Patents

Literature

1734 results about "Metallic aluminum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

Molecular sieve-containing catalyst for cracking hydrocarbons and a method for preparing the same

ActiveUS20040266608A1Reduced activityEasy to crackCatalytic crackingMolecular sieve catalystsReduction ActivityMolecular sieve

A molecular sieve-containing catalyst for cracking hydrocarbons, comprising molecular sieve, refractory inorganic oxide, clay and a metal component, wherein the amount of said molecular sieve is from 1 to 90% by weight, the refractory inorganic oxide is from 2 to 80% by weight, the clay is from 2 to 80% by weight, and the metal component is from 0.1 to 30% by weight, calculated as the oxide of said metal having its maximum valence state, based on the total amount of the catalyst, wherein said metal component exists essentially in a reduction state and is one or more metals selected from the group consisting of metals of Group III A(other than aluminum), and metals of Group IVA, VA, IB, IIB, VB, VIB and VIIB, and non-noble metals of Group VIII of the periodic table. The catalyst has higher cracking activity and higher sulfur reduction activity.

Owner:CHINA PETROCHEMICAL CORP +1

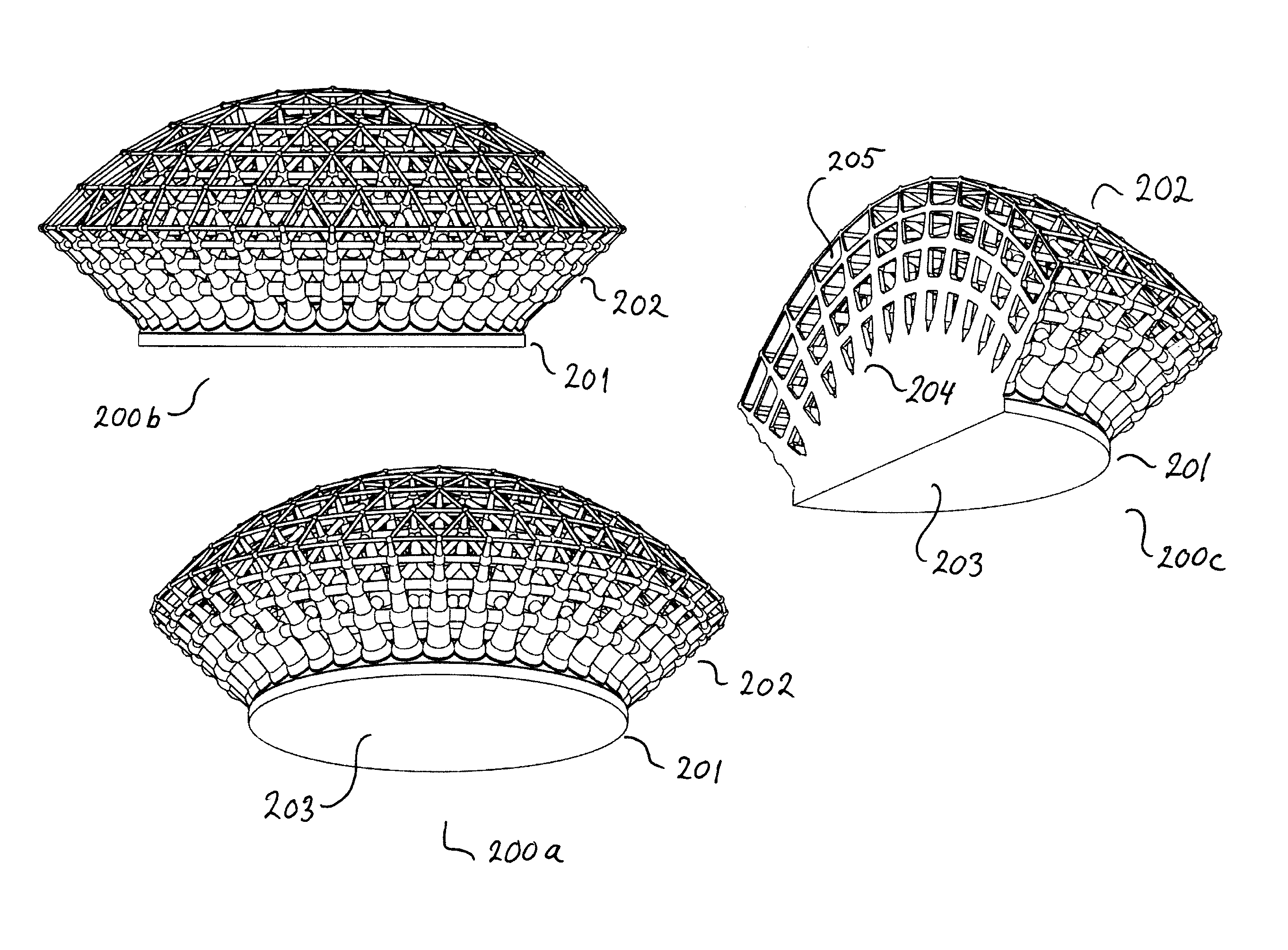

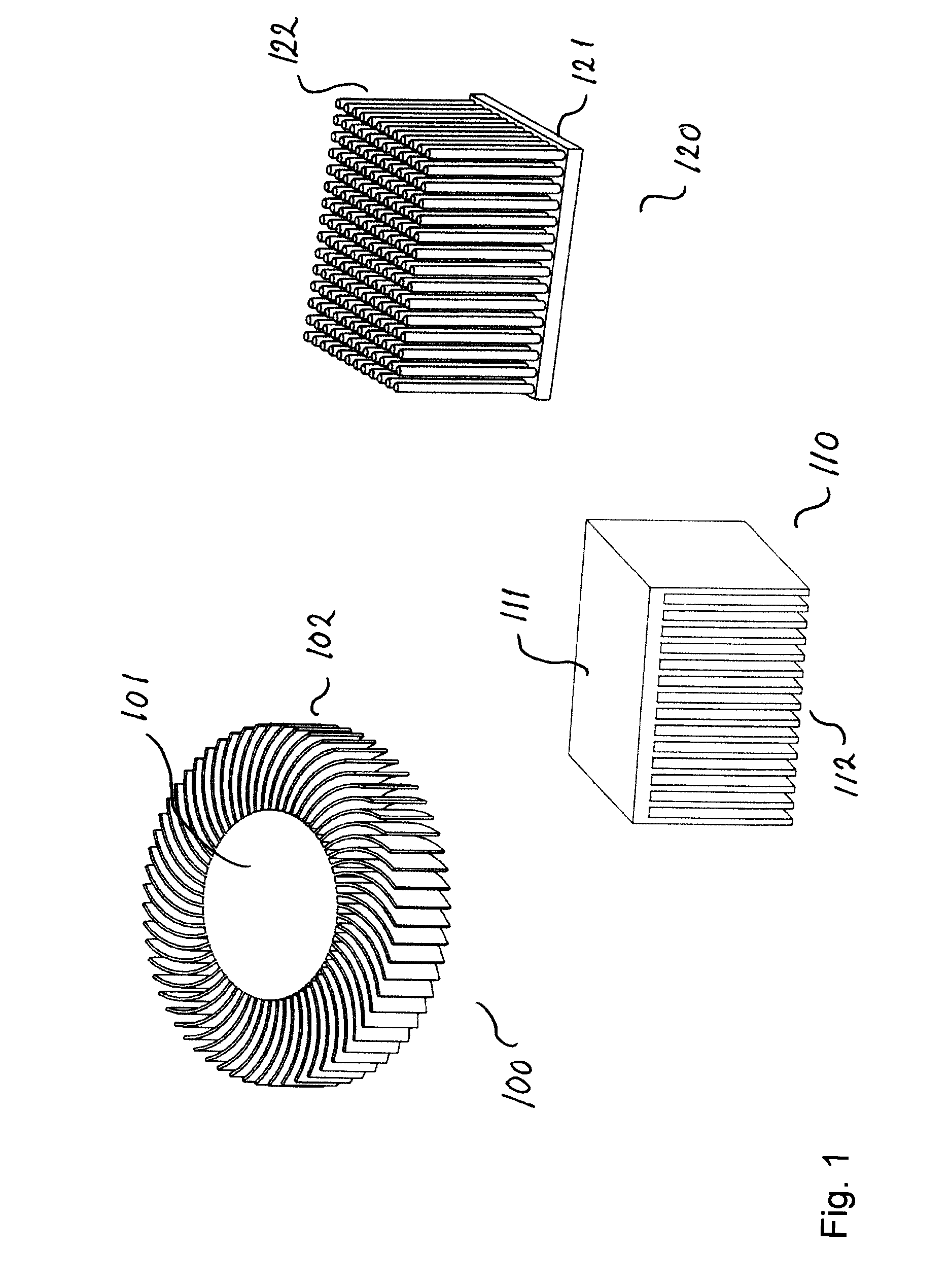

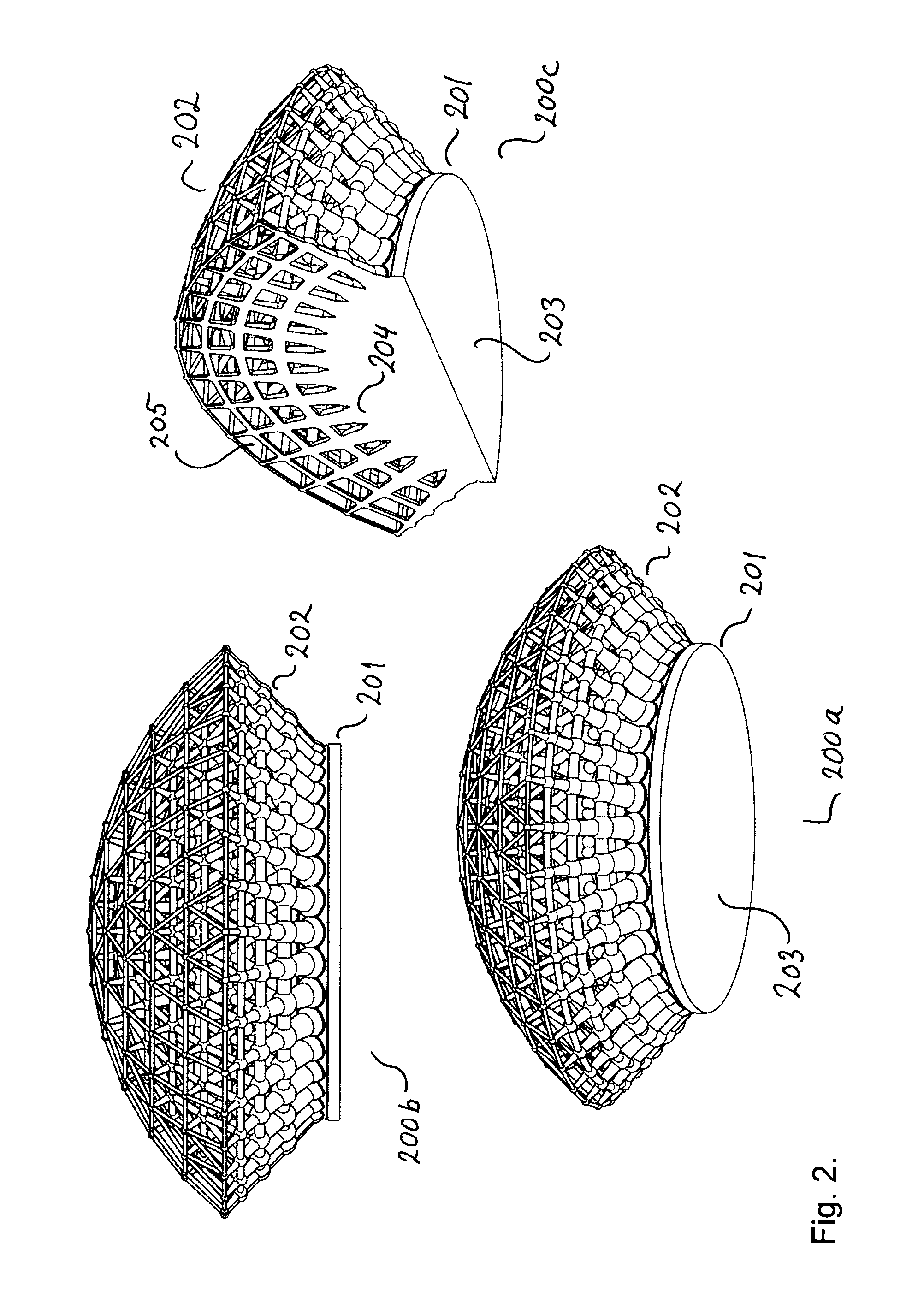

Heat Sink Having a Cooling Structure with Decreasing Structure Density

InactiveUS20160069622A1Increase distanceReduce material densityLighting support devicesDigital data processing detailsSelective laser meltingCarbon nanotube

A heat sink for cooling a heat generating device comprises a body part with a first surface for contacting the heat generating device, and a second surface contacting a cooling part, and the cooling part including a cooling structure. The structure density of the cooling structure decreases with increasing distance to body part. The cooling structure may be a three dimensional structure e.g. a grid or a lattice, but the cooling structure may also be fins projecting or extending from the second surface of the body part. The heat sink can be manufactured using additive manufacturing e.g. selective laser melting process (SLM). The heat sink can be made of metals e.g. aluminum, copper, ceramics e.g. aluminium nitride (AlN), silicon carbide or a composite containing graphite, graphene or carbon nanotubes.

Owner:ALEXIOU & TRYDE HLDG APS

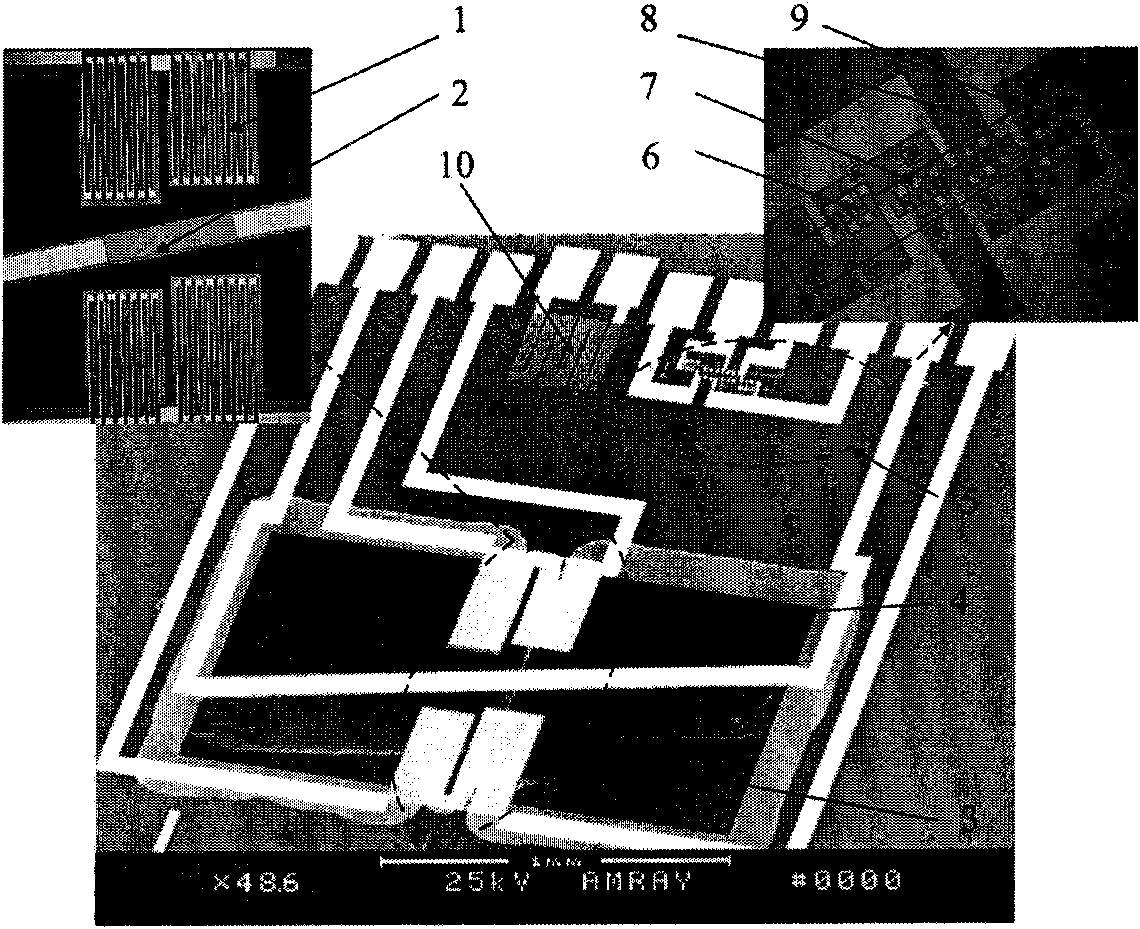

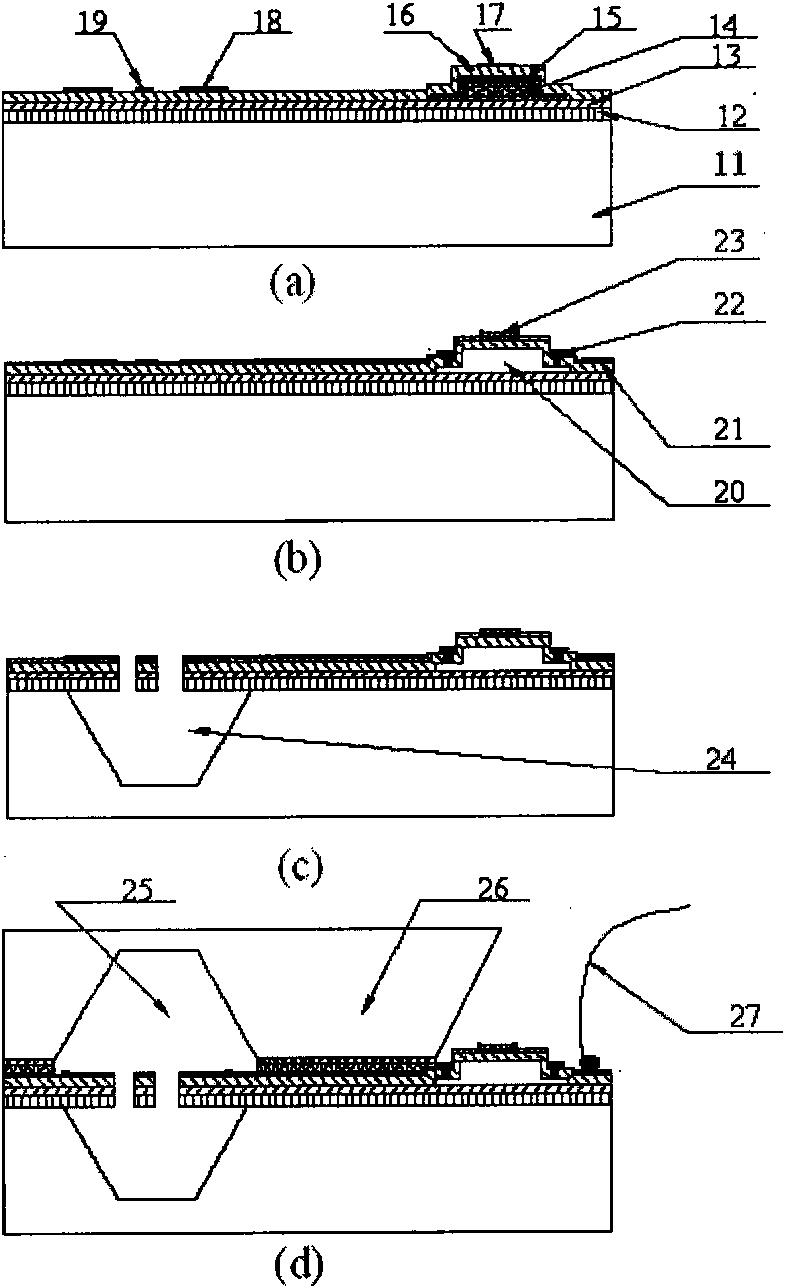

Integrated silicon chip for testing acceleration, pressure and temperature, and manufacturing method thereof

ActiveCN101551403AHigh sensitivityImprove stabilityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsAccelerometerThermopile

The invention relates to an integrated silicon chip for testing acceleration, pressure and temperature, and the manufacturing method thereof. The invention is characterized in manufacturing the pressure sensor, temperature sensor and accelerometers of thermoelectric pile on to one chip by the same micro processing technology. The acceleration is detected by adopting thermal convection type accelerometers, using polysilicon resistor as heater, using a thermoelectric pile composed of two pairs of metals (such as aluminium and tungsten-titanium) and P type or N type polysilicon to detect the temperature difference in the sealed cavity caused by acceleration. The high accurate absolute pressure sensor is manufactured by using silicon nitride film with low stress as the core structure layer of the pressure sensor chip, and forming force sensitive resistor track by polysilicon film, forming vacuum reference cavity by TEOS bolt in LPCVD furnace. At the same time, the temperature sensor is composed by using polysilicon thermistor to detect temperature change. The integrated chip achieves the advantages of microminiaturization, low cost, high precision, high reliability and high stability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

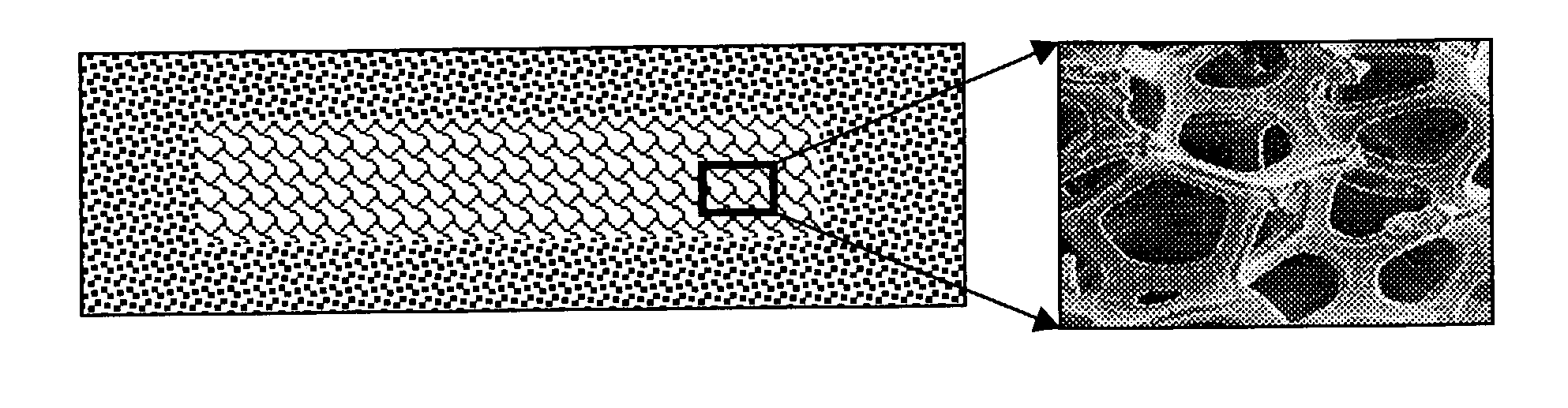

High-strength metal aluminide-containing matrix composites and methods of manufacture the same

(a) The metal matrix composite is suitable for the manufacture of flat or shaped titanium aluminide, zirconium aluminide, or niobium aluminide articles and layered metal composites having improved mechanical properties such as lightweight plates and sheets for aircraft and automotive applications, thin cross-section vanes and airfoils, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. The composite material consists of a metal (e.g., Ti, Zr, or Nb-based alloy) matrix at least partially intercalated with a three-dimensional skeletal metal aluminide structure, whereby ductility of the matrix metal is higher than that of the metal aluminide skeleton. The method for manufacturing includes the following steps: (a) providing an aluminum skeleton structure having open porosity of 50-95 vol. %, (b) filling said skeleton structure with the powder of a reactive matrix metal, (c) compacting the aluminum skeleton / matrix powder composite preform by cold rolling, cold die pressing, cold isostatic pressing, and / or hot rolling, (d) consolidating the initial or compacted composite preform by sintering, hot pressing, hot rolling, hot isostatic pressing, and / or hot extrusion to provide, at least partially, a reaction between aluminum skeleton and matrix metal powder, and (e) diffusion annealing followed by any type of heat treatment needed to provide predetermined mechanical and surface properties of the resulting metal matrix composite. The combination of ductile matrix and metal aluminide skeletal structure results in significant improvement of mechanical properties of the composite material, especially hot strength. This high-strength aluminide-based material can also be used as a core component in multilayer metal matrix composites.

Owner:ADVANCE MATERIAL PRODS ADMA PRODS

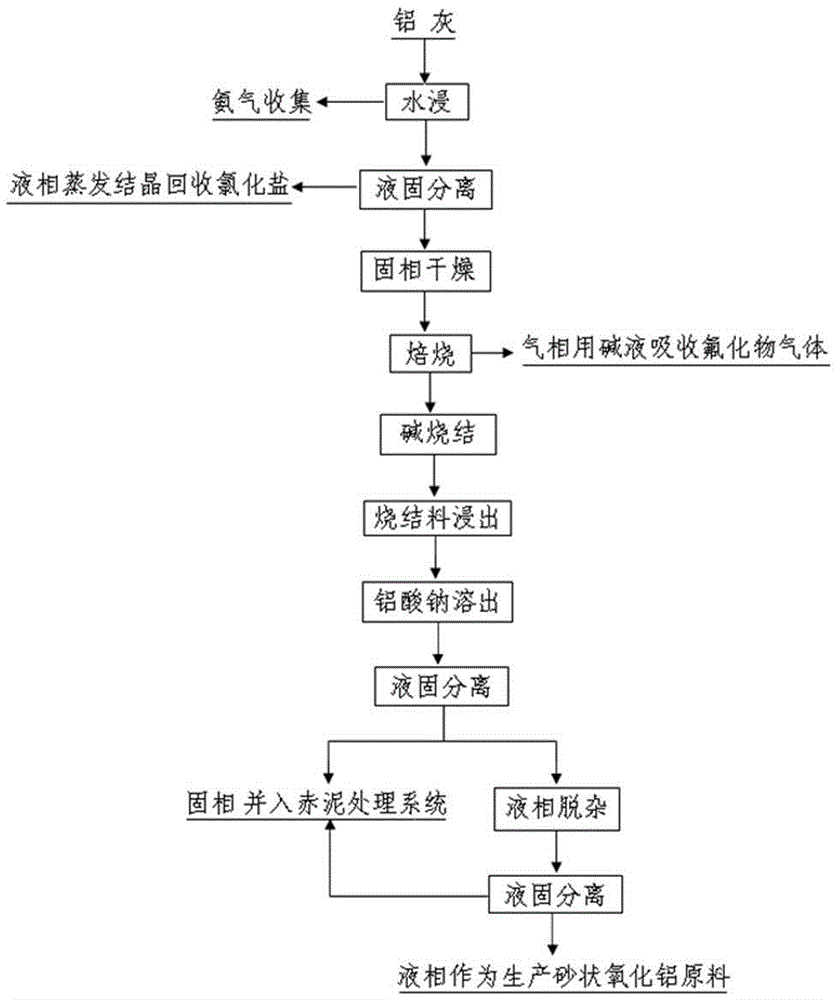

Method for harmless disposal and recycling of aluminum ash

ActiveCN105271327ATo achieve the purpose of comprehensive recycling of resourcesGreat social valueAmmonia preparation/separationAluminium oxides/hydroxidesMetallic aluminumSodium aluminate

The invention discloses a method for harmless disposal and recycling of aluminum ash. The method comprises steps of raw material water immersion nitrogen and chlorine removal, calcination fluorine removal, alkali fusion sintering, sintering material dissolving-out and purifying impurity removal. Aluminum ash generated in metal aluminum smelting process is employed as a raw material, after metal aluminum is recycled through secondary processing, nitrides are removed through water immersion, fluorides are removed through calcinations, alkali fusion sintering is carried out, the sintering materials are dissolved out, impurities are removed through a sodium aluminate solution, the processed aluminum ash is employed as a raw material for producing sand-shaped aluminum oxide. Ammonia gas generated in the aluminum ash harmless disposal process can be employed as an ammonium production raw material, a chlorination liquid generated can be employed as a chlorate production raw material, and silicon fluoride gas generated in the calcination process is absorbed by an aqueous solution. The method is simple and practical, environmental protection benefits are high, the production efficiency is high, the device investment is low, and energy consumption is low. Harmless and recycling disposal of hazardous wastes can be achieved. The obtained product can be applied in practical production.

Owner:YUNNAN WENSHAN ALUMINUM

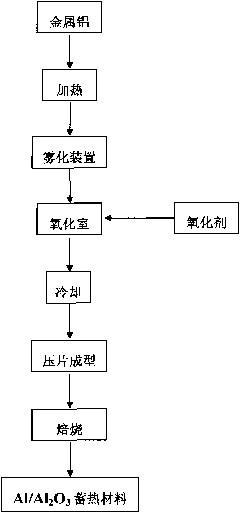

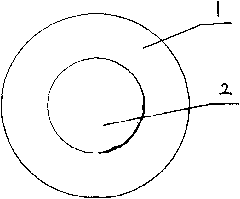

Al/Al2O3 heat storage material and preparation method thereof

The invention discloses an Al / Al2O3 heat storage material and a preparation method thereof. Aluminum oxide serves as a base material; and a spherical metallic aluminum 'core' is enclosed by a layer of aluminum oxide 'enclosure'. In the process of heat storage, metallic aluminum can absorb heat to be changed from a solid state to a liquid state and the temperature of the metallic aluminum rises; at the same time, the external aluminum oxide layer also can absorb the heat, so that the temperature of the external aluminum oxide layer rises; and in the process of heat transfer, the liquid metallic aluminum releases both hidden heat and sensible heat and the aluminum oxide enclosure releases the sensible heat. The preparation process of the Al / Al2O3 heat storage material is obviously different from a conventional method, and comprises the following steps of: atomizing the liquid metallic aluminum (above 660 DEG C) into tiny particles with an atomizing device; and cooling the tiny liquid metallic aluminum particles in an oxidizing atmosphere and oxidizing the external aluminum oxide layer to form the Al / Al2O3 phase-change heat storage material taking the metallic aluminum as the 'core' and taking aluminum oxide as the 'enclosure', wherein the oxidizing atmosphere may adopt oxygen, water vapor, carbon dioxide or air diluted by an inert gas. The preparation method is simple and easy to realize large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

Colored aluminum pigment with high color depth and preparation method thereof

InactiveCN101445675AGood acid and alkali resistanceColorfulInorganic pigment treatmentMetallic aluminumKetone solvents

The invention relates to a colored aluminum pigment with high color depth and a preparation method thereof. The colored aluminum pigment is obtained by depositing a layer of silicon dioxide on a flaky metallic aluminum sheet substrate and then depositing one or more layers of metal oxide on the surface of the silicon dioxide, and the colored aluminum pigment exists in the form of dry powder. The preparation method comprises the following steps: a. stirring to disperse commercially available aluminum pigment slurry in alcohol, alcohol ether or a ketone solvent; b. regulating the temperature to 30-80 DEG C, respectively adding tetraethoxysilane and aqueous solution to the dispersed aluminum pigment slurry with the mol ratio of the tetraethylorthosilicate to the water ranging from 1:0.5 to 1:20, adding a catalyst such as ethylenediamine solution or aqueous ammonia, and obtaining aqueous aluminum pigment slurry by vacuum filtration and washing after the reaction; and c. cladding the aqueous aluminum pigment slurry obtained in the step b with the hydrated metal oxide on the powdered aluminum surface in a liquid phase. The preparation method help prepare the colored aluminum pigment with diversified colors and high color depth without reducing brightness of the original aluminum pigment slurry.

Owner:WENZHOU YOUNGBIO CHEM

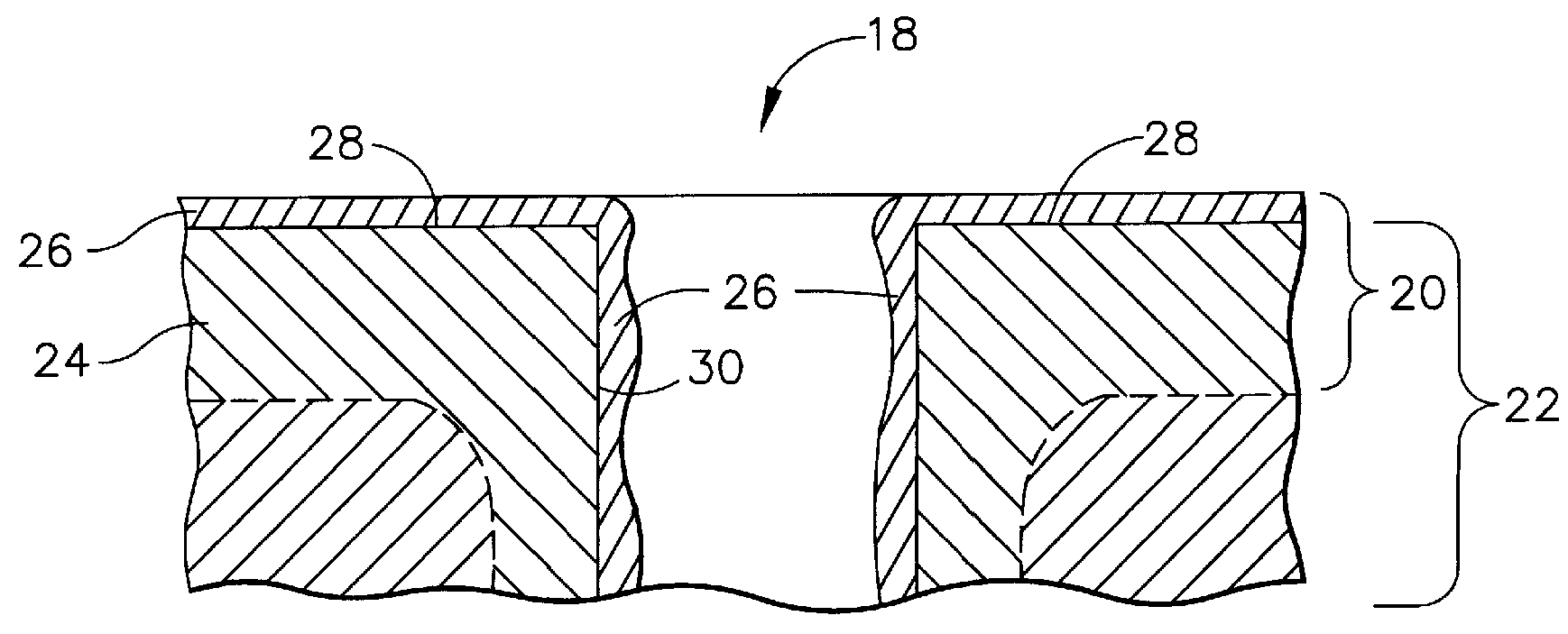

Slurry diffusion aluminide coating composition and process

ActiveUS20090126833A1Easy to disassembleSolid state diffusion coatingAnti-corrosive paintsMetallic aluminumSlurry coating

A slurry and slurry coating process for forming a diffusion aluminide coating on a substrate, including internal surfaces within the substrate. The process involves preparing a slurry of a powder containing a metallic aluminum alloy having a melting temperature higher than aluminum, an activator capable of forming a reactive halide vapor with the metallic aluminum, and a binder containing an organic polymer. The slurry is applied to surfaces of the substrate, which is then heated to burn off the binder, vaporize and react the activator with the metallic aluminum to form the halide vapor, react the halide vapor at the substrate surfaces to deposit aluminum on the surfaces, and diffuse the deposited aluminum into the surfaces to form a diffusion aluminide coating. The process can be tailored to selectively produce an inward or outward-type coating. The binder burns off to form an ash residue that can be readily removed.

Owner:GENERAL ELECTRIC CO

Preparation method of wear-resistant high-chromium cast iron

The invention discloses a preparation method of wear-resistant high-chromium cast iron and belongs to the technical field of metal materials. According to the preparation method, common scrap steel, carburant, ferrochromium, ferromolybdenum, copper plates, ferrochromium nitride, ferrosilicon, ferromanganese, ferroboron and aluminum are smelted in an electric furnace so as to form the wear-resistant high-chromium cast iron. The molten wear-resistant high-chromium cast iron comprises the following chemical components in percentage by mass: 3.0-3.5% of C, 18-25% of Cr, 0.3-0.5% of Mn, 0.3-0.5% of Si, 0.18-0.25% of N, 0.5-0.8% of Mo, 0.2-0.4% of B, 0.08-0.12% of Al, 0.5-1.0% of Cu, less than 0.05% of S, less than 0.05% P and the balance of Fe. Molten iron is treated with an inoculator when taken out from the electric furnace, and is treated with a suspending agent when poured, so as to obtain fine solidification structures. Therefore, the wear-resistant high-chromium cast iron has excellent properties.

Owner:BEIJING UNIV OF TECH

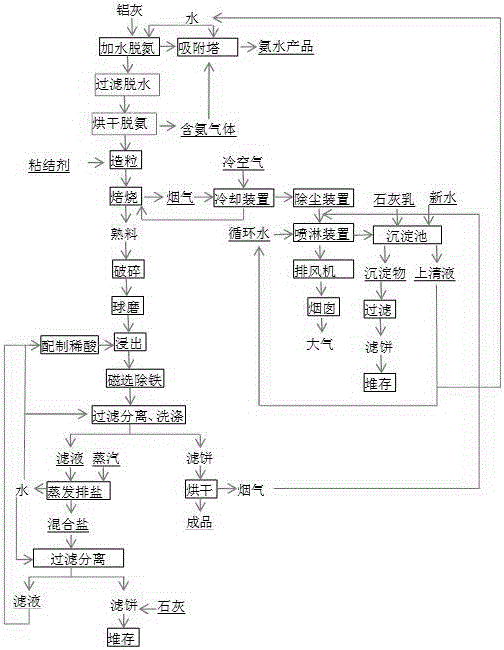

Resourceful treatment method for aluminum ash

ActiveCN106694514AIncrease profitImprove protectionSolid waste disposalTransportation and packagingMetallic aluminumResource utilization

The invention provides a resourceful treatment method for aluminum ash. Firstly, denitrification treatment, defluorination treatment and arsenic removal treatment are conducted so that nitrogen in the aluminum ash can be separated out in the form of ammonia gas to be recycled, harmful substances such as fluorine and arsenic are volatilized out, roasting is conducted, and aluminum ash clinker is obtained; and then metal impurity removing treatment is conducted, the roasted aluminum ash clinker is broken and finely ground and then is leached through diluted acid, metal impurities such as K2O, Na2O, CaO and MgO in the aluminum ash clinker are dissolved out, iron is removed through magnetic separation, and after pressure filtration separation, a finished aluminum oxide product is obtained through drying. According to the resourceful treatment method for the aluminum ash, aluminum oxide, metallic aluminum and the like in the aluminum ash can be recycled, byproducts such as ammonia water and iron are obtained, waste is turned into wealth, the social resource utilization rate is increased, meanwhile, components of fluorine and arsenic in the aluminum ash are removed, innocent treatment is done, and environment protection is facilitated.

Owner:三门峡华森新型材料有限公司 +1

Production process of aliphatic polyetheramine

The invention belongs to the technical field of high molecular materials and provides a production process of aliphatic polyetheramine. In the process, aliphatic polyetheramine is prepared by catalyzing, reducing and aminating polyether polyol of which the number-average molecular weight is over 100 and which serves as a raw material in the presence of hydrogen gas, an aminating agent and a framework nickel catalyst. The framework nickel catalyst consists of 85-95 percent by mass of metal nickel and 15-5 percent of metal aluminum. The framework nickel catalyst and the aminating agent are circularly applied mechanically after being treated. The entire process has the advantages of high route selectivity, high transformation ratio, low environmental pollution and convenience for post-treatment.

Owner:CHINA PETROCHEMICAL CORP +1

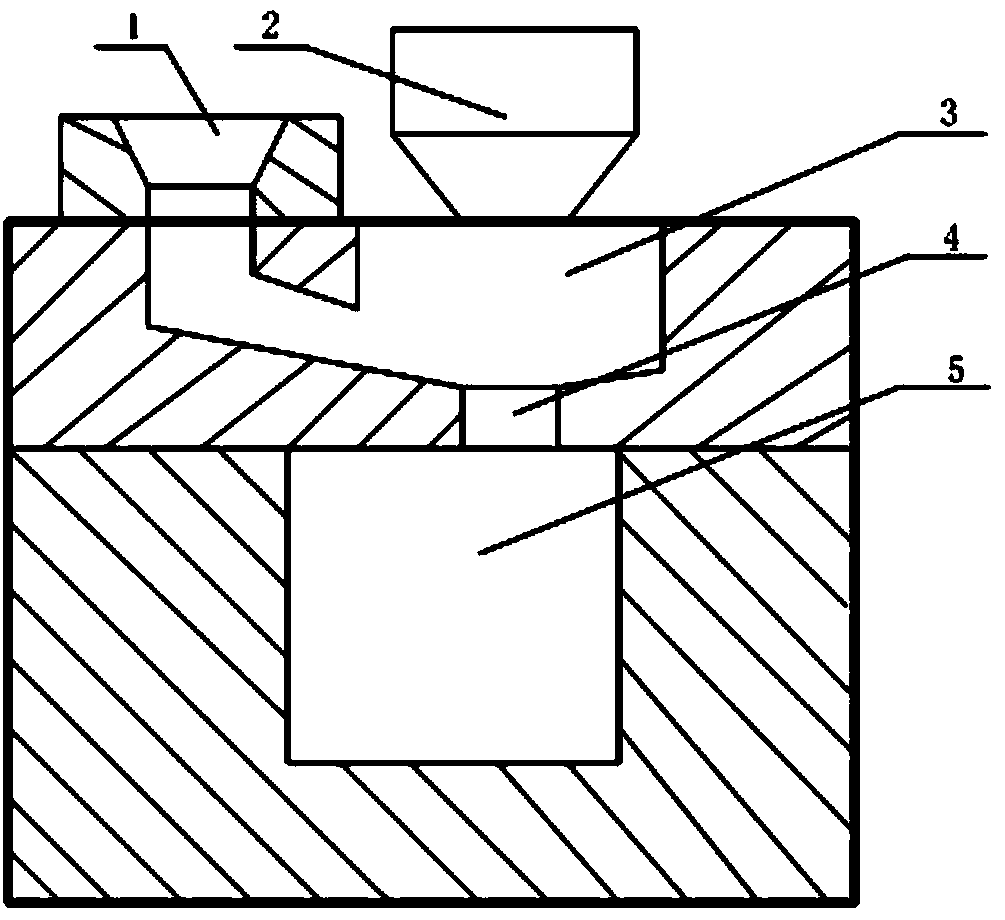

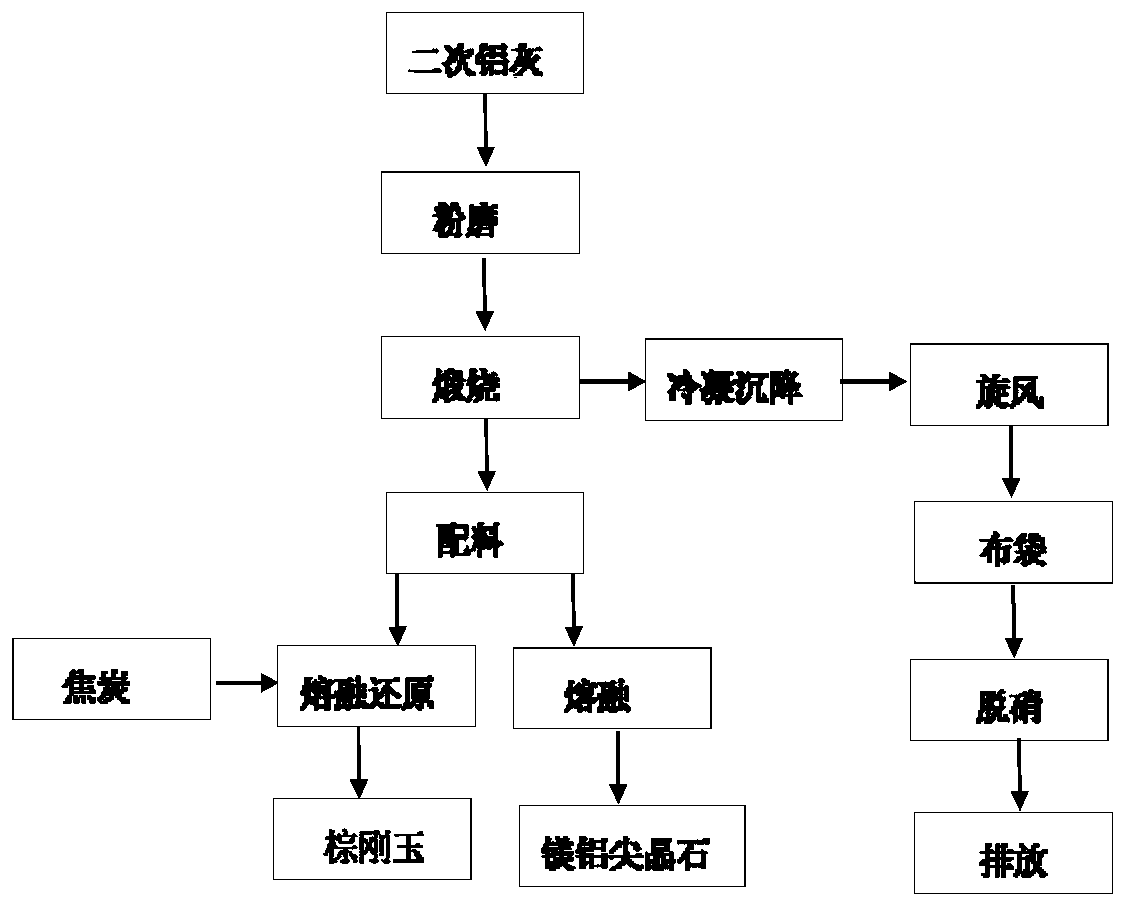

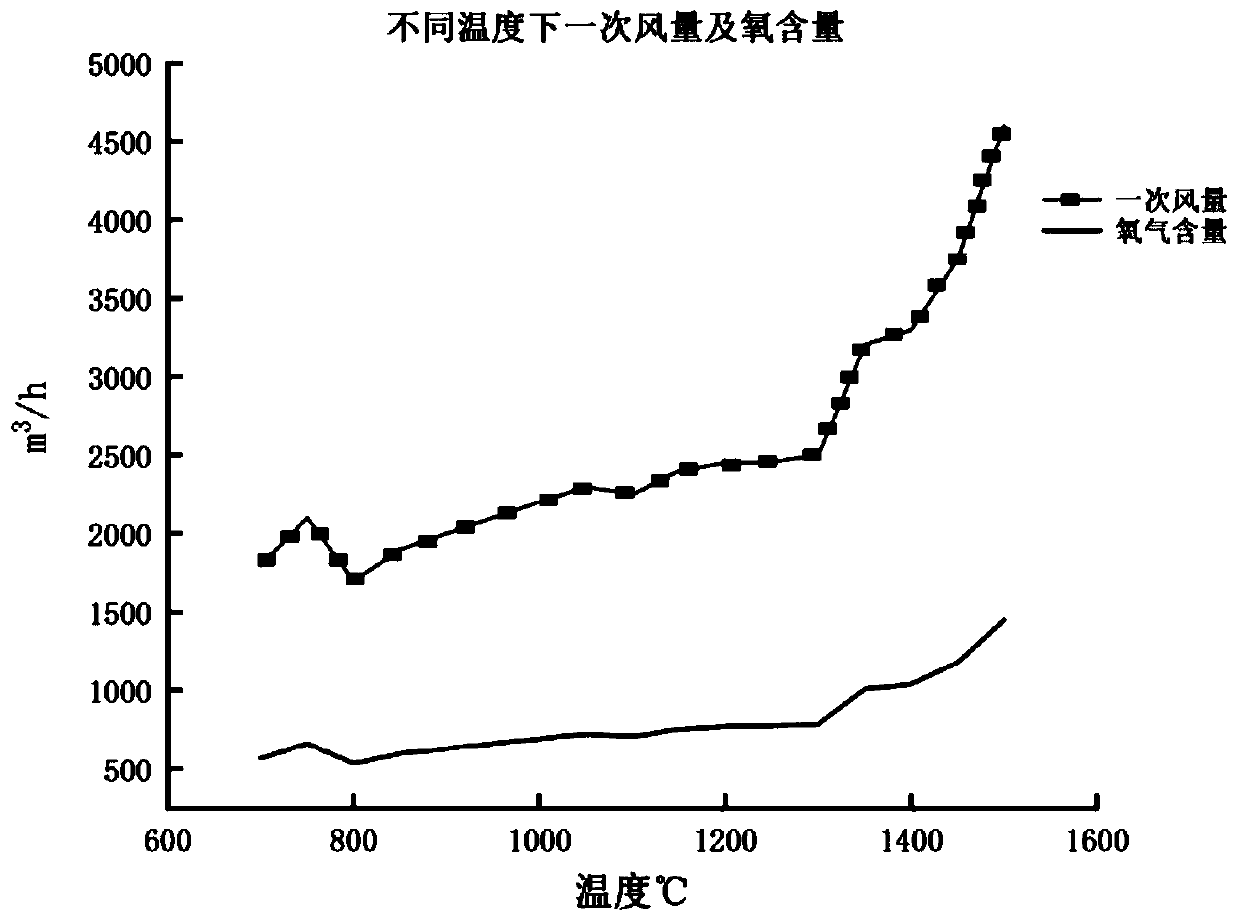

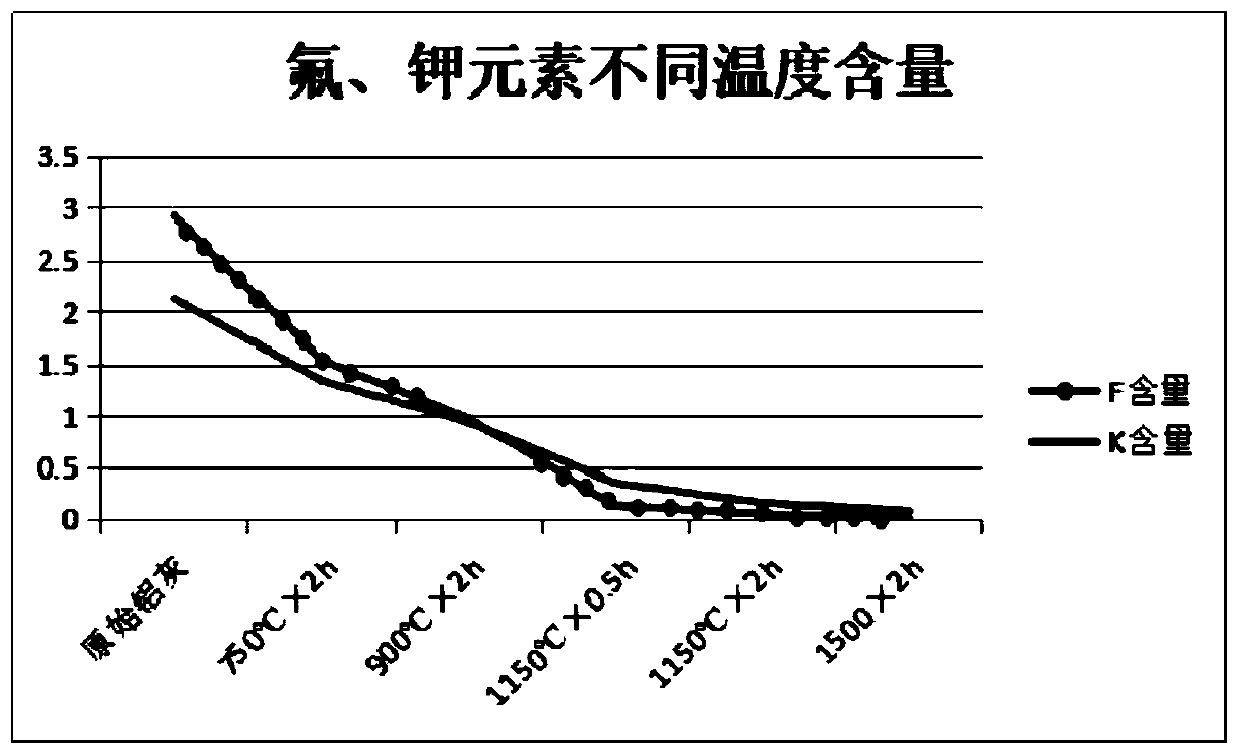

Method of manufacturing refractory material by innocent treatment of secondary aluminum ash

The invention discloses a method for manufacturing a refractory material by innocent treatment of secondary aluminum ash, and belongs to the field of aluminum industry. The method comprises the following steps: further grinding the secondary aluminum ash until 80% of the secondary aluminum ash passes through a screen with the pore diameter of 74 microns; and calcining the secondary aluminum ash for 0.5-4 hours at the temperature of 1150-1550 DEG C in an oxidizing atmosphere with the oxygen content of 12%-18% to convert metal aluminum, aluminum nitride and aluminum carbide in the secondary aluminum ash into aluminum oxide and volatilize the fluoride salt and chloride salt in the secondary aluminum ash, thereby producing a calcined oxide; cooling the waste flue gas containing fluoride salt and chlorate produced in the calcining process for recovery, and denitrifying and discharging the flue gas. The calcined oxide is independently prepared or mixed with an additive, and the aluminum-magnesium refractory material is prepared after electric arc melting. The preparation method can be used for preparing the refractory material with high purity.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

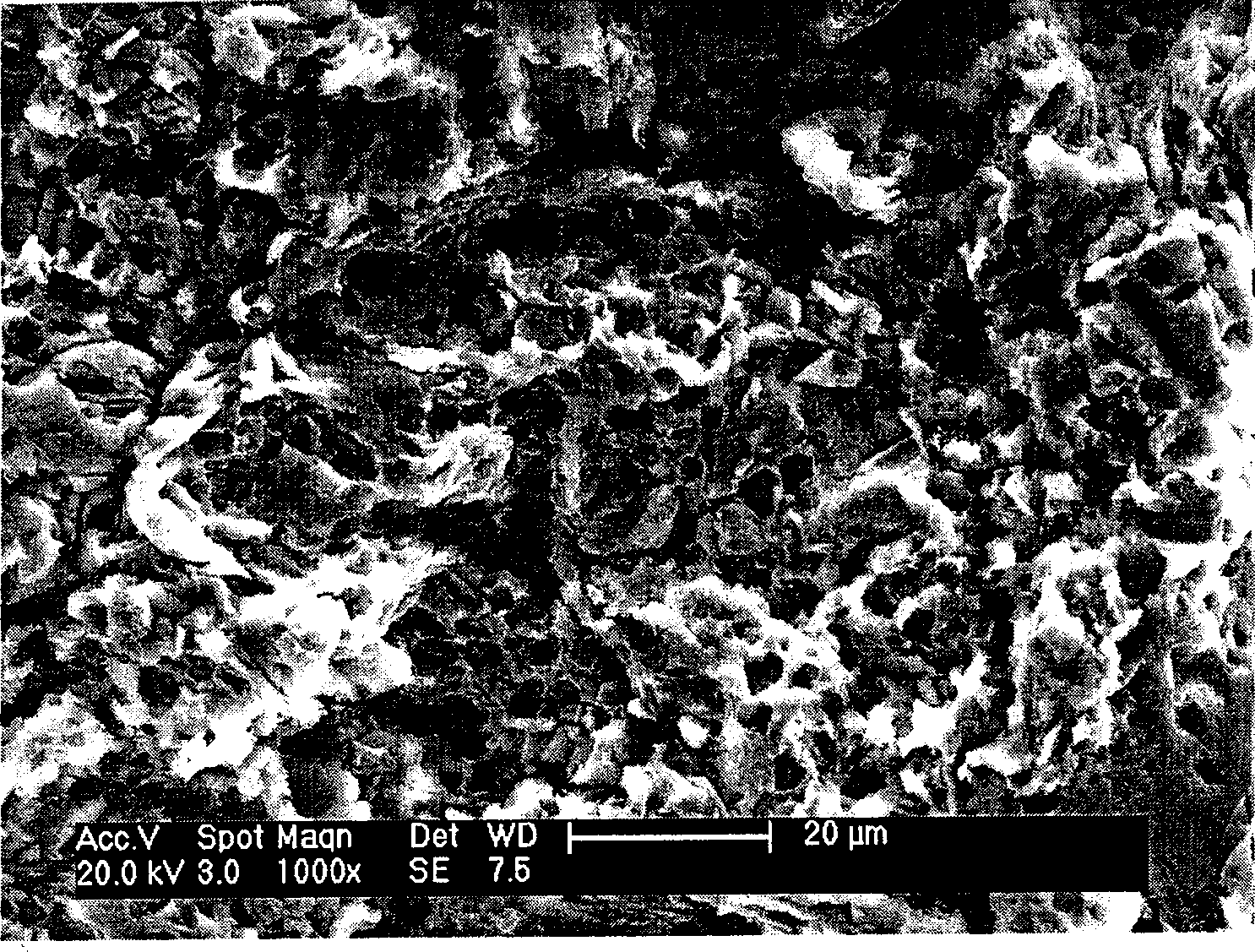

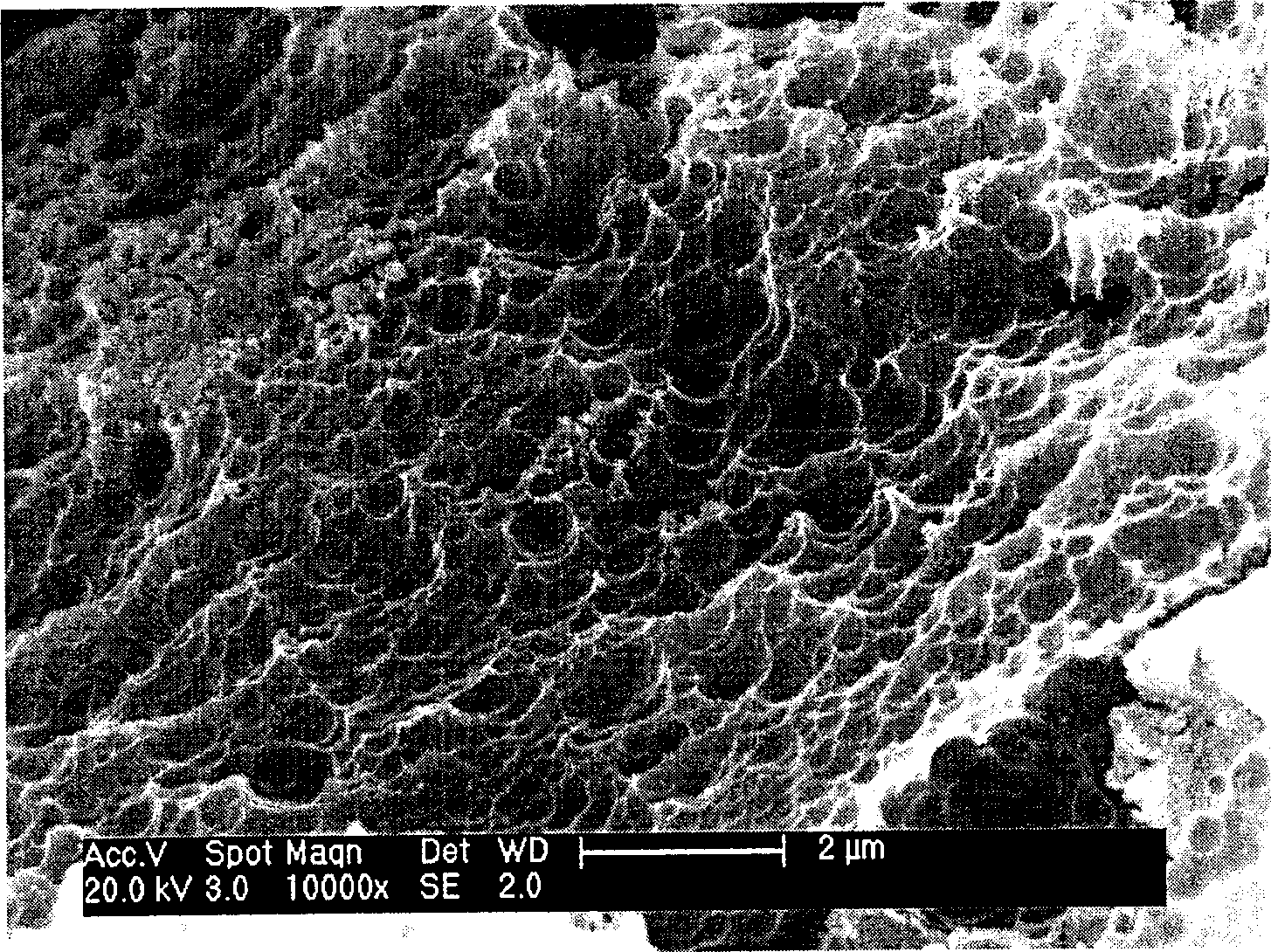

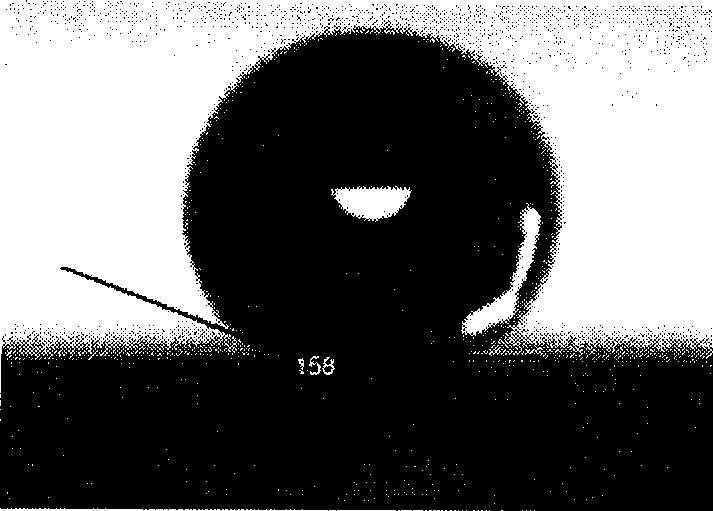

Surface treating method for sea water corrosion-resistant metal aluminum or aluminum alloy

InactiveCN101429672AImprove seawater corrosion resistanceEase of industrial applicationAnodisationMetallic aluminumElectrolysis

The invention relates to a method for treating the surface of seawater corrosion resistant metallic aluminum or aluminum alloy. The method comprises the following steps: 1) sand pellets are used to carry out gritting blasting treatment for the surfaces of aluminum and aluminium alloy through a spray gun so as to bring about the concave and convex surface topography in the micron order for aluminium and aluminium alloy; 2 the aluminium and aluminium alloy is cleaned after degreasing and is taken as the anode of an electrolytic bath, and nickel is taken as a cathode; the electrolyte is prepared and is added into the electrolytic bath, and a DC power supply is connected with the anode and the cathode so as to form nanometer holes on the aluminium or aluminium alloy surface; and 3 silicon fluoride is taken to carry out the surface finish of aluminum or aluminium alloy so as to reduce the surface free energy of aluminium or aluminium alloy. The method for adopting silicone fluoride to carry out the surface finish of aluminum or aluminium alloy comprises the following steps: heating up the aluminium or aluminium alloy processed in step 2 to 90 to 120 DEG C, keeping the temperature for 30 to 40 minutes, taking the aluminium or aluminum alloy out and cooling down the aluminium or aluminum alloy to a room temperature, and then carrying out surface finish through a soak method or a vapor plating method. The processed aluminium metal or aluminum alloy has good resistance to seawater corrosion.

Owner:SOUTHEAST UNIV

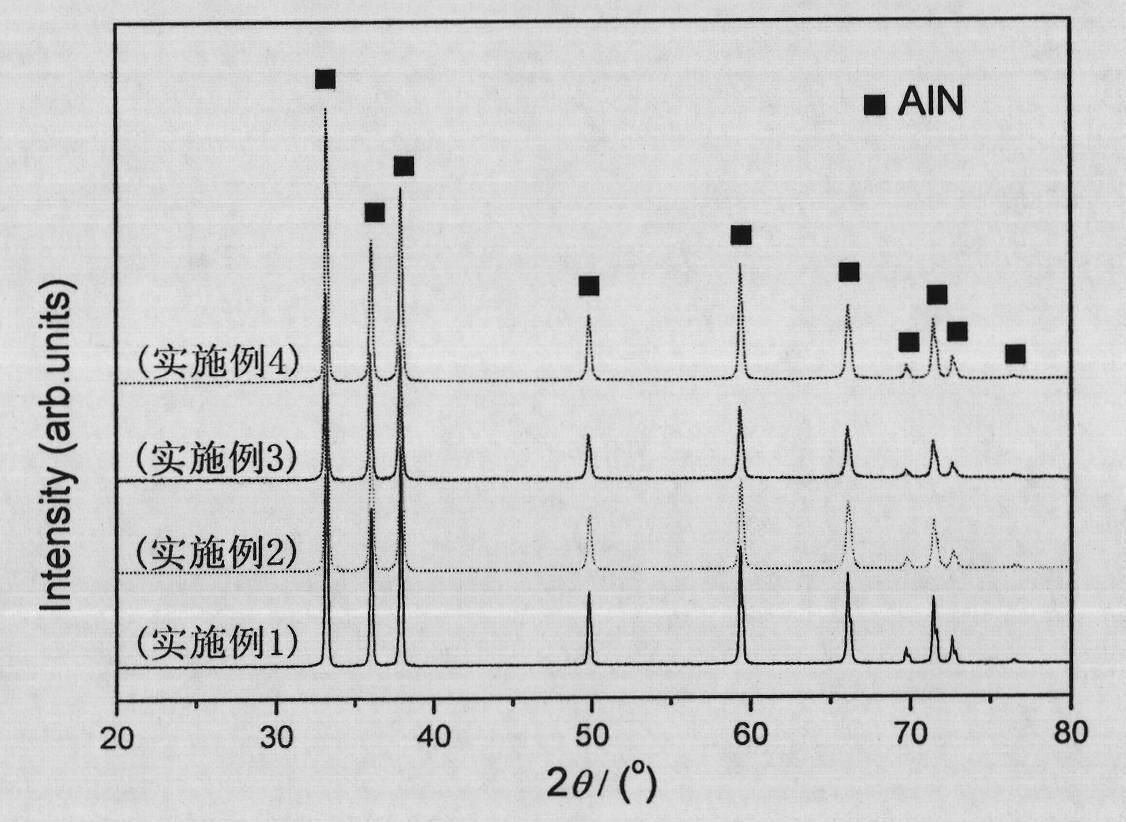

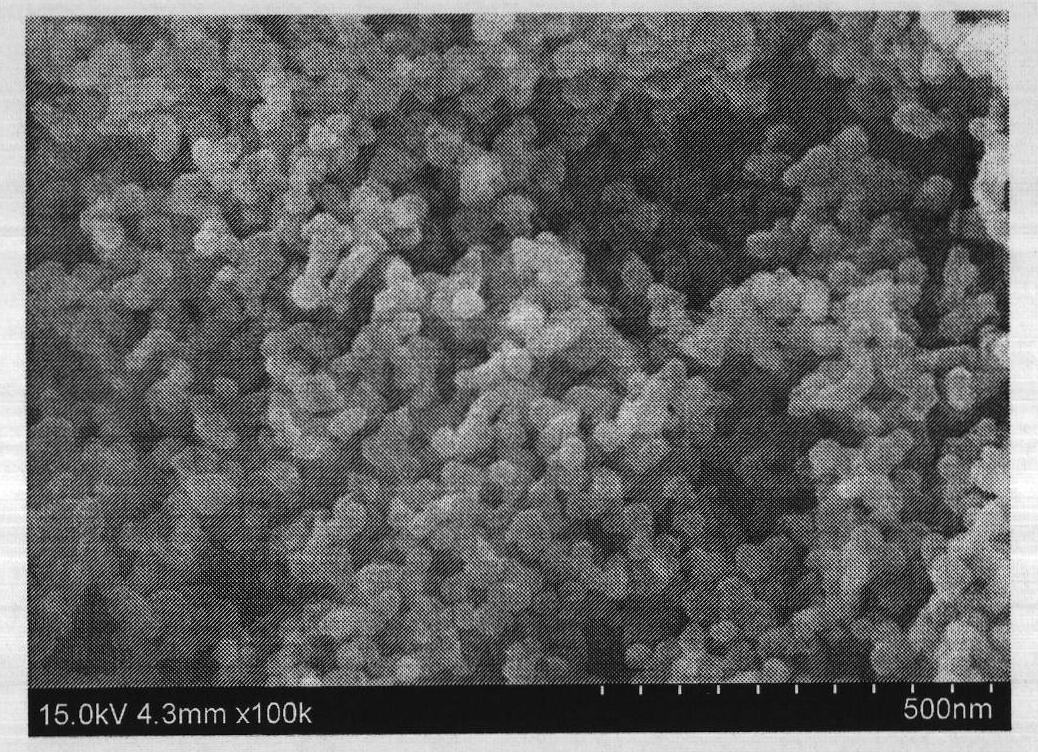

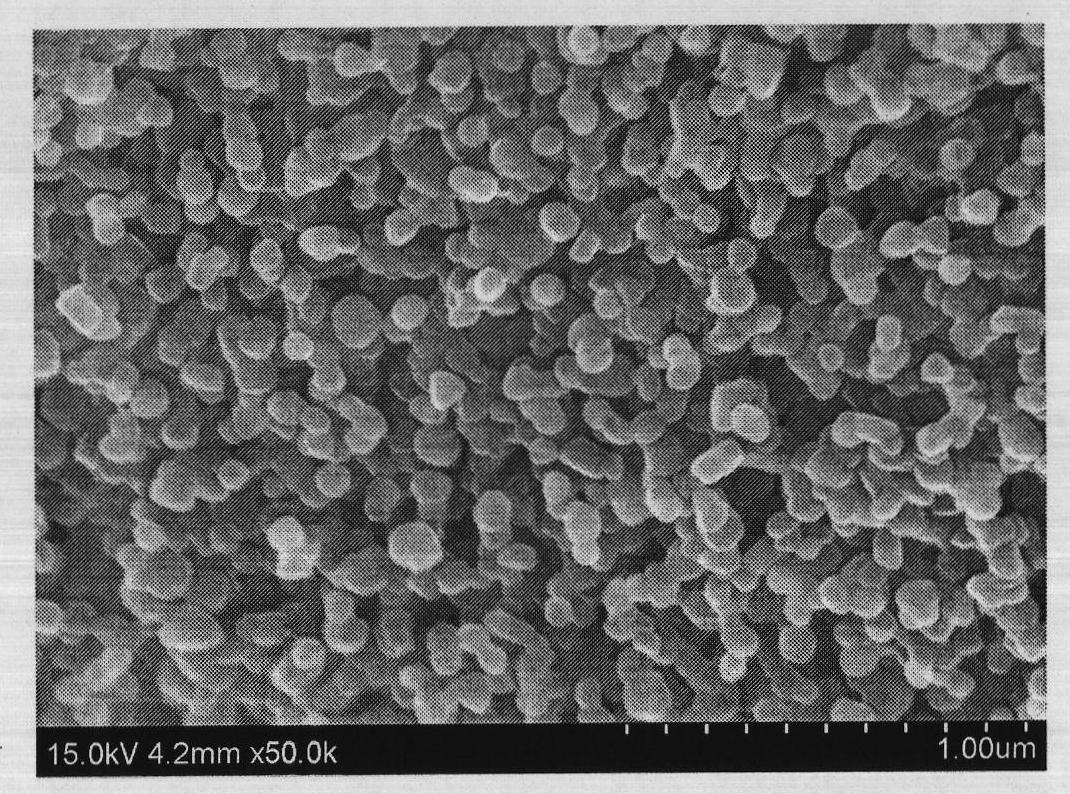

Method for preparing nano aluminum nitride powder

ActiveCN101973532ASmall particle sizeEvenly distributedNanostructure manufactureNitrogen compoundsAluminum IonMetallic aluminum

The invention discloses a method for preparing nano aluminum nitride powder. The method comprises the following steps of: dissolving an aluminum source and a carbon source in a solvent respectively, mixing the dissolved aluminum source and carbon source and glycol solution of citric acid; warming the mixed solution to 125 to 135 DEG C, and keeping the temperature for 2 to 4 hours; continuously warming to 180 to 220 DEG C, and keeping the temperature for 2 to 4 hours to obtain a crisp black substance; calcining the crisp substance at the temperature of between 800 and 1,200 DEG C in vacuum or in the atmosphere of nitrogen; cooling the calcined substance and grinding; and performing a carbothermal reduction reaction at the temperature of between 1,350 and 1,600 DEG C to obtain the nano aluminum nitride powder. Raw materials adopted by the method have a wide source range and are readily available, a preparation process is simple and controllable, and aluminum ions are uniformly distributed in the carbon source by using the complexing action of the citric acid on metallic aluminum ions and the bonding and steric hindrance actions of glycol on the metallic aluminum ions so as to finally obtain the nano aluminum nitride powder with small particle sizes and uniform particle distribution.

Owner:深圳特新界面科技有限公司

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

Preparation method of whole continuous nano-porous copper

The invention relates to a preparation method of whole continuous nano-porous copper, comprising the following steps: (1) heating the pure metallic aluminum and copper to the molten state, stirring and mixing the mixture to form Cu-Al alloy liquid; (2) fast blowing the alloy liquid out with inert gas to solidify the molten liquid metal on the copper rollers which rotate in high speed and prepare alloy strips, or solidify the molten liquid metal in copper molds to prepare alloy plates or alloy bars; and (3) performing dealloying process to the obtained alloy, cleaning the alloy in the distilled water to be neutral and airing the alloy to obtain nano-porous copper. The beneficial effects of the invention are as follows: (1) the produced nano-porous copper is whole continuous and whole continuous nanosize bulk materials can also be prepared; (2) low concentration of corrosion solution is used to prepare nano-porous copper in the method of the invention, and the operation process is simple and the method is suitable for large-scale industrialized production; and (3) according to the components of the mother alloy and the types of corrosion solution, the structure and size of nanoporous copper can be regulated.

Owner:UNIV OF JINAN

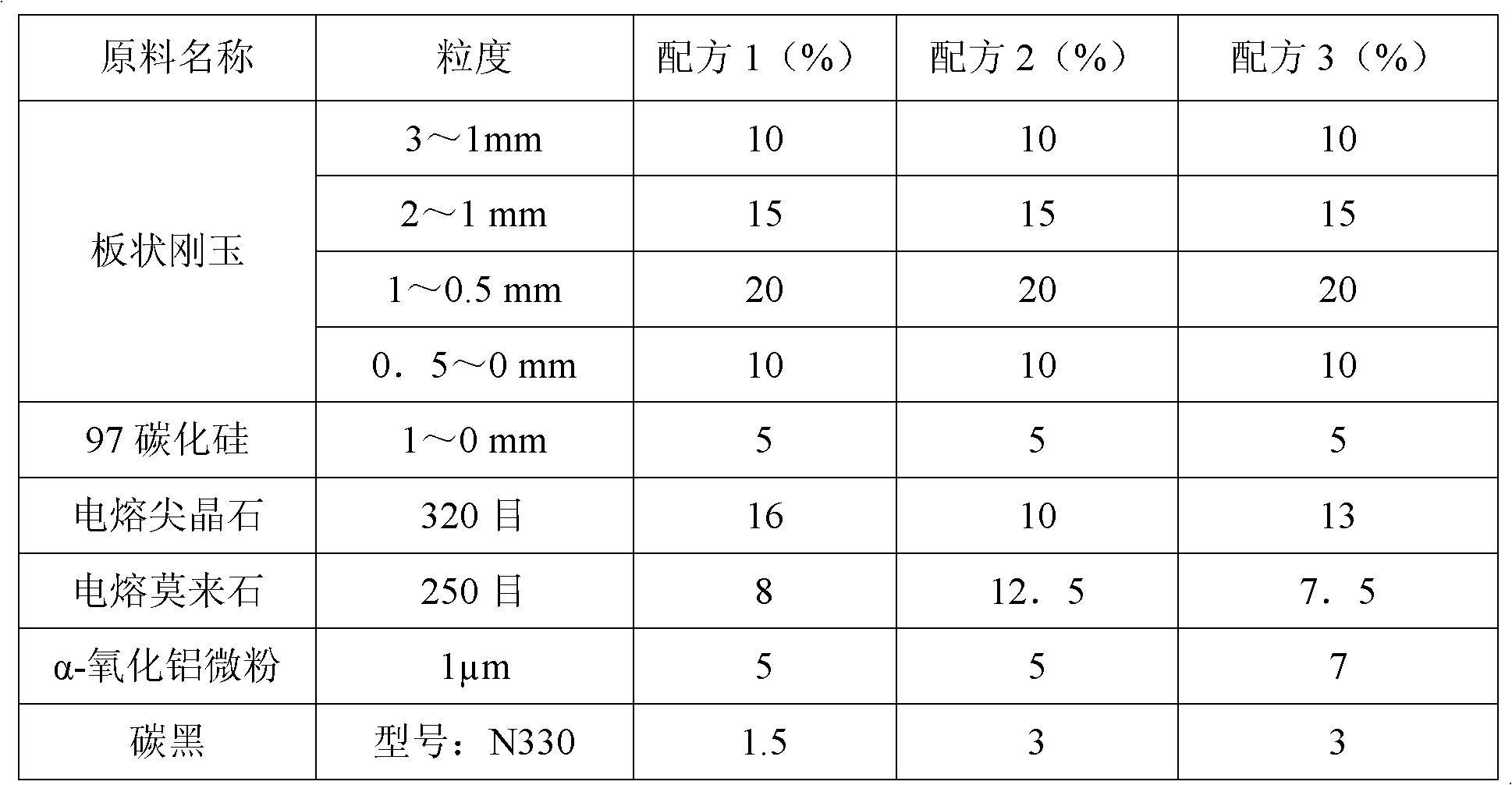

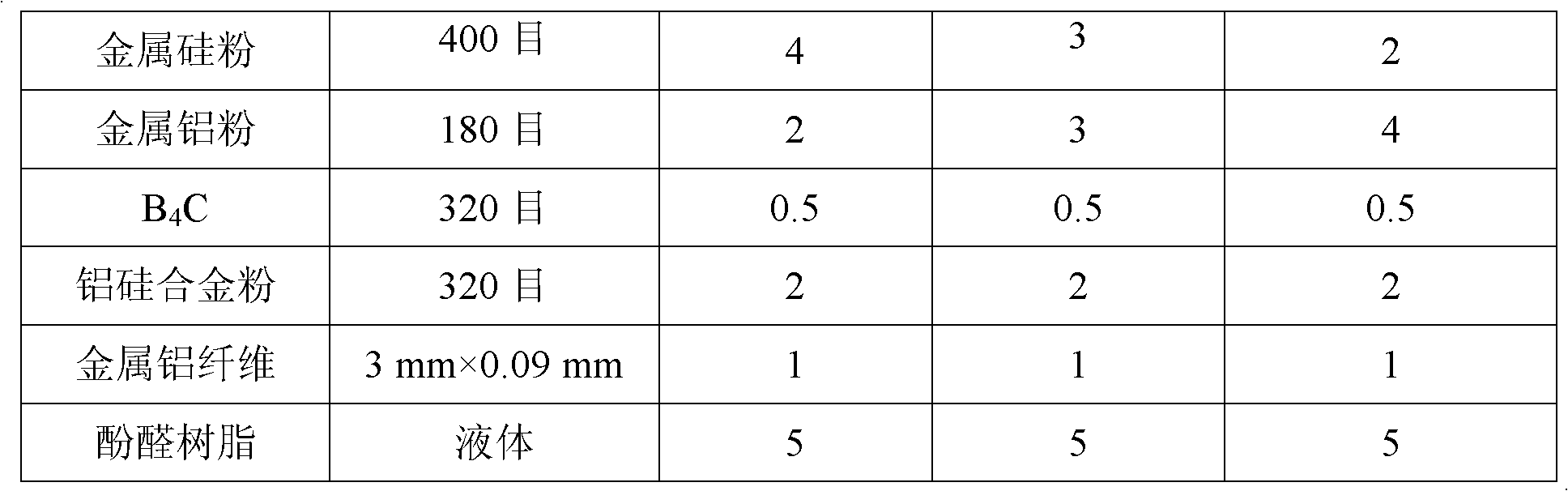

Metal ceramic combination sintering free low carbon sliding plate brick and preparation method thereof

The invention discloses a metal ceramic combination sintering free low carbon sliding plate brick and a preparation method thereof. The sliding plate brick comprises the following components according to weight percentage: 50%-60% of sintered plate shape alundum, 10%-25% of electric melting akerite, 5%-15% of electric melting mullite, 1%-3% of soot carbon, 3%-8% of Alpha- aluminum oxide micropowder, 5%-10% of silicon carbide, 2%-5% of metallic silicon powder,1%-5% of metallic aluminium powder, 0.5%-1% of boron carbide, 1%-3% of aluminum-silicon alloy powder, and 0.5%-2% of metallic aluminium fiber. In the invention, the product has low carbon, high thermal state strength, thermal shock resistance and good oxidation resistance, hole reaming is uniform, galling is less and the crack is verysmall; the process of the invention is characterized in that drying is carried out at a low temperature, the production cycle is shortened from 30 days originally to 7 days, the natural gas consumption is reduced to 2.5% of original technology, and the sintering free low carbon sliding plate brick is indeed belongs to the environmental protective and energy-saving and environmental material resistance product.

Owner:无锡市南方耐材有限公司

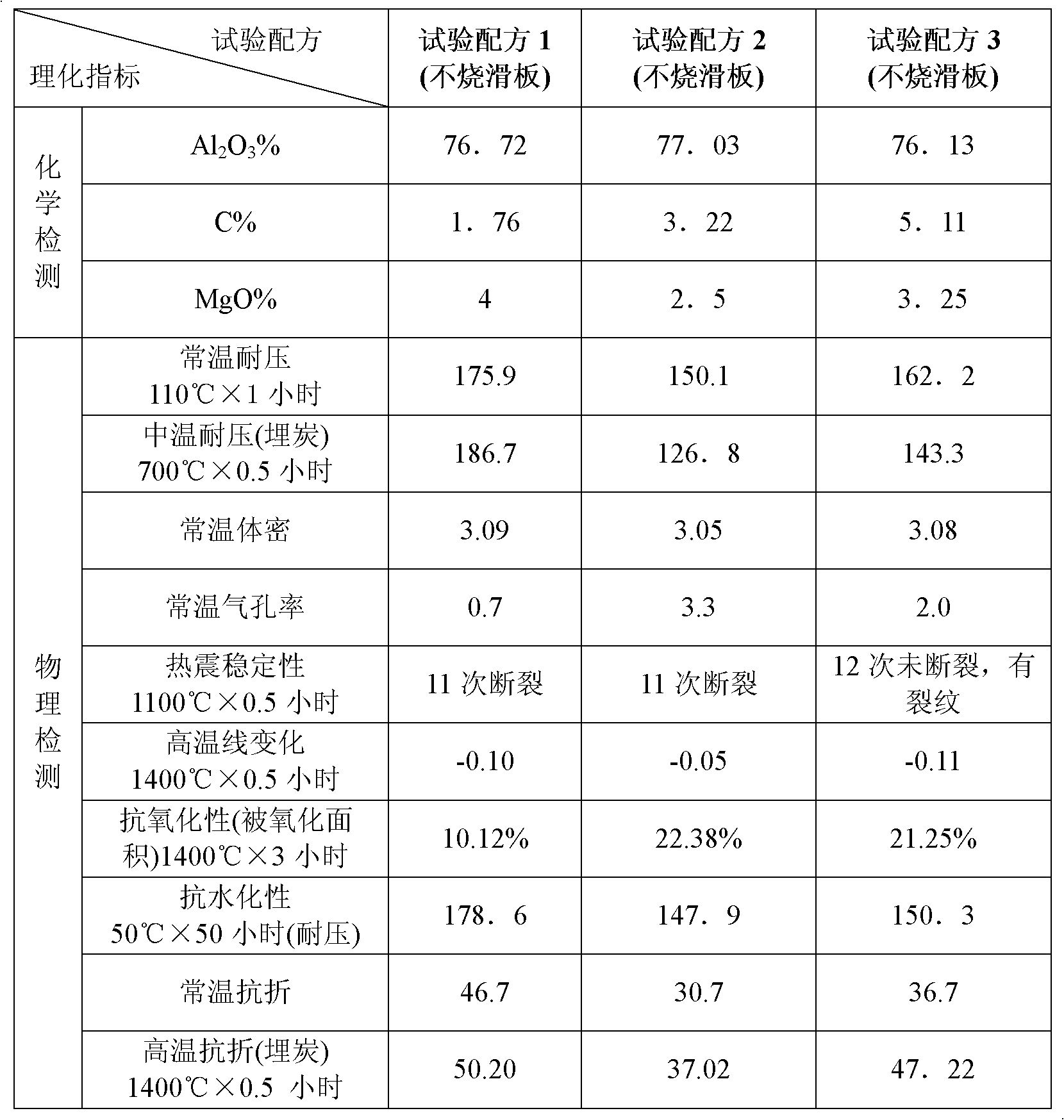

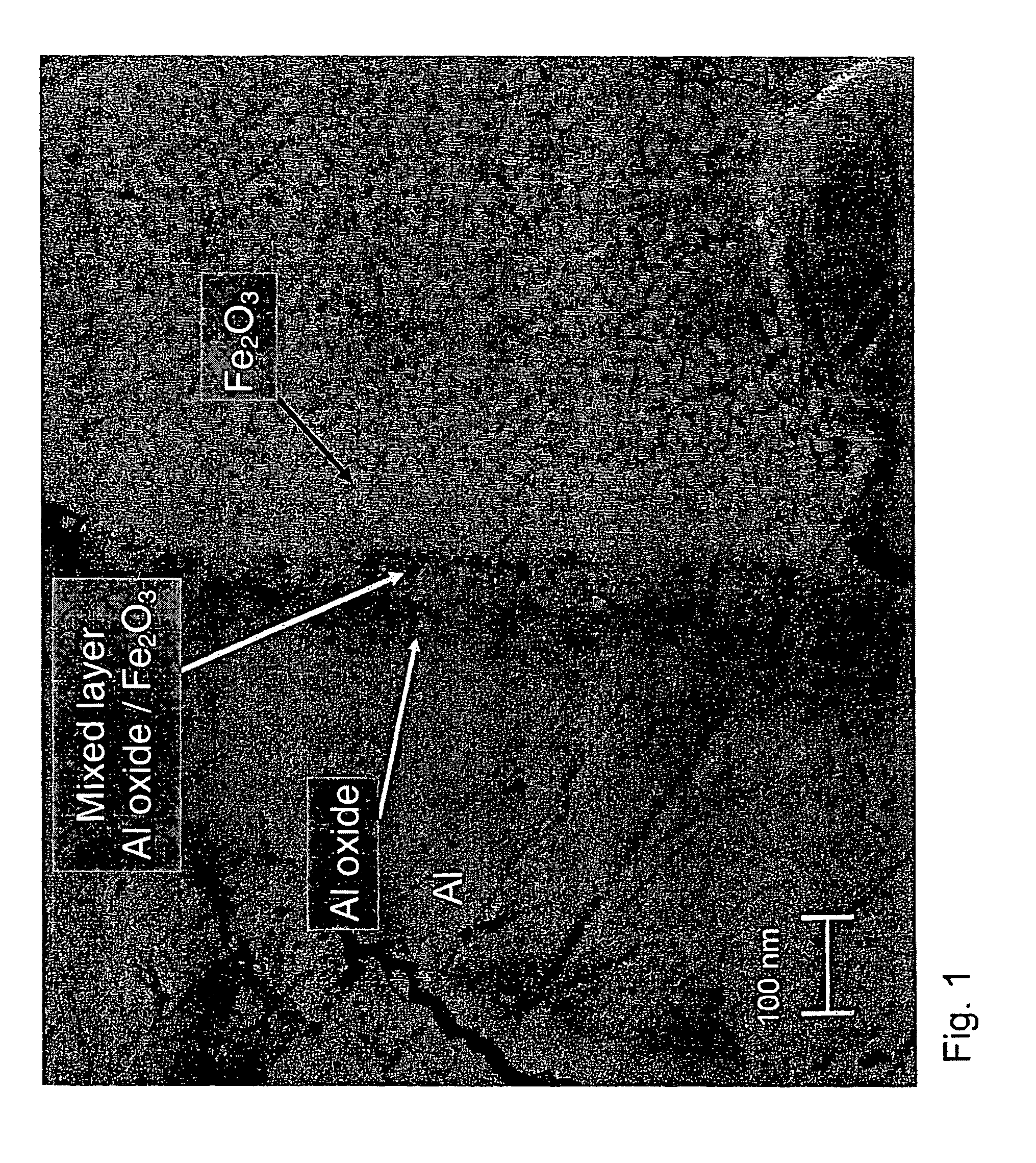

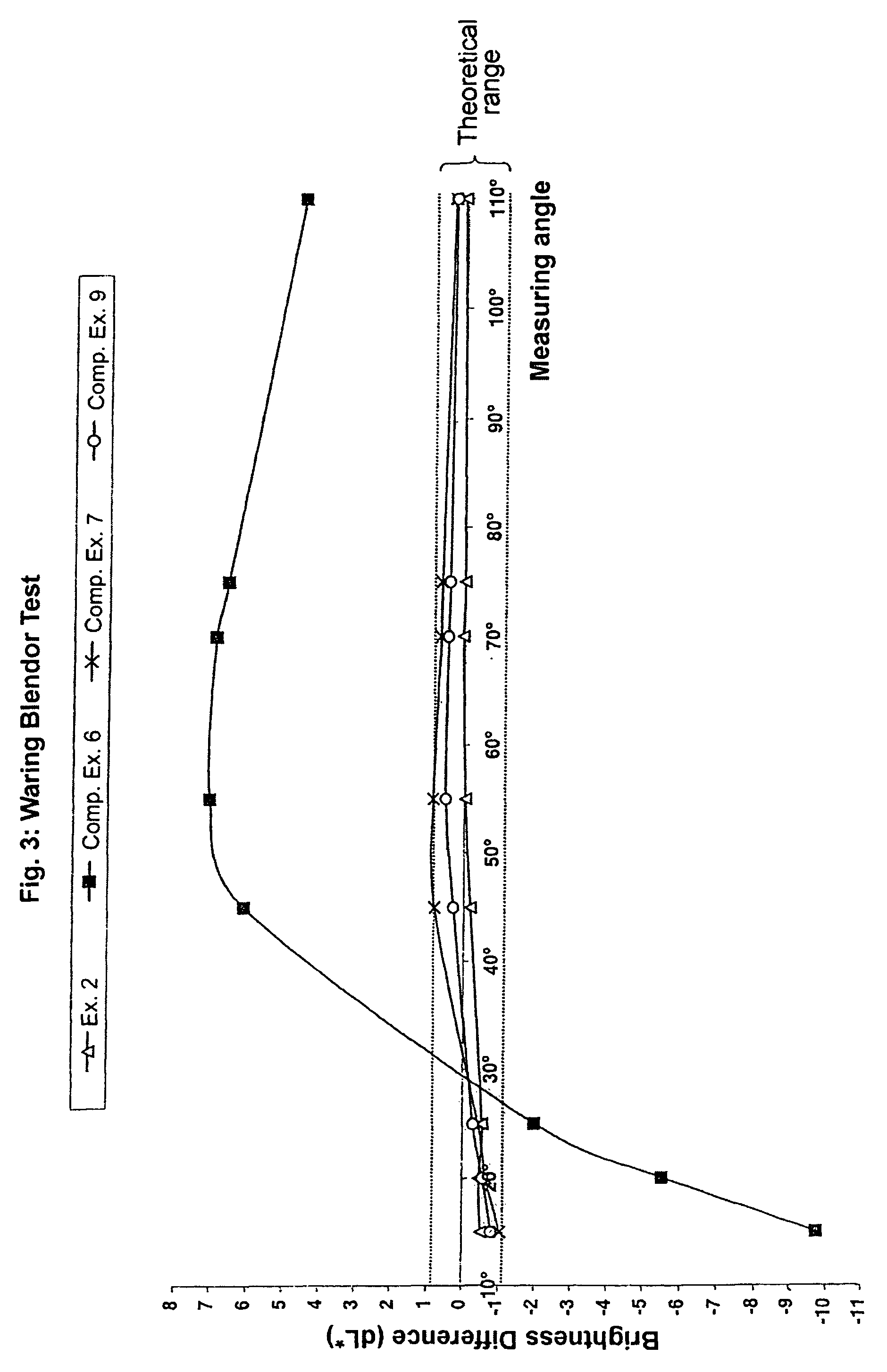

Effect pigments having an aluminum or an aluminum aloy core, process for the production thereof and use thereof

ActiveUS7828890B2Minimal thicknessEasy to useCosmetic preparationsPigmenting treatmentMetallic aluminumRefractive index

The invention relates to effect pigments having an aluminum core or aluminum alloy core and an aluminum oxide-containing or aluminum oxide / hydroxide-containing layer enveloping said aluminum core or aluminum alloy core, obtained by chemical wet-process oxidation of lamellar aluminum pigments or aluminum alloy pigments, the content of metallic aluminum in the aluminum core or aluminum alloy core being not more than 90% by weight, based on the total weight of the pigment, wherein the oxidized aluminum pigments or aluminum alloy pigments exhibit at least one highly refractive metal chalcogenide layer having a refractive index of >1.95, and a mixed layer is formed between the highly refractive metal chalcogenide layer and the enveloping aluminum oxide-containing or aluminum oxide / hydroxide-containing layer. The invention further relates to a process for the production of such effect pigments and to the use thereof.

Owner:ECKART GMBH & CO KG

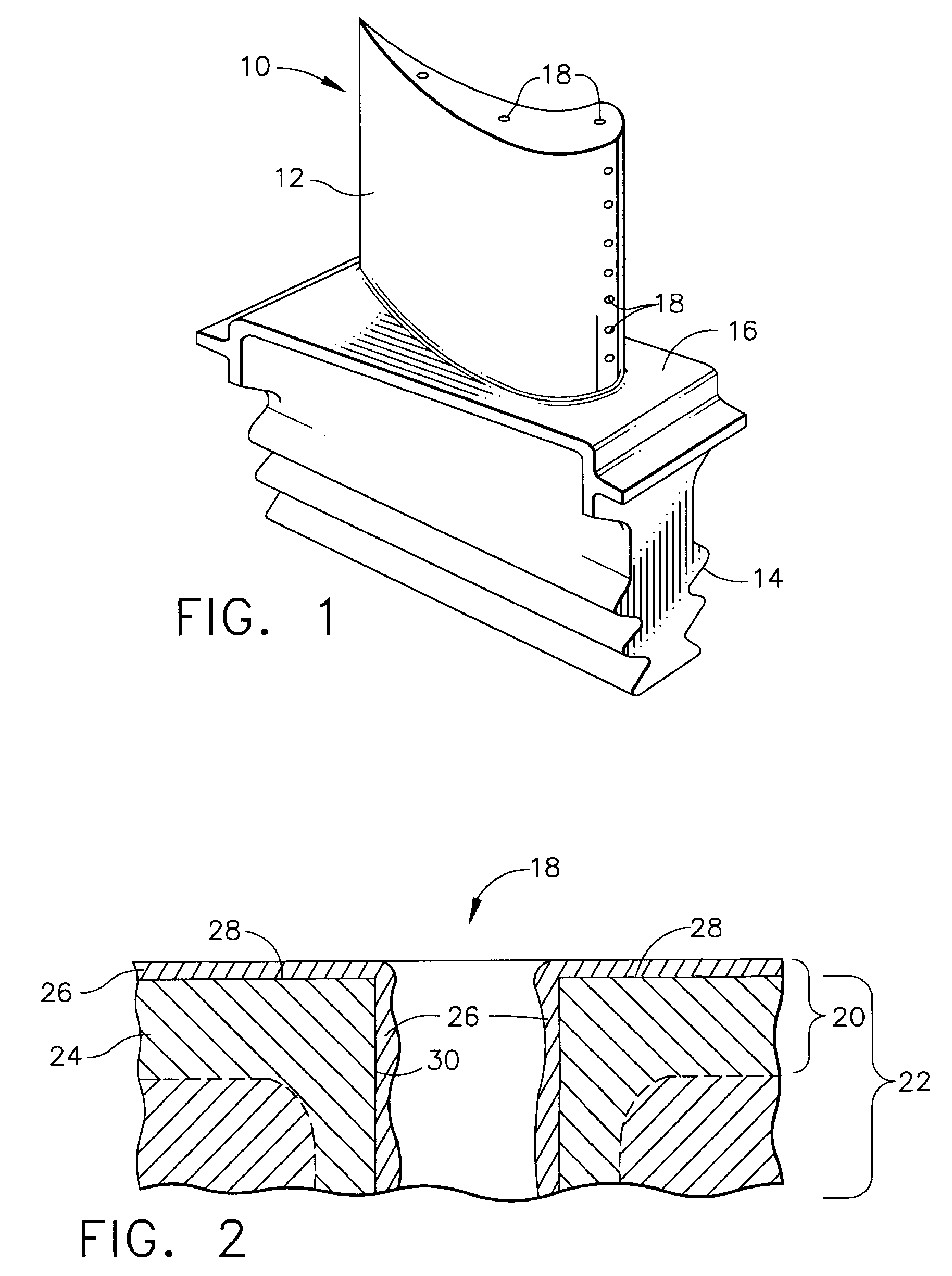

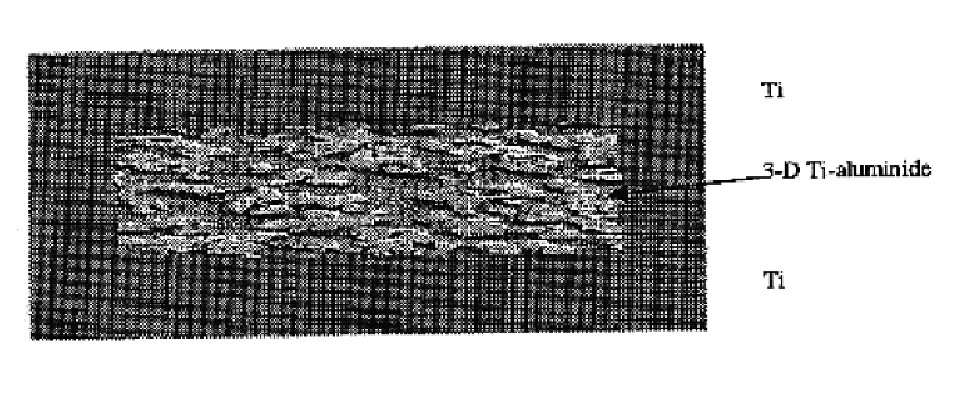

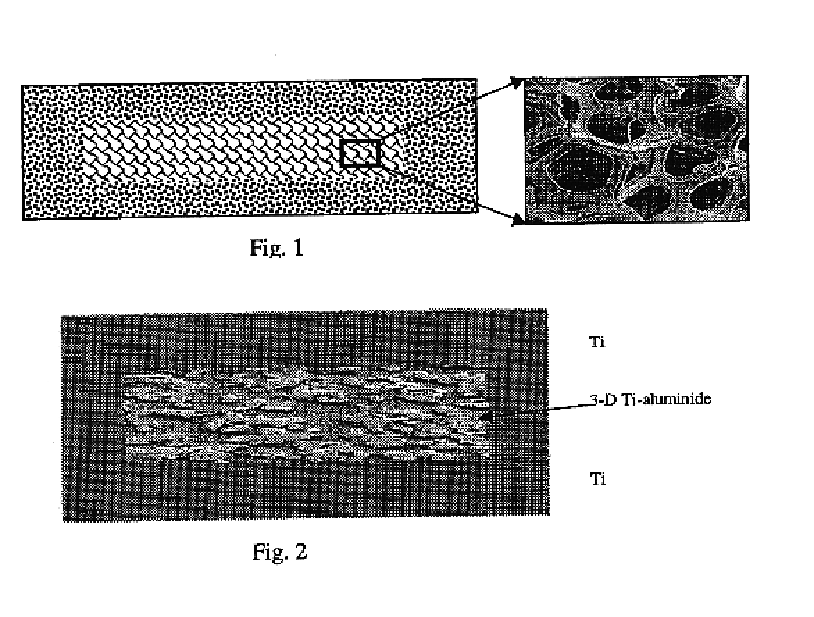

High-strength metal aluminide-containing matrix composites and methods of manufacture the same

InactiveUS6852273B2Improve mechanical propertiesLayered productsSolid state diffusion coatingMetallic aluminumNiobium

(a) The metal matrix composite is suitable for the manufacture of flat or shaped titanium aluminide, zirconium aluminide, or niobium aluminide articles and layered metal composites having improved mechanical properties such as lightweight plates and sheets for aircraft and automotive applications, thin cross-section vanes and airfoils, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. The composite material consists of a metal (e.g., Ti, Zr, or Nb-based alloy) matrix at least partially intercalated with a three-dimensional skeletal metal aluminide structure, whereby ductility of the matrix metal is higher than that of the metal aluminide skeleton. The method for manufacturing includes the following steps: (a) providing an aluminum skeleton structure having open porosity of 50-95 vol. %, (b) filling said skeleton structure with the powder of a reactive matrix metal, (c) compacting the aluminum skeleton / matrix powder composite preform by cold rolling, cold die pressing, cold isostatic pressing, and / or hot rolling, (d) consolidating the initial or compacted composite preform by sintering, hot pressing, hot rolling, hot isostatic pressing, and / or hot extrusion to provide, at least partially, a reaction between aluminum skeleton and matrix metal powder, and (e) diffusion annealing followed by any type of heat treatment needed to provide predetermined mechanical and surface properties of the resulting metal matrix composite. The combination of ductile matrix and metal aluminide skeletal structure results in significant improvement of mechanical properties of the composite material, especially hot strength. This high-strength aluminide-based material can also be used as a core component in multilayer metal matrix composites.

Owner:ADVANCE MATERIAL PRODS ADMA PRODS

Method for producing aerated concrete with refuse incinerator slag

InactiveCN103387411AReduce processing costsReduce manufacturing costCeramicwareAluminiumResource utilization

The invention provides a method for producing aerated concrete with refuse incinerator slag. The method is characterized in that the following raw materials are added by mass percent: 30-60% of fly ash, quartz sand and / or granulated blast furnace slag, 5-15% of Portland cement, 15-25% quicklime, 3-5% of dihydrate gypsum and 10-40% (preferably 9.5-39%) of refuse incinerator slag. Compared with the prior art, the method has the following advantages: (1) the refuse incinerator slag is greatly utilized to produce aerated concrete, so that the method belongs to the resource utilization technology and can substantially reduce the high treatment costs; and (2) the metallic aluminium is fully utilized.

Owner:YANTAI UNIV

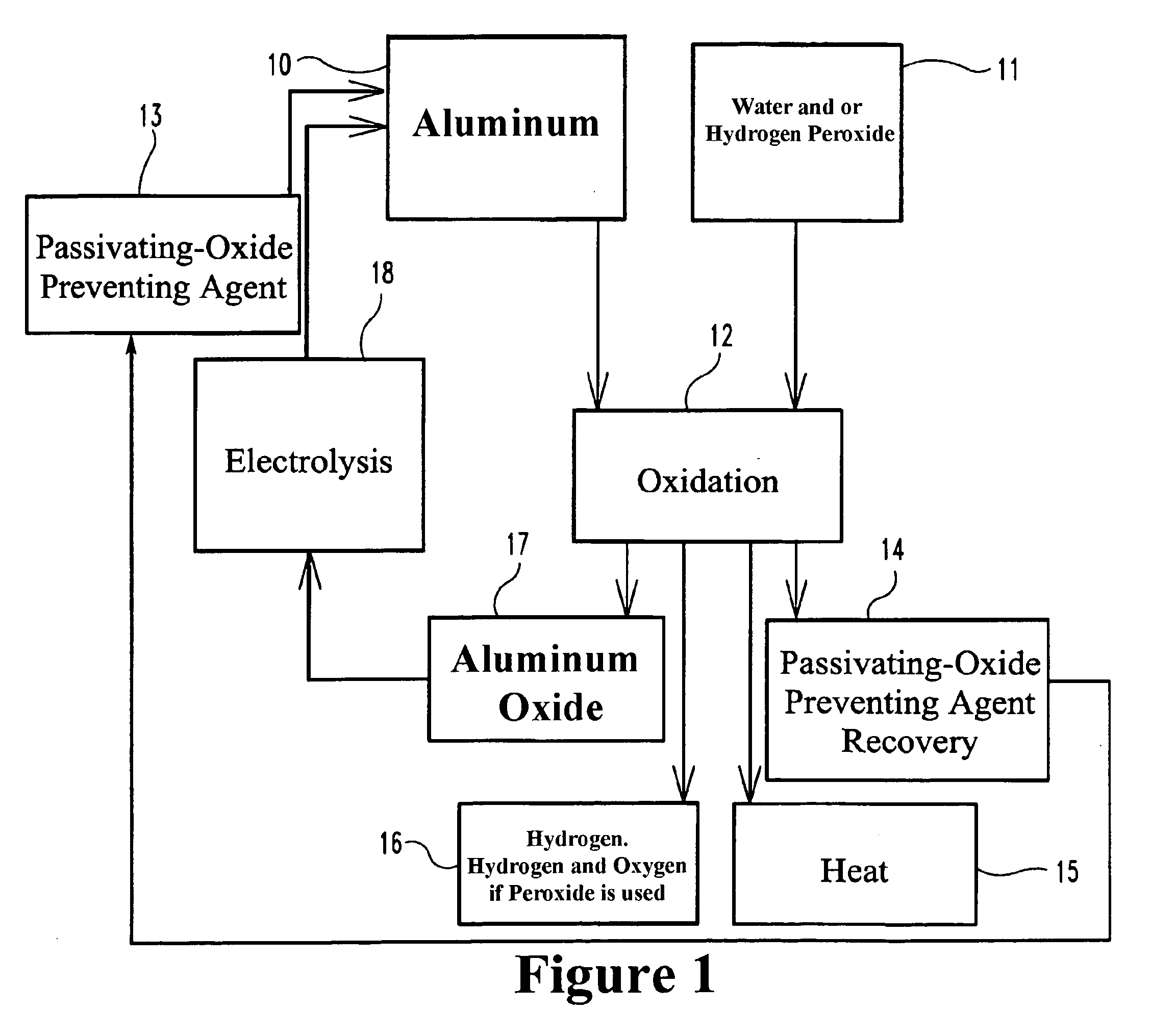

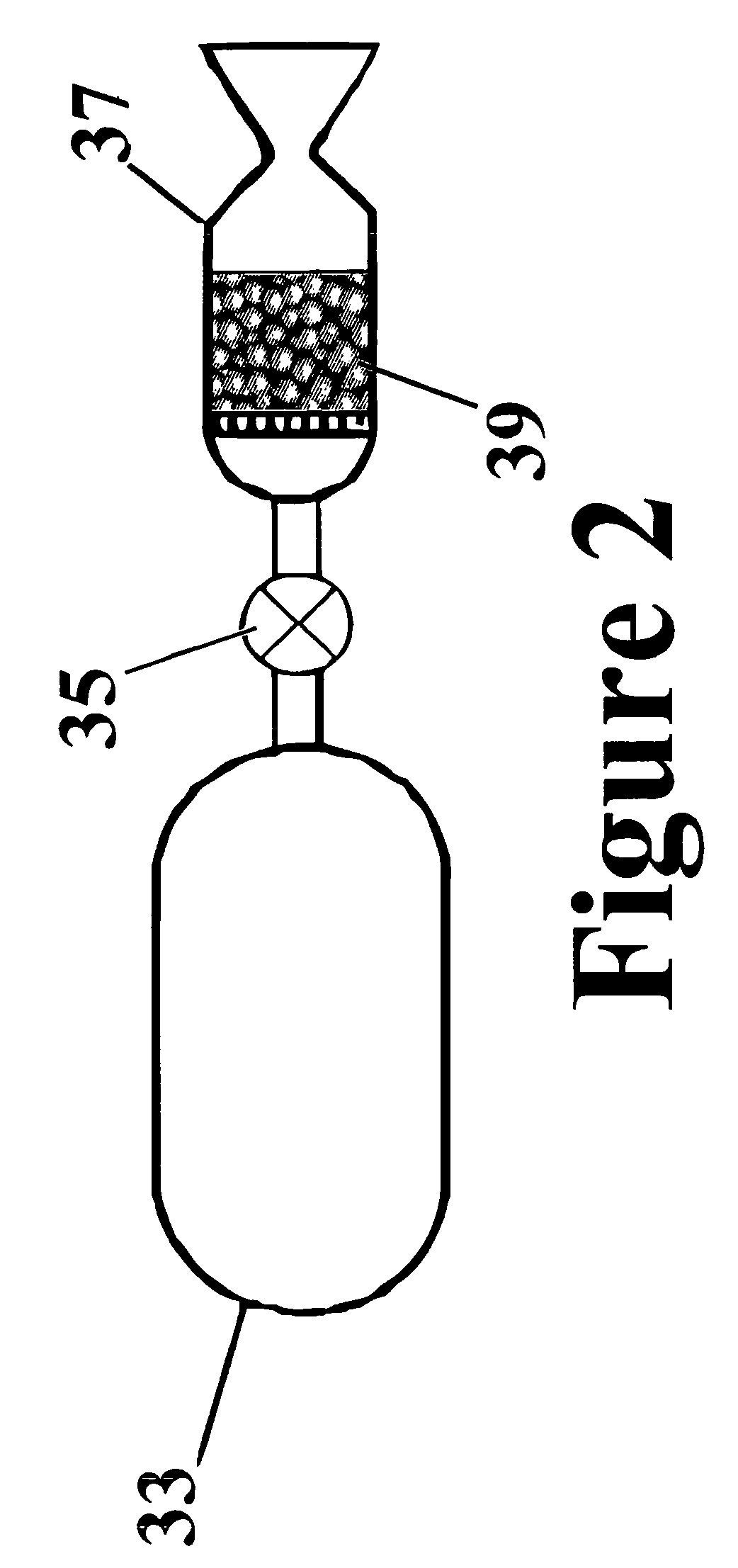

Method for production of power from aluminum

InactiveUS20100028255A1Simple and economical approachDisruptive layerOxygen/ozone/oxide/hydroxideHydrogen productionMetallic aluminumIndium

Aluminum is treated with an agent to prevent passivation of the aluminum during oxidation. The passivation preventing agent is a metal alloy containing gallium, preferably a eutectic alloy of gallium, indium and tin. The surface of the metallic aluminum is wetted with the eutectic alloy, suitably by scouring and / or immersion. The treated aluminum may be mixed with water, hydrogen peroxide or other suitable oxidizer in a controlled manner to produce hydrogen, heat, steam or oxygen for the use in power generation or chemical reactions. The passivation removal agent can be used in small quantities and is readily recoverable following the reaction.

Owner:HATOUM NAGI

Method for preparing premelted refining slag by using converter slag and aluminum slag

InactiveCN101984088ALow costImprove the level of resource utilizationRecycling and recovery technologiesProcess efficiency improvementMetallic aluminumSlag

The invention relates to a method for preparing premelted refining slag by using converter slag and aluminum slag, which comprises the following steps: selecting raw materials according to the requirement that the content of metallic aluminum in the aluminum slag is greater than or equal to 20% in mass percent; proportioning the raw materials under the condition that the mass ratio of the converter slag to the aluminum slag is (2.0-2.5):1; controlling the smelting temperature of the premelted refining slag at 1500-1600 DEG C, adding the aluminum slag in three batches after the converter slag is completely molten down, and standing for 20-30min after the last batch of aluminum slag is added and stirred uniformly, thereby realizing the purpose of separating slag from iron in a molten pool; and cooling the prepared premelted refining slag to the normal temperature, crushing the prepared premelted refining slag to the particles of which the particle size range is within 5-30mm, and then, packaging the particles. On the basis of ensuring the refining effect, the method of the invention completely uses industrial slag materials as raw materials, thereby protecting the natural mineral resources, widening the utilization ways of the converter slag and the aluminum slag as resources, and partially realizing the cyclic utilization of the converter slag in iron and steel production processes.

Owner:NORTHEASTERN UNIV

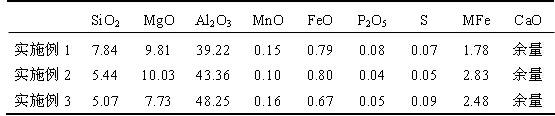

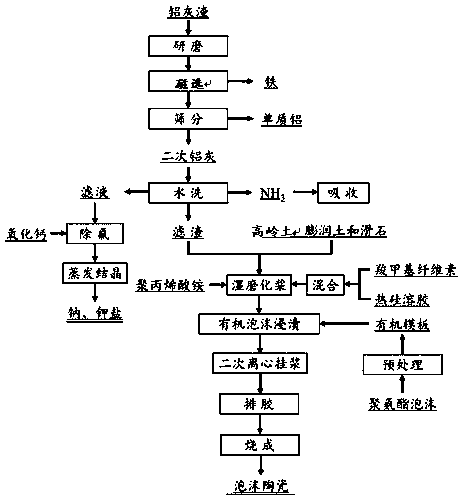

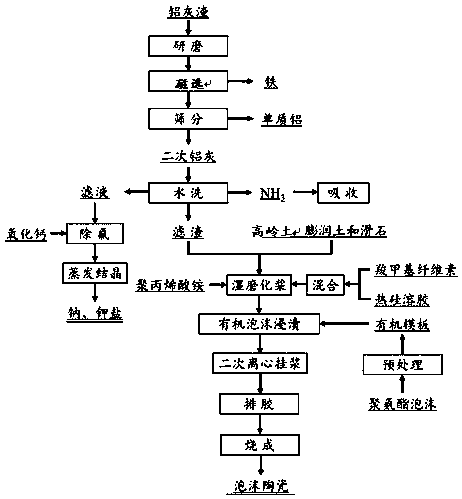

Aluminum ash recovering and reutilizing method

InactiveCN109970456AReduce pollution and other issuesRealize comprehensive utilizationCeramicwareSodium BentoniteScreening method

The invention discloses an aluminum ash recovering and reutilizing method. The method includes the steps of S1, rolling and grinding aluminum ash, separating out iron impurities through a magnetic separation method, and separating out metal aluminum through a screening method to obtain secondary aluminum ash; S2, conducting washing operation on the secondary aluminum ash, and decomposing aluminumnitride and salt in the secondary aluminum ash; S3, adding a certain ratio of kaolin, bentonite and talc to washed aluminum-oxide-containing filter residues to be mixed to obtain wet-milled slurry, and further adding a stabilizer (ammonium polyacrylate) and surfactants (carboxymethylcellulose and thermal silica sol) to prepare slurry; S4, impregnating the slurry obtained in the step S3 through organic foam, and conducting multiple times of slurry hanging and drying to obtain a biscuit; S5, conducting glue discharging and firing on the biscuit obtained in the step S4 to obtain foam ceramic. Thehigh-valued utilization rate of the aluminum ash is effectively increased, and meanwhile the environmental pollution is effectively reduced.

Owner:NANCHANG UNIV

Unburned magnesium-aluminum spinel brick

The invention discloses an unburned magnesium-aluminum spinel brick, which comprises the following components by mass: 50-80% of corundum, 5-30% of magnesia-alumina spinels, 2-5% of magnesia powder, 3-10% of alumina powder, and the balance at least one of elemental silicon powder, metallic aluminum powder and boron carbide powder. All the components of the unburned magnesium-aluminum spinel brick are combined through an additionally added binder. The unburned magnesium-aluminum spinel brick causes no pollution to the environment, has excellent molten steel erosion resistance, slag penetration resistance and scouring resistance, and has a long service life additionally.

Owner:BAOSHAN IRON & STEEL CO LTD

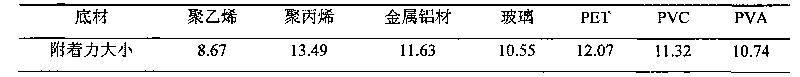

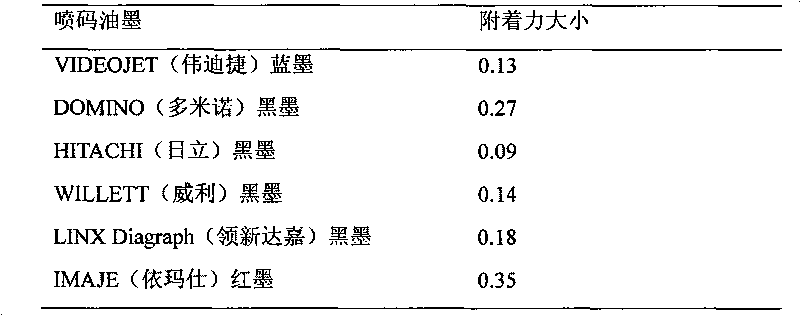

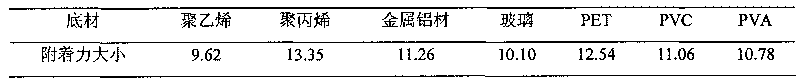

High-adhesion benzene-free environmentally-friendly universal jet ink and preparation method thereof

The invention discloses a high-adhesion benzene-free environmentally-friendly universal jet ink and a preparation method thereof, the jet ink is prepared by the following raw materials and solvents by weight percent: 5-10 of modified chlorinated polypropylene resin; 1-5 of complex resin; 70-89 of butanone; 2-6 of dye; 0.5-1.5 of conductive auxiliary agent; 1-3 of plasticizing agent; 0.5-1.5 of liquid paraffin; and 1-3 of other auxiliary agents. During the preparation, the modified chlorinated polypropylene resin and the complex resin are dissolved in 50-70% of butanone based on the total quantity, the rest butanone is used for the dissolution of other ingredients, the ink jet can be prepared by mixing both, and the resultant ink jet has excellent adhesion for the surface of polyethylene, polypropylene, metallic aluminum material, glass, PET, PVC and PVA materials; since only butanone is used as the solvent, the environmental friendliness of the jet ink is greatly enhanced; and the jet ink with stable system, clear print and fast drying can take the place of a large number of commercial jet ink products at present.

Owner:SOUTH CHINA UNIV OF TECH

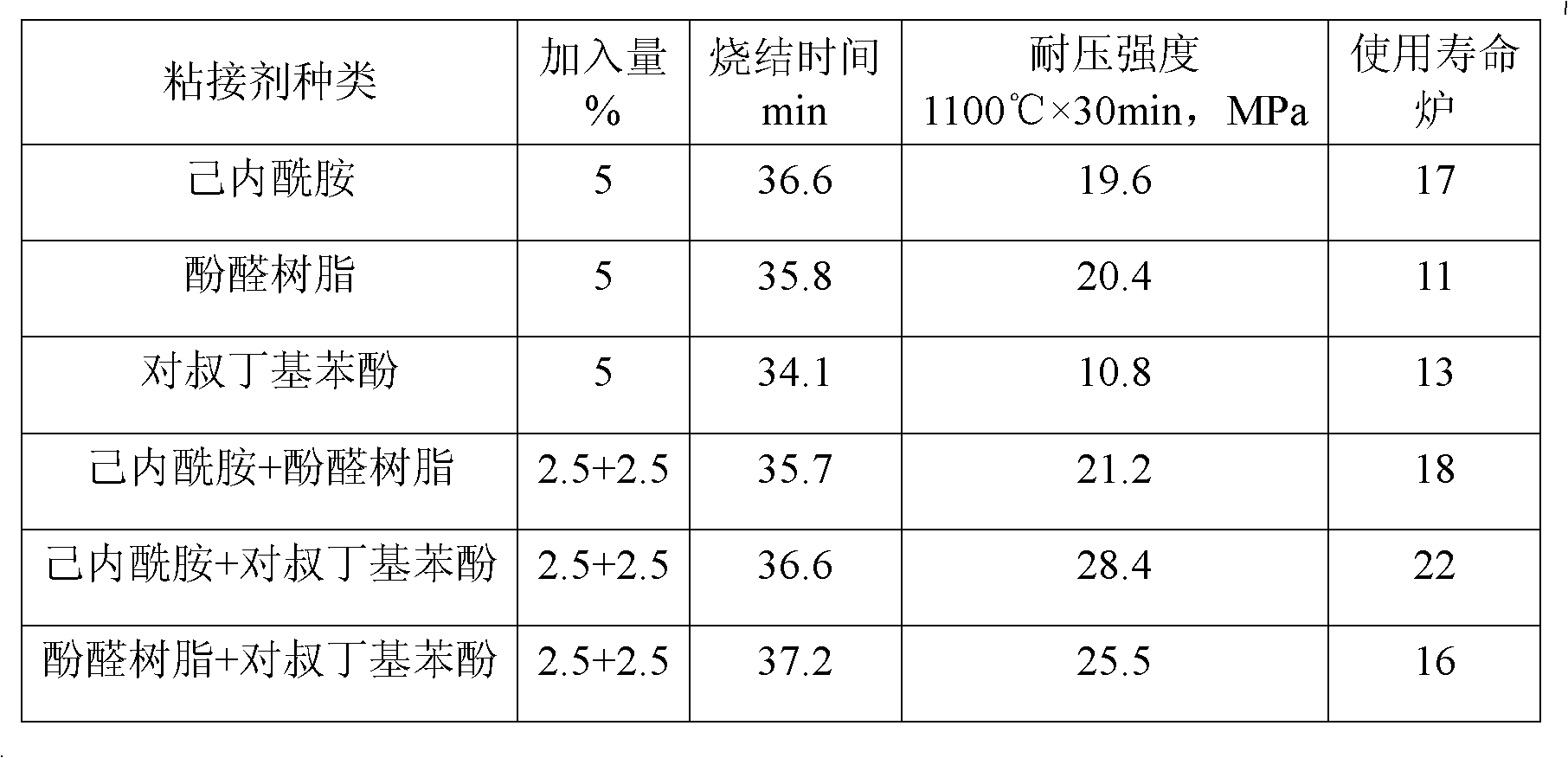

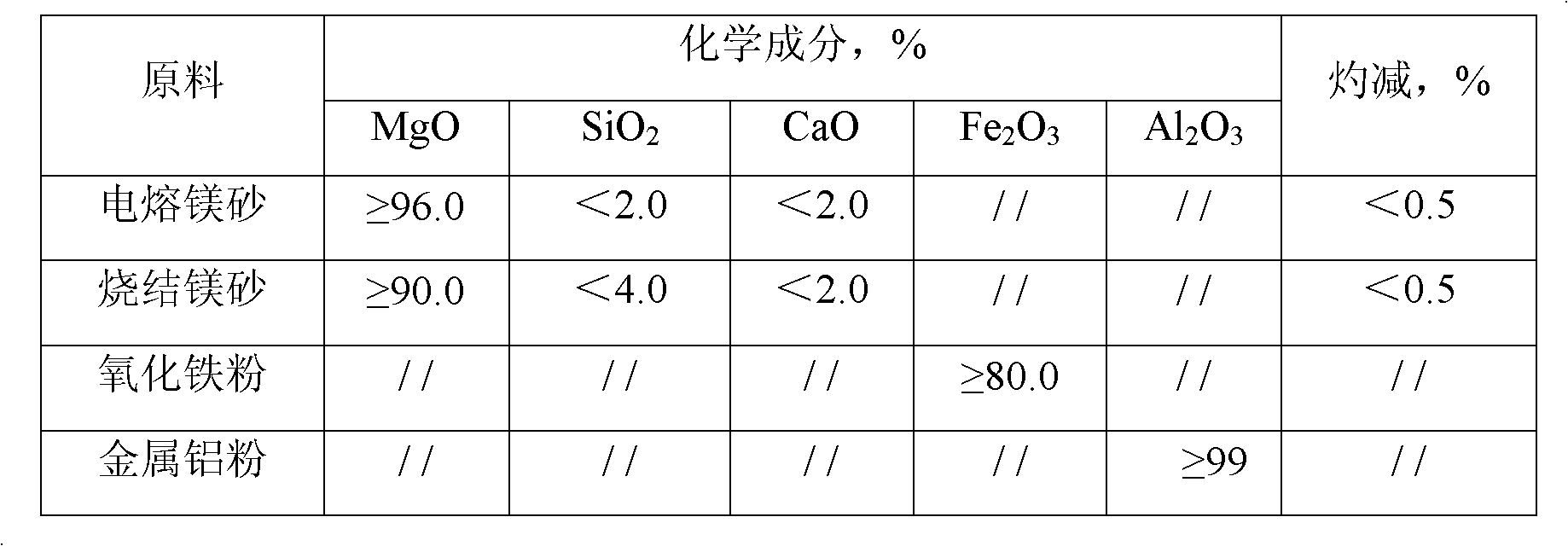

Repairing mass and preparation method thereof

The invention relates to a repairing mass for repairing in the converter production process of steel making and vanadium extracting of steel enterprises, in particular to a repairing mass used for a converter lining made of magnesia carbon bricks and a preparation method thereof, and provides a repairing mass having the advantages of short sintering time and long service life for meeting the requirement of production. The repairing mass per 100 weight parts comprises the following raw materials in parts by weight: 48-60 parts of fused magnesia, 22-28 parts of magnesite clinker, 10-16 parts ofmodified asphalt, 1-5 parts of metallic aluminum powder, 1-4 parts of ferric oxide powder and 2-10 parts of adhesive. The preparation method of the repairing mass is simple and convenient, i.e. all the raw materials are mixed. In the fettling production process of the vanadium extracting converter, when a local breakage appears on the converter lining, the repairing mass is coated on the part to be repaired; the repairing mass is sintered by utilizing the wall temperature of the converter, and production by blending with iron can be carried out after sintering; and under the conditions of lowsmelting temperature (1,360-1,400 DEG C) of the vanadium extracting converter and shorter smelting period (5-10 minutes), the repairing mass still can be quickly sintered with a working lining to form an organic combination with higher strength so as to prolong the service life of the repairing mass.

Owner:攀枝花钢城集团瑞矿工业有限公司

Wind speed sensor based on micro mechanic working and its producing method

ActiveCN1588091ASimple packagingSmall lateral heat transferFluid speed measurement using thermal variablesEtchingPhotolithography

The invention is a wind speed sensor based on micro mechanical process and its manufacturing method, which uses silicon resistance as temperature measuring unit, the invention is a wind speed sensor and its manufacturing method with silicon substrate conduction. The whole structure of the sensor is integrated on the substrate, the manufacturing method is: a) plants a layer of oxidization layer on the silicon substrate, photoetching and corroding the internal ICP slots and external ICP slots, and injects the edge area of the heating bar; b) deposits a layer of multi-crystal silicon on the silicon, and forms a multi-crystal resistance through photoetching; c) photoetchs the injecting area; injects phosphor with high density, which is used as the contacting area of the substrate and the silicon induce; d) carries on low temperature silicon dioxide deposition, and corrodes out the inducing line contact window; e) deposits the aluminum, photoetchs the aluminum inducer, and corrodes aluminum; f) deposits passivation layer; g) photoetchs IPC slots, and carries on ICP etching; h) thins the back surface, and releases out the structure of the silicon resistance.

Owner:SOUTHEAST UNIV

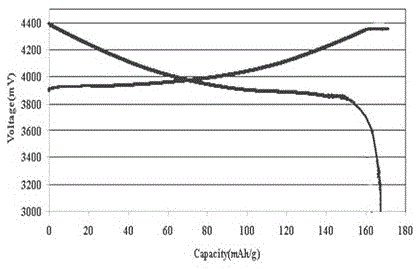

Recycling method of positive electrode piece of lithium ion battery

InactiveCN105576314AEfficient removalImprove structural propertiesSolid waste disposalTransportation and packagingManganeseSodium-ion battery

The invention discloses a recycling method of a positive electrode piece of a lithium ion battery, aiming at solving the problem of recycling of a nickel cobalt lithium manganite (nickel cobalt lithium aluminate) positive electrode piece and a lithium cobaltate positive electrode piece generated in a production process of the lithium ion battery. According to the technical scheme disclosed by the invention, the recycling method comprises the following steps: 1, crushing the electrode pieces by classes; 2, immersing with an organic solvent; 3, carrying out stirring treatment; 4, filtering with a sieve net; 5, carrying out centrifugal separation; 6, immersing with an alkaline solution; 7, carrying out the centrifugal separation again; 8, drying and removing iron; 9, carrying out ICP (Inductively Coupled Plasma) analysis; and 10, calcining the materials. The recycling method disclosed by the invention can be used for effectively recycling waste materials of the positive electrode pieces of the waste lithium ion batteries, so that the cost is saved; and by immersing with the alkaline solution and carrying out a plurality of times of separation and washing, impurities, such as metal aluminum, in powder grains can be effectively removed. With the adoption of the recycling method, a positive electrode material and an aluminum foil can be completely separated, and the positive electrode material keeps a relatively good structure and electrochemical properties; and the synthesis of a precursor is not needed and the adding amount of a lithium salt is relatively less.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

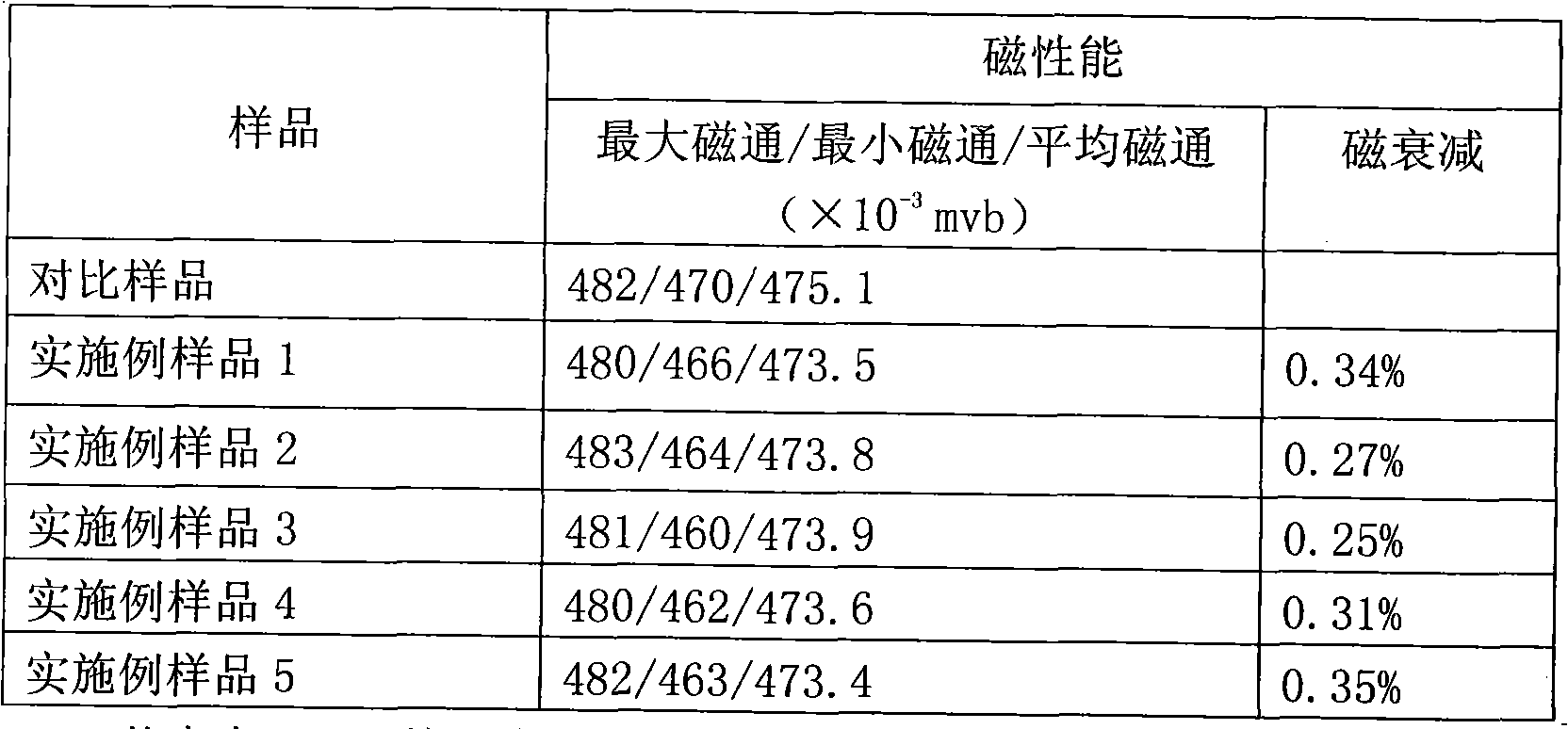

Stripping solution for sintered neodymium-iron-boron surface aluminum coating

The invention discloses stripping solution for a sintered neodymium-iron-boron surface aluminum coating. The stripping solution comprises sodium hydroxide serving as a corroding agent, sodium carbonate serving as an auxiliary salt, a complexing agent capable of promoting the dissolution of metallic aluminum, a corrosion inhibitor for retarding the corrosion of a matrix, and a surfactant for uniformly dissolving an aluminum coating. Compared with the prior art, the stripping solution for the sintered neodymium-iron-boron surface aluminum coating has the advantages of quickly and uniformly stripping the sintered neodymium-iron-boron surface aluminum coating and simultaneously reducing the damage to the sintered neodymium-iron-boron matrix due to the reasonable design of components and content of the stripping solution; and besides, the stripping solution has the characteristics of low production cost, high stability and long service cycle.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com