35% of C, 0.10-0.40% of Si, 0.60-1.35% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.010-0.040% of Nb, 0.010-0.080% of Al, 0.0006-0.0014% of B, 0.005-0.050% of Ti, 0.0010-0.0080 wt% of Ca, not more than 0.080% of V, not more than 0.60% of Cr, not more than 1.00 wt% of W, not more than 0.0080% N, not more than 0.0060% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein Nb+Ti is not less than 0.025% and not more than 0.080%, and Al+Ti is not less than 0.030% and not more than 0.12%. The production method of the wear resistant steel plate comprises the steps of smelting, casting, rolling and directly cooling after rolling. The wear resistant steel plate obtained through the components and the process has the advantages of high intensity, good low temperature toughness, and excellent mechanical processing performance, and is suitable for easily abrasive devices in engineering and mine machinery, such as a grab bucket, a scraper conveyer and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

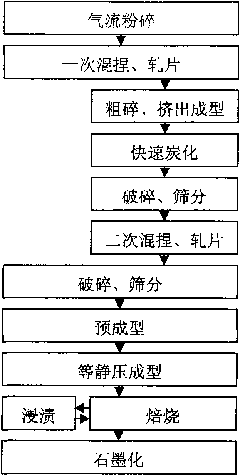

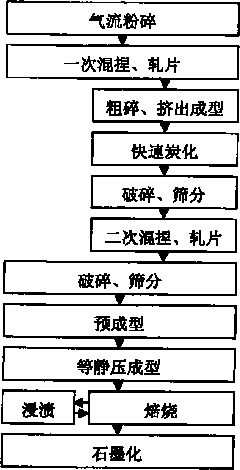

Technical method for producing isostatic pressure graphite

The invention provides a technical method for producing isostatic pressure graphite, which comprises the following steps: using refinery coke or pitch coke as raw materials; crushing raw materials to 5 to 20 mum through airflows; then, carrying out treatment through work procedures such as primary mixing squeezing and sheet milling, extrusion forming, fast carbonization, crushing, sieving, secondary mixing squeezing and sheet milling, crushing, sieving, pre-forming, isostatic pressure forming, calcination, impregnating, graphitization and the like; and obtaining fine particle isostatic pressure isotropical graphite materials. Compared with traditional coarse particle graphite materials, the invention has the characteristics of fine and compact structure, good uniformity, excellent mechanical property, isotropy and the like, and is particularly suitable for the production of large-specification graphite products.

Owner:SICHUAN GUANGHAN SHIDA CARBON +1

Lubricity coatings preparation method on the medical catheter polymers surface

InactiveCN101455861AImprove surface physicochemical propertiesChange adsorption stateCatheterCoatingsPolymer scienceGraft reaction

The invention discloses a method for preparing a lubricant coating on the surface of polymer materials of a medical catheter, which comprises the following steps: (A), pretreating the surface of the polymer materials of the medical catheter, so as to obtain hydrophilic adsorption active sites; (B), soaking the pretreated polymer materials of the medical catheter in step (A) into a prepared precursor solution of the lubricant coating for adsorption; and (C), performing grafting reaction on the soaked polymer materials of the medical catheter in step (B), and washing and drying the polymer materials of the medical catheter. The method can be widely used for preparing medical polymer materials and coating materials on the surface of a medical apparatus.

Owner:SOUTHEAST UNIV

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

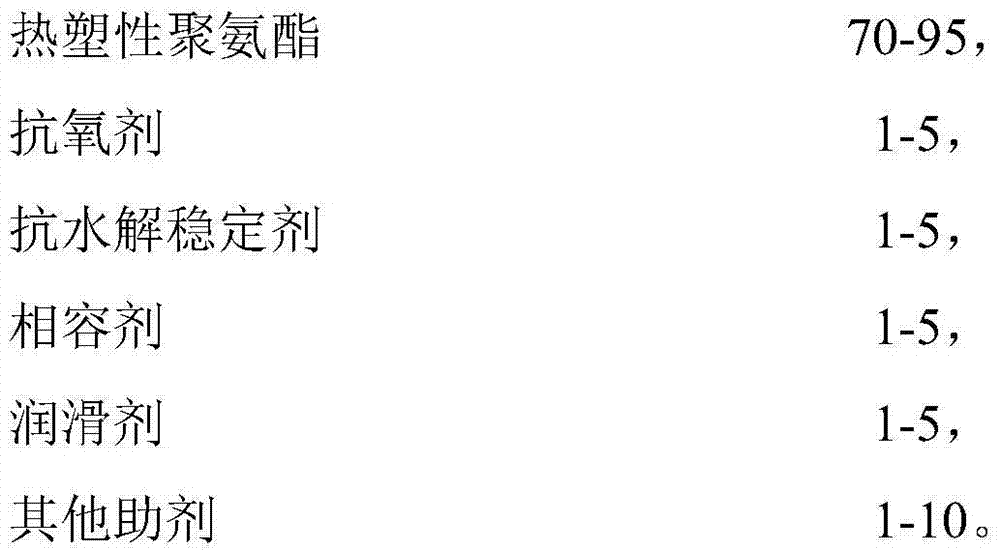

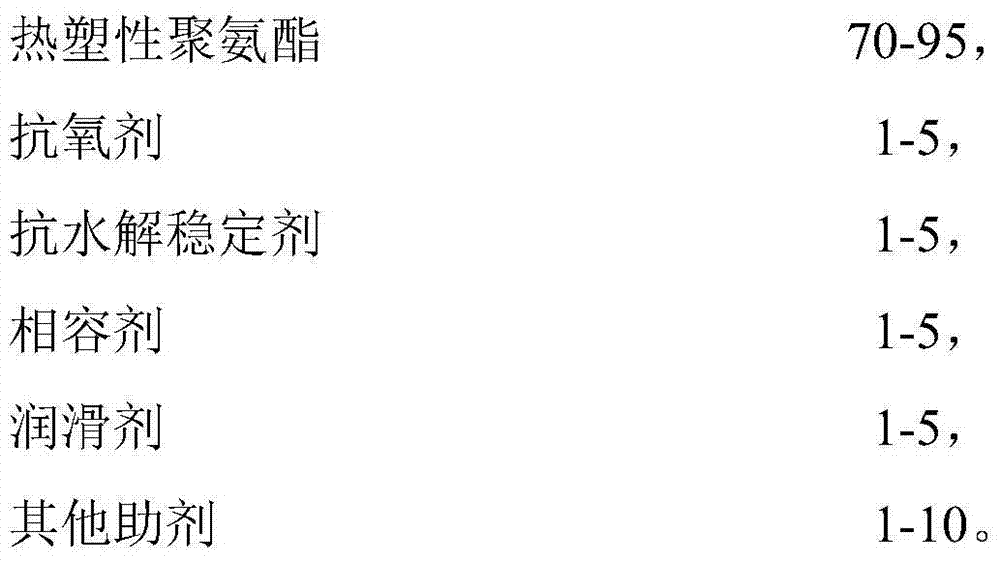

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Carbon composite high-thermal-conductivity plastic material and preparation method thereof

The invention discloses a carbon composite high-performance thermal-conductive plastic and a preparation method thereof; the thermal-conductive insulating plastic is prepared from a resin basic material, a carbon composite material, a thermal-conductive agent, a coupling agent, an antioxidant and other processing agents; by means of the special crystalline structure of the carbon composite material added in the formula of the thermal-conductive insulating plastic disclosed by the invention, the inter-particle bridging effect is realized; a thermal-conductive passage composed of the thermal-conductive agent is more and more perfect; therefore, the thermal conductivity of the composite material can be rapidly increased; a filling material gathering and thermal-conductive passage is more and more perfect; simultaneously, with the help of the processes, such as a pre-mixing process, an extrusion process, a cooling process, an air drying process and a granulating process, the problems of being degraded in high filling property and low in thermal-conductive property of the plastic are solved; the thermal-conductive composite material having excellent mechanical property and good thermal-conductive effect and insulating property can be prepared; and the thermal-conductive composite material can be widely applied in the fields, such as electrons, automobiles and LED (Light Emitting Diode) lamps.

Owner:HUIZHOU KINGBALI TECH

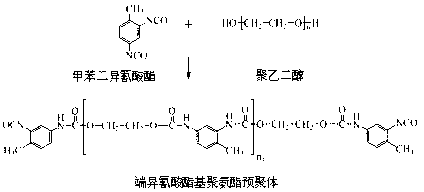

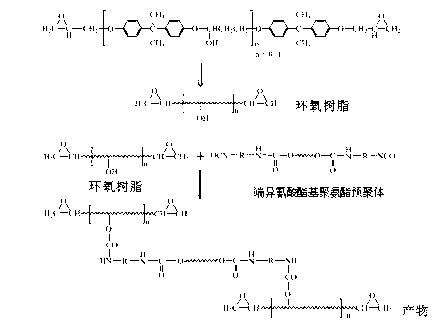

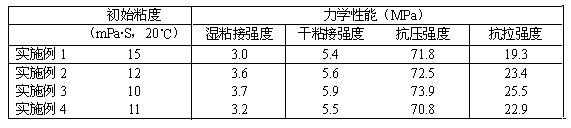

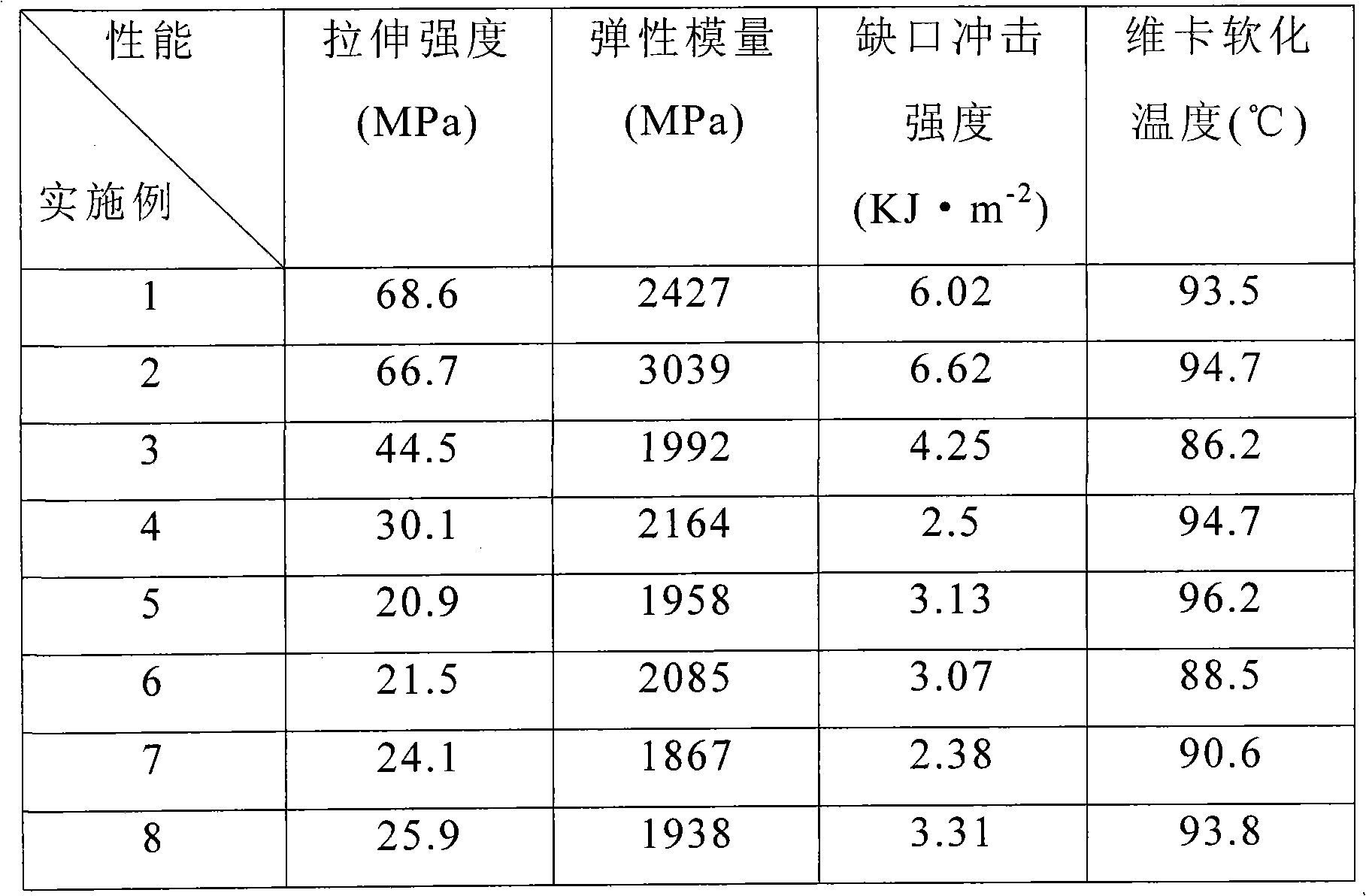

High-permeability polyurethane graft-modified epoxy resin interpenetrating-network polymer grouting material and preparation method thereof

InactiveCN102924692AImprove toughnessImprove wet bond strengthProductsReagentsPolymer scienceFirming agent

The invention belongs to the field of construction materials, and particularly relates to a high-permeability polyurethane graft-modified epoxy resin interpenetrating-network polymer grouting material which is composed of a component A and a component B, wherein the component A is composed of 5-30 parts of isocyanate-terminated polyurethane prepolymer, 95-70 parts of epoxy resin and 10-30 parts of diluter I, and the polyurethane and epoxy resin form a grafted interpenetrating network structure; the component B is composed of 40-60 parts of curing agent, 10-30 parts of diluter II, 0.5-2 parts of accelerator and 0.5-2 parts of defoaming agent; and when in use, the components A and B can be evenly mixed to obtain the grouting material. The interpenetrating network grouting material provided by the invention integrates the advantages of the polyurethane and epoxy resin, has the characteristics of high adhesive strength, moderate toughness, high stability, low viscosity, favorable groutability and excellent cost performance, and can be widely used in seepage prevention, leakage stoppage, reinforcement and strengthening of construction, maintenance and other projects of tunnels, hydropower, rock soil slopes, foundation treatment, ground settlement, railways and highways.

Owner:HUNAN UNIV OF TECH +1

Heat-resistant polylactic acid composite material and preparation method thereof

The invention provides a heat-resistant polylactic acid composite material and a preparation method thereof, which belong to the technical field of polymer materials. The preparation method solves the technical problems of low product biodegradability, high cost, poor mechanical performance and the like of the prior method for preparing polylactic acid crosslinking materials and polymer crosslinking materials. The heat-resistant polylactic acid composite material comprises the following components in portion by weight: 50 to 99 portions of polylactic acid resin with an oligomerization-D lactic acid content, 0.1 to 15 portions of nucleating agent and 1 to 50 portions of starch or modified starch, wherein the content of a poly-D lactic acid in the poly-lactic acid resin with the oligomerization-D lactic acid content is less than 5 weight percent. The preparation method for the composite material comprises the following steps: a, mixing and pelleting; b, injection molding; and c, heat treatment. The composite material has the advantages of high mechanical and heat-resistant performance. The preparation method for the composite material is simple in technical process, high in processability and low in cost and can realize large-scale industrial production.

Owner:ZHEJIANG HISUN BIOMATERIALS

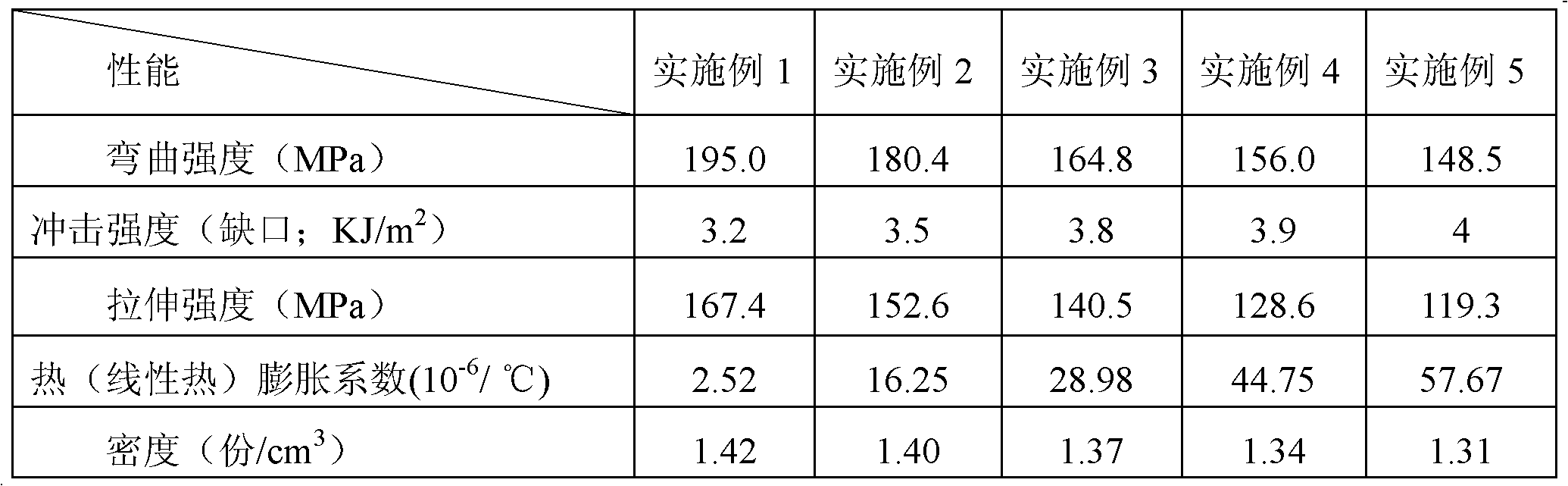

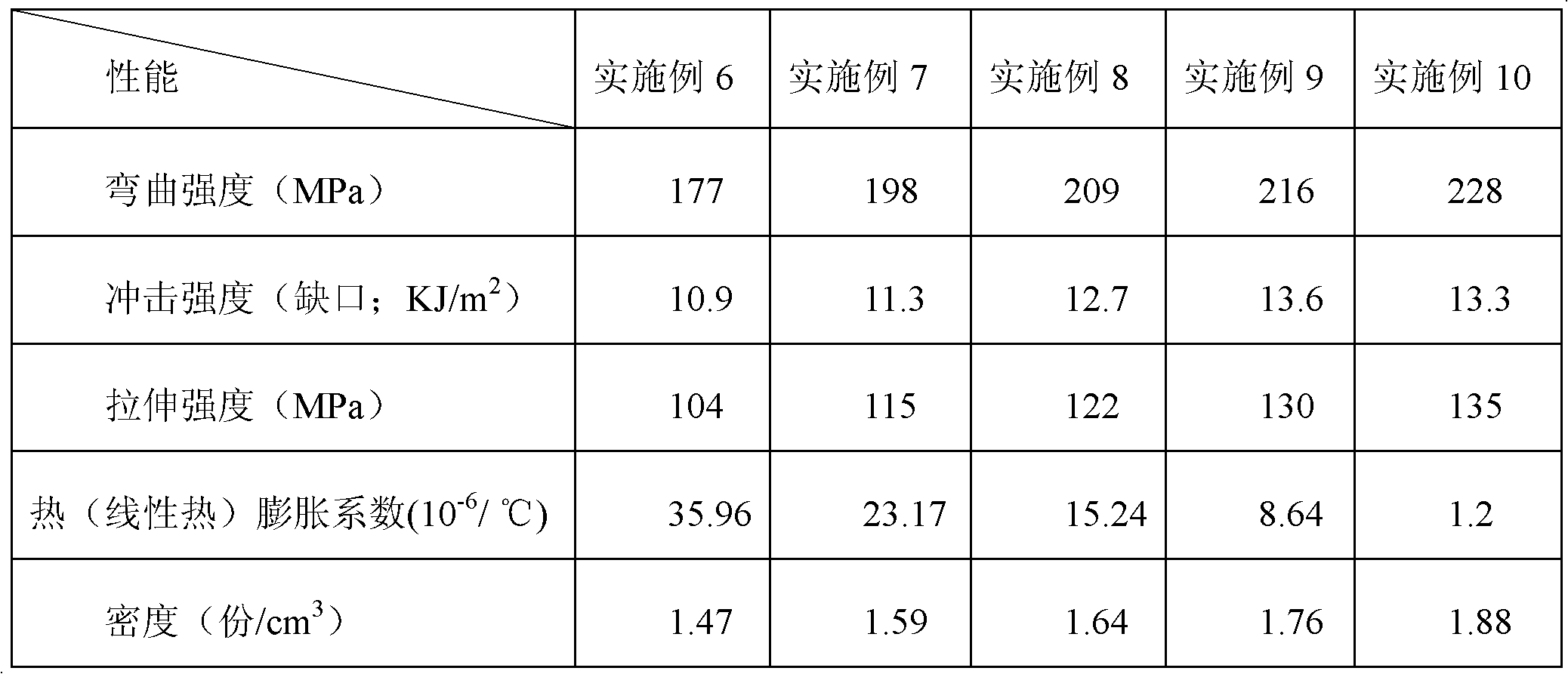

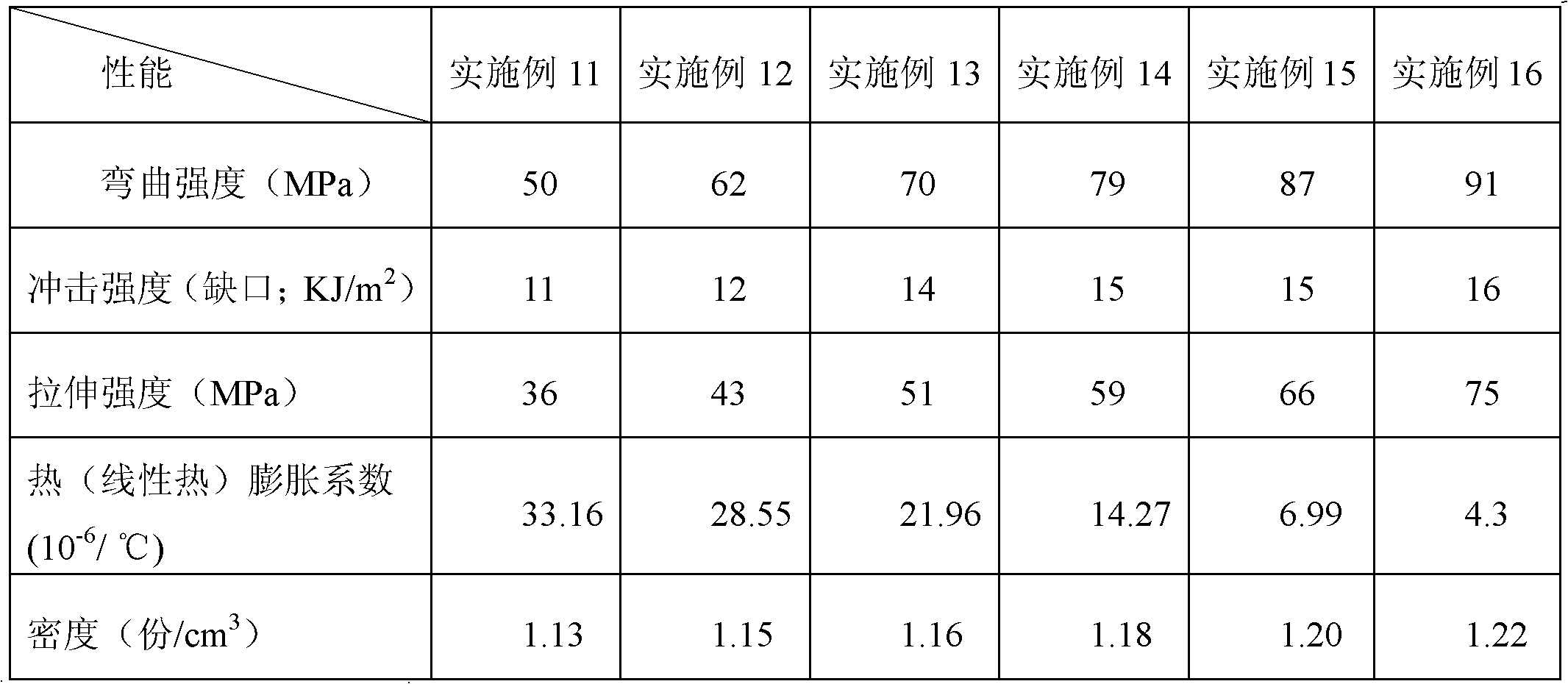

Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

The invention belongs to the technical field of high polymer materials, and discloses low coefficient of thermal expansion thermoplastic resin composition, a preparation method and application of the low coefficient of thermal expansion thermoplastic resin composition. The resin composition is composed of, by weight, 340 to 900 parts of thermoplastic resin, 100 to 500 parts of carbon fibers, 0 to 5 parts of antioxygen, 0 to 5 parts of lubricating agent and 0 to 150 parts of flexibilizer. The preparation method comprises adding the 340 to 900 parts of the thermoplastic resin, the 0 to 5 parts of the antioxygen, 0 to 5 parts of the lubricating agent and the 0 to 150 parts of the flexibilizer to a high mixing machine to mix for 1 to 30 min, adding the mixture to a double-screw extruder, adding the 100 to 500 parts of the carbon fibers from the glass fiber feeding port or the side feeding port of the double-screw extruder to mix evenly, and carrying out extruding, dragging and prilling on mixed materials in the double-screw extruder to obtain the low coefficient of thermal expansion thermoplastic resin composition. The use of the low coefficient of thermal expansion thermoplastic resin composition applied to the fittings of a metal piece is provided. The thermoplastic resin is high in flexural modulus, tensile strength and impact strength, and low in linear expansion coefficient.

Owner:HEFEI GENIUS NEW MATERIALS

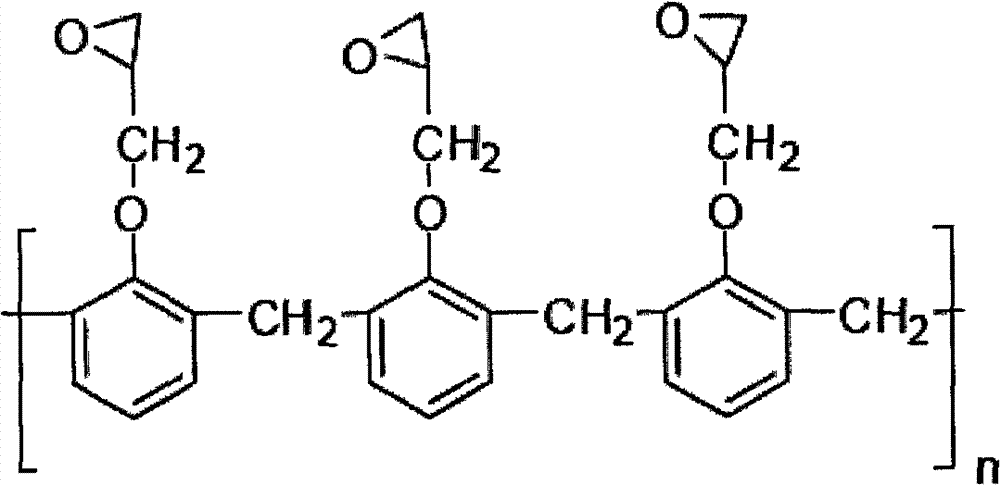

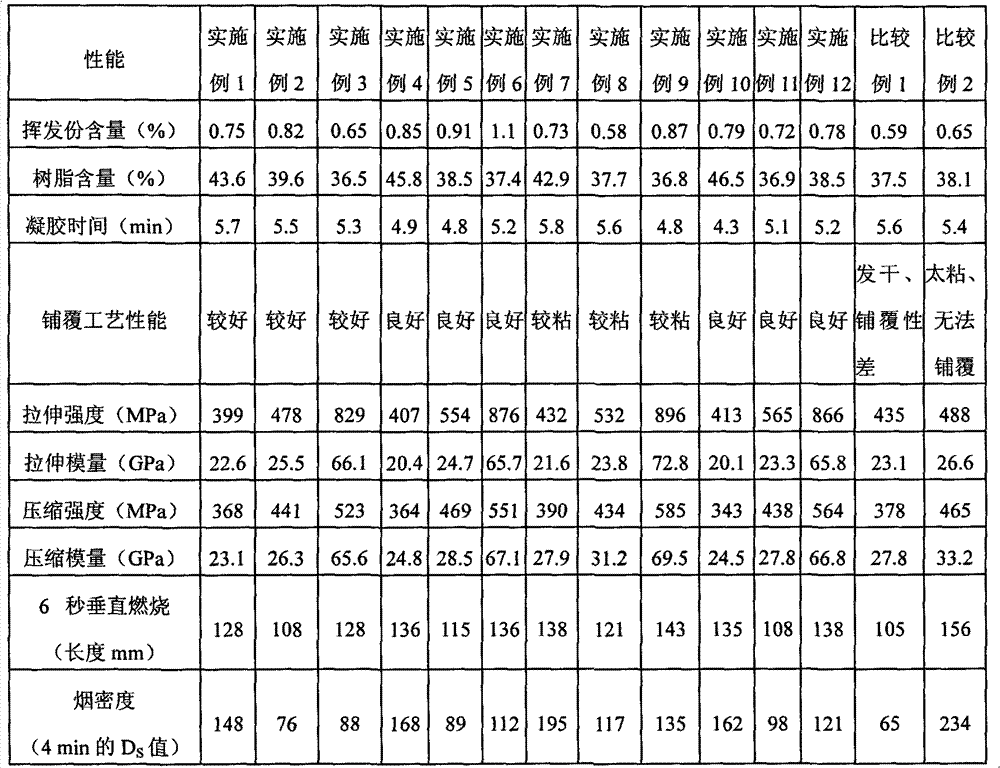

Flame retardant epoxy prepreg composite material and its preparing method and its use

ActiveCN102731969AImprove toughnessImprove flame retardant performanceCabin furnitureEfficient propulsion technologiesTetrabromobisphenol AResin matrix

The present invention relates to a flame retardant epoxy prepreg composite material and its preparation method and its use, the composite material contains 20 to 70% of epoxy resin matrix and 30-80% of fiber reinforced materials; wherein the epoxy resin matrix comprises the following components by mass part: 100 parts of an F type epoxy resin, 10-50 parts of an E type epoxy resin, 5-40 parts of tetrabromobisphenol A, 5-20 parts of a curing agent, 1-10 parts of a curing accelerator, 5-25 parts of a toughening agent, 1-10 parts of antimonous oxide and 20-80 parts of an organic solvent. According to the invention, F46 type epoxy resin containing a rigid frame structure is taken as a main component, the flame retarding and toughening modification are carried out on the resin matrix by a combination technology, the epoxy composite material with high toughness, high flame retardancy and good overlaying manufacturability can be realized, the flue gas density is obviously decreased when the flame is carried out, and the epoxy prepreg composite material possesses important popularization and application prospects in the fields of large aircraft, ships, high-speed rails and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Preparation method of high temperature and high pressure resistant rubber sealing material

InactiveCN101824172AImprove mechanical propertiesImprove heat resistanceSealing/packingPolymer scienceVulcanization

The invention belongs to the technical field of rubber sealing material, and relates to a preparation method of a high temperature and high pressure resistant rubber sealing material which can be applied to an oilfield deep oil production engineering process; first, 100 parts of hydrogenated nitrile rubber is weighed by parts in weight, put into a mixing mill to be plasticated; and then 2 to 20 parts of metal oxide, 1 to 5 parts of stearic acid, 5 to 100 parts of acrylate, 10 to 70 parts of carbon black, 1 to 6 parts of aging inhibitor, 5 to 30 parts of plasticizer, 2 to 10 parts of antiscorcher, 2 to 10 parts of vulcanizer and 2 to 10 parts of vulcanization aid are sequentially added into the mixing mill to be mixed uniformly; mixing rubber is vulcanized primarily in a plate vulcanizing press, the vulcanizing temperature is controlled to be 150 to 180DEG C, the vulcanizing time is 20 to 40min, and the vulcanizing pressure is 10 to 20MPa; after being taken out from the plate vulcanizing press, the rubber is secondarily vulcanized at 150 to 180DEG C to obtain vulcanized rubber with excellent performance; and the preparation method of the high temperature and high pressure resistant rubber sealing material has the advantages of simple process, convenient operation and use, low preparation cost, excellent mechanical performance, and in particular better high-temperature mechanical performance.

Owner:QINGDAO UNIV OF SCI & TECH +1

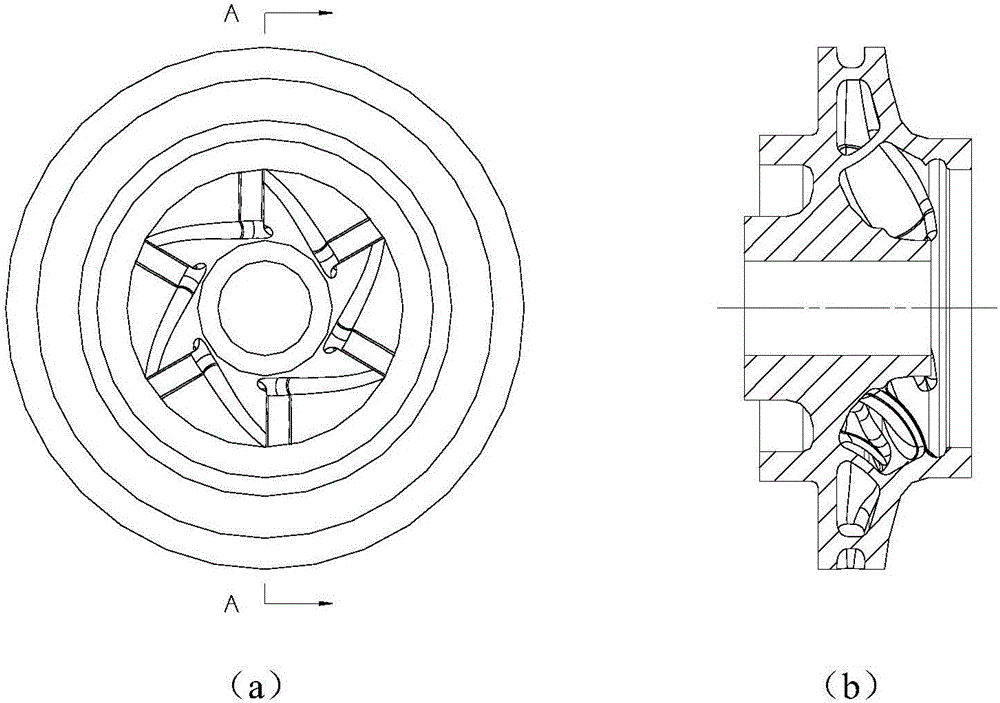

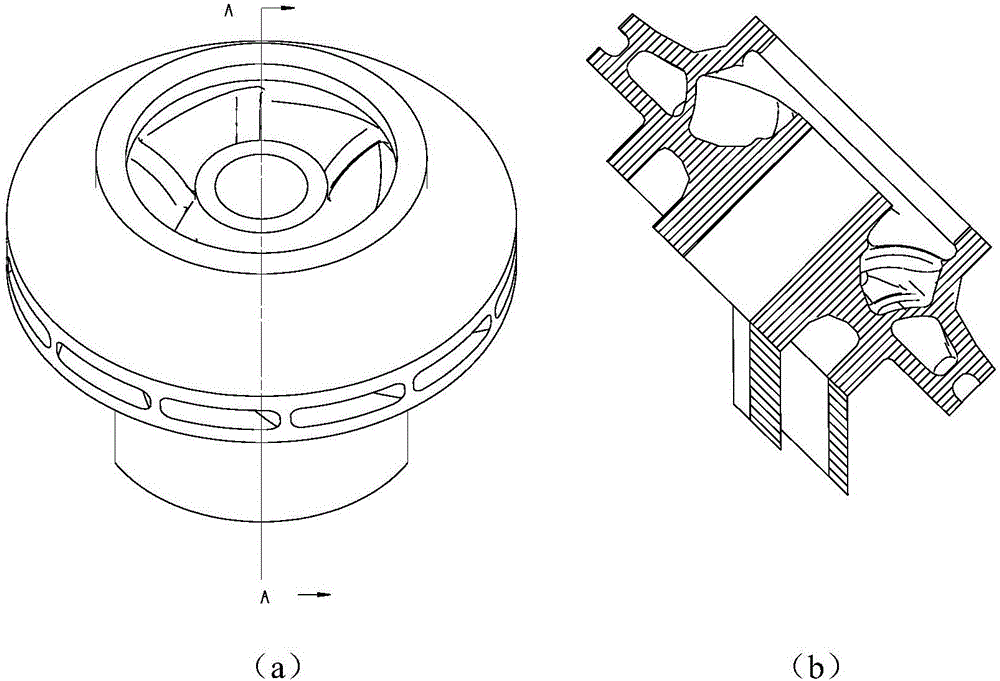

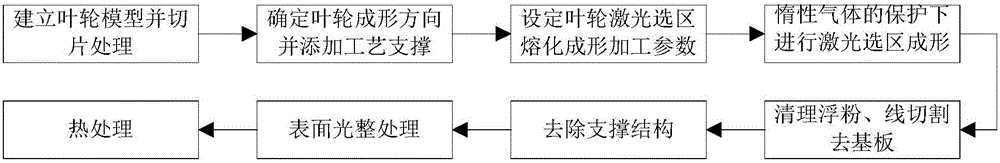

Integral manufacturing method of S-04/S-08 high-strength stainless steel three-dimensional flow shrouded impeller

ActiveCN106077643AShorten the manufacturing cycleCompact structureAdditive manufacturing apparatusEngine manufactureMaterials scienceAustenitic stainless steel

The invention provides an integral manufacturing method of an S-04 / S-08 high-strength stainless steel three-dimensional flow shrouded impeller. The integral manufacturing method comprises the steps of firstly, establishing an impeller three-dimensional model, and carrying out slicing treatment; determining the forming direction and support adding positions according to structural characteristics of the impeller; setting parameters of a laser selective melting forming processing technology according to characteristics of a high-strength stainless steel material; forming under protection of an inert gas; after forming, cleaning floating powder, removing a base plate through linear cutting, and removing supports; and finally, carrying out follow-up treatment such as surface treatment and thermal treatment on the impeller. According to the integral manufacturing method, complex cutters or fixtures do not need to be designed, materials can be directly added for part manufacturing only through the three-dimensional model of the impeller, the manufacturing cycle is greatly shortened, and the integral manufacturing method is applicable to trial manufacturing and middle and small-batch production in the development stage.

Owner:XIAN SPACE ENGINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com