Patents

Literature

311results about How to "Improve welding resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

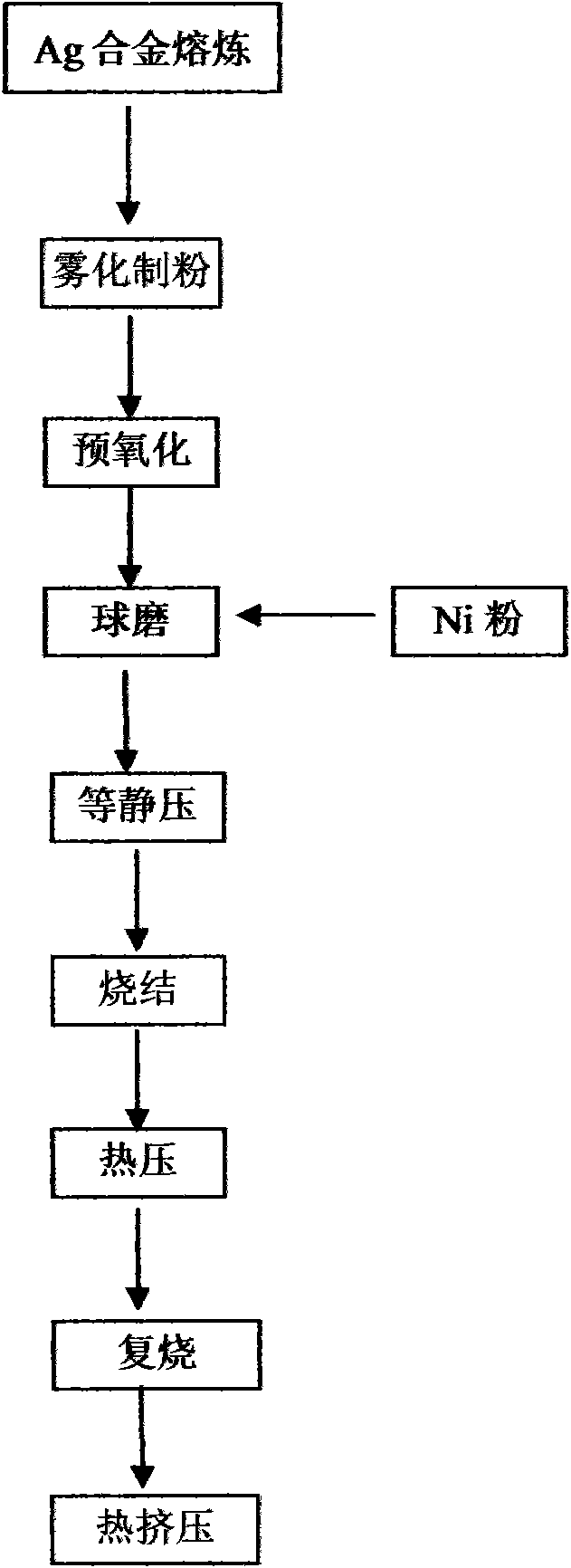

Ag-Ni-oxide electrical contact material and preparation method thereof

The invention discloses an Ag-Ni-oxide electrical contact material and a preparation method thereof. The preparation method comprises the following steps: re-oxidizing Ag alloy powder to obtain oxideparticle reinforced Ag base powder, and then mixing with Ni powder to prepare the new Ni particle and oxide particle reinforced Ag-Ni-oxide base electrical contact material. The material comprises thefollowing components by weight percent: 5%<=Ni<=10%, 0.1%<=oxide particle<=5% and the balance Adding. The oxide particle is one or more of CuO, NiO, SnO2, ZnO, CdO, In2O3 and Bi2O3 and the average grain size of oxide and Ni particle is 0.1-10mu m. The reinforced phase particles of the material of the invention are dispersed evenly and have good bonding strength with Adding, and the Ag-Ni-oxide electrical contact material has good fusion welding resistance and electric arc burning loss resistance and higher electrical life.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

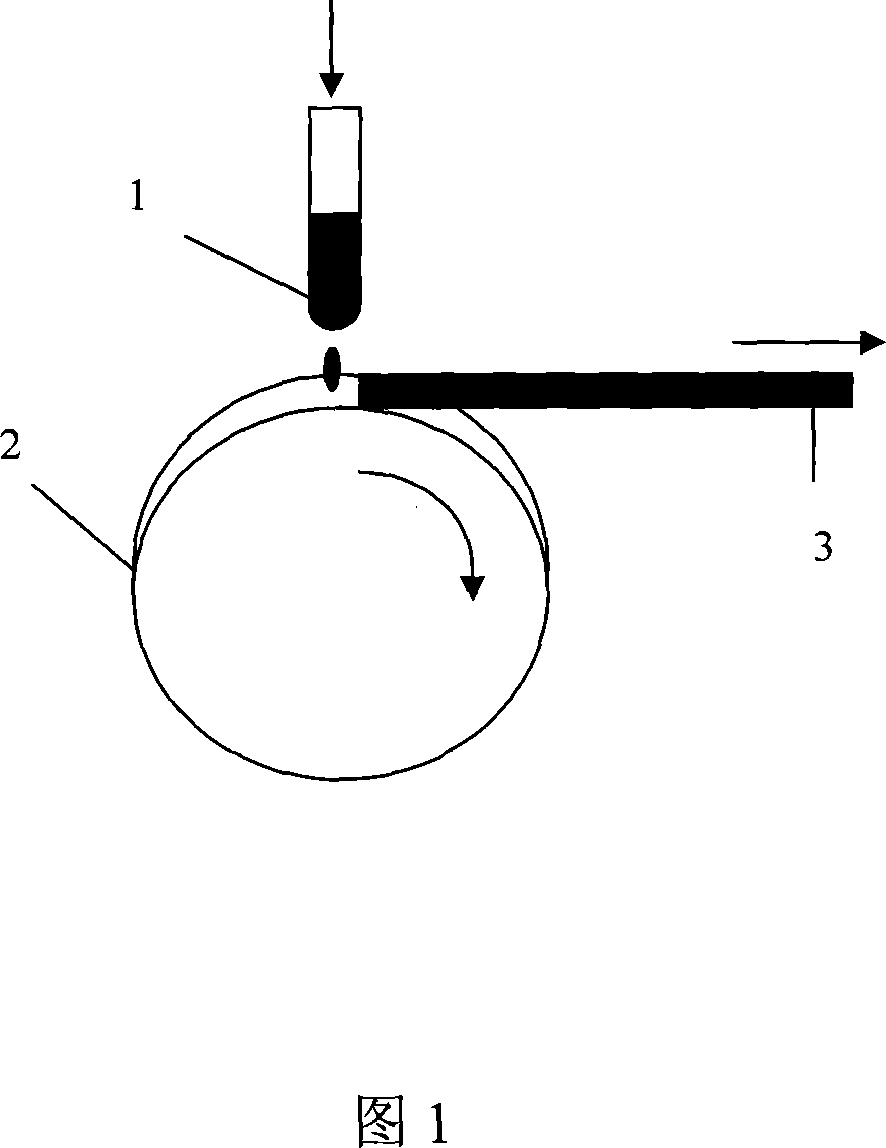

Manufacturing method of silver-tungsten carbide-carbon electrical contact material

InactiveCN1658346AImprove compactnessHigh hardnessContact materialsManufacturing technologyCircuit breaker

This invention relates to a manufacturing method of a silver-tungsten carbide-carbon electric contactor. It adopts silver powder, tungsten carbide and graphite powder as the raw materials and manufactures the silver-tungsten carbide-carbon electric contactor material through chemical coating and solid agglomeration techniques, and belongs to the field of electric components breaker switch manufacturing technology. The characteristic of this invention is: adopt silver powder, slab tungsten carbide powder, graphite powder and a little additive metal powder as the raw materials. At first mix the slab tungsten carbide powder, the graphite powder and the additive metal powder, and use chemical coating technique to get silver coating compound powder, and then pass through cold roll forming, agglomeration, re-rolling to get AgWC12C3 electric contactor material with tungsten carbide grains arrayed directionally. The AgWC12C3 electric contactor material made by this invention has fine compactness, high rigidity and conductive power. This material can be applied to many kinds of breakers with large capacity, the breakers with plastic covers and automatic switches.

Owner:SHANGHAI UNIV

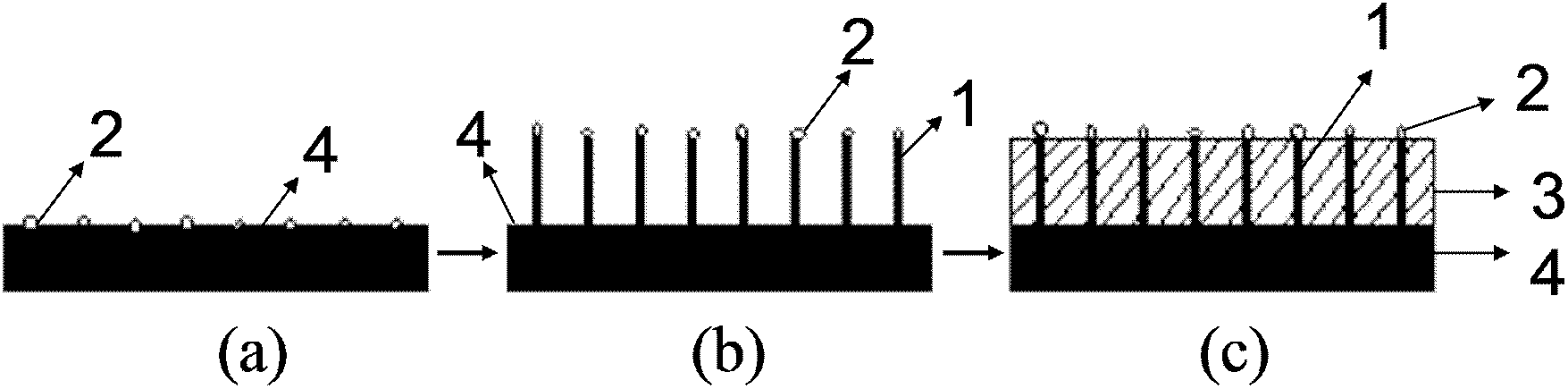

Method for preparing compound electrical contact material

InactiveCN102324335AConducive to play ballistic conduction characteristicsCost-effectiveContact materialsCatalytic pyrolysisCarbon nanotube

The invention discloses a method for preparing a compound electrical contact material. The technical process comprises the following steps of: (1) preparing a catalyst precursor, preparing a Ni-based catalyst from a mixed aqueous solution of hexahydrated nickel nitrate and hexahydrated yttrium nitrate, and depositing on a sample copper sheet which is subjected to plasma treatment and washed to obtain a catalyst precursor, wherein the mass ratio of nickel to yttrium is 1-10; (2) preparing a CNTs (Carbon Nanotube) array, putting the catalyst precursor into a quartz boat, undergoing a decomposition reaction under the protection of argon gas, and undergoing a catalytic pyrolysis reaction to obtain a sample copper sheet on which a CNTs array grows; and (3) preparing a CNTs-Ag-Cu compound electrical contact material, adding a silver nitrate aqueous solution into the sample copper sheet on which the CNTs array grows, soaking the silver nitrate aqueous solution into the CNTs array of the sampler copper sheet under the low ultrasonic action, evaporating and decomposing repeatedly for 3-20 times for 0.2-3 hours every time till the CNTs array is fully filled.

Owner:TIANJIN POLYTECHNIC UNIV

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

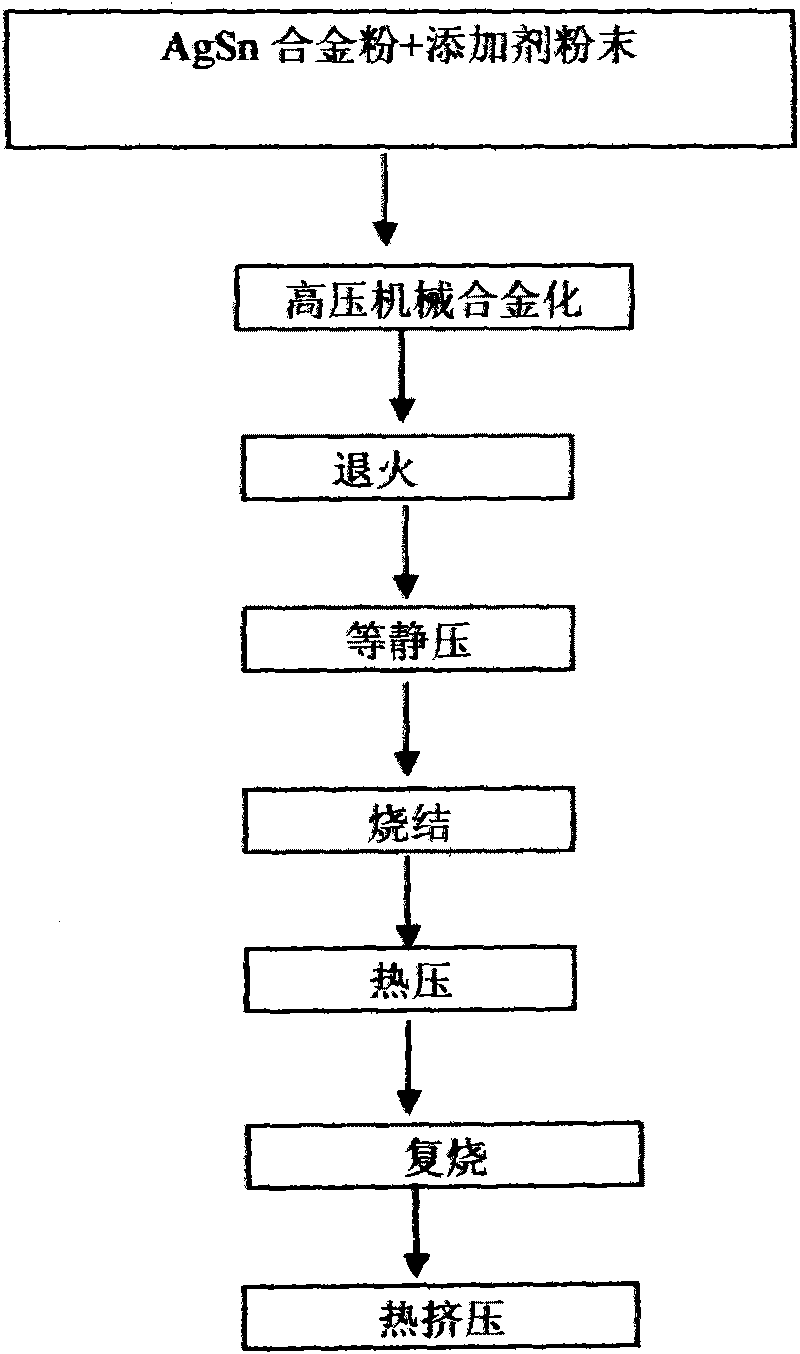

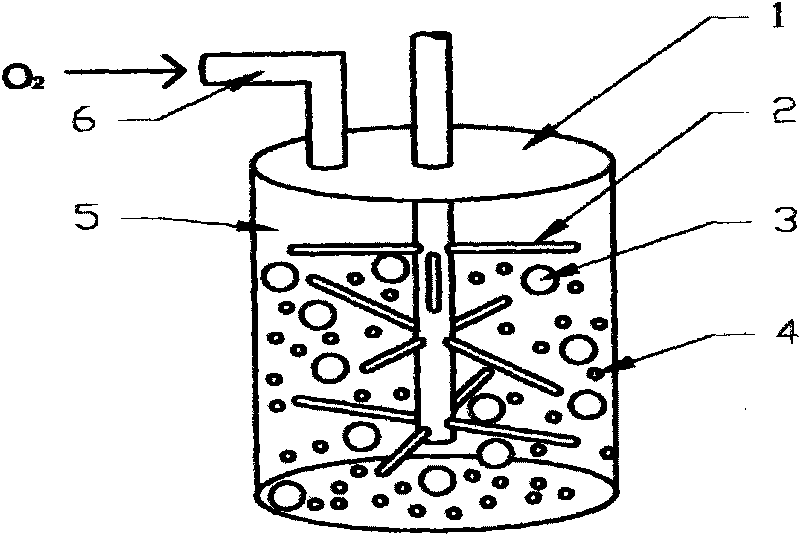

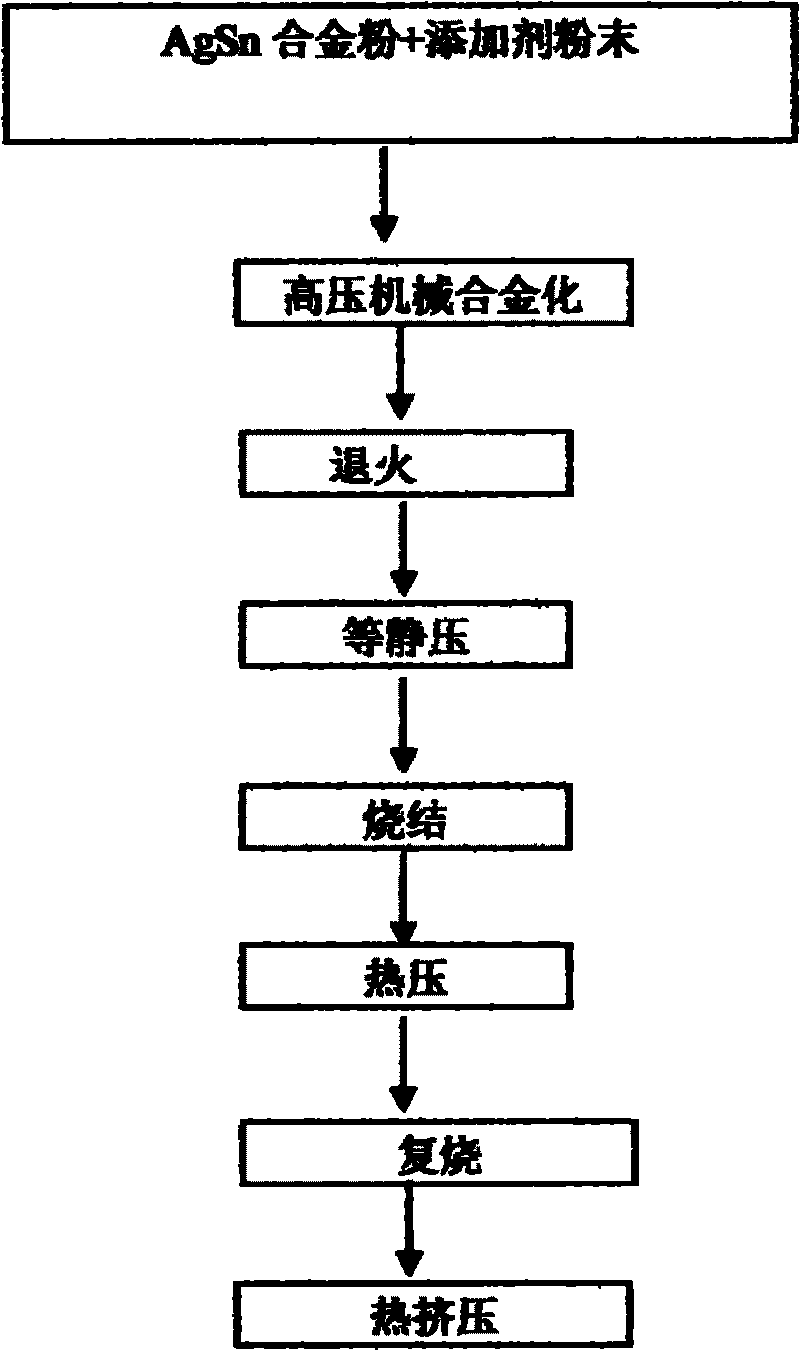

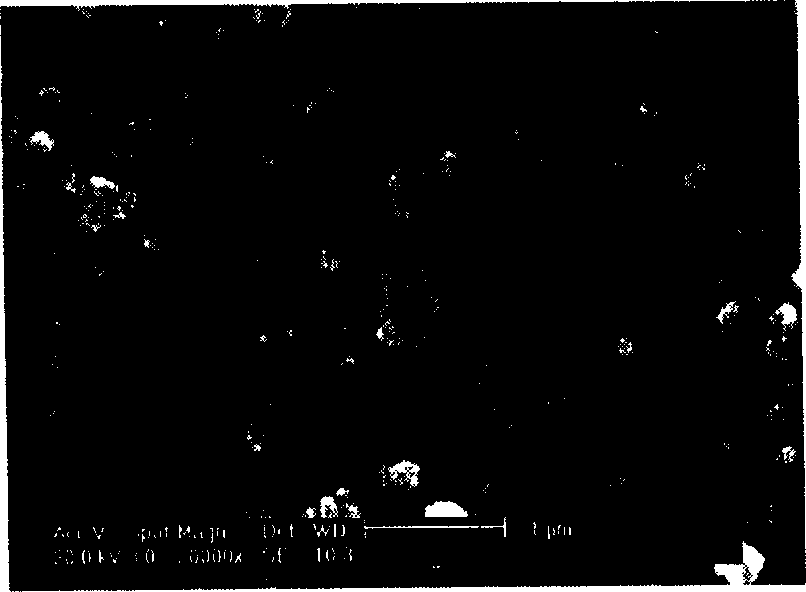

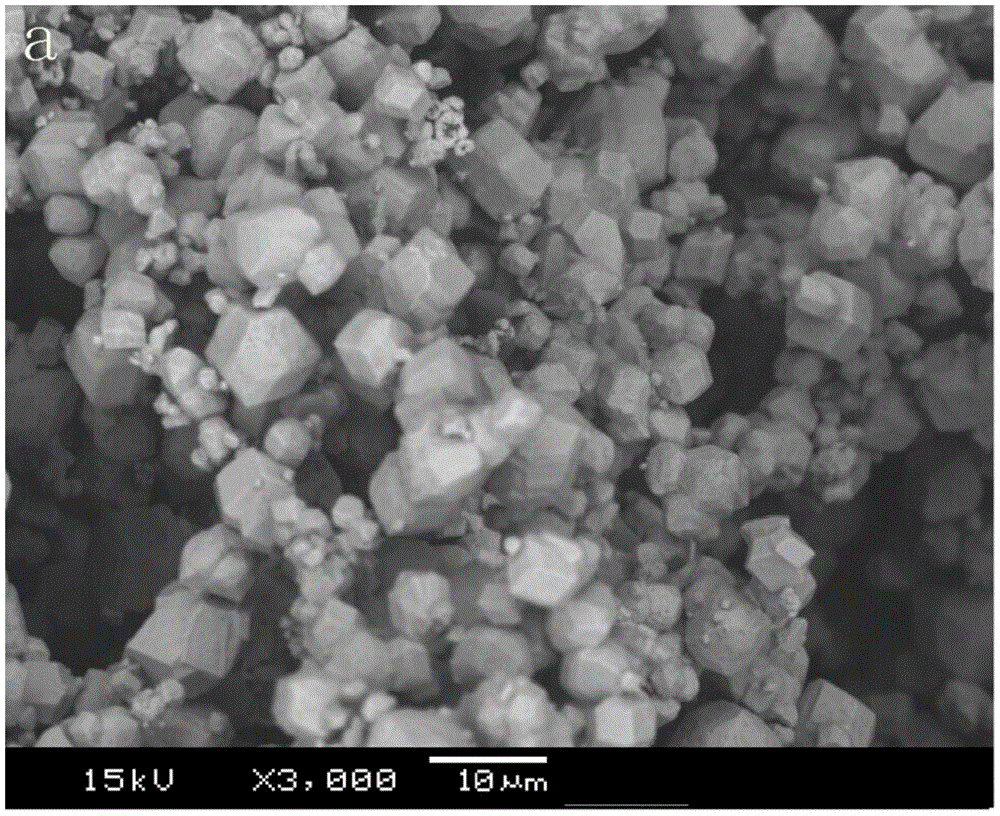

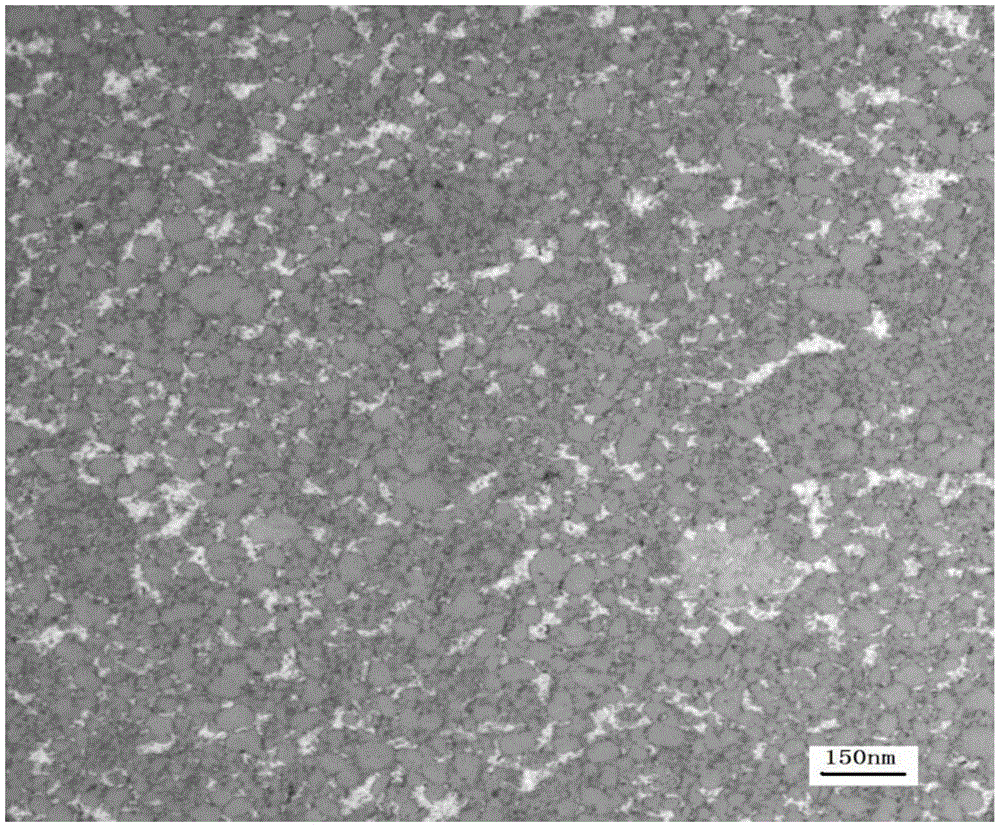

Preparation method of fine-particle stannic oxide reinforced Ag-based electrical contact material

The invention discloses a preparation method of fine-particle stannic oxide reinforced Ag-based electrical contact material, which adopts AgSn alloy powder to be mixed and collide mutually in the ball milling process, and keeps high-pressure oxidative atmosphere in the ball milling process simultaneously to lead the pre-oxidation of the AgSn alloy powder and the ball milling dispersing process to be conducted synchronously, thus greatly shortening the pre-oxidation time of the AgSn alloy, avoiding high-temperature oxidation and improving SnO2 distribution condition. The method has the characteristic of simple and flexible operation, and the silver tin oxide prepared by the method has the ideal structure of submicron or nanometer SnO2 particle reinforced phase dispersed distribution, thus leading the material to have high strength, high electrical conductivity and excellent electrical properties.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Method for manufacturing pure copper/copper chromium alloy composite contact material

InactiveCN101834077AOvercome the serious problem of macro segregationDense tissueElectric switchesMetallic material coating processesMelting tankWear resistance

The invention provides a method for manufacturing pure copper / copper chromium alloy composite contact material, comprising the following steps of: first, carrying out surface pretreatment on pure copper substrate; second, mixing 60-85 percent of copper powder and 15-40 percent of chromium powder evenly according to weight percentage , mixing binder and Cu-Cr powder according to the volume ratio of 1: 1.6-2, adding acetone for dilution and stirring into paste, and coating a Cu-Cr layer with the thickness of 1.2-1.8mm on the surface of the pure copper and drying at 80-100 DEG C in an oven; third, carrying out laser cladding by adopting a 5KW multifunctional CO2 crossflow laser, wherein the process parameters are that the output power is 1.5-2.5KW, the scanning speed is 6-15mm / s, the light spot diameter is 3mm, and single track cladding and overlapping rate of multi-track cladding is 30-45 percent, and protecting a molten pool with argon gas; and fourth, carrying out leveling and polishing treatment on the surface. In the method, a Cu-Cr alloy layer with good wear resistance and electrical erosion resistance can be obtained on the surface of the pure copper, so that the core part can remain the excellent conductivity of the pure copper.

Owner:HENAN POLYTECHNIC UNIV

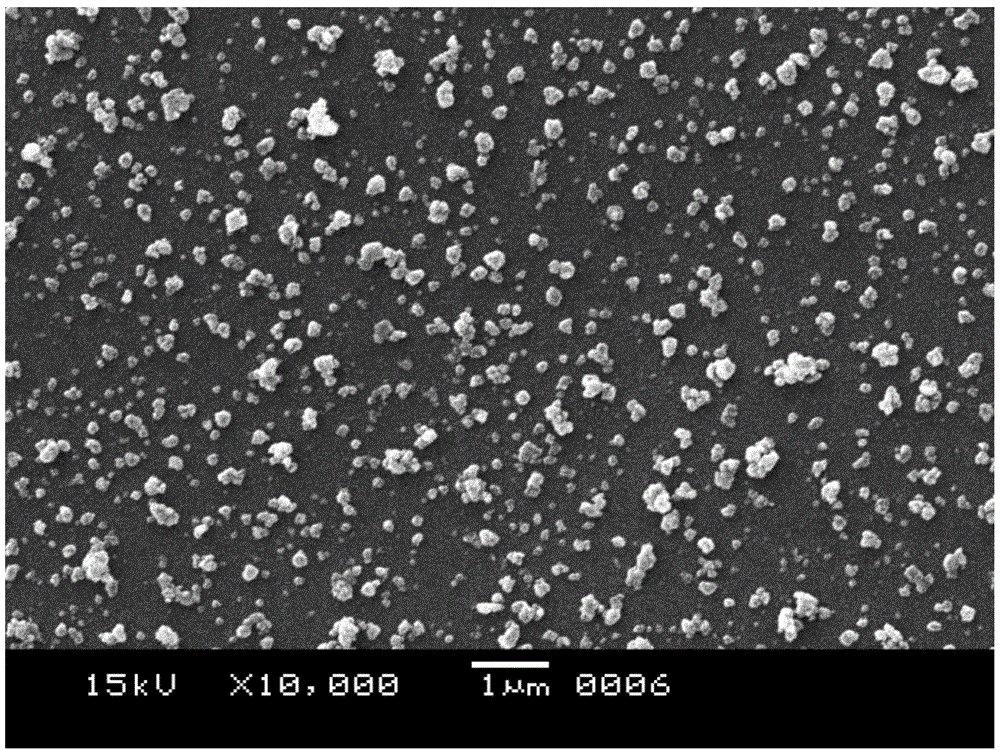

Prepn process of nanometer tin oxide material with surface decorating silver

The present invention relates to the preparation process of nanometer tin oxide material with surface decorating silver, and belongs to the field of electric contact material preparing technology. The preparation process includes the following steps: adding tin oxide powder of 20-30 nm size into anhydrous ethanol and adding polyglycol as dispersant; ultrasonic stirring at room temperature and stoving; adding the treated nanometer tin oxide powder into 10-30 % concentration silver nitrate solution via electromagnetic and ultrasonic stirring for homogeneous dispersion; adding reductant hydrazine hydrate to reduce silver ion and obtain silver coated nanometer tin oxide powder and stoving at 80-120 deg.c. The present invention has the advantages of simple technological process and being suitable for industrial production, and the surface decorated nanometer tin oxide may be used in producing electric contact with excellent mechanical performance and high conductivity.

Owner:TIANJIN UNIV

Copper electrode strontium titanate annular piezoresistor and method for making same

This invention discloses circular piezoresistor and making method thereof, which consists of a circular resistor substrate and three or more than three electrodes wherein the substrate is made of strontium titanate and the electrode is a copper electrode located on upper end face, lower end face or outside face of substrate. The making process contains ceramic cog preparation, printing and drying of copper slurry and deacidizing of copper electrode.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Weak electricity copper base electric contact composite material and method for making same

InactiveCN101106024AStrong welding resistanceImprove arc extinguishing effectContactsWear resistantLow voltage

The invention relates to a copper base electrical contact compound material, in particular to a weak current copper base electrical contact compound material used for low voltage electric switch, and a method to prepare the compound material. The compound material is composed of materials by the following proportions: 0.5-4 percent bismuth, 0.5-4 percent TiAl metal compound, 0.05-0.6 percent rare earth material, and the rest copper and other unavoidable impurities. The preparation method is: mixing powder in ball mill; cold pressing; sintering; secondary molding; and secondary sintering; the compound material produced with the invention has the advantages of strong anti-fusion welding performance, and good arc extinguishing performance and oxidation resistant performance. The electricity conductivity is similar to that of silver base electrical contact compound material, and wearing-resistant performance superior to that of the original boron carbide copper base and silver base electrical contact compound material. Therefore, the compound material is a cheap replacement for silver alloy electrical contact in low voltage switches.

Owner:UNIV OF JINAN

Ag based electrical contact material and preparation method thereof

ActiveCN101707146AExtended service lifeIncrease electrical contact performance such as resistance to fusion weldingContactsPretreatment methodGraphite

The invention discloses an Ag based electrical contact material and a preparation method thereof. The material comprises the following components in percentage by weight: not more than 1 and not less than 5 percent of carbon material, not more than 0.5 and not less than 5 percent of additive and the balance of silver, wherein the carbon material relates to one or more of diamond, graphite and carbon, and the additive relate to one of W and Ni elements. The high melting point character of the carbon material is helpful to improve the melting-welding resistance of the surface of a contact, and the superfine W and Ni elements are added by using a liquid phase deposition surface pretreatment method, thereby ensuring that the W or Ni element is uniformly distributed on the surfaces of carbon reinforced particles, improving the electrical conductivity of the reinforced particles and prolonging the service life of the contact material. The Ag based electrical contact material with fine capabilities of melting-welding resistance and electric arc burn resistance is obtained by combining the working procedures such as mixing powder, compacting, sintering, extruding and the like.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

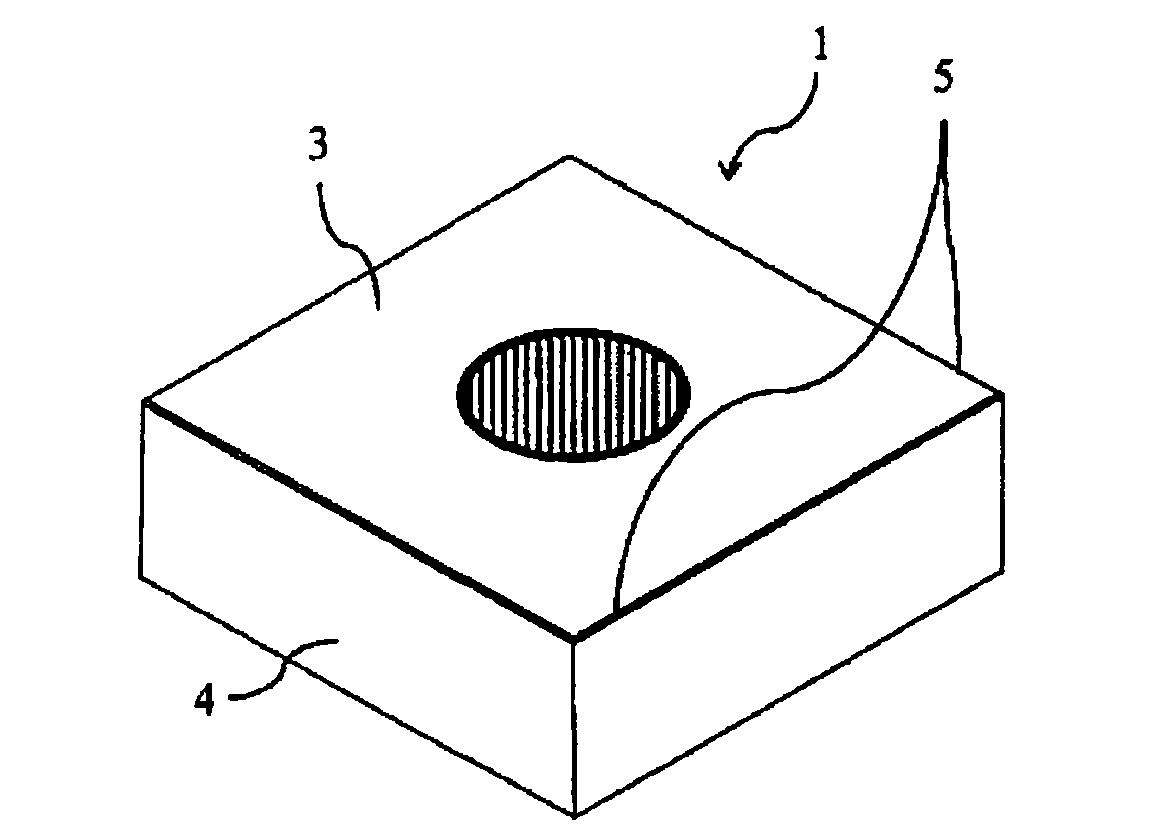

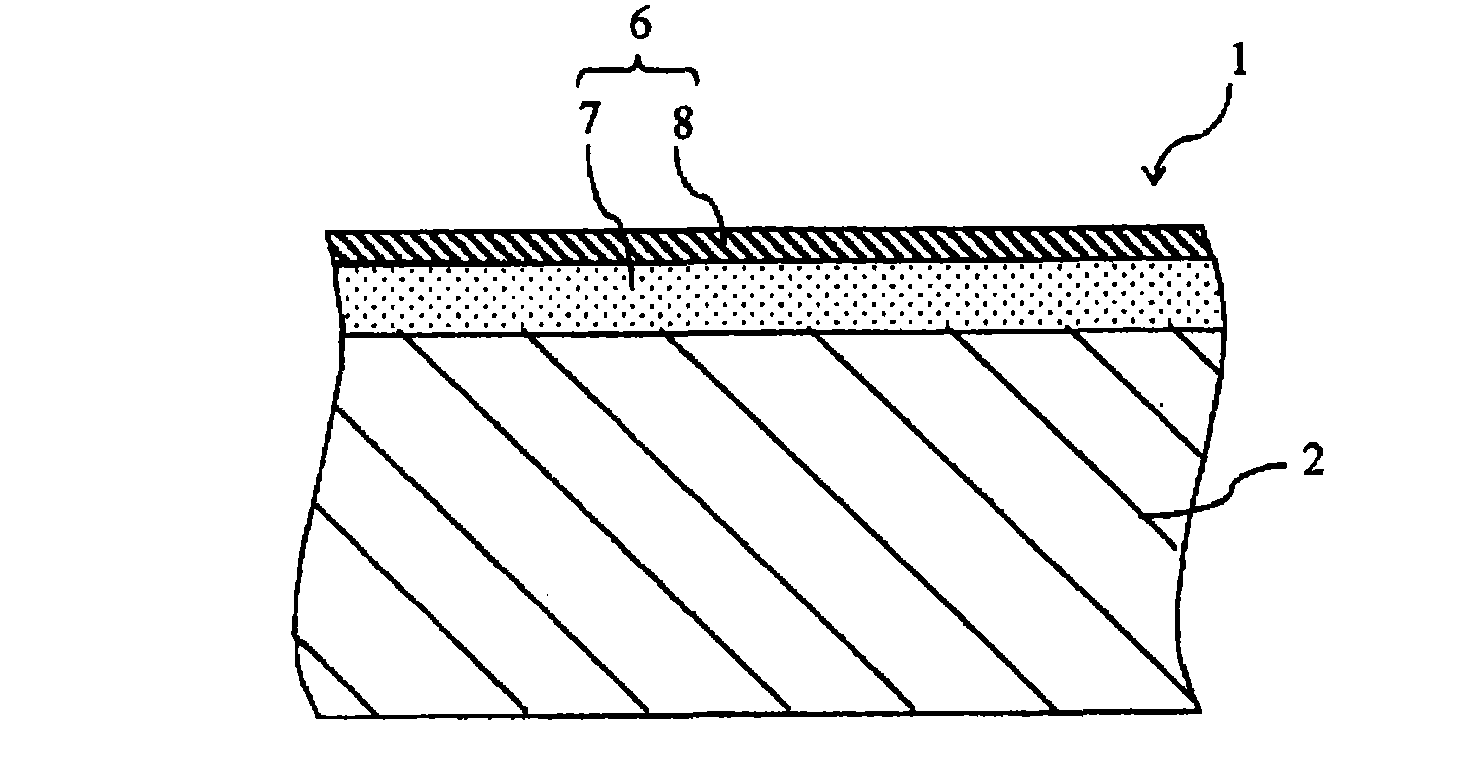

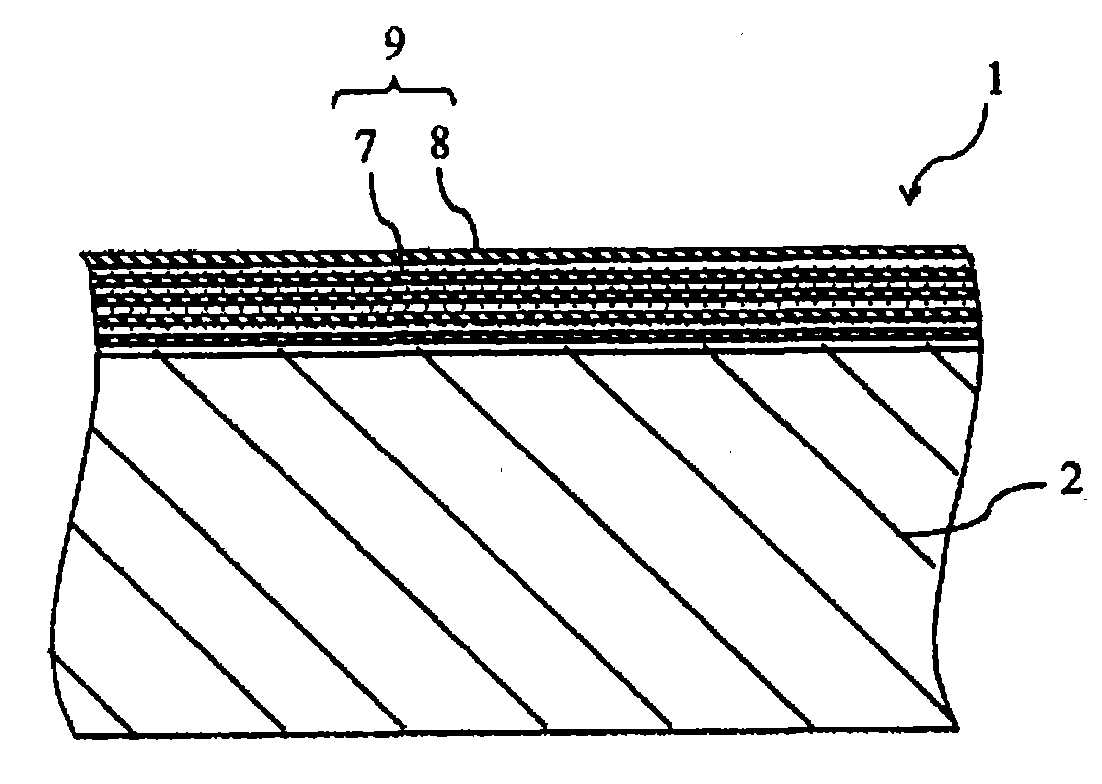

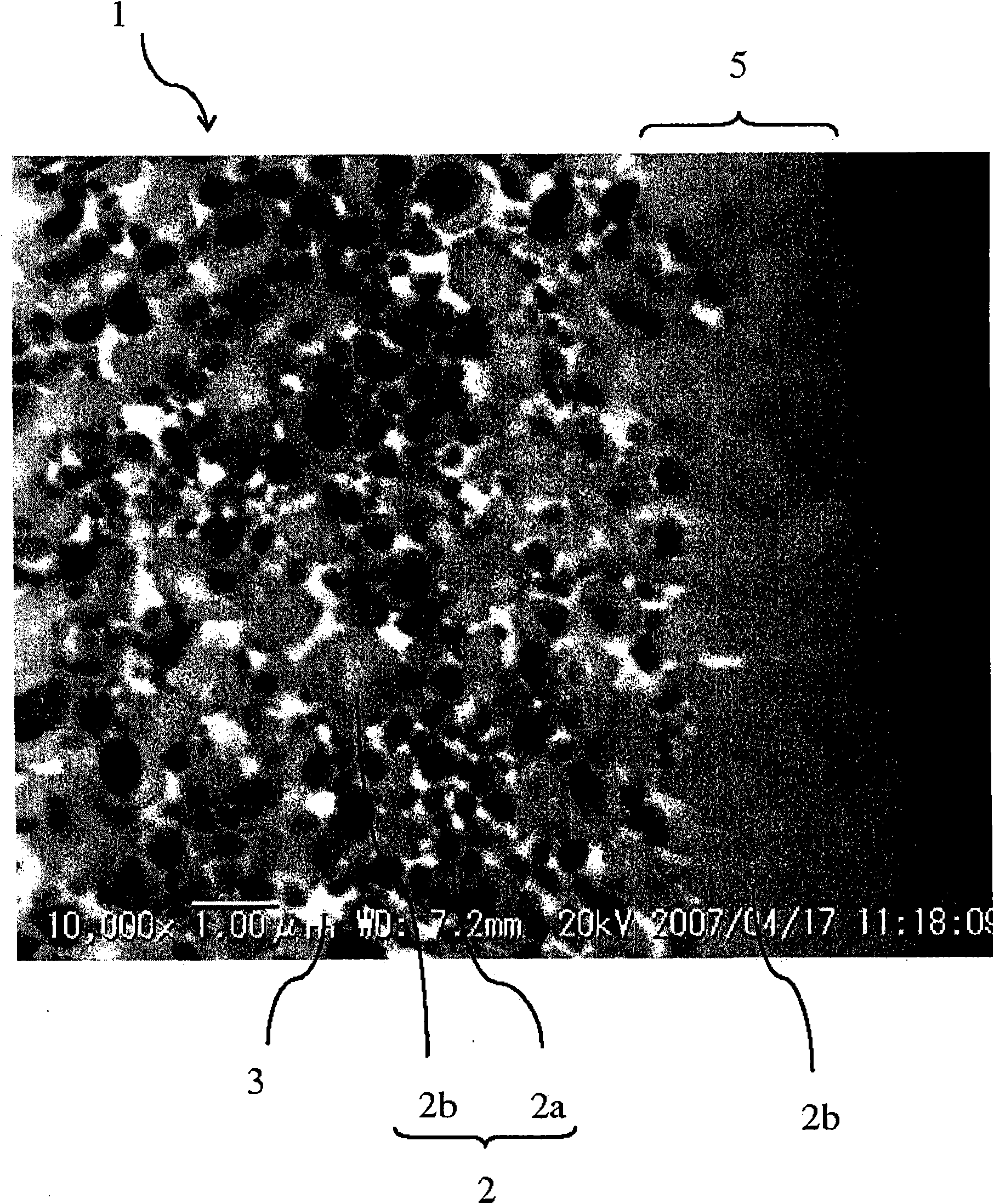

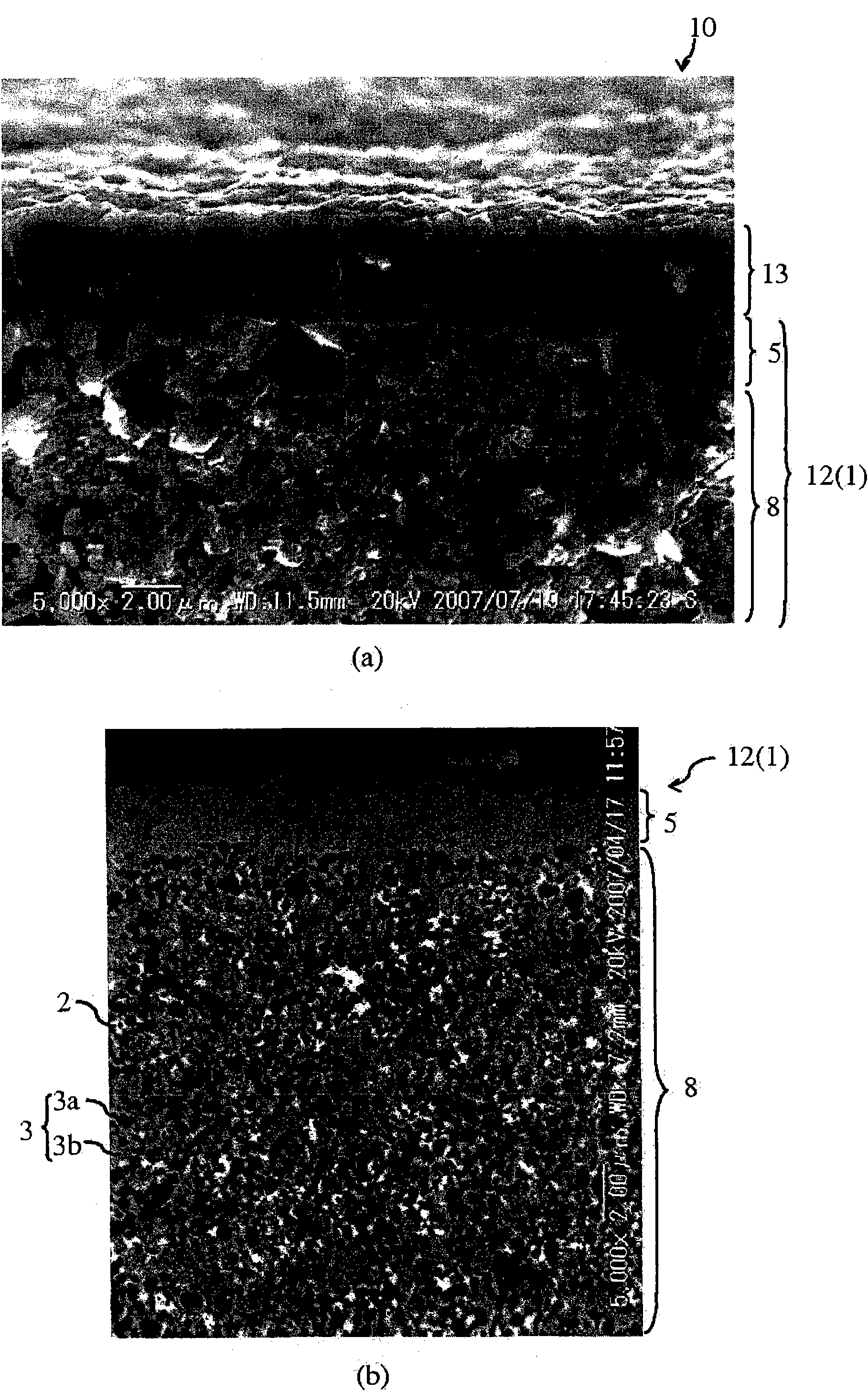

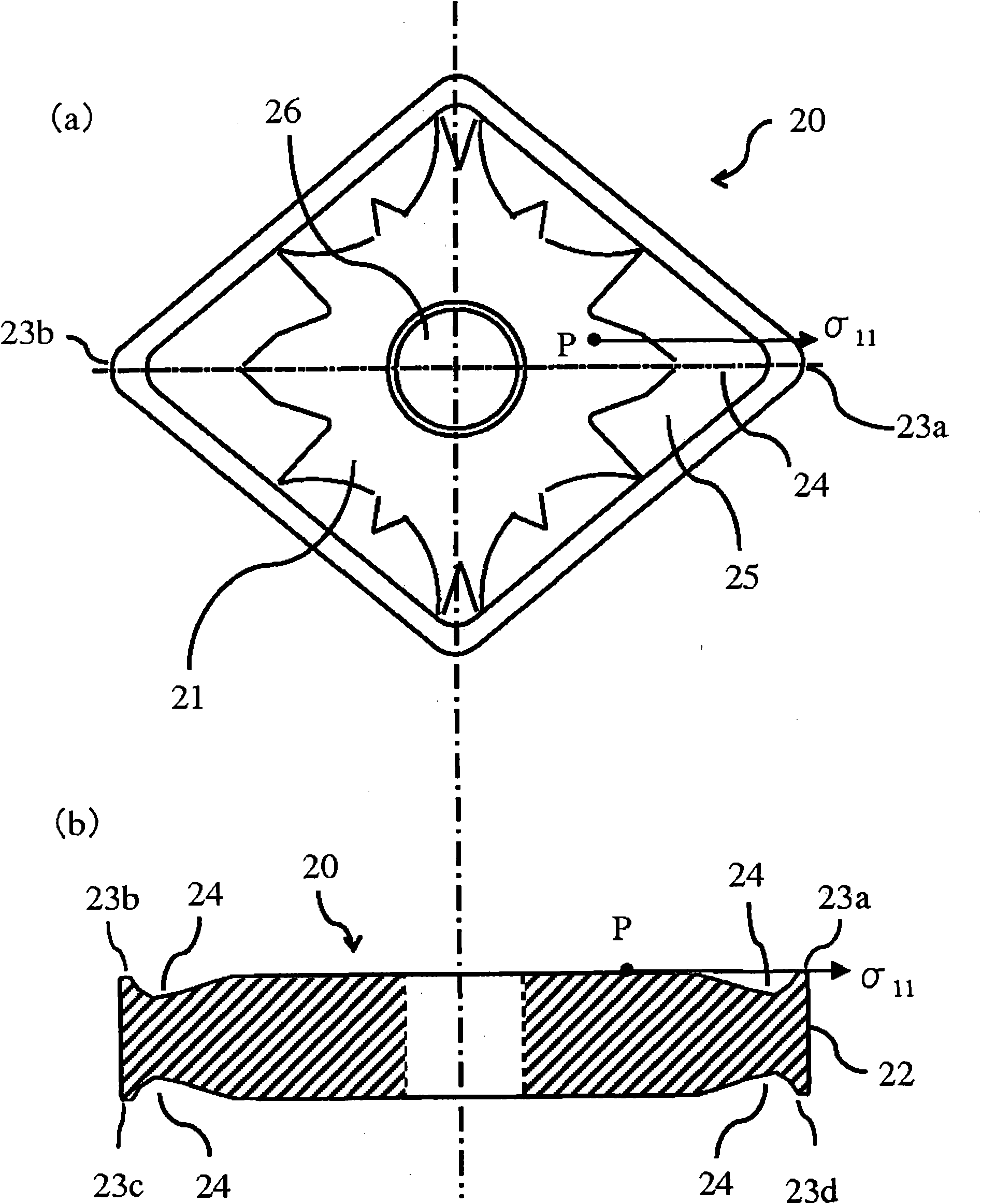

Cutting tool

ActiveCN101848782AImprove wear resistanceImprove welding resistanceVacuum evaporation coatingSputtering coatingMetallurgyHigh wear resistance

Disclosed is a cutting tool having high wear resistance, high lubricating properties and excellent defect resistance. Specifically disclosed is a cutting tool (1) comprising a base (2) and a coating layer (6) or (9) that covers the surface of the base (2), wherein the coating layer (6) or (9) comprises a first layer (7) comprising Ti1-a-b-c-dAlaWbSicMd(C1-xNx) [wherein M represents at least one member selected from Nb, Mo, Ta, Hf and Y; 0.45<=a<=0.55; 0.01<=b<=0.1; 0<=c<=0.05; 0.01=<d=<0.1; and 0=<x<=1] and a second layer (8) comprising Ti1-e-f-gAleSifM'g(C1-yNy) [wherein M' represents at least one member selected from Nb, Mo, Ta, Hf and Y; 0.50<=e<=0.60; 0<=f<=0.1; 0.05<=g<=0.15; and 0<=y<=1].

Owner:KYOCERA CORP

Silver-tin oxide electrical contact material and preparation method thereof

InactiveCN1624838APromote internal oxidationLower internal oxidation temperatureContact materialsRare-earth elementAlloy

The invention discloses silver tin oxide electrician contact material and its preparation method. Its chemical composition (weight ratio) is that the SnO2 is from three percent to ten percent; the mixed rare earth oxide (Sm2O3, Gd2O3, Y2O3) is from 0.1 percent to 2.0 percent; the surplus quantity is Ag. The preparation method is that the Ag, Sn, rare earth element are made up according to the alloy design proportion of ingredients, alloying in the vacuum melting furnace; then the AgSnRE is made after quickly solidification. At first the alloy is formed to thread, panel, profiled bar or rivet by extrusion, rolling, drawing, heat treatment. Then it is formed to AgSnO2 mixed rare earth oxide electrician contact material by produce internal operation. It can be used in AC and DC contactor, relay, controller, circuit breaker, switch, and so on.

Owner:KUNMING INST OF PRECIOUS METALS

Copper-based electrical contact composite material and process for preparing same

This invention relates to a copper-base contact compound material used in low and medium voltage electric appliance switches and its preparation method. The material is composed of materials in the following weight percentage: Sn 0.1-0.5%, B carbide 0.1-5%, the mixed rare earth of fat La or fat Ce 0.05-2%, the rest is Cu. The material is prepared by mixing, cold- pressing powders, cold-pressing again and sintering to finish the product.

Owner:UNIV OF JINAN

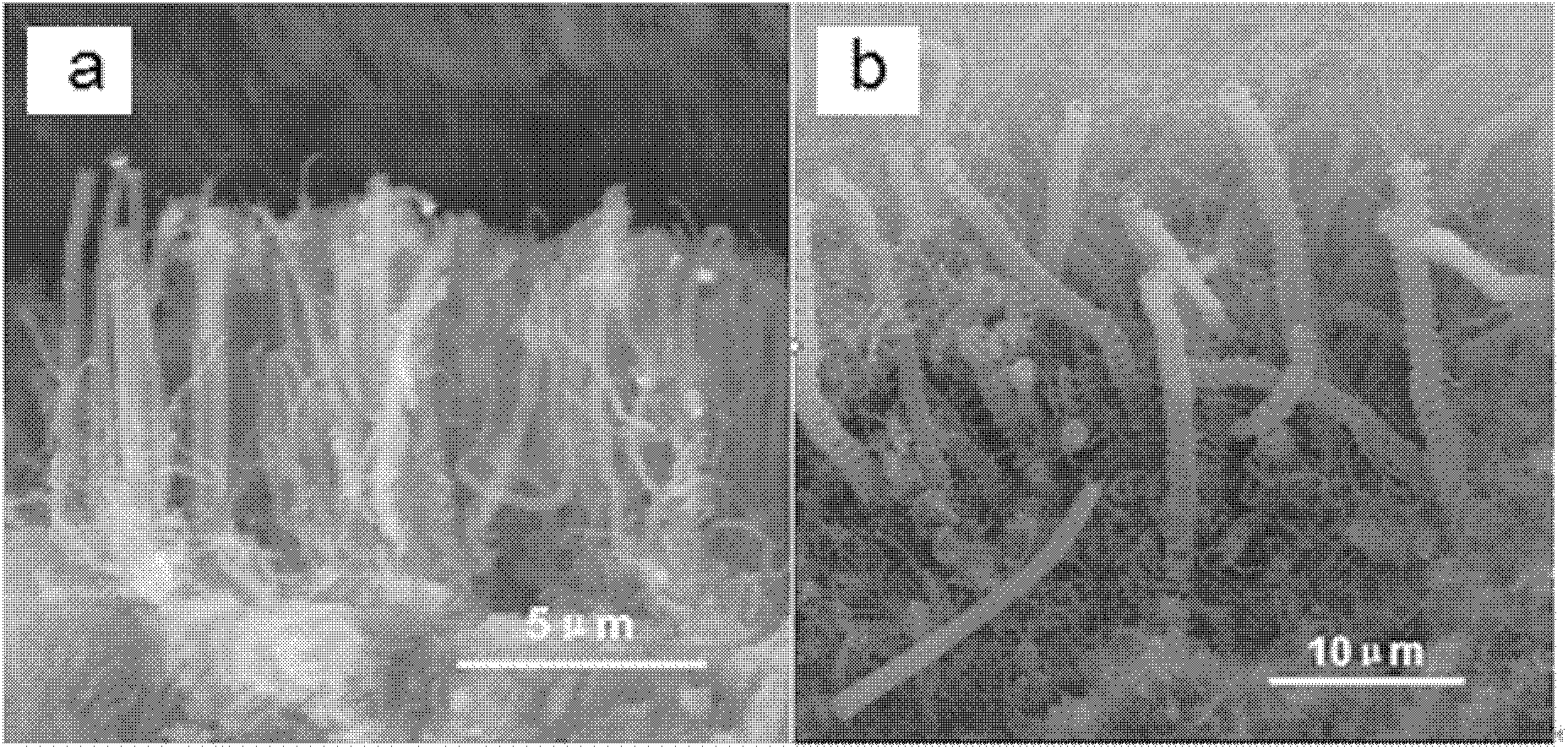

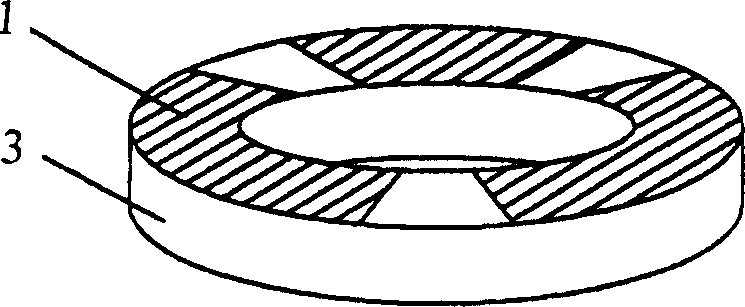

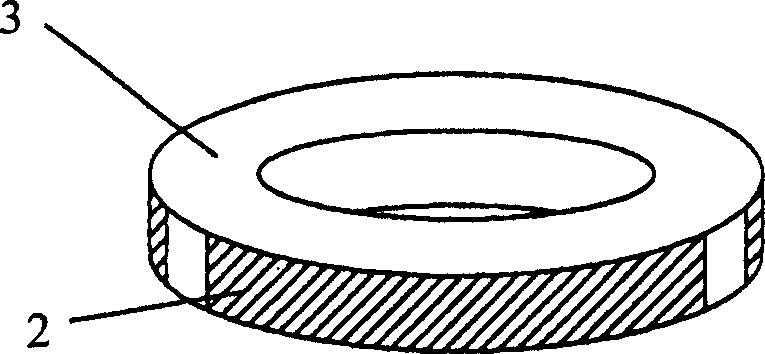

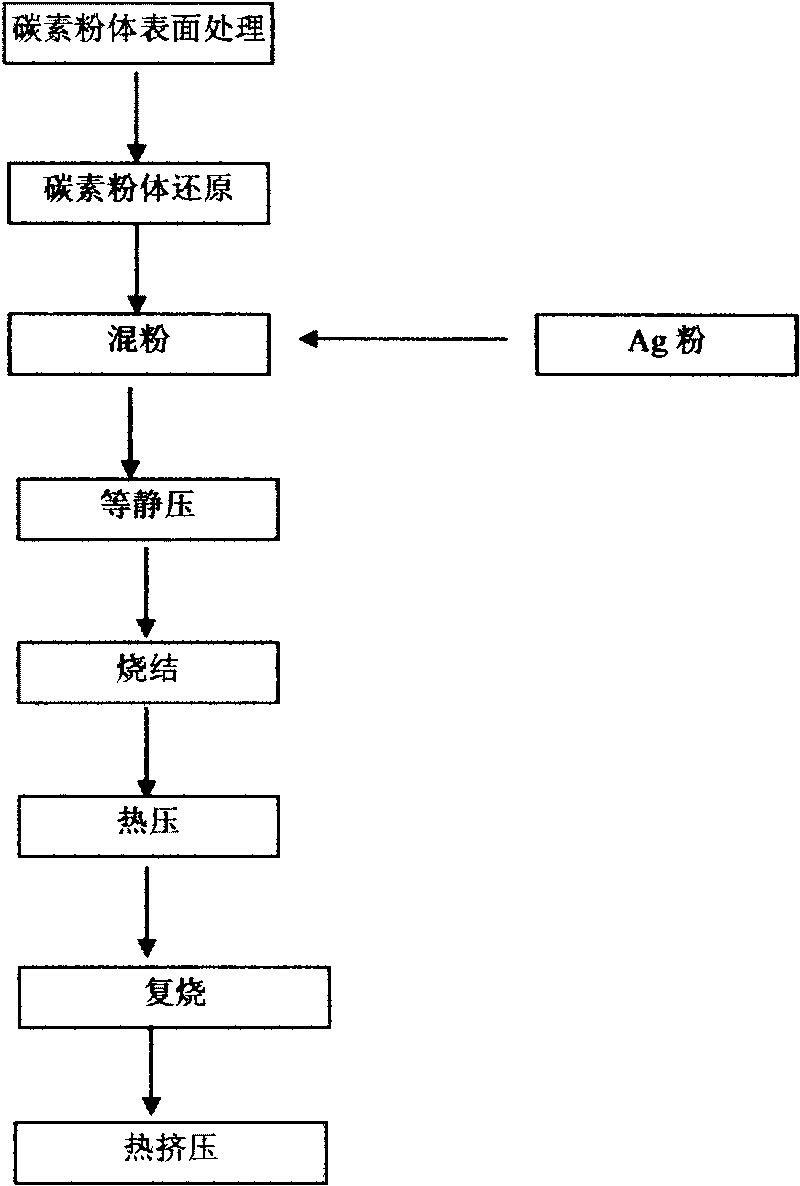

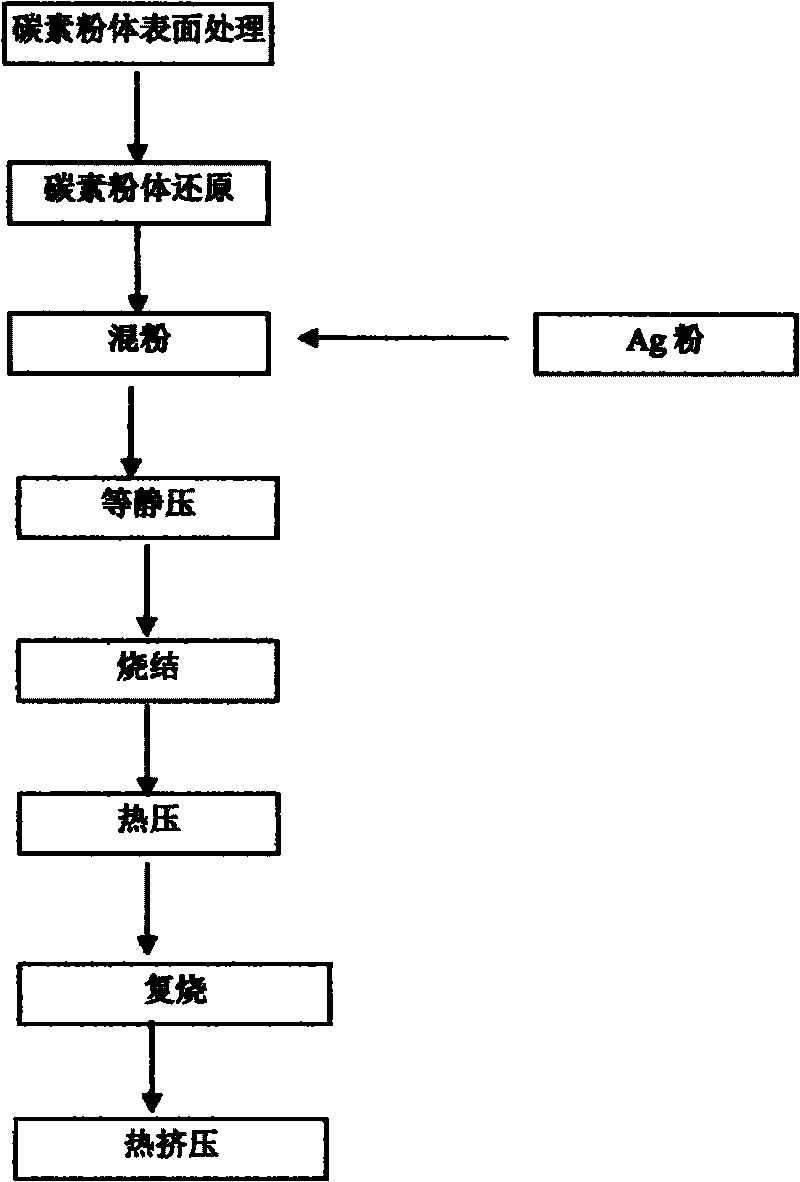

Method for preparing silver-based electrical contact material with fibrous structure

ActiveCN102002651AImproved arc erosion resistanceImprove conductivityContactsFusion weldingElectrical resistivity and conductivity

The invention discloses a method for preparing a silver-based electrical contact material with a fibrous structure, which comprises the following steps: 1, uniformly mixing reinforcing-phase material powder with substrate silver powder uniformly, and ball milling; 2, feeding the obtained mixed powder and substrate silver powder into a powder mixer for mixing powder; 3, performing isostatic cool pressing; 4, sintering; 5, performing hot pressing; and 6, performing hot extrusion and obtaining the silver-based electrical contact material. The method of the invention can prepare the sliver-based electrical contact material with an obvious fibrous structure regardless the processing deformation amount and the levels of the plasticity and ductility of a reinforcing phase; and in the method, theprocess is simple, it is convenient to operate, the cost is low, and special requirements on equipment are avoided. The fusion welding resistance, arc erosion resistance and conductivity of the material prepared by the method are all improved greatly, and the processing performance of the material is high.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Preparing method for silver plating graphene enhanced copper-based electric contact material

ActiveCN105950904AGood electrical and thermal conductivityImprove welding resistanceTransportation and packagingMetal-working apparatusSilver plateChemical plating

The invention relates to a copper-based electric contact material used in a middle-low-voltage electric appliance switch, in particular to a preparing method for a silver plating graphene enhanced copper-based electric contact composite material. The copper-based composite material comprises, 0.5 wt.%-4 wt.% of bismuth, 0.05 wt.%-0.5 wt.% of yttrium, 0.1 wt.%-0.5 wt.% of graphene (silver plating), 1wt.%-5wt. / % of silver and the balance copper and other inevitable impurities. Copper-yttrium alloy powder is prepared and subjected to chemical silver plating, the copper-yttrium alloy powder and graphene subjected to silver plating treatment are subjected to ball milling and mixed evenly, and the electric contact material is finally prepared through pressing and sintering. The surface of copper powder is subjected to silver plating so that the anti-oxidation performance of the material can be improved, the graphene is subjected to silver plating treatment so that combination between the graphene and a copper base body can be enhanced, and therefore the comprehensive performance of the material is improved, and the copper-based electric contact material good in electric conductivity, resistant to electric arc erosion and excellent in welding resistance is finally obtained.

Owner:UNIV OF JINAN

Special powder copper alloy electric contact material and method for making same

ActiveCN101145450AImprove antioxidant capacityImproved arc burn resistanceContactsLow voltageRare earth

The invention provides a method for producing Cu alloy electrical contact material with good antioxidant property. The alloy is composed of rare earth (at least one selected from La, Ce and Yt elements), boron, aluminum, silver, conductive ceramic (TiN2 and / or SnO2), diamond powder and copper. The alloy is processed by powdering, mechanical mixing, isostatic pressing, sintering, extrusion and shaping steps, to make various electrical contact elements. With the inventive method, the produced electrical contact element can overcome the disadvantage of poor antioxidant capability of the prior Cu alloy electrical contact elements, and can be used to replace the silver alloy electrical contact in the field of low-voltage electrical apparatuses, thereby solving the problems of the silver alloy electrical contact, such as high cost due to noble metal silver and bad influence on social sustainable development.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

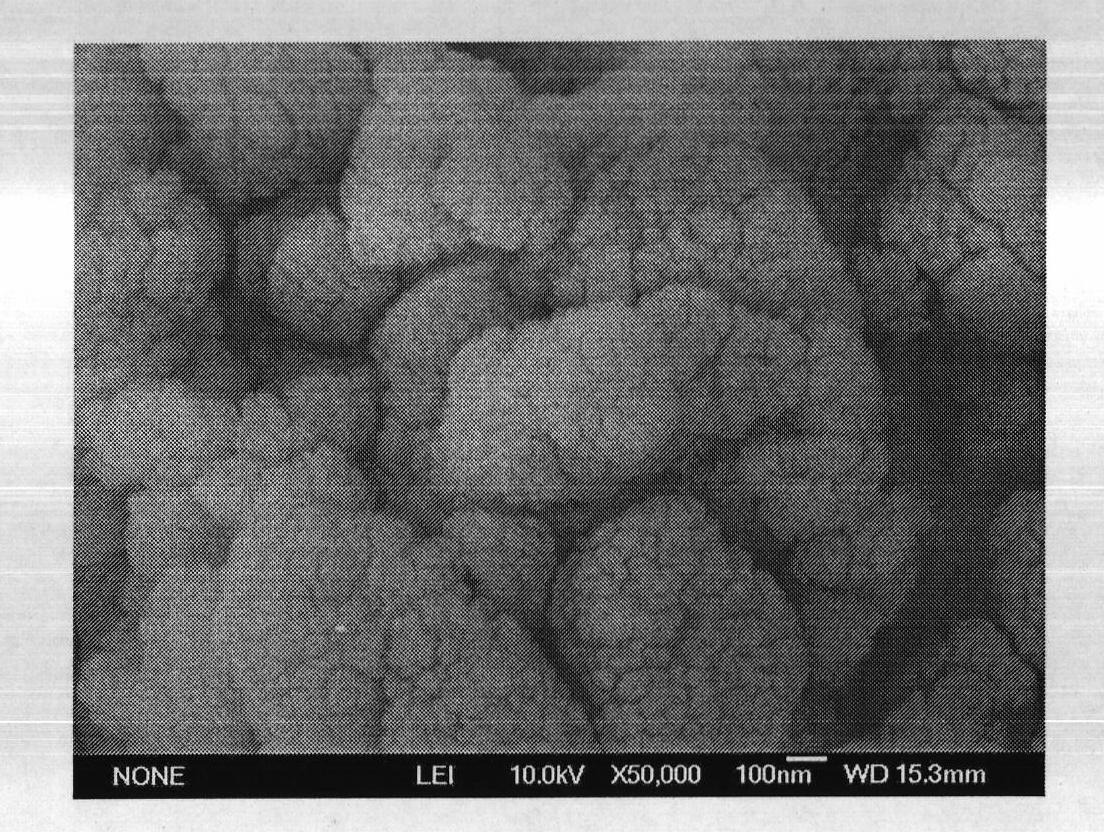

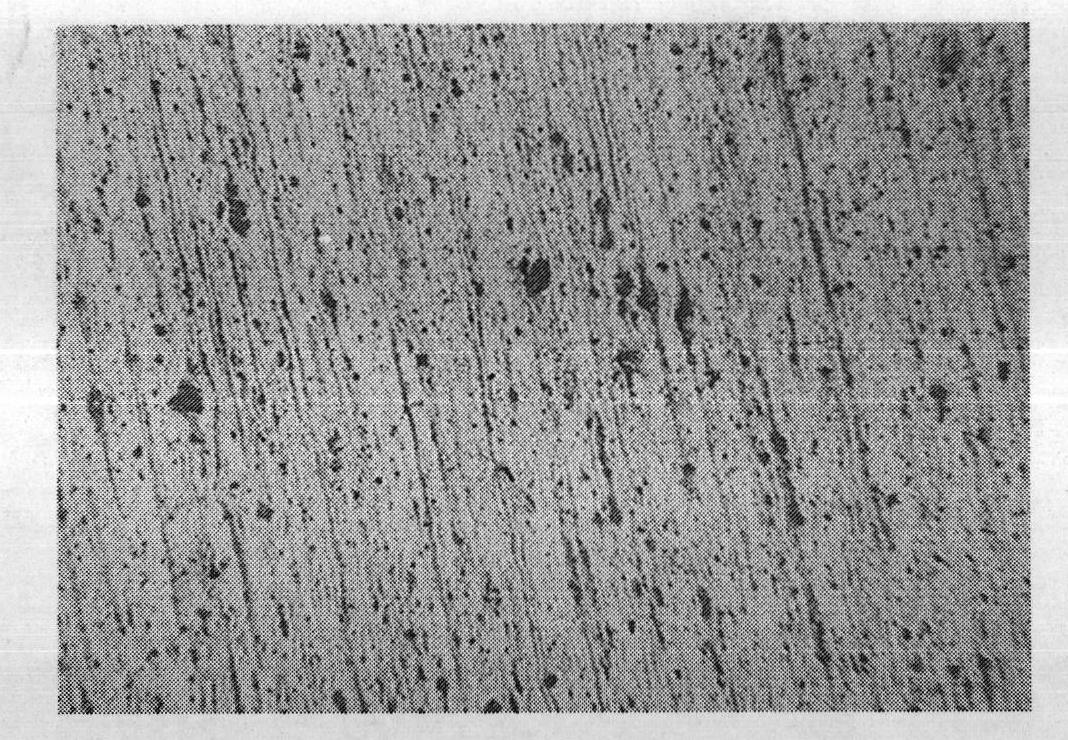

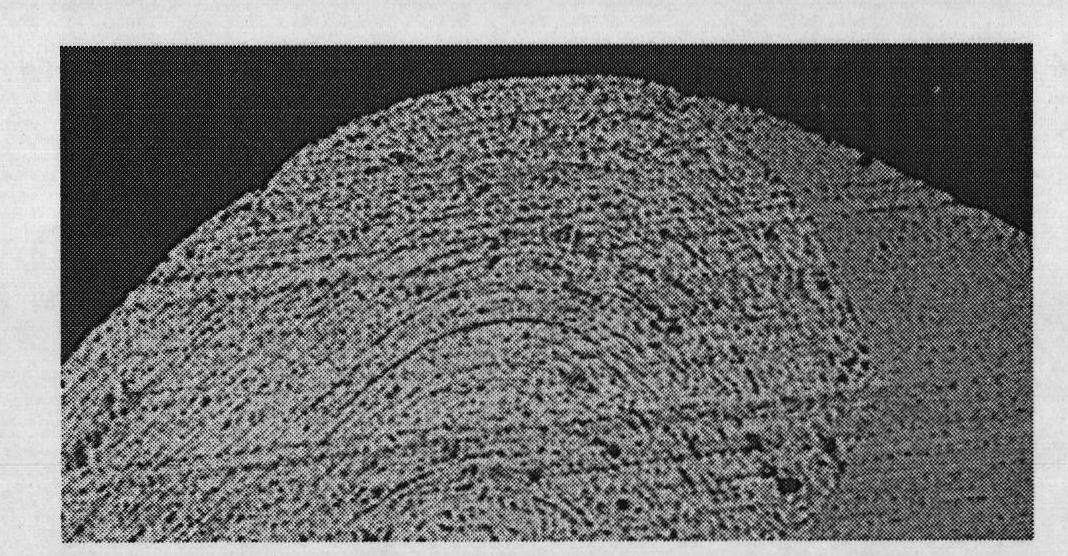

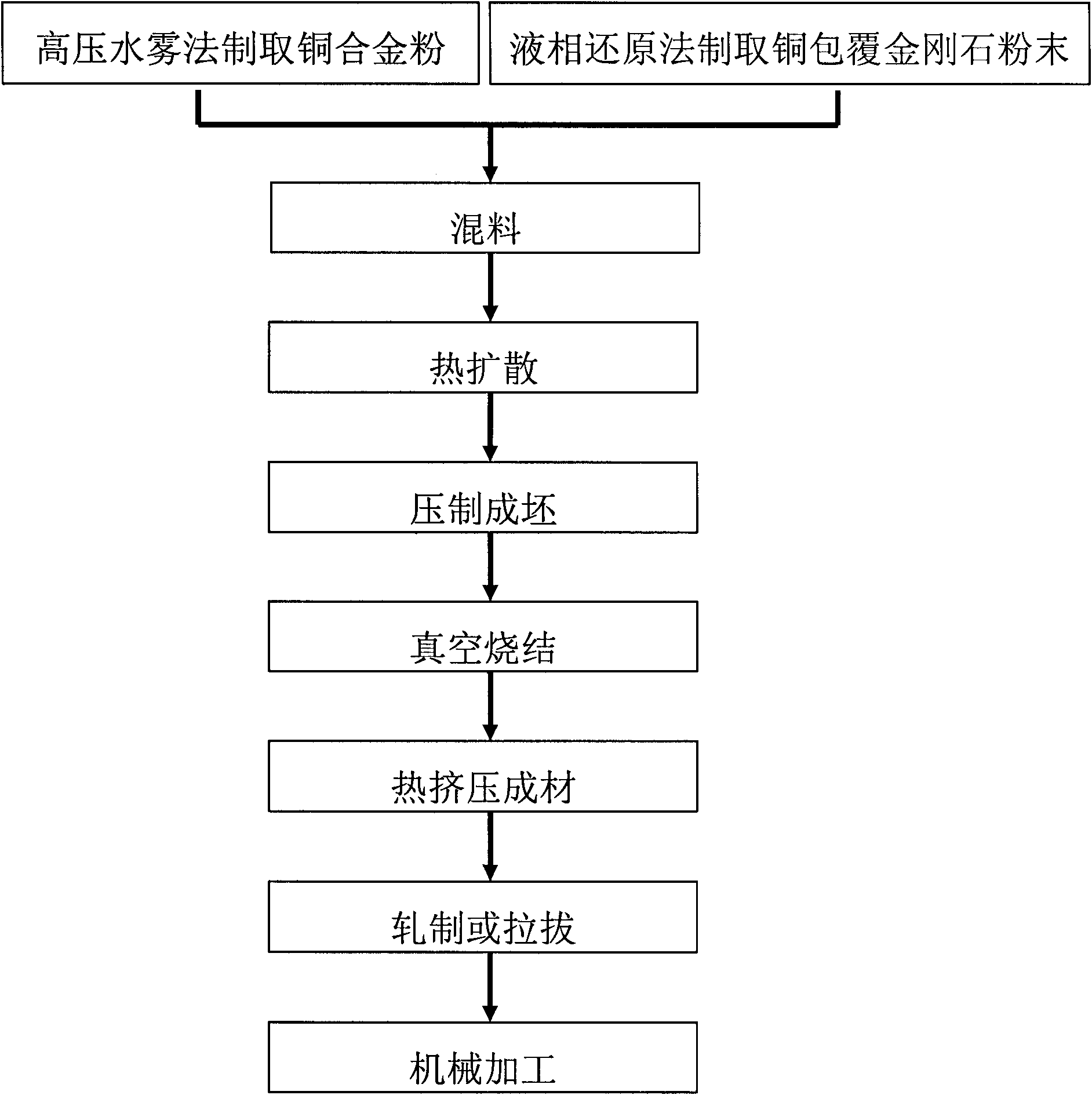

High-performance copper-diamond electrical contact material and preparation process thereof

The invention relates to a preparation process of powder metallurgy material, in particular to high-performance copper-diamond electrical contact material and a preparation process thereof. The high-performance copper-diamond electrical contact material comprises the following raw materials by weight percentage: 0.001%-5.0% of diamond powder and 95%-99.999% of copper alloy powder, wherein the grain size of the diamond powder is 0.1-15 mum, and the surface of the diamond powder is coated with copper. The preparation process of the high-performance copper-diamond electrical contact material comprises the following steps: (1) preparing the raw materials: preparing the copper alloy powder by using a high-pressure spray method, preparing the copper-coated diamond powder by using a liquid-phase reduction method and mixing the copper alloy powder and the copper-coated diamond powder; (2) preparing the electrical contact material: firstly, carrying out thermal diffusion treatment to the mixture of the copper alloy powder and the copper-coated diamond powder, sintering the compressed and moulded mixture in vacuum, and thermally extruding and moulding the mixture; and (3) preparing electrical contact sectional material: rolling or drawing and machining the copper-diamond electric contact into the required-size sectional material.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

Silver nickel electricity-conductive ceramic electrical contact material and its production method

ActiveCN101127253AExtended service lifeReduce and stabilize contact resistanceContact materialsMetal/alloy conductorsHigh energyCerium

The utility model provides a method for manufacturing electrical contact material, and can manufacture silver-nickel conductive ceramics electrical contact material characterized in steady contacting resistance, multiple fusion characteristic, voltaic arc burning tolerance and electric wear resistance. The electrical contact material comprises nickel, conductive ceramics (TiN2, SnO2 single or combination), rare-earth (lanthanum, cerium single or combination), silver and unavoidable impurities. The electrical contact elements are made by producing powder, mechanically mixing, high-energy ball milling, isopressing forming, sintering, extruding and contour machining orderly. The finished electrical contact elements overcomes the defects of prior art electrical contact element such as unstable contacting resistance, insufficient fusion characteristic, high voltaic arc burning loss and low electric wear resistance.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

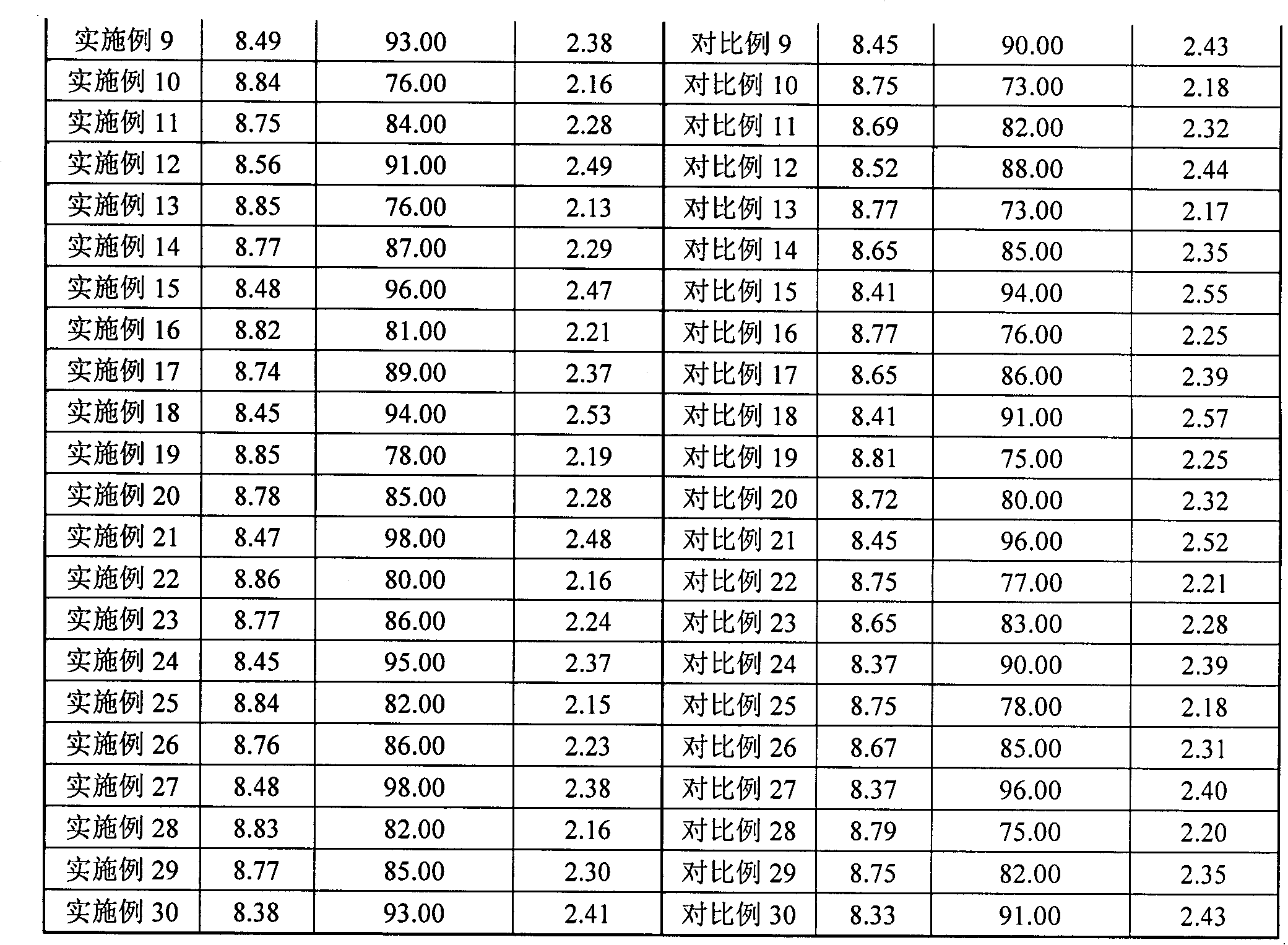

Titanium-base cermet, coated cermet, and cutting tool

A titanium-base cermet suitable for use as cutting tools having high chipping resistance and high wearing resistance. The titanium-base cermet (1) comprises: at least one of cobalt and nickel; at least one of carbides, nitrides, and carbonitrides of at least one element which is selected among the metals in Groups 4, 5, and 6 of the periodic table and comprises titanium as the main component; and0.1-0.5 mass% manganese. When a photograph of any section of the cermet taken with a scanning electron microscope (SEM) is examined, then a rigid phase (2) comprising a first rigid phase (2a) and a second rigid phase (2b) and a bonding phase (3) consisting mainly of at least either of cobalt and nickel are observed in an inner part and the second rigid phase (2b) looks whiter than the first rigidphase (2a). Furthermore, a surface part of the section has a surface region 90% by area of which is accounted for by a second rigid phase (2b).

Owner:KYOCERA CORP

Electric contact material made of silver-tungsten carbide graphite and preparation method thereof

The invention relates to an electric contact material made of silver-tungsten carbide graphite and a preparation method thereof. The electric contact material comprises the following main components in percentage by weight: 11%-14% of tungsten carbide-zirconium carbide solid solution, 2%-6% of graphite, 0.3%-0.6% of additive and the balance of silver, wherein the added element is one or the combination of Ti, Co and Cr. The tungsten carbide and the zirconium carbide are added in form of solid solution with the ratio of (6:4)-(9:1). Compared with the traditional electric contact made of silver-tungsten carbide graphite, the electric contact material has higher welding resistance, electric arc burning resistance and high-temperature oxidation resistance. A low-voltage electric appliance adopting the electric contact material has lower contact resistance, longer electric service life and high reliability. Therefore, the novel electric contact material with high reliability is more suitable for being applied in various different plastic-shell circuit breakers, small high-interruption circuit breakers and alternating-current contactors.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

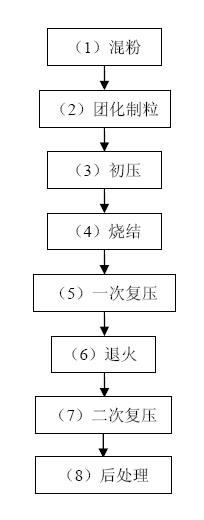

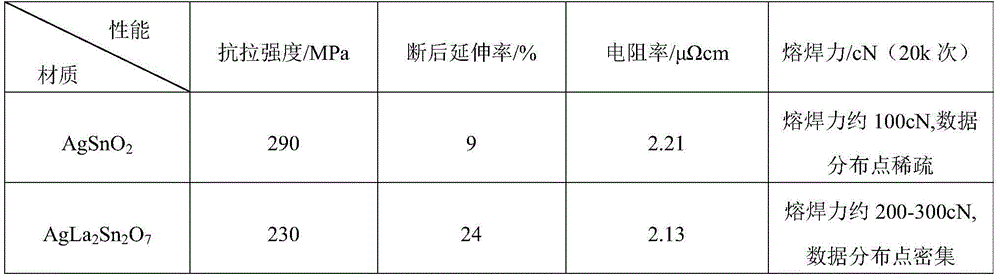

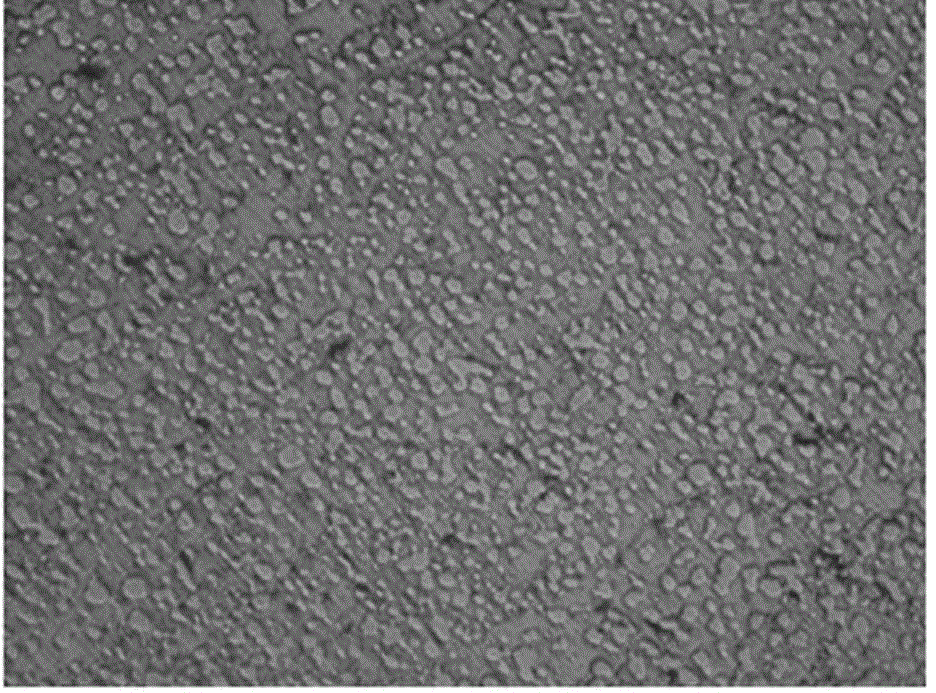

Preparation method of novel Ag-based lanthanum stannate composite electric contact material

The invention relates to preparation of an electric contact material and provides a preparation method of a novel Ag-based lanthanum stannate composite electric contact material. The preparation method comprises carrying out ball-mill mixing on Ag powder and lanthanum stannate nanometer powder to obtain AgLa2Sn2O7 composite powder, carrying out hot pressing sintering treatment to obtain an AgLa2Sn2O7 blank block, and carrying out hot extrusion treatment to obtain an AgLa2Sn2O7 wire rod. The preparation method utilizes a simple AgLa2Sn2O7 composite powder synthesis technology, utilizes a ball milling technology to realize synthesis and has a low cost. Compared with AgSnO2, the AgLa2Sn2O7 wire rod has lower specific resistance, higher elongation percentage after annealing fracture, good tensile strength, excellent mechanical properties and better welding resistance.

Owner:ZHEJIANG UNIV

Electric contact material and preparation method thereof

The invention relates to an electric contact material, in particular to a graphene reinforced copper-matrix electric contact composite material and a preparation method of the material. The electric contact material consists of the following components in percentage by weight: 0.1-1.0% of nickelized graphene and 99.0-99.9% of copper alloy. The preparation method comprises the steps of graphene nickelizing, copper alloy pulverizing, ball-milling and powder mixing, densification processing and vacuum electric arc smelting. According to the electric contact material disclosed by the invention, the nickelized graphene is added in the copper alloy and serves as the framework, so that the material has high hardness, mechanical impact-resistance and electric arc ablation resistance; and the lowering of the electric conductivity and the heat conductivity is avoided. Vacuum electric arc smelting is adopted, so that the smelting time is short; segregation of graphene particles is avoided; and the oxidation of the copper matrix is effectively prevented.

Owner:UNIV OF JINAN

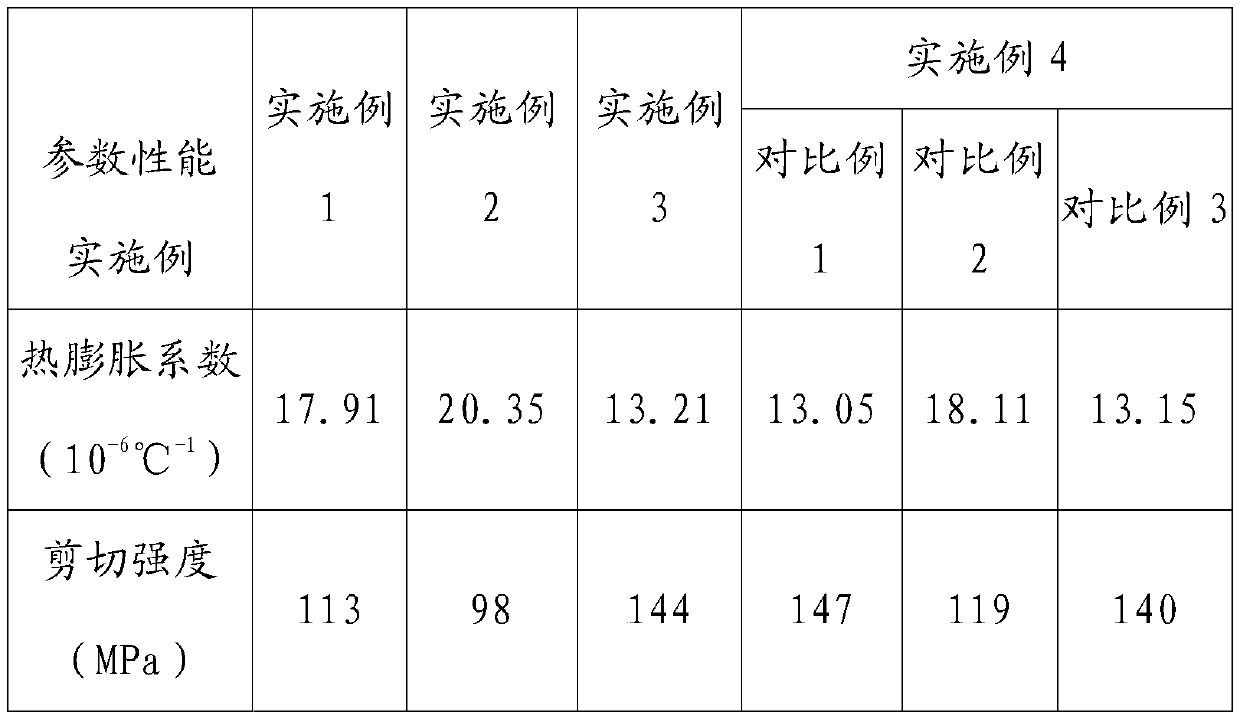

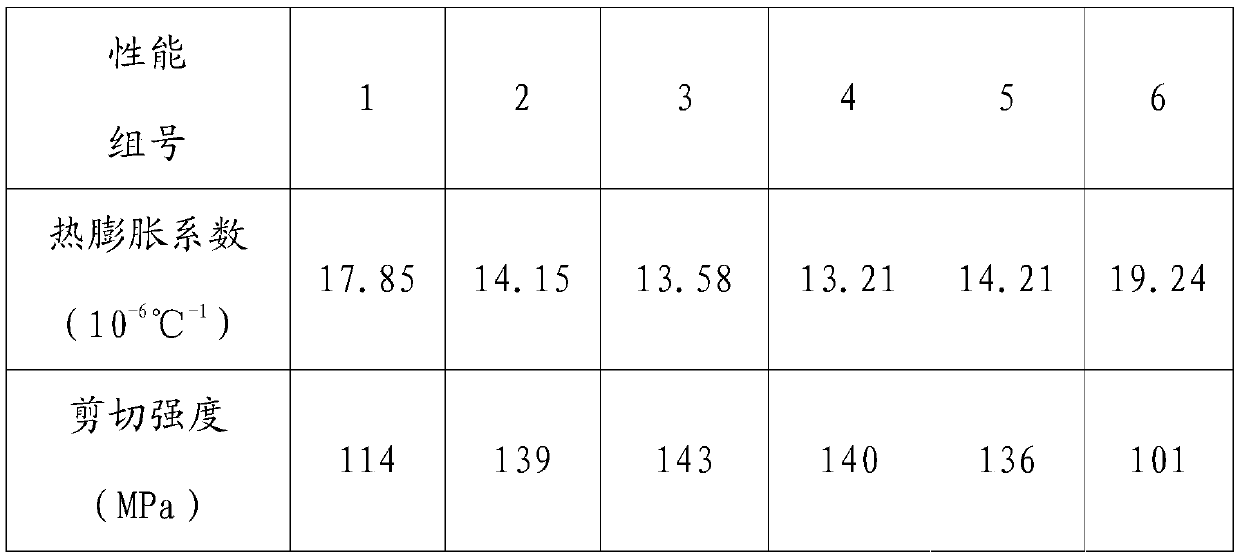

Brazing material for SiC ceramic brazing and brazing method

ActiveCN109877413AImprove plastic deformation abilityImprove conductivityWelding/cutting media/materialsSoldering mediaThermal expansionBrazing

The invention discloses a brazing material for SiC ceramic brazing and a brazing method. The brazing material comprises the following components of, by weight, 40%-63% of Ag, 25%-41% of Cu, 0-2.5% ofSn, 0-5.5% of Ni, 2%-4.5% of Ti, 2%-7% of Mo and 1%-8% of B. The cross-section reaction between the brazing material and ceramic is fully considered, a silver-based brazing material having good wettability to the ceramic material is selected, the contents of Sn and Ni are lowered, the joint strength is improved by adding Mo and B particles, the thermal expansion coefficient of the brazing materialis lowered, the residual stress of a brazed joint is relieved, the joint has good isotropy, and thus the effect that the SiC ceramic joint has good mechanical distribution characteristics can be ensured.

Owner:BEIFANG UNIV OF NATITIES

High temperature resistant silver oxide contact tip material manufacturing method

This invention relates to a manufacturing method for high temperature silver oxide contactor material including: 1, melting any 1-7 kinds of Sn, Cd, Bi, Cu, In and Fe in certain weight ratio with Ag for rest to alloy them completely to get an Ag strip with a single roller rejection rapid quenching machine, in which, the rotation speed of a cold quenching roller is 3-30m / s, 2, oxidating the Ag alloy strip for 12-24h under 0.1-10MPa and 500-750deg.C, 3, processing it to a contactor material by an ordinary method, in which, size of the metal oxide is small, hardness (HV0.3) can reach to 130 and will not be reduced along the rising of temperature and the contactor can work stably under 85deg.C.

Owner:桂林金格电工电子材料科技有限公司

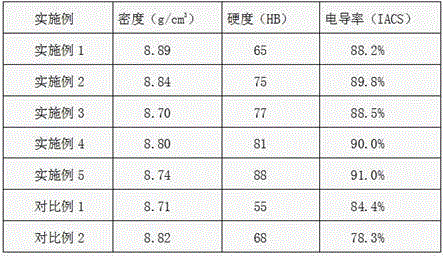

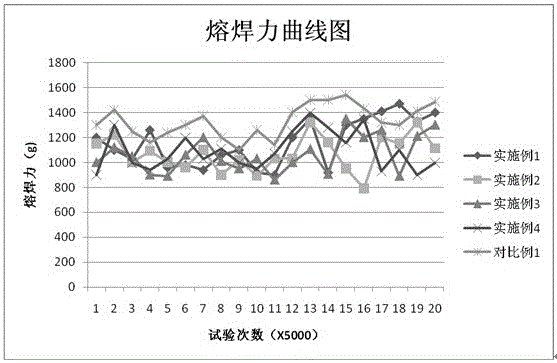

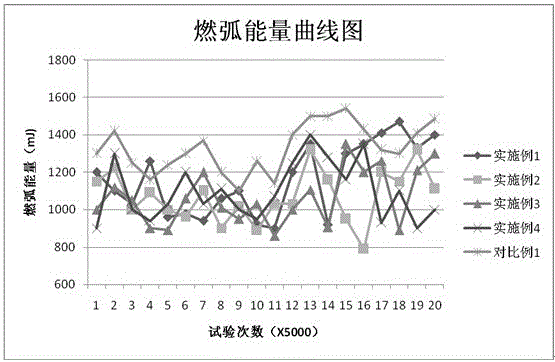

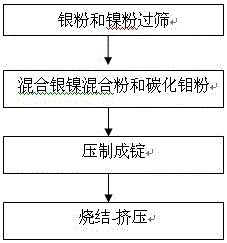

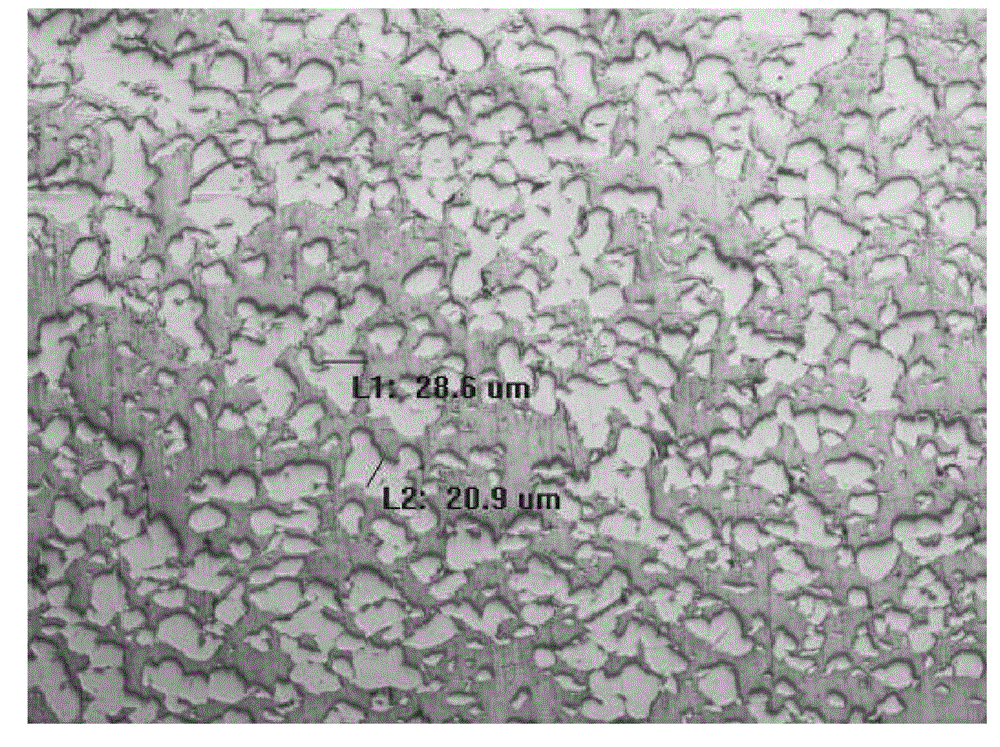

Silver-nickel electric contact material and preparing method thereof

ActiveCN106282640AImprove welding resistanceGuaranteed uniformityContactsElectricityHigh volume manufacturing

The invention relates to the field of electric contact materials, in particular to a silver-nickel electric contact material and a preparing method thereof. The silver-nickel electric contact material comprises, by mass percent, larger than or equal to 8% and smaller than or equal to 30% of nickel, larger than or equal to 0.5% and smaller than or equal to 12% of molybdenum carbide, and the balance silver. A powder mixing-extrusion technology is adopted in a production technology for the silver-nickel electric contact material. Improvement of the welding resistance performance of the silver-nickel material is mainly taken into consideration, the molybdenum carbide is added to serve as a reinforcement phase, and the molybdenum carbide has the beneficial effects that the melting point is high, heat stability is good, and the density of the molybdenum carbide is close to that of silver and nickel; and component uniformity can be guaranteed through the ordinary powder mixing technology, and the silver-nickel electric contact material and the preparing method thereof are suitable for volume production. Compared with ordinary silver and nickel materials, the silver-nickel electric contact material has high welding resistance performance and low electric arc energy and is mainly applied to alternating current contactors and relays.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Chemical coprecipitation preparation of nano-rave-earth blend AgSnO2 electric contacting alloy and its process

InactiveCN1652268AImproved ability to disperse the arcImprove welding resistanceContact materialsRare-earth elementNanoparticle

The invention is relates to components of electric contact material and fabricating technique. Weight percentage of each component is a following: 70-95% Ag, 2.5-20% stannic oxide, 0.025-1% magnesia and 0.025-9% lanthanum or cerium. Compound powder of Ag, SnO2, MgO, La or Ce in Nano amorphous or crystalloid is prepared through high-octane ball milling. Structure, decentrality and dimensional stability of Nano granules are improved by adding lanthanide series into material. Thus, formability and electrical property of electric contact alloy are improved as well as ablation rate of contact is reduced and service life is increased.

Owner:XI'AN POLYTECHNIC UNIVERSITY

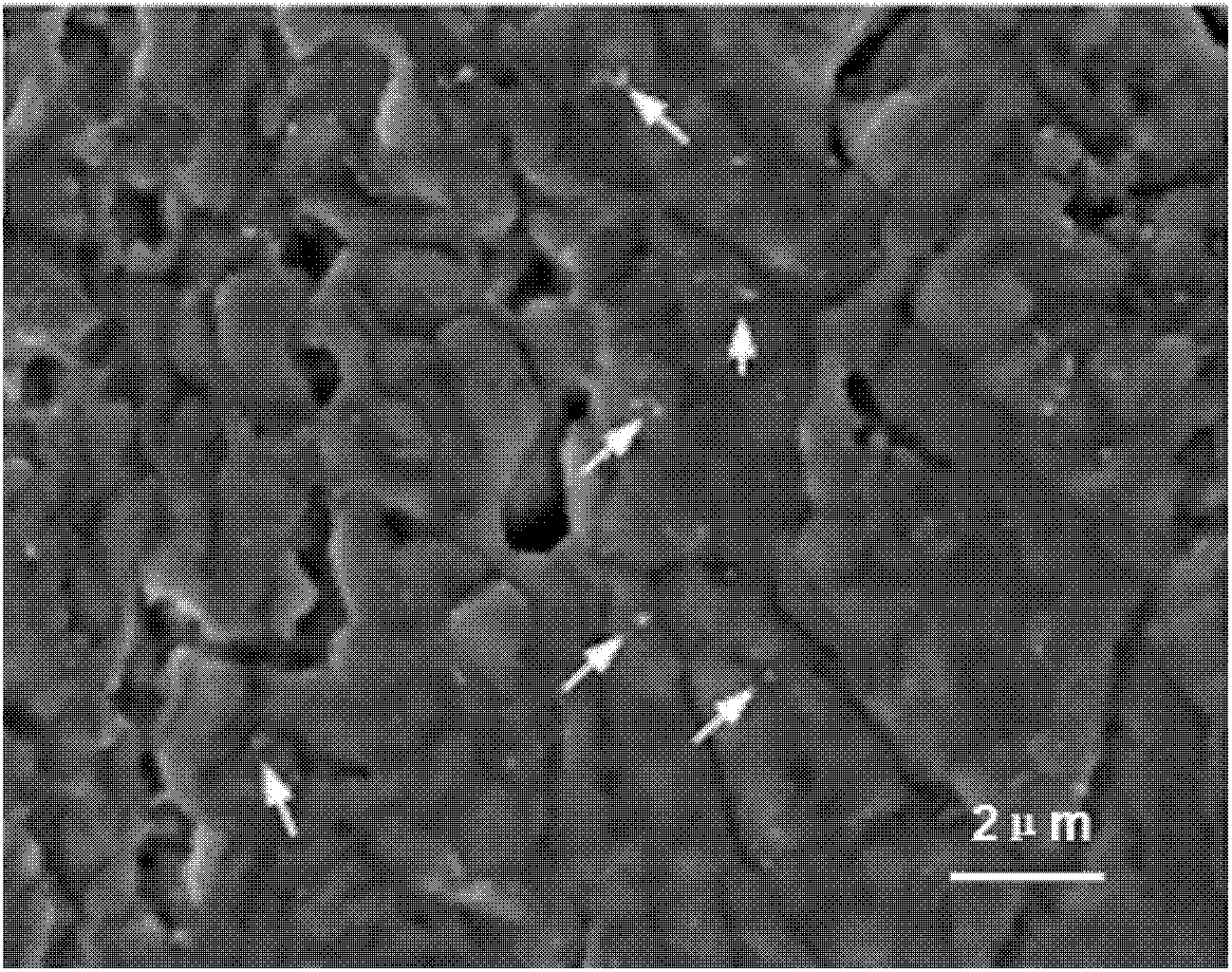

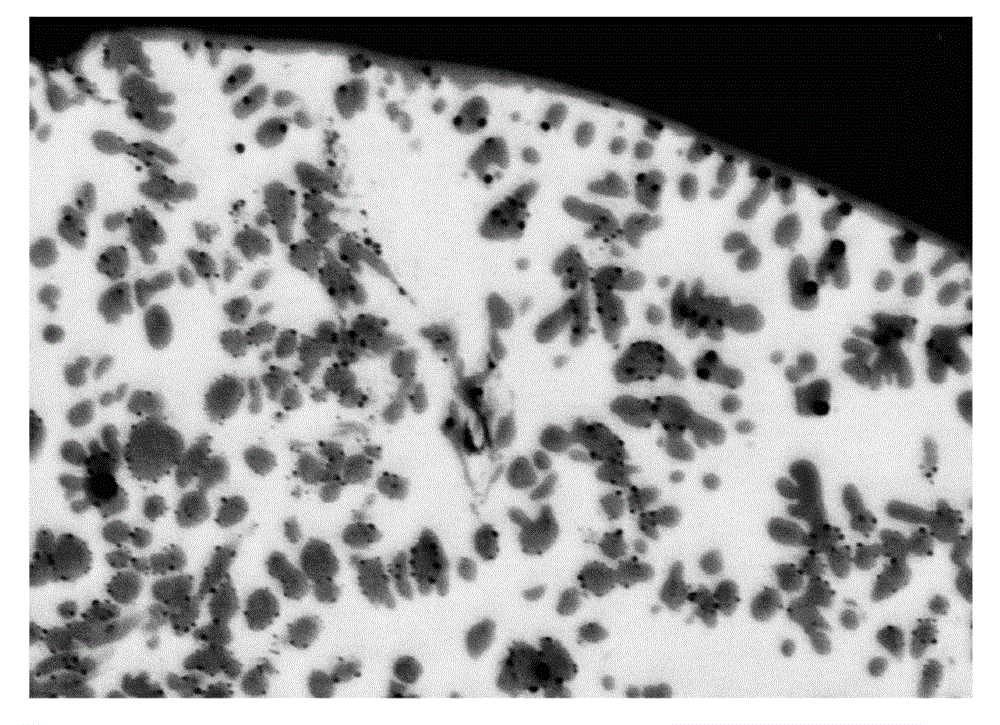

Nanometer tungsten carbide silver contact material and manufacturing method

A nano-tungsten carbide silver contact material and a preparation method thereof, wherein the tungsten carbide silver contact material is mainly composed of tungsten carbide powder, nickel powder, silver powder and stearic acid powder and is ball-milled to obtain a nano-WC / Ag composite powder, After reduction, pressing, sintering, re-pressing, and re-firing, nano-tungsten carbide silver electrical contacts are obtained. The weight ratio of tungsten carbide to silver is 40-80:20-60, and the particle size of the tungsten carbide phase is 50-500nm; The addition of the nickel powder is 0-2% of the mass percentage of the tungsten carbide powder; the addition of the stearic acid powder is 0.5-5% of the mass percentage of the tungsten carbide-silver-nickel mixed powder; the preparation method is: Weigh tungsten carbide powder and nickel powder, cemented carbide balls and alcohol according to the proportion and place them in a planetary high-energy ball mill for 12-72 hours. Take out the mixed powder and dry it, mix it with silver powder and stearic acid powder in a specific proportion and place it on a planetary ball mill. Milled in a high-energy ball mill for another 6-24 hours, the nano-WC / Ag composite powder obtained after ball milling is processed by reduction, pressing, sintering, re-pressing, and re-sintering to obtain uniform structure, high density, high hardness, and good electrical conductivity. , Nano-tungsten carbide silver electrical contacts with good anti-welding properties.

Owner:ZHEJIANG YATONG METAL CERAMICS

Preparation method of copper-chromium alloy powder and preparation method of copper-chromium alloy pig

The invention discloses a preparation method of copper-chromium alloy powder and a preparation method of a copper-chromium contact, and relates to a preparation method for metal powder and application of the metal powder. The preparation method of the copper-chromium alloy powder comprises the following steps of: preparing a copper bar and a chromium block at the mass ratio of (25-50):(75-50); heating and smelting raw materials into an alloy stream by vacuum induction; enabling the above alloy liquid to flow into an atomizing chamber to be atomized; when the alloy liquid is atomized, continuously introducing inert gas at the pressure of 0.1-0.5Mpa; and screening powder size obtained after atomization by a sieve of 150 micrometers or below 150 micrometers to obtain the copper-chromium alloy powder. The invention provides a preparation method of the copper-chromium alloy powder, and the prepared copper-chromium alloy powder has the advantages of small particle, high nodulizing degree and low air content. The invention also provides a preparation method for a copper-chromium alloy pig, and the prepared copper-chromium alloy pig has the advantages of high density and small pressure required for pressing.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Preparation method of silver-based contact material containing graphene

InactiveCN105838914AEffective processing performanceImprove tissue uniformityElectric switchesInsulation layerHeat conducting

The invention discloses a preparation method of a silver-based contact material containing graphene. The silver-based contact material comprises silver oxide, tin oxide, nickel oxide, lanthanum oxide and silver-plated graphene, wherein the content of tin elements is 5-10 wt%, the content of nickel elements is 2-5 wt%, the content of lanthanum elements is 0.5-1 wt%, the content of the silver-plated graphene is 2.5-3.5 wt%, and the balance inevitable impurities, silver and oxygen. Through optimization selection of the ratios and process of the raw materials, the organization uniformity of the silver-based contact material prepared through the method is improved, and the electrical performance of the material is improved. SnO2 powder is prepared through a sol-gel process. Nano SnO2 is uniformly distributed and dispersed in silver base bodies. Contact resistance reduction caused by an insulation layer formed by enrichment of SnO2 can be avoided. The breaking effect of the oxide on the base bodies is reduced. The processing performance of the silver-based contact material can be effectively improved. The capability of welding resistance and electrical arc erosion resistance of the silver-based contact material are improved. The interface wettability between the graphene and metal is improved through the silver-plated grapheme, and the good interface bonding effect can be achieved, so that the electrical conductivity, the heat conducting property and electrical arc erosion resistance of the composite material are further improved, and the requirement for the performance of electrical contacts is met better.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

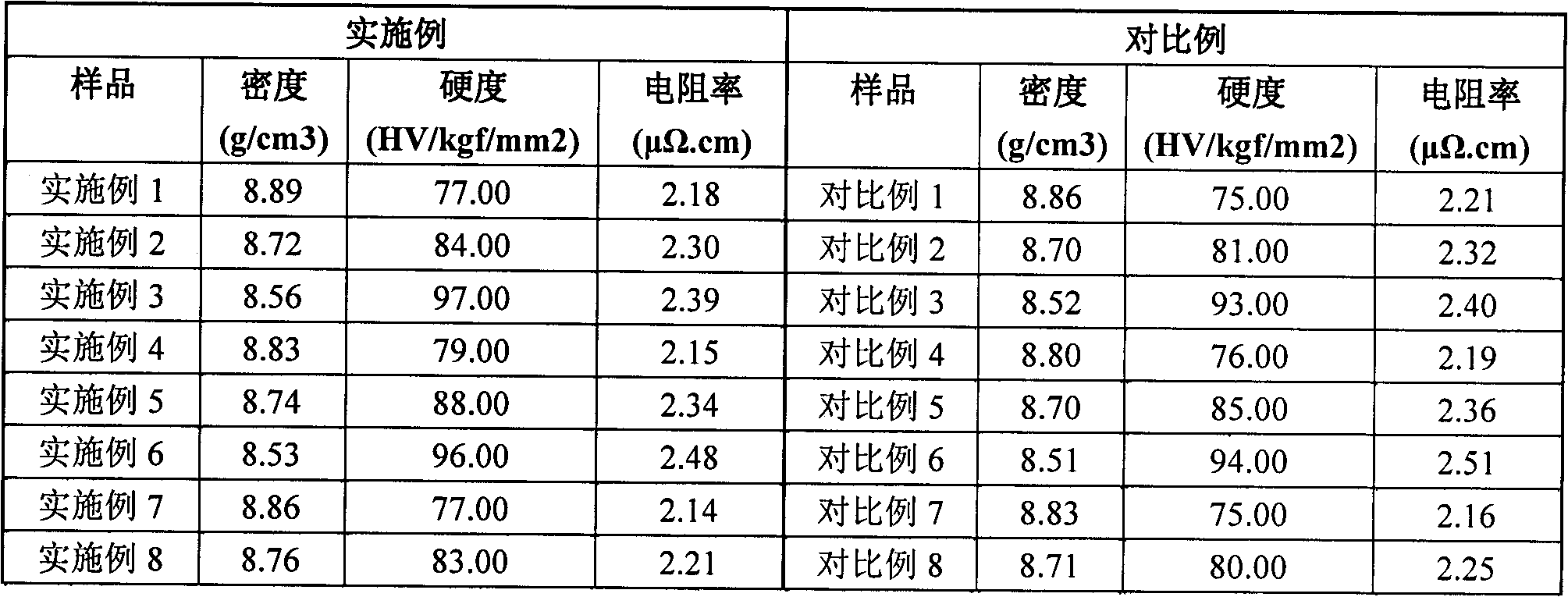

Preparation method and products of silver-copper-nickel-ceramic alloy contact material with high welding resistance

InactiveCN102044347AImprove welding resistanceInhibit oxidationContactsElectrically conductiveCeramic

The invention discloses a preparation method and products of a silver-copper-nickel-ceramic alloy contact material with high welding resistance. The contact material is prepared by adding 0.08-10wt% of rare earth copper alloys, 0.02-1.5wt% of alkaline earth metals, 3-25wt% of nickel and 0.03-5wt% of conductive ceramics to 7-60wt% of copper and balance of silver, wherein the silver and the copper serve as substrates. The contact material can be widely applied to medium load relays and small load contactors, thus greatly reducing cost of wires used for rivets, and the contact material has high welding resistance and low surface contact resistance, thereby being preferential in terms of comprehensive performances such as economy and technology.

Owner:浙江乐银合金有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com