Method and apparatus for preparing aluminium base composite materials under high magnetic field

An aluminum matrix composite material and a technology for preparing devices, which are applied in the field of metal matrix composite materials, can solve the problems of low alignment coefficient of reinforcement materials, uneven distribution of reinforcement particles, and obstacles to the development and wide application of metal matrix composite materials, so as to promote Effect of crystal orientation, improvement of density segregation, and improvement of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

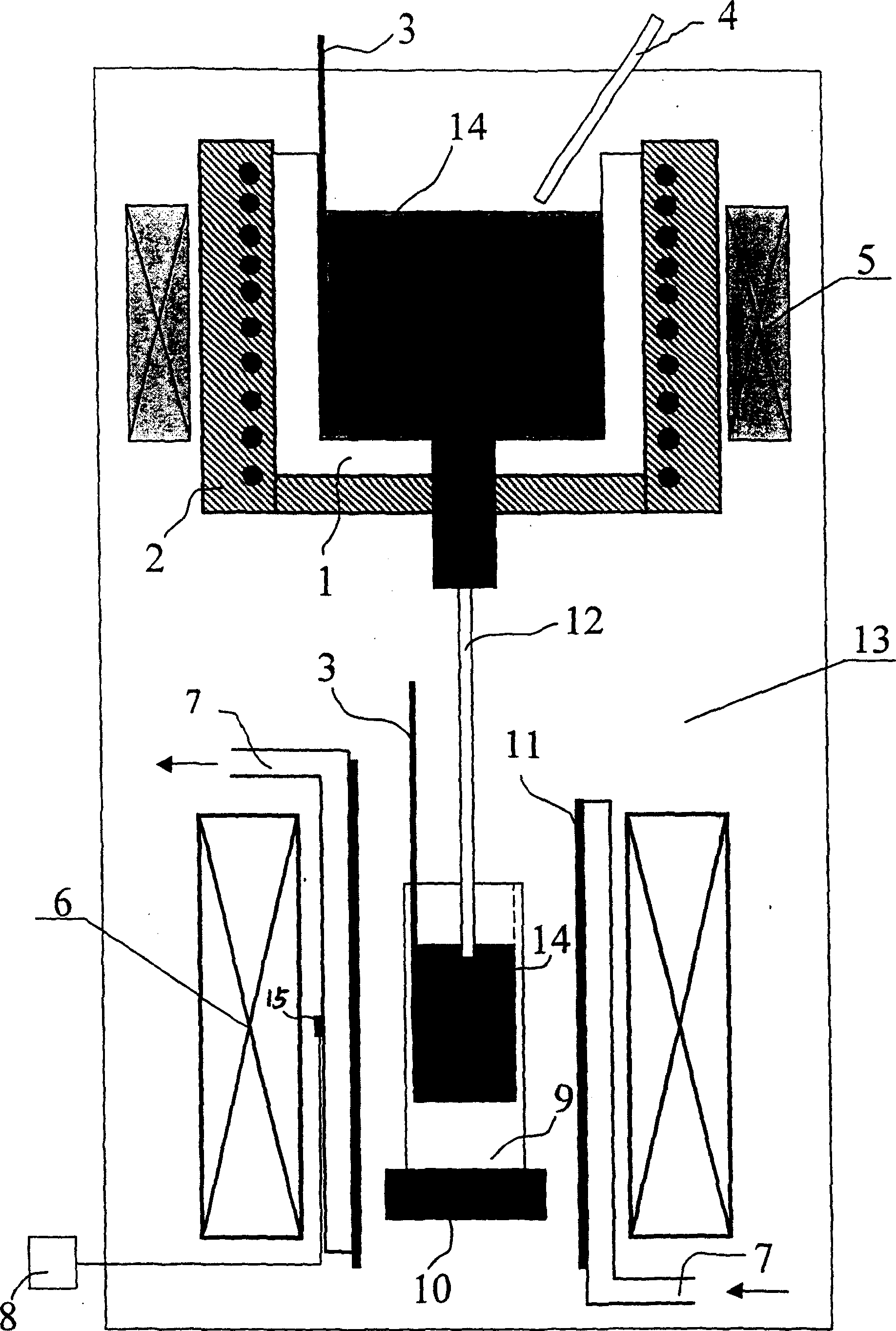

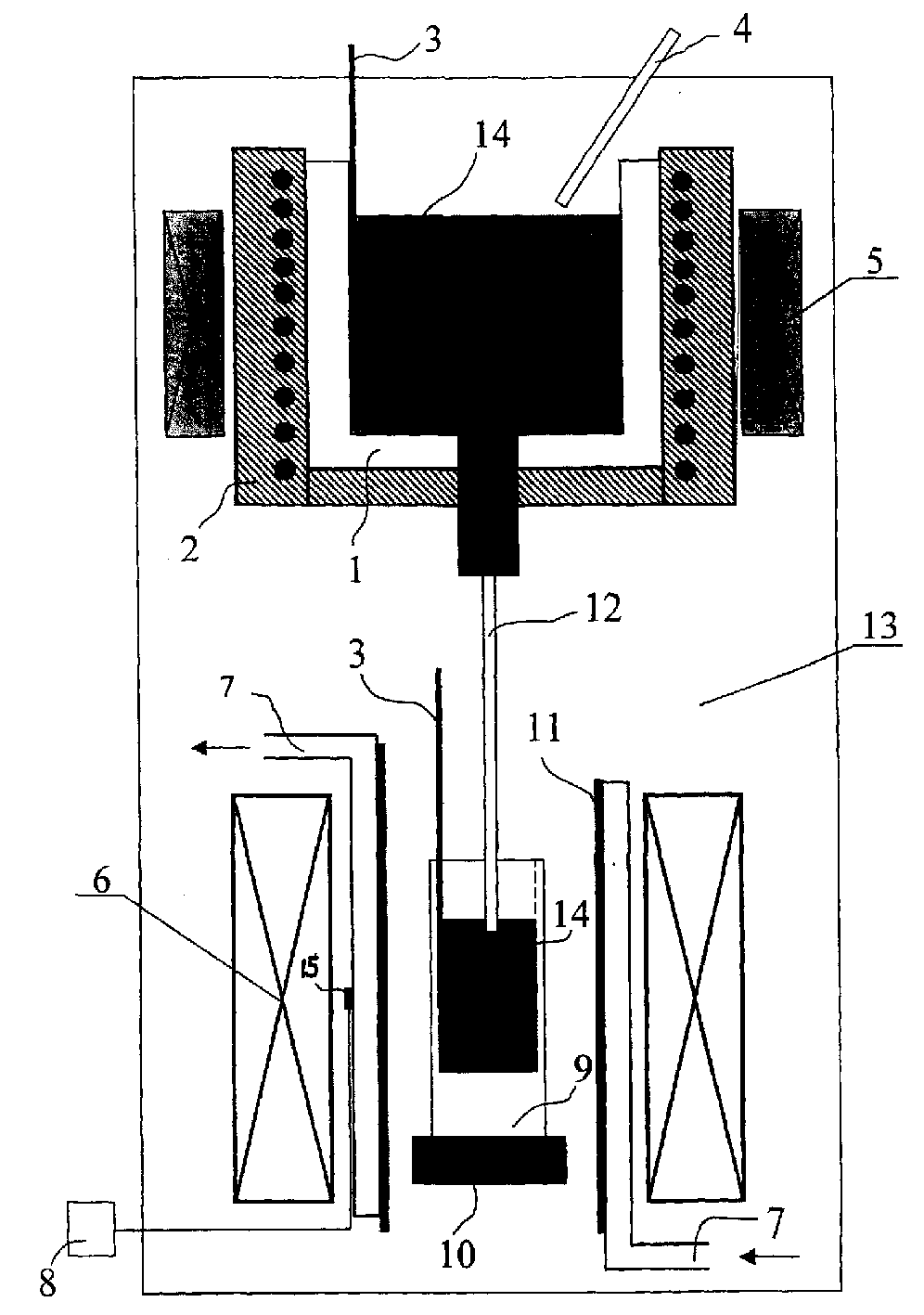

[0011] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing: figure 1 Among them, the composition of the device is divided into upper and lower parts. The upper part is composed of a metal bag 1, a resistance heating or induction heating system 2, and a thermocouple 3 (purchased in the market) is fixed on the outer wall of the vacuum chamber 13 through a sealing ring. In its heating system 2 A stirring coil 5 made of copper is surrounded on the outside or a mechanical stirrer is assembled in the metal bag 1, and the reinforcing body delivery pipe 4 is fixed on the outer wall of the vacuum chamber 13 through a sealing ring; the fixed mold 9 of the lower part is fixed on the support 10 , fixed mold 9 is equipped with a thermocouple 3, its outer wall is covered with insulation material 11, aluminum silicate fiber is selected, the thickness of the insulation layer is 25mm. Between the fixed casting mold 9 and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com