Patents

Literature

68results about How to "Good heat and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-conductive and anti-corrosion coating based on graphene functional material and preparation method of same

InactiveCN104817930AGood heat and corrosion resistanceGood mechanical propertiesAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsGraphene

The invention discloses a heat-conductive and anti-corrosion coating based on a graphene functional material, which includes following components: 0.05-6 parts of the graphene functional material, 60-80 parts of resin, 6-16 parts of a pigment, 8-18 parts of a filling material, 10-20 parts of a diluent, 0.1-0.3 parts of a defoaming agent and 10-30 parts of a curing agent. The invention provides the coating which is excellent in heat conductivity and anti-corrosion property and is based on the graphene functional material, wherein the graphene functional material has the excellent performances of various materials, so that the coating is enhanced in heat conductivity and further is enhanced in compactness and improved in anti-corrosion property.

Owner:山东利特纳米新材料有限公司

Ceramic membrane cooling coating for LED radiator and preparation method of ceramic membrane cooling coating

InactiveCN102911535AExcellent self-cooling functionImprove Radiation PerformanceCoatingsMetallurgyFilling materials

The invention discloses a ceramic membrane cooling coating for an LED radiator and a preparation method of the ceramic membrane cooling coating. The coating comprises a liquid A and a liquid B at the weight ratio of (2:1)-(2.5:1), wherein the liquid A comprises the following materials by weight percent: 40-60 percent of silica sol, 20-40 percent of filling material, 15-20 percent of pigment, 5-10 percent of anti-anti-settling agent; and the liquid B comprises the following materials by weight percent:75-80 percent of organo siloxane, 8-10 percent of catalyst and 10-15 percent of solvent. According to the utility model, the functional coating is coated outside the LED radiator, and a high-radiance filling material is adopted. Compared with a general decorative coating, the ceramic membrane cooling coating has an excellent cooling function, provides radiative heat transfer under the condition of no forced convection and improves the problem that the radiating effect is bad in absence of forced convection. Besides, the coating has an excellent decorative function, and the radiance reaches 0.83-0.92 after a membrane is formed.

Owner:SOUTH CHINA UNIV OF TECH

Third nickel-base high-temperature single crystal alloy in low cost

ActiveCN1966750AGood heat and corrosion resistanceImprove durabilitySingle crystal superalloySingle crystal

The invention belong to the field of nickel-based monocrystal superalloy, specifically a kind of low-cost third generation nickel-based monocrystal superalloy, which is mainly used for producing units bearing high stress under high temperature such as impeller blade in aero-motor. The chemical components of the alloy are (wt.%): Cr 2-4%,Co 11-13%,W 5-7%,Mo 0.5-2%,Re 3- 5%,Al 5-7%,Ta 6-10%,Hf 0.05-0.2%,and Ni as balance. The invention adopts vacuum induction melting for smelting, first smelting mother alloy with chemical components meeting the requirement, growing to monocrystal units. The following technological system for heating treatment is carried out before using: 1300DEG C / 8h,A.C.+1305DEG C / 15h,A.C.+1310DEG C / 8h, A.C.+1315DEG C / 24h,A.C.+1180DEG C / 4h,A.C.+870DEG C / 24h,A.C.. The alloy of the invention has the advantages of excellent persistence correspondent to that of third generation monocrystal superalloy CMSX-10, little Re content, low cost and good causticity resistance.

Owner:辽宁红银金属有限公司

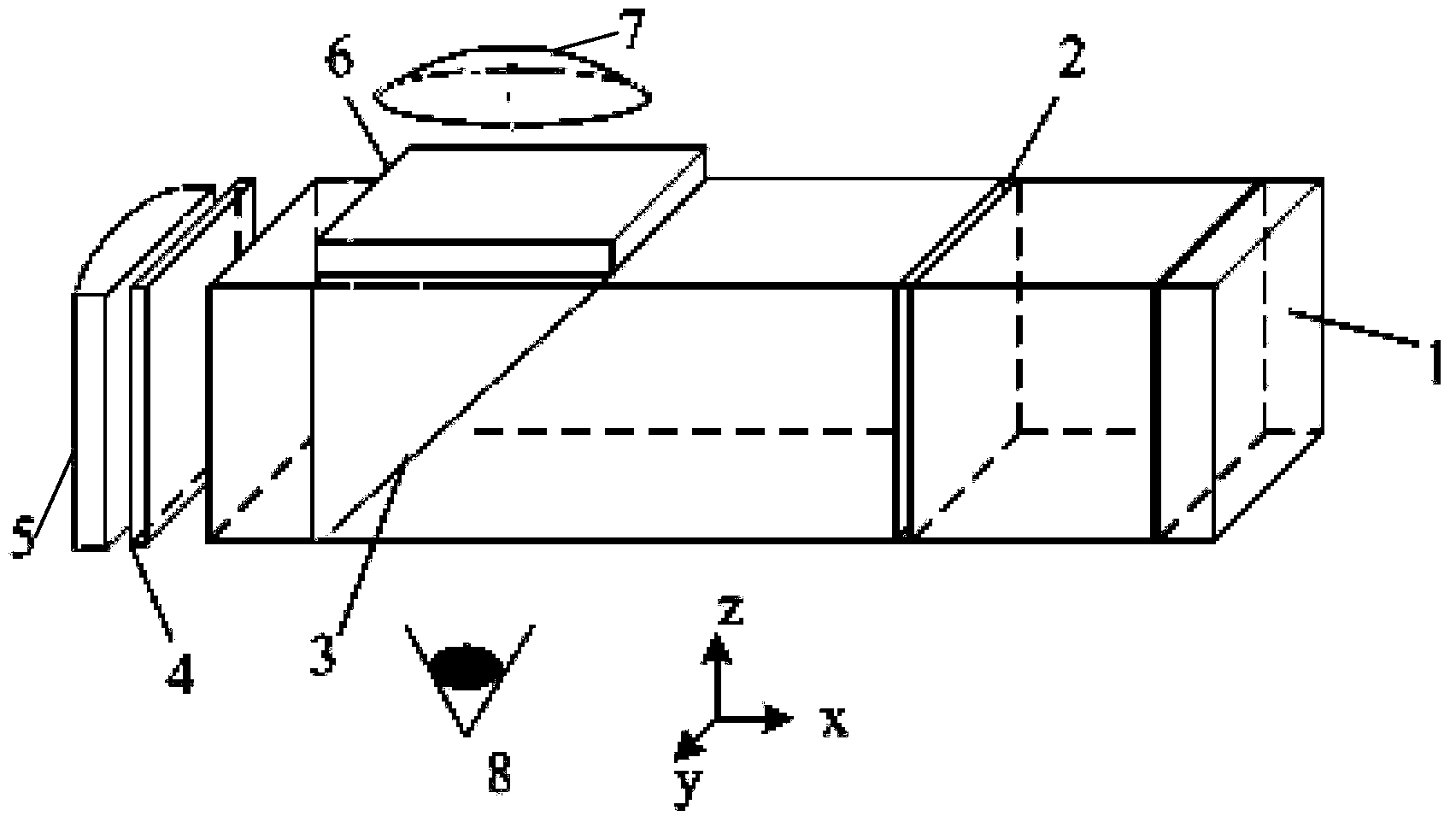

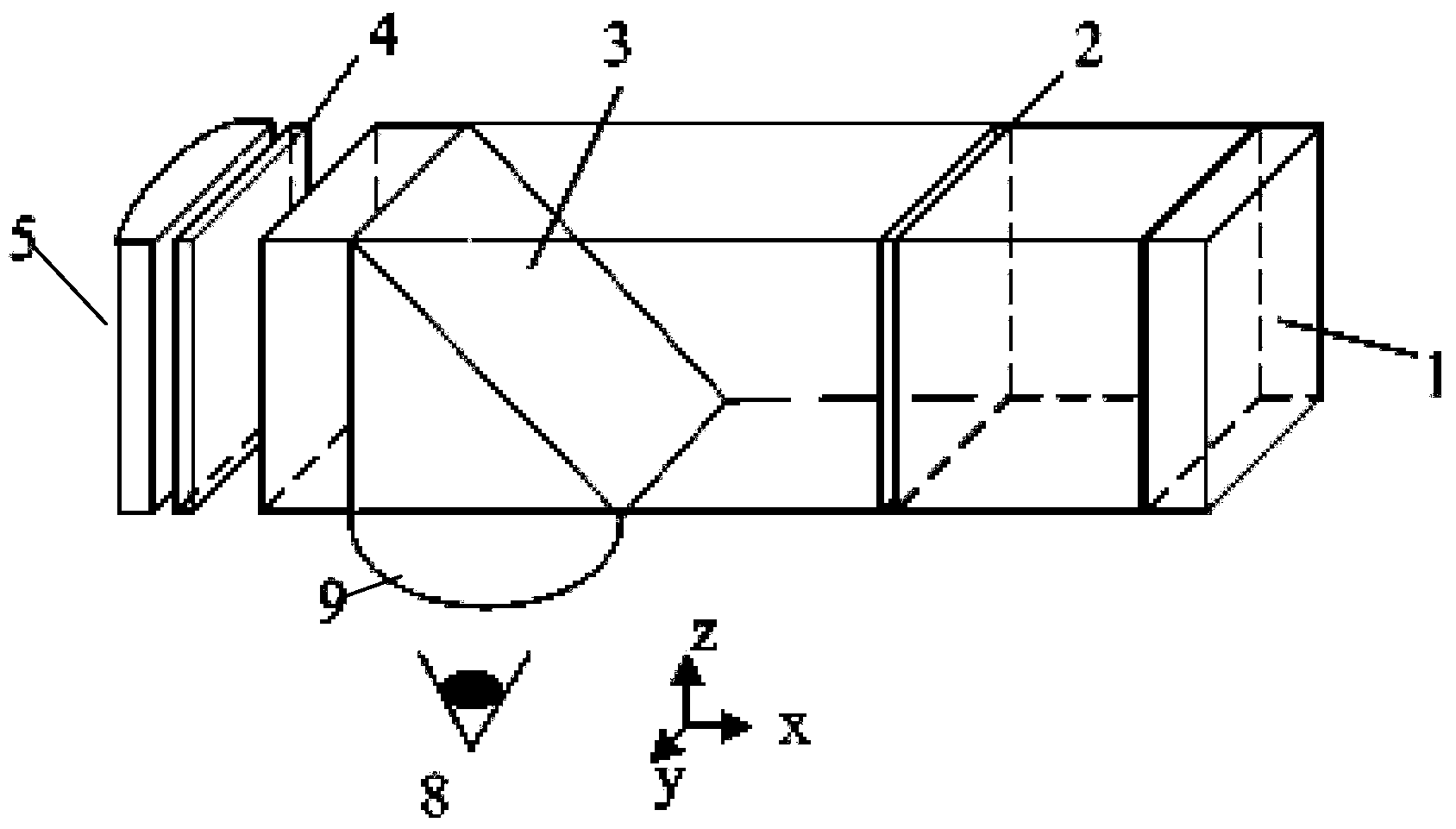

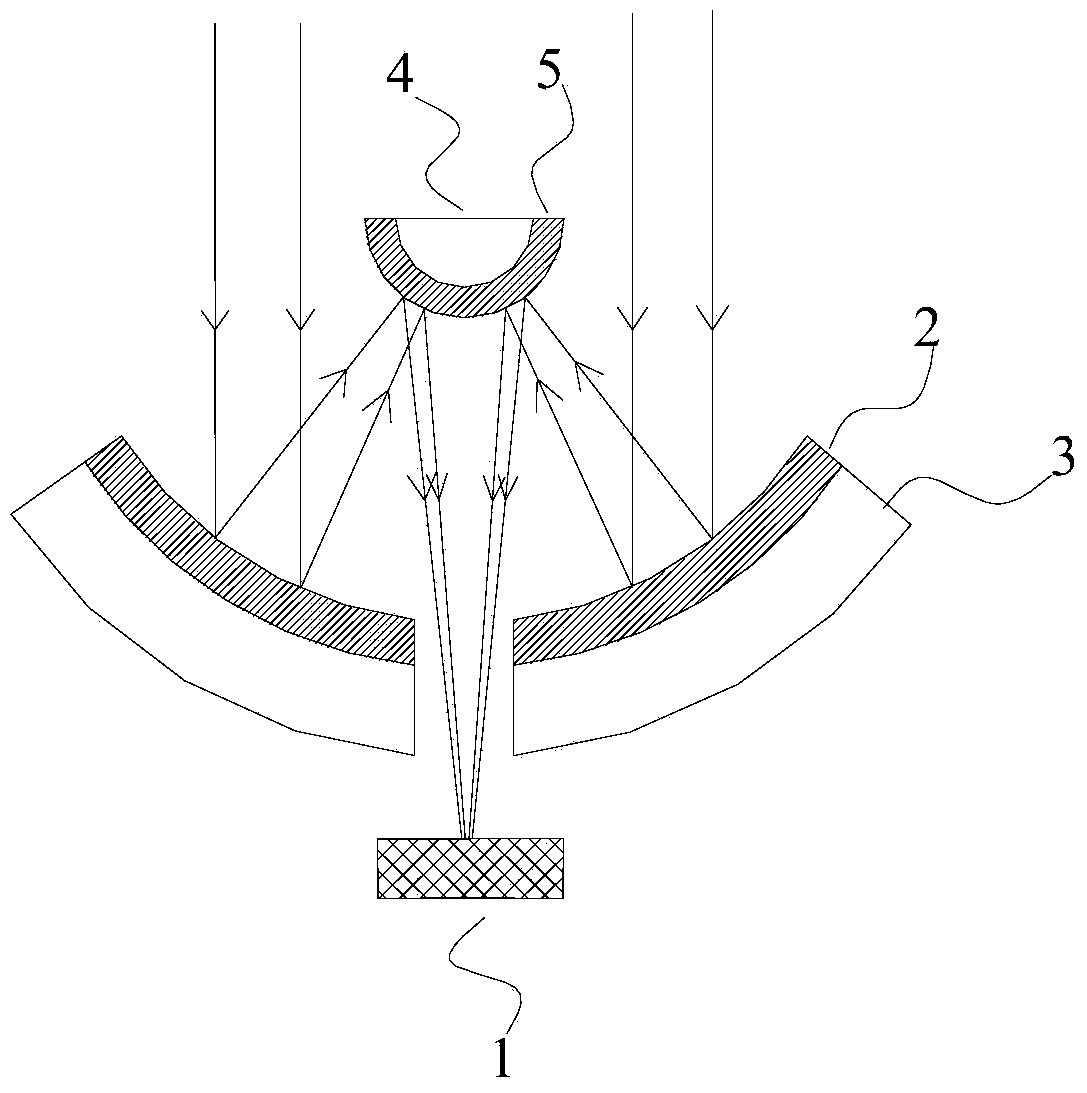

Optical system for dressing display

ActiveCN103728728AEasy to integrateImprove adhesionOptical elementsDisplay deviceComputational physics

The invention discloses an optical system for dressing display. The optical system for the dressing display comprises a display device, a one second wave plate, a polarization splitting prism, a first one fourth wave plate, a reflector and a lens, wherein the display device is used for generating image optical signals, the one second wave plate is arranged on an image optical signal transmission light path of the display device, the polarization splitting prism is arranged at the output end of the one second wave plate, the first one fourth wave plate is used for receiving the image optical signals penetrating through the polarization splitting prism, the reflector is used for reflecting the image optical signals of the first one fourth wave plate back to penetrate through the first one fourth wave plate, and the lens is used for receiving the image optical signals which penetrate through the first one fourth wave plate backwards and are reflected by the polarization splitting prism. The optical system for the dressing display is small in size, convenient to integrate, capable of being used for the dressing display and capable of being adapted to observers of different levels of vision, and has broad application prospect.

Owner:HANGZHOU KOTI OPTICAL TECH

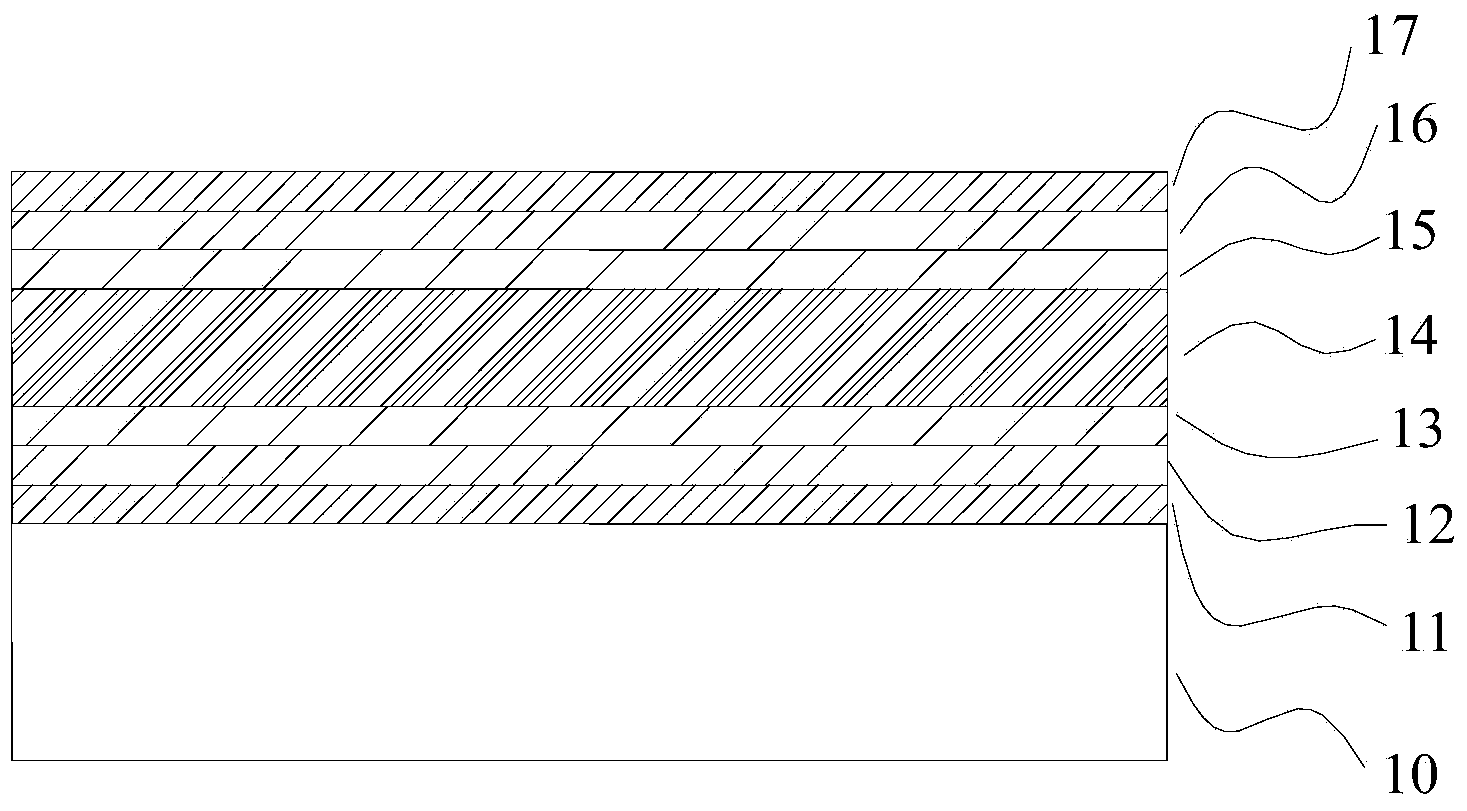

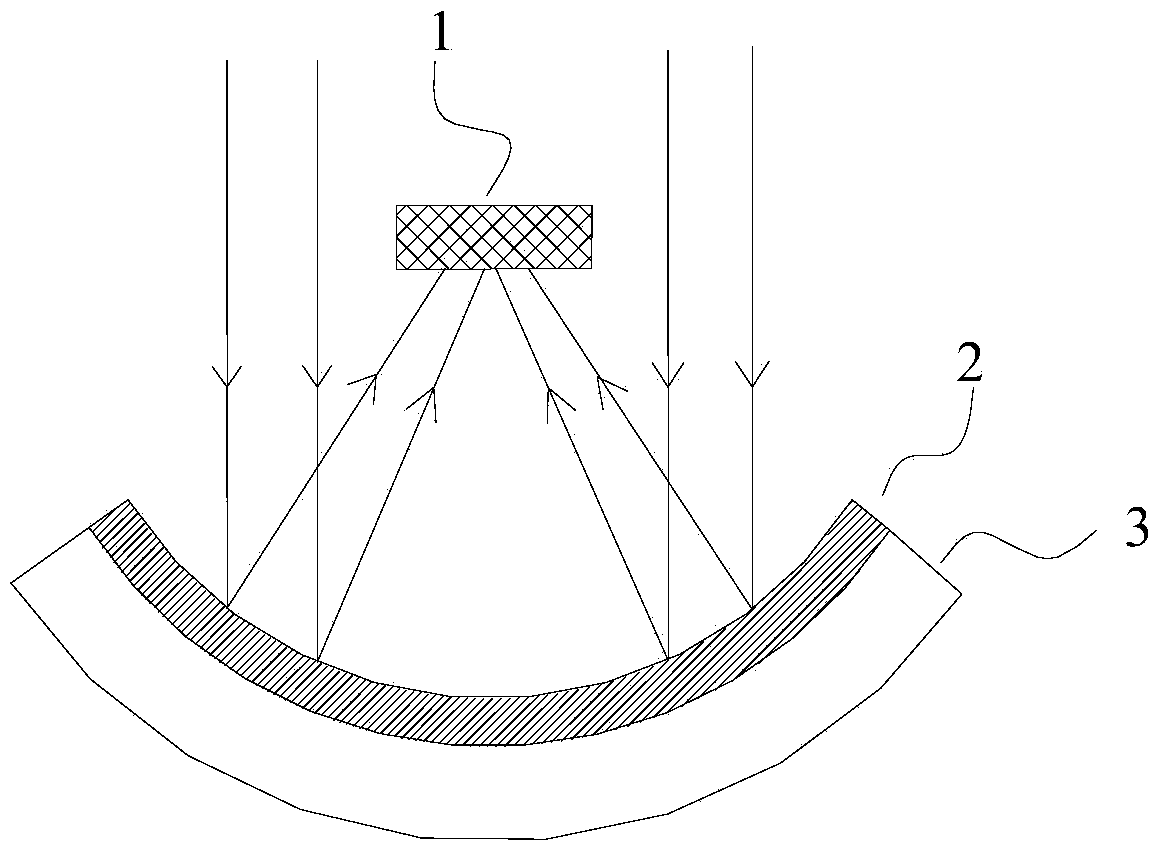

High-reflectance film and manufacturing method thereof

ActiveCN103728684AImprove reflectivityImprove adhesionMirrorsGlass/slag layered productsHigh resistanceProtection layer

The invention discloses a high-reflectance film which comprises a base layer, a high-reflectance layer and a protection layer, wherein the base layer, the high-reflectance layer and the protection layer are sequentially arranged on a substrate. The base layer is tightly attached to the substrate. The high-reflectance layer comprises a silver-copper alloy layer. The protection layer comprises an Al2O3 layer, a SiO2 layer and a Ti3O5 layer, wherein the Al2O3 layer, the SiO2 layer and the Ti3O5 layer are arranged in sequence, and the Al2O3 layer is tightly attached to the high-reflectance layer. The high-reflectance film is high in reflectance and resistant to high temperature and corrosion. The invention further discloses a manufacturing method of the high-reflectance film. The manufacturing method comprises the steps that the substrate is placed in a vacuum chamber of a film plating machine, the substrate is plated with the base layer, the high-reflectance layer and the protection layer in sequence, and then the high-reflectance film is obtained. The manufacturing method is simple and beneficial to formation of the high-reflectance film with good adhesion and compactness, so that the high-reflectance film has excellent reflecting performance and high resistance to high temperature and corrosion.

Owner:HANGZHOU KOTI OPTICAL TECH

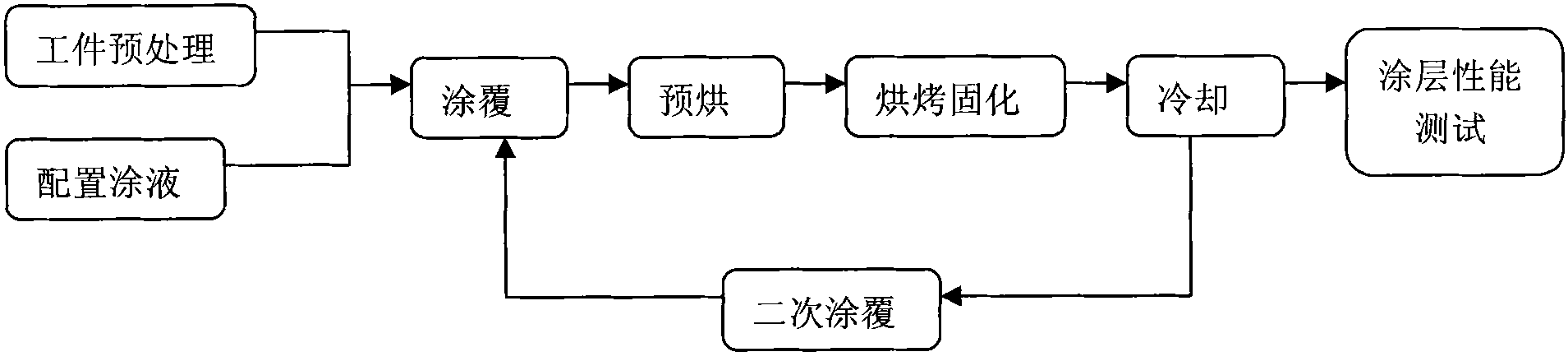

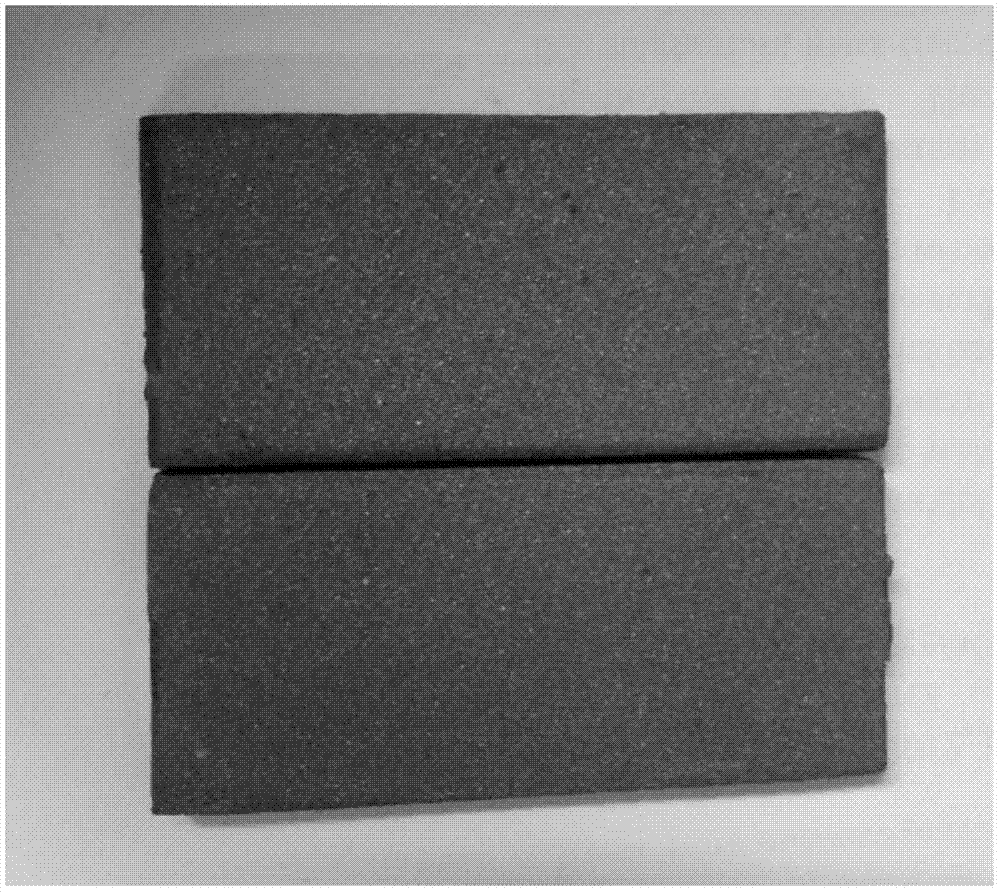

Coating-processing process for marine-climate resisting engineering-part surface coating

ActiveCN102463212AReduce preparation energy consumptionSexual stabilityPretreated surfacesSpecial surfacesOrganic solventSilicon alloy

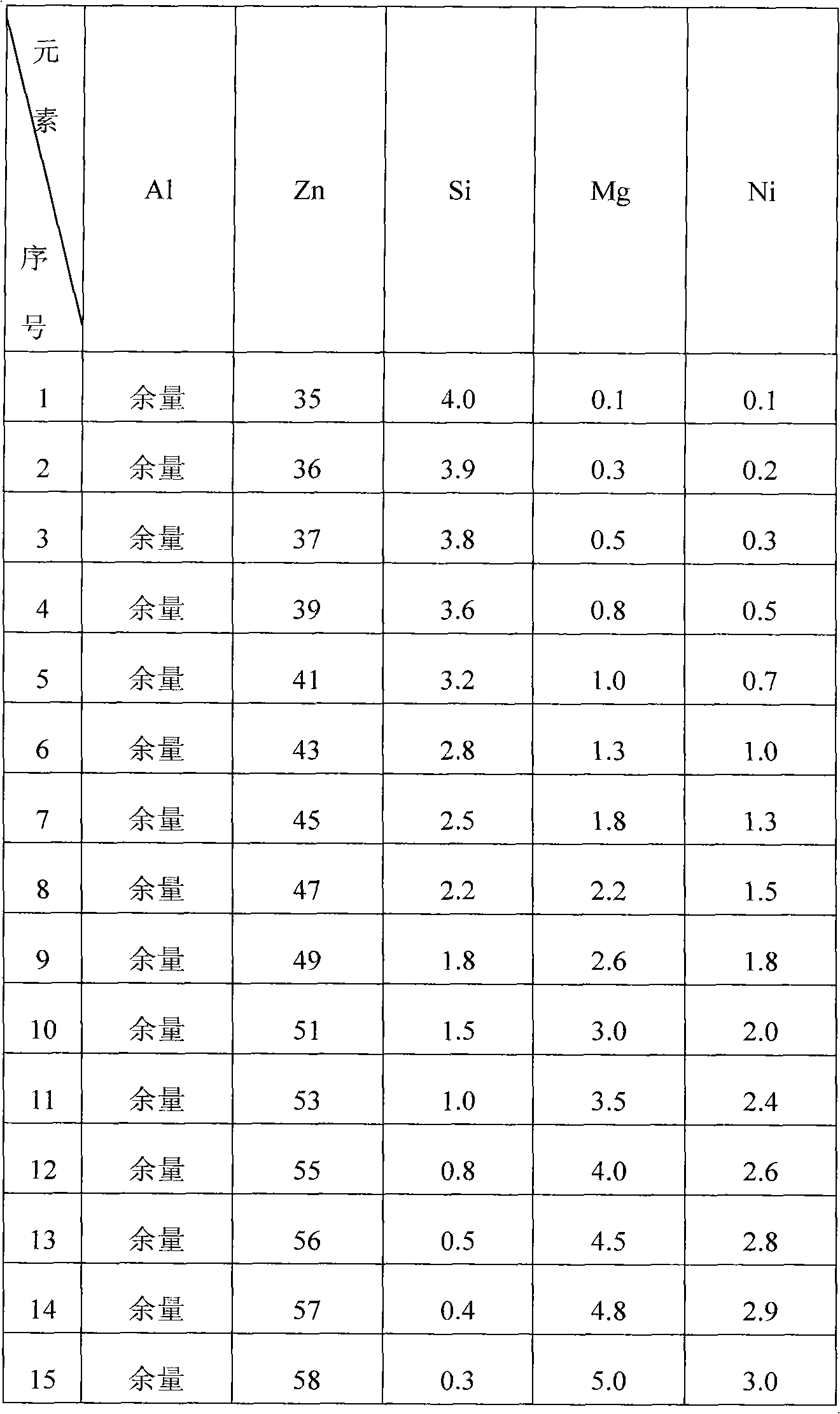

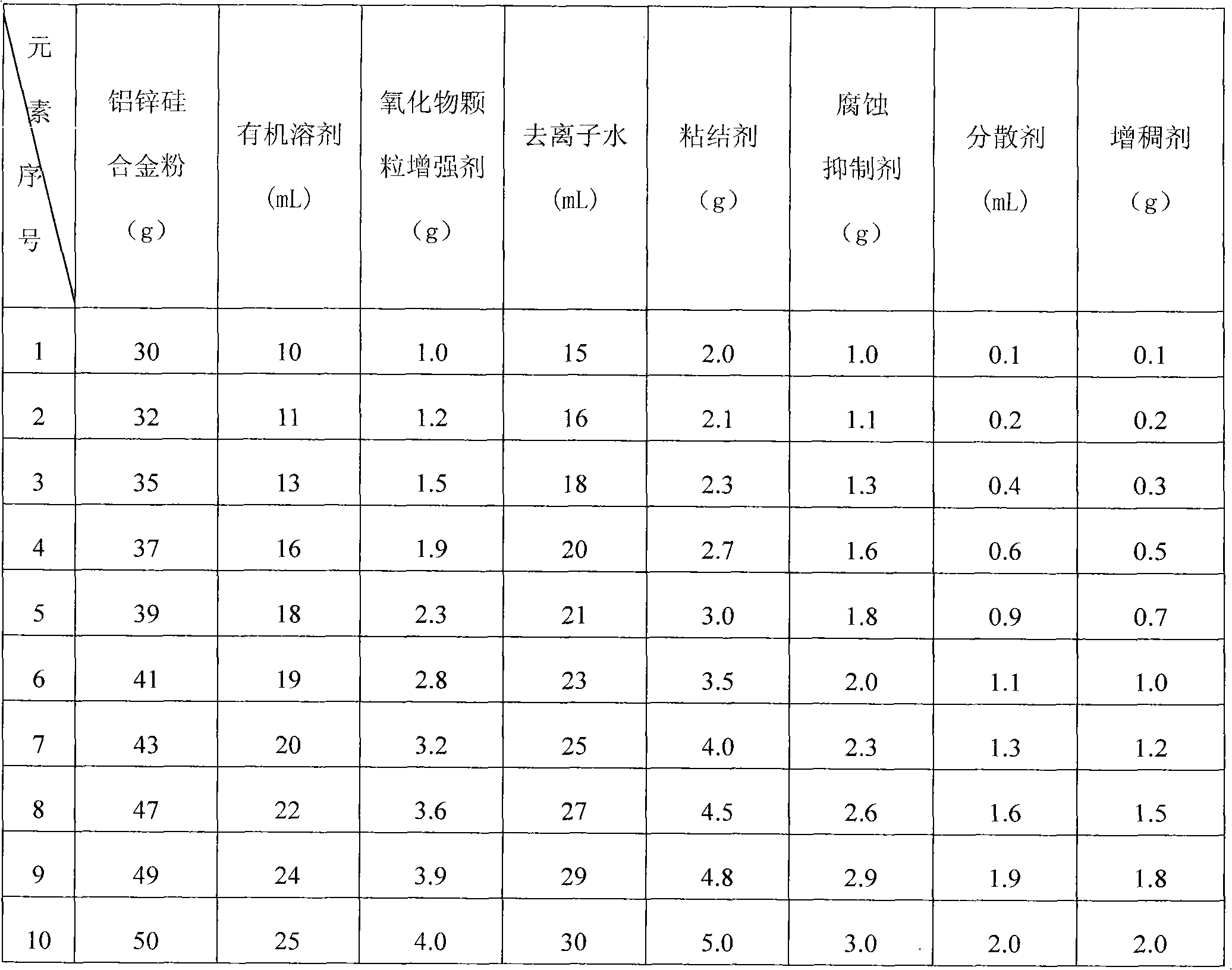

The invention relates to a coating-processing process for marine-climate resisting engineering-part surface coatings, which comprises the followings steps of: preprocessing a workpiece; configuring a coating solution, wherein the coating solution comprises aluminum-zinc-silicon alloy powder, an organic solvent, a nano-oxide particle enhancer, deionized water, a binder, a corrosion inhibitor, a dispersant and a thickener; coating; preliminarily drying; roasting and curing; cooling; and coating for the second time after cooling the roasted workpiece to the room temperature.

Owner:JIANGSU LINLONG NEW MATERIALS

Black high-strength microcrystalline glass and its preparation method

The invention discloses a black high-strength microcrystal glass, which comprises the following parts: 70% SiO2, 3. 5% Lithia, 17% alumina, 0.1%-0.5% ferric trioxide, 0.5%- 1% cobalt trioxide, 0.5%-1% nickel trioxide, 3. 1% -3. 5% at least one of titania, zirconia and phosphorus pentoxide, 1%-1. 5% at least one of magnesia, zinc oxide, barium oxide and boric oxide, 2. 0%-2. 1% potassium oxide and or sodium oxide and 1% arsenic oxide and or antimony oxide. The making method of microcrystal glass comprises the following steps: grinding evenly; adding reducer to allocate composite material; fusing under 1580 -1650 deg. c; shaping; annealing; coring under 600-800 deg. c for 1-4h; heating to 700-1000 deg. c to crystallize for 1-12h.

Owner:ZHEJIANG UNIV

Heat and corrosion resistant Nd-Fe-B permanent magnetic material with good mechanical properties and producing method

InactiveCN1805072AImprove mechanical propertiesGood heat and corrosion resistanceInductances/transformers/magnets manufactureMagnetic materialsCorrosion resistant alloyMiddle frequency

The invention relates to a heat-resistant corrosion-resistant neodymium iron boron permanent magnetic material with better mechanics property, which is formed by Nd, Dy, Pr, Tb, Fe, Co, Nb, Al, Cu, Ga and B. The producing method comprises: mixing the components; using middle-frequency sensing melting to attain casting alloy; breaking the casting alloy to be milled via the airflow into the powder with 3-5 mu m; when the magnetic field direction is larger than 796KA / m, compressing under the pressure of 98-196MPa to be processed with constant stable pressure; then sintering and cooling into room temperature in nitrogen gas to attain the product. The invention has better mechanic property, better heat-resistant and corrosion-resistant properties.

Owner:海安县磁性材料二厂

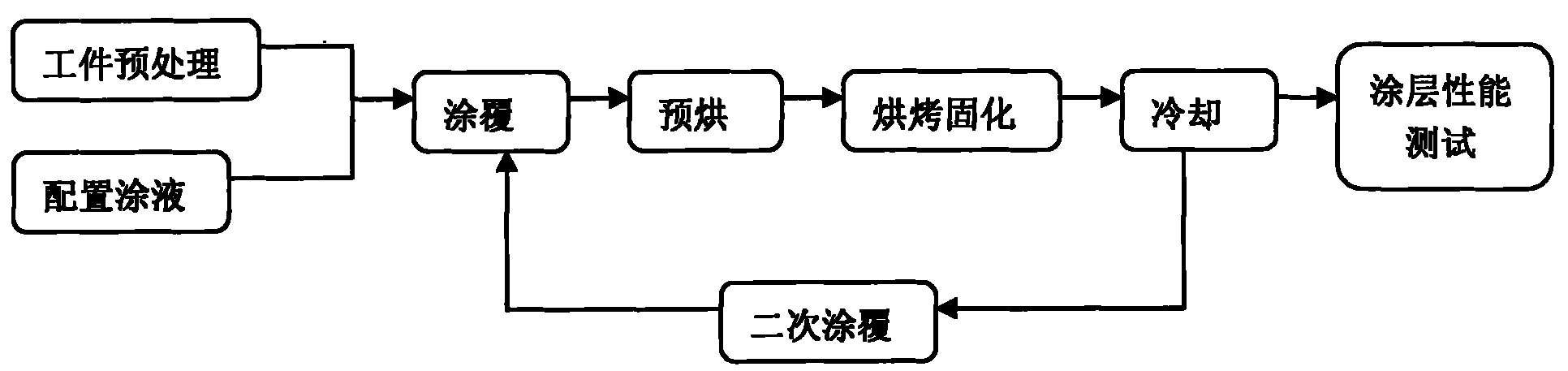

Magnesium-nickel-containing coating for marine climate-resistant preservative treatment

ActiveCN102010624AEnvironmentally friendlySexual stabilityAnti-corrosive paintsOrganic solventAdhesive

The invention relates to a coating for marine climate-resistant engineering part preservative treatment, which comprises 30.0 to 50.0g of aluminum-zinc-silicone alloy powder, 10.0 to 25.0mL of organic solvent, 1.0 to 4.0g of nano-oxide particle reinforcing agent, 15.0 to 30.0mL of deionized water, 2.0 to 5.0g of adhesive, 1.0 to 3.0g of corrosion inhibitor, 0.1 to 2.0mL of a dispersing agent and 0.1 to 2.0g of thickening agent, wherein the aluminum-zinc-silicone alloy powder consists of aluminum, zinc, silicone, magnesium and nickel.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Preparation and application of rare earth-containing nickel-based powder core wire material and coating

ActiveCN103924182AHeat and corrosion resistantGood heat and corrosion resistanceMolten spray coatingThermal sprayingRare earth

The invention discloses preparation and application of a rare earth-containing nickel-based powder core wire material and a coating, belonging to the field of thermal spraying in the material machining engineering. A core the following components in percentage by mass: 20-35% of pure metal chromium powder, 10-31% of nickel boron powder, 0.1-0.3% of rare earth and the balance of nickel, wherein the outer skin of the powder core wire material is made of a 80Ni-20Cr strip; the filling rate of the powder core wire material is 32%; when the rare earth-containing nickel-based coating is prepared in an electric arc spraying mode, a substrate needs to be pretreated; the spraying parameters are as follows: the voltage is 28-34V, the current is 160-220A, the spraying distance is 190-210mm, and the pressure of compressed air is 0.5-0.6MPa. A coating which is good in thermal conversion property and corrosion resistance can be obtained, and the service stability of a water-cooling wall tube and a superheater tube in a waste resource WTE (Waste To Energy) garbage incinerator is improved.

Owner:唐山宝航机械制造有限公司

High-hardness heatproof anti-corrosion polyurethane plate and preparation method thereof

The invention discloses a high-hardness heatproof anti-corrosion polyurethane plate. The high-hardness heatproof anti-corrosion polyurethane plate is prepared from the following raw materials of diisocyanate, polyester polyol, hydroxyl-terminated polybutadiene, polyethylene glycol terephthalate, nano silica, organosilicone, nano titania, a modification additive, modified graphene oxide, sulphur, dicyandiamide, zinc borate, a silane coupling agent KH-570, an antioxidant, a releasing agent, a curing agent, a cross-linking agent, a foaming agent and copper sheet. The invention also provides a preparation method of the high-hardness heatproof anti-corrosion polyurethane plate. The prepared high-hardness heatproof anti-corrosion polyurethane plate is high in hardness and good in heat-resisting and anti-corrosion properties.

Owner:安徽浩丰特种电子材料有限公司

Rare earth-titanium-nickel-containing sea climate resisting paint used for anti-corrosive treatment

ActiveCN102010625AEnvironmentally friendlySexual stabilityAnti-corrosive paintsRheniumOrganic solvent

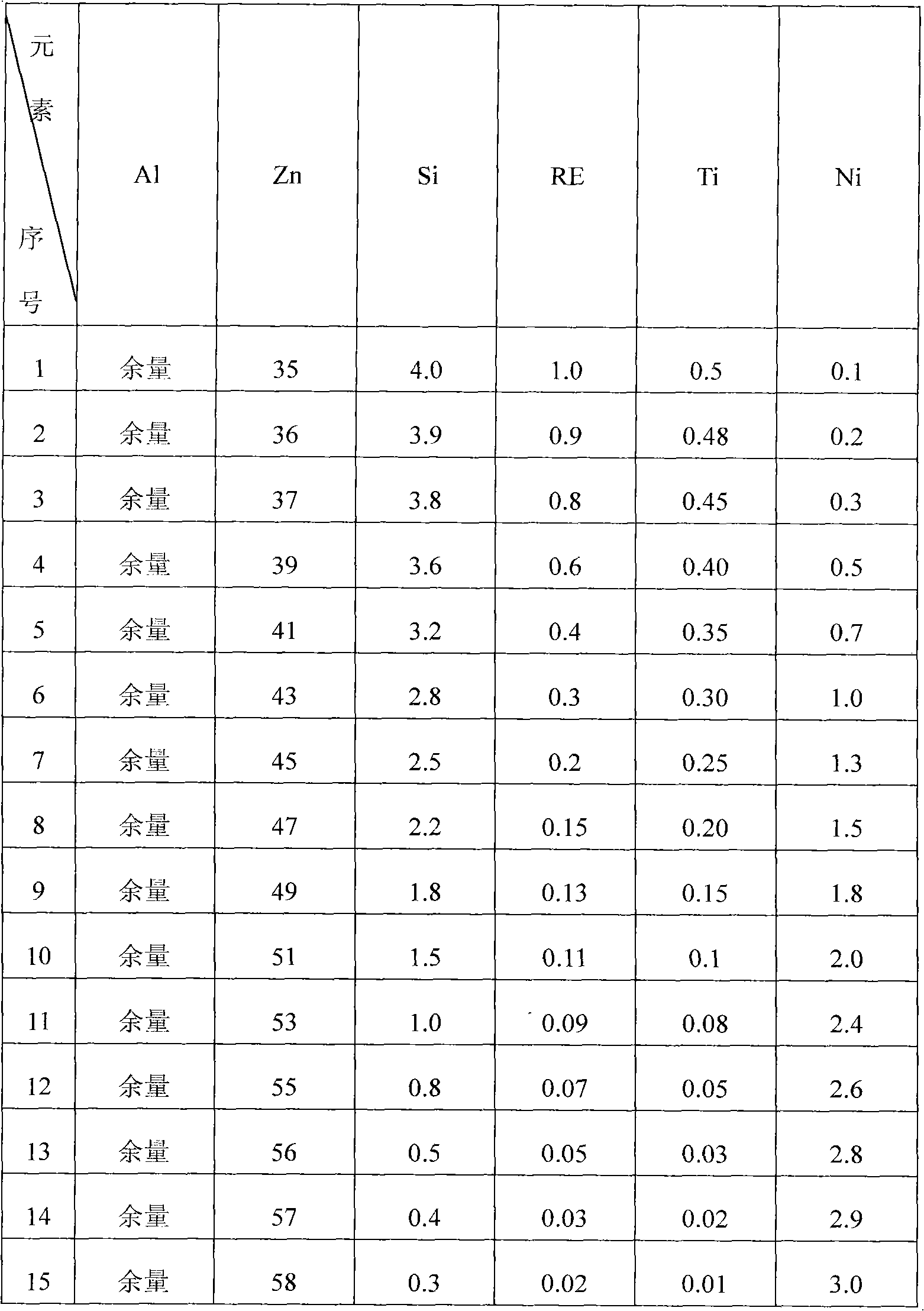

The invention relates to a sea climate resisting paint used for performing anti-corrosive treatment on engineering parts. The paint comprises the following components: 30.0 to 50.0 grams of aluminum-zinc-silicon alloy powder, 10.0 to 25.0 milliliters of organic solvent, 1.0 to 4.0 grams of nanometer-scale oxide particle reinforcing agent, 15.0 to 30.0 milliliters of deionized water, 2.0 to 5.0 grams of binder, 1.0 to 3.0 grams of corrosion inhibitor, 0.1 to 2.0 milliliters of dispersant and 0.1 to 2.0 grams of thickener, wherein the aluminum-zinc-silicon alloy powder consists of aluminum (Al), zinc (Zn), silicon (Si), rhenium (RE), titanium (Ti) and nickel (Ni).

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

High-strength heat-resistant corrosion-resistant polyurethane board and preparation method thereof

The invention discloses a high-strength heat-resistant corrosion-resistant polyurethane board which is prepared from diisocyanate, polycarbonate dibasic alcohol, dioctyl azelate, ethoxylated alkylphenol ammonium sulfate, toluene diisocyanate, heavy calcium carbonate, carbon black, nano attapulgite, nano silicon dioxide, bisphenol a diglycidyl ether, epoxy octyl stearate, a modified filler, methylsilicone oil, sulfur, a phenolic resin, a curing agent, melamine, hypophosphate, a flame-retardant synergistic agent, triallyl isocyanurate, dicumyl peroxide, 3,5-dimethylthiotoluylene diamine and a copper sheet. The invention also discloses a preparation method of the high-strength heat-resistant corrosion-resistant polyurethane board. The polyurethane board has the advantages of high strength, excellent heat resistance and excellent corrosion resistance.

Owner:安徽浩丰特种电子材料有限公司

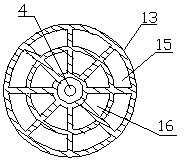

Rotary heat accumulating type heat exchanger

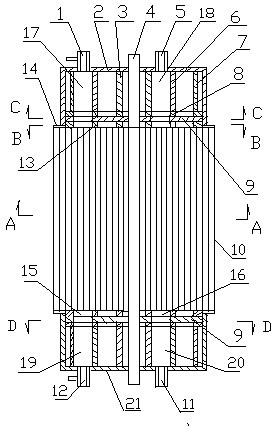

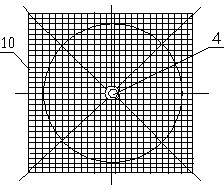

InactiveCN102330994AImprove work performanceEndothermicCombustion processHeat storage plantsEngineeringVALVE PORT

The invention discloses a rotary heat accumulating type heat exchanger, which comprises a heat accumulating body (10), a rotating shaft (4) and disk rotary valves, wherein the rotating shaft movably penetrates through the heat accumulating body, two ends of the heat accumulating body are respectively provided with a cold air box (2) and a hot air box (21), the cold air box is provided with a cold air waste chamber (17) and a combustion air chamber (18), the hot air box is provided with a hot air waste chamber (19) and a high-temperature air chamber (20), the cold air box and the hot air box are internally provided with the disk rotary valves, each disk rotary valve comprises a radial current divider (8) provided with inner current division holes (16) and outer current division holes (15) at intervals, and a circumferential current divider (13); and a valve seat is fixedly arranged on the rotating shaft between the radial current divider and the circumferential current divider. According to the invention, the heat efficiency can be improved to above 90 percent, fuel consumption can be reduced, operation cost of an industrial furnace is reduced, and the quality of combustion air is improved. The rotary heat accumulating type heat exchanger has the advantages of compact structure, stable and reliable use, convenience for installation and maintenance, and long service life.

Owner:林杰 +1

Inner wall brick and preparation method thereof

InactiveCN107162635AHigh strengthImprove insulation effectBuilding componentsCeramicwareBrickThermal insulation

The invention discloses an inner wall brick and a preparation method thereof and relates to the technical field of wall bricks. The inner wall brick is prepared from 55 to 65 portions of cement, 45 to 50 portions of a filler, 25 to 35 portions of plant straws, 20 to 25 portions of water glass, 20 to 23 portions of carboxymethyl cellulose, 15 to 20 portions of natural colored sand, 15 to 17 portions of latex powder, 10 to 15 portions of a reinforcing material, 10 to 13 portions of starch ether, 5 to 10 portions of an accelerator, 5 to 8 portions of a foaming agent and 75 to 95 portions of water. The inner wall brick can be directly used for an inner wall, has light weight, high strength and good thermal insulation effects, and has the characteristics of acid and alkali resistance, water resistance, fire resistance, freezing resistance, aging resistance, sound absorption, low installation and use cost and short construction period.

Owner:合肥市淑芹美装饰工程有限公司

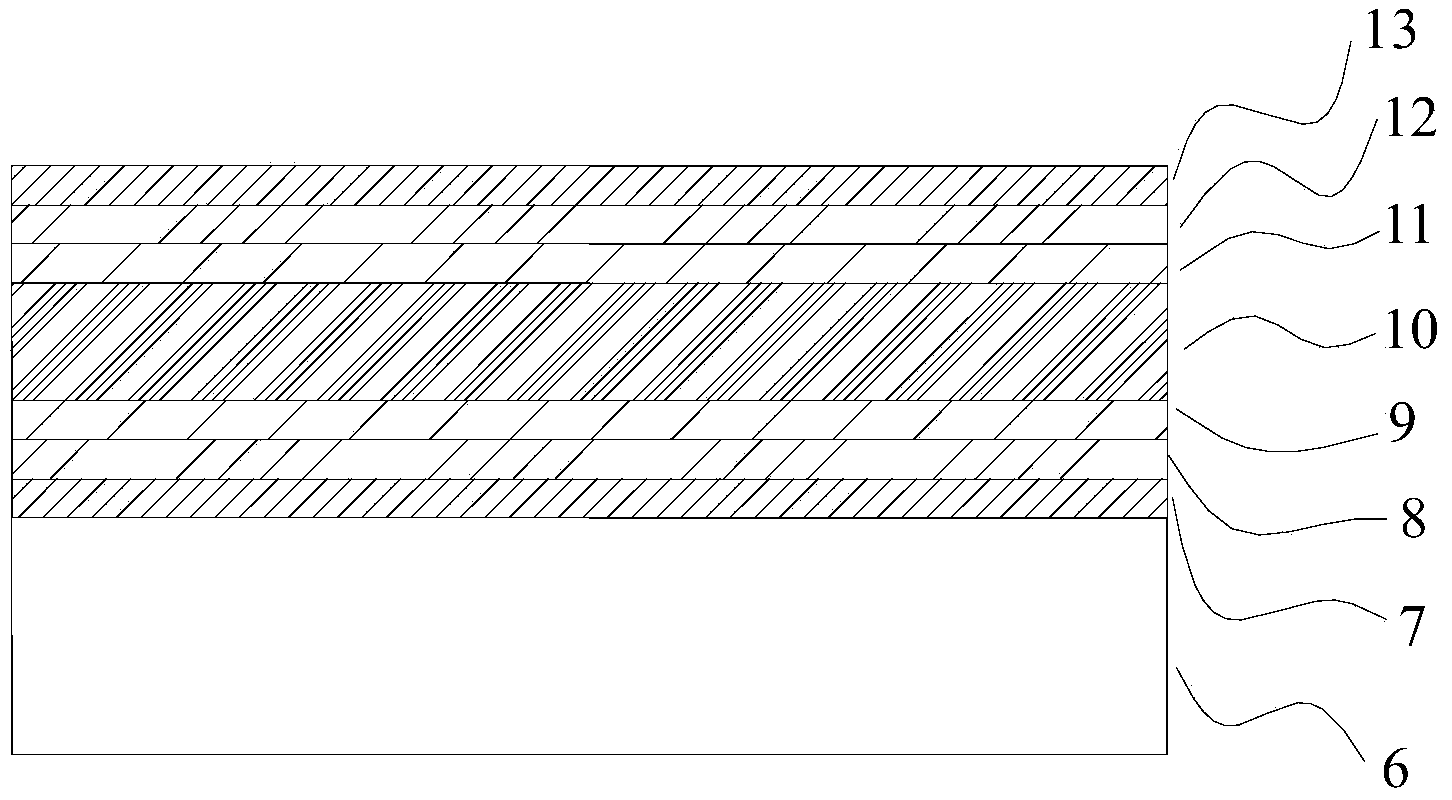

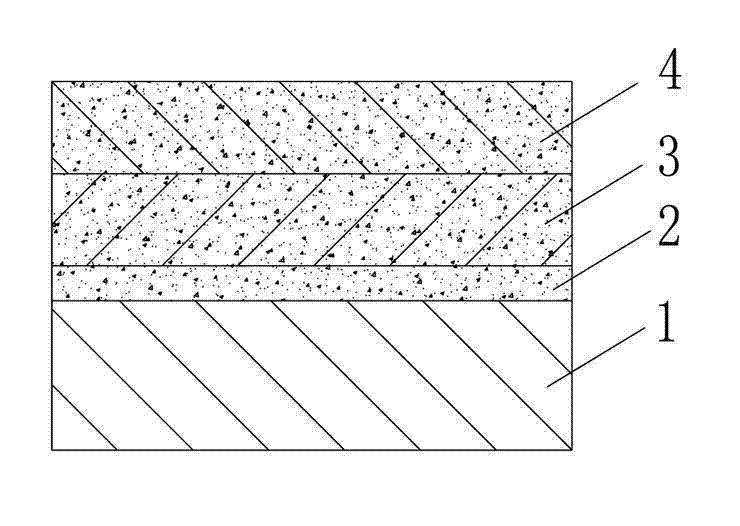

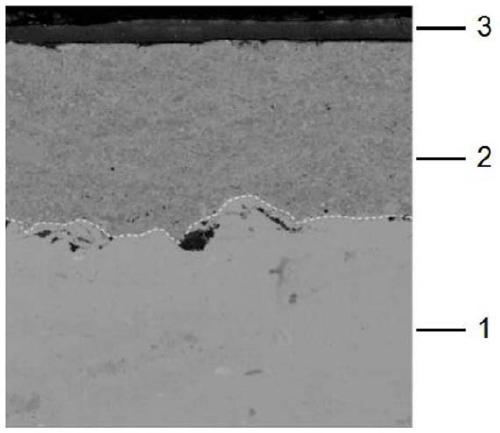

Film structure of 316L alloy steel surface enamel coating

InactiveCN104496181AExcellent adhesionAccelerated corrosionMetal layered productsSurface layerFilm structure

The invention discloses a film structure of a 316L alloy steel surface enamel coating. The film structure of the 316L alloy steel surface enamel coating is mainly characterized in that a 316L alloy steel substrate (1), a reconstruction shallow surface layer (2), an intermediate layer (3) and a surface layer (4) forms a four-layer complex enamel film, and components of an enamel material for the intermediate layer (3) and the surface layer (4) and weight percentage of each component are also disclosed. The film structure of the 316L alloy steel surface enamel coating has the characteristics of reasoned and advanced structure, good corrosion resistance, strong friction pull and the like, and the obtained 316L alloy steel surface enamel coating part can be widely applied to various fields.

Owner:常州宣纳尔新能源科技有限公司

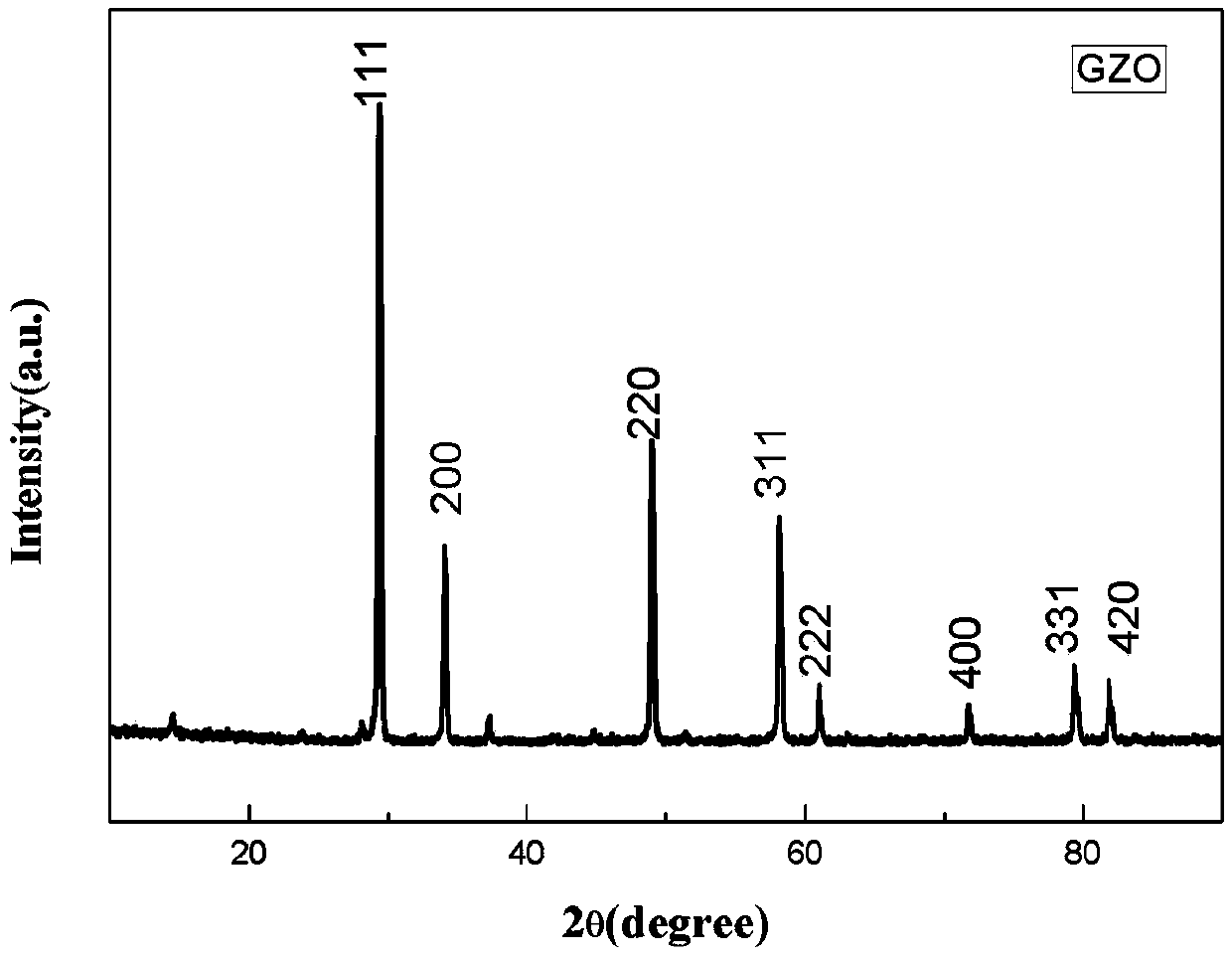

Porous rare-earth zirconate powder for plasma physical vapor deposition thermal barrier coating and preparation method thereof

ActiveCN108675824AHas high temperature phase stabilityLow thermal conductivityCeramicwareOxide ceramicGas phase

The invention discloses porous rare-earth zirconate powder for a plasma physical vapor deposition thermal barrier coating and a preparation method thereof and belongs to the technical field of preparation of oxide ceramic materials and thermal barrier coating protection. The preparation method disclosed by the invention comprises the following steps: firstly, mixing rare-earth oxide and zirconiumoxide powder according to a ratio; carrying out ball milling on a mixture and a solvent medium A, so as to obtain first suspension liquid; then drying and sintering to obtain a phase; then adding a solvent medium B and carrying out second-time ball milling to obtain second suspension liquid; then mixing the suspension liquid with a binding agent and granulating to obtain micron agglomerated spherical powder; finally, after sieving and grading, carrying out low-temperature heat treatment to obtain the porous rare-earth zirconate powder. The powder provided by the invention has high-temperaturephase stability, good thermal corrosion resisting performance, high purity, high sphericity, good flowability and low crushing strength, and high deposition efficiency; a preparation technology is convenient and equipment is simple; enlarged production is easy to realize and the cost is relatively low.

Owner:BEIHANG UNIV

Inorganic particle enhanced PC/PET alloy and preparation method thereof

The invention discloses an inorganic particle enhanced PC / PET alloy and a preparation method thereof. The alloy is composed of the following components in percentage by weight: 30 to 60% of PC, 10 to 30% of PET, 5 to 25% of inorganic particle, 2 to 4% of compatilizer, 0.5 to 2% of light stabilizer, 0.1 to 0.5% of coupling agent, 0.1 to 0.5% of antioxidant, and 0.1 to 1% of lubricant; wherein the inorganic particle has a particle size of 20 nm to 10 [mu]m and is one of heavy calcium carbonate, gas silicon dioxide, and talcum powder. The PC / PET alloy has the advantages of PC and PET, solves the shortages of single components, and moreover has the characteristics of high strength, good rigidity, excellent heat resistant performance, excellent corrosion resistant performance, good weatherability, excellent electric performance, excellent processing ability, and low cost.

Owner:QINGDAO TONGCHUANG ENERGY SAVING ENVIRONMENTAL PROTECTION ENG

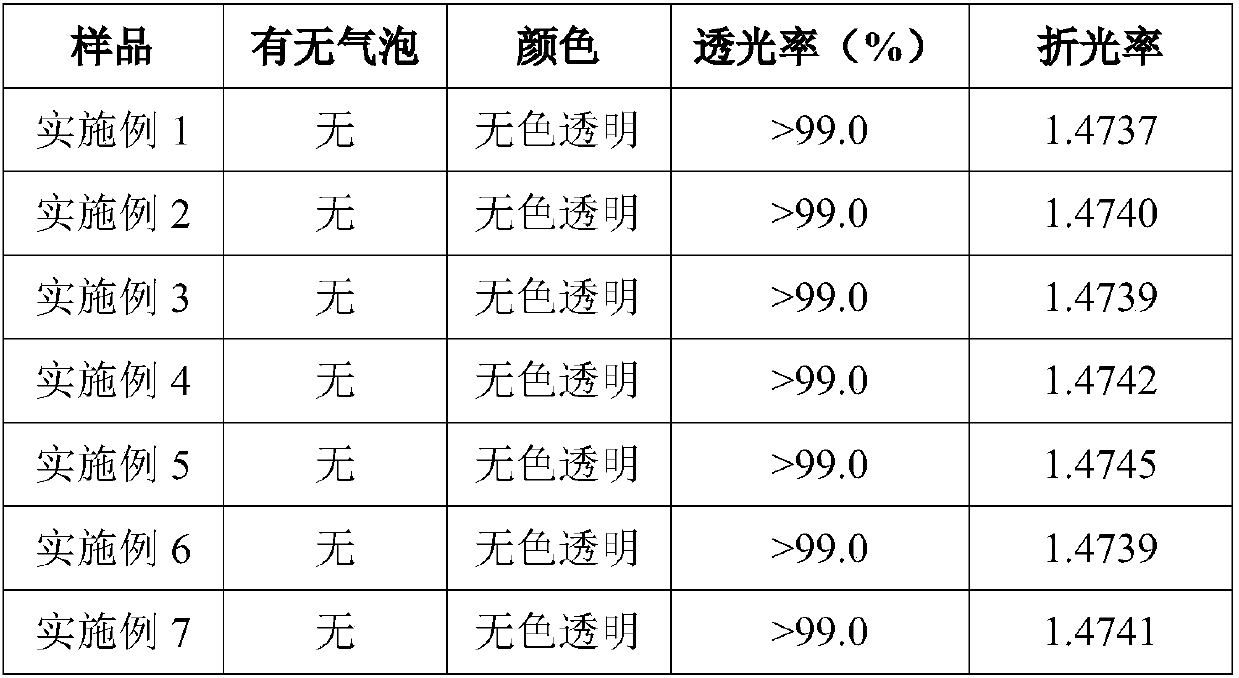

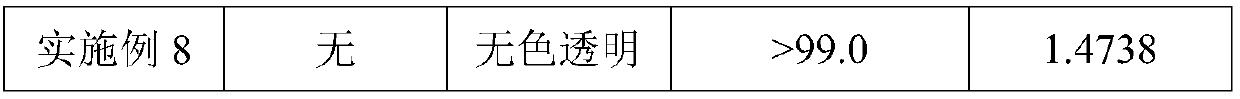

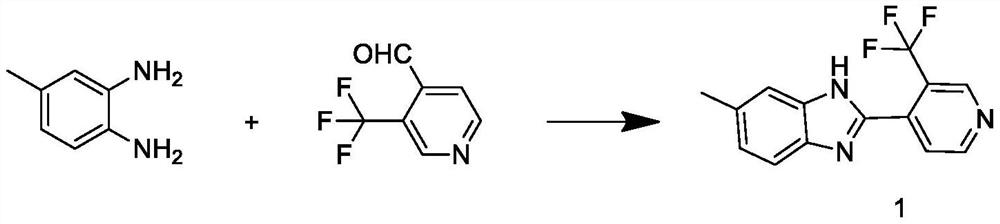

Preparation method of organosilicone adhesive

InactiveCN107674639AGood light transmissionHigh light transmittanceMacromolecular adhesive additivesEpoxy resin adhesivesAdhesiveTransmittance

The invention discloses a preparation method of an organosilicone adhesive. The preparation method comprises following steps: preparation of component A, preparation of component B, mixing of the component A with the component B, and solidification. In the steps of preparation of the component A and the component B, raw materials are introduced into a first material tank for mixing and stirring, preparation is carried out in an open system directly, and protection by certain inert gas or stirring under vacuum conditions is not needed; an obtained mixture is subjected to normal pressure filtering using a 300- to 400-mesh filter screen in the first material tank, and then is introduced into a second material tank, no high pressure extrusion is needed. Compared with conventional organosilicone adhesive preparation technology, the preparation method possesses following advantages: production conditions are simplified, production time is shortened, the organosilicone adhesive prepared via the preparation method is high in refractive index and light transmittance rate.

Owner:FUDAN UNIV +1

Antibacterial toughened polyethylene plastic processing technology

PendingCN113527794AImprove antibacterial propertiesStrong UV Absorbing PropertiesPolymer scienceHigh density

The invention relates to an antibacterial toughened polyethylene plastic processing technology, and belongs to the field of polyethylene plastic processing, and the antibacterial toughened polyethylene plastic processing technology comprises the following steps: 1, preparing the following raw materials in parts by weight: 70-90 parts of high density polyethylene, 1-3 parts of a modified antibacterial agent, 4-10 parts of modified silicon dioxide and 0.5-2 parts of a compatibilizer; 2, adding the raw materials in parts by weight into a mixer, stirring for 20 minutes, heating to 60-70 DEG C, and stirring for 30 minutes to obtain a mixture; and 3, putting the mixture into a twin-screw extruder, keeping the stirring speed of the twin-screw extruder at 220-250r / min and the temperature range of the extruder at 145-200 DEG C, melting, extruding, cooling and granulating to obtain the antibacterial toughened polyethylene plastic. The polyethylene plastic prepared by the method not only has excellent antibacterial property, but also has better ultraviolet absorption property, and the mechanical property of the polyethylene plastic is also improved due to the addition of the modified silicon dioxide.

Owner:JIESHOU JINFENG PLASTIC

High-temperature-corrosion-resistant enamel coating and preparation method thereof

ActiveCN113149439ALower sintering temperatureLow densityCombined combustion mitigationMicrosphereSilicon dioxide

The invention provides a high-temperature-corrosion-resistant enamel coating and a preparation method thereof, the high-temperature-corrosion-resistant enamel coating is prepared by taking silicon dioxide and aluminum oxide as matrix agents, adding borax, quartz sand, nano zirconium oxide and the like to prepare enamel frits, and further adding silica sol, modified POSS, metal-coated hollow SiC microspheres and modified rectorite, by adjusting the preparation method and the sintering process of the enamel coating and adjusting the sintering temperature, the sintering time and the coating thickness, the enamel coating which is low in porosity and excellent in high-temperature oxidation resistance, heat corrosion resistance, thermal shock resistance and thermal shock resistance toughness is obtained, the use requirement of the waste incineration power generation boiler can be met, and the industrial application prospect is great.

Owner:深圳优易材料科技有限公司

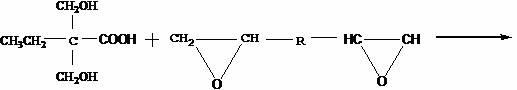

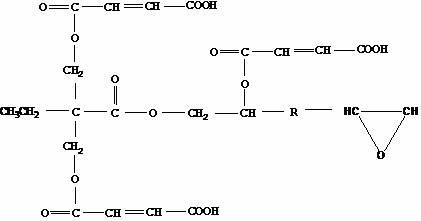

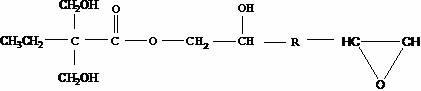

Waterborne epoxy/unsaturated polyester interpenetrating network polymer alloy and preparation method thereof

InactiveCN102690502AGood tensile strengthGood heat and corrosion resistanceEmulsionEnvironmental resistance

The invention relates to a waterborne epoxy / unsaturated polyester interpenetrating network polymer alloy and a preparation method of the alloy; the waterborne epoxy / unsaturated polyester interpenetrating network polymer alloy is composed of a waterborne epoxy / unsaturated polyester component A, a waterborne unsaturated polyester component B and a curing agent component C; a mixing ratio measured by mass of the waterborne epoxy / unsaturated polyester component A and the waterborne unsaturated polyester component B is 2: 1-1: 2; dosage of the curing agent component C is 0.025-0.1% of total mass of the waterborne epoxy / unsaturated polyester component A and the waterborne unsaturated polyester component B; an obtained emulsion C is mixed with the obtained emulsion D, and the curing agent component C of cyclohexanone peroxide and cobalt naphthenate is added into a mixture of the obtained emulsion C and the obtained emulsion D, the mixture is poured into a mould after the mixture is stirred uniformly, is baked at 80-100 degrees centigrade, and is cured to obtain a product that is waterborne epoxy / unsaturated polyester interpenetrating network polymer alloy; the method can effectively play a modification role of epoxy resins, and uses water as disperse phase, so that the method is secure and environment friendly; impact strength and tensile strength of condensates are excellent; heat resistance and corrosion resistance are excellent.

Owner:佘植能 +1

Extra-high voltage lead for intelligent power grid

InactiveCN105869717AImprove conductivityLight in massNon-insulated conductorsPlastic/resin/waxes insulatorsFiberCarbon fibers

The invention belongs to the field of electric power materials, and discloses an extra-high voltage lead for an intelligent power grid. The extra-high voltage lead is formed by twisting multiple strands of carbon fiber conductors, wherein the carbon fiber conductors are prepared by the steps of: (1) preparing a material A; (2) preparing a material B; (3) preparing a material C; (4) preparing a material D; and (5) preparing the carbon fiber conductors. A multi-stand carbon fiber conductor composite structure is adopted by the extra-high voltage lead for the intelligent power grid, so that the extra-high voltage lead is high in strength, light in weight, long in transmission distance and high in capacity.

Owner:JUNAN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

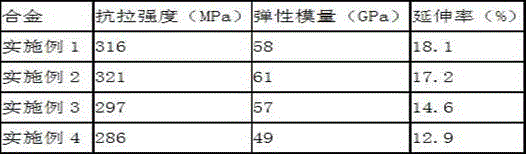

Inorganic particle reinforced alloy material

InactiveCN105462212AMake up for the defects in the performance of a single componentHigh strengthMechanical componentsInorganic particle

The invention discloses an inorganic particle reinforced PC / PET alloy. The inorganic particle reinforced PC / PET alloy contains the ingredients in percentage by mass: 40-60% of PC, 5-30% of PET, 10-20% of inorganic particles, 2-5% of compatibilizer, 0.5-2% of photostabilizer, 0.5-1% of coupling agent, 0.1-0.5% of primary antioxidant, 0.1-0.5% of secondary antioxidant and 0.5-2% of lubricant. The inorganic particle reinforced PC / PET alloy has the beneficial effects that compared with the prior art, the inorganic particle reinforced PC / PET alloy disclosed by the invention has the advantages that the inorganic particle reinforced PC / PET alloy simultaneously has inherent advantages of PC and PET, the property defect of a single ingredient is made up, the inorganic particle reinforced PC / PET alloy also has the characteristics of high strength, good rigidity, excellent heat resistance and corrosion resistance, good weatherability, excellent electric properties and processability and the like, and the cost of the inorganic particle reinforced PC / PET alloy is low, so that the inorganic particle reinforced PC / PET alloy has a very good application prospect in the fields of automobile industry, electronic appliances, mechanical components and parts, architecture and the like.

Owner:QINGDAO YISHIBAO PLASTIC

Heat-resisting anticorrosive material

The invention provides a heat-resisting anticorrosive material. According to the technical scheme adopted by the invention, the heat-resisting anticorrosive material comprises water and a benzoic acid component and is characterized by also comprising the following components in parts by mass: 2-5 parts of chitosan, 3-5 parts of polyolefin acid salt, 1-5 parts of calcium propionate and 7-20 parts of sodium diacetate. Compared with the prior art, the heat-resisting anticorrosive material has the beneficial effects that the heat-resisting anticorrosive material has very good heat-resisting anticorrosive capacity by adding the chitosan, the polyolefin acid salt, the calcium propionate and the sodium diacetate.

Owner:王刚

Magnesium alloy semi-continuous casting process

ActiveCN105568096AImprove liquidityImprove mechanical propertiesMechanical propertyCorrosion resistant

The invention belongs to the field of magnesium alloy semi-continuous casting forming and discloses a magnesium alloy semi-continuous casting process, comprising the following steps: 1), preparing materials, 2), preparing material 1, 3), preheating raw materials, 4), smelting, 5), performing semi-continuous casting, 6), hot rolling and cold rolling, and 7) annealing. The process of the invention is simple and feasible, and a prepared product has the advantages of good resistance to elastic deformation, good mechanical properties, surface smoothness, corrosion resistance and the like.

Owner:山东银光钰源轻金属精密成型有限公司

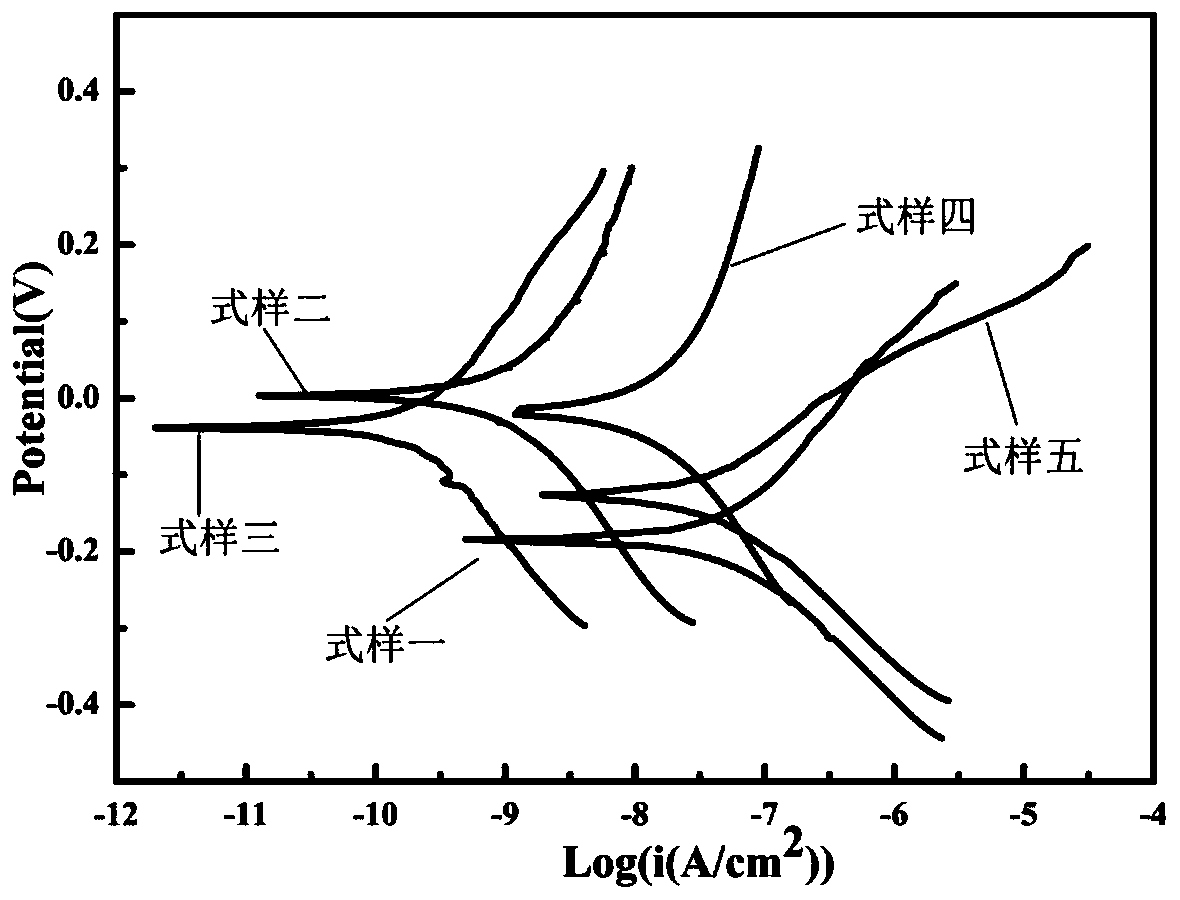

Heat-resistant corrosion-resistant wear-resistant composite coating, preparation method and application

ActiveCN109985784AImprove heat resistanceGood heat and corrosion resistanceMolten spray coatingSpecial surfacesWear resistantRoom temperature

The invention discloses a heat-resistant corrosion-resistant wear-resistant composite coating, a preparation method and an application. The composite coating comprises a working layer and a protectionlayer, wherein the working layer is a Cr3C2-NiCr coating body, the Cr3C2-NiCr coating body comprises Cr3C2 and NiCr with the mass ratio of 3:1, the protection layer is an Al2O3-SiO2-MTMS-Ce(NO3)3 ceramic / high-molecular composite material, and the Al2O3-SiO2-MTMS-Ce(NO3)3 ceramic / high-molecular composite material comprises Al2O3-SiO2 sol, MTMS (methyltrimethoxysilane) and Ce(NO3)3 with the mass ratio of 100:50-70:0.5-2. The preparation method comprises the following steps that Cr3C2-NiCr powder is sprayed on a base material so as to prepare the working layer; the Cr3C2-NiCr working layer is ground and cleaned; the Al2O3-SiO2-MTMS-Ce(NO3)3 protection layer sol is prepared; and the protection layer sol is coated on the surface of the Cr3C2-NiCr working layer, and is put into a muffle furnaceafter aging, heat preservation is carried out for 30 minutes at the temperature of 60 DEG C, then heat preservation is carried out for 30 minutes at the temperature of 120 DEG C, and cooling is carried out to room temperature along with the furnace to obtain the composite coating. The composite coating has good bonding force between the composite coating and a base body, the coating has fewer dense pores, and is resistant to heat corrosion and good in wear resistance, and the coating is excellent in overall performance and long in service life.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Wire applied to LED lamp

InactiveCN109285617AImprove conductivityGood mechanical propertiesInsulated cablesMetal/alloy conductorsMetallurgyRare earth

The invention relates to the field of LED lamp wires, and especially relates to a wire applied to an LED lamp. The main points of the technical scheme are that the wire comprises a wire body and a protective shell, the wire body includes 90% or above of Cu, 0.2%-1.21% of Cr, Zr and Hf, 7.65% of Mg, Zn, Ag, Si, Au, Zn and Fe, and 0.01%-0.35% of rare earth and unavoidable impurities. The wire solvesthe problems of high mass, non-durability and poor guiding performance of the existing wires.

Owner:NINGBO LAIHE CHRISTMAS GIFTS

Weatherproof surface treatment combinational optimization technology for power transmission type slip ring of high-power wind driven generator

InactiveCN102220581AImprove corrosion resistanceReduce pollutionHot-dipping/immersion processesAnodisationWind drivenEngineering

The invention discloses a weatherproof surface treatment combinational optimization technology for a power transmission type slip ring of a high-power wind driven generator, relating to the weatherproof surface treatment technology of the slip ring of the wind driven generator. Aiming at different parts of the slip ring, the following different anti-corrosion technologies are adopted: firstly, stainless steel part: an ion injection method is adopted so as to lead a cerium oxide film to be formed on the surface of the stainless steel; secondly, alloy part: a dacromet coating layer is arranged on the surface of the alloy part; and thirdly, fastening piece: hot dip galvanization or mechanical galvanization is adopted, so that a galvanization layer is formed on the surface. The weatherproof surface treatment combinational optimization technology has less pollution to environment and the treated slip ring is strong in anti-corrosion property.

Owner:JIANGSU SHUANGHUI FUTAI ELECTRIC

Method for manufacturing magnesium alloy bullet train table board supporting arm

The invention belongs to the field of alloy material machining, and discloses a method for manufacturing a magnesium alloy bullet train table board supporting arm. The method comprises the following steps of 1, material preparing, 2, auxiliary material preparing, 3, raw material preheating, 4, smelting and 5, pressure casting. The method is simple and feasible, and a manufactured product has the advantages of being good in mechanical property, resistant to corrosion and the like.

Owner:山东银光钰源轻金属精密成型有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com