Patents

Literature

643 results about "Silver copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver copper is a type of copper alloy. The binary alloy of silver and copper, the copper content in the silver-copper alloy is different, the color is also different, from silver-white to rose red to red. Its outstanding features are strong resistance to sulfides, good electrical conductivity, fluidity,...

Metal pastes and use thereof in the production of positive electrodes on p-type silicon surfaces

InactiveUS20100269893A1Reduce weight percentageReduce weightSemiconductor/solid-state device detailsConductive materialAlloyP type silicon

Metal pastes comprising (a) at least one electrically conductive metal powder selected from the group consisting of silver, copper, and nickel, (b) at least one p-type silicon alloy powder, and (c) an organic vehicle, wherein the p-type silicon alloy is selected from the group consisting of alloys comprising silicon and boron, alloys comprising silicon and aluminum and alloys comprising silicon, boron and aluminum.

Owner:EI DU PONT DE NEMOURS & CO

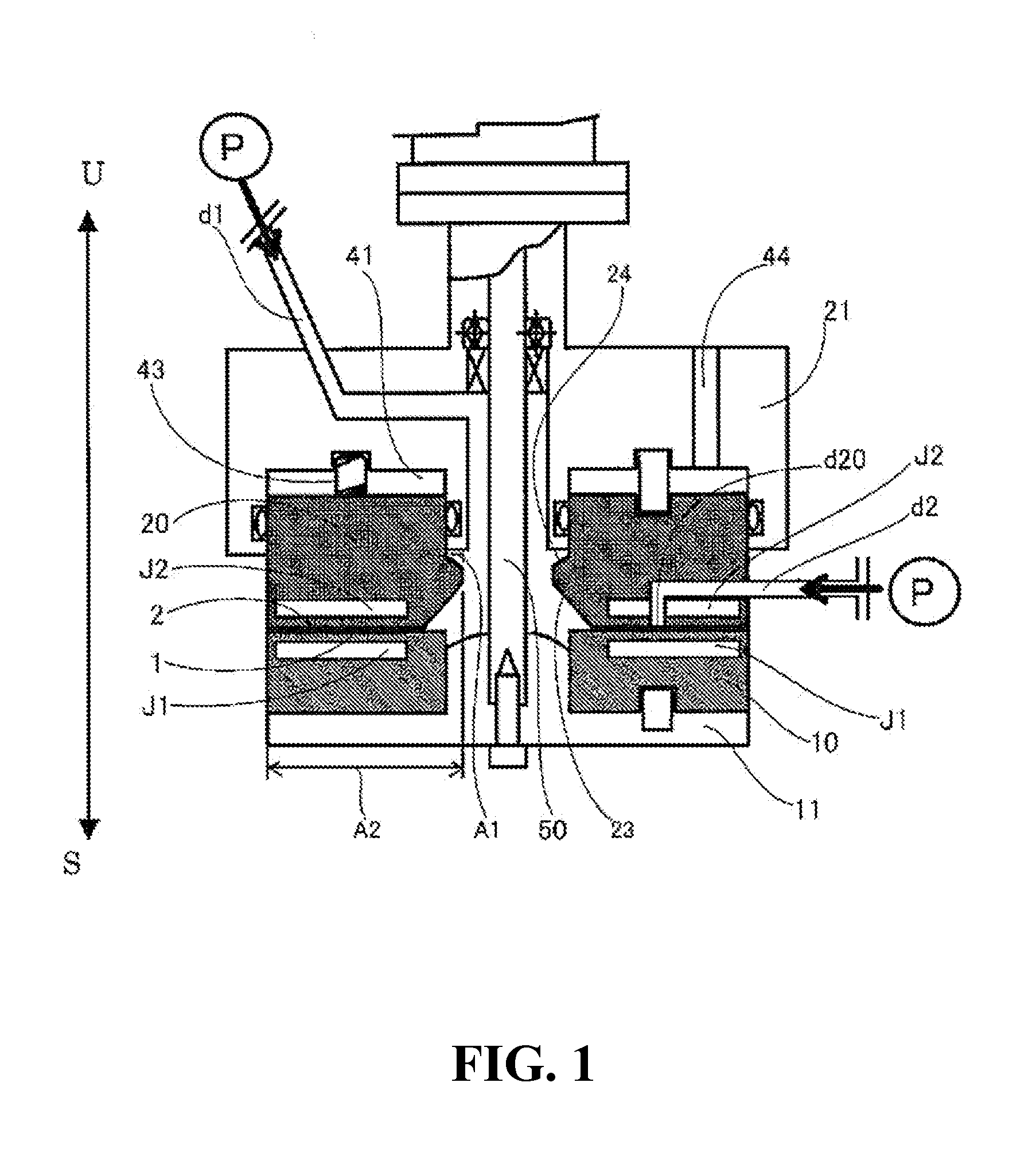

Argon-arc welding-braze welding composite welding method for connecting the titanium alloy and steel

ActiveCN101284336AAvoid crackingAvoid damageSoldering apparatusArc welding apparatusManganeseTitanium

The invention belongs to the welding technology field and relates to an argon-arc welding-composite braze welding method used for welding titanium alloy and steel. When the titanium alloy is welded with the steel, Nb is used as an intermediate layer; arc welding is conducted towards the titanium alloy and the intermediate Nb layer by using a titanium welding wire in an argon chamber; and braze welding is conducted towards the titanium alloy and the intermediate Nb layer. The method uses Nb as the intermediate layer, and utilizes fusion welding and the braze welding to weld Nb with two parent metals of the titanium alloy and the steel respectively, thus avoiding the direct contact of the titanium and iron in the two kinds of parent metal, and preventing cracks from being formed by brittle phase produced when the titanium and the steel are directly welded. Copper manganese matrix solder and silver copper titanium solder are selected for braze welding Nb and the steel, and the corresponding temperature avoids the damage to the property of the parent metals of titanium alloy.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

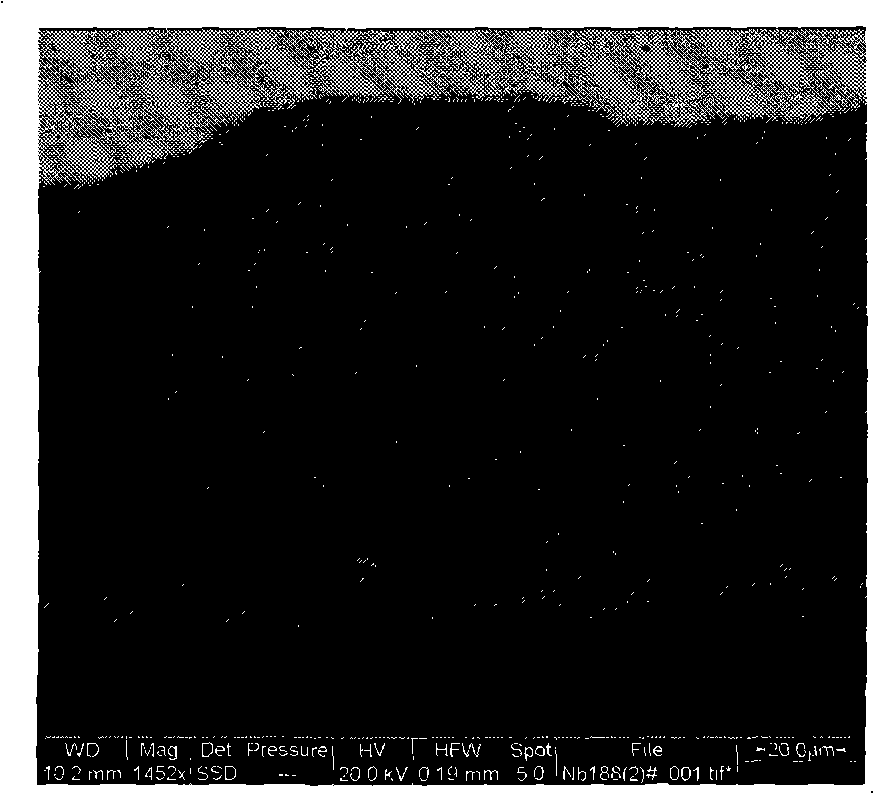

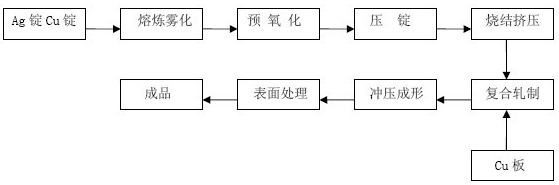

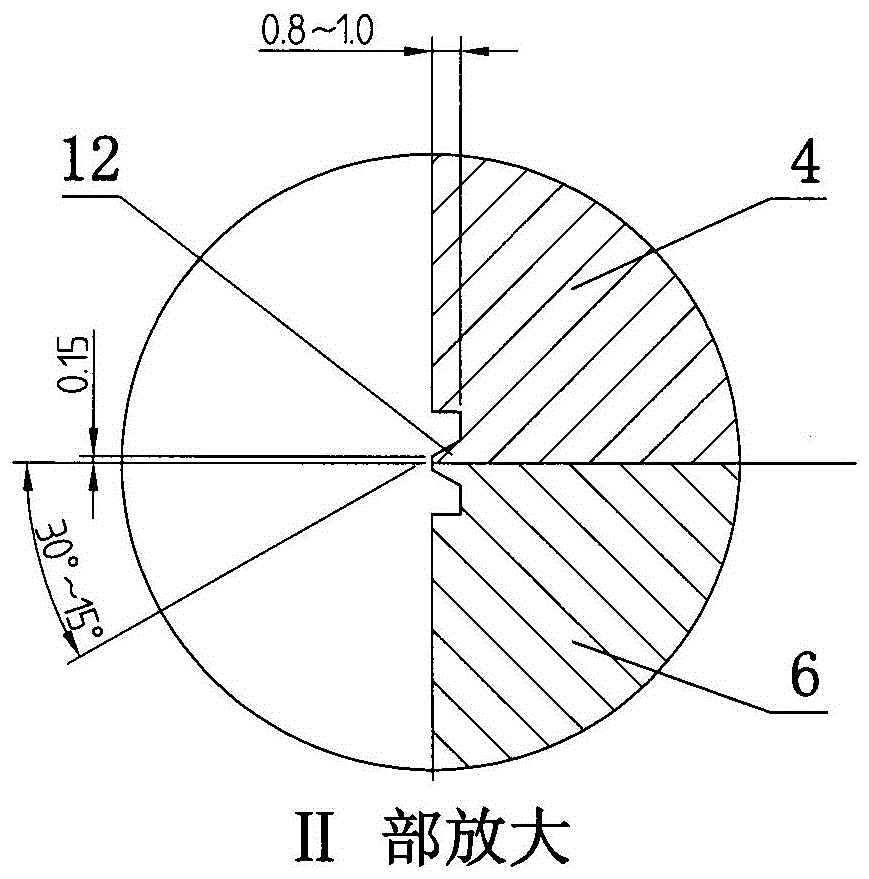

Method for preparing double side mosaic type hot-rolling composite silver copper strip

ActiveCN101053874AHigh bonding strengthMeet the use requirementsRoll mill control devicesHeat treatment process controlInterference fitUltimate tensile strength

A preparation method of bilateral surface mosaictype hot rolling compound silver copper strip material comprises: rolling silver ingot into a plate-shaped blank with a certain thickness, cutting the blank to form silver blank in sections, and processing the silver blank into bilateral groove-shape compound silver preform in machine tooling or deepdrawn manner; processing the copper blank into unilateral protruding shape compound copper preform in machine tooling or deepdrawn manner; hot rolling compositing the compound copper preform / compound silver preform / compound copper preform lateral under argon gas protection after interference fit, with heating temperature of 500-900DEG C., soaking time of 10 minutes-100 minutes, and deflection of 40%-90%, to change mechanical interference fit of the compound copper preform / compound silver preform / compound copper preform into crystal combination between mosaic atoms; and cold rolling, annealing and finishing rolling the strip material to obtain the product which has more strong compound layer with higher bonding strength compared with prior technology.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Clean-free solder paste low in ICT (in circuit testing) false positive rate

InactiveCN104416297AImprove flow characteristicsAvoid stayingWelding/cutting media/materialsSoldering mediaZinc alloysSurface-active agents

The invention discloses clean-free solder paste low in ICT false positive rate. The clean-free solder paste low in ICT false positive rate comprises, by weight, 80%-91% of solder alloy powder and 9%-20% of flux. The key is that the flux is composed, by weight, of 10%-35% of rosin of the softening point below 110 DEG C, 40%-60% of composite solvent, 3%-10% of thixotropic agent of the melting point below 140 DEG C, 5%-15% of composition activator and 0.2%-1.5% of nonionic surface active agent. The solder alloy is a stannum-silver-copper alloy, a stannum-silver alloy, a stannum-copper alloy, a stannum-bismuth-copper alloy, a stannum-zinc alloy, a stannum-zinc-bismuth alloy, a stannum-plumbum alloy or a stannum-plumbum-silver alloy.

Owner:EUNOW ELECTRONICS TECH CO LTD SUZHOU

High-strength high-conductivity oxidation-resisting low-silver copper-base alloy and preparation thereof

A copper base alloy, which possesses high-strength, high conductivity, oxidation resistance and contains silver of low content, is characterized in that said high-strength high-conductivity oxidation-resistance low-silver copper base alloy is composed of low-silver copper base alloy powder, diamond powder of 0.2-1.0% and graphitized nanometer carbon fibre and is prepared through a powder metallurgy technological process, wherein said low-silver copper base alloy powder contains Ag of 0.08 -0.12%, Y, La and Ce of 0.05 -0.5% or one of misch metal or mixture of several misch metal. Said alloy in accordance with the present invention possesses higher intensity and hardness, stronger anti-crackle forming and stomatic expandability, and exhibits definite puddle welding resistance and better electroconductive performances at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

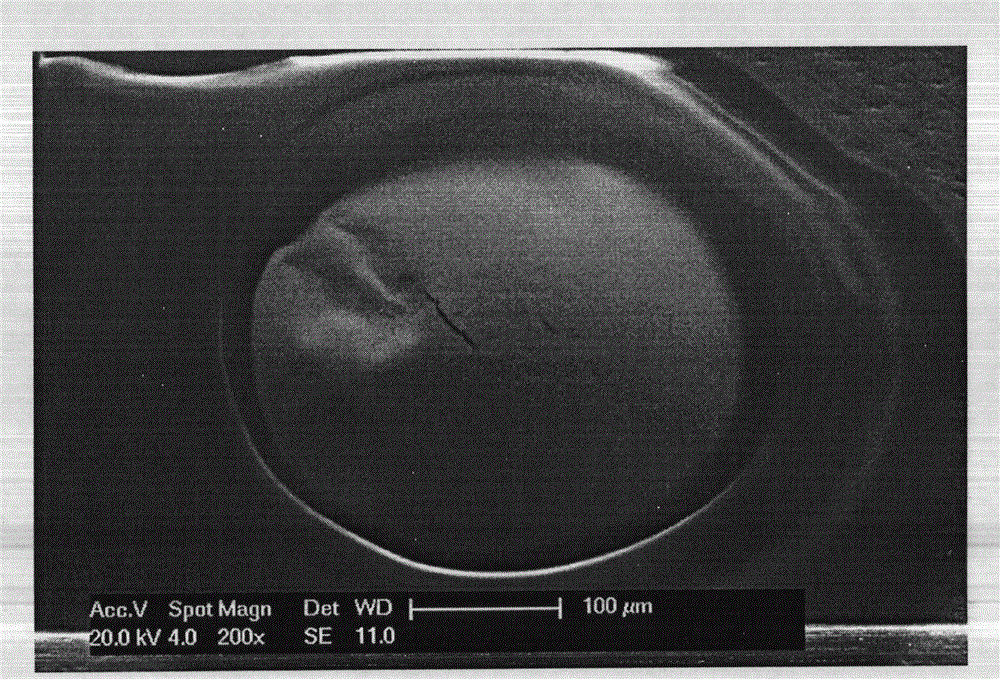

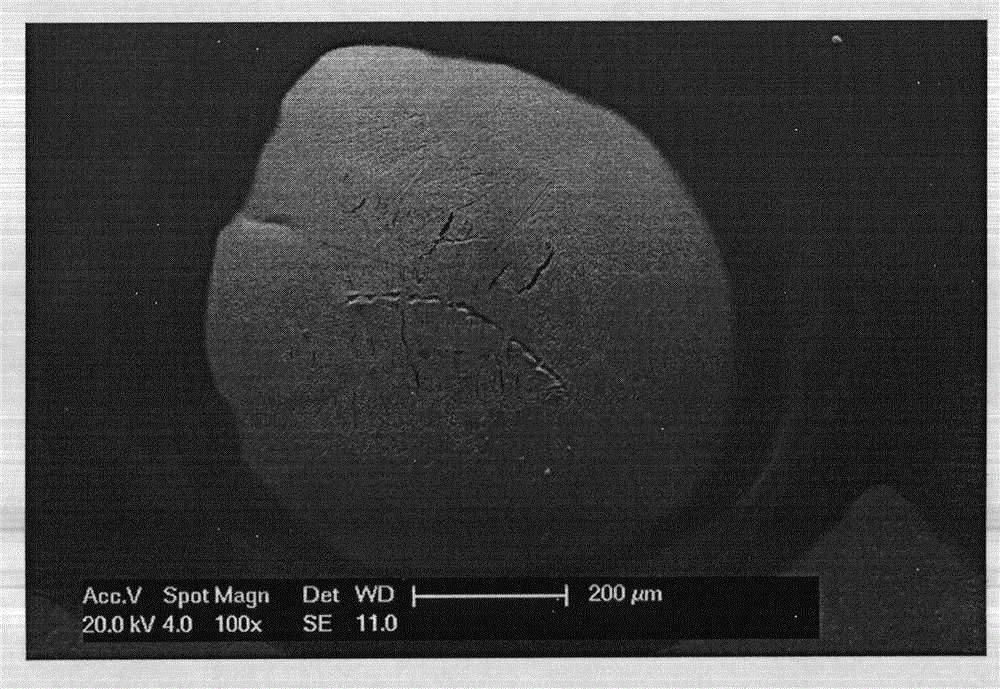

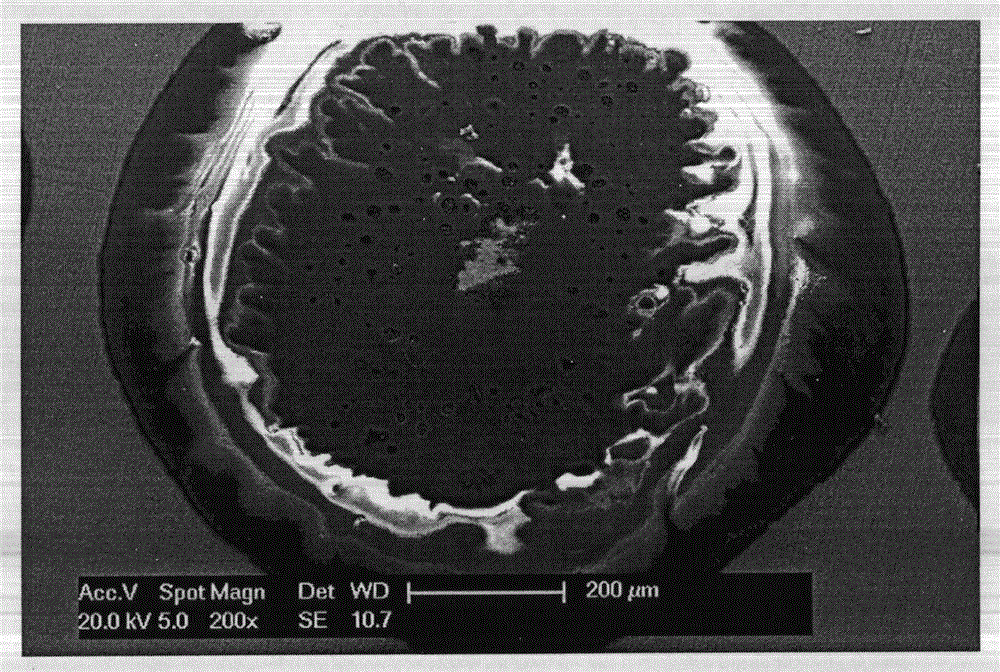

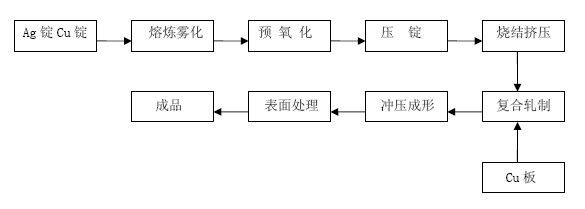

Silver copper oxide/copper composite electrical contact material and preparation process thereof

ActiveCN102054598AGuaranteed uniformityGrain refinementContactsMetal rolling arrangementsCopper oxideHigh pressure water

The invention discloses a silver copper oxide / copper composite electrical contact material and a preparation process thereof. The process comprises the following steps: mixing silver and copper according to certain proportions, and then, smelting the mixture in an intermediate frequency furnace; then, carrying out alloy atomization by using high pressure water atomizing equipment; baking after atomization to obtain powder; screening; putting the screened powder into an internal oxidization furnace for oxidizing at certain temperature and oxygen pressure; carrying out isostatic cool pressing after oxidization to form a billet; sintering and extruding to form a plate; and then, carrying out composite rolling with copper to obtain a finished product. Because the formula and process disclosed by the invention are reasonable, the produced electrical contact has the characteristics of high conductivity, uniform and fine tissue, high bonding strength between a working layer and a welding layer, fusion welding resistance, electrical arc erosion resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

Silver-plated copper powder electrically-conducting paint and method of manufacturing the same

InactiveCN101108947ASimple preparation processProcess parameters are easy to controlEpoxy resin coatingsElectrically-conductive paintsSilver plateConductive coating

The invention relates to a silvering copper powder electro-conductive coating and the preparation method, which belongs to the chemical technology field. The silvering copper powder electro-conductive coating of the invention utilizes the mixed metal as a conductive agent and comprises the following components based on the weight per cent: 18 per cent to 32 per cent of silvering copper powders with grain size of 10Mum, 25 per cent to 35 per cent of copper powders with grain size of 10Mum, 8 per cent to 23 per cent of flake silver powders with grain size of 0.1Mum to 10Mum, 840s10 per cent to 25 per cent of bisphenol A epoxy resins, 10 per cent to 25 per cent of curing agent 2-ethyl-4-methyl-imidazole, 5 per cent to 25 per cent of coupling agent KH-560 and others are water. The silvering copper powder electro-conductive coating prepared by the invention has surface resistivity of 100 Omega cm to 102 Omega cm. The coating has good conductivity and functions of shielding the electromagnetic wave and absorbing, and has broad application prospect in such fields as electronic industry, aviation / aerospace, electric heating, electromagnetic shielding and building warming.

Owner:靳一名

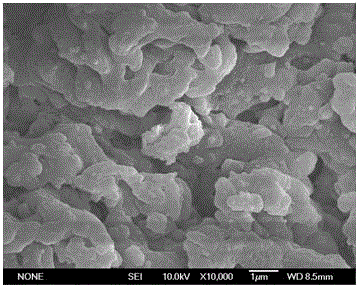

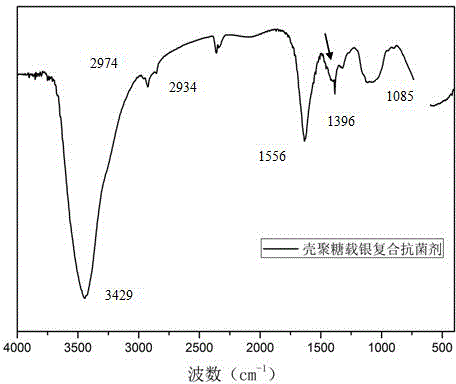

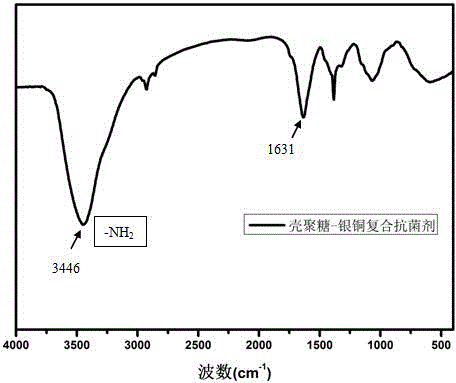

Method for preparing complex antimicrobial agent by blending chitosan and silver copper

InactiveCN104145993AReduce usageImprove antibacterial propertiesAntibacterial agentsOrganic active ingredientsEscherichia coliEnvironmental resistance

The invention relates to a method for preparing a complex antimicrobial agent by blending chitosan and silver copper. The method comprises the following steps: silver nitrate and cupric nitrate are blended according to the concentration ratio of 1:30 to 1:80, and then are blended with chitosan. Therefore, a light blue antibacterial agent powder is prepared. According to the method provided by the invention, the usage amount of silver is reduced, the chitosan is also used as a reducing agent, chemical reagents are no longer added, and the toxicity of an antibacterial agent is reduced. Due to the change of technological conditions, the oxidation-reduction reaction of the chitosan and the cupric nitrate can be performed sufficiently, an aldehyde group (-CHO) is generated in the reaction, Ag<+> is enabled to be completely reduced to elemental silver, Cu<2+> is hibernated in a chitosan basal body, so as to play a synergistic antibacterial effect, a remarkable inhibiting effect on escherichia coli and staphylococcus aureus is detected through an inhibition ring test, an inhibition ring which is equal to or greater than 10 mm is formed under a culture condition of 37 DEG C, a remarkable bacteriostatic effect is played, materials used cause no harm to human body, the price is low, and the novel complex antimicrobial agent is green and environment-friendly.

Owner:TAIYUAN UNIV OF TECH +1

Electrochemical preparation method for medical external use aluminum alloy multifunctional coating

The invention discloses an electrochemical preparation method for a medical external use aluminum alloy multifunctional coating. The medical external use aluminum alloy multifunctional coating prepared by the method has multifunctional purposes of decoration, corrosion resistance, sterilization, self cleaning and the like. According to the electrochemical preparation method, an aluminum alloy base material is subjected to anodic oxidation treatment and electrolytic coloring, so that a porous oxide film is formed on the surface of the aluminum alloy and contains certain metals such as silver, copper, zinc and the like; and the surface of the oxide film has self-cleaning nanometer titanium dioxide, so that the aluminum alloy has the functions of decoration, corrosion resistance, sterilization and self cleaning. The medical external use aluminum alloy multifunctional coating prepared by the electrochemical preparation method has the effects of decoration, corrosion resistance, sterilization and self cleaning, has the advantages of simple process, environmental protection, no toxicity, high stability of film layers and high practicability, meets various requirements on the aluminum alloy in the aspects of medical external use, and expands the application range of the aluminum alloy. According to the multifunctional coating obtained by the method, the aluminum alloy can be used in various fields of medical instruments such as disabled person stair handrails, medical carts, wheelchairs, stretchers, supports, intelligent call and the like.

Owner:湖南迈迪科新材有限公司

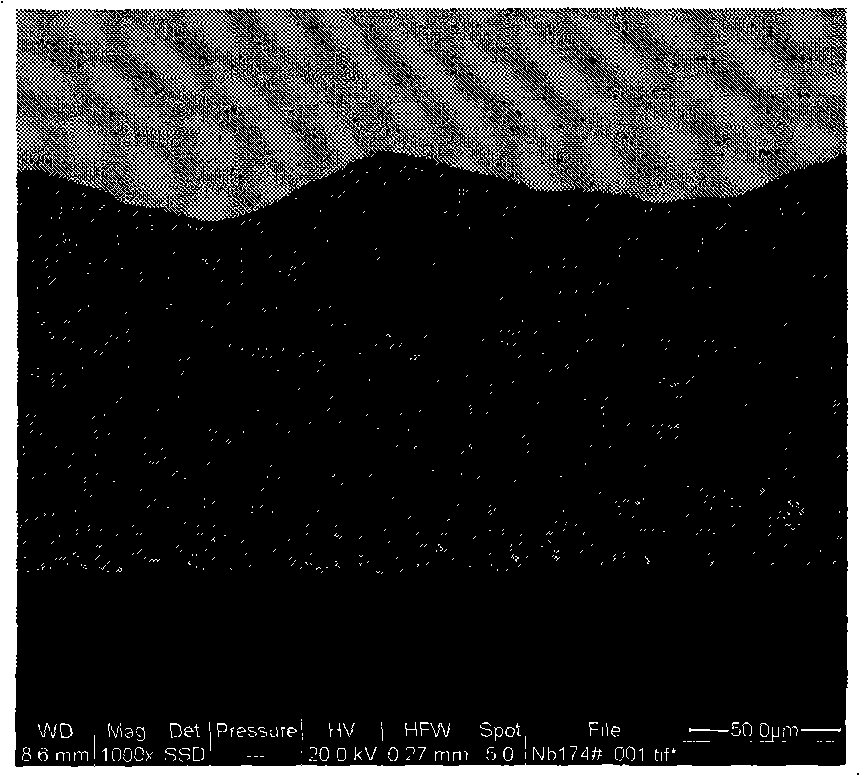

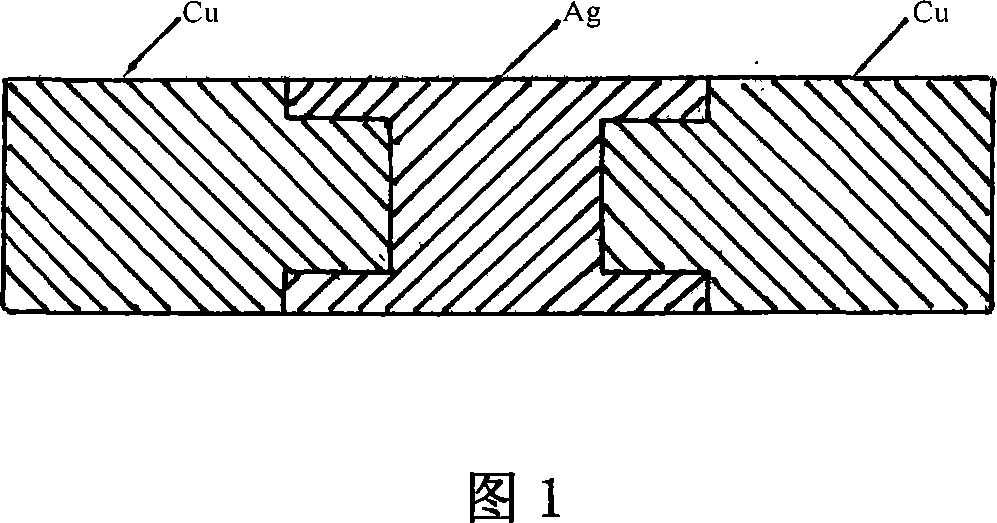

Preparation method of double lateral insert silver-copper composite strip

ActiveCN101670365AImprove stabilityHigh bonding strengthRoll force/gap control deviceSoldering apparatusLow voltageSilver copper

The invention relates to a preparation method of a composite strip, in particular to a preparation method of an interval lateral silver-copper composite strip. The method is characterized in that thepreparation method comprises the following steps: (1) opening strip symmetric through-holes in the centre of a strip copper plate along the length direction; (2) inserting corresponding silver-copperalloy / silver / silver-copper alloy triple composite strips in the strip through-holes to form composite blank; placing the inserted blank in a vacuum brazing furnace, keeping temperature to 780-850 DEGC for 10-30min, brazing to connected the silver-copper alloy / silver / silver-copper alloy triple composite strips inserted in the through-holes with the inner edge of the strip through-holes of the copper plate; and (4) processing the brazed and connected composite blank through cold rolling, annealing and fine rolling to obtain the finished product. The silver-copper composite strip prepared by themethod of the invention has high strength at the lateral connection position of silver and copper strips and good stability; the material can be used in the low-voltage fast acting fuse, thus savinga great number of precious metals -- pure silver and reducing the production cost.

Owner:西安诺博尔稀贵金属材料股份有限公司

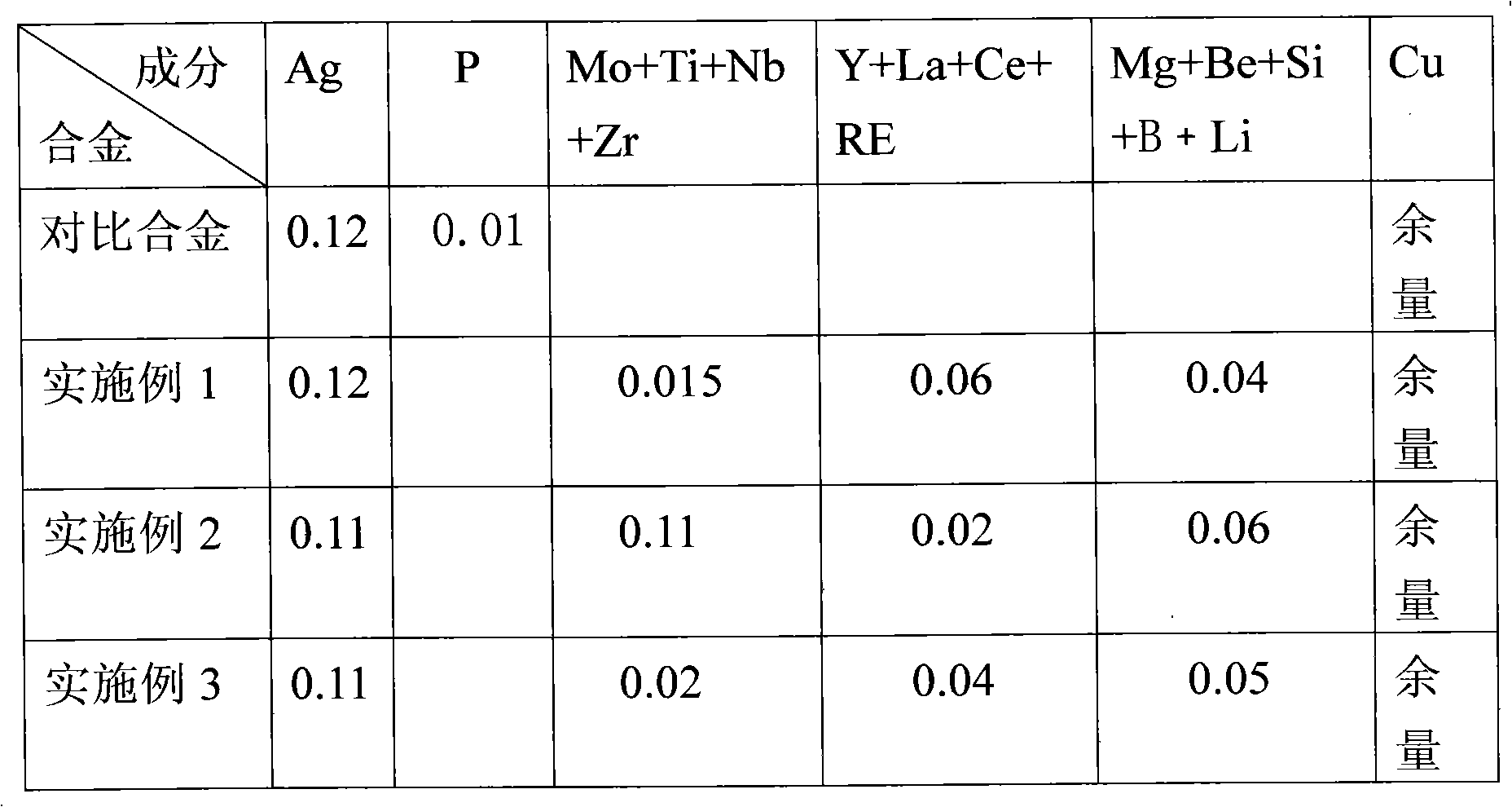

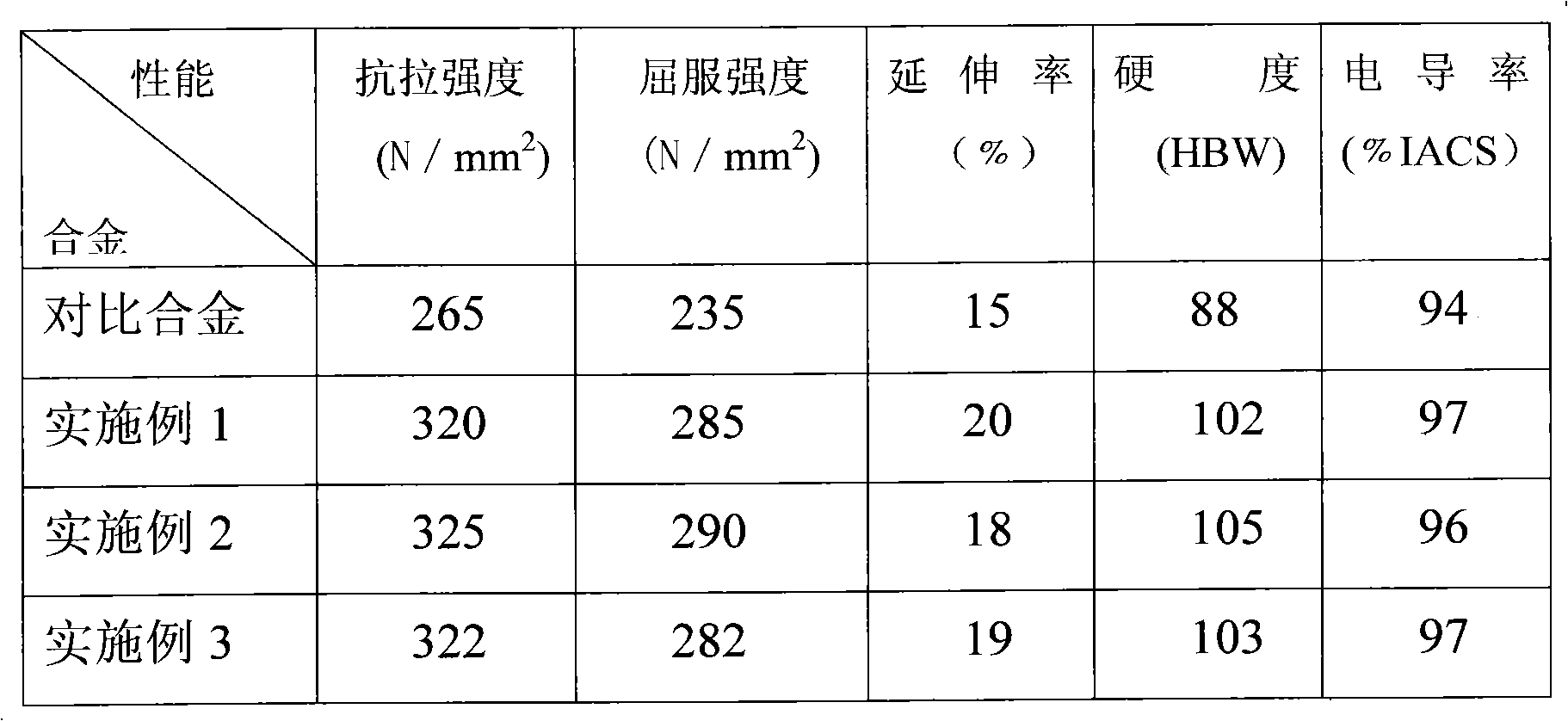

Low silver-copper alloy board for thin slab continuous casting crystallizer and manufacturing method thereof

The invention concretely provides a low silver-copper alloy board for a thin slab continuous casting crystallizer and a manufacturing method thereof. The low silver-copper alloy board comprises the following chemical components in percentage by weight: 0.08-0.12% of Ag, 0.008-0.11% of one or more of Mo, Ti, Nb and Zr, 0.01-0.08% of one or more of Y, La, Ce and RE (mixed rare earth), 0.005-0.09% of one or more of Mg, Be, Si, B and Li and the balance of Cu. After a trace amount of silver is added into copper and a trace amount of one or more of Mo, Ti, Nb and Zr is added into the copper simultaneously, very small influence is generated on electrical conductivity and thermal conductivity of the alloy, the oxidation resistance and the corrosion resistance of the alloy are improved, the strength of the alloy is increased, and the alloy becomes more tough, heat-resistant and wear-resistant.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

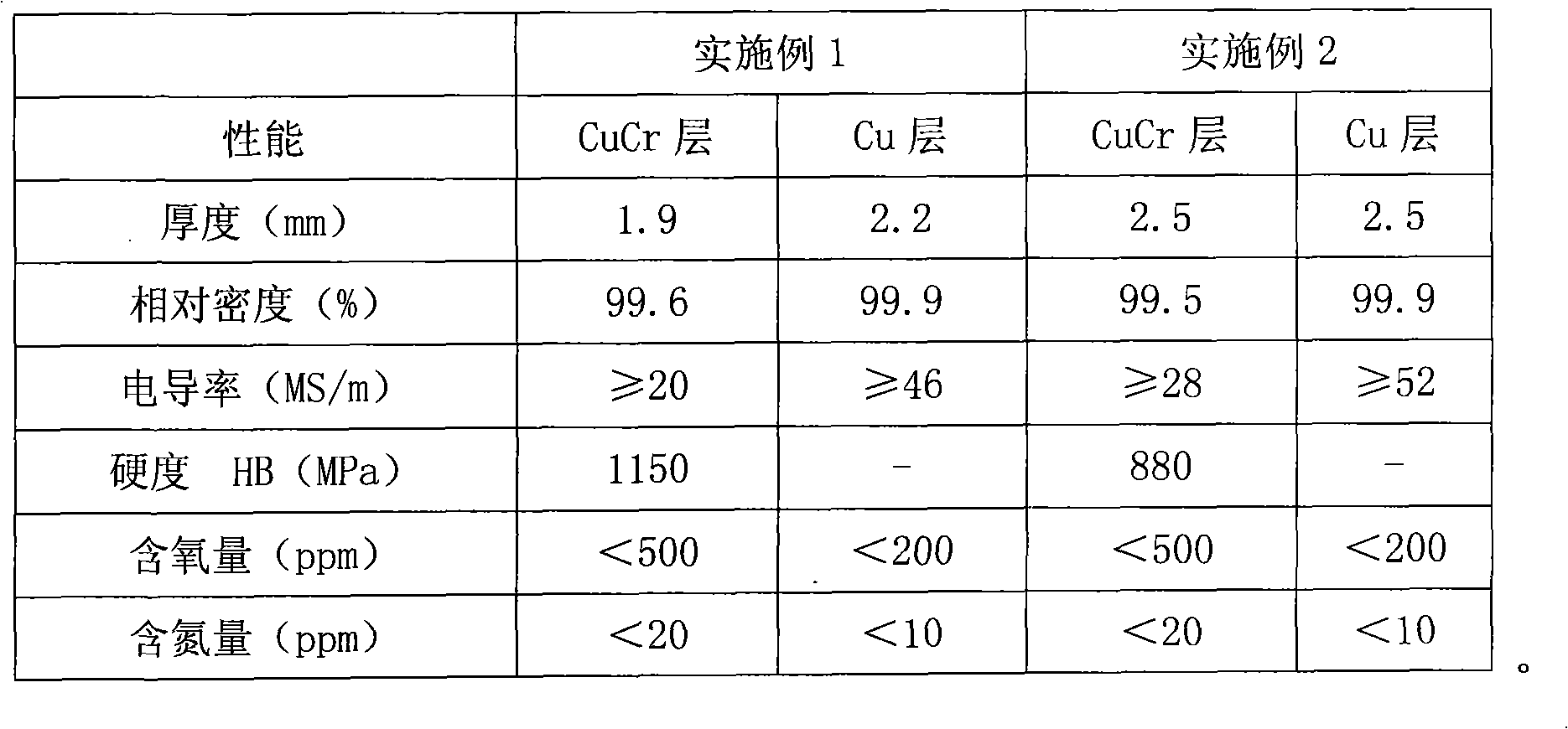

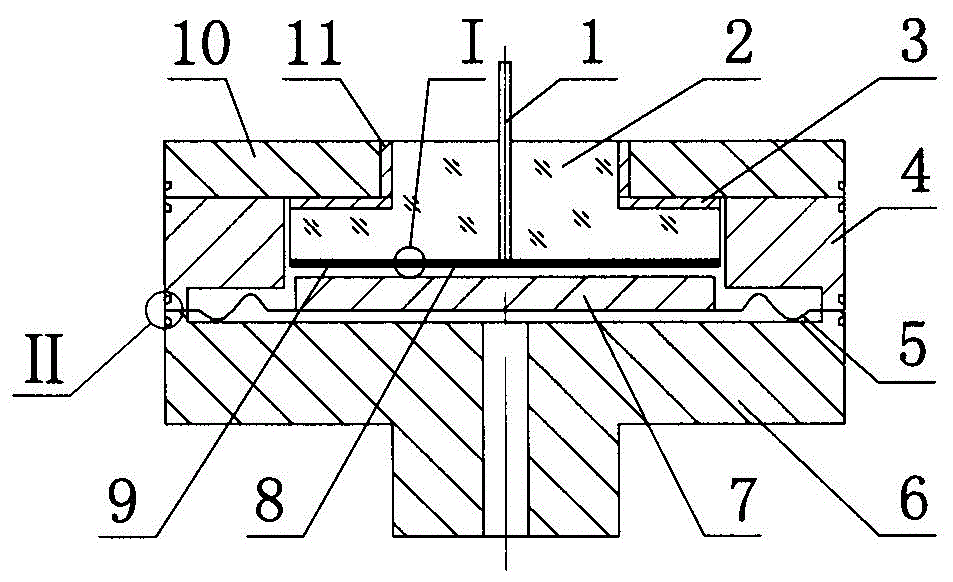

Cuprum chromium-cuprum composite contact material and manufacturing method thereof

ActiveCN101350255AReduce dosageReduce thicknessContactsElectrical resistance and conductanceTotal thickness

The invention relates to a cu-cr-copper composite contact material and the method for making the material, the cu-cr-copper composite contact material mainly comprises a cu-cr layer, a layer of copper is compounded on at least one surface of the cu-cr layer, and the thickness of the cu-cr layer is 1.5-2.5mm, the thickness of the copper layer is 1.5-4.5mm, and the total thickness of the cu-cr layer and the copper layer can be arbitrarily controlled between 3.0-7.0mm according to the requirements. The making method comprises the following steps: firstly, preparing powder materials of the cu-cr layer, secondly, preparing powder materials for the copper layer, thirdly, pressing composite materials, fourthly, carrying out the sintering, the repressing and the after-burning. The manufacturing method has the following technical effects: firstly, the thickness of the cu-cr layer is greatly reduced, the inner electric resistance of the contact material is effectively reduced, and the performance of a vacuum switch tube is improved, secondly, the difficulty of the welding technique of the copper layer and a conducting bar is reduced, the welding is easy and the quality is reliable, thirdly, the dosage of chromium is reduced, thereby the cost of raw materials for manufacturing the contact materials is reduced, fourthly, common silver-copper solder can be directly used, one time sealing and exhausting can be realized and the manufacturing cost of the vacuum switch tube can be greatly reduced.

Owner:ZHEJIANG YATONG METAL CERAMICS +1

High-ductility environment friendly silver-saving medium-temperature brazing filler metal

ActiveCN101342644AReduce brittlenessHigh melting temperatureWelding/cutting media/materialsSoldering mediaCadmium CationFiller metal

The invention relates to a high plasticity environment protection silver-saving intermediate temperature solder in which an intermediate temperature solder is used to replace the silver copper zinc cadmium solder with high content of silver, and a processing technology thereof. Aiming at the defects of the prior silver solder which contains cadmium and lead such as the heavy pollution to environment, the hazard of the cadmium and lead to human body, large brittleness of solder alloy and high cost and so on, the purpose of the invention is to provide a cadmium-free and lead-free high plasticity environment protection silver-saving intermediate temperature solder with low cost, small brittleness of solder alloy, comparatively low melting temperature and comparatively small melting range. The high plasticity environment protection silver-saving intermediate temperature solder of the invention comprises Cu, Sn, P, Ni, Ag, Li and La; wherein, Li and Na are active microelements. The preparation steps of the high plasticity environment protection silver-saving intermediate temperature solder of the invention are that raw materials are weighted by formula; the solder alloy is refined into solder ingot castings which are made into filamentous solders by hot-pressing. The filamentous solder can be made into sizes of solder coiling wire, solder straight wire and solder welding ring.

Owner:浙江信和科技股份有限公司

Low silver copper base medium temperature brazing filler metal

ActiveCN101524798AConserve limited resourcesReduce use costWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention relates to a low silver copper base medium temperature brazing filler metal applicable to braze welding of workpieces such as copper and copper alloy, copper and steel, belonging to the field of medium temperature brazing material. The formula and content of the low silver copper base medium temperature brazing filler by weight percentage is as follows: Ag: 1.8-5%, P: 5.5-7.5%, In: 0.5-2.5%, Ni: 0.01-1%, the rest: Cu. The invention has the advantages of rational design of formula, low manufacture cost, relatively low melting temperature of the brazing filler metal when welding copper and copper alloy and copper and bundy tubes, good wetting property and fluidness, smooth and bright surface of soldered connection, high mechanical strength, fine processing property of braze welding, stable quality and good uniformity and capability of replacing noble metal silver brazing filler metal BAg25CuZnSn.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Low-silver-copper-based brazing filler metal and preparation method thereof

ActiveCN103624418ACover tightlyLarge coverage areaWelding/cutting media/materialsSoldering mediaRare earthFiller metal

The invention relates to a low-silver-copper-based brazing filler metal and a preparation method thereof. The low-silver-copper-based brazing filler metal comprises Ag, Cu and P, wherein Sn, Ni and rare earth are further added, the weight percentages of the components are as follows: 1.5%-2.5% of Ag, 5.5%-6.6% of P, 5%-7% of Sn, 1.0-2.5% of Ni, not more than 0.05% of rare earth and the balance of Cu; the preparation method of the low-silver-copper-based brazing filler metal comprises the following steps of preparing Sn to filament Sn, smelting, continuously casting, continuously extruding, forming and cleaning to obtain the brazing filler metal. The brazing filler metal has the advantages of reasonable formulation design, lower brazing filler metal melting temperature, good wettability and mobility, stable quality of a soldered joint and long service life; a BCu80AgP copper-phosphorus brazing filler metal can be replaced, and the production cost of motor brazing is greatly reduced. The preparation method of the brazing filler metal can effectively solve a segregation problem of Sn, a preparation process is optimized, and the quality of the prepared brazing filler metal is remarkably improved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Composite nano anti-biotic material and preparation method

InactiveCN1742583ANon-cytotoxicNo mucosal irritationBiocideAnimal repellantsNano zinc oxideTitanium oxide

The present invention provides a composite nano antimicrobial material and its preparation method. It includes nano titanium oxide and nano silver system antimicrobial material. The average grain size of said nano material granules is 5-100nm, and the weight ratio of main component is as follows: nano zinc oxide: nano titanium oxide: nano silver system antimicrobial material; nano silver-copper system antimicrobial material=1:0.1-0.5:0.5-1.5:1.5-3.5. Said invention also provides the concrete steps of its preparation method.

Owner:扬州沃尔森医用科技有限公司 +1

Silver-copper-titanium active soldering paste

InactiveCN107322187AReduce the impactPlay the role of restoration protectionWelding/cutting media/materialsWelding/soldering/cutting articlesSolventSolder paste

The invention provides a silver-copper-titanium active soldering paste. The paste comprises, by mass, 85-90% of brazing powder and 10-15% of bonding agent; the brazing powder is mixed powder including silver powder, copper powder and titanium hydride powder, wherein the mixed powder comprises, by mass, 65-93% of silver, 5-35% of copper and 1-4% of titanium; the bonding agent comprises, by mass, 20-30% of paste forming agent, 50-70% of solvent and 2-5% of thixotropic agent. According to the silver-copper-titanium active soldering paste, titanium hydride is added to metal mixed powder of the brazing powder so that hydrogen can be released in the brazing process and have reduction and protection effects on welding; meanwhile, the titanium activates the surface of ceramic so that metal and the ceramic can be subjected to brazing, and the temperature of brazing is lowered to 850 DEG C, so that the influence of high temperature on metal performance is reduced, and meanwhile the technology cost is also lowered.

Owner:GUANGZHOU XIANYI ELECTRONICS TECH

Manufacture of silver-copper-germanium alloy

InactiveCN101218361ANot commercially viableWelding/cutting media/materialsSoldering mediaImpuritySilver copper

Silver alloys containing copper and germanium e.g. about 1 wt % Ge and of very low copper content e.g. about 0.8 wt % Cu can be precipitation hardened to 65 HV or above, whereas alloys of similar copper content and not containing germanium remain soft. In an embodiment, a silver alloy comprises 92.5-97 wt % Ag, 1-4.5 wt % Cu, 0.4-4 wt % Zn, 0.8-1.5 wt % Ge, 0 to 0.2 wt % Si, In or Sn and 0-0.2 wt % Mn, the balance being boron as grain refiner, incidental ingredients and impurities. The said alloy preferably comprises boron as grain refiner added as a boron hydride, e.g. sodium borohydride. A further group of alloys comprises a ternary alloy of silver, copper and germanium containing from more than 93.5 wt % to 95.5 wt % Ag, from 0.5 to 3 wt % Ge and the remainder, apart from incidental ingredients (if any), impurities and grain refiner, copper, the grain refiner being sodium borohydride or another boron hydride. Silicon-containing casting grain that gives rise to bright as-cast products is also disclosed. In a further embodiment, a zinc-containing silver alloy resistant to tarnish under severe conditions e.g. exposure to human sweat or French dressing comprises 1-5 wt % Zn, 0.7-3 wt % Cu, 0.1-3 wt % Ge, 0-0.3 wt % Mn, 0-0.25 wt % Si, B in an amount effective for grain refinement, up to 0.5 wt % incidental ingredients, the balance being Ag in an amount of 92.5-96 wt %, and impurities. A preferred manufacturing method giving an alloy with favourable physical properties involves melting together the ingredients, and incorporating boron by dispersing into molten silver alloy to foirn the whole or a precursor pait of said alloy a compound selecting fiom alkyl boron compounds, boron hydrides, boron halides, boron-containing metal hydrides, boron-containing metal halides and mixtures thereof The alloy is particularly suitable for castings which may be hardened in an oven e.g. at about 300 DEG C. for 30-45 min.

Owner:ARGENTIUM INT

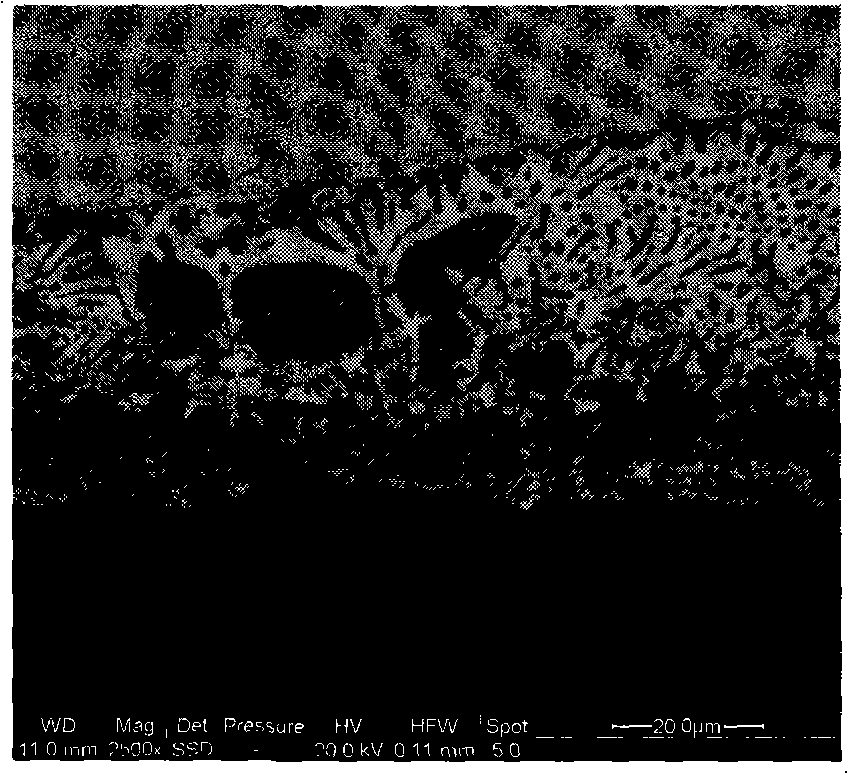

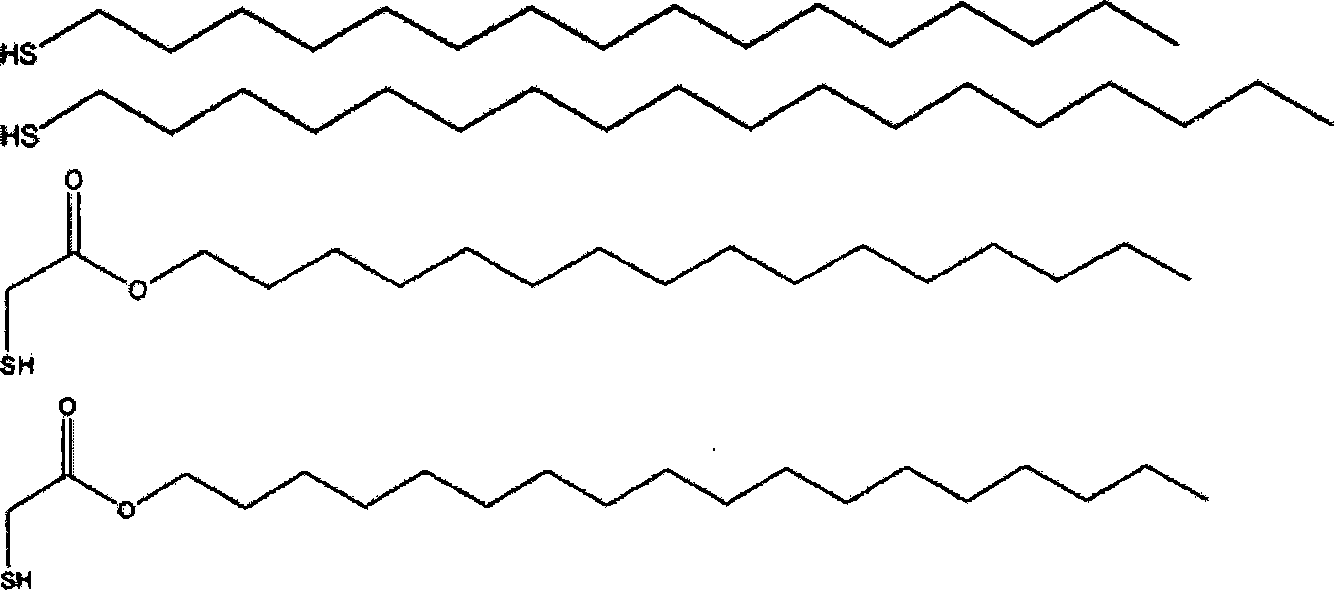

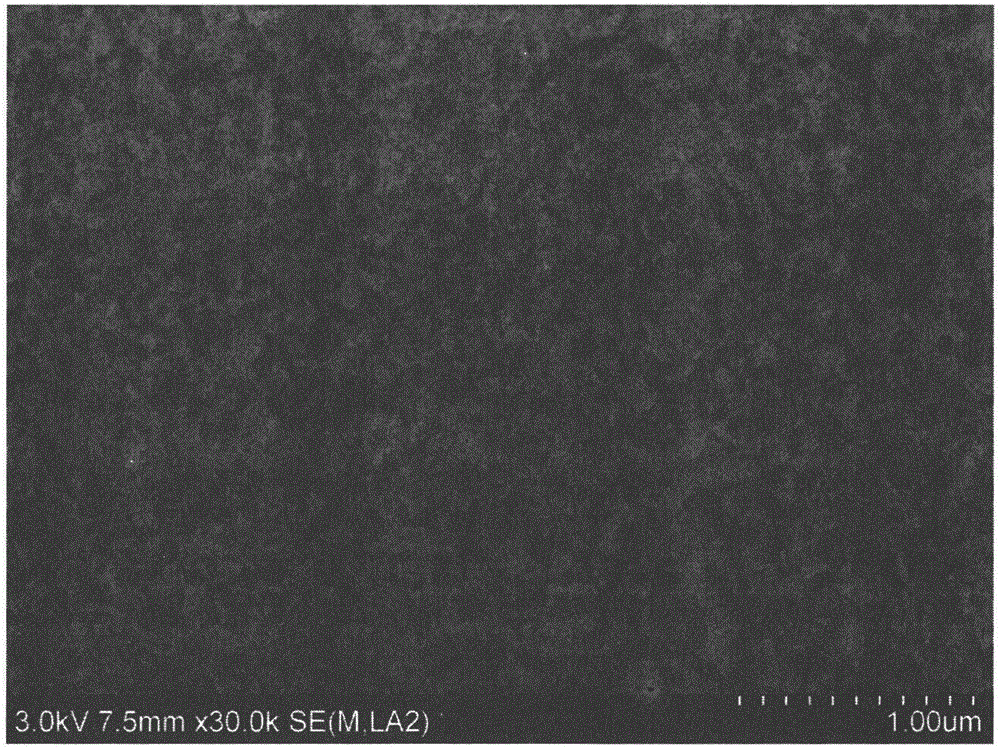

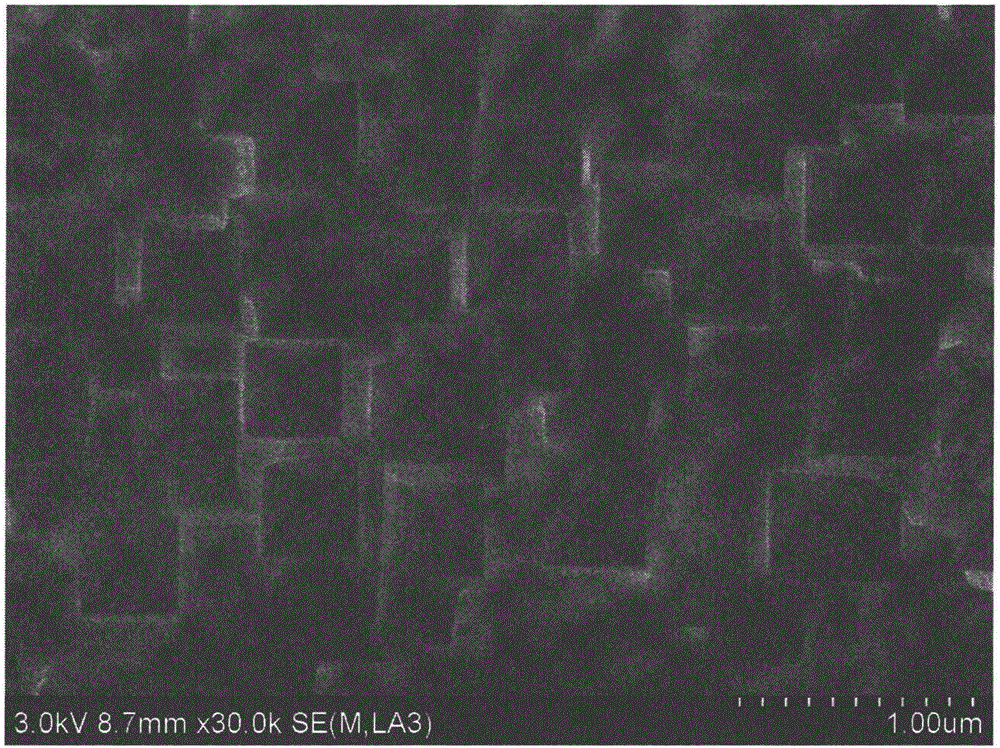

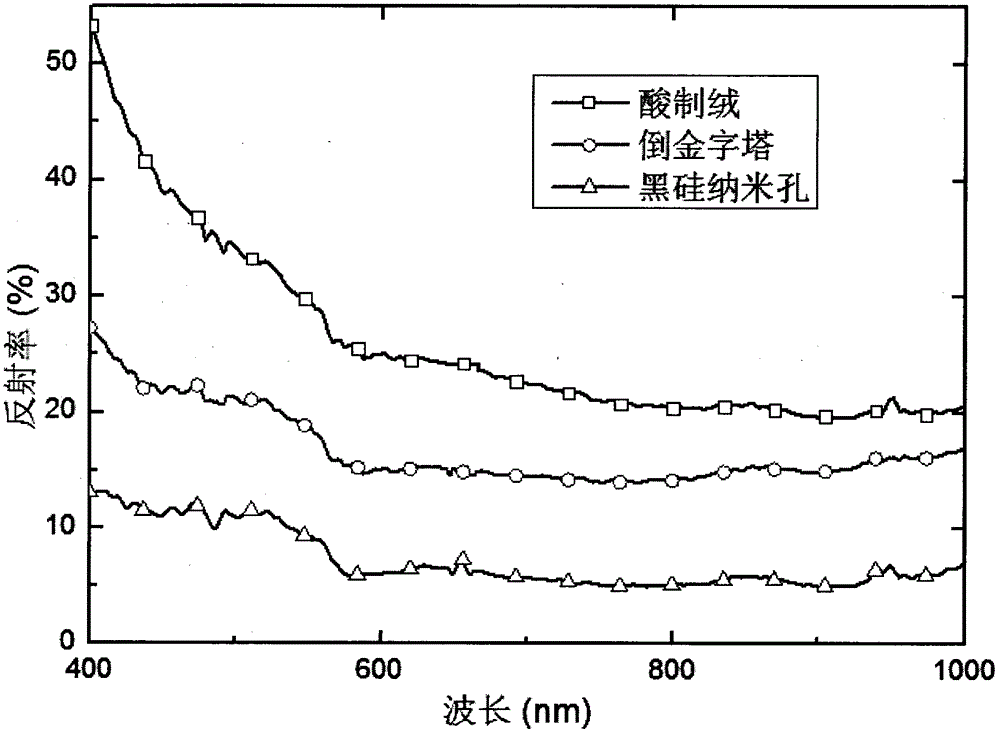

Method for preparing black silicon structure by Ag-Cu (silver-copper) bimetallic MACE (metal-assisted chemical etching) type

ActiveCN106229386AGood repeatabilityReduce dosageAfter-treatment detailsFinal product manufactureEtchingSolar battery

The invention relates to a method for preparing a black silicon structure with low cost, and belongs to the technical field of photoelectricity. The method comprises the following steps of (1) precleaning a solution; (2) putting the cleaned silicon chip into a mixing solution of H2O2 (hydrogen peroxide), HF (hydrogen fluoride), AgNO3 (silver nitrate), Cu(NO3)2 (copper dinitrate) and ultrapure water, and etching, so as to prepare a black silicon nanometer antireflection structure; (3) optimizing the black silicon structure by a nanometer reconstruction solution, so as to form a uniform inverted pyramid-shaped structure. The method has the advantages that the polycrystalline silicon is performed with chemical etching by an Ag-Cu bimetallic assisting type; compared with the existing Ag-assisted chemical etching type, the consumption amount of AgNO3 is decreased by more than several dozens of times; the technology is simple, the preparation cost of black silicon is reduced, and the batch preparation of large-area black silicon is reduced; the black silicon structure is optimized by the nanometer reconstruction solution, and the huge application potential is realized in the preparation of black silicon solar batteries with high conversion efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

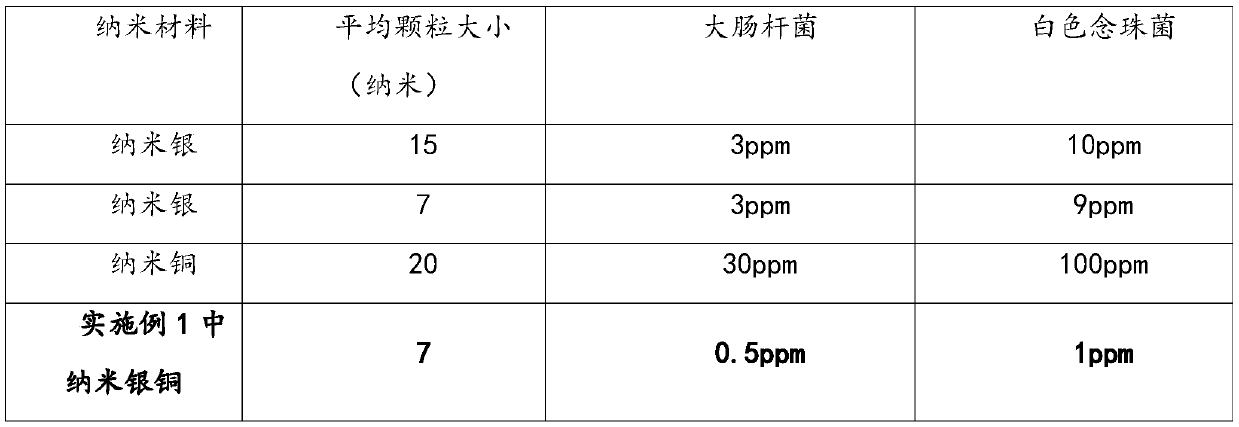

Nano silver copper bimetal colloid/liquid with high antibacterial performance and preparation method thereof

InactiveCN109819979AImprove antibacterial propertiesReduce usageBiocideFungicidesChemical synthesisMinimum inhibitory concentration

The invention discloses nano silver copper bimetallic colloid / liquid with high antibacterial performance.A preparation method of the nano silver copper bimetallic colloid / liquid with high antibacterial performancecomprises the following steps of: adding an aqueous solution or an absolute ethyl alcohol solution of a stabilizing agent into the aqueous solution or the absolute ethyl alcohol solutionof silver nitrate and copper nitrate, stirring uniformly, adding the aqueous solution or the absolute ethyl alcohol solution of a reducing agent, and stirring for 30-60minutes to obtain the nano silver copper bimetallic colloid / liquid.According to the preparation method of the nano silver copper bimetallic colloid / liquid with high antibacterial performance,a chemical synthesis method is utilized to obtain the nano silver copper bimetallic colloid / liquid, and prepared nano particles are within 10 nanometers.The minimum bacteriostatic concentration of the composite nano silver copper bimetal toescherichia coli and candida albicans reaches 0.5ppm and 1ppm respectively.The minimum bacteriostatic concentration of nano silver synthesized by the conventional method is 3ppm and 10ppm respectively.The antibacterial capacity of anano silver copper dispersion is improved by 6 times and 10 times.The use of the nano silver copper bimetal saves the use amount of silver and has high practical value.

Owner:尚蒙科技无锡有限公司

Laminated silver-copper-brazing-filler-metal three-composite electrical contact material manufactured by coating and sleeving method and manufacturing method thereof

InactiveCN106057526AImprove organizational structureImprove welding resistanceContact materialsElectrical performanceFiller metal

The invention discloses a laminated silver-copper-brazing-filler-metal three-composite electrical contact material manufactured by a coating and sleeving method and a manufacturing method thereof. Silver-alloy powder and copper-alloy powder are manufactured by using an atomization method or a powder mixing method; the silver-alloy powder and the copper-alloy powder are manufactured into a silver-alloy / copper-alloy band material; and then compounding is carried out on the silver-alloy / copper-alloy band material and a brazing filler metal to obtain a three-composite electrical contact material. Therefore, an electrical contact material having advantages of low material costs, excellent integrated electrical performances, silver saving and environmental protection is provided to replace the traditional copper-alloy contact material, silver-alloy contact material, and silver-copper-alloy contact material.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

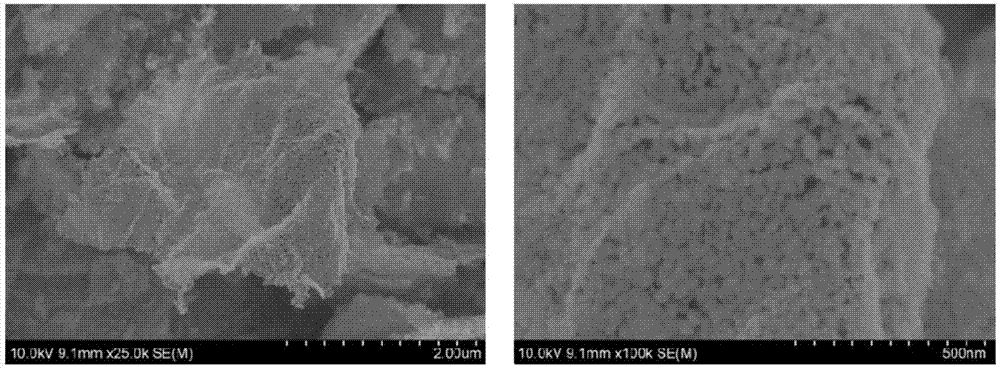

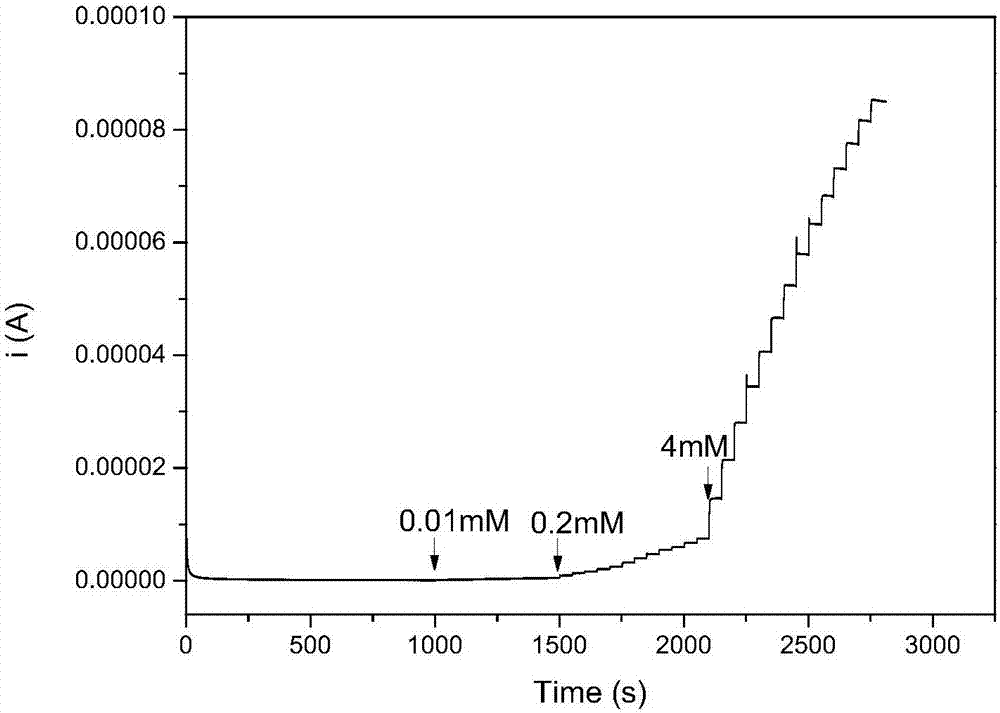

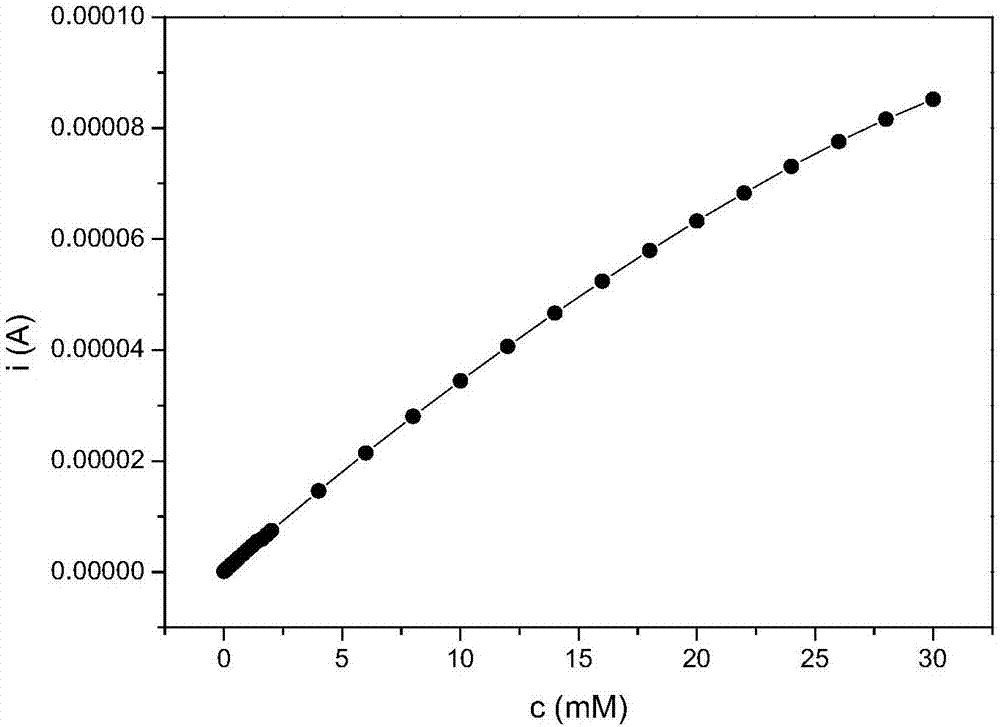

Nano silver-copper oxide particle/graphene-based preparation method of non-enzyme electrochemical glucose sensor

ActiveCN107389767AHigh sensitivityLow detection limitMaterial electrochemical variablesGlucose sensorsGraphene electrode

The invention relates to a nano silver-copper oxide particle / graphene-based preparation method of a non-enzyme electrochemical glucose sensor. The preparation method comprises the following steps: (1) respectively weighing silver salt and copper salt, and dissolving the silver salt and copper salt into water for mixing, so as to obtain a silver-copper precursor solution; (2) dispersing graphene oxide in deionized water, so as to obtain a graphene oxide dispersion liquid; (3) mixing the silver-copper precursor solution with the graphene oxide dispersion liquid, adjusting the pH value, performing hydrothermal reaction, separation and drying, so as to obtain a Ag-CuO nano particle / graphene composite material, and dispersing the material in anhydrous ethano; (4) dropwise adding standby suspension onto a glass carbon electrode, and drying the electrode, so as to obtain Ag-CuO nano particle / graphene electrode; (5) forming a three-electrode system by the Ag-CuO nano particle / graphene electrode, a counter electrode and a reference electrode, connecting the three-electrode system with an electrochemical working station to form an electrochemical sensor which is a target product. Compared with the prior art, the sensor prepared through the preparation method is high in sensitivity to detection of glucose, low in detection limit, wide in detection range, low in cost, environmentally-friendly, harmless and the like.

Owner:SHANGHAI JIAO TONG UNIV

Stannum-silver-copper three-part alloy leadless solder paste

InactiveCN101269444AAvoid damageLower peak temperatureWelding/cutting media/materialsSoldering mediaTin-silver-copperPeak value

The invention relates to a tin-silver-copper ternary alloy lead-free soldering paste. Alloy welding powder is made to the soldering paste through bismuth-tin binary eutectic alloy welding powder Bi48Sn42 and Sn-Ag-Cu ternary alloy welding powder with a melting point between 200 to 230 DEG C as well as scaling powder; wherein, the bismuth-tin binary eutectic alloy welding powder takes the 80 to 90 percent of mass percent; the tin-copper binary eutectic alloy welding powder takes 9.6 to 19.5 percent of mass percent; the scaling powder takes 0.1 to 0.5 percent of mass percent. The tin-silver-copper ternary alloy lead-free soldering paste keeps the peak value temperature in reflow soldering process between 210 to 215 DEG C, greatly reducing the peak value temperature and the possibility of damaging a breadboard and an element device.

Owner:CHANGSHA TAIHUI NETWORK TECH

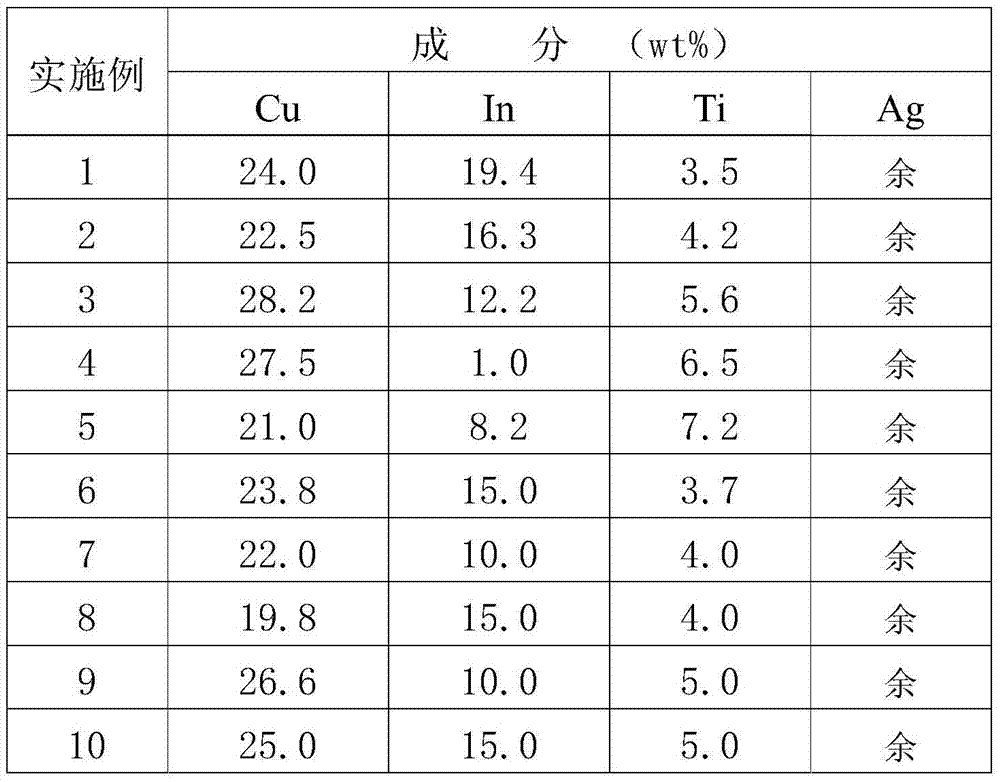

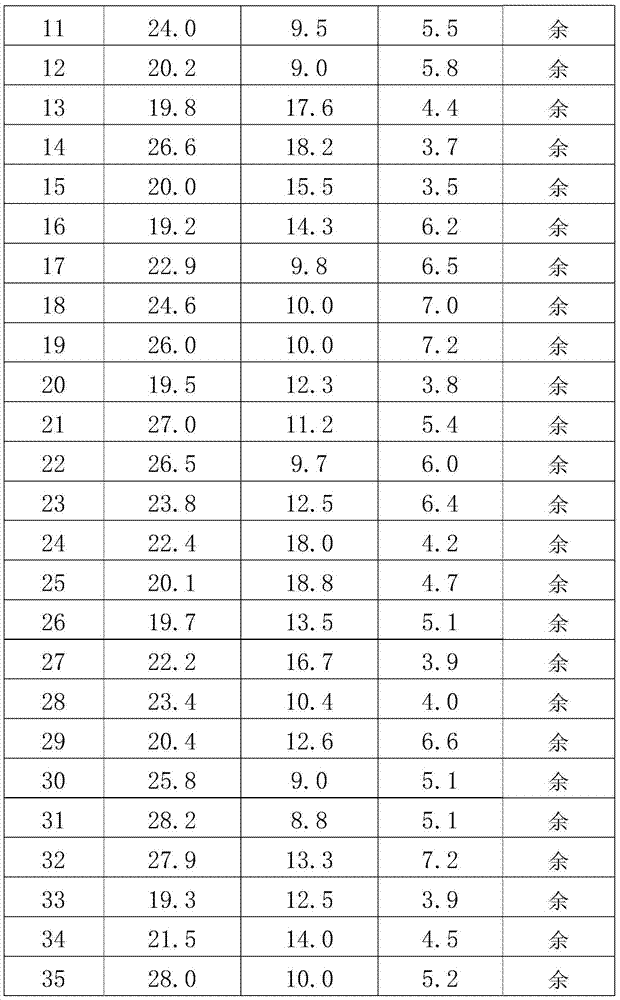

Silver-copper-indium-titanium middle-temperature brazing filler metal

InactiveCN105436741AHigh activityPromote wetting and spreadingWelding/cutting media/materialsWelding/soldering/cutting articlesIndiumNiobium

The invention belongs to the technical field of welding, and relates to a silver-copper-indium-titanium brazing filler metal used for connecting SiO2f / SiO2 composite ceramics and metals (such as tungsten, molybdenum, tungsten-molybdenum alloy, niobium, niobium-molybdenum alloy, invar alloy and kovar alloy). The silver-copper-indium-titanium brazing filler metal is characterized by comprising, by weight percentage, 19.2-28.2% of Cu, 8.2-19.4% of In, 3.5-7.2% of Ti, and the balance Ag. The brazing filler metal is good in machinability, and can be machined into strips, and required brazing temperature is lower than that of a traditional Ag-Cu-Ti brazing filler metal by about 100 DEG C, so that the silver-copper-indium-titanium brazing filler metal has a great significance in the field of ceramic and metal brazing connection in the aspect of reducing post-welding residual thermal stress of joints. The brazing filler metal not only is suitable for connecting the SiO2f / SiO2 composite ceramics and metals, and is also suitable for connecting ceramics, or connecting ceramics and metals, or connecting metals owing to excellent activity of the brazing filler metal.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Silver alloy material

InactiveCN103710566AImprove mechanical propertiesSolve the problem of easy oxidative vulcanization and discolorationSilver copperDuctility

The invention provides a silver alloy material and a preparation technology. The silver alloy material is prepared from the following alloy components in parts by weight: 85-96 parts of silver, 1-3 parts of copper, 1.0-1.6 parts of zinc, 0.2-1.0 part of palladium, 0.2-0.8 parts of cadmium, 1.2-2.0 parts of zirconium, 1.1-2.0 parts of ruthenium and 0.5-1.3 parts of magnesium. By adopting the silver alloy material and the preparation technology thereof, the high temperature resistance, the ductility and the hardness of the silver alloy are improved, so that the silver alloy material is easier to mold; a mesh structure is added to the silver alloy material, so that the overall stability and the ductility of the silver alloy material are improved; the silver alloy is easier to process and mold. A ternary alloy wire with the mesh structure is thin, and coated inside silver-copper binary alloy, so that the fineness of the silver alloy material and the aesthetic degree of the processed ornament are not affected, and a silver alloy material is not easily oxidized after being cleaned by a plasma cleaning machine.

Owner:北海鑫利坤金属材料科技开发有限公司(微型企业)

Solid silver-copper alloy

ActiveUS20140301892A1Suppress oxidation susceptibilitySuppress migration of silverMaterial nanotechnologyTransportation and packagingMetal alloyRoom temperature

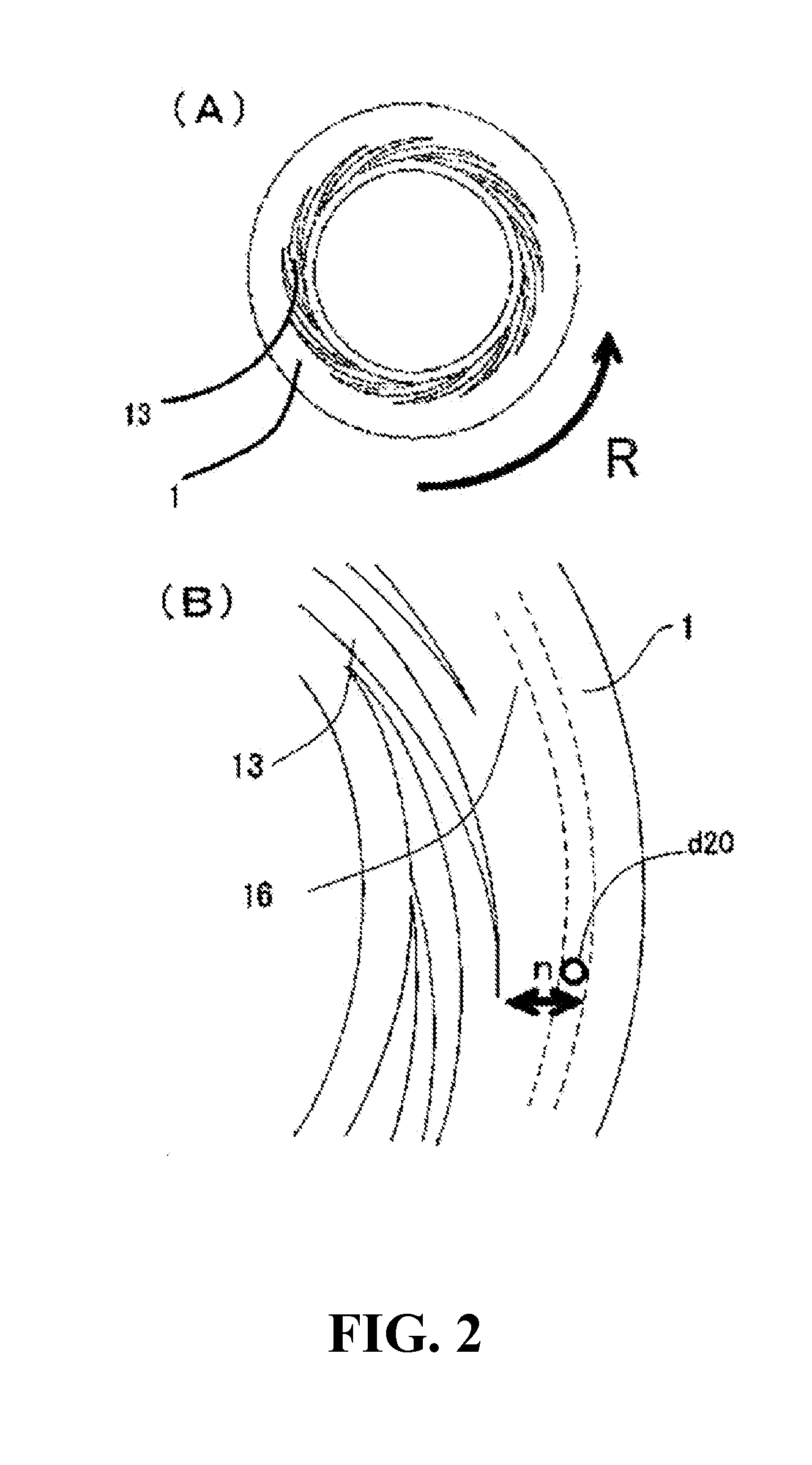

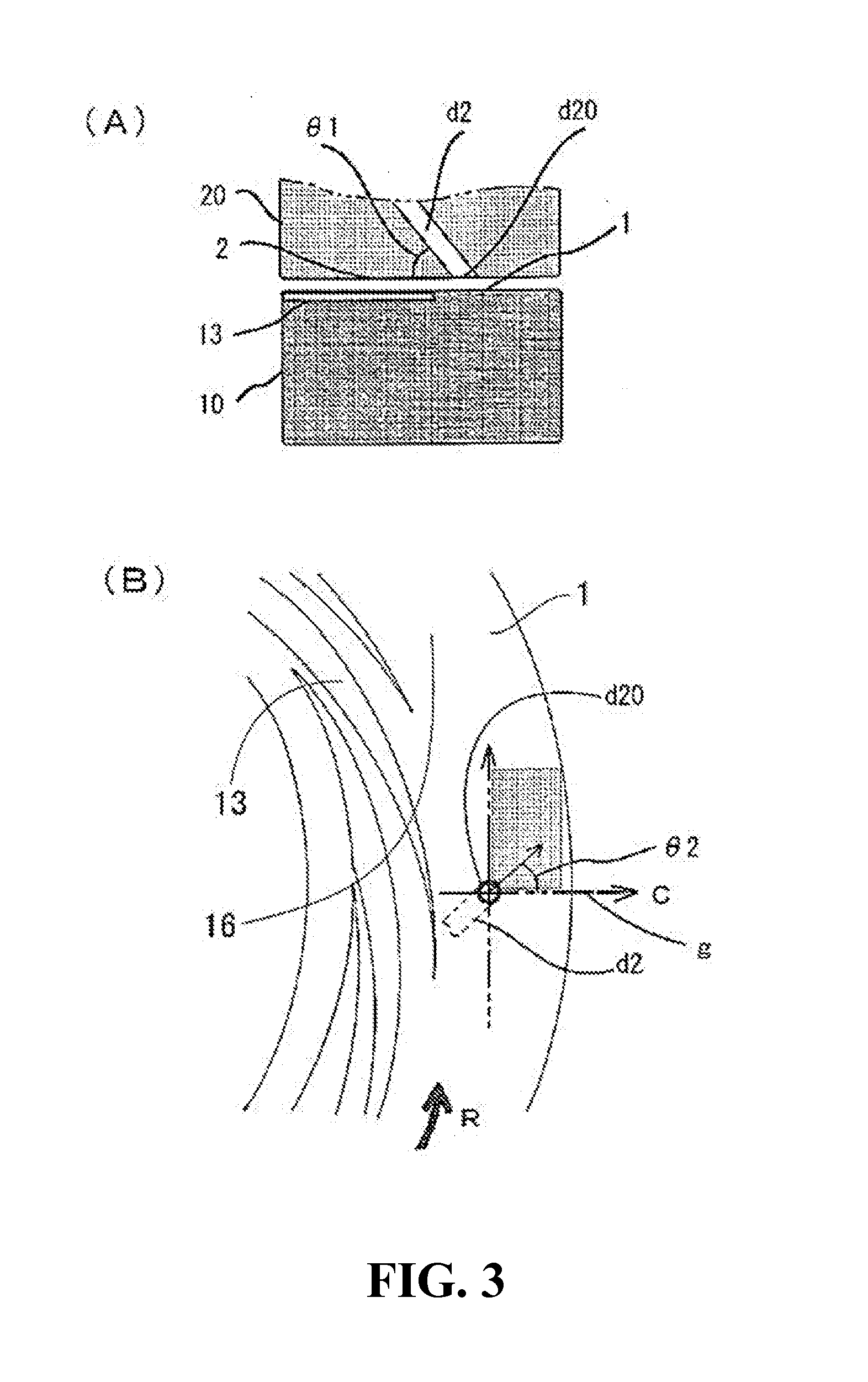

The present invention addresses the problem of providing a novel, solid silver-copper alloy. Provided is a solid silver-copper alloy in which the concentration of copper contained in the silver-copper alloy is 0.1-99.94 wt %, and which has, as the principal constituent thereof, a non-eutectic structure which does not contain a eutectic when the solid silver-copper alloy is at room temperature. This silver-copper alloy can be produced by mixing a fluid containing silver ions and copper ions with a fluid containing a reducing agent, and separating silver-copper alloy particles therefrom. It is preferable to mix the fluid containing the silver ions and copper ions with the fluid containing the reducing agent in a thin-film fluid formed between processing surfaces arranged so as to face one another, capable of approaching toward and separating from one another, and capable of having at least one surface rotate relative to the other. The diameter of the particles of the silver-copper alloy is preferably 50 nm or less. This solid silver-metal alloy may also be a solid alloy comprising one or more types of other metals in addition to silver and copper.

Owner:M TECH CO LTD

Parallel-plate dry-type capacitive pressure sensor

ActiveCN105910751AImprove linearityExcellent range accuracyFluid pressure measurement using capacitance variationManufacturing cost reductionCapacitive pressure sensor

By using a parallel-plate dry-type capacitive pressure sensor, problems that an existing sensor making technology requirement is difficult; a precision measurement and control pressure requirement is not easy to satisfy; a yield is low and so on are solved. The sensor comprises a shell, a plane-plate-type fixed electrode in an assembling shell and a moving electrode. The sensor is characterized in that a sapphire insulator of the moving electrode is fixedly connected to a welding block through a silver copper brazing layer, and a bottom surface of the insulator is plated with a plane metal electrode and an insulating layer in a vacuum mode; the moving electrode formed through fixing a membrane and a whole bottom surface of an electrode plate and the fixed electrode are arranged in a parallel mode in a cavity formed through sealing a support sleeve and a connection seat, and the support sleeve and the connection seat are contacted with upper and lower crests of a membrane edge ripple respectively; and components are welded through cutting edges. The structure is designed reasonably, a making technology is simple, material sources are wide, processing quality is good and parallel plate electrode linearity is good. Compared to a same kind of products, the sensor of the invention has high measuring range precision by using the membrane with the same thickness, earthquake-proof performance is stable and corrosion resisting performance is possessed. Production efficiency and a service life are greatly increased and prolonged, and making cost is reduced.

Owner:SHENYANG SENSOR TECH INST

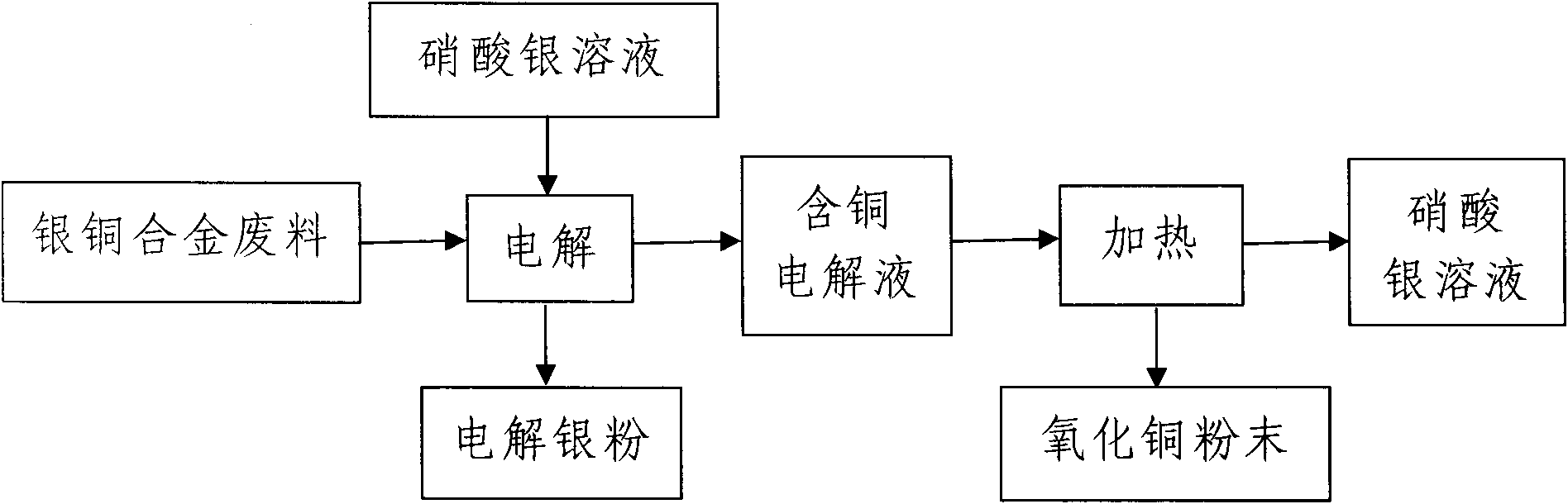

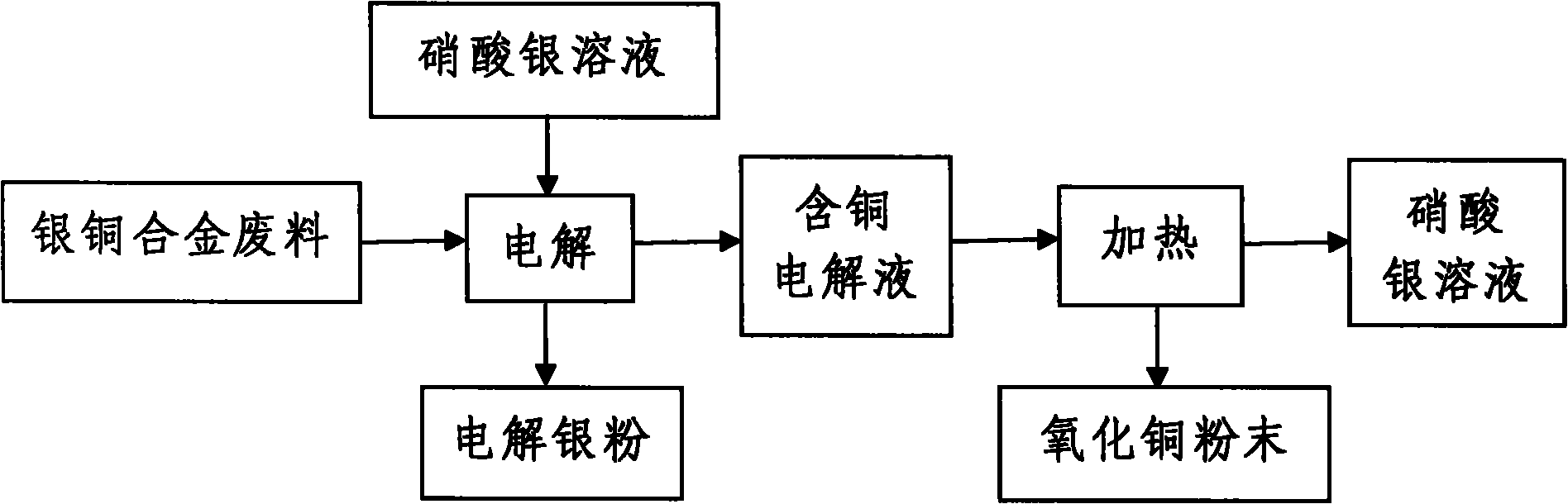

Method for recycling silver and copper from silver-copper alloy scrap

ActiveCN101914785AReduce processReduce pollutionPhotography auxillary processesProcess efficiency improvementCopper nitrateCopper oxide

The invention relates to a method for recycling silver and copper from silver-copper alloy scrap. The method comprises the following steps of: 1, performing electrolysis by taking a titanium plate as a cathode, the silver-copper alloy scrap which is loaded into a titanium anode basket as an anode and the solution of silver nitrate as electrolyte; 2, recycling electrolytic silver powder; 3, heating electrolyzed copper-containing electrolyte to decompose copper nitrate into copper oxide, adding water for dissolving the obtained product, then filtering the dissolved solution to obtain the solution of the silver nitrate and copper oxide powder and recycling the copper oxide powder; and 4, returning the solution of the silver nitrate obtained by the step 3 to an electrolytic bath and recycling the solution of the silver nitrate serving as the electrolyte. In the method, an electrolysis process is combined with a purification process; the silver and the copper are separated and purified; and the copper is recycled in the form of the copper oxide. Compared with the conventional processes of dissolving materials by using nitric acid, immersing the silver by chlorination and reducing by using a reducing agent, the method has the advantages of simple process, low cost, high product quality and light environmental pollution.

Owner:西安诺博尔稀贵金属材料股份有限公司

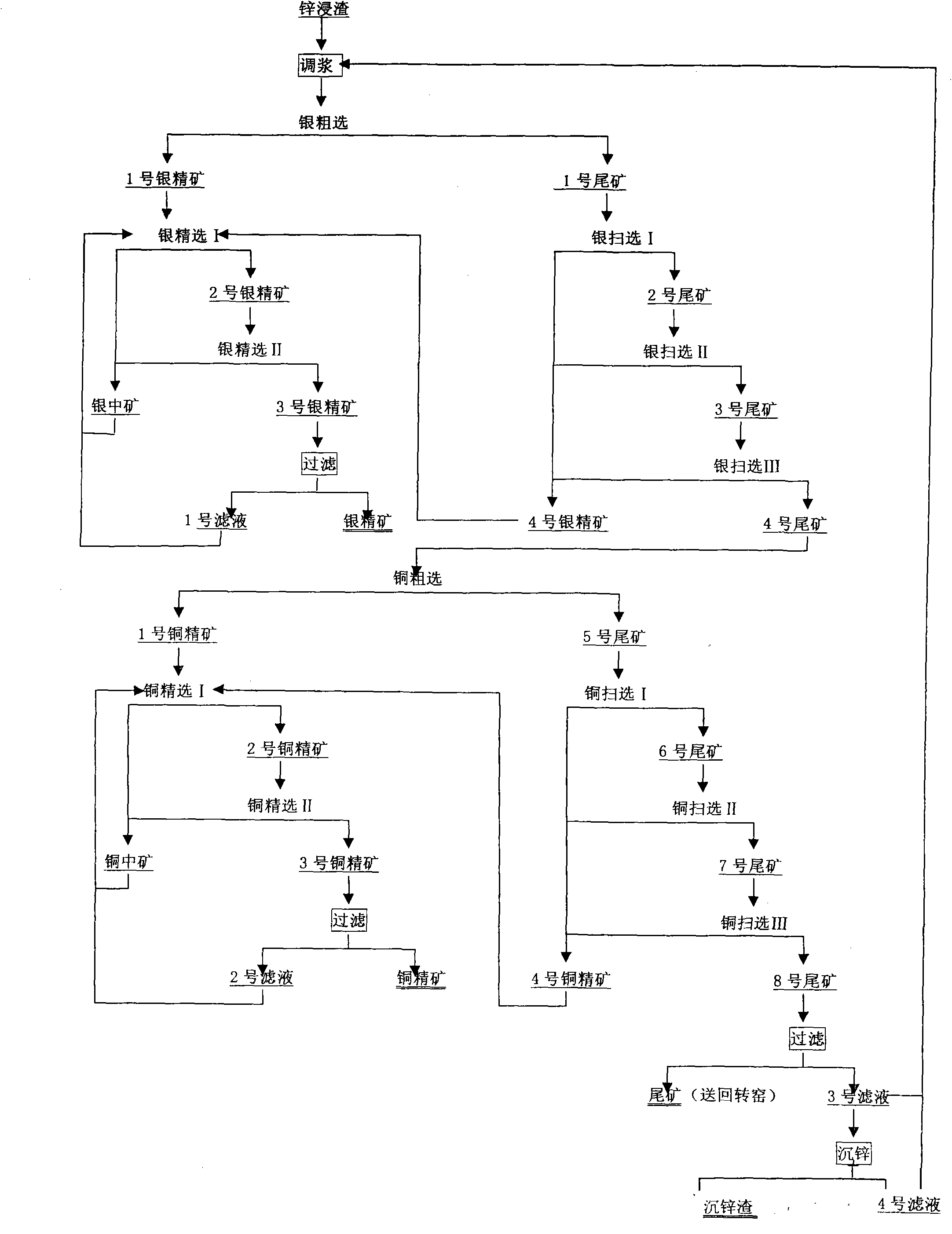

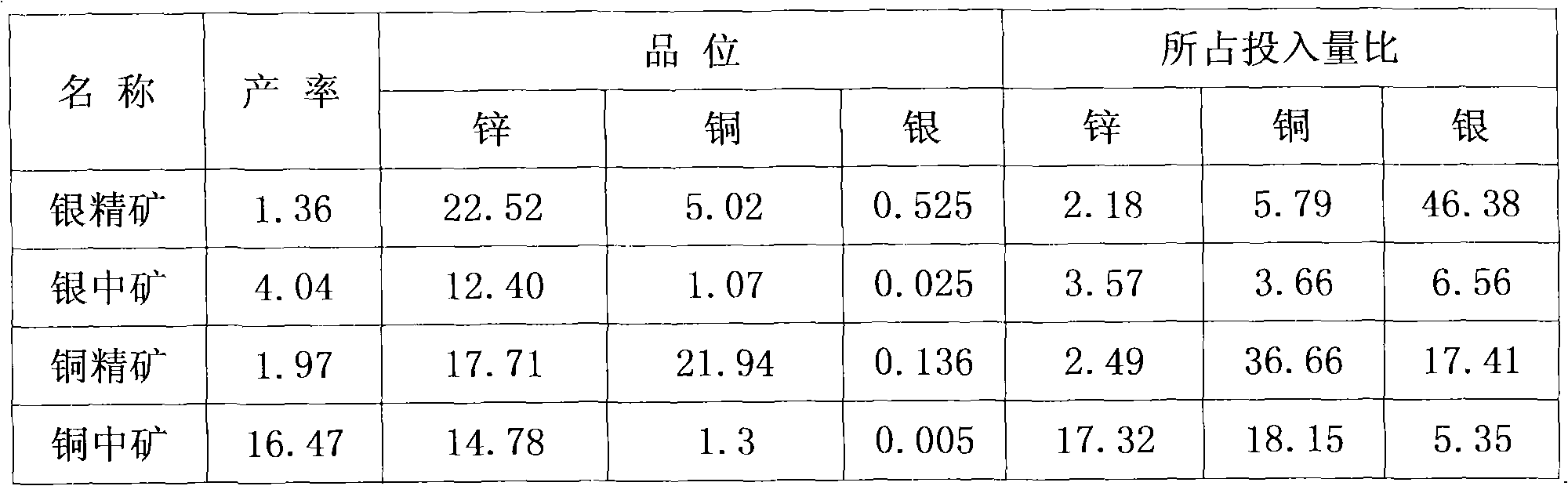

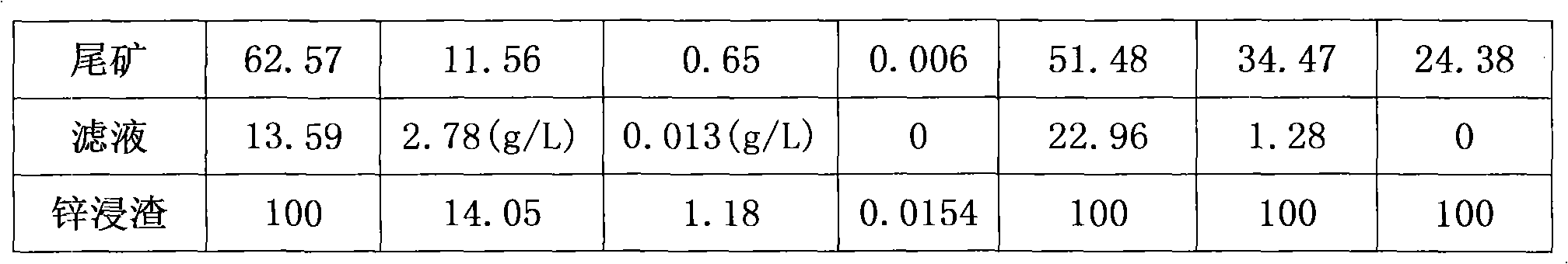

Method for recovering zinc, silver and copper from zinc leaching residue

The invention relates to a method for recovering zinc, silver and copper from zinc leaching residue. In the method, before being processed in a rotary kiln, the zinc leaching residue which is from the fluidized roasting and wet-method zinc refining leaching of zinc ore concentrates and serves as a raw material is subjected to floatation by the floatation technology, so that the silver and the copper are separated from the zinc leaching residue, part of zinc enters solution simultaneously, and the solution is neutralized by using ammonium hydrogen carbonate to precipitate the zinc. In the method, before the zinc leaching residue enters the rotary kiln, the copper, the silver and part of zinc in the zinc leaching residue can be recovered simultaneously, the recovery rate of the silver is between 75 and 85 percent, the recovery rate of the copper is between 53 and 55 percent, and the recovery rate of the zinc is between 20 and 25 percent. In addition, waste water and waste residues are not generated, and the silver, the copper and part of zinc can be recovered simultaneously.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com