High-reflectance film and manufacturing method thereof

A high-reflection film and high-reflection technology, applied in chemical instruments and methods, optics, instruments, etc., can solve problems such as corrosion, serious loss of light energy, corrosion of high-reflection film, etc., and achieve the effect of high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

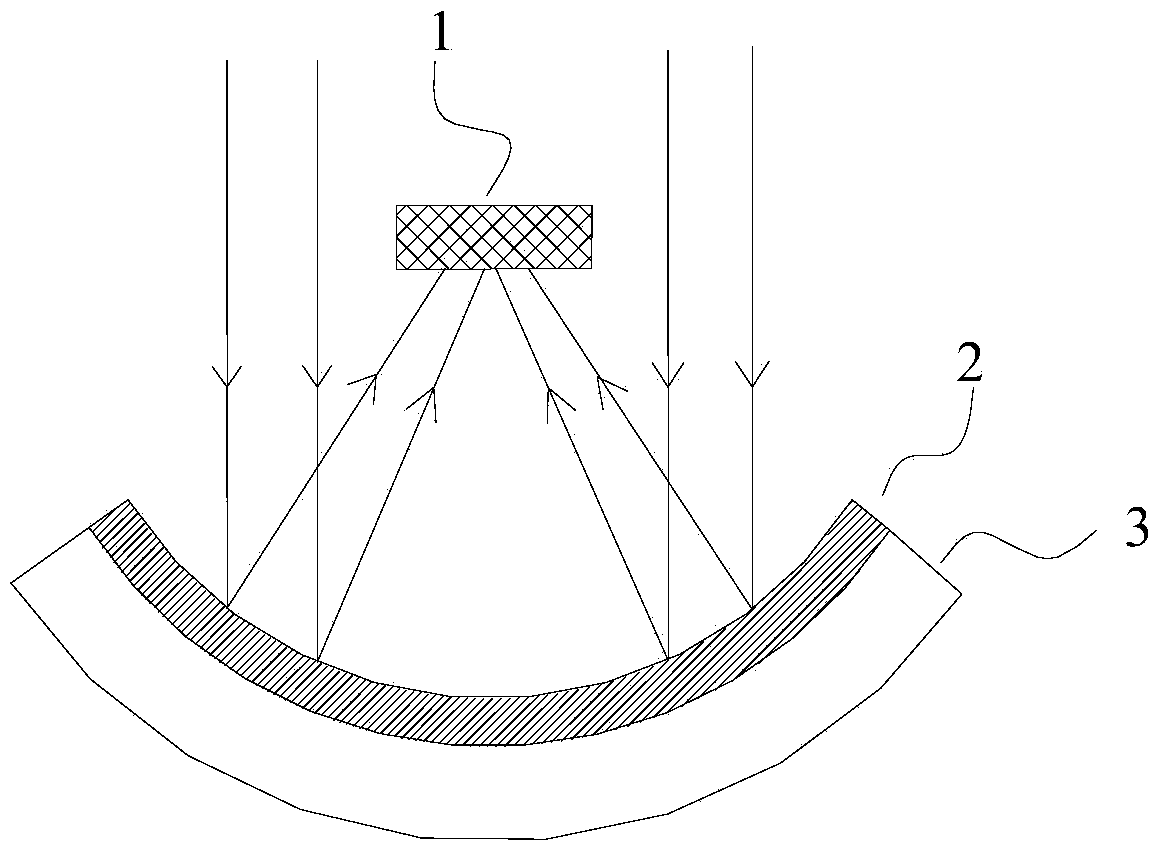

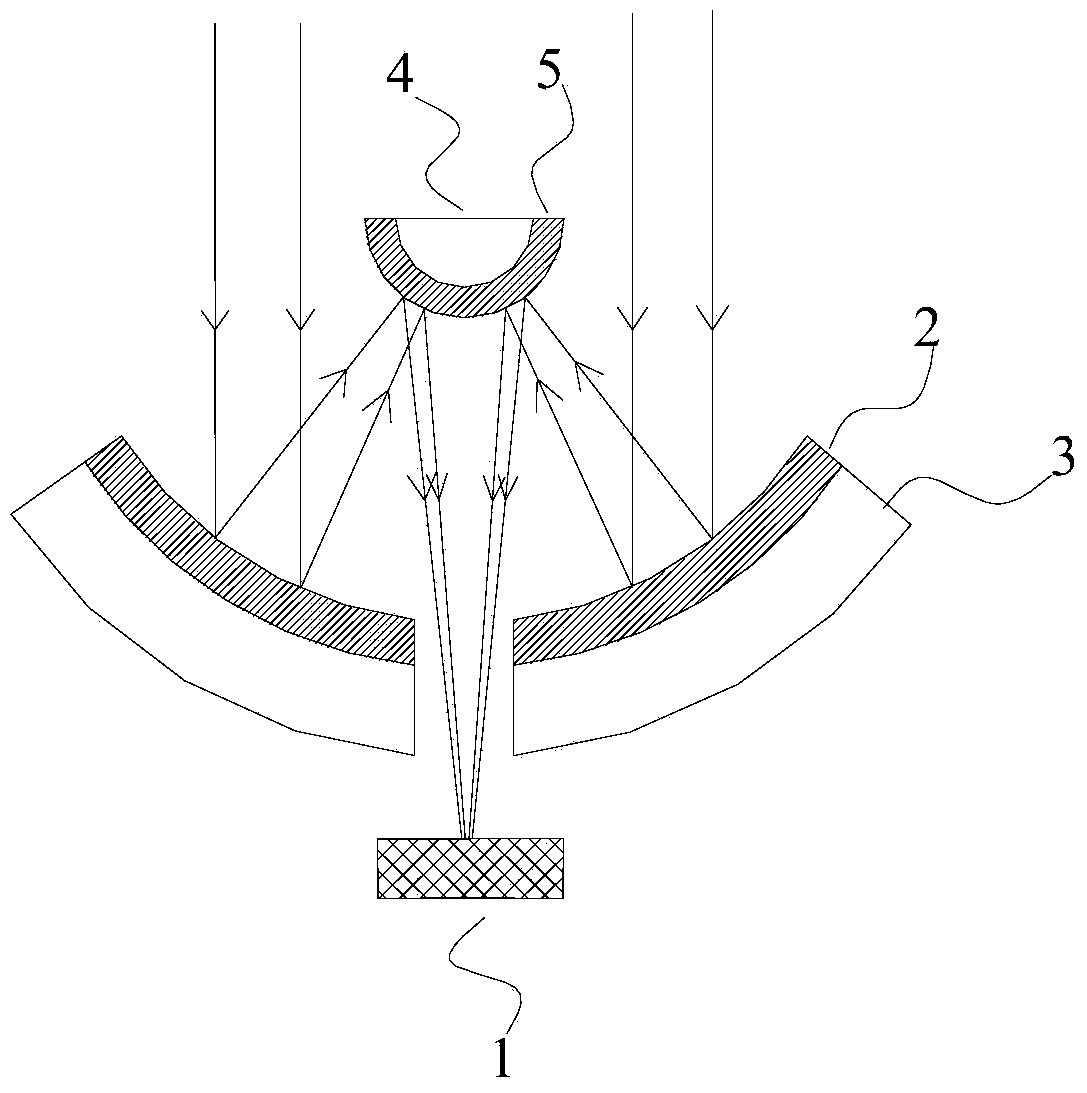

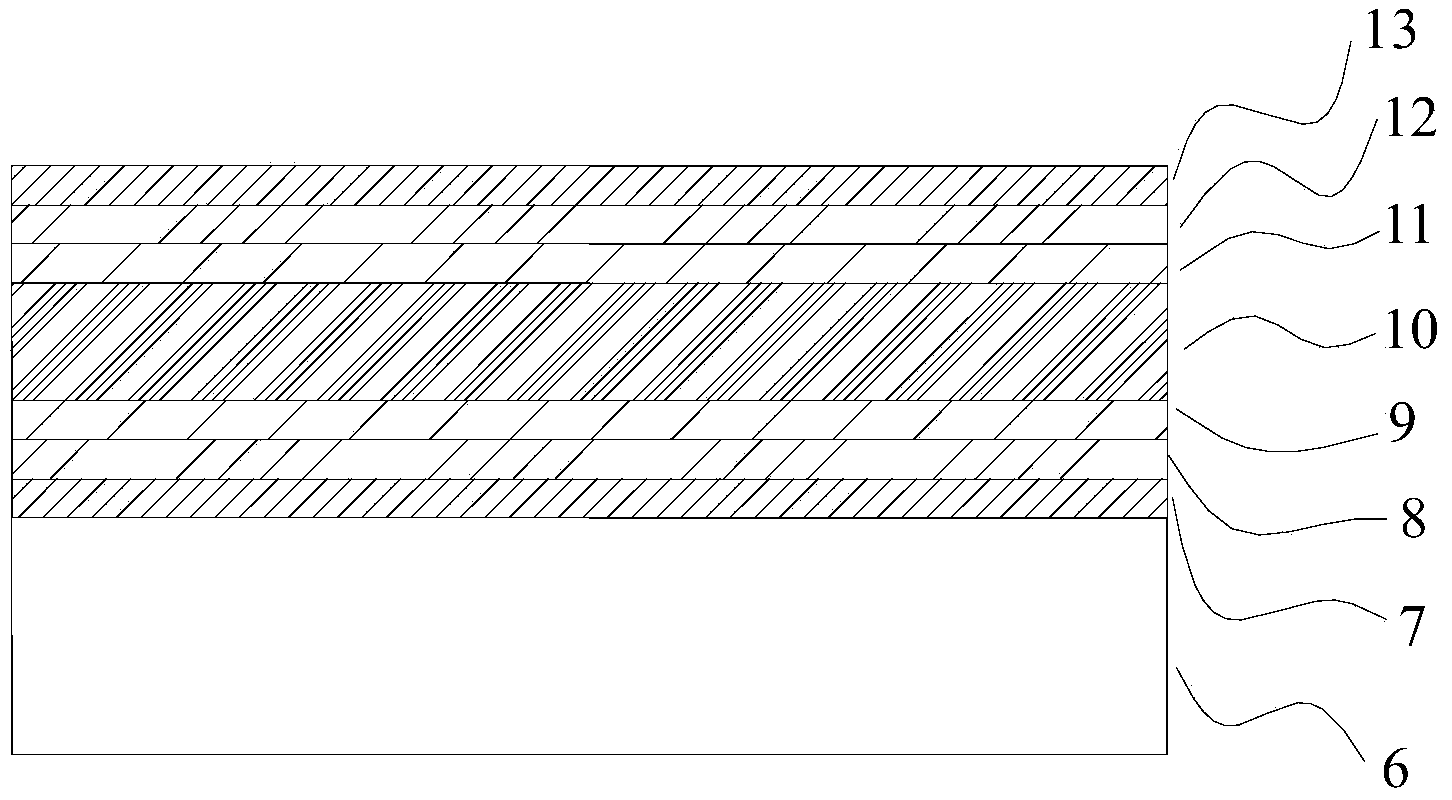

[0046] Such as figure 1 As shown, it is a schematic diagram of the structure principle of the primary reflective focusing system. The primary reflective focusing system includes a solar panel 1 and a reflector for reflecting sunlight to the solar panel 1. The reflector is arc-shaped, and the solar panel 1 is located in a circle In the center of the arc, the reflector includes an arc-shaped substrate 3 and a high-reflection film 2 coated on the arc-shaped substrate 3 , and the high-reflection film 2 is located on the side of the arc-shaped substrate 3 facing the solar panel 1 . The primary reflective focusing system is composed of an arc-shaped substrate 3 coated with a high-reflection film 2 and a solar panel 1. When the sunlight shines on the reflector, it is focused on the solar panel 1. By absorbing the sunlight, the sun will Light is converted into electrical energy by photoelectric effect or chemical effect; since the solar panel 1 of the primary reflection focusing syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com