Nanometer antimony-doped stannic oxide antistatic coating and method for making same

A tin dioxide and antistatic technology, applied in polyamide coatings, coatings and other directions, can solve the problems of poor conductivity, difficult to uniformly disperse, and the direct application of ATO cannot be realized, and achieves a convenient and easy preparation method and application prospects. The effect of considerable and obvious economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 2.00 g of nano antimony-doped tin dioxide (brand name: ESN-185, spherical), 3.14 g of polyamide resin / isopropanol solution with a mass concentration of 30%, and 2.21 g of isopropanol into a ball mill jar for ball milling. 225rpm, ball milling time 7h. The slurry after ball milling is taken out to obtain the antistatic coating of nano antimony-doped tin dioxide.

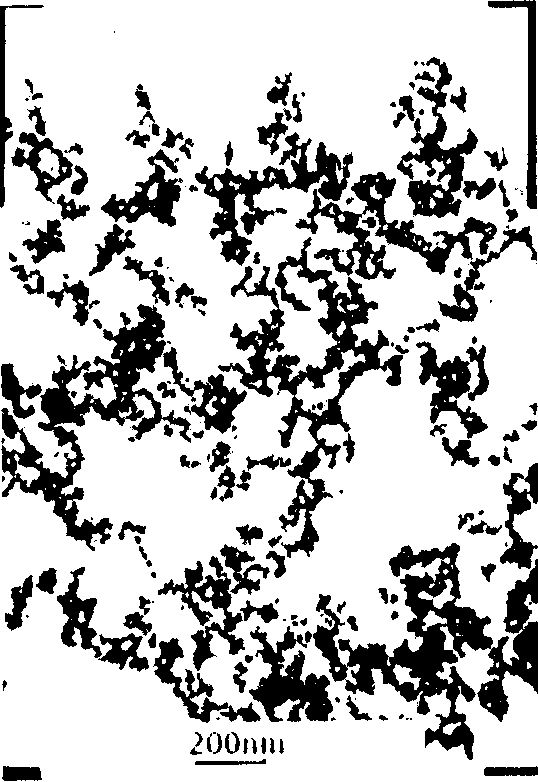

[0044] Dilute the above paint with isopropanol, and coat it on the surface of polyethylene film, and measure the surface resistivity of the coating with a ZC-46A megger to be 4.7×10 7 Ω / sq; the paint diluted with isopropanol was observed and photographed with a transmission electron microscope (JEM-1200EXII) from Japan JEOL Company, and the dispersion state of nano antimony-doped tin dioxide in the paint is shown in figure 1 .

Embodiment 2

[0046] Preparation of water-based nano-ATO antistatic coating: 4g of nano-antimony-doped tin dioxide (brand: ESN-185, spherical), 3g of deionized water, and 3g of KH-550 (γ-aminopropyltriethoxysilane) were placed in the In the ball mill jar, adjust the pH of the mixture to ≈8, and carry out ball milling for 1 hour, with the speed of the ball mill at 225 rpm. The slurry after ball milling was taken out, and 4 g of commercially available styrene-acrylic emulsion with a solid content of 50% was added to obtain the water-based nano-antimony-doped tin dioxide antistatic coating.

[0047] The resulting slurry was brushed on the cement board, dried and cured naturally, the color of the cured coating was grayish blue, the thickness was about 1 mm, and the surface resistivity was measured with a ZC-46A megger to be 4.5×10 5 Ω.

[0048] Gained slurry is observed and photographed with a transmission electron microscope (JEM-1200EX II) of Japan JEOL Company, and the dispersion state of n...

Embodiment 3

[0050] Nano antimony-doped tin dioxide (brand name: ESN-185, spherical) 3.00g, mass concentration 30% polyamide resin / isopropanol solution 4.70g, isopropanol butanone 4.50g, dimethylformamide 0.03g Put it into a ball mill tank for ball milling, the speed of the ball mill is 225rpm, and the ball milling time is 16h. The slurry after ball milling is taken out to obtain the antistatic coating of nano antimony-doped tin dioxide.

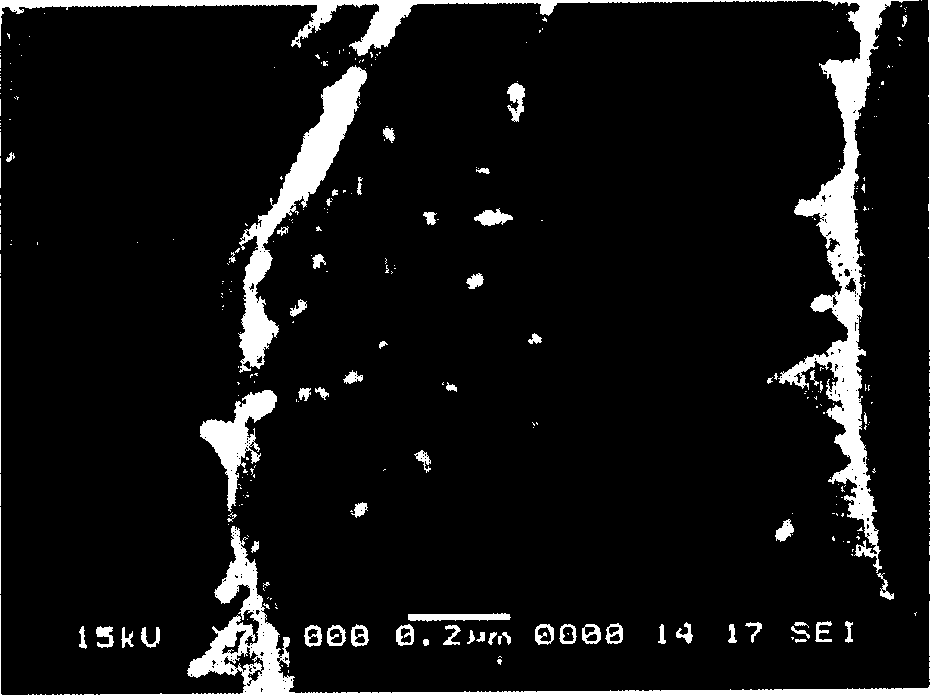

[0051] After diluting the above coating with isopropanol butanone to a coating weight concentration of 30%, the slurry is coated on the surface of the corona-pretreated PET film with a scraper bar, and the coating is measured with a ZC-46A high resistance meter. The surface resistivity of the layer is 10 8 Ω / sq; the film coated with antistatic coating was broken after quenching in liquid nitrogen, and its section was observed and photographed with a scanning electron microscope (JSM-6360-LV type) from Japan JEOL Company. For the dispersed state of tin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com