Patents

Literature

79results about How to "Promote diffuse distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

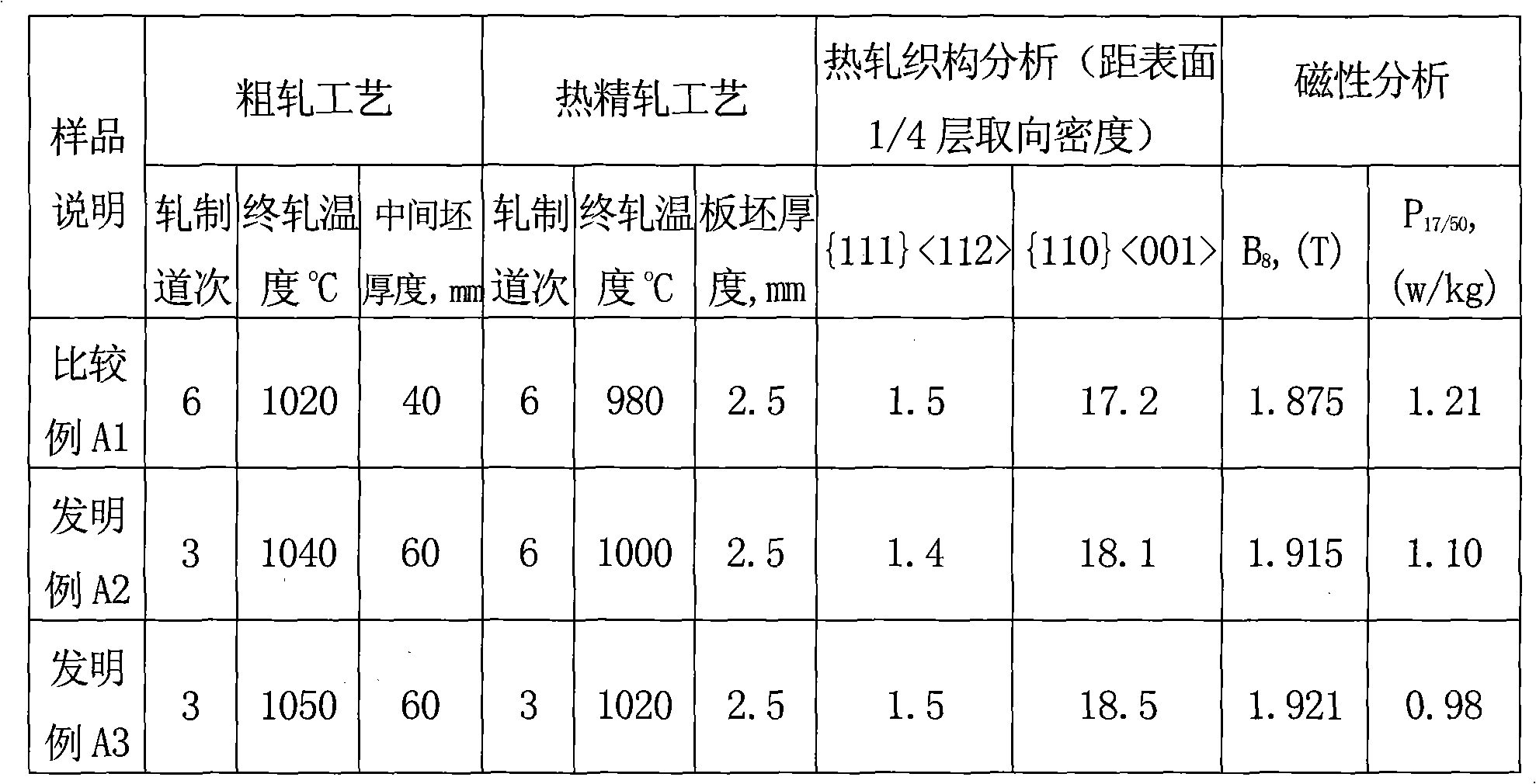

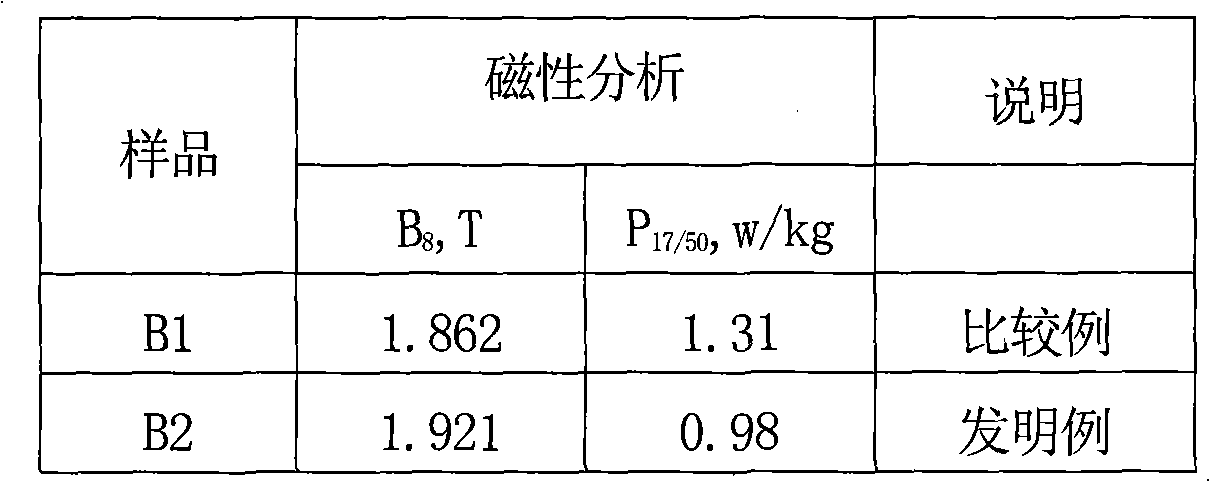

High magnetic induction grain-oriented silicon steel and production method thereof

ActiveCN101353760AReduce contentInhibition formationRoll mill control devicesMetal rolling arrangementsChemical compositionSilicon

The invention discloses a high magnetic induction oriented silicon steel and a production method thereof. The silicon steel comprises the following chemical composition: 0.055wt percent to 0.080wt percent of C, 2.9wt percent to 3.5wt percent of Si, 0.01wt percent to 0.02wt percent of Mn, 0.005wt percent to 0.010wt percent of Als, 0.0050wt percent to 0.0090wt percent of N, 0.25wt percent to 0.55wt percent of Sn, 0.010wt percent to 0.030wt percent of P, 0.10wt percent to 0.20wt percent of Cu, and the rest are Fe and unavoidable impurities. The production method comprises the following steps of: smelting, continuous casting, hot rolling, reeling, cold rolling, decarburizing annealing and high-temperature annealing. The production method effectively overcomes the shortcoming of poor producibility of the prior art and improves the production efficiency as well as the magnetism of the silicon steel.

Owner:BAOSHAN IRON & STEEL CO LTD

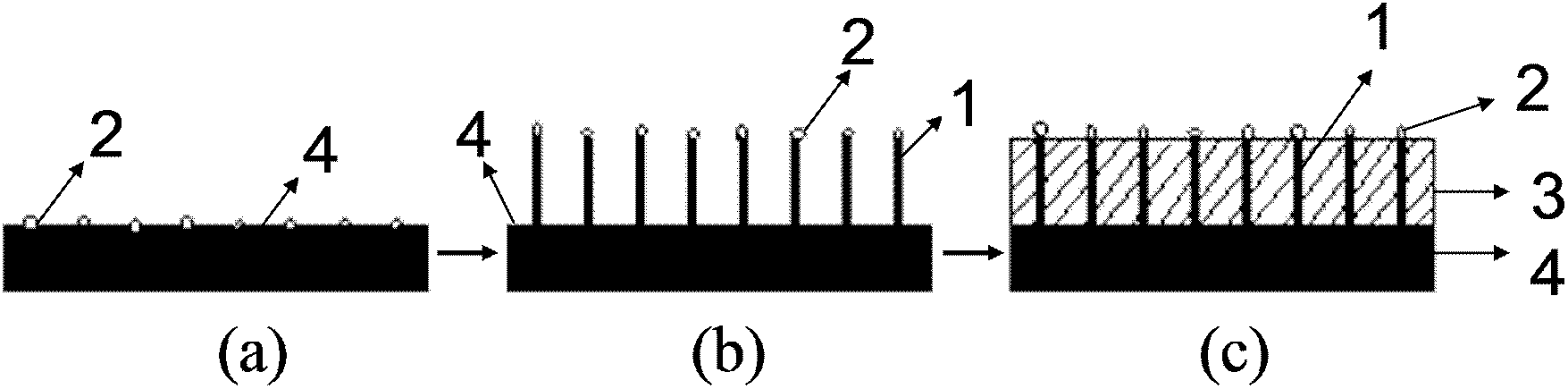

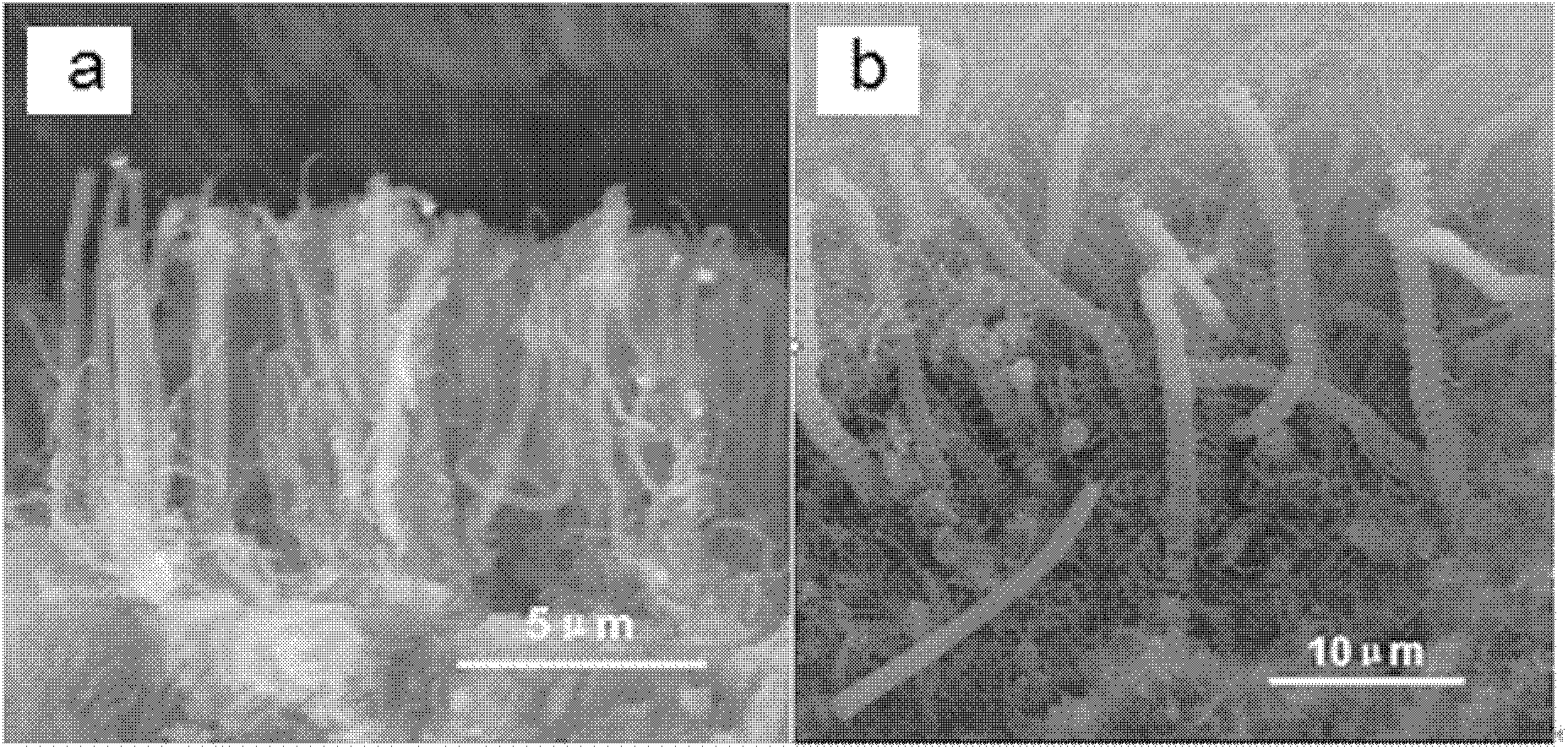

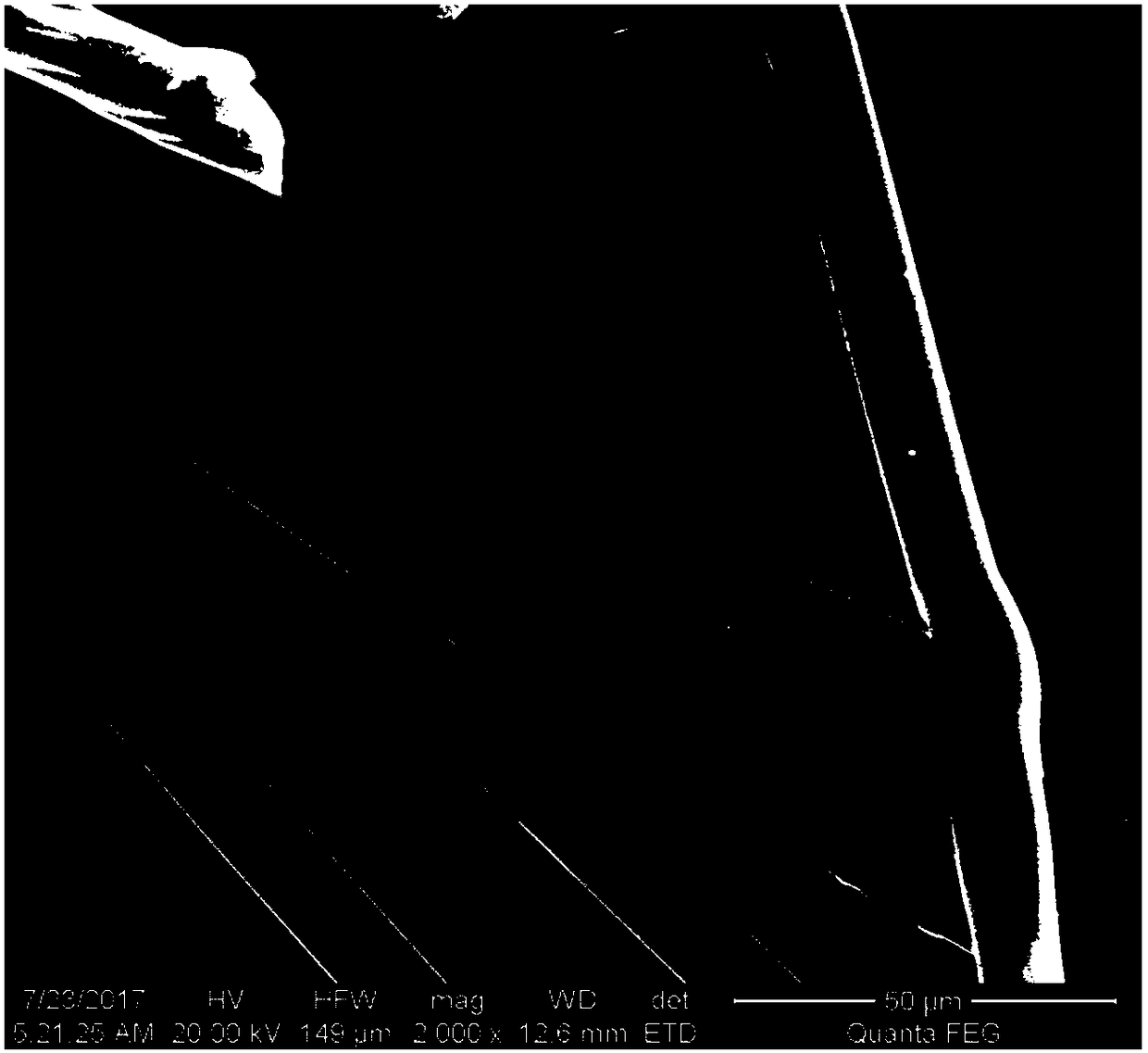

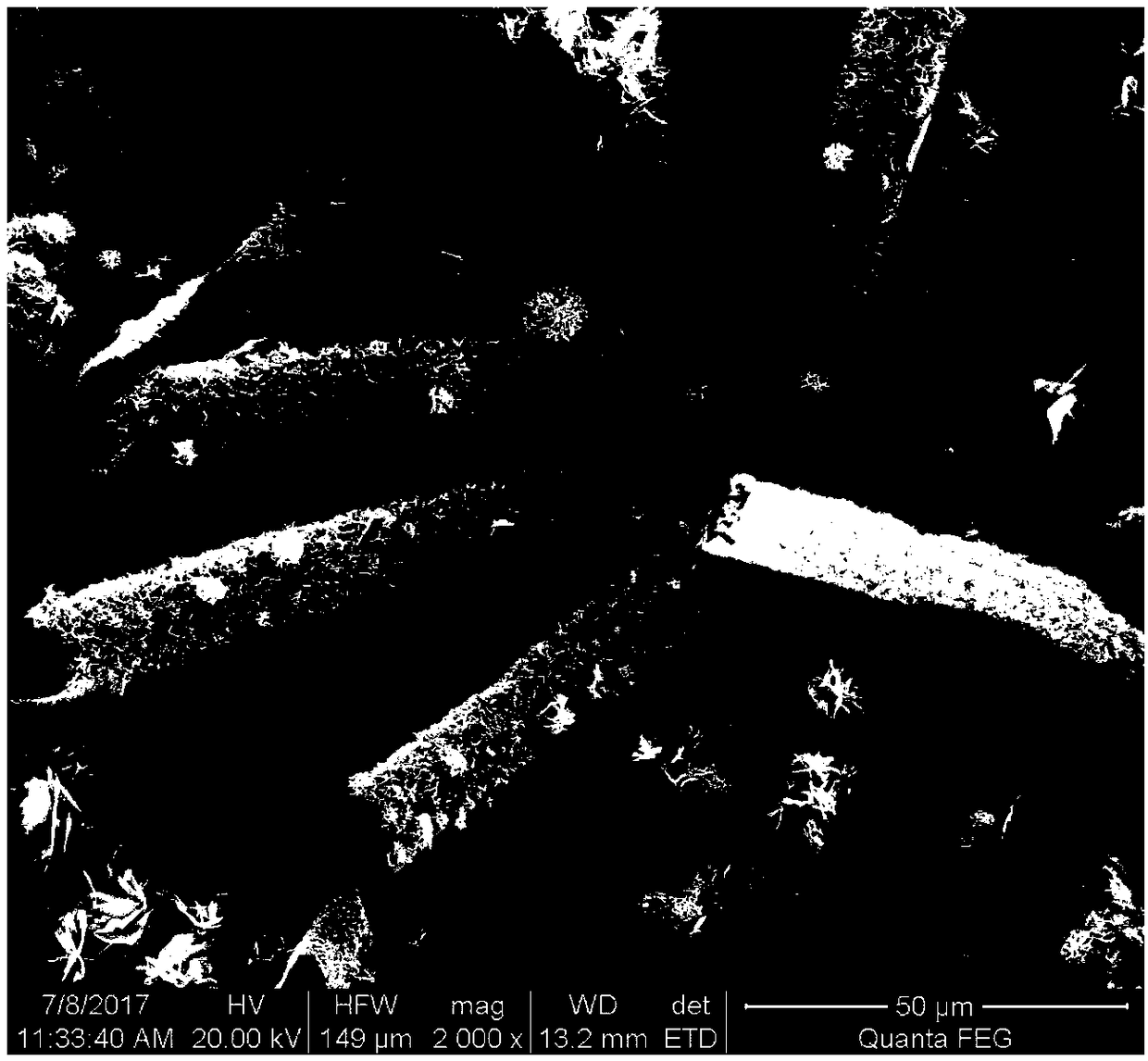

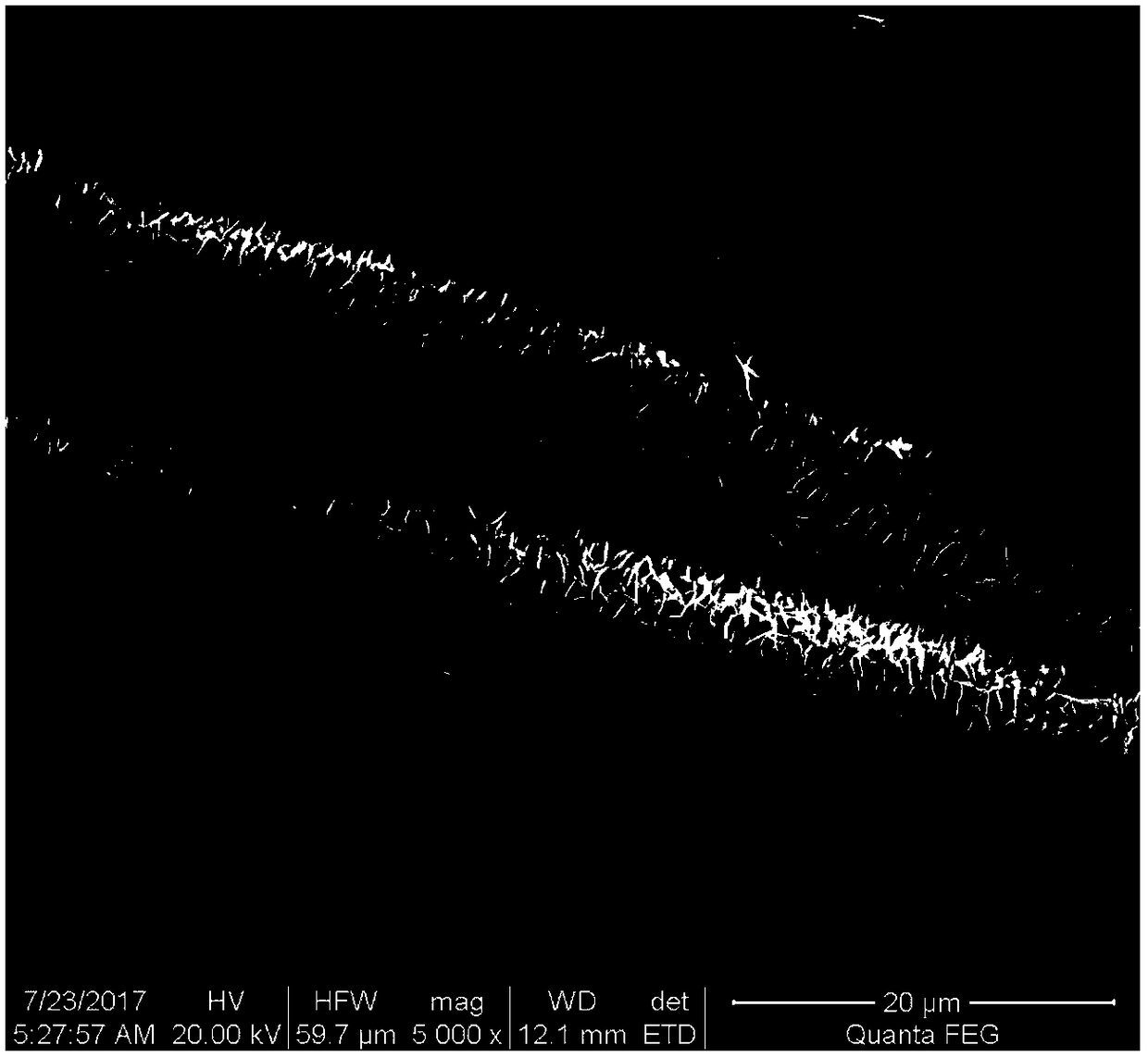

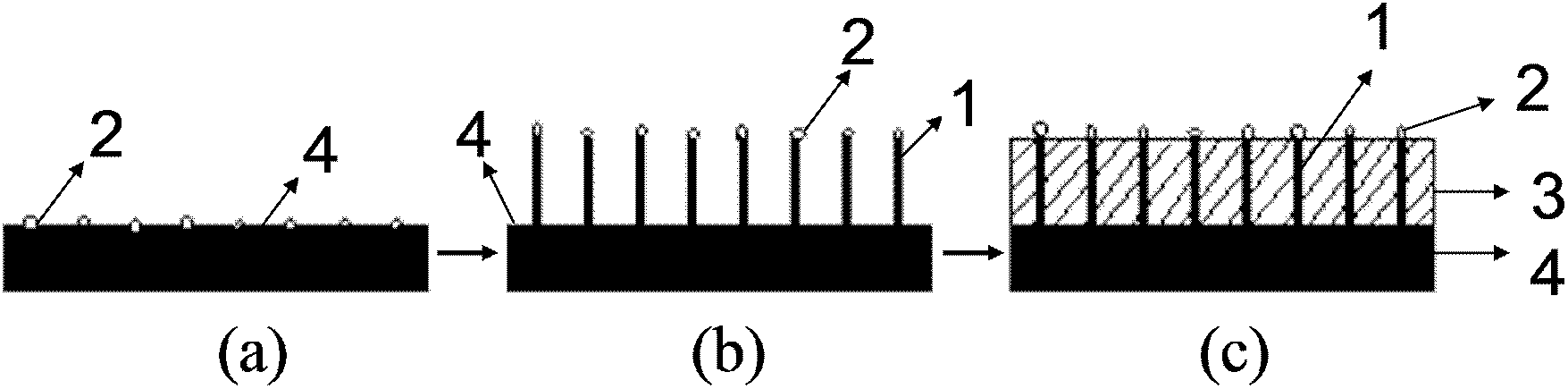

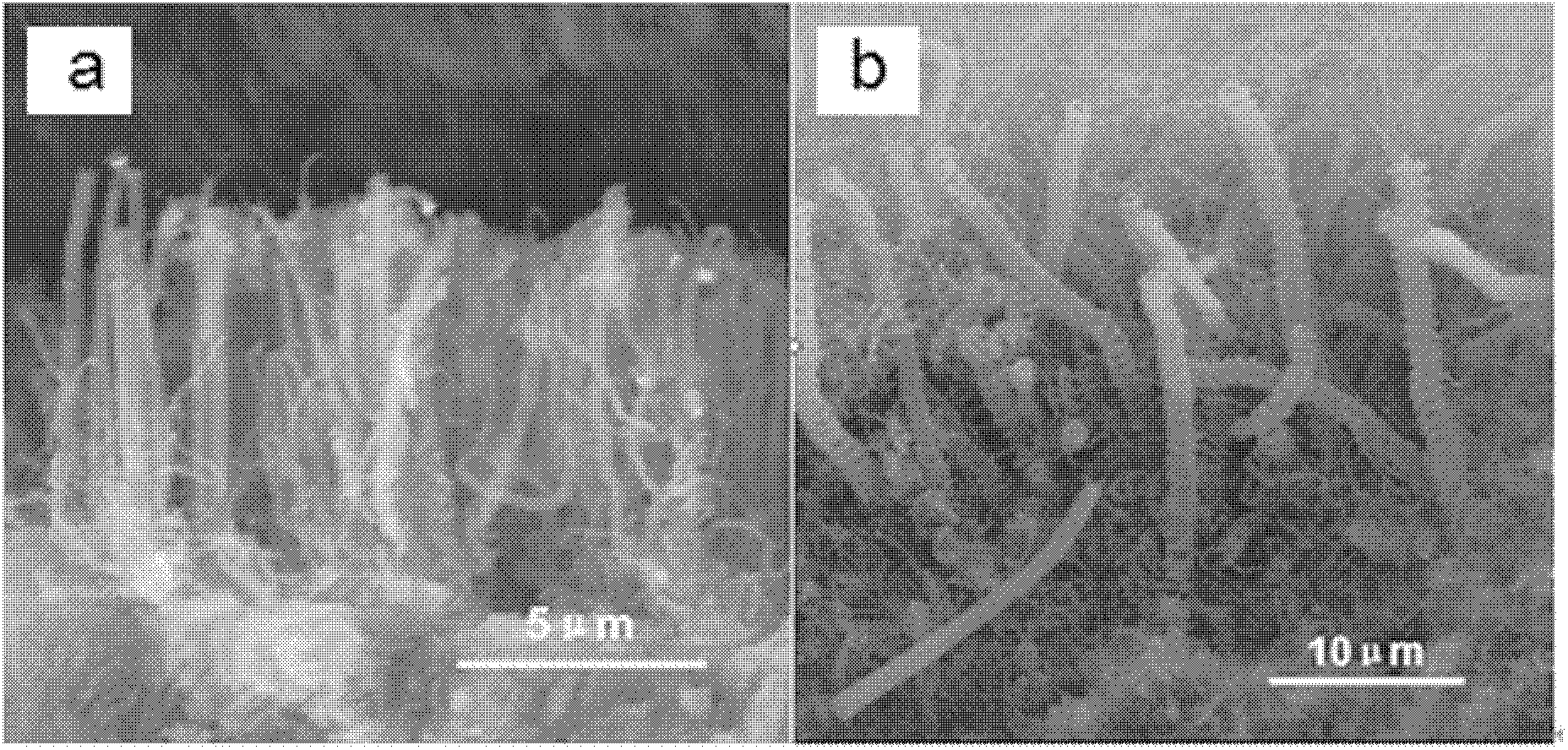

Method for preparing compound electrical contact material

InactiveCN102324335AConducive to play ballistic conduction characteristicsCost-effectiveContact materialsCatalytic pyrolysisCarbon nanotube

The invention discloses a method for preparing a compound electrical contact material. The technical process comprises the following steps of: (1) preparing a catalyst precursor, preparing a Ni-based catalyst from a mixed aqueous solution of hexahydrated nickel nitrate and hexahydrated yttrium nitrate, and depositing on a sample copper sheet which is subjected to plasma treatment and washed to obtain a catalyst precursor, wherein the mass ratio of nickel to yttrium is 1-10; (2) preparing a CNTs (Carbon Nanotube) array, putting the catalyst precursor into a quartz boat, undergoing a decomposition reaction under the protection of argon gas, and undergoing a catalytic pyrolysis reaction to obtain a sample copper sheet on which a CNTs array grows; and (3) preparing a CNTs-Ag-Cu compound electrical contact material, adding a silver nitrate aqueous solution into the sample copper sheet on which the CNTs array grows, soaking the silver nitrate aqueous solution into the CNTs array of the sampler copper sheet under the low ultrasonic action, evaporating and decomposing repeatedly for 3-20 times for 0.2-3 hours every time till the CNTs array is fully filled.

Owner:TIANJIN POLYTECHNIC UNIV

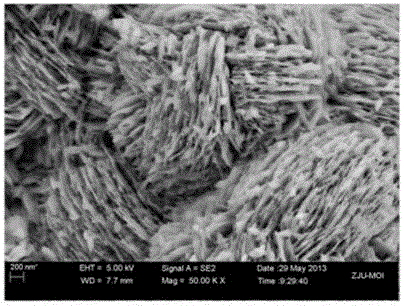

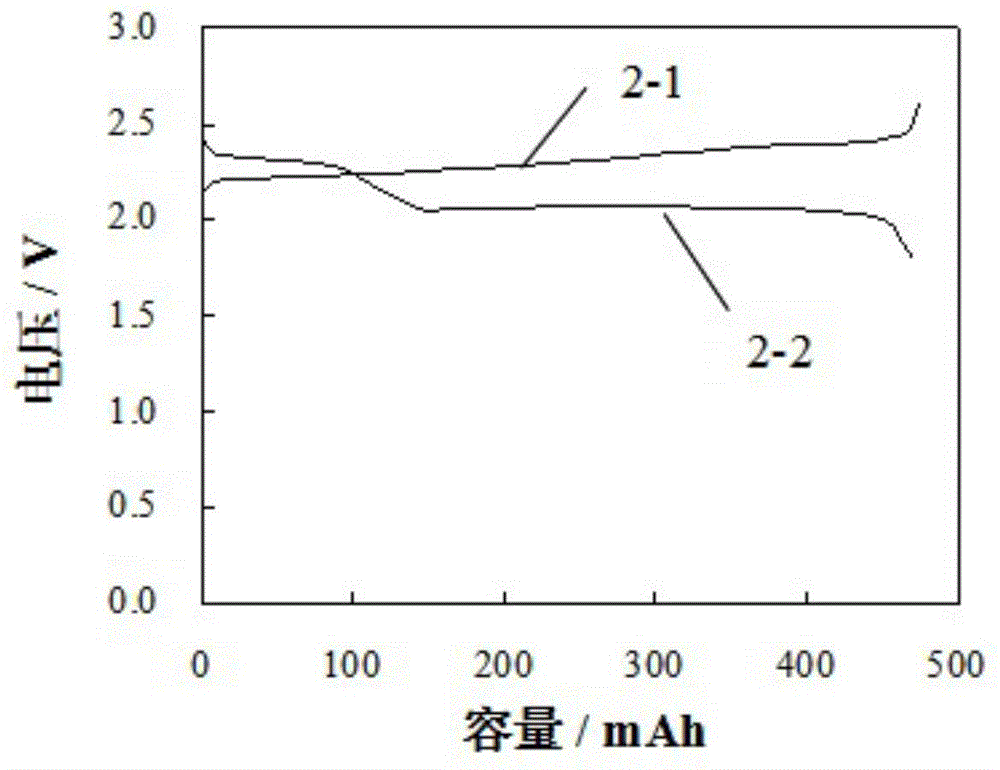

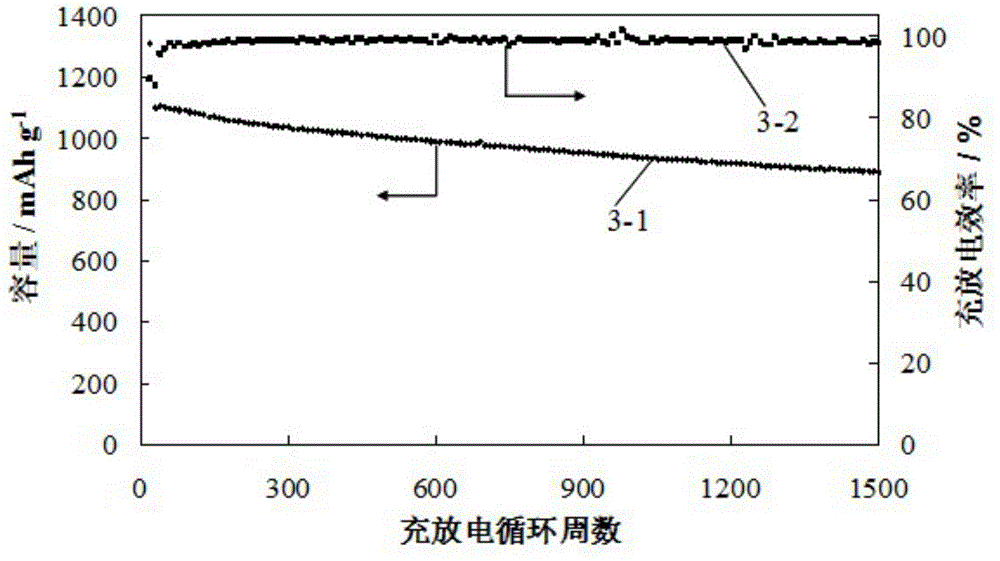

Positive electrode sulfur-carrying material of lithium-sulfur battery and preparation method of lithium-sulfur battery

InactiveCN104577083APromote diffuse distributionImprove efficiencyCell electrodesFinal product manufactureThioureaCarbonization

The invention relates to the field of batteries, and aims at providing a positive electrode sulfur-carrying material of a lithium-sulfur battery and a preparation method of the lithium-sulfur battery. The preparation method comprises the following steps: adding thiourea and water-soluble monosaccharide or polysaccharide into ionized water to prepare a solution, and performing polymerization to prepare thiourea-glucoresin; further adding hydrophilic nano calcium carbonate and nano lithium cobalt oxide, and uniformly stirring to prepare a turbid liquid; and performing spray-drying, heating at 200 DEG C and 700 DEG C with flow N2, sequentially washing a carbonization product with hydrochloric acid and deionized water, and drying at constant temperature, thereby obtaining lithium cobalt oxide modified sulfur-containing macropore carbon. According to preparation method, sulfur in the sulfur-containing macropore carbon has special affinity with Co, the dispersion distribution of the nano lithium cobalt oxide can be intensified, the use efficiency of the lithium cobalt oxide can be improved, the conductivity of the macropore carbon is also improved due to doping the sulfur, a certain sulfion accumulation function can be also achieved, and the speed capacity and the property stability of the lithium-sulfur battery are greatly improved.

Owner:ZHEJIANG UNIV

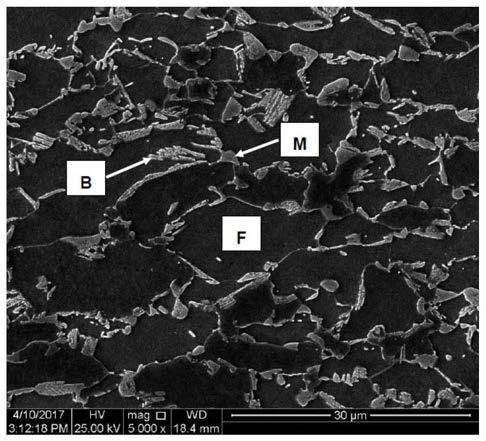

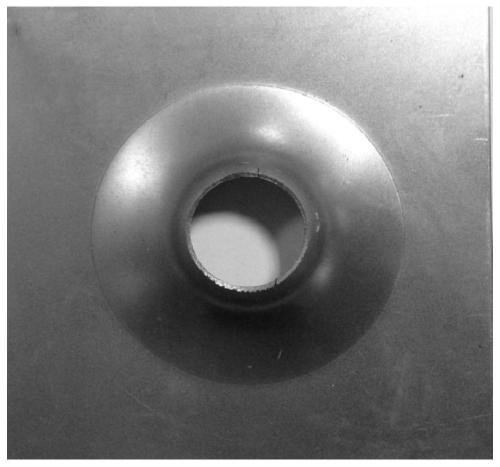

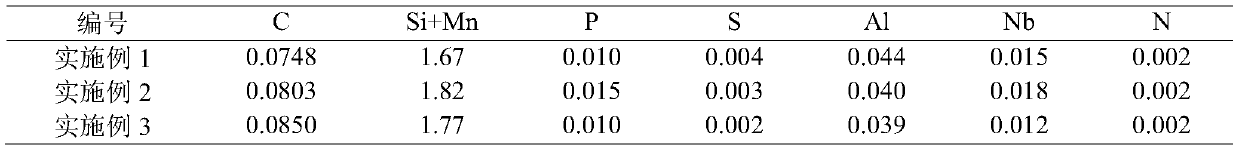

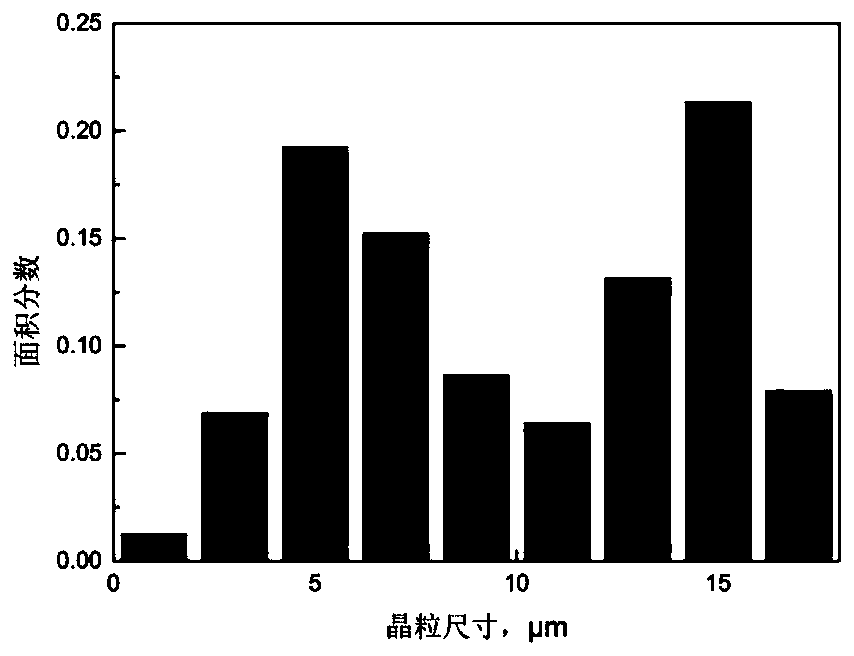

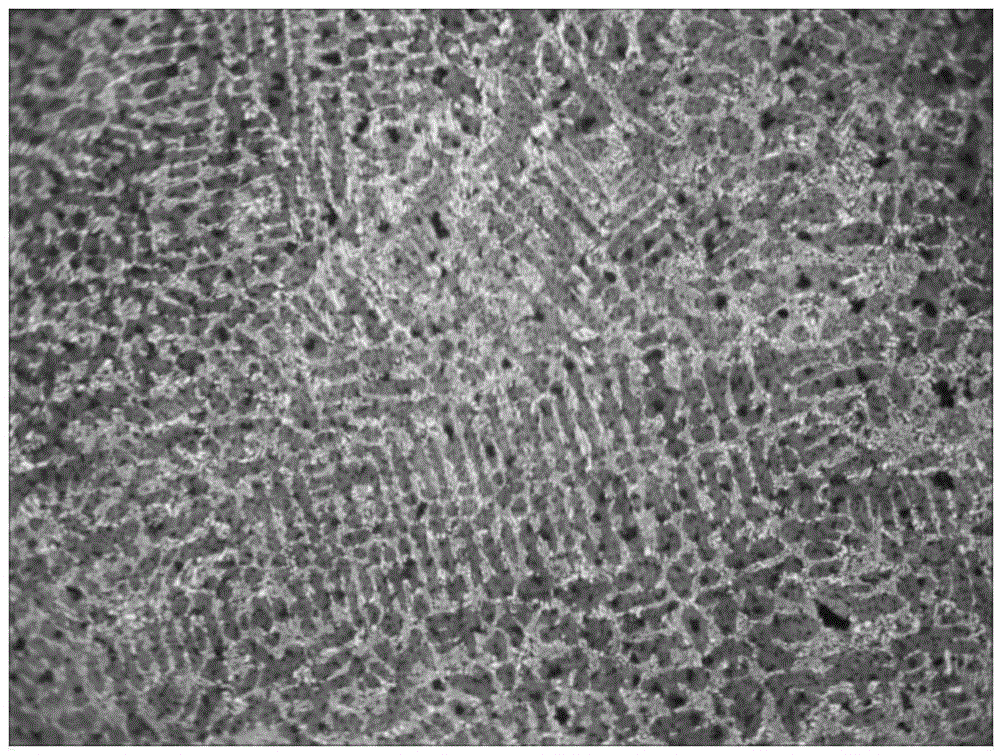

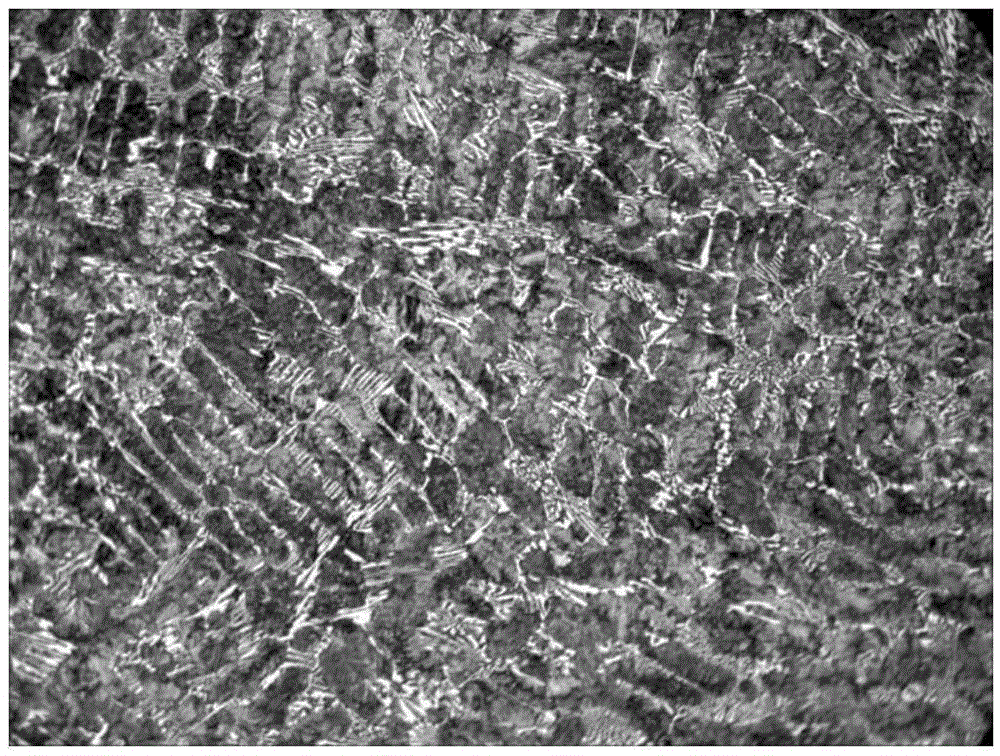

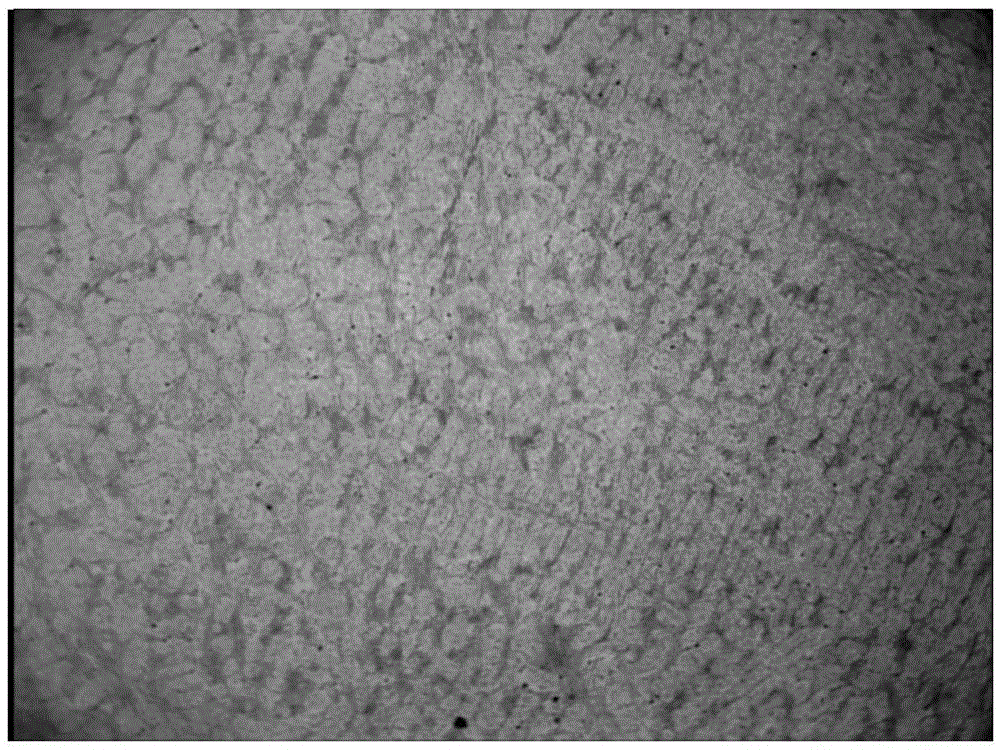

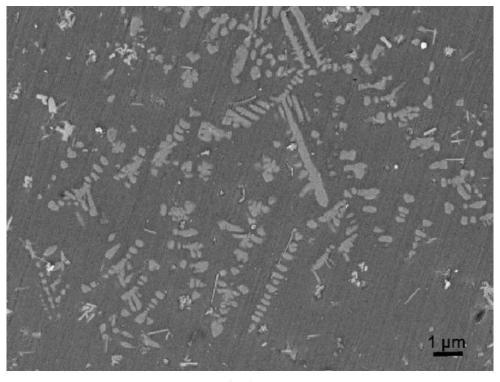

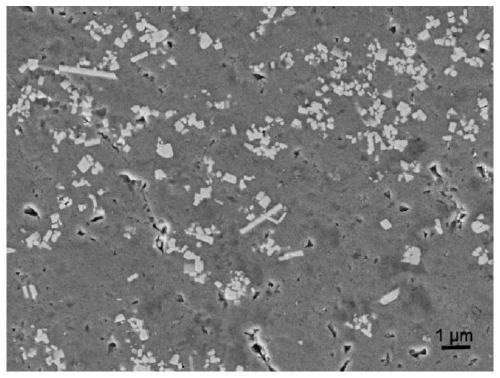

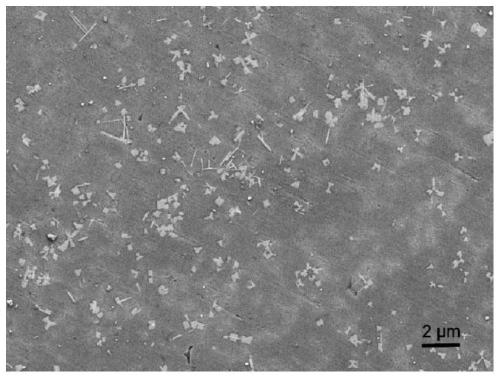

590MPa-grade cold-rolled dual-phase steel with excellent hole-expanding performance and production method thereof

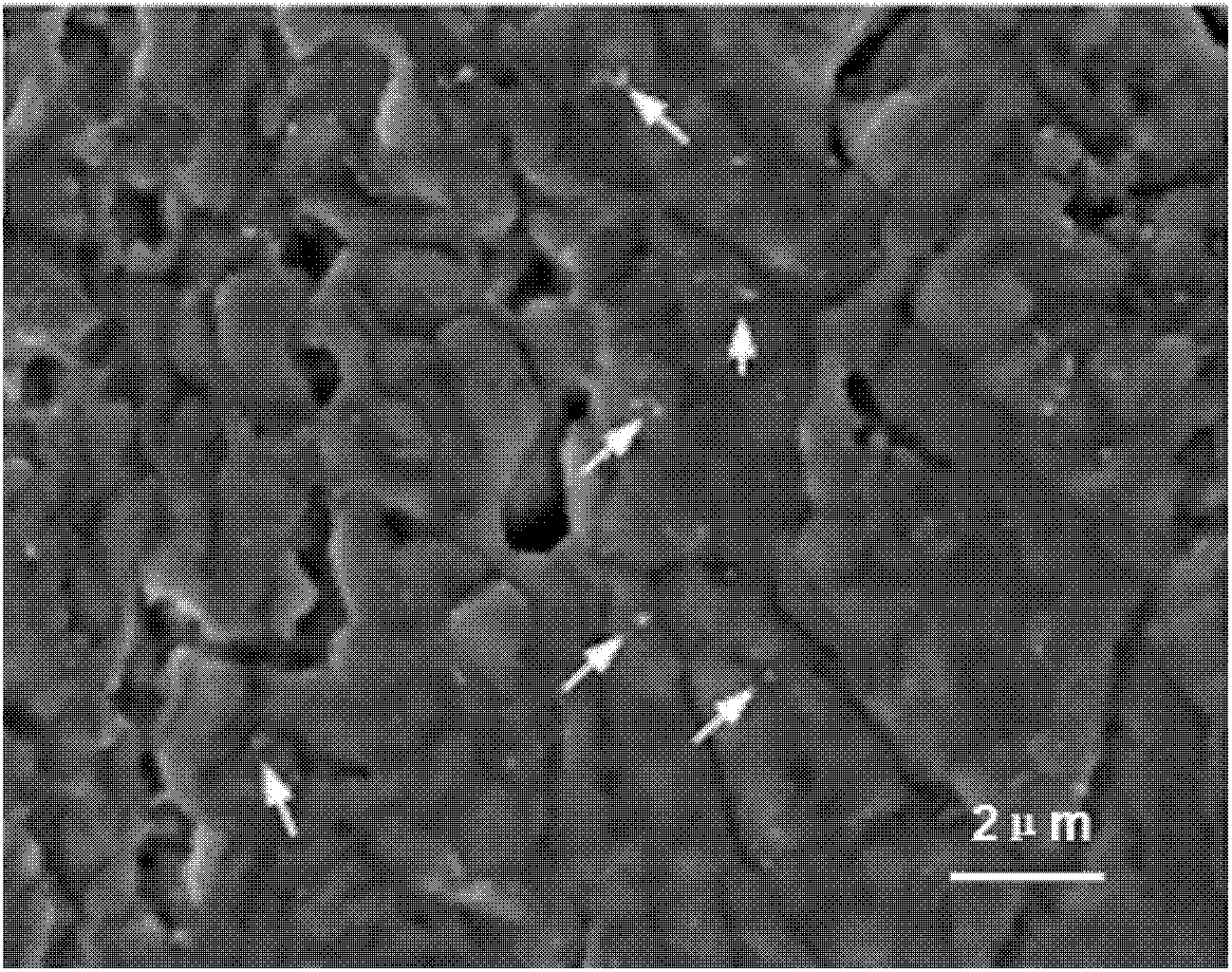

ActiveCN109943778AExcellent hole expandabilityImprove pourabilityMicro structureChemical composition

The invention discloses 590MPa-grade cold-rolled dual-phase steel with excellent hole-expanding performance and a production method thereof, and belongs to the technical field of rolled steel. The 590MPa-grade cold-rolled dual-phase steel is prepared from the following chemical components in percentage by mass: 0.06-0.09% of C, 1.4-2.1% of Si+Mn, 0.01-0.02% of Nb, 0.03-0.06% of Al, less than or equal to 0.06% of P, less than or equal 0.010% of S, less than or equal to 0.006% of N, and the balance of Fe and inevitable impurities. According to the dual-phase steel disclosed by the invention, volume fraction of ferrite in a micro structure is 70-80%, volume fraction of martensite is 10-25% and volume fraction of bainite is 5-10%. Low-Al content is adopted, and smelting casting is improved; crystalline grains are refined by a low-temperature rolling process of 540-600 DEG C and Nb micro-alloying, and diffused distribution of a hard phase (martensite and bainite) is promoted; and a sectional cooling process of slow cooling, quick cooling I and quick cooling II is adopted, so that a proper amount of bainite is obtained, and therefore, hole-expanding performance is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

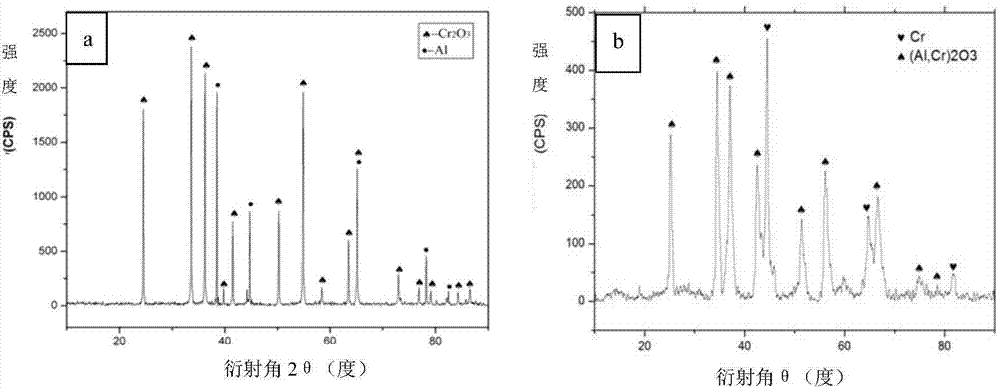

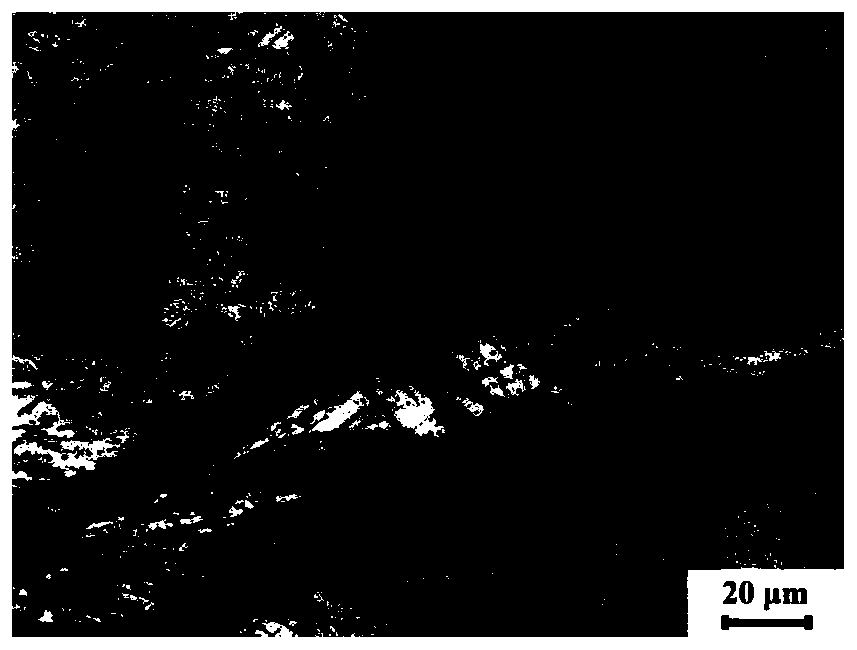

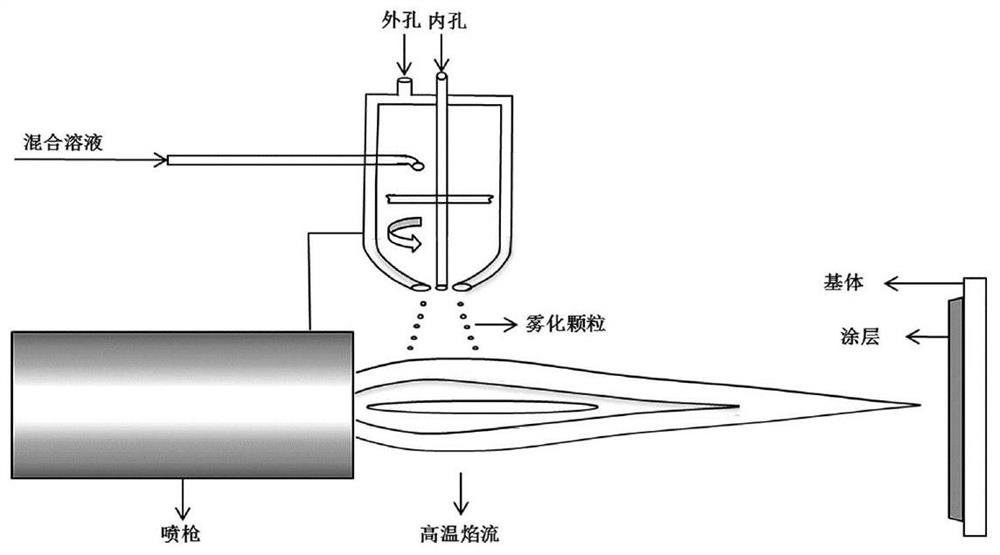

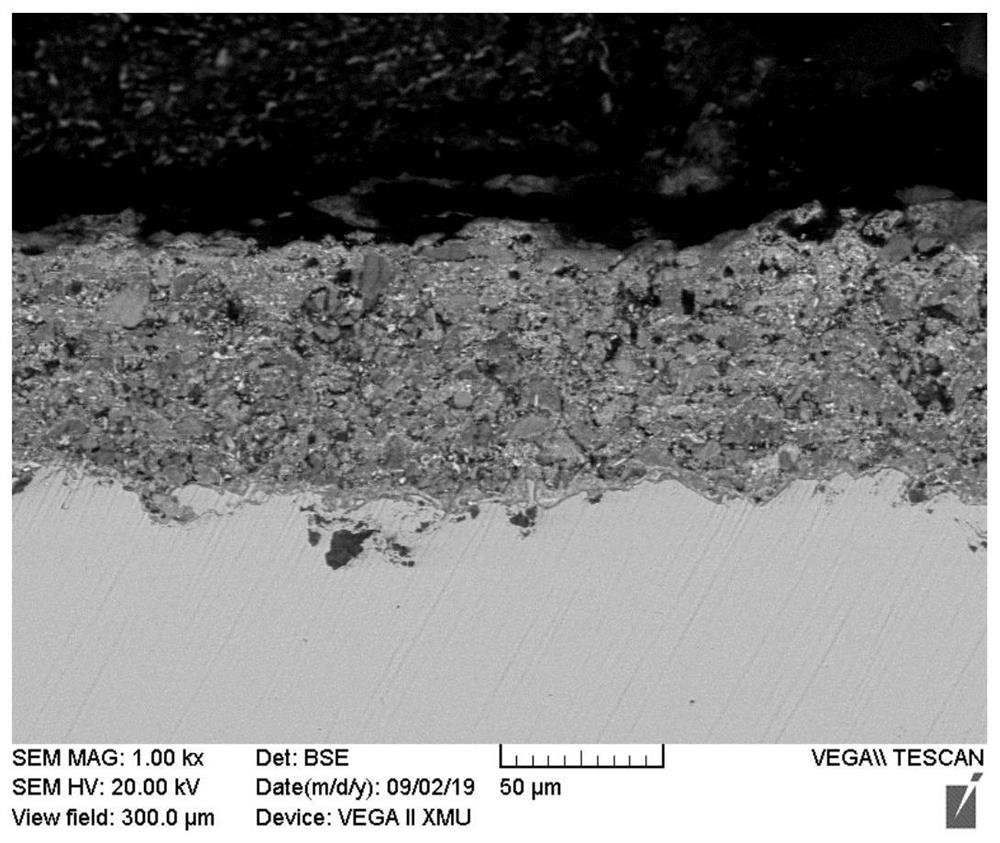

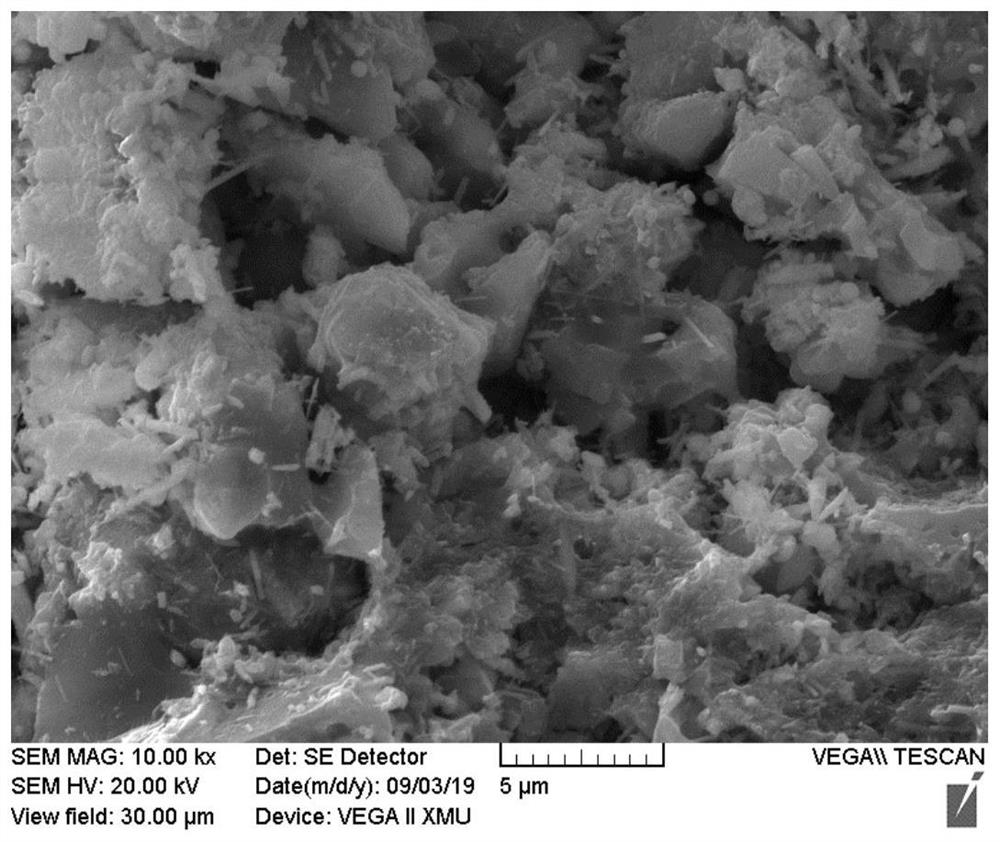

Method for reactive spraying preparation of ceramic solid solution-based ceramic-metal eutectic nanometer composite coating

ActiveCN104762584APerformance adjustableAchieve toughnessMolten spray coatingCeramic coatingComposite ceramic

The invention discloses a method for reactive spraying preparation of a ceramic solid solution-based ceramic-metal eutectic nanometer composite coating. The method comprises the following steps of 1, raw material powder preparation: selecting raw materials for reactive spraying preparation of the ceramic solid solution-based ceramic-metal eutectic nanometer composite coating and a ratio of the raw materials, 2, composite fed material preparation, and 3, eutectic nanometer composite coating preparation: preparing the [Cr+(Crx, Al1-x)2O3] eutectic nanometer composite coating by an atmospheric plasma spraying method. The eutectic nanometer composite ceramic coating is characterized in that a matrix is a component-controllable ceramic solid solution, and a metal phase in a form of nanometer particles (rods) is dispersively distributed on the ceramic matrix so that the ceramic solid solution-based ceramic-metal eutectic nanometer composite coating is obtained. The prepared [Cr+(Crx, Al1-x)2O3] eutectic nanometer composite coating has high toughness, good wear resistance, high temperature oxidation resistance and corrosion resistance.

Owner:HEBEI UNIV OF TECH

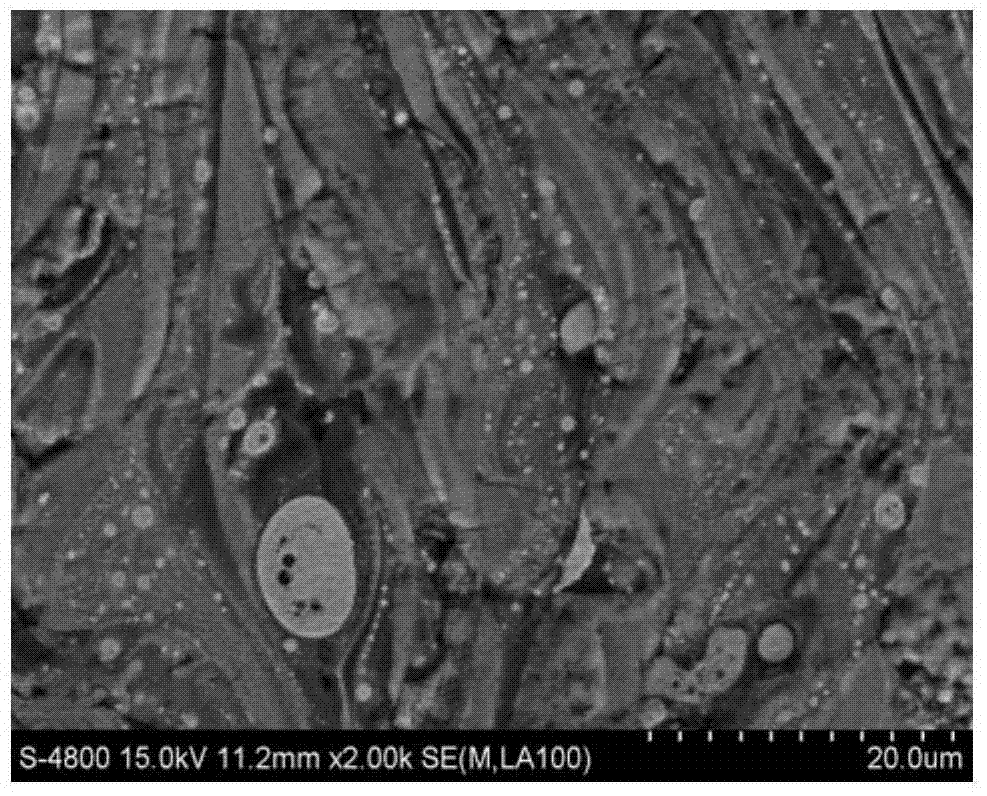

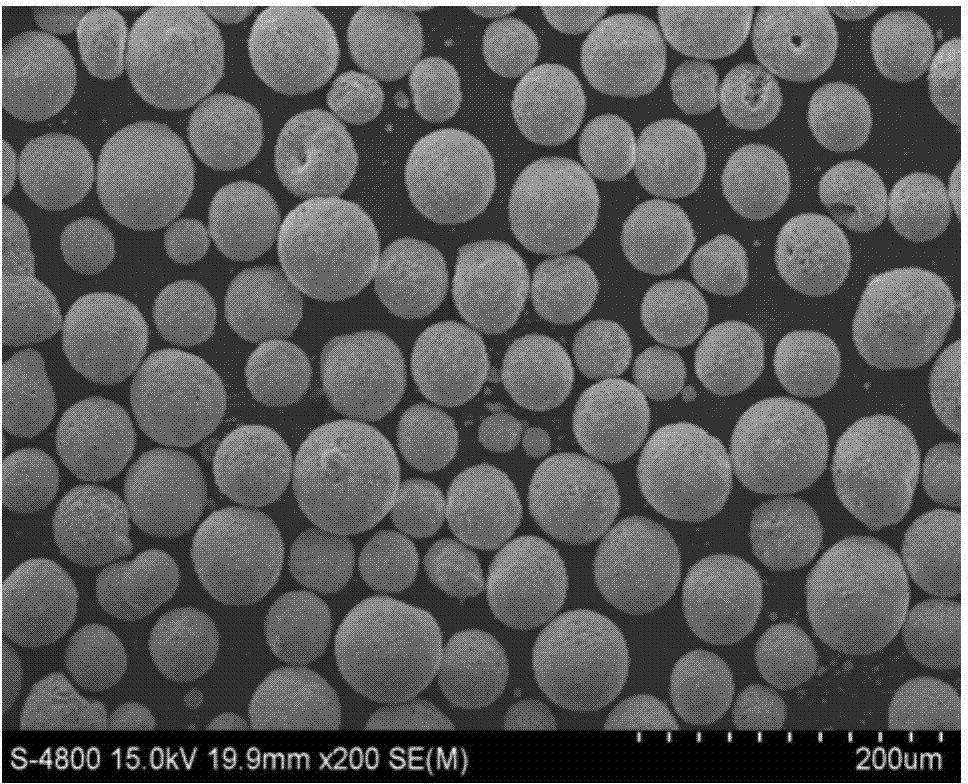

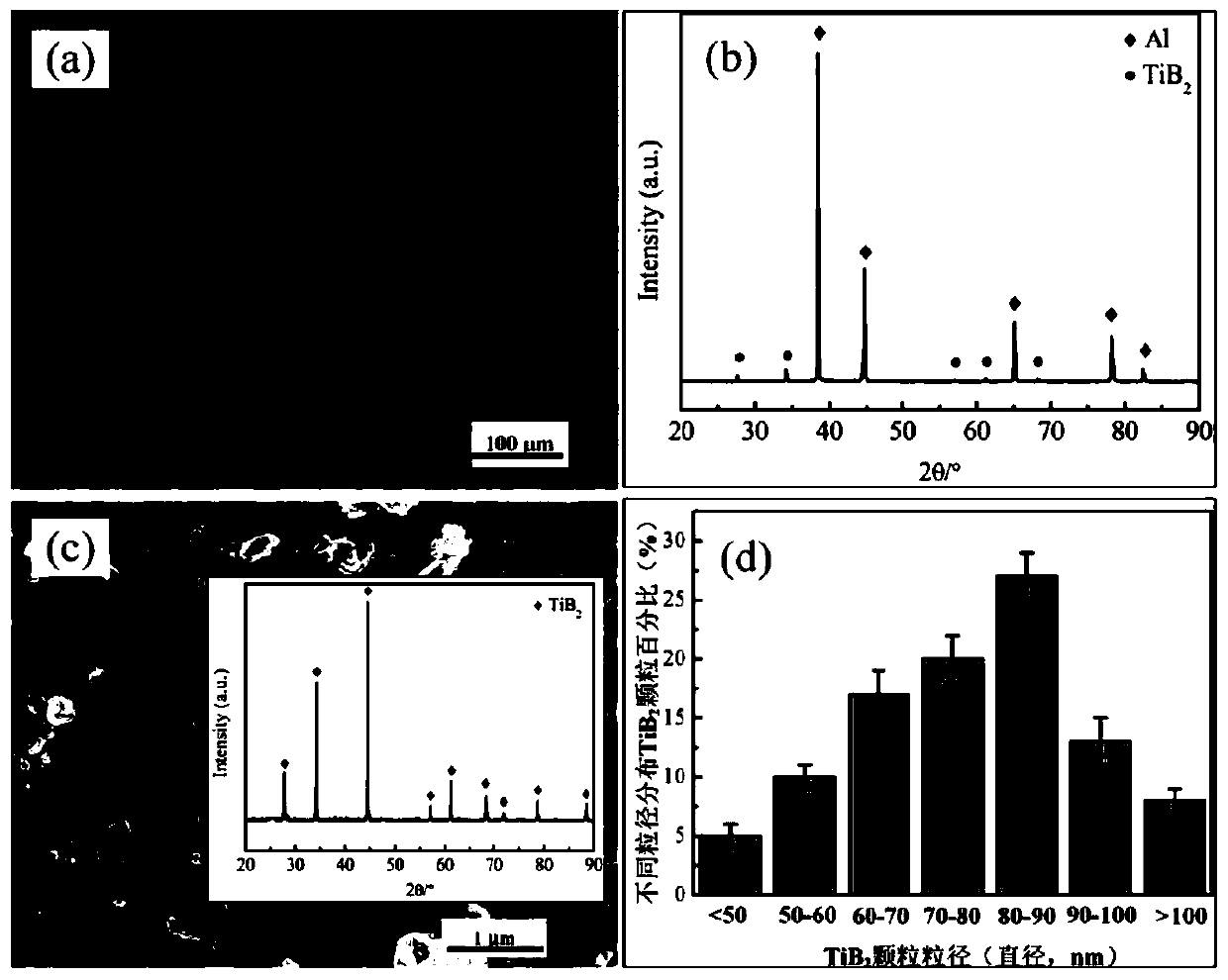

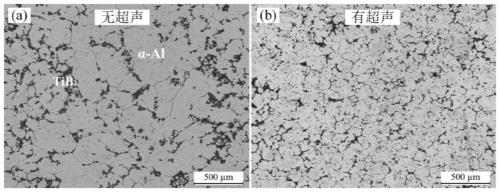

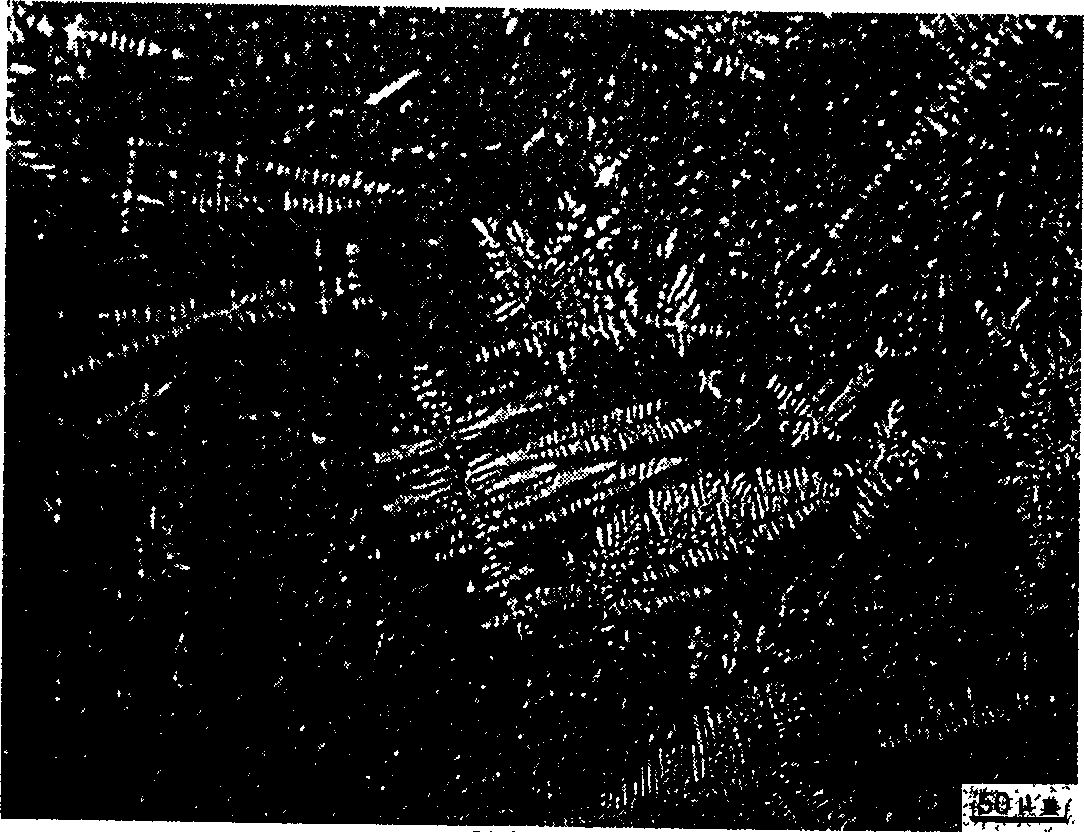

High-dispersive-distribution nano-titanium diboride particle reinforced aluminum matrix composite material and preparation method thereof

The invention discloses a high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material and a preparation method thereof. Firstly, a uniform-structure Al-TiB2 intermediate alloy is prepared through an ultrasound assisted mixed salt reaction (K2TiF6 / KBF4-Al), wherein the average particle diameter of in-situ endogenous TiB2 particles is smaller than 100nm; the Al-TiB2 intermediate alloy and Al are used as raw materials, or Al-TiB2 intermediate alloy, Al and alloy elements are used as raw materials, the nano-TiB2 particles are introduced into an aluminum (alloy) matrix through an intermediate alloy dilution method, ultrasound agitation treatment is used as assistance, then pouring into a mold is performed, and ultrasound is applied during solidification (introduction through a bottom introduction method); and thus the high-dispersive-distribution nano-TiB2 particle reinforced aluminum matrix composite material is obtained.

Owner:咸阳瞪羚谷新材料科技有限公司

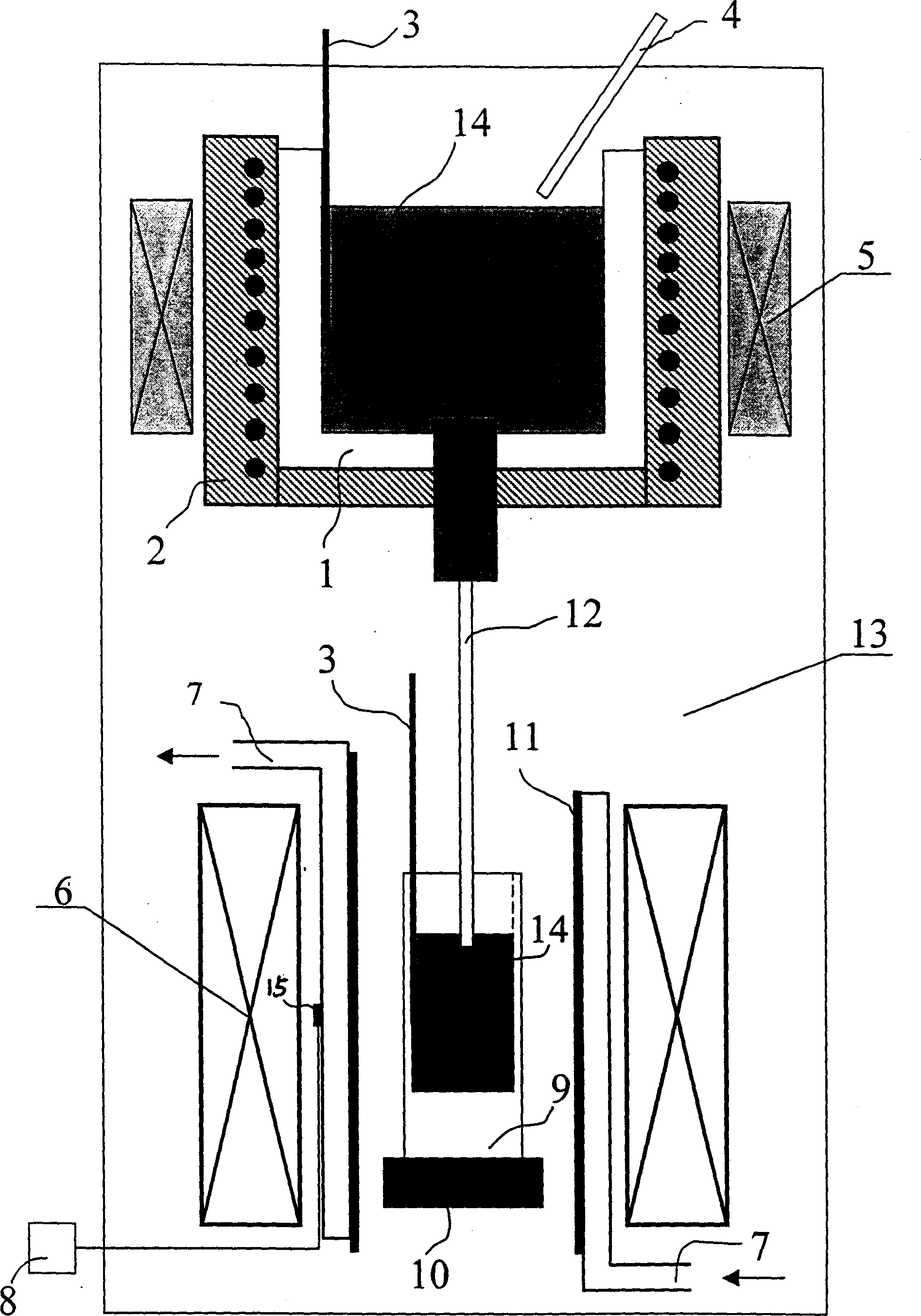

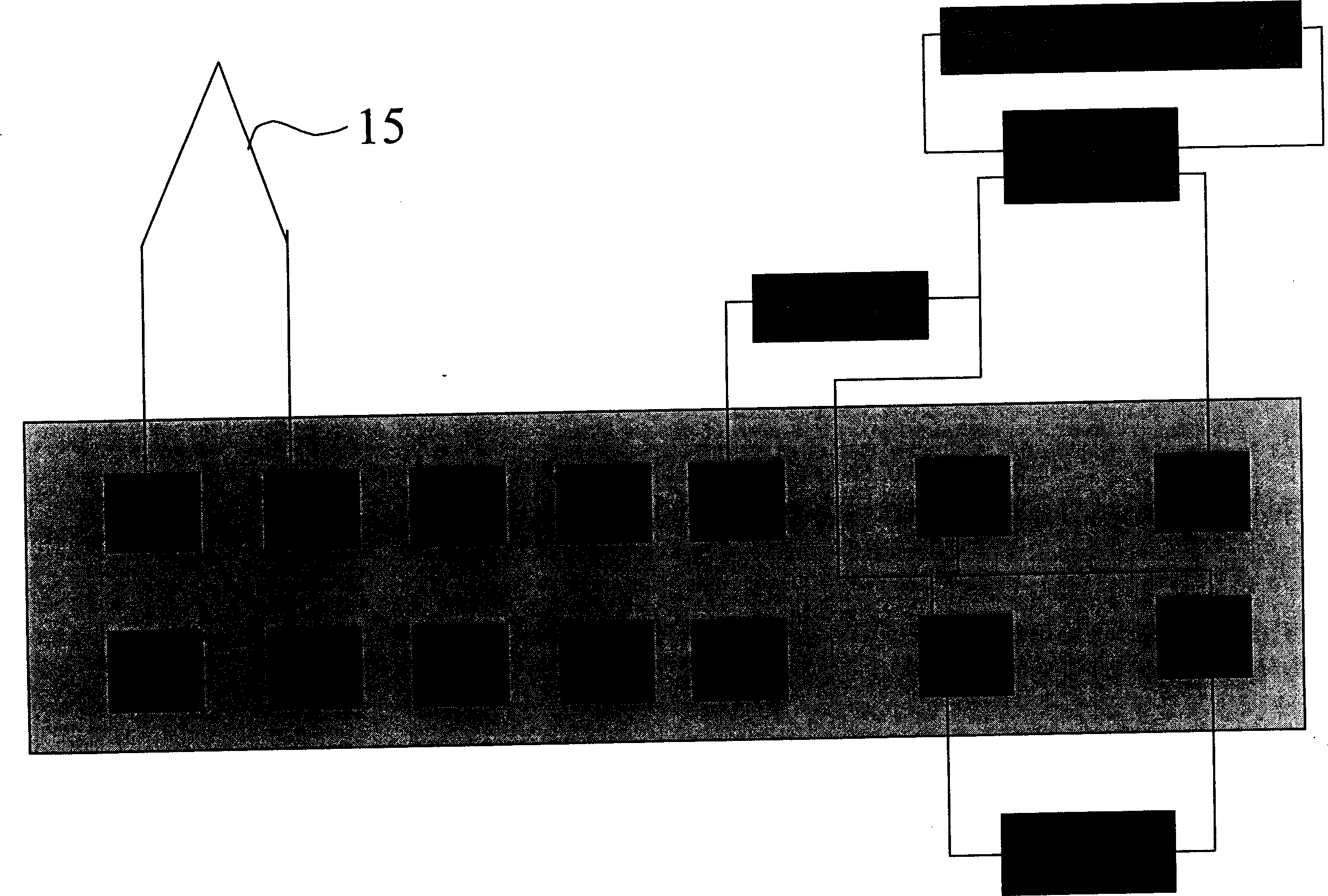

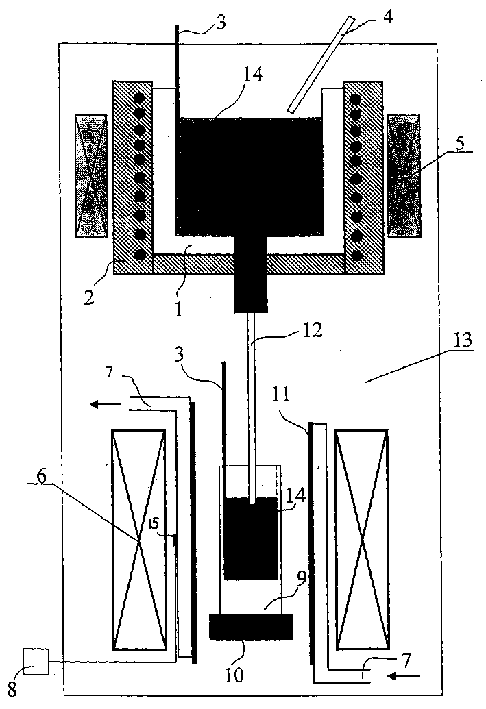

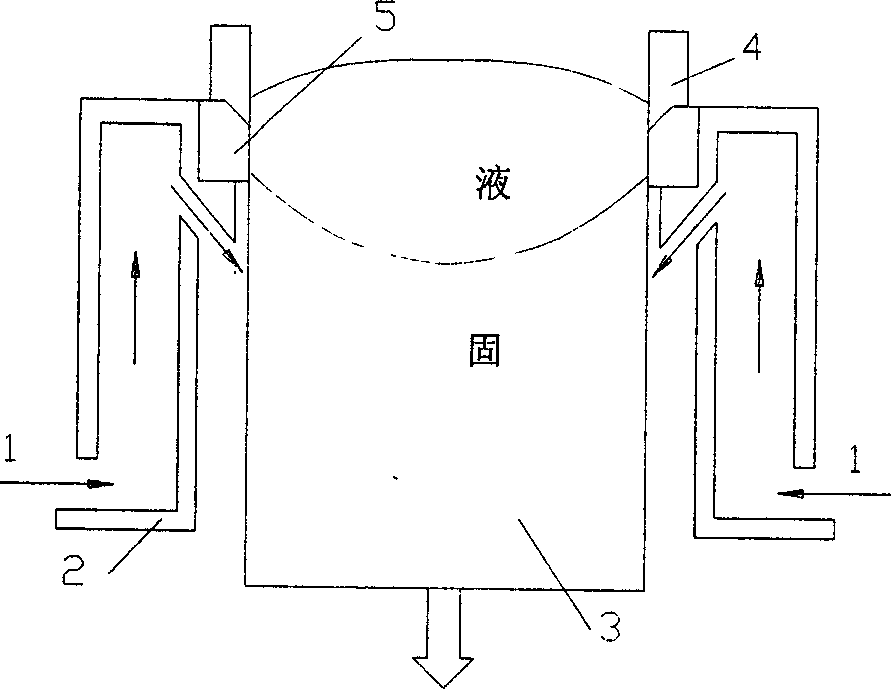

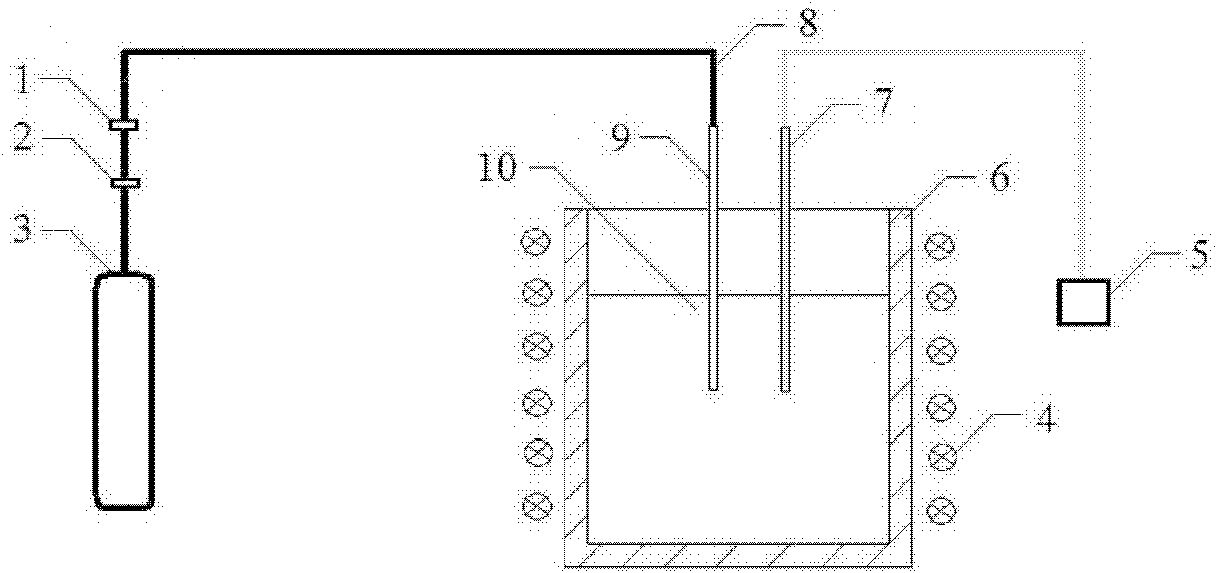

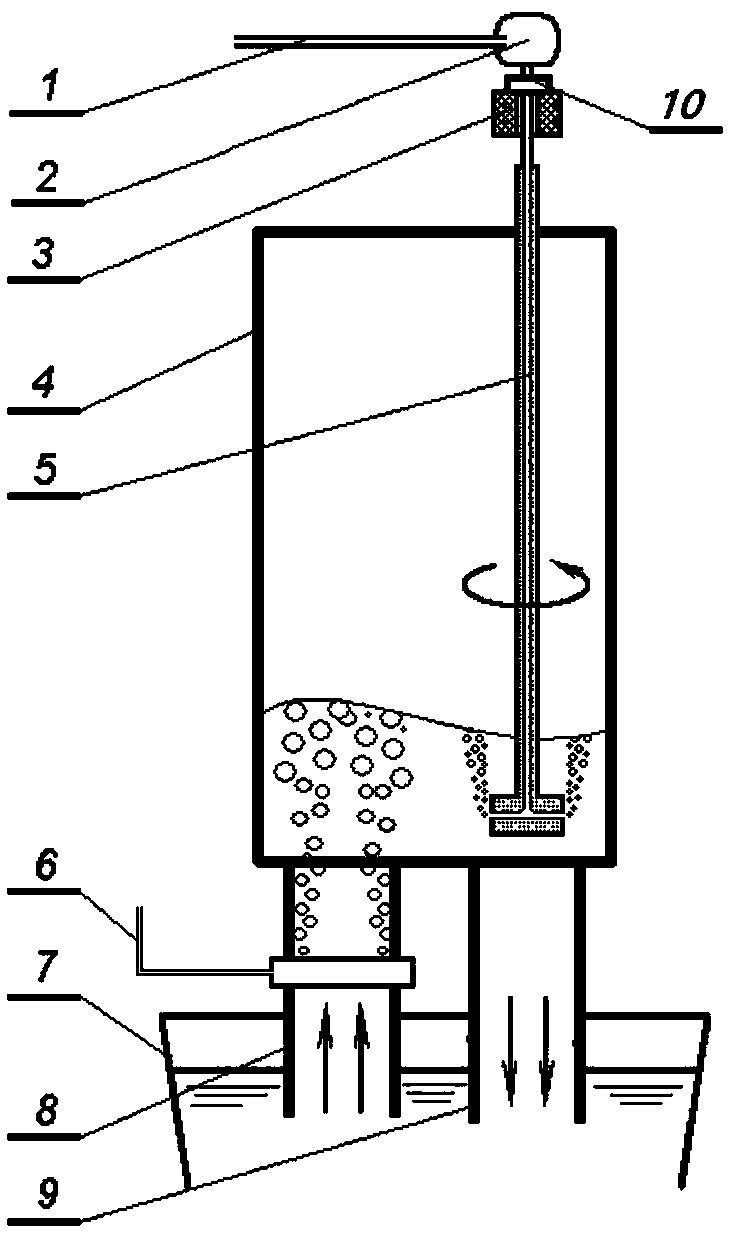

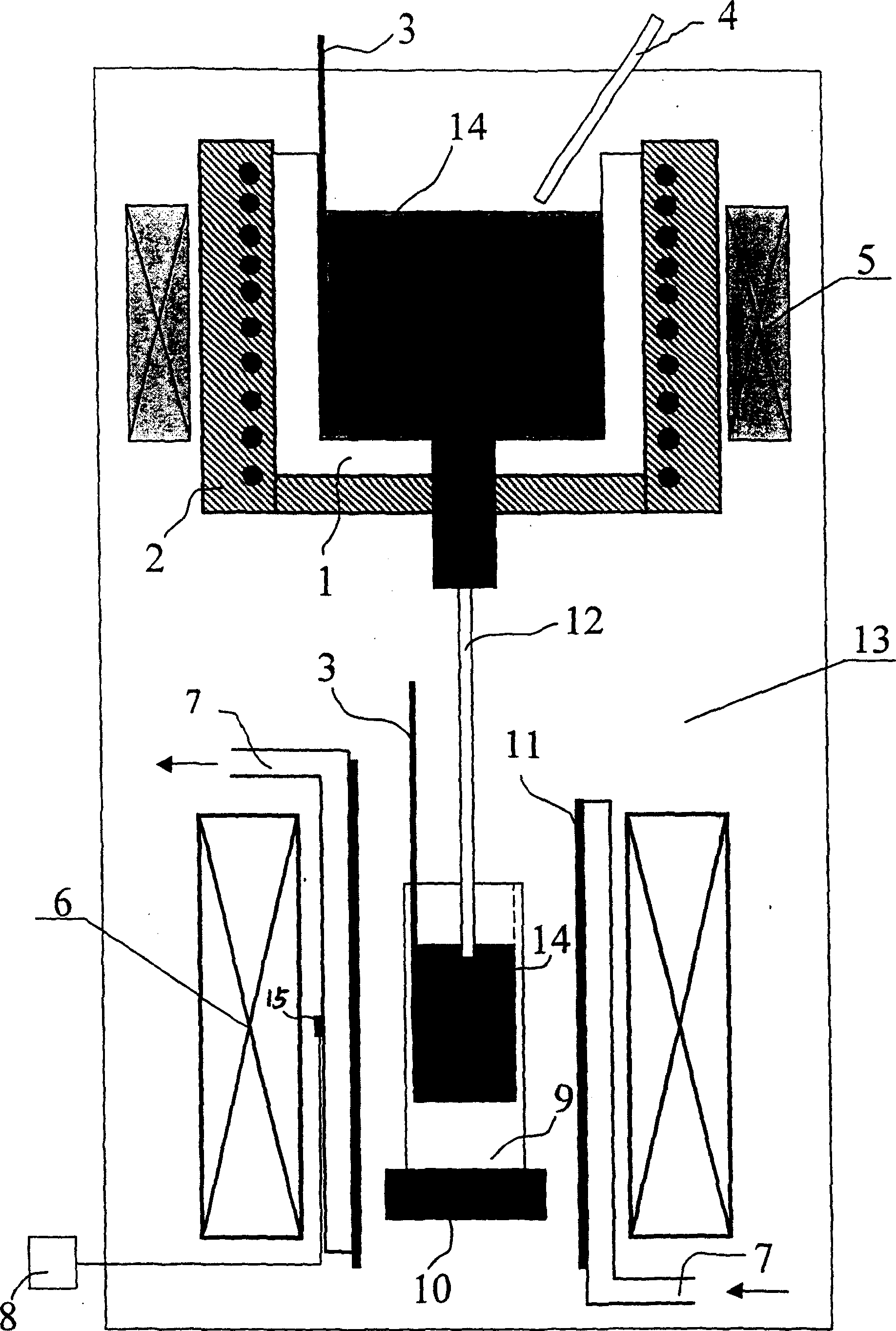

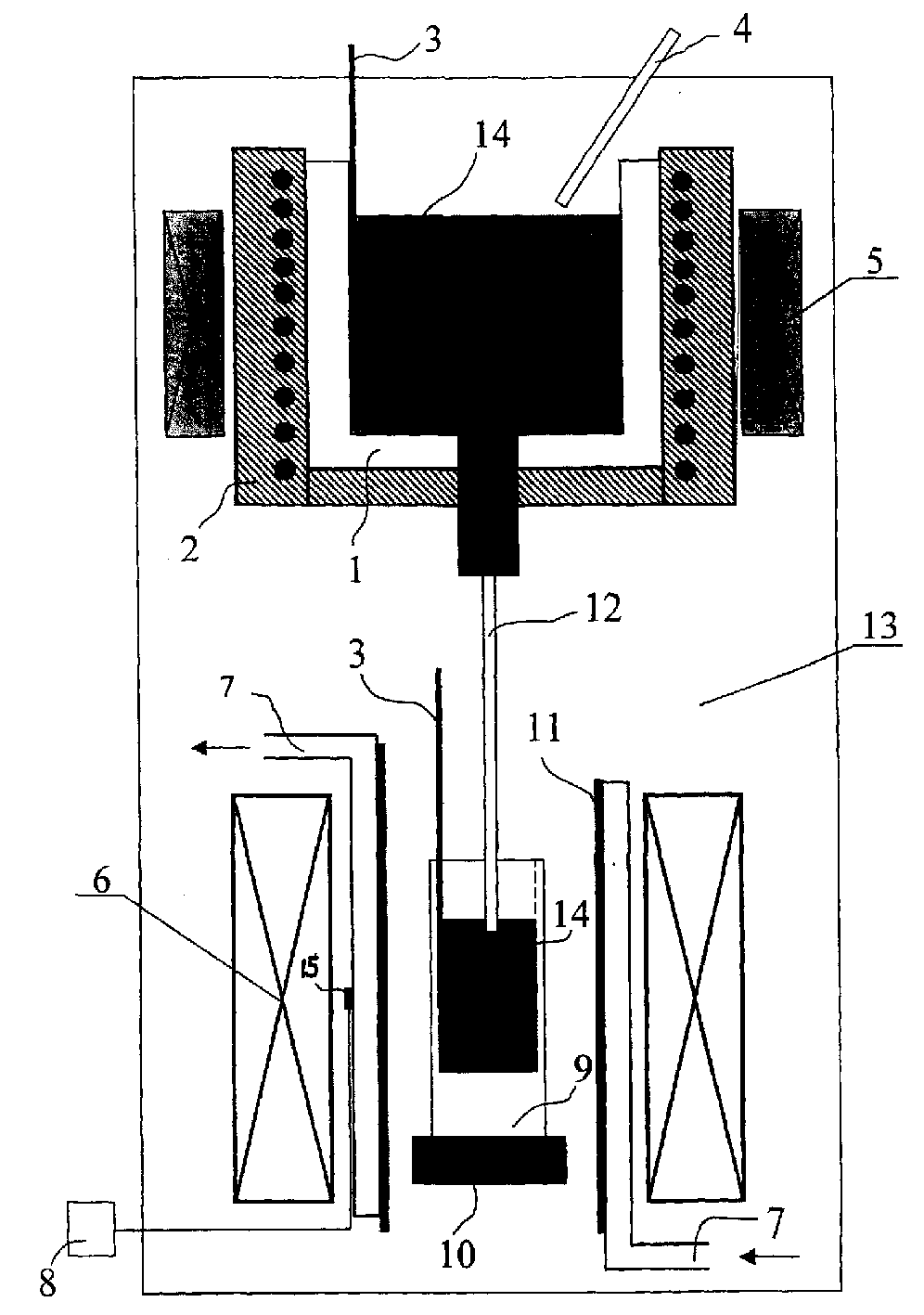

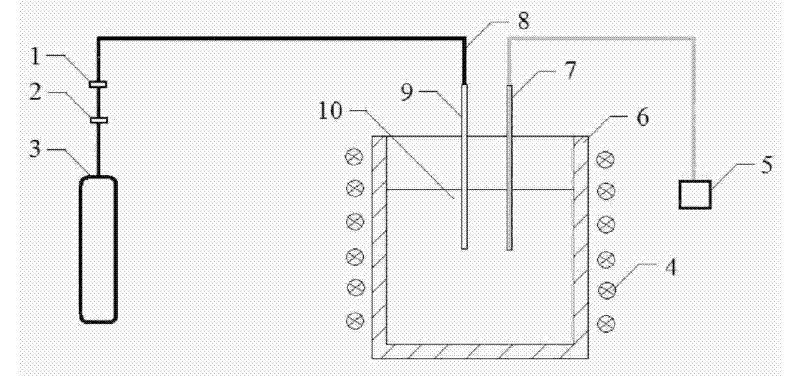

Method and apparatus for preparing aluminium base composite materials under high magnetic field

A process for preparing the Al-base composition under strong magnetic field includes such steps as heating Al to 850 deg.C, holding the temp for 30 min, adding reinforcing Al2O3 particles (or short fibres), stirring, pouring in mould, solidifying for 20 min strong magnetic field system and cooling in air. Its equipment is composed of metallic ladle, heating system, thermoelectric couple, reinforcing material delivering pipe, stirring coil, casting mould, supporter, slide sprue, vacuum chamber or protecting gas chamber, and the strong magnetic field control system consisting of strong magnetic field genrator, cooling water pipe, alarm and temp control unit and insulating layer.

Owner:NORTHEASTERN UNIV

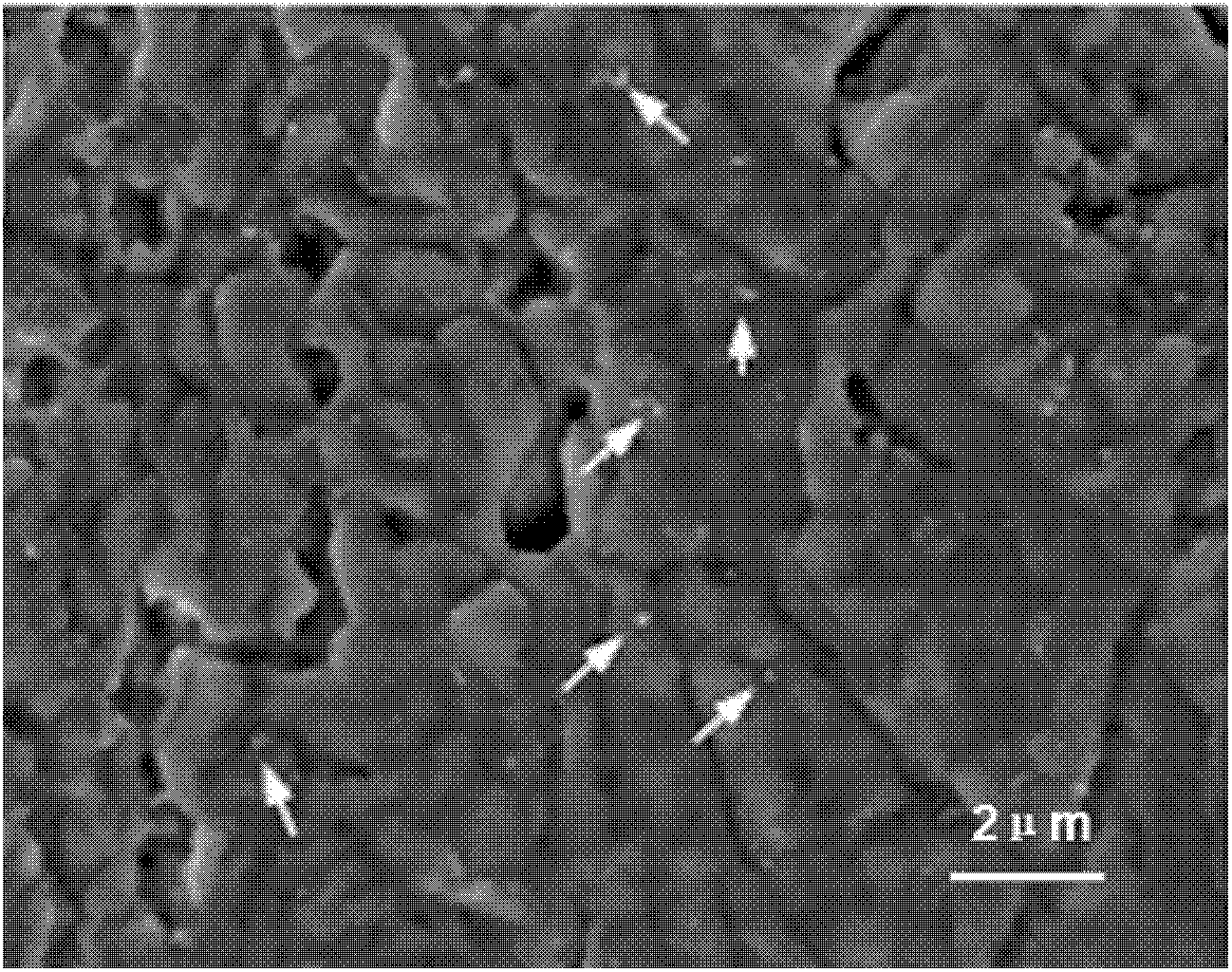

A nanosheet array nickel cobalt oxide-carbon composite material, a method for preparing the same and application of the same

InactiveCN108538611AEasy to operateRaw materials are easy to getMaterial nanotechnologyHybrid capacitor electrodesCobalt oxideUrea

The invention provides a nanosheet array nickel cobalt oxide-carbon composite material, a method for preparing the same and application of the same. The method comprises the steps of: performing ultrasonic processing on wet tissues and obtaining wet tissue fibers after drying; adding nickel nitrate, cobalt nitrate, urea and hexamethylenetetramine into an ethanol aqueous solution to obtain a mixedsolution; soaking the wet tissue fibers into the mixed solution and then performing a hydrothermal reaction to obtain a wet tissue fiber base body carrying an Ni-Co precursor; performing a heating calcination reaction on the wet tissue fiber base body in a mixed gas atmosphere and, after cooling, obtaining the nanosheet array nickel cobalt oxide-carbon composite material. The method utilizes wet tissues which are common in daily life as templates, so that waste in life can be effectively utilized; the material is simple in operation method and is environmentally-friendly and the materials areeasy to obtain; the material has a broad application prospect in fields such as clean energy and catalysis. As an electrode of a super capacitor, the material has high specific capacitance and excellent circulation stability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

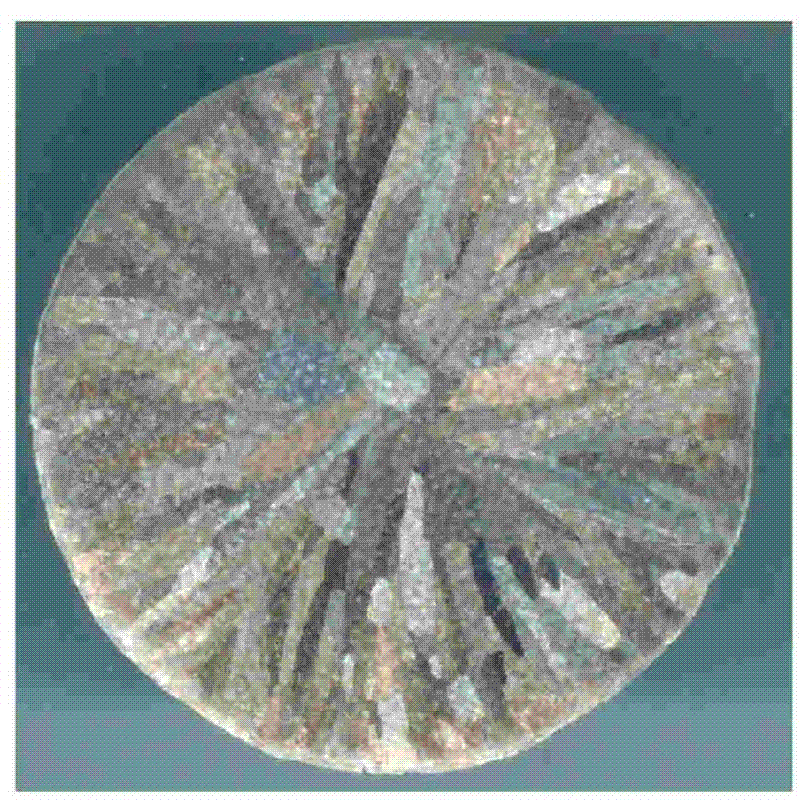

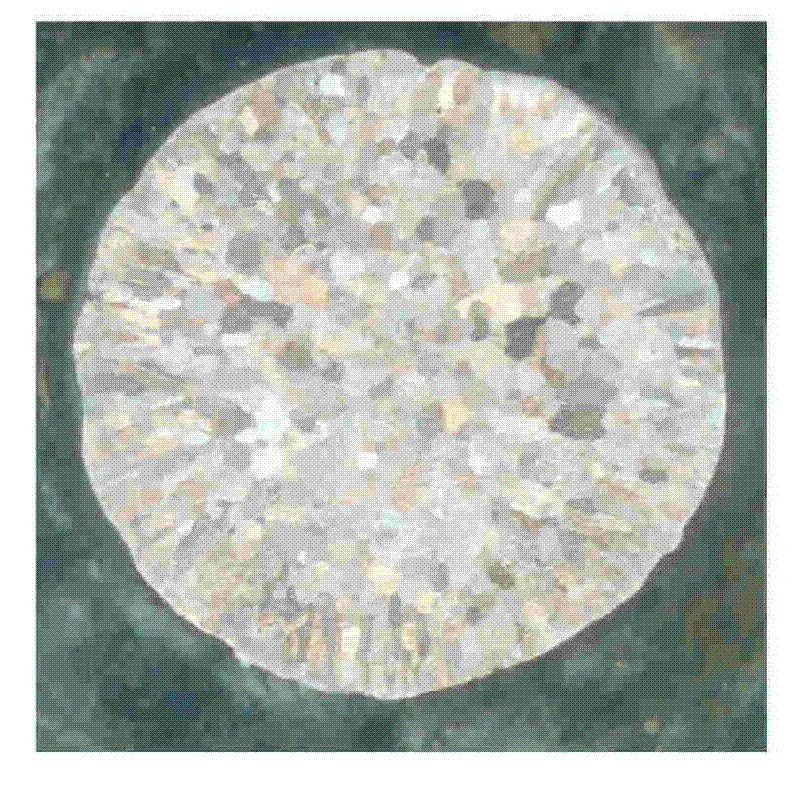

Large-sized hypereutectic high-seleium aluminium alloy billet and preparation method thereof

The invention provides a large scale hypereutectic high-silicon aluminum alloy blank, whose cross-sectional area is between 600-150000mm2, the Si content in the alloy is 13.5-30wt%, it has homogeneous and fine microstructure structure, the Si particles are in dispersed distribution with an average size of less than 5um. The preparing process consists of making ingot blank through semi-continuous casting method, then carrying out subsequent heat treatment for Si particles discretization, finally regulating Si particle size through thermal treatment.

Owner:NORTHEASTERN UNIV

High-strength enamel pan and production technology thereof

The invention discloses a high-strength enamel pan and a production technology thereof. The high-strength enamel pan comprises a cast iron pan body and an enamel glaze layer attached to the surface of the cast iron pan body, wherein the cast iron pan body comprises components including iron, manganese, vanadium, tungsten, aluminum, molybdenum, cerium and carbon, and the enamel glaze layer comprises raw materials including quartz, albite, calcined kaolin, magnets, shell powder, borax, iron oxide powder, aluminum oxide powder, silica powder and an additive. The adopted enamel glaze layer of the high-strength enamel pan adopts conventional ingredients such as the conventional quartz, potash feldspar, the calcined kaolin, the borax and the like, the magnets, the shell powder, the iron oxide powder, the aluminum oxide powder, the silica powder and the additive are also added, so that the enamel glaze layer sintered at the relatively lower temperature can have the same strength and density, and glaze layer damage caused by bumping is reduced as much as possible.

Owner:浙江钰信钢铁有限公司

Aluminum-copper alloy welding wire suitable for wire material additive manufacturing

ActiveCN110885944AEvenly distributedNo generationAdditive manufacturing apparatusManganeseMaterials science

The invention discloses an aluminum-copper alloy welding wire suitable for wire material additive manufacturing. The aluminum-copper alloy welding wire is prepared from the following components of, bymass percentage, 0.3-0.5% of Manganese (Mn), 4.6-5.3% of Cuprum (Cu), 0.15-0.35% of Titanium (Ti), 0.0005-0.006% of Boron (B), 0.05-0.3% of Vanadium (V), 0.05-0.2% of Zirconium (Zr), 0.05-0.2% of Tin(Sn), not larger than 0.15% of Iron (Fe), not larger than 0.06% of Silicon (Si), not larger than 0.05% of magnesium (Mg), not larger than 0.1% of Zinc (Zn), not larger than 0.05% of other single impurity elements, not larger than 0.15% of total other impurity elements and the balance aluminum (Al). According to the welding wire, no toxic soot is generated during production and use, and the additive-forming accumulation body has uniform tissue, high strength and ductility mechanical properties and transverse and longitudinal uniformity and is free of toxic metal oxide on the surface.

Owner:抚顺东工冶金材料技术有限公司

Flexible electrode film and preparation method and application thereof

ActiveCN110098374AGreat suctionImprove liquid retention capacityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsSulfurActive component

The invention discloses a flexible electrode film and a preparation method and an application thereof. The film comprises a carbon fluoride supported sulfur composite material, carbon nanotubes and abinder. The mass ratio of the carbon fluoride supported sulfur composite material to the carbon nanotubes to the binder is (5-12): (0.8-1.2): (0.8-1.2). After hot pressing of the film, a self-supporting flexible cathode is obtained. A preparation method combining atmospheric-pressure low-temperature drying and high-temperature short-time hot pressing is adopted, which can cause secondary melting expansion of sulfur, reduce the resistance of the electrode and achieve the effects of film formation, flexibility improvement and reduction in sulfur loss of active components. The electrode has a compact structure, excellent flexibility and good conductivity.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of layered double-scale magnesium alloy

The invention provides a preparation method of a layered double-scale magnesium alloy, and belongs to the field of light metal material processing. The method comprises the following steps that isothermal heating is carried out on a magnesium alloy plate blank subjected to heating homogenization at 280-370 DEG C for 20-30 min, then the first pass of rolling deformation is immediately carried out to obtain a deformed plate, wherein the strain rate of rolling is 3.5-4.9s<-1>; and after annealing is carried out on the deformed plate, the second pass of rolling deformation is carried out at 280-340 DEG C, wherein the strain rate of rolling is 6.0-7.1s<-1>. According to the preparation method of the layered double-scale magnesium alloy, the high strain rate and gradient cooling double-pass rolling are adopted so that the high-strength toughened magnesium alloy material with the layered double-scale organizational structure can be obtained, the alternate layered distribution of the ultra-fine crystal layer and the micron crystal layer is achieved, and the strength and the plastic toughness of the magnesium alloy are improved.

Owner:YANSHAN UNIV

Tough high-chrome abrasion-resistant cast ball and preparation method thereof

InactiveCN105401057AImprove hardenabilityHigh hardnessFurnace typesHeat treatment furnacesHardnessWear resistance

The invention discloses a tough high-chrome abrasion-resistant cast ball. The tough high-chrome abrasion-resistant cast ball comprises, by weight, 2%-2.2% of C, 10%-12% of Cr, 0.4%-0.6% of Si, 0.5%-0.7% of Mn, 0.5%-2% of Nd, 1%-2.5% of Si, 0.5%-2% of Ti and the balance Fe and inevitable impurities. The invention further discloses a preparation method of the tough high-chrome abrasion-resistant cast ball. The preparation method of the tough high-chrome abrasion-resistant cast ball comprises the steps of smelting, casting and heat treatment. According to the tough high-chrome abrasion-resistant cast ball and the preparation method thereof, a micro amount of Nd, a micro amount of Si and a micro amount of Ti are added based on a conventional high-chrome cast ball, so that on the basis that the high hardness and high abrasion resistance of the high-chrome cast ball are guaranteed, the lower quenching tendency and the lower cracking tendency are achieved in the use process, the preparation technique is simple, and the cost is low.

Owner:ANHUI NINGGUO NINGHU STEEL BALL

Method for preparing whisker toughened composite coating by liquid-phase method spraying process

The invention discloses a method for preparing a whisker toughened composite coating through a liquid-phase method spraying process, and belongs to the field of nano thermal protection coating preparation. Whiskers and ceramic-based nano powder are mixed and then added into a solvent, then a dispersing agent and a softening agent are added to obtain a suspension, the suspension is sprayed out through a centrifugal atomizer after being subjected to ball milling, the atomized suspension is melted under the action of a plasma heat source of plasma spraying and impacts the surface of a base body, and the whisker toughened composite ceramic coating is obtained. The method is short in preparation period, simple in process, easy to control, capable of achieving large-scale production and wide in application market.

Owner:XI AN JIAOTONG UNIV

Method for preparing in-situ particulate reinforced magnesium base composite

InactiveCN102041424AHigh densityLower melting temperatureSelf-propagating high-temperature synthesisParticulates

The invention discloses a method for preparing an in-situ particulate reinforced magnesium base composite material, which comprises three steps of preparing a precast block, preparing reinforced particulates and preparing a composite material. In the method, a Al-Ti-CaC2-C reinforced system is adopted; a self-propagation high-temperature synthesis method is used for producing TiC reinforced particulates and a Al-Ca compound in-situ in the precast block in vacuum or under the protection of inert gases; the reacted precast block is put into a magnesium alloy melt to melt and spread; and sufficient stirring is finished and pouring is carried out to prepare into the particulate reinforced magnesium base composite. The method has the advantages of relatively simple technology and low cost; in the particulate reinforced magnesium base composite, reinforcing phase particulates are fine, are distributed evenly, can be preferably combined with a matrix interface; and the prepared particulate reinforced magnesium base composite material has the advantages of good mechanical property, wear-resisting property and the like.

Owner:JINAN UNIVERSITY

Fe-x-c grain refiner and preparation method thereof

An Fe-X-C grain refiner in the technical field of metal materials and a preparation method thereof. Fe-X-C grain refiner, its composition and mass percentage are: Fe 35-99.4%, C 0.1-15%, X 0.5-50%; wherein, X is one or more of Ti, V and Nb kind. The preparation method of Fe-X-C grain refiner comprises the following steps: step 1, take Fe-C alloy, mix with metal X; Or, take pure iron and graphite, mix with metal X afterwards; The melt is melted in the furnace; in the mixture, Fe is 35-99.4%, C is 0.1-15%, and the balance is X; step 2, when the temperature of the melt is 1550-1650°C, feed argon into the melt , the time is 10s ~ 3h; Step 3, stop feeding argon, cut off the power, and get the Fe-X-C grain refiner. The grain refiner of the invention is easy to prepare; adding the grain refiner of the invention to the steel melt can refine the grains of the steel and increase the ratio of the equiaxed grain area of the as-cast structure of the billet to more than 60%.

Owner:SHANGHAI JIAO TONG UNIV +1

High-specific-strength and high-specific-stiffness aluminum-lithium alloy thick-wall annular piece and preparation method thereof

ActiveCN114058912AThe density drop is not obviousImprove microstructureFoundry mouldsFoundry coresThick wallBoron nitride

The invention provides a high-specific-strength and high-specific-stiffness aluminum-lithium alloy thick-wall annular piece and a preparation method thereof, and belongs to the technical field of aluminum-lithium alloy new materials and manufacturing. The aluminum-lithium alloy thick-wall annular piece comprises the following chemical components: 0.8-2.8 wt% of Cu, 2.4-3.8 wt% of Li, 0.8-1.8 wt% of Mg, 0.5-1.5 wt% of Zn, 0.1-0.5 wt% of Er, 0.05-0.2 wt% of Zr, less than or equal to 0.08 wt% of Fe, less than or equal to 0.05 wt% of Si, and the balance of Al and inevitable impurities, wherein the total amount of the alloy elements is less than or equal to 8.5 wt%. The preparation method comprises the steps of alloy proportioning, boron nitride brushing, smelting, refining, centrifugal casting and heat treatment. According to the invention, the forming process of the aluminum alloy annular piece can be simplified, the internal structure is compact, and the specific strength and specific stiffness of the aluminum alloy annular part are remarkably improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

RH refining powder rotary-jetting and dephosphorizing method

The invention discloses an RH refining powder rotary-jetting and dephosphorizing method. The RH refining powder rotary-jetting and dephosphorizing method comprises the steps that (1) a powder rotary-jetting gun is inserted to the position 400-650 mm below the surface of molten steel, and starts rotary-jetting of powder; (2) the rotation speed of the powder rotary-jetting gun is 130-150 r / min, thecarrier gas flow of the powder rotary-jetting gun is 30-90 Nm<3> / h, the carrier gas pressure is 0.5-0.8 MPa, the powder jetting rate is 0.1-4.5 kg / s, and Ar is adopted as carrier gas; and (3) the spray-blowing time of the powder rotary-jetting gun is 10-20 min, the powder rotary-jetting gun is lifted out of the surface of the molten steel after spray-blowing is completed, the rotation speed is decreased to 5-10 r / min or below, and after the powder rotary-jetting gun is lifted to the position 300-500 mm above the surface of the molten steel, the powder rotary-jetting gun rotates at a higher speed of 50-80 r / min for 10-30 s.

Owner:ANGANG STEEL CO LTD

Method and apparatus for preparing aluminium base composite materials under high magnetic field

InactiveCN1261612CImprove acceleration performanceImprove coagulation tissueMetallic aluminumInsulation layer

A process for preparing the Al-base composition under strong magnetic field includes such steps as heating Al to 850 deg.C, holding the temp for 30 min, adding reinforcing Al2O3 particles (or short fibres), stirring, pouring in mould, solidifying for 20 min strong magnetic field system and cooling in air. Its equipment is composed of metallic ladle, heating system, thermoelectric couple, reinforcing material delivering pipe, stirring coil, casting mould, supporter, slide sprue, vacuum chamber or protecting gas chamber, and the strong magnetic field control system consisting of strong magnetic field genrator, cooling water pipe, alarm and temp control unit and insulating layer.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of Al3Sc-Al3Zr/Al composite material inoculant

The invention discloses a preparation method of an Al3Sc-Al3Zr / Al composite material inoculant, and relates to aluminum-based alloy. The method comprises the steps that raw material preparation is conducted according to the mass percentage of each element in target alloy of 1.00%-2.00% of Sc, 1.00%-2.00% of Zr and the balanced Al; in-situ synthesis preparation and ultrasound treatment of block Al-Sc-Zr intermediate alloy are conducted; a strip-shaped Al3Sc-Al3Zr composite material inoculant product is prepared through a rapid solidifying technology. The method has the advantages that part of Sc with high price is replaced by adding low-cost Zr to reduce the cost of the product, and the defects of the failure of the dispersion distribution of core forming particles on a substrate, non-idealdispersion level, aggregation sedimentation in a melt of particles, large particular size, excessively large Al3Sc particles in Al-Sc alloy and excessively low number in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

Fe-X-C grain refiner and preparation method thereof

The invention discloses a Fe-X-C grain refiner and a preparation method thereof, belonging to the technical field of metal materials. The Fe-X-C grain refiner comprises the following components by weight percent: 35-99.4 percent of Fe, 0.1-15 percent of C and 0.5-50 percent of X, wherein X is one or more selected from Ti, V and Nb. The preparation method of the Fe-X-C grain refiner comprises the following steps : firstly, taking an alloy of Fe and C to mix with a metal X; or taking a pure iron and graphite to mix with the metal X; and smelting a mixture in vacuum in a frequency induction furnace to obtain a fusant, wherein the mixture contains 35-99.4 percent of Fe, 0.1-15 percent of C and X of the balance; secondly, leading argon into the fusant for 10s-3h when the fusant is at 1550-1650DEG C; and thirdly, stopping leading the argon and switching off the electricity to obtain the Fe-X-C grain refiner. The grain refiner has simple preparation; and the grain refiner can be added into a steel fusant to refine the grains of the steel so that the proportion of a billet steel casting tissue equiaxed grain zone is improved by 60 percent.

Owner:SHANGHAI JIAO TONG UNIV +1

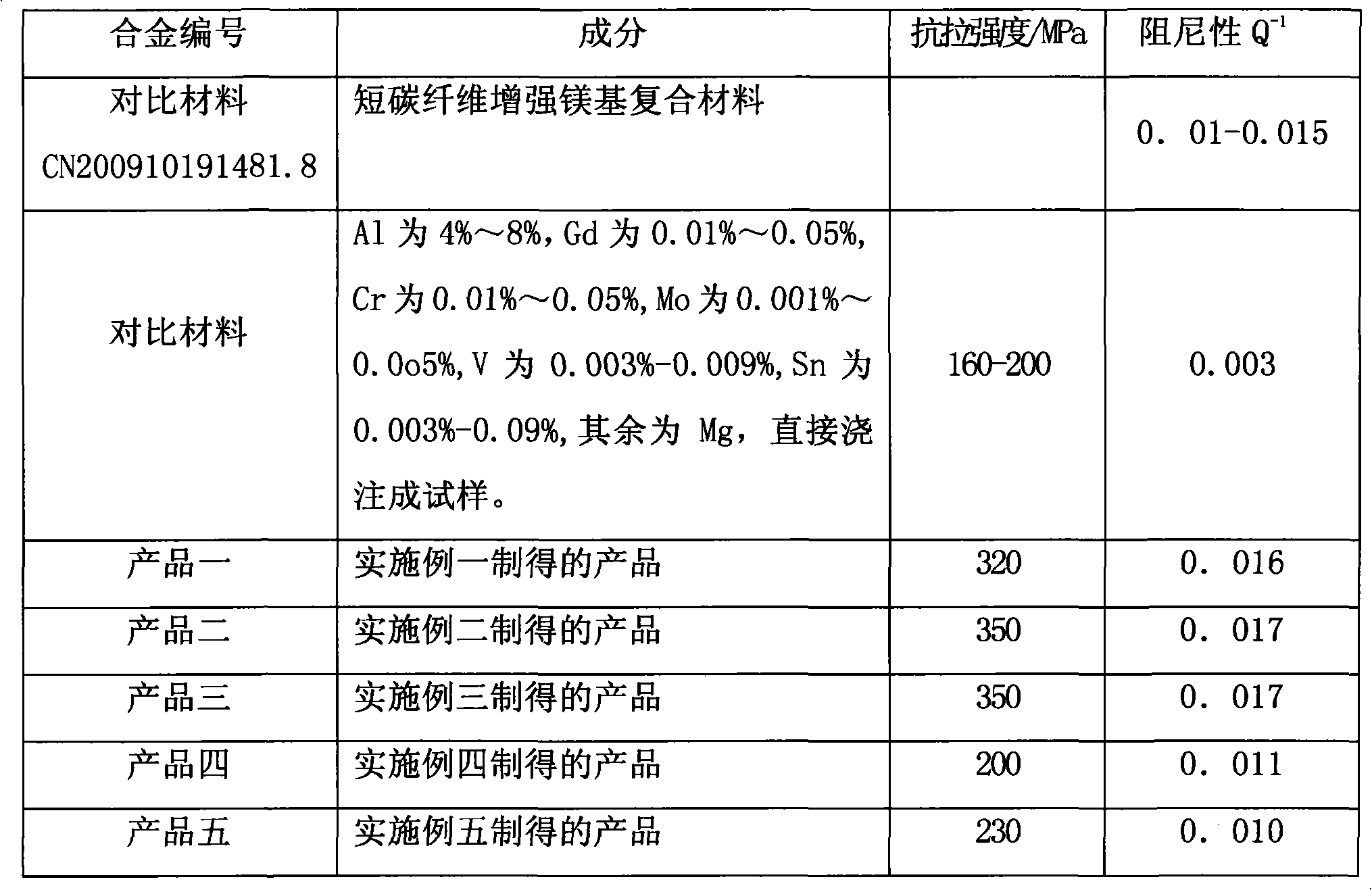

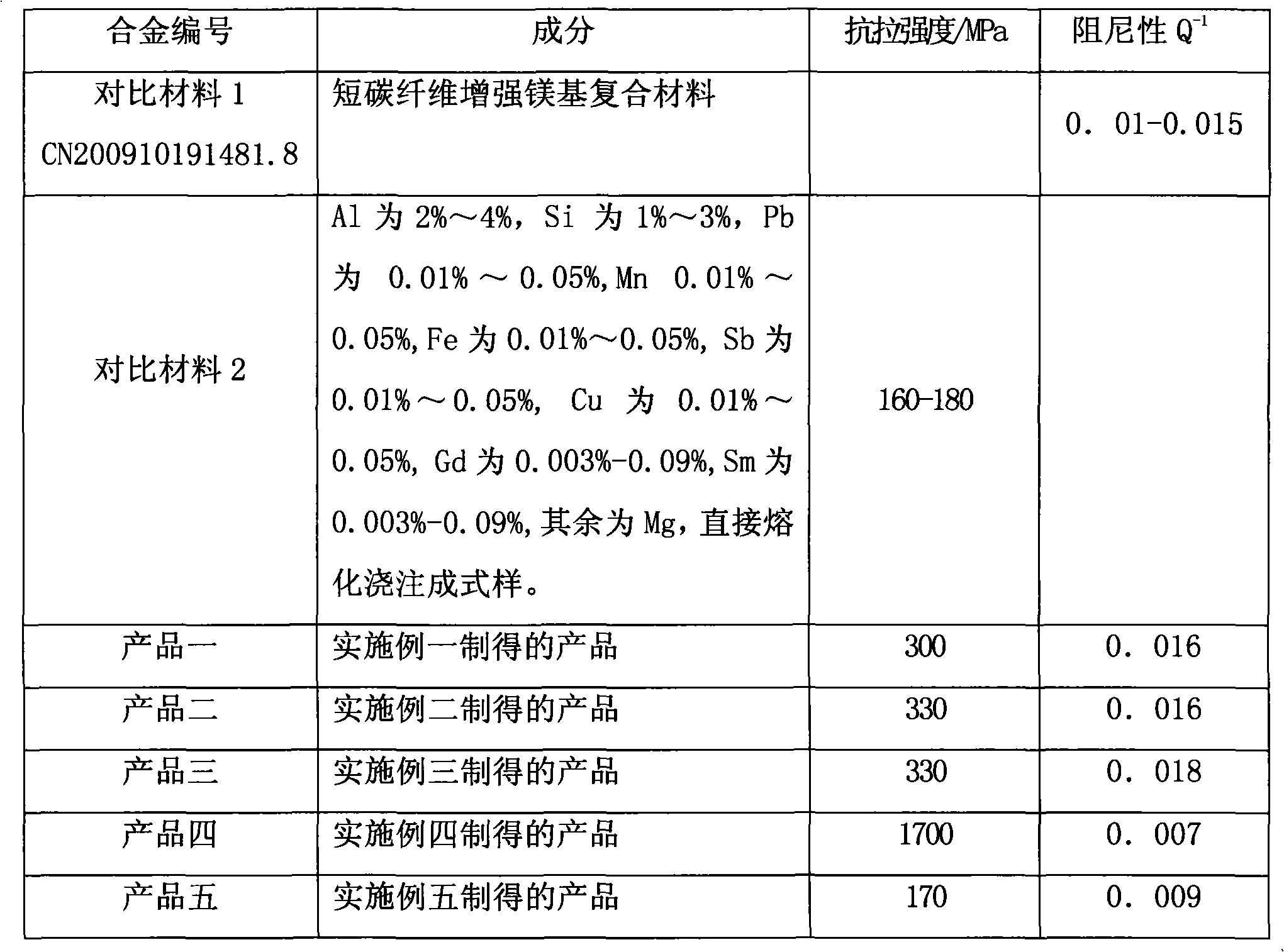

Fine grain titanium fiber pumice magnesium alloy composite material and preparation method thereof

The invention provides a lightweight fine grain titanium fiber pumice magnesium alloy composite material and a preparation method thereof. The composite material has high strength and excellent damping performance. The method has simple process and low production cost and is suitable for industrial production. The composite material takes magnesium alloy as a substrate on which fine grain titanium fibers and pumice particles are distributed, the size of grains of the fine grain titanium fibers is 1-10 mu m, the fine grain titanium fibers and the pumice particles account for 45-55% of the composite material by volume, and the weight ratio of the fine grain titanium fibers to the pumice particles is 1:1. The magnesium alloy substrate comprises the following chemical components in percentage by weight: 4%-8% of Al, 0.01%-0.05% of Gd, 0.01%-0.05% of Gr, 0.001%-0.005% of Mo, 0.03%-0.09% of Si, 0.003%-0.009% of V, 0.003%-0.09% of Sn and the balance Mg.

Owner:淮安市清河区科技转化服务中心

Sn-Ag-Cu lead-free solder with high interface bonding strength and a preparation method thereof

InactiveCN109848606AInhibited DiffusionLow aging resistanceWelding/cutting media/materialsSoldering mediaSurface oxidationMechanical property

The invention discloses improved Sn-Ag-Cu lead-free solder and a preparation method thereof. Zr and Ni are added in Sn-Ag-Cu lead-free solder, the amount of the Zr and the amount of the Ni are controlled, addition of the Ni can further promote the dispersion distribution of the Zr so as to further refine the microstructure of the solder; the surface tension of a molten pool is reduced, a wetting and spreading area is expanded, and the welding wettability and the oxidation resistance of a solder alloy are improved; and formation of the defects such as cavities and bridging in the welding process is inhibited, surface oxidation of welding spots during the long-term use process is prevented, and the welding spots still have excellent electricity and heat conduction performance in long-term use. By means of the synergistic effect of the two elements, the welding wettability as well as the mechanical property, the high-temperature anti-aging performance and the electricity conduction and heat conduction performance of the welding spots are comprehensively improved, and the development requirements of electronic components are met.

Owner:CENT SOUTH UNIV +1

High-hardness titanium-based composite material and preparation method thereof

The invention discloses a high-hardness titanium-based composite material. The titanium-based composite material is prepared from, by mass, 4.5%-5.5% of Al, 5%-6% of Mo, 3%-4% of V, 1%-2% of Cr, 1%-2% of Fe, 3%-5% of TiC and the balance Ti and inevitable impurities. Through the solution treatment strengthening effect of Al, Cr, Fe and Mo, TiC particles and a Ti matrix have good stress decomposition and strain coordination, and the hardening effect is achieved. The invention further provides a preparation method of the high-hardness titanium-based composite material, the micron-sized TiC particles and the raw materials are subjected to non-self-consumption vacuum arc melting, then homogenization, hot rolling, solid solution and aging are sequentially carried out, the high-hardness titanium-based composite material is obtained, the hardness can reach 50 HRC or above, the preparation method is simple in process. The invention is widely applied to the fields of spaceflight, military industry, civil use and the like, and economic benefits are remarkably improved.

Owner:西安稀有金属材料研究院有限公司

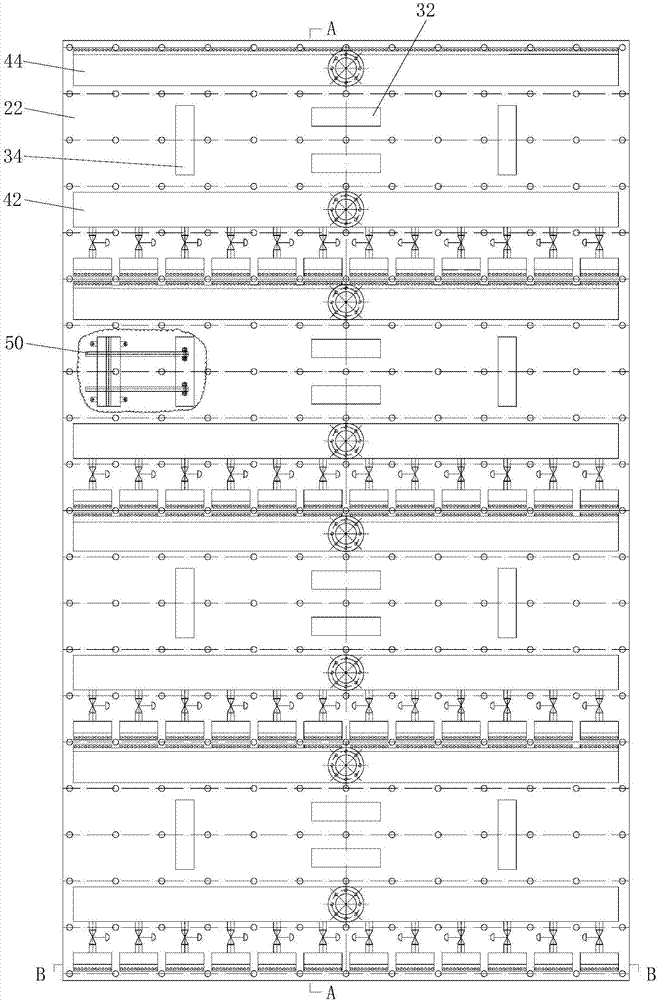

Cooling mold and method for cooling steel ingot

The invention provides a cooling mold and a method for cooling a steel ingot. The cooling mold comprises a pouring chassis and condensation walls, and each condensation wall comprises at least two cooling layers which are vertically arranged in sequence. The cooling mold further comprises at least two pairs of electromagnetic induction components which are arranged on the outer side of the condensation walls, each pair of the electromagnetic induction components are symmetrically arranged on the two sides of a casting cavity, and each cooling layer is provided with at least one pair of electromagnetic induction components; each electromagnetic induction component comprises at least two pairs of coils which can be connected to the corresponding condensation wall in a sliding manner, and the two coils in each pair of the coils are oppositely arranged in parallel; among all the electromagnetic induction components, at least one pair of the coils are vertically arranged, at least one pair of the coils are horizontally arranged, and all the horizontally arranged coils are located between center lines of all the vertically arranged coils; and the two ends of all the coils are sequentially opposite to each other or sequentially connected end to end to form a semi-closed or closed rectangle in an enclosing manner. According to the cooling mold, molten steel can be stirred in the horizontal direction and in the vertical direction separately, and the quality of steel ingots is improved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Method for preparing compound electrical contact material

InactiveCN102324335BConducive to play ballistic conduction characteristicsCost-effectiveContact materialsCatalytic pyrolysisMass ratio

Owner:TIANJIN POLYTECHNIC UNIV

Finely crystalline iron-stibium fiber and pumice magnesium alloy composite material and preparation method thereof

The invention provides a finely crystalline iron-stibium fiber and pumice magnesium alloy composite material and a preparation method thereof. The composite material has high strength, and excellent damping performance. The method has the advantages of simple process, low production cost and suitability for industrial production. The composite material has the magnesium alloy serving as a matrix,finely crystalline iron-stibium fibers and pumice microparticles are distributed on the matrix, the crystalline grains of the iron-stibium fibers are 1 to 10 mu m, and the fibers and the pumice account for 45 to 55 volume percent of the composite material, wherein the weight ratio of the fibers to the pumice is 1:1.

Owner:淮安市清河区科技转化服务中心

Method for preparing in-situ particulate reinforced magnesium base composite

InactiveCN102041424BHigh densityLower melting temperatureSelf-propagating high-temperature synthesisParticulates

The invention discloses a method for preparing an in-situ particulate reinforced magnesium base composite material, which comprises three steps of preparing a precast block, preparing reinforced particulates and preparing a composite material. In the method, a Al-Ti-CaC2-C reinforced system is adopted; a self-propagation high-temperature synthesis method is used for producing TiC reinforced particulates and a Al-Ca compound in-situ in the precast block in vacuum or under the protection of inert gases; the reacted precast block is put into a magnesium alloy melt to melt and spread; and sufficient stirring is finished and pouring is carried out to prepare into the particulate reinforced magnesium base composite. The method has the advantages of relatively simple technology and low cost; in the particulate reinforced magnesium base composite, reinforcing phase particulates are fine, are distributed evenly, can be preferably combined with a matrix interface; and the prepared particulate reinforced magnesium base composite material has the advantages of good mechanical property, wear-resisting property and the like.

Owner:JINAN UNIVERSITY

Nanometer aluminum oxide reinforced 316L stainless steel composite material and preparation method thereof

InactiveCN113201680AFast processingImprove efficiencyAdditive manufacturing apparatusAluminium oxides/hydroxidesNano al2o3SS - Stainless steel

The invention discloses a nanometer aluminum oxide reinforced 316L stainless steel composite material and a preparation method thereof. The preparation method comprises the following steps that mixed powder A is subjected to powder laying and laser forming, and a formed body is obtained; stress regulation and control are carried out on the formed body, and the nanometer aluminum oxide reinforced 316L stainless steel composite material is obtained; the mixed powder A is a mixed powder obtained by ball-milling 316L steel powder and pretreated Al2O3 powder together; and the pretreatment process of the Al2O3 powder comprises the steps that spherical Al2O3 is placed in NH4OH to be subjected to erosion treatment, washing and drying are carried out after erosion, and the pretreated Al2O3 powder is obtained. The nanometer aluminum oxide reinforced 316L stainless steel composite material contains 0.1%-0.2% of nanoscale Al2O3 particles and the balance a 316L matrix. According to the method, the nanometer aluminum oxide reinforced 316L stainless steel composite material is prepared through the laser melting technology, the method has the characteristics of being high in machining speed, high in efficiency and short in working procedure, meanwhile, the ceramic material Al2O3 can be evenly distributed in a 316L stainless steel matrix, the strength of 316L is remarkably improved, and the method has important significance for expanding the applicability of 316L.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com