Heat-resistant corrosion-resistant wear-resistant composite coating, preparation method and application

A composite coating and heat-resistant technology, which is applied in the direction of coating, metal material coating process, and device for coating liquid on the surface, etc. It can solve the problems of pores in the coating, etc., and achieve a dense coating without pores and heat resistance Good corrosion resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

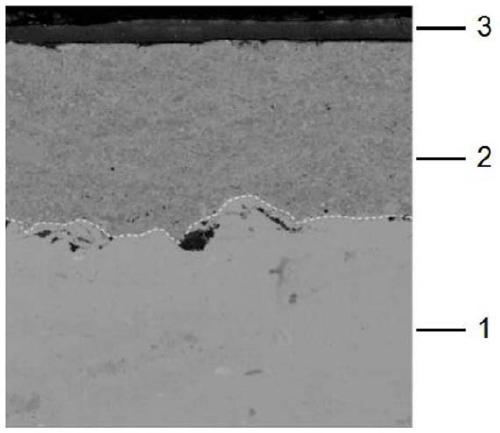

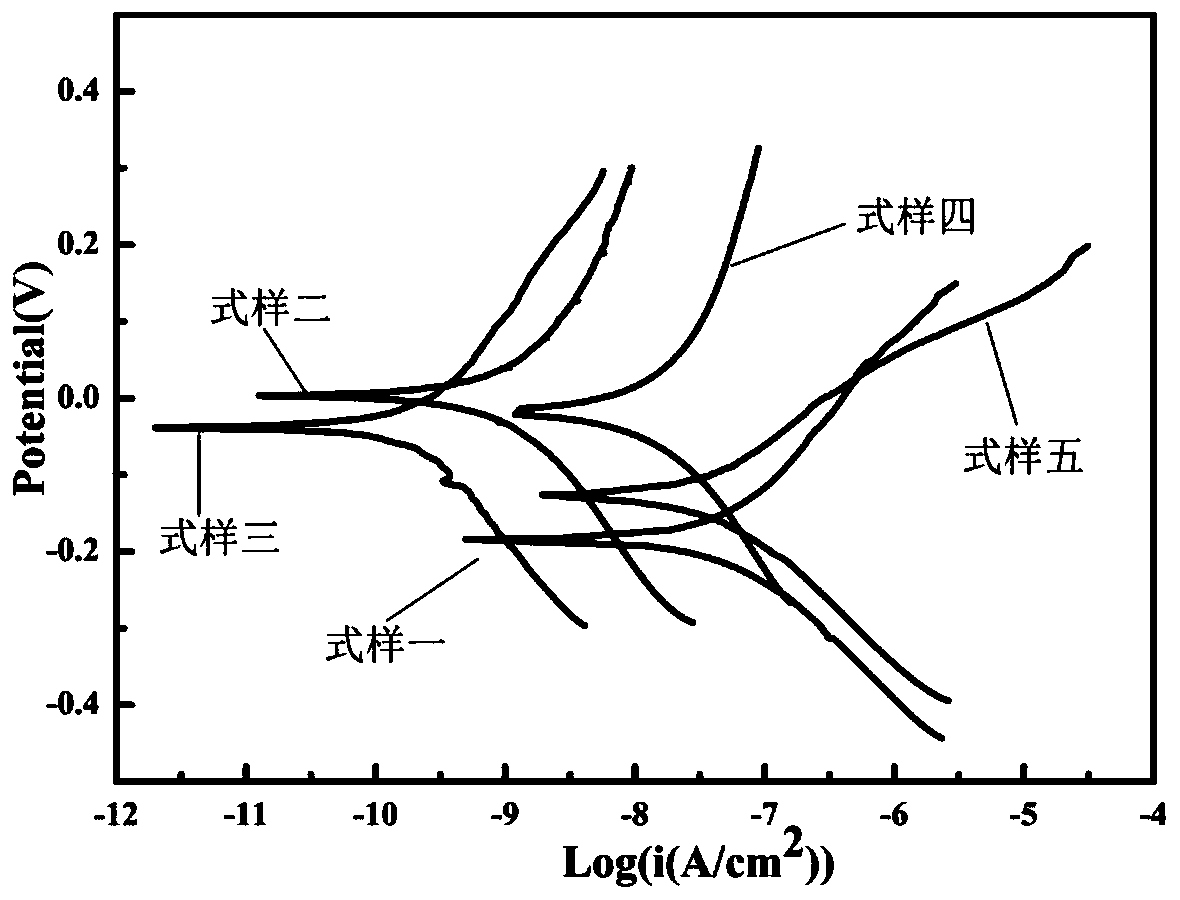

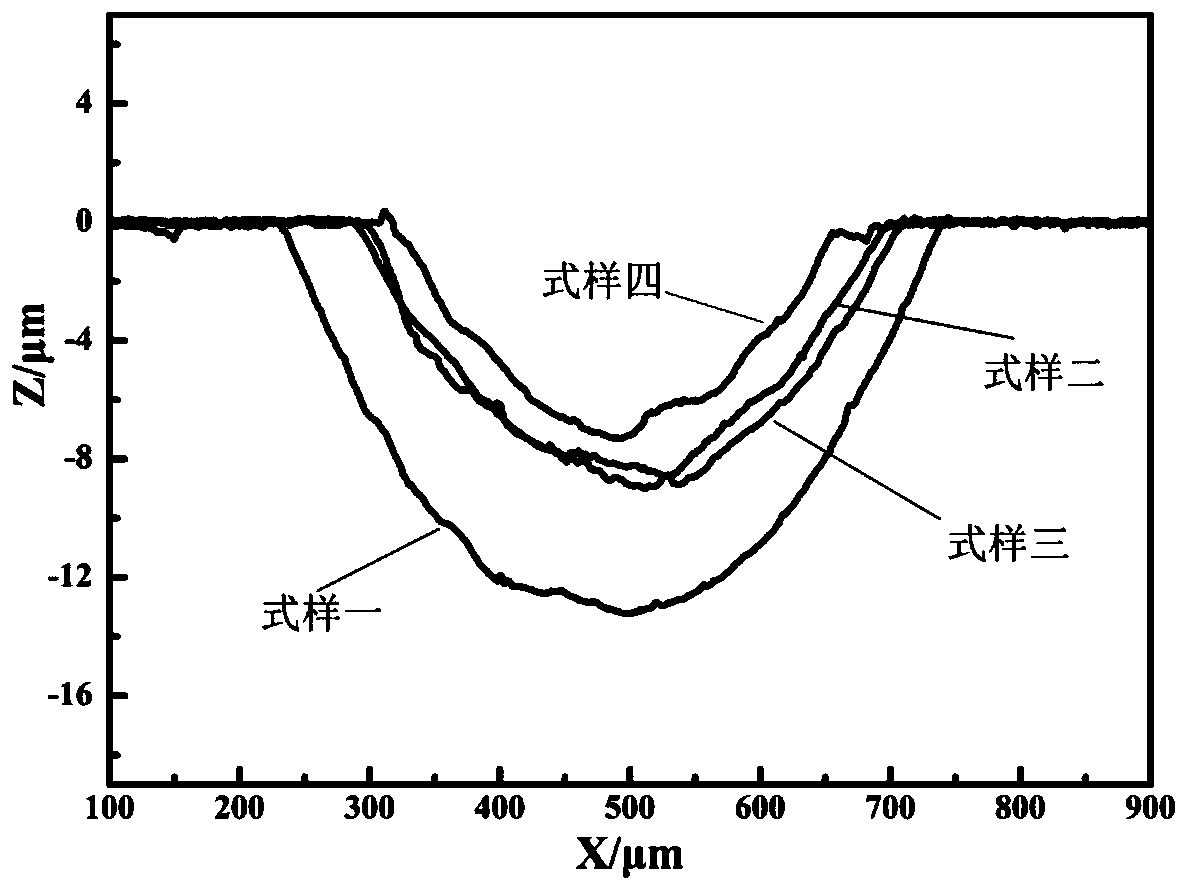

[0032] In this embodiment, the supersonic flame spraying method is used to spray the working layer on the CrZrCu substrate, and the material of the working layer is Cr 3 C 2 -NiCr,Cr 3 C 2 The mass ratio of NiCr and NiCr is 3:1, and the protective layer is not applied to obtain the first pattern, that is, a single coating.

Embodiment 2

[0034] In this embodiment, the surface of pattern one is coated with Al 2 o 3 -SiO 2 -MTMS-Ce(NO 3 ) 3 The protective layer forms a composite coating, and in the protective layer material, Al 2 o 3 -SiO 2 Sol and Ce(NO 3 ) 3 The mass ratio of Al is 100:1.0, Al 2 o 3 -SiO 2 The mass ratio of sol to MTMS is 100:60.

[0035] The protective layer coating steps are:

[0036] (1) Polish and ultrasonically clean Cr in ethanol 3 C 2 -NiCr working layer;

[0037] (2) Preparation of Al 2 o 3 -SiO 2 -MTMS-Ce(NO 3 ) 3 Protective layer sol: first take Al with a particle size of 50nm 2 o 3 -SiO 2 sol, adding Ce(NO 3 ) 3 Stir the particles for 5 minutes until uniform, then add MTMS, and stir magnetically for 3 hours at room temperature;

[0038] (3) Apply the protective layer sol on the Cr by brushing method 3 C 2 -The surface of the NiCr working layer, aged for 3 hours, placed in a muffle furnace, kept at 60°C for 30 minutes, then kept at 120°C for 30 minutes, coole...

Embodiment 3

[0041] In this embodiment, the surface of pattern one is coated with Al 2 o 3 -SiO 2 -MTMS-Ce(NO 3 ) 3 The protective layer forms a composite coating, and in the protective layer material, Al 2 o 3 -SiO 2 Sol and Ce(NO 3 ) 3 The mass ratio of Al is 100:1.0, Al 2 o 3 -SiO 2 The mass ratio of sol to MTMS is 100:60.

[0042] The protective layer coating steps are:

[0043] (1) Polish and ultrasonically clean Cr in ethanol 3 C 2 -NiCr working layer;

[0044] (2) Preparation of Al 2 o 3 -SiO 2 -MTMS-Ce(NO 3 ) 3 Protective layer sol: first take Al with a particle size of 55nm 2 o 3 -SiO 2 sol, adding Ce(NO 3 ) 3 Stir the particles for 5 minutes until uniform, then add MTMS, and stir magnetically for 3 hours at room temperature;

[0045] (3) Apply the protective layer sol on the Cr by brushing method 3 C 2 -The surface of the NiCr working layer, aged for 3 hours, placed in a muffle furnace, kept at 60°C for 30 minutes, then kept at 120°C for 30 minutes, coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com