Surface anti-oxidation processing method for aircraft carbon brake disc

A processing method and technology for carbon brake discs, which are applied in mechanical equipment, friction linings, etc., can solve the problems of mechanical properties, thermal conductivity and friction properties, loose material, material failure, etc., and achieve low cost and good combination of process implementation. high performance, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

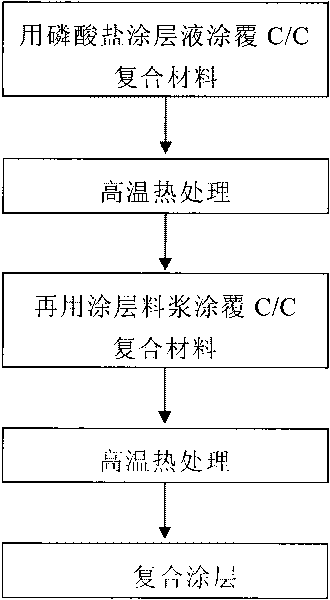

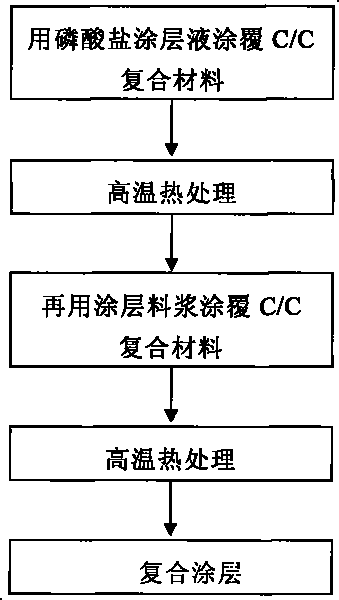

Method used

Image

Examples

Embodiment 1

[0031] The following components (mass percentage): 40% of distilled water, 30% of phosphoric acid, 5% of boron oxide, 15% of aluminum phosphate and 10% of potassium chloride are mixed and stirred evenly to obtain a phosphate coating solution, and the phosphate coating solution is brushed On the non-friction part of the cleaned aircraft carbon brake disc, put it in an oven to dry at 90°C, and then place it in a high-temperature furnace for high-temperature heat treatment at 300°C in a vacuum state to obtain a bottom phosphoric acid with a thickness of 50um Salt coating.

[0032] Then the following components (mass percentage): 10% of alumina, 5% of zirconia, 35% of boron nitride, 20% of titanium oxide and 30% of silicon powder are mixed and ground uniformly to obtain refractory ceramic powder. The coating solution is used as a solution, and the uniformly ground refractory ceramic powder is poured into the phosphate coating solution in a ratio of 1:1 by the mass ratio of the pho...

Embodiment 2

[0034] The following components (mass percentage): 35% of distilled water, 40% of phosphoric acid, 15% of zinc phosphate and 10% of potassium chloride are mixed and stirred evenly to obtain a phosphate coating solution, and the phosphate coating solution is sprayed on the cleaned aircraft carbon The non-friction part of the brake disc is put into an oven to dry at 110°C, and then placed in a high-temperature furnace for high-temperature heat treatment at 550°C under vacuum to obtain a bottom phosphate coating with a thickness of 100um.

[0035] Then the following components (mass percentage): 20% of alumina, 3% of zirconia, 37% of boron powder, 15% of titanium oxide and 25% of silicon carbide are mixed and ground uniformly to obtain refractory ceramic powder, which is coated with the above-mentioned phosphate The layer liquid is used as a solution, and the uniformly ground refractory ceramic powder is poured into the phosphate coating liquid in a ratio of 2:1 by the mass ratio ...

Embodiment 3

[0037] The following components (mass percentage): 30% of distilled water, 50% of phosphoric acid, 3% of boric acid, 10% of aluminum phosphate, and 7% of sodium chloride were mixed and stirred evenly to obtain a phosphate coating solution, and the phosphate coating solution was brushed on Clean the non-friction part of the aircraft carbon brake disc, put it in an oven to dry at 160°C, and then place it in a high-temperature furnace for high-temperature heat treatment at 650°C in a vacuum state to obtain a bottom layer of phosphate with a thickness of 150um coating.

[0038] Then the following components (mass percentage): 15% of alumina, 8% of zirconia, 42% of boron carbide, 20% of silicon oxide, and 15% of silicon powder were mixed and ground uniformly to obtain refractory ceramic powder, which was coated with the above-mentioned phosphate The layer solution is used as a solution, and the uniformly ground refractory ceramic powder is poured into the phosphate coating solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com