Patents

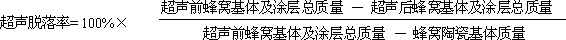

Literature

686 results about "Slurry coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand slurry coating is more commonly referred to as a seal coat with a sand additive. This coating is a combination of water, minerals, and emulsified asphalt. It is ideal for the coating of parking lots and other off-highway areas.

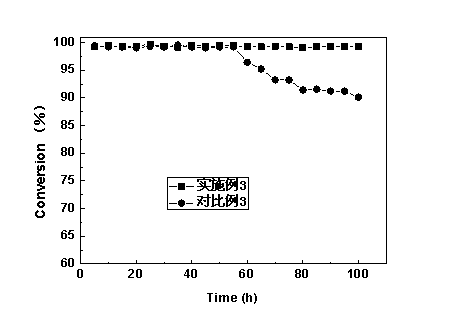

Catalyst and method for reduction of nitrogen oxides

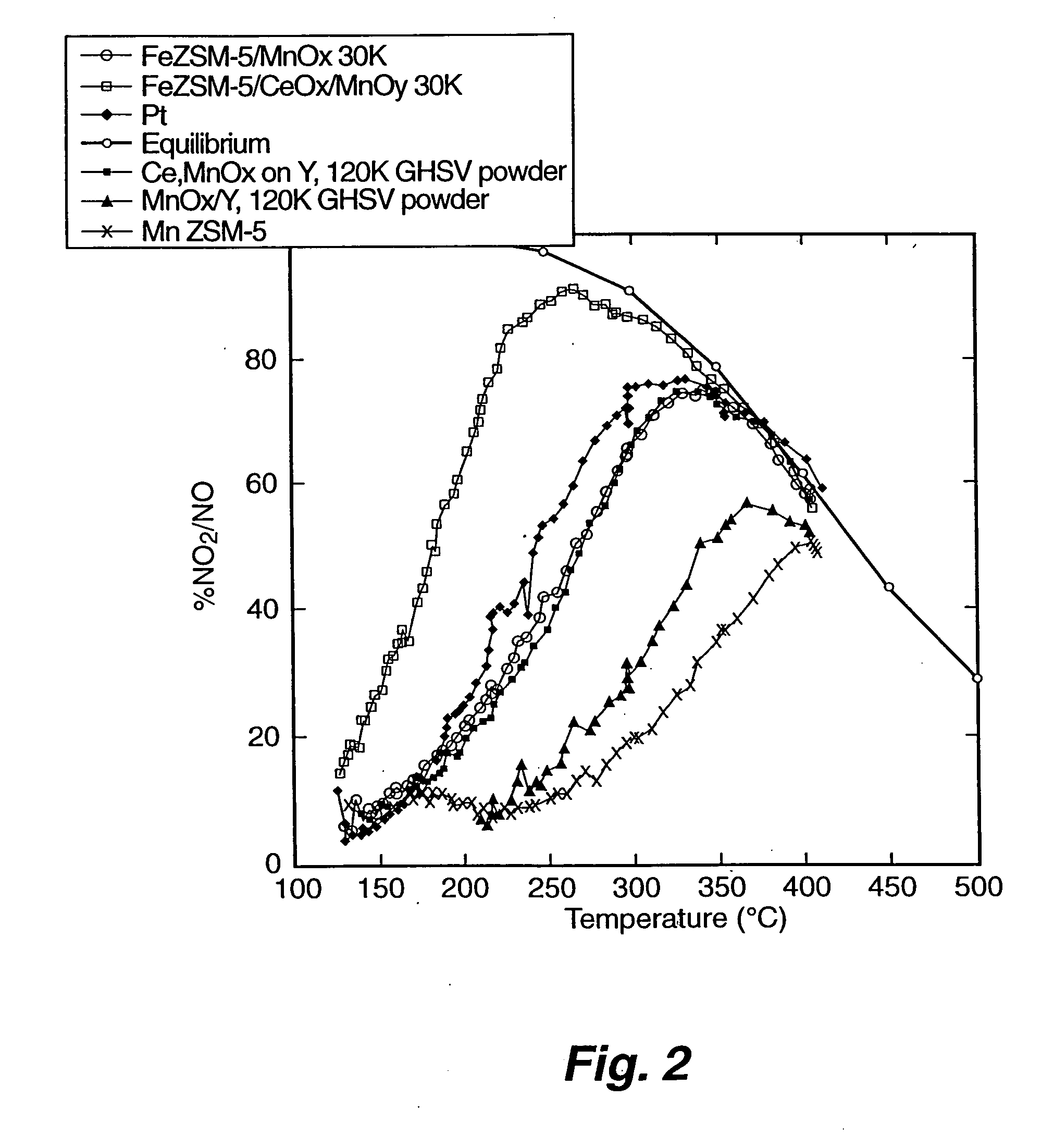

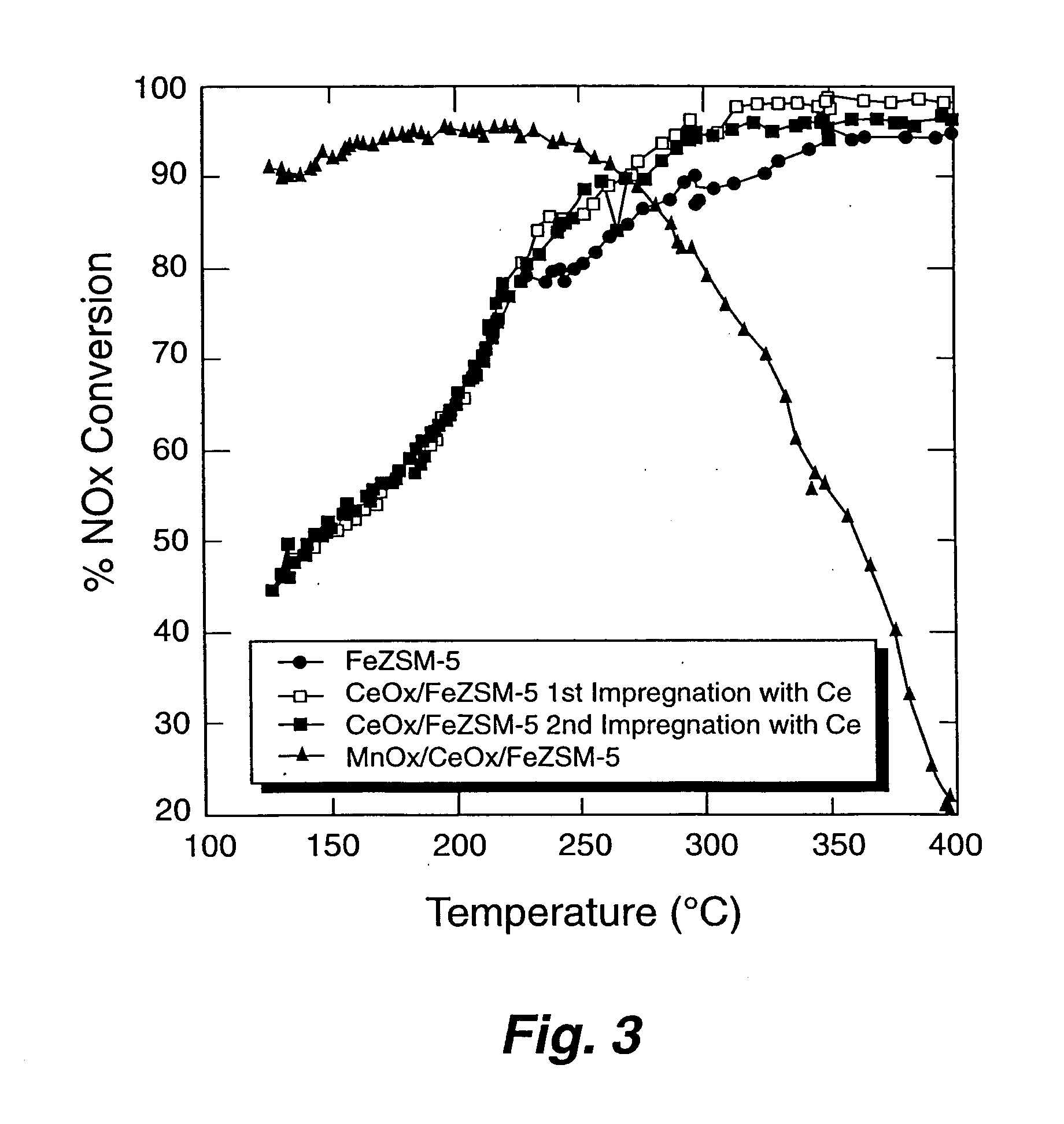

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

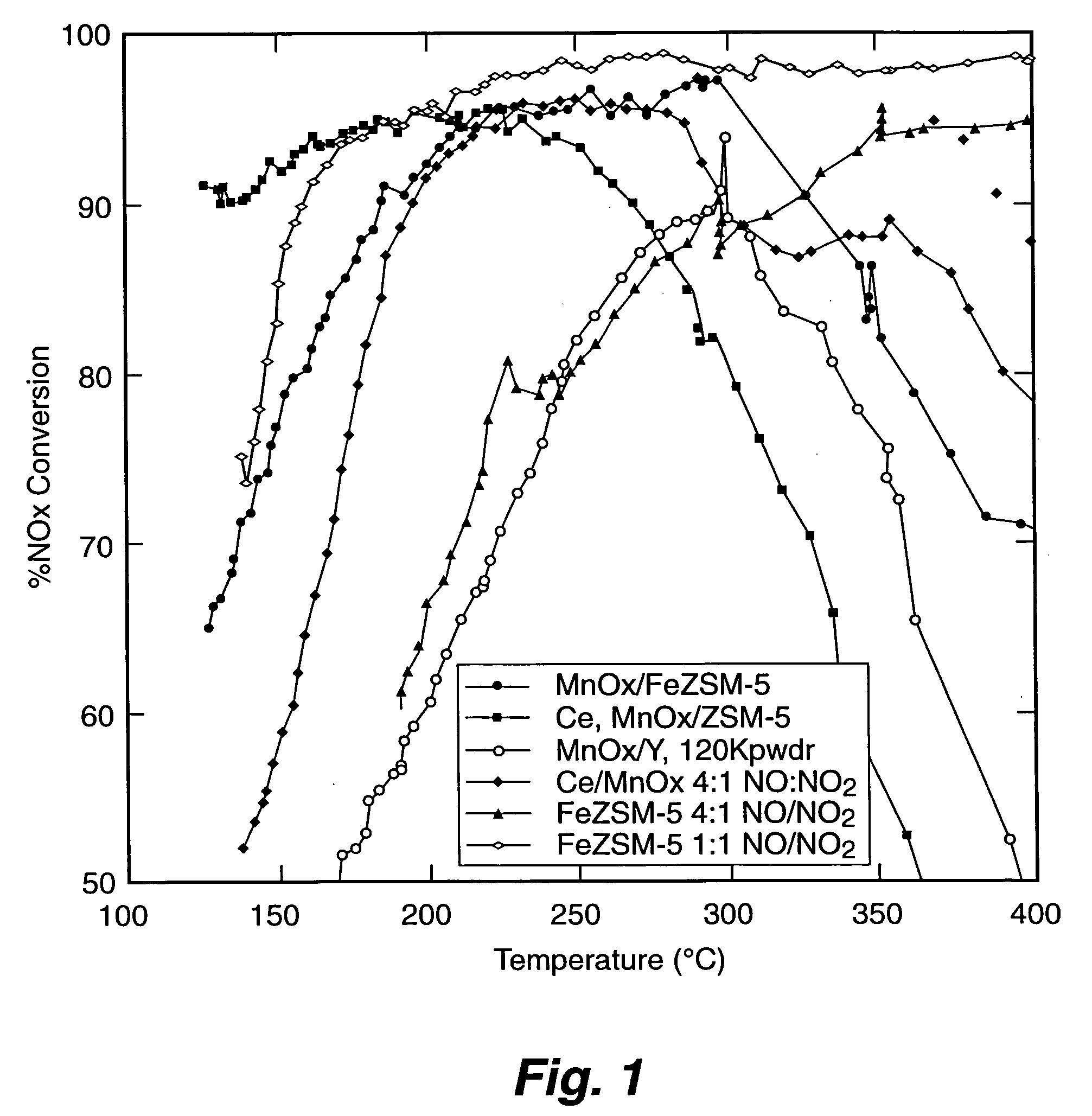

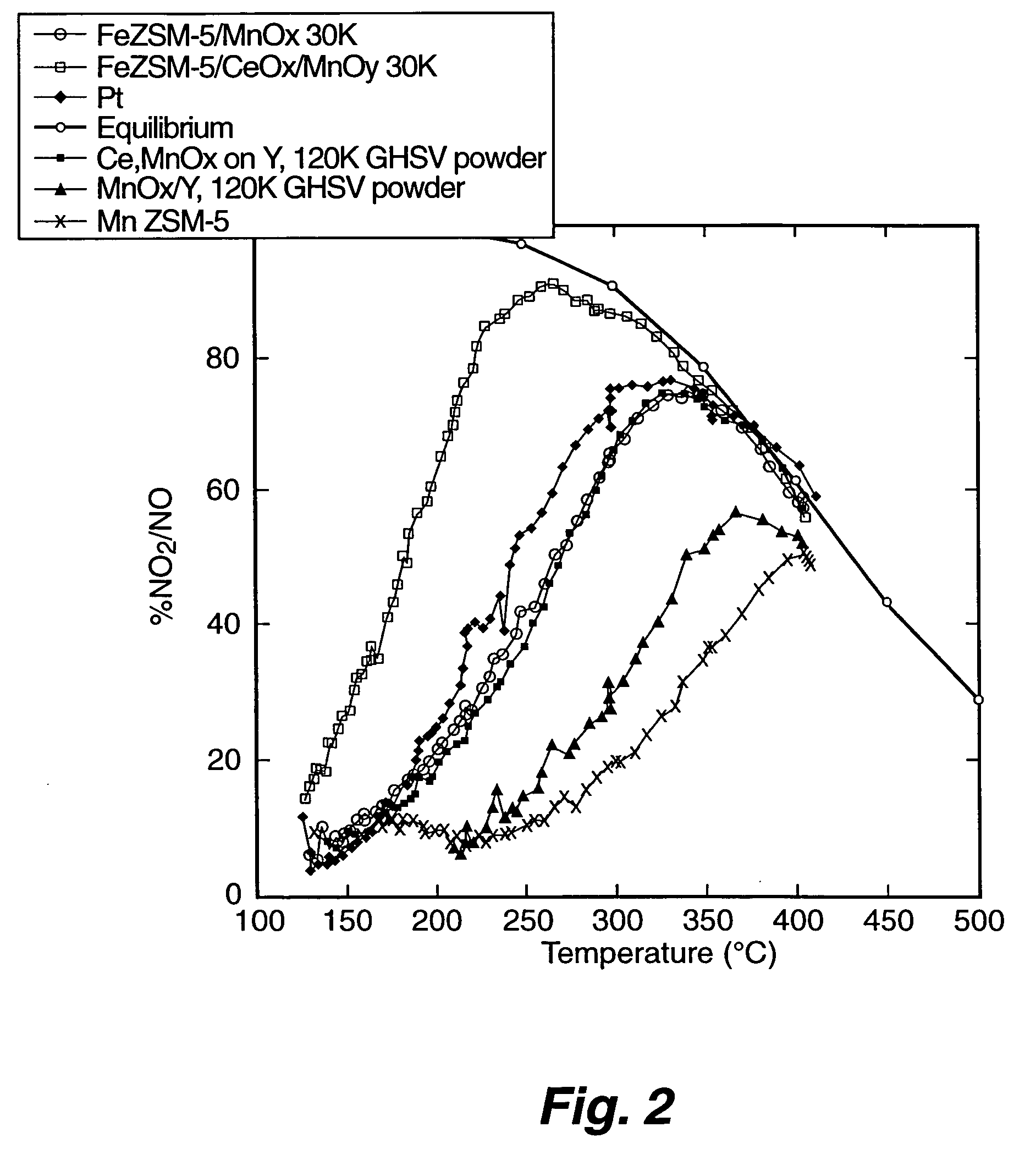

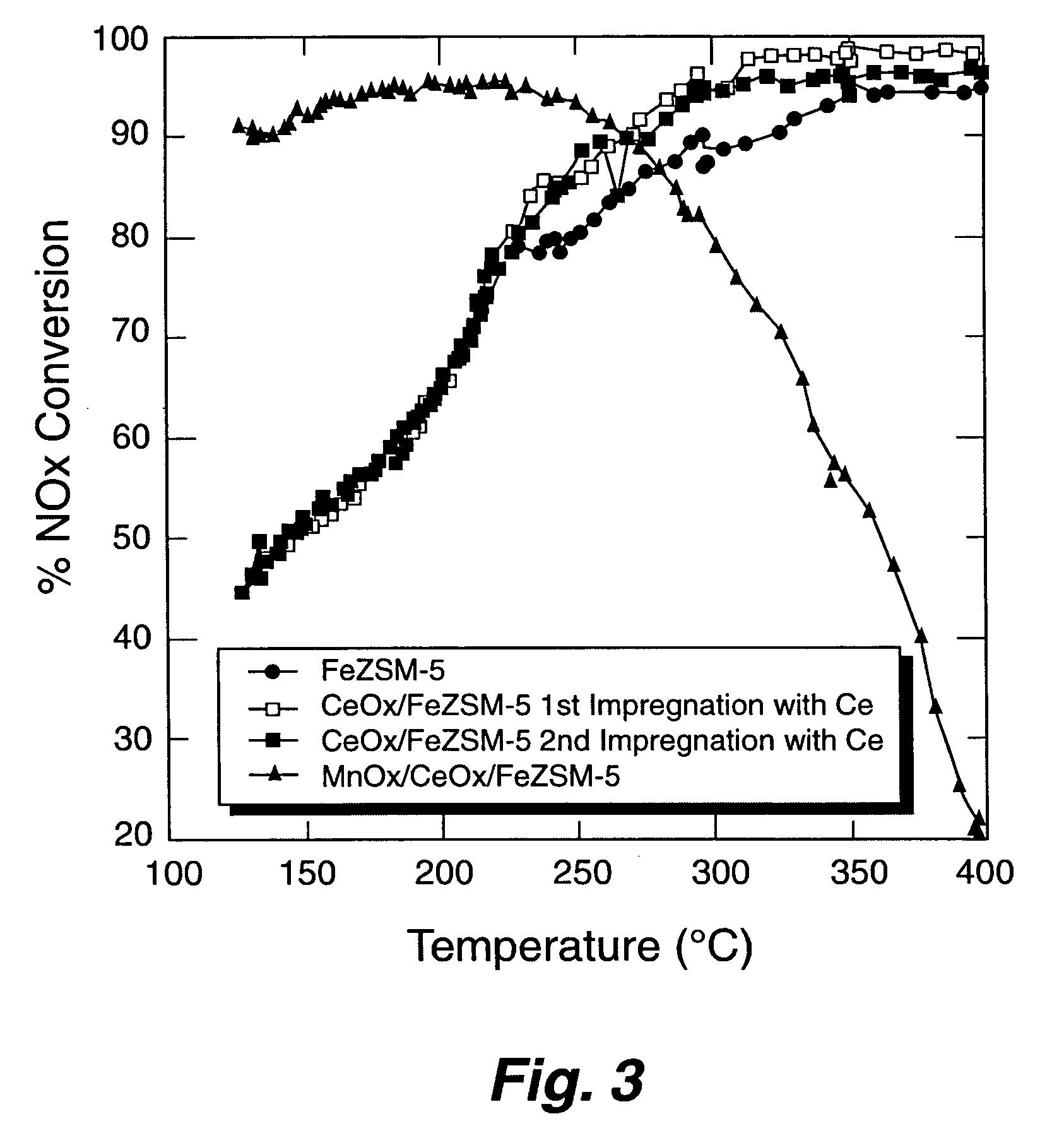

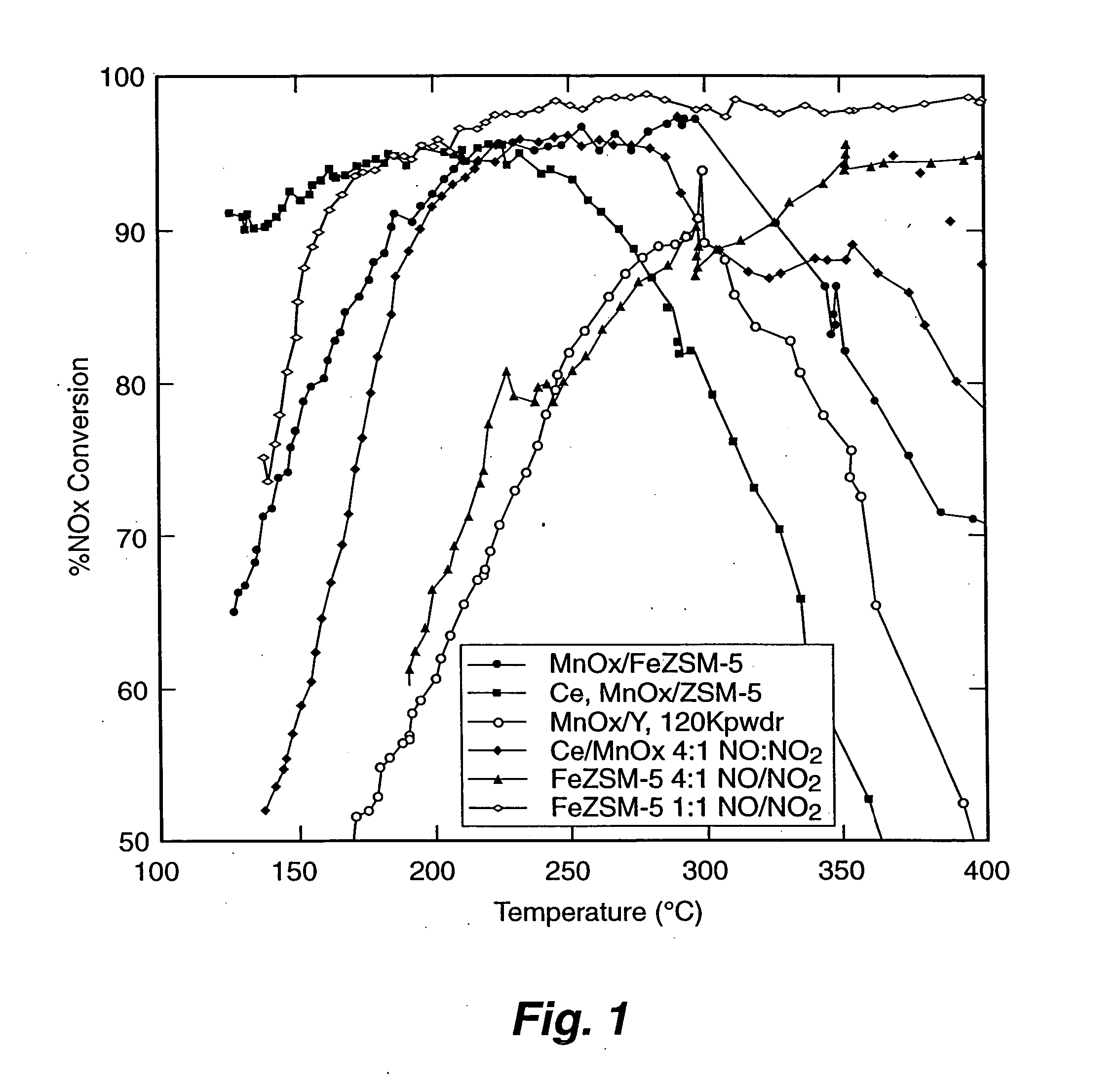

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

Methods of fabricating environmental barrier coatings for silicon based substrates

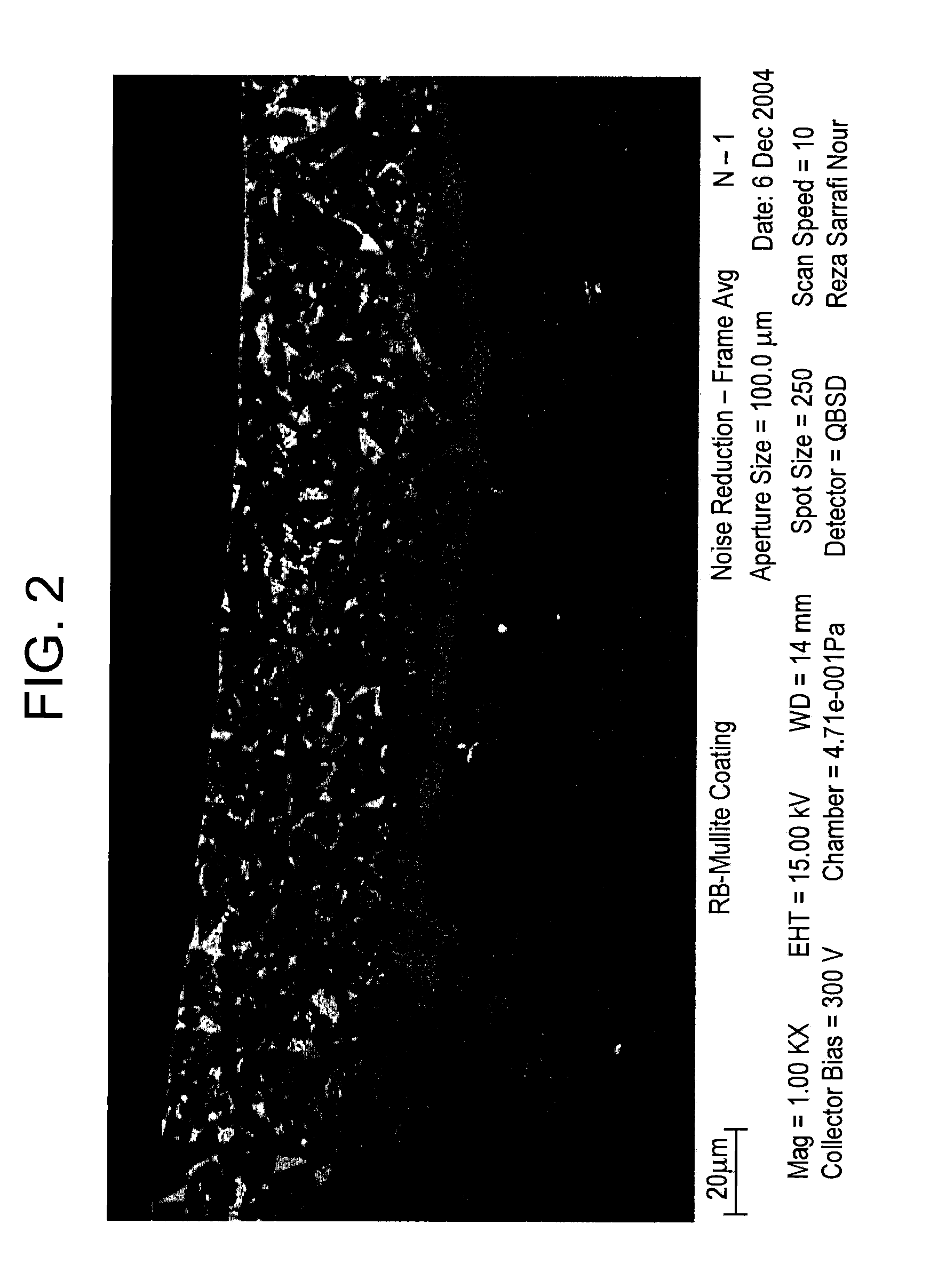

A method of protecting an article from a high temperature environment, the method includes providing a substrate comprising silicon, forming a slurry coating composition, wherein the composition comprises a metallic silicon powder, a rare-earth oxide, an alkaline earth metal oxide, an aluminum oxide, or a combination comprising at least one of the foregoing, and a binder effective to chemically stabilize the slurry coating, applying a layer of the slurry coating over the substrate, and heat-treating the slurry coating under conditions sufficient to oxidize the metallic silicon powder and form an alkaline earth metal aluminosilicate, a rare-earth silicate, an aluminum silicate, or a combination comprising at least one of the foregoing bonded to the substrate.

Owner:GENERAL ELECTRIC CO

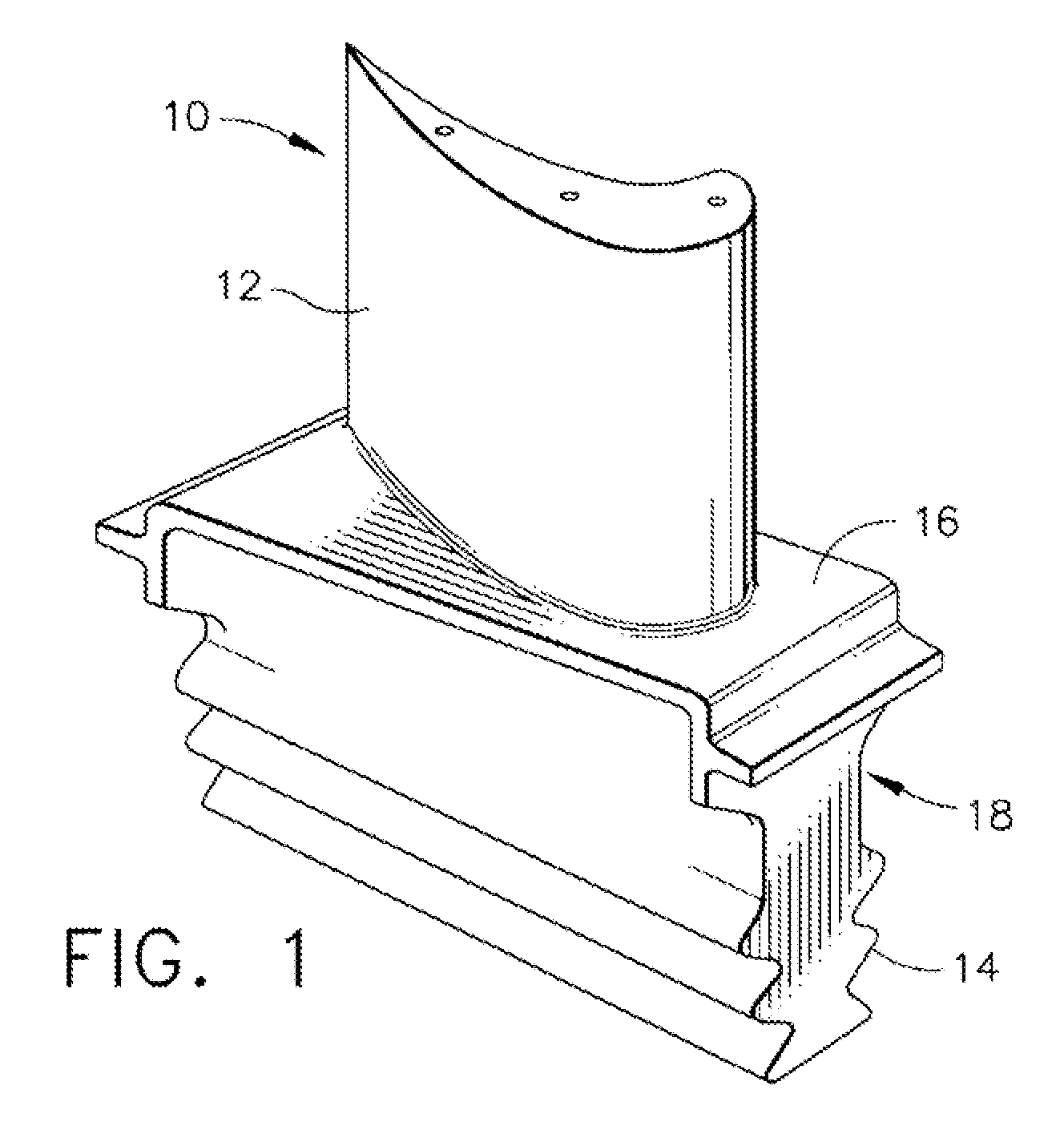

Slurry diffusion aluminide coating composition and process

ActiveUS20090126833A1Easy to disassembleSolid state diffusion coatingAnti-corrosive paintsMetallic aluminumSlurry coating

A slurry and slurry coating process for forming a diffusion aluminide coating on a substrate, including internal surfaces within the substrate. The process involves preparing a slurry of a powder containing a metallic aluminum alloy having a melting temperature higher than aluminum, an activator capable of forming a reactive halide vapor with the metallic aluminum, and a binder containing an organic polymer. The slurry is applied to surfaces of the substrate, which is then heated to burn off the binder, vaporize and react the activator with the metallic aluminum to form the halide vapor, react the halide vapor at the substrate surfaces to deposit aluminum on the surfaces, and diffuse the deposited aluminum into the surfaces to form a diffusion aluminide coating. The process can be tailored to selectively produce an inward or outward-type coating. The binder burns off to form an ash residue that can be readily removed.

Owner:GENERAL ELECTRIC CO

Methods and systems for making battery electrodes and devices arising therefrom

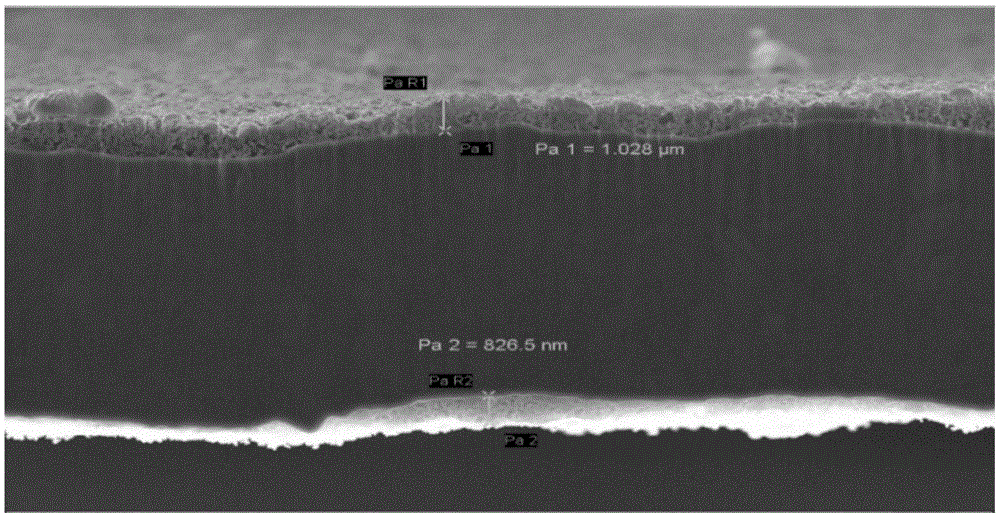

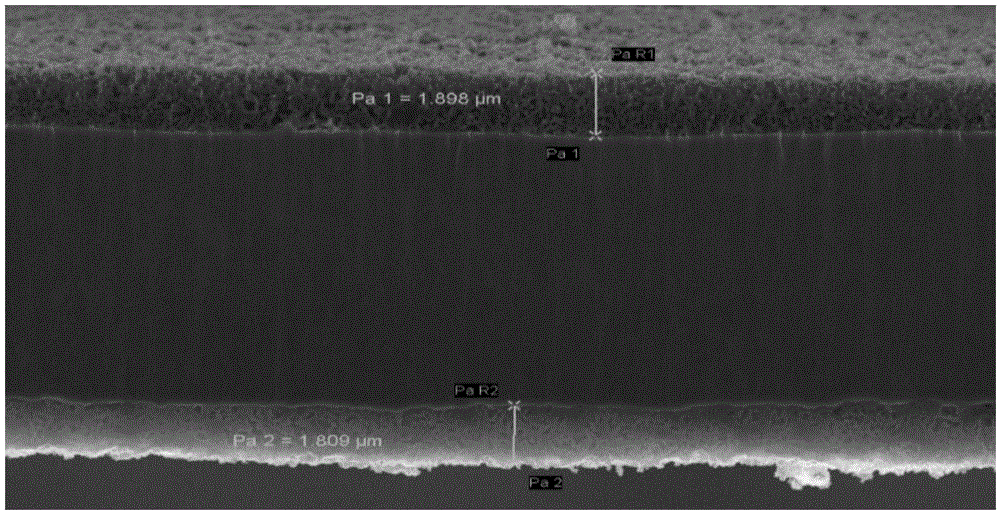

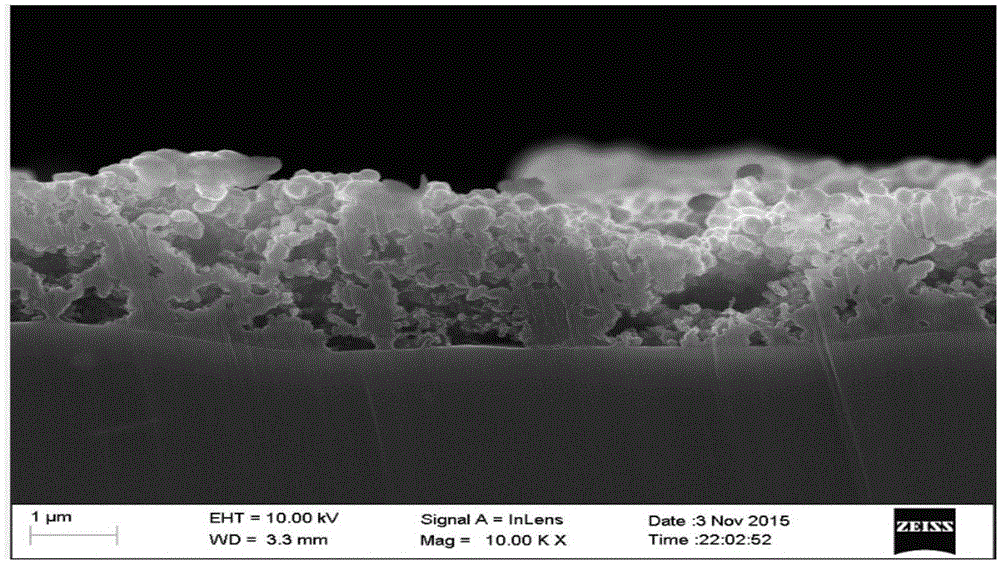

The invention provides, in preferred embodiments, methods, systems, and devices arising therefrom for making battery electrodes, in particular, for lithium-ion batteries. Unlike conventional slurry coating methods that use mechanical means to coat thick pastes of active material, other materials, and solvent(s) onto a substrate, the invention provides for a method to produce electrode coatings onto support in a multi-layer approach to provide highly uniform distribution of materials within the electrode. Problems of differential sedimentation of particles in slurries found in conventional methods are minimized with the methods of the present invention. Also included are systems for producing in large-scale the battery electrodes of the invention. Further included are electrodes produced by the methods and systems described herein.

Owner:MOLECULAR NANOSYST

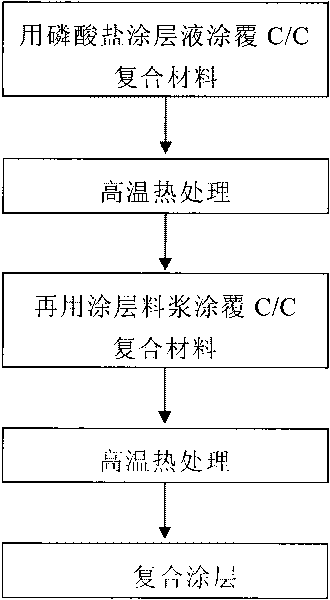

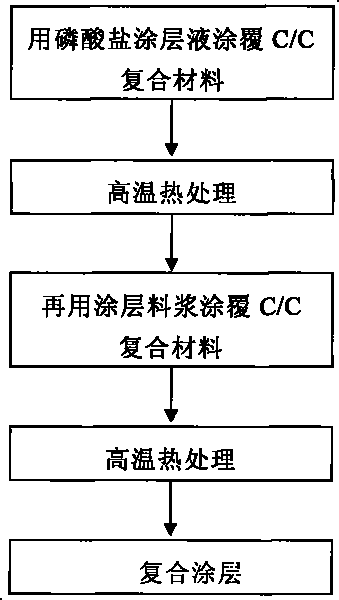

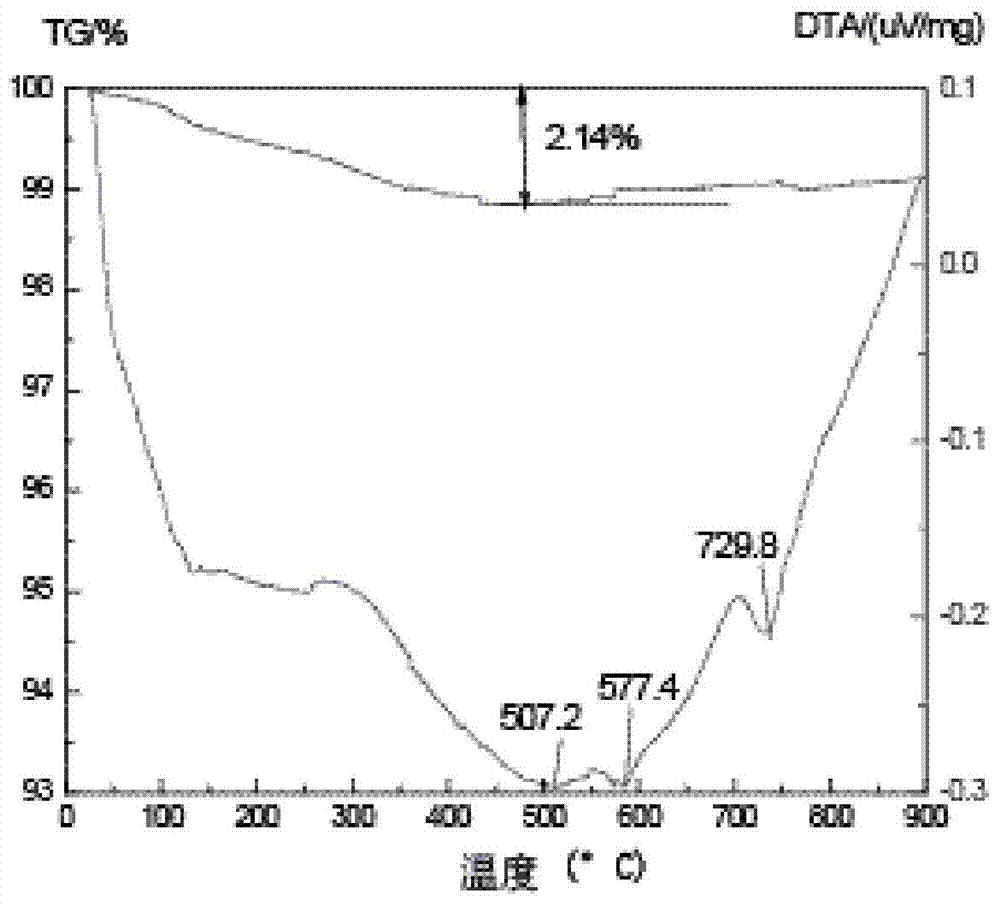

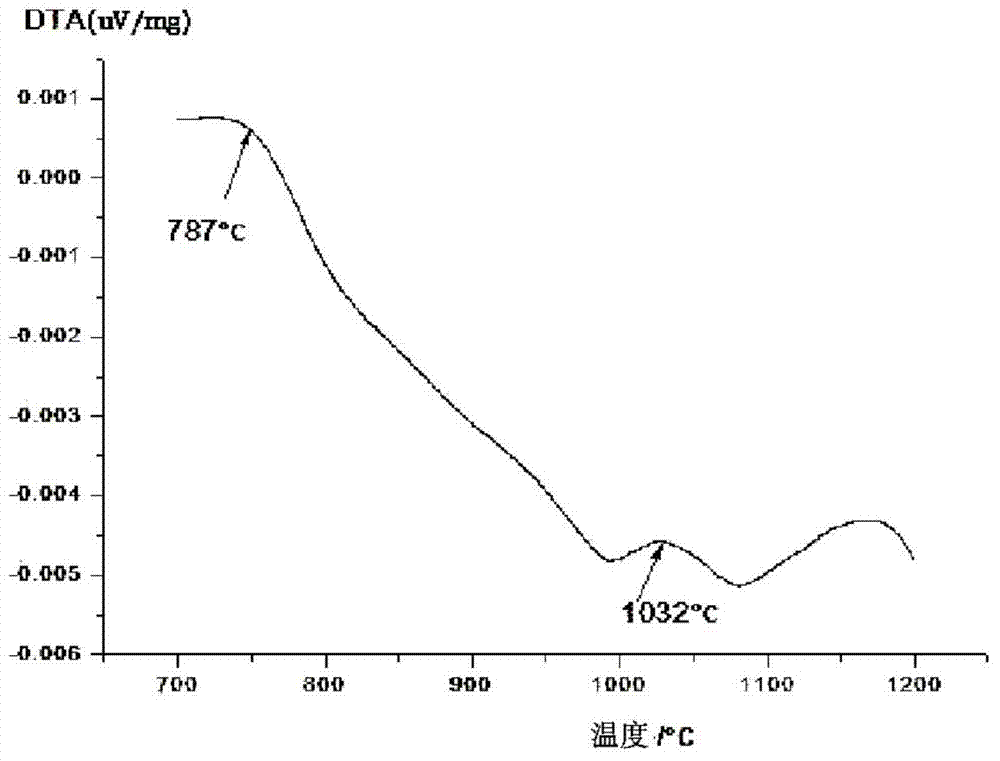

Surface anti-oxidation processing method for aircraft carbon brake disc

The invention discloses a surface anti-oxidation processing method for an aircraft carbon brake disc, which comprises the following steps: firstly, coating a layer of phosphate coating solution on the surface of a material needing to be processed, and forming a bottom phosphate coating through high temperature heat treatment; secondly, coating a layer of slurry coating which uses refractory ceramic powders as the main raw material and uses the phosphate coating solution as solution on the surface of the bottom phosphate coating; and finally forming a composite coating through the high temperature heat treatment. The composite coating of the invention has anticatalytic effect, and can improve the high temperature anti-oxidation capacity of C / C composite materials, such as the aircraft carbon brake disc and the like, under the condition of sea or salt spray pollution; and the ceramic component in the composite coating is melted and flows at high temperature so as to effectively heal the crackles in the coating, delay the time that oxygen is contacted with C / C materials, and improve the oxidation resistance of the composite coating.

Owner:XIAN CHAOMA SCI TECH

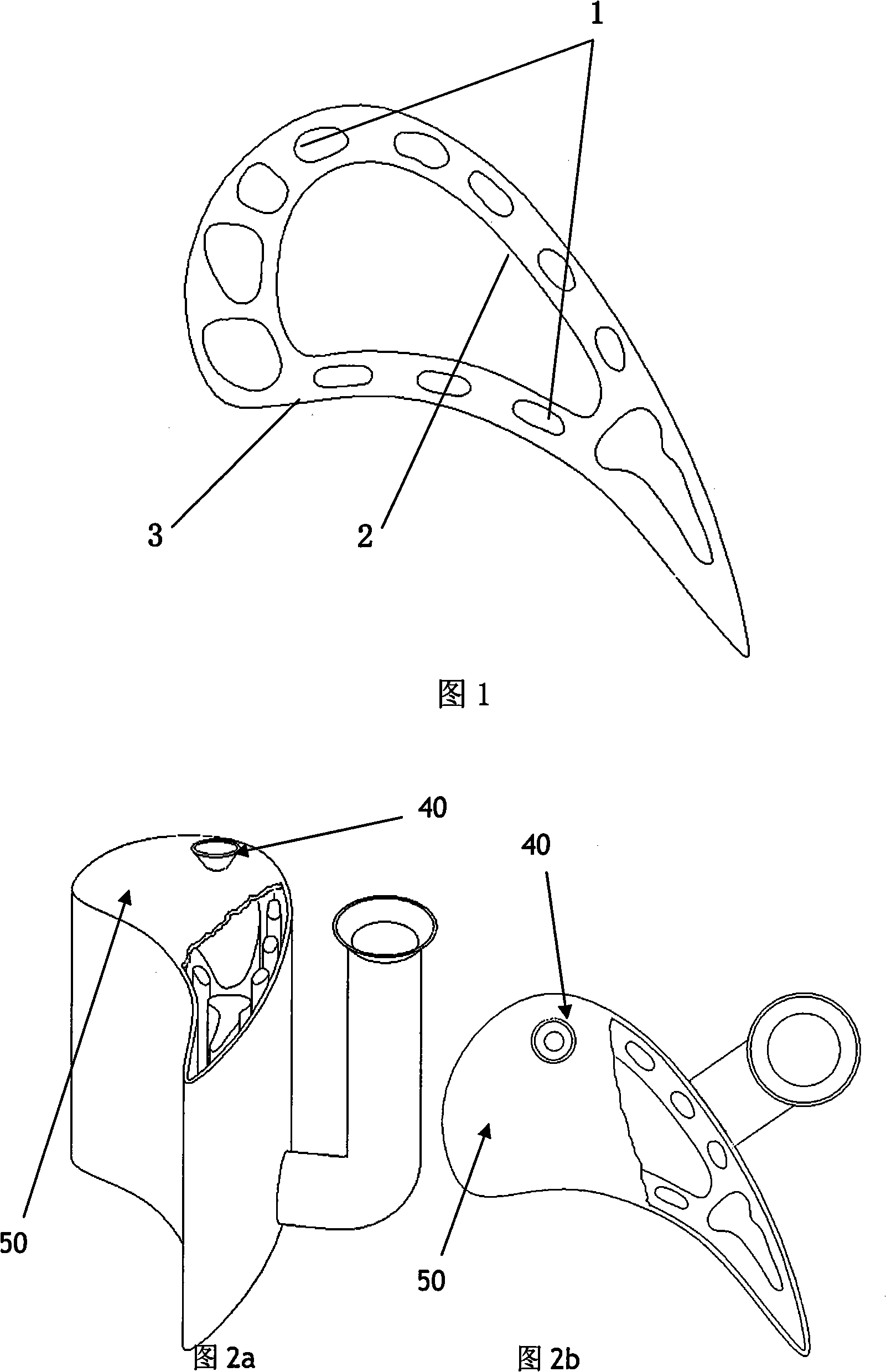

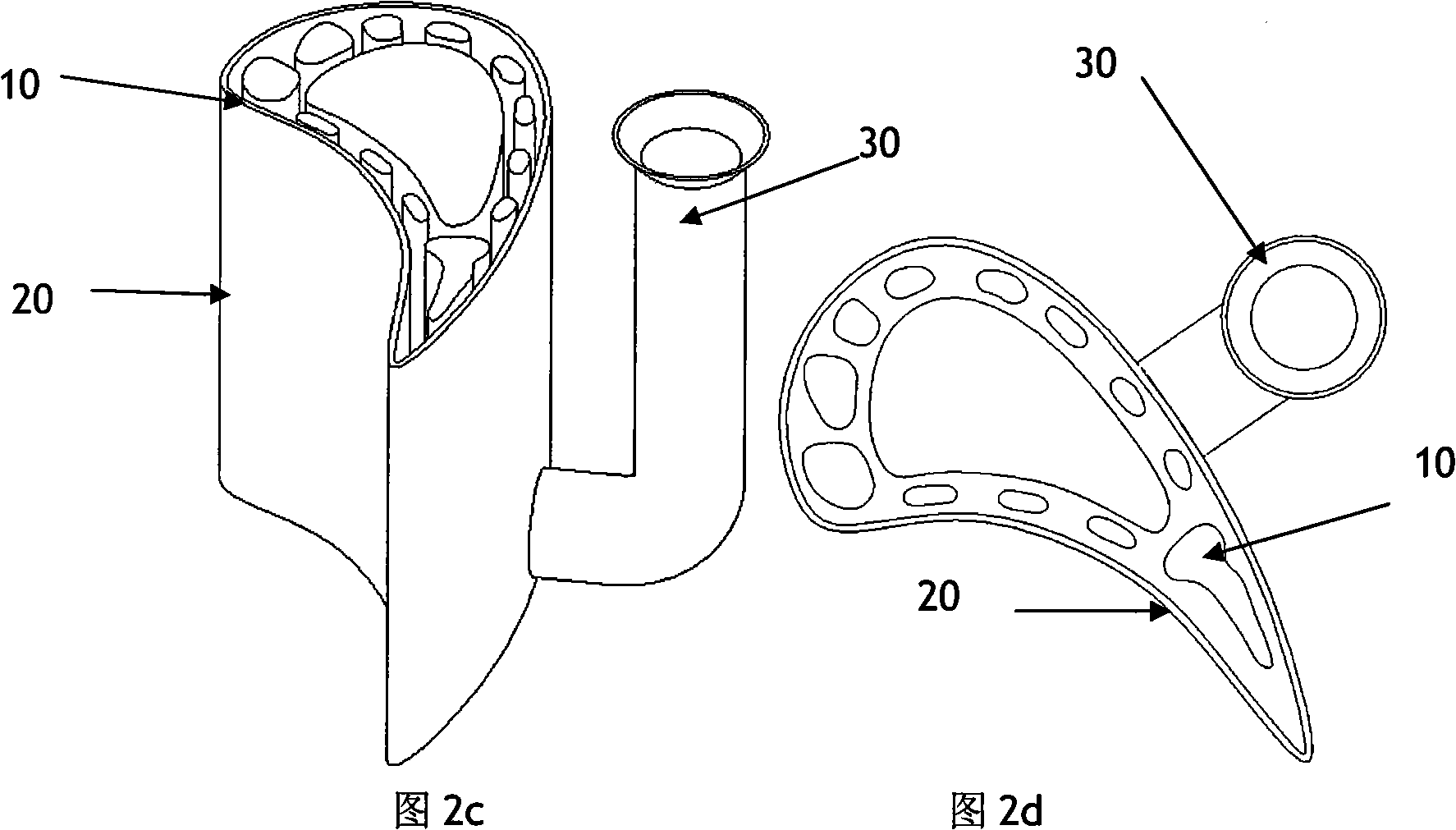

Direct light-curing fabrication method of hollow blade ceramic cast

The invention relates to a method for directly making a hollow blade ceramic mold based on a photo-curing process. The method is as follows: firstly, ceramic powder and pre-mix liquid are evenly mixed so as to make ceramic slurry; secondly, according to a hollow blade model, a hollow blade mold model containing a gating system is obtained, and the ceramic slurry is directly made into a ceramic mold biscuit on a photo-curing forming machine according to the hollow blade mold model; then, the ceramic mold biscuit is dewatered to obtain a dry ceramic mold; finally, the dry ceramic mold is placed in a high-temperature baking furnace so as to carry out degreasing and sintering, thereby making the hollow blade ceramic mold. The ceramic mold can be used in the casting of a hollow blade, and replaces a multi-layer ceramic shell and core manufacturing process adopted in the prior investment casting. The method does not need the processes of investment pattern making, slurry coating and sand spreading adopted in the prior process, and has the characteristics of simple process, short cycle, low cost and quick returns, etc.

Owner:XI AN JIAOTONG UNIV

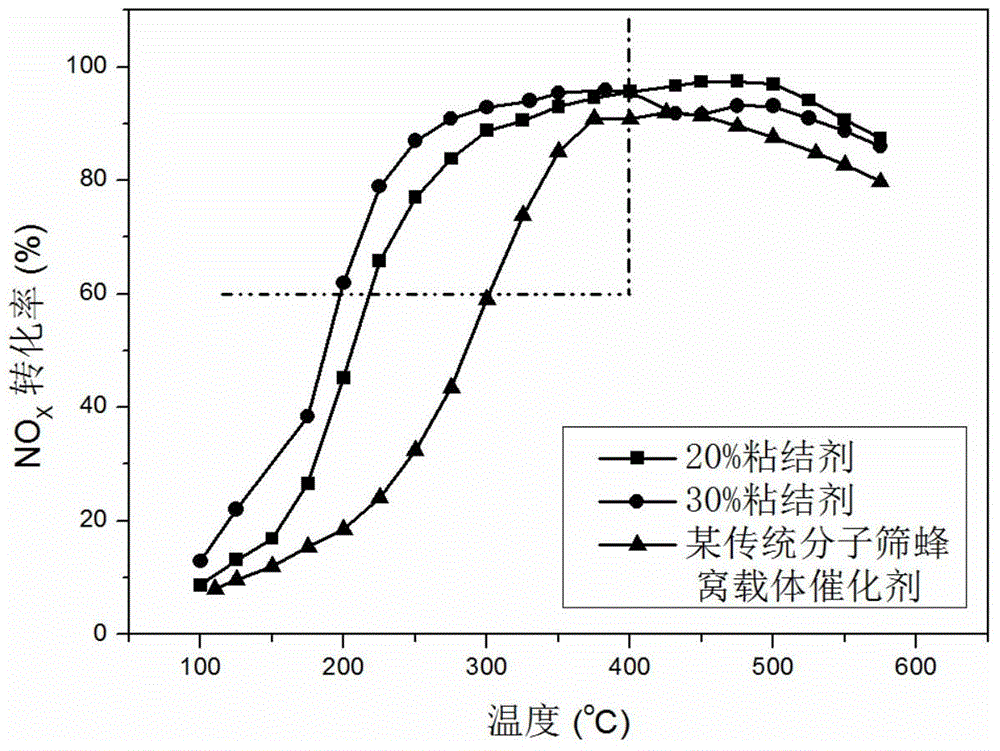

Preparation method of honeycomb carrier catalyst for molecular sieve denitration

InactiveCN104353485AHigh catalytic activityReduce mechanical vibrationMolecular sieve catalystsDispersed particle separationMolecular sieveOrganic solvent

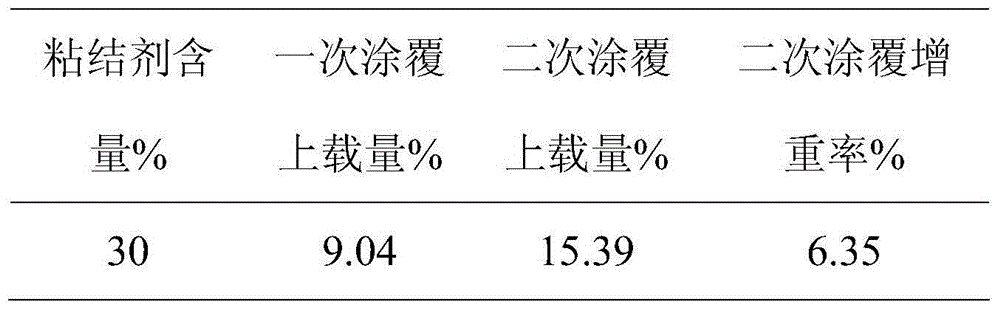

The invention discloses a preparation method of a honeycomb carrier catalyst for molecular sieve denitration. The preparation method comprises the following steps: 1, preparing a Cu / ZSM-5 catalyst which contains 1.5%-2.5% by weight of Cu by adopting an ion exchange method; 2, pretreating and drying a cordierite honeycomb ceramic carrier under the conditions of acid-base and an organic solvent; 3, preparing slurry, wherein the mass ratio of an adhesion agent to Cu / ZSM-5 catalyst to ethanediol to deionized water is (0.2-0.3):1:1.165:1.165 in the slurry; 4, preparing a primary coating honeycomb carrier denitration catalyst; and 5, preparing a secondary coating honeycomb carrier denitration catalyst. The honeycomb carrier catalyst prepared through the method disclosed by the invention is difficultly plugged in a slurry coating process, firm in coating and high in stability; the prepared honeycomb carrier catalyst is high in denitration efficiency, achieves the denitration efficiency more than 90% at a temperature interval of 170-500 DEG C and can be widely applied to the catalytic reduction of nitrogen oxide in a motor vehicle tail gas post-processing system.

Owner:TSINGHUA UNIV

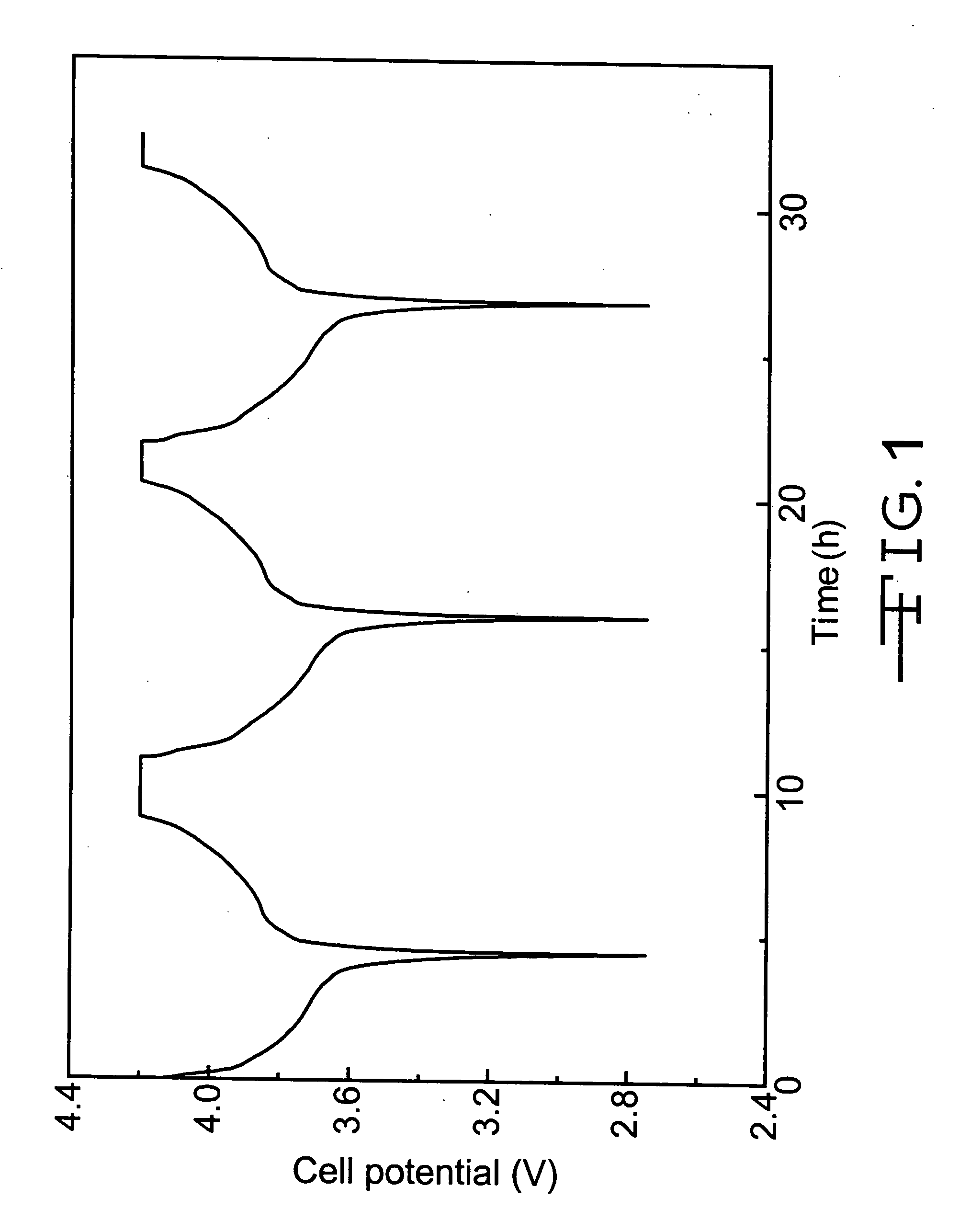

In situ thermal polymerization method for making gel polymer lithium ion rechargeable electrochemical cells

InactiveUS20050227150A1Increase productivitySimple processSilver accumulatorsFinal product manufactureElectrolysisSlurry coating

A single step, in situ curing method for making gel polymer lithium ion rechargeable cells and batteries is described. This method used a precursor solution consisting of monomers with multiple functionalities such as multiple acryloyl functionalities, a free-radical generating activator, nonaqueous solvents such as ethylene carbonate and propylene carbonate, and a lithium salt such as LiPF6. The electrodes are prepared by slurry-coating a carbonaceous material such as graphite onto an anode current collector and a lithium transition metal oxide such as LiCoO2 onto a cathode current collector, respectively. The electrodes, together with a highly porous separator, are then soaked with the polymer electrolyte precursor solution and sealed in a cell package under vacuum. The whole cell package is heated to in situ cure the polymer electrolyte precursor. The resulting lithium ion rechargeable cells with gelled polymer electrolyte demonstrate excellent electrochemical properties such as high efficiency in material utilization, high Coulombic efficiency, good rate capability, and good cyclability.

Owner:WILSON GREATBATCH LTD

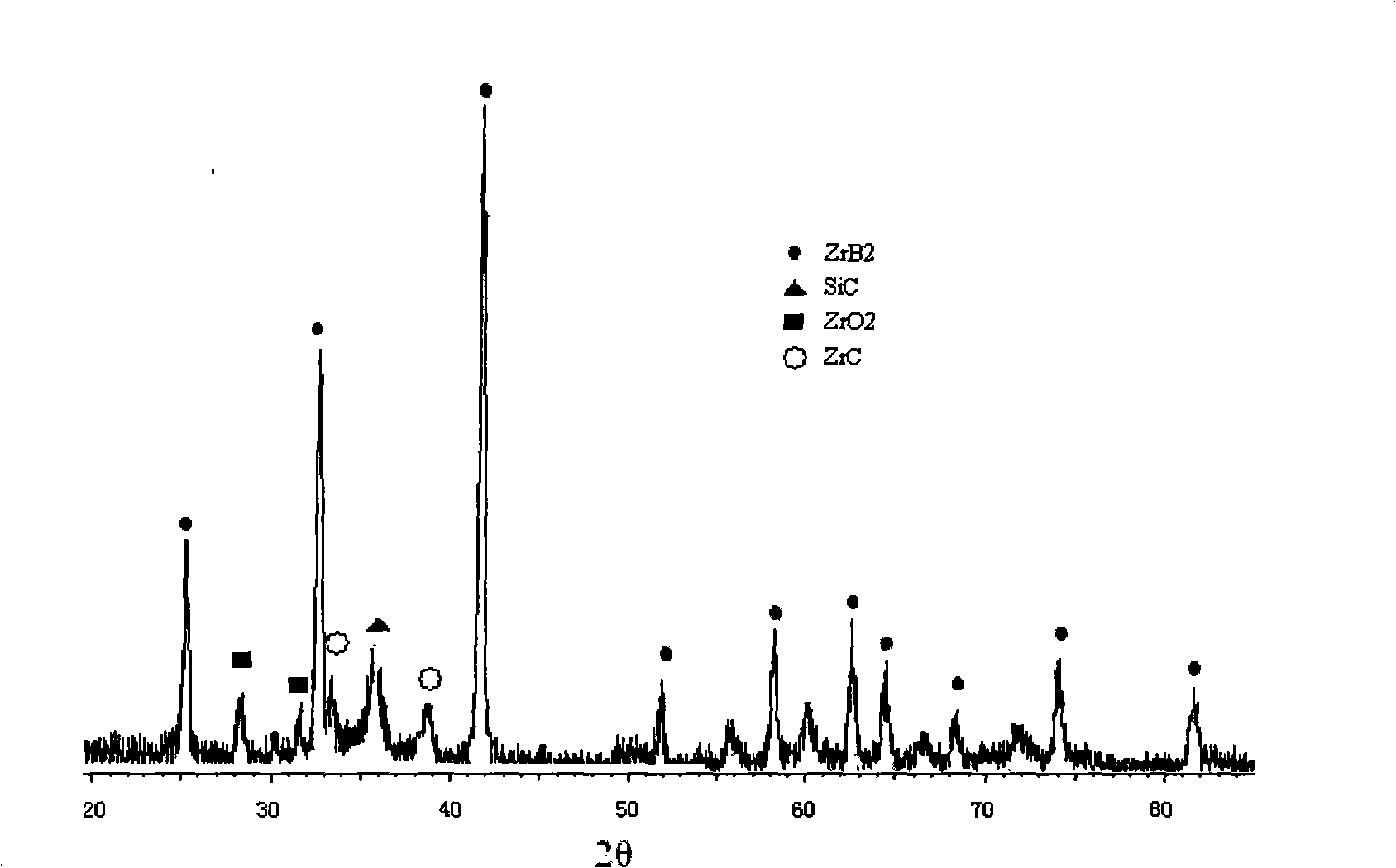

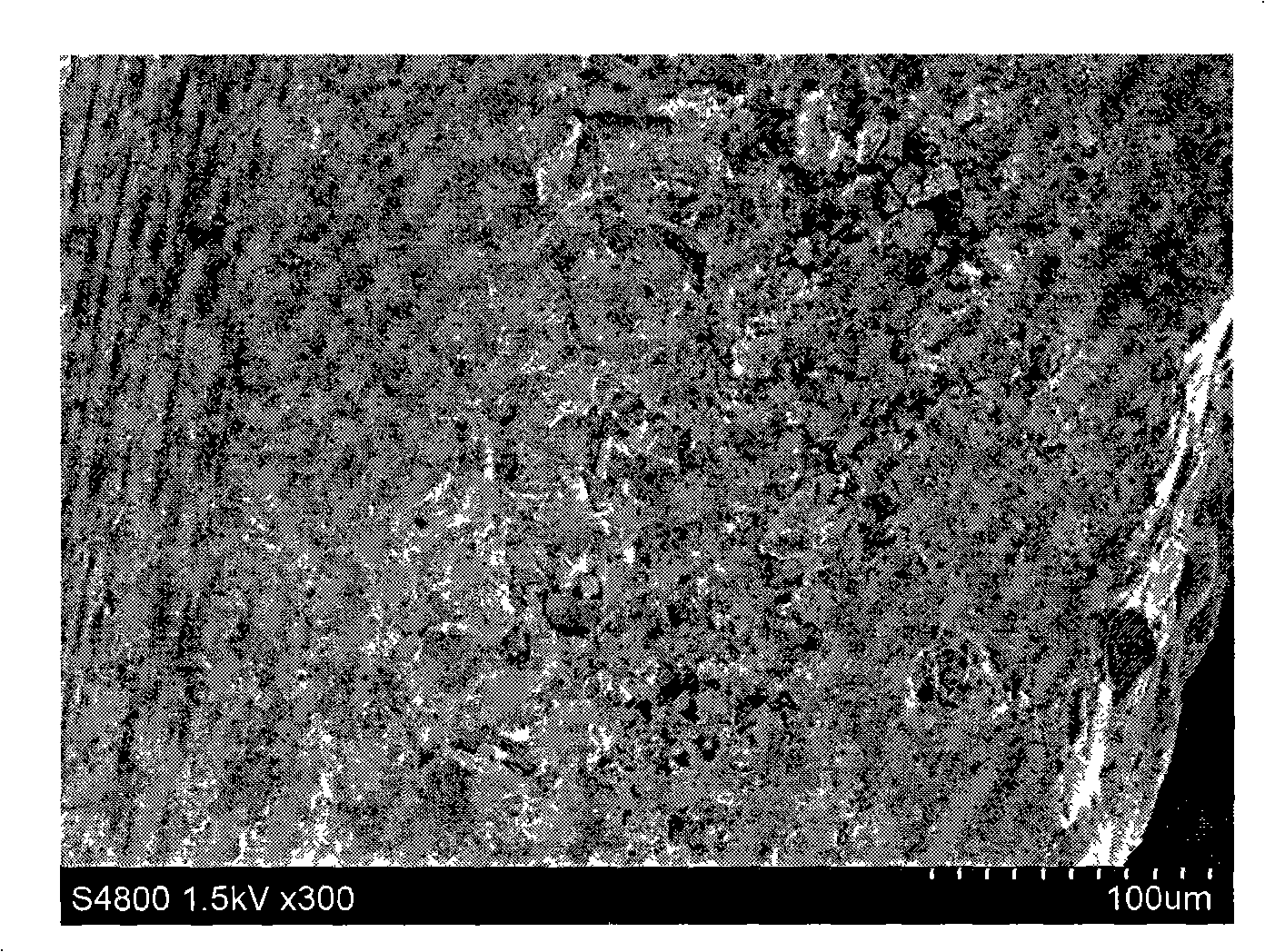

Method for preparing superhigh temperature resistant ceramic coat

InactiveCN101306959AImprove anti-ablation performanceImprove antioxidant capacityCeramic coatingSlurry coating

The invention discloses a method for making a super-high temperature resistant ceramic coating. The method adopts organic polymer as adhesive and mixed powder consisting of high melting metal powder, B powder, C powder and Si powder as raw materials; moreover, through adopting processes such as preparing slurry used in a coating, slurry coating, precoating curing, high-temperature reaction sintering, a super-high temperature resistant ceramic coating is finally made on the surface of a ceramic matrix composite material. The coating making process is simple and has low cost; the made coating has ideal bonding performance with a substrate and has excellent ablation resistance and antioxidation, thereby laying the foundation for the application of a ceramic matrix composite material in the super-high temperature resistant and antioxidation fields.

Owner:NAT UNIV OF DEFENSE TECH

Anti-oxidation coating and preparation method thereof

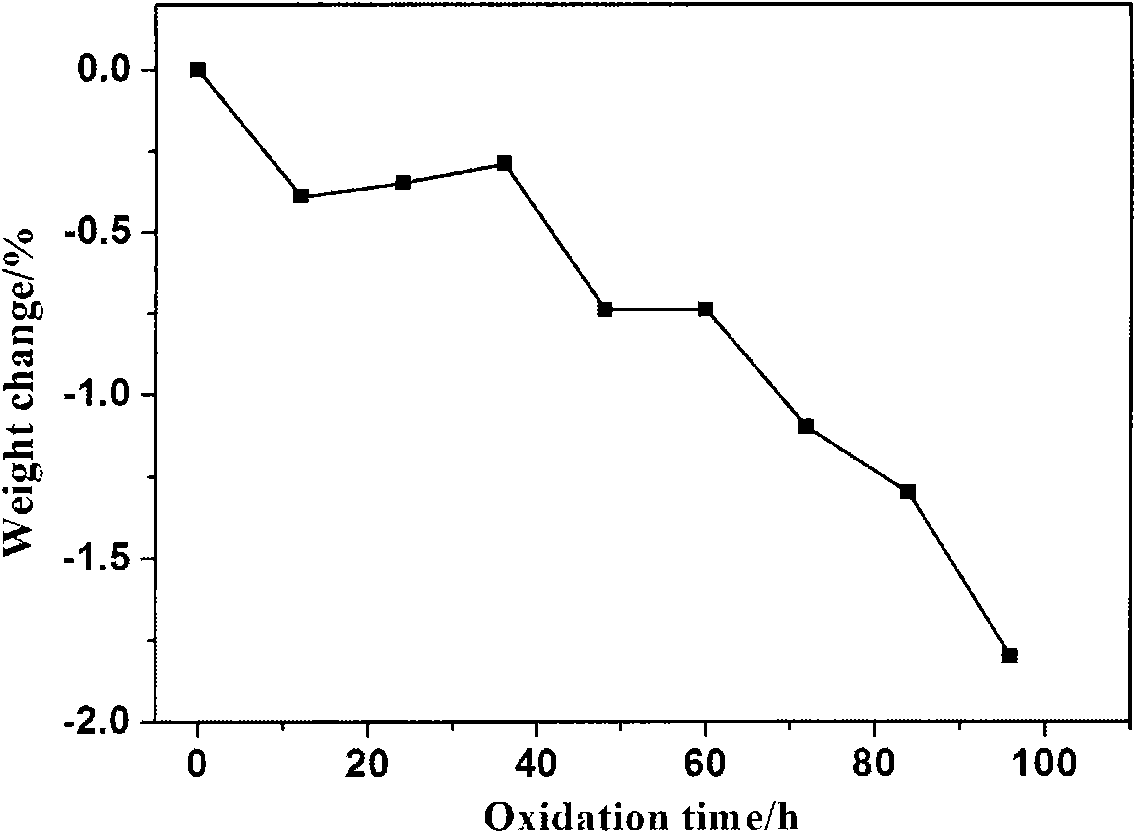

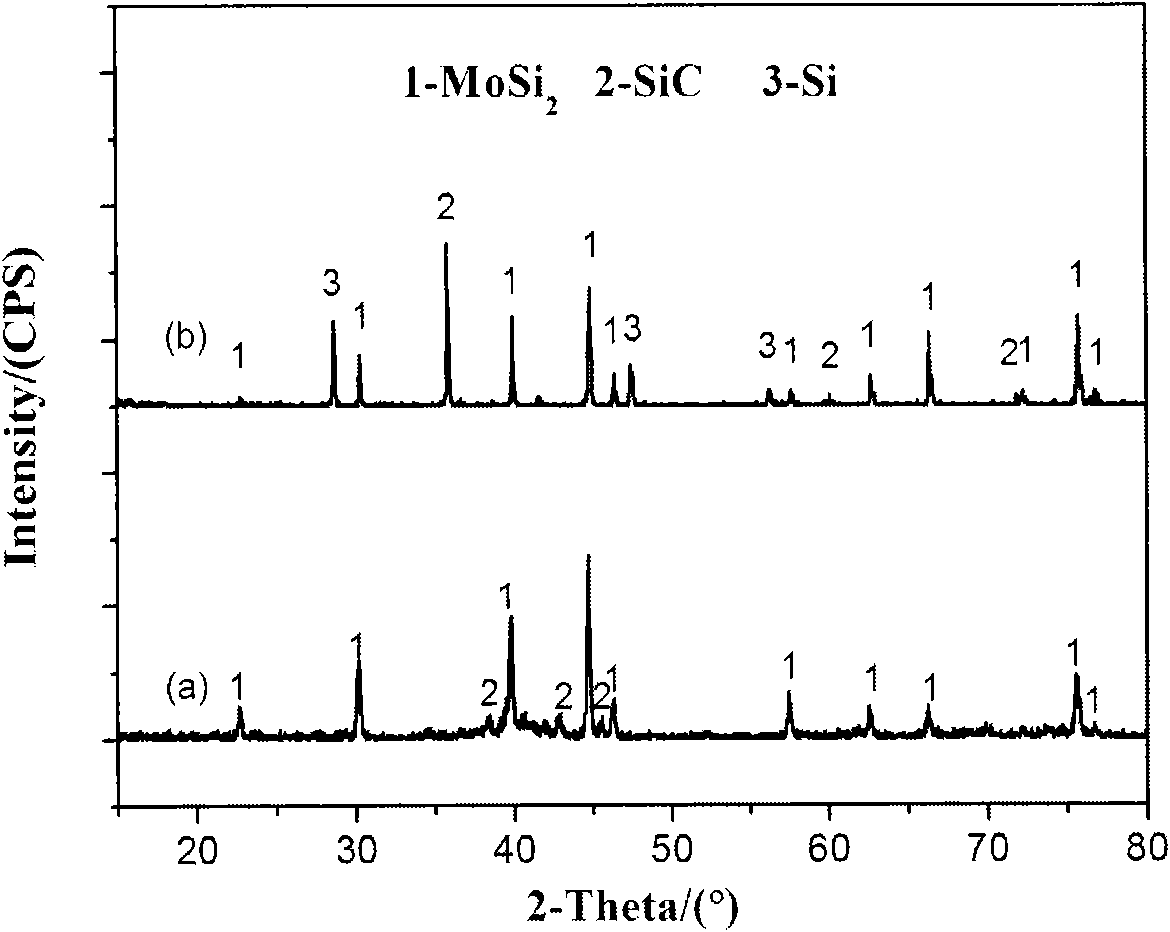

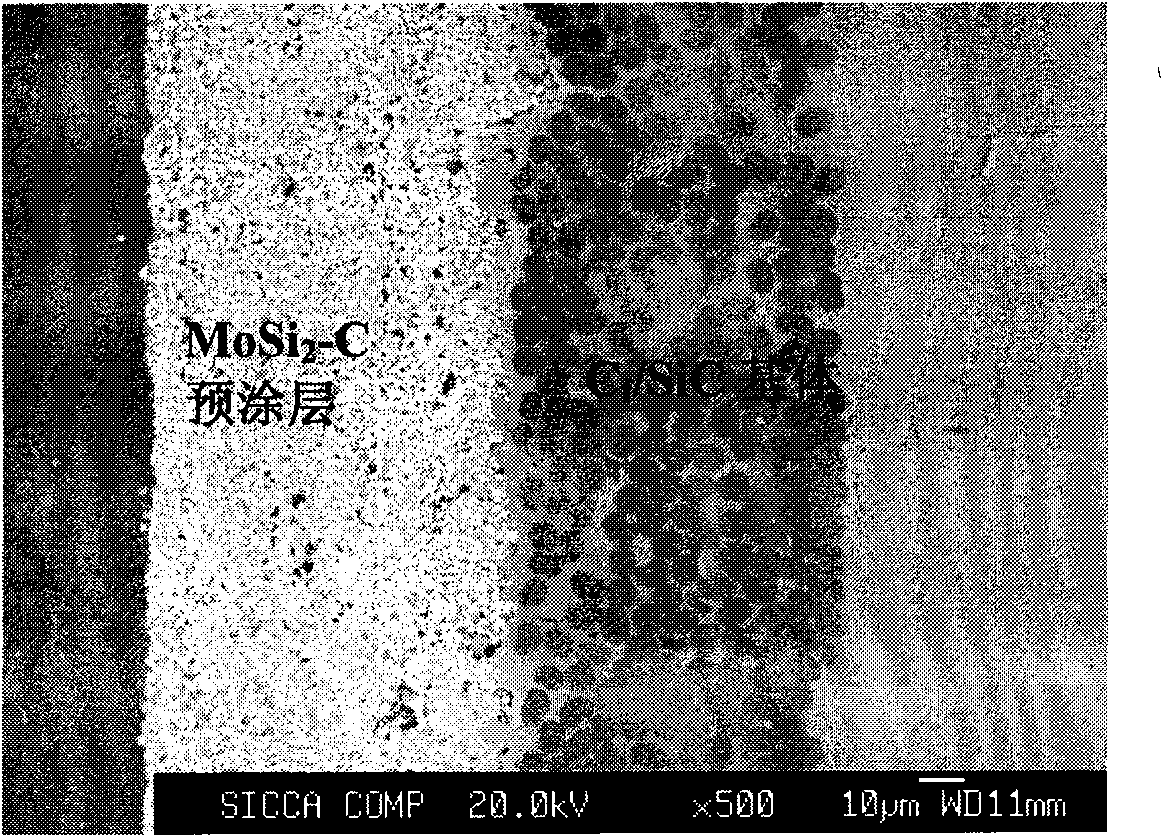

ActiveCN101863683AHigh bonding strengthImprove antioxidant capacityMaterials preparationCoating system

The invention relates to a preparation method of an anti-oxidation coating, which belongs to the field of coating material preparation. In the invention, a composite material is taken as a basal body, and the coating comprises the following main components: a SiC phase, a free Si phase and an M phase, wherein the M phase is an MoSi2, WSi2 and TaSi2 single ceramic phase or a multiple ceramic mixing phase; the thickness of the coating is about 20mu m to 600mu m; the coating adopts a process for preparing the coating by a slurry coating-liquid phase ihrigizing in-suit reaction method; the coating system has wide application range, and contains the whole Si ceramic coatings; and the invention effectively control the thickness and the components of the coating by means of the slurry solid content and slurry coating frequency, thereby meeting the in-service use requirements.

Owner:嘉兴睿创新材料有限公司

Aluminizing slurry compositions free of hexavalent chromium, and related methods and articles

InactiveUS20050031781A1Good chemical stabilityImprove thermal stabilityPretreated surfacesSolid state diffusion coatingColloidal silicaSlurry coating

A slurry coating composition is described, which is very useful for enriching the surface region of a metal-based substrate with aluminum. The composition includes colloidal silica and particles of an aluminum-based powder, and is substantially free of hexavalent chromium. The slurry may include colloidal silica and an alloy of aluminum and silicon. Alternatively, the slurry includes colloidal silica, aluminum or aluminum-silicon, and an organic stabilizer such as glycerol. The slurry exhibits good thermal and chemical stability for extended periods of time, making it very useful for industrial applications. Related methods and articles are also described.

Owner:GENERAL ELECTRIC CO

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060159607A1Reduce the temperatureNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

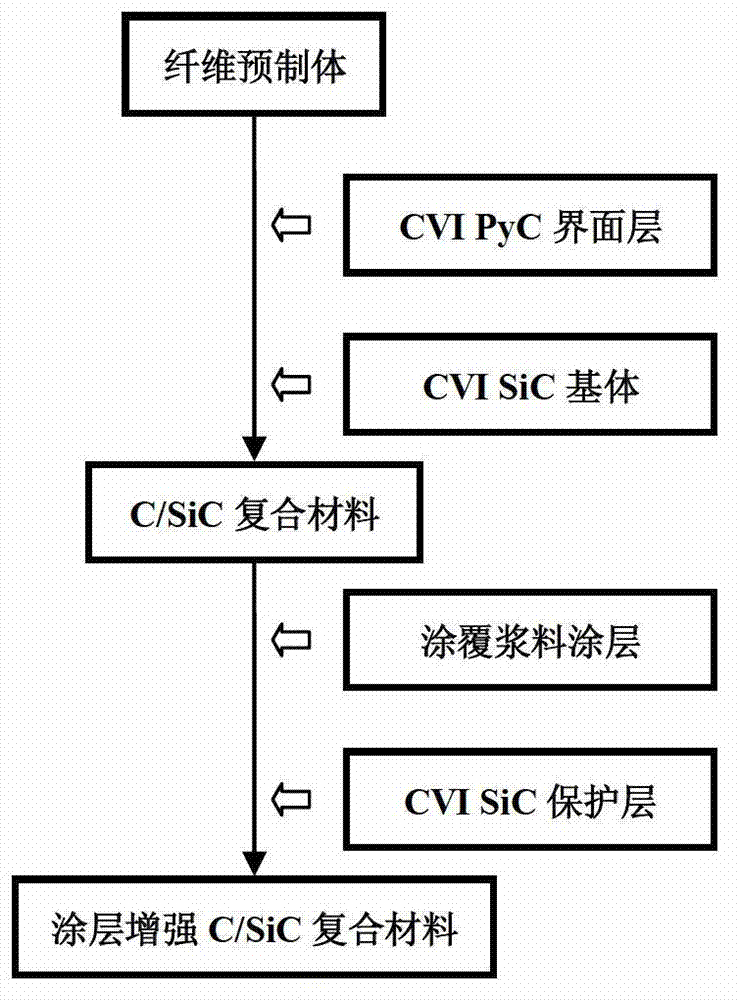

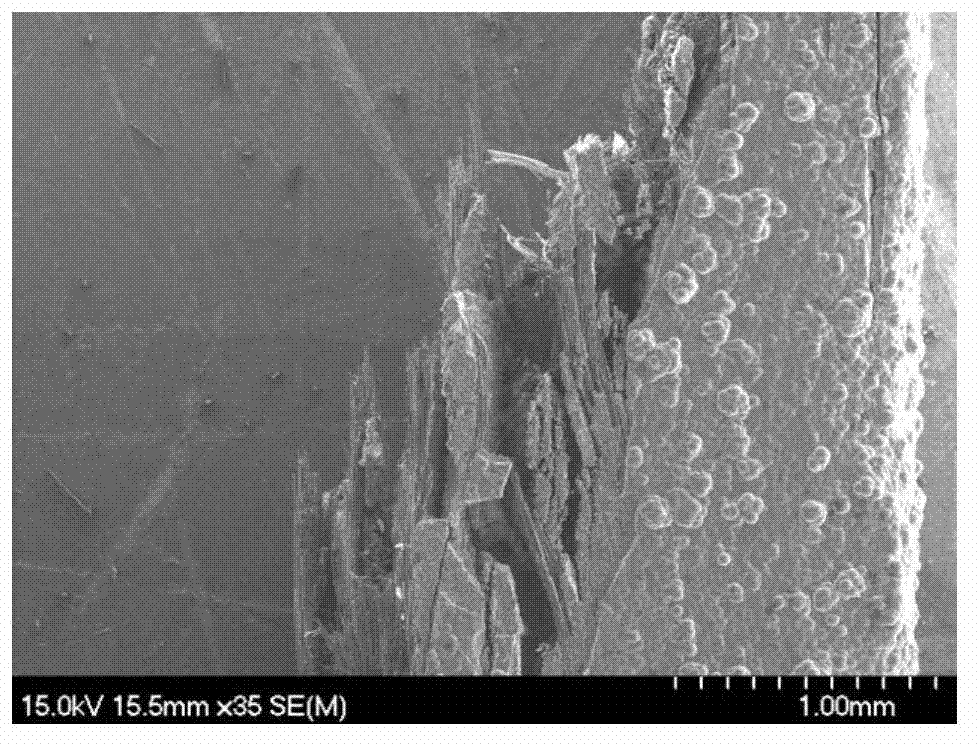

Method for preparing coating reinforced C/SiC composite material

The invention relates to a method for preparing a coating reinforced C / SiC composite material. According to a technical scheme, a slurry coating layer is coated on a test sample surface of a C / SiC composite material to facilitate the filling of aperture gaps remained by a prefabricated body structure and aperture gaps caused by a chemical vapor infiltration bottle neck process, so that the compactness of the composite material is improved, the modulus mismatching between the C / SiC composite material and a SiC protective layer can be effectively relieved and the obdurability of the composite material is improved. Compared with the C / SiC composite material in the prior art, the coating reinforced C / SiC composite material has the advantages that the bending strength of the two-dimensional SiC crystal whisker coating layer reinforced C / SiC composite material is 480-502MPa under the room temperature, the bending strength of the two-dimensional SiC particle coating layer reinforced C / SiC composite material is 440-470MPa, and the bending strength of the two-dimensional (SiC crystal whisker and SiC particle) coating layer reinforced C / SiC composite material is 485-515MPa. The thicknesses of PyC and SiC basal bodies and a protective layer are controlled by controlling deposition time, and the thickness of the slurry coating layer is controlled by controlling the viscosity of the slurry and the coating time the number of coatings so as to realize the control of the composite material structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

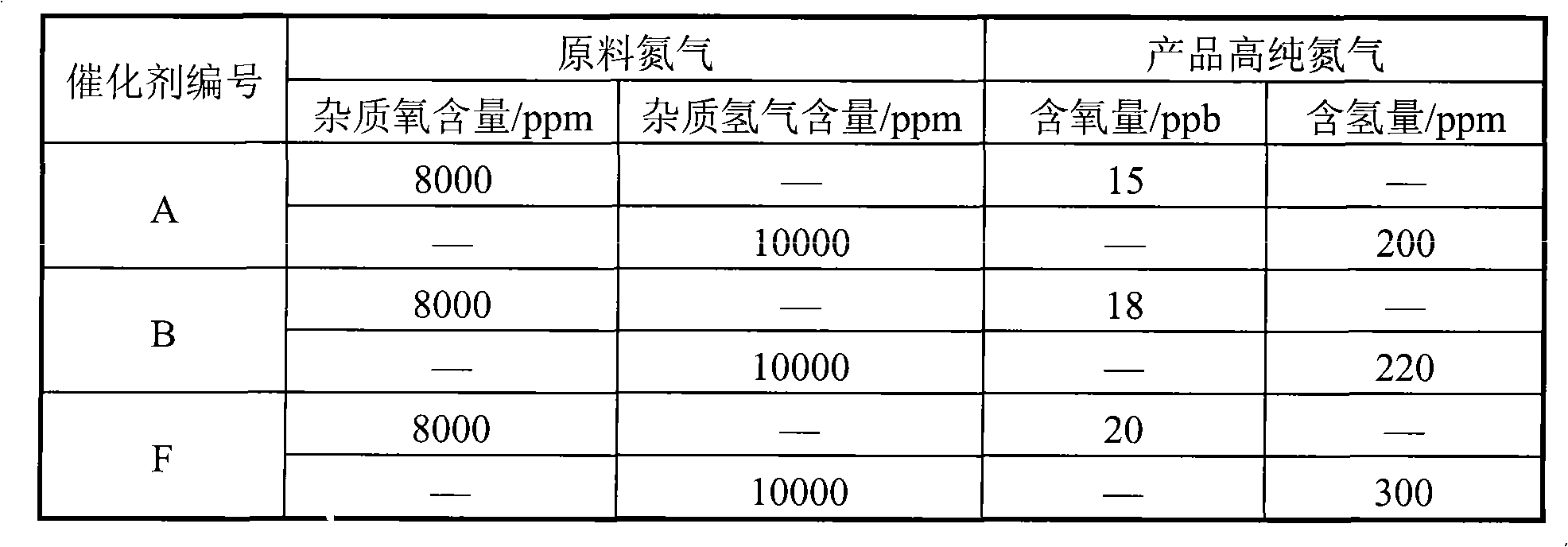

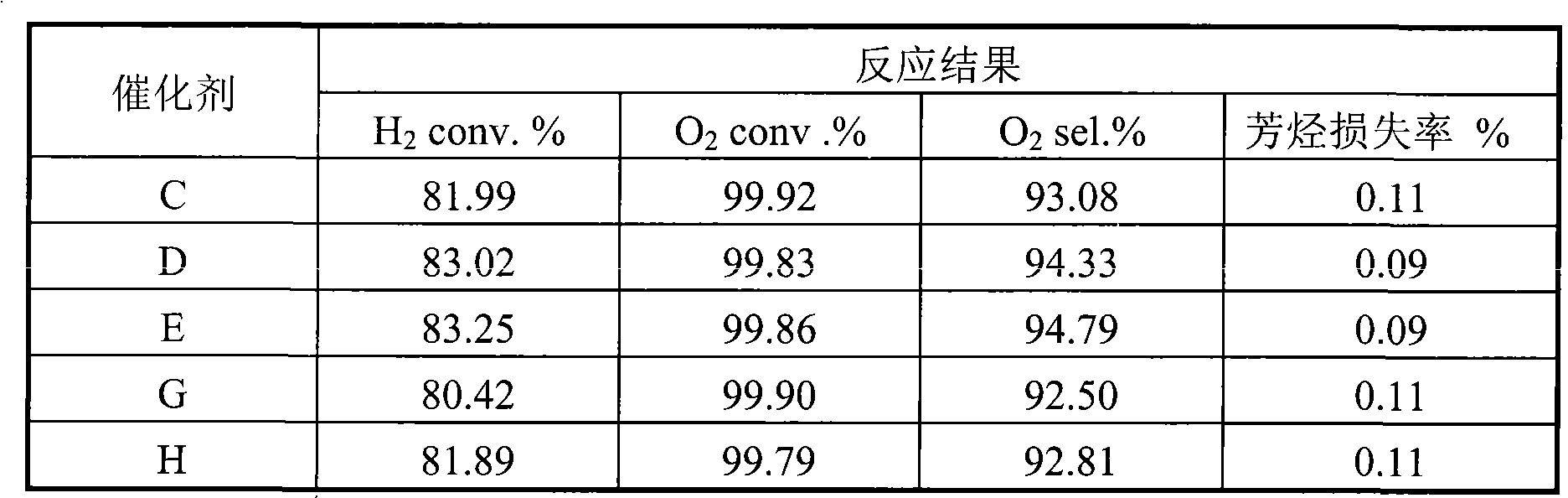

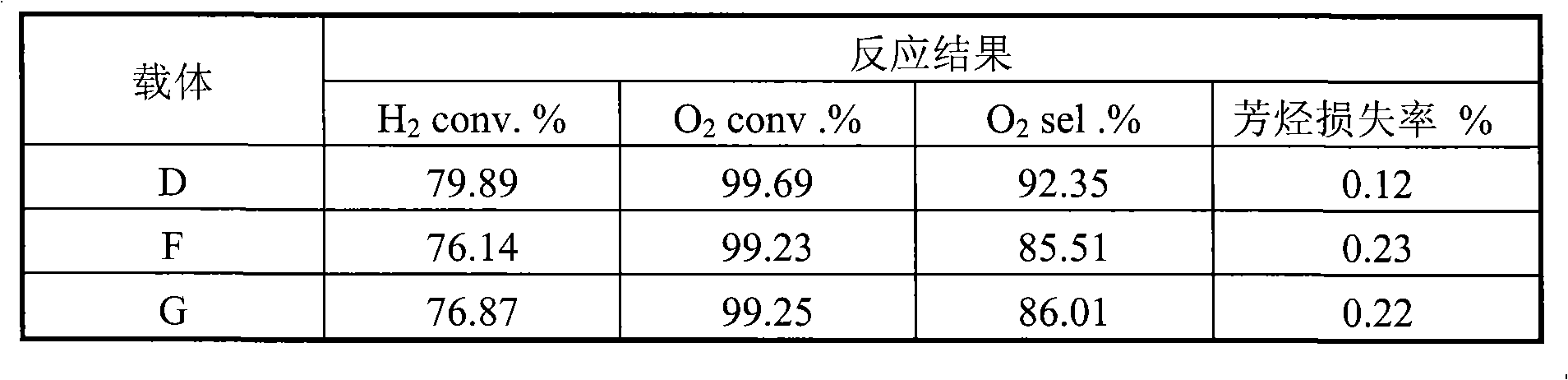

Preparation method of thin shell shaped noble metal catalyst

InactiveCN101491778AExtended service lifeGood dispersionMolecular sieve catalystsCatalyst activation/preparationAlkaneThin shells

The invention relates to a preparation method of thin-shelled noble metal catalyst, and mainly solves the problems of the prior art of high dosage, poor selectivity and short service life of noble metal. The preparation method better solves the technical problems of the prior art by adopting the technical proposal comprising the following steps of: (a) coating the slurry of a coat porous material on the inner core of an inert carrier, drying the slurry coating and baking the slurry coating at a temperature of between 700 and 1,200 DEG C for 0.5 to 10 hours to obtain a laminar composite carrier; (b) impregnating the surface of the laminar composite carrier with a solution containing noble metal and cocatalyst components, drying the laminar composite carrier, and baking the laminar composite carrier in the air at a temperature of between 200 and 700 DEG C for 1 to 24 hours to obtain a thin-shelled catalyst precursor; and (c) reducing the thin-shelled catalyst precursor in a reducing atmosphere at a temperature between 300 and 800 DEG C for 1 to 24 hours to obtain the thin-shelled noble metal catalyst. The preparation method can be used in the industrial production of gas purification materials which are dehydrogenation-deoxidization catalysts, alkanes and aromatic hydrocarbons for selective hydrogen oxidation in a dehydrogenation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

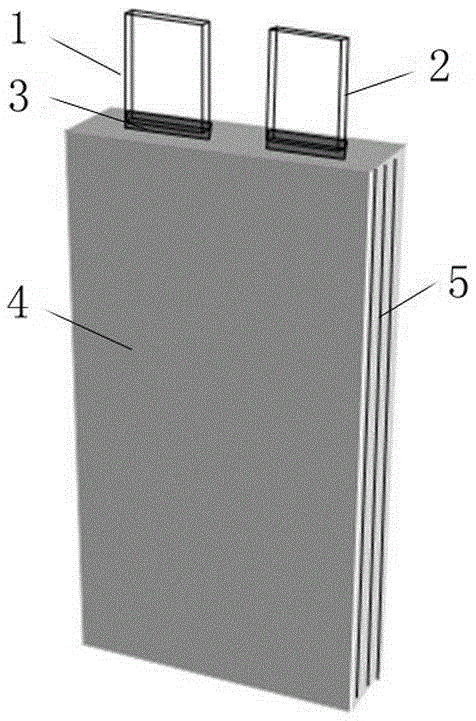

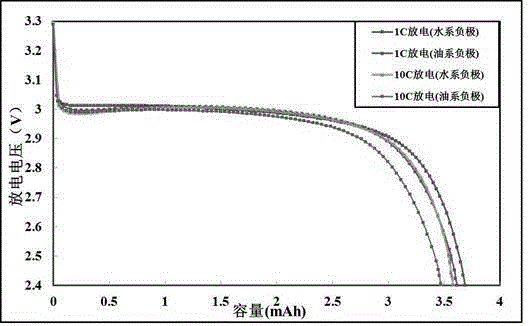

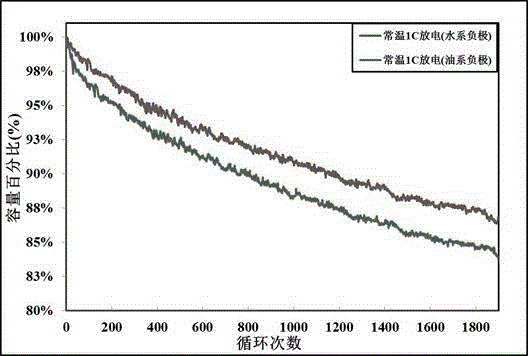

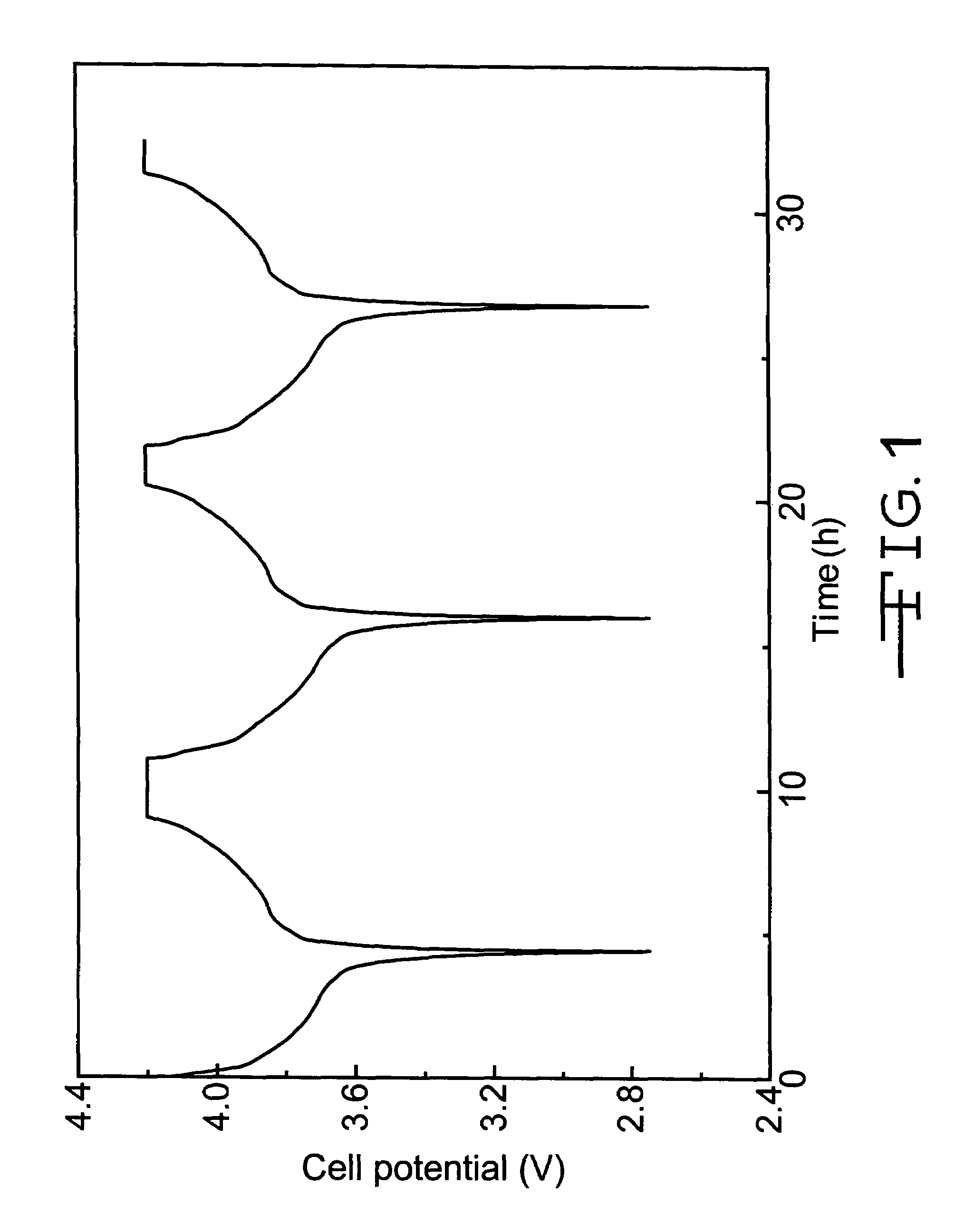

Lithium battery formed on basis of lithium nickel manganese oxide and lithium titanate and preparation method of lithium battery

InactiveCN105336943ALong cycle lifeFast cycle lifeFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention discloses a lithium battery formed on the basis of lithium nickel manganese oxide and lithium titanate and a preparation method of the lithium battery. The lithium battery comprises an aluminum-plastic film casing, an anode lug, a cathode lug and a tab film, wherein the aluminum-plastic film casing contains a battery cell and electrolyte; the battery cell comprises an anode piece, a diaphragm and a cathode piece; materials of the anode piece comprise an anode slurry coating consisting of a positive active material, a binding agent, a conductive agent and a solvent and an anode current collector; the positive active material adopts an Al2O3 coating of lithium nickel manganese oxide; the binding agent adopts one or two of polyvinylidene fluoride and polytetrafluoroethylene; the conductive agent adopts one or more of conductive carbon black, conductive graphite and carbon nanotubes; the solvent adopts N-methyl-2-pyrrolidinone; the anode current collector adopts an aluminum foil; the cathode piece adopts an aqueous cathode or an oil-based cathode. According to the designed lithium battery, the purposes of improvement of the reversible specific capacity, the energy density and the rapid charge-discharge capability, the cycle performance and the safety performance of the battery are achieved while the production cost is reduced.

Owner:四川省有色冶金研究院有限公司

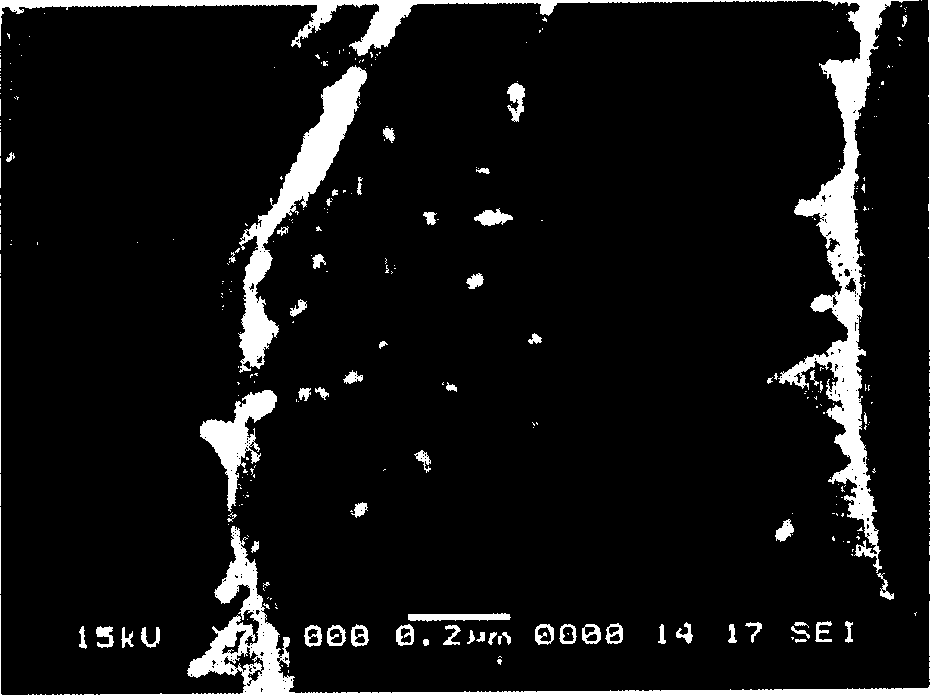

Preparation method of catalyst for catalytic combustion of organic exhaust gas

ActiveCN102872920ASimple preparation processEasy to operateDispersed particle separationCatalyst activation/preparationPtru catalystSlurry coating

The invention discloses a preparation method of a catalyst for catalytic combustion of organic exhaust gas. The method comprises the following steps of: firstly carrying out ultrasonic pretreatment on a honeycomb ceramic matrix in a pretreatment fluid, then loading a nanometer slurry coating, and finally loading an auxiliary agent and a precious metal active component. The catalyst obtained by the adoption of the method has high bonding degree between the coating and the matrix, and is not easy to crack and spall. Therefore, the catalyst has good service performance and good active stability. Even under scouring and thermal shock of an air flow at high space velocity, the catalyst can still maintain high activity so as to guarantee long-term stable operation of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

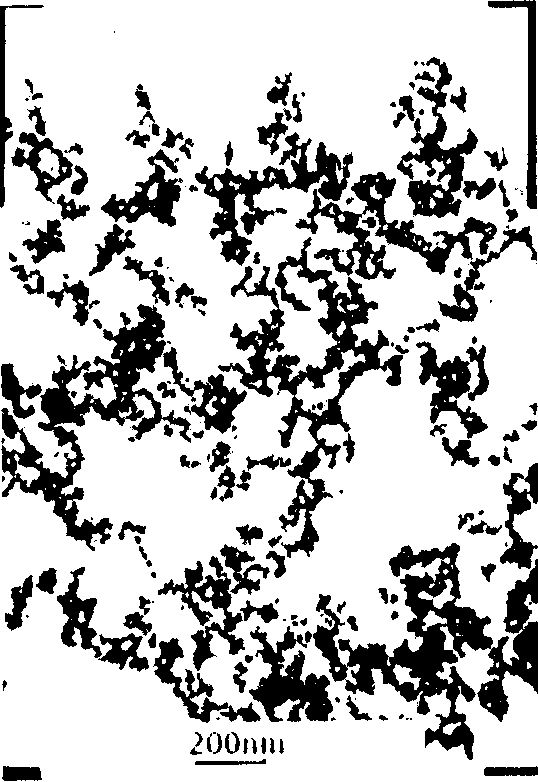

Nanometer antimony-doped stannic oxide antistatic coating and method for making same

The invention discloses the nanometer stannic oxide antistatic coating and preparing method. The invention modifies the nanometer ATO with surface processing agent, reducing the surface free energy and improving ATO dispersity. The slurry coating has network structure after film curing, so it has good electrical conductivity. The coating material can be used in skin layer of high molecular synthetic material, and it has electrostatic resistance action.

Owner:SHANGHAI HUAMING HI TECH GRP

Ultraviolet aluminium-silver size coating with light curing

A ultraviolet light solidified aluminium silver slurry coating consists of acrylic resin 20-50wt%, acrylic ester monomer 10-50wt%, light initiating agent 3-10wt%, aluminium silver slurry 2-15wt%, aluminium silver slurry orienting agent 4-15wt%, assistants 0.3-2.5wt% and solvent 15-30wt%. It achieves fast curing speed, less organic volatile substances, higher production efficiency, better adhesion, hardness and abrasive-resistant performance.

Owner:CHINA LUCKY FILM CORP +1

Aluminizing slurry compositions free of hexavalent chromium, and related methods and articles

A slurry coating composition is described, which is very useful for enriching the surface region of a metal-based substrate with aluminum. The composition includes colloidal silica and particles of an aluminum-based powder, and is substantially free of hexavalent chromium. The slurry may include colloidal silica and an alloy of aluminum and silicon. Alternatively, the slurry includes colloidal silica, aluminum or aluminum-silicon, and an organic stabilizer such as glycerol. The slurry exhibits good thermal and chemical stability for extended periods of time, making it very useful for industrial applications. Related methods and articles are also described.

Owner:GENERAL ELECTRIC CO

In situ thermal polymerization method for making gel polymer lithium ion rechargeable electrochemical cells

InactiveUS7422826B2Increase productivitySimple processFinal product manufactureElectrode carriers/collectorsElectrolysisSlurry coating

A single step, in situ curing method for making gel polymer lithium ion rechargeable cells and batteries is described. This method used a precursor solution consisting of monomers with multiple functionalities such as multiple acryloyl functionalities, a free-radical generating activator, nonaqueous solvents such as ethylene carbonate and propylene carbonate, and a lithium salt such as LiPF6. The electrodes are prepared by slurry-coating a carbonaceous material such as graphite onto an anode current collector and a lithium transition metal oxide such as LiCoO2 onto a cathode current collector, respectively. The electrodes, together with a highly porous separator, are then soaked with the polymer electrolyte precursor solution and sealed in a cell package under vacuum. The whole cell package is heated to in situ cure the polymer electrolyte precursor. The resulting lithium ion rechargeable cells with gelled polymer electrolyte demonstrate excellent electrochemical properties such as high efficiency in material utilization, high Coulombic efficiency, good rate capability, and good cyclability.

Owner:WILSON GREATBATCH LTD

Current collector, preparation method of current collector and lithium ion battery comprising current collector

ActiveCN105375035AImpurity promotionImprove securityElectrode carriers/collectorsSecondary cellsElectron sourceConductive polymer

The invention relates to the technical field of lithium ion batteries, in particular to a current collector, a preparation method of the current collector and a lithium ion battery comprising the current collector. The current collector comprises a two-layer coating which includes a conductive slurry coating and a conductive polymer PEDOT (poly(3,4-ethylenedioxythiophene)):PSS (poly(styrenesulfonate)) coating from inside to outside. The two-layer coating of the current collector has high electrical conductivity at the room temperature, and the electrical conductivity is reduced abruptly at a high temperature. When thermal shock, over-charging and short-circuited failure happen to the lithium ion battery using the current collector, the temperature rises to be higher than 100 DEG C abruptly, the electron conductivity of the two-layer coating is reduced abruptly, transmission of electrons on the current collector is quickly and effectively limited, an electron source for reactions in the battery is cut off, and in-site overheat protection is provided for the battery in time.

Owner:DONGGUAN AMPEREX TECH

Slurry chromizing process

InactiveUS20100151125A1Effectiveness in chromizing metal substrateEasy to adjustPretreated surfacesSolid state diffusion coatingColloidal silicaMetallic aluminum

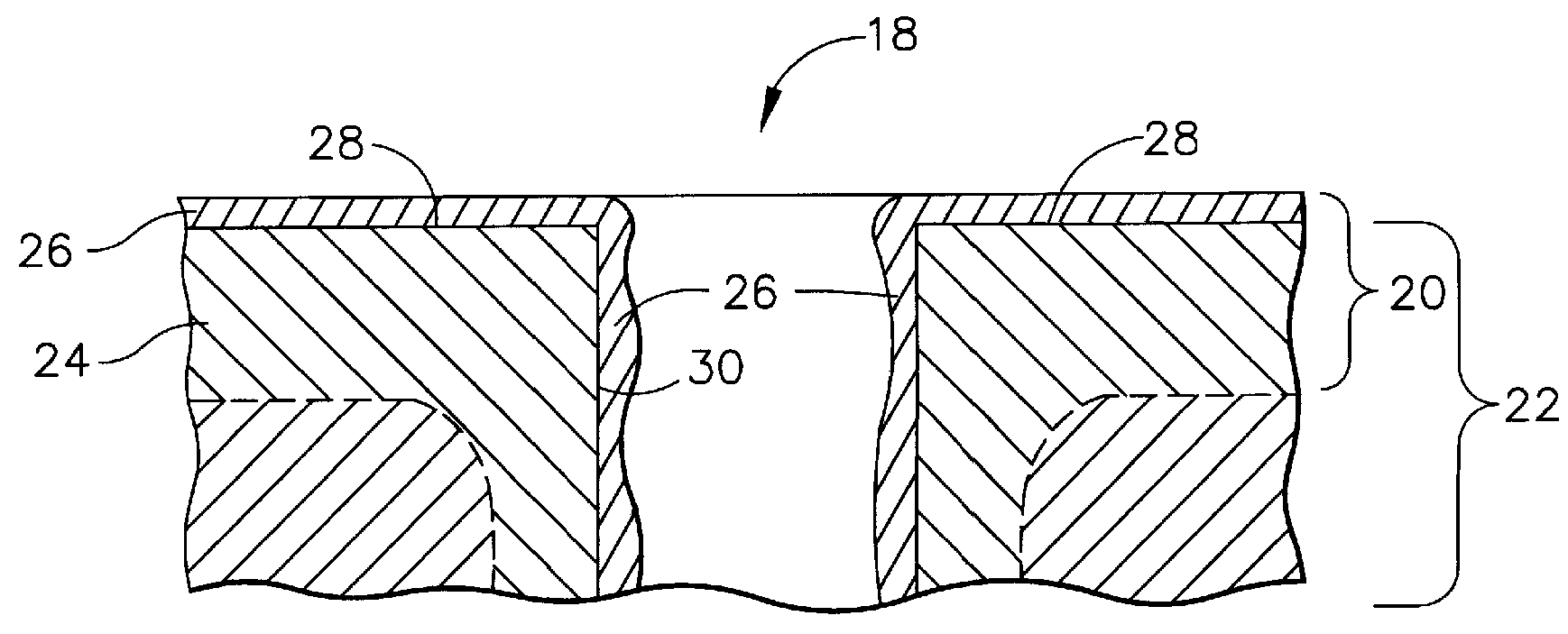

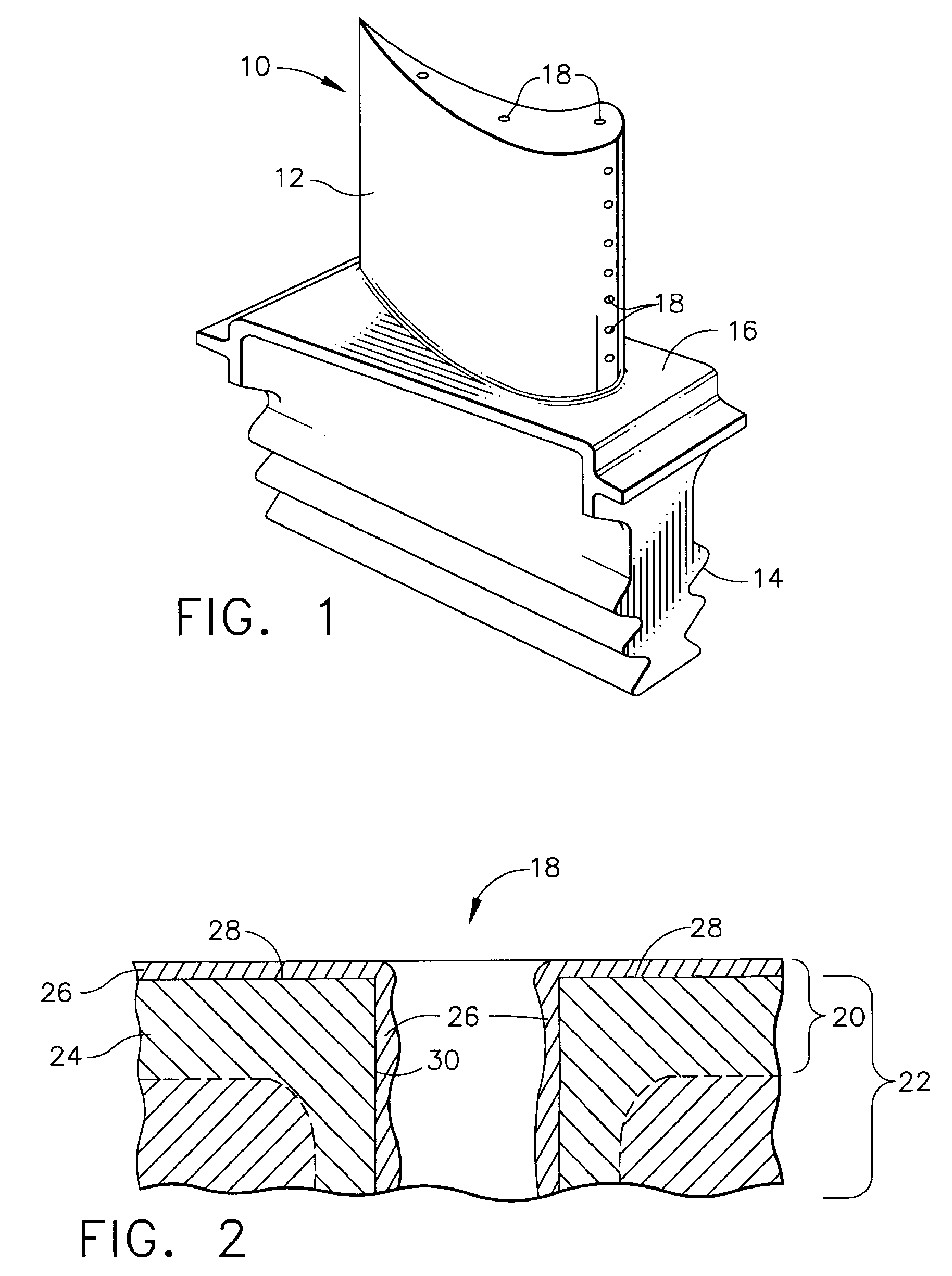

Slurry coating process for selectively enriching surface regions of a metal-based substrate, for example, the under-platform regions of a turbine blade, with chromium. The process employs a slurry coating composition containing metallic chromium, optionally metallic aluminum in a lesser amount by weight than chromium, and optionally other constituents. The composition further includes colloidal silica, and may also include one or more additional constituents, though in any event the composition is substantially free of hexavalent chromium and sources thereof. The coating composition is applied to a surface region to form a slurry coating, which is then heated to remove any volatile components of the coating composition and thereafter cause diffusion of chromium from the coating into the surface region to form a chromium-rich diffusion coating.

Owner:GENERAL ELECTRIC CO

High-stability polymer bonding inorganic oxide battery diaphragm coating and preparation method thereof

InactiveCN106340604AImprove bindingSimple processCell seperators/membranes/diaphragms/spacersNew energySide chain

The invention belongs to the field of new energy resource material and particularly relates to a high-stability polymer bonding inorganic oxide battery diaphragm coating and a preparation method thereof. The high-stability polymer bonding inorganic oxide battery diaphragm coating is characterized in that the characteristic that a surface zata potential is a positive value when the pH value of an aluminum oxide and silicon oxide dual-property inorganic oxide is smaller than an equipotential point is utilized, a polymer binder with negative charge on functional groups and inorganic oxide perform electrostatic self-assembly to form tight chemical bonds, and the inorganic oxide coating stable in structure is formed after coating. The preparation method comprises the main process steps that preparing inorganic oxide-water dispersion solution, measuring the oxide of the solution, regulating the pH value of the inorganic oxide-water dispersion solution to be below the equipotential point, making a polymer with sulfonate radical side chains and the inorganic oxide perform electrostatic self-assembly to form slurry, and performing coating and drying. By the adoption of the method, the bonding power of the binder and the inorganic oxide is strengthened, the slurry coating process of the inorganic oxide battery diaphragm coating is completely consistent with a traditional coating technology, the process is simple, and the cost is controllable.

Owner:武汉格物天成新材料科技有限公司

Coatings for building products and dewatering aid for use with same

InactiveUS7396402B2Improve dehydration propertiesLiquid surface applicatorsConstruction materialBuilding productSlurry coating

A dewatering aid for a slurry coating on a building product in which a coating formulation includes an hydraulic binder. A slurry is produced from said binder and dewatering aid and applied to the product to be coated. The resultant coating is then dewatered through said product. Dewatering can be accomplished with or without vacuum assistance.

Owner:JAMES HARDIE TECH LTD

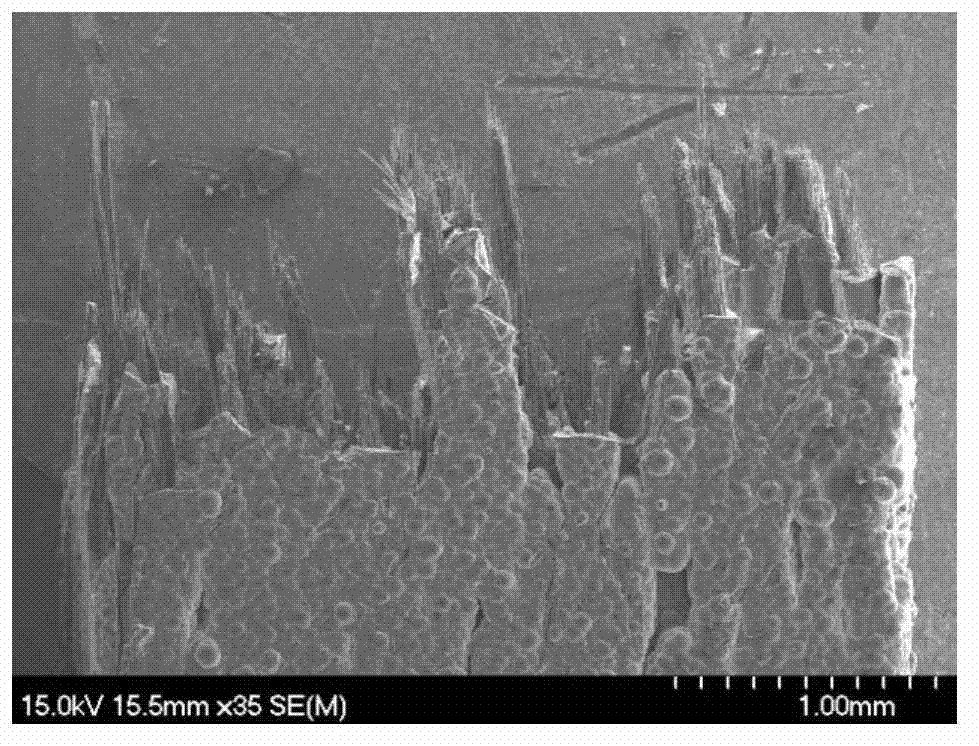

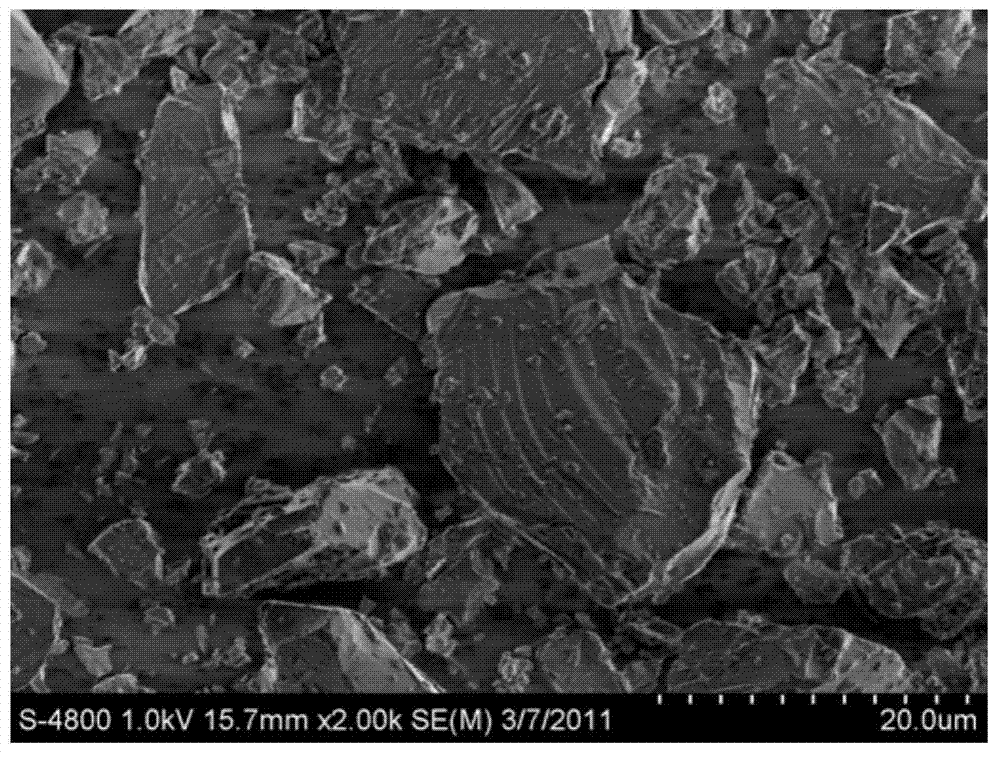

Manufacturing method for composite wear-resistant parts formed by slurry coating surface activation ZTA particles and reinforced iron matrixes

The invention discloses a manufacturing method for composite wear-resistant parts formed by slurry coating surface activation ZTA particles and reinforced iron matrixes. The method comprises the concrete steps that (1) multiple active element powder is mixed to be uniform and then placed into a liquid-containing binder to disperse uniform to form slurry; (2) after the surfaces of the ZTA particles are coated with the slurry, a graphite mould is filled with the ZTA particles, and porous prefabricated blocks are obtained through pressure application and sintering; (3) the prefabricated blocks are fixed on specific positions of a casting mould, molten metal is poured, and the composite wear-resistant parts are obtained after cooling and demoulding. According to the method, the added active element can improve interfacial wettability and bonding strength, and the slurry coating method is beneficial to uniformization of the active element on the surfaces of the particles. The shape and the size of the prefabricated blocks can be controlled through the mould, and therefore the method is applicable to manufacture of different kinds of wear-resistant parts. Wild phases and matrixes distributed in a staggered mode in a composite layer can guarantee that the wear-resistant parts have high wear resistance and long service life under the action of high stress, and therefore economic benefits are greatly improved.

Owner:XI AN JIAOTONG UNIV +1

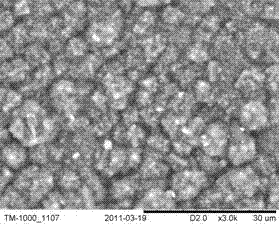

Method for synthesizing molecular sieve membrane

InactiveCN102225314ASimple and fast operationHigh repeatability of film formationSemi-permeable membranesCrystalline aluminosilicate zeolitesMolecular sieveSlurry coating

The invention discloses a method for synthesizing a molecular sieve membrane, which adopts a mode of crystal seed coating by a crystal seed slurry coating method for the synthesis of the molecular sieve membrane. A sol with a composition similar to that of a synthetic fluid for synthesizing the molecular sieve membrane is prepared, and the sol is mixed with molecular sieve crystals and water according to a certain proportion to prepare a crystal seed slurry; a supporting body is soaked with water, and after the surface of the supporting body is dried in the air, the crystal seed slurry is coated on the surface; when the surface is almost dry, the coating is strickled and dried to obtain a supporting body with a crystal seed layer; finally the molecular sieve membrane is synthesized by a hydrothermal synthesis method. The crystal seed layer prepared by the invention can eliminate possible defects on the supporting body surface, is distributed uniformly, and is not easy to be erased from the supporting body surface, so the synthesized molecular sieve membrane has a continuous and dense surface, excellent separation performance, good repeatability, and is applicable to large-scale production.

Owner:ZHEJIANG UNIV

Preparation method of shell mold for investment casting of TiAl based alloy

InactiveCN102601307AQuality improvementHigh surface finishFoundry mouldsFoundry coresWaxInvestment casting

The invention relates to a preparation method of a shell mold for investment casting of a TiAl based alloy, and belongs to the technical field of precision casting. The preparation method comprises the following steps that: firstly, ZrO2 and zirconia sol are prepared into a slurry; after the slurry is coated with a wax pattern, ZrO2 sand with a particle degree of 120 to 180 meshes is spread; Al2O3 and ethyl silicate hydrolyzate are prepared into a slurry, and then after the slurry is coated with a mold shell, Al2O3 sand with a particle degree of 60 to 90 meshes is spread, the slurry coating and the sand spreading are repeated for several times, the sand is Al2O3 sand with the particle degree of 40 to 50, 20 to 30, and 6 to 10 meshes sequentially, and drying is carried out; and dewaxing and roasting are carried out. The preparation method has the advantages that: the strength of the mold shell is sufficient, the production cycle is short, the quality of the inner surface of the mold shell is good, the reaction between TiAl based alloy castings and the mold shell is small after casting, and the castings have high surface quality.

Owner:锆坦生物技术(北京)有限公司

Emulsified SBS modified asphalt and its processing method

InactiveCN1664012AIncrease elasticityStrong low temperature resistanceBuilding insulationsEmulsionSlurry coating

Disclosed is an emulsified SBS modified pitch and the preparing method, belonging to the technology field of pitch modifying and emulsifying processing. The stock comprises base pitch, modifier, emulsion made by emulsifier and water; the invention is characterized in that the said modifier is macromolecular polymer thermoplastic rubber SBS in solid state, the consumption is 1~8% of the base pitch in mass; and said emulsion is 50~100% of the base pitch in mass. The method comprises putting the SBS into pitch to get the modified pitch, feeding the modified pitch and emulsion into emulsifier for emulsion and getting the emulsified SBS modified pitch. The invention is characterized by the reasonable formulation and the improvement in the low temperature resistance, high-temperature resistance, elastic recovery ability and the increase in binding strength and the engineering application in slurry coating etc.

Owner:杨林江

Method for preparation of nano-modified amorphous ceramic coating on metal matrix ceramic coating

InactiveCN103484857AHighlight substantive featuresLow softening temperatureMolten spray coatingSuperimposed coating processCeramic coatingSlurry coating

Relating to plating of metal materials, the invention provides a method for preparation of nano-modified amorphous ceramic coating on a metal matrix ceramic coating. The method includes the steps of: subjecting nano Y-ZrO2 powder and amorphous ceramic mixed powder composed of 1.0-15.0% of B2O3, 1.0-10.0% of Al2O3, 7.0-10.0% of CaO, 1.0-3.0% of MgO, 4.5-6.5% of K2O, 8.0-10.0% of Na2O and the balance SiO2 to wet mixing in a ball mill for 20min, then conducting drying to obtain a mixture of nanocrystalline ceramics and amorphous ceramic mixed powder, blending the mixture with water in a mass ratio of 1:1-5:3 to form a slurry, spray brushing the slurry onto the metal matrix ceramic coating surface of a workpiece by slurry jetting or slurry coating, and finally performing sintering to form the nano Y-ZrO2 modified amorphous ceramic coating, which has a low through hole rate and can resist 650DEG C high temperature liquid zinc corrosion.

Owner:天津市卧龙冶金设备有限公司

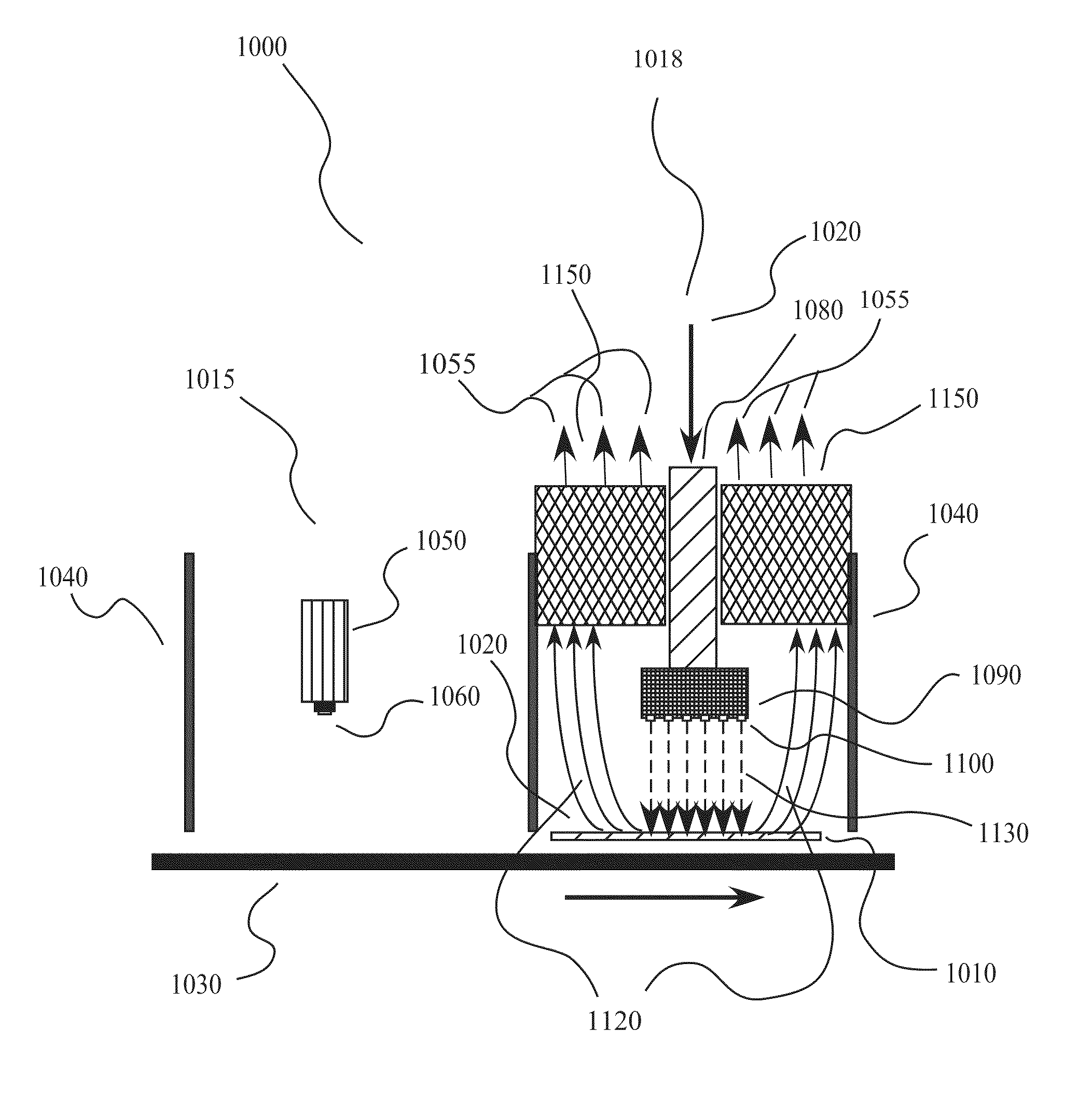

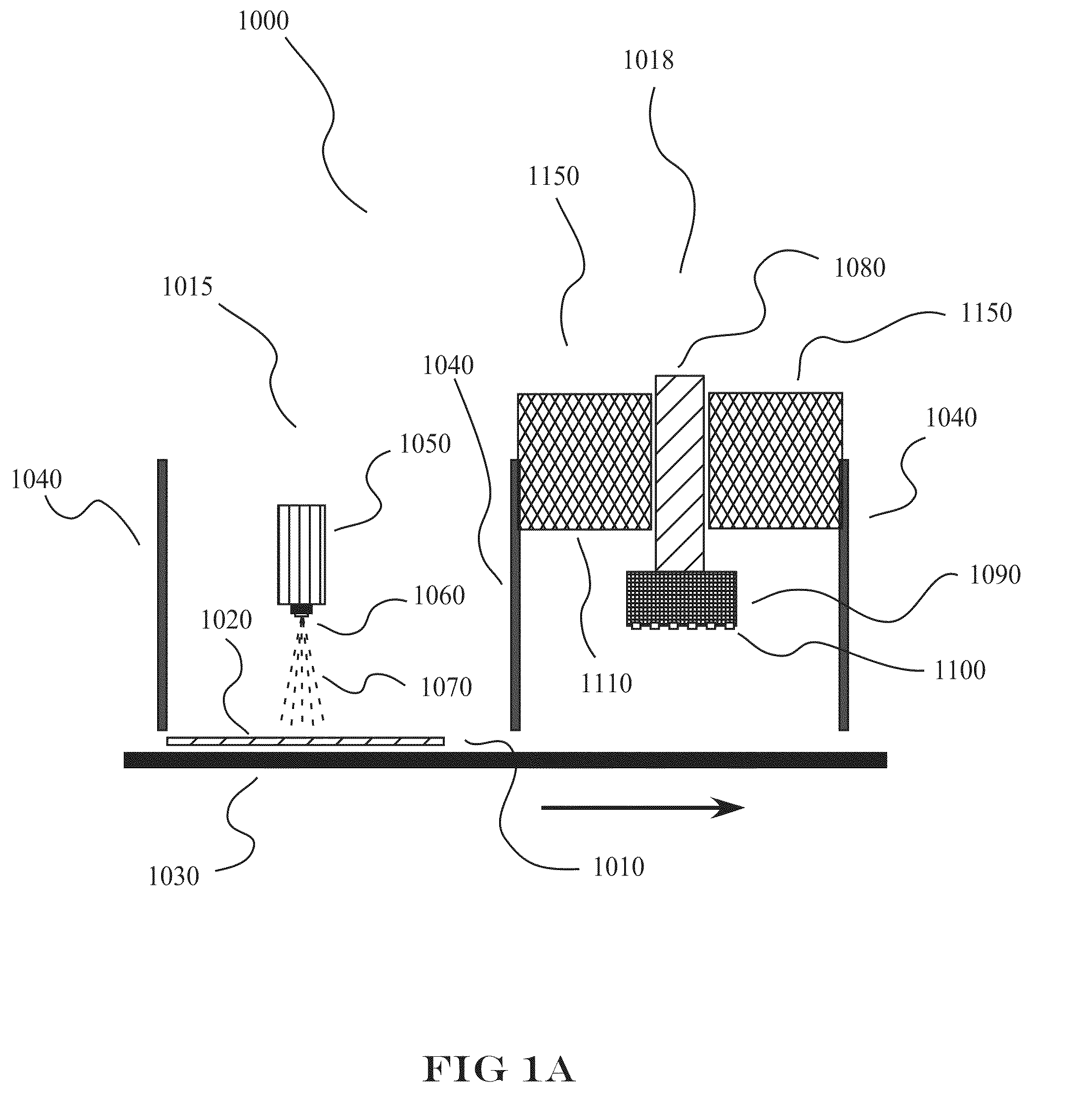

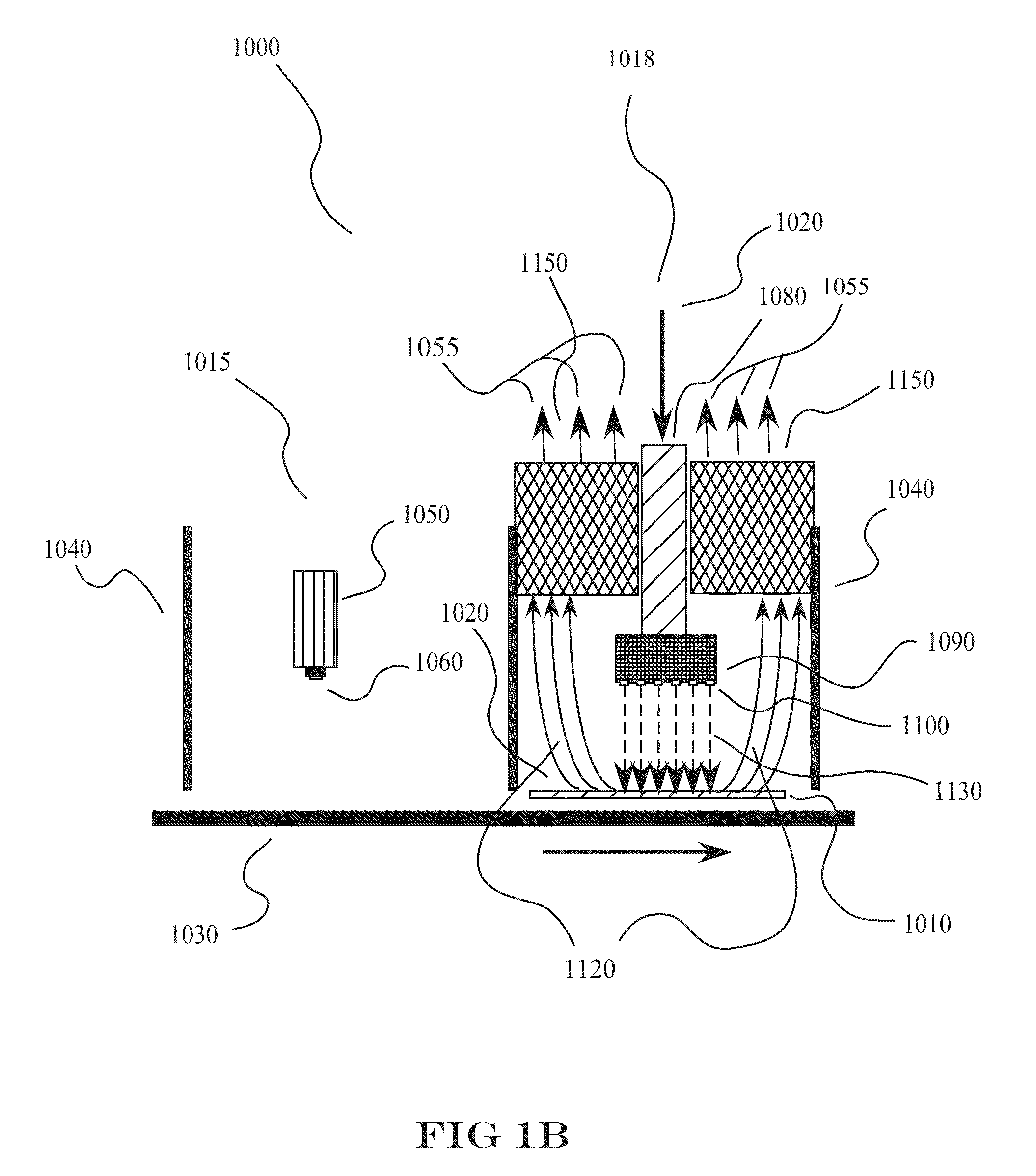

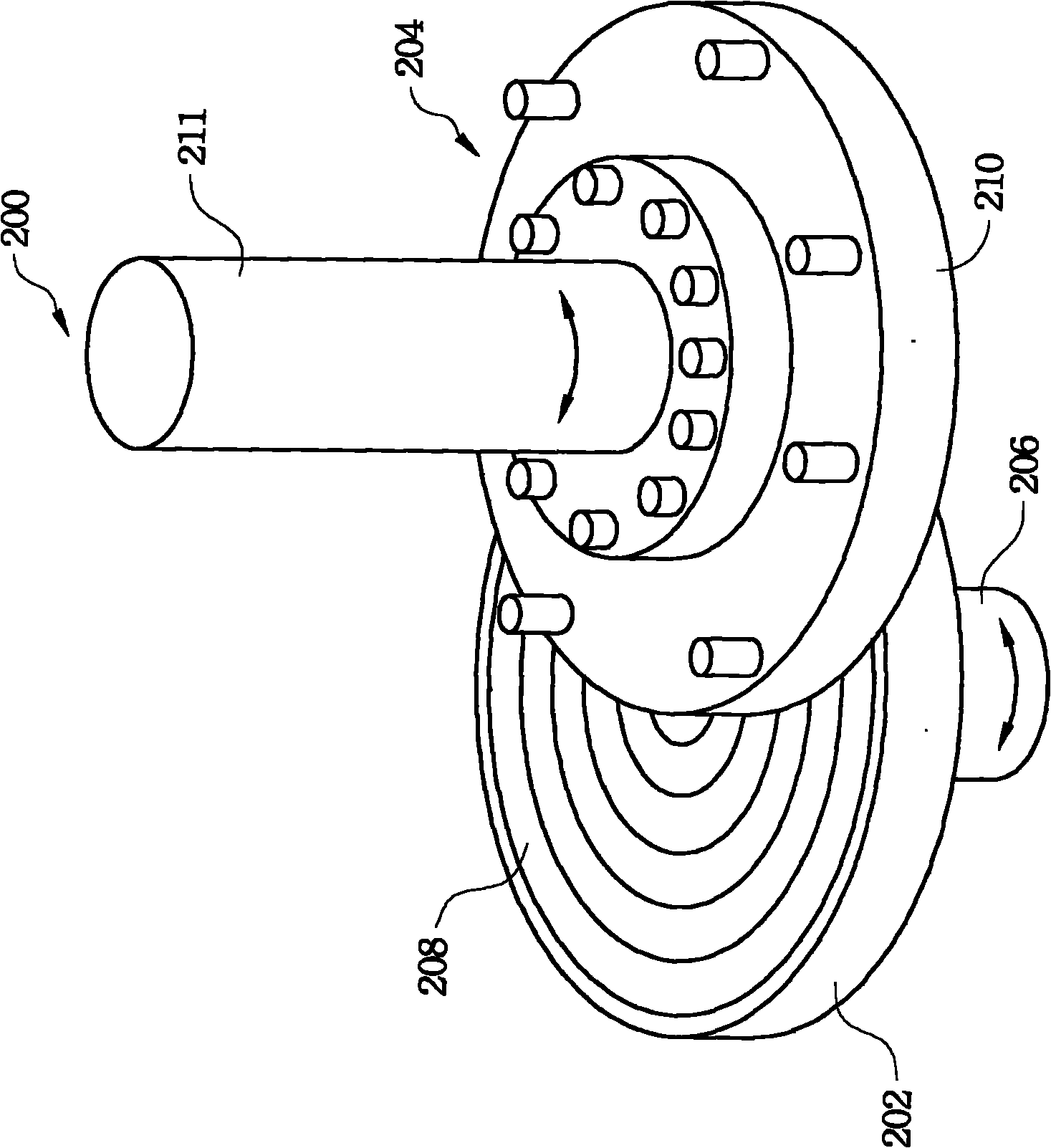

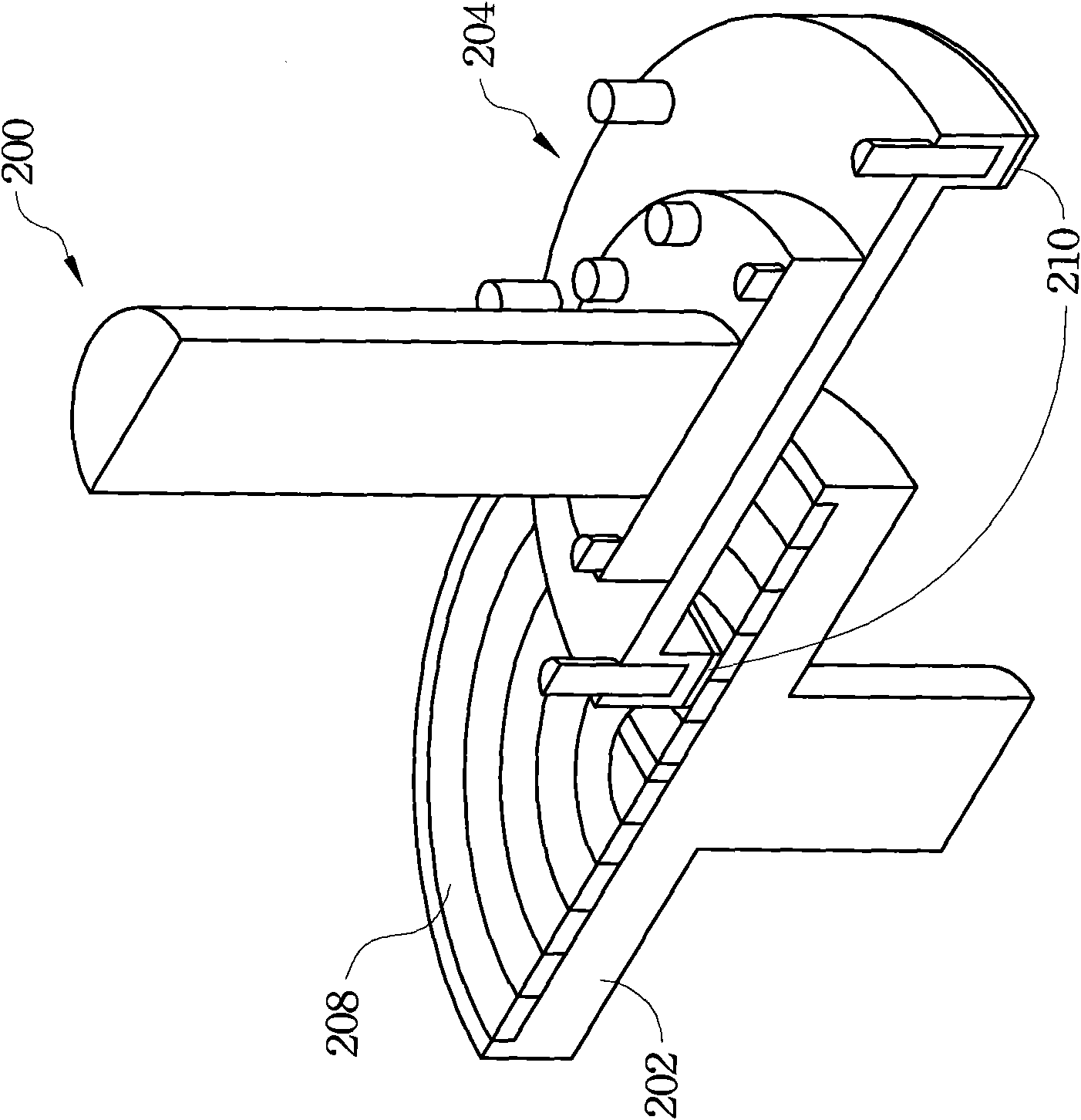

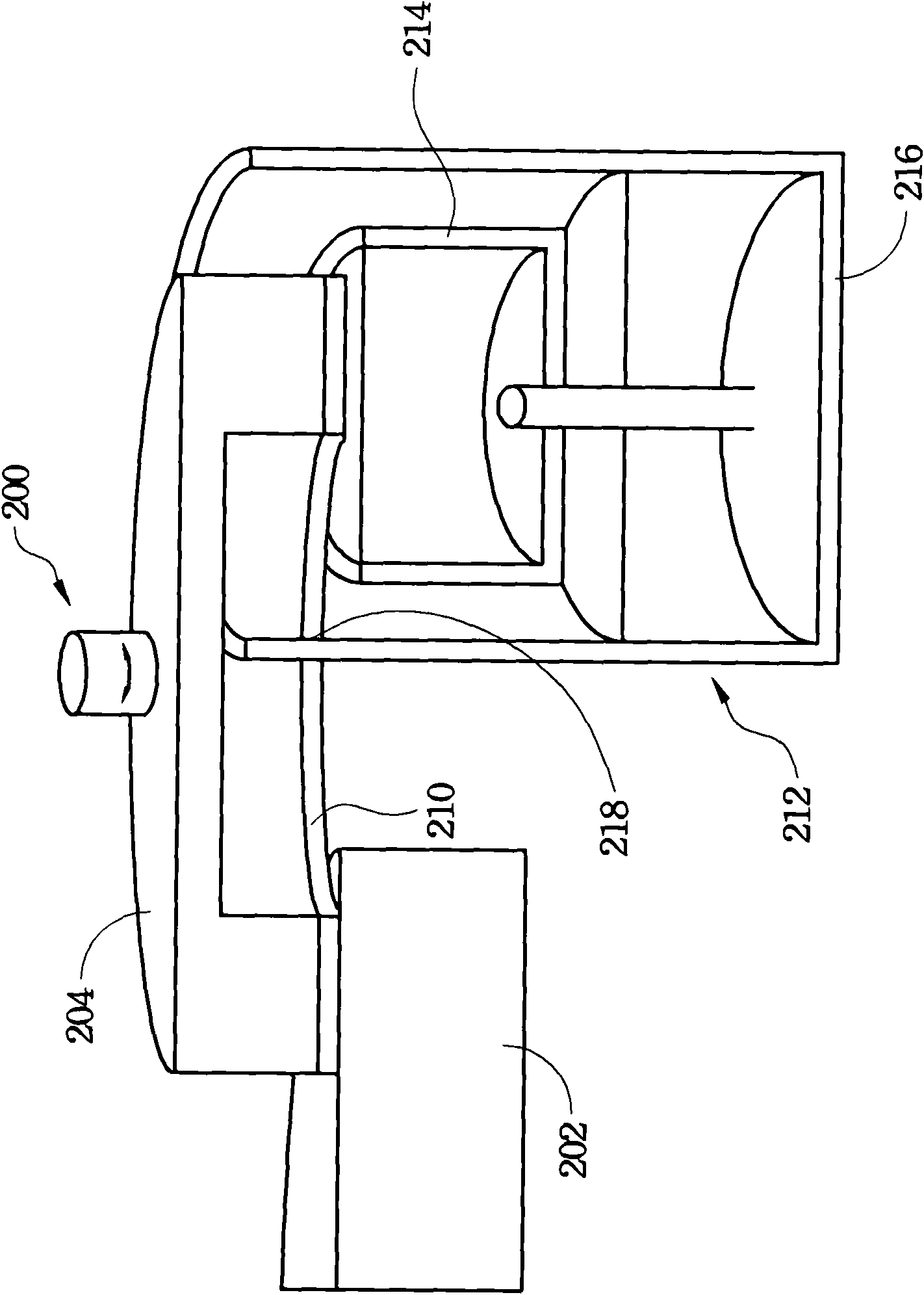

Chemical mechanical polishing device, polishing method and system for wafer

ActiveCN101879700ALess bendingShorten the timeSemiconductor/solid-state device manufacturingLapping machinesChemical reactionSlurry coating

The present invention relates to a chemical mechanical polishing device, and a method and a system of polishing a wafer, wherein the chemical mechanical polishing device for processing the wafer includes a plate for supporting the wafer to be processed in a face-up orientation; a polishing head opposing the plate, wherein the polishing head includes a rotatable polishing pad operable to contact the wafer while the polishing pad is rotating; and a slurry coating system providing a slurry to the polishing pad for polishing the wafer. By means of the invention, it is possible to perform a chemical mechanical polishing process to the face-up wafer; thereby, it is possible to reduce bending degree of the wafer and generate a better whole plainness degree so as to save a process window time of a scanner, it is also possible to reduce chemical reaction time so as to reduce dish-shaped appearance generation or corrosion in micro-shadow treatment. Furthermore, the wafer is faced upwards, such that it is possible to monitor the surface of the in-site wafer simply to implement accurate polishing control so as to be more practical.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com